Exhibit 99.1

LD Micro Conference Investor Presentation June 9, 2016

3 Disclaimer / Forward - Looking Statements Ener - Core, Inc . (“ Ener - Core”) cautions that this presentation (including the oral commentary that accompanies it) may contain forward - looking statements that involve substantial risks and uncertainties . All statements, other than statements of historical facts, contained in this presentation, including statements regarding our future results of operations or financial condition, prospects, business strategy and plans and objectives of management for future operations, the success of our worldwide sales and marketing efforts, the extent of market acceptance for our products and services, our ability to develop and bring to market new or enhanced products and continuing uncertainty in the global economic environment, are forward - looking statements within the meaning of Section 27 A of the Securities Act of 1933 , as amended, and Section 21 E of the Securities Exchange Act of 1934 , as amended . The words “believe,” “will,” “may,” “estimate,” “continue,” “anticipate,” “intend,” “would,” “should,” “plan,” “expect,” “predict,” “could,” “potentially” or other similar expressions are intended to identify forward - looking statements, although not all forward - looking statements contain these identifying words . These statements involve known and unknown risks, uncertainties and other important factors, some of which cannot be predicted or quantified and some of which are beyond our control, that may cause our actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by the forward - looking statements, including those that are described in greater detail in Ener - Core’s annual Form 10 - K and quarterly Form 10 - Q reports filed with the U . S . Securities and Exchange Commission (“SEC ”) . Moreover, we operate in a dynamic industry and economy — new risk factors and uncertainties may emerge from time to time, and it is not possible for management to predict all risk factors and uncertainties that we may face . The forward - looking statements contained in this presentation speak only as of the date of this presentation and are based on information available to us at such date and/or management’s good faith belief as of such date with respect to future events . We assume no obligation to update forward - looking statements to reflect actual performance or results, changes in assumptions or changes in other factors affecting forward - looking information, except to the extent required by applicable securities laws . Accordingly, investors should not put undue reliance on any forward - looking statements . This presentation shall not constitute an offer to sell, or the solicitation of any offer to buy, our securities, nor will there be any sale of our securities in any state or other jurisdiction in which such offer, solicitation or sale would be unlawful prior to the registration or qualification under the securities laws of such state or jurisdiction .

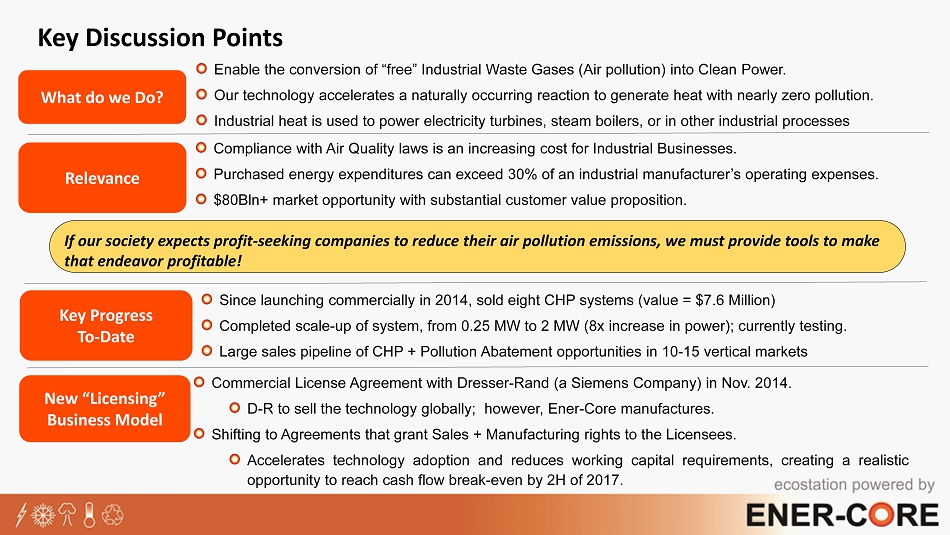

Key Discussion Points Key Progress To - Date What do we Do? Since launching commercially in 2014 , sold eight CHP systems (value = $ 7 . 6 Million) Completed scale - up of system, from 0 . 25 MW to 2 MW ( 8 x increase in power) ; currently testing . Large sales pipeline of CHP + Pollution Abatement opportunities in 10 - 15 vertical markets Enable the conversion of “free” Industrial Waste Gases (Air pollution) into Clean Power . Our technology accelerates a naturally occurring reaction to generate heat with nearly zero pollution . Industrial heat is used to power electricity turbines, steam boilers, or in other industrial processes Compliance with Air Quality laws is an increasing cost for Industrial Businesses . Purchased energy expenditures can exceed 30 % of an industrial manufacturer’s operating expenses . $ 80 Bln+ market opportunity with substantial customer value proposition . Relevance If our society expects profit - seeking companies to reduce their air pollution emissions, we must provide tools to make that endeavor profitable! New “Licensing” Business Model Commercial License Agreement with Dresser - Rand (a Siemens Company) in Nov . 2014 . D - R to sell the technology globally ; however, Ener - Core manufactures . Shifting to Agreements that grant Sales + Manufacturing rights to the Licensees . Accelerates technology adoption and reduces working capital requirements, creating a realistic opportunity to reach cash flow break - even by 2 H of 2017 .

At the turn of the 19 th century, John D . Rockefeller was in the kerosene refinery business . A ll kerosene refiners used to throw away barrels of a “noxious by - product” into the creeks and rivers ; this toxic runoff made Ohio’s Cuyahoga River flammable . It was said that if a steamboat threw away hot coals overboard, the water would catch fire . Rockefeller, on the other hand, worked with his engineers to find uses for this toxic byproduct to fuel part of their refining process, ultimately making his refineries more financially efficient. Utilizing Waste: The Rockefeller Effect Today, this noxious by - product is known as gasoline .

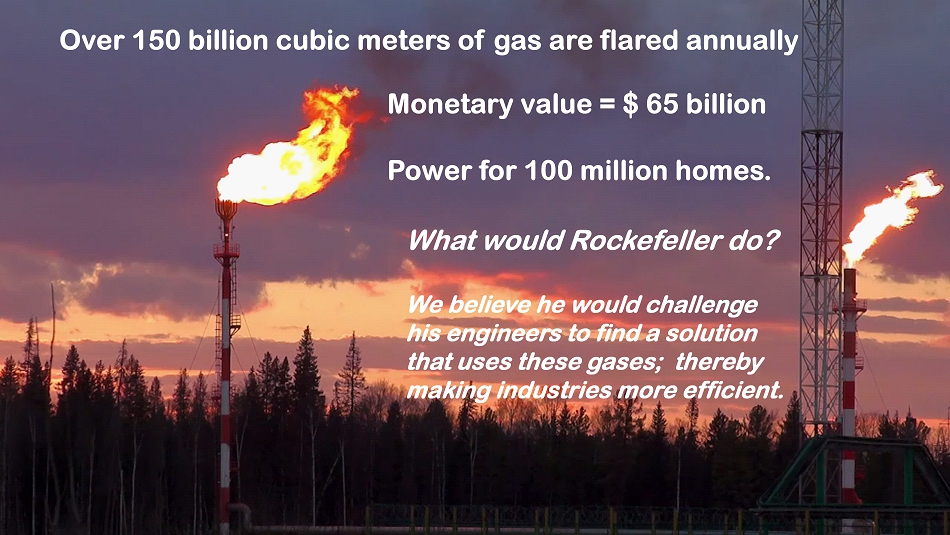

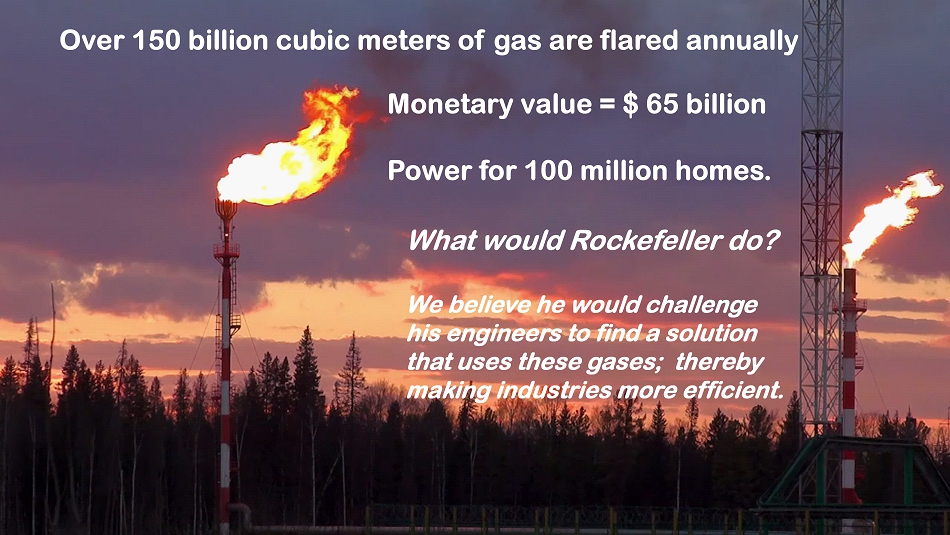

Over 150 billion cubic meters of gas are flared annually Monetary value = $ 65 billion Power for 100 million homes. What would Rockefeller do? We believe he would challenge his engineers to find a solution that uses these gases; thereby making industries more efficient.

