1 High-Productivity Solutions Engineered for the Food Processing and Air Transportation Industries Investor Presentation December 2008 Exhibit 99.1 |

2 These slides and the accompanying presentation contain “forward-looking” statements which represent management’s best judgment as of the date hereof, based on currently available information. Actual results may differ materially from those contained in such forward-looking statements. JBT Corporation’s (the “Company”) Registration Statement on Form 10 filed on July 28, 2008 and subsequent quarterly reports, filed with the Securities and Exchange Commission, include information concerning factors that may cause actual results to differ from those anticipated by these forward-looking statements. The Company undertakes no obligation to update or revise these forward-looking statements to reflect new events or uncertainties. Although the Company reports its results using GAAP, the Company uses non-GAAP measures when management believes those measures provide useful information for its stockholders. The appendices to this presentation provide reconciliations to GAAP for any non-GAAP measures referenced in this presentation. Forward-Looking Statements |

3 • Investment Highlights • Segment Overview • Business Fundamentals & Growth Strategies • Financial Overview Agenda |

Investment Highlights |

5 Investment Highlights Well-positioned to capture future growth opportunities • Long, rich history in markets we helped develop • Technology and market leader with blue chip customer base • Global footprint with extensive capabilities • Track record of profitable growth and stable cash flow • Large installed base drives growth in recurring revenue • Experienced and diverse leadership team |

6 Long, Rich History in Markets We Helped Develop 1962 Introduced the Deicer 1969 Introduced the first Cargo Loader for the Boeing 747 1959 Introduced the first Jetway passenger boarding bridge 1920 Introduced the Cooker Cooler 1950 Introduced the first In-line Juice Extractor 1960 Introduced the first FLoFREEZE Freezer Air Transportation Food Processing Our history of innovation began with John Bean |

7 sterilize more than 50% of the world’s shelf stable canned foods squeeze more than 75% of the world’s citrus juices freeze more than 50% of the world’s frozen foods load 70% of the world’s overnight express packages board 75% of U.S. passengers Market Leader with Blue Chip Customer Base Our Systems: |

8 Global Footprint with Extensive Capabilities ~50% of revenue derived from outside the United States |

9 2005 2006 2007 2005 2006 2007 Revenue ($MM) EBITDA ($MM) $823 $844 $978 Track Record of Profitable Growth $65 $74 $86 9% CAGR 15% CAGR Note: See Appendix I for reconciliation of EBITDA to Net Income Anticipate record performance in 2008 |

10 $336 $298 $280 2005 2006 2007 Delivered Base (units) • FoodTech: 40,000+ • AeroTech: 30,000+ Large Base of Recurring Revenue Recurring Revenue ($MM) 10% CAGR 1. Recurring revenue includes aftermarket parts and services, equipment leases, and airport services. Recurring revenue was 36% of YTD revenue through Q3 2008 1 |

11 63% 61% FY07 Total Revenue FoodTech FoodTech FY07 Total Segment Operating Profit $593MM $56MM We Are With You, Right Down The Line™ |

12 Note: % of 2007 revenue excludes aftermarket parts and service Tomato Paste Tomato Sauces Juices Beverages Fruit Processing 32% of revenue Shelf-Stable Products Formulated Milks Beverages Shelf Stable Sterilization 15% of revenue Poultry & Meat Seafood Protein Processing 17% of revenue Poultry & Meat Seafood Fruit & Vegetables Baking Products Freezing & Chilling 36% of revenue Technologies Applications Customers #1 or #2 in Core Product Offerings |

13 Cost per Unit Throughput and Yield We Are With You, Right Down The Line™ |

14 Higher Performance Through Continuous Innovation Coater 3D Portioner Fryer Oven Freezer DSI Accura™ Portioning System GYRoCOMPACT-II Oven GYRoCOMPACT M-Series Spiral Freezer |

