Exhibit 99.18

AMC Mining Consultants (Canada) Ltd. BC0767129 200 Granville Street, Suite 202 Vancouver BC V6C 1S4 Canada T +1 604 669 0044 E vancouver@amcconsultants.com W amcconsultants.com |  |

Technical Report

NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China

Silvercorp Metals Inc.

Guangdong Province, People’s Republic of China

In accordance with the requirements of National Instrument 43-101 “Standards of Disclosure for Mineral Projects” of the Canadian Securities Administrators

Qualified Persons:

D. Nussipakynova, P.Geo.

H.A. Smith, P.Eng.

A. Riles, MAIG.

A.A. Ross. P.Geo., P.Geol.

S. Robinson, P.Geo., MAIG.

G. Ma, P.Geo.

AMC Project 721004

Effective date: 31 March 2021

Report date: 6 October 2021

Unearth a smarter way

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

Quality control

The signing of this statement confirms this report has been prepared and checked in accordance with the AMC Peer Review Process.

| Project Manager | The signatory has given permission to use their signature in this AMC document | | XX October 2021 |

| Bert Smith | | Date |

| Peer Reviewer | The signatory has given permission to use their signature in this AMC document | | XX October 2021 |

| Mort Shannon | | Date |

| Author | The signatory has given permission to use their signature in this AMC document | | XX October 2021 |

| Multiple authors – see Table 2.1 | | Date |

Important information about this report

Confidentiality

This document and its contents are confidential and may not be disclosed, copied, quoted or published unless AMC Mining Consultants (Canada) Ltd. (AMC) has given its prior written consent.

No liability

AMC accepts no liability for any loss or damage arising as a result of any person other than the named client acting in reliance on any information, opinion or advice contained in this document.

Reliance

This document may not be relied upon by any person other than the client, its officers and employees.

Information

AMC accepts no liability and gives no warranty as to the accuracy or completeness of information provided to it by or on behalf of the client or its representatives and takes no account of matters that existed when the document was transmitted to the client but which were not known to AMC until subsequently.

Precedence

This document supersedes any prior documents (whether interim or otherwise) dealing with any matter that is the subject of this document.

Recommendations

AMC accepts no liability for any matters arising if any recommendations contained in this document are not carried out, or are partially carried out, without further advice being obtained from AMC.

Outstanding fees

No person (including the client) is entitled to use or rely on this document and its contents at any time if any fees (or reimbursement of expenses) due to AMC by its client are outstanding. In those circumstances, AMC may require the return of all copies of this document.

Public reporting requirements

If a client wishes to publish a Mineral Resource or Ore / Mineral Reserve estimate prepared by AMC, it must first obtain the Competent / Qualified Person’s written consent, not only to the estimate being published but also to the form and context of the published statement. The published statement must include a statement that the Competent / Qualified Person’s written consent has been obtained.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

AMC Mining Consultants (Canada) Ltd. (AMC) was commissioned by Silvercorp Metals Inc. (Silvercorp) to prepare an independent Technical Report (the 2021 Technical Report) on the Gaocheng (Gaocheng or GC) property (Property), located in Gaocun Township, Yun’an District, Yunfu City, Guangdong Province, China. AMC has prepared previous Technical Reports on the Property in 2009 (‘NI 43-101 Technical Report Update on the GC Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China’, effective date 18 June 2009), 2012 (‘NI 43-101 Technical Report on the GC Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China’, effective date 23 January 2012), 2018 (‘NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China’, effective date 30 June 2018), and 2019 (‘NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China’, effective date 30 June 2019, (2019 Technical Report)). Two of the independent authors of the 2019 Technical Report, Ms Dinara Nussipakynova and Mr Herbert Smith of AMC, visited the GC property in January 2018. Mr Guoliang Ma of Silvercorp, who takes Qualified Person (QP) responsibility for Section 20 of the 2021 Technical Report, has visited the Property on numerous occasions, including most recently in 2021.

This report has been produced in accordance with the Standards of Disclosure for Mineral Projects as contained in National Instrument 43-101 (NI 43-101) and accompanying policies and documents. NI 43-101 utilizes the definitions and categories of Mineral Resources and Mineral Reserves as set out in the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves (2014) (CIM Definition Standards).

| 1.2 | Location, ownership, and history |

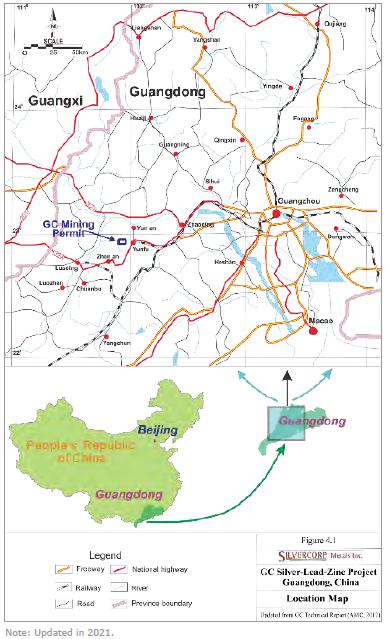

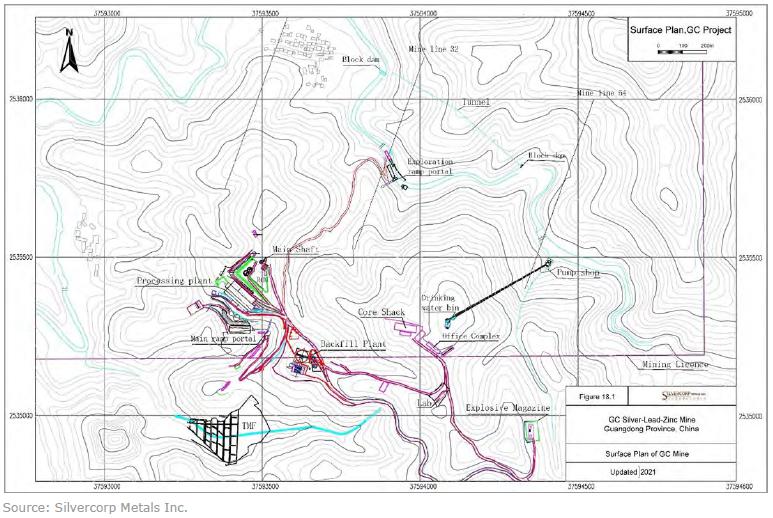

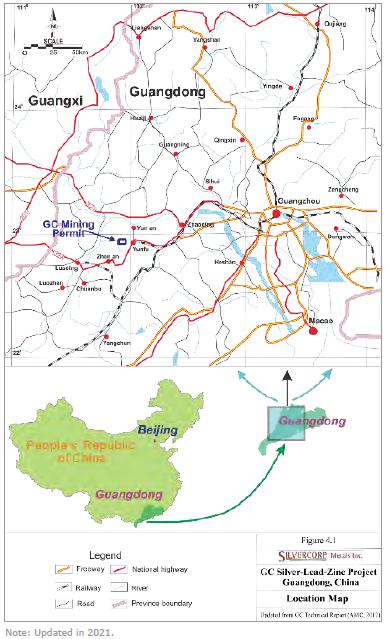

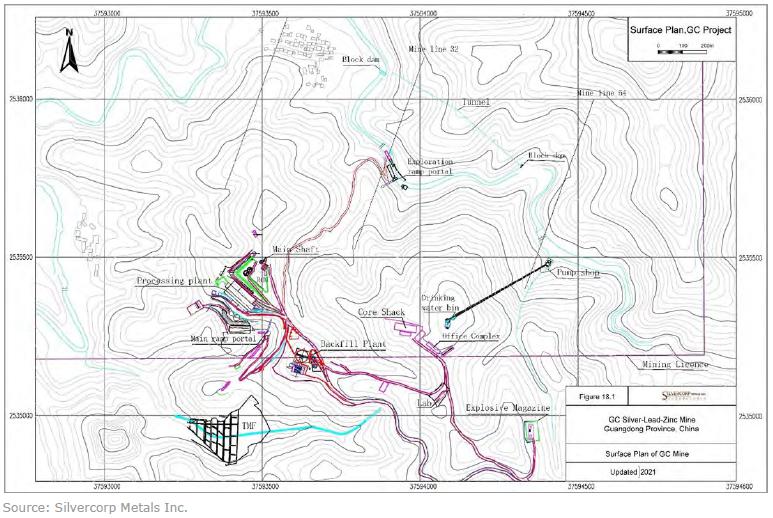

The Property is located in the vicinity of Gaocheng village, Gaocun Township, Yun’an District, Yunfu City, Guangdong Province, People’s Republic of China. The Property is located west of the metropolitan city of Guangzhou, the capital of Guangdong Province. Guangzhou is located about 120 kilometres (km) north-west of Hong Kong and has a total population of about 14 million people. Access to the GC project from Guangzhou is via 178 km of four-lane express highway to Yunfu, then 48 km of paved road to the project site.

Silvercorp owns 95% of the Property through its 100% ownership of the shares of Yangtze Gold Ltd. (Yangtze Gold), which in turn wholly owns Yangtze Mining Ltd. (Yangtze Mining). Yangtze Mining owns a 95% interest in a Sino-Foreign joint venture company, Anhui Yangtze Mining Co. Ltd. (Anhui Yangtze). Anhui Yangtze’s main asset was the GC exploration permit for the GC Mine, which was subsequently converted to a mining permit in November 2010. Guangdong Found Mining Co. Ltd. (China), (Guangdong Found), is the designated joint venture operating company of the GC mine. Yangtze Mining (H.K.) Ltd., a wholly owned subsidiary of Yangtze Mining, owns 95% of Guangdong Found.

The Mining Permit in the name of Guangdong Found is valid for 30 years to 24 November 2040, covers the entire 5.5238 km2 area of the GC Mine and permits mining from 315 metres (m) to minus 530 m elevations. The permit allows for the operation of an underground mine to produce silver, lead, and zinc.

Currently, the GC mine is subject to Mineral Resources taxes, levied at 3% of revenue from lead and zinc and 2% of revenue from silver. The Mineral Resource taxes, together with other government fees that are not tied to revenue, amount to approximately 5% of revenue. The QP is not aware of any additional royalties, back-in rights, payments, agreements, environmental liabilities, or encumbrances particular to the property other than those stated above.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

Various state-sponsored Chinese Geological Brigades and companies have conducted geological and exploration work in the project area, with systematic regional geological surveys commencing in 1959. Historical drilling commenced in 2001.

Prior to Yangtze Mining acquiring the Property in 2005, illegal mining activity resulted in the excavation of several tunnels and small-scale mining of veins V2, V2-2, V3, V4, V5, V6, and V10. It is reported that a total of 1,398 m of excavation comprised of 10 adits and tunnels had been completed on the property through the illegal activity.

A total of 43 diamond drillholes for a combined total of 13,463.74 m was drilled on the Property between 2001 and 2007 prior to the property acquisition by Silvercorp. Diamond drillholes were drilled using PQ size in overburden, then reduced to HQ size for up to 100 m depth.

The Guangdong Provincial Institute of Geological Survey (GIGS) prepared a resource estimate for nine mineralized veins for the GC project after the 2004 – 2005 exploration season. This was not compliant with the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Standards and is not material to the 2021 Technical Report.

| 1.3 | Geology and mineralization |

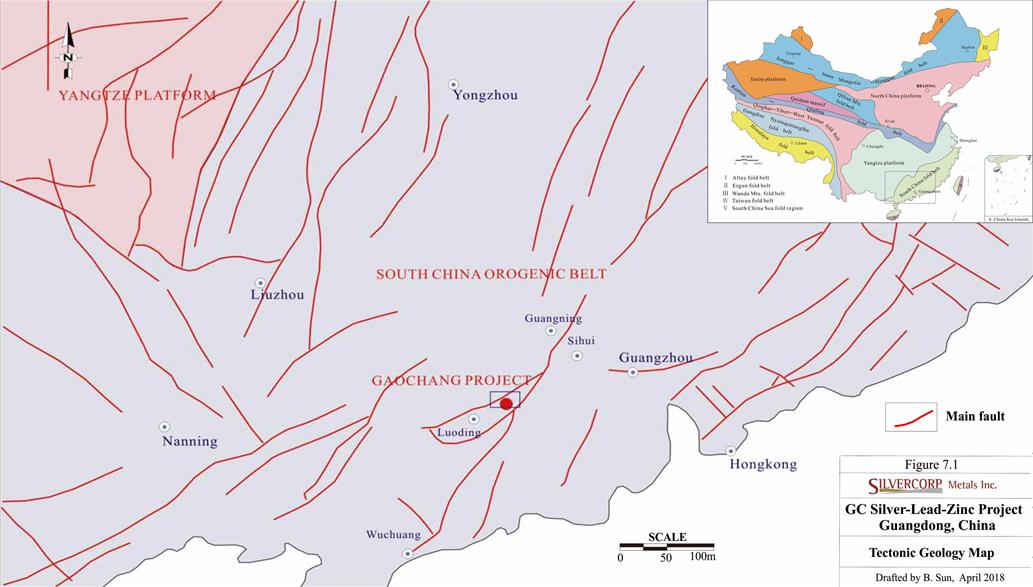

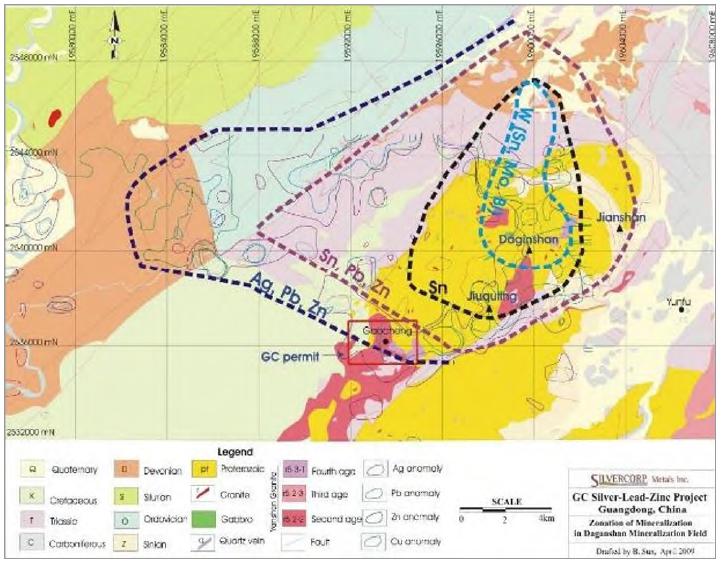

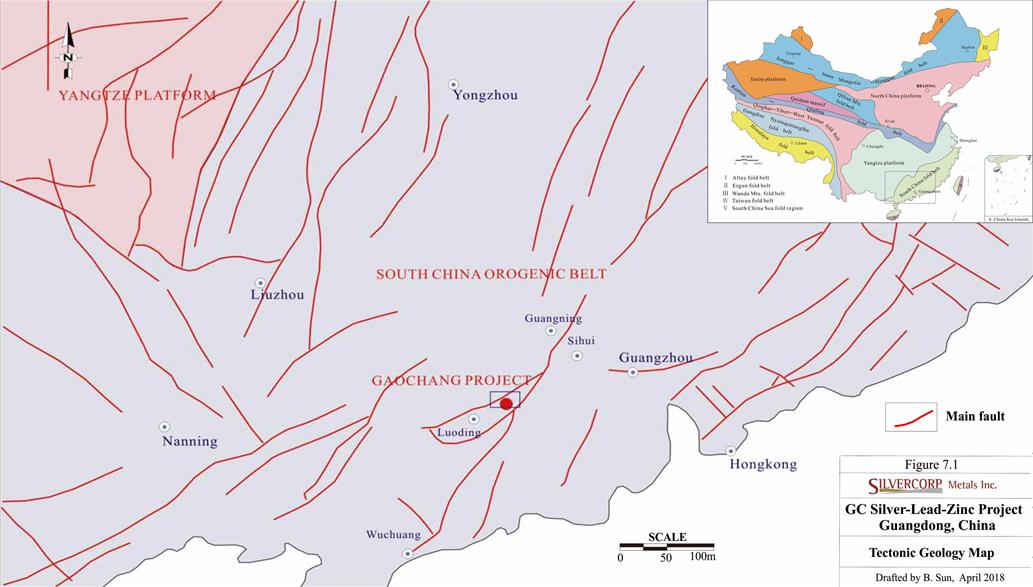

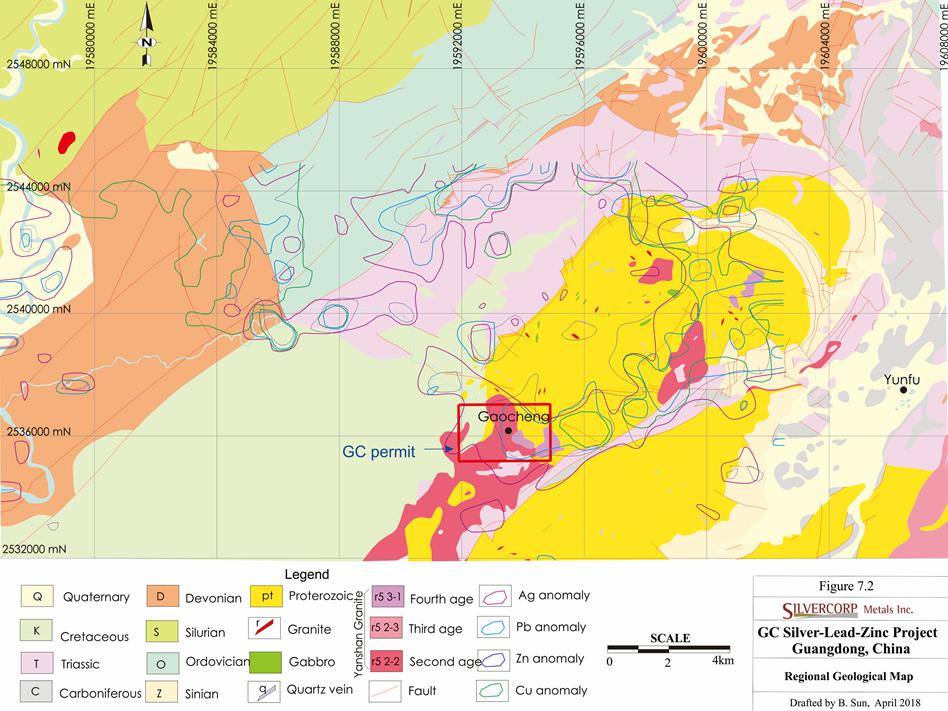

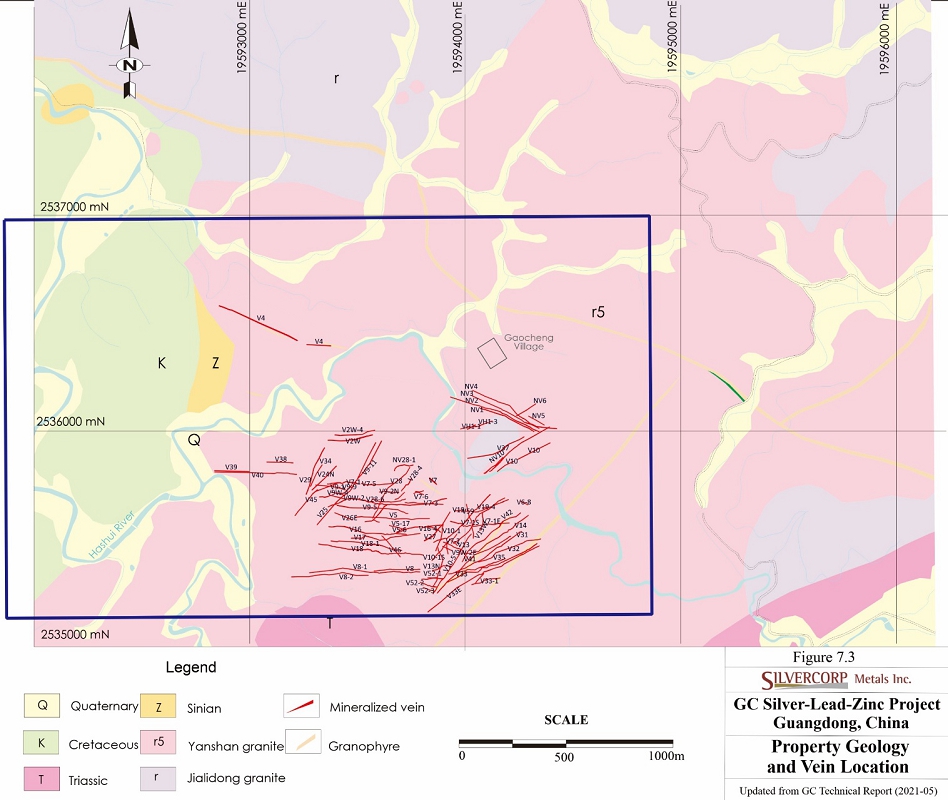

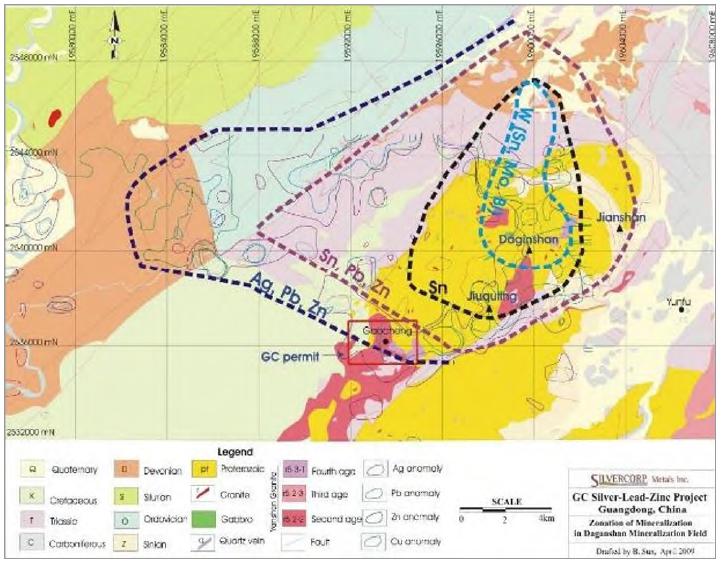

The Property is located on the east margin of the Luoding basin, east of the Wuchuan – Sihui major fault within the north portion of the Yunkai uplift of the South China Orogenic Belt. North-east striking structures and arc structures form the basic geological framework of the region. Deposits on the Property occur at the intersection of a north-easterly striking fault zone and a near east-westerly striking fault zone.

