Exhibit 10.1

| | DRILLING CONTRACT |

| | |

| | between |

| | |

| | VASTAR RESOURCES, INC. |

| | |

| | and |

| | |

| | R&B FALCON DRILLING CO. |

| | |

| | DATED DECEMBER 9, 1998 |

| | |

| | for |

| | |

| | “RBS-8D” |

| | “Deepwater Horizon” |

| | |

| | |

| CONTRACT NO. 980249 | |

| | D-1-87.1 |

| | |

| DISTRIBUTION: | |

| | |

| Houston Legal Files - Signed Original | |

| Houston Distribution (2) | |

| | |

| Vern Buzard | |

DRILLING CONTRACT

RBS-8D

SEMISUBMERSIBLE DRILLING UNIT

VASTAR RESOURCES, INC.

AND

R&B FALCON DRILLNG CO.

| CONTRACT NO. 980249 | DATE: DECEMBER 9, 1998 |

TABLE OF CONTENTS

| ARTICLE 1- | TERM | 2 |

| ARTICLE 2- | DAYRATES | 4 |

| ARTICLE 3- | PERSONNEL AND PAYMENTS | 7 |

| ARTICLE 4- | OTHER PAYMENTS | 8 |

| ARTICLE 5- | DRILLING UNIT MODIFICATIONS | 9 |

| ARTICLE 6- | OTHER REIMBURSEMENTS | 9 |

| ARTICLE 7- | MATERIALS, SUPPLIES, EQUIPMENT, AND SERVICES TO BE FURNISHED BY CONTRACTOR | 10 |

| ARTICLE 8- | MATERIALS, SUPPLIES, EQUIPMENT, AND SERVICES TO BE FURNISHED BY COMPANY | 11 |

| ARTICLE 9- | PAYMENTS | 11 |

| ARTICLE 10- | PAYMENT OF CLAIMS | 12 |

| ARTICLE 11- | TAXES AND FEES | 13 |

| ARTICLE 12- | COMPANY’S RIGHT TO QUESTION INVOICES AND AUDIT | 14 |

| ARTICLE 13- | DEPTH | 14 |

| ARTICLE 14- | DRILLING UNIT | 14 |

ARTICLE 15- | PERFORMANCE OF DRILLING OPERATIONS | 16 |

| ARTICLE 16- | INSPECTION OF MATERIALS | 18 |

| ARTICLE 17- | SAFETY | 18 |

| ARTICLE 18- | PERFORMANCE OF THE WORK | 19 |

| ARTICLE 19- | RECORDS TO BE FURNISHED BY CONTRACTOR | 21 |

| ARTICLE 20- | INSURANCE | 22 |

| ARTICLE 21- | INDEMNITY FOR PERSONAL INJURY OR DEATH | 22 |

| ARTICLE 22- | RESPONSIBILITY FOR LOSS OF OR DAMAGE TO THE EQUIPMENT | 22 |

| ARTICLE 23- | LOSS OF HOLE OR RESERVOIR | 24 |

| ARTICLE 24- | POLLUTION | 25 |

| ARTICLE 25- | INDEMNITY OBLIGATION | 26 |

| ARTICLE 26- | LAWS, RULES, AND REGULATIONS | 27 |

| ARTICLE 27- | TERMINATION | 28 |

| ARTICLE 28- | FORCE MAJEURE | 29 |

| ARTICLE 29- | CONFIDENTIAL INFORMATION, LICENSE AND PATENT INDEMNITY | 30 |

| ARTICLE 30- | ASSIGNMENT OF CONTRACT | 32 |

| ARTICLE 31- | INGRESS AND EGRESS OF LOCATION | 33 |

| ARTICLE 32- | COMPANY POLICIES | 33 |

| ARTICLE 33- | NOTICES | 34 |

| ARTICLE 34- | CONSEQUENTIAL DAMAGES | 35 |

ARTICLE 35- | WAIVERS AND ENTIRE CONTRACT | 35 |

TABLE OF CONTENTS (cont.)

| EXHIBIT A: | Dayrates | Tab A |

| EXHIBIT B-1: | Drilling Unit Specifications | Tab B |

| EXHIBIT B-2: | Material Equipment List | Tab B |

| EXHIBIT B-3: | Consumable Material and Equipment List | Tab B |

| EXHIBIT C: | Insurance Requirements | Tab C |

| EXHIBIT D: | Safety, Health, and Environmental Management System | Tab D |

| EXHIBIT E: | Termination Payment Schedule | Tab E |

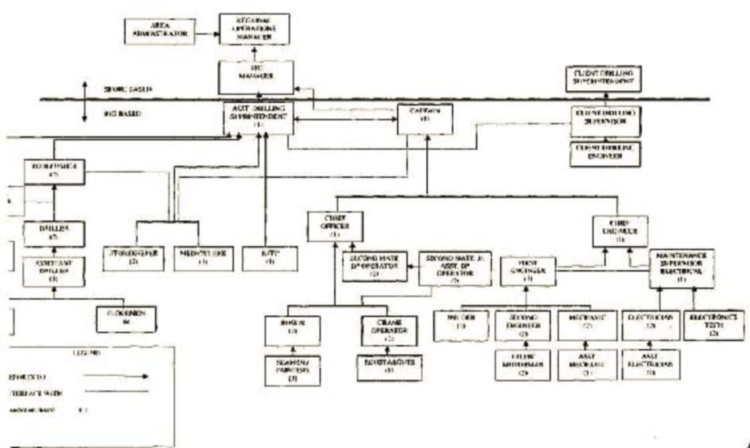

| EXHIBIT F-1: | Rig Manning | Tab F |

| EXHIBIT F-2: | Cost of Additional Personnel | Tab F |

| EXHIBIT G: | Vessel/Equipment Performance/Acceptance Test | Tab G |

| EXHIBIT H: | Project Execution Plan | Tab H |

DRILLING CONTRACT

THIS CONTRACT (“CONTRACT”) is made and entered into this 9th day of December, 1998, by and between Vastar Resources, Inc., a Delaware Corporation, hereinafter referred to as “COMPANY” and R&B Falcon Drilling Co., (“CONTRACTOR”), and shall be effective upon execution by both COMPANY and CONTRACTOR (the date when so effective, shall be referred to herein as the (“Effective Date”). COMPANY and CONTRACTOR are sometimes herein individually referred to as a “Party” and collectively referred to as the “Parties.”

RECITALS

Whereas CONTRACTOR shall cause to be built, a semisubmersible drilling unit, “Drilling Unit”. Whereas COMPANY desires to engage the services of CONTRACTOR, its Drilling Unit, and its equipment and all necessary crews for drilling, completing, testing, and remedial operations and support operations on a well or wells in the federal waters of the Gulf of Mexico, hereinafter referred to as “Operations” or “Work”.

Whereas this CONTRACT and the attached exhibits establishes the terms and conditions contained in this document entitled “DRILLING CONTRACT” and the attached exhibits:

| Exhibit A: | | Dayrates |

| Exhibit B-1: | | Drilling Unit Specifications |

| Exhibit B-2: | | Material Equipment List |

| Exhibit B-3: | | Consumable Material and Equipment List |

| Exhibit C: | | Insurance Requirements |

| Exhibit D: | | Safety, Health, and Environmental Management System |

| Exhibit E: | | Termination Payment Schedules |

| Exhibit F-1: | | Rig Manning |

| Exhibit F-2: | | Cost of Additional Personnel |

| Exhibit G: | | Vessel/Equipment Performance/Acceptance Test |

| Exhibit H: | | Project Execution Plan |

NOW, THEREFORE, COMPANY and CONTRACTOR, for and in consideration of the mutual covenants and agreements contained herein and good and valuable consideration paid by COMPANY to CONTRACTOR, the receipt and sufficiency of which are acknowledged by CONTRACTOR, the Parties hereby agree as follows:

ARTICLE 1

TERM

1.1 EFFECTIVE DATE AND DURATION

1.1.1 This CONTRACT shall remain in full force and effect for three (3) years (the “Initial Contract Term”). The Initial Contract Term shall begin on the Commencement Date. The term of this CONTRACT from its Effective Date through its Initial Contract Term and all Extension Periods shall be herein referred to as the “Contract Period.”

1.1.2 With a three (3) year Initial Contract Term, COMPANY has the option (the “Extension Option”) to extend this CONTRACT for five (5) consecutive one (1) year periods (each such extension period shall be herein referred to as an “Extension Period”) beginning at the end of the Initial Contract Term. Each Extension Option must be exercised by COMPANY by written notice to CONTRACTOR nine (9) months before the end of the Initial Contract Term or the previous Extension Period, as the case may be. This CONTRACT, as it may have been amended as of the date on which COMPANY exercises any Extension Option, shall be extended for one (1) year with further Extension Options available to COMPANY, as provided herein and the various rates shall be mutually agreed in writing. COMPANY shall also have the option within twenty-four (24) months of the Effective Date to exercise any of the one-year options at the three (3) year rate. In addition, this CONTRACT may be extended for any additional period by any other method or manner as the Parties may mutually agree in writing.

1.1.3 COMPANY has the option from the Effective Date up to and including one (1) year after the Commencement Date, to convert this CONTRACT to a five (5) year term (“5 Year Option”). If the 5-Year Option is exercised within six (6) months from the Effective Date, then the five (5) year rate in Exhibit A shall apply. If the 5 Year Option is exercised from six (6) months of the Effective Date to one (1) year from the Effective Date, then the five (5) year rate in Exhibit A plus five thousand dollars ($5,000.00) shall apply. If the 5 Year Option is exercised from one (1) year after the Effective Date to the Commencement Date, then the five (5) year rate in Exhibit A plus seven thousand five hundred dollars ($7,500.00) s hall apply. If the option is exercised from the Commencement Date to the end of the first contract year, the five (5) year rate in Exhibit A plus ten thousand dollars ($10,000.00) shall apply from that date forward and any portion of the first contract year shall become part of the five (5) year commitment.

