Exhibit 99.1

|  |

| Effective Date: | 13 January 2015 | Document No: | 0465-RPT-014 Rev 0 |

Norra Kärr Project PFS

Gränna, Sweden

Prefeasibility Study - NI 43-101 -

Technical report for the Norra Kärr

Rare Earth Element Deposit

Prepared For:

Tasman Metals Ltd

QUALIFIED PERSONS:

Michael Short, BE (Civil), CEng FIMMM, FAusIMM(CP), FIEAust CPEng - Process

Greg Moseley, BSc, MSc, CEng, MIMM, FRGS, Associate, Qualified Person – Geology and Mineral

Resources

Mark Mounde, BEng, CEng, MIMMM, Technical Director, Qualified Person – Mining and Mineral

Reserves

Gareth Digges La Touche (BSc, MSc, FGS, CGeol, EurGeol)

CONTRIBUTING Consultants:

GBM Minerals Engineering Consultants Limited

Wardell Armstrong International Limited

Golder Associates Limited

Compiled By:

GBM Project Number: 0465

| Page i |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

Document Approval

| Role | | Name |

| Prepared by Project Engineer | | Tom Davidson |

| Checked by Project Controls Manager | | Jo Thompson |

| Approved by Qualified Person | | Michael Short |

| Approved by Qualified Person | | Greg Moseley |

| Approved by Qualified Person | | Mark Mounde |

| Approved by Qualified Person | | Gareth Digges La Touche |

Revision History

| Date | | Rev | | Reason | | Prepared | | Checked | | Approved |

| 16/12/2014 | | A | | Initial Draft | | TD | | JFT | | TD |

| 20/02/2015 | | 0 | | Issued as Final | | TD | | JFT | | MS / GM / MM /

GDLT |

IMPORTANT NOTE:

This report was prepared as a National Instrument 43-101 Technical Report, in accordance with Form 43-101F1, for Tasman Metals Ltd by GBM Minerals Engineering Consultants Limited. The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in GBM’s services, based on: i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended to be filed as a Technical Report with Canadian securities regulatory authorities pursuant to National Instrument 43-101, Standards of Disclosure for Mineral Projects. Except for the purposes legislated under provincial securities law, any other use of this report by any third party is at that party’s sole risk.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

TABLE OF CONTENTS

| SECTION 1 | | SUMMARY | 20 |

| | | | |

| 1.1 | | Introduction | 20 |

| | | | |

| 1.2 | | Background | 20 |

| | | | |

| 1.3 | | Norra Kärr Geology | 20 |

| | | | |

| 1.4 | | Metallurgical Testwork and Process Design | 21 |

| | | | |

| 1.5 | | Mineral Resource Estimates | 21 |

| | | | |

| 1.6 | | Mineral Reserve Estimates | 25 |

| | | | |

| 1.7 | | Mineral Extraction Methods | 25 |

| | | | |

| 1.8 | | Tailings storage Facility | 25 |

| | | | |

| 1.9 | | Environmental Studies, Permitting and Social or Community Impact | 26 |

| | | | |

| 1.10 | | Conclusions and Recommendations | 28 |

| | | | |

| SECTION 2 | | INTRODUCTION | 31 |

| | | | |

| 2.1 | | General | 31 |

| | | | |

| 2.2 | | Financial Interest Disclaimer | 31 |

| | | | |

| 2.3 | | Sources of Information | 31 |

| | | | |

| 2.4 | | Qualified Persons | 31 |

| | | | |

| 2.5 | | Qualified Person Site Visit | 32 |

| | | | |

| 2.6 | | Qualified Person Sectional Responsibility | 32 |

| | | | |

| 2.7 | | Units and Currency | 34 |

| | | | |

| SECTION 3 | | RELIANCE ON OTHER EXPERTS | 35 |

| | | | |

| SECTION 4 | | PROPERTY DESCRIPTION AND LOCATION | 36 |

| | | | |

| 4.1 | | Location | 36 |

| | | | |

| 4.2 | | Mineral Title | 37 |

| | | | |

| 4.3 | | Environmental Liabilities | 39 |

| | | | |

| 4.4 | | Permits | 39 |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| SECTION 5 | | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 40 |

| | | | |

| 5.1 | | Access | 40 |

| | | | |

| 5.2 | | Climate and Length of Operating Season | 40 |

| | | | |

| 5.3 | | Proximity to Population Centre and Transport | 41 |

| | | | |

| 5.4 | | Surface Rights, Land Availability, Infrastructure, and Local Resources | 42 |

| | | | |

| 5.5 | | Topography, Elevation, and Vegetation | 43 |

| | | | |

| SECTION 6 | | HISTORY | 45 |

| | | | |

| 6.1 | | Summary of Regional Exploration and Mining History | 45 |

| | | | |

| 6.2 | | Historical Resource Estimates | 47 |

| | | | |

| SECTION 7 | | GEOLOGICAL SETTING AND MINERALISATION | 50 |

| | | | |

| 7.1 | | Regional Geology | 50 |

| | | | |

| 7.2 | | District Geology | 53 |

| | | | |

| 7.3 | | Property Geology | 53 |

| | | | |

| 7.4 | | Norra Kärr Geology and Mineralisation | 55 |

| | | | |

| SECTION 8 | | DEPOSIT TYPES | 64 |

| | | | |

| 8.1 | | General | 64 |

| | | | |

| 8.2 | | REE Deposits – Discussion | 67 |

| | | | |

| SECTION 9 | | EXPLORATION | 70 |

| | | | |

| 9.1 | | Initial Works | 70 |

| | | | |

| 9.2 | | Topographic Mapping | 71 |

| | | | |

| 9.3 | | Geological Mapping | 74 |

| | | | |

| SECTION 10 | | DRILLING | 86 |

| | | | |

| SECTION 11 | | SAMPLE PREPARATION, ANALYSES, AND SECURITY | 89 |

| | | | |

| 11.1 | | Core Cutting | 89 |

| | | | |

| 11.2 | | Sample Preparation | 89 |

| | | | |

| 11.3 | | Analyses | 90 |

| | | | |

| 11.4 | | QA/QC | 92 |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| 11.5 | | Density Determination | 113 |

| | | | |

| SECTION 12 | | DATA VERIFICATION | 114 |

| | | | |

| 12.1 | | Field Verification | 114 |

| | | | |

| 12.2 | | Sampling Verification | 120 |

| | | | |

| SECTION 13 | | MINERAL PROCESSING AND METALLURGICAL TESTING | 121 |

| | | | |

| 13.1 | | Historical Testing | 121 |

| | | | |

| 13.2 | | Current Testing | 121 |

| | | | |

| 13.3 | | Material Issues and Deleterious Elements | 138 |

| | | | |

| 13.4 | | Summary | 138 |

| | | | |

| SECTION 14 | | MINERAL RESOURCE ESTIMATES | 139 |

| | | | |

| 14.1 | | Current Estimate WAI (2014) | 139 |

| | | | |

| 14.2 | | Topography | 139 |

| | | | |

| 14.3 | | Database Compilation | 140 |

| | | | |

| 14.4 | | Geological Interpretation-Wireframe Modelling | 141 |

| | | | |

| 14.5 | | Sample Data Processing | 145 |

| | | | |

| 14.6 | | Variography | 151 |

| | | | |

| 14.7 | | Volumetric Modelling | 160 |

| | | | |

| 14.8 | | Density | 163 |

| | | | |

| 14.9 | | Grade Estimation | 163 |

| | | | |

| 14.10 | | Validation | 169 |

| | | | |

| 14.11 | | Depletion | 180 |

| | | | |

| 14.12 | | Mineral Resource Classification | 180 |

| | | | |

| SECTION 15 | | MINERAL RESERVE ESTIMATES | 186 |

| | | | |

| 15.1 | | Current Estimate | 186 |

| | | | |

| 15.2 | | Open Pit Mine Planning | 186 |

| | | | |

| 15.3 | | Economic Cut-Off Grades | 191 |

| | | | |

| 15.4 | | Pit Shell Selection | 191 |

| | | | |

| SECTION 16 | | MINING METHODS | 194 |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| 16.1 | | Mining Operations and Equipment | 194 |

| | | | |

| 16.2 | | Equipment Fleet Summary | 198 |

| | | | |

| 16.3 | | Mining Operations | 199 |

| | | | |

| 16.4 | | Mine Manpower Requirements | 201 |

| | | | |

| 16.5 | | Mine Production Schedule | 203 |

| | | | |

| 16.6 | | Geotechnical Parameters | 208 |

| | | | |

| 16.7 | | Open Pit Pumping Requirements | 213 |

| | | | |

| 16.8 | | Waste Rock Dumps | 214 |

| | | | |

| SECTION 17 | | RECOVERY METHODS | 216 |

| | | | |

| 17.1 | | PROCESS DESCRIPTION | 216 |

| | | | |

| 17.2 | | Process Plant Infrastructure and Reagents | 220 |

| | | | |

| SECTION 18 | | PROJECT INFRASTRUCTURE | 222 |

| | | | |

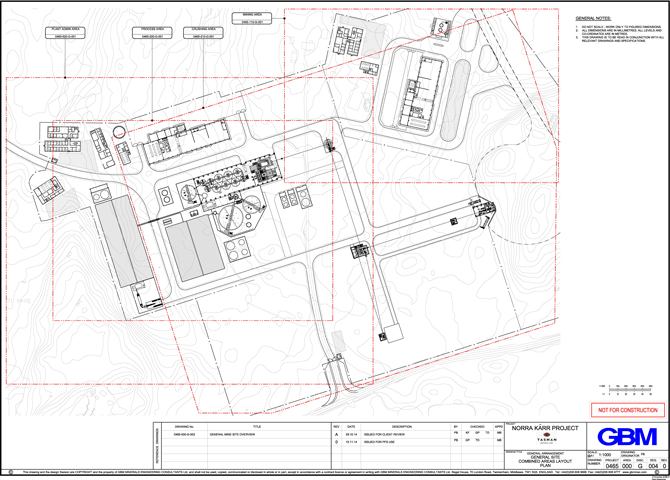

| 18.1 | | Facility Layout | 222 |

| | | | |

| 18.2 | | Access | 222 |

| | | | |

| 18.3 | | Buildings and Structure | 222 |

| | | | |

| 18.4 | | Transportation of Goods and Services | 226 |

| | | | |

| 18.5 | | Power | 226 |

| | | | |

| 18.6 | | Water | 227 |

| | | | |

| 18.7 | | Tailings Facility | 227 |

| | | | |

| SECTION 19 | | MARKET STUDIES AND CONTRACTS | 240 |

| | | | |

| 19.1 | | Overview of Rare Earth Elements and Products | 240 |

| | | | |

| 19.2 | | Rare Earth ELEMENT Production and Supply Forecast | 240 |

| | | | |

| 19.3 | | Rare Earth ELEMENT Consumption and Demand Forecast | 243 |

| | | | |

| 19.4 | | REE Supply/Demand Balance | 248 |

| | | | |

| 19.5 | | REE Pricing and Forecast | 248 |

| | | | |

| 19.6 | | Potential Customers | 251 |

| | | | |

| 19.7 | | Potential Upside From Co-Products | 253 |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| SECTION 20 | | ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 254 |

| | | | |

| 20.1 | | Environmental Summary | 254 |

| | | | |

| 20.2 | | Expected Material Environmental Issues | 279 |

| | | | |

| 20.3 | | Waste and Tailings Disposal | 293 |

| | | | |

| 20.4 | | Site Monitoring | 295 |

| | | | |

| 20.5 | | Water Management | 296 |

| | | | |

| 20.6 | | Permitting | 309 |

| | | | |

| 20.7 | | Social and Community Requirements | 322 |

| | | | |

| 20.8 | | Project Closure | 327 |

| | | | |

| 20.9 | | Health and Safety Issues | 330 |

| | | | |

| SECTION 21 | | CAPITAL AND OPERATING COSTS | 333 |

| | | | |

| 21.1 | | Capital Cost Estimates | 333 |

| | | | |

| 21.2 | | Operating Cost Estimates | 339 |

| | | | |

| SECTION 22 | | ECONOMIC ANALYSIS | 344 |

| | | | |

| SECTION 23 | | ADJACENT PROPERTIES | 349 |

| | | | |

| SECTION 24 | | OTHER RELEVANT DATA AND INFORMATION | 350 |

| | | | |

| 24.1 | | Discounted Cash Flow Model | 350 |

| | | | |

| 24.2 | | Project Execution Plan | 352 |

| | | | |

| SECTION 25 | | INTERPRETATION AND CONCLUSIONS | 353 |

| | | | |

| 25.1 | | Mineral Resources | 353 |

| | | | |

| 25.2 | | Mineral Reserves | 354 |

| | | | |

| 25.3 | | Environmental and Community | 355 |

| | | | |

| SECTION 26 | | RECOMMENDATIONS | 357 |

| | | | |

| 26.1 | | Mineral Reserves | 357 |

| | | | |

| 26.2 | | Tailings Storage Facility | 358 |

| | | | |

| 26.3 | | Metallurgy and Process | 358 |

| | | | |

| 26.4 | | Environmental and Community | 359 |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| SECTION 27 | | REFERENCES | 365 |

| | | | |

| APPENDIX A. | | QUALIFIED PERSONS CERTIFICATES | 370 |

| | | | |

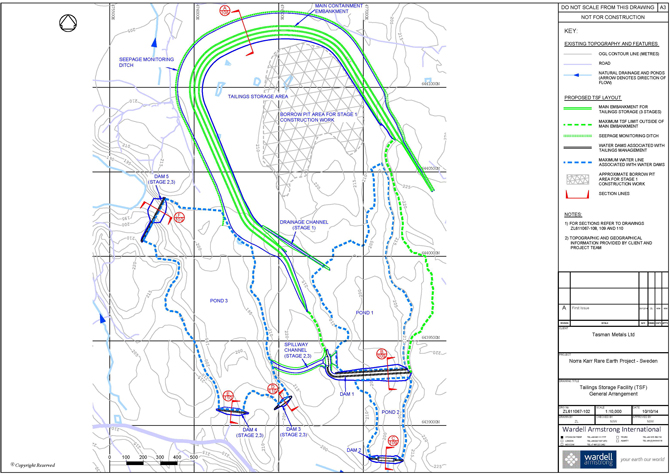

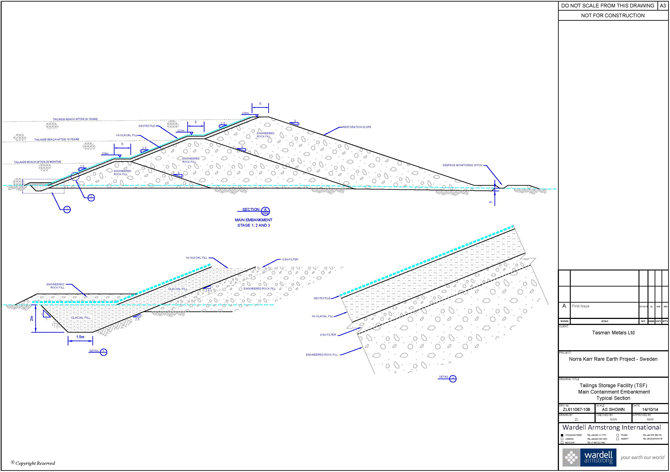

| APPENDIX B. | | WAI TAILINGS DRAWINGS | 371 |

| | | | |

| B.1 | | ZL611067-101-Layout | 371 |

| | | | |

| B.2 | | ZL611067-102-Layout | 371 |

| | | | |

| B.3 | | ZL611067-108-Layout | 371 |

| | | | |

| APPENDIX C. | | GBM LAYOUT DRAWINGS | 372 |

| | | | |

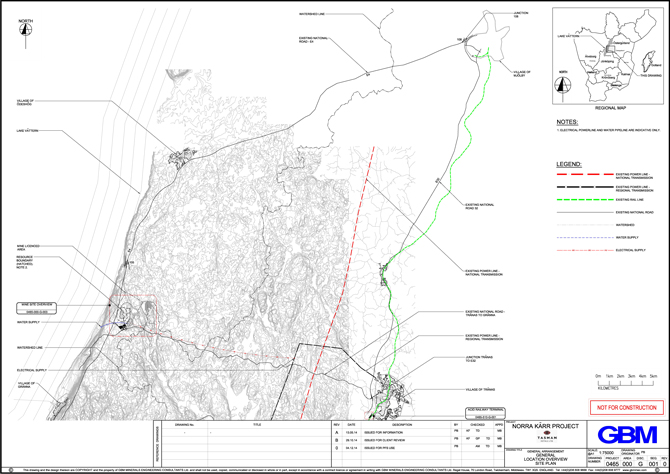

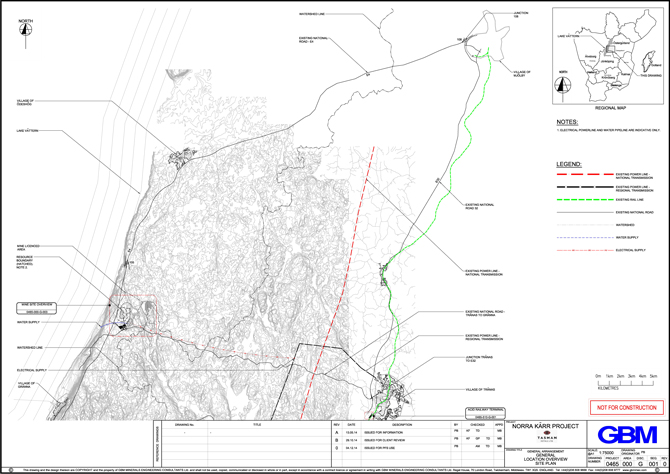

| C.1 | | 0465-000-G-001_Rev0 | 372 |

| | | | |

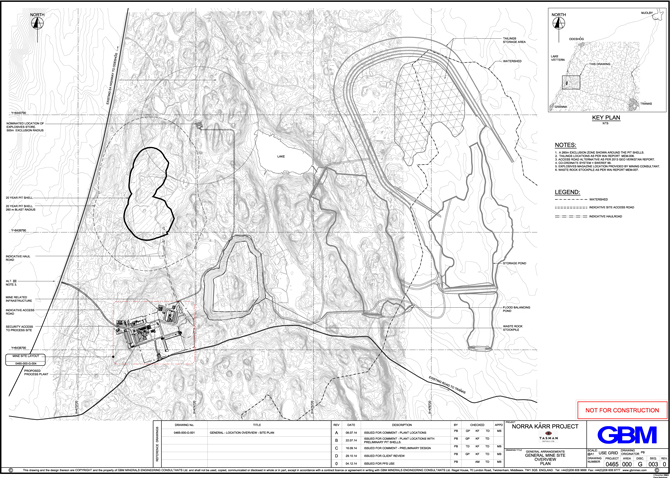

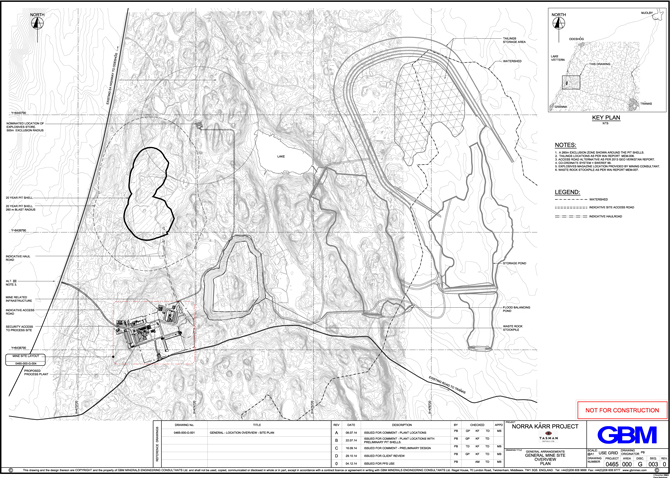

| C.2 | | 0465-000-G-003_Rev0 | 372 |

| | | | |

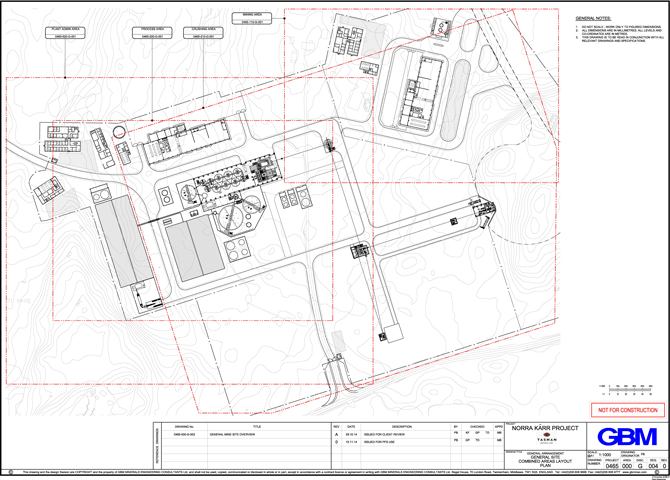

| C.3 | | 0465-000-G-004_Rev0 | 372 |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

LIST OF TABLES

| Table 1-1: Norra Kärr Mineral Resource Estimate (4) | 24 |

| | |

| Table 1-2: Total Project Initial Capital Expenditure | 28 |

| | |

| Table 1-3 Operating Expenditure over Life of Mine | 28 |

| | |

| Table 2-1: Responsible Qualified Persons | 33 |

| | |

| Table 4-1:Tasman Norra Kärr Licence Details | 38 |

| | |

| Table 6-1: Boliden 1974 North Trench Results (PAH, 2012) | 47 |

| | |

| Table 6-2: Boliden 1974 South Trench Results (PAH, 2012) | 47 |

| | |

| Table 6-3: RPM Mineral Resource Statement (March 2012) | 49 |

| | |

| Table 8-1: Primary REE Deposit Types (14) | 64 |

| | |

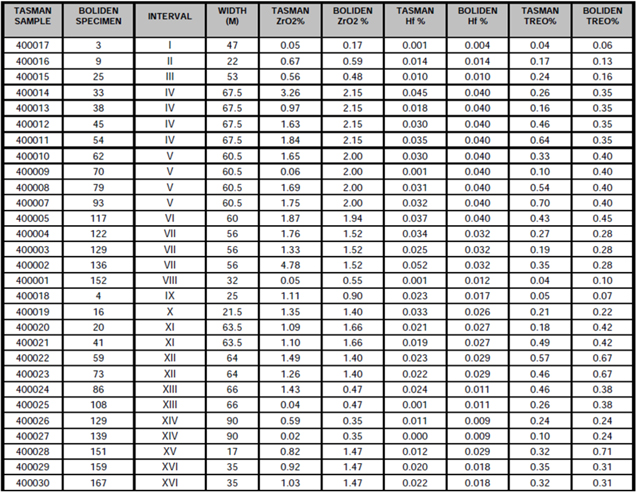

| Table 9-1: Comparison of Tasman Grab Samples vs Boliden Composite Trench Samples | 70 |

| | |

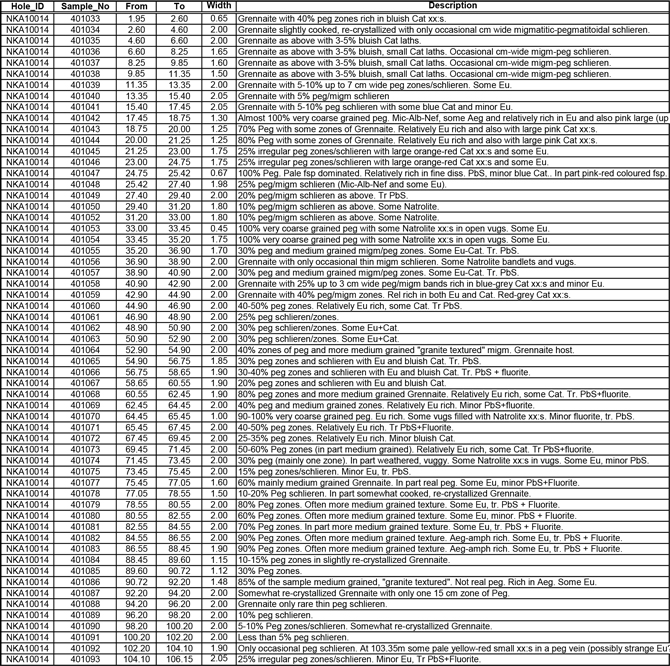

| Table 9-2: Example of Detailed Drill Hole Log (Hole NKA10014) | 81 |

| | |

| Table 10-1: Summary of Tasman Exploration Drilling Activity | 86 |

| | |

| Table 11-1: ALS Chemex ME-MS81 Detection Limits | 91 |

| | |

| Table 11-2: CRM Sample Summary | 102 |

| | |

| Table 11-3: WAI 2014 Duplicate Sample Summary | 109 |

| | |

| Table 11-4: Risk Matrix: QA/QC Sample Auditing | 110 |

| | |

| Table 13-1: RESCOMP Modal Mineralogy | 125 |

| | |

| Table 13-2: Crushing Work Index | 126 |

| | |

| Table 13-3: Bond Mill Work Index | 126 |

| | |

| Table 13-4: Abrasion Index | 126 |

| | |

| Table 13-5: Selected Results for Batch | 132 |

| | |

| Table 13-6: Batch 1 Size-By-Size Yttrium Recovery | 132 |

| | |

| Table 13-7 REE oxalate concentrate chemical analyses | 137 |

| | |

| Table 14-1: Sample Data Summary | 140 |

| | |

| Table 14-2: Selected Sample Summary by LTYPE | 145 |

| | |

| Table 14-3: Decile Analysis – Sm LTYPE 4 | 149 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Table 14-4: Norra Kärr Top-Cut Summary | 150 |

| | |

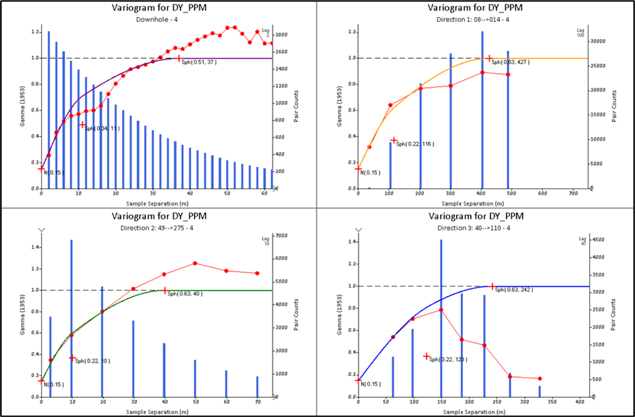

| Table 14-5: Summary of Variogram Models | 155 |

| | |

| Table 14-6: Summary of Block Model Parameters | 160 |

| | |

| Table 14-7: Estimation Parameters for Dip and Dip Direction | 161 |

| | |

| Table 14-8: Density Values Applied by Zone | 163 |

| | |

| Table 14-9: Grade Estimation Parameters | 168 |

| | |

| Table 14-10: Initial Search Ellipse Sizes for Grade Estimation | 168 |

| | |

| Table 14-11: Validation Stats - Composite Grades vs Block Grades | 172 |

| | |

| Table 14-12: Norra Kärr Mineral Resource Estimate Pit Optimisation Parameters (WAI, 2014) | 183 |

| | |

| Table 14-13: Rare Earth Oxide Conversion Factors (PAH, 2011) (4) | 184 |

| | |

| Table 14-14: Norra Kärr Mineral Resource Estimate (WAI, 2014) | 185 |

| | |

| Table 15-1: Norra Kärr Pit Optimisation Parameters | 189 |

| | |

| Table 15-2: Economic Cut-Off Grades (PGT & GTM) | 191 |

| | |

| Table 15-3: Norra Kärr Mineral Reserve Estimate (WAI, November 2014) | 193 |

| | |

| Table 16-1: Loading Parameters | 197 |

| | |

| Table 16-2: Truck Loading and Dumping Parameters | 197 |

| | |

| Table 16-3: Mining Equipment Fleet | 198 |

| | |

| Table 16-4: Haul Road Design Parameters | 200 |

| | |

| Table 16-5: Salary Structure | 201 |

| | |

| Table 16-6: Mining Personnel Requirements | 202 |

| | |

| Table 16-7: Mining Production Schedule | 204 |

| | |

| Table 16-8: Sector Stereographic Analysis | 208 |

| | |

| Table 16-9: Sector Slope Angles | 209 |

| | |

| Table 16-10: Predicted inflow rates | 213 |

| | |

| Table 16-11: Pump Specifications | 214 |

| | |

| Table 17-1 Process design criteria | 216 |

| | |

| Table 17-2 REE Overall Recovery | 217 |

| | |

| Table 18-1 Building and Structure Details of Nora Kärr process plant | 223 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Table 18-2: Assumed Waste Stream Parameters | 234 |

| | |

| Table 18-3: Approximate earthworks quantities for TSF construction | 236 |

| | |

| Table 18-4: Principal TSF dimensions | 237 |

| | |

| Table 19-1: Global Rare Earth Production by Country (t) | 241 |

| | |

| Table 19-2: 2013 REE Production | 241 |

| | |

| Table 19-3: Demand Summary | 245 |

| | |

| Table 19-4 REO Price Deck | 250 |

| | |

| Table 19-5 Estimated REO Demand | 252 |

| | |

| Table 20-1: Baseline studies prepared by other experts | 255 |

| | |

| Table 20-2: Key source documents | 256 |

| | |

| Table 20-3: Baseline Studies Relating to Surface Water | 264 |

| | |

| Table 20-4: Ecology baseline studies | 270 |

| | |

| Table 20-5: Archaeological baseline study | 273 |

| | |

| Table 20-6: Cultural heritage objects | 274 |

| | |

| Table 20-7: Input Meteorological Data and WAI snowmelt adjustment | 299 |

| | |

| Table 20-8: Percentile Annual Precipitation Depths | 299 |

| | |

| Table 20-9: Haul and Access road areas | 302 |

| | |

| Table 20-10: Objectives and area of application of the Environmental Code | 309 |

| | |

| Table 20-11: Required permits | 320 |

| | |

| Table 20-12: Activities Subject to the Permitting Process of Environmental Code | 321 |

| | |

| Table 20-13: Responses, September 2014 telephone survey (Skop / Kristdemokraterna) | 326 |

| | |

| Table 20-14: Responses, August 2014 web panel survey (Novus / P4 radio) | 326 |

| | |

| Table 20-15: Most Relevant Swedish H&S Regulations | 331 |

| | |

| Table 21-1 Total capital cost estimate | 335 |

| | |

| Table 21-2: Mining CAPEX Summary | 336 |

| | |

| Table 21-3 Process Capital estimate summary | 337 |

| | |

| Table 21-4: TSF Budget Cost Summary | 338 |

| | |

| Table 21-5 Operating Summary | 339 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Table 21-6: Mining Operating Costs | 342 |

