- HBM Dashboard

- Financials

- Filings

-

Holdings

- Transcripts

- ETFs

-

Insider

- Institutional

- Shorts

-

6-K Filing

Hudbay Minerals (HBM) 6-KCurrent report (foreign)

Filed: 4 Aug 17, 12:00am

Management's Discussion and Analysis of

Results of Operations and Financial Condition

For the three and six months ended

June 30, 2017

August 3, 2017

INTRODUCTION

This Management's Discussion and Analysis ("MD&A") dated August 3, 2017 is intended to supplement Hudbay Minerals Inc.'s unaudited condensed consolidated interim financial statements and related notes for the three and six months ended June 30, 2017 and 2016 (the "consolidated interim financial statements"). The consolidated interim financial statements have been prepared in accordance with International Financial Reporting Standards (“IFRS"), including International Accounting Standard 34,Interim Financial Reporting, as issued by the International Accounting Standards Board.

References to “Hudbay”, the “Company”, “we”, “us”, “our” or similar terms refer to Hudbay Minerals Inc. and its direct and indirect subsidiaries as at June 30, 2017. "Hudbay Peru" refers to HudBay Peru S.A.C., our wholly-owned subsidiary which owns a 100% interest in the Constancia mine, and “Hudbay Arizona” refers to HudBay Arizona Corporation (formerly named Augusta Resource Corporation), our wholly-owned subsidiary, which indirectly owns a 92.05% interest in the Rosemont project.

Readers should be aware that:

| – | This MD&A contains certain “forward-looking statements” and “forward-looking information” (collectively, “forward-looking information”) that are subject to risk factors set out in a cautionary note contained in our MD&A. | |

| – | This MD&A has been prepared in accordance with the requirements of the securities laws in effect in Canada, which may differ materially from the requirements of United States securities laws applicable to US issuers. | |

| – | We use a number of non-IFRS financial performance measures in our MD&A. | |

| – | The technical and scientific information in this MD&A has been approved by qualified persons based on a variety of assumptions and estimates. |

For a discussion of each of the above matters, readers are urged to review the “Notes to Reader” discussion beginning on page 39 of this MD&A.

Additional information regarding Hudbay, including the risks related to our business and those that are reasonably likely to affect our financial statements in the future, is contained in our continuous disclosure materials, including our most recent Annual Information Form (“AIF”), consolidated financial statements and Management Information Circular available on SEDAR at www.sedar.com and on EDGAR at www.sec.gov.

All amounts are in US dollars unless otherwise noted.

OUR BUSINESS

We are an integrated mining company primarily producing copper concentrate (containing copper, zinc, gold and silver) and zinc metal. With assets in North and South America, we are focused on the discovery, production and marketing of base and precious metals. Directly and through our subsidiaries, we own four polymetallic mines, four ore concentrators and a zinc production facility in northern Manitoba and Saskatchewan (Canada) and Cusco (Peru), and a copper project in Arizona (United States). Our growth strategy is focused on the exploration and development of properties we already control, as well as other mineral assets we may acquire that fit our strategic criteria. Our vision is to become a top-tier operator of long-life, low-cost mines in the Americas. Our mission is to create sustainable value through the acquisition, development and operation of high-quality and growing long-life deposits in mining-friendly jurisdictions. We are governed by theCanada Business Corporations Actand our shares are listed under the symbol "HBM" on the Toronto Stock Exchange, New York Stock Exchange and Bolsa de Valores de Lima. We also have warrants listed under the symbol “HBM.WT” on the Toronto Stock Exchange and “HBM/WS” on the New York Stock Exchange.

1

SUMMARY

In the second quarter of 2017, cash generated from operating activities was $131.9 million, down from $137.5 million in the same period of 2016. Operating cash flow before change in non-cash working capital increased to $124.1 million in the second quarter of 2017 from $69.5 million in the same quarter of 2016. The increase in operating cash flow is the result of growth in sales volumes of most metals and higher realized copper and zinc prices.

Net profit and earnings per share in the second quarter of 2017 were $25.6 million and $0.11, respectively, compared to a net loss and loss per share of $5.7 million and $0.02, respectively, in the second quarter of 2016. Net profit and earnings per share in the second quarter of 2017 were affected by, among other things, the following items:

| Pre-tax | After-tax | Per share | |||||||

| gain (loss) | gain (loss) | gain (loss) | |||||||

| ($ millions) | ($ millions) | ($/share) | |||||||

| Foreign exchange loss | (5.7 | ) | (5.3 | ) | (0.02 | ) | |||

| Mark-to-market adjustments of various items | 6.8 | 6.1 | 0.03 | ||||||

| Non-cash deferred tax adjustments | - | 1.7 | 0.01 |

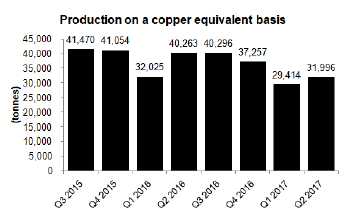

Compared to the same quarter of 2016, production of zinc in concentrate increased as a result of higher zinc grades in Manitoba, while copper production declined due to lower copper grades in Peru.

In the second quarter of 2017, consolidated cash cost per pound of copper produced, net of by-product credits, was $0.85, a marginal increase compared to $0.83 in the same period last year1. Incorporating sustaining capital, capitalized exploration, royalties and corporate selling and administrative expenses, consolidated all-in sustaining cash cost per pound of copper produced, net of by-product credits, in the second quarter of 2017 was $1.49, up from $1.42 in the second quarter of 20161. The increase in all-in sustaining cash cost was driven by higher planned sustaining capital expenditures in Peru and lower copper production compared to the second quarter of 2016.

Net debt1declined by $85.7 million from March 31, 2017 to $949.8 million at June 30, 2017, as approximately $63 million in drawings under our revolving credit facilities were repaid. At June 30, 2017, total liquidity including cash and available credit facilities was $496.8 million, up from $432.9 million at March 31, 2017.

We are on track to meet previously issued 2017 guidance for production, operating costs and capital costs.

__________________________________________________________________________________

1Cash cost and sustaining cash cost per pound of copper produced, net of by-product credits, and net debt are not recognized under IFRS. For more detail on this non-IFRS financial performance measure, please see the discussion under "Non-IFRS Financial Performance Measures" beginning on page 31 of this MD&A.

2

KEY FINANCIAL RESULTS

| Financial Condition | ||||||

| (in $ thousands) | Jun. 30, 2017 | Dec. 31, 2016 | ||||

| Cash and cash equivalents | 152,672 | 146,864 | ||||

| Total long-term debt | 1,102,426 | 1,232,164 | ||||

| Net debt1 | 949,754 | 1,085,300 | ||||

| Working capital | 86,112 | 121,539 | ||||

| Total assets | 4,359,827 | 4,456,556 | ||||

| Equity | 1,794,305 | 1,763,212 |

| Financial Performance | Three months ended | Six months ended | ||||||||||

| (in $ thousands, except per share amounts) | Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||

| 2017 | 2016 | 2017 | 2016 | |||||||||

| Revenue | 324,898 | 246,975 | 578,055 | 500,600 | ||||||||

| Cost of sales | 246,919 | 198,684 | 450,926 | 424,386 | ||||||||

| Profit (loss) before tax | 41,813 | 6,557 | 54,507 | (10,331 | ) | |||||||

| Profit (loss) | 25,586 | (5,703 | ) | 23,281 | (21,491 | ) | ||||||

| Basic and diluted earnings (loss) per share | 0.11 | (0.02 | ) | 0.10 | (0.09 | ) | ||||||

| Operating cash flow before change in non-cash working capital | 124,118 | 69,489 | 204,718 | 141,375 | ||||||||

1Net debt is a non-IFRS financial performance measures with no standardized definition under IFRS. For further information and a detailed reconciliation, please see the discussion under "Non-IFRS Financial Reporting Measures" beginning on page 31 of this MD&A.

3

KEY PRODUCTION RESULTS

| Three months ended | Three months ended | ||||||||||||||||||

| Jun. 30, 2017 | Jun. 30, 2016 | ||||||||||||||||||

| Peru | Manitoba | Total | Peru | Manitoba | Total | ||||||||||||||

| Contained metal in concentrate produced1 | |||||||||||||||||||

| Copper | tonnes | 29,798 | 11,044 | 40,842 | 34,699 | 11,193 | 45,892 | ||||||||||||

| Gold | oz | 3,802 | 22,862 | 26,664 | 8,625 | 21,080 | 29,705 | ||||||||||||

| Silver | oz | 546,295 | 264,051 | 810,346 | 778,448 | 218,063 | 996,511 | ||||||||||||

| Zinc | tonnes | - | 34,896 | 34,896 | - | 26,456 | 26,456 | ||||||||||||

| Payable metal sold | |||||||||||||||||||

| Copper | tonnes | 28,482 | 10,767 | 39,249 | 26,562 | 10,272 | 36,834 | ||||||||||||

| Gold | oz | 3,445 | 22,006 | 25,451 | 4,157 | 22,598 | 26,755 | ||||||||||||

| Silver | oz | 558,617 | 232,090 | 790,707 | 482,332 | 233,541 | 715,873 | ||||||||||||

| Zinc2 | tonnes | - | 29,424 | 29,424 | - | 23,728 | 23,728 | ||||||||||||

| Cash cost3 | $ /lb | 1.24 | (0.18 | ) | 0.85 | 0.97 | 0.37 | 0.83 | |||||||||||

| Sustaining cash cost3 | $ /lb | 1.82 | 0.38 | 1.39 | 1.10 | ||||||||||||||

| All-in sustaining cash cost2 | $ /lb | 1.49 | 1.42 | ||||||||||||||||

| Six months ended | Six months ended | ||||||||||||||||||

| Jun. 30, 2017 | Jun. 30, 2016 | ||||||||||||||||||

| Peru | Manitoba | Total | Peru | Manitoba | Total | ||||||||||||||

| Contained metal in concentrate produced1 | |||||||||||||||||||

| Copper | tonnes | 57,009 | 18,564 | 75,573 | 63,842 | 20,929 | 84,771 | ||||||||||||

