Exhibit 10.1

Confidential treatment has been requested for portions of this exhibit pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended. The copy filed herewith omits the information subject to the confidentiality request. Omissions are designated as [**]. A complete version of this exhibit has been filed separately with the Securities and Exchange Commission.

GENERAL WORK CONSTRUCTION AGREEMENT

between

Graycor Industrial Constructors Inc.

as Contractor

and

OTTER TAIL POWER COMPANY, as agent for

NORTHWESTERN CORPORATION D/B/A/

NORTHWESTERN ENERGY; MONTANA-DAKOTA UTILITIES CO.,

A DIVISION OF MDU RESOURCES GROUP, INC.; and

OTTER TAIL POWER COMPANY,

as Owners

Table of Contents

| | | | | | Page |

| | | | | | |

| | 2 |

| | | |

| | | | | | 2 |

| | | | | | 16 |

| | | | | | 17 |

| | | | | | 18 |

| | | | | | 18 |

| | | |

| | 18 |

| | | |

| | | | | | 18 |

| | | | | | 18 |

| | | |

| | 19 |

| | | |

| | | | | | 19 |

| | | | | | 19 |

| | | | | | 19 |

| | | | | | 20 |

| | | | | | 20 |

| | | | | | 21 |

| | | | | | 21 |

| | | | | | |

| | 21 |

| | | | | | |

| | | | | | 21 |

| | | | | | 22 |

| | | | | | 22 |

| | | | | | 22 |

| | | | | | 23 |

| | | | | | 23 |

| | | | | | 23 |

| | | | | | 24 |

| | | | | | 24 |

| | | | | | 24 |

| | | | | | 25 |

| | | | | | 25 |

| | | | | | 25 |

| | | | | | 25 |

| | | | | | 25 |

| | | | | | 25 |

| | | | | | 26 |

| | | | | | 26 |

| | | | | | 27 |

| | | | | | 28 |

| | | | | | 28 |

| | | | | | 30 |

| | | | | | 31 |

| | | | | | 31 |

| | | | | | 31 |

Table of Contents (Continued)

| | | | | | Page |

| | | | | | |

| | | | | | 32 |

| | | | | | 32 |

| | | | | | 32 |

| | | | | | 32 |

| | | | | | 33 |

| | | | | | 33 |

| | | | | | 33 |

| | | | | | 33 |

| | | | | | 33 |

| | | | | | 33 |

| | | | | | 34 |

| | | | | | 34 |

| | | | | | 34 |

| | | | | | 34 |

| | | | | | 35 |

| | | | | | 36 |

| | | | | | |

| | 36 |

| | | | | | |

| | | | | | 36 |

| | | | | | 36 |

| | | | | | 36 |

| | | | | | 36 |

| | | | | | 37 |

| | | | | | 37 |

| | | | | | 37 |

| | | | | | 37 |

| | | | | | 37 |

| | | | | | 38 |

| | | | | | 38 |

| | | | | | 38 |

| | | | | | |

| | 38 |

| | | | | | |

| | | | | | 38 |

| | | | | | 38 |

| | | | | | 39 |

| | | | | | 40 |

| | | | | | 41 |

| | | | | | 42 |

| | | | | | 42 |

| | | | | | 43 |

| | | | | | 43 |

| | | | | | 43 |

| | | | | | 44 |

| | | | | | |

| | 44 |

| | | | | | |

| | | | | | 44 |

Table of Contents (Continued)

| | | | | | Page |

| | | | | | |

| | | | | | 45 |

| | | | | | 45 |

| | | | | | 45 |

| | | | | | 46 |

| | | | | | 46 |

| | | | | | 46 |

| | | | | | 47 |

| | | | | | 47 |

| | | | | | 47 |

| | | | | | 48 |

| | | | | | 48 |

| | | | | | |

| | 48 |

| | | | | | |

| | | | | | 48 |

| | | | | | 49 |

| | | | | | 51 |

| | | | | | 52 |

| | | | | | 55 |

| | | | | | 57 |

| | | | | | 58 |

| | | | | | 58 |

| | | | | | 58 |

| | | | | | 59 |

| | | | | | 59 |

| | | | | | 60 |

| | | | | | 61 |

| | | | | | 61 |

| | | | | | 62 |

| | | | | | 62 |

| | | | | | 62 |

| | | | | | |

| | 63 |

| | | | | | |

| | | | | | 63 |

| | | | | | 63 |

| | | | | | |

| | 64 |

| | | | | | |

| | | | | | 64 |

| | | | | | 65 |

| | | | | | 65 |

| | | | | | 66 |

| | | | | | 66 |

| | | | | | |

| | 66 |

| | | |

| | | | | | 66 |

| | | | | | 66 |

| | | | | | 66 |

Table of Contents (Continued)

| | | Page |

| | | |

| | 67 |

| | | | | | |

| | | | | | 67 |

| | | | | | 67 |

| | | | | | 67 |

| | | | | | |

| | 67 |

| | | | | | |

| | | | | | 67 |

| | | | | | 68 |

| | | | | | 68 |

| | | | | | 69 |

| | | | | | 69 |

| | | | | | 69 |

| | | | | | 69 |

| | | | | | 69 |

| | | | | | 69 |

| | | | | | 70 |

| | | | | | |

| | 70 |

| | | | | | |

| | | | | | 70 |

| | | | | | 71 |

| | | | | | 71 |

| | | | | | 71 |

| | | | | | 71 |

| | | | | | 71 |

| | | | | | 72 |

| | | | | | 72 |

| | | | | | 72 |

| | | | | | 73 |

| | | | | | 73 |

| | | | | | |

| | 73 |

| | | |

| | | | | | 73 |

| | | | | | 73 |

| | | | | | 74 |

| | | | | | 74 |

| | | | | | 74 |

| | | | | | |

| | 74 |

| | | |

| | | | | | 74 |

| | | | | | 75 |

| | | | | | 76 |

| | | | | | 76 |

| | | | | | 76 |

| | | | | | 76 |

| | | | | | 76 |

| | | | | | 77 |

Table of Contents (Continued)

| | | Page |

| | | |

| | 77 |

| | | |

| | | | | | 77 |

| | | | | | 78 |

| | | | | | |

| | 79 |

| | | | | | |

| | | | | | 79 |

| | | | | | 80 |

| | | | | | 80 |

| | | | | | 80 |

| | | | | | |

| | 81 |

| | | | | | |

| | | | | | 81 |

| | | | | | |

| | 84 |

| | | | | | |

| | | | | | 84 |

| | | | | | 85 |

| | | | | | 86 |

| | | | | | 87 |

| | | | | | |

| | 88 |

| | | | | | |

| | 88 |

| | | | | | |

| | | | | | 88 |

| | | | | | 88 |

| | | | | | 89 |

| | | | | | 89 |

| | | | | | |

| | 89 |

| | | | | | |

| | | | | | 89 |

| | | | | | 89 |

| | | | | | 90 |

| | | | | | |

| | 90 |

| | | | | | |

| | | | | | 90 |

| | | | | | 91 |

| | | | | | 93 |

| | | | | | 94 |

| | | | | | |

| | 94 |

| | | | | | |

| | | | | | 94 |

| | | | | | 94 |

| | | | | | 95 |

| | | | | | 95 |

| | | | | | 96 |

| | | | | | 96 |

| | | | | | 96 |

| | | | | | 96 |

Table of Contents (Continued)

