Exhibit 10.1

Contract No.: LJ20070830

Daqing Longjiang Wind Farm Project

50 MW Wind Power Generator Set

Facilities

Purchase Contract

| Signing Date: Nov. 15, 2007 |

Signed at:Wuhan |

| 1. Definitions | | | 4 | |

| | | | | |

| 2. Subject of Contract | | | 6 | |

| | | | | |

| 3. Scope of Supply | | | 6 | |

| | | | | |

| 4 Contract Price | | | 8 | |

| | | | | |

| 5 Payment | | | 9 | |

| | | | | |

| 6. Delivery and Transport | | | 13 | |

| | | | | |

| 7 Packing and Mark | | | 16 | |

| | | | | |

| 8 Technical Service and Liaison | | | 19 | |

| | | | | |

| 9 Quality Supervision and Inspection | | | 22 | |

| | | | | |

| 10 Installation, Debugging, Commissioning and Acceptance | | | 26 | |

| | | | | |

| 11 Claim | | | 30 | |

| | | | | |

| 12 Insurance | | | 33 | |

| | | | | |

| 13 Taxes and fees | | | 33 | |

| | | | | |

| 14 Assignment, subcontracting and outsourcing | | | 34 | |

| | | | | |

| 15 Change, modification, suspension and termination of contract | | | 34 | |

| | | | | |

| 16 Force Majure | | | 36 | |

| | | | | |

| 17 Settlement of Disputes of the Contract | | | 36 | |

| | | | | |

| 18 Execution of Contract and Valid Period | | | 36 | |

| | | | | |

| 19 Others | | | 37 | |

| | | | | |

Appendix 1 Composing and technical performance of contract equipment | | | | |

| | | | | |

Appendix 2 Supply scope of the seller and itemized price | | | | |

| | | | | |

| Appendix 3 Technical Materials and relevant documents offered by the seller | | | | |

| | | | | |

| Appendix 4 Technical training | | | | |

| | | | | |

| Appendix 5 Requirement and treatment of seller’s technicians | | | | |

| | | | | |

| Appendix 6 Treatment of the buyer’s employees | | | | |

| | | | | |

| Appendix 7 Project schedule | | | | |

| | | | | |

| Appendix 8 Check standard and method | | | | |

| | | | | |

| Appendix 9 Inspection of power curve and availability | | | | |

| Appendix 10 Special tools, spare parts and consumables | | | | |

| | | | | |

| Appendix 11 Acceptance certificate form | | | | |

| | | | | |

| Appendix 12 DNA authentification | | | | |

The contract is signed by and between Daqing Longjiang Wind Power Co., Ltd.(hereinafter referred to as the buyer) and Wuhan Guoce Nordic New Energy Co., Ltd. (hereinafter referred to as the seller ) with friendly negotiation. The items are as follows:

1. Definitions

The terms that are used in this document and in the appendices are hereby defined.

1.1 “The buyer” refers to Daqing Longjiang Wind power Co., Ltd.

1.2 “Seller” refers to Wuhan Guoce Nordic New Energy Co., Ltd.

1.3 “Contract” refers to this document and all parts of its appendices.

1.4 “Contract Price” refers to the part specified in Article 4 herein.

1.5 “Effective date” refers to the effective date of the contract specified in Article 18 herein.

1.6 “Technical Materials” refers to documents (including drawings, various captions, standards and various kinds of software) related to the design, production, inspection, installation, debugging, acceptance and performance acceptance test of the wind farm, and files applied to the correct running and maintenance of the contractual wind farm.

1.7 “Contractual Equipments” refers to the machines, device, materials, things, special tools, spare parts and all other things that are to be supplied by the seller in accordance with the contract.

1.8 “Supervision” refers to that the buyer entrusts a qualified supervisory organization to dispatch a representative or representatives to supervise the quality of the key parts of the contractual equipments in ways of documentary witness and on-site witness during the process of manufacturing the contractual equipments. This kind of quality supervision does not relieve the seller of liabilities for the quality of the contractual equipment quality.

1.9 “Performance Acceptance Test” refers to the test to be made in accordance with the requirements of appendix 7 herein for inspection the guaranteed performance value specified in the technical specifications.

1.10 “Pre-acceptance” refers to the acceptance entering quality guarantee period after the completion of all the tests on and during the installation of equipments supplied by the seller. See appendix 3 herein for pre-acceptance certificate which is to be signed by both parties.

1.11 “Final Acceptance” refers to the acceptance after the quality guarantee period. If tests prove that both performance indexes of each generator and other terms of the contract have been performed and the running of equipments are satisfactory, the buyer will issue a final acceptance certificate on which both the seller and the buyer will sign.

1.12 “Day, Month and Year” refers to the day, month and year by Gregorian calendar; “Day” refers to 24 hours; “Week” refers to 7 days.

1.13 “Contractual Wind Farm” refers to Daqing Longjiang Wind Farm.

1.14 “Technical Service” refers to such all-through services as relevant technical instructions, technical cooperation and technical trainings for the engineering design, equipment construction supervision, inspection, earthwork, installation, debugging, acceptance, performance acceptance test, running and maintenance related to the contractual equipments supplied by the seller.

1.15 “Site” refers to the site of the contractual wind farm. It is the place where the buyer will install the contractual equipments.

1.16 “Spare parts” refers to the parts of the 50 generator sets and its auxiliary equipments to be supplied according to this contract. The spare parts list is shown in appendix 2.

1.17 “Commissioning” refers to the runs during the debugging stage of each system or equipment of the wind power generator sets and the commissioning stage of the wind farm.

1.18 “Generator sets” refers to a complete set of equipments consisting of wind power generator sets and their auxiliary equipments.

1.19 “Written Documents” refers to any manuscript, typed or printed documents with an organization’s official seal.

1.20 “Sub-contractor” or “Sub-supplier” refers to another legal person and her/his successor and an assignee with the approval of this legal person who are subcontracted the five large parts within the contractual scope of supply by the seller.

1.21 “Equipment Defect" refers to such situations that the contractual equipments (including parts, raw materials, castings and forgings, and original parts etc.) may not meet the requirement of performance and quality standard specified in this contract as caused by design, fabrication error or ignorance of the seller.

1.22 “Installation” refers to assembling, installing and connecting each part of materials and equipments within contractual scope to the due locations at the running site according to the drawings.

1.23 “Debugging” refers to start of each wind power generator and the 360-hour-long inspection period for consecutive, unfailing, normal run of the entire system.

1.24 “Quality Guarantee Period” refers to the period from pre-acceptance to final acceptance.

1.25 “Overhaul” refers to regular maintenance and repairing according to the wind power generator sets running manual.

2. Subject of Contract

2.1 Names, Specifications (Types) and Quantities of Equipments

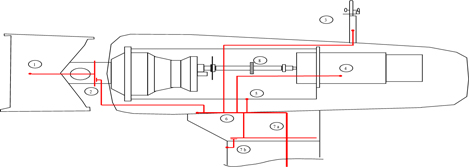

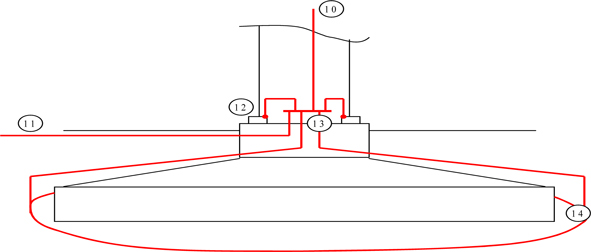

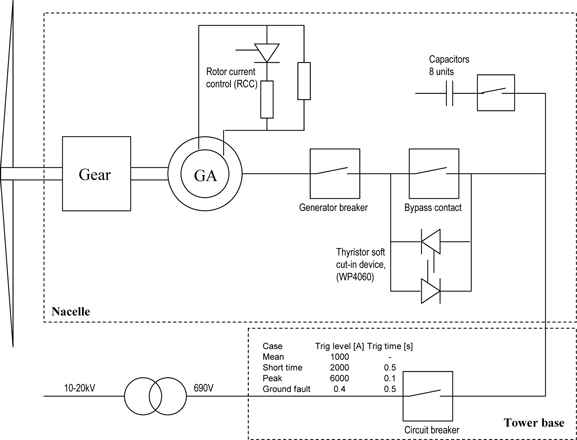

This contract includes manufacturing, transportation, installation, debugging, putting into production and quality guarantee of wind generator sets(excluding manufacturing of fitted tower), and all the auxiliary equipments, spare parts, special tools, consumable materials etc., drawings, each technical service, technical trainings, and necessary technical materials for assembling, inspection, training, technical service, installation, debugging, performance test, normal running and maintenance. See appendix 2 in detail.

