MANAGEMENT’S DISCUSSION AND ANALYSIS

Management’s discussion and analysis (“MD&A”) of the financial condition and results of operations of Harvest Energy Trust should be read in conjunction with our audited consolidated financial statements and accompanying notes for the years ended December 31, 2008 and 2007. The information and opinions concerning our future outlook are based on information available at March 2, 2009.

In this MD&A, reference to "Harvest", "we", "us" or "our" refers to Harvest Energy Trust and all of its controlled entities on a consolidated basis. All references are to Canadian dollars unless otherwise indicated. Tabular amounts are in thousands of dollars unless otherwise stated. Natural gas volumes are converted to barrels of oil equivalent (“boe”) using the ratio of six thousand cubic feet (“mcf”) of natural gas to one barrel of oil (“bbl”). Boes may be misleading, particularly if used in isolation. A boe conversion ratio of 6 mcf to 1 bbl is based on an energy equivalent conversion method primarily applicable at the burner tip and does not represent a value equivalent at the wellhead. In accordance with Canadian practice, petroleum and natural gas revenues are reported on a gross basis before deduction of Crown and other royalties. In addition to disclosing reserves under the requirements of National Instrument 51-101, we also disclose our reserves on a company interest basis which is not a term defined under National Instrument 51-101. This information may not be comparable to similar measures by other issuers.

NON-GAAP MEASURES

Throughout this MD&A we have referred to certain measures of financial performance that are not specifically defined under Canadian GAAP. Cash G&A and Operating Netbacks are non-GAAP measures used extensively in the Canadian energy trust sector for comparative purposes. Cash G&A are G&A expenses excluding the effect of our unit based compensation plans, while Operating Netbacks are always reported on a per boe basis, and include gross revenue, royalties, operating expenses, and transportation and marketing expenses. Gross Margin is also a non-GAAP measure and is commonly used in the refining industry to reflect the net funds received from the sale of refined products after considering the cost to purchase the feedstock and is calculated by deducting purchased products for resale and processing from total revenue. Earnings From Operations is also a non-GAAP measure and is commonly used in the petroleum and natural gas and refining industries to reflect operating results before items not directly related to operations.

FORWARD-LOOKING INFORMATION

This MD&A highlights significant business results and statistics from our consolidated financial statements for the year ended December 31, 2008 and the accompanying notes thereto. In the interest of providing our Unitholders and potential investors with information regarding Harvest, including our assessment of our future plans and operations, this MD&A contains forward-looking statements that involve risks and uncertainties. Such risks and uncertainties include, but are not limited to, risks associated with conventional petroleum and natural gas operations; risks associated with refining and marketing operations; the volatility in commodity prices and currency exchange rates; risks associated with realizing the value of acquisitions; general economic, market and business conditions; changes in environmental legislation and regulations; the availability of sufficient capital from internal and external sources and such other risks and uncertainties described from time to time in our regulatory reports and filings made with securities regulators.

Forward-looking statements in this MD&A include, but are not limited to, the forward looking statements made in the “Outlook” section as well as statements made throughout with reference to production volumes, refinery throughput volumes, royalty rates, operating costs, commodity prices, administrative costs, price risk management activity, acquisitions and dispositions, capital spending, reserve estimates, distributions, access to credit facilities, capital taxes, income taxes, cash from operating activities, and regulatory changes. For this purpose, any statements that are contained herein that are not statements of historical fact may be deemed to be forward-looking statements. Forward-looking statements often contain terms such as “may”, “will”, “should”, “anticipate”, “expects”, and similar expressions.

Readers are cautioned not to place undue reliance on forward-looking statements as there can be no assurance that the plans, intentions or expectations upon which they are based will occur. Although we consider such information reasonable at the time of preparation, it may prove to be incorrect and actual results may differ materially from those anticipated. We assume no obligation to update forward-looking statements should circumstances, estimates or opinions change, except as required by law. Forward-looking statements contained in this MD&A are expressly qualified by this cautionary statement.

1

Consolidated Financial and Operating Highlights – 2008

- Cash from operating activities of $655.9 million, relatively unchanged from $641.3 million in the prior year, as a $321.6 million improvement in the contribution from upstream operations was substantially offset by a $174.5 million increase in the cash settlements on price risk management contracts, an $81.4 million drop in contribution from downstream operations and a $19.1 million realized loss on currency exchange transactions as compared to a gain of $53.6 million in the prior year.

- Upstream operations contributed $945.9 million of cash reflecting average daily production of 55,932 boe with strong commodity prices more than offsetting a strengthening Canadian dollar, lower production and higher operating costs.

- Upstream production was bolstered with the acquisition of 2,650 boe/d of producing assets in the Third Quarter for cash consideration of $167.6 million, representing a cost per flowing barrel of approximately $63,000.

- Capital spending of $271.3 million in our upstream business, plus $128.8 million of net acquisitions, replaced our 2008 production with finding and development costs, including changes in future development costs, of $25.97 per boe of proved reserves and $29.87 per boe for proved plus probable reserves.

- Downstream operations contributed $83.6 million of cash reflecting sound operating performance more than offset by generally lower refining margins as high commodity prices during the first three quarters increased our cost of purchased energy and lower commodity prices in the Fourth Quarter resulted in an inventory write-down.

- Capital expenditures in our downstream operations totaled $56.2 million, including the commissioning of our $30.1 million visbreaker expansion project in November, which is expected to upgrade approximately 1,500 bbls/d of high sulphur fuel oil (“HSFO”) to distillate yield.

- Record high commodity prices resulted in $200.8 million of cash settlements on our price risk management contracts with $225.2 million of net cash settlements during the first three quarters offset by $24.4 million of settlements in our favour during the Fourth Quarter.

- Balance sheet liquidity was improved with the issuance of $250 million principal amount of 7.5% Convertible Unsecured Subordinated Debentures for net proceeds of $239.5 million in April 2008.

- Declared distributions totaling $551.3 million ($3.60 per Trust Unit) reflecting an 84% payout ratio based on cash from operating activities and 81% payout ratio if asset retirement expenditures and non-capital working capital are excluded from the cash flow.

2

SELECTED INFORMATION

The table below provides a summary of our financial and operating results for the years ended December 31, 2008, 2007 and 2006.

| | | Year Ended December 31 | |

| | | | | | | | | | |

| ($000s except where noted) | | 2008 | | | 2007 | | | 2006 | |

| | | | | | | | | | |

| Revenue, net(1) | | 5,489,364 | | | 4,069,600 | | | 1,380,825 | |

Cash From Operating Activities |

|

655,887 |

|

|

641,313 |

|

|

507,885 |

|

| Per Trust Unit, basic | $ | 4.29 | | $ | 4.63 | | $ | 5.00 | |

| Per Trust Unit, diluted | $ | 4.05 | | $ | 4.30 | | $ | 4.84 | |

Net Income (Loss)(2) |

|

212,019 |

|

|

(25,676 |

) |

|

136,046 |

|

| Per Trust Unit, basic | $ | 1.39 | | $ | (0.19 | ) | $ | 1.34 | |

| Per Trust Unit, diluted | $ | 1.39 | | $ | (0.19 | ) | $ | 1.33 | |

Distributions declared |

|

551,325 |

|

|

610,280 |

|

|

468,787 |

|

| Distributions declared, per Trust Unit | $ | 3.60 | | $ | 4.40 | | $ | 4.53 | |

| Distributions declared as a percentage of Cash From Operating Activities | | 84% | | | 95% | | | 92% | |

Bank debt |

|

1,226,228 |

|

|

1,279,501 |

|

|

1,595,663 |

|

| 77/8% Senior Notes | | 298,210 | | | 241,148 | | | 291,350 | |

| Convertible Debentures(3) | | 827,759 | | | 651,768 | | | 601,511 | |

| Total long-term financial debt(3) | | 2,352,197 | | | 2,172,417 | | | 2,488,524 | |

Total assets |

|

5,745,407 |

|

|

5,451,683 |

|

|

5,745,558 |

|

UPSTREAM OPERATIONS |

|

|

|

|

|

|

|

|

|

| Daily Production | | | | | | | | | |

| Light to medium oil (bbl/d) | | 25,093 | | | 27,165 | | | 27,482 | |

| Heavy oil (bbl/d) | | 12,162 | | | 14,469 | | | 13,904 | |

| Natural gas liquids (bbl/d) | | 2,624 | | | 2,412 | | | 2,247 | |

| Natural gas (mcf/d) | | 96,315 | | | 97,744 | | | 96,578 | |

| Total daily sales volumes (boe/d) | | 55,932 | | | 60,336 | | | 59,729 | |

Operating Netback ($/boe) |

|

47.89 |

|

|

29.89 |

|

|

30.54 |

|

Cash capital expenditures |

|

271,312 |

|

|

300,674 |

|

|

376,881 |

|

| Business and property acquisitions, net | | 128,773 | | | 138,156 | | | 2,467,097 | |

DOWNSTREAM OPERATIONS |

|

|

|

|

|

|

|

|

|

| Average daily throughput (bbl/d) | | 103,497 | | | 98,617 | | | 86,890 | |

| Average Refining Margin (US$/bbl) | | 7.16 | | | 10.05 | | | 9.32 | |

Cash capital expenditures |

|

56,162 |

|

|

44,111 |

|

|

21,411 |

|

| (1) | Revenues are net of royalties. |

| (2) | Net Income (Loss) includes a future income tax expense of $108.6 million (2007 – an expense of $65.8 million; 2006 – a recovery of $2.3 million) and an unrealized net gain from risk management activities of $185.9 million (2007 - net losses of $147.8 million; 2006 – net gains of $52.2 million) for the year ended December 31, 2008. Please see Notes 18 and 20 to the Consolidated Financial Statements for further information. |

| (3) | Includes current portion of Convertible Debentures. |

| (4) | Downstream operations acquired on October 19, 2006. |

3

REVIEW OF OVERALL PERFORMANCE

Harvest is an integrated energy trust with our petroleum and natural gas business focused on the operation and further development of assets in western Canada (our “upstream operations”) and our refining and marketing business focused on the safe operation of a medium gravity sour crude oil hydrocracking refinery and a retail and wholesale petroleum marketing business both located in the Province of Newfoundland and Labrador (our “downstream operations”). Our earnings and cash flow from operating activities are largely determined by the realized prices for our crude oil and natural gas production as well as refined product crack spreads, including the effects of changes in the U.S. dollar to Canadian dollar exchange rate. Recently, changes in crude oil and natural gas prices and the exchange rate between U.S. dollars and Canadian dollars have moved together with changes in the currency exchange rate partially offsetting changes in crude oil and natural gas prices.

