UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

Q Annual Report Pursuant To Section 13 or 15(d) of the Securities Exchange Act of 1934

For the fiscal year ended: December 31, 2008

£ Transition Report Under Section 13 or 15(d) of the Securities Exchange Act of 1934

For the transition period from ______ to _______

Commission file number: 000-51527

CHINA GENGSHENG MINERALS, INC.

(Exact name of small business issuer as specified in its charter)

| NEVADA | 91-0541437 |

| (State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) |

No. 88 Gengsheng Road

Dayugou Town, Gongyi, Henan

People's Republic of China, 451271

(Address of Principal Executive Offices)

(86) 371-64059818

(Registrant's Telephone Number, Including Area Code)

Securities registered pursuant to Section 12(b) of the Act: None

Securities registered pursuant to Section 12(g) of the Act: Common Stock, par value 0.001

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes £ No Q

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes £ No Q

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the past 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes Q No £

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. £

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definition for "large accelerated filer," "accelerated filer," and "smaller reporting company" in Rule 12b-2 of the Exchange Act. (Check one):

Large Accelerated Filer £ Non-Accelerated Filer £ Accelerated Filer £ Smaller Reporting Company Q

Indicate by check mark whether registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes £ No Q

The number of shares outstanding of our common stock as of June 30, 2008, was 24,038,183 shares. The aggregate market value of the common stock held by non-affiliates (7,151,359 shares), based on the closing market price ($2.30 per share) of the common stock as of June 30, 2008 was $16,448,125.

There were a total of 24,038,183 shares of the registrant's common stock outstanding as of March 27, 2008.

Documents Incorporated by Reference: None

1

TABLE OF CONTENTS

| Number | | Page |

| PART I | | |

| | | |

| Item 1. | Business | 3 |

| Item 1A. | Risk Factors | 13 |

| Item 1B. | Unresolved Staff Comments | 20 |

| Item 2. | Properties | 20 |

| Item 3. | Legal Proceedings | 20 |

| Item 4. | Submission of Matters to a Vote of Security Holders | 21 |

| | | |

| PART II | | |

| | | |

| Item 5. | Market for Registrant's Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities | 21 |

| Item 6. | Selected Financial Data | 22 |

| Item 7. | Management's Discussion and Analysis of Financial Condition and Results of Operations | 23 |

| Item 7A. | Quantitative and Qualitative Disclosures About Market Risk | 36 |

| Item 8. | Financial Statements and Supplementary Data | 36 |

| Item 9. | Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | 36 |

| Item 9A(T). | Control and Procedures | 37 |

| Item 9B | Other Information | 37 |

| | | |

| PART III | | |

| Item 10. | Directors and Executive Officers of the Registrant and Corporate Governance | 37 |

| Item 11. | Executive Compensation | 39 |

| Item 12. | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | 40 |

| Item 13. | Certain Relationships and Related Transactions and Directors Independence | 42 |

| Item 14. | Principal Accountant Fees and Services | 42 |

| Item 15. | Exhibits and Financial Statement Schedules | 43 |

| | | |

| Financial Statements | |

| Report of Independent Registered Public Accounting Firm | F-1 |

| Consolidated Balance Sheet | F-2 |

| Consolidated Statement of Income | F-3 |

| Consolidated Statement of Cash Flows | F-4 |

| Consolidated Statement of Stockholders' Equity | F-5 |

| Consolidated Notes to Financial Statements | F-6 |

2

Use of Certain Defined Terms

In this Form 10-K, unless indicated otherwise, references to:

| • | "Powersmart" or "GengSheng International" refers to GengSheng International Corporation, a BVI company (formerly, Powersmart Holdings Limited) that is wholly owned by China GengSheng Minerals, Inc.; |

| | |

| • | "Securities Act" refers to the Securities Act of 1933, as amended, and "Exchange Act" refer to Securities Exchange Act of 1934, as amended; |

|

| | |

| • | "China" and "PRC" refer to the People's Republic of China, and "BVI" refers to the British Virgin Islands; |

| | |

| • | "RMB" refers to Renminbi, the legal currency of China; and |

| | |

| • | "U.S. dollar," "$" and "US$" refers to the legal currency of the United States. For all U.S. dollar amounts reported, the dollar amount has been calculated on the basis that $1 = RMB7.2939 for its December 31, 2007 audited balance sheet, and $1 = RMB6.8166 for its December 31, 2008 unaudited balance sheet, which were determined based on the currency conversion rate at the end of each respective period. The conversion rates of $1 = RMB6.9372 is used for the condensed consolidated statement of income and comprehensive income and consolidated statement of cash flows for its December 31, 2008, and $1= RMB7.5930 is used for the condensed consolidated statement of income and comprehensive income and consolidated statement of cash flows for its December 31, 2007; both of which were based on the average currency conversion rate for each respective quarter. |

|

PART I.

ITEM 1. BUSINESS

Overview

We are a Nevada holding company operating in the materials technology industry through our direct and indirect subsidiaries in China. We develop, manufacture and sell a broad range of mineral-based, heat-resistant products capable of withstanding high temperature, saving energy and boosting productivity in industries such as steel and oil, which are mainly referred to as refractory products, industrial ceramics and fracture proppants, and fine precision abrasives.

Currently, we conduct our operations in China through our wholly owned subsidiaries, Henan GengSheng Refractories Co., Ltd. (the "Refractories"), ZhengZhou Duesail Fracture Proppant Co. Ltd. (the "Duesail"), Henan GengSheng Micronized Powder Materials Co., Ltd. (the "Micronized"), and Guizhou Southeast Prefecture GengSheng New Materials Co., Ltd (the "Prefecture") and through our majority owned subsidiary, Henan GengSheng High-Temperature Materials Co., Ltd. (the "High-Temperature"). We manufacture and sell monolithic refractory products, industrial ceramic products, fracture proppants and potentially by the end of 2009, fine precision abrasives products in China and overseas. Through our direct, wholly owned BVI subsidiary, GengSheng International and its direct and wholly owned Chinese subsidiary, Duesail, we manufacture fracture proppant products. Currently, Micronized is constructing its first-phase production line for fine precision abrasives, with an expected annual capacity of 20,000 metric tons.

We sell our products to over 200 customers in the iron, steel, oil, glass, cement, aluminum and chemical businesses located in China and other countries in Asia, Europe and North America. Our refractory customers are companies in the steel, iron, petroleum, chemical, coal, glass and mining industries. Our fracture proppant products are sold to oil and gas companies. Our industrial ceramics are products used by the utilities and petrochemical industries. The Company's fine precision abrasives are targeting solar companies and optical equipment manufacturers. Our largest customers, measured by percentage of our revenue, mainly operate in the steel industry. Currently, most of our revenues are derived from the sale of our monolithic refractory products to customers in China. We expect revenue increase from fracture proppants, and from fine precision abrasives once production begins.

Corporate History & Background

We were originally incorporated under the laws of the State of Washington, on November 13, 1947, under the name Silver Mountain Mining Company. From our inception until 2001, we operated various unpatented mining claims and deeded mineral rights in the State of Washington, but we abandoned these operations entirely by 2001. On August 15, 2006, we changed our domicile from Washington to Nevada when we merged with and into Point Acquisition Corporation, a Nevada corporation. From about 2001 until our reverse acquisition of Powersmart on April 25, 2007, which is discussed in the next section entitled "Acquisition of Powersmart and Related Financing," we were a blank check company and had no active business operations. On June 11, 2007, we changed our corporate name from "Point Acquisition Corporation" to "China Minerals Technologies, Inc." and subsequently changed our name again to "China GengSheng Minerals, Inc." on July 26, 2007 as we found a Delaware company with a similar corporate name.