| | | | | | Page |

| | | | | | |

| | | | | | 96 |

| | | | | | 98 |

| | | | | | 98 |

| | | | | | 98 |

| | | | | | 98 |

| | | | | | 98 |

| | | | | | 98 |

| | | | | | 99 |

| | | | | | 99 |

| | | | | | 99 |

| | | | | | 99 |

| | | | | | 99 |

EXHIBITS

| | | |

| Exhibit A | [Reserved] |

| Exhibit B | Technical Specification B-7808 General Work Contract (GWC) |

| Exhibit C | Initial Target Price & Contractor’s Unit Rates |

| Exhibit D | Project Schedule and Key Dates |

| Exhibit E | Contractor’s Equipment and Rentals |

| Exhibit F | Forms |

| | F-1 | Applications For Payment |

| | F-2 | Certificates |

| | F-2A | Mechanical Completion Certificate |

| | F-2B | Mechanical Completion Checklist |

| | F-2C | Substantial Completion Certificate |

| | F-2D | Substantial Completion Checklist |

| | F-2E | Final Completion Certificate |

| | F-2F | Final Completion Checklist |

| | F-3 | Change Order |

| | F-4 | [Reserved] |

| | F-5 | Lien Waivers and General Release |

| | F-5A | Partial Waiver and Release of Lien |

| | F-5B | Final Waiver and Release of Lien |

| | F-6 | Notice to Proceed |

| | F-7 | [Reserved] |

| Exhibit G | [Reserved] |

| Exhibit H | Health and Safety Requirements |

| Exhibit I | Insurance |

| Exhibit J | Small Tools & Consumables List |

| Exhibit K | Key Personnel |

| Exhibit L | [Reserved] |

| Exhibit M | [Reserved] |

| Exhibit N | [Reserved] |

| Exhibit O | Owners Provided Items |

| Exhibit P | Permits |

| Exhibit Q | [Reserved] |

| Exhibit R | Craft Labor Rates |

| Exhibit S | Site |

| | S-1 | Job Site Description |

| | S-2 | Big Stone Site Description |

| | S-3 | Site Restrictions |

| | S-4 | Contractor Health & Safety Plan Requirements and Expectations |

| | S-5 | Site Work Rules |

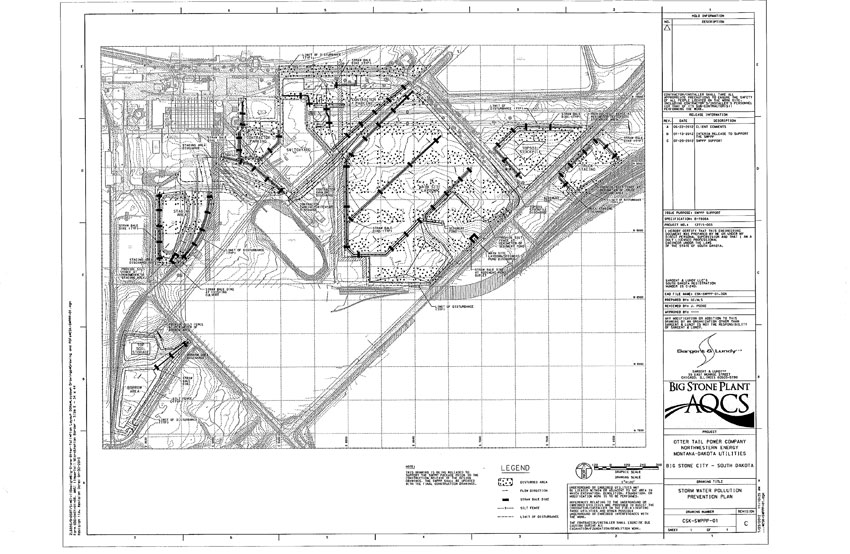

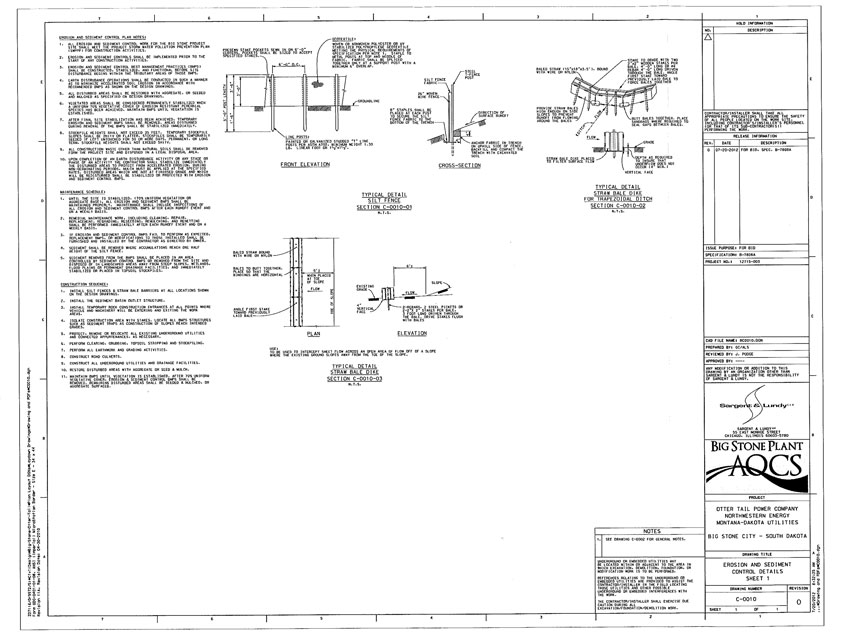

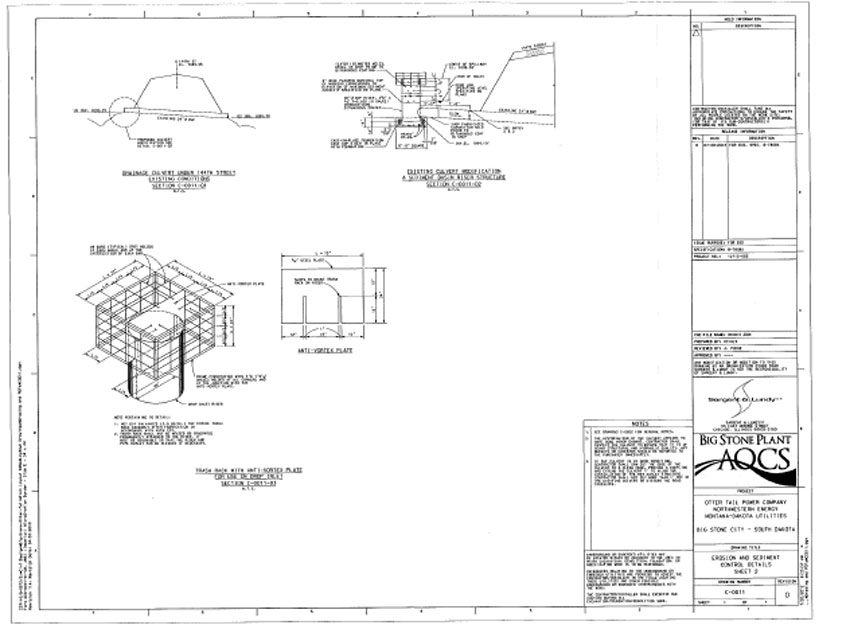

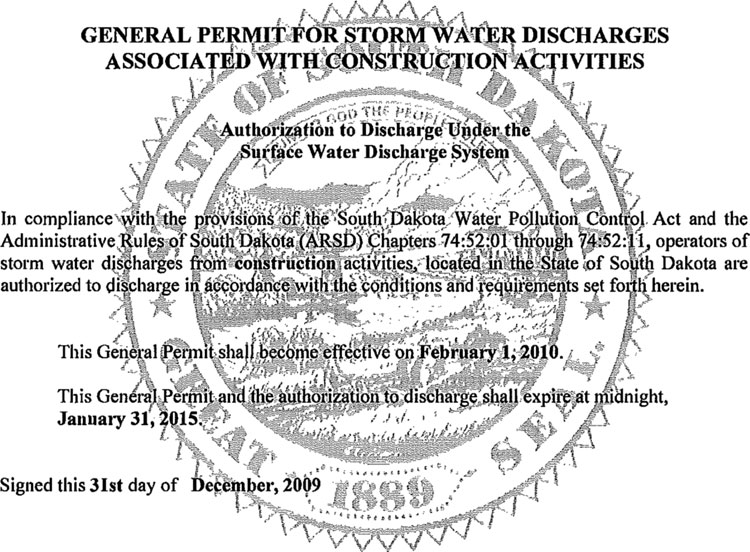

| | S-6 | Storm Water Pollution Prevention Plan |

| | S-7 | Toxic Release Inventory form |

GENERAL WORK CONSTRUCTION AGREEMENT

This General Work Construction Agreement for Work (“Agreement”) is entered into as of the 1st day of February 2013 (“Effective Date”), by and between Graycor Industrial Constructors Inc., an Illinois corporation, as (“Contractor”) and Otter Tail Power Company (“Otter Tail”), as agent for Northwestern Corporation d/b/a/ Northwestern Energy, a Delaware corporation; Montana-Dakota Utilities Co., a division of MDU Resources Group, Inc., a Delaware corporation; and Otter Tail Power Company, a Minnesota corporation as (“Owners”).

R E C I T A L S

WHEREAS, Owners desire to enter into an agreement with a qualified contractor to design, engineer, procure, construct and install the Work (as hereinafter defined), to procure certain Equipment and supplies required therefor, and to inspect and test the Work following the completion of the Work (as hereinafter defined) on a target price basis as set forth in this Agreement;

WHEREAS, Contractor represents that it is qualified to design, engineer, procure, construct and install the Work and to inspect and test the Work following the completion of the Work and Contractor desires to perform all work and services in connection therewith on a target price basis in accordance with the requirements and provisions of this Agreement; and

WHEREAS, Contractor agrees to perform the Work as more specifically described in this Agreement.

NOW, THEREFORE, in consideration of the foregoing and other good and valuable consideration, the receipt and sufficiency of which is hereby acknowledged, the Parties, intending to be legally bound, do hereby agree as follows:

ARTICLE 1

1.1 Definitions. The following terms have the respective meanings specified in this Article 1 when capitalized and used in this Agreement or in any notice delivered under or in respect of this Agreement.

“Actual Cost” has the meaning set forth in Section 8.7.

“Affiliate” means any Person that, directly or indirectly, through one or more intermediaries, controls, is controlled by, or is under common control with, Owners or Contractor.

“Agreed Rate” has the meaning set forth in Section 25.8.

“Agreement” has the meaning set forth in the first paragraph hereof and includes the body of this Agreement (the “Body of this Agreement”) and all Exhibits herein referenced, as amended, modified, or supplemented from time to time.