1.1.4 If COMPANY exercises the 5 Year Option, then COMPANY has the option, (the “Extension Option”) under the five (5) year Initial Contract Term to extend this CONTRACT for three (3) consecutive one (1) year periods (each such extension period shall be herein referred to as an “Extension Period”) beginning at the end of the Initial Contract Term. Each Extension Option must be exercised by COMPANY by written notice to CONTRACTOR at least nine (9) months before the end of the Initial Contract Term or the previous Extension Period, as the case may be. This CONTRACT, as it may have been amended as of the date on which CONTRACTOR exercises any Extension Option, shall be extended for one (1) year with further Extension Options available to COMPANY as provided herein and the various rates shall be

mutually agreed in writing. In addition, this CONTRACT may be extended for any additional period by any other method or as the Parties may mutually agree in writing.

1.1.5 If the Initial Contract Term or any Extension Period of this CONTRACT expires while COMPANY has work in progress on any well or any other operations conducted with respect to a well with the objective of satisfying the well producibility criteria of 30 C.F.R. § 250.11 (1988), then COMPANY shall have the right to have the work in progress on such well or operation completed to COMPANY’S satisfaction under the terms and provisions of this CONTRACT and the term of this CONTRACT shall be deemed to be extended for the period of time required to complete such work.

1.2 COMMENCEMENT DATE

“Commencement Date” means the date and hour that the last of the following conditions has been satisfied: (i) all requirements in Exhibit G and all governmental and regulatory certifications and inspections required of the CONTRACTOR have been obtained, (ii) CONTRACTOR’S full crew is aboard, (iii) the Drilling Unit has cleared customs and other formalities, (iv) the Drilling Unit and CONTRACTOR’S full crew is in all respects ready to commence and sustain continued drilling operations during the Contract Period and (v) the Drilling Unit has arrived at the COMPANY’S first location or an alternative location, if requested by COMPANY. The Parties shall cooperate in the loading of any COMPANY’S drilling equipment and materials to minimize any delay in the Commencement Date. In the event that, despite the Partie s’ best efforts, the loading of COMPANY’S drilling equipment and materials cause a delay in the Commencement Date the CONTRACTOR shall be paid at the Standby and Moving Rate for any such delay. Notwithstanding the foregoing, however, COMPANY may require or allow the Drilling Unit to commence Work at an earlier date in which case such earlier date shall be the Commencement Date and in such event any of the above requirements for the Commencement Date which have not been satisfied shall be deemed satisfied.

The Parties agree that delivery of the Drilling Unit to the U.S. Gulf of Mexico is desired to occur twenty seven (27) months from the Effective Date, with COMPANY agreeing to take delivery as much as three (3) months sooner (“Delivery Date”).

If the Drilling Unit is not delivered to the Gulf of Mexico by thirty (30) months from the Effective Date, then COMPANY shall invoice CONTRACTOR every thirty (30) thirty days after the start of the late delivery charges a sum calculated at a rate of five thousand dollars ($5,000.00) per day during the first six (6) months of the late delivery and then at a rate of ten thousand dollars ($10,000.00) per day for each day until the Drilling Unit is delivered to the Gulf of Mexico with the total amount of such payment not to exceed one million five hundred thousand dollars ($1,500,000.00) for the late delivery of the Drilling Unit.

1.3 COMPLETION OF CONTRACT

1.3.1 Upon completion of this CONTRACT, if CONTRACTOR has no other Work for the Drilling Unit, COMPANY shall provide for tow, if required, of the Drilling Unit to, and securing

in, the anchorage area at Galveston, Texas, or a mutually agreed point of no greater distance from its location of the last Work under this CONTRACT and at applicable dayrates.

1.3.2 Subject to Article 27.4, upon completion of this CONTRACT, if CONTRACTOR has other Work for the Drilling Unit, COMPANY shall have no further responsibility hereunder when all of COMPANY’S equipment has been offloaded, the well secured, and the Drilling Unit is ready to get underway.

ARTICLE 2

DAYRATES

2.1 GENERAL

COMPANY shall pay CONTRACTOR for work performed, services rendered, and materials, equipment, supplies, and personnel furnished by CONTRACTOR at the rates specified in Exhibit A. The period of time for which each rate shall be applicable shall be computed from and to the nearest half (1/2) hour. Subject to Article 2.3, the rates as specified in Exhibit A shall apply during the entire Initial Contract Term. The rates are based on CONTRACTOR’S operations being conducted on a seven (7) day week and a twenty-four (24) hour work day.

2.2 DAYRATES

Each of the dayrate classifications is as follows:

2.2.1 Moving Rate

a) From the moment operations are commenced to release the first mooring line or move the Drilling Unit off location at a drilling location and until the Drilling Unit is properly positioned at COMPANY’S next drilling location, and the Drilling Unit is ready to commence operations.

b) From the moment operations are commenced to release the first mooring line or move the Drilling Unit off location at COMPANY’S final drilling location hereunder until this Contract terminates.

2.2.2 Operating Rate commences at the time of the Commencement Date, time the Drilling Unit is, properly positioned, anchors tested, if any, at drilling draft at the location to be drilled and the Drilling Unit is ready to commence operations and continues until CONTRACTOR has completed operations at the location and the Drilling Unit has been released by COMPANY to move to the next location pursuant to Article 2.2.1(a).

2.2.3 Stand-by Rate with Crews applies while the Drilling Unit is on location with full crews waiting for COMPANY’S orders, and shall be payable during any period of time when CONTRACTOR’S crew is aboard the Drilling Unit and drilling, testing or completion operations hereunder are suspended, as a result of COMPANY’S instructions, COMPANY’S failure to issue

instructions, the mechanical failure of COMPANY’S items, or the failure of COMPANY to timely provide COMPANY’S items or furnish those services set forth in Exhibit B-3.

2.2.4 Stand-by Rate without Crews applies while the Drilling Unit is on location without crews. This rate shall commence seventy-two (72) hours after notification by COMPANY to CONTRACTOR to release crews.

2.2.5(a) Mechanical Downtime applies in the event operations during the term of this CONTRACT are shut down (“Mechanical Downtime”) for inspection, repair or replacement of any surface or subsurface equipment including, but not limited to CONTRACTOR’S items described in Exhibit B, including station keeping equipment, mooring equipment, anchors, chains, shackles, pendent lines, buoys, the riser, slip joint, choke and kill lines, flexible hoses, hydraulic hoses, guidelines, subsea BOP, and BOP control system. CONTRACTOR shall be allowed a maximum of twenty-four (24) hours per calendar month Mechanical Downtime with a maximum accumulation of twelve (12) days; thereafter the dayrate reduces to zero (0). Mec hanical Downtime shall commence immediately upon suspension of well operations and shall continue until completion of the inspection, repair or replacement of the equipment and operations are at the point in well operations prior to suspension. If COMPANY elects to proceed with an alternative operation, then Mechanical Downtime shall cease at the point in well operations where the alternative operation commences. Article 2.2.5(a) shall not apply to the time required to repair or replace CONTRACTOR’S choke manifolds, blowout preventors, and drill string, if the damage or destruction to the equipment is caused by exposure to unusually corrosive or otherwise destructive elements not normally encountered which are introduced into the drilling fluid from subsurface formations or the use of corrosive additives in the fluid. Article 2.2.5(a) shall not apply to normal maintenance, including, without limitation, cutting and/or slipping the drill line, which time shall be limited to 1 hour plus up to thirty (30) minutes per day (fifteen (15) hours per month maximum) for top drive maintenance. Any mobilization and/or demobilization and associated cost required to repair the Drilling Unit under Article 2.2.5(a) will be at CONTRACTOR’S expense. CONTRACTOR shall not be entitled to any compensation for Mechanical Downtime allowance not consumed during this CONTRACT.

2.2.5(b) Performance Downtime applies in the event operations during the term of this CONTRACT are shut down (“Performance Downtime”) for the following reasons (i) CONTRACTOR, CONTRACTOR’S Personnel (as hereinafter defined), or the Drilling Unit should be incapable, incompetent, negligent, unreliable, or consistently poor in performance of the Work, (ii) the equipment listed in Exhibit B is incapable of being operated at the rated specifications in Exhibit B for sustained operation or (iii) CONTRACTOR fails to fulfill any of its obligations under this Contract. In the event of COMPANY’S dissatisfaction with any items identified in (i), (ii) and (iii), Performance Downtime shall commence when COMPA NY provides CONTRACTOR with written notice as to the circumstances of its dissatisfaction and work in progress is suspended and shall continue based on the following remedies. If work in progress is suspended, then Article 2.2.5(a) shall apply. CONTRACTOR shall be allowed five (5) days, from the written notice, to commence good faith efforts to remedy such circumstances. During the remedy period, the Operating Rate shall be reduced to the Standby-rate Without

Crews. In the event such circumstances are not remedied to COMPANY’S satisfaction within thirty (30) days, from the written notice, the Operating Rate shall be reduced to zero (0) dollars.

2.2.6 Hurricane Evacuation Rate applies when all of the crews have been transported to shore. This rate shall include the cost of room and board for all of CONTRACTOR’S personnel including catering personnel and any other of CONTRACTOR’S subcontractor personnel. If COMPANY elects to release CONTRACTOR’S crew, then the Standby Rate Without Crew shall be applicable from the time CONTRACTOR is notified by COMPANY until the CONTRACTOR’S crew returns to the Drilling Unit.

2.2.7 Stack Rate applies when the Drilling Unit has arrived and secured at the nearest safe harbor or stack location in the Gulf of Mexico as designated by CONTRACTOR. The Moving Rate shall apply immediately before the Stack Rate commences. The Stack Rate will continue until the unit is ready to get underway at which time the Moving Rate shall apply, or until the CONTRACT expires pursuant to Article 1.

2.3 ADJUSTMENTS IN DAYRATES

2.3.1 The dayrates set forth in Exhibit A shall remain unadjusted during the Initial Contract Term of this CONTRACT, except for rate changes as described in Article 2.3.2, Article 3, Article 4, Article 5, Article 6, and Article 30.3.

2.3.2 The dayrates set forth in Exhibit A shall be revised to reflect the change in costs from the Effective Date if the costs of any of the items hereafter listed shall vary in an amount equal to or greater than five percent (5%) from the costs thereof not earlier than the Commencement Date and not more frequent than one (1) year after the date of any revision pursuant to this Article 2.3.2.

a. Labor costs, including all benefits, of CONTRACTOR’S personnel listed in Exhibit F;

b. CONTRACTOR’S cost of catering;

c. CONTRACTOR’S cost of spare parts and supplies vary and that the parties shall use the United States Department of Labor’s Producer Price Index Commodity Code No. 1191.02 - Oil Field and Gas Field Drilling Machinery - to determine what extent a price variance has occurred in said spare parts and supplies.

d. Cost of insurance not based solely on CONTRACTOR’S loss or claim record.