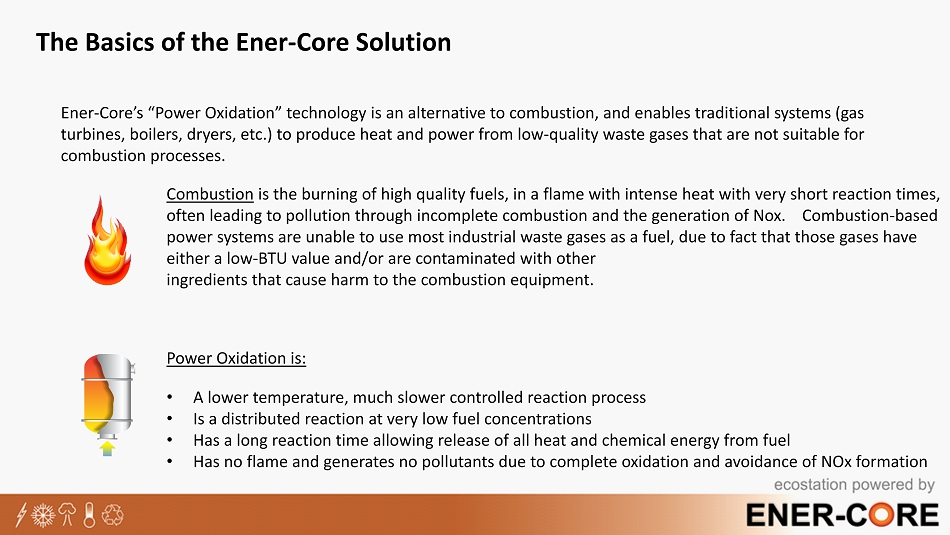

The Basics of the Ener - Core Solution Combustion is the burning of high quality fuels, in a flame with intense heat with very short reaction times, often leading to pollution through incomplete combustion and the generation of Nox . Combustion - based power systems are unable to use most industrial waste gases as a fuel, due to fact that those gases have either a low - BTU value and/or are contaminated with other ingredients that cause harm to the combustion equipment. Power Oxidation is: • A lower temperature, much slower controlled reaction process • Is a distributed reaction at very low fuel concentrations • Has a long reaction time allowing release of all heat and chemical energy from fuel • Has no flame and generates no pollutants due to complete oxidation and avoidance of NOx formation Ener - Core’s “Power Oxidation” technology is an alternative to combustion, and enables traditional systems (gas turbines, boilers, dryers, etc.) to produce heat and power from low - quality waste gases that are not suitable for combustion processes.

Ambient air + waste gases are introduced to vessel Heat generated is: Sent to a turbine to generate electricity; or Sent to a boiler to generate steam The oxidizer vessel creates the environment necessary to facilitate an exothermic oxidation reaction, without ignition (no flame) 1. Waste gases are compressed, heated, and mixed 2. At controlled high temperatures, the molecules have enough energy to react without a flame (combustion) 3. During a “long” residence time ( 0 . 50 - 1 . 25 seconds), gas molecules “collide” with an oxygen molecule and the oxidation reaction occurs 4. Energy is released from the oxidation reaction, heating the gas in the chamber 5. Excess heat is carried out of the oxidation chamber with the gas that is then used to generate power Power Oxidation: how it works

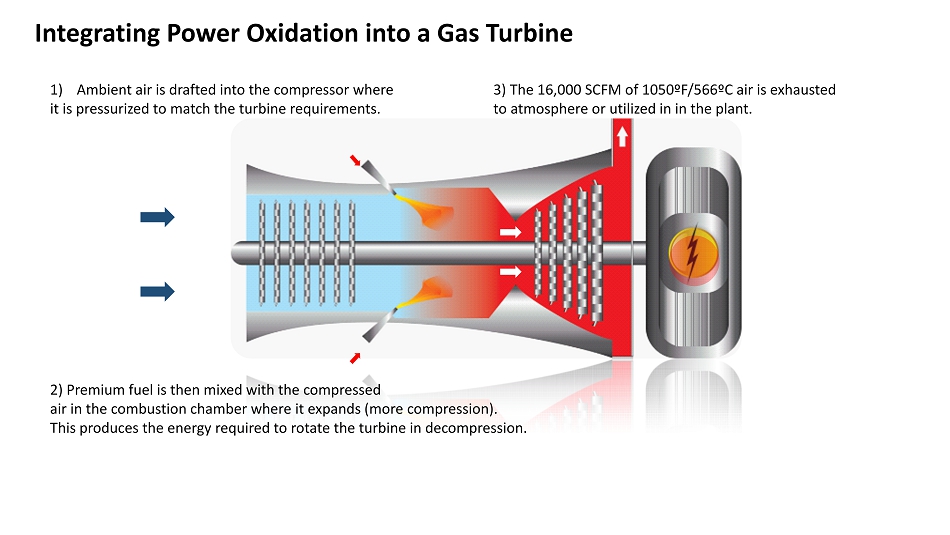

What makes the Ener - Core ecostation different from a standard turbine? It starts with understanding the gas turbine basics Integrating Power Oxidation into a Gas Turbine

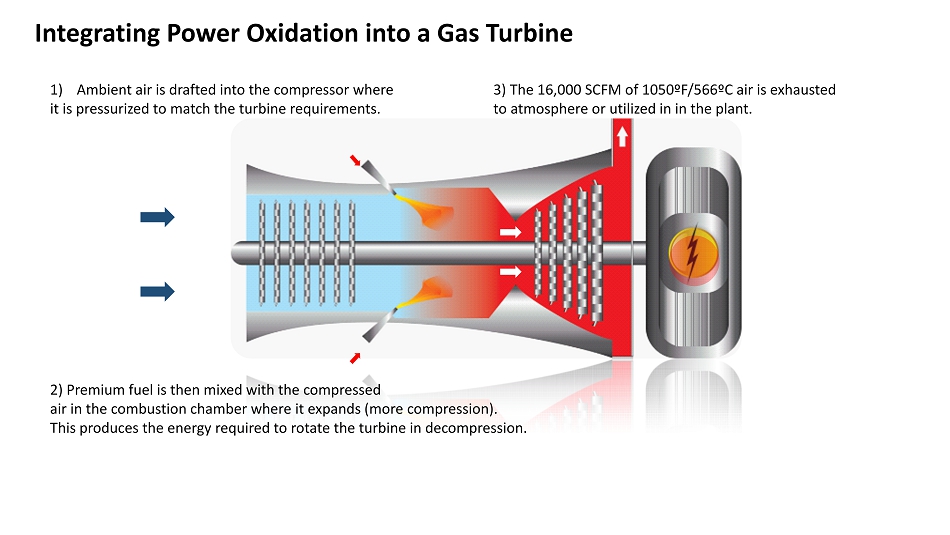

1) Ambient air is drafted into the compressor where it is pressurized to match the turbine requirements . 2) Premium fuel is then mixed with the compressed air in the combustion chamber where it expands (more compression). This produces the energy required to rotate the turbine in decompression. 3) The 16,000 SCFM of 1050ºF/566ºC air is exhausted to atmosphere or utilized in in the plant. Integrating Power Oxidation into a Gas Turbine

