Exhibit 99.1

Technical Report on the Shahuindo Heap Leach Project

Cajabamba, Peru

Prepared for:

SULLIDEN GOLD CORPORATION, LTD

Prepared by:

Prepared by:

Report Date: 9 November 2012

Effective Date of Resources: 17 May 2012

Technical Report Effective Date: 26 September 2012

Authors:

Carl Defilippi

Thomas L. Dyer, PE

Paul Tietz, CPG

| |

|

MINE DEVELOPMENT ASSOCIATES |

TABLE OF CONTENTS

| | | | |

| 1.0 SUMMARY | 1 |

| 1.1 | Terms of Reference | 1 |

| 1.2 | Introduction and Project Overview | 1 |

| 1.3 | Reliance on Other Experts | 2 |

| 1.4 | Property Description & Location | 2 |

| 1.5 | Access, Climate, Local Resources and Physiography | 3 |

| | 1.5.1 | Access | 3 |

| | 1.5.2 | Climate | 3 |

| | 1.5.3 | Local Resources | 4 |

| | 1.5.4 | Physiography | 4 |

| 1.6 | History | 4 |

| 1.7 | Geologic Setting and Mineralization | 5 |

| 1.8 | Deposit Types | 7 |

| 1.9 | Exploration | 7 |

| 1.10 | Drilling | 7 |

| 1.11 | Sample Preparation, Analysis and Security | 8 |

| 1.12 | Data Verification | 9 |

| 1.13 | Mineral Processing and Metallurgical Testing | 10 |

| 1.14 | Mineral Resource Estimate | 10 |

| 1.15 | Mineral Reserve Estimate | 12 |

| 1.16 | Mining Methods | 12 |

| 1.17 | Recovery Methods | 15 |

| 1.18 | Infrastructure | 16 |

| 1.19 | Market Studies and Contracts | 17 |

| 1.20 | Environmental Studies, Permitting and Social or Community Impact | 17 |

| | 1.20.1 | Studies and Permitting | 17 |

| | 1.20.2 | Reclamation and Closure | 18 |

| | 1.20.3 | Social Impact | 19 |

| 1.21 | Capital and Operating Costs | 20 |

| 1.22 | Economic Analysis | 21 |

| 1.23 | Adjacent Properties | 26 |

| 1.24 | Other Relevant Data and Information | 26 |

| | 1.24.1 | Geotechnical Issues | 26 |

| | 1.24.2 | Hydrology | 26 |

| | 1.24.3 | Mine Pit Dewatering | 27 |

| | |

| November 2012 | Shahuindo Project | i |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

| | 1.24.4 | Project Development Schedule | 28 |

| | 1.24.5 | Opportunities and Risks | 29 |

| 1.25 | Interpretation and Conclusions | 31 |

| 1.26 | Recommendations | 32 |

| 2.0 INTRODUCTION | 34 |

| 2.1 | Project Scope and Terms of Reference | 34 |

| 2.2 | Units and Abbreviations | 36 |

| 3.0 RELIANCE ON OTHER EXPERTS | 38 |

| 4.0 PROPERTY DESCRIPTION AND LOCATION | 40 |

| 4.1 | Location | 40 |

| 4.2 | Property Description | 40 |

| 4.3 | Agreements – Settlement of Shahuindo Litigation | 43 |

| 4.4 | Mineral Claims | 45 |

| 4.5 | Surface Rights | 49 |

| 4.6 | Informal Mining Activity | 49 |

| 4.7 | Environmental Considerations | 50 |

| | 4.7.1 | Environmental Regulations | 50 |

| | 4.7.2 | Permits | 52 |

| | 4.7.3 | Existing Environmental Conditions | 54 |

| 5.0 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, AND PHYSIOGRAPHY | 55 |

| 5.1 | Accessibility | 55 |

| 5.2 | Climate | 58 |

| 5.3 | Local Resources & Infrastructure | 58 |

| 5.4 | Physiography | 59 |

| 5.5 | Seismology | 60 |

| 6.0 HISTORY | 61 |

| 6.1 | Historic Mineral Resource Estimates | 62 |

| 6.2 | Previous Mineral Resource Estimates for Sulliden | 63 |

| 6.3 | Prior Mining | 66 |

| 7.0 GEOLOGICAL SETTING | 67 |

| 7.1 | Regional Geology | 67 |

| 7.2 | Property Geology | 70 |

| | 7.2.1 | Lithologies | 73 |

| | 7.2.2 | Structure | 74 |

| 7.3 | Alteration | 76 |

| 7.4 | Gold-Silver Mineralization | 77 |

| 7.5 | Mineral Corridors | 80 |

| 8.0 DEPOSIT TYPES | 82 |

| 8.1 | Shahuindo Deposit | 82 |

| | |

| November 2012 | Shahuindo Project | ii |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

| 9.0 EXPLORATION | 98 |

| 9.1 | Geologic Mapping | 98 |

| 9.2 | Topographic Control | 99 |

| 9.3 | Geophysics | 99 |

| 9.4 | Geochemistry | 100 |

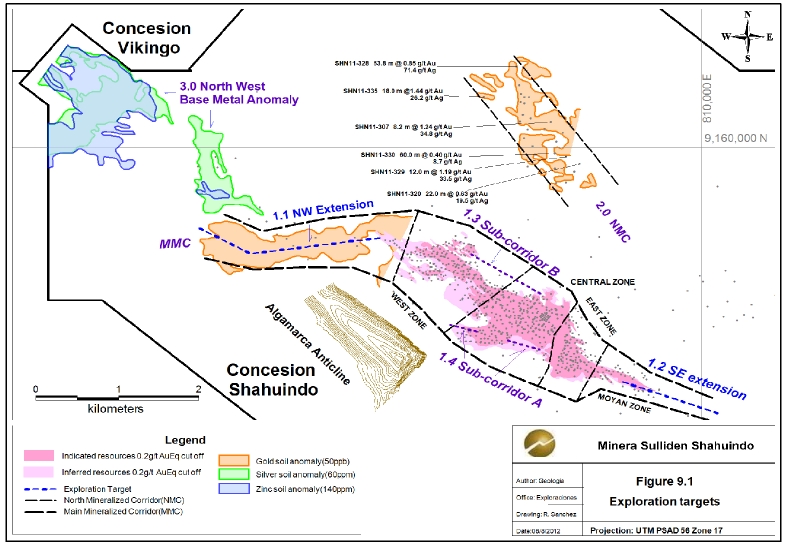

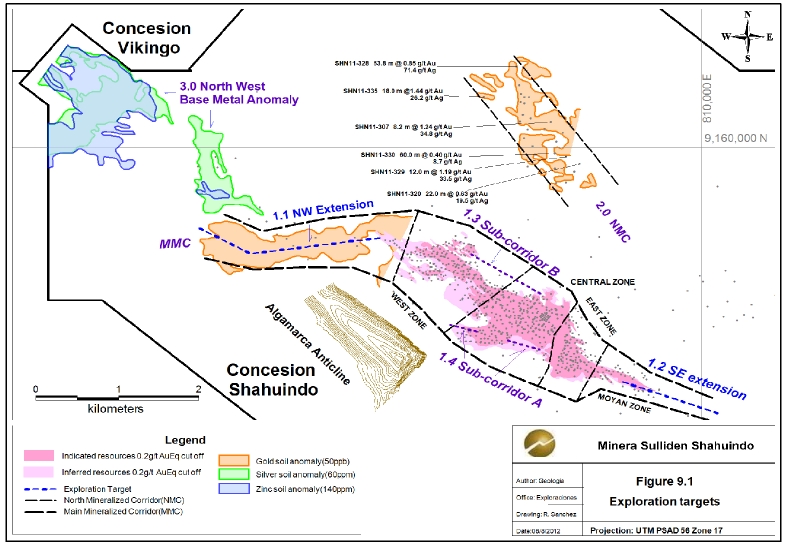

| 9.5 | Exploration Potential | 101 |

| 10.0 DRILLING | 104 |

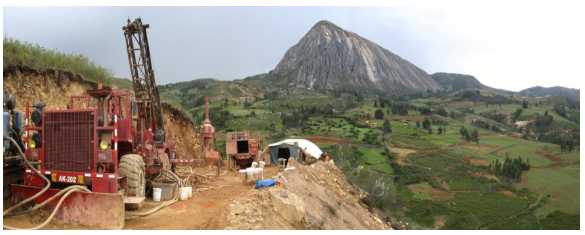

| 10.1 | Drilling Methods and Equipment | 107 |

| 10.2 | Collar Surveys | 108 |

| 10.3 | Down-Hole Surveys | 109 |

| 10.4 | Drill Logging | 110 |

| 10.5 | Drill Database | 110 |

| 10.6 | Core Recovery | 111 |

| 10.7 | Comparison of Core and Reverse Circulation Drilling | 115 |

| 10.8 | Deposit Drilling | 118 |

| 11.0 SAMPLE PREPARATION, ANALYSIS AND SECURITY | 120 |

| 11.1 | Drill Sampling | 120 |

| | 11.1.1 | Diamond Drill Core Sampling | 120 |

| | 11.1.2 | Reverse Circulation Chip Sampling | 120 |

| | 11.1.3 | Sample Storage | 121 |

| 11.2 | Sample Preparation and Analysis | 122 |

| 11.3 | Specific Gravity Determinations | 123 |

| 11.4 | Sample Security | 124 |

| 11.5 | Quality Assurance/Quality Control | 125 |

| | 11.5.1 | Asarco’s Drilling Program | 125 |

| | 11.5.2 | Other Drilling Programs Prior to Sulliden | 125 |

| | 11.5.3 | Sulliden’s Drilling Program | 125 |

| 11.6 | Summary Statement | 127 |

| 12.0 DATA VERIFICATION | 128 |

| 12.1 | AMEC 2009 Database Audit and Verification | 128 |

| 12.2 | MDA Database Audit | 129 |

| | 12.2.1 | Drill-Collar Audit | 130 |

| | 12.2.2 | Down-Hole Survey Audit | 131 |

| | 12.2.3 | Assay Data Audit | 131 |

| | 12.2.4 | Geological Data Audit | 131 |

| | 12.2.5 | Core Recovery and RQD Data | 132 |

| 12.3 | MDA Independent Verification of Mineralization | 132 |

| | 12.3.1 | Site Visits | 132 |

| 12.4 | MDA Analyses of QA/QC Data | 134 |

| | |

| November 2012 | Shahuindo Project | iii |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

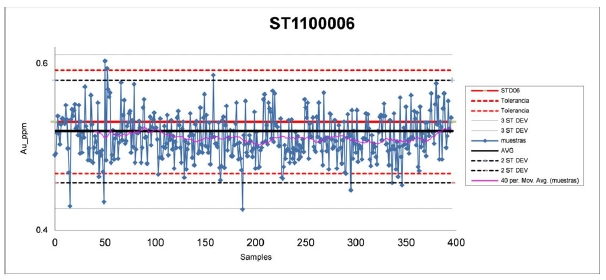

| | 12.4.1 | Standards | 134 |

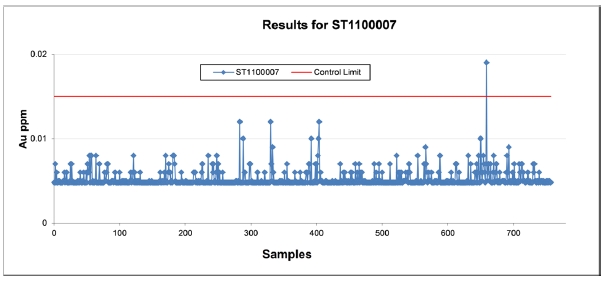

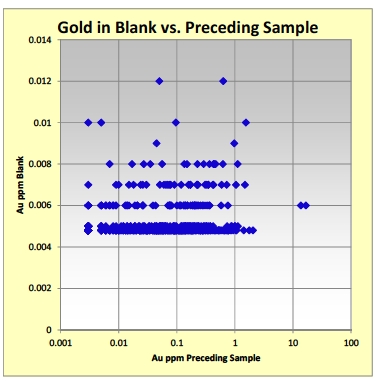

| | 12.4.2 | Blanks | 136 |

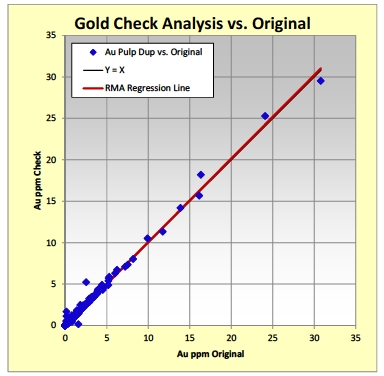

| | 12.4.3 | Duplicate Samples | 139 |

| 12.5 | Summary Statement on Data Verification | 144 |

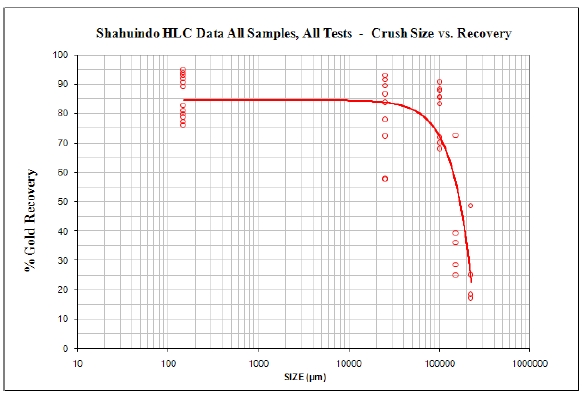

| 13.0 METALLURGICAL TESTING & MINERAL PROCESSING | 146 |

| 13.1 | Metallurgical Testing Summary | 146 |

| | 13.1.1 | HLC Test Program Summary | 148 |

| | 13.1.2 | KCA Test Program Summary | 148 |

| 13.2 | Heap Leach Consultants - 2003-2004 | 150 |

| 13.3 | Kappes, Cassiday & Associates – 2009-2012 | 155 |

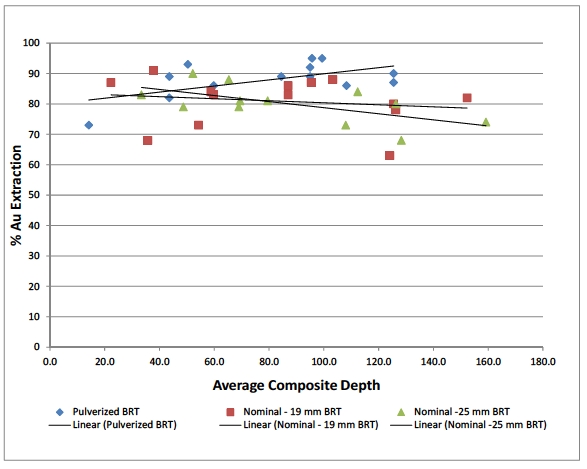

| | 13.3.1 | KCA Bottle Roll Leach Test Results | 155 |

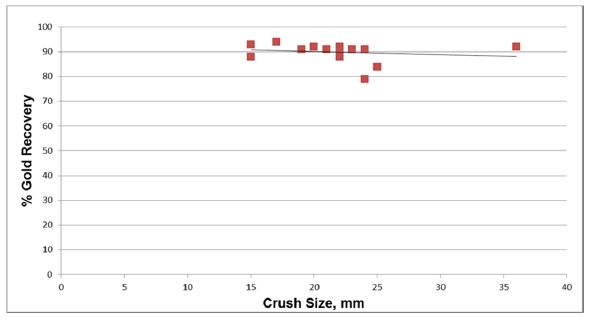

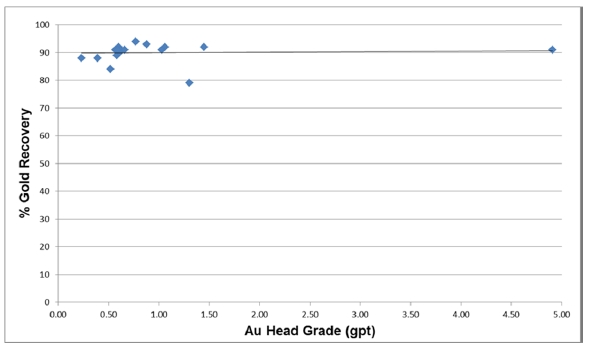

| | 13.3.2 | Kappes, Cassiday & Associates Column Tests | 162 |

| | 13.3.3 | Agglomeration Tests | 168 |

| | 13.3.4 | Detoxification Test Work | 169 |

| | 13.3.5 | Acid-Base Accounting and Humidity Cell Test Work | 169 |

| | 13.3.6 | Acid-Base Accounting | 170 |

| | 13.3.7 | Humidity Cell Test Work | 171 |

| 13.4 | Comminution Tests | 172 |

| 14.0 MINERAL RESOURCE | 173 |

| 14.1 | Introduction | 173 |

| 14.2 | Drill Database | 173 |

| 14.3 | Geology Pertinent to the Resource Model and Estimation | 174 |

| 14.4 | Resource Models | 176 |

| | 14.4.1 | Lithologic Model | 176 |

| | 14.4.2 | Oxidation Model | 177 |

| | 14.4.3 | Silicification Model | 178 |

| | 14.4.4 | Gold Mineral Domain Model | 179 |

| | 14.4.5 | Silver Mineral Domain Model – Mixed and Sulfide Material Only | 186 |

| 14.5 | Density Values for Model | 187 |

| 14.6 | Sample Coding and Capping | 189 |

| 14.7 | Assay Compositing | 191 |

| 14.8 | Block Model Coding | 192 |

| 14.9 | Grade Estimation | 193 |

| 14.10 | Mineral Resources | 195 |

| | 14.10.1 | Resource Model Comments | 206 |

| 15.0 Mineral Reserve | 207 |

| 15.1 | Pit Optimization | 207 |

| | 15.1.1 | Economic Parameters | 208 |

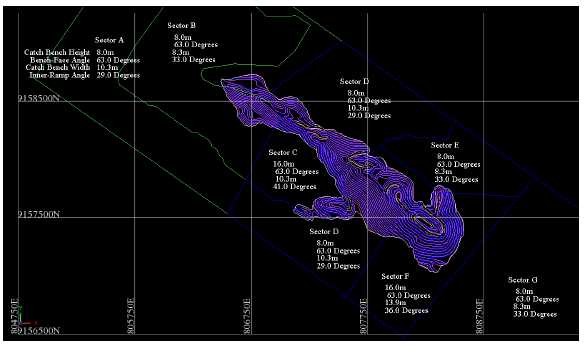

| | 15.1.2 | Slope Parameters | 209 |

| | |

| November 2012 | Shahuindo Project | iv |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