CONTRACTOR must show documented proof for any dayrate adjustments due to changes in CONTRACTOR’S cost of labor, insurance or catering. CONTRACTOR shall provide COMPANY with the base figures for the items specified in Article 2.3.2a.,b.,c., and d., thirty (30) days after the Effective Date. Base figures from which such revisions (either upward or downward) will be determined for the items in this Article 2.3.2 shall be provided by CONTRACTOR sixty (60) days prior to the estimated Commencement Date. These base figures

shall be agreed upon by both parties and approved in writing by COMPANY prior to the Commencement Date.

2.3.3 If, at the request of COMPANY, it becomes necessary for CONTRACTOR to change the work schedule of its personnel or change the location of its Homeport or area of operations, which impacts the CONTRACTOR’S actual cost, the daily rates set out in Appendix A shall be adjusted accordingly, with appropriate back up data.

2.3.4 CONTRACTOR shall be responsible for costs and expenses incurred by CONTRACTOR in complying with any law, regulation, or ruling of a government, governmental agency, or regulatory authority having jurisdiction over the operations of the Drilling Unit to the extent that the law, regulation, or ruling has changed or been imposed subsequent to the Commencement Date. Where compliance with the changed law, regulation, or ruling results in modifications of the Drilling Unit or the purchase of equipment which change CONTRACTOR’S cost, the dayrates shall be adjusted with the additional direct cost and expenses amortized over the life of the Drilling Unit. The increased dayrates shall become effective upon completion of the modifications, and the Drilling Unit commences operations. CONTRACTOR shall be solely responsible for mobilization and demobilization and associated cost; during such time the dayrate shall be zero (0) dollars.

ARTICLE 3

PERSONNEL AND PAYMENTS

3.1 PERSONNEL CLASSIFICATIONS, NUMBERS AND REPRESENTATION

3.1.1 CONTRACTOR shall furnish, at its sole expense, personnel in the numbers and classifications as set forth in Exhibit F.

3.1.2 During any period of time that CONTRACTOR fails to provide on the Drilling Unit the numbers or classifications of personnel specified in Exhibit F, the rate being paid the CONTRACTOR shall be reduced by the overtime hourly rate for the absent crew member(s) as specified in Exhibit F. This reduced rate shall commence on the second day of the crew shortage.

3.1.3 The number of personnel to be furnished by CONTRACTOR under the terms hereof as specified in Exhibit F may be increased or decreased by mutual consent of COMPANY and CONTRACTOR, in which case the rates set forth in Article 2 shall be increased or decreased by an amount equal to the change in CONTRACTOR’S cost.

3.1.4 CONTRACTOR represents that all of CONTRACTOR’S personnel shall be fully qualified, trained, competent, able bodied and fit for their respective assignments and shall have complied with all necessary laws and regulations in connection therewith. The minimum standard for qualification and training is set forth in Exhibit F. CONTRACTOR shall be able to communicate verbally and in writing by means of a common language at all times.

3.2 OVERTIME COMPENSATION

3.2.1 COMPANY shall pay CONTRACTOR for overtime work of personnel employed by CONTRACTOR who are required to work in excess of their regularly scheduled hours, when requested by COMPANY, at the rates specified in Exhibit F.

3.2.2 In the event the departure of the crews from the drilling site is delayed more than two (2) hours after the normal scheduled departure time due to delays in the transportation schedule which are not caused by the negligence or fault of CONTRACTOR, COMPANY shall pay CONTRACTOR for time in excess of two (2) hours at the hourly overtime rate for each employee as specified in Exhibit F.

3.2.3 In the event that the time of transportation of crews between the Drilling Unit and the shorebase or between the shorebase and Drilling Unit is in excess of two (2) hours for each one-way trip, which are not the result of the negligence or other fault of CONTRACTOR, COMPANY shall pay CONTRACTOR for time in excess of two (2) hours for each trip at the hourly overtime rate for each employee as specified in Exhibit F.

ARTICLE 4

OTHER PAYMENTS

4.1 CHANGE IN HOMEPORT OF OPERATIONS

The Homeport of operations for the Drilling Unit under this CONTRACT is any Gulf of Mexico port between and inclusive of Corpus Christi, TX and Pascagoula, MS.

4.2 EXCESS MEALS AND LODGINGS

COMPANY shall pay CONTRACTOR for the cost of meals and lodging for COMPANY’S personnel and subcontractors (other than CONTRACTOR) that are in excess of ten (10) people per day calculated over a period of one (1) calendar month at CONTRACTOR’S actual cost.

4.3 ANCHOR HANDLING AND TOWING VESSEL CHARGES

COMPANY shall pay all anchor handling and towing vessel charges if required, for movement of the Drilling Unit.

4.4 OTHER CHARGES

COMPANY shall pay CONTRACTOR for other charges as per Article 6, Article 7, and Article 8.

ARTICLE 5

DRILLING UNIT MODIFICATIONS

5.1 PRE-COMMENCEMENT

Any modification to the Drilling Unit before the Commencement Date shall be pursuant to Exhibit H.

5.1.1 POST-COMMENCEMENT DATE

Any modification to the Drilling Unit after the Commencement Date shall be as agreed in a separate written agreement. In the event the Drilling Unit is taken out of service or placed into shelter or harbor for COMPANY requested modifications, the rate that shall be payable per day, or pro rata for any part of a day during which such activity occurs shall be Standby Rate, which shall be payable for the period of time beginning when the Drilling Unit ceases operations to move off the drilling or well location until it moves back to location and commences full operations; provided, however, that if the Drilling Unit has changed locations, CONTRACTOR shall be credited at the Moving Rate for the time that would otherwise have been spent moving to the new location. In such case, the related modification costs and harbor expenses including, but not limited to, customs or other duties or imposts, harbor tugs if required, demurrage, wharfage, harbor and port fees and dues, landing, pilotage, lighterage, stevedoring, customs agent fees, anchor handling, any tow in and out, fuel, and canal charges, if applicable will be paid by COMPANY in a mutually agreed adjustment to the daily rates

ARTICLE 6

OTHER REIMBURSEMENTS

6.1 LICENSES AND PERMITS

CONTRACTOR shall be responsible for all licenses, permits, or other authorization which are required to be obtained by CONTRACTOR subsequent to the Commencement Date. COMPANY agrees to reimburse CONTRACTOR for all cost associated with licenses, permits or other authorization which are required to be obtained by CONTRACTOR should COMPANY designate a location outside the federal waters of the Gulf of Mexico. COMPANY will obtain any required licenses, permits or authorizations which are required to be obtained by COMPANY.

ARTICLE 7

MATERIALS, SUPPLIES, EQUIPMENT, AND SERVICES

TO BE FURNISHED BY CONTRACTOR

7.1 MATERIALS, SUPPLIES, EQUIPMENT, & SERVICES

7.1.1 CONTRACTOR shall furnish and maintain at its sole expense all items designated in Exhibit B under the heading FURNISHED BY CONTRACTOR. Any additional items not specifically mentioned elsewhere in this CONTRACT and found necessary to perform work shall be furnished by COMPANY at its sole expense.

7.1.2 All items of equipment, materials, supplies, services, and service personnel required for operations hereunder that are to be FURNISHED BY CONTRACTOR as specified in Exhibit B may be furnished by COMPANY upon the mutual consent of COMPANY and CONTRACTOR and billed to CONTRACTOR at actual invoice cost less all cash discounts obtained by COMPANY plus a five (5) percent handling charge plus applicable taxes if taxes are applied to the cost reimbursement. A copy of invoice(s) for equipment, materials, supplies, services, and service personnel shall accompany COMPANY’S invoice to CONTRACTOR and must have the signature of CONTRACTOR’S representative for reimbursement to COMPANY.

7.1.3 All items of equipment, materials, supplies, services, and service personnel required for operations hereunder that are to be FURNISHED BY CONTRACTOR AND REIMBURSED BY COMPANY as specified in Exhibit B are to be billed to COMPANY at actual invoice cost less all cash discounts obtained by CONTRACTOR plus a five (5) percent handling charge. A copy of invoice(s) for equipment, materials, supplies, services, and service personnel shall accompany CONTRACTOR’S invoice to COMPANY and must have the signature of COMPANY’S representative’s for reimbursement to CONTRACTOR.

7.1.4 Any equipment, materials, or supplies purchased by COMPANY for the account of CONTRACTOR pursuant to Articles 7.1.2 and 7.1.3. above shall thereafter become the property of COMPANY unless agreed to by the Parties.

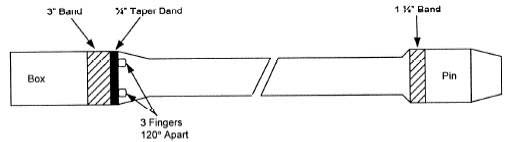

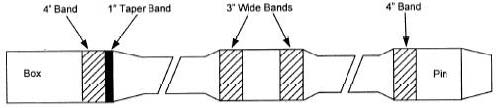

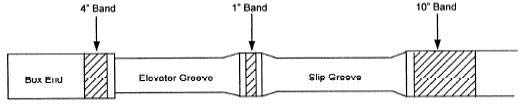

7.1.5 CONTRACTOR shall provide at CONTRACTOR’S expense a drill pipe and drill collar inspection in accordance with API-IADC Standards prior to the Commencement Date. All of the drill pipe and drill collars shall be new. The costs of subsequent drill pipe and drill collar inspections during the term of this CONTRACT shall be borne by the COMPANY or CONTRACTOR as provided in Exhibit B.

ARTICLE 8

MATERIALS, SUPPLIES, EQUIPMENT, AND SERVICES

TO BE FURNISHED BY COMPANY

8.1 MATERIALS, SUPPLIES, EQUIPMENT, & SERVICES

8.1.1 COMPANY shall furnish and maintain at its sole expense all items designated in Exhibit B hereof under the heading “FURNISHED BY VASTAR”.

