UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

______________________________________________________________

Form 10-K

| (Mark One) |

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2012

or

| o | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file number 1-34736

______________________________________________________________

SEMGROUP CORPORATION

(Exact name of registrant as specified in its charter)

| Delaware | 20-3533152 | |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) | |

Two Warren Place

6120 S. Yale Avenue, Suite 700

Tulsa, OK 74136-4216

(918) 524-8100

(Address, including zip code, and telephone number, including area code, of registrant’s principal executive offices)

Securities registered pursuant to Section 12(b) of the Act:

| Title of Each Class | Name of Each Exchange on Which Registered | |

Class A Common Stock, par value $0.01 per share Warrants to Purchase Common Stock | New York Stock Exchange New York Stock Exchange | |

Securities registered pursuant to Section 12(g) of the Act:

None

______________________________________________________________

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes x No o

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes o No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| Large Accelerated Filer | ý | Accelerated Filer | o | ||

| Non-Accelerated Filer | o | (Do not check if a smaller reporting company) | Smaller Reporting Company | o | |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No x

The aggregate market value of the registrant’s Class A and Class B Common Stock held by non-affiliates at June 29, 2012, was $1,326,413,230, based on the closing price of the Class A Common Stock on the New York Stock Exchange on June 29, 2012.

Indicate by check mark whether the registrant has filed all documents and reports required to be filed by Section 12, 13 or 15(d) of the Securities Exchange Act of 1934 subsequent to the distribution of securities under a plan confirmed by a court. Yes x No o

At January 31, 2013, there were 41,930,289 shares of Class A Common Stock and 28,235 shares of Class B Common Stock outstanding.

______________________________________________________________

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s Proxy Statement to be filed pursuant to Regulation 14A of the Securities Exchange Act of 1934, in connection with the registrant’s Annual Stockholders’ Meeting to be held on May 22, 2013, are incorporated by reference into Part III of this Form 10-K.

SEMGROUP CORPORATION AND SUBSIDIARIES

FORM 10-K—2012 ANNUAL REPORT

Table of Contents

| Page | ||

| PART I | ||

| Items 1 and 2. | ||

| Item 1A. | ||

| Item 1B. | ||

| Item 3. | ||

| Item 4. | ||

| PART II | ||

| Item 5. | ||

| Item 6. | ||

| Item 7. | ||

| Item 7A. | ||

| Item 8. | ||

| Item 9. | ||

| Item 9A. | ||

| Item 9B. | ||

| PART III | ||

| Item 10. | ||

| Item 11. | ||

| Item 12. | ||

| Item 13. | ||

| Item 14. | ||

| PART IV | ||

| Item 15. | ||

Cautionary Note Regarding Forward-Looking Statements

Certain matters contained in this Form 10-K include “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended (the “Securities Act”), and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”). We make these forward-looking statements in reliance on the safe harbor protections provided under the Private Securities Litigation Reform Act of 1995.

All statements, other than statements of historical fact, included in this Form 10-K regarding the prospects of our industry, our anticipated financial performance, the anticipated performance of NGL Energy Partners LP, management’s plans and objectives for future operations, business prospects, outcome of regulatory proceedings, market conditions, and other matters, may constitute forward-looking statements. In addition, forward-looking statements generally can be identified by the use of forward-looking words such as “may,” “will,” “expect,” “intend,” “estimate,” “foresee,” “project,” “anticipate,” “believe,” “plans,” “forecasts,” “continue” or “could” or the negative of these terms or variations of them or similar terms. Although we believe that the expectations reflected in these forward-looking statements are reasonable, we cannot assure you that these expectations will prove to be correct. These forward-looking statements are subject to certain known and unknown risks and uncertainties, as well as assumptions that could cause actual results to differ materially from those reflected in these forward-looking statements. Factors that might cause actual results to differ include, but are not limited to, those discussed in Item 1A of this Form 10-K, entitled “Risk Factors,” risk factors discussed in other reports that we file with the Securities and Exchange Commission (“SEC”), and the following:

| • | Our ability to generate sufficient cash flow from operations to enable us to pay our debt obligations or to fund our other liquidity needs; |

| • | Our ability to comply with the covenants contained in, and maintain certain financial ratios required by, our credit facilities; |

| • | Our ability to obtain additional capital on terms that are favorable to us; |

| • | The ability of our subsidiary, Rose Rock Midstream, L.P., to make minimum quarterly distributions to its unitholders, including us; |

| • | The operations of NGL Energy Partners LP, which we do not control; |

| • | Any sustained reduction in demand for the petroleum products we gather, transport, process and store; |

| • | Our ability to obtain new sources of supply of petroleum products; |

| • | Our failure to comply with new or existing environmental laws or regulations or cross border laws or regulations; |

| • | The possibility that the construction or acquisition of new assets may not result in the corresponding anticipated revenue increase; |

| • | Changes in currency exchange rates; |

| • | The risks and uncertainties of doing business outside of the U.S., including political and economic instability and changes in local government laws, regulations and policies; and |

| • | The possibility that our hedging activities may result in losses or may have a negative impact on our financial results. |

New factors that could cause actual results to differ materially from those described in forward-looking statements emerge from time to time, and it is not possible for us to predict all such factors, or the extent to which any such factor or combination of factors, may cause actual results to differ from those contained in any forward-looking statement.

Readers are cautioned not to place undue reliance on any forward-looking statements contained in this Form 10-K, which reflect management’s opinions only as of the date hereof. Except as required by law, we undertake no obligation to revise or publicly release the results of any revision to any forward-looking statements.

______________________________________________________________

As used in this Form 10-K, and unless the context indicates otherwise, the terms the “Company,” “SemGroup,” “we,” “us,” “our,” “ours,” and similar terms refer to SemGroup® Corporation, its consolidated subsidiaries, and its predecessors. We sometimes refer to crude oil, natural gas, natural gas liquids (natural gas liquids, or “NGLs,” include ethane, propane, normal butane, iso-butane, and natural gasoline), refined petroleum products, and liquid asphalt cement, collectively, as “petroleum products” or “products.”