2.2 See appendix 1 for the technical performances of contract equipment, and See appendix 9 for the technical guarantee parameters of the contract equipment by the seller.

2.3 The seller shall be liable for the engineering design related to the contractual equipments and provide technical materials.

2.4 All the equipments supplied by the seller shall be totally new, technologically advanced and mature and reliable, and be marked with mechanical processing equipment and test method. Materials used for the equipments must be attached with qualification certificate.

2.5 Delivery condition for the contractual equipment is: on-site delivery at the buyer’s project site. The seller is responsible for applying for train wagon/ship program and contacting related affairs about railway/waterway transport and for transporting the goods to the designated site by the owner.

3. Scope of Supply

3.1 Scope of contractual equipment supply provided the seller:

3.1.1 Scope of equipment supply of the first batch

| S.N. | | Name of contractual equipment | | Type or specification | | Quantity | | Delivery time | | Delivery place |

| | | | | | | | | | | |

| 1 | | Wind generator sets | | DW1.0/56 | | 10 sets | | Within 10 months after signing contract | | On-site |

| | | | | | | | | | | |

| 2 | | Central monitoring system | | DW-CT02 | | 1 set | | Within 10 months after signing contract | | On-site |

| | | | | | | | | | | |

| 3 | | Spare parts | | | | 1 batch | | Within 10 months after signing contract | | On-site |

| | | | | | | | | | | |

| 4 | | Consumables | | | | 1 batch | | Within 10 months after signing contract | | On-site |

| | | | | | | | | | | |

| 5 | | Special tools | | | | 1 set | | Within 10 months after signing contract | | On-site |

| | | | | | | | | | | |

| 6 | | Training (at home) | | | | 120 persons/days | | Within 6 months after signing contract | | On-site |

| | | | | | | | | | | |

| 7 | | Training (abroad) | | | | 30 persons/days | | Within 6 months after signing contract | | On-site |

| | | | | | | | | | | |

| 8 | | Instruction for installation and debugging | | | | Entire process of installation and debugging | | Within one week after equipments arrive at the site. | | On-site |

| | | | | | | | | | | |

| 9 | | Quality guarantee technical service | | 24 months | | According to the demand | | To begin after completing on-site installation | | On-site |

| | | | | | | | | | | |

| 10 | | Technical documents | | | | 10 sets | | Before signing contract | | On-site |

| | | | | | | | | | | |

| 11 | | Transport and insurance | | | | 10 sets | | Be handled before delivery | | On-site |

3.1.2 Supply scope of equipment of the second batch

| S.N. | | Name of contractual equipment | | Type or specification | | Quantity | | Delivery time | | Delivery place |

| | | | | | | | | | | |

| 1 | | Wind generator sets | | DW1.0/56 | | 40 sets | | Within 10 months after the beginning of the execution time in written form by the buyer | | On-site |

| | | | | | | | | | | |

| 2 | | Spare parts | | | | 1 batch | | Within 10 months after the beginning of the execution time in written form by the buyer | | On-site |

| | | | | | | | | | | |

| 3 | | Consumables | | | | 1 batch | | Within 10 months after the beginning of the execution time in written form by the buyer | | On-site |

| | | | | | | | | | | |

| 4 | | Instruction for installation and debugging | | | | According to the demand | | Within one week after equipments arrive at the site. | | On-site |

| | | | | | | | | | | |

| 5 | | Quality guarantee technical service | | 24 months | | According to the demand | | To begin after completing on-site installation | | On-site |

| | | | | | | | | | | |

| 6 | | Technical documents | | | | 40 sets | | Before signing contract | | On-site |

| | | | | | | | | | | |

| 7 | | Transport and insurance | | | | 40 sets | | To handle before delivery | | On-site |

3.2 The contractual scope of supply includes all the equipments, technical materials, special tools, spare parts and consumables. Any item, which is not listed in the invoice but should have been in the scope of supply by the seller and is necessary for the requirement of the performance guarantee value of contractual equipment meeting technical specifications, is found missing during the process of executing the contract, the seller shall be responsible for supplementing all the missing equipments, Technical materials, special tools and spare parts, for which the incurred fees the buyer does not bear.

4 Contract Price

4.1 The contract price is the total price of the contract

The total price of this contract is 316,900,238 Yuan, which mainly includes:

(1) 50 equipments 287,500,000 Yuan (50 sets×5,750,000Yuan/set);

(2) The sum of other fees is 29,400,238 Yuan, which includes fees of technical materials, technical service, taxes of contractual equipments, transportation and incidental expenses from manufacturer to project site, insurance fee etc. and all the other fees related to this contract.

4.1.1 Price of Contractual equipment

The price of this contractual equipment includes all the taxes, fees, and technical material fees, transport fees from the manufacturer to project site, insurance fees and all the equipment package fees.

4.1.2 Transportation and incidental expenses of the contractual equipments from starting station (on board)/ dock (on board) to the delivery site are born by the seller.

4.1.3 Insurance fees of the contractual equipments from starting station (on board)/ dock (on board) to the delivery site are born by the seller.

4.2 Itemized price see annex 2.

4.3 The above contractual price does not include fees for hoisting equipment at the buyer’s site.

4.4 The total value of this contract does not vary within the effective period of the contract.

5. Payment

5.1 Currency used in this contract is RMB.

5.2 Terms of payment: P.O. or T.M.

5.3 Payment for the contract price of the first batch of equipments paid in accordance with the following terms:

5.3.1 Within 30 days from the date when the contract comes into force, the buyer will pay five percent (5%) of the total price of the contract, i.e. 15,845,000 Yuan to the seller as deposit money.

5.3.2 Within 60 days from the date when the contract comes into force, the buyer will pay twenty five percent (25%) of the price of the first batch of equipments, i.e. 15,687,500 Yuan, as payment in advance, to the seller upon receiving the following receipt of the seller which is found in order by the buyer.

a) Issue a receipt with amount of twenty five percent (25%) of the contract price of the seller’s company sealed with the special financial stamp of the seller’s company, indicating such contents as product name, amount, unit price, total price and contract No. etc.

5.3.3 When the equipments arrive at the site, the buyer will pay thirty five percent (35%) of the price of the first batch of equipment, i.e. 22 151 500 Yuan to the seller after receiving the goods delivered within the specified time according to the delivery progress by the seller upon receiving the following documents of the seller which are found in order by the buyer:

a) Two originals and three duplicate copies of detailed packing list;

b) Two originals and three duplicate copies of manufacturer’s quality and quantity certificates;

c) Tow originals and three duplicate copies of receipt sealed with special financial stamp issued by the seller’s company equivalent to thirty five percent (35%) of the price of the first batch of equipment, i.e. 21,976,500 Yuan, indicating such contents as product name, amount, unit price, total price and contract No. etc..

d) Three copies of delivery receipt/railway transport document/truck receipt/shipping document;

e) Copies of shipping notification to the buyer to notify him of the starting time of shipment, arriving time, quantity, weight and amount etc. of the goods 24 hours after delivery by the seller;

f) Two originals and three copies of origin certificate of products.

