NI 43-101 TECHNICAL REPORT ON RESOURCES

GOLD ROCK PROJECT

Prepared for MIDWAY GOLD CORP.

Report Date: April 10, 2012

Effective Date: February 29, 2012

Endorsed by QP’s:

William J. Crowl, R.G., MMSA-QP

Donald E. Hulse, P.E., SME-RM

Donald J. Baker, PhD, MMSA-QP

| Midway Gold Corp. | Table of Contents |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

TABLE OF CONTENTS

| Section | | Title | | Page No. |

| | | | | | |

| 1. | SUMMARY | | 1 |

| | | | |

| | 1.1 | | Introduction | | 1 |

| | 1.2 | | Property Description, Location and History | | 1 |

| | 1.3 | | Geology and Mineralization | | 2 |

| | 1.4 | | Status of Exploration | | 3 |

| | 1.5 | | Mineral Resource Estimate | | 3 |

| | 1.6 | | Conclusions and Recommendations | | 4 |

| | | | | | |

| 2. | INTRODUCTION | | 6 |

| | | | |

| | 2.1 | | Terms of Reference and Purpose of the Report | | 6 |

| | 2.2 | | Qualified Persons | | 6 |

| | 2.3 | | Personal Inspection | | 6 |

| | 2.4 | | Sources of Information | | 7 |

| | 2.5 | | Units of Measure | | 7 |

| | | | | | |

| 3. | RELIANCE ON OTHER EXPERTS | | 8 |

| | | | | | |

| 4. | PROPERTY DESCRIPTION AND LOCATION | | 9 |

| | | | |

| | 4.1 | | Location | | 9 |

| | 4.2 | | Mineral Tenure and Agreements | | 10 |

| | 4.2.1 | | Mineral Rights | | 10 |

| | 4.2.2 | | Newark Valley Mining Corp. Agreement | | 11 |

| | 4.2.3 | | Anchor Minerals, Inc. Agreement | | 11 |

| | 4.2.4 | | Peart Agreement | | 12 |

| | 4.2.5 | | Pankow Agreement | | 12 |

| | 4.2.6 | | Jordan Agreement | | 13 |

| | 4.2.7 | | Additional Claims | | 13 |

| | 4.3 | | Environmental Liabilities and Permitting | | 13 |

| | 4.3.1 | | Environmental Liabilities | | 13 |

| | 4.3.2 | | Permitting | | 14 |

| | | | | | |

| 5. | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | | 17 |

| | | | |

| | 5.1 | | Accessibility | | 17 |

| | 5.2 | | Topography, Elevation, Vegetation, and Climate | | 17 |

| | 5.3 | | Infrastructure and Local Resources | | 17 |

| | | | | | |

| 6. | HISTORY | | 19 |

| | | | |

| | 6.1 | | Exploration History | | 19 |

| | 6.2 | | Resource and Reserve Estimates | | 19 |

| | | | | | |

| 7. | GEOLOGICAL SETTING AND MINERALIZATION | | 22 |

| | | | |

| | 7.1 | | Regional Geology | | 22 |

| | 7.2 | | Local Geology | | 24 |

| | 7.3 | | Property Geology | | 25 |

| | 7.3.1 | | Late Devonian Devil’s Gate Limestone (Dd) | | 26 |

| | 7.3.2 | | Late Devonian to Early Mississippian Pilot Shale (MDp) | | 26 |

| | 7.3.3 | | Mississippian Joana Limestone (Mj) | | 26 |

| | 7.3.4 | | Mississippian Chainman Shale (Mc) | | 26 |

| | 7.3.5 | | Mississippian Diamond Peak Formation (Md) | | 26 |

| April 10, 2012 | i |  |

| Midway Gold Corp. | Table of Contents |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| | 7.4 | | Structural Geology | | 28 |

| | 7.5 | | Mineralization | | 29 |

| | 7.6 | | Alteration | | 29 |

| | 7.7 | | Geometry of Mineralization | | 30 |

| | | | | | |

| 8. | DEPOSIT TYPES | | 32 |

| | | | | | |

| 9. | EXPLORATION | | 33 |

| | | | |

| | 9.1 | | Previous Operator’s Exploration Work | | 33 |

| | 9.2 | | Historic Geochemical sampling | | 33 |

| | 9.3 | | Historical Geophysics | | 33 |

| | 9.4 | | Historical Mapping | | 33 |

| | 9.5 | | Historical Drilling | | 34 |

| | 9.6 | | MGUS Exploration Work | | 34 |

| | 9.6.1 | | Surface Geochemistry | | 35 |

| | 9.6.2 | | Geological Mapping | | 35 |

| | 9.6.3 | | Geophysical Surveys | | 35 |

| | 9.6.4 | | Drilling | | 35 |

| | | | | | |

| 10. | DRILLING | | 36 |

| | | | |

| | 10.1 | | Historic Drilling | | 38 |

| | 10.2 | | MGUS Drilling | | 38 |

| | 10.2.1 | | 2011 MGUS Drilling Results | | 40 |

| | 10.2.2 | | 2011 MGUS Twin Holes | | 41 |

| | | | | | |

| 11. | SAMPLE PREPARATION, ANALYSES AND SECURITY | | 42 |

| | | | |

| | 11.1 | | Historic Programs | | 42 |

| | 11.1.1 | | Santa Fe Analytical Methods | | 42 |

| | 11.1.2 | | Tenneco/Echo Bay Analytical Methods | | 42 |

| | 11.1.3 | | Alta Bay Joint Venture Analytical Methods | | 42 |

| | 11.1.4 | | Alta Bay Joint Venture Analytical Methods | | 43 |

| | 11.1.5 | | Alta Gold Analytical Methods | | 43 |

| | 11.2 | | MGUS 2011 Program | | 43 |

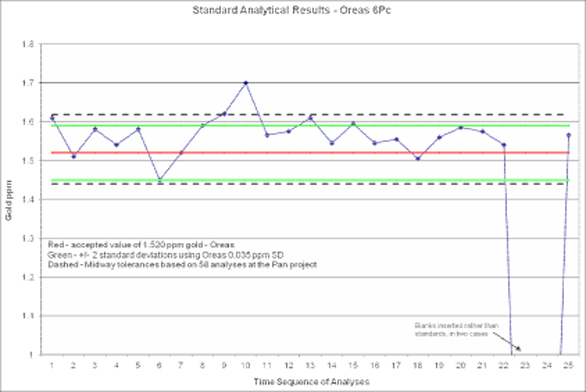

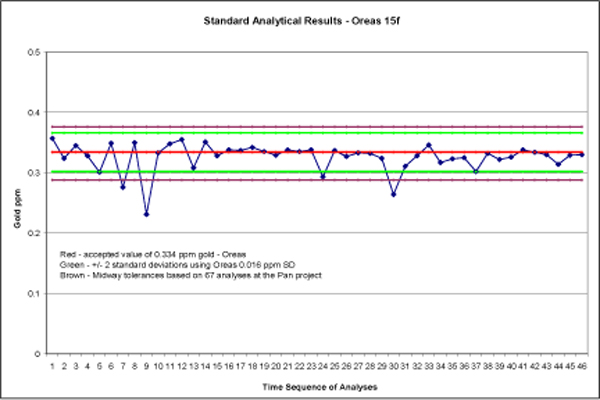

| | 11.2.1 | | MGUS Standard Sample Analyses | | 43 |

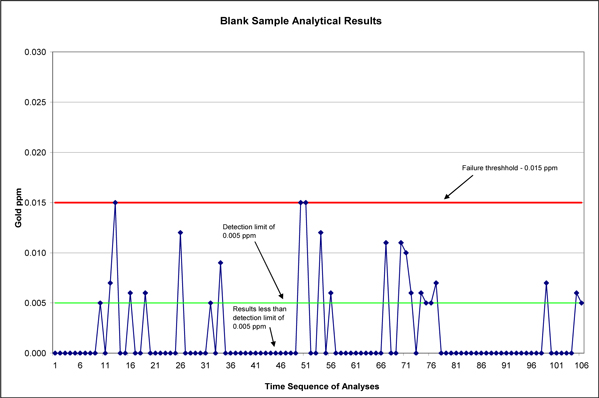

| | 11.2.2 | | MGUS Blank Sample Analyses | | 45 |

| | 11.2.3 | | MGUS Duplicate Sample Analyses | | 46 |

| | | | | | |

| 12. | DATA VERIFICATION | | 49 |

| | | | |

| | 12.1 | | Historic Data Verification | | 49 |

| | 12.1.1 | | Drill Hole Locations | | 49 |

| | 12.1.2 | | Assay Database | | 52 |

| | 12.1.2.1 Check Assay Programs | | 54 |

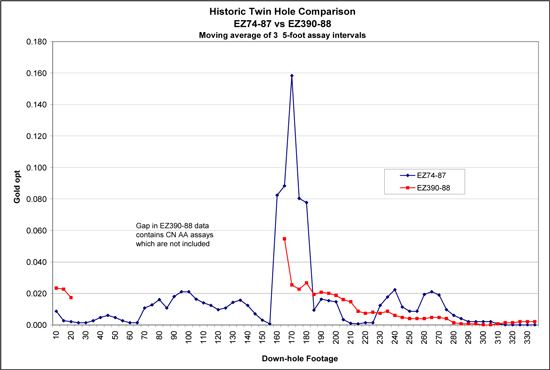

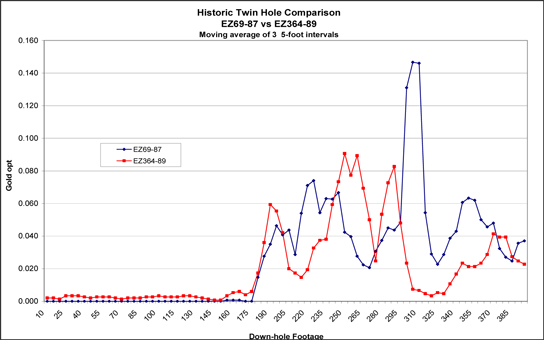

| | 12.1.2.2 Twin Hole Programs | | 57 |

| | 12.2 | | MGUS Data Verification | | 61 |

| | 12.2.1 | | Drill Hole Locations | | 61 |

| | 12.2.2 | | Assay Database | | 61 |

| | 12.2.3 | | Check Assay Programs | | 61 |

| | 12.2.4 | | Twin Hole Programs | | 61 |

| | 12.2.4.1 MGUS – Historic Drill Hole Confirmation Program | | 61 |

| | 12.2.4.2 MGUS – Core-Reverse Circulation Twin Hole Program | | 64 |

| | | | | | |

| 13. | MINERAL PROCESSING AND METALLURGICAL TESTING | | 66 |

| | | | | | |

| 14. | MINERAL RESOURCE ESTIMATE | | 67 |

| | | | |

| | 14.1 | | Data Used for Gold Grade Estimation | | 67 |

| April 10, 2012 | ii |  |

| Midway Gold Corp. | Table of Contents |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

