| | |

|

Independent Technical Report for the El Creston Molybdenum Project, Sonora, Mexico | |

| Prepared for Starcore International Mines Ltd. |

|

| | |

| Prepared by

SRK Consulting (Canada) Inc. CAPR002049 September 2022 |

| | |

| Independent Technical Report for the El Creston Molybdenum Project, Sonora, Mexico |

| September 2022 |

| Prepared for | Prepared by |

| Starcore International Mines Ltd. Suite #750 – 580 Hornby Street Vancouver, BC V6C 3B6 Canada | Dr. Gilles Arseneau, P. Geo. Associate Consultant SRK Consulting (Canada) Inc. Suite #2200 – 1066 West Hastings Street Vancouver, BC V6E 3X2 Canada |

| Tel:+1 604 602 4935 Web:www.starcore.com | Tel:+1 604 681 4196 Web: www.srk.com |

| Project No:CAPR002049 File Name:Starcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docx |

| Copyright © SRK Consulting (Canada) Inc., 2022

|

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 1

Important Notice

This report was prepared as a National Instrument 43-101 Technical Report for Starcore International Mines Ltd. (“Starcore” or the “Company”) by SRK Consulting (Canada) Inc. (“SRK”). The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in SRK’s services, based on i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Starcore subject to the terms and conditions of its contract with SRK and relevant securities legislation. The contract permits Starcore to file this report as a Technical Report with Canadian securities regulatory authorities pursuant to National Instrument 43-101, Standards of Disclosure for Mineral Projects. Except for the purposes legislated under provincial securities law, any other uses of this report by any third party are at that party’s sole risk. The responsibility for this disclosure remains with Starcore. The user of this document should ensure that this is the most recent Technical Report for the property as it is not valid if a new Technical Report has been issued.

© Copyright

This report is protected by copyright vested in SRK Consulting (Canada) Inc. It may not be reproduced or transmitted in any form or by any means whatsoever to any person without the written permission of the copyright holder, other than in accordance with stock exchange and other regulatory authority requirements.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 2

Introduction

In June of 2022, Starcore International Mines Ltd. commissioned SRK Consulting (Canada) Inc. to prepare a technical report for the El Creston Project. This technical report documents a mineral resource statement for the El Creston Project prepared by Dr. Gilles Arseneau, Qualified Person and associate consultant with SRK. It was prepared following the guidelines of the Canadian Securities Administrators’ National Instrument 43-101 and Form 43-101F1.

Property Description and Ownership

The El Creston Project is located in north-central Sonora State in north-western Mexico. The property is about 145 kilometres (“km”) by road north-northeast of Hermosillo, the capital of Sonora State, 5 km southwest of the village of Opodepe. Access from Hermosillo is via Highway 15 north from Hermosillo 70 km to Carbo junction. From the junction, a paved road is followed east for 52 km to Rayon, then north along a well-maintained gravel road for 21 km to the junction with a secondary unpaved road crossing the San Miguel River 5 km south of Opodepe that leads to the Creston Project. The approximate center of the mineral resources described in Section 14 is 29°53’N latitude and 110°39’W longitude.

Electric power and water are available at Opodepe, however a 45 km long power line coming from the west, will likely be required to provide power to any future development at the El Creston property, as Opodepe does not have the capacity for a large industrial site. Discussions with the owners of water rights in the vicinity of the project will be necessary to support any future mining operation.

The property is comprised of nine concessions covering approximately 11,363 hectares (“ha”) wholly owned by Exploraciones Global, S.A. de C.V., a Mexican subsidiary of Starcore. All concessions are subject to a 3% net smelter return (“NSR”). There are no known environmental liabilities to which the project is currently subjected.

Geology and Mineralization

Regionally, the area is part of the Basin and Range Province which is an extensional terrain of fault-bounded ranges and intervening valleys in the western United States that extends southward from Nevada and Utah southwards into the states of Sonora and Chihuahua, Mexico. In northern Mexico, this province is bifurcated by the Sierra Madre Occidental, a north-northwest-trending mountain range about 1,200 km long and 200 km to 300 km wide that forms the spine of northern Mexico. The Creston property lies in the western or Sonoran portion of the Basin and Range Province, close to the western flank of the Sierra Madre Occidental.

The predominant lithologies known at El Creston include metamorphic rocks of Precambrian and perhaps Paleozoic age, intrusions of various compositions, dikes, and breccias of Paleozoic and Tertiary age, and Recent conglomerate, talus, and landslide deposits.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 3

Phyllites, quartzite, gneisses, and metavolcanic rocks were intruded by the Creston granite, which has a weakly developed gneissic texture. The Creston granite has been altered and mineralized, hosting most of the presently defined molybdenum (“Mo”) mineralization in the Main deposit, the older metamorphic rocks intruded by the Creston granite are only locally altered and mineralized.

There are two principal styles of mineralization at the Main deposit: predominantly subvertical quartz-molybdenite-pyrite veinlets hosted by the Creston granite and molybdenite-pyrite within the quartz matrix of magmatic-hydrothermal breccia of the East Breccia body, which cuts the Creston granite. While minor amounts of chalcopyrite accompany the molybdenite mineralization, more significant quantities of copper (“Cu”) occur as chalcocite replacements of pyrite within secondary enrichment blankets that parallel present-day topography. Some chalcocite also occurs below the enrichment blankets, primarily along permeable structural zones such as the Ordoñez fault zone.

The currently defined mineralized area occupies a zone about 1,600 metres (“m”) in an east-west direction, a maximum of 1,200 m in a north-south direction, and 550 m vertically. The Creston and Ordoñez faults terminate the bulk of the molybdenum mineralization at depth, although some mineralization has been intersected in drillholes below the Creston fault at the Red Hill zone to the south. Mineralization at El Creston includes both molybdenum and copper minerals.

Exploration Status

The property has been explored extensively in the past. Starcore has not carried out any recent exploration on the property but has announced a $500,000 US Dollars (“US$”) exploration program for the El Creston Project. The program is to include geological and magnetometry surveys.

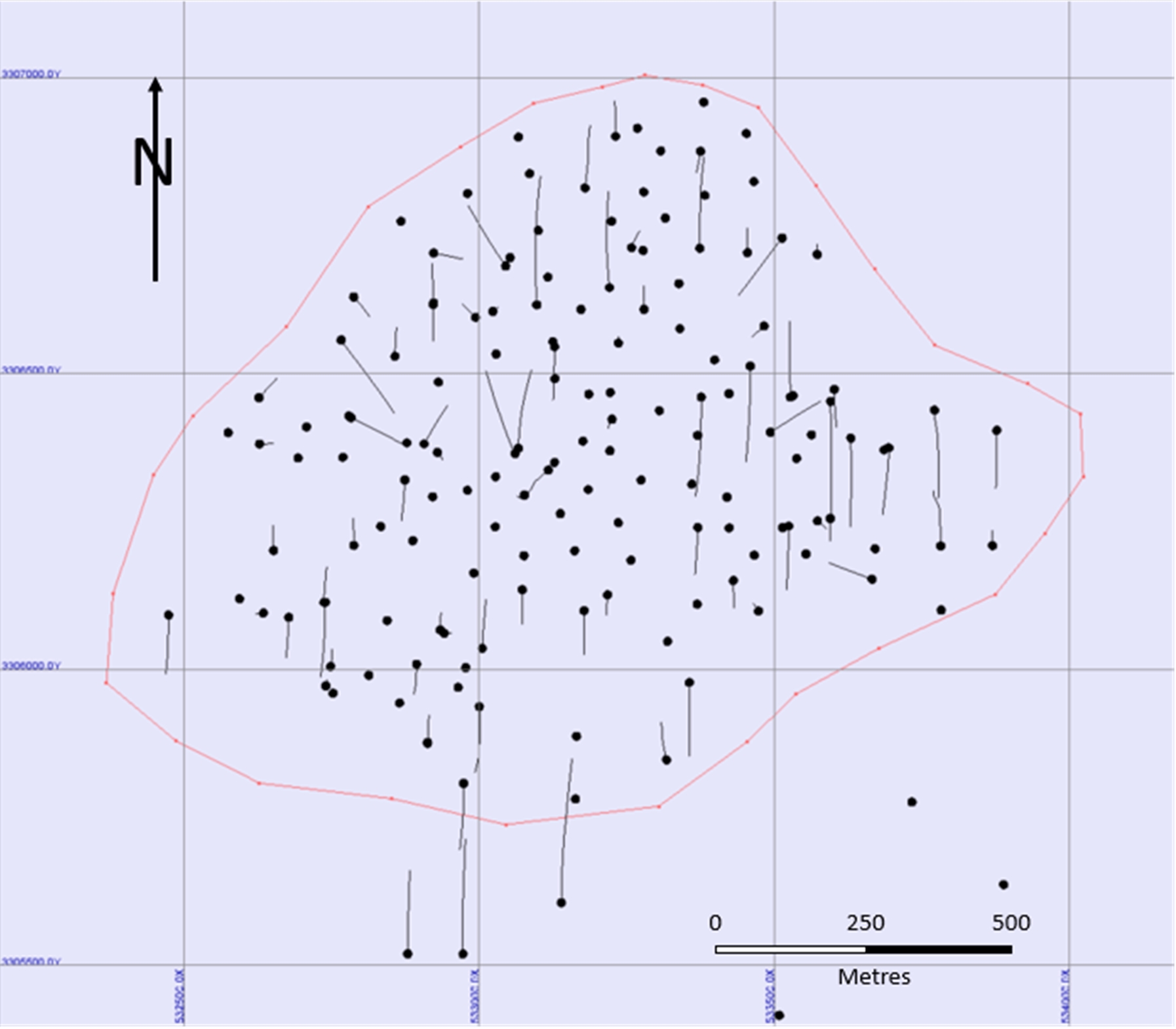

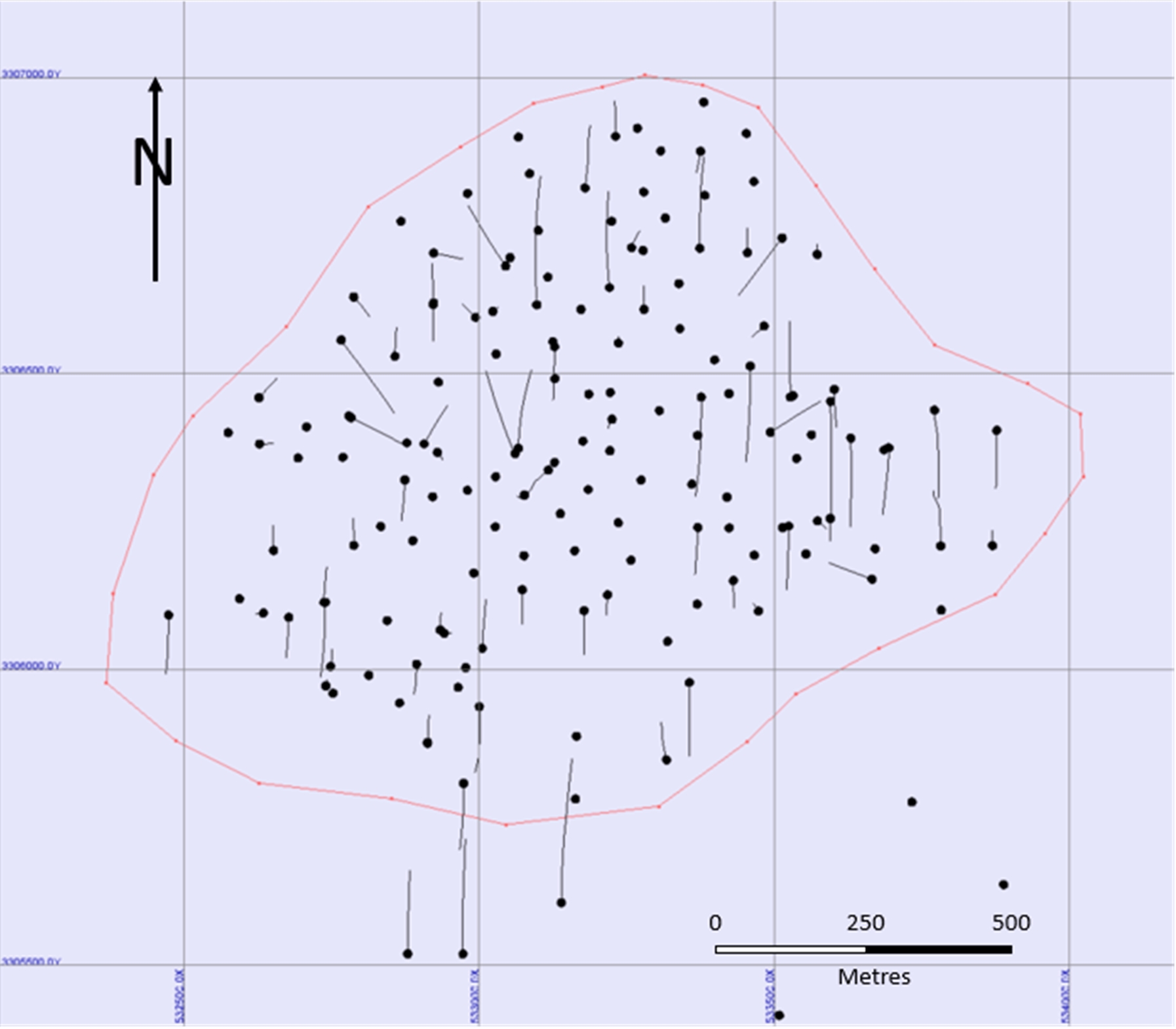

Mineral Resource Estimate

The mineral resource model prepared by the QP considers 181 core holes and three reverse circulation holes, Creston Moly Corporation drilled 156 holes during the period of 2007 to 2011, 28 holes were drilled by AMAX between 1974-1975. The resource estimation work was completed by Dr. Gilles Arseneau, P. Geo. (APEGBC #23474) an appropriate “independent Qualified Person” as this term is defined in National Instrument 43-101.

The mineral resources have been estimated in conformity with generally accepted CIM “Estimation of Mineral Resource and Mineral Reserves Best Practices” guidelines and are reported in accordance with the Canadian Securities Administrators’ National Instrument 43-101.

GEOVIA GEMs™ Version 6.8.4 was used to construct the geological solids, prepare assay data for geostatistical analysis, construct the block model, estimate metal grades and tabulate mineral resources. Sage2001 was used to model the variography of copper and molybdenum.

The oxide surface was modelled from a hard boundary between the dominantly oxidized zone near surface and the sulphide mineralization below using a 30% molybdenum oxide limit. A wireframe was used to model the molybdenum mineralization with the Creston granite and the

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 4

copper mineralization was modelled into high-grade and low-grade domains based on statistical analysis of the assay data.

Assay data were capped prior to modelling based on statistical analysis. Molybdenum values were capped at 0.70% Mo and copper values in the higher-grade zone were capped at 1.0% Cu and 0.45% Cu in the low-grade copper zone. All assays were composited to 3.0 m length within the modelled domains.

Grades were estimated by ordinary kriging inside 10 m by 10 m by 12 m blocks. To determine the quantities of material offering “reasonable prospects for eventual economic extraction” by an open pit, the QP used a pit optimizer and reasonable mining assumptions to evaluate the proportions of the block model (Measured, Indicated and Inferred blocks) that could be “reasonably expected” to be mined from an open pit.

The optimization parameters were based on experience and benchmarking against similar projects. Blocks within the resource shell were classified as Measured if they were populated using more than eleven samples at an average distance of less than 80 m and where the probability of the grade exceeding cut-off was more than 90%. Blocks were considered Indicated if they were populated by more than eight samples at an average distance of less than 100 m. All other estimated blocks were classed as Inferred. Based on the above parameters, the QP estimated that the El Creston deposit contained 56.3 million tonnes (“Mt”) grading 0.076% Mo and 0.04% Cu in the Measured category, and 142.2 Mt grading 0.067% Mo and 0.08% Cu classified as Indicated mineral resources. There are no blocks classified as Inferred mineral resource within the Whittle optimized pit shell (Table 1.1).

