Exhibit 99.1

TECHNICAL SUMMARY REPORT

AMERICAN WEST POTASH, LLC

2011 POTASH RESOURCE ASSESSMENT FOR THE HOLBROOK

BASIN PROJECT HOLBROOK, ARIZONA, USA

Prepared For:

American West Potash, LLC

600 17th Street, Suite #2800 South

Denver, Colorado 80202

Prepared By:

Tabetha A. Stirrett, Professional Geologist

North Rim Exploration, Ltd.

Avord Tower, 1020 — 606 Spadina Crescent East

Saskatoon, Saskatchewan S7K 3H1

Reviewed By:

Earl J. Gebhardt, Professional Engineer

North Rim Exploration, Ltd.

October 17, 2011

FINAL

Report Number: 10-912

Avord Tower, 1020-606 Spadina Crescent East·Saskatoon, Saskatchewan·S7K 3H1·(306) 244-4878

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

| | | | | |

| | | | | |

CONTENTS | | | | |

| | | | | |

| CONTENTS | | | 1 | |

| | | | | |

| LIST OF FIGURES | | | 3 | |

| | | | | |

| LIST OF TABLES | | | 4 | |

| | | | | |

| LIST OF APPENDICES | | | 4 | |

| | | | | |

| 1.0SUMMARY | | | 5 | |

| | | | | |

| 2.0INTRODUCTION AND TERMS OF REFERENCE | | | 10 | |

| | | | | |

| 2.1 INTRODUCTION | | | 10 | |

| | | | | |

| 2.2 AVAILABLE DATA | | | 11 | |

| | | | | |

| 2.3 TERMS OF REFERENCE | | | 12 | |

| | | | | |

| 2.4 SITE VISIT | | | 13 | |

| | | | | |

| 3.0RELIANCE ON OTHER EXPERTS | | | 14 | |

| | | | | |

| 3.1 Other Technical Contributors | | | 14 | |

| | | | | |

| 4.0PROPERTY DESCRIPTION AND LOCATION | | | 15 | |

| | | | | |

| 4.1 PROPERTY DESCRIPTION AND LOCATION | | | 15 | |

| | | | | |

| 4.2 PROPERTY TITLES IN ARIZONA | | | 17 | |

| | | | | |

| 4.3 MINERAL TENURE IN ARIZONA | | | 17 | |

| | | | | |

| 5.0ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY | | | 18 | |

| | | | | |

| 5.1 ACCESSIBILITY | | | 18 | |

| | | | | |

| 5.2 CLIMATE | | | 18 | |

| | | | | |

| 5.3 LOCAL RESOURCES | | | 19 | |

| | | | | |

| 5.4 INFRASTRUCTURE | | | 19 | |

| | | | | |

| 5.5 PHYSIOGRAPHY | | | 20 | |

| | | | | |

| 6.0HISTORY | | | 23 | |

| | | | | |

| 6.1 HISTORY OF POTASH EXPLORATION IN THE HOLBROOK BASIN | | | 23 | |

| | | | | |

| 6.2 RESOURCE EXPLOITATION HISTORY IN THE HOLBROOK BASIN | | | 25 | |

| | | | | |

| 7.0GEOLOGICAL SETTING AND MINERALIZATION | | | 25 | |

| | | | | |

| 7.1 GEOLOGICAL SETTING | | | 25 | |

| | | | | |

| 7.2 LOCAL GEOLOGY AND MINERALIZATION | | | 32 | |

| | | | | |

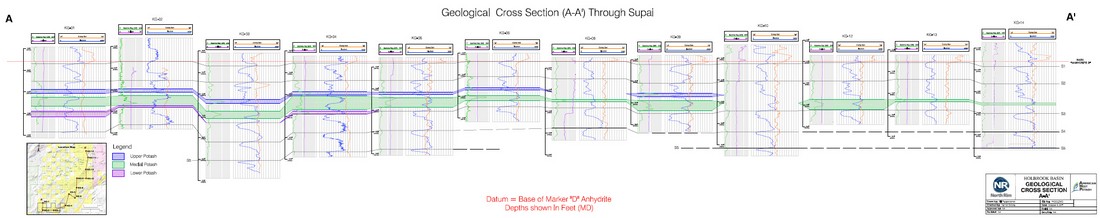

| 7.3 STRUCTURAL GEOLOGY AND GEOLOGICAL CROSS SECTIONS | | | 42 | |

| | | | | |

| 7.4 DISTURBANCES AFFECTING GEOLOGY OF THE POTASH-BEARING MEMBERS | | | 42 | |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

| | | | | |

| 7.5 CARLSBAD POTASH MINE, NEW MEXICO: AN ANALOG | | | 45 | |

| | | | | |

| 8.0DEPOSIT TYPE | | | 46 | |

| | | | | |

| 9.0EXPLORATION | | | 50 | |

| | | | | |

| 9.1 SEISMIC PROGRAM | | | 50 | |

| | | | | |

| 10.0DRILLING | | | 54 | |

| | | | | |

| 10.1 2011 DRILLING PROGRAM | | | 54 | |

| | | | | |

| 10.2 DRILLING PROCEDURES | | | 55 | |

| | | | | |

| 10.3 CORE RETRIEVAL | | | 56 | |

| | | | | |

| 10.4 GEOPHYSICAL WIRELINE PROGRAM | | | 58 | |

| | | | | |

| 11.0SAMPLE PREPARATION, ANALYSIS AND SECURITY | | | 59 | |

| | | | | |

| 11.1 GEOCHEMICAL SAMPLING | | | 59 | |

| | | | | |

| 11.2 CONTROLS ON SAMPLE INTERVAL DETERMINATION | | | 60 | |

| | | | | |

| 11.3 SAMPLING METHOD AND APPROACH | | | 61 | |

| | | | | |

| 11.4 SAMPLE SECURITY | | | 65 | |

| | | | | |

| 11.5 QUALITY CONTROL PROCEDURES | | | 66 | |

| | | | | |

| 12.0DATA VERIFICATION | | | 68 | |

| | | | | |

| 12.1 HISTORICAL DATA | | | 68 | |

| | | | | |

| 12.2 RECENT DATA | | | 69 | |

| | | | | |

| 12.3 ASSAY-TO-GAMMA CORRELATION STUDY | | | 70 | |

| | | | | |

| 12.4 COMPARISON OF GREC METHOD TO ACTUAL HISTORICAL ASSAY DATA | | | 72 | |

| | | | | |

| 12.5 COMPARISON OF GREC METHOD TO 2011 DRILL HOLE ASSAY DATA | | | 75 | |

| | | | | |

| 12.6 REVIEW OF STANDARDS AND REPEAT ANALYSIS | | | 75 | |

| | | | | |

| 13.0MINERAL PROCESSING AND METALLURGICAL TESTING | | | 77 | |

| | | | | |

| 14.0MINERAL RESOURCE ESTIMATES | | | 77 | |

| | | | | |

| 14.1 Mineral and Private Lands | | | 77 | |

| | | | | |

| 14.2 Assumptions and Methodology | | | 77 | |

| | | | | |

| 14.3 Mineral Resource | | | 78 | |

| | | | | |

| 14.3.1 Inferred Mineral Resource | | | 78 | |

| | | | | |

| 14.3.2 Indicated Mineral Resource | | | 79 | |

| | | | | |

| 14.3.3 Measured Mineral Resource | | | 79 | |

| | | | | |

| 14.4 Potential Conventional Mining Intervals | | | 80 | |

| | | | | |

| 14.4.1 KR-1 Inferred Resource Discussion | | | 82 | |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

| | | | | |

| 14.4.2 KR-2 Indicated and Inferred Resource Discussion | | | 82 | |

| | | | | |

| 15.0MINERAL RESERVE ESTIMATES | | | 84 | |

| | | | | |

| 16.0MINING METHODS | | | 84 | |

| | | | | |

| 17.0RECOVERY METHODS | | | 84 | |

| | | | | |

| 18.0PROJECT INFRASTRUCTURE | | | 84 | |

| | | | | |

| 19.0MARKET STUDIES AND CONTRACTS | | | 84 | |

| | | | | |

| 20.0ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | | | 84 | |

| | | | | |

| 21.0CAPITAL AND OPERATING COSTS | | | 84 | |

| | | | | |

| 22.0ECONOMIC ANALYSIS | | | 84 | |

| | | | | |

| 23.0ADJACENT PROPERTIES | | | 85 | |

| | | | | |

| 24.0OTHER RELEVANT DATA AND INFORMATION | | | 87 | |

| | | | | |

| 25.0INTERPRETATION AND CONCLUSIONS | | | 87 | |

| | | | | |

| 26.0RECOMMENDATIONS | | | 88 | |

| | | | | |

| 27.0References | | | 89 | |

| | | | | |

| 28.0Certification of Qualified Person | | | 90 | |

LIST OF FIGURES

| | | | | |

| Figure 4-1: General Location Map of Project Area | | | 16 | |

| | | | | |

| Figure 5-1: Project Area with surrounding infrastructure and rail lines | | | 22 | |

