UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

x ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

FOR THE FISCAL YEAR ENDED DECEMBER 31, 2014

OR

o TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

FOR THE TRANSITION PERIOD FROM TO

COMMISSION FILE NO. 001-36534

IRADIMED CORPORATION

(Exact Name of Registrant As Specified In Its Charter)

Delaware |

| 73-1408526 |

(State or other jurisdiction of |

| (I.R.S. Employer |

1025 Willa Springs Drive Winter Springs, Florida |

| 32708 |

(Address of principal executive offices) |

| (Zip Code) |

Registrant’s telephone number, including area code: (407) 677-8022

SECURITIES REGISTERED PURSUANT TO SECTION 12(b) OF THE ACT:

Title of |

| Name of each exchange |

Each Class |

| on which registered |

Common Stock, $0.0001 par value |

| Nasdaq Stock Market LLC |

|

| (Nasdaq Capital Market) |

SECURITIES REGISTERED PURSUANT TO SECTION 12(g) OF THE ACT:

None.

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes o No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

Yes o No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by checkmark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. Yes o No x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer o |

| Accelerated filer o |

|

|

|

Non-accelerated filer o |

| Smaller reporting company x |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes o No x

As of June 30, 2014, the last business day of the registrant’s most recently completed second fiscal quarter, there was no established public market for the registrant’s common stock. The registrant’s common stock began trading on the NASDAQ Capital Market on July 16, 2014.

There were 10,972,150 shares outstanding of the registrant’s common stock, par value $0.0001 per share, as of February 28, 2015. The registrant’s common stock is listed on the Nasdaq Capital Market under the stock symbol “IRMD.”

Documents Incorporated by Reference: Information required by Items 10, 11, 12, 13 and 14 of Part III are incorporated by reference from the Proxy Statement for the registrant’s 2015 Annual Meeting of Stockholders. Except with respect to information specifically incorporated by reference in the Form 10-K, the Proxy Statement is not deemed to be filed as part hereof.

IRADIMED CORPORATION.

TABLE OF CONTENTS TO ANNUAL REPORT ON FORM 10-K

For the Fiscal Year Ended December 31, 2014

CAUTIONARY STATEMENTS REGARDING FORWARD-LOOKING STATEMENTS

This Annual Report on Form 10-K contains “forward-looking statements” that involve substantial risks and uncertainties. The forward-looking statements are contained principally in the sections entitled “Business,” “Risk Factors” and “Management’s Discussion and Analysis and Results of Operations.” In some cases, you can identify forward-looking statements by the following words: “may,” “will,” “could,” “would,” “should,” “expect,” “intend,” “plan,” “anticipate,” “believe,” “estimate,” “predict,” “project,” “potential,” “continue,” “ongoing” or the negative of these terms or other comparable terminology, although not all forward-looking statements contain these words. These statements relate to future events or our future financial performance or condition and involve known and unknown risks, uncertainties and other factors that could cause our actual results, levels of activity, performance or achievement to differ materially from those expressed or implied by these forward-looking statements. These forward-looking statements include, but are not limited to, statements about:

· our ability to receive clearance of our 510(k) submission, resolve various matters identified in the FDA Warning Letter, additional actions by or requests from the FDA (including a request to cease domestic distribution of products) and unanticipated costs or delays associated with the resolution of these matters;

· our ability to resolve a securities class-action lawsuit that has been filed against us in connection with the FDA Warning Letter and shipment stoppage;

· our reliance on a single product;

· our ability to retain the continued service of our key professionals and to identify, hire and retain additional qualified professionals;

· our expectations regarding the sales and marketing of our products and product candidates;

· our expectations regarding the integrity of our supply chain for our products;

· the timing and likelihood of FDA approvals and regulatory actions on our product candidates and product marketing activities;

· the potential for adverse application of environmental, health and safety and other laws and regulations on our operations;

· our expectations for market acceptance of our new products;

· the potential for our marketed products to be withdrawn due to recalls, patient adverse events or deaths;

· our ability to establish and maintain intellectual property on our products and our ability to successfully defend these in cases of infringement;

· the implementation of our business strategies;

· the potential for exposure to product liability claims;

· our financial performance expectations;

· our ability to compete in the development and marketing of our products and product candidates with other competitors in the industry;

· difficulties or delays in the development, production, manufacturing and marketing of new or existing products and services, including difficulties or delays associated with obtaining requisite regulatory approvals or clearances associated with those activities;

· changes in laws and regulations or in the interpretation or application of laws or regulations, as well as possible failures to comply with applicable laws or regulations as a result of possible misinterpretations or misapplications;

· cost-containment efforts of our customers, purchasing groups, third-party payers and governmental organizations;

· costs associated with protecting our trade secrets and enforcing our patent, copyright and trademark rights, and successful challenges to the validity of our patents, copyrights or trademarks;

· actions of regulatory bodies and other government authorities, including the FDA and foreign counterparts, that could delay, limit or suspend product development, manufacturing or sales or result in recalls, seizures, consent decrees, injunctions and monetary sanctions;

· costs or claims resulting from potential errors or defects in our manufacturing that may injure persons or damage property or operations, including costs from remediation efforts or recalls;

· the results, consequences, effects or timing of any commercial disputes, patent infringement claims or other legal proceedings or any government investigations;

· interruption in our ability to manufacture our products or an inability to obtain key components or raw materials or increased costs in such key components or raw materials;

· uncertainties in our industry due to government healthcare reform;

· competitive pressures in the markets in which we operate;

· the loss of, or default by, one or more key customers or suppliers; and

· unfavorable changes to the terms of key customer or supplier relationships.

Forward-looking statements are not guarantees of future performance and are subject to substantial risks and uncertainties that could cause the actual results to differ materially from those that we predicted in the forward-looking statements. Investors should carefully review the information contained under the caption “Risk Factors” contained in Item 1A for a description of risks and uncertainties that could cause actual results to differ from those that we predicted. All forward-looking statements are based on information available to us on the date hereof, and we assume no obligation to update forward-looking statements, except as required by Federal Securities laws.

Overview

IRADIMED CORPORATION (“IRADIMED”, the “Company”, “we”, “us”, “our”) develops, manufactures, markets and distributes magnetic resonance imaging (“MRI”) compatible products, and today, we are the only known provider of non-magnetic intravenous (“IV”) infusion pump systems. We were the first to develop an infusion delivery system that neutralizes the dangers and problems present during MRI procedures. Standard infusion pumps contain magnetic and electronic components which can create radio frequency (“RF”) interference and are dangerous to operate in the presence of the powerful magnet that drives an MRI system. Our MRidium MRI compatible IV infusion pump system uses a patented non-magnetic ultrasonic motor and other uniquely-designed non-ferrous parts that enable accurate, safe and dependable fluid delivery to patients undergoing an MRI procedure.

With the expanding use of MRI procedures, both traditional procedures and new intraoperative and interventional procedures, safe and reliable infusion delivery in an MRI environment is becoming increasingly important to hospitals and other medical providers. Our founder, President and Chief Executive Officer, Roger Susi, is a pioneer in the MRI compatible medical device industry, having invented the first MRI compatible patient monitoring system in 1986 and the first non-magnetic MRI safe infusion system in 2004. Since launching our first generation MRI compatible IV infusion pump system in 2005, we have continued to modify and improve our system, and we have leveraged our development strengths and unique market position to expand our customer base and profitability. We were incorporated in Oklahoma in July 1992 and reincorporated in Delaware in April 2014.

