QuickLinks -- Click here to rapidly navigate through this document

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| (Mark One) | |

ý | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2004 | |

OR | |

o | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to | |

Commission file number 001-32240

NEENAH PAPER, INC.

(Exact name of registrant as specified in its charter)

| Delaware (State or other jurisdiction of incorporation or organization) | 20-1308307 (I.R.S. Employer Identification No.) | |

3460 Preston Ridge Road Alpharetta, Georgia (Address of principal executive offices) | 30005 (Zip Code) | |

Registrant's telephone number, including area code: (678) 566-6500 | ||

Securities registered pursuant to Section 12(b) of the Act: | ||

Title of Each Class | Name of Each Exchange on Which Registered | |

|---|---|---|

| Common Stock—$0.01 Par Value Preferred Stock Purchase Rights | New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is an accelerated filer (as defined in Rule 12b-2 of the Act). Yes o No ý

The aggregate market value of the registrant's common stock held by non-affiliates on June 30, 2004 (based on the closing stock price on the New York Stock Exchange) on such date was $0 (the registrant became a publicly traded company on December 1, 2004).

As of March 21, 2005, there were 14,763,319 shares of the Company's common stock outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

Certain information contained in the definitive proxy statement for the Company's Annual Meeting of Stockholders to be held on June 20, 2005 is incorporated by reference into Part III hereof.

| | | Page | ||

|---|---|---|---|---|

| Part I | ||||

| Item 1. | Business | 2 | ||

Item 2. | Properties | 25 | ||

Item 3. | Legal Proceedings | 27 | ||

Item 4. | Submission of Matters to a Vote of Security Holders | 27 | ||

Item 4A. | Executive Officers of the Registrant | 27 | ||

Part II | ||||

Item 5. | Market for the Registrant's Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities | 29 | ||

Item 6. | Selected Financial Data | 29 | ||

Item 7. | Management's Discussion and Analysis of Financial Condition and Results of Operations | 32 | ||

Item 7A. | Quantitative and Qualitative Disclosures About Market Risk | 49 | ||

Item 8. | Financial Statements and Supplementary Data | 52 | ||

Item 9. | Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | 52 | ||

Item 9A. | Controls and Procedures | 52 | ||

Item 9B. | Other Information | 52 | ||

Part III | ||||

Item 10. | Directors and Executive Officers of the Registrant | 53 | ||

Item 11. | Executive Compensation | 53 | ||

Item 12. | Security Ownership of Certain Beneficial Owners and Management | 53 | ||

Item 13. | Certain Relationships and Related Transactions | 53 | ||

Item 14. | Principal Accountant Fees and Services | 54 | ||

Part IV | ||||

Item 15. | Exhibits and Financial Statement Schedules | 54 | ||

Signatures | 57 | |||

1

Item 1. Business

Overview

Neenah Paper, Inc. ("Neenah" or the "Company"), a Delaware corporation, was incorporated in April 2004 as a wholly owned subsidiary of Kimberly-Clark Corporation ("Kimberly-Clark"). We had no material assets or activities until the transfer to us by Kimberly-Clark of its fine paper and technical paper businesses in the United States and its Canadian pulp business on November 30, 2004. On that date, Kimberly-Clark completed the distribution of all of the shares of our common stock to the stockholders of Kimberly-Clark (the "Spin-Off"). Kimberly-Clark stockholders received a dividend of one share of our common stock for every 33 shares of Kimberly-Clark common stock held in a tax-free transaction. Following the Spin-Off, we are an independent, public company and Kimberly-Clark has no continuing ownership interest in us.

We are a leading North American producer of premium fine papers and technical papers. We also produce bleached kraft market pulp in Canada, where we own approximately one million acres of timberlands and have non-exclusive rights to harvest wood off approximately 4.8 million acres of other timberlands. We have three primary operations: our fine paper business, our technical paper business and our pulp business.

Our fine paper business is a leading producer of premium writing, text, cover and specialty papers used in corporate annual reports, corporate identity packages, invitations, personal stationery and high-end packaging. Our products include some of the most recognized and preferred papers in North America, where we enjoy leading market positions in many of our product categories. We sell our products primarily to authorized paper distributors, converters and specialty businesses, with sales to distributors and distributor-owned paper stores accounting for approximately 85% of our sales. We believe that our fine paper manufacturing facilities located in Neenah and Whiting, Wisconsin are among the most efficient in their markets and make us one of the lowest cost producers.

Our technical paper business is a leading producer of durable, saturated and coated base papers for a variety of end uses. We sell our technical paper globally into 15 product categories, and we focus on nine categories where we believe we are a market leader, which include, among others, the tape, label, abrasive, medical packaging and heat transfer technical paper markets. We are also a global supplier of materials used to create customer-specific components for furniture, book covers and original equipment manufacturers' products. Our customers are located in 39 countries and include 3M Company, Perfecseal, Avery Dennison Corporation and Saint-Gobain Group. Our technical paper manufacturing facility is located in Munising, Michigan.

Our pulp business consists of two mills located in Pictou, Nova Scotia and Terrace Bay, Ontario, together with related timberlands. The Pictou mill is comprised of a single-line pulp facility, which produces primarily softwood pulp, as well as timberlands encompassing approximately one million acres of owned and 200,000 acres of licensed or managed land in Nova Scotia. In 2004, the Pictou mill produced approximately 260,000 metric tons of bleached kraft pulp. The Terrace Bay mill is comprised of two single-line pulp facilities, which produces both softwood and hardwood pulp, and a timberlands operation. Terrace Bay holds non-exclusive rights under a sustainable forest license to harvest wood off approximately 4.6 million acres of land owned by the Province of Ontario. In 2004, the Terrace Bay mill produced approximately 450,000 metric tons of pulp. As described in "Recent Developments" below, on March 1, 2005, we announced our intention to close one of the two single-line pulp facilities at Terrace Bay in early May 2005.

2

Recent Developments

On March 1, 2005, we announced the planned closure of the smaller of our two single-line pulp mills at the Terrace Bay facility (the "No. 1 Mill"). The No. 1 Mill was originally constructed in 1948 and has annual capacity of approximately 125,000 tons of bleached kraft pulp. In conjunction with the closing, we will offer early retirement and severance packages to approximately 130 employees. The closing was authorized by our Chief Executive Officer on February 28, 2005, pursuant to a resolution of the Board of Directors, and is expected to occur in early May 2005.

We expect to incur approximately $6.0 million of exit costs in connection with the closure, including one-time termination benefits related to early retirement, severance and defined benefit pension plans of approximately $5.5 million and other associated exit costs of $0.5 million. In addition, we expect to incur approximately $1.0 million of general expenses related to training of employees. Approximately $6.3 million of the estimated costs of $7.0 million will result in future cash expenditures during 2005 and 2006.

In addition, in March 2005, we will record a pre-tax, non-cash impairment loss of approximately $0.9 million related to the remaining value of the long-lived assets of the No. 1 Mill (See "Management's Discussion and Analysis of Financial Condition and Results of Operations—Results of Operations and Related Information—Asset Impairment Loss").

As a result of closing the No. 1 Mill, we notified Kimberly-Clark of our intention to terminate a part of our commitment to supply and their requirement to purchase northern bleached hardwood kraft pulp pursuant to the terms of our pulp supply agreement. Under the pulp supply agreement, we were obligated to provide 40,000, 30,000, 20,000 and 10,000 tons of northern bleached hardwood kraft pulp produced at the Terrace Bay mill annually in 2005, 2006, 2007 and 2008, respectively. Our commitment to supply and Kimberly-Clark's requirement to purchase northern bleached hardwood kraft pulp pursuant to the terms of the pulp supply agreement from the Pictou mill (in annual quantities which are identical to those shown above) is unchanged.