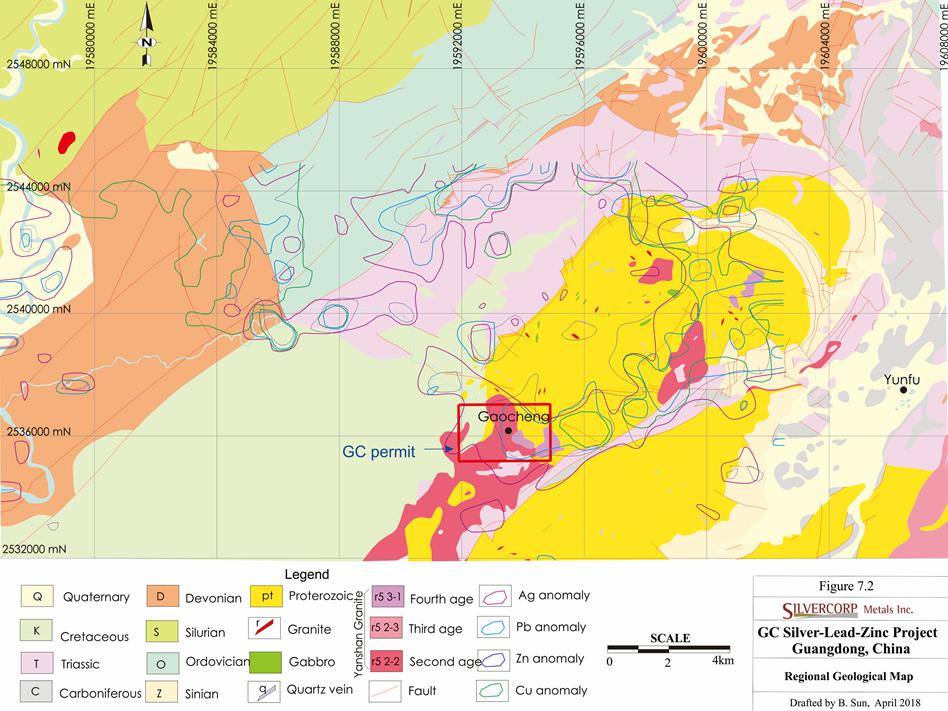

Basement geology in the area comprises late Proterozoic Sinian sedimentary clastics and carbonate rocks; Palaeozoic (Ordovician, Silurian, Devonian, Carboniferous) sedimentary clastics and carbonate rocks; and Mesozoic (Triassic) coal-bearing clastic rocks and Cretaceous red clastic rocks. Ag-Pb-Zn polymetallic deposits occur within late Proterozoic rocks. Cu-Pb-Zn, Mn, and Au-Ag deposits occur within Paleozoic rocks.

The GC Project is located at the intersection between the Wuchuan-Sihui Deep Fault zone and Daganshan Arc-ring structural zone. It is situated in the south-west part of the Daganshan uplift. Structures developed in the area are mainly the NWW-EW striking Gaocheng Fault zone, the NE striking Baimei Fault zone, and the Songgui Fault zone.

Basement rocks within the Property encompass quartz sandstone, meta-carbonaceous siltstone, carbonaceous phyllite, calcareous quartzite, and argillaceous limestone of the Sinian Daganshan Formation; quartz sandstone and shale of the Triassic Xiaoyunwushan Formation, and sandy conglomerate and conglomerate of the Cretaceous Luoding Formation. These rocks are intruded by Paleozoic gneissic, medium-grained biotite granite, and Mesozoic fine- to medium-grained adamellite, brownish, fine-grained, biotite mylonite, granite porphyry, quartz porphyry, diabase, and aplite. The Mesozoic intrusives intruded along the south and south-west contacts of the Paleozoic granites. The majority of Ag-Zn-Pb mineralization is hosted by the Mesozoic granite. The granite dips south and strikes west north-west, parallel to the majority of mineralized veins on the GC property.

