Pampa el Toro Mineral Resource Technical Report

Report Prepared for

Cardero Resource Corp

Report No360457/1

September 10, 2009

![[pampa002.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa002.jpg)

Pampa el Toro Mineral Resource Technical Report

Cardero Resource Corp

Suite 1920 - 1188 West Georgia Street

Vancouver, BC

Canada, V6E 4A2

SRK Project Number 360457

265 Oxford Road

Illovo

2196

South Africa

P O Box 55291

Northlands

2116

South Africa

Tel: (011) 441-1111

Fax: (011) 880-8086

Mark Wanless mwanless@srk.co.za

September 10, 2009

Compiled by:

Reviewed by:

Mark Wanless

Sean Meadon

Victor Simposya

Project Consultants

Partner

Table of Contents

Location

Ownership

Geology and Mineralisation

Exploration Concept

Status of Exploration

Mineral Resource Estimation

Qualified Person’s Conclusions and Recommendations

2.1

Qualifications of SRK

2.2

Terms of Reference

2.3

Purpose of Independent Technical Report

2.4

Site Visit

2.5

Sources of Information

Property Description and Location

4.1

Location

4.2

Land tenure

4.3

Environmental and Socio-Economic Issues

Accessibility, Climate, Local Resources, Infrastructure and Physiography

5.1

Accessibility

5.2

Climate

5.3

Local Resources and Infrastructure

5.4

Physiography

10.1

Surface Sand Sampling

10.1.1

Reconnaissance Surface Sand Sampling Phase

10.1.2

Infill Surface Sand Sampling Phases I and II: Pampa El Toro

10.2

Trenching

11.1

Percussion Drilling

11.1.1

Percussion Drilling Programme: Phase I

11.1.2

Percussion Drilling Programme: Phase II

12.1

Reconnaissance and infill surface sand sampling

12.1.1

Field collection methods

12.1.2

Sample documentation and security

12.1.3

Quality control procedures in the field

12.2

Percussion Drilling

12.2.1

Field collection methods

12.2.2

Sample documentation and security

12.2.3

Quality control procedures in the field

12.3

Trenching

12.3.1

Field collection methods

12.3.2

Sample documentation and security

12.3.3

Quality control procedures in the field

12.4

Bulk Sample Collection

12.4.1

Field Collection Methods

12.4.2

Sample documentation and security

12.4.3

Quality control procedures in the field

Sample Preparation, Analyses and Security

13.1

Magnetic Separation and processing

13.1.1

Magnetic separation and processing of reconnaissance surface sand samples

13.1.2

Magnetic separation and processing of drillhole and infill surface sand samples

13.1.3

Quality control and security

13.2

Sample analysis and assay procedures

13.2.1

Sample Preparation

13.2.2

Analysis

14.1

Cardero Verification

14.1.1

Quality Control Procedures

14.1.2

Internal and External Check Assays

14.2

SRK Verification

Mineral Processing and Metallurgical Testing

16.1

Mineral Processing and Metallurgical Testing 2005 - 2007

16.15.1

SGS Lakefield (2005)

16.15.2

Midrex Test (2005)

16.15.3

Solumet Upgrading Test (2006)

16.15.4

Eriez Magnetic Separation Test (2006)

16.15.5

Midrex Test (2006)

16.15.6

Bateman Engineering Test (2006)

16.15.7

Bateman Engineering Test (2007)

16.16

Mineral Processing and Metallurgical Testing 2008

16.16.1

Mineral Processing

16.21.1

Metallurgical Testing

Mineral Resource and Mineral Reserve Estimates

17.1

Data Statistics

17.2

Semi Variogram analysis

17.3

Density Determination

17.4

Wireframe modeling

17.5

Resource estimation

17.6

Classification and Mineral Resource Reporting

Other Relevant Data and Information

Interpretation and Conclusions

Mark D. Wanless

L. Holland

List of Tables

Table ES1.1:

Pampa el Toro Mineral Resources as at Mineral Resources as at 21 July 2009.1

Table 4.1:

List of existing concessions as relating to the Pampa el Toro Project

Table 14.1:

Certified values of selected variables for OREAS 42P and statistics of assay results

Table 14.2:

Certified values of selected variables for GPAB-6 and statistics of assay results

Table 14.3:

Descriptive statistics of the duplicate datasets for a range of analysed variables.

Table 16.1

Summary of source and results of tests conducted on five bulk samples from Pampa el Toro bulk samples from Carbonera – 2005-2007

Table 16.2

Summary table of amount of sand processed, magnetic concentrate produced, and two weight recoveries and concentrate grades from each of the three pilot plant tests. (std = standard deviation)

Table 16.3

NRRI in-house laboratory results from the screening test on Pampa el Toro magnetic concentrate.

Table 17.1:

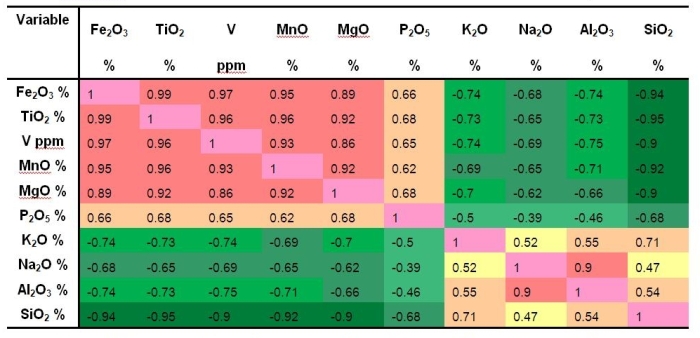

Univariate statistics of selected variables from the 5m composites.

Table 17.2:

Correlation Matrix of selected variables from the 5m composites.

Table 17.3:

Modeled semi-variogram parameters for all variables estimated

Table 17.4:

Mineral Resources for the Pampa el Toro project as at 21 July 2009

List of Figures

Figure 4.1:

Location map of the Pampa el Toro project

Figure 4.2:

Map of Pampa el Toro properties and dune field boundary.

Figure 10.1:

Pampa el Toro reconnaissance surface sand sampling, distribution and results.

Figure 10.2:

Pampa el Toro infill surface sand sampling, phases I and II, distribution and results.

Figure 11.1:

Map of percussion drill hole collars.

Figure 11.2:

Map of percussion drillhole duplicate and trench locations.

Figure 12.1:

Schematic diagram showing field procedure for collecting reconnaissance sand samples at pampa sand sites.

Figure 12.2:

Schematic diagram showing field procedure for collecting reconnaissance sand samples at dune sand sites.

Figure 12.3

Schematic diagram showing procedure for collecting field duplicate samples during reconnaissance sand sampling at dune sand sites.

Figure 12.4

Schematic diagram showing procedure for collecting within-pit duplicate samples during reconnaissance sand sampling at dune sand sites.

Figure 12.5

Typical 20-sample collection “block” used in The Pampa El Toro reconnaissance surface sands sampling programme.

Figure 12.6

Typical quality control scheme used in the sampling of sands from a typical 100 metre-deep percussion borehole at Pampa El Toro.

Figure 14.1:

Time sequence control plot of analytical results ofOREAS 42P and GPAB-6for Fe2O3 %

Figure 14.2:

Time sequence control plot of analytical results ofOREAS 42P and GPAB-6for

SiO2 %

Figure 14.3:

Time sequence control plot of analytical results ofOREAS 42P and GPAB-6for

TiO2%

Figure 14.4:

Time sequence control plot of analytical results ofGPAB-6for V ppm

Figure 14.5:

Scatter plots of Fe2O3 duplicate analyses from Splitter, Preparation and Pulp datasets

Figure 14.6:

Scatter Plot of SiO2 original and duplicate pulp analyses

Figure 14.7:

Scatter Plot of Fe2O3 original and duplicate pulp analyses

Figure 14.8:

Scatter Plot of TiO2 original and duplicate pulp analyses

Figure 14.9:

Scatter Plot of V original and duplicate pulp analyses

Figure 14.10:

HARD Plot of SiO2 duplicate analyses from the pulp dataset

Figure 14.11:

HARD Plot of Fe2O3 duplicate analyses from the pulp dataset

Figure 14.12:

HARD Plot of TiO2 duplicate analyses from the pulp dataset

Figure 14.13:

HARD Plot of V duplicate analyses from the pulp dataset

Figure 16.1:

Illustrated photograph of the Eriez magnetic separation pilot plant.

Figure 16.2

Flow sheet illustrating the magnetic separation process of the pilot plant.

Figure 17.1:

Histograms of grade variable for selected variables from the 5m composites.

Figure 17.2:

Scatter plots of Fe2O3, TiO2, V and SiO2 from the 5m composites indicating the strong correlations that exist in the data.