Table 1.1: Mineral Resource Statement at 0.045% Molybdenum Equivalent*, El Creston Molybdenum Project, Sonora Mexico, SRK Consulting, 30 September 2022

| | | | | | | | |

Category | Quantity | Grade | Metal |

Mo | Cu | Mo | Cu |

(Mt) | (%) | (%) | (Mlb) | (Mlb) |

Open Pit** |

Measured | 56.3 | 0.076 | 0.04 | 94.3 | 49.7 |

Indicated | 142.2 | 0.067 | 0.08 | 210.0 | 250.8 |

Measured Plus Indicated | 198.5 | 0.069 | 0.07 | 304.4 | 300.5 |

Inferred |

Notes:

| * | Mineral resources are reported in relation to a conceptual pit shell. Mineral resources are not mineral reserves and do not have demonstrated economic viability. All figures are rounded to reflect the relative accuracy of the estimate. All composites have been capped where appropriate. |

| ** | Open pit mineral resources are reported at a cut-off grade of 0.045% Mo EQ. Cut-off grades are based on a price of US$9.93 per lb of molybdenum and US$3.50 for copper, recoveries of 88% for molybdenum and 84% for copper were applied. |

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 5

Conclusion and Recommendations

The El Creston Molybdenum Project is an advanced staged exploration property located in Sonora State, Mexico.

The molybdenite mineralization occurs as finely disseminated subhedral crystals 0.1 millimetres (“mm”) to 0.8 mm across, embedded in a pervasive, fine-grained quartz-sericite matrix, and as coarsely crystalline molybdenite along the margins of quartz veins.

The QP believes that the widely spaced drill sampling is suitably adequate to represent the disseminated and veinlet molybdenum mineralization.

While some molybdenum grades do occur below the Creston fault, the grade estimates were limited to the zone between the oxide boundary and the Creston fault.

The QP recommends that Starcore continue to explore the El Creston Project. Specifically, a US$500,000 exploration surface exploration program is recommended.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 6

Table of Contents

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 7

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 8

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 9

List of Tables

Table 1.1: Mineral Resource Statement at 0.045% Molybdenum Equivalent*, El Creston Molybdenum Project, Sonora Mexico, SRK Consulting, 30 September 20224

Table 2.1: List of Abbreviations14

Table 4.1: Mineral Tenure Information18

Table 6.1: Summary of Historical Exploration Work Prior to Creston Moly Corporation23

Table 6.2: Summary of Drilling and Underground Development by Company and Year24

Table 6.3: Selection of Historic Non-NI 43-101 Resource Estimates24

Table 6.4: 2008 P&E and 2008 MDA Historical Resource Estimates Summary25

Table 6.5: El Creston Mineral Resource Estimate (SRK, 2011)26

Table 10.1: Summary of All Drilling at El Creston39

Table 10.2: Significant Drillhole Intersections used in the Mineral Resource Estimate43

Table 10.3: Number of Drillholes Eliminated from the Resource Estimation Database46

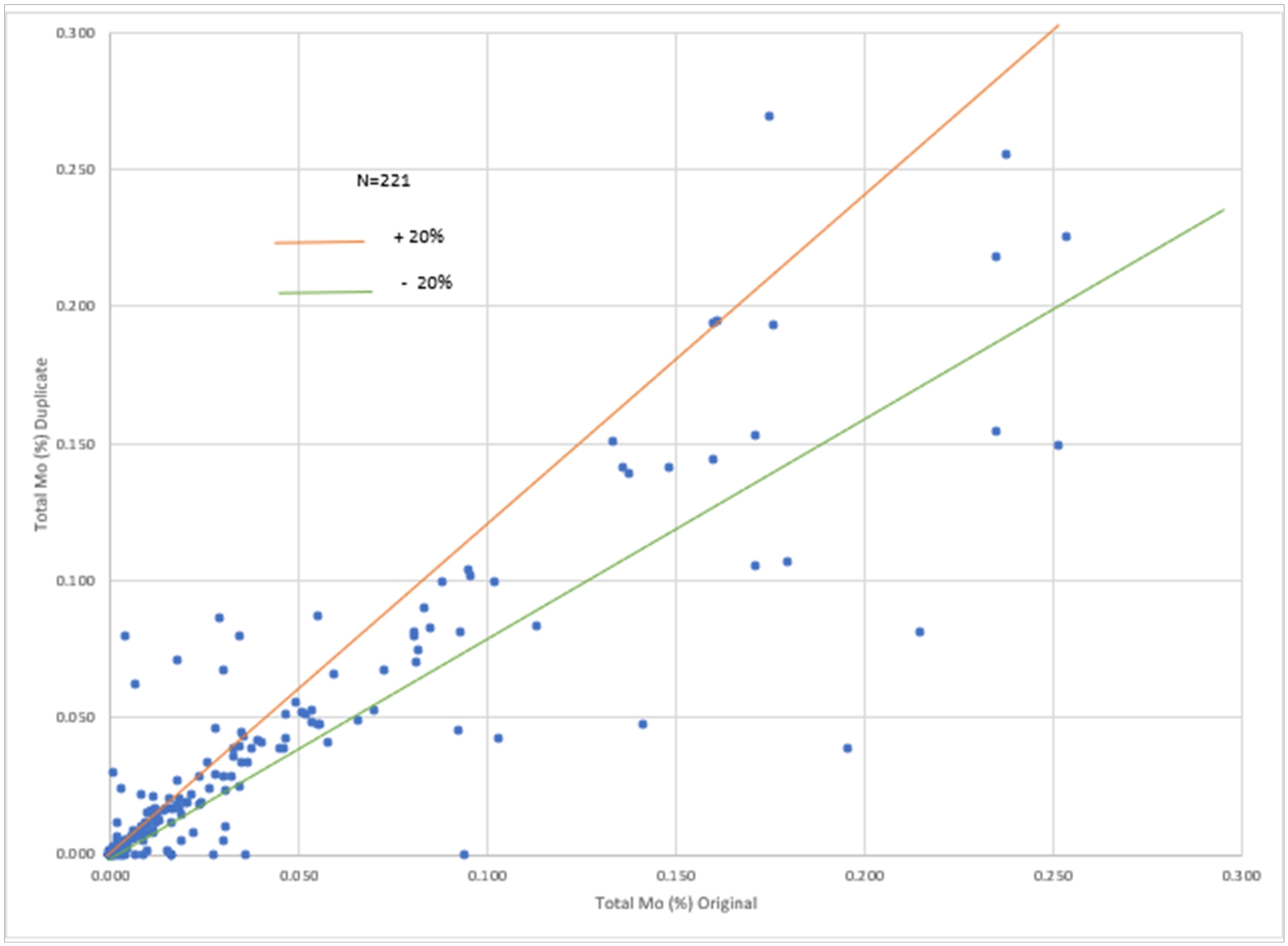

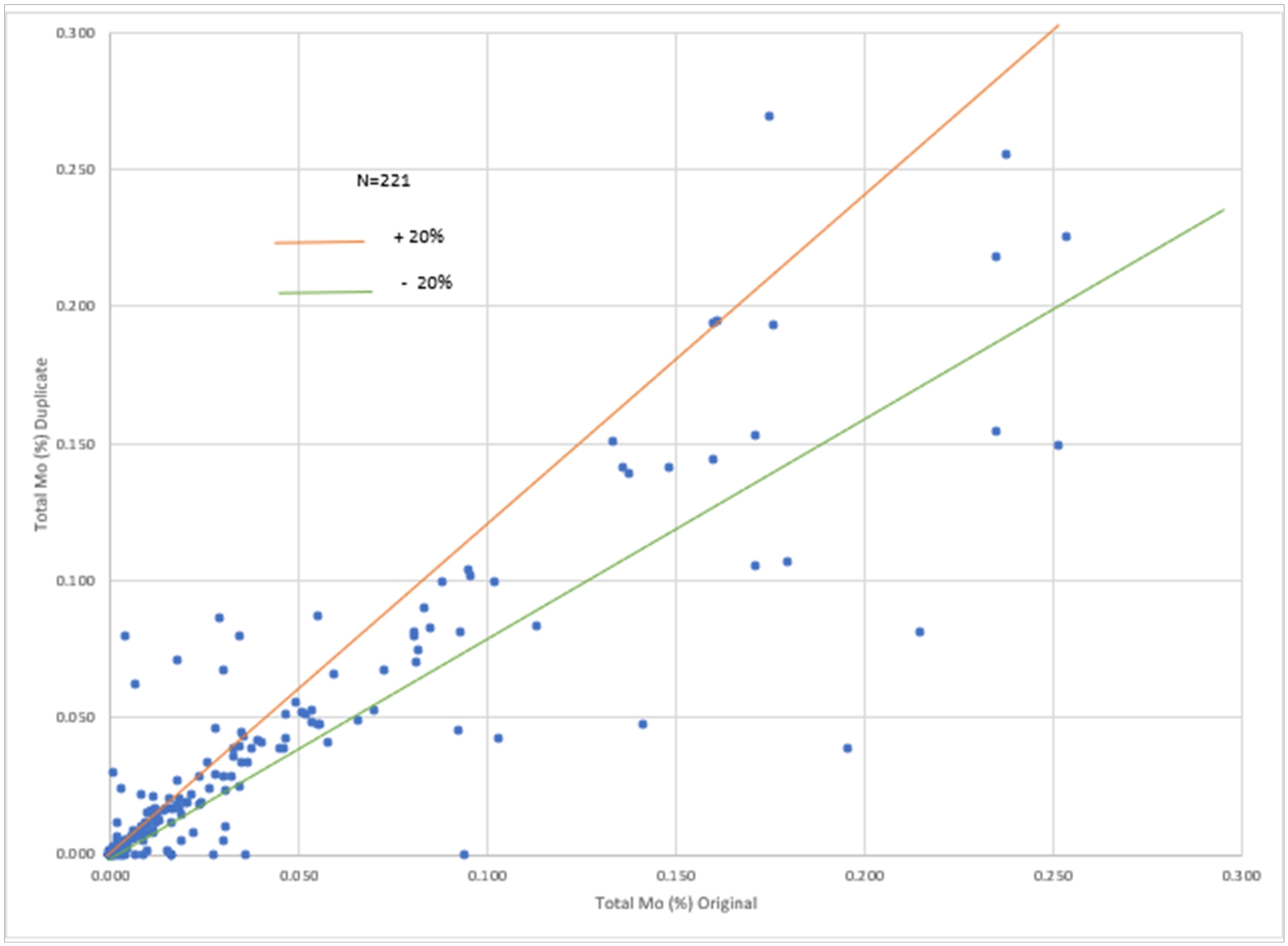

Table 11.1: QA/QC Samples Inserted by Creston Moly from 2007 to 201150

Table 11.2: Standard Reference Material Used by Creston Moly54

Table 12.1: Assay Results for Verification Samples Collected by the QP on the El Creston Project58

Table 13.1: Grindability Results62

Table 13.2: G&T Preliminary Locked Cycle Test Results62

Table 14.1: Drillholes Used for El Creston Resource Estimation64

Table 14.2: Comparison of Density Values for Fresh and Oxide Material68

Table 14.3 Sample Length Descriptive Statistics71

Table 14.4: Resource Block Model Extent74

Table 14.5: Variogram Parameters Used for Ordinary Kriging Estimation75

Table 14.6: Estimation Parameters75

Table 14.7: Assumptions Considered for Conceptual Open Pit Optimization.81

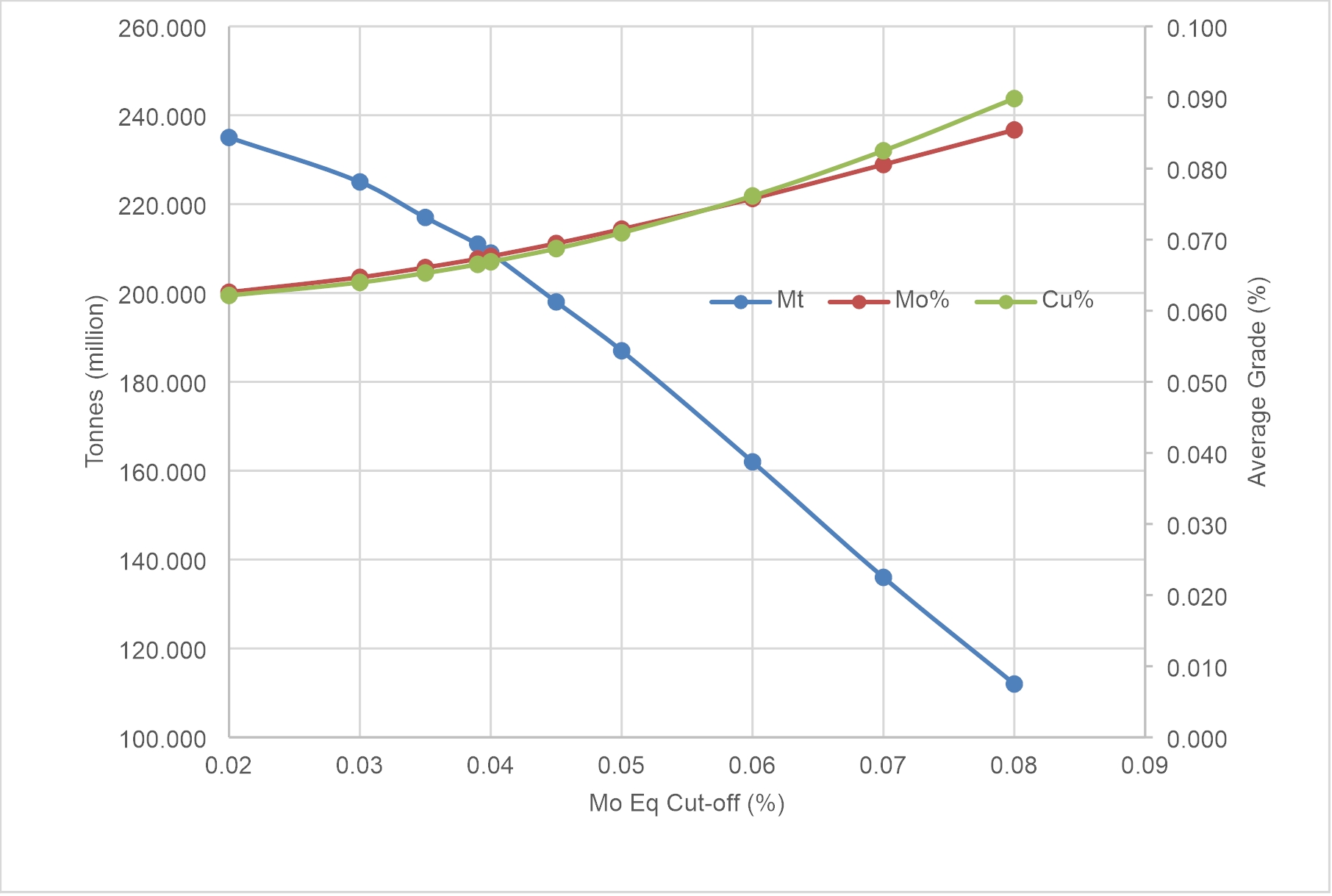

Table 14.8: Mineral Resource Statement at 0.045% Molybdenum Equivalent*, El Creston Molybdenum Project, Sonora Mexico, SRK Consulting, 30 September 202282

