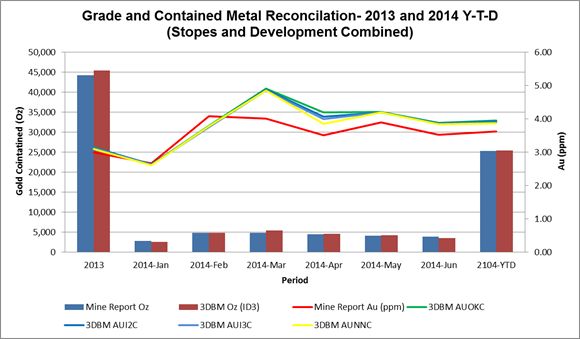

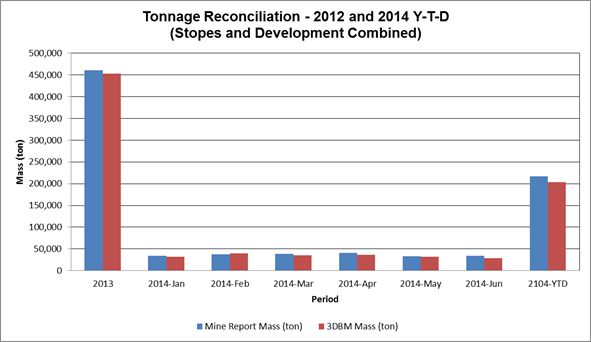

| TABLE 14-12 RECONCILIATION REPORT, 2013 AND 2014 YTD |

| Jaguar Mining Inc. – Turmalina Mine |

| |

| Period | Mine Report | Block Model |

| Tonnes | Au (g/t) | Oz Au | Tonnes | Grade (OK) | Grade (ID2) | Grade (ID3) | Oz Au (OK) | Oz Au (ID2) | Oz Au (ID3) |

| 2013 | 460,731 | 2.99 | 44,301 | 453,035 | 3.15 | 3.14 | 3.12 | 45,949 | 45,673 | 45,429 |

| 2014-Jan | 33,760 | 2.66 | 2,892 | 31,508 | 2.62 | 2.63 | 2.63 | 2,654 | 2,668 | 2,660 |

| 2014-Feb | 37,273 | 4.09 | 4,896 | 40,112 | 3.80 | 3.77 | 3.75 | 4,898 | 4,866 | 4,839 |

| 2014-Mar | 38,099 | 4.02 | 4,920 | 34,894 | 4.91 | 4.88 | 4.85 | 5,511 | 5,478 | 5,437 |

| 2014-Apr | 40,286 | 3.51 | 4,551 | 36,407 | 4.19 | 4.06 | 4.00 | 4,904 | 4,756 | 4,680 |

| 2014-May | 33,043 | 3.89 | 4,137 | 31,487 | 4.21 | 4.20 | 4.20 | 4,259 | 4,252 | 4,249 |

| 2014-Jun | 34,310 | 3.53 | 3,890 | 28,651 | 3.89 | 3.87 | 3.86 | 3,579 | 3,563 | 3,554 |

| 2104-YTD | 216,771 | 3.63 | 25,286 | 203,059 | 3.95 | 3.92 | 3.89 | 25,806 | 25,583 | 25,418 |

| | | | | | | | | | | |

| Total 2013 & 2014 | 677,502 | 3.19 | 69,587 | 656,094 | 3.40 | 3.38 | 3.36 | 71,755 | 71,256 | 70,847 |

| | | | | | | | | | | |

Variance (BM- Actual) | Tonnes | Grade (OK) | Grade (ID2) | Grade (ID3) | Oz Au (OK) | Oz Au (ID2) | Oz Au (ID3) | | | |

| 2013 | -7,696 | 0.16 | 0.15 | 0.13 | 1,648 | 1,372 | 1,129 | | | |

| 2014-Jan | -2,252 | -0.04 | -0.03 | -0.04 | -238 | -224 | -232 | | | |

| 2014-Feb | 2,839 | -0.29 | -0.31 | -0.33 | 2 | -30 | -58 | | | |

| 2014-Mar | -3,205 | 0.90 | 0.87 | 0.83 | 591 | 558 | 517 | | | |

| 2014-Apr | -3,879 | 0.68 | 0.55 | 0.48 | 353 | 205 | 129 | | | |

| 2014-May | -1,556 | 0.31 | 0.31 | 0.30 | 122 | 115 | 111 | | | |

| 2014-Jun | -5,659 | 0.36 | 0.34 | 0.33 | -311 | -327 | -336 | | | |

| 2104-YTD | -13,712 | 0.32 | 0.29 | 0.26 | 519 | 297 | 131 | | | |

| | | | | | | | | | | |

| Total 2013 & 2014 | -21,408 | 0.21 | 0.18 | 0.16 | 2,167 | 1,669 | 1,260 | | | |

| | | | | | | | | | | |

| Variance % | Tonnes | Grade (OK) | Grade (ID2) | Grade (ID3) | Oz Au (OK) | Oz Au (ID2) | Oz Au (ID3) | | | |

| 2013 | -2 | 5 | 5 | 4 | 4 | 3 | 3 | | | |

| 2014-Jan | -7 | -2 | -1 | -1 | -8 | -8 | -8 | | | |

| 2014-Feb | 8 | -7 | -8 | -8 | 0 | -1 | -1 | | | |

| 2014-Mar | -8 | 22 | 22 | 21 | 12 | 11 | 11 | | | |

| 2014-Apr | -10 | 19 | 16 | 14 | 8 | 4 | 3 | | | |

| 2014-May | -5 | 8 | 8 | 8 | 3 | 3 | 3 | | | |

| 2014-Jun | -16 | 10 | 10 | 9 | -8 | -8 | -9 | | | |

| 2104-YTD | -6 | 9 | 8 | 7 | 2 | 1 | 1 | | | |

| | | | | | | | | | | |

| Total 2013 & 2014 | -3 | 6 | 6 | 5 | 3 | 2 | 2 | | | |

MINERAL RESOURCE CLASSIFICATION CRITERIA

The Mineral Resources in this report were estimated in accordance with the definitions contained in CIM (2014).

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-31 |

| www.rpacan.com |

The mineralized material for each wireframe was classified into the Measured, Indicated, or Inferred Mineral Resource category on the basis of the search ellipse ranges obtained from the variography study, the demonstrated continuity of the gold mineralization, the density of drill hole and chip sample information, and the presence of underground access.

On the basis of these criteria, Measured Mineral Resources comprise that material that has been estimated using Pass #1 that is located between developed levels. Indicated Mineral Resources comprise that material that has been estimated using Pass #2, and Inferred Mineral Resources comprise that material that has been estimated using Pass #3. Clipping polygons were used in a final stage of the classification process to ensure continuity and consistency of the classified blocks in the model.

RESPONSIBILITY FOR ESTIMATION

The estimate of the Mineral Resources for the Turmalina Mine presented in this report was prepared by Mr. Helbert Taylor Vieira, Senior Geologist with Jaguar under the supervision of Mr. Jean-Marc Lopez, Director – Mine Geology with Jaguar and Mr. Reno Pressacco, M.Sc.(A), P.Geo., with RPA. Mr. Pressacco is a Qualified Person as defined in NI 43-101, is independent of Jaguar, and takes responsibility for this Mineral Resource estimate.

CUT-OFF GRADE

A cut-off grade of 2.5 g/t Au is used for reporting of Mineral Resources. This cut-off grade was arrived at using a gold price of US$1,400/oz, average gold recovery of 88%, and 2014 actual cost data for the Turmalina Mine. Gold prices used for reserves are based on consensus, long term forecasts from banks, financial institutions, and other sources. For resources, gold prices used are slightly higher than those for reserves.

MINERAL RESOURCE ESTIMATE

The Mineral Resources are inclusive of Mineral Reserves. For those portions of the Mineral Resources that comprise the Mineral Reserve, the stope design wireframes were used to constrain the Mineral Resource reports.

Additional Mineral Resources are present that reside beyond the Mineral Reserves. For these areas, clipping polygons were prepared to aid in the estimation of the Mineral Resources. The clipping polygons were prepared in either plan or longitudinal views, as appropriate. The clipping polygons were drawn to include continuous volumes of blocks whose estimated grades were above the stated cut-off grade, and were not located in mined out areas. The clipping polygons were used to appropriately code the block model and report the Mineral Resources.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-32 |

| www.rpacan.com |

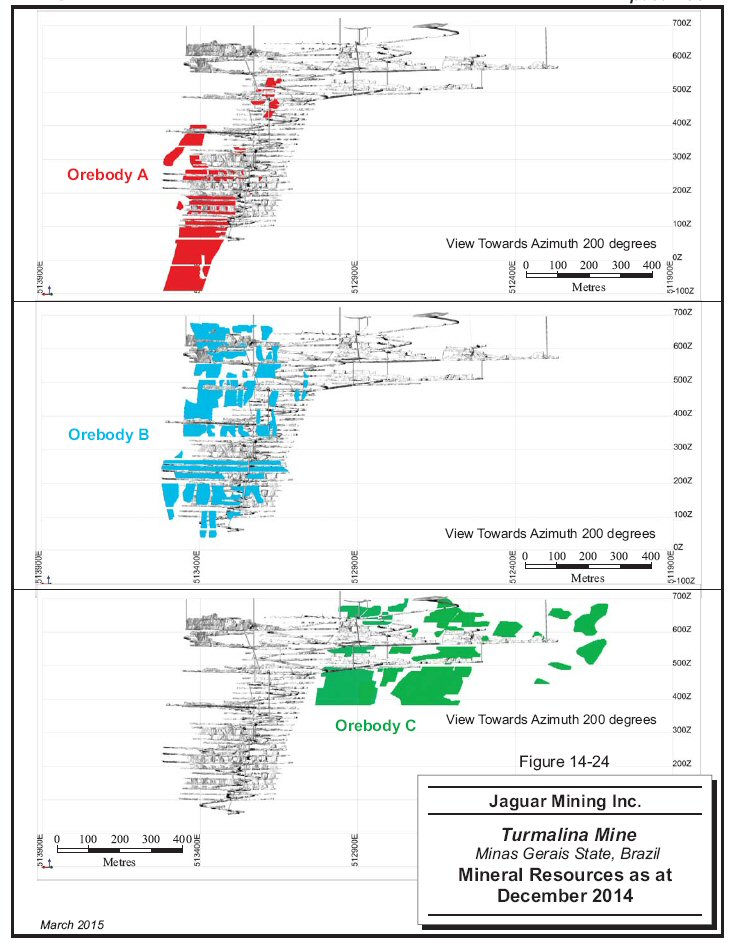

At a cut-off grade of 2.5 g/t Au, the Mineral Resources at the Turmalina Mine comprise 2.18 million tonnes at an average grade of 4.93 g/t Au containing 346,000 ounces of gold in the Measured and Indicated Resource category and 1.6 million tonnes at an average grade of 5.7 g/t Au containing 292,000 ounces of gold in the Inferred Mineral Resource category. The Mineral Resources are presented in further detail in Table 14-13 and Figure 14-24.

| TABLE 14-13 SUMMARY OF MINERAL RESOURCES AS OF DECEMBER 31, 2014 – TURMALINA MINE |

| Jaguar Mining Inc. – Turmalina Mine |

| Category | Tonnage (000 t) | Grade (g/t Au) | Contained Metal (000 oz Au) |

| Orebody A: |

| Measured | 412 | 6.93 | 92 |

| Indicated | 491 | 8.35 | 131 |

| Sub-total M&I | 904 | 7.70 | 224 |

| Inferred | 389 | 11.38 | 142 |

| Orebody B: |

| Measured | 514 | 3.11 | 51 |

| Indicated | 67 | 3.12 | 7 |

| Sub-total M&I | 581 | 3.11 | 58 |

| Inferred | 16 | 2.83 | 1 |

| Orebody C: |

| Measured | 40 | 2.48 | 3 |

| Indicated | 657 | 2.88 | 61 |

| Sub-total M&I | 697 | 2.86 | 64 |

| Inferred | 1,191 | 3.88 | 148 |

| Total Turmalina Mine: |

| Total, Measured | 966 | 4.71 | 146 |

| Total, Indicated | 1,215 | 5.10 | 199 |

| Total Measured & Indicated | 2,182 | 4.93 | 346 |

| Total, Inferred | 1,596 | 5.69 | 292 |

Notes:

| 1. | CIM definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated at a cut-off grade of 2.5 g/t Au. |

| 3. | Mineral Resources are estimated using a long-term gold price of US$1,400 per ounce. |

| 4. | Mineral Resources are estimated using an average long-term foreign exchange rate of 2.5 Brazilian Reais: 1 US Dollar. |

| 5. | A minimum mining width of approximately 2 m was used. |

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-33 |

| www.rpacan.com |

| 6. | Bulk density is 2.76 t/m3 for Orebodies A and B and 2.95 t/m3 for Orebody C. |

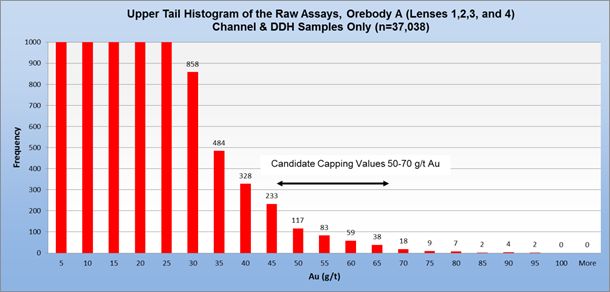

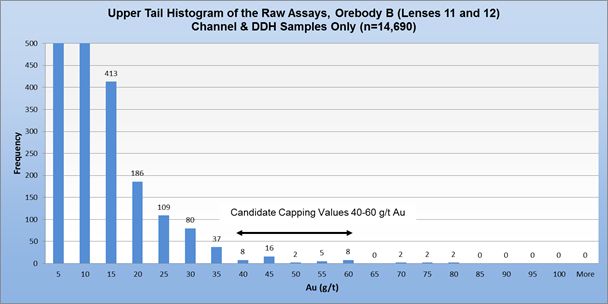

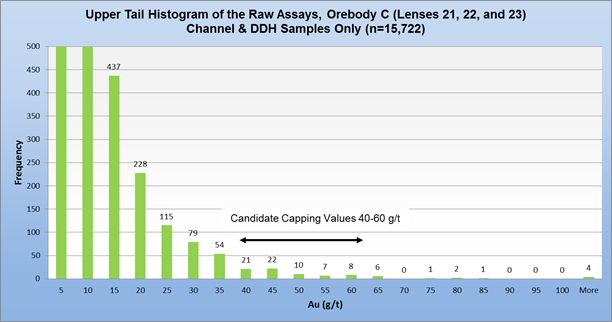

| 7. | Gold grades are estimated by the inverse distance cubed interpolation algorithm using capped composite samples. |

| 8. | Mineral Resources are inclusive of Mineral Reserves. |

| 9. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 10. | Numbers may not add due to rounding. |

RPA is not aware of any environmental, permitting, legal, title, taxation, socio-economic, marketing, political, or other factors that could materially affect the Mineral Resource estimates.

It is RPA’s opinion that the Turmalina Mineral Resource estimates were prepared in a professional and diligent manner by qualified professionals and that the estimates comply with CIM (2014).