Figure 17.3:

Directional semi-variogram for Fe2O3 in the plane approximately parallel to the topography

Figure 17.4:

Plan view of drillhole collars displaying masked drillholes in red

Figure 17.5:

Omni-directional semi-variograms in the plane parallel to the topography surface, for Fe3O2, TiO2, V and SiO2

Figure 17.6:

Cross Validation outputs for Fe2O3 %, from the 5m composites.

Figure 17.7:

Cross Validation outputs for TiO2 %, from the 5m composites.

Figure 17.8:

Cross Validation outputs for Vanadium ppm, from the 5m composites.

Figure 17.9:

Histogram of compacted (left) and un-compacted (right) Bulk Density determination results

Figure 17.10:

Kriging search neighbourhood analysis results

Figure 17.11:

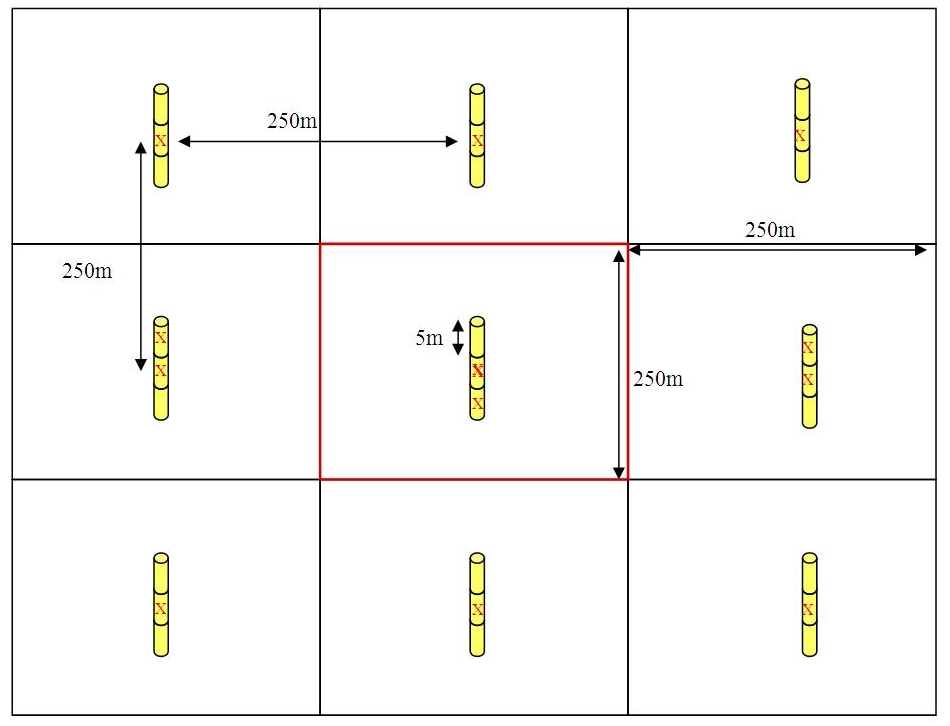

Schematic illustration of the samples selected in a typical search neighborhood

Figure 17.12:

Classified Mineral Resources with drillhole collar locations

10 September 2009

360457

Pampa el Toro Mineral Resource Technical Report

Summary

Cardero is a leader in exploration and development of Iron-ore, Copper and Gold projects in the Americas. Their projects include a highly prospective Iron Oxide Copper Gold (IOCG) project within the Alisitos Arc in Baja California Norte, Mexico, various gold projects in Argentina and Iron Sands projects in Peru. The Pampa el Toro Project is an Iron Sands project situated in the desert coastal region of Southern Peru. During late 2005 Cardero initiated a feasibility study on this project by starting a sand sampling program headed by Cooke Geochemical Consulting, and a trenching and percussion drilling programme managed by their own geologists, This has been followed up by various outsourced metallurgical test programs, initially done by Midrex (2005) and most recently by Bateman Engineering (2007).

Location

The property is located near the city of Nazca in the desert coastal region of southern Peru approximately 45 km northeast of the port of San Juan, close to the large Marcona iron mine (approximate resource of 1.4Bt @ 54% iron), the Mina Justa copper deposit (inferred resource of 218Mt @ 0.8% copper), and to Cardero's Pampa de Pongo iron deposit

Ownership

There are 14 mining concessions within the Pampa El Toro Project area totalling 10 00 hectares. Cardero has direct ownership of the 9 concessions and has signed an option agreement with Minas Ataspacas S.A. to acquire an initial 70% interest in the other 5 concessions.

Geology and Mineralisation

The Lower Paleozoic iron rich Marcona Formation is unconformably overlain by Triassic, Jurassic and Cretaceous volcanic and sedimentary sequences which, in turn, were intruded by stocks and dykes belonging to the Peruvian Coastal Batholith complex. These strata were, in turn, deformed, uplifted and eroded, and formed a base on which Quaternary sediments were deposited.

It is speculated that the iron-bearing minerals contained in the iron sands either partially or wholly originated from the volcanic units overlying the Marcona formation, however additional as yet unidentified sources are possible. However, it is possible that erosion of these Quaternary sediments contributed significant quantities of magnetite material contained in the dune fields.

Mineralogically, the principal iron-bearing minerals in the dunes consist of magnetite, titanomagnetite and ilmenite, with minor to trace amounts of hematite, rutile, titanite, ulvospinel and goethite. Silicate minerals, which make up the bulk of the sands, are primarily quartz, plagioclase, amphibole, chlorite, mica and pyroxene (SGS Lakefield Research, 2005a). The majority of the ilmenite (80-85% by volume) is associated with magnetite, titanomagnetite and hematite, with the remaining 15-20% by volume present as free ilmenite grains.

The dune sands are considered to be the product of aeolian re-distribution of contemporary and ancient beach sands and Quaternary basin sediments derived from erosion of the bedrock, winnowed, and re-distributed, by prevailing winds (Gay, 2005) to produce potentially economic concentrations of magnetite in extensive, and partially active, dune fields.

Exploration Concept

The primary focus of the exploration work has been on the sampling, trenching and percussion drilling of the deposit, combined with significant amounts of metallurgical testwork. This has lead to the development of a robust geological and structural model on which the mineral resource estimation and calculation is based. Exploration is thus at an advanced stage. Detailed metallurgical testwork has also been completed.

Cardero has conducted the exploration program with a set of standard procedures which aim to monitor the quality of the sampling and assay results. The standard procedures include submitting both Certified Reference Materials to monitor the accuracy of the analyses, as well as the analysis of field and laboratory pulp duplicate samples to benchmark the sampling and sample splitting errors as well as the precision and repeatability of the analyses. The quality control samples are checked before accepting the batch analytical results from the laboratory in order to control the quality of the data accepted in the exploration database. The quality control samples indicate that there was no bias introduced in the samples splitting process, as field duplicates and pulp duplicates from the laboratory show very similar characteristics. Analysis of the quality control sample results indicates that the analyses have been conducted to a high level of accuracy and precision, and are acceptable for use in Mineral Resource Estimation.

Status of Exploration

A pilot mineral processing plant has been erected on site in early 2008 and approximately 56.8 tons of magnetic concentrate was produced. In terms of metallurgical testwork The Phase I briquetting work and the Phase II bench-scale pig iron production program has been completed. The Phase III pilot-scale pig iron production program has been completed and the analytical results are currently being determined.

Mineral Resource Estimation

SRK have generated a Mineral Resource estimate based on the data supplied by Cardero from their exploration programs. The assay results of a selected set of elements from the 5m composite samples were analysed and found to represent a relatively well represented single population of all elements. There are strong correlations between the major economic elements (Fe2O3, TiO2, and V) that indicate a common genetic and depositional history. This indicates that these elements are most likely contained within the same, or strongly associated minerals.

SRK generated and modeled experimental semi-variograms that indicate long range continuity in the major elements, but that also indicate a long range trend element within the deposit in a north-south direction. Cross validation tests conducted by SRK on the semi-variograms indicate that the modelled semi-variograms and the selected search neighbourhood parameters should provide robust estimates.

The surface topography contours were used to generate a wireframe representation of the topography. This surface was copied vertically downwards by 30m, and used to constrain the depth extent of the Mineral Resource estimate. Drillhole collars were also projected vertically onto the surface as the various generations of GPS surveys of the collars did not accurately match the surveyed contours.

