UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

FORM 10-K

(Mark One) |

| | |

| | x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2015

Or |

| | |

| | ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Transition Period from ______ to _______.

Commission file number 001-36443

K2M GROUP HOLDINGS, INC.

(Exact name of Registrant as specified in its charter) |

| | |

| Delaware | | 27-2977810 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

| 751 Miller Drive SE, Leesburg, Virginia | | 20175 |

| (Address of principal executive offices) | | (Zip Code) |

(703) 777-3155

Registrant’s telephone number, including area code:

Securities registered pursuant to Section 12(b) of the Act: |

| | |

| Title of each class | | Name of each exchange on which registered |

| Common Stock, $0.001 par value per share | | The NASDAQ Global Select Market |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act of 1933, as amended. Yes o No ý

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes o No ý

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ý No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

|

| | | | | | | | | | | |

| Large accelerated filer | ¨ | | | Accelerated filer | x | | Non-accelerated filer | o | | Smaller reporting company | o |

| | | | | | (Do not check if a smaller reporting company) | |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No ý

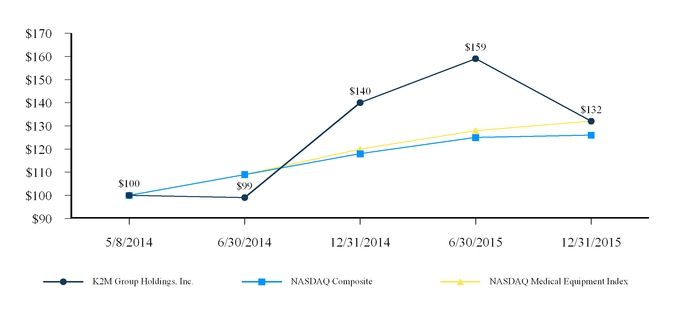

The aggregate market value of the voting and non-voting common equity held by non-affiliates on June 30, 2015, the last business day of the Registrant’s most recently completed second fiscal quarter (based on the closing sale price of $24.02 of the Registrant’s common stock, as reported by the NASDAQ Stock Exchange on such date) was approximately $468 million.

The number of shares the Registrant's common stock outstanding on February 26, 2016 was 41,337,692.

DOCUMENTS INCORPORATED BY REFERENCE

Information included in our definitive proxy statement for our 2016 annual meeting of stockholders scheduled to be held on June 14, 2016 is incorporated by reference in Items 10, 11, 12, 13 and 14 of Part III of this report.

K2M GROUP HOLDINGS, INC.

FORM 10-K

FOR THE PERIOD ENDED DECEMBER 31, 2015

TABLE OF CONTENTS

|

| | | |

| PART I | |

| ITEM 1. | | | |

| ITEM 1A. | | | |

| ITEM 1B. | | | |

| ITEM 2. | | | |

| ITEM 3. | | | |

| ITEM 4. | | | |

| | | | |

| PART II | |

| ITEM 5. | | | |

| ITEM 6. | | | |

| ITEM 7. | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| ITEM 7A. | | | |

| ITEM 8. | | | |

| ITEM 9. | | | |

| ITEM 9A. | | | |

| ITEM 9B. | | | |

| | | | |

| PART III |

| ITEM 10. | | | |

| ITEM 11. | | | |

| ITEM 12. | | | |

| ITEM 13. | | | |

| ITEM 14. | | | |

| | |

| PART IV |

| ITEM 15. | | | |

| | | |

| |

| | |

PART 1

In this Annual Report on Form 10-K, unless the context otherwise requires, references to “K2M Group Holdings, Inc.” “KTWO,” “we,” “our,” “us” and the “Company” refer to K2M Group Holdings, Inc. together with its subsidiaries.

FORWARD-LOOKING STATEMENTS

This filing contains “forward-looking statements” within the meaning of Section 27A of the Securities Act and Section 21E of the Securities Exchange Act of 1934, as amended, or the Exchange Act, that reflect our current views with respect to, among other things, our operations and financial performance. Forward-looking statements include all statements that are not historical facts. In some cases, you can identify these forward-looking statements by the use of words such as “outlook,” “believes,” “expects,” “potential,” “continues,” “may,” “will,” “should,” “could,” “seeks,” “predicts,” “intends,” “plans,” “estimates,” “anticipates” or the negative version of these words or other comparable words. Such forward-looking statements are subject to various risks and uncertainties. Accordingly, there are or will be important factors that could cause actual outcomes or results to differ materially from those indicated in these statements. We believe these factors include but are not limited to those described under Item 1A - Risk Factors and the following risks, uncertainties and factors:

| |

| • | our inability to achieve or sustain profitability in the future |

• our inability to demonstrate to spine surgeons the merits of our products;

| |

| • | our inability to compete effectively; |

| |

| • | collaboration and consolidation in hospital purchasing; |

| |

| • | inadequate coverage and reimbursement for our products from third-party payors; |

| |

| • | lack of long-term clinical data supporting safety and efficacy of our products; |

| |

| • | dependence on a limited number of third-party suppliers; |

| |

| • | our inability to maintain and expand our sales organization; |

| |

| • | proliferation of physician-owned distributorships (“PODs”) in the industry; |

| |

| • | decline in the sale of certain key products; |

| |

| • | our inability to enhance new product offerings through research and development; |

| |

| • | our inability to manage expected growth; |

| |

| • | costs associated with high levels of inventory; |

| |

| • | impairment of our goodwill and intangible assets; |

| |

| • | disruptions in our main facility or information technology systems; |

| |

| • | inability to strengthen our brand; |

| |

| • | fluctuations in insurance cost and availability; |

| |

| • | our inability to prepare, transition to and occupy our new corporate headquarters and operations facilities; |

| |

| • | our inability to comply with extensive governmental regulation; |

| |

| • | our inability to maintain or obtain regulatory approvals and clearances; |

| |

| • | recalls or serious safety issues with our products; |

| |

| • | enforcement actions by regulatory agencies for improper marketing or promotion; |

| |

| • | misuse or off-label use of our products; |

| |

| • | delays or failures in clinical trials and results of clinical trials; |

| |

| • | legal restrictions on our procurement, use, processing, manufacturing or distribution of allograft bone tissue; |

| |

| • | negative publicity concerning methods of tissue recovery and screening of donor tissue; |

| |

| • | costs and liabilities relating to environmental laws and regulations; |

| |

| • | our failure or the failure of our agents to comply with fraud and abuse laws; |

| |

| • | U.S. legislative or Food and Drug Administration (“FDA”) regulatory reforms; |

| |

| • | adverse effects of medical device tax provisions; |

| |

| • | our inability to generate significant sales; |

| |

| • | uncertainty in future capital needs; |

| |

| • | availability of borrowings under our credit facility; |

| |

| • | inability to protect our intellectual property rights; |

| |

| • | patent litigation and product liability lawsuits; |

| |

| • | damages relating to trade secrets or non-competition or non-solicitation agreements; |

| |

| • | risks associated with operating internationally; |

| |

| • | fluctuations in foreign currency exchange rates; and |

| |

| • | inability to comply with the Federal Corrupt Practices Act (“FCPA”) and similar laws. |

These factors should not be construed as exhaustive and should be read in conjunction with the other cautionary statements that are included in this filing.

We operate in a very competitive and challenging environment. New risks and uncertainties emerge from time to time, and it is not possible for us to predict all risks and uncertainties that could have an impact on the forward-looking statements contained in this Form 10-K. We cannot assure you that the results, events and circumstances reflected in the forward-looking statements will be achieved or occur, and actual results, events or circumstances could differ materially from those described in the forward-looking statements.

The forward-looking statements made in this Annual Report on Form 10-K relate only to events as of the date on which the statements are made. We undertake no obligation to publicly update or review any forward-looking statement, whether as a result of new information, future developments or otherwise, except as required by law. We may not actually achieve the plans, intentions or expectations disclosed in our forward-looking statements and you should not place undue reliance on our forward-looking statements. Our forward-looking statements do not reflect the potential impact of any future acquisitions, mergers, dispositions, joint ventures, investments or other strategic transactions we may make.

The Company makes available free of charge on its website or provides a link on its website to the Company's Annual Report on Form 10-K, Quarterly Reports on Form 10-Q and Current Reports on Form 8-K, and any amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as soon as reasonably practicable after

those reports are electronically filed with, or furnished to, the SEC. To access these filings, go to the Company’s website, then click on “Financials and Filings-SEC Filings” under the “Investor Relations” heading.

We use our website (www.k2m.com), our corporate Facebook page (www.facebook.com/K2MInc) and our corporate Twitter account (@K2MInc) as channels of distribution of company information. The information we post through these channels may be deemed material. Accordingly, investors should monitor these channels, in addition to following our press releases, SEC filings and public conference calls and webcasts. In addition, you may automatically receive e-mail alerts and other information about K2M when you enroll your e-mail address by visiting the “Email Alerts” section of our website at http://investors.k2m.com/alerts.cfm. The contents of our website and social media channels are not, however, a part of this report.

