Gediktepe Project - Balıkesir Province, Turkey

NI 43-101 Royalty Technical Report

Prepared for:

Prepared by:

DAMA Engineering Inc.

Ankaralılar Caddesi 2562 Sokak 1/14A, Ankara-Turkey

Qualified Persons:

Mustafa ATALAY, M.Sc., CPG.

Senior Geologist, Dama Engineering

Metin ALEMDAR, M.Sc., MIMMM

Senior Mining and Mineral Processing Engineer, Dama Engineering

Selim YILMAZ, M.Sc., MIMMM

Senior Mining and Mineral Processing Engineer, Dama Engineering.

Arif Umutcan GELİŞEN, B.Sc., MIMMM

Senior Mining and Mineral Processing Engineer, Dama Engineering

Effective Date: February 1, 2022

Report Date: March 21, 2022

Table of Contents

| 1. Summary | 1 |

| 1.1 Introduction | 1 |

| 1.2 Property Description and Ownership | 1 |

| 1.3 Accessibility, Climate, Local Resources, Infrastructure and Physiography | 3 |

| 1.4 Geology, Mineralization, and Deposit Type | 3 |

| 1.4.1 Geology | 3 |

| 1.4.2 Mineralization and Deposit Type | 4 |

| 1.5 History | 5 |

| 1.5.1 Ownership History | 5 |

| 1.5.2 Historical Exploration and Drilling | 5 |

| 1.5.3 Historical Grade Estimation | 5 |

| 1.5.4 Historical Mineral Resources | 5 |

| 1.5.5 Historical Mineral Reserves | 6 |

| 1.5.6 Historical Mining Methods | 7 |

| 1.5.7 Historical Recovery Methods | 8 |

| 1.5.8 Historical Site Infrastructure | 8 |

| 1.5.9 Historical Environmental Studies, Permitting and Social or Community Impact | 8 |

| 1.5.10 Historical Other Relevant Data and Information | 8 |

| 1.5.11 Historical Conclusions and Recommendations | 8 |

| 1.6 Data Verification | 9 |

| 1.7 Conclusions and Recommendations | 9 |

| 2. Introduction | 10 |

| 2.1 Terms of Reference | 10 |

| 2.2 Sources of Information | 10 |

| 3. Reliance on Other Experts | 12 |

| 4. Property Description and Location | 13 |

| 4.1 Project Ownership | 13 |

| 4.2 EMX's Royalty Interests | 14 |

| 4.3 Other Royalties, Permits and Encumbrances | 14 |

| 4.3.1 Government Royalty | 15 |

| 4.3.2 Forestry and Other Permits | 16 |

| 4.4 Other Factors | 16 |

| 5. Accessibility, Climate, Local Resources, Infrastructure and Physiography | 17 |

| 5.1 Location and Access | 17 |

i

| 5.2 Physiography | 19 |

| 5.3 Climate | 20 |

| 5.4 Local Resources | 20 |

| 5.5 Infrastructure | 21 |

| 6. History | 23 |

| 6.1 Prior Ownership and Ownership Changes | 23 |

| 6.2 Licenses and Permits | 23 |

| 6.3 Historical Reports | 24 |

| 6.3.1 Historical Exploration and Drilling | 24 |

| 6.3.2 Historical Mineral Processing and Metallurgical Testing | 26 |

| 6.3.3 Historical Block Model Resource Estimation Methods | 27 |

| 6.3.4 Historical Mineral Resources | 28 |

| 6.3.5 Historical Mineral Reserves | 31 |

| 6.3.6 Historical Mining Methods | 32 |

| 6.3.6.1 General Overview of Historical Production Schedules | 32 |

| 6.3.7 Historical Recovery Methods | 33 |

| 6.3.8 Historical Site Infrastructure | 37 |

| 6.3.9 Historical Environmental Studies, Permitting and Social or Community Impact | 37 |

| 6.3.9.1 Historical Other Relevant Data and Information | 38 |

| 6.3.9.2 Pre-Feasibility Study and Gediktepe Project Oxide Technical Report | 38 |

| 6.3.9.3 Historical Mineral Resources Recommendations | 38 |

| 6.3.9.4 Historical Mining Method Recommendations | 39 |

| 6.3.9.5 Historical Process and Metallurgical Test work Recommendations | 39 |

| 6.3.9.6 Historical Site Infrastructure Recommendations | 40 |

| 7. Geological Setting and Mineralization | 41 |

| 7.1 Regional Geology | 41 |

| 7.2 Deposit Geology | 43 |

| 7.2.1 Dacite and Pyroclastics (Lower-Middle Miocene) | 45 |

| 7.2.2 Calcshist (Upper Paleozoic) | 46 |

| 7.2.3 Quartz-Feldspar Schist (Upper Paleozoic) | 47 |

| 7.2.4 Chlorite-Sericite Schist (Upper Paleozoic) | 48 |

| 7.2.5 Quartz Schist (Upper Paleozoic) | 50 |

| 7.3 Mineralization | 50 |

| 7.3.1 Gossan (Oxide Mineralization) | 51 |

| 7.3.2 Massive Pyrite (MPy) | 53 |

| 7.3.3 Massive Pyrite-Magnetite (MPyMag) | 54 |

| 7.3.4 Enriched (Enrch) | 54 |

ii

| 7.3.5 Disseminated Sulfide Mineralization (Tr-Sulp) | 55 |

| 7.4 Structure | 55 |

| 8. Deposit Types | 57 |

| 9. Exploration | 58 |

| 10. Drilling | 58 |

| 11. Sample Preparation, Analyses and Security | 58 |

| 12. Data Verification | 59 |

| 12.1 Site Visits | 59 |

| 12.2 Limitations | 59 |

| 12.3 QP's Comment | 60 |

| 13. Mineral Processing and Metallurgical Testing | 61 |

| 14. Mineral Resource Estimates | 61 |

| 15. Mineral Reserve Estimates | 61 |

| 16. Mining Methods | 61 |

| 17. Recovery Methods | 61 |

| 18. Project Infrastructure | 61 |

| 19. Market Studies and Contracts | 62 |

| 20. Environmental Studies, Permitting, and Social or Community Impact | 62 |

| 21. Capital and Operating Costs | 62 |

| 22. Economic Analysis | 62 |

| 23. Adjacent Properties | 62 |

| 24. Other Relevant Data and Information | 62 |

| 25. Interpretation and Conclusions | 63 |

| 26. Recommendations | 65 |

| 27. References | 67 |

| 28. Certificate of Qualified Person | 68 |

iii

List of Figures

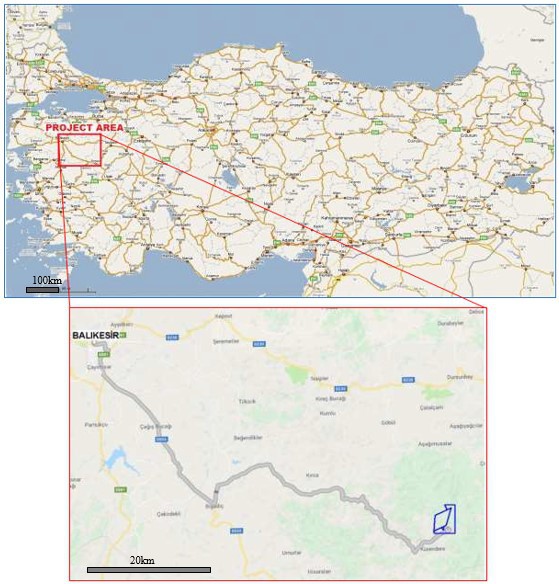

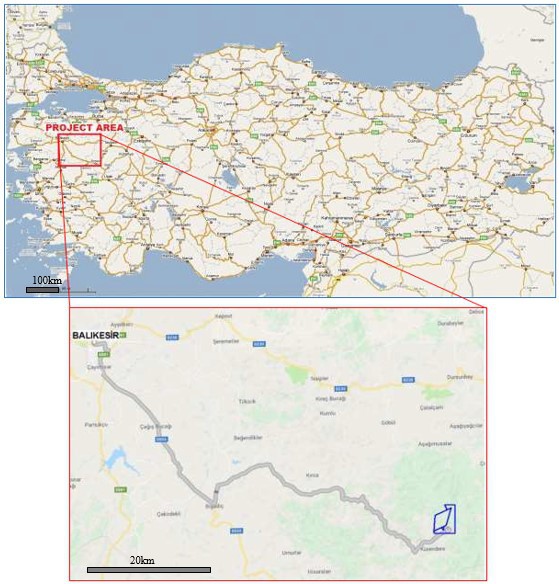

| Figure 1-1: Project Area Location Map | 2 |

| Figure 4-1: Current Gediktepe Operating License | 14 |

| Figure 5-1: Project Location Map | 17 |

| Figure 5-2: Paved Road | 18 |

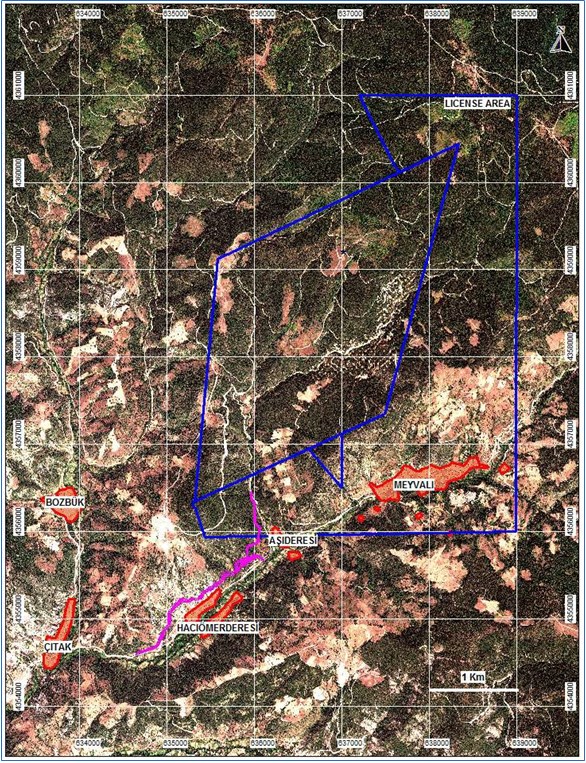

| Figure 5-3: Gediktepe Project Area and By-pass Road. Pink color shows the by-pass road, constructed in 2017 | 19 |

| Figure 5-4: Aerial Photograph of Gediktepe Field Camp | 21 |

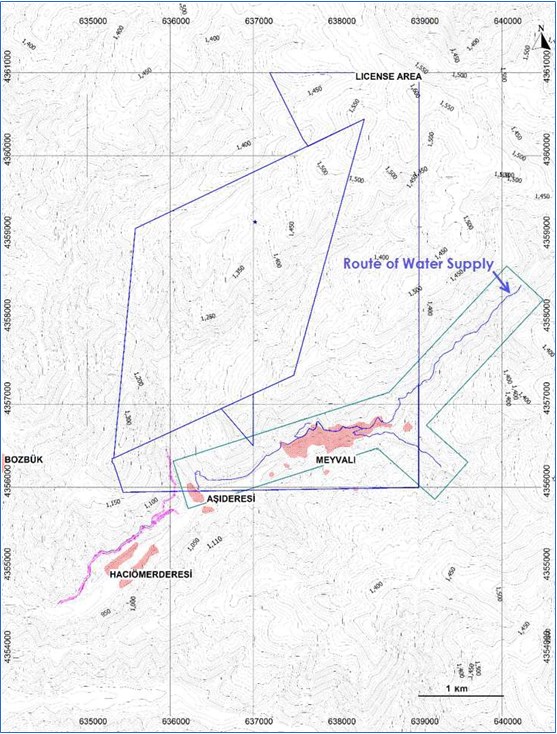

| Figure 5-5: Gediktepe Topography and Water Supply Route. Contoured at 10 m intervals | 22 |

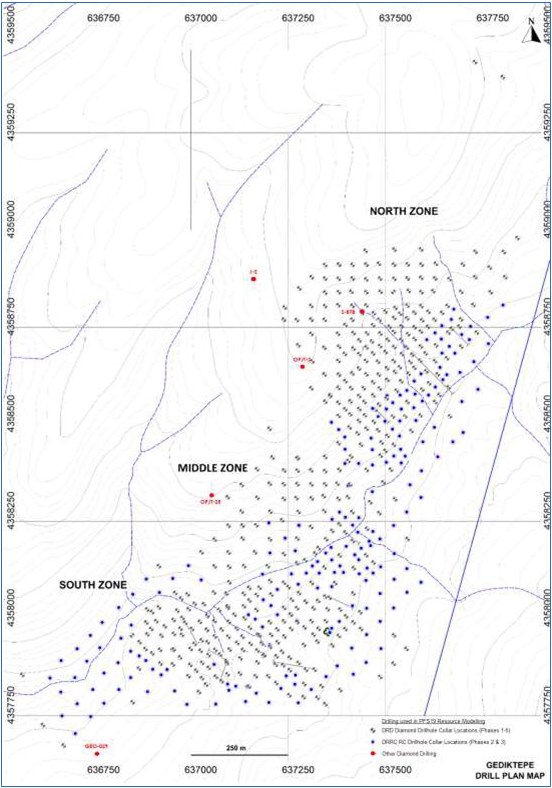

| Figure 6-1: Historical Drillhole Location Plan - PFS19 Drillhole Dataset | 26 |

| Figure 6-2: Historical PFS19 Oblique View of Mineralization Solid Interpretations | 28 |

