SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 10-K

(Mark One)

| | þ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2010

OR

| | ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File No. 001-32331

ALPHA NATURAL RESOURCES, INC.

(Exact name of registrant as specified in its charter)

| Delaware | 42-1638663 |

| (State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification Number) |

| | |

| One Alpha Place, P.O. Box 2345, Abingdon, Virginia | 24212 |

| (Address of principal executive offices) | (Zip Code) |

Registrant's telephone number, including area code:

(276) 619-4410

Securities registered pursuant to Section 12(b) of the Act:

| Title of Each Class | Name of Each Exchange on Which Registered |

| Common stock, $0.01 par value | New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes þ No ¨

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No þ

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes þ No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes þ No

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. þ

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer þ | Accelerated filer o | Non-accelerated filer o | Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Exchange Act Rule 12b-2). Yes ¨ No þ

The aggregate market value of the Common Stock held by non-affiliates of the registrant on June 30, 2010, was approximately $2.7 billion based on the closing price of the Company’s common stock as reported that date on the New York Stock Exchange of $33.87 per share. In determining this figure, the registrant has assumed that all of its directors and executive officers are affiliates. Such assumptions should not be deemed to be conclusive for any other purpose.

Common Stock, $0.01 par value, outstanding as of February 18, 2011 – 120,483,943 shares.

DOCUMENTS INCORPORATED BY REFERENCE

Part III incorporates certain information by reference from the registrant's definitive proxy statement for the 2011 annual meeting of stockholders (the “Proxy Statement”), which will be filed no later than 120 days after the close of the registrant's fiscal year ended December 31, 2010.

2010 ANNUAL REPORT ON FORM 10-K TABLE OF CONTENTS

| | | | | Page |

| PART I | | | | |

| | | | | |

| Item 1. | | | | 5 |

| | | | | |

| Item 1A. | | | | 29 |

| | | | | |

| Item 1B. | | | | 46 |

| | | | | |

| Item 2. | | | | 46 |

| | | | | |

| Item 3. | | | | 51 |

| | | | | |

| Item 4. | | | | 51 |

| | | | | |

| PART II | | | | |

| | | | | |

| Item 5. | | | | 52 |

| | | | | |

| Item 6. | | | | 55 |

| | | | | |

| Item 7. | | | | 59 |

| | | | | |

| Item 7A. | | | | 85 |

| | | | | |

| Item 8. | | | | 86 |

| | | | | |

| Item 9. | | | | 158 |

| | | | | |

| Item 9A. | | | | 158 |

| | | | | |

| Item 9B. | | | | 160 |

| | | | | |

| PART III | | | | |

| | | | | |

| Item 10. | | | | 160 |

| | | | | |

| Item 11. | | | | 160 |

| | | | | |

| Item 12. | | | | 160 |

| | | | | |

| Item 13. | | | | 160 |

| | | | | |

| Item 14. | | | | 160 |

| | | | | |

| PART IV | | | | |

| | | | | |

| Item 15. | | | | 161 |

CAUTIONARY NOTE REGARDING FORWARD LOOKING STATEMENTS

This report includes statements of our expectations, intentions, plans and beliefs that constitute “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934 and are intended to come within the safe harbor protection provided by those sections. These statements, which involve risks and uncertainties, relate to analyses and other information that are based on forecasts of future results and estimates of amounts not yet determinable and may also relate to our future prospects, developments and business strategies. We have used the words “anticipate”, “believe”, “could”, “estimate”, “expect”, “intend”, “may”, “plan”, “predict”, “ project”, “should” and similar terms and phrases, including references to assumptions, in this report to identify forward-looking statements. These forward-looking statements are made based on expectations and beliefs concerning future events affecting us and are subject to uncertainties and factors relating to our operations and business environment, all of which are difficult to predict and many of which are beyond our control, that could cause our actual results to differ materially from those matters expressed in or implied by these forward-looking statements.

The following factors are among those that may cause actual results to differ materially from our forward-looking statements:

| | · | worldwide market demand for coal, electricity and steel; |

| | · | global economic, capital market or political conditions, including a prolonged economic recession in the markets in which we operate; |

| | · | our liquidity, results of operations and financial condition; |

| | · | regulatory and court decisions; |

| | · | competition in coal markets; |

| | · | changes in environmental laws and regulations, including those directly affecting our coal mining and production, and those affecting our customers' coal usage, including potential carbon or greenhouse gas related legislation; |

| | · | changes in safety and health laws and regulations and the ability to comply with such changes; |

| | · | availability of skilled employees and other employee workforce factors, such as labor relations; |

| | · | the inability of our third-party coal suppliers to make timely deliveries and the refusal by our customers to receive coal under agreed contract terms; |

| | · | the inability to collect payments from customers if their creditworthiness declines; |

| | · | potential instability and volatility in worldwide financial markets; |

| | · | future legislation and changes in regulations, governmental policies or taxes or changes in interpretation thereof; |

| | · | inherent risks of coal mining beyond our control; |

| | · | disruption in coal supplies; |

| | · | the geological characteristics of the Powder River Basin, Central and Northern Appalachian coal reserves; |

| | · | our production capabilities and costs; |

| | · | our ability to integrate successfully operations that we may acquire or develop in the future, including those of Massey Energy Company, or the risk that any such integration could be more difficult, time-consuming or costly than expected; |

| | · | our plans and objectives for future operations and expansion or consolidation; |

| | · | the consummation of financing transactions, acquisitions or dispositions and the related effects on our business, including financing related to our proposed acquisition of Massey Energy Company; |

| | · | the outcome of pending or potential litigation or governmental investigations; |

| | · | the ability to obtain governmental approvals of the merger with Massey Energy Company ("Massey Merger") on the proposed terms and schedule; |

| | · | the timing and completion of the Massey Merger, including the approval of the transaction at the Alpha special meeting and the Massey special meeting; |

| | · | uncertainty of the expected financial performance of Alpha following completion of the Massey Merger; |

| | · | our ability to achieve the cost savings and synergies contemplated by the Massey Merger within the expected time frame; |

| | · | disruption from the Massey Merger making it more difficult to maintain relationships with customers, employees or suppliers; |

| | · | the calculations of, and factors that may impact the calculations of, the acquisition price in connection with the Massey Merger and the allocation of such acquisition price to the net assets acquired in accordance with applicable accounting rules and methodologies; |

| | · | our relationships with, and other conditions affecting, our customers; |

| | · | reductions or increases in customer coal inventories and the timing of those changes; |

| | · | changes in and renewal or acquisition of new long-term coal supply arrangements; |

| | · | railroad, barge, truck and other transportation availability, performance and costs; |

| | · | availability of mining and processing equipment and parts; |

| | · | disruptions in delivery or changes in pricing from third party vendors of goods and services that are necessary for our operations, such as diesel fuel, steel products, explosives and tires; |

| | · | our assumptions concerning economically recoverable coal reserve estimates; |

| | · | our ability to obtain, maintain or renew any necessary permits or rights, and our ability to mine properties due to defects in title on leasehold interests; |

| | · | our ability to negotiate new UMWA wage agreements on terms acceptable to us; |

| | · | changes in postretirement benefit obligations, pension obligations and federal and state black lung obligations; |

| | · | increased costs and obligations potentially arising from the Patient Protection and Affordable Care Act; |

| | · | fair value of derivative instruments not accounted for as hedges that are being marked to market; |

| | · | indemnification of certain obligations not being met; |

| | · | continued funding of the road construction business, related costs, and profitability estimates; |

| | · | restrictive covenants in our secured credit facility and the indentures governing the 7.25% notes due 2014 and the 2.375% convertible senior notes due 2015 |

| | · | certain terms of the 7.25% notes due 2014 and the 2.375% convertible senior notes due 2015, including any conversions, that may adversely impact our liquidity; |

| | · | weather conditions or catastrophic weather-related damage; and |

| | · | other factors, including those discussed in Item 1A “Risk Factors” of this Annual Report on Form 10-K. |

When considering these forward-looking statements, you should keep in mind the cautionary statements in this report and the documents incorporated by reference. We do not undertake any responsibility to release publicly any revisions to these forward-looking statements to take into account events or circumstances that occur after the date of this report. Additionally, we do not undertake any responsibility to update you on the occurrence of any unanticipated events, which may cause actual results to differ from those expressed or implied by the forward-looking statements contained in this report.