3

Acquisition and Related Financing

On April 25, 2007, we completed a reverse acquisition transaction through a share exchange with Powersmart Holdings Limited whereby we issued to the sole shareholder of Powersmart Holdings Limited, Shunqing Zhang, 16,887,815 shares of China GengSheng Minerals, Inc. common stock, in exchange for all of the issued and outstanding capital stock of Powersmart Holdings Limited. By this transaction, Powersmart Holdings Limited became our wholly owned subsidiary and Mr. Zhang became our controlling stockholder. Upon the closing of the reverse acquisition, Timothy P. Halter, our sole officer and director, submitted his resignation letter pursuant to which he resigned from all offices of our company effective immediately, and he resigned as our director on May 31, 2007. Shunqing Zhang is currently our sole director.

On April 25, 2007, we also completed a private placement financing transaction pursuant to which we issued and sold 5,347,594 shares of our common stock to certain accredited investors for $10 million in gross proceeds. In connection with this private placement, we paid a fee of $683,618 to Brean Murray Carret & Co., LL, or Brean Murray, and Civilian Capital, Inc. for services as placement agents for the private placement. We also issued to Brean Murray Carret & Co., LLC and Civilian Capital, Inc. warrants for the purchase of 374,331 shares of our common stock in the aggregate. The warrants are immediately exercisable, have piggyback registration rights and have a three-year term.

Also, on April 25, 2007, our majority stockholder, Shunqing Zhang, entered into an escrow agreement with the private placement investors, pursuant to which, Mr. Zhang agreed to deposit in an escrow account a total of 2,673,796 shares of the Company's common stock owned by him, to be held for the benefit of the investors. Mr. Zhang agreed that if the Company does not attain a minimum after-tax net income threshold of $8,200,000 for the fiscal year ended December 31, 2007 and $13,500,000 for the fiscal year ended December 31, 2008, the escrow agent may deliver his escrowed shares to the investors, based upon a pre-defined formula agreed to between the investors and Mr. Zhang. However, if the after-tax net income threshold is met, the shares in escrow will be returned to Mr. Zhang. In addition, on April 25, 2007, Mr. Zhang entered into a similar escrow agreement with HFG International, Limited. Under such agreement, Mr. Zhang placed into escrow a total of 638,338 shares of the Company's common stock to cover the same minimum net income thresholds as described above with respect to the investor make-good. Similarly, if the thresholds are not achieved in either year, the escrow agent must release certain amounts of the make-good shares that were put into escrow. As a result, we met the after-tax net income threshold of $8,200,000 for the fiscal year ended December 31, 2007 and the pro rata shares in escrow were returned to Mr. Zhang.

On May 14, 2007, we filed a registration statement on Form S-1 with the U.S. Securities and Exchange Commission to register shares of our common stock sold to the investors in the private placement as well as shares of common stock issuable upon exercise of the warrants issued to the placement agent and its designee. Our registration statement on Form S-1 became effective on October 15, 2007.

On June 12, 2008, Refractories entered into an equity transfer agreement (the "Equity Transfer Agreement") with Huizong Zhang, Yuanwei Zhang and Shuqin Yu (collectively the "Sellers") for the purchase of 100% ownership of Xinyu Abrasive Co., Ltd. ("Xinyu") from the Sellers. Under the Equity Transfer Agreement, Refractories was required to pay a total consideration of $875,400 (RMB6,000,000) in exchange for 100% ownership of Xinyu and its assets. Xinyu was renamed as Guizhou Southeast Prefecture GengSheng New Materials Co., Ltd ("Prefecture") on June 18, 2008. As of December 31, 2008, $875,400 had been fully paid.

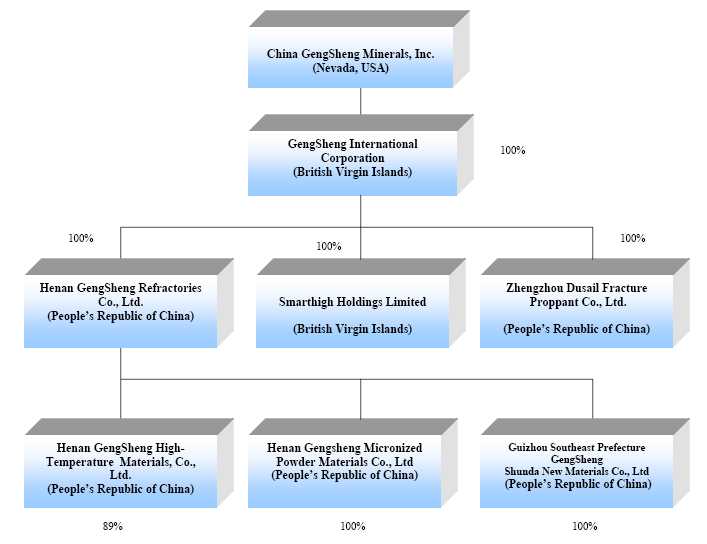

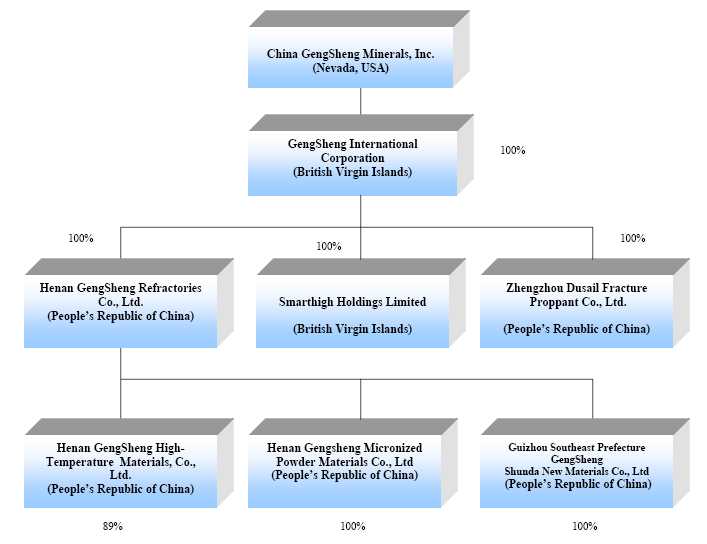

Corporate Structure

We were originally incorporated in the State of Washington on November 13, 1947, but on August 15, 2006, we changed our domicile from Washington to the State of Nevada. We conduct our operations in China through our wholly owned subsidiaries Duesail and Henan Gengsheng, and through our majority owned subsidiary, High-Temperature.

The following chart reflects our organizational structure as of the date of this report.

4

Segmental Information

Our operating segments are categorized by our manufacturing facilities and include four reportable segments:

Our product lines are divided into four major segments: monolithic refractories based on specific mixture formulas, industrial ceramics, fracture proppants and fine precision abrasives. Our largest product segment is the monolithic refractories segment, which accounted for approximately 87% of our total revenue in 2008. Our monolithic refractories are manufactured in a broad range of specifications and applied in a variety of end products, such as steel-making furnaces, industrial kilns and other high temperature vessels to maintain and extend their service lives, minimize heat and mass losses during production, and to reduce the overall production costs. Our monolithic refractories are also applied to the interior surfaces of steel-making furnaces and other high temperature vessels to improve their productivity and reduce the overall production costs. The approximate gross margins of our products have been estimated as follows: shaped refractory products (which are in the refractory segment together with monolithic products) is 25-35%, monolithic refractory products 25-32%, industrial ceramics 10-27%, the fracture proppant products segment 12-32%, and fine precision products (a new product line which will be part of a new product segment to be launched later in 2009) is expected to be in the 40-50% gross margin range. Besides selling our own products, we also purchase and resell small quantities of shaped refractory bricks manufactured by third parties, to fulfill some of our project contract requirements.