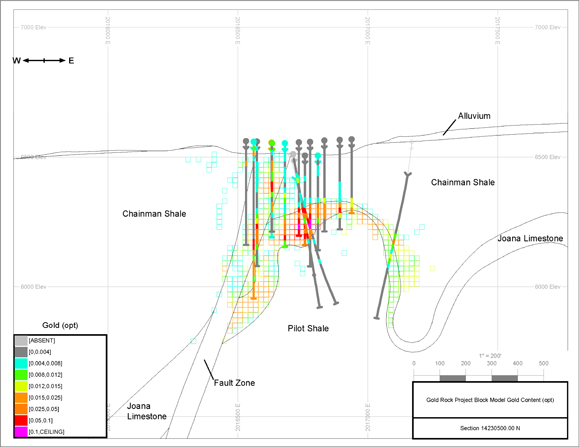

| | 14.2 | | Estimation Domains | | 67 |

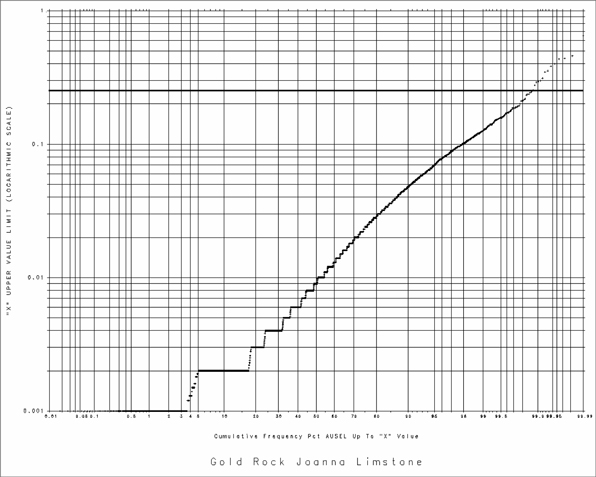

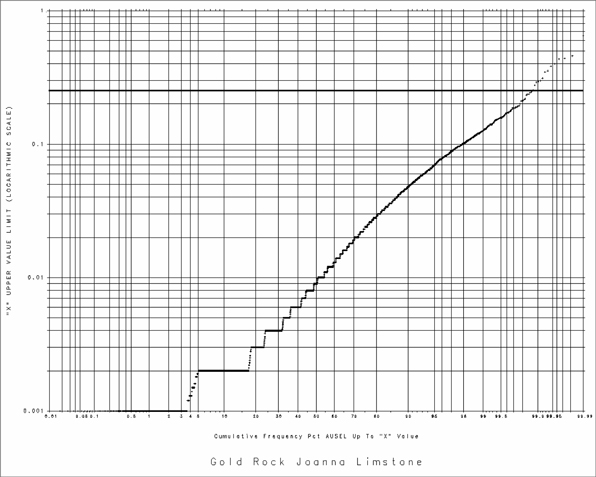

| | 14.3 | | Grade Capping | | 69 |

| | 14.4 | | Compositing | | 70 |

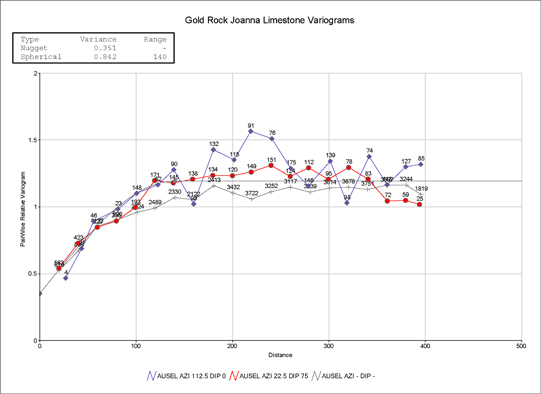

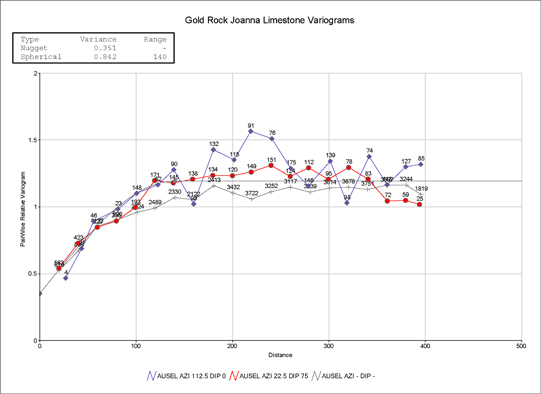

| | 14.5 | | Variography | | 71 |

| | 14.6 | | Estimation Methodology | | 73 |

| | 14.6.1 | | Estimate Validation | | 74 |

| | 14.7 | | Density Rock and Alluvium | | 74 |

| | 14.8 | | Resource Classification | | 74 |

| | 14.9 | | Mineral Resource Estimate | | 75 |

| | | | | | |

| 15. | MINERAL RESERVE ESTIMATES | | 76 |

| | | | |

| 16. | MINING METHODS | | 77 |

| | | | |

| 17. | RECOVERY METHODS | | 78 |

| | | | |

| 18. | PROJECT INFRASTRUCTURE | | 79 |

| | | | |

| 19. | MARKET STUDIES AND CONTRACTS | | 80 |

| | | | |

| 20. | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | | 81 |

| | | | |

| 21. | CAPITAL AND OPERATING COSTS | | 82 |

| | | | |

| 22. | ECONOMIC ANALYSIS | | 83 |

| | | | |

| 23. | ADJACENT PROPERTIES | | 84 |

| | | | |

| 24. | OTHER RELEVANT DATA AND INFORMATION | | 85 |

| | | | |

| 25. | INTERPRETATION AND CONCLUSIONS | | 86 |

| | | | |

| 26. | RECOMMENDATIONS | | 87 |

| | | | |

| 27. | REFERENCES | | 89 |

| | | | |

| 28. | Certificate of Author Forms | | 90 |

| April 10, 2012 | iii |  |

| Midway Gold Corp. | Table of Contents |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

LIST OF FIGURES

| FIGURE | | PAGE |

| | | |

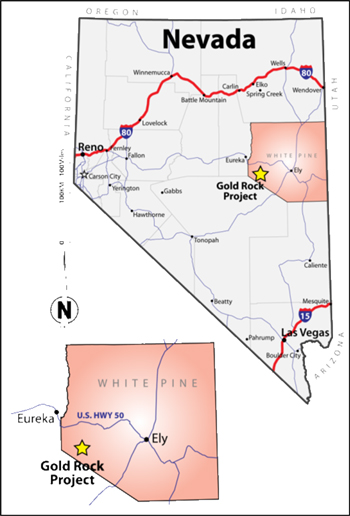

| Figure 4-1 Property Location Map | | 9 |

| Figure 4-2 Mineral Claim Map | | 10 |

| Figure 7-1 Regional Geology (Hose and Blake, 1987) | | 23 |

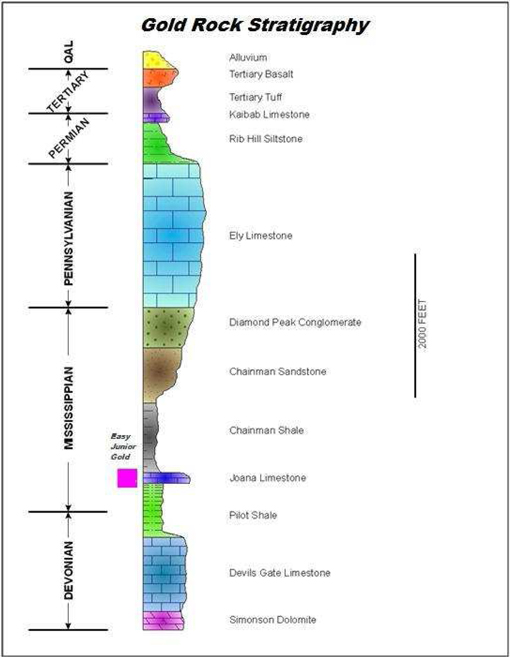

| Figure 7-2 Stratigraphic Column Pancake Range (Smith, 1976, Harris, 2007) | | 25 |

| Figure 7-3 Local Geology | | 27 |

| Figure 7-4 Pre-mining Cross Section of the Easy Junior Deposit (Alta Bay, 1991) | | 29 |

| Figure 7-5 North Facing View of the Easy Junior Pit | | 30 |

| Figure 10-1 Gold Rock Historic Drillikng and Resource Estimate Boundary | | 37 |