“Applicable Credits” has the meaning set forth in Section 25.9.3.

“Applicable Law” means any applicable statute, law (including common law), rule, treaty, regulation, code, ordinance, permit, approval, interpretation, injunction, judgment, decree, writ, order or the like, including NERC Requirements, Codes and Standards, and the Permits, when issued, enacted, or promulgated by a Governmental Authority and interpretations thereof by a Governmental Authority.

“Application For Payment” means a written request by Contractor to Owners for payment, completed in the form required by Exhibit F-1, together with the documentation required by Section 8.10.

“As-Built Drawings” means: (i) all drawings prepared by the Contractor, Subcontractors, or Suppliers in the performance of the Work that are “issued for construction” by Contractor and (ii) the Plans, in each case as modified and updated to accurately show the final actual design and construction of the Work upon Final Completion.

“Big Stone Site” means the site, as more particularly described in Exhibit S-2.

“Business Day” means any Day other than a Saturday, Sunday, or a holiday observed by the United States federal government, the State of South Dakota, or Otter Tail.

“CEII” has the meaning set forth in Section 4.40.

“Certificate” means the applicable Certificate of Mechanical Completion, Substantial Completion, or Final Completion, as the case may be.

“Certificate of Final Completion” will be in the form set forth in Exhibit F-2.

“Certificate of Mechanical Completion” will be in the form set forth in Exhibit F-2.

“Certificate of Substantial Completion” will be in the form set forth in Exhibit F-2.

“Change in Law” means an amendment, modification, or change of Applicable Law enacted, adopted, or promulgated after the Effective Date by a Governmental Authority. A change in Applicable Law with respect to: (i) taxes or levies assessed on the basis of Contractor’s income, profits, revenues, and/or gross receipts (other than the Contractor’s Excise Tax); (ii) other taxes, duties, or imposts for which Contractor is responsible hereunder (other than the Sales Taxes); (iii) taxes, levies, or withholdings that vary the compensation, benefits, or amounts to be paid to, on behalf of or on account of Contractor’s or its Subcontractors’ employees; and (iv) Changes in Law enacted, published, or issued before the Effective Date, whether or not such Changes in Law became effective after the Effective Date, will not constitute a Change in Law hereunder.

“Change Order” has the meaning set forth in Section 10.1.3.

“Change Order Request” has the meaning set forth in Section 10.1.1.

“Change(s)” has the meaning set forth in Section 10.1.1.

“Claim Notice” has the meaning set forth in Section 20.3.1.

“Claims” has the meaning set forth in Section 20.1.

“Climatic Conditions” means weather conditions at the Big Stone Site or at the principal facilities where the Work is to be performed, including temperature, wind, hurricane forces, microbursts, precipitation (rain, snow, ice, hail, flooding), and lightning which, based on weather data for such locations during the ten (10) years prior to the Effective Date, would not reasonably have been expected to occur.

“Codes and Standards” means the most recent edition of the codes, standards, and guidelines applicable to the Work, including those listed in Exhibit B.

“Component” means any and all Systems, subsystems, subassemblies, Contractor Supplied Materials and Equipment, spare parts, and every item of whatever nature, including all documentation related thereto, connected with the Work performed or provided by Contractor or its Subcontractors under this Agreement that is permanently incorporated into the Work or the Unit as part of the Work, provided as part of the Work, and retained by Owners following Final Completion.

“Computer Program(s)” means a sequence of instructions, data, or equations in any form, and explanations thereof, intended to cause a computer, a control data processor or the like to perform any kind of operation, which is provided by Contractor or its Subcontractors under this Agreement.

“Confidential Information” has the meaning set forth in Section 18.1.

“Construction Aids” means all equipment (including construction equipment), apparatus, tools, supplies, construction tools, support services, field office equipment, supplies, structures, form lumber, protective fencing, and other goods and items that are required to construct, clean, commission, or test the Work following the completion of the Work, but which are neither incorporated into the Work nor retained by Owners.

“Construction Equipment and Rentals Amount” mean the amount described in Section 8.2.6.

“Construction Turnovers” mean the events listed in Exhibit B, Section 013216, Article 105.1, Table 1-1, Items No. B.1 through B.21, inclusive.

“Consumables” means items such as compressed air or gases, chemicals, oils, lubricants, cleaning materials, demineralized water, valve packing, lamps, light bulbs, gaskets, fuel filters and comparable items which, by normal industry practices, are considered consumables and are replaced on a regular basis, required for cleaning, preparing, or completing the Work or are required for the proper operation of the Equipment.

“Contractor” has the meaning set forth in the first paragraph of this Agreement.

“Contractor Change Notice” has the meaning set forth in Section 10.2.

“Contractor Default” has the meaning set forth in Section 24.2.1.

“Contractor Hazardous Substances” has the meaning set forth in Section 19.1.1(ii).

“Contractor Indemnitees” has the meaning set forth in Section 20.2.

“Contractor Response” has the meaning set forth in Section 10.1.2.

“Contractor’s Excise Tax” means the excise tax described in South Dakota Codified Laws Chapter 10-46A.

“Contractor’s Representative” means the individual designated by Contractor pursuant to Section 4.6.

“Contractor’s Share” means Contractor’s share of the amount by which the Total Construction Costs is less than or exceeds the Target Price, as such amount is determined in accordance with Section 8.5.

“Contractor Supplied Materials and Equipment” means all Materials and Equipment required to be supplied by Contractor as part of the Work, as identified in the Exhibit B.

“Contractor Taxes” has the meaning set forth in Section 8.6.1.

“Corporate Overhead & Profit Amount” mean the amount described in Section 8.2.1.

“Corrective Action” has the meaning set forth in Section 13.3.

“Cost Reimbursable Portion” means the sum of the Direct Hire Craft Labor Costs, Small Tools and Consumables Costs, Permanent Materials Costs, Subcontractor Costs and Miscellaneous Costs as further defined and set forth within Section 8.3.

“Data & Telecommunications Systems Amount” mean the amount described in Section 8.2.4.

“Day” means a calendar day, including Saturdays, Sundays and legal holidays, except that, in the event that a payment obligation to be performed under this Agreement falls due on a calendar day that is not a Business Day, the payment obligation shall be deemed due on the next Business Day thereafter.

“Defect” (and derivative forms thereof, e.g., “Defective”) means a defect, deficiency, or nonconformity in the Work or other deviations from the warranties set forth in Section 13.1.

“Design” (and derivative forms thereof) means all design, calculation, and engineering products or services and the conduct thereof, including all preliminary and detailed design of the Work that is required to be performed by Contractor pursuant to Exhibit B.

“Design Documents” has the meaning set forth in Section 4.7.

“Direct Hire Craft Labor Costs” mean the costs described in Section 8.3.1.

“Disclosing Party” means a Party disclosing Confidential Information to the other Party.

“Dispute” means a claim, dispute or other controversy arising out of, or relating to, this Agreement which an authorized representative of a Party does not believe can be resolved by the Parties’ authorized representatives.

“Early Operation” means Owners have taken sole control of and operate the Work or the Unit as part of the Work for their own commercial purposes to the exclusion of Contractor, prior to the actual date on which Substantial Completion occurs, other than in connection with or incidental to the start-up, commissioning, and debugging or testing of the Work or the Unit as part of the Work following the completion of the Work.

“Effective Date” has the meaning set forth in the first paragraph of this Agreement.

“Emergency Notification List” means a list of personnel of Owners, with associated contact information, that sets forth the individuals to be notified first in the event of an emergency involving health or safety, including environmental harm, or material damage to property, as such list is amended by Owners and provided to Contractor from time to time.

“Environmental Action” has the meaning set forth in Section 19.1.1(ii).

“Equipment” means any product that: (i) is to be incorporated into the Work or the Unit as part of the Work; (ii) is an assembly of operational and/or non-operational parts, whether motorized or manually operated; and (iii) requires service connections, such as wiring, piping, or other process connections.

“Excusable Events” means the following events to the extent that such event materially and adversely results in an actual delay in the performance of the Work that Contractor demonstrates materially affects the critical path of the Work, an increase in Contractor’s cost of performing the Work or otherwise materially and adversely affects Contractor’s performance hereunder:

| | (i) | material delays caused by Owners’ failure to fulfill any of its obligations under this Agreement, to the extent such delay occurs without the fault or negligence of Contractor or its Subcontractors; |

| | (ii) | material delays caused by acts of Owners, Owners’ separate contractors or those acting on Owners’ behalf, except (a) acts permitted to be taken under this Agreement, including acts taken in accordance with Prudent Utility Practices related to the Big Stone Site or (b) to the extent caused by the fault or negligence of Contractor or its Subcontractors. |

| | (iii) | suspension of the Work, in whole or in part, pursuant to Sections 24.3.2 or 24.4; |

| | (iv) | a change by Owners in the date or duration of the Installation Outage that is not the consequence of the request or fault of Contractor; or |

| | (v) | the discovery of any (a) Owners Hazardous Substance that requires Environmental Action; (b) differing local conditions or Job Site conditions for which Contractor is not responsible pursuant to Sections 4.17 and/or 4.18; or (c) protected or endangered plant or animal species, artifacts, fossils or other items of historical, geological, archeological, or other value in accordance with Section 4.35. |

“Exhibits” means all of the exhibits referenced in this Agreement.

