|

|

MINERAL RESERVES AND MINERAL RESOURCES

OF THE

ZINKGRUVAN MINE

IN SOUTH-CENTRAL SWEDEN

DECEMBER 2008

Prepared by

Lars Malmström, AusIMM, Chief Geologist of Zinkgruvan Mining AB

Per Hedström, AusIMM, Senior Geologist at Zinkgruvan Mining AB

Doug Syme, AusIMM, General Manager, Zinkgruvan Mining AB

31 March 2009

Page1of66

|

|

| 1 | SUMMARY | 5 |

| 2 | INTRODUCTION | 8 |

2.1 Purpose and Data Information | 8 | |

2.2 Qualified Persons | 8 | |

2.3 Units and Currency | 8 | |

| 3 | RELIANCE ON OTHER EXPERTS | 9 |

| 4 | PROPERTY DESCRIPTION AND LOCATION | 10 |

4.1 Location | 10 | |

4.2 Property Description | 11 | |

| 5 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES AND INFRASTRUCTURE AND PHYSIOGRAPHY | 12 |

5.1 Access | 12 | |

5.2 Climate | 12 | |

5.3 Local Resources and Infrastructure | 12 | |

5.4 Physiography | 13 | |

| 6 | HISTORY | 14 |

| 7 | GEOLOGICAL SETTING | 16 |

7.1 Regional and Local Geology | 16 | |

7.2 Deposit Geology | 18 | |

| 8 | DEPOSIT TYPES | 24 |

| 9 | MINERALIZATION | 25 |

9.1 Zinc / Lead Orebodies | 25 | |

9.2 Copper Mineralisation | 25 | |

| 10 | EXPLORATION | 27 |

| 11 | DRILLING | 28 |

| 12 | SAMPLING METHOD AND APPROACH | 29 |

| 13 | SAMPLE PREPARATION, ANALYSES AND SECURITY | 30 |

13.1 Sample Preparation | 30 | |

13.2 Assaying | 30 | |

13.2.1 Zinkgruvan Laboratory Analytical Method | 30 | |

13.2.2 ACME Analytical Method | 31 | |

13.2.3 ALS Analytical Method | 32 | |

13.3 Security | 33 | |

| 14 | DATA VERIFICATION | 34 |

Page2of66

|

|

14.1 QA/QC | 34 | |

14.2 Verification by Authors | 34 | |

| 15 | ADJACENT PROPERTIES | 35 |

| 16 | MINERAL PROCESSING AND METALLURGICAL TESTING | 36 |

| 17 | MINERAL RESOURCE AND MINERAL RESERVE ESTIMATES | 37 |

17.1 Resource and Reserve Areas | 37 | |

17.2 Specific Gravity | 39 | |

17.3 Resource Estimation Procedures | 39 | |

17.3.1 Estimation by Block Model Method | 39 | |

17.3.2 Estimation by Polygonal Method | 40 | |

17.3.3 Estimation by Sectional Method | 41 | |

| 18 | OTHER RELEVANT DATA AND INFORMATION | 48 |

| 19 | INTERPRETATION AND CONCLUSIONS | 49 |

| 20 | RECOMMENDATIONS | 50 |

| 21 | REFERENCES | 51 |

| 22 | DATE AND SIGNATURE | 52 |

22.1 Certificate of Per Hedström | 52 | |

22.2 Certificate of Lars Malmström | 53 | |

22.3 Certificate of Doug Syme | 54 | |

| 23 | ADDITIONAL REQUIREMENTS FOR PRODUCTION PROPERTIES | 55 |

23.1 Mining Operations | 55 | |

23.1.1 Mining Methods | 56 | |

23.1.2 Production Schedule | 58 | |

23.2 Metallurgical Process | 59 | |

23.2.1 Concentrator Flowsheet | 59 | |

23.2.2 Metallurgical Results | 61 | |

23.2.3 Backfill Plant | 61 | |

23.2.4 Tailings | 62 | |

23.2.5 Copper Production | 62 | |

Table 17 – Copper Metallurgical Testwork Results | 62 | |

23.3 Marketing | 63 | |

23.4 Contracts | 63 | |

23.5 Environmental Considerations | 63 | |

23.6 Taxes | 64 | |

23.7 Capital and Operating Cost Estimates | 64 | |

23.8 Economic Analysis | 65 | |

23.9 Payback | 66 | |

23.10 Mine Life | 66 |

Page3of66

|

|

| LIST OF TABLES | ||

| Table 1: | Zinkgruvan Zinc/Lead Mineral Reserves at December 31, 2008 | 6 |

| Table 2: | Zinkgruvan Zinc/Lead Mineral Resources at December 31, 2008 | 6 |

| Table 3: | Zinkgruvan Copper Mineral Reserves at December 31, 2008 | 7 |

| Table 4: | Zinkgruvan Copper Mineral Resources at December 31, 2008 | 7 |

| Table 5: | Detection Limits for ZMAB Laboratory Analyses | 31 |

| Table 6: | ACME ICP-AES Method | 32 |

| Table 7: | ALS ICP-AES Method | 33 |

| Table 8: | Proven Zinc-Lead Mineral Reserve at December 31, 2008 | 42 |

| Table 9: | Probable Zinc-Lead Mineral Reserve at December 31, 2008 | 43 |

| Table 10: | Measured Zinc-Lead Mineral Resource at December 31, 2008 | 44 |

| Table 11: | Indicated Zinc-Lead Mineral Resource at December 31, 2008 | 45 |

| Table 12: | Inferred Zinc-Lead Mineral Resource at December 31, 2008 | 46 |

| Table 13: | Probable Copper Mineral Reserves at December 31, 2008 | 47 |

| Table 14: | Copper Mineral Resources at December 31, 2008 | 47 |

| Table 15: | Mine Production Forecast 2009 – 2018 | 59 |

| Table 16: | Concentrator Operating Results 2004 to 2008 | 61 |

| Table 17: | Copper Metallurgical Testwork Results | 62 |

| Table 18: | Capital Cost Forecast 2008 – 2013 | 64 |

| Table 19: | Operating Cost Forecast 2008 – 2013 | 64 |

| Table 20: | Project Cash Flow (million US dollars) | 65 |

| Table 21: | Sensitivity Analysis (million US dollars) | 66 |

| LIST OF FIGURES | ||

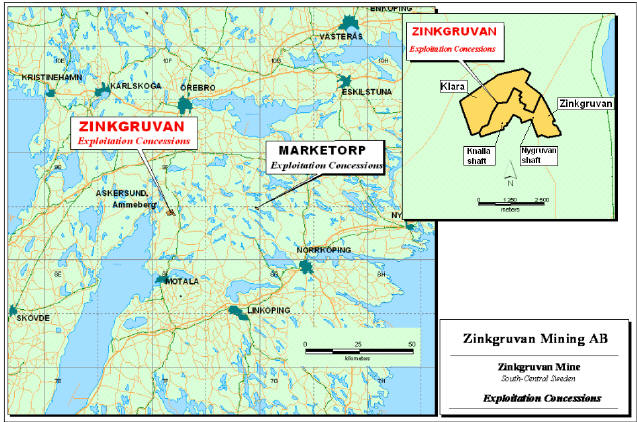

| Figure 1: | Property Location Map | 10 |

| Figure 2: | Exploitation Concessions | 11 |

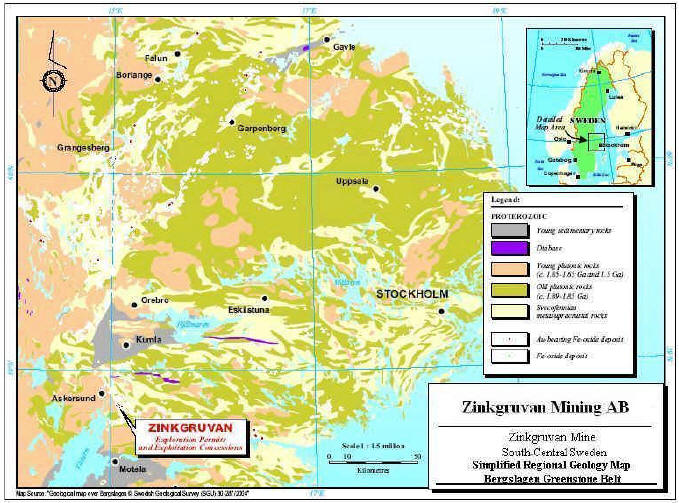

| Figure 3: | Simplified Regional Geology Map | 16 |

| Figure 4: | Generalized Property Geology Map | 17 |

| Figure 5: | 650 Level Plan; Nygruvan Mine | 19 |

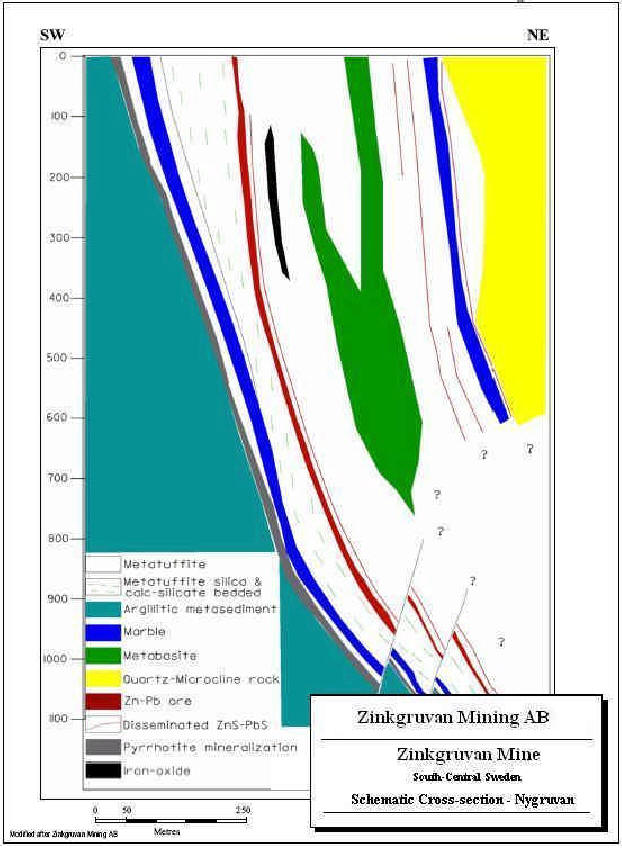

| Figure 6: | Schematic Cross-section - Nygruvan | 20 |

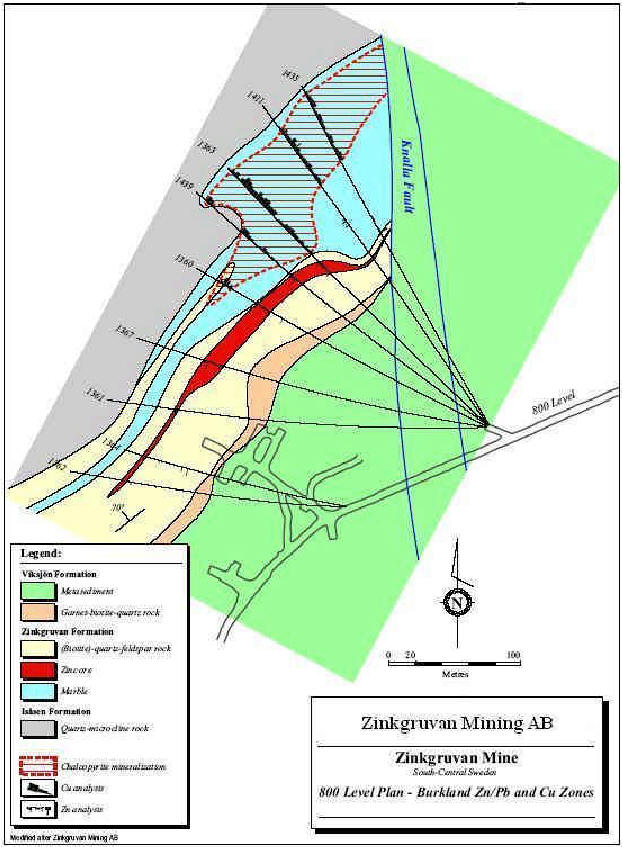

| Figure 7: | 800 Level Plan - Burkland Zn/Pb and Cu Zones | 21 |

| Figure 8: | Schematic Cross-section - Knalla | 22 |

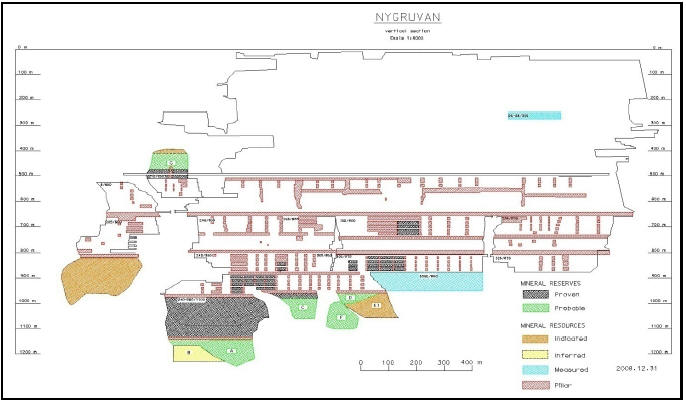

| Figure 9: | Nygruvan Resource and Reserve Long Section | 39 |

| Figure 10: | Knalla Resource and Reserve Long Section | 39 |

| Figure 11: | Schematic 3D Figure over the mine | 55 |

| Figure 12: | General Site Plan | 56 |

| Figure 13: | Schematic of the Panel Stoping Method | 57 |

| Figure 14: | Schematic of the Bench Stoping Method | 58 |

| Figure 15: | Schematic of the Concentrator Flowsheet | 60 |

Page4of66

|

|

1 SUMMARY

This report presents the Mineral Reserves and Resources of the Zinkgruvan mine estimated by the staff of Zinkgruvan Mining AB (Zinkgruvan) as of December 31, 2008. Zinkgruvan owns and operates the Zinkgruvan mine and processing plant, and is a subsidiary of Lundin Mining Corporation (Lundin).