| Figure 10-2 Drill Hole Collar Eye Bolt & Tag – GR11-23c | | 40 |

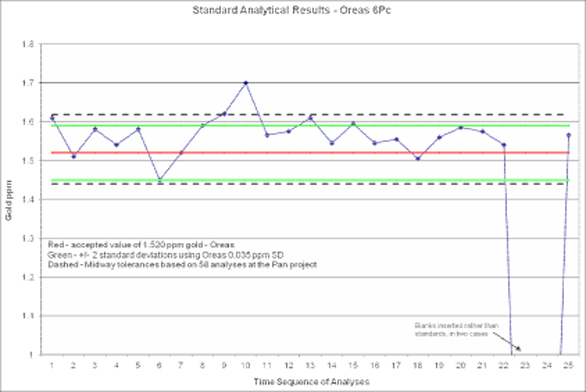

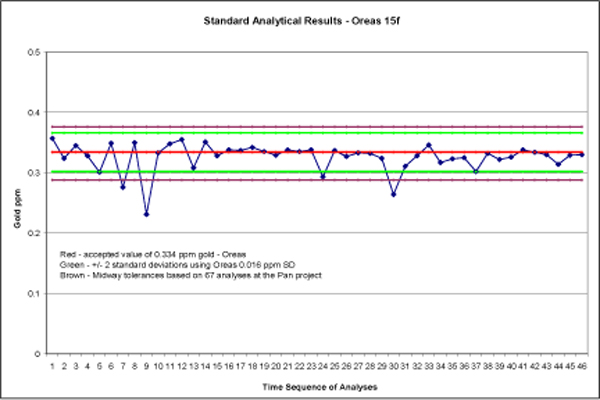

| Figure 11-1 Standard Analytical Results – Oreas 6 Pc | | 44 |

| Figure 11-2 Standard Analytical Results – Oreas 2 Pd | | 44 |

| Figure 11-3 Standard Analytical Results – Oreas 15f | | 45 |

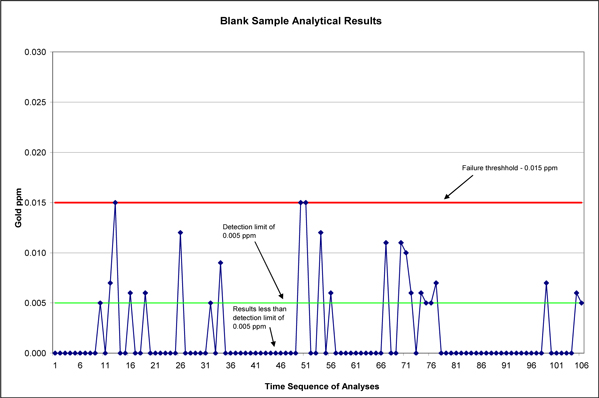

| Figure 11-4 Blank Sample Analytical Results | | 46 |

| Figure 11-5 MGUS Drill Sample Duplicates | | 47 |

| Figure 11-6 Duplicate Sample Analysis | | 48 |

| Figure 12-1 Historic Survey Point “Juan” | | 51 |

| Figure 12-2 Drill Cuttings and Labeled Post – Drill Hole EZ14-86 | | 51 |

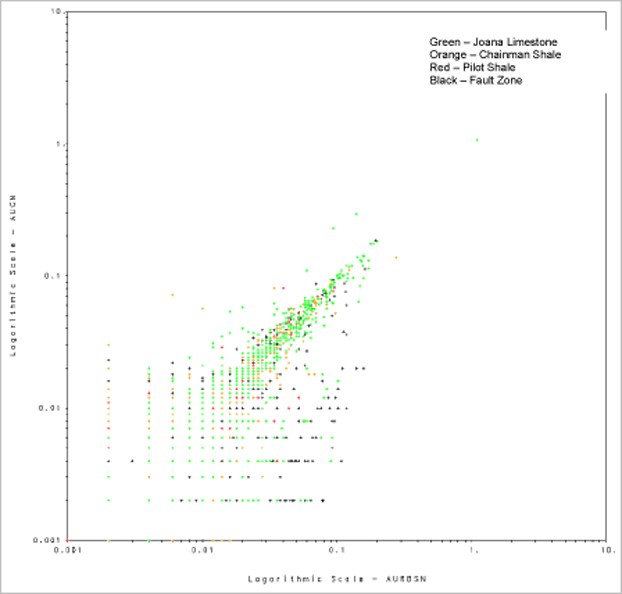

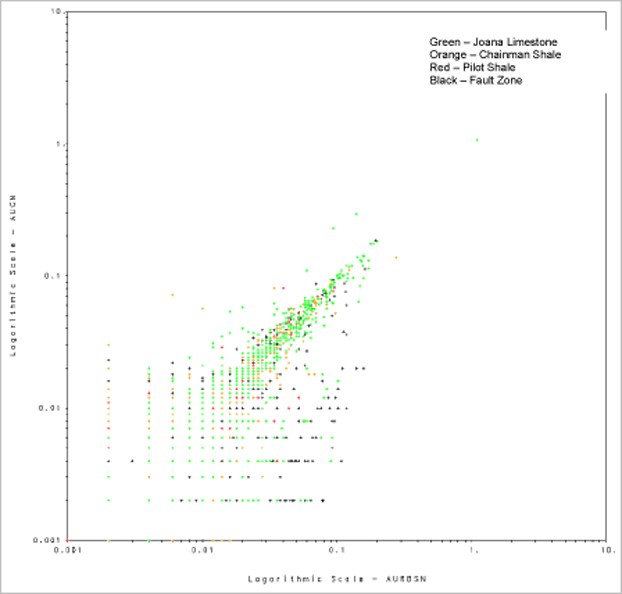

| Figure 12-3 Fire Assay vs Cyanide Assay | | 53 |

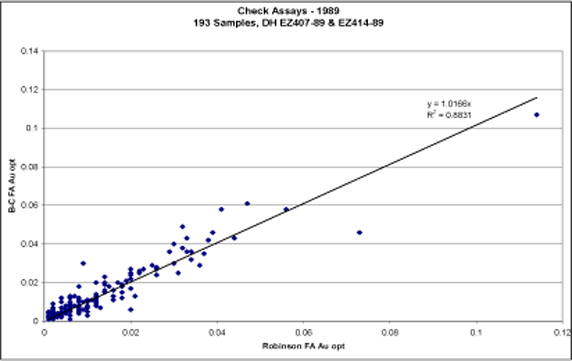

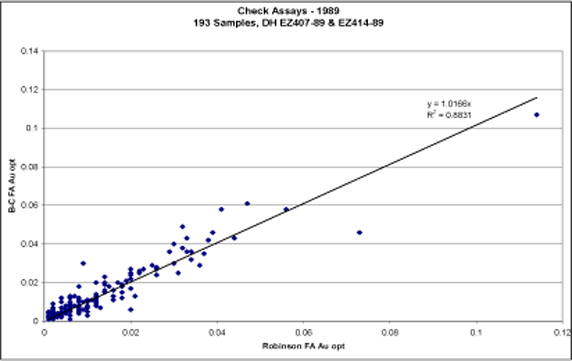

| Figure 12-4 Robinson – Bondar-Clegg Check Assays | | 55 |

| Figure 12-5 Ward – Bondar-Clegg Check Assays | | 55 |

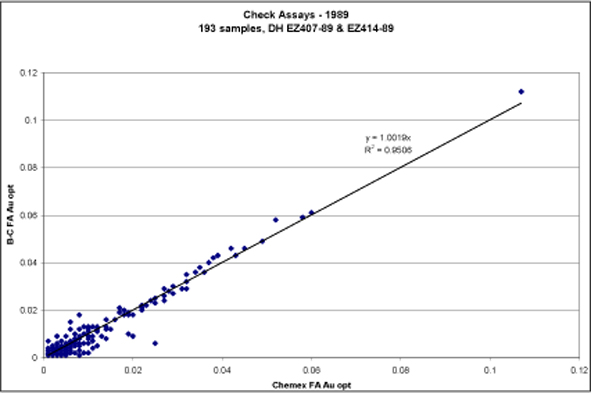

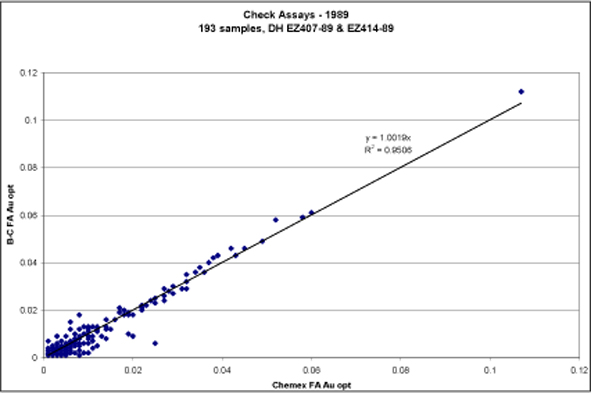

| Figure 12-6 Chemex – Bondar-Clegg Check Assays | | 56 |

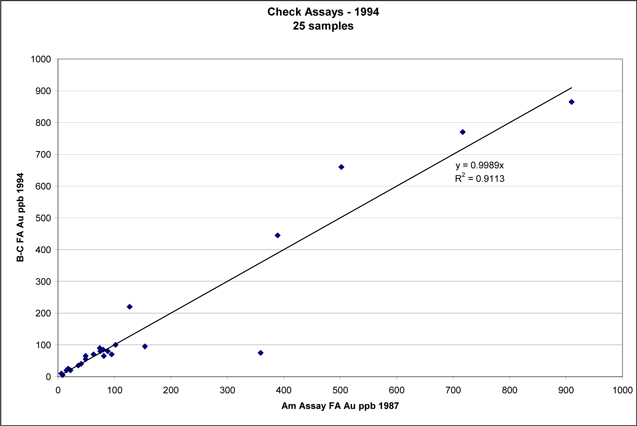

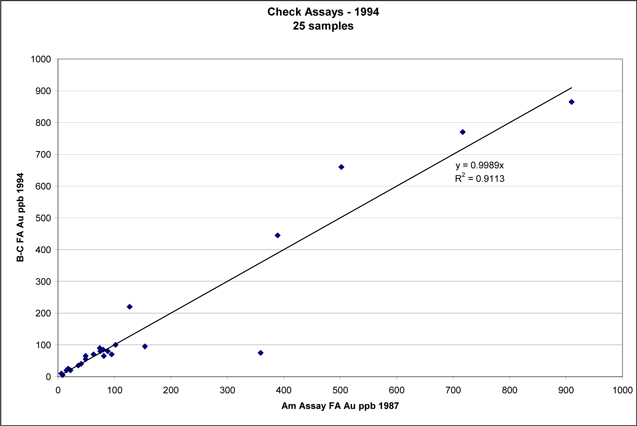

| Figure 12-7 American Assay – Bondar-Clegg Check Assays | | 57 |

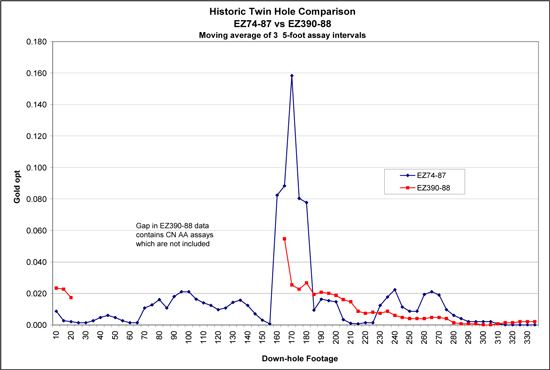

| Figure 12-8 Twin Hole Comparison EZ74-87 and EZ390-88 | | 58 |

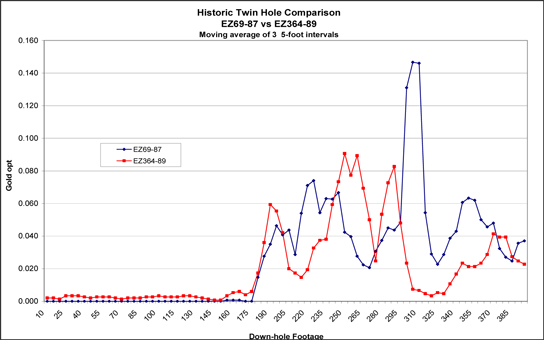

| Figure 12-9 Twin Hole Comparison EZ69-87 and EZ364-89 | | 59 |

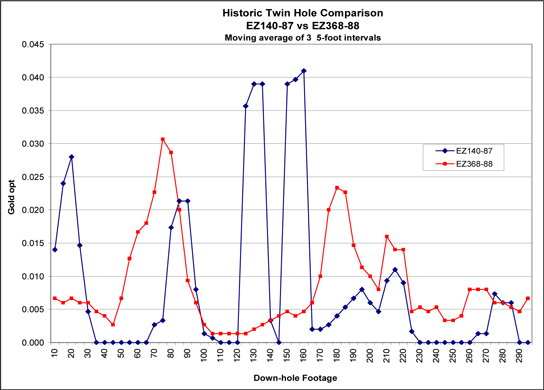

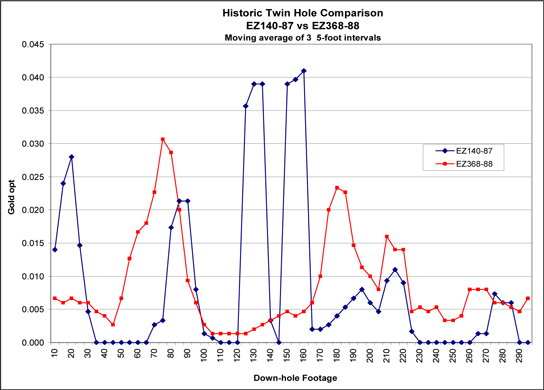

| Figure 12-10 Twin Hole Comparison EZ140-87 and EZ368-88 | | 59 |

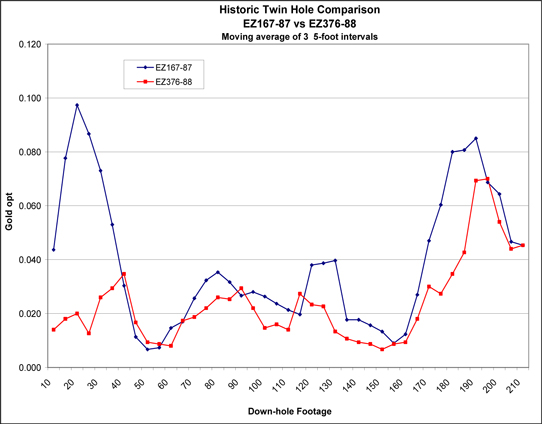

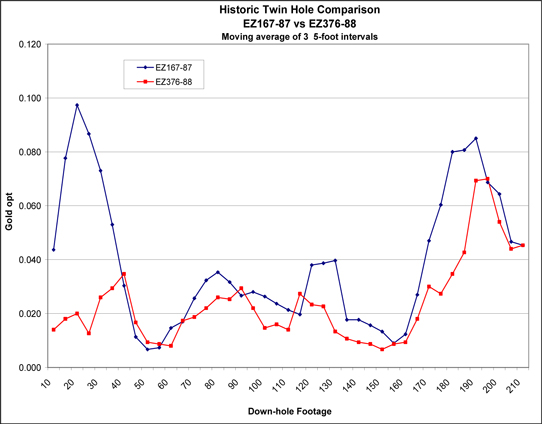

| Figure 12-11 Twin Hole Comparison EZ167-87 and EZ376-88 | | 60 |

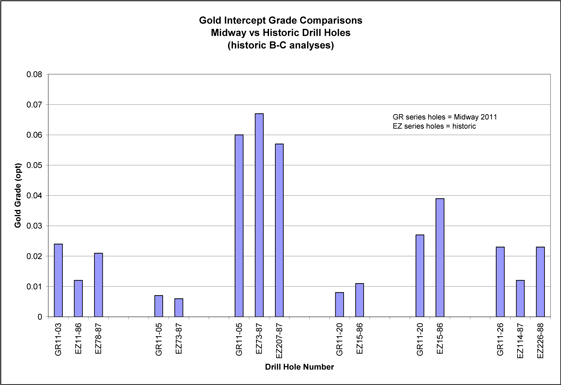

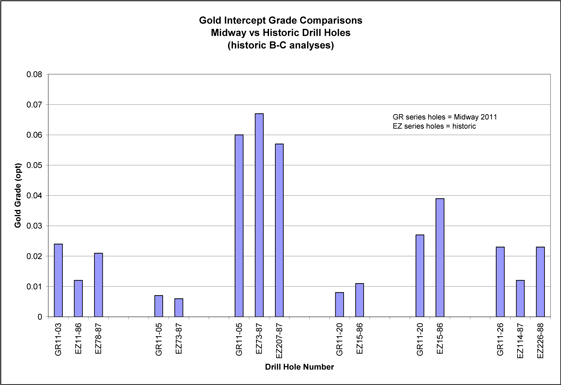

| Figure 12-12 Gold Intercept Grade Comparisons MGUS vs. Historic Drill Holes | | 62 |

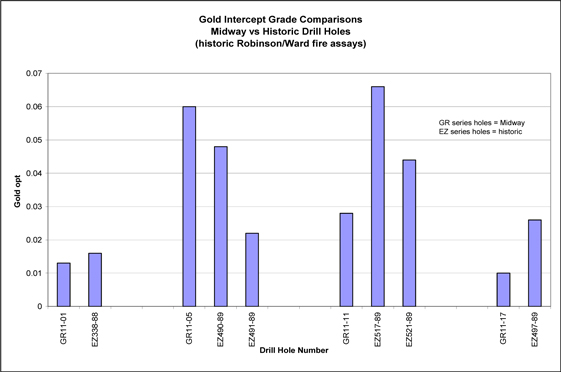

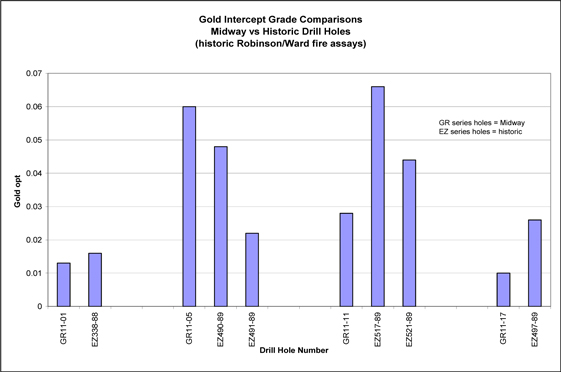

| Figure 12-13 Gold Intercept Grade Comparisons MGUS vs. Historic Drill Holes | | 63 |