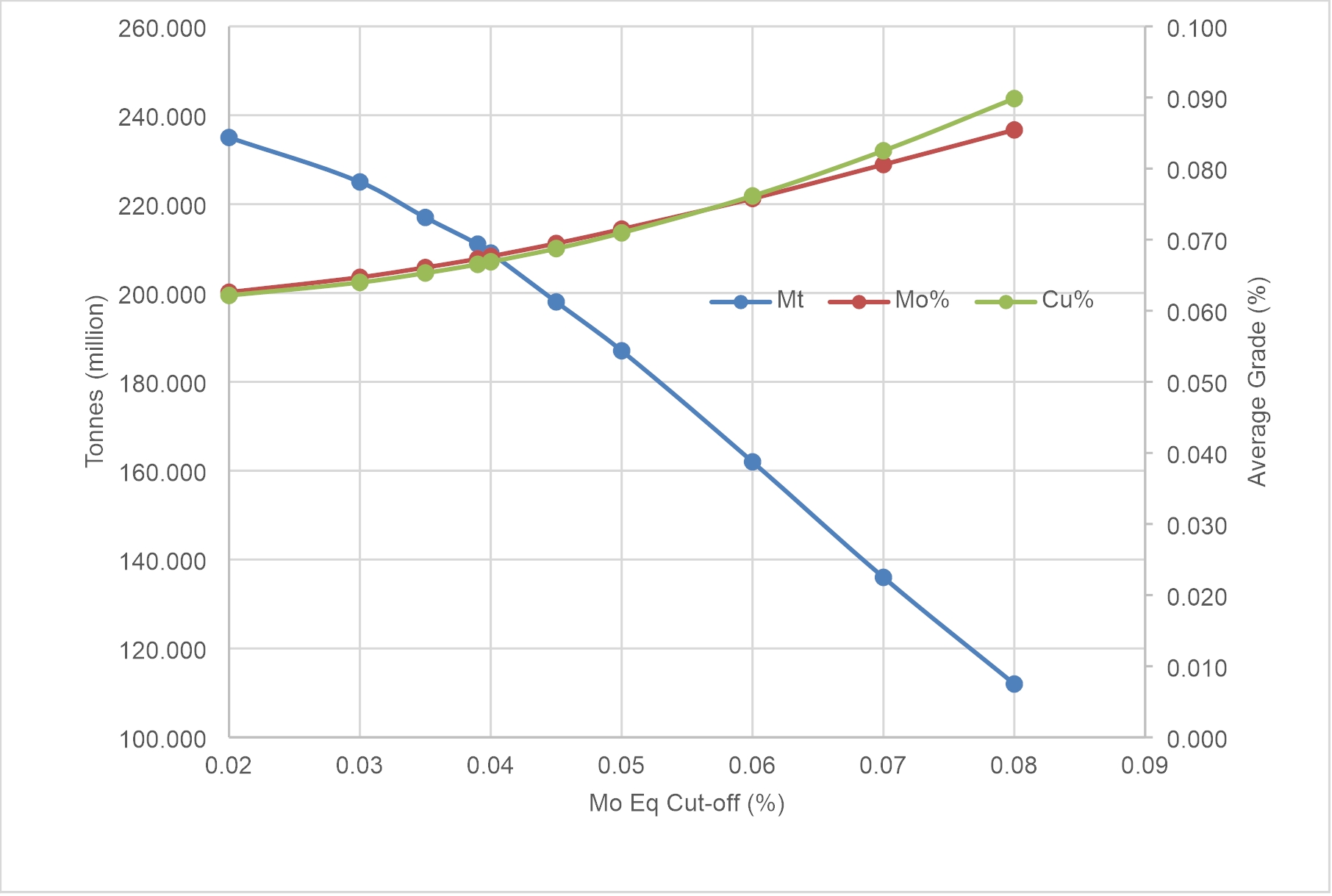

Table 14.9: Measured Quantities and Grade Estimates Within the Resource Shell*, El Creston Molybdenum Project at Various Cut-off Grades83

Table 14.10: Indicated Quantities and Grade Estimates Within the Resource Shell*, El Creston Molybdenum Project at Various Cut-off Grade83

Table 14.11: Comparison of Economic Parameters used for the 2011 and 2022 Resource Estimates84

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 10

Table 14.12 : Comparison of 2022 and 2011 Mineral Resource Statements85

Table 17.1: Mineral Resource Statement at 0.045% Molybdenum Equivalent*, El Creston Molybdenum Project, Sonora Mexico, SRK Consulting, 04 September 202290

Table 18.1: Estimated Cost for the Exploration Program Proposed for the El Creston Project91

List of Figures

Figure 4.1: Project Location Map17

Figure 4.2: Land Tenure Map18

Figure 4.3: El Creston Deposit with Mineral Claims and Surface Rights Ownership19

Figure 5.1: General Physiography of the El Creston Area22

Figure 7.1: Regional Geological Setting27

Figure 7.2: Example of Coarse Crystalline Molybdenite Along Quartz Vein34

Figure 7.3: Molybdenite Mineralization Within East Breccia35

Figure 10.1: Planview Showing Distribution of Pre-Creston Moly Drillholes41

Figure 10.2: Planview Showing the Distribution of Drillholes Drilled by Creston Moly42