SRK created a block model with a block size equivalent to the nominal drillhole spacing of 250m X and Y directions, and 5m vertically. The block model was rotated to approximately match the dip of the topographic surface, which coincided with the plane of best continuity. In order to better model the volume, and the topographic variations, the parent blocks were sub-divided into smaller blocks, with a minimum size in the XY plane of 6.25m by 6.25m. The blocks were created to exactly match the intersection of the wireframe with the block center. Only parent blocks were estimated (i.e. each 250m by 250m by 5m collection of sub-blocks will have the same grade estimate)

The vertical continuity of mineralisation is significantly shorter than the lateral continuity, as would be expected from a deposit emplaced and reworked in thin sheets over time. The search ellipsoid employed by SRK takes this into account using anisotropic search scaling, with the result that samples from adjacent boreholes are given a higher weighting than samples from the same borehole that occur above or below the block being estimated. A minimum of four samples was required to estimate a block, and a maximum of 12 was used, to preserve some local variability in the grades. The maximum number of samples used in the estimation was selected after an optimisation exercise indicated that this was the best balance between generating high quality estimates, and over-smoothing of the estimation.

The Mineral Resources were classified on the basis of the confidence in the geological variation, the quality of the sampling and analytical results, drillhole spacing, and indicators of the quality of the estimation. The central portion of the deposit, which is drilled on approximately 250m centers, which has high quality estimates was classified as in Indicated Mineral Resource. The portion of the deposit surrounding this, drilled on approximately 500m centers, and extending approximately 500m beyond the area drilled on 500 centers is classified as an Inferred Mineral Resource. Portions of the deposit that were estimated further than 500m from the 500m spaced drilling were also excluded from the mineral Resources until further confirmatory work is completed to confirm the grades of the material. The Mineral Resources are reported in Table ES1.1.

Table ES1.1:Pampa el Toro Mineral Resources as at Mineral Resources as at 21 July 2009.1

Category | Volume (m3 '000) | Tons (kT) | Grade (Fe2O3 %) | Grade (TiO2 %) | Grade (V ppm) |

Indicated | 133,608 | 241,831 | 6.67 | 0.72 | 172 |

Inferred | 348,190 | 630,224 | 6.47 | 0.70 | 166 |

1 No grade cut-off has been applied to the material in the Mineral Resource, as the grades are relatively homogenous, would likely be able to be blended, and are projected to be economically viable, based on the assumptions made by Cardero. A Mineral Resource is not a Mineral Reserve and does not have demonstrated economical viability.

Qualified Person’s Conclusions and Recommendations

In the Exploration conducted to date at the Iron Sands Project, the surface sampling and subsequent percussion drillhole testing indicates that the overall magnetite content is relatively homogeneous, particularly in the uppermost 30 meters. Sample density achieved in the investigations is considered to be more than adequate to support these assertions.

The underestimation of magnetic mineral content and Fe grades caused by milling and grinding of sand is not expected to affect the in situ Fe grade which the current Mineral Resource estimate is based.

As an additional upgrading step to dry magnetic separation, screening of the concentrate is both simple and economic. Further testing in this regard is strongly recommended

A robust Mineral Resource estimate has been generated based on a sound geological model and exploration database. The Mineral Resource is classified in terms of the CIM definitions on Standards on Mineral Resources and Reserves – Definitions and Guidelines. An Indicated Mineral Resource of 133,608 kT with a Fe2O3 grade of 6.67% has been defined, along with an Inferred Resource of 348,190 kT with a Fe2O3 grade of 6.47%.

SRK recommend that the metallurgical test work continue to improve the confidence in the ability to upgrade the raw sand material into a saleable product, and that Cardero proceed with the preliminary economic assessment of the project

Introduction

SRK Consulting South Africa (SRK) have prepared an independent Mineral resource estimate of the Pampa el Toro Iron sands project (the Project), based on information supplied to SRK by Cardero, as well as knowledge gained about the property during two site visits to the project by representatives from SRK. The Mineral Resource estimate was generated by Mr. Mark Wanless a Professional Natural Scientist (Pr.Sci.Nat) registered with the South African Council for Natural Scientific Professionals (SACNASP). SACNASP is a statutory body which is recognized as a Recognized Overseas Professional Organization (ROPO) by the Canadian Institute of Mining, Metallurgy and Petroleum. Mr. Wanless served as the Qualified Persons responsible for the preparation of the Independent Technical Report (ITR) as defined in National Instrument 43-101, Standards of Disclosure for Mineral Pro jects, and in compliance with Form 43-101F1 (the Technical Report).

2.1

Qualifications of SRK

SRK is part of an international group (the SRK Group), which comprises more than 800 staff, offering expertise in a wide range of resource engineering disciplines. The SRK Group’s independence is ensured by the fact that it holds no equity in any project, contractor or supplier. This permits SRK to provide its clients with conflict free and objective recommendations on crucial judgement issues.

The SRK Group has a demonstrated track record in undertaking exploration programmes, independent assessments of resources and reserves, technical due-diligence audits, competent person’s reports, project evaluations and independent feasibility evaluations to bankable standards on behalf of exploration and mining companies and financial institutions world wide. The SRK Group has worked on a large number of major international mining operations and projects for all the major stock exchanges and has specific experience in commissions of this nature.

This ITR has been prepared based on a technical review of the exploration processes, and an independent Mineral Resource estimation by SRK.

Neither SRK nor any of its employees and associates employed in the preparation of this report has any significant beneficial interest in Cardero or in the assets of Cardero. SRK will be paid a fee for this work in accordance with normal professional consulting practice. The payment of this fee is not contingent upon the conclusions or opinions expressed in this report.

The individuals who have provided input to this ITR, who are listed below, have extensive experience in the mining industry and is a member in good standing of appropriate professional institutions.

- Mark Wanless, PrSciNat, BSc (Hons) - Geology, Mineral Resources

- L. Holland, B.Sc., C.Eng., FIMMM - Mineral Processing Engineer

The Qualified Person with overall responsibility for the reporting of this ITR is Mark Wanless, PrSciNat, BSc (Hons), who is an employee of SRK. Mr Wanless is a mining geologist with 13 years experience in the mining industry and has been responsible for the reporting of Mineral Resources on various properties in Southern Africa and internationally during the past five years.

L. Holland,B.Sc., C. Eng., FIMM,is theConsultant Minerals Processing Engineer for Holland and Holland Consultants. He is the qualified person responsible for the mineral processing and metallurgical sections of this report (section 16). He is a Mineral Processing Engineer with 41 years experience in the mining and mineral processing industry, is a Qualified Person (QP) with special expertise in Metallurgy/Mineral Processing and is a fellow in good standing with theInstitute of Materials, Minerals, and Mining (FIMM), UK.). He has visited the Pampa el Toro property for six days in May 2008 and four days in June 2008.

2.2

Terms of Reference

SRK was required to prepare an ITR for the Project according to the requirements of National Instrument 43-101 (NI 43-101) in support of the disclosure of a Mineral Resource estimate for the Project. The work involved auditing the exploration practices used to generate the source information, and estimating a Mineral Resource for the project.

2.3

Purpose of Independent Technical Report

This ITR was prepared to support the disclosure made by Cardero on 21 July 2009 of a Mineral Resource estimate for the Project. It has been prepared in accordance with the requirements of NI43-101 and the NI43-101F1, and conforms with generally accepted Canadian Institute of Mining (“CIM”) “Exploration Best Practices” and “Estimation of Mineral Resources and Mineral Reserves Best Practices” Guidelines.

2.4

Site Visit

In compliance with NI 43-101 guidelines, Mr Mark Wanless, a Qualified Person, visited the Project in February 2008. During the site visit, SRK viewed a selection of drilling locations and the extent of the project area. SRK reviewed the sampling procedure as well as the processes used by Cardero to generate magnetic concentrates from the raw samples. SRK recommended that analyses should be done on the feed samples. The analyses were then used in the generation of a Mineral Resource estiamate. Cardero subsequently created a number of sub-samples from the reference samples stored at the drilling locations for the purposes of generating representative 5m composites for the top 30m of all drillholes.

In addition, the project has previously been visited in June 2006 by Mr Andre van der Merwe, employed by SRK at the time. Mr van der Merwe reviewed the drilling and sampling processes used by Cardero during the exploration which was ongoing at that time and made recommendations on improvements to the drilling and sampling processes that were implemented by Cardero.