5.3.4 After the on-site debugging is completed, the buyer will pay thirty percent (30%) of the price of the first batch of the equipments, i.e. 18,837,000 Yuan to the seller after the seller completes equipment installation and received the following documents of the seller in accordance with the contract which are checked by the buyer:

a) Issue a receipt sealed with special financial stamp issued by the seller equivalent to thirty five percent (30%) of the price of the first batch of equipment, i.e. 18,837,000Yuan, indicating such contents as product name, amount, unit price, total price and contract No. etc..

b) Three pre-acceptance certificates issued by the buyer proving that the seller has completed equipment installation and debugging in accordance with the contract;

c) At the same time submit to the buyer the value-added invoice of the contract price of the first batch equipment (the sum is 100% of the contract price of the first batch of equipments, one in original and four in duplicate copies).

5.3.5 Payment condition for quality guarantee deposit: the quality guarantee deposit is five percent of the contract price of the first batch of equipments i.e. 3,139,500 Yuan upon receiving the following documents of the seller which are found in order by the buyer:

a) Two originals and two copies of the final acceptance certificates signed by representatives of both parties;

b) Issue a receipt sealed with special financial stamp issued by the seller’s company equivalent to five percent (5%) of the price of the first batch of equipment, indicating such contents as product name, amount, unit price, total price and contract No. etc.;

c) The buyer has the right to deduct from the above mentioned payment from the claim or penalty that the seller shall pay.

5.4 Payments for the contract price of the second batch of equipments are paid in accordance with the following terms:

5.4.1 Within 30 days after the seller receives the written notification of the buyer and the production of the second batch equipments start, the buyer pay twenty five percent of the total contract price of the second batch of equipments, i.e. 63,527,500 Yuan, as payment in advance to the seller after receiving the following references and find them in order:

a) Issue a receipt with amount of twenty five percent (25%) of the contract price of the seller’s company sealed with the special financial stamp of the seller’s company, indicating such contents as product name, amount, unit price, total price and contract No. etc.

5.4.2 When the equipments arrive at the site, the buyer will pay thirty five percent (35%) of the price of the second batch of equipment, i.e. 88,938,500 Yuan to the seller after receiving the goods delivered within the specified time according to the delivery progress by the seller upon receiving the following documents of the seller which are found in order by the buyer:

a) Two originals and three duplicate copies of detailed packing list;

b) Two originals and three duplicate copies of manufacturer’s quality and quantity certificates;

c) Issue a receipt sealed with special financial stamp issued by the seller’s company equivalent to thirty five percent (35%) of the price of the second batch of equipment, i.e. 88,938,500 Yuan, indicating such contents as product name, amount, unit price, total price and contract No. etc..

d) Three duplicate copies of delivery receipt/railway transport document/truck receipt/shipping document;

e) Copies of shipping notification to the buyer to notify him of the starting time of shipment, arriving time, quantity, weight and amount etc. of the goods 24 hours after delivery by the seller;

f) Two originals and three duplicate copies of origin certificate of products.

5.4.3 Pay thirty percent (30%) of the price of the first batch of the equipments, i.e. 76,233,000 Yuan to the seller after the seller completes equipment installation in accordance with the contract upon receiving the following documents of the seller which are found in order by the buyer:

a) Issue a receipt sealed with special financial stamp issued by the seller’s company equivalent to thirty percent (30%) of the price of the second batch of equipment, i.e. 76,233,000 Yuan, indicating such contents as product name, amount, unit price, total price and contract No. etc..

b) Three certificates issued by the buyer proving that the seller has completed equipment installation and debugging in accordance with the contract.

5.4.4 Payment condition for quality guarantee deposit: the quality guarantee deposit is five percent (5%) of the contract price of the second batch of equipments i.e. 12,705,500 Yuan upon receiving the following documents of the seller which are found in order by the buyer:

a) Two originals and two copies of the final acceptance certificates signed by representatives of both parties;

b) Tow originals and three duplicate copies of receipt sealed with special financial stamp issued by the seller’s company equivalent to five percent (5%) of the price of the second batch of equipment, indicating such contents as product name, amount, unit price, total price and contract No. etc.;

c) The buyer has the right to deduct from the above mentioned payment from the claim or penalty that the seller shall pay.

6. Delivery and Transport

6.1 The delivery date and sequence of this contract equipment shall meet the requirement of equipment installation progress and sequence of the project to guarantee the timeliness and completeness of equipment. The contract equipments should be delivered as a whole as possible. Special tools and spare parts are shipped with the first batch of contract goods.

6.2 Delivery place: the delivery place of the contract equipments is the buyer’s project site.

6.3 Within 45 days from the date when the contract comes into force, the seller shall provide names, total weight, and total volume of each batch of goods, primary delivery plan of delivery date and total product lists under the terms of this contract and total packing lists (including one disc or disk). 30 days before the start of the expected shipment of each batch of goods, the seller shall notify the buyer of content of each item in article 6.5 with fax.

6.4 The seller shall deliver the goods to the destination designated by the buyer the buyer’s project site, and shall be responsible for all the affairs for delivering the goods to the destination designated by the buyer including insurance and middle-way storage specified in the contract and the related fees shall be contained in the contract price; the seller delivers goods at one time and the actual delivery date shall be considered as the day when the goods arrive the site. This date shall be the basis for calculating the penalty for later delivery of good hereof.

6.5 Within 24 hours after the goods are ready and shipping vehicles/ships are sent off, the seller shall notify the seller of the following contents about this batch of goods.

a) Contract No.;

b) Goods delivery starting date;

c) names, codes and price of good;

d) Gross weight of goods;

e) Total volume of goods;

f) Total packed quantities;

g) Handing-over railway station/dock name/vehicle license No./ship License No. and waybill No.;

h) Names, weight, volume and quantities of each product exceeding 20 tons in weight and 9m×3m×3m in size. Center of gravity and hoisting point must be indicated for each piece of such equipment (part) with sketches attached.

i) For special products (equipments or substances having special requirement for environmental factors such as temperature and vibration and explosive, flammable and poisonous substances and other dangerous products), special indications must be made for its name, code, quality, special protective measures, storage method and accident treatment methods.

The seller shall at the same time airmail to the buyer one original and six duplicate copies of a detailed equipment list containing equipment code, specification, quantity, gross weight, total volume and size (length, width and height), unit price, total price, shipment starting place, shipment ready date, estimated arriving date and special requirements and attentions during transporting and storing process. For large parts exceeding 15 tons and 15m, 2m, 2m in length, width and height respectively and parts with special shape, the seller shall airmail to the buyer one original and three duplicate copies of an appearance drawing indicating center of gravity and hanging point. Within 5 days after shipment, the seller shall send to the buyer a set of the following nonnegotiable documents with express mail:

a) Commercial invoice

b) Packing list/weight list

c) Certificates of quality and quantity

d) Copies of transport documents

6.6 Products not invoiced shall be delivered on the basis of installation progress.

6.7 Before the ending of quality guaranteeing period, in case that spare parts in the buyer’s storage for replacing damaged equipment or parts are used because of the damage or potential deflect caused by the seller’s error or neglect, the seller shall be responsible for supplement all the used spare parts for free, and the seller shall transport them to the designated destination railway station/dock not later than 60 days with the knowledge of the buyer.

6.8 The seller shall, in accordance with the provision, provide Technical materials needed for wind farm design, construction supervision, debugging, test, inspection, training, running and maintenance to the sell batch by batch. The seller shall give the technical materials to the buyer with express mail or delivery within 6 weeks after the execution of the contract. Each set of technical materials shall contain one original and six duplicate copies of a detailed packing list. Provide 3 sets of Technical materials and relevant discs for equipment of each set according to the provision. A list of the above mentioned Technical materials shall be listed.