| | | | | |

| Figure 5-2: Solution Collapse Basin with respect to potash basin (modified from Warren, 2006) | | | 23 | |

| | | | | |

| Figure 7-1: Geological map of north east Arizona and Project Area | | | 26 | |

| | | | | |

| Figure 7-2: Isopach map of the Upper Potash Bed interval | | | 29 | |

| | | | | |

| Figure 7-3: Isopach map of the combined Medial and Lower Potash Bed intervals | | | 30 | |

| | | | | |

| Figure 7-4: Isopach map of the total gross potash interval (Upper to Lower Potash Beds) | | | 31 | |

| | | | | |

| Figure 7-5: Simplified stratigraphic column of the Holbrook Basin | | | 36 | |

| | | | | |

| Figure 7-6: Simplified cross section through the Holbrook Basin | | | 37 | |

| | | | | |

| Figure 7-7: Type section of KG-06 correlating geophysical log signatures with core photography in “Cycle 5” beds | | | 38 | |

| | | | | |

| Figure 7-8: Type section of drill hole KG-04 including the potash and resource intervals | | | 41 | |

| | | | | |

| Figure 7-9: Anomalies affecting Potash- bearing horizons | | | 44 | |

| | | | | |

| Figure 9-1: Location of the 2011 Seismic Lines | | | 51 | |

| | | | | |

| Figure 9-2: Supai to Marker 1 Isochron Map | | | 53 | |

| | | | | |

| Figure 10-1: Sunbelt Drilling Rig (left) and Stewart Brothers Drilling’s Rig (right) | | | 55 | |

| | | | | |

| Figure 10-2: Stewart Brothers Drilling performing core recovery with North Rim Core Supervisor | | | 58 | |

| | | | | |

| Figure 11-1: Photograph taken inside of AWP’s Core Lab Facility | | | 61 | |

| | | | | |

| Figure 11-2: AWP’s dry 2-horsepower band saw with dust collection system | | | 63 | |

| | | | | |

| Figure 11-3: Sampling interval from drill hole “KG-06” (Core 3, Box 5) | | | 64 | |

| | | | | |

| Figure 12-1: Bannatyne (1983) GREC Method | | | 71 | |

| | | | | |

| Figure 12-2: Alger and Crain GREC Method (1965) | | | 71 | |

| | | | | |

| Figure 12-3: Historical Drill Hole 01-23 Gamma ray / Assay / GREC Comparison | | | 74 | |

| | | | | |

Figure 12-4: K2O POT003/POT004 Standard Limits | | | 76 | |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

| | | | | |

| Figure 12-5: MgO POT003/POT004 Standard Limits | | | 76 | |

| | | | | |

| Figure 14-1: Resource Buffers for KR-1 and KR-2 (Indicated and Inferred) | | | 83 | |

| | | | | |

| Figure 23-1: Adjacent property land holdings with respect to the Project Area | | | 86 | |

LIST OF TABLES

| | | | | |

| Table 1-1: Resource Summary Table | | | 7 | |

| | | | | |

| Table 2-1: Glossary of Terms and Phrases | | | 12 | |

| | | | | |

| Table 5-1: Approximate Ground Elevation at Well Center for the 2011 Drill Locations | | | 21 | |

| | | | | |

| Table 7-1: Summary of Potash Mineralization | | | 40 | |

| | | | | |

| Table 8-1: Summary of potassium salts | | | 48 | |

| | | | | |

| Table 8-2: Stoichiometric and chemical equivalencies and calculations | | | 49 | |

| | | | | |

| Table 9-1: Summary of 2011 Exploration Program | | | 50 | |

| | | | | |

| Table 10-1: Drill Hole 2011 Wireline Program | | | 59 | |

| | | | | |

| Table 11-1: Assay Intervals Summarized by Test Well | | | 60 | |

| | | | | |

| Table 12-1: Assay vs. GREC Correlation for the Holbrook Basin Historical Wells | | | 72 | |

| | | | | |

| Table 14-1: Project Area Resource Summary Table | | | 81 | |

LIST OF APPENDICES

All appendices are located at the end of the report following Section 27.0

Appendix A — Seismic Data

Appendix B — Geological Cross Section

Appendix C — Assay Standards

Appendix D — Assay Results

Appendix E — Tonnage Tables

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

1.0SUMMARY

Introduction

North Rim Exploration Ltd. (hereinafter referred to as North Rim) was engaged by America West Potash (hereinafter referred to as AWP) to assist with the implementation of an exploration program. The program consisted of seismic, drilling and core assaying in order to complete a National Instrument 43-101 (NI 43-101) compliant Mineral Resource estimation on their potash property located in the Holbrook Basin in Arizona, USA (hereinafter referred to as the “Project Area”). The Project Area is located approximately 50 kilometers (30 miles) east of the city of Holbrook, Arizona and encompasses approximately 94,000 acres (38,000 hectares) of both state and private land for which AWP has negotiated mineral leases, mineral rights, surface rights and state exploratory approvals.

The following Technical Report prepared by North Rim summarizes the Inferred and Indicated potash resources for AWP’s property. The data used in the Mineral Resource calculation incorporates historical data from the surrounding area, recent seismic work, and the results from twelve potash exploration drill holes completed in 2011.

The Holbrook Basin is a 13,000 km2 (5000 mi2) sub-circular to kidney shaped sedimentary basin in east-central Arizona located along the southern edge of the Colorado Plateau. Its basin-fill strata are characterized by Pennsylvanian to Permian aged siliciclastic sediments interbedded with a relatively thick sequence of halite and other evaporites which define its depositional edges. Potash occurs as discreet mineralized horizons within the uppermost halite beds of this evaporite sequence. The most laterally extensive mineralization identified to date occurs within the second uppermost salt bed (“Sequence 2”) of the so-called “5-B Salt Phase.” This interval was the primary exploration target during AWP’s 2011 Phase 1 exploration program.

The Holbrook Basin is similar geologically and in size with other evaporite basins currently producing potash in the United States, namely Intrepid Potash’s mines in Carlsbad, New Mexico and Moab, Utah. The Carlsbad Mine is extracting potash from depths of 243 to 457 m (800 to 1500 ft) using conventional, continuous mining machines that can target potash beds as thin as 40 inches but can cut a minimum bed thickness of 52 inches. The Cane Creek Mine near Moab, Utah originally extracted potash using conventional mining methods at 914 m (3000 ft); however, in 1970 the operation was converted to a solution mine. The minimum K2O grades that have been recovered from Intrepid’s mines are as low as 8.0 % (12.66 % KCl) but are dependent on individual mine operating procedures. The Holbrook Basin potash does not have Langbinite, has lower carnallite content and lower insoluble than currently seen at the Intrepid Carlsbad Mine.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Zonge International Inc. of Colorado recorded 2D seismic data on 70 linear miles (112.7 km) over the Project Area, on behalf of AWP. RPS Boyd Petrosearch of Calgary Alberta interpreted the data to identify possible geological or structural anomalies. In general the Project Area was found to be relatively undisturbed and with generally flat lying geology. As identified in the RPS Boyd PetroSearch seismic report there are no features which would indicate large scale salt dissolution, removal or channelling. Minor features are present and may be avoided or delineated further with additional seismic data to assist in future drill holes or mine planning.

Mineral Resource Estimate

For the purpose of this report the Mineral Resource Estimate is based on the assumption that recovery of the potash will be by conventional underground mining methods as they exist today. No Preliminary Economic Assessment (PEA) or Preliminary Feasibility Study (PFS) has been prepared for potash extraction in the Project Area; therefore no Measured Mineral Resource or Mineral Reserves can be defined at this time. The 2011 program was designed such that future “measured” Mineral Resources may be possible with a favourable economic analysis of either a PEA or PFS.

The calculation was performed through a combination of assay results from 11 of the 12 newly drilled wells and the equivalent K2O values calculated from the numerous historical wells’ Gamma Ray Estimation Curves (GREC). In determining the resource for conventional mining a “Geological Interval” was chosen to calculate the resource. The “Geological Resource” is defined as the laterally correlatable potash horizons occurring within Sequence 2 of the 5-B Salt Phase. These horizons are identified, differentiated and correlated by their unique stratigraphic position within the depositional sequence. The intervals were verified with wireline logs using consistent inflection points off of the gamma ray log.

Three potash horizons were identified on the AWP Project Area and have been deemed, in descending stratigraphic order, the Upper, Medial and Lower potash horizons. For the purposes of the Mineral Resource Calculation, these horizons were grouped into KR-1 (Upper) and KR-2 (Medial and Lower) Geological Resource.

