| 250 Kw/hr Portable Municipal Solid Waste (MSW)–To–Energy System. |

| The MSW is presorted and metals, glass, electronic components, sand, concrete and other non gasifying materials are removed, the waste that is to feed to the plant compost of biowaste, agrowaste, rubber, plastic, paper, cardboard, pvc, plastic bags, leather, textile and etc. |

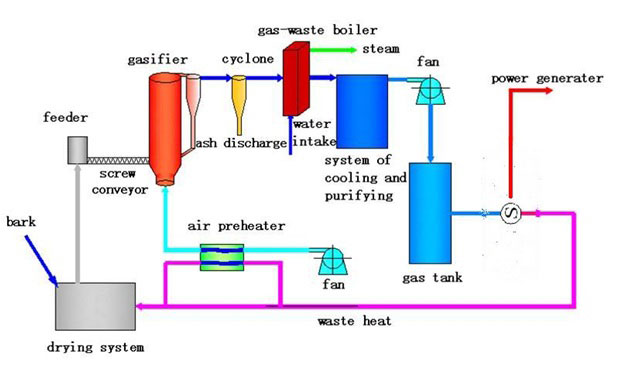

| The MSW is waste is shredded and dried to 20% moisture, then using the feeder the waste is transported gasifying chamber. Where in the absence of oxygen gasification of the MSW is done at very high temperature under pressure, the temperature and pressure are decided by the engineers after carefully studying waste composition and its heating values. |

| The MSW is gasified and the gas is passed through various filters and is chilled using the gas chiller, chilling is important for storing the gas in the tank safely. The tar and other waste are very carefully filtered before the gas is stored in tanks. The residue or ash after gasification is automatically driven out of the chamber and waste ash is can be collected separately. |

| The stored gas from the gas tank is used to run the gas generator, the current model is designed to give output of 250Kw/Hr at standard conditions*. The gas Generators are specially modified by HELIOS to meet combustion values and give maximum output, the output voltage and Hz (50hz/60hz) can be provided as per demand of the buyer. |

| Physical Appearance of The plant: |

| The plant is designed specially by our engineers and technicians after keeping in consideration of today’s need of power generation, usually MSW plant you might have been seen are costly, huge and inefficient. |

| But here we have come up with a leading solution for the buyers with a Portable Model, this plant can be transported and simply operated immediately after transportation by just doing simple assembly inside the container to start the process and foundation or concreting is needed for these portable units. |

| The plant can be operated on a truck or containers in which the plant is installed and can be laid on the ground for operation and the generated output can be connected into a national grid, as long as the rated amount of MSW is fed to the plant, the output of 200Kw/Hr* can be easily be obtained on a continuous 24X7 basis. |

| The Portable System is specially designed by HELIOS to fit in 40” containers after keeping the importance of the land and considering the rising values of the land the Portable Plant consists of 3 nos X 40” containers. The container are not all modified externally, accept they all are “OPEN FRAME“40‘container. Besides this all 3 containers can be easily transported on trucks, to any desired location. |

| The Plant is divided in three parts: |

1st container – Drier and Crusher includes the conveyor belt. |

2nd container – Gasification set. |

3rd container – Gas storage tank and Gas Generator (250kw) |

| The portable system is robust in performance and used to process MSW on almost every location on this Globe. |

| The detail plan can be presented to respective buyer after supply agreement is signed along with advance, the payment modes and terms are specified below in details. |

2. Technical Parameters of genset (250kw)

| Item | Parameter |

| Rated power (KW) | 250 |

| Rated Current (A) | 470 |

| Rated Voltage (V) | 400 |

| Rated Speed (r/min) | 375 |

| Rated Power factor (COSΦ) | 0.8 |

| Rated Frequency (Hz) | 50 |

| Starting Mode | 24V DC |

| Voltage Adjustment | Automatic |

| Speed Adjustment | Electronic Adjustment |

| Heat consumption rate | 15MJ/kWh |

| Gas consumption rate | 2.8Nm3/kW |

| Oil consumption rate g/(kW.h) | ≤1.5 |

| Raw material consumption rate kg/(kW.h) | ≤1.8 |

| Dimension (L×B×H) cm | 500×300×230 |

4.Main Technical Parameters of some equipments:

4.1 Gasification unit

Raw Material consumption; 375kg/h

Gas Generation Amount: 2.0×104Nm3/h

Gas Heat Value; 4600—5300kJ/Nm3

Gasification Unit >70%

4.2 Gas Generators Unit

Rated Voltage; 400V

Rated Capacity: 250KW

Rated frequency: 50-60HZ

Gas consumption: 2.8Nm3/kW

Gas Pressure: Normal pressure.