15 Source: Rabobank Developing Markets Provide a Significant Growth Opportunity for Processed Food Technology 0 0 1 1 1 Diet Profile Survival Staples Variety Convenience High-tech Grain Roots Meat, Dairy Fruit &Veg. Prepared Foods Functional Foods Diet Component Sub-Saharan Africa Eastern Europe L. America China India Developing Markets Developed Markets W. Europe Japan USA |

16 Convenience and Choice Drive Demand in Developed Markets U.S. Poultry Production Source: National Chicken Council 0% 20% 40% 60% 80% 100% 1975 1980 1985 1990 1995 2000 2005 0 10 20 30 40 Whole Cut-Up Further Lbs of Broilers Broiler Production = 5.0% CAGR Further Process = 6.6% CAGR |

17 From Touchdown to Takeoff ™ $386MM $32MM 39% FY07 Total Revenue AeroTech 37% AeroTech FY07 Total Segment Operating Profit |

18 Ground Support 44% of revenue Maintaining and monitoring facilities and equipment Passenger boarding Air and power supply Gate Equipment 24% of revenue Container and palletized cargo loading Aircraft Tow Tractors Air and power supply Military Equipment 6% of revenue Container loading Cargo transporting Baggage loading Pushback/Towing Aircraft Deicing Airport Services 15% of revenue Technologies Applications Customers #1 or #2 in Core Product Offerings Automated Systems 11% of revenue Automated Guided Vehicle Systems for Material Handling Note: % of 2007 revenue excludes aftermarket parts and services for AeroTech’s equipment |

19 Turn Time and Total Cost Reliability From Touchdown to Takeoff ™ |

We Address Multiple Needs Across the Ground Support Spectrum Ground Support Equipment Cargo Loaders Deicers Aircraft Tractors Maintenance & Operation Gate Systems Baggage Handling Systems Ground Support Equipment Airport Facilities Technology Aircraft Support Systems Passenger Boarding Bridges 400Hz Converters Pre-conditioned Air |

21 World Economy Passenger Traffic Cargo Traffic Source: The Boeing Company, 2006 Market Outlook, Summary Outlook 2008-2027 Long-term, Passenger and Cargo Traffic Expected to Grow Faster Than Global Economy 2.9% 4.8% 6.3% Actual Market Growth Rates: 1985 to 2005 4.0% 5.8% Forecast Market Growth Rates: 2007 to 2027 3.2% |

22 • Strong balance sheet and liquidity positions • Large base of recurring revenue & cash flow • Broad product, customer, and geographic diversity • Low capital requirements & efficient working capital utilization • Variable cost structure Solid Fundamentals in the Midst of Uncertainty |

23 • Extend technology leadership • Leverage installed base • Capture international growth opportunities • Acquisitions Strategies for Growth |