2.5

Sources of Information

In preparing this report, the author relied on the technical report (2009) written by Dr. Cruise and Mr. Hoffman of Cardero, who in turn relied on various geological reports and maps, metallurgical and analytical reports and technical papers listed in the References section at the end of this report. Additional information and data for review by Dr. Cruise and Mr. Hoffman in connection with the preparation of their Technical Report were obtained from the Instituto Nacional de Concesiones y Catastro Minero (INACC) in Lima and through consultations with Cardero staff, including Dr. Jayson Ripke, Vice President Technical, Cardero Iron Ore Company Ltd., and Tansy O’Connor-Parsons, Senior Geochemist, Cardero Resource Corp

Reliance on Other Experts

In preparing this report, SRK relied on geological reports and maps, metallurgical and analytical reports and technical papers listed in the References section at the end of this report. SRK Have relied upon Cardero for sections 3 to 8 and 15 of this report, and have based sections 9 to 12 on information supplied by Cardeo, and observations during site visits by SRK Additional information and data in connection with the preparation of this report were obtained from the Instituto Nacional de Concesiones y Catastro Minero (INACC) in Lima and through consultations with Cardero staff, including Dr. Jayson Ripke, Vice President Technical, Cardero Iron Ore Company Ltd., and Ms. Tansy O’Connor-Parsons, Senior Geochemist, Cardero Resource Corp.

SRK have not independently verified the legal status or ownership of any of the properties covered by this ITR, or of any related option agreements, nor have they verified the legal status of any joint venture arrangements covering adjacent third-party-owned properties.

Property Description and Location

4.1

Location

The Pampa el Toro Project (Figure 3.1) is located approximately 450 km southeast of Lima, and is 80 km southeast of Nazca in Peru. The coastal village of Lomas, from which all Project–related field work was conducted, and which hosts the laboratory and storage facilities for the Project, lies 528 km by road from Lima and 7 km from the Panamericana Sur Highway. The magnetic separation pilot plant is located approximately 5 km due west from the center of the Pampa el Toro property, and next to the town of Acari. The Pampa El Toro Dune Field, lies within the confines of the Instituto Geografico Nacional (IGN) 1:100,000-scale topographic sheet 31-n (Acari).

![[pampa003.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa003.jpg)

Figure 4.1: Location map of the Pampa el Toro project

4.2

Land tenure

The 14 mining concessions which now constitute the Pampa el Toro property total 10,300 ha. The distribution of individual concessions and corresponding reference number is shown in Figure 3.2, and a complete list is provided in Table 3.1. The status of each of the concessions in Table 3.1 has been checked by Cardero against the INACC database (effective date June 30, 2009) and found to be correct.

Cardero has assumed, from a private Peruvian company, all rights and obligations under an agreement, dated 16 December, 2005, between the private Peruvian company and Minera Ataspacas S.A. (a Peruvian private company) whereby the private Peruvian company has the option to acquire from Minas Ataspacas S.A. an initial 70% interest in five mineral sands concessions (totalling 3,600 ha) situated adjacent to Cardero’s existing iron sands claims. In order to exercise the option, Cardero is required to pay a total of US$ 2,500,000 over five years to 15 December, 2010, and incur exploration expenditures of not less than US$ 250,000 over the same period. Upon Cardero having the acquired the 70% interest, a joint venture company will be formed with Minas Ataspacas S.A., and each party will thereafter be required to contribute its share of ongoing expendit ure or be diluted. If either party is diluted to less than 10%, such interest will be converted to a 2% NSR royalty. If Minera Ataspacas S.A. is reduced to the 2% NSR, Cardero may purchase half the NSR (1%) for US$ 2,000,000 within 24 months of the exercise of the option, and the remaining half (1%) for US$ 8,000,000 within 36 months of the exercise of the option.

SRK has not independently reviewed the mineral titles to assess the validity of the stated ownership, and relies on documentation provided by Cardero.

Table 4.1: List of existing concessions as relating to the Pampa el Toro Project

![[pampa005.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa005.jpg)

* Reference No’s refer to locations shown inError! Reference source not found.

4.3

Environmental and Socio-Economic Issues

The immediate property area is uninhabited, and the nearest settlement, Acari, subsists predominantly on agriculture. If water is determined to be necessary in the process of extracting the magnetite sands, the local population will need to be consulted.

![[pampa006.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa006.jpg)

Figure 4.2: Map of Pampa el Toro properties and dune field boundary.

Accessibility, Climate, Local Resources, Infrastructure and Physiography

5.1

Accessibility

Access to the Property is via the Panamericana Sur Highway from Lima (528 km to the coastal village of Lomas, approximately six hours by car), and then approximately 60 km by local dirt roads (around 1 hour on average; Figure 3.1) to the Pampa El Toro Dune Field. It is accessed from the Acari Junction on the Panamerican Sur Highway and then via local dirt road to the village of Acari. An access road was built from Acari to the upper levels of the dune field prior to percussion drilling, although access was restricted to dune-buggy or light pick-up trucks due to the steepness of the sandy slopes. A heavy duty road capable of taking drilling equipment was constructed from the Panamericana Sur Highway just south of the village of Chavina in November 2005 (Figure 3.2).

5.2

Climate

The Project area lies within the desert coastal tract of southern Peru, a northward continuation of the Atacama Desert of northern Chile. It is extremely arid, with less than 1cm annual rainfall and is virtually devoid of vegetation, except in irrigated river valleys. During the summer months, the climate is extremely hot and dry, with only gentle breezes along the coast and high temperatures over the dune fields and valleys, with little movement of sand.

During the winter months, the coastal areas below 1,000 m.a.s.l. are cool, and covered by sea mists which contribute to a humidity of around 100% and light drizzle which gives rise to sparse vegetation (“lomas”) on which domestic animals are able to graze. Strong onshore winde (southeast, verging-to-south, and-to-southwest) winds are generated at this time by solar heating of the hinterland pulling cooler air inland from the coastal belt. These winds carry the mist and a considerable burden of aeolian sand with them, the latter being deposited against rising ground as the strength of the winds diminishes.

5.3

Local Resources and Infrastructure

The local economy is very poor, and dominated by agriculture and animal husbandry in the river valleys where irrigation is possible. The dune fields constitute hostile terrain and are generally unvisited.

The deep-water port of San Juan (exit port for the Marcona Iron Mine) is situated around 40 km from the Panamericana Sur Highway and a further 100 km (maximum) from any of the dune fields under investigation.

5.4

Physiography

The large dune fields of southern Peru were described in detail by Gay (2005), who referred to the Pampa El Toro Dune Field (Acari Sand Mass) as resulting from the action of strong, persistent, onshore winds (southeast-to-south-to-southwest) acting on large quantities of coastal beach sands derived from rapid uplift of the Andes (and coastal belt) under the influence of an extremely arid climate. He concluded that the dune fields accumulated at elevations of between 500m and 2000m in the Andean foothills where weakening of the carrying winds against rising topography led to deposition of the sands.

The Pampa El Toro Dune Field comprises a mainly flat-lying to gently-rolling pampa or “erg” (sand sea) in its southern and eastern part, and active dune fields in the north and west.

The Dune Field is oriented roughly north-south around the western and southern flanks of Cerro de Arenas. Surface area amounts to > 120 km2, of which around two-thirds in the south and south-eastern part of the field consists of pampa sands (a flat-to-gently-rolling sand apron surface similar to that of an “erg” or “sand sea”). The remaining third consists of active dunes of small and similar size, mainly in the northern part of the area.

Topographically, the Pampa El Toro Dune Field is a perched dune field situated high above the valley floor at elevations of between 1000m and 1400m.a.s.l., rising in elevation from the south towards the north and northeast.

History

The Pampa el Toro dune sands were investigated for their iron, titanium and vanadium content by the Marcona Mining Company between 1959 and 1961. The high titanium and vanadium content of the magnetite, untreatable at that time, ended the project in the early 1960’s. Later, the Peruvian Ministry of Energy and Mines identified the iron potential of the sands in 1974 as part of a United Nations sponsored national iron inventory study.

The Iron Sands Project was initiated by Cardero Resource Corp. in mid-2005, following the acquisition of magnetite-bearing sand-dune properties located southeast of Nazca. Preliminary surface sampling of magnetite-bearing active dune sands (a suite of 12 samples from the Carbonera Dune Field), and separation of the magnetic fraction, gave magnetic concentrates (MC’s) in the range 0.7 to 21.24 Wt.%, with an average of around 11.0 Wt.%. Geochemical assays of the magnetic concentrates by ALS Chemex Labs, North Vancouver, B.C., returned results of about 61.5% Fe and 4.3 to 6.4 % TiO2.

Also during 2005, magnetic concentrates separated by SGS Lakefield Research, Ontario, from two preliminary bulk samples from the Carbonera Dune Field were sent to Midrex Technologies Inc., a division of Kobe Steel, in North Carolina. An initial Midrex FASTMELT test successfully produced a high-quality low-sulphur, low-phosphorus and low titanium liquid iron of approximately 91.6% iron, 4.88% carbon and <0.21% sulphur (Ripke, 2005). The FASTMELT® Process utilizes the same basic flowsheet and equipment as FASTMET®, but includes an electric melter to produce FASTIRON®, a high quality liquid iron product. Hot Direct Reduced Iron (DRI) is discharged from the Rotary Hearth Furnace (RHF) and melted in an electric furnace or coal-based melter. The FASTMET® Process is a solid carbon-based reduc tion technology using a rotary hearth furnace (www.midrex.com). Waste slag from the process reportedly assayed up to 21.48 Wt.% TiO2 and 3.18 Wt.% V2O5. (Cook, 2006).