Company Structure

Our corporate structure consists of Neenah Paper, Inc., and three wholly owned subsidiaries.

Neenah Paper, Inc. Neenah Paper is a Delaware corporation that holds our trademarks and patents related to all of our businesses, the real estate, the mills and the manufacturing assets associated with our fine paper business, and all of the equity in our subsidiaries which are listed below. The common stock of Neenah Paper is publicly traded on the New York Stock Exchange under the symbol "NP."

Neenah Paper Sales, Inc. Neenah Paper Sales is a Delaware corporation that owns all of our U.S. inventory and certain other assets.

Neenah Paper Michigan, Inc. Neenah Paper Michigan is a Delaware corporation that owns the real estate, the mill and the manufacturing assets associated with our technical paper business.

Neenah Paper Company of Canada. Neenah Paper Company of Canada is a Nova Scotia unlimited liability company and wholly owned subsidiary of Neenah Paper. It owns the real estate, the mills and the manufacturing assets associated with our pulp business operations in Pictou, Nova Scotia and Terrace Bay, Ontario. It also conducts timberlands operations in the Provinces of Ontario and Nova Scotia.

3

History of the Businesses

Fine Paper Business. The fine paper business was incorporated in 1885 as the Neenah Paper Company, which initially operated a single paper mill located adjacent to the Fox River in Neenah, Wisconsin. Kimberly-Clark acquired the mill in 1956. In 1981, Kimberly-Clark purchased an additional mill located in Whiting, Wisconsin to increase the production capacity of the fine paper business. In the late 1980s and early 1990s, Kimberly-Clark expanded the capacity of the fine paper business in response to increased demand by rebuilding Whiting's two paper machines and building two new paper machines at the Whiting mill. The Neenah mill underwent a major expansion in the early 1990s with the installation of a new paper machine, a new finishing center, a new customer service center and a distribution center expansion. As a result of decreased demand, in the 2000s the Neenah mill retired two of its older paper machines.

Technical Paper Business. In 1952, Kimberly-Clark purchased the Munising mill, located in Munising, Michigan, which previously had produced sulfite pulp and butcher wrap paper. Since that time, the technical paper business has operated the Munising mill and produced durable, saturated and coated papers for sale and use in a variety of industrial applications. In 2001, the technical paper business closed a small kraft paper mill located in East Ryegate, Vermont that it had acquired in 1995.

Pulp Business. The Pictou pulp mill was built in 1967 by the Scott Paper Company. Kimberly-Clark acquired the Pictou pulp mill and related timberlands operations in 1995 as part of its merger with the Scott Paper Company. The Terrace Bay pulp mill was built by Kimberly-Clark in 1948 on the north shore of Lake Superior in Ontario, Canada. In the mid-1970s, Kimberly-Clark added a second pulp mill at Terrace Bay and in the early 1980s rebuilt other portions of the pulp mill. The Terrace Bay operation includes the Longlac timberlands operation, in existence since 1937, which harvests wood off land owned by the Ontario government for pulp production at the Terrace Bay mill. In May 1987, Kimberly-Clark closed the Longlac sawmill and later sold it to a third party.

Business Strategy

Sustain and Improve the Paper Businesses' Competitive Position. We intend to sustain and improve our fine and technical paper businesses' competitive positions. Our experienced team of employees and management will pursue business strategies designed to take advantage of our existing strengths—including our strong market positions, efficient paper operations, high-quality products and well recognized brands—while responding to the challenges faced by each of our business units. In addition to maintaining our focus on efficiency and market position, we plan to seek growth opportunities while we continue to strengthen our current business and cost positions.

Leverage Our Low Cost Production Facilities. We believe that our fine and technical paper production assets provide us with a flexible, efficient and low cost platform for growth. As a result of the recent improvements in the global economy, we have experienced increased orders and operating schedules for base paper at our paper mills. More specifically, to support our growth, we are developing the process capability to utilize available, low cost capacity within our fine paper operations to support the increased technical paper demand.

Reinvigorate Research and Development. In connection with the Spin-Off and our focus on core operations, we have commenced a strategy designed to reinvigorate our research and development capabilities. We have begun to further develop our human and technical resources in research and development. We believe this will ensure that we are the development partner of choice for our key customers and will allow us to take advantage of new technical paper product opportunities that we previously were unable to effectively support. This partnering approach has received the strong support of our key customers and is designed to position our business for growth.

4

Improve Pulp Mill Efficiency and Cost Structure. We have developed plans to improve our pulp mill efficiency and cost structure, and business teams are already actively engaged in these programs. To support this effort, we expect to allocate a major share of our planned capital investments during the next several years to improve the competitive position, technical capabilities and efficiency of our pulp operations. For example, we have developed plans to expand the low cost cogeneration of power at our Terrace Bay mill and other process efficiencies in our pulp operations. We also plan to continue to work jointly with the operating employees in the mills and in the Terrace Bay timberlands operation so that employee productivity and involvement remain or become a competitive strength of the Company.

Transition to a Market Pulp Producer. We plan to transition from an internal supplier of pulp as a part of Kimberly-Clark to a market pulp producer. As part of this transition, we have begun to develop our external pulp sales function, and we plan to make appropriate improvements in bale quality, customer support and technical support to enhance our ability to establish a broader pulp market customer base. We believe that our pulp supply agreement with Kimberly-Clark will provide us with a level of stability that will facilitate a successful transition.

Improve Business Focus. We believe our corporate focus on our core paper and pulp operations will allow us to improve our cost structure and supply chain management. In addition, we believe that our strategies as a stand-alone business following the Spin-Off will allow us to better allocate capital and research and development spending on our core businesses. As operating units within Kimberly-Clark, our facilities were managed and operated as parts of larger Kimberly-Clark business segments. We expect to achieve performance improvements through the establishment of common best practices, shared services, strategic capital investments, stretch targets and key performance indicators for cost savings, efficiency gains and process improvements. We intend to centrally manage our capital resources across our businesses by allocating funds based on business priority and financial returns. We plan to achieve improvements in both our supply chain efficiencies and management of working capital through the integration of these efforts within Neenah.

Products

Fine Paper Business. The fine paper business manufactures and sells world-class premium writing, text, cover and specialty papers used in corporate annual reports, corporate identity packages, invitations, personal stationery and high-end packaging. The net sales of the fine paper business were approximately $221 million in 2004, $210 million in 2003 and $225 million in 2002.

Writing papers are used for business and personal stationery, corporate letterhead, corporate identity packages, private watermarked papers, envelopes and similar end-use applications. Market leading writing papers are sold by the fine paper business under the CLASSIC®, ENVIRONMENT®, NEENAH®, ATLAS® and OLD COUNCIL TREE® trademarks, which are denoted by a brand watermark in each sheet of writing paper. The fine paper business also sells private watermarked and other custom manufactured writing papers.

Text and cover papers are used in applications such as corporate annual reports, corporate identity packages, insert advertising, direct mail, facility brochures, business cards, hang tags, scrapbooks, and a variety of other uses where colors, textured finishes or heavier weight papers are desired. The business's brands in this category include CLASSIC®, CLASSIC CREST® and ENVIRONMENT®. A variety of custom paper colors, paper finishes, and duplex/laminated papers are also offered for sale.

The fine paper business produces and sells other specialty papers, including translucent papers, art papers, papers for optical scanning and other specialized applications, under the UV/ULTRA® II trademark and other brands.

5

Technical Paper Business. The technical paper business is a leading producer of durable, saturated and coated base papers for a variety of end uses, including tapes, premask, abrasives, labels, medical packaging, decorative components and heat transfer papers. The net sales of our technical paper business were approximately $132 million in 2004, $122 million in 2003 and $121 million in 2002. KIMDURA® and MUNISING LP® are brands of our technical paper business.