During 2008, cash from operating activities totaled $655.9 million, a $14.6 million increase as compared to $641.3 million in the prior year. While cash generated from our upstream operations of $945.9 million in 2008 was a significant improvement from the $624.3 million in the prior year, the cash generated in our downstream operations of $83.6 million was approximately half the $165.0 million generated in the prior year. The $321.6 million improvement in our upstream operations reflects the year-over-year strength in commodity prices as well as a tightening of heavy crude oil differentials in western Canada. The reduced contribution from our downstream operations should be considered in light of the generally weaker refined product crack spreads in 2008 as well as the impact of significantly lower commodity prices in the Fourth Quarter resulting in inventory write-downs of $35.3 million. The average exchange rate between the Canadian dollar and U.S. dollar was relatively unchanged year-over-year with the 2008 year-end exchange rate of Cdn$1.00 to US$0.80 reflecting a significant strengthening of the U.S. dollar in the last half of 2008 which bolstered our realized crude oil prices and refined product crack spreads, both of which are denominated in U.S. dollars.

Our upstream operations averaged production of 55,932 boe/d in 2008 as compared to 60,336 boe/d in the prior year, reflecting a 7% reduction. Our production in 2008 reflects a modest 4% decline as compared to the 58,416 boe/d averaged in the Fourth Quarter of 2007 as our reduced capital program in 2008 and net acquisitions substantially stabilized our production. In 2007, we benefited from a $148.5 million drilling effort in the First Quarter boosting production to an average of 62,024 boe/d for the quarter as compared to capital expenditures of $79.6 million in the First Quarter of 2008. In 2008, we shifted our efforts to the re-pressurization of a few of our larger oil reservoirs rather than further development drilling and are expecting longer term more stable benefits, as compared to the flush production and accelerated declines associated with some drilling programs. Our operating costs of $300.9 million in 2008 are unchanged from the prior year as the overheated Alberta oilfield services industry did not weaken until late in the year with continued weakening expected in 2009. Our operating netback of $47.89 per boe represents a 60% increase over the prior year and is primarily attributed to higher commodity prices and tightening heavy crude oil differentials in western Canada.

During the Third Quarter of 2008, we completed two acquisitions for an aggregate cash consideration of $167.6 million to acquire approximately 1,645 bbls/d of light oil and 6,200 mcf/d of natural gas which represents an acquisition cost of approximately $63,000 per flowing boe. The principal asset acquired was a large pool of medium gravity oil of which approximately 7% of the original oil in place has been recovered and it is anticipated that with a combination of additional drilling and reservoir management, the recoveries from this pool can be substantially improved. In addition to numerous minor acquisitions/dispositions, we disposed of 481 boe/d of natural gas and natural gas liquids production for $36.8 million, representing proceeds of approximately $76,000 per flowing boe.

Reserve additions in our upstream operations replaced our production during 2008 with our proved plus probable reserves at December 31, 2008 totaling 219.9 million boe substantially unchanged from 220.9 million boe at the end of 2007. Including changes in future development costs, our 2008 finding and development costs averaged $25.97 per boe of proved reserves as compared to $28.44 per boe in the prior year and a three year average of $27.27 per boe while our finding and development costs averaged $29.87 per boe for proved plus probable reserves as compared to $28.10 per boe in the prior year and a three year average of $28.00 per boe. Including changes in future development costs, our 2008 finding, development and acquisition costs averaged $27.90 per boe of proved reserves as compared to $26.98 per boe in the prior year and a three year average of $28.78 per boe while on a proved plus probable basis, our costs were $28.84 per boe in 2008 as compared to $22.97 per boe in the prior year and a three year average of $25.47 per boe, respectively. Proved plus probable reserve additions are 13.7 million boe attributed to our 2008 capital program, enhanced oil recovery plans and new undeveloped reserves which, when coupled with the 5.8 million boe acquired during the year, substantially offsets our 2008 production. Relative to our 2008 netback price of $47.89, our finding and development costs represent a recycle ratio of 1.6 while our finding, development and acquisition costs represent a recycle ratio of 1.7.

4

During 2008, our downstream operations generated $83.6 million of cash as compared to $165.0 million in the prior year with the reduced contribution primarily the result of an $86.8 million drop in gross margin. The drop in North American demand for gasoline that began in mid-2007 continued through 2008 with the slowing US economy and record high prices curtailing consumer driving. As a result, the gasoline crack spread weakened significantly from the US$28.76 averaged during the Second Quarter of 2007 culminating in a negative spread during the Fourth Quarter of 2008. Similarly, the prices for high sulphur fuel oil (“HSFO”) during the first half of 2008 did not proportionately reflect increases in crude oil prices resulting in a significant deterioration of the HSFO crack spread which averaged US$38.75 less than the West Texas Intermediate (“WTI”) benchmark price of US$123.98/bbl during the Second Quarter of 2008 as compared to an average of US$26.52/bbl less than the WTI benchmark for the entire year. In contrast, the strong global demand for distillate products improved the refining margins for heating oil, diesel and jet fuel. Overall, our refining margin in 2008 was US$7.16 per barrel of throughput, a drop of $2.89 per barrel from the prior year.

Our refinery throughput averaged 103,497 bbls/d during 2008 with First Quarter throughput of approximately 112,000 bbls/d somewhat tempered by a four day unplanned outage. Throughput in May through August was reduced to approximately 95,500 bbls/d to optimize margins by minimizing the production of HSFO and reduced to approximately 102,800 bbls/d from September through December due to fouling of heat exchangers. Average daily throughput in 2008 represents a utilization factor of 90% as compared to the refinery’s 115,000 bbls/d nameplate capacity. As compared to the prior year with $34.5 million of turnaround and catalyst costs incurred during an extensive shutdown in the Fourth Quarter, our refinery operations incurred $5.6 million of turnaround and catalyst costs during a partial turnaround of the visbreaker unit in 2008. Our refinery operating costs totaled $78.9 million ($2.08 per bbl of throughput) in 2008 as compared to $83.9 million ($2.33 per bbl of throughput) in the prior year while our cost of purchased energy was $131.9 million ($3.48 per bbl) in the current year as compared to $92.3 million ($2.57 per bbl) in 2007 which when aggregated totals $5.56 per barrel of throughput for 2008 as compared to $4.90 in the prior year, a net increase of $0.66 per barrel.

In 2008, the strength in commodity prices resulted in cash settlements paid of $225.2 million on our price risk management contracts during the first nine months of 2008, offset somewhat by $24.4 million received during the Fourth Quarter of the year as commodity prices weakened significantly.

In April 2008, we raised $239.5 million of net proceeds with the issuance of $250 million principal amount of 7.5% Convertible Unsecured Subordinated Debentures and applied the net proceeds to reduce borrowings under our Extendible Revolving Credit Facility. As the disruptions in the capital markets continued in 2008, we have deferred our request to extend the maturity date of our credit facility beyond April 2010 in an effort to maintain the cost of our bank borrowing as well as retain our $1.6 billion of credit capacity.

In 2008, we declared distributions to Unitholders totaling $551.3 million ($3.60 per Trust Unit) as compared to $610.3 million ($4.40 per Trust Unit) in 2007. We have maintained a monthly distribution of $0.30 per Trust Unit since November 2007 and in light of the significant reduction in commodity prices, we have declared a distribution of $0.05 per Trust Unit for Unitholders of record on March 23, 2009 and payable on April 15, 2009. In the near term, substantially all of our cash flow from operating activities will be directed to enhancing Unitholder value through capital expenditures focused on maintaining our productive capacity as well as low risk profit/growth initiatives with the remaining cash directed towards improving our balance sheet liquidity by repaying bank borrowings.

5

Business Segments

The following table presents selected financial information for our two business segments:

| | Year Ended December 31 |

| | 2008 | 2007 |

| | | | | | | |

| (in $000s) | Upstream | Downstream | Total | Upstream | Downstream | Total |

| Revenue(1) | 1,294,769 | 4,194,595 | 5,489,364 | 971,044 | 3,098,556 | 4,069,600 |

| Earnings From Operations(2) | 498,786 | 14,125 | 512,911 | 169,423 | 92,270 | 261,693 |

| Capital expenditures | 271,312 | 56,162 | 327,474 | 300,674 | 44,111 | 344,785 |

| Total assets(3) | 3,933,632 | 1,775,688 | 5,745,407 | 3,952,337 | 1,482,904 | 5,451,683 |

| (1) | Revenues are net of royalties. |

| (2) | This is a non-GAAP measure; please refer to “Non-GAAP Measures” in this MD&A. |

| (3) | Total assets on a consolidated basis as at December 31, 2008 include $36.1 million (2007 - $16.4 million) relating to the fair value of risk management contracts. |

Our upstream and downstream operations are each discussed separately in the sections that follow. Additionally, we have included a section entitled “Risk Management, Financing and Other” that discusses, among other things, our cash flow risk management program.

UPSTREAM OPERATIONS

2008 Highlights

- Operating cash flow of $945.9 million, an improvement of $321.6 million over the prior year, reflecting the year- over-year strength of crude oil prices as well as a tightening of quality differentials.

- Average production of 55,932 boe/d as compared to production of 60,336 boe/d in the prior year reflects higher decline rates in 2007 and a reduction in 2008 capital spending.

- Operating costs of $300.9 million were unchanged from the prior year, representing $14.70/boe in the current year as compared to $13.66/boe in the prior year.

- Operating netback of $47.89/boe, representing an $18.00/boe (60%) increase over the prior year, attributed to substantially higher commodity prices.

- Completion of two acquisitions for aggregate cash consideration of $167.6 million, to acquire 2,650 boe/d of production representing an average cost per flowing barrel of approximately $63,000 comprised of 1,645 bbls/d of light oil and 6,200 mcf/d of natural gas, offset by divestments of $46.5 million and 640 boe/d.