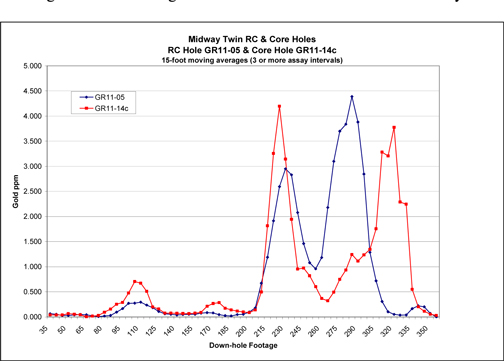

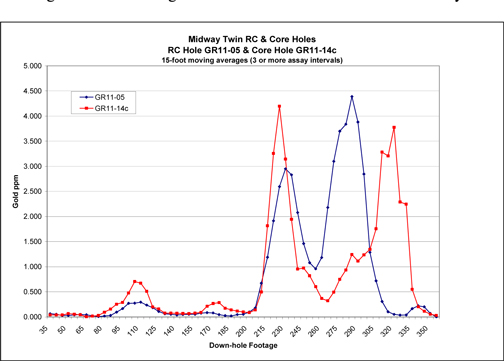

| Figure 12-14 MGUS Twin Holes – RC GR11-05 and Core GR11-14c | | 64 |

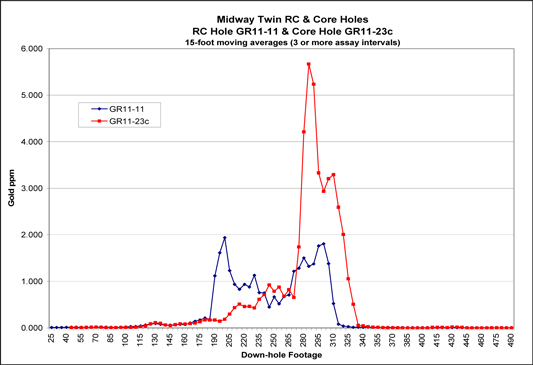

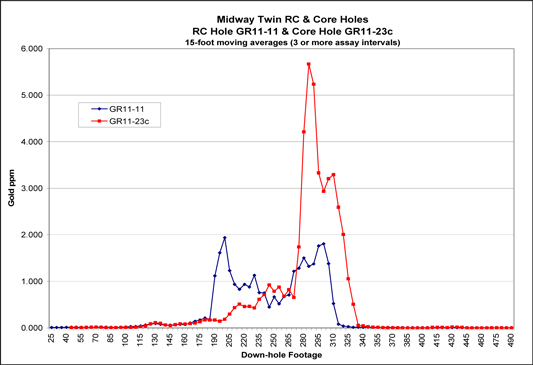

| Figure 12-15 MGUS Twin Holes – RC GR11-11 & Core GR11-23c | | 65 |

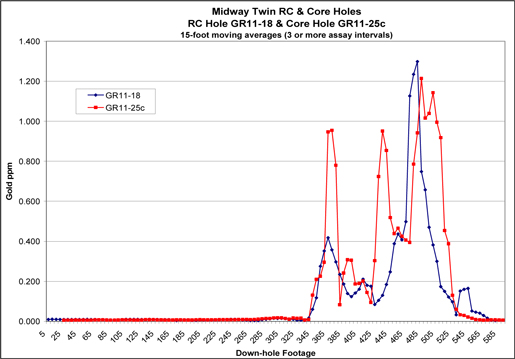

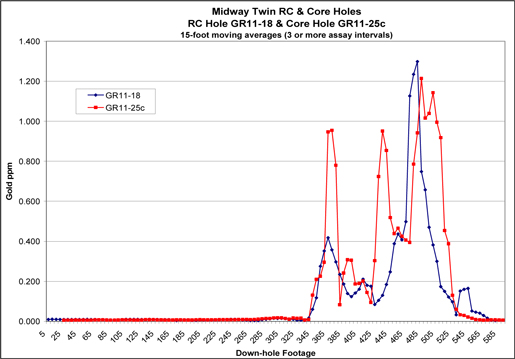

| Figure 12-16 MGUS Twin Holes – RC GR11-18 & Core GR11-25c | | 65 |

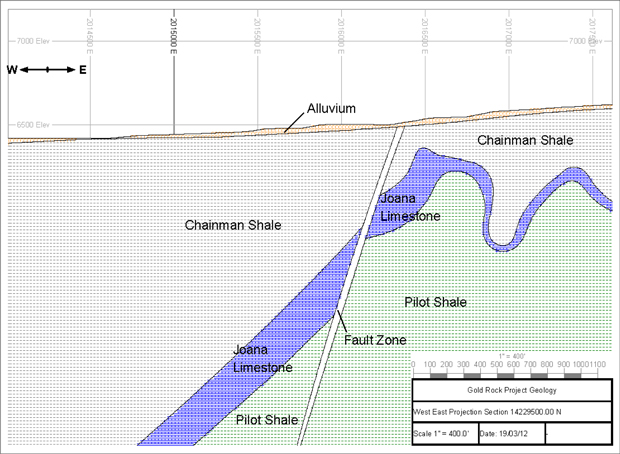

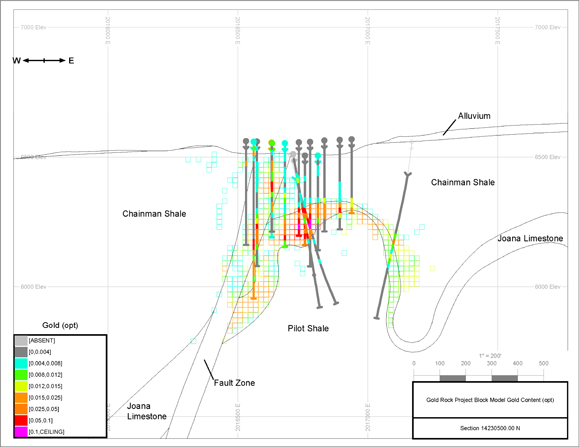

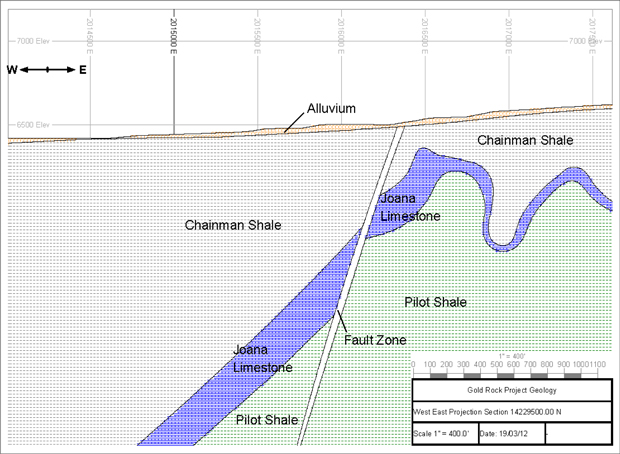

| Figure 14-1 Gold Rock Cross Section Geology and Estimation Domains | | 68 |

| Figure 14-2 Cumulative Frequency Plot | | 70 |

| Figure 14-3 Gold Rock Joanna Limestone Variograms | | 72 |

| Figure 14-4 East-West Section 14,230,500 North, (Looking North) | | 72 |

| April 10, 2012 | iv |  |

| Midway Gold Corp. | Table of Contents |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

LIST OF TABLES

| TABLE | | PAGE |

| | | |

| Table 1-1 The Gold Rock Mineral Resource | | 4 |

| Table 4-1 NVMC Royalty Schedule (Source: MGUS) | | 11 |

| Table 4-2 Peart Advance Minimum Royalty Schedule (Source: MGUS) | | 12 |

| Table 4-3 Peart Royalty Schedule (Source: MGUS) | | 12 |

| Table 4-4 Pankow Advance Minimum Royalty Schedule (Source: MGUS) | | 13 |

| Table 4-5 Pankow Royalty Schedule (Source: MGUS) | | 13 |

| Table 4-6 Major Permits and Authorizations Required for Project Development | | 14 |

| Table 6-1 IMC geological reserve (geologic inventory, no economic constraint) | | 20 |

| Table 6-2 Proven and Probable Reserve | | 20 |

| Table 6-3 Physical Pit Design Criteria | | 21 |

| Table 6-4 Cutoff grade check calculations | | 21 |

| Table 9-1 Historic Exploration and Delineation Drilling at the Gold Rock property, 1980 to 1994 | | 34 |

| Table 10-1 MGUS 2011 Summary Drilling Results | | 41 |

| Table 12-1 Assay Results – 1989 (opt gold) | | 54 |

| Table 14-1 Gold Rock Drill Hole Sample Statistics | | 69 |

| Table 14-2 Gold Rock Composite Statistics | | 71 |

| Table 14-3 Gold Rock Variogram Parameters | | 72 |

| Table 14-4 Gold Rock Estimation Parameters | | 73 |

| Table 14-5 The Gold Rock Mineral Resource | | 75 |

| Table 26-1 Estimated Budget for Verification Drilling Program and Data Compilation | | 88 |

| April 10, 2012 | v |  |

| Midway Gold Corp. | Summary |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Midway Gold Corp., through its wholly owned subsidiary, Midway Gold US Inc. (collectively MGUS) retained Gustavson Associates, LLC (Gustavson) to prepare a Mineral Resource estimate for the Gold Rock Project in White Pine County, Nevada in compliance with Canadian National Instrument 43-101 (NI 43-101) Standards of Disclosure for Mineral Projects and Canadian Institute of Mining, Metallurgy and Petroleum “Best Practices and Reporting Guidelines”.

| 1.2 | Property Description, Location and History |

Midway Gold US Inc. (MGUS), a wholly-owned subsidiary of Midway Gold Corp. has conducted exploration drilling, sampling, mapping, and geophysics since acquiring the project in 2007.

The Gold Rock gold deposit (formerly known as Easy Junior) is a bulk tonnage epithermal gold deposit found in Devonian-Mississippian limestone, shale, and sandstone. These rock types are exposed in a series of north-trending ridges that represent stacked, easterly-directed thrust sheets and low amplitude, open to tight folds.

The Gold Rock property encompasses approximately 19 square miles (4,910 hectares) of the Battle Mountain-Eureka gold trend on the eastern side of the Pancake Range in east-central Nevada. The Gold Rock Project site is located approximately 30 miles southeast of the town of Eureka in White Pine County. Access to the Gold Rock Project site is provided by Green Springs road, an unpaved county road that intersects US Highway 50 approximately 30 miles southeast of Eureka, Nevada. It is approximately 16.5 miles, via road, from US 50 to the Gold Rock property.

The Gold Rock property has a long history of exploration and development, initiated in 1979 under Earth Resources, Inc. Earth Resources, Inc. was acquired by Houston Oil & Gas, which was in turn acquired by Tenneco in 1986. Echo Bay Mines acquired Tenneco in 1986 and thereafter discovered the Easy Junior gold deposit the same year. Alta Gold and Echo Bay formed the Alta Bay joint venture in 1988, with Alta Gold the operator. Open pit mining at Easy Junior was initiated in 1989, with production suspended in 1990 due to low gold prices. Alta Gold acquired the Echo Bay interest in the project in 1992 and initiated re-engineering of the project. Mining under Alta Gold re-started in June 1993 and was concluded in August 1994. Heap leach production continued into 1996. Alta Gold filed for bankruptcy in 1998. MGUS, through its acquisition of Pan-Nevada in 2007, and through additional property leases and claim staking, acquired control of the project in 2007.

| April 10, 2012 | 1 |  |

| Midway Gold Corp. | Summary |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 1.3 | Geology and Mineralization |

The Gold Rock property is located on the east flank of the northern portion of the Pancake Range in east-central Nevada. This lobe of the Pancake Range is underlain by Devonian and Carboniferous carbonate and clastic sedimentary rocks which form the core of the range, and are exposed in bedrock outcrop in the area of the Gold Rock Project site. Although intrusive rocks are present regionally, no intrusive rocks have been mapped on the Gold Rock property. Devonian – Mississippian sedimentary bedrock geology in the vicinity of the Gold Rock Project area is locally nonconformably capped by post-mineral Tertiary volcanic rocks.

The Devonian through Mississippian limestone, shale, and sandstone units are exposed in a series of north-trending ridges that represent stacked, easterly-directed thrust sheets and low amplitude, open to tight folds. Gold mineralization is interpreted to postdate thrusting and folding. Bedrock geology is partially obscured by alluvial and colluvial gravels. Gold mineralization is preferentially hosted in the Mississippian upper Joana Limestone and lower Chainman Shale, especially in areas of tight anticlinal folding (Easy Junior Mine). Jasperoid with anomalous trace elements and locally anomalous gold occur throughout the Gold Rock Property at approximately this same stratigraphic level.

On the Gold Rock property, the primary gold feeder structure is presumed to be a steeply-dipping reverse fault reactivated with extensional dip-slip. This fault is present along the axial surface of the anticline that extends from Meridian Flats through the Easy Junior pit. Mineralization is focused where the steep feeder structure intercepts the Joana Limestone in the core of this anticline, and appears restricted to the Joana Limestone and the base of the overlying Chainman shale.

The Easy Junior deposit on the Gold Rock property is a Carlin-style, sediment-hosted, disseminated gold deposit hosted within the previously discussed Mississippian sedimentary units. Gold particles occur as micron size to sub-micron size disseminations. Free, coarse gold is not common in these types of deposits, and has not been observed at Gold Rock. Source and age of mineralization are uncertain at this time.

Alteration at Gold Rock is typical of Carlin systems in Nevada. Alteration styles include silicification, argillization, decalcification, and oxidation. Silicification occurs as zones of moderate to strong silica flooding along bedding and structures. Strong or complete replacement is commonly referred to as jasperoid by field workers. Silica alteration is found primarily in the Joana Limestone, with only minor small zones identified in shale units. Within the Gold Rock deposit, jasperoid within the Joana Limestone carries significant amounts of gold. In surface outcrops, Joana-hosted jasperoid occurs along strike both north and south of the deposit and is often found in association with anomalous gold values.

| April 10, 2012 | 2 |  |

| Midway Gold Corp. | Summary |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Clay alteration is generally associated with hydrothermal alteration of minerals. Clay along faults and bedding is common. Within limestones and calcareous shales, argillization is often accompanied by decalcification of the host rock. Black carbonaceous accumulations occur locally along the margins of gold mineralization zones. Oxidation is prevalent throughout the deposit, resulting in the formation of iron oxides (hematite and limonite).

The mineralization along the anticline that hosts the mineralization at Gold Rock extends along strike to the south of the open pit of the Easy Junior Mine over 6,000 feet through the Meridian Flats prospect area. To the north of the Easy Junior open pit, the mineralization along the apex of the anticline was followed over 1,000 feet, but post-mineral faulting drops the Joana Limestone below the extent of the drilling, and therefore remains untested.

MGUS has secured and compiled historic project drilling results for 673 drill holes – primarily shallow, vertical reverse circulation holes, as well as 1,790 blast holes within the Easy Junior open pit. Historic soil grid and rock chip results are also compiled.

Since acquiring the Gold Rock Project in 2007, MGUS has completed additional geochemistry on 750 additional soil samples collected which add to the scope and magnitude of the regional sampling grid, and has collected and analyzed an additional 141 rock chip samples. Ground magnetic and gravity surveys have also been conducted over portions of the Property. In 2008, MGUS completed 11 reverse circulation holes in the Anchor Roc prospect at the southeast end of the property. Historic drilling in this area by Nevada Resources yielded a reported intercept of 120 feet of 0.014 opt gold. The best intercept encountered by MGUS was 85 feet at 0.014 opt gold. Results of this exploration by MGUS have not been reviewed and documented in detail by Gustavson, since this report is dedicated toward reviewing the historic data developed at and in the vicinity of the Easy Junior open pit for purposes of evaluating mineral resources. In 2011, MGUS completed a 31 drill hole program in the vicinity of the Easy Junior open pit and Meridian Flats areas, consisting of 25 reverse circulation holes (21,000 feet) and 6 diamond drill core holes (5,260 feet). This program was designed to confirm the geology and mineralization defined by historic drilling as well as to expand mineralization in areas with known historic intercepts.

| 1.5 | Mineral Resource Estimate |

A review of the assay and geologic drill hole data and MGUS database was conducted during the process of preparing this report. The review shows that the data is traceable to the original assay certificates of Echo Bay,Tenneco, Santa Fe Minerals, Inc. and Houston Oil and Gas. Assay certificatesissued to Alta Gold, the operator of the Easy Junior mine and the Alta Bay joint venture with Echo Bay, were generated by the various mine laboratories that they operated (Illipah, Easy Junior, Ward and Robinson labs).

| April 10, 2012 | 3 |  |

| Midway Gold Corp. | Summary |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

The Gold Rock mineral resource estimate is summarized below in Table 1-1. The resource estimate includes all drill data obtained and verified as of February, 2012. The summary below presents the Gold Rock resource at FOUR different cutoff grades.

Table 1-1 The Gold Rock Mineral Resource

Cutoff

(opt) | Indicated Resource | Inferred Resource |

| Tons | Grade

(opt) | Gold

Ounces | Tons | Grade

(opt) | Gold

Ounces |

| 0.015 | 8,620,000 | 0.029 | 247,000 | 8,670,000 | 0.024 | 210,000 |

| 0.012 | 10,574,000 | 0.026 | 273,000 | 11,967,000 | 0.021 | 255,000 |

| 0.008 | 14,294,000 | 0.022 | 310,000 | 19,724,000 | 0.017 | 331,000 |

| 0.004 | 19,852,000 | 0.017 | 343,000 | 33,576,000 | 0.012 | 409,000 |

| 1.6 | Conclusions and Recommendations |

The Gold Rock deposit, formally known as Easy Junior, contains a substantial gold resource that warrants additional exploration and evaluation. The mineralization system is strong, with a known strike length of over 8,000 feet. The lithology, alteration, and mineralization of the Gold Rock deposit are similar to other sediment-hosted Carlin-type systems such as Alligator Ridge, Bald Mountain, Rain, and MGUS’ Pan Project. A portion of the Gold Rock deposit has been explored and mined, but drilling outside that area is very widely spaced, shallow and locally intercepts anomalous gold mineralization. Historic exploration has not cut off mineralization in any direction.