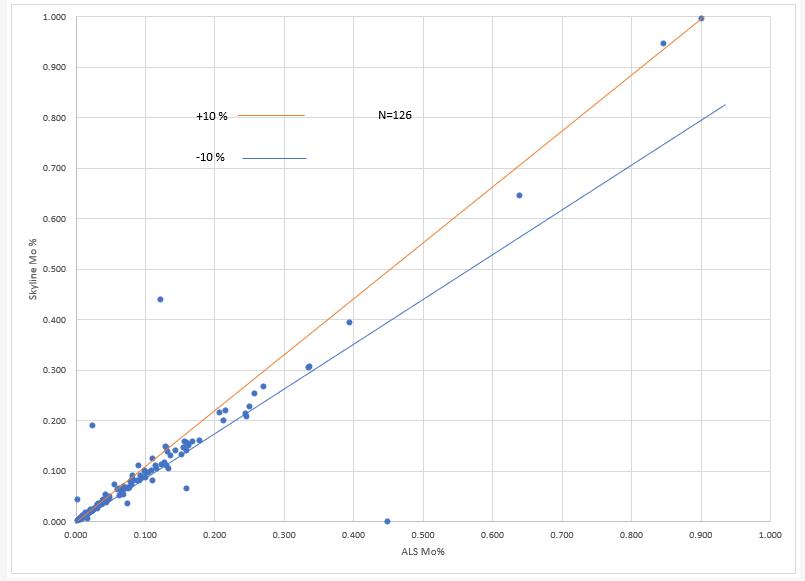

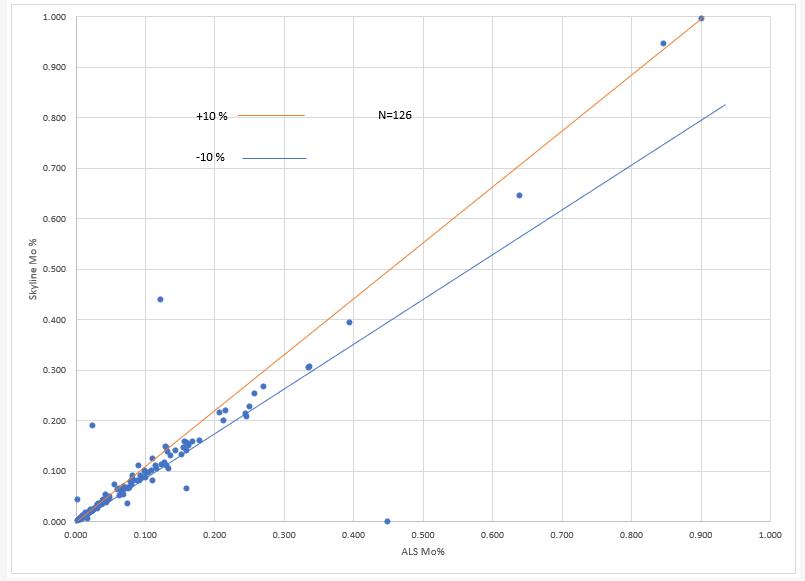

Figure 11.1: Total Molybdenum Reject Duplicates51

Figure 11.2: Copper Reject Duplicates52

Figure 11.3: 2008-2011 Total Molybdenum Umpire Assay Duplicates Compared53

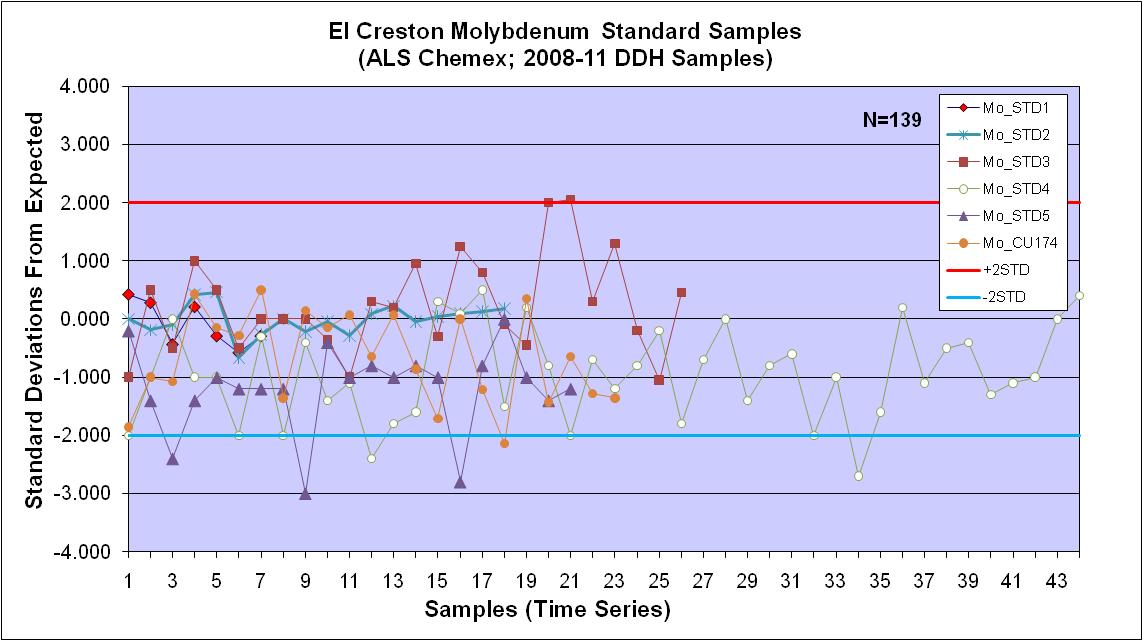

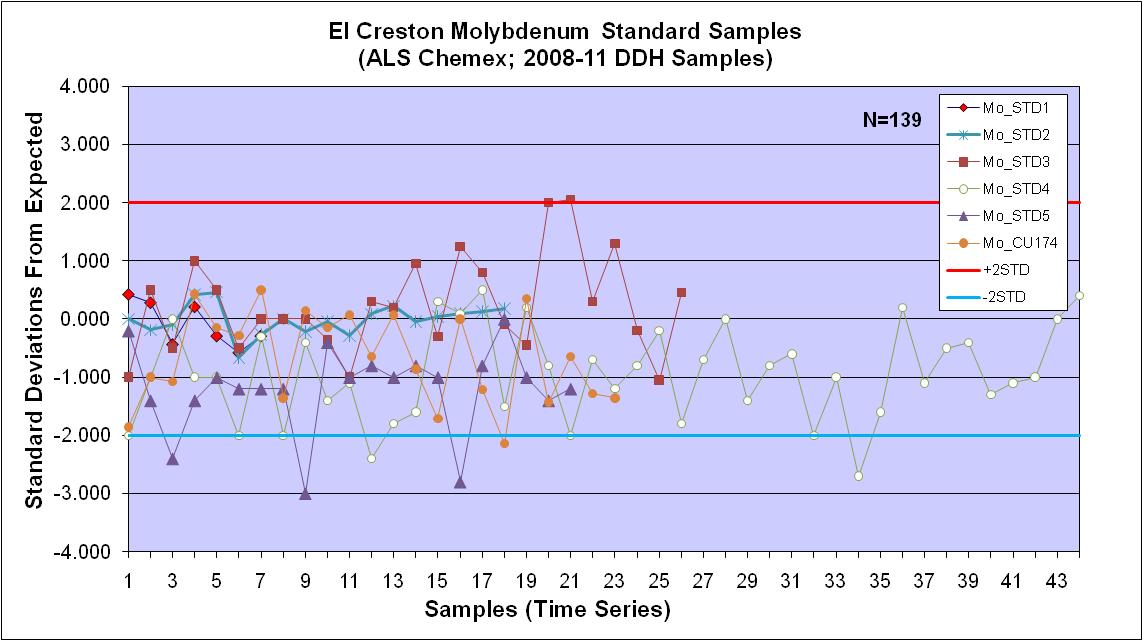

Figure 11.4: Molybdenum Standard Reference Material Performance55

Figure 14.1: Probability Plot of Total Mo (%) showing Grade Populations67

Figure 14.2: Cumulative Probability Plot, Molybdenum (in sulphide) Assays69

Figure 14.3: HGZ, Cumulative Probability Plot, Total Copper Assays70

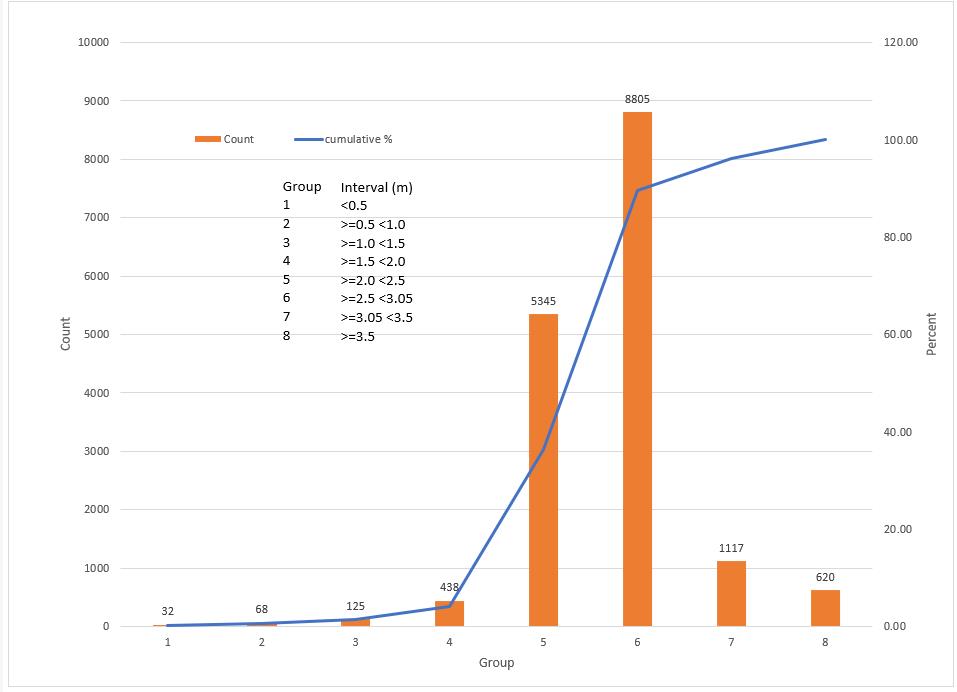

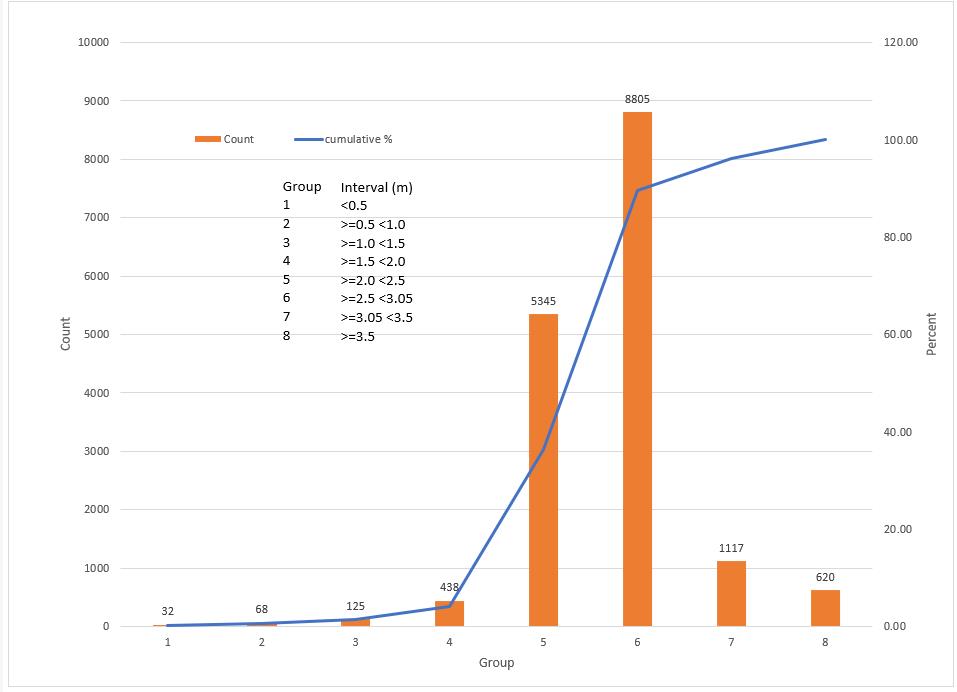

Figure 14.4 Assay Length Histogram71

Figure 14.5: Molybdenum Composite De-Clustered Histogram and Statistics72

Figure 14.6: Copper Composite De-Clustered Histogram and Statistics72

Figure 14.7: Molybdenum Directional Variograms73

Figure 14.8: Copper Directional Variograms73

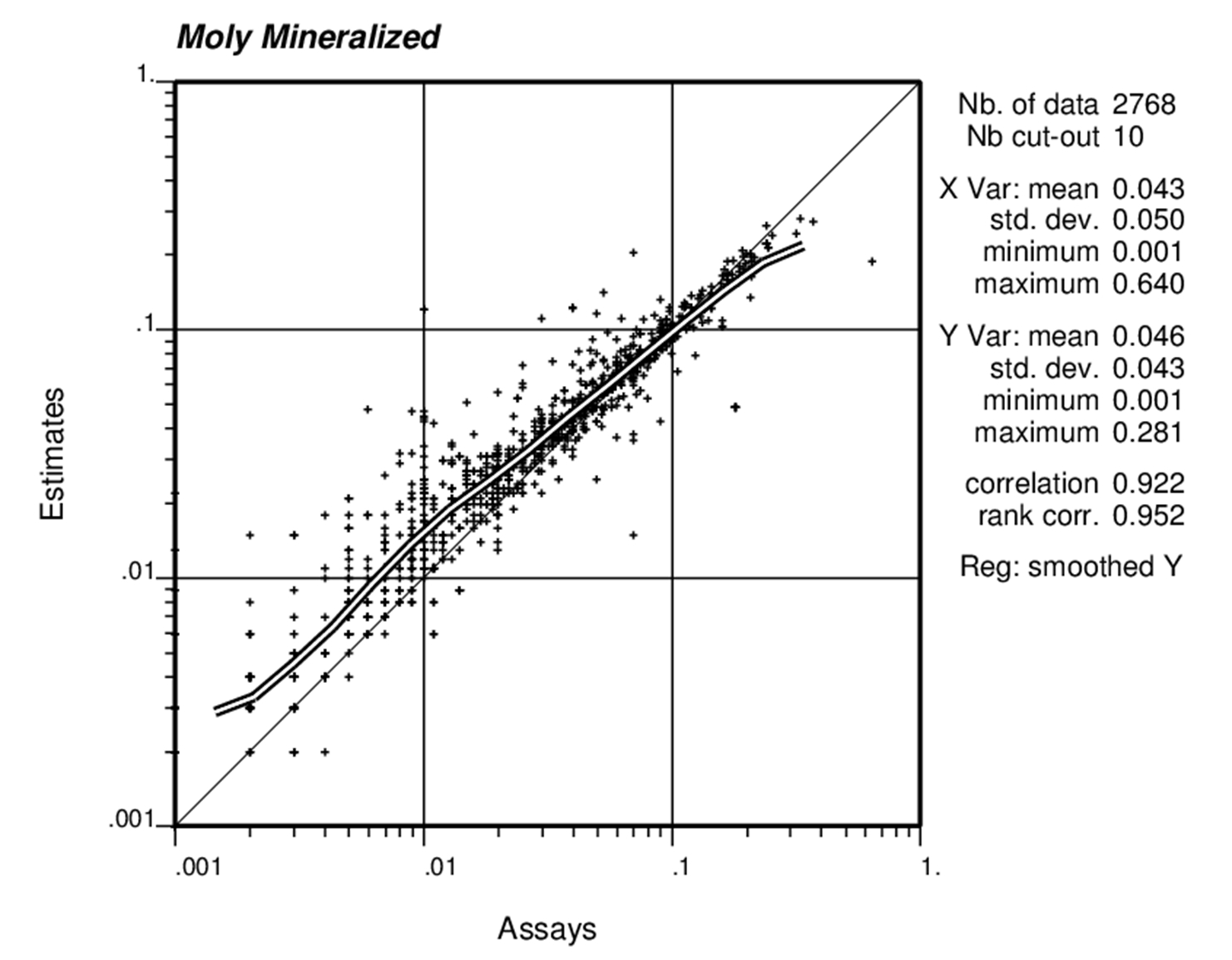

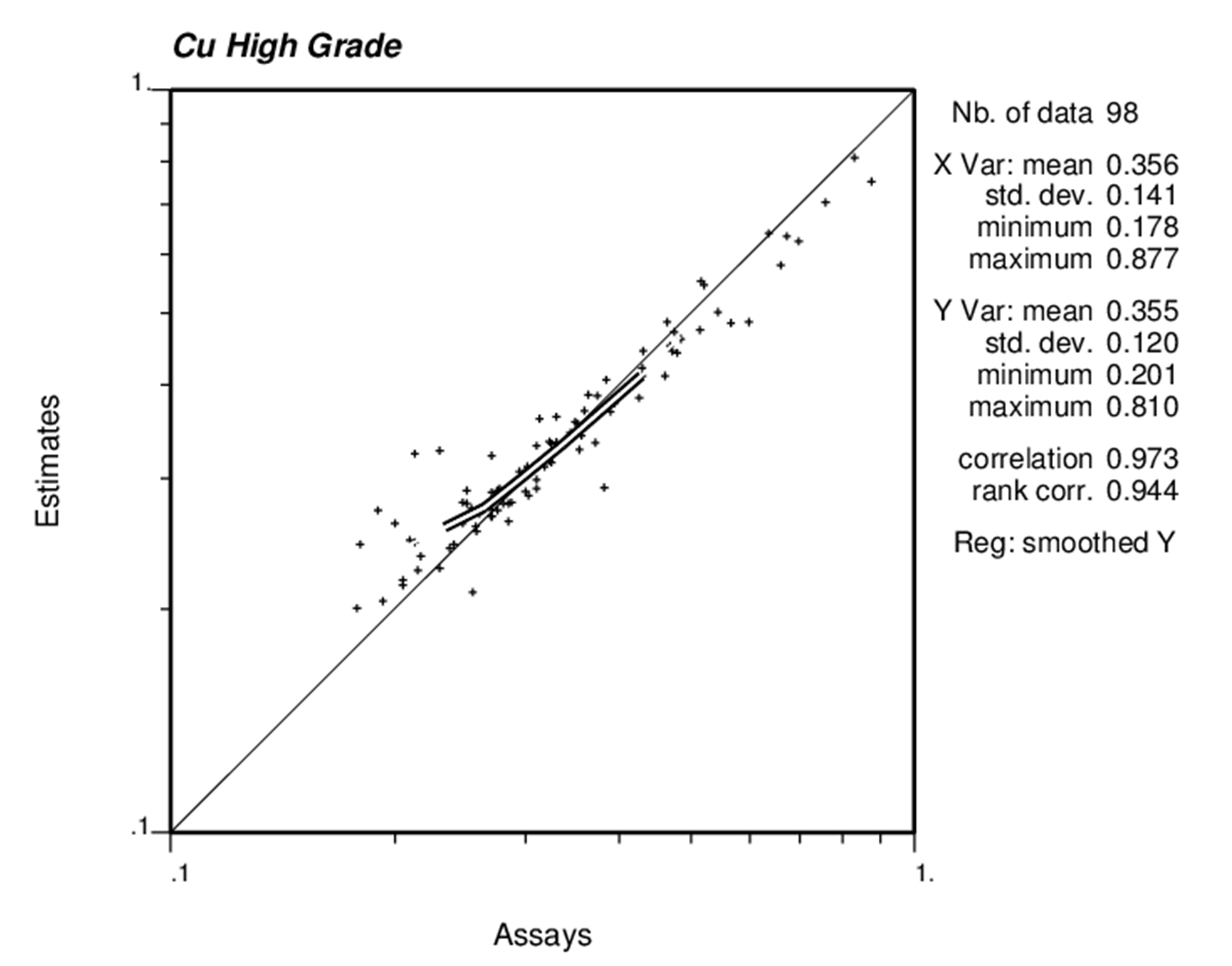

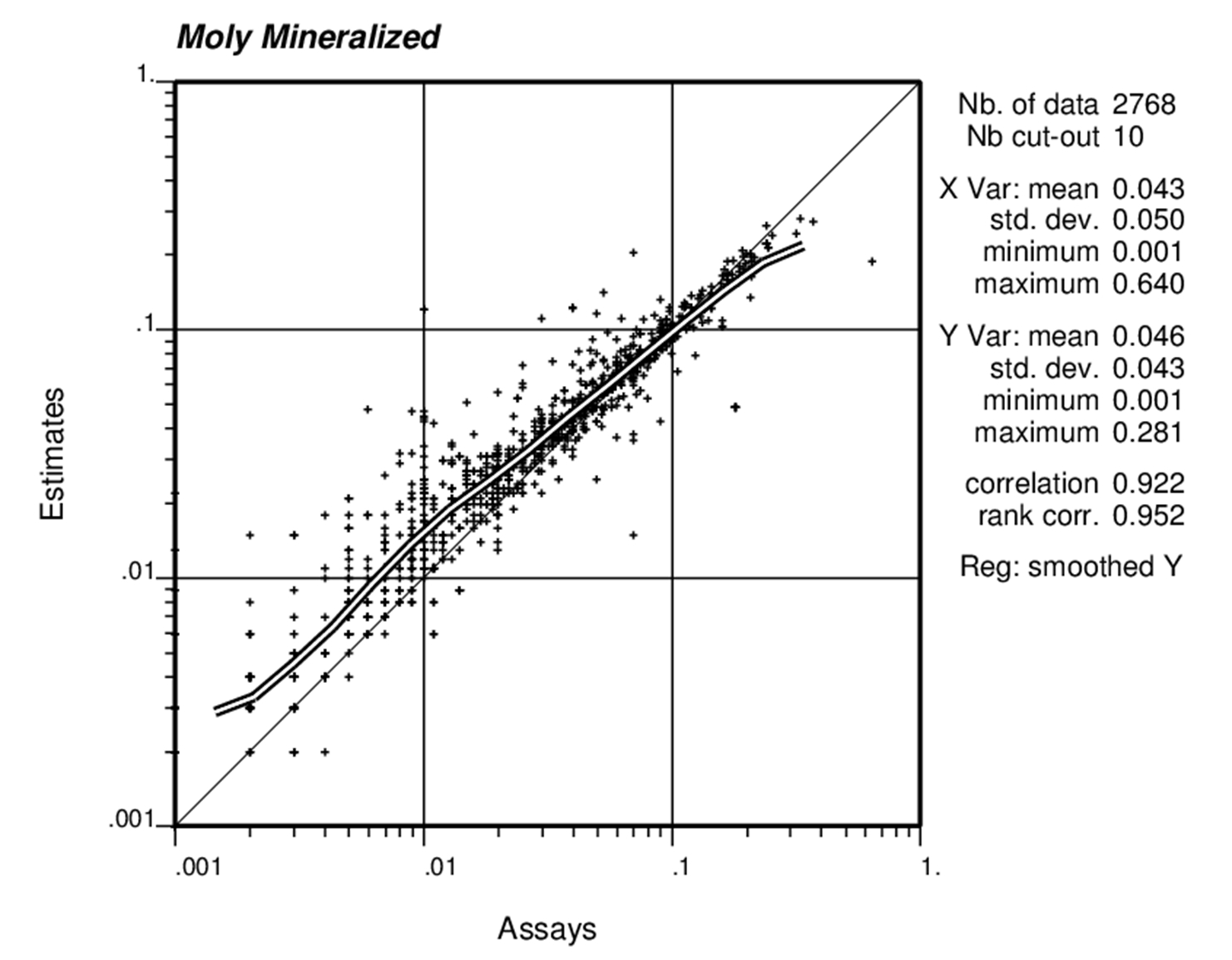

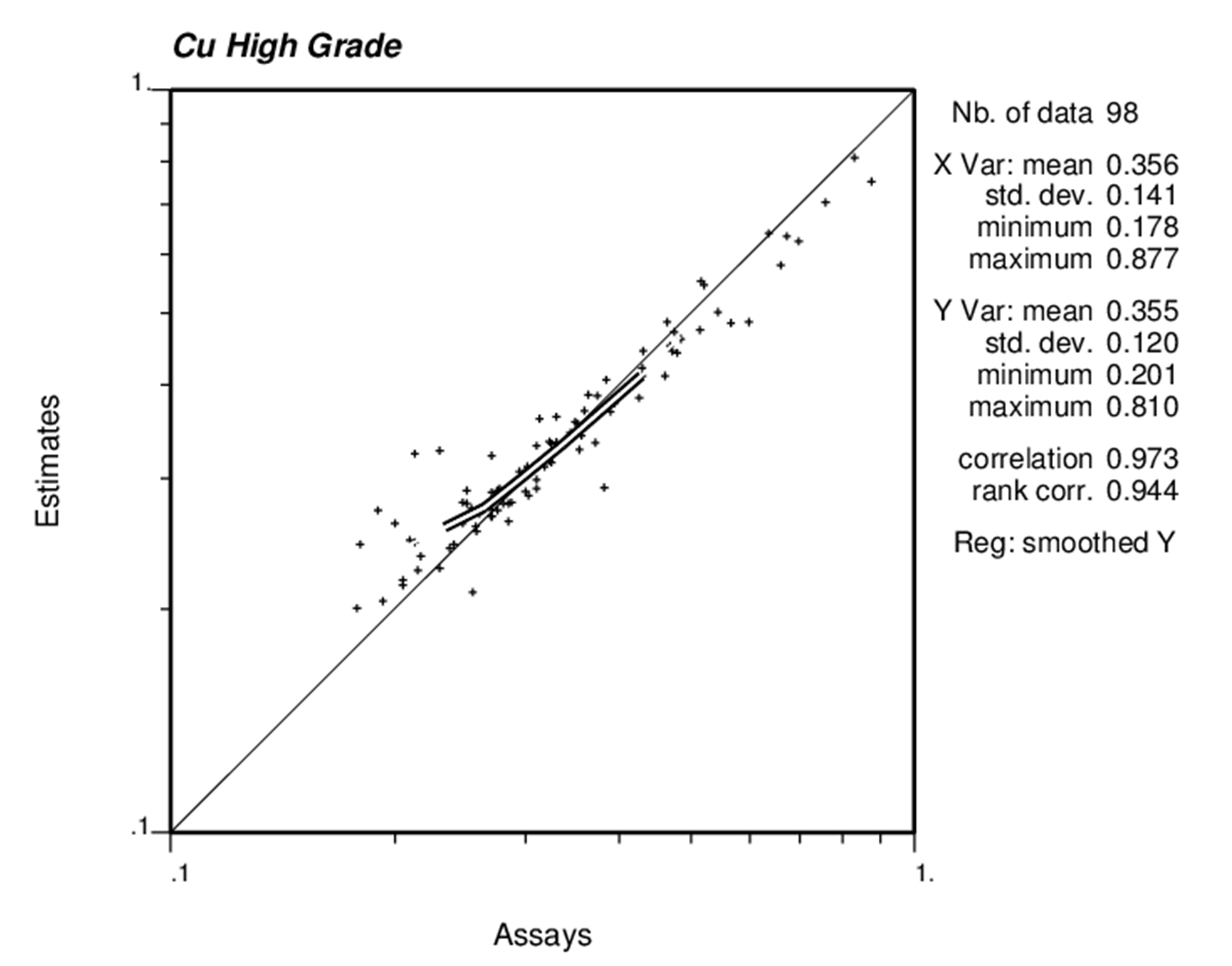

Figure 14.9: Comparison of Molybdenum Estimates with Assay Averages within the Blocks77