8.1.2 All items of equipment, materials, supplies, services, and service personnel required for operations hereunder that are to be “FURNISHED BY VASTAR” as specified in Exhibit B may be furnished by CONTRACTOR upon the mutual consent of COMPANY and CONTRACTOR and billed to COMPANY at actual invoice cost less all cash discounts obtained by CONTRACTOR plus a five (5) percent handling charge plus applicable tax gross up if taxes are applied to the cost reimbursement. A copy of invoice(s) for equipment, materials, supplies, services, and service personnel shall accompany CONTRACTOR’S invoice to COMPANY and must have COMPANY’S representative’s signature for reimbursement to CONTRACTOR.

8.1.3 Any equipment, materials, or supplies purchased by CONTRACTOR for the account of COMPANY pursuant to Article 8.1.2 above shall thereafter become the property of COMPANY.

��

ARTICLE 9

PAYMENTS

9.1 TIME OF PAYMENT

COMPANY shall make payments under this CONTRACT in U.S. currency in accordance with the terms of Article 2, Article 3, Article 4, Article 5, Article 6, Article 7, and Article 8 of this CONTRACT, on or before the last working day of the month following the receipt of a valid invoice form CONTRACTOR if received within five (5) calendar days after the month being invoiced If COMPANY receives an invoice after five (5) calendar days from the end of the month being invoiced then the payment will be due twenty (20) working days after receipt of the invoice. Thereafter, valid and undisputed amounts remaining due and unpaid shall earn simple interest at the rate of one and one-half percent (1 1/2%) per month. Should COMPANY question any item of an invoice, COMPANY may withhold payment of t he amount in question, without interest, until the matter is resolved between the Parties, but COMPANY shall pay promptly the amount not in question. COMPANY shall have the right to set off any undisputed and liquidated amount payable by COMPANY to CONTRACTOR under this CONTRACT or under any instrument executed in connection herewith against any amount payable by CONTRACTOR to COMPANY under this CONTRACT.

9.2 IDENTIFICATION OF CHARGES

All invoices must reference charges by block name and number and well number (e.g., Viosca Knoll Blk. 1001 No. 1). OCS numbers or state numbers are not acceptable references.

9.3 PLACE OF INVOICE PRESENTATION

Invoices, accompanied by copies of the original vouchers or such records, receipts, or other evidence as may be requested by COMPANY to support the invoices rendered, shall be sent to COMPANY’S office in Houston, Texas at the address below on or before the tenth (10th) of each month next succeeding the month during which the Work was performed or the expense incurred. The invoices to COMPANY should be directed as follows:

Vastar Resources, Inc.

P.O. Box 219275

Houston, TX 77218-9275

ATTN: DRILLING INVOICES

9.4 PLACE OF PAYMENT

All payments shall be directed to CONTRACTOR as follows:

Wells Fargo Bank

1000 Louisiana

Houston, TX 77002

Account Number

ABA Number

SWIFT Number

ARTICLE 10

PAYMENT OF CLAIMS

10.1 CLAIMS

CONTRACTOR shall pay all claims for equipment, labor, materials, services, and supplies to be furnished by it hereunder and shall allow no lien or charge resulting from such claims to be fixed upon any well lease or other property of COMPANY. CONTRACTOR shall protect, release, defend, indemnify, and hold harmless COMPANY from and against all such claims and liens. COMPANY may, at its option, pay and discharge any (i) amounts secured by such liens or (ii) overdue charges for CONTRACTOR’S equipment, labor, materials, services, and supplies under this CONTRACT and may thereupon deduct the amount or amounts so paid by COMPANY from any sums due, or which thereafter become due, to CONTRACTOR hereunder.

10.2 NOTICE OF CLAIMS

CONTRACTOR shall promptly give COMPANY notice in writing of any claim made or proceeding commenced against CONTRACTOR for which CONTRACTOR claims to be entitled to indemnification under this CONTRACT. CONTRACTOR shall confer with COMPANY concerning the defense of any such claim proceeding, shall permit COMPANY to be represented by counsel in defense thereof, and shall not effect settlement of, nor compromise, any such claim or proceeding without COMPANY’S written consent.

COMPANY shall promptly give CONTRACTOR notice in writing of any claim made or proceeding commenced against COMPANY for which COMPANY claims to be entitled to indemnification under this CONTRACT. COMPANY shall confer with CONTRACTOR concerning the defense of any such claim proceeding, shall permit COMPANY to be represented by counsel in defense thereof, and shall not effect settlement of, nor compromise, any such claim or proceeding without CONTRACTOR’S written consent.

ARTICLE 11

TAXES AND FEES

11.1 TAXES AND FEES ON DRILLING UNIT, CREW, AND OPERATIONS

CONTRACTOR shall be responsible for, pay, and protect, release, defend, indemnify and hold harmless COMPANY from all taxes, including, income taxes of whatsoever kind, and any addition, penalty, interest, or similar item imposed with respect to such taxes, levies, customs charges, duties, fees, or other charges of whatsoever kind without contribution or indemnity from COMPANY whatsoever which may be levied by any national, territorial possession, state, provincial, local, or municipal government, authority, or other agency having jurisdiction over the Operating Area on, in connection with, or related to the Drilling Unit, its crew, its equipment, and any and all materials, equipment, or operations in performance of this CONTRACT. Notwithstanding any other provision of this CONTRACT, COMPANY shall bear ultimate liability for any end user taxe s such as, but not limited to, value added taxes and sales taxes imposed on COMPANY or which CONTRACTOR is required by law to collect. COMPANY and CONTRACTOR will make payments in accordance with the laws and regulations governing these taxes.

11.2 PAYROLL TAXES

CONTRACTOR shall make all necessary reports and pay all taxes, licenses, and fees levied or assessed on CONTRACTOR in connection with or incident to the performance of this CONTRACT by any governmental agency having jurisdiction over the Operating Area for unemployment compensation insurance, old age benefits, social security, or any other taxes upon the wages or salaries paid by CONTRACTOR, its agents, employees, and representatives. CONTRACTOR shall require the same agreement of, and be liable for any breach of the agreement by, any of its subcontractors.

11.3 TAXES PAID BY COMPANY

CONTRACTOR shall reimburse COMPANY on demand for all the taxes or governmental charges, state or federal, outlined in Articles 11.1 and 11.2, which COMPANY may be required or deems necessary to pay on account of CONTRACTOR or its employees or subcontractors. At its election, COMPANY is authorized to deduct all sums so paid for the taxes and governmental charges from any money due CONTRACTOR hereunder and provide official tax receipts within sixty (60) days.

ARTICLE 12

COMPANY’S RIGHT TO QUESTION INVOICES AND AUDIT

12.1 QUESTION INVOICES

Payment of any invoice shall not prejudice the right of COMPANY to question the propriety of any charges therein, provided that COMPANY, within four (4) years after the date of the invoice in question, shall deliver to CONTRACTOR written notice of objections to any item or items, the propriety of which it questions, specifying the reasons for the objections. Should COMPANY so notify CONTRACTOR, adjustments shall be made as the propriety or impropriety of the item may be mutually determined.

12.2 AUDIT

CONTRACTOR shall maintain a complete and correct set of records pertaining to all aspects of this CONTRACT, including the performance hereof by CONTRACTOR. If any payment provided for hereunder is to be made on the basis of CONTRACTOR’S cost, COMPANY shall have the Drilling Unit to inspect and audit any and all records relating to the cost any time during the term of this CONTRACT and up to a period of four (4) years after the recorded date of the record in question, provided that CONTRACTOR shall have the right to exclude any trade secrets, formulas, or processes from the inspection and audit. Should the results of any audit so require, the Parties will make appropriate adjustments or payments.

ARTICLE 13

DEPTH

13.1 DEPTH

The depth of each well to be drilled hereunder will be specified by COMPANY, which COMPANY may amend from time to time. The depth so specified is hereinafter referred to as the “Contract Depth”, subject to the right of COMPANY to direct, at any time, a stoppage of Work at a lesser depth.

ARTICLE 14

DRILLING UNIT

14.1 REPRESENTATION OF DRILLING UNIT

The Drilling Unit shall be fully equipped as specified in Exhibit B and shall meet the requirements of Exhibit G, and shall be adequate to drill and complete wells in the Operating Area to the depths as specified in Article 14.2 hereof and in water depths as specified in Article l4.3. CONTRACTOR represents that the Drilling Unit satisfies all requirements of Articles 14.1.1, 14.4 and 14.6, and is capable of operating to its full capacity as rated by the

manufacturer. CONTRACTOR shall maintain the Drilling Unit at optimal operating condition, in accordance with good oilfield practices throughout the duration of the CONTRACT.

14.1.1 CONTRACTOR represents that (i) the Drilling Unit and related equipment shall be in a condition to permit its continuous and efficient operation during the Contract Period, subject to required periods of maintenance, repair, drydocking and inspection by regulatory bodies and classification societies, (ii) it will diligently perform the Work in a good workmanlike manner consistent with applicable industry standards and practices, (iii) it will use sound technical principles where applicable, (iv) it will perform the Work in compliance with this Contract, (v) it will furnish material and equipment in good condition to sufficiently meet the applicable CONTRACT requirements and good oilfield practices and (vi) where mutually agreed, it will furnish used material and equipment, fit f or the intended use. CONTRACTOR shall bear any cost incurred in placing the Drilling Unit in a condition to function continuously and efficiently during the entire Contract Period. CONTRACTOR agrees to ensure that the Drilling Unit and all equipment and materials furnished by CONTRACTOR are adequately maintained and in such condition as to permit their continuous and efficient operation. CONTRACTOR shall appropriately protect and secure all COMPANY’S equipment and materials placed in its care. CONTRACTOR also agrees to carry out visual inspection on, and make available to COMPANY to test any of CONTRACTOR’S equipment in the manner prescribed by COMPANY.

Notwithstanding the foregoing, CONTRACTOR shall carry out, at CONTRACTOR’S expense, a full and detailed inspection of its drill pipe, drill collars, bottom hole assemblies and other down-hole and surface drilling equipment in accordance with Exhibit B prior to commencing the Work. COMPANY reserves the right to ensure that such inspection is carried out satisfactorily and, accordingly, shall have access to all related inspection reports. CONTRACTOR shall give COMPANY three weeks notice of inspection in order that COMPANY may have a third person witness the inspections to ensure they are carried out in accordance with Exhibit G.