| Gold | oz | 7,737 | 39,650 | 47,387 | 14,376 | 42,573 | 56,949 | ||||||||||||

| Silver | oz | 1,085,830 | 462,411 | 1,548,241 | 1,287,442 | 431,985 | 1,719,427 | ||||||||||||

| Zinc | tonnes | - | 65,466 | 65,466 | - | 49,832 | 49,832 | ||||||||||||

| Payable metal sold | |||||||||||||||||||

| Copper | tonnes | 47,047 | 18,617 | 65,664 | 57,835 | 20,918 | 78,753 | ||||||||||||

| Gold | oz | 4,919 | 46,001 | 50,920 | 11,537 | 32,935 | 44,472 | ||||||||||||

| Silver | oz | 941,880 | 525,392 | 1,467,272 | 1,148,415 | 341,767 | 1,490,182 | ||||||||||||

| Zinc2 | tonnes | - | 56,256 | 56,256 | - | 49,148 | 49,148 | ||||||||||||

| Cash cost3 | $ /lb | 1.27 | (0.37 | ) | 0.86 | 1.05 | 0.73 | 0.97 | |||||||||||

| Sustaining cash cost3 | $ /lb | 1.72 | 0.34 | 1.44 | 1.67 | ||||||||||||||

| All-in sustaining cash cost2 | $ /lb | 1.48 | 1.59 | ||||||||||||||||

1Metal reported in concentrate is prior to deductions associated with smelter contract terms.

2Includes refined zinc metal sold and payable zinc in concentrate sold.

3Cash cost, sustaining cash cost and all-in sustaining cash cost per pound of copper produced, net of by-product credits are non-IFRS financial performance measures with no standardized definition under IFRS. For further information and a detailed reconciliation, please see the discussion under "Non-IFRS Financial Reporting Measures" beginning on page 31 of this MD&A.

4

RECENT DEVELOPMENTS

Final Record of Decision for Rosemont

On June 7, 2017, the U.S. Forest Service ("USFS") issued the Final Record of Decision ("FROD") related to the Rosemont Project. Receiving the FROD concludes a thorough process involving 17 co-operating agencies at various levels of government, 16 hearings, over 1,000 studies, and 245 days of public comment resulting in more than 36,000 comments. Since receiving the FROD, we have commenced the administrative process working with the USFS to complete the Mine Plan of Operations ("MPO"), and the draft MPO was submitted to the USFS in late June. The other key federal permit outstanding is the Section 404 Water Permit from the U.S. Army Corps of Engineers.

Credit Facility Extension & Amendments

On July 14, 2017, we entered into amendments to our senior credit facilities to secure both facilities with substantially all of our assets other than assets related to the Rosemont project, amend the financial covenants, extend the maturity dates to July 14, 2021 from March 31, 2019 and reduce the interest rate to LIBOR plus 3.00% from LIBOR plus 4.50%, based on financial results for the twelve months ended June 30, 2017. The revised covenants include maintaining gross total debt to EBITDA of less than 4.00 times in 2017, senior secured debt to EBITDA of less than 2.00 times, and interest coverage of more than 3.00 times. The two facilities have substantially similar terms and conditions and continue to provide revolving credit to a maximum amount of up to $550 million.

Dividend Declared

A semi-annual dividend of C$0.01 per share was declared on August 3, 2017. The dividend will be paid on September 29, 2017 to shareholders of record as of September 8, 2017.

5

EXPLORATION UPDATE

Given the strong free cash flow generation of the business year-to-date, additional funds have been allocated to exploration in 2017 with a focus on high-priority drilling targets. We have been active in identifying and acquiring grassroots exploration properties in Peru, Chile and British Columbia during the recent downturn in metals prices. The increase in exploration expenditures is expected to fund drilling on the grassroots exploration properties, as well as testing targets in Manitoba and drilling down plunge at Lalor.

The revised exploration guidance for 2017 is shown below.

| 2017 Exploration Guidance | ||||||

| (in $ millions) | Revised | Original | ||||

| Manitoba | 6 | 4 | ||||

| Peru | 5 | 2 | ||||

| Generative and other | 12 | 4 | ||||

| Total exploration expenditures | 23 | 10 | ||||

| Capitalized Spending1 | (2 | ) | (2 | ) | ||

| Total1 | 21 | 8 |

1Assumes $2 million of Manitoba expenditures will be capitalized

6

CONSTANCIA OPERATIONS REVIEW

| Three months ended | Six months ended | Guidance1 | ||||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | Annual | ||||||||||||

| 2017 | 2016 | 2017 | 2016 | 2017 | ||||||||||||

| Ore mined | tonnes | 7,337,531 | 6,526,635 | 14,550,731 | 13,359,315 | |||||||||||

| Copper | % | 0.55 | 0.64 | 0.55 | 0.61 | |||||||||||

| Gold | g/tonne | 0.04 | 0.09 | 0.04 | 0.07 | |||||||||||

| Silver | g/tonne | 3.81 | 4.75 | 3.92 | 4.24 | |||||||||||

| Ore milled | tonnes | 6,931,690 | 6,726,277 | 13,249,299 | 12,976,109 | |||||||||||

| Copper | % | 0.53 | 0.62 | 0.54 | 0.60 | |||||||||||

| Gold | g/tonne | 0.04 | 0.08 | 0.04 | 0.07 | |||||||||||

| Silver | g/tonne | 3.91 | 5.42 | 4.08 | 5.10 | |||||||||||

| Copper concentrate | tonnes | 118,586 | 139,745 | 227,122 | 254,283 | |||||||||||

| Concentrate grade | % Cu | 25.13 | 24.83 | 25.10 | 25.11 | |||||||||||

| Copper recovery | % | 80.6 | 82.7 | 80.4 | 82.3 | |||||||||||

| Gold recovery | % | 44.8 | 51.3 | 44.7 | 49.1 | |||||||||||

| Silver recovery | % | 62.6 | 66.4 | 62.4 | 60.5 | |||||||||||

| Combined unit operating costs1 | $/tonne | 8.99 | 7.88 | 9.09 | 7.82 | 7.20 - 8.80 | ||||||||||

1Reflects combined mine and mill costs per tonne of ore milled. Peru operations combined mine and mill unit costs include G&A, and reflects the deduction of expected capitalized stripping costs and excludes costs.

Ore mined at our Constancia mine during the second quarter of 2017 increased by 12% compared to the same period in 2016 as we continue to increase stockpiles to improve our ability to blend ore at the processing plant. As expected, milled copper grades in the second quarter were approximately 15% lower than the same period in 2016 as we entered lower grade phases of the mine plan. Despite harder material, mill throughput improved 3% due to plant optimization initiatives during the second quarter of 2017.

Recoveries of copper, gold and silver were lower in the second quarter of 2017, compared to the same period in 2016, due to normal ore variability. Improvements in process recoveries continue to be implemented and evaluated along with consistent positive grade reconciliations.

Combined mine, mill and G&A unit operating costs in the second quarter of 2017 were 14% higher than the same period in 2016 as a result of increased unplanned plant maintenance, costs of operating the molybdenum plant at higher than planned rates, higher community spending, road maintenance costs and other administrative costs.

Combined unit operating costs are expected to decline in the second half of 2017 with full year results expected to fall within the guidance range.

7

| Three months ended | Six months ended | Guidance | ||||||||||||||||

| Contained metal in | Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | Annual | |||||||||||||

| concentrate produced | 2017 | 2016 | 2017 | 2016 | 2017 | |||||||||||||

| Copper | tonnes | 29,798 | 34,699 | 57,009 | 63,842 | 100,000 - 115,000 | ||||||||||||

| Gold | oz | 3,802 | 8,625 | 7,737 | 14,376 | |||||||||||||

| Silver | oz | 546,295 | 778,448 | 1,085,830 | 1,287,442 | |||||||||||||

| Precious metals1 | oz | 11,606 | 19,745 | 23,249 | 32,768 | 55,000 - 65,000 | ||||||||||||

1Precious metals production includes gold and silver production on a gold-equivalent basis. Silver is converted to gold at a ratio of 70:1.

Production of copper, gold and silver in the second quarter of 2017 was lower than the same period in 2016 due to an expected decline in mined grades, while production increased from the first to second quarter of 2017 as a result of improved mill throughput.

We expect to meet our production and cost guidance at Constancia for the year.

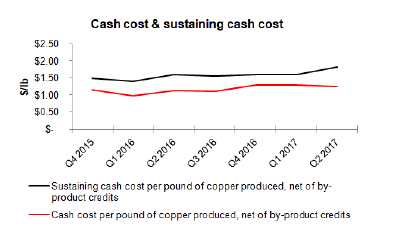

Peru Cash Cost and Sustaining Cash Cost

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||||

| 2017 | 2016 | 2017 | 2016 | ||||||||||

| Cash cost per pound of copper produced, | |||||||||||||

| net of by-product credits1 | $/lb | 1.24 | 0.97 | 1.27 | 1.05 | ||||||||

| Sustaining cash cost per pound of copper | |||||||||||||

| produced, net of by-product credits1 | $/lb | 1.82 | 1.39 | 1.72 | 1.44 | ||||||||

1Cash cost and sustaining cash costs per pound of copper produced, net of by-product credits, are not recognized under IFRS. For more detail on this non-IFRS financial performance measure, please see the discussion under "Non-IFRS Financial Performance Measures" beginning on page 31 of this MD&A.

Cash cost per pound of copper produced, net of by-product credits, for the three months ended June 30, 2017 was $1.24, an increase of 28% from the same period in 2016 mainly as a result of decreased copper grades, together with increased plant maintenance and other costs as described above.