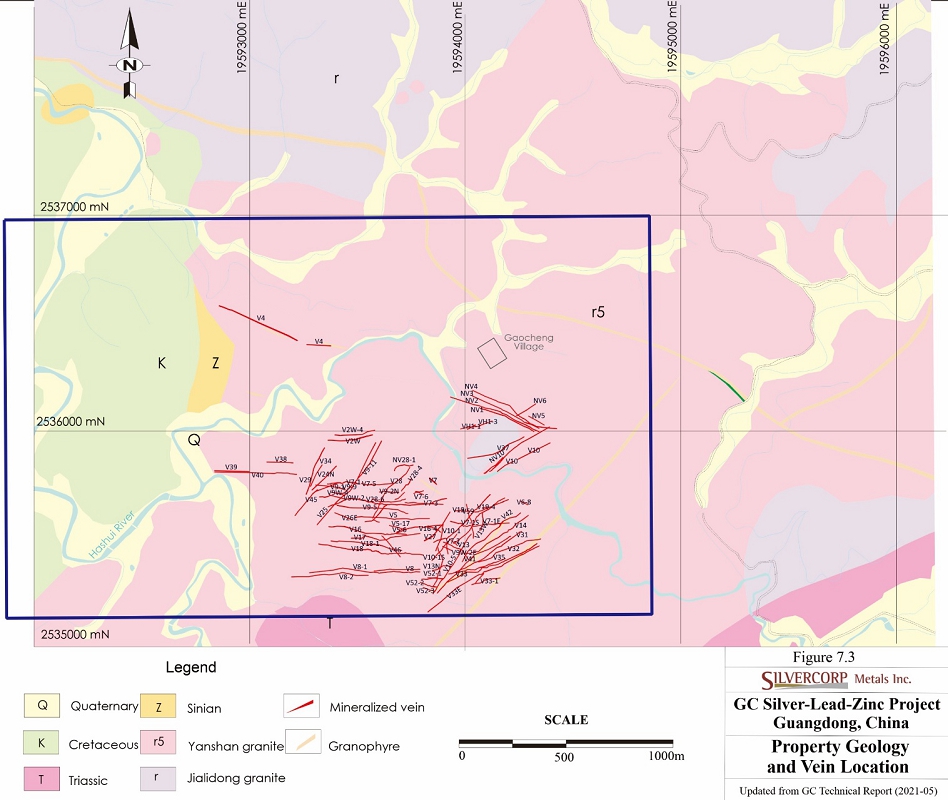

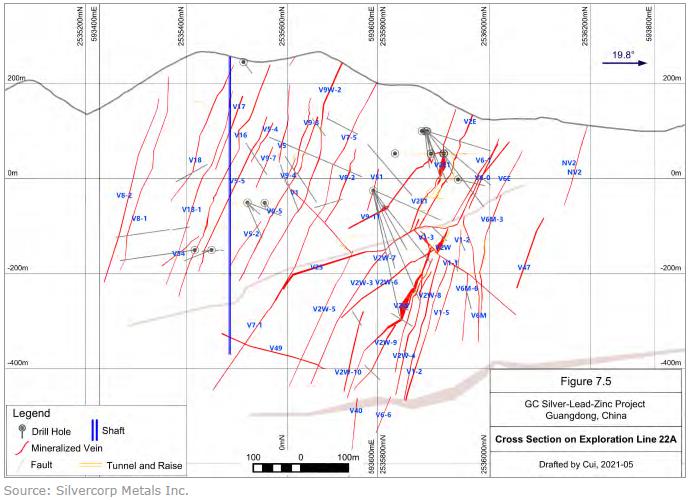

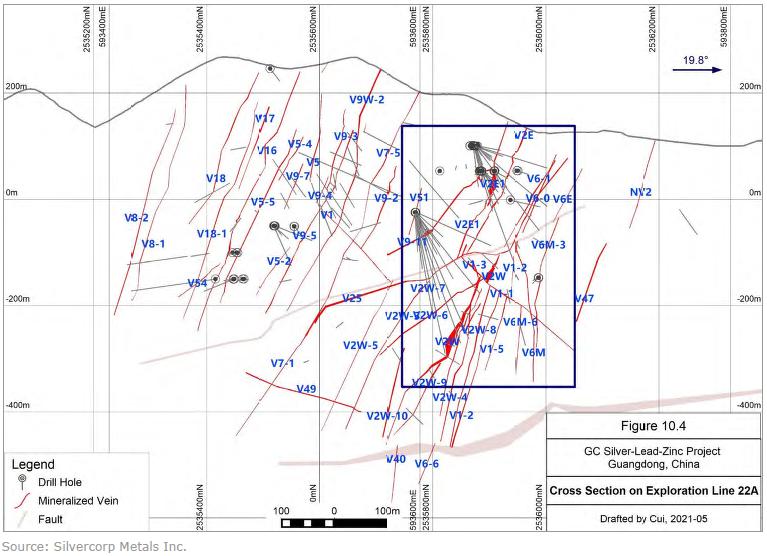

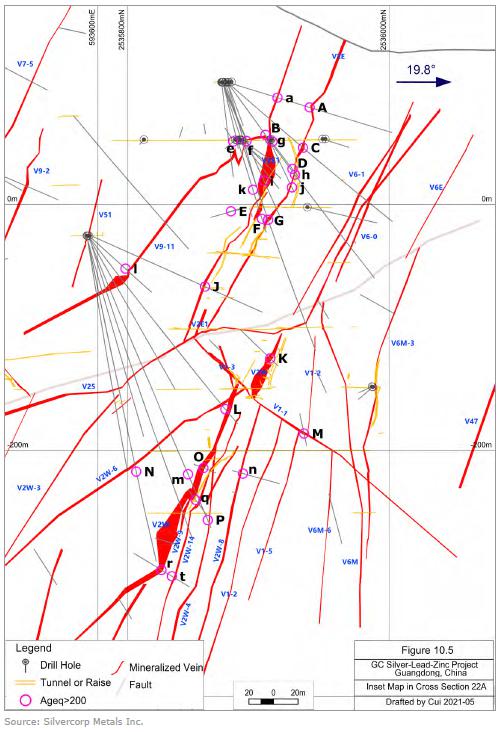

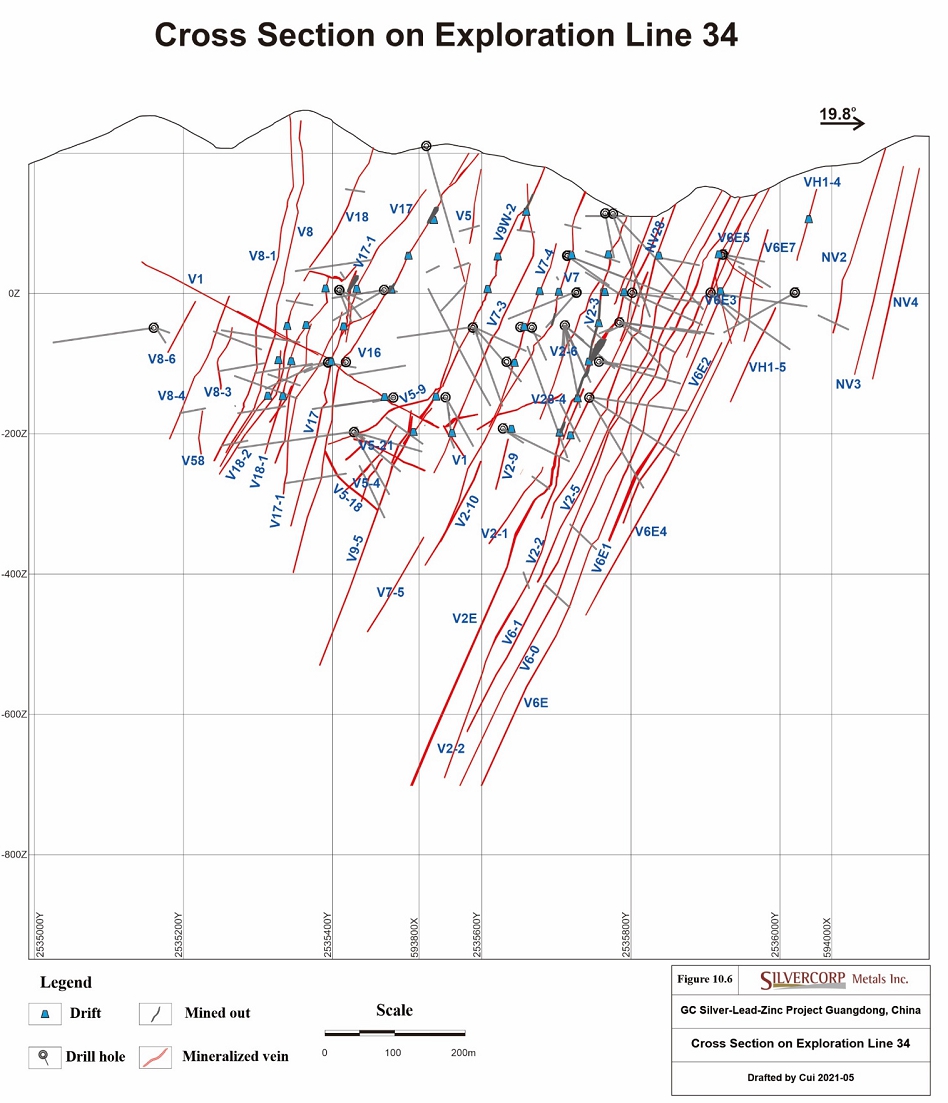

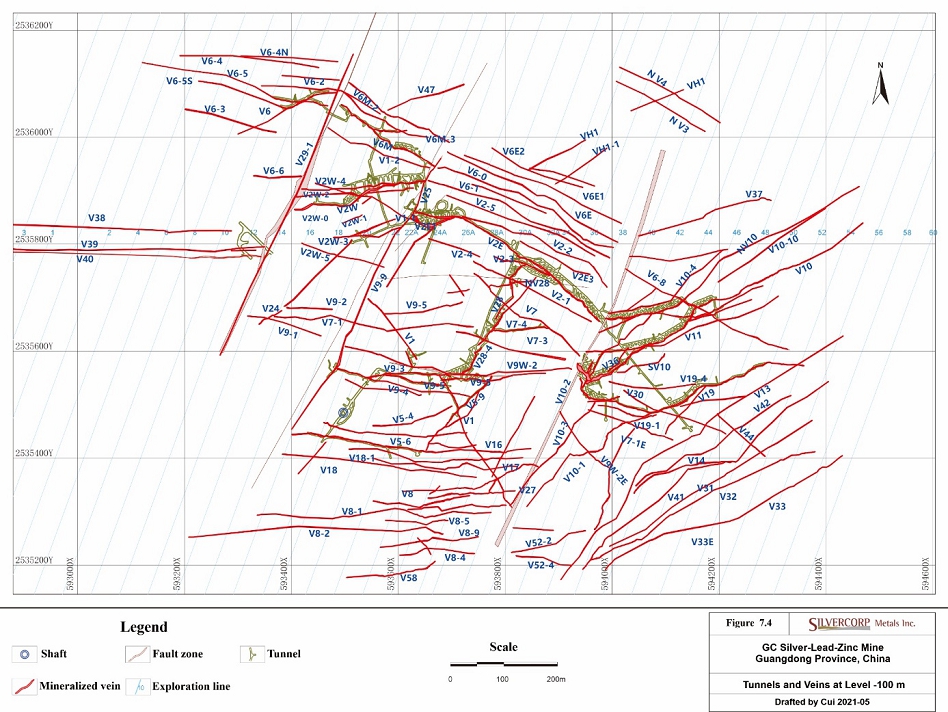

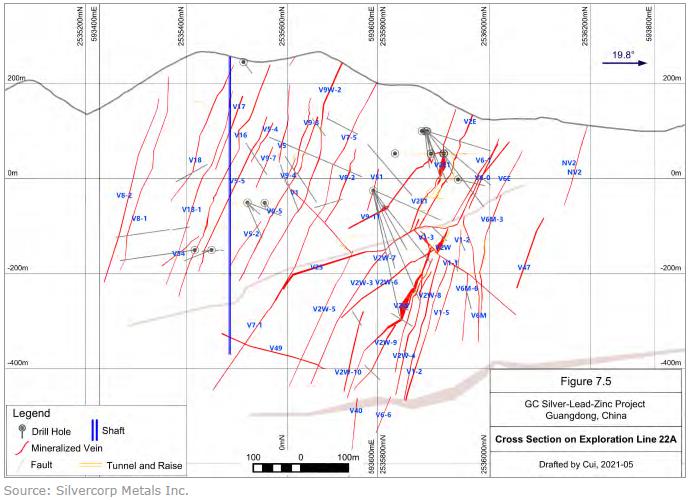

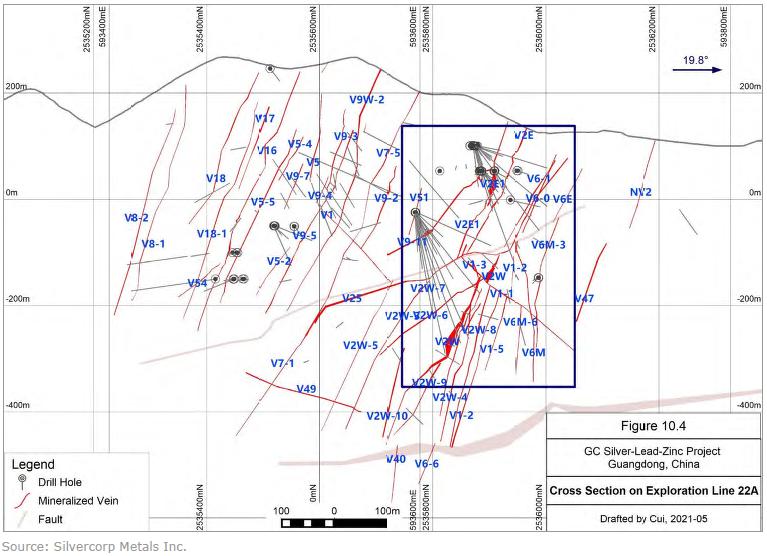

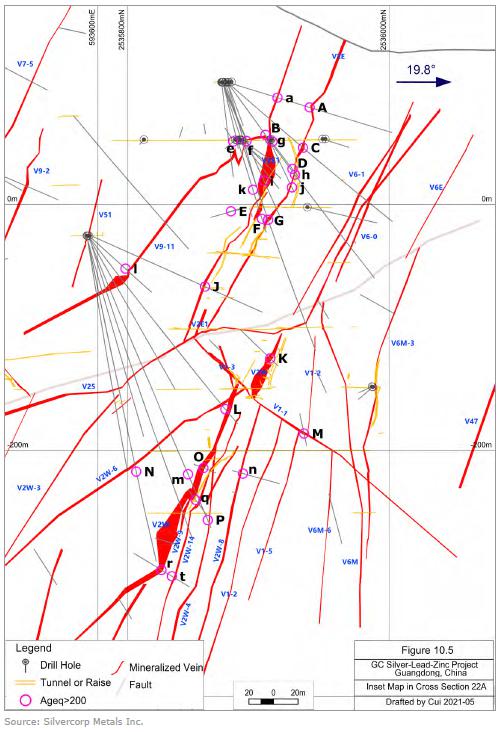

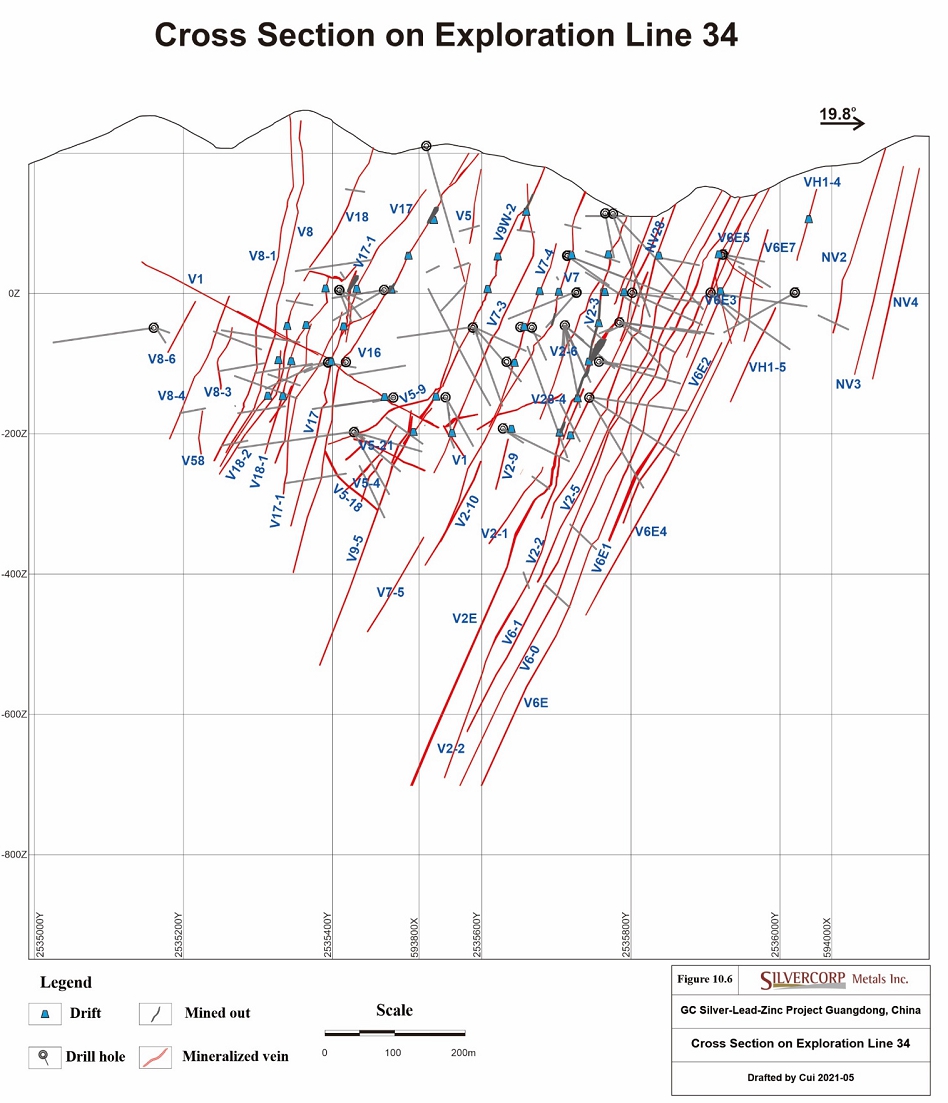

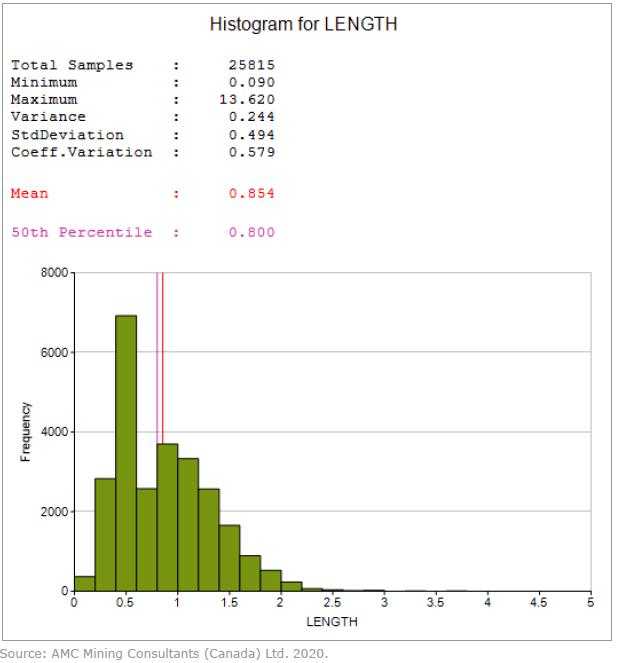

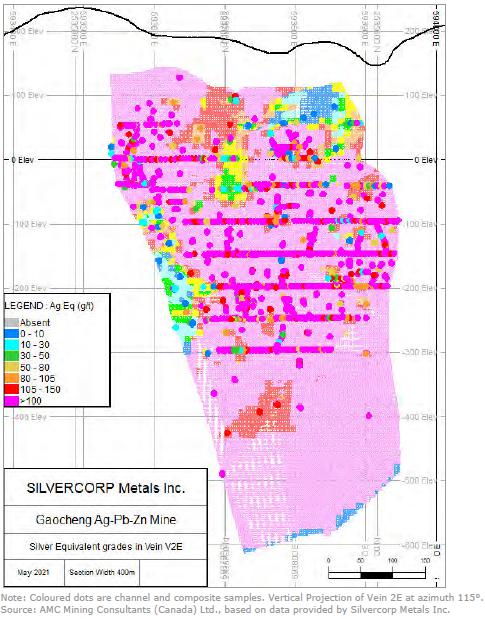

Mineralization at GC is primarily hosted within a WNW-ENE trending, 4.8 km long and 2 km wide fault zone. This zone encompasses numerous veins, with the more common WNW veins generally striking between 90° and 150° and dipping between 55° to sub-vertical. The average thickness of the WNW-ENE veins is about 0.8 m.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

There are also east-west striking veins that typically strike 50° to 130° and dip between 65° and sub-vertical to the SE and SSW. The average thickness is around 0.8 m.

NE-striking faults cut through the NWW-striking structures with no or minor displacement. Mineralized veins form part of this trend. These veins are sub-parallel to two major NE striking faults and generally strike between 10° and 85° and dip between 60° and 75° to the SE. The average thickness of these veins is also about 0.8 m.

Ag-Pb-Zn mineralization at the GC deposit can be divided into two types: primary and oxidized. The primary mineralization is mainly composed of galena-sphalerite-silver minerals, which occur sparsely, as disseminations, veinlets, and lumps. Primary mineralization accounts for 95% of the entire Mineral Resource. Oxide mineralization occurs on and near the surface.

Mineralized veins in the GC area occur in relatively permeable fault-breccia zones. These zones are extensively oxidized from the surface to depths of about 40 m. Veins in these zones exhibit open space and boxwork lattice textures resulting from the leaching and oxidation of sulphide minerals. Secondary minerals present in varying amounts include kaolinite, hematite, and limonite.

The dominant sulphide mineral is pyrite, and other constituents are a few percent of sphalerite, galena, pyrrhotite, arsenopyrite, magnetite, and less than one percent of chalcopyrite and cassiterite. Gangue minerals include chlorite, quartz, fluorite, feldspar, mica, and hornblende, with a small or trace amount of kaolinite, tremolite, actinolite, chalcedony, garnet, zoisite, apatite, and tourmaline.

Alteration minerals associated with the GC vein systems include quartz, sericite, pyrite, and chlorite, together with clay minerals and limonite. Silicification commonly occurs near the centre of the veins. Chlorite and sericite occur near and slightly beyond the vein margins.

Quartz, pyrite, fluorite, and chlorite are closely related to the mineralization.

The poly-metallic mineralization of the GC deposit belongs to the mesothermal vein infill style of deposit.

| 1.4 | Exploration and data management |

Silvercorp has carried out surface and underground exploration activities since 2008.

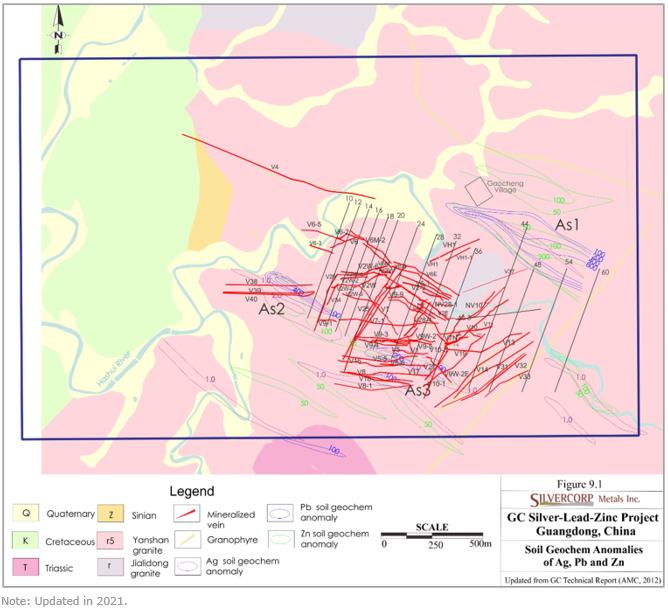

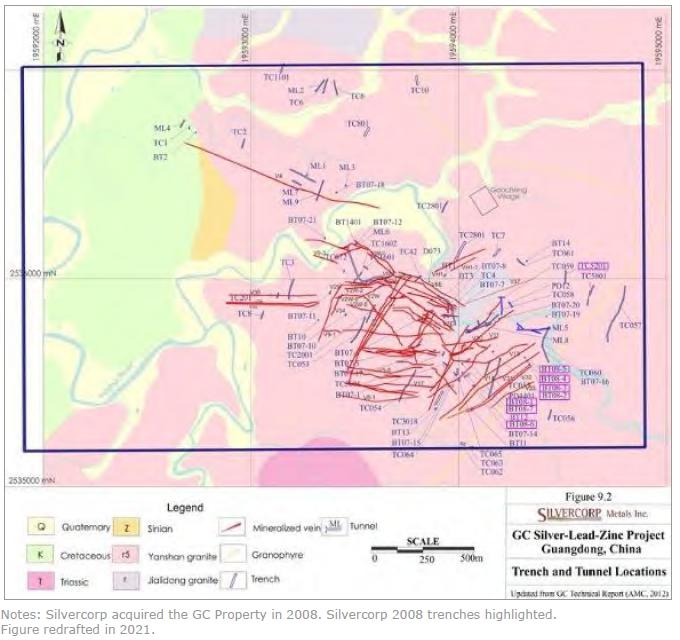

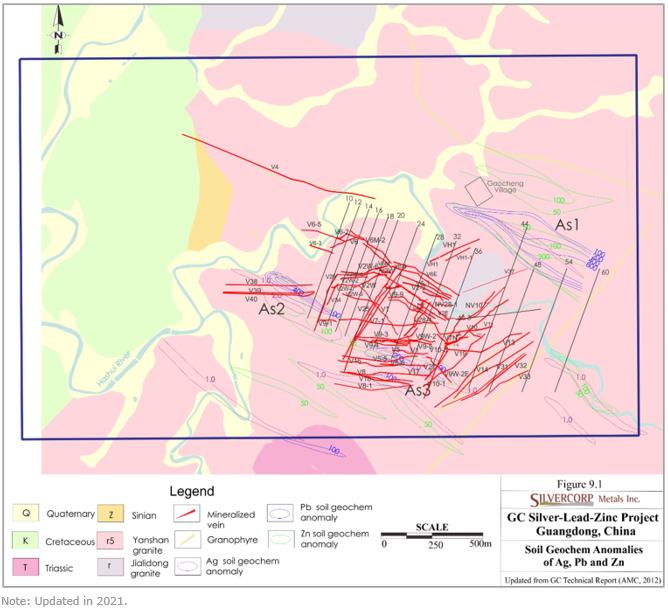

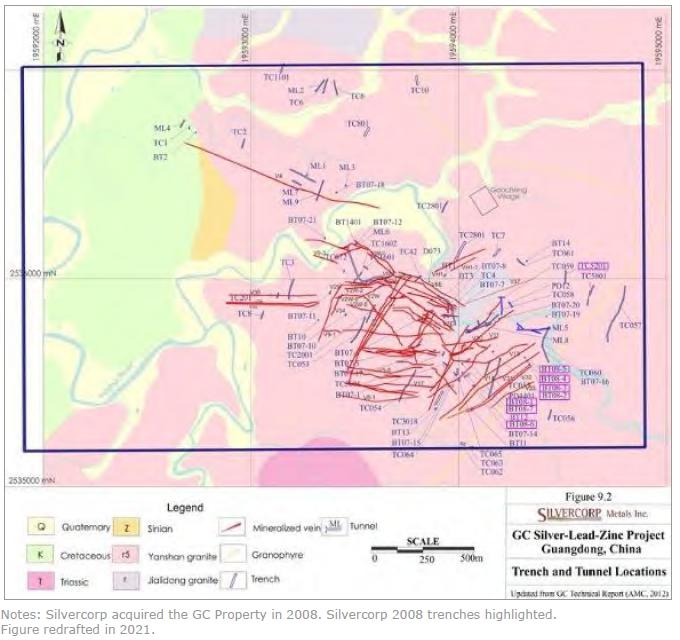

Surface-based exploration occurred primarily during 2008, which included soil sampling, geological mapping and trenching. Following up on geochemical anomalies, Silvercorp conducted trenching and pitting programs that exposed the mineralized veins on the surface and at shallow depth. A total of seven pits and one trench were excavated by Silvercorp exposing three veins.

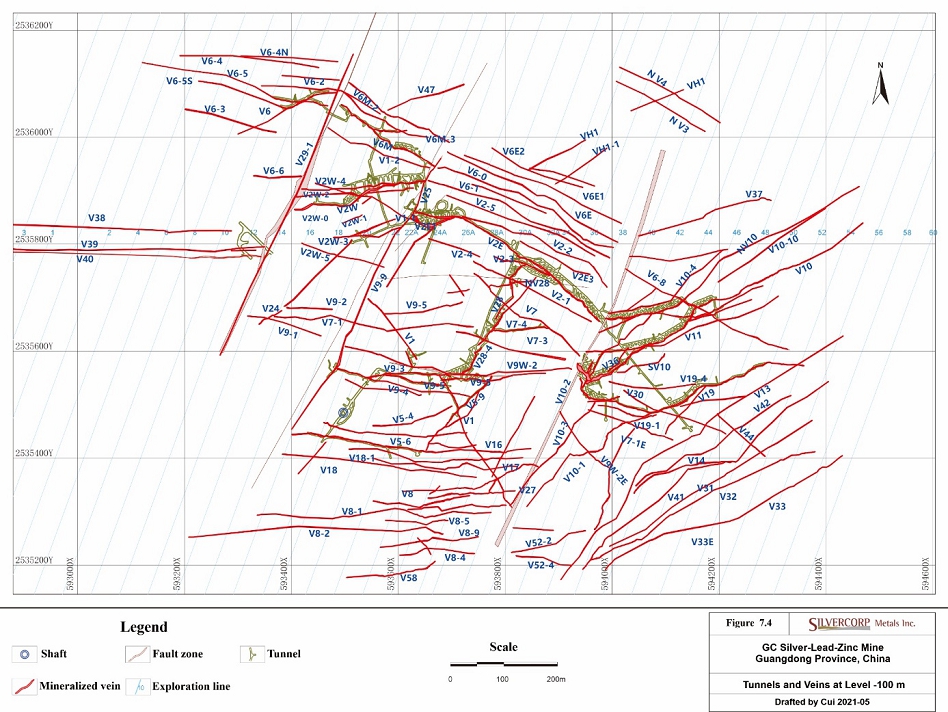

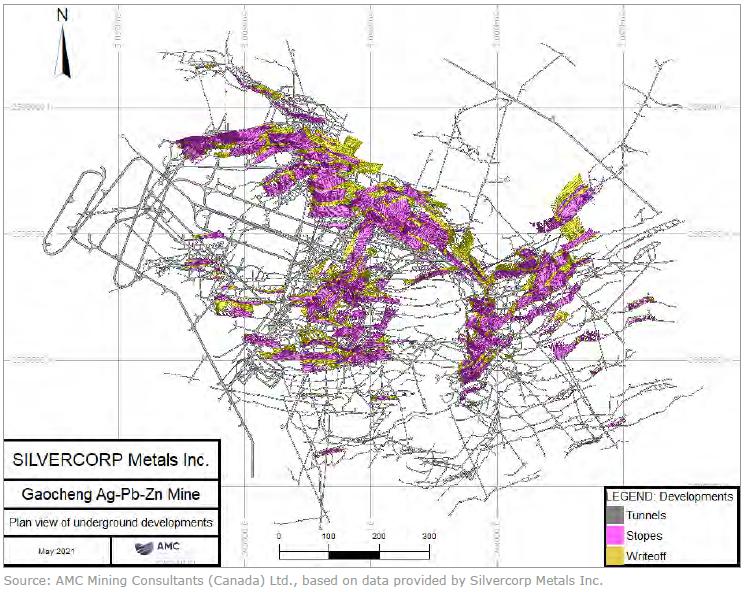

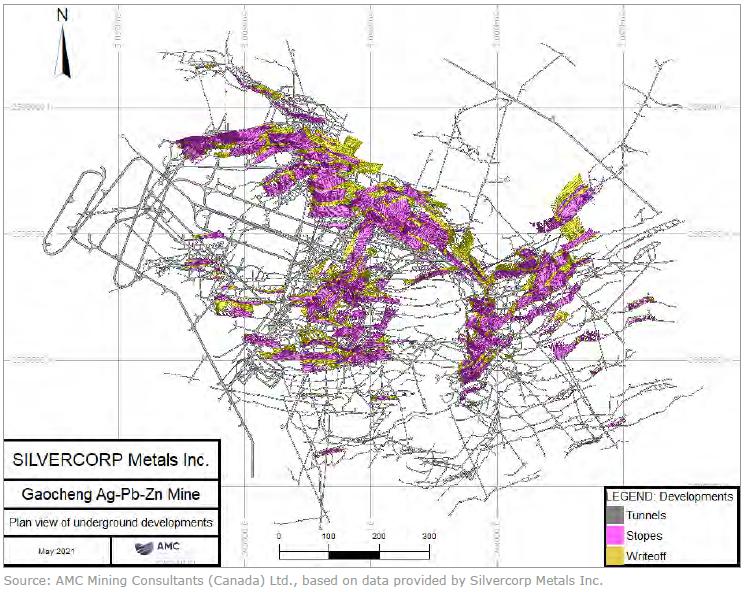

Silvercorp completed more than 51.5 km of underground tunnelling and sampling at the Property through to 2018, and 29.2 km between 2019 and 2020.

The programs through to 2018 comprised 33,297 m of drifting along mineralized structures, 10,147 m of crosscutting across mineralized structures, and 8,833 m of raises. The 2019 and 2020 work comprised 14,940 m of drifting along mineralized structures, 7,288 m of crosscutting across mineralized structures, and 6,951 m of raises. Drifts and crosscuts have been developed at 40 m intervals vertically to increase geological confidence in the Mineral Resource.

50,480 channel / chip samples were collected from the mine areas through to and including 2018, with samples being assayed for Ag, Pb, and Zn. 14,576 channel / chip samples were collected from the mine areas between 2019 and 2020.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

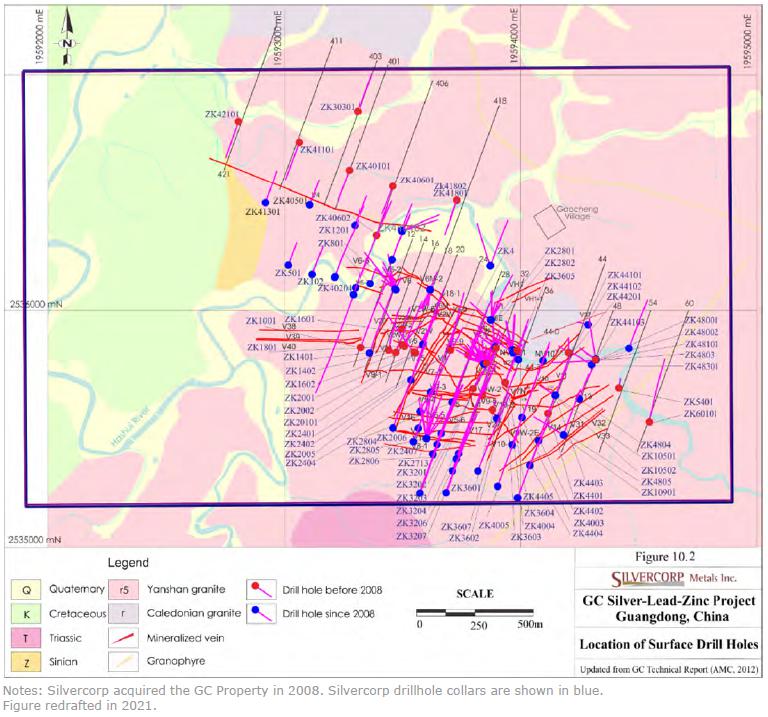

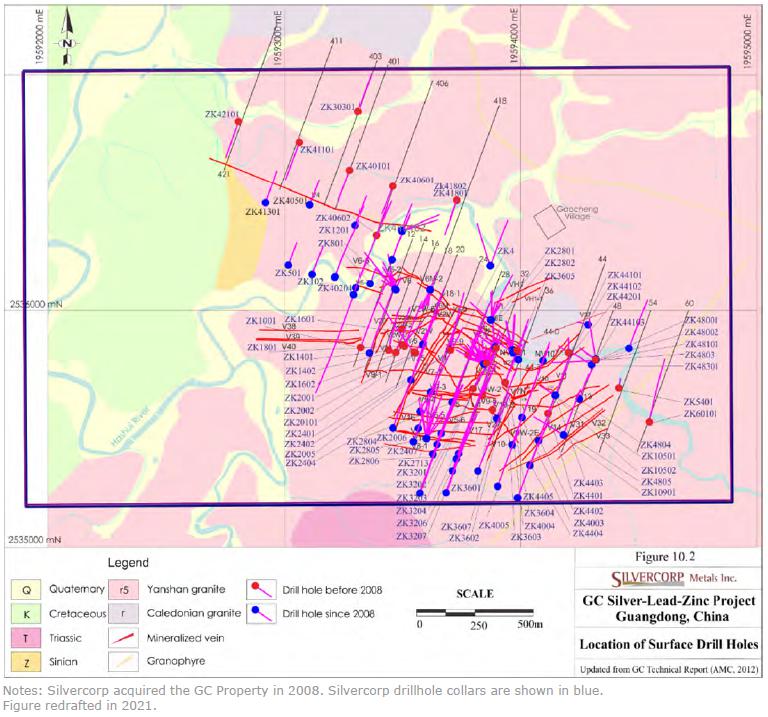

Silvercorp completed its first phase of diamond drilling on the Property in 2008. Systematic drilling commenced on the property in 2011 and continued through to 2020. All Silvercorp drilling was completed as NQ-sized core. Drillhole collars were surveyed using a total station and downhole surveys were completed every 50 m downhole. Surface drillhole collars were cemented after completion and locations of drillholes were marked using 50 x 30 x 20 centimetres (cm) concrete blocks.