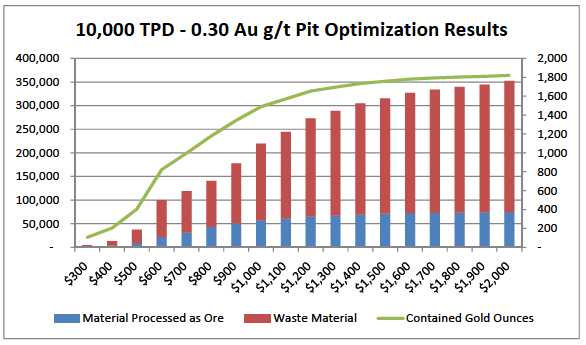

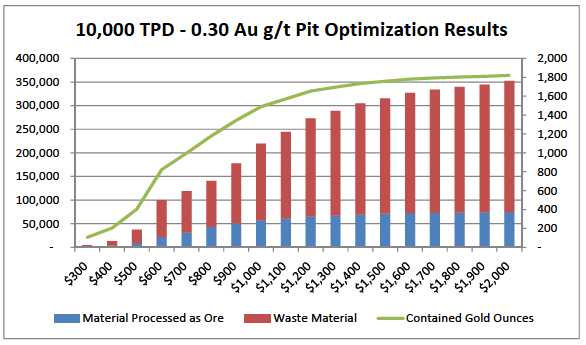

| | 15.1.3 | Pit-Optimization Results | 209 |

| | 15.1.4 | Pit-Shell Selection for Ultimate Pit Limit | 212 |

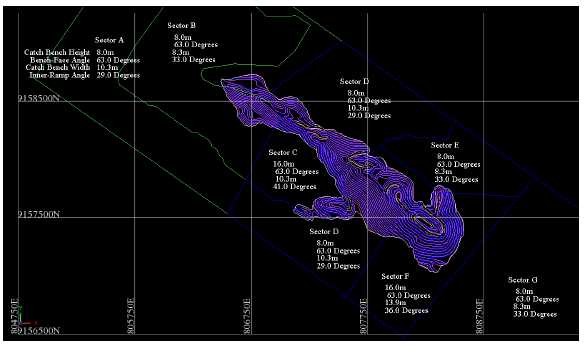

| 15.2 | Pit Designs | 212 |

| | 15.2.1 | Bench Height | 213 |

| | 15.2.2 | Pit Design Slopes | 213 |

| | 15.2.3 | Haulage Roads | 214 |

| | 15.2.4 | Barrow Pit | 215 |

| | 15.2.5 | Ultimate Pit | 215 |

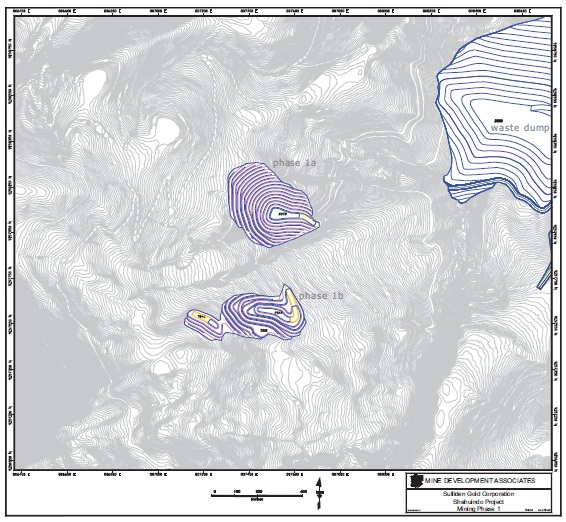

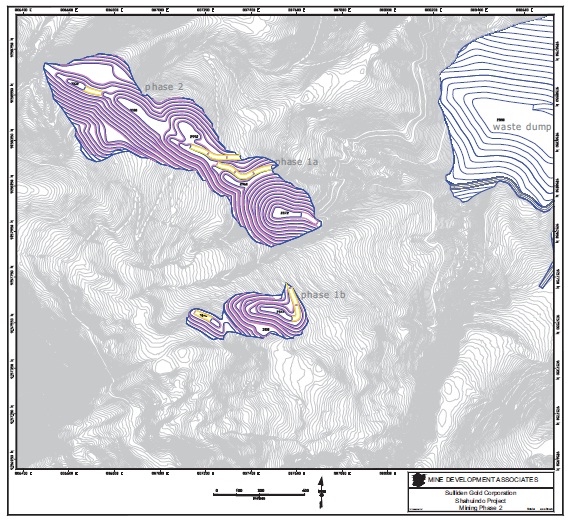

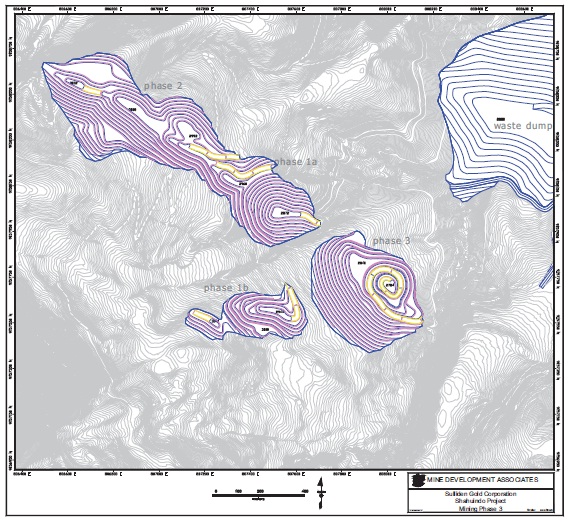

| | 15.2.6 | Pit Phasing | 217 |

| 15.3 | Cutoff Grade | 223 |

| 15.4 | Dilution | 224 |

| 15.5 | Reserves and In-pit Inferred Resources | 224 |

| | 15.5.1 | Bench Reserves | 227 |

| | 15.5.2 | In-pit Inferred Resources | 234 |

| 16.0 MINE OPERATIONS | 236 |

| 16.1 | Mining Method | 236 |

| 16.2 | Mine Material Type Definition | 236 |

| 16.3 | Mine-Waste Facilities | 237 |

| 16.4 | Mine-Production Schedule | 239 |

| 16.5 | Equipment Selection and Productivities | 242 |

| 16.6 | Mine Pit Dewatering Plan | 247 |

| 17.0 RECOVERY METHODS | 251 |

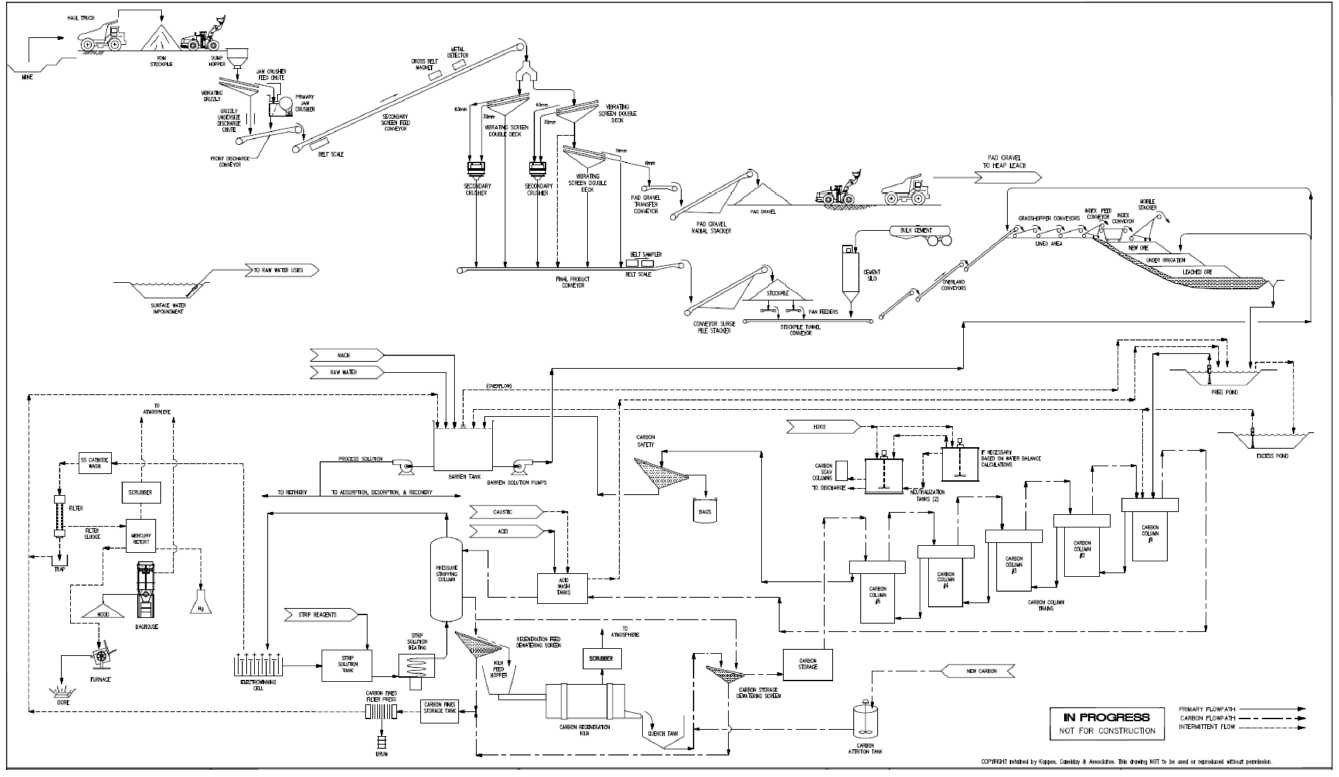

| 17.1 | Process Description Summary | 252 |

| 17.2 | Crushing | 256 |

| 17.3 | Ore Reclamation | 258 |

| 17.4 | Agglomeration | 258 |

| 17.5 | Stacking | 258 |

| 17.6 | Solution Application and Leaching | 259 |

| | 17.6.1 | Leaching Concepts | 259 |

| | 17.6.2 | Leach System Description | 260 |

| 17.7 | Leach Pad | 261 |

| 17.8 | Solution Storage | 262 |

| 17.9 | Solution Management | 263 |

| | 17.9.1 | Excess Solution Impoundment | 264 |

| | 17.9.2 | Pregnant Solution Pond | 265 |

| | 17.9.3 | Waste Dump Seepage Pond | 265 |

| | 17.9.4 | Water Storage Impoundments | 265 |

| | 17.9.5 | Pit Dewatering Water Treatment | 266 |

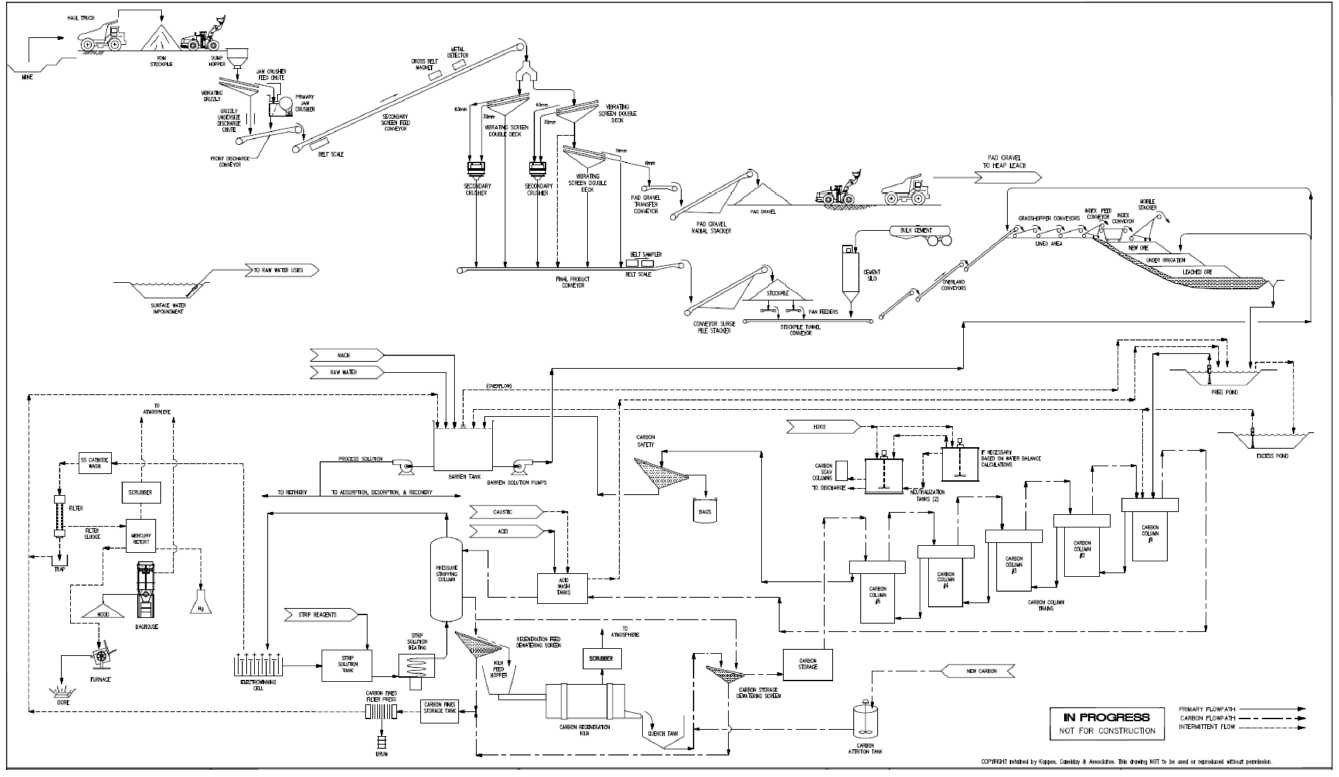

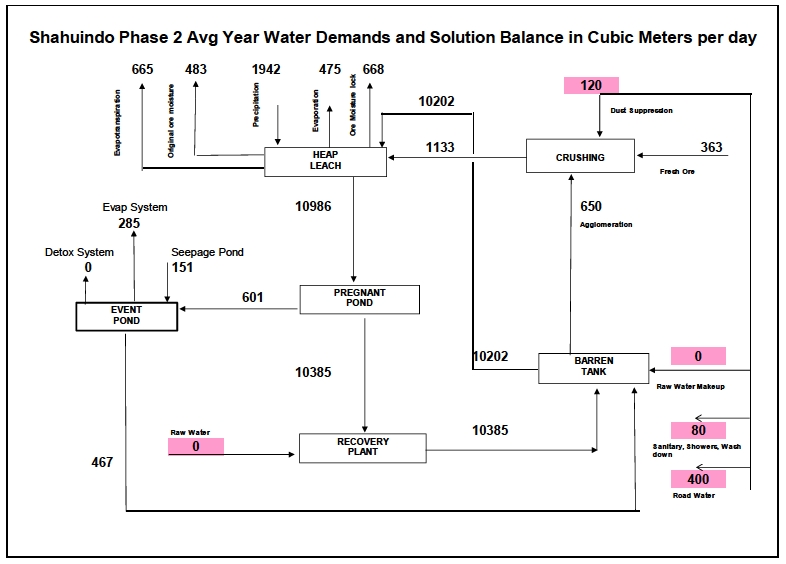

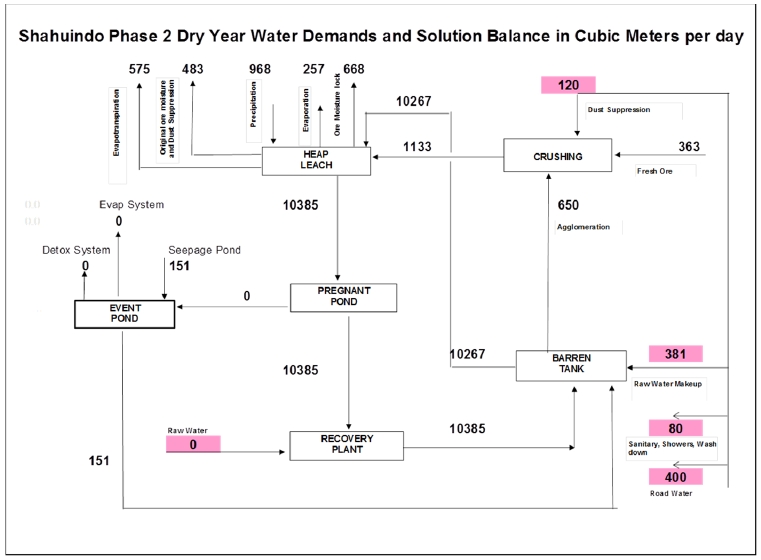

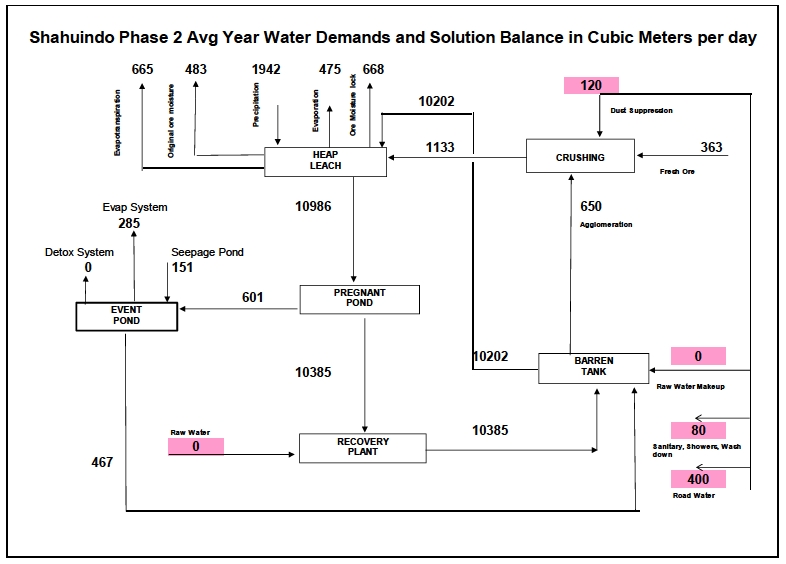

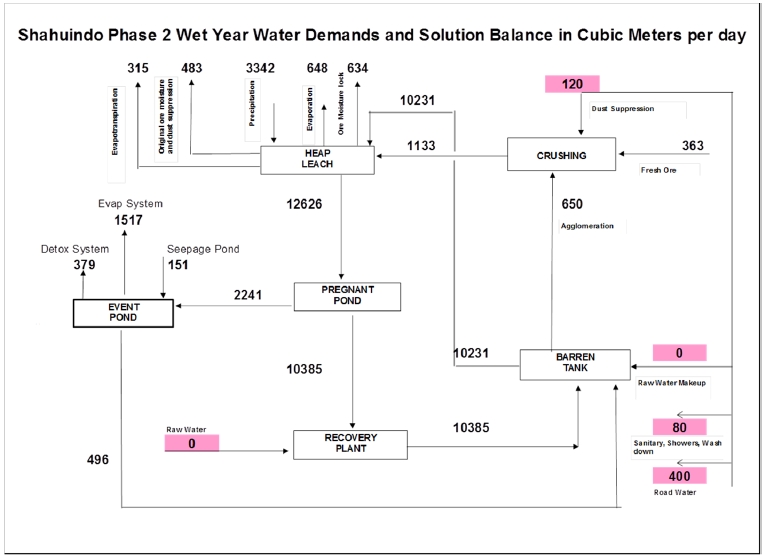

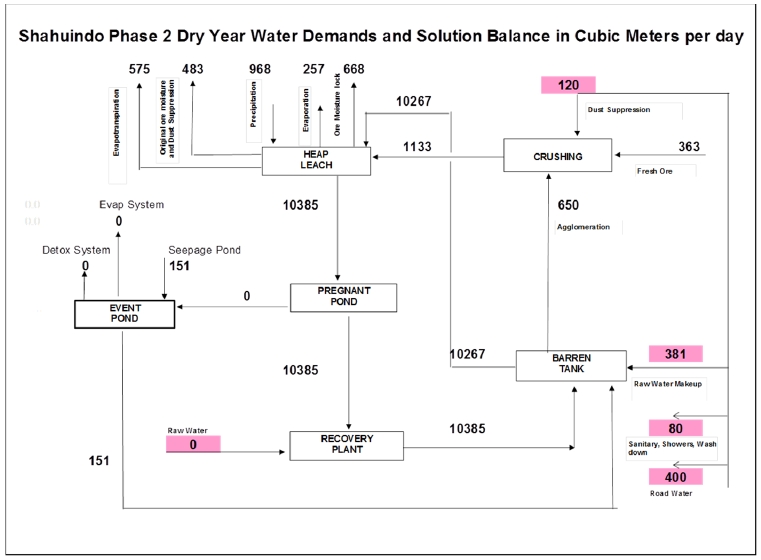

| 17.10 | Process Water Balance | 267 |

| | |

| November 2012 | Shahuindo Project | v |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

| | 17.10.1 | Precipitation Data | 267 |

| | 17.10.2 | Water Balances | 267 |

| 17.11 | ADR Recovery Plant | 273 |

| | 17.11.1 | Adsorption | 273 |

| | 17.11.2 | Carbon Acid Wash | 273 |

| | 17.11.3 | Desorption | 274 |

| | 17.11.4 | Electrowinning | 275 |

| | 17.11.5 | Carbon Thermal Regeneration | 277 |

| | 17.11.6 | Refining and Smelting | 277 |

| 17.12 | ADR Reagent Mixing and Handling Systems | 279 |

| | 17.12.1 | Cyanide | 279 |

| | 17.12.2 | Sodium Hydroxide | 280 |

| 17.13 | Carbon Handling | 280 |

| 17.14 | Process Solution and Makeup Water | 281 |

| 17.15 | Process Reagents and Consumables | 282 |

| | 17.15.1 | Usage and Storage Requirements | 282 |

| | 17.15.2 | Cement | 282 |

| | 17.15.3 | Cyanide | 283 |

| | 17.15.4 | Carbon | 283 |

| | 17.15.5 | Hydrochloric Acid | 284 |

| | 17.15.6 | Diesel Fuel | 284 |

| | 17.15.7 | Antiscalant | 284 |

| | 17.15.8 | Fluxes | 284 |

| | 17.15.9 | Hydrogen Peroxide | 285 |

| | 17.15.10 | Copper Sulfate | 285 |

| | 17.15.11 | Sulfuric Acid | 285 |

| | 17.15.12 | Crusher Liners | 286 |

| 18.0 PROJECT INFRASTRUCTURE | 287 |

| 18.1 | Introduction | 287 |

| 18.2 | Access Roads and Port Access | 288 |

| 18.3 | Power Supply | 289 |

| | 18.3.1 | Estimated Electric Power Consumption | 289 |

| | 18.3.2 | Emergency Power | 290 |

| 18.4 | Water Supply | 290 |

| | 18.4.1 | Operations and Construction Water Balance | 291 |

| | 18.4.2 | Raw Water | 292 |

| | 18.4.3 | Potable Water | 294 |

| | 18.4.4 | Fire Water | 294 |

| 18.5 | Project Buildings | 294 |

| | |

| November 2012 | Shahuindo Project | vi |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

| | 18.5.1 | Administration Building | 294 |

| | 18.5.2 | Laboratory | 294 |

| | 18.5.3 | Process Buildings | 295 |

| | 18.5.4 | Mine Shop | 296 |

| | 18.5.5 | Mine Warehouse and Workshop | 296 |

| | 18.5.6 | Powder Magazine | 296 |

| | 18.5.7 | Construction / Permanent Operations Camp | 297 |

| | 18.5.8 | Dining Facilities | 297 |

| 18.6 | Diesel Fuel Delivery and Storage | 298 |

| 18.7 | Security | 298 |

| 18.8 | First Aid | 298 |

| 18.9 | Communications | 298 |

| 18.10 | Transportation | 298 |

| 18.11 | Waste Disposal | 299 |

| | 18.11.1 | Sewage | 299 |

| | 18.11.2 | Solid Wastes | 299 |

| 19.0 MARKET STUDIES AND CONTRACTS | 302 |

| 20.0 ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | 303 |

| 20.1 | Environmental Studies and Regulations | 303 |

| | 20.1.1 | Permits | 305 |

| | 20.1.2 | Existing Environmental Conditions | 307 |

| 20.2 | Social Impact | 307 |

| | 20.2.1 | Location of the Study Area | 307 |

| | 20.2.2 | Social Baseline Study | 307 |

| | 20.2.3 | Public Consultation and Engagement Plan | 310 |

| | 20.2.4 | Community Development Program | 310 |

| 20.3 | Reclamation and Closure | 311 |

| | 20.3.1 | Reclamation of Open Pits | 313 |

| | 20.3.2 | Reclamation of Waste Rock Facility | 313 |

| | 20.3.3 | Reclamation of Water Storage Ponds | 315 |

| | 20.3.4 | Reclamation of Heap Leach Facility | 315 |

| | 20.3.5 | Ore Neutralization | 316 |

| | 20.3.6 | Passive Treatment of Heap Leach Effluent | 317 |

| | 20.3.7 | Reclamation of Ancillary Facilities | 317 |

| | 20.3.8 | Reclamation of Roads | 318 |

| 21.0 CAPITAL AND OPERATING COSTS | 319 |

| 21.1 | Capital Costs Summary | 320 |

| 21.2 | Mining Capital Costs | 322 |

| | |

| November 2012 | Shahuindo Project | vii |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

| | 21.2.1 | Major Mining Equipment | 326 |

| | 21.2.2 | Mine Support | 327 |

| | 21.2.3 | Maintenance | 327 |

| | 21.2.4 | Mine Facilities | 327 |

| | 21.2.5 | Light Vehicles | 328 |

| | 21.2.6 | Other Capital | 328 |

| 21.3 | Process Capital Costs | 329 |

| | 21.3.1 | Process Cost Basis | 329 |

| | 21.3.2 | Freight | 329 |

| | 21.3.3 | Duties and Customs Fees | 330 |

| | 21.3.4 | Installation | 330 |

| | 21.3.5 | Major Earthworks | 330 |

| | 21.3.6 | Liner | 331 |

| | 21.3.7 | Civils | 331 |

| | 21.3.8 | Structural Steel | 331 |

| | 21.3.9 | Platework | 332 |

| | 21.3.10 | Mechanical Equipment | 332 |

| | 21.3.11 | Piping, Electrical and Instrumentation | 332 |

| 21.4 | Infrastructure Capital Costs | 332 |

| | 21.4.1 | Indirect Costs | 334 |

| | 21.4.2 | Vendor Representatives | 335 |

| | 21.4.3 | Spare Parts | 335 |

| | 21.4.4 | Initial Fills Inventory | 335 |

| | 21.4.5 | Engineering, Procurement and Construction Management | 336 |

| | 21.4.6 | Contingency | 337 |

| 21.5 | Sustaining Capital Costs | 337 |

| 21.6 | Owner’s Costs | 337 |

| 21.7 | Working Capital | 338 |

| 21.8 | Exclusions | 338 |

| 21.9 | Operating Costs Summary | 339 |

| 21.10 | Mining Operating Costs | 341 |

| | 21.10.1 | Drilling Costs | 343 |

| | 21.10.2 | Blasting Costs | 343 |

| | 21.10.3 | Loading Costs | 343 |

| | 21.10.4 | Haulage Costs | 343 |

| | 21.10.5 | Mine-Support Costs | 343 |

| | 21.10.6 | Mine-Maintenance Costs | 343 |

| | | 21.10.7 | Mine General Services, Engineering, and Geology Costs | 343 |

| | 21.10.8 | Mine Dewatering Costs | 344 |

| | |

| November 2012 | Shahuindo Project | viii |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