| | |

| Table 21-7: Bill of Rates – Labour | 343 |

| | |

| Table 22-1 Key input parameters | 344 |

| | |

| Table 22-2 REO Prices used in Financial model | 345 |

| | |

| Table 22-3 DCF results for Norra Kärr in USD | 346 |

LIST OF FIGURES

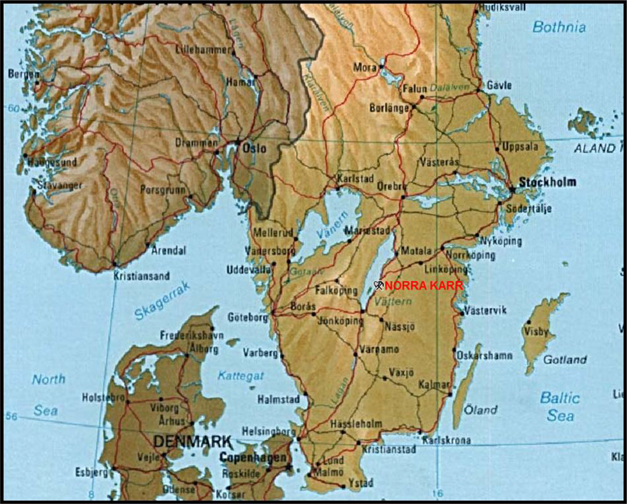

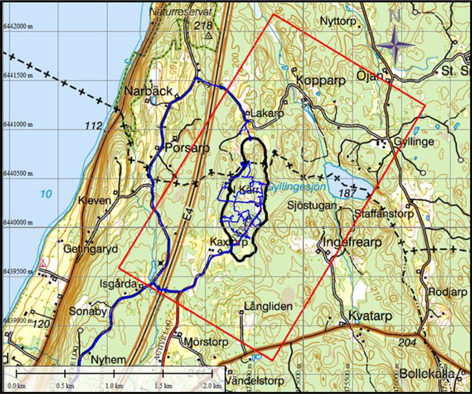

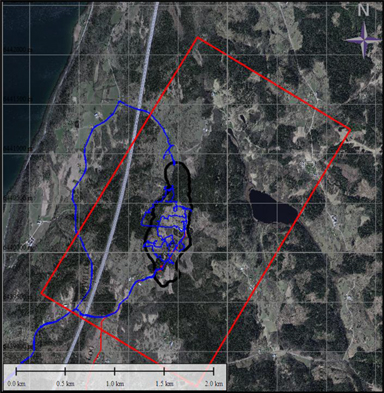

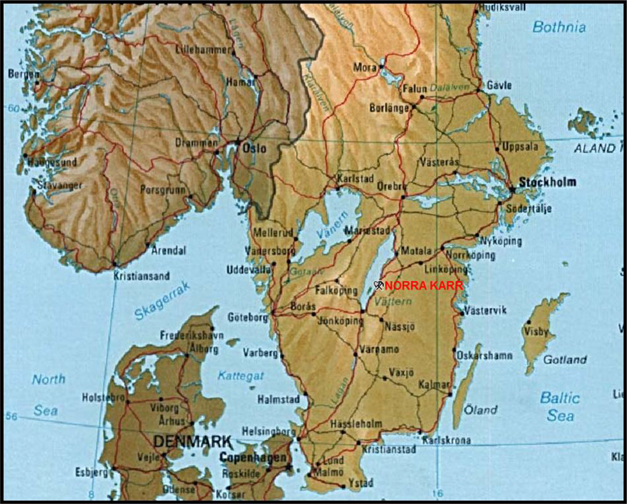

| Figure 4-1: Location of the Norra Kärr Project, Sweden | 36 |

| | |

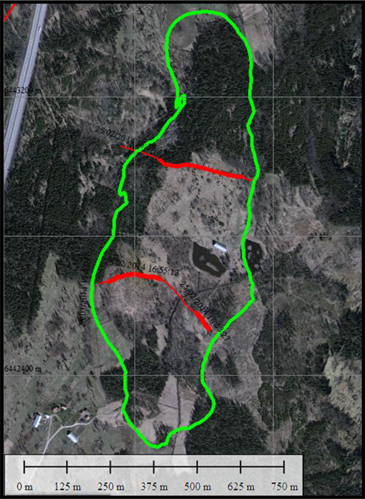

| Figure 4-2: Relative Position of the Norra Kärr Licences (s.l.) | 37 |

| | |

| Figure 6-1: Location of the Boliden 1974 Trenches | 46 |

| | |

| Figure 7-1: Litho-Tectonic and Shear Zone Map of the Sveco-Norwegian Orogen, South-Western Scandinavia | 50 |

| | |

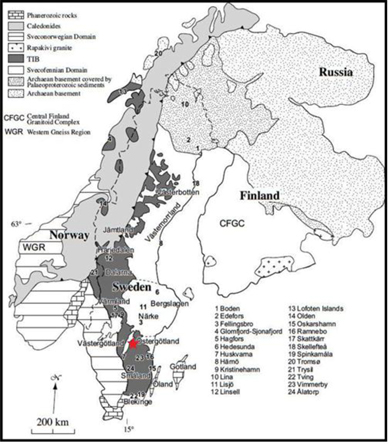

| Figure 7-2: Generalised Geological Map of the Fennoscandian Shield Showing the TIB | 51 |

| | |

| Figure 7-3: Aeromagnetic Anomaly Map of Southern Sweden | 52 |

| | |

| Figure 7-4: Simplified Geological Outline of the Svecconorwegian Orogeny | 53 |

| | |

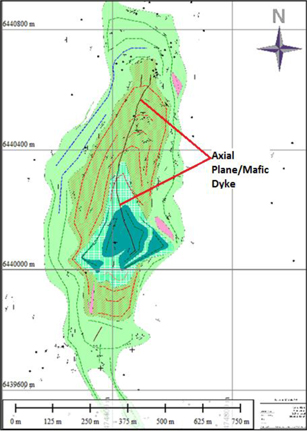

| Figure 7-5: Possible Shearing Movement for the Norra Kärr Intrusive | 55 |

| | |

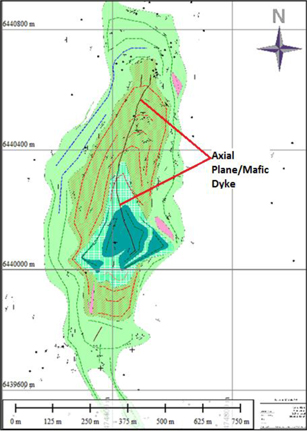

| Figure 7-6 Geological Map of the Norra Kärr Intrusive | 57 |

| | |

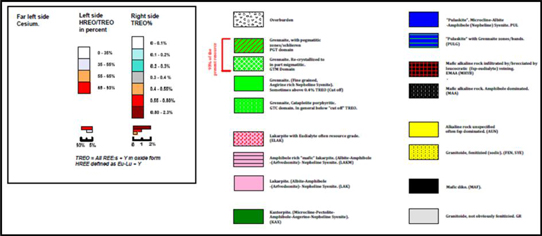

| Figure 7-7: Norra Kärr Intrusive Body Litho Types | 58 |

| | |

| Figure 7-8: Foliated Kaxtorpite | 59 |

| | |

| Figure 7-9: GTM - “Migmatitic” Grennaite Medium Grained | 59 |

| | |

| Figure 7-10: PGT-Pegmatitic Schlieren/Veining in Grennaite, with Elongated Crystals of Catapleiite and Crystals of Eudyalite | 60 |

| | |

| Figure 7-11: GTC-Fine Grained Grennaite with Bluish-White Elongated Catapleiite Crystals | 61 |

| | |

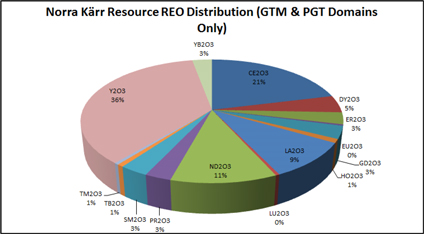

| Figure 7-12: Norra Kärr REE Distribution | 62 |

| | |

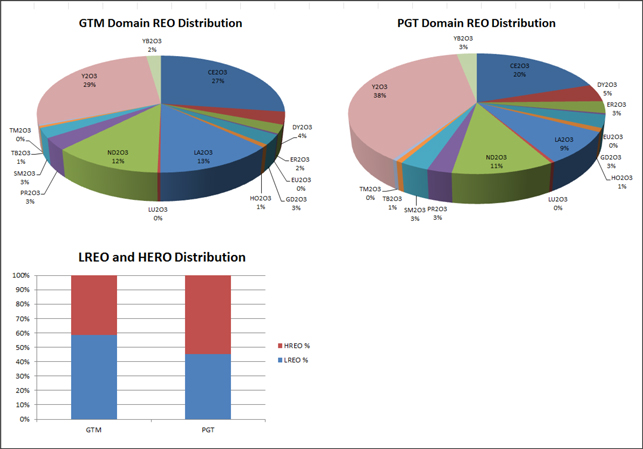

| Figure 7-13: Norra Kärr REO Distribution by Major Ore Types | 62 |

| | |

| Figure 7-14: Norra Kärr REO Distribution by Rock Domain (Chondrite Normalised) | 63 |

| | |

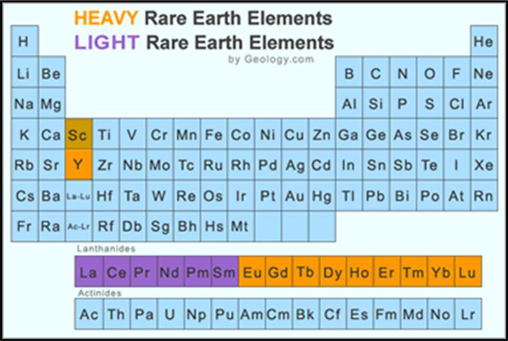

| Figure 8-1: Periodic Table Showing LREO/HERO “Split” | 66 |

| | |

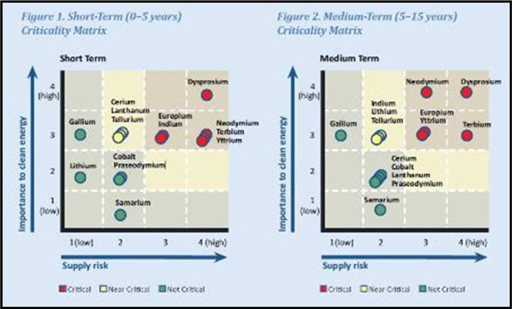

| Figure 8-2: REE Criticality Matrices (14) | 66 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

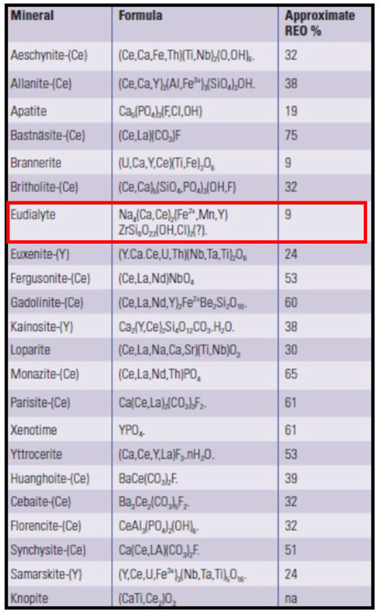

| Figure 8-3: Selection of REE-bearing Mineral (14) | 67 |

| | |

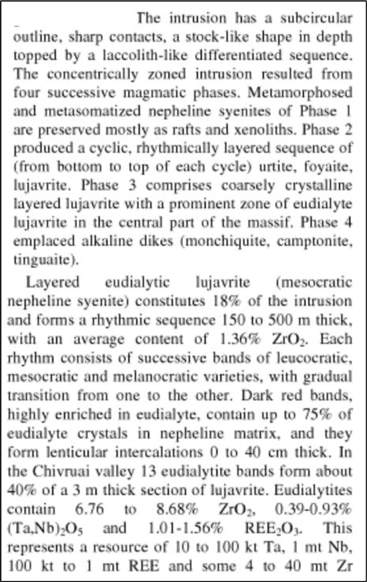

| Figure 8-4: Possible Mode of Formation of the IIimaussaq Intrusion | 69 |

| | |

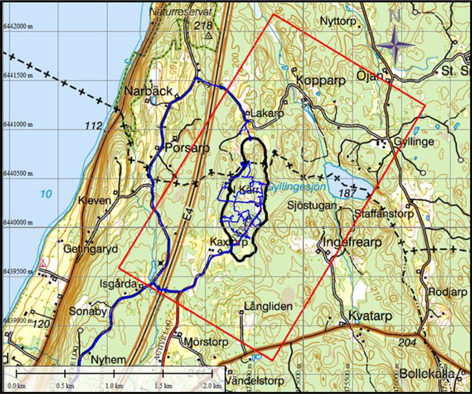

| Figure 9-1: Swedish Survey 1:50 000 Topographic Sheet (56375 DinKarta) | 72 |

| | |

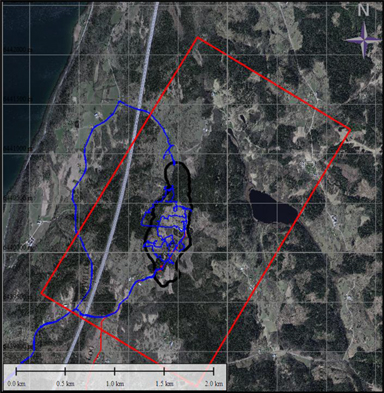

| Figure 9-2: Orthophoto of the Norra Kärr Licence | 72 |

| | |

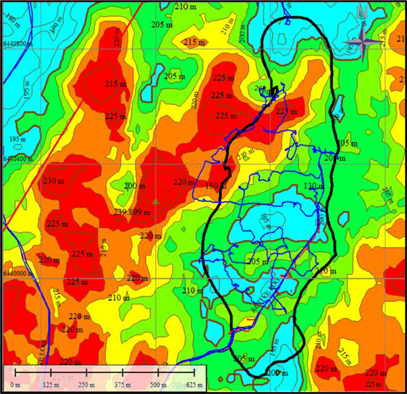

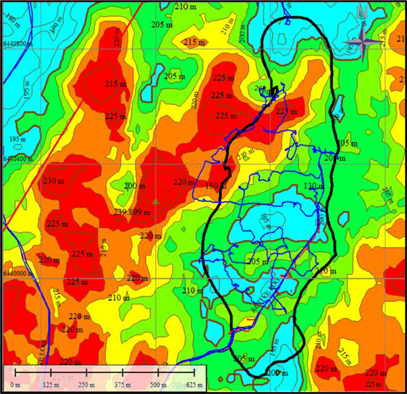

| Figure 9-3: Colour Coded DEM of Norra Kärr | 73 |

| | |

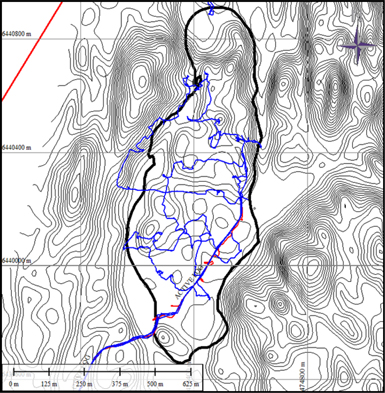

| Figure 9-4: Contour Plan of Norra Kärr at 1 m Intervals | 73 |

| | |

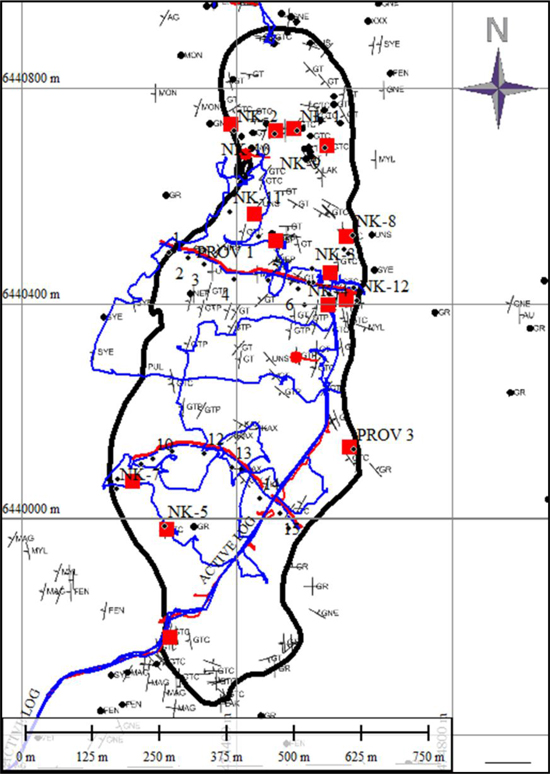

| Figure 9-5: Geological Plan Showing Observation Points and the Old Boliden Pits | 75 |

| | |

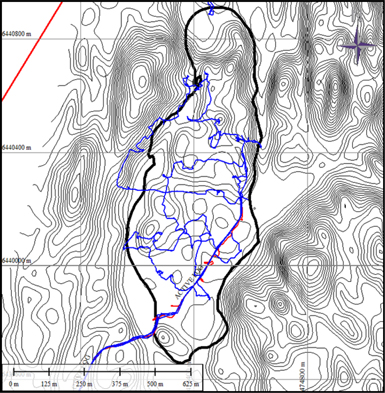

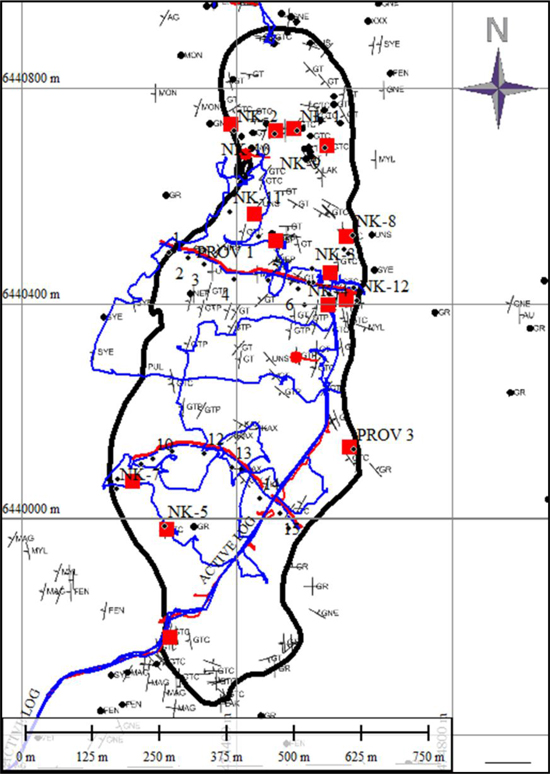

| Figure 9-6 Geological Map of the Norra Kärr Intrusive Showing Drill Hole Traces | 77 |

| | |

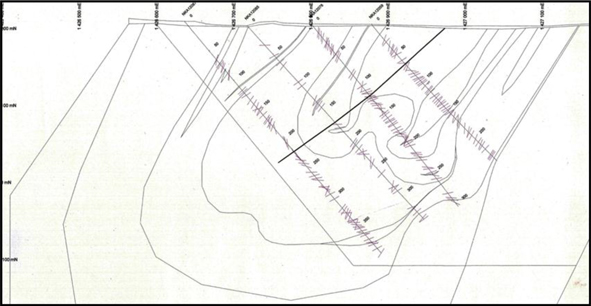

| Figure 9-7: Geological Plan of Norra Kärr Showing Foliation Trends | 79 |

| | |

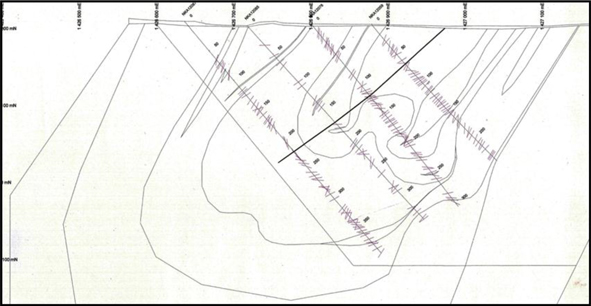

| Figure 9-8: “Typical” Geological Section of Norra Kärr Showing Foliation Trends | 79 |

| | |

| Figure 9-9: Core Photography and Corresponding Strip Log | 80 |

| | |

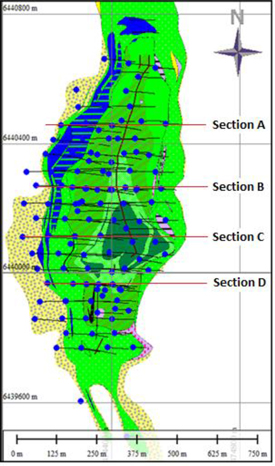

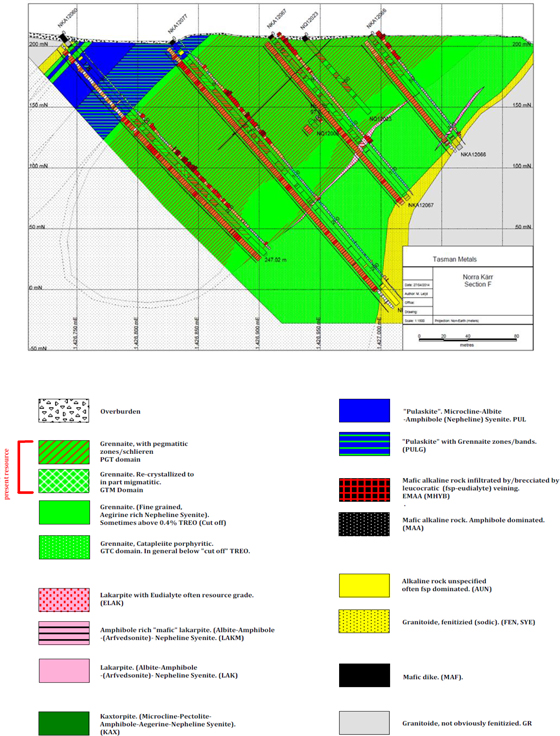

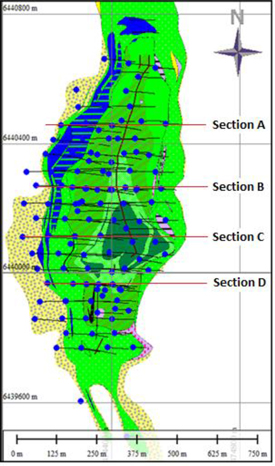

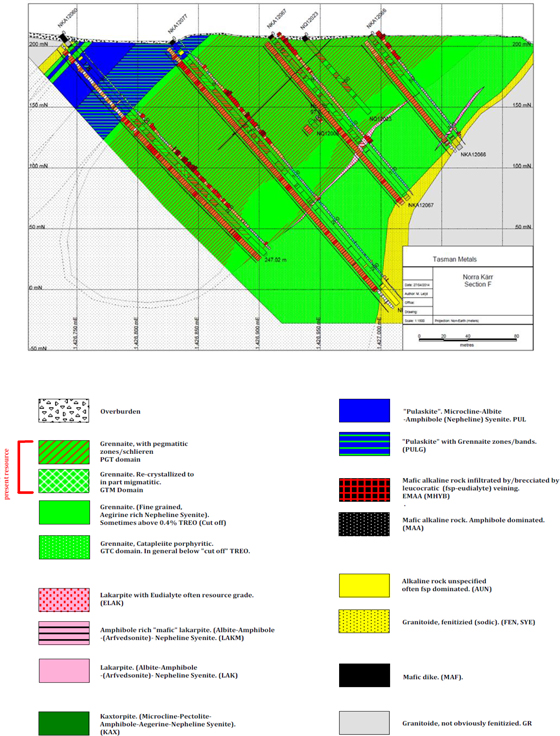

| Figure 9-10: Legend for Geological Sections (Section A | 82 |

| | |

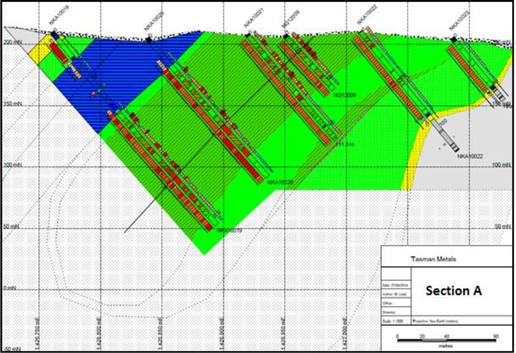

| Figure 9-11: Section A, Geological Cross Section | 82 |

| | |

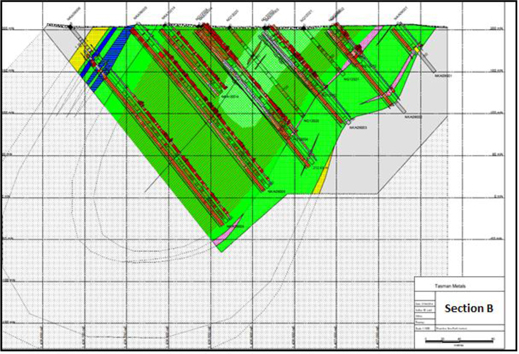

| Figure 9-12: Section B, Geological Cross Section | 83 |

| | |

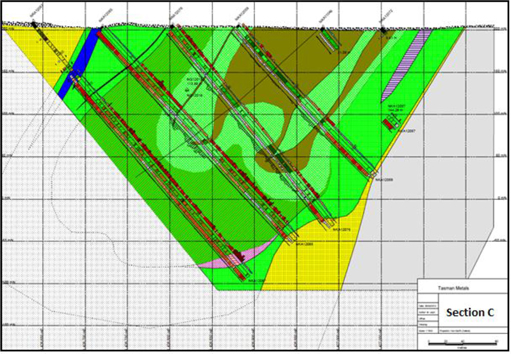

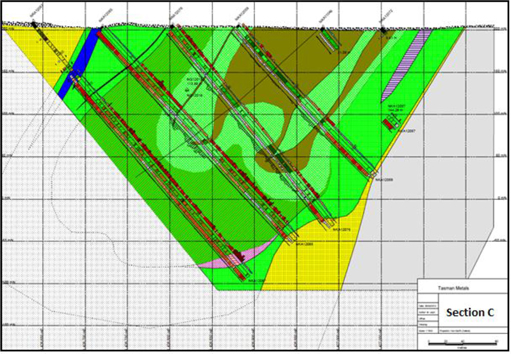

| Figure 9-13: Section C, Geological Cross Section | 84 |

| | |

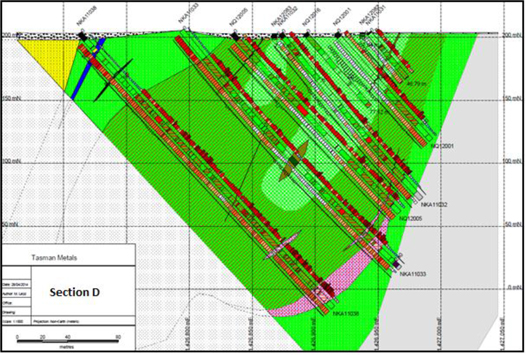

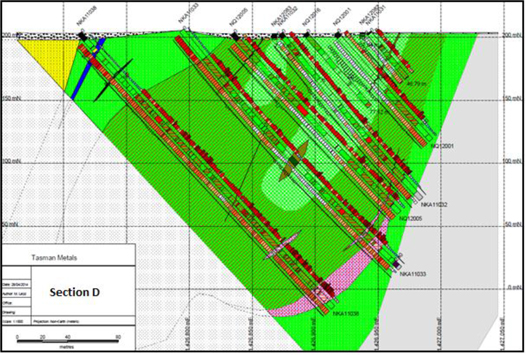

| Figure 9-14: Section D, Geological Cross Section | 85 |

| | |

| Figure 10-1: Core Logging Facility | 88 |

| | |

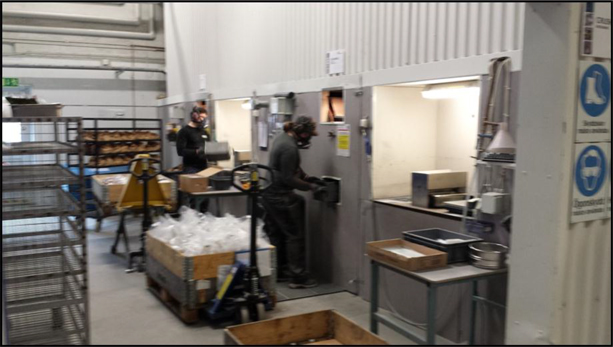

| Figure 11-1: ALS Chemex Sample Preparation Facility Piteå | 90 |

| | |

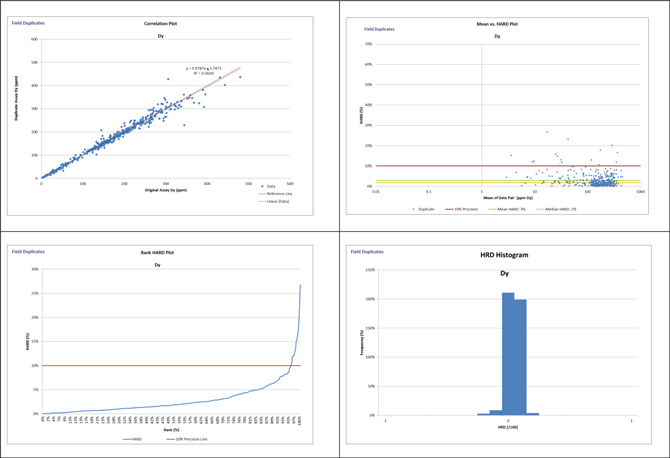

| Figure 11-2: Dy Field Duplicate QA/QC Results | 93 |

| | |

| Figure 11-3: Y Field Duplicate QA/QC Results | 94 |

| | |

| Figure 11-4: Nd Field Duplicate QA/QC Results | 95 |

| | |

| Figure 11-5: Dy Laboratory Duplicate QA/QC Results | 97 |

| | |

| Figure 11-6: Y Laboratory Duplicate QA/QC Results | 98 |

| | |

| Figure 11-7: Nd Laboratory Duplicate QA/QC Results | 99 |

| | |

| Figure 11-8: Dy Blank Sample Results | 100 |

| | |

| Figure 11-9: Y Blank Sample Results | 101 |

| | |

| Figure 11-10: Nd Blank Sample Results | 101 |

| | |

| Figure 11-11: CRM OREAS 100a Dy Results | 105 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Figure 11-12: CRM OREAS 100a Nd Results | 105 |

| | |

| Figure 11-13: CRM OREAS 104 Eu Results | 106 |

| | |

| Figure 11-14: CRM OREAS 45p Y Results | 106 |

| | |

| Figure 11-15: CRM OREAS 45c Dy Results | 107 |

| | |

| Figure 11-16: CRM NKA01 Dy Results | 107 |

| | |

| Figure 11-17: CRM NKA02 Gd Results | 108 |

| | |

| Figure 11-18: Dy ACTLABS External Duplicates | 112 |

| | |

| Figure 12-1: Tasman Geologists at a Typical Norra Kärr Outcrop | 115 |

| | |

| Figure 12-2: Site of Former Boliden Excavation | 115 |

| | |

| Figure 12-3: Pegmatitic Grennaite (PGT Domain) | 116 |

| | |

| Figure 12-4: The “Discovery” Outcrop Showing Pink Eudyalite | 116 |

| | |

| Figure 12-5: Plan Showing Drill Hole Collar Positions and the WAI Site Visit Trajectory | 118 |

| | |

| Figure 12-6: Enlarged Image Showing Drill Hole Sites and WAI Site Visit Trajectory | 119 |

| | |

| Figure 12-7: Drill Hole Collar Marked by Casing | 119 |

| | |

| Figure 13-1: ANZAPLAN composite locations | 123 |

| | |

| Figure 13-2: Norra Kärr Surface Resource Map with Borehole Locations | 124 |

| | |

| Figure 13-3: ANZAPLAN Modal Mineralogy | 127 |

| | |

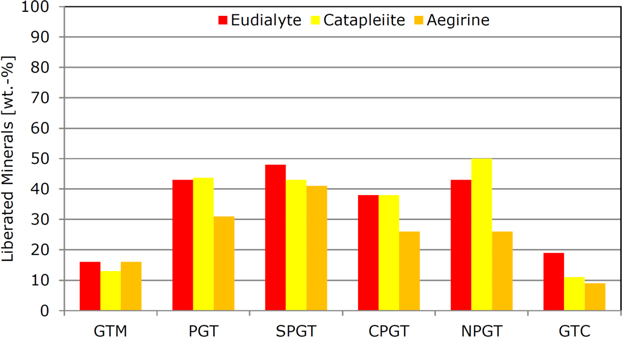

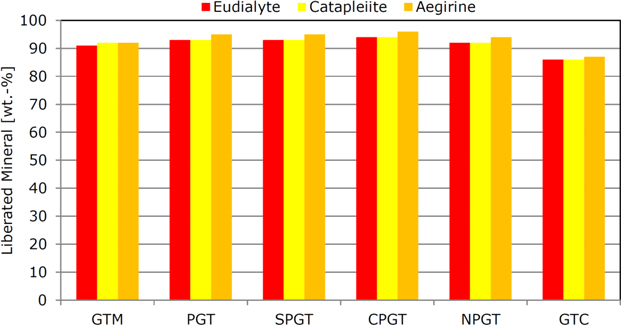

| Figure 13-4: Comparison of mineral liberation for samples GTM, PGT, SPGT, CPGT, NPGT and GTC in fraction 0.1 mm to 0.5 mm | 128 |