The following criteria were used when selecting the “Geological Resource”:

| | • | | G x T = 12 (meters) or 40 (feet) |

| | • | | Minimum bed thickness of 1.2 meters (4 feet) |

| | • | | Less than 8 to 10 % insoluble content |

| | • | | Less than 10 % carnallite |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

At this time no engineering feasibility studies have been conducted on the Project Area so the above criteria may change or may not be applicable after such studies are completed. The thicknesses used for the Resource calculation are not a ‘mining cut’ and will likely be reduced once engineering studies are completed.

Indicated and Inferred Resource Summaries

Inferred and Indicated Resources are based on the results of either the assayed drill holes or GREC calculated grade and the distances between the wells. Based on interpreted geological and property constraints and confidence in lateral continuity of the potash beds the following resource radius of influence (ROI) were selected: Indicated 0 to 1.6 kilometers (0 to 1 mile) and Inferred 1.6 to 3.2 kilometers (1 to 2 miles). All historical wells were assigned to the Inferred category due to a lack of reliable assay data and the lack of historical core available for verification assay. As defined by CIM standards a Measured Resource is not reported at this time based on the lack of production planning and evaluation of economic viability. If a PEA or PFS is completed with favorable economics, some of the reported resource may possibly be placed into a “measured” category.

A summary of Inferred and Indicated potash resources are presented below in Table 1-1 below.

Table 1-1: Resource Summary Table

RESOURCE SUMMARY TABLE

INDICATED1 RESOURCE SUMMARY

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | Weighted | | | Total | | | | | | | K2O | |

| | | | | | | Area with Seismic | | | Weighted | | | Average | | | Sylvinite | | | Total K2O | | | MMT3 | |

| | | Area | | | Deductions of | | | Average | | | K2O | | | Tonnage | | | Tonnage | | | per | |

| Member | | (km2) | | | 15% (km2) | | | Thickness (m) | | | Grade (%)4 | | | (MMT3)5 | | | (MMT3)6 | | | Section7 | |

KR-1 | | | 0.00 | | | | 0.00 | | | | 0.00 | | | | 0.00 | | | | 0.00 | | | | 0.00 | | | | 0.00 | |

KR-2 | | | 45.26 | | | | 38.47 | | | | 1.98 | | | | 10.09 | | | | 158.10 | | | | 15.95 | | | | 1.07 | |

Total | | | 45.26 | | | | 38.47 | | | | N/A | | | | N/A | | | | 158.10 | | | | 15.95 | | | | N/A | |

INFERRED2 RESOURCE SUMMARY

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | Weighted | | | Total | | | | | | | K2O | |

| | | | | | | Area with Seismic | | | Weighted | | | Average | | | Sylvinite | | | Total K2O | | | MMT3 | |

| | | Area | | | Deductions of | | | Average | | | K2O | | | Tonnage | | | Tonnage | | | per | |

| Member | | (km2) | | | 15% (km2) | | | Thickness (m) | | | Grade (%)4 | | | (MMT3)5 | | | (MMT3)6 | | | Section7 | |

KR-1 | | | 42.70 | | | | 36.29 | | | | 1.69 | | | | 13.44 | | | | 127.58 | | | | 17.15 | | | | 1.22 | |

KR-2 | | | 125.56 | | | | 106.72 | | | | 1.95 | | | | 11.39 | | | | 432.75 | | | | 49.29 | | | | 1.20 | |

Total | | | 168.26 | | | | 143.01 | | | | N/A | | | | N/A | | | | 560.33 | | | | 66.44 | | | | N/A | |

| | | |

| 1. | | Indicated Resource radius of influence is 0.0-1.6KM for Potash Units KR-1 and KR-2 |

| |

| 2. | | Inferred Resource radius of influence is 1.6-3.2KM for Potash Units KR-1 and KR-2 |

| |

| 3. | | MMT = Million Metric Tonnes |

| |

| 4. | | “Average K2O Grade” and “Average Thickness” refer to weighted averages. |

| |

| 5. | | “Total Sylvinite Tonnage” refers to total amount of in-situ resource in the Project Area (i.e. Area x Thickness x Density x Deductions) |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

| | | |

| 6. | | “Total K2O Tonnage” refers to the total amount of K2O resource in the Project Area (i.e. Area x Thickness x Density x Deductions x Grade). Deductions include 15% for unknown anomalies (Does not include mining extraction ratio or plant and transport losses) |

| |

| 7. | | Assuming 640 acres or 2,589,988m2per section. |

Conclusions

AWP’s Project Area, when compared to other sedimentary basins hosting potash deposits, exhibits several positive factors that make it favourable for further potash exploration, resource delineation, and possible mine development:

| | • | | The resource calculated at this time for the Project Area appears to be sufficient enough to support further detailed resource, process and PEA studies. |

| | • | | Potash resources appear to be of comparable grade, thickness and with low impurities, such as insolubles and carnallite, when compared to Intrepid’s Carlsbad Mine. |

| | • | | The potash beds in the Project Area occur at relatively shallow depths, less than 551 m (1600 ft). |

| | • | | Seasonal climate variations are minimal compared to Canadian and Russian potash operations which lower operation costs. |

| | • | | Unlike other parts of the world where potash is mined, there is no competition with the Oil and Gas industry in the Holbrook Area (Rauzi S. L., 2008). |

| | • | | The Project Area is close to very large, year round potash markets in Arizona, California and Mexico. The US imports more than 80 % of the potash it consumes and is the second largest consumer of potash in the world. The Project Area is close to four international export ports. |

| | • | | The state of Arizona supports the development of its mineral resources, works closely with the mining industry and has a favourable potash royalty structure. |

| | • | | The Project Area is in close vicinity to infrastructure including rail, major highways, gas and power. |

| | • | | The infill drilling program and additional exploration work should focus in the north central part of the Project Area. The historical work conducted by Rauzi (Rauzi S. L., 2008) and the updated potash isopach figures shown in Section 7.1 suggests that the potash may be of better quality in that part of the Project Area. |

Potential Risks Requiring Further Investigation

Permitting and Licensing: AWP has followed a strategy of acquiring only state and private lands and mineral rights, thus, permitting will be conducted through Arizona State agencies. Primary agencies include:

| | • | | Arizona State Land Department — application for mineral leasing. |

| | • | | Department of Environmental Quality — air, water and wastewater permits. |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

| | • | | Department of Water Resources — fresh water wells and water usage. |

| | • | | State Mine Inspector — permit for mining operations which would include safety, hazardous materials and control. |

Petrified Forest National Park: AWP will have to work closely with State and Park officials in minimizing the impact on the surface areas and Park visitors.

Water Supply: AWP will have to work with the Department of Water Resources to obtain, prove and be granted a water right, or will have to obtain these from area wells and existing rights.

Salt Back Thickness: It has been observed in the core that the roof or “back” above the upper potash resource interval (KR-1) and localized areas of the lower potash resource interval (KR-2) is made up of insoluble materials such as clays and anhydrites. This can present challenges with roof control and the mining progress. Rock mechanics studies will be required to assess the “salt back” and provide recommendations for control.

Recommendations

The Project Area has adequate Indicated and Inferred Resource base to proceed with a PEA or a PFS. The following recommendations are made by the author:

| | • | | Additional seismic that was acquired in the northwest portion of the Project Area during the 2011 program should be processed and interpreted to identify and assist with placing any new wells. Estimated cost $25,000. |

| | • | | Complete a PEA or PFS. This study will focus on determining the economics of a conventional underground mining operation in the Project Area, and may also include beginning baseline environmental studies, metallurgical, hydrogeological and geotechnical studies. Estimated cost $150,000. |

| | • | | Conduct infill drilling of 5 to 10 wells to increase the resource base and define parameters for a Feasibility Study. Estimated cost $2,000,000 to $3,000,000. |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

2.0INTRODUCTION AND TERMS OF REFERENCE

This report was prepared by North Rim Exploration Ltd. (hereinafter referred to as “North Rim) at the request of American West Potash, LLC (hereafter known as “AWP”) to present the Mineral Resource estimate generated for its Holbrook Basin Project (herein referred to as the “Project Area”) following the completion of a potash exploration drilling program. AWP is a corporation based in Denver, Colorado whose goal is to assess the economic potential of potash deposits in the Holbrook Basin. This report discusses historical exploration efforts and AWP’s recent drilling and seismic activities in the Project Area, and outlines the details of a potash Mineral Resource estimate compliant with National Instrument 43-101 Report Form F-1. North Rim is entirely independent of AWP and has no interest in any manner in the property in question.

2.1INTRODUCTION

The information upon which this report is based was obtained from 12 recently drilled test holes completed by AWP, public historical exploration data acquired by various companies between 1960 and 1970, as well as publicly available record sources including technical reports, geological reports, and potash geochemical analyses.