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-34 |

| www.rpacan.com |

14-35

| www.rpacan.com |

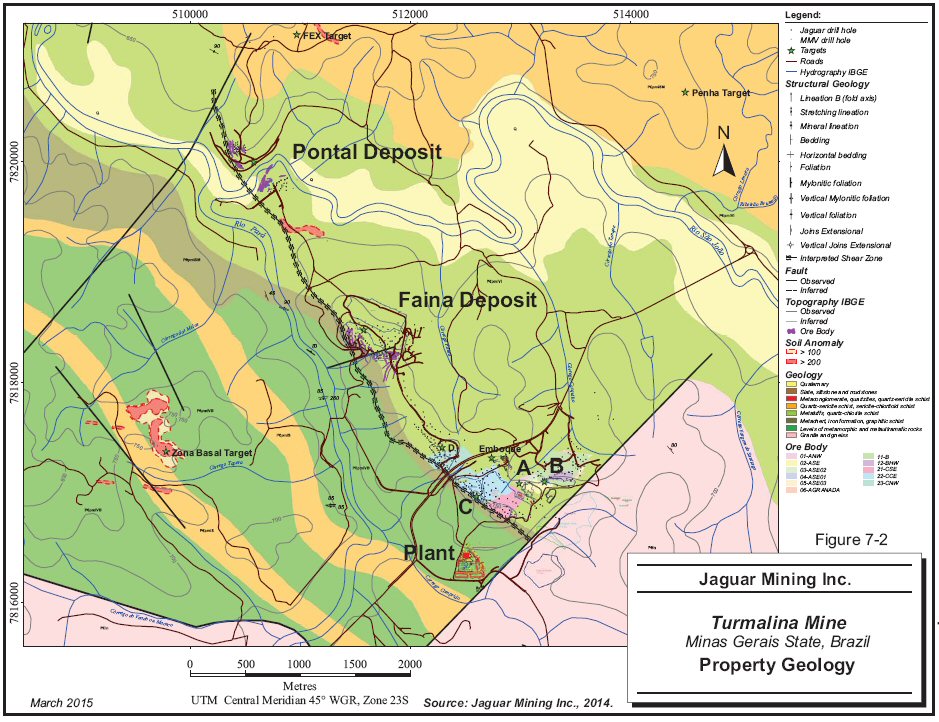

FAINA DEPOSIT

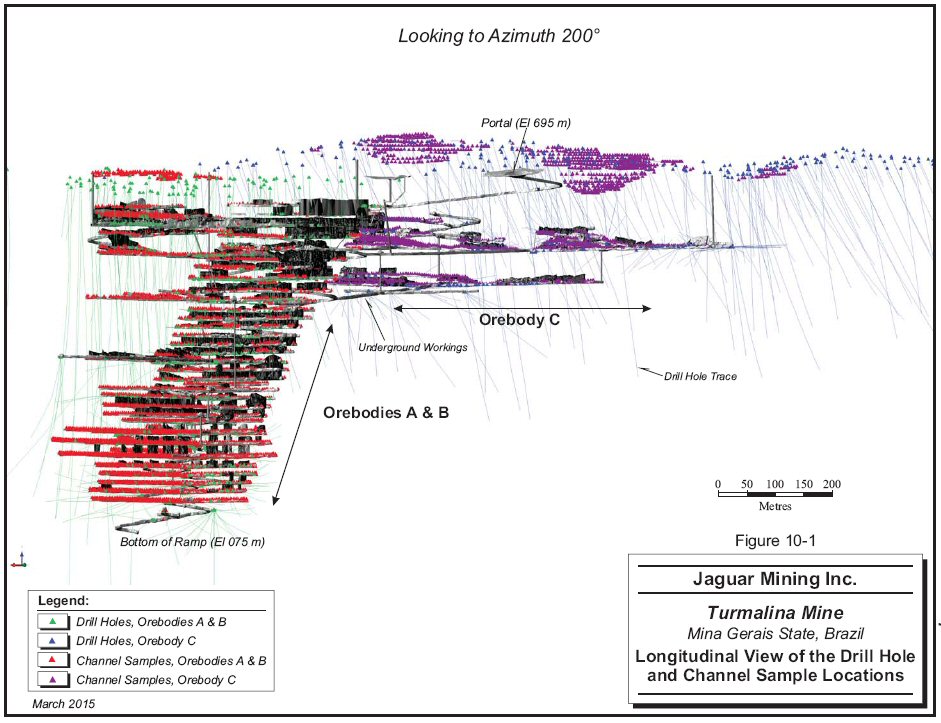

DESCRIPTION OF THE DATABASE

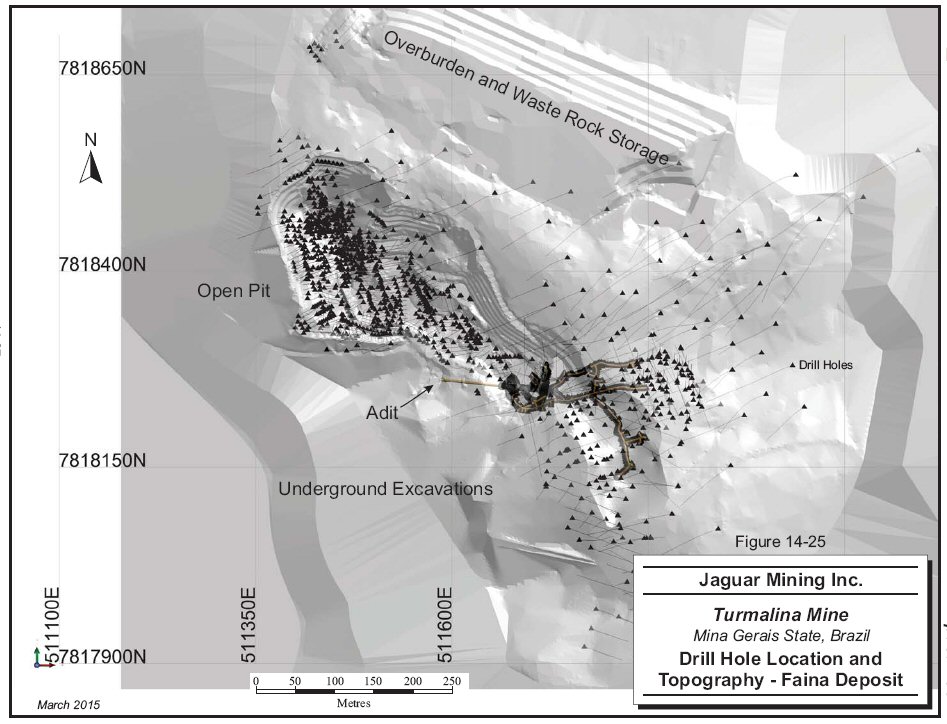

The drill hole database for the Faina deposit includes surface and underground drill holes along with surface trench and underground channel samples taken from the open pit and underground excavations, respectively. The drill hole and trench/channel sample data includes both historical-based samples collected by Mineração Morro Velho (MMV), a prior owner of the property, along with more recently completed drill holes and samples collected by Jaguar.

The drilling and sampling completed by Jaguar was carried out using the UTM Central Meridian 45° WGR, Zone 23S grid coordinate system. The drilling was completed in several campaigns that took place between February 2009 and January 2013.

The historical drill hole and channel sample data were derived from such historical records as drill logs and plan maps.

All historical data and more recently collected information have been entered into Jaguar’s internal master database. The drill hole and channel sample information for the Faina deposit was extracted from this internal database into separate files and imported into the MineSight mine modelling software package for use in preparation of the updated Mineral Resource estimates.

A summary of the drilling and channel sampling information is provided in Table 14-14 and the drill hole and channel sample locations are shown in Figure 14-25.

| TABLE 14-14 SUMMARY OF THE FAINA DRILL HOLE AND CHANNEL SAMPLE DATABASE |

| Jaguar Mining Inc. – Faina Deposit |

| Table | Number of Records |

| Collar (DDH, Chip and Trench) | 3,992 (52,474 m) |

| Survey | 23,239 |

| Assay | 47,667 |

| Lithology | 19,025 |

| Weathering | 8,870 |

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-36 |

| www.rpacan.com |

14-37

| www.rpacan.com |

The database included a number of assay records which contained entries of negative values to represent intervals of no sampling, lost core, lost sample, or no core recovery, some of which are contained within the mineralized wireframes. Depending upon the specific local conditions, these null values can introduce an undesired positive bias upon the grade estimations. Jaguar therefore elected to pursue a conservative approach by inserting a very low gold value of 0.01 g/t Au for these intervals of null values. A total of 8,924 records were adjusted in this process.

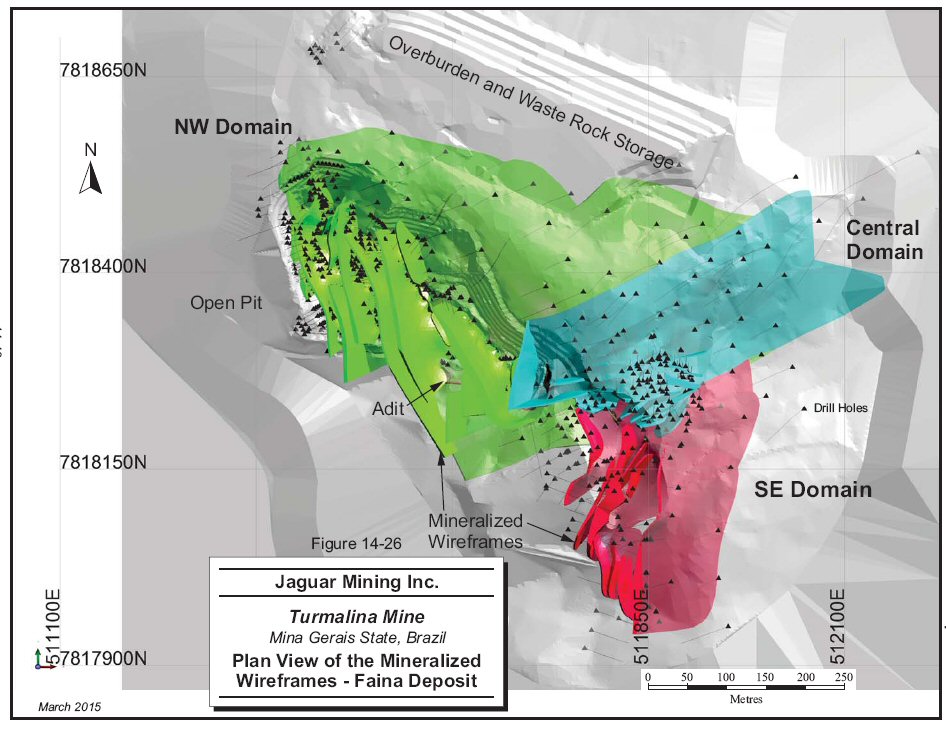

MINERALIZATION WIREFRAMES

The interpreted three-dimensional wireframe models of the gold mineralization have been created using the assay values from surface and underground drill holes, channel sample data as available, and the detailed geological mapping information contained on the historical plan maps of the underground excavations.

Wireframe models of the gold distribution were created using the LeapFrog Geo version 2.0.2 software package. The wireframe limits were drawn using a cut-off grade of 0.50 g/t Au and a nominal minimum width of 2.0 m. Some lower grade gold values were included inside the wireframes to preserve the continuity of the interpretation. The wireframe models were initially projected well above the as-mined surface but were subsequently clipped to the maximum as-mined topography prior to coding of the block model. A total of 39 individual wireframe models were created along a strike length of approximately 750 m and to a vertical depth of approximately 500 m from surface. In general, the wireframe models display a general northwest strike and plunge to the northeast at approximately 40°. The wireframe models were grouped into three domains (NW, Central, and SE Domains) on the basis of their geometries for statistical purposes and for ease of grade interpolation into the block model (Figure 14-26). Integer codes were assigned to each of the individual wireframes to aid in proper coding of the block model.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-38 |

| www.rpacan.com |

Wireframe surfaces were also created for oxidized and transitional weathering volumes using all available drill hole, channel, and trench sample information.

TOPOGRAPHY AND EXCAVATION MODELS

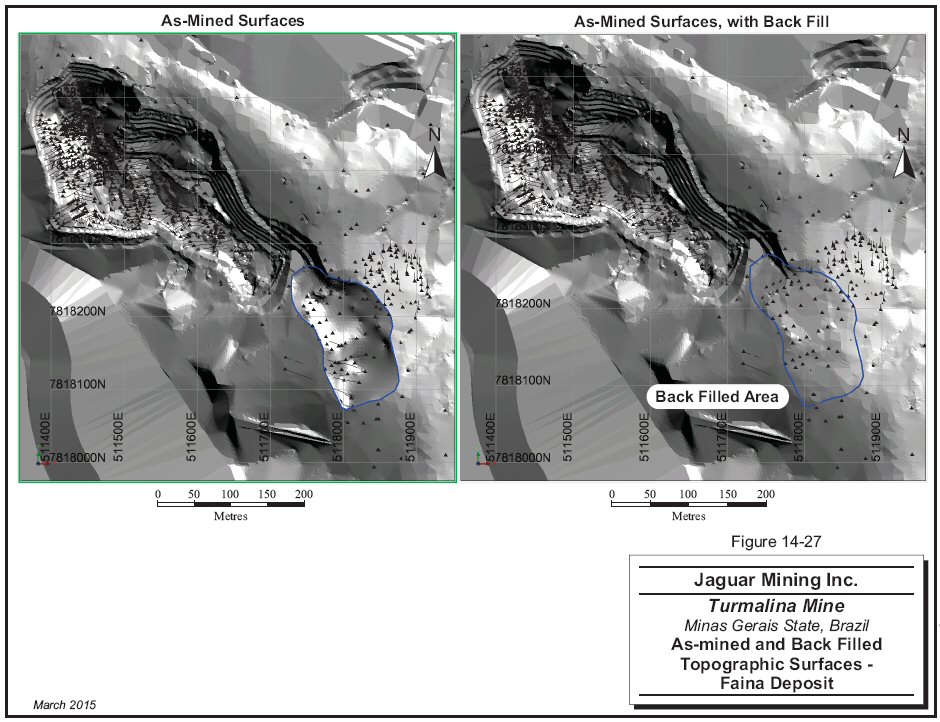

Two topography surfaces have been created that provide coverage over the area of the Faina deposit (Figure 14-27). The first surface represents the limit of open pit excavation, and was used to properly code the block model with the mined out volume. The second surface represents the current topography surface and accounts for the volume in the southeast portion of the mined out pit that was filled in with back fill material. The depth of the back filled area is estimated at approximately 20 m.

A solid model of the underground excavation volume was created using existing centre-line survey data and a general arched cross section profile of 3 m x 3 m. The cross sectional profile was selected based on observations made by Jaguar staff during several visits made to the underground exposures. The underground solid model was used to code the block model with a mined out code.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-39 |

| www.rpacan.com |

14-40

| www.rpacan.com |

14-41

| www.rpacan.com |

The mineralization wireframe models were used to code the drill hole database and identify the resource-related samples. These samples were extracted from the database into their respective domains, and then subjected to statistical analyses by means of histograms, probability plots, capping curves, and decile analyses. A total of 12,419 samples were contained within the mineralized wireframes.