Based on these early positive Midrex results, Cardero decided to continue with the Iron Sands Project with the objective of identifying a logistically easily accessible area containing the potential for sufficient resources of magnetite sand at sufficient concentration to support a viable 20 to 30 year integrated mining operation. To this end, Cardero focussed initial exploration work on the larger Pampa El Toro and Carbonera dune fields, and later over the highest-grade parts of the Pampa El Toro Dune Field.

Geological Setting

Regional basement in the coastal area between Marcona and Yauca consists of gneissic and schistose Precambrian metamorphic rocks separated, by angular discontinuity, from silicified and metamorphosed carbonate rocks of the overlying Lower Palaeozoic Marcona Formation. It is the Marcona Formation which hosts the Marcona Iron Mine, an Iron Ore Copper Gold (IOCG)-style iron oxide deposit of around 1,440Mt at 54.1% Fe (Hawkes et al, 2002). The Marcona Formation is unconformably overlain by Triassic, Jurassic and Cretaceous volcanic and sedimentary sequences which, in turn, were intruded by stocks and dykes belonging to the Peruvian Coastal Batholith complex. These strata were, in turn, deformed, uplifted and eroded, and formed a base on which Quaternary sediments were deposited.

The Marcona iron ore has a different chemical signature than the iron sands, which contain elevated Ti and V concentrations. It is speculated that the iron-bearing minerals contained in the iron sands either partially or wholly originated from the volcanic units overlying the Marcona formation, however additional as yet unidentified sources are possible.

A Cardero consulting geologist, Gary Belik, reported the presence of a Quaternary basin flanking rising ground in the study area, with exposures of friable sand sequences locally containing visible magnetite (Belik, 2005). However, Belik also noted that most of the Quaternary sections were not magnetite-bearing, and were disrupted by lenses and layers of barren conglomerate, clay and volcanic ash, and concluded that the Quaternary sediments did not present an attractive exploration target for iron, relative to the active dune sands (Cook, 2006). However, it is possible that erosion of these Quaternary sediments contributed significant quantities of magnetite material contained in the dune fields.

Mineralogically, the principal iron-bearing minerals in the dunes consist of magnetite, titanomagnetite and ilmenite, with minor to trace amounts of hematite, rutile, titanite, ulvospinel and goethite. Silicate minerals, which make up the bulk of the sands, are primarily quartz, plagioclase, amphibole, chlorite, mica and pyroxene (SGS Lakefield Research, 2005a). The majority of the ilmenite (80-85% by volume) is associated with magnetite, titanomagnetite and hematite, with the remaining 15-20% by volume present as free ilmenite grains.

The dune sands are considered to be the product of aeolian re-distribution of contemporary and ancient beach sands and Quaternary basin sediments derived from erosion of the bedrock, winnowed, and re-distributed, by prevailing winds (Gay, 2005) to produce potentially economic concentrations of magnetite in extensive, and partially active, dune fields.

Deposit Types

The dune sands fall into two deposit types based on dune morphology. The first is stable pampa sand, consisting of a flat-to-gently-rolling sand apron surface similar to an “erg” or “sand sea”, with small active dunes superimposed. The second is active dunes with little evidence of a stable sub-stratum. The deposit may be classified as a heavy minerals deposit, although one generated by wind rather than water processes, as is the norm.

The Pampa El Toro Dune Field is aligned approximately N-S around the western and southern flanks of the Cerro de Arena. Surface area is >120km2, although 2005 sampling was confined to ~63km2in the southern and eastern parts of the field. Around two thirds of this area (~41km2) is comprised mainly of stable pampa sands, predominantly in the south and south east. The remaining 1/3 of the area consists of active sand dunes, mainly in the northern parts of the area. Active sand dunes are relatively small, and of similar size. Cardero holds claims in ~100 km2 of the dune field.

Topographically, the Pampa El Toro Dune Field is a perched dune field, situated high above the desert plain. Most of the area lies between 1000m and 1400m.a.s.l., elevation increasing from the south towards the northeast. This is ~1000m above the level of the adjacent Acari Valley (elevation ~150m a.s.l.). Sand depth is a minimum of 141m over most of the dune filed, and geological reconstruction by Cardero suggests the dune field may attain thickness approaching 300 meters in places, although ultimate depths are unknown.

In general, particle sizes of pampa sands appeared to be somewhat coarser than active sand dunes, perhaps due to active winnowing, although both are fine-grained.

Mineralization

The magnetic minerals component of the dune sands is believed to have been derived from erosion of the bedrock, and also later Quaternary basin sediments which probably received their magnetic minerals from the same source. The magnetic minerals were transported, together with non-magnetic components, by prevailing winds (Gay, 2005), to produce potentially economic concentrations of magnetite in extensive, and still active, dune fields.

Magnetic minerals are distributed throughout the pampa-type surface sands and the active dune sands as rhythmically repetitive millimetre thick stratified bands. The variable intensity of the mineralization, both vertically and horizontally (up to 15.36 Wt% magnetic concentrate) is probably due to differential winnowing of pampa-type and active dune sands by winds of different strengths over different periods and in different locations.

Grain size analysis of sands from Pampa El Toro showed that surface pampa-type sands were generally somewhat coarser-grained than surface sands taken from active dunes in both of those two dune fields. This may be explained by winnowing of the surface sands in areas with stable pampa-type sands.

Le Couteur (2005) screened two active dune sand samples from the Pampa El Toro Dune Field, and found that 63.5% (for the coarser grained of the two samples) and 80% (for the finer-grained sample) of the magnetic mineral concentrate, respectively, was contained in the <150 micron fraction, with most of the remaining magnetic fraction reporting to the slightly coarser 150-250 micron range. Bateman Minerals and Metals (Pty) Ltd., reported an average particle size of 125 micron for MC “sinks” (TBE separation) carried out on a composite of ‘milled’ drillhole samples and consequently is not considered to be representative of the dune field (Rademeyer, 2006). Deeper, pampa-type sands obtained during percussion drilling were finer-grained than either the active dune sands or the pampa sands, although there is overwhelming evidence (in cluding rock flour in recovered samples) that there was milling of the sands during drilling.

During Phase II percussion drilling and accompanying trenching, it was observed that the grain size of material collected from the drillholes was significantly finer than that encountered during trenching (Torres, 2006a).

The presence of fines in drillhole samples was corroborated by SRK who noted that material was being lost as fines through the cyclone exhaust and that fines captured as part of the sample were problematical when passed through the magnetic separator. Fines tended to agglomerate and bounce off the drum during separation (Van der Merwe, 2006b). This raises the possibility that the MCs of drillhole samples are systematically understated due to loss of magnetic minerals to fines. The most recent work by SRK indicates that these should not create any issues from a resource estimate perspective since the resource estimate is done on an in situ basis, before any magnetic concentration, and loss of fines during the drilling is not considered material because of the small weight of material lost. Furthermore the pilot plant tests conducted in 2008 have shown that magnetic concentrate recoveries from Pampa el Toro are a maximum of 7.5 wt% MC (see section 16.16).

Preliminary mineralogical studies by Le Couteur (2005) indicated that the magnetic concentrate consisted mainly of titanomagnetite (Fe2+ Fe3+, Ti2O4), magnetite (Fe3O4) and minor ilmenite (FeTiO3). Detailed point counts of the various minerals were not conducted during this study. However, on the basis of 45 mineral grains in a polished section of the sample, Le Couteur estimated the composition to be around 50% titanomagnetite, 40% magnetite and 10% ilmenite. It was also noted by Le Couteur that titanomagnetite and magnetite have been partially altered by martitization to titanohematite and hematite grains respectively, and that this alteration not only frequently follows octahedral planes bisecting the grains but also forms grain rims.

Exploration

10.1

Surface Sand Sampling

10.1.1

Reconnaissance Surface Sand Sampling Phase

The sampling crew was headed by consulting geochemist Stephen Cook (P. Geo.) of Cook Geochemical Consulting and supplemented by a four-person dune buggy crew of drivers and mechanics. (the two dune buggies working in tandem for safety reasons) Reconnaissance surface sand samples were collected in each dune field at a 1km sample site spacing along north-south lines 500m apart, with samples along adjacent lines being collected at 500m offsets as shown in Figure 9.1. This corresponds to a northwest-southeast / northeast-southwest orientated square grid with a sample spacing of 707m. The area sampled over pampa sands and dune sands at Pampa El Toro amounted to around 70-75 km2

Regional surface sand samples were processed in Canada at Vancouver Indicator Processors Inc. laboratory, Burnaby, B.C. Magnetic concentrates were prepared for each sample and weight-per-cent magnetic concentrate (Wt% MC) content calculated.