14.1.2 COMPANY shall have the right before the Commencement Date to inspect and reject for sound reasons any part of the Drilling Unit not meeting the requirements of this Contract; provided, however, such right shall not in any way relieve CONTRACTOR of its own obligations, including, without limitation, the obligation to inspect and maintain the Drilling Unit and related equipment in efficient operating condition. COMPANY shall have access and the right to review all commissioning, testing, and acceptance documents pertaining to the Drilling Unit. Unless waived by COMPANY, the Commencement Date shall not occur prior to the date on which CONTRACTOR has satisfactorily remedied any defect.

14.2 MAXIMUM DRILLING DEPTH RATING

CONTRACTOR represents that the Drilling Unit is mechanically capable of drilling wells to the depth specified in Exhibit B-1.

14.3 MAXIMUM WATER DEPTH RATING

CONTRACTOR represents that the Drilling Unit is mechanically capable of drilling wells in water depths and during environmental conditions, as specified in Exhibit B-I.

14.4 TECHNOLOGY

CONTRACTOR and COMPANY agree to explore the latest technologies, including riserless drilling, in an effort to incorporate same into the construction and operation of the Drilling Unit. CONTRACTOR shall make such technology available to COMPANY as soon as CONTRACTOR has the right to install and use such technology on its commercial drilling units, subject to any existing third party contracts as of the Commencement Date. Such installation shall be done pursuant to Article 5.

14.5 APPLICABLE LAWS

Subject to Article 2.3.4, CONTRACTOR represents that during the Contract Period, the Drilling Unit is outfitted, conformed, and equipped to meet all applicable laws, rules, requirements, and regulations promulgated by the U.S. Coast Guard, the U.S. Environmental Protection Agency, the United States of America Department of the Interior as well as any other agency, bureau, or department of the U.S. federal, territorial possession, state, municipal, or local governments, any political subdivisions thereof, having jurisdiction over the operations in U. S. federal waters.

14.6 SAFETY OF PORT

COMPANY does not and shall not be deemed to warrant the safety of any port, place, berth, dock, anchorage, location, or submarine line and shall be under no liability in respect thereof, except as specifically provided for under Article 31.

14.7 OPERATING AREA

The Drilling Unit shall be capable of operating year around in the federal waters of the U. S. Gulf of Mexico. Additionally, the Drilling Unit will be designed to allow for operations in other areas of U. S. federal waters, offshore West Africa and the United Kingdom and other areas of the world, all subject to modifications and outfitting required by the controlling jurisdictions of each different operating area and to the operating limits set forth in Exhibit “G”.

ARTICLE 15

PERFORMANCE OF DRILLING OPERATIONS

15.1 OPERATIONS OF DRILLING UNIT

CONTRACTOR shall be solely responsible for the operation of the Drilling Unit, including, without limitation, supervising moving operations, and the positioning of the Drilling Unit on drilling locations as required by COMPANY, as well as such operations on board the Drilling Unit as may be necessary or desirable for the safety of the Drilling Unit.

15.2 PREVENTION OF FIRE AND BLOWOUTS

CONTRACTOR shall maintain well control equipment in accordance with good oilfield practices at all times and shall use all reasonable means to control and prevent fire and blowouts and to protect the hole and all other property of the COMPANY. CONTRACTOR shall use the blowout prevention equipment specified in Exhibit B hereof on all strings of casing unless otherwise directed by COMPANY. CONTRACTOR shall pressure test the blowout prevention

devices as often as instructed by COMPANY, usually once every seven (7) days, and shall function test the blowout prevention devices by opening and closing to assure operating condition at each trip for a bit change. CONTRACTOR shall record the results of all the tests on the Daily Drilling Report Form defined in Section 19.1 hereof. CONTRACTOR shall use kelly sub protectors and drill pipe protectors. In any event, CONTRACTOR, at a minimum, shall use, test, and maintain blowout prevention equipment in accordance with all applicable governmental rules, regulations, and orders then in effect.

15.3 DEVIATION OF THE HOLE

CONTRACTOR shall use precaution in accordance with good oilfield practices in the Area of Operations, to drill a hole which will not deviate excessively from the limits specified by COMPANY. CONTRACTOR shall run angle and directional measuring devices acceptable to, and at the intervals directed by COMPANY. CONTRACTOR shall record the results of the deviation survey on the Daily Drilling Report Form.

15.4 DRILL PIPE MEASUREMENT

CONTRACTOR shall measure the total length of drill pipe in service with a steel tape before setting casing or liner, before logging, after reaching final depth, and whenever requested by COMPANY and shall promptly enter all the measurements on the Daily Drilling Report Form.

15.5 CASING PROGRAM

The casing program shall be as specified by COMPANY.

15.6 MUD PROGRAM

CONTRACTOR shall use all reasonable care to make and maintain drilling mud having weight, viscosity, water loss, and other characteristics to satisfy the requirements as specified by COMPANY. CONTRACTOR shall exercise due diligence to prevent the well from blowing out, and to enable the efficient drilling, logging, and testing of all formations without caving or formation contamination. While drilling, CONTRACTOR shall test drilling mud for weight, viscosity, water loss, and other necessary characteristics as instructed by COMPANY and shall record the results of the tests and the material volume usage on the Daily Drilling Report Form.

15.7 COMPLETION OR ABANDONMENT OF WELLS

CONTRACTOR shall perform all work necessary to tube, equip, and complete or abandon each well in the manner specified by COMPANY.

15.8 SAMPLES

CONTRACTOR shall save and preserve for COMPANY samples of formations penetrated, and properly prepare and label COMPANY’S containers. COMPANY shall designate the sampling frequency.

15.9 CORING

CONTRACTOR shall core at the depths which COMPANY shall specify and shall deliver all cores in COMPANY’S containers, properly labeled, to COMPANY and shall not allow any third

person access to the cores or to the samples referred to in Article 15.8, or to any core or sample data, without COMPANY’S consent.

15.10 FORMATION TESTS

If during the course of drilling CONTRACTOR encounters evidence of oil or gas, or other hydrocarbon substances, then CONTRACTOR shall immediately notify COMPANY, and should COMPANY desire a test to determine the productivity of any formation so encountered then, CONTRACTOR shall make such a test if it is feasible under existing conditions.

15.11 ANCHOR HANDLING AND TOWING

COMPANY shall supply any required anchor handling and towing vessels to move the Drilling Unit between locations.

ARTICLE 16

INSPECTION OF MATERIALS

16.1 INSPECTION BY CONTRACTOR

CONTRACTOR shall carefully perform a visual inspection of all materials and appliances furnished by COMPANY when delivered into CONTRACTOR’S possession and shall notify COMPANY’S representative of any apparent defects so that COMPANY may replace the defective materials or appliances. Upon the termination of this CONTRACT, CONTRACTOR shall return to COMPANY all materials and appliances received by CONTRACTOR from COMPANY or purchased by CONTRACTOR for COMPANY’S account then in CONTRACTOR’S possession.

16.2 INSPECTION BY COMPANY

Excluding the Drilling Unit and its major equipment, COMPANY shall have the right to inspect and reject, for any valid cause, any items furnished by CONTRACTOR in Exhibit B-3. CONTRACTOR at its sole cost, risk and expense shall replace and/or repair the rejected items, or replace them with items free of defects.

ARTICLE 17

SAFETY

17.1 GENERAL

CONTRACTOR shall have the primary responsibility for the safety of all its operations, shall take all measures necessary or proper to protect the personnel and facilities and, in addition, shall observe all safety rules and regulations of any governmental agency having jurisdiction over operations conducted hereunder. CONTRACTOR shall place the highest priority on safety while performing the work. CONTRACTOR shall also observe all of COMPANY’S safety rules and guidelines as set forth in “Safety and Health Manual” of Vastar Resources, Inc., and the requirements contained in Exhibit D. The CONTRACTOR may also have its own safety manual

and when CONTRACTOR’S and COMPANY’S safety manuals conflict, CONTRACTOR’S safety manual shall control.

17.2 UNDER TOW

At all times during movement of the Drilling Unit between locations, CONTRACTOR shall have full responsibility for control of the Drilling Unit and shall have final authority regarding the safety and operation of the Drilling Unit, associated equipment, and personnel on board.

17.3 SAFETY EQUIPMENT

CONTRACTOR shall furnish any needed personal protection equipment that CONTRACTOR’S personnel may require in order to safely perform CONTRACTOR’S obligations under this CONTRACT.

17.4 EMERGENCY EVACUATION PLAN

The CONTRACTOR shall furnish COMPANY with information regarding the Emergency Evacuation Plan (“EEP”) for the CONTRACTOR’S Drilling Unit. The information supplied shall include station bills, a list of fire fighting equipment, list of emergency crafts onboard, and all other information required to describe the EEP in order to meet federal regulations in 46 C.F.R. 109 for MODU’s. The COMPANY shall submit as part of the COMPANY’S EEP, information and/or data as required by 33 C.F.R. 146.2 10.

ARTICLE 18

PERFORMANCE OF THE WORK

18.1 INDEPENDENT CONTRACTOR RELATIONSHIP

In performing the work set forth in this CONTRACT, CONTRACTOR shall act at all times as an independent contractor. Unless otherwise mutually agreed, CONTRACTOR shall not make any commitment or incur any charges or expense in the name of COMPANY. CONTRACTOR expressly agrees, acknowledges and stipulates that neither this CONTRACT nor the performance of CONTRACTOR’S obligations or duties hereunder shall ever result in CONTRACTOR, or anyone employed by CONTRACTOR, being i) an employee, agent, servant, or representative of COMPANY, or ii) entitled to any benefits from COMPANY, including without limitation, pension, profit sharing or accident, health, medical, life or disability insurance benefits or coverage, to which employees of COMPANY may be entitled. The sole and only compensation to which CONTRACTOR shall be entitled to under this CON TRACT are the payments provided for herein. COMPANY shall have no direction or control of CONTRACTOR or its employees and agents except in the results to be obtained. The actual performance and superintendence of all work hereunder shall be by CONTRACTOR, but the work shall meet the approval of COMPANY and be subject to the general right of inspection herein provided in order for COMPANY to secure the satisfactory completion of the work.