October 17th, 2011 is the effective report date. The seismic survey data presented in this report is effective as of September 29, 2011. The geoanalytical assay results obtained from Huffman Laboratories Inc. of Golden, Colorado is effective as of October 4, 2011.

For this report, North Rim performed the following scope of work:

| | • | | Planned and assisted AWP with the implementation of the 2011 exploration drill program; |

| | • | | Reviewed the recovered cores and generated detailed geological core descriptions; |

| | • | | Compiled and interpreted the regional and local geology; |

| | • | | Performed core analysis, geochemical sampling, and summary of assay results; |

| | • | | Reviewed 63 historical wells (LAS and PDF files) of which 57 met the criteria for inclusion in the Resource calculation and 21 of which did not contain potash; |

| | • | | Reviewed land agreements as provided by AWP to verify land tenure; |

| | • | | Reviewed RPS Boyd PetroSearch’s 2D seismic reports; and |

| | • | | Calculated Inferred and Indicated Resources based on NI-43-101 compliance requirements. |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

2.2AVAILABLE DATA

Cores from the 12 recent potash test holes completed on the Project Area, and which are referenced throughout this report, are all available for inspection at AWP’s core facility located in Holbrook, Arizona. The core from four of the 12 test holes has been inspected by the principal author, Mrs. Tabetha Stirrett to verify their contents. The remainder of the core was inspected by other geological professionals under the direction of the principal author.

As with other potash deposits, the Mineral Resource may be affected by geological phenomena that have deleterious effects upon the Mineral Resource, these include but are not limited to:

| | • | | Depositional limitations and local paleotopography; |

| | • | | Absence of material due to erosion; and |

| | • | | Leach, washout, and salt collapse anomalies. |

Although no critical anomalies have yet been identified on the property, the possibility of the above mentioned anomalies does exist for the Project Area (see Section 7.4). While the present study incorporates estimates as to the extent of such anomalous ground based upon knowledge gained in the 2011 2D seismic reports (Edgecombe, 2011), further work, such as regional 2D extensions and possibly a 3D seismic investigation, may identify subsurface anomalies in other portions of the Project Area.

The Permian stratigraphy of the Holbrook Area and the local processes affecting evaporite formation, potash precipitation, preservation, diagenesis, and dissolution are topics of both historical and on-going research by numerous industry, academic, and government bodies. The detailed stratigraphic correlations that are presented herein are based upon these reports; however, they have been modified by the author based on personal experience with other potash deposits.

Property descriptions and land status were obtained from the list of lands as set forth in the documents provided by AWP. No attempt to independently verify the land tenure information was made by the author. Mineral Resource estimate calculations were based upon review of available technical sources and were completed under the direct supervision of Mr. Earl Gebhardt. The economic potential of the Project Area is beyond the scope of this report.

The reader is reminded that the term “ore” should not be used, disclosed, or implied unless proven reserves have been estimated on the property. To be called ore, the economic factor must be taken into account and it must be possible to extract metals or minerals profitably from the ore. Since no proven reserves have been identified during the course of work undertaken to prepare this report, the term “ore” has not be used; however, where the term “ore” is used in this report, it is in the context of a direct quote taken from third-party reports or papers and as such is not compliant with recommendations set forth in NI 43-101.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

2.3TERMS OF REFERENCE

Throughout this report geological, technical, and potash industry specific terminology is commonly employed. Table 2-1, below, provides an alphabetized list of definitions for many of these terms and phrases.

Table 2-1: Glossary of Terms and Phrases.

GLOSSARY OF TERMS

| | | | | |

| | | Chemical | | |

| Term | | Formula | | Definition |

| Assay | | N/A | | A test performed to determine a sample’s chemical content. |

| | | | | |

| Carnallite | | KCl.MgCl2· 6H2O | | A mineral containing hydrated potassium and magnesium chloride. |

| | | | | |

| Halite | | NaCl | | Sodium Chloride — Naturally occurring salt mineral. |

| | | | | |

| G x T | | N/A | | Grade multiplied by thickness in either meters or feet. |

| | | | | |

| Sylvite | | KCl | | Potassium Chloride — A metal halide salt composed of potassium and chorine. Generally known as potash. |

| | | | | |

| Sylvinite | | N/A | | Mineralogical mixture of halite and sylvite +/- minor clay and carnallite. |

| | | | | |

K2O | | K2O | | Potassium Oxide — A standard generally used to indicate and report ore grade. |

| | | | | |

| Insoluble | | N/A | | Water-insoluble impurities, generally clay, anhydrite, dolomite or quartz. |

| | | | | |

| Seismic Anomaly | | N/A | | A structural change in the natural, uniformly bedded geology. |

| | | | | |

| Dissolution and Collapse Anomaly | | N/A | | Occurs where the sylvinite bed has been removed by dissolution of salt and the resulting void is in-filled by material caved from above. |

| | | | | |

| Leach Anomaly | | N/A | | Occurs where the sylvinite bed has been altered such that the sylvite has been removed and replaced by halite. |

| | | | | |

| Washout Anomaly | | N/A | | Occurs where sylvite bed has been replaced or altered to a halite mass that consists of medium to large halite crystals within a groundmass of smaller intermixed halite and clay insolubles. |

| | | | | |

| CIM | | N/A | | The Canadian Institute of Mining, Metallurgy and Petroleum. |

North Rim Exploration Ltd. is a privately held geological and mine engineering consulting firm based in Saskatoon, Saskatchewan that was founded in 1984 by Mr. Steve Halabura, P.Geo, F.E.C. (Hon.). North Rim has been issued a Certificate of Authorization No. C905 with the Association of Professional Engineers and Geoscientists of Saskatchewan (APEGS), and holds a “Permission to Consult” in the field of geology for petroleum, potash, and other precious and industrial minerals resources.

The Qualified Person (QP) for this report is Mrs. Tabetha A. Stirrett, P. Geo. of North Rim Exploration Ltd. Mrs. Stirrett graduated from the University of Saskatchewan in Saskatoon, Saskatchewan in 1997 with a Bachelor of Science in Geology. Mrs. Stirrett has over 14 years of experience in both the mining and oil and gas sectors. In November 2008, she joined North Rim as a senior geologist and has since been part of several potash and coal projects. Among Mrs.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Stirrett’s most recent experiences is the management of a drilling program and Mineral Resource calculation for Encanto Potash Corp.’s Muskowekwan property in Saskatchewan (Stirrett T. A., 2011). She has worked on the Athabasca Potash “Burr Project” and on the Boree Salt Deposit in Queensland, Australia. She was Project Team Lead of an extensive coal exploration and delineation program for NuCoal Energy Corp. in south-central Saskatchewan. Mrs. Stirrett is currently North Rim’s Business Development Manager and is responsible for developing a diversified portfolio of new sustainable clients for North Rim. Mrs. Stirrett is classified under NI 43-101 Rules and Policies as an Independent Qualified Person.

Mr. Earl Gebhardt P. Eng., reviewed the contents of this report. Mr. Gebhardt graduated with a Bachelor of Engineering in mining from the University of Saskatchewan in 1974. He is a Professional Engineer registered with the Association of Professional Engineers and Geoscientists of Saskatchewan since 1977 (Member No. 04239). Mr. Gebhardt has worked in various engineering capacities at the Potash Corporation of Saskatchewan from 1981 to the end of 2004. He was employed for 20 years at the Lanigan operations in Saskatchewan primarily as the Chief Mine Engineer, and held other supervisory and managerial positions. Working on various mining engineering projects, Mr. Gebhardt has spent roughly 10 years working in hard rock mining. Since 2005, he has been acting as an independent contractor to North Rim involved in a number of potash exploration related projects for different clients in Saskatchewan and other Canadian provinces. The projects have ranged from exploration permits to pre-feasibility studies incorporating both geological and mining engineering work aspects. Mr. Earl Gebhardt is classified under NI 43-101 Rules and Policies as an Independent Qualified Person.

2.4SITE VISIT

As required by National Instrument 43-101, a site visit was made by the principal author to the Project Area in 2011 from June 6 to 12th. During this visit the following activities were undertaken:

| | • | | Reviewed the drilling locations; |

| | • | | Monitored core retrieval process for KG-04; |

| | • | | Reviewed the cores from KG-01, KG-02, KG-03 and KG-04; |

| | • | | Assisted and reviewed sampling procedures for KG-04; and |

| | • | | Observed the infrastructure, local communities and general lay of the land surrounding the Project Area. |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

3.0RELIANCE ON OTHER EXPERTS

In the preparation of this report, North Rim has acquired and employed information from publically available technical sources which are based upon the results of previous potash exploration activities carried out in north eastern Arizona. These sources are filed through the Arizona State Energy Offices and contain opinions and statements that were not prepared under North Rim’s supervision. North Rim does not take responsibility for the accuracy of this historical data and these items will hereinafter be referred to as “third-party-reports” or “historical information.” It is not known if the personnel, facilities, or analytical procedures used by previous evaluators were independent, or if the authors of those reports were considered “Qualified Persons” (QP) as defined by National Instrument 43-101.