Gustavson has reviewed the historic information on the project and has verified drill hole locations, down-hole geology as compiled in geologic logs, and gold assays based on original assay certificates. Cross validation of the historic drill assay results was accomplished using a partially documented historic check assay program, twin drill holes and comparison with the geologic and assay results of recent drilling by MGUS in 2011. Certain assay types, specifically neutron activation analyses, were not considered comparable to the historic fire assays and have been excluded from the database for purposes of generation of the resource estimate contained in this report. Fire assay results from the Ward laboratory were determined as biased toward higher gold values and were also excluded from the database for the purposes of this report. CN AA analysis results were included in the database for assay intervals not also assayed by fire assay at the Robinson laboratory. The CN AA results, on average, understate gold values as compared with fire assay results, but are believed to represent a conservative component to the estimate of gold grade. It is the opinion of Gustavson that the historic and MGUS assay data used in the database are of sufficient high quality to support the generation of indicated and inferred mineral resource estimates reported herein.

| April 10, 2012 | 4 |  |

| Midway Gold Corp. | Summary |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Gustavson recommends the following:

| · | That MGUS continue a program of validation and verification of the historic drill hole assay database through an ongoing twin hole program primarily targeting historic drill holes assayed by the Robinson and Ward laboratories. This will enable MGUS to assess potential zones of additional gold mineralization that were previously only analyzed by CN AA. |

| · | A detailed 3-dimensional alteration model should be created to aide in the delineation of the mineralization in shale units in contact with the fault zone and/or Joana Limestone. |

| · | Continued drilling is recommended on an in-fill basis and to expand knowledge of potential mineralization beyond the limits of current drill patterns to potentially enable conversion of inferred resources to higher confidence categories, and to build the global inventory of gold resources. |

| · | A sufficient amount of specific gravity measurements should be collected on the individual lithologies and alteration types identified on the property. |

| · | A metallurgical program should be designed and implemented, targeting the well-known lithologic and alteration types, to characterize the potential range in ore types and to assess process type and metallurgical recoveries. |

| · | Baseline environmental studies should be initiated on a timeline compatible with MGUS corporate objectives and planning. |

| · | There is a significant amount of information in the files including historical metallurgy, geotechnical data, hydrology, and other environmental information. This data should be reviewed as a tool for planning the future needs of a new mining program. |

| · | The surface geology and alteration mapping should be completed and all the historical and modern data compiled as a tool for locating additional drill targets on the property. |

Gustavson considers the estimated budget of $3,200,000 to be sufficient for the designed program of continued historic data verification and in-fill, resource conversion to higher confidence levels, and initial metallurgical and environmental work to position the project for advancement to the pre-feasibility/feasibility level. Drilling is recommended to focus on a continued twin hole program with historic holes assayed by CN AA methods, in-fill drilling to move resources to a higher confidence level, and step-out drilling to potentially expand resources. The program should target the Resource Area outlined in this report; specifically the north and south extensions of the anticlinal trend from the Easy Junior open pit, the Meridian Flats area, and the down-dip projections of the limbs of the anticline and adjacent parallel structures. Holes should also be drilled to obtain samples for metallurgical testing to establish the potential process type and metallurgical recoveries of gold.

| April 10, 2012 | 5 |  |

| Midway Gold Corp. | Introduction |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 2.1 | Terms of Reference and Purpose of the Report |

Midway Gold Corp., through its wholly owned subsidiary, Midway Gold US Inc. (collectively MGUS) retained Gustavson Associates, LLC (Gustavson) to prepare a Mineral Resource estimate for the Gold Rock Project in White Pine County, Nevada. This report presents mineral resource estimate for the Gold Rock Project.

The Gold Rock gold deposit is a bulk tonnage epithermal gold deposit hosted by Devonian-Mississippian limestone, shale, and sandstone. These rock types are exposed in a series of north-trending ridges that represent stacked, easterly-directed thrust sheets and low amplitude, open to tight folds. MGUS has conducted exploration drilling, sampling, mapping, and geophysics since acquiring the project in 2007.

This report was prepared according to Canadian National Instrument 43-101 (NI 43-101) Standards of Disclosure for Mineral Projects and guidelines for technical reporting Canadian Institute of Mining, Metallurgy and Petroleum (CIM) “Best Practices and Reporting Guidelines” for disclosing mineral exploration. The mineral resource estimate and interpretations and conclusions reported here are based on technical data available prior to the effective date of this report,

The qualified persons responsible for this report are:

| · | William J. Crowl, R.G., Vice President, Mining Sector, Gustavson Associates |

| · | Donald E. Hulse, PE, Principal Mining Engineer, Gustavson Associates |

| · | Donald J. Baker, PhD, QP Member MMSA, Associate Principal Geologist, Gustavson Associates |

Dr. Donald Baker is responsible for Sections 7 through 15. William Crowl is responsible for Sections 1 through 6, 17, 18 and 23 through 26. Mr. Donald Hulse is responsible for Sections 1, 17, and 20. Mr. William Crowl reviewed the entire document.

Donald Baker conducted an on-site visit to the Gold Rock property on January 12 – 14, 2012, and reviewed available hard copy and electronic historic records and records of the 2011 MGUS drilling program. The site visit included approximately one day in the field to verify the locations of historic survey control points, historic drill hole locations and locations of MGUS drill holes from its 2011 drilling program. The project geology was also reviewed. One and one-half days were spent in the MGUS office in Ely, Nevada, reviewing and verifying historic drill hole information and the MGUS 2011 drilling program. Electronic files were copied and further reviewed by Gustavson following the site visit.

| April 10, 2012 | 6 |  |

| Midway Gold Corp. | Introduction |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 2.4 | Sources of Information |

The information presented, opinions, conclusions, and estimates made are based on the following:

| · | Information and technical data provided by MGUS; |

| · | Assumptions, conditions, and qualifications as set forth in the report; and |

| · | Data, reports, and opinions from other consulting organizations and previous property owners. |

During preparation of this report, Gustavson relied in good faith on information provided by MGUS regarding technical data, property ownership, and mineral tenure. Gustavson has not independently verified the status of the property ownership or mineral tenure, and is unaware of any material technical data other than that presented by MGUS.

Additional sources of information are presented in Section 27 – References.

Unless stated otherwise, all measurements reported here are in US Commercial Imperial units, and currencies are expressed in constant 2012 US dollars.

| April 10, 2012 | 7 |  |

| Midway Gold Corp. | Reliance on Other Experts |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 3. | RELIANCE ON OTHER EXPERTS |

The information, conclusions, and recommendations contained in this report are based upon review and analysis of digital and hard copy data and information supplied to Gustavson by MGUS. Information was also obtained during discussions with MGUS personnel. This study also relies on information provided by Mr. R.J. Smith, a Registered Landman with MGUS, regarding land agreements, options, claims of accuracy of title, and royalty information, and is presented in Section 4.2.

| April 10, 2012 | 8 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 4. | PROPERTY DESCRIPTION AND LOCATION |

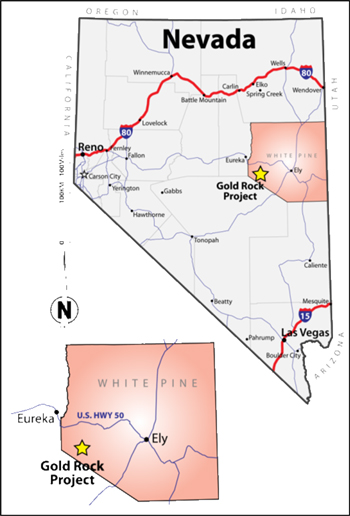

The Gold Rock property encompasses approximately 19 square miles (4,910 hectares) of the Battle Mountain-Eureka gold trend on the eastern side of the Pancake Range in east-central Nevada. The Gold Rock Project site is located approximately 30 miles southeast of the town of Eureka in White Pine County (Figure 4-1).

The location of the Gold Rock property can be found on the USGS Ely 1:100,000 scale topographic map and the USGS Pancake Summit SW and Black Point 1:24,000 scale, 7.5 minute series quadrangle maps. The geographic center of the property is located at 39°17’N latitude and 115°44’W longitude, and the primary zone of mineralization is located in Sections 9, 10 and 16, Township 15 North, Range 56 East, Mount Diablo Base and Meridian (MDBM). Access to the site is provided by Green Springs Road, an unpaved county road which originates at US Highway 50.

Figure 4-1 Property Location Map

| April 10, 2012 | 9 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 4.2 | Mineral Tenure and Agreements |

The Gold Rock Property mining claims and mineral lease encompass an area of approximately 12,133 acres (4,910 ha) (Figure 4-2). The Property consists of 664 contiguous, active unpatented lode and placer mining claims covering portions of Sections 2-10, 15-22, 27-29, 32-34, Township 15 North, Range 56 East; and Sections 22-23, 25-29, 31-35, Township 16 North, Range 56 East, M.D.B.&M. Unpatented mining claims are kept active through payment of a maintenance fee due on 31 August of each year. A complete listing of all claims on file with the Nevada Bureau of Land Management (BLM) and White Pine County is available and will be provided upon request.

The Property is located in surveyed Townships. The unpatented mining claims were individually surveyed at time of location and maps were filed with the BLM and White Pine County.

Figure 4-2 Mineral Claim Map

| April 10, 2012 | 10 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 4.2.2 | Newark Valley Mining Corp. Agreement |

Pursuant to the acquisition of Pan-Nevada Gold Corporation effective April 16, 2007, MGUS acquired a 100 percent interest in the March 20, 2006 mineral lease agreement by and between Pan-Nevada Gold Corporation, formerly Castleworth Ventures, Inc. (PNV) and Newark Valley Mining Corp. (NVMC) (derivative successor in interest to The Lyle F. Campbell Trust). PNV is a wholly owned subsidiary of MGUS. On or before January 5 of each year, PNV must pay an advance minimum royalty of the greater of US$60,000 or the US dollar equivalent of 108.05 ounces of gold valued by the average of the London afternoon fixing for the third calendar quarter preceding January 1 of the year in which the payment is due. All minimum advance royalties will be creditable against a sliding scale gross production royalty of between 2.5 percent and 4 percent (see Table 4-1 below).

If the total amount of gross production royalty due NVMC in any calendar year exceeds the advance minimum royalty due within that year, PNV can credit all un-credited advance minimum royalties paid in previous years against 50 percent of the gross production royalty due NVMC within that calendar year.

PNV must incur a minimum of US$75,000 per year work expenditures, including claim maintenance fees, during the term of the mining lease.

Table 4-1 NVMC Royalty Schedule (Source: MGUS)

| Price of Gold | Gross Percentage |

| To and including $340.00/oz | 2.5 percent |

| From $340.00/oz to $450.00/oz | 3.0 percent |

| $450.00/oz and greater | 4.0 percent |

The original lease encompassed 104 unpatented lode mining claims and established a 1-mile area of interest, within which all new claims located by PNV or an affiliate are subject to the lease agreement. PNV (or its predecessors) expanded the claim holdings within the area of interest to a total of 334 unpatented lode mining claims.

| 4.2.3 | Anchor Minerals, Inc. Agreement |

Effective January 15, 2007, MGUS, executed a lease agreement with Anchor Minerals, Inc. (AMI) for 63 unpatented lode mining claims known as the Anchor Roc target. On or before January 15 of each year, MGUS must pay an advance minimum royalty in the amount of US$67,249. All minimum advance royalties will be creditable against a fixed gross production royalty of 3.5%.

| April 10, 2012 | 11 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

MGUS must incur a minimum of US$30,000 per year work expenditures, including claim maintenance fees, during the term of the mining lease.

The lease encompassed 63 claims and established a 3,000 foot perimeter, within which all new claims located by MGUS or an affiliate are subject to the lease agreement. MGUS expended the claim holdings within the area of interest to a total of 80 unpatented lode claims.

Effective January 24, 2008, MGUS executed a lease agreement with a private party for 13 unpatented lode and placer mining claims covering portions of the previously mined open pit. On or before January 24 of each year, MGUS must pay an advance minimum royalty (see Table 4-2 below). All minimum advance royalties will be creditable against a sliding scale net smelter returns royalty of between 2 and 6 percent (see Table 4-3 below) and a buyout option in the amount of US$5 million. No area of interest applies.

Table 4-2 Peart Advance Minimum Royalty Schedule (Source: MGUS)

| Annual Date | US$ |

| January 24, 2013 | 50,000 |

| January 24, 2014 through January 24, 2018 | 60,000 |

| January 24, 2019 and thereafter | 75,000 |

Table 4-3 Peart Royalty Schedule (Source: MGUS)

| Price of Gold | NSR Percentage |

| To $300/oz | 2.0 percent |

| From $300/oz to $550/oz | 3.0 percent |

| From $551/oz to $800/oz | 4.0 percent |

| From $801/oz to $1,050/oz | 5.0 percent |

| $1,051/oz and greater | 6.0 percent |

Effective February 13, 2008, MGUS executed a lease agreement with a private party for 2 unpatented lode mining claims covering portions of the previously mined open pit and waste dumps. On or before February 13 of each year, MGUS must pay an advance minimum royalty (see Table 4-4 below). All minimum advance royalties will be creditable against a sliding scale net smelter returns royalty of between 2 and 5 percent (see Table 4-5 below) and a buyout option in the amount of US$775,000. No area of interest applies.

| April 10, 2012 | 12 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Table 4-4 Pankow Advance Minimum Royalty Schedule (Source: MGUS)

| Annual Date | US$ |

| February 13, 2013 | 7,750 |

| February 13, 2014 through February 13, 2018 | 9,250 |

| February 13, 2019 and thereafter | 11,500 |

Table 4-5 Pankow Royalty Schedule (Source: MGUS)

| Price of Gold | NSR Percentage |

| To $550/oz | 2.0 percent |

| From $551/oz to $800 | 3.0 percent |

| From $801/oz to $1,050/oz | 4.0 percent |

| $1,051/oz and greater | 5.0 percent |

Subject to a February 13, 2008 assignment from a third party, MGUS acquired a February 15, 2004 lease agreement with a private party for 10 unpatented lode mining claims known as the Meridian Flats target. The assignor reserved a fixed net smelter returns royalty of 0.5%. On or before February 15 of each year, MGUS must pay an advance minimum royalty in the amount of US$15,000. All minimum advance royalties will be creditable against a fixed net smelter returns royalty of 2.5% and a buyout option in the amount of US$2.5 million. The total royalty burden for these claims is a net smelter returns royalty of 3%.

