Exhibit 96.1

|  |

| CONTENTS | ||

1.0 | EXECUTIVE SUMMARY | 1-1 |

1.1 | Property Description | 1-1 |

1.2 | Ownership | 1-1 |

1.3 | Geology and Mineralization | 1-1 |

1.4 | Exploration Status | 1-4 |

1.5 | Recent Development and Operations | 1-4 |

1.5.1 | Palangana | 1-4 |

1.5.2 | Goliad | 1-4 |

1.5.3 | Burke Hollow | 1-5 |

1.6 | Mineral Resource Estimates | 1-5 |

1.7 | Permitting Requirements | 1-5 |

1.8 | QP Conclusion and Recommendations | 1-5 |

2.0 | INTRODUCTION | 2-1 |

2.1 | Registrant/Issuer of Report | 2-1 |

2.2 | Terms of Reference | 2-1 |

2.3 | Data Sources, Units of Measurement and Abbreviations | 2-1 |

2.4 | Personal Inspection | 2-1 |

2.4.1 | QP Qualifications | 2-1 |

2.5 | Previous Technical Report Summaries | 2-2 |

3.0 | PROPERTY DESCRIPTION | 3-1 |

3.1 | Location, Description, Leases and Mineral Rights | 3-1 |

3.1.1 | Hobson CPP | 3-6 |

3.1.2 | Burke Hollow | 3-7 |

3.1.3 | Goliad | 3-7 |

3.1.4 | Palangana | 3-7 |

3.1.5 | Salvo | 3-8 |

3.2 | Encumbrances | 3-8 |

3.3 | Property Risk Factors | 3-10 |

3.4 | Royalties (Confidential) | 3-11 |

4.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 4-1 |

4.1 | Physical Setting | 4-1 |

4.2 | Accessibility and Local Resources | 4-2 |

4.3 | Availability of Infrastructure | 4-3 |

5.0 | HISTORY | 5-1 |

6.0 | GEOLOGICAL SETTING, MINERALIZATION AND DEPOSIT | 6-1 |

6.1 | Regional Geology | 6-1 |

6.1.1 | South Texas Gulf Coastal Plan | 6-1 |

6.2 | Local Geology | 6-4 |

6.2.1 | South Texas Local Geology – Goliad Formation Hosted Mineralization | 6-4 |

6.2.2 | Goliad Formation Hydrogeology | 6-5 |

6.3 | Mineralization and Deposit Type | 6-5 |

7.0 | EXPLORATION | 7-1 |

7.1 | Drilling Programs | 7-1 |

7.2 | Hydrogeologic Information | 7-7 |

|  |

7.3 | Geotechnical Information | 7-8 |

8.0 | SAMPLE PREPARATION, ANALYSES AND SECURITY | 8-1 |

8.1 | Typical and Standard Industry Methods | 8-1 |

8.1.1 | Burke Hollow | 8-1 |

8.1.2 | Goliad | 8-2 |

8.1.3 | Palangana | 8-3 |

8.1.4 | Salvo | 8-5 |

8.2 | QP’s Opinion on Sample Preparation, Security and Analytical Procedures | 8-5 |

9.0 | DATA VERIFICATION | 9-1 |

9.1 | Summary | 9-1 |

9.2 | Limitations | 9-2 |

9.3 | QP’s Opinion on Data Adequacy | 9-2 |

10.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 10-1 |

10.1 | Summary of Properties | 10-1 |

10.2 | QP’s Opinion on Data Adequacy | 10-2 |

11.0 | MINERAL RESOURCE ESTIMATES | 11-1 |

11.1 | Mineral Resource Assumptions and Parameters Applied to Each Project Area | 11-1 |

11.1.1 | Reasonable Prospects of Economic Extraction | 11-4 |

11.1.2 | Confidence Classification of Mineral Resource Estimates | 11-4 |

11.2 | Site-by-Site Summaries | 11-5 |

11.3 | Uncertainties (Factors) That May Affect the Mineral Resource Estimate | 11-8 |

11.4 | QP Opinion on the Mineral Resource Estimate | 11-9 |

12.0 | MINERAL RESERVE ESTIMATES | 12-1 |

13.0 | MINING METHODS | 13-1 |

14.0 | PROCESSING AND RECOVERY METHODS | 14-1 |

15.0 | INFRASTRUCTURE | 15-1 |

16.0 | MARKET STUDIES | 16-1 |

17.0 | ENVIRONMENTAL STUDIES, PERMITTING AND PLANS, NEGOTIATIONS, OR AGREEMENTS WITH LOCAL INDIVIDUALS OR GROUPS | 17-1 |

18.0 | CAPITAL AND OPERATING COSTS | 18-1 |

19.0 | ECONOMIC ANALYSIS | 19-1 |

20.0 | ADJACENT PROPERTIES | 20-1 |

21.0 | OTHER RELEVANT DATA AND INFORMATION | 21-1 |

22.0 | INTERPRETATION AND CONCLUSIONS | 22-1 |

22.1 | Conclusions | 22-1 |

22.2 | Risks and Opportunities | 22-1 |

23.0 | RECOMMENDATIONS | 23-1 |

24.0 | REFERENCES | 24-1 |

25.0 | RELIANCE ON INFORMATION PROVIDED BY THE REGISTRANT | 25-1 |

26.0 | DATE AND SIGNATURE PAGE | 26-1 |

|  |

| TABLES | ||

Table 1-1: | Texas Hub and Spoke Project Measured and Indicated Resource Summary | 1-6 |

