|

|

|

|

| 31 March 2009 |

|

|

|

|

|

|

|

|

|

|

| RIO NARCEA RECURSOS S.A. PART OF |

|

|

|

|

|

|

|

|

|

|

|

|

|

| TECHNICAL REPORT ON THE |

|

|

|

|

| Submitted to: |

|

| Lundin Mining Corporation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NI 43-101 |

|

|

|

|

|

|

| Report Number: 08511150292 |

|

| 2 copies Lundin Mining Corporation |

Aworldof |

| |

|

|

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

|

|

|

Table of Contents | ||||

|

|

|

|

|

1.0 | EXECUTIVE SUMMARY | - 1 - | ||

|

|

|

|

|

2.0 | INTRODUCTION | - 5 - | ||

|

|

| ||

| 2.1 | Preamble | - 5 - | |

|

|

|

| |

| 2.2 | Terms of reference | - 6 - | |

|

|

|

|

|

| 2.3 | Scope of Work | - 7 - | |

|

|

|

|

|

3.0 | RELIANCE ON OTHER EXPERTS | - 8 - | ||

|

|

|

|

|

4.0 | PROPERTY DESCRIPTION AND LOCATION | - 9 - | ||

|

|

|

|

|

5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | - 11 - | ||

|

|

| ||

| 5.1 | Access | - 11 - | |

|

|

|

|

|

| 5.2 | Climate | - 11 - | |

|

|

|

| |

| 5.3 | Landform and vegetation | - 11 - | |

|

|

|

|

|

6.0 | HISTORY | - 12 - | ||

|

|

| ||

| 6.1 | Historical ownership | - 12 - | |

|

|

|

| |

| 6.2 | Historical exploration | - 13 - | |

|

|

|

| |

| 6.3 | Historical resource estimates | - 13 - | |

|

|

|

| |

| 6.4 | Historical production | - 14 - | |

|

|

|

|

|

7.0 | GEOLOGICAL SETTING | - 15 - | ||

|

|

| ||

| 7.1 | Regional Geology | - 15 - | |

|

|

|

| |

| 7.2 | Property description | - 16 - | |

|

|

|

|

|

8.0 | DEPOSIT TYPES | - 18 - | ||

|

|

| ||

| 8.1 | Mineral genesis | - 18 - | |

|

|

|

|

|

9.0 | MINERALIZATION | - 20 - | ||

|

|

| ||

| 9.1 | Mineral zones | - 20 - | |

|

|

|

| |

| 9.2 | Fault systems | - 22 - | |

|

|

|

| |

| 9.3 | Mineral types | - 23 - | |

|

|

|

| |

| 9.3.1 | Massive to semi-massive mineralization (SB) | - 23 - | |

|

|

|

| |

| 9.3.2 | Disseminated mineralization (SS and S) | - 24 - | |

|

|

|

| |

| 9.3.3 | Irregular mineralization in patches (SP) | - 24 - | |

|

|

|

|

|

10.0 | EXPLORATION | - 26 - | ||

|

|

|

|

|

11.0 | DRILLING | - 27 - | ||

|

|

| ||

| 11.1 | Down hole surveying and orientation | - 29 - | |

|

|

|

|

|

|

31 March 2009 | i |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

|

|

|

| 11.2 | Grade control drilling | - 29 - | |

|

|

|

|

|

12.0 | SAMPLING METHOD AND APPROACH | - 30 - | ||

|

|

| ||

| 12.1 | Core collection | - 30 - | |

|

|

|

| |

| 12.2 | Core storage and photography | - 31 - | |

|

|

|

| |

| 12.3 | Sampling | - 32 - | |

|

|

|

| |

| 12.4 | Logging | - 32 - | |

|

|

|

| |

| 12.5 | Densities | - 36 - | |

|

|

|

|

|

13.0 | SAMPLE PREPARATION, ANALYSES AND SECURITY | - 37 - | ||

|

|

| ||

|

| 13.1 | Sample preparation | - 37 - |

|

|

|

|

|

|

| 13.1.1 | Sample reception | - 37 - |

|

|

|

|

|

|

| 13.1.2 | Crushing | - 38 - |

|

|

|

|

|

|

| 13.1.3 | First stage splitting | - 39 - |

|

|

|

|

|

|

| 13.1.4 | Pulverization | - 39 - |

|

|

|

|

|

|

| 13.1.5 | Second stage splitting | - 39 - |

|

|

|

|

|

|

| 13.1.6 | Storage | - 40 - |

|

|

|

| |

| 13.2 | Quality assurance and quality control (QAQC) procedures | - 40 - | |

|

|

|

| |

|

| 13.2.1 | Standards | - 40 - |

|

|

|

|

|

|

| 13.2.2 | Inter-laboratory repeats | - 41 - |

|

|

|

| |

| 13.3 | Assaying | - 41 - | |

|

|

|

| |

|

|

|

|

|

14.0 | DATA VERIFICATION | - 42 - | ||

|

|

| ||

| 14.1 | Introduction | - 42 - | |

|

|

|

| |

| 14.2 | Drilling database | - 42 - | |

|

|

|

| |

| 14.3 | Comparison of geological logs with drill core | - 43 - | |

|

|

|

| |

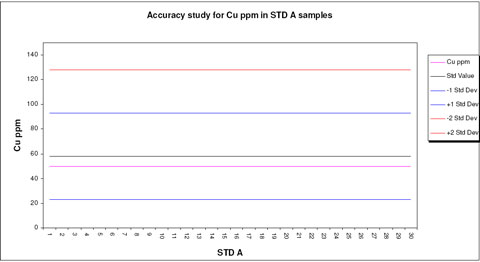

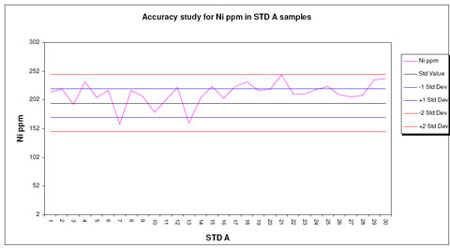

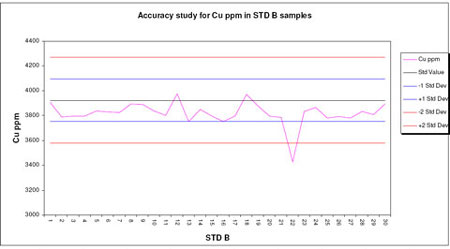

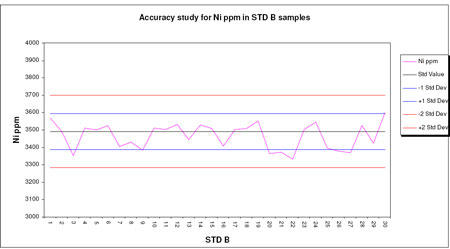

| 14.4 | Standards | - 44 - | |

|

|

|

| |

| 14.5 | Inter-laboratory repeats | - 44 - | |

|

|

|

|

|

15.0 | ADJACENT PROPERTIES | - 46 - | ||

|

|

|

|

|

16.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | - 47 - | ||

|

|

|

|

|

17.0 | MINERAL RESOURCE AND MINERAL RESERVE ESTIMATES | - 48 - | ||

|

|

| ||

| 17.1 | Introduction |

| - 48 - |

|

|

|

|

|

|

| 17.1.1 | Definitions | - 48 - |

|

|

|

| |

| 17.2 | Data provided | - 49 - | |

|

|

|

|

|

|

| 17.2.1 | Drill hole data | - 49 - |

|

|

|

|

|

|

| 17.2.2 | Other data | - 50 - |

|

|

|

| |

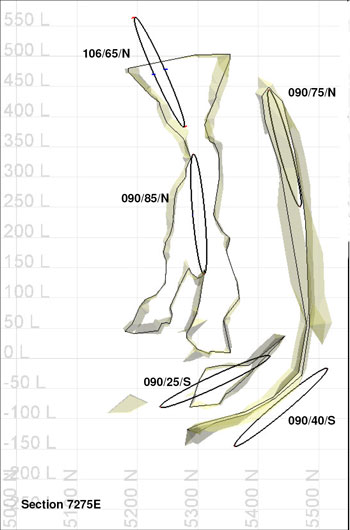

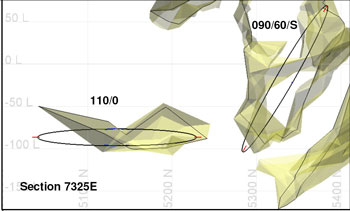

| 17.3 | Geological wireframe modelling | - 50 - | |

|

|

|

|

|

|

31 March 2009 | ii |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

|

|

|

| 17.4 | Exploratory data analysis | - 53 - | |

|

|

| ||

|

| 17.4.1 | Compositing | - 53 - |

|

|

|

|

|

|

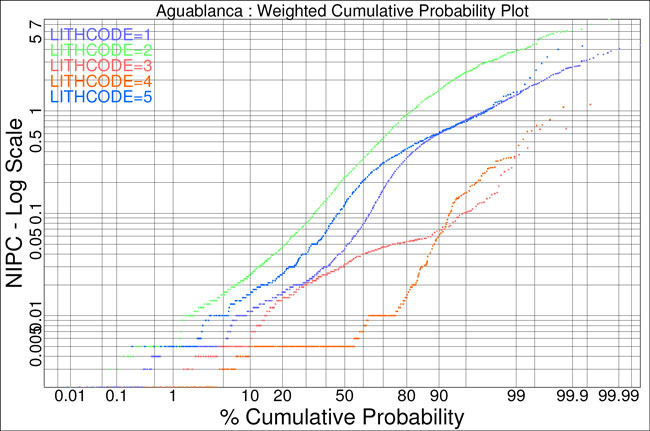

| 17.4.2 | Statistics | - 56 - |

|

|

|

|

|

|

| 17.4.3 | Treatment of high-grade samples during estimation | - 59 - |

|

|

|

|

|

| 17.5 | Variography |

| |

|

|

| ||

|

| 17.5.1 | Variography objectives and approach | - 60 - |

|

|

|

|

|

|

| 17.5.2 | Variogram interpretation and modelling | - 63 - |

|

|

|

|

|

|

| 17.5.3 | Summary of variogram orientations | - 64 - |

|

|

| - 65 - | |

| 17.6 | Geological block modelling |

| |

|

|

| ||

|

| 17.6.1 | Block model parameters | - 65 - |

|

|

|

|

|

|

| 17.6.2 | Geological domain allocation | - 65 - |

|

|

|

| |

| 17.7 | Bulk density | - 67 - | |

|

|

|

| |

| 17.8 | Interpolation plan | - 69 - | |

|

|

| ||

|

| 17.8.1 | Grade interpolation methodology | - 69 - |

|

|

|

|

|

|

| 17.8.2 | High-grade restraining | - 69 - |

|

|

|

|

|

|

| 17.8.3 | Kriging plan | - 70 - |

|

|

|

|

|

|

| 17.8.4 | Search ellipse orientations | - 71 - |

|

|

|

|

|

|

| 17.8.5 | Calculation of dominant lithology and mineralogy | - 72 - |

|

|

|

|

|

|

| 17.8.6 | Assignment of density | - 73 - |

|

|

|

| |

| 17.8.7 | Block size | - 74 - | |

|

|

| ||

|

| 17.8.8 | Block model variables | - 75 - |

|

|

|

| |

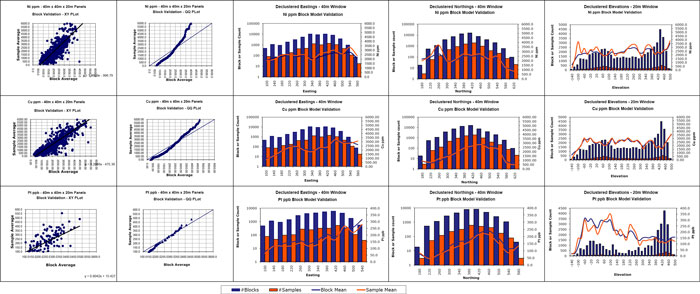

| 17.9 | Validation of grade estimates | - 75 - | |

|

|

| ||

|

| 17.9.1 | Visual Assessment of grade estimates | - 76 - |

|

|

|

|

|

|

| 17.9.2 | Global assessment of grade estimates | - 76 - |

|

|

|

|

|

|

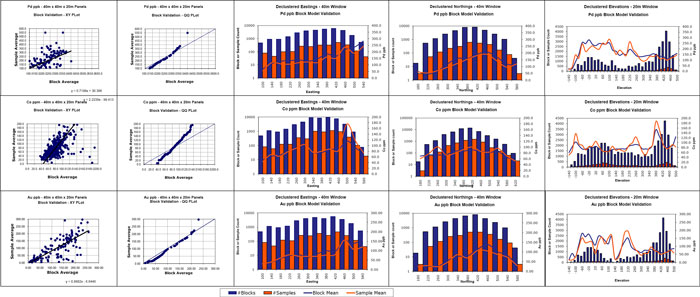

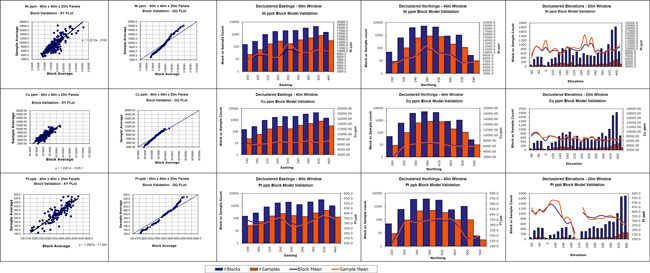

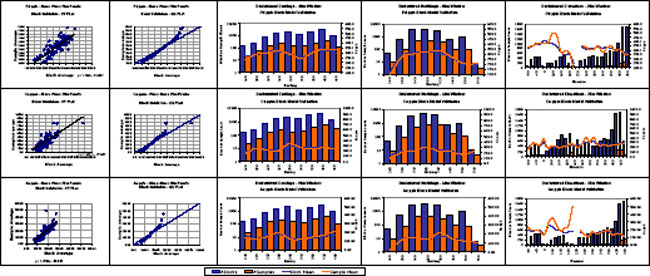

| 17.9.3 | Swath plot validation | - 76 - |

|

|

|

| |

| 17.10 | Mineral Resource classification | - 79 - | |

|

|

|

| |

| 17.11 | December 2008 Aguablanca Mineral Resource Estimate | - 80 - | |

|

|

|

| |

| 17.12 | Mineral Reserve Estimation | - 81 - | |

|

|

| ||

|

| 17.12.1 | Initial topography | - 82 - |

|

|

|

|

|

|

| 17.12.2 | Geotechnical background | - 82 - |

|

|

|

|

|

|

| 17.12.3 | Cost structure | - 83 - |

|

|

|

|

|

|

| 17.12.4 | Mine design parameters | - 83 - |

|

|

|

|

|

|

| 17.12.5 | Commercial parameters | - 84 - |

|

|

|

|

|

|

| 17.12.6 | Metal recovery | - 84 - |

|