- Capital spending of $271.3 million included the drilling of 247 wells (150.3 on a net basis) with a 100% success rate plus $128.8 million in net acquisitions, replaced 2008 production with finding and development costs, including changes in future development costs, of $25.97 per boe of proved reserves and $29.87 per boe for proved plus probable reserves.

6

Summary of Financial and Operating Results

| | Year Ended December 31 |

| (in $000s except where noted) | | 2008 | | | 2007 | | | Change | |

| | | | | | | | | | |

| Revenues | | 1,543,214 | | | 1,184,457 | | | 30% | |

| Royalties | | (248,445 | ) | | (213,413 | ) | | 16% | |

| Net revenues | | 1,294,769 | | | 971,044 | | | 33% | |

Operating expenses |

|

300,890 |

|

|

300,918 |

|

|

0% |

|

| General and administrative | | 32,868 | | | 34,615 | | | (5% | ) |

| Transportation and marketing | | 13,490 | | | 11,946 | | | 13% | |

| Depreciation, depletion, amortization and accretion | | 448,735 | | | 454,142 | | | (1% | ) |

Earnings From Operations(1) |

|

498,786 |

|

|

169,423 |

|

|

194% |

|

Cash capital expenditures (excluding acquisitions) |

|

271,312 |

|

|

300,674 |

|

|

(10% |

) |

| Property and business acquisitions, net of dispositions | | 128,773 | | | 138,158 | | | (7% | ) |

Daily sales volumes |

|

|

|

|

|

|

|

|

|

| Light to medium oil (bbl/d) | | 25,093 | | | 27,165 | | | (8% | ) |

| Heavy oil (bbl/d) | | 12,162 | | | 14,469 | | | (16% | ) |

| Natural gas liquids (bbl/d) | | 2,624 | | | 2,412 | | | 9% | |

| Natural gas (mcf/d) | | 96,315 | | | 97,744 | | | (1% | ) |

| Total (boe/d) | | 55,932 | | | 60,336 | | | (7% | ) |

| (1)This is a non-GAAP measure; please refer to “Non-GAAP Measures” in this MD&A. | | | | | | | | | |

Commodity Price Environment

| | Year Ended December 31 |

| Benchmarks | | 2008 | | | 2007 | | | Change | |

| | | | | | | | | | |

| West Texas Intermediate crude oil (US$ per barrel) | | 99.65 | | | 72.31 | | | 38% | |

| Edmonton light crude oil ($ per barrel) | | 102.02 | | | 76.25 | | | 34% | |

| Bow River blend crude oil ($ per barrel) | | 84.10 | | | 53.36 | | | 58% | |

| AECO natural gas daily ($ per mcf) | | 8.14 | | | 6.45 | | | 26% | |

Canadian / U.S. dollar exchange rate |

|

0.943 |

|

|

0.935 |

|

|

1% |

|

7

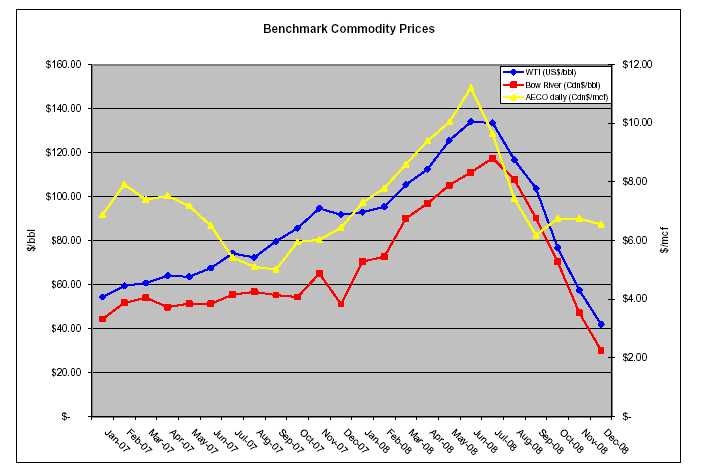

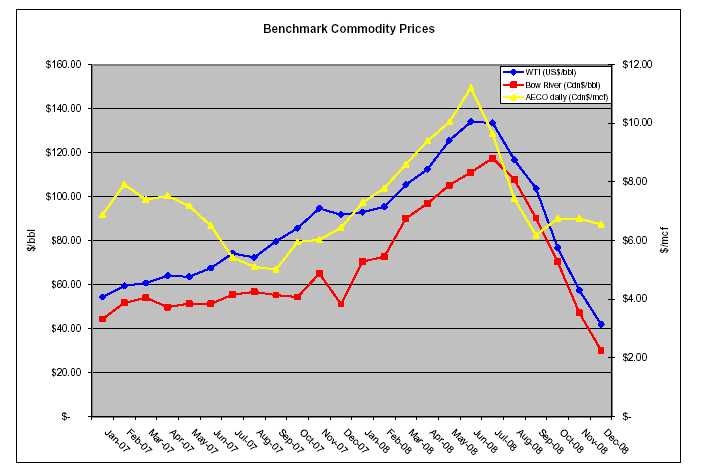

The following graph summarizes benchmark commodity prices for our upstream production for the period of January 2007 to December 2008:

During 2008, the average WTI benchmark price was 38% higher than the prior year. The average Edmonton light crude oil price (“Edmonton Par”) also increased from the prior year to average $102.02 in 2008, an increase of 34%. The increase in Edmonton Par has been less than the increase in WTI due to weaker demand for light crude oil in western Canada as a result of refineries converting to heavier crude blends coupled with the modest strengthening of the Canadian dollar relative to the U.S. dollar in 2008.

Heavy oil differentials fluctuate based on a combination of factors including the level of heavy oil inventories, pipeline capacity to deliver heavy crude to U.S. markets and the seasonal demand for heavy oil. During 2008, the Bow River heavy oil differential relative to Edmonton Par tightened to an average of $17.92/bbl (or 17.6%) compared to $22.89/bbl (or 30.0%) in 2007. On a per barrel basis, heavy oil differentials tightened throughout the year as production shortfalls and increased refinery demand for heavier grades of oil put upward pressure on pricing.

| | 2008 | 2007 |

| Differential Benchmarks | Q4 | Q3 | Q2 | Q1 | Q4 | Q3 | Q2 | Q1 |

| Bow River Blend differential to Edmonton Par ($/bbl) | 14.07 | 16.48 | 21.50 | 19.63 | 29.51 | 23.87 | 21.12 | 17.06 |

| Bow River Blend differential as a % of Edmonton Par | 22.2% | 13.5% | 17.1% | 20.2% | 34.2% | 30.0% | 29.4% | 25.4% |

Compared to the prior year, the average AECO daily natural gas price was 26% higher during the year ended December 31, 2008. Natural gas prices have strengthened in 2008 relative to 2007 due to a general strengthening of commodity prices.

8

Realized Commodity Prices(1)

The following table summarizes our average realized price by product for 2008 and 2007.

| | Year Ended December 31 |

| | 2008 | 2007 | Change |

| Light to medium oil ($/bbl) | 89.72 | 64.09 | 40% |

| Heavy oil ($/bbl) | 77.22 | 46.71 | 65% |

| Natural gas liquids ($/bbl) | 75.16 | 62.26 | 21% |

| Natural gas ($/mcf) | 8.60 | 6.94 | 24% |

| Average realized price ($/boe) | 75.39 | 53.78 | 40% |

| (1)Realized commodity prices exclude the impact of price risk management activities. | | | |

Our realized price for light to medium oil sales increased by $25.63/bbl (or 40%) compared to the prior year, reflecting the $25.77/bbl (or 34%) increase in Edmonton Par pricing. Harvest’s heavy oil price increased by $30.51/bbl (or 65%) compared to the prior year, reflecting the $30.74/bbl (or 58%) increase in the Bow River price. Our average realized price for our natural gas production increased by $1.66/mcf (or 24%) compared to the prior year, reflecting the $1.69/mcf (or 26%) increase in AECO daily pricing over the year.

Sales Volumes

The average daily sales volumes by product were as follows:

| | Year Ended December 31 | | | | |

| | 2008 | 2007 | | | | |

| | | Volume | | | Weighting | | | Volume | | | Weighting | | | % Volume Change | |

| Light to medium oil (bbl/d)(1) | | 25,093 | | | 45% | | | 27,165 | | | 45% | | | (8% | ) |

| Heavy oil (bbl/d) | | 12,162 | | | 22% | | | 14,469 | | | 24% | | | (16% | ) |

| Natural gas liquids (bbl/d) | | 2,624 | | | 5% | | | 2,412 | | | 4% | | | 9% | |

| Total liquids (bbl/d) | | 39,879 | | | 72% | | | 44,046 | | | 73% | | | (9% | ) |

| Natural gas (mcf/d) | | 96,315 | | | 28% | | | 97,744 | | | 27% | | | (1% | ) |

| Total oil equivalent (boe/d) | | 55,932 | | | 100% | | | 60,336 | | | 100% | | | (7% | ) |

| (1) | Harvest classifies our oil production, except that produced from Hay River, as light to medium and heavy according to NI 51-101 guidance. The oil produced from Hay River has an average API of 24o (medium grade) and is classified as a light to medium oil, notwithstanding that, it benefits from a heavy oil royalty regime and therefore would be classified as heavy oil according to NI 51-101. |

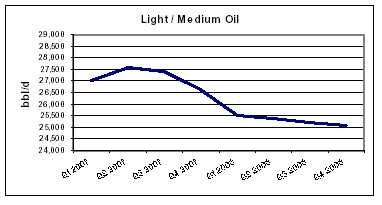

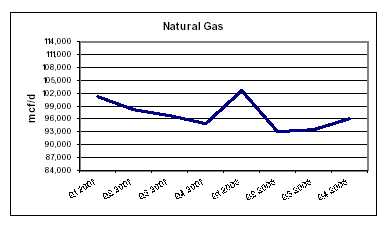

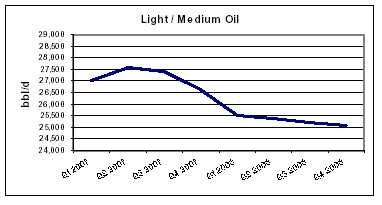

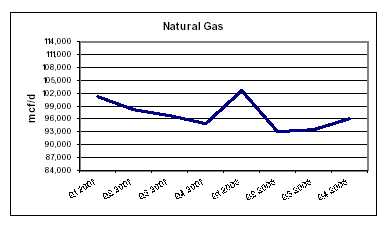

Harvest’s average daily production of light/medium oil in 2008 was 25,093 bbl/d, a 2,072 bbl/d or 8% reduction from the prior year. The 8% reduction is mainly attributed to a lower lever of drilling activity in 2008 and the initial flush production from wells completed in early 2007 stabilized at lower rates by the end of 2007. Light/medium production in 2008 has continued to remain relatively consistent as compared to the 2007 exit rate of production as increased water cuts and production lost to downtime have been substantially offset by new wells drilled in 2008 and the production from acquisitions completed during the Third Quarter. Production at our largest area, Hay River, has remained constant over the past year reflecting our increased water injection in early 2008 which improved recovery.