“Existing Facilities” means the Unit, structures, installations, roadways, walkways, natural features, and the existing generating units, including the Unit, and auxiliary and support facilities located on the Big Stone Site, including all existing facilities used in connection with the generation of electricity; the transportation, handling or storage of fuel; or the transmission of electricity.

“Final Completion” will be deemed to have occurred when all of the following have occurred in respect of the Work: (i) Substantial Completion has been achieved; (ii) all As-Built Drawings, Information, Design Documents, Operating and Maintenance Manuals, submittals and other documents required to be delivered to Owners hereunder have been delivered; (iii) all liquidated damages for which Contractor is liable pursuant to Article 7 and other amounts owed by Contractor to Owners under this Agreement, if any, have been paid to Owners; (iv) all Work, including all items identified on the Punch List, has been completed other than Work and other obligations that require future performance (e.g., warranty Work and indemnification obligations); and (v) Owners have issued the Certificate of Final Completion.

“Final Completion Date” means the date on which Contractor successfully achieves Final Completion.

“Fixed Portion” means the sum of the Corporate Overhead & Profit Amount, Project Staff Amount, Reproduction Expense Amount, Data & Telecommunications Systems Amount, Site Logistics Amount, and Construction Equipment and Rentals Amount as further defined and set forth within Section 8.2.

“Force Majeure” means any condition, event, or circumstance, including the examples set forth below, but only if, and to the extent: (i) such condition, event, or circumstance is not within the reasonable control of the Party affected; (ii) such condition, event, or circumstance, despite the exercise of reasonable diligence, could not be prevented, avoided or removed by such Party; (iii) such condition, event, or circumstance has a material adverse effect on the ability of the affected Party to fulfill its obligations under this Agreement; (iv) the affected Party has taken all reasonable precautions, due care, and reasonable alternative measures in order to avoid the effect of such condition, event, or circumstance on the affected Party’s ability to fulfill its obligations under this Agreement and to mitigate the consequences thereof; and (v) such condition, event, or circumstance is not the result of any failure of such Party to perform any of its obligations under this Agreement. By way of example, such events, conditions and circumstances include war, rebellion, sabotage, civil strife, insurrection, public disorder, Climatic Conditions, earthquake, fire, quarantine, acts of terrorism, industry-wide or national strikes, and Changes in Law. Notwithstanding the foregoing, Force Majeure shall not include the following events, conditions or circumstances:

| | (a) | late delivery of Contractor Supplied Materials and Equipment, Consumables, or Construction Aids required for the Work however caused, including by congestion at a Subcontractor’s plant or elsewhere; oversold market conditions; inefficiencies; transportation delays (except to the extent a transportation delay is caused by the occurrence of an independent condition, event, or circumstance described in and meeting the conditions of the first full paragraph of this definition); or other similar circumstances; |

| | (b) | shortages of supervisors, labor, Contractor Supplied Materials and Equipment, Consumables, or Construction Aids; |

| | (c) | late performance as a consequence of any violation of Applicable Law or decisions of a Governmental Authority related to the conduct of Contractor’s or any Subcontractor’s business, including insolvency or any delay related to the economic, commercial, or labor circumstances of Contractor, any Subcontractor or other business conducted by Contractor or any Subcontractor; |

| | (d) | breakdown, loss, or damage to or theft of Contractor Supplied Materials and Equipment, Consumables, or Construction Aids, except where such breakdown, loss, or damage is directly due to the occurrence of an independent condition, event, or circumstance described in and meeting the conditions of the first full paragraph of this definition; |

| | (e) | failure of a Party to pay amounts due and owing under this Agreement; |

| | (f) | strikes or other labor disturbances affecting Contractor or any of its Subcontractors, except as expressly set forth in the examples described in the first full paragraph of this definition; |

| | (g) | increased costs of the Work, general economic, or industry conditions; or |

| | (h) | weather conditions other than Climatic Conditions. |

Notwithstanding the foregoing, with respect to the performance of the Work in connection with the Installation Outage, the definition of Force Majeure in the first full paragraph of this definition is limited to an event of Force Majeure that occurs on the Big Stone Site (including the Job Site) before or during the scheduled duration of the Installation Outage; provided that Contractor has satisfied the Marshaling Requirement, as more particularly described in Section 6.4.1.

“Governmental Authority” means any federal, state, county, regional, city, parish or local government body, agency, authority, branch, department, arbitrator, court or any subdivision, instrumentality or agency thereof, having or claiming a regulatory interest in or jurisdiction over the Work (or any portion thereof), the Unit, the Big Stone Site, this Agreement, or one or more of the Parties.

“Guaranteed Final Completion Date” means ten (10) Days following the Substantial Completion Date.

“Guaranteed Mechanical Completion Date” means May 24, 2015, which date may be adjusted pursuant to the terms and conditions of this Agreement.

“Guaranteed Substantial Completion Date” means August 24, 2015, which date may be adjusted pursuant to the terms and conditions of this Agreement.

“Hazardous Substance” means: (i) any chemicals, materials, substances, or wastes which are now or hereafter defined as or included in the definition of “hazardous substance,” “hazardous material,” “hazardous waste,” “solid waste,” “toxic substance,” “extremely hazardous substance,” “pollutant,” “contaminant,” or words of similar import under any Applicable Law; (ii) any petroleum, petroleum products (including crude oil or any fraction thereof), natural gas, natural gas liquids, liquefied natural gas, or synthetic gas useable for fuel (or mixtures of natural gas and such synthetic gas), or oil and gas exploration or production waste, polychlorinated biphenyls, asbestos or asbestos-containing materials, mercury, urea formaldehyde insulation, radioactive material, and lead-based paints, or any other substance that has been contaminated, polluted or made toxic; and (iii) any other chemical, material, substances, waste, or mixture thereof which is prohibited, limited, or regulated pursuant to, or that could reasonably be expected to give rise to liability under, any Applicable Law.

“Health and Safety Plan” has the meaning set forth in Section 14.1.

“Hazardous Substance Management Plan” has the meaning set forth in Section 4.21(vii).

“Hold Point” means an inspection point with respect to which Contractor or its Subcontractors may not proceed further with respect to the Work unless and until Owners have either: (i) inspected the applicable Work and authorized Contractor (including its Subcontractors) to proceed or (ii) waived such inspection in writing. Hold Points include those points designated in Exhibit B and those designated by Owners from time to time by formal notice to Contractor.

“Indemnified Parties” has the meaning set forth in Section 20.3.1.

“Indemnifying Parties” has the meaning set forth in Section 20.3.1.

“Information” means all drawings; documents; manuals; training materials; Computer Programs; operating, maintenance, and other guidelines and procedures; and Design, Design Documents, and other data, trade secrets, and information used or supplied by Contractor, whether directly itself or indirectly through Subcontractors, whether paper or electronic media, in performance of this Agreement which would be reasonably useful or necessary in Owners’ operation, maintenance, repair, personnel training, modification, or use of the Work or the Unit as part of the Work following the completion of the Work or the Unit.

“Initial Target Price” has the meaning set forth in Section 8.4.

“Interim Target Price” means the sum of (i) the Fixed Portion and (ii) the Cost Reimbursable Portion, in each case as determined in accordance with Section 8.4.2 as of any True-Up Submittal Date other than the last True-Up Submittal Date and set forth in the applicable Change Order as described in Section 8.4.2.

“Insolvency Event” means, with respect to the Person: (i) the Person’s (a) failure to generally pay its debts as they become due, (b) admission in writing of its inability to pay its debts as they become due or (c) making a general assignment for the benefit of creditors; (ii) any proceeding being instituted by or against the Person seeking: (a) to adjudicate it as bankrupt or insolvent, (b) liquidation, winding up, reorganization, arrangement, adjustment, protection, relief or composition of it or its debts under any Applicable Law relating to bankruptcy, insolvency, reorganization or relief of debtors or (c) the entry of an order for relief or the appointment of a receiver, trustee, custodian or other similar official for it or for any substantial part of its property and, in the case of any such proceeding instituted against the person, either such proceeding remains undismissed for a period of thirty (30) Days or any of the actions sought in such proceeding occur; or (iii) the Person’s taking any action to authorize any of the actions set forth above in this definition.

“Installation Outage” means the period during the scheduled outage of the Unit during which time Contractor must complete the installation of a portion of the Work (the time and date for such outage and the period during which Contractor may perform Work is set forth in Exhibit D). The Installation Outage will commence ninety six (96) hours after the Unit has been taken off-line.

“Installation Start Date” means the date and time set forth in Exhibit D when Contractor may commence the Work required to be performed during the Installation Outage, as such date and time may be adjusted pursuant to this Agreement.

“Intellectual Property” means all patents, patent applications, copyrights, trade secrets and all other intellectual property rights.