PART I

Items 1 and 2. Business and Properties

Overview

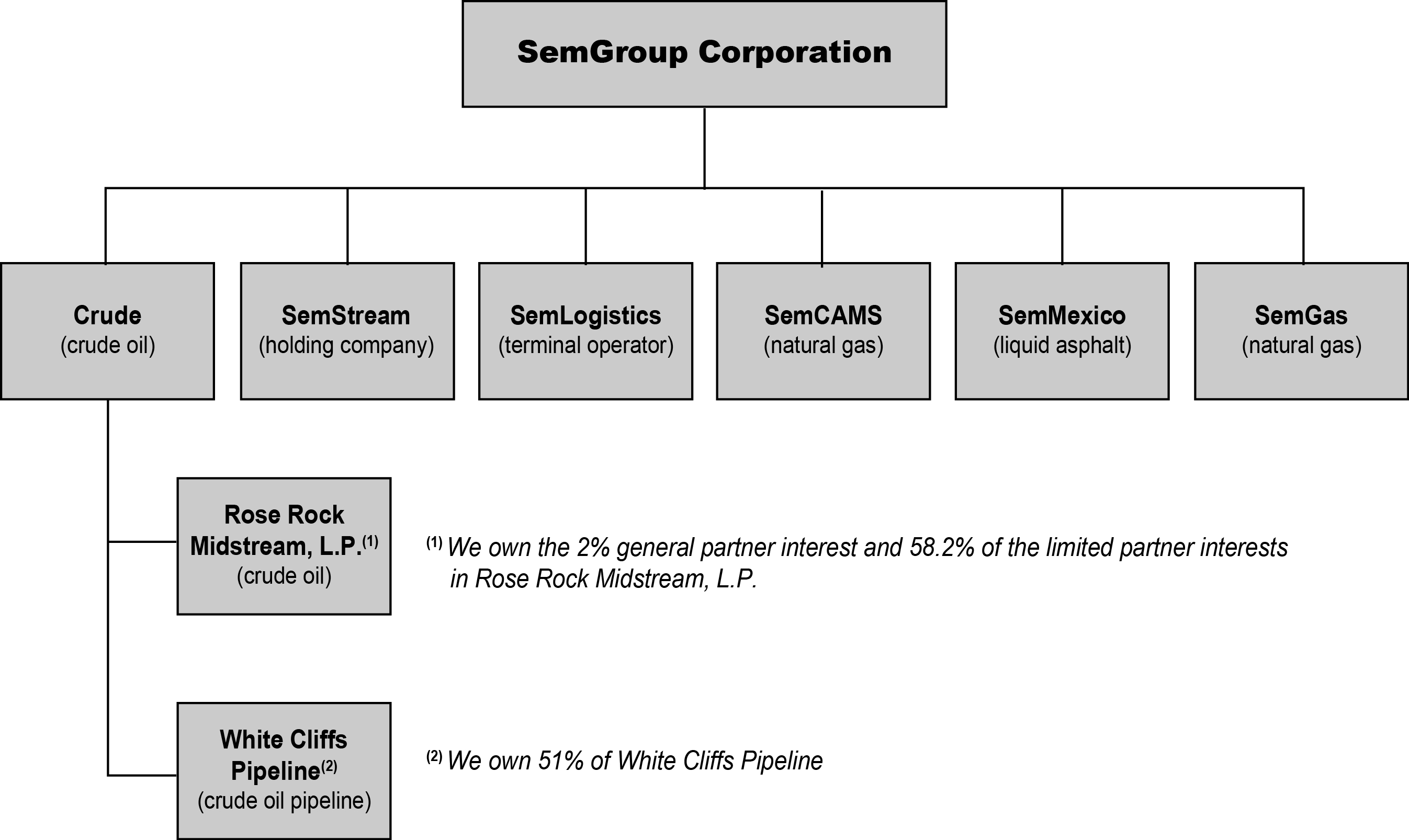

Our business is to provide gathering, transportation, storage, distribution, marketing and other midstream services primarily to independent producers, refiners of petroleum products and other market participants located in the Midwest and Rocky Mountain regions of the United States of America (the “U.S.”), Canada and the west coast of the United Kingdom (the “U.K.”). We, or our significant equity method investees, have an asset base consisting of pipelines, gathering systems, storage facilities, terminals, processing plants and other distribution assets located between North American production and supply areas, including the Gulf Coast, Midwest, Rocky Mountain and Western Canadian regions. We also maintain and operate storage, terminal and marine facilities at Milford Haven in the U.K. that enable customers to supply petroleum products to markets in the Atlantic Basin. We also operate a network of liquid asphalt cement terminals throughout Mexico. Our operations are conducted directly and indirectly through our primary operating segments. The following diagram is a simplified organizational chart of our business segments:

Company Information

Our website is located at www.semgroupcorp.com. Our Annual Report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and all amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Exchange Act, as well as proxy statements and other information we file with, or furnish to, the SEC are available free of charge on our website. We make these documents available as soon as reasonably practicable after we electronically file them with, or furnish them to, the SEC. The information contained on our website, or available by hyperlink from our website, is not incorporated into this Form 10-K or other documents we file with, or furnish to, the SEC. We intend to use our website as a means of disclosing material non-public information and for complying with our disclosure obligations under Regulation FD. Such disclosures will be included on our website in the “Investor Relations” sections. Accordingly, investors should monitor such portions of our website, in addition to following our press releases, SEC filings and public conference calls and webcasts.

1

Industry Overview

We move petroleum products throughout the U.S., Canada, Mexico and the U.K. We provide gathering, transportation, storage, distribution, marketing and other midstream services to producers and refiners of petroleum products. The market we serve, which begins at the point of purchase at the source of production and extends to the point of distribution to the end-user customer, is commonly referred to as the “midstream” market. The midstream market acts as a bridge between energy producers and energy end users and it is only as strong as its ability to link one side of the value chain to the other side. We focus on providing these services, using our asset base and distribution, processing and marketing expertise to provide the independent operators with a stable source of supply and market access for their petroleum products.

Crude Oil Midstream Market

Our crude oil business operates primarily in Colorado, Kansas, North Dakota, Oklahoma and Texas where there is extensive crude oil production. Our assets include gathering systems in and around producing fields and transportation pipelines carrying crude oil to logistic hubs, such as the Cushing Interchange, where we have terminalling and storage facilities that our customers use to manage the delivery of crude oil.

Gathering and Transportation

Pipeline transportation is generally the lowest cost method for shipping crude oil from the wellhead to logistic hubs or refineries. Crude oil gathering assets generally consist of a network of smaller diameter pipelines that are connected directly to the well site or central receipt points delivering into larger diameter trunk lines. Logistic hubs, like the Cushing Interchange, provide storage and connections to other pipeline systems and modes of transportation, such as railroads, trucks and barges. Trucking complements pipeline gathering systems by gathering crude oil from operators at remote wellhead locations not served by pipeline gathering systems. Trucking is generally limited to low volume, short haul movements because trucking costs escalate sharply with distance, making trucking the most expensive mode of crude oil transportation.

Storage Terminals and Supply

Storage terminals complement the crude oil pipeline gathering and transportation systems and address a fundamental imbalance in the energy industry: crude oil is generally produced in different locations and at different times than it is ultimately consumed.

Terminals are facilities in which crude oil is transferred to or from a storage facility or transportation system, such as a gathering pipeline, to another transportation system, such as trucks or another pipeline. Terminals play a key role in moving crude oil to end-users, such as refineries, by providing the following services:

| • | inventory management; |

| • | distribution; and |

| • | upgrading to achieve marketable grades or qualities of crude oil. |

Overview of Cushing Interchange

The Cushing Interchange is one of the largest crude oil marketing hubs in the U.S. and is the designated point of delivery specified in all NYMEX crude oil futures contracts. As the NYMEX delivery point and a cash market hub, the Cushing Interchange serves as a significant source of refinery feedstock for Midwest refiners and plays an important role in establishing and maintaining markets for many varieties of foreign and domestic crude oil.

The Cushing Interchange has multiple inbound and outbound pipeline interconnections. Recently, however, Cushing has experienced a shortfall in takeaway pipeline capacity, which has been cited as a principal reason for the decline in the West Texas Intermediate Index ("WTI Index") price used at Cushing compared to other crude oil price indices. The following planned major pipeline projects, should provide significant additional takeaway capacity, which we believe will allow Cushing to remain the predominant benchmarking and transportation hub for crude oil in the U.S.:

| • | Seaway Pipeline Reversal—In May 2012, Enterprise Products Partners, L.P. and Enbridge Inc. reversed the flow of the Seaway Pipeline to allow it to transport crude oil from Cushing to the U.S. Gulf Coast. The initial capacity was 150,000 barrels per day. In January 2013, the capacity was increased to 400,000 barrels per day. |

| • | TransCanada’s Keystone Pipeline—The Keystone XL Gulf pipeline system will extend from Cushing, Oklahoma to Nederland, Texas on the U.S. Gulf Coast. Construction on the 700,000 barrel per day pipeline began in August 2012 and is expected to be complete in late 2013. |

2

We cannot provide any assurances regarding any of these pipeline projects or the actual effect that any of them may have on crude oil prices at Cushing.

Natural Gas Midstream Market

We operate in the pipeline gathering and processing segments of the natural gas midstream industry in the U.S. and Canada. The natural gas gathering process begins once a well has been completed and the well is connected to a gathering system. Gathering systems typically consist of a network of small diameter pipelines and compression systems that collect natural gas from points near producing wells and transport it to larger pipelines for further transmission to a gas processing plant.

Wellhead gas is often saturated with water vapor. This water vapor must be removed from the gas stream to prevent formation of hydrates and condensation of free water in downstream facilities, to prevent corrosion and to meet downstream pipeline quality specifications. Dehydration is generally performed at central points along the gathering system utilizing either a glycol absorption process or a solid desiccant adsorption process.

