AVALON ADVANCED MATERIALS INC.

THE EAST KEMPTVILLE TIN PRODUCTION

AND SITE REMEDIATION PROJECT

PRELIMINARY ECONOMIC ASSESSMENT

NOVA SCOTIA, CANADA

Report Date: August 30, 2018

PEA Effective Date: July 24, 2018

Updated Mineral Resources Effective Date: May 7, 2018

Report By

Richard Gowans, P.Eng.

Christopher Jacobs, CEng., MIMMM

Dayan Anderson, M.S., MMSA

Jane Spooner, P.Geo.

William Mercer P. Geo.

Donald H. Hains, BSc, MBA, P. Geo.

Reid Smith, M.A.Sc. P.Geo.

900 – 390 BAY STREET, TORONTO ONTARIO, CANADA M5H 2Y2

Telephone +1 416 362 5135 Fax +1 416 362 5763

i

ii

iii

iv

v

vi

vii

viii

ix

x

xi

xii

xiii

xiv

xv

xvi

OVERVIEW OF THE EAST KEMPTVILLE PROJECT

Micon International Limited (Micon) has been retained by Avalon Advanced Materials Inc. (Avalon) to prepare a Technical Report under Canadian National Instrument (NI) 43-101 which discloses the results of the preliminary economic assessment (PEA) for the East Kemptville Tin Project (East Kemptville Project), Yarmouth Co., Nova Scotia.

Avalon intends to recommence operations at the East Kemptville tin mine in Nova Scotia, Canada and in so doing will concurrently rehabilitate the mine site by remediating the existing environmental liability.

The re-development model, as presented in this PEA, is essentially an environmental remediation project that will be financed through the sale of conflict-free tin concentrates recovered in large part from previously-mined mineralized material on the site. From Day 1 of operations, it is Avalon’s intent to continually reduce the long-term environmental liability and eventually result in the full rehabilitation of this brownfields site.

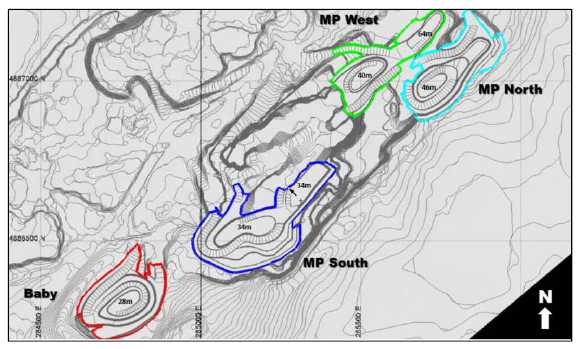

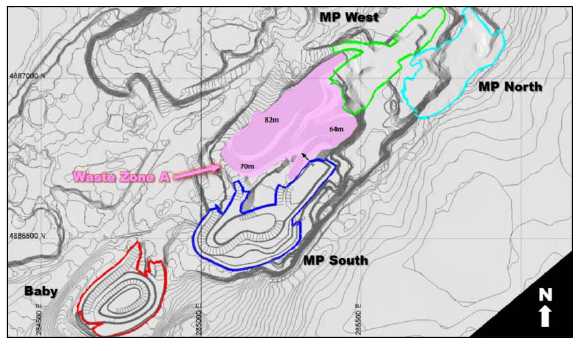

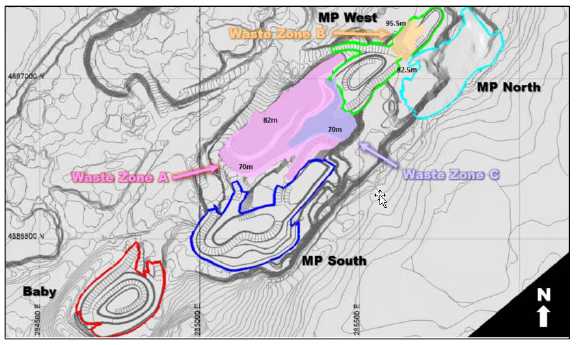

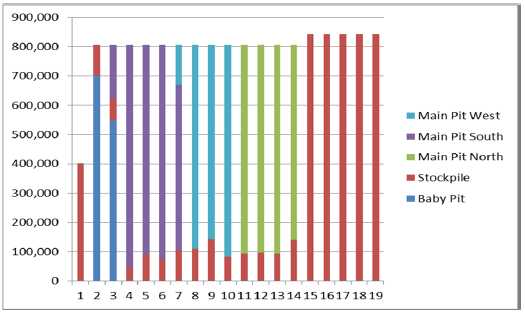

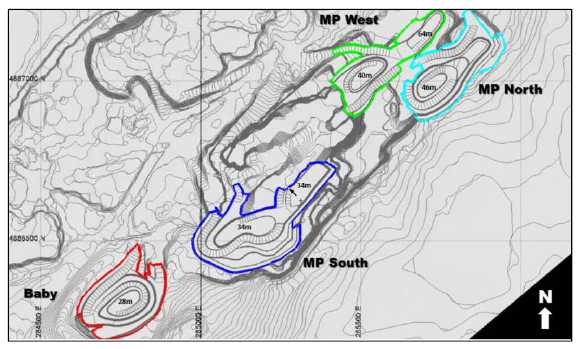

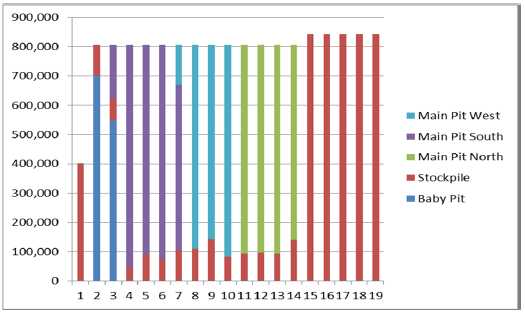

The PEA mine plan as developed by Micon is based on the updated mineral resource estimate disclosed in the Company’s new release dated June 28, 2018. The redevelopment model primarily involves processing of the 5.87 million tonne (Mt) stockpile of previously-mined oxidized low-grade mineralization, supplemented by the selective mining of 9.2 Mt of near-surface fresh higher-grade tin mineralization from the Main and Baby Zone deposits.

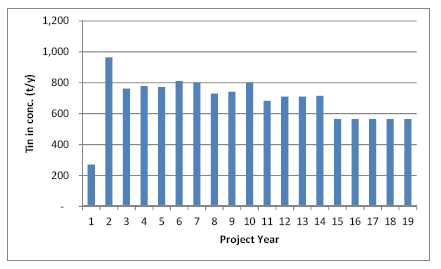

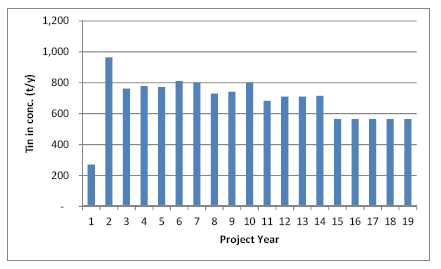

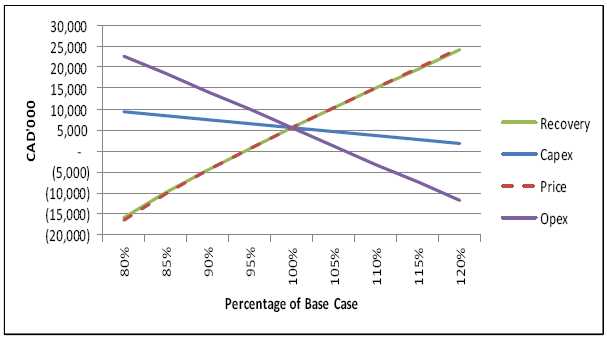

The development model utilized by the PEA contemplates a production schedule averaging 1,300 tonnes per annum of a 55% tin concentrate for 19 years, with tin concentrates being sold and shipped for treatment in international markets. The PEA concludes that the small-scale re-development model is economically viable at current tin prices in the range of USD20,000 to USD22,000/t. Assuming an average go-forward tin price of USD21,038/tonne (as forecast by the World Bank Commodity Price outlook for 2020), and an exchange rate of CAD1.30/USD, the Project has an indicated pre-tax IRR of 15.0% and an NPV of CAD17.9 million at an 8% discount rate. This is after taking into account all costs associated with the proposed environmental rehabilitation process. The initial capital cost is estimated at CAD31.5 million and average annual revenues from sales are calculated as CAD17.75 million vs. annual production costs of CAD11.6 million.

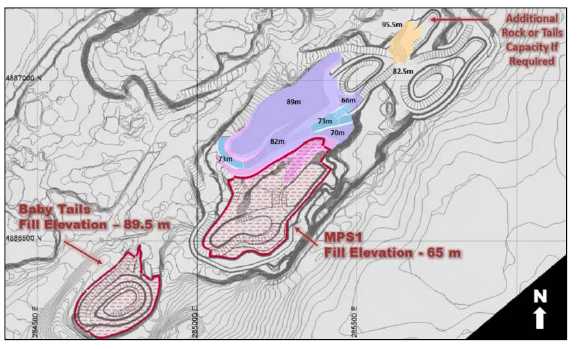

The rehabilitation plan involves both the removal of acid generating surface stockpiles together with the concurrent sealing of the existing tailings storage facility (TMF) to prevent further acid generation. The freshly mined tin mineralization from the Main and Baby Zones will serve an important purpose in the site rehabilitation concept by allowing for the generation of clean tailings (by froth flotation) free of sulphide minerals. These clean tailings will be used to create the cover for the existing TMF which once rehabilitated can then be returned to beneficial use. The zinc/indium/copper/iron sulphide mineralization removed by the flotation will be appropriately disposed of underwater within one of the mined-out pits although recent rises in prices for some of these metals could result in the material becoming a source of additional revenue once up-graded.

Micon understands that Avalon anticipates that through the utilization of an existing TMF and site infrastructure as well as the focus on environmental remediation, the permitting and approvals process for the project will be much shorter than for a new, greenfield mine development. There is strong community support for the Project, as well as from local politicians, First Nations and environmental NGOs. Avalon is also in discussions with a number of local businesses towards collaboration on future opportunities during project development, throughout the operating life and for utilization of the site once rehabilitated.

While the results of the PEA indicate economic potential, there are a number of opportunities that Avalon is pursuing that could further improve Project economics. One of the most promising of these is the potential to upgrade the feed material to the processing plant through ore-sorting. Results from an initial evaluation were very encouraging and the results from a second evaluation are currently awaited. If these results reflect those of the earlier work, then further testwork or a piloting program is being considered.

Successful application of the ore-sorting process technology offers a number of benefits to the Project model. By rejecting non-mineralized waste rock ahead of the mill, the capacity of the processing plant can be reduced and both capital and operating costs lowered. It may also open the door for economic recovery of tin from other mineralized materials close-by that are presently considered too low in grade to justify processing. Alternatively, ore-sorting could provide the means to significantly increase annual tin production from the same sized processing facility over a shorter operating life.

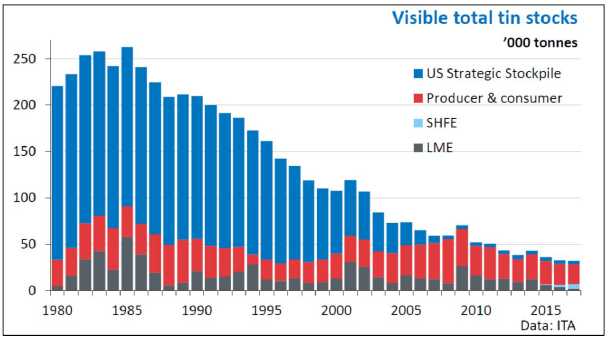

It is Micon’s understanding that prior to completing this PEA, the East Kemptville Project already attracted strong interest from a number of potential partners as well as others interested in securing off-take of the tin concentrates (which are in short supply from non-conflict sources). Avalon has already signed an indicative off-take agreement in the form of a non-binding Memorandum of Understanding (MOU) with a well-known, large tin smelting company for all of the forecast East Kemptville tin production.

Micon International Limited (Micon) has been retained by Avalon Advanced Materials Inc. (Avalon) to prepare a Technical Report under Canadian National Instrument (NI) 43-101 which discloses the results of the preliminary economic assessment (PEA) for the East Kemptville Tin Project (East Kemptville Project), Yarmouth Co., Nova Scotia.

This PEA has been prepared by Micon under the terms of its agreement with Avalon. As discussed in the relevant sections of the report, Micon has prepared a mine plan and schedule, has reviewed the metallurgical testwork carried out on the property, the mineral processing flowsheet, has reviewed infrastructure requirements, prepared capital and operating cost estimates and an economic analysis of the project.

The PEA is based on the open pit mining and processing of mineral resources contained within two existing pits and an existing low-grade stockpile to produce a tin concentrate only. One important aspect of this relatively small-scale mining project is that it provides for a reduction in the long-term environmental liability and eventual full rehabilitation of the brownfield site.

The effective date of the mineral resource estimate on which this PEA is based, is 7 May, 2018 (see Avalon press release dated 28 June, 2018). This resource estimate was prepared by Avalon and is considered not to be materially different from the previous mineral resource by Hains Engineering Company Limited (Hains Engineering), which is described in an Avalon press release dated 31 October, 2014. Hains Engineering is independent of Avalon.

The Qualified Persons for this Technical Report are the following:

| | • | Dayan Anderson, M.S., MMSA (Micon). |

| | | |

| | • | Christopher Jacobs, CEng., MIMMM (Micon). |

| | | |

| | • | Richard Gowans, P.Eng. (Micon). |

| | | |

| | • | Jane Spooner, P.Geo. (Micon). |

| | | |

| | • | William Mercer P. Geo. (Avalon). |

| | | |

| | • | Donald H. Hains, P.Geo. (Hains Engineering) |

| | | |

| | • | Reid Smith P.Geo. (Stantec) |

| 1.1 | EASTKEMPTVILLEPROPERTY |

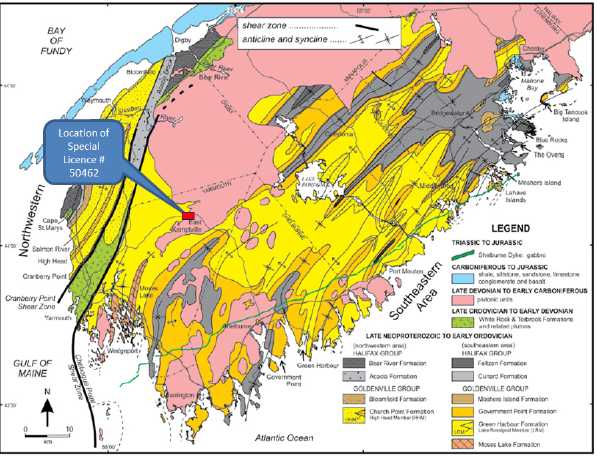

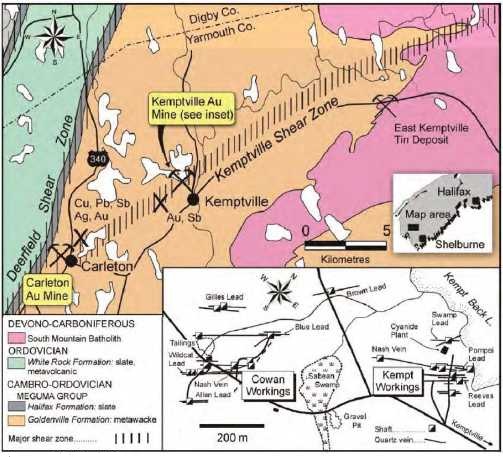

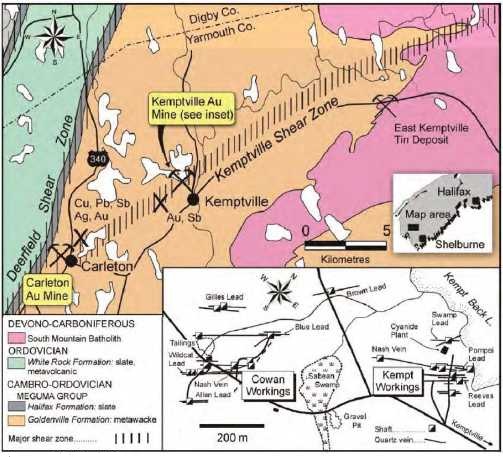

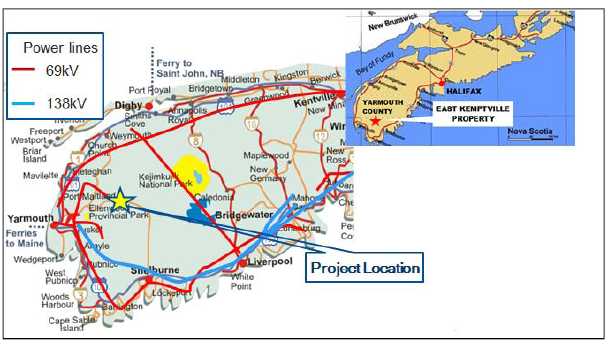

The East Kemptville tin-indium project is located on NTS map sheet 21A/04A and /05B in Yarmouth County, southwestern Nova Scotia. The property is located approximately 180 km southwest of Halifax, the provincial capital, and 55 km northeast of the town of Yarmouth. The site accessed from Yarmouth via Nova Scotia paved Highways 340 to Carleton and then 203 to the site. Yarmouth lies on Highways 103 and 101, approximately 300 km by road from Halifax.

1

Avalon holds a 100% interest in the property via Special Licence 50462. The area covered by Special Licence 50462 includes the Closure Area represented by the former East Kemptville Tin Mine property, which is currently under the management of Rio Algom Ltd (RAL), the surface rights holder. The Special Licence 50462 issued to Avalon on 24 April, 2015 by the Government of Nova Scotia, is for a term of three years, renewable twice for one year. While Avalon’s Special Licence 50462 is active, the Mineral Resources Act provides protection against competing applications to parties with active applications under consideration. As of the date of this report, the Special Licence 50462 has been renewed by the Government of Nova Scotia to 2 February 2019.

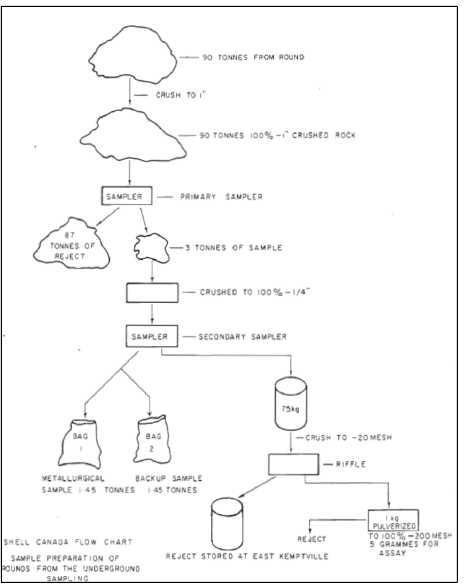

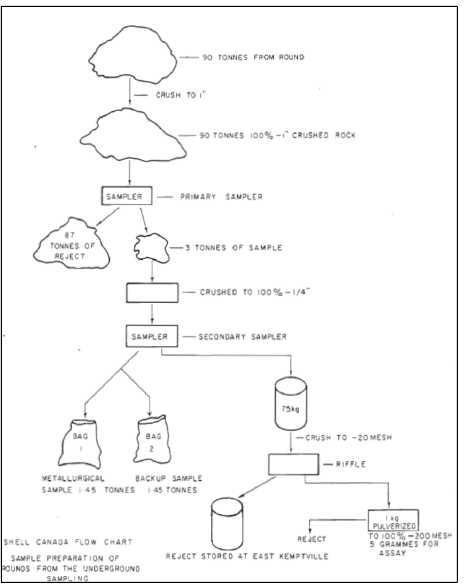

Significant, greisen-style tin mineralization was discovered in granitic outcrop in the East Kemptville area, in 1978, by Shell Canada Resources Limited (Shell). Shell initially drilled a total of 136 diamond drill holes for a total of 12,450 m during 1979 and 1980, followed by a further 23 diamond drill holes totalling 1,840 m in the centre of the deposit to test for grade continuity between existing holes. Subsequently, an additional four diamond drill holes totalling 490 m were drilled as part of an underground exploration and bulk sample program conducted between September, 1981 and February, 1981.

The south-central part of the deposit was also tested by 975 m of underground drifting during the period from September, 1980 to February, 1981. The ramp access tested an area of approximately 500 m by 350 m to a vertical depth of 50 m. A total of 31,600 t of material was extracted as a bulk sample and four underground diamond drill holes totalling 490 m were drilled for comparative purposes. (RAL, 1983)

In 1982, the East Kemptville Deposit and surrounding claims were purchased from Shell by Riocanex, the Canadian exploration arm of RAL. During 1982 to 1983, RAL conducted a detailed due diligence of Shell’s work and drilled a total of 15 drill holes totalling 1,305 m during 1983 in preparation for a feasibility study and production decision also completed in 1983.

The open-pit operation at East Kemptville commenced in the fall of 1985 with a reported planned 17 years of production at rates of 9,000 t/d of plant feed material and 5,000 t/d of waste. This operation produced high (50% Sn) and low (21.4% Sn) grade tin concentrates a copper concentrate (25% Cu) and a zinc concentrate (50% Zn). Shortly after commencing production, the operation ran into serious problems related to the recovery of tin by gravity methods. A dramatic price decline of approximately 50% for tin on world markets in the fall of 1985 put added pressure on the operation. Continued poor tin prices resulted in cessation of operations in early 1992.

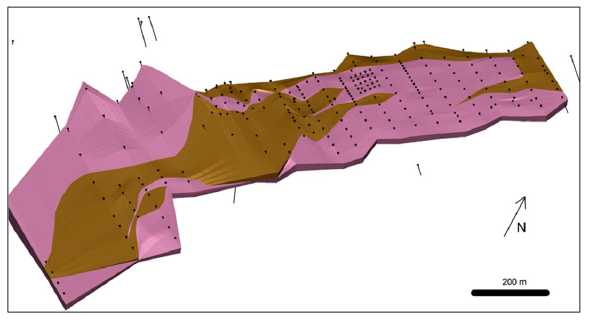

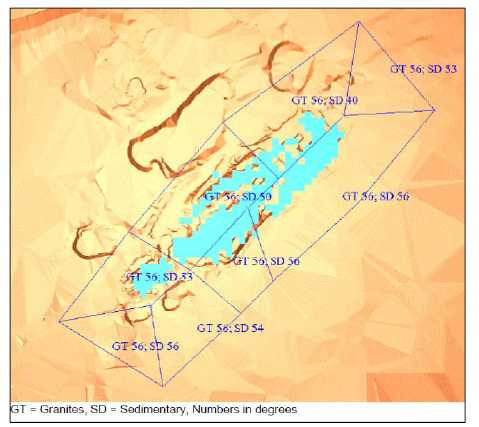

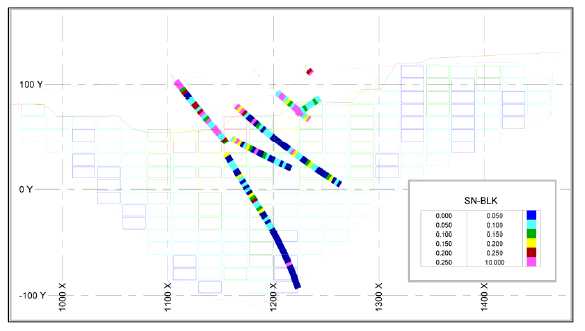

| 1.3 | GEOLOGY ANDMINERALIZATION |

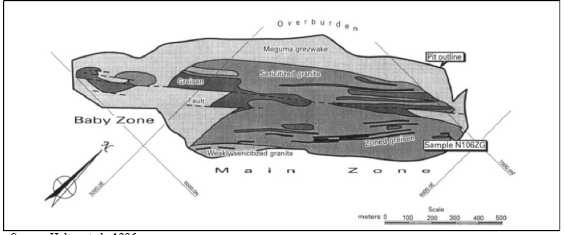

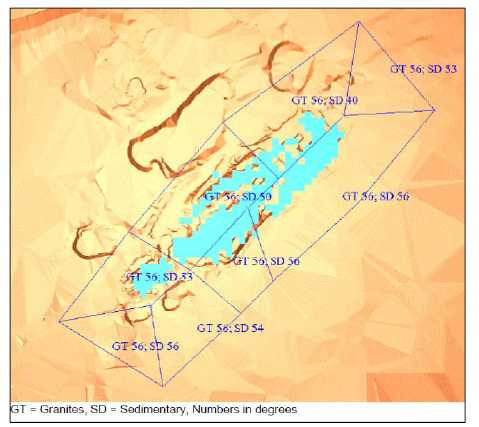

The East Kemptville Project is located within the Cambro-Ordovician aged, Meguma Terrane of mainland Nova Scotia. The East Kemptville deposit is a greisen hosted Sn-Cu-Zn-Ag-In deposit with the alteration and mineralization mostly affecting the East Kemptville leucogranite (EKL).

2

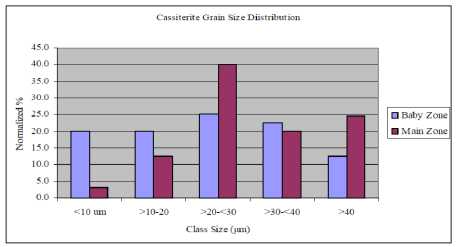

Tin and base metal (Zn-Cu-Ag-W) mineralization within the deposit is primarily fine to medium-grained and is associated with northeast-trending, sub-vertical and zoned, quartz-topaz, sulphide-bearing greisens, veins, and stockworks that occur primarily in the sericite-silica-topaz altered portions of the EKL near where the East Kemptville Shear Zone (EKSZ) meet the roof zone in contact with surrounding metasediments.