|

|

|

|

|

31 March 2009 | iii |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

|

|

|

|

| 17.12.7 | Methodology for pit optimization and design | - 84 - |

|

|

|

|

|

|

| 17.12.8 | Cut-off grade | - 85 - |

|

|

|

|

|

|

| 17.12.9 | Pit optimisation results | - 85 - |

|

|

|

|

|

|

| 17.12.10 | Pit design | - 87 - |

|

|

|

|

|

|

| 17.12.11 | Scheduling | - 90 - |

|

|

|

|

|

|

| 17.12.12 | December 2008 Aguablanca Mineral Reserve Estimate | - 93 - |

|

|

|

|

|

|

| 17.12.13 | Risks | - 94 - |

|

|

|

|

|

|

| 17.12.14 | Conclusions and recommendations | - 95 - |

|

|

|

|

|

18.0 | OTHER RELEVANT DATA AND INFORMATION | - 96 - | ||

|

|

|

|

|

19.0 | INTERPRETATION AND CONCLUSIONS | - 97 - | ||

|

|

|

|

|

20.0 | RECOMMENDATIONS | - 98 - | ||

|

|

|

|

|

21.0 | REFERENCES |

| - 99 - | |

|

|

|

|

|

22.0 | DATE AND SIGNATURE PAGE | - 100 - | ||

|

|

| ||

| 22.1 | Certificate of Juan Alvarez | - 100 - | |

|

|

|

| |

| 22.2 | Certificate of Sia Khosrowshahi | - 101 - | |

|

|

|

| |

| 22.3 | Certificate of Juan Pablo Gonzalez | - 102 - | |

|

|

|

| |

| 22.4 | Certificate of Stephen Gatley | - 103 - | |

|

|

|

|

|

23.0 | ADDITIONAL REQUIREMENTS FOR TECHNICAL REPORTS ON DEVELOPMENT PROPERTIES AND PRODUCTION PROPERTIES |

| ||

|

|

|

| - 104 - |

| 23.1 | Mining operations | - 104 - | |

|

|

|

| |

| 23.2 | Process metal recoveries | - 106 - | |

|

|

|

| |

| 23.3 | Markets |

| - 106 - |

|

|

|

|

|

| 23.4 | Contracts |

| - 106 - |

|

|

|

|

|

| 23.5 | Environmental considerations | - 107 - | |

|

|

|

| |

| 23.6 | Taxes |

| - 107 - |

|

|

|

|

|

| 23.7 | Capital and operating cost estimates | - 107 - | |

|

|

|

| |

| 23.8 | Economic analysis | - 108 - | |

|

|

|

| |

| 23.9 | Payback | - 110 - | |

|

|

|

| |

| 23.10 | Mine life | - 110 - | |

|

|

|

|

|

|

31 March 2009 | iv |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

|

LIST OF TABLES |

| |

|

|

|

Table 1: | Units of measure and abbreviations | - 7 - |

|

|

|

Table 2: | Drill holes removed from the database because of low confidence survey information | - 26 - |

|

|

|

Table 3: | Aguablanca logging codes | - 33 - |

|

|

|

Table 4: | Standards used at Aguablanca | - 40 - |

|

|

|

Table 5: | Drill holes checked against core and original assay sheets | - 43 - |

|

|

|

Table 6: | Comparison between Composite statistics and Raw statistics | - 54 - |

|

|

|

Table 7: | Raw and declustered statistics from composited 2 m map file | - 56 - |

|

|

|

Table 8: | Matrix showing% of total metal content for Ni and Cu, sub-divided by mineralization type and lithology group for a 0.1% Ni cut-off | - 57 - |

|

|

|

Table 9: | Parameters used for variogram generation | - 62 - |

|

|

|

Table 10: | Summary of variogram continuity orientations | - 64 - |

|

|

|

Table 11: | Geological Model Extents and Block Sizes for OK_21jan09_v1.bmf | - 65 - |

|

|

|

Table 12: | Variable assignment in the geological block model | - 66 - |

|

|

|

Table 13: | Kriging parameters | - 71 - |

|

|

|

Table 14: | Search ellipse orientations used during grade estimation | - 72 - |

|

|

|

Table 15: | Lithology grouping used in dominant lithology assignment | - 72 - |

|

|

|

Table 16: | Mineralization codes (variable “type” in the block models) | - 73 - |

|

|

|

Table 17: | Inverse distance interpolation parameters | - 73 - |

|

|

|

Table 18: | Average density values assigned to blocks not already interpolated with density | - 74 - |

|

|

|

Table 19: | Specifications of the block model | - 75 - |

|

|

|

Table 20: | Univariate Statistics of Declustered 2 m composite data (Declustered using 100m window) and OK model | - 78 - |

|

|

|

Table 21: | Resource Report for the Sub-blocked Block model (8x8x4) at 0.1% and 0.2% Ni cut-off grades | - 81 - |

|

|

|

Table 22: | Aguablanca – Cost Summary | - 83 - |

|

|

|

Table 23: | Aguablanca – Design Parameters | - 83 - |

|

|

|

Table 24: | Aguablanca – Recovery Equation | - 84 - |

|

|

|

Table 25: | Life of Mine Plan for the Aguablanca Mine | - 91 - |

|

|

|

Table 26: | Proven and Probable Mineral Reserves in the Aguablanca | - 93 - |

|

|

|

Table 27: | Mineral Reserves Risks | - 94 - |

|

|

|

Table 28: | Production forecast for the Aguablanca open pit reserves | - 105 - |

|

|

|

Table 29: | Historical metal recoveries | - 106 - |

|

|

|

Table 30: | Regression equation for the calculation of process recoveries | - 106 - |

|

|

|

Table 31: | Calculated operating costs | - 108 - |

|

|

|

Table 32: | Sensitivity analysis – base case | - 109 - |

|

|

|

Table 33: | Sensitivity analysis – changes to nickel price, operating costs or exchange rate | - 109 - |

|

|

|

|

|

|

31 March 2009 | v |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

LIST OF FIGURES

|

|

|

Figure 4-1: | Location of the Aguablanca mine | - 9 - |

|

|

|

Figure 4-2: | Aguablanca mining rights | - 10 - |

|

|

|

Figure 7-1: | Geology of the Central part of the Ossa Morena Zone (Tornos.et al, 2006) | - 16 - |

|

|

|

Figure 7-2: | Map of the Aguablanca Stock and surrounding geology (Tornos. et al, 2006) | - 17 - |

|

|

|

Figure 8-1: | General model for the formation of a Ni-Cu-PGM sulphide mineralization (Lundin, 2004) | - 19 - |

|

|

|

Figure 9-1: | Section 7250 E as interpreted by Lundin staff showing South, North and Deep Zones | - 21 - |

|

|

|

Figure 9-2: | Plan 458 Z showing the South and North Zones and important faults as interpreted by Lundin staff | - 22 - |

|

|

|

Figure 9-3: | Magmatic breccia (Gsb) with semi-massive sulphides (SB) | - 23 - |

|

|

|

Figure 9-4: | Porphyritic Gabbro (GP) with disseminated sulphides (S) | - 24 - |

|

|

|

Figure 9-5: | Gabbro with irregular mineralization in patches | - 25 - |

|

|

|

Figure 11-1: | Aguablanca project drilling coverage | - 28 - |

|

|

|

Figure 12-1: | Labelling of core boxes for Aguablanca resource drilling | - 30 - |

|

|

|

Figure 12-2: | Aguablanca core shed | - 31 - |

|

|

|

Figure 12-3: | Example of core photography | - 31 - |

|

|

|

Figure 12-4: | Correct core sawing orientation being used at Aguablanca | - 32 - |

|

|

|

Figure 12-5: | Aguablanca drilling log | - 35 - |

|

|

|

Figure 13-1: | Sample preparation flow sheet as used for Aguablanca resource definition samples | - 37 - |

|

|

|

Figure 13-2: | Bar code system used at the Aguablanca site laboratory | - 38 - |

|

|

|

Figure 13-3: | Splitting of pulverised material using a spatula | - 39 - |

|

|

|

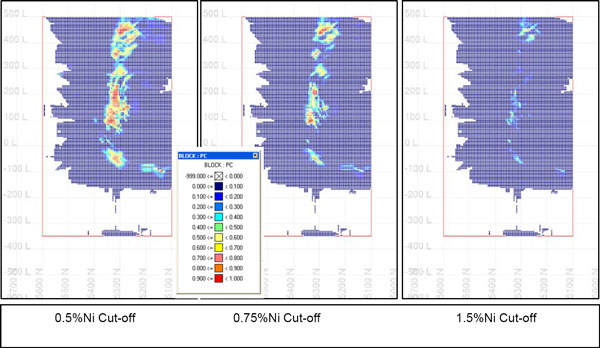

Figure 17-1: | Section 7317E showing a comparison between Indicators using 0.5%, 0.75% and 1.5%Ni cut-offs. The colours represent the probability (0-1) of the Ni grade in a block being above the given cut-off (expressed as a decimal) | - 51 - |

|

|

|

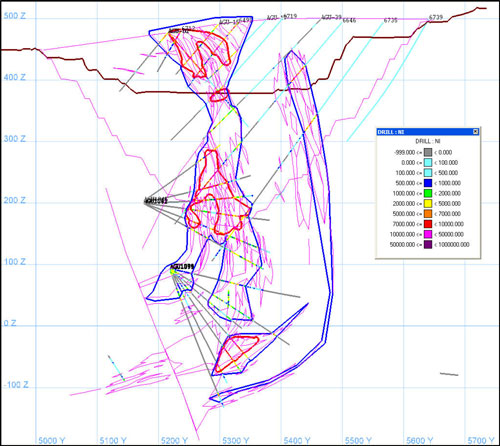

Figure 17-2: | Example of the sectional modelling and wireframe solids modelled by Golder (Section 7275 mE), Blue – 0.1% Ni envelope, Red – 0.5% Ni envelope | - 52 - |