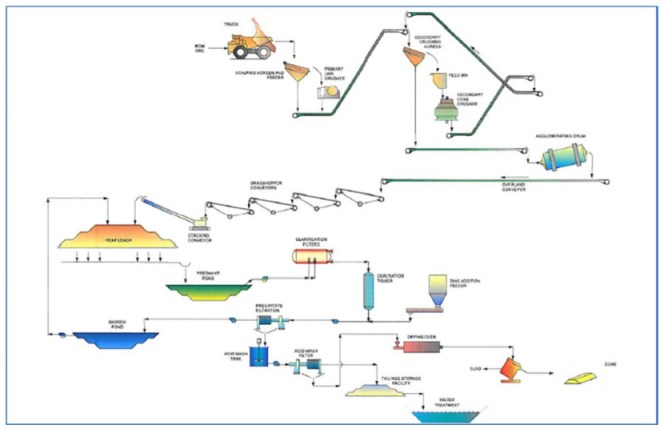

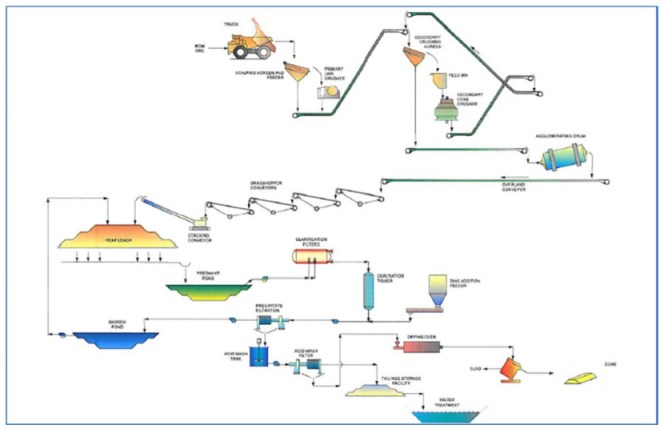

| Figure 6-3: Historical TR20 Flowsheet for Oxide Processing | 35 |

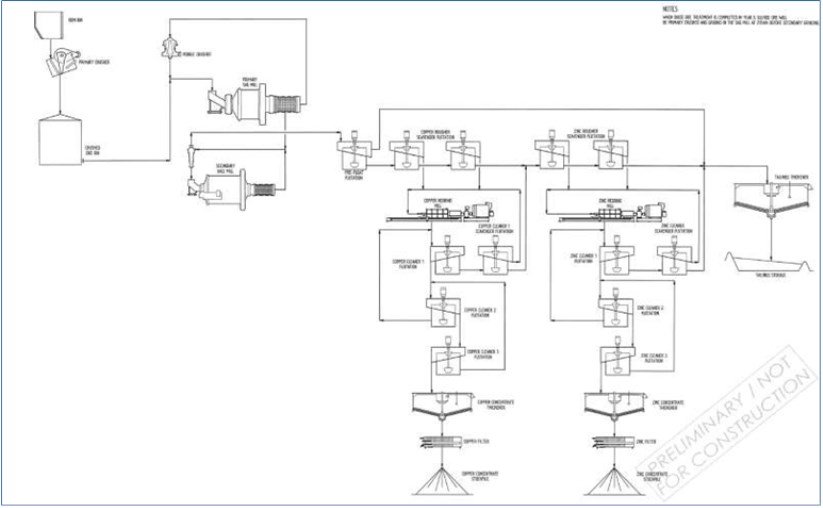

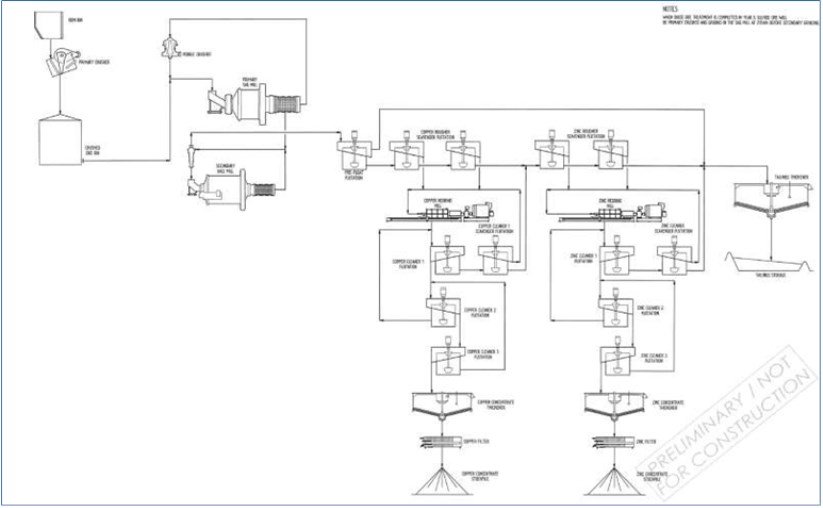

| Figure 6-4: Historical PFS19 Flowsheet for Sulfide Processing | 36 |

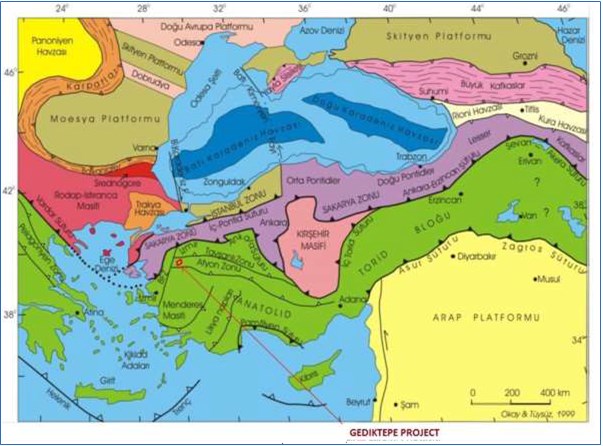

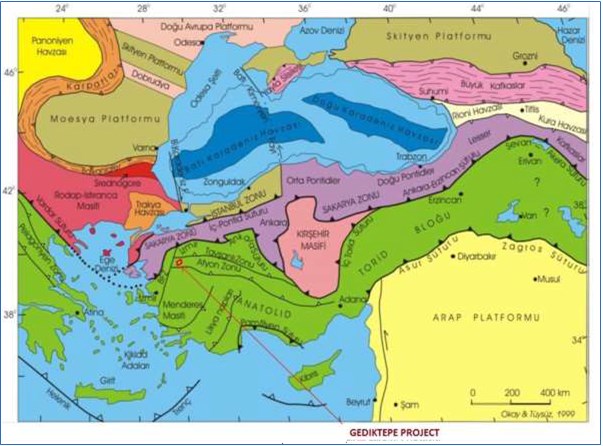

| Figure 7-1: Tectonic Map of Turkey | 41 |

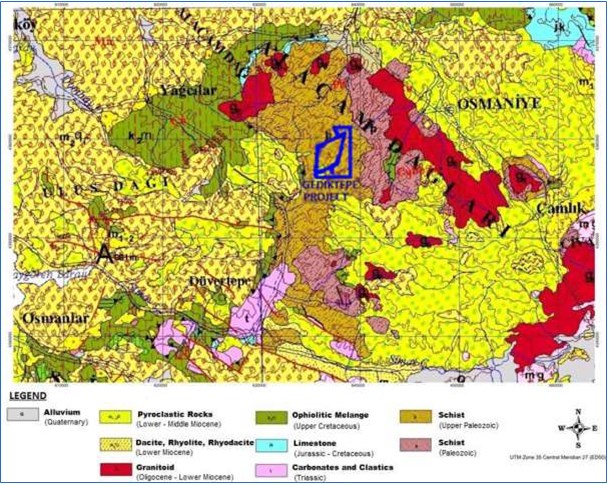

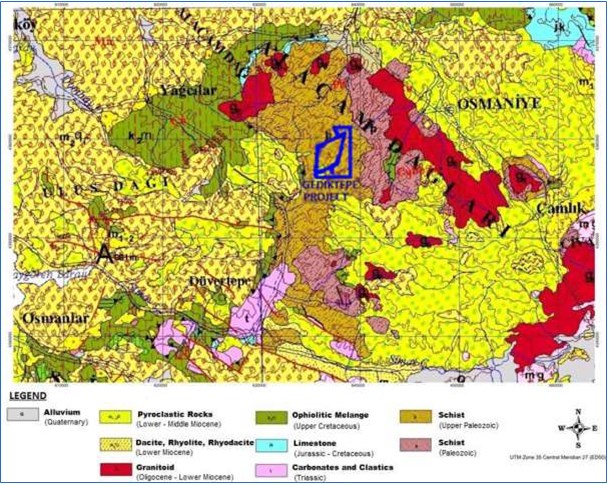

| Figure 7-2: Gediktepe Regional Geology | 42 |

| Figure 7-3: Regional Stratigraphic Column | 43 |

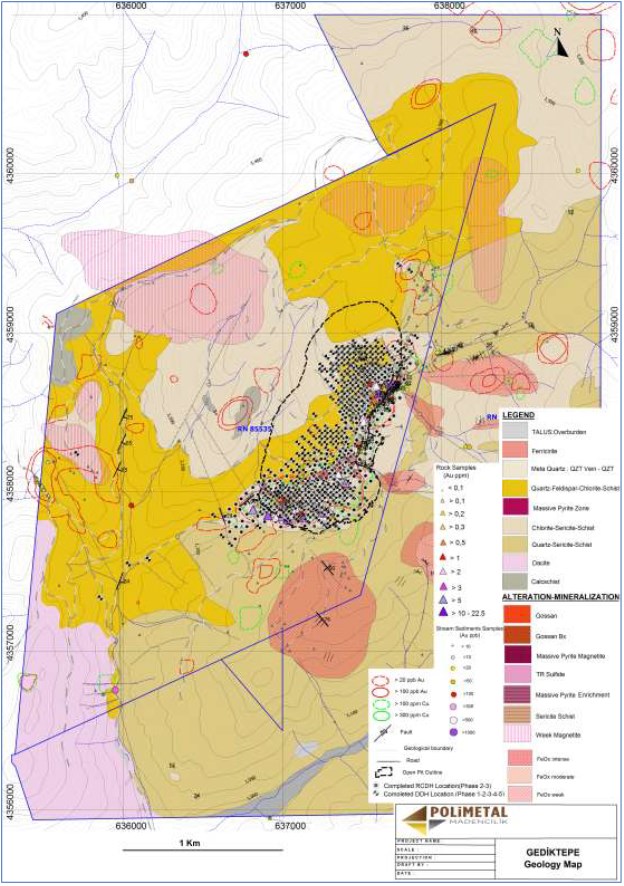

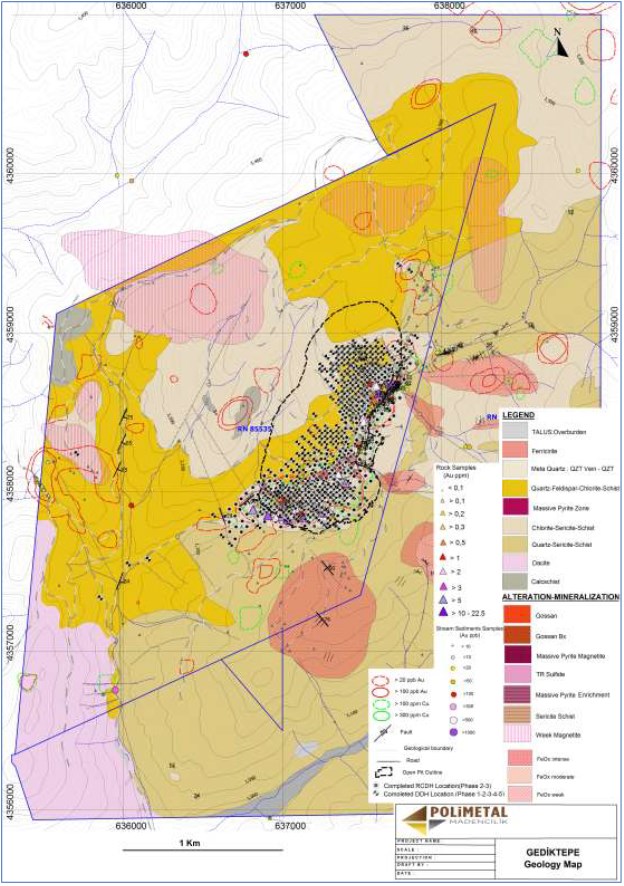

| Figure 7-4: 1:1,000 Scale Project Geological Map | 44 |

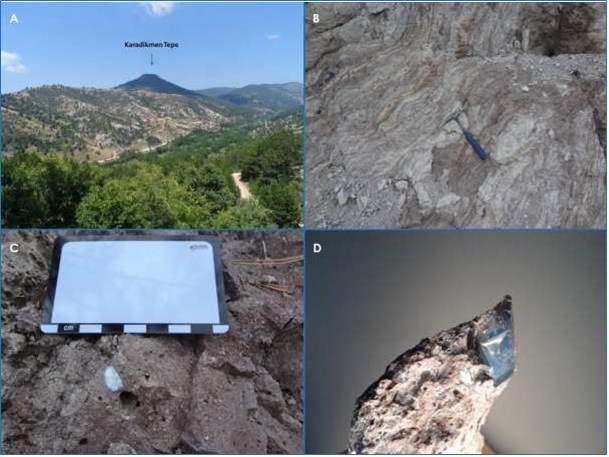

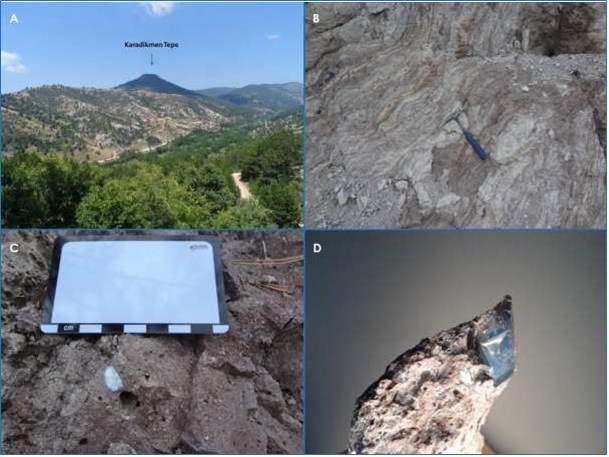

| Figure 7-5: Dacite Features (A): Dacite dome Karadikmen Hill, (B): Flow structure in dacite, (C) and (D): Opal filling in voids | 46 |