TRADEMARKS AND SERVICE MARKS

ALEUTIAN, Basecamp, BLUE RIDGE, CAPRI, CASCADIA, CASPIAN, CAYMAN, CHESAPEAKE, Deformity Cricket, DENALI, EVEREST, Lamellar Titanium Technology, MESA, NILE, PYRENEES, Quicket, Rail 4D Technology, RAVINE, RHINE, SANTORINI, SERENGETI, TERRA NOVA, and tifix (licensed by D. Wolter) and other trademarks, trade names and service marks of K2M appearing in this Annual Report on Form 10-K are the property of K2M and our affiliates.

Solely for convenience, the trademarks, service marks and trade names may be referred to in this filing without the ® and TM symbols, but such references are not intended to indicate, in any way, that we will not assert, to the fullest extent under applicable law, our rights to these trademarks, service marks and trade names. All other trademarks, service marks and trade names appearing in this filing are the property of their respective owners.

ITEM 1. BUSINESS

Overview

We are a global medical device company focused on designing, developing and commercializing innovative and proprietary complex spine and minimally invasive spine technologies and techniques. Our complex spine products are used by spine surgeons to treat some of the most difficult and challenging spinal pathologies, such as deformity (primarily scoliosis), trauma and tumor. We believe these procedures typically receive a higher rate of positive insurance coverage and often generate more revenue per procedure as compared to traditional degenerative spine surgery procedures. We have applied our product development expertise in innovating complex spine technologies and techniques to the design, development and commercialization of an expanding number of proprietary minimally invasive surgery (MIS) products. These proprietary MIS products are designed to allow for less invasive access to the spine and faster patient recovery times as compared to traditional open access surgical approaches. We have also leveraged these core competencies in the design, development and commercialization of an increasing number of products for patients suffering from degenerative spinal conditions.

Our products consist of implants, disposables and instruments which are marketed and sold primarily to hospitals for use by spine surgeons. As of December 31, 2015, our product portfolio contains 71 product lines that are used in complex spine surgeries, MIS and degenerative surgeries, enabling us to favorably compete in the $10.5 billion global spinal surgery market. We believe many of our products offer simplified surgical techniques and promote improved clinical outcomes for patients, although their quality, safety and efficacy are not yet supported by long-term clinical data.

Our focus on our core competences of complex spine and MIS is highlighted by the fact that, for the year ended December 31, 2015, 56.0% of our revenue in the United States was derived from the use of our products in complex spine and MIS surgeries. We believe this represents a greater proportion of total revenue devoted to these markets as compared to our competitors. We further believe the proportion of our international revenue derived from complex spine and MIS is even higher than in the United States.

Some of our key proprietary technologies include the following:

| |

| • | MESA: a low-profile spinal screw technology, which accounted for approximately 29%, 31% and 35% of our revenue for the years ended December 31, 2015, 2014 and 2013, respectively, and is used primarily during deformity correction, featuring our proprietary locking mechanism that eliminates the need for a secondary locking feature and reduces rotational force on the spine during implantation, which has been used to treat more than 45,000 patients; |

| |

| • | Rail 4D: an innovative “beam-like” implant, used with our proprietary MESA spinal screws, that aids in the restoration of spinal balance or sagittal alignment while providing enhanced rigidity and significantly greater strength as compared to existing titanium and cobalt chrome rod offerings; |

| |

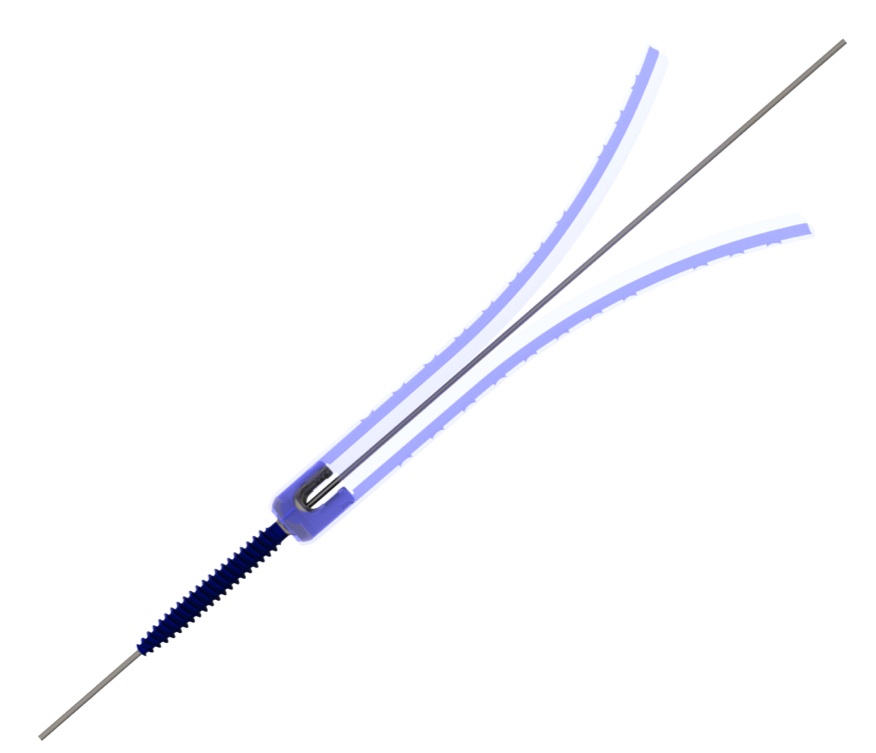

| • | Quicket Deformity: Next generation spinal correction rod reduction instrumentation, used with our proprietary MESA spinal screws, that provides surgeons with an innovative approach to more easily capture, manipulate and align a deformed spine as compared to traditional deformity correction instrumentation; |