|

|

|

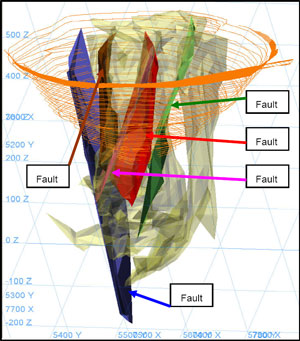

Figure 17-3: | Fault surfaces modelled by Golder superimposed onto the modelled mineral envelope (0.1% Ni) | - 53 - |

|

|

|

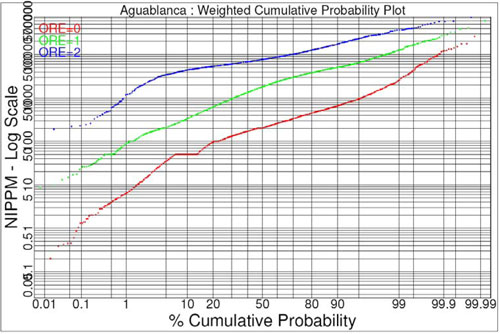

Figure 17-4: | Probability plot showing Ni subdivided into High-grade (ore=2), Low-grade (ore=1) and Waste (ore=0) | - 58 - |

|

|

|

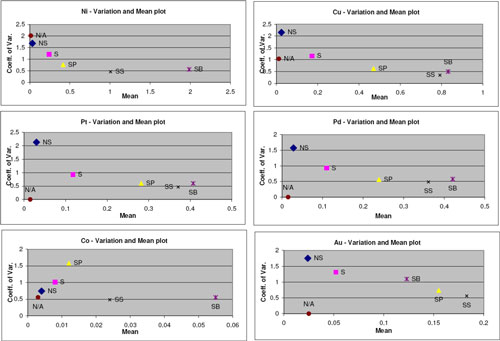

Figure 17-5: | Coefficient of Variation vs. Mean graphs showing the influence of mineralization on grade | - 59 - |

|

|

|

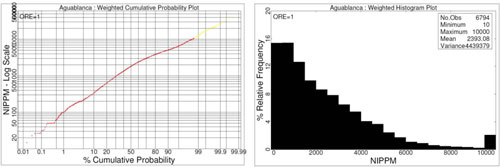

Figure 17-6: | Left: Histogram of low-grade Ni (ore=1), Right: Probability plot (Blue = >5000 Ni ppm) showing samples which were restrained (~10%) | - 60 - |

|

|

|

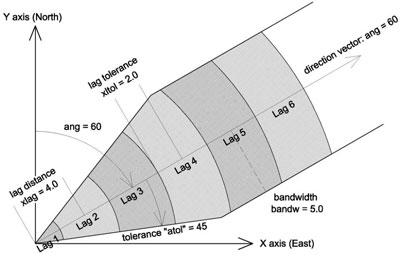

Figure 17-7: | Variogram Search Tolerances | - 61 - |

|

|

|

Figure 17-8: | Semi-major axis variograms (down-dip) for High-grade (top), and Low-grade (bottom), both have a very low nugget and show ranges ~100m | - 63 - |

|

|

|

Figure 17-9: | Section at 7350 mE showing density values limited to the upper half of the deposit | - 68 - |

|

|

|

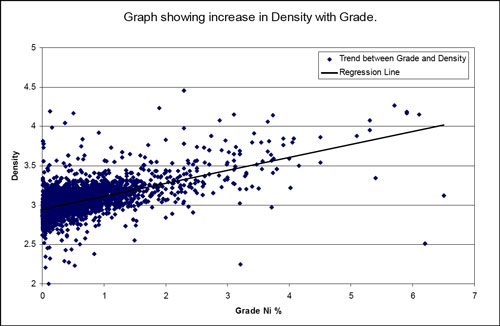

Figure 17-10: | Graph showing the increase in Density with Grade Ni%. This shows density can be linked to the degree of mineralization | - 68 - |

|

|

|

Figure 17-11: | Measured (red) and Indicated (yellow) Resource wireframes governed by the drilling density | - 80 - |

|

|

|

Figure 17-12: | Topographic surface as at December 31 2008 | - 82 - |

|

|

|

|

|

|

31 March 2009 | vi |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

|

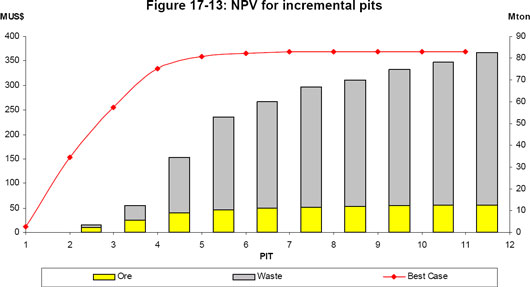

Figure 17-13: | NPV for incremental pits | - 86 - |

|

|

|

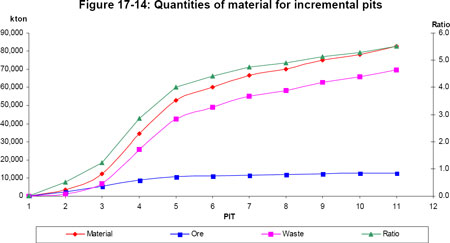

Figure 17-14: | Quantities of material for incremental pits | - 86 - |

|

|

|

Figure 17-15: | Grade-Tonnage curve for the selected pit limit (pit 7) | - 87 - |

|

|

|

Figure 17-16: | Section 5300 North | - 88 - |

|

|

|

Figure 17-17: | Section 7300 East | - 88 - |

|

|

|

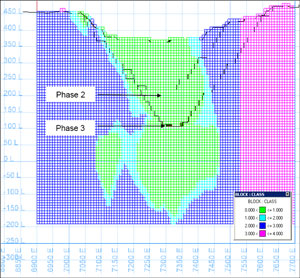

Figure 17-18: | Operational design - Phase 2 | - 89 - |

|

|

|

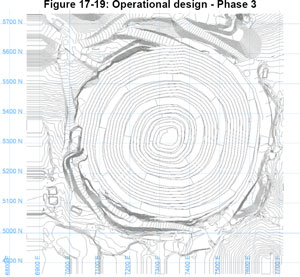

Figure 17-19: | Operational design - Phase 3 | - 89 - |

|

|

|

Figure 17-20: | Final Pit and Block Model | - 90 - |

|

|

|

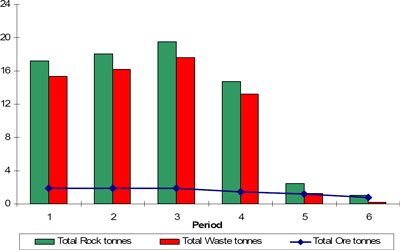

Figure 17-21: | Summary Extraction Materials | - 92 - |

|

|

|

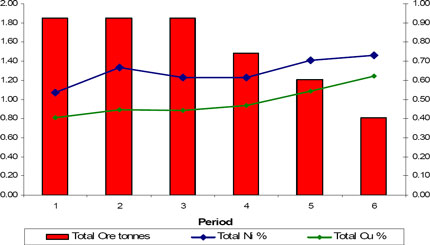

Figure 17-22: | Tonnages and grades by Period | - 92 - |

|

|

|

|

|

|

31 March 2009 | vii |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

APPENDICES | |

|

|

Appendix A | Standards results |

Appendix B | Repeat analysis charts |

Appendix C | List of holes used in the estimation |

Appendix D | Wireframe model sections |

Appendix E | Probability Plots |

Appendix F | Search Ellipse Orientations |

Appendix G | Swath Plots |

|

|

|

|

|

|

|

|

31 March 2009 | viii |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

1.0 | EXECUTIVE SUMMARY |

Introduction

Golder Associates Global Ibérica, S.L. (Golder) was commissioned by Mr Aden Muñoz of Lundin Mining Corporation (Lundin) to complete an independent Mineral Resource and Mineral Reserve estimation of the Aguablanca Deposit of the Aguablanca Mine.

This report details the results of work carried out by Golder between July 2008 and March 2009 and provides a statement of Mineral Resources and Mineral Reserves for the Aguablanca Deposit, which have been classified in conformance with the CIM Mineral Resource and Mineral Reserve definitions referred to in the National Instrument (NI) 43-101, Standards of Disclosure for Mineral Projects. It also involved the preparation of a Technical Report as defined in NI 43-101 and in compliance with Form 43-101F1 (the “Technical Report”).

Property description and location

The Aguablanca Mine is 100% owned by Lundin Mining Corporation and is located approximately 100 km north of Seville within the Monesterio municipal boundary in the south of Badajoz Province (Extremadura Region), and close to the Huelva and Sevilla (Andalucia Region) provincial boundaries, in the south of Spain. It lies at Latitude 37°57´40´´ and Longitude 6°11´7´´.

The Aguablanca Operation consists of an open pit mine and an on-site processing plant. Mining takes place via conventional open pit methods utilizing shovels and haul trucks. At full operating capacity the mine can produce 1.85 million tonnes of ore a year, and in 2008 produced 8,136 tonnes of Ni and 7,071 tonnes of Cu in concentrate.

Geological setting

The Aguablanca Stock is located in the northeast of the Santa Olalla Plutonic Complex which has yielded absolute ages of 338.6±0.8 Ma and 344±1.1 Ma. The intrusion consists of medium grained gabbro and gabbro-norites. Mineralisation occurs in igneous rocks formed by partial melting of the mantle. When basalt magma is emplaced within the crust, it cools slowly at depth and forms gabbro which is the host rock of the Aguablanca mineralization.

A clear transition from semi-massive mineralized breccia in the central part of the Aguablanca mineralization to disseminated mineralization along both sides of the central breccia, suggests a vertical, “feeder like” emplacement of the mineralization. The deepest portion of the main body is still open.

|

|

|

|

|

|

31 March 2009 | 1 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Mineralisation consists of magmatic sulphide mineralization hosted by the gabbro and gabbro-norite units. Sulphide mineralization is predominantly represented by pyrrhotite, pentlandite, chalcopyrite and pyrite with minor marcasite and covellite. Magnetite is often present. Lesser amounts of platinum group minerals (PGM) and gold are also associated with the sulphide minerals.

Mineralization is generally hosted within a chaotic magmatic breccia, rich in fragments, in the matrix of which can be found semi-massive sulphides. The mineralization often grades laterally into more continuous disseminated sulphides and irregular patchy mineralization with variable textures. The mineralized body consists of two sub-parallel zones of mineralization, elongated in an east west direction and dipping subvertically. The larger South or Main Zone can be traced for 400 metres along an N115º orientation and dips between 75º and 80º to the north. This zone is over 100 metres thick and extends to a depth of more than 600 metres. The mineralization has a plunge of N65º to N80ºE. The North Zone contacts with the surrounding metamorphic country rocks and strikes N115º and is approximately 125 metres long in the strike direction, 50 metres thick and extends to a depth of more than 300 metres.

The main types of sulphide mineralization recognized at Aguablanca include massive to semi-massive mineralization (SB). This is further classified into disseminated (SS and S) and irregular (SP) mineralization in patches and lenses..

Exploration history

Exploration has been carried out in the area since the mid 1980’s. Geochemical stream sediment and soil sampling by the Presur/RTM Joint Venture between 1986 and 1994 delineated a drilling target. This target was drilled using diamond drilling methods by RTM and later by RNR and most recently by Lundin. The current drill hole database contains a total of 362 drill holes for a total of 96,515 m.