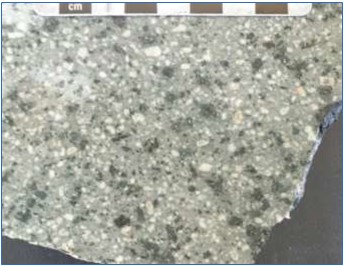

| Figure 7-6: Dacite Hand Specimen. Grey vitreous matrix incl. quartz, biotite, and feldspar phenocryst | 46 |

| Figure 7-7: Calcshist in Outcrop. Fındıkalanı Ridge | 47 |

| Figure 7-8: Quartz-Feldspar Schist in Outcrop. Around Büyük Yellice Hill and the Kaynarsu stream | 47 |

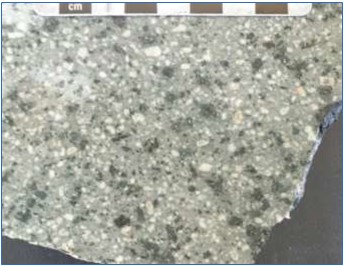

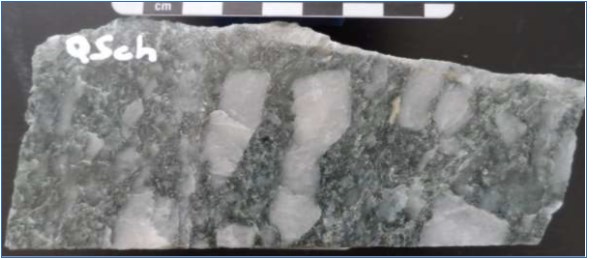

| Figure 7-9: Quartz-Feldspar Schist Core Photograph | 48 |

| Figure 7-10: Chlorite-Sericite Schist in Outcrop | 49 |

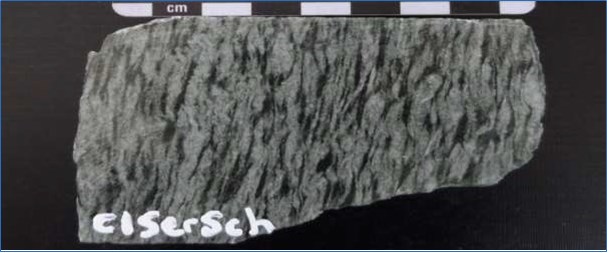

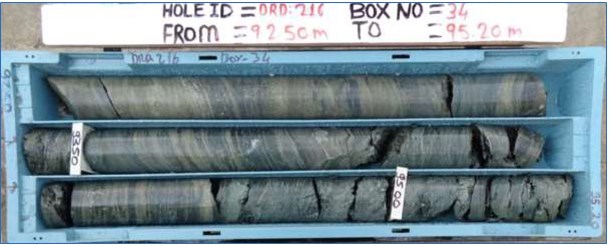

| Figure 7-11: Chlorite-Sericite Schist Core Photograph | 49 |

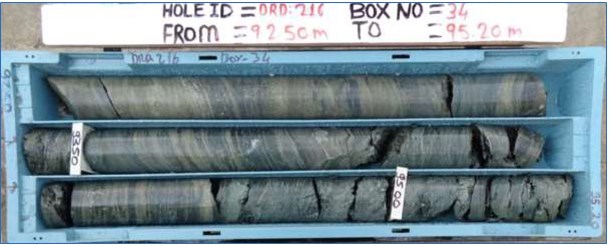

| Figure 7-12: Chlorite-Sericite Schist Altered to Tr-Sulf Core Photograph | 49 |

| Figure 7-13: Quartz Schist Containing Quartz Porphyroblasts in Outcrop. Southeast of Alçakgedik Hill | 50 |

| Figure 7-14: Quartz Schist Core Photograph | 50 |

| Figure 7-15: Gossan in Outcrop | 51 |

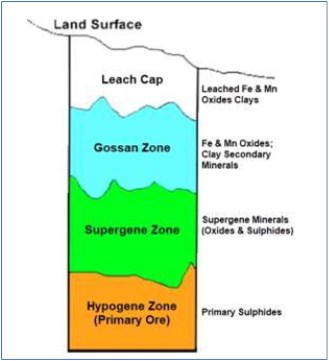

| Figure 7-16: Typical Profile of Mineralization from Oxide to Sulfide | 52 |

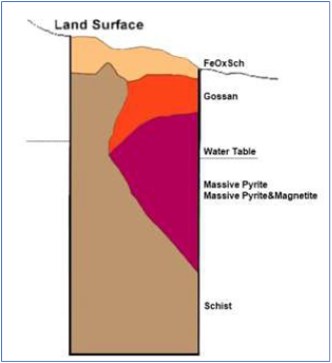

| Figure 7-17: Mineralization Profile at Gediktepe | 52 |

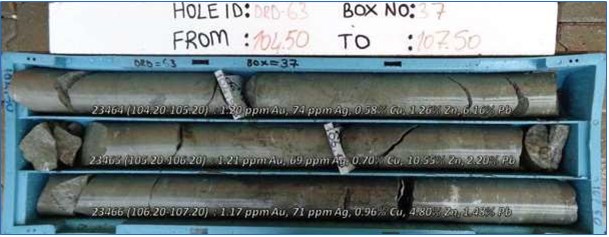

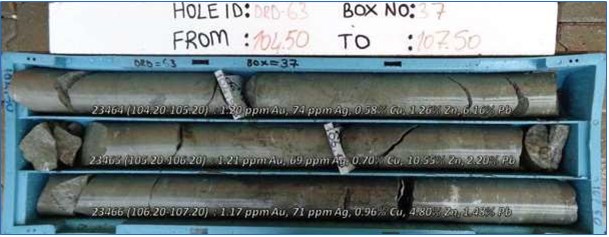

| Figure 7-18: High-Grade Gossan Mineralization Drill Core | 53 |

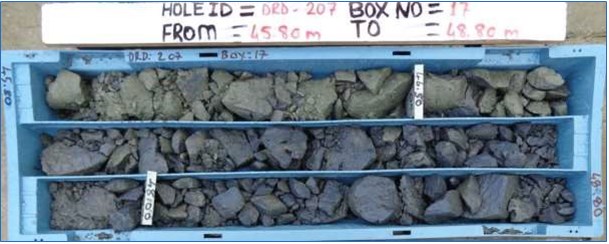

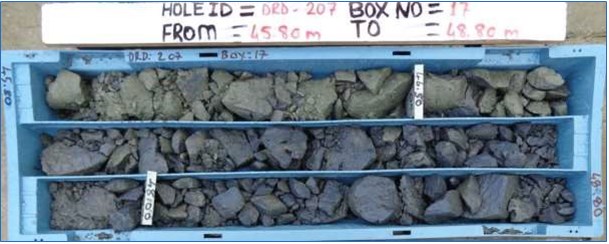

| Figure 7-19: Massive Pyrite Drill Core | 54 |

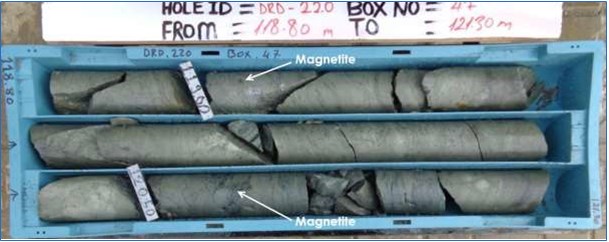

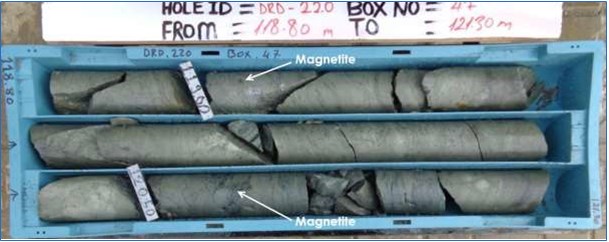

| Figure 7-20: Magnetite Aligned with Schistosity in Core | 54 |

| Figure 7-21: Enriched Mineralization in Drill Core - Blue Color | 55 |

| Figure 7-22: Chlorite-Sericite Schist with Pyrite Veining in Drill Core | 55 |

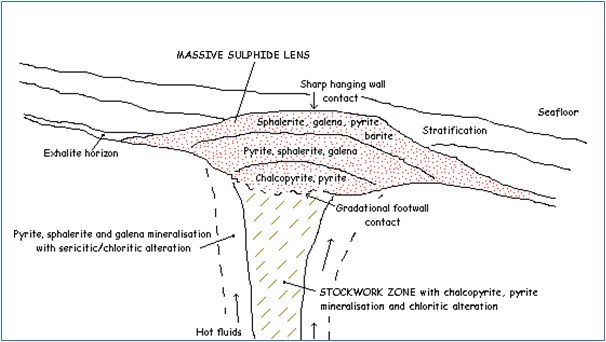

| Figure 8-1: Vertical Section of an Idealized Convex MS Deposit | 57 |

iv

List of Tables

| Table 1.1: Mineralization Types | 4 |

| Table 1.2: Historical Gediktepe PFS19 Mineral Resources | 6 |

| Table 1.3: Historical Gediktepe PFS19 Mineral Reserves | 7 |

| Table 4.1: Government Base Royalty Rate by Commodity and Metal Price | 15 |

| Table 4.2: Royalty Rate by Commodity and Metal Price | 15 |

| Table 6.1: Summary of PFS19 Drillhole Dataset to March 21, 2018 | 25 |

| Table 6.2: Historical Gediktepe PFS19 Mineral Resources - All Classifications | 29 |

| Table 6.3: Historical Gediktepe PFS19 Mineral Reserves | 31 |

| Table 7.1: Mineralization Type Names | 51 |

v

1. Summary

1.1 Introduction

EMX Royalty Corporation (TSX Venture: EMX; NYSE American: EMX) ("EMX" or the "Company") entered into an agreement (the "Royalty Purchase Agreement") dated July 29, 2021, with SSR Mining Inc. and certain of its subsidiaries ("SSR Mining") to purchase a portfolio of royalty interests and deferred payments (the "Royalty Portfolio"). The Royalty Portfolio includes the Gediktepe Project Net Smelter Return ("NSR") royalties (the "Gediktepe Royalties") on the oxide and sulfide mineralized zones of the Gediktepe polymetallic massive sulfide project in Western Turkey (the "Project"). The Project became material to EMX upon closing of the purchase of the Royalty Portfolio on October 21, 2021. EMX is required by Canadian Securities Administrators ("CSA") National Instrument 43-101 ("NI 43-101") to prepare a Technical Report on the Project with respect to the Gediktepe Royalties.

EMX holds royalty interests (not direct ownership) in the Project. Mining companies are not (typically) required to, and as a matter of practice do not normally disclose detailed information to companies that hold a royalty interest in their operations unless legally or contractually mandated to do so. EMX has requested all the current technical data from the private Turkish operator, Polimetal Madencilik Sanayi ve Ticaret A.S. ("Polimetal"), in order to conduct a detailed independent assessment of Gediktepe for this Technical Report. However, EMX has not yet received this data, and according to the underlying royalty agreement, does not have data rights beyond onsite reviews. EMX will continue to request the Project data directly from Polimetal.

There have been two previous Technical Reports describing the Project filed on SEDAR: the first is titled "Technical Report - Prefeasibility Study - Gediktepe Project, Balıkesir Province, Turkey" with an effective date of June 1, 2016 ("PFS16") prepared by Resource Development Inc., SRK Consulting (U.S.) Inc. and Independent Mining Consultants, Inc. for Alacer Gold Corp. ("Alacer") and Polimetal, and the second is titled "Gediktepe Prefeasibility Study" ("PFS19") dated April 3, 2019 with an effective date of March 26, 2019 prepared by OreWin Pty. Ltd. ("OreWin") for Alacer. These reports document the outcome of PFS-level technical work on Gediktepe's oxide and sulfide polymetallic mineralized zones performed on behalf of Polimetal, which was owned 50% by Lidya Madencilik San. ve Tic. A.Ş., a private Turkish company ("Lidya"), and 50% by Alacer, formerly a reporting issuer in Canada. The Project and Polimetal are now 100% controlled by Lidya. Lidya has also provided EMX with a 2020 internal report titled "Gediktepe Project Oxide Technical Report" ("TR20") with an effective date of March 1, 2020. The TR20 report was largely taken from PFS19, although updates and refinements to the oxide processing flowsheet were proposed. Unless otherwise specified, the contents of this Technical Report have been excerpted from, or based upon, the aforementioned PFS16, PFS19, and TR20 reports. In addition, information and Project updates verbally communicated by Lidya during two onsite field visits were noted, and where appropriate, used to provide more recent context for the status of the Project.

For simplicity in this document, references to Lidya also refer to Polimetal, the operating entity, when citing information dated after July 2019, when Lidya acquired 100% interest in Polimetal.