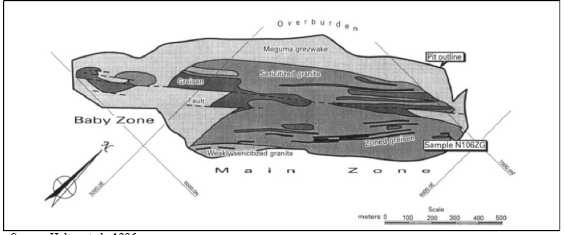

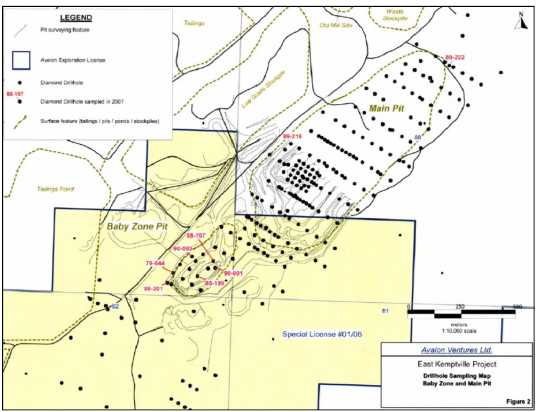

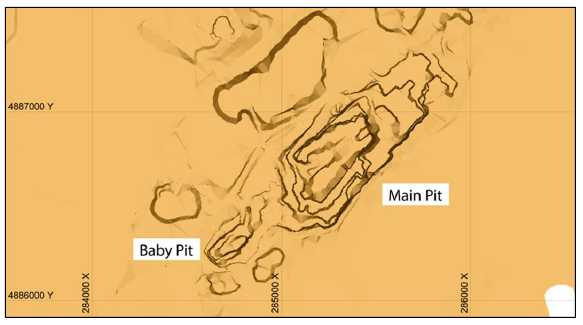

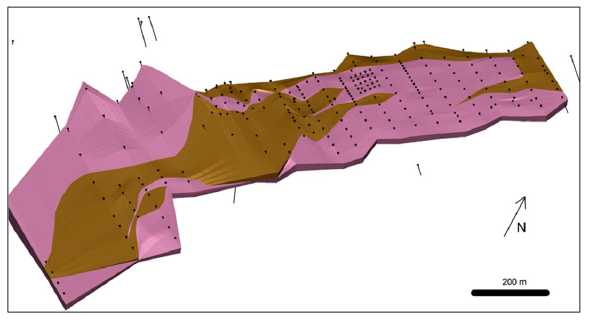

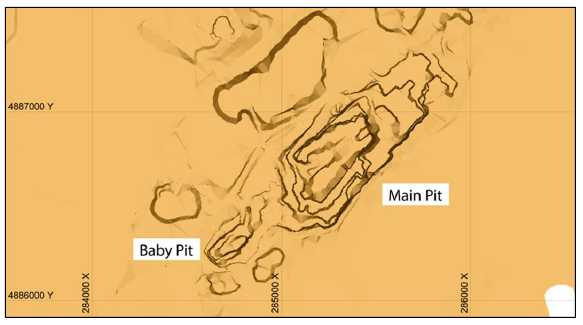

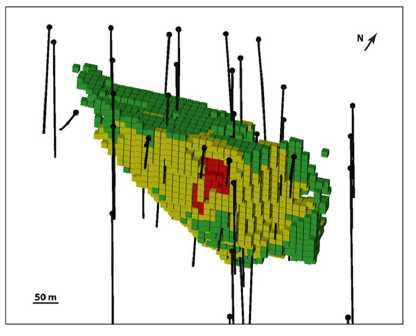

The overall gross dimensions of the original potential economic mineralization at the Main and Baby Zones based on a cut-off grade of approximately 0.05% Sn are in the order of 1,500 m long, 350 m wide and 75 m to 150 m deep. Most of this volume is represented by the larger, Main Zone. The smaller and discrete Baby Zone occurs a few hundred metres southwest of the Main Zone within what is believed to be a structurally controlled, satellite intrusion. Mineralization between the Main Zone and the Baby Pit is referred to as the Southwestern Extension of the Main Zone and is not exposed at surface but intersected in drilling.

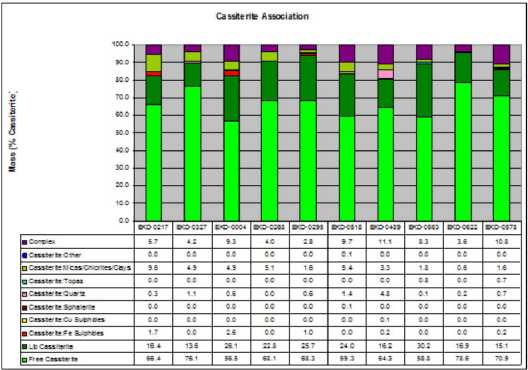

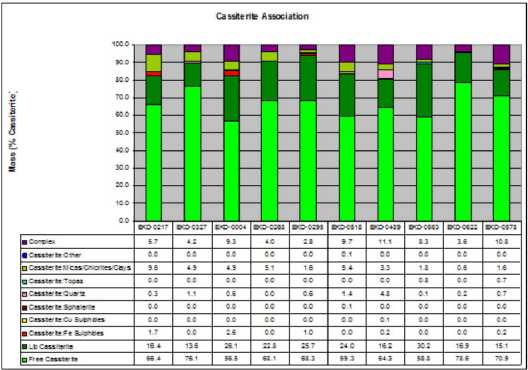

Cassiterite accounts for most (>90%) of the tin mineralization with stannite accounting for the remainder. Zinc is primarily found as sphalerite and indium is associated with the sphalerite. Copper is primarily present as chalcopyrite and other copper sulphide minerals.

Prior to the 2014 and 2015 drill programs, exploration by Avalon has been limited to regional reconnaissance geochemical sampling and limited diamond drilling on the exploration licences outside of the Special Licence area.

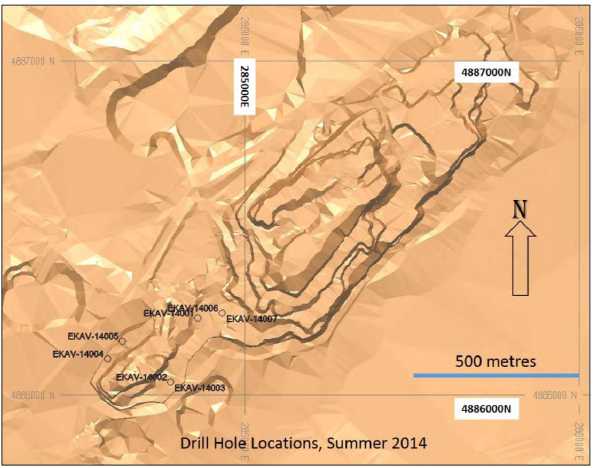

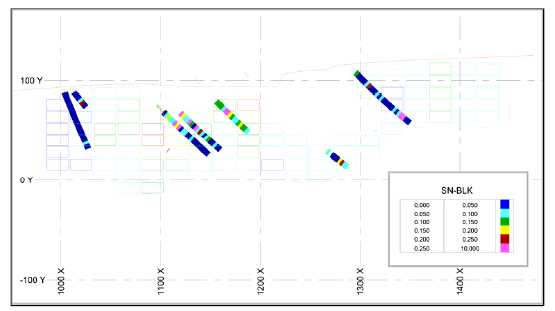

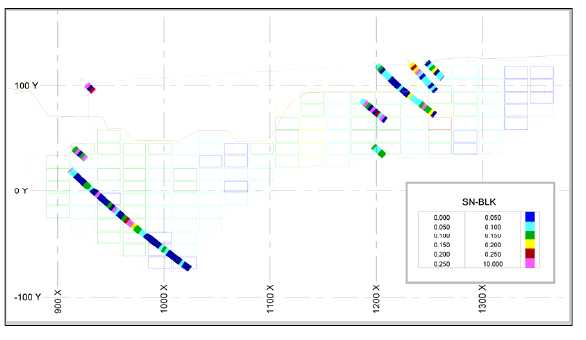

| 1.4.1 | Avalon 2014 Drilling Program |

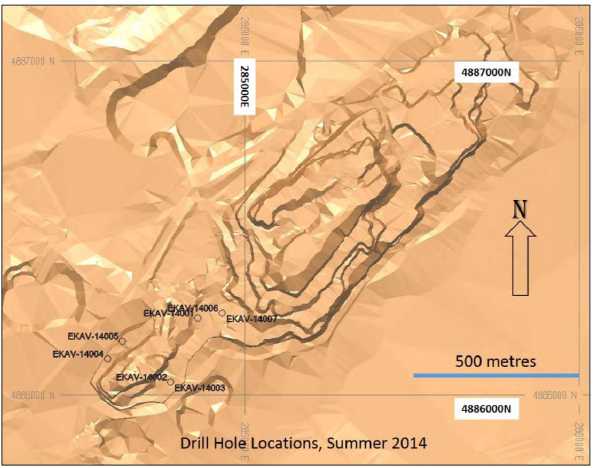

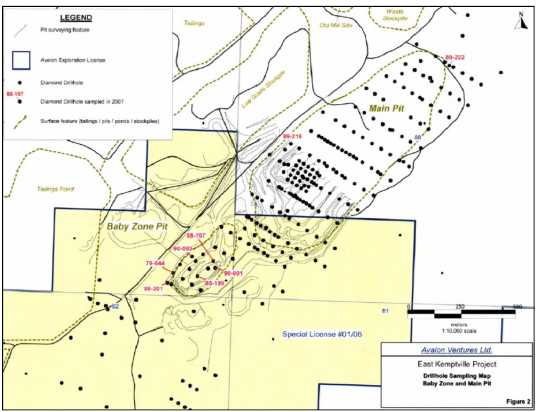

Avalon completed an in-fill/twin hole program consisting of seven HQ diamond drill holes totalling 986 m in 2014. The purpose of Avalon’s 2104 drill program was to investigate mineralization between the Main Zone pit and Baby Pit, referred to as the Southwestern Extension of the Main Zone, and at depth, and to twin some selected historic holes as part of a due diligence program to validate the historical drill results.

In general, the geology and polymetallic Sn + Zn + Cu zones encountered in the drilling are considered to be typical of historic drill results reported by Shell and RAL in the Baby and Southwest Extension Zone Areas. Drilling was successful in confirming the known geology and the mineralization associated with the Southwest Extension of the Main Zone

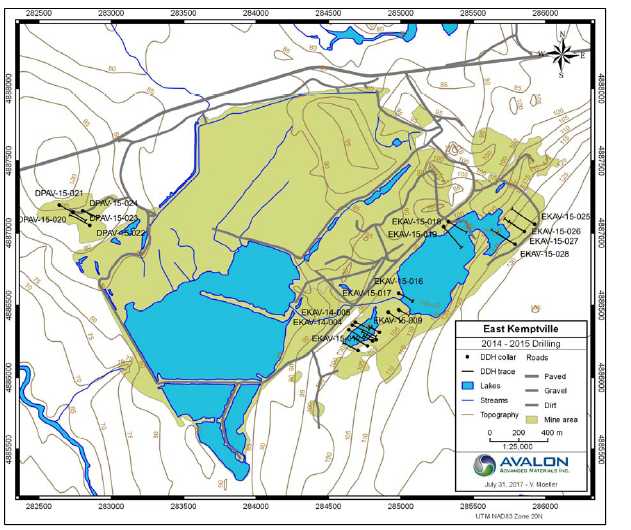

| 1.4.2 | Avalon 2015 Drilling Program |

In 2015, Avalon completed the drilling of twenty-two HQ diamond drill holes totalling 4,514 m. The objectives of this program were to further definition of mineral resources, obtain additional geotechnical information for mine planning and geochemical information for waste rock handling planning, and obtain a bulk sample for potential pilot scale metallurgical testing.