Products of the technical paper business are typically sold as a component of a finished product. The technical paper business sells its products into five major market segments—tape, premask, abrasives, label and medical packaging—and ten other specialty segments. Several key market segments served, including tape and abrasives, are global in scope.

The technical paper business produces tape base sheets from latex saturated crepe and flat papers and sells them to manufacturers to produce finished pressure sensitive products for sale in automotive, automotive aftermarket, industrial general purpose, transportation, manufacturing and building construction applications. Premask paper is used as a protective over wrap for products during the manufacturing process and for applying signs, labeling and other finished products.

The technical paper business is a leading producer of latex saturated and coated abrasive backing papers for use by sandpaper manufacturers. The finished lightweight sandpaper is sold in the automotive, automotive aftermarket, construction, metal and woodworking industries for both waterproof and dry sanding applications.

Label and tag products are produced from saturated (latex impregnated) base label stock and purchased synthetic (bi-axially stretched polypropylene film) base label stock. Top coatings are applied to the base label stock to allow for high quality variable and digital printing. The synthetic label stock of the technical paper business is recognized as a high quality, UV (ultra-violet) stable product used for outdoor applications. The business sells its label and tag stock to pressure sensitive coaters, who in turn sell the coated label and tag stock to the label printing community.

The technical paper business's medical packaging paper is a polymer impregnated base sheet that provides a breathable sterilization barrier. When sealed together with film, this paper becomes a medical packaging material that allows sterilization from steam, ethylene oxide, or gamma radiation and at the same time provides unique barrier properties.

Decorative components papers, designed for durability and flexibility, are made from light and medium weight latex saturated papers. The base paper can be reinforced with synthetic fiber for additional tear strength. Coatings can also be applied for printability. A variety of different base weights, colors and textures are available for sale to coater converters, distributors, publishers and printers for use in book covers, stationery and fancy packaging.

Heat transfer papers are used to transfer an image from paper to tee shirts, hats, coffee mugs, and other surfaces. The technical paper business produces and applies a proprietary imaging coating to its heat transfer papers for use in digital printing applications. Heat transfer papers are primarily sold through large retail outlets and through master distributors who then offer small quantity options and services to the large number of customers in the supply channel.

The technical paper business also produces and sells several other specialty papers including furniture backer, clean room paper and release paper.

Pulp Business. Our Terrace Bay mill produces hardwood and softwood pulp, about 50% of the fiber for which is harvested from approximately 4.6 million acres licensed to us. In 2004, more than 70% of the mill's output was consumed by Kimberly-Clark and approximately 11% was used by our fine paper and technical paper businesses. Terrace Bay's two major products are a fully bleached northern softwood kraft pulp used to manufacture publication, printing and writing, specialty papers and tissue grades and an exceptionally strong, high quality, fully bleached northern hardwood kraft pulp

6

used to manufacture premium printing and writing papers, tissue, specialty and other quality papers. The Terrace Bay operation also sells softwood and hardwood logs from its timberlands operations to sawmills and veneer manufacturers who, in turn, sell wood chips and sawdust to Terrace Bay.

Our Pictou mill also manufactures virgin softwood and hardwood pulp and various blends of each for sale to paper mill customers located primarily in Europe and North America. The mill's two major products are Pictou HARMONY® Softwood (northern bleached softwood kraft pulp) and Pictou Hardwood (northern bleached hardwood kraft pulp). The Pictou mill's principal customer has been Kimberly-Clark, which in 2004 consumed more than 80% of Pictou's bleached kraft output.

The net sales of our pulp business were approximately $449 million in 2004, $405 million in 2003 and $380 million in 2002.

Markets and Customers

Fine Paper Business. Premium writing papers are used primarily for stationery and corporate identification applications. This market segment is divided into cotton and sulfite grades, while the text and cover segment is split between smooth papers and textured papers. Text papers have traditionally been utilized for special, high end collateral material such as corporate brochures, annual reports and special edition books. Cover papers are used as covers primarily for business cards, pocket folders, brochures and report covers including annual corporate reports.

The fine paper business sells its products through our sales and marketing organizations primarily in three channels: authorized paper distributors, converters and direct sales to specialty businesses. Distributor sales account for approximately 85% of our customer base in the fine paper business, including distributor owned paper stores. There is also a small but growing sales channel in office supply catalogs and business copy center stores, primarily to distributors in North America. Less than 5% of the sales of our fine paper business in 2004 were exported to international distributors in Europe, South Africa, Asia and Australia.

Sales by the fine paper business to its three largest customers (two of which are distributors) represented approximately 45% of its total sales in 2004. Although a complete loss of any one of these customers would cause a temporary decline in the business's sales volume, the decline could be partially offset by expanding sales to existing distributors, and further offset over a several month period with the addition of new distributors.

Technical Paper Business. The technical paper business relies on its direct sales team and marketing organizations to sell its products into 15 separate market segments in the U.S. and 38 export markets. Such segments, broadly defined as polymer impregnated and synthetic paper, include papers used as components in the following applications: saturated label, clean room papers, release papers, abrasives, masking tape, decal premask, heat transfer, medical packaging, decorative components, durable printing papers, furniture components, washable tag, and industrial components. Our technical paper business is recognized as a leading specialty paper manufacturer and enjoys either the number one or two market position in the following market segments: furniture components, washable tag, decal premask, saturated label, clean room, saturated release paper, reinforced medical packaging and saturated abrasive backings.

Several traditional products (abrasives, tapes, labels) are used in markets that are directly affected by economic business cycles. Other market segments such as heat transfer papers used in small/home office and consumer applications are relatively stable. Price competition is common in most of the segments served by the technical paper business and has increased recently due to a trend of using film and other lower cost substrates instead of paper in some applications.

The technical paper business relies on a team of direct sales representatives and customer service representatives to market and sell approximately 95% of its sales volume directly to customers and

7

converters in 39 countries. Less than 5% of the sales of the technical paper business are sold through industrial distributors.

The technical paper business has over 500 customers worldwide. The distribution of sales in 2004 was approximately 71% in North America, 16% in Europe, 7% in Latin America and 6% in Asia. Customers typically convert and transform base papers and film into finished rolls and sheets by adding adhesives, coatings and finishes. Such transformed product is then sold to end-users.

Several of the smaller customers of the technical paper business have been acquired by larger multinational corporations with multiple manufacturing locations. These larger organizations have implemented global purchasing strategies which give them increased leverage in price negotiations. The primary global customers of the technical paper business are 3M Company, Perfecseal, Avery Dennison Corporation and Saint-Gobain Group.

Pulp Business. Northern bleached softwood kraft pulp is used by paper mills to manufacture printing and writing paper and tissue. In 2004, worldwide demand for northern bleached softwood kraft market pulp (which excludes pulp produced for internal consumption by integrated pulp manufacturers) was estimated to be 11.6 million metric tons, of which about 6.5 million metric tons were produced in Canada. The United States consumed an estimated 2.3 million metric tons of northern bleached softwood kraft pulp in 2004, followed by Western Europe at 1.9 million metric tons and China at 1.0 million metric tons. Prior to the Spin-Off, the Terrace Bay and Pictou pulp mills transferred over 90% of their output of northern bleached softwood kraft pulp to Kimberly-Clark. Excluding output transferred to our fine paper and technical paper businesses, in 2004 more than 75% of the northern bleached softwood kraft pulp production of the Terrace Bay and Pictou mills was transferred to Kimberly-Clark.