Overview

On July 31, 2009, Alpha Natural Resources, Inc. (“Old Alpha”) and Foundation Coal Holdings, Inc. (“Foundation”) merged (the “Foundation Merger”) with Foundation continuing as the surviving legal corporation of the Foundation Merger which was renamed Alpha Natural Resources, Inc. (“Alpha”). For financial accounting purposes, the Foundation Merger was treated as a “reverse acquisition” and Old Alpha was treated as the accounting acquirer. Accordingly, Old Alpha’s financial statements became the financial statements of Alpha and Alpha’s periodic filings subsequent to the Foundation Merger reflect Old Alpha’s historical financial condition and results of operations shown for comparative purposes. Old Alpha’s results of operations for the year ended December 3 1, 2008 do not include financial results for Foundation. For the year ended December 31, 2009, Foundation’s financial results are included for the five month period following the Foundation Merger from August 1, 2009 through December 31, 2009.

Unless we have indicated otherwise, or the context otherwise requires, references in this report to “Alpha”, “we”, “us” and “our” or similar terms are to Alpha and its consolidated subsidiaries in reference to dates subsequent to the Foundation Merger and to Old Alpha and its consolidated subsidiaries in reference to dates prior to the Foundation Merger.

We are one of America’s premier coal suppliers, ranked third largest among publicly-traded U.S. coal producers as measured by 2010 consolidated revenues of $3.9 billion. We are the nation’s leading supplier and exporter of metallurgical coal for use in the steel-making process and a major supplier of thermal coal to electric utilities and manufacturing industries across the country. We operate 66 mines and 13 coal preparation plants in Northern and Central Appalachia and the Powder River Basin, with approximately 6,500 employees.

We have two reportable segments: Eastern Coal Operations and Western Coal Operations. Eastern Coal Operations consists of the mines in Northern and Central Appalachia, our coal brokerage activities and our road construction business. Western Coal Operations consists of two Powder River Basin mines in Wyoming. Our All Other category includes an idled underground mine in Illinois; expenses associated with certain closed mines; Maxxim Rebuild and Dry Systems Technologies; revenues and royalties from the sale of coalbed methane and natural gas extraction; terminal services; the leasing of mineral rights; general corporate overhead and corporate assets and liabilities.

Steam coal, which is primarily purchased by large utilities and industrial customers as fuel for electricity generation, accounted for approximately 86% of our 2010 coal sales volume. Metallurgical coal, which is used primarily to make coke, a key component in the steel making process, accounted for approximately 14% of our 2010 coal sales volume. Metallurgical coal generally sells at a premium over steam coal because of its higher quality and its value in the steelmaking process as the raw material for coke. We believe that the volume of the coal we sell will grow when and if demand for power and steel increases.

During 2010, we sold a total of 84.8 million tons of steam and metallurgical coal and generated coal revenues of $3.5 billion, EBITDA from continuing operations of $769.1 million and income from continuing operations of $97.2 million. We define and reconcile EBITDA from continuing operations in Item 6-“Selected Financial Data.” Our coal sales during 2010 consisted of 82.6 million tons of produced and processed coal, including 0.8 million tons purchased from third parties and processed at our processing plants or loading facilities prior to resale, and 2.2 million tons of purchased coal which we resold without processing. Approximately 73% of the coal we purchased in 2010 was blended with coal produced from our mines prior to resale. Approximately 35% of our coal revenues combined with freight and hand ling revenues in 2010 was derived from sales made outside the United States, primarily in Brazil, Italy, India, Turkey and Ukraine.

As of December 31, 2010, we owned or leased approximately 2.3 billion tons of proven and probable coal reserves. Of our total proven and probable reserves, approximately 63% are low sulfur reserves, with approximately 53% having sulfur content below 1%. Approximately 64% of our total proven and probable reserves have a high Btu content which creates more energy per unit when burned compared to coals with lower Btu content. We believe that our total proven and probable reserves will support current production levels for more than 20 years.

On January 29, 2011, Alpha and Massey Energy Company (“Massey”) announced a signed definitive agreement under which we will acquire all outstanding shares of Massey common stock, subject to customary closing conditions including stockholder approval of both companies and customary regulatory approvals. Under the terms of the agreement, Massey stockholders will receive, upon consummation of the Massey Merger, 1.025 shares of Alpha common stock and $10.00 in cash for each share of Massey common stock. Upon consummation of the Massey Merger, Alpha and Massey stockholders will own approximately 54% and 46% of the combined company, respectively. The Massey Merger will bring together Alpha’s and Massey’s highly complementary assets, which will include more than 110 mines and combined coal reserves of approxima tely 5.1 billion tons, including one of the world’s largest and highest-quality metallurgical coal reserve bases.

History

Old Alpha was formed under the laws of the State of Delaware on November 29, 2004. On February 15, 2005, an initial public offering of Old Alpha’s common stock occurred and since then, we have grown substantially through a series of acquisitions including the Foundation Merger in 2009 discussed above.

During 2006, Old Alpha acquired certain coal mining operations in eastern Kentucky from Progress Fuels Corp, a subsidiary of Progress Energy. These operations are adjacent to our Enterprise operations and were integrated with Enterprise.

During 2007, Old Alpha completed the acquisition of certain coal mining assets in western West Virginia known as Mingo Logan from Arch Coal, Inc. The Mingo Logan purchase consisted of coal reserves, one active deep mine and a load-out and processing plant, which is managed by our Callaway operations.

During 2008:

| | • | Our subsidiary, Alpha Terminal Company, LLC, increased its equity ownership position in Dominion Terminal Associates (“DTA”) from approximately 33% to approximately 41%, effectively increasing our coal export and terminal capacity at DTA from approximately 6.5 million tons to approximately 8.0 million tons annually. DTA is a 20 million-ton annual capacity coal export terminal located in Newport News, Virginia. |

| | • | Old Alpha sold its interest in Gallatin Materials LLC (“Gallatin”), a start-up lime manufacturing business in Verona, Kentucky, for cash in the amount of $45.0 million. The proceeds were used in part to repay the Gallatin loan facility outstanding with NedBank Limited in the amount of $18.2 million. Old Alpha recorded a gain on the sale of $13.6 million in the third quarter of 2008. |

| | • | Old Alpha entered into a definitive merger agreement pursuant to which, and subject to the terms and conditions thereof, Cliffs Natural Resources Inc. (formerly known as Cleveland Cliffs Inc.) (“Cliffs”) would acquire all of Old Alpha’s outstanding shares. On November 3, 2008, Old Alpha commenced litigation against Cliffs by filing an action in the Delaware Court of Chancery to obtain an order requiring Cliffs to hold its scheduled shareholder meeting. During the fourth quarter of 2008, Old Alpha and Cliffs mutually terminated the merger agreement and settled the litigation. The terms of the settlement agreement included a $70.0 million payment from Cliffs to Old Alpha which, net of transaction costs, resulted in a gain of $56.3 million. |

| | • | Old Alpha announced the permanent closure of the Whitetail Kittanning Mine, an adjacent coal preparation plant and other ancillary facilities (“Kingwood”). The mine stopped producing coal in early January 2009 and we ceased equipment recovery operations by the end of April 2009. The decision resulted from adverse geologic conditions and regulatory requirements that rendered the coal seam unmineable at this location. Old Alpha recorded a charge of $30.2 million in the fourth quarter of 2008, which includes asset impairment charges of $21.2 million, write off of advance mining royalties of $3.8 million, which will not be recoverable, severance and other employee benefit costs of $3.6 million and increased reclamation obligations of $1.9 million. |

| | • | Approximately 17.6 million tons of underground coal reserves in eastern Kentucky that Old Alpha had originally acquired as part of the Progress acquisition were sold to a private coal producer for approximately $13.0 million in cash. |

During 2010, we entered into a 50/50 joint venture with Rice Energy, LP through which we are developing our Marcellus Shale natural gas resource in southwestern Pennsylvania, where we control nearly 20,000 acres of one of the Marcellus’ most productive regions.