Sustaining cash cost per pound of copper produced, net of by-product credits, for the three months ended June 30, 2017 was $1.82, an increase of 31% from the same period in 2016 as a result of the factors noted above, as well as expected higher sustaining capital in heavy civil works during the dry season and mobile equipment overhauls.

8

Metal Sold

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||||

| 2017 | 2016 | 2017 | 2016 | ||||||||||

| Payable metal in concentrate | |||||||||||||

| Copper | tonnes | 28,482 | 26,562 | 47,047 | 57,835 | ||||||||

| Gold | oz | 3,445 | 4,157 | 4,919 | 11,537 | ||||||||

| Silver | oz | 558,617 | 482,332 | 941,880 | 1,148,415 | ||||||||

9

MANITOBA OPERATIONS REVIEW

Mines

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||||

| 2017 | 2016 | 2017 | 2016 | ||||||||||

| 777 | |||||||||||||

| Ore | tonnes | 287,884 | 334,718 | 576,248 | 692,258 | ||||||||

| Copper | % | 1.70 | 1.57 | 1.61 | 1.57 | ||||||||

| Zinc | % | 5.06 | 2.52 | 4.81 | 2.76 | ||||||||

| Gold | g/tonne | 2.10 | 1.39 | 1.93 | 1.36 | ||||||||

| Silver | g/tonne | 24.65 | 17.26 | 22.90 | 17.44 | ||||||||

| Lalor | |||||||||||||

| Ore | tonnes | 337,387 | 281,136 | 617,005 | 543,034 | ||||||||

| Copper | % | 0.65 | 0.55 | 0.60 | 0.57 | ||||||||

| Zinc | % | 7.88 | 7.31 | 7.98 | 6.79 | ||||||||

| Gold | g/tonne | 1.82 | 2.15 | 1.68 | 2.34 | ||||||||

| Silver | g/tonne | 21.44 | 20.32 | 20.75 | 20.05 | ||||||||

| Reed1 | |||||||||||||

| Ore | tonnes | 121,114 | 114,452 | 240,648 | 225,913 | ||||||||

| Copper | % | 4.12 | 4.87 | 3.55 | 4.63 | ||||||||

| Zinc | % | 0.41 | 0.45 | 0.54 | 0.63 | ||||||||

| Gold | g/tonne | 0.47 | 0.60 | 0.45 | 0.57 | ||||||||

| Silver | g/tonne | 6.20 | 7.47 | 5.92 | 7.34 | ||||||||

| Total Mines | |||||||||||||

| Ore | tonnes | 746,385 | 730,306 | 1,433,901 | 1,461,205 | ||||||||

| Copper | % | 1.62 | 1.70 | 1.50 | 1.67 | ||||||||

| Zinc | % | 5.58 | 4.04 | 5.46 | 3.93 | ||||||||

| Gold | g/tonne | 1.71 | 1.56 | 1.58 | 1.60 | ||||||||

| Silver | g/tonne | 20.21 | 16.90 | 19.12 | 16.85 | ||||||||

| 1Includes 100% of Reed mine production. | |||||||||||||

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||||

| Unit Operating Costs | 2017 | 2016 | 2017 | 2016 | |||||||||

| Mines | |||||||||||||

| 777 | C$/tonne | 59.65 | 50.64 | 59.33 | 50.81 | ||||||||

| Lalor | C$/tonne | 77.50 | 63.48 | 80.17 | 66.20 | ||||||||

| Reed | C$/tonne | 59.76 | 43.51 | 57.08 | 44.62 | ||||||||

| Total Mines | C$/tonne | 68.15 | 55.01 | 68.49 | 56.11 | ||||||||

10

Ore mined at our Manitoba operations during the second quarter of 2017 increased by 2% compared to the same period in 2016, primarily as a result of increased production at our Lalor and Reed mines, partially offset by decreased production at our 777 mine. Overall, zinc, gold and silver grades were 38%, 10%, and 20% higher, respectively, while copper grades were 5% lower in the second quarter of 2017 compared to the same period of 2016. Grade variances were due to planned stope sequencing, including the resequencing of the 777 mine plan to prioritize higher grade zinc stopes in 2017. Unit operating costs for all Manitoba mines for the second quarter of 2017 increased by 24% compared to the same period in 2016. Production and costs at 777 and Reed were consistent with expectations during this part of the mine life. Consistent with our revised mine plan, Lalor’s unit costs reflect increased cement rock filling costs as well as substantial operating and capital development work that was undertaken to support our plan to grow Lalor’s production rate to 4,500 tonnes per day.

Year-to-date ore production at our Manitoba mines was 2% lower than the same period in 2016 as a result of lower production at our 777 mine partially offset by higher production at our Reed and Lalor mines. Year-to-date copper and gold grades in 2017, were lower than the same period in 2016 by 10%, and 1%, respectively, while zinc and silver grades were 39% and 13% higher, respectively, which is in line with mine plan expectations. Year-to-date total mine unit costs were 22% higher than the same period in 2016 as a result of the same factors that impacted second quarter total mine unit costs.

11

Processing Facilities

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||||

| 2017 | 2016 | 2017 | 2016 | ||||||||||

| Flin Flon Concentrator | |||||||||||||

| Ore | tonnes | 436,188 | 437,759 | 810,082 | 866,389 | ||||||||

| Copper | % | 2.37 | 2.39 | 2.15 | 2.27 | ||||||||

| Zinc | % | 3.70 | 2.06 | 3.58 | 2.29 | ||||||||

| Gold | g/tonne | 1.62 | 1.20 | 1.50 | 1.18 | ||||||||

| Silver | g/tonne | 19.12 | 14.87 | 17.98 | 15.12 | ||||||||

| Copper concentrate | tonnes | 39,354 | 40,964 | 66,791 | 76,072 | ||||||||

| Concentrate grade | % Cu | 24.19 | 24.05 | 23.92 | 24.10 | ||||||||

| Zinc concentrate | tonnes | 27,415 | 13,770 | 48,953 | 30,574 | ||||||||

| Concentrate grade | % Zn | 50.68 | 51.35 | 51.04 | 51.48 | ||||||||

| Copper recovery | % | 92.1 | 94.0 | 91.8 | 93.1 | ||||||||

| Zinc recovery | % | 86.1 | 78.3 | 86.1 | 79.2 | ||||||||

| Gold recovery | % | 59.9 | 60.9 | 59.7 | 59.5 | ||||||||

| Silver recovery | % | 56.8 | 55.9 | 55.3 | 56.3 | ||||||||

| Contained metal in concentrate produced | |||||||||||||

| Copper | tonnes | 9,518 | 9,850 | 15,976 | 18,333 | ||||||||

| Zinc | tonnes | 13,895 | 7,071 | 24,987 | 15,739 | ||||||||

| Precious metals1 | oz | 15,778 | 11,911 | 27,038 | 22,964 | ||||||||

| Stall Concentrator | |||||||||||||

| Ore | tonnes | 290,301 | 285,434 | 553,453 | 542,534 | ||||||||

| Copper | % | 0.64 | 0.57 | 0.58 | 0.58 | ||||||||

| Zinc | % | 7.88 | 7.33 | 7.93 | 6.80 | ||||||||

| Gold | g/tonne | 1.80 | 2.14 | 1.66 | 2.36 | ||||||||

| Silver | g/tonne | 21.14 | 20.22 | 20.52 | 20.29 | ||||||||

| Copper concentrate | tonnes | 7,083 | 6,682 | 12,856 | 12,593 | ||||||||

| Concentrate grade | % Cu | 21.54 | 20.10 | 20.13 | 20.61 | ||||||||

| Zinc concentrate | tonnes | 40,362 | 37,464 | 77,724 | 66,592 | ||||||||

| Concentrate grade | % Zn | 52.03 | 51.74 | 52.08 | 51.20 | ||||||||

| Copper recovery | % | 81.6 | 81.9 | 80.5 | 81.9 | ||||||||

| Zinc recovery | % | 91.8 | 92.7 | 92.3 | 92.4 | ||||||||

| Gold recovery | % | 55.3 | 55.1 | 55.2 | 55.9 | ||||||||

| Silver recovery | % | 56.7 | 54.5 | 55.7 | 55.1 | ||||||||

| Contained metal in concentrate produced | |||||||||||||

| Copper | tonnes | 1,526 | 1,343 | 2,588 | 2,596 | ||||||||

| Zinc | tonnes | 21,001 | 19,385 | 40,479 | 34,093 | ||||||||

| Precious metals1 | oz | 10,856 | 12,285 | 19,218 | 25,780 | ||||||||

1Precious metals production includes gold and silver production on a gold-equivalent basis. Silver is converted to gold at a ratio of 70:1.

12

| Three months ended | Six months ended | Guidance | ||||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | Annual | ||||||||||||

| Unit Operating Costs | 2017 | 2016 | 2017 | 2016 | 2017 | |||||||||||

| Concentrators | ||||||||||||||||

| Flin Flon | C$/tonne | 17.57 | 16.64 | 19.21 | 16.23 | |||||||||||

| Stall | C$/tonne | 26.60 | 21.09 | 31.08 | 21.38 | |||||||||||

| Combined mine/mill unit operating costs1 | ||||||||||||||||

| Manitoba | C$/tonne | 109.11 | 87.63 | 113.88 | 91.09 | 88 - 108 | ||||||||||

1Reflects combined mine, mill and G&A costs per tonne of milled ore. Includes the cost of ore purchased from our joint venture partner at Reed mine.

Ore processed in Flin Flon in the second quarter of 2017 was consistent with ore processed during the same period in 2016. Copper, gold and silver recoveries in the second quarter of 2017 were consistent with the same period in 2016, while zinc recovery was 10% higher due to higher zinc head grades. Unit operating costs at the Flin Flon concentrator were 6% higher in the second quarter of 2017 compared to the same period in 2016 as a result of higher maintenance expenditures. Ore processed and recoveries at the Stall concentrator in the second quarter of 2017 were consistent with the same period in 2016. Unit operating costs at the Stall concentrator were 26% higher in the second quarter of 2017 compared to the same period in 2016 as a result of higher maintenance expenditures and additional costs related to the use of higher-cost temporary crushing facilities in April. The mill resumed use of its permanent crushing circuit by the end of April 2017.