The Zinkgruvan mine is located in the south-central Sweden, 175 km west-southwest of Stockholm. The Zinkgruvan deposit has been known since the 16thcentury. Large scale production started first in 1857 and has continued uninterrupted since then. At present the annual production of zinc-lead-silver ore is in the order of 900,000 tonnes. Approximately 34 million tonnes have been mined from Zinkgruvan up to the end of 2008. The current remaining mine life is in excess of 10 years.

The warm Gulf Stream in the Atlantic gives southern Sweden a relatively mild climate. The average summer temperature is approximately18° C. The average winter temperature is slightly below freezing. The regional infrastructure of paved highways, electricity, telecommunications and other communications is good. There are several villages and smaller towns in the surrounding area. The nearest large city is Örebro, 60 km to the north, which hosts a university, considerable industry and an airport with flights to Copenhagen.

The Zinkgruvan deposit is located in the SW corner of the Bergslagen mining district, a part of the Proterozoic Svecofennian Domain. This district hosts numerous iron ore and base metal mines in volcano-sedimentary complexes consisting of felsic metavolcanics with intercalated limestone, calcsilicate and mineralized deposits. The district is composed of a series of small elongated basins with felsic metavolcanics overlain by metasediments. The basins are surrounded by mainly granitoid intrusions of which the oldest are of the same age as the felsic metavolcanics.

The Zinkgruvan deposit is situated in an east-west striking synclinal structure. The tabular-shaped Zn-Pb-Ag orebodies occur in a 5- to 25 m-thick stratiform zone in the upper part of the metavolcanic-sedimentary group. In the central part of the deposit disseminated Cu mineralization is situated in the immediate hanging wall of the Burkland Zn-Pb-ore body. The ore deposit is about 5 km long and extends to a depth of at least 1,500 meters below surface. It strikes mainly east-west and dips towards north. One sub-vertical fault splits the ore deposit in to two major parts, the Knalla mine to the west and the Nygruvan mine to the east. In the Nygruvan mine the dip is 60o-80o, while in the Knalla mine folding is extensive and partly isoclinal.

Most of the economic Zn-Pb-Ag mineralization consists of massive layers of sphalerite and galena intercalated with barren layers of quarzitic metatuffite and calcsilicate rock. Layers of disseminated sphalerite and galena occur locally towards the hanging wall. Galena is locally remobilized into veins, particularly in the Knalla mine.

The estimation of Mineral Resources and Mineral Reserves of Zinkgruvan is based on a database of approximately 3,000 diamond drill holes. The majority of the Zn-Pb-Ag Reserves have been estimated by using block modelling and the Ordinary Kriging Method of grade interpolation. In areas with randomly and often sparsely distributed drill holes, estimations, mainly of Resources, have been done by employing the Polygonal Method. The cut-off values employed vary slightly between different areas of the mine, however, a general NSR cut-off of 250 SEK/t has been used for the Zn-Pb-Ag Resource. The Cu Resource is defined by a cut-off of 2.0% Cu. Mineral Resources and Reserves as of December 2008 are shown in the tables below.

Page5of66

|

|

Table 1: Zinkgruvan Zinc/Lead Mineral Reserves at December 31, 2008

| Area | Category | Tonnes | Zn | Pb | Ag |

| ( x1000) | (%) | (%) | (g/t) | ||

| Nygruvan | Proven | 1,619 | 13.7 | 4.1 | 77 |

| Knalla | Proved | 7,143 | 8.6 | 5.5 | 119 |

| Total | Proven | 8,762 | 9.6 | 5.2 | 112 |

| Nygruvan | Probable | 1,086 | 9.7 | 2.4 | 55 |

| Knalla | Probable | 914 | 7.0 | 2.8 | 58 |

| Total | Probable | 2,000 | 8.5 | 2.5 | 56 |

| Total | All Categories | 10,762 | 9.4 | 4.7 | 102 |

For the Burkland deposit, zero-value wall rock (12%) and backfill (3%) dilution, mining recovery (95%) and mining losses (3%) factors are applied to Mineral Resource estimates in arriving at the cut-off figure. For the Nygruvan deposit, the corresponding figures are wall rock dilution 20-25%, mining recovery 95% and mining loss 5%. There is no backfill factor required at Nygruvan. All reported Mineral Resources are exclusive of Mineral Reserves.

Table 2: Zinkgruvan Zinc/Lead Mineral Resources at December 31, 2008

| Area | Category | Tonnes | Zn | Pb | Ag |

| ( x1000) | (%) | (%) | (g/t) | ||

| Nygruvan | Measured | 477 | 6.2 | 0.8 | 23 |

| Knalla | Measured | 76 | 6.5 | 1.7 | 27 |

| Total | Measured | 553 | 6.3 | 0.9 | 24 |

| Nygruvan | Indicated | 940 | 6.8 | 4.0 | 75 |

| Knalla | Indicated | 2,850 | 10.0 | 4.6 | 116 |

| Total | Indicated | 3,790 | 9.2 | 4.4 | 105 |

| Total | Meas. + Ind. | 4,343 | 8.8 | 4.0 | 95 |

| Nygruvan | Inferred | 82 | 9.8 | 3.6 | 62 |

| Knalla | Inferred | 4,117 | 9.7 | 3.1 | 69 |

| Total | Inferred | 4,199 | 9,7 | 3,1 | 68 |

Page6of66

|

|

Table 3: Zinkgruvan Copper Mineral Reserves at December 31, 2008

| Area | Category | Tonnes | Cu | Zn | Pb | Ag |

| ( x1000) | (%) | (%) | (%) | (g/t) | ||

| Knalla | Probable | 2,895 | 2.6 | 0.5 | 0.0 | 28 |

For the Copper deposit, wall rock (8%) and backfill (3%) dilution, mining recovery (95%) and mining losses (5%) factors are applied to Mineral Resource estimates in arriving at the cut-off figure.

Table 4: Zinkgruvan Copper Mineral Resources at December 31, 2008

| Area | Category | Tonnes | Cu | Zn | Pb | Ag |

| ( x1000) | (%) | (%) | (%) | (g/t) | ||

| Knalla | Indicated | 460 | 2.9 | 0.5 | 0.0 | 30 |

| Knalla | Inferred | 550 | 3.0 | 0.1 | 0.0 | 42 |

The Mineral Resource and Mineral Reserves are reported and prepared in accordance with the requirements of National Instrument 43-101 and the guidelines published by the Council of the Canadian Institute of Mining, Metallurgy and Petroleum (¨CIM Standards¨).