| | 21.10.9 | Mine Personnel and Staffing | 344 |

| 21.11 | Process and Support Services Operating Cost | 348 |

| | 21.11.1 | Process Personnel and Staffing | 350 |

| | 21.11.2 | Power | 352 |

| | 21.11.3 | Consumable Items | 353 |

| | 21.11.4 | Mobile Equipment | 356 |

| | 21.11.5 | Repair Materials | 357 |

| 21.12 | General Administrative | 357 |

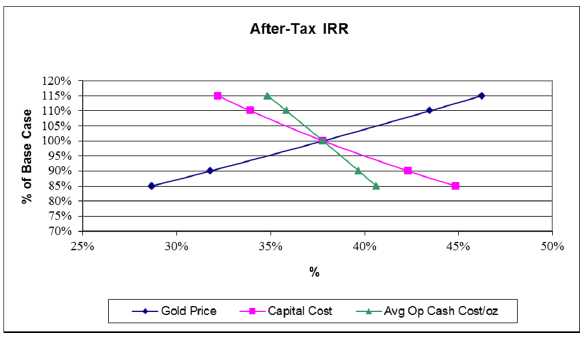

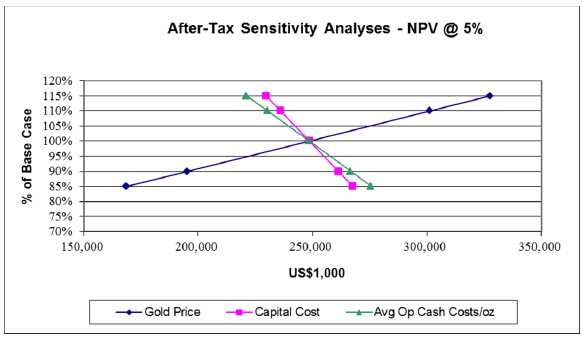

| 22.0 ECONOMIC ANALYSIS | 358 |

| 22.1 | Summary | 358 |

| 22.2 | Methodology | 360 |

| 22.3 | General Assumptions | 360 |

| 22.4 | Capital Cost Estimates | 362 |

| 22.5 | Operating Cost Estimates | 363 |

| 22.6 | Financial Model and Cash Flow | 364 |

| 22.7 | Sensitivity Analysis | 368 |

| 23.0 ADJACENT PROPERTIES | 371 |

| 24.0 OTHER RELEVANT DATA AND INFORMATION | 372 |

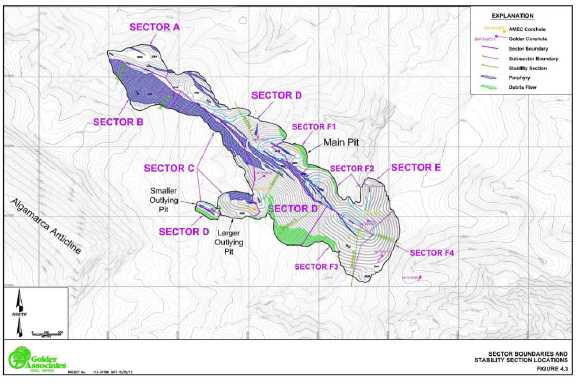

| 24.1 | Geotechnical Issues | 372 |

| | 24.1.1 | Pit Slope Stability Analysis | 372 |

| | 24.1.2 | Heap Leach Facilities Geotechnical | 375 |

| 24.2 | Hydrology | 378 |

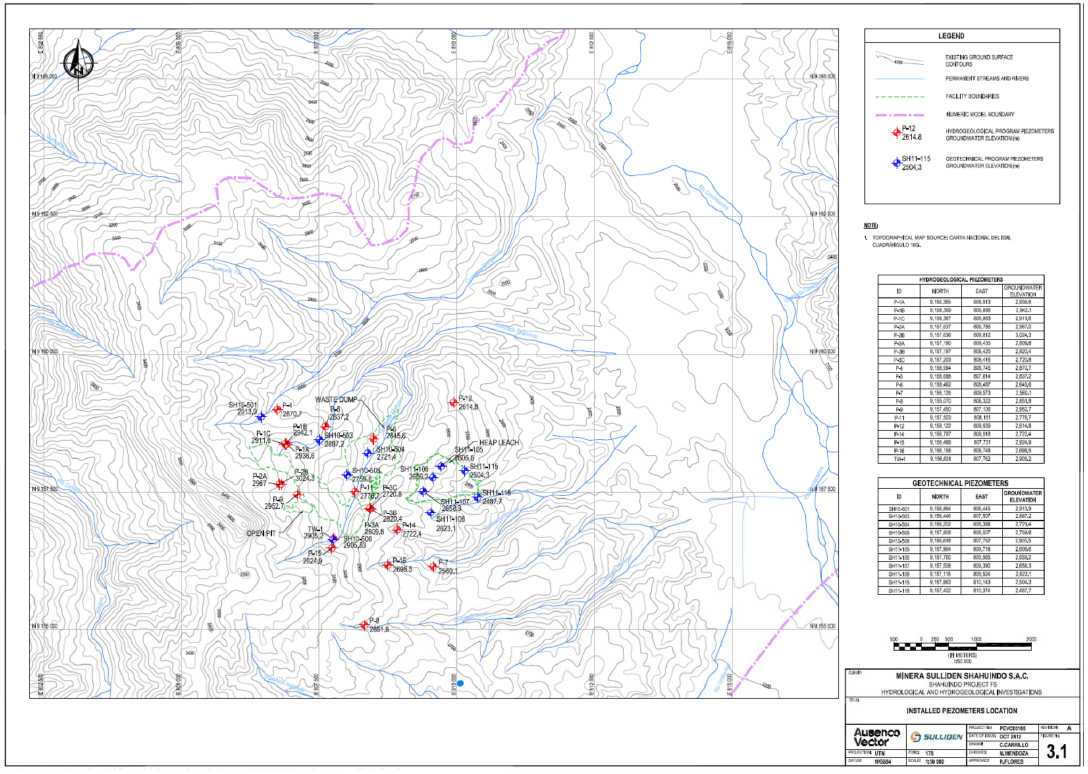

| | 24.2.1 | Field Investigations | 379 |

| | 24.2.2 | Climate and Meteorology | 380 |

| 24.3 | Hydrology | 380 |

| | 24.3.1 | Hydrography | 380 |

| | 24.3.2 | Surface Runoff | 381 |

| | 24.3.3 | Replacement Flows | 382 |

| | 24.3.4 | Water Uses | 382 |

| | 24.3.5 | Water Quality | 383 |

| | 24.3.6 | Surface Water | 385 |

| | 24.3.7 | Water designated for Human Consumption | 385 |

| | 24.3.8 | Underground Water | 385 |

| 24.4 | Hydrogeology | 385 |

| | 24.4.1 | Background | 385 |

| | 24.4.2 | Field Investigation | 386 |

| | 24.4.3 | Groundwater Modeling | 389 |

| | 24.4.4 | Mine Pit Dewatering | 391 |

| 24.5 | Project Implementation | 391 |

| | |

| November 2012 | Shahuindo Project | ix |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | | | |

| | 24.5.1 | Detailed Design | 392 |

| | 24.5.2 | Procurement | 393 |

| | 24.5.3 | Construction Period | 394 |

| | 24.5.4 | Project Schedule | 395 |

| | 24.5.5 | Schedule Comments | 396 |

| 24.6 | Opportunities and Risks | 397 |

| | 24.6.1 | Production Expansion | 397 |

| | 24.6.2 | Mineral Resource Growth and Mineral Resource Conversion | 398 |

| | 24.6.3 | Access to Electrical Power | 398 |

| | 24.6.4 | Pit Geotechnical and Mine Planning | 399 |

| | 24.6.5 | Metallurgy and Processing | 399 |

| | 24.6.6 | Water Management | 400 |

| | 24.6.7 | Heap Leach Design and Operation | 400 |

| | 24.6.8 | Social Opposition | 401 |

| | 24.6.9 | Informal Miners | 401 |

| | 24.6.10 | Land Acquisition & Resettlement | 402 |

| | 24.6.11 | Political Situation | 402 |

| 25.0 INTERPRETATIONS AND CONCLUSIONS | 403 |

| 26.0 RECOMMENDATIONS | 408 |

| 26.1 | Deposit Expansion and Exploration Activities | 408 |

| 26.2 | Pit Slope Stability | 409 |

| 26.3 | Geotechnical Recommendations | 410 |

| 26.4 | Hydrology | 410 |

| 26.5 | Hydrogeology | 411 |

| 27.0 REFERENCES | 413 |

| 28.0 AUTHORS’ CERTIFICATES | 418 |

| | |

| November 2012 | Shahuindo Project | x |

| |

|

MINE DEVELOPMENT ASSOCIATES |

LIST OF TABLES

| | |

| Table 1-1 | Project Statistics | 2 |

| Table 1-2 | Shahuindo Gold and Silver Reported Resource | 11 |

| Table 1-3 | Ultimate Pit Proven and Probable Reserves | 12 |

| Table 1-4 | Annual Mine Production Schedule Summary | 14 |

| Table 1-5 | Shahuindo Project Capital Cost Summary | 21 |

| Table 1-6 | Shahuindo Project Operating Cost Summary | 21 |

| Table 1-7 | Life-of-Mine Summary | 23 |

| Table 4-1 | Mineral Title Summary | 46 |

| Table 4-2 | Summary of Environmental Requirements for Mining Exploration Programs | 52 |

| Table 5-1 | Summary of Parameters for Seismic Design | 60 |

| Table 6-1 | Summary of Exploration Activities on the Shahuindo Property | 61 |

| Table 6-2 | Historic Mineral Resource Estimates for Shahuindo | 63 |

| Table 6-3 | 2004 Mineral Resource Estimate for Shahuindo by Met-Chem | 63 |

| Table 6-4 | 2005 Mineral Resource Estimate for Shahuindo by Met-Chem | 64 |

| Table 6-5 | 2009 Mineral Resource Estimate for Shahuindo by AMEC | 64 |

| Table 6-6 | 2011 Mineral Resource by MDA | 66 |

| Table 7-1 | Major and Trace Element Geochemistry Associated with Mineralization and Oxidation from Multi-Element Analyses | 79 |

| Table 8-1 | Shahuindo Deposit Zones | 91 |

| Table 9-1 | Summary of Sulliden Exploration Activities on the Shahuindo Property .98 |

| Table 10-1 | Drilling Campaigns | 104 |

| Table 10-2 | Core and RC Gold Analyses | 115 |

| Table 10-3 | Pairs Analyses - Core and Closest RC Sample | 117 |

| Table 10-4 | Drill Hole Intercept Summary Table | 119 |

| Table 12-1 | MDA 2010 Verification Sampling – Rock Chip | 133 |

| Table 12-2 | MDA 2010 Verification Sampling – Core | 134 |

| Table 12-3 | Summary of Results Obtained for Standards | 136 |

| Table 12-4 | Summary of Types of Duplicates | 139 |

| Table 12-5 | Summary of Duplicate Results | 143 |

| Table 13-1 | Summary of HLC Column Leach Tests | 148 |

| Table 13-2 | Summary of KCA Column Leach Tests | 150 |

| Table 13-3 | Summary of KCA Bottle Roll Leach Tests | 150 |

| Table 13-4 | HLC Sample Designations and Average Head Grades | 151 |

| Table 13-5 | Summary of HLC Column Leach Test Results | 152 |

| Table 13-6 | Summary of HLC Bottle Roll Leach Test Results | 153 |

| Table 13-7 | Summary of KCA Coarse Ore Bottle Roll Leach Test Results | 156 |

| | |

| November 2012 | Shahuindo Project | xi |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | |

| Table 13-8 | Summary of KCA Pulverized Bottle Roll Leach Test Results | 158 |

| Table 13-9 | Summary of KCA Bottle Roll Recoveries According to Sulfide Level | 161 |

| Table 13-10 | Summary of KCA Crushed Ore Column Test Results | 164 |

| Table 13-11 | Summary of KCA ROM Column Test Results | 165 |

| Table 13-12 | Summary of KCA Screened Material Column Test Results | 165 |

| Table 13-13 | Summary of Detoxification Test Results – Total & WAD Cyanide | 169 |

| Table 13-14 | Summary of Detoxification Test Results – Total & WAD Cyanide | 169 |

| Table 13-15 | Samples Utilized in ABA Testing | 170 |

| Table 13-16 | Bulk Sample Work Index Results | 172 |

| Table 14-1 | Descriptive Statistics of Shahuindo Density Values by Rock Type | 188 |

| Table 14-2 | Descriptive Statistics by Gold Mineral Domain – All Gold Samples | 190 |

| Table 14-3 | Descriptive Statistics by Gold Mineral Domain – Silver Oxide Samples Only | 190 |

| Table 14-4 | Descriptive Statistics by Silver Mineral Domain – Silver Mixed and Sulfide Samples Only | 191 |

| Table 14-5 | Descriptive Statistics by Gold Mineral Domain – All Gold Composites | 191 |

| Table 14-6 | Descriptive Statistics by Gold Mineral Domain – Silver Oxide Composites Only | 192 |

| Table 14-7 | Descriptive Statistics by Silver Mineral Domain – Silver Mixed and Sulfide Composites Only | 192 |

| Table 14-8 | Shahuindo Estimation Parameters | 194 |

| Table 14-9 | Shahuindo Search Ellipse Orientations | 194 |

| Table 14-10 | Shahuindo Mineral Domain Search Restrictions | 195 |

| Table 14-11 | Criteria for Shahuindo Resource Classification | 198 |

| Table 14-12 | Shahuindo Gold and Silver Reported Resource | 200 |

| Table 14-13 | Shahuindo Gold and Silver Resources | 201 |

| Table 15-1 | Scenario Economic Parameters | 208 |

| Table 15-2 | Metallurgical Recoveries | 209 |

| Table 15-3 | 10K TPD – 0.30 g Au/t Cutoff Optimization Results | 210 |

| Table 15-4 | Pit Optimization Results using Final Feasibility Costs | 212 |

| Table 15-5 | Pit Design Slope Parameters | 214 |

| Table 15-6 | Reserve Cutoff Grades (g Au/t) | 223 |

| Table 15-7 | Ultimate Pit Proven and Probable Reserves | 226 |

| Table 15-8 | Proven and Probable Reserves by Phase | 227 |

| Table 15-9 | Phase 1 Proven and Probable Bench Reserves | 228 |

| Table 15-10 | Phase 1B Proven and Probable Bench Reserves | 229 |

| Table 15-11 | Phase 2 Proven and Probable Bench Reserves | 230 |

| Table 15-12 | Phase 3 Proven and Probable Bench Reserves | 231 |

| Table 15-13 | Phase 4 Proven and Probable Bench Reserves | 232 |

| | |

| November 2012 | Shahuindo Project | xii |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | |

| Table 15-14 | Phase 5 Proven and Probable Bench Reserves | 233 |

| Table 15-15 | Total Proven and Probable Bench Reserves | 234 |

| Table 15-16 | In-Pit Inferred Resources | 235 |

| Table 16-1 | In-Pit Mineralized Waste by Phase | 237 |

| Table 16-2 | Waste by Material Type and Phase | 237 |

| Table 16-3 | Waste Storage | 238 |

| Table 16-4 | Annual Mine Production Schedule | 240 |

| Table 16-5 | Annual Long Term Stockpile Balance | 241 |

| Table 16-6 | Maximum Loader Productivity Estimate | 242 |

| Table 16-7 | Annual Load and Haul Equipment Requirements | 245 |

| Table 16-8 | Annual Mine Equipment Requirements (Number of Units) | 246 |

| Table 17-1 | Processing Design Criteria Summary | 251 |

| Table 17-2 | Crushing Circuit Set Points | 257 |

| Table 17-3 | Water Impoundment and Solution Storage Capacities | 264 |

| Table 17-4 | Peru Discharge Standards Liquid Effluents from Mining Activities* | 267 |

| Table 17-5 | Projected Annual Reagents and Consumables | 282 |

| Table 18-1 | Shahuindo Heap Leach Power Demand | 290 |

| Table 18-2 | Reservoirs and Impoundment Capacities | 293 |

| Table 18-3 | Downstream User Compensation Flow Required by Stream (L/s) | 293 |

| Table 21-1 | Shahuindo Project Capital Cost Summary | 319 |

| Table 21-2 | Shahuindo Project Operating Cost Summary | 319 |

| Table 21-3 | Summary of Pre-Production Capital Costs | 321 |

| Table 21-4 | Pre-Production Mining Fleet & Costs | 323 |

| Table 21-5 | Estimated Mine Capital by Year | 325 |

| Table 21-6 | Major Earthworks Unit Rates | 331 |

| Table 21-7 | Buildings | 333 |

| Table 21-8 | Field Indirect Costs | 335 |

| Table 21-9 | Initial Fills | 336 |

| Table 21-10 | Shahuindo Project Operating Cost Summary | 339 |

| Table 21-11 | Annual Mine Operating Costs | 342 |

| Table 21-12 | Mine Personnel Requirements | 345 |

| Table 21-13 | Mine Annual Personnel Costs ($000’s USD) | 347 |

| Table 21-14 | Shahuindo Operating Cost Summary (US$/t) – By Year | 349 |

| Table 21-15 | Shahuindo Project Staffing Levels | 351 |

| Table 21-16 | Process Power and Consumption – By Year | 353 |

| Table 21-17 | Process Consumable Items | 354 |

| Table 22-1 | Life-of-Mine Summary | 359 |

| Table 22-2 | Capital Cost to Completion | 363 |

| Table 22-3 | LOM Operating and G&A Costs | 364 |

| | |

| November 2012 | Shahuindo Project | xiii |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | |

| Table 22-4 | Key Financial Parameters | 365 |

| Table 22-5 | Cash Flow Analysis | 366 |

| Table 22-6 | Sensitivity Analysis | 368 |

| Table 24-1 | Crushing Area Carrying Capacities and Ground Settling Results | 375 |

| Table 24-2 | Processing Area Carrying Capacities and Ground Settling Results | 376 |

| Table 24-3 | Water and Excess Solution Ponds Analysis of Stability Results | 378 |

| Table 24-4 | Procurement Lead Times | 394 |

| Table 26-1 | Exploration Recommendations and Associated Costs | 409 |

| | |

| November 2012 | Shahuindo Project | xiv |

| |

|

MINE DEVELOPMENT ASSOCIATES |

LIST OF FIGURES

| | |

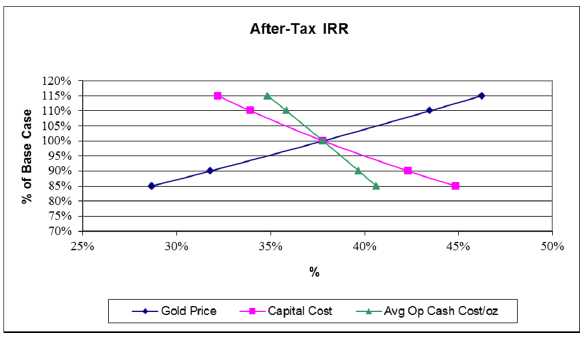

| Figure 1-1 | After-Tax IRR vs. Gold Price, Capital Cost, and Operating Cash Cost | 24 |

| Figure 1-2 | NPV @ 0% vs. Gold Price, Capital Cost, and Operating Cash Cost | 25 |

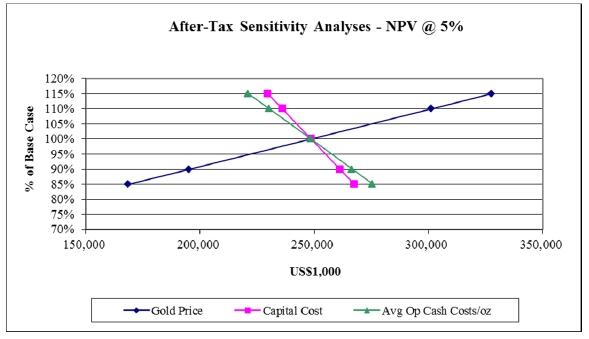

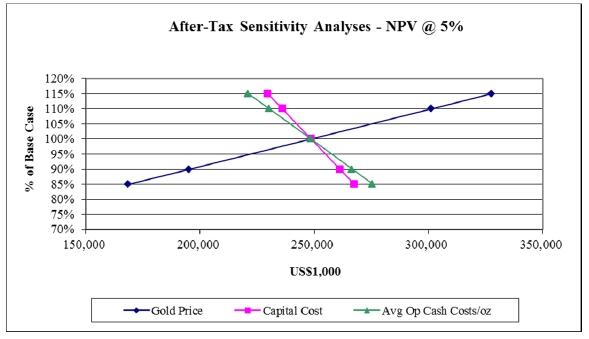

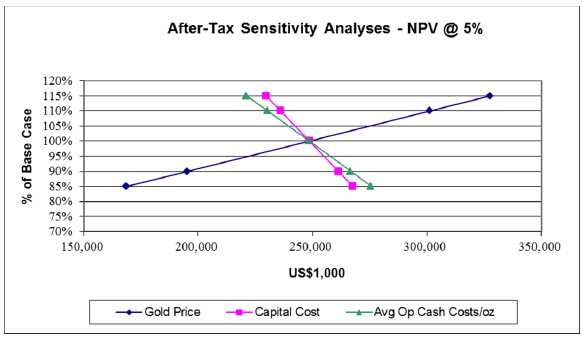

| Figure 1-3 | NPV @ 5% vs. Gold Price, Capital Cost, and Operating Cash Cost | 25 |