Table 1-2: | Texas Hub and Spoke Project Inferred Resource Summary | 1-7 |

Table 1-3: | Texas Hub and Spoke Permits | 1-7 |

Table 2-1: | Previous Technical Report Summaries | 2-2 |

Table 3-1: | Project Area Mineral Lease Summary | 3-6 |

Table 5-1: | Past Operations Summary | 5-2 |

Table 7-1: | Project Area Exploration Drilling Programs Summary | 7-2 |

Table 11‑1: | Palangana Production from 2010-2016 | 11-2 |

Table 11‑2: | Methods, Parameters and Cutoff Summary by Project Area | 11-3 |

Table 11-3: | Resource Classification Criteria by Project Area | 11-4 |

Table 11‑4: | Project Area Measured and Indicated Resources Summary | 11-6 |

Table 11‑5: | Project Area Inferred Resources Summary | 11-7 |

FIGURES | ||

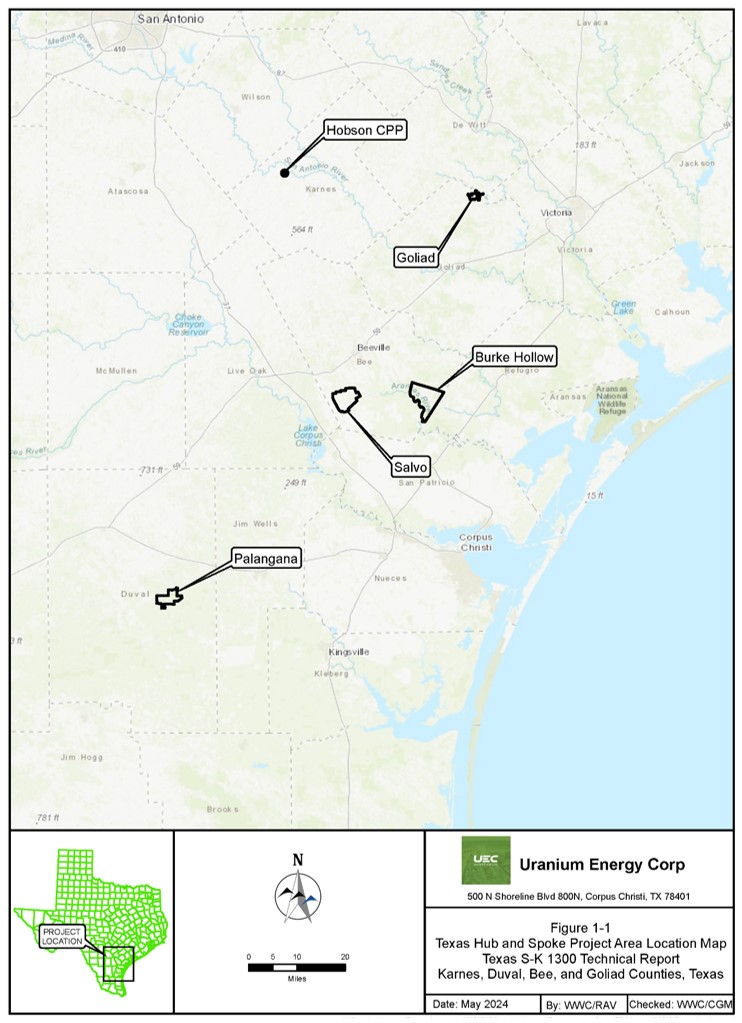

Figure 1‑1: | South Texas Assets Project Area Location Map | 1-2 |

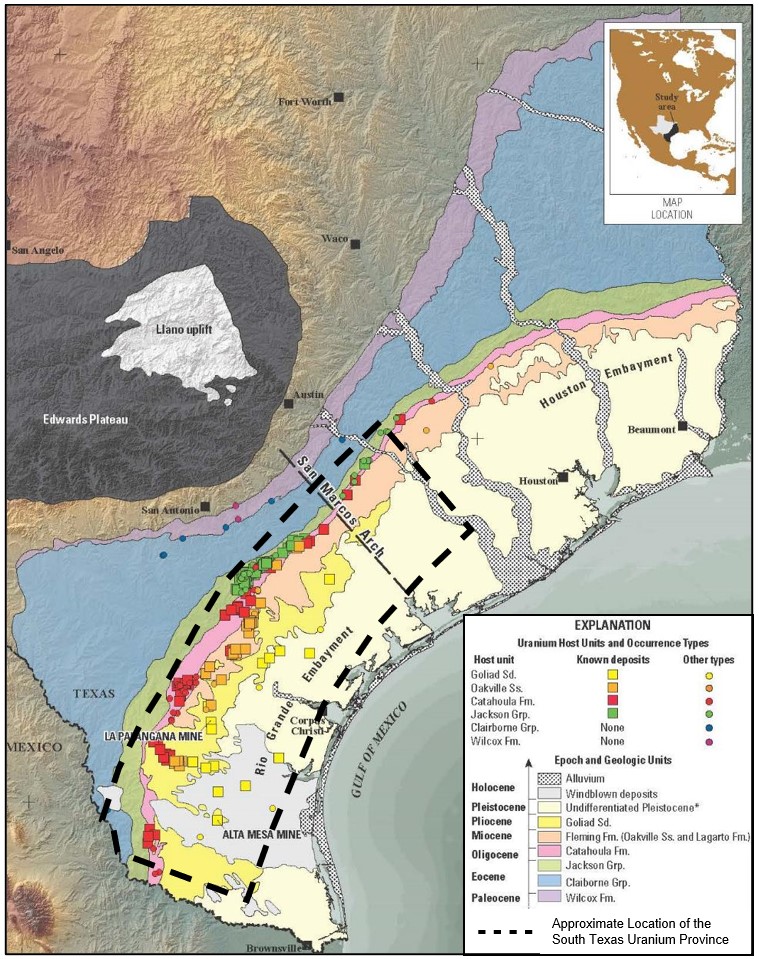

Figure 1‑2: | South Texas Uranium Province | 1-3 |

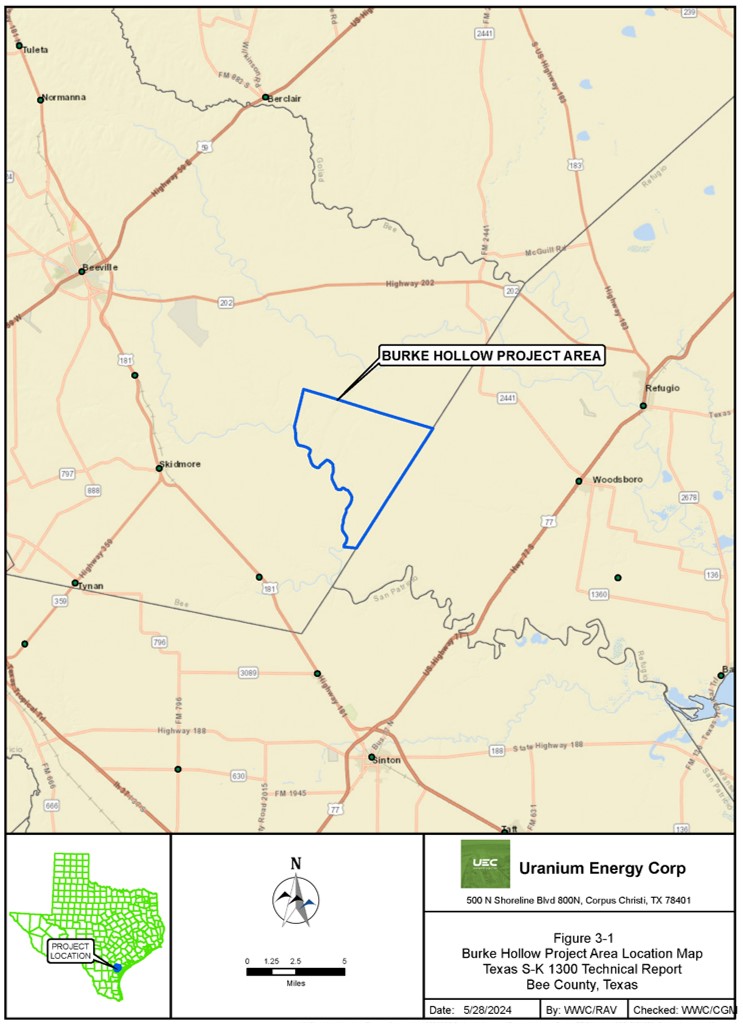

Figure 3‑1: | Burke Hollow Project Area Location Map | 3-2 |

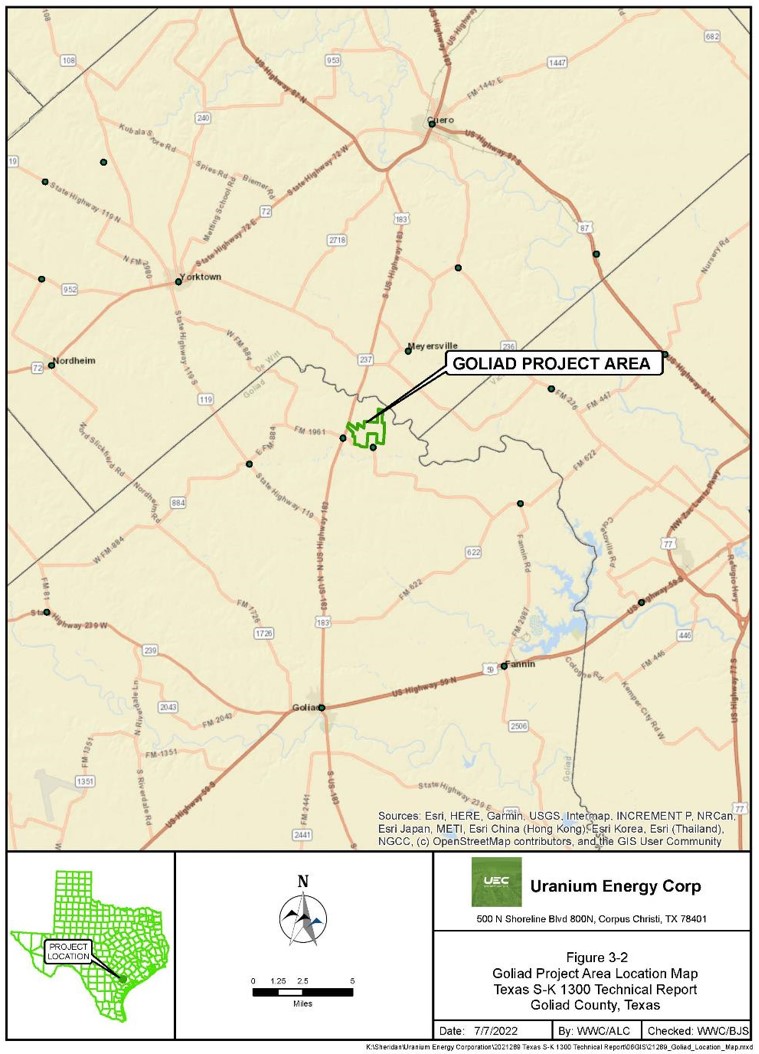

Figure 3‑2: | Goliad Project Area Location Area Map | 3-3 |

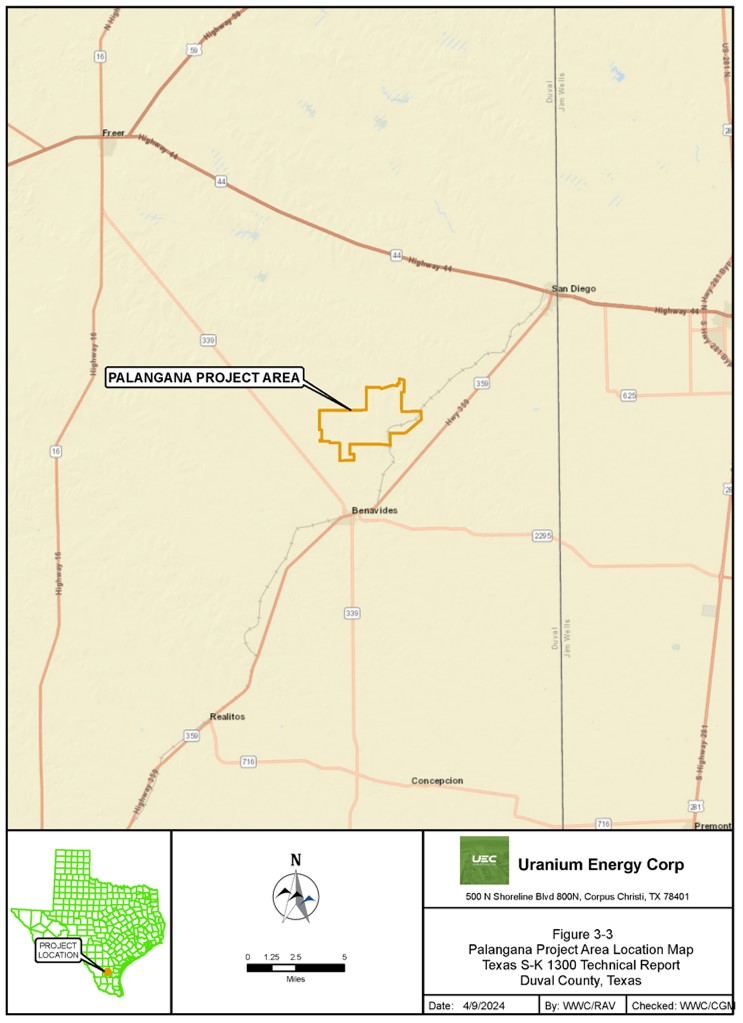

Figure 3‑3: | Palangana Project Area Location Map | 3-4 |

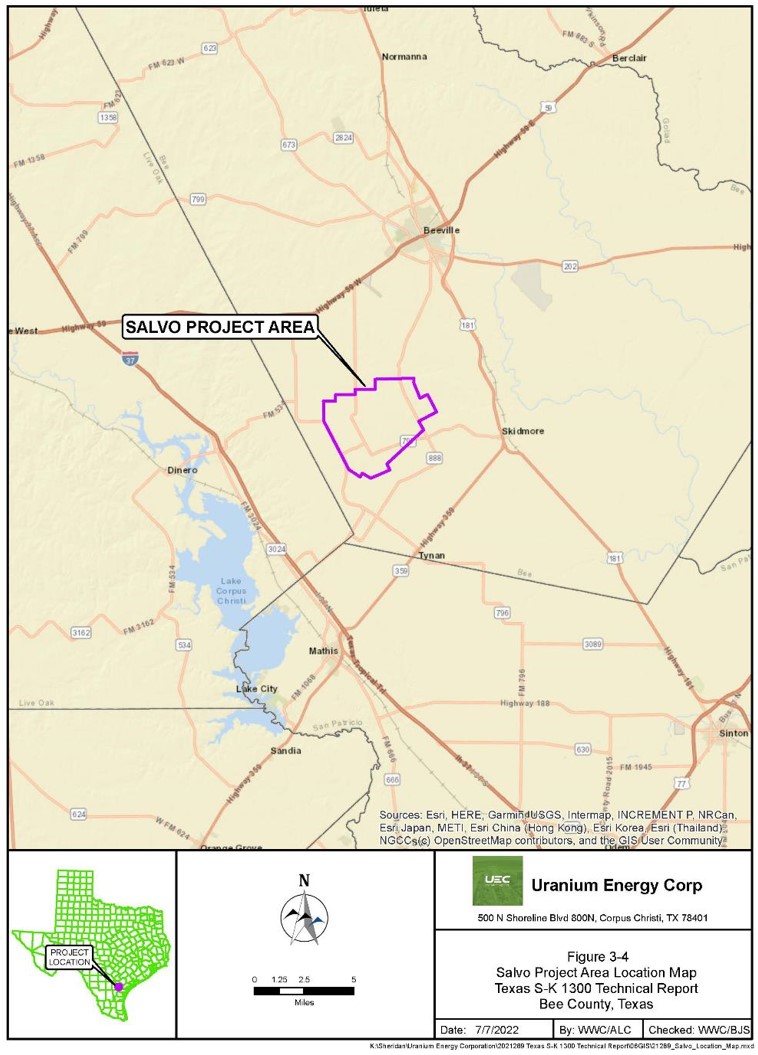

Figure 3‑4: | Salvo Project Area Location Map | 3-5 |

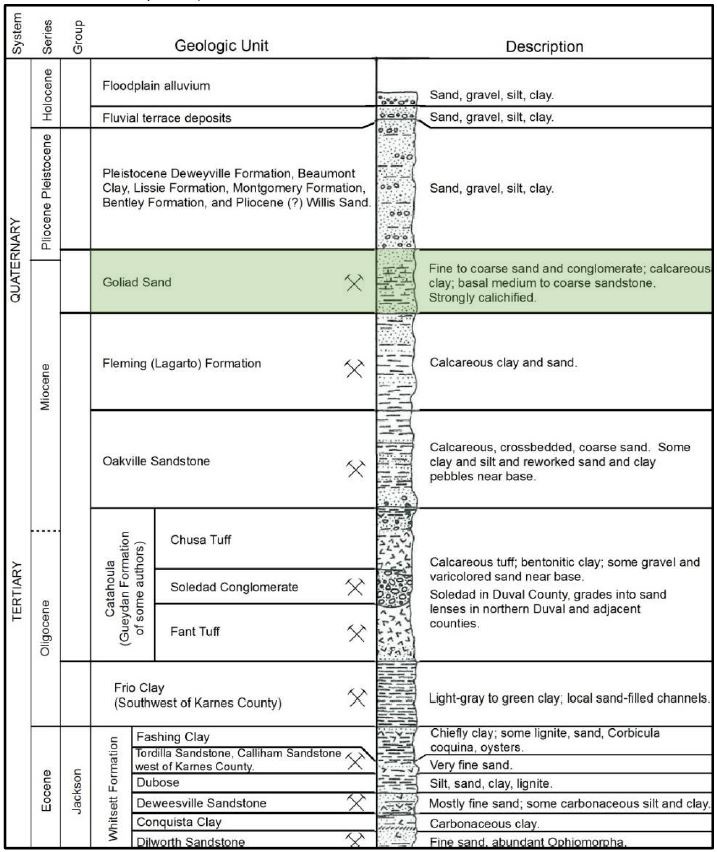

Figure 6‑1: | South Texas Uranium Province Stratigraphic Column (modified from Galloway et al., 1979) | 6-2 |