North Rim has held internal discussions with company management as well as other external experts in the potash industry who have been involved with the Holbrook Potash Project. The author has relied upon the following experts for technical information:

| | • | | Mr. Pat Avery of AWP, who provided North Rim with the land owner agreements and state land agreements (Section 4). |

| | • | | Roger Edgecombe of RPS Boyd PetroSearch, for the 2D seismic interpretations used in calculating the Mineral Resource (Section 9). |

| | • | | Mr. Ron Keil from Huffman Laboratories, for geochemical analyses (Section 11). |

| | • | | Mr. Jim Lewis and Mr. Hugh Eisler formerly of Intrepid Potash Carlsbad, for guidance on selection of parameters utilized in the Mineral Resource calculations. |

| | • | | Lawyer Jeff Knetsch of Brownstein, Hyatt, Farber, Schreck LLP is the lead attorney who represents AWP, and was the law firm responsible for creating and reviewing the legal agreements made between AWP and the private land owners in the area. |

| | • | | Mr. Roger Smith, an independent consultant, who assisted in planning and permitting during the 2011 exploration program, assisted North Rim with the non-potash, shallow geology well site services for the duration of the 2011 drilling program. |

3.1Other Technical Contributors

Mr. Tanner Soroka of North Rim, geologist who performed detailed geological core descriptions, geochemical assay sampling, and provided geological expertise (Sections 7, 8, and 12).

Ms. Kelsey Mayes of North Rim, geologist who performed detailed geological core descriptions, geochemical assay sampling, and provided geological expertise (Section 7, 11, 12 and 23).

Mr. Brett Dueck of North Rim, engineer who performed detailed resource calculations, and provided engineering and drilling expertise (Sections 10 and 14).

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Mr. Alan Bent of North Rim, engineer who performed detailed resource calculations, and provided engineering expertise (Sections 12 and 14).

Ms. Tricia Fehr of North Rim, geologist who performed detailed geological core descriptions, geochemical assay sampling, and provided geological expertise.

4.0PROPERTY DESCRIPTION AND LOCATION

4.1PROPERTY DESCRIPTION AND LOCATION

The Holbrook Salt Basin spans the Coconino, Navajo and Apache Counties in Arizona, USA. AWP’s Project Area is completely located within Apache County, immediately east of the Petrified Forest National Park (PFNP), and south of Navajo, Arizona. The map shown in Figure 4-1 illustrates AWP’s current land positions. As of the time of writing this report, AWP has control of 157 sections of land comprising of approximately 94,000 acres. This total was calculated in ArcGIS. The Client has leased 42 sections from Arizona State Land Department (ASLD) and approximately 115 sections from private landowners.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 4-1: General Location Map of Project Area.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

4.2PROPERTY TITLES IN ARIZONA

Land in Arizona is owned by a wide variety of organizations including Federal, Indian Trust, private interest, and the State Trust. According to the 2009-2010 Arizona State Land Department (ASLD) Annual Report (Brewer, 2010), the ASLD’s “mission has been to manage the Land Trust and to maximize its revenue for its beneficiaries. All uses of the land must benefit the Trust, a fact that distinguishes it from the way public land, such as parks or national forests, may be used.” The State Trust has 13 beneficiaries, of which, state education accounts for over 90 % of revenue disbursements. Historically, most State Trust lands have been leased for grazing; however, in recent years revenue from mineral exploration, development and production activities have significantly increased in revenue.

4.3MINERAL TENURE IN ARIZONA

Pursuant to the ASLD’s application for Mineral Exploration Permits, the ASLD requires an “Exploration Plan of Operation” to be filed and approved by that agency before any exploration work begins. AWP’s permit was approved on November 17th, 2010.

The State of Arizona issues Exploration Permits which are valid for a period of one year and are renewable for a period of up to five years. The annual rental fee for an exploration permit is as follows:

| | • | | $2.00 per acre for the first year, which payment also covers the second year’s rental fee. |

| | • | | For years three through five, $1.00 per acre per year. |

| | • | | $500 fee associated with each annual renewal. |

The State of Arizona requires the following minimum exploration expenditures and allows cash payment in lieu of exploration activity:

| | • | | $10.00 per acre per year for years one and two. |

| | • | | $20.00 per acre per year for years three through five. |

The client has indicated that each state lease, 42 in total, is either in its first or second lease year. This converts to the following required expenditure amount due for 2011 payments:

25,710 acres x $10 = $257,100.00

The holder of the permit has the surface rights necessary for prospecting and exploration and the right to access the land covered by the permit. The permit holder is liable to and must compensate the owner and any lessee of the surface of the State Land covered by the permit for any loss to the owner and for any damage resulting from exploration activities. An Exploration Plan of Operation must be valid during all exploration activities annually and be approved by the Arizona State Land Department prior to startup of exploration activities. An exploration permit is not a right to mine and a mineral lease must be obtained before mining activities can begin.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

On the privately owned sections, AWP has negotiated nearly 100 % of the potash mineral rights and also has a long term surface rights lease agreement that can be extended indefinitely as long as AWP continues to actively pursue the exploration, development, operations and/or reclamation of mineral deposits on these privately owned sections. These lease agreements allow AWP the ability to perform the necessary exploration activities on the property as required. The following details AWP’s obligations to the private leases:

| | • | | On 5,107 acres the agreement is as follows: |

| | o | | $1.00 per acre per year for the first two years. |

| |

| | o | | $2.00 per acre per year for years three and four. |

| |

| | o | | $5.00/acre per year thereafter. |

| |

| | o | | This equates to a $5,075 lease payment for 2011. |

| | • | | On 61,238 acres the agreement is as follows: |

| | o | | Annual rental fee and access fees of $90,000 per year in aggregate starting on January 1, 2012. |

5.0ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY

5.1ACCESSIBILITY

The Project area is located within the Holbrook Salt Basin and is situated entirely within Apache County in northeastern Arizona. Access to the area is provided via Interstate Route 40 (I-40) to Navajo, Arizona, and then south on Kerr McGee Road and Route 2015. It is defined as having the Navajo Indian Reservation at its north and northeastern boundary and the PNFP to the west, and does not extend south of Township 16. The area is well covered by both highways and secondary roads. Secondary and ranch roads allow all-weather access to most locations in the Project Area. All locations not accessible via existing roads can be accessed by either four-wheel drive or all-terrain vehicles. The Santa Fe Railway transects the Northern part of the Project Area.

5.2CLIMATE

The Project Area is located in a high desert, semi-arid region. Weather patterns are characterized by relatively dry conditions with hot spring, summer, and fall temperatures ranging from 11°C to 34°C (52°F to 93°F), and cool winter temperatures ranging from -7°C to 17°C (18°F to 63°F). The area experiences two rainy seasons occurring in the winter,

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

caused by cold fronts originating from the Pacific Ocean, and the other occurring as a monsoon during the summer. The worst operating hazard to drilling and field operations are monsoon induced flash floods (Cox, 1965). Aside from this, seasonal variations do not hinder industrial operations. The average annual rainfall is 21.6 cm (Butrenchuk, 2009), mostly occurring as thunder showers with little recharge. The winter months are generally cool and precipitation is of a low-energy type. Seasonal variations in weather do not typically constrain exploration or mining.

5.3LOCAL RESOURCES

The nearby towns of Holbrook, St. Johns, and Show Low provide locations for personnel, supplies, equipment and accommodation. Holbrook was utilized as a base of operations during the 2011 exploration program. These centers can serve as shipping locations, and also as the sources of gas and water (Butrenchuk, 2009). Electricity is provided to the area by a coal-fired power station, the Cholla Plant, which is located just east of Holbrook near Joseph City. In addition, water for drilling can also be obtained from range tanks, wells, and the Little Colorado River. Drilling mud, diesel and other resources can be obtained locally or from Silver City, New Mexico which is approximately 370 km (231 miles) from the project. The Project Area is well covered by an electrical distribution network and a gas supply system. The gas and power lines follow the general trend of historic Route U.S. 66 and the Santa Fe Railway; however, in some areas the power line extensions are somewhat limited (Cox, 1965).

5.4INFRASTRUCTURE

The Project Area is bound on the north by the heavy service Interstate 40 (1-40). I-40 is the third longest major west—east Interstate Highway in the United States with its western end extending to Interstate 15 in Barstow, California. Spanning from Oklahoma City to Barstow, the modern part of the I-40 overlays historic U.S. Route 66. I-40 intersects with eight of the ten primary north—south interstates, and five in the western United States. Through Texas, New Mexico, Arizona and California it connects and crosses over 20 connecting federal or state highways. These routes connect essentially all neighboring states; Nevada, Utah, and Colorado. Other connecting highways flow to three US-Mexico crossings.