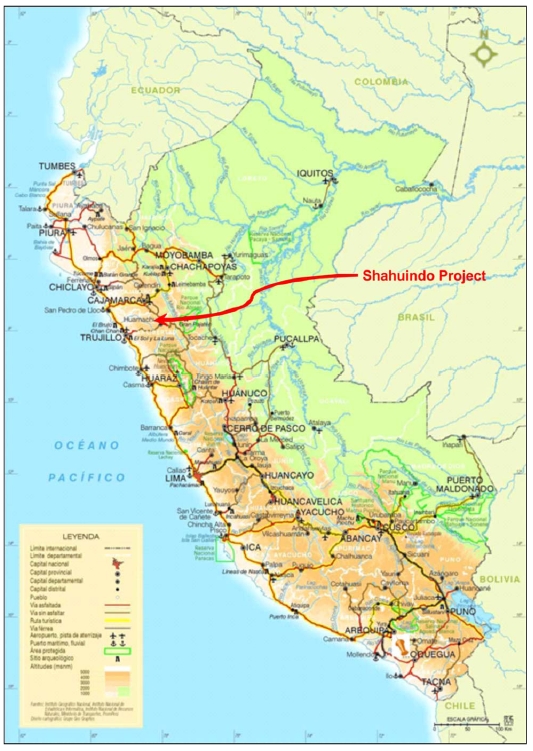

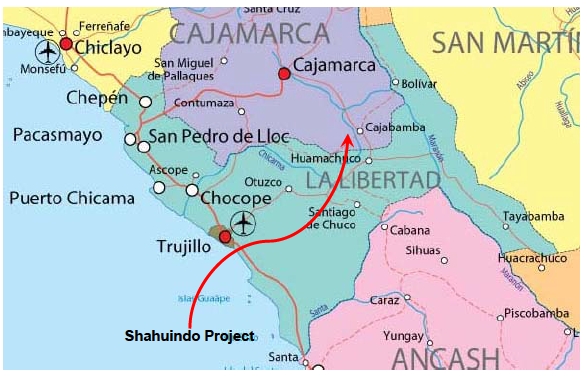

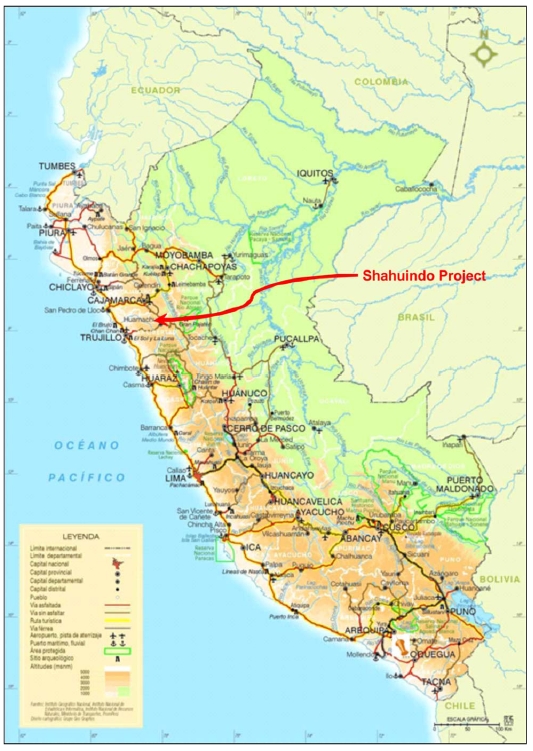

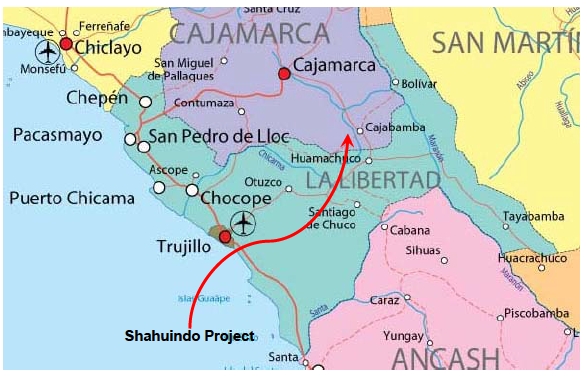

| Figure 4-1 | Shahuindo Project Location Map | 42 |

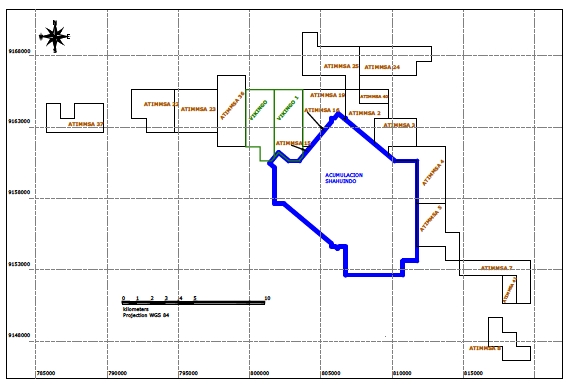

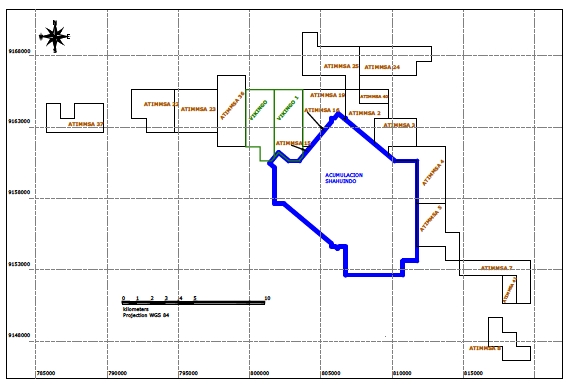

| Figure 4-2 | Mineral Claim Location Map | 47 |

| Figure 4-3 | Mineral Claim Location Map Detail Showing Deposit Area | 48 |

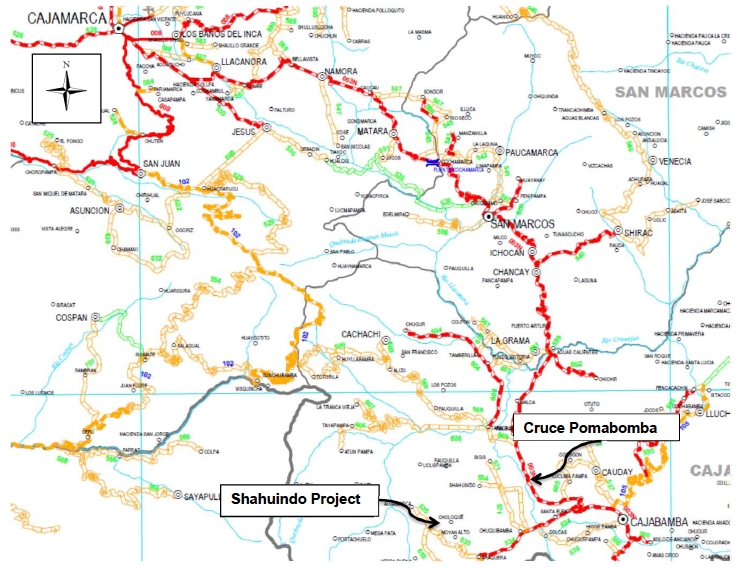

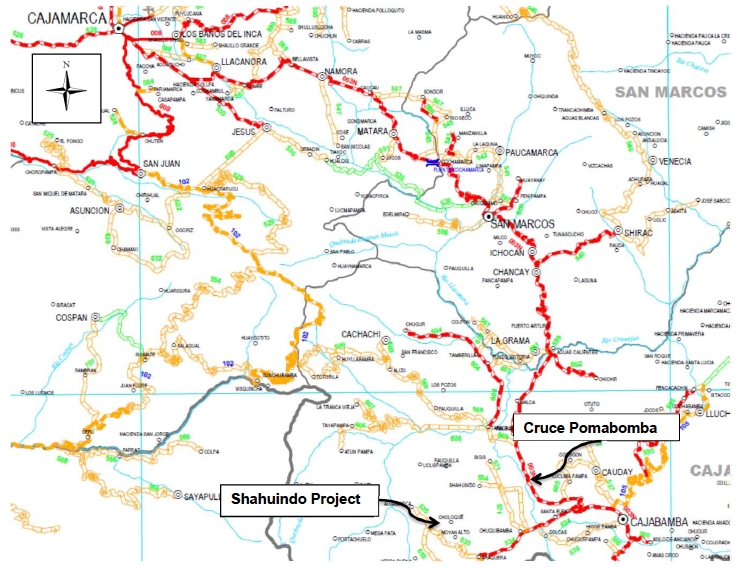

| Figure 5-1 | Shahuindo Road Route from Cajamarca | 56 |

| Figure 5-2 | Shahuindo Access Road Upgrade Cruce Pomabomba to Shahuindo Site | 57 |

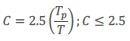

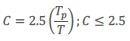

| Figure 7-1 | Shahuindo Property Regional Geologic Map | 68 |

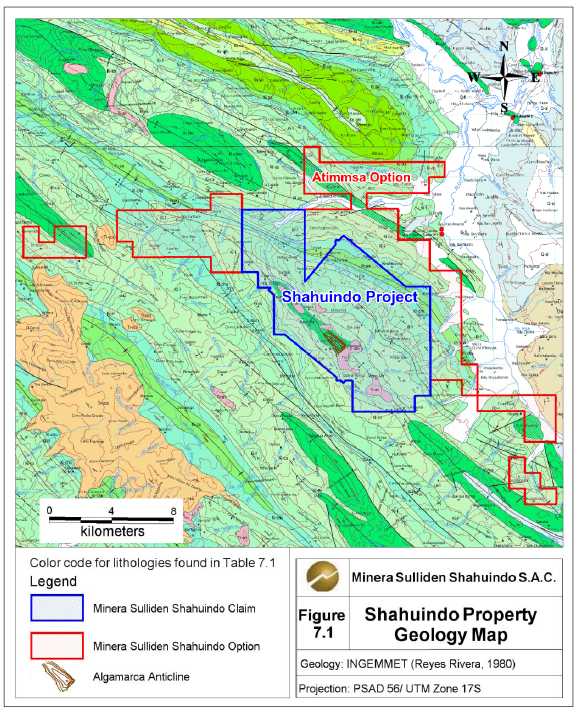

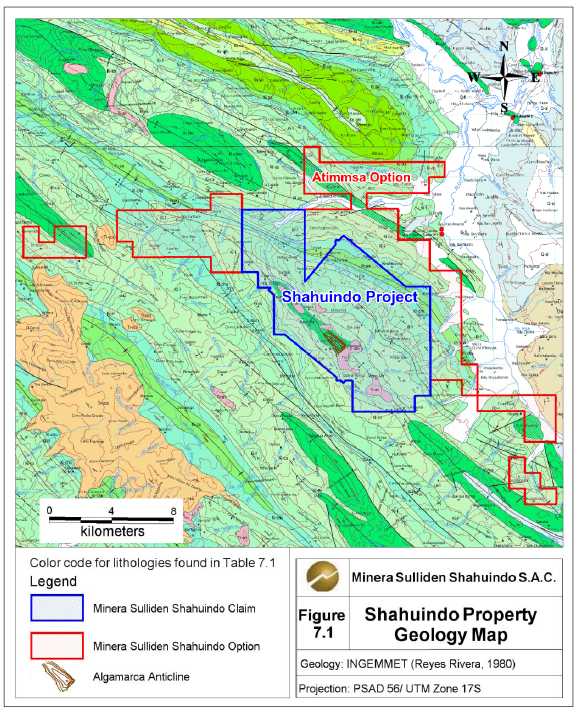

| Figure 7-2 | Regional Stratigraphy with Location of Some Deposits in the District | 69 |