In 2004, worldwide demand for hardwood market pulp was estimated to be 18 million metric tons of which an estimated 1.9 million metric tons were northern bleached hardwood kraft pulp produced in Canada. In 2004, the United States and Asia consumed approximately 0.5 million metric tons of Canadian northern bleached hardwood kraft pulp, followed by Europe at 0.41 million metric tons.

In 2004, Terrace Bay and Pictou produced about 113,000 metric tons and 40,000 metric tons of northern bleached hardwood kraft pulp, respectively. In 2004, the Terrace Bay and Pictou mills transferred approximately 102,000 metric tons and 24,000 metric tons of northern bleached hardwood kraft pulp to Kimberly-Clark and our fine paper business, respectively. The balance of the pulp mills' output of northern bleached hardwood kraft pulp was sold to paper mills in the northeastern and midwestern United States.

Northern bleached softwood kraft pulp and northern bleached hardwood kraft pulp are commodity products whose prices are subject to substantial increase or decrease depending on production capacity and customer demand. Northern bleached hardwood kraft pulp is subject to increasing competition, primarily from lower priced South American eucalyptus pulp and excess capacity of northern bleached hardwood kraft pulp.

Historically, the Pictou and Terrace Bay pulp mills have transferred their pulp directly to Kimberly-Clark and used brokers for sales to external customers.

For the years ended December 31, 2004, 2003 and 2002, we had net sales for pulp transferred to Kimberly-Clark of $351.0 million, $305.1 million and $262.1 million, respectively. No single customer, other than Kimberly-Clark, accounted for more than 10% of our net sales in those years.

Raw Materials and Energy

Fine Paper Business. Wood pulp is the primary fiber used to produce products of the fine paper business. Our fine paper business consumed approximately 54,000 and 48,000 metric tons of hardwood

8

pulp in 2004 and 2003, respectively, approximately 45% to 50% of which was supplied by the Terrace Bay pulp mill. Other significant raw material inputs in the production of products of the fine paper business include cotton fiber, recycled fiber, dyes and fillers. Except for pulp, the fine paper business purchases all of its raw materials externally.

Technical Paper Business. The technical paper business purchases latex, a primary raw material used to produce its products, from various suppliers. Wood pulp is the other main raw material consumed, approximately two-thirds of which is supplied by the Terrace Bay pulp mill. Except for pulp, the technical paper business purchases all of its other raw material requirements externally. We believe that all of the raw materials that we must purchase for our technical paper operations, except for certain specialty latex grades, are readily available from several sources and that the loss of a single supplier would not cause a shutdown of our manufacturing operations. An interruption in supply of a latex specialty grade, however, could disrupt and eventually cause a shutdown of production of certain technical paper latex specialty grades.

Pulp Business. Wood chips are the primary raw material needed to produce hardwood and softwood pulp. The Terrace Bay mill operation produces pulpwood and logs, about 50% of which is harvested from timberlands licensed to us by the Province of Ontario. The Pictou mill obtains its wood chips from several sawmills under agreements whereby Pictou supplies to the sawmills wood harvested from its own timberlands and 200,000 acres of licensed and managed land in Nova Scotia, and in return the sawmills supply wood chips to the Pictou mill. The price of wood chips can vary significantly based on the cost of logs and the strength of demand in the lumber and pulp markets. Other important raw materials used by the Terrace Bay and Pictou pulp mills are chemicals and supplies. The Terrace Bay and Pictou pulp mills purchase all of these other raw materials externally.

Except for wood chips used by our pulp mills and certain specialty latex grades used by our technical paper business, we are not aware of any significant concentration of business transacted with a particular supplier that could, if suddenly eliminated, have a material adverse affect on our operations. In 2004, over 60% of the wood chips used by the Pictou mill were supplied by two suppliers and approximately 55% of the wood chips used by the Terrace Bay mill were supplied by one supplier. While we believe that alternative sources of critical supplies, such as wood chips, would be available, disruption of our primary sources could create a temporary, adverse effect on product shipments. An interruption in the supply of a latex specialty grade to our technical paper business, which we currently obtain from a single source, could disrupt and eventually cause a shutdown of production of certain technical paper latex specialty grades.

The pulp and paper making processes use significant amounts of energy, primarily electricity, natural gas, oil, coal and bark fuel to operate the equipment and paper machines used in the manufacture of pulp and the products of the fine paper and technical paper businesses. We generate substantially all of our electrical energy at the Munising and Pictou mills and approximately one-third of the electrical energy at the Terrace Bay mill. We are evaluating potential cogeneration arrangements to supply the balance of the power requirements at the Terrace Bay mill, which would lower the cost of electricity. We also purchase electrical energy from external sources. Availability of energy is not expected to be a problem in the foreseeable future, but the purchase price of such energy can and likely will fluctuate significantly based on fluctuations in demand and other factors. We currently have forward purchase contracts that fix our cost for certain quantities of electricity through 2005 and natural gas through 2006. The ratification of the Kyoto Protocol by Canada may result in lower limits for the emission of carbon dioxide and other greenhouse gases. The specific emission limitations in respect of our Canadian operations are unknown and uncertain and may increase costs.

An adequate supply of water is needed to manufacture our products. We believe that there is an adequate supply of water for this purpose at each of our manufacturing locations.

9

Working Capital

Fine Paper Business. The fine paper business maintains approximately 20 to 22 days of raw material inventories to support its paper making operations and about 30 days of finished goods inventory to fill customer orders. Its sales terms range between 20 and 30 days for payment by its customers, with 20-day terms used most often. Supplier invoices are typically paid within 30 days.

Technical Paper Business. On average, the technical paper business maintains approximately 10 to 12 days of inventory of raw materials and supplies to support its manufacturing operations and approximately 18 to 20 days of finished goods inventory to support customer orders for its products. Sales terms in the technical paper business vary depending on the type of product sold and customer category. Extended credit terms of up to 60 days are typically offered to customers located in export markets. On average during 2004, supplier invoices were paid in approximately 20 days.

Pulp Business. The Pictou and Terrace Bay pulp operations maintain harvested log inventories on the ground for up to three months and six months, respectively. They also maintain other raw material and supplies inventories ranging from 3 to 30 days to support their pulp making operations. The pulp mills typically maintain finished pulp inventories of 7 to 8 days to fill customer orders, and inventories related to a few grades for up to 60 days. For purchases other than wood chips, the pulp mills typically carry accounts payable at 30 to 45-day levels in accordance with various purchasing terms. Chip purchases are generally paid in 5 to 10 days from receipt. Sales terms generally range from 30 to 60 days with the majority at 45 days pursuant to the pulp supply agreement with Kimberly-Clark.

Competition

Fine Paper Business. We believe that our fine paper business is a leading supplier of premium writing, text, cover and specialty papers in North America. The fine paper business competes directly in the sale of these papers in this market with large competitors, including International Paper Company, Fox River Paper Company, Wausau-Mosinee Paper Corporation, Mohawk Paper Mills, Inc. and five to six smaller companies. We believe that the primary bases of competition for premium writing, text and cover papers are brand recognition, product quality, service, availability, and promotional support, with price being a less important factor. We have and will continue to invest in advertising and other programs aimed at graphic designers, printers and corporate end-users in order to communicate the advantages of using our products.

Technical Paper Business. In the tapes, abrasives, medical packaging, label and decorative components segments, our technical paper business competes in North American and global markets with a number of competitors, including FiberMark, Inc., Arjo Wiggins USA, Inc., MeadWestvaco Corporation, Arkwright, Inc. and Ahlstrom Corporation. It also competes in some, but not all, of these segments with smaller regional manufacturers, such as Monadnock. We believe the bases of competition in most of these segments are price and the ability to design and develop customized product features to meet customer specifications while maintaining quality and customer service. We believe that our research and development program gives us an advantage in customizing base papers to meet customer needs. Although delivered pricing has become an increasingly important factor in supplier selection, our technical paper business has been able to retain and to grow its customer base in recent years.