Financial Overview |

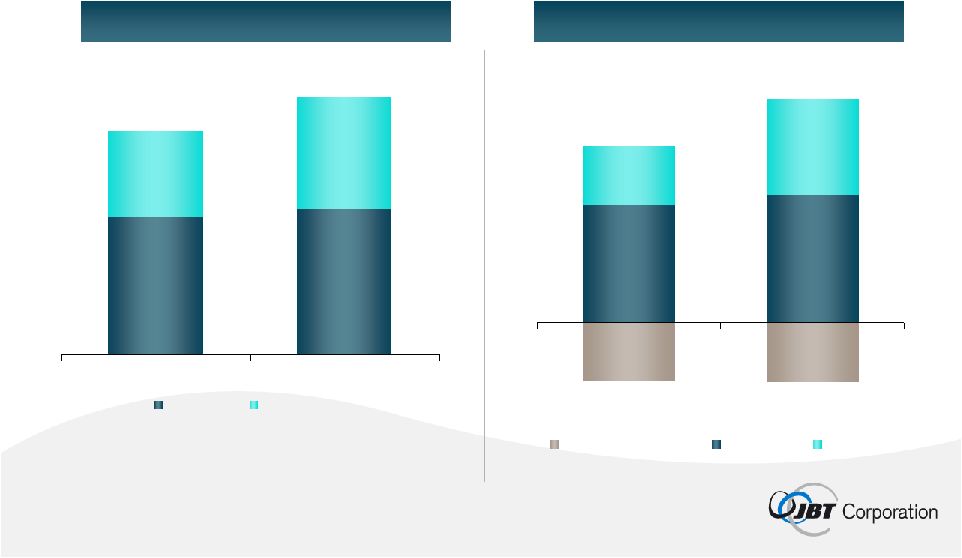

25 $497 $496 $593 $386 $327 $349 2005 2006 2007 FoodTech AeroTech $823 $978 $844 (23) (23) (27) $56 $46 $40 $27 $25 $32 2005 2006 2007 Corporate FoodTech AeroTech $42 $61 $50 Track Record of Profitable Growth Revenue 1 ($MM) EBIT 2 ($MM) 1. Total revenue will not foot due to other revenue and intercompany eliminations 2. See Appendix I for reconciliation of EBIT (a non-GAAP measure) to Net Income |

26 ($19) ($20) $42 $38 $19 $31 Q3 2007 YTD Q3 2008 YTD Corporate & Other FoodTech AeroTech $424 $451 $265 $344 Q3 2007 YTD Q3 2008 YTD FoodTech AeroTech $688 $794 $38 $53 Revenue 1 ($MM) EBIT 2 ($MM) 1. Total revenue will not foot due to other revenue and intercompany eliminations 2. See Appendix II for reconciliation of EBIT (a non-GAAP measure) to Net Income Third Quarter YTD Performance |

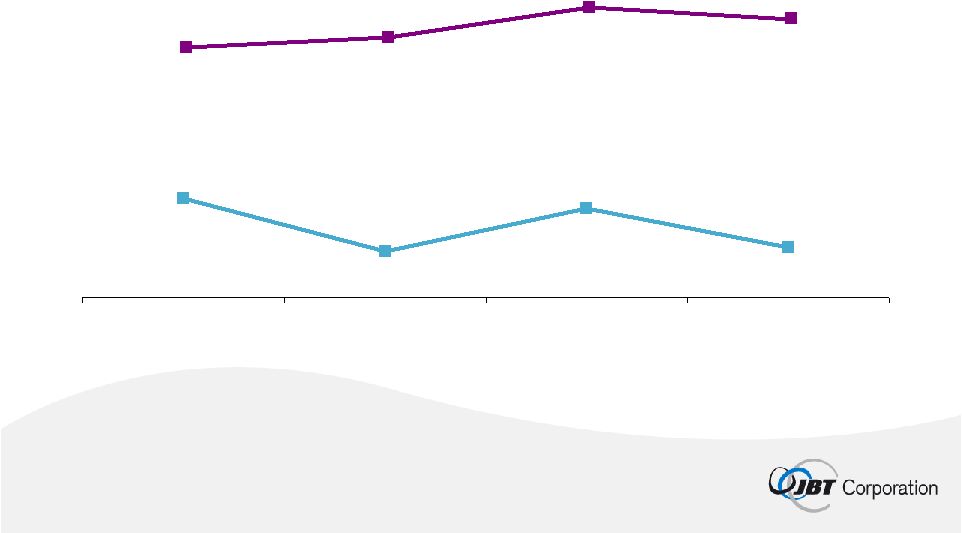

27 Efficient Working Capital Management (% of Revenue) 1. Adjusted working capital is calculated as current assets (excluding cash and short term investments) less current liabilities (excluding current portion of debt). 2. Utilized Q3 2008 YTD Annualized Revenue in calculation. 3. See Appendix III for reconciliation to GAAP measure. 4. See Appendix V for a list of the companies included in the selected industrials. JBT Selected Industrials Mean 2 16.3% 16.8% 18.4% 17.8% 1 5.6% 2.9% 6.2% 3.1% 2005 2006 2007 Q3 2008 YTD |