| |

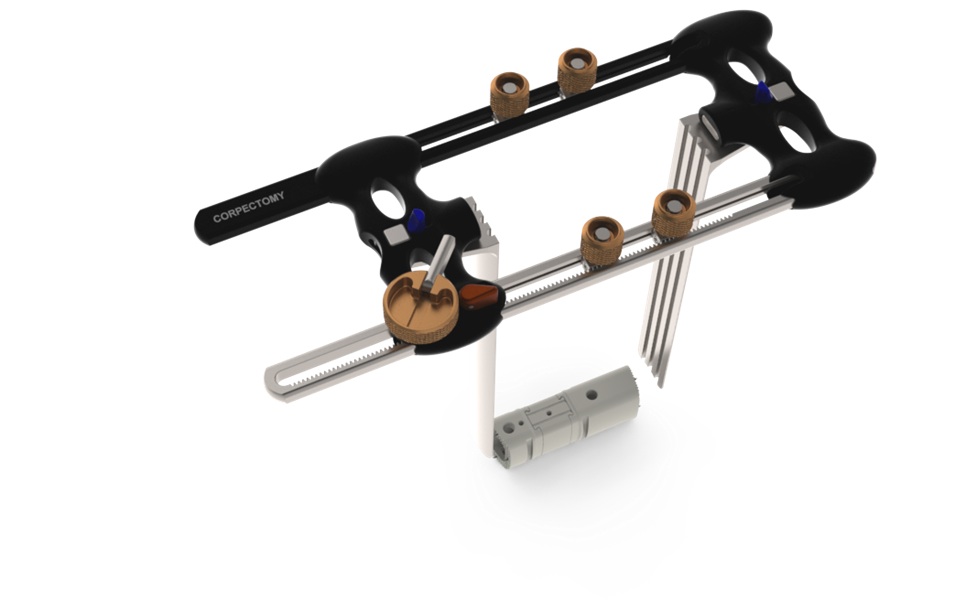

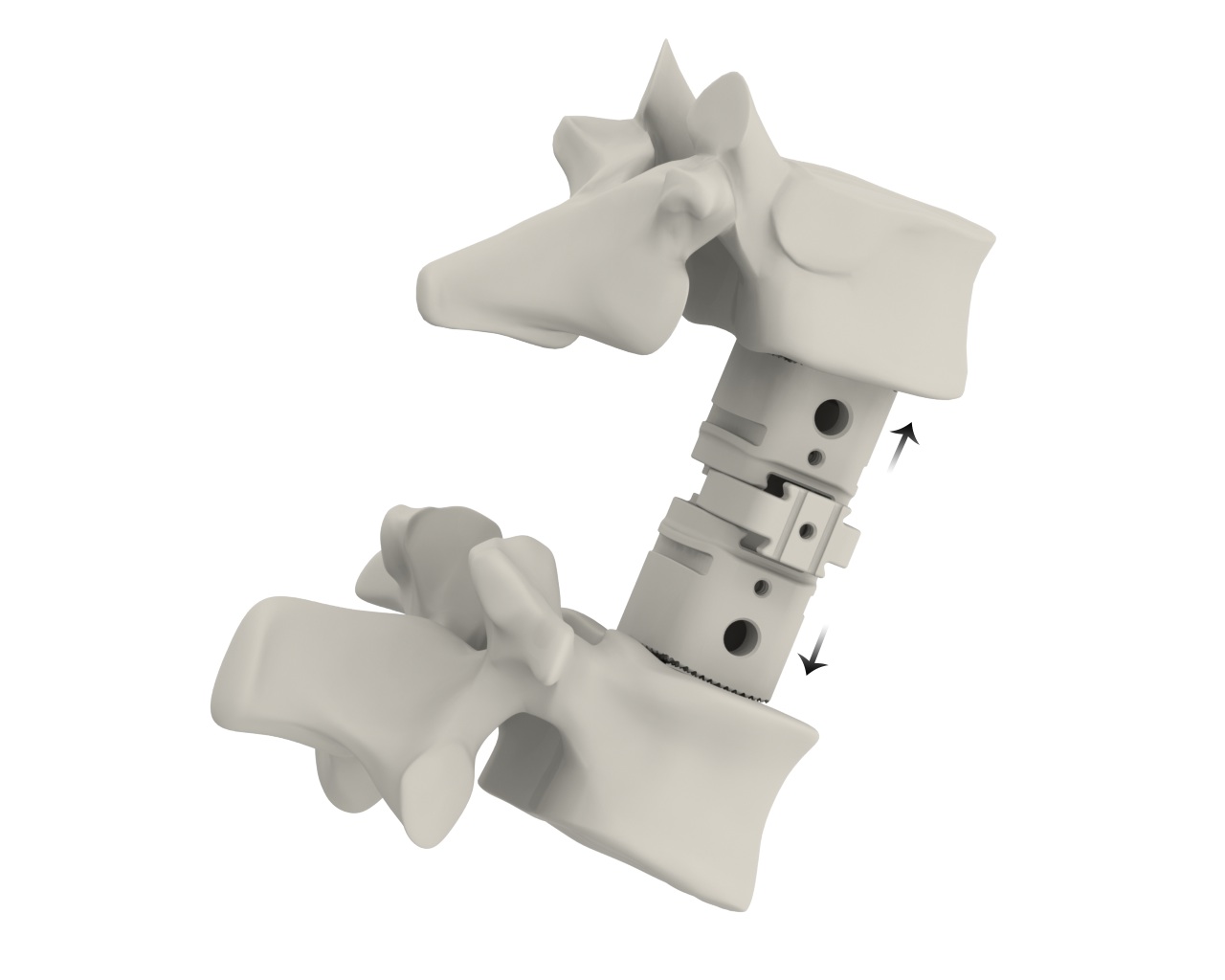

| • | CAPRI: a corpectomy cage system which provides an innovative solution for stabilization of the spine in cases of vertebral body resections resulting from trauma or tumor. Offered in various configurations, this versatile system allows for in-situ height expansion and endplate angulation; |

