Exhibit 99.1

Enphase Energy

Analyst Day

November 2015

Safe harbor

Use of forward-looking statements

This presentation contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, as amended, including, but not limited to, statements related to Enphase Energy’s financial performance, advantages of its technology, product cost reductions and market trend.

These forward-looking statements are based on Enphase’s current expectations and are inherently subject to risks and uncertainties. They should not be considered guarantees of future results, which could differ materially from the results set forth in, contemplated by, or underlying this presentation.

Factors that could cause actual results to differ materially from the Company’s expectations are described in the reports filed by the

Company with the Securities and Exchange Commission pursuant to the Securities Exchange Act of 1934 and we encourage you to review our filing carefully, especially the sections entitled “Risk Factors” in our quarterly report on form 10-Q for the quarter ended September 30, 2015.

Enphase Energy undertakes no duty or obligation to update any forward-looking statements contained in this presentation as a result of new information, future events or changes in its expectations.

2 © 2015 Enphase Energy, Inc.

Agenda

Paul Nahi Enphase Energy vision Martin Fornage Technology for cost reduction

Greg Steele Engineering for cost reduction

Darien Spencer Operations and automation for cost reduction Stefan Zschiegner Product cost reduction roadmap Raghu Belur Home energy systems roadmap

Stefan Zschiegner Enlighten demo

3 | | © 2015 Enphase Energy, Inc. |

Paul Nahi

President and CEO

Enphase focus and priorities

Enphase is executing on its strategy to address market-driven cost pressures in the near term, while positioning the company for long-term growth:

[1] Significantly reduce the cost of a solar system through product cost reduction and simplification of the installation process

[2] Create a total energy solution for homes and businesses through the development of new products, features and services

5 | | © 2015 Enphase Energy, Inc. |

Enphase goals

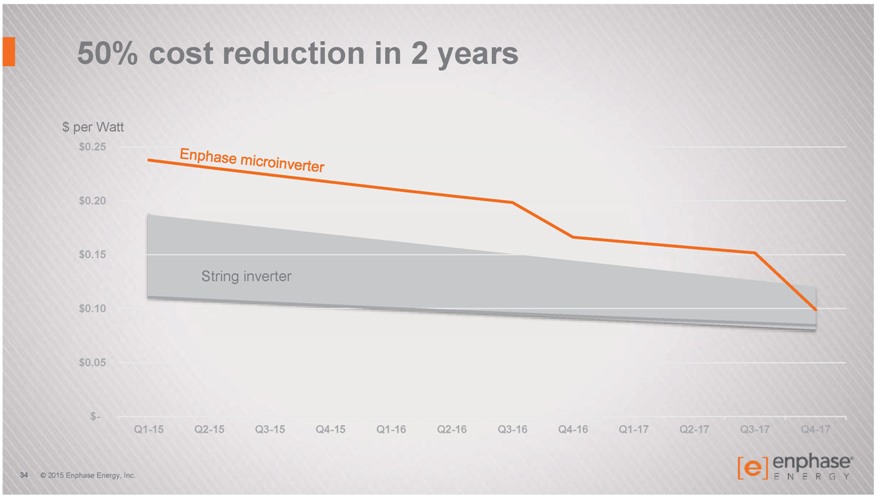

[1] Invest in our next generation technology to reduce costs by 50% in 24 months, towards $0.10 per Watt

[2] Provide our partners with best-in-class power electronics, storage solutions, communications, and load control all managed by a cloud based energy management system

6 | | © 2015 Enphase Energy, Inc. |

Enphase in more than 375,000 systems in 95 countries

7 | | © 2015 Enphase Energy, Inc. |

Martin Fornage

Chief Technology Officer

Enphase 10 years of innovation

First predictive digital control system

First custom chip

First Mixed signal ASIC

Next Gen power train control design

Next Gen power train first operation

Next Gen enclosure prototypes

2006 2015

First microinverter system introduced

Enphase expands globally

Fourth-generation technology introduced

AC battery announced

Fifth-generation

Introduced

9 © 2015 Enphase Energy, Inc.

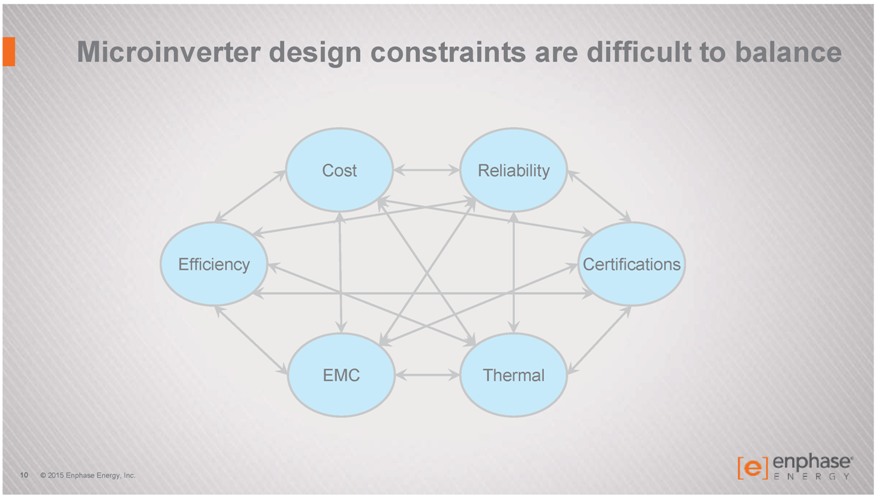

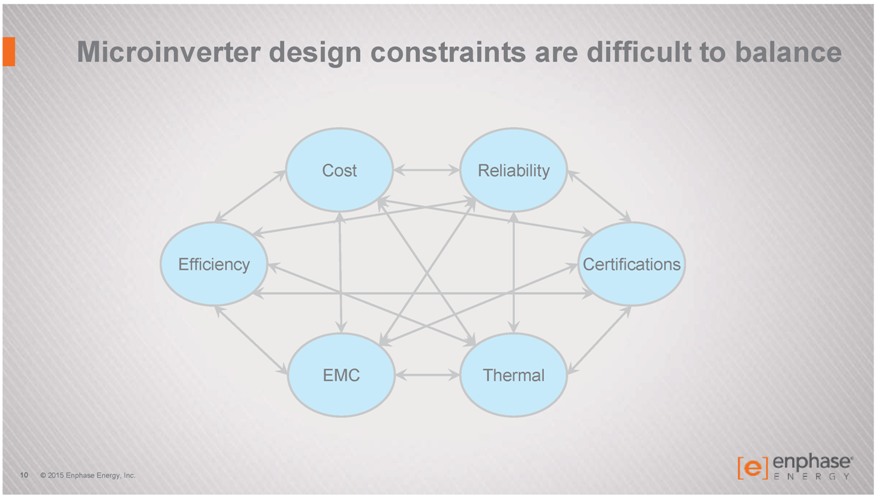

Microinverter design constraints are difficult to balance

Cost Reliability

Efficiency Certifications

EMC Thermal

10 © 2015 Enphase Energy, Inc.

General design philosophy

The System approach is critical

System behavior is defined by Software

Distributed architecture wins

Digital control wins

11 © 2015 Enphase Energy, Inc.

The approach to inverter system design

• | | Choose a low noise, high efficiency power train |

• | | Move to a polymeric enclosure |

• | | Simplify the installation |

12 © 2015 Enphase Energy, Inc.

Enphase power train and control

• | | Advanced power train features |

• | | Fully resonant, soft-switched, bidirectional, single-stage converter |

• | | World’s first sub-cycle control capability |

• | | Much improved EMC signature |

• | | WBG semiconductors can be used to further reduce cost and increase efficiency |

• | | Additional integration opportunities |

13 © 2015 Enphase Energy, Inc.