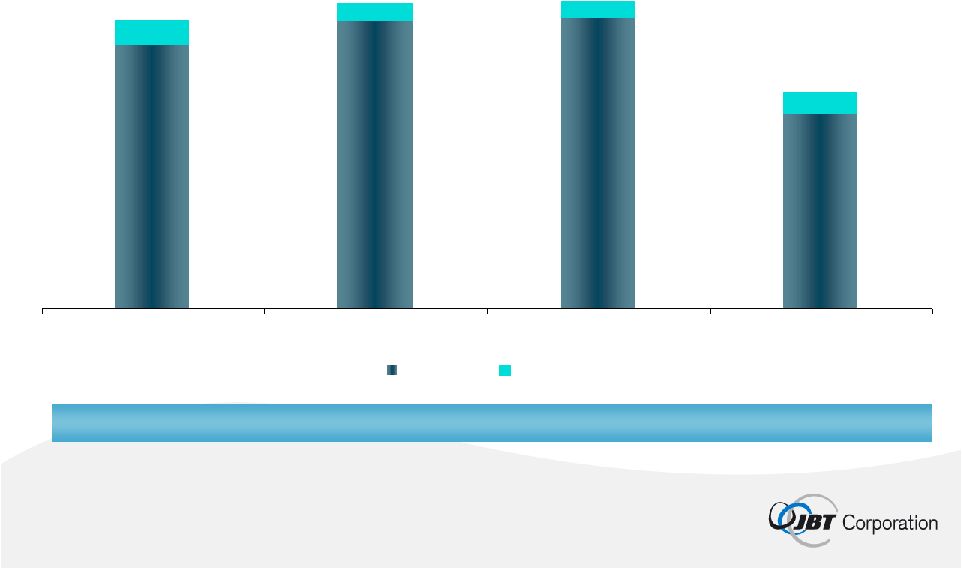

28 Capital Expenditures ($MM) 1. Total capital expenditures include corporate but not shown 2. Excludes acquisitions Capital expenditures have historically averaged ~2% of revenues 2 1 $14.2 $1.9 $1.3 $1.2 $1.6 $21.3 $21.1 $19.3 2005 2006 2007 Q3 2008 YTD FoodTech AeroTech $21.6 $23.0 $22.7 $16.6 |

29 Strong Free Cash Flow Generation $44.9 5.5 13.7 (1.3) (21.6) 22.2 $26.4 2005 $76.0 (0.7) 12.8 28.6 (22.7) 23.2 $34.8 2006 $21.6 2.5 19.2 (42.3) (23.0) 25.1 $40.1 2007 $51.3 0.6 8.1 10.4 (21.1) 19.5 $33.8 Q3 2008 YTD +/- Other 1 +/- Discontinued Operations +/- Change in Operating Assets & Liabilities - Capital Expenditures Adjusted Free Cash Flow 2 + Depreciation & Amortization Net Income from Continuing Operations $MM 1. ‘Other’ contains stock based compensation, disposal of assets, purchase of treasury stock, and other changes in balance sheet accounts 2. See Appendix IV for reconciliation of Adjusted Free Cash Flow (a non-GAAP measure) to cash provided by operations Cumulative cash flow to Parent from 2005-2007 equal to $142.5 million |

30 1. Return on Investment (ROI) is calculated as income from continuing operations as a percentage of average owner’s net equity, and long term debt. 2. ROI is calculated with annualized Q3 YTD Net Income from continuing operations Attractive Return on Investment 1 2 24.0% 20.2% 17.6% 12.5% 2005 2006 2007 Q3 2008 YTD |

31 Debt Structure Private Placement Credit Facility Amount Term Pricing Security Covenants • $225 MM • $65 MM drawn as of Q3 2008 • LIBOR +175 bps • $50MM swapped to 4.9% fixed rate • Max. Total Debt / EBITDA of 3.0x • Min. EBITDA / Interest Expense of 3.5x • 5 years • Unsecured • $75 MM • $75 MM drawn as of Q3 2008 • 6.7% • Min. EBITDA / Interest Expense of 2.75x • Max. Total Debt / EBITDA of 3.25x • 7 years • Unsecured |