Page7of66

|

|

2 INTRODUCTION

2.1 Purpose and Data Information

This report has been prepared in order to present the 2008 year-end inventory of Mineral Resources and Mineral Reserves at the Zinkgruvan Mine and to update previously issued Technical Reports. The Zinkgruvan mine is owned by Zinkgruvan Mining AB (ZMAB), a subsidiary to Lundin Mining Corporation, Canada since 2004. The Zinkgruvan mine is situated in South Central Sweden and has been in continuous operation since 1857.

The information and data used for this report (except for chemical assaying of geological samples) has been sourced from ZMAB, and the interpretation and evaluation of it has been done in-house.

2.2 Qualified Persons

The estimation of the Mineral Resource and Mineral Reserves of the Zinkgruvan Mine has been prepared under the supervision of Lars Malmström and Per Hedström, both Members of The Australasian Institute of Mining and Metallurgy (AusIMM). Lars Malmström, Chief Geologist of the Zinkgruvan Mining AB, has worked at the mine since 1982 as Mining Geologist and Senior Mining Geologist. Per Hedström, Senior Geologist at The Zinkgruvan Mining AB, has been working at the Zinkgruvan mine since 1981, during the period 1984-2004 as Chief Geologist. Doug Syme who is also a member of AusIMM and the current General Manager at Zinkgruvan has prepared Section 23 of this report.

2.3 Units and Currency

Metric units are used throughout this report unless noted otherwise. Currency is primarily Swedish Kronor or Crowns ("SEK") and United States Dollars ("US$"). The currency exchange rate used is 7.6 SEK per US$.

Page8of66

|

|

3 RELIANCE ON OTHER EXPERTS

Bengt-Arne Bergström, Mill Manager Zinkgruvan Mining AB has provided the information on mineral processing in this report. Hannah Nilsson, Environmental Engineer Zinkgruvan Mining AB provided information on environmental matters.

Page9of66

|

|

4 PROPERTY DESCRIPTION AND LOCATION

4.1 Location

The Zinkgruvan mine is located in south-central Sweden in Närke County at approximately 58°49’N latitude, 15°06’E longitude. As shown in Figure 1, it lies 175 west-southwest of Stockholm and 210 km northeast of Goteborg. While there is a small village called Zinkgruvan surrounding the mine installations, the nearest significant communities are Åmmeberg and Askersund, 10 km and 15 km NW respectively from the mine. These towns house the majority of the mine employees.

Figure 1: Property Location Map

Page10of66

|

|

4.2 Property Description

Zinkgruvan holds two exploitation concessions covering the deposit and its immediate area (Figure 2). The “Zinkgruvan Concession”, consisted originally of a large number of small mining rights, was consolidated in 2000 into one concession covering an area of 254 ha. The “Klara Concession” was granted in 2002 and covers 355 ha, mainly over “new areas” in the western part of the deposit. “Zinkgruvan” and “Klara” are valid until 2025 and 2027. If mining continues after these years, the concessions can be extended for periods of 10 years.

The two exploitation concessions are entirely held by ZMAB. The surface land in the concessions areas belong mainly to private individuals. The regulations of the exploitation concessions involve no particular restrictions on the mining operation. The Klara concession has, however, one restriction stipulating that mining must always be done under a minimum rock cover of at least 150m thick and in planned residential areas the cover has to be 400m. This restriction has no impact on mining because the ore zones in the Klara concession are found at depths below 400m.

Figure 2: Exploitation Concessions

Page11of66

|

|

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES AND INFRASTRUCTURE AND PHYSIOGRAPHY

5.1 Access

The property can be reached from Stockholm along highway E18 in a westerly direction for a distance of 200 km to Örebro; from Örebro southward on highway E20 and County Road 50 for a distance of 50 km to Askersund, and then by a secondary paved road for a further 15 km through Åmmeberg to Zinkgruvan. Access to Örebro is also possible by rail and by aircraft on scheduled flights from Copenhagen amongst other locations.

Askersund is located at the north end of Lake Vättern, the second largest lake in Sweden. The largest lake in the country, Lake Vänern, is some 50 km due west of Askersund. The port of Otterbäcken on Lake Vänern is about 100 km from Zinkgruvan by road. The port of Göteborg on Sweden's west coast is accessible by lake and canal from Otterbäcken, a distance of some 200 km.

5.2 Climate

The warm Gulf Stream in the Atlantic gives Sweden a milder climate than other areas at the same latitude. Stockholm, the capital, is at almost the same latitude as southern Greenland but has an average temperature of 18ºC in July. The winter temperatures average slightly below freezing and snowfall is moderate.

Temperature records for Zinkgruvan show that the mean annual temperature is 5.5ºC. Mean monthly temperatures are below freezing from December through March. The coldest month is February, with an average maximum temperature of -4.1ºC and an average minimum of -11.1ºC. The warmest month is August with an average maximum temperature of 18.2ºC and an average minimum of 12.2ºC. Annual precipitation is about 750 mm, ranging from a low of 11 mm in March to a high of 144 mm in August.

5.3 Local Resources and Infrastructure

The community of Askersund has a population of about 14,000. The village of Zinkgruvan has about 290 inhabitants. Zinkgruvan is the largest private employer in the municipality with about 280 employees. Other local economic activities include agriculture, construction and light service industries. The town of Askersund has a modest tourist industry in the summer and is a full service community.

The nearest airport is in Örebro with flights to Copenhagen and other centres. Örebro also hosts a university and considerable light and heavy industry. As with virtually all of southern Sweden there is an extensive network of paved highways, rail service, excellent telecommunications facilities, national grid electricity, an ample supply of water and a highly educated work force.

Page12of66

|

|

5.4 Physiography

The property is located in very gently rolling terrain at about 175 metres above mean sea level ("masl") and relief in the area is 30 m to 50 m. The land is largely forest and drift covered and cut by numerous small, slow moving streams, typical of glaciated terrain and very reminiscent of boreal-forested areas of Canada such as the Abitibi area of northern Ontario and Quebec. Outcrop is scarce.

Page13of66

|

|

6 HISTORY

The Zinkgruvan deposit has been known since the 16thcentury but it was not until 1857 that large scale production began under the ownership of the Vieille Montagne Company of Belgium. Vieille Montagne merged into Union Miniere in 1990. The earliest recorded mining activity in the area dates from approximately 1700. This was from the Isåsa mine, immediately to the north of the present Zinkgruvan operation. The mine operated intermittently until the mid 1800s, but never made a profit and was shut down permanently in 1845.

Interest in the present Zinkgruvan area as a potential zinc producer dates from 1846 - 47. Trial mining and smelting were carried out but the operation was unprofitable because of the large quantities of coal required for reducing the ore.

The Swedish owner of the property subsequently made contact with Vieille Montagne, the world leader in the mining and processing of zinc ores at that time. The Belgian company agreed to purchase the properties, including mineral rights and extensive surface rights in farm and forest land and in 1857 a Royal Warrant was issued by the Swedish Crown authorizing this purchase by a foreign company and documenting the terms of operation of the mine.

The first shipment of ore from Zinkgruvan to Belgium was made in 1860. Vieille Montagne metallurgists, accustomed to treating oxidized ores in carbonate gangues, encountered severe technical problems in smelting the sulphide ores, however, the problem was eventually solved by the addition of a roaster on site in 1864.

Processing, including roasting was carried out at Åmmeberg, with its small port facility on Lake Vättern. Zinkgruvan still has some real estate holdings in and around the village. The former tailings area now forms a golf course. From the port, shipments of ore and (later) concentrate were shipped out through the Swedish lake and canal system to the sea and on to Belgium.

In the years immediately following the opening of the mine, production was carried out on a modest scale. Hand sorting and heavy media separation were sometimes employed to upgrade mined material. The rate of production was around 300,000 tonnes annually ("tpa") until the end of 1976.

In the mid-1970s, the company decided to expand production to 600,000 tpa. A new main shaft was sunk to gain access to additional deeper ore and the mining method was modified to allow for heavier, mechanized equipment. A new concentrator and tailings disposal facility were built adjacent to the mine and the Åmmeberg facilities were largely rehabilitated and abandoned. The new facilities were brought on line at the beginning of 1977 and the rate of production gradually began to increase towards the target of 600,000 tpa, which was achieved in 1982. Since then the production rate has been further increased and in 2008 the production was 900,000 tonnes.

Page14of66

|

|

In late 1995, North Limited of Australia purchased the mine from Union Miniere as part of a zinc strategy and in addition to mining, carried out an aggressive exploration program in the immediate and surrounding area. In August 2000, Rio Tinto became the owner of Zinkgruvan when it acquired North Limited. Lundin Mining Corporation acquired the mine from Rio Tinto in June 2004 and is now the owner of Zinkgruvan Mining AB.

In December 2004, Silver Wheaton Corp. purchased the life of mine silver production from the Zinkgruvan mine.

Page15of66

|

|

7 GEOLOGICAL SETTING

7.1 Regional and Local Geology

Zinkgruvan is located in the SW corner of the Proterozoic-aged Bergslagen greenstone belt/mining district, famed for its numerous iron ore and base metal mines, notably the Falun deposit (200 km north of Zinkgruvan), which saw production from before the year 1000 until 1992. The belt is shown in Figure 3.

Figure 3: Simplified Regional Geology Map

The ore-bearing Bergslagen district is part of the southern volcanic belt of the Svecofennian Domain. The supracrustal rocks are dominated by felsic metavolcanic successions that can be up to 10 km thick. Limestones, calcsilicates and mineralized deposits are commonly found within the metavolcanics. The district is comprised of a series of small proximal basins in a continental rift environment. The active extensional stage was characterized by felsic volcanism and intrusions followed by subsidence and sedimentation.

The Zinkgruvan deposit is situated in an east-west striking synclinal structure within the lower Proterozoic Svecofennian supracrustal sequence (Figure 4). This sequence consists of metavolcanic and metasedimentary rocks 1.90 to 1.88 billion years old, which rest on an unknown basement.