“Job Site” means that portion of the Big Stone Site on which the Work or the Unit as part of the Work is located, including areas for parking, storage, laydown, and administrative facilities, as more particularly described in Exhibit S-1.

“Liabilities” has the meaning set forth in Section 20.1.

“Lien Indemnitees” has the meaning set forth in Section 20.4.

“Liens” has the meaning specified in Section 20.4.

“List of Submittals” has the meaning specified in Section 7.2.

“Major Milestone” has the meaning set forth in Exhibit B, Section 013216, Article 105.1, Table 1-1.

“Major Subcontractor” means a Subcontractor providing labor, services, and/or Contractor Supplied Materials and Equipment in relation to the Work under this Agreement that has a value of Fifty Thousand Dollars ($50,000) or more.

“Marshaling Requirement” has the meaning set forth in Section 6.4.1.

“Materials” means any products, supplies, bulks, materials, logic, or Computer Programs that are to be incorporated into the Work or the Unit as part of the Work, whether or not substantially shaped, cut, worked, mixed, finished, refined, or otherwise fabricated or processed, and which are not items of Equipment, Consumables, or Construction Aids.

“Mechanical Completion” means when, with respect to the Work, all of the following have occurred: (i) all Contractor Supplied Materials and Equipment have been furnished and installed in accordance with Exhibit B and manufacturers’ requirements (and in a manner that does not void any warranty) and the terms of this Agreement and, as appropriate, checked for alignment, lubrication, rotation, and hydrostatic and pneumatic pressure integrity; (ii) Turnover Acknowledgement of all Systems has been achieved; (iii) all Systems have been installed, cleaned and statically tested and cold commissioning has been completed and all automation from control work stations required by the Exhibit B have been achieved; (iv) all initial tests have been completed and all instruments have been calibrated; (v) the Work or the Unit as part of the Work is capable of safe operation; (vi) the Work or the Unit as part of the Work is ready to commence testing, and integrated operations without the use of temporary equipment or installations; (vii) an initial Punch List has been established and mutually agreed upon by Owners and Contractor; (viii) the classroom training required by Section 017900 of Exhibit B has been completed; and (ix) Owners have executed the Certificate of Mechanical Completion.

“Miscellaneous Costs” mean the costs described in Section 8.3.6.

“Modification” means: (i) a written amendment to this Agreement signed by both Parties; (ii) a Change Order; or (iii) an Owners Authorization.

“MSDSs” has the meaning set forth in Section 19.1.2.

“NERC” means the North American Electric Reliability Corporation, a reliability organization responsible for the oversight of the regional reliability organizations established to ensure the reliability and stability of the regions.

“NERC Requirements” has the meaning set forth in Section 4.40.

“Notice to Proceed” means the written instruction given by Owners to Contractor to commence the Work under and in accordance with this Agreement in the form of Exhibit F-6.

“Operating and Maintenance Manuals” has the meaning set forth in Section 017823 of Exhibit B.

“Otter Tail” has the meaning set forth in the first paragraph of this Agreement.

“Outage Day” has the meaning set forth in Section 7.1.

“Owners” has the meaning set forth in the first paragraph of this Agreement.

“Owners Authorization” has the meaning set forth in Section 10.1.4.

“Owners Default” has the meaning set forth in Section 24.3.1.

“Owners Engineer” means a third party engineering firm selected by Owners.

“Owners Hazardous Substance” means a Hazardous Substance existing on the Big Stone Site as of the Effective Date or a Hazardous Substance that was not introduced to or created on the Big Stone Site by Contractor or its Subcontractors, which Hazardous Substance, in either case, is of a nature or is found in an amount that requires special handling, disposal or remediation under Applicable Law.

“Owners Indemnitees” has the meaning set forth in Section 20.1.

“Owners Permits” means Permits that are to be obtained by Owners as set forth in Exhibit P.

“Owners Provided Items” means those items, Equipment, Materials, and services set forth in Exhibit O that will be provided by Owners.

“Owners Representative” has the meaning set forth in Section 5.1.

“Owners Response Period” has the meaning set forth in Section 10.1.3.

“Owners Review Period” has the meaning set forth in Section 6.3.2.

“Owners’ Share” means Owners’ share of the amount by which the Total Construction Costs is less than or exceeds the Target Price, as such amount is determined in accordance with Section 8.5.

“Parts Vendor” has the meaning set forth in Section 4.26.

“Party” or “Parties” means either Owners, Contractor, or both of them, as the context or the usage of such term may require.

“Payment Amount” means the sum of (without duplication) the (i) Fixed Portion actually paid or payable to Contractor pursuant to this Agreement, without deducting Retainage held by Owners; and (ii) the Cost Reimbursable Portion actually paid or payable to Contractor pursuant to this Agreement, without deducting Retainage held by Owners.

“Payment and Performance Bonds” has the meaning set forth in Section 25.13.

“Permanent Materials Costs” mean the costs described in Section 8.3.3.

“Permits” means any waiver, exemption, variance, franchise, permit, authorization, approval, identification number, inspection, certification, license, clearance or similar order, filing, registration, application of, from or to any Governmental Authority, including those set forth in Exhibit P.

“Person” means any individual, company, corporation, firm, joint venture, partnership, association, limited liability entity, organization, trust, Governmental Authority, or similar entity.

“Plans” mean the contract drawings prepared by Owners’ Engineer and issued for construction showing the design, location, and dimension of the Work, generally including plans, elevations, sections, details, schedules and diagrams.

“Prime Rate” means the per annum (365 or 366 Days, as appropriate) prime rate as published from time-to-time in the “Money Rates” table of The Wall Street Journal; provided, however, if more than one such prime rate is published, the average shall be used for purposes of this Agreement, unless an equivalent bank rate is agreed to by the Parties.

“Professional Standards” means those standards and practices used by, and the degree of skill and judgment exercised by, recognized United States national engineering and/or construction firms when performing first class quality services in connection with retrofitting operating coal-fired generation facilities with a scale similar to the Work.

“Project Requirements” means with respect to the Work or any portion thereof: (i) Applicable Law; (ii) Codes and Standards; (iii) the provisions of this Agreement; (iv) the requirements and warranties of Subcontractors, including Contractor Supplied Materials and Equipment provided by Subcontractors; (v) the requirements of insurers providing insurance pursuant to Article 21; (vi) the Operating and Maintenance Manuals; and (vii) Professional Standards.

“Project Schedule” means the critical path method project schedule, including key dates and milestones for completion of the Work established in accordance with and as set forth in Exhibit D, as such Project Schedule may be adjusted pursuant to this Agreement.

“Project Staff” has the meaning set forth in Section 8.2.2.

“Project Staff Amount” mean the amount described in Section 8.2.2.

“Prudent Utility Practices” means the practices, methods, materials, supplies, equipment, and standards of safety, performance, and service that are commonly applied in the electric utility industry in the United States to operate and maintain generating facilities similar to the Unit, including the use of, and adherence to, equipment, practices and methods, applicable industry codes, standards, and regulations that in the exercise of reasonable judgment and in light of the facts and circumstances known at the time the decision was made would be reasonably expected to accomplish the desired result while protecting the Work, the Existing Facilities, the interconnection facilities, individuals, and the environment from damage, loss, or injury. Prudent Utility Practices are not intended to be limited to the optimum practice or method to the exclusion of all others, but rather to be a spectrum of possible, but reasonable practices and methods having due regard for vendor warranty requirements, Applicable Law, and the operating and maintenance procedures of generation and associated facilities.

“Punch List” or “Punch List Items” means and refers to a comprehensive list initially prepared prior to certification of Mechanical Completion, and revised prior to Substantial Completion, which may be supplemented thereafter, to identify those minor defects or deficiencies in the Work that require repair, completion, correction or re-execution, the non-completion of which do not interfere with the occupancy, use, operation, safety, or reliability of the Work or the Unit.

“Receiving Party” means a Party to whom Confidential Information is disclosed.

“Records” has the meaning set forth in Section 25.9.1.

“Reproduction Expense Amount” mean the costs described in Section 8.2.3.

“Retainage” has the meaning set forth in Section 8.15.1.

“Retainage Amount” has the meaning set forth in Section 8.15.1.

“Sales Taxes” has the meaning set forth in Section 8.6.1.

“Senior Officer” means the chief executive officer, president or any senior vice president of a Party.

“Site Logistics Amount” means the amount described in Section 8.2.5.

“Small Tools and Consumables Costs” mean the costs described in Section 8.3.2.

“Special Tools” means tools that are described in the Technical Specification or are provided by a Subcontractor for the installation, checking, inspection, operation, repair, or maintenance of Contractor Supplied Materials and Equipment.

“Start-Up” following the commencement of an outage (of any kind), means the time that the Unit is released to station operations.

“Subcontractor” means and refers to a Person (at any tier other than Contractor) which has a contract, agreement, or other arrangement to perform a portion of the Work, including the supply of services, Contractor Supplied Materials and Equipment, Consumables, and Construction Aids in connection with the Work.

“Subcontractor Costs” mean the costs described in Section 8.3.4.