The lease encompassed 10 claims and established a 2,400 foot area of interest, within which all new claims located by MGUS or an affiliate are subject to the lease agreement. MGUS expended the claim holdings within the area of interest to a total of 17 unpatented lode claims.

Over the years, MGUS has staked 198 additional unpatented lode claims (MT, GR series) within and adjacent to the Gold Rock property. These additional claims are without royalty burden and are not subject to any outside interest.

| 4.3 | Environmental Liabilities and Permitting |

| 4.3.1 | Environmental Liabilities |

No known environmental liabilities exist currently at the site.

| April 10, 2012 | 13 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

MGUS exploration activities are permitted under the NOI process approved by the BLM in 2008 and 2011, allowing for up to 45 reverse circulation holes and 5 diamond core holes from 40 drill sites. Currently MGUS is bonded at $24,870, which allows for drilling disturbance on approximately 5.45 acres at the project site. The disturbance is updated annually and the bonding level is updated every three years, as required by the BLM.

An exploration Plan of Operations (PoO) was submitted in October of 2011. An Environmental Assessment (EA) is in progress for this PoO. An amendment to this PoO may be required to allow drilling to continue until an Environmental Impact Statement (EIS) can be completed on the mine PoO. If required, an expedited EA would be prepared and would not likely impact the project schedule.

The Gold Rock project will require a number of permits and environmental studies. It is expected that these permits and studies will be similar in nature to those required at MGUS Gold’s Pan Project. We would expect the permits and studies to include:

Table 4-6 Major Permits and Authorizations Required for Project Development

| Permit/Approval; | Granting Agency | Permit Purpose |

| Federal Permits Approvals and Registrations |

| Plan of Operations/EA Amendment | US Bureau of Land Management | Prevent undue degradation in relation to exploration activities or expansion areas. |

| Plan of Operations/EIS | U.S. Bureau of Land Management | Prevent unnecessary or undue degradation associated with Plan of Operations, EIS to disclose environmental impacts and project alternatives. Requires financial assurance. Currently have Plan for exploration with EA in progress |

| Explosives Permit | U.S. Bureau of Alcohol, Tobacco & Firearms | Storage and use of explosives |

| EPA Hazardous Waste ID No. | U.S. Environmental Protection Agency | Registration as a small-quantity generator of wastes regulated as hazardous |

| April 10, 2012 | 14 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| Permit/Approval; | Granting Agency | Permit Purpose |

| Notification of Commencement of Operations | Mine Safety & Health Administration | Mine safety issues, training plan, mine registration |

| Nationwide Section 404 Permit | U.S. Army Corps of Engineers | Installation of any required culverts on the access road (not anticipated to be necessary |

| Endangered Species Act | U.S. Fish and Wildlife Service | Only if project affects species listed as threatened or endangered (not anticipated to be necessary) |

| Federal Communications Commission | FCC | Frequency registrations for radio/microwave communication facilities |

| State Permits |

| Air Quality Operating Permit | NV Division of Environmental Protection/Bureau of Air Pollution Control | Regulates project sources of air emissions. Will require compliance with the new |

| Mercury Operating Permit to Construct Air | NV Division of Environmental Protection/Bureau of Air Quality Planning/ Nevada Mercury Air Emissions Control Program | Requires use of NVMACT for all thermal units that have the potential to emit mercury |

| Reclamation Permit | NV Division of Environmental Protection/Bureau of Mining Regulation & Reclamation | Reclamation of surface disturbance due to mining and mineral processing includes financial assurance requirements. Site currently operates under Reclamation Permit No. 0228. |

| Water Pollution Control Permit | NV Division of Environmental Protection/Bureau of Mining Regulation & Reclamation | Prevent degradation of waters of the state from mining, establishes minimum facility design and containment requirements. Site currently operates under WPCP NEV70010. |

| Petroleum-Contaminated Soil Management Plan | NV Division of Environmental Protection/Bureau of Mining Regulation & Reclamation | On-site treatment and management of hydrocarbon-contaminated soils |

| Solid Waste Class III Landfill Waiver | NV Division of Environmental Protection/Bureau of Solid Waste | On-site disposal of non-mining, non-hazardous solid wastes |

| General Stormwater Discharge Permit | NV Division of Environmental Protection/Bureau of Water Pollution Control | Management of site stormwater |

| April 10, 2012 | 15 |  |

| Midway Gold Corp. | Property Description and Location |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| Permit/Approval; | Granting Agency | Permit Purpose |

| Permit to Appropriate Water | NV Division of Water Resources | Water appropriation |

| | | |

| Permit to Construct Impoundments | NV Division of Water Resources | Design and construction of a tailings embankment or other structures with a crest height 20 feet or higher, as measured from the downstream toe to the crest, or that will impound 20 acre-feet or more |

| | | |

| Industrial Artificial Pond Permit | NV Department of Wildlife | Ponds containing chemicals directly associated with the processing of ore. |

| | | |

| Liquefied Petroleum Gas License | NV Board of the Regulation of Liquefied Petroleum Gas | Tank specification and installation, handling, and safety requirements |

| | | |

| Potable Water System Permit | NV Bureau of Safe Drinking Water | Water system for drinking water and other domestic uses (e.g., lavatories) |

| | | |

| Radioactive Materials License | NV Bureau of Safe Drinking Water | Nuclear flow and mass measurement devices if used in the mineral processing facilities |

| | | |

Septic Treatment Permit Sewage Disposal System | NV Division of Environmental Protection/Bureau of Water Pollution Control | Design, operation, and monitoring of septic and sewage disposal systems |

| | | |

| Hazardous Materials Storage Permit | Nevada Fire Marshall | Hazardous materials safety |

| | | |

| Local Permits |

| Building Permits | White Pine County Building Planning Department | |

| | | |

| Conditional Special Use Permit | White Pine County Building Planning Department | |

| | | |

| County Road Use and Maintenance Permit | White Pine County Building Planning Department | Use and maintenance of county roads |

| | | |

| April 10, 2012 | 16 |  |

| Midway Gold Corp. | Accessibility Climate Resources Infrastructure & Physiography |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 5. | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

Access to the Gold Rock Project site is provided by Green Springs road, an unpaved county road that intersects US Highway 50 approximately 30 miles southeast of Eureka, Nevada. It is approximately 16.5 miles, via road, from US 50 to the Gold Rock property. The property is accessible year-round, but weather conditions occasionally make access and on-site travel difficult during the winter months.

| 5.2 | Topography, Elevation, Vegetation, and Climate |

Local terrain at the Gold Rock project site is gentle to moderate with rolling hills and no major stream drainages. Elevation at the property ranges from 6,400 to 7,600 feet above sea level. Vegetation is typical of northern Nevada, including a mix of sparse Juniper and Pinion pine forest broken by areas of sagebrush and grass. No springs are known to exist on the Gold Rock property.

The local climate is typical for the high desert of east-central Nevada and the Basin and Range province. Climate data for nearby Eureka, Nevada shows an average of 11.85 inches of precipitation per year and average temperatures ranging from 17°F in the winter to 86.4° F in the summer, with daytime temperatures commonly exceeding 90°F during the months of July and August (Western Regional Climate Center, 2008). Operating season can be year-round.

No perennial surface waters exist on or near the project site. The nearest surface water is Bull Creek, 8.8 miles to the southeast of the site and on the opposite side of the Pancake Range. The project site is located outside of the 100-year flood plain. The Easy Junior mine’s water supply well was drilled approximately 5 miles southeast of the mine area, and the water produced is of potable quality. The water table at the Gold Rock project site (Easy Junior mine area) occurs at a depth of approximately 1,300 feet below surface (NDEP, 1995a).

| 5.3 | Infrastructure and Local Resources |

The Gold Rock Project is a bulk tonnage disseminated gold deposit amenable to the open pit heap leach technology and mining methods common to Nevada. The Gold Rock Project is wholly located on MGUS land holdings.

The town nearest to the project site, Eureka, Nevada, hosts a population of 610 according to 2010 US Census data. Greater Eureka County and White Pine County host area populations of 1,987 and 10,030 respectively (US Census Bureau, 2008), though population is centered primarily in Eureka and Ely, Nevada. Elko, Nevada, population of 18,297, is the nearest city to the project site, and is located approximately 110 miles to the north by road.

| April 10, 2012 | 17 |  |

| Midway Gold Corp. | Accessibility Climate Resources Infrastructure & Physiography |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Electrical power is available via a power line which runs adjacent to and 6 miles north of highway US 50, approximately 20 miles from the project site. MGUS is currently permitting a power line to its Pan Project site, approximately 10 miles to the NNW, and has included an extension of the power line to the Gold Rock Project site in the design for future permitting. Water for exploration, mine production and process efforts will need to be identified and secured.

Logistical support is available in Eureka, Ely, and Elko, all of which currently support large open pit mining operations. Barrick Gold Corporation currently operates the Ruby Hill Mine near Eureka and the Bald Mountain Mine approximately 60 miles to the north. QuadraFNX Mining Ltd. operates the Ruth Copper pit near Ely, and large scale mining by Barrick and Newmont Mining Corporation is ongoing near Elko and Carlin, Nevada to the north.

Mining history in the area of the Gold Rock Project dates back to 1876, when underground silver mining and smelting were based in Eureka. Mining personnel and resources for exploration and potential operations at Gold Rock are expected to be available from Eureka and Ely, as well as from outlying areas in White Pine and Elko Counties.

| April 10, 2012 | 18 |  |

| Midway Gold Corp. | History |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

The following history of the Gold Rock property is presented from records of the Alta Gold Company and Alta Gold and Echo Bay including Carden (1988, 1991) and Alta Bay (1990, 1991):

| · | The property was first staked in 1979 by Earth Resources, Inc. |

| · | Earth Resources was purchased by Houston Oil & Gas in 1980 |

| · | The property was sub-leased to various parties between 1981 and 1986, but was returned to Tenneco, who had acquired Houston Oil & Gas in 1986 |

| · | Following a 1,200-sample soil sampling program in 1986, rock chip sampling results in the Easy Junior Ridge area included 32 samples that averaged 0.58 ppm gold |

| · | In September of 1986, Echo Bay exploration acquired Tenneco and subsequent drilling at Easy Junior resulted in a discovery; 42 RC holes were drilled, and the best intercept recorded intercept is 320’ of 0.066 opt gold |

| · | Echo Bay drilled a total of 229 holes in 1987 and 1988 in an effort to delineate the Easy Junior deposit |

| · | The Alta Bay Joint Venture was formed between Echo Bay and Alta Gold in 1988 |

| · | Mine development was initiated in 1989 under the Alta Bay Joint Venture, with Alta Gold as operator |

| · | Mining was suspended in 1990 due to low gold prices |

| · | Alta gold purchased Echo Bay’s interest in 1992 and began detailed re-engineering studies |

| · | Mining resumed at Easy Junior in June 1993 |

| · | Mining was completed at Easy Junior in August 1994; total production for the life of the mine was 52,400 ounces gold |

| · | Heap leach processing was completed in 1996 |

| · | Alta Gold declared bankruptcy in 1998 |

There is no record of new drilling or significant exploration after 1994, until 2008, following MGUS’s acquisition of the property and re-initiation of exploration efforts.

| 6.2 | Resource and Reserve Estimates |

Records regarding historical resource and reserve estimates are fragmentary. For most of the life of the project, the operators relied on in-house estimates to determine the value of the property. Only two reports were produced by independent sources. The resource and reserve estimates described below were not necessarily completed according to present NI 43-101 standards and have not been verified by a qualified person. These estimates do not represent current mineral resources or reserves, and are disclosed here for historical completeness only.

| April 10, 2012 | 19 |  |

| Midway Gold Corp. | History |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

In 1988, Echo Bay contracted with Independent Mining Consultants, Inc. (IMC) of Tucson, Arizona. IMC built a resource model using a kriged estimate from 20 foot drillhole composites and 25- by 25-foot blocks. IMC did not apply any economic constraints to the model, but reported tons and grade from a series of cut-offs. This model was created prior to any mining at Easy Junior and it must be assumed that significant portions were subsequently mined.

Table 6-1 IMC geological reserve (geologic inventory, no economic constraint)

| | | | |

| 0.050 | 758,000 | 0.064 | 48,512 |

| 0.030 | 3,552,000 | 0.043 | 152,736 |

| 0.025 | 4,953,000 | 0.039 | 193,167 |

| 0.020 | 6,963,000 | 0.034 | 236,742 |

| 0.015 | 9,934,000 | 0.029 | 288,086 |

| 0.010 | 12,641,000 | 0.025 | 316,025 |

In 1989, Alta Gold commissioned Pincock Allen and Holt (“PAH”) of Lakewood, Colorado to conduct an audit and verification of the reserves at Easy Junior. Details are lacking, but the Alta Gold model was constructed using Inverse Distance Cubed estimation. The geologic inventory of mineralization at a cut-off of 0.008 opt was 15,400,000 tons at a grade of 0.028 opt for 400,000 ounces gold.

PAH estimated a Proven and Probable reserve after applying expected mining costs and recoveries, as shown in Table 6-2.