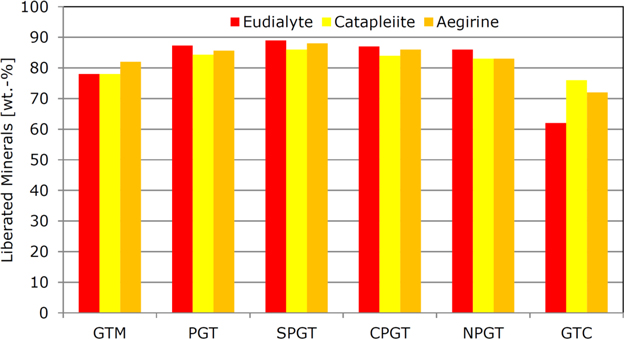

| | |

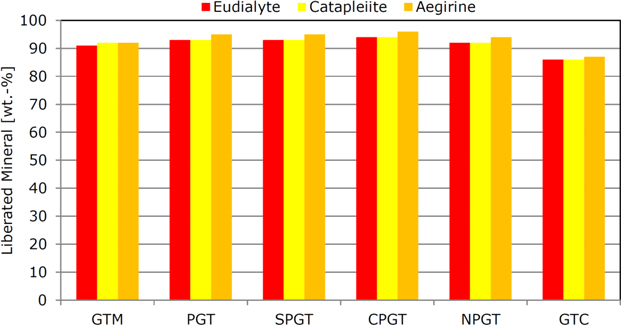

| Figure 13-5: Comparison of mineral liberation for samples GTM, PGT, SPGT, CPGT, NPGT and GTC in fraction 0.02 mm to 0.1 mm | 128 |

| | |

| Figure 13-6: Comparison of mineral liberation for samples GTM, PGT, SPGT, CPGT, NPGT and GTC in fraction <0 02 mm | 129 |

| | |

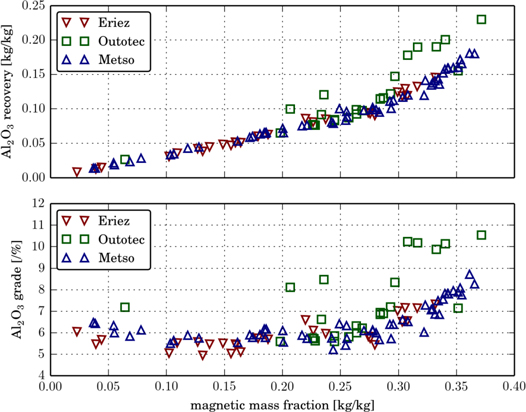

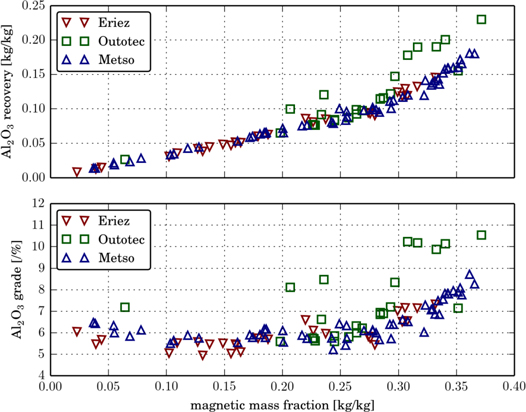

| Figure 13-7: Aluminium Grade and Recovery Versus Magnetic Mass Fraction | 130 |

| | |

| Figure 13-8: Yttrium Grade and Recovery Versus Magnetic Mass Fraction | 131 |

| | |

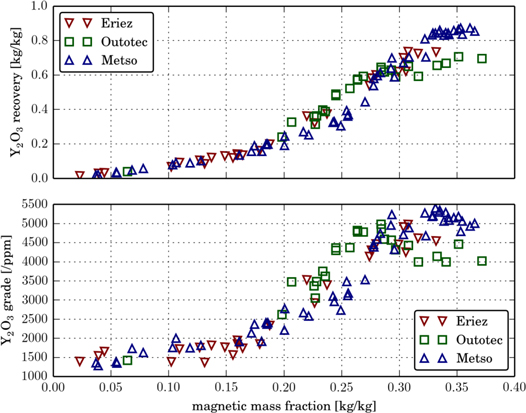

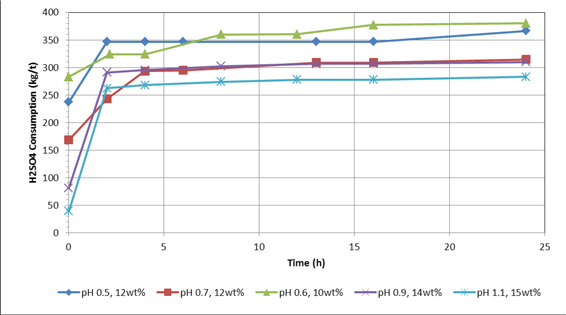

| Figure 13-9 Acid consumption | 134 |

| | |

| Figure 13-10 Acid consumption | 134 |

| | |

| Figure 13-11 Cerium equilibrium loading isotherm | 136 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Figure 13-12 Yttrium equilibrium loading isotherm | 136 |

| | |

| Figure 14-1: Drill Hole Layout and Topographic Plan (WAI, 2014) | 139 |

| | |

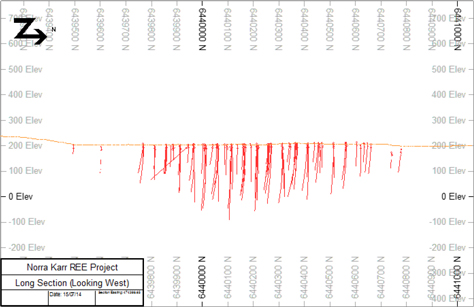

| Figure 14-2: Long Section of Norra Kärr Drill Holes, Easting Line 474398.65 | 141 |

| | |

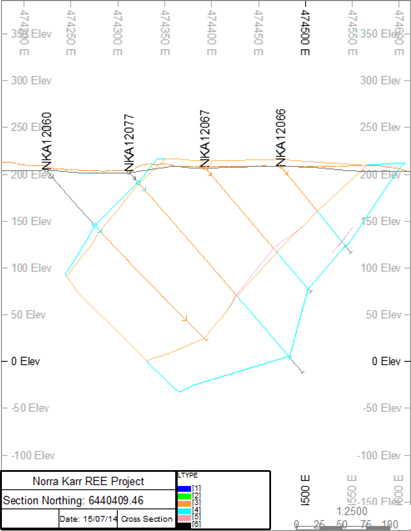

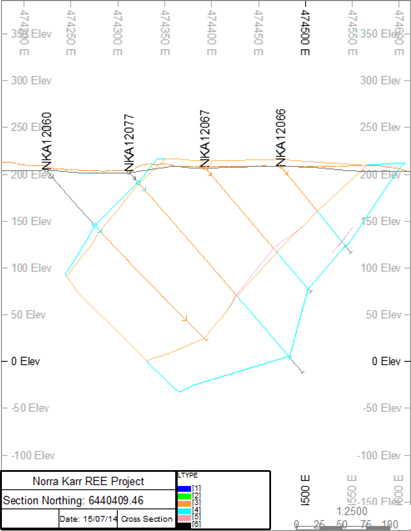

| Figure 14-3: Tasman Geological Interpretation Cross Section – Northing 6440409.46 | 143 |

| | |

| Figure 14-4: WAI Mineralised Wireframe Cross Section – Northing 6440409.46 (SWEREF99TM) | 144 |

| | |

| Figure 14-5: WAI Mineralisation Wireframes Longsection – Looking West | 145 |

| | |

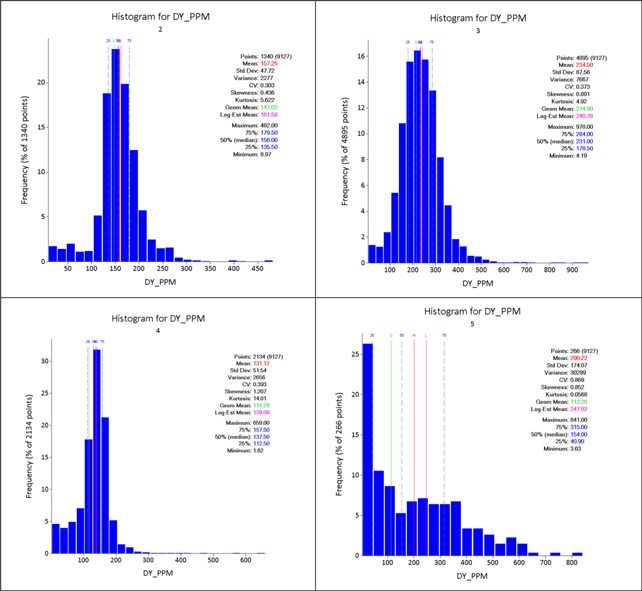

| Figure 14-6: Dy Histogram Plots for LTYPES 2 to 5 | 147 |

| | |

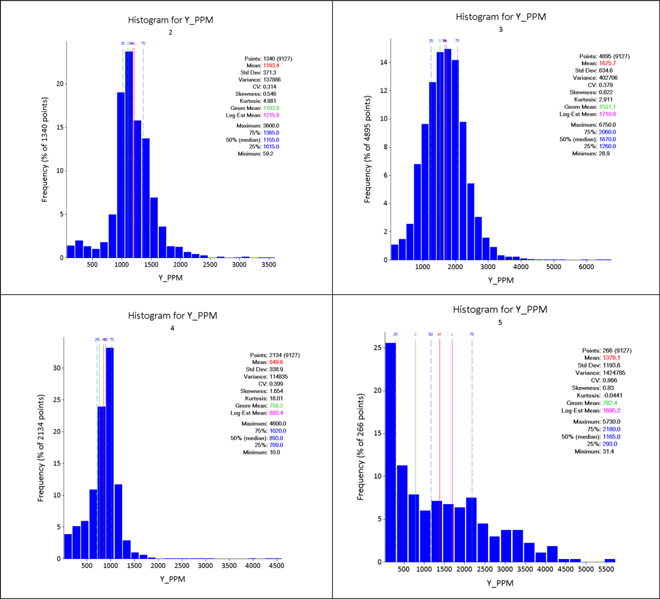

| Figure 14-7: Y Histogram Plots for LTYPES 2 to 5 | 148 |

| | |

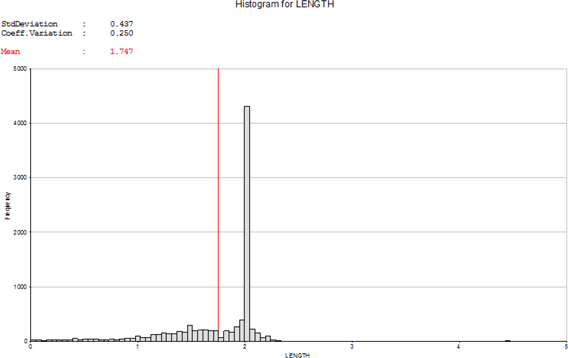

| Figure 14-8: Average Sample Length Histogram | 151 |

| | |

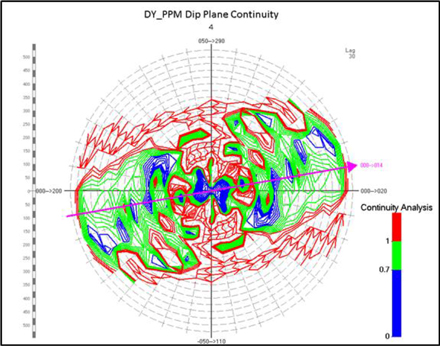

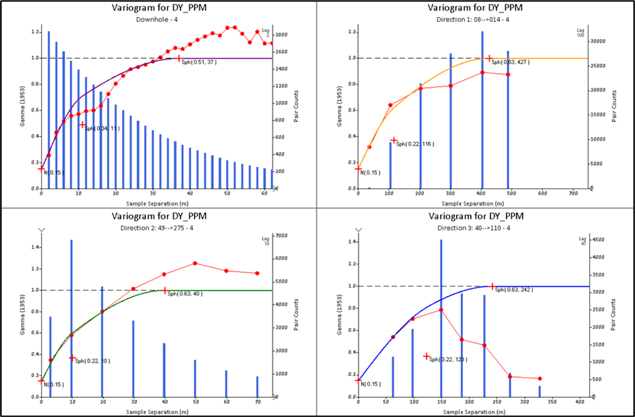

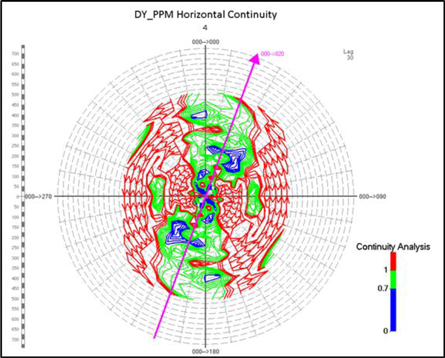

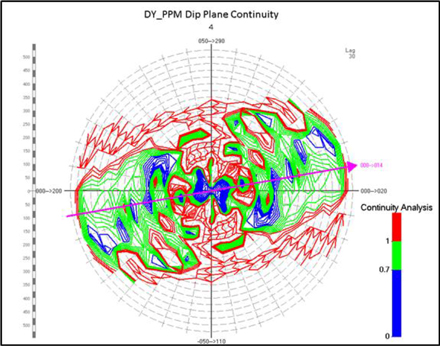

| Figure 14-9: Continuity Maps of Dy for the Porphyritic Grennaite (LTYPE=4). Horizontal Continuity (Top) and Dip Plane Continuity (Bottom) | 153 |

| | |

| Figure 14-10: Variogram Models for Dy – Porphyritic Grennaite (LTYPE=4) | 154 |

| | |

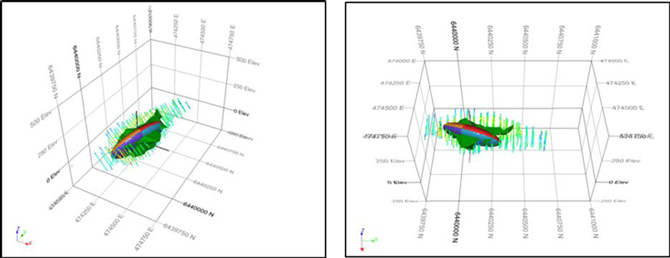

| Figure 14-11: Ellipse Representing Variogram Ranges and GTM Wireframe | 159 |

| | |

| Figure 14-12: Ellipse Representing Variogram Ranges and Grennaite with Pegmatitic Zones Wireframe | 159 |

| | |

| Figure 14-13: Ellipse Representing Variogram Ranges with Porphyritic Grennaite Wireframe | 160 |

| | |

| Figure 14-14: Vertical Section Showing Estimated Dip and Dip Direction at Y=6,440,015 | 162 |

| | |

| Figure 14-15: Vertical Section Showing Estimated Dip and Dip Direction at Y=6,440,115 | 162 |

| | |

| Figure 14-16: KNA Results for Block Size Using Dy in Grennaite with Pegamatitic Zones | 164 |

| | |

| Figure 14-17: KNA Results for Varying Number of Samples Used During Estimation Using Dy in Grennaite with Pegmatitic Zones | 165 |

| | |

| Figure 14-18: KNA Results for Varying Search Ellipse Sizes Using Dy in Grennaite with Pegmatitic Zones | 166 |

| | |

| Figure 14-19: KNA Results for Varying Block Discretisation Using Dy in Grennaite with Pegmatitic Zones | 167 |

| | |

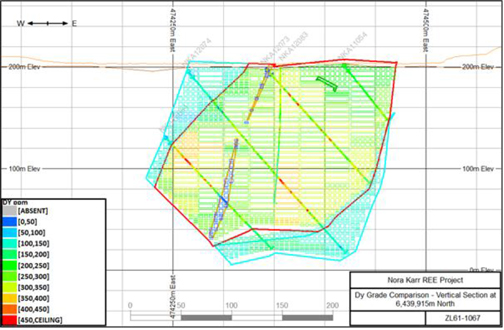

| Figure 14-20: Example East-West Vertical Section Showing Composite and Estimated Grades at Northing=6439915 | 170 |

| | |

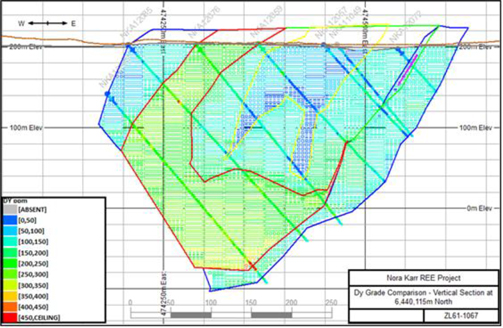

| Figure 14-21: Example East-West Vertical Section Showing Composite and Estimated Grades at Northing=6440115 | 170 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Figure 14-22: Example East-West Vertical Section Showing Composite and Estimated Grades at Northing=6440215 | 171 |

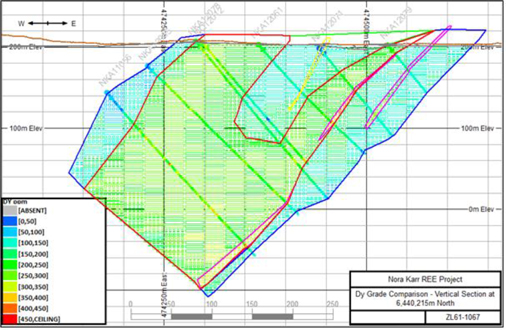

| | |

| Figure 14-23: Example East-West Vertical Section Showing Composite and Estimated Grades at Northing=6440315 | 171 |

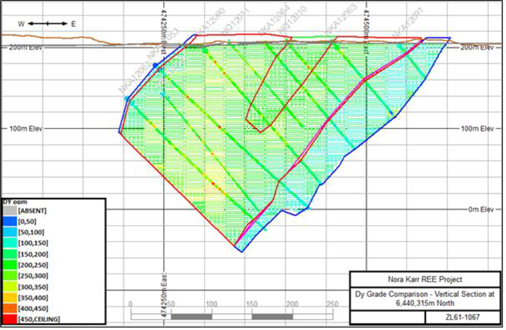

| | |

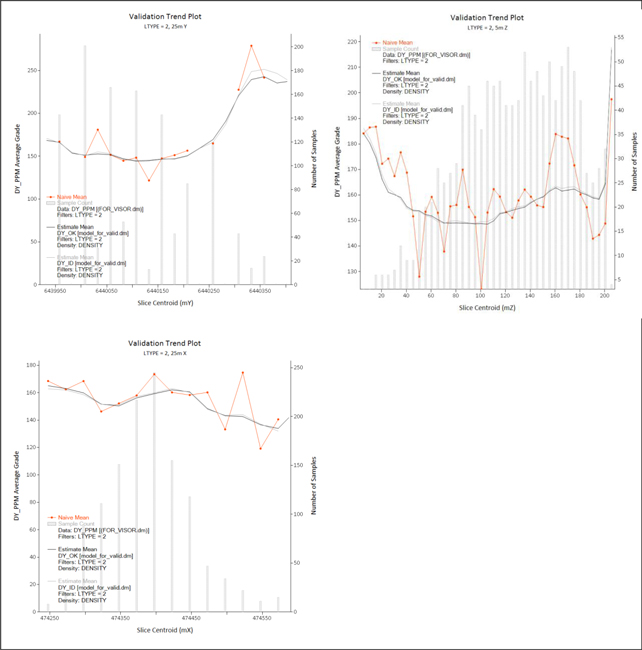

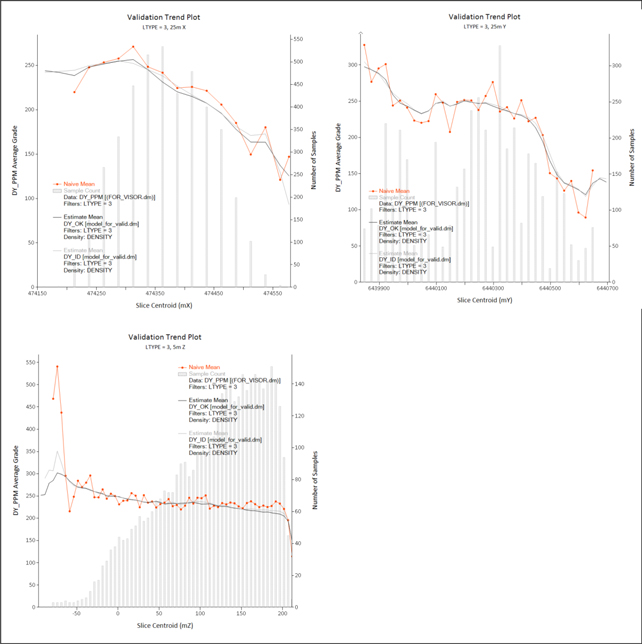

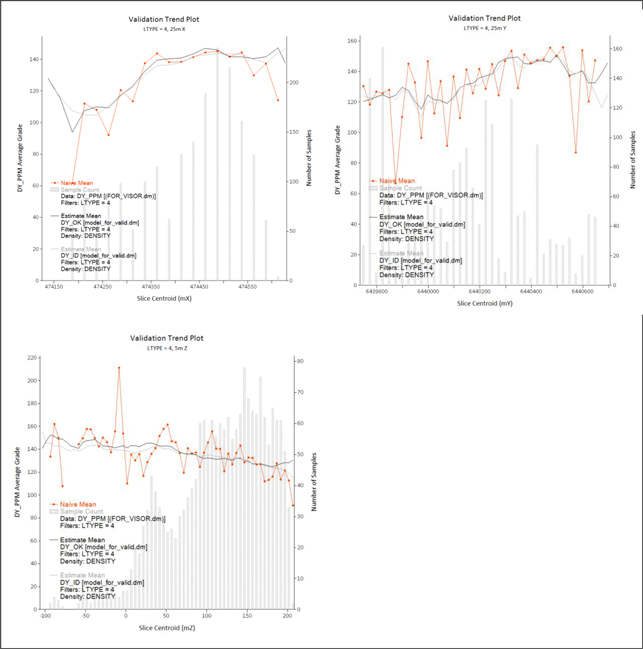

| Figure 14-24: Grade Profile Plots for Dy | 177 |

| | |

| Figure 14-25: Grade Profile Plots for Dy in Grennaite with Pegmatitic Zones | 178 |

| | |

| Figure 14-26: Grade Profile Plots for Dy in Porphyritic Grennaite | 179 |

| | |

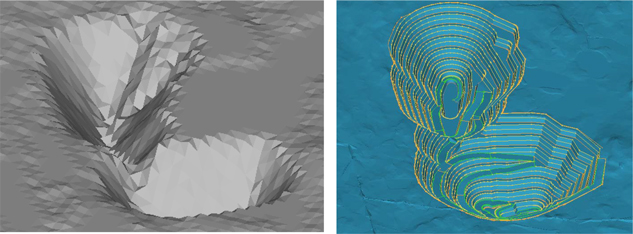

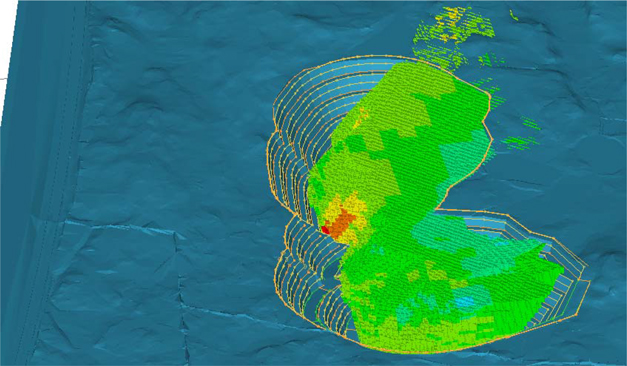

| Figure 15-1: Norra Kärr – Cut away view – Pit Design and Block Model | 188 |

| | |

| Figure 15-2: Norra Kärr – Optimised Ultimate Pit and Design Pit Shell | 188 |

| | |

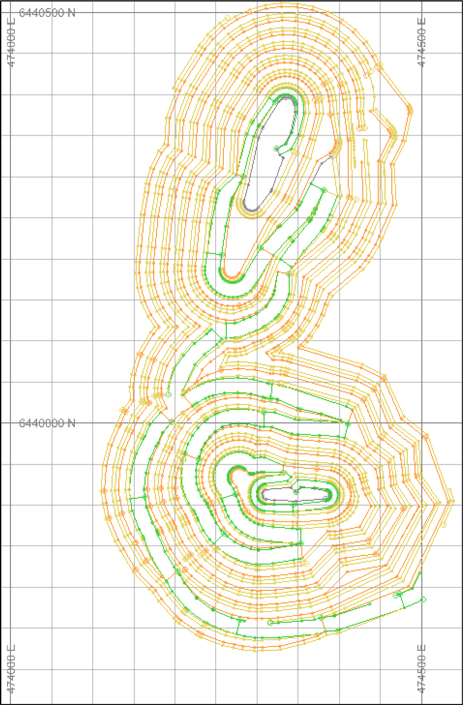

| Figure 15-3 Norra Kärr – Plan of Final Pit Design | 192 |

| | |

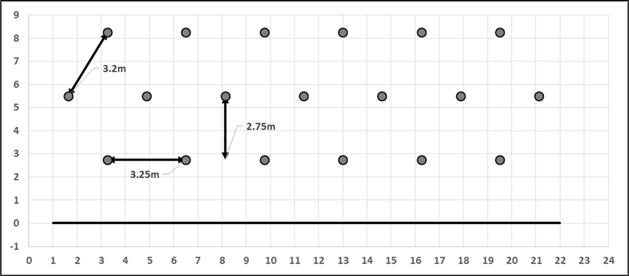

| Figure 16-1: Example Blast Pattern | 195 |

| | |

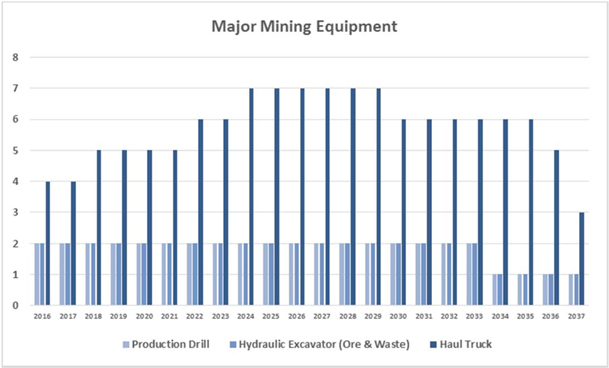

| Figure 16-2: LOM Equipment Profile | 198 |

| | |

| Figure 16-3: Site Plan, Main Haul Roads | 200 |

| | |

| Figure 16-4: Typical Haul Road Construction (CAT Publication) (14) | 201 |

| | |

| Figure 16-5: Mining Schedule Summary | 203 |

| | |

| Figure 16-6 Norra Kärr – Pushbacks and Final Designs | 206 |

| | |

| Figure 16-7 Norra Kärr – Final Design with Topography and E4 Highway | 207 |

| | |

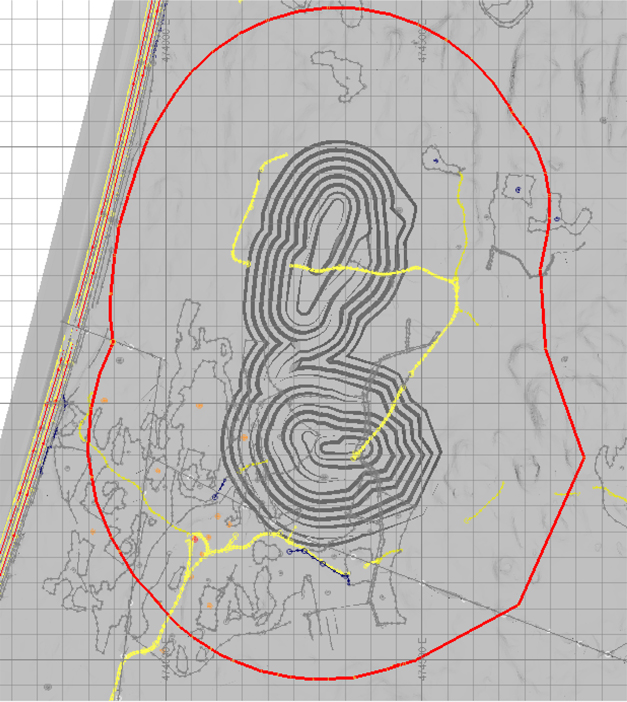

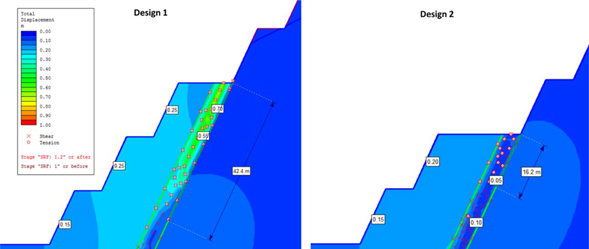

| Figure 16-8: Phase2 Models of Total Displacement of South East Fault Design 1 and 2 | 210 |

| | |

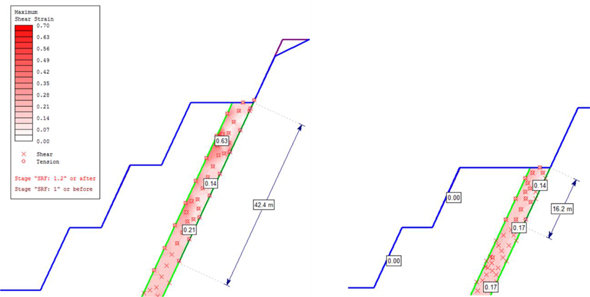

| Figure 16-9: Phase2 Models of Maximum Shear Strain of SE Fault Design 1 and 2, | 211 |

| | |

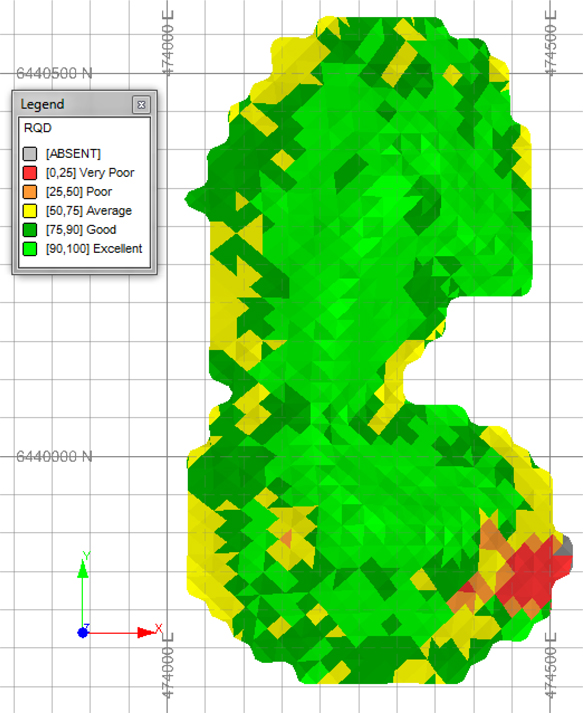

| Figure 16-10: Optimised Pit Shell with Interpolated RQD on Shell Surface | 212 |

| | |

| Figure 16-11: Proposed Mine Waste Dump Site | 215 |

| | |

| Figure 17-1 Comminution and Beneficiation Block Flow Diagram | 218 |

| | |

| Figure 17-2: Hydrometallurgical Extraction and Recovery Block Flow Diagram | 220 |

| | |

| Figure 18-1 Plant and Infrastructure layout | 222 |

| | |

| Figure 18-2: Localisation Study TSF option sites | 228 |

| | |

| Figure 18-3: Proposed Layout of TSF | 230 |

| | |

| Figure 18-4: Geology of TSF site | 231 |

| | |

| Figure 19-1: Estimated Global REO Supply (by Element) | 243 |

| | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Figure 19-2: Breakdown of Rare Earth Usage by Element 2013 | 244 |

| | |

| Figure 19-3: Identification of Critical Rare Earth Elements - Percentage Over/Under Supply | 248 |

| | |

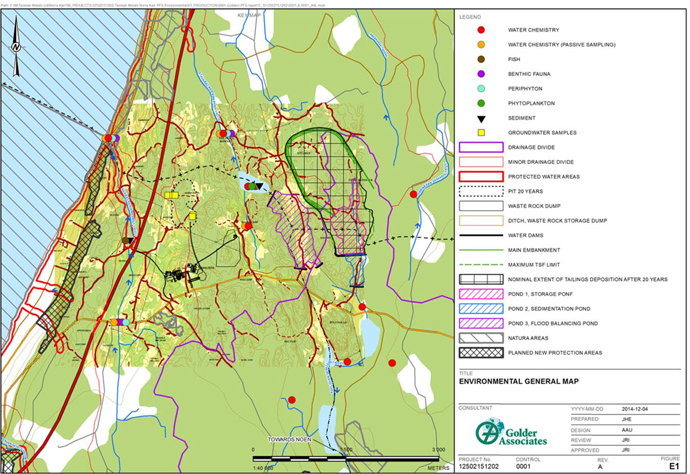

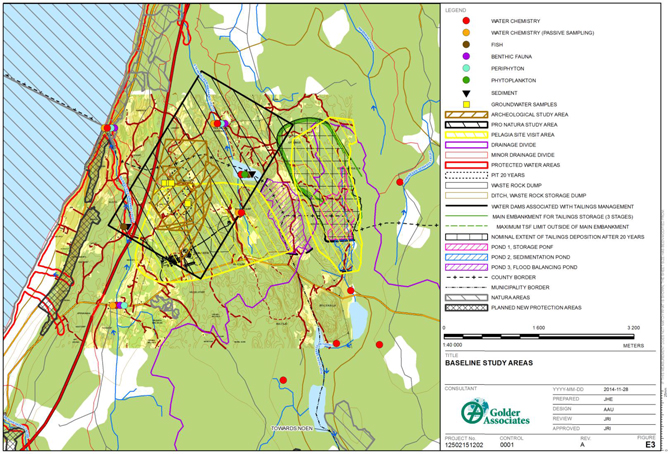

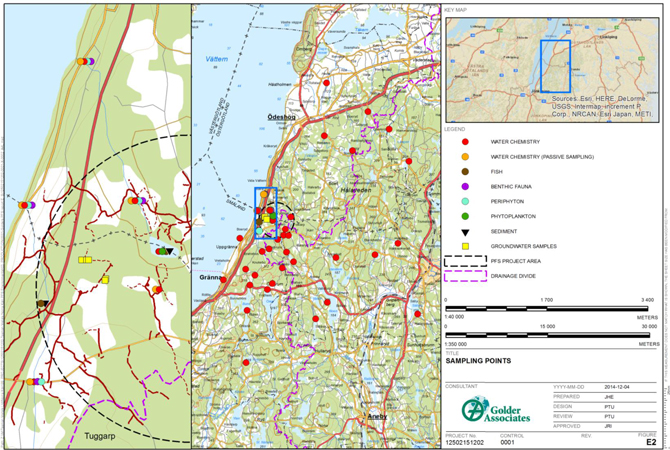

| Figure 20-1: Environmental context | 258 |

| | |

| Figure 20-2: Environment within and near the Project site is characterised by an interaction of human and natural factors. Typical landscape includes agricultural land and deciduous trees | 259 |

| | |

| Figure 20-3: Lush vegetation at Natura 2000 site Narbäck | 261 |

| | |

| Figure 20-4: Adelövån stream at Häggebäcken (between Gransjön and Hultsjön) | 266 |

| | |

| Figure 20-5: Lake Gyllingesjön | 267 |

| | |

| Figure 20-6: A mosaic of environments typical of the project area and environs | 269 |

| | |

| Figure 20-7: Great ash trees in the exploitation concession area, near the outcrop | 272 |

| | |

| Figure 20-8: Areas covered by terrestrial baseline studies | 275 |

| | |

| Figure 20-9: Sampling Point Locations | 277 |

| | |

| Figure 20-10: This pond within the concession area is home to great crested newt | 288 |

| | |

| Figure 20-11: Conceptual Water Balance flow diagram | 303 |

| | |

| Figure 20-12: Indicated required additional storage volumes (all climatic scenarios) | 305 |

| | |

| Figure 20-13: Total discharge to Adelövån (Extreme Wet scenario) | 306 |

| | |

| Figure 20-14: Swedish mining permitting process. Permits needed to open a mine in Sweden | 313 |

| | |

| Figure 20-15: Permitting process according to Environmental Code | 314 |

| | |

| Figure 21-1 Total project operating costs breakdown | 340 |

| | |

| Figure 21-2 Reagent cost breakdown | 341 |

| | |

| Figure 22-1 Percent of Design Capacity versus Months since Commissioning | 345 |

| | |

| Figure 22-2 Norra Kärr at 10 % discount rate | 346 |

| | |

| Figure 22-3 Norra Kärr Project at 10 % discount rate | 347 |

| | |

| Figure 22-4 Norra Kärr Project at 10 % discount rate | 348 |

| | |

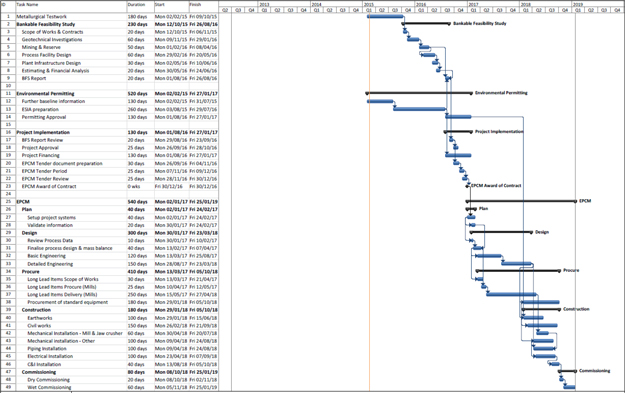

| Figure 24-1 Norra Kärr Implementation schedule | 352 |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