Ore processed year-to-date in 2017 in Flin Flon was 6% lower than the same period in 2016 as a result of lower production at our 777 mine. Year-to-date recoveries of copper, gold, and silver, were fairly consistent with the same period in 2016, while zinc recovery was 9% higher due to higher zinc head grades. Year-to-date unit operating costs at the Flin Flon concentrator were 18% higher than the same period in 2016 as a result of lower production as well as increased maintenance costs. Ore processed year-to-date and recoveries for all metals in 2017 at the Stall concentrator were consistent with the same period in 2016. Year-to-date unit operating costs at the Stall concentrator were 45% higher than the same period in 2016 as a result of higher maintenance expenditures and the use of higher-cost temporary crushing facilities primarily during the first quarter.

The strong ramp up of ore production from the Lalor mine in the first half of 2017 has resulted in the accumulation of an ore stockpile as Lalor’s production has exceeded the Stall concentrator’s current milling capacity. We have started to truck some of the stockpiled ore to the Flin Flon mill for processing in the second half of 2017.

Manitoba combined mine, mill and G&A unit operating costs in the second quarter and year-to-date in 2017 were 25% higher than in the same periods in 2016 for the reasons outlined above. In addition, the stockpiling of Lalor ore described above increases combined mine/mill unit costs as that metric is expressed as total costs during the period (irrespective of inventory changes), divided by the tonnes of ore milled. This factor should reverse as stockpiles reduce, although costs in the second half will be affected by higher Reed mine unit costs as the capitalization of development costs will cease, and additional costs will be incurred to truck Lalor ore to the Flin Flon mill. Processing the additional Lalor production in Flin Flon is expected to drive economies of scale and additional revenues through a faster ramp up.Combined unit costs are expected to be within the guidance range for 2017.

13

| Three months ended | Six months ended | Guidance1 | ||||||||||||||

| Manitoba contained metal in | Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | Annual | |||||||||||

| concentrate produced1,2 | 2017 | 2016 | 2017 | 2016 | 2017 | |||||||||||

| Copper | tonnes | 11,044 | 11,193 | 18,564 | 20,929 | 32,500 - 42,500 | ||||||||||

| Gold | oz | 22,862 | 21,080 | 39,650 | 42,573 | |||||||||||

| Silver | oz | 264,051 | 218,063 | 462,411 | 431,985 | |||||||||||

| Zinc | tonnes | 34,896 | 26,456 | 65,466 | 49,832 | 125,000 - 150,000 | ||||||||||

| Precious metals3 | oz | 26,634 | 24,195 | 46,256 | 48,744 | 90,000 - 110,000 | ||||||||||

1Includes 100% of Reed mine production.

2Metal reported in concentrate is prior to deductions associated with smelter terms.

3Precious metals production includes gold and silver production on a gold-equivalent basis. Silver is converted to gold at a ratio of 70:1.

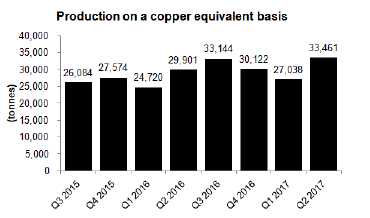

In the second quarter of 2017, production of copper was consistent with the same period in 2016. Zinc, gold, and silver production was 32%, 8%, and 21% higher, respectively, compared to the same period of 2016 as a result of higher grades at 777 and Lalor as well as higher production at Lalor. Production is expected to be within guidance ranges for 2017.

Manitoba’s production of copper equivalent tonnes achieved record levels in the second quarter of 2017 mainly due to higher mill throughput and higher grades.

Zinc Plant

| Three months ended | Six months ended | Guidance | ||||||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | Annual | ||||||||||||||

| Zinc Production | 2017 | 2016 | 2017 | 2016 | 2017 | |||||||||||||

| Zinc Concentrate Treated | ||||||||||||||||||

| Domestic | tonnes | 53,026 | 47,206 | 110,161 | 99,021 | |||||||||||||

| Refined Metal Produced | ||||||||||||||||||

| Domestic | tonnes | 25,476 | 22,859 | 54,294 | 47,136 | 95,000 - 115,000 | ||||||||||||

14

| Three months ended | Six months ended | Guidance | ||||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | Annual | ||||||||||||

| Unit Operating Costs | 2017 | 2016 | 2017 | 2016 | 2017 | |||||||||||

| Zinc Plant1 | C$/lb | 0.44 | 0.48 | 0.42 | 0.48 | 0.40 - 0.50 | ||||||||||

1Zinc unit operating costs include G&A costs.

Production of cast zinc in the second quarter of 2017 and year-to-date in 2017 was 11% and 15% higher, respectively, than in the same periods in 2016 as a result of increased production of zinc concentrate. Operating costs per pound of zinc metal produced in the second quarter of 2017 and year-to-date were 8% lower and 13% lower, respectively, compared to the same periods in 2016 as a result of increased production. Refined zinc metal production and operating costs are expected to be within guidance ranges for 2017.

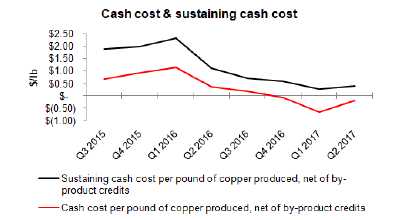

Manitoba Cash Cost and Sustaining Cash Cost

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||||

| 2017 | 2016 | 2017 | 2016 | ||||||||||

| Cost per pound of copper produced | |||||||||||||

| Cash cost per pound of copper produced, | |||||||||||||

| net of by-product credits1 | $/lb | (0.18 | ) | 0.37 | (0.37 | ) | 0.73 | ||||||

| Sustaining cash cost per pound of copper | |||||||||||||

| produced, net of by-product credits1 | $/lb | 0.38 | 1.10 | 0.34 | 1.67 | ||||||||

| Cost per pound of zinc produced | |||||||||||||

| Cash cost per pound of zinc produced, | |||||||||||||

| net of by-product credits1 | $/lb | 0.21 | 0.22 | 0.25 | 0.32 | ||||||||

| Sustaining cash cost per pound of zinc | |||||||||||||

| produced, net of by-product credits1 | $/lb | 0.39 | 0.53 | 0.45 | 0.72 | ||||||||

1Cash cost and sustaining cash cost per pound of copper & zinc produced, net of by-product credits, are not recognized under IFRS. For more detail on this non-IFRS financial performance measure, please see the discussion under "Non-IFRS Financial Performance Measures" beginning on page 31 of this MD&A.

In Manitoba, cash cost, net of by-product credits, in the second quarter of 2017 was negative $0.18 per pound of copper produced compared to $0.37 in the second quarter of 2016. The decrease is primarily a result of significantly increased zinc by-product credits, partially offset by expected higher costs at our 777 and Reed mines during this part of their mine life. Sustaining cash cost, net of by-product credits, in the second quarter of 2017 decreased to $0.38 per pound of copper produced compared to $1.10 in the second quarter of 2016 as a result of the same factors described above and lower capitalized underground mine development. On a year-to-date basis, the declines in cash cost, net of by-product credits and sustaining cash cost, net of by-product credits were the result of the same factors impacting second quarter results.

Cash cost and sustaining cash cost per pound of zinc produced, net of by-product credits, was lower compared to the same period last year as a result of increased zinc production, higher grades realized with the revised 777 mine plan and lower sustaining capital spending, partially offset by the higher mining costs associated with the 777 mine at this stage of its mine life.

15

In the past three quarters, Manitoba cash cost and sustaining cash cost have declined due to increased by-product credits realized. Cash costs in the first quarter of 2017 benefited from cost reduction initiatives and higher than usual by-product credits.

Metal Sold

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | ||||||||||

| 2017 | 2016 | 2017 | 2016 | ||||||||||

| Payable metal in concentrate | |||||||||||||

| Copper | tonnes | 10,767 | 10,272 | 18,617 | 20,918 | ||||||||

| Gold | oz | 22,006 | 22,598 | 46,001 | 32,935 | ||||||||

| Silver | oz | 232,090 | 233,541 | 525,392 | 341,767 | ||||||||

| Zinc | tonnes | 1,760 | - | 1,760 | - | ||||||||

| Refined zinc | tonnes | 27,664 | 23,728 | 54,496 | 49,148 | ||||||||

Due to increased Lalor mine throughput and higher zinc grades at 777, zinc concentrate production is exceeding the processing capacity of the Flin Flon zinc plant. As a result, sales of excess zinc concentrate inventory began in the second quarter of 2017 and will continue as long as concentrate production exceeds zinc plant processing capacity.

FINANCIAL REVIEW

Financial Results

In the second quarter of 2017, we recorded a profit of $25.6 million compared to a loss of $5.7 million for the same period in 2016, an increase in profit of $31.3 million.

Year-to-date in 2017, we recorded a profit of $23.3 million compared to a loss of $21.5 million in the same period in 2016, an increase in profit of $44.8 million.

16

The following table provides further details on these variances:

| Three months ended | Six months ended | |||||

| (in $ millions) | Jun. 30, 2017 | Jun. 30, 2017 | ||||

| Increase (decrease) in components of profit or loss: | ||||||

| Revenues | 77.9 | 77.5 | ||||

| Cost of sales | ||||||

| Mine operating costs | (35.5 | ) | (26.6 | ) | ||

| Depreciation and amortization | (12.8 | ) | 0.1 | |||

| Finance expense | 3.6 | 7.1 | ||||

| Other | 2.1 | 6.8 | ||||

| Tax | (4.0 | ) | (20.1 | ) | ||

| Increase in profit in 2017 compared to 2016 | 31.3 | 44.8 |

Revenue

Revenue for the second quarter of 2017 was $324.9 million, $77.9 million higher than the same period in 2016, primarily as a result of higher copper, silver and zinc sales volumes and higher metal prices for copper and zinc.