Figure 14.10: Comparison of HGZ Copper Estimates With Assay Averages Within the Blocks77

Figure 14.11: Comparison of LGZ Copper Estimates With Assay Averages Within the Blocks78

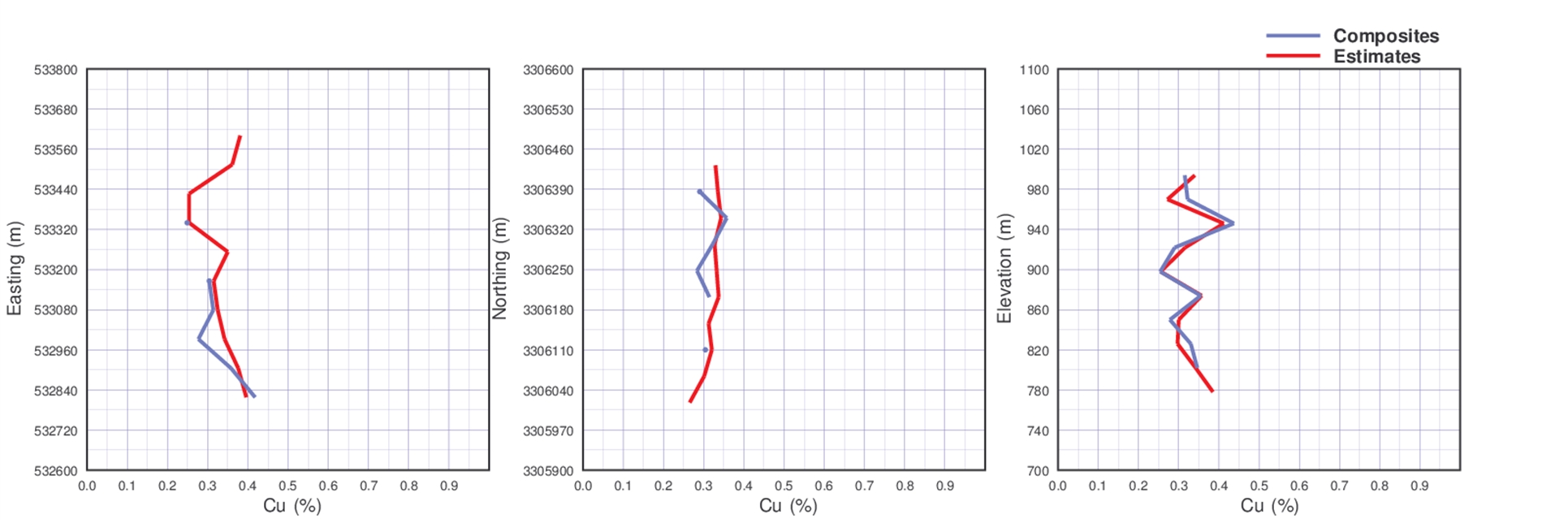

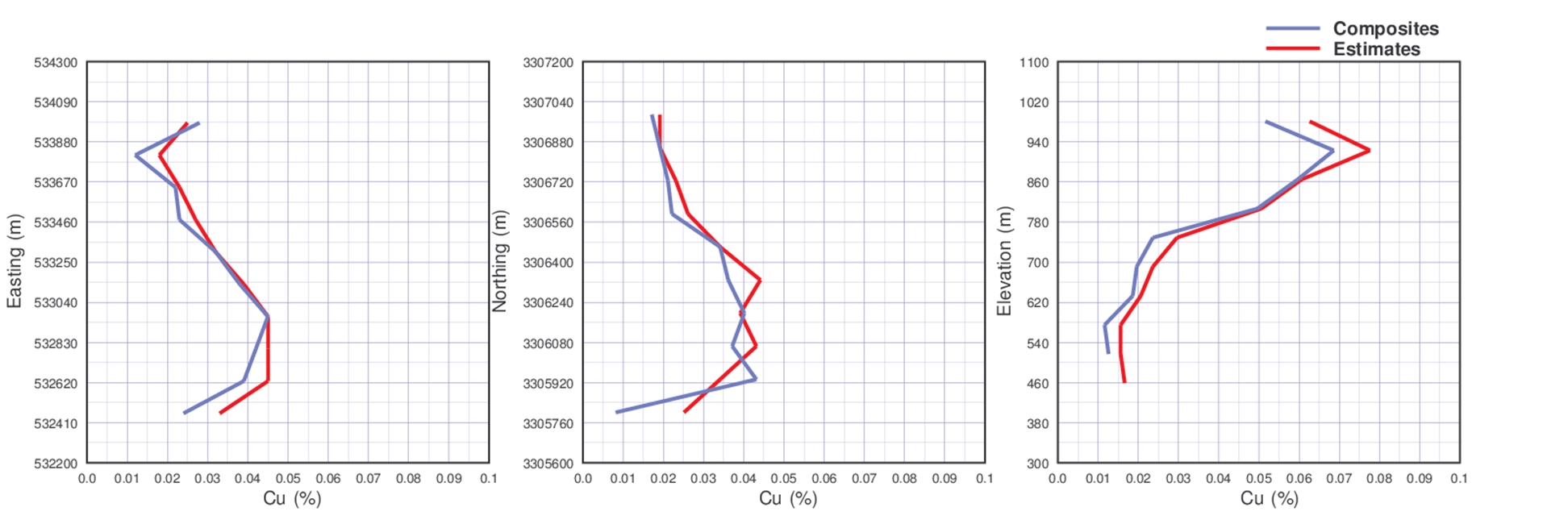

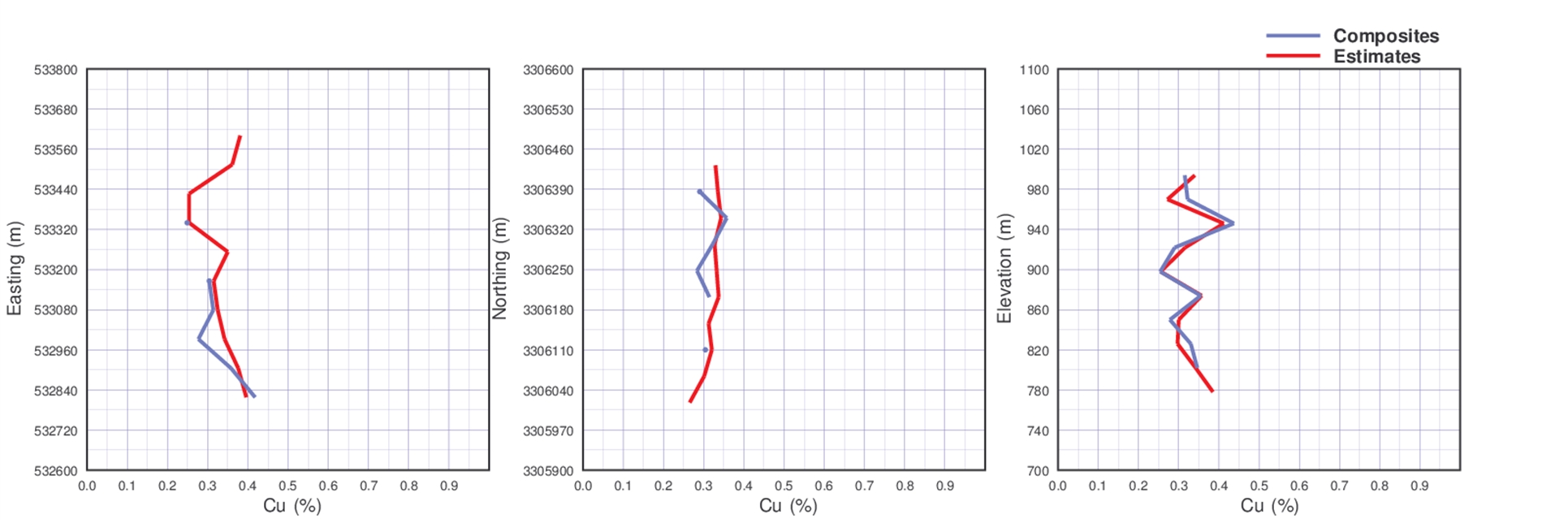

Figure 14.12: Molybdenum Composites Compared to Block Estimates78

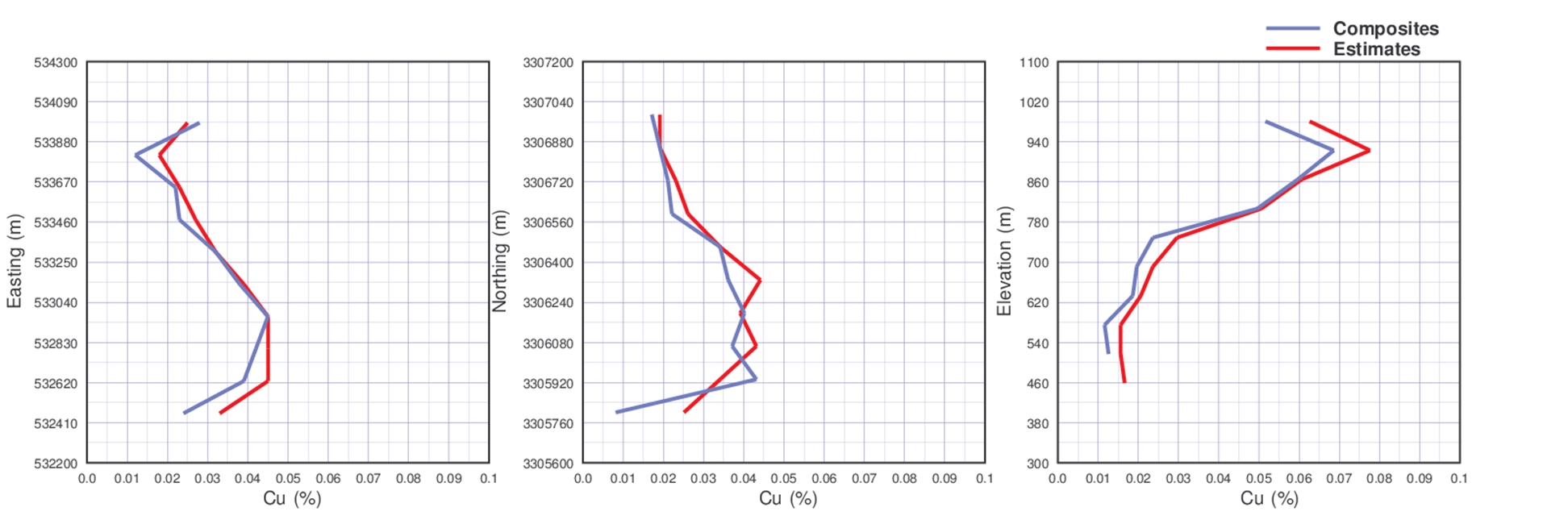

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 11

Figure 14.13: HGZ Copper Composites Compared to Block Estimates79

Figure 14.14: LGZ Copper Composites Compared to Block Estimates79

Figure 14.15: Grade Tonnage Curves for the El Creston Molybdenum Project84

Figure 14.16: Comparison of 2011 and 2022 Resource Shells85

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 12

2 | Introduction and Terms of Reference |

The El Creston Molybdenum Project is an advanced staged exploration property located in Sonora State, Mexico. It is located approximately 100 km north of the city of Hermosillo, capital of Sonora. Starcore International Mines Ltd. acquired a 100% interest in the Project in February 2015 through the acquisition of all the shares of Creston Moly as part of the bankruptcy of Mercator Minerals Ltd. (“Mercator”).

In June of 2022, Starcore commissioned SRK Consulting (Canada) Inc. to prepare a technical report for the El Creston Project. The services were rendered between July and September of 2022 leading to the preparation of the mineral resource statement reported herein.

This technical report documents a mineral resource statement for the El Creston Project prepared by SRK. It was prepared following the guidelines of the Canadian Securities Administrators’ National Instrument 43-101 and Form 43-101F1. The mineral resource statement reported herein was prepared in conformity with generally accepted CIM “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines.”

The scope of work, as defined in a letter of engagement executed in June 2022 between Starcore International Mines Ltd. and SRK includes the construction of a mineral resource model for the stockwork molybdenum mineralization delineated by drilling on the El Creston Project and the preparation of an independent technical report in compliance with National Instrument 43-101 and Form 43-101F1 guidelines. This work typically involves the assessment of the following aspects of this project:

| • | Topography, landscape, access; |

| • | Regional and local geology; |

| • | Audit of exploration work carried out on the Project; |

| • | Mineral resource estimation and validation; |

| • | Preparation of a mineral resource statement; and |

| • | Recommendations for additional work. |

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 13

The mineral resource statement reported herein is a collaborative effort between Starcore and SRK personnel. The exploration database was compiled and maintained by Mercator, the previous owners of the Project, and made available to SRK as part of an earlier technical report prepared by SRK in 2011 for Creston Moly Corporation. The Project database was audited and validated by Dr. Arseneau, the QP of this technical report. The geological model and outlines for the molybdenum mineralization were constructed by the QP using GEOVIA GEMs™ Version 6.8.4. In the opinion of the QP, the geological model is a reasonable representation of the distribution of the targeted mineralization at the current level of sampling. The geostatistical analysis, variography and grade models were completed by the QP.

The mineral resource statement reported herein was prepared in conformity with generally accepted CIM “Exploration Best Practices” and “Estimation of Mineral Resource and Mineral Reserves Best Practices” guidelines. This technical report was prepared following the guidelines of the Canadian Securities Administrators National Instrument 43-101 and Form 43-101F1.

The technical report was assembled in Vancouver, Canada during the month of August 2022.

This report is based on information collected by the QP during the site visits. The author has relied extensively on information in the technical report prepared by SRK for Creston in 2011 (SRK, 2011) and with discussions with Starcore technical personnel. The principal sources of information used to compile this report comprised of digital data and some published information relevant to the operation area and the region in general.

Assay data was mostly provided by independent, internationally recognized laboratories and standards used included a combination of standard samples provided by an independent company.

In summary, the following key digital data were provided:

| • | Drillhole database containing collar location, downhole survey, assay and geology data. |

| • | A 3-dimensional (“3-D”) model of the topography. |

| • | All original assay and survey certificates. |

| • | Quality control procedures and results. |

| • | Internal and external quality control data. |

| • | Representative geological cross-sections. |

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 14

The QP has made all reasonable enquiries to establish the completeness and authenticity of the information provided and identified, and a final draft of this report was provided to Starcore.

2.4 | Qualifications of SRK and SRK Team |

The SRK Group comprises over 1,600 professionals, offering expertise in a wide range of resource engineering disciplines. The SRK Group’s independence is ensured by the fact that it holds no equity in any project and that its ownership rests solely with its staff. This fact permits SRK to provide its clients with conflict-free and objective recommendations on crucial judgment issues. SRK has a demonstrated track record in undertaking independent assessments of mineral resources and mineral reserves, project evaluations and audits, technical reports and independent feasibility evaluations to bankable standards on behalf of exploration and mining companies and financial institutions worldwide. The SRK Group has also worked with a large number of major international mining companies and their projects, providing mining industry consultancy service inputs.

The resource evaluation work and the compilation of this technical report was completed by Dr. Gilles Arseneau, P. Geo. (APEGBC, 23474). By virtue of his education, membership to a recognized professional association and relevant work experience, Dr. Arseneau is an “independent Qualified Person (“IQP”)” as this term is defined by National Instrument 43-101.

Chris Elliott, FAusIMM, a Principal Consultant with SRK, reviewed drafts of this technical report prior to their delivery to Starcore as per SRK internal quality management procedures.

In accordance with National Instrument 43-101 guidelines, Dr. Arseneau visited the El Creston Project on 12 to 15 September 2022 accompanied with Salvador Garcia of Starcore. Dr. Arseneau also visited the Project between 03 to 06 August 2010 when the drill program was underway.

The purpose of the site visits was to review the digitalization of the exploration database and validation procedures, review exploration procedures, define geological modelling procedures, examine drill core, interview Project personnel and to collect all relevant information for the preparation of a mineral resource model and the compilation of a technical report.