6.9 The Technical materials are usually delivered in the way of postal express. After each batch of Technical materials are delivered, the seller shall notify the buyer of the delivery date, mail No.; detailed list of Technical materials, quantity and weight and contract No. etc. with fax within 24 hours.

6.10 The actual delivery date is considered as the postal mark date on the consignment notice of the postal department. This date will be used as the basis for delay penalty calculation for any late document delivery according to article 11.10 of the contract. If it is found that technical materials are missed, lost or damaged after checked by representatives of the buyer or seller, and not caused by the buyer, the seller shall supplement and provide to the site the missed, lost or damaged parts thereof for free within 14 days (7 days for urgent affairs) upon receiving notification of the buyer. If the Technical materials are missed, lost or damaged because of the buyer, the seller shall supplement and provide to the site the missed, lost or damaged parts thereof within 14 days (7 days for urgent affairs) upon receiving notification of the buyer and the fees are born by the buyer.

6.11 The buyer can dispatch a representative to the seller’s factory and shipment station to check packing quality and monitor loading situation. The seller shall inform the buyer of the delivery date 20 days in advance. If the representative of the buyer can not participate in inspection in time, the seller has the right to send out goods. Inspection and monitoring of the above mentioned representative may not relieve the seller of its due liabilities.

6.12 The seller is required to delay equipment delivery because of the buyer(when the equipment fabrication is already completed), the buyer shall bear storage fee and maintenance fee if necessary.

6.13 The seller is liable for the loss of good during delivering process.

6.14 Station of arrival: Beidagang, Bayan Chagan village, Mongolian self-government county of Duerbote.

6.15 Goods acceptance unit: Daqing Longjiang Wind power Co., Ltd.

6.16 Mailing address of technical data

Unit: Daqing Longjiang Wind power Co., Ltd.

Address: ICBC Building, No. 37 of Dongfeng Rd. Saertu district, Daqing city.

Zip code: 163311

Fax: 0549-4621899

Tel.: 0459-4627259

Contact: Lin Baojun

7 Packing and Mark

7.1 All the goods delivered by the seller shall comply with provisions in GB191-73 packing, storage and shipping direction mark and firm packages applicable to long-distance transport, repetitious moving, loading and unloading specified by the national supervisory organ. The packaging shall be complete and intact during transport, loading and unloading process equipped with vibration-reducing and impact-proofing measures. If the packages can not prevent the equipments from damages caused by vertical and horizontal added speed during transport, loading and unloading process, the buyer shall solve the problem in the design structure of equipments. The packaging shall be equipped with protective measures for preventing humidity, mold, corrosion and rust when needed according to equipment characteristics. Consider to prevent freezing when in severe winter. Deliver the goods safely to the installation site, ensuring there is no any damage or corrosion of the goods. Before product packaging, the seller is responsible for inspection and cleaning without foreign things left and guaranteeing complete parts and components.

7.2 The seller shall clearly mark component No. and part No. in the installation daring for each bulked parts and components within the packing box.

7.3 The seller shall print the following marks at the four neighboring sides of each packing box in Chinese characters with striking unfading paint.

a) Contract No.;

b) Shipment station/dock;

c) Destination station/dock;

d) Names of supply and receiving units;

e) Name of equipment, set No. and drawing No.;

f) Box No./Piece No.;

g) Gross weight/net weight (kilogram);

h) Volume (length×width×height, expressed with mm).

For goods with or exceeding two tons, the side of the packing box shall be indicated with center of gravity and hoisting point with common mark and pattern for the convenience of loading, unloading and transport. According to the goods features, different requirement for loading, unloading and transport, such words as “gently place” “no upside-down” and “anti-rain” shall be brushed on the packing box.

For nude packed goods, the above mentioned relevant contents shall be indicated with metal label or directly on the equipment. Large goods shall be equipped with sufficient support or packing cushions.

7.5 Within each packing box, detailed packing list for names of sub-items, quantity, price and set No., qualification certificate and related equipment technical materials etc. shall be attached. One technical instruction and one quality certificate for product acceptance respectively should be in the packing box of the purchased parts. Another two packing lists shall be sent by mail.

7.6 Spare parts listed in the contract shall be packed respectively according to each set of equipment, and indication shall be made at the external side of the packing box as one-time delivery.

7.7 Spare parts shall be packed separately, and in accordance with article 7.2, special tools shall also be separately packed. Special tools and spare parts are shipped with the main contract goods.

7.8 Bulked parts for equipment of each set shall adopt good packing method and put into suitable box, and send out within one vehicle if possible to reduce transport fees.

7.9 Latticed box and/or similar packages shall be capable of containing equipments and spare parts that may not be stolen or damaged by other substances or rain.

7.10 All ports of all pipes, pipe fittings, valves and other equipments must be protected with covers or otherwise properly protected.

7.11 The seller and/or other sub-contract shall not indicate any two boxes with one box No..

7.12 For goods with bright and cleaning process surface in need of accurate assembly, the process surface shall be protected with fine and durable layer (no paint is allowed) to prevent the occurrence of rust corrosion o r damages before installation.

7.13 The seller shall, 6 weeks after the contract comes into force, use packages applicable for long-distance, repetitious moving, rain prevention and humidity prevention for the Technical materials delivered and files together with equipments. The cover of each technical material package shall indicate the following contents:

a) Contract No.;

b) Names of supply and receiving units;

c) Destination station/dock;

d) Gross weight;

e) Box No./Piece No..

Within each material package, one original and two duplicate copies of a detailed list of technical materials indicating Technical materials’ sequence No., Document Item No., Name and pages shall be attached.

7.14 Where the good are damaged or lost because of the bad packing or keeping of the seller, anytime or anywhere, once validated, the seller shall be responsible for timely repairing, replacement or compensation according to Article 11 of this contract. When the goods are damaged or lost during the transport, the seller is responsible for negotiate with insurance company and transport-undertaking department, and at the same time shall supplement the goods as soon as possible to the buyer to meet the demand of construction period.

7.15 The buyer shall return to the seller the special packing box and frames for multiple uses after the parts and components are delivered and confirmed (the seller shall bear the fees).

7.16 Within 5 working days after the equipment transport, the seller shall inform the buyer of storage and transport methods with fax and the buyer shall strictly follow the direction as possible.

7.17 If the contract equipments are damaged or lost because of the incorrect packing by the seller before loading and shipment, the seller shall be responsible for replacing, repairing and compensating according to the contract.

8 Technical Service and Liaison

8.1 The seller shall timely provide such all-through services as relevant technical instructions, technical cooperation and technical trainings for the engineering design, equipment construction supervision, inspection, earthwork, installation, debugging, acceptance, performance acceptance test, running and maintenance related to the contractual equipments supplied by the seller.

8.2 The seller shall send representatives to the site of the contractual wind farm to provide technical service and instruct the buyer through the process of installation, partial commissioning, debugging and start-up according to the Technical materials from the seller. And the seller shall also be liable for settlement any problem concerning manufacture quality and performance that arises during installation, debugging and commissioning.

8.3 The seller shall submit the plan for carrying out the services stated in item 8.1 and 8.2 in duplicate to the buyer by mail within 60 days after the contract comes into effect.

8.4 Both parties shall determine the frequency, time and place of the technical liaison meeting within 30 days after the contract comes into effect.

8.5 The seller is under the obligation to invite the buyer to participate in the seller’s technical design when necessary and is also liable for the interpretation of the design.

8.6 In case there are big problems that call for the immediate negotiation of both parties, either of the two parties can propose a meeting and generally the other party shall agree to attend the meeting.