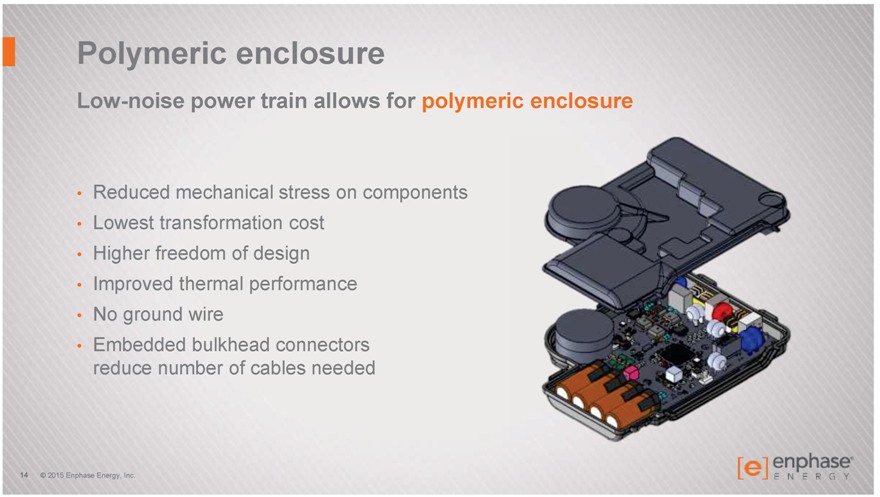

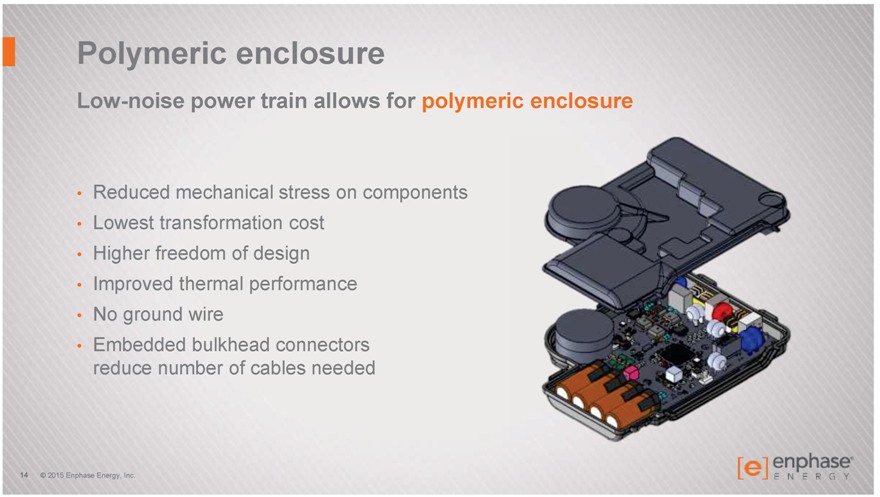

Polymeric enclosure

Low-noise power train allows for polymeric enclosure

• | | Reduced mechanical stress on components |

• | | Lowest transformation cost |

• | | Higher freedom of design |

• | | Improved thermal performance |

• | | Embedded bulkhead connectors reduce number of cables needed |

14 © 2015 Enphase Energy, Inc.

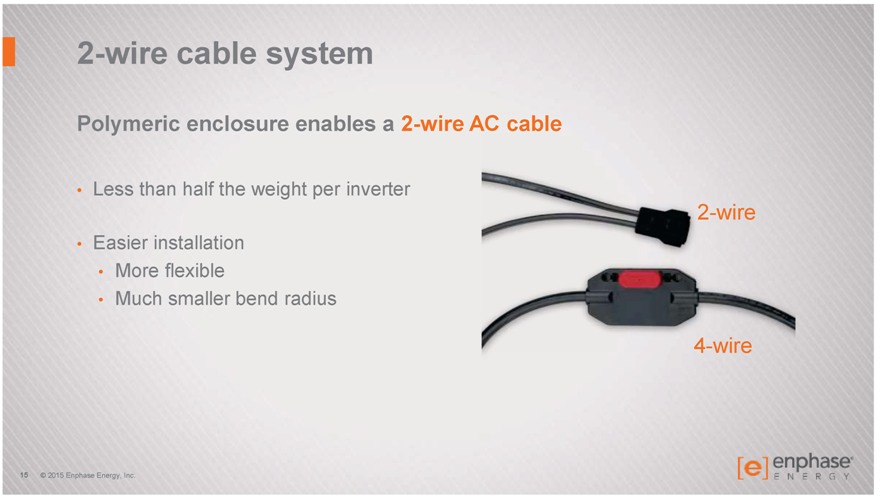

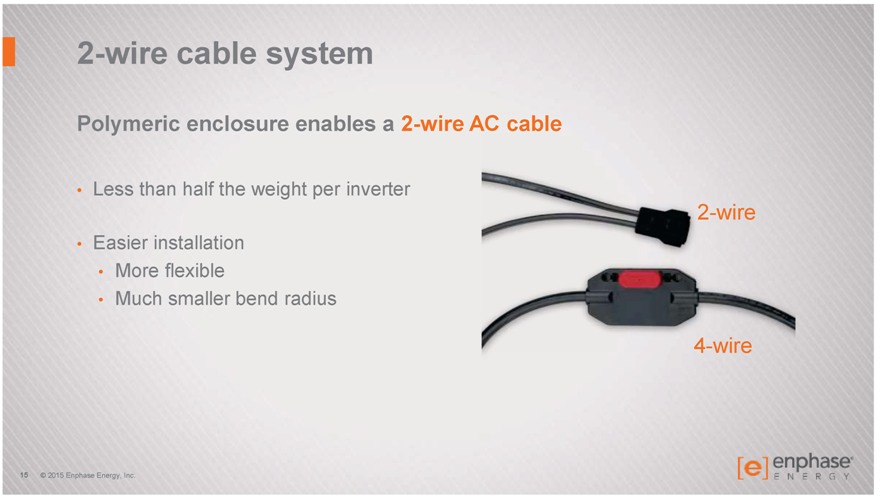

2-wire cable system

Polymeric enclosure enables a 2-wire A

• | | Less than half the weight per inverter |

2-wire

• | | Much smaller bend radius |

4-wire

15 © 2015 Enphase Energy, Inc.

AC module

Advances in size, weight and technology enable the AC module

• | | Next level of integration with PV module |

• | | Eliminates unnecessary components like extra wire and bypass diodes |

• | | Possible removal of PV junction box |

16 © 2015 Enphase Energy, Inc.

Greg Steele

Senior VP of Engineering

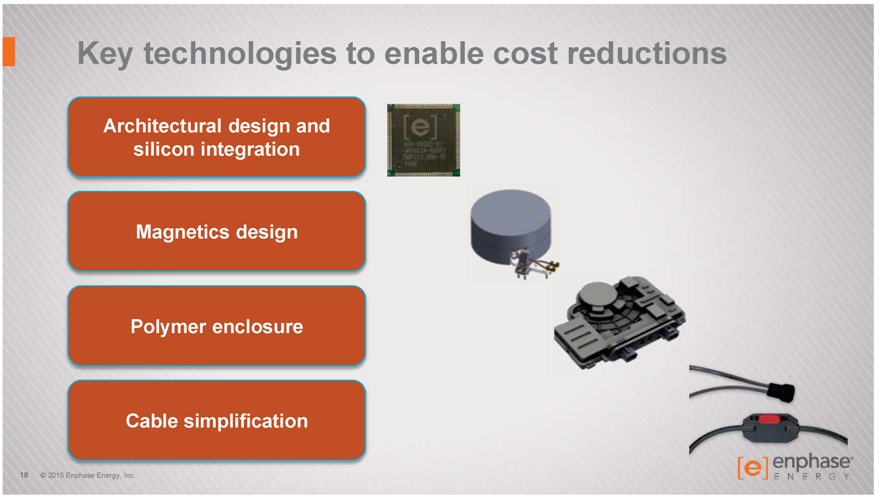

Key technologies to enable cost reductions

Architectural design and silicon integration

Magnetics design Polymer enclosure Cable simplification

18 © 2015 Enphase Energy, Inc.

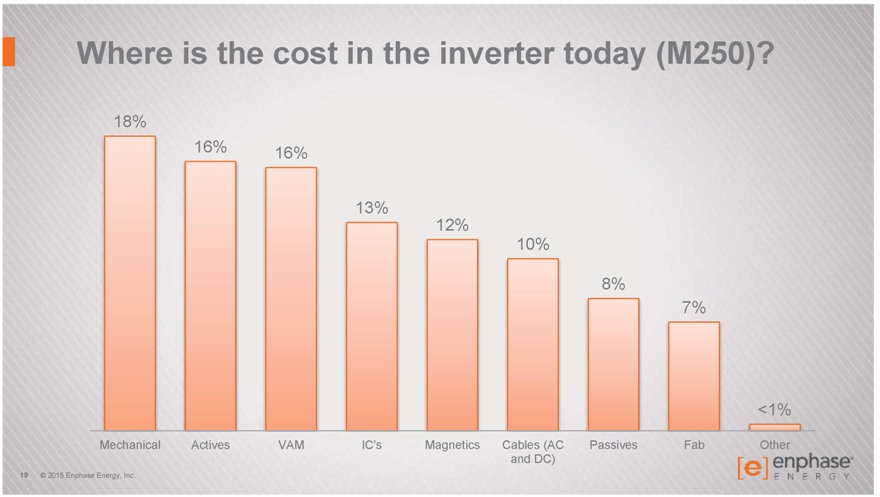

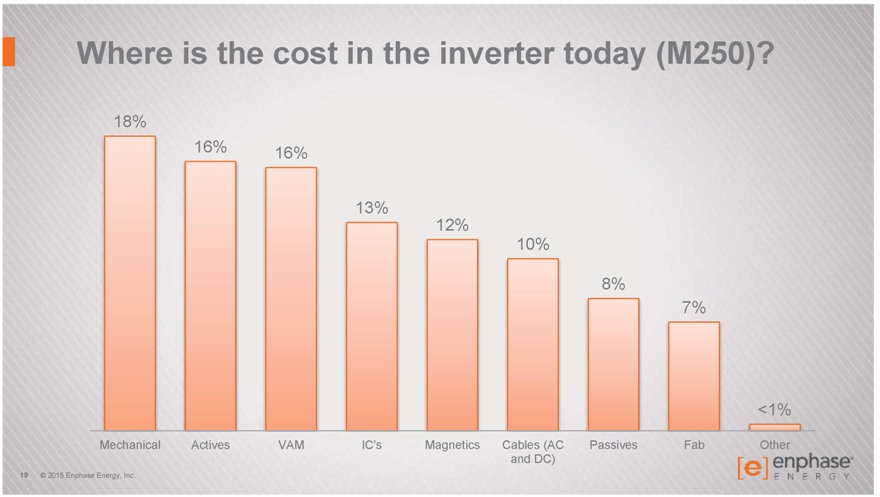

Where is the cost in the inverter today (M250)?