Page16of66

|

|

Figure 4: Generalized Property Geology Map

During early stages of the orogeny 1.87 to 1.85 billion years ago, differentiated, I-type granitoids, ranging from gabbro to granite in composition intruded the Svecofennian sequence. From 1.84 billion years ago until 1.77 billion years ago further intrusion occurred, forming late orogenic, undifferentiated, S-type plutons and dikes associated with migmatites, comprising granites, aplites and a large number of pegmatites. Finally, post-orogenic granites belonging to the NNW trending Transscandinavian granite-porphyry belt created a large volume of granitic intrusion about 1.73 billion years ago.

The supracrustal rocks are divided into the following three lithostratigraphic groups:

- Metavolcanic groupin the lower part of the stratigraphy;

- Metavolcano-sedimentary group; and

- Metasedimentary group, which occupies the highest stratigraphic position of the supracrustal rocks in the Zinkgruvan area.

Themetavolcanic groupcomprises mainly massive, fine-grained, red, felsic metavolcanic rocks which are in part quartz-microcline porphyritic with a low ( 5%) biotite content. They occur mainly in the northern part of the area and south of the Zinkgruvan basin structure. Some of the rocks in themetavolcanic groupare assumed to have an ignimbritic origin.

Page17of66

|

|

The rocks of themetavolcano-sedimentary groupare composed of mixed, chemically precipitated, and tuffaceous metasediments. The major rock type in this group is a metatuffite, which is commonly well banded and sometimes extremely finely laminated. Calc-silicate rocks, marbles, calc-silicate-bearing quartzites, quartzitic tuffaceous metasediments and sulphide ores are intercalated with the metatuffites. All of these rocks are intruded by metabasic sills and dikes, usually 2 to 3 m wide.

Themetasedimentary groupcontains mainly argillic, clastic metasediments, which have a high biotite content (>30%). They are strongly recrystallized and transformed to veined gneisses. In upper parts of the stratigraphy these have been migmatized and have undergone some anatexis to form grey, medium grained, biotite-rich, massive granitoids. In the lower part of the group, disseminated pyrrhotite occurs in garnet-bearing siliceous beds of primary exhalative origin.

Most of the mineralization in the district is associated with the metavolcano-sedimentary group. The Zinkgruvan deposit, together with a number of small bodies of Zn-Pb mineralization are situated in the higher part of the metavolcano-sedimentary group. Higher up in the stratigraphy a stratiform pyrrhotite mineralization occurs in the uppermost part of the metavolcano-sedimentary group and in the lower part of the metasedimentary group.

As a result of repeated deformation during the Svecofennian orogeny, the relatively incompetent supracrustal rocks were isoclinally folded together with the more competent, primorogenic granitoid massifs. The metamorphism is low-pressure, upper amphibolite facies with migmatization and partial melting of the biotite-rich rocks in the metasedimentary group. Sillimanite and cordierite are common index minerals in these rocks. The low biotite rocks of the metavolcano-sedimentary group,which underwent the same high-temperature metamorphism exhibit well preserved, recrystallized, primary bedding.

Regional deformation ended before regional metamorphism, as the late orogenic granites have not been affected by the regional deformation. The later granites of the Transscandinavian granite-porphyry belt have deformed the country rock during their intrusion, causing a local folding parallel to subparallel to their margins.

Brittle fracturing is marked by NNE-trending fault systems resulting in large-scale block movements between sections of the country rock. The Knalla fault, separating the Nygruvan and Burkland ore zones is likely an example of such a fault. Movements of several hundred metres are occasionally observed along such faults (Figure 4). These fault systems postdate an east trending dolerite dike swarm, which has an age of about 1.53 billion years.

7.2 Deposit Geology

The massive sulphide Zn-Pb-Ag and disseminated Cu mineralisation are hosted by a metavolcano-sedimentary sequence with associated carbonates and cherts and extend for some 5 km along strike. Structurally, the deposit has undergone several phases of folding and is divided into two distinct areas by the regional NNE-SSW-trending Knalla fracture/fault zone. The deposit geology is shown in Figures 4 and 5.

Page18of66

|

|

Stratigraphy is overturned such that the stratigraphic footwall forms the structural hanging wall. From the stratigraphic footwall (oldest) to the hanging wall (youngest), the deposit geology is presented schematic as follows:

- Felsic metatuffite (sometimes quartzitic and with occasional oxide iron formation beds);

- Marble, hosting the copper mineralization in the Burkland-Sävsjön area;

- Massive sulphide Zn, Pb;

- Calcsilicate bedded metatuffite;

- Marble;

- Felsic metatuffite with disseminated pyrrhotite near the upper stratigraphic contact; and

- Argillic metasediment.

Figure 5: 650 Level Plan; Nygruvan Mine

The Nygruvan section of the mine, which has provided the bulk of the production until recently, is situated to the east of the Knalla fracture/fault zone and consists of a single, fairly regular, tabular 5 m - 25 m thick ore horizon, striking NW-SE, dipping 60° to 80° to the NE and with a near-vertical plunge. It outcrops and persists to at least 1,300 m vertical depth. Figures 5 and 6 show the 650 level plan and schematic cross-section through the Nygruvan area respectively.

Page19of66

|

|

Figure 6: Schematic Cross-section - Nygruvan

The western or Knalla section of the mine, striking generally NE-SW (although quite variable locally) and dipping NW, consists of several bodies of highly contorted Zn-Pb mineralization of quite variable thickness (3 m – 40 m). Dips are variable from near vertical to sub-horizontal. Plunges are also variable with the Burkland body plunging moderately NE and Cecilia and Dalby plunging NW.

Page20of66

|

|

Burkland extends from 200 m to depths in excess of 1,500 m vertical. It flattens considerably at depth making exploration drilling and interpretation of results difficult. Figures 7 and 8 show the 800 level Burkland plan and a schematic cross-section through the Knalla area respectively.

Figure 7: 800 Level Plan - Burkland Zn/Pb and Cu Zones

Page21of66

|

|

Sitting in the immediate structural hanging wall of the Sävsjön-Burkland ore body is a copper (chalcopyrite) stringer zone hosted by dolomitic marbles, in turn overlain by the oldest unit in the mine area, a metatuffite hyrothermally altered to a quartz-microcline rock (Figure 7).

The copper mineralization can be followed sporadically from the Sävsjön area in the west to the Burkland area in the east at depths of between 300 and 400 m. At Burkland, it thickens and follows continuously the plunge of Burkland Zn-Pb-Ag orebody down dip. Core drilling has indicated the copper mineralization at a depth of 1,500m.

The copper zone dips steeply NW in its upper part but flattens out at depth. It is cut off latterly to the NE by the Knalla fault and has been closed off by drilling to the SW.

Figure 8: Schematic Cross-section - Knalla

The plan position of the chalcopyrite copper zone is shown in Figure 7.

The metavolcano-sedimentary group consists mainly of a potassium-rich metatuffite with intercalations of calcsilicate rocks, marbles, quartzites and sulphides. These intercalations give the metavolcano-sedimentary group, a pronounced stratification especially in the ore zone and its stratigraphic hanging wall.

Page22of66

|

|

The metatuffite is a homogenous, usually massive, quartz-microcline-biotite rock of rhyolitic to dacitic composition. It has a granoblastic texture and is often gneissic. The stratigraphy of the metavolcano-sedimentary group is best developed in the eastern part of the Nygruvan area where the sequence is thickest. Metabasic sills and dikes intruding the metavolcanic and the sedimentary group are the oldest intrusions. Dykes and irregular, massive, grey, usually coarse-grained pegmatites of granitic composition are relatively common in the folded areas.

There is clear evidence of hydrothermal alteration in the mine sequence. Altered rocks have been heavily depleted of Mg, Mn and Fe, although there is some disagreement regarding Mn depletion.Sodium depletion is less evident in the mine area, although the Na/K ratio decreases upwards through the footwall sequence of progressively more altered metatuffite. There is significant enrichment in Ba, K, S and Ca.

Page23of66

|

|

8 DEPOSIT TYPES

While the most appropriate genetic model for Zinkgruvan is still somewhat controversial, evidence, particularly the presence of what appears to be a copper rich stringer zone stratigraphically below the Burkland ore body, seems to favour a volcanogenic ("VMS") model in a distal environment. In this model, mineralized hydrothermal fluids ascended through a vent system and deposited copper mineralization just below the paleosea floor and lead-zinc sulphide mineralization in shallow, fairly flat-lying sea floor depressions during a particularly quiescent period. However, some researchers prefer a sedimentary-exhalitive ("SEDEX") model.

Page24of66

|

|

9 MINERALIZATION

9.1 Zinc / Lead Orebodies

Sphalerite and galena are the dominant sulphide minerals. They generally occur as massive, well banded and stratiform layers between 5 to 25 m thick. At Nygruvan there are two parallel horizons (mainly in the eastern portion of the orebody), separated by 3 to 8 m of gneissic metatuffite (quartz, microcline, biotite, and minor muscovite, chlorite and epidotic). Chalcopyrite is present in small amounts (<0.2% Cu). Pyrrhotite, pyrite and arsenopyrite are present although the amount of pyrrhotite and pyrite is typically low (<1% each).

Metamorphism and deformation have mobilised galena into veins and fissures sub-parallel to original bedding in places. Native silver was even more mobile and is often found in small fissures. Remobilization is most commonly observed in the Pb-rich western part of Nygruvan and in the Burkland area. In both the Nygruvan and Knalla areas there is an increase in Zn-Pb grades towards the stratigraphic hanging wall of the massive sulphide horizon. Contacts of the mineralization with the host stratigraphy are generally very sharp, more so on the stratigraphic hangingwall than footwall.

In the Knalla portion of the mine, the structure is more complex and structural thickening is common. There are often two to four parallel ore horizons separated by narrow widths of metatuffite. The Knalla area consists of five individual Zn-Pb bodies for which Mineral Reserves and/or Mineral Resources have been estimated. Exploration is ongoing to further define and expand them along what is a continuous although highly contorted horizon.