18.2 COMPANY’S REPRESENTATIVE

COMPANY shall be entitled to designate a representative(s), who shall at all times have complete access to the Drilling Unit for the purpose of observing or inspecting operations

performed by CONTRACTOR in order to determine whether, in COMPANY’S sole opinion, CONTRACTOR has complied with the terms and conditions of this CONTRACT. The representative(s) shall be empowered to act for COMPANY in all matters relating to CONTRACTOR’S daily performance of the work. CONTRACTOR shall cooperate at all times with and render reasonable assistance to the representative(s) of COMPANY or representative(s) of any of COMPANY’S other contractor(s).

18.3 DISCIPLINE

CONTRACTOR shall maintain at all times strict discipline and good order among its employees. Should COMPANY determine, for just cause, that the conduct of any of CONTRACTOR’S personnel is detrimental to COMPANY’S interest, COMPANY shall notify CONTRACTOR in writing of the reasons for requesting removal of such personnel and CONTRACTOR shall replace the personnel at CONTRACTOR’S expense.

18.4 TAKEOVER BY COMPANY

In the event that CONTRACTOR shall fail to take proper steps to supply properly skilled workmen or tools, machinery or appliances for the performance of the work on any well hereunder, or shall otherwise neglect or willfully discontinue or delay commencement of the work to be performed on any such well, for a period of five (5) consecutive days after notice by COMPANY, then COMPANY shall have the right, by giving CONTRACTOR notice of its intention to do so, to take possession of the well, and the supervision and control of the drilling equipment and tools, machinery and appliances of CONTRACTOR and drill the well to completion or otherwise complete the work on said well. CONTRACTOR shall continue to have custody of and be solely responsible for its Drilling Unit and the locating and maintaining of it, and COMPANY or its representatives shall have supervision and control of such facilities only to the extent of the drilling or other operations involved. Following any such taking of possession by COMPANY, whether COMPANY is successful or unsuccessful in completing the well, or restoring same to production, the actual incremental cost directly related to the assumed operations to COMPANY (with no allowance to CONTRACTOR, other than dayrate, for the use of its drilling equipment and tools, machinery and appliances), shall be deducted from the applicable dayrate during such period and the balance, if any, paid to CONTRACTOR. COMPANY shall be liable for the return of such drilling equipment and tools, machinery and appliances to CONTRACTOR in as good condition as when received, natural wear and weathering, accidental loss or breakage excepted.

COMPANY SHALL INDEMNIFY, DEFEND AND HOLD CONTRACTOR HARMLESS FROM AND AGAINST ANY AND ALL LOSS, COST, CLAIM OR CAUSE OF ACTION ARISING DIRECTLY OR INDIRECTLY FROM COMPANY’S SUPERVISION OF CONTRACTOR’S DRILLING EQUIPMENT AND TOOLS DURING THAT PERIOD OF TIME IN WHICH COMPANY HAS TAKEN OVER SUPERVISION AND CONTROL OF CONTRACTOR’S DRILLING EQUIPMENT AND TOOLS. THE LIABILITY PROVISIONS HEREOF AND CONTRACTOR’S INDEMNITY OBLIGATIONS HEREUNDER SHALL REMAIN IN FULL FORCE AND EFFECT AS TO ANY AND ALL DAMAGE, LOSS, COST, CLAIM OR CAUSE OF ACTION

ARISING DIRECTLY OR INDIRECTLY PRIOR TO COMPANY’S TAKEOVER OF CONTRACTOR’S DRILLING EQUIPMENT AND TOOLS OR AFTER SUCH DRILLING EQUIPMENT AND TOOLS ARE RETURNED TO THE POSSESSION OF CONTRACTOR. During such a takeover, COMPANY shall obtain insurance coverage with the same coverages as the insurance required to be carried by CONTRACTOR, naming CONTRACTOR and endorsed to waive subrogation.

18.5 CHANGE OF SUPERVISORY PERSONNEL

CONTRACTOR shall notify OPERATOR of any proposed change in supervisory personnel prior to the proposed change.

ARTICLE 19

RECORDS TO BE FURNISHED BY CONTRACTOR

19.1 DAILY DRILLING REPORTS

CONTRACTOR shall keep and furnish to COMPANY one (1) copy of the Daily Drilling Report Form showing the depth of the hole, formation penetrated, and any other data required by COMPANY or governmental authority. CONTRACTOR shall supply the report on the standard API-IADC Report Form. When CONTRACTOR prepares such form, it shall be referred to as the “Daily Drilling Report Form”.

19.2 ACCIDENT REPORTS

CONTRACTOR shall report to COMPANY, as soon as possible, all accidents or occurrences resulting in injuries to CONTRACTOR’S employees or to any third parties, as well as any damage to property of third persons, arising out of or during the course of operations of CONTRACTOR or its subcontractors. CONTRACTOR shall furnish COMPANY with a copy of all reports made by CONTRACTOR to its insurer or to others as requested by COMPANY of the accidents and occurrences.

19.3 DELIVERY TICKETS

CONTRACTOR shall furnish to COMPANY delivery tickets covering any materials or supplies furnished to CONTRACTOR by vendors for which COMPANY is obligated to reimburse CONTRACTOR. These shall be turned in to COMPANY’S representative as received with the Daily Drilling Report Form. The quantity, description, and condition of materials and supplies so furnished shall be verified and checked by CONTRACTOR. The delivery tickets shall be properly certified as to receipt by CONTRACTOR and must have COMPANY’S representative’s signature for reimbursement to CONTRACTOR.

19.4 LOGS

CONTRACTOR shall diligently maintain navigational logs, equipment maintenance, and testing logs, and such other logs and documentation designated by COMPANY. Any maintained log or documentation shall not create any additional burden on CONTRACTOR that is not already required elsewhere in this CONTRACT. CONTRACTOR shall provide a copy of any log upon COMPANY’S request.

ARTICLE 20

INSURANCE

20.1 INSURANCE

Without limiting the indemnity obligation or liabilities of CONTRACTOR or its insurer, at all times during the term of this CONTRACT, CONTRACTOR shall maintain insurance covering the operations to be performed under this CONTRACT as set forth in Exhibit C.

ARTICLE 21

INDEMNITY FOR PERSONAL INJURY OR DEATH

21.1 CONTRACTOR’S PERSONNEL

CONTRACTOR SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY AND HOLD HARMLESS COMPANY FROM AND AGAINST ALL CLAIMS, DEMANDS AND CAUSES OF ACTION ASSERTED BY CONTRACTOR, CONTRACTOR’S SUBSIDIARIES AND AFFILIATED COMPANIES, CONTRACTORS OF ANY SUCH PARTIES, AND THEIR RESPECTIVE OFFICERS, DIRECTORS, AGENTS, INVITEES, EMPLOYEES AND ANY OF THEIR RELATIVES FOR PERSONAL INJURY (INCLUDING BODILY INJURY), ILLNESS, OR DEATH, THAT ARISE OUT OF OR ARE RELATED TO WORK PERFORMED HEREUNDER.

21.2 COMPANY’S PERSONNEL

COMPANY SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY AND HOLD HARMLESS CONTRACTOR FROM AND AGAINST ALL CLAIMS, DEMANDS AND CAUSES OF ACTION ASSERTED BY COMPANY, COMPANY’S SUBSIDIARIES, CO-OWNERS AND JOINT VENTURERS (IF ANY), CONTRACTORS OF ANY SUCH PARTIES (EXCEPT CONTRACTOR, AS SET FORTH IN ARTICLE 21.1 HEREOF), AND THEIR RESPECTIVE OFFICERS, DIRECTORS, AGENTS, INVITEES, EMPLOYEES AND ANY OF THEIR RELATIVES FOR PERSONAL INJURY (INCLUDING BODILY INJURY), ILLNESS, OR DEATH, THAT ARISE OUT OF OR ARE RELATED TO WORK PERFORMED HEREUNDER.

ARTICLE 22

RESPONSIBILITY FOR LOSS OF OR DAMAGE TO THE EQUIPMENT

22.1 CONTRACTOR’S DRILLING UNIT

EXCEPT AS SPECIFICALLY PROVIDED FOR IN ARTICLE 22.3, CONTRACTOR SHALL ASSUME ALL RISK OF LOSS OF OR DAMAGE TO AND SHALL PROTECT,

RELEASE, DEFEND, INDEMNIFY AND HOLD HARMLESS COMPANY FROM AND AGAINST ANY AND ALL CLAIMS FOR LOSS OF OR DAMAGE TO (INCLUDING SALVAGE OR REMOVAL COSTS) ITS DRILLING UNIT AND EQUIPMENT.

FOR PURPOSES OF THIS ARTICLE 22, ALL EQUIPMENT BELONGING TO CONTRACTOR’S PARENT, SUBSIDIARIES, AFFILIATES, SUBCONTRACTORS, PARTNERS, JOINT VENTURERS, EMPLOYEES, OR AGENTS SHALL BE CONSIDERED TO BE CONTRACTOR’S EQUIPMENT.

22.2 USE OF CONTRACTOR’S EQUIPMENT

COMPANY shall have unrestricted right to use all of CONTRACTOR’S equipment provided under this CONTRACT during such times as COMPANY or both COMPANY and CONTRACTOR are engaged in bringing a well being drilled under this CONTRACT under control, provided however, that such use, in CONTRACTOR’S sole opinion, does not endanger CONTRACTOR’S personnel or the Drilling Unit.