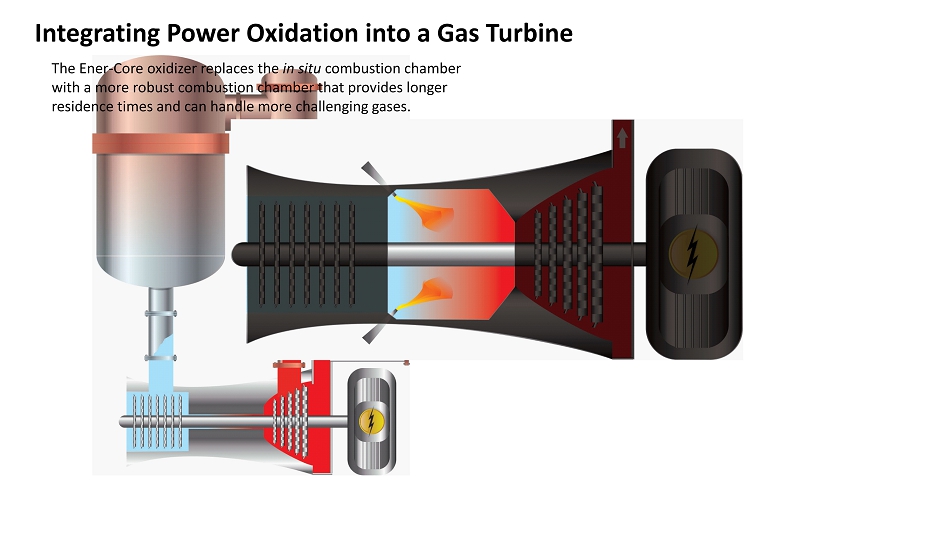

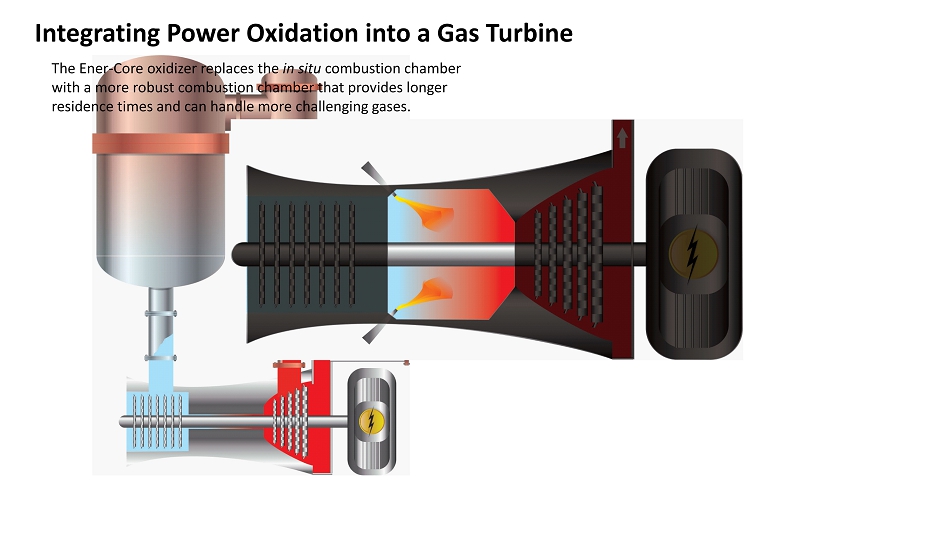

The in situ combustion chamber is effectively what prevents a gas turbine (or other power equipments ) from being able to operate on low - quality waste gases. Combustion Chamber Air Intake Turbine Integrating Power Oxidation into a Gas Turbine

The Ener - Core oxidizer replaces the in situ combustion chamber with a more robust combustion chamber that provides longer residence times and can handle more challenging gases. Integrating Power Oxidation into a Gas Turbine

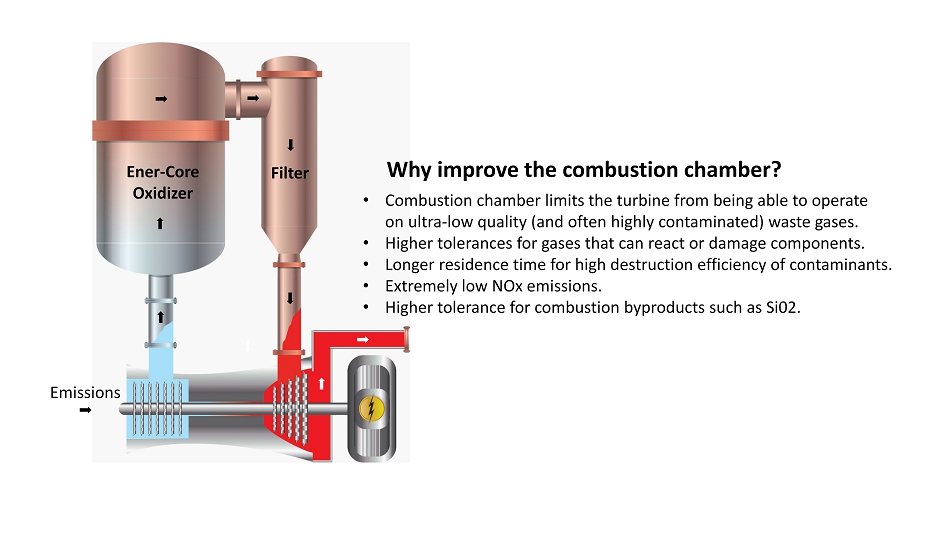

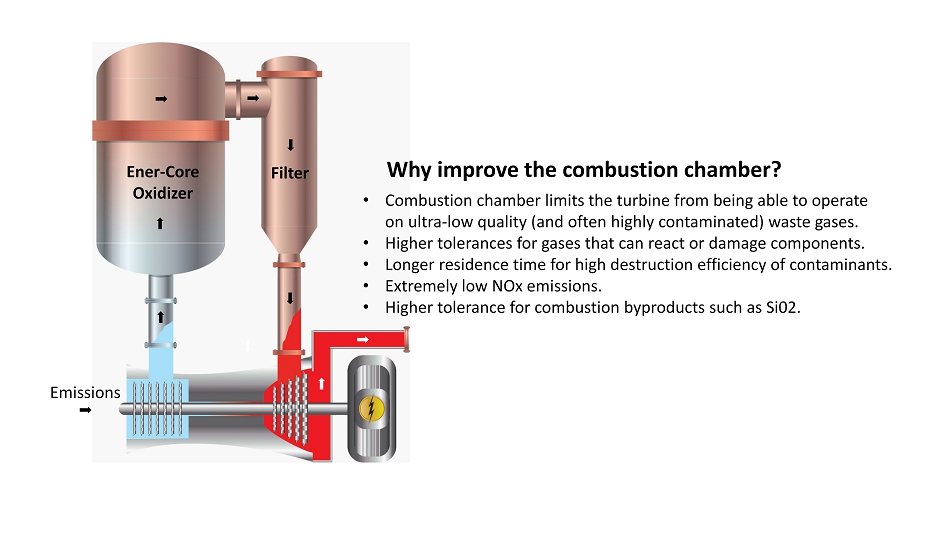

Ener - Core Oxidizer Emissions Filter • Combustion chamber limits the turbine from being able to operate on ultra - low quality (and often highly contaminated) waste gases. • Higher tolerances for gases that can react or damage components. • Longer residence time for high destruction efficiency of contaminants. • Extremely low NOx emissions. • Higher tolerance for combustion byproducts such as Si02. Why improve the combustion chamber?