The mineralised bodies are, from NE to SW, Burkland, Savsjon, Mellanby, Cecilia and Borta Bakom. In addition, the Lindangen zone occurs close to surface above Mellanby on the longitudinal section and was exploited earlier in the mine’s life. It hosts a small resource, which is unlikely to be exploited because of its proximity to surface.

The only significant difference in mineralogy from Nygruvan to Knalla is that the Co and Ni content are higher in the Burkland - Sävsjön deposit and are of a sufficient level that to impact metallurgy and concentrate quality.

9.2 Copper Mineralisation

Copper stockwork mineralization was noted on the structural hanging wall of the Burkland deposit early in its exploration history. During 1996-1997 resource definition drilling at Burkland led to the recognition of significant hanging wall copper mineralization and a copper-specific drilling program was undertaken.

A Probable Mineral Reserve of 2.9 Mt grading 2.6% Cu, 0.5% Zn, 28 g/t Ag, an Indicated Mineral Resource of 0.46 Mt grading 2.9% Cu, 0.5% Zn, 30 g/t Ag and an Inferred Mineral Resource of 0.55 Mt grading 3.0% Cu, 0.1% Zn, 42 g/t Ag have since been defined. Infill drilling (30 x 30m) and further exploration drilling are ongoing.

Page25of66

|

|

The dip of the copper resource is steep (80 degrees) at higher levels (600-700m). It flattens out to 45 degrees at depths below 1,000m. The plunge is about 60 degrees towards the NNE.

The host rock is a dolomitic marble with variable amounts of porphyroblastic Mg-silicates. Chalcopyrite is the main copper mineral and occurs as fine-grained disseminations infilling between dolomite grains or massive lumps and irregular veins up to several cm thick.Cubanite, CuFe2S3, isalso present and occurs as lamellae in chalcopyrite. Bornite is present, while tetrahedrite is rare. Minor amounts of arsenopyrite are found locally. In its footwall plunge the copper mineralization sometimes merges with the Burkland Zn-Pb ore body (Figure 7). Here it usually contains significant amounts of sphalerite and some galena.

The Burkland copper resource is best developed at depths between 700 and 1,100 m. It has a strike length of 100 to 180 m while the width varies from 5 up to 60 m with an average around 20 m. Up dip the copper resource wedges out and become uneconomic above the 600 m level. From 1,100 m and down to a depth of 1,200 m the width of the mineralization decreases to10 m. Infill drilling has not taken place below this depth and no resource has yet been defined. However, the copper mineralisation has been shown to extend to a depth of 1,500 m by core drilling.

The disseminated character of the mineralization makes it sensitive to changes in the copper cut off grade (Cu %). Decreasing the present used cut off grade of 2.0% to 1.5% Cu, the amount of Cu metal increases by approximately 25% and the ore tonnage by approximately 33%.

Page26of66

|

|

10 EXPLORATION

The Zinkgruvan deposit has been known since the 16thcentury but it was not until 1857 that large scale production began under the ownership of the Vieille Montagne Company of Belgium. Since then exploration of the deposit has progressed continuously.

With the expansion of the mine capacity in the mid-1970’s exploration increased and became more aggressive in the beginning of the 1980’s. At first, focus was on the continuation of the Nygruvan mine at depth, but after that and at present the focus is towards the western half of the mining area and the Knalla Mine at depth.

Exploration by core drilling dominates, undertaken both from surface and underground. Most of the exploring drilling takes place underground from dedicated exploration drifts. Since the 1980’s approximately 3,100 drill holes have been completed and the total length of drill core amounts to approximately 480 km.

Page27of66

|

|

11 DRILLING

Diamond drilling data is the only data used for resource definition, stope definition and grade control. In the last 10 years between 5,700 and 34,000 m of drilling have been completed on the mine site annually and approximately 20% of that was of a reconnaissance nature.

Reconnaissance drilling for new mineralization is normally carried out from exploration drifts and underground holes may be up to 1,200 m long. Occasionally surface holes are drilled.

To qualify as Inferred Resources drill spacing is generally 100m vertical by 100m horizontal with no mineralization exposed by development. Indicated Resource drill spacing is in general 50 by 50m with some mineralization exposed by development. Measured Resources have drill spacing of 30 to 50m and are often well exposed by development. Stope definition holes generally have a maximum spacing of 15 to 20 m.

Diamond drilling is done by contractors. Holes over 100 m in length are surveyed using a Maxibor instrument with readings taken every 3 m. Core size is generally 28 - 36 mm for underground holes and 28 – 39 mm for surface holes. Recovery is considered excellent, averaging near 100%.

Drill core is delivered to a modern, well lit core shack on the mine site. It arrives in labelled wooden core trays. The geologist calculates Q values (a geotechnical measurement combining several measures) and proceeds to geologically log the core using Prorok a software (developed and employed in Sweden) data entry module and predefined lithological codes. There is also a provision for a written description. One geologist is assigned to enter all drill logs into the database.

Page28of66

|

|

12 SAMPLING METHOD AND APPROACH

The geologist marks the "from - to" for assay samples on the box and this "from - to" serves as the sample number, which he or she enters on a sample record sheet. The sample length is chosen based on sulphide content and varies up to a maximum length of 3.0 m (minimum of 0.10 m). The request for analysis follows the sample from the core shed until the sample has undergone all stages of sample preparation.

A technician splits the core using a hydraulic splitter and then places the split portion in a bag marked with the geologist supplied sample number. A diamond saw is used occasionally. The drill core samples are transported in manually labelled paper bags to the sample preparation facility.

Since 2007, photographs have been taken of all drill cores. The exploration drill cores are all stored in a warehouse on site. In-fill drilling cores are disposed of after logging and sampling.

Page29of66

|

|

13 SAMPLE PREPARATION, ANALYSES AND SECURITY

13.1 Sample Preparation

On arrival at the on-site laboratory, located in the concentrator, the drill core samples are dried and jaw crushed to <5 mm. The samples are then split to 100 – 150 g by a mechanical splitter.

Prior to 2002, the sample grain size was reduced to <38 µm in a “Tema mill”, and since then, a Herzog automated pulveriser capable of handling 60 samples at a time has been used and with the sample reduced to <36 microns. The pulveriser is air and water cleaned between sample runs.

The entire milled sample is stored in a manually labelled, sealed plastic cup.

Before samples are submitted, QA/QC duplicate and dolerite blanks are inserted and samples for external check assay are selected.

All QA/QC samples are inserted or selected at irregular intervals. Duplicate frequency varies between every 17thand 21stsample, dolerite blanks between every 23rdand 25thand external check samples are selected for every 23rdand 27thsample.

Shipments are made when a level of at least 250 samples is reached or when results are requested from important samples.

13.2 Assaying

Prior to 2001, all geological samples were assayed in the Zinkgruvan laboratory. From April 2001, assaying was moved to the ACME Analytical Laboratories, Vancouver, by shipping 10 g (40 g since September 2008) pulverised samples. Since September 2002, all geological samples have been assayed by ACME.

ALS Chemex has been used for the quality control samples since autumn 2004.

13.2.1 Zinkgruvan Laboratory Analytical Method

In the period 1979-2002 all geological samples were analysed by Atomic Absorption Spectroscopy at Zinkgruvan.

All geological samples were assayed for Zn, Pb, Ag, Cu, Fe, Co and Ni in two separate digestions:

| 1) | 250 mg was collected from the pulp by a spoon and was boiled in 10 ml HNO3,HF was added and boiled off. Sublimate was re dissolved in HCl. After cooling, the sample was diluted by H2O to 250 ml. Analyse for Zn, Pb, Ag, Cu and Fe by Atomic Absorption (AAS) was finally completed. |

Page30of66

|

|

| 2) | 500 mg was collected from the pulp by a spoon and was boiled in 15 ml Aqua Regia with 6 ml HF and 5 ml HClO4. Boiling reduced solution and residue was dissolved in H2O. Analyse for Co and Ni was carried out by AAS. |

Analytical results were collected manually and entered by hand, first on the original request for analysis, and then entered manually into Excel spreadsheets (one per drill hole/analytical request) with the same format as the request for analysis.

Data was entry checked by the laboratory personnel before release to the project geologists. The project geologist checked correspondence between the assay results and the geological logging before the data was approved for incorporation in the drill hole database.

The AAS instrument routine detection limits are presented in table 5.

Table 5: Detection Limits for ZMAB Laboratory Analyses

| Element | Routine limits of detection |

| Zn | 0.05 % |

| Pb | 0.05 % |

| Ag | 5 g/t |

| Cu | 5 ppm |

| Fe | 0.02 % |

| Co | 5 ppm |

| Ni | 5 ppm |

13.2.2 ACME Analytical Method

From September 2002, all geological samples have been assayed by ACME. Routine assaying is by ICP-ES, program G7AR, a program that uses a 1 g pulp sample diluted in hot Aqua Regia, which is then analyzed by ICP-ES.

The program covers 23 elements, those of critical importance being Zn, Pb, Ag, Cu, Co, Ni and in addition Al, As, Bi, Ca, Cd, Cr, Fe, Hg, K, Mg, Mn, Mo, Na, P, Sb, Sr and W.

Over limit analysis on Ag (Ag >300 ppm) is done by fire assay (FA).

Elements and detection limits are presented in Table 6.

Page31of66

|

|

Table 6: ACME ICP-ES Method

| Element | Detection limit |

| Ag | 2 g/t |

| Al | 0.01% |

| As | 0.01% |

| Bi | 0.01% |

| Ca | 0.01% |

| Cd | 0.001% |

| Co | 0.001% |

| Cr | 0.001% |

| Cu | 0.001% |

| Fe | 0.01% |

| Hg | 0.001% |

| K | 0.01% |

| Mg | 0.01% |

| Mn | 0.01% |

| Mo | 0.001% |

| Na | 0.01% |

| Ni | 0.001% |

| P | 0.001% |

| Pb | 0.01% |

| Sb | 0.001% |

| Sr | 0.001% |

| W | 0.001% |

| Zn | 0.01% |

| Note: Highlights in table indicate partial digestion if refractory minerals are present | |

13.2.3 ALS Analytical Method

Comparative quality control analyses are done using ICP-AES, program OG46, which uses Agua Regia dilution of the sample. The analysis is run for Ag, Co, Cu, Fe, Ni, Pb and Zn.