9

Our heavy oil production has decreased steadily over the past twelve months resulting in a 16% reduction with year-to-date production of 12,162 bbl/d as compared to 14,469 bbl/d in 2007. This reduction is largely the result of cold and wet weather related operational problems in the first half of 2008. Additionally, increased water cuts on our larger producing wells in the west central Saskatchewan and Lloydminster areas were only partially offset by new wells drilled in the year.

Our 2008 natural gas production decreased by 1% relative to 2007, averaging 96,315 mcf/d. Harvest’s 2008 average daily production is lower than in 2007 due to continued declines and production disruptions throughout the Fourth Quarter of 2007 and Second Quarter 2008 offset by incremental production resulting from our 2008 winter drilling program, acquisitions completed in the Third Quarter of 2008, and improved run time on our largest producing wells in the Fourth Quarter of 2008.

Revenues

| | | Year Ended December 31 |

| | | | | | | | | | |

| (000s) | | 2008 | | | 2007 | | | Change | |

| Light to medium oil sales | $ | 824,014 | | $ | 635,470 | | | 30% | |

| Heavy oil sales | | 343,717 | | | 246,674 | | | 39% | |

| Natural gas sales | | 303,303 | | | 247,499 | | | 23% | |

| Natural gas liquids sales and other | | 72,180 | | | 54,808 | | | 32% | |

| Total sales revenue | | 1,543,214 | | | 1,184,451 | | | 30% | |

| Royalties | | (248,445 | ) | | (213,413 | ) | | 16% | |

| Net Revenues | $ | 1,294,769 | | $ | 971,038 | | | 33% | |

Our revenue is impacted by changes to production volumes, commodity prices and currency exchange rates. Our 2008 total sales revenue of $1,543.2 million is $358.8 million higher than the prior year, of which $442.4 million is attributed to higher realized prices offset by a $83.6 million negative variance in respect of lower production volumes. The price increase reflects the 34% increase in Edmonton Par pricing and the 26% increase in AECO daily natural gas pricing in 2008 as compared to 2007, while our decreased production volume is attributed to decline rates, particularly in 2007, and a reduction in 2008 capital spending.

As discussed earlier, light to medium oil sales revenue for 2008 was $188.5 million higher than the prior year due to a $235.4 million favourable price variance offset by a $46.9 million unfavourable volume variance. Heavy oil sales revenue of $343.7 million in 2008 was $97.0 million higher than in the prior year due to a $135.8 million favourable price variance offset by a $38.8 million unfavourable volume variance. Natural gas sales revenue increased by $55.8 million in 2008 compared to 2007 due to a $58.8 million favourable price variance offset by a $3.0 million unfavourable volume variance.

10

During 2008, natural gas liquids and other sales revenue increased by $17.4 million compared to the prior year resulting from a $12.4 million favourable price variance and a $5.0 million favourable volume variance. Generally, the natural gas liquids volume variance will be aligned with our production of natural gas while the price variances will be aligned with the prices realized for our oil production. The positive volume variance is attributed to a few natural gas wells drilled near the end of 2007 and throughout 2008, which yielded significant natural gas liquids.

Royalties

We pay Crown, freehold and overriding royalties to the owners of mineral rights from which production is generated. These royalties vary for each property and product and our Crown royalties are based on a sliding scale dependent on production volumes and commodity prices.

Throughout 2008, net royalties as a percentage of gross revenue were 16.1% (2007 - 18.0%) and aggregated to $248.4 million (2007 - $213.4 million). Our royalty rate for the year was slightly lower than the expected rate of 17% due to various credits received throughout the year.

Operating Expenses

| | Year Ended December 31 |

| | | | | | | | | | | | | | | | |

| | 2008 | 2007 | | | Per BOE | |

| (000s except per boe amounts) | | Total | | | Per BOE | | | Total | | | Per BOE | | | Change | |

| Operating expense | | | | | | | | | | | | | | | |

| Power and fuel | $ | 80,162 | | $ | 3.92 | | $ | 64,053 | | $ | 2.91 | | | 35% | |

| Well Servicing | | 52,561 | | | 2.57 | | | 59,500 | | | 2.70 | | | (5% | ) |

| Repairs and maintenance | | 51,462 | | | 2.51 | | | 50,244 | | | 2.28 | | | 10% | |

| Lease rentals and property taxes | | 27,953 | | | 1.37 | | | 23,803 | | | 1.08 | | | 27% | |

| Processing and other fees | | 15,073 | | | 0.74 | | | 17,556 | | | 0.80 | | | (8% | ) |

| Labour – internal | | 23,785 | | | 1.16 | | | 22,757 | | | 1.03 | | | 13% | |

| Labour – contract | | 17,128 | | | 0.84 | | | 15,511 | | | 0.70 | | | 20% | |

| Chemicals | | 15,968 | | | 0.78 | | | 14,910 | | | 0.68 | | | 15% | |

| Trucking | | 11,297 | | | 0.55 | | | 11,833 | | | 0.54 | | | 2% | |

| Other | | 5,501 | | | 0.26 | | | 20,751 | | | 0.94 | | | (72% | ) |

| Total operating expense | $ | 300,890 | | $ | 14.70 | | $ | 300,918 | | $ | 13.66 | | | 8% | |

| | | | | | | | | | | | | | | | |

| Transportation and marketing expense | $ | 13,490 | | $ | 0.66 | | $ | 11,946 | | $ | 0.54 | | | 22% | |

Our 2008 operating costs totaled $300.9 million, unchanged from 2007. On a per barrel basis, operating costs have increased to $14.70/boe as compared to $13.66/boe in the prior year, an 8% increase substantially attributed to reduced production volumes. The largest components of operating expense are power and fuel costs, well servicing, and repairs and maintenance costs. Well servicing and repairs and maintenance costs continue to reflect the high demand for oilfield services, although with reduced activity compared to the prior year, these costs have remained relatively stable.

Power and fuel costs, comprised primarily of electric power costs, represented approximately 27% of our total operating costs during 2008. The average Alberta electric power price of $89.95/MWh in the year was 35% higher than the average 2007 price of $66.84/MWh and this increase is reflected in our 35% per boe increase in power and fuel costs compared to the prior year. To mitigate our exposure to electric power price fluctuations we had electric power price risk management contracts in place which resulted in a gain of $10.0 million compared to a gain of $3.1 million in the prior year. The risk management contracts for electric power costs ended in December 2008 and accordingly our electricity usage in Alberta will be exposed to market prices beginning January 1, 2009. The following table details the electric power costs per boe before and after the impact of our price risk management program.

11

| | | Year Ended December 31 |

| (per boe) | | 2008 | | | 2007 | | | Change | |

| Electric power and fuel costs | $ | 3.92 | | $ | 2.91 | | | 35% | |

| Realized gains on electricity risk management contracts | | (0.49 | ) | | (0.14 | ) | | 250% | |

| Net electric power and fuel costs | $ | 3.43 | | $ | 2.77 | | | 24% | |

| Alberta Power Pool electricity price (per MWh) | $ | 89.95 | | $ | 66.84 | | | 35% | |

Transportation and marketing expense for 2008 was $13.5 million or $0.66/boe, an increase of 22% per boe from $11.9 million or $0.54 per boe in 2007. These costs relate primarily to delivery of natural gas to Alberta’s natural gas sales hub, the AECO Storage Hub, and to a lesser extent, our costs of trucking clean crude oil to pipeline receipt points. As a result, the total dollar amount of costs fluctuates in relation with our natural gas production volumes while the cost per boe typically remains relatively constant. The increased transportation and marketing expense in 2008 is primarily due to increased clean oil trucking costs associated with the two acquisitions completed in the Third Quarter.

Operating Netback

| | Year Ended December 31 |

| (per boe) | | 2008 | | | 2007 | |

| Revenues | $ | 75.39 | | $ | 53.78 | |

| Royalties | | (12.14 | ) | | (9.69 | ) |

| Operating expense | | (14.70 | ) | | (13.66 | ) |

| Transportation and marketing expense | | (0.66 | ) | | (0.54 | ) |

| Operating netback(1) | $ | 47.89 | | $ | 29.89 | |

| (1)This is a non-GAAP measure; please refer to “Non-GAAP Measures” in this MD&A. | | | | | | |

Harvest’s operating netback represents the net amount realized on a per boe basis after deducting directly related costs. In 2008, our operating netback increased by $18.00/boe or 60% over the prior year. The increase in our operating netback is primarily attributed to a $21.61/boe increase in realized commodity prices, reflecting the increase in Edmonton Par, Bow River and AECO pricing over the prior year, offset by an increase in royalties of $2.45/boe resulting from higher realized prices.

General and Administrative (“G&A”) Expense

| | Year Ended December 31 | |

| (000s except per boe) | | 2008 | | | 2007 | | | Change | |

| Cash G&A | $ | 33,643 | | $ | 31,892 | | | 5% | |

| Unit based compensation expense (recovery) | | (775 | ) | | 2,723 | | | (128% | ) |

| Total G&A | $ | 32,868 | | $ | 34,615 | | | (5% | ) |

Cash G&A per boe ($/boe) |

$ |

1.64 |

|

$ |

1.45 |

|

|

13% |

|

For the year ended December 31, 2008, Cash G&A costs increased by $1.8 million (or 5%) compared to the prior year, reflecting higher employee costs in a continued tight market for technically qualified staff in the western Canadian petroleum and natural gas industry. Generally, approximately 75% of our Cash G&A expenses are related to salaries and other employee related costs.