3

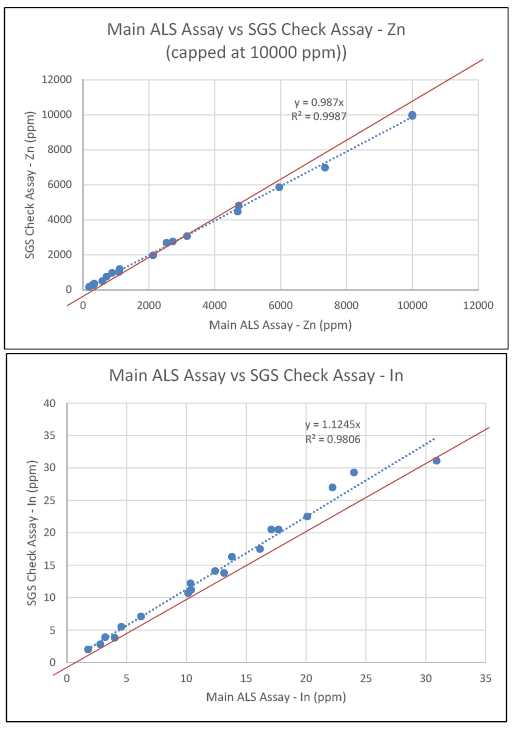

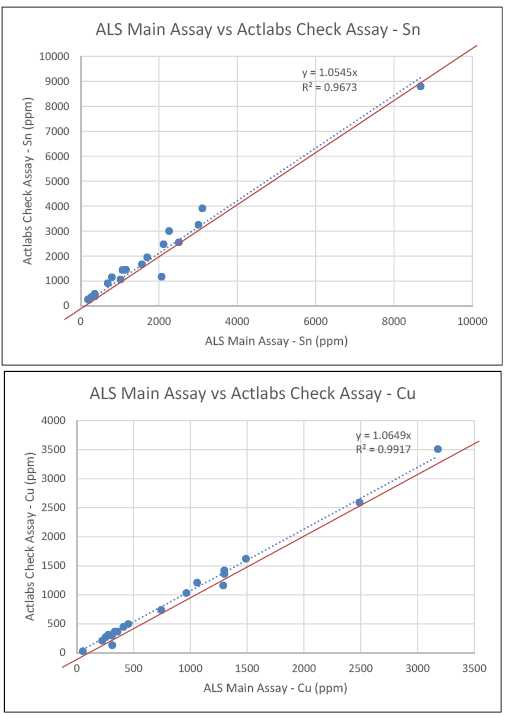

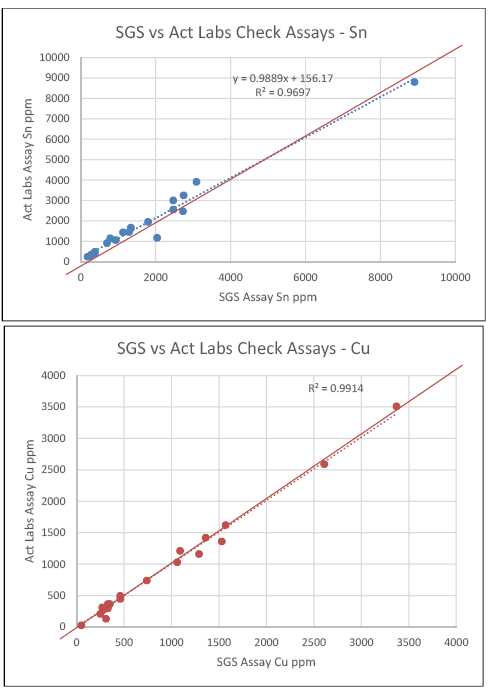

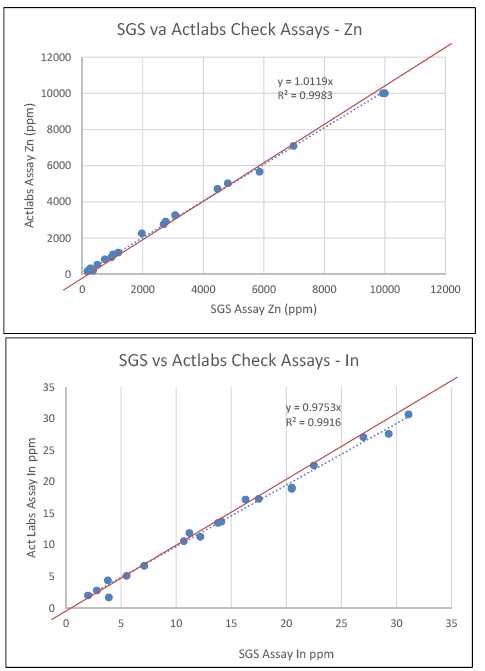

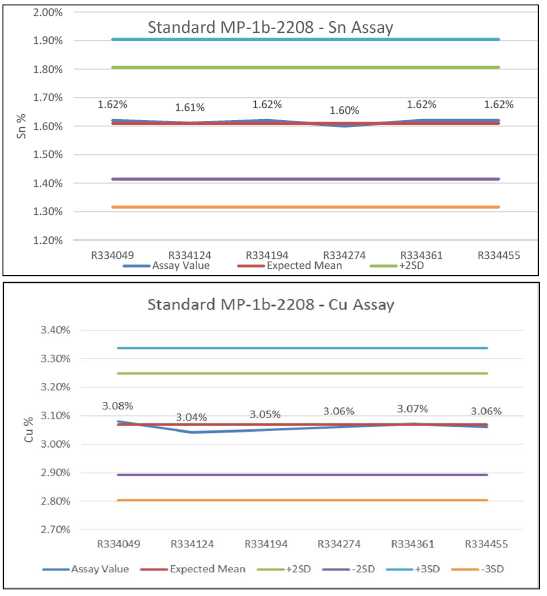

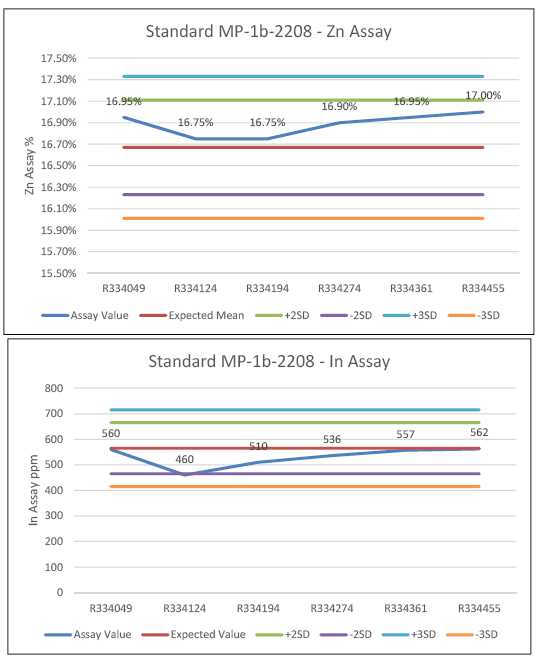

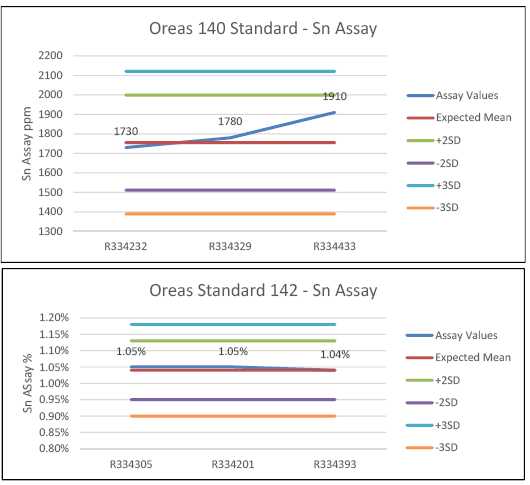

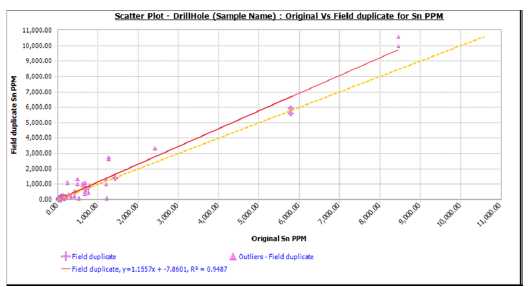

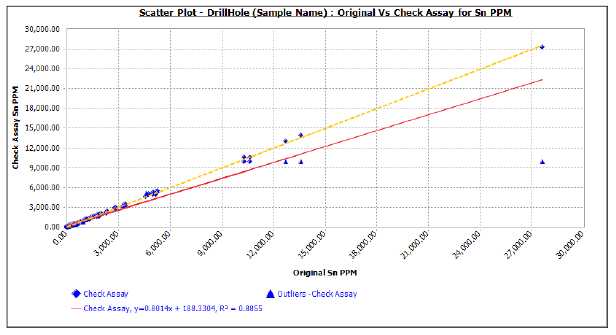

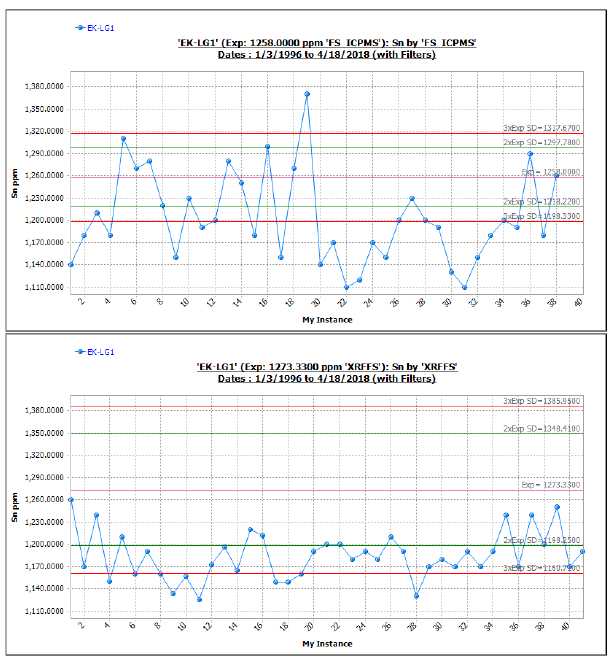

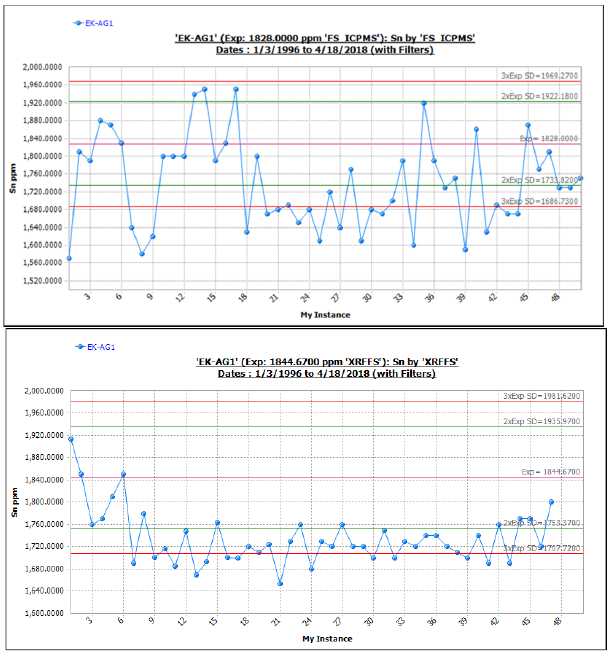

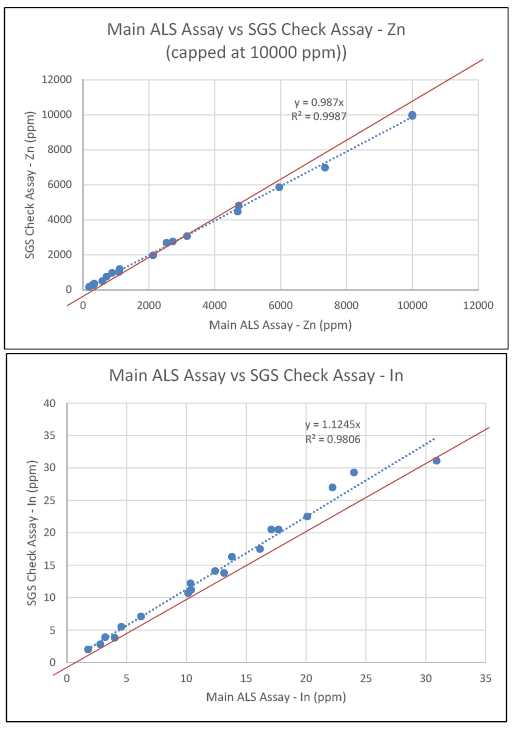

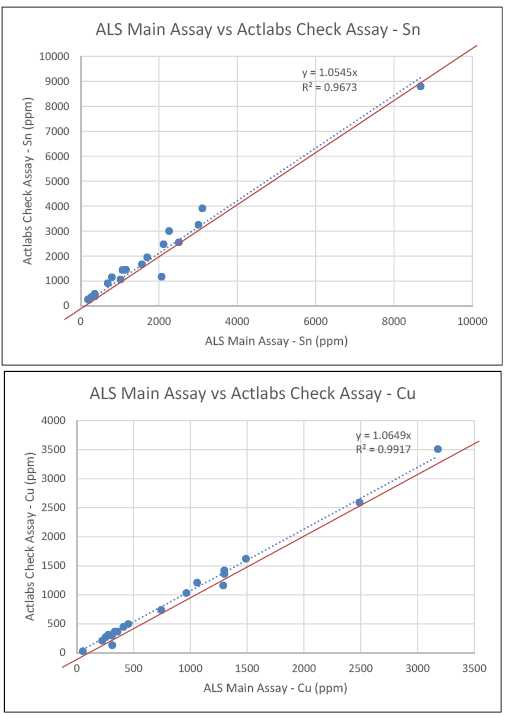

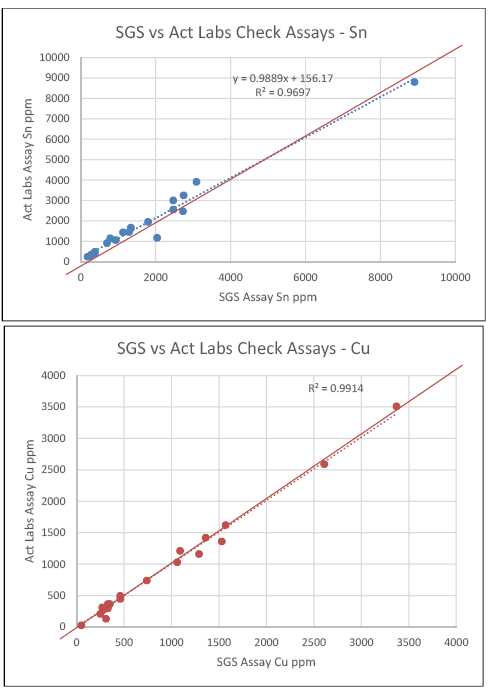

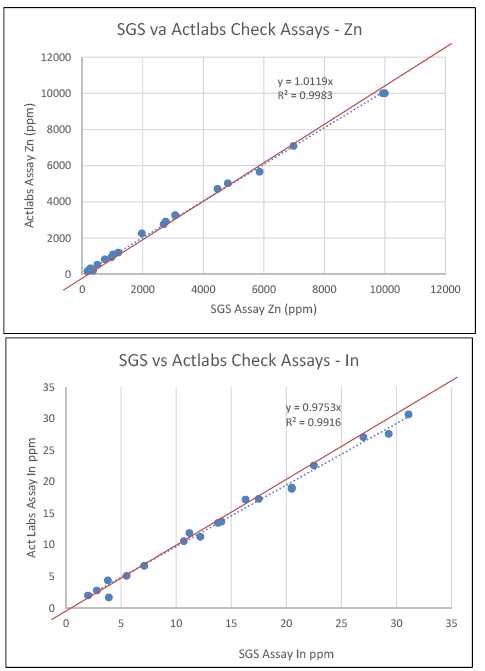

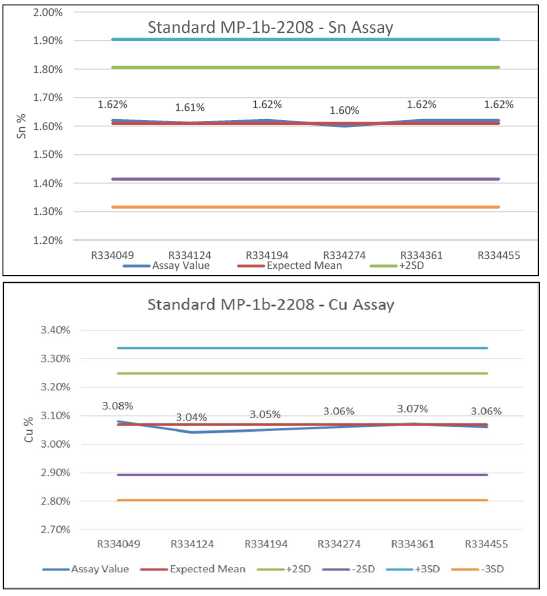

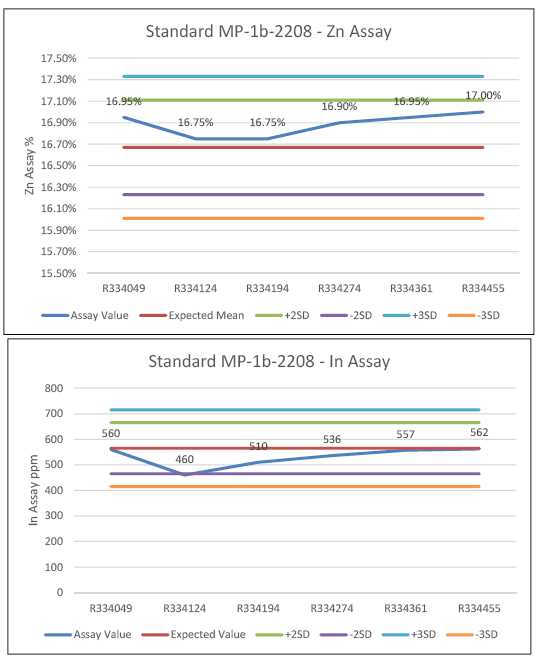

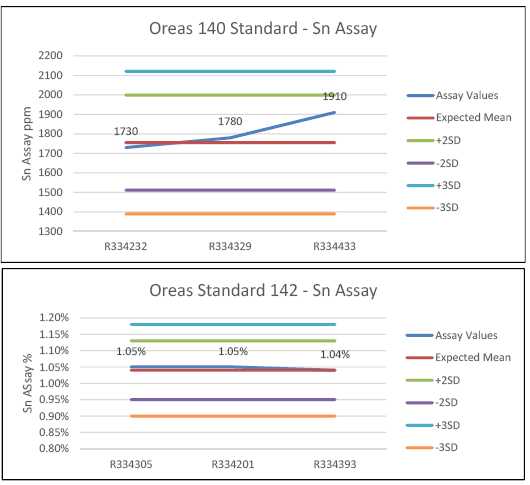

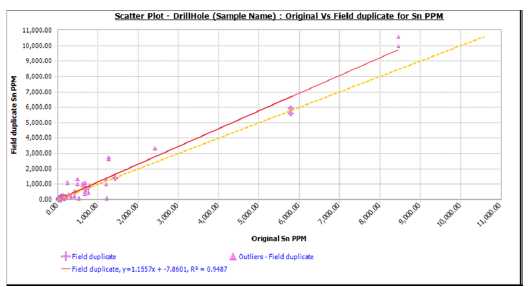

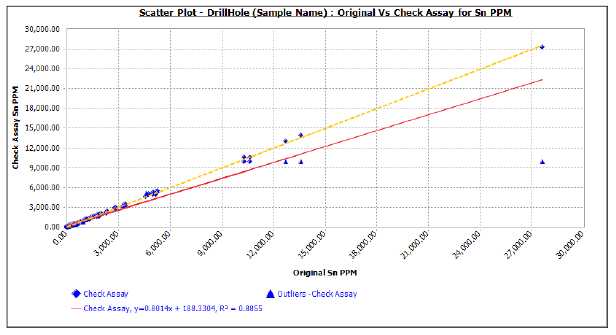

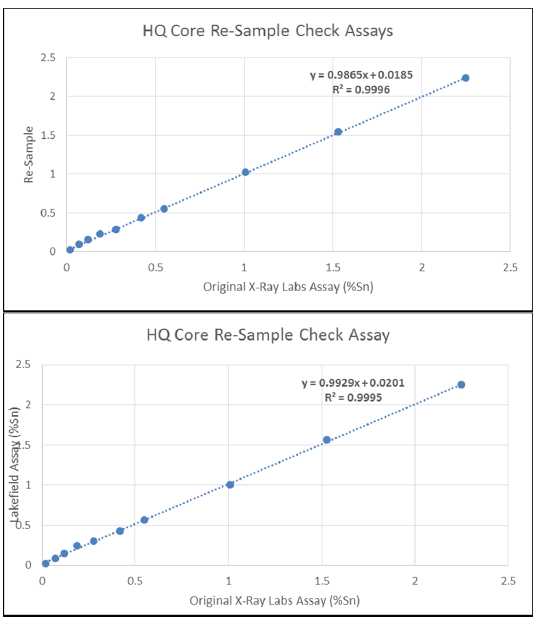

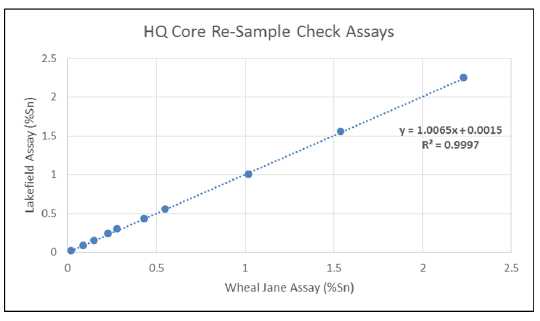

The drill hole sample preparation and assays conducted under best practice QA/QC procedures with insertion of blanks and standards, as well as duplicate coarse sample analyses at a secondary laboratory and core duplicates.

| 1.5 | SAMPLEPREPARATION, ANALYSES ANDSECURITY |

| 1.5.1 | Avalon 2014 Drilling Program |

Core was placed in numbered and marked core boxes at the drill site and a quick log prepared. Avalon personnel transferred boxes to the core logging area where drill core was logged in detail and marked for sampling and all core photographed prior to sampling.

Sampling was typically undertaken on 1.5 m intervals within mineralized sections. Core was split using a manual core splitter, with the remaining ½-core reassembled in order in the core box. Sample material was placed in plastic sample bags with sample number marked on the outside of the bag and a sample tag stapled to the inside fold of the bag. A duplicate tag was placed in the core box. Duplicate samples were obtained from drill core by splitting core in half, with one half noted as the main sample and the other half noted as the duplicate in the sample log. Standards and blanks were inserted in the sample list on a pre-determined basis.

Bagged samples were placed in 20-L plastic pails. The pails were sealed with secure lids and taped closed and the sample numbers noted on the outside of the pail. Once a sufficient number of samples had been prepared, samples were shipped by courier to ALS Canada Ltd. (ALS) in Sudbury for initial sample preparation. After initial sample preparation, ALS shipped the samples to its Vancouver facility for assaying. Check sample splits were shipped by ALS to SGS Canada in Lakefield, Ontario, and to Activation Laboratories Ltd. (Actlabs) in Ancaster, Ontario.

A total of 404 samples (excluding the 57 duplicates, standards and blank samples) were submitted to ALS for multi-element analyses. Sixteen blanks, 15 standards and 13 field duplicates were inserted into the three sample shipments to monitor contamination, accuracy and precision.

| 1.5.2 | Avalon 2015 Drilling Program |

For the 2015 drill program, the sample treatment at the core logging facility was similar to 2014, with the exception that the samples were shipped to Actlabs’ sample preparation facility in either New Brunswick or Ontario, with the New Brunswick facility utilized except in some cases where a backlog had built up in New Brunswick. In the latter case, the samples were shipped direct to the Actlabs laboratory in Ancaster, Ontario.

4

For the 2014 program, only a limited amount of sampling was undertaken in non-mineralized sections (limestone and greywacke). However, in 2015, in light of the occurrence of mineralization to the boundary of sampling, prior to the start of the 2015 drill program, additional sections of unsampled 2014 core were split and assayed and, in some cases, contained significant mineralization that was contiguous with existing known mineralization.

The initial sample processing and analysis was completed by Actlabs (Ancaster, Ontario) and the check samples sent to ALS (Vancouver, BC) for analysis.

| 1.5.3 | Low Grade Stockpile Surface Sampling Program |

In order to verify the metal grade of the low-grade stockpile, a surface sampling program was completed in 2015. A program was completed with two samplers to reduce sample bias, each independently taking a sample at points at 50 m intervals across the length and width of the low-grade stockpile, plus samples around one side of the bottom of the pile. The two samples from the two individuals from each site were kept separate for analysis in order to investigate any sampling bias on the part of one or other sampler. A total of approximately 270 kg was collected with each sample being about 5 kg.

Samples collected from each site were shipped to Actlabs for analysis. Comparing these analyses with the RAL Closure Plan (RAL, 1993) showed that the Avalon estimates for Sn and Zn grades are within 11% of the surface samples quoted by RAL.

Data verification for the 2014 drill program and the resource database included the following:

| | 1. | Comparison of 2014 drill core sample numbers against assay sample shipment lists and sample receipt list. |

| | | |

| | 2. | Survey of drill collar coordinates by a qualified Nova Scotia land surveyor. |

| | | |

| | 3. | Site visit and inspection of 2014 drilling procedures, core logging, and sampling by Hains Engineering. |

| | | |

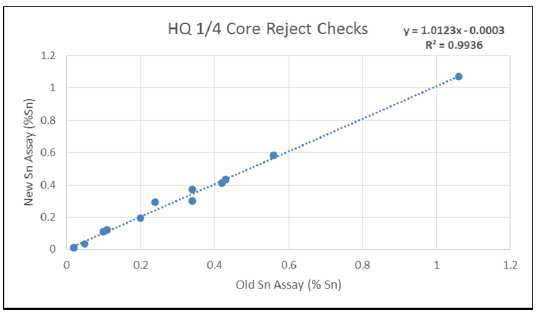

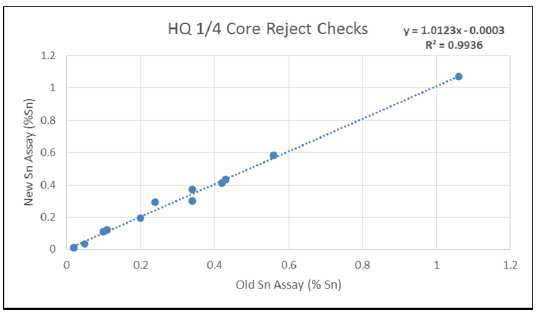

| | 4. | Collection of due diligence ¼-core samples and independent assaying of samples by Hains Engineering. |

| | | |

| | 5. | Comparison of 2014 drill core assays against assay certificates. |

| | | |

| | 6. | Comparison of historic drill logs and assay certificates against the historic Excel database used in the resource estimate. |

| | | |

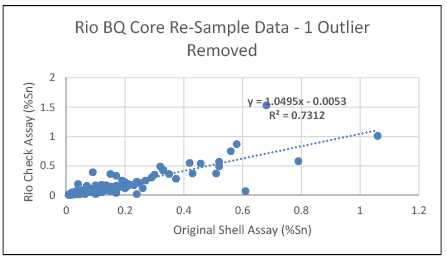

| | 7. | Verification of historic Rio Algom Limited (RAL) QA/QC data. |

| | | |

| | 8. | Inspection of selected historic drill core stored at the NSDNR Core Library in Stellarton, Nova Scotia and verification of descriptions in historic drill logs by Hains Engineering. |

5

| | 9. | Collection of due diligence ¼-core samples and independent assaying of samples from selected drill core intervals of historic drill core stored at Stellarton by Hains Engineering. |

In the opinion of author, the 2014, sampling and assay data and the historic drill hole and assay data, as represented in the resource database, are reliable and can be used in resource estimation.

QA/QC measures employed for the 2014 drill program included the following:

| | 1. | Insertion of standards and blanks in the main sample batches. |

| | | |

| | 2. | Assays of coarse duplicates to check sample preparation procedures and laboratory precision. |

| | | |

| | 3. | Assays of pulp duplicates to laboratory analytical precision. |

| | | |

| | 4. | Coarse check samples assayed at two separate laboratories to check sample preparation procedures and analytical bias. |

| | | |

| | 5. | Insertion of certified standard reference materials in check sample assay batches. |

| | | |

| | 6. | Internal laboratory QA/QC protocols incorporating the use of certified standards and blanks and duplicate and repeat assays. |

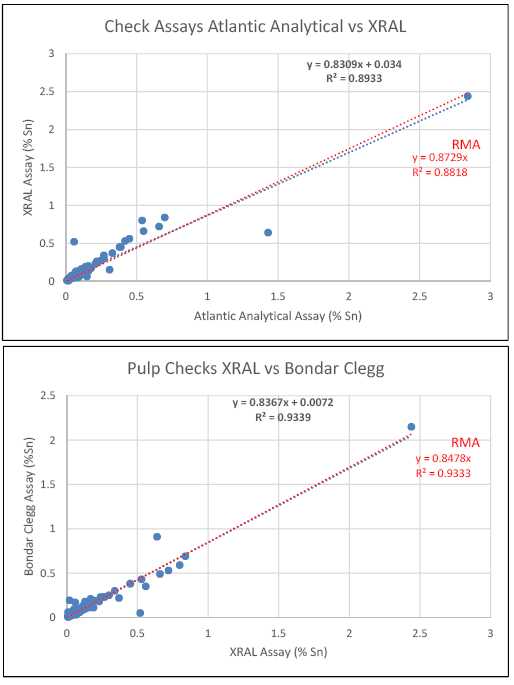

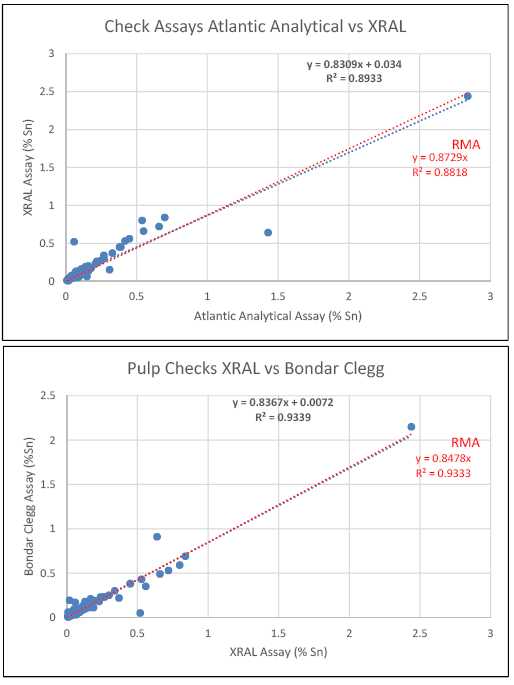

The review of the QA/QC data indicates no significant issues with respect to sample preparation, assaying and laboratory precision.

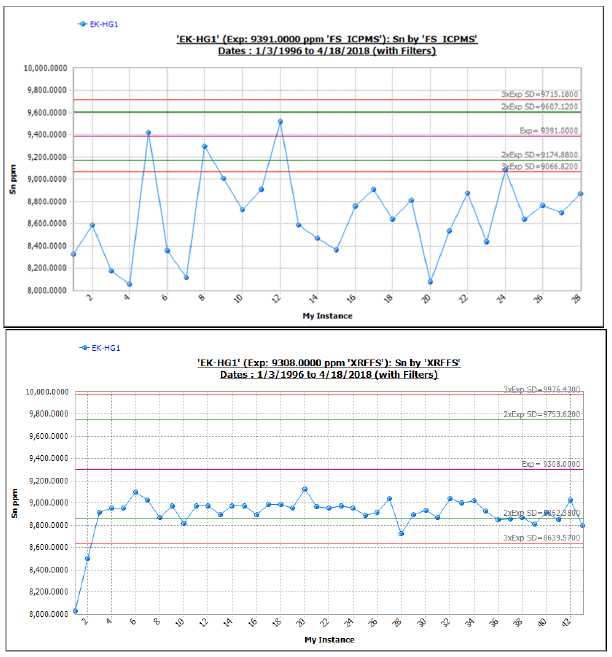

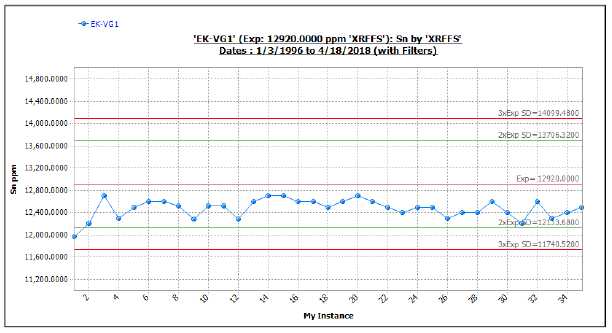

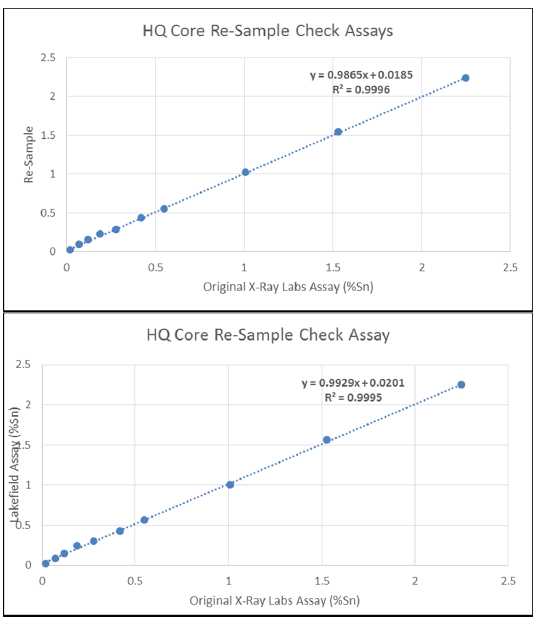

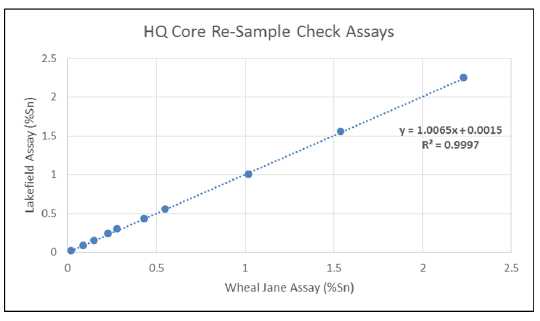

Similar QA/QC protocols were followed in the 2015 drill program as previously used in 2014. The results on the standards and duplicates suggest that Actlabs may have a slight negative bias in analyses in tin. As all biases present are indicated at levels below 10% and in most cases less than 5%, the analytical data is considered acceptable for resource estimation.

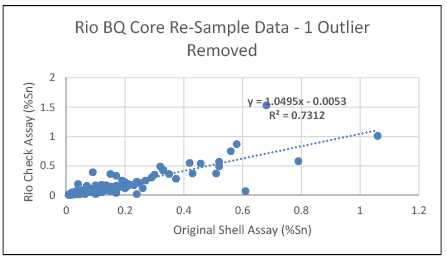

Data verification of the historic sampling and assay data consisted of checking the reported assay values contained in the QA/QC appendix of the RAL feasibility study against the current assay data base and the available drill logs. The current assay data base is a compilation undertaken by Avalon of all available assay certificates, drill logs and survey data. The Shell and RAL drill core assays are considered as acceptable for resource estimation purposes.

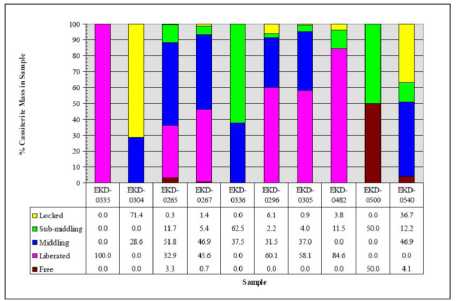

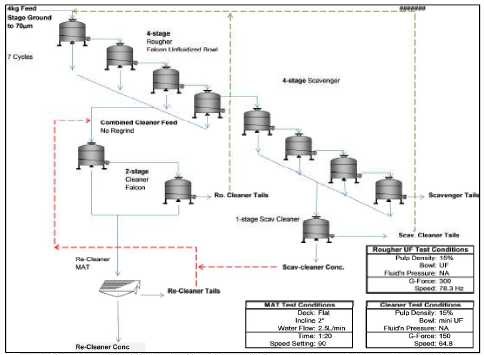

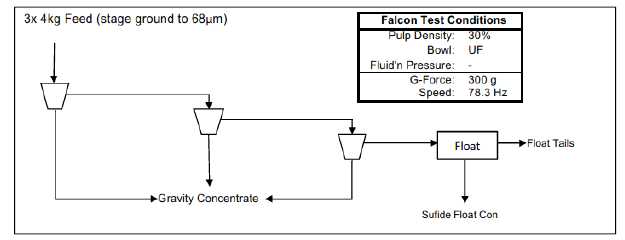

| 1.7 | MINERALPROCESSING ANDMETALLURGICALTESTING |

Avalon has conducted a number of testwork programs on samples representing the East Kemptville deposit. Work began with SGS UK in Cornwall, UK, to develop a comprehensive flowsheet to produce tin, copper, and zinc/indium concentrates using mineralized samples from the Baby Zone deposit. This set the baseline for a subsequent test campaign, in 2016, at Met-Solve, who investigated recovering tin (only) from the existing low-grade stockpile.

6

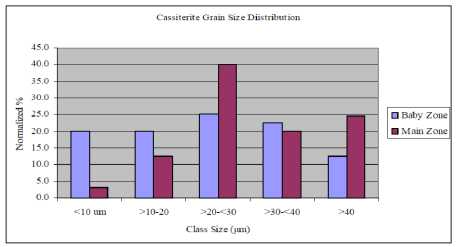

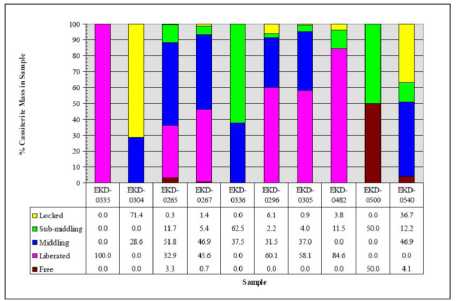

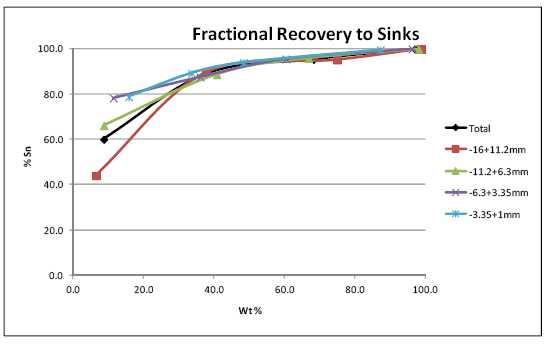

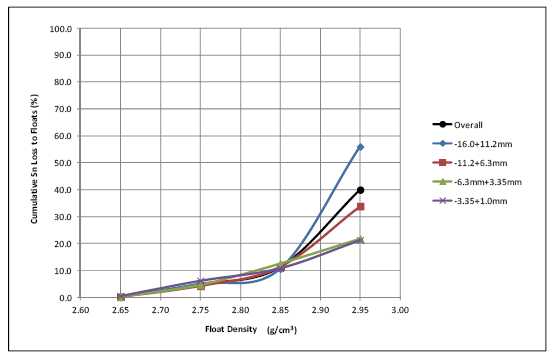

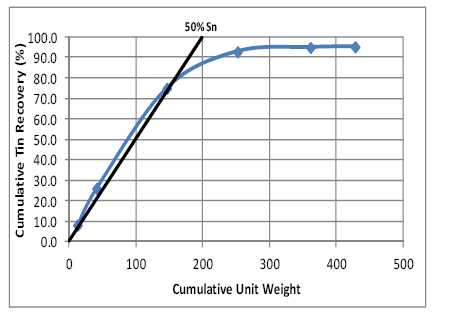

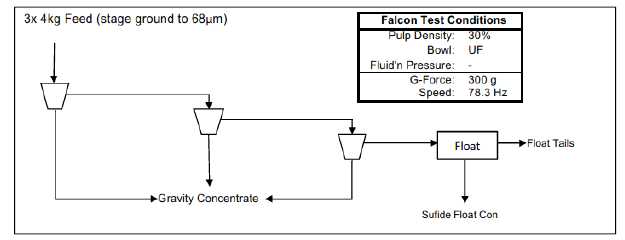

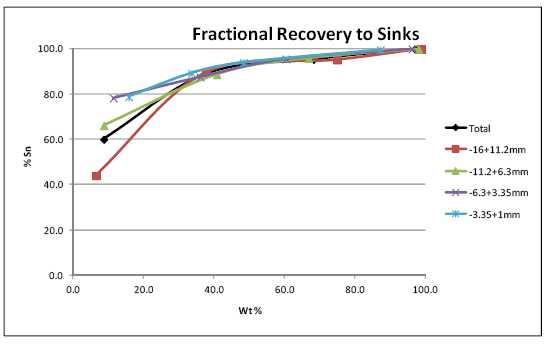

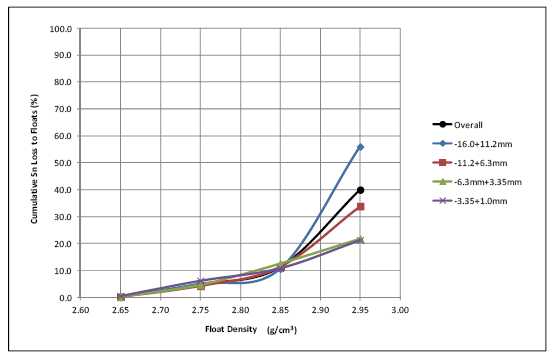

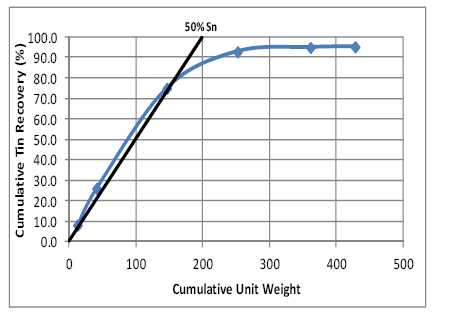

Testwork was undertaken by SGS UK using a 290 kg blended composite from 1,140 kg of material comprising 394 split drill core from the Baby Zone. The testwork completed included heavy liquid sink/float tests, Bond rod and ball mill grindability tests, gravity separation tests and flotation tests.