Over limit analysis on Pb (Pb>20%) and Zn (Zn>30%) is run by volumetric analysis using titration. Over limit analysis on Ag (Ag>1500 ppm) is run by FA and routine bullion assays are done by fire assay with gravimetric finish.

Elements and detection limits are presented in Table 7.

Page32of66

|

|

Table 7: ALS ICP-AES Method

| Element | Detection range |

| Ag | 1-1500 ppm |

| Co | 0,001-20 % |

| Cu | 0,001-40 % |

| Fe | 0,01-100 % |

| Ni | 0,001-10 % |

| Pb | 0,001-20 % |

| Zn | 0,001-30 % |

13.3 Security

The drill core remains within the secure mine compound during the entire logging and splitting process, and sample preparation is also carried out on site in secure facilities. All sample batches are packaged securely and sample numbering is checked at each stage of the process.

Page33of66

|

|

14 DATA VERIFICATION

14.1 QA/QC

From 2002, Zinkgruvan has had a systematic QA/QC program in place. As noted in Section 13, duplicate and blanks are inserted at irregular intervals in the Zinkgruvan preparation laboratory prior to shipment to Vancouver and check assays are selected for external assay (ALS Chemex) at irregular intervals. In additional to the Zinkgruvan quality control samples, ACME inserts additional blanks, pulp duplicates and commercial standards.

Before any data set is accepted for incorporation in to the Drillhole Database, a standardized format, quality report, documenting all internal and external information with respect to QC is compiled. The batch quality report also includes checks against control charts with pre-set warning and action limits.

14.2 Verification by Authors

The principal authors of this report have been employed at Zinkgruvan for more than 20 years and have overseen and directly supervised the collection of most of the data used in the resource estimation.

Page34of66

|

|

15 ADJACENT PROPERTIES

The Zinkgruvan property is situated at the southernmost end of the Bergslagen mineralised belt, which to the north hosts numerous iron ore and base metal deposits many of which have seen production. At the present time, the only significant other production from the belt is from the Garpenberg zinc-silver mine, operated by Boliden, which is located 175 km to the north (see Figure 3).

Page35of66

|

|

16 MINERAL PROCESSING AND METALLURGICAL TESTING

The current processing plant, its metallurgical performance and copper metallurgical testwork is described in Section 23.2 of this report.

Page36of66

|

|

17 MINERAL RESOURCE AND MINERAL RESERVE ESTIMATES

The Zinkgruvan Mineral Reserve and Mineral Resource estimates are shown in Tables 8, 9, 10, 11, 12, 13 and 14. The Mineral Resources are reported exclusive of the Mineral Reserves.

The Mineral Resource and Mineral Reserves are reported and prepared in accordance with the requirements of National Instrument 43-101 and the guidelines published by the Council of the Canadian Institute of Mining, Metallurgy and Petroleum (¨CIM Standards¨).

Zinc-Lead Mineral Resources at Zinkgruvan are calculated using Net Smelter Return (NSR) cut-off values which vary slightly between different mining areas with an average of 250 SEK/t and minimum mining widths varying from 3 to 5 m.

In converting Zinc-Lead Mineral Resources to Mineral Reserves an average economic cut-off of 250 SEK/t is used. For the Burkland deposit, 12% zero-value wall rock and 3% zero-value backfill dilution, 95% mining recovery and 3% mucking loss factors are applied to Mineral Resource estimates . For the Nygruvan deposit, the corresponding figures are wall rock dilution 20 - 25%, mining recovery 95% and mucking loss 5%. There is no backfill factor required for Nygruvan.

The NSR cut-off values are calculated using the following factors: zinc 1% /t = 81.6 SEK, lead 1%/t = 69.2 SEK and silver 1g/t = 0.92 SEK.

In calculating the Copper Resources and Reserve a cut-off of 2.0% Cu has been used.

17.1 Resource and Reserve Areas

The bulk of the Reserves and Resources are hosted by the Burkland deposit, with a smaller portion remaining in the Nygruvan deposit. Smaller tonnages are hosted by the Savsjon, Mellanby, Cecilia, Borta Bakom and Lindangen deposits, all of which lie south west of Burkland. Apart from Lindangen, a portion of which lies within the crown pillar, none of these deposits are fully defined.

Mineral Resources and Mineral Reserves are reported for both zinc-lead and copper mineralization. Copper Mineral Resources for the copper zone that lies on the hanging wall of the Burkland deposit have been reported previously, however this is the first time reporting of a copper Mineral Reserve at Zinkgruvan. Resource and Reserve blocks for the Nygruvan and Knalla zones are shown in Figures 9 and 10 respectively.

Page37of66

|

|

Figure 9 Nygruvan Resource and Reserve Long Section

Figure 10 Knalla Resource and Reserve Long Section

Page38of66

|

|

17.2 Specific Gravity

The Zinkgruvan deposit has been extensively drilled from exploration and development drifts underground. The mineral resources presented in this report are defined by approximately 3,000 drill holes.

The density of individual drill core sections (and ore blocks) of zinc-lead mineralisation is estimated by a regression formula using the assayed grade of zinc and lead. In the formula, these grades are transformed to sphalerite and galena with densities of 4.0 and 7.5 g/cm3, respectively The rest of the mass of the assayed sections are assumed to consist of gangue minerals (quartz, feldspar, calcite and skarn minerals) with an average density of 2.7 g/cm3.

The following formula is used in calculating density of zinc-lead mineralisation.

100

D = ------------------------------------------------------------------------------------------------------------------------

100 – Zn% x 1,49 - Pb% x 1,15 + Zn% x 1,49 + Pb% x 1,15

2,7 4,0 7,5

In calculating the average grade and tonnage of the copper resources, no specific density formula has been developed. It is assumed that the average density is 2.86 g/cm3. This figure is the average of a large number of density measurements taken of copper mineralisation samples from drill cores.

17.3 Resource Estimation Procedures

During the long history of Zinkgruvan the method used to estimate resources and reserves has changed with time. This is partly due to general technical developments but also to the use of different mining methods. At present two primary methods are used; Block Modelling with Ordinary Kriging and estimation by the Polygonal Method. In Nygruvan, a small tonnage is estimated using a third technique, the Sectional Method.

17.3.1 Estimation by Block Model Method

Block modelling with Ordinary Kriging is the main estimation method. This method is applied to the entire Burkland area, which contains most of the present zinc-lead reserves as well as those of copper.

The calculations are done using the Propack software (Prorock AB). The CAD program Microstation (Bentley Ltd) is used for wireframe modelling and data is stored in a secure Oracle database.

Page39of66

|

|

The mineralized wireframe solids are based on drill core intersections. In mining areas with development in the ore zone, the wireframe are adjusted to match the geological mapping of the underground exposures.

The block models comprise parent blocks measuring 10 m x 5 m x 10 m (length x width x height). In order to better match the geometry of the wireframe the parent block can, at the boundary of the wireframe, be sub-divided into a 2 x 2 x 2 array of sub-blocks, with up to 8 sub-blocks in total. In a second step these sub-blocks can be subdivided into an additional 2 x 2 x 2 array, resulting in sub-blocks that are 1/64 of the volume of the parent block.

Drill hole samples within the wireframe model are composited to a maximum of 2.0 metres. A search ellipse with a radius of 100 m x 20 m x 200 m (strike x width x dip) is used for the lead-zinc zones and 45m x 9m x 18m for the copper zone. Separate variogram parameters have been developed for lead, zinc and copper. The Ordinary Kriging Method is used in estimating block grades.

17.3.2 Estimation by Polygonal Method

The Polygonal Method is mainly used in areas with randomly, and often sparsely, distributed drill-holes. Most of the zinc-lead mineralization classified as Inferred and Indicated Resources (except Burkland) are estimated by this method. A large proportion of Reserves and Resources in Nygruvan are estimated by the Polygon Method.

The irregular polygons around the drill holes are constructed by using perpendicular bisectors to tie-lines between the drill holes. The polygons are projected towards a vertical plane, sub-parallel with the strike direction. The intersections of the holes are oriented horizontally and perpendicully towards the projection plane. The grade and the horizontal thickness of each hole are assumed to remain constant throughout the polygon area.

In the estimation of resource grades and tonnage, Mass Weighted Means of grades are used. The average grade of a series of adjacent drill hole intersections are calculated by weighting their grades in proportion to their masses (mass = volume x density). As the drill cores have an almost constant cross sectional area, lengths of the intersections are used instead of volumes, in calculating masses of intersections. The densities of intersections are calculated by using the formula shown above. The formula below shows how the average Zn grade of three adjacent intersections in a drill hole is calculated.

Zn = Zn1 x L1 x D1 + Zn2 x L2 x D2 + Zn3 x L3 x D3

L1 x D1 + L2 x D2 + L3 x D3

D = density, L = length of section.

Page40of66

|

|

17.3.3 Estimation by Sectional Method

The Sectional Method was used historically at Zinkgruvan, primarily in the Nygruvan Mine, where sublevel benching was employed. Reserves of about 300,000 tonnes above the 875m level are calculated by this method.

In the development stage of sublevel benching, the roof of each horizontal longitudinal drift inside the relatively narrow (<8m) ore is geologically mapped. This mapping, locally supported by drilling (ore width >8 m), defines the shape and size of the horizontal sections used in the estimation of the volume/tonnage by extending its area for half a section spacing on either side. The grades are estimated from the core drilling and local channel sampling in the roof of the development drifts within the ore body. The average grades and density of the channel samples are calculated in the same way as the drill cores (see section 17.3.2) . The overall grade and density of each intersection is assigned to an area of ore defined on the basis of half the distance to the adjacent bore hole / row of channel samples.

17.4 Mineral Resource and Reserve Tabulation

The Zinkgruvan Mineral Reserve and Mineral Resource estimates are shown in Tables 8, 9, 10, 11, 12, 13 and 14 below. The Mineral Resources are reported exclusive of the Mineral Reserves.