Competitive Strengths

We believe that the following competitive strengths enhance our prominent position in the United States:

We are the third largest publicly traded coal producer in the United States based on 2010 consolidated revenues and have significant coal reserves. Based on 2010 consolidated revenues of $3.9 billion, we are the third largest publicly traded coal producer in the United States. As of December 31, 2010, we controlled approximately 2.3 billion tons of proven and probable coal reserves.

We have a diverse portfolio of coal mining operations and reserves. We operate a total of 66 mines and have reserves in the three major U.S. coal producing regions: Northern and Central Appalachia and the Powder River Basin. Our mines are located in Wyoming, Pennsylvania, West Virginia, Virginia, Illinois and Kentucky. We sell coal to domestic and foreign electric utilities, steel producers and industrial users. We believe we are the only producer with significant operations and major reserve blocks in both the Powder River Basin and Northern Appalachia, two U.S. coal production regions for which future demand is expected to increase. We believe that this geographic diversity provides us with a significant competitive advantage, allowing us to source coal from mu ltiple regions to meet the needs of our customers and reduce their transportation costs.

We are a recognized industry leader in safety and environmental performance. Our focus on safety and environmental performance results in a lower likelihood of disruption of production at our mines, which leads to higher productivity and improved financial performance. We operate some of the nation’s safest mines, with 2010 total injury incident rates, as tracked by the Mine Safety and Health Administration (“MSHA”), below industry averages.

Our ability to blend coals from our operations allows us to increase our coal revenues and gross margins while meeting our customer requirements. The strategic locations of our mines and preparation plants provide us the ability to blend coals from our operations and increase coal revenues and gross margins while meeting our customer requirements.

We have long-standing relationships and long-term contracts with many of the largest coal-burning utilities in the United States. We supply coal to numerous power plants operated by a diverse group of electricity generators across the country. We believe we have a reputation for reliability and superior customer service that has enabled us to solidify our customer relationships.

We are the largest producer of metallurgical coal in the United States and have access to international customers. We are the largest producer of metallurgical coal in the United States and have the ability to serve international customers. We have the capacity to ship approximately 8 million tons annually through our 41% ownership interest in DTA and through our access to other international shipping points.

Our management team has a track record of success. Our management team has a proven record of generating free cash flow, reducing costs, developing and maintaining long-standing customer relationships and effectively positioning us for future growth and profitability.

Business Strategy

Our objective is to increase shareholder value through sustained earnings growth and free cash flow generation. Our key strategies to achieve this objective are described below:

Maintaining our commitment to operational excellence. We seek to maintain our operational excellence with an emphasis on investing selectively in new equipment and advanced technologies. We will continue to focus on profitability and efficiency by leveraging our significant economies of scale, large fleet of mining equipment, information technology systems and coordinated purchasing and land management functions. In addition, we continue to focus on productivity through our culture of workforce involvement by leveraging our strong base of experienced, well-trained employees.

Capitalizing on industry dynamics through a balanced approach to selling our coal. Despite the volatility in coal prices over the past several years, we believe the long-term fundamentals of the U.S. coal industry are favorable. We plan to continue employing a balanced approach to selling our coal, including the use of long-term sales commitments for a portion of our future production while maintaining uncommitted planned production to capitalize on favorable future pricing environments.

Selectively expanding our production and reserves. Given our broad scope of operations and expertise in mining in major coal-producing regions in the United States, we believe that we are well-situated to capitalize on the expected continued growth in U.S. and international coal consumption by evaluating growth opportunities, including expansion of production capacity at our existing mining operations, further development of existing significant reserve blocks in Northern and Central Appalachia, and potential strategic acquisition opportunities that arise in the United States or internationally. We will prudently act to expand our reserves when appropriate.

Continuing to provide a mix of coal types and qualities to satisfy our customers’ needs. By having operations and reserves in three major coal producing regions, we are able to source and blend coal from multiple mines to meet the needs of our domestic and international customers. Our broad geographic scope and mix of coal qualities provide us with the opportunity to work with many leading electricity generators, steel companies and other industrial customers across the country.

Continuing to focus on excellence in safety and environmental stewardship. We intend to maintain our recognized leadership in operating some of the safest mines in the United States and in achieving environmental excellence. Our ability to minimize workplace incidents and environmental violations improves our operating efficiency, which directly improves our cost structure and financial performance.

Coal Mining Techniques

We use four different mining techniques to extract coal from the ground: longwall mining, room-and-pillar mining, truck-and-shovel mining and truck and front-end loader mining.

Longwall Mining

We utilize longwall mining techniques at our Pennsylvania Services business unit. Longwall mining is the most productive and safest underground mining method used in the United States. A rotating drum is trammed mechanically across the face of coal, and a hydraulic system supports the roof of the mine while the drum advances through the coal. Chain conveyors then move the loosened coal to a standard underground mine conveyor system for delivery to the surface. Continuous miners are used to develop access to long rectangular blocks of coal which are then mined with longwall equipment, allowing controlled subsidence behind the advancing machinery. Longwall mining is highly productive and most effective for large blocks of medium to thick coal seams. High capital costs associated with longwall mining demand large, contiguous reserves. Ultim ate seam recovery of in-place reserves using longwall mining is much higher than the room-and-pillar mining underground technique. All of the raw coal mined at our longwall mines is washed in preparation plants to remove rock and impurities.

Room-and-Pillar Mining

Our AMFIRE, Southern West Virginia, Northern West Virginia, and Virginia/Kentucky business units utilize room-and-pillar mining methods. In this type of mining, main airways and transportation entries are developed and maintained while remote-controlled continuous miners extract coal from so-called rooms by removing coal from the seam, leaving pillars to support the roof. Shuttle cars and battery coal haulers are used to transport coal to the conveyor belt for transport to the surface. This method is more flexible than longwall mining and often used to mine smaller coal blocks or thin seams. Ultimate seam recovery of in-place reserves is typically less than that achieved with longwall mining. All of this production is also washed in preparation plants before it becomes saleable clean coal.

Truck-and-Shovel Mining and Truck and Front-End Loader Mining

We utilize truck-and-shovel mining methods in both of our mines in the Powder River Basin. We utilize the truck and front-end loader method at the surface mines in our AMFIRE, Southern West Virginia, Northern West Virginia, and Virginia/Kentucky business units. These methods are similar and involve using large, electric or hydraulic-powered shovels or diesel-powered front-end loaders to remove earth and rock (overburden) covering a coal seam which is later used to refill the excavated coal pits after the coal is removed. The loading equipment places the coal into haul trucks for transportation to a preparation plant or loadout area. Ultimate seam recovery of in-place reserves on average exceeds 90%. This surface-mined coal rarely needs to be cleaned in a preparation plant before sale. Productivity depends on overburden and coal thickness (strip ratio), equipment utilized and geologic factors.

Coal Characteristics

In general, coal of all geological compositions is characterized by end use as either steam coal or metallurgical coal. Heat value, sulfur and ash content, and in the case of metallurgical coal, volatility, are the most important variables in the profitable marketing and transportation of coal. These characteristics determine the best end use of a particular type of coal. We mine, process, market and transport sub-bituminous and bituminous coal, characteristics of which are described below.

Heat Value. The heat value of coal is commonly measured in British thermal units, or “Btus.” A Btu is the amount of heat needed to raise the temperature of one pound of water by one degree Fahrenheit. Alpha mines both sub-bituminous and bituminous coal. Bituminous coal is located primarily in Appalachia, Arizona, the Midwest, Colorado, Wyoming and Utah and is the type most commonly used for electric power generation in the United States. Sub-bituminous coal is used for industrial steam purposes, while bituminous coal, depending on its quality, can be used for both metallurgical and industrial steam purposes. Of our estimated 2.3 billion tons of proven and probable reserves, approximately 64% have a heat value above 12,500 Btus per pound, which is considered high bt u coal.