18%

16% 16%

13%

12%

10%

8%

7%

<1%

Mechanical Actives VAM IC’s Magnetics Cables (AC Passives Fab Other

19 © 2015 Enphase Energy, Inc.

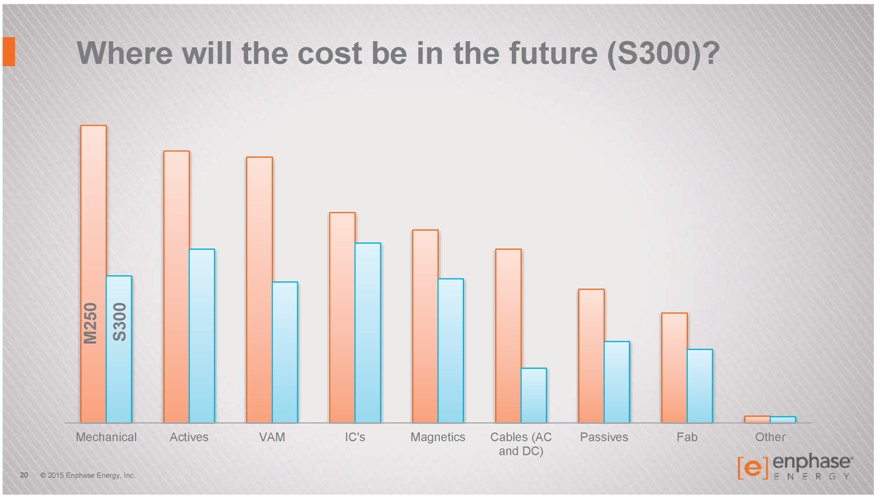

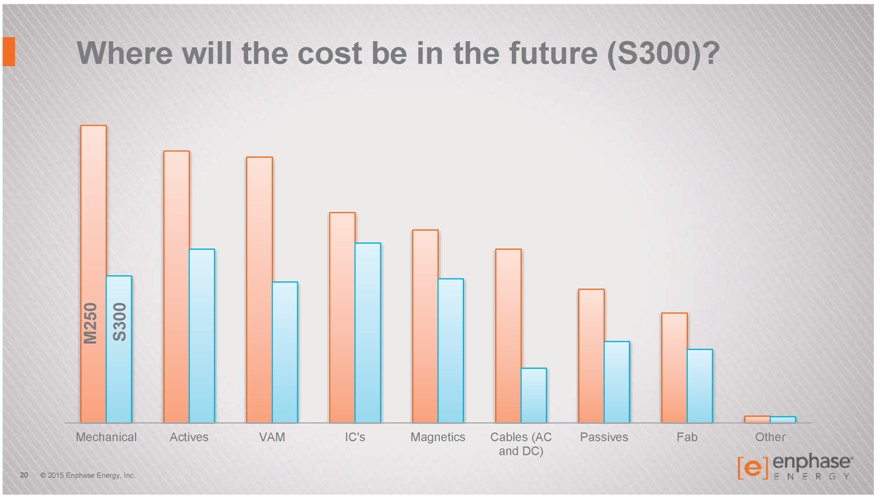

Where will the cost be in the future (S300)?

M250 S300

Mechanical Actives VAM IC’s Magnetics Cables (AC Passives Fab Other and DC)

20 © 2015 Enphase Energy, Inc.

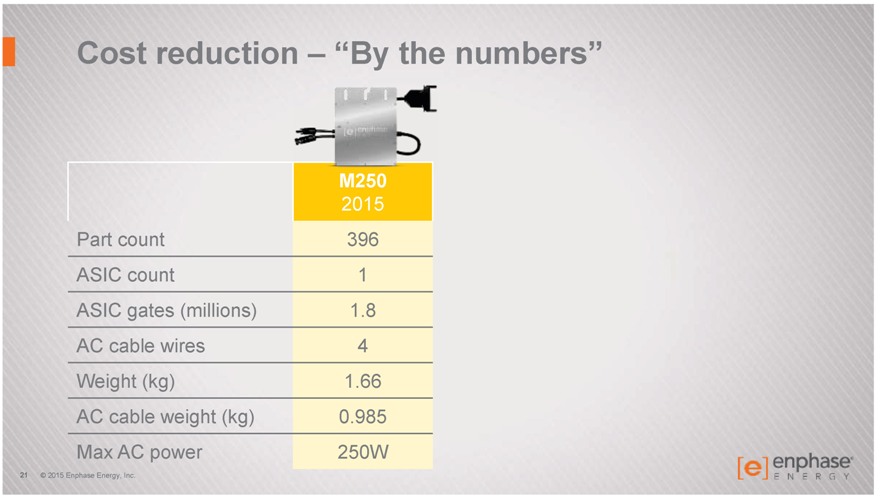

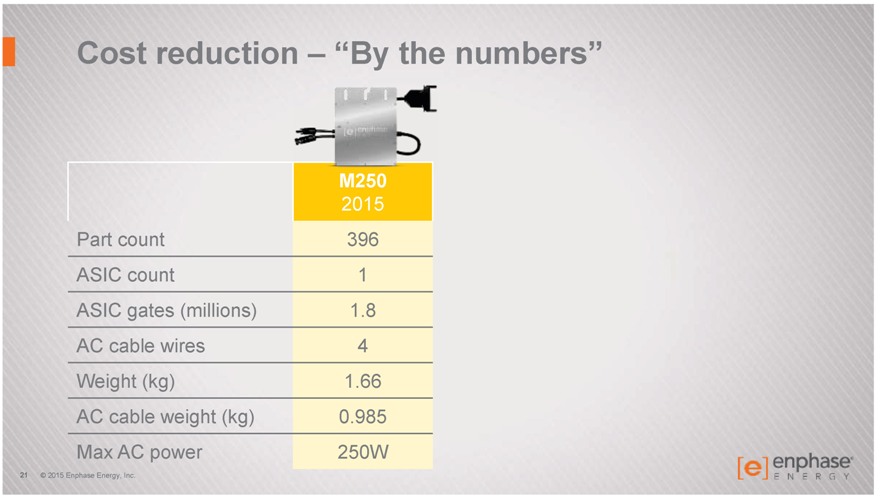

Cost reduction – “By the numbers”

M250

2015 Part count 396 ASIC count 1 ASIC gates (millions) 1.8 AC cable wires 4 Weight (kg) 1.66 AC cable weight (kg) 0.985 Max AC power 250W

21 © 2015 Enphase Energy, Inc.

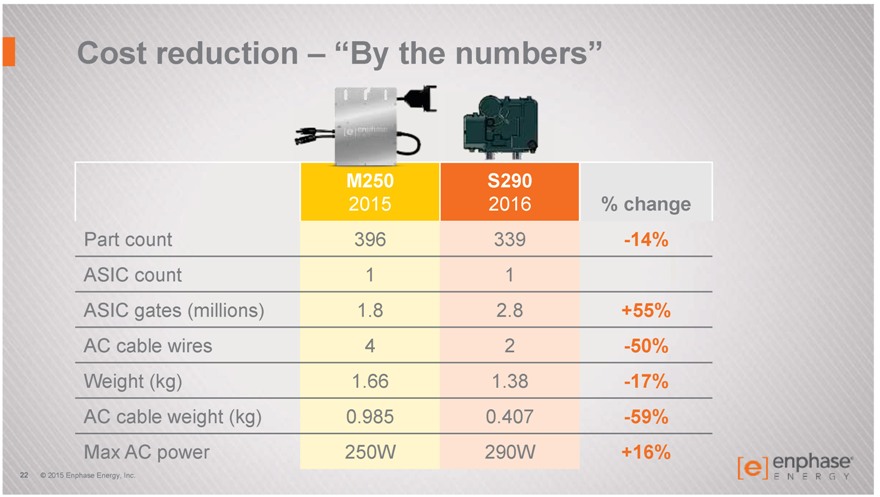

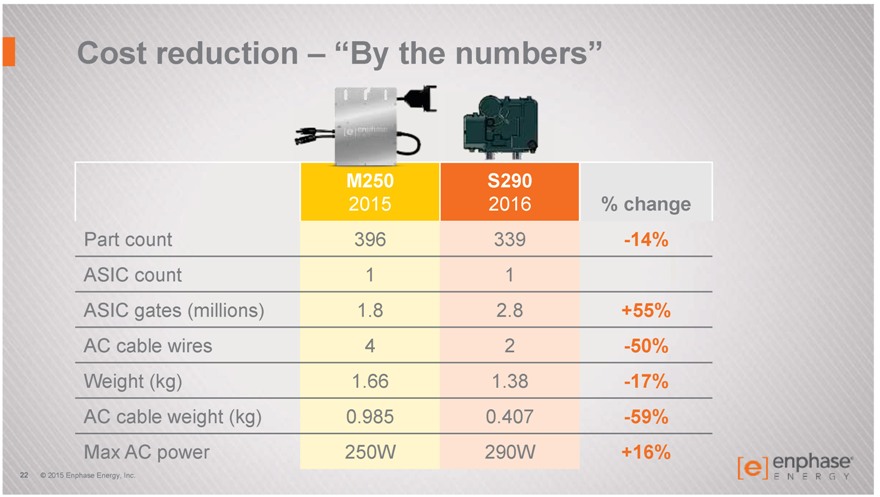

Cost reduction – “By the numbers”

M250 S290

2015 2016 % change Part count 396 339 -14% ASIC count 1 1 ASIC gates (millions) 1.8 2.8 +55% AC cable wires 4 2 -50% Weight (kg) 1.66 1.38 -17% AC cable weight (kg) 0.985 0.407 -59% Max AC power 250W 290W +16%

22 © 2015 Enphase Energy, Inc.