We sell our products primarily to acute care facilities and outpatient imaging centers, both in the United States and internationally. In fiscal year 2012, we undertook a direct sales strategy in the United States. Today, our direct sales force consists of ten sales representatives, supplemented by two clinical support representatives. Our goal is to expand our U.S. sales force to 14 by the end of 2015. We have distribution agreements with 35 independent distributors selling our products internationally.

As of December 31, 2014 we estimate that we had approximately 2,300 MRI compatible IV infusion pump systems installed globally. Each system consists of an MRidium MRI compatible IV infusion pump, mobile stand, and proprietary disposable IV tubing sets and many of these systems contain additional optional upgrade accessories. We generate revenue from the one-time sale of pumps and accessories, ongoing service contracts and the sale of disposable IV tubing used during each scan. Our revenue growth has accelerated since initiating our direct sales effort. In fiscal year 2014, our revenue reached $15.6 million and our operating profit was $3.1 million representing an operating margin of 19.6%. This operating margin reflects the blended results of our IV infusion pumps, pump upgrades and disposable IV tubing sets.

History and Development

Mr. Susi founded Invivo Research Inc. in 1979 where he developed the first MRI compatible patient monitoring system. Mr. Susi served as the President of Invivo Research Inc. from 1979 until 1998, and as its Chairman of the Board of Directors from 1998 until 2000. Under Mr. Susi’s leadership, Invivo Research matured from a start-up medical device company into a leading producer of vital signs monitoring devices during MRI procedures. Invivo Research was acquired by Invivo Corporation in 1992, which began trading on the NASDAQ Stock Exchange in 1994. Mr. Susi served as a Director of Invivo Corporation from 1998 until 2000 and oversaw technical areas from 2000 to 2004. Invivo Corporation was acquired by Intermagnetics General Corporation in 2004 for $152 million. The Invivo system, currently owned by Koninklijke Philips NV (NYSE: PHG), continues to maintain its position as the market-leading MRI compatible vital signs monitor.

Mr. Susi began exploring the market for an MRI compatible IV infusion pump while at Invivo. Invivo subsequently disclaimed any interest in the infusion pump and acknowledged that Mr. Susi was free to pursue the infusion pump development for his own account. Accordingly, after leaving Invivo in January 2004, Mr. Susi began the formal and detailed development of what subsequently has become our MRidium MRI compatible IV infusion pump system. During 2005, he assembled a team of individuals experienced in the medical device industry, many of whom were former employees of Invivo. This first generation MRI compatible IV infusion pump system and its associated proprietary IV tubing sets obtained FDA market clearance in March 2005 after which point we began our sales and marketing efforts.

We initially marketed the product ourselves in the U.S. with limited sales staff, and within one year, commenced international sales through a network of distributors. In 2006, we signed an exclusive distribution agreement with Mallinckrodt/Tyco Healthcare (now part of Medtronic plc (NYSE: MDT) for domestic and Canadian distribution of our products including the MRidium 3850 MRI compatible IV infusion pump system. The exclusive arrangement ended in 2010, allowing us to implement a direct marketing strategy with our own sales force in the U.S. and Canada.

In 2009, we introduced our second generation MRI compatible IV infusion pump system, the MRidium 3860+ which improved upon the previous 3850 version in a number of areas, including the addition of SpO2, blood oxygen saturation monitoring, and remote wireless monitoring capability. An SpO2 monitor can signal when an insufficient level of oxygen is being supplied to the body. Our MRidium 3860+ is the leading MRI compatible IV infusion pump system on the market today. In 2011, we introduced the iMagox product line, a standalone SpO2 patient monitor which was based on our MRI compatible SpO2 monitoring system with a wireless remote control for international distribution only.

Industry

We currently compete in the MRI compatible IV infusion pump systems market.

Need for MRI Compatible IV Infusion Pumps

MRI is a widely-used, non-invasive medical imaging technique to visualize vital organs, body function and to identify blockages, abnormalities and growths. MRI is generally considered safer than other scanning techniques that expose the body to radiation. This is particularly true for children. As such, hospitals and other medical facilities have been increasingly developing and using MRI for new procedures. These procedures include cardiac stress testing, intraoperative MRI and neurology MRI techniques. Our MRidium MRI compatible IV infusion pump offers a way to deliver critical IV fluids safely and accurately, thereby allowing the expanded use of MRI procedures.

While the benefits and utility of interventional MR are known, there are hazards intrinsic to the MR environment which must be respected. These hazards may be attributed to a powerful static magnetic field, pulsed gradient magnetic fields, and pulsed radio frequency fields. The MRI suite is a harsh place for medical devices, and safe and proper patient care requires specialty equipment that is specifically designed and built for the MR environment. Many of the dangers and problems present in the MR environment can be solved through use of non-magnetic equipment that have operational safeguards and that maintain performance standards within a harsh magnetic environment while maintaining patient safety. Designing an IV infusion pump system to operate safely and effectively in the MR environment requires overcoming significant technical hurdles.

Intravenous fluids are needed during MRI procedures for many different reasons. Infusion pumps provide sedation to patients who are not able to lie still during an MRI scan and a continuous flow of critical medications to seriously ill patients. Given the benefits to patient safety, radiology departments performing the scan, anesthesia departments delivering sedation and critical care specialists responsible for delivering critical medications during MRI procedures often initiate requests for an MRI compatible IV infusion pump.

Conventional Infusion Pumps and Other Inadequate Alternatives

For those medical facilities that do not currently own an MRI compatible IV infusion pump, there are five general methods that are used to deal with patients undergoing an MRI who require IV medications during their imaging procedure: (1) use conventional (magnetic) pumps with long IV lines that extend outside the MRI scanner room; (2) do not offer MRI treatment to patients requiring IV medications or sedation; (3) proceed and accept patients for an MRI procedure but stop the flow of IV fluids during the procedure; (4) allow the uncontrolled free drip of IV fluids; and (5) attempt to shield a conventional IV infusion pump. All of these approaches have drawbacks.

Use of multiple lengths of extension tubing can cause inaccuracies, waste and false alarms or, more seriously, delayed alarms for equipment issues such as occlusion, especially when low flow rates are being used. Such makeshift extension sets can also affect the effectiveness of fluid delivery. A clinician’s adjustment of dosage and other settings may take longer to reach the patient due to the over-extended tubing.

Further, there are risks in using a conventional IV infusion pump that is mistakenly believed to be at a safe distance from the MR scanner. The powerful magnetic fields may cause metal objects in the MR environment to be drawn with great force into the bore of the MR system, resulting in potentially deadly projectiles. Moreover, an MR scanner’s gradient magnetic field and RF fields can send currents in cables and other conductive materials that are near the MR system and cause the cables to heat. Hot cables may result in burns if they come into contact with a patient. Other problems include devices malfunctioning if they are not properly designed for use in the harsh MR environment and low-quality images due to artifacts caused by RF interference emitted from ancillary equipment.

To deal with the harsh environment of MR, some manufacturers have offered a “shielded box” solution for use with their conventional IV pumps, but the approach was not widely adopted. The major problem with this approach is that a highly magnetic conventional IV infusion pump is still being introduced into a hazardous MRI environment which can lead to projectile accidents. Moreover, a Faraday cage with the conventional IV infusion pump must be kept approximately 5 to 10 feet from the scanner. By contrast, our product can be safely placed anywhere in the scanner room including next to the scanner. We are not aware of any “shielded box” installations in use in the U.S. or any with a FDA 510(k) clearance and hence, we expect little current competition from this approach in the U.S.

We believe that our MRidium MRI compatible IV infusion pump system is the first and only product to provide an easy-to-operate, non-magnetic, safe and RF-quiet solution and hence a truly MRI compatible product.