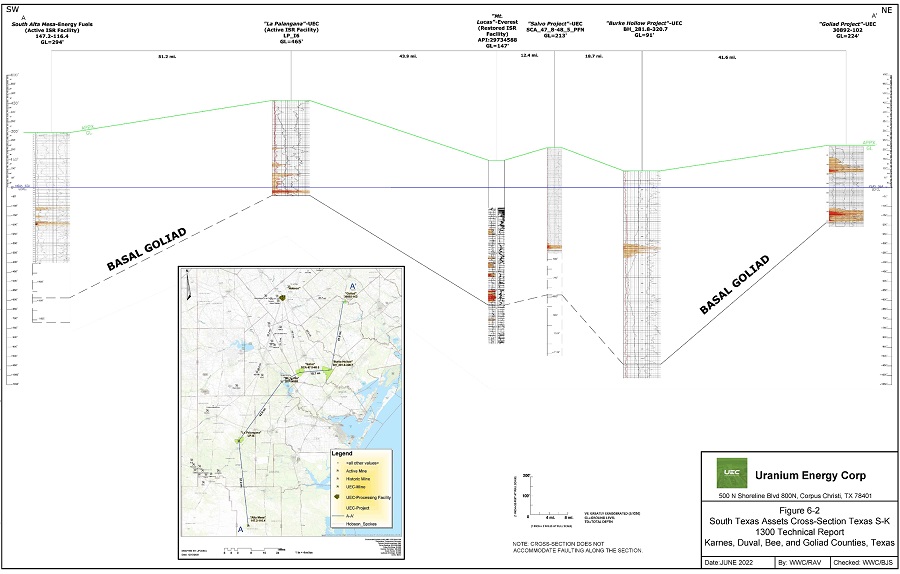

Figure 6‑2: | South Texas Assets Cross-Section | 6-3 |

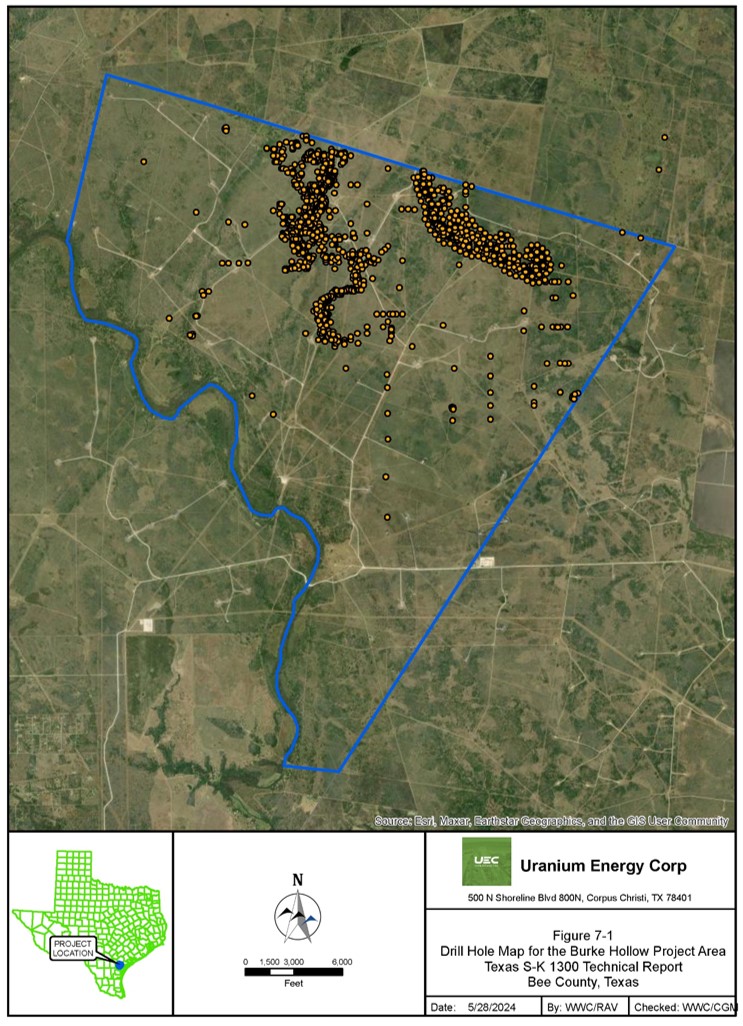

Figure 7‑1: | Drill Hole Map for the Burke Hollow Project Area | 7-3 |

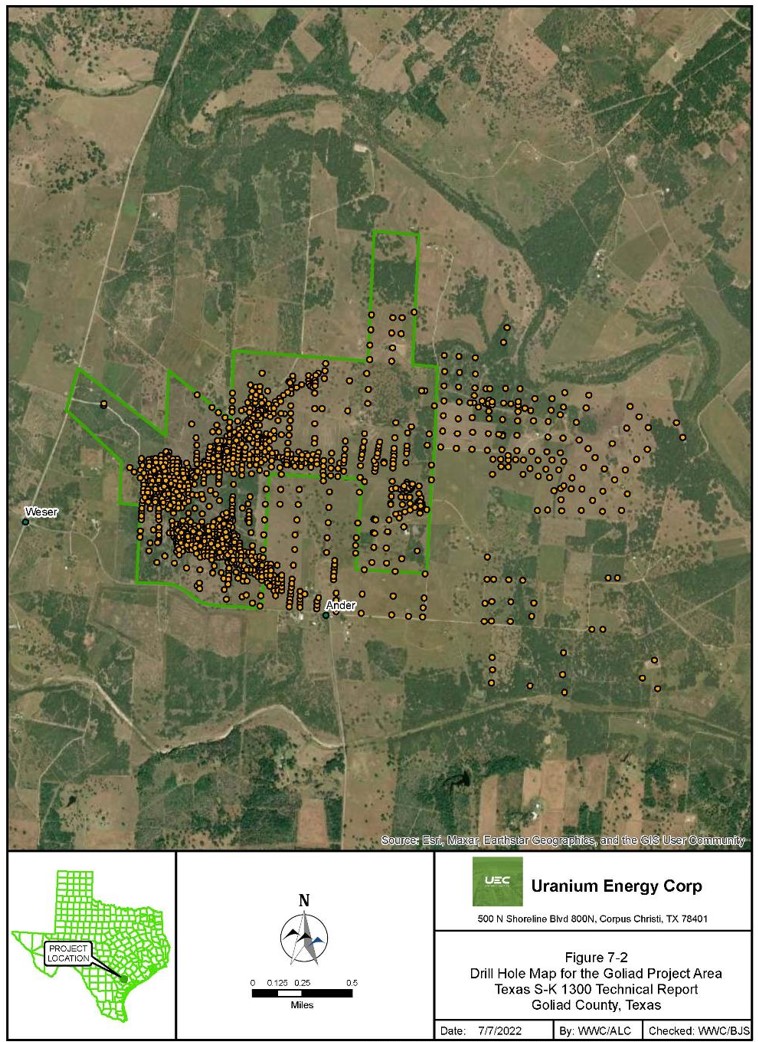

Figure 7‑2: | Drill Hole Map for the Goliad Project Area | 7-4 |

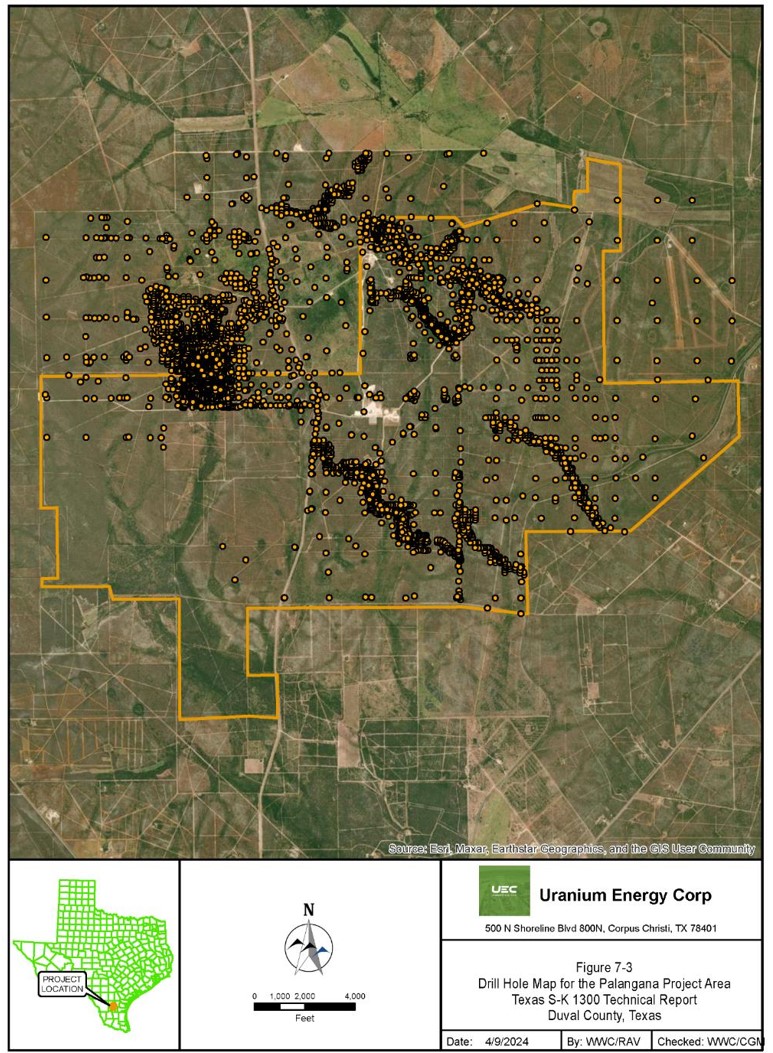

Figure 7‑3: | Drill Hole Map for the Palangana Project Area | 7-5 |

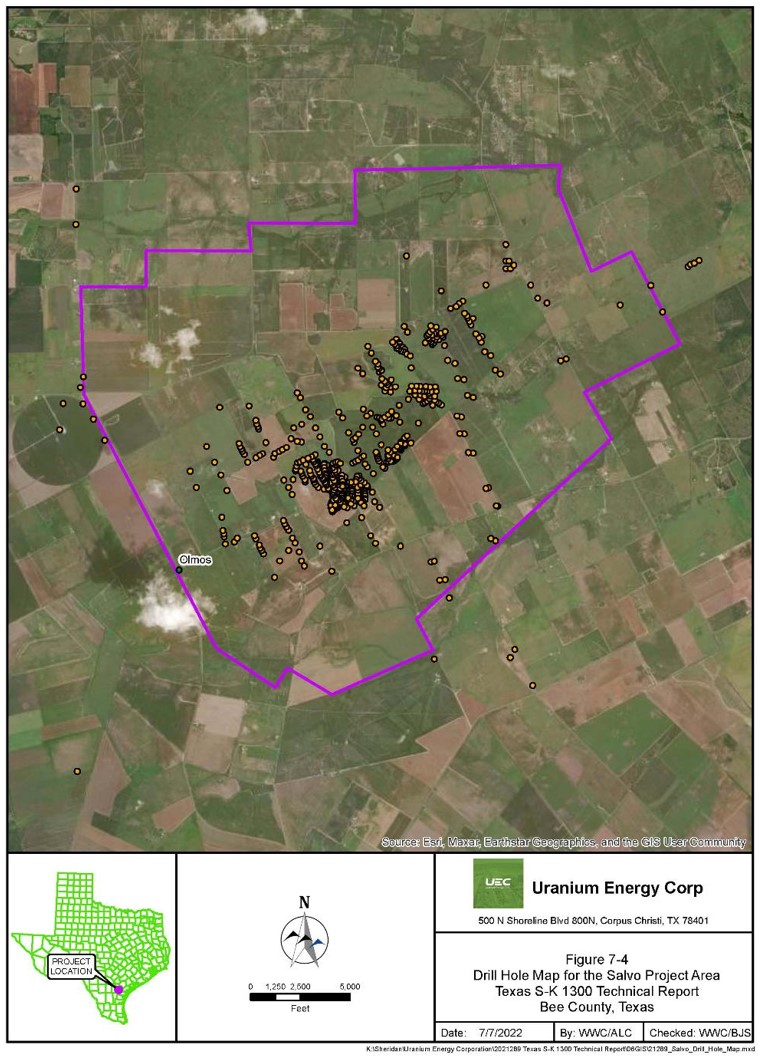

Figure 7‑4: | Drill Hole Map for the Salvo Project Area | 7-6 |

[The remainder of this page is intentionally left blank.]

|  |

1.0 | EXECUTIVE SUMMARY |

This independent Technical Report Summary (TRS) for the Texas Hub and Spoke In-Situ Recovery (ISR) Project (the Project) has been prepared for Uranium Energy Corp. (UEC), under the supervision of Western Water Consultants, Inc., d/b/a WWC Engineering (WWC), pursuant to Regulation S-K Subpart 1300, “Modernization of Property Disclosures for Mining Registrants” (S‑K 1300). This TRS identifies and summarizes the scientific and technical information and conclusions reached from the Initial Assessment (IA) to support disclosure of mineral resources on the Project. The objective of this TRS is to disclose the mineral resources on the Project.

1.1 | Property Description |

The Project consists of five project areas: Hobson Central Processing Plant (Hobson CPP), Burke Hollow, Goliad, Palangana and Salvo. The Project is located in Karnes, Bee, Goliad and Duval counties, Texas, USA (Figure 1-1). The Hobson CPP will serve as the ‘hub’ of the Project, with the other project areas serving as satellite facilities, or the ‘spokes.’ The Hobson CPP will process all the mineral mined on each of the other project areas. The Project is located in the South Texas Uranium Province (STUP) (Figure 1-2), which is part of the South Texas coastal plain portion of the Gulf of Mexico Basin (GMB).