Our Products and Services

Monolithic Refractory Products

Refractory products possess excellent high-temperature-resistant qualities and can function under thermal stress that is common in many heavy industrial production environments. Because of their unique high-temperature-resistant qualities, the refractory products are used as linings and key components in many industrial furnaces, such as steel production furnaces, ladles, vessels, and other high-temperature processing machines that must operate at high temperatures for a long period of time without interruption. Our major customers are in the iron, steel, cement, chemical, coal, glass, petro-chemical, and nonferrous industries that use refractory products.

5

We provide a customized solution for every monolithic materials order based on their uniquely requested formulas. Upon delivery to customers, the monolithic materials are applied to the inner surfaces of our customers' furnaces, ladles, or other vessels, to improve the productivity of that expensive equipment. The products' strength is to lower the overall cost of production and improve financial performance for our customers. The reasons that the monolithic materials can help our customers improve productivity, lower production costs, and achieve stronger financial performance include the following: (i) monolithic refractory castables can be cast into complex shapes which are unavailable or difficult to achieve by alternative products such as shaped bricks; (ii) monolithic refractory linings can be repaired, and in some cases, even reinstalled, without furnace cool-down periods or steel-production interruptions, and therefore improve the steel makers' productivity; (iii) monolithic refractories can form an integral surface without joints, enhancing resistance to penetration, impact and erosion, and thereby improving the equipment's operational safety and extending their useful service lives; (iv) monolithic refractories can be installed by specialty equipment either automatically or manually, thus saving construction and maintenance time as well as costs; and (v) monolithic refractories can be customized to specific requirements by adjusting individual formulas without the need to change batches of shaped bricks, which is a costly procedure.

Some examples of our products and the description of their features are set forth as follows:

- Castable, coating, and dry mix materials. Offerings within this product line are used as linings in containers such as a tundish used for pouring molten metal into a mold. The primary advantages of these products are speed and ease of installation for heat treatment.

- Low-cement and non-cement castables. Our low-cement and non-cement castable products are typically used in reheating furnaces for producing steel. These castable products are highly durable and can last up to five years.

- Pre-cast roofs. These products are usually used as a component of electric arc furnaces. They are highly durable, and in the case of our corundum-based, pre-cast roof, products, can endure approximately 160 to 220 complete operations of furnace heating.

On April 28, 2008, we completed a new production line for pressed bricks, a type of "shaped" refractory, for steel production. The annual designed production capacity is 15,000 metric tons. The line has begun its commercial production and sales. The average price for our specialty pressed bricks is expected to be more than twice that of the monolithic products. On June 12, 2008, Refractories acquired Prefecture, a refractories supplier in order to secure the supplies our material sources and stabilize the purchase prices.

We provide full-service to our steel customers in the form of refractory product installation, testing, maintenance, repair and replacement. Refractory product sales are often enhanced by our on-site installation and technical support personnel. Our installation services include applying refractory materials to the walls of steel-making furnaces and other high temperature vessels to maintain and extend their lives. Our technical service staff provides assurances that our customers will achieve their desired productivity objectives. They also measure the refractory wear at our customer sites to improve the quality of maintenance and overall performance of our customers' equipment. Full-service customers contributed approximately 51% of the Company's total sales in 2008, compared with 38.3% in 2007. We have renewed our full-service contracts for refractory products with two key customers for another year in the beginning of 2009. We believe that these services together with our refractory products provide us with a strategic advantage to secure our profits.

Industrial Ceramics

Our industrial ceramic products, including abrasive balls and tiles, valves, electronic ceramics and structural ceramics, are components for a variety of end-use products such as fuses, vacuum interrupters, electrical components, mud slurry pumps, and high-pressure pumps. Such end use products are used in the electric power, electronic component, industrial pump, and metallurgy industries. We install and maintain some of these products.

Some examples and description of our products and their benefits are introduced as follows:

- Ceramic plates, tubes, elbows, and rollers. These products are used in heavy machines for steel production, power generation, and mining. They are highly resistant to heat, erosion, abrasion, and impact.

- Ceramic cylinders and plugs.Our ceramic cylinders and plugs are often used in plug pumps for drilling crude oil. They are highly resistant to pressure.

- Wearable ceramic valves. Our wearable ceramic valves are used for transferring gas and liquid products. They are highly resistant to wash out, erosion, abrasion, and impact.

On April 21, 2008, we signed a five-year collaboration agreement with the Ceramics Research Institute of Zhengzhou University (the "CRI") in Henan province of China, to research and develop innovative ways of improving the manufacturing process and functionality of an array of bauxite-based materials. Specifically, we will work with CRI to optimize and reduce costs for the production of fine precision abrasives, which are bauxite-based, ultra-fine, grain-like materials used to polish fine-metal or optical equipment surfaces, including solar panels. CRI will also help us develop next-generation industrial ceramics that can reduce energy use and pollution. In addition, we and CRI will jointly apply for government grants for bauxite-based materials research.

6

Fracture Proppant Products

We first produced fracture proppant products in December 2006, through our direct, wholly owned Chinese subsidiary, Duesail. Our fracture proppants are very fine ball-like pellets, used to reach pockets of oil and natural gas deposits that are trapped in the fractures under the ground. Oil drillers inject the pellets into those fractures, squeezing out the trapped oil or natural gas, which leads to higher yield. Our fracture proppant products are available in several different particle sizes (measured in millimeters). They are typically used to extract crude oil and natural gas, which increases the productivity of crude oil and natural gas wells. These products are highly resistant to pressure. In October 2007, our fracture proppant products were certified by PetroChina Company Limited (the "PetroChina"), China Petroleum & Chemical Corporation (the "Sinopec") and the China National Offshore Oil Corporation (the "CNOOC") as we became a first-tier supplier of fracture proppants for their oil and gas-drilling operations. Our products have also passed the tests conducted by the China Petroleum and Chemical Industry Association (CPCIA), which will enable our competitiveness in the market compared to our competitors. During 2008, Duesail signed a total of approximately $10.9 million in contracts during 2008 for the supply of fracture proppants to major oil companies in China. Our ability to succeed in this segment must be considered in light of the problems, expenses, difficulties, complications and delays frequently encountered in connection with the development and marketing of new products as well as the competition from well established manufacturers. Our main competitors for the production of fracture proppants are Carbo Ceramics Inc. and Saint-Gobain Proppants (Guanghan) Co., Ltd. Carbo Ceramics, Inc. is our strongest competitor with approximately a 5% share of the domestic market share and 40% share of the international market share in this segment.

On May 19, 2008, Duesail entered into a supply contract for fracture proppants valued at approximately $2.2 million (RMB15, 072,500) with PetroChina, which is China's largest oil and gas producer and distributor. Fracture proppant is a light, bauxite-based, grain-like material that has a round and smooth surface, and it is capable of resisting high pressure and acid corrosion. It is used by drillers to release trapped pockets of oil and natural gas to boost yields. Following the 230-ton contract with CNOOC signed in early April, this new contract was another Company milestone and it was a major success in strengthening our relationships with major oil companies in China.

On June 2, 2008, Duesail entered into another sales contract for fracture proppants valued at approximately $1.9 million (RMB13, 418,200) after taxes, with Jilin Petroleum Group Co. Ltd. ("Jilin Petroleum"), a wholly owned subsidiary of China National Petroleum Corporation (the "CNPC"). With this contract, we are now supplying fracture proppants to all three major Chinese oil companies, CNOOC, Sinopec and CNPC. We expect that our sales of this important yield-boosting product will continue to accelerate this year.

On June 24, 2008, Duesail entered into the third sales contract for fracture proppants valued at approximately $1.5 million (RMB10, 220,000) after taxes, with China National Petroleum Group Co., Ltd. ("China Petroleum"). Fracture proppants are used by oil and gas drillers to extract pockets of oil and natural gas scattered underground. High-density and high-strength proppants are considered a more technologically advanced product, and Chinese oil companies currently source them mostly from overseas manufacturers. This is the second sales contract signed with CNPC in this month following the contract signed with Jilin Petroleum, a CNPC's subsidiary on June 2, 2008.