Market Opportunities

Exit of Competitor from Market

During 2012, our only direct competitor in the MRI compatible IV infusion pump business, Bayer Radiology (formerly MEDRAD, Inc.), became the subject of an FDA recall with respect to its then market-leading Continuum device. In mid-2012, Bayer Radiology announced that it was discontinuing, until further notice, all new sales of Continuum leaving us as the only known global supplier of MRI compatible IV infusion pumps. During 2013, Bayer Radiology announced its decision to commence removal of its pump systems from the U.S. market, and to discontinue support throughout the world by June 30, 2015 due to ongoing regulatory issues, at which time Bayer Radiology will end its limited supply of its proprietary consumable IV sets that some current customers are receiving.

As a result of Bayer Radiology’s announced exit from the market, we anticipate that many Continuum customers will replace their MRI compatible IV infusion pumps with our MRidium 3860+ system. We are continuing to expand our direct sales force in the U.S. and believe that our pump sales will be favorably impacted by the exodus of Bayer. We intend to market aggressively to this existing user base as well as to new potential users.

Expansion of Inter-Hospital Use of MRI Compatible IV Infusion Pumps

We currently market our MRI compatible infusion pumps primarily to the MRI departments of hospitals. We believe, however, that there is potential for expanded deployment of our MRI compatible IV infusion pumps within the Intensive Care Unit (“ICU”), Emergency Room (“ER”), and other locations within the hospital with a high probability that interventional radiology procedures will need to be performed on patients. Expanded use of our additional MRI compatible IV infusion pumps would serve as a type of transport pump and allow for consistent administration of IV fluids without interruption and easy transfer from the ICU or ER to the MRI scanner room.

It frequently becomes necessary for a patient in the ICU or ER who is connected to an IV infusion pump that is delivering critical medications to be quickly moved to the MRI facility for immediate imaging. The presence of multiple MRI compatible IV infusion pumps or pump channels, for each IV line, enables the orderly and rapid transfer between IV infusion pumps by allowing patients to be prepared for an MR procedure and setup on our MRidium MRI compatible IV infusion pump in the ICU or ER. Seriously ill patients are generally at higher risk when they are away from the resources of the ICU or ER, and efficient IV infusion pump transfer minimizes the time the patient spends away from the ICU or ER.

We believe there is a link between the number of infusions and infusion pumps and the onset of equipment-related adverse events during the intra-facility transport of critically ill patients. We therefore believe that placing our MRI compatible IV infusion pumps in ICU and ER facilities could reduce patient adverse events associated with the transport and pump exchange within the hospital.

Recently some hospitals have begun to use MRI during surgical procedures. Neurosurgical interventions have been at the forefront of this development in image-guided surgery, followed by otolaryngological procedures. As MR-guided intervention during surgery has been deployed, the degree of complexity in supplemental devices has increased markedly. Much of the effort required for successful implementation of intraoperative MRI has been in development and testing of anesthesia equipment, patient monitoring devices, infusion pumps and surgical instruments and accessories, all of which need to be MRI compatible if used near the MRI scanner. Intraoperative MRI is expanding demand for our MRI compatible IV infusion pump system from the MRI suite to the surgical suite of the hospital, again with multiple pump channels for multiple IV lines.

Strategy

Company Objective

Our objective is to become the leader in providing safe and effective care for all patients undergoing MRI procedures through the development and commercialization of a portfolio of MRI compatible products. By increasing the safety parameters of equipment operating within the harsh magnetic environment of the MRI scanner room, we hope to enable hospitals and other healthcare providers to offer the MRI diagnostic procedures patients require. In particular, our goal is to increase the safety of MRI diagnostics for critically ill patients and children by minimizing potential complications with IV infusions and vital signs monitoring.

We seek to grow our business by, among other things:

Driving market awareness of MRI compatible IV infusion pumps and the safety risks associated with using conventional IV pumps with long IV lines.

We believe that the largest potential market for our MRI compatible IV infusion pumps is the segment of the market that is currently using workaround solutions. Such solutions include using conventional pumps outside the MRI scanner room and attaching multiple extension lines of IV tubing sets through the wall or under the door into the MRI scanner room to reach the patient. This practice of makeshift setups is fraught with risks to the patient and unnecessary costs and inefficiencies. These risks and inefficiencies include:

· Infection risk from running lengthy IV tubing sets through the wall or under the door;

· Risk of inaccuracy from using a conventional IV infusion pump with multiple extension lines;

· Potential medication occlusion and lengthy alarm notification delays due to multiple extension lines, posing a great risk to a patient on critical medications;

· Excess medication costs due to the disposal of multiple extension IV tubing sets filled with unused medication at the end of the procedure; and

· Lost productivity and MRI scanning time due to the lengthy set up time required for multiple extension lines.

We believe that increased market awareness and education will be required for potential customers to appreciate the value for patients and the hospital of an efficient and patient-safe MRI environment which includes MRI compatible IV infusion pumps.

Continuing to innovate with MRI compatible patient care products.

Our management team collectively has more than 100 years of experience with MRI compatible products. We have entrenched relationships with many of the industry’s top thought leaders and we have, and will continue to, closely collaborate with them to build upon MRidium’s innovative MRI compatible technologies to create next generation pump systems. We intend to leverage this experience and collaboration to innovate and commercialize other technologically-advanced MRI patient care products, such as a device for assisting resuscitation and a thermal management unit.

Developing a New Resuscitation/Monitoring System.

We currently have under development a new resuscitation device with a separate multi-parameter vital signs monitor that is MRI compatible. We plan to launch the vital signs monitor in 2016. When providing anesthesia care in the MRI environment, the same requirements for safe resuscitation and monitoring that apply in a typical operating room must be satisfied. Our device is being developed using MRI compatible technology to safely deliver therapy and monitor all of the required basic vital signs parameters including electrocardiography, pulse oximetry, non-invasive blood pressure, capnography, and temperature. Our device will be designed to have a monitoring/remote station, with wireless communication capability outside of the scanner room (in the control room).

Acquiring synergistic MRI patient care companies, products or technology licenses to accelerate our product development and leverage our existing direct sales organization in the U.S.

We have an experienced team of engineering and operations managers committed to improving on existing MRI patient care designs through our internal development efforts and the acquisition of technologies and intellectual property of others. We have an effective and growing direct sales organization in the U.S. and a team of experienced international distributors that can effectively go to market with additional MRI patient care products. We intend to actively analyze opportunities to improve our product mix and profitability.

Commercial Strategy

We believe that the MRI compatible IV infusion pump market is still in its early stages of growth given the low rate of market penetration, and we aim to drive increased awareness and adoption of our products by:

Expanding our MRI-focused U.S. direct sales force and our international sales efforts.

We believe the most meaningful aspect of our commercialization strategy in the U.S. is the continued development and expansion of our direct sales force. Since there is no current direct competitor for an MRI compatible IV infusion pump, our focus is on expansion of the market through better education on advantages to patients, clinicians and hospitals of our products and the shortcomings of current workaround solutions. Our challenge in the past has been an understaffed direct sales team and a limited ability to educate our potential customers.

Since 2011, our U.S. sales team has grown from one sales representative to a team of ten direct sales representatives and two clinical support representatives. We intend to continue to grow our specialized, MRI product-focused sales team and to support it with clinical support representatives as the business dictates. We will market to current users of the Continuum system of our former competitor, Bayer Radiology, who will soon be without a viable solution. In addition, we believe that we can significantly increase sales of our MRidium MRI compatible IV infusion pump by also calling on anesthesia and critical care departments, to help influence hospitals’ purchasing decisions. We believe that this strategy will likely expand the number of acute care facilities using our MRI compatible products and increase the average number of MRI compatible IV infusion pumps per acute MRI.