Page41of66

|

|

Table 8: Proven Zinc-Lead Mineral Reserve at December 31, 2008

| Location | Mining Area | ktonnes | Zn % | Pb % | Ag g/t | Method | Dilution |

| NYGRUVAN | |||||||

| 650 | 10 | 104 | 12,2 | 7,8 | 118 | Polygonal | 25% |

| 800 | 305 | 52 | 6,9 | 0,7 | 20 | Polygonal | 25% |

| 875 | 305 | 82 | 6,0 | 0,6 | 21 | Polygonal | 25% |

| 950 | 240-260 | 106 | 10,7 | 2,5 | 51 | Polygonal | 22% |

| 980 | 240-260 | 74 | 14,9 | 2,7 | 73 | Block Model | 22% |

| 1133 | 240-260 | 1 201 | 14,9 | 4,4 | 82 | Block Model | 22% |

| Total | 1 619 | 13,7 | 4,1 | 77 | |||

| KNALLA | |||||||

| Burkland | 450 | 393 | 7,0 | 5,5 | 123 | Block Model | 15%* |

| 650 | 1 268 | 7,1 | 5,4 | 112 | Block Model | 15%* | |

| 800 | 244 | 9,7 | 6,0 | 107 | Block Model | 15%* | |

| 960 | 1 332 | 6,9 | 4,8 | 93 | Block Model | 15%* | |

| 1300 | 3 795 | 9,9 | 5,8 | 133 | Block Model | 15%* | |

| Sävsjön | 450 | 111 | 6,5 | 2,7 | 70 | Polygonal | 25% |

| Total | 7 143 | 8,6 | 5,5 | 119 | |||

| TOTAL | 8762 | 9,6 | 5,2 | 112 |

Note:-

- Standard polygonal modelling method uses calculated horizontal economic thicknesses and a Minimum Width (MMW) based on orientation of mineralisation and planned mining method.

- Similarly, calculated economic intervals are used for wireframe interpretation, which are then used to constrain block modelling.

- Ordinary kriging has been used for block model grade interpolation.

- Economic cut-off values vary according to planned mining method.

- Tonnage and grades are adjusted to estimated dilution (including fill dilution) and recovery at the conversion of resources to reserves.

Page42of66

|

|

Table 9: Probable Zinc-Lead Mineral Reserve at December 31, 2008

| Location | Mining Area | ktonnes | Zn % | Pb % | Ag g/t | Method | Dilution |

| NYGRUVAN | |||||||

| 475 | G | 186 | 8,1 | 6,1 | 100 | Polygonal | 25% |

| 1060 | C | 224 | 14,7 | 2,1 | 63 | Block Model | 25% |

| 1000 | D | 114 | 7,3 | 0,8 | 41 | Block Model | 25% |

| 1100 | F | 319 | 6,3 | 0,8 | 26 | Block Model | 25% |

| 1250 | A | 243 | 12,1 | 2,5 | 58 | Block Model | 25% |

| Total | 1 086 | 9,7 | 2,4 | 55 | |||

| KNALLA | |||||||

| Sävsjön | 350 - 469 | 143 | 8,1 | 2,6 | 63 | Polygonal | 20% |

| Cecilia | 450 - 637 | 544 | 7,5 | 1,9 | 39 | Polygonal | 20% |

| Burkland | 1310-1365 | 227 | 5,2 | 5,0 | 99 | Blockmodel | 15%* |

| Total | 914 | 7,0 | 2,8 | 58 | |||

| TOTAL | 2 000 | 8,5 | 2,5 | 56 |

Notes:-

- Standard polygonal modelling method uses calculated horizontal economic thicknesses and a Minimum Mining Width (MMW) based on orientation of mineralisation and planned mining method.

- Similarly calculated economic intervals are used for wireframe interpretation, which are then used to constrain block modelling.

- Ordinary kriging has been used for block model grade interpolation.

- Economic cut-off values vary according to planned mining method.

- Tonnage and grades are adjusted to estimated dilution (including fill dilution) and recovery

Page43of66

|

|

Table 10: Measured Zinc-Lead Mineral Resource at December 31, 2008

| Location | Mining Area | ktonnes | Zn % | Pb % | Ag g/t | Method |

| NYGRUVAN | ||||||

| 305 E | 950 | 425 | 5,8 | 0,7 | 21 | Polygonal |

| 300 | 96-97 | 52 | 9,6 | 1,8 | 42 | Polygonal |

| Total | 477 | 6,2 | 0,8 | 23 | ||

| KNALLA | ||||||

| Cecilia | 637-680 | 76 | 6,5 | 1,7 | 27 | Polygonal |

| Total | 76 | 6,5 | 1,7 | 27 | ||

| TOTAL | 553 | 6,3 | 0,9 | 24 |

Notes:-

- Standard polygonal modelling method uses calculated horizontal economic thicknesses and a Minimum.

- Mining Width (MMW) based on orientation of mineralisation and planned mining method.

Page44of66

|

|

Table 11: Indicated Zinc-Lead Mineral Resource at December 31, 2008

| Location | Mining Area | ktonnes | Zn % | Pb % | Ag g/t | Method |

| NYGRUVAN | ||||||

| 10 | 410 | 15 | 4,1 | 2,9 | 39 | Polygonal |

| 1000 | K1 | 253 | 6,4 | 0,8 | 31 | Block Model |

| 819-1003 | 205 | 672 | 7,0 | 5,2 | 92 | Polygonal |

| Total | 940 | 6,8 | 4,0 | 75 | ||

| KNALLA | ||||||

| 150 | I | 312 | 7,4 | 5,0 | 109 | Polygonal |

| 350 | J | 149 | 7,2 | 4,4 | 58 | Polygonal |

| 250 | U | 173 | 8,1 | 3,6 | 112 | Polygonal |

| Burkland | 1365 - 1475 | 1008 | 11,2 | 6,6 | 186 | Block Model |

| Sävsjön Z | 469 - 560 | 192 | 7,7 | 3,1 | 108 | Polygonal |

| Cecilia | 250-450 | 1 016 | 10,9 | 2,8 | 58 | Polygonal |

| Total | 2 850 | 10,0 | 4,6 | 116 | ||

| TOTAL | 3 790 | 9,2 | 4,4 | 105 |

Notes:-

- Standard polygonal modelling method uses calculated horizontal economic thicknesses and a Minimum Mining Width (MMW) based on orientation of mineralisation and planned mining method.

- Similarly calculated economic intervals are used for wireframe interpretation, which are then used to constrain block modelling.

- Ordinary kriging has been used for block model grade interpolation.

Page45of66

|

|

Table 12: Inferred Zinc-Lead Mineral Resource at December 31, 2008

| Location | Mining Area | ktonnes | Zn % | Pb % | Ag g/t | Method |

| NYGRUVAN | ||||||

| B | 1225 | 82 | 9,8 | 3,6 | 62 | Polygonal |

| Total | 82 | 9,8 | 3,6 | 62 | ||

| KNALLA | ||||||

| Borta Bakom | 500-750 | 1 270 | 11,2 | 3,5 | 59 | Polygonal |

| Mellanby | 570-680 | 565 | 8,2 | 3,7 | 77 | Polygonal |

| Mellanby | 770-830 | 330 | 10,3 | 4,1 | 87 | Polygonal |

| I | 150 | 109 | 11,5 | 3,8 | 75 | Polygonal |

| Sävsjön XY | 650 | 1 080 | 7,6 | 3,1 | 77 | Polygonal |

| Sävsjön VW | 525 | 648 | 9,6 | 1,0 | 47 | Polygonal |

| Burkland | 1475-1500 | 115 | 17,1 | 5,5 | 117 | Block Model |

| Total | 4 117 | 9,7 | 3,1 | 69 | ||

| TOTAL | 4 199 | 9,7 | 3,1 | 68 |

Notes:-

- Standard polygonal modelling method uses calculated horizontal economic thicknesses and a Minimum Mining Width (MMW) based on orientation of mineralisation and planned mining method.

- Similarly calculated economic intervals are used for wireframe interpretation, which are then used to constrain block modelling.

- Ordinary kriging has been used for block model grade interpolation.

Page46of66

|

|

Table 13: Probable Copper Mineral Reserves at December 31, 2008

| Location | Level | ktonnes | Zn % | Pb % | Ag g/t | Cu % | Method | Dilution |

| KNALLA | ||||||||

| Cu | 590-1040 | 2 895 | 0.5 | 0.0 | 28 | 2.6 | Block Model | 11%* |

Notes:

- Ordinary kriging has been used for block model grade interpolation.

- Tonnage and grades are adjusted to estimated dilution and recovery and includes fill dilution.

Table 14: Copper Mineral Resources at December 31, 2008

| Location | Level | ktonnes | Zn % | Pb % | Ag g/t | Cu % | Method |

| KNALLA | |||||||

| Indicated Mineral Resource | |||||||

| Cu | 1090 | 460 | 0,5 | 0,0 | 30 | 2.9 | Block Model |

| Inferred Mineral Resources | |||||||

| Cu | 1200 | 550 | 0,1 | 0,0 | 42 | 3,0 | Block Model |

Notes:

- Ordinary Kriging has been used for block model grade interpolation.

Page47of66

|

|

18 OTHER RELEVANT DATA AND INFORMATION

There is no other relevant data or information to report.

Page48of66

|

|

19 INTERPRETATION AND CONCLUSIONS

Zinkgruvan is a mature mining operation with well established technical parameters in both the mine and processing plant. The orebody geology and geometry are well understood, and the mine has a longstanding, successful record of upgrading Resources and converting Resources to Reserves through systematic underground development,diamond drilling and mine planning.

The mine operates in a well-established fiscal and legal setting. Environmental issues are clearly understood and have been managed in a professional manner. The local infrastructure and workforce are both stable and predictable.

The Mineral Resource and Mineral Reserve estimation methodology is in accordance with industry standards, and has been proven over time through the exploration and mining cycle. Technical parameters used to convert Resources to Reserves are based on years of experience and have proven to be appropriate. Mineral Resources and Mineral Reserves are estimated in accordance with NI 43-101.

The metallurgical performance of the zinc-lead mineralisation is also well established and consistent. There is little variation in run-of-mine ore over time and recoveries and concentrate grades are stable and predictable.