On the basis of its review of the assay statistics, RPA believes that a capping value of 30 g/t Au for channel samples and 25 g/t Au for drill hole samples is appropriate for each of the three domains. This capping value is consistent with that presented in Machado (2011). The updated descriptive statistics for both the uncapped and capped assays are provided in Table 14-15.

| TABLE 14-15 DESCRIPTIVE STATISTICS BY DOMAIN - FAINA DEPOSIT |

| Jaguar Mining Inc. – Faina Deposit |

| | | | | |

| | NW Domain | Central Domain | SE Domain | All Domains Combined |

| Item | Uncapped (g/t Au) | Capped (g/t Au) | Uncapped (g/t Au) | Capped (g/t Au) | Uncapped (g/t Au) | Capped (g/t Au) | Uncapped (g/t Au) | Capped (g/t Au) |

| Mean | 2.06 | 2.01 | 2.06 | 1.94 | 2.21 | 2.13 | 2.08 | 2.01 |

| Median | 0.66 | 0.66 | 0.58 | 0.58 | 0.72 | 0.72 | 0.64 | 0.64 |

| Mode | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Std Dev | 4.32 | 3.59 | 5.06 | 4.04 | 4.47 | 3.86 | 4.52 | 3.73 |

| Sample Variance | 18.70 | 12.87 | 25.63 | 16.35 | 19.96 | 14.90 | 20.42 | 13.90 |

| Minimum | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Maximum | 143.86 | 30.00 | 78.00 | 30.00 | 48.19 | 30.00 | 143.86 | 30.00 |

| Count | 8,177 | 8,177 | 2,844 | 2,844 | 1,398 | 1,398 | 12,419 | 12,419 |

COMPOSITING METHODS

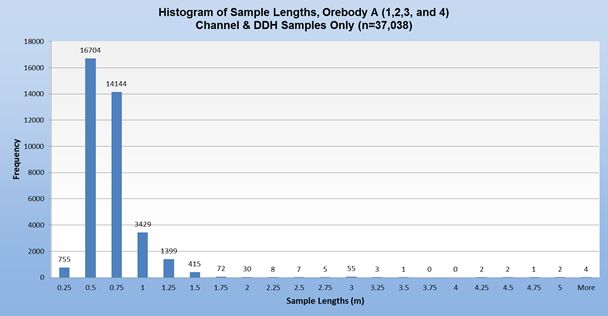

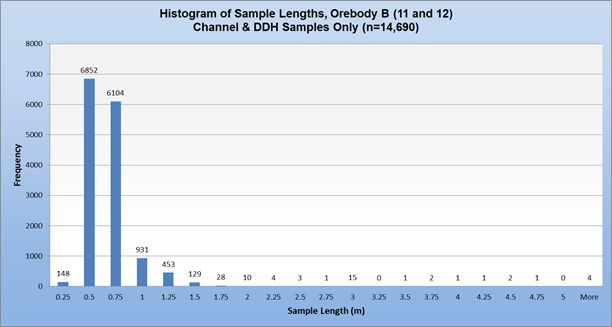

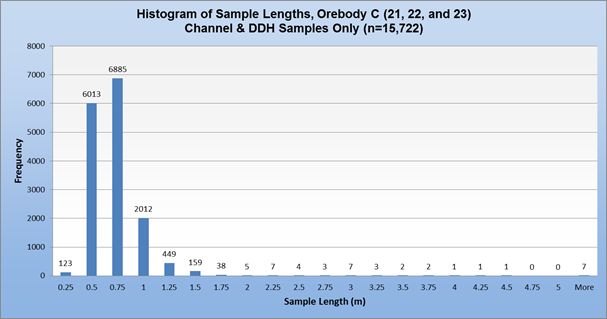

The selection of an appropriate composite length began with examination of the descriptive statistics of the raw assay samples and preparation of frequency histograms. Consideration was also given to the size of the blocks in the model.

On the basis of the available information, RPA believes that a composite length of one metre for all samples is reasonable. All samples contained within the mineralized wireframes were composited to a nominal one metre length using the best-fit function of the MineSight software package. The descriptive statistics are provided in Table 14-16.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-42 |

| www.rpacan.com |

| TABLE 14-16 DESCRIPTIVE STATISTICS OF THE COMPOSITED SAMPLES |

| Jaguar Mining Inc. – Faina Deposit |

| Item | Uncapped (g/t Au) | Capped (g/t Au) |

| Mean | 1.79 | 1.74 |

| Median | 0.56 | 0.56 |

| Mode | 0.01 | 0.01 |

| Standard Deviation | 3.69 | 3.23 |

| Sample Variance | 13.61 | 10.46 |

| Minimum | 0.01 | 0.01 |

| Maximum | 73.86 | 30.00 |

| Count | 7,495 | 7,495 |

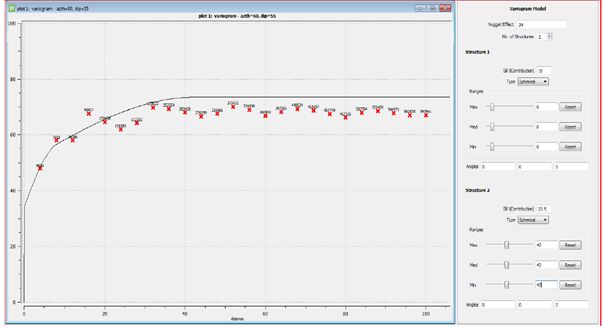

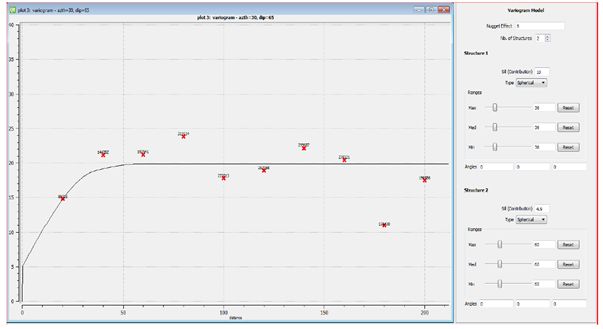

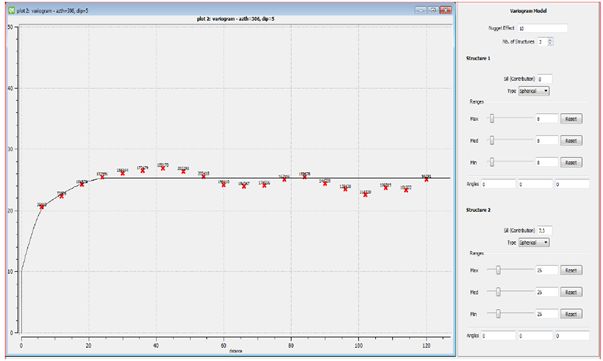

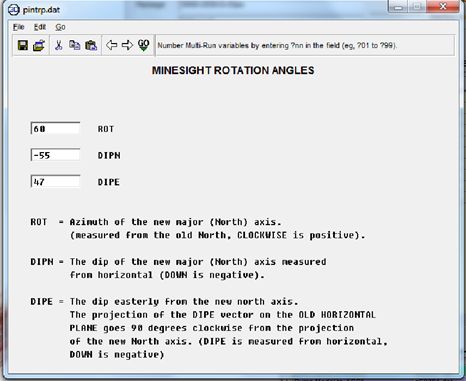

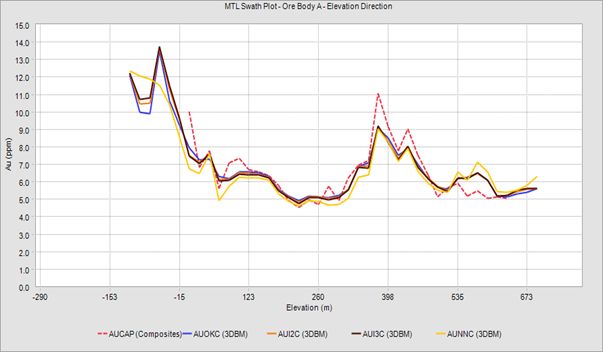

VARIOGRAPHY

Jaguar began its analysis of the spatial continuity by constructing separate omnidirectional variograms using the capped, composited sample data for each of the three domains, with the objective of determining an appropriate value for the global nugget (C0). The analysis proceeded with the evaluation of any anisotropies that may be present in the data which resulted in successful variograms with reasonably good model fits for the down-plunge direction. Due to the spatial complexities inherent in the mineralized wireframe models, poor model fits were obtained for the along-strike and across-dip directions. The variography package of the MineSight software package was used to construct the variograms. A summary of the variography and interpolation parameters is presented in Table 14-17.

Four passes were used to interpolate block grades. Pass #1 used search ellipses that were one-half of the variogram ranges, Pass #2 used search ellipses with the variogram ranges as defined, Pass #3 used twice the variogram ranges, and Pass #4 used four times the variogram ranges. A single search ellipse orientation was used for the NW Domain and SE Domain, however, two search ellipse orientations were used for the Central Domain due to the complex spatial geometry in this area. The number of samples per quadrant was relaxed from two to one for passes #3 and #4, and the maximum number of composites per hole were relaxed from two to one for pass #4.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-43 |

| www.rpacan.com |

| TABLE 14-17 SUMMARY OF VARIOGRAPHY AND INTERPOLATION PARAMETERS |

| Jaguar Mining Inc. – Faina Deposit |

| | | | |

| Item | NW Domain | Central Domain | SE Domain |

| Nugget (C0) | 5.0 | 6.0 | 4.0 |

| Sill, Major Axis (C1) | 5.45 (40 m) | 4.28 (30 m) | 6.62 (65 m) |

| Model Type | Spherical | Spherical | Spherical |

| Orientation* | 070/-50/15 | 60/-55/-45 & 60/-55/60 | 60/-50/-25 |

| Anisotropy Ratio (Major/Semi-Major) | 2.67 | 1.88 | 1.91 |

| Anisotropy Ratio (Major/Minor) | 6.67 | 6.0 | 3.61 |

| Minimum Number of Samples | 3 | 3 | 3 |

| Maximum Number of Samples | 8 | 8 | 8 |

| Maximum Number of Samples per Hole | 2 | 2 | 2 |

| Maximum Number of Samples per Quadrant | 2 | 2 | 2 |

*Note: MineSight rotation parameters. See Figure 14-20 for explanation.

BLOCK MODEL CONSTRUCTION

The block model was constructed using the MineSight version 7.60 software package and comprised an array of 2 m x 2 m x 2 m sized blocks using a partial percentage attribute. The model is oriented parallel to the coordinate grid system (i.e., no rotation or tilt). The selection of the block size for this model was based upon the block size employed at the mine. The block model origin, dimensions, and attribute list are provided in Table 14-18. A number of attributes were created to store such information as rock code, material densities, estimated gold grades, mineral resource classification, mined out material and the like (Table 14-19).

Gold grades were estimated into the blocks by means of ID2, ID3, OK, and NN interpolation algorithms. A total of four interpolation passes were carried out using distances derived from the variography results and the search ellipse parameters presented above.

In general, “hard” domain boundaries were used along the contacts of each of the 39 individual mineralized domain models. Only data contained within the respective individual wireframe model were allowed to be used to estimate the grades of the blocks within the wireframe in question, and only those blocks within the wireframe limits were allowed to receive grade estimates.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-44 |

| www.rpacan.com |

| TABLE 14-18 BLOCK MODEL DEFINITION |

| Jaguar Mining Inc. – Faina Deposit |

| |

| Type | Y (Northing) | X (Easting) | Z (Elevation) |

| Minimum Coordinates | 7,817,800 | 511,200 | 0 |

| Maximum Coordinates | 7,818,888 | 512,200 | 800 |

| User Block Size | 2 | 2 | 2 |

| Min. Block Size | 2 | 2 | 2 |

| Rotation | 0.000 | 0.000 | 0.000 |

| TABLE 14-19 LIST OF BLOCK MODEL ATTRIBUTES |

| Jaguar Mining Inc. – Faina Deposit |

| | | | |

| Attribute Name | Decimals | Background | Description |

| au_id2_cap | 2 | 0 | gold by inverse distance power 2, capped assays |

| au_id2_raw | 2 | 0 | gold by inverse distance power 2, uncapped assays |

| au_id3_cap | 2 | 0 | gold by inverse distance power 3, capped assays |

| au_id3_raw | 2 | 0 | gold by inverse distance power 3, uncapped assays |

| au_nn_cap | 2 | 0 | gold by nearest neighbour, capped assays |

| au_nn_raw | 2 | 0 | gold by nearest neighbour, uncapped assays |

| au_ok_cap | 2 | 0 | gold by ordinary kriging, capped assays |

| au_ok_raw | 2 | 0 | gold by ordinary kriging, uncapped assays |

| avg_distance | 1 | 0 | average distance of informing samples |

| class | - | 0 | 1=measured, 2=indicated, 3=inferred, 4 and 5 =? |

| density | 2 | 0 | Saprolite 1.7, rock 2.85 |

| mined_out | - | -1 | 1=mined out |

| no_holes | - | 0 | number of informing drill holes |

| no_quadrants | - | 0 | number of quadrants |

| no_samples | - | 0 | number of informing samples |

| ore_pct_100 | 2 | 0 | Percent inside wireframe, 0 to 100 |

| rock | - | 0 | Wireframe code |

| rsrc | - | -1 | Resource/Reserve Reporting Flag (1=resource) |

| topo_pct_100 | - | 0 | Percent below topo, 0 to 100 |

| vokc | 2 | 0 | kriging variance, capped assays |

| vokr | 2 | 0 | kriging variance, uncapped assays |

| weather | - | 0 | 1=oxide, 2=transition, 3=fresh |

MINERAL RESOURCE CLASSIFICATION CRITERIA

The Mineral Resources in this report were estimated in accordance with CIM (2014).

The mineralized material for each wireframe was classified into the Measured, Indicated, or Inferred Mineral Resource category on the basis of the search ellipse ranges obtained from the variography study, the demonstrated continuity of the gold mineralization, the density of drill hole and chip sample information, and the presence of underground access.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-45 |

| www.rpacan.com |

RESPONSIBILITY FOR ESTIMATION

The estimate of the Mineral Resources for the Faina deposit presented in this report was prepared by Mr. Helbert Taylor Vieira, Senior Geologist with Jaguar, under the supervision of Mr. Jean-Marc Lopez, Director – Mine Geology with Jaguar and Mr. Reno Pressacco, M.Sc.(A), P.Geo., with RPA. Mr. Pressacco is a Qualified Person as defined in NI 43-101, is independent of Jaguar, and takes responsibility for this Mineral Resource estimate.

CUT-OFF GRADE

The conceptual operational scenarios considered during preparation of previous Mineral Resource estimates envisioned that the fresh, unoxidized mineralization from the Faina deposit would be excavated on a satellite deposit basis and transported by truck to the existing Turmalina plant for processing. Preliminary metallurgical tests have been completed on samples of fresh, unoxidized mineralization from the Faina deposit from that conceptual perspective. They have yielded unacceptably low recoveries when the material is considered as potential feed to the existing Turmalina plant, and have concluded that the mineralization at the Faina deposit is refractory. While the arsenical nature of the mineralization at Faina is suspected to play a role in the poor recoveries, RPA believes that the testwork completed to date has not definitively supported this conclusion.