| |

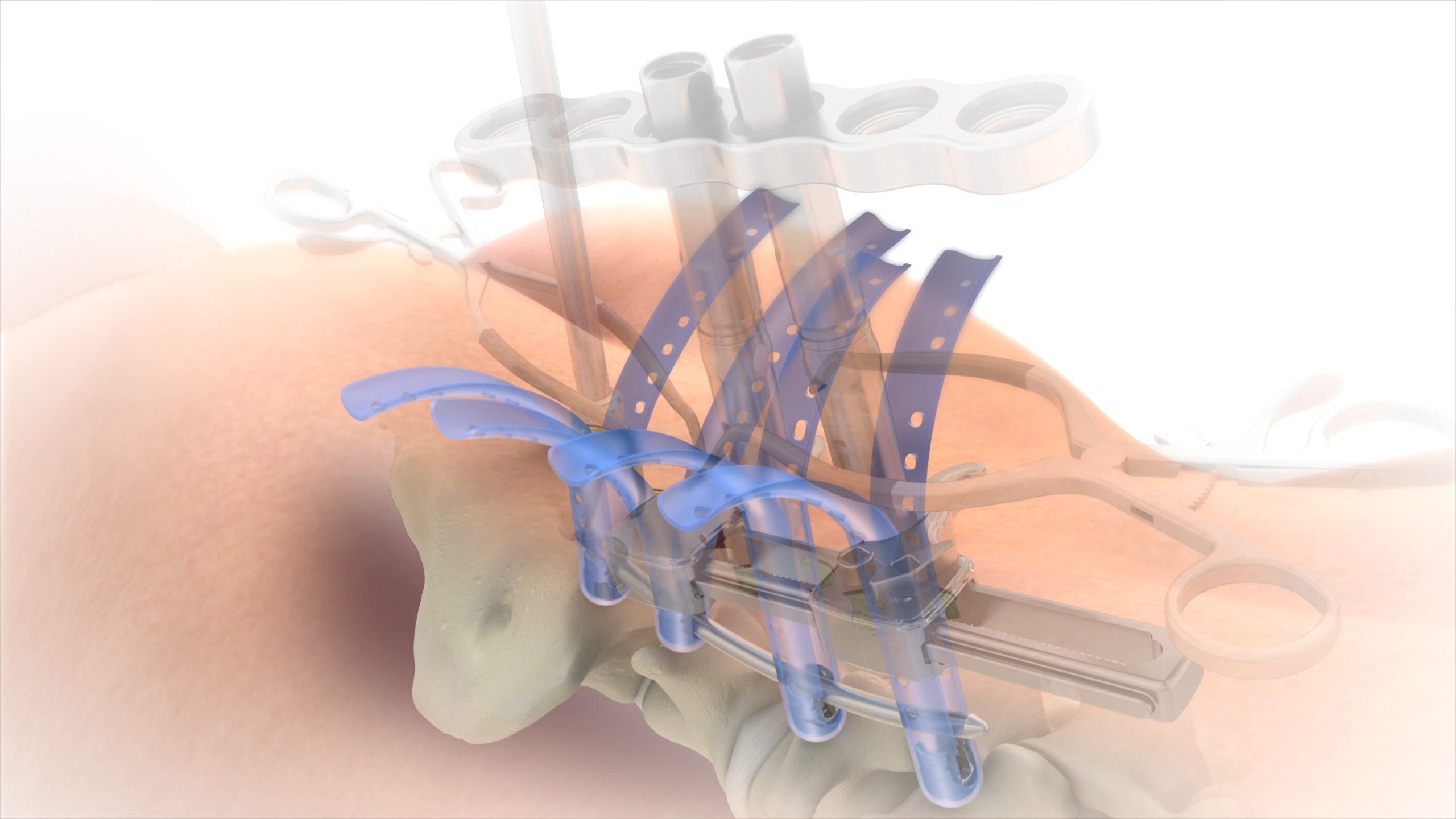

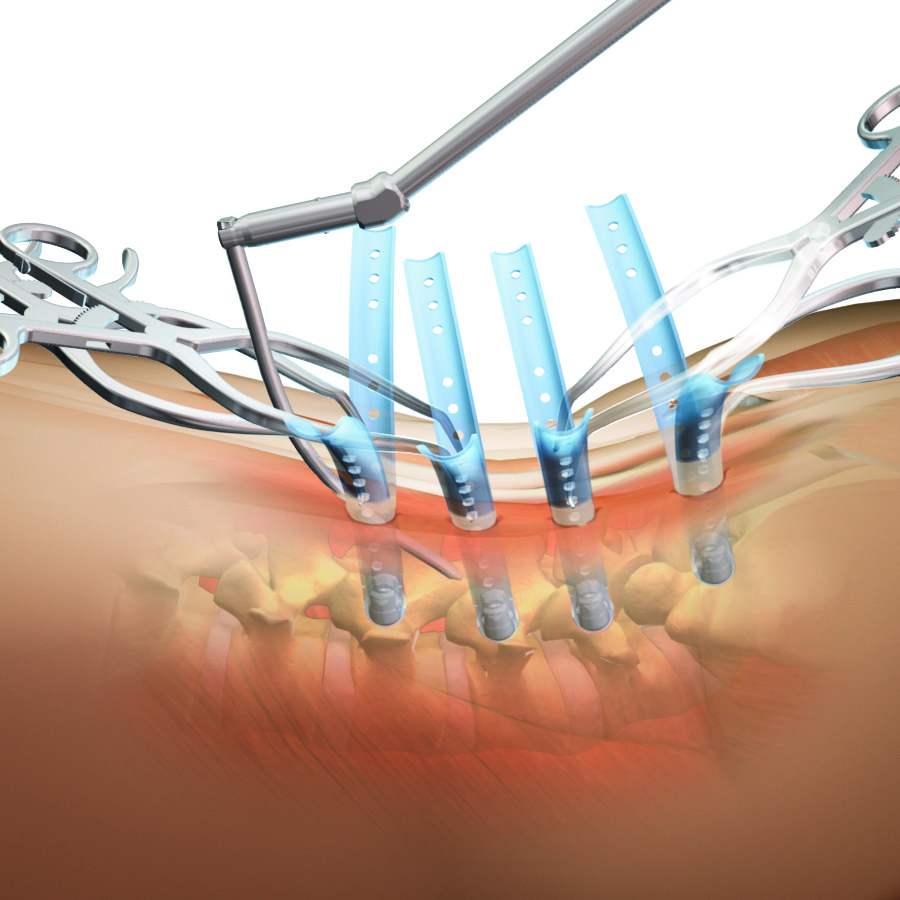

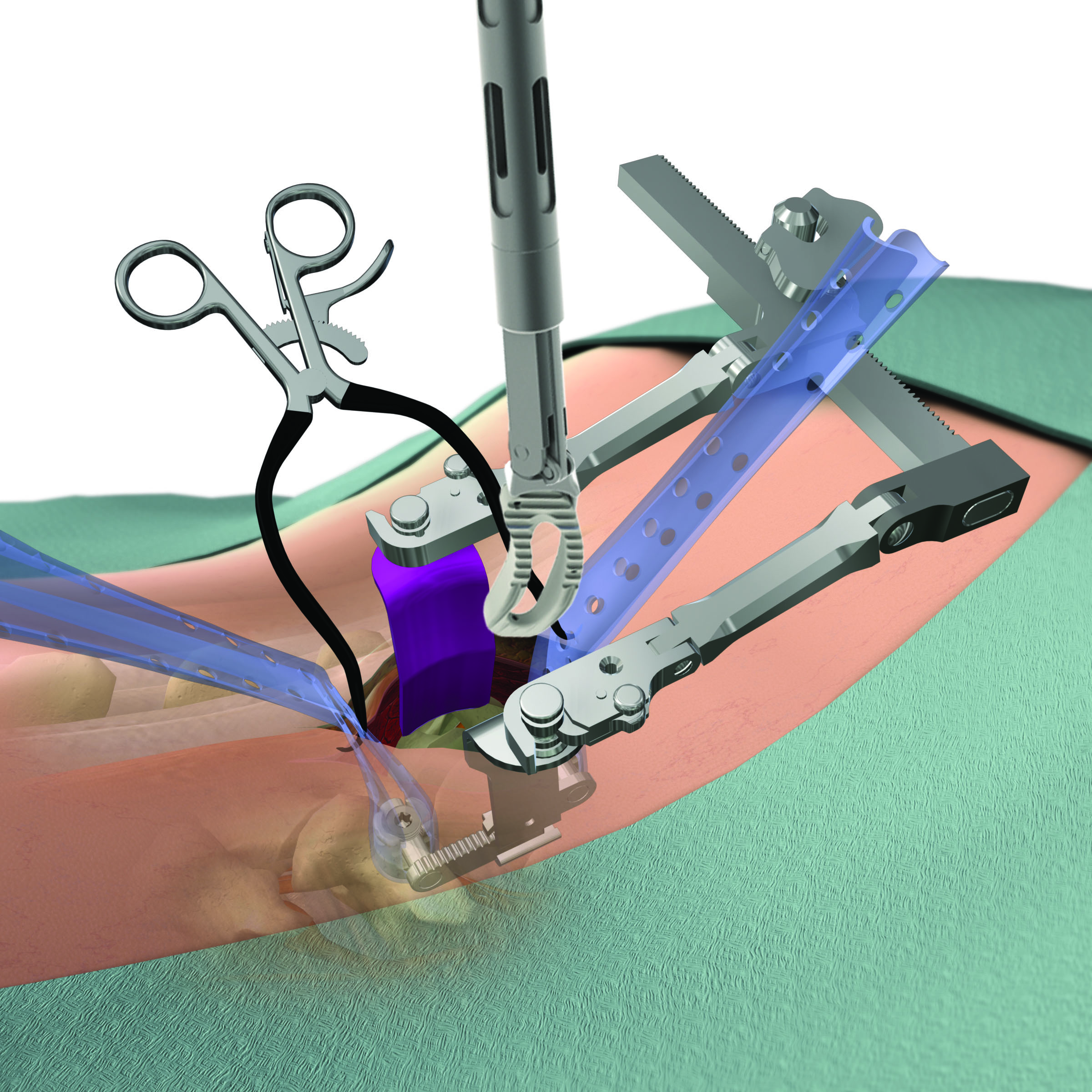

| • | SERENGETI: minimally invasive retractor systems featuring one-step placement of screws and retractors, thereby reducing the number of surgical steps, while allowing for direct visualization and improved access to the spine; |

| |

| • | RAVINE: minimally invasive retractor systems that represent an innovative design departure from standard tubular retractors, facilitating retractor placement, positioning and fixation to the patient’s anatomy to allow for endplate to endplate visualization and multi-level alignment through a lateral access approach; |

| |

| • | EVEREST: a spinal screw technology that we believe, based on internal testing, provides for improved insertion speed, industry-leading pull-out strength and the versatility to accommodate a variety of titanium and cobalt chrome rods of two different diameters; |

| |

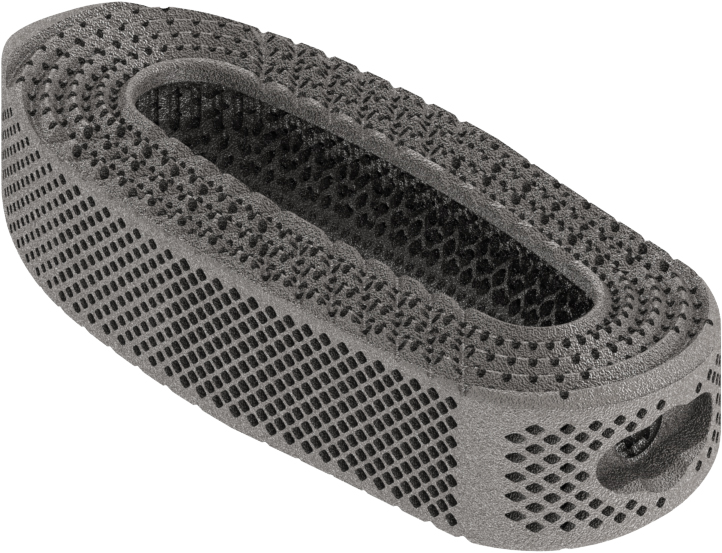

| • | CASCADIA: a titanium 3D printed implant technology based on our Lamellar Titanium Technology, which exploits the material properties of titanium in conjunction with a product design that incorporates an approximately 70% porosity to mitigate the device's radiographic signature; and |

| |

| • | tifix: a locking technology integrated into a number of our interbody and plate implants providing surgeons with the flexibility to insert screws at various angles and lock them to an implant with a one-step locking mechanism that eliminates the need for a secondary locking feature. |

We have grown our revenue to $216.0 million in 2015 from $100.5 million in 2010, representing a five-year CAGR of 17% between 2010 and 2015. For 2015, 2014 and 2013 our net loss was $39.2 million, $59.6 million and $37.9 million and our Adjusted EBITDA was $(0.1) million, $(8.8) million and $(5.3) million, respectively. For information about how we calculate Adjusted EBITDA, see Non-GAAP Financial Measures below. We expect to continue to incur additional losses as we invest in the global expansion of our business. As of December 31, 2015, our accumulated deficit was $169.4 million.

We have developed and maintain an expanding portfolio of intellectual property, which included 298 issued patents globally and 228 pending patent applications globally as of December 31, 2015. In addition to our current product offerings, we continue to invest in the research and development necessary to design, develop and commercialize new surgical solutions for unmet clinical needs. Our highly efficient product development process utilizes an integrated design team approach that involves collaboration among select teams of leading surgeons in their respective specialties, our product management team, our engineers and our clinical and regulatory personnel. We believe that utilizing these integrated design teams enables us to develop innovative and differentiated technologies and techniques that meet the needs of the market and allow surgeons and hospitals to better serve their patients. As of December 31, 2015, our product portfolio contains 71 product lines, which include our MESA, EVEREST and CASCADIA technologies, demonstrating our ability to leverage our product development process to rapidly innovate new products.

We currently market or sell our products in the United States and 36 other countries. In 2015, international sales represented approximately 28.1% of our revenue. We have made significant investments in building a global hybrid sales organization consisting of direct sales employees, independent sales agencies and distributor partners. As of December 31, 2015, our U.S. sales force consisted of 124 direct sales employees and 85 independent sales agencies and our international distribution network consisted of 39 direct sales employees, 10 independent sales agencies and 26 independent distributorships. We expect to continue to invest in the expansion of our global hybrid sales organization. We believe the continuing expansion of our global sales force will provide us with significant opportunities for future growth as we increase our penetration of existing geographic markets and enter new ones. We do not sell our products through or

participate in PODs.

Corporate History

K2M, Inc. was incorporated in 2004 and began working with leading spine surgeons for the purpose of designing, developing and commercializing innovative and proprietary complex spine technologies and techniques. Between 2005 and 2010, we continued to develop our product portfolio while expanding our business, including the investment of venture capital raised from Ferrer Freeman & Company, LLC, or FFC. On August 12, 2010, K2M Group Holdings, Inc., an entity then controlled by Welsh, Carson, Andersen & Stowe, acquired K2M, Inc. Welsh, Carson, Anderson & Stowe XI, L.P. and certain of its affiliated funds are referred to herein as “WCAS,” and WCAS, together with the other owners of K2M Group Holdings, Inc. prior to our May 2014 initial public offering, are collectively referred to as our “pre-IPO owners.” Since 2010, we have continued to invest in our business by expanding our global distribution network, including through the investment of additional capital raised from our pre-IPO owners, our initial public offering in May 2014, and subsequent public offerings in February 2015 and July 2015.