Year-to-date revenue was $578.1 million, $77.5 million higher than the same period in 2016, due to significantly higher realized sales prices for copper and zinc metals, and lower treatment and refining charges, partially offset by lower copper concentrate sales volumes.

| Three months ended | Six months ended | |||||

| (in $ millions) | Jun. 30, 2017 | Jun. 30, 2017 | ||||

| Metals prices1 | ||||||

| Higher copper prices | 40.5 | 68.2 | ||||

| Higher zinc prices | 21.8 | 51.2 | ||||

| Lower gold prices | (6.2 | ) | (9.9 | ) | ||

| Lower silver prices | (2.3 | ) | (2.9 | ) | ||

| Sales volumes | ||||||

| Higher (lower) copper sales volumes | 11.2 | (63.1 | ) | |||

| Higher zinc sales volumes | 11.7 | 13.8 | ||||

| (Lower) higher gold sales volumes | (1.6 | ) | 12.2 | |||

| Higher silver sales volumes | 1.2 | 1.2 | ||||

| Other | ||||||

| Derivative mark-to-market decrease | (3.1 | ) | (7.2 | ) | ||

| Other volume and pricing differences | 4.4 | 4.9 | ||||

| Effect of lower treatment and refining charges | 0.3 | 9.1 | ||||

| Increase in revenue in 2017 compared to 2016 | 77.9 | 77.5 |

1 See discussion below for further information regarding metals prices.

17

Our revenue by significant product type is summarized below:

| Three months ended | Six months ended | |||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | |||||||||

| (in $ millions) | 2017 | 2016 | 2017 | 2016 | ||||||||

| Copper | 223.0 | 171.3 | 375.0 | 369.9 | ||||||||

| Zinc | 82.3 | 52.0 | 160.2 | 102.5 | ||||||||

| Gold | 28.8 | 36.6 | 59.8 | 57.5 | ||||||||

| Silver | 11.9 | 12.9 | 21.8 | 23.4 | ||||||||

| Other | 5.0 | 0.6 | 6.2 | 1.3 | ||||||||

| Gross revenue1 | 351.0 | 273.4 | 623.0 | 554.6 | ||||||||

| Treatment and refining charges | (26.1 | ) | (26.4 | ) | (44.9 | ) | (54.0 | ) | ||||

| Revenue | 324.9 | 247.0 | 578.1 | 500.6 | ||||||||

1Copper, gold and silver revenues include unrealized gains and losses related to non-hedge derivative contracts including fixed for floating swaps, that are included in realized prices. Zinc revenues include unrealized gains and losses related to non-hedge derivative contracts that are not included in realized prices.

18

Realized sales prices This measure is intended to enable management and investors to understand the average realized price of metals sold to third parties in each reporting period. The average realized price per unit sold does not have any standardized meaning prescribed by IFRS, is unlikely to be comparable to similar measures presented by other issuers, and should not be considered in isolation or a substitute for measures of performance prepared in accordance with IFRS.

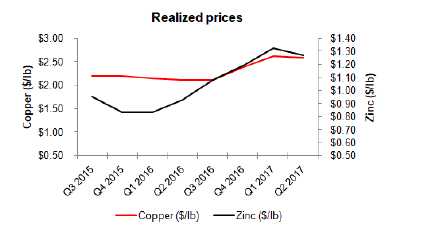

For sales of copper, gold and silver we may enter into non-hedge derivatives (“QP hedges”) which are intended to manage the provisional pricing risk arising from quotational period terms in concentrate sales agreements. The QP hedges are not removed from the calculation of realized prices. We expect that gains and losses on QP hedges will offset provisional pricing adjustments on concentrate sales contracts. Our realized prices for the second quarter and year-to-date in 2017 and 2016, respectively, are summarized below:

| Realized prices1for the | Realized prices1for the | ||||||||||||||||||

| Three months ended | Six months ended | ||||||||||||||||||

| LME QTD | Jun. 30, | Jun. 30, | LME YTD | Jun. 30, | Jun. 30, | ||||||||||||||

| 20172 | 2017 | 2016 | 20172 | 2017 | 2016 | ||||||||||||||

| Prices | |||||||||||||||||||

| Copper | $/lb | 2.57 | 2.58 | 2.11 | 2.61 | 2.59 | 2.13 | ||||||||||||

| Zinc3 | $/lb | 1.18 | 1.27 | 0.93 | 1.22 | 1.29 | 0.88 | ||||||||||||

| Gold4 | $/oz | 1,130 | 1,368 | 1,174 | 1,293 | ||||||||||||||

| Silver4 | $/oz | 15.02 | 18.09 | 14.83 | 15.70 | ||||||||||||||

| 1 | Realized prices exclude refining and treatment charges and are on the sale of finished metal or metal in concentrate. Realized prices include the effect of provisional pricing adjustments on prior period sales. |

| 2 | London Metal Exchange average for copper and zinc prices. |

| 3 | This amount includes a realized sales price of $1.27 for cast zinc metal and $1.25 for zinc concentrate sold for the three months ended June 30, 2017. Zinc realized prices include premiums paid by customers for delivery of refined zinc metal, but exclude unrealized gains and losses related to non-hedge derivative contracts that are included in zinc revenues. For the three months ended June 30, 2017, the unrealized component of the zinc derivative resulted in a gain of $0.00/lb. For the three months ended June 30, 2016, the unrealized component of the zinc derivative resulted in a gain of $0.06/lb. |

| 4 | Sales of gold and silver from our 777 and Constancia mines are subject to our precious metals stream agreement with Wheaton Precious Metals, pursuant to which we recognize deferred revenue for precious metals deliveries and also receive cash payments. Stream sales are included within realized prices and their respective deferred revenue and cash payment rates can be found on page 21. |

19

The following table provides a reconciliation of average realized price per unit sold, by metal, to revenues as shown in the consolidated financial statements:

| Three months ended June 30, 2017 | ||||||||||||||||||

| (in $ millions)1 | Copper | Zinc | Gold | Silver | Other | Total | ||||||||||||

| Revenue per financial statements | 223.0 | 82.3 | 28.8 | 11.9 | 5.0 | 351.0 | ||||||||||||

| Derivative mark-to-market2 | - | (0.2 | ) | - | - | - | (0.2 | ) | ||||||||||

| Revenue, excluding mark-to-market on non-QP hedges | 223.0 | 82.1 | 28.8 | 11.9 | 5.0 | 350.8 | ||||||||||||

| Payable metal in concentrate sold3 | 39,249 | 29,424 | 25,451 | 790,707 | - | - | ||||||||||||

| Realized price4 | 5,682 | 2,790 | 1,130 | 15.02 | - | - | ||||||||||||

| Realized price5 | 2.58 | 1.27 | - | - | - | - | ||||||||||||

| Six months ended June 30, 2017 | ||||||||||||||||||

| (in $ millions)1 | Copper | Zinc | Gold | Silver | Other | Total | ||||||||||||

| Revenue per financial statements | 375.0 | 160.2 | 59.8 | 21.8 | 6.2 | 623.0 | ||||||||||||

| Derivative mark-to-market2 | - | 0.1 | - | - | - | 0.1 | ||||||||||||

| Revenue, excluding mark-to-market on non-QP hedges | 375.0 | 160.3 | 59.8 | 21.8 | 6.2 | 623.1 | ||||||||||||

| Payable metal in concentrate sold3 | 65,664 | 56,256 | 50,920 | 1,467,272 | - | - | ||||||||||||

| Realized price4 | 5,711 | 2,848 | 1,174 | 14.83 | - | - | ||||||||||||

| Realized price5 | 2.59 | 1.29 | - | - | - | - | ||||||||||||

| Three months ended June 30, 2016 | ||||||||||||||||||

| (in $ millions)1 | Copper | Zinc | Gold | Silver | Other | Total | ||||||||||||

| Revenue per financial statements | 171.3 | 52.0 | 36.6 | 12.9 | 0.6 | 273.4 | ||||||||||||

| Derivative mark-to-market2 | - | (3.3 | ) | - | - | - | (3.3 | ) | ||||||||||

| Revenue, excluding mark-to-market on non-QP hedges | 171.3 | 48.7 | 36.6 | 12.9 | 0.6 | 270.1 | ||||||||||||

| Payable metal in concentrate sold3 | 36,834 | 23,728 | 26,755 | 715,873 | - | - | ||||||||||||

| Realized price4 | 4,650 | 2,052 | 1,368 | 18.09 | - | - | ||||||||||||

| Realized price5 | 2.11 | 0.93 | - | - | - | - | ||||||||||||

| Six months ended June 30, 2016 | ||||||||||||||||||

| (in $ millions)1 | Copper | Zinc | Gold | Silver | Other | Total | ||||||||||||

| Revenue per financial statements | 369.9 | 102.5 | 57.5 | 23.4 | 1.3 | 554.6 | ||||||||||||

| Derivative mark-to-market2 | - | (7.1 | ) | - | - | - | (7.1 | ) | ||||||||||

| Revenue, excluding mark-to-market on non-QP hedges | 369.9 | 95.4 | 57.5 | 23.4 | 1.3 | 547.5 | ||||||||||||

| Payable metal in concentrate sold3 | 78,753 | 49,148 | 44,472 | 1,490,182 | - | - | ||||||||||||

| Realized price4 | 4,697 | 1,940 | 1,293 | 15.70 | - | - | ||||||||||||

| Realized price5 | 2.13 | 0.88 | - | - | - | - | ||||||||||||

1Average realized price per unit sold may not calculate based on amounts presented in this table due to rounding.

2Derivative mark-to-market excludes mark-to-market on QP hedges.

3Copper and zinc shown in tonnes and gold and silver shown in ounces.

4Realized price for copper and zinc in $/metric tonne and realized price for gold and silver in $/oz.