1.2 Property Description and Ownership

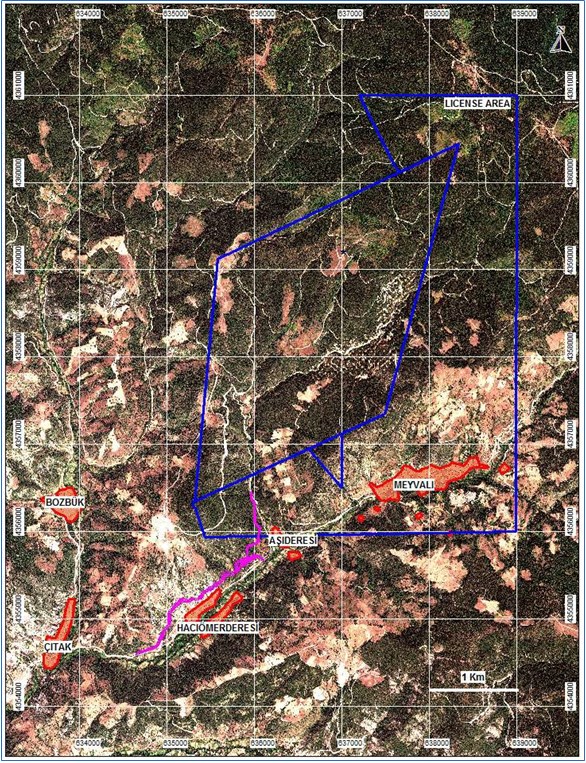

The Gediktepe Project is located in the Balıkesir province of Western Turkey (Figure 1-1). The UTM Zone 35N, European Datum coordinates of the approximate center of the Project are 636,000E, 4,358,000N.

Figure from OreWin, 2019

Figure 1-1: Project Area Location Map

EMX completed the purchase of the Gediktepe Royalties based upon the terms and conditions of the Royalty Purchase Agreement with SSR Mining and certain of its subsidiaries to purchase the Royalty Portfolio. The Royalty Portfolio included the Gediktepe Royalties consisting of: (i) a perpetual 10% NSR royalty over metals produced from the oxide zone (predominantly gold and silver) after cumulative production of 10,000 gold-equivalent oxide ounces; and (ii) a perpetual 2% NSR royalty over metals produced from the sulfide zone (predominantly copper, zinc, lead, silver, and gold), payable after cumulative production of 25,000 gold-equivalent sulfide ounces (gold equivalent as referenced from the 2019 Share Purchase Agreement between Alacer and Lidya).

The following Project license and permits have been confirmed as being current and in good standing.

The General Directorate of Mining and Petroleum Affairs (GDMPA) approved the merging of Operating License (OL) 20054077 and Exploration License (EL) 201400291 into one OL (RN 85535) on July 29, 2016. RN 85535 is valid until June 23, 2036. The Gediktepe OL (RN 85535) covers a total area of 1,486.99 ha and is held by Polimetal (now wholly owned by Lidya).

On February 21, 2018, the GDMPA also approved Polimetal's application for a production permit for clay and aggregate for three locations within RN 85535.

The Gediktepe mining licenses do not have any associated royalties to a third party other than EMX's Gediktepe Royalties and a government royalty, which consists of royalty rates defined by commodity and metal price.

As of the effective dates of the PFS19 and TR20 reports, a series of final permits were pending in anticipation of a follow-on Feasibility Study and initiation of construction. However, it is known from site visits conducted by DAMA in 2021 that Project construction and initial mining of the oxide phase of the Project had commenced, implying that the necessary permits had been received.

To DAMA's knowledge, there are no significant factors or risks that may affect access, title, or the right ability to perform work on the Project, and by extension Lidya's ability to meet its royalty payment obligations to EMX.

1.3 Accessibility, Climate, Local Resources, Infrastructure and Physiography

The Project is located 67 km (air distance) southeast of Balıkesir Province center and 38 km east-southeast of the Bigadiç township. It is accessed along 102 km of paved road from the city of Balıkesir (population 1,189,075) on highway D555 through the town of Bigadiç (population 48,470). The closest settlements to the Gediktepe Project site are the Hacıömerderesi neighborhood, the Aşıderesi neighborhood, affiliated with the Hacıömerderesi neighborhood, and the Meyvalı neighborhood.

The terrain at the Project is mountainous with steep erosional valleys. Elevations in the Project area range from 974-1,482 m above sea level (masl). Coniferous trees cover most of the Project site, with occasional open meadows in areas of less-steep terrain.

The local climate is hot and arid during the summer and warm during the fall. There is snow from December through February but typically not as a significant accumulation. Spring is often the rainy period.

The main economic income sources in the area are forestry, agriculture, and animal husbandry.

As of the effective dates of PFS19 and the TR20 reports, an adequate water supply system needed to be established for the Project as there was no developed system in the area capable of supporting a project of Gediktepe's size. From DAMA's site visits, it appears that Lidya has been taking the steps to develop a pipeline to provide the necessary water for the Project.

A 39.6 km-long 34.5 kV power transmission line (PTL) was constructed between Dursunbey substation and Kürendere to provide power to the Project. This PTL will provide adequate electrical power for site operations.

Given Gediktepe's physiographic and climatic conditions DAMA believes that year-round operations of the Project are possible. Adequate local manpower is available to support mining operations. To DAMA's knowledge, with adequate power and access to suitable areas for Project infrastructure, the principal contingency requiring final confirmation of resolution is Polimetal's completion of the pipeline to provide an adequate water supply for the Project.

1.4 Geology, Mineralization, and Deposit Type

1.4.1 Geology

The Gediktepe regional geology comprises Upper Paleozoic metamorphic rocks and Lower to Middle Miocene intrusives and volcanics. These rocks are stratigraphically overlain by Triassic carbonates and fragmental units, Jurassic limestone, and an Upper Cretaceous ophiolitic mélange. Oligocene and Lower Miocene intrusions cut the Paleozoic metamorphic and Upper Cretaceous ophiolitic rocks, establishing in the region what is now called the Alaçam Mountains granites, which outcrop in an arc-shaped geometry over an area of nearly 30 km2. Lower Miocene volcanic rocks are positioned stratigraphically above Paleozoic to Upper Paleozoic metamorphics and Upper Cretaceous ophiolitic mélanges.

Upper Paleozoic metamorphics are the most common units at Gediktepe, with the stratigraphic sequence, from top to bottom, being:

- Dacite and Pyroclastic (top)

- Calcschist

- Feldspar-Quartz Schist

- Chlorite-Sericite Schist

- Quartz Schist (bottom)

The second-most common rocks at the Project are the Lower to Middle Miocene volcanics, observable around Karadikmen Hill, southwest of Gediktepe. These rocks are comprised of altered dacite-rhyodacites characterized by lava flows and pyroclastics.

The youngest units at the Project are mineralized gossan and ferricrete, along with talus, colluvium, and alluvium, all being weathering products of the host rock.

1.4.2 Mineralization and Deposit Type

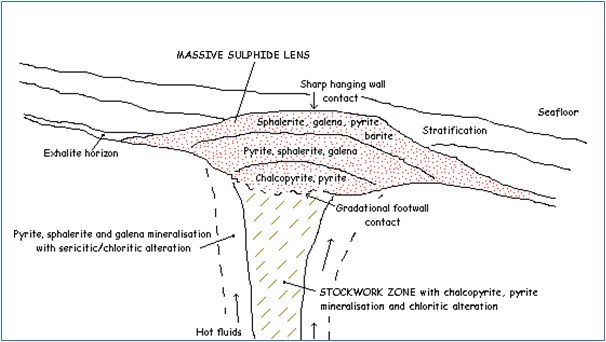

The Project is a massive sulfide deposit hosted in schists. The sulfide zone is polymetallic with potentially economic values of zinc, copper, gold, and silver. The upper portions of the Gediktepe deposit have been weathered, leached, and oxidized by naturally occurring acidic surface water and ground water. The oxide zone hosts gold-silver mineralization, but is nearly devoid of base metals.

Mineralization at the Project is associated with greenschist facies units that are interpreted to represent massive sulfide deposition that was syngenetic with sedimentary units. These units are now elongated along a north-easterly trending structural zone that has been metamorphosed to schist. The massive sulfide-type mineralization occurs as lens-shaped units trending north-easterly and dipping at approximately 20° to 40° to the northwest. The major sulfide zone minerals are sphalerite and chalcopyrite. Pyrite is ubiquitous.

Potentially economic gold-silver-copper-zinc mineralization is present to varying degrees, and is divided into five main types, as summarized in Table 1.1.

Table 1.1: Mineralization Types

| Horizon | Mineralization Type |

| Oxide | Gossan |

| Sulfide | Massive Pyrite |

| Massive Pyrite-Magnetite |

| Enriched |

| Disseminated Sulfide |

| Table from OreWin, 2019 |

The units are cut by later north-westerly trending post-mineralization structures.

The characteristics of the Gediktepe mineralization have been interpreted as a convex-up massive sulfide type deposit, which implies a syngenetic style of sulfide mineralization. Subsequent weathering and oxidation are responsible for the development of the oxide and gossan horizons.

1.5 History

1.5.1 Ownership History

The Gediktepe mining licenses are held by Polimetal Mining Industry and Trade Inc., otherwise known as Polimetal Madencilik San. ve Tic. A.Ş., which was formed in 2011 as a joint venture (JV) company between Lidya (50%) and Alacer (50%). The Gediktepe deposit was discovered in 2012-2013 by the JV. Alacer entered into an agreement (the "2019 Share Purchase Agreement") with Lidya in July 2019 to sell its 50% non-operating ownership interest in the Project to Lidya, whereby Alacer retained the Gediktepe Royalties, consisting of a) a 10% NSR royalty on all oxide ore production, and b) a 2% NSR on all sulfide ore production. The sale to Lidya resulted in Lidya consolidating 100% control of Polimetal and the Gediktepe Project. Subsequently, Alacer and SSR Mining completed a merger transaction in September 2020, whereby Alacer became a wholly owned subsidiary of SSR Mining. EMX purchased the Gediktepe Royalties from SSR Mining upon closing of the Royalty Purchase Agreement on October 21, 2021.

1.5.2 Historical Exploration and Drilling

There were five phases of core (DD) and reverse circulation (RC) exploration drilling at Gediktepe, commencing in 2013 and ending in 2018. This resulted in 438 DD holes totaling 56,898 meters and 191 RC holes totaling 13,229 meters. Of the total drillhole database, a subset of drilling comprised of 624 DD and RC holes totaling 68,968 m was used for geological modelling and resource estimation work in the PFS19 report by OreWin.

1.5.3 Historical Grade Estimation

Historical resource block model grades were estimated using either ordinary kriging (OK) or inverse distance weighting to the power of two (ID2). Depending on the domain being estimated, composites of either 1 m or 2 m (notional) length were used. The modelled estimates were assessed for levels of geological confidence, and classified into Measured, Indicated, and Inferred categories, referencing CIM guidelines (CIM, 2014). The Mineral Resource tonnages and grades were reported using NSR cut-offs and constrained within an optimized pit.

1.5.4 Historical Mineral Resources

The PFS19 historical Measured, Indicated, and Inferred Mineral Resources and combined Measured plus Indicated Resources for the Project at specified NSR cut-offs are presented in Table 1.2. The more-detailed breakdown of Mineral Resources by mineralogy-type is included in Table 6.2.

Table 1.2 summarizes "Historical Estimates" within the meaning of NI 43-101. The source of the estimates is Section 14 of PFS19, as repeated in TR20. The historical estimates set forth in Table 1.2 do not use categories of mineral resources other than the ones set out in the CIM Definition Standards and Section 1.2 of NI 43-101. For further details on the parameters utilized in the estimates, the reader is referred to Section 14 of PFS19.

A qualified person has not performed sufficient work to classify the historical resource estimates as current mineral resources, and DAMA is not treating the historical estimates as current. Significant data compilation, confirmation drilling, re-sampling and data verification may be required by, or under the supervision of, a qualified person before the historical estimates can be classified as current mineral resources. The historical resource estimates are considered to be relevant and are presented for the purpose of describing the extent and nature of mineralization as presently understood. The historical resource estimates should not be relied upon until verified by a qualified person.

Table 1.2: Historical Gediktepe PFS19 Mineral Resources

| MEASURED | Tonnes

(kt) | Grade | Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Pb

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Total Oxide | - | - | - | - | - | - | - | - | - | - |

| Total Sulfide | 3,999 | 0.67 | 25.1 | 1.01 | 1.83 | 0.34 | 86 | 3,221 | 40 | 73 |

| Total Measured | 3,999 | 0.67 | 25.1 | 1.01 | 1.83 | 0.34 | 86 | 3,221 | 40 | 73 |

| | | | | | | | | | | |

| INDICATED | Tonnes

(kt) | Grade | Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Pb

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Total Oxide | 2,674 | 2.71 | 66.3 | 0.1 | 0.1 | 0.47 | 233 | 5,703 | 3 | 3 |

| Total Sulfide | 23,544 | 0.74 | 27.6 | 0.85 | 1.69 | 0.33 | 560 | 20,865 | 200 | 399 |

| Total Indicated | 26,217 | 0.94 | 31.5 | 0.78 | 1.53 | 0.34 | 792 | 26,568 | 203 | 402 |

| | | | | | | | | | | |

| INFERRED | Tonnes

(kt) | Grade | Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Pb

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Total Oxide | 23 | 0.95 | 21.8 | 0.23 | 0.14 | 0.12 | 1 | 16 | 0 | 0 |

| Total Sulfide | 2,958 | 0.53 | 20.2 | 0.76 | 1.16 | 0.27 | 51 | 1,926 | 22 | 34 |

| Total Inferred | 2,981 | 0.54 | 20.3 | 0.76 | 1.16 | 0.27 | 51 | 1,941 | 23 | 34 |

| | | | | | | | | | | |

MEASURED +

INDICATED | Tonnes

(kt) | Grade | Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Pb

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Total Oxide | 2,674 | 2.71 | 66.3 | 0.1 | 0.1 | 0.47 | 233 | 5,703 | 3 | 3 |

| Total Sulfide | 27,542 | 0.73 | 27.2 | 0.87 | 1.71 | 0.33 | 645 | 24,086 | 241 | 472 |

| Total M + I | 30,216 | 0.9 | 30.7 | 0.81 | 1.57 | 0.34 | 878 | 29,790 | 243 | 475 |

Table from OreWin, 2019

Notes (reference to Mineral Resources is used in the context as Historical Mineral Resources):

1 CIM definitions were followed for the Mineral Resources.

2 Effective Date of the Mineral Resources is March 5, 2019.

3 Mineral Resources were estimated within geologic domains by either ordinary kriging or inverse distance.

4 Mineral Resources are reported at NSR cut-offs of $20.72/t for oxide and $17.79/t for sulfide using the mineral reserve metal prices x 1.14 (+14%) and variable metal recoveries according to material and mineralization type (refer to Table 1.3 of this Technical Report and the PFS19 report for details).