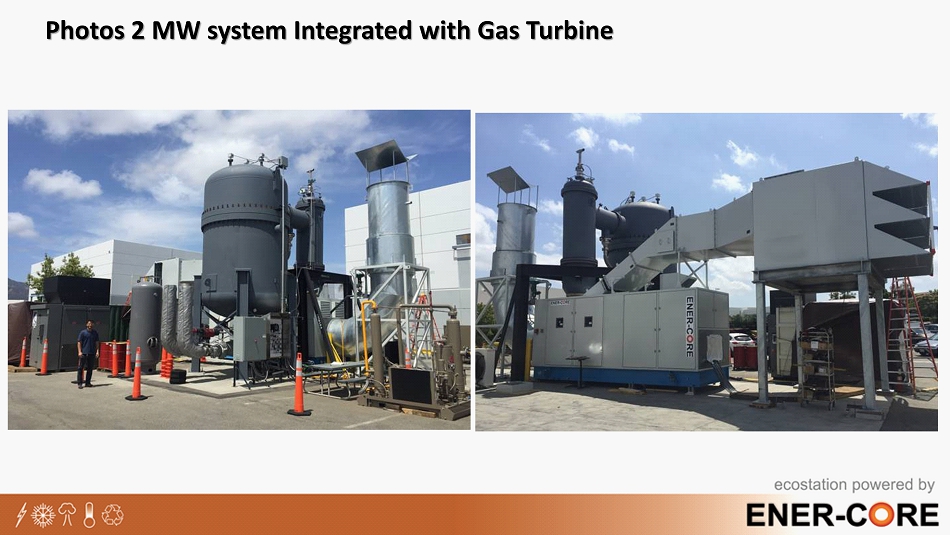

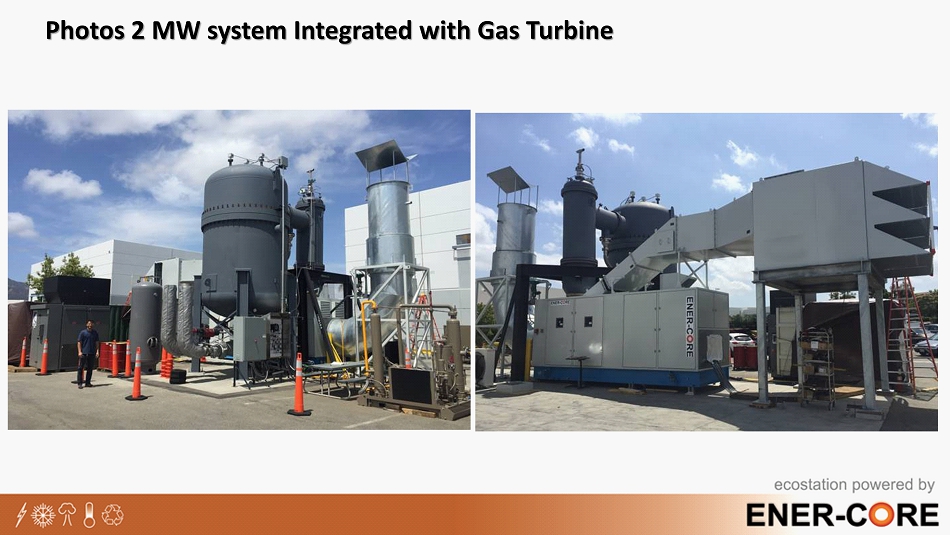

Photos 2 MW system Integrated with Gas Turbine

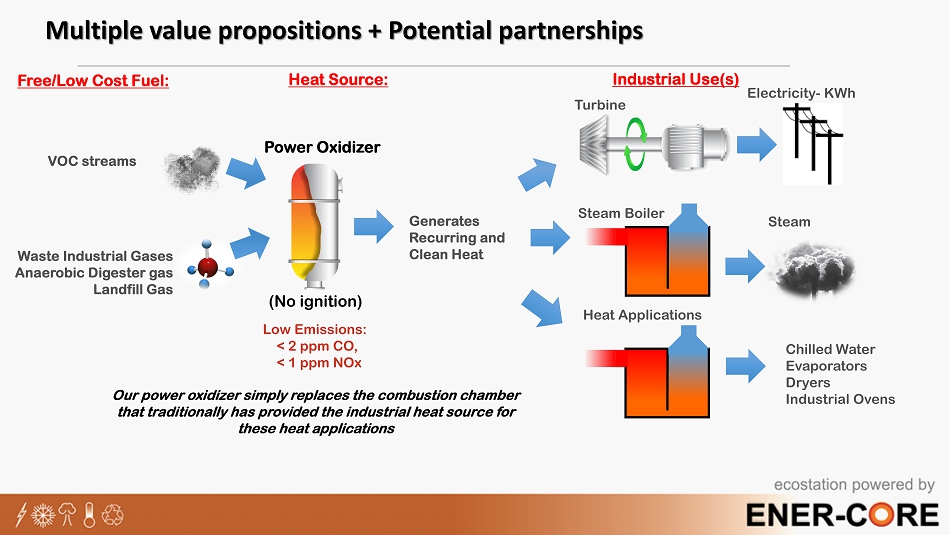

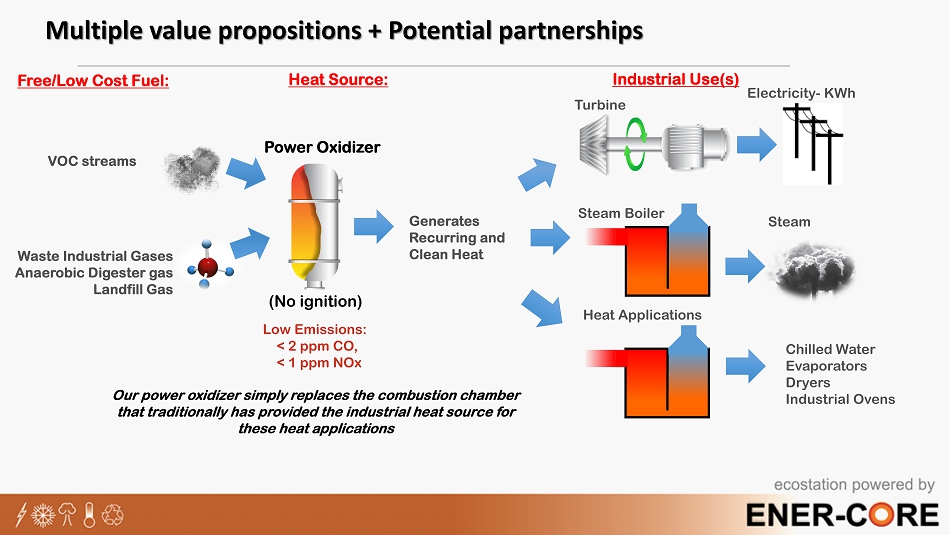

Multiple value propositions + Potential partnerships Power Oxidizer Generates Recurring and Clean Heat (No ignition) Waste Industrial Gases Anaerobic Digester gas Landfill Gas VOC streams Low Emissions: < 2 ppm CO, < 1 ppm NOx Turbine Steam Boiler Steam Electricity - KWh Heat Applications Chilled Water Evaporators Dryers Industrial Ovens Our power oxidizer simply replaces the combustion chamber that traditionally has provided the industrial heat source for these heat applications Free/Low Cost Fuel: Heat Source: Industrial Use(s)

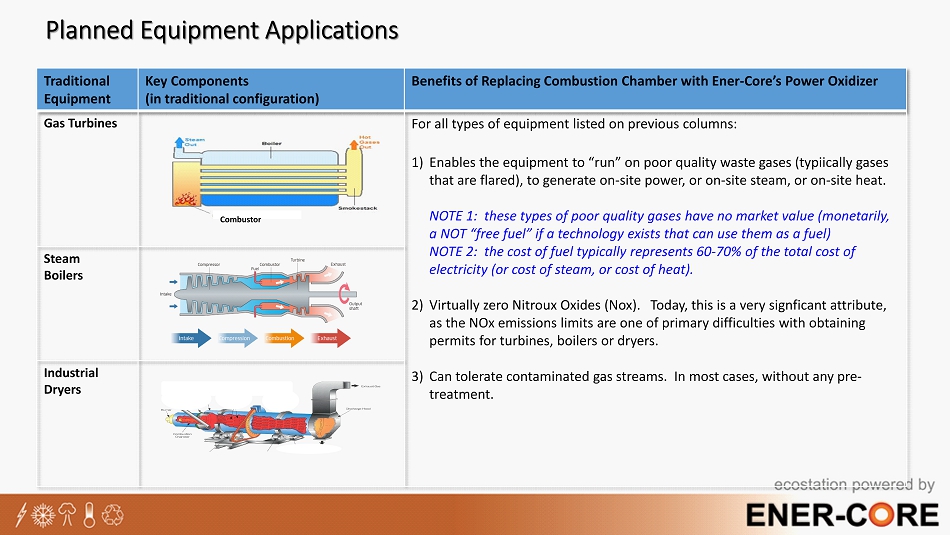

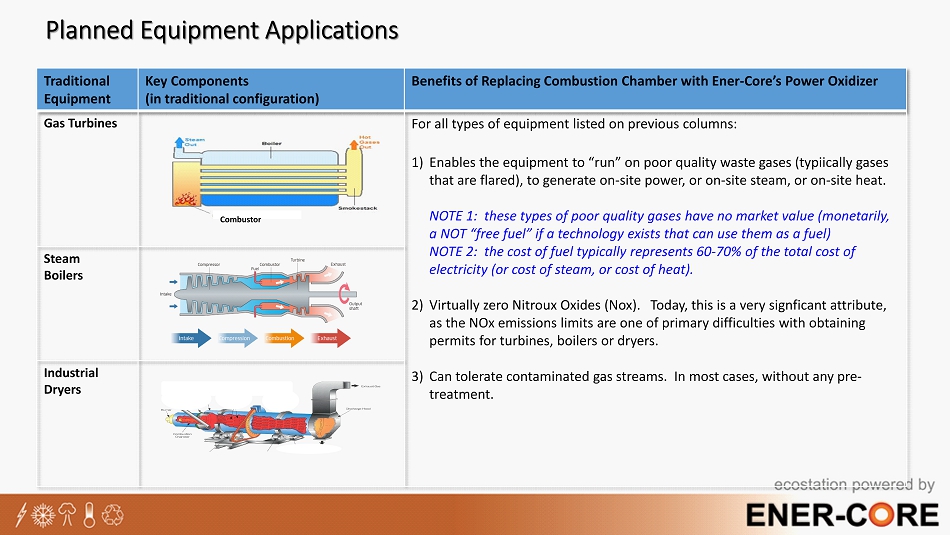

Traditional Equipment Key Components (in traditional configuration) Benefits of Replacing Combustion Chamber with Ener - Core’s Power Oxidizer Gas Turbines For all types of equipment listed on previous columns: 1) Enables the equipment to “run” on poor quality waste gases ( typiically gases that are flared), to generate on - site power, or on - site steam, or on - site heat. NOTE 1: these types of poor quality gases have no market value (monetarily, a NOT “free fuel” if a technology exists that can use them as a fuel) NOTE 2: the cost of fuel typically represents 60 - 70% of the total cost of electricity (or cost of steam, or cost of heat). 2) Virtually zero Nitroux Oxides ( Nox ). Today, this is a very signficant attribute, as the NOx emissions limits are one of primary difficulties with obtaining permits for turbines, boilers or dryers. 3) Can tolerate contaminated gas streams. In most cases, without any pre - treatment. Steam Boilers Industrial Dryers Combustor Planned Equipment Applications

Rendering and Animal Processing Byproducts (>600 U.S. facilities) Coal Mines (>1,000 U.S. mines) Aerospace and Defense; Semiconductor and Electronics Manufacturing (>2,200 U.S. facilities) Ethanol Plants / Distilleries (>500 U.S. facilities) Oil & Gas (>600 U.S. facilities) Targeted Industries and Market Opportunity Worldwide, we see a total market opportunity of between $ 80 - 100 Billion with a US based opportunity in excess of $ 10 billion in approximately 15 vertical markets . Market approach : We filter our vertical market opportunities to identify those industries and locations that are best suited for our value proposition : • Identify geographic locations with a high prevailing electricity rate ( $ 0 . 08 /KWh+) • Identify industries that generate sufficient waste gases with pollution abatement costs • Identify industries that can utilize residual heat for ovens, drying, chilling, etc . In addition to the industries shown to the right, we also see significant opportunities in closed landfill sites and wastewater treatment facilities due to recent regulatory changes .