Mineral rights for the Project are all private (fee) mineral leases. Fee mineral leases are obtained through negotiation with individual mineral owners. Section 3 discusses the different mineral leases for each project area. All costs associated with these leases are confidential.

1.2 | Ownership |

This Project is owned and operated by UEC. UEC has executed surface use and access agreements and fee mineral leases with surface and mineral owners within and outside the various Project boundaries.

1.3 | Geology and Mineralization |

The Project resides in the GMB. The GMB extends over much of South Texas and includes the Texas coastal plain and STUP where the Project is located. The coastal plain is bounded by the Rocky Mountain uplift to the west and drains into the Gulf of Mexico. The coastal plain is composed of marine, non-marine and continental sediments ranging in age from Paleozoic through Cenozoic.

Uranium mineralization at the Project is typical of Texas roll-front sandstone deposits. The formation of roll-front deposits is largely a groundwater process that occurs when uranium-rich, oxygenated groundwater interacts with a reducing environment in the subsurface and precipitates uranium. The most favorable host rocks for roll-fronts are permeable sandstones with large aquifer systems. Interbedded mudstone, claystone and siltstone are often present and aid in the formation process by focusing groundwater flux.

|  |

Figure 1‑1: | South Texas Assets Project Area Location Map |

|  |

Figure 1‑2: | South Texas Uranium Province |

USGS, 2015

|  |

1.4 | Exploration Status |

To date, UEC holds data from approximately 9,135 drill holes that have been completed by UEC and prior uranium exploration companies on and nearby the Burke Hollow, Goliad, Palangana and Salvo project areas held by UEC. Data from the drilling, including survey coordinates, collar elevations, depths and grade of uranium intercepts, have been incorporated into UEC’s database.

1.5 | Recent Development and Operations |

Recent development and operations include all work that has been done to develop and operate the Project properties since the last TRS was written to update the resources and development at each project area. All other development and operations from the past are included in Section 5.0.

Summary capital and operating cost estimates are not included with this TRS, since UEC is reporting the results of an IA without economic analysis. No new construction/development has occurred at Salvo since the 2010-2012 drilling campaign. However, UEC initiated drilling projects on Palangana in 2010-2015 and in 2023, on Goliad in 2014, and on Burke Hollow in 2019-2024. UEC also activated several wellfields at Palangana to produce uranium from 2010-2016. In 2023, the licensed capacity of the Hobson CPP was increased to 4 million pounds of uranium concentrates (yellowcake or U3O8) per year.

1.5.1 | Palangana |

From 2010-2015, UEC drilled 891 drill holes at Palangana. Most of the drilling occurred in 2010 (391 holes), 2011 (281 holes) and 2012 (186 holes), with the remaining holes drilled from 2013-2015. The majority of these holes were drilled for delineation purposes, and the rest were drilled for monitor and production wells. In 2010, UEC activated wellfields in Production Area 1 (PA-1), PA-2 and PA-3 at Palangana. From 2010-2016, 563,600 lbs of uranium were produced by ISR methods.

In 2023, UEC drilled 30 holes in PA-4 for delineation purposes. Also in 2023, license and mine area applications were submitted to the Texas Commission on Environmental Quality (TCEQ) to reduce acreage inside the existing license and mine area boundary that did not have mineral resources for production. The mine area boundary reduction has been approved, and the license boundary reduction application is under technical review and awaiting approval for release to unrestricted use.

1.5.2 | Goliad |

In 2014, UEC conducted a drilling program at Goliad for exploration and water wells. 35 holes were drilled and logged for exploration and water supply purposes, with a majority of the holes being drilled in PA-1 and PA-2.

|  |

1.5.3 | Burke Hollow |

In 2019, UEC completed 129 drill holes, mostly focusing on delineating the Lower B1 and Lower B2 sands in the proposed PA-1. In addition, UEC began installing perimeter monitor wells in PA‑1. In total, 57 holes were drilled solely for delineation and exploration purposes and 72 holes were drilled for monitoring purposes.

From 2021 to present, UEC conducted another drilling program to upgrade a portion of the resources from inferred to measured and indicated, to better define the mineralization in PA‑1, PA-2 and PA-3 and to install monitor wells. As of April 11, 2024, 714 delineation and exploration holes and 44 monitor wells were drilled. This program is ongoing for the purpose of completing additional holes for delineation, exploration and monitor wells. No historical data were used in the Burke Hollow mineral estimate, only data from drilling conducted by UEC from 2012-2024. In total, 887 new holes were drilled and logged between 2019 and April 11, 2024, to complete this estimate.

1.6 | Mineral Resource Estimates |

Cautionary Statement:

This TRS is preliminary in nature and includes mineral resources. Mineral resources that are not mineral reserves do not have demonstrated economic viability. There is increased risk and uncertainty to commencing and conducting production without established mineral reserves which may result in economic and technical failure and may adversely impact future profitability.

The in-place resources were estimated separately for each project area. Table 1-1 and Table 1‑2 list the resources by project area.

1.7 | Permitting Requirements |

The Hobson CPP is fully permitted. Burke Hollow, Goliad and Palangana are fully permitted to mine. Salvo still requires all mining permits. Regulatory agencies include the TCEQ, the Railroad Commission of Texas (RRC) and the U.S. Environmental Protection Agency (EPA). Table 1-3 lists the permits for each project area and their corresponding regulatory agencies.

1.8 | QP Conclusion and Recommendations |

Key conclusions and recommendations from WWC, a third-party firm, which employs professionals meeting the definition of “qualified person” (QP) set out in S-K 1300, are as follows:

● | The QP considers the scale and quality of the mineral resources at the Project to indicate favorable conditions for future extraction. |

● | Hobson CPP, Burke Hollow, Goliad and Palangana are fully permitted for ISR operations. |

● | UEC should develop a Preliminary Feasibility Study for the Project and continue to maintain mineral leases along with surface use agreements to accommodate future development. |

|  |

● | UEC should advance the baseline studies necessary to obtain regulatory authorizations required to mine at Salvo. |

● | UEC should complete the design and purchase of long-lead items for the Burke Hollow satellite ion exchange plant. |

● | UEC should advance the design and acquisition of any long-lead items for the Underground Injection Control (UIC) Class I disposal well(s) at Burke Hollow. |

Table 1-1: | Texas Hub and Spoke Project Measured and Indicated Resource Summary |

Mineral Resource | GT Cutoff | Average Grade (% eU3O8) | Ore Tons (000s) | eU3O8 (lbs) |

Burke Hollow | ||||

Measured | 0.30 | 0.086 | 581 | 964,000 |

Indicated | 0.30 | 0.083 | 3,329 | 5,191,000 |

Total Measured and Indicated | 0.30 | 0.083 | 3,910 | 6,155,000 |

Goliad | ||||

Measured | 0.20 | 0.053 | 1,595 | 2,667,900 |

Indicated | 0.20 | 0.102 | 1,504 | 3,492,000 |

Total Measured and Indicated | 0.20 | 0.085 | 3,099 | 6,159,900 |

Palangana | ||||

Measured | - | - | - | - |

Indicated | None | 0.134 | 232 | 643,100 |

Total Measured and Indicated | None | 0.134 | 232 | 643,100 |

Salvo | ||||

All mineral resources at Salvo are classified as Inferred. | ||||

Project Totals | ||||

Measured | 3,631,900 | |||

Indicated | 9,326,100 | |||

Total Measured and Indicated | 12,958,000 | |||

Notes:

1. | Pounds reported with Disequilibrium Factor (DEF) applied (except at Burke Hollow). |

2. | Measured and indicated mineral resources as defined in 17 CFR § 229.1300. |

3. | All reported resources occur below the static water table. |

4. | The point of reference for mineral resources is in-situ at the Project. |

5. | Mineral resources are not mineral reserves and do not have demonstrated economic viability. |

6. | Delineation drilling conducted at Palangana after 2010 was not incorporated into the resource estimate as in the experience of the QP, this type of drilling does not generally substantially change the resource estimates. |

7. | An 80% metallurgical recovery factor was considered for the purposes of determining the reasonable prospect of economic extraction. |

8. | The reasonable prospects of economic extraction are discussed in Section 11.1.1. |

[The remainder of this page is intentionally left blank.]

|  |

Table 1-2: | Texas Hub and Spoke Project Inferred Resource Summary |

Mineral Resource | GT Cutoff | Average Grade (% eU3O8) | Ore Tons (000s) | eU3O8 (lbs) |

Burke Hollow | ||||

Inferred | 0.30 | 0.104 | 2,596 | 4,883,000 |

Goliad | ||||

Inferred | 0.20 | 0.195 | 333 | 1,224,800 |

Palangana | ||||

PA-1 and PA-2 Inferred | None | 0.100 | 96 | 192,500 |

Dome, NE Garcia, SW Garcia, CC Brine, Jemison Fence, Jemison East Inferred | 0.10 | 0.110 - 0.300 | 206 | 808,800 |

Salvo | ||||

Inferred | 0.30 | 0.091 | 1,125 | 2,839,000 |

Project Totals | ||||

Total Inferred | 4,356 | 9,948,100 | ||

Notes:

1. | Pounds reported with DEF applied (except at Burke Hollow). |

2. | A range of grades is presented for the Palangana inferred mineral because the resource estimation methods differed between PA-1/PA-2 and the rest of the trends. There was no cutoff for PA-1 and PA-2 block models. See Section 11.1 for a more detailed explanation. |

3. | Inferred mineral resources as defined in 17 CFR § 229.1300. |

4. | All reported resources occur below the static water table. |

5. | The point of reference for mineral resources is in-situ at the Project. |

6. | Mineral resources are not mineral reserves and do not have demonstrated economic viability. |

7. | Delineation drilling conducted at Palangana after 2010 was not incorporated into the resource estimate as in the experience of the QP, this type of drilling does not generally substantially change the resource estimates. |

8. | An 80% metallurgical recovery factor was considered for the purposes of determining the reasonable prospect of economic extraction. |

9. | The reasonable prospects of economic extraction are discussed in Section 11.1.1. |

Table 1-3: | Texas Hub and Spoke Permits |

| Permits | |||||

| Property | RRC (Surface Mining and Reclamation Division) Exploration Permit | TCEQ Class I Waste Disposal Well Permit(s) | TCEQ Underground Injection Control Mine Area Permit | TCEQ Area Permit | TCEQ/EPA Aquifer Exemption | TCEQ Materials License |

Hobson CPP | N/A | 2 | N/A | N/A | N/A | ✔ |

Burke Hollow | ✔ | 2 | ✔ | ✔ | ✔ | ✔ |

Goliad | ✔ | 2 | ✔ | ✔ | ✔ | ✔ |

Palangana | ✔ | 2 | ✔ | ✔ | ✔ | ✔ |

Salvo | - | - | - | - | - | - |

Note: Some permits are not applicable to the Hobson CPP because no mineral is being mined there.

|  |

2.0 | INTRODUCTION |

2.1 | Registrant/Issuer of Report |

This TRS was prepared for UEC to report the results of an IA and describe the Project, which includes the Hobson CPP and the Burke Hollow, Goliad, Palangana and Salvo project areas. This IA was prepared for UEC, under the supervision of WWC. The project areas are located in Karnes, Bee, Goliad and Duval counties, Texas, USA. The Hobson CPP will serve as the ‘hub’ of the Project with the other project areas serving as satellite facilities, or the ‘spokes.’ For the purposes of this TRS, the satellite facilities are considered material to the Hobson CPP. Mineral is mined at the project areas and is then transported to the Hobson CPP for processing.

UEC is incorporated in the State of Nevada, with principal offices located at 500 North Shoreline Boulevard, Suite 800N, Corpus Christi, Texas, 78401 and at 1030 West Georgia Street, Suite 1830, Vancouver, British Columbia, Canada, V6E 2Y3.

2.2 | Terms of Reference |

The Project is owned and operated by UEC. This TRS has been prepared for UEC to report mineral resources for the Project. The Project includes multiple project areas located in Karnes, Bee, Goliad and Duval counties, Texas. The objective of this TRS is to disclose the mineral resources on the Project.

2.3 | Data Sources, Units of Measurement and Abbreviations |

The information and data presented in this TRS were gathered from various sources listed in Chapters 24.0 and 25.0 of this TRS.