Core recoveries from Silvercorp drilling programs varied between 35.66% and 100.00% averaging 99.36%. The QP reviewed the relationship between grade and core recovery and found no bias.

All drill core is stored in a clean and well-maintained core shack in the GC camp complex. This core shack is locked when unattended and monitored by two security personnel 24 hours a day.

The majority of drillholes were drilled as inclined holes to test multiple vein structures. Underground drillholes were drilled as fans of multiple holes from single set-ups.

Drill core processing is completed by Silvercorp employees in accordance with a standard procedure. Core recovery is measured followed by detailed logging of the core with lithological, vein and mineralization contacts identified and recorded. The core is photographed and sampled on 2.0 m maximum intervals and at geological or mineralization contacts. Core is cut in half with a rock saw with one half bagged and secured for shipment to the laboratory, and the other half retained in the core tray for future reference.

Channel samples are collected along sample lines perpendicular to the mineralized vein structure as well as from walls of cross-cut tunnels and bottom of trenches. Samples include vein material and associated wallrock.

Samples were shipped from the Gaocheng site to an ALS Laboratory in Guangzhou between 2008 and 2014. Since 2014, as a primary laboratory, samples have been shipped to the onsite laboratory at Gaocheng, which is owned and operated by Silvercorp. It is not certified by any standards association.

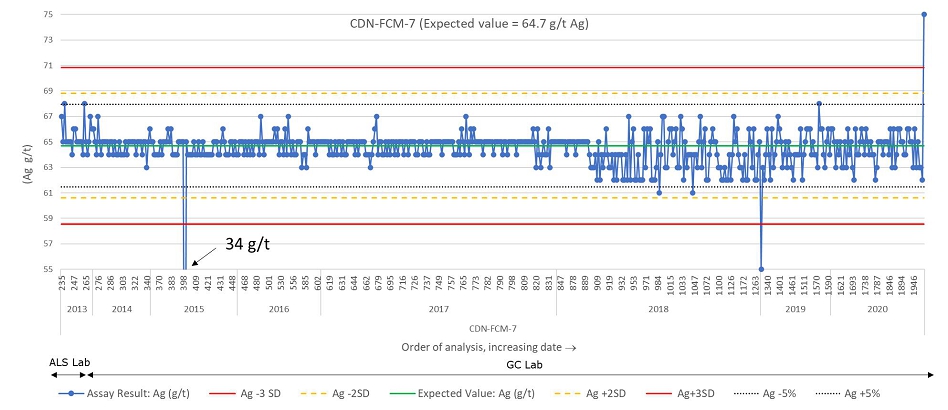

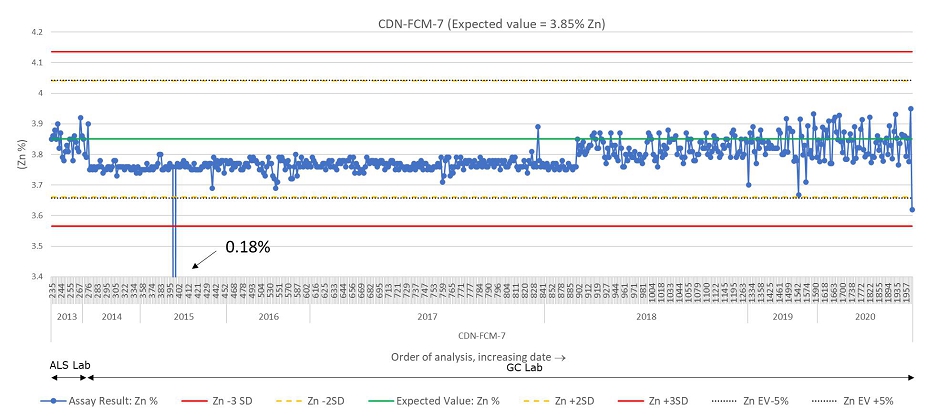

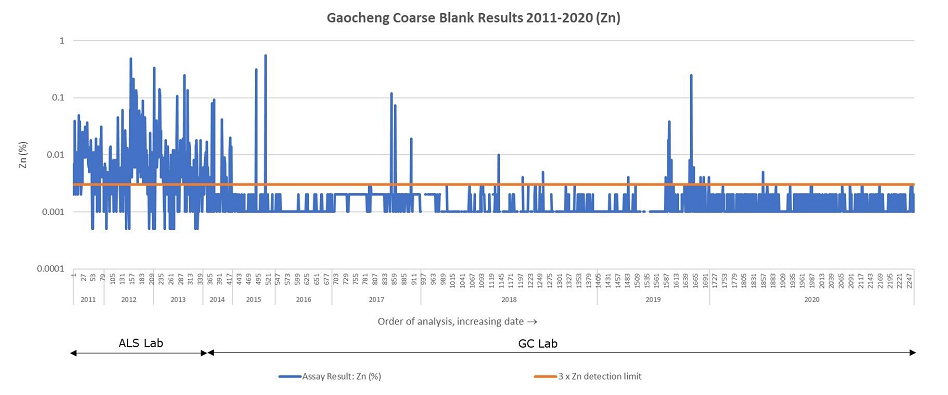

Silvercorp has established Quality Assurance / Quality Control (QA/QC) procedures that cover sample collection and processing at the Property. These QA/QC protocols have been progressively refined since 2011. Certified Reference Materials (CRMs) and coarse crushed blanks have been included with drilling samples since 2011, and with underground samples since 2014. Field duplicates have been included with drilling samples since 2012 and with underground samples since 2014. Check (umpire) samples (pulp duplicates) have been sent to a separate ‘umpire’ laboratory since 2012.

In 2018, Silvercorp further improved their QA/QC protocols to include regular and more frequent submission of CRMs, coarse blanks, and field duplicates with drilling and underground samples. Coarse reject duplicates and pulp duplicates were also incorporated into drill sampling programs. The proportion of check samples sent to a different laboratory was also increased. In 2019, Silvercorp initiated real-time monitoring of QA/QC protocols.

The QP has reviewed QA/QC data collected to date. While some issues have been noted with data collected prior to 2014, all data collected thereafter shows reasonable analytical accuracy and precision. The QP does not consider issues noted with pre-2014 data to be a material concern and considers the Gaocheng sample database acceptable for Mineral Resource estimation.

A series of recommendations has been provided for the improvement of QA/QC processes (see Section 1.13 Recommendations).

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| 1.5 | Mineral Resource estimates |

The Mineral Resources for the Property have been prepared by Mr Shoupu Xiang, Resource Geologist of Silvercorp. Ms Dinara Nussipakynova, P.Geo., of AMC, has reviewed the methodologies and data used to prepare the Mineral Resource estimates and, after some adjustment to the Mineral Resource classification and capping, is satisfied that they comply with reasonable industry practice. Ms Nussipakynova takes responsibility for these estimates.

The QP is not aware of any known environmental, permitting, legal, title, taxation, socioeconomic, marketing, political, or other similar factors that could materially affect the stated Mineral Resource estimates. It is noted that approximately 1% of the Mineral Resources lie below the lower limit of the current mining lease (-530 m elevation), but this is not seen as a material risk.

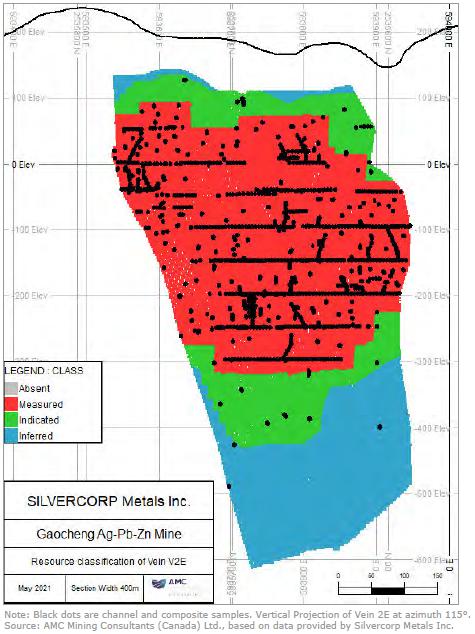

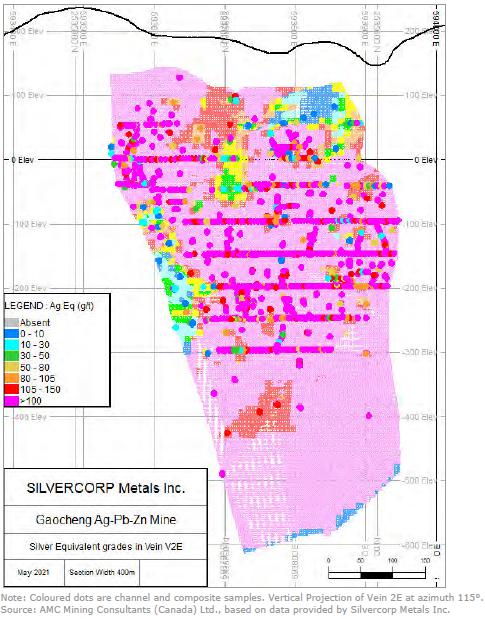

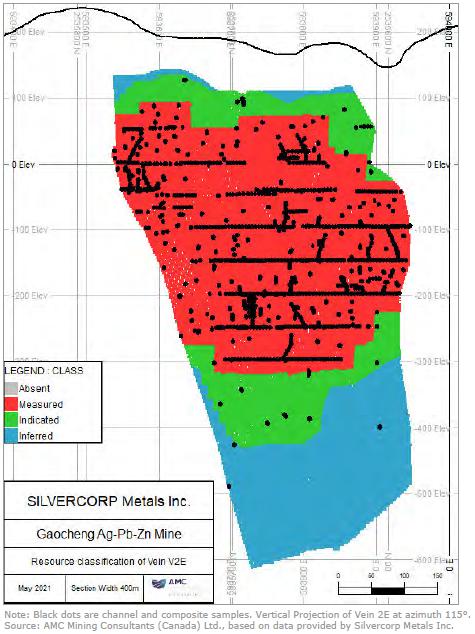

The data used in the Mineral Resource estimation includes results of all drilling carried out on the Property to 31 December 2020. The estimation was carried out in Micromine™ software. Interpolation was carried out using inverse distance squared (ID2) for all the veins.

| Table 1.1 | Summary of Mineral Resources as of 31 December 2020 |

| Classification | Tonnes (Mt) | Ag (g/t) | Pb (%) | Zn (%) | Contained metal |

| Ag (koz) | Pb (M lbs) | Zn (M lbs) |

| Measured | 5.286 | 88 | 1.3 | 3.1 | 14,906 | 154 | 360 |

| Indicated | 4.747 | 75 | 1.1 | 2.5 | 11,457 | 111 | 259 |

| Measured and Indicated | 10.033 | 82 | 1.2 | 2.8 | 26,363 | 265 | 619 |

| Inferred | 8.441 | 87 | 1.0 | 2.4 | 23,562 | 195 | 442 |

Notes:

| · | CIM Definition Standards (2014) were used for reporting the Mineral Resources. |

| · | Mineral Resource are reported at a silver equivalent (AgEq) cut-off grade of 105 g/t AgEg. |

| · | The equivalency formula is Ag g/t+50.46*Pb%+43.53*Zn% using prices of US$18.20/oz Ag, US$0.94/lb Pb, and US$1.08/lb Zn and estimated recoveries of 82.6% Ag, 89.5% Pb, and 87.3% Zn. |

| · | Sample results up to 31 December 2020. |

| · | Mineral Resources have been depleted to account for mining to 31 December 2020. |

| · | Veins factored to a minimum extraction width of 0.4 m. |

| · | Mineral Resources are inclusive of Mineral Reserves reported in Section 15. |

| · | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. An Inferred Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of Inferred Mineral Resources could be upgraded to Indicated Mineral Resources with continued exploration. |

| · | The numbers may not compute exactly due to rounding. |

Source: Silvercorp Metals Inc., reproduced as a check by AMC Mining Consultants (Canada) Ltd.

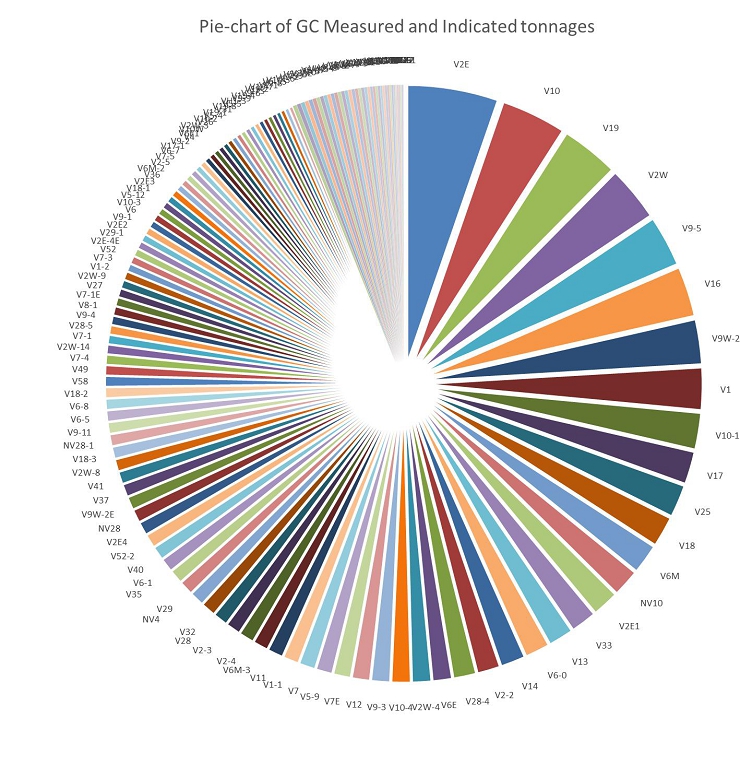

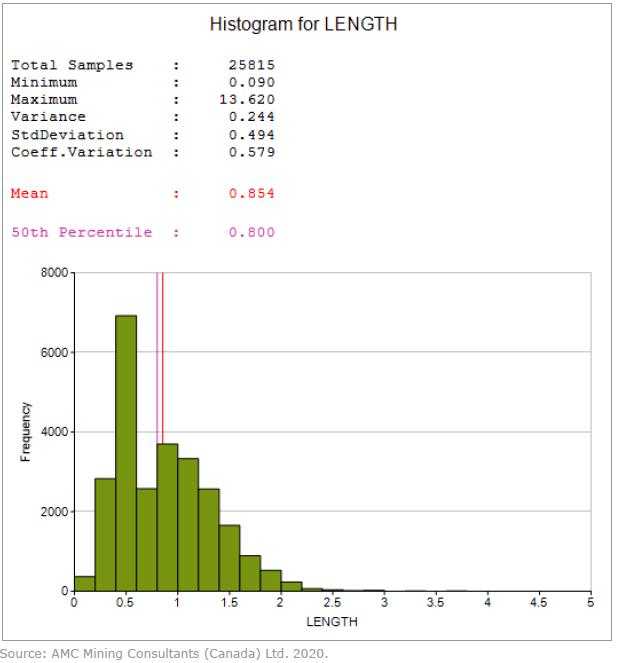

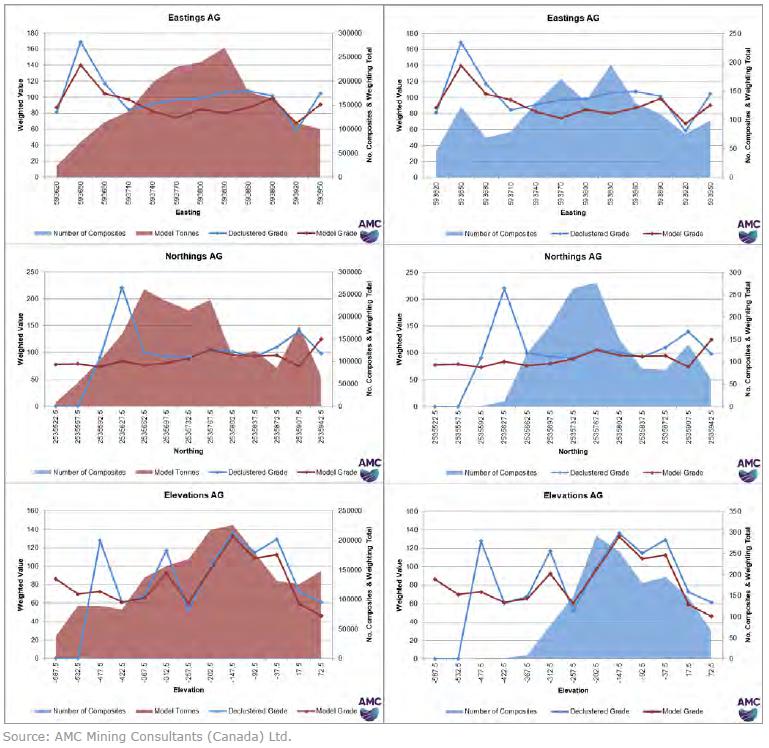

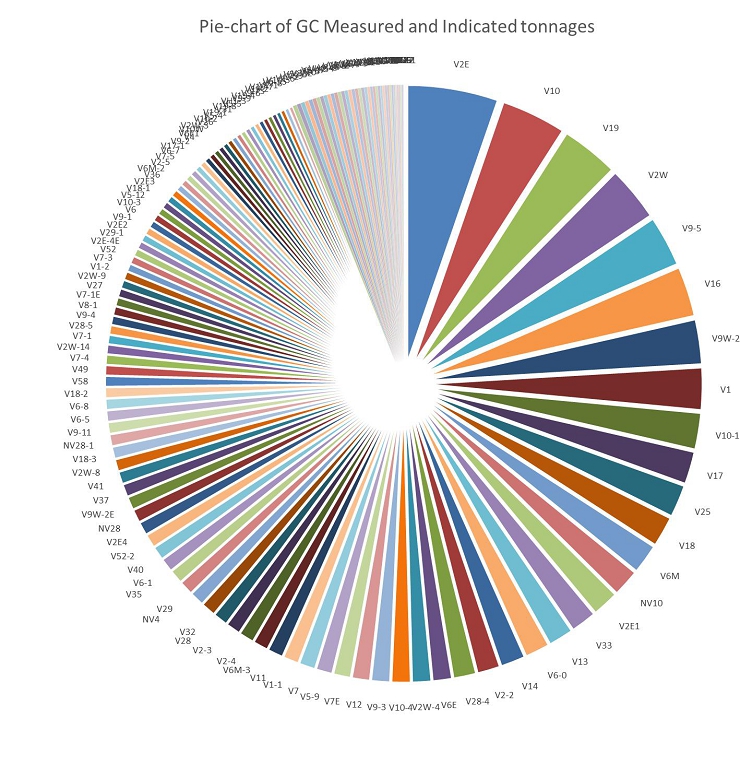

The GC deposit consists of 156 veins, each of which has a separate block model. Approximately 31,844 m of channel samples and 265,965 m of core samples from 1,854 drillholes form the basis of the estimate. A composite length of 0.4 m was used. Capping was applied after compositing.

The parent block size for all veins was 0.8 m by 10 m by 10 m (x, y, z), with sub-cells employed. The sub-celling resulted in minimum cell dimensions of 0.2 m by 2 m by 2 m (x, y, z). The QP imported all 156 block models into Datamine software. The volume comparison of the original models versus the Datamine models showed a difference of less than 1%.

Interpolation was carried out using the ID2 method. Mining depletion and write-offs based on survey information to 31 December 2020 were coded into the block models by Silvercorp.