Deep intersections of ore grade material at the same stratigraphic position as the main Zinkgruvan ore horizon strongly suggest continuation to depth of the main ore zones in three areas. The areas are Burkland below 1,500m, the western part of Nygruvan at depth and the extension of the Mellanby/Cecilia zones (see figures 9 and 10). Based on past experience it is considered likely that the Mineral Resources will continue to expand with additional exploration work. Given the depth of likely new discoveries and extensions and that of the current underground working, further exploration work will involve more underground development and diamond drilling.

The planned initiation of copper production in 2011 at Zinkgruvan offers the potential to increase the overall production rate and provide diversification of metal production, reducing the economic sensitivity of the mine to lead and zinc prices.

Page49of66

|

|

20 RECOMMENDATIONS

This section is not applicable.

Page50of66

|

|

21 REFERENCES

Hedström, P., Simeonov, A., Malmström, L., 1989; The Zinkgruvan Deposit, South-Central Sweden: A Proterozoic, Proximal Zn-Pb-Ag Deposit in Distal Volcanic Facies: Economic Geology, v 84, pp 1235-1261.

Sädbom, S., 2002; Extern och intern analysering av geologiska prover samt kvalitetskontroll vid analysering (External and internal assaying of geological samples and quality control at assaying), Internal Report, ZMAB.

Sullivan, J., MacFarlane, R., Cheeseman, S., 2004; A Technical Review of The Zinkgruvan Mine in South-Central Sweden, a report from Watts, Griffis and McQuart Limited to South Atlantic Ventures Ltd.

Page51of66

|

|

22 DATE AND SIGNATURE

22.1 Certificate of Per Hedström

I, Per Hedström, of Åmmeberg, Sweden, do hereby certify that as an author of this technical report on ”Mineral Reserves and Mineral Resources of the Zinkgruvan mine in South Central Sweden December 2008”, I hereby make the following statements:

I am employed as Senior Geologist with Zinkgruvan Mining AB with a business address SE- 696 81, Zinkgruvan, Sweden.

I am a graduate of the University of Lund, Sweden (BSc Geology and Chemistry 1972).

I am a member of the Australasian Institute of Mining and Metallurgy and am an approved Qualified Person in accordance to the rules of SveMin and FAERI regarding disclosure of mineral resources.

I have worked in the base metal mining industry since graduation and have over 35 years of experience.

I have read the definition of “qualified person” set out in National Instrument 43-101 (NI 43-101) and certify, that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purpose of NI 43-101.

I have worked at the Zinkgruvan mine since 1981.

I am responsible for the preparation of Sections 1-22 of this Technical Report titled “Mineral Reserves and Mineral Resources of the Zinkgruvan mine in South-Central Sweden, December 2008” dated March 2009

Due to my position as Senior Geologist with Zinkgruvan Mining I am not considered independent of the issuer applying all of the tests in section 1.4 of the instrument.

As of the date of this certificate, to my knowledge, information and belief, the sections of this Technical Report for which I am responsible contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

I have read National Instrument 43-101 and sections for which I am responsible in this Technical Report have been prepared in compliance with NI 43-101 and Form 43-101F

Signed dated this 31stday of March, 2009 at Zinkgruvan, Sweden

/s/ Per Hedström

Per Hedström

Page52of66

|

|

22.2 Certificate of Lars Malmström

I, Lars Malmström, of Zinkgruvan, Sweden, do hereby certify that as an author of this technical report on ”Mineral Reserves and Mineral Resources of the Zinkgruvan mine in South Central Sweden December 2008”, I hereby make the following statements:

I am employed as Chief Geologist with Zinkgruvan Mining AB with a business address SE-696 81 Zinkgruvan, Sweden.

I am a graduate with a degree in B.Sc. from the University of Lund in Geology and Chemistry in 1975.

I am a member of the Australasian Institute of Mining and Metallurgy (Membership Number 208639) and am also an approved Qualified Person in accordance to the rules of SveMin and FAERI regarding disclosure of mineral resources (certificate no. 56).

I have worked in the base metal mining industry since graduation and have over 26 years of experience.

I have read the definition of “qualified person” set out in National Instrument 43-101 (NI 43-101) and certify, that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purpose of NI 43-101.

I have worked at the Zinkgruvan mine since 1982.

I am responsible for the preparation of Section 1 to 22 of this Technical Report titled “Mineral Reserves and Mineral Resources of the Zinkgruvan mine in South-Central Sweden, December 2008” dated March 2009.

Due to my position as Chief Geologist with Zinkgruvan Mining AB I am not considered independent of the issuer applying all of the tests in section 1.4 of the instrument.

As of the date of this certificate, to my knowledge, information and belief, the sections of this Technical Report for which I am responsible contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

I have read National Instrument 43-101 and sections for which I am responsible n this Technical Report have been prepared in compliance with NI 43-101 and Form 43-101F

Signed dated this 31stday of March, 2009 at Zinkgruvan, Sweden.

/s/ Lars Malmström

Lars Malmström

Page53of66

|

|

22.3 Certificate of Doug Syme

I, Doug Syme, of Zinkgruvan, Sweden, do hereby certify that as an author of this technical report on ”Mineral Reserves and Mineral Resources of the Zinkgruvan mine in South Central Sweden December 2008”, I hereby make the following statements:

I am employed as General Manager with Zinkgruvan Mining AB with a business address SE- 696 81 Zinkgruvan, Sweden.

I am a graduate with a degree in Bachelor of Engineering from Curtin University (Western Australian School of Mines)

I am a member of the Australasian Institute of Mining and Metallurgy (CP) (Membership Number 108998)

I have worked in the base metal mining industry since 1990 and have over 18 years of experience.

I have read the definition of “qualified person” set out in National Instrument 43-101 (NI 43-101) and certify, that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purpose of NI 43-101.

I have worked at the Zinkgruvan mine as General Manager since December 2008.

I am responsible for the preparation of Section 23 of this Technical Report titled “Mineral Reserves and Mineral Resources of the Zinkgruvan mine in South-Central Sweden, December 2008” dated March 2009.

Due to my position as General Manager with Zinkgruvan Mining AB I am not considered independent of the issuer applying all of the tests in section 1.4 of the instrument.

As of the date of this certificate, to my knowledge, information and belief, the sections of this Technical Report for which I am responsible contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

I have read National Instrument 43-101 and sections for which I am responsible n this Technical Report have been prepared in compliance with NI 43-101 and Form 43-101F

Signed dated this 31stday of March, 2009 at Zinkgruvan, Sweden.

/s/ Doug Syme

Doug Syme

Page54of66

|

|

23 ADDITIONAL REQUIREMENTS FOR PRODUCTION PROPERTIES

23.1 Mining Operations

The long mining history of Zinkgruvan has seen a dramatic development in the technologies and systems used to mine and process the ores. A new shaft and processing facility was build in 1977 and since that time new equipment and automation have been introduced to both the mine and mill operations.

In the mid-1990s, the increasing size of the underground mined out areas, coupled with the inherently high horizontal ground stress led to increasing difficulty in maintaining stability of the stope hangingwalls. As a result, the mining methods and sequences were changed and a new paste backfill system was installed in 2001. Mine production reached 900,000 tonnes in 2008 which was the highest level in the history of the operation.

A schematic 3D figure over the mine is shown in Figure 11 and a plan of the general site of the Zinkgruvan operations is shown in Figure 12

Figure 11: Schematic 3D figure over the mine

Page55of66

|

|

Figure 12: General Site Plan

The Zinkgruvan underground mine has three shafts with current mining focused on the Burkland and Nygruvan deposits. Shafts P1 and P2 at Nygruvan are 735 and 900m deep respectively, with P1 used for hoisting personnel and P2 used for ore and waste hoisting, materials and personnel. In 2008, a ramp from surface down to a depth of 350 m was started to connect to the existing internal infrastructure in the mine. The Knalla shaft, P3, is 350 m deep and is not a significant part of the current or future operating plan and serves only as an emergency egress and to support mine ventilation.

23.1.1 Mining Methods

In the Burkland deposit, long hole panel stoping is used with a sequence of primary and secondary stopes. Stope dimensions are 38 m high by 20 m wide for the primary stopes and 25 m wide for the secondary stopes. Stope access is typically developed in the footwall from the ramp system with this development at 5 m x 5 m size. Stope accesses are developed on the upper horizon for drilling and on the lower level for mucking with remote control LHDs. The panel stoping mining method and sequence are shown in Figure 13.

Page56of66

|

|

Figure 13: Schematic of the Panel Stoping Method

On completion of mining, the stopes are backfilled with paste fill with 4% cement content for the primaries and a lower strength 2% cement content for the secondaries.

Sill pillars at the 800 m, 650 m, and 450 m levels have been left to separate mining areas and provide ground support between active mining areas and previously mined and backfilled areas.

In the Nygruvan deposit, sublevel benching is employed followed by paste backfilling. Rib pillars previously left between stopes for ground support have become unnecessary with the introduction of the tight paste fill system. Stoping is carried out with 15 m sublevels and stope lengths of 30 m. (see Figure 14).

Page57of66

|

|

Figure 14: Schematic of the Bench Stoping Method

Ore from Burkland and Nygruvan is fed through an ore pass system to the 800 and 900 levels respectively, where it is transported by truck to the crusher at the P2 shaft.

23.1.2 Production Schedule

A long term mine production forecast, based on the reserves reported in Section 17, has been developed. The plan aims to increase and then maintain zinc-lead output at circa 1.0 mtpa and to ramp copper production up to 300,000 tpa from 2012. Close attention is paid to the development needs of the production forecast to ensure that development metres are achievable and smoothed, and that total extraction needs do not exceed the shaft capacity.

The estimated mine production forecast over the next 10 years is as follows in Table 15:

Page58of66

|

|

Table 15: Mine Production Forecast 2009-2018

Zinc Lead | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 |

Tonnes, kt | 990 | 929 | 947 | 900 | 1,033 | 870 | 899 | 1,092 | 918 | 982 |

Grade, %Zn | 8.0 | 8.0 | 8.6 | 8.3 | 8.6 | 8.6 | 8.2 | 8.5 | 7.7 | 9.1 |

Grade, %Pb | 4.4 | 4.8 | 4.7 | 4.4 | 3.9 | 4.3 | 4.0 | 4.0 | 3.1 | 4.1 |