Industry Background

Overview of Spine Anatomy

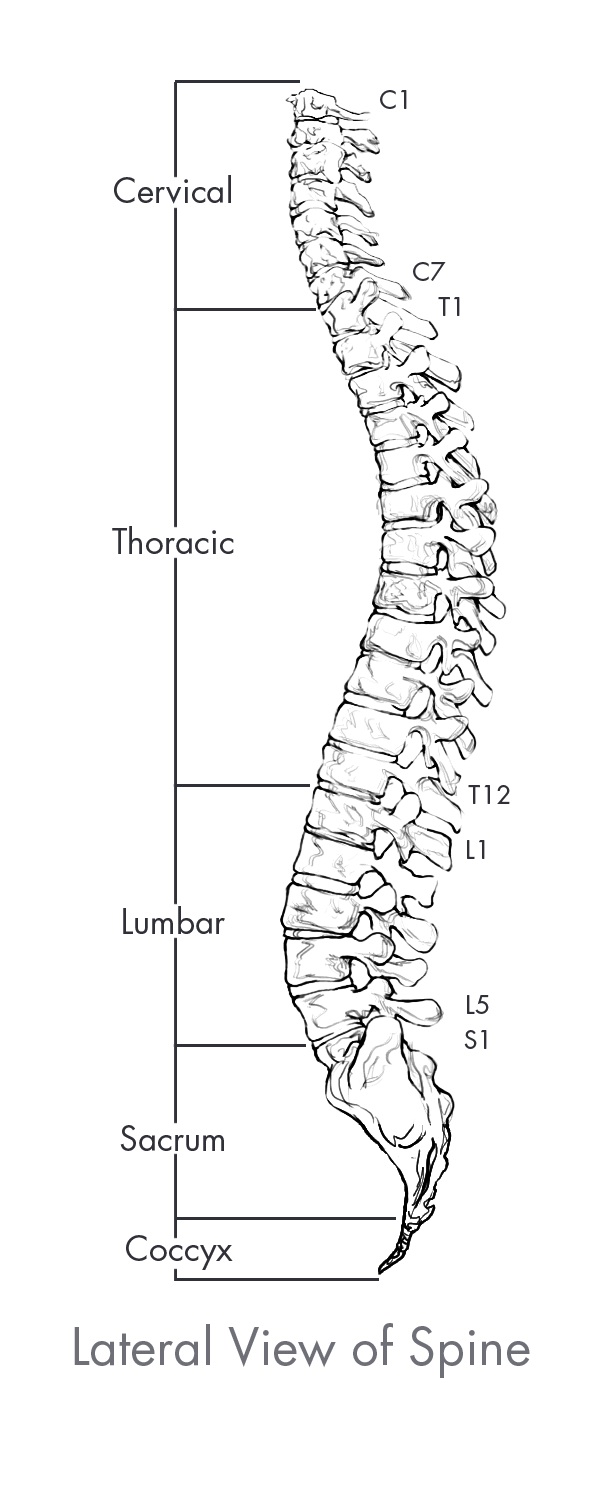

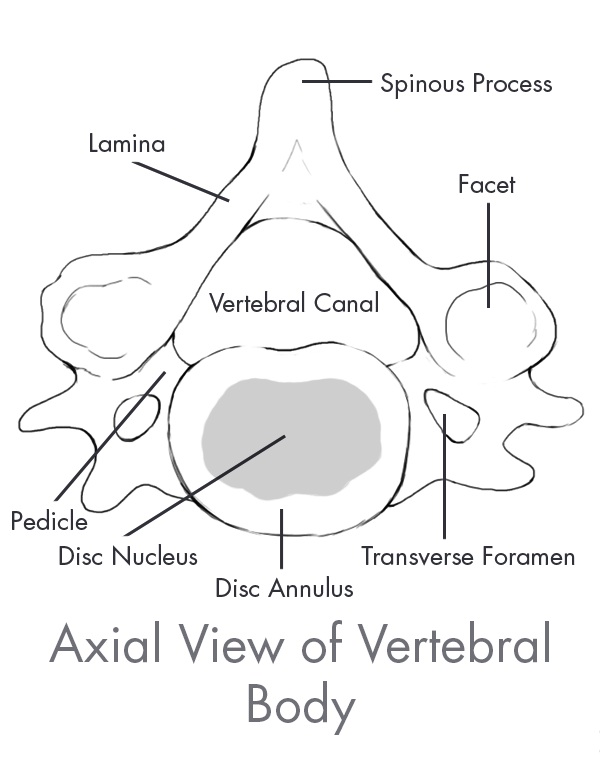

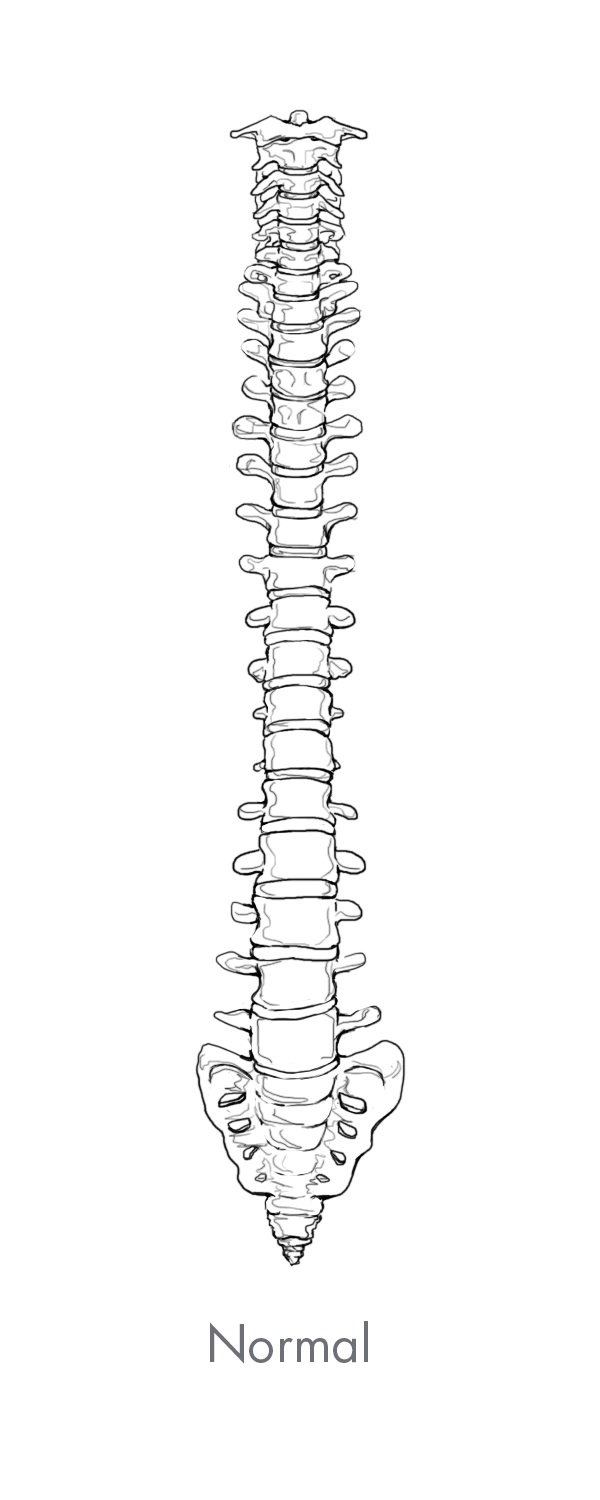

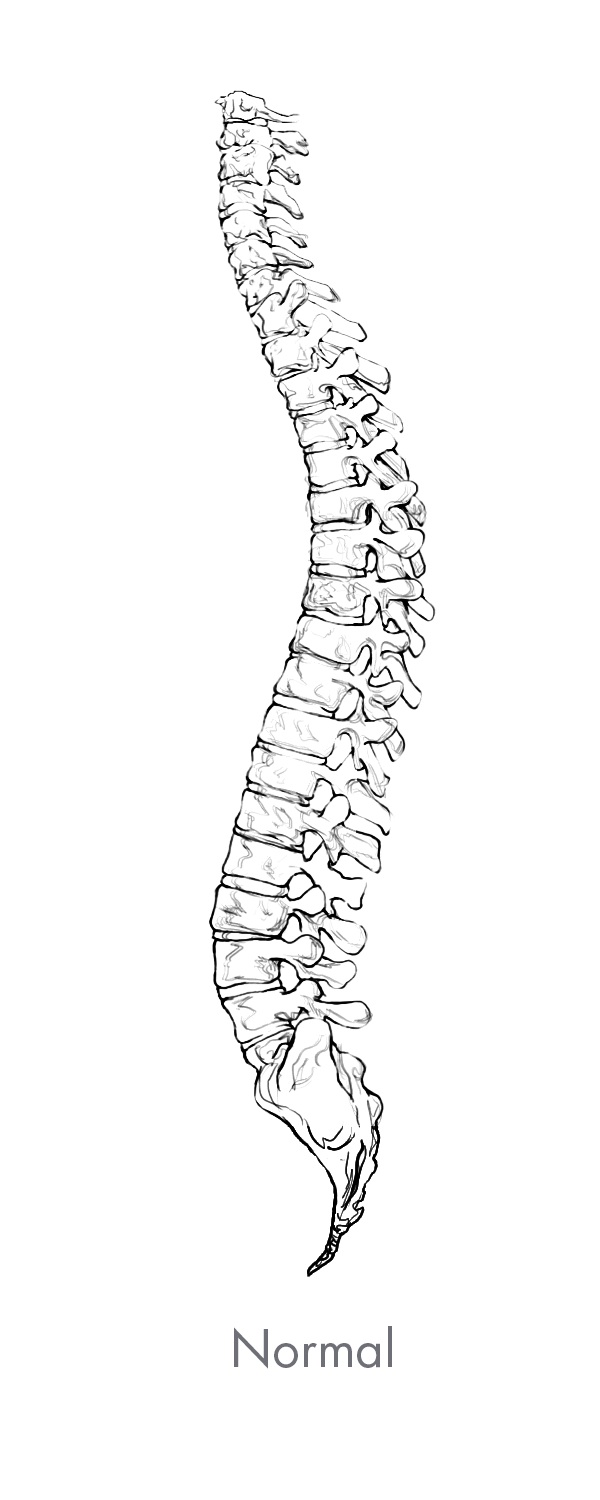

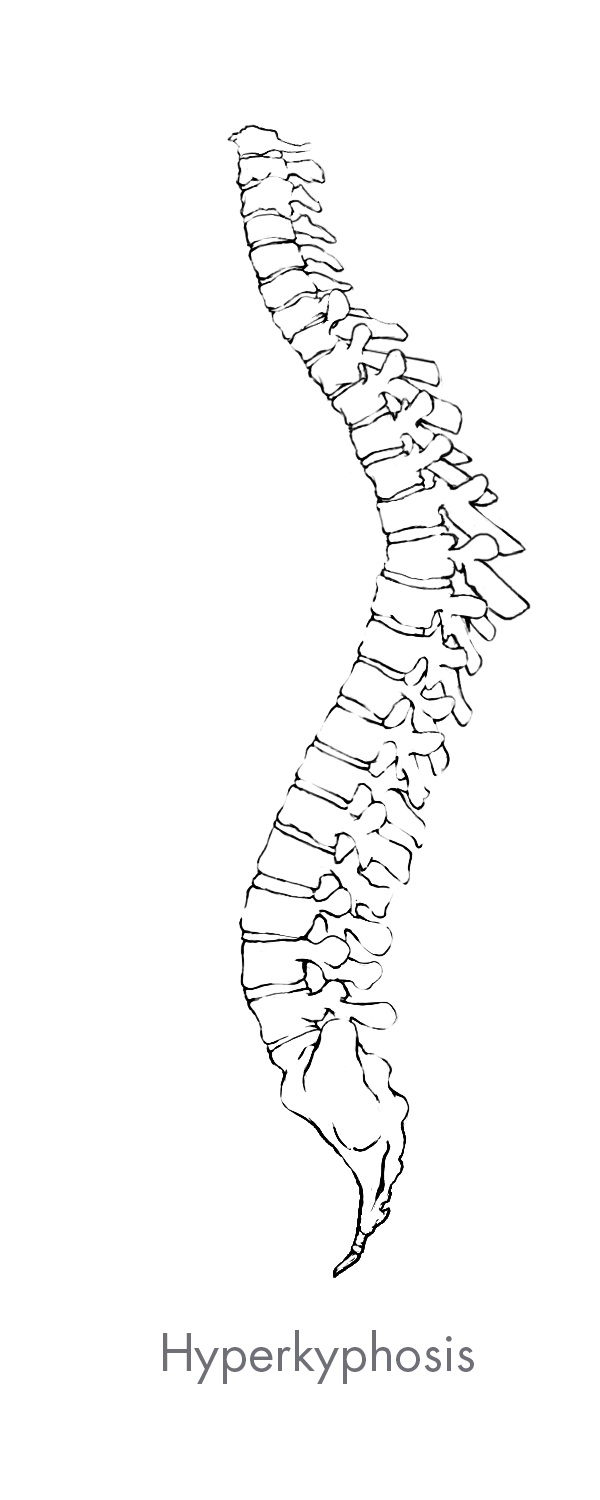

The spine is the central core of the human skeleton and provides structural support, alignment and flexibility to the body. It consists of 24 interlocking bones, called vertebrae, which are stacked on top of one another. The spine is comprised of five regions, of which there are three primary regions: cervical, thoracic and lumbar. There are seven vertebrae in the cervical, or neck, region of the spine, 12 vertebrae in the thoracic, or central, region of the spine, and five vertebrae in the lumbar, or lower back which is the primary load-bearing region of the spine. The bottom of the spine, comprised of the sacrum and the coccyx, consists of naturally fused vertebrae connected to the hip bones to provide support for the spine. A healthy spine has a natural curvature when viewed from the side and is straight when viewed from the front or back. The cervical and lumbar regions contain forward convex curves referred to as lordosis while the thoracic region contains a backward concave curve referred to as kyphosis. Between each pair of vertebrae is an intervertebral disc that acts as a shock absorber during movement. Vertebrae are paired as motion segments, or