In November of 2008, Duesail entered into four sales contracts with AMSAT International for fracture proppants valued at approximately $ 5.3 million through December 31, 2009.

Overall, we entered into a total of approximately $10.9 million contracts during 2008 to supply fracture proppants to major oil companies in China. Our fracture proppants business continues to stably grow. We expect the sales of fracture proppants sales will continue to grow and help to meet our 2009 commercial objectives.

Fine precision abrasives

Fine precision abrasives are for producing a super-fine, super-consistent finish. A high-strength polyester backing provides a uniform base for a coating of micron-graded mineral particles that are uniformly dispersed for greater finishing efficiency. Our fine precision abrasives are made from silicon carbide (the "SiC"). They are ultra-fine, high-strength pellets with uniform shape, and they have applications in surface-polishing and slicing of precision instrument such as solar panels. Currently, the type of abrasives that we plan to launch are in high demand among solar-energy companies. Solar energy companies use such products to slice the silicon bar and to polish the equipment surface to become very smooth and shining. Currently, most precision abrasives used in China are imported from Japan. Compared with Japanese products, our strengths are our ability to eliminate the big particle, reduce the cost for polishing larger particles and remove disqualified particles during the production process. Our products can be applicable in a broader range of areas including machine manufacture, electronics industry, optical glass, architecture industry development, semiconductor, silicon chip, plastic and lens. We expect to see the burgeoning solar industry in China and elsewhere catalyzing our rapid growth in this new product. One of our products below will be introduced soon:

7

- Ultrafines as precision abrasives.They are such fine alumina or silicon carbide powders that their sizes are in microns, with controlled surface characteristics suitable for wire slicing and specific polishing.

Our Competition Strength

With over 1,500 manufacturers, the refractory market in which we compete is highly fragmented and highly competitive. In each of our product segments, there is at least one major competitor. Many of our products are made to industry specifications and may be interchangeable with our competitors' products. Some of our competitors are large and well-established companies, and their financial resources and ability to gain market share may be greater than ours. Due to the diversity of our product offering, we believe that we enjoy a competitive advantage because most of our competitors do not offer the entire spectrum of our product line.

Through our wholly owned Chinese subsidiary Henan Gengsheng and its direct majority-owned Chinese subsidiary, High-Temperature, we manufacture monolithic refractory products, industrial ceramic products and fracture proppants in China. We are well positioned to compete in the monolithic refractories segment and the industrial ceramics segment, because of our long-standing business relationships with the major steel companies, the quality and diversity of our products and our price differential. We have provided full services to major steel companies and the revenues of our full-services sales totaled in 17.72 million throughout China, which accounted for 41% of refractories sales and 35.6% our total sales during 2008. In addition, our patented integral casting technology for mixer furnaces has been licensed by more than twenty steel plants since 2000. Furthermore, we recently took the lead in developing small and medium-sized aluminum-magnesium spinel castables which were recognized in May 1995 by the Henan Science and Technology Committee as "key new products" of the State. Refractories, our wholly owned subsidiary, was granted a AAA credit rating by the Zhengzhou Enterprise Creditworthiness Evaluation Committee ("the Committee") in Henan Province in December of 2008. Our fracture proppant products were certified by PetroChina Company Limited (the "PetroChina"), China Petroleum & Chemical Corporation (the "Sinopec") and the China National Offshore Oil Corporation (the "CNOOC") as we became a first-tier supplier of fracture proppants for their oil and gas-drilling operations. Our products have also passed the tests conducted by the China Petroleum and Chemical Industry Association (CPCIA), which will enable our competitiveness in the market compared to our competitors.

We have distinguished ourselves through our excellent customer service team that provides a full-range of monolithic refractory services, including refractory construction and on-site maintenance and technical support. Our nationally registered laboratory with its excellent research team is available to meet our customer's diverse product requirements in a timely manner based on the differences of construction sites. Our products are largely marketed based on our comparatively more efficient operations, our price differential and our quality of service. We have also made ourselves more competitive through competitive pricing.

Our largest customers, measured by percentage of our revenue, operate in the steel industry. The steel industry is characterized by intense price competition, which results in a continuing emphasis on our need to increase product productivity and performance. We are able to generally keep our prices lower than those of our competitors because we have contracted a supplier who provides high quality products at relatively lower prices. Our strategy has been to fulfill the steel industry's need by developing technologically advanced refractory products to help our customers increase their productivity. We believe that the trend towards even greater productivity in the highly competitive steel industry will continue to provide a growing opportunity for our products, especially monolithic refractories.

As a result of the foregoing factors, we are in a more advantageous position than our major competitors Puyang Refractories Co., Ltd., Wuhan Ruisheng Specialty Refractory Materials Co., Ltd., and Beijing Lier Refractories Co., Ltd., who all offer less service and product choices but with similar prices to ours. We are confident that we will continue to be competitive based on our diverse product offerings, comprehensive maintenance services and better prices.

Overall, we believe that our competitive strengths include the following:

Market Position.We believe that we hold a competitive position in the monolithic refractory marketplace. According to a Chinese steel industry publication, during 2007, total national sales of refractories were RMB79.3 billion (or approximately $10.5 billion), 65% of which were from refractories applied in steel making, of which 35-40% are monolithic refractories. Based on our sales of monolithic refractories during fiscal 2007, which was RMB289 million (or approximately, $38.09 million), we believe that our market share for monolithic refractories applied in steel making is approximately 1.25% . Because our industry is highly competitive and consists of more than 1,500 manufacturers, we believe that a market share of 1.25% is significant and places us in a strong competitive position in the monolithic refractory marketplace, relative to our competition. Our position affords us a broad customer base, superior recognition of the "Gengsheng" brand, procurement leverage and pricing advantages with our suppliers, flexible manufacturing capabilities and easily accessed distribution channels. These capabilities and distribution channels enable us to introduce new refractory products and product categories to our customers efficiently and cost effectively.

8

Broad Product Offering.Our refractory product segment offers over 25 product categories that can be tailored to a wide range of customers' specifications for use in the iron and steel manufacturing industries, in industrial furnaces, and in other heavy machinery. Our broad product offerings allow us to offer our customers a single source for many of their refractory product requirements.

Diversified End Markets/Customer Base.We sell our refractory products in over 25 provinces in China and we plan to expand our market overseas. In the 2008 fiscal year, we had 200 customers, ten of which accounted for more than 60.3% of 2008 net sales. One customer, Rizhao Steel Co., Ltd, accounted for 17.5% of 2008 net sales. We believe that our broad product line and diverse target markets and customer base have contributed to greater stability in our sales and operating profit margin. We have long term relationships with significant steel and iron industry leaders in China, such as Bao Steel, Wuhan Steel and Maanshan Steel.

Experienced Management Team.Our management team has, in the aggregate, over 25 years of experience in the refractory industry and over 20 years with Gengsheng International.

Access to Raw Materials.We are located in Gongyi, Henan Province, an area of China which has an abundant reserve of bauxite and other key raw materials used in refractory manufacturing. We have diversified our access to raw materials by acquiring the Prefecture, a subsidiary of our wholly own subsidiary Refractories to secure and stabilize the supply and the prices of raw materials.

Research and Development Capabilities.We utilize our research and development capabilities to supply our customers with cutting edge refractory products designed to meet their specific demands. To ensure the highest quality product developments, we established a modern, state-of-the-art laboratory in China dedicated to quality control and testing.

Maintenance Service Capabilities. The selling prices of our refractory products also includes installation and ongoing maintenance services, which we believe can be developed into a high margin business if our products continue to be reliable and do not require extraordinary servicing other than ordinary maintenance. We dedicate over 300 employees to the installation and service of our products. We believe the services offered strengthens our business relationship with our customers and makes our products more attractive to them.