Mineral Resource Estimation

The December 31, 2008 Aguablanca Mineral Resource Estimate was completed by Mr J. Alvarez, Mr J. Purchase Dr. S. Khosrowshahi, and reviewed by Dr W Shaw. The Mineral Resource Estimate is based on diamond drill hole data provided by Lundin. Golder has reviewed the sources of the data provided by Lundin through validation checks against the digital data provided.

|

|

|

|

|

|

31 March 2009 | 2 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

The Resource report for the Aguablanca Deposit is shown in Table ES-1

Table ES-1: Resource Report for the Sub-blocked Block model (8x8x4) at 0.1% and 0.2% Ni cut-off grades

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CLASS |

| Cut-off grade |

| Tonnes |

| Ni |

| Cu |

| Pt |

| Pd |

| Co |

| Au |

| ||||||||

Measured |

|

| 0.1 |

|

| 19,774 |

|

| 0.450 |

|

| 0.382 |

|

| 0.240 |

|

| 0.215 |

|

| 0.013 |

|

| 0.119 |

|

Indicated |

|

| 0.1 |

|

| 3,966 |

|

| 0.200 |

|

| 0.175 |

|

| 0.113 |

|

| 0.105 |

|

| 0.008 |

|

| 0.066 |

|

Measured+Indicated |

|

| 0.1 |

|

| 23,740 |

|

| 0.408 |

|

| 0.347 |

|

| 0.219 |

|

| 0.197 |

|

| 0.012 |

|

| 0.110 |

|

Inferred |

|

| 0.1 |

|

| 1,834 |

|

| 0.178 |

|

| 0.140 |

|

| 0.108 |

|

| 0.102 |

|

| 0.007 |

|

| 0.057 |

|

Measured |

|

| 0.2 |

|

| 14,966 |

|

| 0.545 |

|

| 0.457 |

|

| 0.256 |

|

| 0.230 |

|

| 0.015 |

|

| 0.128 |

|

Indicated |

|

| 0.2 |

|

| 1,569 |

|

| 0.279 |

|

| 0.236 |

|

| 0.132 |

|

| 0.124 |

|

| 0.011 |

|

| 0.077 |

|

Measured+Indicated |

|

| 0.2 |

|

| 16,535 |

|

| 0.520 |

|

| 0.436 |

|

| 0.244 |

|

| 0.220 |

|

| 0.014 |

|

| 0.123 |

|

Inferred |

|

| 0.2 |

|

| 525 |

|

| 0.271 |

|

| 0.189 |

|

| 0.138 |

|

| 0.133 |

|

| 0.010 |

|

| 0.066 |

|

Mineral Reserve Estimation

A Mineral Reserve Estimate for Aguablanca has also been carried out by Golder. This estimate has only considered the Measured and Indicated Mineral Resources. The estimate has used the pit geometry at December 31, 2008, taking into account recently revised geotechnical parameters. Based on the geometry and geotechnical parameters an optimized pit limit and production schedule was developed, adequately supported by an operational mine design. In particular, dilution and mining recovery were properly addressed and supported by historical data.

|

|

|

|

|

|

31 March 2009 | 3 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Proven and Probable Reserves are summarized in Table ES-2.

Table ES-2: Proven and Probable Mineral Reserves in the Aguablanca Mine as at December 31, 2008 at a cut-off grade of 0.25% Ni

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Aguablanca |

| Tonnes |

| Ni |

| Cu |

| Pt |

| Pd |

| Co |

| Au |

| |||||||

Proven Reserves |

|

| 8,668 |

|

| 0.65 |

|

| 0.48 |

|

| 0.222 |

|

| 0.208 |

|

| 0.017 |

|

| 0.106 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Probable Reserves |

|

| 370 |

|

| 0.30 |

|

| 0.29 |

|

| 0.088 |

|

| 0.090 |

|

| 0.012 |

|

| 0.073 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Subtotal |

|

| 9,038 |

|

| 0.63 |

|

| 0.47 |

|

| 0.218 |

|

| 0.203 |

|

| 0.017 |

|

| 0.105 |

|

Conclusions and recommendations

The completed project has met its objectives by providing a statement of Mineral Resources and Mineral Reserves for the Aguablanca Deposit, which have been classified in conformance with the CIM Mineral Resource and Mineral Reserve definitions referred to in the National Instrument (NI) 43-101, Standards of Disclosure for Mineral Projects.

Lundin’s QAQC program is considered acceptable by Golder but could be improved by implementing the following recommendations:

|

|

|

| • | Improving the splitting of the pulverised material by employing a small laboratory scale Jones riffle splitter or a rotary sampling device. |

|

|

|

| • | The pulverising size for the currently prepared standards is coarser than is generally used and the mixing (homogenisation) procedure may not be sufficient. The quality of the standards should be further evaluated as being suitable for QC. |

The methodology for measuring the bulk density of the rock types currently employed by Lundin may lead to a risk of bias in highly absorbent rocks. The sequence in which the measurements are taken may lead to the sample absorbing more water when P3 is measured than was present when P1 was measured thereby increasing the dry density. Golder does not believe this has a material impact on the estimation of densities but should be investigated.

|

|

|

|

|

|

31 March 2009 | 4 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

2.0 | INTRODUCTION |

|

|

2.1 | Preamble |

Golder Associates Global Ibérica, S.L. (Golder) was commissioned by Mr Aden Muñoz of Lundin Mining Corporation (Lundin) to complete an independent Mineral Resource and Mineral Reserve estimation of the Aguablanca Deposit of the Aguablanca Mine.

This report details the results of work carried out by Golder between July 2008 and March 2009 and provides a statement of Mineral Resources and Mineral Reserves for the Aguablanca Deposit, which have been classified in conformance with the CIM Mineral Resource and Mineral Reserve definitions referred to in the National Instrument (NI) 43-101, Standards of Disclosure for Mineral Projects. It also involved the preparation of a Technical Report as defined in NI 43-101 and in compliance with Form 43-101F1 (the “Technical Report”).

This report is intended to be used by Lundin subject to the terms and conditions of its contract with Golder. That contract permits Lundin to file this report as a Technical Report with Canadian Securities Regulatory Authorities pursuant to provincial securities legislation. Except for the purposes legislated under provincial securities laws, any other use of this report by any third party is at that party’s sole risk.

The qualified persons (QP) responsible for the preparation of this Technical Report are Dr. Sia Khosrowshahi PhD, MSc, BSc, FAusIMM, Mr. Juan Alvarez, BSc, MAusIMM, Mr. Juan Pablo Gonzalez, MBA, MAusIMM and Mr. Stephen Gatley, IMMM, CEng. Mr. Alvarez was responsible for the preparation Sections 1.0 to 14.0, Section 17.1 to 17.3 and Sections 19.0 to 22.0 Dr. Khosrowshahi was responsible for the preparation Sections 17.4 to 17.11. Mr. Gonzalez was responsible for the preparation of the Reserve Estimation section of the report (Section 17.12). Mr. Gatley was responsible for the preparation of Sections 15.0 16.0, 18.0 and 23.0 of the report.

A site visit was conducted by Mr. J. Alvarez for four days from July 21 2008 and for five days from August 18 2008, to observe drilling, drill hole survey systems, core logging and sampling preparation procedures as defined by Aguablanca’s QAQC sampling protocols. During the site visit, both Ni and Cu mineralization were observed in quantities that are consistent with the Mineral Resource reported for this deposit.

A site visit was conducted by Mr. J.P. Gonzalez for three days from August 6 2008, to discuss mine stability and geotechnical aspects and to observe mining operations carried out on site. During the visit it was possible to observe and discuss on Reserve Estimation parameters with Aguablanca personnel. Mining production was also observed in quantities that are consistent with the production capacity used to define the Mineral Reserves reported for this deposit.

|

|

|

|

|

|

31 March 2009 | 5 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

The sources of information that were provided in the preparation of the independent mineral resource estimate (Section 11.0 to 14.0 and 17.1 to 17.11) were provided by Lundin under the direction of Mr Enrique Martínez (Chief Geologist, Aguablanca Mine) and also referenced from sections of the Aguablanca Nickel-Copper Feasibility Report (MDM, 2002) and Tornoset. al. 2006. These sources of information include:

|

|

• | Various internal geological presentations; |

|

|

• | Drill hole database as at August 28, 2008 including results of quality assurance and quality control (QAQC) check assays and rock densities; |

|

|

• | Digitised geological sectional interpretations prepared by Lundin; |

|

|

• | Topographic surface; and |

|

|

• | Pit and underground development plans in digital format. |

The sources of information that were provided in the preparation of the independent mineral reserve estimate (Section 17.12) were provided by Lundin under the direction of Mr Andén Muñoz (Mine Manager, Aguablanca Mine) and also referenced from sections of the Aguablanca Nickel-Copper Feasibility Report (MDM, 2002).

The effective date of the updated Aguablanca property Technical Report is March 31 2009.

|

|

2.2 | Terms of reference |

All units of measure (see Table 1) used in this report are in the metric system, unless stated otherwise. The contained metal abundances shown in the mineral resource estimate for nickel, copper and cobalt are in parts per million (ppm) while platinum, palladium and gold and silver are expressed in parts per billion (ppb). Currencies outlined in the report are in US dollars unless otherwise stated.

|

|

|

|

|

|

31 March 2009 | 6 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Table 1: Units of measure and abbreviations

|

|

Centimetre | cm |

comma separated values | csv |

Degree | ° |

Degrees Celsius | °C |

Drawing Exchange Format | dxf |

From Origin of Business | FOB |

Gram | g |

Grams per tonne | g/t |

Greater than | > |

Hectare (10,000 m2) | ha |

Inverse Distance to the Power | IDP |

Kilogram | kg |

Kilometre | km |

Less than | < |

Life of mine | LOM |

Meter | m |

Micrometre (micron) | µm |

Millimetre | mm |

Million pounds | Mlbs |

Million Tonnes | Mt |

Ordinary Kriging | OK |

Percent | % |

Parts per million | ppm |

Parts per billion | ppb |

Quality assurance and quality control | QAQC |

|

|

2.3 | Scope of Work |

The scope of work involves the production of Mineral Resources and Mineral Reserves for the Aguablanca Deposit, classified in conformance with the CIM Mineral Resource and Mineral Reserve definitions referred to in the National Instrument (NI) 43-101, Standards of Disclosure for Mineral Projects and the preparation of a Technical Report as defined in NI 43-101 and in compliance with Form 43-101F1 (the “Technical Report”).

|

|

|

|

|

|

31 March 2009 | 7 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

3.0 | RELIANCE ON OTHER EXPERTS |

The first Technical Report for the Aguablanca Property was published by Metallurgical Design and Management (Pty) Ltd (MDM, 2002). Information provided with respect to mineral tenure, environment, accessibility, permitting, geology and history were relied upon from the MDM Technical Report.

The authors have made no attempt to independently verify the legal status and ownership of the property claims and have relied on the information provided by Lundin.

|

|

|

|

|

|

31 March 2009 | 8 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

4.0 | PROPERTY DESCRIPTION AND LOCATION |

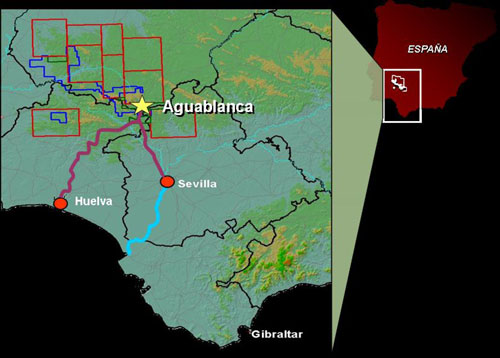

The Aguablanca Mine is 100% owned by Lundin Mining Corporation and is located approximately 100 km north of Seville within the Monesterio municipal boundary in the south of Badajoz Province (Extremadura Region), and close to the Huelva and Sevilla (Andalucia Region) provincial boundaries, in the south of Spain. It lies at Latitude 37°57´40´´ and Longitude 6°11´7´´.

The closest villages are Real de la Jara, 2 km south-east, and Santa Olalla de la Cala, 10 km southwest. The village of Santa Olalla del Cala is on the N630 national route, between Sevilla in the south and Merida in the north. Monesterio, with a population of approximately 10,000 is located approximately 30 km north.

A location diagram is shown in Figure 4-1.