Uranium mineral resource estimates and mapping for the Project are based on data from approximately 9,135 drill holes that included survey coordinates, collar elevations, depths and grade of uranium intercepts.

Units of measurement unless otherwise indicated are feet (ft), miles, acres, pounds (lbs), short tons (2,000 lbs), grams (g), milligrams (mg), liters (L) and parts per million (ppm). Uranium production is expressed as pounds U3O8, the standard market unit. ISR refers to in-situ recovery, sometimes also termed in-situ leach (ISL). Unless otherwise indicated, all references to dollars ($) refer to United States currency.

2.4 | Personal Inspection |

WWC professionals most recently visited the Hobson CPP, Palangana and Salvo facilities on November 2, 2021, the Goliad facilities on November 4, 2021, and the Burke Hollow facilities on February 6, 2024.

2.4.1 | QP Qualifications |

This TRS was completed under the direction and supervision of WWC. WWC is a third-party QP as defined by Regulation S-K 1300. Additionally, WWC has approved the technical disclosure contained in this TRS.

|  |

2.5 | Previous Technical Report Summaries |

UEC filed a TRS for the Hobson CPP, Burke Hollow, Goliad, Palangana and Salvo projects in 2022 and an Amended TRS for the same projects in 2023. Although they were filed in 2022 and 2023, respectively, the current or effective date for both the TRS and the Amended TRS is March 7, 2022, as no underlying data were updated in the preparation of the Amended TRS. Additionally, UEC has previously filed Technical Reports conforming to Canadian National Instrument 43-101 (NI 43-101) standards for the Project. The previous Technical Reports and TRSs are listed in Table 2-1.

Table 2-1: | Previous Technical Report Summaries |

Property | TRS Title | Report Type | Effective Date |

Burke Hollow | Technical Report for UEC's Burke Hollow Uranium Project, 2017 Update, Bee County, Texas, USA | NI 43-101 | November 27, 2017 |

Goliad | Technical Report for Uranium Energy Corp's Goliad Project In-situ Recovery Uranium Property, Goliad County, Texas | NI 43-101 | March 7, 2008 |

Palangana | NI 43-101 Technical Report on Resources, Uranium Energy Corp., Palangana ISR Uranium Project, Deposits PA-1, PA-2 and Adjacent Exploration Areas, Duval County, Texas | NI 43-101 | January 15, 2010 |

Salvo | Technical Report for Uranium Energy Corp, Salvo Project In-situ Recovery Uranium Property, Bee County, Texas | NI 43-101 | March 31, 2011 |

Texas Hub and Spoke ISR Project | S-K 1300 Mineral Resource Report, Texas Hub and Spoke ISR Project, TX, USA. | S-K 1300 | March 7, 2022 |

Texas Hub and Spoke ISR Project | Amended S-K 1300 Mineral Resource Report, Texas Hub and Spoke ISR Project, TX, USA. | S-K 1300 | March 7, 2022 |

[The remainder of this page is intentionally left blank.]

|  |

3.0 | PROPERTY DESCRIPTION |

3.1 | Location, Description, Leases and Mineral Rights |

The Project includes the Hobson CPP, Burke Hollow, Goliad, Palangana and Salvo project areas located in Karnes, Bee, Goliad and Duval counties, Texas, USA. The locations of the project areas are depicted in Figure 1-1, while Figures 3-1 through 3-4 depict the Burke Hollow, Goliad, Palangana and Salvo project areas in more detail. Each project area is described in detail in Sections 3.1.1 through 3.1.5.

Mineral rights for the Project are private (fee) mineral leases. Fee mineral leases were obtained through negotiation with individual mineral owners. Table 3-1 summarizes the mineral leases for each project area and their expiration dates.

Fee minerals have varying royalty rates and calculations, depending on the agreements negotiated with individual mineral owners. In addition, surface use and access agreements may include a production royalty, depending on agreements negotiated with individual surface owners at various levels. UEC’s average combined mineral plus surface production royalty applicable to the Project is variable and based upon the selling price of U3O8.

Most of the leases have term periods of 5 years with a 5-year renewal option. The primary lease stipulation for ISR mining is the royalty payments as a percentage of production. Royalties at the Project vary by lease and are confidential. The various lease fees and royalty conditions are negotiated with individual lessors, and conditions may vary from lease to lease. No resources are reported in areas outside of the project area boundaries, which are determined by the leases within each project area.

Surface ownership at the Project consists of fee lands predominantly used for agriculture and wind turbine development. On the project areas that are currently permitted, UEC has surface use agreements in place with the private landowners where appropriate. Obtaining surface access rights is a standard process in mine permitting, and UEC does not anticipate that maintaining these rights presents a significant risk to UEC’s ability to perform work on the Project.

The QP has not verified the leases within the various project areas or how the leases are mapped or plotted. The QP has relied on information provided by UEC with regards to royalty rates and has not independently verified royalty agreements, rates or surface use and access agreements.

[The remainder of this page is intentionally left blank.]

|  |

Figure 3‑1: | Burke Hollow Project Area Location Map |

|  |

Figure 3‑2: | Goliad Project Area Location Area Map |

|  |

Figure 3‑3: | Palangana Project Area Location Map |

|  |

Figure 3‑4: | Salvo Project Area Location Map |

|  |

Table 3-1: | Project Area Mineral Lease Summary |

Project Area | Fee Mineral Leases | County | Expires |

Hobson CPP | |||

Acreage | 7.29 | Karnes | Renewable Annually |

Leases | 1 | ||

Burke Hollow | |||

Acreage | 17,511 | Bee | 2/2027 |

Leases | 1 | ||

Goliad | |||

Acreage | 636 | Goliad | 10/2024, 8/2024, 8/2025 and 12/2025 |

Leases | 7 | ||

Palangana | |||

Acreage | 6,182 | Duval | 1/2023, held by shut-in royalty, 2/2025 and 5/2027 |

Leases | 4 | ||

Salvo | |||

Acreage | 800 | Bee | 9/2026 and 7/2027 |

Leases | 2 | ||

3.1.1 | Hobson CPP |

The Hobson CPP (Figure 1-1) is located in Karnes County, Texas, northwest of Karnes City, within the GMB and approximately 100 miles northwest of Corpus Christi and 40 miles southeast of San Antonio at latitude 28.9447 and longitude -97.9887 in decimal degrees. This facility represents the ‘hub’ of UEC’s ‘hub-and-spoke’ business model, which comprises a central processing facility supplied with uranium-loaded ion exchange resin from ISR mining at one or more of the project areas. The Hobson CPP was constructed in 1978 when the project area was mined. In 2008, the plant was refurbished. The Hobson CPP has previously processed uranium from the Palangana satellite facility (i.e., the first UEC ‘spoke’), and UEC plans to also process uranium from the Burke Hollow, Goliad and Salvo satellite facilities in the near future.

The CPP consists of a resin transfer circuit for loading/unloading ion exchange resin from tanker trucks, an elution circuit to strip uranium from the ion exchange resin, a circuit to precipitate uranium oxide solids, a yellowcake thickener (if necessary) and a modern, zero-emission vacuum dryer. Other facilities and equipment include an advanced laboratory with inductively coupled plasma mass spectrometry, office building, yellowcake and 11e.(2) byproduct material storage area, chemical storage tanks and one permitted and constructed waste disposal well. Another waste disposal well is permitted but has not been drilled, because additional disposal capacity is not needed at present. The Hobson CPP is permitted for 4 million lbs per year of uranium concentrates (yellowcake or U3O8). With an average dryer cycle time of 40 hours and a current dryer loading capacity of 8 to 10 drums, the plant appears capable of yielding up to 1.5 million lbs per year without requiring physical modifications. WWC personnel visited the Hobson CPP on November 2, 2021, and found it to be in a well-maintained and apparently fully operational condition, although the plant was inactive (i.e., not processing a batch of uranium-loaded resin) during the site visit.

|  |

3.1.2 | Burke Hollow |

The Burke Hollow project area is located within the STUP and currently consists of a 17,511-acre lease area. The project area is about 18 miles southeast of the town of Beeville, west of US Highway 77 (Figure 3-1) and northeast of US Highway 181. The approximate center of the Burke Hollow project area is located at latitude 28.2638 and longitude -97.5176, in decimal degrees. Site drilling roads are entirely composed of caliche and gravel, allowing access for trucks and cars in most weather conditions. Four-wheel drive vehicles may be needed during high rainfall periods.

Virtually all uranium mining in Texas is on private lands with leases negotiated between companies and each individual landowner/mineral owner. Burke Hollow consists of one fee (private) mineral lease comprising 17,511 acres. UEC has indicated to the QP that payments for the private lease are up to date as of the effective date of this TRS. Table 3-1 lists the leases as provided to the QP. No resources are reported in areas outside of the Burke Hollow project area boundary.

UEC has fully permitted Burke Hollow with state and federal agencies and the production area authorization (PAA) application for PA-1 is under review with TCEQ (see Section 3.2).

3.1.3 | Goliad |

The Goliad project area is located in South Texas near the northeast end of the STUP. The Goliad project area consists of multiple contiguous leases that would allow the mining of uranium by ISR methods. The project area is about 14 miles north of the town of Goliad on the east side of US Highway 77A/183, a primary highway that intersects with US Highway 59 in Goliad and I-10 to the north (Figure 3-2). The approximate center of the project area is at latitude 28.8686 and longitude -97.3433, in decimal degrees. Site drilling roads are mostly gravel based and allow access for trucks and cars in most weather conditions. Four-wheel drive vehicles may be needed during high rainfall periods.

There are seven fee (private) mineral leases comprising 636 acres on the Goliad project area. UEC has indicated to the QP that payments for the private leases are up to date as of the effective date of this TRS. A list of leases that make up the Goliad project area are shown in Table 3-1. Moore Energy Corporation (Moore Energy) obtained leases for exploration work in the project area in the early 1980s and completed an extensive drilling program resulting in a historical uranium mineral resource estimate in 1985. UEC obtained mining leases by assignment from a private entity (Brad A. Moore) in 2006. No resources are reported in areas outside of the Goliad project area boundary.

UEC has completed all the required permitting in order to mine at Goliad.

3.1.4 | Palangana |

The Palangana project area is located in Duval County, Texas, 25 miles west of the town of Alice along US Highway 359. More specifically, the site lies 5 miles north of the town of Benavides, 15 miles southeast of the town of Freer and 10 miles southwest of the town of San Diego (Figure 3-3). Freer, San Diego and Benavides are small rural agricultural towns. The approximate center of the Palangana project area is located at latitude 27.6732 and longitude -98.3934, in decimal degrees.

|  |

The Palangana project area has been developed by several operators since the 1950s and has several wellfields that are drilled and ready for operations. In addition, Palangana produced 563,600 lbs U3O8 from 2010-2016 and currently has the infrastructure to begin mining immediately.

There are four fee mineral leases comprising 6,182 acres at the Palangana project area. In 2023, license and mine area applications were submitted to the TCEQ to reduce acreage inside the existing license and mine area boundary that did not have mineral resources for production. The mine area boundary reduction has been approved, and the license boundary reduction application is under technical review and awaiting approval for release to unrestricted use.

Table 3-1 lists the leases as provided to the QP. No resources are reported in areas outside of the Palangana project area boundary. UEC has indicated to the QP that payments for the private leases are up to date as of the effective date of this TRS.

UEC has completed all the required permitting in order to mine at Palangana.

3.1.5 | Salvo |

The Salvo project area is located in South Texas near the northeast end of the STUP. The Salvo project area consists of two leases that would allow the mining of uranium by ISR methods. The project area is about 10 miles south of the city of Beeville and approximately 5 miles west of US Highway 181 (Figure 3-4), a primary highway that intersects with US Highway 59 in Beeville and I-10 to the north. Site drilling roads are mostly based of caliche and gravel and allow access for trucks and cars in most weather conditions. Four-wheel drive vehicles may be needed during high rainfall periods. The approximate center of the Salvo project area is located at latitude 28.2632 and longitude -97.7889, in decimal degrees.

The Salvo project area is located in an area of Texas that has extensive farming activity. Most of the property is used for farming and has a high level of crop cultivation.

A listing of current individual leases that make up the Salvo project area are shown in Table 3‑1. No resources are reported in areas outside of the project area boundary.

No historical uranium mining is known to have occurred on any of the Salvo project area leases; only state permitted (RCC) uranium exploration drilling has taken place. Prior to any mining activity at Salvo, UEC will need to acquire all the necessary permits from the RCC, TCEQ and EPA.