“Substantial Completion” will have been achieved when all of the following have occurred: (i) Mechanical Completion; (ii) an revised Punch List of Work remaining after Substantial Completion has been established and mutually agreed upon by Owners and Contractor; (iii) the Work is complete except Punch List Items; (iv) the training required by Section 4.10 has been completed; (v) all obligations of Contractor expressly required to have been performed as of the Substantial Completion Date have been properly discharged; (vi) the Work, including all Systems provided and installed by Contractor, and the Unit are capable of being operated in the normal course of business up to full Unit generating capacity; (vii) Owners have received from Contractor all Permits (including Permits (other than Owners Permits) necessary to allow transfer of care, custody, and control of the Work to Owners), all of which shall be valid and in full force and effect; (viii) levels of Consumables associated with the Work are fully charged; (ix) final versions of the Operating and Maintenance Manuals approved by Owners have been delivered; (x) currently marked drawings showing as-built conditions or the As-Built Drawings (current as of Substantial Completion) have been delivered to Owners; (xi) other submittals required under the Agreement to be submitted prior to or as of Substantial Completion have been delivered to Owners; (xii) all spare parts and Special Tools have been delivered to Owners; and (xiii) Owners have executed the Certificate of Substantial Completion.

“Substantial Completion Date” means the date on which Substantial Completion is achieved.

“System” means a system or subsystem of the Work set forth in the plan established pursuant to Section 6.3.

“System Turnover Package” means the collection of enumerated items of Information including diagnostic equipment tests that comprise a complete description of a System and its operating requirements in form and substance reasonably acceptable to Owners and established pursuant to Section 6.3.

“Target Price” means the sum of (i) the Fixed Portion and (ii) the Cost Reimbursable Portion, in each case as determined in accordance with Section 8.4 as of last True-Up Submittal Date, as such amounts may be adjusted by Change Order in accordance with this Agreement.

“Technical Specification” means and refers to Exhibit B attached hereto, and documents specified therein that define the requirements and scope of the Work.

“Total Construction Cost” means the sum of (i) the Payment Amount; plus (ii) costs incurred by Owners that are chargeable against the Target Price pursuant to this Agreement; plus (iii) if the Total Construction Cost exceeds the Target Price, amounts included in Applications For Payment for which Contractor would have been entitled to be paid but for the fact that the Total Construction Cost exceeds the Target Price.

“Total Cost” means, in the event of a termination of this Agreement for a Contractor Default, the sum of (i) all Cost Reimbursable Portion payments made to Contractor; (ii) all Fixed Portion payments made to Contractor; and (iii) all costs expended by Owners to complete the Work.

“True-Up Submittal Date” has the meaning specified in Section 8.4.

“Turnover Acknowledgment” has the meaning set forth in Section 6.3.2.

“Unit” means the existing coal-fired unit operating on the Big Stone Site that is commonly identified as Big Stone Plant Unit 1.

“Warranty Period” means the period described in Section 13.2, as it may be extended in accordance with this Agreement.

“Work” means all of the work, services, Contractor Supplied Materials and Equipment, Consumables, and Construction Aids to be performed, provided, or installed by Contractor in accordance with this Agreement, including all Job Site preparation, Design, reconditioning, procurement, transportation, expediting, construction, training, start-up, commissioning, testing, clean-up and waste disposal, and other services or items that are necessary or appropriate to complete the Work, achieve Final Completion and fulfill Contractor’s obligations during the Warranty Period, in accordance with this Agreement.

1.2 Contract Interpretation. In this Agreement, unless the context otherwise requires:

| | (i) | the singular includes the plural and vice versa; |

| | (ii) | reference to any Person includes such Person’s successors and assigns, to the extent that such successors and assigns are permitted by this Agreement; |

| | (iii) | reference to any agreement (including this Agreement), document, insurance policy or instrument means such agreement, document or instrument as amended or modified and in effect from time to time in accordance with the terms thereof; |

| | (iv) | any accounting term used and not otherwise defined in the Agreement has the meaning assigned to such term in accordance with generally accepted accounting principles consistently applied; |

| | (v) | “including” (and “include”) means (a) including without limiting the generality of any description preceding such term and (b) with respect to any description following such term, means “including, without limitation” or “including, but not limited to”; |

| | (vi) | reference to Applicable Law means Applicable Law as amended, modified, codified, or reenacted, in whole or in part, and in effect from time to time; |

| | (vii) | when applied to Contractor Supplied Materials and Equipment, or Systems, “furnish,” “provide” or words of similar import means to secure, pay for, deliver to the Job Site (or other portions of the Big Stone Site, as appropriate), unload, inspect and uncrate, store per manufacturer’s recommendations and any other services or activities appropriate to that portion of the Work; |

| | (viii) | when applied to Contractor Supplied Materials and Equipment, or Systems, “install” or “installation” or words of similar import mean to assemble, place in position, incorporate, adjust, clean, make fit for use and any other services or activities appropriate to that portion of the Work; |

| | (ix) | unless the context specifically requires otherwise, the terms “approval,” “consent,” “accept,” “acceptance,” “authorization,” and terms of similar import shall be deemed to be followed by the phrase “which shall not be unreasonably withheld, unreasonably conditioned or unreasonably delayed”; |

| | (x) | the words “shall” and “will” have equal force and effect; |

| | (xi) | the words “herein,” “hereof,” or “hereunder” or similar terms refer to this Agreement as a whole and not to any specific section or article; |

| | (xii) | the table of contents and article, section and exhibit titles and similar headings are inserted for convenience only and are not be used for the purposes of construing or interpreting this Agreement; |

| | (xiii) | the Work is intended to be a term that encompasses all of the necessary performance obligations of Contractor. Any listing of types of work such as “construct,” “erect,” “check” or “align” is not meant to be exclusive in the context of this Agreement or exclude similar or other services or activities appropriate to that portion of the Work; |

| | (xiv) | words and abbreviations not defined in this Agreement which have well known technical or design, engineering or construction industry meanings are used in this Agreement in accordance with such recognized meanings; |

| | (xv) | all documentation to be supplied under this Agreement shall be provided in the English language; |

| | (xvi) | all dimensions must be specified in the U.S. customary system; and |

| | (xvii) | payments under this Agreement which are due must be made exclusively in United States dollars. |

1.3 Owners’ Agent. The Parties acknowledge that Otter Tail is the authorized agent of Owners for the purpose of administering this Agreement and managing the performance of Owners’ rights and obligations under this Agreement; provided, however, each Owner retains its right to audit Records and to inspect or witness events for the purpose of monitoring its interest in this Agreement. The acts and omissions of Otter Tail are the responsibility of Owners and Contractor shall not have recourse under this Agreement against Otter Tail, in its capacity as Owners’ agent hereunder. Contractor further acknowledges that (i) it will accept the acts and directions of Otter Tail as the acts and directions of Owners, (ii) it will render performance to Otter Tail, as agent for Owners, (iii) only Otter Tail has the power and authority to direct Contractor and/or enter into any modification, in each case unless and until notified in a writing signed by Otter Tail.

1.4 Owners’ Liability Several. The liability of each of the Owners under this Agreement shall be several, and not joint, in accordance with such entities’ pro-rata percentage interest in the Unit. Owners are not partners or joint venturers and this Agreement shall not be interpreted to impose any liability attributable to such a relationship upon Owners.

1.5 Inclusion; Order of Precedence. The Body of this Agreement and the Exhibits hereto are to be considered complementary and what is required by one will be binding as if required by all. In addition, the Work includes all that should be properly included and all that would be customarily included within the general scope and magnitude of the Work. The failure to specifically list a requirement in one document, once such requirement is specifically listed in another, does not imply the inapplicability of such requirement and Contractor shall provide or perform, as appropriate, as part of this Agreement all Work or items required to conform to the Technical Specification, the other Exhibits and the standards herein contained. In the event of a conflict between the Body of this Agreement and the Exhibits, the Body of this Agreement governs. In the event of a conflict in an Exhibit or between or among Exhibits, the requirement most favorable to Owners will take precedence, except as may be otherwise determined by Owners. Each Modification will take precedence over that part of this Agreement (including, as applicable, any prior Modification) which it supersedes.

EFFECTIVENESS

2.1 Effectiveness; Notice to Proceed.

2.1.1 Effectiveness. This Agreement shall be effective and the Parties shall be bound by the conditions applicable to their conduct upon execution of this Agreement.

2.1.2 Notice to Proceed. Owners are entitled to issue the Notice to Proceed to Contractor any time on or after the Effective Date. If Owners fail to give the Notice to Proceed on or prior to March 1, 2013, this Agreement will terminate and neither Party will be liable to the other under this Agreement. Upon receipt of the Notice to Proceed, Contractor agrees to commence the Work. Contractor agrees to acknowledge its receipt of the Notice to Proceed by countersigning it and returning such acknowledged copy to Owners on the date the Notice to Proceed is received by Contractor. Execution of the Notice to Proceed by each Party indicates that the conditions precedent to such Party’s obligations have been satisfied or waived.