SGS UK was able to develop a flowsheet for the East Kemptville deposit to produce copper, zinc and tin concentrates. Copper recovery was estimated at 86.4% into a 20.7% grade copper concentrate, zinc recovery was estimated at 84.5% into a 51.4% grade zinc concentrate and tin recovery into a 50.5% Sn concentrate was estimated at 76.8% .

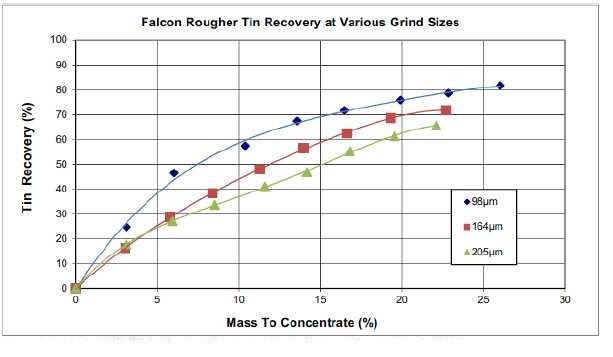

Using the SGS UK test results as a basis, Avalon contracted Met-Solve in Langley, BC (Met-Solve), in 2016, to undertake further flowsheet development testwork to recover tin from East Kemptville mineralization. The testwork program was divided into three phases:

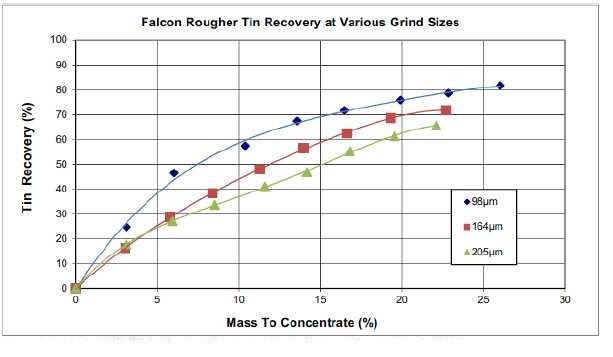

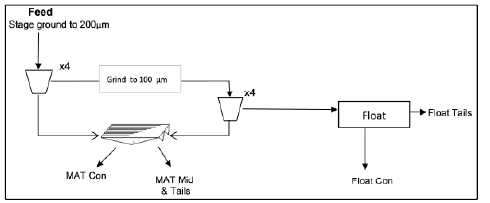

| | • | Phase I: Use of falcon gravity concentrators at 3 different grind sizes (200, 150 and 100 µm) to determine the sample’s response to gravity concentration for the recovery of tin. |

| | | |

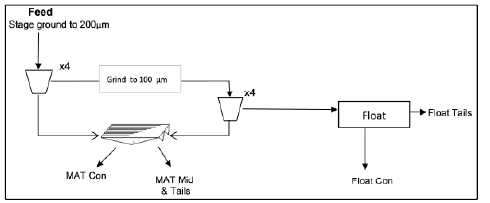

| | • | Phase II: Grind material to 200 µm for the gravity rougher stage, followed by a regrind to 100 µm for gravity scavenging. Gravity tailings were then floated to attempt to recover additional tin. |

| | | |

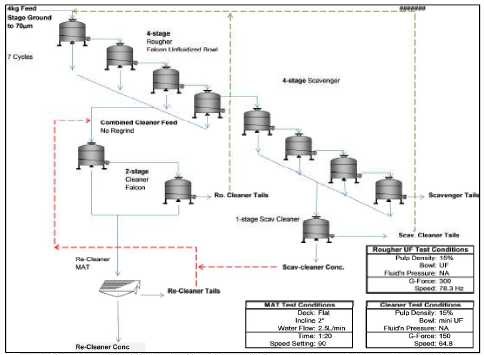

| | • | Phase III: Locked Cycle tests of the best flowsheet configuration previously identified in Phases I and II. |

The sample provided by Avalon for the Met-Solve testwork comprised approximately 178 kg of crushed samples from the East Kemptville low-grade stockpile.

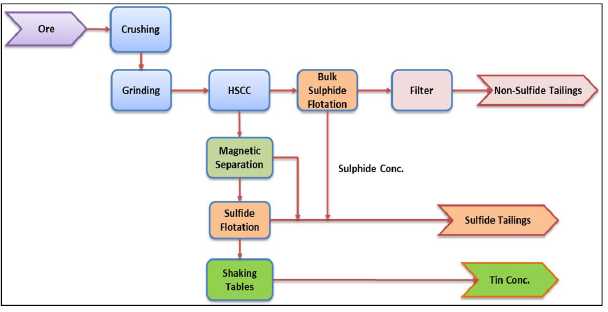

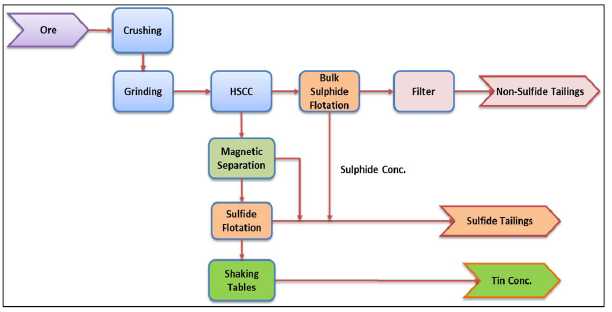

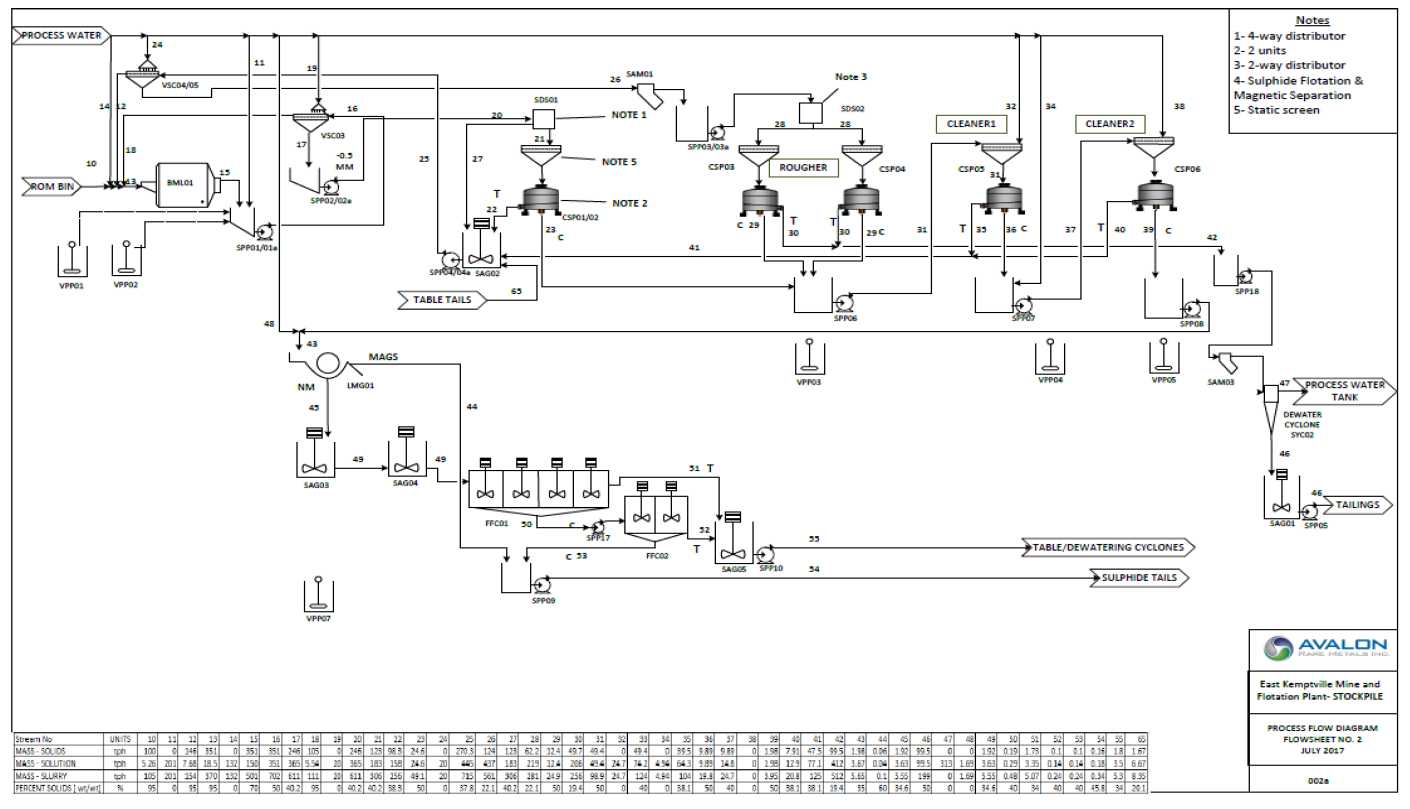

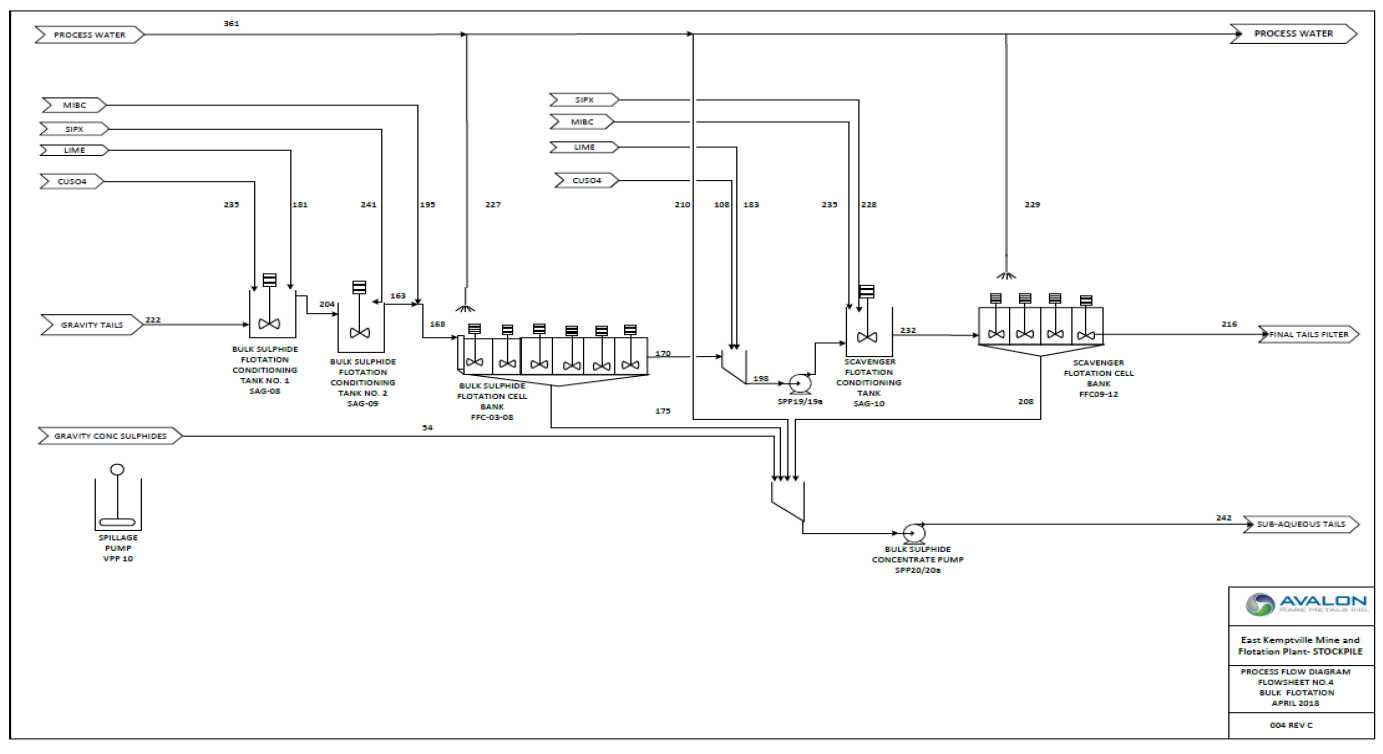

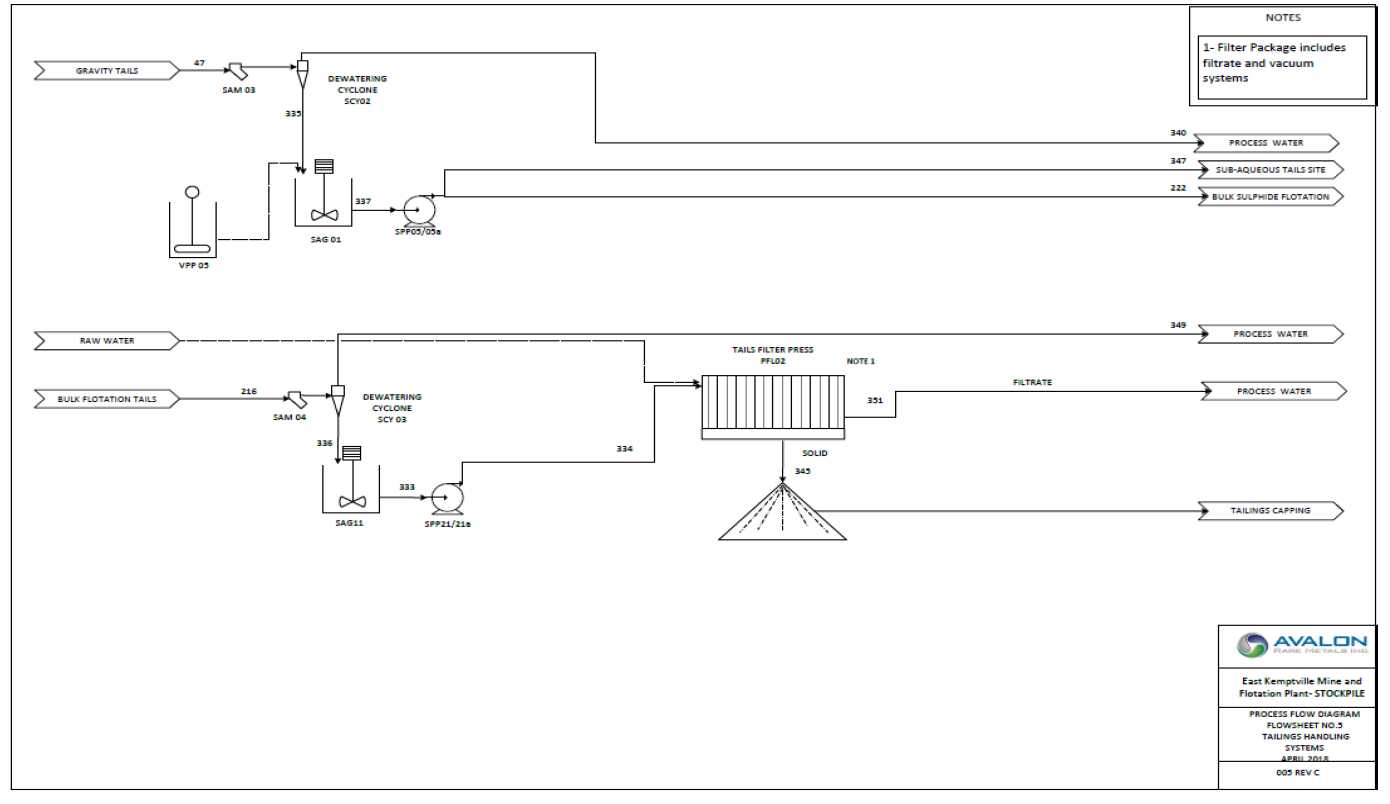

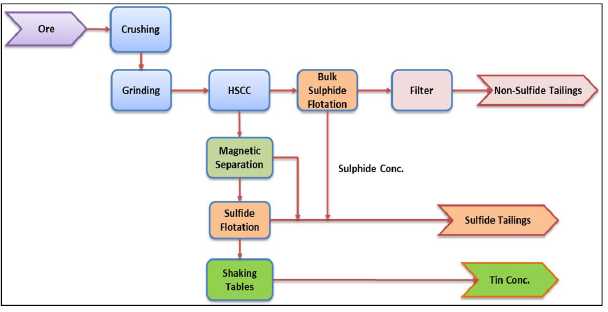

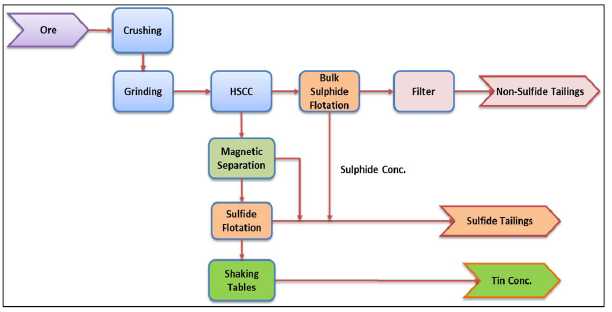

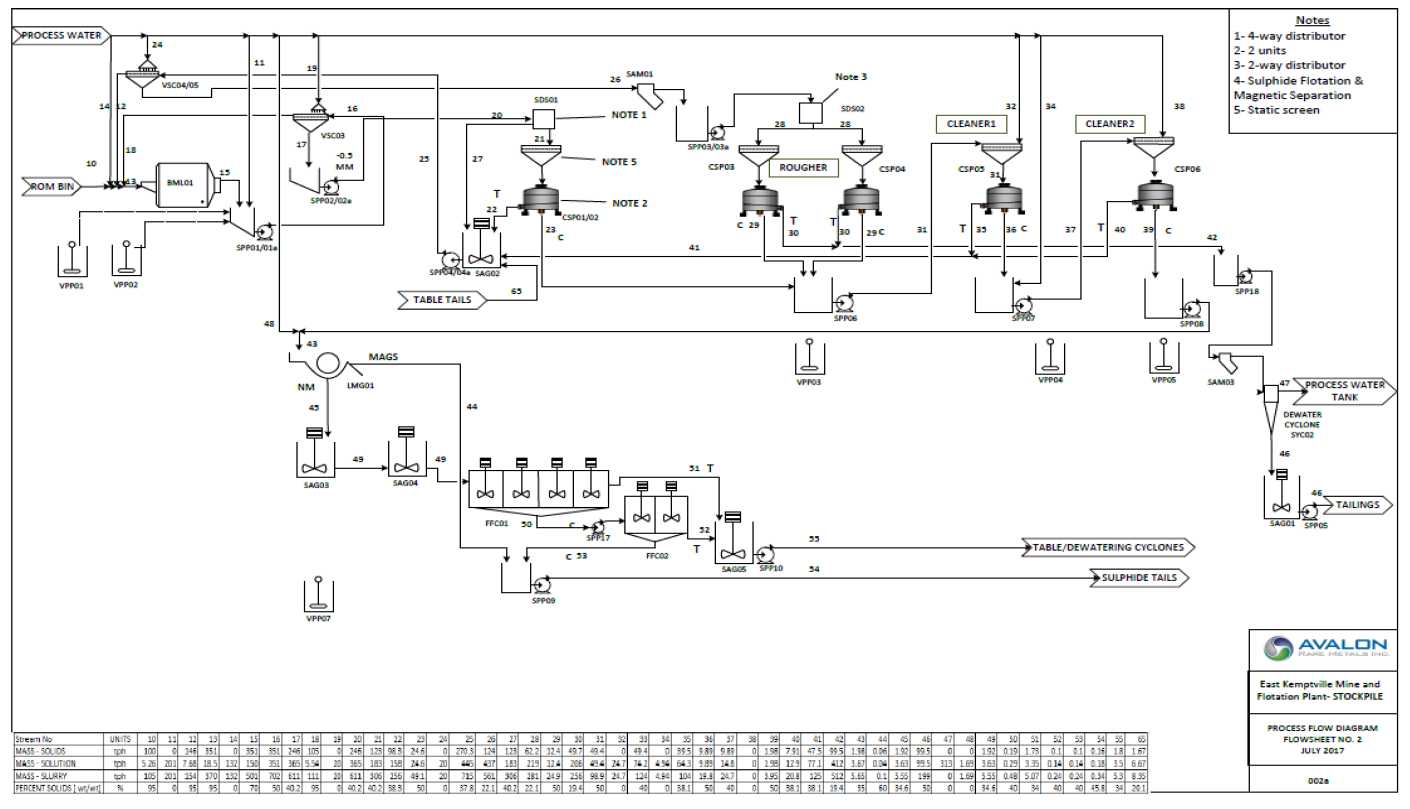

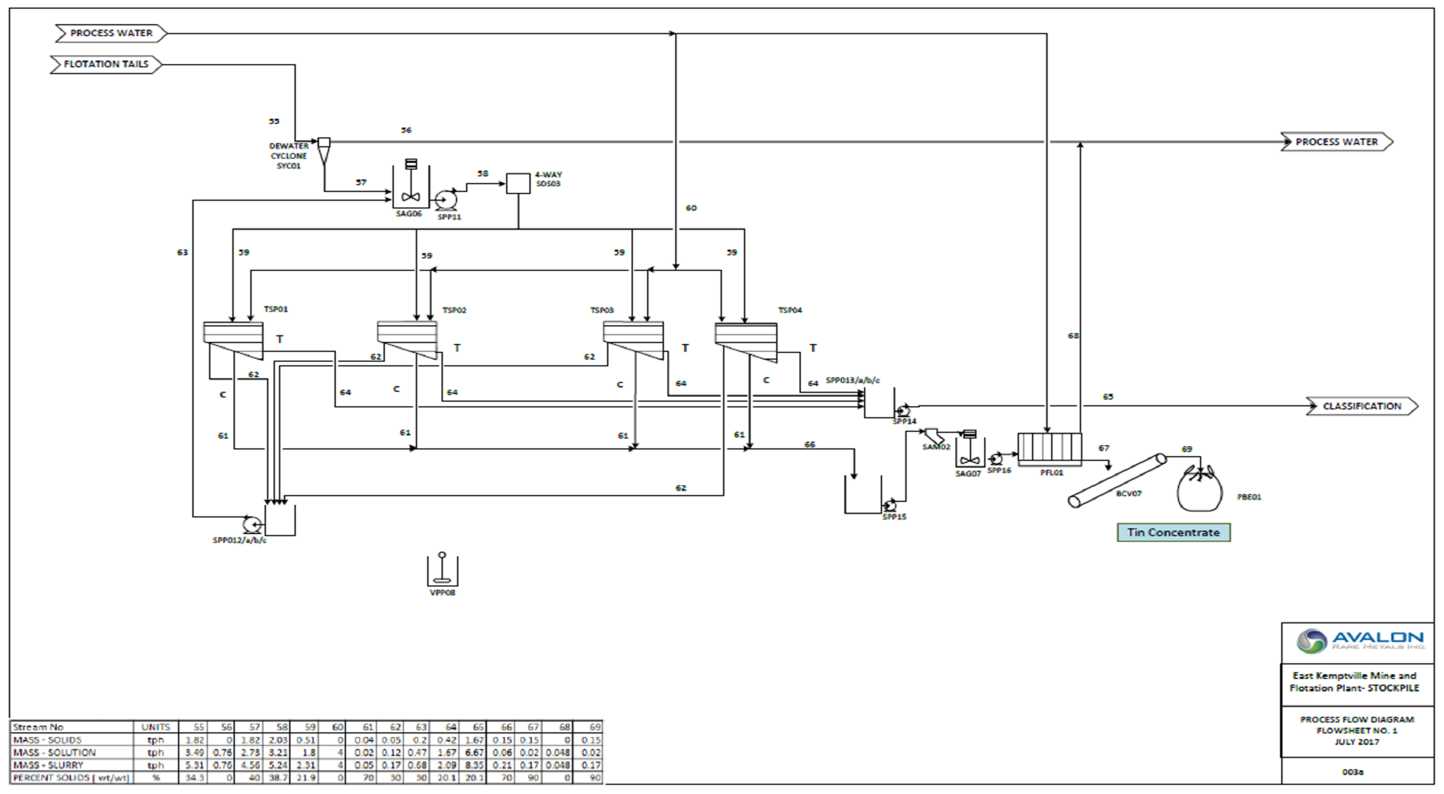

The testwork resulted in the development of a flowsheet capable of producing a tin concentrate containing up to 55% Sn with a tin recovery of approximately 60%. The material will be milled to P80 ±80 microns before being put through a series of centrifugal gravity concentrators. The gravity concentrates will feed a magnetic separation circuit followed by a simple sulphide flotation circuit to remove sulphides. The non-sulphide flotation tailings will be cleaned using final shaking table gravity circuit, the concentrates from which will be collected and dewatered before being shipped to potential customers.