5Realized price for copper and zinc in $/lb.

The price, quantity and mix of metals sold, affect our revenue, operating cash flow and profit. Revenue from metals sales can vary from quarter to quarter due to production levels, shipping volumes and transfer of risk and title to customers.

20

Stream Sales

The following table shows stream sales included within realized prices and their respective deferred revenue and cash payment rates:

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, 2017 | Jun. 30, 2017 | ||||||||||||

| Manitoba | Peru | Manitoba | Peru | ||||||||||

| Gold | oz | 6,321 | 2,623 | 12,607 | 4,671 | ||||||||

| Silver | oz | 124,757 | 558,617 | 266,863 | 941,880 | ||||||||

| Gold deferred revenue drawdown rate1 | $/oz | 1,089 | 431 | 1,101 | 431 | ||||||||

| Gold cash rate2 | $/oz | 408 | 400 | 408 | 400 | ||||||||

| Silver deferred revenue drawdown rate1 | $/oz | 16.80 | 7.39 | 17.00 | 7.39 | ||||||||

| Silver cash rate2 | $/oz | 6.02 | 5.90 | 6.02 | 5.90 | ||||||||

| Three months ended | Six months ended | ||||||||||||

| Jun. 30, 2016 | Jun. 30, 2016 | ||||||||||||

| Manitoba | Peru | Manitoba | Peru | ||||||||||

| Gold | oz | 10,381 | 3,340 | 17,518 | 8,272 | ||||||||

| Silver | oz | 130,447 | 482,332 | 215,870 | 1,148,415 | ||||||||

| Gold deferred revenue drawdown rate1 | $/oz | 1,074 | 436 | 1,049 | 436 | ||||||||

| Gold cash rate2 | $/oz | 404 | 400 | 404 | 400 | ||||||||

| Silver deferred revenue drawdown rate1 | $/oz | 19.61 | 7.39 | 19.14 | 7.39 | ||||||||

| Silver cash rate2 | $/oz | 5.96 | 5.90 | 5.96 | 5.90 | ||||||||

| 1 | Deferred revenue amortization is recorded in Manitoba at C$1,464/oz and C$22.60/oz for gold and silver, respectively, (2016 - C$1,382/oz and C$25.23/oz) and converted to US dollars at the exchange rate in effect at the time of revenue recognition. |

| 2 | The gold and silver cash rate for Manitoba increased by 1% from $400/oz and $5.90/oz effective August 1, 2015. Subsequently every year, on August 1, the cash rate will increase by 1% compounded. The weighted average cash rate is disclosed. |

21

Cost of Sales

Our detailed cost of sales is summarized as follows:

| Three months ended | Six months ended | |||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | |||||||||

| (in $ thousands) | 2017 | 2016 | 2017 | 2016 | ||||||||

| Peru | ||||||||||||

| Mine | 12,611 | 14,381 | 25,900 | 26,913 | ||||||||

| Concentrator | 35,758 | 27,905 | 68,069 | 54,534 | ||||||||

| Changes in product inventory | 2,534 | (9,873 | ) | (15,024 | ) | (2,788 | ) | |||||

| Depreciation and amortization | 45,136 | 32,030 | 75,519 | 77,532 | ||||||||

| G&A | 11,964 | 10,701 | 25,423 | 20,057 | ||||||||

| Freight, royalties and other charges | 12,600 | 12,952 | 22,554 | 29,009 | ||||||||

| Total Peru cost of sales | 120,603 | 88,096 | 202,441 | 205,257 | ||||||||

| Manitoba | ||||||||||||

| Manitoba mines | 35,965 | 29,713 | 69,880 | 58,768 | ||||||||

| Manitoba concentrators | 11,440 | 10,326 | 24,578 | 19,317 | ||||||||

| Zinc plant | 15,590 | 16,393 | 32,196 | 32,190 | ||||||||

| Purchased ore and concentrate (before inventory changes) | 5,867 | 4,996 | 9,268 | 8,219 | ||||||||

| Changes in product inventory | 1,039 | 3,468 | 1,298 | 4,962 | ||||||||

| Depreciation and amortization | 31,385 | 31,716 | 62,552 | 60,627 | ||||||||

| G&A | 11,907 | 5,263 | 25,303 | 16,561 | ||||||||

| Freight, royalties and other charges | 13,123 | 8,713 | 23,410 | 18,485 | ||||||||

| Total Manitoba cost of sales | 126,316 | 110,588 | 248,485 | 219,129 | ||||||||

| Cost of sales | 246,919 | 198,684 | 450,926 | 424,386 | ||||||||

Total cost of sales for the second quarter of 2017 was $246.9 million, reflecting an increase of $48.2 million from the second quarter of 2016. Cost of sales related to Peru was $32.5 million higher primarily due to higher sales and higher depreciation related to an inventory build up in the second quarter of 2016, together with higher depreciation per unit of copper production due to lower grades. In Manitoba, cost of sales increased by $15.7 million compared to the second quarter of 2016 as a result of higher mining, freight and profit sharing costs.

Cost of sales year-to-date in 2017 was $450.9 million, an increase of $26.5 million compared to 2016. The increase is mostly attributable to Manitoba which had higher year-to-date costs of $29.4 million compared to the same period last year due to the reasons outlined above and additional costs due to utilization of temporary crushing facilities at the Stall mill primarily during the first quarter.

For details on unit operating costs refer to the respective tables in the “Operations Review” section beginning on page 7 of this MD&A.

For the second quarter of 2017, other significant variances in expenses from operations, compared to the same period in 2016, include the following:

– | Selling and administrative expenses decreased by $4.2 million, which was the result of decreased share based compensation expenses resulting from the revaluation of these rewards to lower share prices during the current quarter compared to the same period last year. |

22

| – | Finance expenses decreased by $3.6 million mainly as a result of lower interest costs on our senior unsecured notes after we completed our refinancing in December 2016. In addition, there were lower interest costs realized on our senior secured revolving credit facilities (the “Credit Facilities”), which were a function of reduced outstanding amounts on these Credit Facilities compared to the same period last year. |

| – | Other finance expenses increased by $1.6 million primarily as a result of: |

| – | Foreign exchange losses of $5.7 million in the second quarter of 2017 compared to gains of $1.1 million in the second quarter of 2016; | |

| – | Disposals, impairment and mark-to-market adjustments on held for trading and available-for-sale investments resulted in a net loss of $0.3 million during the current period of 2017 compared to a gain of $1.3 million during the same period last year; | |

| – | A fair value adjustment on the embedded derivative related to the senior unsecured notes and our gold option liability related to the acquisition of the New Britannia mine and mill (“NBM Mill”) resulted in a gain of $0.2 million in the second quarter of 2017 compared to losses of $0.4 million in the second quarter of 2016; and | |

| – | Mark-to-market gain on warrants of $5.0 million compared to a loss of $1.2 million in the same period last year. |

For 2017 year-to-date, other significant variances in expenses from operations, compared to 2016 year-to-date, include the following:

| – | Selling and administrative expenses decreased by $2.2 million, which was primarily the result of decreased share based compensation expenses of $1.8 million resulting from the revaluation of these rewards to lower share prices during the current year-to-date period compared to the same period last year. |

| – | Other operating income was $3.4 million during the 2017 year-to-date period compared to other operating losses of $6.2 million in the comparable period mainly as a result of a recovery of $8.7 million for insurance proceeds received in 2017 related to the Constancia grinding line 2 failure in 2015. |

| – | Finance expenses decreased by $7.1 million mainly as a result of lower interest costs on our senior unsecured notes after we completed our refinancing in December 2016. In addition, there were lower interest costs realized on our Credit Facilities, which were a function of reduced outstanding amounts on these Credit Facilities compared to the same period last year. |

| – | Other finance expenses increased by $3.4 million primarily as a result of: |

| – | Foreign exchange losses of $8.0 million in 2017 year-to-date compared to losses of $0.2 million in the same period in 2016; | |

| – | Disposals, impairment and mark-to-market adjustments on held for trading and available-for-sale investments resulted in a net loss of $0.3 million during the current period of 2017 compared to a gain of $1.1 million during the same period last year; | |

| – | A fair value adjustment on the embedded derivative related to the senior unsecured notes and our gold option liability related to the acquisition of the NBM Mill resulted in a gain of $0.1 million in the current year-to-date period of 2017 compared to losses of $1.1 million in the same period of 2016; and | |

| – | Mark-to-market adjustments on warrants resulted in a gain of $3.7 million compared to a loss of $0.8 million in the same period last year. |

23

Tax Expense (Recovery)

For the three and six months ended June 30, 2017, tax expense increased by $4.0 million and $20.1 million, respectively, compared to the same periods in 2016. The following table provides further details:

| Three months ended | Six months ended | |||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | |||||||||

| (in $ thousands) | 2017 | 2016 | 2017 | 2016 | ||||||||

| Deferred tax expense - income tax1 | 14,457 | 5,841 | 17,444 | 1,018 | ||||||||

| Deferred tax expense - mining tax1 | 184 | 1,114 | 962 | 2,260 | ||||||||

| Total deferred tax expense | 14,641 | 6,955 | 18,406 | 3,278 | ||||||||

| Current tax (recovery) expense - income tax | (3,601 | ) | 2,114 | 3,429 | 3,901 | |||||||

| Current tax expense - mining tax | 5,187 | 3,191 | 9,391 | 3,981 | ||||||||

| Total current tax expense | 1,586 | 5,305 | 12,820 | 7,882 | ||||||||

| Tax expense | 16,227 | 12,260 | 31,226 | 11,160 | ||||||||

1Deferred tax expense (recovery) represents our draw down/increase of non-cash deferred income and mining tax assets/liabilities.