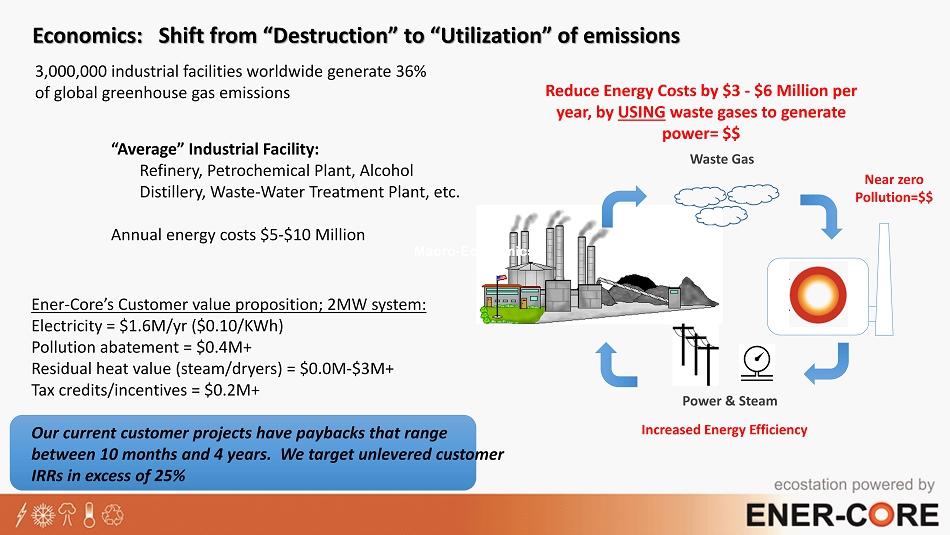

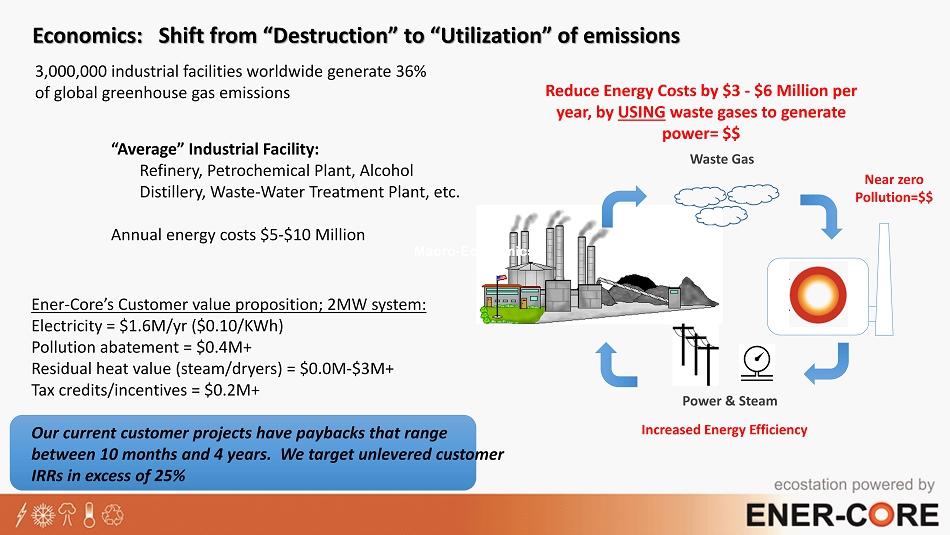

Jan 2015 “Average” Industrial Facility: Refinery, Petrochemical Plant, Alcohol Distillery, Waste - Water Treatment Plant, etc. Annual energy costs $5 - $10 Million Waste Gas Near zero Pollution=$$ Reduce Energy Costs by $3 - $6 Million per year, by USING waste gases to generate power= $$ Increased Energy Efficiency Power & Steam Macro - Economics Economics : Shift from “Destruction” to “Utilization” of emissions Ener - Core’s Customer value proposition; 2MW system: Electricity = $1.6M/ yr ($0.10/KWh) Pollution abatement = $0.4M+ Residual heat value (steam/dryers) = $0.0M - $3M+ Tax credits/incentives = $0.2M+ Our current customer projects have paybacks that range between 10 months and 4 years. We target unlevered customer IRRs in excess of 25% 3,000,000 industrial facilities worldwide generate 36% of global greenhouse gas emissions

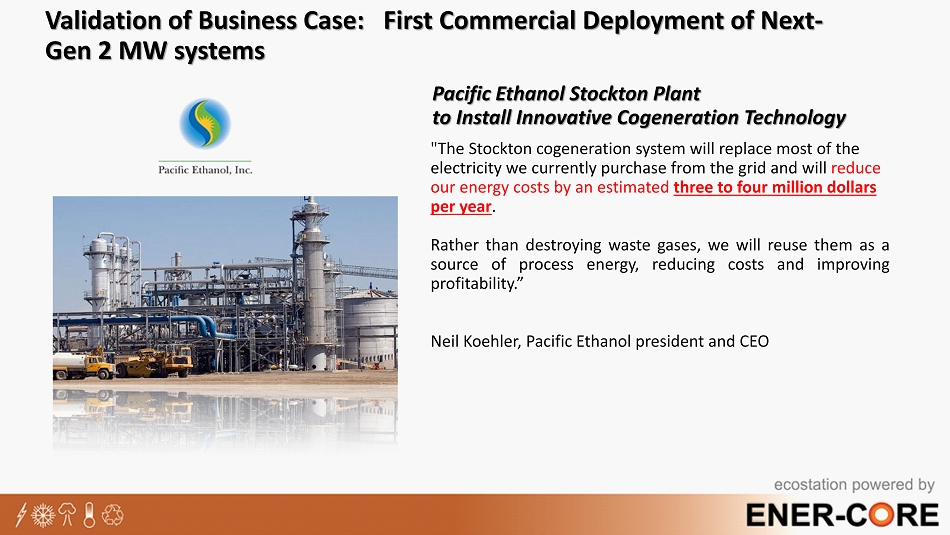

Pacific Ethanol Stockton Plant to Install Innovative Cogeneration Technology "The Stockton cogeneration system will replace most of the electricity we currently purchase from the grid and will reduce our energy costs by an estimated three to four million dollars per year . Rather than destroying waste gases, we will reuse them as a source of process energy, reducing costs and improving profitability . ” Neil Koehler, Pacific Ethanol president and CEO Validation of Business Case: First Commercial Deployment of Next - Gen 2 MW systems

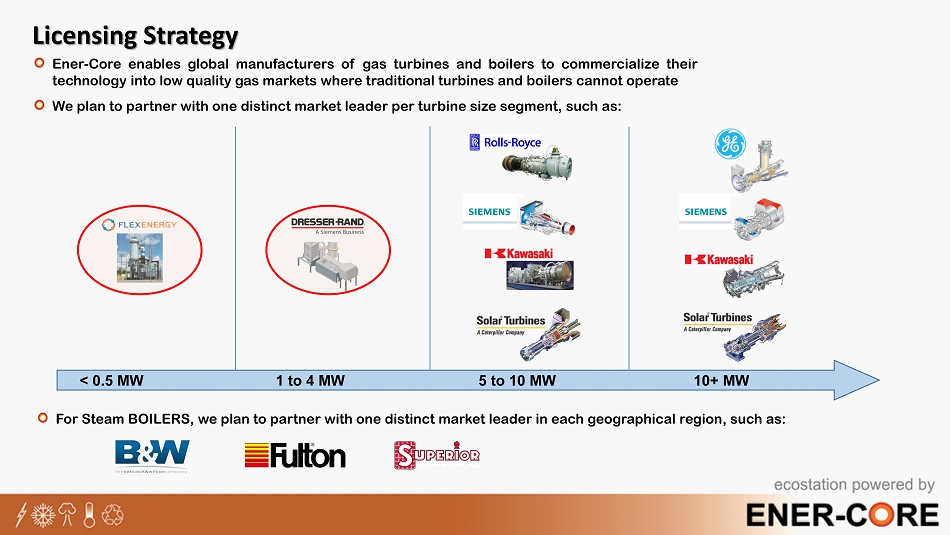

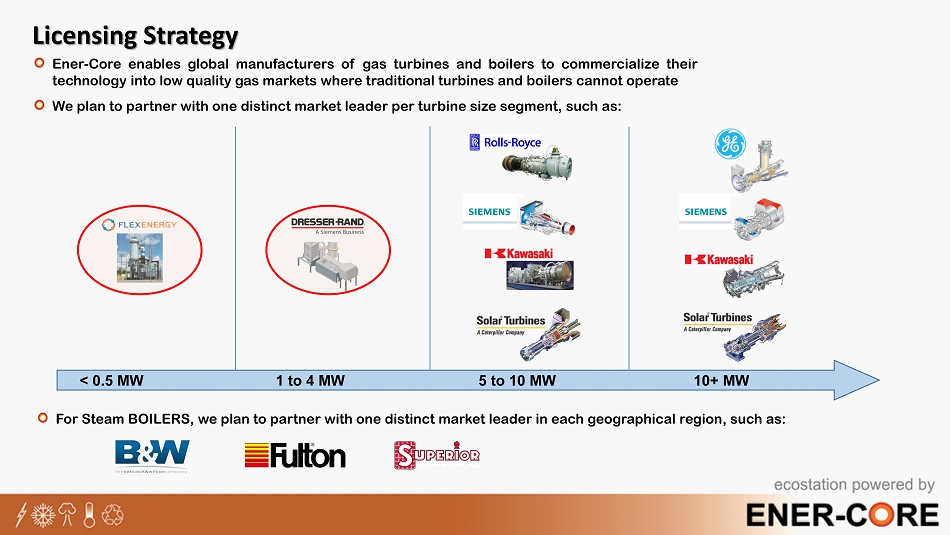

Licensing Strategy < 0.5 MW 1 to 4 MW 5 to 10 MW 10+ MW For Steam BOILERS, we plan to partner with one distinct market leader in each geographical region, such as : Ener - Core enables global manufacturers of gas turbines and boilers to commercialize their technology into low quality gas markets where traditional turbines and boilers cannot operate We plan to partner with one distinct market leader per turbine size segment, such as :