An alternative conceptual operational scenario was developed for the current update of the Mineral Resources in which the mineralized material will be excavated by means of underground mining methods and transported to the Turmalina plant for processing. A gold-rich flotation concentrate is envisioned to be generated after appropriate upgrades have been made to the existing plant. The gold-rich flotation concentrate would then be shipped or sold to a domestic source for recovery of the gold.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-46 |

| www.rpacan.com |

Input parameters to the estimate of an appropriate reporting cut-off grade considered this revised conceptual operating scenario along with the potential mining methods that are suitable for the narrow widths, short strike-length lenses, and highly convoluted nature of the mineralized wireframes at the Faina deposit. Consideration was also given to the actual costs incurred at the Turmalina plant where appropriate.

A cut-off grade of 3.8 g/t Au is used for reporting of Mineral Resources. This cut-off grade was arrived at using a gold price of US$1,400/oz, average gold recovery of 85% to flotation concentrate, 2014 actual cost data for the Turmalina Mine, along with estimated transportation and treatment charges. The gold prices used for resources are based on consensus, long term forecasts from banks, financial institutions, and other sources.

MINERAL RESOURCE ESTIMATE

At Faina, the Mineral Resources are dominated by fresh, unoxidized material, but also contain a small proportion of oxide- and transition-hosted weathered material.

At a cut-off grade of 3.8 g/t Au, the Mineral Resources at the Faina deposit total 261,000 tonnes at an average grade of 6.87 g/t Au containing 57,500 ounces of gold in the Measured and Indicated Resource category and 1,542,000 tonnes at an average grade of 7.3 g/t Au containing 360,200 ounces of gold in the Inferred Mineral Resource category (Table 14-20).

No Mineral Reserves are present at the Faina deposit.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-47 |

| www.rpacan.com |

| TABLE 14-20 SUMMARY OF MINERAL RESOURCES AS OF DECEMBER 31, 2014 – FAINA DEPOSIT |

| Jaguar Mining Inc. – Faina Deposit |

| Category | Tonnes (000 t) | Grade (g/t Au) | Contained Metal (000 oz Au) |

| Oxide |

| Measured | 11 | 6.81 | 2 |

| Indicated | 7 | 6.48 | 2 |

| Sub-total M&I | 18 | 6.68 | 4 |

| Inferred | 3 | 5.65 | 1 |

| | | | |

| Transition |

| Measured | 5 | 6.65 | 1 |

| Indicated | 3 | 6.20 | 1 |

| Sub-total M&I | 8 | 6.48 | 2 |

| Inferred | 2 | 6.30 | 0 |

| | | | |

| Fresh |

| Measured | 56 | 7.51 | 14 |

| Indicated | 179 | 6.85 | 39 |

| Sub-total M&I | 235 | 6.88 | 52 |

| Inferred | 1,537 | 7.27 | 359 |

| | | | |

| Total: Oxidized, Transition and Fresh |

| Measured | 72 | 7.39 | 17 |

| Indicated | 189 | 6.66 | 42 |

| Sub-total M&I | 261 | 6.87 | 58 |

| Inferred | 1,542 | 7.26 | 360 |

Notes:

| 1. | CIM definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated at a cut-off grade of 3.8 g/t Au. |

| 3. | Mineral Resources are estimated using a long-term gold price of US$1,400 per ounce. |

| 4. | Mineral Resources are estimated using an average long-term foreign exchange rate of 2.5 Brazilian Reais: 1 US Dollar. |

| 5. | A minimum mining width of approximately 2 m was used. |

| 6. | Bulk density is 1.70 t/m3 for oxidized material, 2.25 t/m3 for transition, and 2.85 t/m3 for fresh, un-weathered material. |

| 7. | Gold grades are estimated by the inverse distance cubed interpolation algorithm using capped composite samples. |

| 8. | No Mineral Reserves exist for the Faina deposit. |

| 9. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 10. | Numbers may not add due to rounding. |

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-48 |

| www.rpacan.com |

DESCRIPTION OF THE DATABASE

The drill hole database for the Pontal deposit includes surface and underground drill holes along with surface trench samples and underground channel samples. The drill hole and trench/channel sample data includes both historical-based samples collected by MMV, a prior owner of the property, along with more recently collected samples taken by Jaguar.

The historical drill hole and channel sample data were derived from such historical records as drill logs and plan maps.

All historical data and more recently collected information have been entered into Jaguar’s internal master database. The drill hole and channel sample information for the Pontal deposit was extracted from this internal database into separate files and imported into the MineSight mine modelling software package for use in preparation of the updated Mineral Resource estimates. The drilling and sampling was carried out using the UTM Central Meridian 45° WGR, Zone 23S grid coordinate system.

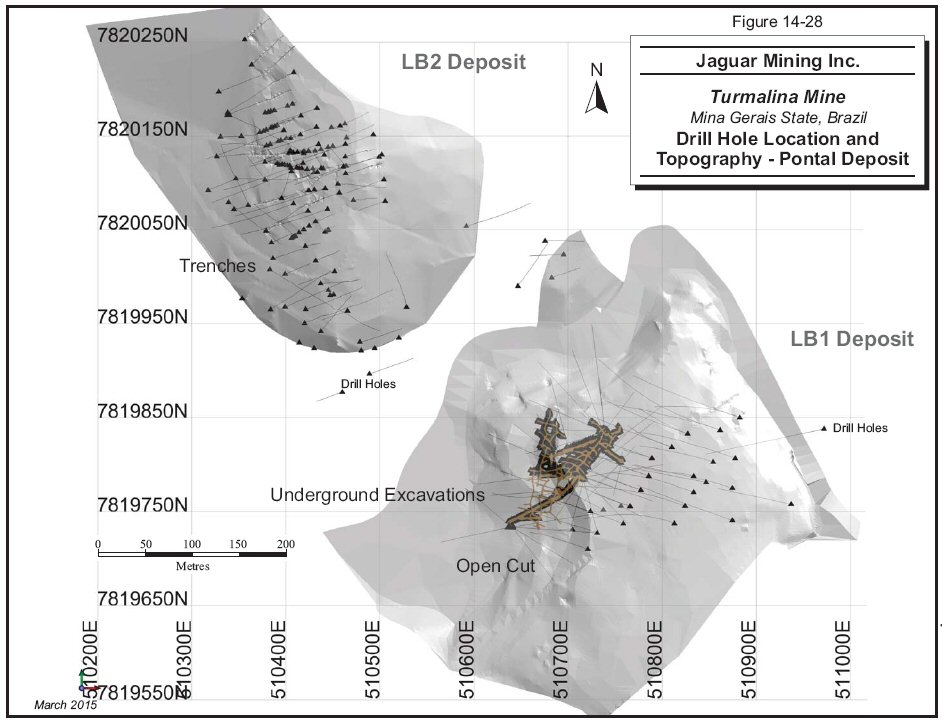

A summary of the drilling, trench and channel sampling information is provided in Table 14-21 and drill hole and channel sample locations are shown in Figure 14-28.

| TABLE 14-21 SUMMARY OF THE PONTAL DRILL HOLE AND CHANNEL SAMPLE DATABASE |

| Jaguar Mining Inc. – Pontal Deposit |

| Table | Number of Records |

| Collar (DDH, Trench and Chip) | 3,590 (19,283 m) |

| Survey | 8,783 |

| Assay | 17,043 |

| Lithology | 8,904 |

| Weathering | 3,624 |

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-49 |

| www.rpacan.com |

14-50

| www.rpacan.com |

The database included a number of assay records which contained entries of negative values to represent intervals of no sampling, lost core, lost sample, or no core recovery, some of which are contained within the mineralized wireframes. Depending upon the specific local conditions, these null values can introduce an undesired positive bias upon the grade estimations. Jaguar therefore elected to pursue a conservative approach by inserting a very low gold value of 0.01 g/t Au for these intervals of null values.

MINERALIZATION WIREFRAMES

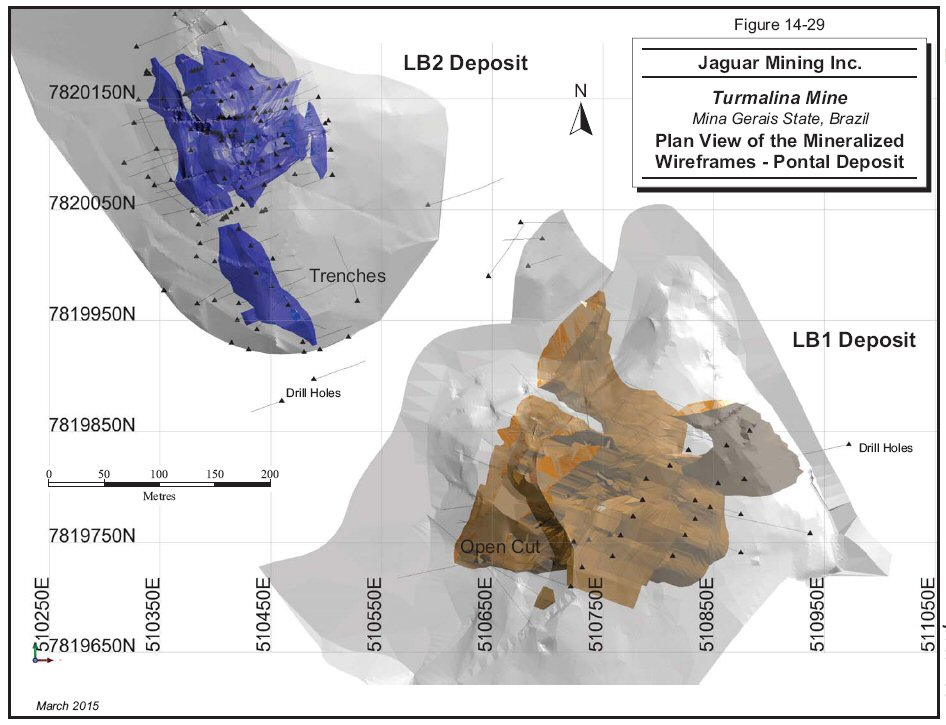

The interpreted three-dimensional wireframe models of the gold mineralization have been created using the assay values from surface and underground drill holes, trench and channel sample data as available, and the detailed geological mapping information contained on the historical plan maps of the underground excavations. The gold values are hosted in two principal deposits known as LB1 and LB2 (Figure 14-29).

Wireframe models of the gold distribution were updated using the MineSight v.7.60 software packages. The wireframe limits were drawn using a cut-off grade of 0.50 g/t Au and a nominal minimum width of 2.0 m. Some lower grade gold values were included inside the wireframes to preserve the continuity of the interpretation. The wireframe models were clipped to the as-mined surface. A total of 16 individual wireframe models were created, including seven wireframes for the LB1 deposit and nine wireframes for the LB2 deposit.

In general, the LB1 wireframe models measure approximately 250 m x 250 m in plan view and continue downwards to a vertical depth of approximately 300 m from surface. The mineralization at the LB1 deposit has been traced by drilling along a dip of approximately -60° to the east.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-51 |

| www.rpacan.com |

14-52

| www.rpacan.com |

Wireframe surfaces were also created for oxidized and transitional weathering volumes using all available drill hole, channel, and trench sample information.

TOPOGRAPHY AND EXCAVATION MODELS

Two topography surfaces were created that covered the local area of each of the two deposits using contour lines from available topography maps along with local spot heights derived from the locations of any drill hole or trench sample data.

An approximation of the underground excavations was created by digitizing the outlines in plan view from historical underground mapping and sampling programs carried out at the LB1 deposit. The digitized plan view strings were projected upwards by a constant distance of 2.5 m to create the solid model of the underground excavations. In total, two levels were excavated – the upper level was excavated at a toe elevation of approximately 609 m and the lower level was excavated at a toe elevation of approximately 603 m.

SAMPLE STATISTICS AND GRADE CAPPING

The mineralization wireframe models were used to code the drill hole database and identify the resource-related samples. These samples were extracted from the database into their respective domains, and then subjected to statistical analyses by means of histograms, probability plots, capping curves, and decile analyses. A total of 6,569 samples were contained within the LB1 mineralized wireframes and a total of 1,308 samples were contained within the LB2 mineralized wireframes.

On the basis of its review of the assay statistics, RPA believes that a capping value of 30 g/t Au is appropriate for the LB1 wireframes and a capping value of 10 g/t Au is appropriate for the LB2 wireframes. This capping value is consistent with that presented in Machado (2011). The updated descriptive statistics for both the uncapped and capped assays are provided in Table 14-22.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-53 |

| www.rpacan.com |

| TABLE 14-22 DESCRIPTIVE STATISTICS OF THE RAW ASSAYS – PONTAL DEPOSIT |

| Jaguar Mining Inc. – Pontal Deposit |

| | | |

| | LB1 | LB2 |

| Item | Uncapped | Capped 30 g/t | Uncapped | Capped 10 g/t |

| Length-Weighted Mean | 1.56 | 1.47 | 1.32 | 1.28 |

| Median | 0.88 | 0.88 | 0.71 | 0.71 |

| Mode | 0.01 | 0.01 | 0.01 | 0.01 |

| Standard Deviation | 5.68 | 2.62 | 2.24 | 1.56 |

| Coefficient of Variation-Weighted | 3.64 | 1.79 | 1.70 | 1.22 |

| Sample Variance | 32.31 | 6.87 | 5.03 | 2.44 |

| Minimum | 0.01 | 0.01 | 0.01 | 0.01 |

| Maximum | 352.00 | 30.00 | 57.60 | 10.00 |

| Count | 6,569 | 6,569 | 1,308 | 1,308 |

COMPOSITING METHODS

The selection of an appropriate composite length began with examination of the descriptive statistics of the raw assay samples and preparation of frequency histograms. Consideration was also given to the size of the blocks in the model.

On the basis of the available information, RPA believes that a composite length of one metre for all samples is reasonable. All samples contained within the mineralized wireframes were composited to a nominal one metre length using the best-fit function of the MineSight software package. The descriptive statistics are provided in Table 14-23.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-54 |

| www.rpacan.com |

TABLE 14-23 DESCRIPTIVE STATISTICS OF THE GOLD COMPOSITES-PONTAL DEPOSIT

Jaguar Mining Inc. – Pontal Deposit

| | LB1 | | LB2 | |

| Item | Uncapped | Capped | Uncapped | Capped |

| Length-Weighted Mean (g/t) | 1.65 | 1.56 | 1.38 | 1.34 |

| Median (g/t) | 0.85 | 0.85 | 0.80 | 0.80 |

| Mode (g/t) | 0.01 | 0.01 | 0.01 | 0.01 |

| Standard Deviation (g/t) | 5.98 | 2.47 | 2.04 | 1.46 |

| Coefficient of Variation-Arithmetic | 3.54 | 1.57 | 1.49 | 1.10 |

| Coefficient of Variation-Weighted | 3.62 | 1.59 | 1.47 | 1.09 |

| Sample Variance (g/t) | 35.81 | 6.11 | 4.15 | 2.13 |

| Minimum (g/t) | 0.01 | 0.01 | 0.01 | 0.01 |

| Maximum (g/t) | 352.00 | 30.00 | 51.26 | 10.00 |

| Count | 5,511 | 5,511 | 1,304 | 1,304 |

VARIOGRAPHY

Jaguar verified the analysis of the spatial continuity of the mineralization contained within the LB1 wireframe models as presented in Machado (2011) using the variography package contained in the SGeMS software package. Its work resulted in construction of a successful omnidirectional variogram using the capped, composited sample data. The analysis proceeded with the evaluation of any anisotropies that may be present in the data which resulted in a successful variogram with reasonably good model fits for the down-plunge direction.

Unfortunately, no successful model fits were possible for the LB2 deposit due to the lack of sufficient sample pairs.