Our Customers

We have over 200 customers in 25 Chinese provinces, as well as in greater Asia, North America and Europe. Our customers include some of the largest steel and iron producers and petroleum and chemical producers in China and in other countries. During each of the fiscal years 2008, 2007 and 2006, only one of our customers Rizhao Steel Co., Ltd., or Rizhao Steel, represented 10% or more of our consolidated sales. Our sales to Rizhao Steel amounted to 16.6% or $4,553,646 of our revenues for 2006, 16.1% or $6,393,685 of our revenues for 2007, and 17.5%, or $8,698,230 of our revenues for 2008.

During the fiscal year 2008, our top ten customers among our segmental lines, which are listed below, accounted for approximately 60.3% of our consolidated revenues.

Our Top 10 Customers

(As of December 31, 2008)

| Customers | | Sales | | | Percentage | | | Locations | |

| | | (in US dollars) | | | of our net sales | | | of Customers | |

| Rizhao Steel Co., Ltd. | | 8,698,230 | | | 17.5% | | | Rizhao City | |

| Jiuquan Iron & Steel Group Ltd. | | 4,524,375 | | | 9.1% | | | Jiayuguan City | |

| Anhui Yangtze Steel Ltd. | | 2,902,211 | | | 5.8% | | | Maanshan City | |

| Heilongjiang Jianlong Iron & Steel Ltd | | 2,692,393 | | | 5.4% | | | Heilongjiang City | |

| Jilin Petroleum Group Co. Ltd. | | 2,644,896 | | | 5.3% | | | Jinlin Province | |

| Ispat Group Limited | | 2,040,913 | | | 4.1% | | | India | |

| Anshan Baode Iron & Steel Ltd. | | 1,979,739 | | | 4.0% | | | Anshan City | |

| Nachan Changli Iron & Steel Co., Ltd. | | 1,715,498 | | | 3.4% | | | Beijing City | |

| China Petroleum & Chemical Corporation | | 1,417,618 | | | 2.8% | | | Shengtian City | |

| Beijing Litong Energy-environmental High-Tech Development Ltd. | | 1,404,509 | | | 2.8% | | | Nanchan City | |

| Total | | 30,020,382 | | | 60.3% | | | | |

9

Our Suppliers of Raw Materials

The principal raw materials used in our refractory products are various forms of aluminum oxide, including bauxite, corundum, processed AI203, magnesia, calcium aluminates cement, resin, and silica. Bauxite is used in the production of refractory materials, fracture proppants and some industrial ceramic products. Bauxite is abundantly available from mines nearby our manufacturing facilities. We purchase a significant portion of our magnesia requirements from sources within Liaoning province. We strive to source raw materials from geographically proximate suppliers as shipping costs increase when raw materials are purchased from farther regions. If we experience supply interruptions of our refractory raw material requirements, we believe that we could obtain adequate supplies from alternate sources in local areas or elsewhere in China at reasonable costs. Some of our raw materials costs from 2006 to 2008 are as follows:

| (Stated in US dollar) | |

| | | | | | | | | | |

| | | 2008 | | | 2007 | | | 2006 | |

| Ordinary bauxite | | 58.23 | | | 50.77 | | | 34.66 | |

| Refined bauxite | | 223.41 | | | 108.32 | | | 85.28 | |

| Middle class magnesia | | 181.82 | | | 96.89 | | | 139.45 | |

| High class magnesia | | 262.56 | | | 177.67 | | | 137.08 | |

| Silica | | 297.18 | | | 278.51 | | | 269.17 | |

| Calcium aluminates cement | | 750.00 | | | 679.66 | | | 677.83 | |

| Processed aluminum oxide | | 721.14 | | | 680.68 | | | 545.84 | |

| Brown fused corundum | | 509.71 | | | 503.19 | | | 265.24 | |

| White fused corundum | | 816.72 | | | 689.89 | | | 610.59 | |

We typically have supplier agreements with terms of one to two years terms that do not impose minimum purchase requirements. The costs of raw materials purchased during the term of a supplier agreement usually are the market price for the raw materials at the time of purchase. Our centralized procurement department makes an ongoing effort to reduce and contain raw material costs. We generally do not engage in speculative raw material commodity contracts and attempt to reflect raw material price changes in the sale price of our products. Our ability to achieve anticipated operating results depends in part on having an adequate supply of raw materials for its manufacturing operations.

We will share the cost of any increase in the price of raw materials with customers if and when such prices increase. We generally pass 50% of such price increases on to our customers, except for large volume customers whose products and services we are required to deliver at a reasonable cost to those customers.

Our Sales and Marketing

Our sales and marketing group is comprised of 98 employees who focus on managing specific product lines across several distribution channels. Our marketing process involves an integrated process of screening sales leads, preparing bid documents (in response to customer requests for a proposal, or RFP), making competitive bids and negotiating and executing definitive sales agreements.

To maximize the accessibility of our product offerings to a diverse group of end users, we market our products through a variety of distribution channels. We have separate sales and marketing groups that work directly with our customers in each of our target markets. Marketing and sales are accomplished through the mailing of brochures, industry trade advertising, trade show exhibitions, website applications and sales presentations.

Our Growth Strategy

We are committed to growing our business in the coming years. The key elements of our growth strategy are summarized below:

Adjust Cost Structure Through Operating Efficiency and Productivity Improvements.We regularly evaluate our operating productivity and efficiency to focus on decreasing our manufacturing and distribution costs. We have plans to improve our internal capacity for new refractory products and new product development, while continuing to enhance our capabilities of completing orders throughout our supply chain. We believe that these initiatives will provide significant cost savings and improve operating profits.

10

Expand Product Lines and Specialty Product Lines.We are actively seeking to identify, develop and commercialize new products that use our core technology and manufacturing competencies. In particular, we intend to develop a variety of specialty, high-margin, mineral-based products, including fracture proppant and fine precision abrasive.

Pursue Sales Opportunities in Existing and New Markets.We believe that we have significant opportunities to grow our business by increasing our penetration within our existing customer base, adding new customers, expanding our already broad refractory product offerings, and pursuing additional marketing channels for other segmental line products. In addition to further targeting the leading steel and iron manufacturers to become their single source provider of refractory products, we have been awarded contracts by major Chinese oil and chemical manufacturers which has demonstrated our ability to penetrate these markets with our fracture proppant products.

Selectively Pursue Strategic Acquisitions.As a strong competitor in our core refractory manufacturing market, we believe that we are well-positioned to benefit from the consolidation of manufacturers in these markets. We also believe that our management has the ability to identify, execute and integrate strategic acquisitions. We will continue to selectively consider acquisitions that will improve our market position within our existing target markets, expand our product offerings for(?) end markets, or increase our manufacturing efficiency.

Expand International Operations.We have alternatively expanded operations to potential overseas markets to leverage resources from our existing operations and to increase our presence and sales efforts in countries outside of China. We have received supply contracts from other countries in Asia, Europe and North America. We expect to experience higher export volumes in the future.

Regulation

Because our operations are based in China, we are regulated by the national and local laws of the People's Republic of China. The refractory materials industry is generally subject to state, local laws and regulations relating to the environment, health, and safety. The operation of refractory materials involves the release of powder and dust which are classified as environmental pollutants under applicable government laws and regulations. We regularly monitor and review our operations, procedures, and policies for compliance with these laws and regulations. We have made substantial capital investments in our facilities to ensure compliance with environmental and regulatory laws. We believe our operations are in substantial compliance with the laws and regulations and there are no violations that would have a material effect on us. The cost of compliance with these laws and regulations is not expected to have a large financial impact on our operations.