Mineral Resources are classified as Measured, Indicated, and Inferred. The QP reviewed the classification of each vein and requested changes when the classification needed to be modified.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

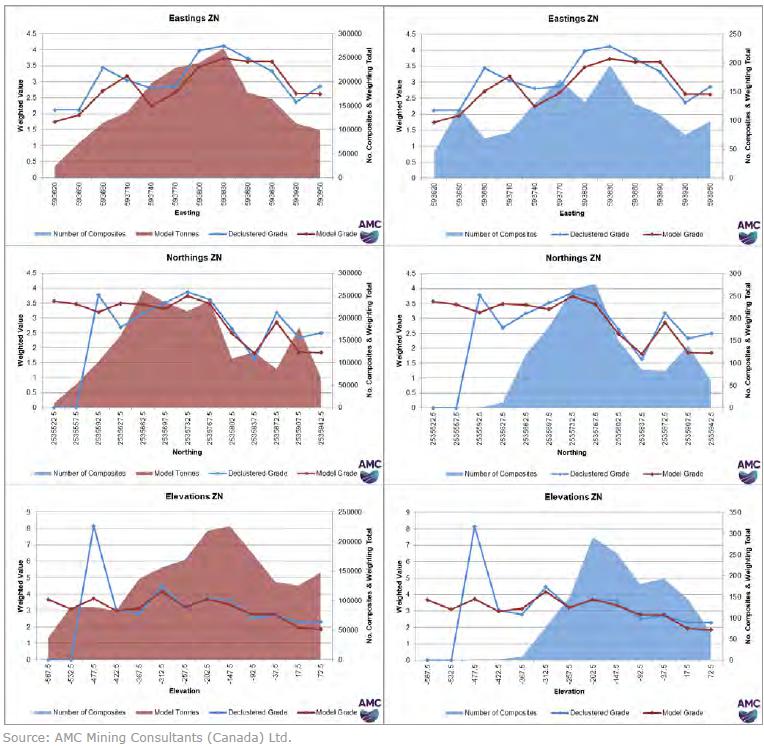

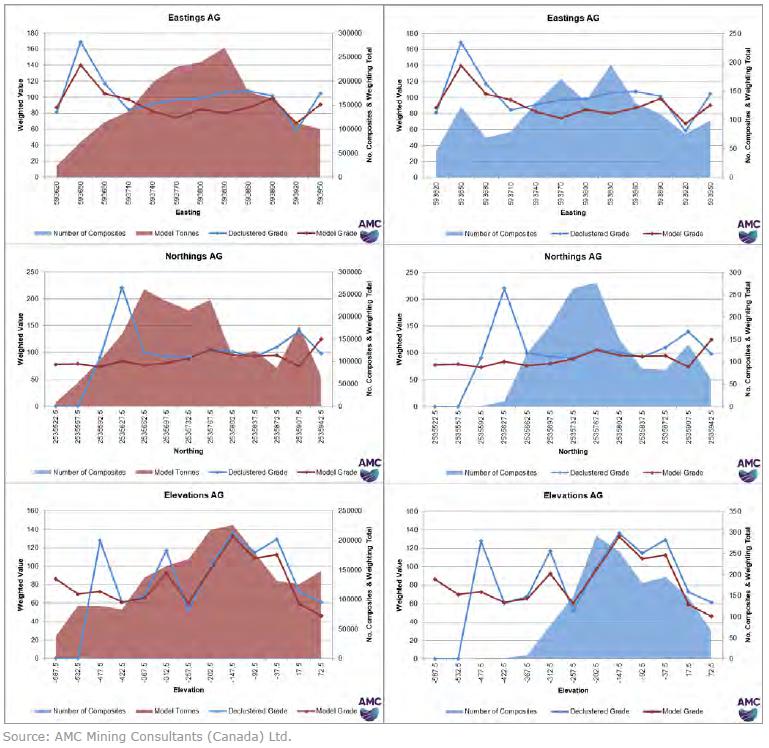

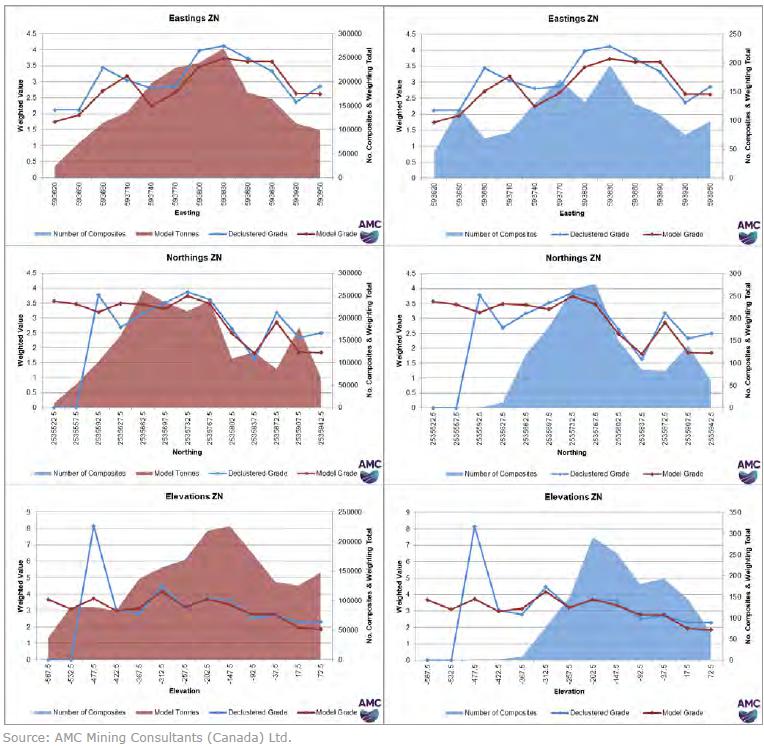

The block models were validated by the QP in three ways. First, visual checks were carried out to ensure that the grades respected the raw assay data. Secondly, swath plots were reviewed. Thirdly, the estimate was statistically compared to the composited assay data, with satisfactory results.

The following observations have been made by the QP from a comparison of the 2019 Mineral Resource estimate and the 2020 Mineral Resource estimate:

| · | Measured and Indicated tonnes have increased by 11%. This number is a result of the discovery of new veins and new vein interpretation. |

| · | Measured tonnes have increased by 57%. This number is a result of the discovery of new veins, new vein interpretation and conversion of Indicated tonnes (which have decreased by 17%) to Measured classification. |

| · | In the Measured category silver grade has decreased by 9% and lead and zinc grades have both decreased by 6%. |

| · | In the Indicated category silver grades have decreased by 3%, lead grades have increased by 6% and zinc grades have decreased by 1%. |

| · | In the Inferred category silver grades have decreased by 5%, lead grades have increased by 5% and zinc grades have decreased by 1%. |

| · | The net result in the Measured category has been a significant increase in contained metals due to the increase in tonnes. Silver and lead metal have each increased by 44% and zinc contained metal has increased by approximately 47%. |

| · | The net result in the Indicated category has been a decrease in the contained silver metal of 19%; lead and zinc contained metals have decreased by 12% and 19%, respectively. This is a result of conversion of Indicated material to Measured material. |

| · | The net result in the Inferred category has been an increase of 11% in the contained silver metal; contained lead metal has increased by 17% and contained zinc metal has increased by 13%. |

Reasons for the differences in grade, tonnes, and contained metal include:

| · | Updated interpretation of the veins. |

| · | Conversion of Indicated Mineral Resources to a Measured classification. |

| · | Depletion through mining. |

| 1.6 | Mineral Reserve estimates and mining |

To convert Mineral Resources to Mineral Reserves, mining cut-off grades (COGs) have been applied, mining dilution has been added and mining recovery factors assessed on an individual vein mining block basis. Only Measured and Indicated Resources have been used for Mineral Reserves estimation.

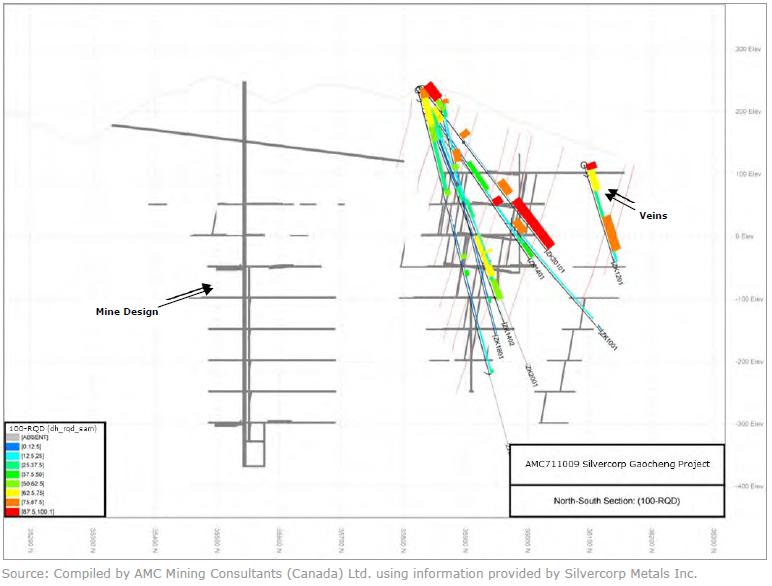

The Mineral Reserve estimates for the Property were prepared by Silvercorp under the guidance of independent QP, Mr H. Smith, P.Eng., who takes QP responsibility for those estimates.

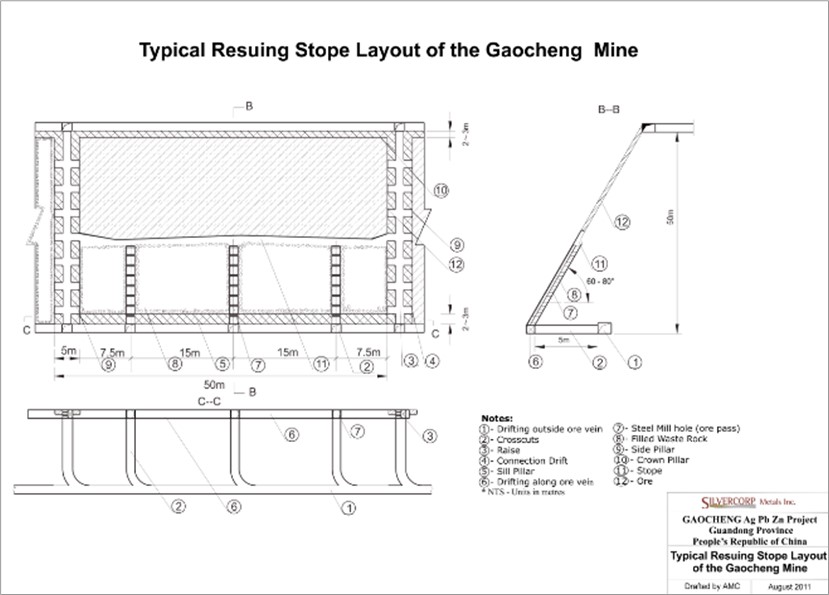

The Mineral Reserve estimation is based on the assumption that current stoping practices will continue at the Gaocheng property, namely predominantly shrinkage stoping but also with some cut and fill resuing. Minimum mining widths of 1.0 m for shrinkage and 0.5 m for resuing, and minimum dilution of 0.20 m total for shrinkage and 0.10 m for resuing cut and fill stopes are assumed. Full breakeven COGs used are 215 g/t AgEq for shrinkage and 275 g/t AgEq for resuing.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

Table 1.2 summarizes the Mineral Reserves estimate for the Gaocheng mine. 63% of the Mineral Reserve tonnage is categorized as Proven and 37% is categorized as Probable.

| Table 1.2 | Gaocheng Mineral Reserve estimate at 31 December 2020 |

| Classification | Tonnes (Mt) | Ag (g/t) | Pb (%) | Zn (%) | Contained metal |

| Ag (koz) | Pb (Mlbs) | Zn (Mlbs) |

| Proven | 2.587 | 93 | 1.5 | 3.3 | 7,743 | 84 | 189 |

| Probable | 1.544 | 95 | 1.5 | 3.0 | 4,740 | 51 | 103 |

| Proven and Probable | 4.131 | 94 | 1.5 | 3.2 | 12,483 | 135 | 293 |

Notes to Mineral Reserve Statement:

| · | Canadian Institute of Mining, Metallurgy and Petroleum Standards (2014) were used for reporting the Mineral Reserves. |

| · | Full breakeven cut-off grades: Shrinkage = 215 g/t AgEq: Resuing = 275 g/t AgEq. |

| · | Marginal material cut-off grade: Shrinkage = 185 g/t AgEq; Resuing = 250 g/t AgEq. |

| · | Dilution (zero grade) assumed as a minimum of 0.1 m on each wall of a shrinkage stope and 0.05 m on each wall of a resuing stope. |

| · | Mining recovery factors assumed as 92% for shrinkage and 95% for resuing. |

| · | Metal prices: Silver US$18.20/troy oz, lead US$0.94/lb, zinc US$1.08/lb, with respective payables of 65.5%, 86.2%, and 66.3%. |

| · | Processing recovery factors: Ag – 82.6%, Pb – 89.5%, Zn – 87.3%. |

| · | Effective date 31 December 2020. |

| · | Exchange rate assumed is RMB6.80: US$1.00. |

| · | Rounding of some figures may lead to minor discrepancies in totals. |

From the start of commercial operations at Gaocheng in 2014 through to the end of 2020, 1,853,662 tonnes have been mined at average head grades of 94 g/t silver, 1.6% lead, and 2.9% zinc. Compared to the average production head grades recorded up to the end of 2020, the current Mineral Reserve estimates show the same silver grade, a reduction in lead grade of 7%, and an increase in zinc grade of 9%.

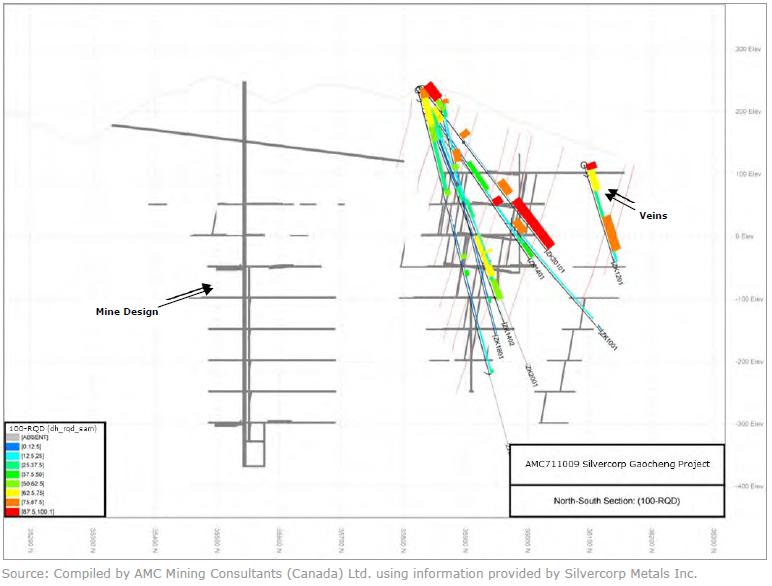

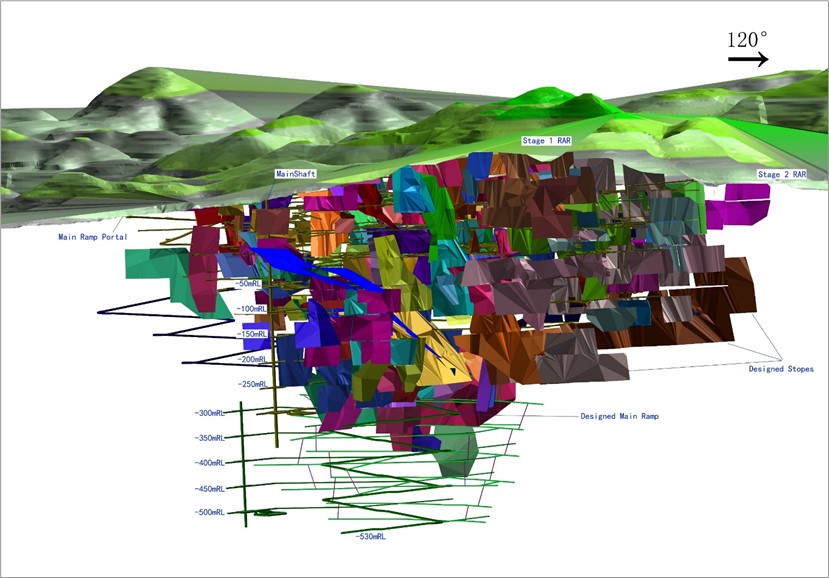

Mining to date has been conducted in two stages. Stage 1 targeted bringing the project into production as soon as practicable using mobile, rubber-tired, diesel-powered equipment (development jumbo, loader, and truck) with surface declines access down to -50 mRL. Stage 2 development from -50 mRL down to -300 mRL employs conventional tracked equipment (battery powered locomotives, rail cars, electric rocker shovels and pneumatic hand-held drills) via a surface shaft access. In-stope rock movement is by gravity to draw points or hand-carting to steel-lined passes.

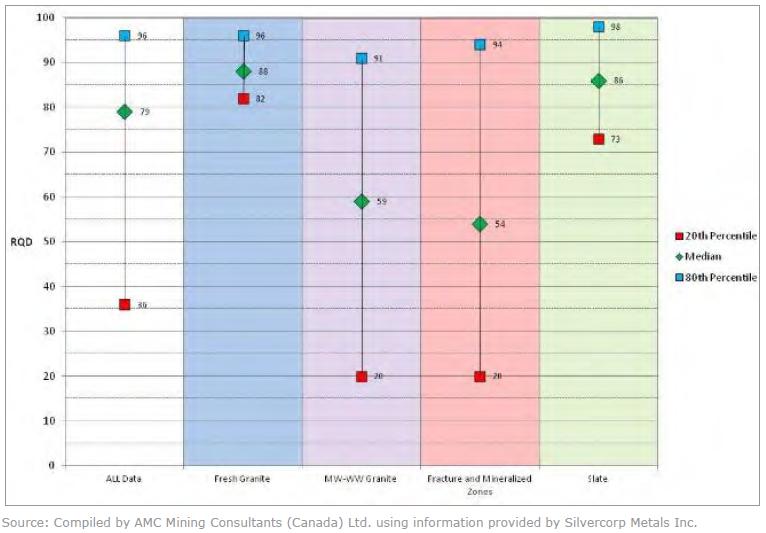

The rock mass condition is categorized as Fair to Good and it is anticipated that the vein and host rocks in the mine area will continue to be largely competent and require minimal ground support other than in weaker ground areas.

The Main Shaft radius is 3 m. A 30 m radius around the Main Shaft is categorized as a safety pillar, with no mining or development allowed in the pillar area, other than for actual shaft access.

Relative to the Mineral Reserve estimates in the previous Technical Report (2019 Technical Report), there is a 39% increase in Proven Mineral Reserve tonnes and a 21% decrease in Probable Mineral Reserve tonnes, with an increase in Mineral Reserve total tonnes of 8% (311,000 t).

| 1.7 | Metallurgy and processing |

Since the metallurgical testing reported in the 2012 Technical Report, no further testing has been done. The mill functioned in a trial mode up to 2014 and, from that point (FY2015 starting Q2 2014), has been in commercial production.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

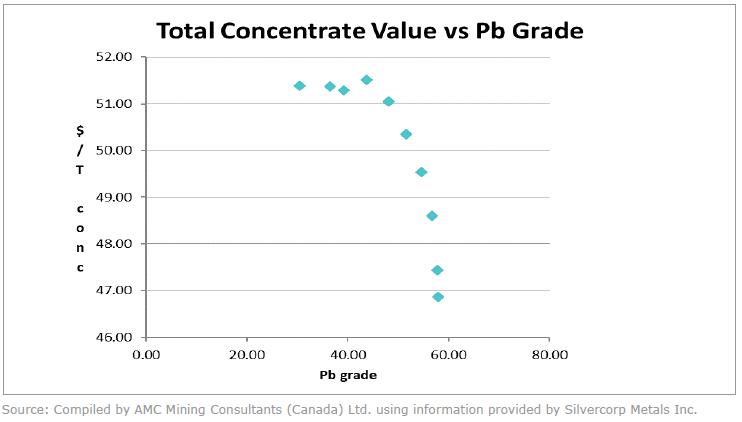

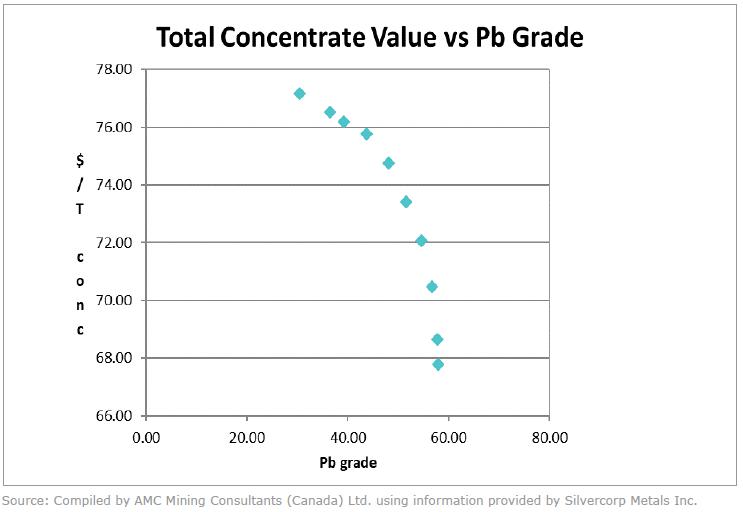

Metallurgical testing for the GC project was carried out by the Hunan Research Institute of Non-Ferrous Metals and reported in May 2009 in the report ‘Development and Research of the Comprehensive Recovery Test of Lead Zinc Silver Tin Sulphur for the Lead Zinc Ore Dressing in GC Mine Area’. This report was made available to AMC in English translation by Silvercorp. The testwork was also summarized in the January 2011 GMADI report as part of the “Design Instructions” for the plant design.