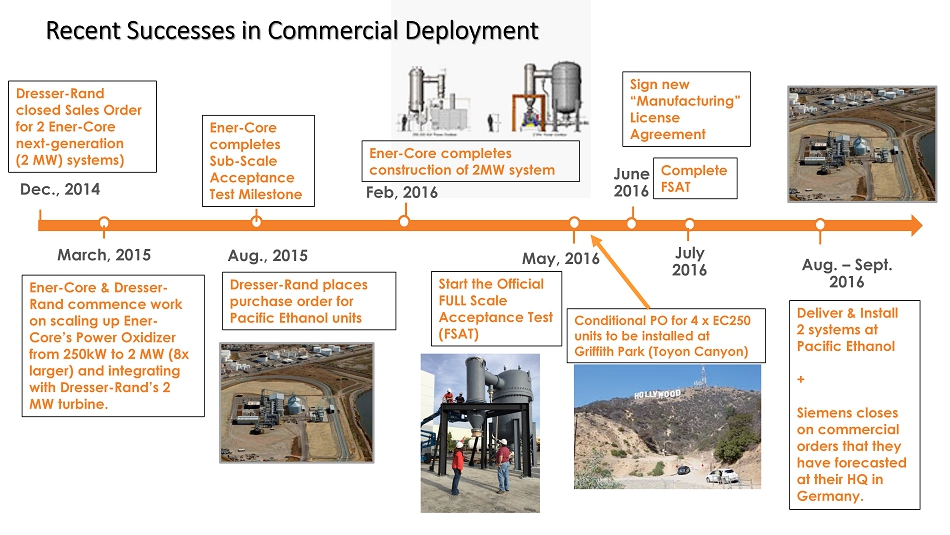

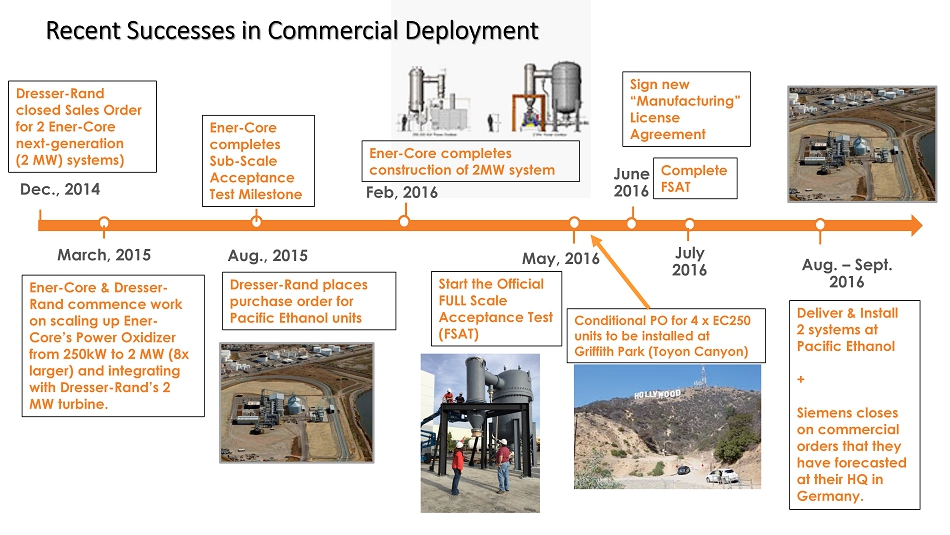

Recent Successes in Commercial Deployment May, 2016 June 2016 Dec., 2014 March, 2015 Dresser - Rand closed Sales Order for 2 Ener - Core next - generation (2 MW) systems) Ener - Core & Dresser - Rand commence work on scaling up Ener - Core’s Power Oxidizer from 250kW to 2 MW (8x larger) and integrating with Dresser - Rand’s 2 MW turbine. Feb, 2016 Ener - Core completes construction of 2MW system Start the Official FULL Scale Acceptance Test (FSAT) Complete FSAT Ener - Core completes Sub - Scale Acceptance Test Milestone Aug., 2015 July 2016 Aug. – Sept. 2016 Deliver & Install 2 systems at Pacific Ethanol + Siemens closes on commercial orders that they have forecasted at their HQ in Germany. Dresser - Rand places purchase order for Pacific Ethanol units Conditional PO for 4 x EC250 units to be installed at Griffith Park (Toyon Canyon) Sign new “Manufacturing” License Agreement

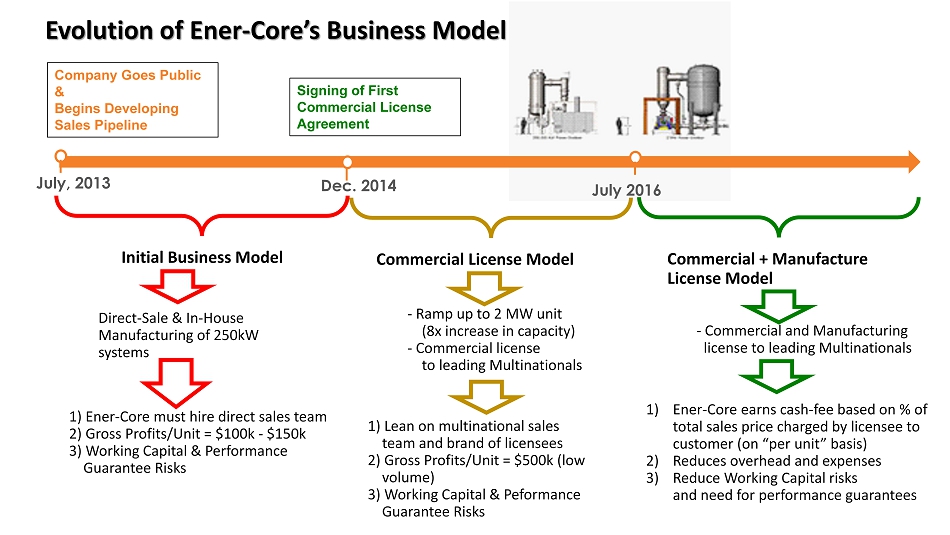

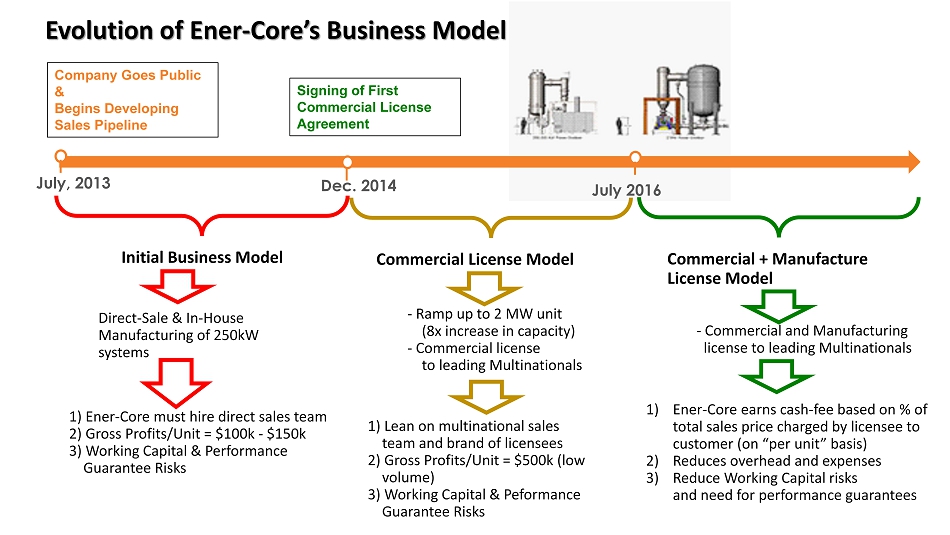

Evolution of Ener - Core’s Business Model July, 2013 Company Goes Public & Begins Developing Sales Pipeline Dec. 2014 July 2016 Initial Business Model Direct - Sale & In - House Manufacturing of 250kW systems 1) Ener - Core must hire direct sales team 2) Gross Profits/Unit = $100k - $150k 3) Working Capital & Performance Guarantee Risks Commercial License Model - Ramp up to 2 MW unit (8x increase in capacity) - Commercial license to leading Multinationals 1) Lean on multinational sales team and brand of licensees 2) Gross Profits/Unit = $500k (low volume) 3) Working Capital & Peformance Guarantee Risks Commercial + Manufacture License Model - Commercial and Manufacturing license to leading Multinationals 1) Ener - Core earns cash - fee based on % of total sales price charged by licensee to customer (on “per unit” basis) 2) Reduces overhead and expenses 3) Reduce Working Capital risks and need for performance guarantees Signing of First Commercial License Agreement