Standard Terms and Nomenclature

The following abbreviations are used throughout this report:

| Abbreviation | | Description |

| 5DP | | Studio 5D Planner® |

| AMSL | | Above mean sea level |

| BFA | | Bench Face Angle |

| BGS | | British Geological Survey |

| CAPEX | | Capital Expenditure |

| CRM | | Certified Reference Materials |

| DCF | | Discounted Cash Flow |

| EIA | | Environmental Impact Assessment |

| EPCM | | Engineering Procurement Construction Management |

| EQS | | Environmental Quality Standards |

| EU | | European Union |

| Ga | | Gigaannum (one billion years) |

| GBM | | GBM Minerals Engineering Consultants Limited |

| Golder | | Golder Associates |

| HGMS | | High Grade Material Separation |

| HREE | | Heavy Rare Earth Elements |

| HREO | | Heavy Rare Earth Oxides |

| ICP | | Inductively Coupled Plasma |

| ICP-AES | | Inductively Coupled Plasma – Atomic Emission Spectrometry |

| ICP-MS | | Inductively Coupled Plasma – Mass Spectrometry |

| IDW2 | | Inverse Power of Distance Squared |

| IRA | | Inter-ramp Angle |

| IRR | | Internal Rate of Return |

| IUCN | | International Union for Conservation of Nature and Natural Resources |

| KNA | | Kriging Neighbourhood Analysis |

| LOM | | Life of Mine |

| LREE | | Light Rare Earth Elements |

| LREO | | Light Rare Earth Oxides |

| MLA | | Mineral Liberation Analysis |

| MMCRM | | Matrix-matched Certified Reference Material |

| MREE | | Medium Rare Earth Elements |

| n/a | | Not applicable |

| NN | | Nearest Neighbour |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Abbreviation | | Description |

| NPV | | Net Present Value |

| NPVS | | NPV Scheduler® |

| NSD | | North Scandinavian Drilling |

| OEM | | Original Equipment Manufacturers |

| OK | | Ordinary Kriging |

| Olstam BT | | Olstam Borrteknik AB |

| OPEX | | Operating Expenditure |

| OREAS | | Ore Research and Exploration Pty Ltd |

| PEA | | Preliminary Economic Assessment |

| PFS | | Pre-Feasibility Study |

| PLS | | Pregnant Leach Solution |

| QA/QC | | Quality Assurance/Quality Control |

| REE | | Rare Earth Elements |

| REO | | Rare Earth Oxides |

| RL | | Relative Level |

| RO | | Reverse Osmosis |

| ROM | | Run of Mine |

| RPM | | Runge Pincock Minarco |

| RQD | | Rock Quality Designation |

| SGU | | Swedish Geological Survey |

| SWWB | | Site Wide Water Balance |

| TIB | | Trans Scandinavian Igneous Belt |

| TREE | | Total Rare Earth Elements |

| TREO | | Total Rare Earth Element Oxides |

| USA | | United States of America |

| USD | | United States Dollar |

| WAI | | Wardell Armstrong International |

| SRF (FoS) | | Strength Reduction Factor (Factor of Safety) |

The following terms and definitions are used throughout this report:

| Term | | Description |

| | | |

| Effective Date (1) | | The date of the most recent scientific or technical information, included in the Technical Report. |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Term | | Description |

| | | |

| Feasibility Study (FS) (2) | | A Feasibility Study is a comprehensive technical and economic study of the selected development option for a mineral project, that includes appropriately detailed assessments of realistically assumed mining, processing, metallurgical, economic, marketing, legal, environmental, social and governmental considerations, together with any other relevant operational factors and detailed financial analysis, that are necessary to demonstrate at the time of reporting that extraction is reasonably justified (economically mineable). The results of the study may reasonably serve as the basis for a final decision by a proponent or financial institution to proceed with, or finance, the development of the project. The confidence level of the study will be higher than that of a Pre-Feasibility Study. |

| | | |

| Inferred Mineral Resources (2) | | An Inferred Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality can be estimated on the basis of geological evidence and limited sampling and reasonably assumed, but not verified, geological and grade continuity. The estimate is based on limited information and sampling gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drillholes. |

| | | |

| Indicated Mineral Resources (2) | | An Indicated Mineral Resource is that part of a Mineral Resource for which quantity, grade or quality, densities, shape and physical characteristics, can be estimated with a level of confidence sufficient to allow the appropriate application of technical and economic parameters, to support mine planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drillholes that are spaced closely enough for geological and grade continuity to be reasonably assumed. |

| | | |

| Measured Mineral Resources (2) | | A Measured Mineral Resource is that part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are so well established that they can be estimated with confidence sufficient to allow the appropriate application of technical and economic parameters, to support production planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration, sampling and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drillholes that are spaced closely enough to confirm both geological and grade continuity. |

| | | |

| Mineral Reserves (2) | | A Mineral Reserve is the economically mineable part of a Measured or Indicated Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. A Mineral Reserve includes diluting materials and allowances for losses that may occur when the material is mined. |

| | | |

| Mineral Resources (2) | | A Mineral Resource is a concentration or occurrence of diamonds, natural solid inorganic material, or natural solid fossilised organic material including base or precious metals, coal and industrial minerals in or on the Earth’s crust in such form and quantity and of such a grade or quality that it has reasonable prospects for economic extraction. The location, quantity, grade, geological characteristics and continuity of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge. |

| | | |

| Ore | | A naturally occurring solid material from which a metal or valuable mineral can be extracted profitably. Ore implies technical feasibility and economic viability that should only be attributed to Mineral Reserves. |

| | | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Term | | Description |

| | | |

| Preliminary Feasibility Study or Pre-Feasibility Study (PFS) (2) | | A Preliminary Feasibility Study is a comprehensive study of a range of options for the technical and economic viability of a mineral project that has advanced to a stage where a preferred mining method, in the case of underground mining, or the pit configuration, in the case of an open pit, is established and an effective method of mineral processing is determined. It includes a financial analysis based on reasonable assumptions on mining, processing, metallurgical, economic, marketing, legal, environmental, social and governmental considerations and the evaluation of any other relevant factors which are sufficient for a Qualified Person, acting reasonably, to determine if all or part of the Mineral Resource may be classified as a Mineral Reserve. |

| | | |

| Preliminary Economic Assessment (PEA) (2) | | Means a study, other than a Pre-Feasibility Study or Feasibility Study, that includes economic analysis of the potential viability of mineral resources. |

| | | |

| Probable Mineral Reserve (2) | | A Probable Mineral Reserve is the economically mineable part of an Indicated and, in some circumstances, a Measured Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. |

| | | |

| Proven Mineral Reserve (2) | | A Proven Mineral Reserve is the economically mineable part of a Measured Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction is justified. |

| | | |

| Qualified Person (2) | | A Qualified Person means an individual who is an engineer or geoscientist with at least five years of experience in mineral exploration, mine development or operation or mineral project assessment, or any combination of these; has experience relevant to the subject matter of the mineral project and the Technical Report; and is a member or licensee in good standing of an approved professional association. |

| | | |

| Technical Report (2) | | Means a report prepared and filed in accordance with National Instrument 43-101 and includes, in summary form, all material scientific and technical information in respect of the subject property as of the effective date of the technical report. |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

Section 1 Summary

This technical report has been prepared by GBM Minerals Engineering Consultants Limited (GBM), Wardell Armstrong International Limited (WAI) and Golder Associates (Golder) on behalf of Tasman Metals Limited (Tasman), who engaged them to prepare a Technical Report in compliance with Canadian Securities Administrators’ National Instrument 43-101 on the Preliminary Feasibility of the Norra Kärr Alkaline Complex Rare Earth Element Deposit (the Norra Kärr project), which is located in Gränna, Sweden.

Located in south-central Sweden, approximately 300 km south-west of Stockholm the project is positioned approximately 15 km north-east of the small town of Gränna in a rural agrarian setting. The Norra Kärr project consists of four claims, Norra Kärr No. 1, Norra Kärr No. 2, Norra Kärr No. 3 and Norra Kärr No. 4, comprising approximately 5 079 hectares.

The project occurs along the border of two counties (Län), the Jönköpings Län in the south and the Östergötlans Läns in the north. The Norra Kärr property is an intermediate stage exploration project whose surface has been disturbed only by exploration drilling, trenching and sampling.

Tasman holds its mineral properties indirectly through its 100 percent owned subsidiary, Tasman Metals AB. holds a 100 percent interest in the four exploration claims, with Claim 1 holding an exploitation concession, that together form the Norra Kärr project.

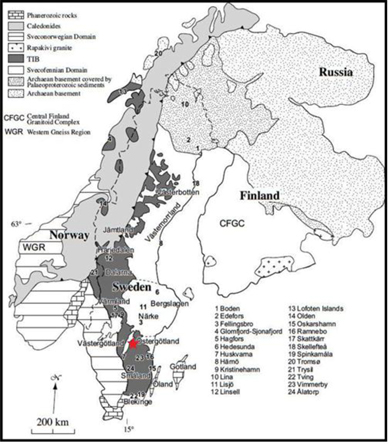

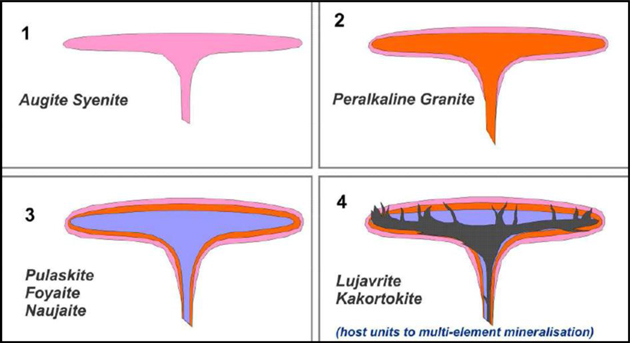

The Norra Kärr complex is a zoned agpaitic, peralkaline, nepheline syenite - similar in many respects to other well-known peralkaline complexes, e.g. Ilimaussaq in Greenland and Lovozero on the Kola Peninsula of Russia. Norra Kärr has been emplaced in a rift setting (Lake Vättern, 2 km to the west of Norra Kärr) within the Trans Scandinavian Igneous Belt (TIB). The TIB comprises a giant elongated array of batholiths extending c. 1 400 km across the Scandinavian Peninsula from south eastern most Sweden to north western Norway. The Norra Kärr complex is intruded into rocks of the TIB – specifically the Växjö Granite of the Småland-Värmland belt and is developed as an ovoid mass with an areal extent of some 1.3 km by 450 m.

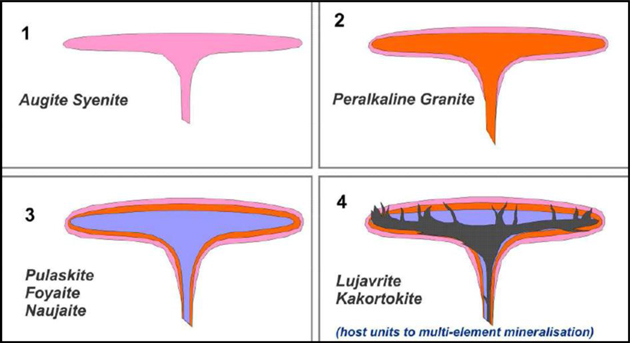

The Norra Kärr intrusive exhibits a clear concentric layering. It is not clear if this is primary igneous layering or not and in this respect there are again similarities with the type localities of Ilimaussaq and Lovozero. By analogy, it is probable that there is at least a degree of igneous differentiation but the

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

mechanics of this are not yet understood. Layering at Norra Kärr from the centre to the flanks comprises:

| · | A central (but off-set) core of kaxtorpite (KAX) surrounded by; |

| · | A migmatitic grennaite zone (GTM); |

| · | A “pegmatitic” grennatite (GPG or PGT) ± lakarpite (LAK); |

| · | Fine-grained grennaite containing catapleiite (GTC); and |

| · | Various other relatively minor alkaline rocks and mafic intrusives. |

Approximately 75 % of the intrusive consists of varieties of “grennaite” (the name is taken from the nearby town of Gränna), an aegirine-rich nepheline syenite carrying the rare, zircono-silicate minerals, eudialyte and catapleiite. Nearly all of the rare earth element (REE) mineralisation is to be found in the complex zircono-silicate mineral eudialyte with lesser amounts of REE occuring as Ca-LREE-F-silicate (britholite) and trace mosandrite. The eudialyte at Norra Kärr is, relatively rich in REE compared to most other similar deposits and also contains a very high proportion of heavy rare earth oxides (HREO).

| 1.4 | Metallurgical Testwork and Process Design |

The mineral processing and hydrometallurgical plant design was prepared based on information generated by the testwork conducted by WAI, JKTech, Geological Survey of Finland, Dorfner ANZAPLAN and ANSTO Minerals as well as design experience provided by GBM. The process design is preliminary in nature and subject to change based on ongoing and future testwork programmes. The design philosophy for the process plant is a zero liquid discharge policy which ensures the risk to the environment by means of water contamination is mitigated.

The process plant and associated infrastructure have been designed to Swedish and International standards and for the full duration of the project. The process plant where possible will be inside of buildings where dust and noise can be contained.

The reagents consumed at the process plant will be received from both international and domestic suppliers, and will be received at the Tranas rail siding and directly by truck to the plant site.

| 1.5 | Mineral Resource Estimates |

The Mineral Resource estimate for the Nora Kärr project has been carried out following the guidelines of the CIM Code (3). The Mineral Resource estimation was completed using a 3D block modelling approach utilising CAE Mining Studio 3® software. Mineral Resource estimate is dated 30 June 2014.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

WAI was supplied with a geological database in Microsoft Access® format dated 06 May 2014 which comprised geological and geotechnical logging as well as assay results. The database comprises sample data from surface diamond drilling containing a total of 119 holes (20 420.33 m) from which 9 986 samples have been assayed.

Wireframes to represent the Norra Kärr alkaline igneous intrusive body and associated REE mineralisation have been constructed based on the geological logging carried out by Tasman. WAI was provided with geological cross sections and plans by Tasman showing the interpreted structure based on the detailed lithology logs, geochemical assay results and the foliation measurements. In total six key lithologies were modelled:

| · | LTYPE 1 (KAX) – Kaxtorpite (Microcline-Pectolite-Amphibole-Aegerine-Nepheline Syenite); |

| · | LTYPE 2 (GTM) – Grennaite (Recrystallised to in part migmatitic); |

| · | LTYPE 3 (PGT/GT) – Grennaite with pegmatititc zones and Grennaite (Fine grained aegerine rich nepheline syenite); |

| · | LTYPE 4 (GTC) – Grennaite (Catapleiite porphyritic – low grade TREO); |

| · | LTYPE 5 (ELAK) – Lakarpite with eudialyte; and |

| · | LTYPE 6 (MAF) – Mafic dyke material. |

Based on the mineralisation wireframes sample data was selected and coded according to the host lithology and reviewed statistically. Very few outlier grades were identified that could present an issue during the variography or grade estimation stages, those that presented a problem have been top-cut.

To ensure all samples in the variography and grade estimation stages have equal support the sample data was composited to 2 m corresponding to the median sample length. Semi-variogram analysis was undertaken for 20 elements in each of the six mineralised domains using the 2 m composited samples contained within the mineralised domain wireframes.

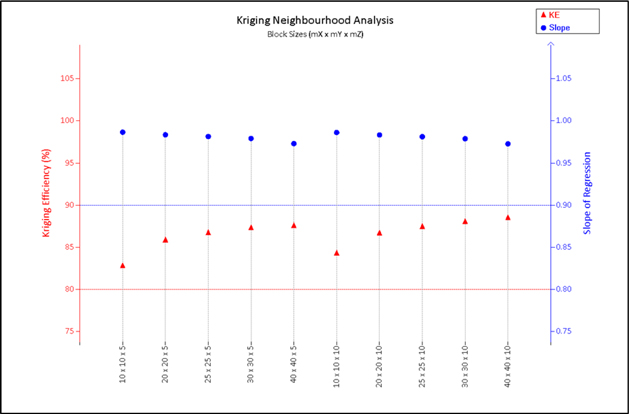

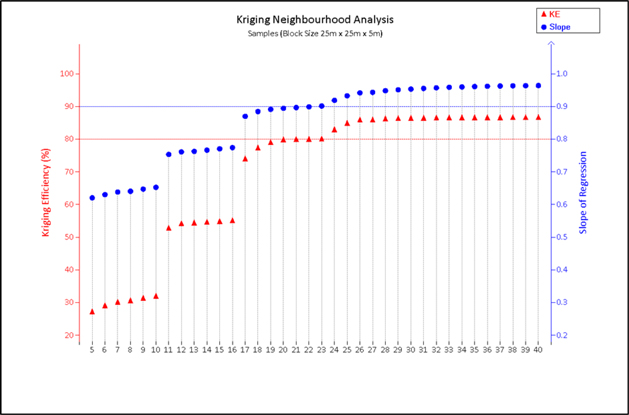

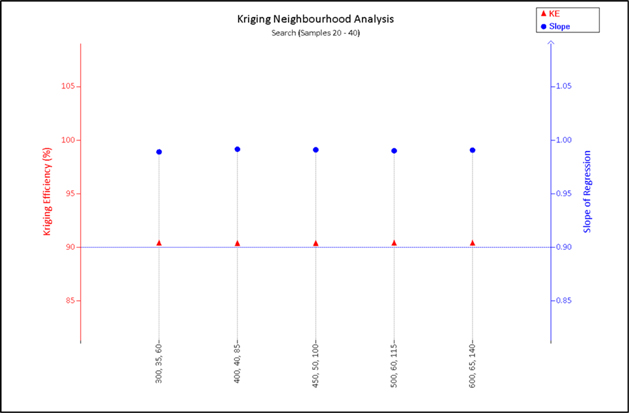

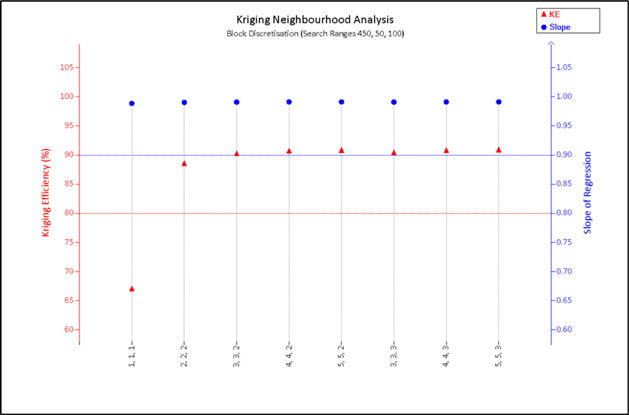

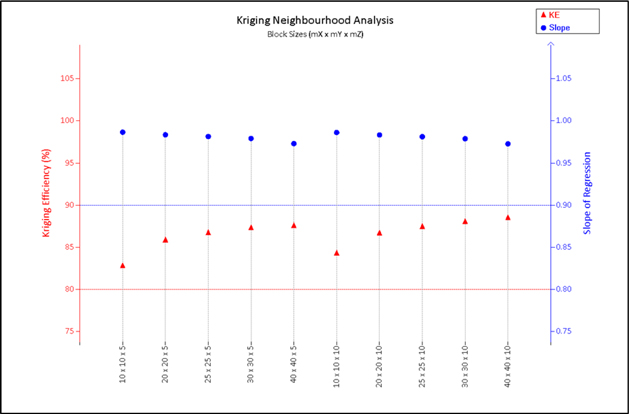

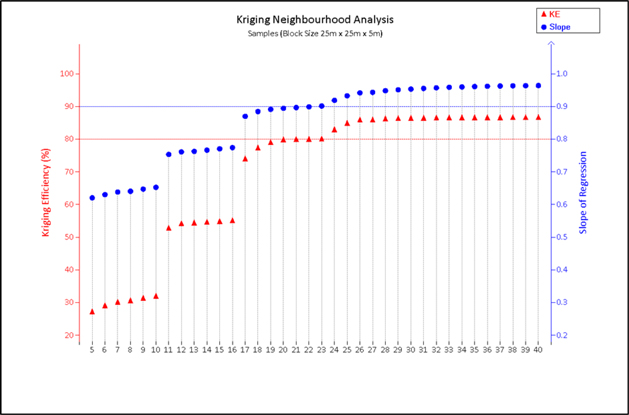

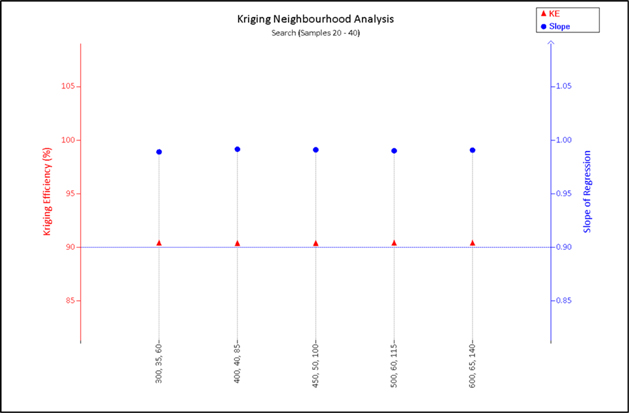

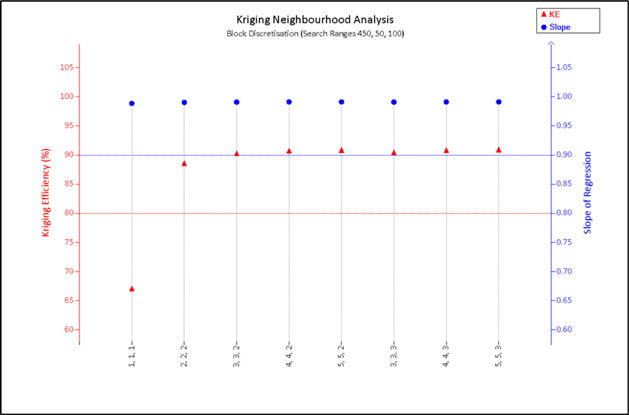

Based on the semi-variograms produced by WAI, Qualitative Kriging Neighbourhood Analysis (QKNA) was undertaken to ascertain the optimum block sizes, minimum and maximum numbers of samples, optimum search ellipse size and optimum block discretisation.

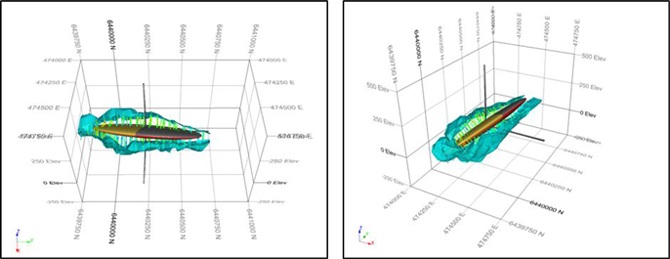

A non-rotated block model with a parent cell size of 25 m x 25 m x 5 m (northing x easting x vertical) was selected for the Mineral Resource estimation. Key fields were established within the block model to identify and separate the individual mineralised zones for control on grade estimation. A minimum subcell size of 5 m x 5 m x 1 m was allowed to get a close fit to the wireframe surfaces.

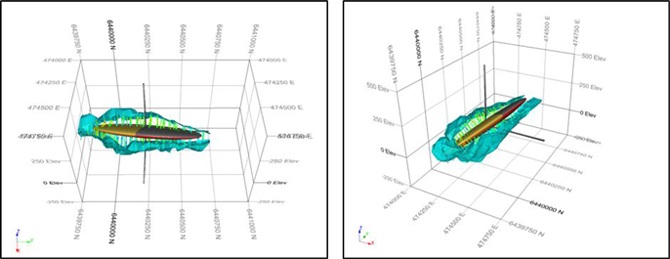

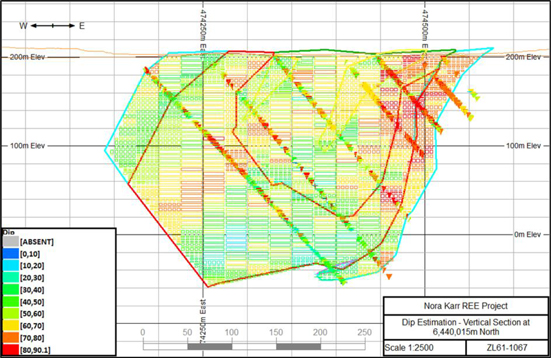

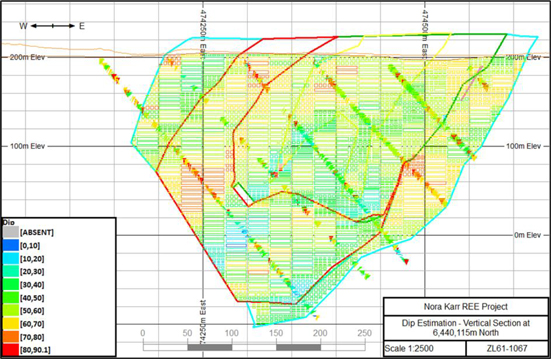

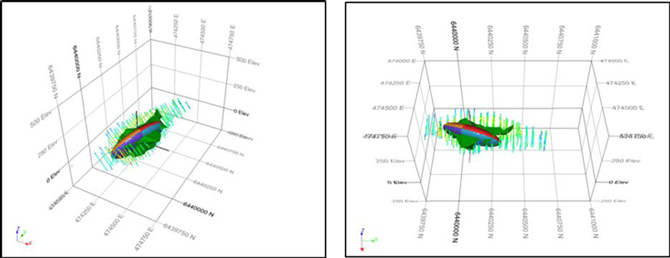

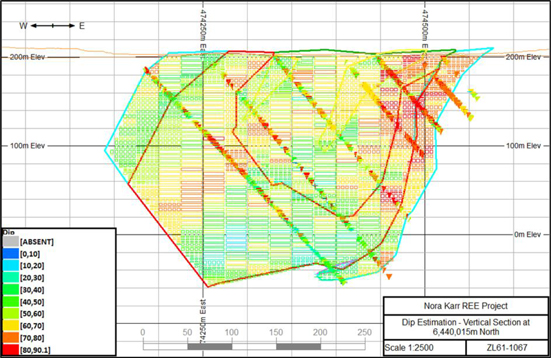

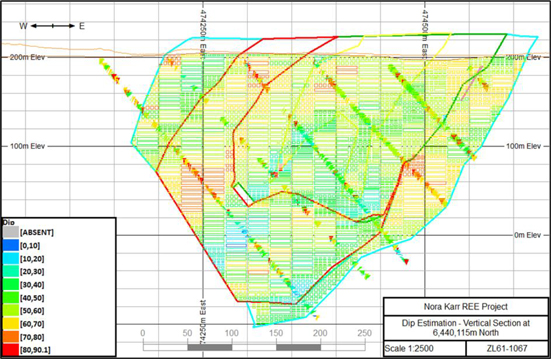

To enable the grade estimation search ellipse to honour the mineralisation WAI utilised dynamic anisotropy whereby each block in the model contained dip and dip orientation angles. Dip and dip directions were estimated in to the volumetric block model using Inverse Power of Distance Cubed

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

(IDW3) and the foliation information supplied by Tasman which was converted to point sample locations with consistent lengths of 0.02 m.

A total of 1 692 bulk density tests have been carried out by Tasman with the resultant database supplied to WAI. WAI has coded the density samples according to their corresponding lithological unit and applied the mean density value for each of the six modelled lithologies to the relevant block model lithology.

Grade estimation has been carried out using Ordinary Kriging (OK) as the principle interpolation method with Inverse Power of Distance Squared (IDW2) and Nearest Neighbour (NN) also used for comparative purposes for each element. Following the grade estimation process, statistical and visual model validation assessments were undertaken. Globally no indications of significant over or under estimation are apparent in the model nor were any obvious interpolation issues identified. In terms of conformance to the drill hole composite data, WAI considers the OK interpolation method to most closely represent the drill hole data.

The Mineral Resource classification for the Norra Kärr REE deposit is in accordance with the guidelines of the CIM Definition Standards for Mineral Resources and Mineral Reserves [CIM (2010) (3)]. Criteria for defining Mineral Resource categories are based on geostatistical studies, QA/QC data review and the overall degree of confidence in the geological and grade continuity exhibited at the deposit.

WAI has classified the Norra Kärr deposit as Indicated.