Internationally, our focus in 2015 and beyond is to work with our distributors in key target markets, such as Europe and Japan, to expand the business and augment our market penetration rates. In the future, we plan to expand our internal capacity to serve these high potential markets by adding dedicated regional sales managers located outside the U.S. to oversee our relationships at the local level.

Supporting commercial efforts with evidence-based information.

We have developed a white paper that documents the risks and additional costs associated with using a workaround solution of running long lines from conventional IV pumps outside the MRI scanner room. We believe that this kind of evidence-based documentation will help us to provide widespread education to the clinicians that are driving clinical practice. We also believe that documented evidence will serve to inform the quality and risk management leaders in these organizations, which in turn may help drive the overall adoption of our MRidium MRI compatible IV infusion pump.

Providing best in class customer service and user experience.

We believe that the expectations of our customers for service and a superior user experience have risen with the advancement of technology. Once a customer purchases an MRidium MRI compatible IV infusion pump, it is imperative that they receive first-class clinical education and support to encourage usage of our products. We have devoted a significant amount of time and training to ensure that this educational experience is a success. This training is performed most commonly by our sales staff and is augmented by our clinical support representatives; however, we intend to hire more clinical support specialists to improve our initial training experience and ongoing customer support. We believe that a positive user experience will be critical to driving increased rates of utilization of our products.

Our Products

The MRidium MRI compatible IV infusion pump system is based upon a patented non-magnetic ultrasonic motor and other uniquely-designed non-ferrous parts in order to provide accurate and dependable fluid delivery to patients undergoing an MRI procedure. Our MRidium MRI compatible IV infusion pump system has been designed to offer numerous advantages to hospitals, clinicians and patients. MRidium’s strengths include the following:

· The only non-magnetic MRI compatible IV infusion pump system specifically designed and built for the MRI environment.

· A mobile, rugged, easy-to-operate, and reliable system with a strong safety record.

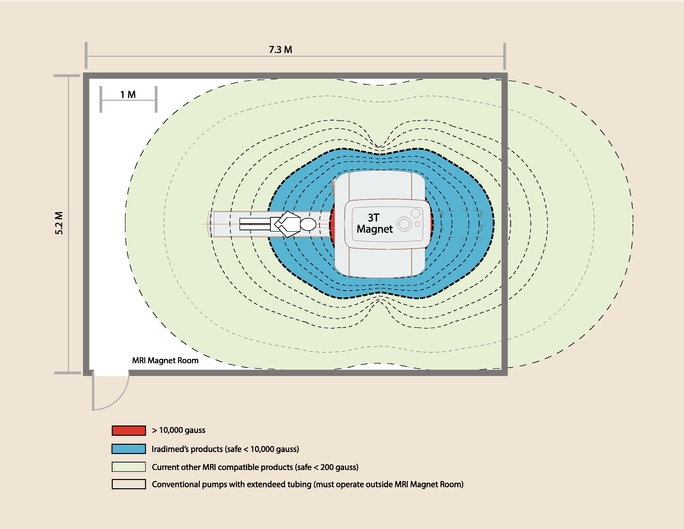

· Able to operate virtually anywhere in the MRI scanner room; approved for use in the presence of 0.2T to 3T magnets and fully operational up to the 10,000 gauss-line.

· The only non-magnetic MRI compatible IV infusion pump available with a Dose Error Reduction System (“DERS”) to reduce the risk of medication errors and simplify clinician monitoring.

· Available with a wireless remote display/control providing clinicians and technicians control and visibility from outside of the MRI scanner room.

· Available with an add-on channel allowing for the easy addition of a second IV line for patients requiring multiple IV medications at a low incremental cost to the hospital.

· Available with a built-in SpO2 monitor using Masimo SET® technology and a specially designed fiber optic SpO2 sensor allowing one device to monitor oxygen saturation levels while safely providing IV infusion during an MRI procedure.

The following diagram is an aerial view of an MRI scanner room with a top-of-the-line 3T magnet. The gauss-lines illustrate the distance from the magnet where various types of infusion pumps can safely operate. Our MRidium MRI compatible IV infusion pump is the only pump on the market approved to operate safely and reliably near the patient (area shown in blue). All of the other pumps must either be placed at a distance from the MRI scanner or outside of the scanner room entirely.

Our MRI compatible IV infusion pump system includes the 3860+ MRI compatible IV infusion pump, proprietary single-use IV tubing sets, a non-magnetic pole and a lithium battery. In addition, we offer optional upgrade systems including the 3865 Remote Display/Control, 3861 Side Car, DERS, and an SpO2 monitor as discussed below.

MRidium 3860+ MRI Compatible IV Infusion Pump

The MRidium 3860+ MRI compatible IV infusion pump system was introduced in 2009 and improved upon the strong performance and features of our first generation MRidium 3850 MRI compatible IV infusion pump system. Our pump systems can operate dependably in the presence of 0.2T to 3T magnets and are fully operational up to the 10,000 gauss-line. This means they are highly versatile and can operate virtually anywhere in the MRI scanner room, including close to the MRI scanner. The MRidium 3860+ MRI compatible IV infusion pump system has a 10-key numeric input keypad making our system easy to accurately program and operate. Our pumping range of 0.1 mL per hour to 1,400 mL per hour provides a broad range of fluid flow control. Our broad range of infusion rates support differing patient needs including low levels for pediatric sedation, mid-levels for continued IV infusion of medications to critically-ill patients and high levels in the event of emergency situations. Our MRidium 3860+ MRI compatible IV infusion pump system offers a dose rate calculator, bolus dose programming, full alarm settings, and a rechargeable battery with a 12-hour battery life.

MRidium 3860+ IV Tubing Sets

The MRidium 3860+ MRI compatible IV infusion pump system utilizes proprietary fluid delivery tubing sets, each known as an “IV tubing set.” Each use of our MRI compatible IV infusion pump requires a disposable IV tubing set. We offer a variety of IV tubing sets for varying MRI scenarios and these include our standard “spike” infusion set, syringe adapter infusion set and extension infusion set. Each of our IV tubing sets is latex-free and DEHP-free.

· MRidium 1056 Standard Infusion Set. Our standard “spike” infusion set features the ability to accurately deliver liquids from either a bottle or IV bag. Our standard infusion set contains two needle-free injection ports and is typically used when starting a new infusion from a bottle or bag.

· MRidium 1057 Syringe Adapter Infusion Set. Our syringe adapter IV set enables users to provide accurate delivery of IV fluids directly from standard syringes. The vented syringe adapter set benefits from a low priming volume of 4 ml, which minimizes inefficient waste of medication. This product is most commonly used for cardiac medications, anesthesia, and pediatric drug delivery.

· MRidium 1058 Extension Infusion Set. Our extension infusion set allows users to transfer a patient on a non-MRI infusion pump to our MRidium MRI compatible IV infusion pump. The user simply disconnects the existing IV tubing at the patient site and connects and primes the MRidium extension set to the existing IV tubing. Once removed from the conventional infusion pump and connected to our MRidium MRI compatible IV infusion pump, the user can program the pump and begin the infusion. The extension set includes one needle-free injection port and is typically used to provide uninterrupted critical medications to a severely ill patient during an MRI procedure.

MR IV Pole

We offer a fully-functional and weighted non-magnetic IV pole that is designed for mobility within the hospital and the MRI scanner room. The IV pole can support two MRidium MRI compatible IV infusion pumps, each with a side car. The IV pole is 66 inches (1.68 meters) high, stabilized with a wide pole radius and mobilized with five casters designed to roll easily during transport. The IV pole is equipped with four hooks for holding fluids.