8.7 As to each meeting and other types of liaison, the meeting or liaison minute shall be signed and enforced by both parties. In case the contract terms and conditions are to be amended, it shall be approved by the legal representative of both parties and the amended version shall be the standard.

8.8 In case the seller is to amend the scheme for installation, debugging, running and technical service proposed by the seller and confirmed by both parties at the meeting, the seller shall inform the buyer in written form for confirmation. In order to meet the requirements of site conditions, the buyer has the right to suggest alteration or amendment and shall inform the seller in written form. The seller shall take full consideration and meet the requirements of the buyer as possibly as it can.

8.9 The seller or the buyer has the right to distribute the materials related to the contractual equipments provided by the counterpart to all parties involved in the project, and no forms of tort thus arises. However, in no circumstances shall the materials be provided to the third party who is not involved in the project.

8.10 As to the materials of the seller and the buyer which are sealed with “CONFIDENTIAL”, both parties undertake the confidentiality liabilities and obligations.

8.11 In case the seller’s sub-contractor needs part of the technical service related to the contractual equipments or works in the site, it shall be organized by the seller and approved by the buyer. All the expenses shall be borne by the sub-contractor itself.

8.12 The seller (including subcontracting and outsourcing) shall undertake the full liability for supply, equipment, technical interface and technical service involved in the contract.

8.13 As to other equipments connected with the contractual equipments, the seller is under the obligation to provide interface and technical cooperation and no other expenses thus arises beyond the contract price.

8.14 The technicians who are sent to the site by the seller to offer services shall be experienced and competent. The technicians shall be confirmed by the buyer within 60 days after the contract comes into effect. The buyer has the right to suggest replacing those who fail to meet the requirements, and the seller shall assign new technicians recognized by the buyer. In case the seller fails to make a timely reply to the request for replacing incompetent technicians by the buyer, it shall be regarded as the delay of the project according to item 11.11.

8.15 The seller shall be liable for the loss caused by the technicians’ negligence or faults in instructing the installation, debugging and commissioning or by the seller’s failure in assigning personnel for instruction according to the requirements.

8.16 Specific requirements for technical service and liaison

8.16.1 Technical materials and design of liaison meeting

The seller and the buyer shall prepare technical materials for technical liaison meetings. The content, time, place and participant of the meetings shall be determined by both parties. As to the scope of the seller’s technical materials, please refer to appendix 6 — list of technical materials

In the course of designing and interpreting, solution for problems shall be reached by all parties so as to ensure the economy and efficiency of the project and the reliability of technology.

The acceptance of the technical materials by the buyer does not exempt the buyer from any liability in the contract.

8.16.2 Drawing, planning and calculating

The seller shall prepare essential detailed drawings. The drawings shall be authentic and complete so that the buyer can consider the design of the project accurately.

The seller shall examine the drawings provided by the subcontractors in terms of dimension, components size and materials and sign the date of approval when they are considered to be up to the requirements and technical criteria. In case the drawings are not accurate or with error, the seller shall return them to the subcontractor for amendment before submitting them to the buyer.

The drawings submitted by the seller shall be noted with names of the drawings and confirmed by both the seller and the subcontractor. The drawings shall be supplied according to the specified number of copy.

The drawings are supplied by filling in the assignment note/form with serial number and caption.

Each drawing has one caption, serial number, issue number and scale.

Each drawing shall adopt metric scale and be note with proportion.

Design the calculation tables that can be checked and the calculation in manuscript are not accepted

The drawings for final installation and running shall be regularly renewed. In the process of debugging, the renewed drawings shall be examined by the seller and confirmed by the representative of the buyer. The “as-built drawings” shall be based on the renewed drawings.

The seller shall prepare the final complete drawings, i.e. the “as-built drawings” which are to be one part of the final operation and maintenance manual. After the final drawings are completed, the seller shall provide them in quintuplicate to the buyer.

All documents shall be specific enough for the buyer to operate each part of maintenance, disassembly and debugging.

8.16.3 Training program

o The seller’s liability of training: the seller shall bear all the buyer’s expenses on transport, accommodation, training materials as well as other expenses during the training in the seller’s factory; the seller is also liable for the second-round training in the course of installation and debugging.

o The seller’s commitment for the training effect: The seller must guarantee adequate training time and training quality and ensure the technicians from the buyer can master the skills in full maintenance of the equipments.

8.16.4 Others

According to the contract, during the operating period of the equipments, the seller and the buyer shall answer the questions concerning the design and technology posed by the counterpart.

Besides the formal training, the buyer has the right to send technicians to the seller to receive training at their own expenses.

During the period of training, the personnel from the buyer shall be permitted to have access to the seller’s workshop and similar operating equipments for the sake of installation, debugging and maintenance.

8.16.5 Time for maintenance of wind power generator breakdowns: On receiving the maintenance notification from the buyer, the seller shall arrive at the site within 36 hours after ascertaining the status of the breakdown.

9 Quality Supervision and Inspection

9.1 Supervision

9.1.1 The seller should offer design, fabrication and inspection standard catalog for the contract to the buyer in 30 days on the date when the contract takes effect.

9.1.2 The buyer will consign supervision units who are qualified or delegate representatives, together with identifiers from the seller, to do equipment construction supervision and test before leaving factory to understand the instance of equipment assembling, inspection, testing and casing quality, and sign. The seller has the responsibility to cooperate with supervisors to offer relative data and standards without assuming any charge from them in time.

9.1.3 Supervising range and detailed supervising testing/witness item include full course of products involved in the contract.

9.1.4 The seller should offer data follows to the supervising test of factory stationed representatives and supervising representatives:

9.1.4.1 When delivering equipment materials according to the contract, producing plan of the whole equipment and producing schedule and inspection project per month should be offered.

9.1.4.2 Offer supervising content and inspection time for equipment 7 days before action.

9.1.4.3 Offer standards (including factory standard), drawing, data, craftwork and practical craftwork course, inspection record, relevant files and copies related to the equipment supervision in the contract.

9.1.4.4 Give working and living convenience to the supervising representatives.

9.1.5 Supervising inspection/witness (usually on-site witness) should not affect the producing schedule in gear (not including shutdown inspection when significant problem appears), and should take practical producing course of the seller into account. If supervising representatives can not arrive to the locale on the informed time from the seller, testing work of the seller’s factory can be on the rails, with the results in effect, but the supervising representatives have the right to know, consult and copy the report and results of inspection and testing after (assignment to documentary witness). If the seller checks separately without informing supervising representatives, the buy will not accept the inspection results, and the seller should test with the seller’s representatives on the site.

9.1.6 Through supervision, when finding equipments and materials not matching standards and casing in the contract, supervising representatives have the right to make remarks and not to sign. And the seller should improve to ensure product quality. No matter the supervising representatives know or claim to know, the seller has the responsibility to tell initiatively and timely the big quality defects and problems through fabrication of contracted equipment. Keeping back is not allowed and the seller should not handle separately when the supervising unit knows nothing about it.

9.1.7 No matter supervising representatives are concerned with supervision and leaving factory check, or supervising representatives attend supervision and inspection, and sign the supervision and check report, it can not be considered as the seller unchaining the quality insurance responsibility under contract item 11, and it can not prevent the responsibility the seller should take on the equipment quality.

9.2 Factory Inspection and Open package inspection

Factory Inspection:

9.2.1 The seller should check and test the product under quality test project in appendix 7. The seller should offer quality certification, or quality certification of the producer the seller affirms, including physics and chemistry analysis certification. The seller should take all charge on check and test. And the seller should inform the buyer the exact date 2 weeks in advance before equipment check and test.

9.2.2 All contracted equipment/parts (including subcontracting and outsourcing) applied by the seller should be check and test strictly through producing process, and parts and/or the complete machine should be equipped and tested before leaving factory. All check, test and assembling should be recorded formally. And acceptance certification, as a part of technique data, should be posted to the buyer for data save. Besides, the seller should offer acceptance certification and quality certification in random files.