In order to report a Mineral Resource in accordance with CIM for disclosure in an NI 43-101 report, there needs to be the reasonable prospect for eventual economic extraction. To ensure that the Norra Kärr Mineral Resource reported by WAI has reasonable prospects of economic extraction the mineral inventory has been constrained by a pit optimisation and only mineralisation falling within the open pit has been disclosed as a Mineral Resource as shown in Table 1-1.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

Table 1-1: Norra Kärr Mineral Resource Estimate (4)

| Classification | | TREO % Cut-

Off Grade | | | Tonnes (kt) | | | Density (t/m3) | | | TREO (%) | | | % HREO in

TREO | | | Dy2O3(%) | | | Y2O3(%) | | | Eu2O3(%) | | | La2O3(%) | | | Nd2O3(%) | | | Ce2O3(%) | | | Gd2O3(%) | | | Tb2O3(%) | | | Pr2O3(%) | | | Sm2O3(%) | | | Lu2O3(%) | |

| Indicated | | | 0.2 | | | | 36 821.60 | | | | 2.71 | | | | 0.55 | | | | 53.18 | | | | 0.02532 | | | | 0.20053 | | | | 0.00203 | | | | 0.05190 | | | | 0.06025 | | | | 0.11560 | | | | 0.01825 | | | | 0.00371 | | | | 0.01504 | | | | 0.01647 | | | | 0.00227 | |

| | | | 0.4 | | | | 31 109.16 | | | | 2.70 | | | | 0.61 | | | | 52.60 | | | | 0.02729 | | | | 0.21775 | | | | 0.00222 | | | | 0.05729 | | | | 0.06680 | | | | 0.12823 | | | | 0.01997 | | | | 0.00403 | | | | 0.01668 | | | | 0.01815 | | | | 0.00238 | |

| | | | 0.6 | | | | 17 124.71 | | | | 2.72 | | | | 0.68 | | | | 52.23 | | | | 0.02994 | | | | 0.24290 | | | | 0.00253 | | | | 0.06214 | | | | 0.07686 | | | | 0.14413 | | | | 0.02260 | | | | 0.00447 | | | | 0.01896 | | | | 0.02083 | | | | 0.00251 | |

Notes:

| 1. | Mineral Resources are not reserves until they have demonstrated economic viability based on a Feasibility Study or Pre-feasibility study. |

| 2. | Mineral Resources are reported inclusive of any reserves. |

| 3. | The Mineral Resources reported have been constrained on the basis of a 20 year pit. |

| 4. | Mineral Resources are reported for the combined GTM, PGT, GTC and ELAK mineralisation only. |

| 5. | The Mineral Resources reported represent estimated contained metal in the ground and has not been adjusted for metallurgical recovery. |

| 6. | Total Rare Earth Oxides (TREO) includes: La2O3, Ce2O3, Pr2O3, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3. |

| 7. | Heavy Rare Earth Oxides (HREO) includes: Eu2O3, Gd2O3, Tb2O3, Dy2O3, Ho2O3, Er2O3, Tm2O3, Yb2O3, Lu2O3, Y2O3. |

| 8. | Preferred Base Case Mineral Resources are reported at a TREO % cut-off grade of 0.4 % TREO. |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| 1.6 | Mineral Reserve Estimates |

WAI has undertaken an open pit design based on the Mineral Resource block model of Norra Kärr. Datamine NPV Scheduler software was used to generate an optimised design; economic parameters have been supplied from Tasman, GBM, and WAI calculations. Taking account of modifying factors (loss/dilution, geotechnics) an open pit mine design was based on the optimised design to provide an estimate of Mineral Reserves. OnlyProbable Mineral Reserves are reported at this stage due to the confidence of Mineral Resources.

Probable Mineral Reserves total over 23.5 Mt of ore material at 0.59 % TREO. Mined waste totals 17.3 Mt for total rock movement of 40.8 Mt and LOM stripping ratio (tw:to) of 0.73. Mineral Reserve estimates have been based on a targeted 20 year mine life, the unconstrained mine life, at current economic parameters, is in excess of 60 years. Mineral Reserve estimates have been based on GTM and PGT ore types only.

| 1.7 | Mineral Extraction Methods |

Mineral extraction methods have taken account of two constraints, blasting fragmentation and a nearby highway. Fragmentation has been required to meet a maximum size of 600 mm and in conjunction, planned blasting has been designed within a safety envelope for a nearby highway to the west of the project site.

Open pit mining operations consist of conventional hydraulic shovel and rigid body trucks, a support loader for clean-ups, oversize transport, and muck pile construction. Open pit mine design has targeted the pit ramp entrance on the southern end of the pit, directly towards the processing facilities. Ore will be hauled from within the pit directly to the ROM, where a wheel loader will load material into a primary jaw crusher and into the processing circuit.

| 1.8 | Tailings storage Facility |

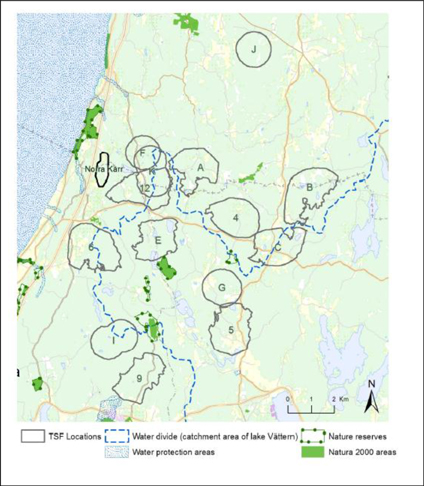

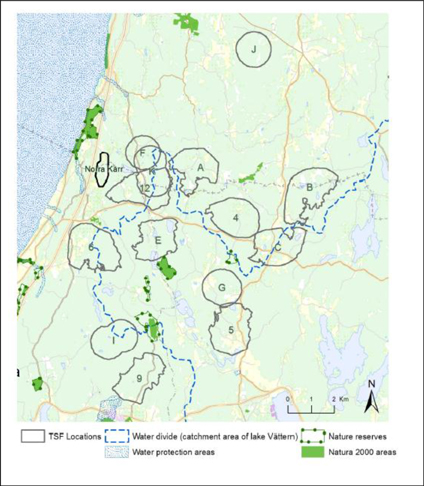

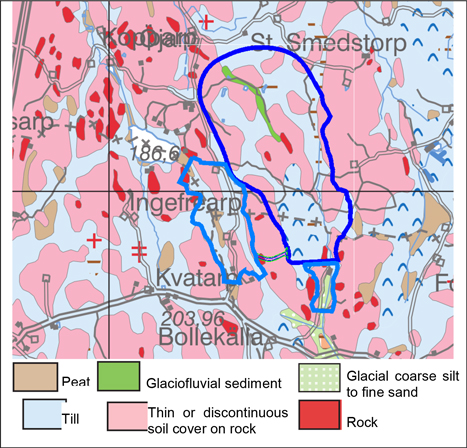

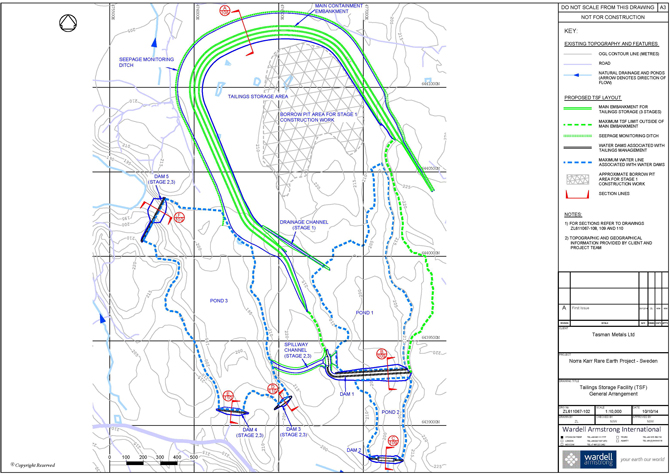

The tailings comprise waste from the beneficiation and leach residue processing stages, combined with gypsum sludge waste generated by the neutralisation process following solvent extraction. Brine (sodium sulfate) produced by water treatment will be sent off site for disposal at an appropriate landfill. The combined tailings waste stream will be stored as a thickened slurry in a single cell located about 3 km to the north-east of the process plant in an area identified as suitable for tailings storage by a preliminary localisation study.

The storage facility has been designed to accommodate tailings generated during the 20 year mine life. The tailings throughput is 155 tpd, resulting in about 24.8 Mt tailings. In calculating volumetric storage requirements, an allowance has been made for parameter uncertainty at this preliminary

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

stage. The facility is designed to store about 22 Mm3 of tailings, and the design could be extended if needed to accommodate additional tonnages.

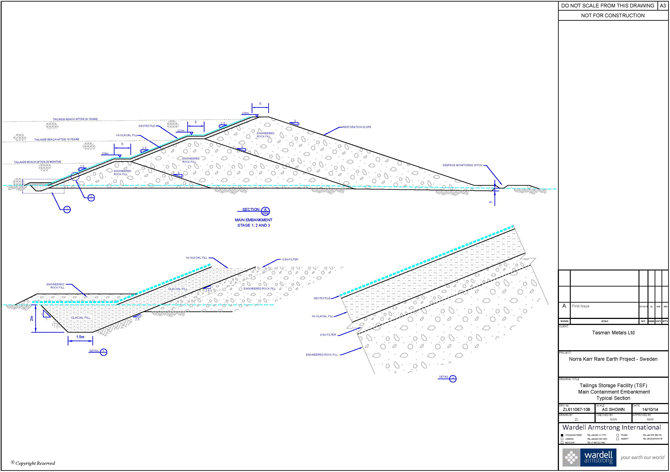

The storage facility comprises a main containment embankment designed to allow tailings discharge to take place from multiple spigots located around the northern part of the embankment crest. The embankment will be constructed initially from an internal borrow pit, and then be raised in stages during the operational life using mine waste. A downstream raise strategy has been adopted for this stage of design.

The facility is designed to accept thickened slurry deposited in a sub-aerial manner so that the pond water is kept largely separate to the tailings solids. Sub-aerial deposition offers the advantage of minimising the water contained in the facility, which reduces the seepage risk and the risk of leaching elements from the tailings mass. It is desirable from a dam safety and operational perspective to minimise the amount of water held within the storage basin. Water in the impoundment area will be directed southwards from the points of discharge and stored in a series of ponds before being decanted to the environment.

The facility is designed so that all water discharged from the system is decanted into the Baltic rather than the Lake Vättern catchment via a series of ponds designed to allow water clarification and to accommodate high flows due to flood events. This is not so much a technical consideration, but more a recommendation to reduce local concerns over potential pollution of the waters at Lake Vättern.

A dry closure strategy will be adopted, using mine waste, as well as till and topsoil sourced at the TSF from site clearance operations to cover the tailings and to generate the closure landform. The water dams will be removed at closure, and water courses rehabilitated to accept flows off the rehabilitated landform.

| 1.9 | Environmental Studies, Permitting and Social or Community Impact |

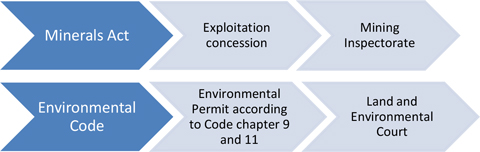

In addition to the exploitation concession, an environmental permit must be granted to the project pursuant to the provisions of the Swedish Environmental Code (1998:808). The permit application must include an Environmental Impact Assessment.

Baseline studies have been undertaken encompassing the area around the exploitation concession. However further studies are expected to be needed for environmental permitting. The entire Project area as well as the surrounding area are considered to represent an anthropogenic environment. Certain nature values have been identified on site, however these are not expected to present major obstacles to project development. Furthermore it is considered unlikely that nature values of such character or magnitude as to stop project from progressing would be found in any further studies. However various mitigation measures may be required to be undertaken in order to secure the required permits.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

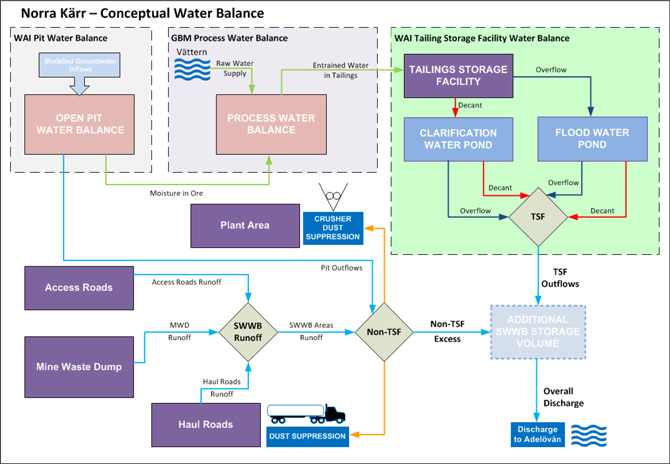

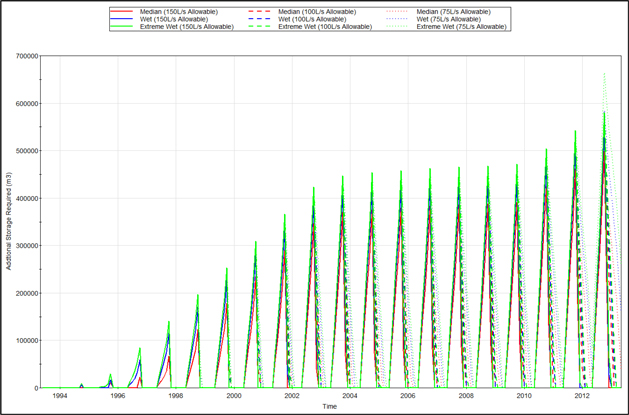

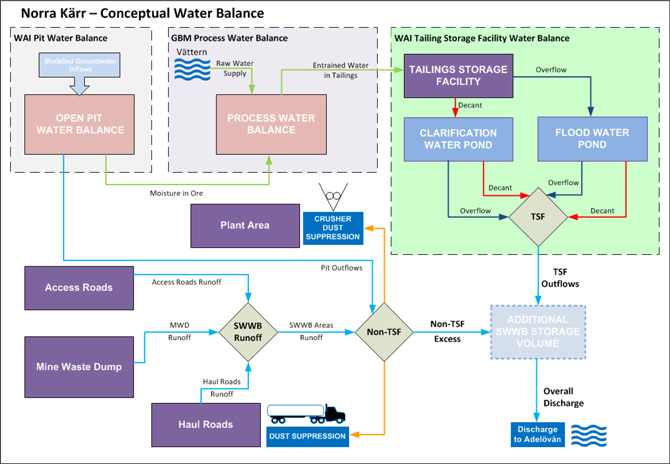

A preliminary water management strategy has been developed and a Site Wide Water Balance modelling undertaken. The plan is to collect all water coming into contact with any activities of the mining operation, including surface runoff on site roads, roof areas etc. into the TSF pond system. Water will be discharged into the environment only from the TSF ponds. Current process design incorporates a water recycling plant, resulting in a considerable reduction of both make up water intake and the discharge water flow rate. No discharge of liquid water from the process is planned; water leaves the process only as the moisture content of the tailings

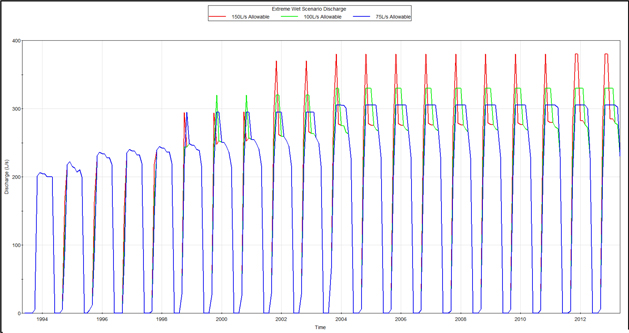

All discharge will be directed away from the catchment area of the nearby Lake Vättern. The receiving watercourse, a smallish stream named Adelövån, flows southward of the site area towards smaller lakes and eventually into the Baltic Sea. The predicted discharge from the mine is very high compared to natural flow rates in the stream and would represent a significant portion of the entire streamflow. This is expected to result in strict control of discharge water quality. A detailed water management plan should be developed in later stages of project development. The water management plan should be based on further information about quality as well as quantity of the water discharge. Potential need for treatment of the discharge will be investigated in the detailed water management plan.

A conceptual level closure plan has been prepared for the project. The closure plan should be further defined in the design stage and during operations. The environmental permit will set conditions related to closure planning. Initially the closure targets are set so as to ensure safety and no significant off-site impact.

Biodiversity values likely to be affected by the project include the great crested newt as well as features related to long agricultural land use in the area. It is expected that a compensation programme for the great crested newt is likely to be required. It could also be possible to preserve and/or compensate some of the values related to the agricultural environment for a very minor cost, if the issue was taken into consideration from early on in the project design. There are also some cultural heritage targets within the area warranting closer study before works disturbing the remains are started.

Social and community issues relevant to the project have been identified to include employment and economic benefits, resettlement and stakeholders. Some houses will need to be purchased by Tasman Metals or the owners compensated as per Swedish practice. There has been some vocal opposition towards the project in the local area. The opposition is being led by a small number of anti-mining activists. Based on experience from many other projects, and supported by surveys undertaken in the area, it is expected that the general public’s attitudes towards the project are much more positive than the activist-led discussion would at first glance indicate. The support of the state of Sweden was demonstrated by the fact that Tasman Metals was granted the exploitation concession in January 2014.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| 1.10 | Conclusions and Recommendations |

| 1.10.1 | Capital and Operating Estimate |

The total capital expenditure for the Norra Kärr project is USD 423 M, a summary of initial capital investment which is to be spent over a two year design and construction phase is shown in Table 1-2. All estimates have been reported in US dollars.

Table 1-2: Total Project Initial Capital Expenditure

| Initial Capital Expenditure | | | Value (USD) | |

| Total Capital Investment | | | 378 276 359 | |

| FIXED CAPITAL TOTAL | | | 352 963 553 | |

| DIRECT TOTAL | | | 231 319 303 | |

| General | | | 7 563 513 | |

| Mining | | | 21 894 872 | |

| Process | | | 169 467 528 | |

| Waste Management | | | 14 300 000 | |

| Product Handling | | | - | |

| Infrastructure and Utilities | | | 18 093 388 | |

| INDIRECT TOTAL | | | 121 644 250 | |

| EPCM | | | 36 165 294 | |

| Field Indirect | | | 45 295 295 | |

| Contingency | | | 40 183 660 | |

| WORKING CAPITAL TOTAL | | | 25 312 805 | |

The operating costs over the 20 year life of mine are summarised in Table 1-3.

Table 1-3 Operating Expenditure over Life of Mine

| Area | | | | Total Cost per

annum | | | USD/t ROM

Ave | | | USD/kg

REO Ave | | | % | |

| 000 GENERAL | | General and Admin | | | 5,079,832.07 | | | | 4.53 | | | | 1.04 | | | | 5.04 | |

| | | | | | - | | | | - | | | | - | | | | 0.0 | |

| 100 Mining | | Ore mining cost | | | 3,849,852.58 | | | | 3.43 | | | | 0.79 | | | | 3.82 | |

| 100 Mining | | Waste mining cost | | | 2,724,248.43 | | | | 2.43 | | | | 0.56 | | | | 2.7 | |

| 100 Mining | | Overhead mining cost | | | - | | | | - | | | | - | | | | 0.0 | |

| 100 Mining | | | | | - | | | | - | | | | - | | | | 0.0 | |

| | | | | | | | | | | | | | | | | | | |

| 200 PROCESSING | | Maintenance & Operating Spares | | | 6,233,849.12 | | | | 5.55 | | | | 1.28 | | | | 6.18 | |

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

| Area | | | | Total Cost per

annum | | | USD/t ROM

Ave | | | USD/kg

REO Ave | | | % | |

| 200 PROCESSING | | Consumable - Grinding media and liners | | | 1,660,921.74 | | | | 1.48 | | | | 0.34 | | | | 1.65 | |

| 200 PROCESSING | | Labour | | | 8,347,749.52 | | | | 7.44 | | | | 1.71 | | | | 8.28 | |

| 200 PROCESSING | | Reagents | | | 35,699,032.18 | | | | 31.81 | | | | 7.32 | | | | 35.39 | |

| 200 PROCESSING | | Utilities - Disel | | | 6,427,982.83 | | | | 5.73 | | | | 1.32 | | | | 6.37 | |

| 200 PROCESSING | | Consumable – Electricity | | | 6,449,553.24 | | | | 5.75 | | | | 1.32 | | | | 6.39 | |

| 280WATER TREATMENT | | Water treatment | | | 21,311,567.24 | | | | 18.99 | | | | 4.37 | | | | 21.13 | |

| | | | | | | | | | | | | | | | | | | |

| 300 WASTE MANAGEMENT | | Waste Management | | | 3,084,568.94 | | | | 2.75 | | | | 0.63 | | | | 3.06 | |

| Grand Total | | | | | 100,870,000 | | | | 89.97 | | | | 20.69 | | | | 100 | |

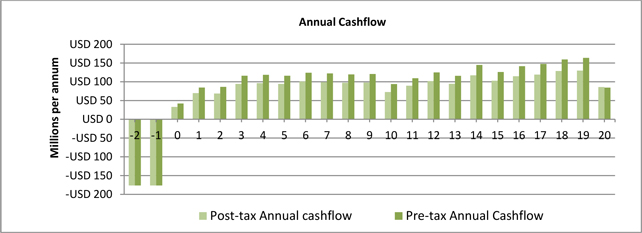

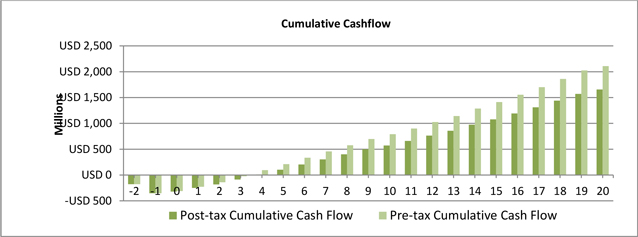

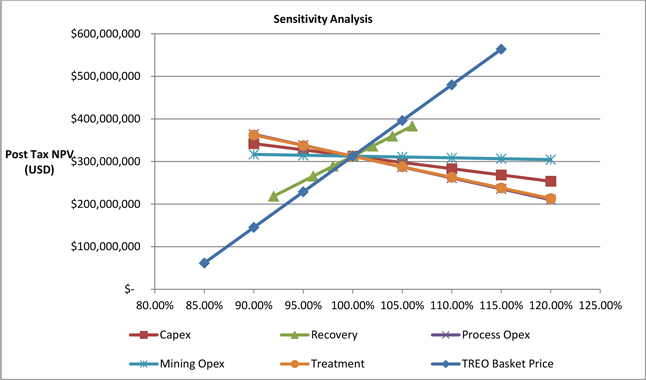

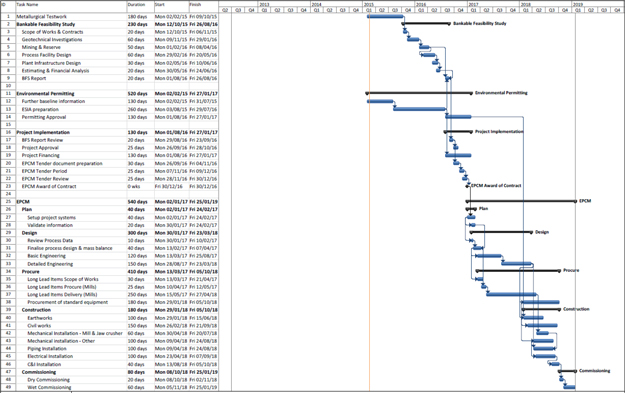

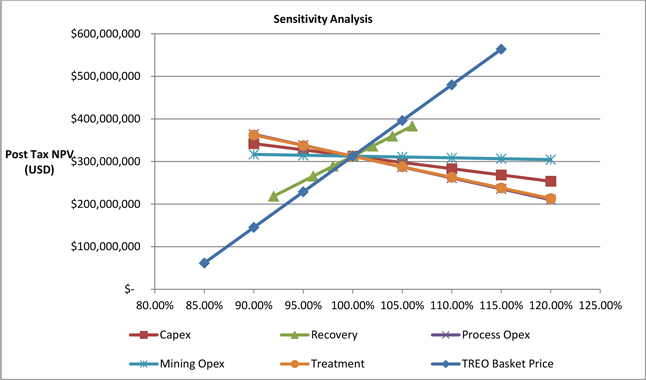

The economic analysis conducted for the Norra Kärr project was undertaken utilising the discounted cash flow methodology (DCF) at various discount rates. A 10 % discount rate yielded a post-tax net present value of USD 312.7 M and an internal rate of return of 20 %.

The Norra Kärr project has accounted for a conservative ramp up period. The process plant has been scheduled to reach full production by Year 4, and this has been reflected in the DCF model.

The REO prices are applied individually per kilogram of REO recovered, rather than applying a discounted basket price. The overall basket price of saleable REOs is 64.46 USD/kg which excludes Ho, Er, Tm and Yb.

| 1.10.3 | Rare earth pricing and Forecasting |

Rare earth pricing is more complex than for commodities and is definitely more opaque. Historically, there has been no open market for rare earths (which are primarily ‘traded’ individually – all 17 of them) and most of the sales up to this point have been in the form of long term supply agreements, which are subject to a number of variables including volume discounts, cost structure of the buyer, potential cost subsidies, and effect of co-products at the producing mine. Furthermore, there is a range of rare earth products sold, which has an impact on price. In this report the focus is on REOs (typically 99.9 %), which is the common product reported.

There are a few agencies/companies reporting rare earth pricing (Metal Pages, Asian Metal, Industrial Minerals) although not all contracts are reported and volumes are unclear. As a result, there is typically a variance around pricing although directional movements are believed accurate.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

Rare earth pricing is impacted by more than just supply and demand. Prices have been volatile for the last decade as China introduced export quotas in 2005 and significantly reduced them in 2010, which sent some rare earth prices up over ten times. Prices in 2011 were at unprecedented highs, which resulted in stockpiling, recycling and ‘thrifting’ in applications. Currently, prices are depressed as demand growth has slowed and inventory (including illegal product) continues to work through the system.

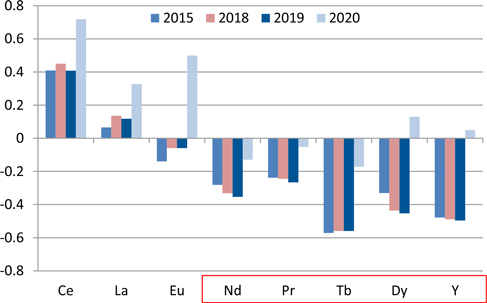

The long term price forecast is lower than the trailing 3-year average for all elements (except Pr) but above current prices for some elements today (Nd, Tb, Dy and Y). Higher prices are primarily supported by demand growth for permanent magnets and the slower ramp up of heavy rare earth mines outside of China.

GBM considers that the Norra Kärr project to have fulfilled its purpose of demonstrating to a satisfactory degree of confidence, the potential to cost effectively and profitably mine and process the REE deposit.

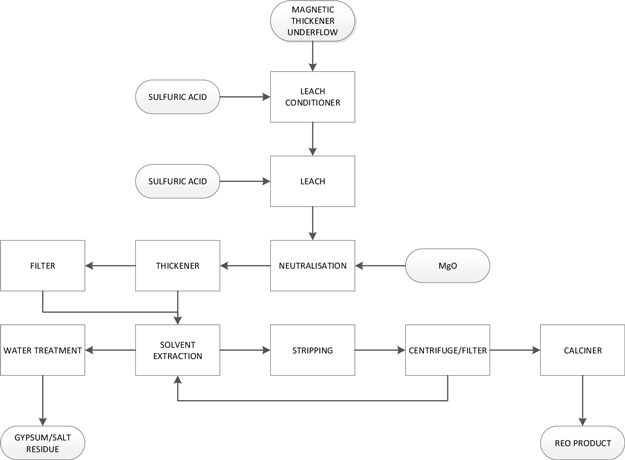

The metallurgical testwork conducted to-date has identified a processing route which enables the extraction and recovery of REE from the Norra Kärr deposit to an average efficiency of 76.4 %. On the basis of the commissioned testwork a process flowsheet was developed with associated mass and energy balances. The process flowsheet employs equipment routinely available from equipment manufacturers and operates at both low temperatures and pressures, reducing the technological risk of the project. These were then used to prepare capital and operating expenditure estimates.

No fatal flaws at this stage of project development have been identified, in terms of mineral resource, process, waste management, logistics and environmental impact, however further testwork is required to confirm the projects full feasibility.

The DCF model yielded economic indicators including, a post-tax NPV of USD 312.7 M (10 % discount rate) and an IRR of 20 % which demonstrate the project to be both technically and economically feasible. On this basis it is recommended Tasman pursue a programme of further investment and development to confirm the preliminary results present.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

Section 2 Introduction

GBM Minerals Engineering Consultants Limited (GBM) is an independent firm of engineering consultants specialising in the development, design and construction of mining projects. GBM was commissioned by Tasman Metals Limited (Tasman) to carry out a Pre-Feasibility Study (PFS) to determine the REE recovery process and to design and cost a process facility to produce a saleable concentrate for the Norra Kärr project. This included the development of the process flowsheet, the processing and infrastructure engineering design, the capital and operating cost estimates to an accuracy of +25 % to -25 %, and the compilation of this PFS report.

Wardell Armstrong International (WAI) is a leading multidisciplinary consultancy whose Mining, Quarrying and Minerals Division has derived a Mineral Reserve and cost estimates for the mining for the project.

Golder Associates (Golder) are a leading multidisciplinary consultancy whose Environmental Division has been responsible for environmental studies and social impact assessment on the project. Golder has also provided information in regards to undertaking the permitting process.

| 2.2 | Financial Interest Disclaimer |

Neither GBM, WAI, Golder nor any of their consultants employed in the preparation of this report, have any beneficial interest in the assets of Tasman.

GBM, WAI and Golder have been paid fees and will continue to be paid fees for this work in accordance with normal professional consulting practices.

| 2.3 | Sources of Information |

Information used to support this PFS was provided by GBM, WAI, Golder and Tasman internal experts, previous reports on the property and from the reports listed in the references section of this technical report.