The objectives of the testwork were, following on from previous testwork of 2007 on samples from artisanal mining dumps, to i) maximize silver recovery to the lead concentrate, ii) investigate the potential for tin recovery, iii) develop a process flow sheet with appropriate operating parameters as a basis for the industrial scale implementation of lead, zinc, sulphur (and possibly tin) recovery, and iv) determine the product quality characteristics relative to the relevant national standards.

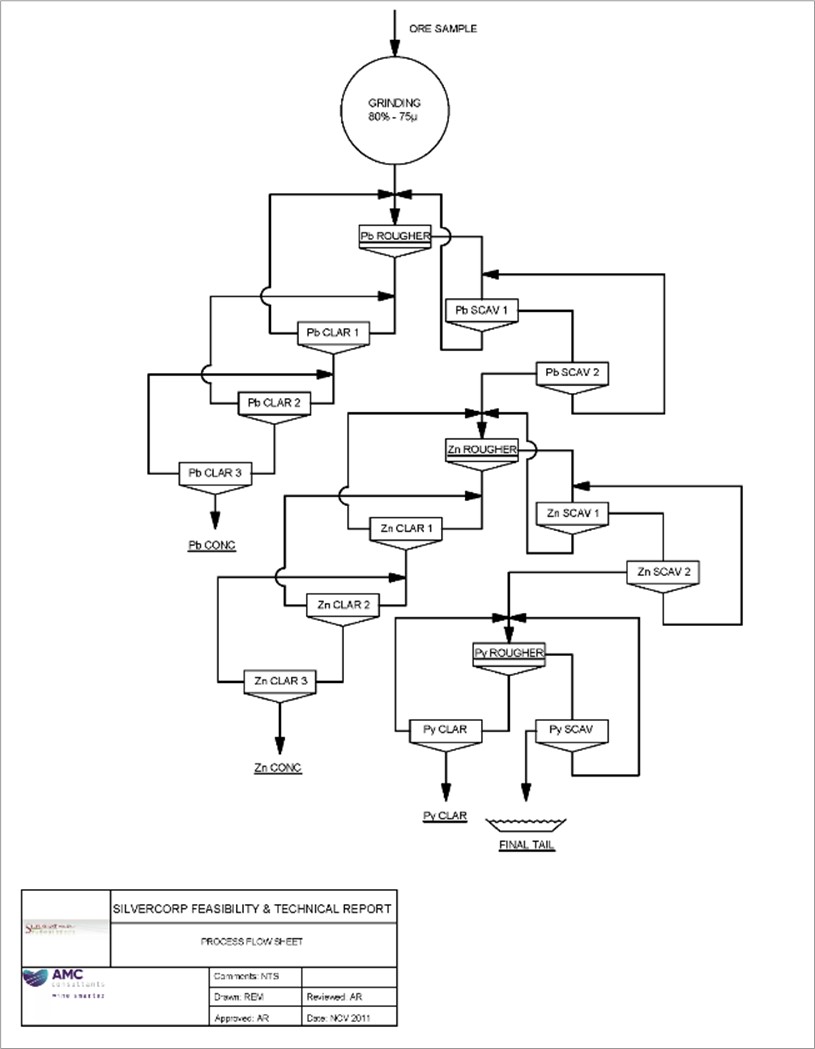

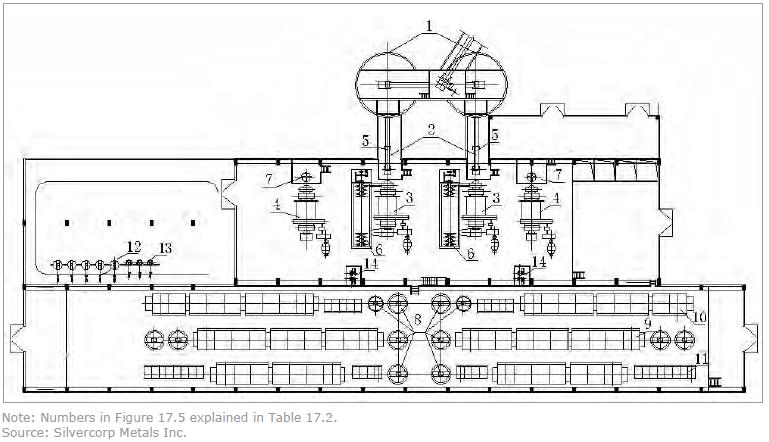

Since the start of trial operations in 2013 and commercial production in 2014, lead and zinc concentrates have been produced in commercial quantities at the Gaocheng mill. The overall process consists of crushing, grinding, sequential flotation of lead, zinc, and pyrite concentrates, and concentrate dewatering by disc filtration. An experimental tin recovery gravity separation circuit is installed on pyrite flotation tails.

Two-stage crushing is carried out, with the second stage in closed circuit. Run of mine ore at -350 millimetres (mm) is reduced to crusher product at -10 mm. This is followed by two-stage grinding in ball mills to a product size of 80% passing 75 µm (P80 of 75 µm).

The flotation process consists of a standard flotation of lead, with three-stage cleaning of the lead concentrate, then flotation of zinc concentrate with three-stage cleaning, leaving pyrite tailings as sulphur concentrate. Concentrates are dewatered by conventional thickening and filtration.

In 2019, the lead-zinc-sulphur priority flotation process was optimized by changing from zinc-sulphur process priority flotation to zinc-sulphur mixed flotation and then zinc-sulphur separation flotation process. The quantity of ore processed has increased to around 300 ktpa.

Trucks under escort by security personnel are used to transport lead and zinc concentrates from the mine site to refineries. A front-end loader is used to load the concentrate from storage sheds near filters at the mill site to the concentrate shipping trucks.

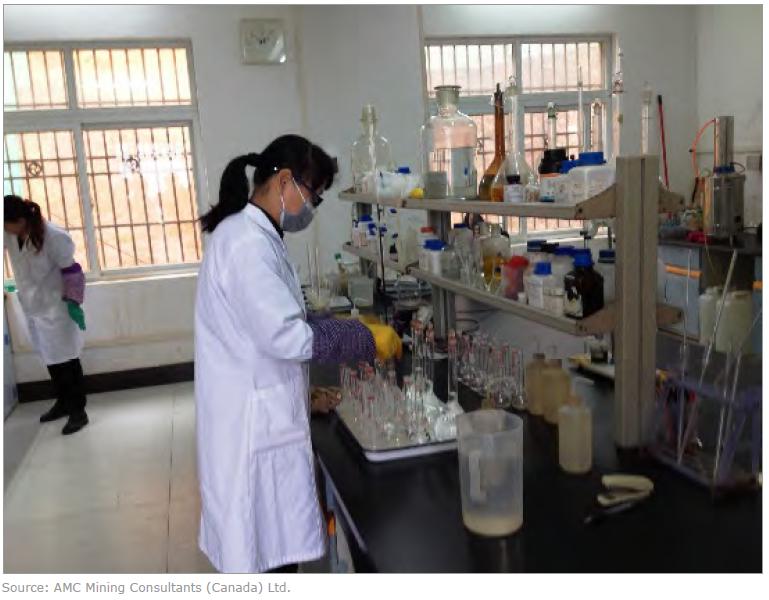

There is a laboratory on site equipped with the customary sample preparation, wet chemistry, and basic photometric analytical equipment; as well as crushing, grinding, flotation, and gravity-separation metallurgical testing equipment.

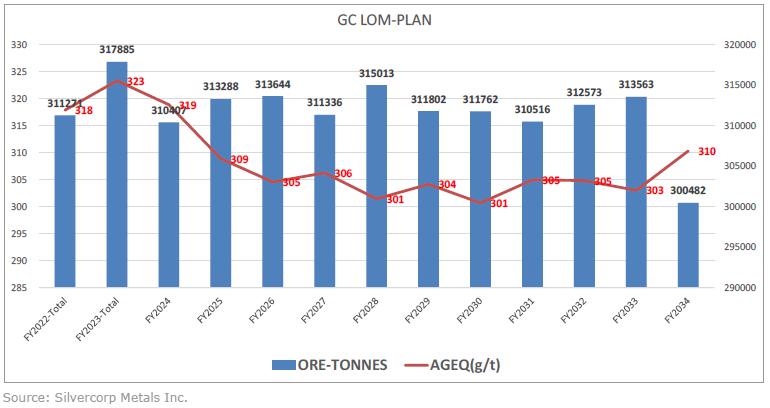

Table 1.3 shows the projected life-of-mine (LOM) mill feed and metal production profile.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| Table 1.3 | Gaocheng LOM mill feed and metal production |

| Item | Unit | 2021 Q4 | 2022 | 2023 | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 | Total |

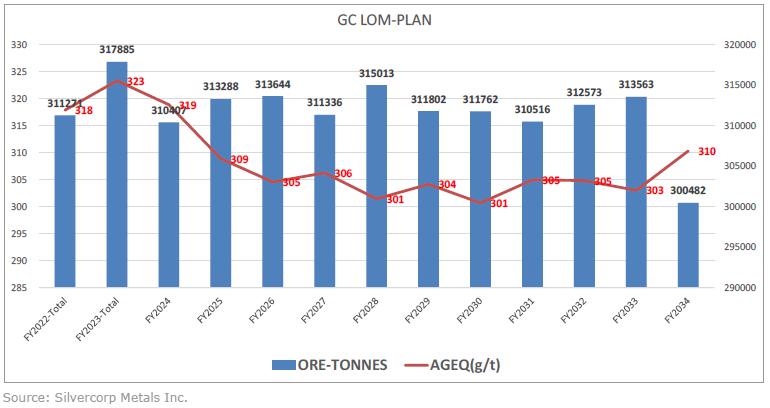

| Mill Feed - Ore tonnes | t | 77,496 | 311,271 | 317,885 | 310,407 | 313,288 | 313,644 | 311,336 | 315,013 | 311,802 | 311,762 | 310,516 | 312,573 | 313,563 | 300,482 | 4,131,039 |

| Head grade, Ag | g/t | 88 | 86 | 92 | 96 | 96 | 94 | 96 | 93 | 95 | 94 | 94 | 94 | 98 | 97 | 94 |

| Head grade, Pb | % | 1.51 | 1.46 | 1.55 | 1.47 | 1.47 | 1.35 | 1.51 | 1.58 | 1.49 | 1.26 | 1.40 | 1.60 | 1.43 | 1.69 | 1.48 |

| Head grade, Zn | % | 3.72 | 3.64 | 3.52 | 3.42 | 3.20 | 3.29 | 3.08 | 2.95 | 3.08 | 3.28 | 3.21 | 2.99 | 3.06 | 2.95 | 3.22 |

| Planned metal - Ag mined | t | 6.79 | 26.75 | 29.21 | 29.78 | 30.02 | 29.36 | 29.85 | 29.39 | 29.56 | 29.35 | 29.30 | 29.26 | 30.64 | 29.01 | 388.27 |

| Planned metal - Pb mined | t | 1,173 | 4,544 | 4,940 | 4,565 | 4,592 | 4,224 | 4,706 | 4,965 | 4,651 | 3,929 | 4,354 | 5,007 | 4,492 | 5,084 | 61,225 |

| Planned metal - Zn mined | t | 2,883 | 11,317 | 11,175 | 10,607 | 10,011 | 10,304 | 9,591 | 9,308 | 9,604 | 10,238 | 9,974 | 9,361 | 9,581 | 8,863 | 132,818 |

| Planned metal - Ag recovered | t | 5.61 | 22.10 | 24.13 | 24.60 | 24.79 | 24.25 | 24.65 | 24.28 | 24.42 | 24.24 | 24.20 | 24.17 | 25.31 | 23.96 | 320.71 |

| Planned metal - Pb recovered | t | 1,050 | 4,067 | 4,422 | 4,086 | 4,109 | 3,780 | 4,212 | 4,444 | 4,162 | 3,516 | 3,897 | 4,482 | 4,020 | 4,550 | 54,797 |

| Planned metal - Zn recovered | t | 2,517 | 9,880 | 9,756 | 9,260 | 8,740 | 8,995 | 8,373 | 8,125 | 8,384 | 8,938 | 8,708 | 8,173 | 8,364 | 7,738 | 115,950 |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| 1.8 | Project infrastructure |

The filtered tailings are conveyed to the TMF area via conveyor and then spread by bulldozer on a bench-by-bench basis. The tailings deposition method is dry stacking and filling (from bottom to top and stacking by bench to form the embankment), with concurrent rolling and compaction to the desired dry density standards.

The waste rock dump is located a short distance to the east of the mine portal. It is understood to have an immediate capacity of the order of 275,000 m3 (~558 kt). Underground waste rock produced to date has largely been used for construction purposes by Silvercorp or transported off site by local area persons, free of charge, again to be used for construction activities. The removal of waste rock from site is anticipated to continue for the foreseeable future. Waste rock could opportunistically be disposed of into shrinkage stope voids, but this is not in the current mine plan.

Based on the GC environmental assessment report, the QP understands that waste rock at the GC mine has no significant acid-generating potential.

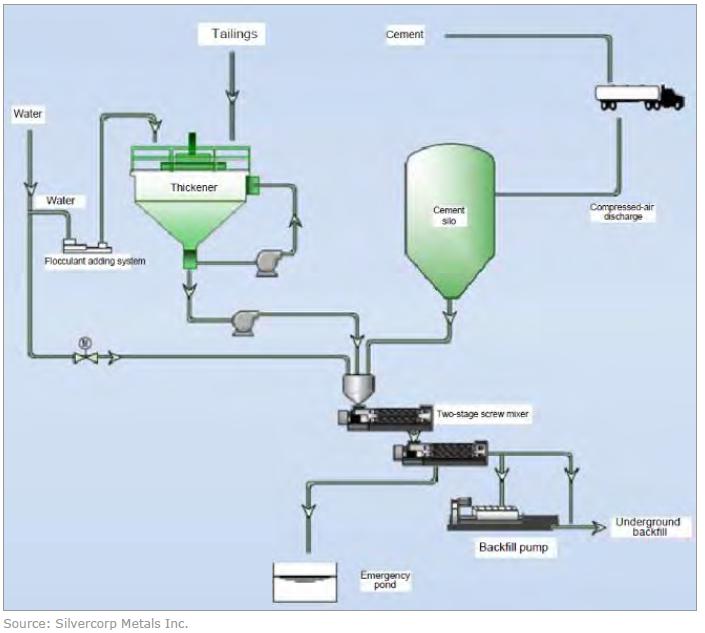

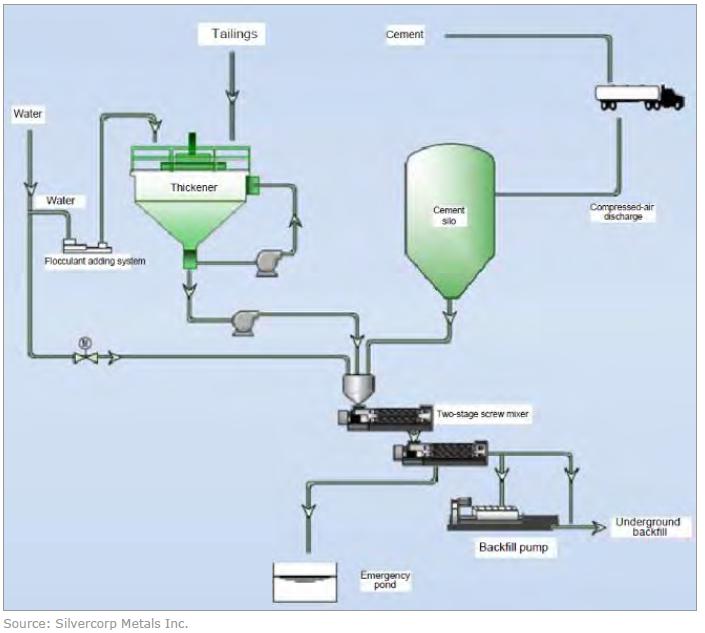

The construction of a cemented tailings backfill plant was completed in December 2019. The design capacity is 60 – 80 m3/hr, or around 450 m3/day assuming seven hours operation. After surface and underground full-process backfilling tests and adjustment, the system began operating in July 2020. In 2020, the total backfill volume delivered was 43,091 m3, and the backfill guidance for 2021 is 70,626 m3.

There is a 110 kilovolt (kV) substation near Gaocun, about 6 km from the mining area. This is fed from the Guangdong Province electrical grid system. Silvercorp uses this substation as the main source of power for the mine. Currently there are two overhead power lines for the 6 km route. Two 1,500 kV diesel generators are designated for emergency backup to the man-hoist, underground ventilation system, water pumping and essential services in the plant.

A 10 kV substation within the mining area provides power service for the entire operations area. The power supply and distribution in the process plant, mining area, administrative and living areas are configured based on needs.

Sewage treatment and water treatment plants operate at the mine site. Any water that is not recycled and is released to the environment is treated to comply with standing regulations.

Underground water is discharged to surface using conventional centrifugal pumps via pipelines installed in the Ramp, Ramp Shaft, and Main Shaft. Underground water pumped to surface is collected in ponds at the Ramp portal or Main Shaft for sediment settling prior to being pumped to the process plant water treatment station. In 2020, a total volume of 497,659 m3 of underground water was treated, including 290,577 m3 discharged and 207,082 m3 recycled.

Mobile equipment repairs (trucks, loaders, etc.), other equipment breakdowns and equipment major services are conducted in the mining contractor’s surface workshop adjacent to the Ramp portal, with minor services conducted in redundant stockpile areas. Other fixed and mobile equipment (primary pumps, surface electric locomotive, rail cars, vehicles, etc.) are serviced in Silvercorp’s surface workshop located adjacent to the Main Shaft. This is fully equipped with overhead crane, welding, electrical, hydraulic, lathe services, etc.

The explosives warehouse is sited in the valley to the south-east of the GC Mining Area.

A properly constructed containment for storage of fuel is located in the vicinity of the diesel generators and fuel dispensing facilities.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

There is a mine dry facility near the portal accommodating lockers, change room, showers, and washrooms for the miners. The mine office complex is for administration and engineering functions and to provide working space for management, supervision, geology, engineering, and other operations support staff.

Silvercorp operates the mine using contractors for development and production. The operation and maintenance of Silvercorp’s fixed plant is via Silvercorp personnel. Silvercorp provides its own management, technical services, and supervision staff to manage the GC mine operation.

Sales contracts are in place for the lead concentrates with Shandong Humon Smelting Co. Ltd., and for the zinc concentrates with Chenzhou Qiantai Industrial Co. Ltd. and Chenzhou Jieyin Minerals Co. Ltd. All contracts have an effective period of one year, with key elements of the contracts subject to change based on market conditions when monthly supplemental agreements to the annual contracts are negotiated. Arsenic (As) levels in the concentrates are acceptable to the Chinese smelters. All contracts have freight and related expenses to be paid by the customers.

Silvercorp has all the required permits for its operations on the Property and, in conjunction with safety and environmental certificates, these give Silvercorp the right to carry out full mining and mineral processing operations.

An Environmental Impact Assessment (EIA) report on the GC Project was prepared by the Guangdong Environmental Technology Centre (GETC) initially, and reassessment is done periodically as required by regulations. An Environmental Permit was issued by the Department of Environmental Protection of Guangdong Province in June 2010.

There are no cultural minority groups within the general area surrounding the project. No records of cultural heritage sites exist within or near the GC project areas. The surrounding land is used predominantly for agriculture. The mining area does not cover any natural conservation, ecological forests, or strict land control zones.

Silvercorp has made a range of cash donations and contributions to local capital projects and community support programs, sponsoring university students and undertaking projects such as village road construction, and school upgrading and construction. Silvercorp has also made economic contributions to the local economy in the form of direct hiring and retention of local contractors, suppliers, and service providers.

A monitoring plan has been negotiated between the company and the local environmental protection department to meet the environmental management requirements of the project. Key components of the monitoring plan are water pollution monitoring, together with environmental air and noise monitoring. The monitoring work is carried out by QPs and / or a third-party contractor and is undertaken on a regular basis.

Full-time Silvercorp environment management personnel are mainly responsible for environment and rehabilitation management work in the mining area. They also visit various GC workplaces regularly to check the equipment for environmental protection and coordinate the environmental protection work.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

As Silvercorp is a producing issuer, an economic analysis for the Gaocheng mine is not required.