| Figure 7-3 | Geologic Map of the Shahuindo Concession | 71 |

| Figure 7-4 | Shahuindo Project Cross-section A-A’ | 72 |

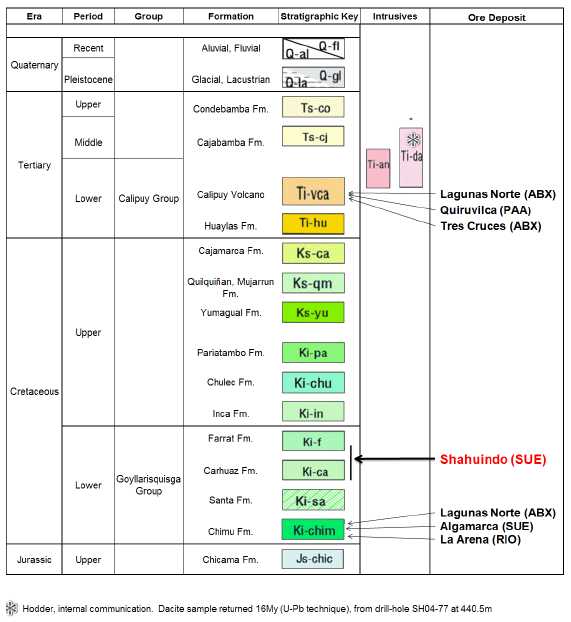

| Figure 7-5 | Shahuindo Mineral Corridors | 81 |

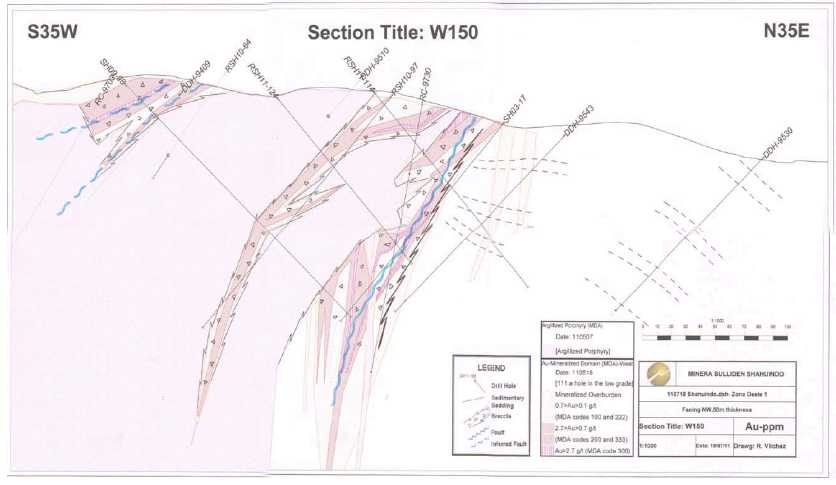

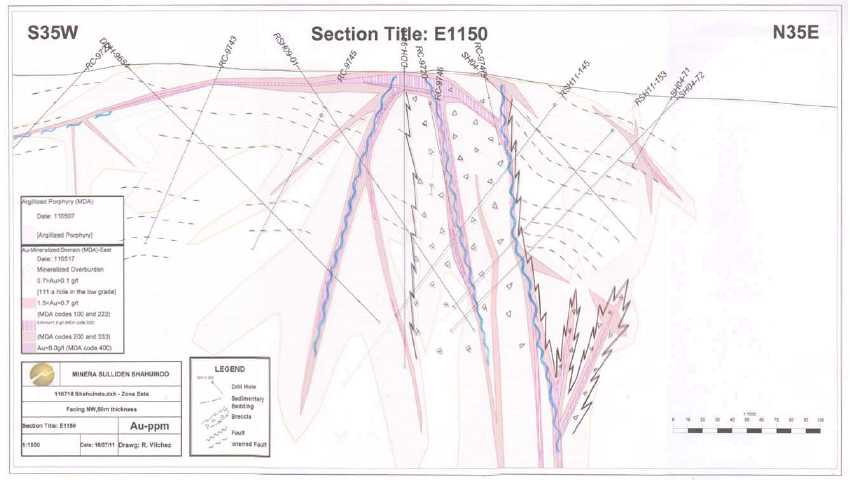

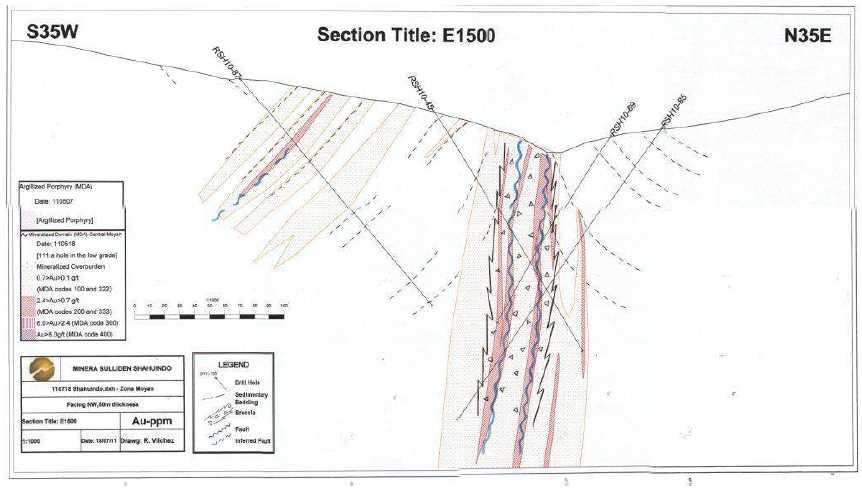

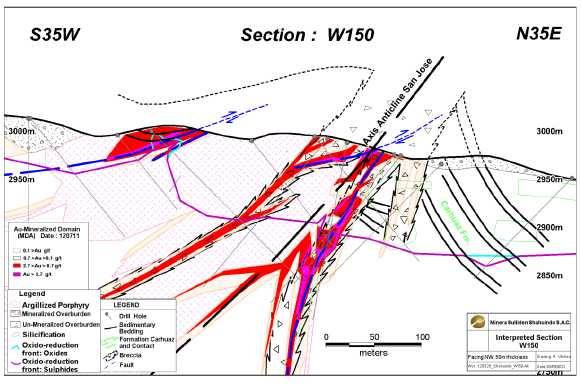

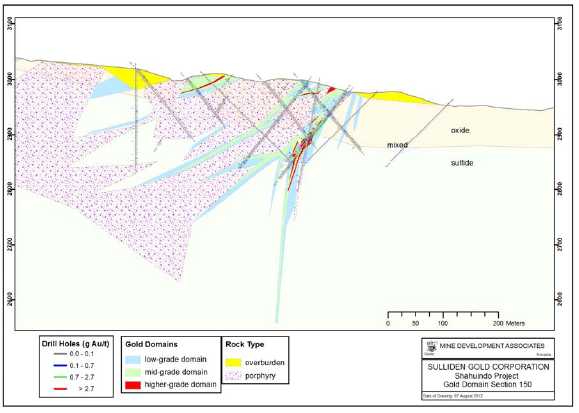

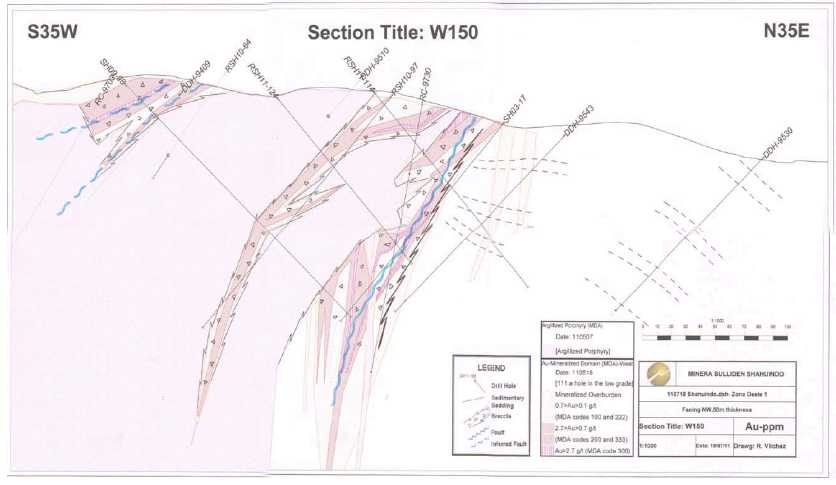

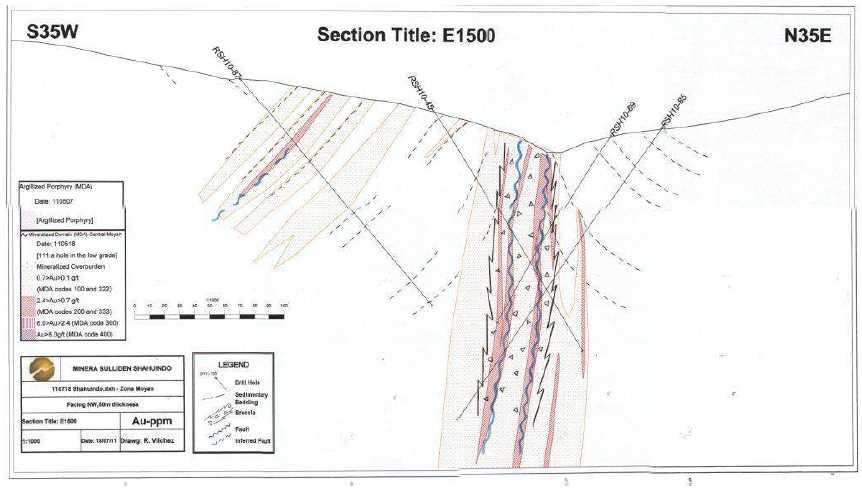

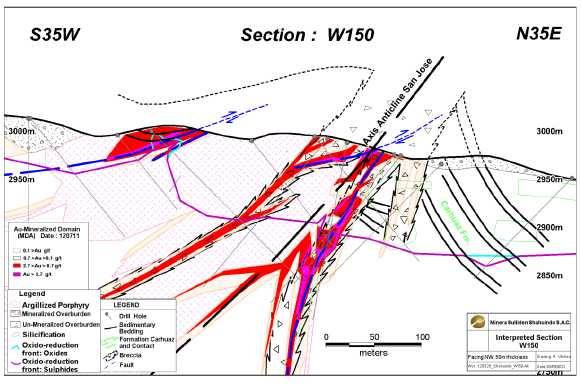

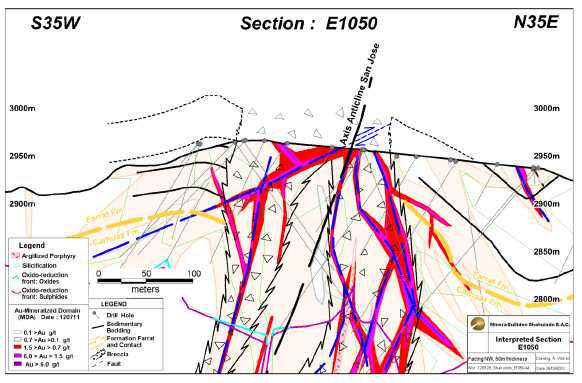

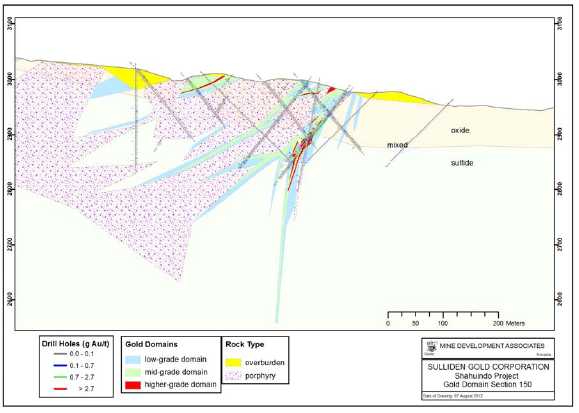

| Figure 8-1 | West Zone Geologic Cross-section W150 | 84 |

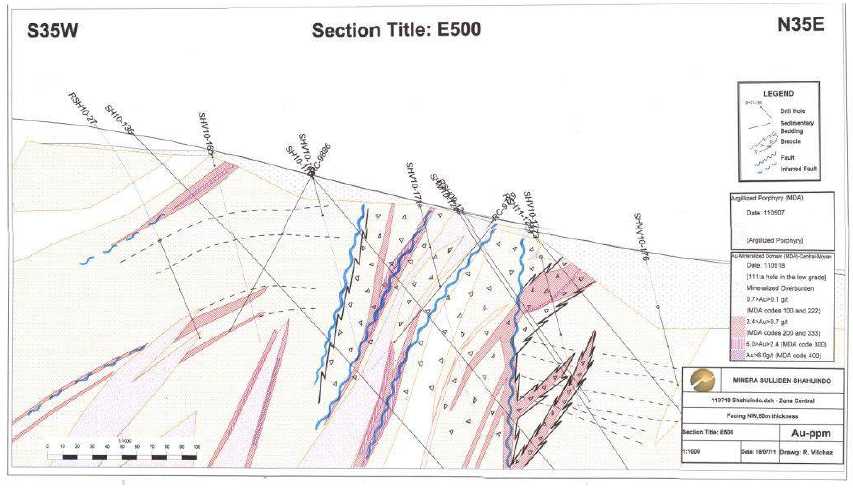

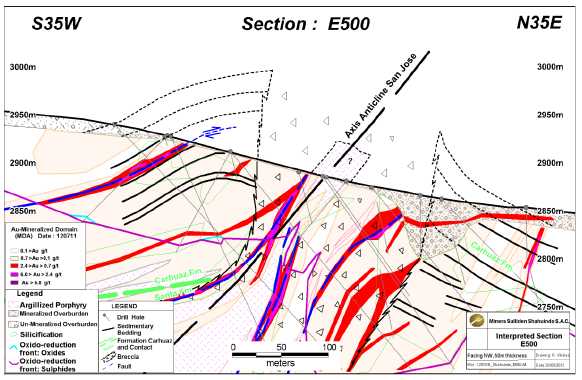

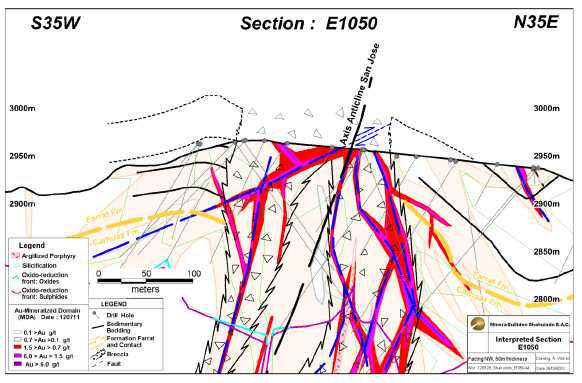

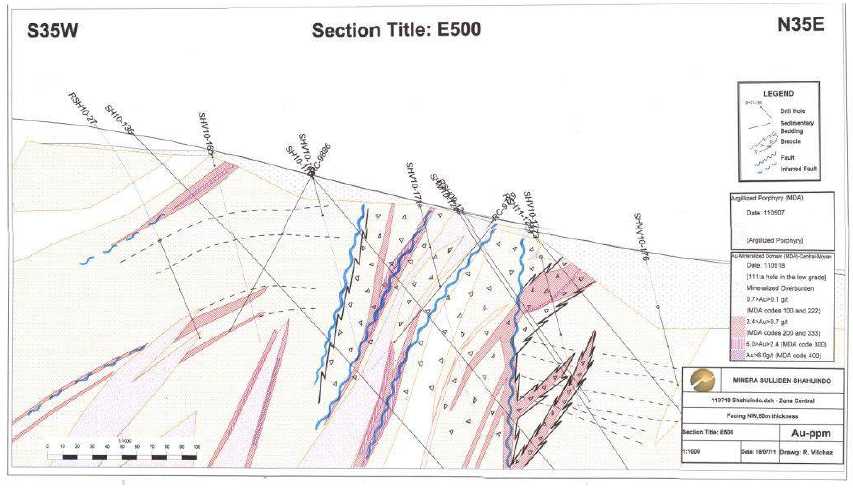

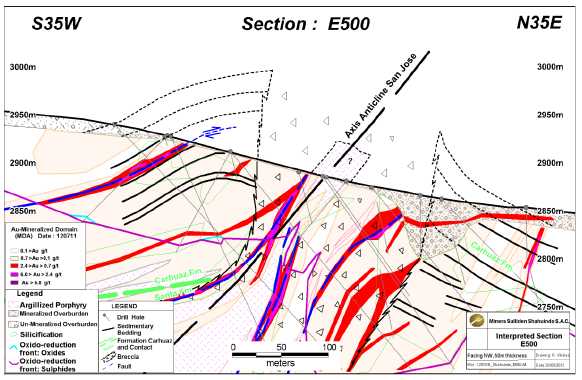

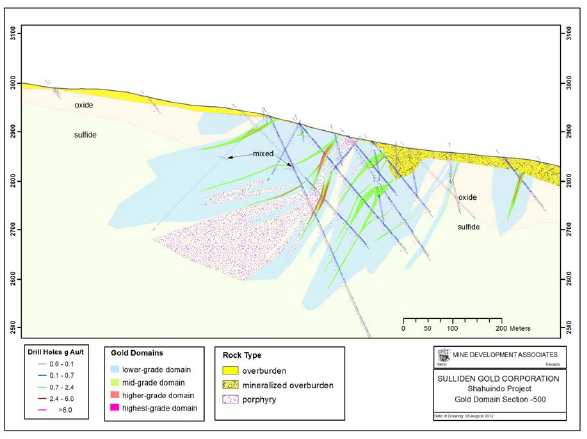

| Figure 8-2 | Central Zone Geologic Cross-section E500 | 86 |

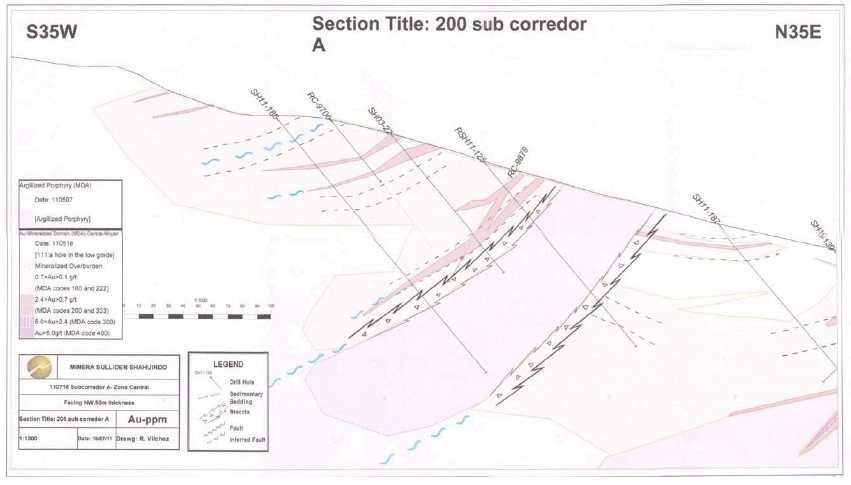

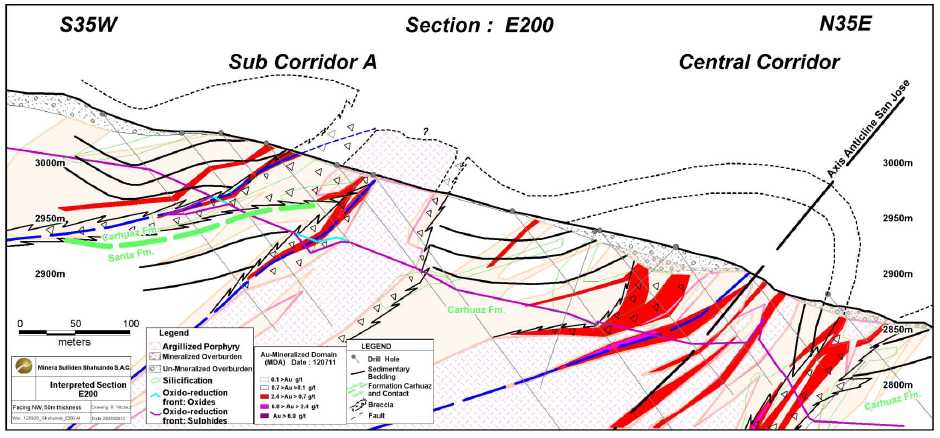

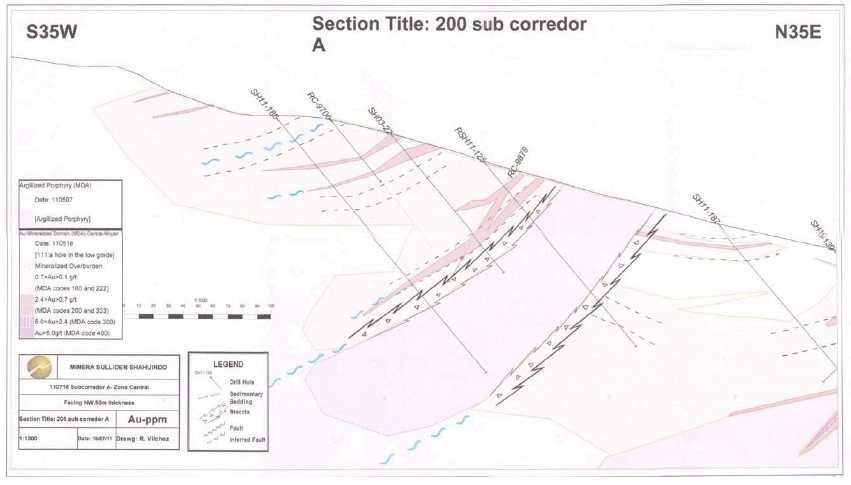

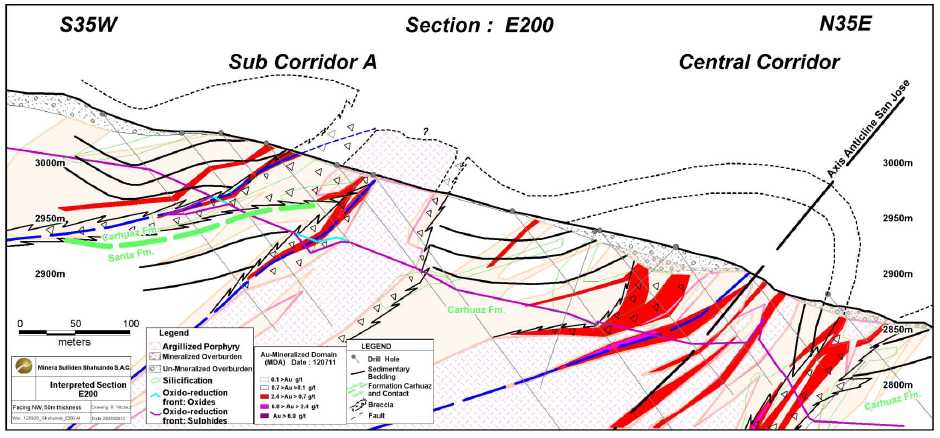

| Figure 8-3 | Sub-Corridor A Geologic Cross-section E200 | 87 |

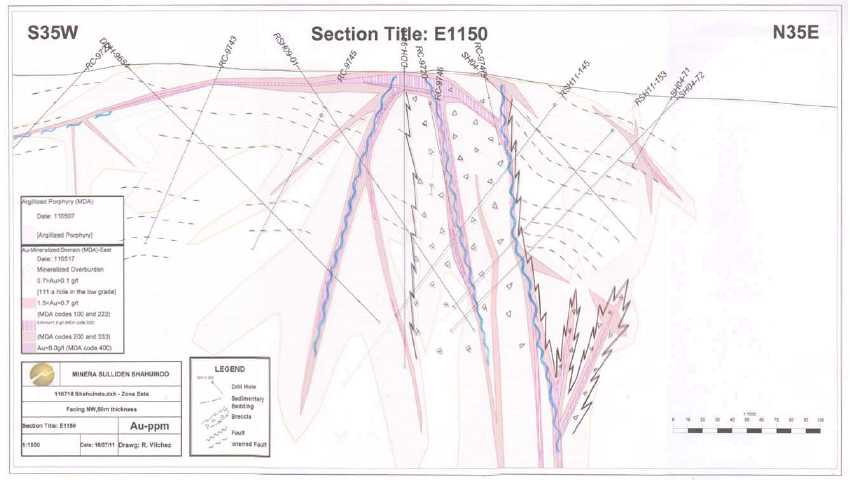

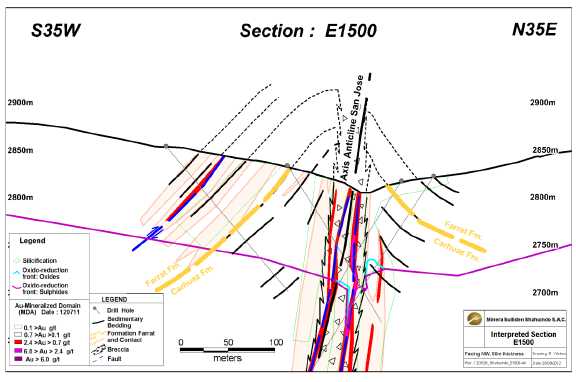

| Figure 8-4 | East Zone Geologic Cross-section E1150 | 89 |

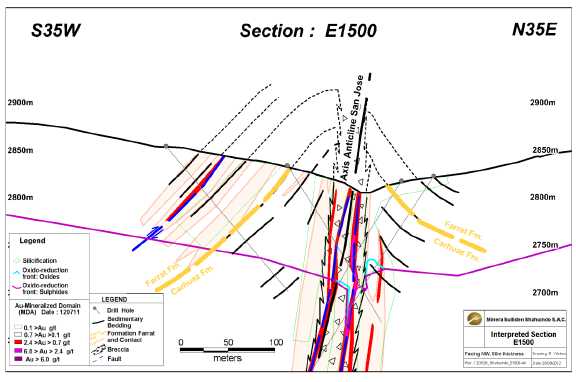

| Figure 8-5 | East Zone Geologic Cross-section E1500 | 90 |

| Figure 8-6 | West Zone Geologic Cross-section W150 | 93 |

| Figure 8-7 | Central Zone Geologic Cross-section E500 | 94 |

| Figure 8-8 | Sub-Corridor A Geologic Cross-section E200 | 95 |

| Figure 8-9 | East Zone Geologic Cross-section E1150 | 96 |

| Figure 8-10 | Moyan Alto Zone Geologic Cross-section E1500 | 97 |

| Figure 9-1 | Exploration Targets | 103 |

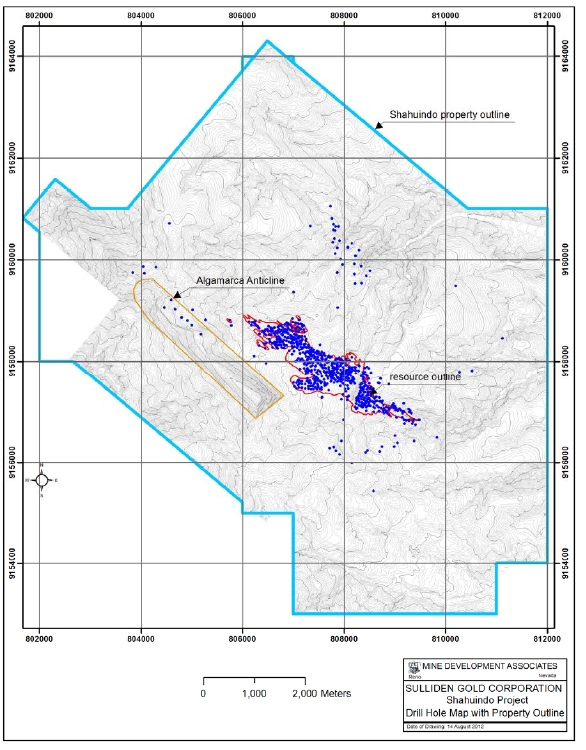

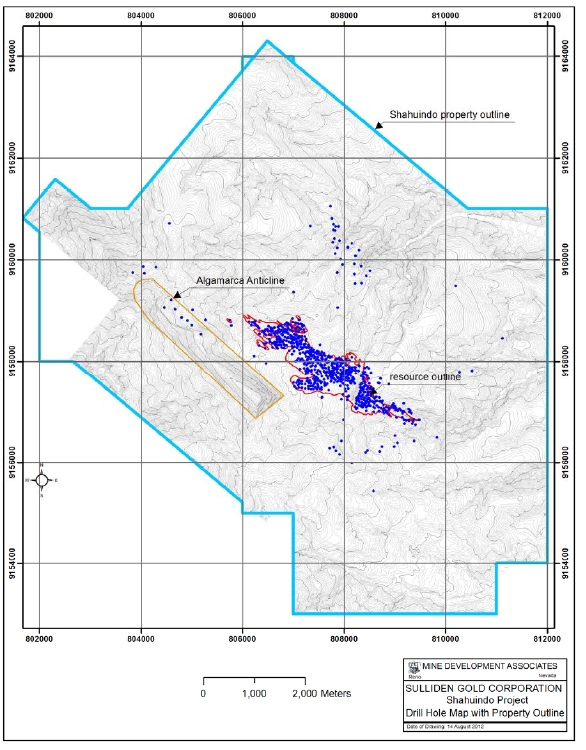

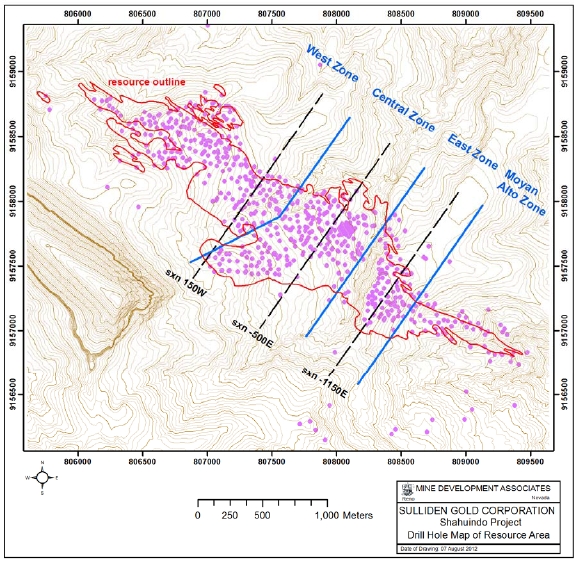

| Figure 10-1 | Drill-Hole Location Plan | 106 |

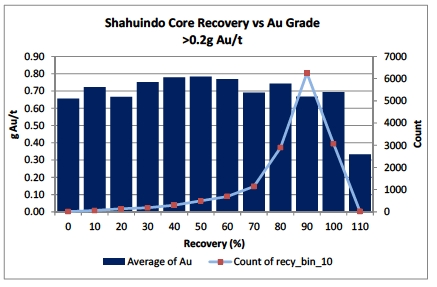

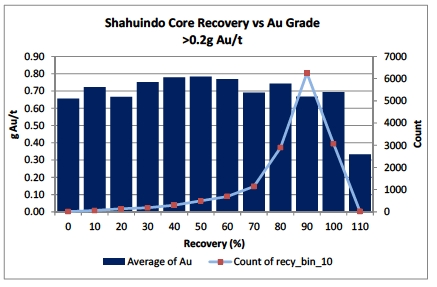

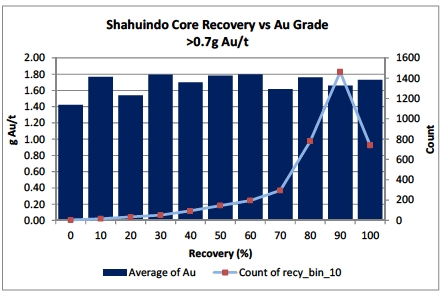

| Figure 10-2 | Core Recovery and Gold Grades - >0.2 g Au/t Samples Only | 112 |

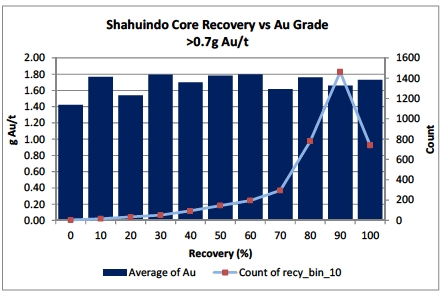

| Figure 10-3 | Core Recovery and Gold Grades - >0.7 g Au/t Samples Only | 113 |

| Figure 10-4 | Core Recovery and Gold Grades – Mineral Domains 200, 300, and400 | 113 |

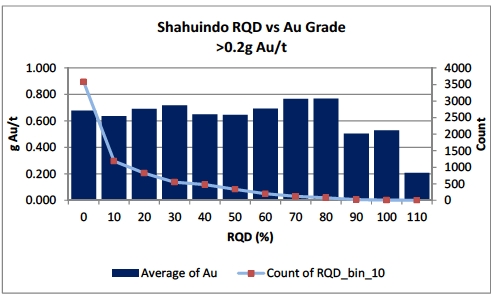

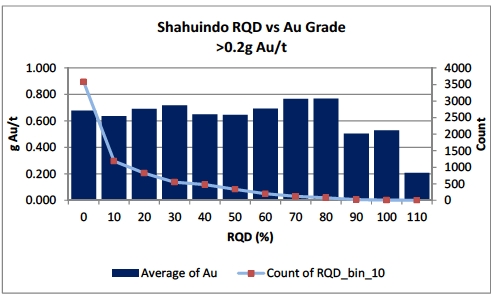

| Figure 10-5 | RQD and Gold Grades | 115 |

| Figure 10-6 | Quantile Plot of Core and RC Assays | 116 |

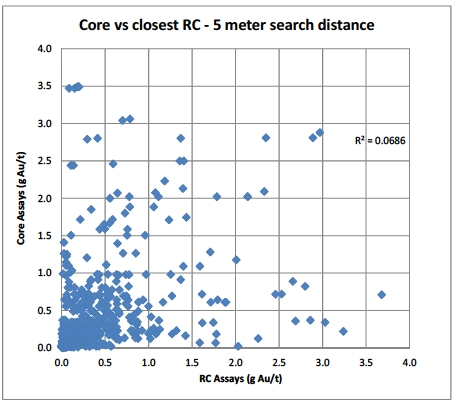

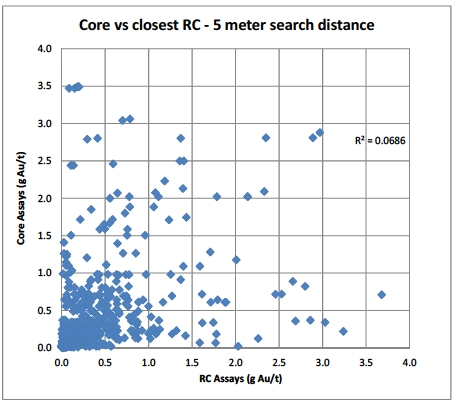

| Figure 10-7 | Core and RC Sample Pairs – 5 meter search | 117 |

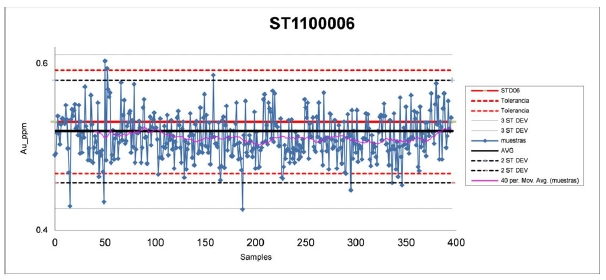

| Figure 12-1 | Control Chart for ST1100006 | 135 |

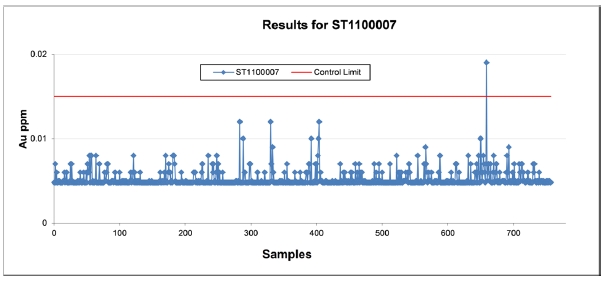

| Figure 12-2 | Results for Blank ST1100007 | 137 |

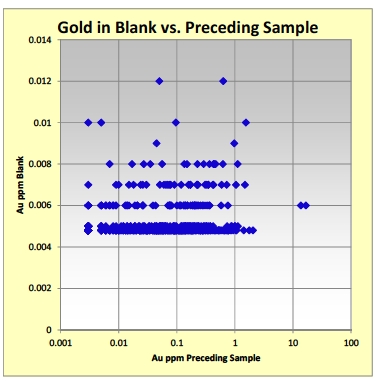

| Figure 12-3 | Gold in Blank ST1100007 vs. Preceding Sample | 138 |

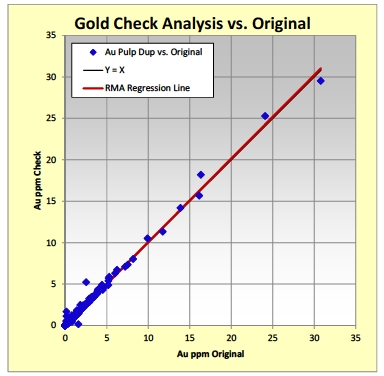

| Figure 12-4 | Gold Pulp Check Analysis vs. Original | 140 |

| | |

| November 2012 | Shahuindo Project | xv |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | |

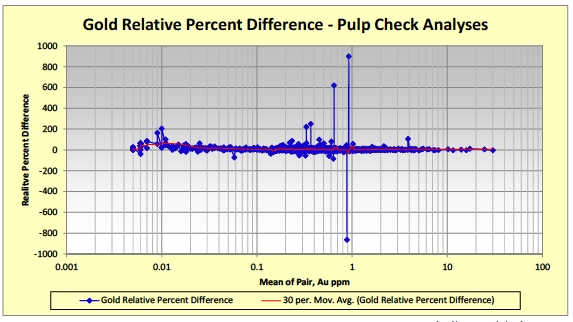

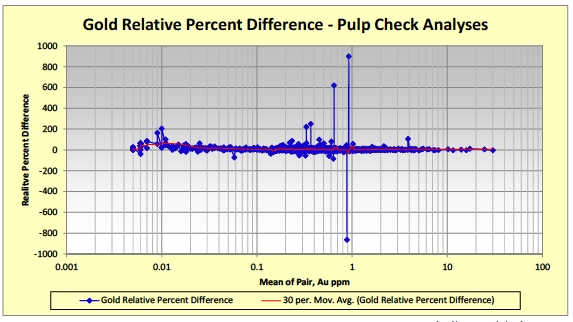

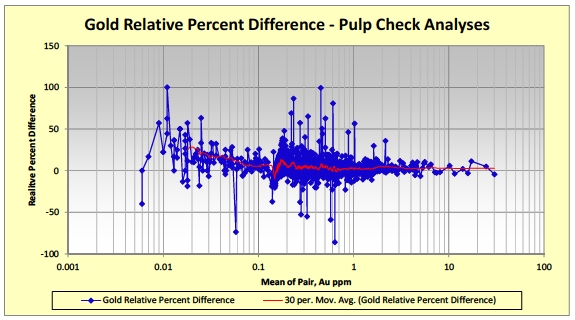

| Figure 12-5 | Gold Pulp Check Analyses - Relative Percent Difference | 141 |

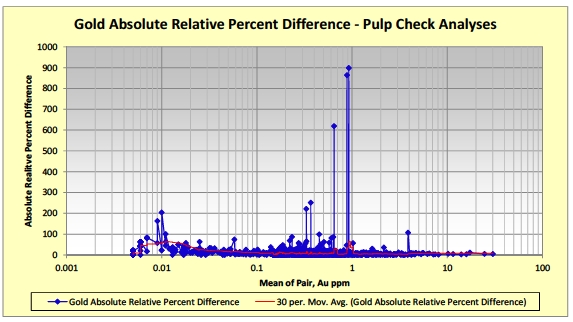

| Figure 12-6 | Gold Pulp Check Analyses – Absolute Value of Relative Percent Difference | 141 |

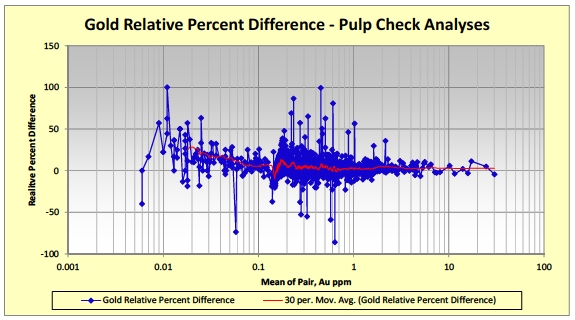

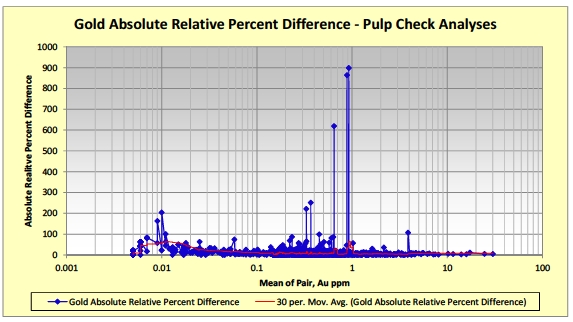

| Figure 12-7 | Gold Pulp Check Analyses - Relative Percent Difference (Filtered) | 142 |

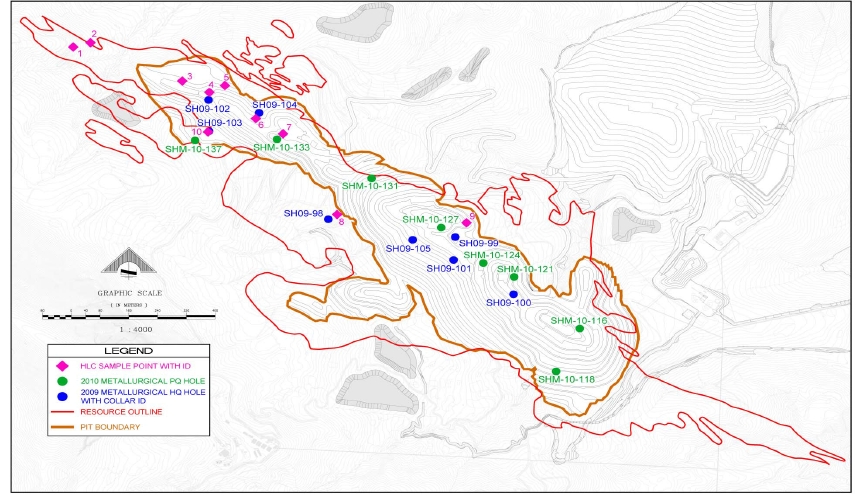

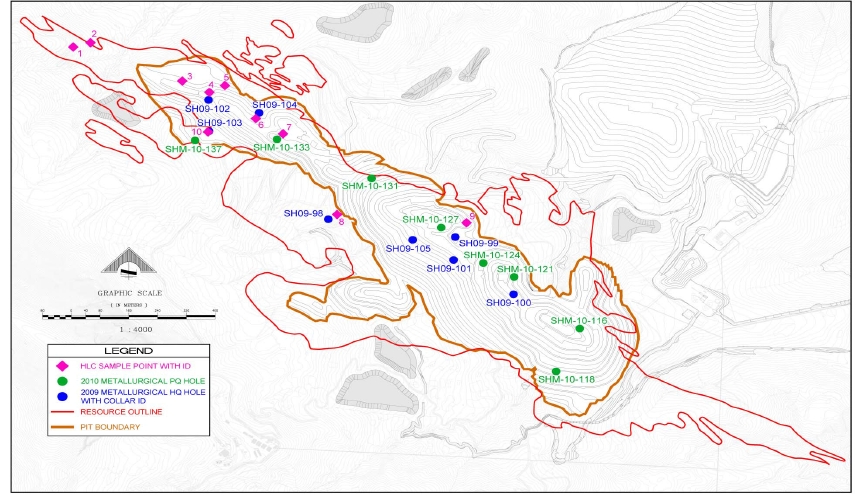

| Figure 13-1 | Location of Metallurgical Drill Holes and Samples | 147 |

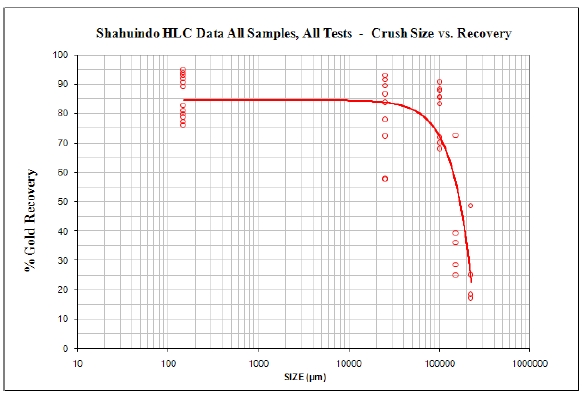

| Figure 13-2 | Summary Results of HLC Size vs. Recovery | 154 |

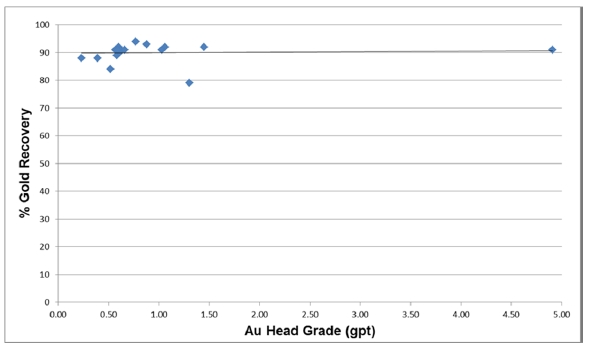

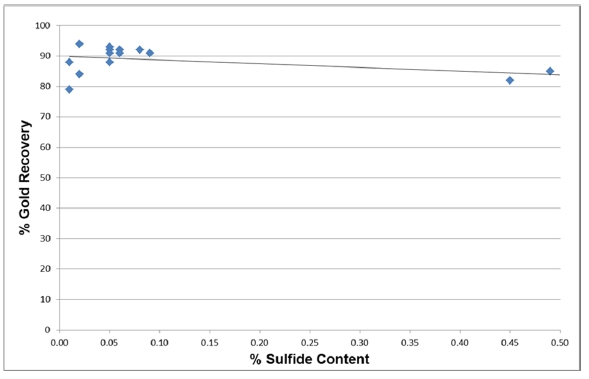

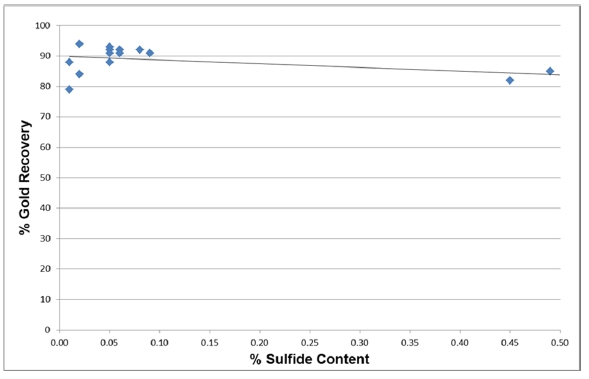

| Figure 13-3 | KCA Bottle Roll Tests at 19 mm, % Sulfide Content and Gold Recovery | 161 |

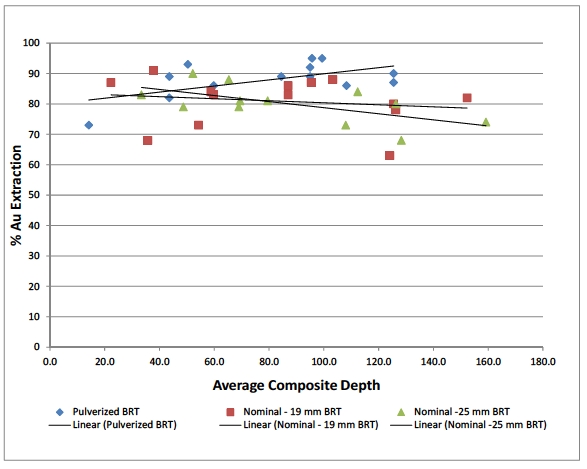

| Figure 13-4 | Bottle Roll Test Results vs. Average Interval Depth, Composites Containing <0.1% Sulfide Sulfur | 162 |

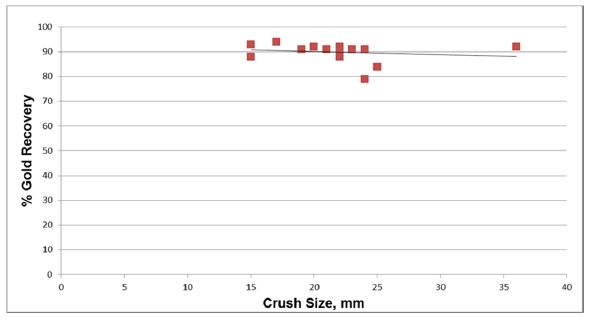

| Figure 13-5 | KCA Crushed Ore Column Leach Tests, % Gold Recovery vs. P80Crush Size, <0.1% Sulfide | 166 |

| Figure 13-6 | KCA Crushed Ore Column Leach Tests, <0.1% Sulfides, % Gold Recovery vs. Au Head Grade | 167 |

| Figure 13-7 | KCA Crushed Ore Column Tests, % Sulfide Content vs. Gold Recovery | 168 |

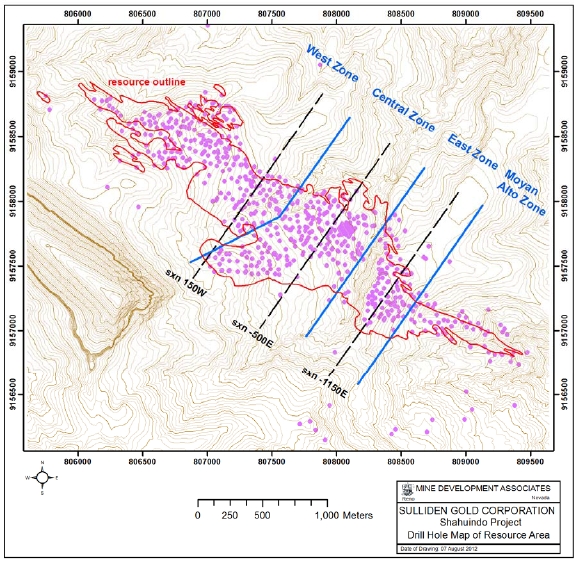

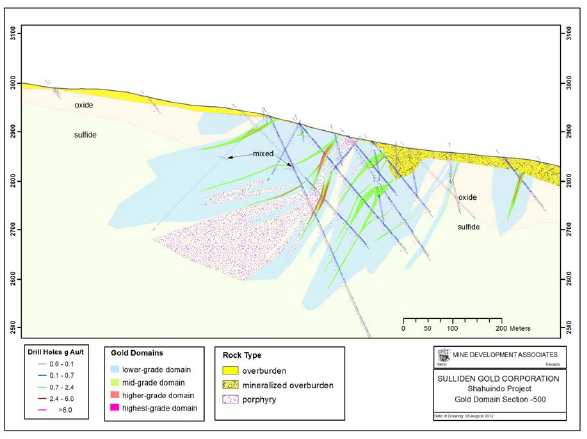

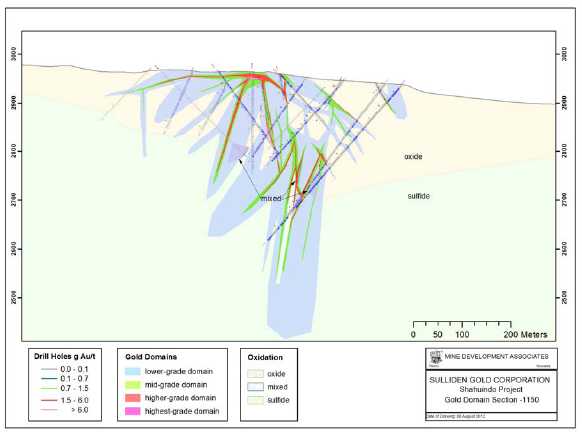

| Figure 14-1 | Shahuindo Deposit Drilling with Resource Zones and Cross-section Locations | 182 |

| Figure 14-2 | Shahuindo Deposit West Zone Cross Section 150W Showing Gold Mineral Domains | 183 |

| Figure 14-3 | Shahuindo Deposit Central Zone Cross Section -500E Showing GoldMineral Domains | 184 |

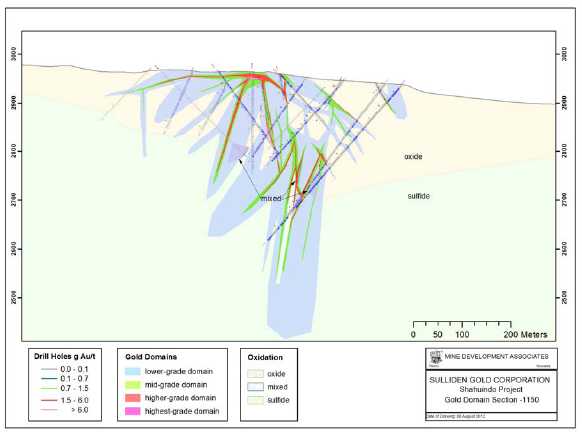

| Figure 14-4 | Shahuindo Deposit East Zone Cross Section -1150E Showing Gold Mineral Domains | 185 |

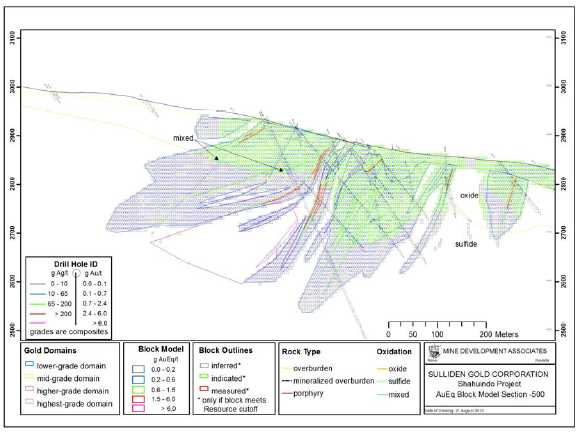

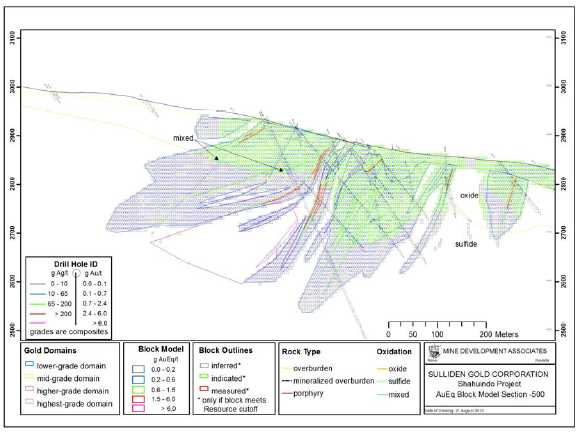

| Figure 14-5 | Gold Equivalent Block Model Grades in Shahuindo Deposit West Zone Cross Section 150W | 203 |

| Figure 14-6 | Gold Equivalent Block Model Grades in Shahuindo Deposit Central Zone Cross Section -500E | 204 |

| Figure 14-7 | Gold Equivalent Block Model Grades in Shahuindo Deposit East Zone Cross Section -1150E | 205 |

| Figure 15-1 | Graph of Whittle Results | 211 |

| Figure 15-2 | Pit Design Slope Parameters by Sector | 214 |

| Figure 15-3 | Shahuindo Ultimate Pit and Dump Design | 216 |

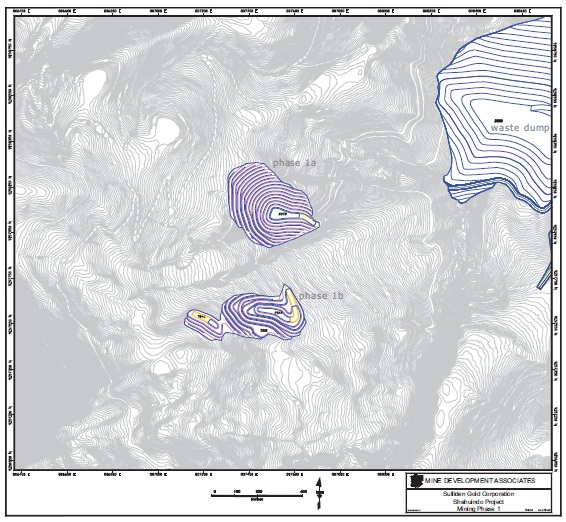

| Figure 15-4 | Phase 1 and Phase 1B Pit Designs | 218 |

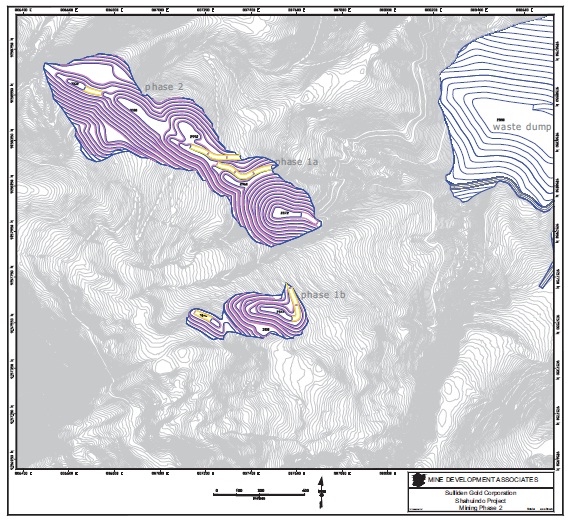

| Figure 15-5 | Phase 2 Pit Design | 219 |

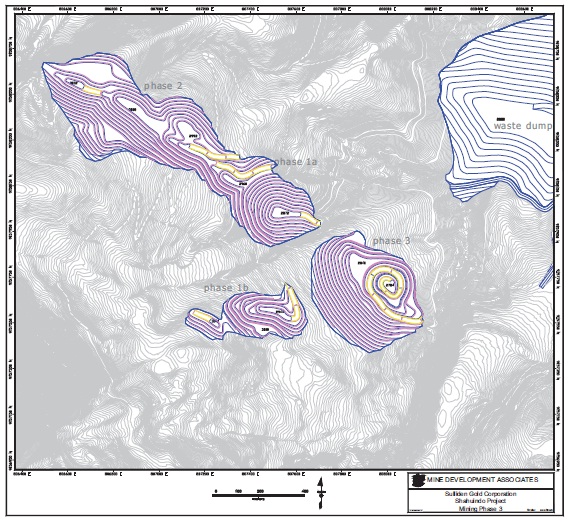

| Figure 15-6 | Phase 3 Pit Design | 220 |

| Figure 15-7 | Phase 4 Pit Design | 221 |

| Figure 15-8 | Phase 5 Pit Design | 222 |

| Figure 17-1 | Shahuindo Project General Arrangement | 254 |

| | |

| November 2012 | Shahuindo Project | xvi |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| | |

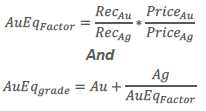

| Figure 17-2 | Heap Leaching Flow Sheet | 255 |

| Figure 17-3 | Average Year Daily Water Balance Schematic | 270 |

| Figure 17-4 | 100 Year Wet Year Daily Water Balance Schematic | 271 |

| Figure 17-5 | Dry Year Daily Water Balance Schematic | 272 |

| Figure 18-1 | Project Location and Access – Surrounding Region | 289 |

| Figure 20-1 | Location of Direct Influence Area | 309 |

| Figure 22-1 | After-Tax IRR vs. Gold Price, Capital Cost, and Operating Cash Cost | 369 |

| Figure 22-2 | NPV @ 0% vs. Gold Price, Capital Cost, and Operating Cash Cost | 369 |

| Figure 22-3 | NPV @ 5% vs. Gold Price, Capital Cost, and Operating Cash Cost | 370 |