9.2.3 Identifiers from the buyer have the right to make remarks when they find defects on the equipment or unconformity to the contract. The seller should think over and adopt necessary measure to eliminate the defects, and all fees shall be born by them. After deflects are cleared, the seller should test and check once again, with all fees born by the seller.

9.2.4 Quality inspection and testing made by identifiers from the seller in fabricating factory of the seller does not equal to open package inspection and testing after the equipment reaches the building site, so the seller should still take quality responsibility.

9.2.5 The seller should offer necessary working facilities, technical data, drawing, testing tools and outfits to the buyers for free.

Open package inspection:

9.2.6 When products reach the destination, the buyer should reach the locale within 4 days after receiving the notice from the seller on his own expense, and check the casing, appearance and amount according to the waybill and packing list together with the buyer. Any unconformity that is affirmed to be the seller’s responsibility by the two parties should be solved by the seller. After the product reaching the locale, the buyer should open the box and test the amount, specs and quality as soon as possible. The buyer should inform the date of box opening test to the seller 2 day before test, and the seller should sent identifiers to attend locale test. The buyer should give working and living convenience to the identifiers from the seller. If the seller’s personnel do not reach the locale on time, the buyer has the right to open the box and test separately, and the test results and records have the effect to both sides and are the evidence in effect when the buyer claims compensation to the seller.

9.2.7 When any damage, defect, shortage or unconformity to quality standard and criterion in the contract on the equipment for the seller’s reason is found through locale test, record should made and be signed by both parties, each side keeping one as the gist for claiming repairing and/or changing and/or compensation; if the seller asks the buyer to repair the equipment, all the repairing charge should be taken by the seller; if damage or shortage for the buyer’s reason are found, the seller should offer or change relevant parts as soon as possible after receiving notice from the buyer, with all charge taken by the buyer.

9.2.8 If the seller dissents the requirements of repairing, changing and compensation from the buyer, he should bring forward it within 7 days after receiving written notice from the buyer, or the requirements will come into existence. If dissenting, the seller should send representatives to the locale on his own expense to test again within 15 days after receiving the notice.

9.2.9 If representatives from the two parties can not be unanimous on the test records, they can consult wind farm testing institution to test. The test results have sanction to both sides and the test charge should be taken by the responsible party.

9.2.10 When receiving compensation claim from the buyer under the contract items, the seller should repair, change or reissue the shortage as soon as possible, all charge, including fabricating, repairing, carriage, and insurance should be taken by the responsible party. The compensation claim laid before will be deducted from contract fulfilling guarantee or the next payment by the buyer.

9.2.11 For the repairing or changing time of equipment or parts for the seller’s reason, under the principle that without affecting the building progress, but no later than 7 days after finding the defect, damage or shortage, or it will be solved under item 11.11.

9.2.12 The time of the buyer claims for compensation on the tested product will be not later than 180 days after products’ reaching on equipment storing field of contracted wild farm.

9.2.13 Inspection in item 9.2.2 to item 9.2.10 is only for the test of arrival products. Though no problem is found or the seller has changed or repaired under compensation claim, it can not be taken as the seller’s unchaining of quality assurance responsibility under item 11.

9.3 Quality Check and Accept of Fan Tower and Fan Foundation

Quality Check and Accept of Fan Tower: the seller should send personnel to attend the quality check and accept of the tower when leaving factory, and signs and issues tower leaving factory quality check and accept certification together with the buyer and tower producing and supervising party.

Quality Check and Accept of Fan Foundation: the seller should send personnel to attend the quality check and accept of finish of fan foundation, and signs and issues tower foundation finish quality check and accept certification together with the buyer and supervising party.

10 Installation, Debugging, Commissioning and Acceptance

10.1 The contract equipments are installed, adjusted, run and maintained see appendix 2.

.10.2 The acceptance after the completion of the contract equipment installation shall be conduced according to the requirement of the installation check list in appendix 8.

10.3 After the contract equipment is finished installation, the seller shall dispatch people to instruct debugging and solve equipment problems during the debugging as possible. The time needed for settlement equipment problems shall not exceed 14 days, otherwise it will be treated as delaying construction period according to article 11.11.

10.4 Performance acceptance test shall be conducted after all the equipments of each set run stably and run consecutively and stably for 360 hours. The buyer is responsible for this acceptance test and the seller participates. After the performance acceptance test is completed, and the contract equipments reach each performance guarantee index specified by power curve and availability in appendix 9, the seller shall sign the equipment performance pre-acceptance certificate with the seller within 10 days. If the contract equipments can not reach one or several indexes specified by the power curve and availability in appendix 9, it is treated according to article 10.6 and 11.7.

10.5 Subject to the condition of not affecting safe and reliable run of the contract equipments, if there is certain small flaw, and that the seller repairs the above mentioned flaws within the agreed time by both parties, the seller may agree to sign the performance pre-acceptance certificate.

10.6 If the first performance acceptance test can not reach one or several performance guarantee values specified by the power curve and availability in appendix 9, both parties shall analyze the reasons together and clarify liabilities which shall be born by the responsible party for taking measures, and within 30 days after the completion of the first acceptance test conduct the second acceptance test and conduct commissioning that is consecutive, unfailing, safe and stable for 360 hours.

10.7 After the second performance acceptance test, if there are still one or several technical indexes that can not reach the performance guarantee values specified by the technical specification of this contract, both parties shall study and analyze reasons together and clarify liabilities: if it is because of the seller, article 11 of this contract is executed; if because of the buyer, this contract equipment should be considered as passed the performance acceptance, and within 10 days thereafter, the representative of the buyer will sign the performance pre-acceptance certificate of this contract together with the representative of the seller. But the seller is still obligatory to take measures with the buyer to make the performance of the contract equipment to reach the guarantee value.

10.8 If the commissioning and performance acceptance test on the contract equipments can not be made due to the buyer’s reason, after 24 months after the arrival of the contract equipment at the site, it will taken as passed final acceptance, and within 10 days thereafter, the buyer shall sign the final acceptance certificate together with the seller. 360 hours after the stable running of the contract equipments, the delaying period of the performance acceptance test caused by the buyer exceeds 5 days, within 10 days thereafter, the buyer shall sign the performance acceptance certificate together with the seller.

10.9 Whether the performance acceptance test of the contract equipment is made once or twice, the buyer will issue the final acceptance certificate within 5 days after finishing claim from the day when the pre-acceptance certificate is issued to 24 months according to the provision of article 11.4.

10.10 Performance acceptance certificate issued according to article 10.4 and 10.7 only prove that the equipment performance and parameters are accepted up to the time when the performance acceptance certificate is issued according to the contract requirement, but can not be considered as evidence for relieving relevant liabilities of the seller for possible existing deflect that may cause damage of the contract equipments. Likewise, the final acceptance certificate shall also not be considered as evidence for relieving relevant liabilities of the seller for possible existing deflect that may cause damage of the contract equipments.

Potential deflect reforest to the potential danger of the equipment that can not be found under normal situation during manufacturing and short-term running process. The period of liability of the seller for correcting potential deflects shall last till the termination of the 24 months guarantee period to the first overhaul. When such potential deflect is found (through confirmation of both parties), the seller shall repair or replace according to the specification of article 6.7 and 11.3.1 hereof.

10.11 Anytime during the process of executing the contract, for the request of the seller on inspection testing, retesting, repairing or replacing work out of the need of the seller’s responsibilities, the buyer shall make arrangement to cooperate with the above mentioned work. The seller shall bear fees for repairing, replacement or labors. If the seller entrusts constructor of the buyer to process and/or repair and replace equipment, or there is re-work caused by the error of the design drawings of the seller, instruction errors of the seller, the seller shall pay fees to the buyer according to the following formula: (all the fees are calculated according to the rate at the time when the fees happen).