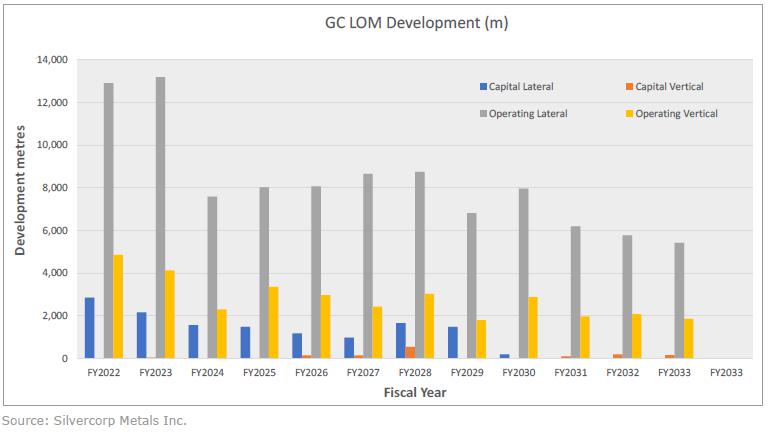

The 2021 Technical Report cost estimates for FY2022 are based on mining 311,271 tonnes of ore and milling the same amount. Other major operational items assumed are waste development tunnelling at 10,200 m, exploration and development tunnelling at 10,300 m, and drilling at 58,500 m. Sustaining development tunnelling of 500 m is also assumed.

All major infrastructure for operation of the Gaocheng mine is in place, including that for a potential production rate increase to 1,600 tons per day (tpd), although that is not currently envisaged. FY2022 non-sustaining capital for further main ramp development is assumed at $0.4 million. FY2022 sustaining capital is assumed at $4.0 million, which equates to $12.85 per tonne of ore projected to be mined.

Mining operating costs are categorized by direct mining (shrinkage or resuing), waste development, exploration tunnelling, drilling, and common costs. Other estimated operating costs are for milling, general and administrative items, and government fee, Mineral Resources tax, and other taxes. The FY2022 operating cost breakdown in the 2021 Technical Report is as follows: mining – $45.34/tonne, milling – $14.23/tonne, G&A – $8.17/tonne, Mineral Resources tax, etc. – $4.93/tonne, for a total estimated operating cost of $72.61/tonne.

Contractor costs are the major component of the mining cost. The principal components of the milling costs are utilities (power and water), consumables (grinding steel and reagents), and labour.

The QP considers the operating cost estimates to be reasonable relative to the methods and technology used and to the scale of the Gaocheng operation. The QP notes that the 2021 Technical Report estimate for combined total operating and sustaining capital cost for FY2022 on a unit basis is $85.46/t of ore mined and milled, and is within the range of cost estimates for FY2022 indicated by Silvercorp in its MD&A of May 2021.

The Gaocheng mine has been in commercial production for six years. From FY2021 onwards, a 13-year LOM is envisaged for the resource as currently understood at an average annual production rate of about 310,000 tonnes. Average silver equivalent grades are projected to be of the order of 309 g/t.

| 1.12 | Interpretation and conclusions |

Polymetallic mineralization at the Gaocheng project comprises over 150 distinct veins, ranging in thickness from a few centimetres to several metres, with a general east-west orientation and dipping generally south at 55o to subvertical. The Mineral Resource estimates described in the report were prepared by Silvercorp using Micromine software and reviewed, classified, and signed off by Ms D. Nussipakynova, P.Geo. of AMC, who is a QP for the purposes of the Technical Report.

Using a 105 g/t AgEq COG, Measured and Indicated Resources (inclusive of Mineral Reserves) are estimated at 10.03 Mt grading 82 g/t Ag, 1.2% Pb, and 2.8% Zn; and Inferred Mineral Resources are estimated at 8.44 Mt grading 87 g/t Ag, 1.0% Pb, and 2.4% Zn.

Compared to the previous estimate of Mineral Resources in the 2019 Technical Report, Measured Resource tonnes increased by 57% and Indicated Resource tonnes have decreased by 11%. This is mainly due to conversion of the Indicated material into the Measured category, new resource delineation and an updated geological interpretation. Inferred Mineral Resource tonnes have increased by 17%. The QP notes that at the time of the 2019 Technical Report there were 110 veins identified at GC and now there are 156 veins. In the Measured category the silver grade has decreased by 9% and lead and zinc grades have both decreased by 6%. In the Indicated category

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

silver grades have decreased by 3%. Lead grades have increased by 6% and zinc grades have decreased by 1%. In the Inferred category, grades have decreased for silver and zinc by 5% and 1% respectively. Lead grades have increased by 5%.

The results of the underground drilling program at GC show that vein structures are still open at depth.

Silvercorp has established QA/QC procedures that cover sample collection and processing at the Property. These QA/QC protocols have been progressively refined since 2011. Certified Reference Materials (CRMs) and coarse crushed blanks have been included with drilling samples since 2011, and with underground samples since 2014. Field duplicates have been included with drilling samples since 2012 and with underground samples since 2014. Check (umpire) samples (pulp duplicates) have been sent to a separate ‘umpire’ laboratory since 2012.

In 2018, Silvercorp further improved their QA/QC protocols to include regular and more frequent submission of CRMs, coarse blanks, and field duplicates with drilling and underground samples. Coarse reject duplicates and pulp duplicates were also incorporated into drill sampling programs. The proportion of check samples sent to a different laboratory was also increased. In 2019, Silvercorp initiated real-time monitoring of QA/QC protocols.

The QP has reviewed QA/QC data collected to date. While some issues have been noted with data collected prior to 2014, all data collected thereafter shows reasonable analytical accuracy and precision. The QP does not consider issues noted with pre-2014 data to be a material concern and considers the Gaocheng sample database acceptable for Mineral Resource estimation and the development of a long-term planning model.

A series of recommendations has been provided for the improvement of QA/QC processes (see Section 1.13 Recommendations).

Mineral Reserves have been estimated using a full breakeven COG of 215 g/t AgEq for shrinkage stoping and 275 g/t AgEq for resuing, based on a mine design and plan prepared by Silvercorp engineers and reviewed by Mr H. Smith, P.Eng. of AMC, who is a QP for the purposes of the Technical Report. Total Proven and Probable Reserves are 4.13 Mt grading 94 g/t silver, 1.5% lead, and 3.2% zinc, containing 12.5 million ounces silver, 135 million pounds lead, and 293 million pounds zinc.

Metal prices used in determining COGs for both Mineral Resources and Mineral Reserves are: silver - $18.20/troy ounce; lead - $0.94/lb; zinc - $1.08/lb. An exchange rate of RMB6.8 to US$1 and mining costs of $49/t for shrinkage and $68/t for resuing have been assumed. Average metallurgical recovery assumptions are: silver – 82.6%; lead – 89.5%, zinc – 87.3%. Average payable assumptions are: silver – 65.5%, lead – 86.2%, zinc – 66.3%.

In comparison with the Mineral Reserve estimate in the 2019 Technical Report, there is a 39% increase in Proven Mineral Reserve tonnes and a 21% decrease in Probable Mineral Reserve tonnes, resulting in an increase in total Mineral Reserve tonnes of 8% (311,000 tonnes). Silvercorp received a mining permit in December 2010. From the start of commercial operations at Gaocheng in 2014 through to 31 December 2020, 1,853,662 tonnes have been mined at average head grades of 94 g/t silver, 1.6% lead, and 2.9% zinc.

The predominant shrinkage mining method uses the blasted ore as the working platform for each stope lift. The ore is removed on completion of stope mining leaving an empty void. There is potential to opportunistically dispose of development waste into these voids, but this is not envisaged in current mine plans. The resue method uses blasted waste from the footwall as the working platform for each stope lift. The waste remains in the stope at completion of stope mining. Some hand sorting of ore from waste is conducted.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

The rock mass conditions are categorized as Fair to Good. Previous AMC assessment had anticipated that the vein and host rocks in the mine area would generally be competent and require minimal ground support. This has largely been confirmed in operations, with most areas deemed to require little or no support. Where Poor ground conditions have been encountered, ground support is provided, with a range of strategies available depending on the local situation.

Based on Proven and Probable Reserves only, the GC mine is a viable operation with a projected LOM of 13 years through to 2034, with an average annual production rate of approximately 310,000 tonnes, and with average silver equivalent grades of 309 g/t. GC also has the potential to extend the LOM beyond 2034, via conversion of existing Mineral Resources to Mineral Reserves and further exploration and development.

Since the start of trial operations in 2013 and commercial production in 2014 (FY2015), lead and zinc concentrates have been produced in commercial quantities at the GC processing plant. Small amounts of tin concentrate and sulphur have also been produced but these quantities have not been significant enough to be material to mine economics. In all sections of the plant, space / capacity has been allocated for an expansion to 1,600 tpd, but such expansion is not contemplated at this time.

Sales contracts are in place for the lead concentrates with Shandong Humon Smelting Co. Ltd., and for the zinc concentrate with Chenzhou Qiantai Industrial Co. Ltd. and Chenzhou Jieyin Minerals Co. Ltd.

All contracts have an effective period of one year, with key elements of the contracts subject to change based on market conditions when monthly supplemental agreements to the annual contracts are negotiated. All contracts have freight and related expenses to be paid by the customers.

The QP understands that an acceptable arsenic level in base metal concentrates, without penalty, for the Chinese smelters with which Silvercorp has contracts is of the order of 1.0%, and notes that the GC lead and zinc concentrates are acceptable to those smelters.

All pertinent facilities are in place at the GC site, inclusive of security, accommodation, catering, engineering and administration building, mine dry, mine ventilation, main power sub-station, mine rescue, water supply, compressed air, underground dewatering, sewage treatment, explosives magazines, water treatment plant, maintenance / repair facilities, storage, laboratory, communications, fuel farm, fire prevention, waste rock dump, and TMF.

With respect to waste rock, all such material brought to surface is either used by Silvercorp for construction / maintenance activities or is removed from the site, free of charge, by local persons, again as construction material. The environmental assessment has indicated that waste rock at the GC mine has no significant acid-generating potential.

The TMF utilizes dry stacking and filling (from bottom to top and stacking by bench to form the embankment) with concurrent rolling and compaction. The QP notes that the most recent TMF risk assessment (report dated 30 July 2020) was done by Guangdong Huasheng Safety Occupation Evaluation Co., Ltd. After the issuing of the report, a new TMF Safety Production Certificate was granted on 3 September 2020, following a satisfactory on-site assessment organized by the local government. The certificate is valid until 3 September 2023.

Silvercorp has also entrusted Sinochem Mingda (Fujian) Geological Survey Co., Ltd., a survey company with China Grade A qualification, to conduct an engineering survey of the dry tailings area. Silvercorp has further entrusted the designer of the dry tailings area, Guangdong Metallurgical Architectural Design and Research Institute Co. Ltd., to assess the current flood control safety and dam stability of the dry tailings facility. This Project is expected to be completed by the end of 2021.

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

Silvercorp utilizes contract labour for mining at GC on a rate per tonne or a rate per metre basis. The contract includes all labour, all fixed and mobile equipment, materials, and consumables, including fuel and explosives, which are purchased through the company. Ground support consumables such as timber and power are the responsibility of the company.

All major infrastructure for operation of the Gaocheng mine is in place. FY2022 non-sustaining capital for further main ramp development is assumed at $0.4 million. FY2022 sustaining capital is assumed at $4.0 million, which equates to $12.85 per tonne of ore projected to be mined.

The FY2022 operating cost estimate breakdown in the 2021 Technical Report is as follows: mining – $45.34/tonne, milling – $14.23/tonne, G&A – $8.17/tonne, Mineral Resources tax, etc. – $4.93/tonne, for a total estimated operating cost of $72.61/tonne.

Contractor costs are the major component of the mining cost. The principal components of the milling costs are utilities (power and water), consumables (grinding steel and reagents), and labour.

The QP considers the operating cost estimates to be reasonable relative to the methods and technology used and to the scale of the Gaocheng operation. The QP notes that the 2021 Technical Report estimate for combined total operating and sustaining capital cost for FY2022 on a unit basis is $85.46/t of ore mined and milled.

The GC mine has been in commercial production for six years. From FY2021 onwards, a 13-year LOM is envisaged for the resource as currently understood at an average annual production rate of about 310,000 tonnes. Average silver equivalent grades are projected to be of the order of 309 g/t.

The QP recommendations for the GC mine are indicated below. The QPs consider that the associated costs can be accommodated within existing operating budgets.

| · | All database records (drillhole and channel samples) to be assigned a consistent year between the collar and assay files. |

| · | Each density sample to be geologically logged, with particular attention to the degree of oxidation and the presence or absence of vughs or porosity. |

| · | The minimum size of the density samples to be 1 kg. The part of the sample that is selected for assaying should be as representative as possible of the mineralization in the part used for density measurement. Assaying of the density sample itself is preferable, but only if the wax does not lead to problems with assay sample preparation. |

| · | Iron and / or sulphur to be added to the regular assay suite for samples used for resource estimation. |

| · | Undertake additional bulk density measurements on representative samples with varying base metal and pyrite content. |

| · | Take bulk density measurements on samples from the bounding waste material to allow more accurate estimation of the density of diluted Mineral Resources. |

| · | Estimate the density of oxidized and fresh ores separately. |

| · | Consider procurement of an additional CRM to monitor low grades and the anticipated COGs. |

| · | Consider purchasing one or more ‘pigeon pair’ CRMs with similar, but not identical, expected values to CRMs currently in use. This will provide an additional check on laboratory accuracy. |

| · | Revise protocols so that CRMs are inserted using a systematic approach at a rate of 1 CRM in every 20 samples (5%) for both drilling and underground samples. Consider implementation of practises such as assigning CRM samples in the sample tag books prior to actual sampling, so that CRM samples occur regularly and within each batch of samples. |

| | |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| · | Continue monitoring CRM results on a ‘real-time’ basis and ensure that sample batches where consecutive CRMs return results outside of two standard deviations, or one CRM outside of three standard deviations, are investigated and reanalyzed. |

| · | Revise protocols so that blanks are inserted using a systematic approach at a rate of at least one blank in every 25 samples (4%) for both drilling and underground samples. |

| · | Insert blanks immediately after expected high grade mineralization to assess contamination occurring during sample preparation. |

| · | Implement the use of both coarse and fine (pulp) blank material to enable sample preparation and analytical processes to be monitored for contamination. |

| · | Revise and further reduce failure rates for Pb and Zn from current level of 0.1% Pb and 0.1% Zn. |

| · | Implement the monitoring of blanks results on a ‘real-time’ basis and ensure that sample batches where blanks exceed failure limits are investigated and reanalyzed. |

| · | Implement procedures to collect and submit coarse reject and pulp duplicates into the underground sample stream. |

| · | Duplicate insertion rates to be increased to match that of drilling samples (approximately 5 - 6%). |

| · | Investigate the cause of poor field duplicate performance in both core and underground samples. This could include a test phase which incorporates the following: |

| ¾ | Completing polished section petrology to understand the particle size and nature of mineralization. |

| ¾ | Submitting the second half of the core, instead of quarter core, as the field duplicates (if required, a thin slice (fillet) of core could be sliced off and retained for archival storage before cutting the core into halves). |

| ¾ | Consider increasing the size of underground samples. |

| · | Submit at least 5% of drilling and underground samples to a third-party umpire laboratory for check analysis on a regular basis. |

| · | Maintain a ‘table of fails’ that documents the remedial action completed on any failed batches. |

| · | Implement a system whereby the original assays of failed batches are retained in the sample database and are available for audit. |

| · | Continue to submit all QA/QC samples (with no identification), so that the results are not known by the laboratory. |

| · | Insert QA/QC samples randomly within sample batches as opposed to the present practise of consistently inserting consecutive CRMs, blanks, and duplicates. |

| · | Continue communication between the geology department and laboratory to ensure that any sample biases noted are investigated and addressed in a timely fashion. |

| · | Sample on a minimum sample length of 0.4 m. |

| · | Validate the master sample database and ensure that all fields are fully populated. Date fields should be reviewed and made consistent between collar, assay, and QA/QC datasets to enable consistent year-to-year reporting of results. Laboratory and laboratory report IDs should also be fully populated in the assay and QA/QC databases. |

| · | Modify the central database so that assay data are recorded without rounding to accurately reflect the original assay certificates. |

| · | Internally validate the existing sample database to ensure that any other sample prefix issues are addressed. |

| · | Review database and sample procedures to ensure that sample prefix issues do not reoccur. |

| | |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| · | Assess ground conditions on a round-by-round basis in all development headings (ore and waste) to determine the requirement for ground support. Doing so will help prevent the occurrence of significant failures from backs and walls, which require timely rehabilitation and expose the workforce to rock fall hazard. |

| · | Ensure scaling of the development headings on a round-by-round basis. |

| · | Maintain a focus on dilution and grade control. |

| · | Conduct routine check scaling of all unsupported development at the mine. This process can help identify areas of the mine in which rock mass deterioration is occurring and allow rehabilitation works to be planned. |

| · | As part of overall mine design, consider possible destabilizing effects associated with major structures such as faults or shear zones. These should be considered on a case-by-case basis. Where possible, avoid mining development intersections in fault zones, and design drifts to cross fault zones at right angles (to minimize the exposure length within the drift). |

| · | Assess specific rock mass conditions for critical underground infrastructure, including shafts and chambers, to determine ground support and pillar requirements to ensure serviceability of the excavation for the LOM. |

| · | Ensure that an assessment of crown pillar requirements has been incorporated into the detailed mine design with particular focus on surface pillar requirements in the vicinity of Hashui Creek valley, and any other streams (or drainage paths) that traverse the mine area. |

| · | As part of ongoing operations at the mine, continuously review geotechnical aspects and ground support in a formal, recordable manner, bearing in mind previous recommendations, local and mine-wide operating experience in all rock types encountered, data collection protocols, and also looking to future mining development. |

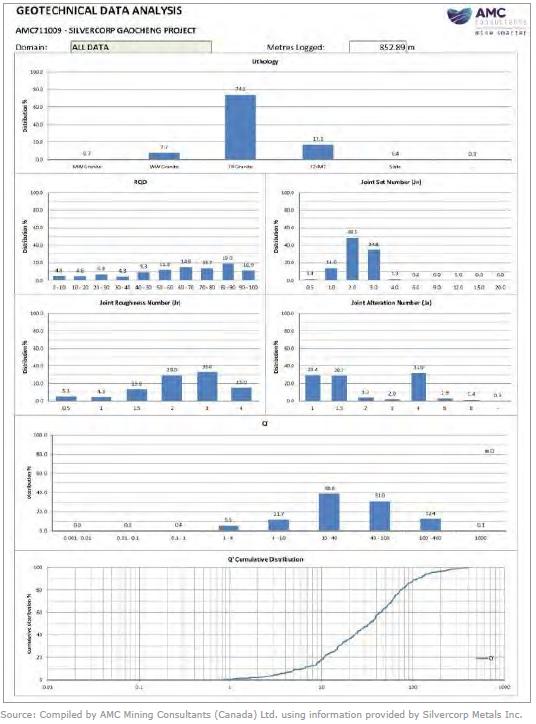

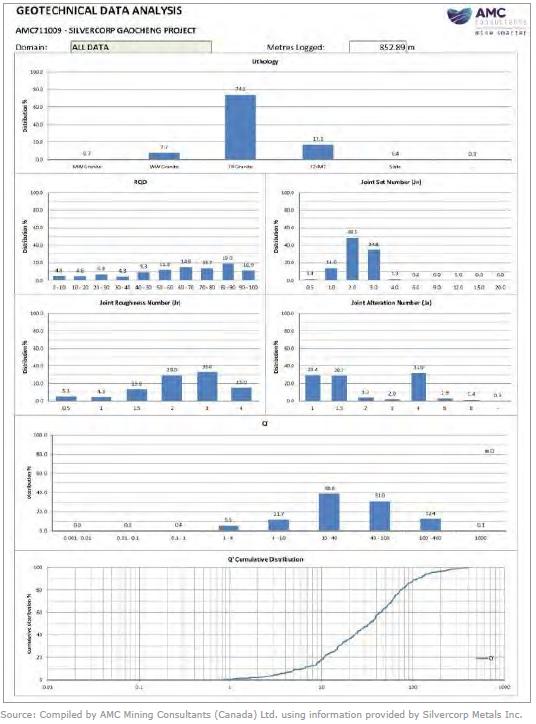

| · | Collect additional detailed geotechnical logging data, from drill core and mapping of underground workings, to incorporate collection of structural orientation data. Data collection to allow rock mass classification using an internationally recognized system, such as the Q-System (after Barton et al., 1974) or RMR (after Bieniawski, 1989). |

| · | Develop a three-dimensional geotechnical model with interpretations of primary lithologies and structures (such as faults and shear zones). |

| · | As the mine moves deeper, undertake further investigation of in situ stresses to confirm assumptions made in the mine design and stability assessments. |

| · | Consider the advisability of any further hydrogeological assessments. |

| · | With respect to the TMF, Silvercorp to continue to satisfy itself, as per best industry practice, that all fundamental aspects of the TMF design, construction and operation have been and continue to be satisfactorily addressed. This may include geotechnical drilling of the dam foundation area, as it is the QP’s understanding that such activity has not specifically been undertaken. |

| · | Continue with a focus on safety improvement, including implementation of a policy whereby the more stringent of either Chinese or Canadian safety standards is employed. |

| · | Place a strong focus on stockpiling and record keeping procedures and ensure that the summation of individual ore car weights by stope and zone is, as far as practicable, fully integrated into the tracking and reconciliation process. |

| · | Undertake periodic mill audits aimed at ensuring optimum process control and mill performance. |