10.1.2

Infill Surface Sand Sampling Phases I and II: Pampa El Toro

An infill surface sand sampling programme (Phase I Infill Survey) was initiated in mid-January, 2006, over Toro West, broadly covering the extent of sites reporting high (>5.0 Wt.% MC) values which were known from analytical results at that time. The area covered by Phase I Infill Survey is shown in Figure 9.2. The objective of the infill surface sampling was to provide a more detailed understanding of grade and MC distribution in the surface sands by increasing the original reconnaissance grid spacing (1000m x 500m, with 500m offset) to one of 250 m x 250 m along a N-S and E-W oriented grid. A total of 235 sites were sampled, covering an area of approximately 15 km2.

Following the infill surface sand sampling at Toro West, a Phase II infill survey commenced in April, 2006, over the smaller Toro Southeast Zone, and also an area adjacent to the southwest corner of Toro West (Figure 9.2). The distribution of samples, together with those of Phase I Infill Survey, are shown in Figure 9.2. A total of 168 sites were sampled in Phase II Infill Survey (of which results are available for 164), covering an area of approximately 10 km2.

![[pampa007.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa007.jpg)

Figure 10.1: Pampa el Toro reconnaissance surface sand sampling, distribution and results.

![[pampa008.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa008.jpg)

Figure 10.2: Pampa el Toro infill surface sand sampling, phases I and II, distribution and results.

10.2

Trenching

The results from Phase I percussion drilling showed a marked fall-off in MC values and grain size of material recovered from the first few meters of the drill holes, downwards. Therefore, it was decided to trench alongside existing drillhole sites to the maximum depth (5-6 metres) attainable with the equipment available in order to try to resolve this discrepancy.

A total of 41 trenches were excavated variously by bulldozer and excavator (as detailed in Section 12.3.1) adjacent to previously drilled Phase II percussion drillholes. The objective was to compare Wt.% MC separated from paired drillhole and trench samples over the 0 – 6 m depth interval from surface.

Reconnaissance surface sampling, Phase I infill surface sampling, the Toro West Zone of Phase II infill surface sampling, and Phase I Percussion Drilling Programme were all carried out by contractor Cook Geochemical Consulting, of Victoria, BC, Canada.

The Toro Southeast Zone of Phase II infill surface sampling, Phase II Percussion Drilling Programme and trenching were carried out by Cardero personnel under the supervision of Cardero’s Project Geologist following the protocols previously established by Cook Geochemical Consulting.

Drilling

11.1

Percussion Drilling

11.1.1

Percussion Drilling Programme: Phase I

A widely-spaced percussion drilling programme was conducted in November and December, 2005, over the Pampa El Toro Dune Field. Nine drillholes were drilled mainly on the flat-to-gently-rolling pampa sands in the southern and central part of the dune field. The holes were drilled with nominal 2 km spacing along E-W oriented lines, with drill sites along adjacent lines being offset by 1km. Most of the drillholes were drilled to a depth of 100m, with two holes (PET-5 and PET-6) drilled to 141m. Eight of the drillholes terminated in sand and therefore remain open in depth. However, drillhole PET-12, one of two along the southern edge of the dune field, encountered bedrock at 38 m depth. All these, and later drillholes, were drilled vertically.

Collar elevations of the drillholes ranged from 1,000 m.a.s.l. in the southern part of the area to a high of 1,529m.a.s.l. in the northeast. The percussion drilling programme was truck-supported and operated from a base in Lomas. Drilling services were provided by GeoTech of Lima, equipment including a truck-mounted percussion drilling unit, a second truck with hydraulic crane to remove casings, a D-8 bulldozer to pull the trucks from site to site across the dune field and a local tractor contracted for miscellaneous tasks.

Preparation of magnetic concentrates from these drillholes, and their subsequent assay for %Fe2O3, %TiO2 and related constituents were carried out at Acme Labs in Vancouver.

11.1.2

Percussion Drilling Programme: Phase II

Following a recommendation from SRK (Van de Merwe, 2006), a 72 drillhole definition campaign was designed and conducted between May and July 2006, to systematically drill-test an approximately 6.5km2 area of the Pampa El Toro dune field to a depth of 60m. The programme included a combination of holes at both 500m drill centres and 250 meter drill centres (Error! Reference source not found.). Approximately 2.5 km2 of the pampa sands were tested by holes with 250m centre separations.

The definition drill program was designed to test the central part of Toro West Zone where Phase II surface sand sampling had defined a broad area containing >5.0 Wt.% MC within which were two higher-grade areas, shown as Zone “A” and Zone ”B” inError! Reference source not found., reporting mean values of 8.6 and 9.7 Wt.% MC respectively. Additional holes were drilled at the end of the programme to capture parts of zones “C” and “D” (Error! Reference source not found.). All of the drillholes were targeted to 60m.

Following the completion of the 72 drillhole definition campaign, a repeat of Phase I drillhole PET-08 was drilled 5 m from the original in order that the results might be compared between Phase I and Phase II drilling. It was during the process of splitting the samples from the PET-08 repeat hole that it became clear that the material retrieved appeared to be much finer grained than the surface sands with a significant amount of dust-particle-size fines, or “rock flour”.

At the drilling company’s suggestion, and in order to check whether or not the percussion bit in use was grinding the sand during drilling, a different type of bit with characteristics that might not generate the same amount of in-hole friction was employed for the remainder of the Phase II drilling programme. This included a) the additional 10 drillholes capturing parts of zones “C” and “D”, mentioned above, b) duplicates (or “twins”) of 10 Phase II drillholes already drilled and c) a further 10 drillholes (an “L” set), to provide details for geostatistical analysis, also on the recommendation- of SRK Consultants (Figure 11.2). The characteristics of the samples appeared to be unchanged.

Field and laboratory processing of Phase II drillhole samples was carried out under the supervision of Cardero’s Project geologist. Representative splits of borehole sand samples were processed at Cardero’s on-site magnetic separation laboratory at Lomas.

![[pampa009.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa009.jpg)

Figure 11.1: Map of percussion drill hole collars.

![[pampa010.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa010.jpg)

Figure 11.2: Map of percussion drillhole duplicate and trench locations.

Sampling Method and Approach

12.1

Reconnaissance and infill surface sand sampling

12.1.1

Field collection methods

In all cases, field sampling equipment consisted of a Jones riffle splitter with stainless steel catch pans, a series of steel sample collection pans, and a short-handled shovel.

Two different sampling techniques were employed for the pampa and active dune sands respectively.

a)

Pampa sands

After digging an 80-90 cm deep pit in the relatively flat-lying pampa, three vertical channel samples were taken by sweeping a shovel blade upwards from base to top along different parts of one sidewall of the pit (Figure 12.1). Each of the three channel samples was split once in a Jones splitter, and a composite sample made by combining one of each of the three splits. The remaining halves of the three splits were discarded. The final sample weighed 10-12 kg.

![[pampa012.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa012.jpg)

Figure 12.1: Schematic diagram showing field procedure for collecting reconnaissance sand samples at pampa sand sites.

b)

Active dune sands

A different collection method was adopted for the active dune sands, where a greater variation in results was considered possible from the constantly-shifting dunes. Nine individual sub-samples were collected on a north-oriented cross, with the designated sample site location at its centre (Figure 12.2). Each of the nine sub-samples were taken as one “spade-full”, after scraping away the upper several centimetres of surface sand. These individual samples were then riffle-split twice, and composited to produce a final sample weighing around 10-12 kg.

![[pampa014.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa014.jpg)

Figure 12.2: Schematic diagram showing field procedure for collecting reconnaissance sand samples at dune sand sites.

12.1.2

Sample documentation and security

Sample site locations (UTM coordinates, WGS 84 datum, 18S zone) were selected in advance to ensure that any sample site selection biases were eliminated. Sites were located by pre-entering coordinates into a Garmin GPS and utilizing the “go-to” feature to travel to the spot with a horizontal accuracy of approximately 5m. Only a few sites were moved, minimally, from their pre-ordained locations as a result of local conditions such as steep dune slopes.

At each site, UTM coordinates were re-read and recorded on field cards, along with sample number, site number, sample-type information, site elevation, duplicate / standard status (if applicable), reference to digital photo of sample site and other relevant data as required. Sample numbers were written two or three times onto heavy-duty polythene sample bags using indelible markers, and a numbered ticket detached from the respective field card placed in each bag. Each sample bag was secured with heavy string and placed within protective rice sacks for transport via dune buggy and truck to the field camp at Lomas.