Pulp Business. The principal competitors of the Pictou and Terrace Bay pulp mills in the production of softwood and hardwood kraft pulp are Tembec, International Paper Company, The SFK Group, Bowater Incorporated and Domtar Inc. In addition, competition is increasing from lower priced eucalyptus pulp manufacturers in South America. Most of this pulp is sold to paper mills in the eastern and midwestern United States and in Europe. The basis of competition for pulp is primarily price, including the freight cost to customer locations, pulp performance attributes and consistent quality.

10

Pulp pricing is cyclical with increases and decreases primarily driven by general economic conditions and pulp production capacity.

Research and Development

Our main research and development laboratory is located in Roswell, Georgia.

The technical paper business also maintains a research and development laboratory in Munising, Michigan to support its strategy of developing new products and technologies, and to support growth in its existing product lines and other strategically important markets. The technical paper business has continually invested in product research and development with $1.4 million in 2004, $1.5 million in 2003 and $1.6 million being spent in 2002.

The Pictou and Terrace Bay pulp mills spent about $1.1 million in total over the last three years on pulp research and development focused on improving pulp strength and pulp process improvements such as bleaching. Development in these areas has led to reduced manufacturing costs at each of the pulp mills and in customers' operations.

Intellectual Property

We own 53 trademarks with registrations in 50 countries. Our business has built its market leading reputation on trademarked brands that date back as far as 1908. The CLASSIC family of brands is one of the most well known and respected trademarks in the printing and writing industry. The CLASSIC family includes CLASSIC CREST®, The CLASSIC® Laid, CLASSIC® Linen, CLASSIC COLUMNS® and CLASSIC COTTON® papers. The CLASSIC family of products with the addition of the ENVIRONMENT®, ATLAS™, OLD COUNCIL TREE® and UV/ULTRA® II brands have played an important role in the marketing of the product lines of the fine paper business, which are recognized as an industry leader for quality, consistency and printing applications.

The KIMDURA® and MUNISING LP® trademarks have made a significant contribution to the marketing of synthetic film and clean room papers of the technical paper business.

We own 38 patents and have 11 pending patent applications in the United States, Canada, Western Europe and certain other countries covering heat transfer paper, abrasives, medical packaging and fiber modification in the pulping process. We believe that our heat transfer patents have contributed to establishing the technical paper business as a leading supplier of heat transfer papers.

Backlog and Seasonality

Fine Paper Business. The fine paper business has historically experienced a steady flow of orders with a 1 to 2% reduction in the fourth quarter due to a slow down in the printing industry and adjustment of customer inventories. Orders for stock products are typically shipped within two days, while custom orders are shipped within two to three weeks of receipt. Raw material purchases and manufacturing schedules are planned based on a combination of historical trends, customer forecasts and current market conditions. The order backlogs in the fine paper business on December 31, 2004 and December 31, 2003 were $4.3 million and $4.7 million, respectively, representing 5.1 and 5.7 days, respectively, of sales.

Technical Paper Business. Historically, the technical paper business has had a steady quarter to quarter shipments flow with small reductions in the third and fourth quarters due to international customer vacations and other downtime in July and August and a reduction in inventory levels by our customers in November and December. Notwithstanding relatively steady shipments from quarter to quarter, the order flow for the technical paper business is subject to seasonal peaks for several of its products, such as the larger volume grades of tape, abrasives, premask, and label stock used primarily in the downstream finished goods manufacturing process. To assure timely shipments during these

11

seasonal peaks, the technical paper business has agreements with customers accounting for approximately 35% of its annual sales to manufacture orders and hold them in inventory for later shipment. The technical paper business also manages these peaks with sales on consignment representing about 8% of its annual sales. Orders are typically shipped within six to eight weeks of receipt of the order. However, the technical paper business periodically experiences periods where order entry levels surge, and backlog increases substantially, such as in 2004 when backlogs reached 43 weeks. Raw materials are purchased and manufacturing schedules are planned based on customer forecasts, current market conditions and individual orders for custom products. The order backlogs in the technical paper business on December 31, 2004 and December 31, 2003 were $32 million and $24 million, respectively, representing approximately 24 and 20 percent of prior year sales, respectively.

Pulp Business. The Pictou and Terrace Bay pulp mills take 10 to 14-day shutdowns each year for major maintenance, typically in either May or September, thereby reducing pulp shipments in the second and third quarters. Shutdowns for maintenance and capital projects are sometimes taken in other quarters, resulting in a variation in quarter-to-quarter pulp shipments. Customer order patterns are consistent, except for a moderate reduction in European orders in the summer. In North America, orders are generally placed one month in advance, while European orders are based on a three-month rolling forecast.

Employee and Labor Relations

As of December 31, 2004, we had 2,060 regular full time employees of whom 626 hourly and 252 salaried employees were located in the United States and 936 hourly and 246 salaried employees were located in Canada.

Hourly employees at the Neenah, Whiting and Munising mills are represented by locals of the Paper, Allied Industrial, Chemical and Energy Worker's International Union. The collective agreements for the Neenah and Munising mills expire on July 1, 2005 and July 15, 2005, respectively. The collective agreement at the Whiting mill expired on February 1, 2005 and contract negotiations are currently in process. Additionally, these mills have bargained jointly with the union on pension matters. The agreements on pension matters for these mills expire June 30, 2007. We believe that employee and union relations at each of our U.S. locations are good.

Hourly employees at the Terrace Bay pulp mill are represented by locals of the Paper, Allied Industrial, Chemical and Energy Worker's International Union and the International Brotherhood of Electrical Workers with each collective bargaining agreement expiring on May 1, 2007. Hourly employees at our Longlac, Ontario operations are represented by Local I-2693 of the United Steelworkers of America with a collective bargaining agreement which expires on September 1, 2005. Hourly employees at the Pictou pulp mill are represented by Local 440 of the Communication, Energy and Paper Workers Union with a collective bargaining agreement which expired on June 1, 2004. By operation of Nova Scotia labor law, the terms of the expired collective bargaining agreement remain in effect until completion of the collective bargaining process. We believe that employee and union relations at these locations are good.

Environmental, Health and Safety Matters

Our operations are subject to federal, state, provincial and local laws, regulations and ordinances relating to various environmental, health and safety matters. Our operations are in compliance with, or we are taking actions designed to ensure compliance with, these laws, regulations and ordinances. However, the nature of our operations exposes us to the risk of claims concerning non-compliance with environmental, health and safety laws or standards, and there can be no assurance that material costs or liabilities will not be incurred in connection with those claims. Except for certain orders issued by environmental, health and safety regulatory agencies with which we believe we are in compliance and

12

which we believe are immaterial to our financial condition, results of operations and liquidity, we are not currently named as a party in any judicial or administrative proceeding relating to environmental, health and safety matters.

While we have incurred in the past several years, and will continue to incur, capital and operating expenditures in order to comply with environmental, health and safety laws, regulations and ordinances, we believe that our future cost of compliance with environmental, health and safety laws, regulations and ordinances, and our exposure to liability for environmental, health and safety claims will not have a material adverse effect on our financial condition, results of operations or liquidity. However, future events, such as changes in existing laws and regulations, or contamination of sites owned, operated or used for waste disposal by us (including currently unknown contamination and contamination caused by prior owners and operators of such sites or other waste generators) may give rise to additional costs which could have a material adverse effect on our financial condition, results of operations or liquidity.