P=ah+M+cm

Among which P – total fees (Yuan)

a – labor fee (Yuan/hour·person)

h – Person time (hour·person)

M – Material fee (Yuan)

C – Set & shift number (set·shift)

M – Set & shift fee for each equipment (Yuan/set·shift)

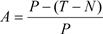

10.12 Penalty for insufficient performance of equipment

When the equipment performance does not meet the requirement, the seller shall repair it in time free of charge until the requirement is met. If the requirement still can not be met after correction, for each lowering percentage point of power curve, the penalty is 1% of the price of each equipment; for each lowering percentage point of availability, the penalty is 1% of the total price of each batch of equipments; but the final total penalty shall not exceed 5% of the total price of the contract.

10.13 Work at workplace

10.13.1 Installation preparation

The installation plan of wind generator equipment is proposed by the seller and handed to the buyer before installation and studied and approved by both parties. Before installation, the seller’s people shall check once on the delivered wind generator equipment and point out the final deflects caused by transport or other reasons. These deflects will affect the quality guarantee for the equipments delivered by the seller.

Before installation, technicians of both parties shall check whether the design, drawings and materials of equipment are complete in an all-round way, and the buyer is responsible for whether framework, earthwork and electricity etc. are equipped with installation conditions.

10.13.2 Experienced technicians of the seller

The seller shall dispatch experienced technicians in charge of installation, completion test and commissioning of the supplied equipments and instruments and other possible necessary tests to ensure the installation may be done smoothly according to the contract.

10.13.3 Supervision of the seller’s employee

The seller’s employee will instruct the buyer’s employee responsible for installation to complete the work according to the required preciseness and quality.

10.13.4 Water, power and others

For the purpose of the engineering, the buyer will provide the seller with working and living service facilities such as on-site water and power, offices, and office equipments.

10.13.5 Safety measures

The equipment installation plan must put forward safety measures which shall be observed by employees of both parties. Workers of both parties must observe all the applicable safety rules on site.

10.13.6 Test after project completion

The test after project completion is made jointly by both the seller and the buyer.

10.13.7 Commissioning

The commissioning of the equipments provided by the seller is conducted by the seller and assisted by the buyer. The commissioning shall be conducted immediately after finishing “test after project completion.”

11 Claim

11.1 Quality warranty

11.1.1 Start point and termination of quality warranty

Quality warranty to the contract equipment to be supplied by seller starts from the signature of acceptance certificate for individual works. Warranty period is good for 24 months. At the end of warranty period, performance will be conducted on contract equipment, especially for the reliability under the warranty.

At the end of 24-month quality warranty period, both parties will sign off relevant certificates (final acceptance certificate) in triple copies of both original and duplicate.

11.1.2 Extension of warranty period

If equipment availability proves to not meet specified requirement during warranty period due to quality problems on seller side, 24-month warranty period under this contract will be prolonged by the same period of down time and maintenance time.

11.2 Seller guarantees all the equipment to be supplied under this contract is fresh new, accommodating general and safe operation and demonstrating long life. Also they must meet requirement specified in the contract. Equipment must be fabricated with advanced, mature technology and best quality. Equipment must demonstrate reliable and economical operation and is easy for maintenance.

11.3 Seller guarantees the technical materials to be provided as required in the technical specification under the contract are integral and the contents are correct and accurate. Such documents must accommodate design, installation, commissioning, operation and maintenance of contract equipment. Warranty period secured by seller for contract equipment will not expire until the buyer issues acceptance certificate.

11.3.1Seller guarantees that the technical parameters for the equipment are tested and proved by manufacturer. Their integrity also is qualified through test to comply with contract. Drawings and document to be provided by seller must be correct and free of errors, meeting requirement for design, installation, commissioning, operation and maintenance.

During performance of contract, if the equipment provided by seller is found defective and Technical materials are full of mistakes or rework or scrap are caused to the project due to negligence by technicians of seller, seller should immediately make repair or replacement at its own cost. If replacement is needed, seller will take over all the costs to be incurred from occurrence to the installation of new equipment is completed. Replacement or repair timing should not be more than 30 days since the date when seller is proved to assume the responsibility. If not, clause 11.11 will apply.

11.3.2 If the buyer fails to follow the technical document, drawings, instructions or follow the instructions given by site service technicians of seller while carrying out construction, installation or commissioning and such actions lead to equipment damage, the buyer will assume responsibility for replacement and repair. However, seller has the obligation to provide needed replacement parts. For parts urgently requested by the buyer, seller should arrange the fastest delivery at its own cost.

11.3.3 To accommodate design, installation, commissioning, operation and maintenance, seller will provide installation supervision, training to staffs of the buyer and 24-month quality warranty as requested in the “service” part of the contract.

11.4 After warranty expires, the buyer will issue within 30 days the certificate of acceptance against contract equipment. The conditions are: Seller must finish handling all the claims and compensation which are implemented by the buyer prior to the expiry of such warranty. However, seller assumes no liabilities for any abnormal maintenance or wrong operation or losses from normal wearing.

11.5 Within warranty period, if equipment is found defective and not conforming to contract, it is deemed as responsibility of seller. In this case, the buyer has rights to make claim against seller. In case of doubt by seller, clause 9.2.7 will apply. Otherwise, seller will provide immediate and free of chare repair or replacement, claim or arrange other parties for repair work right after seller receives notice from the buyer regarding the claim. Both parties will arrive within 30 days of the claim request on site where equipment should be replaced.

If minor defects are found with equipment, seller can make the replacement by its own. The costs incurred will be borne by seller.

For the defects found during quality warranty, claim request which is presented within 14 days after warranty period is still valid.

11.6 If defective equipment needs to be replaced or repaired due to fault on the side of seller, such occurrence causes stop to delivery or delay to installation, then warranty period will be prolonged by the period equivalent of actual repair or replacement.

11.7 If equipment fails to maintain requirement as specified in the specification for the warranty period due to fault on side of seller, then the buyer has rights to make claim. Seller should within 1 month of the notice take possible actions. If such actions fail, seller should pay penalty following clause 10.12.

After seller pays penalty, he still has the obligation to provide technical service to the buyer and take all the possible actions needed to maintain performance of such equipment.

11.8 For serious defects with contract equipment during warranty period due to fault on side of seller, that is, six main components (vane, gear box, generator, deviation system, electrical control system and tower) cannot continue the operation due to such defects, then the warranty period for such components will be 24 months starting from the date of corrections are corrected. Downtime cannot exceed 14 days. If yes, claim will be based on the power generation.

11.9 If seller fails (except for force majeure) to deliver the goods to the schedule in the contract not because of the fault on side of the buyer, actual delivery date is calculated according to clause 6.1 and 6.4. The buyer has rights to claim penalty against seller based on following rates:

A. When delivery or payment is delayed for 1-4 weeks, for each week, the penalty is 0.25% of the delayed amount.

B. When delivery or payment is delayed for 5-8 weeks, for each week, the penalty is 0.4% of the delayed amount.

C. When delivery or payment is delayed for over 8 weeks, for each week, the penalty is 1% of the delayed amount.

For above calculation, if the delay is less than 1 week, then 1 week will be used in the calculation. However, total of the penalty from the delayed delivery of equipment under the contract will not exceed the total amount of contract equipment by 5%. Price reduction or indemnity does not relieve seller of his reliabilities during warranty period. Seller paying penalty does not relieve seller of the obligation to continue the delivery of contract equipment. For equipments which are delayed for over 6 months and have significant impact on installation and trial operation, the penalty to be paid by seller to the buyer can exceed the total amount of equipment by 5%. At the same time, the buyer has rights to terminate the contract in partial or in full.