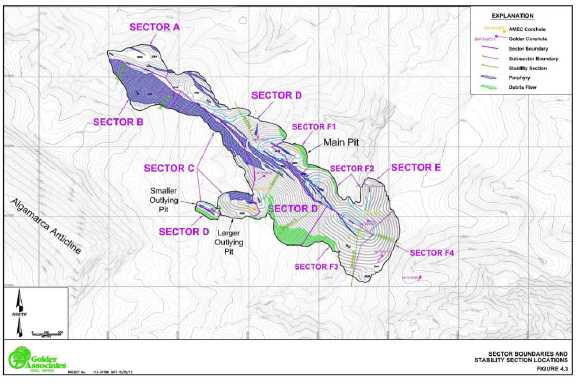

| Figure 24-1 | Pit Slope Stability Sectors and Section Locations | 374 |

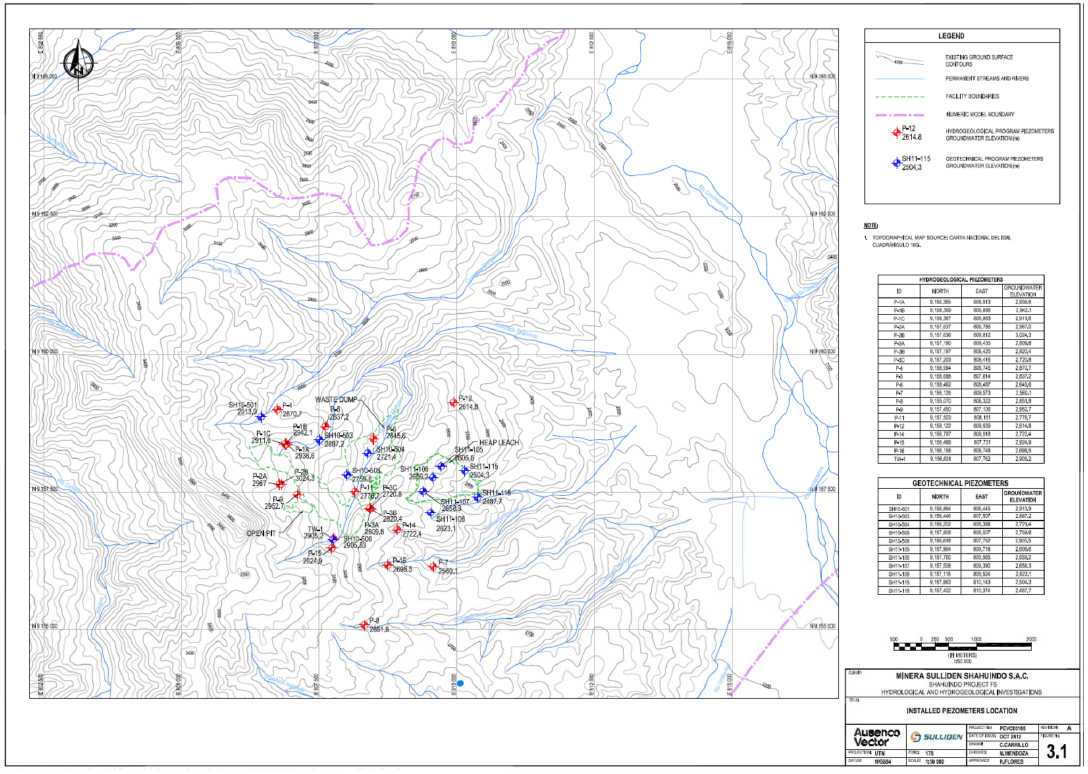

| Figure 24-2 | Installed Piezometer Locations | 388 |

| | |

| November 2012 | Shahuindo Project | xvii |

| |

|

MINE DEVELOPMENT ASSOCIATES |

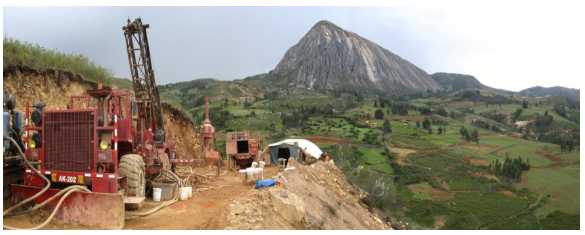

Sulliden Gold Corporation Ltd. (Sulliden) commissioned Kappes, Cassiday & Associates (KCA) in conjunction with Mine Development Associates (MDA) to prepare a feasibility study for the Shahuindo Project, located in Peru, near Cajamarca. This project consists of an open pit mine and processing of ore by standard heap leaching methods. This Technical Report summarizes the results of the feasibility study.

This Technical Report has been prepared in compliance with the disclosure and reporting requirements set forth in the Canadian Securities Administrators’ National Instrument 43-101, Companion Policy 43-101CP, and Form 43-101F1 (NI 43-101), as well as with the Canadian Institute of Mining, Metallurgy and Petroleum’s “CIM Definition Standards - For Mineral Resources and Reserves, Definitions and Guidelines” (CIM Standards) adopted by the CIM Council on December 2000 and modified in 2005 and 2010.

| |

| 1.2 | Introduction and Project Overview |

The Shahuindo Project is located approximately 80 kilometers southeast of the town of Cajamarca, and 15 kilometers west of the town of Cajabamba. Shahuindo is 100% owned by Sulliden. The project contains Reserves of 1.02 million ounces of gold and 11.56 million ounces of silver in 37.85 million tonnes of oxide and mixed ore and represents approximately 40% of the reported resource. The 72.3 million tonnes of waste to be mined results in a waste to ore ratio is 1.91:1. Metallurgical testing has demonstrated the project is amenable to cyanidation using heap leaching with average projected field recoveries of 85.8% for the gold and 15% for silver. An overview of the production statistics is presented in Table 1-1.

| | |

| November 2012 | Shahuindo Project | 1 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| |

| Table 1-1 | Project Statistics |

| |

| Item | Value |

| Tonnes of Ore Treated | 37,847,000 t |

| Average Gold Grade | 0.84 g/t |

| Average Silver Grade | 9.50 g/t |

| Average Gold Equivalent Grade | 1.02 g/t |

| Recoverable Gold Ounces | 876,000 oz |

| Recoverable Silver Ounces | 1,734,000 oz |

| Recoverable Gold Equivalent Ounces | 909,500 oz |

| Waste Tons | 72.267,000 t |

| Strip Ratio | 1.91:1 |

Note: Reserve definition uses a variable cut-off scheme to enhance the project value.

See Section 15.3 for details.

| |

| 1.3 | Reliance on Other Experts |

The authors of this report, state that the information, opinions, estimates, and conclusions contained herein are based on:

Information available at the time of preparing this report

Assumptions, conditions, and qualifications as set forth in this report

Data, reports, and other information supplied by Sulliden and other third partysources

The authors of this report have relied on the following in preparation of this report:

| | | | |

| | ● | Pit Slope Stability Analyses: | Golder Associates | |

| ● | Pit Dewatering Parameters: | Ausenco | |

| ● | Hydrology: | Ausenco | |

| ● | Heap Leach Geotechnical Analyses: | Ausenco | |

| ● | Property Description, Ownership Issues, Permits: | Sulliden | |

| |

| 1.4 | Property Description & Location |

The Shahuindo Project is situated at latitude 7 degrees 25 minutes south, longitude 78 degrees 25 minutes west (Universal Transverse Mercator (UTM) coordinates 9,158,000-North and 807,000-East Zone 17S, datum PSAD 56), approximately 80 kilometers southeast of Cajamarca.

| | |

| November 2012 | Shahuindo Project | 2 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

Sulliden entered into a Transfer of Mineral Rights and Properties Contract with Compania Minera Algamarca S.A. and Exploraciones Algmarca S.A. (collectively Algamarca) in 2002. The contract covered 26 mineral claims and 41 surface rights. In 2003, legal proceedings against Sulliden commenced which concluded with a Settlement Agreement in 2009 giving Sulliden 100 percent ownership of the project. Sulliden’s title to the mineral claims is registered in the Peruvian Public Registry.

Sulliden has accumulated the 26 mineral rights in one new right named ACUMULACION SHAHUINDO. The title of ACUMULACION SHAHUINDO has been granted by the competent governmental agency on March 12, 2012 and is registered in Peruvian Public Registry (Registro Público de Minería).

| |

| 1.5 | Access, Climate, Local Resources and Physiography |

The Shahuindo Project is located in Northern Peru approximately 970 kilometers by road north-north west of Lima. The project site can be accessed from Lima by traveling north on Highway 1 (the Pan-American Highway) to Ciudad de Dios, then east on Highway 8 to Cajamarca. The site is approximately 115 km from Cajamarca via asphalt-paved highway (100 km on Highway 3N), and gravel and dirt roads. Travel time from Cajamarca is about 3½ hours by road, including approximately 2½ hours from Cajamarca via asphalt paved Highway 3N to Cruce Pomabomba, and an additional hour from the junction with Highway 3N to the project site on gravel and dirt roads.

The port sites for project development support are the Port of Callao (Lima) and the Port of Paita in the north. The project site can be accessed from the Port of Callao by traveling north from Lima as described above. From the Port of Paita, the project site can be accessed by traveling south on Highway 1 to Ciudad de Dios, then to site via Cajamarca as indicated earlier. Ciudad de Dios is approximately 350 km south of Paita. Cajamarca is roughly 180 km from Ciudad de Dios.

The climate is humid during the wet season and cold and dry during the dry season: a typical climate of the sierra region. The wet season occurs during the months of October through April and the dry season occurs during the months of May through September. The average annual rainfall is 999.7 mm.

| | |

| November 2012 | Shahuindo Project | 3 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

Temperatures range from 15.7 to 23.1oC during the day decreasing to 7.5oC overnight.Wind speeds range from 0 to 3.1 m/s with a prevailing east by northeast direction.

The Shahuindo Project is located in an economically depressed area where subsistence agriculture is the main activity.

Manning requirements for the project will come from the local area and surrounding communities including Cajabamba whenever possible.

The main power supply to the site will be from the Peruvian Carhuamayo-Paragsha-Conococha Kiman Ayllu-Cajamarca Norte-Cerro Corona-Carhuaquero Trans-national 220 kV transmission line which was recently completed. This transmission line passes within 3 km of the site. It is currently planned to connect to this power line to supply grid power to the project site.

The Shahuindo Project will require a water supply for mining, processing and other supporting activities (including outside users and compensation flows). The make-up water required by the heap leach system during the dry season, particularly during abnormally dry years, will be met from storage ponds and pit dewatering drains and wells.

The Shahuindo site is located on the west side of the Condebamba River valley. The topography varies from rolling hillsides to steep ravines. Elevation across the project varies from 2,400 m above sea level to 3,600 m above sea level. The project area is classified as neo-tropical Peruvian “Yungas” by the World Wildlife Fund.

The first mining activities on the Shahuindo Project were conducted by the Spanish after their conquest of the Inca Empire in the 1530’s. These comprised multiple small-scale adits of very limited length.

Algamarca commenced exploitation of the Algamarca mine in the 1940’s and mined 1.5 Mt through 1989. In the 1980s, Algamarca conducted limited small-scale mining of gold-silver mineralization from the San José and Shahuindo mines located on the northeast limb of the Algamarca anticline.

| | |

| November 2012 | Shahuindo Project | 4 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

From 1990 to 1998, Alta Tecnología e Inversión Minera y Metalúrgica S.A. (Atimmsa), Asarco LLC (Asarco), and Southern Peru Copper Corp. (Southern Peru) explored the Shahuindo Project area. Work by Asarco and Southern Peru led to identification of four major low-grade gold-silver zones at Shahuindo – San José, Porphyry, South Contact, and East Zone, which are now part of the resource area.

Sulliden acquired the property and commenced exploration activity in 2002. Sulliden’s work since acquisition has comprised an initial technical review of all available data collected prior to 2002; numerous geophysical surveys; detailed geochemical sampling and geologic mapping; trenching; metallurgical testing; and extensive exploration and geotechnical drilling. .

Mineral resources were estimated in 2004, 2005, 2009, 2011 and updated in 2012. A preliminary economic assessment was completed for Sulliden by AMEC in 2010. Prior to the current feasibility study, though, no mineral reserves had been estimated for the Shahuindo property.

| |

| 1.7 | Geologic Setting and Mineralization |

The Shahuindo Project lies in the Western Cordillera of the Peruvian Andes within a regional fold and thrust belt of predominantly Mesozoic sedimentary rocks that have been cut by intrusions provisionally dated at 25 Ma and 16 Ma. The Lower Cretaceous Goyllarisquizga Group is the predominant unit exposed on the property, consisting of six formations of orthoquartzite, shale, siltstones, sandstones, and marine carbonate rocks. These rocks have been intruded by weakly altered to unaltered diorite porphyry, altered dacite porphyry, and variably-altered quartz diorite porphyry.

The Algamarca anticline, a prominent west-northwest-trending structural and topographic feature, is located along the southwestern part of the property. A sub-parallel fault set, interpreted to be imbricated thrust faults, lies to the north, parallel to the hinge of the anticline. These imbricate faults are cut at high angles by late, mostly normal faults.

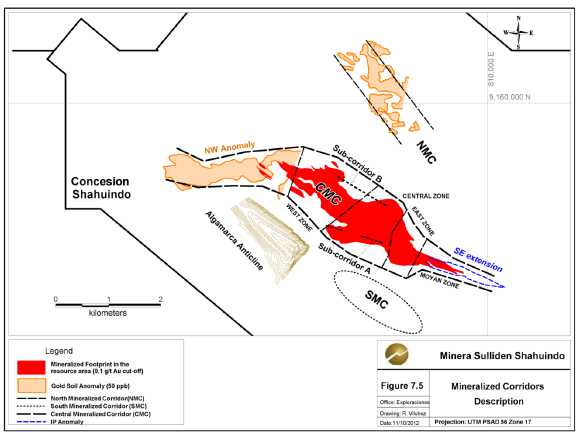

The Shahuindo property has been divided into three sub-parallel mineral corridors which occur within the west-northwest-striking thrust fault set: the Central Mineralized Corridor (CMC), North Mineralized Corridor (NMC), and Southern Mineralized Corridor (SMC).

| | |

| November 2012 | Shahuindo Project | 5 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

The NMC encompasses the adits and workings occurring along a strike length of 500 to 700 meters in the historic Shahuindo mine area. Gold mineralization in outcrops has been noted at intermittent intervals along the entire strike length of the NMC, which is defined by a 1.2 square kilometer gold-in-soil anomaly. An initial exploration program recently conducted on the NMC was successful in demonstrating the presence of near-surface oxide mineralization that is similar to that of the Central Corridor. The SMC consists of mineralization along strike from the Cerro Redondo prospect. A surface gold anomaly has been noted along a 3 kilometer-long trend and includes northeast-trending veins found on top of the Algamarca anticline.

The CMC is defined by mineralization over a 6-kilometer strike length along the northeast limb of the Algamarca anticline. The Shahuindo resource lies within the CMC. The resource has been sub-divided along strike, due to variations in geology and mineralization, into four resource zones: the West, Central, East, and Moyan Alto zones.

For the Shahuindo deposit, the most important characteristic is the relatively continuous, near-surface mineralization extending over a strike length of more than 4 kilometers. Within the large, continuous lower-grade mineralized shell, higher-grade gold and silver mineralization is related to generally near-vertical to southwest-dipping structures hosted within variably silicified sedimentary rocks, primarily the Carhuaz Formation, or along sedimentary rock/porphyry intrusive contacts. Within the Central area of the resource, the mineralized bedrock is covered by a colluvial overburden horizon that is up to 70 meters thick. The overburden contains weakly mineralized debris, a portion of which is included in the current resource.

Supergene weathering and oxidation occur to variable depths ranging from 15 meters to over 200 meters below the topographic surface. In the oxide facies, gold and silver are associated with jarosite and hematite. In the sulfide facies, gold is typically extremely fine grained; the mineral species have not been identified. Fine-grained pyrite forms a close association with gold mineralization and occurs as disseminations, veinlets, and semi-massive replacement bodies. Silver is usually found in sulfo-salts.

Deposit-wide, the silver to gold ratio averages 12:1 within the oxide portion of the deposit, 35:1 within the sulfide facies, and approximately 50:1 within the transitional “mixed” zone that occurs at the base of oxidation of the deposit. The metal ratios reflect the strong leaching of silver from the near-surface oxide material with subsequent supergene enrichment at the base of the zone of oxidation.

| | |

| November 2012 | Shahuindo Project | 6 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

Field evidence suggests that the Shahuindo mineralization belongs to the epithermal type of gold-silver deposit (Guilbert and Park, 1986; Hedenquistet al.,1999, 2000; White and Hedenquist, 1995; and Taylor, 2007), although earlier work by Montoyaet al.(1995) suggested the mineralization could be Carlin type.

The Shahuindo deposit consists of four major zones, interpreted to be down-faulted blocks (east-side down) along the strike of the deposit. Each of the four zones is bounded by transect faults, and each zone has distinct geological characteristics. Common to all of them is that high-grade mineralized shoots (1-5 meters wide of >1.0 g Au/t material) are structurally controlled and are surrounded by a large halo of low-grade material (0.2 g Au/t). Hydrothermal alteration consists mostly of muscovite and silicification (Hodder 2010a). In a general way, “vuggy silica” facies and “lithocap” facies are found along the strike of the deposit, with the former more prevalent in the western part of the deposit. The intensity of hydrothermal alteration may be assessed by the composition of Fe/K and Na/K ratios in the muscovite. Minute amounts of acidic clays (pyrophyllite, alunite, diaspore) have also been identified in open fractures in the lithocap facies. Quartz veining is rare.

Prior to 1990, exploration was conducted by Algamarca on the Shahuindo property though no public records are available to provide details of Algamarca’s work. From 1990 to 1998, Alta Tecnología e Inversión Minera y Metalúrgica S.A. (Atimmsa), Asarco LLC (Asarco), and Southern Peru Copper Corp. (Southern Peru) explored the Shahuindo Project area, completing mapping, geochemical sampling, and reverse circulation (RC) and core drilling.

Sulliden’s work since acquisition in 2002 has comprised an initial technical review of all available historic data; grid establishment; survey of historic drill-hole collars where such could be identified; resistivity, induced polarization (IP) and magnetic geophysical surveys; detailed soil sampling; geological mapping and outcrop sampling; trenching; adit sampling; metallurgical testing; and drilling of 390 core holes and 252 RC holes for exploration purposes.

Through 2011, a total of 827 holes have been drilled by Atimmsa, Asarco, Southern Peru, and Sulliden within the current Shahuindo Project area. The drill-hole database

| | |

| November 2012 | Shahuindo Project | 7 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

used for the 2012 resource estimate includes 826 of 827 holes drilled at Shahuindo; one Asarco core hole was not used because the collar location was uncertain. Of the 827 holes drilled, 453 were core, and 374 were RC; 629 of the 827 holes were drilled by Sulliden.

The majority of project drill holes have been collared at azimuths around 35 degrees or 215 degrees to intersect the main structural trend of the deposit at a high angle. Results of down-hole surveys are available for 576 of the holes drilled. Drill-core recovery during the 2003 through 2011 Sulliden programs was generally good, averaging 89 percent for all drill holes. Within the five resource zones, average core recovery for the mineralized intervals ranges from 77 percent in the Moyan Alto area to 89 percent in the Central area. The West and East zones average between 85 and 87 percent core recovery.

For the 826 drill holes in the Shahuindo Project assay database, there is a total of 94,441 gold assays, 93,073 silver assays, 69,103 total-sulfur analyses, and 9,800 sulfide-sulfur analyses.

Approximately 90 percent of the project drill data (378 core and 372 RC holes for a total meterage of 131,905.1 meters) are within or adjacent to the current mineral resource area and were used in the creation of the geologic models and subsequent resource estimation.

The current drill-hole database includes all holes drilled by Sulliden through the end of 2011. Sulliden drilling has continued into the first half of 2012 with the completion of 13 core holes. The 2012 drilling is primarily outside the current resource area and has not been evaluated; its effect on the resource has not been quantified.

| |

| 1.11 | Sample Preparation, Analysis and Security |

During the Sulliden drill programs, core was logged and sampled at the Shahuindo exploration camp. Drill holes were sampled entirely and the core split into two equal parts using a rotary saw.

Sulliden maintains a secure centralized storage facility in Cajamarca with all drill core, reverse circulation chip trays, coarse rejects, and pulps. All are organized, labeled, and racked for ready retrieval.

Previous operators used the following established laboratories for sample analyses: Skyline Laboratories, Inc. (now Skyline Assayers & Laboratories), SGS, CIMM Peru

| | |

| November 2012 | Shahuindo Project | 8 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

S.A., and Actlabs, Inc. Sample certificates are available for the drill campaigns in 1994, 1995, 1996, 1997, and 1998 and some details about the analytical procedures can be established from the historic certificates. During the Asarco drill programs, all drill hole samples were analyzed by fire assay (one ton standard) for both gold and silver. Assay certificates from the 1997 and 1998 campaigns show that samples were analyzed by CIMM laboratories in Lima for gold and silver plus copper, lead, zinc, molybdenum, arsenic, bismuth, antimony, and mercury.

During the Sulliden campaigns, sampling and sample dispatch for the Shahuindo Project have been carried out under the supervision of Sulliden staff. Samples are sent to ALS Minerals (ALS; formerly known as ALS Chemex) in Lima for sample preparation and analysis. Certificates are issued by ALS digitally and on paper. The ALS laboratory in Lima is ISO 9001:2008 and ISO 17025:2005 certified.

For Sulliden’s samples, gold has been assayed with a 50-gram fire assay (FA) with atomic absorption (AA) finish. For samples with greater than 10 grams per tonne gold in the initial FA-AA assay, the fire assay is repeated using a gravimetric finish. In 2003 and 2004, silver was assayed from a 5-gram split, which was digested by aqua regia and read by AA. Since 2007, a separate split was taken and digested in aqua regia for analysis with inductively coupled plasma atomic emission spectroscopy to determine 31 major and trace elements including silver, copper, arsenic, bismuth, and antimony. For samples having greater than 100 g Ag/t, a silver assay was carried out from another 5-gram split, which was digested in aqua regia and read by AA. For samples having greater than 1,000 g Ag/t, silver was assayed by a 50-gram fire assay and a gravimetric finish.

MDA is of the opinion that the sampling methods, security, and analytical procedures are adequate for mineral resource estimation. The authors are not aware of any sampling or assaying factors that may materially impact the mineral resources.

The data verification programs undertaken on the data collected from the project support the geological interpretations, and the analytical and database quality. Therefore the Shahuindo database is adequate for use in estimating and classifying a Mineral Resource. Principal findings from the data verification are:

| | |

| November 2012 | Shahuindo Project | 9 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

The drill data support the geologic interpretations and style of mineralization usedin the resource model.