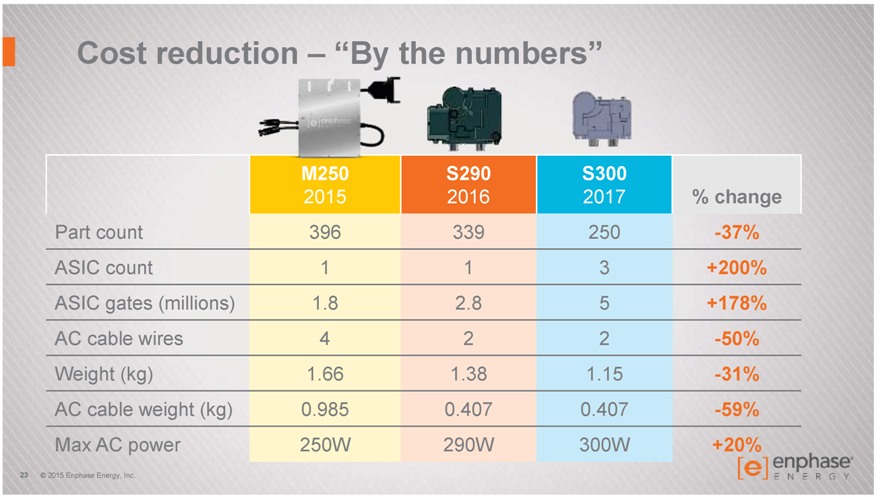

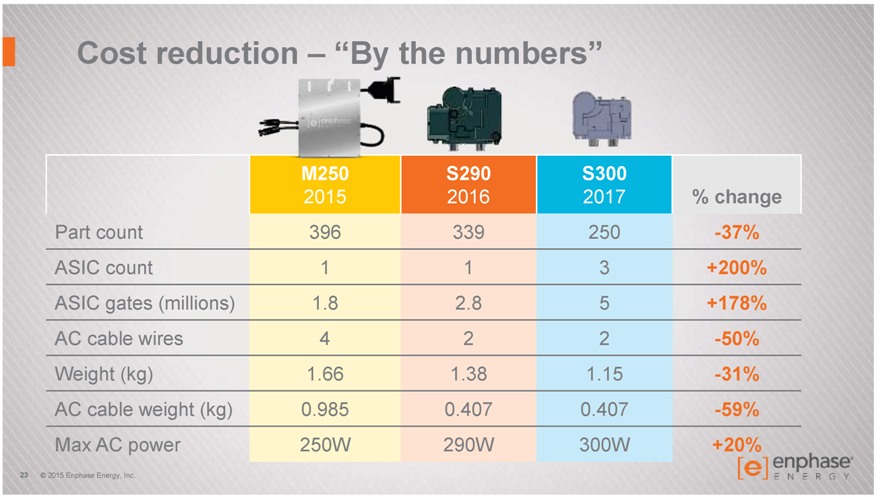

Cost reduction – “By the numbers”

M250 S290 S300

2015 2016 2017 % change Part count 396 339 250 -37% ASIC count 1 1 3 +200% ASIC gates (millions) 1.8 2.8 5 +178% AC cable wires 4 2 2 -50% Weight (kg) 1.66 1.38 1.15 -31% AC cable weight (kg) 0.985 0.407 0.407 -59% Max AC power 250W 290W 300W +20%

23 © 2015 Enphase Energy, Inc.

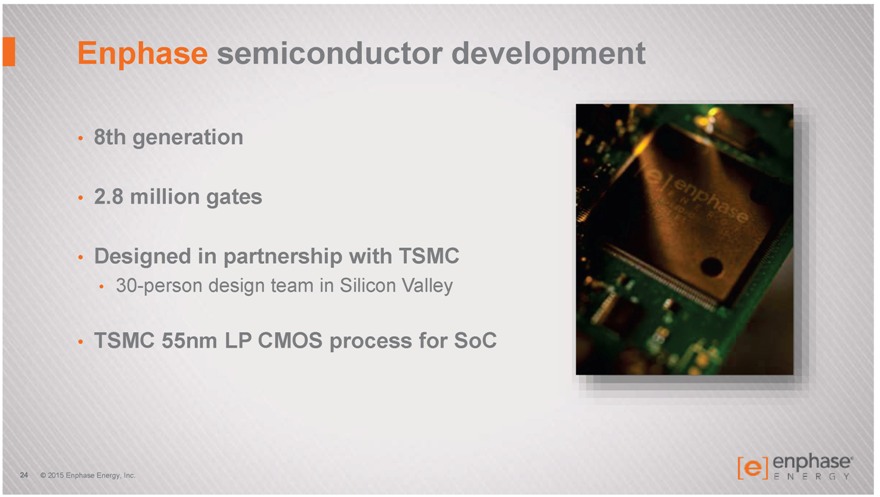

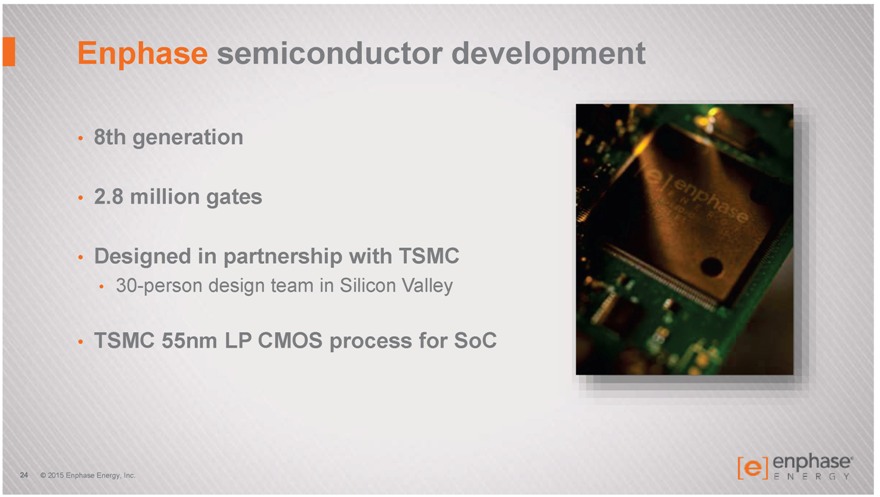

Enphase semiconductor development

• | | Designed in partnership with TSMC |

• | | 30-person design team in Silicon Valley |

• | | TSMC 55nm LP CMOS process for SoC |

24 © 2015 Enphase Energy, Inc.

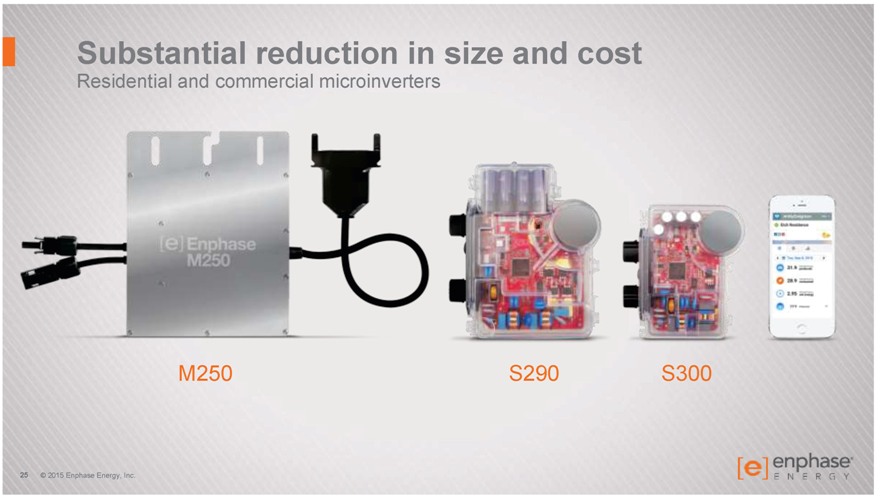

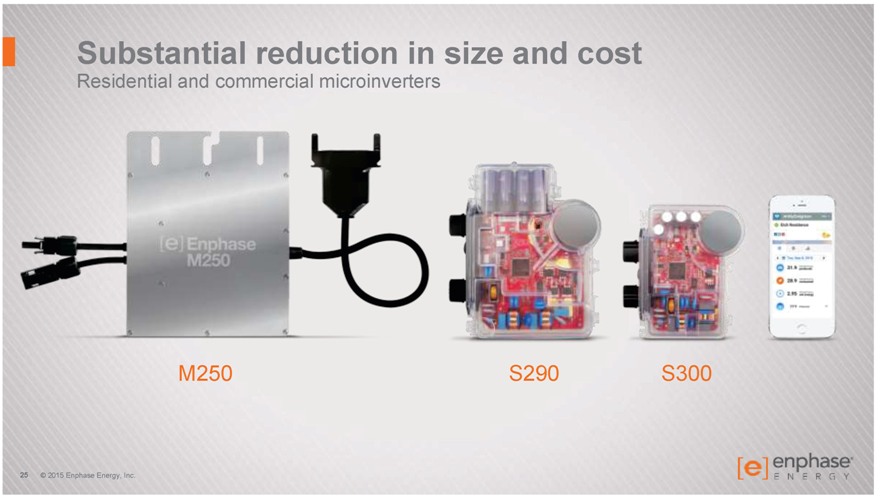

Substantial reduction in size and cost

Residential and commercial microinverters

M250 S290 S300

© 2015 Enphase Energy, Inc.