A summary of the variography and interpolation parameters for the two deposits is presented in Table 14-24.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-55 |

| www.rpacan.com |

| TABLE 14-24 SUMMARY OF VARIOGRAPHY AND INTERPOLATION PARAMETERS |

| Jaguar Mining Inc. – Pontal Deposit |

| | | |

| Item | LB1 Deposit | LB2 Deposit |

| Nugget (C0) | 3.0 | 3.0 |

| Sill, Major Axis (C1) | 2.9 (90 m) | 2.9 (30 m) |

| Model Type | Spherical | Spherical |

| Orientation* | 115/-60/-15 | 0/0/0 |

| Anisotropy Ratio (Major/Semi-Major) | 2.37 | 1.0 |

| Anisotropy Ratio (Major/Minor) | 9.0 | 3.0 |

| Minimum Number of Samples | 3 | 3 |

| Maximum Number of Samples | 8 | 8 |

| Maximum Number of Samples per Hole | 2 | 2 |

| Maximum Number of Samples per Quadrant | 2 | 2 |

Four passes were used to interpolate block grades. Pass #1 used search ellipses that were one-half of the variogram ranges, Pass #2 used search ellipses with the variogram ranges as defined, Pass #3 used twice the variogram ranges, and Pass #4 used four times the variogram ranges. The number of samples per quadrant was relaxed from two to one for passes #3 and #4, and the maximum number of composites per hole were relaxed from two to one for pass #4.

BLOCK MODEL CONSTRUCTION

The block model was constructed using the MineSight version 7.60 software package and comprised an array of 2 m x 2 m x 2 m sized blocks using a partial percentage attribute. The model is oriented parallel to the coordinate grid system (i.e., no rotation or tilt). The selection of the block size for this model was based upon the block size employed at the mine. The block model origin, dimensions, and attribute list are provided in Table 14-25. A number of attributes were created to store such information as rock code, material densities, estimated gold grades, mineral resource classification, mined out material and the like (Table 14-26).

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-56 |

| www.rpacan.com |

| TABLE 14-25 BLOCK MODEL DEFINITION |

| Jaguar Mining Inc. – Pontal Deposit |

| |

| Type | Y (Northing) | X (Easting) | Z (Elevation) |

| Minimum Coordinates (m) | 7,819,600 | 510,300 | 300 |

| Maximum Coordinates (m) | 7,820,300 | 511,000 | 700 |

| User Block Size (m) | 2 | 2 | 2 |

| Min. Block Size (m) | 2 | 2 | 2 |

| Rotation (°) | 0.000 | 0.000 | 0.000 |

| TABLE 14-26 LIST OF BLOCK MODEL ATTRIBUTES |

| Jaguar Mining Inc. – Pontal Deposit |

| | | | |

| Attribute Name | Decimals | Background | Description |

| au_id2_cap | 2 | 0 | gold by inverse distance power 2, capped assays |

| au_id2_raw | 2 | 0 | gold by inverse distance power 2, uncapped assays |

| au_id3_cap | 2 | 0 | gold by inverse distance power 3, capped assays |

| au_id3_raw | 2 | 0 | gold by inverse distance power 3, uncapped assays |

| au_nn_cap | 2 | 0 | gold by nearest neighbour, capped assays |

| au_nn_raw | 2 | 0 | gold by nearest neighbour, uncapped assays |

| au_ok_cap | 2 | 0 | gold by ordinary kriging, capped assays |

| au_ok_raw | 2 | 0 | gold by ordinary kriging, uncapped assays |

| avg_distance | 1 | 0 | average distance of informing samples |

| class | - | 0 | 1=measured, 2=indicated, 3=inferred, 4 and 5 =? |

| density | 2 | 0 | Saprolite 1.7, rock 2.85 |

| mined_out | - | -1 | 1=mined out |

| no_holes | - | 0 | number of informing drill holes |

| no_quadrants | - | 0 | number of quadrants |

| no_samples | - | 0 | number of informing samples |

| ore_pct_100 | 2 | 0 | Percent inside wireframe, 0 to 100 |

| rock | - | 0 | Wireframe code |

| rsrc | - | -1 | Resource/Reserve Reporting Flag (1=resource) |

| topo_pct_100 | - | 0 | Percent below topo, 0 to 100 |

| vokc | 2 | 0 | kriging variance, capped assays |

| vokr | 2 | 0 | kriging variance, uncapped assays |

| weather | - | 0 | 1=oxide, 2=transition, 3=fresh |

Gold grades were estimated into the blocks by means of ID2, ID3, OK, and NN interpolation algorithms. A total of four interpolation passes were carried out using distances derived from the variography results and the search ellipse parameters presented above.

In general, “hard” domain boundaries were used along the contacts of each of the 16 individual mineralized domain models. Only data contained within the respective individual wireframe model were allowed to be used to estimate the grades of the blocks within the wireframe in question, and only those blocks within the wireframe limits were allowed to receive grade estimates.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-57 |

| www.rpacan.com |

The Mineral Resources in this report were estimated in accordance with the definitions contained in CIM (2014).

The mineralized material for each wireframe was classified into the Measured, Indicated, or Inferred Mineral Resource category on the basis of the search ellipse ranges obtained from the variography study, the demonstrated continuity of the gold mineralization, the density of drill hole and chip sample information, and the presence of underground access.

On the basis of these criteria, Measured Mineral Resources comprise that material that has been estimated using Pass #1. Indicated Mineral Resources comprise that material that has been estimated using Pass #2, and Inferred Mineral Resources comprise that material that has been estimated using Pass #3.

RESPONSIBILITY FOR ESTIMATION

The estimate of the Mineral Resources for the Pontal deposit presented in this report was prepared by Mr. Helbert Taylor Vieira, Senior Geologist with Jaguar, under the supervision of Mr. Jean-Marc Lopez, Director – Mine Geology with Jaguar and Mr. Reno Pressacco, M.Sc. (A), P.Geo., with RPA. Mr. Pressacco is a Qualified Person as defined in NI 43-101, is independent of Jaguar, and takes responsibility for this Mineral Resource estimate.

CUT-OFF GRADE

The conceptual operational scenarios considered during preparation of previous Mineral Resource estimates envisioned that the fresh, unoxidized mineralization from the Pontal deposit would be excavated on a satellite deposit basis and transported by truck to the existing Turmalina plant for processing. Preliminary metallurgical tests have been completed on samples of fresh, unoxidized mineralization from the Pontal deposit from that conceptual perspective. They have yielded unacceptably low recoveries when the material is considered as potential feed to the existing Turmalina plant, and have concluded that the mineralization at the Pontal deposit is refractory. While the arsenical nature of the mineralization at Pontal is suspected to play a role in the poor recoveries, RPA believes that the testwork completed to date has not definitively supported this conclusion.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-58 |

| www.rpacan.com |

An alternative conceptual operational scenario was developed for the current update of the Mineral Resources in which the mineralized material will be excavated by means of underground mining methods and transported to the Turmalina plant for processing. A gold-rich flotation concentrate is envisioned to be generated after appropriate upgrades have been made to the existing plant. The gold-rich flotation concentrate would then be shipped or sold to a domestic source for recovery of the gold.

Input parameters to the estimate of an appropriate reporting cut-off grade considered this revised conceptual operating scenario along with the potential mining methods that are suitable for the mineralized wireframes at the Pontal deposit. Consideration was also given to the actual costs incurred at the Turmalina plant where appropriate.

A cut-off grade of 2.9 g/t Au is used for reporting of Mineral Resources. This cut-off grade was arrived at using a gold price of US$1,400/oz, average gold recovery of 85% to flotation concentrate, 2014 actual cost data for the Turmalina Mine, along with estimated transportation and treatment charges. The gold prices used for resources are based on consensus, long term forecasts from banks, financial institutions, and other sources.

MINERAL RESOURCE ESTIMATE

The Mineral Resources are dominated by fresh, unoxidized material, but also contain a small proportion of oxide- and transition-hosted weathered material.

At a cut-off grade of 2.9 g/t Au, the Mineral Resources at the Pontal deposit total 410,000 tonnes at an average grade of 4.72 g/t Au containing 62,200 ounces of gold in the Measured and Indicated Resource category and 130,000 tonnes at an average grade of 5.0 g/t Au containing 21,000 ounces of gold in the Inferred Mineral Resource category (Table 14-27).

No Mineral Reserves are present at the Pontal deposit.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-59 |

| www.rpacan.com |

| TABLE 14-27 SUMMARY OF MINERAL RESOURCES AS OF DECEMBER 31, 2014 - PONTAL DEPOSIT |

| Jaguar Mining Inc. – Pontal Deposit |

| Category | Tonnes (000 t) | Grade (g/t Au) | Contained Metal (000 oz Au) |

| Oxide |

| Measured | 30 | 4.13 | 4 |

| Indicated | 1 | 3.41 | 0 |

| Sub-total M&I | 31 | 4.11 | 4 |

| Inferred | 9 | 6.24 | 2 |

| | | | |

| Transition |

| Measured | 9 | 4.33 | 1 |

| Indicated | 2 | 3.34 | 0 |

| Sub-total M&I | 11 | 4.17 | 1 |

| Inferred | 2 | 7.28 | 1 |

| | | | |

| Fresh |

| Measured | 212 | 5.16 | 35 |

| Indicated | 157 | 4.29 | 22 |

| Sub-total M&I | 369 | 4.79 | 57 |

| Inferred | 119 | 4.89 | 19 |

| | | | |

| Total: Oxidized, Transition and Fresh |

| Measured | 251 | 5.00 | 40 |

| Indicated | 159 | 4.28 | 22 |

| Sub-total M&I | 410 | 4.72 | 62 |

| Inferred | 130 | 5.03 | 21 |

Notes:

| 1. | CIM definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated at a cut-off grade of 2.9 g/t Au. |

| 3. | Mineral Resources are estimated using a long-term gold price of US$1,400 per ounce. |

| 4. | Mineral Resources are estimated using an average long-term foreign exchange rate of 2.5 Brazilian Reais: 1 US Dollar. |

| 5. | A minimum mining width of approximately 2 m was used. |

| 6. | Bulk density is 1.46 or 1.52 t/m3 for oxidized material, 2.24 or 2.28 t/m3 for transition, and 2.73 t/m3 for fresh, un-weathered material. |

| 7. | Gold grades are estimated by the inverse distance cubed interpolation algorithm using capped composite samples. |

| 8. | No Mineral Reserves exist for the Pontal deposit. |

| 9. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 10. | Numbers may not add due to rounding. |

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 14-60 |

| www.rpacan.com |

Mineral Reserves for Turmalina are based on the Mineral Resources as of December 31, 2014, mine designs, and external factors. Table 15-1 summarizes the Mineral Reserves.

| TABLE 15-1 MINERAL RESERVE ESTIMATE – DECEMBER 31, 2014 |

| Jaguar Mining Inc. – Turmalina Mine |

| Orebody | Classification | Tonnes (000) | Grade (g/t Au) | Contained Metal (000 oz Au) |

| A | Proven | 333 | 5.00 | 54 |

| A | Probable | 566 | 6.96 | 127 |

| C | Probable | 367 | 3.14 | 37 |

| Total | Proven & Probable | 1,266 | 5.33 | 217 |

Notes:

| 1. | CIM definitions were followed for Mineral Reserves. |

| 2. | Mineral Reserves were estimated at a break-even cut-off grade of 2.9 g/t Au. Some stopes were included using an incremental cut-off grade of 1.5 g/t Au. |

| 3. | Mineral Reserves are estimated using an average long-term gold price of US$1,200 per ounce. |

| 4. | A minimum mining width of 3 metres was used. |

| 5. | Bulk density is 2.7 t/m3. |

| 6. | Numbers may not add due to rounding. |

The reserves consist of selected portions of the Measured and Indicated Resources that are within designed stopes and associated development, designed by MCB Serviços E Mineraçào (MCB), a Brazilian consulting group. A breakdown by location is given in Table 15-2.

| TABLE 15-2 MINERAL RESERVES BY LOCATION |

| Jaguar Mining Inc. – Turmalina Mine |

| Orebody | Area | Tonnes (000) | Grade (g/t Au) | Contained Metal (000 oz Au) |

| A | Level 6 | 68 | 4.50 | 10 |

| | Level 7 | 63 | 5.40 | 11 |

| | Level 8 | 266 | 5.73 | 49 |

| | Level 9 | 503 | 6.83 | 111 |

| C | Level 1 | 65 | 3.66 | 8 |

| | Level 2 | 20 | 3.43 | 2 |

| | Level 3 | 283 | 3.00 | 27 |

| Total | | 1,266 | 5.33 | 217 |

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 15-1 |

| www.rpacan.com |

DILUTION AND EXTRACTION

Dilution and extraction (mining recovery) have been included in the reserve estimate through the following:

| · | Areas within the stope designs below 2.9 g/t Au. The resource wireframes were constructed at a cut-off grade of 0.5 g/t Au, and therefore include material below the reserve cut-off grade for continuity. |

| · | In Orebody A, planned dilution includes areas where the stope designs run outside of the resource wireframe, to achieve minimum width and due to irregularities in geometry. An allowance of 0.5 m on each of the hangingwall and footwall sides has been added. This allowance is built into the stope design. |

| · | In Orebody C, ground conditions are good, and planned dilution due to geometry was deemed sufficient. Stope designs do not include the extra allowance of 0.5 m. |

| · | In both A and C, unplanned dilution from over-break into the surrounding rock was based on an estimate of 15%. |

| · | Extraction is assumed to be 100%. Although some losses are encountered during blasting and mucking, they are minimal, and reconciliation to mill results indicates that high dilution/high extraction assumptions match up well. |

| · | Pillar recovery stopes on Level 6 (a mostly mined-out area) are treated differently, with a dilution factor of 50% and extraction factor of 70% applied. |

CUT-OFF GRADE

A break-even cut-off grade of 2.9 g/t Au was estimated for Mineral Reserves, using a gold price of US$1,200/oz, and average gold recovery of 88% and 2014 cost data for the Turmalina Mine. Gold prices used for reserves are based on consensus, long term forecasts from banks, financial institutions, and other sources.

Cost data was stated in US dollars, using the exchange rate at the time (approximately 2.5 BRL to the US dollar). The US dollar has strengthened considerably against the BRL recently, with a rate of 3.2 BRL to the US dollar at the time of reporting. A majority of Turmalina costs are denominated in BRL, which means that the US dollar costs stated in this report are likely to be conservative estimates.

An incremental cut-off grade of 1.5 g/t Au was estimated using variable costs only. Some stopes with diluted grades between 1.5 g/t Au and 2.9 g/t Au were included in Mineral Reserves. For Orebody A, incremental-grade stopes make up approximately 10% of the total, a proportion that RPA considers to be reasonable. For Orebody C, approximately 50% of stopes are incremental-grade – a higher proportion than is typical.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 15-2 |

| www.rpacan.com |

Although the cost data available from Turmalina is not easily categorized by Orebody, it is reasonable to assume lower costs in Orebody C, given better ground conditions and shorter haulage to surface.

The mill has excess production capacity, not otherwise put to use. Additional incremental ore will not displace better grade material. On this basis, RPA considers the high proportion of incremental material (approximately 20% of total reserves) to be acceptable.