The QA/QC data indicate that the assay data are sufficiently accurate for use inMineral Resource estimation, although the observed low bias in the ALS assaystandard sample and pulp duplicate results, as compared to the SGS values,indicates a possible conservatism in the estimate.

| |

| 1.13 | Mineral Processing and Metallurgical Testing |

Metallurgical testing of the ore from the Shahuindo ore bodies have been conducted by Heap Leach Consultants in Lima, and Kappes, Cassiday & Associates in Reno, Nevada, USA. The results of the testing programs indicate excellent gold recoveries at a moderate crush size with low to moderate reagent requirements, implying amenability to heap leaching. Gold estimated field recovery is 86% on oxide ore and 50% on transition ore. Silver recovery is low, with estimated field recovery of 15% on both the oxide and transition ore. Cyanide consumption is estimated to be 0.27 kg/t, and cement for agglomeration is estimated to be 6 kg/t.

| |

| 1.14 | Mineral Resource Estimate |

The mineral resource estimate is based on drilling completed through the end of 2011 and the subsequent drill information provided to MDA by Sulliden up through May 17, 2012. The resource estimates were finalized July 13, 2012.

The gold and silver resources at Shahuindo were modeled and estimated by evaluating the drill data statistically, utilizing the geologic interpretations provided by Sulliden to interpret mineral domains on 83 unique cross sections spaced at 50-meter intervals (except for the three westernmost sections, which are spaced 100 meters apart), rectifying the mineral domain interpretations on level plans spaced at 8-meter intervals, analyzing the modeled mineralization statistically to establish estimation parameters, and interpolating grades into a three-dimensional block model. Lithology, oxidation, silicification, and gold and silver mineral-domain models were created for the Shahuindo Project. All modeling of the Shahuindo resources was performed using Gemcom Surpac® mining software.

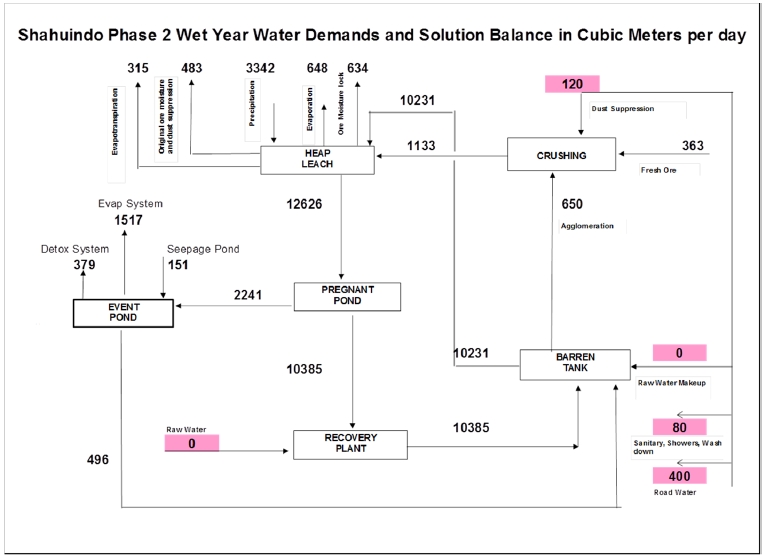

The stated resource is fully diluted to 8 meters by 8 meters by 4 meters blocks and tabulated on gold-equivalent (AuEq) grade cutoffs that are reasonable for deposits of this nature and for the expected mining conditions and methods. The block dimensions were chosen as practical sizes for open-pit mining a deposit of this kind. The AuEq

| | |

| November 2012 | Shahuindo Project | 10 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

grade is calculated using the individual gold and silver grades of each block, along with a gold price of $1,300.00 per ounce gold and a silver price of $25 per ounce silver. For the oxide and mixed resource estimates, the AuEq grade calculation includes a 5:1 difference in gold versus silver recovery in the proposed heap-leach processing scenario.

The formulas used to calculate the AuEq grade are:

| | | |

| Oxide Material: | g AuEq/t = g Au/t + (g Ag/t x 0.003846) | |

| Mixed Material: | g AuEq/t = g Au/t + (g Ag/t x 0.006410) | |

| Sulfide Material: | g AuEq/t = g Au/t + (g Ag/t x 0.019231) | |

Shahuindo Reported Resources are presented in Table 1-2.

| |

| Table 1-2 | Shahuindo Gold and Silver Reported Resource |

| | | | | | | |

| Class | Cutoff

(g AuEq/t) | Tonnes | g AuEq/t | g Ag/t | oz Ag | g Au/t | oz Au |

| Measured-Oxide | 0.200 | 40,500,000 | 0.619 | 8.1 | 10,530,000 | 0.588 | 766,000 |

| Measured-Mixed | 0.350 | 780,000 | 0.964 | 33.7 | 850,000 | 0.748 | 19,000 |

| Measured Total | variable | 41,280,000 | 0.626 | 8.6 | 11,380,000 | 0.591 | 785,000 |

| | | | | | | | |

| Indicated-Oxide | 0.200 | 104,840,000 | 0.506 | 6.3 | 21,080,000 | 0.482 | 1,624,000 |

| Indicated-Mixed | 0.350 | 1,190,000 | 0.919 | 23.8 | 910,000 | 0.766 | 29,000 |

| Indicated Total | variable | 106,030,000 | 0.511 | 6.5 | 21,990,000 | 0.485 | 1,653,000 |

| | | | | | | | |

| Meas. + Ind. Total | variable | 147,310,000 | 0.543 | 7.1 | 33,370,000 | 0.515 | 2,438,000 |

| | | | | | | | |

| Inferred-Oxide | 0.200 | 9,570,000 | 0.419 | 4.3 | 1,330,000 | 0.402 | 124,000 |

| Inferred-Mixed | 0.350 | 20,000 | 0.762 | 12.2 | 10,000 | 0.684 | - |

| Inferred-Sulfide | 0.500 | 61,410,000 | 1.202 | 22.9 | 45,220,000 | 0.762 | 1,504,000 |

| Inferred-Total | variable | 71,000,000 | 1.096 | 20.4 | 46,560,000 | 0.713 | 1,628,000 |

Note: rounding may cause apparent inconsistenciesThere are Measured, Indicated, and Inferred resources within the Shahuindo deposit. Measured resources are restricted to well-defined oxide and mixed mineralization. Sulfide resources are restricted to Inferred, primarily due to: a) limited metallurgical characterization of this material type; and b) some spatial and geologic uncertainty in the model. The mineralized overburden is restricted to Indicated and Inferred due to the uncertainties in grade continuity.

| | |

| November 2012 | Shahuindo Project | 11 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

The informal mining activity by local small miners in the west half of the West zone has created some uncertainty in the resource tonnes and total ounces. As a result, MDA has decided to classify all material within the area of informal mining as Inferred. Because this restriction affects only one to two percent of the total resource, MDA does not consider the effects of the informal mining materially significant to the overall resource.

| |

| 1.15 | Mineral Reserve Estimate |

MDA has used Measured and Indicated resources as the basis to define reserves. Reserve definition is done by first identifying ultimate pit limits using economic parameters and pit optimization techniques. The resulting optimized pit shells were then used for guidance in pit design to allow access for equipment and personnel. Several phases of mining were defined to enhance the economics of the project, and MDA used the phased pit designs to define the production schedule to be used for cash-flow analysis for the feasibility study.

Table 1-3 presents the Proven and Probable reserves. These reserves are shown to be economically viable based on cash-flows provided by KCA. MDA has reviewed the cash-flows and believes that they are reasonable for the statement of Proven and Probable reserves.

| |

| Table 1-3 | Ultimate Pit Proven and Probable Reserves |

| | | | | | | | | |

| | Proven | Probable | Proven & Probable |

| | Oxide | Mixed | Total | Oxide | Mixed | Total | Oxide | Mixed | Total |

| K Tonnes | 14,994 | 165 | 15,159 | 22,595 | 93 | 22,688 | 37,589 | 258 | 37,847 |

| g Au/t | 0.90 | 0.71 | 0.90 | 0.80 | 0.87 | 0.80 | 0.84 | 0.76 | 0.84 |

| K Ozs Au | 434 | 4 | 437 | 582 | 3 | 584 | 1,015 | 6 | 1,022 |

| g Ag/t | 10.4 | 17.6 | 10.5 | 8.8 | 21.3 | 8.9 | 9.4 | 18.9 | 9.5 |

| K Ozs Ag | 5,008 | 93 | 5,102 | 6,396 | 64 | 6,459 | 11,404 | 157 | 11,561 |

| g AuEq/t | 0.91 | 0.72 | 0.91 | 0.81 | 0.89 | 0.81 | 0.85 | 0.78 | 0.85 |

| K Ozs AuEq | 438 | 4 | 441 | 588 | 3 | 591 | 1,026 | 6 | 1,032 |

Note: Proven and Probable Reserves are stated based on variable cutoff grades in g Au/t where:

Oxide: 0.35, 0.35, 0.30, 0.35, 0.30, 0.30 for Phases 1, 1B, 2, 3, 4, and 5 respectively; and

Mixed: 0.35, 0.35, 0.33, 0.35, 0.33, 0.33 for Phases 1, 1B, 2, 3, 4, and 5 respectively.

The Shahuindo Project has been planned as an open pit truck and front end loader operation. The truck and loader method provides reasonable cost benefits and selectivity for this type of deposit. Mine production is achieved using up to four front loaders with 6.9 cubic-meter buckets. The proposed truck fleet will consist of conventional trucks with a 22 cubic-meter end dump bed.

| | |

| November 2012 | Shahuindo Project | 12 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

For production scheduling, material types were classified into either ore or waste categories. Ore consists of only Measured or Indicated material, which includes oxide or transition material. All Inferred material is considered waste. Note that there are no sulfide Measured or Indicated resources, thus all sulfide material is considered to be waste.

Waste material was defined as all material inside of the pit designs that did not meet Proven and Probable reserve classifications. This includes Inferred material. Among the waste material is approximately 21 million tonnes of mineralized material that is above the economic cutoff grade, however, since the material was below the operational cutoff grades, the material is considered waste and is not included in Proven and Probable reserves or in the production schedule.

Pit dewatering will be required to meeting pit slope stability criteria. Recommendations for pit dewatering were provided by Ausenco.

The annual mine production schedule is summarized in Table 1-4.

| | |

| November 2012 | Shahuindo Project | 13 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| |

| Table 1-4 | Annual Mine Production Schedule Summary |

| | | | | | | | | | | | | | |

| | | Pre-

Prod | Yr 1 | Yr 2 | Yr 3 | Yr 4 | Yr 5 | Yr 6 | Yr 7 | Yr 8 | Yr 9 | Yr 10 | Yr 11 | Total |

Total Ore

Mined | K Tonnes | 792 | 3,305 | 3,253 | 4,435 | 5,500 | 4,443 | 5,228 | 3,660 | 3,226 | 3,650 | 352 | - | 37,847 |

| g Au/t | 0.82 | 0.98 | 1.08 | 0.94 | 0.89 | 0.69 | 0.67 | 0.91 | 0.86 | 0.63 | 0.82 | - | 0.84 |

| K Ozs Au | 21 | 104 | 113 | 135 | 158 | 99 | 112 | 107 | 89 | 73 | 9 | - | 1,022 |

| g Ag/t | 15.3 | 11.5 | 11.0 | 13.0 | 7.4 | 7.5 | 6.8 | 8.8 | 9.4 | 10.7 | 14.1 | - | 9.5 |

| K Ozs Ag | 390 | 1,217 | 1,154 | 1,856 | 1,308 | 1,075 | 1,137 | 1,039 | 973 | 1,252 | 160 | - | 11,561 |

| Total Waste | K Tonnes | 2,517 | 8,587 | 9,682 | 8,193 | 9,170 | 11,474 | 10,828 | 4,277 | 4,788 | 2,641 | 111 | - | 72,267 |

| Total Mined | K Tonnes | 3,309 | 11,892 | 12,935 | 12,629 | 14,670 | 15,917 | 16,056 | 7,937 | 8,015 | 6,291 | 463 | - | 110,114 |

| | |

| November 2012 | Shahuindo Report | 14 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

Processing will take place at a rate of 10,000 tonnes of ore per day. The Shahuindo Project is projected to have a 10.4 year mine life with a Proven and Probable reserve of 37.5 million tonnes of ore. Ore will be delivered to a modular-style 2-stage crushing plant near the pit. The product size will be 100% passing 32 mm. The final product from the crusher circuit discharges to a kidney shaped stockpile, which is reclaimed from beneath the stockpile and is transported to the heap leach pad using overland conveyors. Cement and dilute cyanide are added to the ore on the final conveyor and is discharged to a mobile stacking system.

Stacked ore is leached using a sprinkler irrigation system for solution application. After percolating through the ore, the gold and silver bearing solution drains to a pregnant (PLS) pond where it is collected and pumped to an activated carbon adsorption-desorption-recovery (ADR) plant.

Adsorption will takes place in a single train of five gravity-cascade carbon columns. Barren solution discharge from the final columns flows by gravity to a barren tank and is then pumped to the heap for further leaching. High strength cyanide solution will be injected into the barren solution to maintain the cyanide concentration in leach solution at the desired level.

Desorption of gold and silver from the carbon utilizes a pressurized elution column followed by recovery of gold and silver from pregnant eluant solution in electrolytic cells containing stainless steel cathodes. Loaded cathodes are washed and the resulting precious metal sludge is retorted to remove and recover mercury followed by smelting in a diesel-fired crucible furnace to produce a doré final product

Enhanced evaporation will be required to maintain process water balance during average precipitation years. A series of land mounted evaporation units will be used to evaporate solution as required. During 100-year wet years, treatment and discharge of solutions will be required.

There is a pit dewatering treatment plant included to remove heavy metals and adjust pH as required from any water transferred out of the pit that cannot be used in processing.

| | |

| November 2012 | Shahuindo Project | 15 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

The principle access to the Shahuindo property is via paved and dirt and gravel roads from Cajamarca. Approximately 15 km of dirt and gravel roads on the route from Cruce Pomabomba (between Cajamarca and Project site) require upgrades for access to the Shahuindo site. Power will be supplied to the project site by connecting to the existing trans-national 220 kV power line which passes within three kilometers of the site. Diesel-fired backup generators are present to supply emergency power to critical areas and to the man camp in the event of a power failure.

Water required for the project will be met from several potential sources:

Solution previously stored in the storm water excess solution pond

Well water and/or water from pit dewatering

Water from the water catchment ponds

Fire water storage tanks and pumping systems will be installed in the process plant area, in the camp area, and in the mine shop area. Bottled water will be supplied for drinking water.

Sewage treatment systems will be installed in the camp and process areas on site. Solid wastes will be transported off site as per Peruvian regulations.

Project buildings are summarized below. Where possible, the buildings are expected to be a combination of prefabricated modular buildings and local concrete masonry unit construction.

Administration Building (exists)

Dining Facilities (exists)

Mine Shop

Mine Warehouse and Workshop

Process Maintenance and Warehouse Area

Process Area Office

Locker Rooms

ADR Facility, including Refinery and Reagent Storage

Construction and Permanent Man Camp (expansion of existing facilities required)

| | |

| November 2012 | Shahuindo Project | 16 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| |

| 1.19 | Market Studies and Contracts |

There were no market studies conducted or contracts considered as gold and silver can easily be sold on the world market.

| |

| 1.20 | Environmental Studies, Permitting and Social or Community Impact |

The operation is designed to comply with Peruvian environmental requirements and Sulliden Gold Corporation’s environmental policy. The project has been designed to industry “best practice” standards.

| |

| 1.20.1 | Studies and Permitting |

The General Mining Law of Peru is the primary body of law with regard to environmental regulation of exploration and mining activities. The General Mining Law is administered by the Ministry of Energy and Mines.

Generally, the Ministry of Energy and Mines requires exploration and mining companies to prepare an Environmental Impact Statement (DIA) – Category I, Environmental Impact Study Semi Detailed (EIAsd) – Category II, an Environmental Impact Assessment, a Program for Environmental Management and Adjustment, and a mine closure plan. The category II EIAsd has been completed while the other documents are currently in progress. Mining companies are also subject to annual environmental audits of operations by the Organismo de Evaluación y Fiscalización Ambiental (OEFA).

Besides the relevant local and national exploration permits, additional permits will be required for Project development. Key permits identified that could impact either development or construction timetables include:

Certificate for the Inexistence of Archaeological Remains (CIRA)

Environmental Impact Assessment (EIA)

Mine Closure Plan

Establishment of a financial guarantee for closure

Beneficiation Concession

Mining Transportation Concession

Permanent Power Concession

Water Usage Permits

| | |

| November 2012 | Shahuindo Project | 17 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

Easements and Rights-of-way

District and Provincial Municipality Licenses

Construction and Operation Permits

| |

| 1.20.2 | Reclamation and Closure |

The Shahuindo Project has been designed to meet and comply with the environmental standards and legislated closure requirements of Peru.

In accordance with Peruvian requirements, company standards, and accepted industry practices, the development, operation, and conceptual reclamation plans have been proposed to accomplish:

Protection of public health and safety.

Minimization or elimination of environmental damage.

Return of the land to a state fit for its original use or an acceptable alternativeuse.

The conceptual closure and reclamation plan proposes that the following actions be taken:

The open pits will remain as permanent features, berms will be installed and roads closed to prevent public access. Any potential acid generating materials on the pit floor will be covered with non-acid generating waste. It is expected that the pit will eventually fill with water, form a pit lake and overflow.

The heap leach will be rinsed to remove trace cyanide to adequate discharge levels. The heap will undergo minor re-contouring, a low-permeability soil capping will be placed over the facility and it will be re-vegetated.

The solution ponds will be closed with the procedures established in the approved closure plan. These procedures will include conversion of the

| | |

| November 2012 | Shahuindo Project | 18 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

Work is well underway on the Social Baseline Study, which is a critical component of Sulliden’s social impact assessment. This study describes the people and locations within the area of influence of the project, which may experience either positive and or negative effects from the future development of the mine. The Area of Influence has been further divided into the Direct and Indirect Areas of Influence. The Direct Area of Influence is defined as those people and or places, which may directly experience either positive or negative social effects from the project in varying degrees. The Indirect Area of Influence is composed of people and or places that may experience positive social

| | |

| November 2012 | Shahuindo Project | 19 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

impacts and reduced negative social impacts than those located in the direct area of influence.

Sulliden is committed to proactive and transparent engagement with the communities, public institutions and government agencies located within the project’s area of influence. The company also recognizes its role to contribute to local sustainable development by utilizing its ability to mobilize technical and financial resources, to support the implementation of local initiatives for local development during the construction and operational stages.

| |

| 1.21 | Capital and Operating Costs |

Capital and operating costs for the Shahuindo Project were estimated by MDA and KCA with input from Sulliden on pre-production owner’s costs and general and administrative operating costs. The estimated capital and operating costs are considered to have an accuracy of +/-15%.

The required capital expenditures include the estimation of costs for all mining equipment, pre-production mining, process facilities, and infrastructure for the project. The capital costs have been estimated primarily by KCA with input from MDA on mine pre-production and equipment costs. Capital cost estimates have been made primarily using budgetary supplier quotes for all major and most minor equipment items. All capital cost estimates are based on the purchase of equipment quoted new from the manufacturer, or estimated to be fabricated new.

Operating costs for the project have been estimated from first principals using labor cost, material consumptions and costs. Labor costs are estimated using project specific staffing, salary, wage, and benefit requirements. Unit consumption of materials, supplies, power, water, and delivered supply costs are also estimated.

The operating costs were determined by year. They are based upon ownership of all project production equipment and site facilities, as well as the Owner employing and directing all operating, maintenance, and support personnel. The operating costs have been estimated and are presented without any added contingency allowances.

All costs are presented in 2ndquarter 2012 US dollars (US$). Where prices were supplied in Peruvian Nuevo Soles (PNS), an average conversion rate of 2.65 PNS per US dollar was used. These costs do not include IGV (Value Added Tax).

| | |

| November 2012 | Shahuindo Project | 20 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

The total capital cost is US$ 188.2 million. The total life of mine (LOM) operating cost for the Shahuindo Project is US$ 11.94 per tonne of ore. Table 1-5 and Table 1-6 present the capital and operating cost requirements for the project.

| |

| Table 1-5 | Shahuindo Project Capital Cost Summary |

| |

| Description | Cost (USD) |

| Pre-Production Capital | $132,746,000 |

| Working Capital (60 days) | $7,637,000 |

| Sustaining (Future) Capital | $47,789,000 |

| Total | $188,172,000 |

| |

| Table 1-6 | Shahuindo Project Operating Cost Summary |

| |

| Description | LOM Cost

(USD / t ore) |

| Mine | $5.66 |

| Process | $4.00 |

| Service & Support | $0.51 |

| Site G & A | $1.76 |

| Total | $11.94 |

Note – differences in totals due to rounding.

Based on the estimated production parameters, capital costs, and operating costs, a cash flow model was prepared by KCA for the economic analysis of the Shahuindo Project. The project economics were evaluated using a discounted cash flow (DCF) method, which measures the Net Present Value (NPV) of future cash flow streams. The final economic model was developed by KCA, with input from Sulliden, using the following assumptions:

Period of Analysis of 16 years (includes two years of pre-production andinvestment), 10.4 years of production, and 3.6 years for closure and reclamation

Three year trailing average (as at August 31, 2012) gold price of US$ 1,415/ozand silver price of US$ 27.00/oz

Processing rate of 10,000 tpd ore

Heap leach recoveries of 86% and 15% for gold and silver, respectively, for oxideore and recoveries of 50% and 15% for gold and silver for the transition ore.

| | |

| November 2012 | Shahuindo Project | 21 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

Capital and operating costs used for this model as developed in Section 21 ofthis report.

IGV tax, the Peruvian value added tax, is recovered in the year it was incurredduring the production phase. IGV rebate during pre-production is delayed 90days.

The project economics based on these criteria from the cash flow model are summarized in Table 1-7.

| | |

| November 2012 | Shahuindo Project | 22 |

| |

|

MINE DEVELOPMENT ASSOCIATES |

| |

| Table 1-7 | Life-of-Mine Summary |

| |

| Financial Analysis | |

| Internal Rate of Return (IRR), Pre-Tax | 52.2% |

| Internal Rate of Return (IRR), After-Tax | 37.8% |

| Average Annual Cash Flow (Pre-Tax)1 | $ 70.1 M |

| NPV @ 5% (Pre-Tax) | $ 382.9 M |

| Average Annual Cash Flow (After-tax)1,2 | $ 52.1 M |

| NPV @ 5% (After-Tax) | $ 248.6 M |

| Gold Price Assumption (US$/Ounce) | $1,415 |

| Silver Price Assumption (US$/Ounce) | $27 |

| Pay Back Period (Years based on After-tax) | 2.2 Years |

| Capital Costs (Excluding IGV Tax) | |

| Initial Capital | $ 131.8 M |

| Working Capital and Initial Fills | $ 8.5 M |

| Sustaining Capital (life of mine)3 | $ 47.8 M |

| Operating Costs (Average Life of Mine) | |

| Mining | $ 5.66/Tonne |

| Processing & Support | $ 4.51/Tonne |

| G&A | $ 1.77/Tonne |

| Total Operating Cost/Tonne Ore4 | $ 11.94/Tonne |

| Cash Operating Costs (per ounce of gold)5 | $ 552/Ounce |