Table 6-2 Proven and Probable Reserve

| | | | | | | |

| 5,058,000 | 0.032 | 161,900 | | 1,460,000 | 0.01 | 14,600 |

Mining costs have changed significantly since the time of these estimations, and available information is not sufficient to determine which portions of the resource or reserve were mined as ore or waste.

| April 10, 2012 | 20 |  |

| Midway Gold Corp. | History |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

The physical design criteria and cutoff grade calculations used by Alta Gold for development of the Easy Junior Pit are presented in Tables 6-3 and 6-4 (from PAH 1989):

Table 6-3 Physical Pit Design Criteria

| |

| |

| Maximum Slope Angle (deg) | 53 |

| Bench Height (ft) | 15 |

| Catch Bench Interval (ft) | 45 |

| Catch Bench Width (ft) | 20 |

| Road Width (ft) | 55 |

| Road Grade (%) | 10 |

| Tonnage Factor (ft3/ton) | 13 |

Table 6-4 Cutoff grade check calculations

| |

| |

| | Internal Cutoff |

| | Ore | ROM |

| Mining Cost | N/A | N/A |

| Mine Equip. Repl. Cost | N/A | N/A |

| Processing Cost | 2.74 | 1.10 |

| G & A Cost | 1 | N/A(1) |

| Total Costs, $/ton | 3.34 | 1.10 |

| | | |

| Gold Price, $/oz | 375.00 | 375.00 |

| | | |

| Net Smelter Return, Percent | 99.5 | 99.5 |

| Recovery, Percent | 75 | 60 |

| Net Revenue, $/oz | 279.84 | 223.88 |

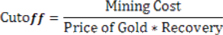

| Cutoff, oz/ton(2) | 0.012 | 0.005 |

| Alta Gold Cutoff | 0.013 | 0.009 |

Notes:

(1) Not including G&A costs is only valid so long as ROM heap leach is a secondary process.

(2) Cutoff = Total costs/Net Revenue

| April 10, 2012 | 21 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 7. | GEOLOGICAL SETTING AND MINERALIZATION |

The Gold Rock property is located on the east flank of the northern portion of the Pancake Range in east-central Nevada. The Pancake Range is part of the Basin and Range Province, a large physiographic region characterized by a series of normal faults expressed as a sequence of north-south trending narrow mountain ranges separated by flat, arid valleys. The Pancake Range is approximately 85 miles long and 8 to 10 miles wide, and is primarily composed of Paleozoic carbonate and clastic sedimentary rocks, Cretaceous igneous intrusives, and Tertiary volcanics. A regional geologic map of the northern Pancake Range is presented as Figure 7-1.

| April 10, 2012 | 22 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Figure 7-1 Regional Geology (Hose and Blake, 1987)

| April 10, 2012 | 23 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

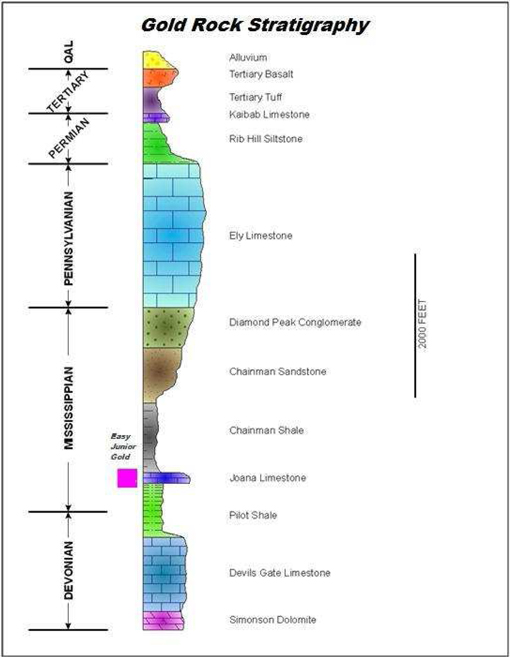

The Gold Rock property is located in an eastern lobe of the Pancake Range. Devonian and Carboniferous carbonate and clastic sedimentary rocks form the core of the range, and are exposed in bedrock outcrops and within the Easy Junior pit in the area of the Gold Rock Project. A stratigraphic section representative of the Pancake Range is presented as Figure 7-2. The Pancake stock, a Cretaceous-aged quartz monzonite intrusive, is located to the north and west of the property, and a prominent sill is noted in associated regional mapping. These intrusives appear to be age equivalents of the Mount Hamilton stock, which lies in the White Pine Range to the east. No intrusive rocks have been mapped on the Gold Rock property. The local geology has been capped in places by post mineral Tertiary aged gravels and alluvium. No intrusive rocks have been mapped on the Gold Rock property.

| April 10, 2012 | 24 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Figure 7-2 Stratigraphic Column Pancake Range (Smith, 1976, Harris, 2007)

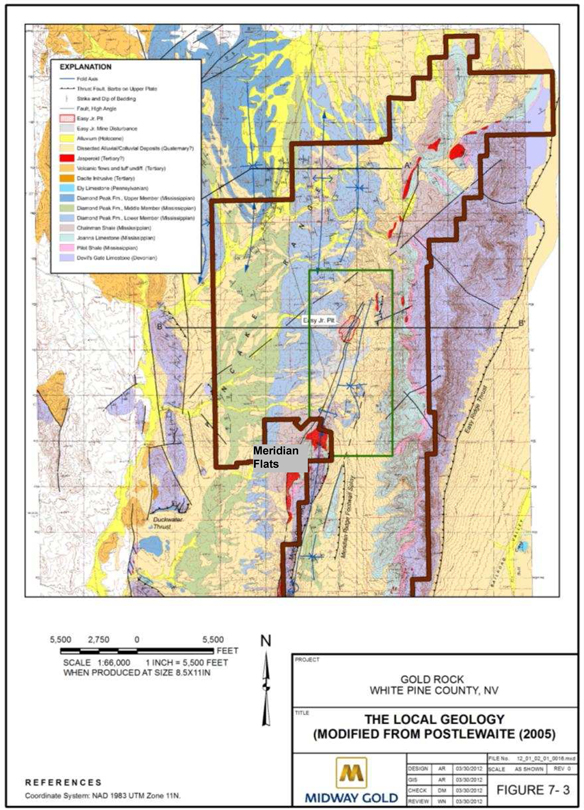

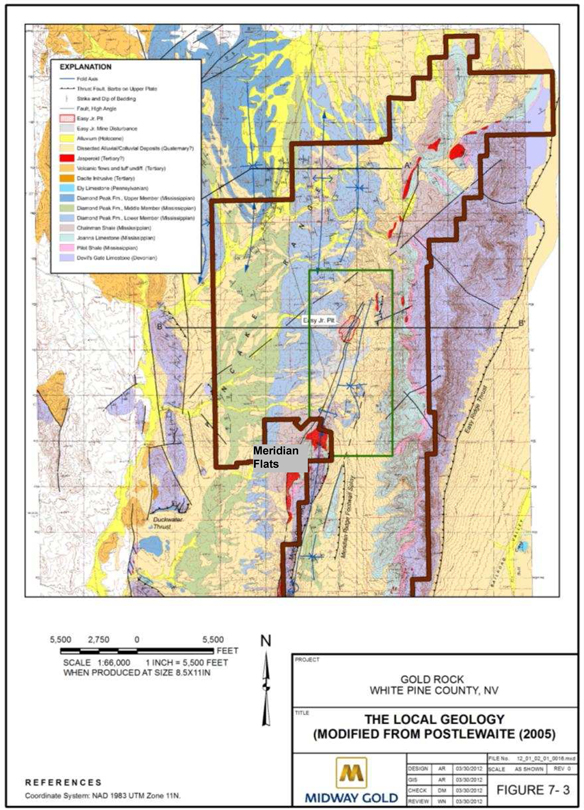

A detailed geologic map of the Gold Rock property is presented in Figure 7-3. The geology of the Gold Rock property is dominated by Devonian through Mississippian limestone, shale, and sandstone. These rock types are exposed in a series of north-trending ridges that represent stacked, easterly-directed thrust sheets and low amplitude, open to tight folds. Mineralization is interpreted to postdate thrusting and folding. Bedrock geology is partially obscured by alluvial and colluvial gravels. Individual lithologic units identified at the project site are described below, from oldest to youngest:

| April 10, 2012 | 25 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 7.3.1 | Late Devonian Devil’s Gate Limestone (Dd) |

The oldest lithologic unit exposed in the northern Pancake Range is the Late Devonian Devil’s Gate Limestone. This unit is a massive to thinly bedded, medium to dark gray, fine to coarse grained limestone. Thickness of the unit ranges from about 1000 ft to 2500 ft locally.

| 7.3.2 | Late Devonian to Early Mississippian Pilot Shale (MDp) |

The Pilot Shale can be divided into an upper series of thinly interbedded dolomitic and calcareous siltstone and silty shale, and a lower section of more thickly bedded calcareous siltstone with local limestone beds.

| 7.3.3 | Mississippian Joana Limestone (Mj) |

The Joana Limestone is a gray, medium grained, unevenly bedded limestone with abundant fossil fragments and detrital limestone interbeds. Fossil types include echinoderm, bryozoans, foraminifera, algae, and crinoids. Locally, light brown calcareous sandstone is present at the base of the unit. Thickness of the Joana Limestone reportedly ranges from 90 to 500 ft throughout the county (Smith, 1976). The Joana Limestone is the primary host to known mineralization and historic resources and reserves at the Gold Rock property. This unit is commonly silica altered (mapped as jasperoid) throughout the project area, including beyond zones of currently known mineralization.

| 7.3.4 | Mississippian Chainman Shale (Mc) |

The Chainman Shale consist of dark gray to black shale with thin interbeds of olive gray silty shale and siltstone. Thickness of the unit ranges from 1000 to 2000 ft (Smith, 1976) and is generally at the lower end of that range at the Gold Rock property. Mineralization occurs in the lower portions of the Chainman Shale at Gold Rock, particularly where it lies adjacent to mineralized Joana Limestone.

| 7.3.5 | Mississippian Diamond Peak Formation (Md) |

The Diamond Peak Formation consists of medium beds of coarse grained, quartz-rich sandstone and olive gray siltstone overlain by thick to massive conglomerate. Thickness of the Formation ranges from less than 1,000 to 3,700 ft. This unit outcrops just west of the Gold Rock claim block.

| April 10, 2012 | 26 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Figure 7-3 Local Geology

| April 10, 2012 | 27 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

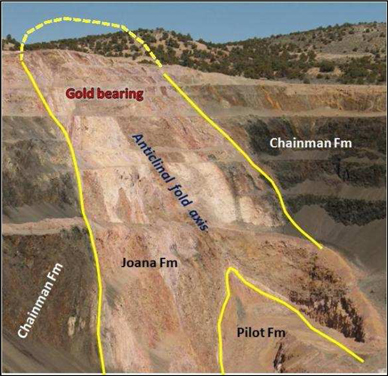

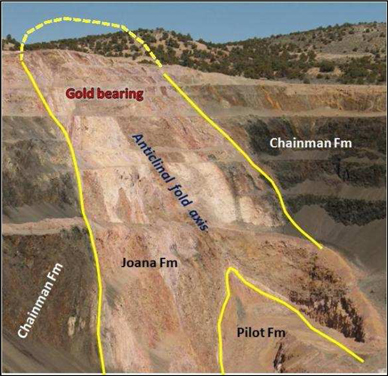

The Gold Rock property is characterized by a relatively subdued topography of shale and limestone partially covered by a thin veneer of gravel. The subdued character masks a complexly thrust-faulted and folded terrain. Several thrust faults, reverse faults, and associated folds transect the property, generally striking about 15 degrees (N15E). A very tight fold of altered and mineralized Mississippian Joana Limestone is clearly exposed in the Easy Junior open pit. The structural style is typical of the east-west directed compressional orogenic activity common in the Mesozoic era in this part of North America, possibly during the Antler orogeny.

Later Basin and Range extension likely reactivated the steep reverse faults created during the Antler orogeny, creating deep-seated high-angle fractures that were exploited as flow pathways by gold-rich hydrothermal fluids (Carden, 1988, 1991). Gold was deposited where the steep feeder structures intercepted rock types that are strongly reactive to the hydrothermal fluids.

On the Gold Rock property, the primary gold feeder structure is presumed to be a steeply-dipping reverse fault reactivated with extensional dip-slip. This fault is present near and within the axial surface of the anticline that extends from Meridian Flats through the Easy Junior open pit (Figure 7-4). Mineralization is found where the steep feeder structure intercepts the Joana Limestone at the crest of this anticline, and appears restricted to the Joana Limestone and the base of the overlying Chainman shale, at least to the extent drilled to depth to date.

Mineralization may have been enhanced where offset of this primary feeder structure caused deformation and increased porosity and permeability over a larger volume. The main feeder structure appears to be offset by post-mineral high-angle faults. Most of these observed post-mineral structures trend 60 to 75 degrees (N60 to N75E).

| April 10, 2012 | 28 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Figure 7-4 Pre-mining Cross Section of the Easy Junior Deposit (Alta Bay, 1991)

Gold mineralization at Gold Rock is typical of Carlin-style, sediment hosted deposits:

| · | Disseminated, micron sized gold |

| · | Hosted in sedimentary rock, usually impure calcareous rocks |

| · | Near a vertical or sub-vertical deep seated feeder fault and associated folds |

| · | Characteristic alteration assemblage associated with strongly oxidizing fluids |

Alteration at Gold Rock is typical of Carlin systems in Nevada. Alteration styles include silicification, argillization, decalcification, and oxidation.

Silicification occurs as zones of moderate to strong silica flooding along bedding and structures. Strong or complete replacement is commonly referred to as jasperoid by field workers. Silica alteration is found primarily in the Joana Limestone, with only minor small zones identified in shale units. Within the Easy Junior deposit, jasperoid within the Joana Limestone carries significant amounts of gold. In surface outcrops, Joana-hosted jasperoid occurs along strike both north and south of the deposit and is often found in association with anomalous gold values.

| April 10, 2012 | 29 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Clay alteration is generally associated with hydrothermal alteration of minerals. Clay along faults and bedding is common. Within limestones and calcareous shales, argillization is often accompanied by decalcification of the host rock. Black carbonaceous accumulations occur locally along the margins of gold mineralization zones.