RPA recommends that Jaguar undertake a detailed incremental cost analysis, split by Orebody, to ensure that uneconomic material is not sent to the mill.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 15-3 |

| www.rpacan.com |

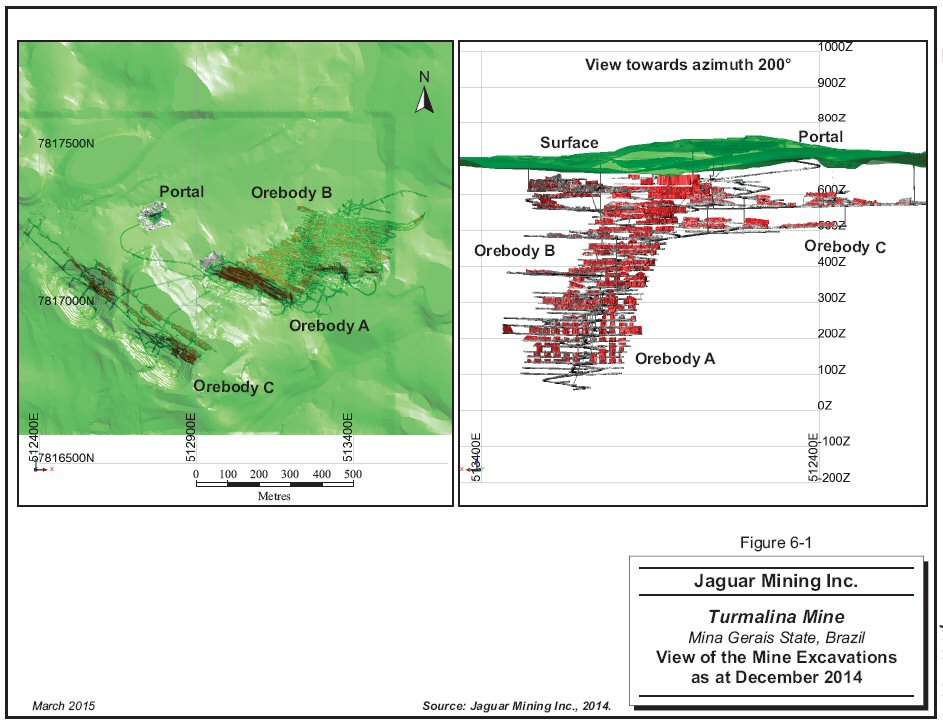

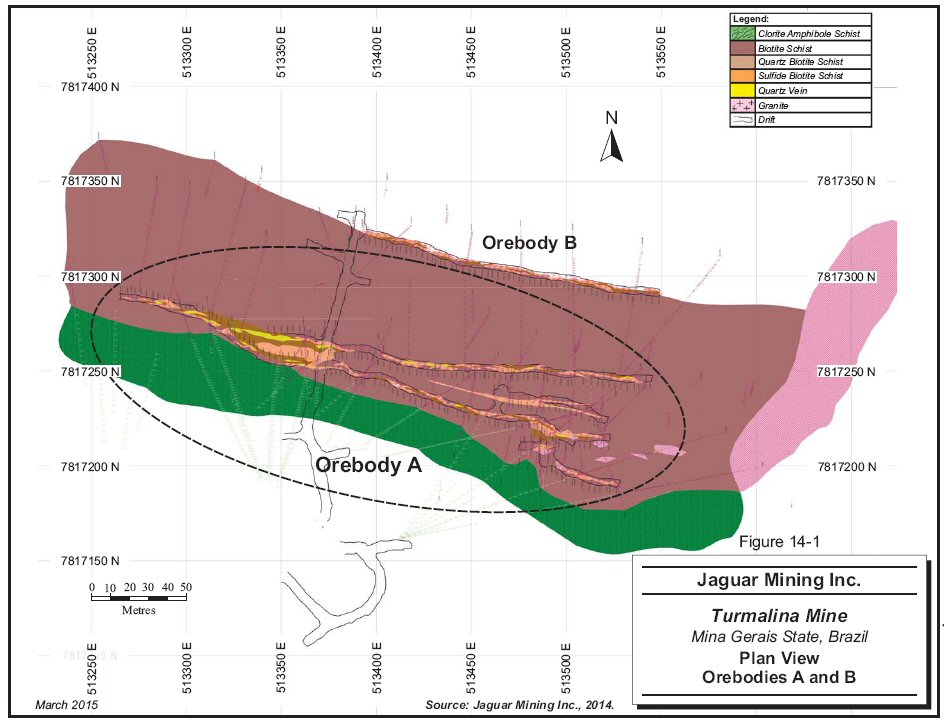

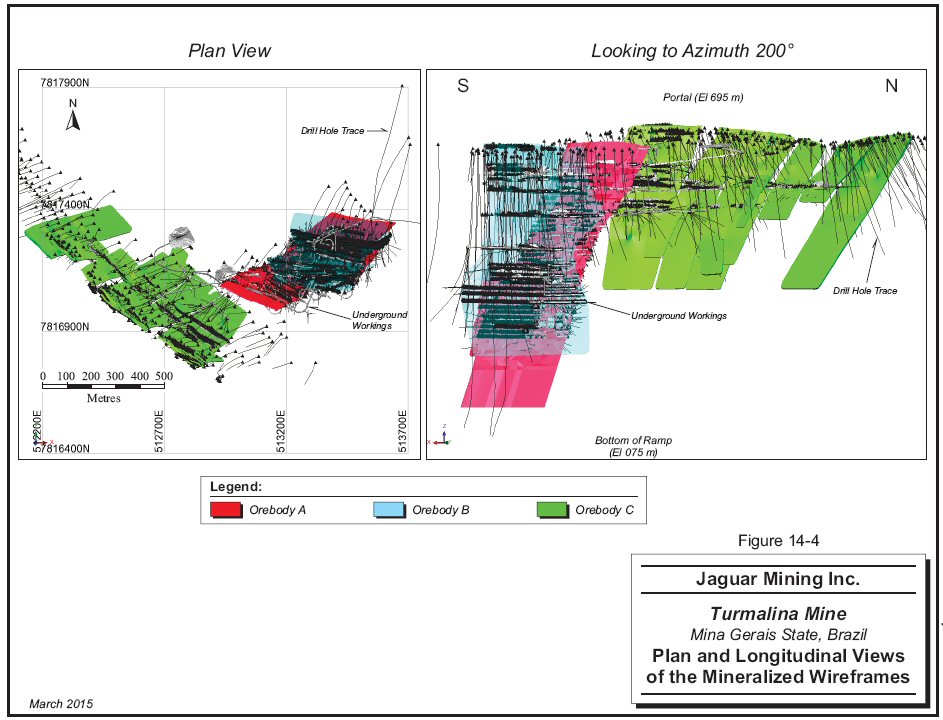

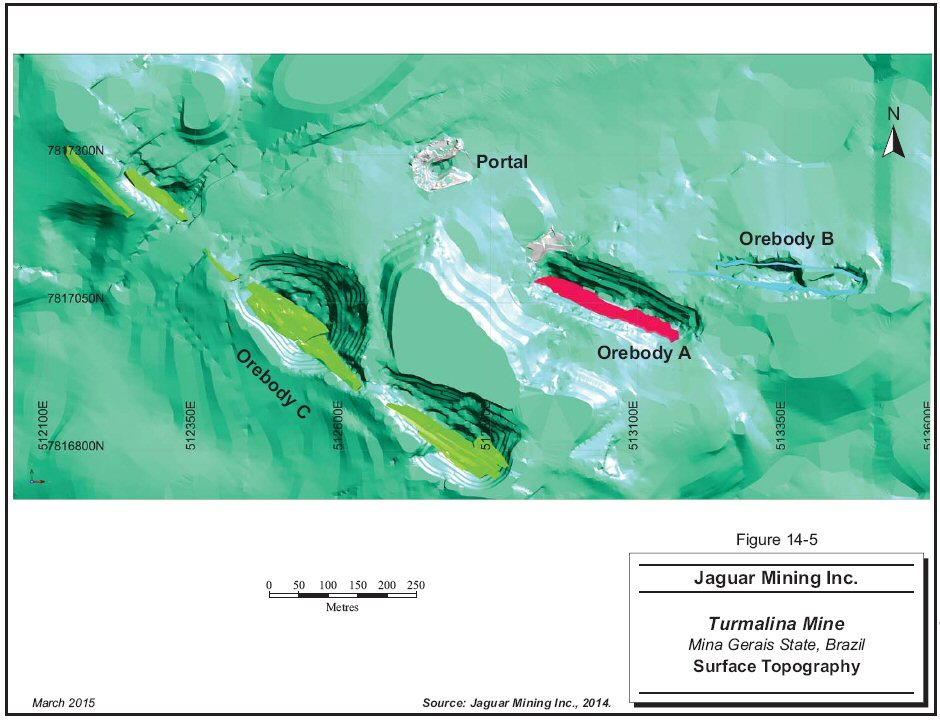

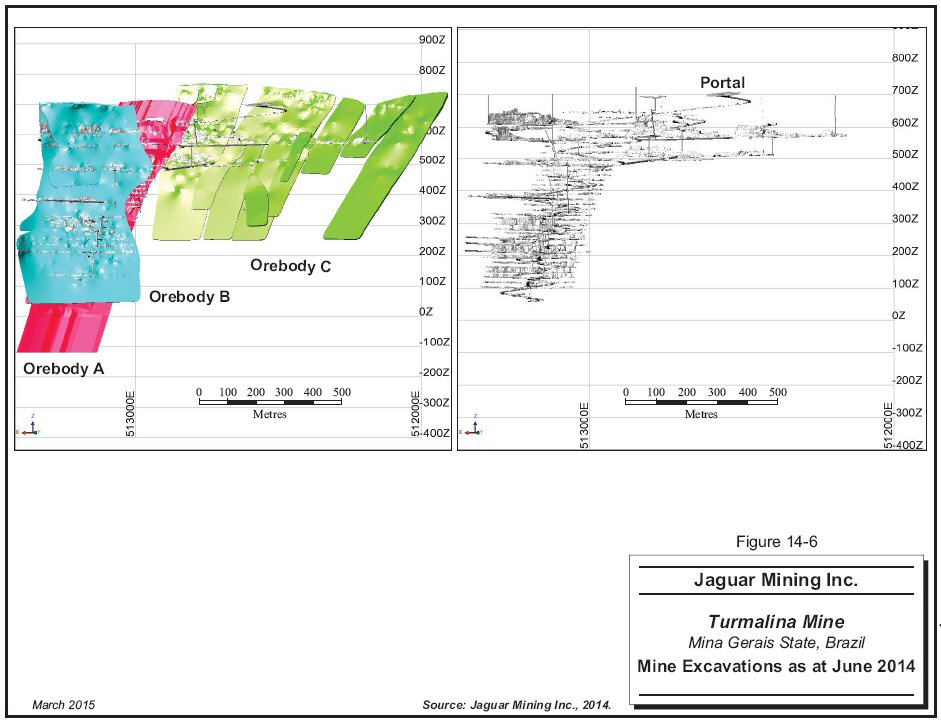

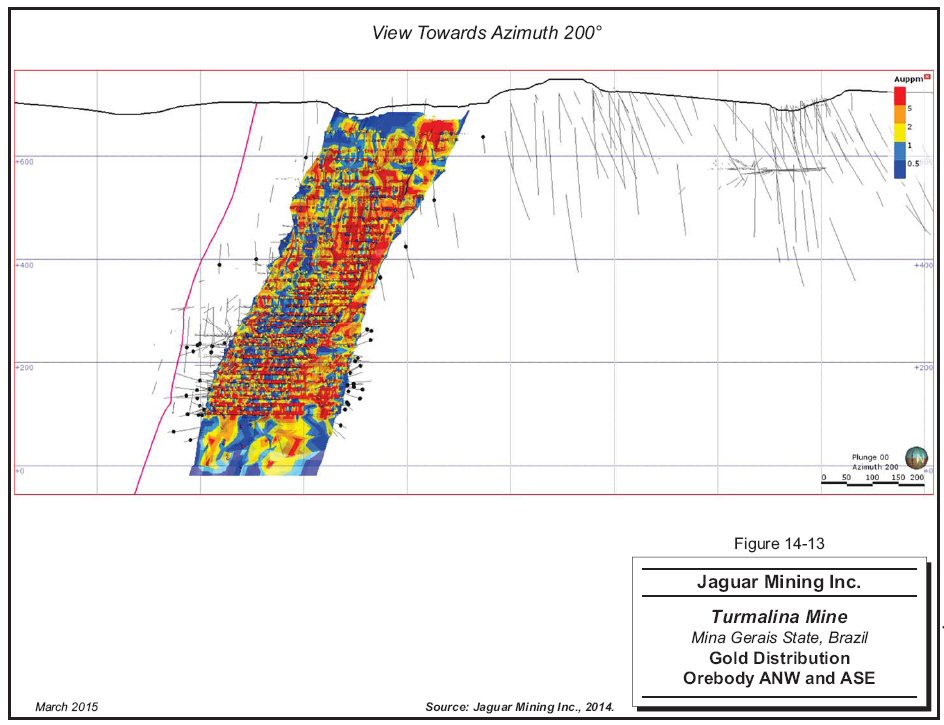

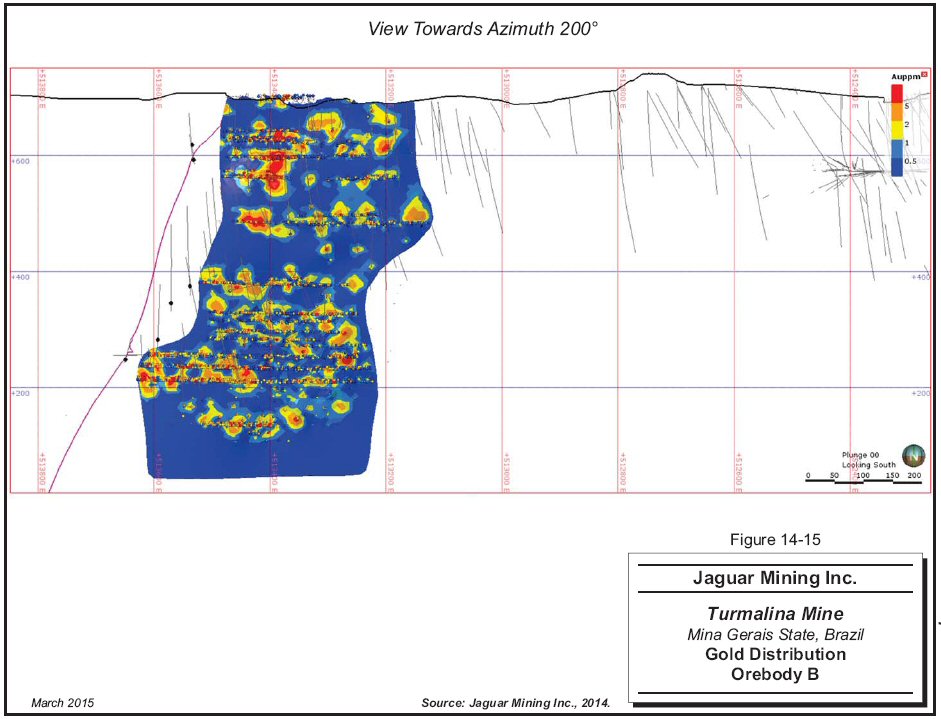

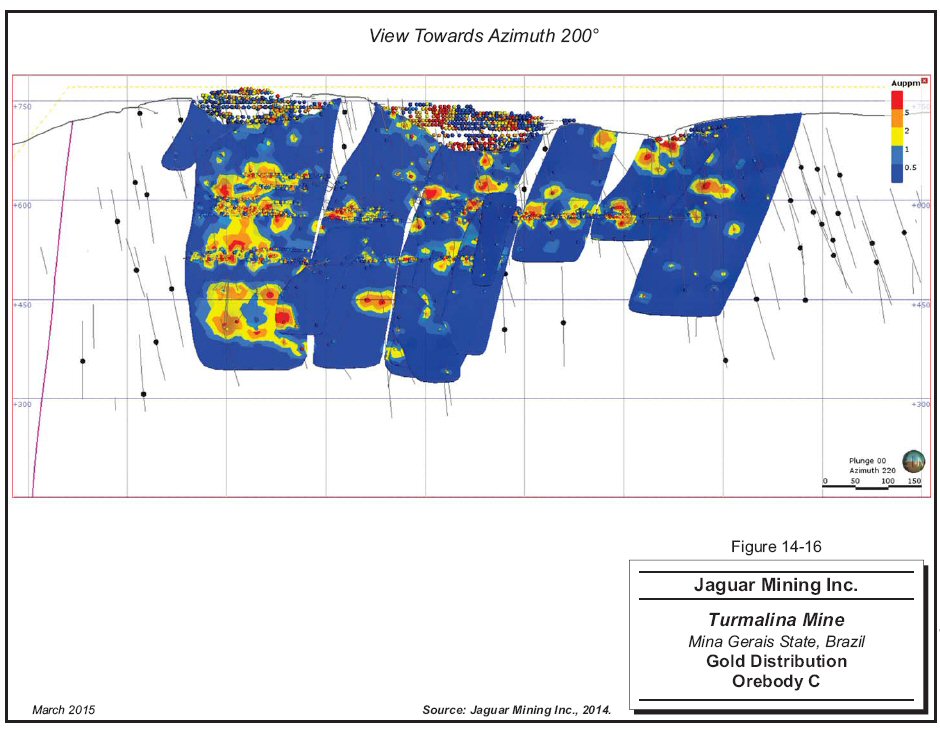

The Turmalina Mine consists of a number of tabular bodies known as Orebodies A, B, and C.