Income Tax Expense

Applying the estimated Canadian statutory income tax rate of 27.0% to our income before taxes of $54.5 million for the year-to-date period in 2017 would have resulted in a tax expense of approximately $14.7 million; however, we recorded an income tax expense of $20.9 million. The significant items causing our effective income tax rate to be different than the 27.0% estimated Canadian statutory income tax rate include:

| – | Certain deductible temporary differences with respect to Peru mostly relating to decommissioning and restoration liabilities were not recognized as we have determined that it is not probable that we will realize the recovery based on the timing of the reversals of the deductible temporary differences and the future projected taxable profit of the Peru operations, resulting in an increase in deferred tax expense of approximately $5.7 million (2016 year-to-date - $4.5 million); |

| – | Certain deductible temporary differences with respect to Manitoba mostly relating to decommissioning and restoration liabilities were not recognized as we have determined that it is not probable that we will realize the recovery based on the timing of the reversals of the deductible temporary differences and the future projected taxable profit of the Manitoba operations, adjusted for the average annual effective rate methodology, resulting in an increase in deferred tax expense of approximately $3.3 million (2016 year-to-date - $7.9 million); and |

| – | A decrease in the deferred tax expense of $4.3 million (2016 year-to-date - $3.0 million) due to the fact that certain Canadian non-monetary assets are recognized at historical cost while the tax bases of the assets change as exchange rates fluctuate, which gives rise to taxable temporary differences. |

Mining Tax Expense

Applying the estimated Manitoba mining tax rate of 10.0% to our income before taxes of $54.5 million for the year-to-date period in 2017, would have resulted in a tax expense of approximately $5.5 million and we recorded a mining tax expense of $10.4 million (2016 – $6.2 million). Effective mining tax rates can vary significantly based on the composition of our earnings and the expected amount of mining taxable profits. Corporate costs and other costs not related to mining operations are not deductible in computing mining profits. A brief description of how mining taxes are calculated in our various business units is discussed below.

Manitoba

The Province of Manitoba imposes mining tax on profit related to the sale of mineral products mined in the Province of Manitoba (mining taxable profit) at the following rates:

24

| – | 10% of total mining taxable profit if mining profit is C$50 million or less; |

| – | 15% of total mining taxable profit if mining profits are between C$55 million and C$100 million; and |

| – | 17% of total mining taxable profit if mining profits exceed C$105 million. |

We estimate that the tax rate that will be applicable when temporary differences reverse will be approximately 10.0% .

Peru

The Peruvian government imposes two parallel mining tax regimes, the Special Mining Tax and the Modified Royalty, on companies' operating mining income on a sliding scale, with progressive rates ranging from 2.0% to 8.4% and 1.0% to 12.0%, respectively. Based on financial forecasts, we have recorded a deferred tax liability as at June 30, 2017 at the tax rate we expect to apply when temporary differences reverse.

LIQUIDITY AND CAPITAL RESOURCES

Senior Unsecured Notes Refinancing

On December 12, 2016, we completed an offering of $1.0 billion aggregate principal amount of senior notes in two series: (i) a series of 7.250% senior notes due 2023 in an aggregate principal amount of $400 million and (ii) a series of 7.625% senior notes due 2025 in an aggregate principal amount of $600 million. The proceeds from this offering were used to redeem all US$920 million of our 9.50% senior unsecured notes due 2020.

Senior Secured Revolving Credit Facilities

As at June 30, 2017, between our Credit Facilities we have drawn $79.1 million in cash and $126.8 million in letters of credit, leaving total undrawn availability of $344.1 million. As at June 30, 2017, we were in compliance with our covenants under the Credit Facilities.

As noted under “Recent Developments” above, the Credit Facilities were amended on July 14, 2017 to secure both facilities with substantially all of our assets other than assets related to the Rosemont project, amend the financial covenants, extend the maturity dates from March 31, 2019 to July 14, 2021 and reduce the interest rate from LIBOR plus 4.50% to LIBOR plus 3.00%, based on financial results for the twelve months ended June 30, 2017. The revised covenants include maintaining gross total debt to EBITDA of less than 4.00 times in 2017, senior secured debt to EBITDA of less than 2.00 times, and interest coverage of more than 3.00 times.

Equipment Finance Facility

As at June 30, 2017, we had approximately $46.1 million owing under the facility.

25

Financial Condition

Financial Condition as at June 30, 2017 compared to December 31, 2016

Cash and cash equivalents increased by $5.8 million from December 31, 2016 to $152.7 million as at June 30, 2017. This increase was partly a result of cash generated from operating activities of $242.2 million, and a net release of restricted cash of $16.9 million. These inflows were partly offset by $94.0 million of capital investments primarily at our Peru and Manitoba operations, debt repayments of $131.2 million and interest payments of $15.8 million. We hold the majority of our cash and cash equivalents in low-risk, liquid investments with major Canadian and Peruvian financial institutions.

Working capital decreased by $35.4 million to $86.1 million from December 31, 2016 to June 30, 2017. In addition to the increased cash and cash equivalents position:

| – | Current inventories increased by $24.5 million; |

| – | Trade and other receivables decreased by $65.8 million primarily due to the timing of sales and receipts of statutory amounts owing; and |

| – | Trade and other payables increased by $17.2 million primarily as a result of the timing of capital spending resulting in higher trade payables at June 30 2017; |

Cash Flows

The following table summarizes our cash flows for the three months and three and six months ended June 30, 2017 and June 30, 2016:

| Three months ended | Six months ended | |||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | |||||||||

| (in $ thousands) | 2017 | 2016 | 2017 | 2016 | ||||||||

| Profit (loss) for the period | 25,586 | (5,703 | ) | 23,281 | (21,491 | ) | ||||||

| Tax expense | 16,227 | 12,260 | 31,226 | 11,160 | ||||||||

| Items not affecting cash | 86,006 | 63,438 | 158,594 | 158,534 | ||||||||

| Taxes paid | (3,701 | ) | (506 | ) | (8,383 | ) | (6,828 | ) | ||||

| Operating cash flow before changes in non-cash working capital | 124,118 | 69,489 | 204,718 | 141,375 | ||||||||

| Change in non-cash working capital | 7,734 | 68,032 | 37,527 | 97,696 | ||||||||

| Cash generated from operating activities | 131,852 | 137,521 | 242,245 | 239,071 | ||||||||

| Cash used in investing activities | (36,234 | ) | (69,485 | ) | (76,519 | ) | (120,826 | ) | ||||

| Cash used in financing activities | (76,594 | ) | (11,085 | ) | (161,197 | ) | (30,584 | ) | ||||

| Effect of movement in exchange rates on cash and cash equivalents | 1,065 | (765 | ) | 1,279 | 390 | |||||||

| Increase in cash and cash equivalents | 20,089 | 56,186 | 5,808 | 88,051 | ||||||||

26

Cash Flow from Operating Activities

Cash generated from operating activities was $131.9 million during the second quarter of 2017, a decrease of $5.7 million compared with the same period last year. Operating cash flow before change in non-cash working capital was $124.1 million during the second quarter of 2017, reflecting an increase of $54.6 million compared to the second quarter of 2016. Operating cash flow benefited from higher overall realized sales prices and higher sales volumes compared to the second quarter of 2016. The second quarter of 2016 benefited from substantial cash inflows from non-cash working capital changes.

Year-to-date cash generated from operating activities was $242.2 million in 2017, an increase of $3.2 million compared to 2016. Operating cash flow before changes in non-cash working capital were $204.7 million, an increase of $63.3 million compared to the same year-to-date period in 2016. Operating cash flow benefited from higher copper and zinc realized sales prices compared to the same year-to-date period in 2016.

Cash Flow from Investing and Financing Activities

During the second quarter of 2017, we used $112.8 million in investing and financing activities, primarily driven by the repayment of $67.1 million in principal on our Credit Facilities and capital expenditures of $53.5 million.

Year-to-date, we used $237.7 million of cash in investing and financing activities, primarily driven by net principal repayments on our debt borrowings of $131.2 million, capital expenditures of $94.0 million and interest paid of $15.8 million, partially offset by funds released from restricted cash of $16.9 million.

27

Capital Expenditures

The following summarizes accrued and cash additions to capital assets for the periods indicated:

| Three months | |||||||||||||||

| ended | Six months ended | Guidance | |||||||||||||

| Jun. 30, | Jun. 30, | Jun. 30, | Jun. 30, | Annual | |||||||||||

| (in $ millions) | 2017 | 2016 | 2017 | 2016 | 20171 | ||||||||||

| Manitoba sustaining capital expenditures | 10.5 | 15.1 | 23.3 | 38.7 | 65.0 | ||||||||||

| Peru sustaining capital expenditures | 35.9 | 30.8 | 53.4 | 51.1 | 120.0 | ||||||||||

| Total sustaining capital expenditures | 46.4 | 45.9 | 76.7 | 89.8 | 185.0 | ||||||||||

| Arizona other capitalized costs | 3.1 | 5.2 | 9.3 | 16.7 | 20.0 | ||||||||||

| Peru growth capitalized expenditures | 0.5 | - | 0.5 | - | 25.0 | ||||||||||

| Peru other capital costs | 5.6 | 9.0 | 9.2 | 16.2 | |||||||||||

| Manitoba growth capitalized expenditures | 5.7 | - | 7.4 | - | 55.0 | ||||||||||

| Manitoba other capitalized costs | 4.7 | 9.7 | 7.6 | 14.0 | |||||||||||

| Capitalized exploration | 0.5 | 0.9 | 0.8 | 1.3 | 2.0 | ||||||||||

| Capitalized interest | 3.3 | 3.7 | 6.6 | 7.4 | |||||||||||

| Other capitalized costs | - | - | 0.2 | - | |||||||||||

| Total other capitalized costs | 23.4 | 28.5 | 41.6 | 55.6 | |||||||||||

| Total accrued capital additions | 69.8 | 74.4 | 118.3 | 145.4 | |||||||||||

| Reconciliation to cash capital additions: | |||||||||||||||

| Decommissioning and restoration obligation | (7.2 | ) | (14.5 | ) | (13.0 | ) | (23.2 | ) | |||||||

| Capitalized interest | (3.3 | ) | (3.7 | ) | (6.6 | ) | (7.4 | ) | |||||||

| Changes in capital accruals and other | (5.8 | ) | (3.8 | ) | (4.7 | ) | (16.1 | ) | |||||||

| Total cash capital additions | 53.5 | 52.4 | 94.0 | 98.7 | |||||||||||

1Sustaining capital expenditure guidance excludes capitalized interest.