Sulfur Content. Sulfur content can vary from seam to seam and sometimes within each seam. When coal is burned, it produces sulfur dioxide, the amount of which varies depending on the chemical composition and the concentration of sulfur in the coal. Low sulfur coals have a sulfur content of 1.5% or less. Approximately 63% of our proven and probable reserves are low sulfur coal.

High sulfur coal can be burned in plants equipped with sulfur-reduction technology, such as scrubbers, which can reduce sulfur dioxide emissions by 50% to 90%. Plants without scrubbers can burn high sulfur coal by blending it with lower sulfur coal or by purchasing emission allowances on the open market, allowing the user to emit a predetermined amount of sulfur dioxide. Some older coal-fired plants have been retrofitted with scrubbers, although most have shifted to lower sulfur coals as their principal strategy for complying with Phase II of the Clean Air Act's Acid Rain regulations. We expect that any new coal-fired generation plants built in the United States will use clean coal-burning technology and will include scrubbers.

Ash & Moisture Content. Ash is the inorganic residue remaining after the combustion of coal. As with sulfur content, ash content varies from seam to seam. Ash content is an important characteristic of coal because electric generating plants must handle and dispose of ash following combustion. The absence of ash is also important to the process by which metallurgical coal is transformed into coke for use in steel production. Moisture content of coal varies by the type of coal, the region where it is mined and the location of coal within a seam. In general, high moisture content decreases the heat value and increases the weight of the coal, thereby reducing its value and making it more expensive to transport. Moisture content in coal, as sold, can range from approximately 5% to 30% of the coal's weight.

Coking Characteristics. The coking characteristics of metallurgical coal are typically measured by the coal's fluidity, ARNU and volatility. Fluidity and ARNU tests measure the expansion and contraction of coal when it is heated under laboratory conditions to determine the strength of the coke that could be produced from a given coal. Typically, higher numbers on these tests indicate higher coke strength. Volatility refers to the loss in mass, less moisture, when coal is heated in the absence of air. The volatility of metallurgical coal determines the percentage of feed coal that actually becomes coke, known as coke yield, all other metallurgical characteristics being equal. Coal with a lower volatility produces a higher coke yield and is more highly valued than coal with a hi gher volatility.

Business Environment

Coal is an abundant, efficient and affordable natural resource used primarily to provide fuel for the generation of electric power. According to the U.S. Department of Energy's Energy Information Administration "EIA" 2010 International Energy Outlook, world-wide economically recoverable coal reserves using today’s technology are estimated to be approximately 909 billion tons. Also according to the 2010 EIA International Energy Outlook, the United States is one of the world’s largest producers of coal and has approximately 29% of global coal reserves, representing nearly 228 years of supply based on current usage rates. According to the U.S. Department of Energy, the energy content of the United States coal reserves exceeds that of all the known oil supplies in the world.

Coal Markets. Coal is primarily consumed by utilities to generate electricity. It is also used by steel companies to make steel products and by a variety of industrial users to heat and power foundries, cement plants, paper mills, chemical plants and other manufacturing and processing facilities. In general, coal is characterized by end use as either steam coal or metallurgical coal. Steam coal is used by electricity generators and by industrial facilities to produce steam, electricity or both. Metallurgical coal is refined into coke, which is used in the production of steel. Over the past forty years, total annual coal consumption in the United States (excluding exports) has more than doubled to over one billion tons in 2010. The growth in the demand for coal ha s coincided with an increased demand for coal from electric power generators.

| | | Actual (1) | | | Preliminary (1) | | | Projected (1) | | | Annual Growth | |

| Consumption by Sector | | 2007 | | | 2008 | | | 2009 | | | 2010 | | | 2015 | | | 2030 | | | 2010-2015 | | | 2015-2030 | |

| | | (Tons in millions) | |

| Electric Generation | | | 1,045 | | | | 1,041 | | | | 937 | | | | 980 | | | | 932 | | | | 1,105 | | | | (5 | )% | | | 19 | % |

| Industrial | | | 57 | | | | 54 | | | | 45 | | | | 48 | | | | 49 | | | | 48 | | | | 3 | % | | | (2 | )% |

| Steel Production | | | 23 | | | | 22 | | | | 15 | | | | 21 | | | | 22 | | | | 19 | | | | 7 | % | | | (13 | )% |

| Coal-to-Liquids Processes | | | - | | | | - | | | | - | | | | - | | | | 11 | | | | 65 | | | | | | | | 473 | % |

| Residential/Commercial | | | 4 | | | | 4 | | | | 3 | | | | 3 | | | | 3 | | | | 3 | | | | 3 | % | | | (3 | )% |

| Export | | | 59 | | | | 82 | | | | 59 | | | | 77 | | | | 70 | | | | 76 | | | | (9 | )% | | | 9 | % |

| Total | | | 1,188 | | | | 1,202 | | | | 1,059 | | | | 1,129 | | | | 1,087 | | | | 1,316 | | | | (4 | )% | | | 21 | % |

| (1) | Data sourced from the U.S. Department of Energy’s EIA’s 2010 and 2011 Annual Energy Outlook. |

Much of the nation’s power generation infrastructure is coal-fired. As a result, coal has consistently maintained a 46% to 53% market share during the past 10 years according to the U.S. Department of Energy EIA's Short-Term Energy Outlook, principally because of its relatively low cost, reliability and domestic abundance. Coal is a low-cost fossil fuel used for base-load electric power generation, typically being considerably less expensive than oil and generally competitive with natural gas. Coal-fired generation is also competitive with nuclear power generation especially on a total cost per megawatt-hour basis. The production of electricity from existing hydroelectric facilities is inexpensive, but its application is limited both by geography and susceptibility to seasonal and climatic conditions. Through 2010, non-hydropower r enewable power generation accounted for only 3.5% of all the electricity generated in the United States, and wind and solar power represented only 2.4% of United States power generation according to the U.S. Department of Energy EIA's Short-Term Energy Outlook.

Coal consumption patterns are also influenced by the demand for electricity, governmental regulation impacting power generation, technological developments, transportation costs, and the location, availability and cost of other fuels such as natural gas, nuclear and hydroelectric power.

Coal’s primary advantages are its relatively low cost and availability compared to other fuels used to generate electricity. According to the EIA, the estimated levelized cost of generation for various power generation technologies, including levelized capital costs, fixed operating and maintenance (O&M), variable O&M (including fuel) and transmission investment are as follows:

Levelized Cost of Electricity(1) | |

| | | $/MWh | |

| | | Mean | | | Minimum | | | Maximum | |

| Supercritical Pulverized Coal | | $ | 62.0 | | | $ | 49.0 | | | $ | 82.0 | |

| Integrated Gasification Combined Cycle | | $ | 62.5 | | | $ | 53.0 | | | $ | 71.0 | |

| Natural Gas Combined Cycle | | $ | 70.5 | | | $ | 58.0 | | | $ | 87.0 | |

| Nuclear | | $ | 81.5 | | | $ | 65.0 | | | $ | 110.0 | |

| Onshore Wind | | $ | 119.6 | | | $ | 50.0 | | | $ | 156.0 | |

| Offshore Wind | | $ | 123.7 | | | $ | 71.0 | | | $ | 181.0 | |

| Biomass Circulating Fluidized Bed | | $ | 146.0 | | | $ | 73.0 | | | $ | 180.0 | |

| Hydro | | $ | 154.0 | | | $ | 45.0 | | | $ | 262.0 | |

| Solar Thermal | | $ | 246.3 | | | $ | 175.0 | | | $ | 324.0 | |

| Solar Photovoltaic | | $ | 1,017.8 | | | $ | 226.0 | | | $ | 2,031.0 | |

| (1) | Figures represent the minimum, maximum and average values of levelized costs of electricity from multiple studies depicted in the IEA report Projected Costs of Generating Electricity, 2010 Edition, tables 11.1B and 11.2. |