The vast assortment of highways in the area means that there is full service truck transport and support system throughout the southwest U.S. by way of route I-40. AWP plans to use, highly cost effective, lower freight cost truck service, in the nearest 320 — 480 km (200 — 300 miles). This would conceivably work within New Mexico, Arizona, Utah, Colorado and southern California. AWP estimates that the freights run would cost approximately $15 to $25 per ton range.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

The Project Area is bound on the north by the Burlington Northern Santa Fe (BNSF) mainline (Figure 5-1). This is a dual track, dual direction mainline for heavy duty service. It is part of the Southwest system and runs through Fort Worth Texas, BNSF headquarters, westward through New Mexico, Arizona and into California. At the Barstow California Yard, a main line splits and services the Los Angeles area and the other one north to Stockton, Sacramento and northern exchanges. Branch lines and independent short lines serve every western state. These lines will be practical to ship any produced product locally. If international shipments of product are planned export is readily possible from the Ports of Stockton, Long Beach and the Mexican Ports of Guymas and Topolabampo. BNSF directly serves Long Beach and Stockton and has rail service to the two Mexican ports, through the BNSF affiliate FXE, a rail line in Mexico. BNSF provides tariff and specialty rates across its system. The BNSF webpage (About BNSF Railway) provides information on tariff rates.

BNSF also runs a heavy duty spur line southward on the Southwest Line. This East Coronado Junction Line parallels the Project Area on the eastern boundary and would be well suited for a potash rail loading facility. This heavy duty line carries unit trains (65-100 cars) of coal to the coal fired power plants, Coronado Generating Station (Salt River Project) and Springerville Station (Tucson Electric Power).

In addition to the two coal-fired power plants, a third named Pacific Power’s Cholla Station mentioned in Section 5.3 is found near Holbrook. AWP staff has communicated with the power stations and has confirmed that they do sell to new users and quoted preliminary rates in the 6-7 cent/kw range.

5.5PHYSIOGRAPHY

The regional lands are flat in general with minor low lying rolling hills, supporting ranching, light industry and areas of historical mining. Limited vegetation in the range land consists of minor salt cedar and scrub grasses. There is a little hay production in the valley bottoms and there are numerous ranches scattered throughout the Project Area. The area is transected by the Little Colorado, a permanent stream, and the Puerco River, an intermittent stream (Cox, 1965). Their confluence lies about three miles east of Holbrook and tends to generally produce fresh water. It is reported to be brackish to saline in the surrounding areas. The divide area between the rivers is characterized by generally low grassland ridges, broad drainage areas and ledge form buttes and mesas. The topography remains similar south of the Little Colorado, but with considerable pinon and cedar cover (Carr, 1966). Ground water occurs throughout the area within the Coconino Sandstone Formation and forms a regional aquifer. There are extensive areas of sink holes reaching the land surface which suggests major salt solution that likely contributes to the salinity of the water in the Coconino Sandstone (Cox, 1965). These features are located approximately 50-60 km (31 to 37 miles) south of the Project Area and are shown in Figure 5-2. Ground level elevations from the 2011 drilling program are located in Table 5-1 and range from 1708 to 1876 m (5604 to 6155 ft) Mean Sea Level. These elevations are taken from the USGS Digital Elevation Model and are reported to be accurate within five feet.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Table 5-1: Approximate Ground Elevation at Well Center for the 2011 Drill Locations.

| | | | | | | | | |

| Drill Hole ID | | Elevation (Feet) | | | Elevation (Meters) | |

| KG-1 | | | 5608 | | | | 1709 | |

| KG-2 | | | 5650 | | | | 1722 | |

| KG-3 | | | 5605 | | | | 1708 | |

| KG-4 | | | 5640 | | | | 1719 | |

| KG-5 | | | 5795 | | | | 1766 | |

| KG-6 | | | 5745 | | | | 1751 | |

| KG-8 | | | 5860 | | | | 1786 | |

| KG-9 | | | 6020 | | | | 1835 | |

| KG-10 | | | 5995 | | | | 1827 | |

| KG-12 | | | 6155 | | | | 1876 | |

| KG-13 | | | 5990 | | | | 1826 | |

| KG-14 | | | 5980 | | | | 1823 | |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 5-1: Project Area with surrounding infrastructure and rail lines.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 5-2: Solution Collapse Basin with respect to potash basin (modified from Warren, 2006).

6.0HISTORY

6.1HISTORY OF POTASH EXPLORATION IN THE HOLBROOK BASIN

Potash exploration in the Holbrook Basin can be traced back more than fifty years. Prior to AWP’s exploration program there have been many companies exploring potash in this area since the 1970’s.

In the 1960’s and 1970’s, a total of 135 holes were drilled to delineate the potash in the area. Arkla Exploration Company and Duval Corporation drilled 105 holes. Other potash holes were drilled by Kern County Land, National Potash, New Mexico and Arizona Land, St. Joe American, and U.S. Borax. Indications of potash in previously drilled oil tests started the potash play (Cox, 1965). Only five holes penetrated the entire salt package, but 127 holes were drilled into the upper 30 to 90 m (100 to 300 ft) of salt where the potash is typically present. Most of the historical holes were cored through the upper 30 m (100 ft) of salt to get direct information about the nature of the potash deposits. Arkla and Duval reported the presence of potassium minerals sylvite (KCl), carnallite (KMgCl3), and polyhalite (K2Ca2Mg(SO4)4•H2O) in the main potash

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

“pay zone” (Cox,1965); (Carr,1966). Cox further indicated that carnallite was only locally present in the ore and that none of Duval’s holes encountered carnallite at the time of his report. Six holes drilled by Kern County Land and Arkla contained as much as 3.0 % K2O (4.75 % KCl) as carnallite and a section below the main potash “pay zone” contained as much as 6.0 % K2O (9.50 % KCl) as carnallite (Cox, 1965). Duval made a visual estimate of the K2O content by dragging a sharp 4-H pencil across the surface of a core. The hardness of sylvite was such that the 4-H pencil gouged the sylvite but left a black mark on the halite. As a result, the geologist was able to estimate the K2O content within 2.0 % to 3.0 % (Cox, 1965). Scattered blebs and traces of potash persist to about 9 m (30 ft) below the main potash “pay zone”. Well logs, samples, core descriptions, and six assay reports from the potash drilling are available in the well files of the Arizona Oil and Gas Conservation Commission at the Arizona Geological Survey in Tucson.

To date, there has been no commercial production of potash in Arizona, either by conventional or solution mining, even though drilling by late 1965 indicated about 450 million tons of potential K2O covering an area of 80 square miles (Cox, 1965). Cox estimated that 100 million tons of at least 60.0 % K2O (94.97 % KCl) product were economically recoverable. By early 1966, Arkla estimated a potential of more than 285 million tons of nearly 20.0 % average grade K2O (31.66 % KCl) to be underlying its lease block, which left about 92.0 % of nearly 55,000 acres untested (Carr, 1966). Carr reported that the amount of potash under Arkla’s prospective area exceeded the minimum economic requirement to justify installation of mining and ore-processing facilities by 540.0 %. Overproduction of potash in Saskatchewan during a period of government subsidies and a global glut of potash in the late 1960s may have been the biggest factors in preventing development of Arizona potash at the time.

For Historical Mineral Resource estimates the reader is cautioned that a qualified person has not done sufficient work to classify the historical estimates as current Mineral Resources or Mineral Reserves. The Issuer is not treating the historical estimate as current Mineral Resources or Mineral Reserves as defined in Sections 1.2, 1.3 and 2.4 of NI 43-101.

Another factor in the lack of exploration of Arizona potash may be that the area underlain by potash in east-central Arizona is approximately centered under Petrified Forest National Park (PFNP). The Petrified Forest Expansion Act of 2004 substantially increases the area of potash underlying the park. Isopach mapping originally performed by Rauzi suggests that some of the thickest potash may lie beneath the southern part of the PFNP. A combination of State Trust and public and private land is available for potential development east and southwest of the PFNP (Rauzi S.L., 2008).

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

6.2RESOURCE EXPLOITATION HISTORY IN THE HOLBROOK BASIN

The first discovery of salt in the Holbrook Basin seems to have been in 1920 during petroleum exploration drilling near Holbrook (Peirce W., 1981). Indications of potash among previously drilled oil tests started the potash play in the early 1960’s (Cox, 1965). Since then, many additional drill holes in this region have penetrated salt, and as a consequence have helped to outline the Holbrook Salt Basin.