levels, and are connected to each other by facet joints in the rear region of the spine that provide flexibility and enable the spine to bend and twist. The back, or posterior, part of each vertebra is comprised of a bony arch called the lamina and the spinous process. Soft tissues, including ligaments, tendons and muscles are attached to these structures, which provide stability to the spinal column and facilitate movement of the spine. The largest load bearing bony structure, which is in the front, or anterior, and middle part of each vertebra, is referred to as the vertebral body. These collective spinal elements serve as a protective cage for the spinal cord, which runs through the center of the spine, or spinal canal, carrying nerves that exit through openings between the vertebrae, or foramen, which run from every area of the body to the brain, delivering sensation and control to the entire body.

Overview of Spine Disorders

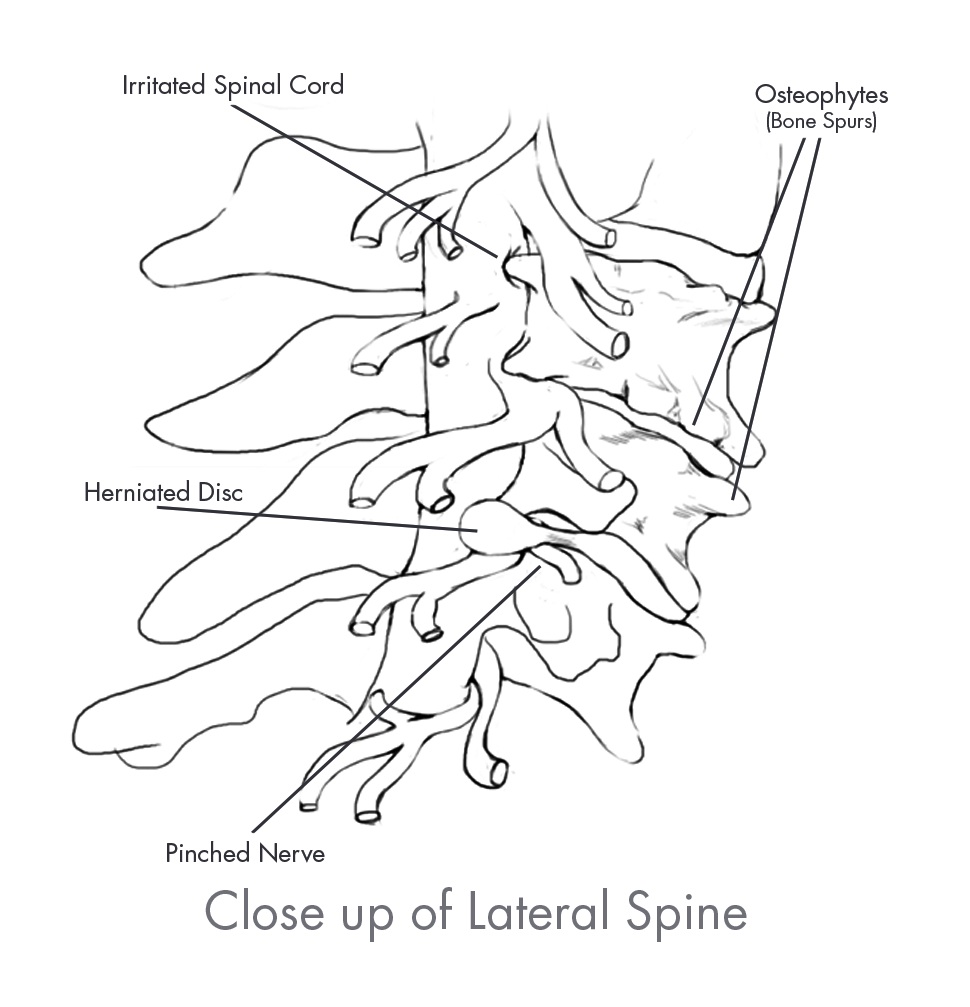

Complex spine pathologies and back pain related to spine disorders affect more than 31 million people in the United States and are a leading driver of healthcare costs globally. Spine disorders range in severity from mild discomfort and numbness, to curvatures of the spine, extreme pain and paralysis. Spine disorders can be categorized as either complex, which consists of deformity (primarily scoliosis), trauma and tumor, or degenerative.