In addition to water vapor, wellhead gas contains impurities such as carbon dioxide, nitrogen, hydrogen sulfide, helium, oxygen and other inert components. These impurities must be removed from the gas stream to protect downstream equipment, prevent corrosion and meet downstream pipeline quality specifications. They are removed through a variety of processes utilizing chemical reaction, absorption, adsorption or permeation. Natural gas delivered to the burner tip is almost pure methane. However, natural gas is produced from the reservoir containing impurities and heavier hydrocarbons entrained in the gas stream.

As natural gas is processed to remove unwanted elements that interfere with pipeline transportation, higher value natural gas liquids known as NGLs and condensate are separated from the raw natural gas stream. NGLs include ethane, propane, normal butane, iso-butane and natural gasoline. These products are used as petrochemical feedstock, heating and transportation fuels and refinery feedstock. Condensate is a mixture of petroleum products consisting primarily of pentanes and heavier liquids. It is used as refinery feedstock and as a diluent used to dilute crude bitumen so that it can be transported by pipeline.

Mexican Asphalt Industry

Mexico has a large and diverse road network in place. Mexico’s land transportation network is one of the most extensive in Latin America with over 354,000 kilometers of roads, with one third paved. Roads are a critically important component of Mexico’s transportation infrastructure. As a result, the authorized budget for the Secretary of Communications and Transportation ("SCT") in 2013, is 57.8 billion Mexican pesos for infrastructure investment. Over 40% of that budget (24.8 billion Mexican pesos) is allocated to improve highway infrastructures, the majority of which will be invested in the construction and modernization of 800 kilometers of highways and 23% (13.7 billion Mexican pesos) for maintenance of 43,600 kilometers of the federal network not including toll roads that have additional funds. Toll highways network has over 7,500 kilometers built with private and/or public investment.

Mexico’s highway infrastructure is comprised of three main components: the federal network (which includes both toll and toll-free roads) accounting for approximately 14% of all roads, the regional network accounting for approximately 20% and the rural network consisting of approximately 66%. The federal road system is the responsibility of the SCT, while the regional network of roads is the responsibility of state government. Rural and state roads and low-volume roads are also improved by state government. These networks help establish the annual demand for asphalt. Asphalt demand can increase, or decline, at a pace comparable to the level of on-going highway expansion and/or maintenance projects. Such projects rely on the availability of government concessions, continued public-private partnership undertakings and locally funded ventures.

European Petroleum Products Storage Industry

Storage for refined products and crude oil is critical to the European economy. Fluctuations in demand for crude oil and transportation fuels, combined with changing flows of petroleum product production and refining capacity, means storage is necessary to balance demand. Additionally, supply and demand disruptions due to weather, industry upsets, political tensions and terrorism have led industry participants to appreciate the significance that access to storage, and the availability of storage, will have over the future years.

The independent storage industry has experienced fluctuating demand for its services over recent years from major oil companies, oil traders and strategic storage agencies (government entities that store fuel to protect against significant fluctuations in supply or demand as mandated by the European Union and the International Energy Agency). The construction of new tank storage facilities has historically been restricted, resulting in a supply shortage. However, high crude oil prices and

3

backwardated market conditions (i.e., prices for future deliveries are lower than current prices) have had a negative effect on storage economics. As a result, demand for such storage facilities is currently weak.

Our Property, Plant and Equipment

Assets include:

| • | a 51% ownership interest (34% directly and 17% indirectly, through our interest in Rose Rock Midstream, L.P. ("Rose Rock")) in White Cliffs Pipeline, L.L.C ("White Cliffs"), which owns a 527-mile crude oil pipeline running from Platteville, Colorado to Cushing, Oklahoma (the "White Cliffs Pipeline"), that Crude operates; |

| • | the 2% general partner interest and 58.2% of the limited partner interest in Rose Rock, which owns an approximately 640-mile crude oil pipeline network in Kansas and Oklahoma and a crude oil storage facility in Cushing, Oklahoma with a capacity of 7.0 million barrels and an additional 0.6 million barrels currently under construction, and a 17% ownership interest in White Cliffs; |

| • | 9.1 million common units of NGL Energy Partners LP ("NGL Energy") and a 6.42% interest in NGL Energy Holdings LLC, the general partner of NGL Energy; |

| • | approximately 1,600 miles of natural gas and NGL transportation, gathering and distribution pipelines in Kansas, Oklahoma and Texas and Alberta, Canada; |

| • | 8.7 million barrels of owned multi-product storage capacity located in the U.K.; |

| • | 12 liquid asphalt cement terminals and modification facilities and two emulsion distribution terminals in Mexico; |

| • | majority interest in four natural gas processing plants located in Alberta, Canada, with a combined operating capacity of 694 million cubic feet per day; and |

| • | three natural gas processing plants located in the U.S., with 98 million cubic feet per day of capacity. |

We believe that the variety of our petroleum product assets creates opportunities for us and our customers that avoid seasonal fluctuations of less diverse businesses.

Business Strategy

Our principal business strategy is to utilize our assets and operational expertise to:

| • | move petroleum products throughout the U.S., Canada, Mexico and the U.K.; |

| • | provide consistently reliable high-quality midstream services under predominantly fee and margin-based contractual arrangements; |

| • | mitigate commodity price risk exposure; |

| • | aggressively manage operating costs to maintain and improve operating margins; |

| • | expand business by improving, enhancing and expanding services at existing facilities and gaining new customers; |

| • | pursue complementary “bolt-on” growth opportunities having acceptable risks and returns; and |

| • | generate consistent operating margins, earnings and cash flows. |

Our Business Segments

We conduct our business through six business segments:

| • | Crude; |

| • | SemStream; |

| • | SemLogistics; |

| • | SemCAMS; |

| • | SemMexico; and |

| • | SemGas |

For information relating to revenue and total assets for each segment, refer to Note 8 of our consolidated financial statements beginning on page F-1 of this Form 10-K.

4

The following sections present an overview of our business segments, including information regarding the principal business and services rendered, assets and operations and markets and competitive strengths. Our results of operations and financial condition are subject to a variety of risks. For information regarding our key risk factors, see “Item 1A. Risk Factors.”

Crude

Crude’s business operations are conducted through its 51% ownership interest in White Cliffs, and the 2% general partner interest and 58.2% of the limited partner interest in Rose Rock. These operations include crude oil transportation, storage, terminalling, gathering and marketing in Colorado, Kansas, Montana, North Dakota, Oklahoma and Texas for third party customers as well as for itself. The Crude business unit consists of four primary operations: (i) Cushing storage; (ii) Kansas and Oklahoma pipeline system; (iii) Bakken Shale operations; and (iv) Platteville Facility. A majority of Crude’s revenue is generated from fee-based contractual arrangements that, in some instances, are fixed and not dependent on usage.

Assets and Operations

Cushing Storage. Crude owns and operates 28 crude oil storage tanks in Cushing with an aggregate storage capacity of approximately 7.0 million barrels and an additional 600,000 barrels of storage currently under construction. Our storage terminal has a combined capacity to deliver 480,000 barrels of crude oil per day, and has inbound connections with the White Cliffs Pipeline from Platteville, Colorado, the Great Salt Plains Pipeline, the Cimarron Pipeline from Boyer, Kansas, our Kansas and Oklahoma gathering system and two-way interconnections with all of the other major storage terminals in Cushing, including the delivery point specified in all crude oil futures contracts traded on the NYMEX. Connection with this terminal provides our customers with access to multiple pipelines outbound from Cushing. Our Cushing terminal also includes truck unloading facilities.