Optional Features

Our 3860+ MRI compatible IV infusion pump system gives customers the ability to adapt their systems to meet their specific needs. In addition to our standard product features, we also offer system upgrades which include a wireless remote control/display, a modular add-on second IV channel through our “Side Car,” DERS and an imbedded SpO2 monitor. We also offer rechargeable lithium polymer battery packs which have 12-hour battery life when not connected to an electrical outlet.

3865 MRidium Wireless Remote Display/Control

Our wireless remote control units allow for complete control and monitoring of the MRidium MRI compatible IV infusion pump system from the control room (outside of the MRI scan room). The 3865 MRidium Wireless Remote relays all commands and displays information bi-directionally between the MRI compatible IV infusion pump and the remote control unit. Utilizing the same user interface and large bright display as the MRidium pump, our wireless remote control unit permits clinicians to adjust all pump parameters, including SpO2 monitoring parameters, rates, dose, volume, pump run/stop, alarms (adjust or reset), as well as real-time titration. Our remote control unit utilizes a proven MRI compatible 2.4 GHz FH (frequency hopping) spread spectrum radio technology for artifact-free operation that does not disturb the MRI imaging process. Clinicians may also use the remote control unit to adjust a second pump channel when used in combination with our Side Car unit discussed below. Our 3865 MRidium Wireless Remote also functions as a battery charger for our MRidium battery pack.

3861 Side Car Pump Module

Our Side Car Pump Module can be attached to our 3860+ MRidium MRI compatible IV infusion pump to provide a second channel for infusion delivery. This flexible option allows hospitals to convert their single-channel infusion pump into a dual-channel system designed to deliver both large and small volume fluids in the MRI scanner room. The side car is fully functional with our 3865 MRidium Wireless Remote, allowing clinicians the ability to control both channels with one remote control unit outside of the MR scanner room. The additional delivery line has all of the same features and benefits as the 3860+ MRidium MRI compatible IV infusion pump, as described above.

Dose Error Reduction System (“DERS”)

Our DERS for use with our MRidium 3860+ MRI compatible IV infusion pump system incorporates the latest drug safety features for patients. The DERS system enables users to create a unique drug library and establish nominal values and limits for dose and concentration for specified infusion protocols. With DERS, patient safety and user convenience are supported by user-programmed infusion hard limits (maximum and minimum) and soft limits (high and low limits that require user confirmation to exceed). The dose applied via DERS is displayed and can be adjusted directly on the running screen at any time during the infusion. The universal memory card port allows for easy archiving and updating of the drug library.

SpO2 Monitoring with Sensor and Accessories

Our MRidium 3860+ MRI compatible IV infusion pump system also offers state-of-the-art Masimo SET® SpO2TM capability providing a unique ability to have SpO2 monitoring and IV delivery combined in one unit. This feature offers users the ability to start sedations outside of the MRI scanner room, transport to the scanner, and then back to recovery without having to discontinue SpO2 monitoring on the patient. In addition, our fiber optic MRI-SpO2 sensor and accessories provide a safe connection between the patient and our MRI compatible IV infusion pumps. This fiber optic-based SpO2 sensor delivers outstanding performance while avoiding potentially hazardous heating or image artifact during MR scans. The method of patient attachment uses a medical-grade silicone rubber sensor grip that allows easy and convenient attachment to the patient’s hand or foot, and accommodates pediatric, adult, and infant patients with various size grips.

We believe our MRidium 3860+ MRI compatible IV infusion pump system and its customizable features comprehensively and uniquely address the needs of MRI departments within hospitals and other medical facilities.

We also offer two products exclusively to non-U.S. customers. These products consist of the 2460 iMagox MRI SpO2 Monitor and the 2465 iMagox Remote Control.

iMagox 2460 MRI Pulse Oximeter — Available for Use Outside of the U.S.

The iMagox 2460 MRI Pulse Oximeter System uses Masimo SET® Technology and is approved for use in the presence of 0.2T to 3T magnets and operational up to the 10,000 gauss-line. Our digital MRI pulse oximeter simultaneously measures and displays the functional oxygen saturation and pulse rate of adult, pediatric and infant patients. The large display provides digital and waveform data with SpO2 alarms and user messages, which can be easily seen within the MR scanner room. When fully charged, the battery supporting this system will provide up to 24 hours of continuous operation. The unique rear clamp mechanism swivels to allow mounting on either a non-magnetic IV pole, or for mounting to a bed side rail. This portability combined with the system’s extended battery life gives clinicians at medical facilities the freedom to administer continuous patient monitoring before, during and after an MRI scan. Our iMagox system also provides an optional wireless remote and display described below.

iMagox 2465 MRI Oximeter Remote and Display — Available for Use Outside of the U.S.

The iMagox 2465 Wireless Remote and Display allows for monitoring and control of the MRI Pulse Oximeter from outside the MR scanner room. Our remote allows users to adjust all oximeter parameters and reset alarms. The wireless remote, which is designed for plug-and-play use and requires no installation, is fitted with a large display and utilizes the same user interface as the 2460 MRI Pulse Oximeter. The remote also acts as a charger for a backup or spare battery pack for the iMagox 2460 MRI Pulse Oximeter. It utilizes a wireless link at 2.4 GHz for reliable communication with no image artifacts.

Intellectual Property

We protect our proprietary technology through a combination of trade secrets, confidentiality agreements and patents. During the development of our products, our founder, Roger Susi, obtained a number of patents regarding our MRI compatible IV infusion pump and related systems. Mr. Susi has irrevocably assigned these patents to us. We consider our patents important but do not believe our future success is dependent upon patents. We have ten issued U.S. patents and four issued foreign patents. We also have a number of U.S. patent applications pending. These patents and patent applications relate to several of our products, including our MRI compatible IV infusion pump system and its components. We intend to file patent applications with respect to future patentable developments and improvements when we believe that such protection is in our best interest.

We also rely on trade secret, copyright and other laws and on confidentiality agreements to protect our technology, but we believe that neither our patents nor other legal rights will necessarily prevent third parties from developing or using similar or related technology to compete against our products. Moreover, our technology may be viewed as improvements or adaptations of known MRI infusion technology, which might be duplicated or discovered through our patents, reverse engineering or both.

Sales and Marketing

We sell our MRI compatible products through our direct sales force in the U.S. and independent distributors internationally. In the U.S., we sell our products through our ten direct sales representatives and two clinical support representatives. We have distribution agreements for our products with 35 independent distributors selling our products internationally. We have developed an experienced team of distributors that have a strong MRI/radiology product portfolio and focus. Our international distributors are managed by our VP of International Sales, an industry veteran with over 20 years in the IV infusion pump business and nine years as our sales manager.

In fiscal year 2014, 72.6% of our revenue was generated from U.S. sales and 27.4% was generated from international sales.

As of December 31, 2014, our backlog was approximately $19.5 million. We include all purchase orders received from customers in backlog. As part of our commitment to customer service, our goal has been to ship products to meet the customers’ requested shipment dates. Our backlog is occasionally subject to cancellation or rescheduling by the customer on short notice with little or no penalty. Because of the uncertainty of order cancellations or rescheduling, we do not believe our backlog as of any particular date is indicative of actual sales for any future period and, therefore, should not be used as a measure of future revenue.