The GBM Qualified Person is Michael Short BE (Civil), CEng FIMMM, FAusIMM(CP), FIEAust CPEng.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

The WAI Qualified Persons are:

| - | Greg Moseley, BSc, MSc, CEng, MIMM, FRGS, Associate, Qualified Person – Geology and Mineral Resources |

| - | Mark Mounde, BEng, CEng, MIMMM,Technical Director, Qualified Person – Mining and Mineral Reserves |

The Golder Qualified Personis Gareth Digges La Touche (BSc, MSc, FGS, CGeol, EurGeol).

| 2.5 | Qualified Person Site Visit |

A number of visits by various Qualified Persons and other parties have been carried out to inspect the project site and verify its characteristics. The following site visits directly applicable to this PFS have been carried out by GBM, WAI and Golder representatives:

| · | Greg Moseley (WAI) visited the site in April 2014; |

| · | Janna Riikonen (Golder), Marion Thomas (Golder) and Erik Karlsson (Golder) visited the site in May 2014; |

| · | Michael Bateson (GBM), Thomas Davidson (GBM), Kurt Forrester (GBM), Mark Mounde (WAI) and Nick Watson (WAI) visited the site in June 2014; and |

| · | Janna Riikonen (Golder) and Gareth Digges La Touche (Golder) visited the site in September 2014. |

The following Tasman personnel were available during the site visits:

| · | Jim Powell – Vice President (Tasman AB); |

| · | Johan Berg – Geologist (Tasman AB); |

| · | Magnus Leijd – Senior Geologist (Tasman AB); |

| · | Henning Holmstrom - Managing Director (Tasman AB); and |

| · | Olof Ekstrand – Senior Advisor (Tasman AB). |

| 2.6 | Qualified Person Sectional Responsibility |

This PFS was prepared by or under the supervision of the Qualified Person(s) identified in Table 2-1 against the respective sections of this report.

|  |

| | Prefeasibility Study - NI 43-101 - Technical report for the Norra Kärr

Rare Earth Element Deposit - 0465-RPT-014 Rev 0 |

Table 2-1: Responsible Qualified Persons

| Section | | Section Title | | Qualified Person(s) |

| 1 | | Summary | | GBM (Michael Short) |

| 2 | | Introduction | | GBM (Michael Short) |

| 3 | | Reliance On Other Experts | | GBM (Michael Short) |

| 4 | | Property Description And Location | | GBM (Michael Short) |

| 5 | | Accessibility, Climate, Local Resources, Infrastructure And Physiography | | Golder (Gareth Digges La Touche) |

| 6 | | History | | GBM (Michael Short) |

| 7 | | Geological Setting And Mineralisation | | WAI (Greg Moseley) |

| 8 | | Deposit Types | | WAI (Greg Moseley) |

| 9 | | Exploration | | WAI (Greg Moseley) |

| 10 | | Drilling | | WAI (Greg Moseley) |

| 11 | | Sample Preparation, Analyses, And Security | | WAI (Greg Moseley) |

| 12 | | Data Verification | | WAI (Greg Moseley) |

| 13 | | Mineral Processing And Metallurgical Testing | | GBM (Michael Short) |

| 14 | | Mineral Resource Estimates | | WAI (Greg Moseley) |

| 15 | | Mineral Reserve Estimates | | WAI (Mark Mounde) |

| 16 | | Mining Methods | | WAI (Mark Mounde) |

| 17 | | Recovery Methods | | GBM (Michael Short) |

| 18 | | Project Infrastructure | | GBM (Michael Short) |

| 19 | | Market Studies And Contracts | | GBM (Michael Short) |

| 20 | | Environmental Studies, Permitting, And Social Or Community Impact | | Golder (Gareth Digges La Touche) |