32 2008 Outlook • Continued top line growth – Anticipated year over year revenue increase of 6-10% • Stable segment margins • Pro Forma EPS range of $1.30 to $1.40 includes: – Full year of interest expense – Corporate expenses in line with previous year – Effective tax rate of 35-37% • Pro Forma 2007 EPS of $1.20 |

33 Investment Highlights Well-positioned to capture future growth opportunities • Long, rich history in markets we helped develop • Technology and market leader with blue chip customer base • Global footprint with extensive capabilities • Track record of profitable growth and stable cash flow • Large installed base drives growth in recurring revenue • Experienced and diverse leadership team |

High-Productivity Solutions Engineered for Food Processing and Air Transportation |

35 Appendix I Reconciliation of Non-GAAP measures (as required by Regulation G) (In millions) FY 2005 FY 2006 FY 2007 Net income (GAAP measure) $24.5 $34.6 $36.4 add-back: loss from discontinued operations, net of taxes 1.9 0.2 3.7 add-back: provision for income taxes on operating income 16.0 16.0 21.5 less: interest income, net (0.1) (0.4) (0.5) EBIT (non-GAAP measure) $42.3 $50.4 $61.1 add-back: depreciation expense 17.5 18.8 19.8 add-back: amortization expense 4.7 4.4 5.3 EBITDA (non-GAAP measure) $64.5 $73.6 $86.2 |

36 Appendix II Reconciliation of Non-GAAP measures (as required by Regulation G) (In millions) Q3 2008 YTD Q3 2007 YTD Net income (GAAP measure) $34.1 $23.7 less: income from discontinued operations, net of taxes (0.3) 1.7 add-back: provision for income taxes on operating income 18.2 13.1 less: interest income, net 1.2 (0.2) Adjusted EBIT (non-GAAP measure) $53.2 $38.3 |

37 Appendix III Reconciliation of Non-GAAP measures (as required by Regulation G) (In millions) FY 2005 FY 2006 FY 2007 Q3 2008 YTD Current assets $293.9 $313.4 $369.8 $366.5 Current liabilities 240.4 279.2 306.2 341.6 Working capital (GAAP measure) $53.5 $34.2 $63.6 $24.9 less: cash and cash equivalents (2.7) (10.3) (9.5) (31.1) less: short-term investments 0.0 0.0 0.0 0.0 plus: short-term debt and current portion 0.1 0.2 1.1 39.0 of long-term debt Adjusted working capital (non-GAAP measure) $50.9 $24.1 $55.2 $32.8 Revenue $823.3 $844.3 $978.0 $1,058.1 Adjusted working capital as a percentage of revenue 6.2% 2.9% 5.6% 3.1% 1 1. Annualized Q3 2008 YTD Revenue |

38 Appendix IV Reconciliation of Non-GAAP measures (as required by Regulation G) (In millions) FY 2005 FY 2006 FY 2007 Q3 2008 YTD Cash provided by operating activities (GAAP measure) $59.6 $96.0 $33.7 $70.0 less: capital expenditures (21.6) (22.7) (23.0) (21.1) Free cash flow $38.0 $73.3 $10.7 $48.9 plus: net cash provided (required) by investing (0.1) (0.4) 7.8 0.7 activities of discontinued operations plus: proceeds from disposal of assets 7.0 3.1 3.1 1.8 plus: other cash provided (required) by investing 0.0 0.0 0.0 0.6 activities less: purchase of stock held in treasury 0.0 0.0 0.0 (0.7) Adjusted free cash flow (non-GAAP measure) $44.9 $76.0 $21.6 $51.3 |

39 Appendix V Listing of Selected Industrials Tennant Company 11. A.O. Smith Corporation 10. Regal-Beloit Corporation 9. Oshkosh Corporation 8. NACCO Industries 7. Gardner Denver Inc. 6. Federal Signal Corporation 5. Enpro Industries Inc. 4. Briggs & Stratton 3. Baldor Electric Company 2. AAR Corporation 1. |