We incur capital expenditures necessary to meet legal requirements and otherwise relating to the protection of the environment at our facilities in the United States and Canada. For these purposes, we have planned capital expenditure programs for which we anticipate incurring approximately $4 million in 2005 and approximately $14 million in 2006, of which no material amount is the result of environmental fines or settlements. These capital expenditures are not expected to have a material adverse effect on our financial condition, results of operations or liquidity.

We have recently become subject to the reporting requirements of the Securities Exchange Act. As such, we will file quarterly and current reports and other information, and we will file annual reports and proxy statements, with the Securities and Exchange Commission ("SEC"). Our SEC filings are available to the public over the Internet at the SEC's web site at www.sec.gov. You may also read and copy any document we file at the SEC's public reference room in Washington, D.C., 450 5th Street, N.W., Washington, D.C. 20549. Please call the SEC at 1-800-SEC-0330 for further information on the public reference room. Our common stock is traded on the New York Stock Exchange under the symbol "NP". You may inspect the reports, proxy statements and other information concerning us at the offices of the New York Stock Exchange, 20 Broad Street, New York, New York 10005.

Our web site is www.neenah.com. Our reports on Form 10-K, Form 10-Q and Form 8-K, as well as amendments to those reports, are and will be available free of charge on our web site as soon as reasonably practicable after we file or furnish such reports with the SEC. In addition, you may request a copy of any of these reports (excluding exhibits) at no cost by writing to us at: Investor Relations, Neenah Paper, Inc., Preston Ridge III, 3460 Preston Ridge Road, Suite 600, Alpharetta, Georgia 30005.

13

You should carefully consider each of the following risks and all of the other information contained in this Annual Report on Form 10-K. Some of the risks described below relate principally to our business and the industry in which we operate, while others relate principally to our separation from Kimberly-Clark. The remaining risks relate principally to the securities markets generally and ownership of our common stock.

Our business, financial condition, results of operations or liquidity could be materially adversely affected by any of these risks, and, as a result, the trading price of our common stock could decline. The risks described below are not the only ones we face. Additional risks not presently known to us or that we currently deem immaterial may also impair our business operations.

Risks Related to Our Business and Industry

Our historical financial data is not representative of our results as a separate company and, therefore, will not be reliable as an indicator of our future performance.

The historical combined financial data we have included in this Annual Report present the results of operations and financial position of the businesses transferred to us as they were historically operated by Kimberly-Clark. Accordingly, this data is not indicative of our future performance, nor does it reflect what our financial position and results of operations would have been had we operated as a separate, independent company during the periods presented. This is because, among other things:

- •

- our pulp mills now supply pulp to Kimberly-Clark on terms that are significantly different than those in place prior to the Spin-Off (for a description of what our results of operations would have been if the new terms had been in place during periods prior to the Spin-Off, see "Management's Discussion and Analysis of Financial Condition and Results of Operations—Business Outlook");

- •

- we now supply pulp to other customers instead of supplying more than 90% of our production to Kimberly-Clark;

- •

- we have made adjustments and allocations, primarily with respect to corporate and administrative costs, because Kimberly-Clark did not account for us as, and we were not operated as, a single, stand-alone business for periods presented prior to the Spin-Off;

- •

- the information does not reflect changes that we expect to occur in the future as a result of our separation from Kimberly-Clark, including taxes, capital spending projects, employee and transition services matters, the establishment of new offices and certain ongoing full-year incremental expenses such as selling, general and administrative expenses; and

- •

- we will incur interest expense related to the issuance of $225 million principal amount of 7.375% senior notes due 2014 and our entry into a credit agreement that provides for up to $150 million of secured borrowings.

For additional information about our past financial performance, see "Selected Financial Data," "Management's Discussion and Analysis of Financial Condition and Results of Operations" and our audited and unaudited historical consolidated and combined financial statements included elsewhere in this Annual Report.

Our pulp business operates in a cyclical industry which can have an impact on our operating results.

Wood pulp is a commodity for which there are multiple other suppliers. Typically, commodities businesses compete primarily on the basis of price and availability. The revenues from producing a commodity tend to be cyclical, with periods of shortage and rapidly rising prices leading to increased production and increased industry investment until supply exceeds demand. Those periods are then typically followed by periods of reduced prices and excess and idled capacity until the cycle is repeated.

14

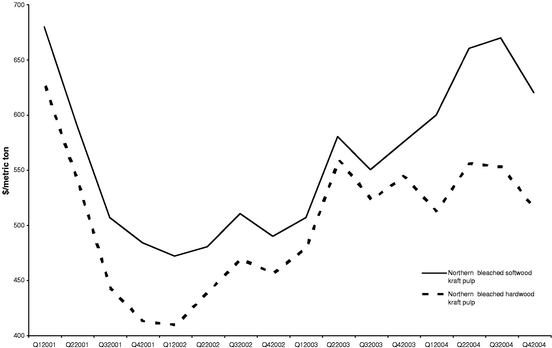

The following chart shows price information for northern softwood kraft pulp from 1980 to 2004 and illustrates the cyclical nature of the pulp industry:

Pulp Price Trends

Northern Bleached Softwood Kraft Pulp

Source: Resource Information Systems, Inc.

The markets and profitability of have been, and are likely to continue to be, cyclical. Accordingly, we must continuously and effectively manage our production and capacity to be able to respond effectively to business cycles in the pulp industry.

If we are unable to effectively respond to the significant challenges faced by our pulp business, which has experienced losses in recent periods, our financial condition and results of operations will be materially and adversely affected.

We expect that our pulp business will continue to face a number of significant challenges relating to, among other things, the cyclical nature of the pulp industry (as described in the risk factor above), our cost structure, particularly at our Terrace Bay mill, and other factors.

Because our pulp business competes primarily on the basis of price and availability, the financial success of our pulp mills depends on their ability to produce pulp at a competitive cost. Our ability to contain or reduce costs at our pulp mills is significant to our business. We believe that our Terrace Bay mill currently has an unfavorable cost structure, with the cost of wood at Terrace Bay being the single most important contributing factor.

If our pulp business had been operated on a stand-alone basis during 2004 (prior to the Spin-Off), 2003 and 2002 and if transfers of pulp to Kimberly-Clark in those years had reflected the prices at which we expect to sell pulp to Kimberly-Clark after the Spin-Off, we estimate that our pulp business would have reported gross profit (losses) of approximately $19 million, $21 million and $7 million in 2004, 2003 and 2002, respectively. Those pro forma gross profit (losses) would have represented in 2004, 2003 and 2002 a decrease in our gross profit of about $26 million, about $25 million and about $18 million, respectively. The decrease in gross profit would have resulted primarily from lower market prices for pulp during those years, the resulting prices at which we would have transferred pulp to Kimberly-Clark during those years, the high costs at our Terrace Bay mill and the impact of a

15

weakening U.S. dollar relative to the Canadian dollar in 2004 and 2003. For our pulp business to be profitable after the Spin-Off, we must reduce costs at our Terrace Bay mill even if pulp prices increase. Although we are attempting to implement strategies to reduce costs at the mill, we can give you no assurance that we will be able to reduce those costs to a level at which we can profitably sell pulp produced by our Terrace Bay mill.

For a description of additional challenges and risk factors facing our pulp business see "Management's Discussion and Analysis of Financial Condition and Results of Operations—Introduction" and "—Business Outlook."

The terms of our pulp supply agreement with Kimberly-Clark may require us to sell pulp at prices that are lower than the prices at which we may be able to sell pulp to other customers.