Coal Production. United States coal production was approximately 1.1 billion tons in 2010. The following table, derived from data prepared by the EIA, sets forth production statistics in each of the major coal producing regions for the periods indicated.

| | | Actual (1) | | | Preliminary (1) | | | Projected (1) | | | Annual Growth | |

| Production by Region | | 2007 | | | 2008 | | | 2009 | | | 2010 | | | 2015 | | | 2030 | | | | 2010-2015 | | | | 2015-2030 | |

| | | (Tons in millions) | |

| Powder River Basin | | | 480 | | | | 452 | | | | 417 | | | | 434 | | | | 436 | | | | 559 | | | | 0 | % | | | 6 | % |

| Central Appalachia | | | 227 | | | | 234 | | | | 197 | | | | 193 | | | | 114 | | | | 103 | | | | (8 | )% | | | (2 | )% |

| Northern Appalachia | | | 133 | | | | 136 | | | | 128 | | | | 133 | | | | 143 | | | | 163 | | | | 1 | % | | | - | |

| Illinois Basin | | | 96 | | | | 102 | | | | 106 | | | | 110 | | | | 114 | | | | 124 | | | | 1 | % | | | - | |

| Other | | | 211 | | | | 248 | | | | 227 | | | | 228 | | | | 237 | | | | 298 | | | | 1 | % | | | 1 | % |

| Total | | | 1,147 | | | | 1,172 | | | | 1,075 | | | | 1,098 | | | | 1,044 | | | | 1,246 | | | | (1 | )% | | | 1 | % |

| (1) | Data sourced from the EIA’s 2010 and 2011 Annual Energy Outlook |

Coal Regions. Coal is mined from coal fields throughout the United States, with the major production centers located in the Western United States, Northern and Central Appalachia and the Illinois Basin. The quality of coal varies by region. Physical and chemical characteristics of coal are very important in measuring quality and determining the best end use of particular coal types.

Competition. The coal industry is intensely competitive. With respect to our U.S. customers, we compete with numerous coal producers in the Appalachian region and with a large number of western coal producers. Competition from coal with lower production costs shipped east from western coal mines has resulted in increased competition for coal sales in the Appalachian region. In 2010, imports accounted for a relatively small percentage of total U.S coal consumption. Approximately 2% of total U.S. coal consumption in 2010 was imported. Excess industry capacity, which has occurred in the past, tends to result in reduced prices for our coal. The most important factors on which we compete are delivered coal price, coal quality and characteristics, transportat ion costs from the mine to the customer and the reliability of supply. Demand for coal and the prices that we will be able to obtain for our coal are closely linked to coal consumption patterns of the domestic electric generation industry, which has accounted for greater than 93% of 2010 domestic coal consumption. These coal consumption patterns are influenced by factors beyond our control, including the demand for electricity, which is significantly dependent upon summer and winter temperatures and commercial and industrial outputs in the United States, environmental and other government regulations, technological developments and the location, availability, quality and price of competing fuels for power such as natural gas, nuclear, fuel oil and alternative energy sources such as hydroelectric power. Demand for our low sulfur coal and the prices that we will be able to obtain for it will also be affected by the price and availability of high sulfur coal, which can be marketed in tandem with emissions allow ances in order to meet Clean Air Act requirements.

Demand for our metallurgical coal and the prices that we will be able to obtain for metallurgical coal will depend to a large extent on the demand for U.S. and international steel, which is influenced by factors beyond our control, including overall economic activity and the availability and relative cost of substitute materials. In the export metallurgical market, during 2010 and 2009, we largely competed with producers from Australia, Canada, and other international producers of metallurgical coal.

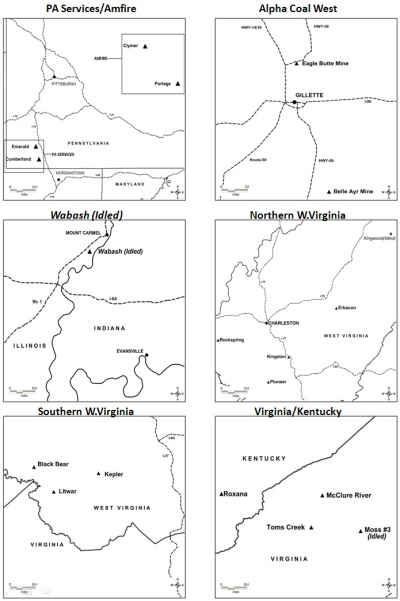

Mining Operations

We currently have six regional business units, operating in Virginia, West Virginia, Pennsylvania, Kentucky and Wyoming. As of December 31, 2010, these business units include 13 preparation plants, each of which receive, blend, process and ship coal that is produced from one or more of our 66 active mines (some of which are operated by third parties under contracts with us), using four mining methods: longwall mining, room-and-pillar mining, truck-and-shovel mining and truck and front-end loader mining. Our underground mines generally consist of one or more single or dual continuous miner sections which are made up of the continuous miner, shuttle cars or continuous haulage, roof bolters, and various ancillary equipment. We have two large underground mines that employ a longwall mining system. Our Eastern surface mines are a c ombination of contour highwall miner, auger operations using truck/loader-excavator equipment fleets along with large production tractors and a small percentage using mountain top removal. Our Western surface mines are large open-pit operations that use the truck-and-shovel mining method. Most of our preparation plants are modern heavy media plants that generally have both coarse and fine coal cleaning circuits. We employ preventive maintenance and rebuild programs to ensure that our equipment is modern and well-maintained. During 2010, most of our preparation plants also processed coal that we purchased from third party producers before reselling it to our customers. Within each regional business unit, mines have been developed at strategic locations in close proximity to our preparation plants and rail shipping facilities. Coal is transported from our regional business units to customers by means of railroads, trucks, barge lines, and ocean-going vessels from terminal facilities.

The following table provides location and summary information regarding our six regional business units and the preparation plants and active mines associated with these business units as of December 31, 2010:

Regional Business Units

| | | | | | | Number and Type of Mines as of December 31, 2010 | | | | | |

| Business Unit | | Location | | Preparation Plants/Shipping Points as of December 31, 2010 | | Underground | | | Surface | | | Total | | Transportation | | 2010 Production of Saleable Tons (in thousands) (1) | |

| | | | | | | | | | | | | | | | | | |

| Pennsylvania Services | | Pennsylvania | | Cumberland and Emerald | | | 2 | | | | - | | | | 2 | | Barge, Truck, CSX, NS | | | 10,666 | |

| AMFIRE | | Pennsylvania | | Clymer and Portage | | | 5 | | | | 11 | | | | 16 | | NS, Truck | | | 2,590 | |

| Southern West Virginia | | West Virginia, Virginia | | Litwar, Kepler and Black Bear | | | 13 | | | | 3 | | | | 16 | | NS | | | 5,136 | |

| Northern West Virginia | | West Virginia | | Erbacon, Kingston, Rockspring and Pioneer | | | 5 | | | | 3 | | | | 8 | | Barge, CSX, NS, RJCC, Truck | | | 7,456 | |

Virginia/Kentucky (2) | | Virginia, Kentucky | | Toms Creek, Roxana, McClure River and Moss #3 | | | 13 | | | | 9 | | | | 22 | | CSX, NS, Truck | | | 7,313 | |

| Alpha Coal West | | Wyoming | | Belle Ayr and Eagle Butte | | | - | | | | 2 | | | | 2 | | BNSF, UP, Truck | | | 48,992 | |

| | | Total from active operations | | | | | 38 | | | | 28 | | | | 66 | | | | | 82,153 | |

| | (1) | Includes coal purchased from third-party producers that was processed at our subsidiaries' preparation plants in 2010. |

| | (2) | In November 2010, Alpha placed Moss #3 preparation plant on idle status. |

BNSF = BNSF Railway

CSX = CSX Transportation

RJCC = R.J. Corman Railroad Company

NS = Norfolk Southern Railway Company

UP = Union Pacific Railroad Company

The coal production and processing capacity of our mines and processing plants is influenced by a number of factors including reserve availability, labor availability, environmental permit timing, and preparation plant capacity.