The site visits were also aimed at investigating the geological and structural controls on the distribution of the molybdenum mineralization to aid the construction of three-dimensional mineralization domains.

The QP was given full access to relevant data and conducted interviews of Mercator and Starcore personnel to obtain information on the past exploration work, to understand procedures used to collect, record, store and analyze historical and current exploration data.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 15

The QP would like to acknowledge the support and collaboration provided by Starcore personnel for this assignment. Their collaboration was greatly appreciated and instrumental to the success of this Project.

The QP’s opinion contained herein and effective 30 September 2022, is based on information collected by the QP and SRK throughout the course of the QP’s investigations, which in turn reflect various technical and economic conditions at the time of writing. Given the nature of the mining business, these conditions can change significantly over relatively short periods of time. Consequently, actual results may be significantly more or less favourable.

This report may include technical information that requires subsequent calculations to derive sub-totals, totals and weighted averages. Such calculations inherently involve a degree of rounding and consequently introduce a margin of error. Where these occur, the QP does not consider them to be material.

The QP and SRK are not insider, associates, or affiliates of Starcore, and neither SRK nor any affiliate have acted as advisors to Starcore, its subsidiaries or its affiliates in connection with this Project. The results of the technical review by the QP and SRK are not dependent on any prior agreements concerning the conclusions to be reached, nor are there any undisclosed understandings concerning any future business dealings.

A listing of abbreviations used in this report is provided in Table 2.1 below.

Table 2.1: List of Abbreviations

| |

Name | Abbreviation |

±3 Standard Deviation | ±3δ |

Association of Professional Engineers and Geoscientists in British Columbia | APEGBC |

ALS Chemex Labs, Ltd. | ALS |

AMAX Corporation Ltd. | AMAX |

Bad Quality | BQ |

Canadian Institute of Mining, Metallurgy and Petroleum | CIM |

Canadian National Instrument 43-101 | NI 43-101 |

Centimetre(s) | cm |

Creston Granite | CG |

Degree(s), Degrees Celsius | °, °C |

Diamond Drilling | DDH |

Energy & Metal Consensus Forecasts | EMCF |

Environmental Impact Statement | EIS |

Exploraciones Global, S.A. de C.V. | Global |

Exploration Preventive Report | PR |

G&T Metallurgical Services Ltd | G&T |

General and Administration | G&A |

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 16

| |

Name | Abbreviation |

Grams per Metric Tonne | g/t |

Hectare(s) | ha |

High Quality | HQ |

High-Grade Zone-Supergene | HGZ |

Hour(s) | h |

Hydrothermal Breccia | HBx |

Inductively Coupled Plasma Atomic Emission Spectroscopy | ICP-AES |

Inductively Coupled Plasma Mass Spectrometry | ICP-MS |

JDS Energy & Mining Inc. | JDS |

Kilogram(s) | kg |

Kilometre(s) | km |

Kilowatt Hour per Tonne | kwh/t |

Lead | Pb |

Litre(s) | L |

Lower Grade Zone-Primary | LGZ |

MDA Engineering Inc. | MDA |

Million Year(s) | Ma |

Meter(s) | m |

Micron(s) | µ |

Millimetre(s) | mm |

Million (million tonnes, million ounces, million years, million pounds) | M (Mt, Moz, Ma, Mlb) |

Ministry of Environment and Natural Resources | SEMARNAT |

Molybdenum | Mo |

Molybdenum Disulfide | OxMo |

Molybdenum Oxide | MoS2 |

Net Smelter Return | NSR |

No Quality | NQ |

Not Available/Applicable | N/A |

Original Kriging | OK |

Ounce (troy)/Ounces per Year | oz, oz/y |

P&E Engineering Co. | P&E |

Parts per Million | ppm |

Percent(age) | % |

Potential of Hydrogen | pH |

Pound(s) | lb |

Power of Two | ID2 |

Preliminary Economic Assessment | PEA |

Professional Geologist | P. Geo |

Qualified Person(s) | QP(s) |

Quality Assurance and Quality Control | QA/QC |

Reverse Circulation | RC |

Silver | Ag |

Skyline Assayers & Laboratories | Skyline |

Sodium Hydrosulfide | NaHS |

Sodium Isopropyl Xanthate | SIPX |

Square Centimeter(s) | cm3 |

SRK Consulting (Canada) Inc. | SRK |

Starcore International Mines Ltd. | Starcore |

System for Electronic Document Analysis and Retrieval | SEDAR (www.sedar.com) |

Three-Dimensional | 3-D |

Tonne (metric), Tonnes per Day, Tonnes per Hour | t, t/d, t/h |

United States Dollar(s) | USD, US$ |

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 17

| |

Name | Abbreviation |

Universal Transverse Mercator | UTM |

Zinc | Zn |

3 | Reliance on Other Experts |

The QP has not performed an independent verification of the land title and tenure information as summarized in Section 4 of this report. The QP did not verify the legality of any underlying agreement(s) that may exist concerning the permits or other agreement(s) between third parties but have relied on Jose Enrique Rodrigues del Bosque (RB abogados) as expressed in a legal opinion provided to Creston Mining Corporation (a Starcore subsidiary) on 3 October 2022. The reliance applies solely to the legal status of the rights disclosed in Section 4.1 below.

The QP was informed by Starcore that there are no known litigations potentially affecting the El Creston Project.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 18

4 | Property Description and Location |

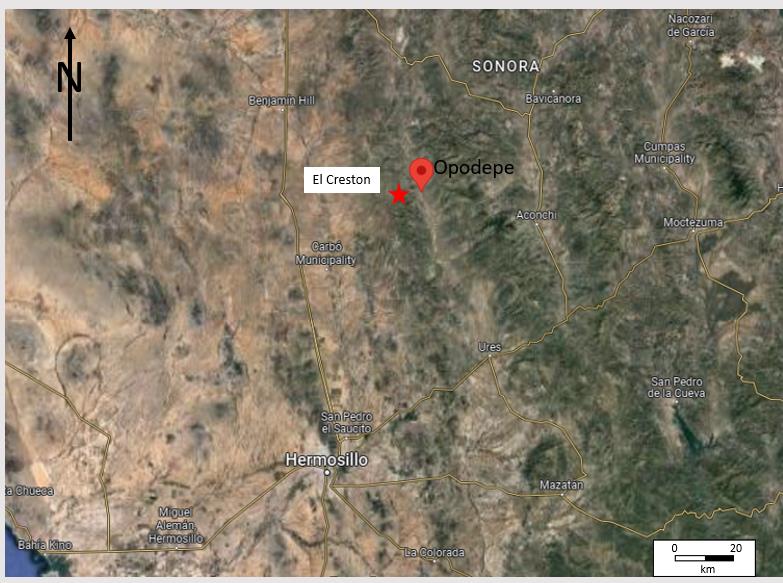

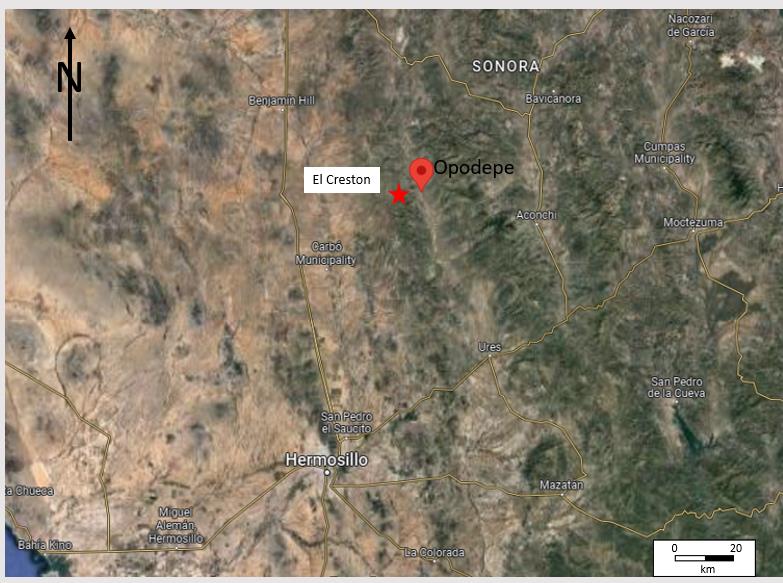

The El Creston Project is located in the north-central part of the state of Sonora in north-western Mexico. The property is about 145 km by road north-northeast of Hermosillo, the capital of Sonora, and 5 km southwest of the village of Opodepe (Figure 4.1). The approximate center of the mineral resources described in Section 14 is 29°53’N latitude and 110°39’W longitude.

Source: Google Earth™ (2022)

Figure 4.1: Project Location Map

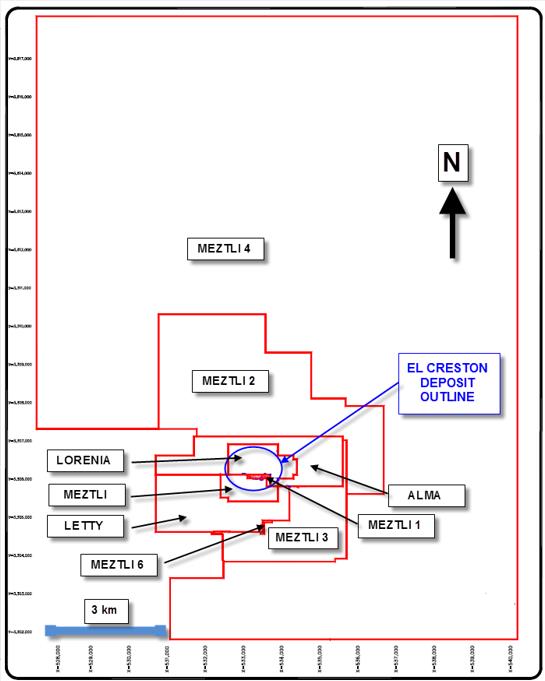

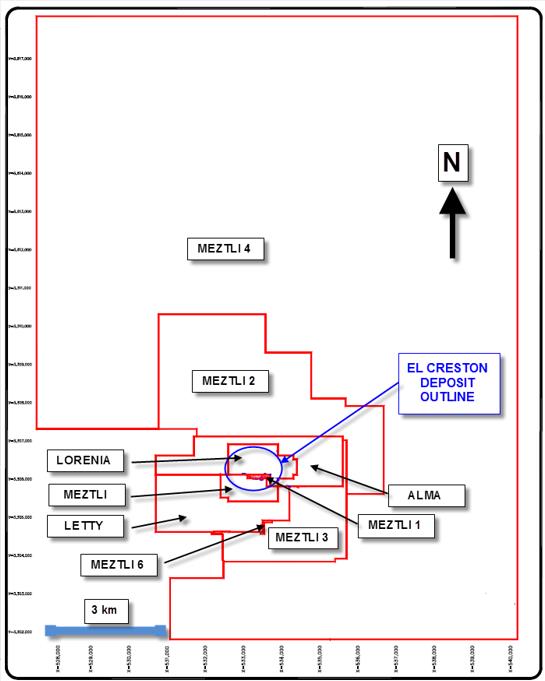

The El Creston property is comprised of nine concessions covering approximately 11,363 ha (Table 4.1 and Figure 4.2). Exploraciones Global, S.A. de C.V. (“Global”), the owner of the concessions, is a wholly owned Mexican subsidiary of Starcore. All concessions are subject to a 3% NSR.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 19

Table 4.1: Mineral Tenure Information

| | | | |

Concession | Date Granted | Expiry Date | Title No | Area (ha) |

Meztli | 16 April 2003 | 15 April 2053 | 219813 | 89.00 |

Meztli-1 | 16 July 2003 | 15 July 2005 | 220332 | 8.00 |

Lorenia | 25 June 2004 | 24 June 2053 | 222321 | 138.00 |

Letty | 15 October 2004 | 14 October 2054 | 223111 | 391.51 |

Alma | 13 August 2004 | 12 August 2054 | 222700 | 359.00 |

Meztli-2 | 30 September 2005 | 29 September 2055 | 225638 | 1,455.98 |

Meztli-3 | 18 January 2008 | 17 January 2058 | 231151 | 457.06 |

Meztli-4 | 12 May 2014 | 7 September 2057 | 243807 | 8,465.04 |

Meztli-6 | 4 July 2007 | 3 July 2057 | 229984 | 0.0032 |

Total | | | | 11,363.59 |

Source: Starcore (2022)

Figure 4.2: Land Tenure Map

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 20

Early in 2008, Global acquired surface rights to 1,200 ha from the Ejido of Opodepe by means of a purchase agreement finalized in early 2008 (Creston Moly Corp., 2008). These surface rights cover the main deposit and the surrounding area. In 2010, a certain member of the Ejido sued the Company claiming that the process for purchasing the surface rights had not been done correctly (done after the Ejido got the payment for the surface rights). The court agreed with the members of the Ejido. The Ejido never returned the cash but, as it stands, the Company does not have the surface rights to Parcels 38 and 39 which covers most of the Creston deposit (Figure 4.3). For the Project to go forward the Company will have to negotiate a new deal with the Ejido.

Figure 4.3: El Creston Deposit with Mineral Claims and Surface Rights Ownership

In September 2010, an additional 1,725 ha contiguous to the above were purchased from Francisco Navarro. In addition, Mercator entered into an Occupancy Agreement with Mr. Navarro for an additional 573 ha contiguous to the above. An Occupancy Agreement is a 20-year agreement allowing the Company to conduct mineral exploration and development. Surface rights are sufficient to support a mining operation with tailings.

Notwithstanding the acquisition of surface rights to the property, the Opodepe Ejido has blocked the access road to the property from Opodepe and is currently refusing all access to the El Creston main deposit area.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 21

A secondary access north and west of Opodepe is currently the only viable property access until Starcore can renegotiate access via the Opodepe Ejido.

4.3 | Environmental Considerations |

The QP is not aware of any unusual, or insurmountable environmental or social encumbrances associated with potential mining at the site. There are no known environmental liabilities to which the Project is currently subject to.

4.4 | Mining Rights in Mexico |

Exploration concessions in Mexico are separate from surface rights. Permission for surface access must be granted with the owners of the surface rights to the areas covered by any exploration program inside the concessions. It commonly involves negotiations and agreements detailing the exploration program and agreement for access and remuneration to the owners.

The Mexican Mining Law was amended in 2005, with removal of distinction between an Exploration Concession and an Exploitation Concession. As a result, the property was converted under the new legislation and given expiry dates that are 50 years from the date they were originally recorded with the Public Registry of Mining.

Under the Mexican Mining Law, duties are assessed against each exploration concession, and they are calculated by multiplying a rate defined by the Mexican Government based on the age of the respective concessions by the number of hectares of the respective concession. These duties are paid semi-annually in January and July, to the Secretariy of Finance (Secretaria de Hacienda y Crédito Público).

Prior to starting any work and/or exploration activity, an authorization from the Ministry of Environment and Natural Resources ("SEMARNAT") must be obtained.

To request the authorization for an exploration project, the filing of an Exploration Preventive Report (“PR”) or an Environmental Impact Statement (“EIS”) is required.

A PR may be submitted if the project meets the specifications provided in the Official Mexican Standard NOM-120-SEMARNAT-2011. Once filed, SEMARNAT determines if the submission of an EIS is required with respect to the project in question.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 22

5 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

The Creston property lies east of Highway 15, a four-lane highway that links Hermosillo, Sonora, with Nogales, Arizona. Access to the property from Hermosillo is via Highway 14 north from Hermosillo 70 km to Carbo junction. From the junction, a paved road is taken east 52 km to Rayon, then north along a well-maintained gravel road for 21 km to the junction with a secondary unpaved road crossing the San Miguel River 5 km south of Opodepe that leads to the Creston project. Opodepe is also connected with Ures to the south by a gravel road, providing an alternate route to Hermosillo.

5.2 | Local Resources and Infrastructure |

The El Creston property is located about 145 km by road, north-northeast of Hermosillo the capital of Sonora State with a population of approximately 940,000. The village of Opodepe, approximately 7 km northeast of El Creston, has a population of about 300. Many of the residents have experience in the mining industry.