All field samples were temporarily stored in a locked warehouse with night-watchman cover in Lomas, prior to being double bagged, trucked to Lima, and sea-freighted to Vancouver.

12.1.3

Quality control procedures in the field

Quality control procedures used to help quantify the extent of site and sampling variations included the collection of field duplicate samples, within-pit duplicate samples and splitter (check) duplicates at regular intervals, and also the incorporation of field standards into the collection suite.

Field duplicates were collected at the rate of one pair every ten samples. Pampa site duplicates were collected by the method noted above (11.1.1a) from two adjacent pits dug approximately 3.5m apart. Dune sand site duplicates were collected by the method noted above (11.1.1b) but by moving the sites of individual sub-samples (and therefore the north-oriented cross as a whole), 3 metres to the east and 1 m to the north to create a new identical sampling cross with individual sub-sample separation equivalent to that between pampa sample duplicates (Figure 12.3).

Within-pit duplicates also were collected at the rate of one pair every ten samples. Pampa sands within-pit duplicates were taken by the same methodology from the opposite wall of the same pit. Dune sands “within-pit” duplicates were produced by repeating the process described in 11.1.1b above with a second sub-sample “spade-full” taken immediately adjacent to the first (Figure 12.4).

Splitter duplicates also were collected at the rate of one pair for each ten samples, and involved bagging separately but numbering identically each of the respective splits for a given sample site. However, the practice of taking riffle splitter duplicates to test for variations introduced by the splitting method was later discontinued in the surface sampling programme as no significant differences in results were detected between splitter duplicate pairs.

Slots for insertion of field standard samples, included to monitor magnetic concentrate separation processing accuracy and precision, were left open every 20 samples. As no standards are commercially available for the separation of magnetic minerals from iron sands, a field standard was prepared from a high-magnetite site at Pampa El Toro. In the analytical assay suites, the magnetic concentrate from this sample was used as a drift monitor.

![[pampa016.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa016.jpg)

Figure 12.3: Schematic diagram showing procedure for collecting field duplicate samples during reconnaissance sand sampling at dune sand sites.

![[pampa018.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa018.jpg)

Figure 12.4: Schematic diagram showing procedure for collecting within-pit duplicate samples during reconnaissance sand sampling at dune sand sites.

![[pampa020.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa020.jpg)

Figure 12.5: Typical 20-sample collection “block” used in The Pampa El Toro reconnaissance surface sands sampling programme.

A typical 20-sample collection block used in the Pampa El Toro surface sands sampling program, showing duplicate, field standard insertion frequency and labelling protocol is shown in Figure 12.5

12.2

Percussion Drilling

12.2.1

Field collection methods

Sand samples were obtained from the drill rig at one metre intervals, discharged into heavy polythene bags, tied, labelled, and left onsite for splitting. Each 1 metre sample weighed approximately 40-45kg. Five-metre composite samples were prepared by splitting the sand recovered from each interval using a large “Jones Riffle Splitter”. In each case, composites were prepared by pouring the five bags (approximately 200-250kg total) onto large plastic trays, homogenizing, and splitting three times to produce a single 25-30kg composite sand sample for each 5m interval. These samples were transported to the Lomas laboratory for magnetic separation. Reject drilling samples are stored at the drilling site, buried and covered with sand to prevent deterioration of the bags due to ultraviolet radiation.

In 2008, the reject drilling samples were recovered, re-split, employing the same procedures, and reduced to 5kg representative composite samples for each 5m interval of drilling. These samples were transported to the laboratory in Lomas and are stored as representative raw (unseparated) sand samples from the drilling campaigns.

12.2.2

Sample documentation and security

Sample documentation and security followed the same protocol as that adopted for reconnaissance and infill surface sand sampling described above. However, differential rather than hand-held GPS was used to position holes, and later to check coordinates of drill sites with greater confidence.

12.2.3

Quality control procedures in the field

Quality control procedures included the collection of splitter duplicates at regular intervals and the incorporation of field standards (for magnetic separation) and certified reference materials (for analytical quality control) into the sample suite. Given the limitations of collecting drill hole samples compared to surface samples, it was not possible to collect the equivalent of field duplicate or within-pit duplicate samples. It should be noted that in this case (cf. surface samples) the numbering scheme used for splitter duplicates ensures that their relation to adjacent samples remains blind to the processing laboratory (Figure 12.6).

Splitter duplicates were collected at a rate of one pair every 10 samples for the magnetic separation work, and one pair every 20 samples for the analytical work. The location of splitter duplicates in the drill hole were chosen in advance, and the duplicates were prepared by retaining both halves of the third, and final, split of these samples during riffle splitting. In these cases the usual split was retained for the routine sample, and the other split was retained as the splitter duplicate sample.

In the case of the raw (unseparated) sand samples, analytical (pulp) duplicates were also inserted, by means of leaving an ‘open’ sample number (empty bag) every 1 in 20 samples. This alerted the laboratory to take a split of the previous sample after the pulverization stage.

Slots for insertion of a control standard were left open at a rate of one in 20 drilling samples. A thoroughly-homogenized field standard was inserted for monitoring the quality of the magnetic separation work and as an analytical drift monitor in magnetic concentrate analyses. Certified reference materials were inserted to monitor analytical accuracy in the raw (unseparated) sand samples. An internal standard was created (MAG-1) from pulverized and homogenized magnetic concentrate material and inserted into the magnetic concentrate analytical sample batches.

A typical 20-sample collection block used in drill hole sampling, showing splitter duplicate, control standard insertion frequency and labelling protocol is shown in Figure 12.6. In the case of Phase II drilling at Pampa El Toro, where the holes were drilled to 60 m depth, it was ensured that a single pair of splitter duplicates and a single field standard were included in each drillhole.

![[pampa022.jpg]](https://capedge.com/proxy/40-F/0001378296-10-000019/pampa022.jpg)

Figure 12.6: Typical quality control scheme used in the sampling of sands from a typical 100 metre-deep percussion borehole at Pampa El Toro.

12.3

Trenching

12.3.1

Field collection methods

Trenching methods included the use of both a Cat D-8 Bulldozer, when this was on site to assist with the percussion drilling phase, and a Cat 330C Excavator. Trenches were dug immediately adjacent to actual borehole sites for direct comparison purposes, and care was taken to avoid areas where the pampa surface had been disturbed by drilling-related activity or contaminated by drill-generated fines. In the case of the bulldozer, four samples were taken in the same way as pampa sands (section 11.1.1a, above), with the first metre being sampled via an 80-90 cm deep pit. The first metre of sand was then scraped off with the bulldozer blade, using a graduated pole as depth reference, to form a platform from which the next pit could be dug to sample the 1.0-2.0 m interval. In this way it was possible to sample 1.0 m intervals to a depth of 4.0m to 5.0 m (Torres, 2006a; Torres, 2006b).

In the case of the 37samples obtained by excavator, the first sample from surface to a depth of 1.0 m was collected with a single rotation of the excavator bucket. This was unloaded well away from the sides of the designed trench to form a small pile, from which a representative sample of around 25 kg was then taken and bagged. The surrounding sand was then excavated to a depth of 1.0m over an area sufficient to ensure that the walls of the trench did not collapse into the trench and contaminate subsequent samples as the trench was deepened. The second sample was then collected with a single rotation of the excavator bucket between 1.0m and 2.0m. This process was repeated in 1.0m intervals to 5.0m or 6.0m, depending on operating conditions.

12.3.2

Sample documentation and security

Sample documentation and security followed the same protocol as that adopted for reconnaissance and infill surface sand sampling described above. Samples were numbered in a way which related them to the adjacent borehole and depth from which they were collected.

12.3.3

Quality control procedures in the field

Trench sites were located adjacent to existing percussion drillhole sites in order to verify the consistency of data obtained by percussion drilling over the first five metres. Due to the instability of loose, dry sand under trenching conditions, and the probability of “run-in” of loose material and contamination of repeat samples taken from the same point, field duplicate and within-pit duplicate samples were not included in the sample suite. Splitter duplicates were also omitted because of the lack of significant differences detected between splitter duplicate pairs in the results from reconnaissance and infill surface sand sampling.

12.4

Bulk Sample Collection

12.4.1

Field Collection Methods

A 2500 ton bulk sand sample from the Pampa el Toro property was collected in November-December 2007 for processing at a magnetic separation pilot plant facility in the town of Acari. The sample was taken from two separate areas within the high-grade core of the property to a depth of 1m with the use of a backhoe and transported by truck to a secure pilot plant site facility in Acari.