22.3 CONTRACTOR’S IN HOLE-EQUIPMENT

COMPANY SHALL ASSUME ALL RISK OF LOSS OF OR DAMAGE TO CONTRACTOR’S IN-HOLE, SUBSEA AND MOORING EQUIPMENT WHEN THE EQUIPMENT IS IN THE HOLE OR IN USE BELOW THE SURFACE OF THE WATER TO THE EXTENT CONTRACTOR’S INSURANCE DOES NOT COMPENSATE CONTRACTOR, REGARDLESS OF WHEN OR HOW THE DESTRUCTION OR DAMAGE OCCURS, UNLESS SAID LOSS OF OR DAMAGE IS A RESULT OF CONTRACTOR’S SOLE NEGLIGENCE, GROSS NEGLIGENCE OR WILLFUL MISCONDUCT, IN WHICH CASE CONTRACTOR IS SOLELY RESPONSIBLE FOR ALL LOSS OF OR DAMAGE. FOR PURPOSES OF THIS SECTION 22.3, ALL EQUIPMENT BELONGING TO CONTRACTOR’S SUBCONTRACTORS, PARTNERS, JOINT VENTURERS, EMPLOYEES, OR AGENTS SHALL BE CONSIDERED TO BE CONTRACTOR’S EQUIPMENT. COMPANY’S RESPONSIBILITY FOR LOSS OF CONTRACTOR’S INHOLE, SUBSEA AND MOORING EQUIPMENT IS LIMITED TO CONT RACTOR’S CIF REPLACEMENT COST LESS DEPRECIATION AT THE RATE OF THREE-FOURTHS OF ONE PERCENT (0.75%) PER MONTH OF USE UNDER THIS CONTRACT.

COMPANY SHALL ASSUME THE RISK OF LOSS FOR AND PROTECT, RELEASE, DEFEND, INDEMNIFY AND HOLD HARMLESS CONTRACTOR FOR DAMAGE TO OR DESTRUCTION OF CONTRACTOR’S CHOKE MANIFOLDS, BLOWOUT PREVENTORS, AND DRILL STRING CAUSED BY EXPOSURE TO UNUSUALLY CORROSIVE OR OTHERWISE DESTRUCTIVE ELEMENTS NOT NORMALLY ENCOUNTERED WHICH ARE INTRODUCED INTO THE DRILLING FLUID FROM SUBSURFACE FORMATIONS OR THE USE OF CORROSIVE ADDITIVES IN THE FLUID, UNLESS SAID LOSS OF OR DAMAGE IS A RESULT OF CONTRACTOR’S NEGLIGENCE, GROSS NEGLIGENCE OR WILLFUL MISCONDUCT IN WHICH CASE CONTRACTOR IS SOLELY RESPONSIBLE FOR ALL LOSS OR DAMAGE.

22.4 COMPANY’S EQUIPMENT

COMPANY SHALL ASSUME THE RISK OF LOSS FOR AND PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD HARMLESS CONTRACTOR FROM AND AGAINST ANY AND ALL CLAIMS FOR LOSS OF OR DAMAGE TO COMPANY’S EQUIPMENT AND PROPERTY. FOR THE PURPOSE OF THIS ARTICLE 22 ONLY, ALL EQUIPMENT AND PROPERTY BELONGING TO COMPANY’S PARENT, SUBSIDIARIES, AFFILIATES, CONTRACTORS (OTHER THAN CONTRACTOR) SUBCONTRACTORS, PARTNERS, JOINT VENTURERS, EMPLOYEES, OR AGENTS SHALL BE CONSIDERED TO BE COMPANY’S EQUIPMENT.

22.5 RESPONSIBILITY DURING MOBILIZATION FROM KOREA

CONTRACTOR SHALL ASSUME FULL RESPONSIBILITY FOR AND SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD HARMLESS COMPANY AND ITS’ JOINT OWNERS HARMLESS FROM AND AGAINST ANY LOSS, CLAIM, DAMAGE, FINE, PENALTY, DEMAND OR LIABILITY, FOR POLLUTION OR PROPERTY DAMAGE, WITHOUT MONETARY LIMITATIONS, MADE BY ANY ENTITY OR PERSON WHILE THE DRILLING UNIT IS MOBILIZING FROM KOREA TO THE GULF OF MEXICO PRIOR TO THE COMMENCMENT DATE.

ARTICLE 23

LOSS OF HOLE OR RESERVOIR

23.1 LOSS OR DAMAGE TO THE HOLE

SHOULD THE HOLE BE LOST OR DAMAGED, THE LOSS OR DAMAGE WILL BE BORNE BY COMPANY AND COMPANY SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD HARMLESS CONTRACTOR FROM AND AGAINST ALL CLAIMS FOR LOSS OF OR DAMAGE TO THE HOLE. NOTWITHSTANDING THE PREVIOUS SENTENCE, IF THE HOLE IS LOST OR DAMAGED DUE TO CONTRACTOR’S NEGLIGENCE, GROSS NEGLIGENCE, WILLFUL MISCONDUCT OR ITS AGENTS’, OR SUBCONTRACTORS OR THEIR FAILURE TO COMPLY WITH COMPANY’S INSTRUCTIONS, THEN AS CONTRACTOR’S SOLE LIABILITY, CONTRACTOR SHALL BE OBLIGATED AT COMPANY’S ELECTION TO REDRILL THE HOLE TO THE POINT AT WHICH THE HOLE WAS LOST AT EIGHTY PERCENT (80%) OF THE OPERATING RATE BUT OTHERWISE SUBJECT TO THIS DRILLING CONTRACT.

23.2 COST OF CONTROL OF BLOWOUT OR CRATER

IN THE EVENT ANY WELL BEING DRILLED HEREUNDER SHALL BLOWOUT, CRATER OR CONTROL BE LOST FROM ANY CAUSE, COMPANY SHALL BEAR THE ENTIRE COST AND EXPENSE OF KILLING THE WELL OR OF OTHERWISE BRINGING THE WELL UNDER CONTROL AND SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD HARMLESS CONTRACTOR FROM AND

AGAINST ALL CLAIMS, SUITS, DEMANDS, AND CAUSES OF ACTION FOR COSTS ACTUALLY INCURRED IN CONTROLLING THE WELL.

23.3 UNDERGROUND DAMAGE

COMPANY SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD HARMLESS CONTRACTOR FOR ANY AND ALL CLAIMS ON ACCOUNT OF (I) INJURY TO, DESTRUCTION OF, LOSS, OR IMPAIRMENT OF ANY PROPERTY RIGHT IN OR TO OIL, GAS, OR OTHER MINERAL SUBSTANCES OR WATER, IF AT THE TIME OF THE ACT OR OMISSION CAUSING THE INJURY, DESTRUCTION, LOSS, OR IMPAIRMENT, THE SUBSTANCE HAD NOT BEEN REDUCED TO PHYSICAL POSSESSION ABOVE THE SURFACE OF THE EARTH, OR (II) ANY LOSS OR DAMAGE TO ANY FORMATION, STRATA, OR RESERVOIR BENEATH THE SURFACE OF THE EARTH.

ARTICLE 24

POLLUTION

24.1 CONTRACTOR RESPONSIBILITY

CONTRACTOR SHALL ASSUME FULL RESPONSIBILITY FOR AND SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD COMPANY AND ITS JOINT OWNERS HARMLESS FROM AND AGAINST ANY LOSS, DAMAGE, EXPENSE, CLAIM, FINE, PENALTY, DEMAND, OR LIABILITY FOR POLLUTION OR CONTAMINATION, INCLUDING CONTROL AND REMOVAL THEREOF, ORIGINATING ON OR ABOVE THE SURFACE OF THE LAND OR WATER, FROM SPILLS, LEAKS, OR DISCHARGES OF FUELS, LUBRICANTS, MOTOR OILS, PIPE DOPE, PAINTS, SOLVENTS, BALLAST, AIR EMISSIONS, BILGE SLUDGE, GARBAGE, OR ANY OTHER LIQUID OR SOLID WHATSOEVER IN POSSESSION AND CONTROL OF CONTRACTOR AND WITHOUT REGARD TO NEGLIGENCE OF ANY PARTY OR PARTIES AND SPECIFICALLY WITHOUT REGARD TO WHETHER THE SPILL, LEAK, OR DISCHARGE IS CAUSED IN WHOLE OR IN PART BY THE NEGLIGENCE OR OTHER FAULT OF COMPANY, ITS CONTRACTORS, (OTHER THAN CONTRACTOR) PARTNE RS, JOINT VENTURERS, EMPLOYEES, OR AGENTS. IN ADDITION TO THE ABOVE, CONTRACTOR TO A LIMIT OF FIFTEEN MILLION DOLLARES (US$ 15,000,000.00) PER OCCURANCE, SHALL RELEASE INDEMNIFY AND DEFEND COMPANY FOR CLAIMS FOR LOSS OR DAMAGE TO THIRD PARTIES ARISING FROM POLLUTION IN ANY WAY CAUSED BY THE DRILLING UNIT WHILE IT IS OFF THE DRILLING LOCATION, WHILE UNDERWAY OR DURING DRIVE OFF OR DRIFT OFF FROM THE DRILLING LOCATION.

24.2 COMPANY RESPONSIBILITY

COMPANY SHALL ASSUME FULL RESPONSIBILITY FOR AND SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD CONTRACTOR HARMLESS FROM AND AGAINST ANY LOSS, DAMAGE, EXPENSE, CLAIM, FINE, PENALTY,

DEMAND, OR LIABILITY FOR POLLUTION OR CONTAMINATION, INCLUDING CONTROL AND REMOVAL THEREOF, ARISING OUT OF OR CONNECTED WITH OPERATIONS UNDER THIS CONTRACT HEREUNDER AND NOT ASSUMED BY CONTRACTOR IN ARTICLE 24.1 ABOVE, WITHOUT REGARD FOR NEGLIGENCE OF ANY PARTY OR PARTIES AND SPECIFICALLY WITHOUT REGARD FOR WHETHER THE POLLUTION OR CONTAMINATION IS CAUSED IN WHOLE OR IN PART BY THE NEGLIGENCE OR FAULT OF CONTRACTOR.

24.3 CLEAN UP OPERATIONS

Initiation of clean up operations by either Party shall not be an admission or assumption of liability by such initiating Party or Parties.