Helium was explored and produced near the northeastern limit of the potash deposit area from 1961 to 1976. Two helium fields, the Pinta Dome and Navajo Springs produced nearly 700 million cubic feet of grade-A helium from the Coconino Sandstone Formation (Rauzi S. L., 2008). Concentrations of helium from these fields reached 10.0 % with an average of 8.0 %, making it some of the richest helium-bearing gas ever produced (Rauzi S. L., 2008).

In the early 1970’s the salt commonly associated with potash was first used as a subsurface storage facility to store liquefied petroleum gas (LPG) at Adamana, east of Holbrook, AZ. Stable and clean areas of salt were dissolved underground to create the storage caverns, creating 11 storage wells at Adamana still operating today and served by the BNSF railroad (Rauzi S. L., 2008). The total capacity of the 11 caverns is approximately 90 million gallons, with individual cavern volumes ranging from 7 to 11 million gallons (Rauzi S. L., 2008).

7.0GEOLOGICAL SETTING AND MINERALIZATION

7.1GEOLOGICAL SETTING

The Holbrook Basin is a 13,000 km2 (5000 mi2) sub-circular to kidney shaped sedimentary basin in east-central Arizona located along the southern edge of the Colorado Plateau. The basin is orientated roughly northeast-southwest and spans the Coconino, Navajo and Apache Counties in Arizona with its eastern limits extending just over the Arizona-New Mexico State border. It is situated along the gently north-dipping slope of the Mogollan Rim, a topographic high delineating the southern escarpment edge of the Colorado Plateau. The basin is bound to the northeast by the Defiance Uplift (Figure 7-1).

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 7-1: Geological map of north east Arizona and Project Area.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Basin-fill halite deposits of the Pennsylvanian to Permian aged Supai Group define the depositional edges of the Holbrook Basin. Within the basin area, the Supai Group can be subdivided into four Members as described by Winters (1963). In ascending stratigraphic order they are the; “Amos Wash”, “Big A Butte”, “Fort Apache”, and “Corduroy” Members. The “Amos Wash” and “Big A Butte” Members are comprised predominantly of reddish-brown siliciclastics, the latter of which is interbedded with gypsum and limestone (Winters, 1963). The “Fort Apache” Member is a wide-spread fossiliferous limestone marker and the “Corduroy” Member, while lithologically similar to the “Big A Butte” Member in most parts of Arizona, contains thick accumulations of evaporite strata and halite within the confines of the Holbrook Salt Basin. The Supai Group is overlain by the Permian Coconino Sandstone Formation, and underlain by the Pennsylvanian Naco Formation carbonates, which onlap unconformably onto Precambrian basement lithologies.

The majority of the salt deposits occur within the medial strata of the “Corduroy” Member, extending nearly 160 km (99 miles) in width from east to west and 60 km (37 miles) from north to south. These beds underlie Arizona Townships 10 through 20 north and Ranges 16 through 31. The salt is thickest in the basin center near Section 19, Township 16 north, Range 24 east, where it reaches a maximum composite thickness of approximately 180.0 m (590 ft) in historical test well “Arkla #1 NMA” (Figure 7-1). Towards the basin margins the halite deposits intertongue with gypsum and anhydrite and eventually give way to siliciclastic-dominated “Corduroy” Member lithologies. Structurally, the salt-bearing strata remain relatively flat-lying and undeformed, with little evidence of dissolution and faulting. Seismic interpretation from 2011 suggests that faulting propagating from the underlying basement is present along the north easternmost edge of the basin.

During the Early Permian when east-central Arizona was characterized by an arid climate and vast dry coastal plains, the Holbrook Basin salt deposits are interpreted to have been laid down in restricted low-energy marine conditions (Rauzi S. L., 2000). During this time, the Holbrook Basin was a shallow isolated epeiric sea with prolonged periods of hypersaline sabkah-like conditions. These conditions occurred due to restricted brine communication between the basin waters and the ancient world ocean, in turn, over saturating the waters with salt (Rauzi S. L., 2000). These basinal conditions likely arose due to the presence of a naturally-restrictive geological barrier between the sea and the ancient ocean. This barrier inhibited brine mixing and resulted in the formation of extensive bedded evaporite sequences. The exact nature of this barrier is uncertain, but researchers interpret that its position may have been roughly coincident with the position of the present Mogollan Rim escarpment (Rauzi S. L., 2000).

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Five cycles of salt deposition within the Holbrook Basin are described by Carr (1966) below. As summarized by Rauzi (2000) “... each cycle starts with halitic mudstone and halite and ends with a fining upward sequence of siltstone and shale overlain by carbonate, which could represent flooding of the marginal and inner sabkha by marine water.” Carbonate laminites deposited during brine freshening events mark the start of each cycle. These deposits are interpreted to represent marine re-connection and flooding of the Basin during a rapid influx of sea water. As brine communication again became restricted, evaporation and brine concentration progressed until gypsum and halite precipitated. Continued evaporation of the basin waters resulted in sub-aerial exposure and the deposition of oxidized siliciclastics during desiccation of the basin and influx of terrestrial sediments (Carr, 1966).

Using this stratigraphic scheme, “Cycle 1” starts at the base of the “Big A Butte” Member, and ends with the deposition of the “Fort Apache” Member limestone which marks the start of “Cycle 2”. “Cycle 2” through “Cycle 5” subdivides the “Corduroy” Member, with a correlatable carbonate unit marking the start of each new cycle. “Cycle 5”, the uppermost cycle described by Carr (1966), is further subdivided into smaller-scale depositional events and is described in more detail in Section 7.2.

According to Rauzi (2000), nearly 1,000 km2 of salt within the northeastern and deepest parts of the Holbrook Basin are thought to host stratiform potash mineralization. The mineralization occurs as relatively thin continuous beds within the uppermost salt sequences of the last major brining-upward cycle (Carr, 1966). The “final cycle” salt beds are capped by several regionally-correlatable anhydrite marker beds which straddle the contact with the overlying Upper Supai Group redbed shales. These anhydrite markers serve as excellent stratigraphic indicators as the potash mineralization is observed to occur at relatively consistent and uniform depths below them, although the salt between them can vary in thickness to some degree.

Figure 7-2, Figure 7-3 and Figure 7-4 depict the thicknesses over the Project Area of the known “Cycle 5” potash mineralized portion of the Holbrook Salt Basin.

It is important to note when looking at the above mentioned figures that the Resource Calculated thicknesses may vary from those listed on the isopach maps due to conditions and requirements outlined in Section 14.0 for calculating Resource areas and volumes. Due to limited well control in certain portions of the Project Area the potash thicknesses have not been extrapolated beyond what was reviewed for the purposes of this report and in no way does North Rim confirm or deny the presence of potash beyond the maps extents or the limitations of the current well control.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 7-2: Isopach map of the Upper Potash Bed interval.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 7-3: Isopach map of the combined Medial and Lower Potash Bed intervals.

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 7-4: Isopach map of the total gross potash interval (Upper to Lower Potash Beds).

Note: Interbedded salts have been included.

7.2LOCAL GEOLOGY AND MINERALIZATION

The subsurface stratigraphy of the Project Area was interpreted through examination of several datasets which included historical exploration records, seismic investigations, geophysical borehole logs, drill cuttings and cores. A simplified stratigraphic column of the Holbrook Basin within the Project Area is provided in Figure 7-5. For practical purposes, the geology of the Holbrook Basin within the Project Area can be broadly subdivided as follows into:

| | 1) | | A thick uppermost Triassic to Permian-aged shale-dominated clastic sequence of interbedded mudstones, siltstones, and minor sandstones. This sequence includes the Lower Triassic Chinle Formation and the underlying Permian Moenkopi Formation. Also considered to be included within this stratigraphic interval are the sands and silts of the Bidahochi Formation, which caps the entire sequence locally and forms surface exposures within the Puerco Ridge Area; |

| | 2) | | A relatively thick “upper-medial” sandstone unit with minor shaley interbeds termed the Permian Coconino Formation. This unit is ubiquitous across the Project Area and its upper contact with the overlying Moenkopi is easily identifiable on geophysical well logs. The Coconino Sandstone is characterized by highly porous, water saturated, cross bedded quartzose sandstone and exhibits good intergranular porosity and pore fluid communication. The Coconino Sandstone is the principal source of groundwater in much of northern Arizona (Montgomery 2003), and is considered a significant brackish to fresh-water aquifer. This unit is observed along surface exposures in the Holbrook Basin area to exhibit prominent regional fracturing (Lorenz & Cooper, 2001) and often is accountable for numerous drilling issues and circulation losses. |

| | 3) | | A “lower-medial” sequence of Pennsylvanian to Permian-aged Supai Group sediments comprised of a lowermost unit of clastic sands, silts, and muds which are separated from an uppermost “redbed” shale unit by a relatively thick package of cyclically-bedded evaporite-carbonate rocks. The evaporite beds are found at depths ranging from approximately 300 to 550 m (1000 to 1600 ft) in the Project Area. Potash mineralization is hosted within the uppermost salt beds of the evaporite unit; and |

| | 4) | | A basal sequence comprised of Devonian and Lower Pennsylvanian carbonate rocks. These include the limestones and sandstones of the Pennsylvanian Naco Formation and local remnant occurrences of Devonian Martin Formation dolostones. These rocks lie unconformably onto Precambrian basement rocks to the northeast (Rauzi S. L.,2000). |

| | |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

A simplified SW-NE geological section (Figure 7-6) modified from Peirce et al. (1966) provides a generalized summary of the spatial and stratigraphic relationships between these four subdivided units within the Project Area.