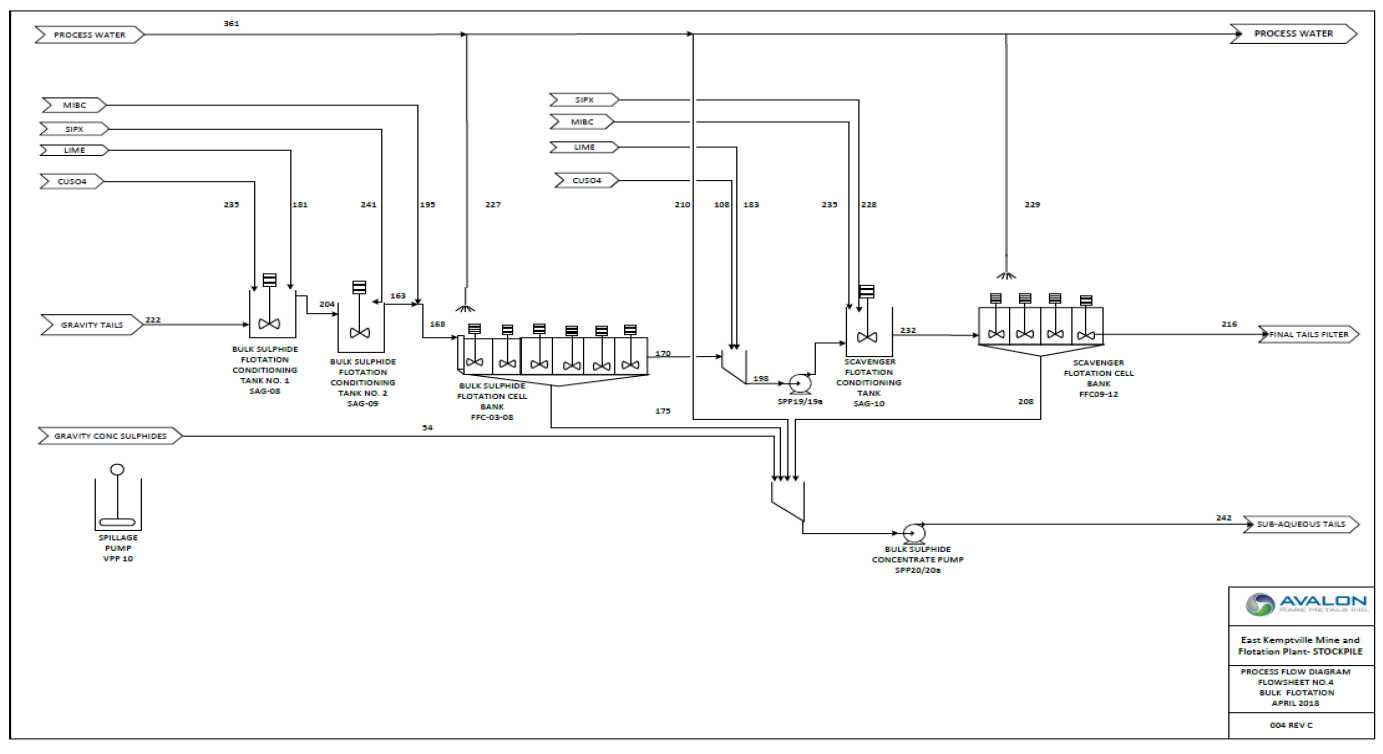

Testwork also showed that tailings from the gravity circuit can be treated through a bulk sulphide flotation process to reduce contained sulphur to approximately 0.05% S, making it a suitable material for capping of the tailings dam

7

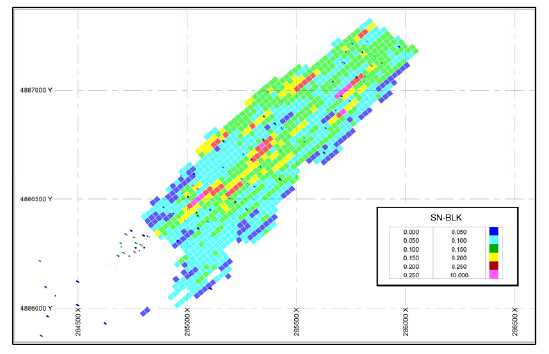

| 1.8 | MINERALRESOURCEESTIMATES |

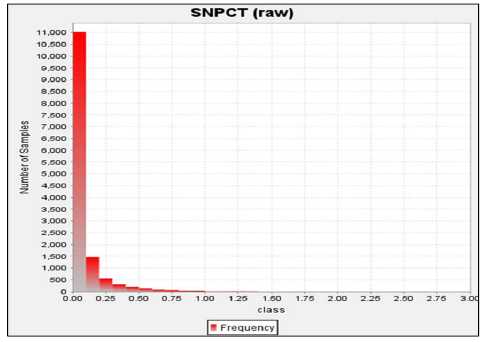

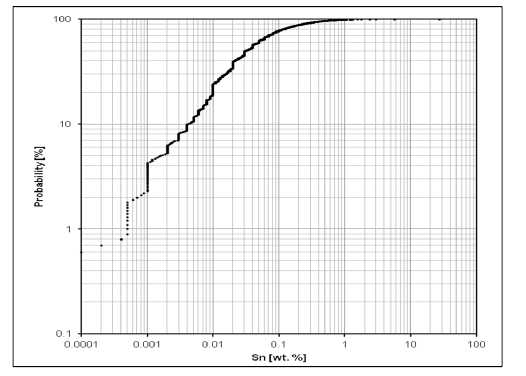

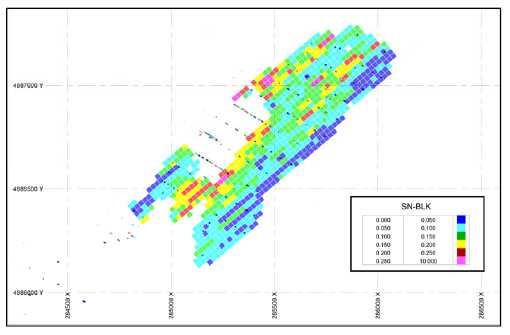

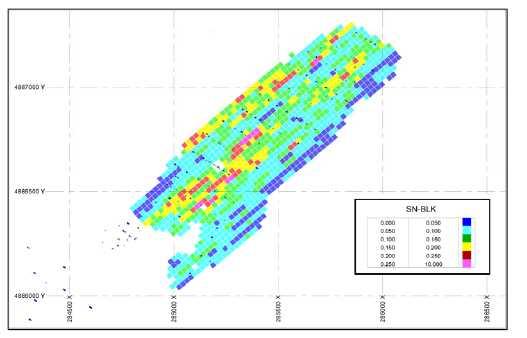

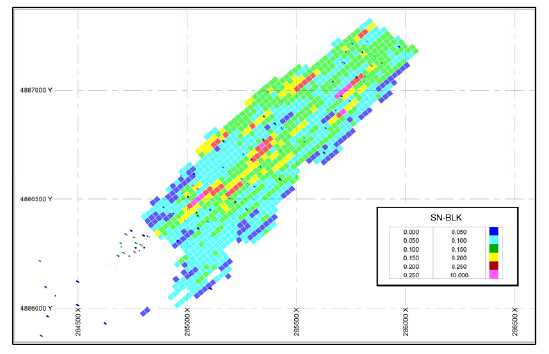

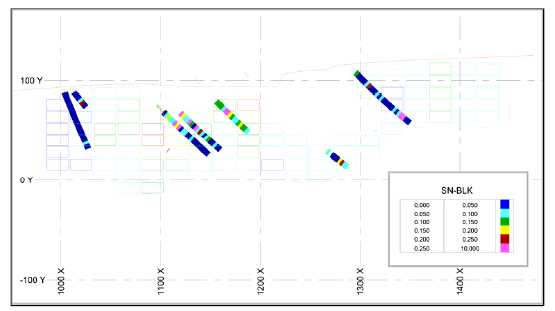

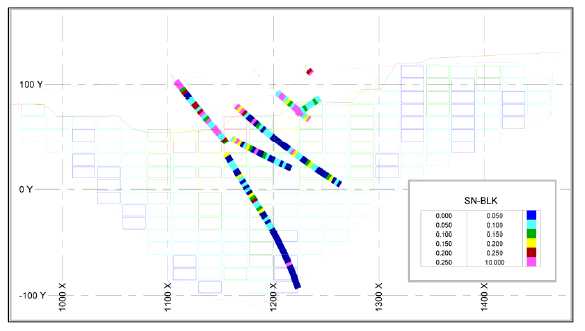

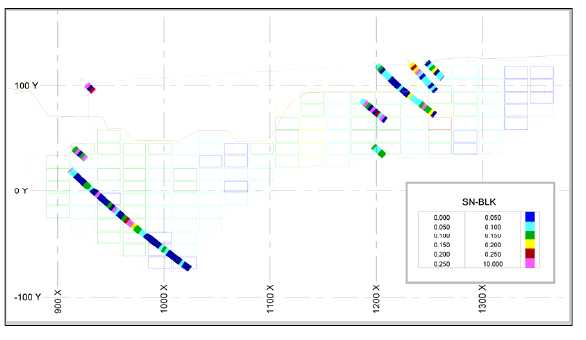

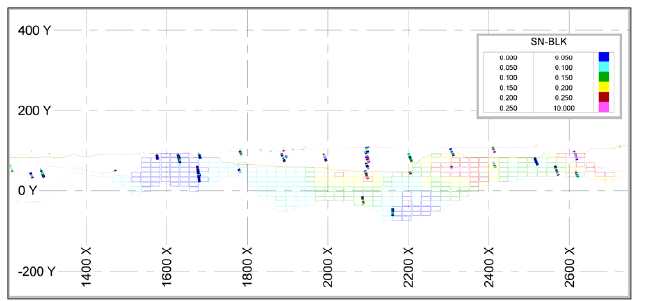

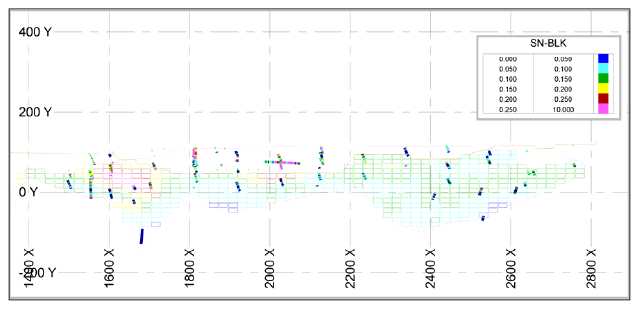

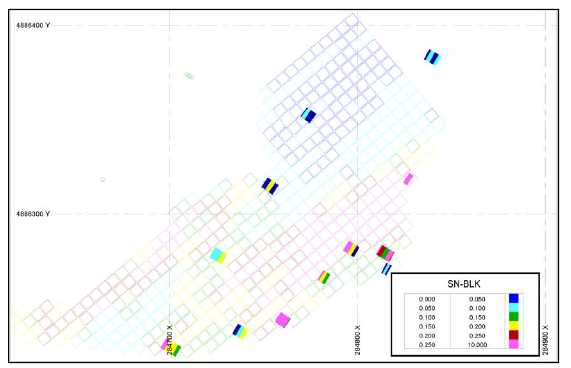

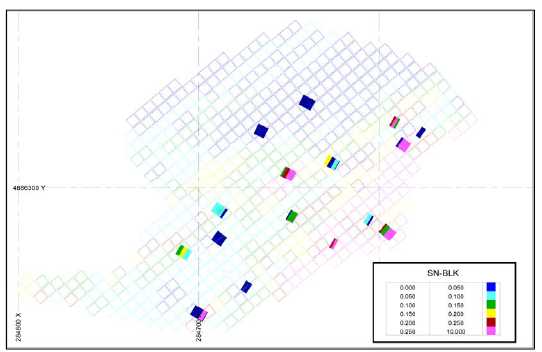

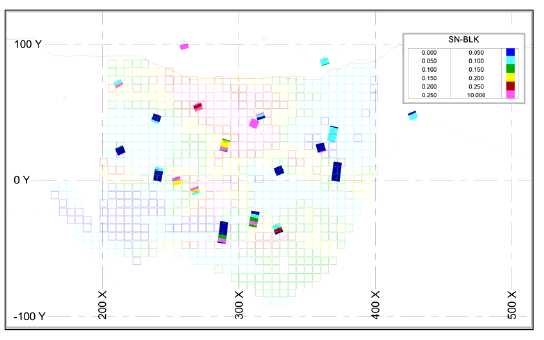

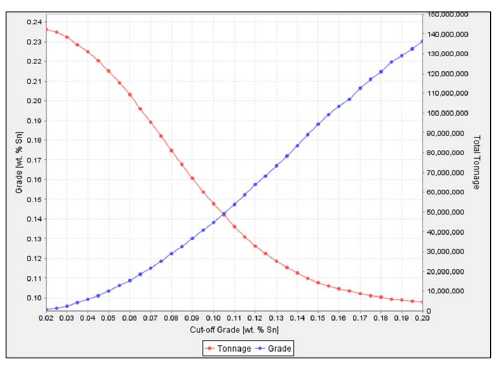

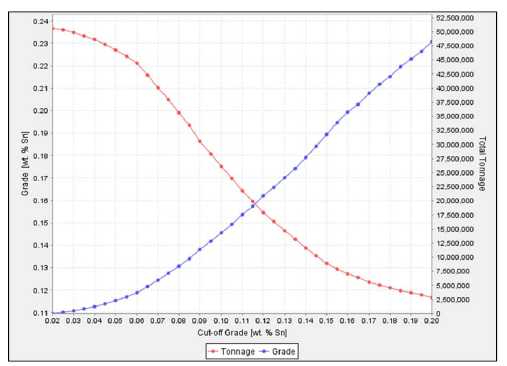

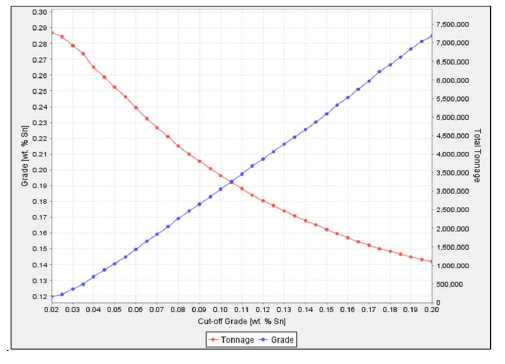

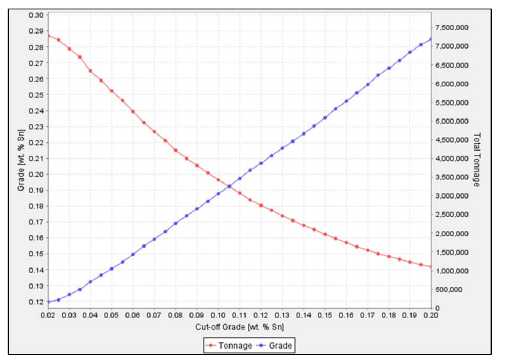

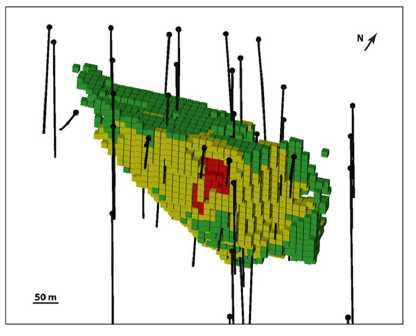

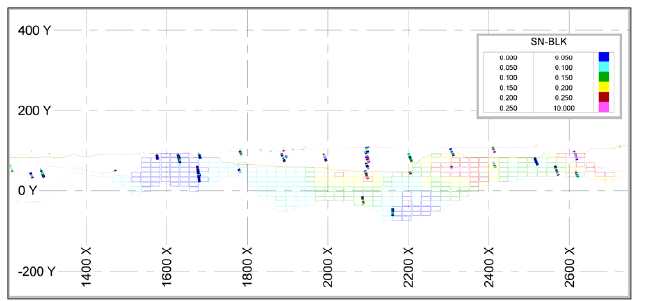

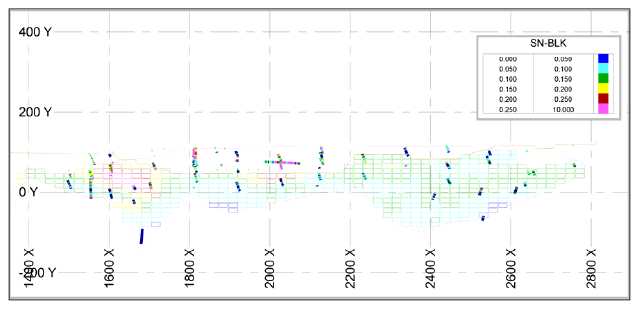

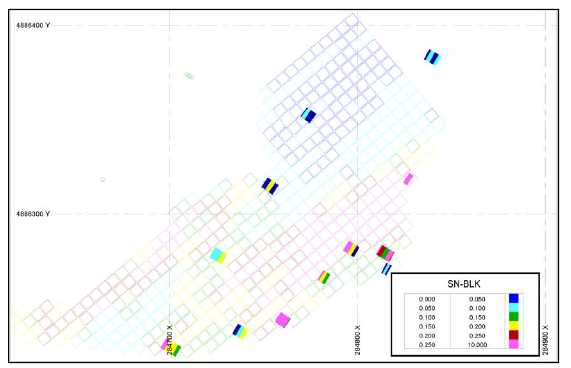

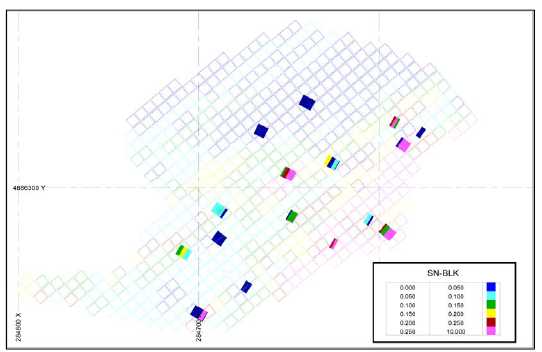

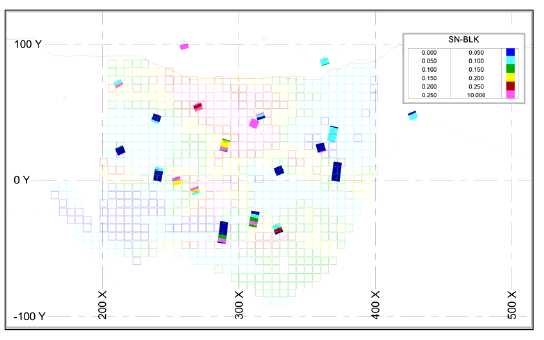

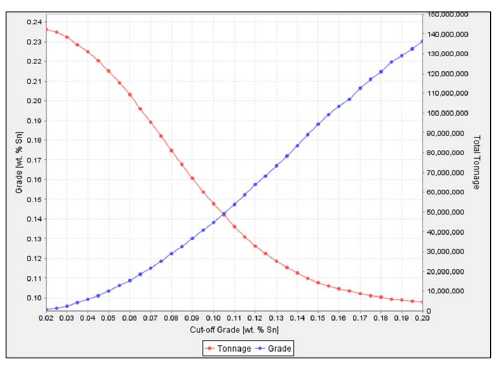

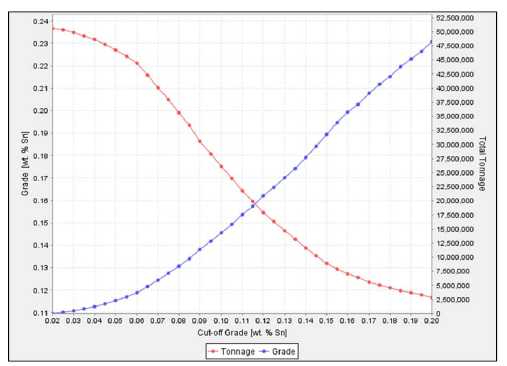

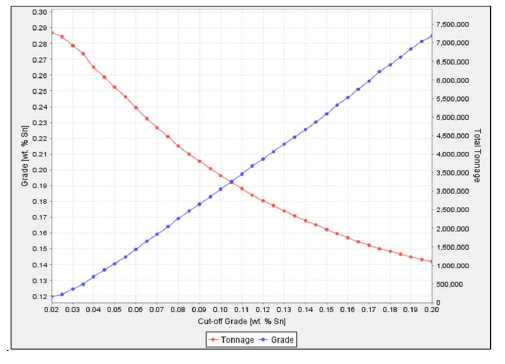

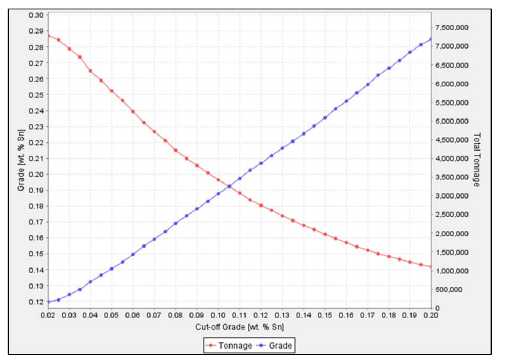

An updated mineral resource estimate for the East Kemptville project was completed on 7 May, 2018 (see Avalon news release dated 28 June, 2018). The mineral resource estimate is based on a block model prepared by Avalon and is summarized in Table 1.1. The deposit was subdivided into the Main Zone and the Baby Zone, which were interpolated separately. The in situ unmined tin resources were estimated using historic drill holes, data from drill holes completed by Avalon in 2014 and 2015, and a post-mining topographic model. A tin cut-off grade of 0.10% was considered as reasonable based on current mine plans and historic cut-off grade used at the East Kemptville mine.

Table 1.1

Updated Mineral Resource Estimate for the Main and Baby Zones

| Classification | Cut-off

grade Sn

(%) | Main Zone NE | Baby Zone | Total |

| Tonnes (Mt) | Sn (%) | Tonnes (Mt) | Sn (%) | Tonnes

(Mt) | Sn (%) |

|

|

| Measured | 0.08 | 0.40 | 0.173 | 0.22 | 0.241 | 0.61 | 0.197 |

| 0.10 | 0.38 | 0.177 | 0.20 | 0.251 | 0.58 | 0.203 |

| 0.12 | 0.32 | 0.188 | 0.19 | 0.259 | 0.51 | 0.214 |

| Indicated | 0.08 | 27.89 | 0.133 | 1.72 | 0.194 | 29.61 | 0.137 |

| 0.10 | 20.91 | 0.148 | 1.48 | 0.211 | 22.39 | 0.152 |

| 0.12 | 14.84 | 0.163 | 1.27 | 0.228 | 16.11 | 0.168 |

Measured +

Indicated | 0.08 | 28.28 | 0.134 | 1.93 | 0.199 | 30.22 | 0.138 |

| 0.10 | 21.29 | 0.148 | 1.68 | 0.216 | 22.97 | 0.153 |

| 0.12 | 15.16 | 0.164 | 1.46 | 0.232 | 16.62 | 0.170 |

| Inferred | 0.08 | 18.54 | 0.125 | 0.90 | 0.153 | 19.43 | 0.126 |

| 0.10 | 13.56 | 0.137 | 0.69 | 0.172 | 14.25 | 0.139 |

| 0.12 | 8.11 | 0.156 | 0.51 | 0.193 | 8.62 | 0.158 |

Notes:

| | 1. | CIM Definition Standards for Mineral Resources, 2014, were followed. |

| | 2. | The Qualified Person for this Mineral Resource estimate is William Mercer, Ph.D., P. Geo. (Nova Scotia). The mineral resources are current as of May 7, 2018. |

| | 3. | The mineral resource estimate is based on 194 drill holes totalling 21,456 m drilled between 1979 and 1991 by previous operators and 23 holes totalling 4190 m drilled by Avalon in 2014 and 2015. |

| | 4. | Drill data were organized in Maxwell DataShed and for estimation purposes were transferred to the Geovia GEMS 6.8.1 software, wherein the block model was developed. |

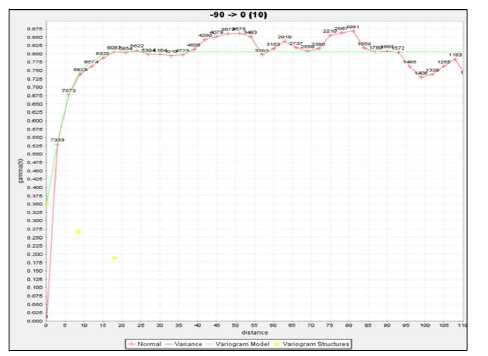

| | 5. | Resources were estimated by interpolating composites within block models of 24 m by 24 m by 12 m blocks in the Main Zone and 6 m by 6 m by 6 m in the Baby Zone. Interpolation used the Ordinary Kriging method. |

| | 6. | In the Main Zone, Measured material was defined as blocks interpolated with a search ellipse with radii of 40x20x15 m using 18-36 samples, corresponding to 3-6 drill holes, indicated material with a 120x40x18 m search ellipse and the same number of samples, and inferred material with a 315x85x18 m search ellipse using 12-24 samples corresponding to 2-4 drill holes. In the Baby Zone, Measured material was defined as blocks interpolated with a search ellipse with radii of 30x20x8 m using 6-12 samples, corresponding to 3-6 drill holes, indicated material with a 48x33x12 m search ellipse and the same number of samples, and inferred material with a 95x65x24 m search ellipse using 4-8 samples corresponding to 2-4 drill holes (see Section 1.12 Resource Classification). |

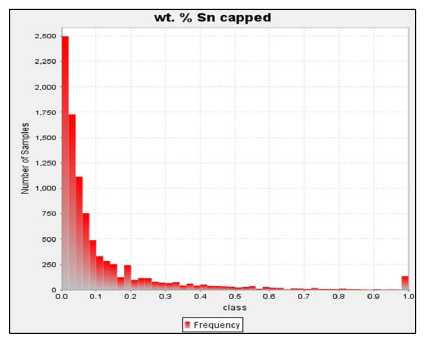

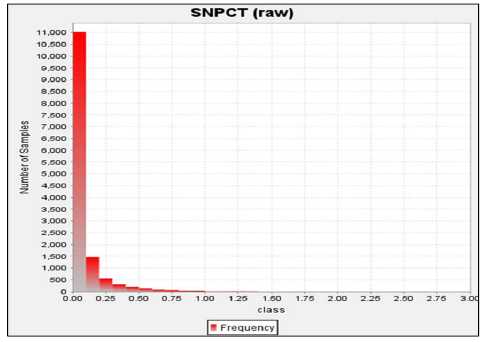

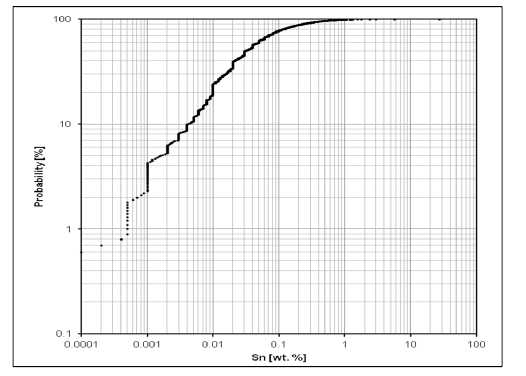

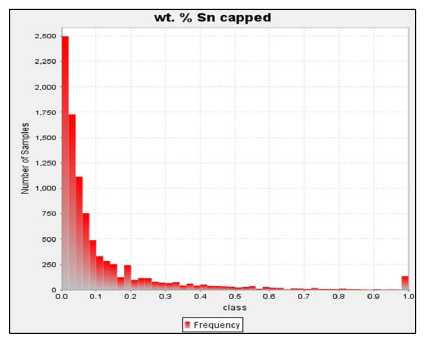

| | 7. | Prior to compositing, the assays were capped at 1% Sn, which corresponds to the 99th percentile of the tin assay data, reducing the length-weighted mean of the tin assays by 9.4%. |

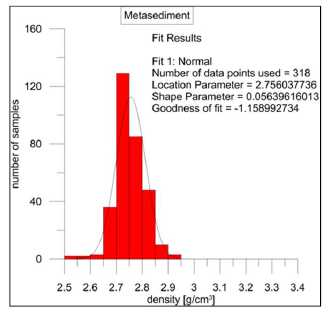

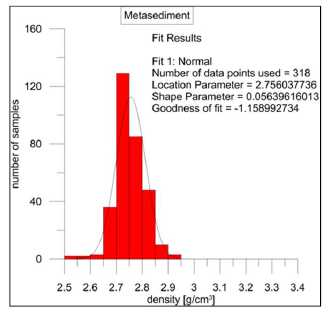

| | 8. | Mean density values of available data of 2.728 t/m3and 2.784 t/m3were used for the Main and Baby Zones, respectively. |

| | 9. | The resource estimate has been constrained using the Whittle pit described previously (Avalon News Release 15-02, February 25, 2015). |

8

| | 10. | Several possible cut-off grades are reported in this resource estimate. Based on past mining practice at East Kemptville, a cut-off grade of 0.1% Sn is reasonable and preliminary cost and revenue values at the time of estimation also suggest this is reasonable. |

| | 11. | Mineral resources do not have demonstrated economic viability and their value may be materially affected by environmental, permitting, legal, title, socio-political, marketing, or other issues. |

The Qualified Person (QP) for the Baby and Main Zone mineral resources reported in the PEA is William Mercer, P. Geo. who is not independent from Avalon. However, these current resource estimates have not changed significantly since the previous versions that were prepared independently by Hains Engineering with its principal, Donald H. Hains (P.Geo), serving as the independent QP for the purpose of NI 43-101 (News Release 14-13, October 31, 2014).