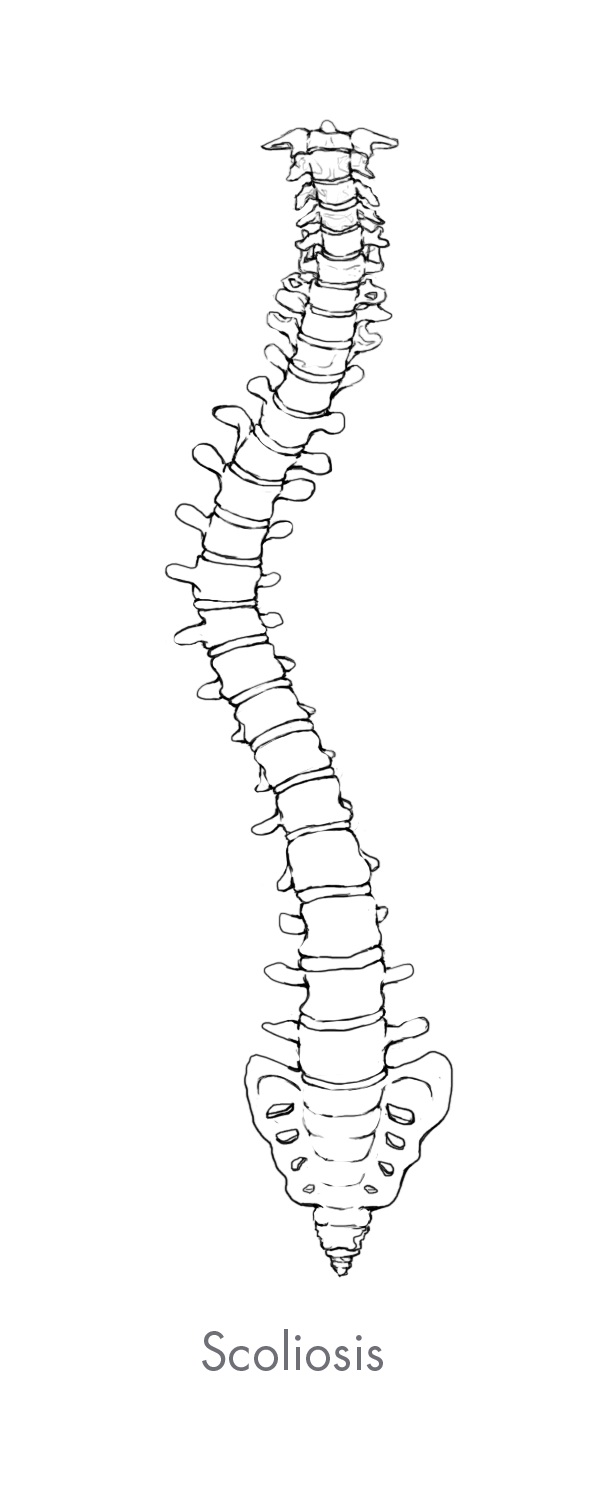

Spine deformity is any variation in the natural curvature of the spine. The most common form of spine deformity is scoliosis which is either a lateral, or side-to-side curvature of the spine, or an extreme rotation of the vertebral body. Other common types of deformity include hyperlordosis which is an over-extension of the normal convex curvature of the cervical and lumbar spine, and hyperkyphosis which is an over-flexion of the normal concave curvature of the thoracic spine.

Spine deformity can be further grouped into the following four categories which are known to have different spine characteristics:

| |

| • | Pediatric infantile scoliosis, presents in children under 10 years of age as a result of conditions present at birth or congenital conditions; |

| |

| • | Adolescent scoliosis, presents in patients between the ages of 10 and 18 as a result of congenital conditions, neuromuscular conditions such as cerebral palsy or muscular dystrophy, or other unknown previously existing conditions; |

| |

| • | Adult scoliosis, presents in patients between the ages of 19 and 64 as a result of scoliosis, which typically starts after the age of 40 due to arthritis or other conditions of aging, or as a result of scoliosis that started when the patient was younger; and |

| |

| • | Aging spine, presents in patients 65 years of age or older as a result of a pre-existing deformity that has progressed or the onset of severe degenerative spine disorders. |

Spine trauma is often the result of impact from a fall, car accident or other external forces. Spine traumas include fractures, dislocations, soft tissue damage and other musculoskeletal and nervous system injuries.

Spine tumors are relatively rare. Benign tumors are typically removed surgically while malignant tumors are more difficult to treat and often originate in other areas of the body such as the lungs, thyroid or kidneys.

Degenerative spine disorders are typically the result of repetitive stresses experienced during the normal aging process and are the most common type of spine disorders. Degenerative spine disorders occur when the intervertebral disc at a motion segment weakens and loses its normal height, thereby compressing the spinal nerves. Compression of the spinal nerves often leads to pain and/or loss of feeling in the arms, back and legs.

Treatment Alternatives for Degenerative Spine Disorders

Treatment for degenerative spine disorders usually begins with conservative therapies including observation to determine if the spine disorder is progressing, lifestyle changes such as exercise and weight loss, anti-inflammatory and pain medication and physical therapy. If and when conservative therapies fail to provide adequate quality of life improvements, patients may ultimately require spine surgery.

The goals of spine surgery are to reduce patient pain and restore structural support and alignment while maintaining natural flexibility within the spine, if possible. Surgical options for degenerative spine disorders vary greatly depending on each patient’s unique pathology and include procedures that either (1) do not use spinal implants or (2) use spinal implants.

Decompression procedures are typically performed earlier in the continuum of care and may or may not include the use of spinal implants. These procedures include discectomies and laminectomies, which involve the removal of part of a damaged disc or lamina in order to relieve pressure on the spinal nerves. Decompression procedures may occasionally result in spinal instability due to the removal of these spinal elements and as a result require the utilization of spinal implants.

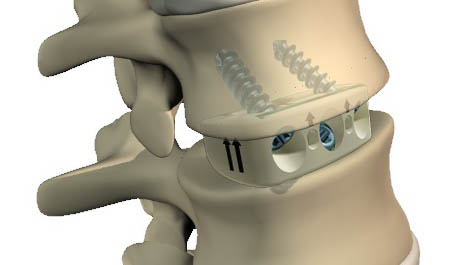

In the case of advanced degenerative spine disorders, treatment often turns to procedures that involve the use of spinal implants, the most common of which is a fusion procedure. The goal of fusion is to permanently decompress the spinal nerves exiting the spine by restoring the natural height of the disc and eliminating motion at the affected level. A fusion procedure involves the surgical removal of bone and/or diseased or damaged disc material that is believed to be the source of the pain and insertion of spinal implants to the spine to stabilize the affected vertebrae. Spinal implants used in fusion procedures include interbody devices that replace the disc space between the vertebrae, as well as spinal implants such as Rails, stabilization rods, screws, plates and biomaterials that provide stability and promote fusion between the vertebrae. Treatments for degenerative spine disorders may also include motion preservation technologies such as cervical and lumbar disc replacement, dynamic stabilization, annular closure, nucleus replacement and facet arthroplasty devices. In some instances, degenerative spine disorders may progress to complex spine disorders, depending on the severity and advancement of the pathology or structural deformity.

Treatment Alternatives for Complex Spine Disorders

Treatments for complex spine disorders, such as deformity, address patients with severe curves in their spine seeking to prevent curve progression and obtain curve correction. The treatment pathway for deformity cases may begin with bracing or casting which are designed to slow or correct the progression of the adverse curvature of the spine. Bracing and casting are typically used as the first course of treatment in young children who are still growing. If a child’s curve has shown progression despite bracing or casting, surgery is often considered. Surgical treatment for deformity conditions in young patients that have not stopped growing, such as pediatric infantile scoliosis, typically seek to correct the deformity while avoiding long fusions of the spine. These procedures include the use of spinal implants, such as pedicle screws and expandable rods that are periodically lengthened, to control the spine deformity while still allowing for the spine to grow until the child reaches an appropriate size or age for a more permanent solution, such as spinal fusion. When these patients mature and reach spinal maturity, spinal fusions are typically considered.

Treatment of more intricate complex spine disorders, such as traumas and tumors, may require the use of one or several procedural alternatives, such as (1) decompression, (2) fusion or (3) corpectomy techniques, where the vertebral body may be completely removed and replaced by a vertebral body replacement device.

The indications for surgical treatment of complex spine disorders such as deformity are determined by anatomical angle measurements that are established and well defined among hospitals, physicians and third-party payors. Conversely, fusion procedures for degenerative conditions are typically indicated when the source of the patient’s pain originates from the vertebral level in question and a diagnostic confirmation of degenerative disc disease is made. Current techniques to identify the source of a patient’s degenerative back pain are imprecise and it may be difficult to locate the source of pain. Third-party payors typically require a confirmed diagnosis of degenerative disc disease in order to reimburse for surgical procedures. We believe complex spine procedures typically receive a higher rate of positive insurance coverage and often generate more revenue per case, as compared to degenerative procedures.