As mentioned in Section 7.1, the Supai Group sediments within the Holbrook Basin can be subdivided into five high order depositional cycles (Carr, 1966) with potash mineralization restricted to only the uppermost “Cycle 5” beds. “Cycle 5”, in turn, can be subdivided into several smaller-scale depositional sequences. These sequences are readily identifiable in drill core (Figure 7-7) and show up especially well on gamma-ray and neutron logs. Figure 7-7 shows the relationship between the upper evaporite stratigraphy of the “Cycle 5” beds of the Holbrook Basin and the wire line log response. It highlights the specific correlation of gamma-ray and neutron log signatures to multiple brining-upwards sequences and local potash mineralization. Potash mineralization is recognized as an abrupt increase in radioactivity on the gamma ray log curve due to the concentration of naturally radioactive potassium (K40) bound within the crystal lattice of various potash ore minerals (e.g. sylvite and carnallite).

The detailed “Cycle 5” stratigraphy within the Project Area is summarized in descending stratigraphic order as follows:

| | | |

Upper Supai Redbed Shale: | | Readily identified in drill cuttings by its distinct reddish-brown color and high shale content, the upper contact of the Supai Redbed Shale intercalates with the overlying Coconino Sandstone. Silty mudstone characterizes the upper portion of this Supai unit and grades downwards into mud-dominated laminated redbed lithologies where it contains multiple gypsum-anhydrite stringers and seams. Two relatively thick regionally correlatable “Marker Anhydrites” (“A” and “B”) occur near its base. In the Project Area the Upper Supai Redbed Shale is between 27.0 to 37.0 m (90.0 to 120.0 ft) in vertical thickness from top to the base of the Marker “B” anhydrite. |

| | | |

Marker “A” Anhydrite: | | The Marker “A” Anhydrite is the uppermost correlatable evaporite marker bed in the Project Area and occurs approximately 15.0 m (50.0 ft) below the top of the Supai Group. It is observed to pinch and swell across the Project Area, ranging in thickness from less than 1.5 m to more than 3.0 m (5.0 to ≥10.0 ft). Anhydrite beds are observed to occur above the Marker “A” Anhydrite, but their distribution is typically local and their use as a stratigraphic marker is limited. |

| | | |

Marker “B” Anhydrite: | | The Marker “B” Anhydrite is present in all potash test wells drilled in the Project Area to date. It is separated from the overlying Marker “A” Anhydrite by a sequence of redbed mudstones of variable thickness, ranging anywhere from 3.0 to 9.0 m (10.0 to 30.0 ft). The Marker “B” is actually a dual-bedded unit comprised of a thin (~ 0.6 m or 2 ft) upper anhydrite and a thick (~ 3.0 to 6.0 m) (10.0 to 20 ft) to lower anhydrite which are separated by a thin (~ 0.6 m or 2 ft) mud layer. This leads to a distinctive “double boxcar” gamma ray-neutron log response that serves as a good stratigraphic marker. The base of the Marker “B” Anhydrite directly overlies top of the uppermost Holbrook Salt beds. |

| | | |

“5-A” Salt: | | The “5-A” Salt is the uppermost preserved halite package in the Project Area and is comprised of multiple stacked brining-upwards (shallowing) sequences of halite and redbed mudstone. Each sequence is characterized by a clean, fine-grained basal halite (± anhydrite stringers) that grades upwards into a coarser, mudstone-rich salt that is capped by a thin redbed mudstone. The start of the subsequent overlying sequence is then marked by an abrupt transition to clean fine-grained halite, sometimes with a thin argillaceous gypsum band marking its base. Four sequences of similar composition comprise the “5-A” Salt within the Project Area. For simplicity, the uppermost sequence is deemed “5-A Salt 1” and the lowermost “5-A Salt 4”. Each sequence is 1.5 to 6.0 m (5.0 to 20.0 ft) thick, resulting in an average “5-A” Salt package thickness of 14.0 to 18.0 m (45.0 to 60.0 ft). Where post-depositional salt dissolution has occurred, the amount of material separating the Marker “B” and Marker “D” Anhydrites is reduced, in some cases to less than 4.5 m (15 ft). |

| | | |

| | | A relatively thin (~ 0.6 to 1.0 m) but correlative gypsum/anhydrite bed, deemed the Marker “C” Anhydrite, occurs within the third “5-A” Salt sequence. This marker is generally thin and difficult to identify on well logs, therefore Marker “C” Anhydrite is not considered a significant stratigraphic horizon. |

| | | |

Marker “D” Anhydrite: | | Anhydrite “D”, historically referred to as the “Puerco Anhydrite”, is present in all potash test wells located within the Project Area and marks the base of the “5-A” Salt Phase. It has historically been used as a stratigraphic datum as it is readily identified in drill core because of its thickness (~4.5 m or 15 ft) and characteristic mottled appearance. Its textural attributes are due to a network of coarse halite crystals entrained within its basal sulphate beds. |

| | | |

| | | The Marker “D” Anhydrite directly overlies the top of the “5-B” Salt Phase. |

| | | |

“5-B” Salt: | | The “5-B” Salt Phase is represented by six stacked brining-upwards sequences of halite and mud below the Marker “D” Anhydrite that have gamma-ray-neutron log signatures similar to the overlying “5-A” Salt Phase on account of their similar lithologies. Sequences range in thickness from 3.0 to 9.0 m (10.0 to 30.0 ft) each, yielding a total average package thickness of approximately 30.0 m (100 ft). The uppermost “5-B” Salt sequence is deemed “5-B Salt 1” and the lowermost sequence the “5-B Salt 6.” Within the Project Area, the “5-B Salt 6” sequence contains two to three thin argillaceous anhydrite beds, the lowermost of which denotes the base of the “5-B” Salt Phase. |

| | | |

| | | The “5-B” Salt is the primary targeted exploration horizon in the Holbrook Salt Basin. All of the potash mineralization within the Basin to date has been found within these beds. |

| | | |

“5-C” Salt: | | The “5-C” Salt is the basal salt unit of “Cycle 5.” Similar to the “5-A” and “5-B” Salt Phases, the “5-C” Salt Phase is comprised of seven or eight stacked brining-upwards sequences of salt and mud that can be differentiated from the overlying “5-B” Salt Phase by their reduced neutron log response (i.e. increased mud content). Only the upper two sequences of the “5-C” Salt Phase (“5-C Salt 1” and “5-C Salt 2”) were penetrated in a few of the 2011 potash test wells and where cored they were not observed to contain potash mineralization. The entire “5-C” Salt Phase is estimated at 40.0 to 43.0 m (130.0 to 140.0 ft) thick. |

| | | |

| | | The base of the “5-C” Salt terminates with a basal carbonate bed marking the base of “Cycle 5.” |

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 7-5: Simplified stratigraphic column of the Holbrook Basin.

Page 36 of 100

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 7-6: Simplified cross section through the Holbrook Basin.

Page 37 of 100

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Figure 7-7: Type section of KG-06 correlating geophysical log signatures with core photography in

“Cycle 5” beds

(Note: “5-B” Sequence 3 continues below 1480’, but appears truncated as it is simply correlated to the photographs).

Page 38 of 100

| | | |

| | American West Potash, LLC Holbrook Basin Project

2011 Potash Resource Assessment

October 17, 2011 |

Although historically potash minerals have been identified within each of the six “5-B” sequences (Carr, 1966), only the “5-B Salt 2” sequence exhibits laterally continuous potash beds with thicknesses and grades of economic potential. The “5-B Salt 2” sequence is actually a dual-bedded unit that is separated into upper and lower halite beds by a regionally correlatable 0.5 to 1.0 m (2.0 to 3.0 feet) thick insoluble-bearing salt marker band (Figure 7-7) that occurs 6.0 to 7.0 m (20.0 to 22.0 feet) below the top of the “5-B Salt 2” sequence. The “5-B Salt 2” sequence is essentially comprised of two brining-upwards sub-sequences:

| | 1) | | A lower incomplete sub-sequence grading upwards from ‘clean’ pink halite into brown clay-rich halite; and |

| |