The main production of the mine has been from Orebody A, which is folded, steeply east dipping, with a strike length of approximately 250 m to 300 m and an average thickness of six metres. Mineralization has been outlined to depths of 700 m to 750 m below surface. The southern portion of Orebody A is composed of two parallel narrow veins. The northern portion of Orebody A is much the same as the southern, however, the two parallel zones nearly or completely merge and therefore the zone is much wider overall (up to 10 m).

Orebody B includes three thinner, lower grade lenses parallel to Orebody A. Two of the lenses are located approximately 50 m to 75 m in the structural hangingwall and are accessed by a series of cross-cuts that are driven from Orebody A. The third lens is located possibly along the axial plane. The mineralization in this deposit has been outlined along a strike length of approximately 350 m to 400 m and to depths of 650 m to 700 m below surface. Orebody B is narrow along its entire strike length.

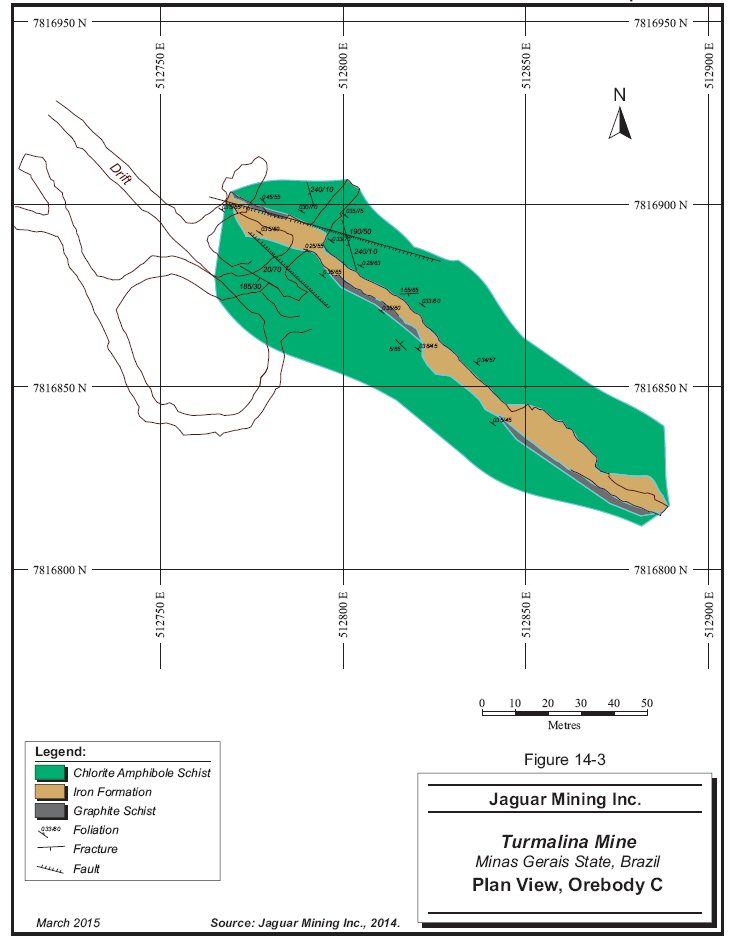

Orebody C is a series of 14 lenses that are located to the west in the structural footwall of Orebody A and are generally of lower grade. They strike northwest and dip steeply to the northeast. A minor amount of production has been achieved from these lenses to date. The mineralization in this deposit has been outlined along a strike length of approximately 800 m to 850 m and to depths of 400 m to 450 m below surface.

MINING METHOD

The mining method currently in use is longhole sublevel stoping with delayed backfill. For the fill material, a paste fill product is prepared from detoxified carbon-in-pulp (CIP) tailings in a plant located near the mill.

The mine is accessed from a five metre by five metre primary decline located in the footwall of the deposit. The portal is located at elevation 695 m. The mine is divided into levels with Level 01 established at elevation 626 MASL (Table 16-1). Starting at this level, the vertical clearance between levels is 114 m in the upper portions of the mine (i.e., Level 02 is at elevation 512 m). Five sublevels, spaced 20 m apart vertically, are driven from the main ramp. Since the initial development phases, level spacing has been modified so that the mining method could more easily adapt to changing conditions and modifications to the mining method. The current level spacing is 75 m with sublevels placed every 15 m vertically. A three metre thick sill pillar is left at each level, except for Level 3.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 16-1 |

| www.rpacan.com |

At each level and sublevel, drifts are developed in the mineralized zone to expose the footwall and the hangingwall contacts. The drift is extended in both directions along strike, under geological control for alignment, continuing to expose the contacts until the limits of the orebody are reached.

Orebodies A and C are the primary structures being mined, while mining in Orebody B has recently been halted. Orebody A is located in the footwall of the shear zone and Orebody B in the hangingwall of the shear structure.

Orebody A is closest to the main ramp and is accessed first. Development is currently progressing to Level 9 in Orebody A.

Orebody C is a secondary system being mined to the west of the portal. It is of lower grade than Orebodies A or B. Orebody C is accessed from the main ramp at Level 02. A separate internal ramp is near completion, which will reduce the haul distance to the run-of-mine ore stockpile.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 16-2 |

| www.rpacan.com |

TABLE 16-1 DISTRIBUTION OF LEVELS AND SUBLEVELS, OREBODIES A AND B |

| Jaguar Mining Inc. – Turmalina Mine |

| | | | |

Level | Level/Sublevels | Elev. (m) | Height (m) |

Level 1 29 m - 1 Sublevel of 15 m and 1 Sublevel of 14 m | AN1SN2 | 640 | 15 |

| AN1SN1 | 626 | 14 |

| Total | | 29 |

| | SILL PILLAR (5m) | 621 | |

| Level 2 109 m | AN2SN6 | 606 | 15 |

| AN2SN5 | 586 | 20 |

| AN2SN4 | 566 | 20 |

| AN2SN3 | 546 | 20 |

| AN2SN2 | 526 | 20 |

| AN2SN1 | 513 | 13 |

| Total | | 108 |

| | SILL PILLAR (5m) | 508 | |

Level 3 95 m - 5 Sublevels of 15 m and 1 Sublevel of 20 m | AN3SN6 | 493 | 15 |

| AN3SN5 | 475 | 20 |

| AN3SN4 | 460 | 15 |

| AN3SN3 | 445 | 15 |

| AN3SN2 | 430 | 15 |

| AN3SN1 | 415 | 15 |

| Total | | 95 |

| Level 4 75 m - 5 Sublevels of 15 m | AN4SN5 | 400 | 15 |

| AN4SN4 | 385 | 15 |

| AN4SN3 | 370 | 15 |

| AN4SN2 | 355 | 15 |

| AN4SN1 | 340 | 15 |

| Total | | 75 |

| | SILL PILLAR (4m) | 336 | |

Level 5 60 m - 1 Sublevel 5 m + 1 Sublevel 10 m + 3 Sublevels of 15 m | AN5SN5 | 331 | 5 |

| AN5SN4 | 321 | 10 |

| AN5SN3 | 306 | 15 |

| AN5SN2 | 291 | 15 |

| AN5SN1 | 276 | 15 |

| Total | | 60 |

| | SILL PILLAR (5m) | 271 | |

Level 6 65 m - 1 Sublevel 5 m + 3 Sublevels of 20 m | AN6SN4 | 266 | 5 |

| AN6SN3 | 246 | 20 |

| AN6SN2 | 226 | 20 |

| AN6SN1 | 206 | 20 |

| Total | | 65 |

| | SILL PILLAR (5m) | 201 | |

Level 7 72 m - 1 Sublevel 12 m + 4 Sublevels of 15 m | AN7SN4 | 189 | 12 |

| AN7SN3 | 174 | 15 |

| AN7SN2 | 159 | 15 |

| AN7SN1 | 144 | 15 |

| AN7SN0 | 129 | 15 |

| Total | | 72 |

| | SILL PILLAR (5m) | 124 | |

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 16-3 |

| www.rpacan.com |

| Level | Level/Sublevels | Elev. | Height |

Level 8 72 m - 1 Sublevel 12 m + 4 Sublevels of 15 m | AN8SN4 | 112 | 12 |

| AN8SN3 | 97 | 15 |

| AN8SN2 | 82 | 15 |

| AN8SN1 | 67 | 15 |

| Total | | 57 |

| | SILL PILLAR (5m) | 62 | |

Level 9 72 m - 1 Sublevel 12 m + 4 Sublevels of 15 m | AN9SN4 | 47 | 15 |

| AN9SN3 | 32 | 15 |

| AN9SN2 | 17 | 15 |

| AN9SN1 | 2 | 15 |

| AN9SN0 | -13 | 15 |

| Total | | 75 |

| | SILL PILLAR (5m) | -18 | |

Level 10 72 m - 1 Sublevel 12 m + 4 Sublevels of 15 m | AN10SN4 | -33 | 15 |

| AN10SN3 | -48 | 15 |

| AN10SN2 | -63 | 15 |

| AN10SN1 | -78 | 15 |

| AN10SN0 | -93 | 15 |

| Total | | 75 |

| | SILL PILLAR (5m) | -98 | |

The retreat sequence, and the need to complete Orebody B mining before cutting off access by mining Orebody A, reduced productivity by limiting the number of stopes available for mining at a given time.

The current Life of Mine plan (LOMP) does not consider mining of Orebody B, and involves a change in mine design. Orebody A will be mined in a primary/secondary sequence via transverse access to the thick centre portion of Orebody A, requiring additional accesses developed in waste. Each primary or secondary stope is 15 m along strike, with no pillars. The design change has the effect of increasing the number of available workplaces, and de-links the narrow, lower-productivity ends from the centre.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 16-4 |

| www.rpacan.com |

In RPA’s opinion, this innovation is critical to improving the mine’s ability to fill the mill to capacity with high grade ore.

Although Orebody B is not in the LOMP, and no longer included in Mineral Reserves, future access is possible, either by mining through cemented paste fill and supporting appropriately, or by mining concurrently with the thinner ends of Orebody A.

GEOMECHANICS

Ground conditions were observed by RPA to be very good. The main decline, portions of which were developed up to ten years ago, did not exhibit any roof or wall deterioration. Primary support in the mine is provided by the use of split sets, grouted rebar and, in the wider areas, grouted cable bolts.

MINING EQUIPMENT

Development is completed using two-boom jumbos and six cubic yard load-haul-dump (LHD) units. In order to create adequate working space for the equipment, minimum widths of four metres must be maintained, causing excessive quantities of dilution in areas where the orebodies are narrow.

Development drilling is undertaken using two-boom electric-hydraulic jumbos. Two single-boom jumbos are used for the installation of ground support. Development mucking is completed using a fleet of six 7 t to 14 t capacity LHD units and haulage to surface is by a fleet of seven Volvo 30 t and three Iveco 25 t off-highway surface trucks.

Drilling of the production holes is completed using a fleet of three Atlas Copco Simba longhole drills. Stope mucking is performed by remote control LHDs.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 16-5 |

| www.rpacan.com |

LIFE OF MINE PLAN

Stope and development designs, and production scheduling were carried out by MCB using Deswik mine design software, and modified by Jaguar to deplete for stopes mined out as of December 31, 2014.

The production schedule covers a mine life of four years based on Mineral Reserves, and it is summarized in Table 16-2.

| TABLE 16-2 LOMP PRODUCTION SCHEDULE |

| Jaguar Mining Inc. – Turmalina Mine |

| Item | Units | 2015 | 2016 | 2017 | 2018 | Total |

| Mining | | | | | | |

| Orebody A | Tonnes | 316,937 | 257,673 | 267,631 | 57,285 | 899,526 |

| | g/t Au | 5.42 | 6.54 | 7.00 | 5.77 | 6.23 |

| | | | | | | |

| Orebody C | Tonnes | 53,002 | 108,641 | 147,330 | 58,028 | 367,000 |

| | g/t Au | 2.79 | 3.84 | 3.10 | 2.24 | 3.14 |

| | | | | | | |

| Total Mill Feed | Tonnes | 369,939 | 366,313 | 414,961 | 115,313 | 1,266,526 |

| | g/t Au | 5.04 | 5.74 | 5.61 | 3.99 | 5.33 |

| | | | | | | |

| Recovery | % | 90.5% | 90.5% | 90.5% | 90.5% | 90.5% |

| | | | | | | |

| Gold Produced | Ounces | 54,246 | 61,156 | 67,748 | 13,388 | 196,539 |

Scheduling was based on productivities achieved in recent operations. Development was limited to 60 m per month on the main ramp, and 30 m per month on any single heading elsewhere.