There are two mineral leases comprising 800 acres at the Salvo project area. UEC has indicated to the QP that payments for the private lease are up to date as of the current date of this TRS.

3.2 | Encumbrances |

To the QP’s knowledge, there are no unusual encumbrances to the project areas. However, there are general regulatory and permitting liabilities, depending on the specific project area.

|  |

The environmental liability for the Project falls under the jurisdiction of the RRC and TCEQ, which regulates mining operations and the extraction of minerals and provides mine permits and radioactive material licenses. No environmental liabilities are present at the Project.

The Burke Hollow, Goliad and Palangana project areas are fully permitted with all state and federal agencies. UEC has obtained all the necessary permits and licenses to begin ISR mining operations at Palangana and Goliad. In contrast, the resources in the Salvo project area are not permitted.

Other potential permitting requirements, depending on the status of each project area, may include the following:

● | The TCEQ will require UEC to apply for and obtain a radioactive material license pursuant to Title 30 Texas Administrative Code Chapters 305 and 336. The application must address a number of matters including, but not limited to, site characteristics (ecology, geology, topography, hydrology, meteorology, historic and cultural landmarks and archaeology), radiological and non-radiological impacts, environmental effects of accidents, decommissioning, decontamination and reclamation. |

● | To produce uranium from subsurface deposits, an operator must obtain an area permit and PAA pursuant to the Texas Water Code, Chapter 27. Underground injection activities cannot commence until the TCEQ has issued an area permit and PAA to authorize such activities. In addition, all portions of the proposed production zone in groundwater with a total dissolved solids concentration less than 10,000 mg/L, which will be affected by mining solutions, are included within an aquifer exemption approved by TCEQ and the EPA. The PAA application may be developed concurrently with or after the area permit application. As additional production areas are proposed to be activated within the area permit, additional PAA applications must be submitted to the TCEQ for processing and issuance before injecting within the production area. |

● | In 1975, the Texas Legislature gave the RRC jurisdiction to regulate surface mining for coal and uranium. No surface mining for uranium is currently conducted at the Project, but uranium exploration for ISR operations is administered by the Surface Mining and Reclamation Division of the RRC. Active uranium exploration sites are inspected monthly (RRC, 2022). The RRC requires exploration permits for any uranium exploration in the state. |

● | Texas state law does not provide any agency with the authority to regulate the use or production of groundwater unless the location lies within a water conservation district (WCD). Burke Hollow and Salvo are both located in the Bee County WCD, Goliad is located in the Goliad County WCD and Palangana resides in the Duval County WCD. Prior to initiating uranium recovery at the Project, UEC will need to acquire industrial permits to withdraw groundwater from the host sandstones (L. Yosko personal communication, 2022). |

● | Class I and III injection wells are also regulated by the TCEQ. Therefore, UEC is required to acquire the appropriate permits in order to construct and operate these wells. |

|  |

3.3 | Property Risk Factors |

A variety of property risk factors exist but are not unique to the specific project areas. Many uranium deposits occur in relatively compact special areas. Large horizontal well pads or wind turbine pads sited on top of mineralization could limit the ability to access resources. Oil and gas development or wind turbines are common in South Texas. Property risk factors are included in the following list, with accompanying descriptions of the risk:

● | Drill Hole Reclamation |

o | The drilling, reclamation and abandonment of uranium exploration holes on any of the leases is permitted by the RRC. Potential future environmental liability as a result of the mining must be addressed by the permit holder jointly with the permit granting agency. Permits have bonding requirements for ensuring that the restoration of groundwater, the land surface and any ancillary facility structures or equipment is properly completed. It is the opinion of the QP that uranium exploration holes present a low risk of impacting development of the resources. |

● | Oil and gas horizontal pads and development |

o | Aquifer dewatering due to shallow water supply wells used in oil and gas operations could impact target aquifers and limit the ability to conduct ISR. Large horizontal well pads could limit surface accessibility, placement of wellfields and the ability to recover resources through ISR. It is the opinion of the QP that oil and gas development presents a low risk of impacting development of the uranium resources. |

● | Industrial wells impacting aquifers |

o | Industrial wells could impact available water in target aquifers but will not impact the resources. It is the opinion of the QP that industrial wells present a low risk of impacting development of the resources. |

● | Commercial oilfield waste disposal facilities (COWDFs) and/or lined ponds |

o | COWDFs or other lined ponds may limit surface access and could impact optimal placement of wellfields. It is the opinion of the QP that COWDFs and other lined ponds present a low risk of impacting development of the resources. |

● | Utility corridors |

o | Utility corridors consisting of high voltage electrical transmission lines or buried natural gas pipelines are present at Burke Hollow. Due to the width of the right-of-way, there is a moderate risk that these corridors could limit the development of a portion of the uranium resources at the Burke Hollow project area. It is the opinion of the QP that utility corridors present a low risk of impacting development of the resources at the other project areas. |

● | Commercial wind power |

o | Commercial wind power could limit surface accessibility and impact optimal placement of wellfields. Some of the project areas have wind turbines constructed on the property. However, UEC already has an agreement in place with the operators and landowners to prevent any further wind development on top of ore bodies. It is the opinion of the QP that there is a low risk that commercial wind power could limit development of uranium resources. |

|  |

3.4 | Royalties (Confidential) |

Due to the confidentiality of royalties in private agreements, these data are not included in the TRS.

[The remainder of this page is intentionally left blank.]

|  |

4.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

4.1 | Physical Setting |

The Hobson CPP, Burke Hollow, Goliad, Palangana and Salvo project areas are located in Karnes, Bee, Goliad and Duval counties in South Texas. The physiographic settings for the project areas are similar and located in the coastal plain/prairies and interior portion of the Gulf Coastal Plain Physiographic Province (Texas Bureau of Economic Geology (BEG), 1987). Nearly flat strata in the coastal plain/prairies at Burke Hollow transitions to strata tilted towards the Gulf of Mexico at the Palangana, Salvo and Goliad project areas. Surface stratigraphy includes deltaic sands and muds near the coast transitioning to unconsolidated sands and muds in the interior (BEG, 1987).

The Gulf Coastal Plain is part of a passive continental margin along the Gulf of Mexico. The tectonic setting yields low relief and a relatively flat landscape along the coast from Mexico and Texas to Mississippi. Thick formations of Quaternary and Tertiary fluvial clastic sediments were deposited on the continental shelf from the Mississippi Embayment (USGS, 2022 and Galloway et al., 1979).

The surface is characterized by rolling hills with parallel to sub-parallel ridges and valleys. Changes in relief typically range from 10 to 100 ft near the coast to upwards of 200 ft further inland. Ground surface elevations at the project areas range from a low of 92 ft above mean sea level (msl) at Burke Hollow to a high of 500 ft above msl at Palangana.

Livestock grazing and open pastures with woodlands are common in the region and are typical for this type of habitat in the Southern Great Plains Eco-region. Vegetation consists primarily of mesquite and post oak woods, forests and grassland mosaic vegetation/cover types (BEG, 2000). Native and introduced grasses and woody species such as honey mesquite, blackjack oak, eastern redcedar, black hickory, live oak, sandjack oak and cedar elm are common for this cover type.

Shrub species in the region include hackberry, yaupon, poison oak, American beautyberry, hawthorn, supplejack, trumpet creeper, dewberry, coral-berry, little bluestem, silver bluestem, sand lovegrass, beaked panicum, three-awn, spranglegrass and tickclover. Interspersed among these major vegetation communities, within and along the drainages, are grasslands and meadow grasslands with some seeded grasslands and improved pastures for agriculture (Texas Parks & Recreation, 2022).

The region's temperatures in the summer range from about 75° to 95°F, although highs above 100°F are common; winter temperatures range from about 45° to 65°F (U.S. Climate Data, 2022). Humidity is generally over 85 percent (%) year-round and commonly exceeds 90% during the summer months. Average annual rainfall ranges from about 26 to 30 inches. The climate is characterized by a warm desert-like to subtropical climate. Periods of freezing temperatures are generally very brief and infrequent. Tropical weather systems from the Gulf of Mexico can occur during the hurricane season and may affect the Project with large rainstorms and wind.

|  |

4.2 | Accessibility and Local Resources |

The combined Project includes multiple assets in four Texas counties with various accessibility and resource options for the five project areas. Corpus Christi is about 65 miles east of Palangana (Duval County). This project area can be accessed off Texas Highway 44 toward Freer. Halfway between San Diego and Freer is a turn-off to the south called Ranch Road 3196 that runs through the project area. The road continues south, after passing Palangana, for about 6 miles to the town of Benavides. Access is excellent with major two-lane paved roads connecting the three surrounding towns and dirt secondary roads connecting to Palangana. For water supply, shallow wells in the Goliad Formation in Duval County generally yield mineralized water, whereas deeper wells yield water of comparatively low mineral content and are used for water supply (USGS, 1937). Corpus Christi, with a population of 317,773, and Alice, with a population of 17,761 (U.S. Census Bureau, 2020), are the largest nearby cities that should provide an ample workforce and any necessary supplies for the Project.

Salvo and Burke Hollow are located in Bee County. The Salvo project area can be accessed from several routes including I-37, Texas Route 359 and Farm to Market (FM)-797, which runs northeast to southwest through the project area. The southern portion of the project area can also be accessed from US Highway 181 and FM-797. Salvo and Burke Hollow have several other secondary gravel roads that provide access to the project areas. The nearest population centers are Skidmore (about 3 miles east of Salvo with a population of 863), Tynan (about 4 miles south with a population of 254) and Beeville (about 10 miles north with a population of 13,641) (U.S. Census Bureau, 2020). While Skidmore and Tynan are relatively small towns, they provide basic needs for food and lodging and some supplies. Beeville is a much larger city and provides a well-developed infrastructure, resulting from regional oil and gas exploration and production. The Salvo project area has very good accessibility for light to heavy equipment.

The Burke Hollow project area is located about 10 miles east of the Salvo project area. The nearest population centers are Skidmore, approximately 11 miles west, Refugio, about 15 miles east with a population of 2,712 (U.S. Census Bureau, 2020) and Beeville, approximately 18 miles northwest. Refugio is a relatively small town but offers basic needs for food and lodging and some supplies. The Burke Hollow project area has good accessibility for light to heavy equipment. There is an excellent network of county, state and federal highways that serve the region. The topography is composed of dominantly sandy, well-drained soils, which provide satisfactory construction conditions for building gravel access site roads.

The Salvo and Burke Hollow projects areas located in Bee County are rural, but have excellent county, state and federal highways that serve the region and good construction conditions. Water supply in the project areas is from private water wells, mostly tapping sands of the Goliad Formation (Kurrus and Yancey, 2017 and Myers and Dale, 1966). Water supply for potential future mine development would be from the same sources. The Salvo and Burke Hollow project areas are about 30 to 35 miles north of Corpus Christi, the closest metropolitan district to the Bee County project areas.

|  |

The Goliad project area is in Goliad County. The project area is accessed using route US 77A-183 that runs north-south to the west of the project area. FM-1961 intersects with 77A-183 at the crossroad town of Weser. FM-1961 to the east of the intersection trends along the south side of the project area. Access onto the project area is via vehicular traffic on private gravel roads. The project area is in a rural setting at the north end of Goliad County. The nearest population centers are Goliad (14 miles south with a population of 1,620), Cuero (16 miles north with a population of 8,128) and Victoria (about 30 miles east with a population of 65,534) (U.S. Census Bureau, 2020). While Goliad and Cuero are relatively small towns, they provide basic needs for food and lodging and some supplies. Victoria is a larger city, which provides excellent infrastructure and serves as a regional support center for oil and gas exploration and production. The Goliad project area has very good accessibility for light to heavy equipment. There is an excellent network of county, state and federal highways that serve the region, and the moderate topography with dominantly sandy, well-drained soils provides good construction conditions for building gravel roads necessary for site access. Groundwater from the Goliad Formation is used for water supply over much of the northern portion of Goliad County (Carothers, 2007). Water quality in the Goliad Formation is variable, and wells typically can yield small to moderate amounts of water according to Dale et al. (1957). The Project is about 60 miles from San Antonio (population of 1,451,853), the closest metropolitan district to the Goliad project area.

The Hobson CPP is about 40 miles west of the Goliad project area, about 55 miles northwest of the Burke Hollow project area, about 50 miles north-northwest of the Salvo project area and about 90 miles north of the Palangana project area.