Sustaining capital expenditures in Manitoba for the three and six months ended June 30, 2017 were $10.5 million and $23.3 million, respectively, a decrease of $4.6 million and $15.4 million, respectively, compared to the same periods in 2016. This decrease is primarily due to decreases in capitalized underground mine development.

Sustaining capital expenditures in Peru for the three and six months ended June 30, 2017 were $35.9 million and $53.4 million, respectively, an increase of $5.1 million and $2.3 million, respectively, compared to the same periods in 2016. The increase is mainly the result of higher capital costs for tailings impoundment construction.

Other Peru and Other Manitoba capitalized costs include decommissioning and restoration adjustments.

28

Sustaining capital is expected to be higher in the second and third quarters of 2017 due to increased heavy civil earthworks during the dry season in Peru.

Capital Commitments

As at June 30, 2017, we had outstanding capital commitments in Canada of approximately $31.8 million primarily related to committed long-lead orders for the paste plant, of which approximately $0.3 million cannot be terminated by Hudbay; approximately $29.7 million in Peru related to sustaining capital costs, of which all can be terminated by Hudbay; and approximately $161.2 million in Arizona, primarily related to the Rosemont project and expected to be paid after the commencement of Rosemont construction, of which approximately $77.4 million cannot be terminated by Hudbay.

Contractual Obligations

The following table summarizes our contractual obligations as at June 30, 2017:

| Less than | 1-3 | 4-5 | After 5 | ||||||||||||

| Payment Schedule (in $ millions) | Total | 1 Year | Years | Years | Years | ||||||||||

| Long-term debt obligations1 | 1,654.6 | 64.5 | 269.7 | 151.0 | 1,169.4 | ||||||||||

| Capital lease obligations | 20.5 | 5.2 | 10.4 | 4.9 | - | ||||||||||

| Operating lease obligations | 18.6 | 4.6 | 7.6 | 4.0 | 2.4 | ||||||||||

| Purchase obligation - capital commitments | 222.7 | 82.3 | 11.1 | - | 129.3 | ||||||||||

| Purchase obligation - other commitments2 | 618.4 | 87.4 | 207.1 | 125.8 | 198.1 | ||||||||||

| Pension and other employee future benefits obligations | 146.1 | 22.1 | 31.5 | 6.7 | 85.8 | ||||||||||

| Decommissioning and restoration obligations3 | 195.2 | 1.0 | 10.8 | 5.2 | 178.2 |

1Long-term debt obligations include scheduled interest payments.

2Primarily made up of long-term agreements with operational suppliers, obligations for power purchase, concentrate handling, fleet and port services.

3Before inflation.

29

Liquidity

As at June 30, 2017, we had total liquidity of approximately $496.8 million, including $152.7 million in cash and cash equivalents, as well as $344.1 million in availability under our Credit Facilities. We expect that our current liquidity and future cash flows will be sufficient to meet our obligations in the coming year.

Outstanding Share Data

As of August 3, 2017, there were 237,271,188 common shares of Hudbay issued and outstanding. In addition, Hudbay warrants to acquire an aggregate of 22,391,490 common shares of Hudbay were outstanding and options for an aggregate of 690,020 common shares outstanding.

TREND ANALYSIS AND QUARTERLY REVIEW

The following table sets forth selected consolidated financial information for each of our eight most recently completed quarters:

| 2017 | 2016 | 2015 | ||||||||||||||||||||||

| (in $ millions) | Q2 | Q1 | Q4 | Q3 | Q2 | Q1 | Q4 | Q3 | ||||||||||||||||

| Revenue | 324.9 | 253.2 | 316.7 | 311.4 | 247.0 | 253.6 | 336.6 | 269.8 | ||||||||||||||||

| Profit (loss) before tax | 41.8 | 12.7 | (26.1 | ) | 42.0 | 6.6 | (16.9 | ) | (325.6 | ) | (16.1 | ) | ||||||||||||

| Profit (loss) | 25.6 | (2.3 | ) | (47.3 | ) | 33.6 | (5.7 | ) | (15.8 | ) | (255.5 | ) | (11.8 | ) | ||||||||||

| Earnings (loss) per | ||||||||||||||||||||||||

| share: | ||||||||||||||||||||||||

| Basic | 0.11 | (0.01 | ) | (0.20 | ) | 0.14 | (0.02 | ) | (0.07 | ) | (1.09 | ) | (0.05 | ) | ||||||||||

| Diluted | 0.11 | (0.01 | ) | (0.20 | ) | 0.14 | (0.02 | ) | (0.07 | ) | (1.09 | ) | (0.05 | ) | ||||||||||

| Operating cash flow1 | 124.1 | 80.6 | 122.3 | 124.2 | 69.5 | 71.9 | 117.4 | 79.0 | ||||||||||||||||

1Operating cash flow before changes in non-cash working capital

Copper and zinc prices were volatile during the second quarter of 2017. In all, during the quarter, notwithstanding the volatility, realized prices were flat. Higher volumes of copper concentrate and zinc metal sales drove higher revenues, gross profits and operating cash flow before changes in non-cash working capital in the second quarter of 2017 compared to the first quarter. Finance expenses have also declined since the fourth quarter of 2016 due to principal repayments and the refinancing of our senior unsecured notes.

Higher copper and zinc prices during the first quarter of 2017 allowed us to increase our gross profit compared to the fourth quarter of 2016, notwithstanding lower revenues as a result of lower production due to planned and unplanned maintenance activities at our operations. In addition, the increases in margins allowed us to continue our voluntary repayment of principal amounts on our Credit Facilities. The voluntary repayments of principal and the lower interest rates on our refinanced senior notes lowered the finance expenses on long term debt compared to previous quarters. In addition, we recorded a recovery of $8.7 million in our Peru business unit in respect of insurance proceeds.

We benefited from rising copper and zinc prices during the fourth quarter of 2016 and from lower unit operating costs as a result of our cost containment commitment for 2016. The higher and stable operating cash flow generated from our operations enabled the net repayment of $95 million in principal on our Credit Facilities during the fourth quarter of 2016. In addition, during the fourth quarter, we re-financed our senior notes which now have later maturities and lower interest rates. We incurred a $47.7 million call premium during the fourth quarter of 2016 to facilitate the early redemption of the previously outstanding $920 million notes.

In the third quarter of 2016, the steady increase in production and sales continued the trend of increasing revenues as compared to prior quarters. The increase in production of concentrate in both Peru and Manitoba resulted in lower unit costs as a result of the economies of scale achieved and the focus on cost optimization at all sites. The result of this production driven growth has been an increase in gross profits compared to the prior year and prior quarters. Despite volatility in commodity price markets, particularly precious metals, realized prices in the third quarter were marginally higher than the most recent prior quarters.

30

In the second quarter of 2016, revenues remained consistent with the first quarter of 2016 as higher realized prices for precious metals offset marginal declines in sales volumes due to the timing of production. Gross margins and cash generated from operating activities improved compared to the first quarter of 2016 as costs at Constancia benefited from continued site optimization and the Manitoba business unit benefited from cost reduction efforts as well as the weaker Canadian dollar.

In the first quarter of 2016, we continued to benefit from increased sales volumes following the achievement of commercial production at Constancia. Lower average realized prices of copper compared to the same quarter of 2015 partially offset the continued strong production volumes from the Peru operations and caused both gross profit and operating cash flow generated from our operations to be lower than in the fourth quarter of 2015.

For information on previous trends and quarterly reviews, refer to our MD&A dated February 22, 2017.

NON-IFRS FINANCIAL PERFORMANCE MEASURES

Net debt is shown because it is a performance measure used by the Company to assess our financial position. Cash cost, sustaining and all-in sustaining cash cost per pound of copper produced are shown because we believe they help investors and management assess the performance of our operations, including the margin generated by the operations and the company. Cash cost and sustaining cash cost per pound of zinc produced are shown because we believe they help investors and management assess the performance of our Manitoba operations. These measures do not have a meaning prescribed by IFRS and are therefore unlikely to be comparable to similar measures presented by other issuers. These measures should not be considered in isolation or as a substitute for measures prepared in accordance with IFRS and are not necessarily indicative of operating profit or cash flow from operations as determined under IFRS. Other companies may calculate these measures differently.

Net Debt

The following table presents our calculation of net debt as at June 30, 2017 and December 31, 2016:

| Jun. 30, | Dec. 31, | |||||

| (in $ thousands) | 2017 | 2016 | ||||

| Total long-term debt | 1,102,426 | 1,232,164 | ||||

| Cash and cash equivalents | (152,672 | ) | (146,864 | ) | ||

| Net debt | 949,754 | 1,085,300 |

31

Cash Cost, Sustaining and All-in Sustaining Cash Cost (Copper Basis)

Cash cost per pound of copper produced (“cash cost”) is a non-IFRS measure that management uses as a key performance indicator to assess the performance of our operations. Our calculation designates copper as our primary metal of production as it has been the largest component of revenues. The calculation is presented in four manners:

| – | Cash cost, before by-product credits -This measure is gross of by-product revenues and is a function of the efforts and costs incurred to mine and process all ore mined. However, the measure divides this aggregate cost over only pounds of copper produced, our primary metal of production. This measure is generally less volatile from period to period, as it is not affected by changes in the price received for by-product metals. It is, however, significantly affected by the relative mix of copper concentrate and finished zinc production, where the sale of the zinc will occur later, and an increase in production of zinc metal will tend to result in an increase in cash cost under this measure. |