There is no private ownership of land in China. All land ownership is held by the government of the PRC, its agencies and collectives. Land use rights can be obtained from the government for a period up to 50 years, and are typically renewable. Land use rights can be transferred upon approval by the land administrative authorities of the Chinese State Land Administration Bureau upon payment of the required land transfer fee. We have received the necessary land use right certificate for our primary operating facility which is located at No. 88 Gengsheng Road, Dayugou Town, Gongyi, Henan Province.

In addition, we are also subject to PRC's foreign currency regulations. The PRC government has control over Renminbi reserves through, among other things, direct regulation of the conversion or Renminbi into other foreign currencies. Although foreign currencies which are required for "current account" transactions can be bought freely at authorized Chinese banks, the proper procedural requirements prescribed by Chinese law must be met. At the same time, Chinese companies are also required to sell their foreign exchange earnings to authorized Chinese banks and the purchase of foreign currencies for capital account transactions still requires prior approval of the Chinese government.

We do not face any significant government regulation in connection with the production of our products. We do not require any special government permits to produce our products other than those permits that are required of all corporations in China.

Our Intellectual Property

While we consider our patents and trademarks to be valuable assets, we do not consider any single patent or trademark to be of such material importance that its absence would harm or cause a material disruption of our business. We also consider the production of our monolithic refractories to involve proprietary knowledge, and we adjust and test the specific composition formulas to ensure optimal product performance.

11

Patents

We own four Chinese patents which are registered with the China State Intellectual Property Office. The following table lists our patents:

| Patent Name | | Patent Number | | | Application Date | | | Patent Term | | | Country | |

| Integral casting technology for mixer furnace | | ZL00137106.1 | | | December 29, 2000 | | | 20 years | | | PRC | |

| Ceramic pressurizing double flashboard and brake valve | | ZL200520029858.7 | | | January 24, 2005 | | | 10 years | | | PRC | |

| Straight burning gas regeneration kiln | | ZL200520030706.9 | | | May 23, 2005 | | | 10 years | | | PRC | |

| Pump-used ceramic post stopper | | ZL200520029859.1 | | | March 8, 2006 | | | 10 years | | | PRC | |

| Oversized particles removal method | | ZL01127585.5 | | | October 30, 2001 | | | 20 years | | | PRC | |

Trademarks

We also own the following registered trademarks associated with the brand "Gengsheng" that were issued by the State Industrial and Commercial Administration Bureau of the PRC.

| Trademark | Registered Number | Termination Date | Use |

| 560614 | August 9, 2011 | Used for products with high-carbon black lead catalogued as class number 1 |

| 561260 | August 9, 2011 | Used for refractories catalogued as class number 19 |

Our Research and Development

We believe the development of new products and new technology is critical to our success. We continuously work to improve the quality, efficiency and cost-effectiveness of our existing products, and to develop technology to expand the range of specifications of our products.

We have spent $104,695, $86,990and $11,596 on Company-sponsored research and development activities in fiscal years 2008, 2007 and 2006, respectively. The expenses on research and development include salary, cost of raw material consumed, testing expenses and other costs incurred for research and development of potential new products. We have not spent any money on customer-sponsored research and development activities.

Litigation

From time to time, we may become involved in various lawsuits and legal proceedings which arise in the ordinary course of business. We are currently not a party to any legal proceeding and are not aware of any legal claims that we believe will have a material adverse affect on our business, financial condition or operating results.

Our Employees

As of December 31, 2008, we employed approximately 1,300 employees, all of whom are salaried employees and members of a labor union. Over 25% of our employees hold a bachelor's degree, and approximately 1% of our employees hold a master's degree. We actively recruit our employees from the local market and expect to focus our recruiting efforts on bachelor degree candidates in the fields of material science, refractory materials and marketing as we implement our expansion plans. We have implemented a comprehensive training program for our employees that focus on skills and knowledge training for their specific duties, and also on our corporate philosophy and our product concepts.

Our employees participate in a mandated state pension plan and social insurance programs organized by Chinese municipal and provincial governments which cover pensions, unemployment and injury insurance. We are required to contribute to the plan at a rate of 20% of the average monthly salary for employee pensions, 2% of the average monthly salary for the state unemployment fund and 1% of the monthly average salary for injury insurance. Our compensation expenses related to this plan were $336,157, $150,097 and $150,595 for the years ended December 31, 2008, 2007 and 2006, respectively.

12

Our Chinese subsidiaries have joined certain unions which protect employees' rights, aim to assist in the fulfillment of our economic objectives, encourage employee participation in management decisions, and assist in mediating disputes between us and union members. We believe that we maintain a satisfactory working relationship with our employees and we have not experienced any significant labor disputes or any difficulty in recruiting staff for our operations.

China enacted a new Labor Contract Law, which became effective on January 1, 2008. We have updated our employment contracts and employee handbook and so we are in compliance with the new law. We will work with the employees and the labor union to ensure that employees obtain the full benefit of the law. We do not anticipate that changes in the law will materially impact the Company's balance sheet.

ITEM 1A. RISK FACTORS

RISKS RELATED TO OUR BUSINESS

A downturn or negative changes in the highly volatile steel and iron industry will harm our business and profitability.

The iron and steel industries accounted for approximately 60%-70% of consumption in the Chinese refractory industry according to the industry association statistics. Because our largest customers are in the steel industry, our business performance is closely tied to the performance of the steel industry. The sector as a whole is cyclical and its profitability can be volatile as a result of general economic conditions, labor costs, competition, import duties, tariffs and currency exchange rates. These macroeconomic factors have historically resulted in wide fluctuations in the Chinese and the global economies in which steel companies sell their products. In our case, future economic downturns, stagnant economies or currency fluctuations in China or globally, could decrease the demand for steel products both in China and overseas and, could in turn, negatively impact our sales, margins and profits.

Industry growth rate for refractory products may decelerate and may affect our future revenue growth.

In China, the production of refractory materials has experienced fast growth in recent years driven largely by growth in China's steel production. China has become the largest country for producing and consuming refractories, among which 60%-70% were demanded by steel industries. According to data provided by the Association of China Refractories Industry, total output of refractory in 2006 was 32.43 million tons, representing an annualized growth rate of 30.4% . Total sales of refractories grew from RMB 19,300 million to RMB 64,000 million, representing an annualized growth rate of 27.1% . Our industry's growth has been primarily driven by the growth in the Chinese steel industry. According to figures provided by the National Statistics Bureau of China, the Chinese steel output grew from an annual output of 157 million tons in 2001 to 419 million tons in 2006, representing a compounded average growth rate (CAGR) of 21.7% . Going forward, however, the forecast provided by the China International Capital Corporation suggests that the annual output of steel in China is expected to grow to 651 million tons by 2010, representing a CAGR of 11.6 % over the next two years.

If the steel industry experiences such a slowdown, our growth prospects will likewise be curtailed. Additionally, the market for monolithic refractories in China is still in the developmental stage, and successful market penetration of the monolithic refractories depends heavily on two factors. First, successful market penetration depends on technological progress that results in products that provide better performance by our customers, new varieties of products that meet our customer's future requirements, and more efficient and effective installation and maintenance methods. Second, successful market penetration also depends on our marketing strategy and our ability to execute that strategy while maintaining a high quality of service to our customers. Our future revenue growth—without acquisitions—may maintain growth, but nevertheless, we may not match our past growth rate.

Our inability to overcome fierce competition in the highly fragmented and highly competitive Chinese refractory market could reduce our revenue and net income.

The refractory market in China is highly fragmented with over 2,000 producers of refractory products, according to the Chairman of the Association of China Refractory Industry. Our competitors manufacture products that are similar to and directly compete with the products that we manufacture and market. We compete with many other refractory manufacturers in China, on a region-by-region basis, and with international competitors on a world-wide basis. Our main competitors are located in China and include Puyang Punai High-temperature Materials Co., Ltd., Wuhan Ruisheng Specialty Refractory Materials Co., Ltd., Beijing Lirr Refractories Co., Ltd. and others. Currently, our primary international competitor is Mineral Technologies, Inc. in the United States.