5 Mineral Resources have been constrained using an optimized pit shell, to reflect reasonable prospects of economic extraction.

6 Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

7 Mineral Resources are inclusive of Mineral Reserves, except for mining losses and grade dilution, which are determined through re-blocking of the resource model after declaration of the Mineral Resource.

8 Mineral Resources are quoted on a 100% project basis.

9 Totals may not match due to rounding.

1.5.5 Historical Mineral Reserves

The historical PFS19 Gediktepe Mineral Reserves, reported according to the CIM guidelines, are summarized in Table 1.3. Due to their polymetallic nature, the oxide and sulfide portions of the historical Mineral Reserves are quoted at different NSR cut-offs based on metal prices, metal recoveries, and on and off-site processing costs.

Table 1.3 summarizes "Historical Estimates" within the meaning of NI 43-101. The source of the estimates is Section 15 of PFS19, as repeated in TR20. The historical estimates set forth in Table 1.3 do not use categories of mineral reserves other than the ones set out in the CIM Definition Standards and Section 1.3 of NI 43-101. For further details on the parameters utilized in the estimates, the reader is referred to Section 15 of PFS19.

A qualified person has not performed sufficient work to classify the historical reserve estimates as current mineral reserves, and DAMA is not treating the historical estimates as current mineral reserves. Significant data compilation, confirmation drilling, re-sampling, data verification and updating of metal prices, engineering assumptions, and economic parameters may be required by a qualified person before the historical estimates can be classified as current. The historical reserve estimates are considered to be relevant and are presented for informational purposes to describe the extent and nature of mineralization on the Project as presently understood. The historical reserve estimates should not be relied upon until verified by a qualified person.

Table 1.3: Historical Gediktepe PFS19 Mineral Reserves

| Classification | Tonnes (kt) | Grade | Contained Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Oxide |

| Proven | - | - | - | - | - | - | - | - | - |

| Probable | 2,755 | 2.34 | 56.7 | - | - | 207 | 5,020 | - | - |

| Proven & Probable | 2,755 | 2.34 | 56.7 | - | - | 207 | 5,020 | - | - |

| Sulfide |

| Proven | 3,620 | 0.68 | 26.7 | 1.03 | 1.93 | 79 | 3,105 | 37 | 70 |

| Probable | 14,960 | 0.89 | 33.1 | 0.89 | 1.99 | 429 | 15,903 | 133 | 298 |

| Proven & Probable | 18,580 | 0.85 | 31.8 | 0.92 | 1.98 | 509 | 19,008 | 170 | 368 |

Table from OreWin, 2019

Notes (reference to Mineral Reserves is used in the context as Historical Mineral Reserves):

1 CIM definitions were followed for the Mineral Reserves.

2 Effective Date of the Mineral Reserve is March 5, 2019.

3 Mineral Reserves were reported using an NSR based on metal prices of $1,300/oz Au, $18.5/oz Ag, $3.30/lb Cu, and $1.28/lb Zn, smelter terms for treatment and refining charges and transport including ocean freight for sulfide concentrates.

4 Cut-offs applied were: oxide $20.67/t and sulfide $17.74/t. Additionally, enriched mineralization with a Cu/Zn grade ratio < 0.75 is considered to be waste.

5 Reported Mineral Reserves incorporate and include mining losses and grade dilution that are not reported in the Mineral Resource.

6 Only Measured Mineral Resources (and dilution) were used to report Proven Mineral Reserves and only Indicated Mineral Resources (and dilution) were used to report Probable Mineral Reserves.

7 Mineral Reserves are a subset of, not additive to, the Mineral Resources and are quoted on a 100% project basis.

8 Totals may not match due to rounding.

1.5.6 Historical Mining Methods

The historical PFS19 and TR20 reports propose a conventional open pit mining operation using excavators and trucks. The operation will start with the oxide zone of the deposit based on AMC Consultants Pty Ltd's ("AMC") and Lidya's mining studies. After finishing the oxide zone, the sulfide zone of the reserve will be produced. Open pit mining will be carried out by conventional diesel-powered truck and excavator, with small mining equipment (3-4 m3-excavator) used for selective mining. An experienced mining contractor will be employed for both waste removal and ore mining. The mining activities will be supervised by Lidya's team. The oxide zone operation will be performed on benches of 5 m considering ore control block dimension & slope. The operation bench height might have to change to 2.5 m as sulfide zone mining starts in order to be more selective and to decrease dilution.

1.5.7 Historical Recovery Methods

The laboratory metallurgical test work programs demonstrated that oxide and sulfide types of material require different treatment methods for the Gediktepe deposit.

In the treatment of oxide material, two different cyanidation alternatives have been described in the PFS19 and TR20 reports. One flowsheet alternative summarized in PFS19 is a heap leach circuit with application of 45 days cyanidation followed by Merrill Crowe processing (zinc precipitation) to produce gold-silver dore. The other alternative proposed in the PFS19 is carbon in pulp (CIP) circuit comprising metal adsorption onto carbon, desorption of recovered metal and refining. The TR20 report focused entirely on a refined heap leach - Merrill Crowe recovery approach.

The sulfide sample test results showed that saleable flotation concentrate products can be produced from conventional comminution and flotation processes.

1.5.8 Historical Site Infrastructure

The Project requires several infrastructure items in order to operate, including: Heap Leach Pad, Waste Storage Facility, Water and Power Supply, Access Road, Mine Site Buildings, and Water Diversion Channels. Additional infrastructures will be added during the sulfide ore stage which include a Tailing Storage Facility (TSF), ROM Pad and Stockpile Area, and both Copper and Zinc Concentrate Areas.

1.5.9 Historical Environmental Studies, Permitting and Social or Community Impact

Various environmental baseline studies are described in PFS19 including an EIA. Another EIA report will be compiled when the Project design is finalized at the end of the Project feasibility studies, which remains pending as of the effective date of this Technical Report. The Project has had the support of the local community since 2012. There are no protection areas near the Project area.

1.5.10 Historical Other Relevant Data and Information

Various components of other relevant data and information have been addressed in TR20. The Project execution plan developed by Lidya includes two main stages; 1) Finalize detailed design and construction of the oxide portion of the Project, and 2) Further feasibility studies of the sulfide portion of the Project. Progress regarding the execution plan was observed during DAMA's site visits as outlined in Section 12.

1.5.11 Historical Conclusions and Recommendations

Recommendations from PFS19 and TR20 are included for the Mineral Resources, Mining Methods, Process and Metallurgical Test Work, and Site Infrastructure. Historical PFS19 and TR20 suggest further work be completed to reduce uncertainty in resource classification categories, mining methods, processing and metallurgical of sulfides, and infrastructure design in order to complete a feasibility study.

1.6 Data Verification

Polimetal (Lidya) granted DAMA (Sabri Karahan, General Manager, and Mustafa Atalay, Senior Geologist, CPG) and EMX personnel (Eric Jensen, EMX General Manager of Exploration) two limited pre-planned site visits. These site visits were on August 16, 2021, and December 9, 2021. EMX has requested access to technical and other key data (e.g., ESG, permitting, etc.) from Polimetal (Lidya). However, these requests have not yet been granted as of the effective date of this Technical Report. EMX will continue seeking access to key data to further understand the Gediktepe Project's exploration potential, resources and reserves, and anticipated near term and life of mine production schedules.

1.7 Conclusions and Recommendations

Based upon the historical information available from the pre-feasibility reports, and a more recent internal report provided by Lidya, DAMA is unaware of any significant factors or risks that may affect access, title, or the right or ability for Polimetal (Lidya) to continue to advance the Project to commercial production. The Project is covered by EMX NSR royalty interests as described in this Technical Report. Conclusions and recommendations include:

Resource classification categories assigned to Gediktepe estimates are sufficient for a prefeasibility assessment. However, more work is recommended in an effort to reduce uncertainty associated with variations in confidence levels of the resource classification categories.

A more detailed plan will need to be outlined to maintain grade control with a high degree of accuracy.

Mining studies have outlined a robust starter project focusing on the oxide portion of the deposit. As mining continues, precise pit slope excavation and management of in-pit water are crucial to liberate sulfide material found at the bottom of the pit and avoid prohibitive declines in recoveries.

Polimetal (Lidya) selected a two stage crushing, conventional heap - Merrill Crowe processing flowsheet. DAMA has noted the following risks for oxide processing: "clayey' nature of ore during blending, slumping in open pit operations, and accumulation of copper in leach solution during oxide processing. DAMA recommends further investigation, clarification, and planning be conducted to resolve these risks.

For the sulfide ore, OreWin identified risks associated with processing of enriched ore due to the pre-activation of zinc. OreWin recommends careful management of stockpile residence time to mitigate this risk. DAMA agrees with OreWin's assessment.

2. Introduction

EMX Royalty Corporation (TSX Venture: EMX; NYSE American: EMX) ("EMX" or the "Company") is required by Canadian Securities Administrators ("CSA") National Instrument 43-101 ("NI 43-101") to prepare a Technical Report on the Gediktepe Project (the "Project") with respect to its Gediktepe royalty interests, which are material to the Company. The Project is located in the Balıkesir province of Western Turkey, some 67 km (air distance) southeast of Balıkesir province centre and 38 km east-southeast of the Bigadiç township. The Project is owned by Lidya Madencilik Sanayi ve Ticaret A.S. (Lidya), a private Turkish company, and operated by its 100% owned subsidiary, Polimetal Madencilik San. ve Tic. A.Ş. ("Polimetal").

2.1 Terms of Reference

EMX entered into an agreement (the "Royalty Purchase Agreement") dated July 29, 2021, with SSR Mining Inc. and certain of its subsidiaries ("SSR Mining") to purchase a portfolio of royalty interests and deferred payments (the "Royalty Portfolio"). The Royalty Portfolio consisted of multiple royalties, with the most important being those covering Gediktepe (the "Gediktepe Royalties"). The Gediktepe Royalties became material to EMX upon completion of the purchase and sale of the Royalty Portfolio on October 21, 2021, and consist of: (i) a perpetual 10% NSR royalty over metals produced from the oxide zone (predominantly gold and silver) after cumulative production of 10,000 gold-equivalent oxide ounces; and (ii) a perpetual 2% NSR royalty over metals produced from the sulfide zone (predominantly copper, zinc, lead, silver, and gold), payable after cumulative production of 25,000 gold-equivalent sulfide ounces (gold-equivalent as referenced from the 2019 Share Purchase Agreement between Alacer and Lidya).

This Technical Report has been prepared to support the information disclosed in its Annual Information Form (AIF) filing for the year 2021. EMX holds a royalty interest (not direct ownership) in the Project. Mining companies are not (typically) required to, and as a matter of practice, do not normally disclose detailed information to companies that hold a royalty interest in their operations unless legally or contractually mandated to do so. In the case of Gediktepe, the royalty agreement covering the Gediktepe Royalties does not provide data rights to EMX beyond onsite reviews.

2.2 Sources of Information

Generally, National Instrument 43-101 - Standards of Disclosure for Mineral Projects requires that the qualified person responsible for preparing (or supervising the preparation of) all or part of a technical report to have completed a current inspection on the property that is the subject of a technical report, and to personally perform data verification and document inspection. Polimetal (Lidya) granted DAMA (Sabri Karahan, General Manager, and Mustafa Atalay, Senior Geologist, CPG) and EMX (Eric Jensen, EMX General Manager of Exploration) two limited pre-planned site visits. These site visits were conducted on August 16, 2021, and December 9, 2021. During the site visits, DAMA and EMX personnel were given access to inspect the site, view facilities, and observe development progress. EMX has requested access to technical and other key data (e.g., ESG, permitting, etc.) from Polimetal (Lidya). However, these requests have not yet been granted as of the effective date of this Technical Report.

This Technical Report has been prepared for EMX by DAMA Engineering Inc. DAMA was unable to conduct a detailed and thorough independent technical assessment, other than that which could be sourced from public domain sources, including SEDAR filed Pre-feasibility studies, an internal Polimetal (Lidya) report (TR20), and the aforementioned site visits. Therefore, the data available for the preparation of this Technical Report was limited, with the information, conclusions, and opinions contained herein relating to technical and scientific information, tax, legal, political, environmental, historical mineral resource and mineral reserve estimates, historical capital and operating costs, and historical commodity pricing that relied on the following reports:

NI 43-101 Prefeasibility study titled "Gediktepe 2016 Prefeasibility Study" prepared by Resource Development Inc., SRK Consulting (U.S.), Inc., Independent Mining Consultants, Inc. on behalf of Polimetal Madencilik Sanayi ve Ticaret A.S. and Alacer Gold Corp. (Alacer) with an effective date of June 1, 2016 ("PFS16")

NI 43-101 Prefeasibility study titled "Gediktepe 2019 Prefeasibility Study" prepared by OreWin Pty Ltd. on behalf of Alacer Gold Corp. (Alacer) with an effective date of March 26, 2019 ("PFS19")

Internal report titled "Gediktepe Project Oxide Technical Report" prepared by Oğuz Atıl Karamercan, BSc. Mining Engineer, MBA, Competent Person, for Polimetal Madencilik Sanayi ve Ticaret A.Ş. and Lidya Madencilik Sanayi ve Ticaret A.Ş. with an effective date: March 1, 2020 ("TR20")

DAMA notes that some of the information residing in the public domain has been generated internally by the OreWin consulting group, especially the Historical Mineral Resources and Historical Mineral Reserves, and required adherence to CIM guidelines and NI 43-101 requirements at the time of public disclosure by Alacer.