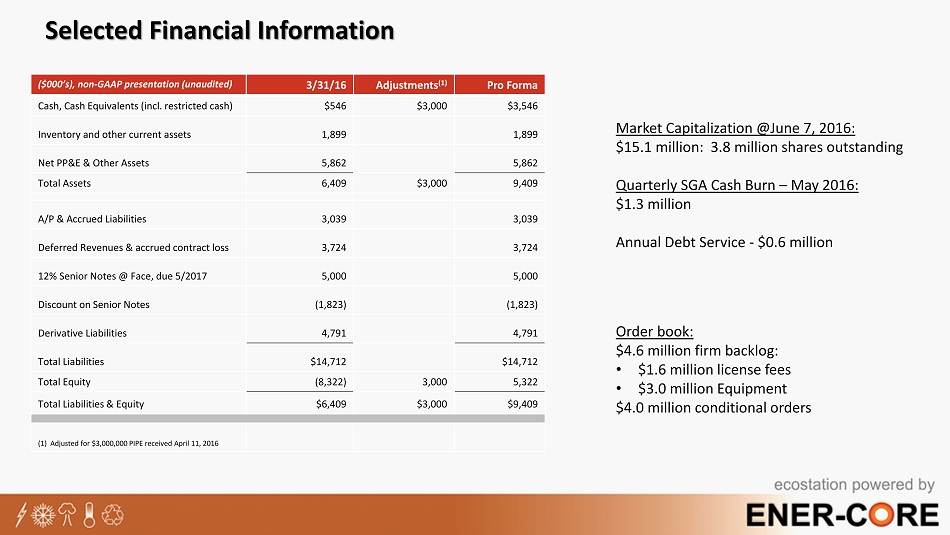

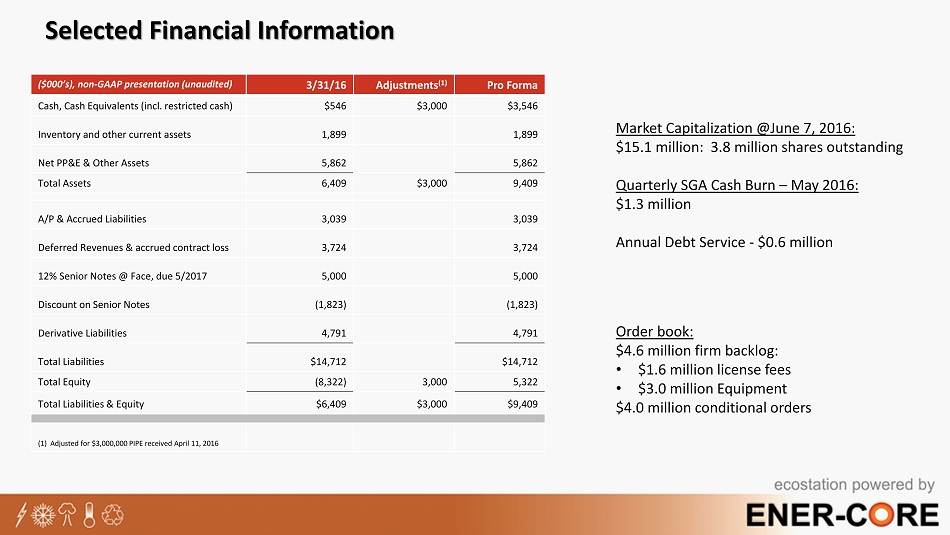

($000’s), non - GAAP presentation (unaudited) 3/31/16 Adjustments (1) Pro Forma Cash, Cash Equivalents (incl. restricted cash) $546 $3,000 $3,546 Inventory and other current assets 1,899 1,899 Net PP&E & Other Assets 5,862 5,862 Total Assets 6,409 $3,000 9,409 A/P & Accrued Liabilities 3,039 3,039 Deferred Revenues & accrued contract loss 3,724 3,724 12% Senior Notes @ Face, due 5/2017 5,000 5,000 Discount on Senior Notes (1,823) (1,823) Derivative Liabilities 4,791 4,791 Total Liabilities $14,712 $14,712 Total Equity (8,322) 3,000 5,322 Total Liabilities & Equity $6,409 $3,000 $9,409 (1) Adjusted for $3,000,000 PIPE received April 11, 2016 Order book: $4.6 million firm backlog: • $1.6 million license fees • $3.0 million Equipment $4.0 million conditional orders Market Capitalization @June 7, 2016: $15.1 million: 3.8 million shares outstanding Quarterly SGA Cash Burn – May 2016: $1.3 million Annual Debt Service - $0.6 million Selected Financial Information

Intellectual Property and Industry Awards Ener - Core owns the exclusive rights to protect the design and utilization of Power Oxidation 69 patent applications filed worldwide 39 patents granted worldwide, all awarded in last 2 years More than 150 total independent claims and 1 , 000 dependent claims Other key components are protected as trade secrets Jan . 2015 – Inc . Magazine features Ener - Core as one of “Three of the Hottest CleanTech Companies on the Planet” Jan . 2015 – Ener - Core wins the 2014 New Economy Award for Best Air and Environment Solutions – Award announced at the World Economic Forum in Davos, Switzerland – Cited as a “Ground Breaking” solution for the world’s methane pollution problem June 2015 – Ener - Core wins best paper at POWER - GEN Europe in Renewable Energy Strategy, Business & Integration

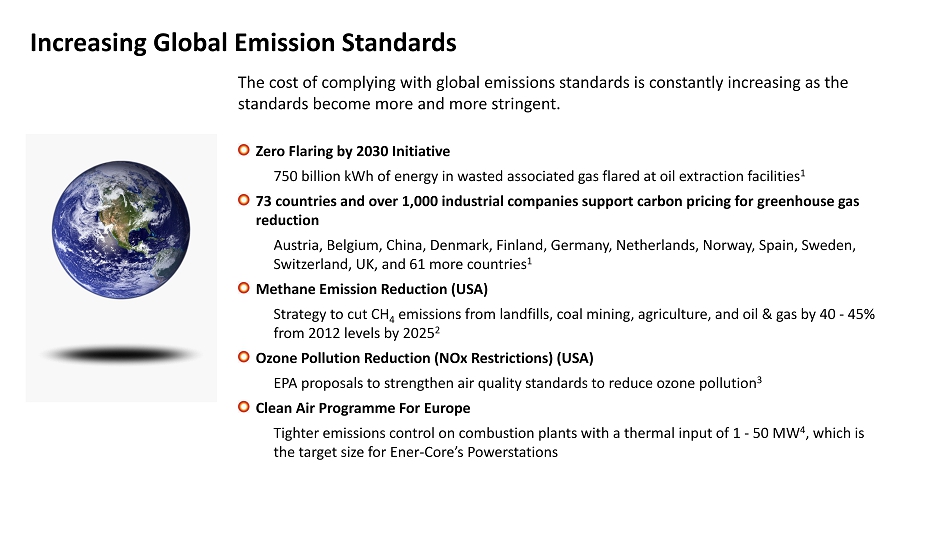

The cost of complying with global emissions standards is constantly increasing as the standards become more and more stringent. Zero Flaring by 2030 Initiative 750 billion kWh of energy in wasted associated gas flared at oil extraction facilities 1 73 countries and over 1,000 industrial companies support carbon pricing for greenhouse gas reduction Austria, Belgium, China, Denmark, Finland, Germany, Netherlands, Norway, Spain, Sweden, Switzerland, UK, and 61 more countries 1 Methane Emission Reduction (USA) Strategy to cut CH 4 emissions from landfills, coal mining, agriculture, and oil & gas by 40 - 45% from 2012 levels by 2025 2 Ozone Pollution Reduction (NOx Restrictions) (USA) EPA proposals to strengthen air quality standards to reduce ozone pollution 3 Clean Air Programme For Europe Tighter emissions control on combustion plants with a thermal input of 1 - 50 MW 4 , which is the target size for Ener - Core’s Powerstations Increasing Global Emission Standards