There has been no change of the mineral resource estimate for the low-grade stockpile since the previous estimate by Hains Engineering with an effective date of 16 November, 2015 (see Table 1.2) .

Table 1.2

Low Grade Stockpile Estimated Inferred Mineral Resource

| Category | Tonnes (Mt) | Grade (%) |

| Sn | Zn | Cu |

| Inferred | 5.87 | 0.112 | 0.100 | 0.61 |

Notes:

| | 1. | This estimate is as of 16 November 2015. |

| | 2. | CIM Definition Standards 2014 were followed for mineral resources. |

| | 3. | The independent Qualified Person for this Mineral Resource estimate is Donald Hains, P.Geo., of Hains Engineering. |

| | 4. | Resources were estimated by examination of historical RAL data and Avalon’s 2015 sampling of the Low-Grade Stockpile. |

| | 5. | Mineral resources do not have demonstrated economic viability and their value may be materially affected by environmental, permitting, legal, title, socio-political, marketing or other issues. |

| 1.9 | MINERALRESERVEESTIMATES |

No mineral reserves have been estimated for the East Kemptville tin project.

Avalon plans to engage a locally (Eastern Canada) based mining contractor to mine material from the Rio Algom Ltd. (RAL) legacy stockpile, the Baby Zone pit and the Main Zone pit. This contractor will be responsible for supplying, operating and maintaining all mining equipment, trucks and mining related infrastructure.

The mine is envisaged as an open pit operation using a conventional drill and blast process and conventional truck and shovel methods for material movement.

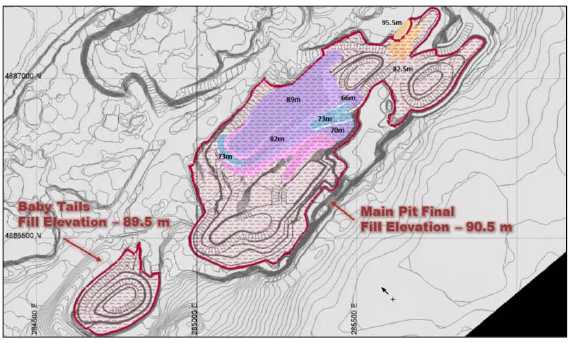

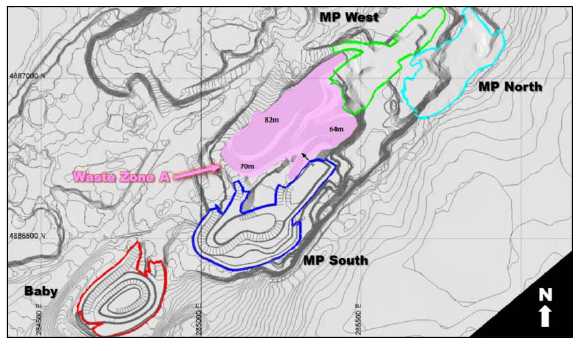

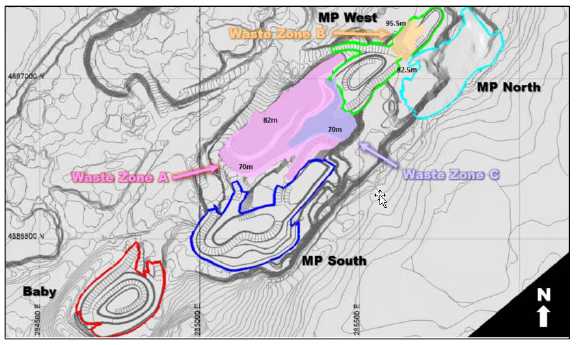

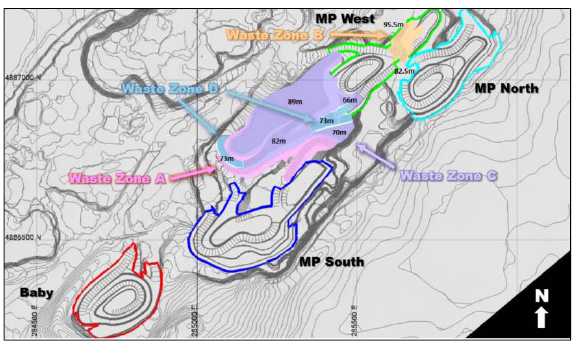

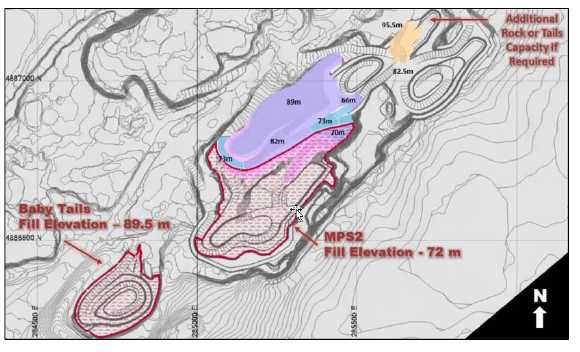

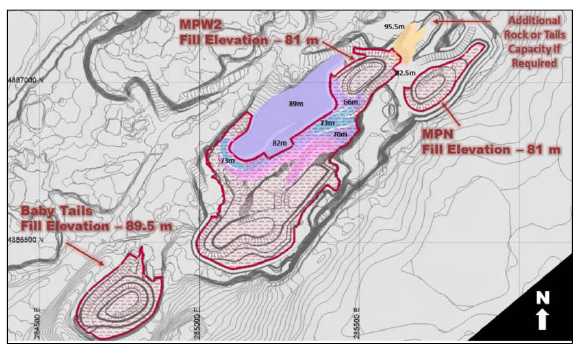

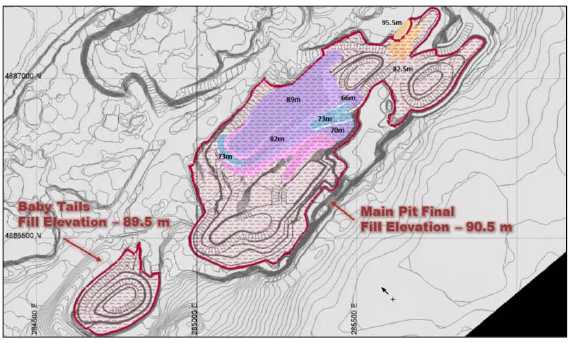

For the PEA, the life-of-mine (LOM) open pit mineable plant feed material within the conceptual pit designs is 9.22 Mt, inclusive of Measured, Indicated and Inferred resources, with a total waste movement of 3.24 Mt for an average stripping ratio of 0.35:1. With the inclusion of an additional 5.87 Mt of Inferred resource from the RAL legacy stockpile, the mine life is extended to 19 years. The mill feed rate used for the design is 806,000 t/y.

9

The economic parameters used as inputs for the mine optimization and design are summarized in Table 1.3.

Table 1.3

Pit Optimization Criteria East Kemptville Tin Project

| Parameter | Unit | Value |

| Mining Cost (Mill Feed) | CAD/t mined | 4.70 |

| Mining Cost (Waste) | CAD/t mined | 4.70 |

| Legacy Stockpile Rehandle | CAD/t moved | 1.25 |

| Process Cost (Concentrator) | CAD/t mill feed | 7.85 |

| Process Cost (Sulphide Flotation) | CAD/t mill feed | 0.63 |

| G&A | CAD/t mill feed | 1.54 |

| Overall Pit Slope | degrees | 48 |

| Processing Recovery (Sn) | % | 60.0 |

| Metal Price (Sn) | USD/t | 20,656 |

| Treatment Charge | CAD/t conc | 455 |

| Transportation | CAD/t conc | 225 |

| Exchange Rate | USD to CAD | 1.30 |

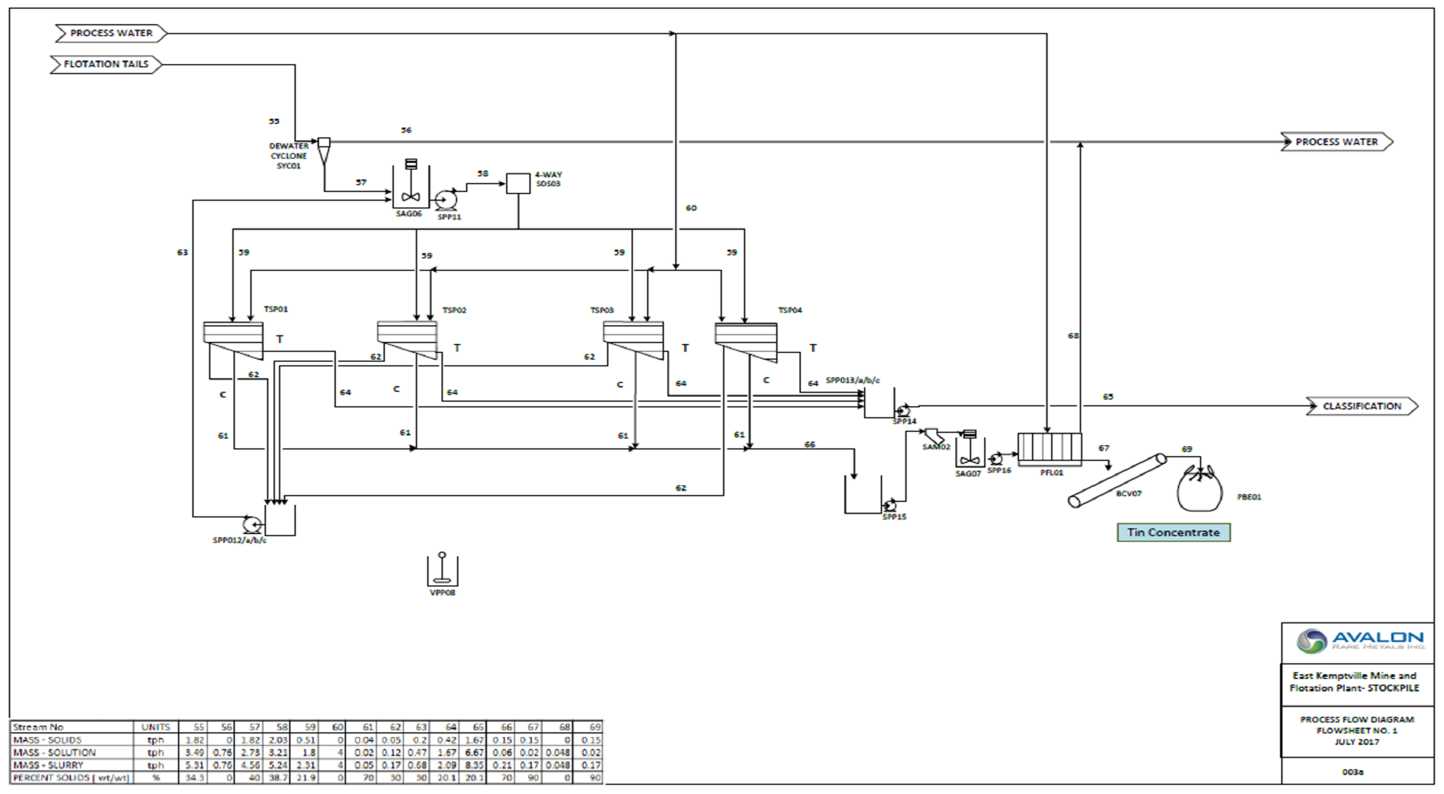

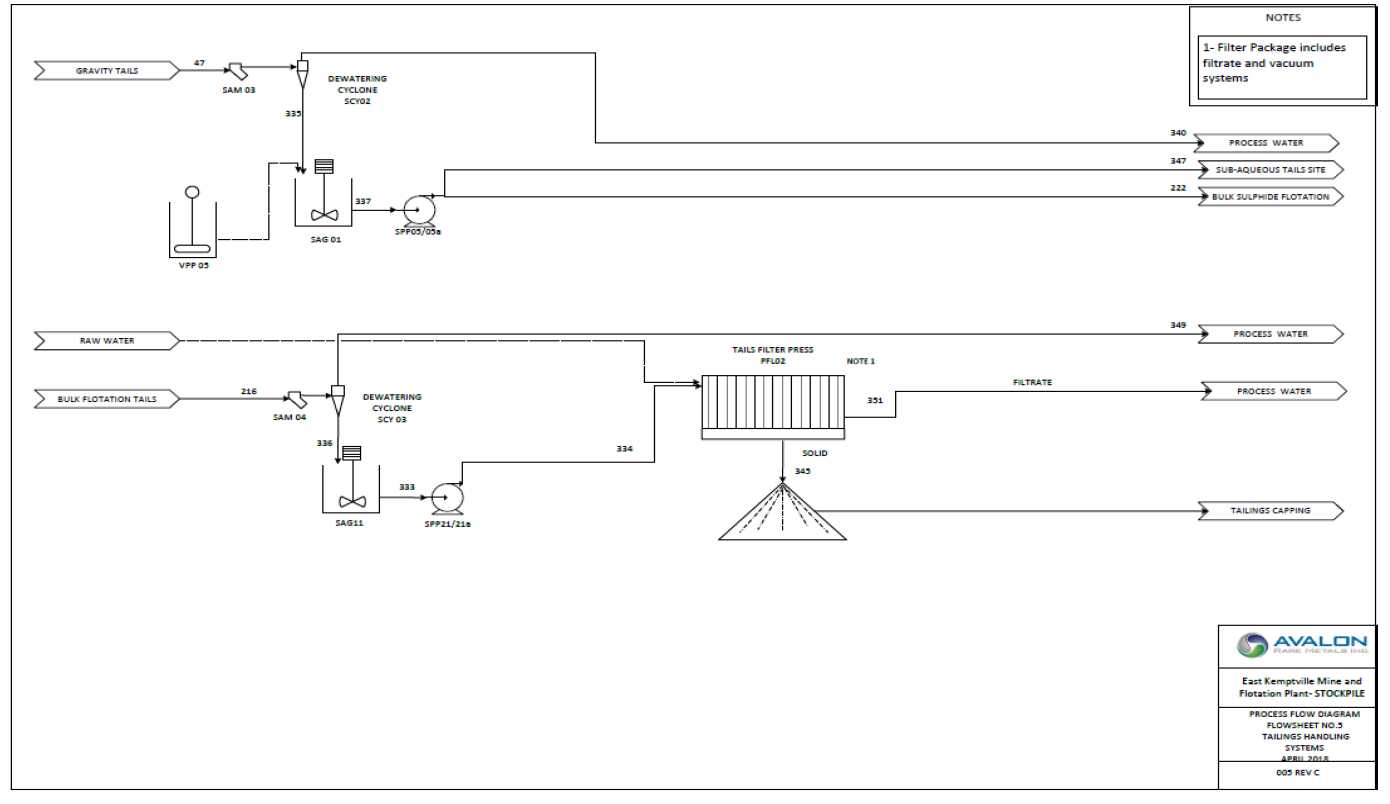

The metallurgical process flowsheet for the Project is based on the mineral separation and recovery of a tin concentrate with a target grade of 55 wt.% Sn. A small portion of the copper, zinc, iron and indium will be collected into a sulphide concentrate which will be appropriately disposed of in the tailings facility unless a buyer for the material is found. Data gathered from both the SGS UK and Met-Solve metallurgical test programs along with historical information from previous operations and operating personnel was reviewed and used as the basis for developing the flowsheet.

Avalon’s objective is to construct a simple plant with as few unit operations as possible and focused purely on tin recovery. It is acknowledged that this approach will result in a lower than possible metal recovery, but it is believed that the low costs associated with such an approach will out-weigh any drop in recovery.

The PEA is based on the following assumptions derived from the testwork results:

| | • | 806,000 t/y of stockpiled mineralized material will be fed to the concentrator at a rate of 100 t/h. |

| | | |

| | • | Target primary grind P80= 80 Microns. |

| | | |

| | • | The tin gravity concentrate grade of 55% Sn and tin recovery to concentrate of ~60%. |

| | | |

| | • | Plant availability of 91.3% for the concentrator (8,000 h/y operating time). |

10

| | • | Preliminary tin recovery will be by centrifugal concentrators with shaking tables used to produce the final product. |

| | | |

| | • | Concentrate cleaning will include magnetic separation and flotation to remove iron, copper and zinc sulphides. |