Pennsylvania Services

Our Pennsylvania Services business unit consists of our Cumberland and Emerald mining complexes, which collectively shipped 11.1 million tons in 2010. Coal is mined primarily by using longwall mining systems supported by continuous miners. We control approximately 775.3 million tons of contiguous reserves through our Pennsylvania Services business unit. Approximately 175.0 million tons are assigned to active mines and 600.3 million tons are unassigned. Both mines operate in the Pittsburgh No. 8 Seam, the dominant coal-producing seam in the region, which is six to eight feet thick in the mines. The mines sell high Btu, high sulfur coal primarily to eastern utilities. There are 1,515 salaried and hourly employees at our Pennsylvania Services business unit. The hourly work force at each mine is represented by the United Mine Workers of America (“UMWA”).

Cumberland shipped 5.8 million tons of coal in 2010. All of the coal at Cumberland is processed through a preparation plant before being loaded onto Cumberland’s owned and operated railroad for transportation to the Monongahela River dock site. At the dock site, coal is then loaded into barges for transportation to river-served utilities or to other docks for subsequent rail shipment to non-river-served utilities. The mine can also ship a portion of its production by truck.

Emerald shipped 5.3 million tons of coal in 2010. Emerald has the ability to store clean coal and blend variable sulfur products to meet customer requirements. All of Emerald’s coal is processed through a preparation plant before being loaded into unit trains operated by the Norfolk Southern Railway or CSX Transportation. The mine also has the option to ship a portion of its coal by truck.

AMFIRE

Our AMFIRE business unit consists of five underground mines operated by AMFIRE employees and eleven surface mines, six of which are operated by independent contractors. Coal is mined primarily using continuous miners employing the room-and-pillar mining method at the underground mines and the truck and front end loader method at our surface mines. We control approximately 83.7 million tons of coal reserves through our AMFIRE business unit. Approximately 34.3 million tons are assigned to active mines and approximately 49.4 million tons are unassigned. AMFIRE employs 480 salaried and hourly employees. The mines sell high Btu, low, medium, and high sulfur coal to eastern utilities and steel companies. All of the underground mining operations at AMFIRE a re staffed and operated by AMFIRE employees. The underground coal is delivered directly by truck to the customer, or transported to the Clymer or Portage coal preparation plants or raw coal loading docks where it is cleaned, blended and loaded onto rail, belt or truck for shipment to customers. The surface mined coal is delivered directly by truck to the customer or transported to the Clymer or Portage coal preparation plants or raw coal loading docks where it is blended and loaded onto rail, belt or truck for shipment to customers. During 2010, AMFIRE shipped 2.5 million tons, which included 0.1 million tons of coal purchased from third parties that was blended with AMFIRE's coal and shipped to our customers.

Southern West Virginia

Our Southern West Virginia business unit consists of our Brooks Run South and Callaway operations, which collectively shipped 5.1 million tons in 2010. Coal is mined primarily using continuous miners employing the room-and-pillar mining method at our underground mines and the truck and front end loader method at our surface mines. We control approximately 96.3 million tons of coal reserves through our Southern West Virginia business unit. Approximately 44.7 million tons are assigned to active mines and approximately 51.6 million tons are unassigned. There are 670 salaried and hourly employees at our Southern West Virginia business unit.

Brooks Run South produces coal from twelve underground mines, four of which are underground mines operated by our employees, and eight that are operated by independent contractors. The mines sell high Btu, low sulfur coal to eastern utilities and metallurgical coal to steel companies. The coal is transported by truck or rail to the Litwar and Kepler preparation plants operated by Brooks Run South, where it is cleaned, blended and loaded onto rail for shipment to customers. During 2010, Brooks Run South shipped 2.2 million tons, which included approximately 0.5 million tons of coal purchased from third parties that was blended with other coals and shipped to our customers.

Callaway produces coal from three surface mining operations operated by our Callaway employees and one underground mine operated by our subsidiary Cobra Natural Resources, LLC (“Cobra”) using continuous miners and the room-and-pillar mining method. The mines sell high Btu, low sulfur coal to eastern utilities and metallurgical coal to steel companies. Callaway also recovers coal from the road construction business operated by our subsidiary Nicewonder Contracting, Inc. (“NCI”). Coal from the three surface mines and NCI is transported by truck to the Black Bear preparation plant or the Ben Creek or Mate Creek loadouts operated by Cobra or the Virginia Energy loadout operated by Callaway where the coal is cleaned, blended, and loaded onto rail for shipment to customers. Coal from the underground mine is b elted to the Black Bear preparation plant where it is cleaned and then loaded into railcars at the Ben Creek loadout for shipment to our customers. During 2010, Callaway shipped 2.9 million tons, which included less than 0.1 million tons of coal purchased from third parties.

Northern West Virginia

Our Northern West Virginia business unit consists of our Brooks Run North, Kingston, Rockspring, and Pioneer operations, which collectively shipped 7.6 million tons in 2010. Coal is mined primarily using continuous miners employing the room-and-pillar mining method at our underground mines and the truck and front end loader method at our surface mines. We control approximately 258.1 million tons of coal reserves through our Northern West Virginia business unit. Approximately 70.5 million tons are assigned to active mines and approximately 187.6 million tons are unassigned. There are 1,100 salaried and hourly employees at our Northern West Virginia business unit.

Brooks Run North produces coal from two underground mines and one surface mine operated by our Brooks Run North employees. The mines sell high Btu, medium sulfur coal primarily to eastern utilities. The coal is transported by truck to the Erbacon preparation plant operated by Brooks Run North where it is cleaned, blended and loaded onto rail for shipment to customers. During 2010, Brooks Run North shipped 2.4 million tons.

Kingston produces coal from two underground mines operated by Kingston employees. Kingston sells primarily metallurgical coal. The coal is trucked to the Kanawha River for shipment by barge or to CSX Transportation or the Norfolk Southern Railway load-outs for shipment by rail. During 2010, Kingston shipped 1.1 million tons.

Rockspring operates a large multiple section mining complex called Camp Creek that produces coal from one underground mine operated by our Rockspring employees. The mine sells mid Btu, low and medium sulfur coal primarily to southeastern utilities. Rockspring has a mine site rail loadout served by Norfolk Southern Railway. The mine can also ship a portion of its production by truck. Rockspring shipped 3.1 million tons of coal in 2010.

Pioneer produces coal from two surface mines: Paynter Branch and Pax. These mines sell high Btu, low and medium sulfur steam coal primarily to eastern utilities and metallurgical coal to steel companies. The Pioneer mines shipped 1.0 million tons of steam and metallurgical coal in 2010. Coal from Paynter Branch is shipped by truck to our on-site rail loading facility on the Norfolk Southern Railway and then on to domestic utilities and exported to metallurgical coal customers. Coal from Pax is shipped to customers primarily via rail, with coal being trucked from the mine to our on-site train loading facility served by CSX Transportation and R.J. Corman Railroad. Pax coal may also be trucked to the Kanawha River for shipment by barge. In late 2010, Paynter Branch completed mining the reserves at its current mine. The equipment and em ployees were subsequently redeployed to the Pax mine.

Virginia/Kentucky

Our Virginia/Kentucky business unit consists of our Paramont, Dickenson-Russell and Enterprise operations, which collectively shipped 7.3 million tons in 2010. Coal is mined primarily using continuous miners employing the room-and-pillar mining method at our underground mines and the truck and front end loader method at our surface mines. We control approximately 354.9 million tons of coal reserves through our Virginia/Kentucky business unit. Approximately 176.8 million tons are assigned to active mines and approximately 178.1 million tons are unassigned. There are approximately 1,385 salaried and hourly employees at our Virginia/Kentucky business unit.