5: Input and Output:

5.1 Input:

A: 600 kg/hr – Wet Waste of 40% moisture feed at drier and shredder

B: 375kg/hr – Dry Waste of 20% moisture feed to gasifier.

C: 5 liter of crude oil/diesel needed for starting heating process.

D: 50 Kw/hr Electricity is consumed by portable system to carry out its operation.

5.2 Output:

A: Electricity Net Output : 250kw/hr.

B: Electricity Available for sells: 200Kw/hr.

5.3 Required space: 250sq.meter

5.4 Other requirement:

A: Water Pond

B: Heavy duty vehicles to transport these 3 Containers

6.0 Labor:

A: 3 unskilled Labor/shift (8hrs)

B: 1 Manger.

7.0 Equipment List : ( there are some main equipments or devices for standard per set )

| No. | Description | Technical Parametersd delivery goods as follows:HREE ONLY.E HUNDRED AND T | Unit | Qty | Weight | Remark |

| 1. | Electrical Control Switchgear | | unit | 1 | | for examining and controlling |

| 2. | Up-gasifier | | unit | 1 | | |

| 3. | Middle Gasifier | | unit | 1 | | |

| 4. | Down-gasifier | | unit | 1 | | |

| 5. | Wind box | | unit | 1 | | |

| 6. | fastigiate wind plate | | pc | 1 | | |

| 7. | hood wind plate | | pc | 1 | | |

| 8. | Cyclone separator | | unit | 2 | | |

| 9. | Discharge device | | unit | 2 | | |

| 10. | Venturi sparator | | unit | 1 | | |

| 11. | Spraying purifier | | unit | 2 | | |

| 12. | Automatic relif valve | | unit | 1 | | |

| 13. | Oil-water separator | | unit | 1 | | |

| 14. | feeder | | unit | 1 | | |

| 15. | hopper | | pc | 1 | | |

| 16. | Hopper for storage of ash | | pc | 1 | | |

| 17. | Screw discharger | | unit | 1 | | |

| 18. | burner | | unit | 1 | | |

| 19. | Oil tank | | pc | 1 | | |

| 20. | Oil pipe | | pc | 4 | | |

| 21. | Closed box for burner | | pc | 1 | | |

| 22. | Circle water pump | | unit | 2 | | |

| 23. | Roots draft fan | | unit | 1 | 350 | |

| 24. | Roots blower | | unit | 1 | 350 | |

| 25. | Polymer electrostatic filter | | unit | 1 | | |

| 26. | rupture membrane | | unit | 1 | | |

| 27. | Temperature of indicator | | unit | 2 | | |

| 28. | Thermocouple of Ni-Cd and Ni-Si | WRN-230, | unit | 10 | 3.2 | For examining and controlling |

| 29. | Electric contact pressure gauge | Y-100,0-1.6MPa | pc | 2 | 1.4 | For examining and controlling |

| 30. | Hot resistance | 0-400℃ | pc | 3 | | Protection of gas inlet |

| 31. | differential pressure transmitter | | unit | 4 | | For examining and controlling |

| 32. | glass tube float flowmeter | | unit | 1 | | For examining and controlling |

| 33. | Vortex Flowmeter | | unit | 1 | | |

| 34. | oxygen meter | | unit | 1 | | For examining and controlling |

| 35. | 250kw genset* | | unit | 1 | | Low speed genset for biomass special (general technical parameters see below) |

| 36. | Some spare parts like pipe and flange | | | | | For installation |

7.1 Specification of Syngas Generator Set

| | |

| Diesel Engine No. | 8300DM-1 |

| Type | Four stroke , in-line 、spark plug ignition |

| Cylinder | 8 |

| Diameter of Cylinder /travel of piston mm | 300/380 |

| Displacment L | 215 |

| Rated Power of diesel engine kW | 495 |

Speed r/min | 600 |

| Rated Power kW | 250 |

| Rated Voltage V | 400 |

| Rated Current A | 812 |

Rated Frequency Hz | 50 |

| Power Factor COSΦ | 0.8 |

| Regulation Rate % | ±2.5 |

| Pressure of gas kPa | 2 |

Consumption g/kWּh | ≤2 |

| Starting Type | Air |

| Phase | Three phase four wires |

| Excitation Type | brushless |

| Size(L×W×H)mm | 5800×1820×3000 |

| Weight Kg | 14000 |