Stope scheduling follows the primary/secondary sequence and includes delays for backfilling and cement curing.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 16-6 |

| www.rpacan.com |

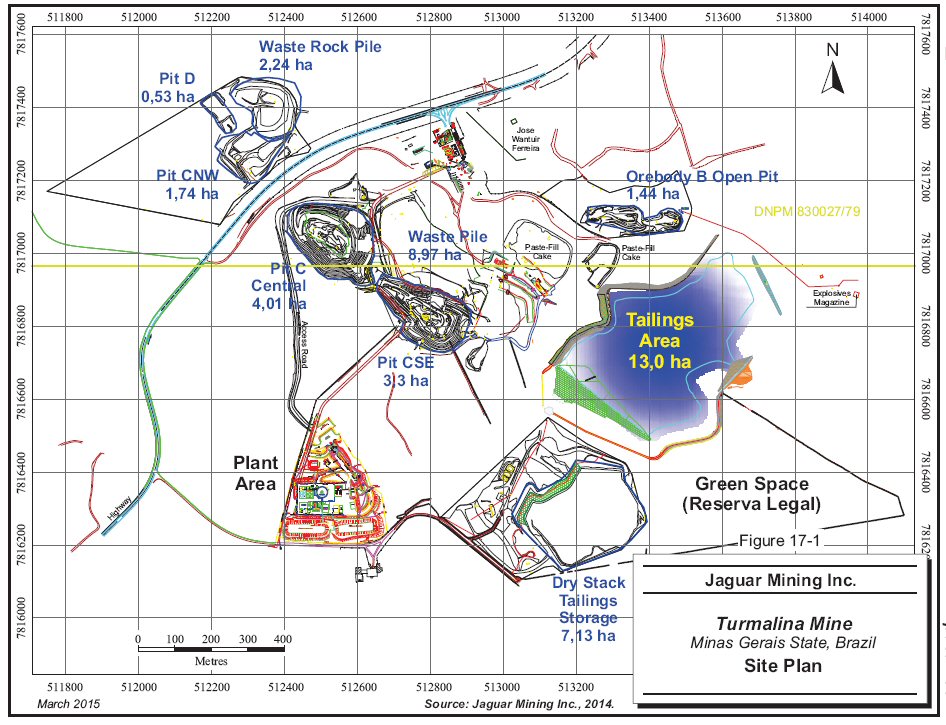

17 RECOVERY METHODS

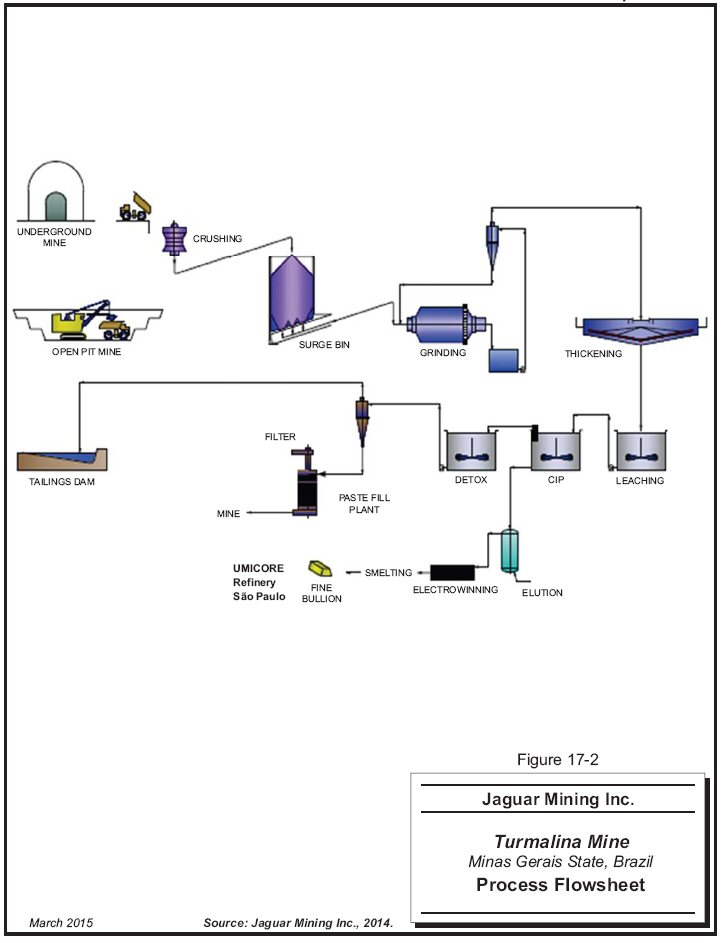

The plant has a nominal processing capacity of 2,000 dmt per day, or 610,000 dmt per year. Since inception, the plant has been achieving annual overall recoveries of between 87% and 92%. The process flowsheet includes three-stage crushing and screening to minus 3/8 inches, primary grinding using a ball mill, secondary grinding using a ball mill, thickening, cyanide leaching, CIP, elution, electrowinning, and smelting. The tailings are conveyed to a detoxification unit for arsenic removal and cyanide destruction and then are pumped to the paste fill plant to be used either for mine backfill or deposited on a purpose-built dry-stack storage area. Process tailings have also been stored in completed open pits on the mine site (Figure 17-1).

A process control system has been established at the supervisory level via a conventional PLC (programmable logic controller) system. It is based on a process control philosophy that is compatible to harbor an online optimizing system (Advanced Control System, or ACS) in the future. The ACS entails both Expert and AI-based levels, the highest objective-function being throughput. PIMS, LIMS, and MES Corporate Systems are also envisioned to be implemented when appropriate. The control room is located close to the hydrometallurgical plant. Three dedicated PLCs control the crushing and screening plant, the thickener, grinding plant, hydrometallurgical plant, the paste fill plant, and the Detox plant.

The current flowsheet is shown in Figure 17-2 and is described below. A summary of the mill production history and recovery has been presented in Table 6-1 in Section 6 of this report.

CRUSHING AND SCREENING

Run-of-mine material is stored in a surge pile and fed to the primary jaw crusher using a front end loader at a nominal rate of 140 tonnes per hour (tph). The crushing plant has a design capacity of 180 tph. Oversized material is managed with a grizzly and rock breaker. The primary crusher product is fed to secondary and tertiary cone crushers. The final product, minus 3/8 inches, is stored in a grinding plant surge bin.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 17-1 |

| www.rpacan.com |

GRINDING, CLASSIFICATION AND THICKENING

The feed grade to the primary mills is determined by sampling with an automatic sampler. Material is fed from the surge bin to the grinding circuit that consists of ball mills of three different sizes, although only two mills are currently operating on a continual basis. The first ball mill is 10.5 ft x 15.5 ft in size with a maximum capacity of 25 tph and is operated by a 1,000 HP motor. The second mill is 12.5 ft x 18 ft in size with a maximum capacity of 60 tph and is operated with a 1,400 HP motor. The third mill is 13 ft x 21.8 ft in size with a maximum capacity of 70 tph and is operated by a 1,500 HP motor. Lead nitrate [Pb(NO3)2] is added at a rate of 250 g/t in the grinding feeds in order to avoid excessive NaCN consumption by the formation of thiocyanides (SCN), ferrocyanides (Fe(CN)6)4-, and ferricyanides (Fe(CN)6)3- .

The primary mill product is sized with cyclones to 80% passing one millimetre (P80 = 1 mm). The overflow is fed to the secondary grinding unit, while the underflow (oversize) is recycled to the primary mill. The secondary (12.5 ft x 18 ft) ball mill operates at approximately 19 RPM, driven by a 1,800 HP motor. Secondary cyclones size the product to 80% passing 200 mesh (P80 = 200 mesh), with the overflow passing on to the thickener and the underflow recycling to the secondary mill. The grinding circuit is automated. A particle size analyzer (PSA) is positioned in the secondary cyclone overflow stream to supply on-line data to the grinding and classification plant control system. All mills have automatic water addition systems. The secondary mill has an automatic ball addition system. The overall grind is 80% passing 200 mesh.

The secondary cyclone overflow stream is fed to a 100 ft thickener where flocculants are added to optimize the settling cycle of the pulp. The thickener underflow, 53% solids by weight, is pumped to the pulp conditioning system of the CIP plant, which is instrumented to maintain the pulp at a density of approximately 50%, by weight, solids. The water addition flow rate is monitored and controlled by a magnetic flow meter and pulp densitometer. The thickener overflow is directed to the process water tank as make-up water.

LEACHING CIRCUIT

The leaching circuit consists of eight agitation tanks. Lime is added to the first tank to adjust the pH. Cyanidation begins in the first tank with the addition of sodium cyanide (NaCN). Lead nitrate is also added in the grinding circuit to control excessive NaCN consumption. Compressed air is injected in the bottom of all the tanks at a rate of 2,000 Acfm and at a pressure of 3.5 kgf/cm2, as the process consumes large amounts of oxygen. The residence time in the leaching circuit is approximately 25 hrs.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 17-2 |

| www.rpacan.com |

ADSORPTION CIRCUIT

The adsorption circuit is a conventional CIP circuit. The gold-bearing pulp passes through seven adsorption tanks arranged to operate in two parallel trains. One train will include four tanks and the other will have three tanks. Activated carbon with a size range of 8 mesh to 16 mesh and a minimum pulp concentration of 20 g/L is added to the last in the series of tanks, and is pumped in the opposite direction from the sludge flow. Thus, the carbon adsorbs the gold from the pulp as the process continues. When the adsorption cycle is completed, approximately ten hours, the loaded carbon, containing approximately 5 kg of gold per tonne of carbon, is pumped from the bottom of the first tank in the series to the elution and electrowinning circuit.

ELUTION AND ELECTROWINNING

The loaded carbon is screened and the minus 28 mesh material is redirected back to the adsorption circuit. The oversize feeds the elution circuit, comprising four columns, two of which are stripping while the other two are loading. The estimated carbon load in each column (1.25 m in diameter and 6.25 m high) is approximately 2.7 t. Loaded carbon is stripped using caustic soda, injected into the elution columns from bottom to top at a concentration of 1% by weight with 200 L of ethylic alcohol (per batch) kept at 95°C. The pregnant solution is stored in a tank, with overflow to feed the electrowinning circuit. The electrowinning circuit consists of six cathodes and seven anodes, energized with a 360 A current and a voltage of 3.5 V to 4.0 V.

Up to 2012, Jaguar was shipping the steel wool and sludge to the refinery. Since 2012, it has shipped the cake resulting from alcoholic carbon elution of the steel wool.

ACID WASHING

The activated carbon first undergoes a stripping process in the elution columns, where the adsorbed gold is removed by a 1% (by weight) NaOH alcoholic solution at 95°C. It is then conveyed to a surge tank via an ejector directed towards a 28 mesh circular vibrating screen for the removal of fines (undersize). The screen oversize is conveyed to a 6 m3 fibreglass acid washing tank. Acid washing is necessary to maintain the loading capacity of the activated carbon since the mineral matrix possesses other cations such as calcium, iron, copper, zinc, and lead that compete with gold in the interstices of the activated carbon. The acid washing is completely effected by passing an acid solution of HCl at 10%, removing the impurities that diminish the capacity of the carbon to adsorb gold, mainly carbonates and basic metals.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 17-3 |

| www.rpacan.com |

The acid solution of HCl at 10% (by weight) is prepared in a fibreglass HCl solution tank by adding water and HCl at 33% by weight. This solution is injected at the bottom and discharged at the top of the acid washing tank by overflow, returning to the HCl solution tank by gravity. The time involved in the acid washing is approximately 16 hours.

Once acid washing is completed, the acid solution is drained towards a neutralization tank. The carbon will be neutralized with a 1% (by weight) NaOH solution using a procedure identical to the one used for the acid solution. The neutralization time ranges from one to two hours, depending on the pH control of the recycled solution. The remaining solution is also drained to the neutralization pond. Thereafter, the carbon is washed with water in open circuit with regard to the neutralization pond. This operation lasts approximately two hours. After these stages, the carbon is transferred to the 28 mesh circular screen and can be conveyed either to the thermal regeneration process in a regenerating kiln or to the carbon addition circuit in the volumetric control vessel, and then to the last adsorption tank in the CIP circuit.

CARBON THERMAL REGENERATION CIRCUIT

The activated carbon is transferred to the thermal regeneration system in a regeneration kiln after having undergone acid washing. The complementary thermal regeneration will give rise to volatilization and/or thermal decomposition of organic compounds and the pyrolysis of other compounds. This allows the carbon to regain its original pore structure, thus recovering almost its original gold adsorption capability.

The existing carbon regeneration kiln – a 100 kW Mintek Model 75/2 Vertical Kiln – has a 75 kg/h carbon regeneration capacity (dry basis) and is able to operate 24 hours a day. The kiln is sufficient to cope with the expanded production (610,000 tpa), regenerating every third elution stripped carbon charge. The operations staff at Turmalina reported that this regime has proven to be effective during current operations, not showing losses of dissolved gold. The carbon is discharged into a water tank (“quench” tank).

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 17-4 |

| www.rpacan.com |

Thereafter, the carbon is conveyed through an ejector towards the 28 mesh circular screen, whose oversize makes up the regenerated carbon stream and is conveyed by gravity to the volumetric control vessel and then to the last tanks of the CIP adsorption circuit.

DETOXIFICATION PLANT

The adsorption tank tailings (86 tph at 46% solids) are conveyed by gravity to a belt screen in order to avoid carbon loss and then to a tailings pulp treatment plant (TPTP or Detox plant) and then to the paste fill plant. This material is used as backfill in the mine for structural purposes, when required. In some cases, its addition to a mechanical waste fill is required.

PASTE FILL PLANT

The treated tailings from the Detox plant, a pulp at 46% solids by weight, are conveyed to a pumping station where they are sent by rubber lined centrifugal pumps (3 x 150 HP – 1 standby) to the paste fill plant, which is located about one kilometre away from the pumping station. The slurry is received in a pulp storage tank, from which it is pumped to a hydrocyclone cluster, and the overflow feeds a thickener. The cyclone underflow, together with thickener underflow, feeds three drum filters (10 ft x 16 ft). The filtration process generates a cake and a filtrate (liquid phase). The thickener overflow is recycled to the industrial water tank, while the filtrate (up to 8% ultra-fines solids) is conveyed to the tailings dam.

The cake from the filters, after having gone through the stages of the filtration cycle (cake formation, washing, drying, blow, and discharge), contains approximately 30% moisture. It is conveyed through a 36 in. wide, 27 m long conveyor belt to the cake preconditioning hopper, after which the cake is sent to the weigh hopper where additives such as Portland cement or, alternatively, “Fosbinder” are added in proportion to the cake mass flow. Other binders aimed to impart structural properties to the paste, as well as to neutralize excess acidity due to its high carbonate content, can also be added. The cake is then directed to the paste mixer for the final paste production. The paste will be used as fill in the underground mine.

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 17-5 |

| www.rpacan.com |

During periods when paste fill is not needed for structural purposes in the mine, the tailings bypass the paste fill plant and are directed to the tailings dam, along with the filtrate (8% ultra-fine solids).

Jaguar Mining Inc. – Turmalina Mine, Project 2347 Technical Report NI 43-101 – March 27, 2015 | Page 17-6 |

| www.rpacan.com |

17-7

| www.rpacan.com |

17-8

| www.rpacan.com |

18 PROJECT INFRASTRUCTURE

The Turmalina Mining Complex includes a nominal 2,000 tpd processing plant and tailings disposal area. Electrical power is obtained from the national grid.

All ancillary buildings are located near the mine entrance: gate house including a reception area and waiting room, administration building, maintenance shops, cafeteria, warehouse, change room, first aid, and compressor room. The explosives warehouse is located 1.2 km away from the mine area, in compliance with the regulations set forth by the Brazilian Army.

Other ancillary buildings are located near the processing plant and include an office building, a laboratory, warehousing, and a small maintenance shop.

RPA noted that the Turmalina Mine Complex was well run and organized, a reasonably safe environment for the mine workforce, and had well maintained maintenance and equipment facilities.

There is no infrastructure related to the Faina and Pontal historic open pit operations.