The pulp supply agreement that we have entered into with Kimberly-Clark requires us to supply and Kimberly-Clark to purchase pulp from our Pictou and Terrace Bay mills over several years. The prices at which we sell pulp to Kimberly-Clark under the new supply agreement reflect a discount from published industry index prices that may be greater than the discount reflected in sales to other customers, particularly during periods in which demand for pulp exceeds supply. The pulp supply agreement also contains minimum and maximum prices for northern bleached softwood kraft pulp shipped to North America prior to December 31, 2007 which may result in us charging Kimberly-Clark prices that are lower than those we could obtain from other customers.

Furthermore, the new pulp supply agreement is a supply-or-pay arrangement. Accordingly, if we do not supply the required minimum quantities of pulp to Kimberly- Clark, we must pay Kimberly-Clark for the shortfall based on the difference between the contract price and any higher price that Kimberly-Clark otherwise pays to purchase the pulp, plus 10% of the difference. If such an event were to occur, our business could be materially adversely affected.

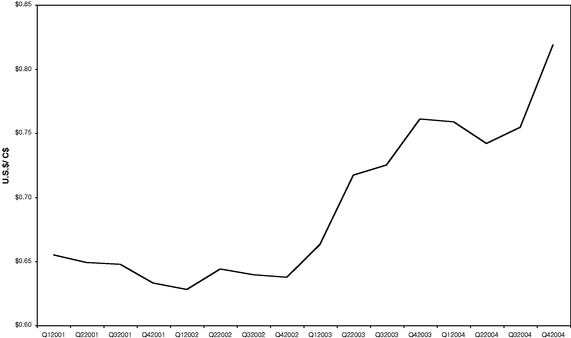

Fluctuations in currency exchange rates could adversely affect our results.

Changes in the Canadian dollar exchange rate relative to the U.S. dollar have an effect on our results of operations and cash flows. Exchange rate fluctuations can have a material impact on our financial results because substantially all of our pulp mills' expenses are incurred in Canadian dollars and our pulp revenues are denominated in U.S. dollars. For example, in 2004, a hypothetical $0.01 increase in the Canadian dollar relative to the U.S. dollar would have decreased our income before income taxes by approximately $6 million, excluding additional currency remeasurement losses. We anticipate continued strength for the Canadian dollar relative to the U.S. dollar. See "Management's Discussion and Analysis of Financial Condition and Results of Operations—Business Outlook."

We use hedging arrangements to reduce our exposure to exchange rate fluctuations, although these arrangements could result in us incurring higher costs than we would incur without the arrangements.

16

The following chart shows changes in the U.S./Canadian dollar exchange rate from 1980 to 2004:

U.S. $/Canadian $ Exchange Rate History

Source: Resource Information Systems, Inc.

In addition, because we transact business in other foreign countries, some of our revenues and expenses are denominated in a currency other than the local currency of our operations. As a result, changes in exchange rates between the currency in which the transaction is denominated and the local currency of our operations into which the transaction is being recorded can impact the amount of local currency recorded for such transaction. This can result in more or less local currency revenues or costs related to such transaction, and thus have an effect on our income before income taxes.

The availability of and prices for raw materials and energy will significantly impact our business.

We purchase a substantial portion of the raw materials and energy necessary to produce our products on the open market, and, as a result, the price and other terms of those purchases are subject to change based on factors such as worldwide supply and demand and government regulation. We do not have significant influence over our raw material or energy prices and generally do not possess enough power to pass increases in those prices along to purchasers of our products, unless those increases coincide with increased demand for the product. Therefore, raw material or energy prices could increase at the same time that prices for our products are decreasing. In addition, we may not be able to recoup other cost increases we may experience, such as those resulting from inflation or from increases in wages or salaries or increases in the health, pension or other employee benefits costs, insurance costs or other costs.

We obtain most of the wood fiber we require for our Terrace Bay pulp mill and a portion of the wood fiber required for our Pictou pulp mill from timberland areas licensed by the Ontario and Nova Scotia provincial governments, respectively. These governments have granted us non-exclusive licenses for substantial timberland areas from which we obtain fiber, and we also obtain fiber harvested from timberland areas licensed to others by these governments. There can be no assurance that the amount of fiber that we are allowed to harvest from these licensed areas will not be decreased, or that our licenses will continue to be renewed or extended by the governments on acceptable terms. In each of

17

the areas where our Canadian pulp mills are located, there is increasing competition for wood fiber from various other users. Concerns over the sustainability of forestry practices, particularly in the "boreal forest" area of northern Canada, may also lead to reductions in the timberlands available for harvest to supply our pulp mills. A number of North American non-governmental environmental organizations have launched a campaign to permanently set aside and protect from harvesting significant portions of boreal forest, including portions of the timberlands that supply wood to the Terrace Bay mill. In addition, aboriginal groups have made land claims against various levels of government which, if successful, would further reduce the timberlands from which wood could be harvested for our mills. Changes in governmental practices and policies as they apply to us and to others from whom we obtain fiber also may result in less fiber being available, increased costs to obtain the fiber and additional expense in meeting forestry and silvicultural standards. These results could have a material adverse effect upon our financial position, liquidity and results of operations.

In addition, in 2004, over 60% of the wood chips used by the Pictou mill were supplied by two suppliers, and approximately 55% of the wood chips used by the Terrace Bay mill were supplied by one supplier. While we believe that alternative sources of critical supplies, such as wood chips, would be available, disruption of our primary sources could create a temporary, adverse effect on product shipments. Also, an interruption in supply of a latex specialty grade to our technical paper business, which we currently obtain from a single source, could disrupt and eventually cause a shutdown of production of certain technical paper latex specialty grades.

Our mills may experience unexpected or prolonged shutdowns, which would adversely affect our financial position and results of operations.

Our pulp mills require annual shutdowns to perform major maintenance because they normally operate continuously. We generally schedule shutdowns of two weeks each year at our mills. The annual scheduled shutdown of our pulp mills impacts our profitability and cash flow in the fiscal quarter in which the shutdown occurs. The annual pulp mill maintenance shutdowns at Terrace Bay and Pictou occurred in September and October 2004, which resulted in substantially lower operating results and lower production volumes for those months. In addition to scheduled shutdowns, as described above, depressed pulp prices may cause pulp mills to shut down for a period of time if pulp prices fall to a level where it would be uneconomic to operate the mill.

Unexpected production disruptions could also cause us to shut down any of our mills. Those disruptions could occur due to any number of circumstances, including shortages of raw materials, disruptions in the availability of transportation, labor disputes and mechanical or process failures. Specifically, the failure of any of our recovery boilers would result in a significant disruption to our business.

If our mills are shut down, they may experience prolonged startup periods, regardless of the reason for the shutdown. Those startup periods could range from several days to several weeks, depending on the reason for the shutdown and other factors. The shutdown of any of our mills for a substantial period of time for any reason could have a material adverse effect on our financial position and results of operations.

The results of our pulp business will depend on our pulp supply agreement with Kimberly-Clark and our ability to supply other customers.

The historical results of our pulp business have been based almost entirely on pulp transfers to Kimberly-Clark. Kimberly-Clark is our largest customer and purchases pulp from us pursuant to the terms of a pulp supply agreement. If the pulp supply agreement were to be terminated, our financial condition and results of operations would be materially and adversely affected.

We have begun to supply increasing quantities of pulp to customers other than Kimberly-Clark. The success of our pulp business will depend in part upon our ability to effectively market our pulp to

18

new customers, to earn customer acceptance of our pulp and to continue to effectively supply those new customers. If we are unable to effectively market our pulp to customers other than Kimberly- Clark, our financial condition, results of operations and liquidity would be materially and adversely affected.

Our business will suffer if we are unable to effectively respond to decreased demand for some of our products.