DAMA conducted time-limited field visits to inspect the site, but did not have time to independently sample and assay portions of the deposit, and did not review source materials for the following items prescribed by NI 43-101 as it did not have access to the relevant material and data:

i) geological investigations, reconciliation studies, independent check assaying, data verifications and independent audits;

ii) mineral processing and metallurgical testing;

iii) estimates and classification of Mineral Resources and Mineral Reserves, including the methodologies applied by the Lidya and OreWin in determining such estimates and classifications, such as check calculations; or

iv) mining methods, recovery methods, project infrastructure, environmental studies and supporting documentation, and technical parameters, including assumptions regarding future operating costs, capital expenditures, cash flow models and saleable metal forecast for the Project.

Unless otherwise specified, the following sections of this Technical Report are excerpted from PFS19, with relevant updates as given in TR20. Changes to tables, figure numbers, section numbers, and standardization have been made to suit the format of this report. Updates to the text has been made to reflect current tense, data, and/or information as annotated by the use of brackets, italicized, and labelled.

3. Reliance on Other Experts

DAMA has not researched royalty, property title or mineral rights for the Gediktepe Project and has relied on other experts as to the ownership status of the Project and EMX's royalty rights.

For property title information disclosed in Section 4.1 of this report, DAMA has fully relied on the title opinion document provided by EMX:

- Gediktepe Mining License, August 16, 2021, by Gozde Esen Sakar of Bener Law Office ("Bener").

Gozde Esen Sakar is an attorney and Senior Partner at Bener, an Istanbul based law firm with practice area expertise that includes mining and commercial law. DAMA considers it reasonable to rely on a long-established Turkish law firm (i.e., since 2001) with subject matter expertise to provide a title opinion for the Project (Bener, 2021).

For Gediktepe Royalties ownership information in Section 4.2 of this Technical Report DAMA has fully relied on the confidential royalty agreement document provided by EMX:

- NSR Royalty Agreement, effective date July 17, 2019, between Lidya Madencilik Sanayi ve Ticaret A.S., Polimetal Madencilik Sanayi ve Ticaret A.S. and Alacer Gold Madencilik A.S.

It is considered reasonable to rely on the definitive NSR Royalty Agreement for EMX's Gediktepe Royalties interest.

4. Property Description and Location

The Gediktepe Project is located in the Balıkesir Province of Western Turkey, east-southeast of the Bigadiç township. The UTM Zone 35N, European Datum coordinates of the approximate center of the Project are 636,000E, 4,358,000N.

4.1 Project Ownership

The following licenses and permits have been confirmed as being current and in good standing based upon a title opinion report (Skara, 2021). The Operating License (OL) for the Project is held by Polimetal (now wholly owned by Lidya) and is subject to EMX's Gediktepe Royalties.

Operating License - RN 85535. RN 85535 is the main OL for the Project and covers a total area of 1,486.99 ha. The General Directorate of Mining and Petroleum Affairs (GDMPA) approved the merging of OL 20054077 and Exploration License (EL) 201400291 into one OL (RN 85535) on 29 July 2016. RN 85535 is valid until June 23, 2036. Figure 4-1 shows RN 85535.

Descriptions of the predecessor licenses to RN 85535 are summarized below.

Operating License - 20054077. On July 01, 2005, the Gediktepe EL was acquired from GDMPA by tender on behalf of Yeni Anadolu Mineral Madencilik San. Tic. Ltd. Sti. (YAMAS). The license area covered 657.87 ha. That EL was changed to an OL on June 23, 2011 and was valid for ten years. The OL was transferred to Polimetal (Lidya) from YAMAS on July 26, 2011.

An Environmental Impact Assessment (EIA) permit application was submitted, and the EIA Permit was granted on March 14, 2012. A Forest Permit was granted on October 11, 2013, and a Workplace Opening and Working Permit (GSM) was obtained on October 24, 2013.

After obtaining all the necessary permits, the operation permit was acquired on December 30, 2014.

Exploration License - 201400291. On September 17, 2014, the EL, which is on the east side of 20054077, was acquired by Polimetal (Lidya) from GDMPA by auction tender. The license area covered 829.12 ha.

On February 21, 2018, GDMPA also approved Polimetal's application for a production permit for clay and aggregate for three locations within RN 85535.

Operating License - 200700250

OL 200700250, which covers an area of 480.88 ha, was transferred from EL to the operational stage on May 13, 2014 by the previous owner, Hakki Musa Nogay. Polimetal purchased the OL from Hakki Musa Nogay during June of 2014. Transfer of the license to Polimetal was completed on November 18, 2015. To the knowledge of DAMA, no work has been completed on this license area, and it does not form part of PFS19.

Figure from OreWin, 2019

Figure 4-1: Current Gediktepe Operating License

4.2 EMX's Royalty Interests

EMX entered into an agreement (the "Royalty Purchase Agreement") dated July 29, 2021, with SSR Mining Inc. and certain of its subsidiaries ("SSR Mining") to purchase a portfolio of royalty interests and deferred payments (the "Royalty Portfolio"), including the Gediktepe Royalties. The Royalty Purchase Agreement closed on October 21, 2021. The Gediktepe Royalties cover production from Operating License RN 85535 and consist of:

(i) A perpetual 10% NSR royalty over metals produced from the oxide zone (predominantly gold and silver), payable after cumulative production of 10,000 gold-equivalent oxide ounces (as referenced from the 2019 Share Purchase Agreement between Alacer and Lidya); and

(ii) A perpetual 2% NSR royalty over metals produced from the sulfide zone (predominantly copper, zinc, lead, silver, and gold), payable after cumulative production of 25,000 gold-equivalent sulfide ounces (as referenced from the 2019 Share Purchase Agreement between Alacer and Lidya).

Customary NSR deductions for the Gediktepe Royalties include charges for smelting, refining or other processing, penalty substances, sampling, assaying, and transportation.

4.3 Other Royalties, Permits and Encumbrances

The Gediktepe mining license does not have an associated royalty to a third party other than the government royalty payment.

4.3.1 Government Royalty

Royalties are payable to the Turkish government at rates based on the commodity and the metal price, as detailed in Table 4.1. These government royalty rates were adopted into law in 2019.

Table 4.1: Government Base Royalty Rate by Commodity and Metal Price

| Rate (%) | Gold ($/oz) | Silver ($/oz) | Copper ($/t) | Zinc ($/t) |

| 1 | < 800 | < 10 | < 5,000 | < 1,000 |

| 2 | 801-900 | 11-12 | 5,001-5,300 | 1,001-1,175 |

| 3 | 901-1,000 | 13-14 | 5,301-5,600 | 1,176-1,350 |

| 4 | 1,001-1,100 | 15-16 | 5,601-5,900 | 1,351-1,525 |

| 5 | 1,101-1,200 | 17-18 | 5,901-6,200 | 1,526-1,700 |

| 6 | 1,201-1,300 | 19-20 | 6,201-6,500 | 1,701-1,875 |

| 7 | 1,301-1,400 | 21-22 | 6,501-6,800 | 1,876-2,050 |

| 8 | 1,401-1,500 | 23-24 | 6,801-7,100 | 2,051-2,225 |

| 9 | 1,501-1,600 | 25-26 | 7,101-7,400 | 2,226-2,400 |

| 10 | 1,601-1,700 | 27-28 | 7,401-7,700 | 2,401-2,575 |

| 11 | 1,701-1,800 | 29-30 | 7,701-8,000 | 2,576-2,750 |

| 12 | 1,801-1,900 | 31-32 | 8,001-8,300 | 2,751-2,925 |

| 13 | 1,901-2,000 | 33-34 | 8,301-8,600 | 2,926-3,100 |

| 14 | 2,001-2,100 | 35-36 | 8,601-8,900 | 3,101-3,275 |

| 15 | > 2,100 | > 37 | > 8,901 | > 3,276 |

Table from OreWin, 2019

Based on commodity type, license-holders can obtain a royalty discount depending on the commodity. Table 4.2 shows the royalty discount for the Gediktepe products and the resultant effective royalty rate.

Table 4.2: Royalty Rate by Commodity and Metal Price

| Royalty | Gold | Silver | Copper | Zinc |

| Base Royalty (%) | 7 | 5 | 8 | 10 |

| Incentive Reduction | 40% | 40% | 50% | 50% |

| Effective Royalty (%) | 4.2 | 3 | 4 | 5 |

Table from OreWin, 2019

Royalties payable on metal sales are estimated after all applicable deductions are made from gross sales revenue. Alacer had advised that these deductions include:

- Processing costs at the mine, including administration overheads, but excluding mining and related expenses;

- All off-site doré and concentrate realization charges, including land and sea transport, port handling, smelting and refining, and penalties; and

- Applicable depreciation and amortization (D&A) charges (estimated at 80% of total D&A for the Project).

Application of deductions from revenue that are not metal-specific are allocated pro-rata, based on the relative metal gross revenue share.

4.3.2 Forestry and Other Permits

A forestry permit is required for any forest land that will be used by the Project. To obtain the forestry permit, an application must be prepared by the forest engineer and submitted to the Regional Management of Forestry Department. Permit applications will be assessed and approved by the Operation Chief of Forestry Dept., Regional Management of Forestry Dept., General Management of Forestry Dept., and Prime Ministry, respectively.

The cost of obtaining a forestry permit depends on the location of the project, type of project (operating a mine, infrastructure or power line, etc.), type of forest and the quantum of trees.

After obtaining approval, an agreement will be signed, and the forestry land permit fee will be paid every year until the end of the permit period, a one-time re-forestation fee and a deposit must also be paid. After reclamation of the used area, the deposit will be reimbursed.

As of the PFS19, a series of final permits were pending in anticipation of a follow-on Feasibility Study and construction. DAMA has been advised by EMX that necessary permits have been received, that construction of the oxide project commenced after receiving the necessary permits by Lidya, and the project has since entered into its initial stages of production (Jensen 2021). An operating permit is also necessary for the Project, which was issued just prior to commencement of initial mining and production (Jensen, 2021).

4.4 Other Factors

To DAMA's knowledge, there are no significant factors, risks, or issues, including environmental, permitting, access, or title to Lidya's right or ability to perform work and advance development of the Gediktepe Project. Further, to DAMA's knowledge there are no factors or issues regarding EMX's future interest in the Gediktepe Royalties.

5. Accessibility, Climate, Local Resources, Infrastructure and Physiography

5.1 Location and Access

The Project is located in the Balıkesir Province of Western Turkey, 67 km (air distance) southeast of Balıkesir Province center and 38 km east-southeast of the Bigadiç township (Figure 5-1).

Figure from OreWin, 2019

Figure 5-1: Project Location Map

The Project is accessed along 102 km of paved road from the city of Balıkesir (population 1,189,075) on highway D555 through the town of Bigadiç (population 48,470). The road from Bigadiç to the Project site was widened and paved to be suitable for light and heavy vehicles (Figure 5-2). The road currently serves lumber trucks, concrete trucks, buses, and light vehicles. A 3.1 km by-pass road was constructed in 2017 to divert around the local Hacıömerderesi neighborhood (Figure 5-3).

Figure from OreWin, 2019

Figure 5-2: Paved Road

The nearest airport, Balıkesir Koca Seyit Airport serving Balıkesir and Edremit, is approximately 185 km by road from site. There are also airline services to the nearest major city of Izmir, which is approximately 242 km by road via Bigadiç.

The Project site is centrally located to access several ports by road (distances are approximate from site via Bigadiç):

- Bandırma port is 194 km to the north,

- Dikili port is 207 km to the west,

- Aliağa port is 224 km to the west, and

- Izmir port is 242 km to the southwest

The nearest railway stations are in Dursunbey to the north and Balıkesir to the northwest.

The Project land position consists of a single operating license number (OL) RN85535, with a total area of 1,486.99 ha, of which 76% is forest area (Figure 5-3).

The region covering the Project area is classified as "1st Degree Earthquake Zone" according to the Seismic Zone Map of Turkey.

There are nearby population centers to the Project to supply manpower, and adequate access to support mining operations at Gediktepe,

Figure from OreWin, 2019

Figure 5-3: Gediktepe Project Area and By-pass Road. Pink color shows the by-pass road, constructed in 2017

5.2 Physiography

The terrain at the Project is mountainous with steep erosional valleys. Elevations in the Project area range from 974-1,482 m above sea level (masl). Coniferous trees cover most of the Project site, with occasional open meadows in areas of less-steep terrain. Figure 5-5 is a topographic map of the area.

5.3 Climate

Three climates are dominant in Balıkesir Province. The Mediterranean climate is seen in the Aegean coasts, the Marmara climate in the north, and the Continental climate in the inner regions. The temperature difference between summer and winter is small on the coastline. This difference is bigger in the interior of the province. In the mountainous eastern region, winters are harsh, and summers are cool.

The local climate is hot and arid during the summer and warm during the fall. There is snow from December through February but not a significant accumulation. Spring is often the rainy period. According to data from Dursunbey Meteorological Station for the years 1965-2014, the annual average temperature is 12.2°C. The highest measured temperature was recorded as 40.3°C in 2007 and the lowest temperature was recorded as -16°C in 1985.

The wind generally blows from the north or northeast.

Average evaporation from the Dursunbey Meteorological Station data is 943 mm per year with the highest average monthly evaporation of 190 mm experienced during July.

A meteorological station was installed at site at the end of 2014 as part of the environmental base line data collection.