Figure 4-1: Location of the Aguablanca mine

|

|

|

|

|

|

31 March 2009 | 9 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

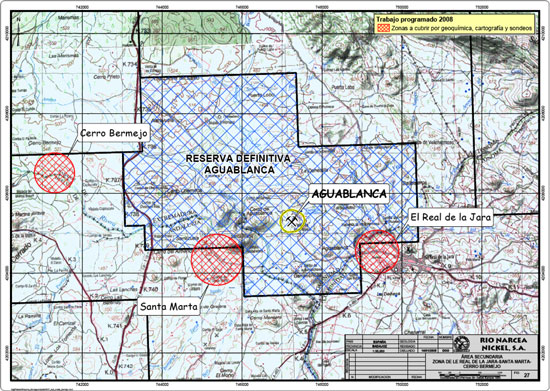

Lundin holds various mineral licenses and exploration permits covering an area greater than 350 hectares (ha). The mining rights are covered under theReserva Definitiva a favor del Estado called La Moneguera which covers 95 contiguous claims with a surface area of 2,861.94 ha. AReserva Definitivadenotes a state mineral or “strategic” reserve and therefore the responsible government agencies for its control are the central government, not the regional government. The boundaries are valid for 30 years extendable for another 30. TheReserva Definitiva is shown in Figure 4-2.

The Aguablanca Operation consists of an open pit mine and an on-site processing plant. Mining takes place via conventional open pit methods utilizing shovels and haul trucks. At full operating capacity the mine can produce 1.85 million tonnes of ore a year, and in 2008 produced 8,136 tonnes of Ni and 7,071 tonnes of Cu in concentrate.

Figure 4-2: Aguablanca mining rights

|

|

|

|

|

|

31 March 2009 | 10 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

Accessibility, physiography, climate and infrastructure sections were summarized in the MDM Report (2002) and are as follows.

|

|

5.1 | Access |

The Aguablanca Mine is accessed via the paved, four lane N630 national highway from Seville. The highway runs approximately 100 km north from Seville towards the town of Santa Olalla del Cala. Visitors to the mine then turn off the N630 and head east on the paved A-5301 for approximately 8.5 km to the town of El Real de la Jara. Visitors access the mine via the paved Camino de Aguablanca for approximately 3 km directly to the mine.

|

|

5.2 | Climate |

The Aguablanca region has a Mediterranean climate. Temperatures in the summer months (May to October), range from 10° C to 33°C. Temperatures in the cool winter months (November to April) range from 3° C to 18°C. Rainfall and light snow prevail in this period.

|

|

5.3 | Landform and vegetation |

The Aguablanca Mine is at an elevation of 450 m to 500 m above sea level and the geography comprises low hills with moderate relief. The area is covered with trees and bushes forming the classical type of Mediterranean forest of the mountains of central and southern Spain. The area is vegetated with meadows comprising grass, oak trees and small olive trees.

|

|

|

|

|

|

31 March 2009 | 11 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

6.0 | HISTORY |

The historical ownership and exploration are summarized in the MDM Report (2002) and are as follows.

|

|

6.1 | Historical ownership |

|

|

| Exploration for nickel and copper deposits has been carried out in the area since the mid 1980’s. In 1986, the areas known as “La Monaguera” and “La Remonta”, which covered a total area of over 620,000 ha in the Provinces of Huelva and Badajos, were declared a State Reserve for Mineral Investigation and the investigation rights were awarded to Presur, the State Corporation which later entered into a joint venture agreement with Rio Tinto Minera (RTM). |

|

|

| In 1993, the Presur/Rio Tinto Minera Joint Venture discovered the Aguablanca target by further geochemical stream sediment and soil sampling and in 1994 discovered the Aguablanca Ni-Cu deposit by diamond drilling. During 1996, Freeport McMoRan Copper and Gold Company acquired Rio Tinto’s Spanish assets and later transferred their interest in the deposit to the newly formed subsidiary, Atlantic Copper S.A. |

|

|

| By March 1997, the State Reserves were categorised as either a “Priority Area”, in which Atlantic and Presur each had a 50% interest with the remainder categorized as “Secondary Area” in which Presur had a 100% interest. Under the terms of the Joint Venture agreement Atlantic had the option to include areas within the “Secondary Area” in the “Priority Area”, thereby giving Atlantic the right to a 50% interest. |

|

|

| In March 2001, Rio Narcea Recursos (RNR), a wholly owned Spanish subsidiary of Rio Narcea Gold Mines Ltd (RNGM) signed an option agreement with Atlantic Copper S.A. and the Spanish Government and in mid 2001, after due diligence work, exercised its option to acquire 100% interest in the Aguablanca project by purchasing 50% interest in the Monaguera Mineral Reserve from Atlantic Copper S.A. |

The Aguablanca mine was acquired by Lundin in July 2007, through its purchase of RNGM. Commercial production started in January 2005 and the first nickel-copper concentrate was sold in May 2005. In conjunction with the commencement of open pit operations, a 2,700 m long ramp to access the mineralization below the Aguablanca open pit was developed and completed in 2005. This facilitated commencement of an underground exploration drilling program to test the continuation of mineralization at depth. This was completed in 2008.

|

|

|

|

|

|

31 March 2009 | 12 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

6.2 | Historical exploration |

|

|

| Exploration has been carried out in the area since the mid 1980’s. |

|

|

| From 1986 to 1994, the Presur/RTM Joint Venture carried out geochemical stream sediment and soil sampling and diamond drilling in the area leading to the delineation of the Aguablanca target. Between 1994 and 1997, RTM carried out some 32,000 m of diamond drilling, completed a 65 m long adit for bulk sampling and a Pre-feasibility Study on an open pit. |

|

|

6.3 | Historical resource estimates |

|

|

| RTM estimated an initial Mineral Resource totalling some 18.9 million tonnes at an average grade of 0.67% Ni and 0.46% Cu with a stripping waste to ore ratio of 4.3 to 1. RTM then estimated the in-pit Mineral Resources to total some 12.4 million tonnes at an average grade of 0.80% Ni and 0.54% Cu with a stripping ratio of 4.45 to 1. |

|

|

Golder believes that the RTM historical resource estimates was not estimated in conformity with the categories outlined in Sections 1.2 and 1.3 of NI 43-101, are not current and should not be relied upon. | |

| |

| In August 2000, a Mineral Resource was estimated by Alan C. Noble of O.R.E. Reserves Engineering, Colorado USA (ORE). This estimate was based on a three-dimensional geological block model within an envelope of 0.1% Ni and was estimated using a 0.2% Ni cut-off based on a 4*4*4 block model using the results of drilling completed by RTM + RNR. Block grades for Ni, Cu, Au, Co, Pt + Pd were interpolated using IDP methods. |

|

|

| As an internal check, ORE utilized three other methods of estimating Mineral Resources and reported that the tonnage and grade estimates varied by about 8%. |

|

|

| The Measured and Indicated Resources of ORE estimate are reported as 19.7 million tonnes at an average grade of 0.66% Ni, 0.48% Cu, 0.50 g/t PGE (combined), 0.13 g/t Au and 0.02% Co. ORE also estimated an Inferred Resource of 6 million tonnes at an average grade of 0.53% Ni, 0.46% Cu, 0.40 g/t PGE (combined), 0.13 g/t Au and 0.02% Co. |

According to Lundin staff, the ORE Mineral Resource was estimated in conformity with the categories outlined in sections 1.2 and 1.3 of NI 43-101.

|

|

|

|

|

|

31 March 2009 | 13 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

6.4 | Historical production |

There was no historical production of the deposit before the current mining operation, started by RNR in 2005.

|

|

|

|

|

|

31 March 2009 | 14 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

7.0 | GEOLOGICAL SETTING |

|

|

7.1 | Regional Geology |

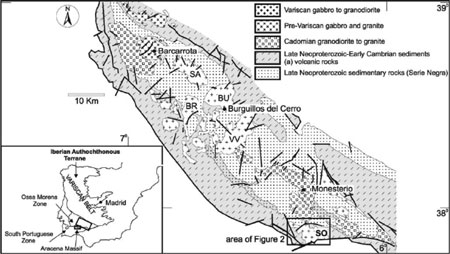

The regional geology of the area is described in detail in Tornos,et al (2006) and is as follows.

|

|

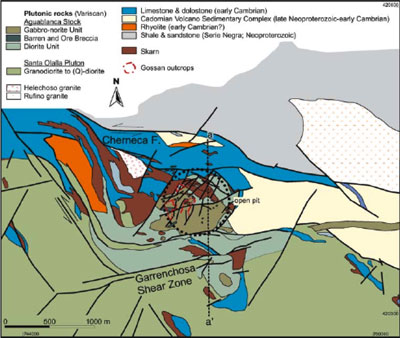

| The Aguablanca nickel-copper-PGM deposit is located in the Aguablanca Stock which forms part of the north eastern zone of the Santa Olalla Plutonic Complex, within the southernmost part of the Ossa Morena Zone of the Varsican Belt of Iberia. (Figure 7-1). |

|

|

| The Ossa Morena Zone underwent a complex geodynamic evolution with a Neoproterozoic Cadomian basement reworked by the Variscan Orogeny. The Cadomian Orogeny resulted from the subduction and subsequent collision of the exotic Ossa Morena terrane with the autochthonous Iberian terrane in the Late Neoproterozoic to Early Cambrian. The Variscan Orogeny resulted from the oblique collision of the South Portuguese terrane with the southern margin of the Iberian Massif in the Devonian to Early Carboniferous. The Ossa Morena Zone hosts a wide suite of igneous rocks related to the two orogenies and to an intermediate rift-related pulse of Cambrian–Ordovician age. |

|

|

| Variscan plutonism is volumetrically dominant and consists of calcalkaline metaluminous composite intrusions ranging in composition from gabbro to granodiorite and minor peraluminous granite. During the Variscan deformation, the Ossa Morena Zone underwent thick-skinned deformation with the development of south-verging longitudinal fold-and-thrust zones that involved both the Cadomian basement and the Palaeozoic sedimentary cover. There are abundant contemporaneous and younger strike-slip faults. All these structures show evidence of formation in a transpressional setting in response to oblique subduction and played a major role in focusing magma ascent and pluton formation. |

|

|

| The Aguablanca Stock and other intrusions are part of the Santa Olalla Plutonic Complex within the Ossa Morena Zone. The Plutonic Complex reached its final emplacement level after the main thrusting and folding phase of the Variscan Orogeny and produced an aureole of contact metamorphism about 2 km wide. Temperatures within the aureole attained values of the hypersthene hornfels facies (ca. 750°C) near the contact with the Aguablanca Stock, resulting in local partial melting. A depth of 1.7 to 3.5 km (0.5–1 kbar) was inferred for its emplacement from metamorphic mineral equilibria. Widespread garnet-pyroxene± magnetite skarn and minormagnesian skarn were formed by replacement of the marble and calc-silicate rocks before final emplacement of the Aguablanca Stock. |

|

|

|

|

|

|

31 March 2009 | 15 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Figure 7-1: Geology of the Central part of the Ossa Morena Zone (Tornos.et al, 2006)

|

|

7.2 | Property description |

|

|

| The Aguablanca Property hosts the Aguablanca Stock and is located in the northeast of the Santa Olalla Plutonic Complex which has yielded absolute ages of 338.6±0.8 Ma and 344±1.1 Ma. It is a small (ca. 10 km2) and highly heterogeneous intrusion. The outer contacts are both concordant and discordant, and the internal architecture of the stock is interpreted as a half bell jar. Detailed surface mapping suggests that the roof of the intrusion is close to the present erosion level as evidenced by the presence of roof pendants of skarnified marble and calc-silicate hornfels. |

|

|

| The intrusion consists of medium grained gabbro and gabbro-norites. They have an inequigranular subeuhedral texture and consist of 2 to 3-mm sized crystals of weakly zoned plagioclase of intermediate composition, diopside–augite, actinolitic hornblende, and biotite–phlogopite. Accessory minerals include quartz and trace amounts of apatite, pyrrhotite, and zircon. |

|

|

| The gabbro-norite, which hosts the majority of the mineralization, consists for the most part of medium-grained massive gabbronorite with lesser amounts of pyroxene gabbro and norite. Subhorizontal veins of pegmatitic gabbro and scapolite are locally present. At the contact with the host metasedimentary rocks, there is a discontinuous and up to 5 to 6 m thick margin of fine-grained, phlogopite-rich gabbro. |

|

|

| The Aguablanca Stock has abundant xenoliths of the host rocks, ranging in size from centimetres to several metres, particularly garnet-pyroxene skarn and pelitic and calc-silicate hornfels. |