As a market leader in the monolithic refractory marketplace, we can buy raw materials in large quantities allowing us to negotiate volume pricing resulting in lower prices than our smaller competitors pay for their raw materials. As our smaller competitors consolidate and grow larger, they may able to negotiate similar volume pricing from raw material suppliers. Under that scenario, any cost advantage that we currently enjoy may be reduced or eliminated altogether. Although our smaller competitors may pay higher materials costs relative to our material costs, their operating and administrative costs may be lower than ours, which may allow our competitors to quote very competitive prices for their products and services. Their competitive prices may force us to lower our prices, and to sell products and services at a loss in order to maintain our market share. Currently, we have a policy for setting a pricing floor so that we do not sell products at a loss; however, we cannot assure that we can maintain this policy indefinitely. Thus, increased competition in our industry could reduce our revenue and net income.

13

Any decrease in the availability, or increase in the cost, of raw materials and energy could materially increase our costs and jeopardize our current profit margins and profitability.

The principal raw materials used in our refractory products are several forms of the minerals SiO2, Al203, and MgO, including bauxite, mullite, corundum, processed Al203 , Spinel, magnesia, calcium aluminate cement, and silica. We primarily use bauxite in the production of refractory materials, fracture proppants and some industrial ceramic products. The availability of these raw materials and energy resources may decrease and their prices can become volatile as a result of, among other things, changes in overall supply and demand levels and new laws or regulations. Our ability to achieve our sales target depends on our ability to maintain what we believe to be adequate inventories of raw materials to meet reasonably anticipated orders from our customers. In 2008, raw material costs accounted for 83% of the production cost for refractory products and 75.3% for industrial ceramics products.

Our production facilities are located in Gongyi, Henan Province, where there is currently an abundant reserve of bauxite and corundum for refractory manufacturing. Although our proximity to bauxite allows us to benefit from a relatively short delivery time and lower shipping costs to our production facilities, we may experience supply shortages or price increases or both due to sharp increases in overall industry demand for bauxite. Besides purchasing bauxite from local suppliers, we also purchase bauxite, mullite, magnesia, calcium aluminates cement and other raw materials from suppliers in Shanxi Province, Shandong Province, Liaoning Province and Gansu Province. All these locations are outside of Henan Province. Higher shipping costs will increase our cost of raw materials from these sources and will decrease our revenues and profitability.

Further, if our existing suppliers are unable or unwilling to deliver our raw materials requirements on time to meet our production schedules, we may be unable to produce certain products, which could result in a decrease in revenues and profitability, a loss of good will with our customers, and could tarnish our reputation as a reliable supplier in our industry. In the event that our raw material and energy costs increase, we may not be able to pass these higher costs on to our customers in full or at all due to contractual agreements or pricing pressures in the refractory market. Any increase in the prices for raw materials or energy resources could materially increase our costs and therefore lower our earnings and profitability.

Actions by the Chinese government could drive up our material costs and could have a negative impact on our profitability.

In the past years, the Chinese government has shut down some outdated mineral mines in China. These shutdowns have decreased the overall supply of raw materials needed to produce refractory products. As a result, the materials costs for our products have increased. If the Chinese government shuts down more mineral mines, we could experience further supply shortages and price increases that could have a negative impact on our profitability.

We may not be able to implement our business plan because we may be unable to both fund the substantial ongoing capital and maintenance expenditures that our operations require and invest in new projects at the same time.

Our operations are capital intensive and the nature of our business and our business strategy will require substantial additional working capital investment. We require capital for building new production lines, acquiring new equipment, maintaining the condition of our existing equipment and maintaining compliance with environmental laws and regulations, and to pursue new market opportunities. Our current business plan estimates our anticipated capital expenditures for the year ending on December 31, 2009 to be approximately $5,328,000. We may not be able to fund our capital expenditures from operating cash flow and from the proceeds of borrowings available for capital expenditures under our credit facilities, and we may require additional debt or equity financing. We cannot assure that this type of financing will be available or, if available, it may result in increased interest's expenses, increased leverage and decreased income available to fund further expansion. In addition, future debt financings may limit our ability to withstand competitive pressures and render us more vulnerable to economic downtowns. If we are unable to fund our capital requirements, we may be unable to implement our business plan, and our financial performance may be adversely impacted.

Approximately 60.3% of our sales revenues were derived from our ten largest customers, and any reduction in revenues from any of these customers would reduce our revenues and net income.

While we have over 200 active customers, approximately 60.3% of our sales revenue came from our top ten customers in fiscal year 2008, with Rizhao Steel Co., Ltd. alone accounting for approximately 17.5% of our sales revenue. If we cease to do business at or above current levels with Rizhao Steel Co., Ltd. or any one of our other largest customers which contribute significantly to our sales revenues, and we are unable to generate additional sales revenues with new and existing customers that purchase a similar amount of our products, then our revenues and net income would decline considerably.

14

A significant interruption or casualty loss at any of our facilities could increase our production costs and reduce our sales and earnings.

Our manufacturing process requires large industrial facilities for crushing, smashing, batching, molding and baking raw materials. After the refractory products come off the production line, we need additional facilities to inspect, package, and store the finished goods. Our facilities may experience interruptions or major accidents and may be subject to unplanned events such as explosions, fires, inclement weather, acts of God, terrorism, accidents and transportation interruptions. Any shutdown or interruption of any facility would reduce the output from that facility, which could substantially impair our ability to meet sales targets. Interruptions in production capabilities will inevitably increase production costs and reduce our sales and earnings. In addition to the revenue losses, longer-term business disruption could result in the loss of goodwill with our customers. To the extent these events are not covered by insurance, our revenues, margins and cash flows may be adversely impacted by events of this type.

Environmental regulations impose substantial costs and limitations on our operations.

Our products are not considered environmentally hazardous materials, however, the dust produced during our production process is considered hazardous to the environment. We have environmental liability risks and limitations on operations brought about by the requirements of environmental laws and regulations. We are subject to various national and local environmental laws and regulations concerning issues such as air emissions, wastewater discharges, and solid and hazardous waste management and disposal. These laws and regulations are becoming increasingly stringent. While we believe that our facilities are in material compliance with all applicable environmental laws and regulations, the risks of substantial unanticipated costs and liabilities related to compliance with these laws and regulations are an inherent part of our business. It is possible that future conditions may develop, arise or be discovered that create new environmental compliance or remediation liabilities and costs. While we believe that we can comply with environmental legislation and regulatory requirements and that the costs of compliance have been included within budgeted cost estimates, compliance may prove to be more limiting and costly than anticipated.

If our customers and/or the ultimate consumers of products which use our products successfully assert product liability claims against us due to defects in our products, our operating results may suffer and our reputation may be harmed.

Our products are widely used as protective linings in industrial furnaces operating in highly hazardous environments because those furnaces must operate under extremely high temperatures in order to produce iron, steel and other industrial products. Significant property damage, personal injuries and even death can result from the malfunctioning of high temperature furnaces as a result of defects in our refractory products. The costs and resources needed to defend product liability claims could be substantial. We could be responsible for paying some or all of the damages if found liable. We do not have product liability insurance. The publicity surrounding these sorts of claims is also likely damage our reputation, regardless of whether such claims are successful. Any of these consequences resulting from defects in our products would hurt our operating results and stockholder value.

If we are not able to adequately secure and protect our patent, trademark and other proprietary rights our business may be materially affected.