We have experienced and may continue to experience decreased demand for some of our existing products. For example, our fine paper business has experienced decreased demand as a result of the growing use of digital and electronic communications media, while our technical paper business must cope with a trend to replace durable papers with synthetic films. Our pulp business, and in particular the northern bleached hardwood kraft pulp produced at our Terrace Bay mill, must compete with an increasing supply of, and in some cases customer preference for, lower priced eucalyptus pulps produced by competitors in the southern hemisphere. If we are unable to implement our business strategies to develop new sources of demand to effectively respond to decreased demand for our existing products, our financial position and results of operations would be adversely affected.

Our activities are subject to extensive government regulation, which could increase our costs, cause us to incur liabilities and adversely affect the manufacturing and marketing of our products.

Our operations are subject to federal, state, provincial and local laws, regulations and ordinances in both the United States and Canada relating to various environmental, health and safety matters. The nature of our operations requires that we invest capital and incur operating costs to comply with those laws, regulations and ordinances and exposes us to the risk of claims concerning non-compliance with environmental, health and safety laws or standards. We cannot assure you that significant additional expenditures will not be required to maintain compliance with, or satisfy potential claims arising from, such laws, regulations and ordinances. Future events, such as changes in existing laws and regulations, increasingly strict enforcement policies or contamination of sites owned, operated or used for waste disposal by us (including currently unknown contamination and contamination caused by prior owners and operators of such sites or other waste generators) may give rise to additional costs that could require significantly increased capital expenditures and operating costs, which would reduce the funds otherwise available for operations, capital expenditures, future business opportunities or other purposes. For example, the ratification of the Kyoto Protocol by Canada may result in lower limits for the emission of carbon dioxide and other greenhouse gases. The specific limitations in respect of our Canadian operations are unknown and uncertain and may increase costs.

The outcome of legal actions and claims may adversely affect us.

We are involved in legal actions and claims arising in the ordinary course of our business. As described under "Legal Proceedings," we will indemnify Kimberly-Clark for certain liabilities and costs arising out of a lawsuit involving a vehicle accident in which the plaintiff sustained severe injuries, including paralysis, as a result of the accident. The outcome of that lawsuit and other legal actions and claims against us cannot be predicted with certainty. That lawsuit and other legal actions and claims against us could have a material adverse effect on our financial condition, results of operations and liquidity.

We have significant pension liabilities.

We have significant pension liabilities which could require future funding beyond that which we have funded in the past or which we currently anticipate. For example, in 2004 total contributions to our pension trust were $16.6 million. A material increase in funding requirements could have a material adverse effect on our cash flows and liquidity.

19

The markets for all of our products are affected by general economic conditions.

The markets for all of our products are affected to a significant degree by general economic conditions. Any downturn in the U.S. economy or in our export markets could adversely affect our business.

Labor interruptions would adversely affect our business.

All of our hourly paid employees are unionized. In addition, some of our key customers and suppliers are also unionized. Several of our labor agreements have expired or are scheduled to expire in 2005. Strikes, lockouts or other work stoppages or slow downs involving our unionized employees could have a material adverse effect on us.

Our operating results are likely to fluctuate.

Our operating results are subject to substantial quarterly and annual fluctuations due to a number of factors, many of which are beyond our control. Such factors may include, among others, the effects of competitive pricing pressures, decreases in average selling prices of our products, production capacity levels and manufacturing yields, availability and cost of products from our suppliers, the gain or loss of significant customers, our ability to develop, introduce and market new products and technologies on a timely basis, changes in the mix of products produced and sold, seasonal customer demand and environmental costs. Operating results also could be adversely affected by increasing interest rates and other general economic and other conditions causing a downturn in the market for paper products. The foregoing factors are difficult to forecast, and these or other factors could materially adversely affect our quarterly or annual operating results.

We face many competitors, several of which have greater financial and other resources.

We face competition in each of our business segments from companies that produce the same type of products that we produce or that produce alternative products that customers may use instead of our products. Many of our competitors have greater financial, sales and marketing, or research and development resources than we do. Greater financial resources and product development capabilities may also allow our competitors to respond more quickly to new opportunities or changes in customer requirements.

Risks Related to the Spin-Off and Our Separation from Kimberly-Clark

We could incur significant tax liabilities if the Spin-Off becomes a taxable event.

Kimberly-Clark received a private letter ruling from the U.S. Internal Revenue Service regarding the U.S. federal income tax consequences of the Spin-Off substantially to the effect that, for U.S. federal income tax purposes, the transfer of our business to us by Kimberly-Clark and the distribution of our common stock qualified as a tax-free transaction under Sections 368(a)(1)(D) and 355 of the Internal Revenue Code of 1986, as amended. Although the private letter ruling is generally binding on the Internal Revenue Service, if the factual representations and assumptions made in the private letter ruling were incorrect in any material respect at the time of the Spin-Off, the private letter ruling could be retroactively revoked or modified by the Internal Revenue Service. If, notwithstanding the private letter ruling, the Spin-Off is determined to be a taxable transaction, our stockholders and Kimberly-Clark could be subject to significant U.S. federal income tax liability.

The Spin-Off could become taxable as a result of actions or events that occur after the Spin-Off. In that case, we and Kimberly-Clark could be liable for, and we could be required to indemnify and pay Kimberly-Clark for, taxes and resulting liabilities imposed upon Kimberly-Clark stockholders with respect to the Spin-Off. As part of the Spin-Off, we entered into a tax sharing agreement with Kimberly-Clark that allocated between Kimberly-Clark and us the taxes and liabilities relating to any failure of the Spin-Off to be tax-free.

20

The Spin-Off could become taxable to Kimberly-Clark (but not its stockholders) under Section 355(e) of the Internal Revenue Code if, pursuant to a plan or series of transactions related to the Spin-Off, we engage in, or enter into an agreement to engage in, a transaction that would result in a 50% or greater change by vote or value in our stock ownership, or if Kimberly-Clark engages in, or enters into an agreement to engage in, a transaction that would result in a 50% or greater change by vote or value in its stock ownership. Such transactions are presumed to occur pursuant to a plan or series of transactions related to the Spin-Off if they occur during the four-year period beginning on the date that begins two years before the date of the Spin-Off, unless it is established that such transactions did not occur pursuant to a plan or series of transactions related to the Spin-Off. If an acquisition or issuance of our stock causes the Spin-Off to be taxable to Kimberly-Clark under Section 355(e), we would be required to indemnify Kimberly-Clark against that tax.

Both Kimberly-Clark and its stockholders could be taxed on the Spin-Off if the Spin-Off were to not qualify for tax-free treatment for U.S. federal income tax purposes for other reasons.

Although the taxes described above generally would be imposed on Kimberly-Clark and its stockholders, under the tax sharing agreement, we may be required to indemnify Kimberly-Clark for all or a portion of these taxes. In addition, under U.S. federal income tax laws, we and Kimberly-Clark would both be liable for Kimberly-Clark's U.S. federal income taxes resulting from the Spin-Off being taxable even though Kimberly-Clark may be required under the tax sharing agreement to indemnify us for such taxes. If we were to be required to indemnify Kimberly-Clark for taxes incurred as a result of the Spin-Off being taxable, or were otherwise liable for and required to pay such taxes and were not indemnified for such taxes, it would have a material adverse effect on our profitability and financial condition.

We may not realize potential benefits from our separation from Kimberly-Clark.

We cannot assure you that we will realize the potential benefits that we expected from our separation from Kimberly-Clark. In addition, we will incur significant costs, which may be greater than those for which we have planned, and we will bear the negative effects of our separation from Kimberly-Clark, including loss of access to the financial, managerial and professional resources from which we have benefited in the past.

Prior to the Spin-Off, we had not previously operated as an independent company, and our new management team has been assembled for only a short time.