Kansas and Oklahoma Pipeline. Crude owns and operates an approximately 640-mile crude oil gathering and transportation pipeline system and over 660,000 barrels of associated storage in Kansas and northern Oklahoma. This system gathers crude oil from throughout the region and delivers it to third-party pipelines and refineries and our Cushing terminal. During the years ended December 31, 2012 and 2011, we transported an average of approximately 52,000 and 36,000 barrels per day, respectively, from multiple receipt points. The system has pipeline diameters ranging from four to twelve inches and has 25 pump stations. This system also includes 18 truck unloading stations.

Bakken Shale. Crude owns and operates a crude oil gathering, storage, transportation and marketing business in the Bakken Shale area in western North Dakota and eastern Montana. Using our fleet of trucks and two truck unloading facilities, we purchase crude oil at the wellhead, transport it via our trucks and third-party pipelines, including the Enbridge North Dakota System (utilizing historically accrued allocation rights), and market it to customers, historically at the crude oil marketing hub in Clearbrook, Minnesota. Recently, this activity has shifted to dispatch trucks to rail facilities or redirect pipeline throughput in order to take advantage of more profitable markets. We own tanks in Trenton and Stanley, North Dakota, with an aggregate storage capacity of 61,800 barrels that connect into the Enbridge North Dakota System. During the year ended December 31, 2012, we handled and marketed an average of approximately 7,100 barrels per day.

Platteville Facility. Crude owns and operates a modern, sixteen-lane crude oil truck unloading facility in Platteville, Colorado, which connects to the origination point of the White Cliffs Pipeline. Much of the crude oil production from the DJ Basin and the nearby Niobrara Shale must initially be transported by truck due to a shortage of gathering capacity. Throughput at the facility averaged 43,500 and 32,400 barrels per day for the years ended December 31, 2012 and 2011, respectively. The facility includes 230,000 barrels of crude oil storage capacity. The Platteville facility also allows customer pipeline gathering systems to connect to the origination point of the White Cliffs Pipeline. The White Cliffs Pipeline is the only direct pipeline out of the DJ Basin to the Cushing market and to Mid-Continent refineries.

Other

White Cliffs Pipeline. Crude owns 51% of White Cliffs, which owns the White Cliffs Pipeline, a 527-mile common carrier, crude oil pipeline system that originates in Colorado and terminates in Cushing, Oklahoma. The White Cliffs Pipeline provides the Denver-Julesburg Basin ("DJ Basin") producers in Colorado direct access to the Cushing market and to refiners in the Midwest area. A 100,000 barrel crude oil storage tank and a truck unloading facility owned and operated by Crude is located and connected at the White Cliffs Pipeline’s origination point at Platteville, Colorado. The White Cliffs Pipeline’s capacity is 70,000 barrels of crude oil per day.

Crude currently owns 51% of White Cliffs. The other 49% is owned as follows: 35.5% by Plains Pipeline, L.P., 10% by Anadarko Wattenberg Company, LLC (“AWC”), and 3.5% by Samedan Pipe Line Corporation (“Noble Energy”). AWC and Noble Energy have each entered into throughput agreements with us for the shipment of their product on the White Cliffs

5

Pipeline. (See Note 5 of our consolidated financial statements beginning on page F-1 of this Form 10-K for additional information.)

New Developments

Glass Mountain Pipeline. SemGroup and Gavilon LLC have formed a joint venture named Glass Mountain Pipeline to construct and operate a 210-mile pipeline in western and north central Oklahoma. The pipeline will have an initial capacity of approximately 140,000 barrels per day, 440,000 barrels of intermediate storage and deliver crude oil to a one million barrel storage facility at Gavilon's terminal in Cushing, Oklahoma. The pipeline is being constructed by SemGroup. The total cost of the pipeline is estimated to be approximately $126 million, of which approximately $74.4 million has been spent as of December 31, 2012. Following completion of construction, which is expected in the fall of 2013, the pipeline will be operated by Rose Rock. Chesapeake Energy entered into a long-term transportation agreement with Glass Mountain Pipeline which provided the economic incentive to construct the pipeline. This pipeline project is intended to meet the growing midstream requirements resulting from the drilling activity in western Oklahoma and the Mississippi Lime Play.

Wattenberg Oil Trunkline. SemGroup is constructing a new crude oil gathering system in the DJ Basin called the Wattenberg Oil Trunkline. The project is a 37-mile, 12-inch diameter pipeline with 200,000 barrels of operational storage extending north from Rose Rock's Platteville Station, the origin point of the White Cliffs Pipeline. The pipeline will connect to Noble Energy, Inc.'s crude oil production area and will include truck unloading facilities. Noble Energy, Inc. has entered into a long-term agreement to use the assets. The total cost of the pipeline is estimated to be approximately $39 million, of which approximately $12.5 million has been spent as of December 31, 2012. The project is expected to be operational in the fourth quarter of 2013.

Revenue and Marketing

A majority of Crude’s revenue is derived from fee-based contractual arrangements with third party customers. The Kansas and Oklahoma pipeline system provides transportation, gathering and storage services to customers on fee-based arrangements, typically based on usage with varying term lengths. Cushing storage capacity is provided to customers under fixed-fee contractual arrangements, typically based on the amount of storage capacity reserved for each customer.

In addition to third party customer revenue, Crude generates revenue from limited marketing activities. Crude’s marketing includes purchasing crude oil for its own account from producers and aggregators and selling crude oil to traders and refiners.

We mitigate the commodity price exposure of our crude oil marketing operations by limiting our net open positions through (i) the concurrent purchase and sale of like quantities of crude oil to create “back-to-back” transactions intended to lock in positive margins based on the timing, location or quality of the crude oil purchased and delivered, or (ii) derivative contracts. All of our marketing activities are subject to our Comprehensive Risk Management Policy which establishes limits in order to manage risk and mitigate financial exposure. Our marketing activities account for a portion of the revenue we generate through our Kansas and Oklahoma pipeline system and our Bakken Shale operations.

Market and Competitive Strengths

Crude’s pipelines move crude oil to third party pipelines and refineries and to Cushing. The Cushing Interchange is one of the largest crude oil marketing hubs in the U.S. and the designated point of delivery specified in all NYMEX crude oil futures contracts. As the NYMEX delivery point and a cash market hub, the Cushing Interchange serves as a significant source of refinery feedstock for refiners and plays an important role in establishing and maintaining markets for many varieties of foreign and domestic crude oil. The Kansas and Oklahoma pipeline system allows Kansas producers and purchasers access to regional refineries, third party pipelines and to Cushing.

SemStream

Until December 31, 2012, SemStream was engaged in the residential propane supply business through its wholly-owned subsidiary, SemStream Arizona Propane, L.L.C. (“SemStream Arizona”), with operations in Page and Payson, Arizona. In September 2012, we entered into a definitive agreement to sell those assets. The sale was finalized on December 31, 2012, after receiving the required approval by the Arizona Corporation Commission ("ACC").

Assets and Operations

SemStream holds SemGroup's ownership interests in NGL Energy, a master limited partnership, publicly traded on the New York Stock Exchange as "NGL". NGL Energy owns and operates midstream wholesale and retail propane storage and distribution assets, crude oil logistics and water treatment services.

6

SemLogistics

SemLogistics owns the largest independent petroleum products storage facility in the U.K. The main activities of SemLogistics are the receipt, storage and redelivery of clean petroleum products and crude oil at the Milford Haven site.

Assets and Operations

SemLogistics operates a tank storage business and offers build-bulk (importing small cargo, building volume and exporting larger cargo) and break-bulk (importing larger cargo and exporting smaller cargo) operations to its customers that transport products between the Middle East and Europe, the east coast of the U.S. and the west coast of Africa. The terminal is strategically located to access the U.K. market and to service numerous global markets.

SemLogistics’ storage facility includes approximately 8.7 million barrels of above ground storage tanks and has received approval from Pembrokeshire County Council to build nine new tanks with a total storage capacity of 1.5 million barrels. The construction of new tankage is dependent on, and will commence when, demand for additional product storage dictates. The terminal has two deep water jetties, one of which can accommodate vessels of up to 165,000 dead weight tons. It also has access to Mainline Pipeline Limited (pipeline from Milford Haven to Manchester and Nottingham), which is owned by Valero Energy Limited.