Selling cycles for our medical devices vary widely but are typically three to six months in duration. To supplement the efforts of our sales and clinical support representatives, we produce and distribute videos that provide users of our MRidium products an easy means for learning clinical applications. These videos guide users through a detailed step-by-step process in using our products, including initial product set-up, selection of infusion sets, loading the infusion pump, programming the pump, managing alarms and alerts and prompts, SpO2 monitoring, and other advanced functions. Users also benefit from our detailed operator manuals and 24/7 technical support via telephone.

The principal customers for our MRI compatible products include hospitals and acute care facilities. A customer’s decision to use our products is typically made by the radiologist and anesthesiologist, or department administrative director. We serve these customers through our sales and service specialists and believe that our specialists are well-positioned to build upon these customer relationships. We communicate with our customers on a regular basis in an attempt to understand potential issues or concerns as well as to improve our products and services in response to their needs. Product orders and inquiries are handled by trained service representatives who communicate with customers after equipment shipments, installations and service repair calls. We have implemented various other programs which enable us to assess our customers’ needs. These programs include regular surveys and visits to customer sites.

As of December 31, 2014, two international customers accounted for approximately 35% of gross accounts receivable. As of December 31, 2013, one international customer accounted for approximately 11% of gross accounts receivable. Revenue for 2013 included sales to an international customer for 129 of our MRI compatible IV infusion pumps, which represented approximately 11% of total revenue for 2013.

We enter into agreements with healthcare supply contracting companies, commonly referred to as GPOs in the U.S., which enable us to sell and distribute our MRidium MRI compatible IV infusion pump systems to their member hospitals. GPOs negotiate volume purchase prices for hospitals, group practices, and other clinics that are members of a GPO. Our agreements with GPOs typically include the following provisions:

· Negotiated pricing for all group members;

· Volume discounts and other preferential terms on their members’ purchases from us;

· Promotion of our products by the GPO to its members; and

· Payment of administrative fees by us to the GPO, based on purchases of our products by group members.

Under these agreements, we are required to pay the GPOs a fee of three percent of the sales of our products to hospitals, group practices, and other acute care facilities that are members of the GPO. We currently have contracts with four major GPOs that effectively give us the ability to sell to more than 95% of all U.S. acute care facilities.

Our MRidium MRI compatible IV infusion pump system received the Frost and Sullivan Technology award in 2005.

Manufacturing and Suppliers

We assemble our products in our facilities in Winter Springs, Florida, from components and sub-assemblies purchased from outside suppliers. We perform final assembly, testing and packaging to control quality and manufacturing efficiency. We purchase components and sub-assemblies from qualified suppliers that are subject to our stringent quality specifications and inspections by us. We conduct quality audits of our key suppliers, several of which are experienced in the supply of components to manufacturers of finished medical devices or disposables for use with these medical devices. Our historical track record of producing MRI compatible IV infusion pump systems has been good; however, there can be no assurance that this trend will continue or that we will be able to produce sufficient units to reach our expected revenue growth rates.

The non-magnetic ultra-sonic motor which drives our MRI compatible IV infusion pump is sole-sourced from a major multinational Japanese manufacturing company with whom we have an excellent long-term relationship. This company has exclusively provided us with these motors since 2005, and we recently renewed our exclusive supply agreement with this company for another five years through 2019. We have never encountered a significant supply interruption from this manufacturer and have received no indications that there might be disruptions of the supply of these motors in the future. We have routinely averaged no more than a two-month supply of these motors in our inventory. The supplier has committed to maintaining our supply and delivering on a timely basis. We have identified two additional suppliers who may be able to produce an ultra-sonic motor essentially identical to our current motor. However, we believe that adding or switching to an alternate supplier would require six months to a year.

We have two alternate suppliers of our IV sets. The first is our own in-house IV set manufacturing capability, and the second is an OEM located in central Florida. We expect our in-house capabilities coupled with production capacity of the OEM should be sufficient to meet expected customer demand for the foreseeable future.

Other sole or limited supply devices and components of our products include the following:

· Force Sensor. This device is used to measure the fluid pressure within the IV tubing set and provide certain alarm functions. This part is supplied by a large multinational U.S.-based manufacturer. We have never experienced a delivery problem of this part, and we typically maintain three to six months inventory in supply. However, we have had an internal development effort underway to create and manufacture this device in-house. In the event of a failure of our current supplier to furnish sufficient force sensors, we believe we could assume the manufacture of this device in three to five months.

· Bubble Detector. This device provides safety and alarm upon detection of air in the IV fluid line. We have never experienced delivery issues with this part, which is supplied by a major multinational U.S.-based company, and we generally maintain a three-month supply on hand. There is one alternate supplier whose part we have tested on a preliminary basis, and we believe we could switch to that source if needed, within approximately three or four months.

· Lithium Polymer Battery Cells. This device is used to power our MRI compatible IV infusion pump. Though we keep several months’ supply on hand and have alternate sources qualified, due to regulatory issues, changing to an alternate source could require three to four months.

· LCD Displays. This component is currently a sole-sourced assembly from a large Chinese supplier who has a history of late delivery. We typically maintain a three-month supply on hand. We have an active ongoing effort to cultivate a second source, which we expect to be finalized by late 2015.

· Various Molded and Cast Components. These custom tooled and molded/cast parts are subject to supply interruption should the tools become damaged. Replacement of these tools could require up to eight months. Our inventory of such custom molded and cast parts is typically on the order of six months.

We place significant emphasis on providing quality products and services to our customers. Quality management and oversight play an essential role in understanding and meeting customer requirements, effectively resolving quality issues and improving our products and services. We have a network of quality systems throughout our facilities that relate to the design, development, assembly, packaging, sterilization, handling, distribution and labeling of our products. To assess and facilitate compliance with applicable requirements, we periodically review our quality systems to determine their effectiveness and identify areas for improvement.

We also conduct compliance training programs for our sales and marketing personnel and perform assessments of our suppliers of raw materials, components and finished goods. In addition, we conduct quality management reviews designed to inform management of key issues that may affect the quality of our products. From time to time, we may determine that products manufactured or marketed by us do not meet our specifications, published standards or regulatory requirements. When a quality issue is identified, we investigate the issue and seek to take appropriate corrective action, such as withdrawal of the product from the market, correction of the product at the customer location, notice to the customer of revised labeling or a combination of these or other corrective actions.

In January 2007, we received ISO 9001 and ISO 13485 certification and met the requirements under the European Medical Device Directive to use the CE Mark, thereby allowing us to continue to market our products in the European Community. These certificates were last renewed on January 17, 2013, and will need renewal again in January 2016.

Competition

We do not believe there is currently any direct competition for our MRI compatible IV infusion pump systems. Our only direct competitor in the MRI compatible IV infusion pump market, Bayer Radiology, formerly MEDRAD, Inc., announced during 2013 its decision to remove its competing Continuum pump system from the market, and to discontinue support throughout the world by June 30, 2015 due to ongoing regulatory issues. As a result, we believe that our MRidium 3860+ MRI compatible IV infusion pump is the only true MRI compatible IV infusion pump available today. Bayer Radiology’s announcement provided that it planned to remove the actual product from customers in the field, and that it would no longer offer the disposable proprietary IV tubing sets after June 30, 2015.

The medical device and IV infusion market is highly regulated and is typically one of the areas that the FDA scrutinizes closely for new market introductions. Because of this, the 510(k) FDA clearance process for new pumps is usually long and requires significant testing and documentation. This long development timeline coupled with the low market penetration to date may discourage new competitors from undertaking a complex project like building an MRI compatible IV infusion pump. However, the medical products industry is generally characterized by intense competition and extensive research and development. We believe, that the market for MRI compatible IV infusion pump products is in relatively early stages of development and may become highly competitive if, and when, the market develops further.