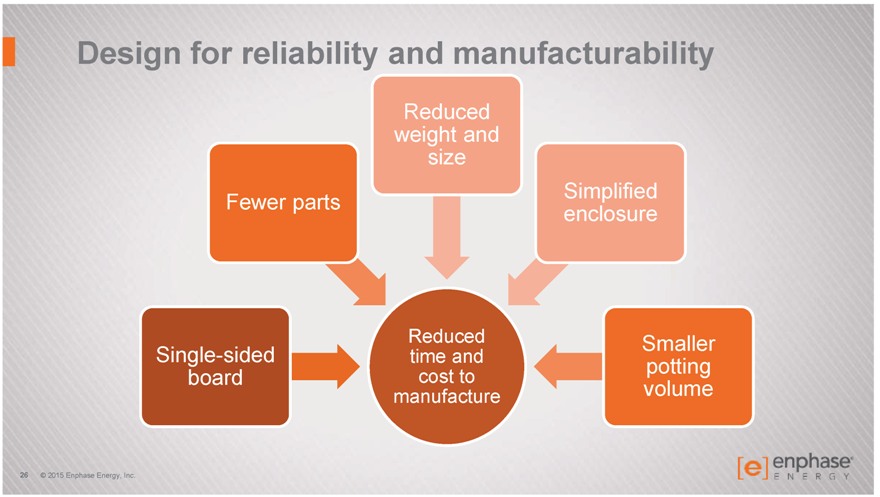

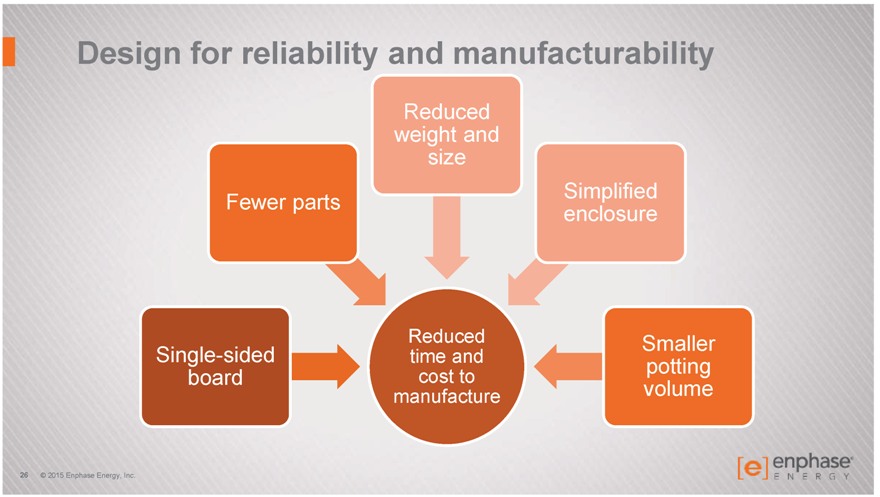

Design for reliability and manufacturability

Reduced weight and size

Fewer parts

Simplified enclosure

Single-sided board

Reduced time and cost to manufacture

Smaller potting volume

26 © 2015 Enphase Energy, Inc.

Darien Spencer

VP of Manufacturing and Operations

Global industry-leading operations

Costs

• | | 15% year-over-year cost reduction demonstrated |

Partners

Quality & reliability

• | | >25 year useful life for microinverters |

Factories

• | | Global, scalable, flexible |

Inventory carrying

Few SKUs

Distribution

28 © 2015 Enphase Energy, Inc.

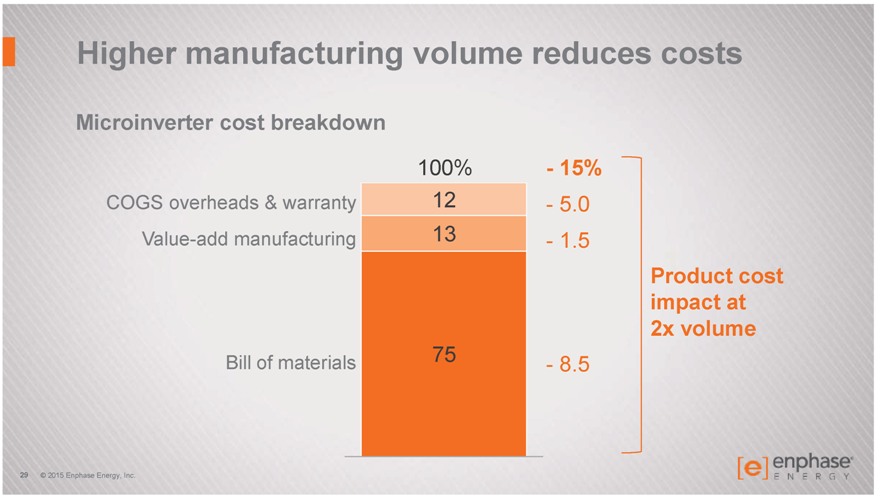

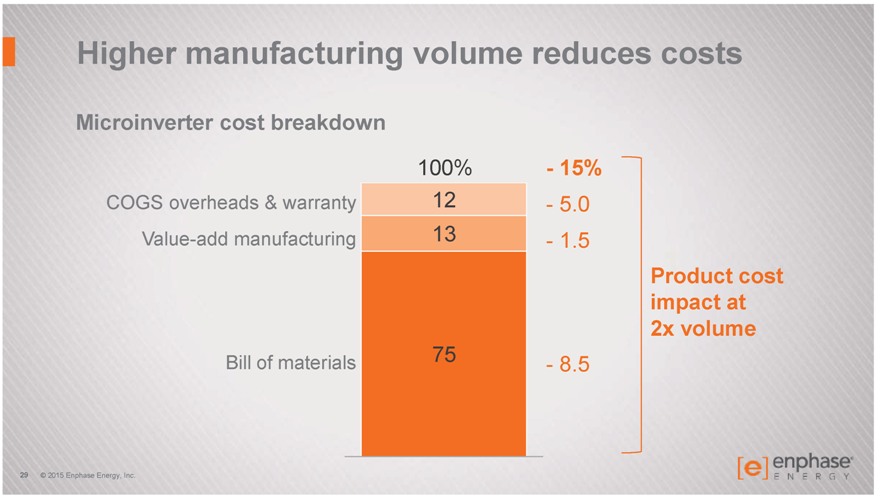

Higher manufacturing volume reduces costs

Microinverter cost breakdown

100%—15%

COGS overheads & warranty 12—5.0 Value-add manufacturing 13—1.5

Bill of materials 75—8.5

Product cost impact at

2x volume

29 © 2015 Enphase Energy, Inc.

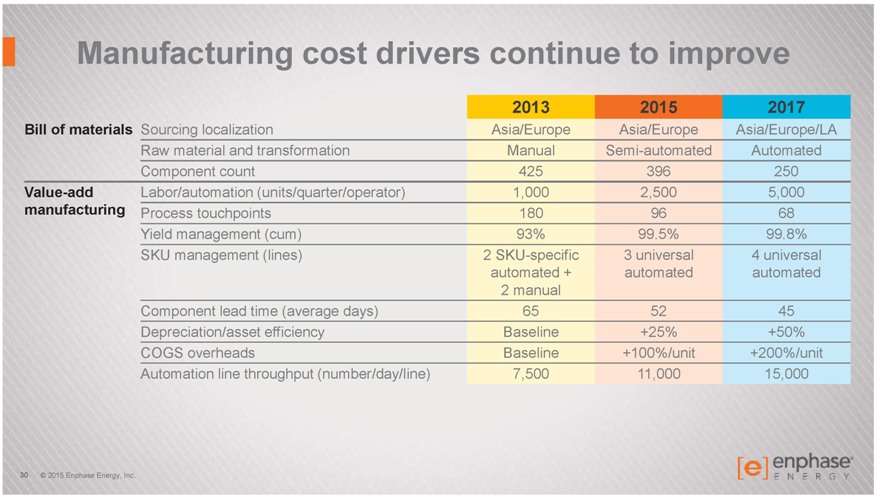

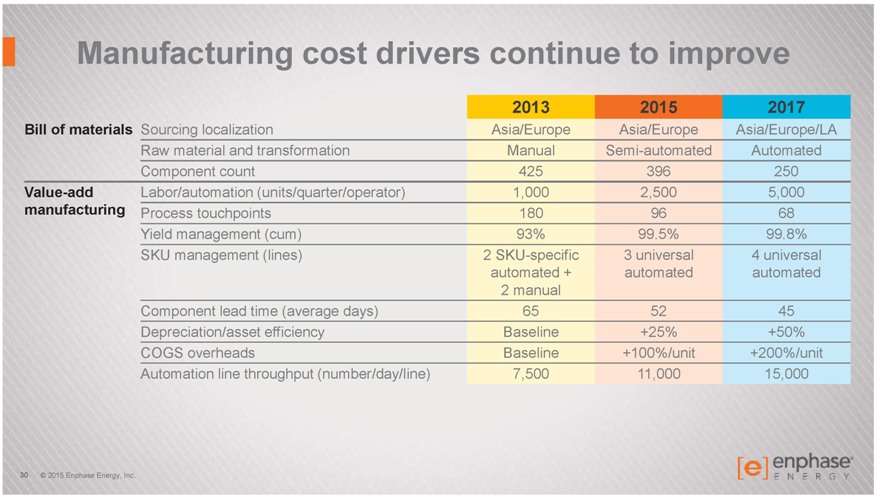

Manufacturing cost drivers continue to improve

2013 2015 2017

Bill of materials Sourcing localization Asia/Europe Asia/Europe Asia/Europe/LA Raw material and transformation Manual Semi-automated Automated Component count 425 396 250 Value-add Labor/automation (units/quarter/operator) 1,000 2,500 5,000 manufacturing Process touchpoints 180 96 68 Yield management (cum) 93% 99.5% 99.8% SKU management (lines) 2 SKU-specific 3 universal 4 universal automated + automated automated 2 manual Component lead time (average days) 65 52 45 Depreciation/asset efficiency Baseline +25% +50% COGS overheads Baseline +100%/unit +200%/unit Automation line throughput (number/day/line) 7,500 11,000 15,000

30 © 2015 Enphase Energy, Inc.