Oxidation is prevalent throughout the deposit, resulting in the formation of iron oxides (hematite and limonite). Liesegang banding has formed in association with oxidation, and is prevalent in and around gold mineralization. The mineralization is strongly oxidized, and reference to sulfide minerals in drill logs is very rare.

| 7.7 | Geometry of Mineralization |

Figure 7-4 illustrates the cross-sectional geometry of mineralization of the Easy Junior deposit as interpreted from drilling. A steep west-dipping fault cuts the west side of a north-trending anticline. Mineralizing fluids deposited gold both within the fault zone and in the Joana Limestone and surrounding rocks at the apex of the Easy Junior Anticline. A view looking at the pit after mining shows the fold with the fault structure cutting the hinge area of the fold (Figure 7-5).

Figure 7-5 North Facing View of the Easy Junior Pit

| April 10, 2012 | 30 |  |

| Midway Gold Corp. | Geological Setting and Mineralization |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

The mineralization along the anticline extends along strike to the south of the Easy Junior Mine over 6,000 feet through the Meridian Flats prospect area. To the north of Easy Junior, the mineralization along the apex of the anticline was followed over 1,000 feet, but post-mineral faulting drops the Joana Limestone below the extent of the drilling, and therefore remains untested.

Mineralization was exposed at the pre-mining surface of the Easy Junior open pit. Along strike, the mineralized lower Chainman Shale and upper Joana Limestone are covered by 300 to 500 feet of poorly exposed Chainman shale. Mining at Easy Junior extracted a small portion of the near surface resource. Historic drill intercepts indicate that significant mineralization still exists below the Easy Junior open pit and along strike to the north and south.

Historic drilling at Meridian Flats, nearly a mile south of the Easy Junior open pit, intersected significant mineralization along trend within the same faulted anticline geometry, as shown in Figure 7-4.

| April 10, 2012 | 31 |  |

| Midway Gold Corp. | Deposit Types |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

The Easy Junior deposit on the Gold Rock property is a Carlin-style, sediment-hosted, disseminated gold deposit within Mississippian sedimentary units, largely in the Joana Limestone and in the lower portions of the overlying Chainman shale. Gold particles occur as micron size to sub-micron size disseminations. Free, coarse gold is not common in these types of deposits, and has not been observed at Gold Rock. The source and age of mineralization is uncertain at this time.

Gold is often associated with anomalous concentrations of arsenic, antimony, and mercury. Other elements of note include barium, zinc, and tungsten. Similar gold deposits in the surrounding area include the Pan deposit 10 miles to the north; Maverick Springs, approximately 70 miles north of Gold Rock; and Emigrant Springs.

| April 10, 2012 | 32 |  |

| Midway Gold Corp. | Exploration |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 9.1 | Previous Operator’s Exploration Work |

The central part of the Gold Rock property includes the historically mined Easy Junior area. Past activity by the historic operators generated a significant amount of data covering all aspects of exploration and mining. MGUS has compiled a significant amount of the historic data for use in assessing the potential resource and exploration targets. Historic operators include Nevada Resources, Houston Oil and Minerals, Tenneco, Echo Bay, Santa Fe, Amselco, and Alta Gold. Available data include:

| · | Drilling logs and assays |

| · | Geochemical sampling maps and assays |

| · | Geophysical survey results |

| 9.2 | Historic Geochemical sampling |

From 1985 to 1993, Tenneco, Echo Bay, and Alta Gold collected 2,800 soil samples over a 6.5 square mile area. Most of these samples were analyzed for gold, barium, antimony and mercury. Historic data was also compiled from 970 rock chip samples, many of which were analyzed for gold, mercury, arsenic, antimony, barium and zinc.

Limited geophysical study was conducted at Gold Rock as part of the historic Easy Junior exploration. In 1986, Tenneco conducted VLF-EM over selected lines attempting to define structural complexities. In 1989 Alta Gold gathered induced polarization and resistivity data, again in an attempt to define structural complexities. No significant property-wide surveys were conducted.

A detailed geologic map was generated by Tenneco in 1986, which covers a portion of the Gold Rock property. This is the most detailed historic map of the region. Postlethwaite (2005) compiled a regional map that included the Gold Rock property in an effort to describe the relationship of fold and thrust faulting relative to gold mineralization (Postlethwaite (2005) is the source of the mapping provided in Figure 7-3.

MGUS continues to compile these sources of data, in addition to data from several smaller maps of individual prospect areas, in order to create and upgrade a property-wide geologic map. New geologic mapping continues on the project lands, and will provide more detailed information with regard to structure and alteration.

| April 10, 2012 | 33 |  |

| Midway Gold Corp. | Exploration |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

The long history of exploration and production at the Easy Junior deposit includes 14 years of drilling, from 1980 to 1994, and periodic mine production from 1989 to 1994. The compiled database now contains records from 673 historic drill holes. Most of this drilling was completed between 1986 and 1988 by Echo Bay, and later, the Alta Bay JV (1988 to 1992). The results of this drilling have provided the basis of the understanding of the distribution and magnitude of the remaining gold mineralization at the Gold Rock property developed by MGUS since acquisition of the property in 2007.

Table 9-1 Historic Exploration and Delineation Drilling at the Gold Rock property, 1980 to 1994

| Company | No. of holes | Drilling Method | Years | Notes |

| Houston Oil & Gas | 16 | ? | 1980-1983 | |

| Nevada Resources | 64 | | 1981 | FOG Claims |

| Amselco | 6 | | 1983 | Monte Claims |

| Sante Fe | 19 | RC | 1984-1985 | |

| Tenneco/Echo Bay | 241 | RC* | 1886-88 | *includes 12 core holes for metallurgy |

| Alta Bay | 284 | RC | 1988-1992 | Exploration/Delineation |

| Alta Gold | 47 | RC | 1993-1994 | |

| TOTAL | 673 | | | |

Substantial portions of this historic data, particularly that provided by the results of the 673 historic drill holes, have been combined with the exploration program results developed by MGUS since 2007 to generate an estimation of potentially available new and remaining resources.

Additionally, and not included in the above tabulation, Mobile Oil drilled a series of 160-foot deep seismic exploration holes in two parallel lines across the north end of the Gold Rock property in 1987. Although some distance from any current gold resource, this data may prove useful in future exploration work on the Gold Rock Project.

MGUS has been active in all phases of exploration work on the Gold Rock property since acquiring the project in 2007. Exploration programs have included soil and rock chip geochemistry, geologic mapping, geophysics and drilling. The most relevant of these programs for purposes of this Report, is the drilling conducted in 2011, which focused on verification and expansion of the knowledge of the geology and mineralization as defined by the historic drilling. A brief summary of the MGUS efforts is provided below, with more detailed discussion of the MGUS 2011 drilling program in Sections 10, 11 and 12.

| April 10, 2012 | 34 |  |

| Midway Gold Corp. | Exploration |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

| 9.6.1 | Surface Geochemistry |

During 2010, MGUS completed a soil geochemistry survey to complement the historic soil grid. An additional 750 soil samples were collected in an area generally east of the historic soil grid. The grid was designed to target new structural and alteration targets outside of the previously known mineralization.

In conjunction with the soil sampling program, 141 rock samples were collected from the Gold Rock property in 2010. These samples have been added to the Gold Rock Database and will be used to assess potential for additional targets outside the trend of known mineralization.

MGUS mapped the geology of the central portion of the Gold Rock property in 2010 in order to better define the distribution of alteration and generate future drill targets. Correlating alteration near known gold mineralization with the distribution of alteration throughout the property may provide a useful tool in identifying additional gold occurrences and, potentially, resources.

In 2008, MGUS conducted reconnaissance level ground magnetic and gravity surveys over portions of the Gold Rock Property, and, in 2010, conducted an additional reconnaissance ground magnetic program, testing for buried intrusives in several parts of the property.

During the 2008 field season, MGUS drilled 11 RC holes near the south end of the Gold Rock property at the Anchor Roc prospect. Drilling in that area by Nevada Resources in 1981 included an intercept of 120 feet of 0.014 opt gold. MGUS’s best intercept was 85 feet of 0.014 opt gold. The program was prematurely curtailed when a series of large voids in the bedrock prevented the drill from reaching target depths. MGUS plans to drill the remaining targets in this area with a different drill that can get past the voids. The Anchor Roc prospect does not currently host a defined resource.

Drilling conducted during the 2011 program, completing 31 holes, is discussed in detail in the following sections.

Sampling methods and quality are further discussed in Section 11.

| April 10, 2012 | 35 |  |

| Midway Gold Corp. | Drilling |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

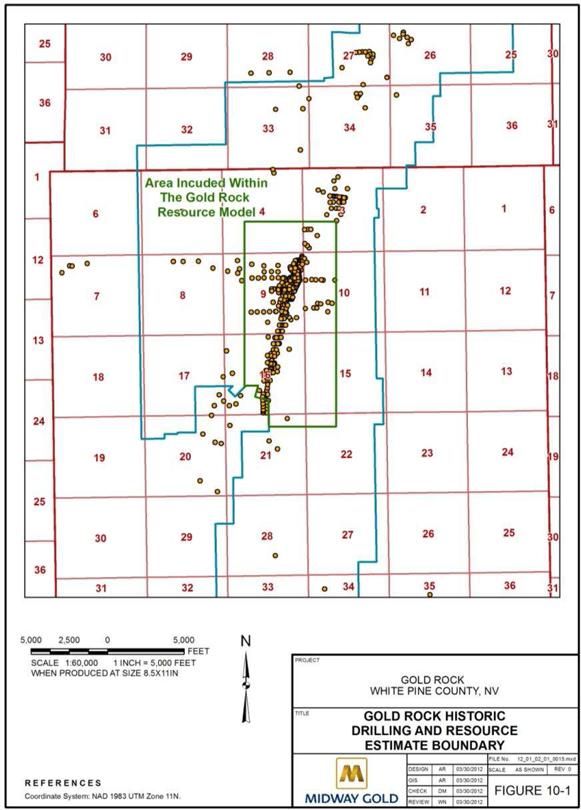

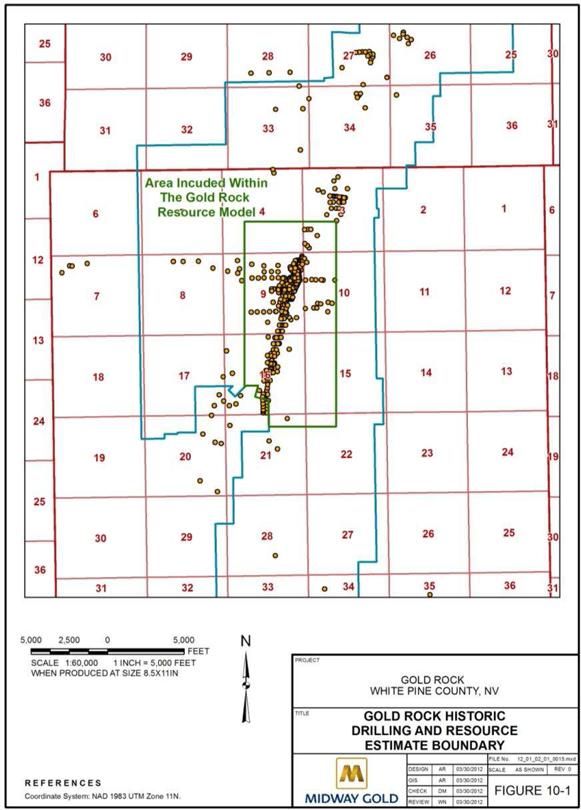

A total of 715 drill holes have been completed on or in the immediate vicinity of the current Gold Rock property; 673 of which are considered historic, and 42 having been more recently completed by MGUS. Of this total, approximately 548 lie within an area modeled (“Resource Area”) in this Report to assess geology and mineral resources (Figure 10-1). Of the 548 drill holes within the Resource Area, 78 are excluded from the resource analysis owing to non-verified collar coordinates and surface locations, or issues with assay type (specifically neutron activation analyses for gold).

| April 10, 2012 | 36 |  |

| Midway Gold Corp. | Drilling |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Figure 10-1 Gold Rock Historic Drillikng and Resource Estimate Boundary

| April 10, 2012 | 37 |  |

| Midway Gold Corp. | Drilling |

| Gold Rock Project | NI 43-101 Technical Report on Resources |

Historic drilling in the Resource Area was overwhelmingly completed by reverse circulation techniques, although detailed documentation on a drill hole by drill hole basis is not available in the database. Carden (1991) documented the following (see Table 9-1):

| · | Santa Fe drilling of 19 holes in 1984 and 1985 was by reverse circulation methods; |

| · | Of the 241 holes completed by Echo Bay prior to consummation of the Alta Bay Joint Venture, only 12 were completed as diamond drill holes for metallurgical purposes. The remaining 229 holes were all completed by reverse circulation methods; and, |

| · | After formation of the Joint Venture, the partners grid-drilled the known deposit on a 50 x 100 foot grid (50 foot spacing of holes on approximately east-west lines; with lines spaced 100 feet) using two reverse circulation drill rigs. |

Protocols practiced by drilling contractors and mining company personnel at drill sites are not known, although all drill hole sampling was completed on 5-foot intervals based on results posted in the assay database. Nearly all drilling was in vertical holes of undocumented diameter (typically 4.5 inches or more in diameter, by standard industry practices at the time). Collar coordinates and elevation were determined by theodolite surveys, employing the Nevada State Plane East, NAD 27 projection, and are well-documented in the database. There were no down-hole surveys completed or documented. Based on observations from the MGUS drilling in 2011, all of the historic holes, except for two deeper holes, were likely completed above the water table (except for possible local perched water tables or water-bearing structures).

MGUS completed 11 reverse circulation drill holes in 2008 at the Anchor Roc prospect southeast of the Resource Area. As this drilling is outside the Resource Area, drilling methods will not be discussed further.