Outside of the U.S., we also compete with manufacturers of “shielded box” solutions that are intended to permit use of conventional IV pumps inside the MR scanner room. The providers of shielded boxes include B. Braun, Fresenius Kabi, MIPM Mammendorfer Institut für Physik und Medizin, and Arcomed. The market for medical products is subject to rapid change due to

an increasingly competitive, cost-conscious environment and to government programs intended to reduce the cost of medical care. Many of these manufacturers and distributors of medical equipment are large, well-established companies whose resources, reputations and ability to leverage existing customer relationships might give them a competitive advantage over us. Our SpO2 products, which measure blood oxygen saturation, also compete indirectly with many other methods currently used to measure blood oxygen levels or the effects of low blood oxygen levels.

Another potential competitor may be CareFusion Corporation (NYSE: CFN). CareFusion is a major medical device manufacturer that has a dominant position in the conventional IV infusion pump market and made an investment in Caesarea Medical Electronics (“CME”) in December 2013. CME manufactured Bayer Radiology’s Continuum Pump System. In addition, B. Braun may seek to obtain FDA clearance for its SpaceStation MRI Trolley, currently only available outside the U.S., which allows traditional B. Braun IV infusion pumps to be used in the MR environment.

Many of our potential customers opt not to purchase our MRI compatible IV infusion pump systems and instead use makeshift workarounds, such as placing conventional IV infusion devices outside of the MR scanning room and utilizing extension tubing to reach the patient. To this extent, we are in competition with conventional IV infusion pump manufacturers and distributors.

There are many manufacturers of conventional IV infusion pump devices, and if any of these manufacturers, or other potential competitors, decide to enter into the MRI compatible IV infusion pump market, they may have competitive advantages over us. Many of these potential competitors have established reputations, customer relationships and marketing, distribution and service networks. In addition, they have substantially longer histories in the medical products industry, larger product lines and greater financial, technical, manufacturing, management, and research and development budgets. Many of these potential competitors may have long-term product supply relationships with our potential customers.

We believe that a company’s reputation for producing accurate, reliable and technologically-advanced products, references from users, features (speed, safety, ease of use, patient convenience and range of applicability), product effectiveness and price are the principal competitive factors in the medical products industry.

Seasonality

Our business is seasonal. Our third quarter sales have typically been lower, compared to other fiscal quarters, principally because the fiscal quarter coincides with the summer vacation season, especially in the U.S., Europe, and Japan.

Research and Development

Our research and development efforts focus on developing innovative products by utilizing our established core competencies in MR compatible technologies and feedback from strategic relationships with hospitals, acute medical facilities and medical equipment manufacturers for new product ideas. Our research and development efforts are driven by the leadership of our founder, Roger Susi, assisted by five engineers and technical professionals with significant experience in product design.

Employees

As of December 31, 2014, we had 54 full-time employees, including 5 in research and development, 24 in manufacturing, 17 in sales and marketing and customer support services and 8 in finance and administration. No employees are represented by a labor union. We have not experienced any work stoppages and consider our relations with our employees to be good.

Regulatory Matters

Governmental Regulation and Other Matters

Our medical device products are subject to extensive, complex and increasing oversight and regulation by the U.S. Food & Drug Administration (“FDA”), and other domestic and foreign governmental authorities. Our manufacturing and other

facilities, and those of our suppliers, are subject to periodic inspections to verify compliance with current FDA and other governmental regulatory requirements. If it were determined that we were not in compliance with these laws and regulations, we could be subject to criminal or civil liability, or both, and other material adverse effects. We have compliance programs in place to support and monitor compliance with these laws and regulations. All of our products and facilities and those of our suppliers are subject to drug and medical device laws and regulations promulgated by the FDA and national and supranational regulatory authorities outside the U.S., including, for example, Health Canada’s Health Products and Foods Branch, the U.K.’s Medicines and Healthcare Products Regulatory Agency, and Australia’s Therapeutic Goods Agency. These authorities regulate a range of activities including, among other matters, manufacturing, post-marketing studies in humans, advertising and promotion, product labeling, post-marketing surveillance and adverse event reporting.

Regulation of Medical Devices in the United States

The development, manufacture, sale and distribution of our medical device products are subject to comprehensive governmental regulation. Most notably, all of our medical devices sold in the United States are subject to the Food, Drug, and Cosmetic Act of 1938, as amended (“FDC Act”), as implemented and enforced by the FDA. The FDA, and in some cases other government agencies, such as the U.S. Federal Communications Commission (“FCC”), administer requirements covering the design, testing, safety, effectiveness, manufacturing, labeling, promotion and advertising, distribution and post-market surveillance of our products.

Unless an exemption applies, each medical device that we market must first receive either premarket notification (by making what is commonly called “a 510(k) submission”) clearance or premarket approval (by filing a premarket approval application (“PMA”) from the FDA pursuant to the FDC Act. In addition, certain modifications made to marketed devices also may require 510(k) clearance or approval of a PMA supplement. The FDA’s 510(k) clearance process usually takes up to twelve months, but it can last longer. The process of obtaining PMA approval is much more costly, lengthy and uncertain. It generally takes from two to three years or even longer. All of our current products that are available in the U.S. were originally cleared through the 510(k) process. However, on September 2, 2014, we received a warning letter from the FDA requesting that we cease commercial distribution of our products and submit a new 510(k). Refer to the section below captioned “FDA Facility Inspection and Warning Letter.” We cannot be sure that future products or modifications of current products, will qualify for the 510(k) pathway or whether 510(k) clearance or PMA approval will be obtained for any future product that we propose to market.

In December 2014, the FDA issued guidance entitled “Infusion Pumps Total Product Life Cycle.” This guidance established substantial additional pre-market requirements for new and modified infusion pumps. Through this guidance, the FDA indicated more data demonstrating product safety will be required for future 510(k) submissions for infusion pumps, including the potential for more clinical and human factors data. The impact of this guidance is likely to result in a more time consuming and costly process to obtain regulatory clearance to market infusion pumps. In addition, new requirements could result in longer delays for the clearance of new products, modification of existing infusion pump products or remediation of existing products in the market. Future delays in the receipt of, or failure to obtain, approvals could result in delayed or no realization of product revenues.

After a device is placed on the market, numerous regulatory requirements continue to apply. Those regulatory requirements include the following: product listing and establishment registration; adherence to the Quality System Regulation (“QSR”), which requires stringent design, testing, control, documentation and other quality assurance procedures; labeling requirements and FDA prohibitions against the promotion of off-label uses or indications; adverse event reporting; post-approval restrictions or conditions, including post-approval study commitments; post-market surveillance requirements; the FDA’s recall authority, whereby it can ask for, or require, the recall of products from the market; and requirements relating to voluntary corrections or removals.

All aspects of our manufacturing and distribution of regulated products and those of our suppliers are subject to substantial governmental oversight. Facilities used for the production, packaging, labeling, storage and distribution of medical devices must be registered with the FDA and other regulatory authorities. All manufacturing activities for these products must be conducted in compliance with current good manufacturing practices (“cGMPs”). Our manufacturing facilities and those of our suppliers are subject to periodic, routine and for-cause inspections to verify compliance with cGMPs. If, upon inspection, the FDA or another regulatory agency finds that a manufacturer has failed to comply with cGMPs, it could institute a wide variety of enforcement actions, ranging from a public warning letter to more severe sanctions, such as product recalls or seizures, monetary sanctions, consent decrees, injunctions to halt manufacturing and distributing products, civil or criminal sanctions, refusal to

grant clearances or approvals or delays in granting such clearances or approvals, import detentions of products made outside of the United States, restrictions on operations or withdrawal or suspension of existing approvals. The FDA also has the authority to request repair, replacement or refund of the cost of any medical device manufactured or distributed by us. These actions could result in, among other things, substantial modifications to our business practices and operations; a total or partial shutdown of production in one or more facilities while we or our suppliers remedy the alleged violation; the inability to obtain future pre-market clearances or approvals; and withdrawals or suspensions of current products from the market. Any of these events could disrupt our business and have a material adverse effect on our revenues, profitability and financial condition.