| 21 | | Capital And Operating Costs | | GBM (Michael Short) |

| 22 | | Economic Analysis | | GBM (Michael Short) |

| 23 | | Adjacent Properties | | GBM (Michael Short) |

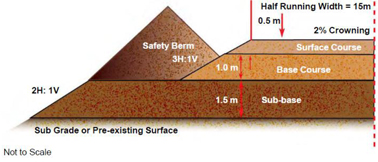

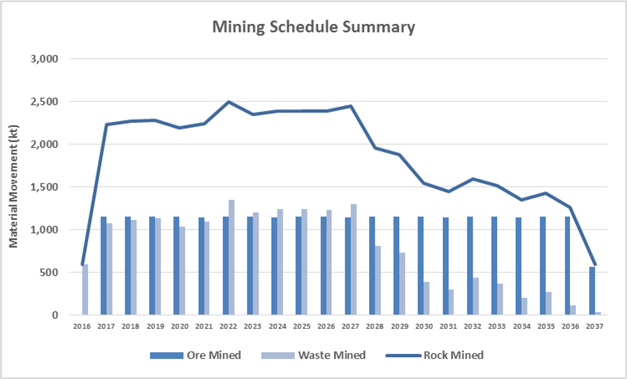

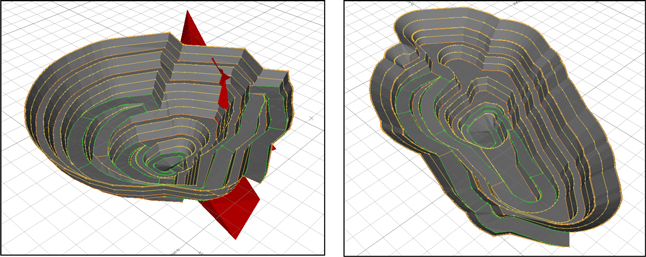

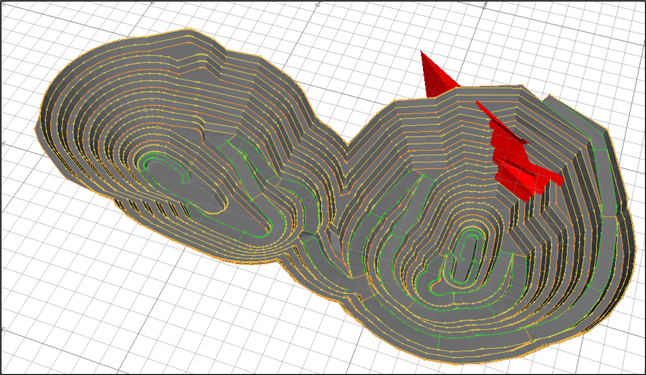

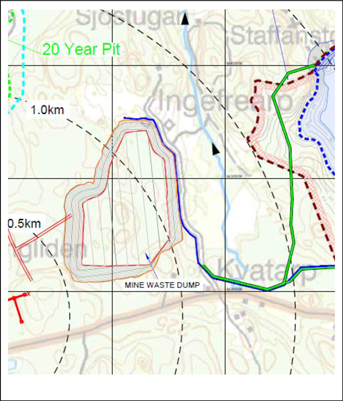

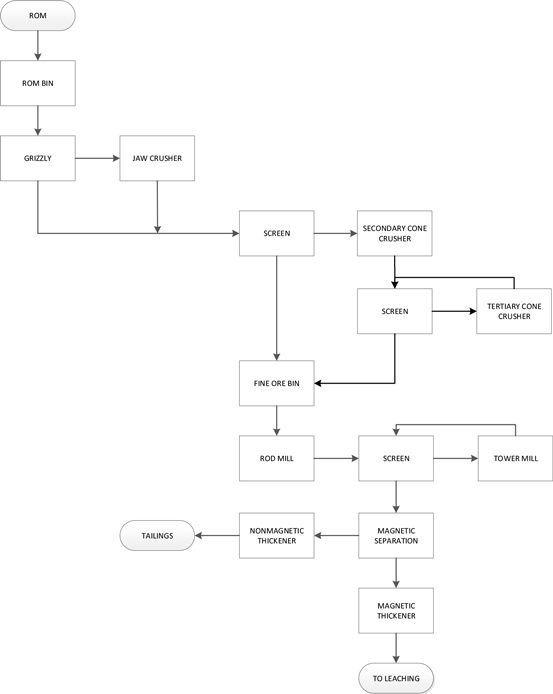

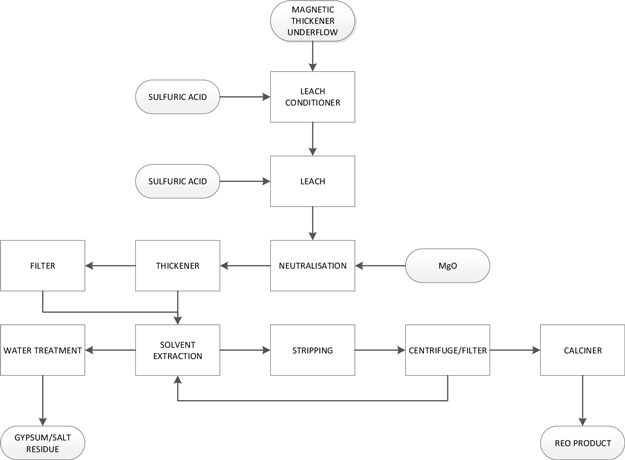

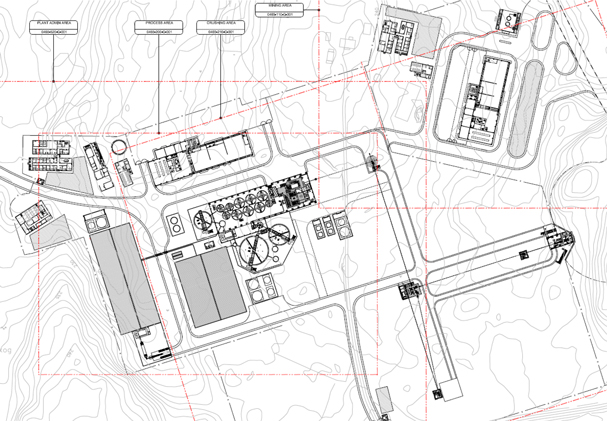

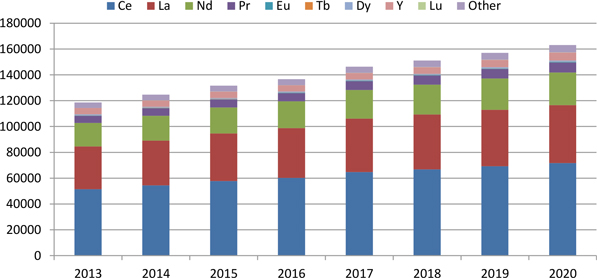

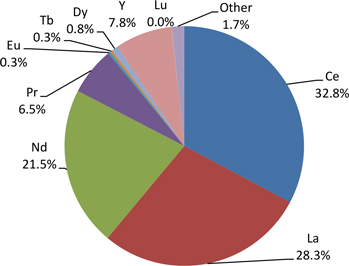

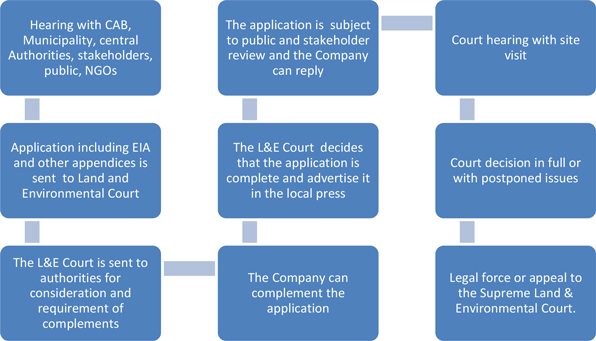

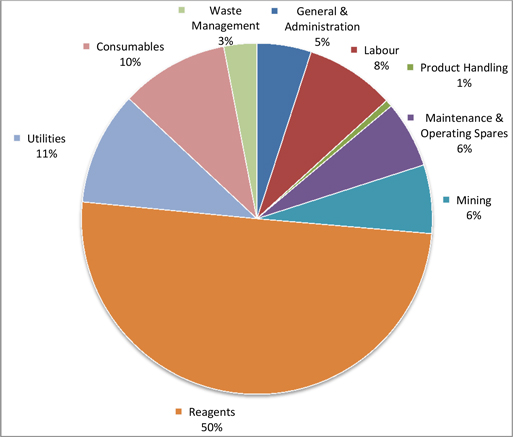

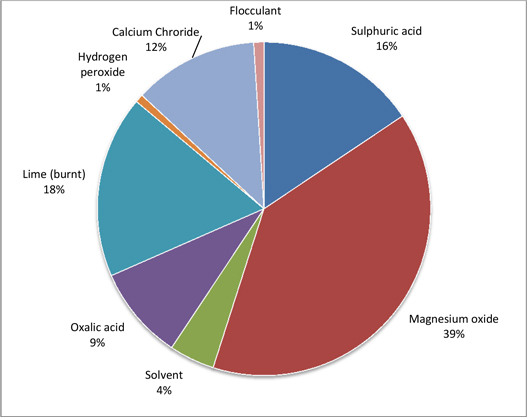

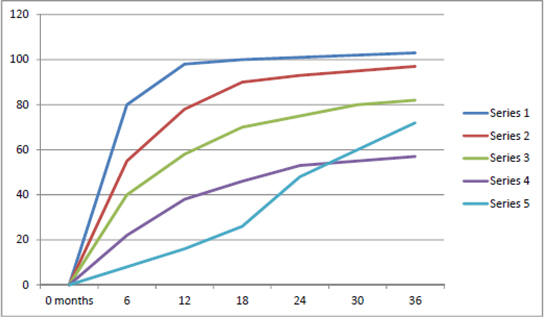

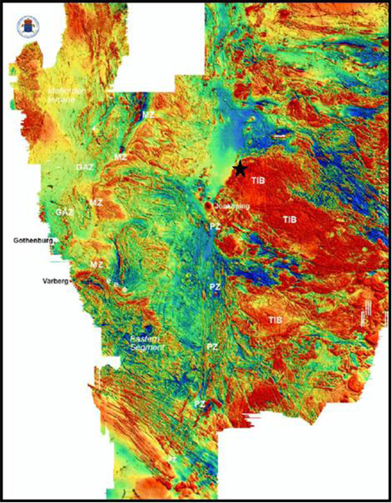

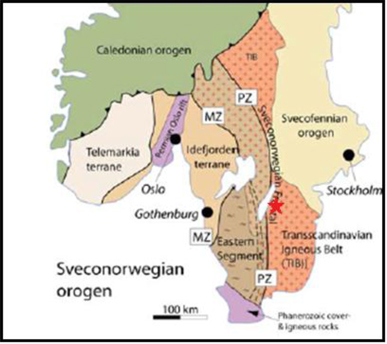

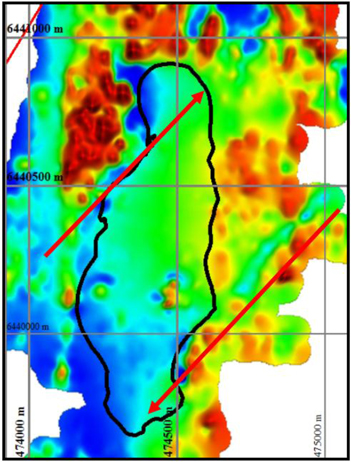

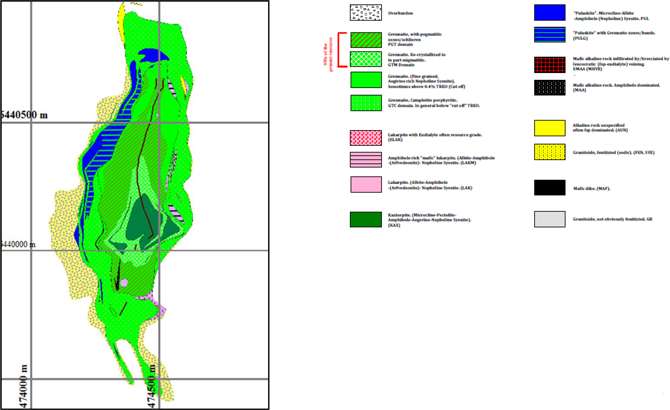

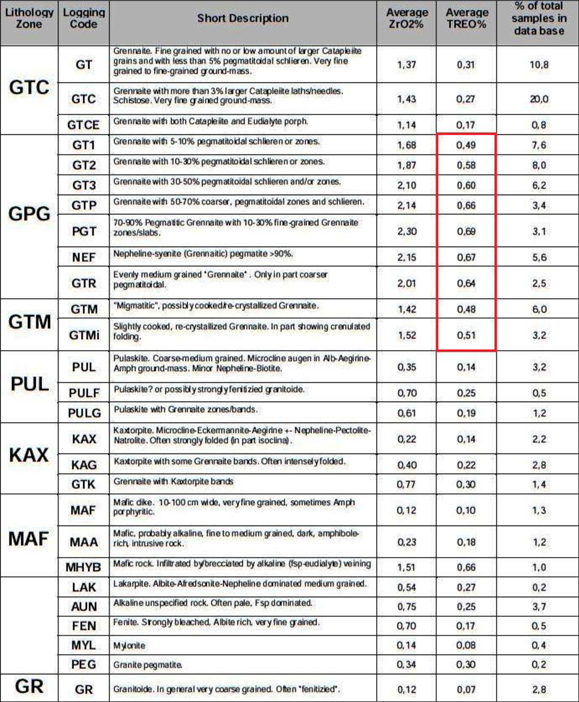

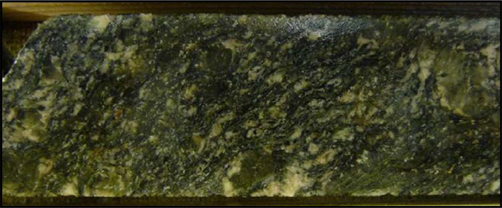

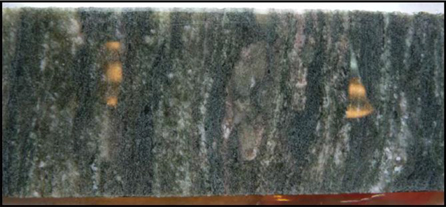

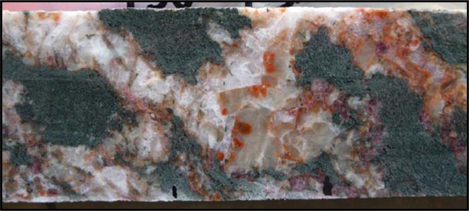

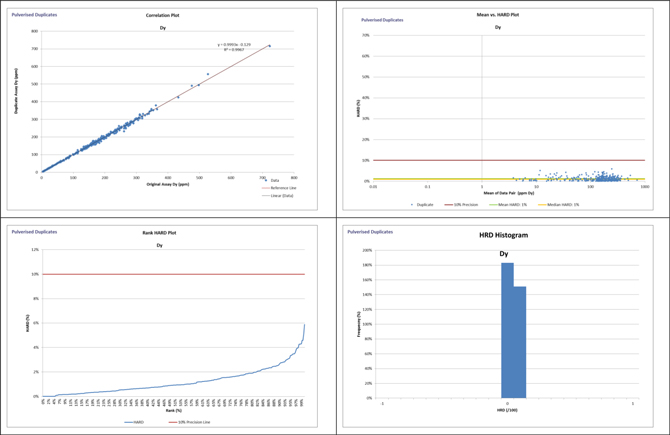

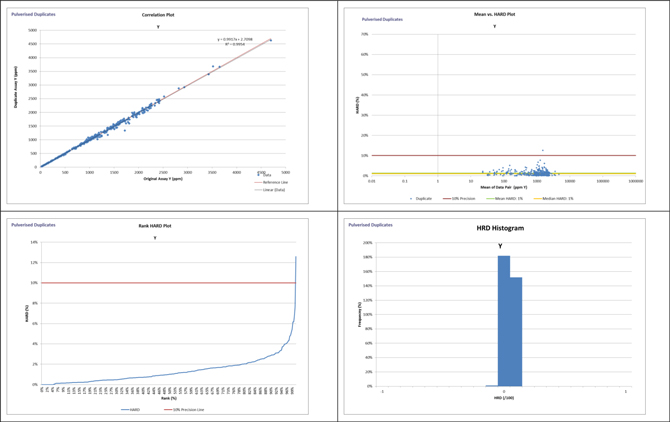

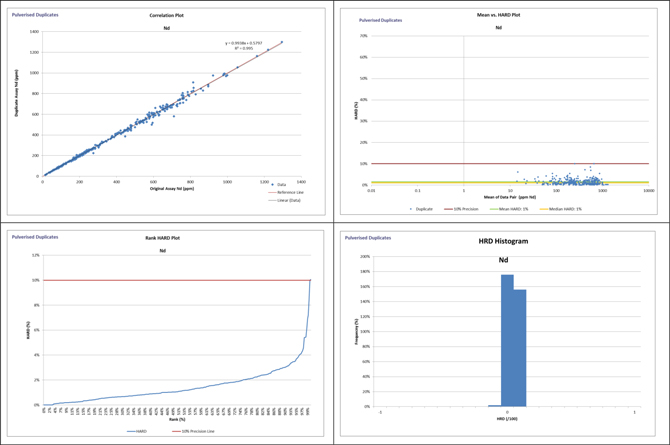

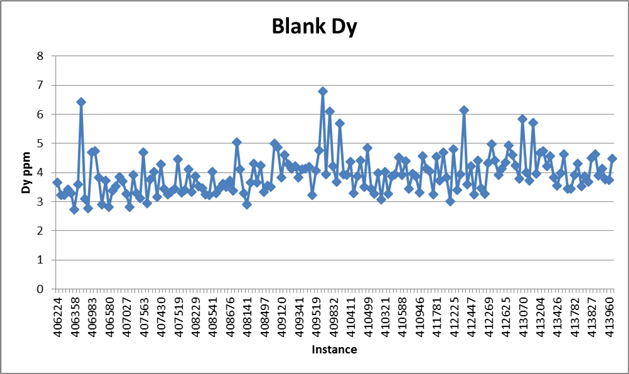

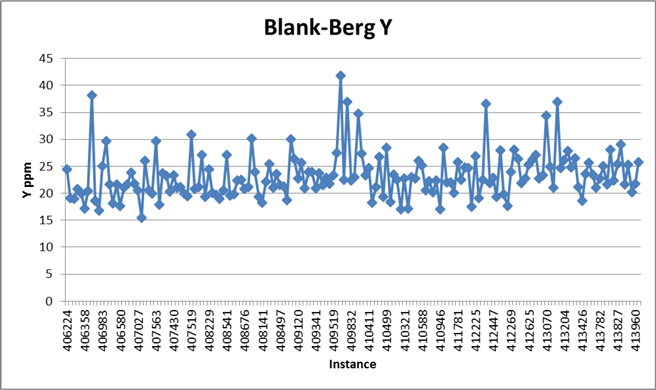

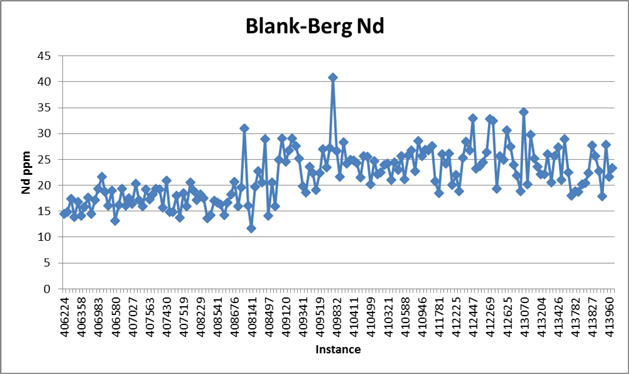

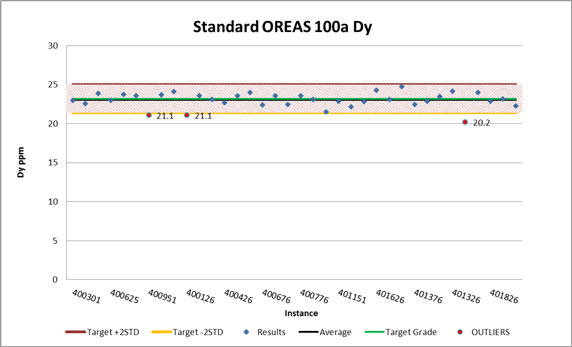

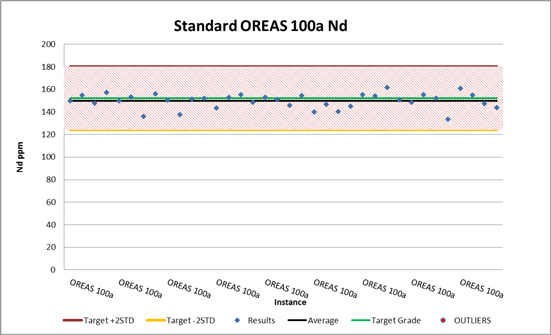

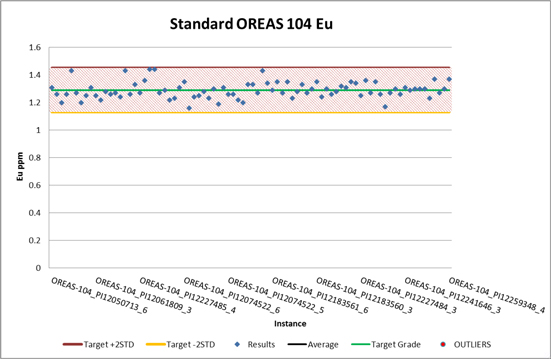

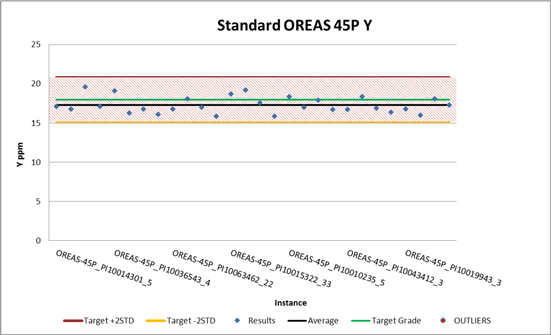

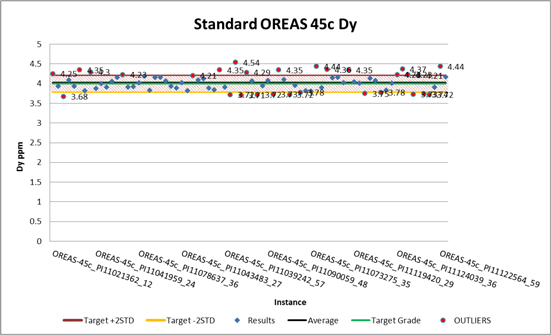

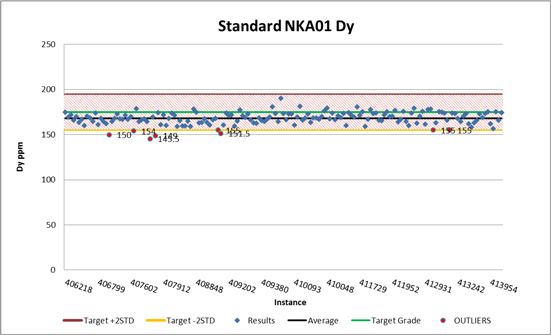

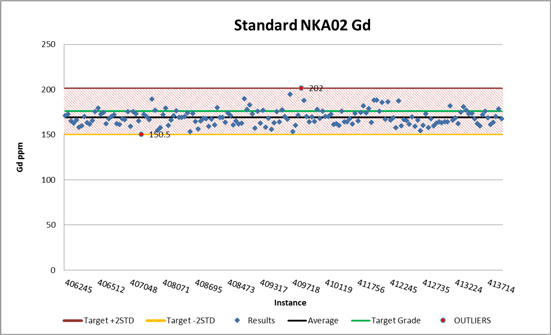

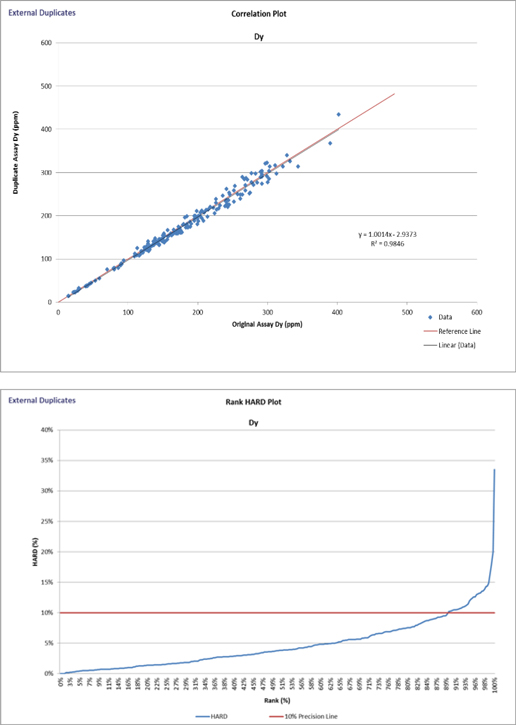

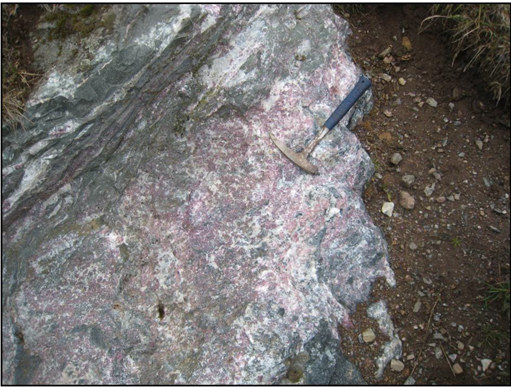

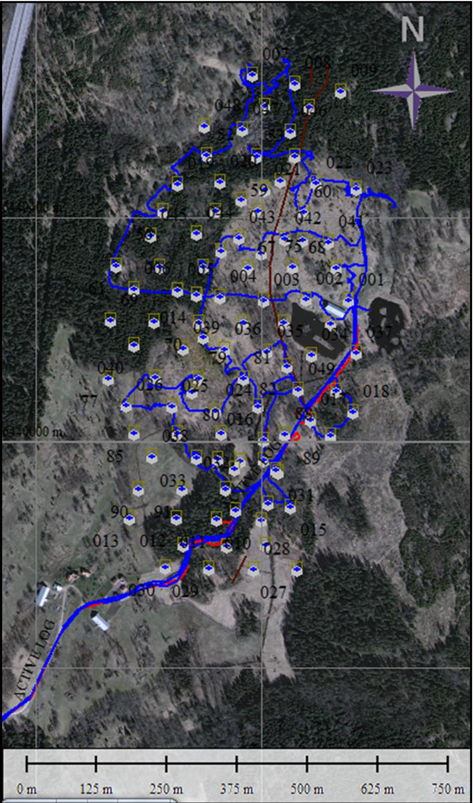

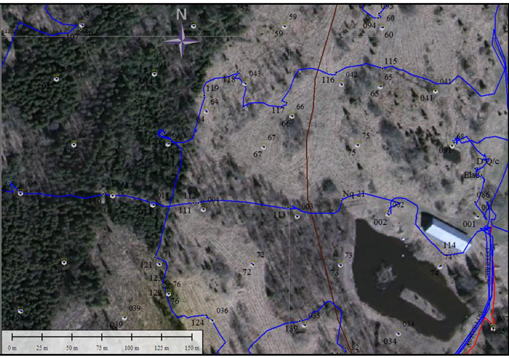

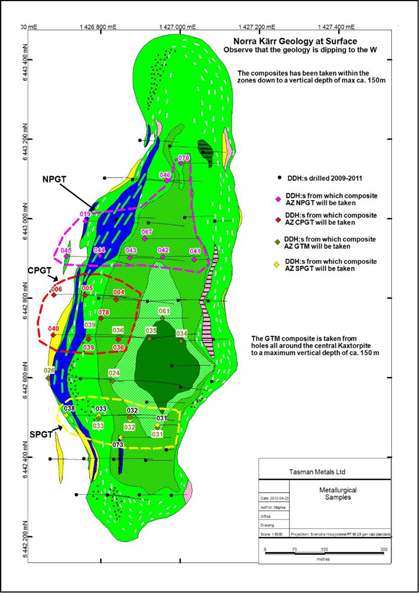

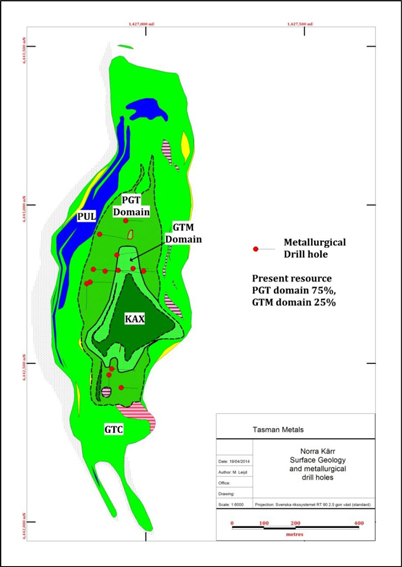

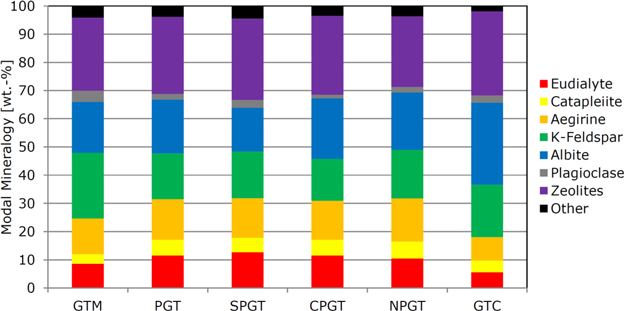

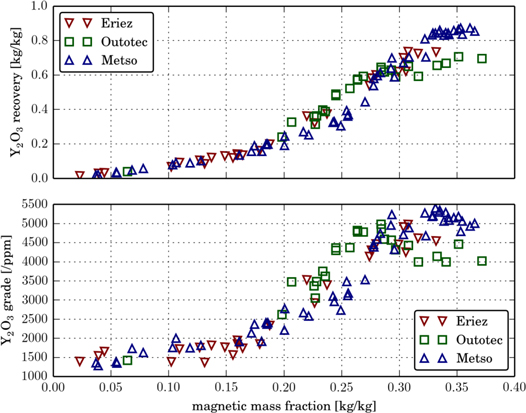

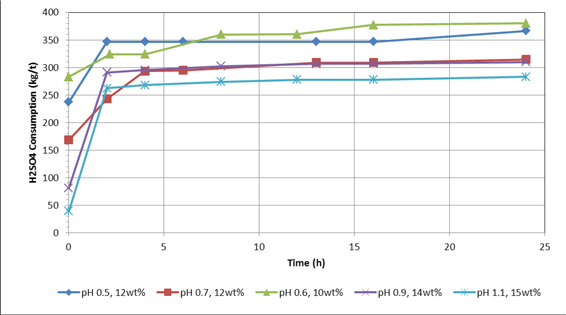

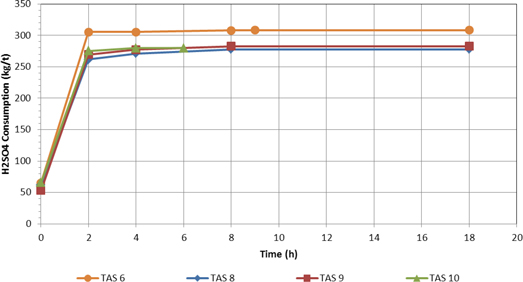

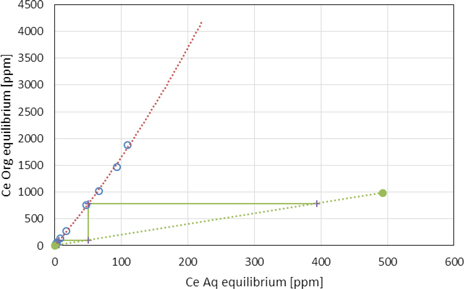

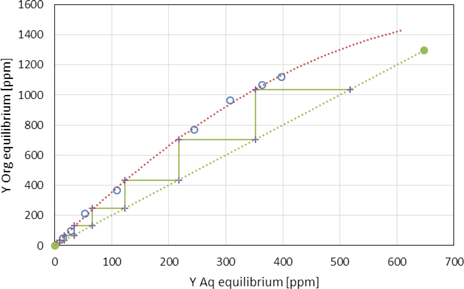

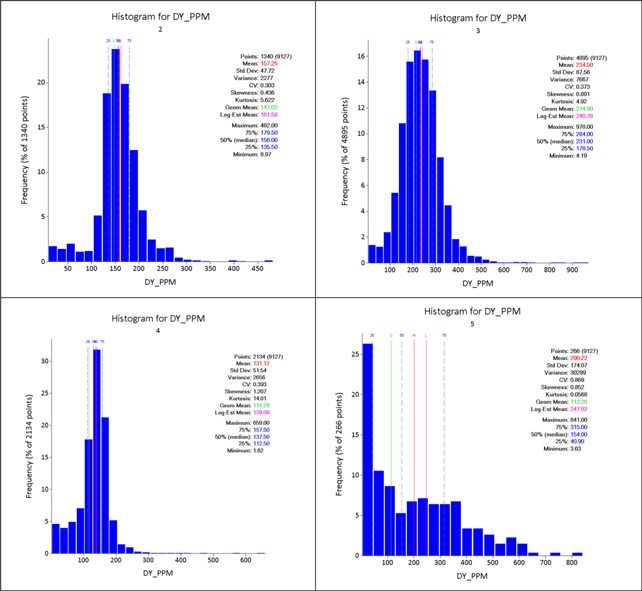

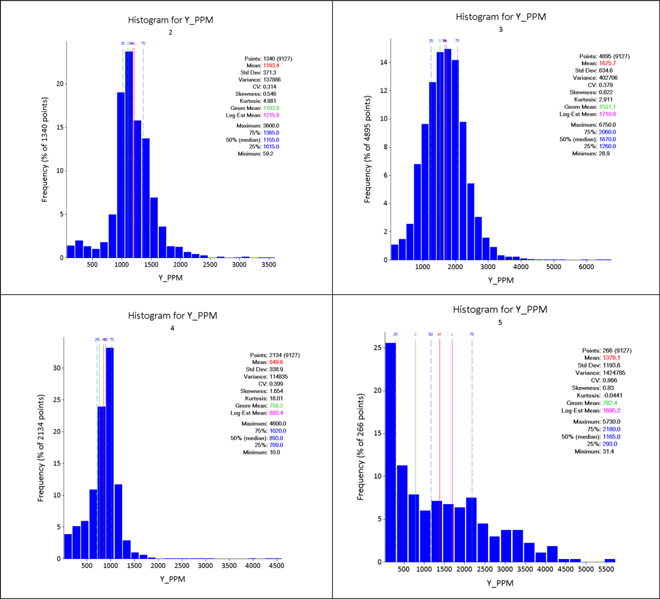

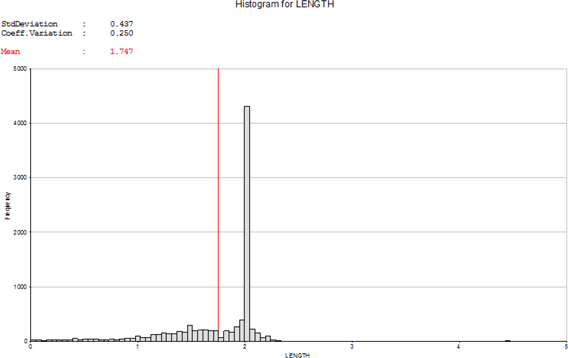

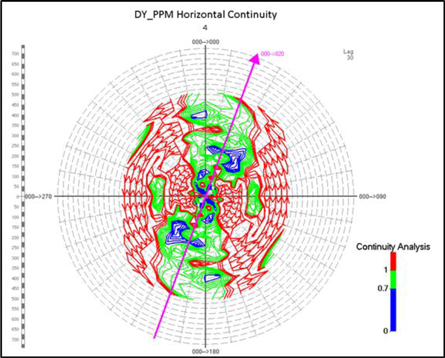

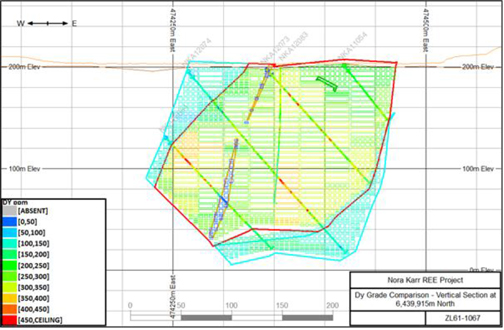

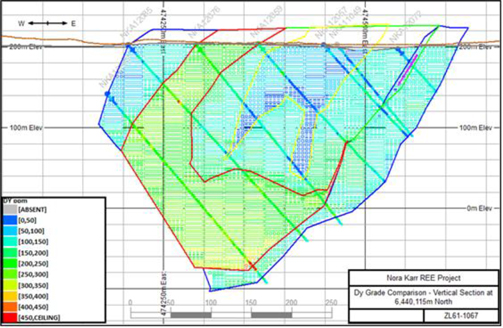

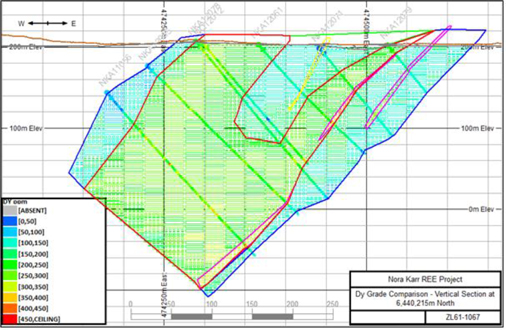

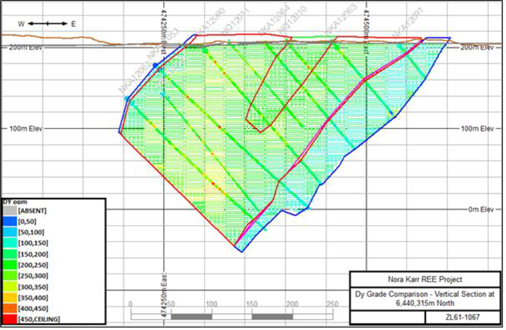

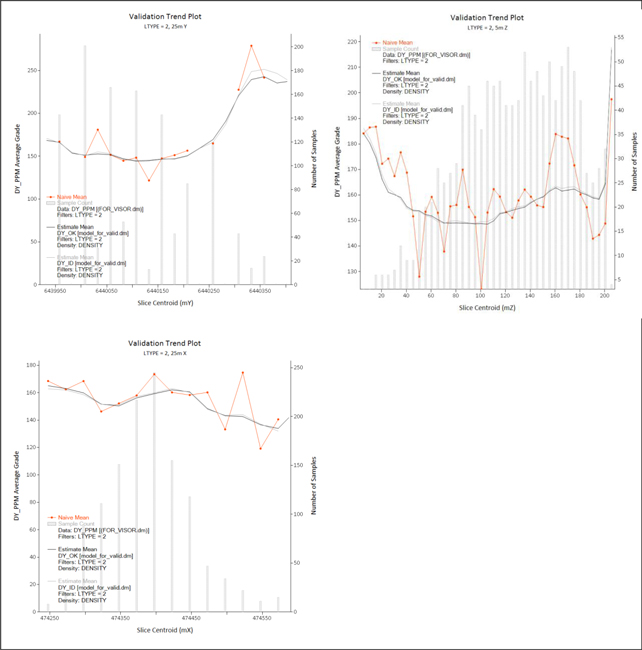

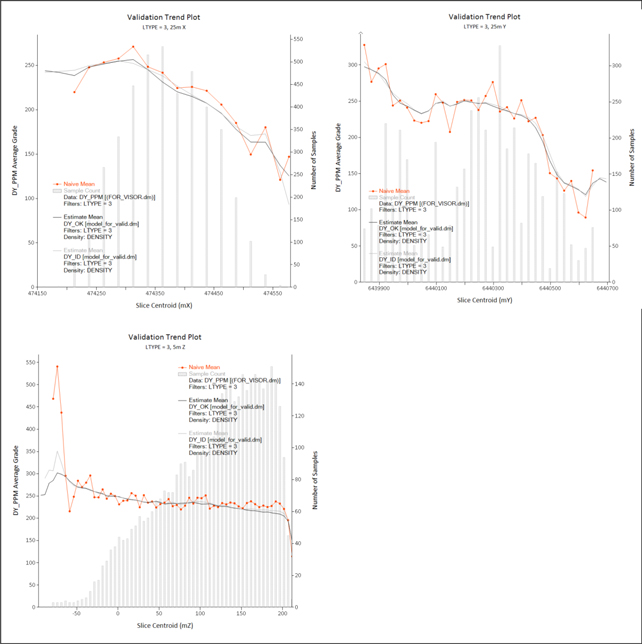

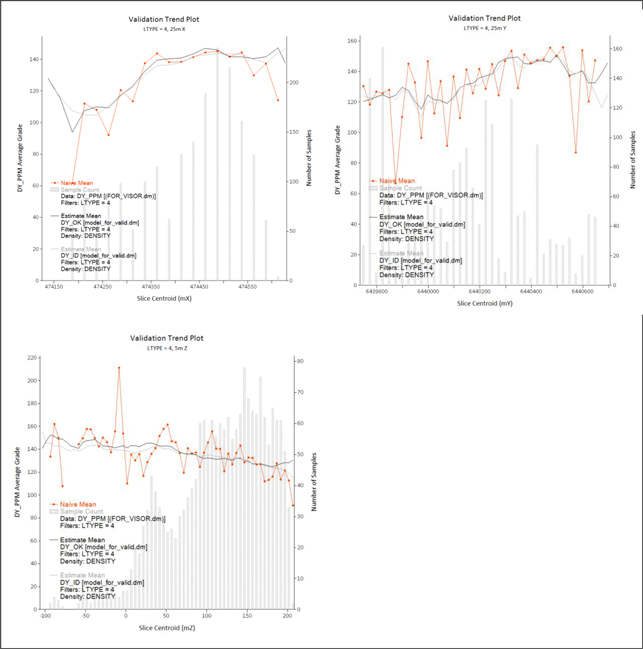

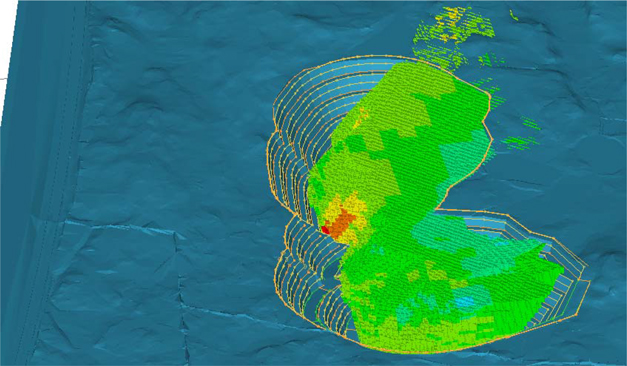

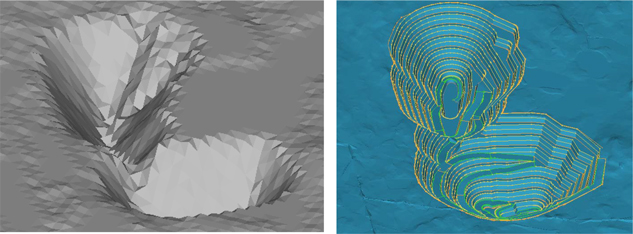

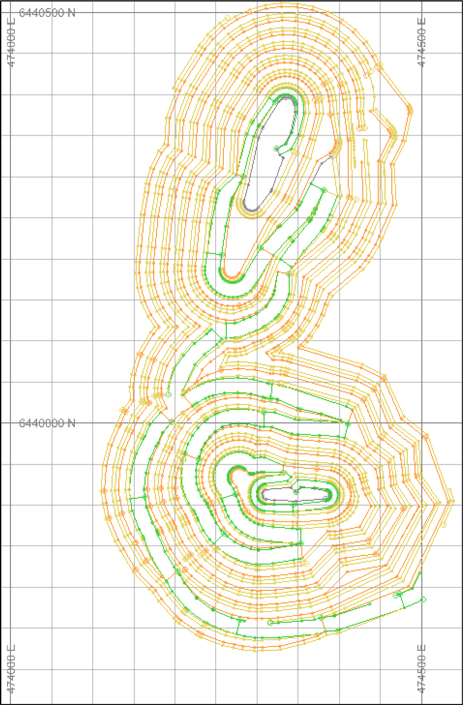

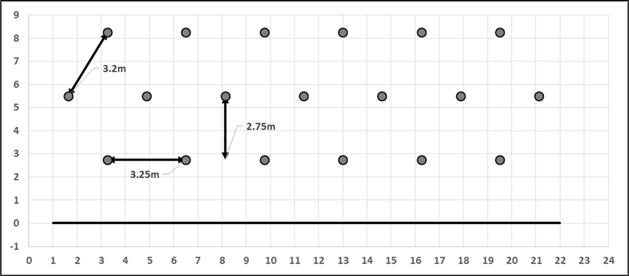

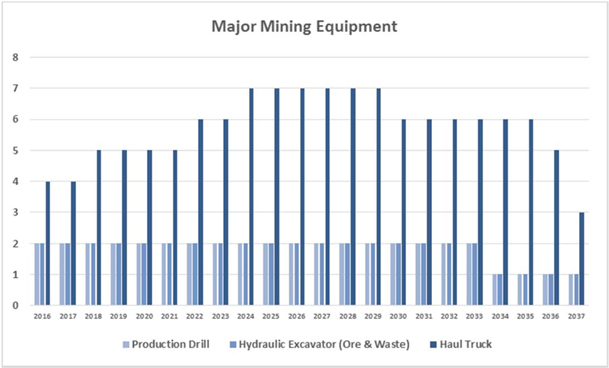

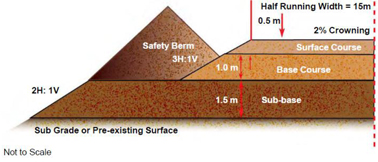

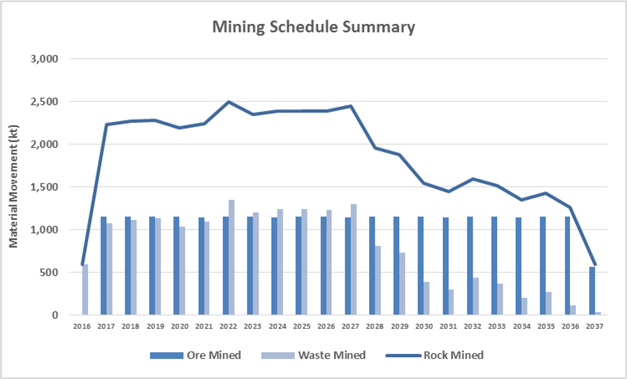

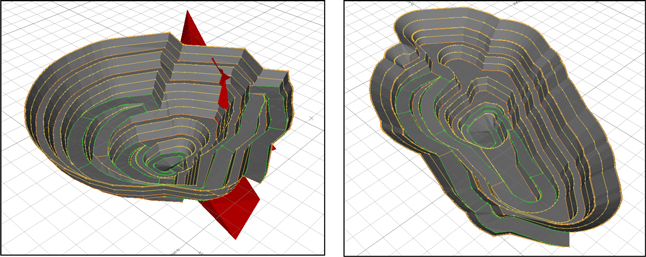

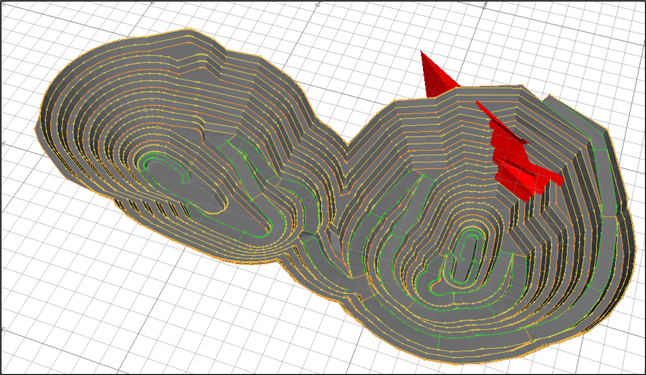