Quality and reliability throughout the process

Enphase continues investment in quality and reliability infrastructure with commissioning of New Zealand QA lab

31 © 2015 Enphase Energy, Inc.

Manufacturing automation creates efficiencies

32 © 2015 Enphase Energy, Inc.

Stefan Zschiegner

VP of Product Management

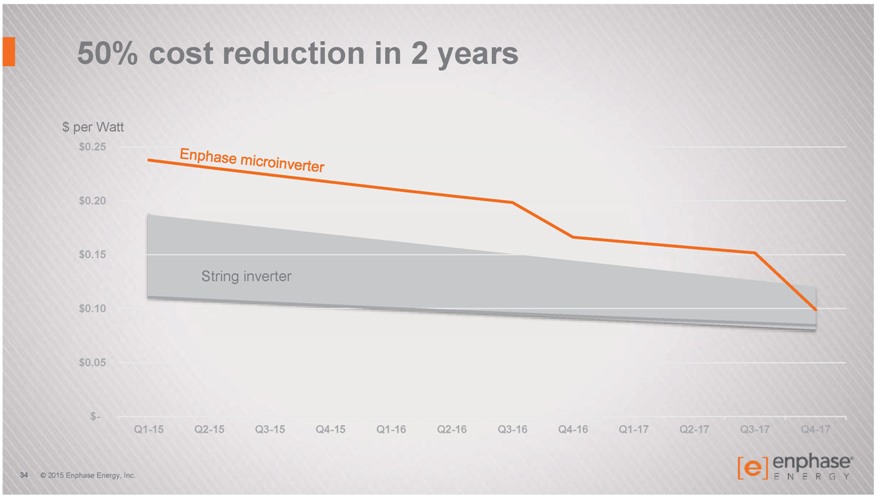

50% cost reduction in 2 years

$ per Watt

$0.25

$0.20

$0.15

String inverter

$0.10

$0.05

$-

Q1-15 Q2-15 Q3-15 Q4-15 Q1-16 Q2-16 Q3-16 Q4-16 Q1-17 Q2-17 Q3-17 Q4-17

34 © 2015 Enphase Energy, Inc.

AC Module: A solar module with an integrated microinverter

• | | Microinverter cost savings: 2 cents per Watt |

• | | Module cost savings: 3 cents per Watt |

• | | Installation cost savings: 2 cents per Watt |

35 © 2015 Enphase Energy, Inc.

AC Module: A solar module with an integrated microinverter

• | | Microinverter cost savings: 2 cents per Watt |

• | | Module cost savings: 3 cents per Watt |

• | | Installation cost savings: 2 cents per Watt |

• | | Simplified installation and logistics |

• | | Simplified design and installation process |

36 © 2015 Enphase Energy, Inc.

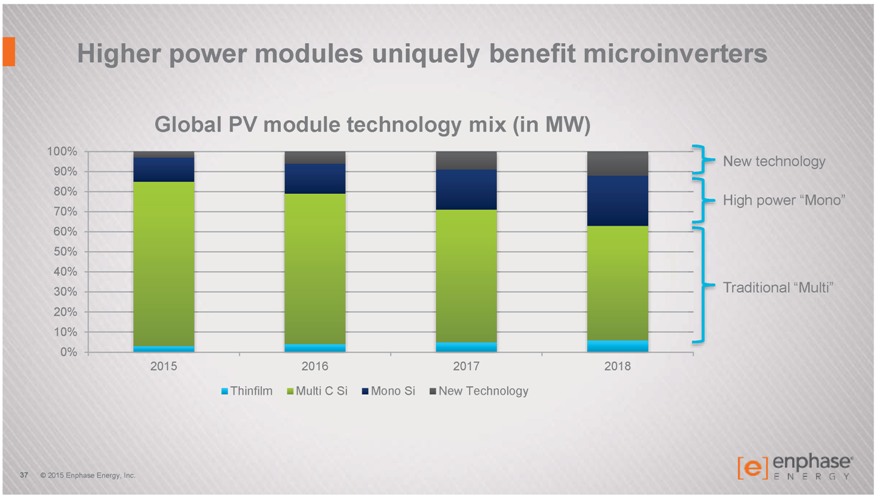

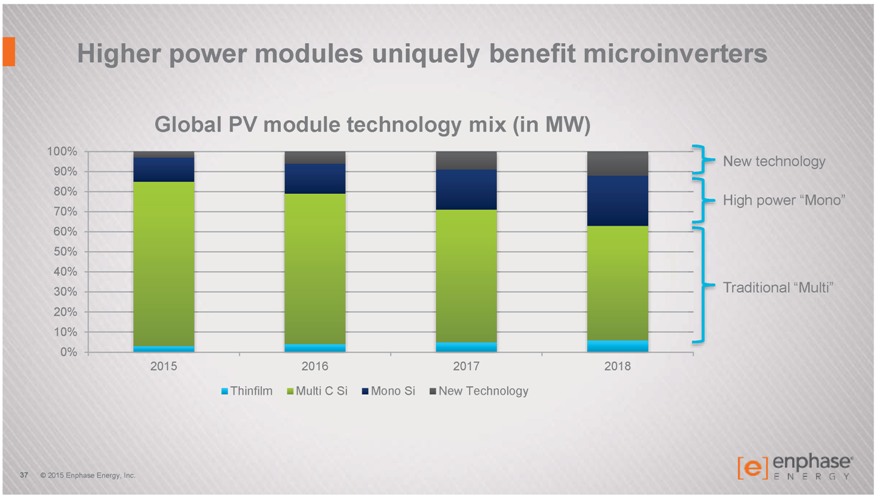

Higher power modules uniquely benefit microinverters

Global PV module technology mix (in MW)

100%

New technology

90% 80%

70% High power “Mono”

60% 50% 40%

30% Traditional “Multi”

20% 10% 0%

2015 2016 2017 2018

Thinfilm Multi C Si Mono Si New Technology

37 © 2015 Enphase Energy, Inc.

Raghu Belur

VP of Products and Strategic Initiatives

The Enphase home: Complete energy solution

Increase revenue per home from +$1,000 to +$6,000

ENERGY

GENERATION

MANAGEMENT Enphase Enphase S-Serie Enlighten Microinverter

Enphase

Envoy Enphase C Battery

ENERGY USE CONTROL

STORAGE

39 © 2015 Enphase Energy, Inc.

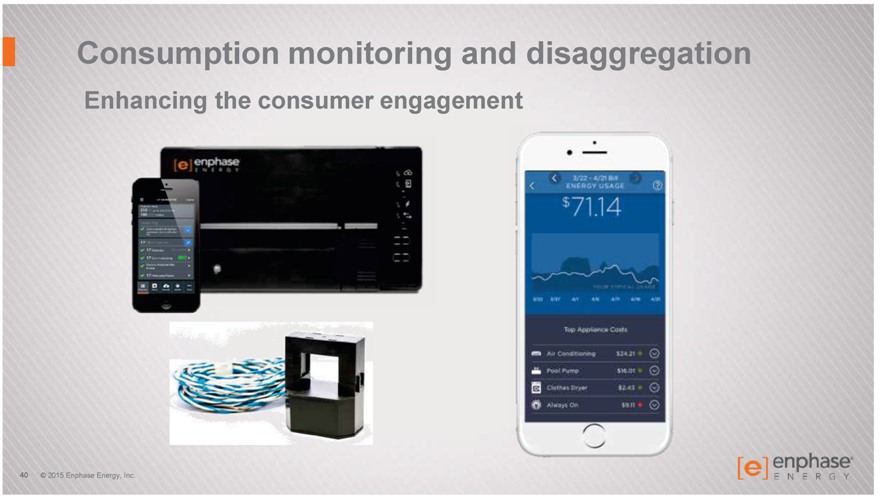

Consumption monitoring and disaggregation

Enhancing the consumer engagement

40 © 2015 Enphase Energy, Inc.