Electric power and water are available at Opodepe, however a 45 km long power line will likely be required to provide power to any future development at the El Creston property, as Opodepe does not have the capacity for a large industrial site, discussions with the owners of water rights in the vicinity of the project will be necessary to support any future mining operation.

A gravel airstrip for a relatively small aircraft is located near Opodepe. A major power line and railroad are located at Carbo, which is 45 km southwest of the El Creston property. No surface infrastructure exists at the El Creston property itself.

The Cumpas molybdenum custom smelter operated by Molymex, S.A. de C.V. is located approximately 80 km east by direct line from Opodepe.

The Creston property is located in the Sonoran Desert. Daytime temperatures in the region may reach 46°C in the summer months of April to November but generally range from 41°C to 28°C. Winters are dry and mild, generally around 20°C, with occasional nights dropping to freezing in late December or January. Average temperatures for the Sonoran Desert region are 11°C for January, 18°C for April, 30°C for July, and 22°C for October.

Precipitation at Creston occurs generally in July and August. There is no surface water on the property. Water for drilling and maintaining the camp is transported from the San Miguel River, about 5 km east of Creston. Potential water sources, including the alluvial valley of Rio San Miguel de Horcasitas, are presently being studied by Creston Moly Corporation and its consultants.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 23

Exploration and mining activity can proceed year-round on the Creston Project.

The Creston property is in the foothills of the Sierra Madre Occidental, a largely volcanic, northwest-trending mountain range forming the spine of north-western Mexico. The property lies within an area of considerable relief (Figure 5.1). The main prospect is along the base of an east-trending ridge which rises about 400 m above east-trending arroyos to the north and south. The crest of the ridge is formed by nearly continuous cliffs which range from 30 m to 100 m high and are largely inaccessible. The north face of the ridge is in most places precipitous, whereas the southern and eastern slopes are less rugged.

Cerro Creston, the central physiographic feature in the project area that forms a prominent ridge within the Main deposit, reaches a height of 1,000 m above sea level, with rugged terrain from there down to the 600 m level where there are more gentle foothills (Lodder et al., 1975). The Creston property lies primarily along the western bank of the San Miguel River.

Small woody desert shrubs and cacti characterize the lower elevations with trees at higher elevations. In areas with a high-water table, honey or velvet mesquite may form dense woodlands (Georgia Ventures Inc., 2007).

Photo: SRK Site Visit (2010)

Figure 5.1: General Physiography of the El Creston Area

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 24

Exploration on the El Creston property commenced in approximately 1936 after its molybdenum potential was identified in the early 1900’s. Surficial sampling, drilling, core sampling and mapping were completed by a variety of companies since this time. Creston Moly Corporation began work on the property in September 2007 and in 2011, Mercator acquired Creston Moly Corporation with plans to develop the El Creston property. In 2014, Mercator declared bankruptcy. Subsequently all the assets held by Creston Moly Corporation were acquired by Starcore for CA$2M on 19 February 2015.

Table 6.1 briefly summarizes the historic work completed by various companies prior to Creston Moly Corporation’s work.

Table 6.1: Summary of Historical Exploration Work Prior to Creston Moly Corporation

| | |

Work Period | Company | General Work Description |

1900 to 1935 | Unknown | An open cut into the main deposit, surficial sampling |

1936 to 1938 | H.C. Dudley | Diamond drilling, underground adits, mapping, chip sampling, geochemical analysis |

1960 to 1972 | AMAX, Guggenheim Exploration & New Jersey Zinc | Diamond drilling, core sampling (assays), mapping, geophysical surveying |

1973 to 1993 | Penoles, AMAX, Climax & Fresnillo | Geological mapping, geophysics, diamond drilling, core sampling, surficial sampling, geochemical analysis, RC drilling, underground adits |

1994 and 1995 | Orcana Resources | Geophysics, RC drilling |

6.1 | Historical Drilling & Underground Workings |

Drilling in the property was completed using both diamond drilling (“DDH”) and reverse circulation (“RC”) drilling methods, although by the number of holes and meters, diamond drilling dominates. Underground adits were completed as well, first in the 1930’s and then again in 1982.

Table 6.2 summarizes the historic drilling programs which comprises more approximately 16,000 m of core and RC drilling and five underground adits totalling 851 m.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 25

Table 6.2: Summary of Drilling and Underground Development by Company and Year

| | | | | | | |

Company | Year | Core | RC | Underground Adit |

Number | Total Length | Number | Total Length | Number | Total Length |

H.C. Dudley | 1930’s | 2 | 202 | | | 2 | 188 |

AMAX | 1960 | 2 | 317 | | | | |

Guggenheim | 1966-1967 | 8 | 851 | | | | |

NJ Zinc | Late 1960’s | 4 | 924 | | | | |

AMAX | 1974-1982 | 39 | 11,763 | 6 | 1,500 | 3 | 663 |

Fresnillo | 1986-1988 | 2 | 434 | | | | |

Orcana | 1995 | | | 12 | 3,495 | | |

All Companies, All Years | 57 | 14,491 | 18 | 1,500 | 5 | 851 |

6.2 | Historical Mineral Resource Estimates |

Numerous historic resource estimates were completed for the Creston mineralization prior to the enactment of NI 43-101. Estimates have been recorded between 1975 and 1996. A selection of these estimates is summarized in Table 6.3.

Table 6.3: Selection of Historic Non-NI 43-101 Resource Estimates

| | | | | |

Year | Company | Tonnes | Grade Mo (%) | Cut off Mo (%) | Cu (%) |

1975 | AMAX | 43,500,000 | 0.119 | Unknown | n/a |

1978 | AMAX | 87,100,000 | 0.096 | 0.10 | n/a |

1979 | AMAX | 143,000,000 | 0.091 | 0.06 | n/a |

1979 | AMAX | 198,000,000 | 0.073 | 0.06 | n/a |

1983 | AMAX | 185,000,000 | 0.067 | 0.03 | n/a |

1996 | Orcana | 103,000,000 | 0.111 | Unknown | 0.38 |

The methodologies used to prepare the historical estimates presented in Table 6.3 are not known. The estimates are no longer relevant because they were prepared before the 2011 drilling was completed. The historical estimates do not use the mineral resource classification categories prescribed in NI 43-101. The QP has not done the work necessary to verify the historical estimates and they should not be relied upon as they are all superseded by the estimates presented in Section 14 of this report. The historical estimates are only quoted here for historical reasons. The Company is not treating the historical estimates as current mineral resource estimates. None of the above estimates reflect the current supporting data for the deposit and all were completed before NI 43-101 regulations were in effect. These historical estimates are all relevant in that they demonstrate the size and grade of mineralization at El Creston as it changed through time with additional exploration and drilling.

In 2007, P&E Engineering Co. (“P&E”) completed the first NI 43-101 technical report on the El Creston Moly Property on behalf of Georgia Ventures Inc. (P&E, 2007). This work was based

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 26

upon historic drilling and assays completed up to 1995. Creston Moly Corporation completed significant drilling between 2007 and later 2008 and MDA Engineering Inc. (“MDA”) utilized this additional work to complete an updated mineral resource in late 2008 (MDA, 2008).

The P&E mineral resource from 2007 and the MDA mineral resource from 2008 are summarized in Table 6.4.

Table 6.4: 2008 P&E and 2008 MDA Historical Resource Estimates Summary

| | | | | | | | |

Year | Consult. | Company | Resource Class | Tonnes | Grade Mo | Grade Cu | Contained Mo | Contained Cu |

Mo (%) | Cu (%) | (Mlb) | (Mlb) |

2007 | P&E | Georgia Ventures | Measured | | | | | |

Indicated | 92,873,000 | 0.083 | 0.06 | 169.9 | 122.8 |

Inferred | 84,221,000 | 0.076 | 0.05 | 141.1 | 92.8 |

2009 | MDA | Creston Moly Corp. | Measured | 52,240,000 | 0.074 | 0.05 | 85.5 | 58.1 |

Indicated | 124,650,000 | 0.070 | 0.04 | 192.7 | 121.1 |

Inferred | 16,300,000 | 0.051 | 0.06 | 18.3 | 21.9 |

The P&E estimate included both the Main zone and the Red Hill zone; however, the two were modelled as separate and distinct zones (P&E, 2008). The MDA estimate included only the Main zone, with the Red Hill zone being left out due to a lack of historic drilling quality assurance and quality control (“QA/QC”) and insufficient 2007/2008 drilling to accurately estimate the zone. The QP has not done the necessary work to fully verify these estimates, they are only quoted here for historical reasons and the historical estimates are being superseded by the estimate presented in this report.

The P&E and MDA historical estimate was prepared by using inverse distance square while the MDA estimate was prepared using ordinary kriging (“OK”) both applied geological wireframes representing the mineralized intervals to restrict the estimations. These estimates are no longer relevant because they were prepared before all the current drilling was completed. The historical estimates do use the mineral resource classification categories as prescribed in NI 43-101. The QP has not done the work necessary to verify the historical estimates and they should not be relied upon as they are all superseded by the estimates presented in Section 14 of this report. The historical estimates are only quoted here for historical reasons. The Company is not treating the historical estimates as current mineral resource estimates.

In 2011, SRK prepared a mineral resource estimate for the El Creston deposit on behalf of Creston Moly Corporation. The estimate used all drillholes drilled to June 2011. Mineral resources were estimated by ordinary kriging inside 10 m by 10 m by 12 m blocks using GEOVIA Surpac™ modelling software. Molybdenum and copper grades were estimated in three passes and resources were classified using resource categories as defined in NI 43-101. The historical resource is reliable and relevant but not current in that it doesn’t include all the current drill results. The estimate is superseded by the current mineral resource estimate presented in

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 27

Section 14 of this report. The mineral resources were reported at a grade of 0.035% molybdenum equivalent inside a Lerchs-Grossman optimized pit shell. Table 6.5 summarizes the SRK 2011 mineral resource. The Company is not treating the historical estimates as current mineral resource estimates. These historical estimates are relevant in that they demonstrate the size and grade of mineralization at El Creston as it changed through time with additional exploration and drilling.

Table 6.5: El Creston Mineral Resource Estimate (SRK, 2011)

| | | | | |

Resource Class | Total Tonnes | Mo | Contained Mo | Cu | Contained Cu |

(%) | (lbs) | (%) | (lbs) |

Measured | 67,200,000 | 0.080 | 118,800,000 | 0.06 | 89,400,000 |

Indicated | 199,100,000 | 0.058 | 255,000,000 | 0.06 | 280,400,000 |

Inferred | 21,900,000 | 0.043 | 20,600,000 | 0.06 | 27,700,000 |

Measured + Indicated | 266,300,000 | 0.064 | 373,900,000 | 0.06 | 369,800,000 |

Note:

| * | Reported at a cut-off grade of 0.035% molybdenum-equivalent within a Lerchs-Grossman optimized pit shell. Mineral resources are not mineral reserves and do not have demonstrated economic viability. All numbers have been rounded to reflect the relative accuracy of the estimates. |

The 2010, Creston Moly commissioned JDS Energy & Mining Inc. (“JDS”) to prepare a preliminary economic study (“PEA”) for the El Creston Project. The PEA envisaged mining by open pit method employing a conventional open pit truck shovel operation. The mine plan was developed following the selection of an optimized pit shell and subsequent design of an ultimate pit with ramps and designed slopes (JDS, 2010).

The stripping ratio for the life-of-mine averaged approximately 1:1. The inferred mineral resources included in the mine production plan represented 3.4% of the total plant feed. The PEA study was to be updated with the 2011 SRK resource estimate but after the purchase of Creston Moly by Mercator all engineering work on the El Creston Project ceased and the Project has remained inactive until now.

Despite having been explored by five adits, there has been no production from the El Creston Project.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 28

7 | Geological Setting and Mineralization |

Regionally, the area is part of the Basin and Range Province. The Basin and Range Province is an extensional terrain of fault-bounded ranges and intervening valleys in the western United States that extends southward from Arizona and New Mexico into the states of Sonora and Chihuahua, Mexico. In northern Mexico, this province is bifurcated by the Sierra Madre Occidental, a north-northwest-trending mountain range about 1,200 km long and 200 km to 300 km wide that forms the spine of northern Mexico. The Creston property lies in the western or Sonoran portion of the Basin and Range Province, close to the western flank of the Sierra Madre Occidental (Figure 7.1).

Source: Wikipedia.org (with modifications)

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 29

Figure 7.1: Regional Geological Setting

The Sonoran portion of the Basin and Range Province is dominated by elongate, northwest-trending ranges separated by wide alluvial valleys. Precambrian gneiss, metamorphosed andesite, and granite form the basement. Basement rocks are overlain by Proterozoic quartzite and limestone, Paleozoic and Mesozoic carbonate sedimentary rocks, and Mesozoic volcanic and clastic and carbonate sedimentary rocks (Silberman et al., 1988). Mesozoic plutons cut these older units, and Tertiary extrusive and intrusive rocks, related to volcanic activity in the Sierra Madre, are widely distributed in the region.

The province exhibits widespread extension, similar to that seen in Arizona and south-eastern California. Northwest-trending, high-angle normal faults bound the ranges. There are also numerous low-angle thrust and detachment faults throughout the region.

The Creston area lies within a large roof pendant of Precambrian to Paleozoic metamorphic rocks which includes the Creston granite and the Tertiary-aged Sonoran batholith. The Sonoran batholith includes intrusions ranging from granodiorite to quartz monzonite in composition. Emplacement of the Tertiary batholith caused extensive fracturing of the roof pendant, which may have provided rock preparation prior to the Creston mineralization. Leon & Miller (1981) stated that although conclusive evidence of a younger intrusion responsible for the molybdenum mineralization at Creston has not been encountered, it is highly conceivable that such an intrusion does exist within the Project area.

The following geological description is taken from SRK (2011) with minor modifications.

The predominant lithologies known at El Creston include metamorphic rocks of Precambrian and perhaps Paleozoic age, intrusions of various compositions, dikes, and breccias of Paleozoic and Tertiary age, and Recent conglomerate, talus, and landslide deposits. The combination of strong hydrothermal alteration, post-mineralization structural events, and supergene effects makes some of the rock types virtually unrecognizable. This is particularly true in the Main deposit area, where contact relationships are difficult to map.

Phyllites, quartzite, gneisses, and metavolcanic rocks were intruded by the Creston granite, which has a weakly developed gneissic texture. While the Creston granite has been altered and mineralized, hosting most of the presently defined molybdenum mineralization in the Main deposit, the older metamorphic rocks intruded by the Creston granite are only locally altered and mineralized.

The Creston granite exhibits two phases. A coarse-grained, dark gray, predominantly equigranular rock is the main phase of the meta-granite and displays weakly developed foliation. Fine- to medium-grained, buff-white to brown, equigranular to locally porphyritic rocks form the weakly foliated fine-grained phase, which some authors have speculated may represent the chilled border or contact phase of the main granite. In the central part of the Creston deposit,

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 30

hydrothermal alteration related to the molybdenum mineralization has obliterated the original contacts and mineral contents of both phases of the Creston granite; the granite is generally fresh and unaltered only in the northern part of the property.

The most striking feature of the Creston granite within the Main deposit is its hololeucratic appearance. The rock is composed of quartz, potassium feldspar and altered plagioclase, with only local remnants of altered mafic minerals.

Creston Mining (2006) reported that the Creston granite is Mesozoic-Cenozoic in age, rather than Precambrian-Paleozoic as proposed by Leon (1978), Lodder et al. (1975), and Leon & Miller (1981). However, Creston Moly Corporation (2008) reports that the Creston granite is Proterozoic and that a recent regional geologic map of Sonora reports it is 1.4 Ga.

Foliation in the Creston granite trends N70°E and dips steeply both north and south (P&E, 2007 & 2008). Davis (1974) proposed that the foliation in the granite was produced by directed fracturing recrystallization. The metamorphic rocks, including the Creston granite, were structurally deformed sometime between the Proterozoic and Late Tertiary and were also intruded by a quartz monzonite stock during the Late Cretaceous to mid-Tertiary.