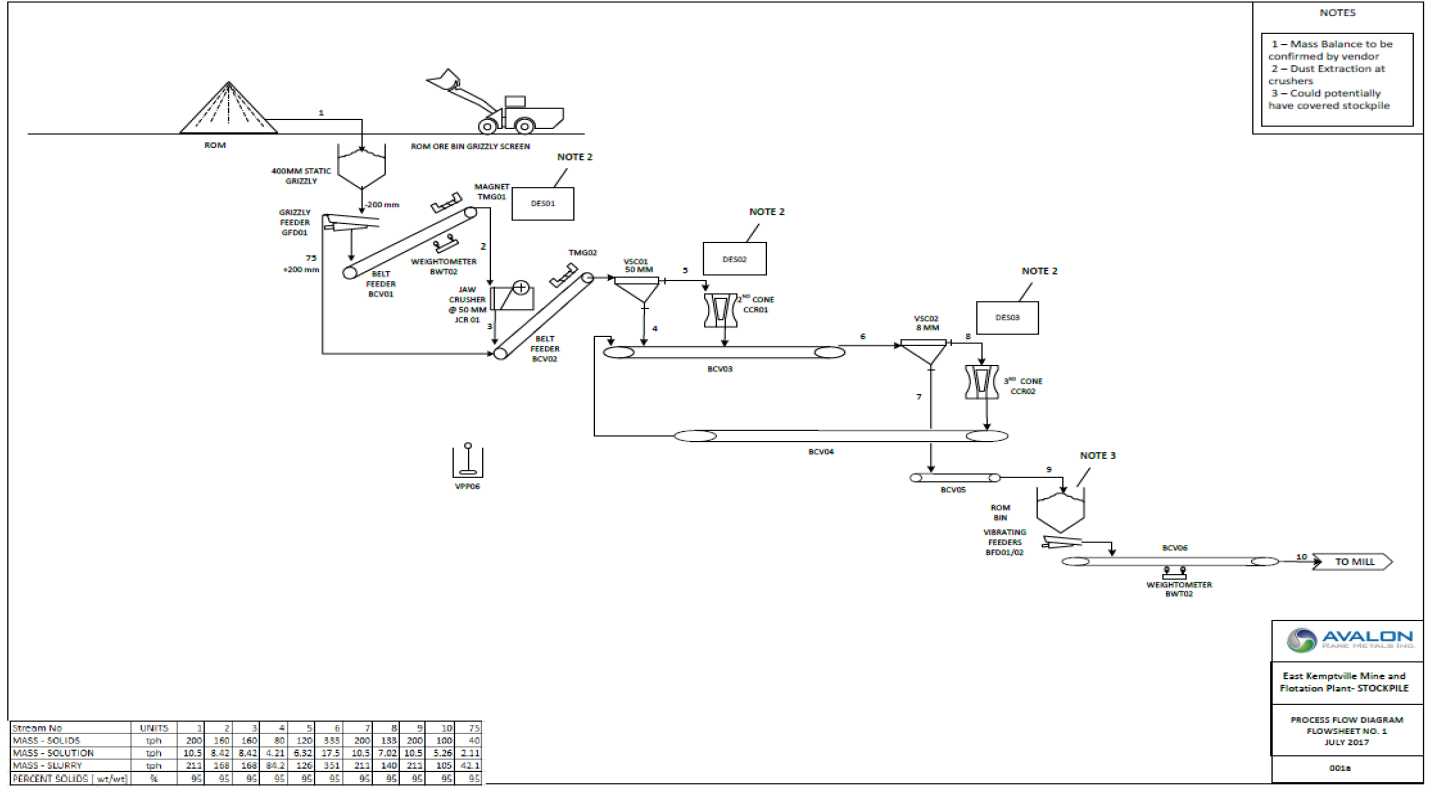

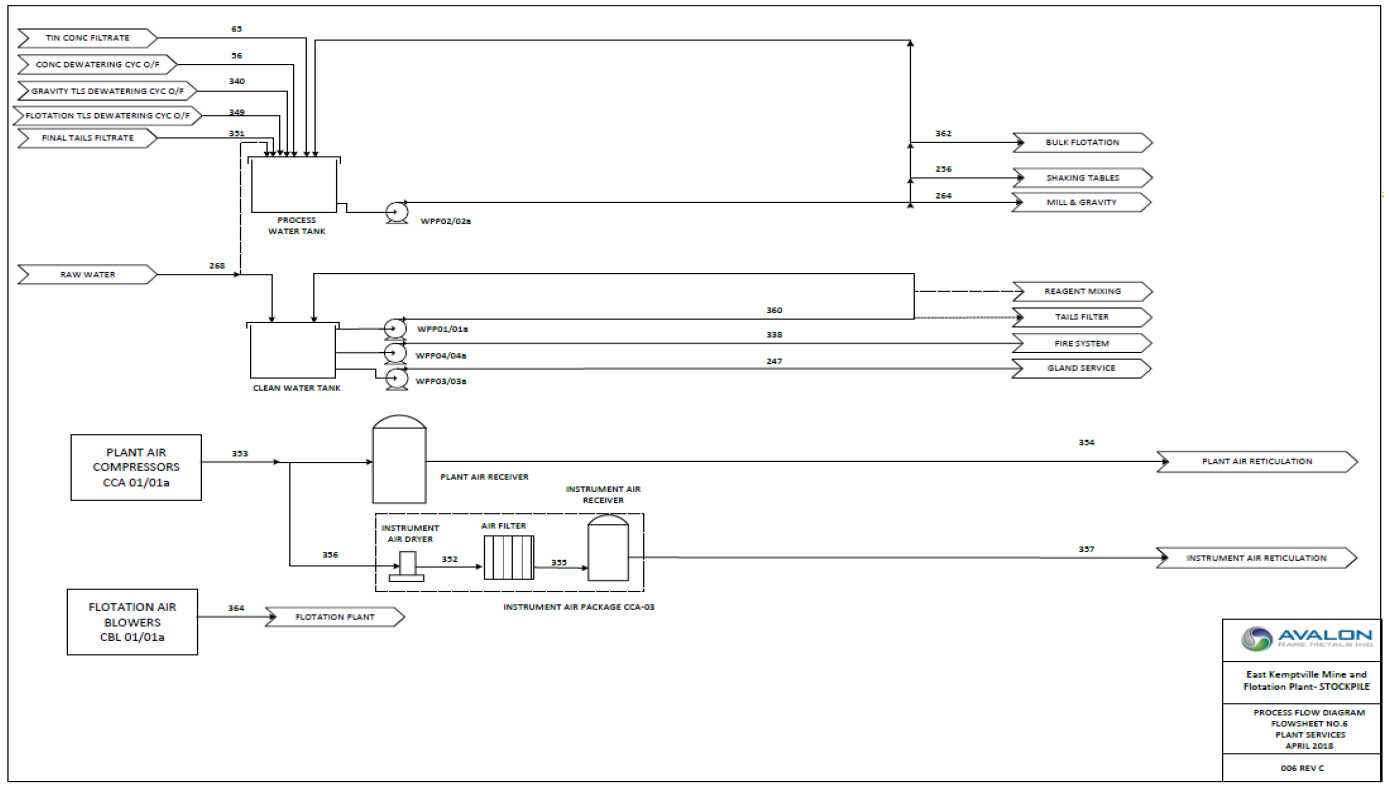

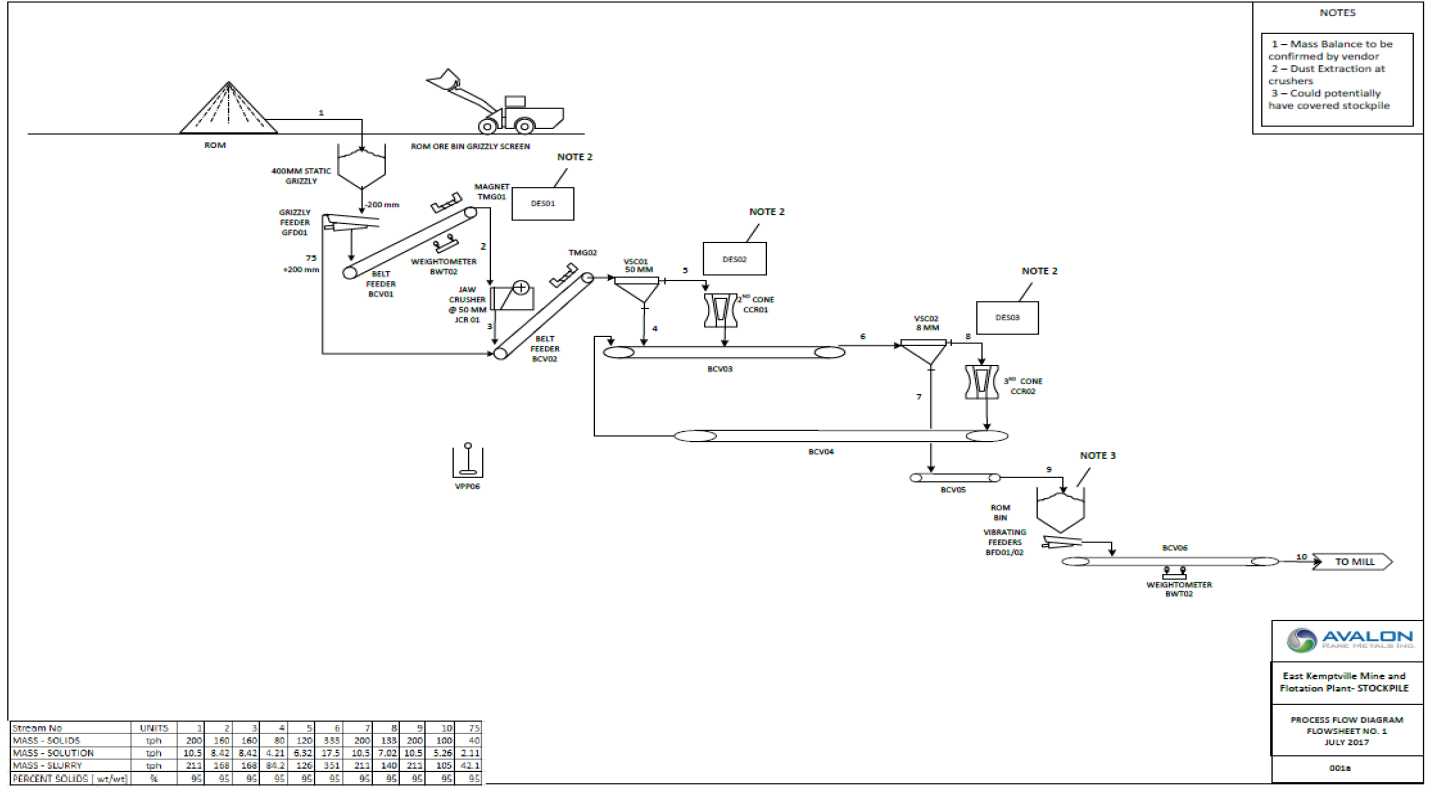

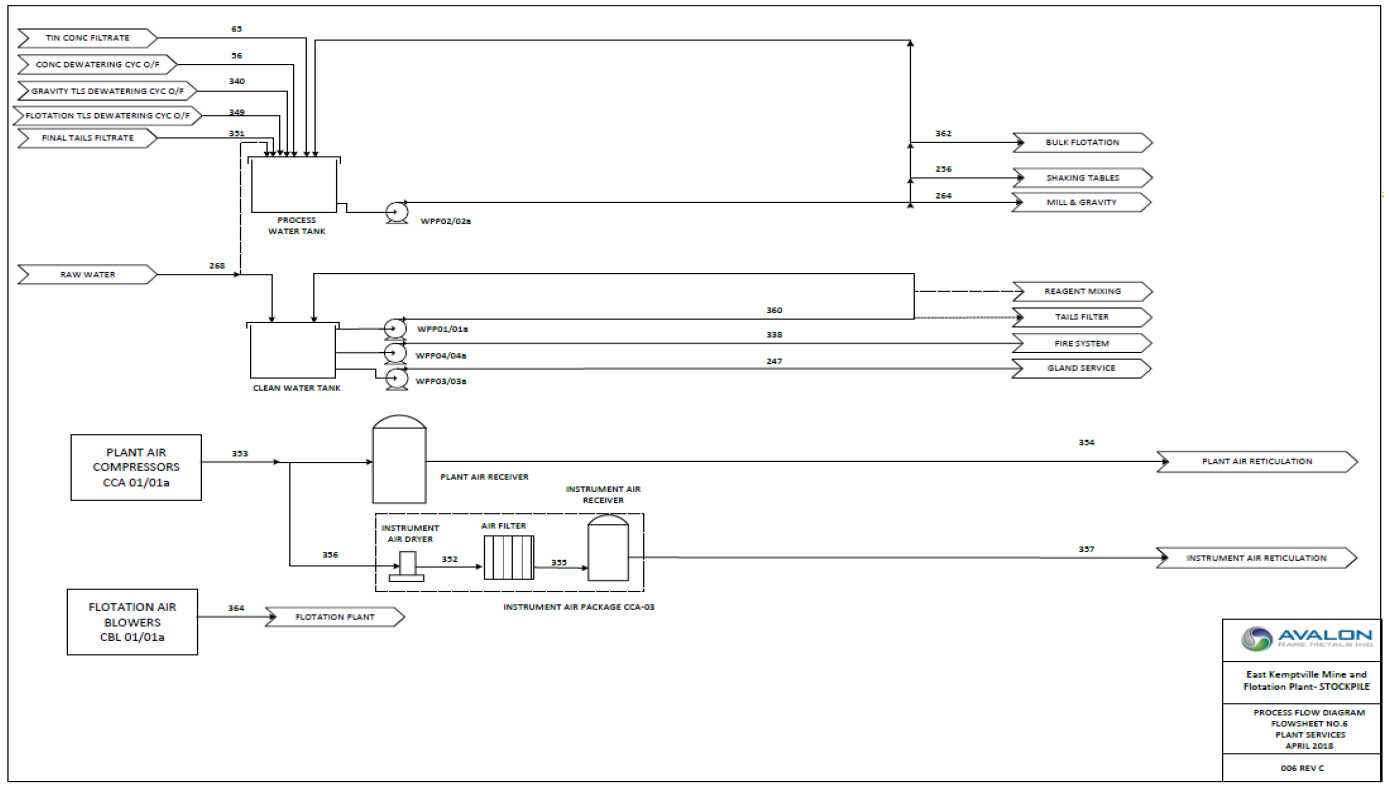

A copy of the simplified flowsheet is included in Figure 1.1. The flowsheet consists of several conventional processes to produce a tin concentrate. This includes crushing, milling and classification, a series of gravity circuits using high-speed centrifugal concentrators (HSCCs), magnetic separation and flotation to remove the metal sulphide before going through a series of shaking tables. A bulk sulphide flotation circuit is also included in Year 6 of the operation to remove sulphides from the gravity tailings.

Benign flotation tailings will be filtered and used for capping the tailings facility. The bulk sulphides concentrate removed from the gravity tailings will be combined with the sulphide concentrate from the tin gravity circuit and stored under a cover of water to prevent oxidation.

Figure 1.1

Simplified Flowsheet

| 1.12 | PROJECTINFRASTRUCTURE |

Existing roads on site allow easy access to the entire site for operations and maintenance. A new haul road will be required from the mine pits to the processing plant. There is sufficient infrastructure in the area to support the labour force required for the project operations and no need is seen for accommodations at site.

11

| 1.12.1 | Power, Fuel and Water |

Primary power to the site will be provided by Nova Scotia Power via an existing line which will feed a new substation at site. Emergency/back-up power will be provided by a diesel generator.

Diesel storage and fueling stations will be provided on site for mobile equipment.

Raw water from the Tusket River will supply potable, fire and process water requirements. Process water will be recycled to keep make-up water requirements to a minimum. Process water will also be extracted from the 2 existing pits or recycled from the TMF in order to minimize raw water consumption and to also make the pits accessible for mining.

The existing water treatment facility which treats run-off from the tailing facility will be maintained for ongoing operations and modified as required to meet the new project demands, although minimal changes are anticipated to be required.

| 1.12.2 | Buildings, Communication and Waste Handling |

The intention is to erect a single pre-engineered and pre-fabricated building that can house the main processing plant (excluding crushing circuit), stores and workshop areas all under a single roof.

Proven, reliable and state-of-the-art telecommunications systems will be provided at the site for permanent operations and maintenance.

Waste materials (organic waste, hazardous and recyclable wastes, etc.) will be sorted on site and disposed of off-site using local contracting companies or existing municipal handling facilities.

| 1.12.3 | Concentrate Storage and Shipping |

Concentrate will be bagged, containerized and stored at site before shipment on a regular basis to the laydown area at the port in Shelburne or Halifax. On average, approximately 120 t of concentrate will be produced per month requiring the transportation of 4-5 truckloads per month from the site to the port.

| 1.13 | MARKETSTUDIES ANDCONTRACTS |

For the purposes of the PEA, Avalon has undertaken an in-house analysis of the markets for tin concentrates during the course of which it has consulted with industry participants and specialist consultants.

12

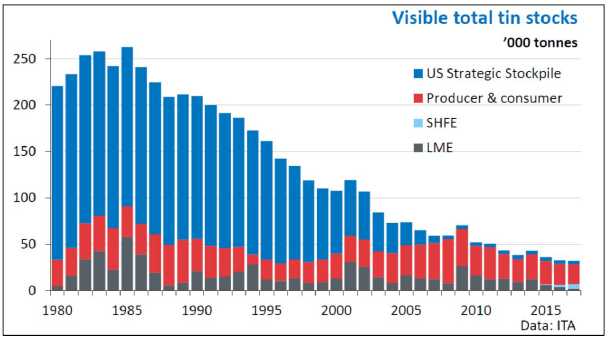

A tin price of USD21,038 /tonne has been used for the PEA, which is not only the World Bank forecast for 2020, but also is consistent with the LME price for tin during the first quarter of 2018 (USD21,187).

| 1.14 | ENVIRONMENTALSTUDIES, PERMITTING ANDSOCIAL ORCOMMUNITYIMPACT |

Following the completion of an environmental baseline study, impact assessment and permitting, the East Kemptville mine operated between 1983 and 1992 at a production rate approximately 4 times higher than that envisioned for this project. The overall site is currently considered a brownfields site with ongoing perpetual treatment of runoff water.

The East Kemptville site has long term environmental liabilities that are the result of sulphide minerals that remain in the pit walls, low grade and waste rock stockpiles, and tailings, all of which generate acid mine drainage (AMD) to greater or lesser extents. At this time, these liabilities are being effectively managed by the surface rights holder through the collection, treatment and release of treated water.

An agreement between Avalon, the surface rights holder and the Government of Nova Scotia will be required, prior to development of this project, which details how and when Avalon will assume care and custody of the closed site. A letter describing this requirement was signed by the Ministry of Natural Resources (now Nova Scotia Energy and Mines).

The start of operations is not anticipated to be subject to approvals under the Canadian Environmental Assessment Act 2012 (CEAA) as the mine does not exceed any of the CEAA triggers, including mine and mill tonnages. The project is not anticipated to have any new impacts to terrestrial, fish or fish habitat, and will not impact any federally designated wildlife conservations areas. The project will be subject to the Nova Scotia Environment Act and associated regulations (including the Environmental Assessment Regulations), via the provincial “One Window” approach to mineral resource development chaired by Nova Scotia Energy and Mines.

Planned operations are an integral component of the overall mine rehabilitation strategy and to mitigate the present and ongoing sources of environmental liability. The brownfields site has known sources of AMD to both surface and groundwater. These are now well understood by Avalon and appropriate mitigations and closure plans identified for these historical impacts have been developed, as well as for any impacts anticipated from future operations.

Avalon is recognized for its leadership in Indigenous Engagement. It has already reached out to the Mi’kmaq First Nation to make them aware of recent small drill programs and to initiate dialog with them. Avalon has also initiated engagement with the local community.

13

| 1.15 | CAPITAL ANDOPERATINGCOSTS |

| 1.15.1 | Capital Cost Estimate |

The estimated Project capital requirements are summarized in Table 1.4. All costs are reported as Canadian Dollars (CAD or $) with a base date of first quarter, 2018. It should be noted that, apart from the sulphide removal circuit in Year 5, provisions for what might normally be designated as “sustaining capital” are included in the operating costs.

The capital cost estimate for this Project is considered to be at a scoping level with an accuracy of +50%/-35% and carrying an average contingency of 18.6% on total initial estimated capital.

Table 1.4

Initial Capital Cost Estimate

| Area | Capex CAD x 1,000 |

| Initial Plant | Sulphide Removal

(Year 5) |

|

| Mining | 0 | 0 |

| Concentrator | 18,472 | 4,076 |

| Tailings Disposal | 544 | 0 |

| Infrastructure | 946 | 0 |

| Total Direct Costs | 19,962 | 4,076 |

| EPCM | 1,497 | 306 |

| Freight & Transportation | 861 | 188 |

| Other Indirects | 1,778 | 446 |

| Total Indirect Costs | 4,136 | 940 |

| Owners Costs | 1,000 | 500 |

| Buildings & Tailings | 750 | 100 |

| Contingency | 4,820 | 1,003 |

| Total Capital Costs | 30,688 | 6,620 |

Mining capital costs are assumed to be zero as the operation will engage a contract miner and all mining related capital costs are built into the contract mining operating costs.

Excluded from the pre-production capital cost estimate is the allowance for dewatering the two pits. This amount is estimated at CAD850,000, which increases the estimate to CAD31.5 million.

| 1.15.2 | Operating Cost Estimate |

A summary of the LOM average annual costs is presented in Table 1.5.

14

Table 1.5

Summary of Operating Costs

| Category | Ave. Annual Costs

(CAD’000) | CAD/t

Milled | CAD/t

Tin | CAD/t

Conc. |

| Stockpile Reclaim & Mining | 3,588 | 4.40 | 5,076 | 2,792 |

| Concentrator Processing | 6,556 | 8.04 | 9,274 | 5,102 |

| Concentrate Transport | 289 | 0.36 | 409 | 225 |

| Remediation & Site Management | 848 | 1.04 | 1,200 | 660 |

| General & Administration | 340 | 0.42 | 480 | 264 |

| Total Production Costs CAD | 11,583 | 14.25 | 16,439 | 9,044 |

| Total Production Cost USD | 8,910 | 10.96 | 12,646 | 6,957 |

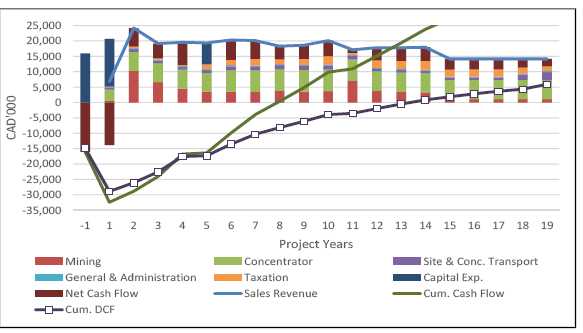

Micon has prepared this PEA of the Project on the basis of a discounted cash flow model, from which Net Present Value (NPV), Internal Rate of Return (IRR), payback and other measures of Project viability can be determined.

The technical parameters, production forecasts and estimates described elsewhere in this report are reflected in the base case cash flow model.

| 1.16.1 | Macro-Economic Assumptions |

An exchange rate of CAD1.30/USD is applied in the base case, approximately equal to current rates and to the trailing average over the past two years.

Micon has applied a real discount rate of 8% in its base case evaluation, approximating the weighted average cost of capital (WACC) for the Project.

The base case cash flow projection assumes a constant price of USD21,038/t tin metal.

Nova Scotia mining taxes, and Canadian federal and provincial income taxes payable on the Project have been provided for in the cash flow forecast.

No royalty has been provided for in the cash flow model.

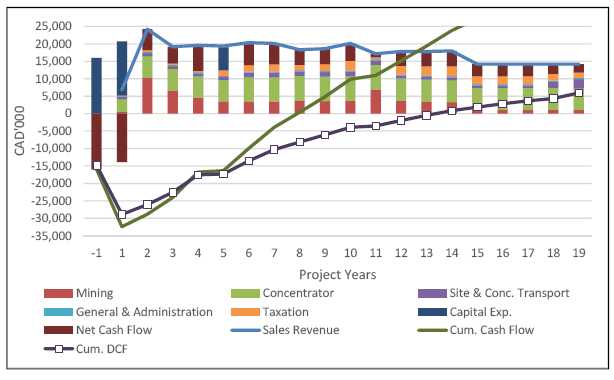

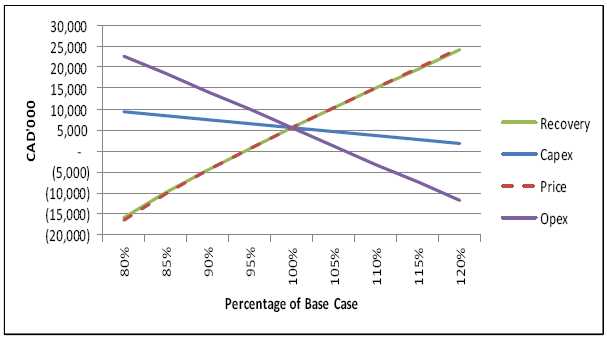

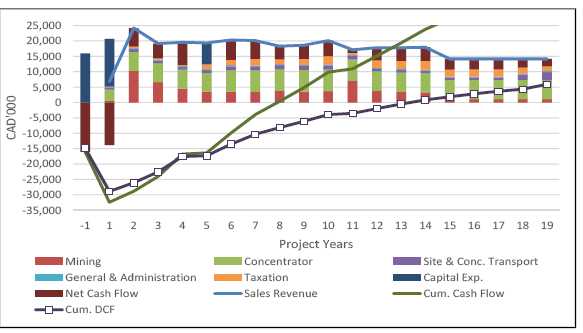

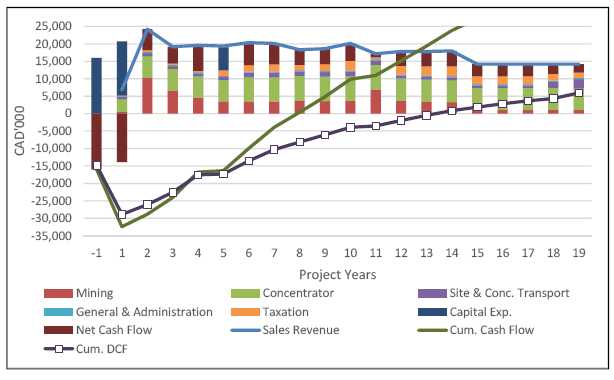

The base case Project annual cash flows are presented in Figure 1.2.

This PEA is preliminary in nature; it includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that the preliminary economic assessment will be realized.

Before tax, the base case demonstrates an undiscounted payback period of 6.7 years, and an IRR of 15.0% . At an annual discount rate of 8%, the Project has a net present value (NPV8) before tax of CAD17.8 million, and the payback period extends to 9.2 years.

15

After tax, the base case undiscounted payback period is 8.0 years, leaving a tail of 11 years planned production, and the Project has an IRR of 10.6% . The NPV8 after tax is CAD5.6 million, and the payback period extends to 13.6 years.

Figure 1.2

Annual Cash Flow

| 1.17 | RISKS ANDOPPORTUNITIES |

The Project as currently envisaged presents the following risks and opportunities.

The opportunity presented by the drill hole spacing is that there may be areas of potential high-grade mining that are poorly defined and unrecognised at present due to the wide drill hole spacing thus increasing the mine life and financial return. The operating cost schedule provides CAD250,000 in each of Years 2 and 3 for conducting suitable drill programs within both pits once they are dewatered.

Opportunities exist to increase resources for the Project. This includes expanding the existing deposit resources as well as additional areas, such as the Duck Pond Zone and area west of the Baby Pit.

There has been no examination of the possibility of underground mining. Deep drilling on the Baby Zone has suggested that tin mineralization continues close to 100 m below the bottom of the presently planned pits. A detailed examination of this data may reveal underground mining potential in this and other areas of the property.

16

There are additional very low-grade stockpiles on surface which could potentially be processed if methods such as ore-sorting are demonstrated to have the ability to pre-concentrate the tin prior to the milling circuit.

An analysis of recent historical tin prices indicates that the LME listed price for tin has been above that value virtually continuously for more than the past 10 years. The LME listed price as of 1 May 2018 is USD21,395 and the World Bank Commodity Price forecast indicates tin a long-term price forecast of USD20,169 for 2025.

The tin recovery of 60% is based on the testwork program by Met-Solve, and Avalon believes that once the plant is up and running, this figure can be improved upon. With bench scale testwork, it is difficult to simulate the impact of recirculating streams and to optimize recovery over time so material that would be captured from such streams often reports to tailings during bench testing. With an operating plant, these streams are fully recycled, and operators have the opportunity to optimize recovery.

The forecast mining costs represent almost 30% of total production costs and are estimated using typical industry contractor rates for open pit operations of this size. Upon completion of the proposed drilling to update the resource model, further mine design work and haulage analyses are required before costing of the final tonnages of material (plant feed plus waste) to be mined can be more accurately defined.

The grade of the material in the stockpile has been estimated by two surface sampling programs and by reviewing historical information, all of which produced similar results, and as a consequence an “inferred” resource has been determined by an external consultant. It is, however, planned to complete a drill program of the stockpile as soon as financing is available, partly to confirm the overall grade, but more importantly to map the internal grade distributions and produce a more representative schedule of feed grades shipped to the processing plant from this source.

17

The current operating life is 18.5 years; however, Avalon is confident that additional feed sources will be identified, and that the operating life will be extended.

| 1.17.8 | Purchasing Used/Refurbished Equipment |

The capital cost estimate has assumed all equipment is purchased new, but there are significant opportunities to reduce equipment costs, particularly for the crushers and mill, by purchasing used/refurbished items. Avalon is also aware of a number of used screens and gravity concentrators that could potentially be acquired.

| 1.17.9 | Revenue from By-products |

No provision has been made for up-grading the sulphide concentrate into marketable copper and zinc/indium concentrates for sale.

| 1.17.10 | Foreign Exchange Rate |

A lot of the mechanical equipment is being sourced from outside Canada and is priced in American dollars. Similarly, all revenue is in USD. An exchange rate of CAD1.30:USD1 has been used. Should the Canadian dollar strengthen this would be positive in terms of initial capex, but then negative with respect to subsequent revenue once in production.

| 1.17.11 | Environmental Liability |

By re-activating the Project, Avalon will be inheriting a number of (currently) long term environmental liabilities. However, by removing the low-grade stockpile, capping the tailings facility and depositing the balance of the tailings along with waste rock into the two pits, Avalon believes a “walk-away” closure strategy has been developed, eliminating these long-term liabilities.

Avalon has the opportunity to re-commence commercial tin production from the East Kemptville mine by establishing a small-scale operation processing an on-surface, low-grade stockpile and higher grade, near surface occurrences within the existing pits.

Avalon considers the tin concentrate produced (see Table 1.6) to be highly marketable. In early 2018, Avalon has entered into a non-binding MOU for the sale of all its forecast production with a well-known company that owns a large tin smelter. The formula used by this customer for determining concentrate pricing has been used by Avalon in the financial model.

18

Table 1.6

Final Tin Concentrate Analysis

| Element | Sn | Cu | Zn | Fe | S | Pb | As | Cd |

| Value (%) | 55.22 | 0.009 | 0.014 | 0.57 | 0.08 | 0.005 | 0.002 | <0.0001 |

| Element | Ni | Co | Bi | Hg | Se | SiO2 | Mn | CaF2 |

| Value (%) | 0.006 | <0.001 | <0.0001 | <0.0001 | 0.0001 | 9.04 | 0.35 | 0.55 |

The re-development model, as presently conceived, is an environmental remediation Project that will be financed through the sale of tin concentrates recovered in large part from previously-mined mineralized material on the site.

The Project enjoys strong support from the community as well as from local politicians, First Nations and environmental NGOs. Avalon is also in discussions with a number of local businesses towards collaboration on future opportunities including, among others, a long-term vision for re-development of the rehabilitated site.

The start of operations is not anticipated to be subject to approvals under the Canadian Environmental Assessment Act 2012 (CEAA) as the mine does not exceed any of the CEAA triggers including mine and mill tonnages. The Project will not have any new impacts to fish or fish habitat, nor will it impact on any Federal Wildlife Areas or Migratory Bird Sanctuaries. Final Permitting and Approval for the Project is therefore expected to be relatively short and simple.

The preliminary economic assessment presents an attractive Project and the opportunity to generate significant revenue for Avalon as well as remediating an environmental problem. It is recommended therefore that the Project continues to the next stage of development.

| 1.19.1 | Recommendations for the Next Phase of Project Development |

| | • | The low-grade stockpile should be drilled, sampled and assayed to increase the confidence of the mineral resource estimate from an inferred category. |

| | | |

| | • | Once de-watered, a program of infill drilling is recommended for the Main and Baby zones in order to improve the geological data base and to improve understanding of the controls on mineralization and variability of grade. Also, it is likely there are other areas of shallow, high grade material which could be added to the feed stock particularly if the tin price continues to trend upwards. |

| | | |

| | • | During the course of operations, additional exploration should be conducted on other areas within and adjacent to the current property boundary in order to identify additional resources (e.g., Duck Pond area where prospective economic mineralization has already been identified). |

19

| | • | The mine designs and Project schedules should be completed to a more detailed level using the revised mineral resources resulting from the work recommended above. |

| | | |

| | • | Mining contractors should be requested to provide a more detailed mining contract proposal using these updated detailed mine plans and schedules. |

| | | |

| | • | The economic potential of mining deeper (either through open pit or underground methods) should be investigated for the Main and Baby Zone mineralization. |

| | • | During the next phase of engineering, the proposed modular off-site fabrication and assembly philosophy should be adhered to as it will not only keep the up-front capital cost lower than normal but will also facilitate either future expansion or plant relocation to elsewhere once the East Kemptville resources have been exhausted. |

| | | |

| | • | There is an opportunity to run a short pilot campaign to assess and optimize the initial “rougher” tin recovery performance. The purpose of this will be predominantly to fully optimize the grinding and classification circuit as minimizing over-grinding of the cassiterite is a key operating component. The rougher circuit operation will also provide an opportunity to optimize performance and confirm the expectation that a recovery >60% is achievable. |

| | | |

| | • | The potential for using ore-sorting to upgrade the plant feed should be further investigated. This could have significant impacts on capital and/or operating costs either through the use of a smaller, cheaper processing plant or by significantly increasing the tin output through the same plant but over a shorter time frame. The pre-treatment by ore-sorting, of the “very low” grade stockpiles may also generate a suitably graded material to allow plant operations over a longer period. |

| 1.19.1.4 | Project Implementation |

| | • | The current 16-18-month implementation schedule is tight, and where possible, development activities should continue whilst Project funding is being secured. Such activities could include finalizing fixed equipment prices, confirming fabricators to be used and negotiating various service and supply contracts. |

| | | |

| | • | There are various minor permitting studies which still need to be completed in order to gain site access for initiating construction activities. These studies should be completed as soon as possible in order to prevent any potential impact on the implementation schedule. |

| | | |

| | • | Securing a final agreement with BHP still needs to be completed but this must be subject to finalizing a mutually beneficial transition arrangement to minimize Avalon’s up-front exposure to the existing environmental liability. |

| | | |

| | • | The start of operations is not anticipated to be subject to approvals under the Canadian Environmental Assessment Act 2012 (CEAA) as the mine does not exceed any of the CEAA triggers including mine and mill tonnages. The Project will not have any new impacts to fish or fish habitat, nor will it impact on any Federal Wildlife Areas or Migratory Bird Sanctuaries. Final Permitting and Approval for the Project is therefore expected to be relatively short and simple. |

20

The budget prepared by Avalon for the next phase of work to develop the East Kemptville Project towards production is presented in Table 1.7 below.

Table 1.7

Budget for the Next Phase of Project Development

| Proposed Work | Estimated Cost

(CAD) |

| Drilling and Resources Update |

| Drilling Stockpile | 250,000 |

| Economic Study Update |

| Mini Pilot Plant Trial | 100,000 |

| Preliminary Engineering and detailed cost estimates | 300,000 |

| Updated economic study and NI 43-101 report | 100,000 |

| Environmental |

| General studies and permitting applications | 100,000 |

| Total Proposed Budget (all items) | 850,000 |

Micon has reviewed Avalon’s budget for the next phase of work on the East Kemptville Project and considers it to be reasonable.

21

Micon International Limited (Micon) has been retained by Avalon Advanced Materials Inc. (Avalon) to prepare a Technical Report under Canadian National Instrument (NI) 43-101 which discloses the results of the preliminary economic assessment (PEA) for the East Kemptville Tin Project (East Kemptville Project), Yarmouth Co., Nova Scotia.

| 2.1.1 | Mineral Resource Estimate |

The mineral resource estimate on which this PEA is based is dated 7 May, 2018. This resource estimate was prepared by Avalon and is considered not to be materially different from the previous mineral resource by Hains Engineering Company Limited (Hains Engineering), which is described in an Avalon press release dated 31 October, 2014.