The Ener - Core Team

Key Management Alain Castro, Chief Executive Officer and Board Member • 23 years experience in energy sector . • Previously, President of Akuo Energy Americas, which has developed and financed approx . € 1 Billion in renewable energy infrastructure projects . • Previously Partner at Ernst & Young Consulting, responsible for the oil & gas consulting practice in 5 countries . • London Business School : Sloan Fellowship, Executive Masters Degree, Business and Management ; University of Texas, B . S . , Industrial and Mechanical Engineering . Dr . Boris Maslov, President and Chief Technology Officer • Experienced energy technology company executive . Served as CEO of EnergyOne, CEO of Ecron Corp, EO of GlobalGate, as well as CTO of WaveCrest Labs . • VP of Corporate Development at FlexEnergy where he led Strategic Planning and Technology Development . • Moscow Institute of Physics and Technology : Ph . D . , Electrical Engineering ; B . S . , M . S . , Electrical Engineering and Computer Science . Domonic J . Carney, Chief Financial Officer • Over 24 years of experience in high - growth environments including over eight years as the CFO for NYSE MKT and Nasdaq OTC public companies . • Previous CFO of DeWind, a wind turbine manufacturing company . • Dartmouth : Bachelors degrees in Economics ; Northeastern University : Masters in Accounting . Douglas A . Hamrin, Vice President - Engineering • Leads technical development of the Power Oxidizer . • 17 patents filed on Ener - Core technology over recent 4 years . • Previously Technical Manager, Applications for Honeywell Turbo Technologies and Director of Fuel Systems at Capstone Turbine Corporation . • Massachusetts Institute of Technology : M . S . , Mechanical Engineering ; Illinois Institute of Technology : B . S . , Mechanical Engineering . Mark Owen, Director of Sales • 30 years of experience in the commercialization, installation and operational servicing of various types of air pollution control & waste treatment systems . • Previously senior project manager for several high profile environmental projects across many manufacturing sectors including aerospace, pharmaceuticals, and oil & gas . • Recent projects include NGL processing, landfill leachate processing, and rail to barge crude oil transfer stations .

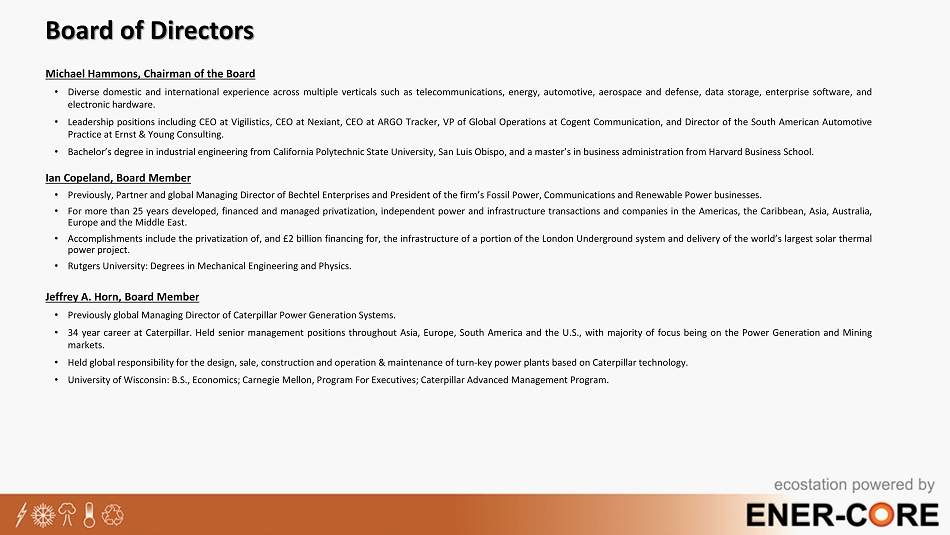

Board of Directors Michael Hammons, Chairman of the Board • Diverse domestic and international experience across multiple verticals such as telecommunications, energy, automotive, aerospace and defense, data storage, enterprise software, and electronic hardware . • Leadership positions including CEO at Vigilistics, CEO at Nexiant, CEO at ARGO Tracker, VP of Global Operations at Cogent Communication, and Director of the South American Automotive Practice at Ernst & Young Consulting . • Bachelor’s degree in industrial engineering from California Polytechnic State University, San Luis Obispo, and a master’s in business administration from Harvard Business School . Ian Copeland, Board Member • Previously, Partner and global Managing Director of Bechtel Enterprises and President of the firm’s Fossil Power, Communications and Renewable Power businesses . • For more than 25 years developed, financed and managed privatization, independent power and infrastructure transactions and companies in the Americas, the Caribbean, Asia, Australia, Europe and the Middle East . • Accomplishments include the privatization of, and £ 2 billion financing for, the infrastructure of a portion of the London Underground system and delivery of the world’s largest solar thermal power project . • Rutgers University : Degrees in Mechanical Engineering and Physics . Jeffrey A . Horn, Board Member • Previously global Managing Director of Caterpillar Power Generation Systems . • 34 year career at Caterpillar . Held senior management positions throughout Asia, Europe, South America and the U . S . , with majority of focus being on the Power Generation and Mining markets . • Held global responsibility for the design, sale, construction and operation & maintenance of turn - key power plants based on Caterpillar technology . • University of Wisconsin : B . S . , Economics ; Carnegie Mellon, Program For Executives ; Caterpillar Advanced Management Program .

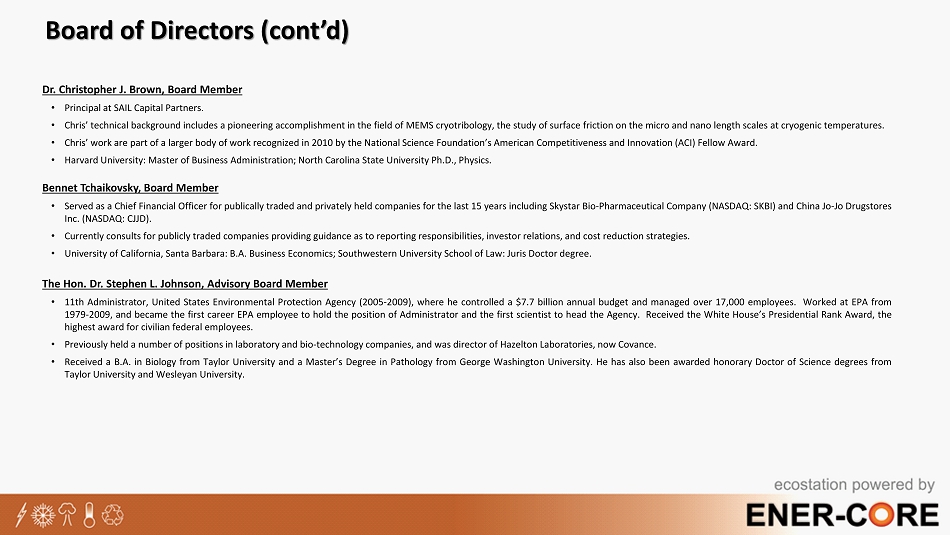

Board of Directors (cont’d) Dr . Christopher J . Brown, Board Member • Principal at SAIL Capital Partners . • Chris’ technical background includes a pioneering accomplishment in the field of MEMS cryotribology , the study of surface friction on the micro and nano length scales at cryogenic temperatures . • Chris’ work are part of a larger body of work recognized in 2010 by the National Science Foundation’s American Competitiveness and Innovation (ACI) Fellow Award . • Harvard University : Master of Business Administration ; North Carolina State University Ph . D . , Physics . Bennet Tchaikovsky, Board Member • Served as a Chief Financial Officer for publically traded and privately held companies for the last 15 years including Skystar Bio - Pharmaceutical Company (NASDAQ : SKBI) and China Jo - Jo Drugstores Inc . (NASDAQ : CJJD) . • Currently consults for publicly traded companies providing guidance as to reporting responsibilities, investor relations, and cost reduction strategies . • University of California, Santa Barbara : B . A . Business Economics ; Southwestern University School of Law : Juris Doctor degree . The Hon . Dr . Stephen L . Johnson, Advisory Board Member • 11 th Administrator, United States Environmental Protection Agency ( 2005 - 2009 ), where he controlled a $ 7 . 7 billion annual budget and managed over 17 , 000 employees . Worked at EPA from 1979 - 2009 , and became the first career EPA employee to hold the position of Administrator and the first scientist to head the Agency . Received the White House’s Presidential Rank Award, the highest award for civilian federal employees . • Previously held a number of positions in laboratory and bio - technology companies, and was director of Hazelton Laboratories, now Covance . • Received a B . A . in Biology from Taylor University and a Master’s Degree in Pathology from George Washington University . He has also been awarded honorary Doctor of Science degrees from Taylor University and Wesleyan University .

THANK YOU Ener - Core.com Closing Remark

”As the world continues to take greenhouse gas emissions more seriously, most companies seem to be focused on destroying or sequestering the industrial emissions . We believe that industrial emissions are not really the problem, but are actually the symptom of the underlying problem . The underlying problem is industrial inefficiency . If we can enable industries to productively utilize (and financial benefit from) their industrial emissions, they reduce their costs, and they become more operationally and financially efficient . And, by addressing this real underlying problem, the challenge of reducing industrial emissions occurs quite naturally . ” - Alain Castro, Chief Executive Officer, Ener - Core