Over 40% of SemLogistics’ storage capacity is multi-product, providing customers with tank storage for clean petroleum products, including gasoline, gasoline blendstocks, jet fuel and gas oil. The remaining tankage is either dedicated to crude oil or dual-purpose tankage for at least two clean petroleum products (gasoline/jet fuel or gasoline/gas oil or jet fuel/gas oil). SemLogistics also provides related services, e.g., tank-to-tank transfers, mixing of gasoline blendstocks and kerosene marking.

Revenue and Marketing

SemLogistics generates revenue from fixed-fee storage tank leasing and related services by making available to third parties all of the terminal’s available tank capacity for the storage of crude oil and refined products. Customers fall into three broad categories: trading, structural marketing storage and compulsory strategic storage.

Markets and Competitive Strength

SemLogistics’ ability to handle multiple products provides flexibility to change its operations in response to market conditions. Demand for independent storage terminals can be impacted by a wide range of influences such as the forward price curve, expanding oil production, security of supply concerns, European compulsory stock holding requirements, and mismatches in regional production and consumption of oil and refined petroleum products.

SemLogistics’ terminal size (approximately 23% of the total independent storage in the U.K.) and its vessel handling capabilities make it unique compared with other terminals. In addition to being the only independent U.K. facility that serves the bulk trans-shipment sector, it is also the only facility capable of handling crude oil, with the only other comparable facility in the British Isles being a terminal in Ireland. However, the owner of this other facility, a major oil company, uses its terminal exclusively for proprietary storage and storage of Irish strategic stocks.

SemCAMS

We own and operate four natural gas processing and gathering facilities in Alberta, Canada. The principal process performed at the processing plants is to remove contaminants and render the gas saleable to downstream pipelines and markets. At our sour gas plants we also “sweeten” sour natural gas by removing sulfur. Approximately two-thirds of the total natural gas throughput at our processing plants is sour gas. All of SemCAMS’ assets are located in West-Central Alberta, in the heart of the Western Canadian Sedimentary Basin, which accounts for approximately 80% of Canada’s sour natural gas production.

Assets and Operations

SemCAMS operates and owns varying working interests in (i) two sour natural gas processing plants known as the Kaybob South No. 3 plant (the “K3 Plant”), and the Kaybob Amalgamated plant (the “KA Plant”); (ii) two sweet gas plants known as the West Fox Creek plant and the West Whitecourt plant (the “WW Plant”), and (iii) a network of more than 600 miles of natural gas gathering and transportation pipelines. The sour gas plants are dually connected to two major long-haul natural gas pipelines that serve Canada and the U.S. The plants also have the ability to load certain products for transportation by truck and railcar.

7

Revenue and Marketing

SemCAMS generates revenue from the processing plants through volumetric fees for services under contractual arrangements with working interest owners and third party customers. SemCAMS does not have direct exposure to commodity prices. In addition, SemCAMS generates fee-based revenue from volume throughput on its pipelines. SemCAMS’ customers include producers of varying sizes.

SemCAMS also derives revenue as the owner and operator of pipeline gathering systems that gather gas from multiple wells located in the same production unit and as the owner and operator of pipeline transportation systems that deliver the gathered gas to each plant.

To support operations at our plants, several producers have committed to process all of their current and future natural gas production from lands owned by them, or their subsequent assignees, within a “dedicated area” comprised of approximately 180 townships located in and around our plants. The dedicated area covers approximately 27% of the volumes in the area surrounding our plants. This dedication continues until field depletion.

Market and Competitive Strengths

SemCAMS’ natural gas gathering and processing operations are located in an area that generates more than 70% of Canada’s total natural gas production and approximately 80% of Canada’s total sour gas production. Natural gas is used for a variety of purposes in Canada including heating, electricity production and other industrial processes.

SemMexico

SemMexico provides a variety of liquid asphalt cement products and product application services to the Mexican market. SemMexico purchases, produces, stores and distributes asphalt products throughout Mexico. SemMexico’s primary supplier of asphalt is Pemex, Mexico’s state-owned petroleum company. SemMexico is the largest asphalt distributer in Mexico and, in addition to direct asphalt cement sales, further processes asphalt materials in combination with other raw materials to produce value-added products. These products, such as polymer modified asphalts and asphalt emulsions, are then sold to road contractors and government agencies.

Assets and Operations

SemMexico currently operates an in-country network of 12 asphalt cement terminals and modification facilities, two emulsion distribution terminals and two portable rail unloading facilities to import asphalt from the U.S. SemMexico’s national technical center and headquarters are located in the city of Puebla, Mexico.

Revenue and Marketing

SemMexico generates revenues through the sale of asphalt product to customers. In general, SemMexico’s sales and purchases of asphalt cement are matched; SemMexico procures product on an as-needed basis, thereby limiting exposure to price movements of inventory. SemMexico’s focus is to maintain its reputation as a quality supplier of asphalt products by consistently producing high quality products and introducing technologically advanced products and solutions to Mexico’s asphalt market, while simultaneously increasing production capacity and product distribution availability.

Market and Competitive Strengths

SemMexico is a leader in asphalt pavement technologies and capabilities. It is the only liquid asphalt cement company with a national footprint in Mexico. These factors have resulted in a long-term supply relationship with Pemex and continuous business transactions with its customers. SemMexico is exposed to market risk, such as the sustainability of road construction and maintenance funds from the Mexican government. However, we believe that SemMexico’s significant market position, reputation, technology and long-term relationships with suppliers and customers are strategic strengths that will benefit SemMexico if funding or demand should increase.

SemGas

SemGas provides natural gas gathering and processing services. It has gathering and processing plants and assets in Kansas, Oklahoma and Texas. SemGas aggregates gas supplies from the wellhead and provides various services to producers that condition the wellhead gas production for downstream markets.

8

Assets and Operations

SemGas currently owns and operates over 980 miles of gathering pipelines in Kansas, Oklahoma and Texas. SemGas has one processing plant located in Sherman, Texas, with a processing capacity of 23 million cubic feet per day and over 400 miles of low pressure gathering lines. SemGas also has two plant facilities in Northern Oklahoma (Nash and Hopeton) located roughly 20 miles apart, with a combined processing capacity of approximately 75 million cubic feet per day. This area, also called the Mississippi Zone, has emerged into a key oil resource play with associated gas. There are approximately 690,000 acres dedicated to SemGas, from several area producers, with approximately 70,000 acres in the core of the Mississippi Lime Play.

Additionally, SemGas owns a Eufaula gathering system which gathers, dehydrates and compresses gas in eastern Oklahoma, and a gathering system in Kansas.

Revenue and Marketing

SemGas generates revenue from a portfolio of contracts. Initial contract terms can range from monthly and interruptible to the life of the reserves and, upon expiration, continue to renew on a month-to-month or year-to-year evergreen basis. The majority of the contracts provide upside potential by providing SemGas participation in commodity price and processing margin upswings through percent-of-proceeds and percent-of-index contracts. On these contracts, SemGas is generally responsible for marketing the gas and NGLs for both its and the producers’ share of the products. Percent-of-proceeds contracts are based on SemGas paying the producers a percentage of the sale proceeds from the products and percent-of-index contracts are based on SemGas paying the producers a percentage of the sale proceeds based on an index price. SemGas also has fee-based contracts for processing and gathering services. SemGas’ customers include producers, operators, marketers and traders.

Market and Competitive Strengths

SemGas’ gathering and processing volumes can be impacted by market demand for the products it handles, as well as the price for crude oil, because the Mississippi Zone is primarily a crude oil play with associated natural gas and natural gas liquids. Gathering and processing activities are also reliant on continued drilling and production activity by producers in our areas of operation. While price increases in natural gas might lead to increased drilling and supply, price increases can also adversely affect demand.