The mineral resource estimates in this PEA have been prepared in accordance with the requirements of Canadian securities laws, which differ from the requirements of United States securities laws. Unless otherwise indicated, all mineral resource estimates included in this PEA have been prepared following CIM Definition Standards in accordance with NI 43-101. The NI 43-101 is a rule developed by the Canadian Securities Administrators which establishes standards for all public disclosure an issuer makes of scientific and technical information concerning mineral projects. No reserves have been determined.

Canadian standards, including NI 43-101, differ significantly from the requirements of the United States Securities and Exchange Commission (the SEC), and reserve and resource information contained in this Technical Report may not be comparable to similar information disclosed by United States companies. In particular, and without limiting the generality of the foregoing, the term “resource” does not equate to the term “reserve”. Under the SEC standards, mineralization may not be classified as a “reserve” unless the determination has been made that the mineralization could be economically and legally produced or extracted at the time the reserve determination is made. The SEC’s disclosure standards normally do not permit the inclusion of information concerning “measured mineral resources”, “indicated mineral resources” or “inferred mineral resources” or other descriptions of the amount of mineralization in mineral deposits that do not constitute “reserves” by United States standards in documents filed with the SEC. United States investors should also understand that “inferred mineral resources” have a great amount of uncertainty as to their existence and as to their economic and legal feasibility. It cannot be assumed that all or any part of an “inferred mineral resource” exists, is economically or legally mineable, or will ever be upgraded to a higher category. Under Canadian rules, estimated “inferred mineral resources” may not form the basis of feasibility or pre-feasibility studies. Disclosure of the amount of minerals contained in a resource estimate is permitted disclosure under Canadian regulations; however, the SEC normally only permits issuers to report mineralization that does not constitute “reserves” by SEC standards as in-place tonnage and grade without reference to unit measures. The requirements of NI 43-101 for identification of “reserves” are also not the same as those of the SEC, and reserves reported by Avalon in compliance with NI 43-101 may not qualify as “reserves” under SEC standards. Accordingly, information concerning mineral deposits set forth herein may not be comparable with information made public by companies that report in accordance with United States standards.

22

| 2.1.2 | Preliminary Economic Assessment |

This PEA has been prepared by Micon under the terms of its agreement with Avalon. As discussed in the relevant sections of the report, Micon has prepared a mine plan and schedule, has reviewed the metallurgical testwork carried out on the property, the mineral processing flowsheet, has reviewed infrastructure requirements, prepared capital and operating cost estimates and an economic analysis of the Project.

Avalon owns the mineral rights to the East Kemptville Project and has been investigating various conceptual re-development plans and economic assessments to evaluate the potential for re-starting tin production at the mine.

Avalon initially investigated re-starting the East Kemptville tin mine in Nova Scotia based on the concept of returning the Project to its previous scale of production processing 10,000 tonnes per day (t/d) of material to generate tin, copper and zinc concentrates. Once it became apparent that the necessary capital for such an operation would likely prove difficult to source, Avalon continued the study assuming only the mining and processing of mineral resources contained within a low-grade stockpile and some shallow, relatively high-grade zones close to the surface of the two existing pits (the Main Zone Pit and the Baby Zone Pit). This new operation would target treating these plant feed sources at an annual rate of 806,000 tonnes to produce a tin concentrate only.

In addition to producing tin, the Project has expanded to include the key objective of remediation of the existing site through the treatment and sub-aqueous deposition of the acid generating Low Grade Stockpile and capping of the existing tailings facility with low sulphide tailings generated by the processing plant. This has the significant benefit of reducing the existing site environmental risk and long-term economic liability associated with the Project. The mining of the high-grade mineralization ensures subaqueous deposition of all tailings and waste rock as well as helps to ensure the economic return to incentivize investors, government and the present surface rights owner to support the Project.

The capital and operating cost estimates were developed from first principles and generated a production profile based on the mineralization available and metallurgical performance indicators from various testwork programs. This data was consolidated into a cash flow model which generated IRR and NPV figures used for assessing the likely economic viability and performance of the Project.

This report documents the findings and economic evaluation of Avalon’s East Kemptville Project.

23

| 2.2 | QUALIFIEDPERSONS ANDSITEVISITS |

The Qualified Persons for this Technical Report are the following:

| | • | Richard Gowans, P.Eng. |

| | | |

| | • | Christopher Jacobs, CEng., MIMMM |

| | | |

| | • | Dayan Anderson, M.S., MMSA(QP). |

| | | |

| | • | Jane Spooner, P.Geo. |

| | | |

| | • | William Mercer P. Geo. |

| | | |

| | • | Donald Hains P.Geo. |

| | | |

| | • | Reid Smith. P.Geo. |

Site visits have been carried out by the Qualified Person as follows:

| William Mercer P. Geo. | Various occasions during 2014-2016 |

| | |

| Donald H. Hains, P.Geo. | 23-25 July and 3 September, 2014. |

This report is intended to be used by Avalon subject to the terms and conditions of its agreement with Micon. Subject to the authors’ consent, that agreement permits Avalon to file this report as an NI 43-101 Technical Report on SEDAR (www.sedar.com) pursuant to Canadian provincial securities legislation. Except for the purposes legislated under provincial securities laws, any other use of this report, by any third party, is at that party’s sole risk.

The requirements of electronic document filing on SEDAR necessitate the submission of this report as an unlocked, editable PDF (portable document format) file. Micon accepts no responsibility for any changes made to the file after it leaves its control.

The conclusions and recommendations in this report reflect the authors’ best judgment in light of the information available to them at the time of writing. The Authors have relied on data available in published and unpublished reports, information supplied by the various companies that have conducted exploration on the property, and information supplied directly by Avalon. Micon has no reason to doubt its validity.

The authors and Micon reserve the right, but will not be obliged, to revise this report and conclusions if additional information becomes known to them subsequent to the date of this report. Use of this report acknowledges acceptance of the foregoing conditions.

Some of the figures and tables for this report were reproduced or derived from reports written for Avalon and Rio Algom Ltd (RAL).

24

Units in this PEA are in the Système International d’Unités (SI), unless otherwise noted.

Cost estimates and other inputs to the cash flow model for the Project have been prepared using constant money terms, i.e., without provision for escalation or inflation. All costs are presented in Canadian dollars (CAD) unless otherwise noted. Prices for metals are given in United States dollars (USD) unless otherwise noted.

The CAD:USD exchange rate assumption of 1.3:1 has been used for cost estimates and the financial analysis.

Table 2.1 provides a list of the abbreviations used in this report.

Table 2.1

List of Abbreviations

| Abbreviation | Term |

| ° | Degree(s) |

| °C | Degree(s) Centigrade |

| °F | Degree(s) Fahrenheit |

| < | Less than |

| > | Greater than |

| μm | Micrometre(s) (micron = 0.001 mm) |

| % | Percent, percentage |

| %RSD | Percent relative standard deviation |

| A | Ampere(s) |

| AA | Atomic absorption |

| ABA | Acid Base Accounting |

| Actlabs | Activation Laboratories Ltd. |

| Ag | Silver |

| ALS | ALS Canada Ltd. |

| AMD | Acid mine drainage |

| ANFO | Ammonium Nitrate and Fuel Oil |

| As | Arsenic |

| Avalon | Avalon Advanced Material Inc. |

| B | Billion |

| BMA | Bulk mineral analysis |

| BQ | Diamond drill core size 36.5 mm (inside diameter of core tube) |

| Btu | British thermal units |

| C | Carbon |

| ca. | Circa, approximately |

| CAD | Canadian dollar(s) |

| CAD/t | Canadian dollars per tonne |

| CANMET | CANMET Mining and Mineral Sciences Laboratories |

| CEAA | Canadian Environmental Assessment Act |

| CDN | CDN Resource Laboratories Limited |

| cfm | Cubic feet per minute |

25

| Abbreviation | Term |

| CIF | Cost insurance freight |

| cm | Centimetre(s) |

| CNF | Cost and freight |

| CTP | Coarse Tailings Pile |

| Cu | Copper |

| CV | Coefficient of variation |

| d | Day(s) |

| DDH | Diamond drill hole |

| DLC | Davis Lake Complex |

| DMS | Dense media separation |

| dmt | Dry metric tonne(s) |

| dtpd | Dry metric tonnes per day |

| dwt | Dead weight tonne(s) |

| d/y | Days per year |

| EKL | East Kemptville leucogranite |

| EKSZ | East Kemptville Shear Zone |

| EMP | Electron microprobe |

| ESIA | Environmental and Social Impact Assessment |

| F | Fluorine |

| Fe | Iron |

| FOB | Free On Board |

| ft | Foot, feet |

| ft3 | Cubic foot, feet |

| FW | Footwall |

| g | Gram(s) |

| g | Acceleration due to gravity |

| g/cm3 | Grams per cubic centimetre |

| g/L | Gram(s) per litre |

| g/t | Gram(s) per tonne |

| GA | General Arrangement |

| gal | Gallon(s) |

| GHG | Green House Gas (emissions) |

| gpm | Gallons per minute |

| GPS | Global positioning system |

| GWh | Gigawatt-hour(s) |

| H | Hydrogen |

| h | Hour(s) |

| h/d | Hours per day |

| ha | Hectare(s) |

| HCl | Hydrochloric acid |

| HDPE | High density polyethylene |

| HF | Hydrofluoric acid |

| HIMS | High intensity magnetic separation |

| HP | Horsepower |

| HQ | Diamond drill core size 63.5 mm (inside diameter of core tube) |

| HSCC | High-speed centrifugal concentrators |

| Hz | Hertz |

| IP | Induced polarization |

| ICP | Inductively coupled plasma |

| ICP-AES | Inductively coupled plasma atomic emission spectroscopy |

| ICP-MS | inductively coupled plasma mass spectrometry |

26

| Abbreviation | Term |

| ICP-OES | inductively coupled plasma optical emission spectrometry |

| ID2 | Inverse distance squared |

| in | Inch(es) |

| In | Indium |

| INAA | Instrumental neutron activation analysis |

| IRR | Internal rate of return |

| ITA | International Tin Association |

| ITRI | International Tim Research Institute |

| K | Potassium |

| k | Kilo (thousand) |

| kg | Kilogram(s) |

| kg/h | Kilograms per hour |

| kg/m3 | Kilograms per cubic metre |

| kg/t | Kilograms per tonne |

| km | kilometre(s) |

| km/h | Kilometres per hour |

| kPa | Kilopascal(s) |

| kV | Kilovolt(s) |

| kVA | Kilovolt-ampere |

| kW | Kilowatt(s) |

| kWh | Kilowatt hour(s) |

| kWh/t | Kilowatt hours per tonne |

| L | Litre(s) |

| L/s | Litres per second |

| LAN | Local area network |

| lb | Pound(s) |

| lb/ft3 | Pounds per cubic foot |

| LCT | Locked cycle test |

| LHD | Load-haul-dump |

| LIMS | Low intensity magnetic separator |

| LME | London Metal Exchange |

| LOI | Loss on ignition |

| LOM | Life of mine |

| M | Mega (million) |

| m | Metre(s) |

| m3 | Cubic metre(s) |

| Mm3 | Million cubic metres |

| Ma | Million years |

| m/min | Metres per minute |

| m/s | Metres per second |

| mA | Milliampere(s) |

| masl | Metres above sea level |

| Mg | Magnesium |

| mg/L | Milligrams per litre |

| MIBC | Methyl isobutyl carbinol |

| min | Minute(s) |

| ML | Million litres |

| mm | Millimetre(s) |

| MMI | Mobile Metal Ion |

| Mo | Molybdenum |

| MOU | Memorandum of Understanding |

27

| Abbreviation | Term |

| MPa | Megapascal(s) |

| Mt | Million tonnes |

| MW | Megawatt(s) |

| MWh | Megawatt hour(s) |

| n.a. | Not applicable |

| Na | Sodium |

| NAD | North American Datum |

| NAG | Net acid generating |

| NDB | Non directional beacon |

| NGO | Non-Government Organization |

| NI 43-101 | Canadian National Instrument 43-101 |

| NN | Nearest neighbour |

| NPV | Net present value |

| NTS | National topographic system |

| NSDNR | Nova Scotia Department of Natural Resources |

| NSR | Net smelter return |

| NQ | Diamond drill core size 47.6 mm (inside diameter of core tube) |

| ORE | Ore Research & Exploration Pty Ltd. |

| oz | Ounce(s) |

| PAG | Potentially acid generating |

| P&ID | Process and instrument diagram |

| Pa | Pascal(s) |

| Pa.s | Pascal-second |

| PAX | Potassium amyl xanthate |

| Pb | Lead |

| PMA | Particle mineral analysis |

| ppb | Parts per billion |

| ppm | Parts per million |

| QA | Quality assurance |

| QA/QC | Quality assurance/quality control |

| QEMSCAN | Quantitative Evaluation of Minerals by Scanning electron microscopy |

| QC | Quality control |

| RAL | Rio Algom Limited |

| RC | Refining charge |

| RMA | Reduced major axis |

| RNAV | Random area navigation |

| ROM | Run-of-mine |

| RQD | Rock quality designation |

| RSD | Relative standard deviation |

| s | Second(s) |

| S | Sulphur |

| SAG | Semi-autogenous grind |

| Sb | Antimony |

| SD | Standard deviation |

| SEM | Scanning electron microscope |

| SG | Specific gravity |

| SI | International system of units |

| Si | Silicon |

| SIPX | Sodium isopropyl xanthate |

| SMB | South Mountain Batholith |

| Sn | Tin |

28

| Abbreviation | Term |

| Sn(eq) | Tin equivalent |

| t | Tonne(s) (metric = 1,000 kg) |

| t/d | Tonnes per day |

| t/h | Tonnes per hour |

| t/y | Tonnes per year |

| Ta | Tantalum |

| TC | Treatment charge |

| TMF | Tailings Management Facility |

| TSS | Total suspended solids |

| UCS | Unconfined compressive strength |

| VHF | Very high frequency |

| VOR | VHF omni-directional range |

| WACC | Weighted average cost of capital |

29

| 3.0 | RELIANCE ON OTHER EXPERTS |

Micon has reviewed and analyzed data provided by Avalon and its consultants and has drawn its own conclusions therefrom. Micon has not carried out any independent exploration work, drilled any holes or carried out any sampling and assaying on the property.

While exercising all reasonable diligence in checking, confirming, and testing it, Micon has relied upon Avalon’s presentation of the Project data from previous operators and from Avalon’s exploration experience at the East Kemptville Project in formulating its opinion.

Micon has not reviewed any of the documents or agreements under which Avalon holds title to the East Kemptville Project or the underlying mineral concessions and Micon is not qualified to comment as to the validity of the mineral titles claimed. A description of the properties, and ownership thereof, is provided for general information purposes only. The existing environmental conditions, liabilities and remediation have been described where required by NI 43-101 regulations. These statements also are provided for information purposes only and Micon is not qualified to comment in this regard.

30

| 4.0 | PROPERTY DESCRIPTION AND LOCATION |

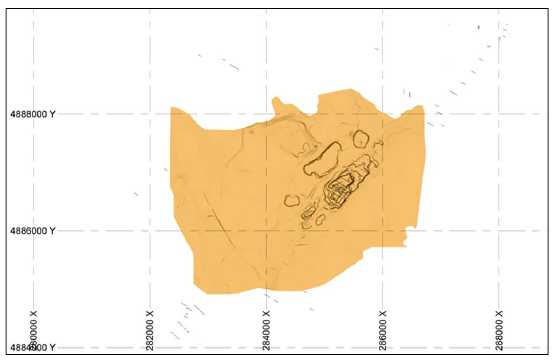

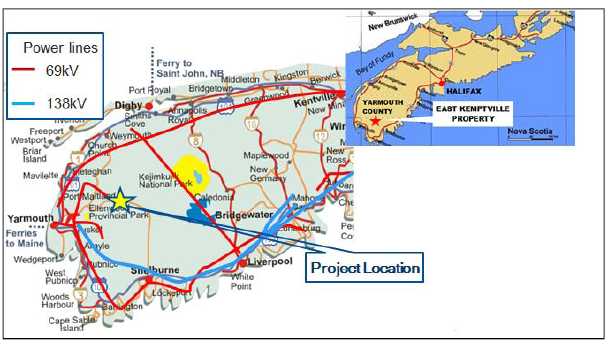

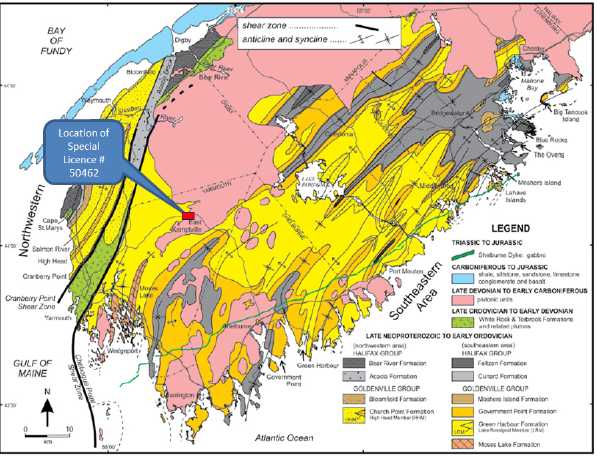

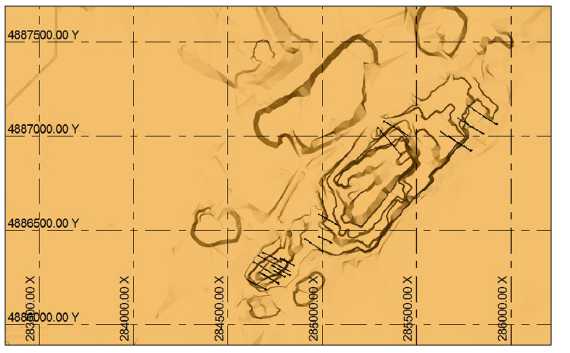

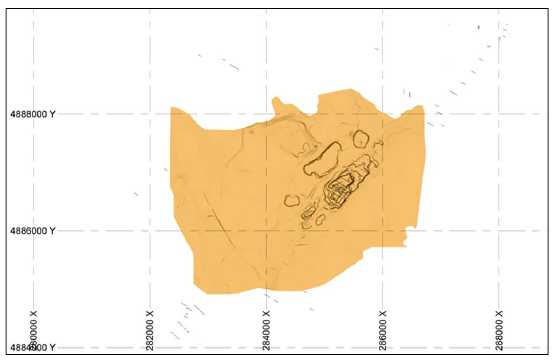

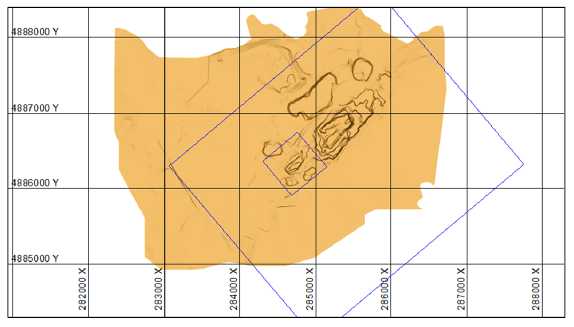

The East Kemptville tin-indium Project is located on NTS map sheet 21A/04A and /05B in Yarmouth County, southwestern Nova Scotia. The property is located approximately 180 km southwest of Halifax, the provincial capital, and 55 km northeast of the town of Yarmouth, a port with population of approximately 7,500 (see Figure 4.1) .

Figure 4.1

Property Location Map

Source: Avalon, 2015.

Highway 203, constructed in the 1800s to facilitate the transportation of metal concentrates to the port of Shelburne, crosses the property and links it with Shelburne and the port of Yarmouth, both of which are on the Atlantic Ocean. Yarmouth is located some 45 km to the southeast of the property. The highway is in reasonable condition eastwards from the junction with Highway 101 but requires upgrading from the old mine entrance southwards to Shelburne which is the intended port of shipment for concentrates from East Kemptville.

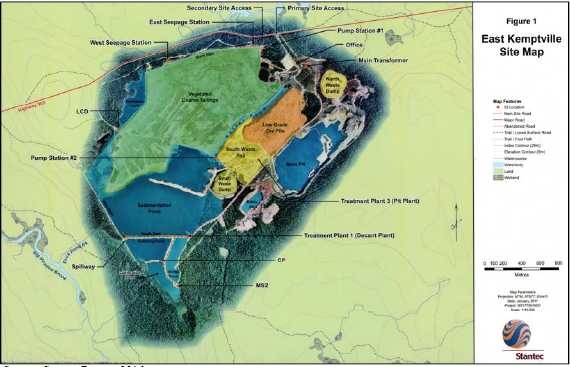

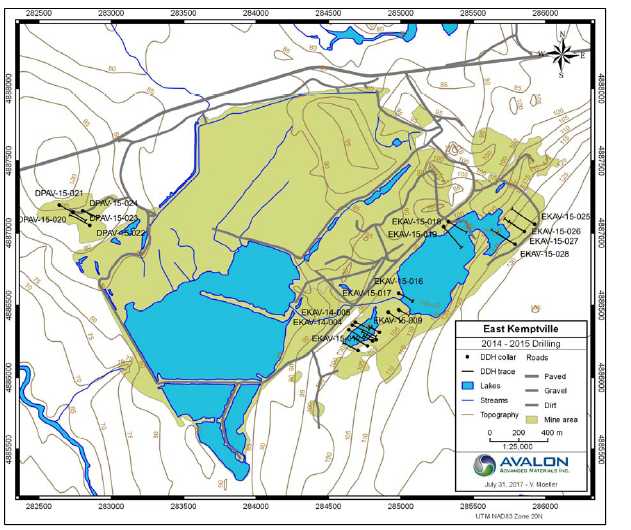

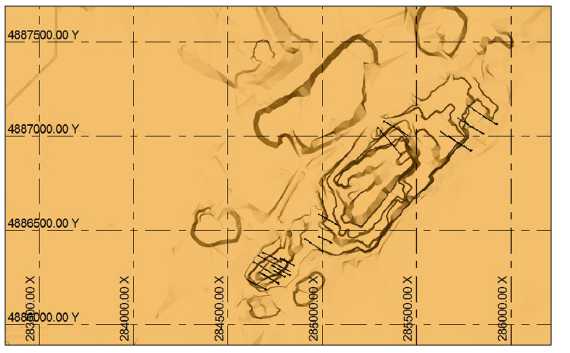

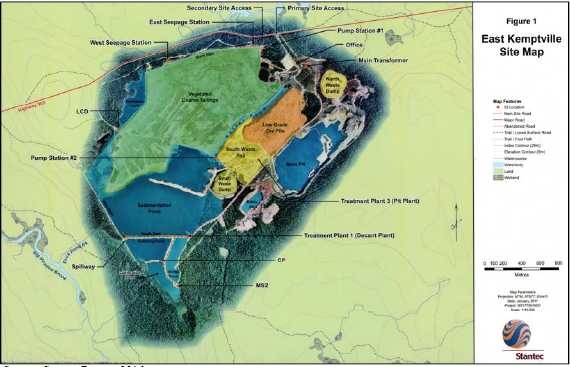

Site facilities at the East Kemptville property are shown in Figure 4.2.

31

Figure 4.2

Site Facilities Map

Source: Stantec Report, 2016.

Avalon holds a 100% interest in the property via Special Licence 50462, which combines Special Licence 1/12 (now expired) and supersedes Application 40032. The area covered by Special Licence 50462 includes the Closure Area represented by the former East Kemptville Tin Mine property, which is currently under the management of RAL, the surface rights holder.

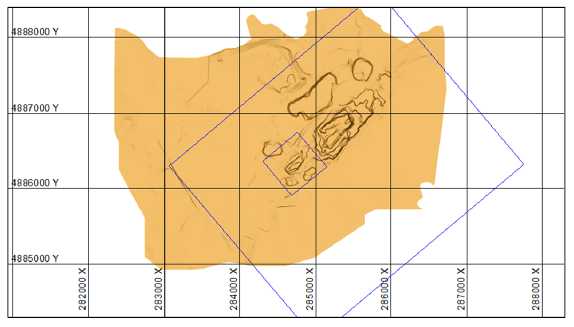

Figure 4.3 shows the location of Special Licence 50462.

32

Figure 4.3

East Kemptville Property Claim Map

Source: Avalon, 2018.

The details of the claims within Special Licence 50462 are summarized in Table 4.1.

Table 4.1

East Kemptville Tin-Indium Project – Claims within Special Licence 50462

| Map Number | Tract

Number | Special Licence 50462 |

| Claim Designation | Units |

| 21A/4A | 81 | M,N,O,P | 4 |

| 21A/4A | 82 | A,B,C,E,F,G,H,J, K,L,M,N,O,P,Q | 15 |

| 21A/4A | 83 | J,Q | 2 |

| 21A/4A | 86 | A,B,G,H,J,K,P,Q | 8 |

| 21A/4A | 87 | A to Q | 16 |

| 21A/4A | 88 | A to Q | 16 |

| 21A/4A | 105 | A,B,C,D,E | 5 |

| 21A/4A | 106 | A,B,C,D | 4 |

| 21A/4A | 107 | A,B | 2 |

| Total Claim Units | | | 72 |

| Ha | | | 1,165.5 |

| Acres | | | 2,880 |

Except for claims 81M and 82A, B and C, the property is located on the site of a former tin mine with existing closure and reclamation activities carried out by the private surface rights owner. Given the closure and reclamation activities at the site, the lands were deemed withdrawn by the Government of Nova Scotia and exploration rights permitted only by way of a special licence or special lease granted by the Minister with the approval of the Governor in Council in accordance with Section 22 of the Mineral Resources Act, SNS 1990, c 18 (the East Kemptville Closure Area). The East Kemptville Closure Area is that property withdrawn by the Government of Nova Scotia, with the boundaries clearly indicated on the mineral licence maps of the government NOVAROC online map system.

33

Pursuant to Section 22 of the Mineral Resources Act, the mineral rights covering a portion of the East Kemptville Closure Area were first acquired by Avalon (then Avalon Ventures Ltd.) as Special Licence 1/06 dated 1 August, 2006 and approved by Order in Council on 21 September, 2006 (Special Licence 1/06). Special Licence 1/06 was for a three-year term ending 31 July, 2009, with allowance for two subsequent renewals of one year each with the approval of the Minister of Natural Resources. Special Licence 1/06 covered the area described in NTS 21A4A, tracts 81, 82, 87, 88 for a total of 880 acres or 356 ha. Renewal was contingent on Avalon undertaking work acceptable to the Minister. The work program for Special Licence 1/06 totalled CAD2,250,000 to be completed by 31 July, 2009.