Paramont produces coal from eight underground mines, four of which are operated by independent contractors. Paramont also operates seven surface mines, three of which are operated by independent contractors. These mines sell high Btu, low sulfur coal primarily to eastern utilities and metallurgical coal to steel companies. The coal produced by the underground mines is transported by truck to the Toms Creek preparation plant operated by Paramont, or the McClure River preparation plant operated by Dickenson-Russell. At the preparation plant, the coal is cleaned, blended and loaded onto rail for shipment to customers. The coal produced by the surface mines is transported to one of our preparation plants or raw coal loading docks where it is blended and loaded onto rail for shipment to customers. During 2010, Paramont shipped 4.2 million ton s, which included less than 0.1 million tons of coal purchased from third parties that was blended with Paramont's coal and shipped to our customers.

Dickenson-Russell produces coal from three underground mines. These mines sell high Btu, low sulfur coal primarily to eastern utilities and metallurgical coal to steel companies. The coal is transported by truck to the McClure River preparation plant operated by Dickenson-Russell or the Toms Creek preparation plant operated by Paramont where it is cleaned, blended and loaded on rail or truck for shipment to customers. During 2010, Dickenson-Russell shipped 0.9 million tons, which included less than 0.1 million tons of coal purchased from third parties that was blended with Dickenson-Russell's coal and shipped to our customers.

Enterprise produces coal from two underground mines. Enterprise also has two surface mines, one of which is operated by an independent contractor. These mines sell high Btu, low, medium, and high sulfur coal primarily to eastern utilities and metallurgical coal to steel companies. The coal produced by the underground mines is transported by truck to the Roxana coal preparation plant operated by Enterprise where it is cleaned, blended and loaded onto rail for shipment to customers. The coal produced by the surface mine is transported to the Roxana preparation plant and Pioneer loadout facility where it is blended and loaded onto rail for shipment to customers. During 2010, Enterprise shipped 2.2 million tons, which included less than 0.1 million tons of coal purchased from third parties that was blended with Enterprise's coal and shipped to our customers.

Alpha Coal West

Our Alpha Coal West business unit is located in the Powder River Basin. Alpha Coal West consists of our Belle Ayr and Eagle Butte operations, which collectively shipped 49.0 million tons in 2010. Coal is mined primarily using the truck and shovel mining method. We control approximately 653.2 million tons of coal reserves through our Alpha Coal West business unit and all of the coal reserves are assigned to active mines. There are approximately 660 salaried and hourly employees at our Alpha Coal West business unit.

Belle Ayr consists of one mine that produces sub-bituminous, low sulfur coal for sale primarily to utility companies. Belle Ayr extracts coal from a coal seam that is 75 feet thick. The mine sells 100% raw coal mined and no washing is necessary. Belle Ayr shipped 25.8 million tons of coal in 2010. We plan to apply to lease several hundred million tons of surface mineable federal coal reserves that adjoins Belle Ayr’s property under the lease by application (“LBA”) process. If we prevail in the bidding process and obtain these reserves, we will be able to extend the life of the mine. Belle Ayr has the advantage of shipping its coal on both of the major western railroads, the BNSF Railway and the Union Pacific Railroad, to power plants located throughout the West, Midwest and the South.

Eagle Butte consists of one mine that produces sub-bituminous, low sulfur coal for sale primarily to utility companies. Eagle Butte extracts coal from coal seams that total 100 feet thick. The mine sells 100% raw coal mined and no washing is necessary. Eagle Butte shipped 23.2 million tons of coal in 2010. Coal from Eagle Butte is shipped on the BNSF Railway to power plants located throughout the West, Midwest and the South. The mine also ships a small portion by truck.

Other Operations

We have other operations and activities in addition to our coal production, processing and sales business, including:

Road Construction Business. NCI operates a road construction business under a contract with the State of West Virginia Department of Transportation. Pursuant to the contract, NCI is completing approximately 11 miles of rough grade road in West Virginia over approximately the next year and, in exchange, NCI will be compensated by West Virginia based on the number of cubic yards of material excavated and/or filled to create a road bed, as well as for certain other cost components. As the road is constructed, any coal recovered is sold by NCI as part of its coal operations. We also have other minor road construction projects in conjunction with other surface mining operations.

Maxxim Rebuild and Dry Systems Technologies. Our subsidiary Maxxim Rebuild Co., LLC, is a mining equipment company with facilities in Kentucky and Virginia. This business largely consists of repairing and reselling equipment and parts used in surface mining and in supporting preparation plant operations. Our subsidiary Dry Systems Technologies manufactures patented particulate scrubbers and filters for underground diesel engine applications and rebuilds underground mining equipment for external customers and our subsidiaries.

Coalbed Methane and Natural Gas Extraction. A subsidiary engages in degassing services in advance of mining in Pennsylvania. Coal bed methane is directed through pipelines and sold to third parties. We also control approximately 20,000 acres of Marcellus Shale natural gas holdings in southwest Pennsylvania in one of the Marcellus’ most productive regions. During 2010, we entered into a 50/50 joint venture with Rice Energy, LP to develop a portion of these holdings.

Dominion Terminal Associates. Through our subsidiary Alpha Terminal Company, LLC, we hold a 41% interest in Dominion Terminal Associates (“DTA”), a 20 million-ton annual capacity coal export terminal located in Newport News, Virginia. The terminal, constructed in 1984, provides the advantages of unloading/transloading equipment with ground storage capability, providing producers with the ability to custom blend export products without disrupting mining operations. During 2010, we shipped a total of 2.2 million tons of coal to our customers through the terminal. We make periodic cash payments in respect of the terminal for operating expenses, which are offset by payments we receive for transportation incentive payments and for renting our unused storage space in the terminal to third parties. In 2010, we received cash payments related to the terminal of $16.7 million, partially offset by payments we made for expenses of $8.3 million. The terminal is held in a partnership with subsidiaries of two other companies, Arch Coal, Inc. and Peabody Energy Corp.

Coal Brokerage. Our coal brokerage group purchases and sells third party coal and serves as an agent of our coal subsidiaries.

Miscellaneous. We engage in the sale of certain non-strategic assets such as timber, gas and oil rights as well as the leasing and sale of non-strategic surface properties and reserves. We also provide coal and environmental analysis services.

Marketing, Sales and Customer Contracts

Our marketing and sales force, which is principally based in Abingdon, Virginia, included 60 employees as of December 31, 2010, and consists of sales managers, distribution/traffic managers, contract administrators and administrative personnel. In addition to marketing coal produced in our six regional business units, we are also actively involved in the purchase and resale of coal mined by others, the majority of which we blend with coal produced from our mines. We have coal supply commitments with a wide range of electric utilities, steel manufacturers, industrial customers and energy traders and brokers. Our marketing efforts are centered on customer needs and requirements. By offering coal of both steam and metallurgical grades to provide specific qualities of heat content, sulfur and ash, and other characteristics relevan t to our customers, we are able to serve a diverse customer base. This diversity allows us to adjust to changing market conditions and provides us with the ability to sustain high sales volumes and sales prices for our coal. Many of our larger customers are well-established public utilities and steel manufacturers who have been stable long-term customers of ours and our acquired companies.

We sold a total of 84.8 million tons of coal in 2010, consisting of 82.6 million tons of produced and processed coal and 2.2 million tons of purchased coal that we resold without processing. A portion of purchased coal was blended prior to resale, meaning the coal was mixed with coal produced from our mines prior to resale, which generally allows us to realize a higher overall margin for the blended product than we would be able to achieve selling these coals separately. Approximately 0.8 million tons of our 2010 purchased coal sales were processed by us, meaning we washed, crushed or blended the coal at one of our preparation plants or loading facilities prior to resale.

We sold a total of 47.2 million tons of coal in 2009, consisting of 45.7 million tons of produced and processed coal and 1.5 million tons of purchased coal that was resold without processing. Of the total purchased coal sales of 1.9 million tons in 2009, approximately 1.5 million tons were blended prior to resale. Approximately 0.4 million tons of 2009 purchased coal sales were processed by us.