|

|

|

|

|

|

31 March 2009 | 16 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

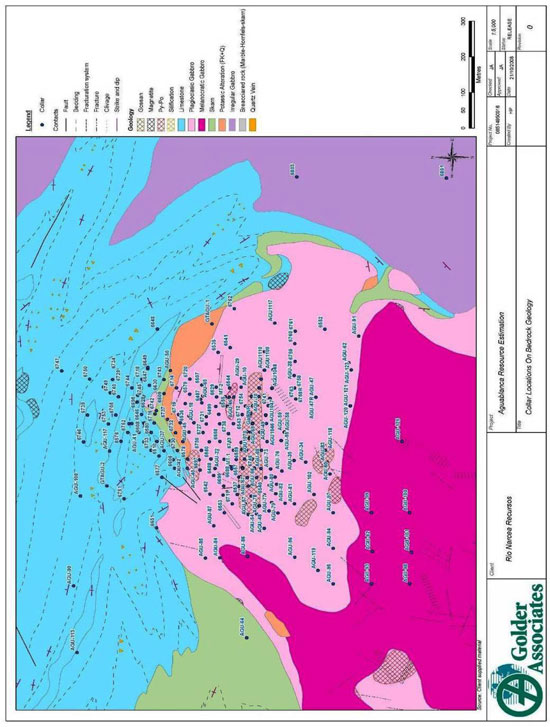

Figure 7-2: Map of the Aguablanca Stock and surrounding geology (Tornos. et al, 2006)

|

|

|

|

|

|

31 March 2009 | 17 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

8.0 | DEPOSIT TYPES |

|

|

8.1 | Mineral genesis |

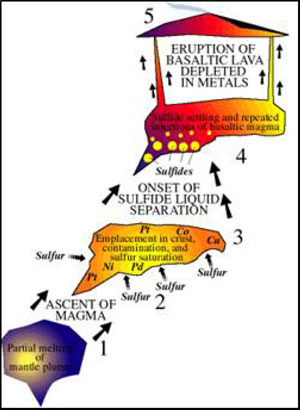

The following model for the genesis of mineralization at Aguablanca has been proposed by Lundin staff on site.

Mineralization at Aguablanca occurs in igneous rocks formed by partial melting of the mantle. When basalt magma is emplaced within the crust, it cools slowly at depth and forms gabbro which is the host rock of the Aguablanca mineralization.

Mantle derived magmas, however, have the potential to form a separate, immiscible magma or liquid of iron sulphide composition into which the small amounts of Ni and Cu may be concentrated and eventually crystallize as discrete sulphide minerals.

At Aguablanca, the sulphur necessary to concentrate Ni and Cu in the magma is abundantly found in the Proterozoic to Cambrian pyrite-rich sediments. Magma rising through the crust passes through sulphur-rich sedimentary rock unit. Sulphur is dissolved in the gabbroic magma.

The magma is emplaced in the upper part of the crust and as it cools droplets of immiscible iron sulphide liquid appear in the magma. These droplets are denser than the gabbro, and fall through the magma to accumulate at the bottom of the magmatic chamber, forming massive to semi-massive mineralization. As the sulphide droplets pass through the magma, they pick up trace metals that partition preferentially into sulphide liquid rather than the silicate magma. Traces of metals such as Cu and Ni, and others such as Co, Pt and Pd, will also be concentrated in the sulphide liquid. This sulphide liquid will eventually cool and form sulphide minerals. The last droplets of sulphide liquid to separate would be trapped by the crystallizing magma as disseminated sulphide mineralization. A schematic diagram of the mineral genesis model of the Aguablanca deposit is shown in Figure 8-1.

A clear transition from semi-massive mineralized breccia in the central part of the Aguablanca mineralization to disseminated mineralization along both sides of the central breccia, suggests a vertical, “feeder like” emplacement of the mineralization. The deepest portion of the main body is still open and it is precisely here that most of the evidence for a chamber bottom is found (increasing mafic lithologies and layering or oriented patches of sulphides), although the relationship of the chamber bottom to the upper mineralized zones has not yet been established.

|

|

|

|

|

|

31 March 2009 | 18 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Figure 8-1: General model for the formation of a Ni-Cu-PGM sulphide mineralization (Lundin, 2004)

|

|

|

|

|

|

31 March 2009 | 19 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

9.0 | MINERALIZATION |

|

|

9.1 | Mineral zones |

The Aguablanca deposit consists of magmatic sulphide mineralization hosted by the gabbro and gabbro-norite units. Sulphide mineralization is predominantly represented by pyrrhotite, pentlandite, chalcopyrite and pyrite with minor marcasite and covellite. Magnetite is often present. Lesser amounts of platinum group minerals (PGM) and gold are also associated with the sulphide minerals.

Mineralization is generally hosted within the Aguablanca Stock in a chaotic magmatic breccia, rich in fragments, in the matrix of which can be found semi-massive sulphides. The mineralization often grades laterally into more continuous disseminated sulphides and irregular patchy mineralization with variable textures. The main mineralization types are discussed in detail in Section 9.3.

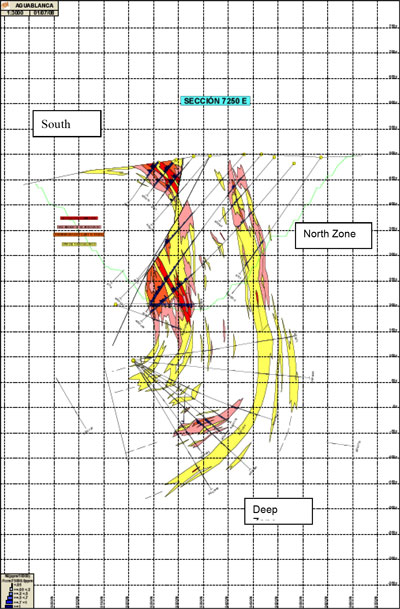

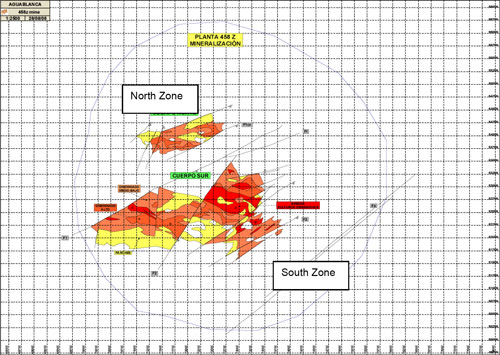

The mineralized body consists of two sub-parallel zones of mineralization, elongated in an east west direction and dipping subvertically. The larger South or Main Zone can be traced for 400 metres along an N115º orientation and dips between 75º and 80º to the north. This zone is over 100 metres thick and extends to a depth of more than 600 metres. The mineralization has a plunge of N65º to N80ºE. The North Zone contacts with the surrounding metamorphic country rocks and strikes N115º and is approximately 125 metres long in the strike direction, 50 metres thick and extends to a depth of more than 300 metres.

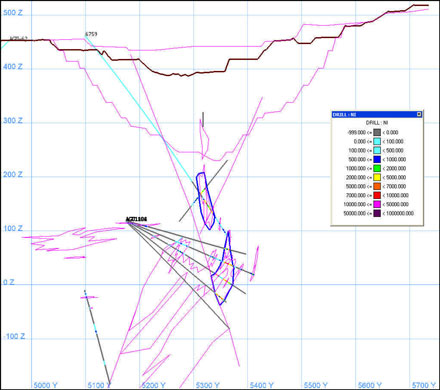

The deepest portion of the South Zone (called the deep zone) appears to have an average true thickness of approximately 50 metres. The deep zone is different from the upper mineralization in geometry, geochemistry and magmatic texture. Its relationship to the uppermost mineralized zone has not yet been determined but the presence of ultramafic rocks including pyroxenites and peridotites in some of the deepest drill holes suggest magmatic segregation.

Controlled by the geometry of the lithologies, both mineralized zones have a similar shape, with a central axis where the magmatic breccias (Gsb and Gb) are developed in and frequently associated with irregular gabbros. The central lithologies of the mineralized zones grade laterally into melanocratic, porphyritic and plagioclase gabbro.

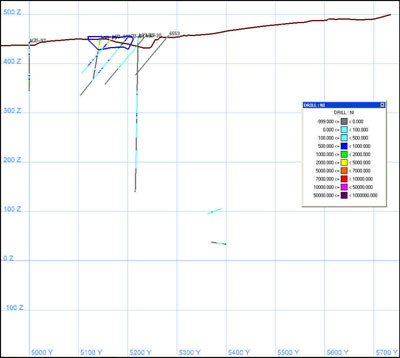

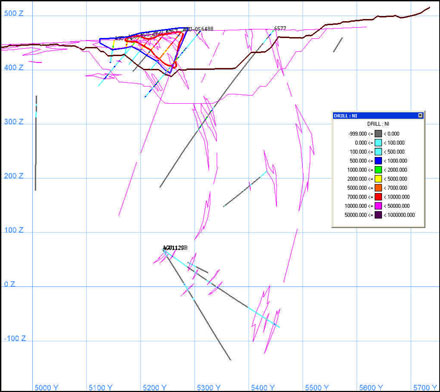

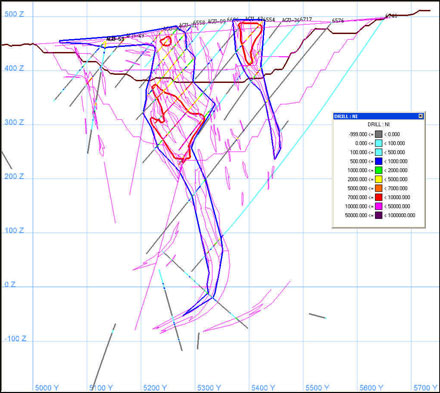

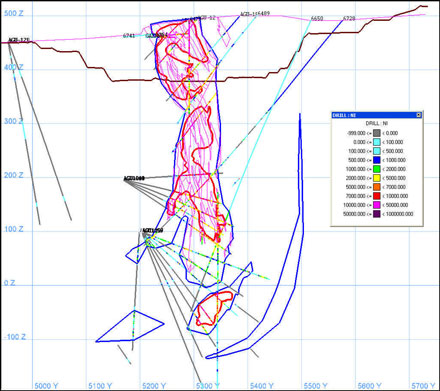

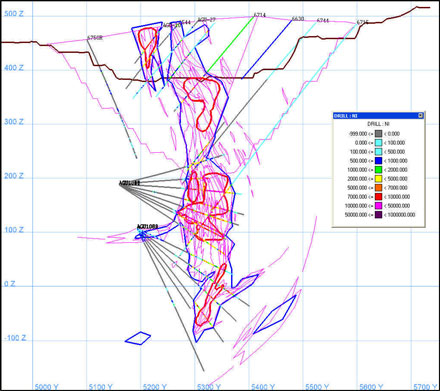

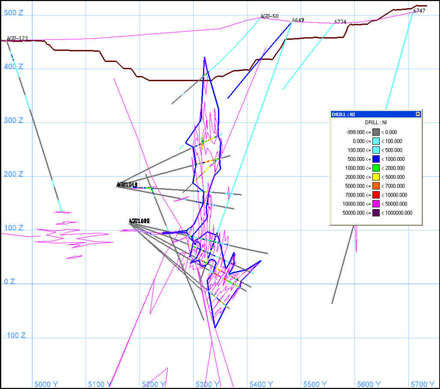

Figure 9-1 is a section view at 7250 E local grid of the Aguablanca mineralized body as interpreted by Lundin staff showing the typical geometry of the mineralized zones.