Our unit based compensation plans provide employees with the option of settling outstanding awards with cash. As a result, unit based compensation expense is determined using the intrinsic method, being the difference between the Trust Unit trading price and the strike price of the unit awards adjusted for the proportion that is vested. The market price of our Trust Units was $20.63 at December 31, 2007 and on December 31, 2008, the price was $10.50. Total unit based compensation expense decreased $3.5 million in 2008 compared to 2007 as the market price of Harvest Trust Units decreased by $10.13 per Trust Unit in 2008 which was greater than the $5.60 per Trust Unit decrease in 2007.

12

Depletion, Depreciation, Amortization and Accretion Expense

| | Year Ended December 31 |

| (000s except per boe) | | 2008 | | | 2007 | | | Change | |

| Depletion, depreciation and amortization | $ | 414,969 | | $ | 420,184 | | | (1% | ) |

| Depletion of capitalized asset retirement costs | | 15,135 | | | 15,621 | | | (3% | ) |

| Accretion on asset retirement obligation | | 18,631 | | | 18,337 | | | 2% | |

| Total depletion, depreciation, amortization and accretion | $ | 448,735 | | $ | 454,142 | | | (1% | ) |

| Per boe | $ | 21.92 | | $ | 20.62 | | | 6% | |

Our overall depletion, depreciation, amortization and accretion (“DDA&A”) expense for the year ended December 31, 2008 was $5.4 million lower compared to the prior year. The decrease is attributed to lower production volumes partially offset by slightly higher finding, development and acquisition costs that have increased our depletion rate compared to the same periods of the prior year.

Capital Expenditures

| | | Year Ended December 31 | |

| (000s) | | 2008 | | | 2007 | |

| Land and undeveloped lease rentals | $ | 7,762 | | $ | 2,785 | |

| Geological and geophysical | | 6,782 | | | 6,058 | |

| Drilling and completion | | 164,628 | | | 146,941 | |

| Well equipment, pipelines and facilities | | 81,680 | | | 134,423 | |

| Capitalized G&A expenses | | 10,235 | | | 8,353 | |

| Furniture, leaseholds and office equipment | | 225 | | | 2,114 | |

| Development capital expenditures excluding acquisitions and non-cash items | | 271,312 | | | 300,674 | |

| Non-cash capital additions (recoveries) | | (251 | ) | | 371 | |

| Total development capital expenditures excluding acquisitions | $ | 271,061 | | $ | 301,045 | |

In 2008, approximately 61% of our development capital expenditures were incurred to drill 247 gross wells with a success rate of 100%, compared to 182 gross wells with a success rate of 98% in 2007. While we continued to focus our drilling activity on oil opportunities (68% of net wells drilled) given the strong oil price environment through most of the year, our natural gas drilling in central Alberta resulted in some particularly successful wells. At Chedderville, we benefited from our 2006 exploration discovery with the drilling of 3 additional wells into this prolific Mannville channel. Additional pipeline infrastructure was completed by the end of the year and the wells were brought on stream bringing our production from this once undeveloped area to approximately 1,800 boe/d.

Over 80% of our 2008 drilling activity focused on our Markerville, Lloydminster/Hayter, southeast Saskatchewan, southeast Alberta and Rimbey properties. In Markerville we drilled 63 gross wells focusing on infill opportunities in our Edmonton sands shallow gas play as well as deeper targets in the Ostracod and Ellerslie channel systems. At Lloydminster/Hayter, we drilled 34 gross wells, primarily horizontal wells targeting infill locations in both the Lloydminster and Dina sandstone formations. In southeast Saskatchewan, we drilled 45 gross horizontal wells pursuing light oil accumulations in both the Souris Valley and Tilston formations with a 100% success rate. A horizontal test well into the Bakken formation provided us with information to further assess the Bakken potential on Harvest’s Bakken rights of approximately 12,000 net acres. In southeast Alberta, we drilled 40 gross wells including the transferring of our horizontal well experience in Lloydminster to the development of a new heavy oil play in the Sunburst sandstone formation at Murray Lake where we drilled 4 horizontal wells. At Rimbey, we continued to pursue primarily gas opportunities by drilling 21 gross wells to continue our successful exploration activities pursuing Ostracod channel sands as well as shallow Edmonton sands opportunities.

Our enhanced oil recovery (“EOR”) efforts continue. At Hay River, rather than executing a large drilling program, we focused on enhancing our infrastructure and water injection to better manage the performance of our Bluesky reservoir. By increasing injection in early 2008, we were able to maintain our production levels throughout 2008 without drilling any new wells, our December 2008 production was 1,600 boe/d ahead of our original expectations.

13

At Bellshill Lake, an independent engineering study, as well as field trials, confirmed that increased water injection would reduce our production decline rate and result in an overall improved recovery from this large Ellerslie medium gravity oil pool. In 2008, we completed the installation of a water transfer line from our south Bellshill pool to bring incremental produced water to our main Bellshill Lake pool which has allowed us to further increase the volume of water injection in the Fourth Quarter of 2008.

At Suffield, we launched an enhanced water flood pilot with the installation of a water transfer line from our main Batus facility to our Lark oil pool. Suffield produces heavy gravity oil from Basal Quartz sandstone reservoirs and produced water collected from a number of separate oil pools (including Lark) was not re-distributed to the pools resulting in reduced reservoir pressure as fluids were produced over time. By redistributing water from Batus to the other pools, we will be able to access incremental oil reserves as we “re-charge” the reservoirs. Our main Batus reservoir will also benefit as we will be reducing the amount of “over-injection” which can result in this heavier oil being bypassed in favor of the more mobile water. Injection was initiated in the Third Quarter of 2008.

At Wainwright, we completed the majority of our laboratory testing and completed the acquisition of our polymer injection skid with injection scheduled to begin late in the First Quarter of 2009. The polymer injection represents the first phase of our pilot testing the enhanced recovery impact on this medium gravity Sparky oil pool. We will be initially testing the benefit of polymer injection alone, to be followed up with an Alkaline Surfactant Polymer pilot should the test results be favorable.

The $81.7 million of well equipment, pipelines and facilities expenditures during 2008 includes the equipping of wells drilled during the year, and also a number of infrastructure initiatives to optimize the production performance of our asset base. Approximately $9 million was invested at various properties to ensure the integrity of our transportation and processing infrastructure. At Chedderville, we completed an expansion to our gathering infrastructure for approximately $1 million to allow new wells to be brought on stream, and to fully optimize the production from our original discovery well. At southeast Saskatchewan, we installed a free water knockout vessel at our Kenossee pool for total capital of approximately $1 million to allow production to be optimized from our infill and step out drilling program. Approximately $8 million was part of our EOR implementation at Bellshill Lake, Suffield, Hay River and Wainwright as noted above.

The following summarizes Harvest’s participation in gross and net wells drilled during 2008:

| | Total Wells | Successful Wells | Abandoned Wells |

| Area | Gross(1) | Net | Gross | Net | Gross | Net |

| | | | | | | |

| Southeast Saskatchewan | 45.0 | 35.5 | 45.0 | 35.5 | - | - |

| Southeast Alberta | 40.0 | 15.5 | 40.0 | 15.5 | - | - |

| Red Earth | 12.0 | 11.3 | 12.0 | 11.3 | - | - |

| Suffield | 12.0 | 12.0 | 12.0 | 12.0 | - | - |

| Lloydminster/Hayter | 34.0 | 31.8 | 34.0 | 31.8 | - | - |

| Rimbey | 21.0 | 7.3 | 21.0 | 7.3 | - | - |

| Markerville | 63.0 | 26.9 | 63.0 | 26.9 | - | - |

| Northwest Alberta | 10.0 | 3.8 | 10.0 | 3.8 | - | - |

| Other Areas | 10.0 | 6.2 | 10.0 | 6.2 | - | - |

| Total | 247.0 | 150.3 | 247.0 | 150.3 | - | - |

| (1)Excludes 18 additional wells that we have an overriding royalty interest in. | | | | |

Our 2008 capital program, along with our acquisitions and divestitures, replaced our production on a proved plus probable basis with 2008 year end reserves of 219.9 million boe, substantially unchanged from 220.9 million boe at the end of 2007. Including changes in future development costs, our 2008 finding and development costs averaged $25.97 per boe of proved reserves while our finding, development and acquisition costs averaged $27.90 per boe of proved reserves as compared to $28.44/boe and $26.98/boe, respectively, in the prior year and a three year average of $27.27/boe and $28.78/boe, respectively. Based on the forecast prices and costs of our independent reservoir engineers as at December 31, 2008, the net present value of our future net revenues from proved reserves using a 10% discount rate is $2,941.8 million and $3,893.8 million from proved plus probable reserves. With 2008 netback price of $47.89/boe in 2008, our finding and development costs result in a recycle ratio of 1.6 while our finding, development and acquisition costs result in a recycle ratio of 1.7. Based on our 2008 production of 20.5 million boe, our 2008 year end proved reserves represent a reserve life index of 7.5 years while our proved plus probable reserves represent a reserve life index of 10.8 years.

14

Acquisitions and Divestitures

In late July 2008, we acquired a private oil and natural gas company for cash consideration of $36.8 million. The associated production was approximately 390 bbl/d of light oil in an area immediately adjacent to our existing operations in Red Earth plus 2,300 mcf/d of natural gas from a shallow gas play in north central Alberta. An independent engineering report prepared effective April 1, 2008 estimated proved and probable reserves of 1,800 mboe.

In early September 2008, we acquired conventional oil and gas properties in the Peace River Arch area of northern Alberta with approximately 1,900 boe of daily production (66% oil and 24% natural gas) in exchange for cash consideration of $130.8 million plus some minor natural gas interests which produced approximately 85 boe/d during the first half of 2008. During the first half of 2008, the acquired properties averaged production of approximately 1,255 bbl/d of light gravity oil and natural gas liquids plus 3,900 mcf/d of natural gas. An independent engineering report prepared effective December 31, 2007 estimated proved reserves at 7,260 mboe and proved plus probable reserves at 9,899 mboe.

During the Third Quarter, we disposed of various non-operated properties in the Pouce Coupe area in exchange for cash consideration of $36.8 million plus some freehold mineral interests in southeast Saskatchewan. These properties had average daily production of approximately 2,800 mcf/d of natural gas and 14 boe/d of natural gas liquids.