ARTICLE 25

INDEMNITY OBLIGATION

25.1 INDEMNITY OBLIGATION

EXCEPT TO THE EXTENT ANY SUCH OBLIGATION IS SPECIFICALLY LIMITED TO CERTAIN CAUSES ELSEWHERE IN THIS CONTRACT, THE PARTIES INTEND AND AGREE THAT THE PHRASE “SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY AND HOLD HARMLESS” MEANS THAT THE INDEMNIFYING PARTY SHALL PROTECT, RELEASE, DEFEND, INDEMNIFY, AND HOLD HARMLESS THE INDEMNIFIED PARTY OR PARTIES FROM AND AGAINST ANY AND ALL CLAIMS, DEMANDS, CAUSES OF ACTION, DAMAGES, COSTS, EXPENSES (INCLUDING REASONABLE ATTORNEYS FEES), JUDGMENTS AND AWARDS OF ANY KIND OR CHARACTER, WITHOUT LIMIT AND WITHOUT REGARD TO THE CAUSE OR CAUSES THEREOF, INCLUDING PREEXISTING CONDITIONS, WHETHER SUCH CONDITIONS BE PATENT OR LATENT, THE UNSEAWORTHINESS OF ANY VESSEL OR VESSELS (INCLUDING THE DRILLING UNIT), BREACH OF REPRESENTATION OR WARRANTY, EXPRESSED OR IMPLIED, BREACH OF CONTRACT, S TRICT LIABILITY, TORT, OR THE NEGLIGENCE OF ANY PERSON OR PERSONS, INCLUDING THAT OF THE INDEMNIFIED PARTY, WHETHER SUCH NEGLIGENCE BE SOLE, JOINT OR CONCURRENT, ACTIVE, PASSIVE OR GROSS OR ANY OTHER THEORY OF LEGAL LIABILITY AND WITHOUT REGARD TO WHETHER THE CLAIM AGAINST THE INDEMNITEE IS THE RESULT OF AN INDEMNIFICATION AGREEMENT WITH A THIRD PARTY.

25.2 BENEFIT OF INDEMNITIES

TO THE EXTENT A PARTY IS ENTITLED TO INDEMNIFICATION IN ARTICLES 21, 22, 23, AND 24, SUCH PARTY’S PARENT, SUBSIDIARIES, AFFILIATES, CO-OWNERS AND JOINT VENTURERS (IF ANY), AND THEIR RESPECTIVE OFFICERS, DIRECTORS, AGENTS AND EMPLOYEES, THE DRILLING UNIT AND ITS LEGAL AND BENEFICAL OWNERS, IN REM OR IN PERSONAM SHALL ALSO BE ENTITLED TO SUCH INDEMNIFICATION AND DEFENSE THEREUNDER. ANY

SUCH PERSON SO ENTITLED TO INDEMNIFICATION AND DEFENSE UNDER THIS ARTICLE 25.2 ARE HEREINAFTER REFERRED TO AS AN “EXTENDED BENEFICIARY OF INDEMNIFICATIONS.

25.3 Third Party Beneficiaries

Except as otherwise specifically agreed nothing in this Contract shall be construed or applied so as to permit any person or entity not a direct signatory party hereto (except for a successor or permitted assignee of such direct signatory party) to enforce or seek damages against either signatory party hereto for any breach of this Contract. The definition of CONTRACTOR and COMPANY herein shall not be construed to enable or entitle any person or entity other than the signatory parties hereto or a successor or permitted assignee of such a signatory party to directly sue or seek relief against the other signatory party hereto except to the extent that any Extended Beneficiary of Indemnification (as defined in Article 25.2) shall be expressly permitted to enforce such rights of indemnification against the indemnitor. Except for any EXTENDED BEN EFICIARY OF INDEMNIFICATION, no persons or entities are intended to be or become third party beneficiaries of this contract.

ARTICLE 26

LAWS, RULES, AND REGULATIONS

26.1 LAWS, RULES AND REGULATIONS

CONTRACTOR and COMPANY shall comply with all governmental laws, rules, and regulations or orders which are now or hereafter shall become applicable to its operations covered by this CONTRACT or arising out of the performance of such operations.

26.2 EQUAL OPPORTUNITY CLAUSE

To the extent applicable and in connection with the performance of work under this CONTRACT, CONTRACTOR agrees to comply with the following Equal Employment Opportunity and/or Affirmative Action requirements and all other similar requirements as the same are enacted or become applicable to the CONTRACT: Section 202 of Executive Order 11246, as amended by Executive Order 11375, relating to equal employment opportunities, the implementing rules and regulations of the Secretary of Labor and all contract clauses and requirements which are applicable and set forth therein are incorporated herein by specific reference. In particular, CONTRACTOR hereby certifies that it does not maintain segregated facilities. In making this certification, CONTRACTOR incorporates each and all of the provisions of the approved form of certification contained in 41 C .F.R. Section 60-1.8(b) the same as if such provisions were fully set forth herein and signed by CONTRACTOR. Sections 503 and 504 of the Rehabilitation Act of 1973 and Title IV of the Vietnam Era Veterans Readjustment Assistance Act of 1974 relating to employment and advancement of employment of qualified handicapped individuals, disabled veterans and veterans of the Vietnam Era, the implementing rules and regulations of the Secretary of Labor and all contract clauses and requirements which are applicable and set forth therein are incorporated herein by specific reference pursuant to 41 C.F.R. Section 60-741.22 and 41 C.F.R. Section 60-250.22.

26.3 CERTIFICATE OF FINANCIAL RESPONSIBILITY

COMPANY, in cooperation with the CONTRACTOR, shall obtain, at COMPANY’S expense, and maintain evidence of a Certificate of Financial Responsibility from the U.S. Coast Guard covering the Drilling Unit as required by 33 C.F.R. Part 135 and the Outer Continental Shelf Lands Act of 1978. COMPANY will file for the certificate before the well is spud and will coordinate the filing with COMPANY. A copy of filed certificate shall be furnished to CONTRACTOR prior to spud and CONTRACTOR must maintain a copy on the Drilling Unit.

ARTICLE 27

TERMINATION

27.1 TERMINATION BY COMPANY

27.1.1 COMPANY shall have the option to terminate this CONTRACT subject only to (i) payment of amounts earned by CONTRACTOR before termination, and demobilization of the Drilling Unit pursuant to Article 1.3 and (ii) payment of the Lump Sum set forth in Exhibit E. Terminating pursuant to Article 27.1.1 does not limit any other right of termination which COMPANY may have. The termination shall not affect any right or obligation which accrued prior to the termination.

27.1.2 In the event the shipyard where the Drilling Unit is being constructed fails or is unable to deliver the Drilling Unit within the time limits and operational specifications of its contract with CONTRACTOR such that CONTRACTOR has the ability to terminate the construction contract, CONTRACTOR shall so advise COMPANY in writing.

If COMPANY desires to accept the Drilling Unit with later delivery or reduced operational specifications, then COMPANY shall so notify CONTRACTOR within a reasonable time following COMPANY’S receipt of notice under this Article, and upon timely receipt of notice by CONTRACTOR, CONTRACTOR shall not terminate the construction contract and this CONTRACT shall be suitably amended to reflect the later delivery and the reduced operational specifications in Exhibit G, with all other terms and conditions remaining in full force and effect. If such later delivery or reduced operational specifications result in a claim by CONTRACTOR against the Drilling Unit constructor, any net savings to CONTRACTOR as a result of such claim shall be credited to COMPANY against CONTRACTOR’S invoices or remitted to COMPANY as COMPANY shall direct.

If COMPANY does not desire to accept the Drilling Unit with such later delivery or reduced operational specifications, then COMPANY shall so notify CONTRACTOR within a reasonable time following COMPANY’S receipt of notice under this Article, and upon timely receipt of such notice by CONTRACTOR, this CONTRACT shall terminate and COMPANY shall have no obligations under Exhibit E.

27.2 TERMINATION BY CONTRACTOR

CONTRACTOR may cancel this CONTRACT for non-payment of its invoices for services under this CONTRACT, except for portions of the invoices which COMPANY may dispute in good faith. However, CONTRACTOR may cancel under this Article no sooner than one hundred and twenty (120) days after payment was due and only after giving ninety (90) days notice thereof, during which period COMPANY shall have the opportunity to correct the breach.

27.3 LOSS OF DRILLING UNIT

In the event of actual or constructive total loss of the Drilling Unit (as determined by CONTRACTOR’S underwriters), termination shall be immediate with neither CONTRACTOR nor CONTRACTOR’S underwriters having any recourse against COMPANY, or obligations pursuant to Exhibit E, except for CONTRACTOR’S claim to amounts CONTRACTOR earned up to the date of such loss. Contractor shall be responsible for any removal or salvage costs.

27.4 PROVISION AFTER EXPIRATION OF CONTRACT

Notwithstanding the termination of this CONTRACT, COMPANY and CONTRACTOR shall continue to be bound by the provisions of this CONTRACT that reasonably require some action or forbearance after the expiration of the term of this CONTRACT.

ARTICLE 28

FORCE MAJEURE

28.1 FORCE MAJEURE

The term Force Majeure as used in this Article 28 shall mean acts of God, adverse sea or weather conditions beyond the design operating perimeters of the Drilling Unit including wind, sea and current, earthquakes, flood, war, civil disturbances, strikes, lockouts or other industrial disturbances by persons other than employees of CONTRACTOR, governmentally imposed rules, regulations or moratoriums or any other cause whatsoever, whether similar or dissimilar to the causes herein enumerated, not within the reasonable control of either Party which, through the exercise of due diligence said party is unable to foresee or overcome. In no event shall the term Force Majeure include normal, reasonably foreseeable, or reasonably avoidable operational delays or strikes, lockouts or other industrial disturbances by employees of CONTRACTOR. In the event that either Party hereto is rendered unable, wholly or in part, by Force Majeure to carry out its obligations under this CONTRACT, it is agreed that such Party shall give notice and details of the Force Majeure in writing to the other Party as promptly as possible after its occurrence. In such cases, the obligations of the Party giving the notice shall be suspended during the continuance of any inability so caused, except that COMPANY shall be obligated to pay to CONTRACTOR the applicable Dayrates. Should a condition of Force Majeure continue for more than thirty (30) consecutive days, this CONTRACT may be immediately terminated at the option of COMPANY by delivering written notice thereof to CONTRACTOR.

Except for its obligation to make payments of monies hereunder, neither Party to this CONTRACT shall be considered in default in performance of such obligations hereunder to the

extent that the performance of such obligations, or any of them is delayed or prevented by Force Majeure.

ARTICLE 29

CONFIDENTIAL INFORMATION, LICENSE AND PATENT INDEMNITY

29.1 CONFIDENTIAL INFORMATION