We hold patents for (a) integral casting technology for mixer furnaces (which expires on December 29, 2020), (b) a ceramic pressurizing double flashboard and brake valve (which expires on January 24, 2015), (c) a straight burning gas regeneration kiln (which expires on May 23, 2015) and (d) a pump-used ceramic post stopper (which expires on March 8, 2016) and (e) a oversized particles removal method, (which will be expires on October 30, 2021). We also rely on non-disclosure agreements and other confidentiality procedures to protect our intellectual property rights in various jurisdictions. These technologies are very important to our business and it may be possible for unauthorized third parties to copy or reverse engineer our products, or otherwise obtain and use information that we regard as proprietary. Furthermore, third parties could challenge the scope or enforceability of our patents. In certain foreign countries, including China where we operate, the laws do not protect our proprietary rights to the same extent as the laws of the United States. Decided court cases in China's civil law system do not have binding legal effect on future decisions and even where adequate law exists in China, enforcement based on existing law may be uncertain and sporadic and it may be difficult to obtain enforcement of a judgment by a court of another jurisdiction. In addition, the relative inexperience of China's judiciary in many cases creates additional uncertainty as to the outcome of any litigation, and interpretation of statutes and regulations may be subject to government policies reflecting domestic political changes. Any misappropriation of our intellectual property could have a material adverse effect on our business and results of operations, and we cannot assure you that the measures we take to protect our proprietary rights are adequate.

Expansion of our business may strain our management and operational infrastructure and impede our ability to meet any increased demand for our products.

Our business plan is to significantly grow our operations by meeting the anticipated growth in demand for existing products and by introducing new product offerings. Growth in our business may place a significant strain on our personnel, management, financial systems and other resources. Our business growth also presents numerous risks and challenges, including:

15

- Our ability to successfully and rapidly expand sales to potential customers in response to potentially increasing demand;

- The costs associated with such growth, which are difficult to quantify, but could be significant; and

- The costs associated with developing new products to keep pace with rapid technological changes.

To accommodate this growth and compete effectively, we may need to obtain additional funding to improve information systems, procedures and controls and expand, train, motivate and manage existing and additional employees. Funding may not be available in a sufficient amount or on favorable terms, if at all. If we are not able to manage these activities and implement these strategies successfully to expand to meet any increased demand, our operating results could suffer.

Improvements in the quality and lifespan of refractory products may decrease product turnover and our sales revenues.

Technological and manufacturing improvements have made refractory products more durable and more efficient. While making products more durable and more efficient is generally a positive development, the increased quality and durability of refractory products could lead to declining consumption and turnover of refractory products, which is usually measured in kilograms consumed per ton of steel produced. According to the Association of China Refractories Industry, in the developed nations, the average refractory consumption per ton of steel produced dropped from 60 kilograms consumed per ton of steel produced in the 1950s to 13 kilograms consumed per ton of steel produced in 2005. In China, the current average consumption rate is approximately 28 kilograms consumed per ton of steel produced. With the growth rate in the steel industry decelerating and with the consumption rate of refractory products per ton of steel produced decreasing, the refractory industry's future growth rate may decelerate. We can increase our prices to offset a decrease in product consumption, but we cannot assure that price increases will be acceptable to our customers.

Our new products are complex and may contain defects that are detected only after their release to our customers, which may cause us to incur significant unexpected expenses and lost sales.

Our products are highly complex and must operate at high temperatures for a long period of time. Although our new products are tested prior to release, they can only be fully tested when they are used by our customers. Consequently, our customers may discover defects after new products have been released. Although we have test procedures and quality control standards in place designed to minimize the number of defects in our products, we cannot guarantee that our new products will be completely free of defects when released. If we are unable to quickly and successfully correct the defects identified after their release, we could experience significant costs associated with compensating our customers for damages cause by our products, costs associated with correcting the defects, costs associated with design modifications, and costs associated with service or warranty claims or both. Additionally, we could lose customers, lose market share, and suffer damage to our reputation.

We may be exposed to potential risks relating to our internal controls over financial reporting and our ability to have those controls attested to by our independent auditors.

As directed by Section 404 of the Sarbanes-Oxley Act of 2002 or SOX 404, the SEC adopted rules requiring public companies to include a report of management on the company's internal controls over financial reporting in their annual reports, including Form 10-K. In addition, the independent registered public accounting firm auditing a company's financial statements must also attest to and report on management's assessment of the effectiveness of the company's internal controls over financial reporting as well as the operating effectiveness of the company's internal controls. We were not subject to these requirements for the fiscal year ended December 31, 2007; accordingly, we have not evaluated our internal control systems in order to allow our management to report on, and our independent auditors to attest to, our internal controls as required by these requirements of SOX 404. Under current law, we have been subject to these requirements beginning with our annual report since the fiscal year 2008. We can provide no assurance that we will comply with all of the requirements imposed thereby. There can be no assurance that we will receive a positive attestation from our independent auditors. In the event we identify significant deficiencies or material weaknesses in our internal controls that we cannot remediate in a timely manner or we are unable to receive a positive attestation from our independent auditors with respect to our internal controls, investors and others may lose confidence in the reliability of our financial statements.

We do not have any independent directors which may negatively affect the recognition of our credibility regarding our management and internal control process.

We currently do not have any independent directors. In the near future, we will appoint a number of independent directors which will constitute a majority of our board of directors before our common stock is listed on a national securities exchange or NASDAQ. Before that, there might be concerns regarding our auditing and internal control process of our operation and management.

Our holding company structure may limit the payment of dividends.

We have no direct business operations, other than our ownership of our subsidiaries. While we have no current intention of paying dividends, should we decide in the future to do so, as a holding company, our ability to pay dividends and meet other obligations depends upon the receipt of dividends or other payments from our operating subsidiaries and other holdings and investments? In addition, our operating subsidiaries, from time to time, may be subject to restrictions on their ability to make distributions to us, including as a result of restrictive covenants in loan agreements, restrictions on the conversion of local currency into U.S. dollars or other hard currency and other regulatory restrictions as discussed below. If future dividends are paid in RMB, fluctuations in the exchange rate for the conversion of RMB into U.S. dollars may reduce the amount received by U.S. stockholders upon conversion of the dividend payment into U.S. dollars.

16

Chinese regulations currently permit the payment of dividends only out of accumulated profits as determined in accordance with Chinese accounting standards and regulations. Our subsidiaries in China are also required to set aside a portion of their after-tax profits according to Chinese accounting standards and regulations to fund certain reserve funds. Currently, our subsidiaries in China are the only sources of revenues or investment holdings for the payment of dividends. If they do not accumulate sufficient profits under Chinese accounting standards and regulations to first fund certain reserve funds as required by Chinese accounting standards, we will be unable to pay any dividends.

We have not completed our new fine precisions production line and earned any revenues in 2008 as planned and we cannot guarantee that we will earn the estimated revenues on this product line in the future or that it will ultimately be profitable.

We initiated the construction of fine precisions line in the mid year of 2008 and planned to have the production at the fourth quarter of 2008. Unfortunately, we ceased the construction and delay the productions due to the lack of working capital resulting from the monetary restraint because of the worldwide financial crisis occurred in the fourth quarter of 2008. We have planned to resume the construction and the productions by stages in 2009 depending on the progress of the receipt of financing activities from the banks domestically and nationally. However, the likelihood of the implementation of our plan would be measured in light of the problems, expenses, difficulties, complications and delays frequently encountered in connection with the marketing of new products. There can be no assurance that we will be able to complete the construction of facilities and initiate the production in time, and that future revenues from the sales will be significant, that any sales will be profitable or that we will have sufficient funds available to continue the manufacturing and marketing of these products. However, we do not expect our other operations to be materially affected by our failure to successfully market our new fine precisions products.

RISKS RELATED TO DOING BUSINESS IN CHINA

New corporate income tax law could adversely affect our business and our net income.