Goodwill

Goodwill is recorded when the purchase price of an acquired business exceeds the fair value of the net identifiable assets and liabilities of that acquired business. At December 31, 2008, we had $677.6 million of goodwill on our balance sheet related to our upstream segment, of which $0.8 million was added during 2008 with our purchase of a private oil and natural gas company. The goodwill balance is assessed annually for impairment or more frequently if events or changes in circumstances occur that would reasonably be expected to reduce the fair value of the acquired business to a level below its carrying amount. Although commodity prices decreased significantly in the second half of 2008 no goodwill impairment charges have been made due to the historical cost of the oil assets, which were acquired based on oil prices consistent or lower compared to prices prevalent in the market today.

Asset Retirement Obligation (“ARO”)

In connection with property acquisitions and development expenditures, we record the fair value of the ARO as a liability in the same year the expenditures occur. The associated asset retirement costs are capitalized as part of the carrying amount of the assets and are depleted and depreciated over our estimated net proved reserves. Once the initial ARO is measured, it is adjusted at the end of each period to reflect the passage of time as well as changes in the estimated future cash flows of the underlying obligation. Our asset retirement obligation increased by $63.8 million during 2008 as a result of accretion expense of $18.6 million, new liabilities recorded of $7.2 million, and upward revisions in estimates of $49.4 million, offset by $11.4 million of actual asset retirement expenditures incurred.

15

DOWNSTREAM OPERATIONS

2008 Highlights

- Cash from downstream operations totaled $83.6 million (2007 - $165.0 million) with sound operating performance more than offset by generally lower refining margins, higher costs for purchased energy and, in the Fourth Quarter, an inventory write-down due to significantly lower commodity prices.

- An average refining margin of US$7.16/bbl reflects a US$2.89 decrease over the prior year primarily attributed to lower margins on gasoline and high sulphur fuel oil (“HSFO”) products partially offset by improved margins on distillate products and higher discounts on feedstock, all relative to the WTI benchmark price.

- Refinery throughput averaged 103,497 bbls/d, representing a 90% utilization rate, with throughput limited from May through August in an effort to optimize refining margins by minimizing the production of HSFO and from September through December due to fouling of heat exchangers.

- Refining operating costs of $2.08/bbl of throughput as compared to $2.33/bbl in the prior year reflects increased throughput and cost containment efforts resulting in a relatively stable level of spending at $78.9 million.

- Cost of purchased energy increased to $3.48/bbl of throughput as compared to $2.57/bbl in the prior year reflecting a significantly higher commodity price environment during the first three quarters of 2008, while turnaround and catalyst costs reflect a modest visbreaker turnaround in 2008 as compared to an extensive shutdown in 2007.

- Capital spending totaled $56.2 million as compared to $44.1 million in the prior year with $30.1 million incurred for the visbreaker expansion project commissioned in November 2008.

Summary of Financial and Operational Results

| | Year Ended December 31 |

| (in $000’s except where noted below) | | 2008 | | | 2007 | | | Change | |

| | | | | | | | | | |

| Revenues | | 4,194,595 | | | 3,098,556 | | | 35% | |

| Purchased feedstock for processing and products purchased for resale(4) | | 3,850,507 | | | 2,667,714 | | | 44% | |

| Gross margin(1) | | 344,088 | | | 430,842 | | | (20% | ) |

Costs and expenses |

|

|

|

|

|

|

|

|

|

| Operating expense | | 98,736 | | | 102,476 | | | (4% | ) |

| Purchased energy expense | | 131,878 | | | 92,328 | | | 43% | |

| Turnaround and catalyst expense | | 5,645 | | | 34,486 | | | (84% | ) |

| Marketing expense and other | | 20,753 | | | 34,970 | | | (41% | ) |

| General and administrative expense | | 1,875 | | | 1,713 | | | 9% | |

| Depreciation and amortization expense | | 71,076 | | | 72,600 | | | (2% | ) |

| Earnings From Operations(1) | | 14,125 | | | 92,269 | | | (85% | ) |

Cash capital expenditures |

|

56,162 |

|

|

44,111 |

|

|

27% |

|

Feedstock volume (bbl/day)(2) |

|

103,497 |

|

|

98,617 |

|

|

5% |

|

Yield (000’s barrels) |

|

|

|

|

|

|

|

|

|

| Gasoline and related products | | 12,068 | | | 11,515 | | | 5% | |

| Ultra low sulphur diesel and jet fuel | | 15,668 | | | 14,406 | | | 9% | |

| High sulphur fuel oil | | 9,952 | | | 9,843 | | | 1% | |

| Total | | 37,688 | | | 35,764 | | | 5% | |

Average refining margin (US$/bbl)(3) |

|

7.16 |

|

|

10.05 |

|

|

(29% |

) |

| (1) | These are non-GAAP measures; please refer to “Non-GAAP Measures” in this MD&A. |

| (2) | Barrels per day are calculated using total barrels of crude oil feedstock and vacuum gas oil. |

| (3) | Average refining margin is calculated based on per barrel of feedstock throughput. |

| (4) | Purchased feedstock for processing and products purchased for resale includes inventory write-downs of $35.3 million in the Fourth Quarter of 2008. |

16

Overview of Downstream Operations

Our downstream operations are comprised of an 115,000 bbls/d medium gravity sour crude oil hydrocracking refinery and a retail and wholesale petroleum marketing business both located in the Province of Newfoundland and Labrador. Our petroleum marketing business is comprised of the retail and wholesale distribution of gasoline, diesel, jet and other transportation fuels as well as home heating fuels and related appliances and the revenues from our marine services including tugboat revenues.

The financial performance of our refinery reflects its throughput, feedstock selection, operating effectiveness, refining margins and operating costs. Our refining margin is dependent on the sales value of the refined products produced and the cost of crude oil feedstock purchased as well as the yield of refined products from various crude oil feedstocks. We continuously evaluate the market and relative refinery values of several different crude oils and vacuum gas oils to determine the optimal feedstock mix. We analyze our refining margin on each refined product and our sales revenue relative to benchmark prices for the refined product and the WTI benchmark price. With respect to feedstock costs, we analyze our price discounts relative to the WTI benchmark price and segregate crude oil sources by country of origin.

We purchase substantially all of our refinery feedstock and sell our distillate and gasoline products, with the exception of products sold in Newfoundland through our petroleum marketing division, to Vitol Refining S.A. (“Vitol”) pursuant to the Supply and Offtake Agreement. Effective January 20, 2008, our HSFO is sold to a wholly-owned affiliate of one of the world’s largest integrated energy companies; prior to this, our HSFO had been sold to Vitol. During the year ended December 31, 2008, approximately 67% of our refined product sales were to Vitol.

The Supply and Offtake Agreement with Vitol contains pricing terms that reflect market prices based on an average ten day delay which results in our purchases from and sales to Vitol being priced on future prices as compared to pricing at the time of delivery. With the exception of the sales to Vitol, our refined products are sold at prices that reflect market prices at the time that the product is delivered to the purchaser. For more information on the Supply and Offtake Agreement with Vitol, see the description in our Annual Information Form for the year ended December 31, 2007 as filed on SEDAR atwww.sedar.com.

For the year ended December 31, 2008, our refining gross margin was $287.6 million as compared to $386.7 million in the prior year, a decrease of $99.1 million. The decrease in refining gross margin is primarily due to weaker gasoline and HSFO margins which resulted in negative price variances of $224.9 million and $66.5 million, respectively, partially offset by improved distillate margins and improved discounts to WTI on our feedstock which resulted in positive price variances of $92.3 million and $121.7 million, respectively.

For the year ended December 31, 2008, our marketing division earned a gross margin of $56.5 million as compared to $44.1 million in the prior year, an increase of 28% primarily due to a significant increase in the price of sulphur, which is sold through a profit sharing agreement with a third party processor and contributed $8.5 million in 2008 as compared to $0.3 in 2007.

17

Refining Benchmark Prices

The following average benchmark prices and currency exchange rates are the reference points from which we discuss our refinery’s financial performance:

| | Year Ended December 31 |

| | 2008 | 2007 | Change |

| WTI crude oil (US$/bbl) | 99.65 | 72.31 | 38% |

| Brent crude oil (US$/bbl) | 98.38 | 72.67 | 35% |

| Basrah Official Sales Price Discount (US$/bbl) | (7.40) | (6.84) | 8% |

| RBOB gasoline (US$/bbl/gallon) | 104.40/2.49 | 86.86/2.07 | 20% |

| Heating Oil (US$/bbl/gallon) | 119.89/2.85 | 85.65/2.04 | 40% |

| High Sulphur Fuel Oil (US$/bbl) | 73.13 | 54.02 | 35% |

| Canadian / U.S. dollar exchange rate | 0.943 | 0.935 | 1% |

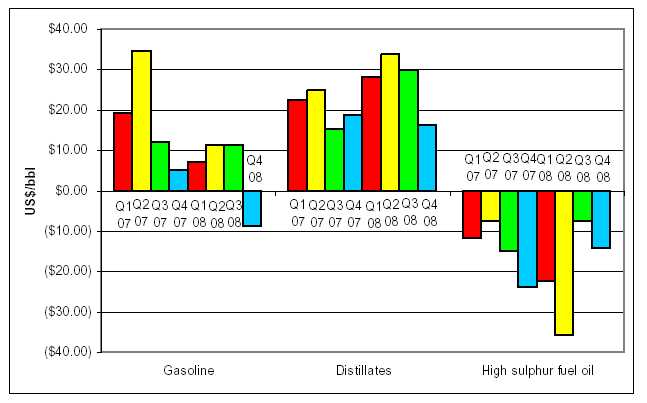

The following graph summarizes the crack spreads between the respective benchmark prices for refined products and WTI for the period of January 2007 to December 2008:

During 2008, the Heating Oil Crack Spread averaged US$20.24/bbl, an increase of US$6.90/bbl over the US$13.34/bbl averaged in the prior year, as strong demand for distillate products in North America, Europe and Asia improved margins. The RBOB Gasoline Crack Spread averaged US$4.75/bbl in 2008, a drop of US$9.80/bbl from the US$14.55/bbl averaged in the prior year, as North American demand for gasoline continued to weaken subsequent to June 2007 due to slowing economic activity and consumer response to the record setting prices for gasoline in the summer of 2008. Similarly, the HSFO Crack Spread differential averaged US$26.52/bbl less than WTI in 2008, an increase of US$8.23/bbl from the average differential of US$18.29/bbl less than WTI in the prior year, as margins in the Second Quarter of 2008 were particularly weak.