2.2 Conditions Precedent to Obligations.

2.2.1 Owners’ Conditions. The issuance of the Notice to Proceed by Owners is subject to the satisfaction or written waiver by Owners of the conditions precedent set forth below:

| | (i) | Contractor shall have advised Owners in writing that as of the Effective Date there exist no grounds on which a claim by Contractor pursuant to Article 9 or Section 10.2 may be based; |

| | (ii) | Contractor shall have delivered the Payment and Performance Bonds as required by Section 25.13; |

| | (iii) | Contractor shall have provided to Owners copies of insurance policies and certificates required to be obtained by Contractor in accordance with Exhibit I, Part A; |

| | (iv) | Contractor shall have delivered the Project Schedule in no less than a Level 3 Primavera® P6 format, with a fully logic-tied schedule showing engineering, procurement, and construction developed and resource-loaded; and |

| | (v) | Owners shall have received all necessary information from Contractor to allow Owners to have submitted all necessary filings to Governmental Authorities that are required prior to the commencement of construction. |

2.2.2 Contractor Conditions. Contractor’s obligations to commence the Work in its entirety and to acknowledge the Agreement are subject to the satisfaction or written waiver by Contractor of the condition precedent set forth below:

| | (i) | Owners shall have delivered the Emergency Notification List and the Notice to Proceed to Contractor. |

GENERAL PROVISIONS

3.1 Intent of Contract Documents. It is the intent of the Parties that this Agreement be a cost reimbursable contract with a Target Price and Project Schedule which will not be increased or lengthened, except in accordance with Article 10.

3.2 Independent Contractor. Contractor will perform and execute the provisions of this Agreement as an independent contractor to Owners. Contractor is not and may not act as an agent of Owners for any purpose or reason whatsoever.

3.3 Subcontracting. Subject to Section 3.4, Contractor may have portions of the Work performed by Subcontractors, including entities related to or affiliated with Contractor; provided, however, Contractor may not subcontract all or substantially all of the Work. Owners shall have the right of approval of all Subcontractors and their respective subcontracts. No contractual relationship will exist between Owners and any Subcontractor with respect to the Work to be performed hereunder, except pursuant to Sections 3.6 and 13.4. Notwithstanding any provision of this Agreement or whether any provision specifically refers to Contractor’s Subcontractors, Contractor will be fully liable for all acts, omissions, failures or faults of any Subcontractor and any other Person for whom Contractor or its Subcontractors are responsible) as fully as if they were the acts, omissions, failures or faults of Contractor. Contractor will require its Subcontractors to provide or perform their portion of the Work in a manner applicable to the performance of Contractor’s obligations under this Agreement. If any Subcontractor fails to perform any portion of the Work as such Work is required to be performed in accordance with this Agreement, Contractor is responsible therefor and hereby binds itself to promptly and diligently correct such failure in accordance with this Agreement, at no cost or expense to Owners. The exercise of the right to subcontract will not in any way increase the cost, expense, or liability of Owners hereunder. Contractor shall require any Subcontractor to perform its portion of the Work: (i) under Contractor’s supervision and (ii) in accordance with the requirements of this Agreement. Contractor shall bind all Major Subcontractors to terms that protect Owners’ rights and benefits hereunder and are otherwise not in conflict with the provisions of this Agreement applicable to the subcontracted Work (including the provision of Contractor Supplied Materials and Equipment).

3.4 Specified Equipment Subcontractors. For those items of Contractor Supplied Materials and Equipment specified in Exhibit B, Contractor will only use the services of, or procure Contractor Supplied Materials and Equipment from those Subcontractors listed under the headings specified in Exhibit B. Contractor will be responsible for the negotiation of the terms and conditions of any purchase orders or subcontracts entered into with such identified Subcontractors (including cost, performance guarantees and equipment warrantees), and, subject to Section 8.6.3, it will enter into written purchase orders and/or subcontracts in its own name directly with such Subcontractors, it being the intent of the Parties that such Subcontractors will be subcontractors of Contractor and not of Owners. Operability, maintainability, reliability, quality, and compatibility with Equipment, Materials, and Consumables utilized in the Existing Facilities must be material selection factors in Contractor’s procurement decisions. Contractor agrees that before submitting specifications for bids to Major Subcontractors it will give Owners a reasonable opportunity to comment on such specifications and Owners agree that if they wish to comment, Owners will submit such comments within the time period specified for that item in Exhibit B and if not so specified, within fifteen (15) Days after delivery of the specifications to Owners; provided, however, if the last day of such period is not a Business Day, the period will be extended to and until the next Business Day. Notwithstanding Owners’ right to review and comment in accordance with this Section 3.4, no such review or comment will relieve Contractor or otherwise serve as a defense to Contractor’s full performance of its obligations hereunder.

3.5 Certain Provisions in Subcontracts. All subcontracts or other arrangements with a Major Subcontractor must contain provisions, which Contractor may not waive, release, modify, or impair: (i) giving Contractor an unrestricted right, without the consent of the Subcontractor, to assign and thereafter reassign the relevant subcontract and any or all benefits, interests, rights and causes of action arising under it to Owners and/or their designees (and such assignment right will be assigned as part of such assignment); (ii) complying with the provisions of Section 20.4; (iii) authorizing either Owners or Contractor to enforce guarantees and warranties; (iv) requiring Subcontractors that will have a presence on the Big Stone Site to comply with the plan provided for in Section 14.1 of this Agreement; (v) indemnifying Owners on the terms and conditions set forth in Section 20.1; (vi) incorporating Section 16.3; and (vii) causing any Subcontractor that supplies: (a) Contractor Supplied Materials and Equipment having a value equal to or greater than [**] Dollars ($[**]); (b) fabricated structural steel; (c) fabricated piping; or (d) fabricated grating, to segregate such Contractor Supplied Materials and Equipment at their facilities and identify such Contractor Supplied Materials and Equipment as Owners’ property as necessary under Applicable Law to obtain and maintain Owners’ title thereto. Contractor shall notify Owners prior to entering into any subcontract(s) or other arrangements with a Subcontractor and shall provide Owners with an electronic copy of such subcontracts and all change orders and amendments thereto.

[**] Represents text deleted pursuant to a confidentiality treatment request filed with the Securities and Exchange Commission pursuant to Rule 24b-2 under the Securities Exchange Act of 1934, as amended

3.6 Assignment of Subcontracts. Contractor shall, if so requested by Owners after termination of Contractor pursuant to Article 24 or the expiration of the Warranty Period, as it may be extended, assign: (i) any subcontract with a Subcontractor together with any retainage, guaranty, letter of credit or other security provided by such Subcontractor for such Subcontractor’s obligations and/or (ii) the benefits of any remaining Subcontractor warranty to Owners or their Affiliates, which assignment must not require the consent of the Subcontractor.

3.7 Subcontracts. All subcontracts with Subcontractors shall provide that title, if applicable, will be transferred in the name of Owners in accordance with Section 22.1. Each such subcontract shall limit recourse exclusively to Contractor, except upon the assignment of such subcontract in accordance with Section 3.6. Subcontracts shall allow for suspension of all or a portion of the Work to be performed thereunder and shall be terminable for cause or convenience pursuant to a termination payment schedule.

CONTRACTOR’S RESPONSIBILITIES

4.1 The Work. Contractor hereby covenants and agrees that it shall continuously and diligently provide, perform, install, and complete the Work and its other obligations hereunder in accordance with Project Requirements and the Project Schedule. Contractor further covenants and agrees that it shall procure, provide and pay for all Contractor Supplied Materials and Equipment, Consumables (other than Consumables to be provided by Owners pursuant to Section 5.3), Construction Aids, and other items or services necessary for the proper execution and completion of the Work, whether temporary or permanent and whether or not incorporated or to be incorporated into the Work, including all installation, construction services, Design, drafting and procurement, all administration, reporting, expediting, inspection, testing, training, scheduling, and coordination; all start-up, commissioning and testing services; all labor (skilled and unskilled); all insurance to be provided by Contractor as set forth in Exhibit I; Permits and inspections required to be supplied by Contractor under this Agreement; all tools, machinery, storage, and transportation and all other facilities and services necessary to provide and complete the Work in accordance with Exhibit B and this Agreement, it being understood that to the extent Exhibit B does not expressly delineate an aspect of the Work the Parties intend that the Work be completed consistent with the Plans and Professional Standards. Contractor shall order, expedite, receive, furnish, handle, transport, inspect, store, maintain and install Contractor Supplied Materials and Equipment, and Consumables, and shall receive, handle, inspect, store, maintain and install all Owners Provided Items delivered to Contractor, in accordance with vendor/manufacturer requirements and, in the absence thereof, in accordance with Professional Standards. Contractor shall have care, custody and control of Owners Provided Items from and after delivery to the Job Site until the earlier of Substantial Completion or Early Operation. Contractor will perform all managerial, supervisory, and administrative services that may be necessary to ensure the proper and timely completion of all such activities which form a part of the Work. As such, Contractor agrees that Contractor shall be ultimately responsible for the proper and timely completion of the entirety of the Work in accordance with this Agreement, whether performed by Contractor or by any Subcontractor.