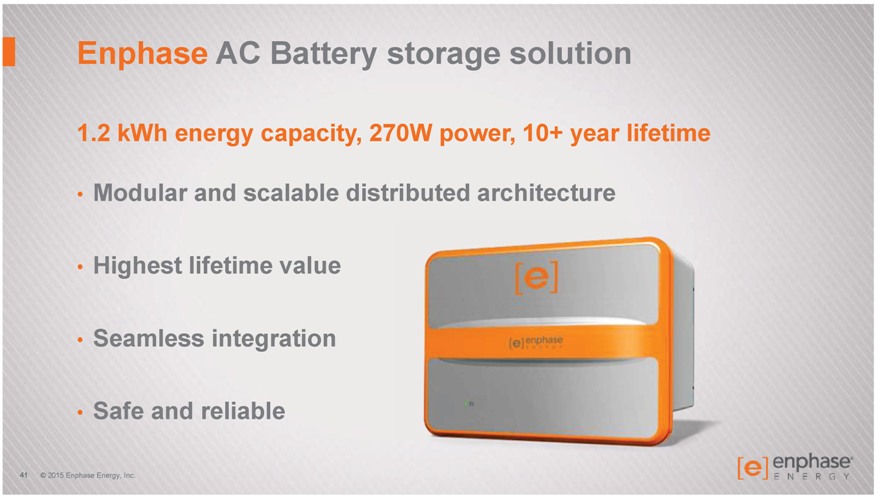

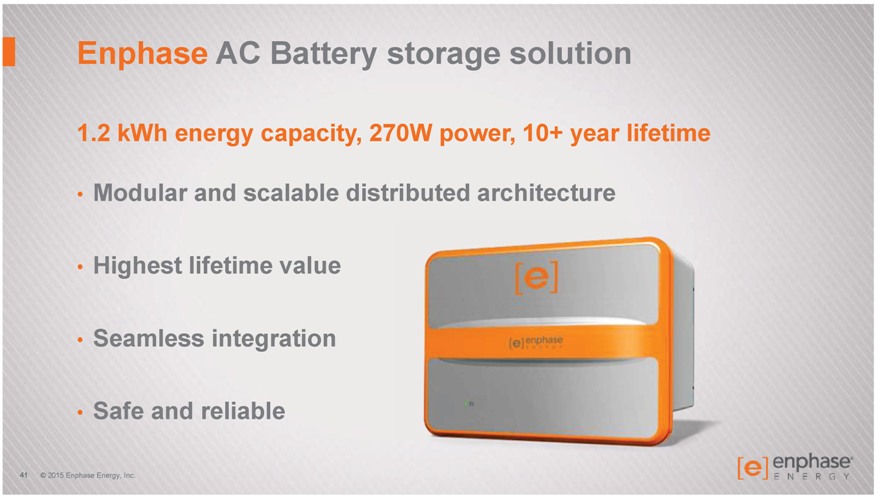

Enphase AC Battery storage solution

1.2 kWh energy capacity, 270W power, 10+ year lifetime

Modular and scalable distributed architecture

Highest lifetime value

Seamless integration

Safe and reliable

41 © 2015 Enphase Energy, Inc.

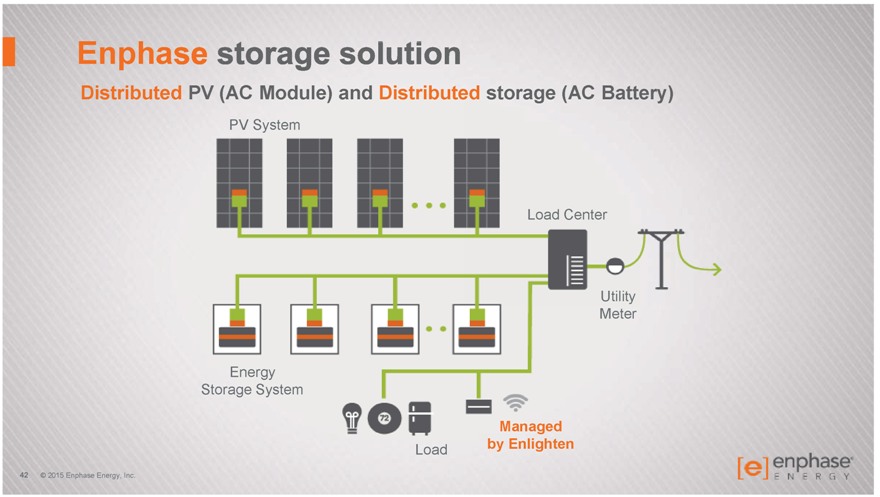

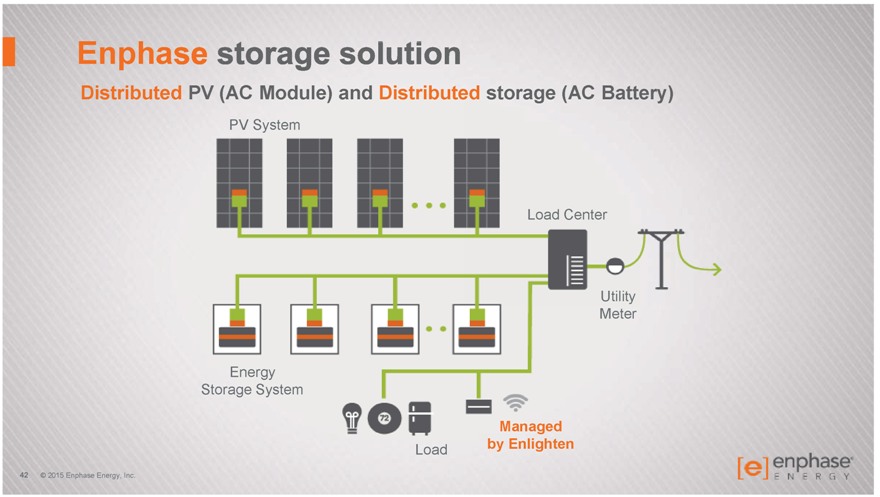

Enphase storage solution

Distributed PV (AC Module) and Distributed storage (AC Battery)

PV System

Load Center

Utility Meter

Energy Storage System

Managed by Enlighten

Load

42 © 2015 Enphase Energy, Inc.

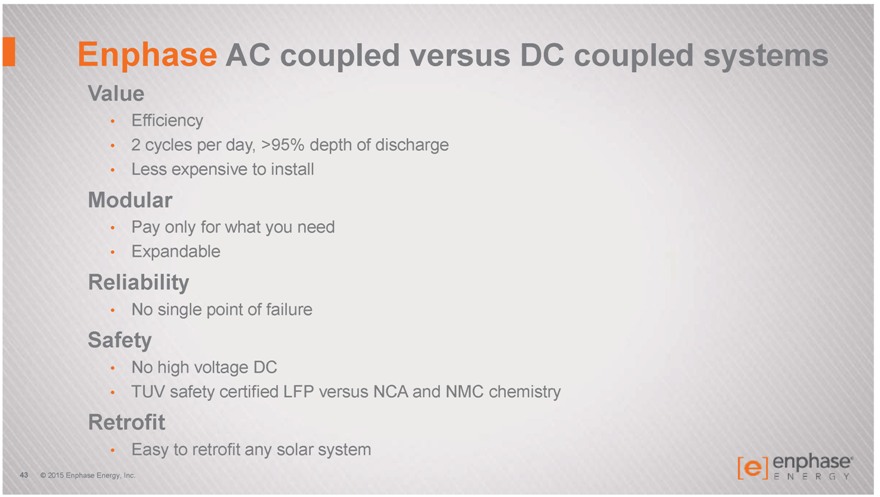

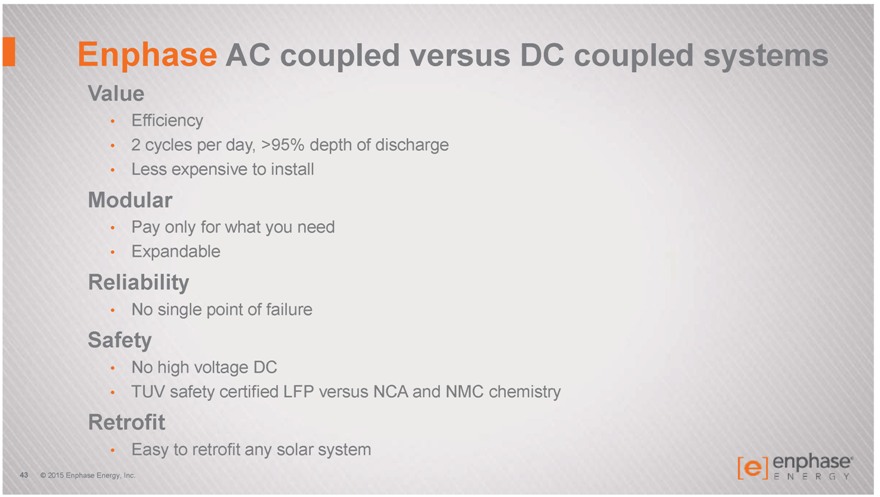

Enphase AC coupled versus DC coupled systems

Value

• | | 2 cycles per day, >95% depth of discharge |

• | | Less expensive to install |

Modular

• | | Pay only for what you need |

Reliability

• | | No single point of failure |

Safety

• | | TUV safety certified LFP versus NCA and NMC chemistry |

Retrofit

• | | Easy to retrofit any solar system |

43 © 2015 Enphase Energy, Inc.