18

During 2008, the Canadian/U.S. dollar exchange rate averaged 0.943, an increase of 0.008 from the prior year. The relative strength of the Canadian dollar resulted in a nominal decrease in our cash flows from downstream operations in 2008, as refined product and crude oil prices are denominated in U.S. dollars.

Summary of Gross Margin

The following table summarizes our downstream gross margin for the years ended December 31, 2008 and 2007 segregated between refining activities and petroleum marketing and other related businesses.

| | | Year Ended December 31 |

| | | 2008 | | | 2007 | |

| (000’s of Canadian dollars) | | Refining | | | Marketing | | | Total | | | Refining | | | Marketing | | | Total | |

| | | | | | | | | | | | | | | | | | | |

| Sales revenue(1) | | 4,092,555 | | | 670,686 | | | 4,194,595 | | | 2,982,655 | | | 504,375 | | | 3,098,556 | |

| Cost of feedstock for processing and products | | | | | | | | | | | | | | | | | | |

| for resale(1) | | 3,804,952 | | | 614,201 | | | 3,850,507 | | | 2,595,907 | | | 460,281 | | | 2,667,714 | |

| Gross margin(2) | | 287,603 | | | 56,485 | | | 344,088 | | | 386,748 | | | 44,094 | | | 430,842 | |

Average refining margin (US$/bbl) |

|

7.16 |

|

|

|

|

|

|

|

|

10.05 |

|

|

|

|

|

|

|

| (1) | Downstream sales revenue and cost of products for processing and resale are net of intra-segment sales of $568.6 million for the year ended December 31, 2008 (2007 - $388.5 million) reflecting the refined products produced by the refinery and sold by the Marketing Division. |

| (2) | This is a non-GAAP measure; please refer to “Non-GAAP Measures” in this MD&A. |

Refining Gross Margin

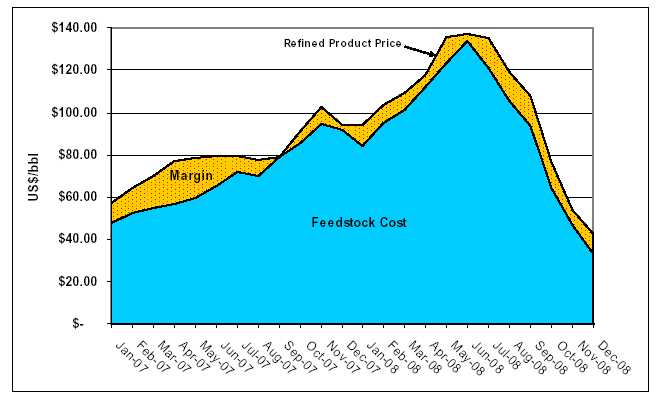

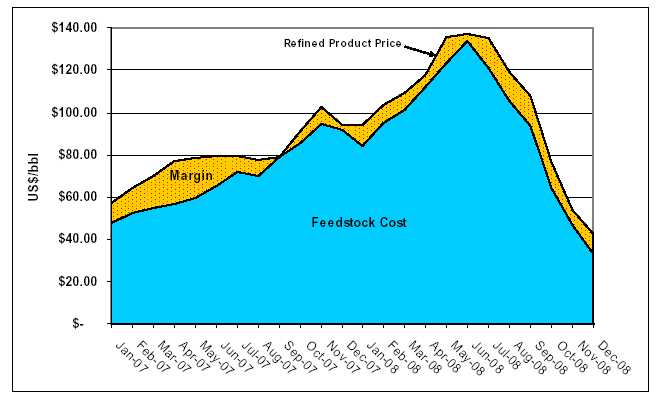

The following graph summarizes our average refining margin relative to the cost of feedstock for the period of January 2007 to December 2008:

19

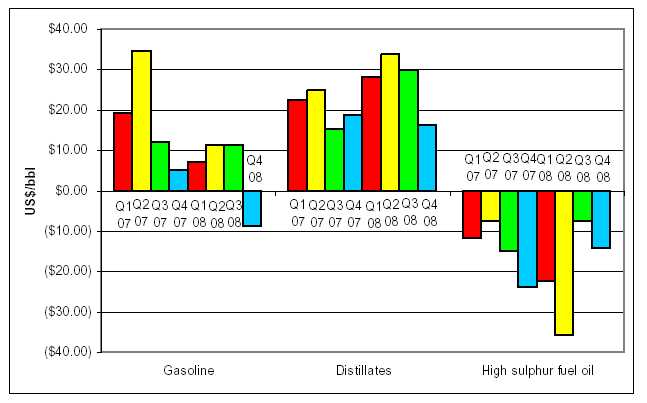

The following chart summarizes our refining margin by refined product over the same time period by quarter:

Crack spreads on gasoline and HSFO peaked during the first half of 2007, resulting in an average refining margin of US$13.69 per bbl with the distillate refining margin averaging US$23.52 per bbl. However, during the second half of 2007 and the first half of 2008 as feedstock costs continued to rise, crack spreads on gasoline and HSFO declined considerably from their peak, and were only partially offset by improved crack spreads on distillate products, which resulted in our average refining margin dropping to US$4.16 per bbl and US$7.36 per bbl for the six month periods ended December 31, 2007 and June 30, 2008, respectively. During the second half of 2008, although feedstock costs decreased significantly, crack spreads on gasoline continued to deteriorate, particularly in the Fourth Quarter when gasoline crack spreads were negative, resulting in an average refining margin of US$6.95 per bbl.

20

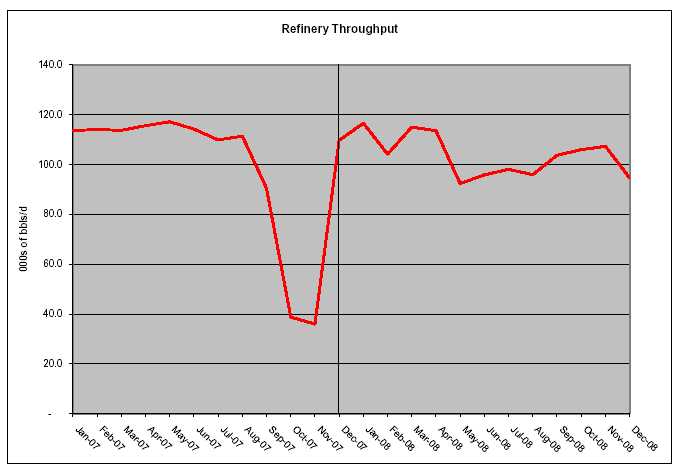

Refinery Throughput

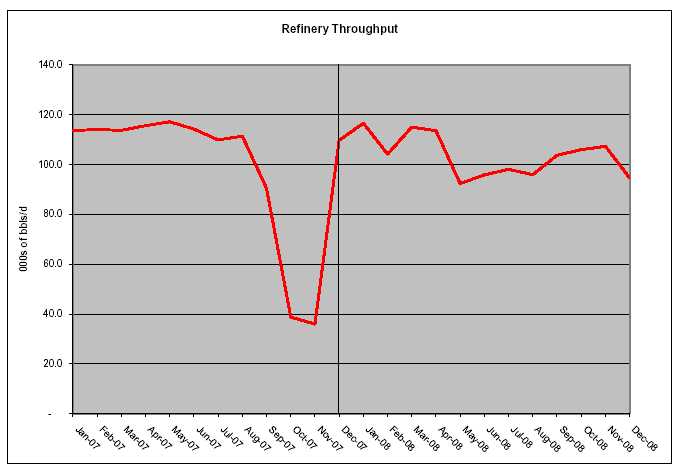

The throughput of our refinery for the period of January 2007 to December 2008 is illustrated below in thousands of barrels of feedstock per day:

During 2008, our feedstock was comprised of 93,697 bbl/d of medium sour crude oil and 9,800 bbl/d of vacuum gas oil (“VGO”) as compared to 87,060 bbl/d of crude oil and 11,557 bbl/d of VGO in the prior year. Our aggregate total throughput in 2008 was 103,497 bbls/d, a 4,880 bbls/d increase over the prior year reflecting a utilization rate of 90% relative to an 115,000 bbls/d nameplate capacity. While the refinery experienced limited planned or unplanned downtime in 2008, our throughput was intentionally reduced from May through August in an effort to improve overall gross margin by reducing feedstock to eliminate the production of vacuum tower bottoms (“VTB’s”) in excess of our visbreaker unit capacity, thereby eliminating the need to downgrade middle distillate valued streams to blend the excess VTB’s into lower valued HSFO. Throughput during September through December was reduced due to fouling in heat exchangers, including an online partial exchanger cleaning in December. The remaining exchangers will be cleaned during the ISOMAX catalysts replacement planned for April 2009. During the Fourth Quarter of 2007, we completed a turnaround of the crude unit and vacuum tower and positioned the refinery for uninterrupted operations in 2008 except for the visbreaker turnaround in the Fourth Quarter of 2008.

21

Refinery Sales Revenue

A comparison of our refinery yield, product pricing and revenue for the years ended December 31, 2008 and 2007 is presented below:

| | Year Ended December 31 |

| | | 2008 | | | 2007 | |

| | Refinery | Volume | Sales | Refinery | Volume | Sales |

| | Revenues | | Price(1) | Revenues | | Price(1) |

| | (000’s of Cdn $) | (000s of bbls) | (US$ per bbl/ | (000’s of Cdn $) | (000s of bbls) | (US$ per bbl/ |

| | | | US$ per US gal) | | | US$ per US gal) |

| | | | | | | |

| Gasoline products | 1,327,599 | 12,830 | 97.58/2.32 | 1,088,215 | 11,726 | 86.77/2.07 |

| Distillates | 2,006,406 | 15,661 | 120.81/2.88 | 1,339,388 | 14,245 | 87.91/2.09 |

| High sulphur fuel oil | 758,550 | 9,651 | 74.12 | 555,052 | 9,740 | 53.28 |

| | 4,092,555 | 38,142 | 101.18 | 2,982,655 | 35,711 | 78.09 |

| Inventory adjustment | | (454) | | | 53 | |

| Total production | | 37,688 | | | 35,764 | |

| Yield (as a % of Feedstock)(2) | 100% | | | 99% | |

| (1) | Average product sales prices are based on the deliveries at our refinery loading facilities. |

| (2) | After adjusting for changes in inventory held for resale. |

Our refinery sales revenue is dependent on the selling price of the refined products produced as well as the yield of refined products produced from the crude oil and other feedstocks. Although our yield can be altered slightly by adjusting refinery operations to react to market conditions and seasonal demand, product yields are primarily impacted by the type of crude oil feedstock processed and refinery performance. For the year ended December 31, 2008, our refinery yield was comprised of 32% gasoline products, 42% distillates and 26% HSFO compared to 32%, 40% and 28% for the same products respectively during 2007. The shift in product yield in 2008 from HSFO to distillates is primarily attributed to feedstock selection, process unit optimization and reduced throughput.