|

|

|

|

|

|

31 March 2009 | 20 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Figure 9-1: Section 7250 E as interpreted by Lundin staff showing South, North and Deep Zones

|

|

|

|

|

|

31 March 2009 | 21 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

9.2 | Fault systems |

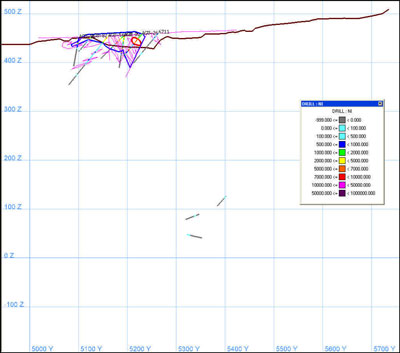

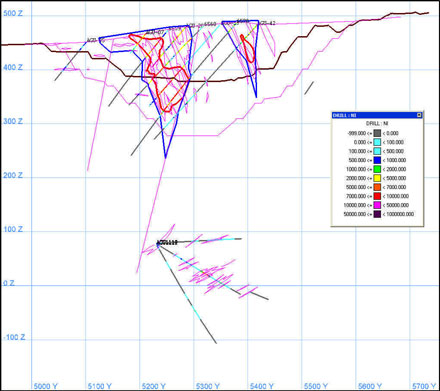

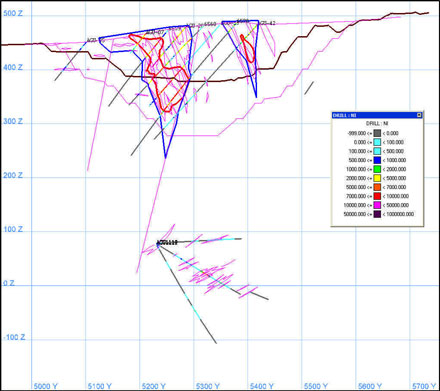

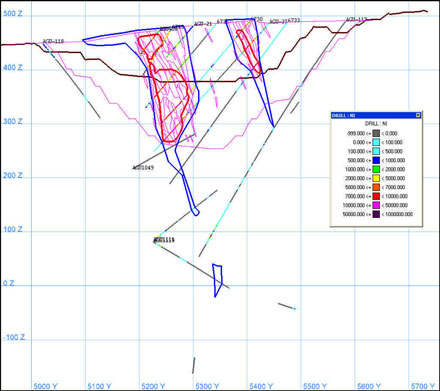

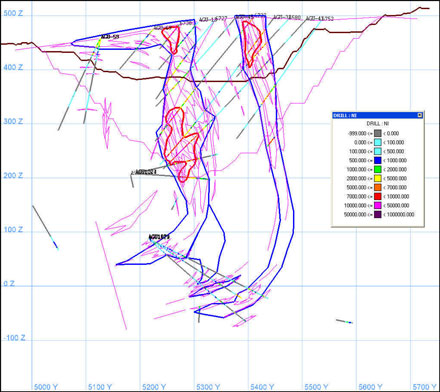

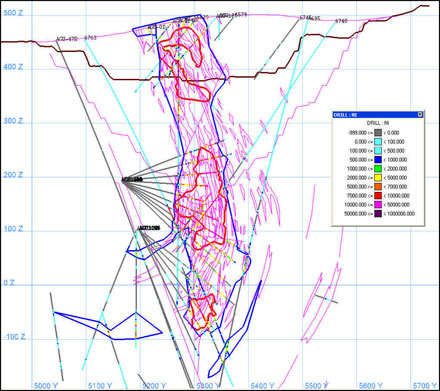

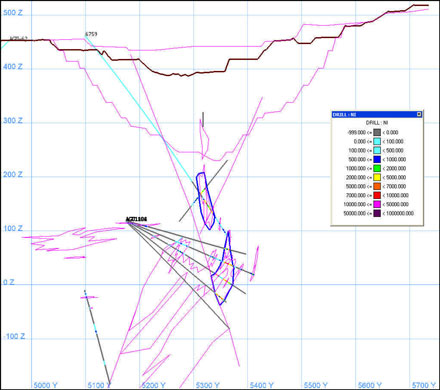

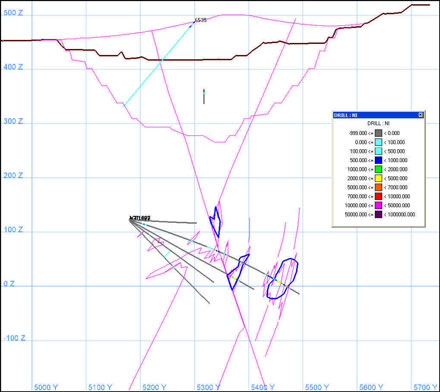

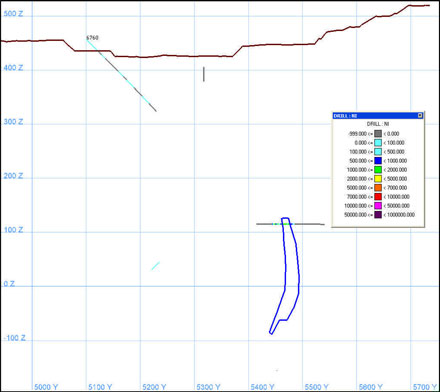

The mineralized body is cut by a series of post mineralization strike slip faults (F1 to F3) striking N40°E and dipping between 75° to 80° to the SE. In plan, the apparent movement is minor, left lateral with one major fault of this system which is cutting both zones at surface and at depth. Each of the faults has a significant 50 to 100 meter vertical component of displacement.

This fault system forms the lateral limits of both the mineral zones and has a strong control on the mineralization. In particular, high grade Ni-Cu-PGE mineralization abruptly terminates against one of these faults at the eastern limit of the Main Zone. The major faults and their relationship with the Aguablanca mineralization is shown in Figure 9-2.

Figure 9-2: Plan 458 Z showing the South and North Zones and important faults as interpreted by Lundin staff

|

|

|

|

|

|

31 March 2009 | 22 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

9.3 | Mineral types |

The main types of sulphide mineralization recognized at Aguablanca include massive to semi-massive mineralization (SB). This is further classified into disseminated (SS and S) and irregular (SP) mineralization in patches and lenses.

|

|

9.3.1 | Massive to semi-massive mineralization (SB) |

This mineralization is associated with magmatic breccia which consists of sub-angular fragments of unmineralized clinopyroxenes and gabbros in a matrix of semi-massive sulphides. It is often narrow and discontinuous. Sulphides constitute 30% to 60% of the rock and pyrrhotite and pentlandite are dominant, while chalcopyrite is less common and cobaltite is occasionally present. Typical grades for this style of mineralization are between 1% and 4% Ni and less than 1% Cu. Within the higher-grade portions of the deposit (>1.0% Ni) the Ni/Cu ratios range from 3 to 5. The PGM’s identified include sperrylite (PtAs2) and michenerite [(Pd,Pt),BiTe)]. An example is shown in Figure 9-3.

Figure 9-3: Magmatic breccia (Gsb) with semi-massive sulphides (SB)

|

|

|

|

|

|

31 March 2009 | 23 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

9.3.2 | Disseminated mineralization (SS and S) |

This type of mineralization is categorised by Lundin staff as either “Strong” (SS) or “Weak” (S) and is characterised by sulphides interstitial to the silicates (pyroxene, amphibole and plagioclase). It is generally associated with porphyritic gabbro (GP) and sometimes occurs in melanocratic gabbro (GM). It is much more continuous than massive sulphide type and often present as an envelope of disseminated sulphide (0.2% Ni to 1.0% Ni) surrounding the higher-grade brecciated zones. Pyrrhotite, chalcopyrite and pentlandite are the main sulphides and constitute up to 20% of the rock, with the Ni/Cu ratios ranging from 1 to 1.5.

The “Strong” type of mineralization typically contains between 10% and 20 % sulphides and more than 0.7% Ni. The “Weak” type typically contains between 5% to 10% sulphides and less than 0.7% Ni. An example of disseminated mineralization is shown in Figure 9-4.

Figure 9-4: Porphyritic Gabbro (GP) with disseminated sulphides (S)

|

|

9.3.3 | Irregular mineralization in patches (SP) |

This mineralization contains variable amounts of sulphides in patches, lenses, aggregates or bands. It is associated with irregular gabbro (GI) and magmatic breccia (Gb), where the crystallization of the magma was turbulent or irregular and associated with contamination from the surrounding host rocks. It is typical of the distal parts of the deposit and represents the transition zone from the disseminated mineralization to the barren lithologies. An example is shown in Figure 9-5.

|

|

|

|

|

|

31 March 2009 | 24 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Figure 9-5: Gabbro with irregular mineralization in patches

The mineralization type is closely related to a specific lithology. Although several types of mineralization occur in the breccia, semi-massive sulphides occur only in the breccia. Regular disseminated sulphides occur in gabbros with well developed crystalline frames (GM, GP, GPL, etc), and variable amounts of sulphides in patches are found in the gabbros with irregular textures (GI). Consequently the same symmetrical sketch is observed for the mineralization; a central breccia with semi-massive, disseminated or patchy mineralization, irregular mineralization in patches associated with irregular gabbro, and disseminated sulphides decreasing away from the central core.

|

|

|

|

|

|

31 March 2009 | 25 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

10.0 | EXPLORATION |

Exploration has been carried out in the area since the mid 1980’s. Geochemical stream sediment and soil sampling by the Presur/RTM Joint Venture between 1986 and 1994 delineated a drilling target. This target was drilled using diamond drilling methods by RTM and later by RNR and most recently by Lundin. A full account of the exploration history is shown in Section 6.2.

Since 2001, RNR/Lundin has drilled more than 260 diamond drill holes for some 64,000 m of surface and underground drilling. The drilling program was completed in 2008. RNR also completed a 2,700 m underground decline in 2005.

The current drill hole database includes over 32,000 m of diamond drilling, carried out by RTM from 1994 and 64,000 m of surface and underground drilling completed since 2001 by RNR and Lundin as detailed in Section 6.2. The drill hole database supplied to Golder contains a total of 362 drill holes for a total of 96,515 m.

AGU prefixes denote drilling undertaken by Rio Narcea. Drilling numbers without alpha numeric prefixes identify legacy holes drilled by RTM. The legacy drilling used single shot down hole surveying methods, measuring only the dip of the holes and not the azimuth. The holes were re-logged and re-assayed by Lundin and plotted on sections. Twenty drill holes which were considered by Lundin to have unacceptable down hole survey readings were removed from the drilling database. These holes are listed in Table 2.

Table 2: Drill holes removed from the database because of low confidence survey information

|

|

Hole id | |

6739 | 6758 |

6536 | 6758R |

6735 | AGU-46 |

6646 | AGU-47R |

6741 | 6715 |

6754 | 6630 |

Adit | 6750 |

6740 | 6718 |

6763 | 6729 |

6739 | AGU-46 |

6536 | AGU-47R |

6735 | 6715 |

6646 | 6630 |

6741 | 6750 |

6754 | 6718 |

Adit | 6729 |

6740 | 6763 |

|

|

|

|

|

|

31 March 2009 | 26 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

11.0 | DRILLING |

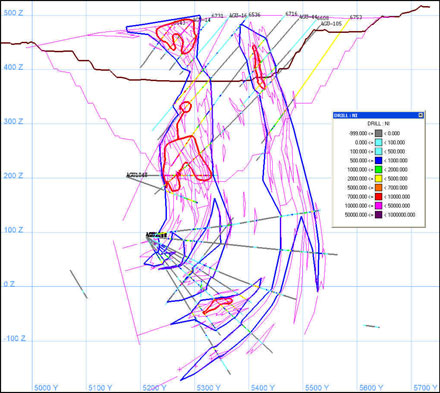

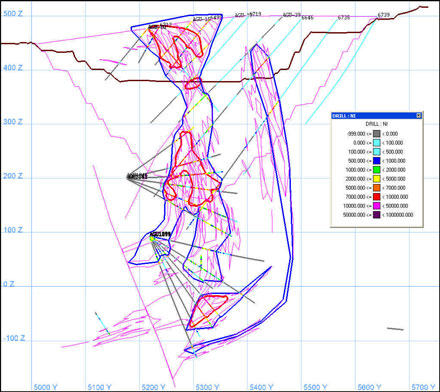

Resource definition and infill drilling at the Aguablanca Mine used two underground drill rigs and one surface drill rig around the periphery of the pit. These rigs are operated by Geonor Ltd and CGS Spanish drill contractors.