North-south rail lines (Union Pacific) and east-west rail lines (Kansas City Southern Railway) are located approximately 10 air miles from the Palangana project area and about 10 to 20 air miles from the Salvo, Burke Hollow and Goliad project areas (Texas Department of Transportation, 2021).

4.3 | Availability of Infrastructure |

Equipment, supplies and personnel needed for exploration and day-to-day operation are available from population centers such as San Antonio and Corpus Christi. Specialized equipment for the wellfields is often available in Texas but may need to be acquired from outside of the state. The local economy for all five project areas is geared toward oil and gas exploration, energy production and farming and ranching operations, providing a well-trained and capable pool of workers for ISR production and processing operations. Workers will reside locally and commute to work daily (Carothers, 2007). As a result of energy development since the early 1900s, all the project areas have existing or nearby electrical power, natural gas and adequate telephone and internet connectivity.

Generally, the local and regional infrastructure is in place for all five project areas including roads, power and maintenance facilities. The exceptions include local access roads, wellfield development, local power and well control facilities that must be constructed. Specific information for available infrastructure for each project area is described below.

The Palangana project area has a history of past use and existing access roads (SRK Consulting, 2010). Power for operating the Palangana wellfield is already established. Existing buildings and ancillary facilities include a maintenance facility and office in the project area. Manpower requirements targeting field technicians, welders, electricians, drillers and pipefitters exist within a 12-mile radius in the local communities. The technical workforce for facility operations has largely disappeared from the area, although ample qualified resources can be found in the South Texas area from the petrochemical industry (SRK Consulting, 2010). The necessary rights for constructing surface processing facilities at the Palangana project area are in place with the uranium leaseholders. Most of the current leases have conveyed the surface rights under certain conditions of remuneration. These conditions require payments for surface area taken out of usage.

|  |

For the Salvo and Burke Hollow project areas, good access roads exist and sufficient electrical power is available in the area within a reasonable distance from the sites (Kurrus and Yancey, 2017 and Carothers, 2011). New power lines may be needed to bring additional service to the project areas. Within a 7-mile radius of the Salvo project area there is sufficient population to supply the necessary mining personnel including technicians, welders, electricians, drillers and pipefitters. For the Burke Hollow project area, there is sufficient population available within a 20-mile radius to provide the required workforce. The technical workforce for both facility operations can be found in the South Texas area from the petrochemical industry. The necessary rights for constructing the needed surface processing facilities are in place on selected lease agreements for both project areas.

The Goliad project area is similar to the Burke Hollow and Salvo project areas. Sufficient access roads exist and electrical power is available in the area within a reasonable distance of several miles (Carothers, 2007). New power lines may be needed to bring additional service to the project area. However, the area is further from populated areas compared to the other project areas and there is a sufficient population to supply the required workforce within a 30-mile radius. The necessary rights for constructing surface processing facilities are in place on selected lease agreements.

[The remainder of this page is intentionally left blank.]

|  |

5.0 | HISTORY |

Uranium exploration and mining in South Texas primarily targets sandstone formations throughout the Coastal Plain bordering the Gulf of Mexico (Adams and Smith, 1981). The area has long been known to contain uranium oxide, which was first discovered in Karnes County, Texas in 1954 using airborne radiometric survey (Bunker and MacKallor, 1973). The uranium deposits discovered were within a belt of strata extending 250 miles from the middle coastal plain southwestward to the Rio Grande. This area includes the Carrizo, Whitsett, Catahoula, Oakville and Goliad geologic formations (Larson, 1978). Open-pit mining began in 1961, and ISR mining was initiated in 1975. The uranium market experienced lower demand and price in the late 1970s, and in 1980 there was a sharp decline in all Texas uranium operations (Eargle and Kleiner, 2022).

During the late 1970s and early 1980s, exploration for uranium in South Texas had evolved towards deeper drilling targets within the known host sandstone formations (Carothers, 2011). Deeper exploration drilling was more costly and excluded many of the smaller uranium mining companies from participating in the down-dip, deeper undrilled trend extensions. Uranium had been mined by several major oil companies in the past in South Texas, including Conoco, Mobil, Humble (later Exxon), Atlantic Richfield (ARCO) and others. Mobil had found numerous deposits in South Texas in the past, including the O’Hern, Holiday-El Mesquite and several smaller deposits, mostly in Oligocene-age Catahoula Formation tuffaceous sands. ARCO discovered several Oakville Formation (Miocene-age) uranium-bearing deposits and acquired other deposits located nearby in Live Oak County. They were exploring deeper extensions of Oakville Formation trends when they discovered the Mt. Lucas Goliad Formation deposit, located near Lake Corpus Christi in Live Oak County near the Bee County line (Carothers, 2011).

Ownership, control and operation of the project areas has varied greatly since the 1950s. Table 5-1 summarizes the operations and activities of various companies, the timeframe during which these activities were completed and the results of the work. Table 5-1 also summarizes historical drilling and the number of drill holes completed during each period. Cited references and supporting literature can be found following Table 5-1 and in Section 24.0.

[The remainder of this page is intentionally left blank.]

|  |

Table 5-1: | Past Operations Summary |

Year | Company | Operations/Activity | Amount (No. of Drill holes) | Results of Work |

Hobson CPP | ||||

1979-1988 | Everest Minerals Corporation (later Everest Exploration, Inc. [EEI]) | Hobson CPP facility constructed | N/A | N/A |

2005 | Standard Uranium | N/A | N/A | N/A |

2006 | Energy Metals Corporation | ~ Standard Uranium and Energy Metals Corporation merger | N/A | N/A |

2007 | Uranium One | ~ Renovation of the plant | N/A | CPP capable of processing 1.5 million lbs per year |

2009 | UEC | Acquired the Hobson Plant through acquisition of South Texas Mining Venture (STMV)/Uranium One | N/A | N/A |

Burke Hollow – Primary Source: Kurrus and Yancey (2017) | ||||

1982-1993 | Mobil Corporation subsidiary Nufuels Corporation (Nufuels) | Original controller of the project area | ~ 18 exploration holes on or near the Welder lease | Nufuels drilled 18 exploration holes on or nearby UEC’s 1,825-acre Welder lease in conjunction with a larger regional program, which was conducted by Nufuels. Exploration holes were drilled to ~1,100 ft below ground surface (bgs) and tested the entire prospective Goliad Formation. Results showed the presence of a reduction-oxidation interface in sands of the lower Goliad Formation, but there were insufficient data to link economically viable uranium mineralization. |

1993–2011 | Total Minerals Corp. (Total) | Exploration program | ~ 12 exploration holes on or near the Thomson-Barrow lease | Total conducted a short reconnaissance exploration drilling program on the Thomson-Barrow lease. Total drilled 12 holes on permitted acreage that they negotiated for exploration. 11 of the 12 drill holes intersected anomalous gamma ray log signatures indicative of uranium mineralization, but there were insufficient data to link economically viable uranium mineralization. |

2011-2017 | UEC | Burke Hollow project area acquired by UEC from Total | ~ From 2012-2017, 707 uranium exploration drill holes, including 30 monitor wells, completed at the Welder lease (Kurrus and Yancey. 2017) | The historical data package was obtained and reviewed by UEC for portions of the current Burke Hollow project area (Kurrus and Yancey, 2017). Based on the limited number of drill holes, no meaningful resource or reserve determination was made using the historical exploration data. However, the actual drilling and geophysical logging results were determined to be properly conducted per industry standards. UEC completed two drilling campaigns to delineate the open-ended Lower B1 and B2 trends (Carothers, Davis & Sim, 2013). The results of historical and contemporary borehole gamma-ray, spontaneous potential and resistance logs, as well as prompt fission neutron (PFN) logs indicate that uranium mineralization occurs in the upper to lower Goliad Formation sand/sandstone units below the water table at depths from approximately 180 to 1,100 ft bgs. Evidence indicates ISR would likely be the most suitable mining method for this project. In 2017, UEC utilized these data to develop a resource estimate for the combined Graben and Eastern Lower B trends. |

[The remainder of this page is intentionally left blank.]

|  |

Table 5-1: | Past Operations Summary (Continued) |

Year | Company | Operations/Activity | Amount (No. of Drill holes) | Results of Work |

Goliad – Primary Source: Carothers (2007) | ||||

1979-1980 | Coastal Uranium, Inc. (Costal Uranium) | Exploration program | ~ 12 exploration holes | Coastal Uranium drilled widely spaced exploration holes in the region as part of the Coastal States wide-spaced drilling exploration effort. Eight of these holes were drilled at or near the Goliad project area. Addition information on the exploration is described below. |

1980-1984 | Moore Energy Corporation (Moore Energy) | Review of data and leases from Coastal Uranium and exploration program | ~ 479 exploration and delineation holes | Moore Energy reviewed the Coastal States exploration data and soon after acquired several leases from Coastal Uranium, including several in the Goliad project area. From March 1983 through August 1984, Moore Energy conducted an exploration program at Goliad. All of the boreholes were drilled using truck-mounted drilling rigs contracted with various drilling companies. Samples were taken by the driller for review and logged by a geologist. The holes were logged for gamma ray, self-potential and resistance by contract logging companies. No down-hole deviation tool was available. Historical resource estimates were prepared by Moore Energy from data gathered in 1983-1985. For each drill hole, a Grade x Thickness (GT) was determined and the mineral was outlined with a 0.3 GT contour. The average GT of the holes within the contoured outline was used to estimate the resources meeting the specified criteria. Moore Energy developed a historical resource estimate with an average grade of 0.05% equivalent U3O8 (eU3O8) and an average disequilibrium factor of 1.494 (Moore Energy, 1986). |

1984-2006 | N/A | N/A | N/A | N/A |

2006-2008 | UEC | Goliad Project Area acquired by UEC | ~ 360 exploration and delineation holes | UEC obtained mine leases by assignment from Brad A. Moore for the current Goliad project area in 2006. UEC drilled 360 more holes at the property from May 2006 through June 2007. These holes include closer-spaced delineation work on the areas drilled by Moore Energy. Additionally, several of the UEC holes were drilled to further exploration on contiguous leases to the east of the property. A 2007/2008 report by Thomas Carothers, PG estimated historical mineral resources based on the UEC 2006-2007 confirmation drilling results and the Moore Energy historical estimate. The author concluded that significant uranium resources from the work in 1983-85 described by Moore Energy appear to be backed and supported by the more recent UEC exploration data. |

Palangana – Primary Source: SRK Consulting (2010) | ||||

1952-1958 | Columbia Southern Inc. (CSI), a subsidiary of Pittsburgh Plate Glass Corp. | Original controller of project area | Records of CSI's exploration work was unavailable | Right to mine secured. Uranium mineralization was discovered during potash exploration drilling of the Palangana Dome in 1952 by CSI. CSI conducted active uranium exploration drilling on the property starting in March 1956. CSI and the U.S. Atomic Energy Commission estimated underground mineable uranium resources. The estimation method included identifying 0.15% eU3O8, a minimum mining thickness of 3 ft and exploration using widely spaced drilling on a nominal 200 ft exploration grid. |

1958-1981 | Union Carbide Corporation (UCC) | UCC acquired project area in 1958 and ceased operations shortly after until 1967 when operations resumed for over a decade due to new technology. UCC placed the project up for lease in 1980. | 1,117 exploration and development holes in 1960s and 70s (296 cores) | Early development work was quickly abandoned because of concentrations of hydrogen sulfide gas. The property was reacquired in 1967 after emerging ISR mining technologies were available. ISR operation occurred from 1977 through 1979. About 340,000 lbs of U3O8 were produced from portions of a 31-acre wellfield block. The production lbs indicate a 32% to 34% recovery rate. The ISR work was conducted at a research level in contrast to the current level of knowledge. Historical production lies on the western flank of the dome and is not part of this resource estimate. |

1981 – Unknown | Chevron Corporation (Chevron) | Chevron acquired the UCC leases and conducted their own resource evaluation. | 163 | Chevron completed a historical estimate on the entire site within unclassified material containing 0.125% eU3O8. |

Unknown to late 1990s | General Atomics | General Atomics acquired project area for restoration work. | N/A | General Atomics acquired the property and dismantled the process plant in a property-wide restoration effort. Upon formal approval of the cleanup by the Texas Natural Resources Conservation Commission and the U.S. Nuclear Regulatory Commission, the property was returned to the landowners in the late 1990s. |

Late 1990s to 2005 | N/A | Project area returned to surface rights landowners. | N/A | N/A |