Given Gediktepe's physiographic and climatic conditions DAMA has no reason to believe that year-round operations of the Project are not possible.

5.4 Local Resources

The closest settlements to the Project site are:

- Hacıömerderesi neighborhood,

- Aşıderesi neighborhood, affiliated with the Hacıömerderesi neighborhood, and

- Meyvalı neighborhood.

The main economic income sources in the area are forestry, agriculture, and animal husbandry.

The local area is serviced by a family doctor, who visits the neighborhoods once per month, accompanied by a nurse and a midwife when necessary. The closest hospital is the Bigadiç State Hospital, and there is a university hospital in Balıkesir Province.

A field camp was constructed at Kürendere, approximately 7 km (air distance) southwest of the Project area and is currently partially in use. The field camp includes accommodation, kitchen, and social facilities (Figure 5-4).

There is an open pit borax mine in Bidagiç, operated by the State Enterprise, and an open pit gold mine in Sındırgı. Regionally, gold, silver, lead, copper, zinc, molybdenum, and chromite mines have operated for many years. The regional authorities and residents are familiar with co-existing mining operations.

Figure from OreWin, 2019

Figure 5-4: Aerial Photograph of Gediktepe Field Camp

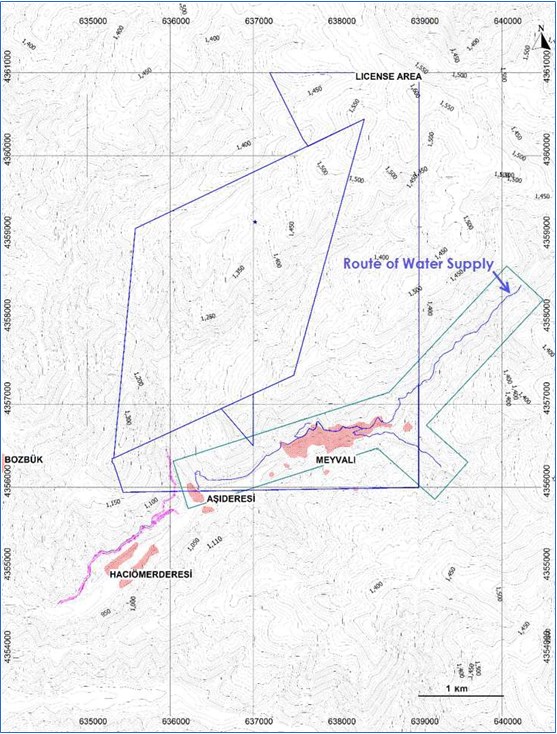

5.5 Infrastructure

As of the effective date of the historical PFS19 and TR20 reports, a water supply needed to be established for the Project as there was no developed system in the area capable of supporting a project of Gediktepe's size. For that reason, a clean water pond with 682,497 m3 active reservoir capacity was engineered after signing the Protocol with DSI (State Water Works) and a village water supply pipeline was designed and approved by the Balıkesir Water Sewage Authority (BASKI). As per Environmental Impact Assessment (EIA) commitments, a water supply pipeline will be constructed before any site work will start (Figure 5-5).

A 39.6 km-long 34.5 kV power transmission line (PTL) was constructed between Dursunbey substation and Kürendere to provide power to the Project.

The historical PFS19 and TR20 reports outlined tailings storage areas, heap leach pad areas, and processing sites within the Project Operating License.

With accessible power and access to areas for infrastructure for the Project, the principal contingency requiring final resolution to support mining operations at Gediktepe is securing an adequate water supply. See Section 12 for updates based upon 2021 site visits.

Figure from OreWin, 2019

Figure 5-5: Gediktepe Topography and Water Supply Route. Contoured at 10 m intervals

6. History

6.1 Prior Ownership and Ownership Changes

The Gediktepe mining licenses are held by Polimetal Mining Industry and Trade Inc., otherwise known as Polimetal Madencilik San. ve Tic. A.Ş. ("Polimetal"), which was formed in 2011 as a joint venture (JV) company between Lidya Madencilik San. ve Tic. A.Ş. ("Lidya") (50%) and Alacer Gold Corp. ("Alacer") (50%). The Gediktepe deposit was discovered in 2012-2013 by the JV.

Alacer sold its 50% non-operating ownership interest in the Project to Lidya in 2019, with Alacer retaining a) a 10% NSR royalty on all oxide ore production, and b) a 2% NSR on all sulfide ore production. The sale to Lidya resulted in Lidya consolidating 100% control of the Gediktepe Project. Subsequently, Alacer and SSR Mining Inc. completed a merger transaction in 2020, whereby Alacer became a wholly owned subsidiary (along with the Gediktepe royalties) of SSR Mining.

6.2 Licenses and Permits

Alacer obtained the first exploration license for the Gediktepe Project in 2005. That license, number 20054077, constituted the central area of the Project. Also refer to Section 4.1 of this Technical Report.

Alacer completed geochemical stream sampling prior to June 23, 2011, at which time the license was transferred to Polimetal (now wholly owned by Lidya), the current operator.

Permit applications have been submitted at various times for site activities necessary to support technical investigations leading to the ultimate approval of a mining and mineral processing project.

Permit activity related to this license has included:

An EIA Permit was obtained on August 22, 2012 for Phase 1 drilling that included 21 drill locations. The forestry permit for 11 drill locations was obtained on March 17, 2013. An EIA permit to undertake drilling at 234 locations was obtained on March 14, 2012 and June 18, 2013 and a forestry permit was obtained on October 11, 2013.

For Phase 2 drilling, an EIA permit to undertake drilling at 139 locations was obtained on December 18, 2013 and February 4, 2014 and a forestry permit was obtained on September 2, 2014.

For Phase 3 drilling, an EIA Permit to undertake drilling at 264 locations was obtained on April 2, 2014 and a forestry permit was obtained on September 2, 2014.

In mid-2014, Polimetal (Lidya) commissioned a Preliminary Economic Assessment (PEA) of the Project to determine its economic potential. The PEA identified a combined oxide and sulfide Indicated Mineral Resource of approximately 10 Mt. Oxide processing was by heap leaching, while the subsequent sulfide processing was through a concentrator.

Based on the PEA findings, Polimetal (Lidya) continued site investigations, including additional drilling aimed at increasing the size of the Mineral Resource.

A Phase 4 Drilling EIA permit was obtained on June 27, 2014 for 344 drill locations, 175 of which received subsequent forestry approval.

For the meteorological station, an EIA permit was obtained on February 3, 2014 and a forestry permit was obtained on September 2, 2014.

Based on a PEA, a revised project operation was submitted to the General Directorate of Mining and Petroleum Affairs (GDMPA) on September 25, 2014 to enlarge the operation permit area and to change the annual production and processing capacity to as much as 2,375 kt of run of mine-ore.

An EIA Permit was obtained to undertake 242 drill and trench locations on June 27, 2014. The forestry permits for 17 drill and trench locations were received on November 13, 2015. Forestry permit approval of another 61 drill and trench locations planned for Stage 2 geotechnical investigations followed.

An EIA application for oxide and sulfide mining and processing was submitted on July 9, 2015 and a public participation meeting was held on August 11, 2015. The EIA report was submitted to the Ministry of Environment and Urbanisation on December 15, 2015 and received a positive certificate on July 1, 2016.

Forestry permits for drilling locations within the EIA boundary were received on May 15, 2017 & December 16, 2019, respectively.

On July 17, 2019, Alacer announced at the Toronto Stock Exchange the sale of its 50% non-operating interest in the Gediktepe Project to its joint venture partner Lidya. The process of the share transfers was completed at the General Directorate of Mining and Petroleum Affairs (MAPEG). Lidya now owns 100% of Polimetal and the Gediktepe Project.

On July 19, 2019, Polimetal applied for a 169-hectare (ha) forest permit area.

6.3 Historical Reports

This section summarizes sections from PFS19 and also references material from PFS16 and TR20 as appropriate and as noted. Information concerning sulfide processing as well as oxide processes have been sourced from PFS19. TR20 covers more recent information concerning oxide processing plans.

6.3.1 Historical Exploration and Drilling

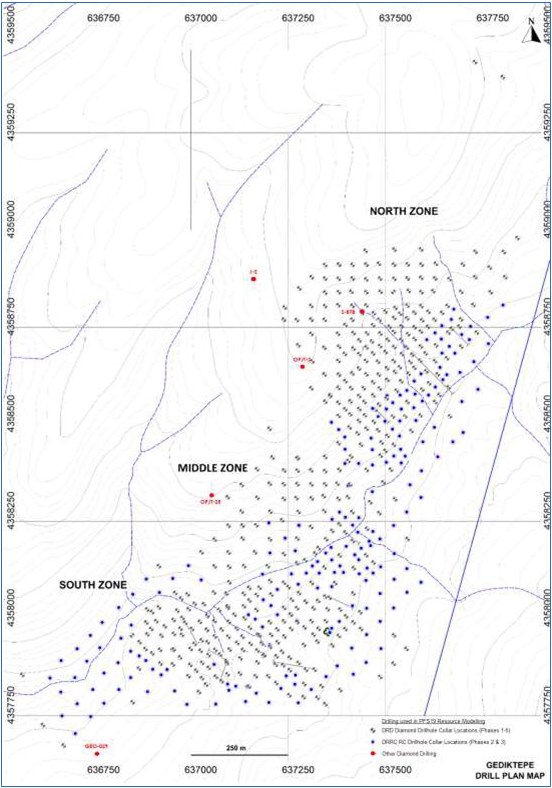

There were five phases of core (DD) and reverse circulation (RC) exploration drilling at Gediktepe, commencing in 2013 and ending in 2018. This resulted in 438 DD holes totaling 56,898 meters and 191 RC holes totaling 13,229 meters.

Exploration drilling (Phase 1) commenced in April 2013. Throughout the phases drilling was completed by local contractors. Diamond drill holes were predominantly started using PQ core size, and rarely with HQ. Most deeper holes, however, needed to switch to HQ at depth.

Eight of the initial 11 Phase 1 holes were angled holes, with the remainder of the holes vertical or sub-vertical. The average deviation of the surveyed holes is less than 1° per 100 m. The count of drillholes used in the PFS19 dataset from Phase 1 was 11 drillholes totaling 1,529 meters.

RC drilling was restricted to Phases 2 and 3 and was conducted on the margins of the deposit to define extensions or set limits, and for infill. The count of drillholes used in the PFS19 was 228 drillholes totaling 24,078 meters from Phase 2, and 260 drillholes totaling 32,853 meters from Phase 3.

A drilling EIA permit was obtained for Phase 4 in June 2014 for 344 drill locations, 175 of which received subsequent forestry approval. The total amount of drillholes used in the PFS19 dataset from Phase 4 was 93 DD totaling 5,252 meters. Phase 5 drilling included 36 drillholes totaling 6,414 meters.

At the end of each phase of drilling, drillhole collars were surveyed by a local surveying firm. RC drillholes were not downhole surveyed.

During 2015, Polimetal and Alacer commissioned a prefeasibility study (PFS16) on the Project. This study used all drilling performed up to August 2015. PFS16, which was filed on SEDAR in June 2016, identified a significant combined oxide and sulfide Measured plus Indicated Mineral Resource and based on favorable technical and economic factors, identified a combined oxide and sulfide Mineral Reserve and a potential mining and processing operation with a 12-year mine-life. The PFS16 technical report was superseded by the 2019 Prefeasibility Study.

Of the total drillhole database, a subset of drilling comprised of 624 DD and RC holes totaling 68,968 m of drilling was used for geological modelling and resource estimation work in the PFS19 report by OreWin. Of the 438 diamond drillholes in the PFS19 Drillhole Dataset, 388 have downhole survey data.

Table 6.1 summarizes the PFS19 Drillhole Dataset and Figure 6-1 shows the drillhole dataset locations in plan view.

The cut-off date for the PFS19 Drillhole Dataset was March 21, 2018.

Table 6.1: Summary of PFS19 Drillhole Dataset to March 21, 2018

| Drilling Phase | Period | Diamond

Drilling | Reverse

Circulation

Drilling |

No.

of

Holes | Meters

Drilled | No.

of

Holes | Meters

Drilled |

| 1 | 2013 | 11 | 1,529 | - | - |

| 2 | 2013/2014 | 144 | 17,158 | 84 | 6,920 |

| 3 | 2014/2015 | 153 | 26,544 | 107 | 6,309 |

| 4 | 2017 | 93 | 5,252 | - | - |

| 5 | 2017/2018 | 36 | 6,414 | - | - |

| Total | 438 | 56,898 | 191 | 13,229 |

Table from OreWin, 2019

Figure from OreWin,2018

Figure 6-1: Historical Drillhole Location Plan - PFS19 Drillhole Dataset

6.3.2 Historical Mineral Processing and Metallurgical Testing

Details of metallurgical test work completed between 2015-2019 for both the oxide and sulfide zones of the Gediktepe deposit are reviewed and summarized in this section. The test work was generally carried out to support PFS16 and PFS19. The investigation largely focused on cyanidation of oxidized material tests for gold and silver recovery, and sulfide ore tests to recover marketable copper and zinc concentrates by sequential flotation methods. DAMA notes that one of the significant differences between the two pre-feasibility studies is the change in the treatment of oxide material from the crush-agglomerate-heap leach-zinc precipitation flowsheet proposed in the PFS16 to crush-grind-leach-CIP-elution flowsheet in PFS19. In TR20, Polimetal (Lidya) selected the crush-agglomerate-heap leach-zinc precipitation flowsheet outlined in PSF16, but with two-stage crushing as opposed to three-stage crushing as the operable choice.