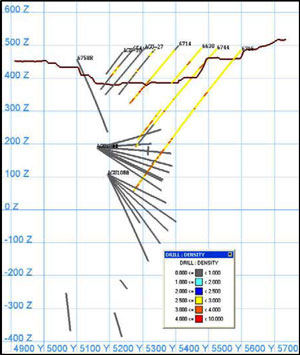

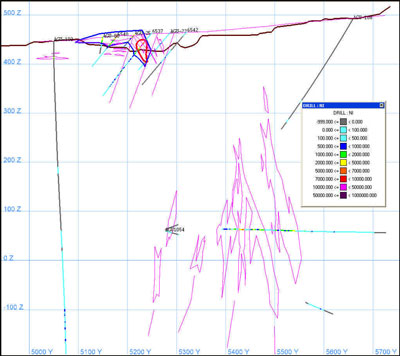

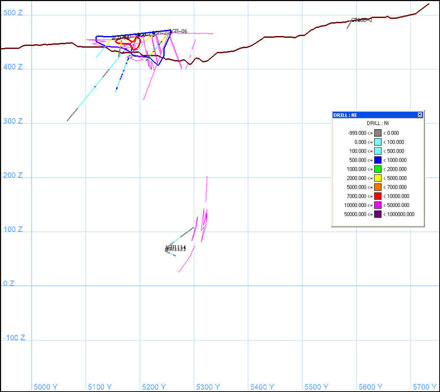

The current Aguablanca drill hole database contains a total of 362 drill holes for a total of 96,515 m. Lundin has completed 64,000 m of surface and underground drilling since 2001. The drilling coverage for the Aguablanca Project used in the 2009 Resource Estimate is shown in Figure 11-1.

The resource definition drill fleet currently comprises a Sandvik DE 140 underground diamond drill rig, an Omran wireline underground diamond drill rig and an ACKER MP8 surface diamond drill rig. Both the underground rigs are capable of drilling at least 400 m deep HQ (77.8 mm) and NQ (60.3 mm) diameter core.

The core diameter depends on the planned length of the hole (i.e. smaller diameter for longer holes), the information being targeted (i.e. larger diameter for geotechnical holes), and the likely geological units to be encountered (i.e. larger diameter if the hole is likely to go through a major fault zone).

Golder believes the drilling method of wireline with diamond core triple-tube is appropriate for the deposit. Golder believe the drill hole orientations are appropriate to intersect the mineralized zone.

|

|

|

|

|

|

31 March 2009 | 27 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

Figure 11-1: Aguablanca project drilling coverage

|

|

|

|

|

|

31 March 2009 | 28 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

11.1 | Down hole surveying and orientation |

Surveying of some historical holes was carried out by single shot methods as detailed in Section 10.0 which is considered by Golder to be a poor quality down hole survey method as only the dip was measured.

Down hole survey is currently carried out at 3 m intervals using Maxibore surveying equipment. The tool collects the dip and azimuth of the hole and this data is input into the drilling database. Magnetic rocks will not affect the performance of this survey tool.

Validation of the Maxibore tool is carried out by site personnel by running the tool through a 40 m length poly-pipe (simulating a drill hole) located on surface which has been surveyed using a total station. The results of the Maxibore and the total station survey are compared. This test is carried out every few months. The results were made available to Golder and these and the method are considered by Golder to be appropriate for the style of deposit. Rio Narcea has instigated a method for validating and checking the performance of the down hole survey tool which should be continued.

The core orientation is carried out using the Reflex method (see description at http://www.reflexinstruments.com/products.php?ID=16). This method has been examined and accepted by Golder at other sites.

|

|

11.2 | Grade control drilling |

Additional drilling and sampling is carried out by open hole percussion rigs for the purpose of grade control drilling. These holes are drilled to the depth of one bench (8 m), plus 0.5 m of sub drill. The sample is collected by spearing through the various parts of the cuttings around the drill collar using a stainless steel tube until a sample of approximately 10 to 15 kg in the mineral zone and 4 kg on the mineral/waste boundary is achieved. These samples are sent to the on-site laboratory for sample preparation and chemical analysis. This sampling practice is common amongst operating mines but the quality of the data gathered from the practice is considered by Golder to be poor due to the nature of the drilling and sampling methods employed and therefore these are not included in the Mineral Resource database.

|

|

|

|

|

|

31 March 2009 | 29 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

12.0 | SAMPLING METHOD AND APPROACH |

|

|

12.1 | Core collection |

Drill core is recovered in 3 m runs from the drill rig and placed in purpose built, wooden core trays. Wooden depth markers are placed in the boxes at the end of each ‘run’ or at regular depth intervals. The core boxes are appropriately numbered and labelled with indelible ink and incorporate the hole number, box number, metres and depth (Figure 12-1). Core is transported to the site core shed by utility vehicle. The labels were observed by Golder to be correct and appropriately reflect core intervals. It was also observed that core blocks were present and correct in the holes inspected by Golder.

Golder considers that the core handling procedures and core box labelling are appropriate.

Figure 12-1: Labelling of core boxes for Aguablanca resource drilling

|

|

|

|

|

|

31 March 2009 | 30 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

12.2 | Core storage and photography |

The core is stored in a covered core shed located at the mine site (Figure 12-2). The core is systematically photographed using a rack and a standard labelling system. This is shown in Figure 12-3.

Figure 12-2: Aguablanca core shed

Figure 12-3: Example of core photography

|

|

|

|

|

|

31 March 2009 | 31 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

12.3 Sampling

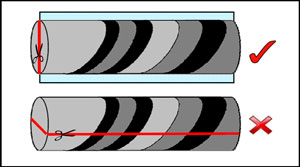

The drill core is cut in half with a core saw perpendicular to the predominant foliation of the rock (Figure 12-4) and sampled at approximately 2 m intervals, always sampling the same side of the core. Sampling intervals are broken by lithology. The maximum sampling interval is 2.2 m and the minimum sampling interval is 0.5 m.

The core samples are placed in a thick plastic bag with a sample identification tag placed inside the bag and sent to a site laboratory.

Figure 12-4: Correct core sawing orientation being used at Aguablanca

Potential loss of fines material from the core during sawing is not considered by Golder to impact on the sampling of mineralisation due to the competency of the core.

The current sampling interval and methodology is considered by Golder to be suitable for this style of deposit.

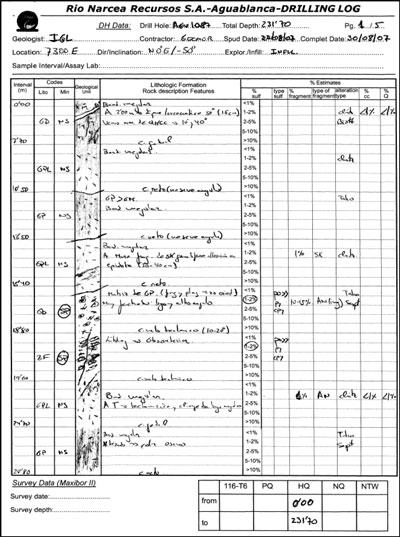

12.4 Logging

Drilled core is received at the Aguablanca core shed for logging and sampling. The core is simultaneously logged for geology and geotechnical parameters, and marked out for sampling. Geologists mark the sampling contacts onto the core box with a suitable marker and logging information is recorded on paper and later transposed to Microsoft Excel spreadsheets.

The core is logged using 23 codes for lithology and 4 codes for mineralogy. The geological unit, major faults, fragments types, alteration type, and estimated sulphide percentage are also logged.

|

|

|

|

|

|

31 March 2009 | 32 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

The list of codes for logging is shown in Table 3 and an example of a completed logging sheet is shown in Figure 12-5.

Table 3: Aguablanca logging codes

|

|

|

|

|

|

|

Rock Type |

| Code |

| Description | ||

Igneous rocks |

| Gabbros |

| GM |

| Melanocratic gabbro: low plagioclase content |

|

| GP |

| Porphyritic gabbro (gabbro-norite): porphyritic crystals of euhedral plagioclase in a pyroxenite matrix | ||

|

| GPL |

| Plagioclase gabbro: abundant plagioclase. | ||

|

| GD |

| Doleritic gabbro: abundant plagioclase connected with doleritic textures | ||

|

| GI |

| Irregular gabbro: variable texture variable, zones of poor crystallization and/or contaminates | ||

|

| GC |

| Contact gabbro: chilled texture chilled, fine grained, generally brecciated and/or banded | ||

|

| Gsm |

| Gabbro with abundant alteration to serpentinite-magnetite-talc. Associated with skarn | ||

| ||||||

| Breccias |

| Gb |

| Magmatic Breccia with enclosed fragments. Gabbroic Matrix gabbroic with or without sulphides | |

|

| Gsb |

| Magmatic Breccia with enclosed fragments. Semi massive sulphide matrix | ||

| ||||||

| Others |

| PX |

| Pyroxenite | |

|

| DI |

| Dioritic rocks | ||

|

| GR |

| Granite-Granodiorite | ||

|

| AN |

| Anorthosite bands and fragments, Calc silicate rocks | ||

Metamorphics |

|

|

| M |

| Banded marble |

|

|

| SK |

| Pyroxenite skarn | |

|

|

| ES |

| Endoskarn | |

|

|

| H |

| Hornfels | |

|

|

| VS |

| Volcano-sedimentary rocks | |

|

|

| PZ |

| Slates with volcanic intercalations | |

Others |

|

|

| OX |

| Gossan |

|

|

| ZF |

| Fault zone. Very fractured gabbro | |

|

|

| REC |

| Fold | |

|

|

| NR |

| Not recovered | |

| ||||||

|

|

|

|

|

|

31 March 2009 | 33 |

|

|

|

| TECHNICAL REPORT AGUABLANCA NI-CU DEPOSIT |

|

|

|

|

|

|

|

|

|

Mineralization |

| Code |

| Description |

| % |

| % |

|

|

|

|

|

|

|

|

|

Sterile |

| NS |

| No sulphides |

| <1 |

| <0.05 |

Disseminated |

| S |

| Disseminated intergranular, weak to moderate po- pn>=cpy>>py |

| 5-10 |

| <0.7 |

| SS |

| Disseminated intergranular, strong po-pn>=cpy>>py |

| 10-20 |

| >0.7 | |

Breccia |

| SB |

| Fragments in a semi massive sulphide matrix (po-pn>>cpy) |

| 20-60 |

| >1.0 |

Patchy |

| SP |

| Regular patches (net-texture) or irregular (associated with a GI y Gb) po-pn-py-cpy |

| variable |

| variable |

Core recovery is calculated by measuring actual core lengths and comparing it to the down hole depths listed as the start of each core run (marked on the core trays). Core recovery for the current drilling is generally around 80 to 95% in mineralized and waste zones.

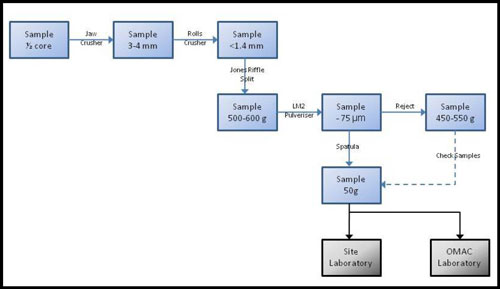

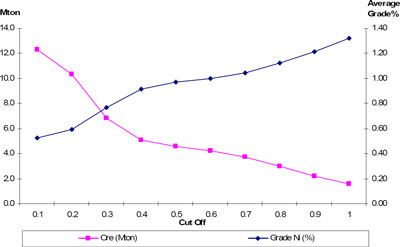

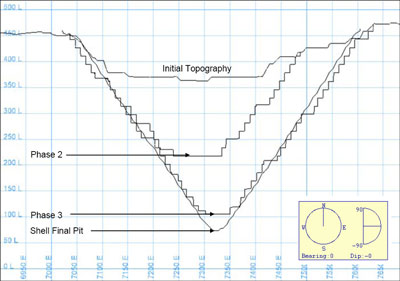

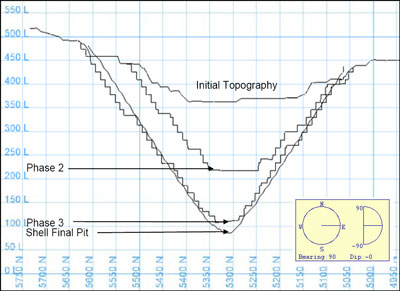

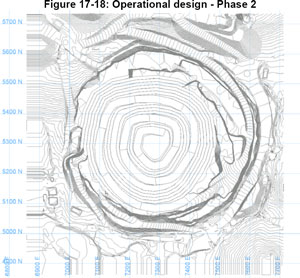

Core logging procedures are appropriate for the geological setting and mineralization. Core recoveries above 85% are appropriate for Mineral Resource estimation.