| · | Continue exploration tunnelling and diamond drilling at Gaocheng. The exploration tunnelling is used to upgrade the drill-defined Resources to the Measured category, and the diamond drilling is used to expand and upgrade the previous drill-defined Resources, explore for new mineralized zones within the unexplored portions of vein structures, and test for extensions of the vein structures. |

| | |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

Contents

| 1 Summary | iii |

| 1.1 Introduction | iii |

| 1.2 Location, ownership, and history | iii |

| 1.3 Geology and mineralization | iv |

| 1.4 Exploration and data management | v |

| 1.5 Mineral Resource estimates | vii |

| 1.6 Mineral Reserve estimates and mining | viii |

| 1.7 Metallurgy and processing | ix |

| 1.8 Project infrastructure | xii |

| 1.9 Concentrate contracts | xiii |

| 1.10 Environment | xiii |

| 1.11 Costs and economics | xiv |

| 1.12 Interpretation and conclusions | xiv |

| 1.13 Recommendations | xvii |

| 2 Introduction | 30 |

| 3 Reliance on other experts | 32 |

| 4 Property description and location | 33 |

| 4.1 Location | 33 |

| 4.2 Ownership and permits | 34 |

| 4.3 Obligations of Silvercorp with respect to the GC Mine | 35 |

| 4.4 Taxes and royalties | 36 |

| 4.5 Other | 36 |

| 5 Accessibility, climate, local resources, infrastructure, and physiography | 37 |

| 6 History | 38 |

| 6.1 Prior ownership | 38 |

| 6.2 Exploration and development work | 38 |

| 6.3 Production | 39 |

| 6.4 Historical Mineral Resource estimates | 40 |

| 7 Geological setting and mineralization | 41 |

| 7.1 Regional geology | 41 |

| 7.2 Property geology | 42 |

| 7.2.1 Structures | 43 |

| 7.3 Mineralization | 46 |

| 7.4 Characteristics of the mineralized veins | 46 |

| 7.5 Other mineralization features | 51 |

| 8 Deposit types | 52 |

| 9 Exploration | 53 |

| 9.1 Soil geochemical program | 53 |

| 9.2 Topographic and geological mapping | 54 |

| 9.3 Trenching and pitting | 54 |

| 9.4 Underground works | 56 |

| 10 Drilling | 61 |

| 10.1 Historical drilling (pre-2008) | 61 |

| 10.2 Silvercorp drilling (2008 – 2020) | 61 |

| 10.2.1 2008 surface drill program | 62 |

| 10.2.2 2011 to 2020 drill programs | 62 |

| 10.2.3 Bulk density | 71 |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| 10.3 Recommendations | 73 |

| 10.4 Conclusion | 73 |

| 11 Sample preparation, analyses, and security | 74 |

| 11.1 Introduction | 74 |

| 11.1.1 Drillhole sampling | 74 |

| 11.1.2 Underground sampling | 74 |

| 11.2 Sample preparation and analysis | 75 |

| 11.2.1 Sample shipment and security | 75 |

| 11.2.2 ALS Guangzhou | 75 |

| 11.2.3 Gaocheng mine laboratory | 76 |

| 11.3 QA/QC monitoring program | 76 |

| 11.3.1 Overview | 76 |

| 11.4 Certified Reference Materials | 79 |

| 11.4.1 Description | 79 |

| 11.4.2 Discussion on CRMs | 80 |

| 11.4.3 CRM recommendations | 89 |

| 11.5 Blank samples | 90 |

| 11.5.1 Description | 90 |

| 11.5.2 Blank discussion | 90 |

| 11.5.3 Blank recommendations | 93 |

| 11.6 Duplicate samples | 93 |

| 11.6.1 Description | 93 |

| 11.6.2 Duplicate samples discussion | 94 |

| 11.6.3 Duplicate samples recommendations | 96 |

| 11.7 Check (umpire) samples | 96 |

| 11.7.1 Description | 96 |

| 11.7.2 Check sample discussion | 97 |

| 11.7.3 Check sample recommendations | 99 |

| 11.8 General comments and conclusions | 99 |

| 11.9 Recommendations | 99 |

| 12 Data verification | 100 |

| 12.1 Site visit | 100 |

| 12.2 Assay data verification | 100 |

| 12.3 Data validation | 101 |

| 12.4 AMC discussion | 101 |

| 12.5 Recommendations | 102 |

| 12.6 Conclusions | 102 |

| 13 Mineral processing and metallurgical testing | 103 |

| 13.1 Introduction | 103 |

| 13.2 Metallurgical samples | 103 |

| 13.3 Mineralogy | 104 |

| 13.4 Metallurgical testwork | 105 |

| 13.4.1 Lead flotation conditions | 105 |

| 13.4.2 Zinc and pyrite flotation conditions | 106 |

| 13.4.3 Sulphide circuit flotation tests | 106 |

| 13.4.4 Copper-lead separation tests | 108 |

| 13.4.5 Tin recovery tests | 108 |

| 13.4.6 Optimization opportunities | 109 |

| 13.5 Concentrate quality considerations | 110 |

| 13.6 Summary of testwork outcomes | 111 |

| 13.6.1 Metallurgical samples | 111 |

| 13.6.2 Mineralogy | 111 |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| 13.6.3 Laboratory testwork | 111 |

| 13.6.3.1 Grinding | 111 |

| 13.6.3.2 Flotation | 111 |

| 13.6.3.3 Tin recovery | 111 |

| 13.6.4 Optimization opportunities | 111 |

| 13.6.5 Concentrate quality | 111 |

| 13.7 Mill operation FY2015 to end-2020 (Q3 FY2021) | 112 |

| 14 Mineral Resource estimates | 114 |

| 14.1 Introduction | 114 |

| 14.2 Data used | 115 |

| 14.2.1 Drillhole database | 115 |

| 14.2.2 Bulk density | 116 |

| 14.3 Geological interpretation | 116 |

| 14.4 Statistics, compositing, and capping | 118 |

| 14.5 Block model | 121 |

| 14.5.1 Block model parameters | 121 |

| 14.5.2 Grade estimation | 122 |

| 14.5.3 Mining depletion | 123 |

| 14.5.4 Resource classification | 124 |

| 14.5.5 Block model validation | 125 |

| 14.5.6 Mineral Resource reporting | 131 |

| 14.6 Comparison with previous Mineral Resource estimate | 132 |

| 14.7 Recommendations | 134 |

| 15 Mineral Reserve estimates | 135 |

| 15.1 Introduction and Mineral Resources base | 135 |

| 15.2 Mineral Reserve estimation methodology | 135 |

| 15.3 Cut-off grades | 135 |

| 15.3.1 QP comment on cut-off grades | 136 |

| 15.4 Bulk density | 136 |

| 15.5 Dilution and recovery factors | 137 |

| 15.5.1 Dilution | 137 |

| 15.5.2 Mining recovery factors | 137 |

| 15.6 Mineral Reserve estimate | 137 |

| 15.7 Conversion of Mineral Resources to Reserves | 138 |

| 15.8 Comparison of 2021 and 2019 Mineral Reserve estimates | 139 |

| 16 Mining methods | 140 |

| 16.1 Conventions | 140 |

| 16.2 Introduction | 140 |

| 16.3 Geotechnical conditions | 140 |

| 16.3.1 Introduction | 140 |

| 16.3.2 Available data | 141 |

| 16.3.3 Data analysis | 142 |

| 16.3.4 Characterization of geotechnical conditions | 144 |

| 16.3.5 In situ stress | 145 |

| 16.3.6 Hydrogeology | 145 |

| 16.3.7 Mine design considerations | 145 |

| 16.3.7.1 Rock mass conditions | 145 |

| 16.3.7.2 Surface requirements | 146 |

| 16.3.7.3 Stability assessment for stoping | 146 |

| 16.3.7.4 Stope pillars | 147 |

| 16.3.7.5 Main Shaft pillar | 147 |

| 16.3.7.6 Ground support requirements | 147 |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| 16.3.7.7 Conclusions | 148 |

| 16.4 Extraction sequence | 149 |

| 16.5 Production rate | 149 |

| 16.6 Mining methods | 149 |

| 16.6.1 Shrinkage stoping | 149 |

| 16.6.2 Resue stoping | 150 |

| 16.6.3 Stope management and grade control | 152 |

| 16.7 Mine design | 153 |

| 16.7.1 Pre-existing development | 155 |

| 16.7.2 Mine access | 156 |

| 16.8 Mine development | 156 |

| 16.8.1 Development requirement | 157 |

| 16.8.2 Shafts | 158 |

| 16.9 Mine production | 158 |

| 16.9.1 Commercial production to end-2020 | 158 |

| 16.9.2 LOM plan production | 159 |

| 16.10 Rock handling | 160 |

| 16.10.1 Shaft hoisting | 160 |

| 16.10.2 Waste material | 162 |

| 16.11 Mine services | 162 |

| 16.11.1 Ventilation | 162 |

| 16.11.1.1 Primary ventilation | 162 |

| 16.11.1.2 Secondary ventilation | 163 |

| 16.11.2 Water supply | 163 |

| 16.11.3 Dewatering | 163 |

| 16.11.4 Power supply | 165 |

| 16.11.5 Fuel storage and dispensing | 165 |

| 16.11.6 Compressed air | 165 |

| 16.11.7 Communications | 165 |

| 16.11.8 Explosives storage | 165 |

| 16.11.9 Mine equipment maintenance | 165 |

| 16.12 Mine equipment details | 166 |

| 16.12.1 Equipment productivities | 167 |

| 16.13 Mine personnel | 167 |

| 16.14 Mine safety | 168 |

| 16.14.1 Fire prevention | 169 |

| 16.14.2 Mine rescue | 169 |

| 16.14.3 Dust | 169 |

| 16.14.4 Emergency egress | 169 |

| 16.14.5 Mine refuge stations | 170 |

| 16.14.6 Ablutions | 170 |

| 17 Recovery methods | 171 |

| 17.1 Introduction | 171 |

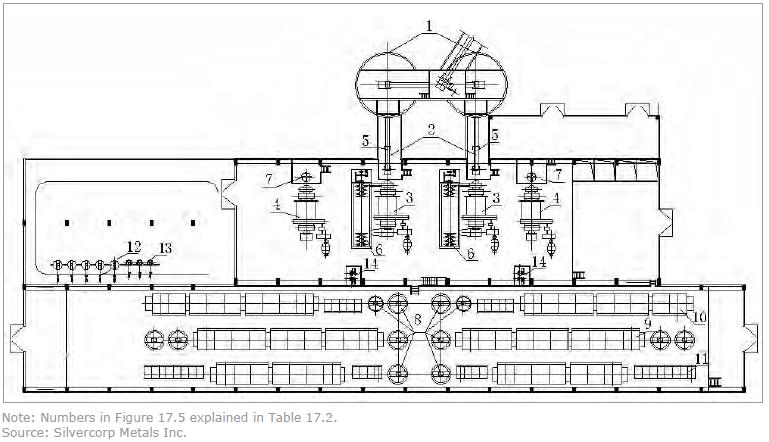

| 17.2 Process flowsheet | 171 |

| 17.3 Process description | 172 |

| 17.3.1 Summary | 172 |

| 17.3.2 Crushing | 174 |

| 17.3.3 Grinding | 174 |

| 17.3.4 Flotation | 175 |

| 17.3.5 Concentrate handling | 177 |

| 17.3.6 Tin recovery circuit | 177 |

| 17.4 Process control and automation | 178 |

| 17.5 Ancillary facilities | 179 |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| 17.5.1 Laboratory | 179 |

| 17.5.2 Maintenance workshops | 179 |

| 17.6 Key inputs | 180 |

| 17.6.1 Power | 180 |

| 17.6.2 Water | 180 |

| 17.6.3 Reagents | 180 |

| 17.7 Mill feed schedule | 180 |

| 17.8 Summary | 182 |

| 18 Project infrastructure | 183 |

| 18.1 Tailings Management Facility (TMF) | 183 |

| 18.1.1 Overview | 183 |

| 18.1.2 Site selection | 184 |

| 18.1.3 TMF design and assessment | 185 |

| 18.1.4 Tailings delivery | 188 |

| 18.2 Waste rock dump | 188 |

| 18.3 Backfill plant | 188 |

| 18.4 Power supply | 190 |

| 18.5 Roads | 191 |

| 18.6 Transportation | 191 |

| 18.7 Water supply | 191 |

| 18.8 Sewage treatment | 191 |

| 18.9 Mine dewatering | 191 |

| 18.10 Water treatment facility | 191 |

| 18.11 Site communications | 192 |

| 18.12 Camp | 192 |

| 18.13 Dams and tunnels | 193 |

| 18.14 Surface maintenance workshop | 193 |

| 18.15 Explosives magazines | 193 |

| 18.16 Fuel farm | 194 |

| 18.17 Mine dry | 194 |

| 18.18 Administration building | 194 |

| 18.19 Assay laboratory | 194 |

| 18.20 Security / gatehouse | 194 |

| 19 Market studies and contracts | 195 |

| 19.1 Concentrate marketing | 195 |

| 19.2 Smelter contracts | 195 |

| 19.3 Commodity prices | 196 |

| 20 Environmental studies, permitting and social or community impact | 197 |

| 20.1 Introduction | 197 |

| 20.2 Laws and regulations | 197 |

| 20.2.1 Regulation guidelines | 198 |

| 20.3 Waste and tailings disposal management | 199 |

| 20.4 Site monitoring | 199 |

| 20.4.1 Monitoring plan | 199 |

| 20.4.2 Water management | 200 |

| 20.4.3 Groundwater | 201 |

| 20.4.4 Wastewater | 201 |

| 20.4.5 Gas emission monitoring | 203 |

| 20.4.6 Noise monitoring | 204 |

| 20.4.7 Soil testing | 204 |

| 20.5 Permitting requirements | 205 |

| 20.6 Social and community interaction | 206 |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| 20.6.1 Cultural minorities and heritages | 206 |

| 20.6.2 Relationships with local government | 206 |

| 20.6.3 Labour practices | 206 |

| 20.7 Remediation and reclamation | 207 |

| 20.8 Site closure plan | 207 |

| 21 Capital and operating costs | 208 |

| 21.1 Key cost items | 208 |

| 21.2 Capital cost estimates | 208 |

| 21.2.1 Non-sustaining capital | 208 |

| 21.2.2 Sustaining capital | 208 |

| 21.3 Operating cost estimates | 209 |

| 22 Economic analysis | 211 |

| 23 Adjacent properties | 212 |

| 24 Other relevant data and information | 213 |

| 25 Interpretation and conclusions | 214 |

| 26 Recommendations | 217 |

| 27 References | 220 |

| 28 QP Certificates | 222 |

Tables

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

Figures

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |

| Silvercorp Metals Inc. | 721004 |

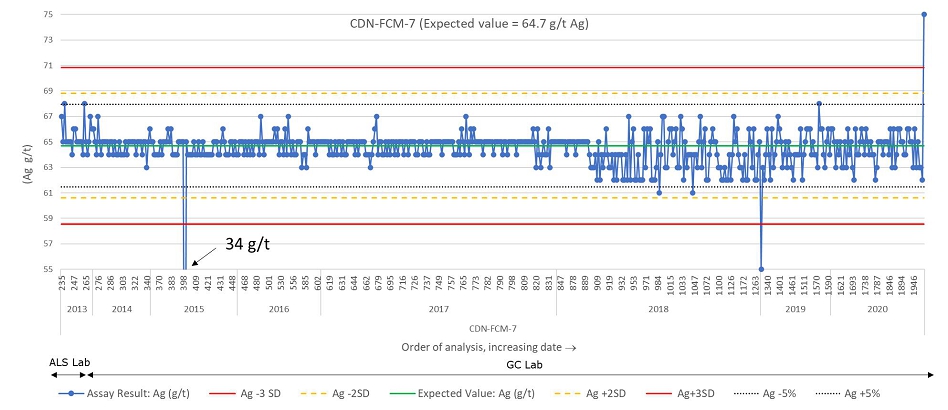

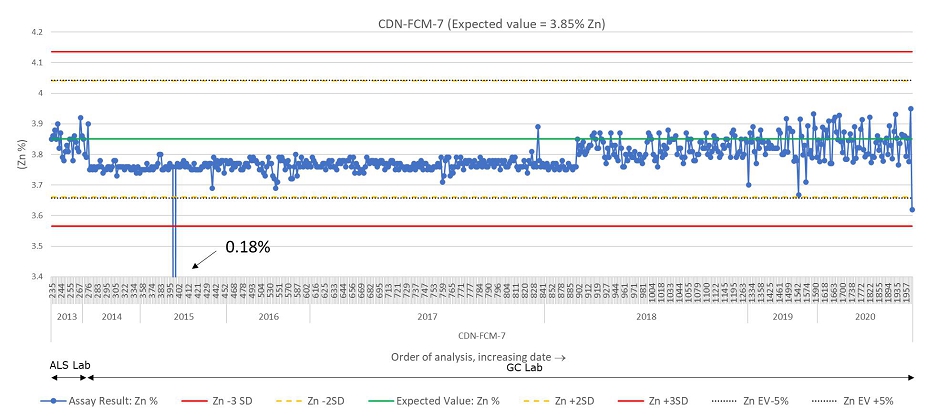

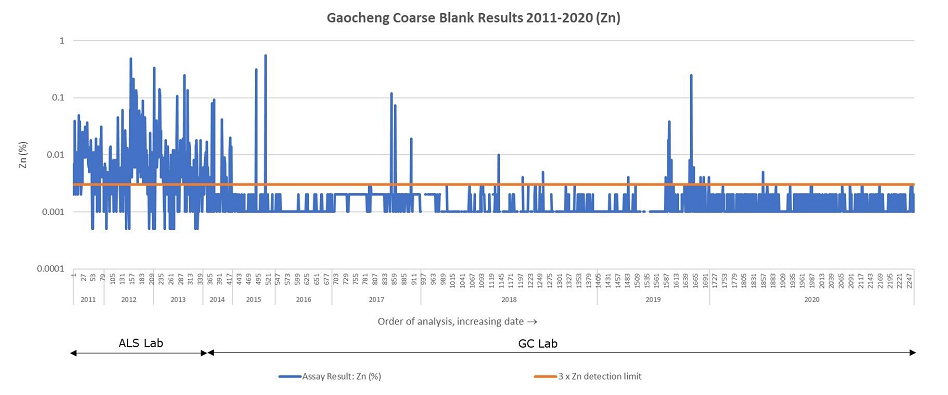

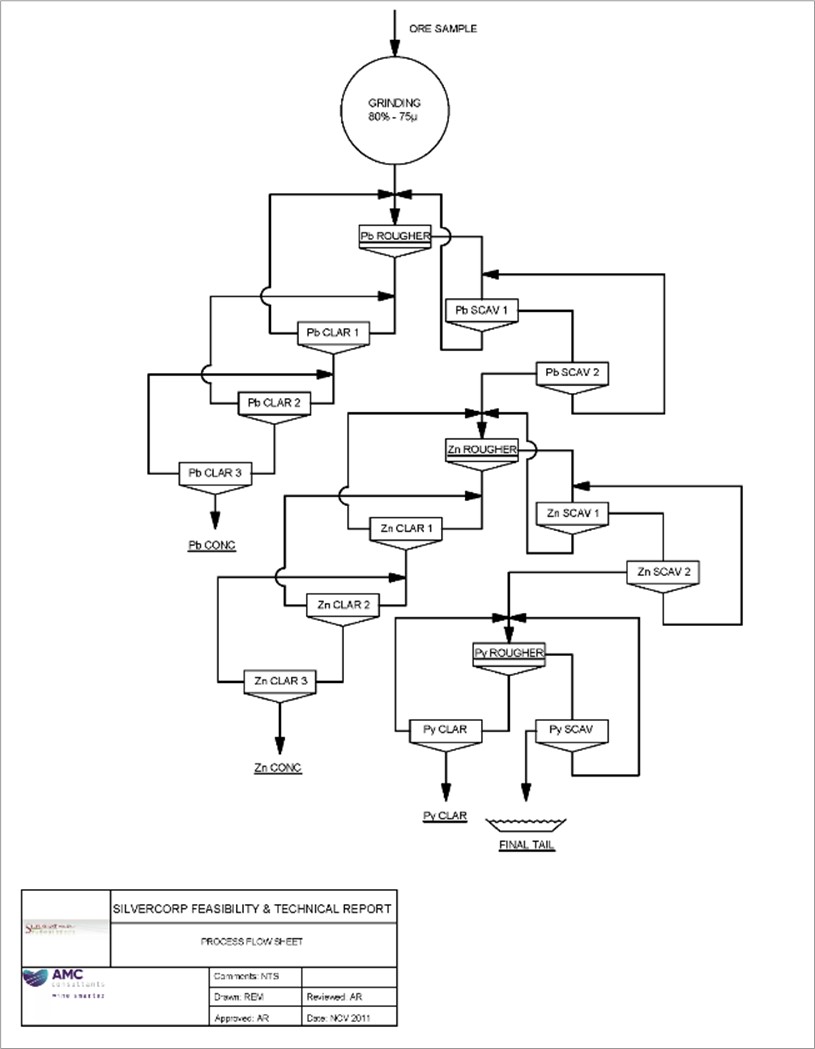

| NI 43-101 Technical Report Update on the Gaocheng Ag-Zn-Pb Project in Guangdong Province, People’s Republic of China |