The Creston granite is the principal host of the molybdenum and copper mineralization at the Main deposit. It is the primary lithology in the upper plate of the low-angle Creston fault and lies adjacent to the quartz monzonite stock.

Three main types of unmetamorphosed intrusions, along with younger acidic to intermediate dikes, have been identified on the Creston property. The Meztli diorite is a medium-grained, porphyritic intrusion that forms an elongated, tabular body along the southern flanks of Cerro Creston. Although this intrusion does not contain any significant molybdenum mineralization, it does host supergene copper mineralization. A petrographic report by Rossetti (2007) concluded that the Meztli is actually strongly altered microgranite, probably a finer-grained variety of the Creston granite, and that the term “Meztli diorite” should be abandoned.

Fine-grained diorite that may be of Paleozoic age occurs over a large portion of the southeast part of the Main deposit area and also occurs as dikes in the central part of the Main deposit. This unit is a dark greenish white, fine- to locally medium-grained equigranular rock that is generally not mineralized. According to Rossetti (2007), this rock also can range in composition to monzodiorite.

Quartz monzonite porphyry was intruded between Late Cretaceous and mid-Tertiary time; it has been dated by K-Ar methods at 55.4 + 2.1 million years (“Ma”). (Krueger, 1978; Leon & Miller, 1981). The quartz monzonite porphyry is exposed immediately northeast and about 4 km west-southwest of the Creston deposit. It is also found as the most common unit below the Creston fault in the Main deposit area, as well as small apophyses above the fault. According to Lodder et al. (1975), the quartz monzonite forms part of an intrusive sequence of stocks, plugs, dikes, and

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 31

breccias that intruded the basement rocks along an east-west trend and probably underlies most of the Creston area.

Intrusion of a variety of acidic to intermediate dikes followed emplacement of the quartz monzonite. According to Lodder et al. (1975), these dikes and/or sills form a 4 km to 5 km-wide belt whose east-west axis follows the Precambrian tectonic grain and roughly coincides with the Cerro Creston ridge. About 80% of the exposed dikes are rhyolitic in composition, with the remaining 20% mainly diorite and minor aplite dikes (Lodder et al., 1975).

It should be noted that Krueger (1978) also reported a K-Ar date of 56.2 + 2.2 Ma on a sample identified only as “granite,” with no location given; MDA has no information on the relationship of this sample to any of the igneous rocks described above.

AMAX Corporation Ltd. (“AMAX”) identified numerous breccia bodies in the Cerro Creston area, which they classified as either “c” or “i” types (Leon & Miller, 1981). According to Leon (1978; Leon & Miller, 1981), the “c” breccias are composed of angular fragments of phyllite, meta-andesite, and occasional Creston granite within a quartz-rich matrix that exceeds 10% of the rock volume. Fragments in the “c” breccias are not rotated, and quartz contents in the breccia matrix are less than 10%. In the Red Hill area, the matrix of “c” breccias consists of quartz, epidote, chlorite, and pyrite, with local molybdenite. Within the Main deposit, the matrix is composed of quartz-sericite-molybdenite-pyrite.

According to Leon (1978; Leon & Miller 1981), the “i” breccias are represented by the centrally located breccia at Creston and the East Breccia about 1 km to the east (Leon, 1978). They are characterized by rotated, sub-angular to rounded fragments of Creston granite, porphyritic quartz monzonite, and rhyolite in a vuggy quartz or quartz-sericite matrix with minor rock flour. The volume of matrix material averages about 30%. According to Leon (1978), the central “i” breccia at Creston appears to be a breccia pipe; it is well exposed in the West adit. The East Breccia is a tabular breccia that seems to plunge to the southeast. The “i” breccias may be intrusive breccias related to the mineralization event (Leon, 1978).

In contrast to the AMAX interpretations about “c” and “i” breccias, Nuttycombe (1977) proposed that there are as many as five different types of breccias at Creston. Four formed as a result of intrusion and are pre-mineral; the fifth is of recent surficial origin, although it can be difficult to distinguish from the pre-mineral breccias.

Of the four pre-mineral varieties, contact dilation breccias, chimney-collapse breccias, and sheeted-collapse breccias are closely related and are of limited areal and volumetric extent. In contrast, gravity plate breccia is much larger in area and volume; although not directly related to the other three, Nuttycombe (1977) proposed that it also probably was related to emplacement of intrusions.

The gravity plate breccia is thick, shallowly dipping, and is bounded below by a sharp fault but gradually dies out upwards. Nuttycombe (1977) proposed that the gravity plate breccia was

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 32

intrusive-related because it often separates the underlying quartz monzonite porphyry from the overlying older basement rocks.

MDA modelled two breccias of significance within the Main deposit. The East Breccia is in the eastern portion of the resource area and continues well beyond the defined mineralization to the east. It is a tabular body that is elongated in a west-northwest direction, dips steeply to the south, and is floored by the Creston fault. While highly mineralized along its western extent, the East Breccia appears to be devoid of significant molybdenum mineralization to the east. A smaller body of breccia underlies the Cerro Creston ridge and is cut off at its base by the Gemini fault, and, although mineralized, it is mostly oxidized.

Massive veins of white, barren quartz are common and represent the latest event in the intrusive history at Creston (Leon, 1978). They are especially common in the eastern half of the Creston area.

Unconsolidated to Poorly Consolidated Units. Iron and manganese-cemented conglomerate with fragments from all of the above rock types is present as scattered occurrences throughout the property. Much of the Creston deposit is covered by a large mass of talus, consisting mainly of fragments of quartz monzonite porphyry and Creston granite in a loose matrix of crushed rock.

A N50°E to N60°E structural trend appears to have controlled emplacement of the Late Cretaceous-Tertiary quartz monzonite porphyry and also may have influenced Mo-Cu and Pb-Ag-Zn mineral zoning (Leon, 1978).

Low-angle normal faults that post-date mineralization are the most significant structural elements recognized at Creston with the Creston fault being the most important of these structures. The Creston fault, which strikes north-westerly and dips about 25˚ to 30˚ to the northeast, marks the contact between highly altered and mineralized Creston granite in the hanging wall and generally barren, fresh-appearing quartz monzonite porphyry in the footwall. The Creston fault is a zone of brecciation up to 50 m in width, with most of the brecciation lying in the upper plate Creston granite, but the fault plane itself at the contact is often marked by a zone of foliated gouge with widths measured in centimetres. The surface trace of the fault is marked by a wide zone of shattering, changes in rock type, breccia, and change in topographic slope. The amount and sense of displacement of the Creston fault is not known for certain, but this information is vital to further exploration at the project as the fault cuts off the Main deposit mineralization. AMAX believed the Creston fault to be a low-angle gravity structure with dip-slip offset of between 300 m and 450 m.

MDA modified this interpretation somewhat to suggest that the Creston fault, and the numerous associated faults that lie in the hanging wall of the structure, are low-angle normal faults related to extensional tectonics that post-date the Creston mineralization.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 33

MDA modelled two faults originally identified by AMAX that occur in the upper plate of, and subparallel to, the Creston fault: the Gemini and Ordoñez faults. The Ordoñez fault generally lies a few tens of meters above the Creston fault and is characterized by a zone of intense brecciation that has been intruded by numerous dikes of varying compositions of both pre- and post-mineralization ages. The Ordoñez fault appears to merge into the Creston fault in the eastern portion of the Main deposit.

In the western portion of the Main deposit, the Ordoñez fault, as modelled, terminates the molybdenum mineralization, whereas the Creston fault cuts the mineralization in the eastern half of the deposit.

The Gemini fault is the uppermost low-angle fault in the upper plate of the Creston fault at Creston. The Gemini fault forms the floor of the breccia located along the Cerro Creston ridge and may have dip-slip movement of at least 200m (Leon & Miller, 1981).

The Carlos fault is located about halfway between the Creston and Gemini faults and is largely covered at the surface by talus. It is nearly parallel to the Creston and Gemini faults and appears to have had 20 m to 50 m of normal dip-slip movement (Leon, 1978).

There are many other structural zones, some of which have demonstrable shallow dips that were intersected by drillholes but have not been modelled. Lodder et al. (1975) reported the presence of several major, sub-horizontal, tabular tectonic breccias that occur in a roughly circular pattern around Cerro Creston, separating isolated patches of Creston granite from the underlying quartz monzonite stock. He believed that while these breccias have a wide variation in their strike, they generally appear to dip away from Cerro Creston at low angles (4° to 10°). Lodder et al. (1975) interpreted these tectonic breccia sheets as the brecciated bases of gravitational sliding blocks. AMAX also reported that the Creston fault was but one of a series of nearly parallel, low-angle, en-echelon faults located within the hanging wall of the fault. The series of upper plate faults are generally intruded by dikes of various compositions, and the faults are likely to be anastomosing.

Extensive steep faulting and shearing with both north-south and east-west trends are also reported to be common on the Creston property; however, the impact of these faults on the distribution of mineralization is believed to be minimal. There are reported to be at least four major vertical to sub-vertical faults with inferred vertical displacement of up to several hundred meters on the property. The most dominant one trends N70°E and dips 80°S in the basement rocks along the southern slopes of Cerro Creston. This fault is offset by three northwest-trending faults with horizontal displacements of up to 500 m.

The extensive system of faults at Creston have resulted in large areas of highly broken rock, which is reflected in low Rock Quality Designation (“RQD”) values measured in the core from Creston Moly Corporation. The RQD values are especially low, averaging less than 50% in the southern portion of the Main deposit, beneath the southern slopes of Cerro Creston ridge.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 34

The Creston granite is extensively altered to potassic, phyllic, argillic, and propylitic alteration assemblages, and is locally strongly silicified, over an area measuring 2.5 km by 6 km. Most of the molybdenite is associated with potassic and phyllic (quartz-sericite) alteration and is often accompanied by various degrees of silicification. According to Leon & Miller (1981), there is evidence for at least two distinct alteration events – an early potassium-rich event and a later silica-rich hydrothermal event that was molybdenum bearing. Extensive post-mineralization faulting has made interpretation of the spatial relationships of alteration patterns difficult. Strong silicification occurs locally adjacent and peripheral to intrusive breccias, and this silicification clearly post-dates the potassic, phyllic, and propylitic alteration (Lodder et al., 1975).

Potassic alteration is characterized by pervasive potassium-feldspar flooding and veining and the formation of fine-grained secondary biotite. This alteration is interpreted by Leon & Miller (1981) to be related to the emplacement of the porphyritic quartz monzonite, and it is very widespread both on the surface and at depth. Biotite, quartz, sericite, topaz, and tourmaline, with pyrite, molybdenite, chalcopyrite, and locally traces of bornite, torbernite, and possible wolframite, are associated with the potassic alteration. Later hydrothermal events have altered the secondary biotite to chlorite or sericite.

Lodder et al. (1975) stated that mineralization markedly increases away from the intense pervasive potassic zone and towards the phyllic alteration zone, with part of the higher-grade molybdenite mineralization occurring at the contact of the two alteration zones.

Phyllic alteration occurs over most of the mineralized area and is characterized by pervasive sericitization of feldspars and biotite; Rossetti (2007) reported that rutile is also a common component. Sericite alteration ranges from weakly developed to zones of massive, fine- to medium-grained sericite. Zones of silicification are common in the phyllic zone. Leon & Miller (1981) believed that the phyllic alteration was directly associated with economic grades of molybdenum, however Rossetti (2007) disagrees. Creston Moly Corporation geologists have noted that some of the high-grade molybdenite mineralization intersected in the drillholes is associated with zones of strong phyllic alteration characterized by coarse-grained sericite.

There are two separate phases of silicification (Leon & Miller, 1981). The first phase was intimately associated with most of the molybdenum veinlet-hosted mineralization and generally contains molybdenite and pyrite with rare chalcopyrite. The second phase is barren to weakly mineralized and occurs as the matrix in the unmineralized portions of the East Breccia and as bull-quartz veins. In places, silicified zones have no associated sulfide mineralization, whereas in other cases strong molybdenum mineralization lies within strongly silicified zones, usually accompanied by phyllic alteration.

Propylitic alteration is characterized by chloritization of biotite, minor epidote, calcite, and fine-grained pyrite. Chloritization of secondary biotite is found at depth and beyond significant mineralization. High-grade Pb-Zn-Ag-Cu in quartz veins are found in the propylitic assemblage at the outer edges of the hydrothermal system (Lodder et al., 1975).

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 35

Argillic alteration is characterized by pervasive clay (kaolin) alteration of feldspar and the absence of ferromagnesian minerals and is not associated with significant molybdenum mineralization. Argillic alteration most strongly affects the Meztli diorite. Although it is generally weakly developed within the Creston granite, argillic alteration does occur where the granite is strongly sheared.

The Creston granite has been affected by all four types of alteration. Other rock types are either not pervasively altered, such as the phyllites and meta-andesites, or are altered by only one type of alteration assemblage, such as the argillized Meztli diorite.

The currently defined mineralized area occupies a zone about 1,600 m in an east-west direction, a maximum of 1,200 m in a north-south direction, and 550 m vertically. The Creston and Ordoñez faults terminate the bulk of the molybdenum mineralization in the Main deposit at depth, although some mineralization has been intersected in drillholes below the Creston fault at the Red Hill zone to the south. Mineralization at El Creston includes both molybdenum and copper minerals.

7.5.1 | Molybdenum Mineralization |

There are two principal styles of molybdenum mineralization at Creston: veinlet-hosted and breccia-hosted mineralization. The veinlet-hosted mineralization occurs primarily in the Creston granite and is the dominant style of molybdenum mineralization within the Main deposit resources. Molybdenite occurs as finely disseminated subhedral crystals 0.1 mm to 0.8 mm across, embedded in a pervasive, fine-grained quartz-sericite matrix, and also as coarsely crystalline molybdenite along the margins of quartz veins (Figure 7.2). The bulk of the molybdenite in this mode occurs as disseminations, but considerable amounts is present in quartz veins.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 36

Source: MDA (2008)

Figure 7.2: Example of Coarse Crystalline Molybdenite Along Quartz Vein

The vertical to sub-vertical, sub-parallel molybdenite-bearing veins of this mode are numerous (up to 40 per metre). The veins are often of a vuggy nature and locally show cross-cutting relationships. The molybdenite in these veins is loosely bounded and is normally concentrated along the vein margins as coarse, subhedral to euhedral crystals up to 4 mm across. Locally, especially in the quartz veins, this combined mode carries possible recoverable amounts of chalcopyrite.

Creston Moly Corporation measured the orientations of a number of veins in outcrop within the Main deposit area and found the predominant orientation to be northwest striking (~315°) with high-angle dips to both the northeast and southwest. Lodder, et al., (1975) stated that the sub-vertical to vertical quartz veins normally trend 040° to 080°, are especially abundant over the central portion of the property, vary from hairline veinlets to 1 cm wide veins, and are spaced from one every 2 cm to one every 5 m.

The other important style of molybdenum mineralization in the Main deposit is hosted by the magmatic-hydrothermal East Breccia body. In this case, molybdenite typically occurs as fine-grained (0.05 mm to 1 mm) flakes at the contact of the quartz matrix with breccia fragments (Figure 7.3). There are also occasional high-grade, coarse-grained blebs of molybdenite in the breccia (Leon & Miller, 1981). Quartz-pyrite veinlets with molybdenite can also be found in fragments of the breccias and occasionally in the matrix.

GA / CAEStarcore_ElCreston_ResourceUpdate_Report_CAPR002049_20221113_SRK.docxSeptember 2022

SRK Consulting

El Creston Moly Property NI 43-101 Resource UpdatePage 37

Source: MDA (2008)

Figure 7.3: Molybdenite Mineralization Within East Breccia

Molybdenum also occurs as disseminated rosettes, ranging from 0.10 mm to 3mm in size, located in short high-grade intersections of massive coarse sericite within the Creston granite. Molybdenite may also occur with quartz along pre-mineralization structures (Lodder et al., 1975). Up to 8% pyrite is associated with molybdenite in irregular, parallel streaks or lenses in ribbon quartz veins. Finally, a particularly high-grade occurrence consists of fracture fillings and/or slip surfaces consisting of almost pure molybdenite.