From the TR20 report, Lidya focused on optimizing the processing of the oxide zone material using cyanidation for the recovery of gold and silver from heap leaching, Merrill Crowe, and tank leaching. Considering the initial capital expenditures, operational expenditures and long delivery time of a SAG mill, the treatment of oxide material was selected as the crush- agglomerate-heap leach-zinc precipitation flowsheet with the only difference being two-stage crushing proposed in TR20 as opposed to the three-stage crushing proposed in PFS16. The results of the additional TR20 oxide test work suggests potential improvements to the PFS19 recoveries of 80% for gold and 45% for silver on the order of +- 5%.

The oxide processing facility was designed to treat 0.72 Mtpa of ore for three years at full capacity and 0.51 Mtpa in yar four.

Regarding sulfide processing, the PFS19 identified performance variations between 2016-2018 sulfide test works due to the following reasons.

- Surface oxidation (aging effect),

- Mineralogical and head grade variations,

- Material type blends, and

- Pulp chemistry conditions.

To assess the metallurgical performance of the sulfide flotation flowsheet, the results of locked cycle tests (LCT) were used with additional batch roughing and cleaning tests.

6.3.3 Historical Block Model Resource Estimation Methods

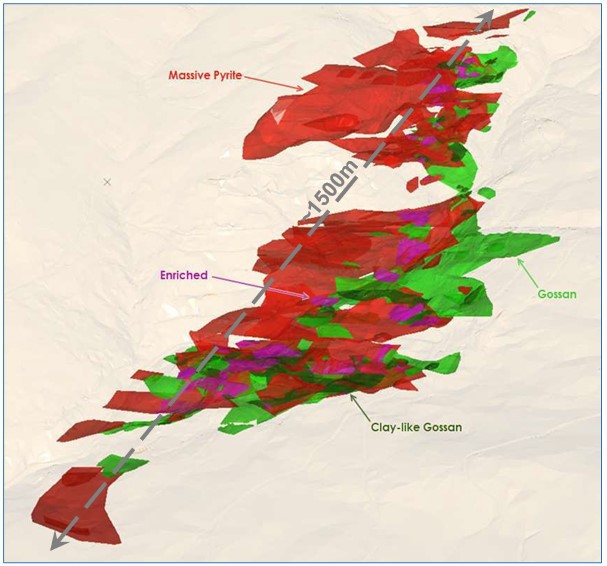

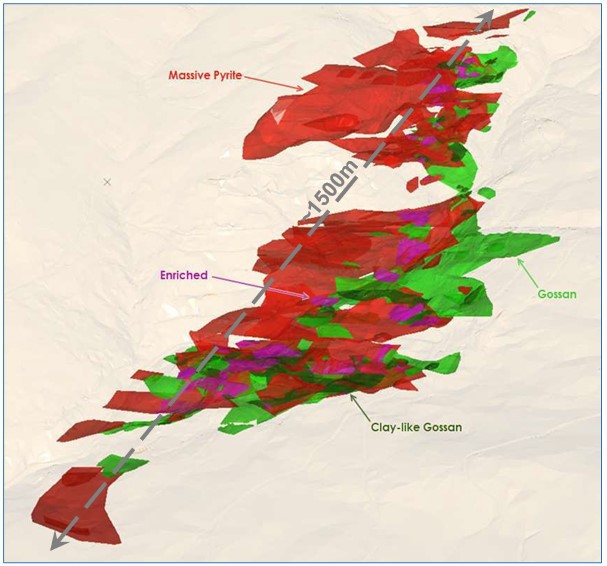

The block model was built on the basis of a parent cell dimension of 20 m (E) x 20 m (N) x 10 m (RL) and constructed with coding applied to represent volumes of geological units, and mineralization and weathering domains. The sample dataset was coded in a corresponding fashion and evaluated statistically and geostatistically. The major grades of economic interest to the Project, namely Au, Ag, Cu, and Zn, were estimated into the mineralization domains and background material portions of the block model. The minor grades Pb, As, C, Pb, S, Fe, and Hg, along with bulk densities, were similarly estimated into both mineralization and background domains. Figure 6-2 shows the mineralization domain interpretations.

Figure from OreWin, 2019

Figure 6-2: Historical PFS19 Oblique View of Mineralization Solid Interpretations

Grades were estimated using either ordinary kriging (OK) or inverse distance weighting to the power of two (ID2). Depending on the domain being estimated, composites of either 1 m or 2 m (notional) length were used. Following grade estimation, any cells coded as being within a mineralized domain that failed to receive an estimate were assigned default values using the same values as those used for unsampled sample intervals. Global and zonal statistics were generated to confirm that estimated model grades values fell within acceptable limits.

The modelled estimates were assessed for levels of geological confidence, and accordingly classified into Measured, Indicated, and Inferred categories, referencing CIM guidelines (CIM, 2014). The Mineral Resource tonnages and grades have been reported using NSR cut-offs and constrained within an optimized pit.

6.3.4 Historical Mineral Resources

The PFS19 historical resource is reported using cut-offs based on calculations of NSR. This method is considered to be appropriate for polymetallic deposits such as Gediktepe. Separate NSR cut-offs are applied to each of the oxide and sulfide zones.

CIM guidelines required that a Mineral Resource must have: "reasonable prospects of economic extraction". To meet this requirement, the classified resource has been constrained to those model blocks falling within an optimized pit shell that was developed using the metal price parameters used for the determination of Mineral Reserves but increased by 14%, and where all categories of material (including Inferred) have been considered in the pit optimization. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

Table 6.2 shows "Historical Estimates" within the meaning of NI 43-101. The source of the estimates is Section 14 of PFS19. The historical estimates set forth in Table 6.2 do not use categories of mineral resources other than the ones set out in the CIM Definition Standards and Section 1.2 of NI 43-101.

A qualified person has not performed sufficient work to classify the PFS19 historical resource estimates as current mineral resources, and DAMA is not treating the historical estimates as current. Significant data compilation, confirmation drilling, re-sampling and data verification may be required by a qualified person before the historical estimates can be classified as current mineral resources. The historical PFS19 resource estimates are considered to be relevant and are presented for the purpose of describing the extent and nature of mineralization as presently understood. The historical PFS19 resource estimates should not be relied upon until verified by a qualified person.

Table 6.2: Historical Gediktepe PFS19 Mineral Resources - All Classifications

| MEASURED | Tonnes

(kt) | Grade | Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Pb

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Oxide | Gossan | - | - | - | - | - | - | - | - | - | - |

| Low Oxide | - | - | - | - | - | - | - | - | - | - |

| Total Oxide | - | - | - | - | - | - | - | - | - | - |

| Sulfide | Massive Pyrite | 3,999 | 0.67 | 25.1 | 1.01 | 1.83 | 0.34 | 86 | 3,221 | 40 | 73 |

| Diss. Sulfide | - | - | - | - | - | - | - | - | - | - |

| Enriched | - | - | - | - | - | - | - | - | - | - |

| Total Sulfide | 3,999 | 0.67 | 25.1 | 1.01 | 1.83 | 0.34 | 86 | 3,221 | 40 | 73 |

| Total Measured | 3,999 | 0.67 | 25.1 | 1.01 | 1.83 | 0.34 | 86 | 3,221 | 40 | 73 |

| INDICATED | Tonnes

(kt) | Grade | Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Pb

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Oxide | Gossan | 2,562 | 2.79 | 67.6 | 0.1 | 0.1 | 0.48 | 230 | 5,571 | 3 | 2 |

| Low Oxide | 112 | 0.83 | 36.9 | 0.22 | 0.18 | 0.21 | 3 | 132 | 0 | 0 |

| Total Oxide | 2,674 | 2.71 | 66.3 | 0.1 | 0.1 | 0.47 | 233 | 5,703 | 3 | 3 |

| Sulfide | Massive Pyrite | 17,049 | 0.83 | 30.4 | 0.87 | 1.92 | 0.38 | 454 | 16,681 | 148 | 327 |

| Diss. Sulfide | 5,588 | 0.4 | 15.9 | 0.43 | 0.87 | 0.18 | 71 | 2,853 | 24 | 48 |

| Enriched | 907 | 1.19 | 45.7 | 3.14 | 2.61 | 0.22 | 35 | 1,331 | 28 | 24 |

| Total Sulfide | 23,544 | 0.74 | 27.6 | 0.85 | 1.69 | 0.33 | 560 | 20,865 | 200 | 399 |

| Total Indicated | 26,217 | 0.94 | 31.5 | 0.78 | 1.53 | 0.34 | 792 | 26,568 | 203 | 402 |

| | | | | | | | | | | | |

| INFERRED | Tonnes

(kt) | Grade | Metal |

Au

(g/t) | Ag

(g/t) | Cu

(%) | Zn

(%) | Pb

(%) | Au

(koz) | Ag

(koz) | Cu

(kt) | Zn

(kt) |

| Oxide | Gossan | 12 | 1.09 | 22.4 | 0.08 | 0.08 | 0.15 | 0 | 9 | 0 | 0 |

| Low Oxide | 11 | 0.78 | 21 | 0.4 | 0.21 | 0.09 | 0 | 7 | 0 | 0 |

| Total Oxide | 23 | 0.95 | 21.8 | 0.23 | 0.14 | 0.12 | 1 | 16 | 0 | 0 |

| Sulfide | Massive Pyrite | 2,847 | 0.52 | 20 | 0.77 | 1.15 | 0.27 | 47 | 1,832 | 22 | 33 |

| Diss. Sulfide | 111 | 1.01 | 26.3 | 0.43 | 1.39 | 0.26 | 4 | 94 | 0 | 2 |

| Enriched | - | - | - | - | - | - | - | - | - | - |

| Total Sulfide | 2,958 | 0.53 | 20.2 | 0.76 | 1.16 | 0.27 | 51 | 1,926 | 22 | 34 |

| Total Inferred | 2,981 | 0.54 | 20.3 | 0.76 | 1.16 | 0.27 | 51 | 1,941 | 23 | 34 |

Table from OreWin, 2019

Notes (reference to Mineral Resources is used in the context as Historical Mineral Resources):

1 CIM definitions were followed for the Mineral Resources.

2 Effective Date of the Mineral Resources is March 5, 2019.

3 Mineral Resources were estimated within geologic domains by either ordinary kriging or inverse distance.

4 Mineral Resources are reported at NSR cut-offs of $20.72/t for oxide and $17.79/t for sulfide using the mineral reserve metal prices x 1.14 (+14%) and variable metal recoveries according to material and mineralization type (refer to Table 6.3 of this Technical Report and the PFS19 report for details).

5 Mineral Resources have been constrained using an optimized pit shell, to reflect reasonable prospects of economic extraction.

6 Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

7 Mineral Resources are inclusive of Mineral Reserves, except for mining losses and grade dilution, which are determined through re-blocking of the resource model after declaration of the Mineral Resource.

8 Mineral Resources are quoted on a 100% project basis.

9 Totals may not match due to rounding.

6.3.5 Historical Mineral Reserves

The historical PFS19 Gediktepe Mineral Reserves, reported according to the CIM guidelines, are shown in Table 6.3. Due to its polymetallic nature, the oxide and sulfide portions of the historical Mineral Reserves are quoted at different NSR cut-offs based on metal prices, metal recoveries, plus on and off-site processing costs.

Table 6.3 shows "Historical Estimates" within the meaning of NI 43-101. The source of the estimates is Section 15 of PFS19. The historical estimates set forth in Table 6.3 do not use categories of mineral reserves other than the ones set out in the CIM Definition Standards and Section 1.3 of NI 43-101. For further details on the parameters utilized in the estimates, the reader is referred to Section 15 of the PFS19 report.

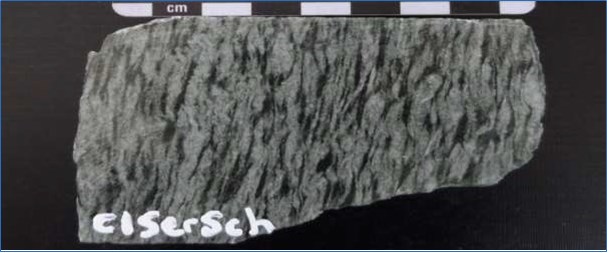

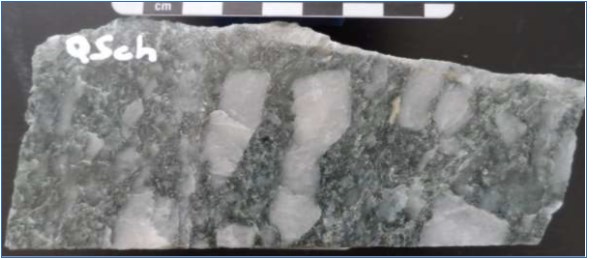

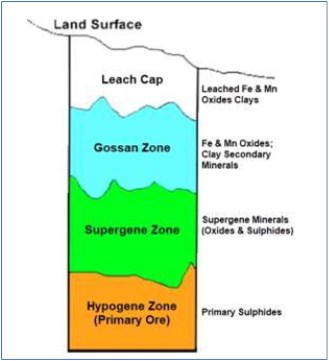

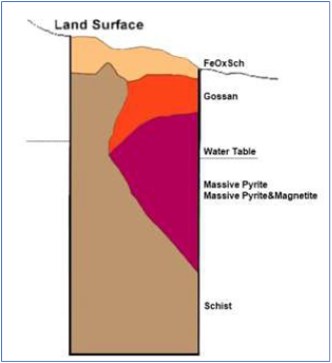

A qualified person has not performed sufficient work to classify the historical PFS19 reserve estimates as current mineral reserves, and EMX is not treating the historical estimates as current mineral reserves. Significant data compilation, confirmation drilling, re-sampling, data verification and updating of metal prices, engineering assumptions, and economic parameters may be required by a qualified person before the historical PFS19 estimates can be classified as current. The historical PFS19 reserve estimates are considered to be relevant and are presented for informational purposes to describe the extent and nature of mineralization on the Project as presently understood. The historical PFS19 reserve estimates should not be relied upon until verified by a qualified person.