The sample is determined to be representative of the known magnetic concentrate grade over the high-grade core of the property where contingent on ongoing results any future mining operation is most likely to commence; however, it was not possible to adequately test the sub-surface below 1m depth.

12.4.2

Sample documentation and security

Tonnage by truck haul was tallied at the site and 2500 tons were collected. The stockpile was covered securely in tarpaulin to avoid contamination and/or upgrade of the bulk sample due to aeolian processes. The site facility is a secure area with guarded surveillance twenty-four hours a day.

12.4.3

Quality control procedures in the field

The sample areas were located by GPS, staked and flagged in the field.

Sample Preparation, Analyses and Security

13.1

Magnetic Separation and processing

13.1.1

Magnetic separation and processing of reconnaissance surface sand samples

All reconnaissance surface sand samples were trucked from the Lomas field warehouse to Lima, Peru and then shipped to North America. Samples were shipped in secure wooden crates to protect against any damage to the plastic sample bags while in transit. They were forwarded to Vancouver Indicator Processors Inc. laboratory (VIPI), Burnaby, B.C., Canada, for magnetic separation of magnetite grains from the sands, and subsequent determination of the percent magnetic concentrate in each sample.

VIPI laboratory was primarily a heavy mineral lab for the diamond exploration industry, and was equipped with suitable magnetic concentration equipment for processing iron sands samples. All magnetic separation work was conducted by or under the direction of Dr. Peter Le Couteur of VIPI, and the following details of the equipment and the separation procedure are taken from his report (Le Couteur, 2005).

The field samples, generally between 9kg and 13kg each in weight, were weighed as received at the Burnaby laboratory, and magnetic concentrates prepared using a ‘scalper’ magnet to remove only ferromagnetic mineral grains (ie. only magnetic, not paramagnetic, mineral particles). The scalper unit comprises an Eriez sample hopper and vibratory feed chute coupled with a new Outukumpu Model LP10 dry permanent magnet with a weak magnetic field (approx. 0.05 Tesla). The sample was fed from the hopper down the vibrating chute, and slides under gravity across the magnet. The magnet attracts ferromagnetic particles into one receiving pan beneath the magnet, allowing all other non-magnetic grains to pass undeflected into a second receiving pan. A single-pass procedure was used for all sand samples.

13.1.2

Magnetic separation and processing of drillhole and infill surface sand samples

Magnetic separation of drillhole and infill surface sand samples from the Toro West and Toro Southeast infill surveys, was carried out on-site at Cardero’s Lomas field facility beginning in January, 2006, using an Eriez Model FR ferrite radial drum magnetic separator. This work was carried out by, or under the direction of, Cardero’s Project Geologist.

The equipment and laboratory was tested by Dr. P. Le Couteur in January, 2006, and set up for optimum performance on-site (Le Couteur, 2006).

Drillhole and/or infill surface sand samples were weighed in the warehouse using a high-capacity Bascula PCR-40 electronic balance (40 kg capacity), and then processed using the magnetic separator. Material was fed from the sample hopper onto the rotating magnetic drum using a vibratory chute feeder. Non-magnetic reject material passes over the rotating drum and was captured by a large tray prior to re-bagging and storage. Ferromagnetic minerals attracted to the drum were captured in a smaller tray positioned beneath it. After primary magnetic separation, the magnetic concentrate was fed through the separator a second time to remove any adhering silicate grains. The subsequent, second-pass concentrate was retained, bagged and weighed using a Bascula LEQ-5 electronic balance (5kg capacity), and the weight per cent magnetic concentrate content calculated. The weight of the first-pass concentrate was also recorded, and the resulting ‘middlings’ sample fraction from the second pass bagged and retained for any possible future use (Cook, 2006).

Following observations by SRK during an April 2006 visit to the Lomas field facility (Van der Merwe, 2006b), Cardero field operators introduced a third pass to the separation process whereby the second pass concentrate was fed through the separator a third time to remove remaining non-magnetic material and to further clean the concentrate. Van der Merwe had noted that a comparison of four samples that were processed by both the Vancouver Indicator Processors Inc. and the Lomas facility showed consistent better recovery of ‘magnetic concentrate’ by the Lomas separator. It is possible that the Lomas machine might have been over-recovering “magnetic concentrate” by including some non-magnetic fraction (Van der Merwe, 2006). Therefore, from April 2006, it was the third-pass concentrate that was retained, bagged and weighed, and the weight per cent magnetic concentrate content calculated. The weight of the second-pass concentrate was also recorded, and rejects from the third pass were added to the ‘middlings’ sample fraction from the second pass noted above.

13.1.3

Quality control and security

a)

VIPI Laboratory

Le Couteur (2005) conducted several tests to determine the efficiency of magnetic separation at the VIPI Laboratory. Results of these tests suggested that the VIPI scalping magnet recovers most (approximately 90% of the total ferromagnetic material) in the first pass. Tests of several samples which were processed using between four passes and ten passes through the magnetic separator showed that most of the magnetite, about 87-94% of the total, was removed in the first pass. Typically the second pass yielded only a small amount of magnetite, in the range 3.3–4.7%, and subsequent passes yielded progressively smaller and smaller amounts. Nevertheless the single sample which was subjected to ten passes through the separator (87% magnetic mineral recovery on the first pass) yielded a small amount of magnetic material even on the tenth pa ss (0.6%).

Reproducibility testing, involving two samples which were processed 5 times each, showed a high degree of replicate precision in the magnetic separation results. Replicate results were within about ±3% of mean values, varying only narrowly in the range 4.11-4.21% in one case, and in the range 1.77-1.87% in the second case (Le Couteur, 2005).

b)

Lomas Facility

Following initial set up of the magnetic separator at the Lomas field facility in December, 2005, testing of optimal operating parameters for processing iron sands samples was carried out VIPI Laboratory during a visit to Lomas in mid-January 2006 (Le Couteur, 2006). Le Couteur determined that an extraction efficiency of about 98% magnetite was achieved from test samples using a feed rate of 3.5 kg/minute and a drum rotation speed of about 118 rpm. These settings were adopted as the standard separator operation settings for the Pampa El Toro sand samples although, as he notes in his report, a wider range of feed rate settings is possible. Tests showed that a 25kg sand sample could, ideally, be processed in about 7 minutes at the recommended settings.

A calibration standard, prepared by Le Couteur, was run at the start of every magnetic separation processing session in Lomas in order to test the functioning of the magnets and the apparatus in general. This calibration standard is separated, the weights are recorded, and the standard is subsequently re-combined for processing at the start of the next session. The reproducibility of the results has shown to be exemplary, and this demonstrates that any over-time-drift of the magnet and/or apparatus function is insignificant.

13.2

Sample analysis and assay procedures

Raw (unseparated) sand samples from all boreholes (5 m intervals) were submitted for analysis. In addition, a subset of magnetic concentrates and ‘middlings’ samples were analysed at Acme Analytical Laboratory (ISO 9001:2000 accredited), Vancouver, British Columbia. These samples form the basis of the data that was used for Mineral Resource estimation.

13.2.1

Sample Preparation

For raw (unseparated) sand analyses, 250-300 g of material are riffle-split from the representative drilling interval samples (5kg each) at the Lomas facility by Cardero employees. The samples are forwarded to Acme Labs for pulverization by ceramic ring mill and analysis.

Upon arrival at the Acme Analytical Laboratory, Vancouver, each magnetic concentrate sample is rolled thoroughly on a large clean piece of paper to ensure that it was adequately mixed prior to the separation of an approximately 200-250 g sub-sample. The sample is pulverized, using a ceramic, rather than steel, ring mill to prevent any possible iron contribution to (and contamination of) the concentrate during ring milling. All unused magnetic concentrate material are retained in the original sample bag; and the pulverized magnetic concentrate pulp material is retained in an additional bag.

13.2.2

Analysis

All samples were analyzed at Acme laboratories for potentially economic elements including total iron, titanium and vanadium, and for potentially deleterious constituents such as %SiO2, %Al2O3, %MgO and %P2O5, by the following total-decomposition methods:

a)

Group 4A major element oxide suite

This whole rock package uses a LiBO2 fusion and dilute nitric acid digestion of a 0.2 g sub-sample with an Inductively Coupled Plasma – Optical Emission Spectroscopy (ICP-OES) finish. Constituents determined are SiO2, Al2O3, Fe2O3, CaO, MgO, Na2O, K2O, MnO, TiO2, P2O5, Cr2O3, LOI, Total C and Total S. The analytical upper limits of each of these determinations are stated by Acme Labs to be 100%, suitable for the high-iron composition of the magnetic concentrates.

b)

Total vanadium