We face competition in acquiring new natural gas supplies. The natural gas gathering and processing industry is generally characterized by regional competition, based on the proximity of gathering systems and processing plants to natural gas producing wells. SemGas’ gathering and processing assets tend to have relatively long-term contracts and, in some instances, are the only assets that can provide the offered services to the customers.

SemGas generally sells all natural gas and NGLs it obtains under its percentage-of-proceeds and percentage-of-index contracts immediately in the spot market and, therefore, has little commodity price risk with respect to inventory or other physical commodity positions. SemGas’ percentage-of-proceeds and percentage-of-index processing contracts intrinsically have commodity price risk since SemGas’ revenue, with respect to these contracts, vary with the level of natural gas and commodity prices. SemGas may elect to use financial derivatives to hedge this risk. SemGas is limited in the amount, and in the time period, for which it may hedge its commodity price risk associated with its contracts pursuant to our Comprehensive Risk Management Policy. More generally, all of our marketing and hedging activities are subject to our Comprehensive Risk Management Policy, which establishes a set of limits, both at the SemGas and the SemGroup Corporation levels, to manage risk and mitigate financial exposure.

Risk Governance and Comprehensive Risk Management Policy

We expect to generate the majority of our earnings from owning and operating strategic assets while endeavoring to prudently manage all risks, including commodity price risk, associated with the ownership and operations of our assets. We have a Comprehensive Risk Management Policy that reflects an enterprise-wide approach to risk management and considers both financial and non-financial risks.

Our Board of Directors is responsible for the oversight of our enterprise-wide risk and has approved our Comprehensive Risk Management Policy. The Comprehensive Risk Management Policy is designed to ensure we:

| • | identify and communicate our risk appetite and risk tolerances; |

| • | establish an organizational structure that prudently separates responsibilities for executing, valuing and reporting our business activities; |

| • | value (where appropriate), report and manage all material business risks in a timely and accurate manner; |

9

| • | effectively delegate authority for committing our resources; |

| • | foster the efficient use of capital and collateral; and |

| • | minimize the risk of a material adverse event. |

The Audit Committee of our Board of Directors has oversight responsibilities for the implementation of, and compliance with, our Comprehensive Risk Management Policy.

Our Executive Management Committee, comprised of corporate officers, oversees the financial and non-financial risks associated with all activities governed by our Comprehensive Risk Management Policy including:

| • | asset operations; |

| • | marketing and trading; |

| • | investments, divestitures, and other capital expenditures and dispositions; |

| • | credit risk management; and |

| • | other strategic activities. |

We also have a Risk Management Group that is assigned responsibility for independently monitoring compliance with, reporting on, and enforcing the provisions of our Comprehensive Risk Management Policy.

Our Comprehensive Risk Management Policy provides a set of limits or thresholds for activities related to owned assets, physical commodities, and derivatives and capital transactions involving market and credit risk. Our limits monitor these risks for each individual segment and on a consolidated basis. Our Comprehensive Risk Management Policy also specifies the types of transactions that may be executed by incumbents of named positions without specific approval of our Board of Directors or our Executive Management Committee. It also restricts proprietary trading activities within limits significantly more restrictive than the corporate market risk management limits.

Competition

We face intense competition in the operations of each of our segments. Our competitors include other midstream companies, major integrated oil companies and their marketing affiliates, crude oil pipeline companies and independent gatherers, brokers and marketers of petroleum products of widely varying sizes, financial resources and experience. Some of these competitors have capital resources many times greater than ours and control greater supplies of crude oil and petroleum products. Competition for customers of petroleum products is based primarily on price, access to supply, access to logistical assets, distribution capabilities, the ability to meet regulatory requirements and maintenance of quality of service and customer relationships.

Operational Hazards and Insurance

Pipelines, terminals, storage tanks, processing plants or other facilities may experience damage as a result of an accident, natural disaster or deliberate act. These hazards can also cause personal injury and loss of life, severe damage to, and destruction of, property and equipment, pollution or environmental damage and suspension of operations. Through the services of a major national insurance broker, we have maintained insurance of various types and varying levels of coverage similar to that maintained by other companies in the industry and which we consider adequate, under the circumstances, to cover our operations and properties, including coverage for natural catastrophes, pollution related events and acts of terrorism and sabotage. The limit of operational insurance maintained covering loss of, or damage to, property and products is $300 million per loss and includes business interruption loss. For claims arising under general liability, automobile liability and excess liability, the limits maintained total $250 million per occurrence/claim. Primary and excess liability insurance limits maintained for pollution liability claims vary by location for claims arising from gradual pollution with limits ranging from $20 million to $40 million in the aggregate. The combined primary and excess liability insurance limits for claims arising from sudden and accidental pollution total $270 million per claim and $290 million in the aggregate. This insurance does not cover every potential risk associated with the operating pipelines, terminals and other facilities. We have a favorable claims history enabling us to self-insure the “working layer” of loss activity utilizing deductibles and self-insured retentions commensurate with our financial abilities and in line with industry standards, in order to create a more efficient and cost effective program and a consistent risk profile. The working layer consists of high frequency/low severity losses that are best retained and managed in-house. Sizable or difficult self-insured claims or losses may be handled by professional adjusting firms hired by us. We will continue to monitor the appropriateness of our deductibles and retentions as they relate to the overall cost and scope of our risk and insurance program.

10

With a few limited exceptions, our customers have not agreed to indemnify us for losses arising from a release of petroleum products, and we may instead be required to indemnify our customers in the event of a release or other incident.

Regulation

General

Our operations are subject to extensive regulation. The following discussion of certain laws and regulations affecting our operations should not be relied on as an exhaustive review of all regulatory considerations affecting us, due to the myriad of complex federal, state, provincial, foreign and local regulations that may affect our business.

Regulation of U.S. Pipeline, Transportation and Storage Operations

Interstate Storage and Transportation

The White Cliffs Pipeline is subject to regulation by FERC because it is a common carrier pipeline that transports crude oil in interstate commerce. Under the Interstate Commerce Act ("ICA") and the rules and regulations promulgated under those laws, tariff rates for interstate service on common carrier oil pipelines, including such pipelines that transport crude oil and petroleum products, must be just and reasonable and must not be unduly discriminatory or confer any undue preference upon any shipper. FERC regulations require that transportation rates and terms and conditions of service be filed with FERC and posted publicly.

The ICA permits interested persons to challenge new or changed rates or rules and authorizes FERC to investigate such changes and to suspend their effectiveness for a period of up to seven months. If, upon completion of an investigation, FERC finds that the new or changed rate is unlawful, it may require the pipeline to refund the revenues together with interest in excess of the prior tariff during the term of the investigation. FERC may also investigate, upon complaint or on its own motion, rates and related rules that are already in effect and may order a pipeline to change them prospectively. Upon an appropriate showing, a shipper may obtain reparations and refunds for a period of up to two years prior to the filing of its complaint.

Gathering and Intrastate Pipeline Regulation

The ICA does not address gathering and natural gas gathering is generally exempt from regulation by FERC under the Natural Gas Act (the "NGA"). We own a number of natural gas pipelines that we believe operate wholly intrastate and are, therefore, exempt from FERC regulation under the NGA. We also own a number of intrastate crude oil gathering systems that are subject to certain state and local, but not federal regulation. Some of these gathering systems are currently operated as proprietary systems. We cannot provide assurances that we will not be subject to regulation by FERC in the future.

In the states in which we operate, regulation of intrastate natural gas and crude oil gathering facilities and intrastate crude oil pipeline service generally includes various safety, environmental and, in some circumstances, nondiscriminatory take requirements and complaint-based rate regulation. For example, our natural gas gathering facilities are, in some cases, subject to state ratable take and common purchaser statutes. Ratable take statutes generally require gatherers to take, without undue discrimination, natural gas production that may be tendered to the gatherer for handling. Common purchaser statutes generally require gatherers to purchase without undue discrimination as to source of supply or producer. These statutes are designed to prohibit discrimination in favor of one producer over another producer or one source of supply over another source of supply. These statutes have the effect of restricting our right, as an owner of gathering facilities, to decide with whom we contract to purchase or transport natural gas.