2005-2009 | EEI and Energy Metals/Uranium One | EEI acquired Palangana and joint ventured with Energy Metals by forming the STMV. In 2008, Energy Metals was acquired by Uranium One. | ~ Approximately 236 exploration and confirmation holes | Blackstone (2005) completed a historical estimate in the area referred to as the Dome trend proximal to the dome on the west side, north of the prior UCC leach field. In 2006 and 2007, Energy Metals drilled approximately 200 additional confirmation and delineation holes. The PA-1 and PA-2 areas were delineated during this drilling program. During 2008 and 2009, the remainder of the holes were drilled by Uranium One. During this time, five exploration trends on the east side of the dome were identified and partially delineated. |

2009-2023 | UEC | Palangana project area acquired by UEC from Uranium One. | 30 | UEC acquired Palangana. SRK Consulting, Inc. (SRK) was retained by UEC in 2010 to provide an independent resource and reserve evaluation on PA-1 and PA-2 and adjacent exploration areas. SRK concluded the sandstone, roll-front deposits on the east side of the Palangana Dome contain significant resources of eU3O8. Specifically, PA-1 and PA-2 bodies are adequately delineated for the calculation of Measured and Indicated Resources. SRK developed resource estimates within distinct sand and roll-front zones utilizing detailed computer block modeling of grade and GT modeling. The results of the resource estimation are complex and presented in more detail in this TRS. In 2010, UEC resumed production at Palangana. Approximately 563,600 lbs were produced from 2010 to 2016 in PA-1, PA-2 and PA-3. In 2023 UEC drilled 30 delineation holes in PA-4 and reduced the size of the permit and license area by removing an area that had been restored and released for unrestricted use. |

|  |

Table 5-1: | Past Operations Summary (Continued) |

Year | Company | Operations/Activity | Amount (No. of Drill holes) | Results of Work |

Salvo – Primary Source: Carothers (2011) | ||||

Unknown to 1983 | Mobil Corporation subsidiary Nufuels | Original controller of project area | ~ 111 exploration holes | Nufuels discovered uranium mineralization in La Para sands of the Miocene-aged Goliad Formation in 1982 in Bee County, Texas. Mobil’s reconnaissance drilling located two areas of interest, known as the Salvo and Seger projects. Mobil had drilled a total of 111 exploration holes at Salvo and Seger in 1982. Shortly after conducting their exploration drilling in this area, Mobil elected to discontinue their uranium exploration efforts and sell their uranium production facilities. The early Salvo exploration drilling conducted by Nufuels indicated significant uranium mineralization was present. |

1983–1993 | Uranium Resources Inc. (URI) joint venture with Saaberg Interplan Uran Gmbh (SIPU) (URI/SIPU) | URI formed a joint venture exploration program with SIPU, a German utility. The joint venture acquired Salvo from Mobil, along with the Seger Project, an eastward extension along the same geochemical roll-front system. URI/SIPU leased the property until about 1993 when secondary lease expired. | ~ 295 exploration and delineation holes in 1984 | URI/SIPU completed a historical estimate at Salvo in 1984 using a 0.5 GT cutoff. Average GT was modeled at 0.989, with a ratio of 0.194, width of 45 ft, length of 140 ft and tonnage factor of 1.236 lbs/ft2. Due to low uranium prices, URI/SIPU elected not to permit the project at that time (R.B. Smith, 2005). URI utilized a Monte Carlo-based computer simulation to calculate the historical resource (URI, 1984). |

1993-2005 | N/A | N/A | N/A | N/A |

2005-2010 | R.B. Smith & Associates Inc. (R.B. Smith) | Review of past exploration data | N/A | R.B. Smith (2005) completed an evaluation of the Goliad Formation trend project data at the Salvo and Seger projects. Data were on loan from URI/SIPU. Smith did not retain copies of maps or electric logs and the original data set of logs and maps was returned to URI. URI held the data in storage until 2010. |

2010 | UEC | Salvo project area acquired by UEC from URI/SIPU. UEC negotiated a purchase of available data from URI. URI and UEC reached agreement on sales of Salvo and Seger project data in 2010. The adjacent Seger property is no longer included in UEC’s Salvo leases. | 105 exploration holes | Ownership transition. UEC received 425 exploration log files and several drill hole location maps and land maps. The 425 log files include good quality electric logs from Mobil’s activities at Seger and Salvo in 1982, as well as URI/SIPU’s drill hole logs from exploration activities in 1984. Each log file also contains a detailed lithological report based on drill hole cuttings prepared by Mobil’s and later by URI’s field geologists supervising and monitoring drilling activity. Four core holes were drilled by URI and core analysis reports were included in the appropriate log files. Eight holes were logged by Princeton Gamma-Tech (PGT, an early form of PFN), a logging company which specialized in uranium chemical assay logging. The PGT logs were utilized and verified as having excellent correlation to actual chemical uranium content by several south Texas ISR mining operations. These results are believed to be pertinent to the understanding of this deposit and indicated a generally positive DEF like other known Goliad Formation sandstones in the region. The historical mineralized intercepts from URI exploration boreholes were presented in the initial NI 43-101 UEC Salvo Project TRS dated July 16, 2010. |

[The remainder of this page is intentionally left blank.]

|  |

6.0 | GEOLOGICAL SETTING, MINERALIZATION AND DEPOSIT |

6.1 | Regional Geology |

6.1.1 | South Texas Gulf Coastal Plan |

The Project is located in the STUP, which lies along the GMB (Figure 1-2). The coastal plains of the GMB were formed by the downfaulting and down warping of Paleozoic Era (252-541 Mya) basement rocks during the breakup of the Paleozoic supercontinent, Pangaea and the opening of the North Atlantic Ocean in the Late Triassic Epoch (201-237 Mya). The Rocky Mountain Uplift in the Paleogene Period (43-65 Mya) gave rise to the vast river systems that flowed toward the Gulf of Mexico, carrying abundant sediments. Deposits typically thicken down-dip towards the Gulf of Mexico from western-northwestern sources. Stratigraphy in this area can be complex because of the cyclic deposition of sedimentary facies. Shallow inland seas formed broad continental shelves that covered most of Texas and deposited sedimentary units that are dominantly continental clastic with some near shore and shallow marine facies. Volcanic episodes during deposition (more than 20 Mya) are credited as being the source of the uranium deposits through ash-fall and related sediments (Nicot et al., 2010).

Three main structural zones are present in the STUP: the Balcones Fault Zone, the San Marcos Arch and the Rio Grande Embayment (Figure 1-2). The Balcones Fault Zone is north of the Project and divides the Upper Cretaceous and Eocene strata. The Balcones Fault Zone is composed of mainly normal faults that displace sediments by up to 1,500 ft, moving downward to the Gulf of Mexico. The San Marcos Arch, northeast of the Project between the Rio Grande Embayment and East Texas Basin, is a broad area of lesser subsidence and a subsurface extension of the Llano Uplift. The arch is crossed by basement-related normal faults that parallel the buried Ouachita Orogenic Belt of Paleozoic age. The Rio Grande Embayment is a small, deformed basin that lies between the El Burro Uplift in northeast Mexico and the basin marginal Balcones Fault Zone to the south. Some data indicate that the embayment was possibly compressed during the Laramide Orogeny in the Late Cretaceous–Paleogene (Nicot et al., 2010).

The uranium-bearing units in the STUP include most sands and sandstones in Tertiary formations ranging in age from Eocene (oldest) to Lower Pliocene (youngest). A STUP stratigraphic column is shown in Figure 6-1, and a cross-section of the Project can be viewed in Figure 6-2.

All mineralization at the Project occurs in the Goliad Formation. The Goliad Formation was originally classified as Pliocene in age by most sources, but the formation has been reclassified as early Pliocene to middle Miocene after recent research revealed the presence of indigenous Pliocene-aged mega-fossils occurring in upper Goliad sands, whereas the lower Goliad fluvial sands are correlative with down-dip strata containing benthic foraminifera, indicating a Miocene age (Baskin and Hulbert, 2008). The Geology of Texas map published by BEG in 1992 classifies the Goliad as Miocene in age.

The BEG’s geologic map of Texas describes the Goliad Formation as clays, sandstones, marls, caliches, limestones and conglomerates with a thickness of 100 to 500 ft. Above the Goliad Formation lies the Deweyville Formation, Beaumont Clay, Lissie Formation, Montgomery Formation and the Willis Sand, which are composed of sand, gravel, silt and clay.

|  |

Figure 6‑1: | South Texas Uranium Province Stratigraphic Column (modified from Galloway et al., 1979) |

Note: The Goliad Sand is the target for the Project and is highlighted in green

|  |

Figure 6‑2: | South Texas Assets Cross-Section |

|  |

Uranium mineralization occurs along oxidation/reduction interfaces in fluvial channel sands of the Goliad Formation. These deposits consist of multiple mineralized sand horizons, which are separated vertically by confining beds of silt, mudstone and clay.

6.2 | Local Geology |

6.2.1 | South Texas Local Geology – Goliad Formation Hosted Mineralization |

Burke Hollow

The uranium-bearing sands of the Goliad Formation at Burke Hollow occur beneath a thin layer of Pleistocene-aged Lissie Formation gravels, sands, silts and clays, which overlie much of the project area. The Goliad Formation uncomformably underlies the Lissie Formation. Uranium mineralization discovered to date occurs within three of the four sand members of the Goliad, designated as the uppermost Goliad A, Goliad B and the lowermost Goliad D.

There are two northeast-southwest trending faults at the Burke Hollow project area that are likely related to the formation of the uranium mineralization. The northwesterly fault is a typical Gulf Coast normal fault, downthrown toward the coast, while the southeastern fault is an antithetic fault downthrown to the northwest, forming a large graben structure. The presence of the increased mineralization at the site is likely related to these faults. The faulting may have served as conduits for reducing waters and natural gas to migrate upward from deeper horizons, as well as altering the groundwater flow system in the uranium-bearing sands.

Goliad

The Goliad Formation occurs at surface on the Goliad project area. The mineralized units are sandstones within the Goliad Formation designated by UEC as the A through D sands from younger (upper) to older (lower), respectively. The sand units are generally fine to medium-grained sands with silt and varying amounts of secondary calcite. The sand units vary in color depending upon the degree of oxidation-reduction, from light brown-tan to grays. The sand units are generally separated from each other by silty clay or clayey silts that serve as confining units between the sand units.

The four sandstone units (A-D) designated as containing uranium mineralization at the site are all considered to be a part of the Gulf Coast Aquifer on a regional basis. At the project area, each unit is a hydrogeologic unit with similar but variable characteristics. Groundwater from sands of the Goliad Formation is used for water supplies over much of the northern portion of Goliad County.

The Goliad structures include two faults that intersect and offset the mineralized units. These faults are normal faults, with one downthrown toward the coast and one downthrown toward the northwest. The fault throws range from about 40 to 80 ft.

Palangana

The local geology at Palangana is characterized by the occurrence of a Gulf Coast piercement salt dome. This dome is approximately 2 miles in diameter and is overlain by Pliocene sediments of the Goliad Formation. The Palangana dome is marked at the surface by a shallow circular basin surrounded by low hills rising above the basin floor. The Palangana dome has an almost perfectly circular salt core with a remarkably flat top that is approximately 10,000 ft across and occurs from 800 to 850 ft bgs. Radial faulting is present in all Goliad Formation sands on the flanks of the dome due to uplift during the intrusion of the dome. Faults and fractures also exist in a random nature in the sands above the caprock due to dissolution of the salt dome from groundwater. Once the salt was solubilized and removed, the overlying sediment collapsed, creating the basin and associated faults.

|  |

The Goliad Formation at the Palangana project area is composed of fine- to medium-grained, often silty, channel sands interbedded with lenses of mudstone and siltstone. For the most part, the sand is very sparsely cemented although it varies from friable to indurated. There is known to be minor faulting on the north end of the PA-1 deposit. The Palangana stratigraphy is horizontal to sub-horizontal, with a 2º to 3º southeasterly dip at most.

Salvo

The Salvo project area is situated in the major northeast-southwest trending Goliad Formation of fluvial origin. The Geologic Map of Texas (BEG, 1992) indicates that a thin layer of Pleistocene-aged Lissie Formation uncomformably overlies the Miocene Goliad Formation. The Lissie Formation consists of unconsolidated deposits of sand, silt and clay, with minor amounts of gravel.

The uranium-bearing Goliad Formation underlies the Lissie Formation and is present at depths ranging from near-surface to approximately 600 ft on the eastern side of the project area. URI determined that uranium mineralization occurs within six individual sand units in the lower Goliad La Para member at depths generally ranging from 400 to 600 ft.