FDA Facility Inspection and Warning Letter

The FDA conducted a routine inspection of our prior facility between April 7 and April 16, 2014. This was the first FDA inspection of our facility since the voluntary product recall in August 2012 of certain infusion sets and the voluntary recall in July 2013 of our DERS software. The FDA issued a Form 483 on April 16, 2014 that identified eight observations. In general, the observations involved issues related to the 2012 and 2013 product recalls (described in more detail under Product Recalls, below). The majority of the observations related to procedural and documentation issues associated with the design, development, validation testing and documentation of software used in certain of our products. Other observations were related to the design validation of pump labeling, design analysis of tube stretching, procedures for post-market design review, and control and procedures related to handling certain reported complaints. We submitted a response to the Form 483 in May 2014 and June 2014 in which we described our proposed corrective and preventative actions to address each of the FDA’s observations.

On September 2, 2014, we received a warning letter from the FDA relating to this inspection (the “Warning Letter”). The Warning Letter stated that the FDA accepted as adequate several of our responses to Form 483 observations, identified two responses whose accuracy will be determined in the next scheduled inspection of our facility and identified issues for which our response was determined to be inadequate. The issues identified as inadequate concern our procedures for validating device design primarily related to software quality assurance.

Also, the Warning Letter raised a new issue. The Warning Letter stated that modifications made to software on our previously cleared infusion pumps, the MRidium 3860 and MRidium 3850, were “significant” and required submission of new premarket notifications under Section 510(k) (a “510(k) submission”) of the FDC Act. These modifications were made over time. We believe they were insignificant and did not require premarket notification submissions. However, the FDA indicated that the modifications of the software for the MRidium 3860 and the software for the MRidium 3850 were “significant” modifications because they could significantly affect the safety or effectiveness of these devices. As a result, the Warning Letter states that the products being sold by us are “adulterated” and “misbranded” under the FDC Act. The Warning Letter also indicates that the MRidium 3860+ infusion pump requires separate FDA clearance from the MRidium 3860 and MRidium 3850.

The Warning Letter requested that we immediately cease activities that result in the misbranding or adulteration of the MRidium 3860 MRI infusion pump, MRidium 3850 MRI infusion pump, and the MRidium 3860+ MRI infusion pump, including the commercial distribution of the devices. We immediately complied with the Warning Letter and ceased sale and distribution of the identified products in the United States.

On September 4, 2014, we submitted to the FDA our initial response to the Warning Letter and on September 17, 2014 we sent an additional response that included supplemental information related to the Form 483 inspection observations for which the FDA considered our initial responses inadequate.

On November 25, 2014, we announced that we filed the 510(k) submission related to our MRidium 3860+ MRI IV infusion pumps and on December 12, 2014 we were notified that our 510(k) submission had been formally accepted for review by the FDA. On December 22, 2014, under FDA enforcement discretion, we announced that we resumed domestic distribution of our MRI compatible MRidium 3860+ MRI IV infusion pump systems, without the DERS option.

We continue to work with the FDA to fully resolve the Warning Letter and complete the review of the 510(k) submission.

Overall Financial Impact from the Warning Letter. Our financial results for 2014 were significantly impacted by the Warning Letter and resulting stoppage of domestic shipments. We expect to continue to incur higher than normal financial expenses until the issues raised in the Warning Letter are completely resolved.

Product Recalls

Dose Error Reduction System (“DERS”) Software Recall. Some of our MRidium 3860+ MRI compatible IV infusion pumps are equipped with a DERS. Due to a software issue observed on June 19, 2013, the drug dosage calculation indicated an incorrect recommended value for the flow rate when a specific key sequence was used during the infusion setup. As a result, a patient was infused with an incorrect flow rate. No harm to the patient was reported. On July 1, 2013, we issued an urgent medical device recall notice (the “DERS Recall”) and promptly made available to our customers a software update to resolve the error. On July 2, 2013, the subject of the recall was discussed with the FDA by phone. On July 12, 2013, we provided written notification to the FDA of the DERS Recall and submitted a Medical Device Report (MDR) with the FDA describing the incident, the investigative and corrective actions taken, the reason for the DERS Recall and the recall strategy. On September 18, 2013, we notified the FDA that all of the pumps sold with the DERS kits had been successfully upgraded with the software correction and reported that the DERS Recall was completed as of September 16, 2013. We requested that the FDA officially close the DERS Recall. The FDA has not yet responded to our request of September 16, 2013 or more recent requests to close the DERS Recall. It is likely that the FDA wanted to conduct a follow-up inspection prior to closing the DERS Recall. The FDA completed an inspection of our facility on April 16, 2014. Refer to the section above captioned “FDA Facility Inspection and Warning Letter.”

Overall Financial Impact from the Recalls. We believe the financial expenses incurred related to the recall were not significant to our operations or financial results. We expect to incur only minor additional charges over the next several months in connection with the final closeout activities related to the recall.

Corrective Actions from the Recall. We take recalls and related matters seriously and we have responded and will continue to respond fully, and in a timely manner, to the FDA and other governmental regulatory agencies.

We have made substantial investments in quality systems over the past two years. We will continue to make improvements to our products and systems to further reduce potential issues related to patient safety and avoid recalls in the future. Product quality plays a critical role in our success. While we believe that we have made significant improvements to our product quality and overall quality systems, further quality concerns, whether real or perceived, could adversely affect our results. Conversely, improving quality can be a competitive advantage and improve our results. For more information about risks related to these matters, see the section captioned “Defects or failures associated with our products and/or our quality systems could lead to the filing of adverse event reports, recalls or safety alerts and negative publicity and could subject us to regulatory actions” in the “Risk Factors” section.

Healthcare Fraud and Abuse Laws

As a manufacturer and distributor of medical devices to hospitals and other healthcare providers, we and our customers are subject to laws which apply to Medicare, Medicaid, and other federal and state healthcare programs in the U.S. One such law, the Anti-kickback Statute, prohibits the solicitation, offer, payment or receipt of remuneration in return for referral or purchase, or in return for the recommending or arranging for the referral or purchase, of products covered by the programs. The Anti-kickback Statute provides a number of exceptions or “safe harbors” for particular types of transactions. While we generally do not file claims for reimbursement from government payers, the U.S. federal government has asserted theories of liability against manufacturers under the Federal False Claims Act, which prohibits the submission of false claims to Medicare, Medicaid, and other state and federal programs. Many states have similar fraud and abuse laws which may apply to us. Violations of these fraud and abuse-related laws are punishable by criminal or civil sanctions, including substantial fines, imprisonment and exclusion from participation in healthcare programs such as Medicare and Medicaid and health programs outside the United States. We have developed and implemented business practices and processes to train our personnel to perform their duties in compliance with healthcare fraud and abuse laws. While we conduct informal oversight to detect and prevent these types of fraud and abuse, we lack formal written policies and procedures at this time. If we were unable to document and implement the controls and procedures required in a timely manner or otherwise violate such laws, we might suffer adverse regulatory consequences or face criminal sanctions, which could harm our operations, financial reporting or financial results.

Regulation of Medical Devices Outside of the United States