Department of Transportation

Interstate pipelines and certain intrastate pipelines are subject to regulation by the Department of Transportation (the “DOT”) with respect to the design, construction, operation and maintenance of the pipeline systems. The DOT routinely conducts audits of the regulated assets and we must make certain records and reports available to the DOT for review as required by the Secretary of Transportation. In some states, the DOT has given a state agency authority to assume all or part of the regulatory and enforcement responsibility over the intrastate assets.

Trucking Regulation

Through our interest ownership in Rose Rock, we operate a fleet of trucks to transport crude oil. We are licensed to perform both intrastate and interstate motor carrier services and are subject to certain safety regulations issued by the DOT. DOT regulations cover, among other things, driver operations, maintaining log books, truck manifest preparations, the placement of safety placards on the trucks and trailer vehicles, drug and alcohol testing, safety of operation and equipment and many other aspects of truck operations.

11

Cross-Border Regulation

We are subject to regulatory matters specific to border crossing, which include export licenses, tariffs, customs and tax issues and toxic substance certifications. Regulations include the Short Supply Controls of the Export Administration Act, the North American Free Trade Agreement, National Energy Board Reporting and Certification and the Toxic Substances Control Act. Violations of license, tariff and tax reporting requirements under these regulations could result in the imposition of significant administrative, civil and criminal penalties. Furthermore, the failure to materially comply with applicable tax requirements could lead to the imposition of additional taxes, interest and penalties.

Regulation of Canadian Gathering, Processing, Transportation and Marketing Businesses

National Energy Board (“NEB”)

Our Canadian assets are not currently regulated by the NEB. The importation and exportation of natural gas and crude oil to and from Canada, however, are regulated by the NEB. The Government of Alberta tracks volumes exported from Alberta and reserves the right to limit the volume of natural gas that may be removed from Alberta in the event of domestic supply constraint.

Energy Resources Conservation Board (“ERCB”)

The ERCB’s purpose is to ensure that the discovery, development and delivery of Alberta’s resources take place in an orderly and efficient manner and in the public interest.

Among other matters, the ERCB has the authority to regulate the exploration, production, gathering, processing, transmission and distribution of natural gas within the province. With respect to natural gas gathering and processing activities, the ERCB’s primary role is to serve as a licensing authority for the construction and operation of the facilities used in those activities.

While the ERCB has jurisdiction to regulate the rates and fees charged for services provided by these types of facilities using a public complaint process, this authority is discretionary and historically has not commonly been exercised. Generally, the complaint-based method of regulation has meant that parties have had the opportunity to use alternative means to resolve disputes without resorting to the ERCB.

Sulphur Recovery Standards

In 2001, the ERCB set more stringent sulphur recovery standards for older sour gas processing plants, as set out in ID 2001-3. This interim directive directed older, “grandfathered” plants to either gradually increase their sulphur recovery to current standards or accept a reduction in their licensed capacity.

The K3 Plant and the KA Plant are capable of meeting “de-grandfathered” recovery requirements. The K3 Plant was “de-grandfathered” in 2006 after installation of a new Super Claus Sulphur recovery process. The KA Plant can be “de-grandfathered” via simple administrative application.

Other Provincial Regulatory Agencies

The Alberta Boilers Safety Association (“ABSA”) is the regulatory agency for pressure vessels and related systems in Alberta with a mandate to ensure that pressure equipment is constructed and operated in a manner that protects public safety. SemCAMS maintains an approved program for such requirements.

Regulation of U.K. Operations

In the U.K., the Department of Energy and Climate Change’s Energy Resources Development Unit is responsible for the regulation of a number of relevant areas, including licensing, national oil stocks policy (including their compulsory oil stocking obligations as a member of the European Union and International Energy Agency), policy on oil disposal, offshore environmental policy, oil sharing arrangements and decommissioning. Other regulatory bodies include the Health and Safety Executive, which regulates health and safety in the upstream and downstream oil industry (among others) and the Hazardous Installations Directorate, which is responsible for inspection and enforcement of health and safety regulation with respect to the downstream oil industry (among others). There is no regulator dedicated specifically to the oil industry. The activities of SemLogistics may also be regulated as a result of the European Union’s participation in the International Carriage of Dangerous Goods by Road and Rail agreements, as well as the International Maritime Dangerous Goods Code, which governs the safe transport of dangerous goods (including oil) by sea and, in due course, by the Marine Management Organization when it comes into being pursuant to the Marine and Coastal Access Bill.

12

The Department for Environment Food and Rural Affairs is responsible for setting legislation, policy, regulations and guidance for a number of environmental issues. There are also several European and international laws and policies that apply. SemLogistics’ activities are regulated by the Environment Agency Wales (“EAW”), this organization will become Natural Resources Wales on April 1, 2013. EAW also oversees spills and their cleanup, as well as new construction of tanks, bunds (spill control berms or dikes in the U.S.) and other improvements, and whose regulations require us to maintain a Pollution Prevention and Control permit.

At a local level, SemLogistics’ storage facility falls within the jurisdiction of the Milford Haven Port Authority (the “MHPA”). Under the Milford Haven Port Authority Act 2002, the MHPA has the power to publish directions for the purpose of promoting or securing conditions conducive to the ease, convenience or safety of navigation in Milford Haven and the approaches to it. MHPA is currently consulting on the Milford Haven Port Authority General Directions (2006). MHPA also has powers and obligations under various regulations, including, among others, the Dangerous Substances in Harbour Areas Regulations 1987 and the Harbour Docks and Piers Clauses Act 1847, as well as responsibility for the enforcement of the Port Marine Safety Code.

Regulation of Mexican Operations

SemMexico is primarily engaged in the purchasing, production, modification, storage and distribution of liquid asphalt cement products throughout Mexico. These activities are subject to compliance with environmental laws and regulations under Mexican technical “Official Standards” and other provisions that establish minimum technical requirements. Companies are required to obtain, from the corresponding federal, local and/or municipal authorities, the relevant permits and authorizations to construct and operate asphalt modification plants and carry out the activities described above.

Mexico’s Ministry of Communications and Transportation has published several construction standards establishing the specifications required for pavement surfaces conditions and asphalt products in connection with infrastructure projects, as well as certain manuals identifying the procedures for verifying compliance therewith. SemMexico is in compliance with all standards.

Asphalt treatment, storage and distribution activities are considered hazardous under applicable environmental laws and regulations and are subject to the scrutiny of the Ministry of the Environment and Natural Resources, which is the governmental agency in charge of granting the authorization for the handling, transportation, treatment, storage, importation, exportation and final disposal of asphalt, among others. These authorizations are essential for SemMexico to be able to perform its activities in Mexico.

Coupled with the authorizations and permits that may be granted by the Ministry of the Environment and Natural Resources, asphalt transportation activities within Mexico are subject to having obtained a number of other federal permits, including transportation companies to have environmental damage insurances and federal licenses for the operators of transportation units mobilizing SemMexico’s liquid asphalt cement products.

Mexico agencies impose similar, but not necessarily always as stringent, detailed requirements as in the U.S. concerning water management, water resources and the protection of water quality. These requirements regulate the discharge of pollutants and other harmful substances into water sources. SemMexico is currently in compliance with all water management requirements.

Certain operations in Mexico require obtaining an air emissions license at the time such operations begin, and to report on a yearly basis thereafter, the stack emissions to state environmental agencies, assuring such emissions comply with the National Official Standards. Mexico has national, state and local laws which regulate releasing hazardous substances or solid wastes into soils, groundwater and surface water. These regulations include taking measures to prevent and control pollution as well as the handling of hazardous waste. SemMexico is currently in compliance with all such air and hazardous materials and waste requirements.