Our average sales price for our refined products relative to the average WTI price in the current year was US$4.25/bbl lower than in the prior year. In 2008, our average sales price was US$101.18/bbl (a premium of US$1.53/bbl over WTI) as compared to an average selling price of US$78.09/bbl in the prior year (a premium of US$5.78bbl over WTI). This reduction in premium represents a $171.9 million price variance in 2008.

During 2008, the average sales price of our gasoline products of US$97.58/bbl was a US$2.07/bbl discount to the average WTI price as compared to a US$14.46/bbl premium over WTI realized in 2007 representing a $224.9 million decrease in gross margin as compared to the prior year. This US$16.53 drop in our gasoline refining margin relative to WTI reflects generally weaker demand for gasoline in North America.

During 2008, the average sales price for our distillate products of US$120.81/bbl was a US$21.16/bbl premium over the average WTI price as compared to a US$15.60/bbl premium over WTI realized in 2007 representing a $92.3 million increase in gross margin as compared to the prior year. During 2008, the international demand for distillate products was strong supporting improved distillate margins. During 2008, we received US$7.9 million of incremental revenue from delivering approximately 7.5 million barrels of distillate products to Europe pursuant to our profit sharing arrangement with Vitol.

During 2008, the average sales price of our HSFO of US$74.12/bbl was a US$25.53/bbl discount to average WTI price as compared to a US$19.03/bbl discount in 2007 representing a $66.5 million reduction in gross margin as compared to the prior year. The US$5.56/bbl improvement in our distillate pricing relative to WTI and the shift in product yield from HSFO to distillates was insufficient to fully offset the US$16.53/bbl and US$6.50/bbl margin reductions for gasoline products and HSFO, respectively.

22

Refinery Feedstock

The volatility of WTI prices throughout 2008 makes it difficult to compare the economics of crude types when our consumption of crude type varies from month to month and costs are aggregated over the year. Further, our refinery competes for international waterborne crude oils and VGOs and the WTI benchmark price generally reflects a land-locked North American price with limited access to the international markets. A comparison of crude oil and VGO feedstock processed for the years ended December 31, 2008 and 2007 is presented below:

| | Year Ended December 31 |

| | 2008 | | 2007 | |

| | | Cost of | | | Volume | | | Cost per | | | Cost of | | | Volume | | | Cost per | |

| | | Feedstock | | | | | | Barrel(1 | ) | | Feedstock | | | | | | Barrel(1 | ) |

| | | (000’s of Cdn $ | ) | | (000s of bbls | ) | | (US$/bbl) | | | (000’s of Cdn $ | ) | | (000s of bbls | ) | | (US$/bbl) | |

| | | | | | | | | | | | | | | | | | | |

| Iraqi | | 1,963,882 | | | 21,218 | | | 87.28 | | | 1,608,356 | | | 23,230 | | | 64.74 | |

| Russian | | 614,187 | | | 5,973 | | | 96.97 | | | 237,449 | | | 3,367 | | | 65.94 | |

| Venezuelan | | 676,777 | | | 7,102 | | | 89.86 | | | 362,868 | | | 5,180 | | | 65.50 | |

| Crude Oil Feedstock | | 3,254,846 | | | 34,293 | | | 89.50 | | | 2,208,673 | | | 31,777 | | | 64.99 | |

| Vacuum Gas Oil | | 396,676 | | | 3,586 | | | 104.31 | | | 354,858 | | | 4,218 | | | 78.66 | |

| | | 3,651,522 | | | 37,879 | | | 90.90 | | | 2,563,531 | | | 35,995 | | | 66.59 | |

Net inventory adjustment(2) |

|

(8,990 |

) |

|

|

|

|

|

|

|

(36,378 |

) |

|

|

|

|

|

|

| Additives and blendstocks | | 127,136 | | | | | | | | | 68,754 | | | | | | | |

| Inventory write-down(3) | | 35,284 | | | | | | | | | - | | | | | | | |

| | | 3,804,952 | | | | | | | | | 2,595,907 | | | | | | | |

| (1) | Cost of feedstock includes all costs of transporting the crude oil to refinery in Newfoundland. |

| (2) | Inventories are determined using the weighted average cost method. |

| (3) | Inventory write-downs are calculated on a product by product basis using the lower of cost or net realizable value. |

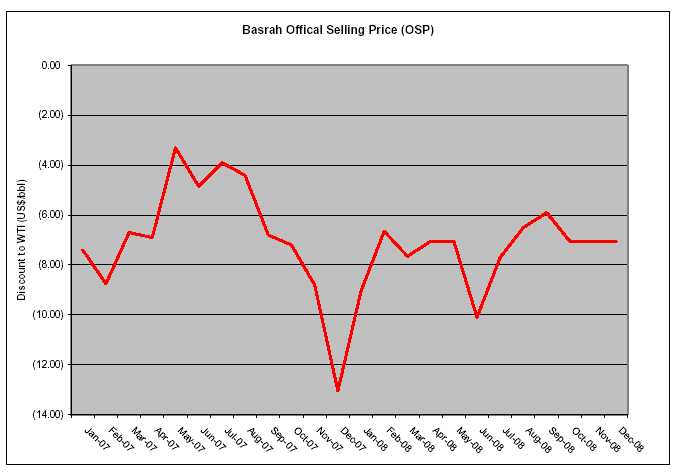

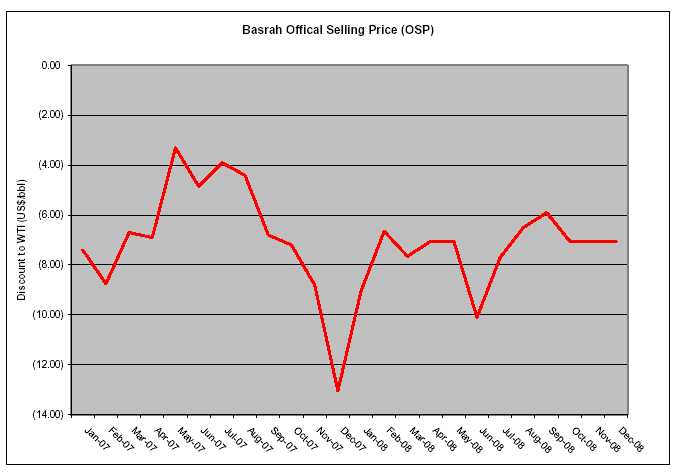

Changes to the cost of our feedstock reflect numerous factors beyond changes in WTI price, including the quality of the crude oil processed, the mix of crude oil types, the costs of transporting the crude oil to our refinery, the ten day delay in pricing pursuant to the Supply and Offtake Agreement and for Iraqi crude oil purchased, the Official Selling Price (“OSP”) as set by the Oil Marketing Company of the Republic of Iraq. The discount of Iraqi crude oil relative to the WTI benchmark price is influenced by the quality of the crude oil as well as by the demand from other purchasers who may not be North American based. On a monthly basis, the OSP discount is announced as a discount to the WTI benchmark price for North American deliveries. Since our acquisition of North Atlantic in October 2006, the OSP has fluctuated from a low of US$3.30 in May 2007 to a high of US$13.05 in December 2007. The following graph illustrates the volatility of the OSP for Basrah Light since January 2007 which, relative to our US$7.16 average refining margin for 2008, is a significant factor to our downstream financial performance:

23

Although the OSP discount may change between the date of loading in Iraq and its consumption a few months later at our refinery, the OSP discount applicable at the time of loading does not change for our purchase. For example, the OSP discount of US$7.05 in April 2008 was a component of the cost of our feedstock processed in June and July recognizing the 30 to 45 days required to load in Iraq, in transit time and unloading at our refinery. While we are able to “operationally hedge” the WTI component of our feedstock costs between the date we purchase crude oil and our processing of the crude oil we are not able to hedge or otherwise manage the basis risk associated with the medium sour crude oils we typically process.

The cost of our crude oil feedstock averaged US$89.50/bbl during 2008 representing a US$10.15/bbl discount from WTI as compared to a cost of US$64.99/bbl and a discount of US$7.32/bbl in the prior year. While the increased discount to WTI aggregates to a $102.9 million improved gross margin, the year-over-year US$27.34 increase in the average WTI price added $994.2 million to our crude oil feedstock cost during 2008. The US$89.50/bbl average cost of crude oil feedstock during the year represents a 38% increase over the average cost in the prior year, which impacts Vitol’s working capital required and increases our “Time Value of Money” charges paid to Vitol as part of the Supply and Offtake Agreement.

The average cost of purchased VGO during 2008 was US$104.31/bbl representing a premium of US$4.66/bbl relative to the WTI benchmark price as compared to US$78.66/bbl and a US$6.35/bbl premium in the prior year. The higher premium in 2007 is attributed to supply and demand disruptions in that year in the very tightly balanced VGO market. We processed 3.6 million barrels of VGO during the year, as such the US$1.69/bbl lower premium aggregates to a $6.4 million decrease in feedstock costs and a corresponding increase in gross margin compared to 2007.

The benchmark refining crack spreads closely track refining margins if the accounting for feedstock is on a last-in-first-out (“LIFO”) basis. Our financial statements account for feedstock on a weighted average cost basis which is in accordance with Canadian generally accepted accounting principles. In a stable commodity price environment, weighted average cost and LIFO accounting results should not be significantly different from market benchmarks and individual refinery results. In a rapidly declining commodity price environment, such as the Fourth Quarter of 2008, the result is that the cost of crude oil feedstock consumed under weighted average cost is higher than on a LIFO basis due to the time lag between crude feedstock

24