4.2 Sufficient Personnel. Contractor shall, at all times during the term of this Agreement, employ a sufficient number of qualified supervisory personnel, craft persons, and other persons, so that the Work and the other obligations to be performed by Contractor hereunder are completed in an efficient, prompt, economical, and professional manner. Without in any way limiting the foregoing, such personnel must include sufficient qualified buyers, inspectors, and expediters necessary to provide Contractor Supplied Materials and Equipment, and Consumables in a timely manner consistent with the Project Schedule. Whenever required by Applicable Law, professional engineers licensed in the State of South Dakota will perform any Design services required to be performed as part of the Work and, to the extent required by Applicable Law, stamp drawings and Design Documents produced by Contractor. Other portions of the Work shall be performed by properly licensed personnel as required by Applicable Law and Professional Standards. Contractor shall also provide all construction and technical services, supervision, and craft personnel as required for system adjustments during start-up, commissioning, and testing. During start-up, testing or the operation of the Work until Substantial Completion, Contractor shall maintain qualified personnel available to the Job Site twenty-four (24) hours a Day to advise Owners’ operators regarding operation and maintenance of the Work.

4.3.1 Labor Peace. Contractor shall be responsible for labor peace on the Job Site among its employees and/or those of its Subcontractors and will assist Owners in maintaining labor harmony on the Big Stone Site. Contractor shall reasonably support Owners’ efforts to maintain good labor relations with local labor organizations. Contractor shall at all times exert its best efforts and judgment as an experienced contractor to adopt and implement policies and practices designed to avoid work stoppages, slowdowns, disputes, or strikes by its personnel, when reasonably possible and practical under the circumstances, and shall at all times comply with the Site Work Rules set forth in Exhibit S-5. Contractor shall advise Owners promptly, in writing, of any actual, anticipated, or threatened labor dispute of which it is aware, that might affect the completion of the Work by Contractor or by any of its Subcontractors in accordance with the Project Schedule.

4.3.2 Verification of Employment Eligibility. Contractor shall comply with the Immigration Reform and Control Act of 1986.

4.4 Discipline and Protection. Contractor shall enforce strict discipline and good order among Contractor’s employees, Subcontractors’ employees, and any other Persons carrying out portions of the Work on the Big Stone Site and provide for the protection and maintenance of the Work and of all Persons and property related thereto. Contractor shall at all times take all necessary precautions to prevent any unlawful or disorderly conduct by or amongst its employees and those employees of Subcontractors and for the preservation of peace and protection of individuals and property on, or in the vicinity of, the Big Stone Site. Contractor shall not permit the employment of unfit individuals or individuals not skilled in tasks assigned to them. Contractor understands the importance of maintaining good relations with the community in which the Existing Facilities are located and shall emphasize the importance of good community relations to its employees and other Persons under its supervision on the Job Site.

4.5 Supervision. Contractor shall supervise, coordinate, and direct the Work, using Contractor’s best skill, judgment, and attention. Contractor is responsible for the conduct of Persons under its supervision.

4.6 Contractor’s Key Personnel. Exhibit K contains a list of Contractor’s key personnel who will be responsible for supervising the performance of Contractor’s obligations hereunder. Such list includes the designation of Contractor’s principal representative (the “Contractor’s Representative”), who will be Contractor’s authorized representative having the responsibility and authority to direct and manage the Work, administer this Agreement, serve as Contractor’s primary point of contact from and with Owners and be authorized to make decisions related to the Work and bind Contractor. Contractor recognizes that a good working relationship must exist between its key personnel and Owners. Owners have the right to request replacement of key personnel upon reasonable written notice after having given Contractor a reasonable opportunity (not to exceed ten (10) Days) to rectify the situation leading to such request. Upon the expiration of such period, if Owners remain unsatisfied, Contractor shall promptly effect such replacement. Contractor shall not relocate any of Contractor’s Key Personnel to another project without Owners’ prior written consent. Any replacement of key personnel will be subject to the prior written approval of Owners. Contractor’s Representative shall act as Contractor’s liaison with Owners.

4.7 Design and Engineering.

4.7.1 Design Requirements. Contractor shall engage all supervisors, engineers, designers, draftsmen, Subcontractors, and others necessary for the Design of such portions of the Work as are required by Exhibit B to be performed by Contractor and the preparation of all drawings, specifications, calculations, plans, reports and other Design documentation (including all media) for such portion of the Work (collectively the “Design Documents”). Contractor shall Design such portions of the Work in accordance with Project Requirements. During performance of the Work, Contractor shall upload to and maintain the Design Documents on a web-based database as and when such Design Documents (or iterations thereof) are completed or revised and Owners shall have unlimited access (including download capability) to the Design Documents on such web-based database. Contractor will provide hard-copy Design Documents upon request.

4.7.2 Reviews and Hold Points. Design Documents will be available to Owners electronically in an agreed format and in hard copy. Owners will be entitled, but not obligated, to review and comment upon the Design Documents and other required submittals in accordance with Exhibit B prior to Contractor commencing with any subsequent phase of the Work related to such Design Documents or submittals. Owners’ comments, if any, will be provided in accordance with Exhibit B. Contractor shall not proceed further with Design Documents and submittals that are designated as Hold Points until Contractor has either received Owners’ comments thereon or the time for comment as set forth in Exhibit B has elapsed. Contractor shall give due consideration to Owners’ comments in the final version of the Design Documents or submittals. Design Documents that are required to be certified or under seal must be certified or sealed by professional engineers, licensed and qualified to perform engineering services in the State of South Dakota. In no event will any review, comment, or approval of Owners, or acceptance or acknowledgment of any of the Work, in any way, relieve Contractor of any of its guarantees or obligations hereunder, including its full responsibility for errors and omissions, confirming all quantities, selection of fabrication processes, construction techniques, the accuracy of the dimensions, details and the quality of its instruments of service prepared in connection with the Work as well as its responsibility for the quality, integrity, safety, and timely performance of the Work.

4.8 Quality Control. Contractor shall develop, implement, and maintain a quality assurance plan for the Work which must include: quality assurance; management and control of the Design, engineering, construction, procurement, and supply services; and management and control of Subcontractors and their subcontracts. Such plan must be designed to meet Project Requirements, as provided in accordance with Exhibit B, including Section 014500 of Exhibit B. Contractor shall diligently revise the plan as necessary to obtain Owners’ approval. Contractor shall also require Major Subcontractors to establish, implement, and maintain comparable quality control and safety programs with respect to their respective portions of the Work. Compliance with the quality assurance plan will not relieve Contractor of any duty, obligation or responsibility under this Agreement.

4.9 Materials from Outside the U.S.A. Materials and/or products that are sourced, milled or fabricated outside of the U.S.A. to U.S. Codes and Standards or other recognized codes and standards may be acceptable; however, it will be Contractor’s obligation to demonstrate, at its cost, that such foreign material and/or products meet the quality requirements of the specified U.S. Codes and Standards. This demonstration may include additional quality surveillance, testing (both non-destructive and destructive), and certification by U.S. testing agencies. Contractor shall identify in its proposal all foreign material supply sources and all foreign fabrication facilities on which its pricing is based and the means to assure that such material and/or product meets specification. These quality requirements apply to all materials and fabricated products to be incorporated into the Work. Owners and Owners’ Engineer will monitor Contractor’s compliance with these quality requirements to the level appropriate to the criticality of the material or product. Items shall not be sourced from the Peoples Republic of China without Owners’ prior written consent.

4.10 Training. Contractor shall develop and implement a program to adequately instruct and train personnel made available by Owners in accordance with the provisions of Section 017900 of Exhibit B. Notwithstanding any other provision of this Agreement, training materials do not constitute Confidential Information. In addition to the training materials to be provided by Contractor, Contractor grants Owners the right to record all such training sessions and replay or otherwise provide such recordings for retraining or training of others. Contractor shall provide technical assistance to Owners’ operating personnel in connection with the development of training procedures.

4.11 Certain Contractor-Provided Items. Contractor shall obtain and provide for all utilities (not provided or paid for by Owners pursuant to Section 5.3) required prior to the earlier of Substantial Completion or Early Operation, including telephone service, Internet service, water, Consumables, sanitary facilities, and waste and sewage disposal, including sanitary sewage, and wastewater disposal. Contractor shall provide its own information technology and telecommunications, cable, or satellite communications. Contractor shall be responsible for providing a first fill of all Consumables as well as refills and replacements during the period prior to the earlier of Substantial Completion or Early Operation. Contractor shall use its best efforts to use the same products for Consumables that are used by Owners in the Existing Facilities.

4.12 Subcontractor Presence. Contractor shall obtain Owners prior approval prior to bringing any Equipment Subcontractor representative on site, and Owners approval will not be unreasonably withheld. Contractor shall be responsible for notifying any Equipment Subcontractor representative that it deems necessary to be present: (i) at any of the training sessions; (ii) for erection supervision; or (iii) for commissioning. The Contractor shall provide each Equipment Subcontractor representative with site orientation and safety training prior to granting site access without an escort.