Environmental, Health and Safety Regulation

General

Our operations, including Canadian, U.K. and Mexican operations, are subject to varying degrees of stringent and complex laws and regulations by multiple levels of government relating to the production, transportation, storage, processing, release and disposal of petroleum and natural gas based products and other materials or otherwise relating to protection of the environment, safety of the public and safety of employees. As with the industry generally, compliance with current and anticipated environmental laws and regulations increases our overall costs of business, including our capital costs to construct, maintain and upgrade pipelines, equipment and facilities. The failure to comply with these laws and regulations may result in

13

the assessment of administrative, civil and criminal penalties, the imposition of removal or remedial obligations, and the issuance of injunctions limiting or prohibiting our activities.

The clear trend in environmental regulation, particularly with respect to petroleum product facilities, is the placement of more restrictions and limitations on activities that may affect the environment and, thus, any changes in environmental laws and regulations or re-interpretations of enforcement policies that result in costly waste handling, storage, transport, disposal or remediation requirements could have a material adverse effect on our operations and financial condition. We may be unable to pass on such increased costs to our customers. Moreover, accidental releases, leaks or spills may occur in the course of our operations and we may incur significant costs and liabilities as a result, including those related to claims for damage to property, natural resources or persons. While we believe that we are in substantial compliance with existing applicable environmental laws and regulations and that continued compliance with existing requirements would not have a material adverse effect on us, there is no assurance that the current conditions will continue in the future.

The following is a summary of the more significant current environmental, health and safety laws and regulations to which our operations are subject.

Water Discharges

Our operations can result in the discharge of pollutants, including oil. The Oil Pollution Act (“OPA”) was enacted in 1990 and amends provisions of the Federal Water Pollution Control Act of 1972, as amended, the Clean Water Act, as amended, and other statutes as they pertain to prevention of, and response to, oil spills. The OPA, the Clean Water Act and analogous state, provincial and local laws, subject owners of facilities to strict, joint and potentially unlimited liability for containment and removal costs, natural resource damages and certain other consequences of an oil spill, where such spill is into navigable waters, along shorelines or in the exclusive economic zone of the U.S. In the event of an oil spill from one of our facilities into navigable waters, substantial liabilities could be imposed. Spill prevention, control and countermeasure requirements of these laws require appropriate containment berms or dikes and other containment structures at storage facilities to limit contamination of soils, surface waters and groundwater in the event of an oil overflow, rupture or leak.

The federal Clean Water Act and analogous state and local laws impose restrictions and strict controls regarding the discharge of pollutants into waters of the U.S. and state waters, including groundwater in many jurisdictions. Permits must be obtained to discharge pollutants into these waters. The Clean Water Act and analogous state and local laws provide significant penalties for unauthorized discharges and can impose liability for responding to and cleaning up spills. In addition, the Clean Water Act and analogous state and local laws require individual permits or coverage under general permits for discharges of storm water runoff from certain types of facilities. These permits may require us to monitor and sample the storm water runoff from certain of our facilities.

Similar measures are in place in Canada at both a federal and provincial level.

In addition, national, local and European Union regulations and directives in the U.K., and federal, state and local laws in Mexico, impose similar, but not necessarily always as stringent and detailed, requirements as in the U.S. concerning water resources and the protection of water quality, including those that regulate the discharge of pollutants and other harmful substances into water, require permits, impose clean-up obligations for spills and releases and impose fines and penalties for non-compliance. However, these countries continue to implement stricter requirements that approach the requirements in the U.S.

Air Emissions

Our operations are subject to the federal Clean Air Act, as amended, and comparable state and local laws, as well as the federal, provincial and local Canadian, U.K., European Union and Mexican laws applicable to our Canadian, U.K. and Mexican operations, although not necessarily always as stringent as found in the U.S., at least not presently. These laws and regulations regulate emissions of air pollutants from various sources, including certain of our plants, compression stations and other facilities, and impose various monitoring and reporting requirements. Pursuant to these laws and regulations, we may be required to obtain environmental agency pre-approval for the construction or modification of certain projects or facilities expected to produce or significantly increase air emissions, obtain and comply with the terms of air permits containing various emissions and operational limitations and utilize specific emission control technologies to limit emissions. We may be required to incur certain capital expenditures in the future for air pollution control equipment and leak detection and monitoring systems in connection with obtaining or maintaining operating permits and approvals for air emissions. There are significant potential monetary fines for violating air emission standards and permit provisions.

14

SemCAMS conducts on-going air, soil and ground water monitoring in accordance with license requirements. SemCAMS is required to annually report all specified emissions from its major facilities to a publicly accessible National Pollutant Release Inventory database.

Sour Gas

SemCAMS operates facilities which process and transport sour gas (gas containing hydrogen sulfide, generally at concentrations of 10 parts per million or more). Due to the highly toxic and corrosive nature of sour gas, sour gas handling is regulated in Canada, at both the provincial and federal level, from the wellhead to the point of disposal of the sulfur content removed from processing the sour gas. Environmental legislation can also affect the operations of facilities and limit the extent to which facility expansion is permitted. Proposed facilities are facing increased resistance from community groups which are, in turn, increasing demand for alternate sources of sweetening. In addition, legislation requires that facility sites be abandoned and reclaimed to the satisfaction of provincial authorities and local landowners. A breach of such legislation may result in the imposition of fines and the issuance of clean-up orders.

To protect the public, pipelines transporting sour gas are required to be equipped with monitoring stations and valves that automatically shut down the flow of the pipeline in response to sudden changes in pressure or detection of sour gas in the atmosphere. SemCAMS’ sour gas pipelines are monitored 24 hours per day from a centralized pipeline control center and can be shut down by the attending operators. The distance between automatic pipeline valves is determined, based on regulated sour gas dispersion modeling, to meet approved emergency protection zone size and public exposure requirements. The integrity of the sour gas pipelines is maintained through the injection of corrosion inhibition chemicals on an on-going basis. SemCAMS’ sour gas pipelines are inspected on a regular basis to ensure the integrity of the pipelines and associated facilities.

SemCAMS’ sour gas plants have continuous sour gas detection equipment, as well as other safety systems which can automatically shut down and depressure the full plant to a controlled flare system. The plants are attended 24 hours per day and can also be shut down by attending operators.

At SemCAMS’ sour gas processing plants, sulfur recovery and air quality are constantly monitored to ensure required sulfur recovery and emission standards are met. SemCAMS’ licensed sulfur recovery is 98.4% for the KA plant and 98.5% for the K3 plant. Residual sulfur that cannot be removed by processing is incinerated to meet a minimum stack top temperature based on a regulator approved dispersion model.

The facilities in Mexico are required to obtain an air emissions license at the initial start-up of facility operations and to annually report the stack emissions to the state environmental agency, assuring that such emissions comply with the National Official Standards.

Climate Change

In response to concerns suggesting that emissions of certain gases, commonly referred to as greenhouse gases (“GHGs”) (including carbon dioxide (“CO2”) and methane), are contributing to the warming of the earth’s atmosphere and other climatic changes, the U.S. Congress has been considering legislation to reduce such emissions. In addition, more than one-third of the states, either individually or through multi-state regional initiatives, have already begun implementing legal measures to reduce emissions of GHGs, primarily through the planned development of GHG emission inventories and/or GHG cap and trade programs. As an alternative to cap and trade programs, Congress may consider the implementation of a carbon tax program. The cap and trade programs could require major sources of emissions, such as electric power plants, or major producers of fuels, such as refineries or NGL fractionation plants, to acquire and surrender emission allowances. Depending on the particular program and scope thereof, we could be required to purchase and surrender allowances for GHG emissions resulting from our operations. Depending on the design and implementation of carbon tax programs, our operations could face additional taxes and higher cost of doing business. Although we would not be impacted to a greater degree than other similarly situated midstream energy service providers, a stringent GHG control program could have an adverse effect on our cost of doing business and could reduce demand for the petroleum products we gather, process, transport, store, distribute and market.