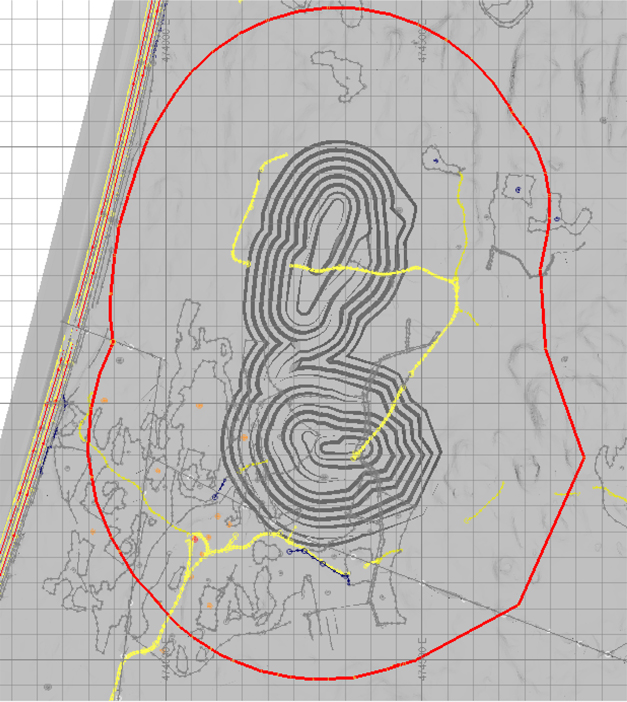

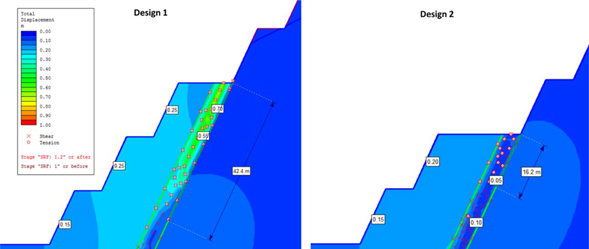

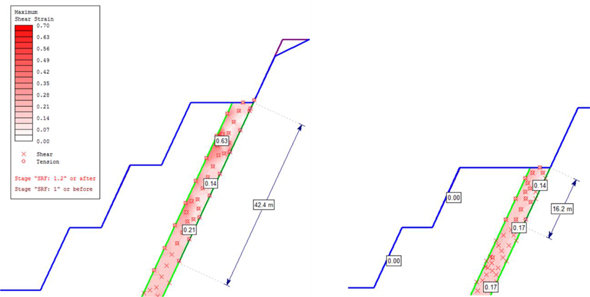

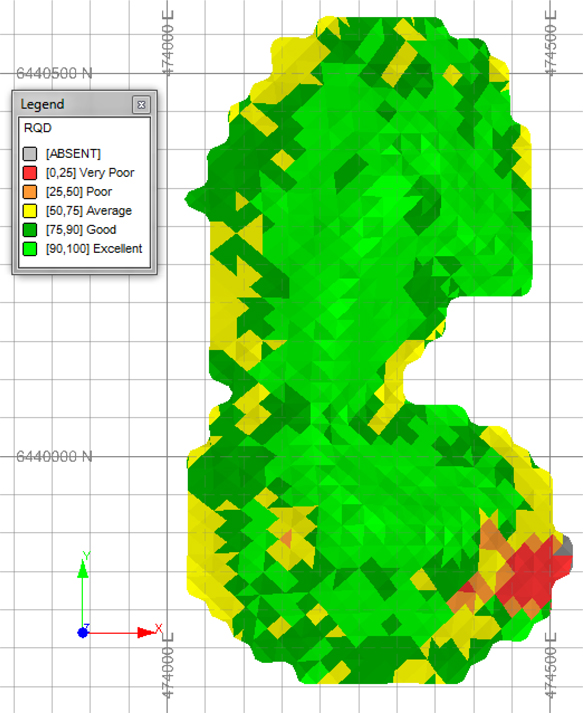

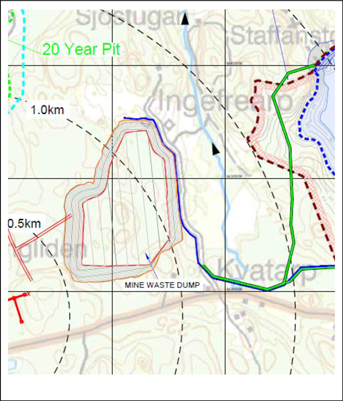

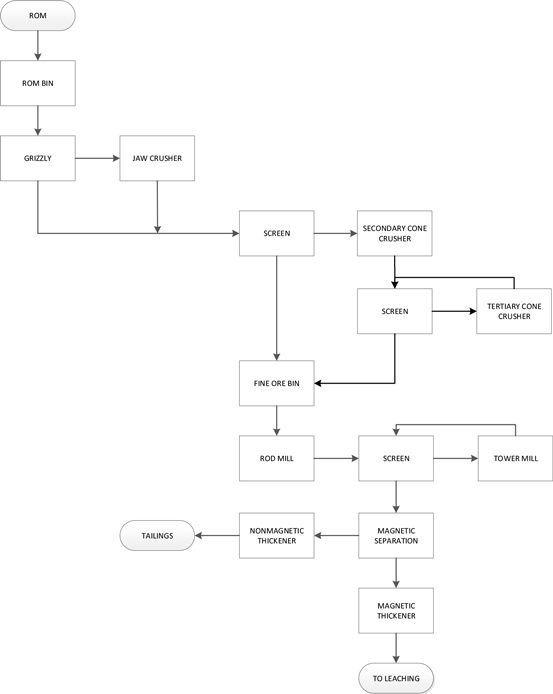

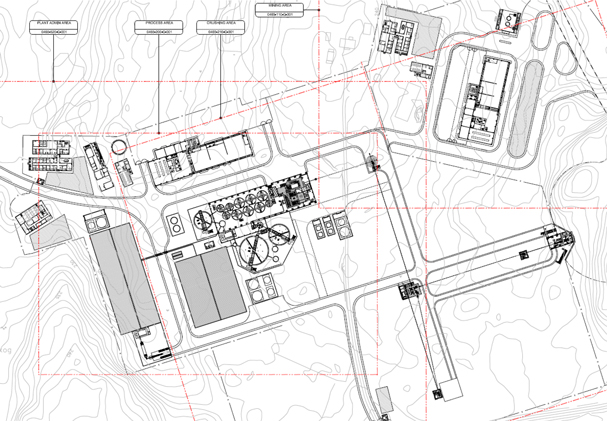

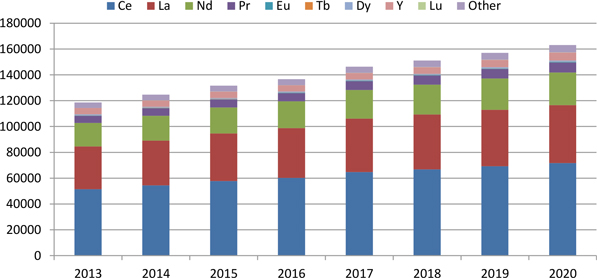

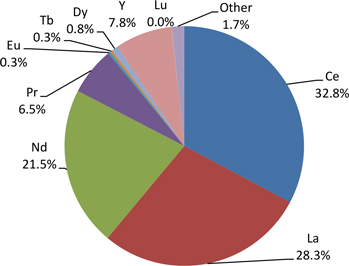

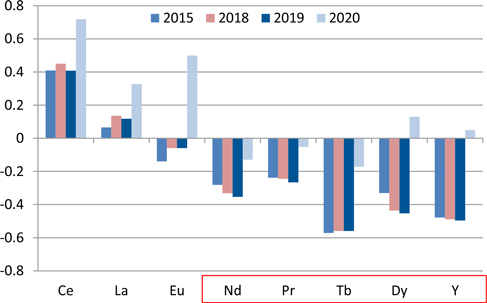

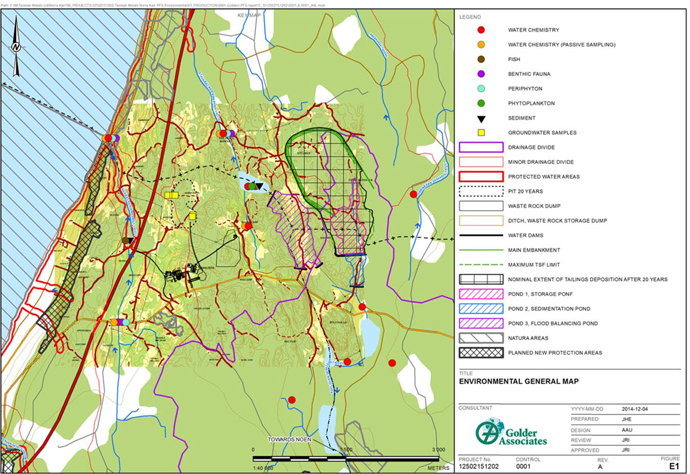

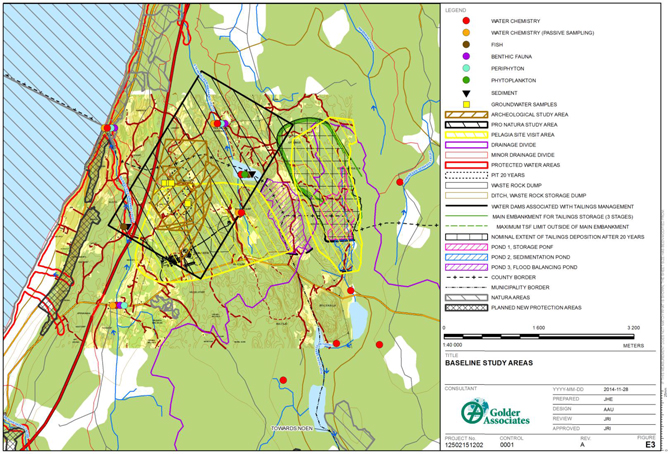

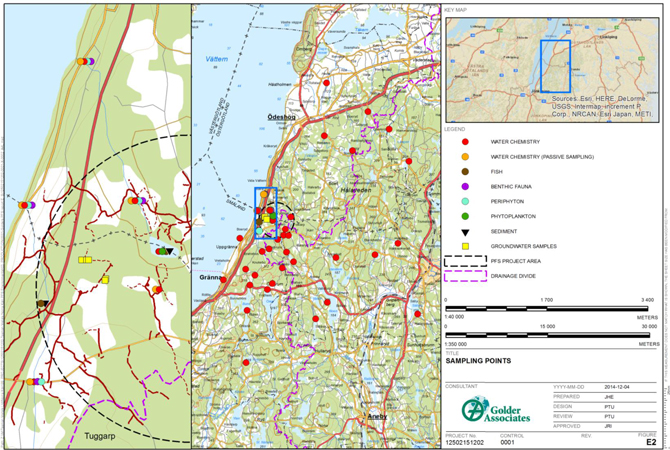

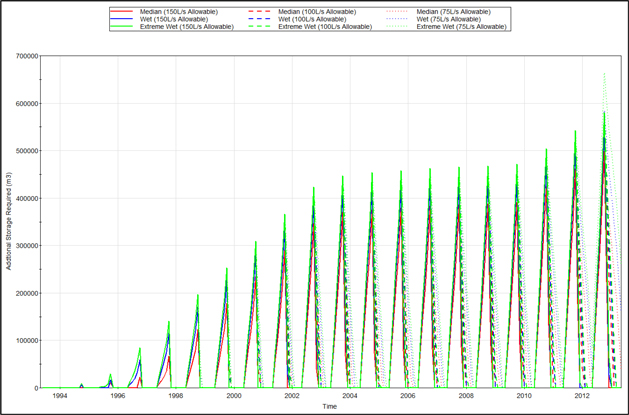

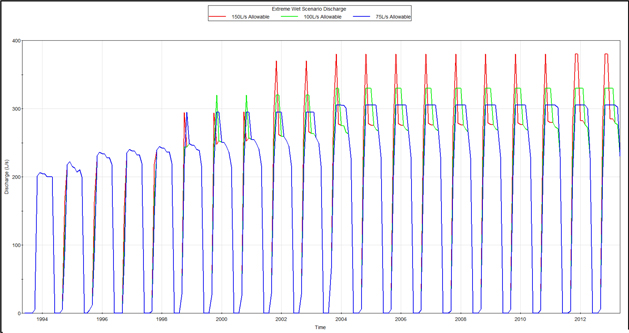

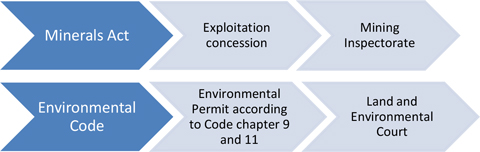

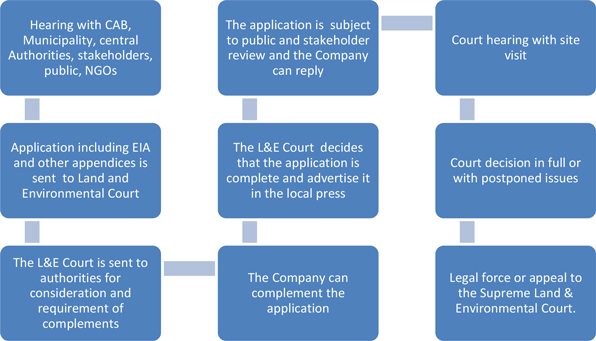

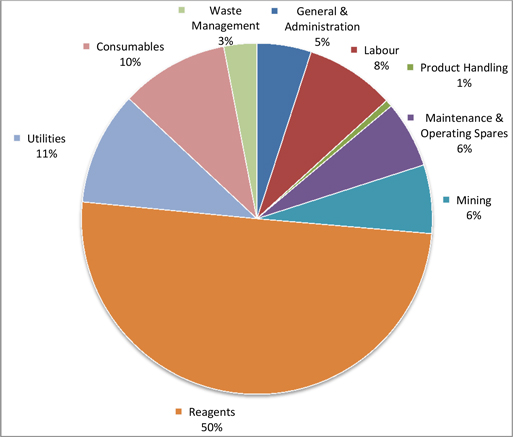

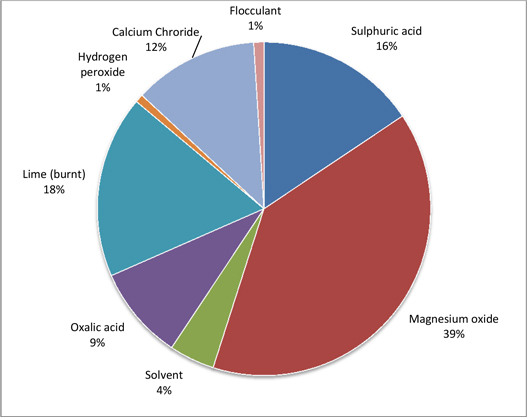

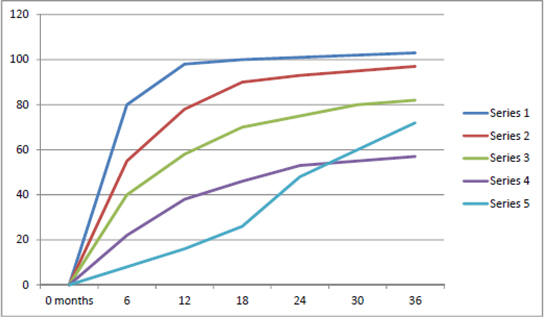

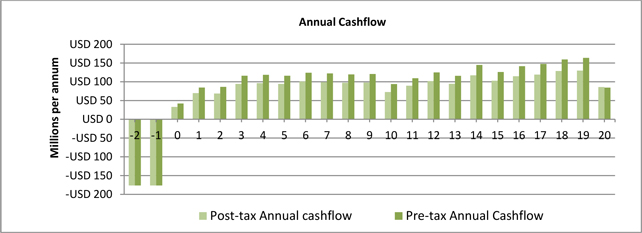

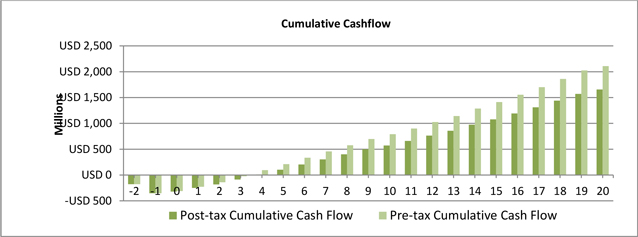

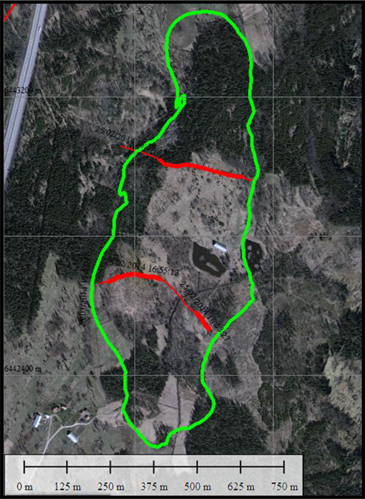

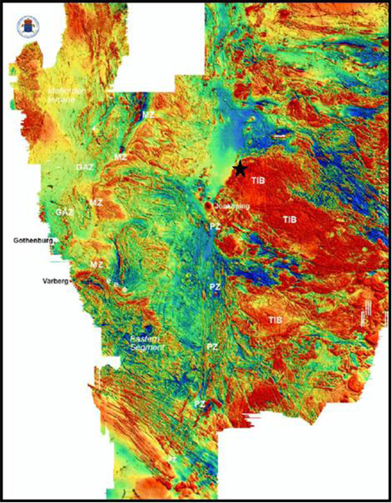

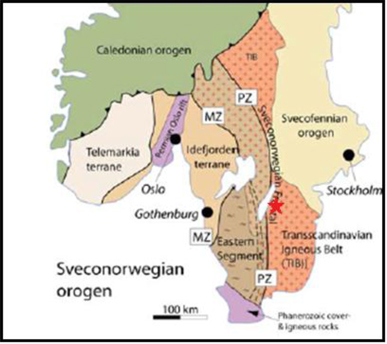

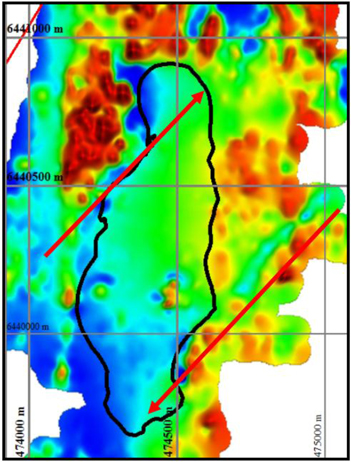

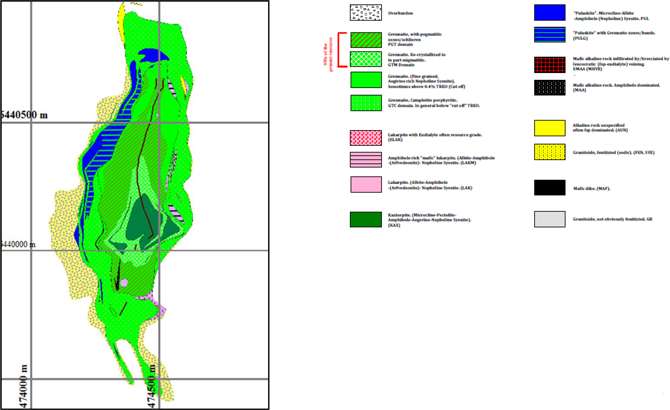

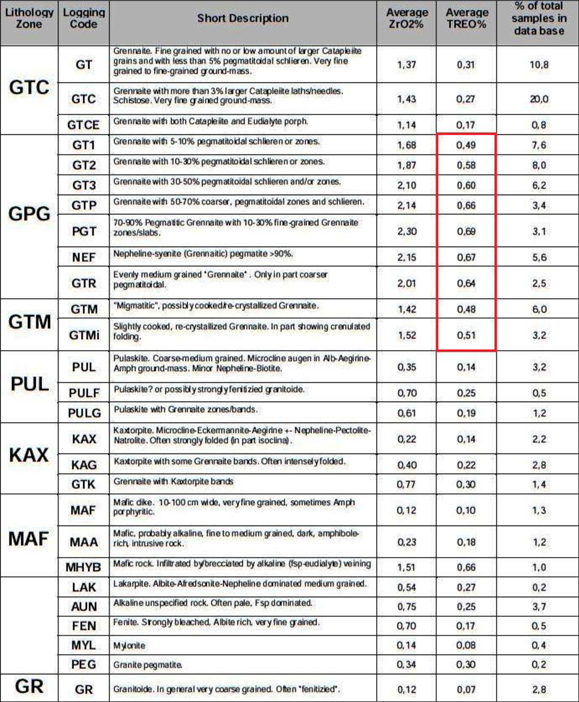

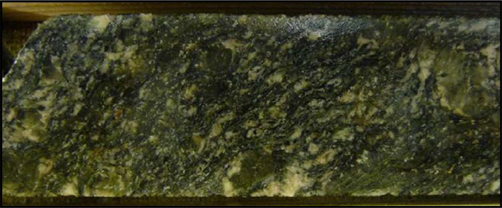

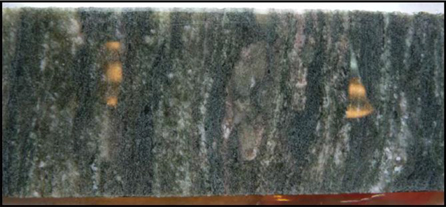

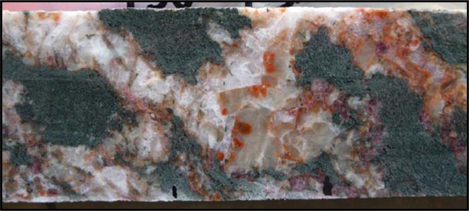

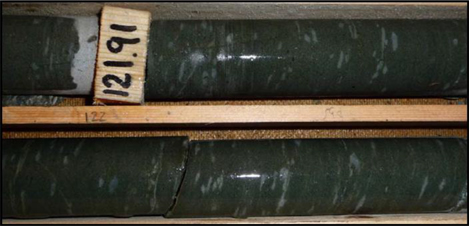

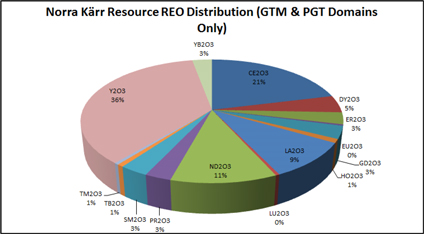

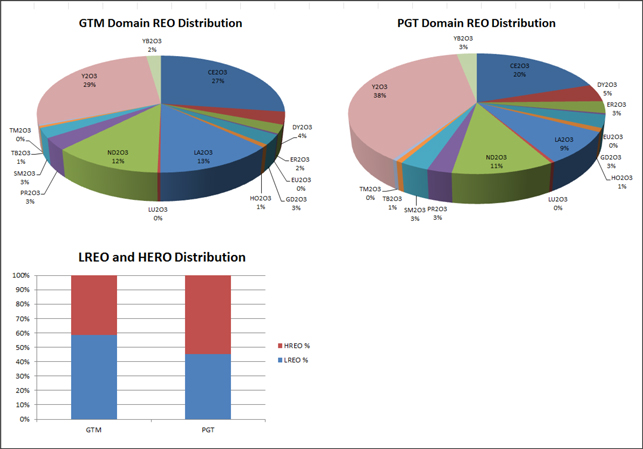

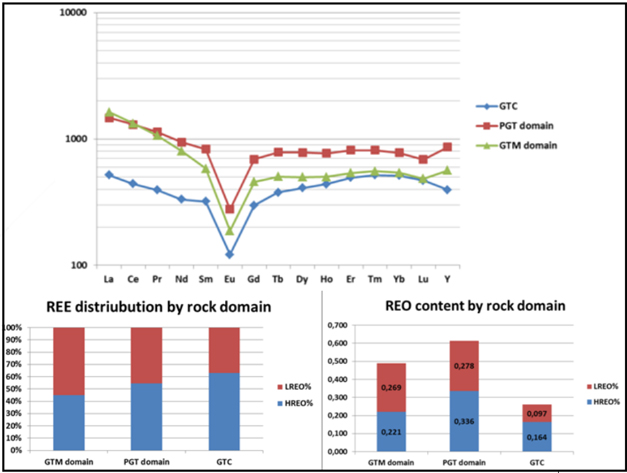

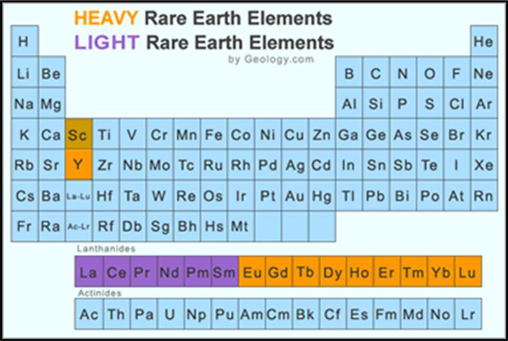

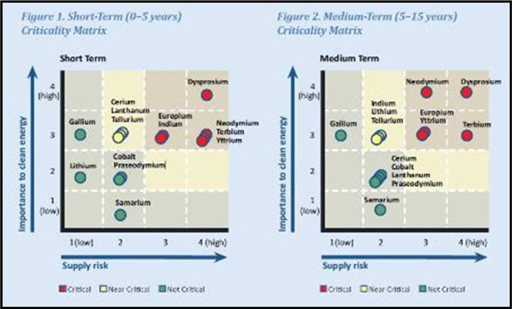

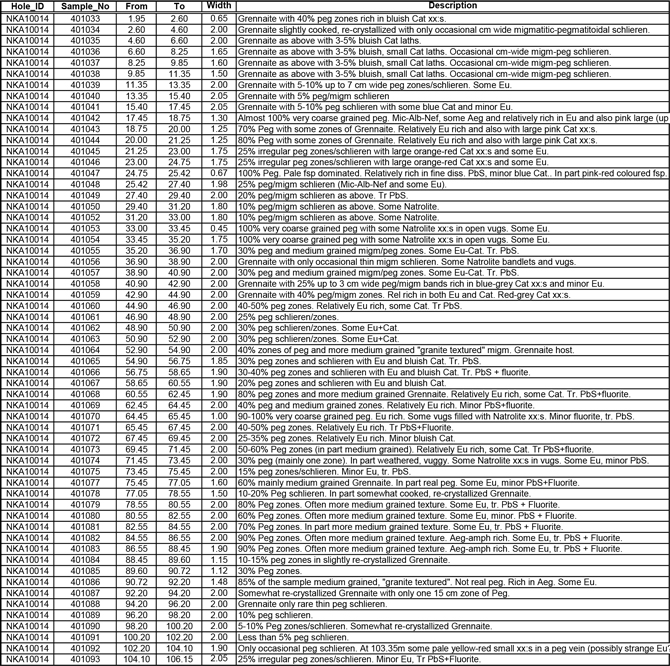

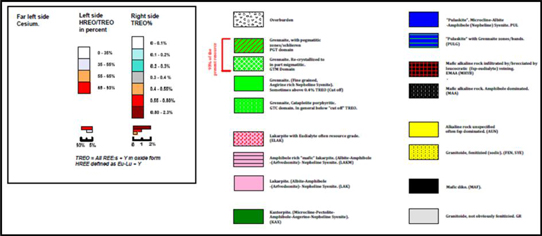

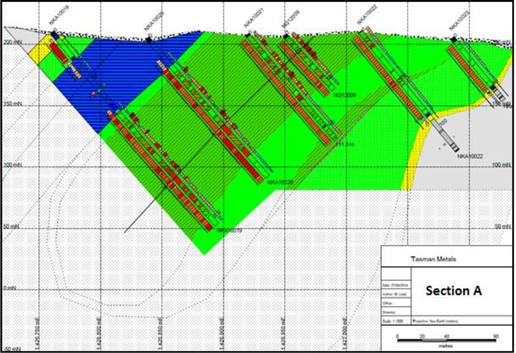

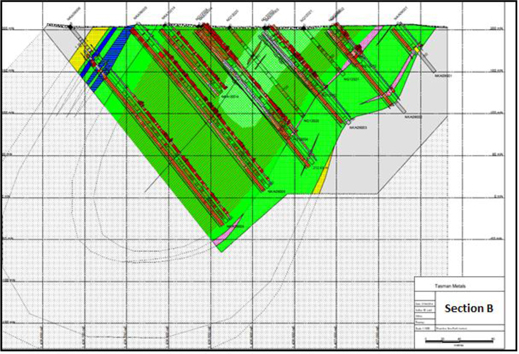

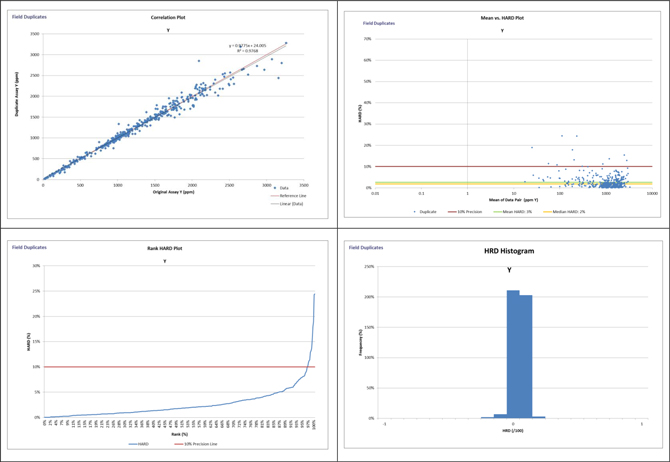

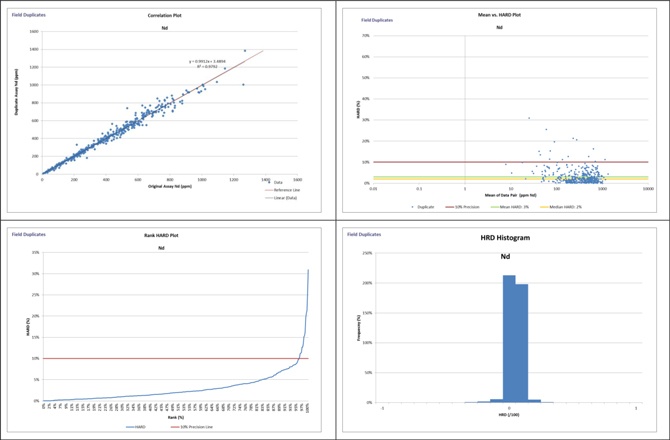

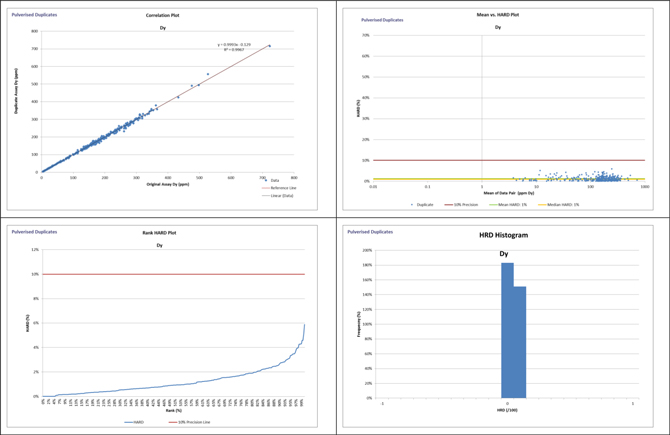

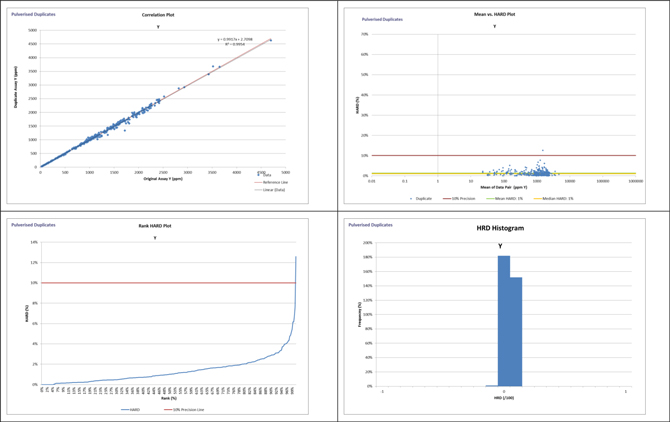

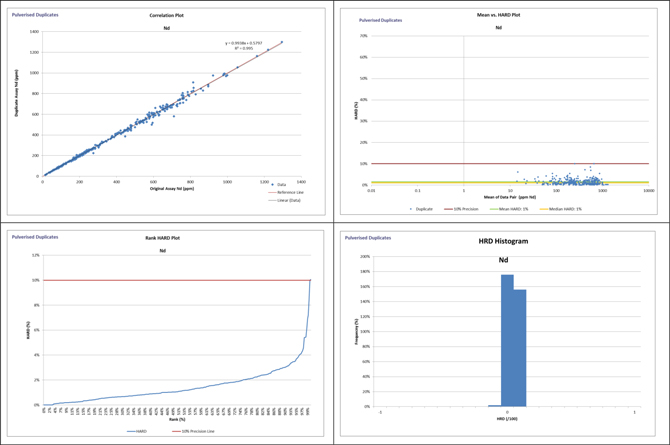

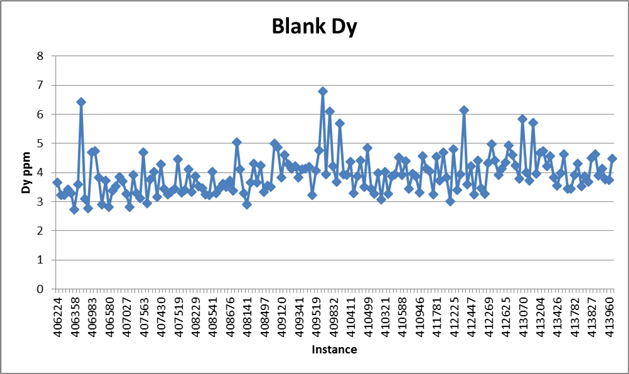

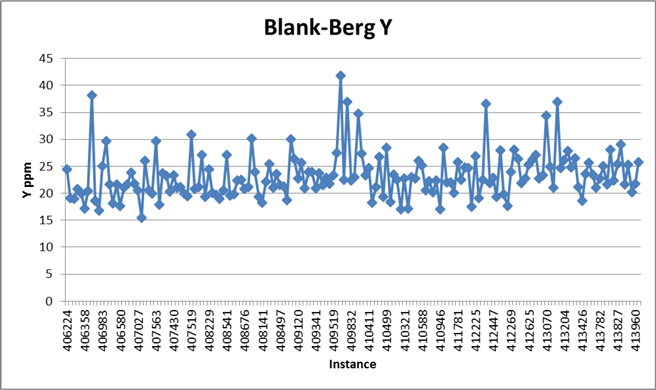

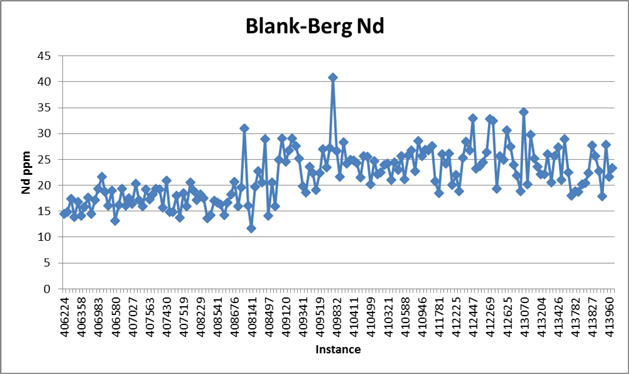

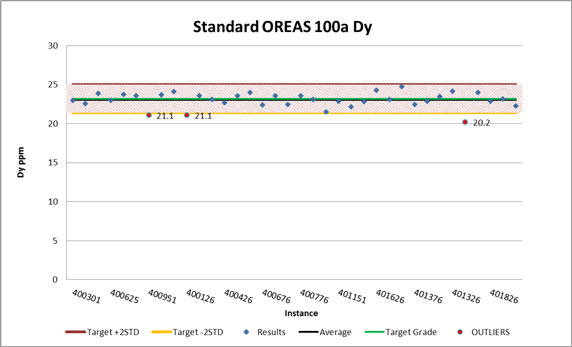

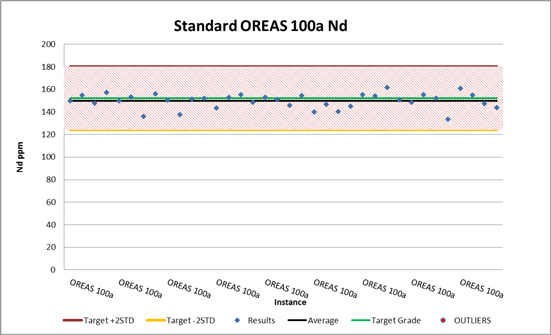

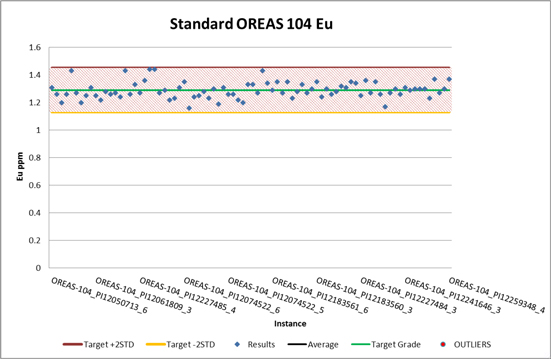

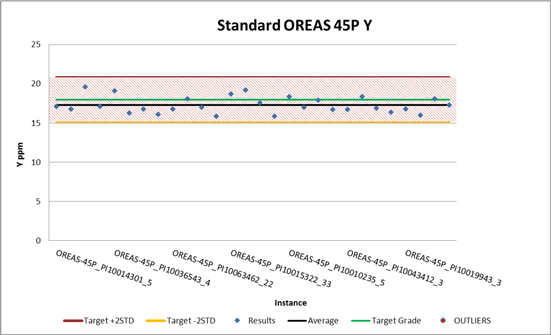

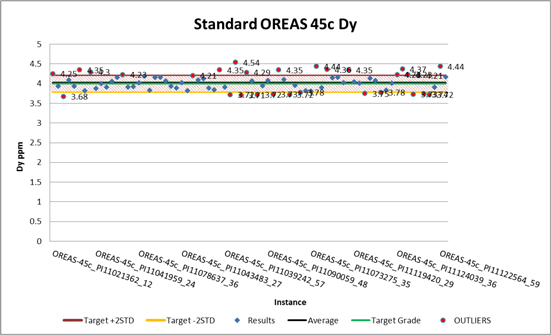

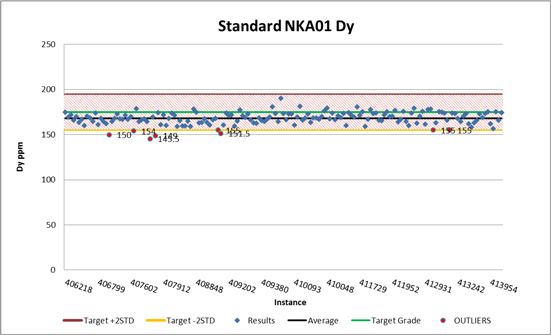

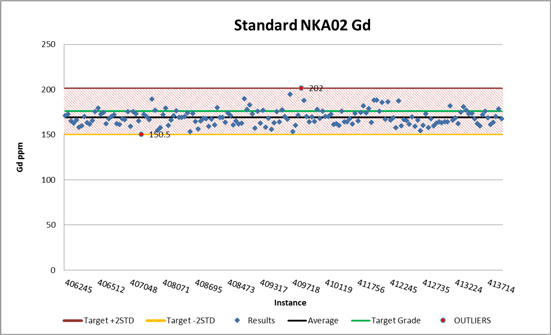

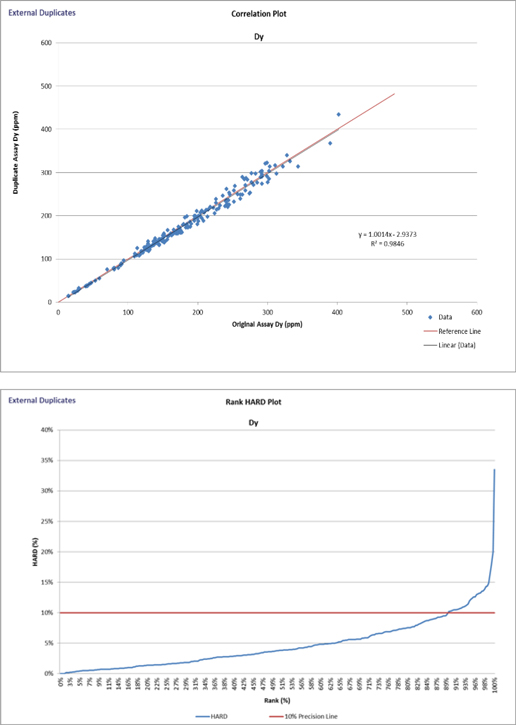

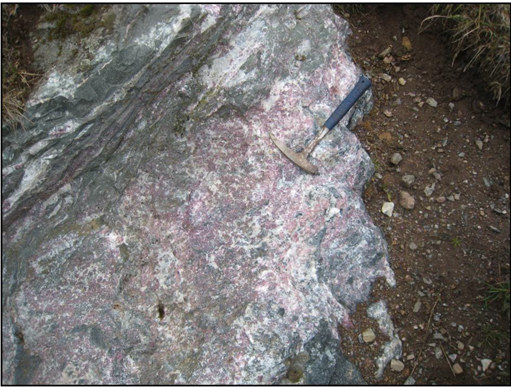

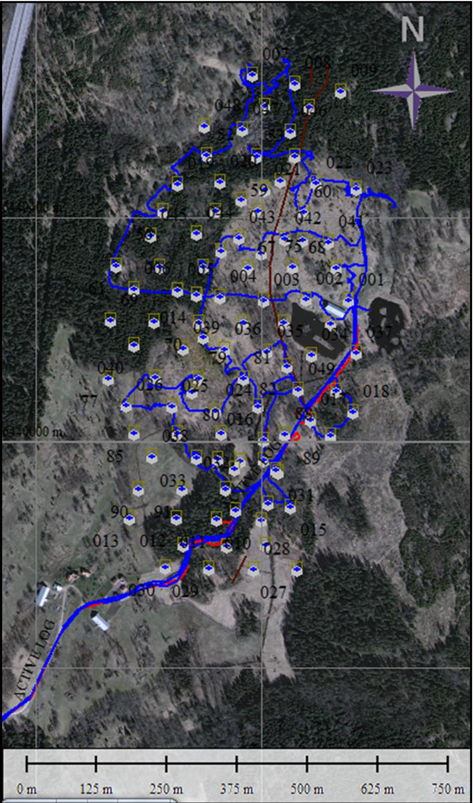

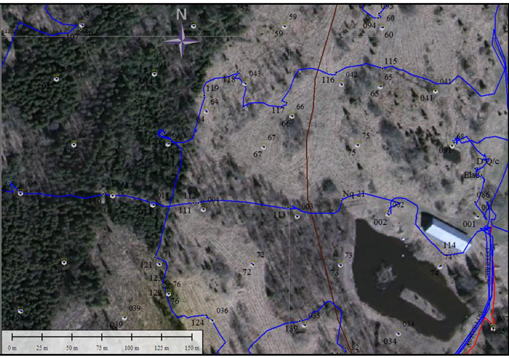

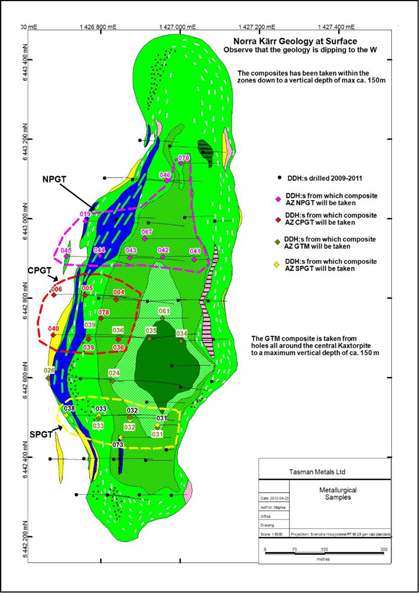

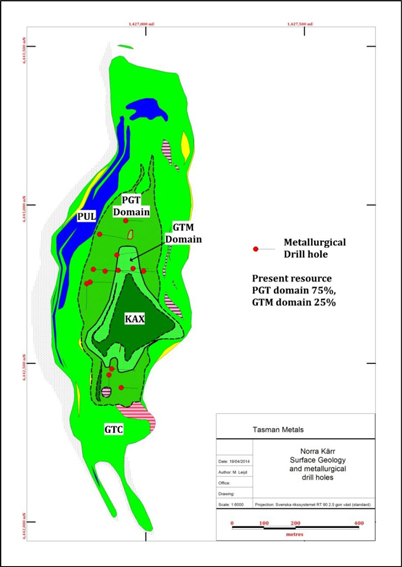

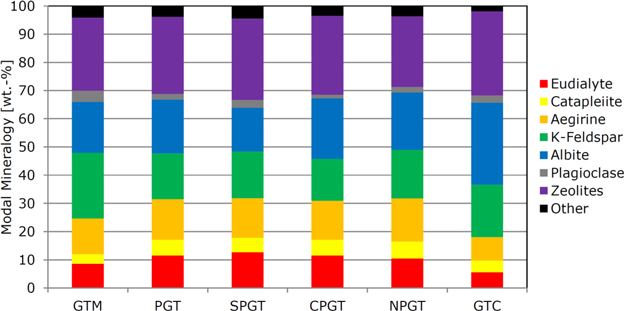

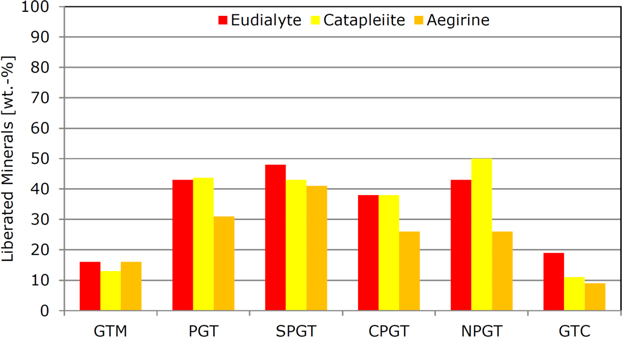

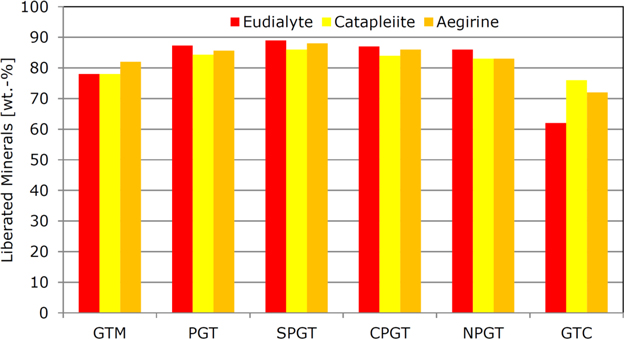

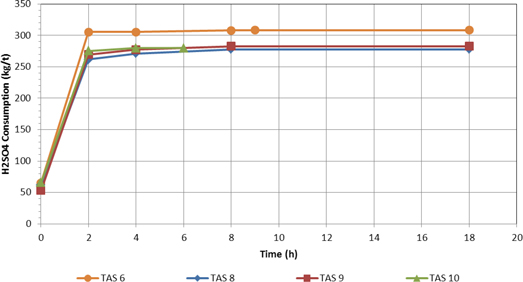

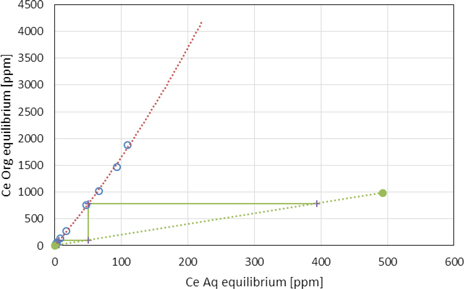

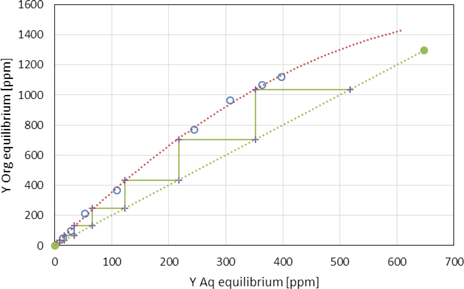

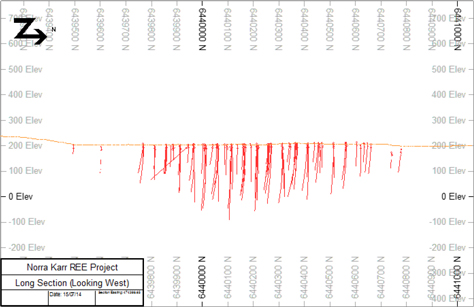

| 24 | | Other Relevant Data And Information | | GBM (Michael Short) |