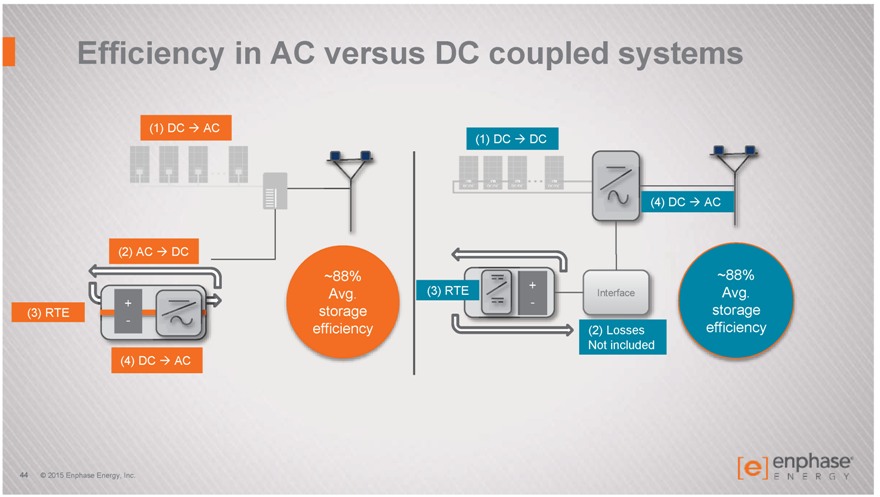

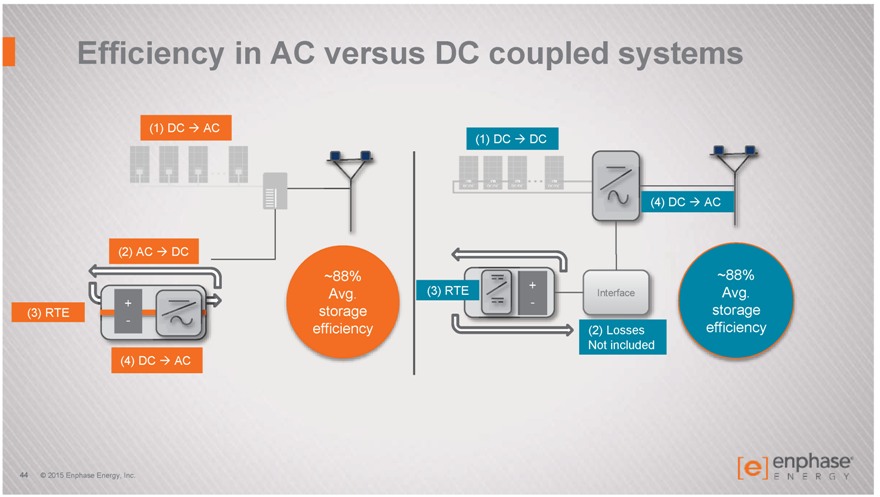

Efficiency in AC versus DC coupled systems

~88% Avg.

+

-efficiency

~88%

+

-storage

(2) | | Losses efficiency Not included |

44 © 2015 Enphase Energy, Inc.

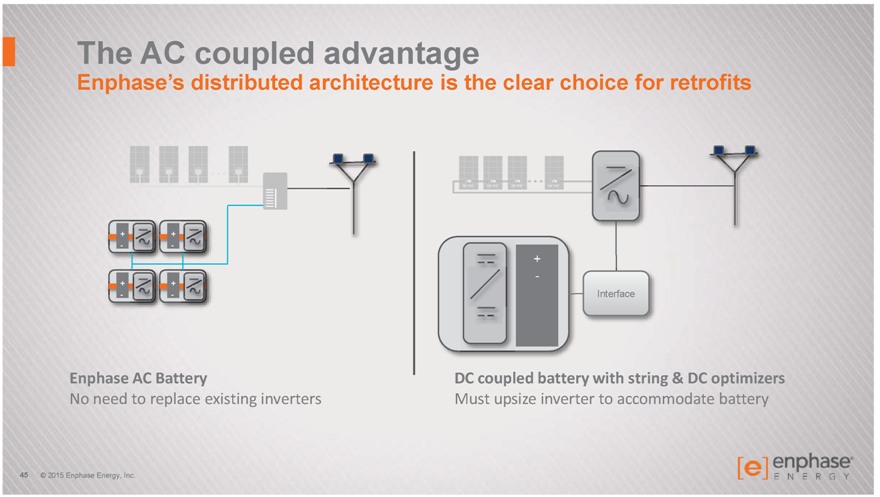

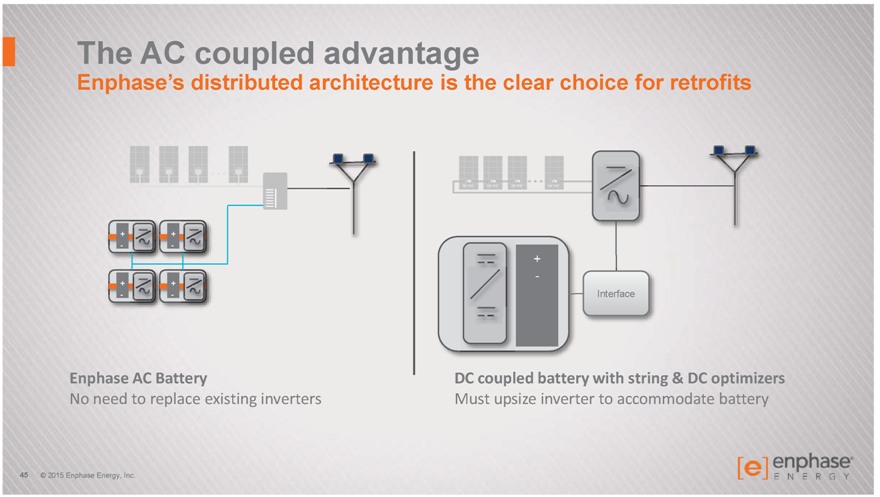

The AC coupled advantage

Enphase’s distributed architecture is the clear choice for retrofits

Enphase AC Battery

No need to replace existing inverters

DC coupled battery with string & DC optimizers

Must upsize inverter to accommodate battery

45 © 2015 Enphase Energy, Inc.

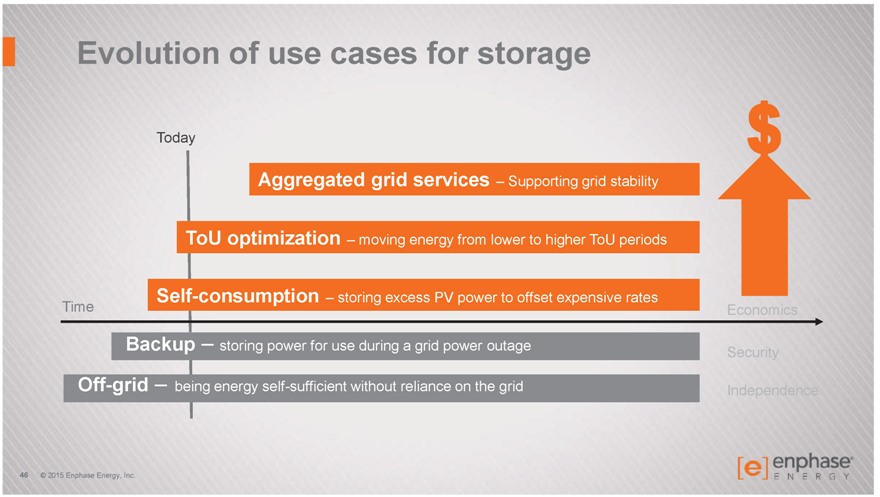

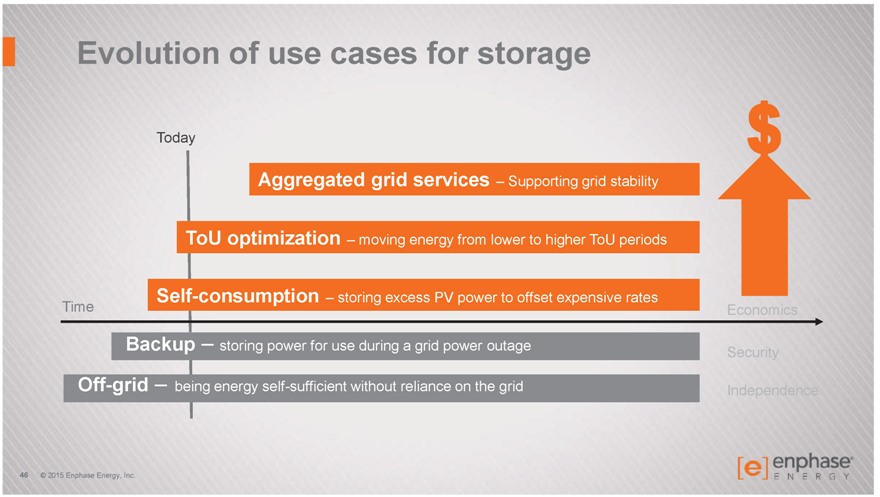

Evolution of use cases for storage

Today

Aggregated grid services – Supporting grid stability

ToU optimization – moving energy from lower to higher ToU periods

Self-consumption – storing excess PV power to offset expensive rates Time

Backup – storing power for use during a grid power outage Off-grid – being energy self-sufficient without reliance on the grid

Economics Security Independence

46 © 2015 Enphase Energy, Inc.

Stefan Zschiegner

VP of Product Management

Enlighten demo

Paul Nahi

President and CEO

Enphase goals

[1] Invest in our next generation technology to reduce costs by 50% in 24 months, towards $0.10 per Watt

[2] Provide our partners with best-in-class power electronics, storage solutions, communications, and load control all managed by a cloud based energy management system

49 © 2015 Enphase Energy, Inc.

The Enphase Promise:

We make solar simple and energy smart.