Old Alpha sold a total of 26.9 million tons of coal in 2008, consisting of 22.0 million tons of produced and processed coal and 4.9 million tons of purchased coal that was resold without processing. Of the total purchased coal sales of 6.2 million tons in 2008, approximately 4.0 million tons were blended prior to resale. Approximately 1.3 million tons of 2008 purchased coal sales were processed by us.

The breakdown of tons sold for 2010, 2009 and 2008 is set forth in the table below:

| | | Steam Coal Sales (1) | | | Metallurgical Coal Sales (1) | |

| Year | | Tons | | | % of Total Sales Volume | | | Tons | | | % of Total Sales Volume | |

| | | (In millions, except percentages) | |

| | | | | | | | | | | | | |

| 2010 | | | 73.0 | | | | 86 | % | | | 11.8 | | | | 14 | % |

2009 (2) | | | 39.1 | | | | 83 | % | | | 8.1 | | | | 17 | % |

| 2008 | | | 15.5 | | | | 58 | % | | | 11.4 | | | | 42 | % |

| | (1) | Sales of steam coal during 2010, 2009, and 2008 were made primarily to large utilities and industrial customers throughout the United States and sales of metallurgical coal during those years were made primarily to steel companies in the Northeastern and Midwestern regions of the United States and in countries in Europe, Asia and South America. |

| | (2) | The amounts for 2009 include the results of operations for Old Alpha for the period from January 1, 2009 through July 31, 2009 and the results of operations for the combined company for the period from August 1, 2009 through December 31, 2009. |

We sold coal to over 150 different customers in 2010. Our top ten customers in 2010 accounted for approximately 42% of 2010 total revenues and our largest customer during 2010 accounted for approximately 9% of 2010 total revenues. The following table provides information regarding exports in 2010, 2009 and 2008 by revenues and tons sold:

| Year | | Export Tons Sold | | | Export Tons Sold as a Percentage of Total Coal Sales Volume | | | Export Sales Revenues | | | Export Sales Revenue as a Percentage of Total Revenues | |

| | | | | | | | | | | | | |

| 2010 | | | 9.6 | | | | 11 | % | | $ | 1,351.0 | | | | 34 | % |

2009 (1) | | | 6.6 | | | | 14 | % | | $ | 768.0 | | | | 31 | % |

| 2008 | | | 8.5 | | | | 31 | % | | $ | 1,292.1 | | | | 52 | % |

| | (1) | The amounts for 2009 include the results of operations for Old Alpha for the period from January 1, 2009 through July 31, 2009 and the results of operations for the combined company for the period from August 1, 2009 through December 31, 2009. |

Export shipments during 2010, 2009 and 2008 serviced customers in 27, 19 and 20 countries, respectively, across North America, Europe, South America, Asia and Africa. Brazil was the largest export market in 2010, 2009 and 2008, with sales to Brazil accounting for approximately 11%, 23% and 15%, respectively, of total export revenues and 4%, 7% and 8%, respectively, of total revenues. All of our sales are made in U.S. dollars, which reduces foreign currency risk. A portion of our coal sales volume is subject to seasonal fluctuation, with sales to certain customers being curtailed during the winter months due to the freezing of lakes that we use to transport coal to those affected customers.

As is customary in the coal industry, when market conditions are appropriate and particularly in the steam coal market, we enter into long-term contracts (exceeding one year in duration) with many of our customers. These arrangements allow customers to secure a supply for their future needs and provide us with greater predictability of sales volume and sales prices. A significant majority of our steam coal sales are shipped under long-term contracts. During 2010, approximately 87% and 78% of our steam and metallurgical coal sales volume, respectively, was delivered pursuant to long-term contracts and during 2009, approximately 71% and 55% of our steam and metallurgical coal sales volume, respectively, was delivered pursuant to long-term contracts.

Our sales backlog, including backlog subject to price reopener and/or extension provisions, was approximately 195.9 million tons as of January 26, 2011 and approximately 208.9 million tons at the beginning of 2010. Of these tons, approximately 43% and 38%, respectively, were expected to be filled within one year.

The terms of our contracts result from bidding and negotiations with customers. Consequently, the terms of these contracts typically vary significantly in many respects, including price adjustment features, provisions permitting renegotiation or modification of coal sale prices, coal quality requirements, quantity parameters, flexibility and adjustment mechanisms, permitted sources of supply, treatment of environmental constraints, options to extend and force majeure, suspension, termination and assignment provisions, and provisions regarding the allocation between the parties of the cost of complying with future governmental regulations.

Distribution

We employ transportation specialists who negotiate freight and terminal agreements with various providers, including railroads, trucks, barge lines, and terminal facilities. Transportation specialists also coordinate with customers, mining facilities and transportation providers to establish shipping schedules that meet the customer's needs. Our produced and processed coal is loaded from our 13 preparation plants, loadout facilities, and in certain cases directly from our mines. The coal we purchase is loaded in some cases directly from mines and preparation plants operated by third parties or from an export terminal. Virtually all of our coal is transported from the mine to our preparation plants by truck or rail, and then from the preparation plant to the customer by means of railroads, trucks, barge lines, lake-going and ocean-going v essels from terminal facilities. Rail shipments constituted approximately 80% of total shipments of coal volume produced and processed from our mines to the preparation plant to the customer in 2010. The balance was shipped from our preparation plants, loadout facilities or mines via truck. In 2010, approximately 8% of our coal sales volume was delivered to our customers through transport on the Great Lakes and domestic rivers, approximately 5% was moved through the Norfolk Southern export facility at Norfolk, Virginia, approximately 3% was moved through the coal export terminal at Newport News, Virginia operated by DTA, and approximately 2% was moved through the export terminals at Baltimore, MD and New Orleans, LA. We own a 41% interest in the coal export terminal at Newport News, VA operated by DTA. See “-Other Operations.”

Transportation

Coal consumed domestically is usually sold at the mine and transportation costs are normally borne by the purchaser. Export coal is usually sold at the loading port, with purchasers responsible for further transportation. Producers usually pay shipping costs from the mine to the port.

We depend upon rail, barge, trucking and other systems to deliver coal to markets. In 2010, our produced coal was transported from the mines and to the customer primarily by rail, with the main rail carriers being CSX Transportation, Norfolk Southern Railway Company, BNSF Railway and Union Pacific Railroad Company. The majority of our sales volume is shipped by rail, but a portion of our production is shipped by barge and truck.

We have positive relationships with rail carriers and barge companies due, in part, to our modern coal-loading facilities and the experience of our transportation and logistics employees.

Suppliers

We incur a substantial amount of expenses per year to procure goods and services in support of our business activities in addition to capital expenditures. Principal goods and services include maintenance and repair parts and services, electricity, fuel, roof control and support items, explosives, tires, conveyance structure, ventilation supplies and lubricants. We use suppliers for a significant portion of our equipment rebuilds and repairs both on- and off-site, as well as construction and reclamation activities and to support computer systems.

Each of our regional mining operations has developed its own supplier base consistent with local needs. We have a centralized sourcing group for major supplier contract negotiation and administration, for the negotiation and purchase of major capital goods, and to support the business units. The supplier base has been relatively stable for many years, but there has been some consolidation. We are not dependent on any one supplier in any region. We promote competition between suppliers and seek to develop relationships with suppliers that focus on lowering our costs. We seek suppliers who identify and concentrate on implementing continuous improvement opportunities within their area of expertise.

Employees

As of December 31, 2010, we had approximately 6,500 employees. As of December 31, 2010, the UMWA represented approximately 21% of our employees located in Virginia, West Virginia and Pennsylvania. UMWA-represented employees produced approximately 13% of our coal sales volume during the fiscal year ended December 31, 2010. Relations with organized labor are important to our success, and we believe our relations with our employees are satisfactory.

ENVIRONMENTAL AND OTHER REGULATORY MATTERS