11.10 If it is verified that seller’s fault causes seller to fail to make the delivery as scheduled in the specification of the contract, both parties will verify the key technical materials, design and planned materials which affect construction progress. For each week delay, penalty is 0.2% of contract amount. Delayed delivery is counted as specified in clause 6.10.

11.11 If contract performance is delayed due to delay, negligence and or mistakes with the technical service by seller, for each week delay, seller will pay as penalty to the buyer 0.5% of the amount for each equipment package. However, such penalty should not exceed 5% of total contract amount for equipment. Also seller will pay for all the direct losses due to his faulty technical service or breach of contract.

11.12 Delay by other organizations

In addition to contract equipment, this project also covers civil work and other mechanical and electrical works. The buyer should guarantee the completion of all other works to the schedule. Completion date and delivery of civil works are very important for seller. Such delivery must be specified in the timing plan as in annex 10.

11.13 If additional costs occur to seller due to delay to civil, mechanical or electrical works, the seller will make claim request to the buyer. Such compensation will be calculated based on physical costs, including inventory, but not including profit. However, if above delays are longer than 30 days, seller cannot make claim request. In case of excess of 30 days, compensation payout will be counted from the 30th day.

11.14 After hoisting was completed, the fan could not be in long-term shutdown and the failure must be disposed within 14 days. The seller should pay for the loss of the buyer according to the reduced generated energy.

12 Insurance

12.1 The insurance paid by seller will last until goods arrive on site. Insurance amount will be 110% of contract amount (one hundred and ten percent)

12.2 Seller will pay insurance for all the people he sent to site.

13 Taxes and fees

13.1 Seller will pay all the taxes and fees rated to this contract in accordance with applicable national tax laws, codes and regulations.

13.2 All the taxes and fees occurred outside China in relation to the performance of this contract will be paid by seller.

13.3 The prices contained in this contract are tax included. Taxes and fees for equipment, technical materials, service (including transportation) and imported equipment/parts are all included in the contract prices and will be paid by seller.

14 Assignment, subcontracting and outsourcing

14.1 Seller is not allowed to assignment in partial or full of any part of the contract to any other parties.

14.2 Annex 6 is the list of subcontractors for seller. Five big components of the wind power generation system are not allowed for subcontracting without consent with the buyer. If subcontract is allowed, the contents and ratio of subcontract items must be approved by the buyer.

14.3 Technical service for the equipment/components under subcontract will be handled according to clause 8.11, 8.12 and 8.13.

14.4 Seller assumes all the liabilities for all the subcontracted equipment and components under the contract.

14.5 Without obtaining agreement, seller can purchase materials or sign contract with manufacturers or suppliers specified in the contract to purchase small items or any commodities for the project.

14.6 Seller assumes liabilities for their behavior, negligence or violation by its subcontractors or agent or its employees. Seller assumes liabilities for its agent or employees for their behavior, negligence or violation.

14.7 The buyer has the rights to access workshops or other places at designated subcontractors and suppliers

14.8 If the seller is detected as violation in the subcontracting, the buyer has rights to perform the contract on behalf of the seller while original liabilities of the seller are not reduced.

15 Change, modification, suspension and termination of contract

15.1 Once contract becomes effective, neither party is allowed to make and unilateral and arbitrary modification to contracts (including appendices). Changes to contract subject, quantity, quality, price, duration, quality standard and inspection standard and methods must be agreed to between both parties through negotiations in supplementary agreement, which has the same legal effect as the contract. In case of conflict between supplementary agreement and contract, the former will apply.

15.2 In case either party has violation or refuses to perform the contract, the other party will notify such party in writing. The violating party will within 15 days of the notice will make corrections to such violations or refusal. If corrections cannot be corrected in 15 days, correction plan is needed. If correction fails or correction plan cannot be proposed, the other party will reserve the rights to terminate in partial or in full the contract. For such termination, the other party will not issue change order. All the costs, fees and claims incurred from this will be the liability of the opposite party. If there are other clauses available with regards to such violation, such clauses will be applied for.

15.3 During term of contract, if the contract cannot be further performed due to change to national planning, the seller and/or the buyer can propose to the other party to terminate or modify affected clauses.

15.4 If the returned goods are requested by the buyer during term of the contract, the buyer will pay penalty to the seller. Such penalty will be 10% of the amount for returned equipment. Also losses caused to seller will be paid to the seller.

15.5 If the equipment cannot be delivered due to fault on seller side, the seller will pay penalty to the buyer. Such penalty will be 10% of the amount for returned equipment. Also losses caused to the buyer will be paid to the buyer.

15.6 If the seller has bankruptcy, ownership change (merged, enquired, disbanded or cancelled) or insolvency or carries out operation under bankruptcy just for the interest of creditor, the buyer has rights to immediately notify in writing the seller or trustee-in-bankruptcy or the new owner of the contract to terminate the contract or propose different choices to trustee-in-bankruptcy, liquidator or the new owner of the contract. Depending on their reasonable guarantee the performance of such contract, the contract which was agreed to by the buyer will be performed.

15.7 In case of occurrence related to clause 15.6, the buyer has rights to obtain the takeover of all the contract equipment related tasks. Also he can at appropriate time take away all the contract equipment related design, drawing, instructions and materials in the premises of the seller. The ownership of such items belongs to the buyer. The seller will provide the buyer with all the convenience for such handling so that the buyer can remove above design, drawings and materials. The buyer will assume no liabilities for any direct or indirect claims against the seller from termination of such contract. In addition, both parties will reach agreement on the evaluation of the performed part of the contract. Also they will handle all the consequences because of advance contract termination.

15.8 Work suspension due to violation to contract

If one party violates the contract or has negligence during performance, the other party can request the violating party to stop any further violation and make corrections. In such case, liability borne parties have no rights to request extension. Nor has he the right to stop work and request for compensation. Nor has he the rights to be relieved of penalty.

16 Force Majure

16.1 Force Majure means that when signing the contract , the incidents unforeseeable , unavoidable , and unsolvable , including but not limited to severe natural disaster or calamity (such as typhoon , flood , earthquake , fire or explosion etc.) , war (no matter declared or not) , rebellion , commotion etc . Any party of the contract , because of force majure, and execution of the contract was influenced , will delay the time limited of pursuing the obligation of contract with the time limit equal to the duration of force majure , but can not adjust the price of the contract due to delay caused by force majure.

16.2 The party influenced by force majure should notify by fax about the detail of force majure to the other party after happening of force majure, and within 15 days delivered the proving documents issued by the authority to the other party, the party influenced should try his best to reduce the influence and the delayed caused, once the influence of force majure is finished, he should notify the other party.

16.3 If both party estimate that the influence of force majure might be prolonged to over 120 days, each party should solve the execution problem of this contract through friendly negotiation.(including delivery, installation, commissioning and acceptance etc.)。

17 Settlement of Dispute of the Contract

17.1 All the disputes related and caused by this contract should be solved through friendly negotiation, if negotiation failed, any party of the contract has the right to apply for arbitration at the arbitration institute at the location of the buyer, and the arbitration will have power upon both parties.

17.2 Unless other agreements exist, the arbitration will not influence that each party continue pursue his own obligations under the contract.

18 Execution of contract and valid period

18.1 The starting condition of this contract is as followed:

Authorized Representatives of both parties sign;

The buyer received the indemnity money of the seller.

The seller received the down payment of the buyer according to the contract;

18.2 The effective date will start from the action date of the contract to when the final acceptance document is issued, compensation finished, money paid and goods delivered. After the contract is finished, any unfinished debt and debit will not be influenced by the contract finished date. The debit party will continue his obligations to the debt party.

18.3 This contract is written in Chinese, in four duplicates, each party holds two copies.

18.4 The appendices of this contract is the crucial part of this contract, and has the same legal power as the main body of the contract. If the appendices have some difference with the main body of the contract, the main body of the contract has the priority.