MIS Treatment Alternatives for Complex and Degenerative Spine Disorders

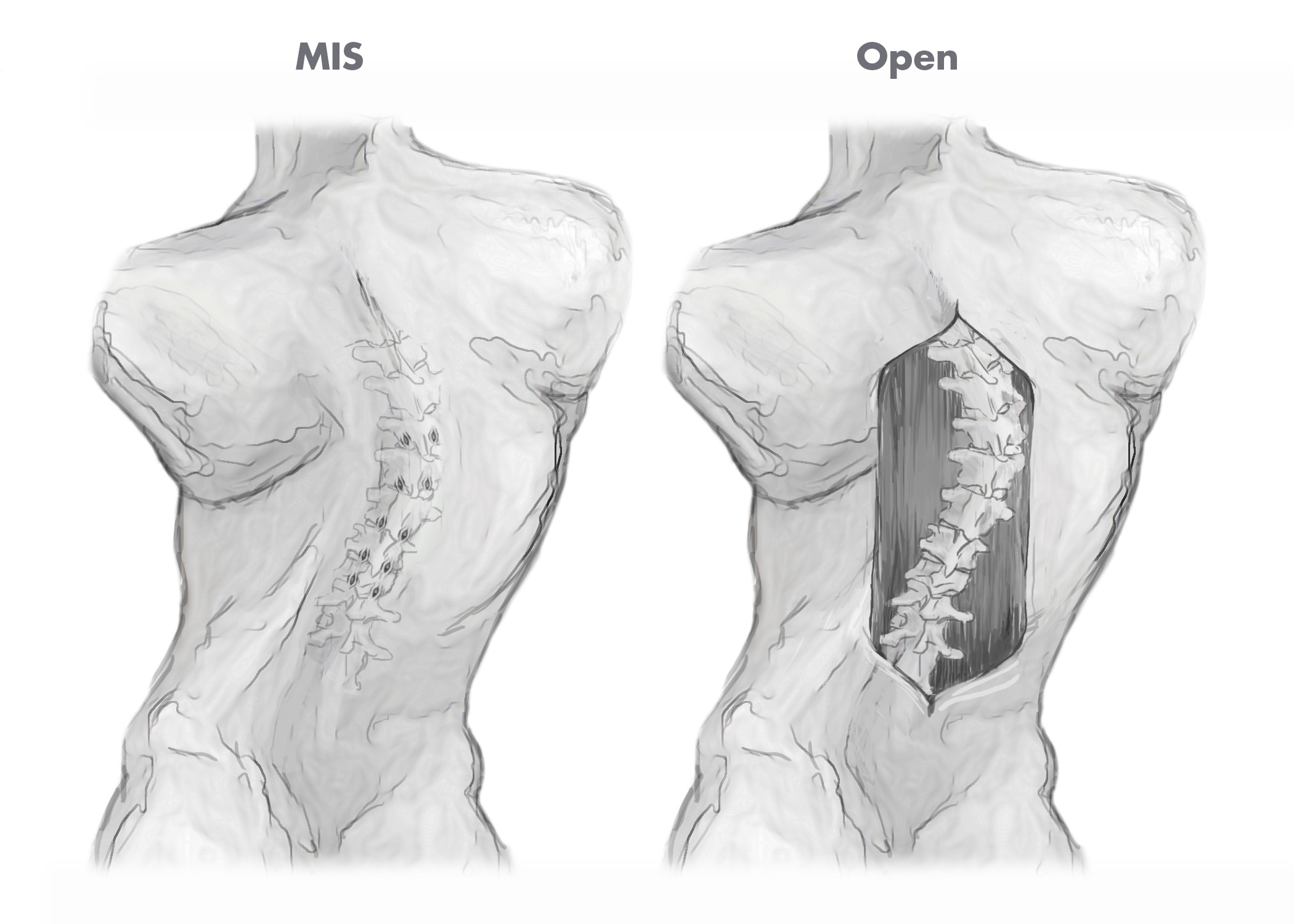

Traditional approaches for complex spine and degenerative spine surgery require large incisions in order to provide surgeons with access to, and visibility of, the spine and surrounding areas. Consequently, traditional surgical procedures are considered highly invasive and are often associated with several limitations including significant blood loss, extensive soft tissue disruption, long operative times, extended hospital stays and lengthy patient recovery times.

Over time, there has been significant increase in surgeon and patient interest for less invasive surgical techniques for treating both complex and degenerative spine disorders. MIS techniques are designed to allow for less invasive access to the spine and, as a consequence, faster patient recovery times as compared to traditional open access surgical techniques. The figures below illustrate the different incision sizes in a multi-level deformity case utilizing both traditional open and MIS surgical techniques.

Biomaterials Treatment Alternatives for Complex and Degenerative Spine Disorders

Biomaterial treatments are typically derived from human bone or synthetic sources and come in a variety of forms. These biomaterials are used by spine surgeons during the surgical treatment of certain complex spine and degenerative pathologies to augment spinal implants and to promote fusion by accelerating, augmenting or substituting for the normal regenerative capacity of bone.

Market Opportunity

According to iData, the global spine surgery market was estimated at approximately $10.5 billion in 2014:

|

| | | | | | | | | | | | | | | | | | | |

| | 2014 Estimated Global Spine Market Size (dollars in millions) |

| | United States | | Europe | | Asia/ Pacific | | Latin America | | Total |

| Complex Spine | $ | 1,044 |

| | $ | 198 |

| | $ | 268 |

| | $ | 75 |

| | $ | 1,585 |

|

| MIS (Degenerative) | 1,189 |

| | 61 |

| | 93 |

| | 28 |

| | 1,371 |

|

| Degenerative Spine | 4,284 |

| | 912 |

| | 998 |

| | 309 |

| | 6,503 |

|

| Spine Implants and Instrumentation | $ | 6,517 |

| | $ | 1,171 |

| | $ | 1,359 |

| | $ | 412 |

| | $ | 9,459 |

|

Biomaterials (1) | 759 |

| | 90 |

| | 170 |

| | * |

| | 1,019 |

|

| Total | $ | 7,276 |

| | $ | 1,261 |

| | $ | 1,529 |

| | $ | 412 |

| | $ | 10,478 |

|

(1) We report revenue related to the sale of biomaterials as part of our complex spine, MIS and degenerative spine revenue categories.

Source:iData Research, Inc.

| |

| * | Not included in market sizing estimates |

Overviews of the global spine markets in which we compete, and their associated growth drivers, are as follows:

Complex Spine

The approximately $1.6 billion global complex spine market includes technologies used to treat cases of spine deformity, trauma and tumor, including those treated through a minimally invasive approach. While many advancements in the treatment of complex spine disorders have been made, considerable challenges and limitations associated with performing complex spine surgery remain. For example, many of the spinal implants and instruments currently used to perform complex spine surgeries are not designed to sufficiently address the variable and unpredictable nature of complex spine surgeries caused by the different sizes, shapes, densities and growth characteristics of each individual spine. It is not always possible for spine surgeons to anticipate which of these variables will be present in any given spine surgery, which may result in suboptimal patient outcomes and longer procedure times if they do not have the proper spinal implants and instruments readily available during the procedure. Further, many existing complex spine surgery implants, instruments and surgical approaches are not designed to concurrently access multiple levels of the spine through a MIS approach.

We believe the global complex spine market has been underserved and underdeveloped by major spine market competitors, which generally focus on the larger degenerative spine market. As a result, we believe the complex spine patient population has and will continue to benefit from innovative technologies and techniques that enable simplified surgical procedures, MIS approaches and surgical treatment earlier in the continuum of care.

MIS

The approximately $1.4 billion global MIS market includes technologies used in treating degenerative spine disorders through minimally invasive approaches to the spine.

These technologies and techniques include MIS pedicle screws that are affixed to the spine through either percutaneous, or puncture-like, incisions or retractors that provide direct visualization of the spine with a smaller incision than traditional open procedures. The MIS market also includes minimally invasive interbody devices, including posterior, transforaminal and lateral lumbar interbody fusion (“LLIF”) devices. LLIF devices are inserted from the side and are associated with less disruption to the soft tissues of the back. We believe the vast majority of surgeons and patients, when given the option, will utilize MIS procedures rather than traditional open procedures due to the advantages of MIS approaches, which often include less soft tissue disruption, reduced frequency of surgical morbidity, faster operating times, reduced scarring and, as a consequence of these advantages, shorter patient recovery times. Finally, we believe the overall improvement to the standard of care resulting from the introduction of new MIS products will increase global demand for MIS technologies and techniques.

Degenerative Spine

The approximately $6.5 billion global degenerative spine market includes technologies and techniques used to treat degenerative spine disorders. These technologies and techniques include products such as cervical, thoracic and lumbar spinal fusion devices, interbody devices, motion preservation technologies and vertebral compression fracture devices. We believe that several factors will continue to influence the growth in the global degenerative spine market, including aging patient demographics, increased life expectancies, the desire for maintaining and/or improving lifestyles and demand from patients and surgeons for innovative technologies and techniques that enable simplified surgical procedures, faster procedure times and improved clinical outcomes.

Our Competitive Strengths

Our executive management team is highly experienced in the spinal surgery industry. We believe this experience and the following competitive strengths have been instrumental to our success and continue to enable us to grow our revenue and market share.

| |

| • | Focus in Complex Spine and MIS. Our strategic focus and core competencies are the design, development and commercialization of innovative complex spine and MIS technologies and techniques. In addition to our innovative product portfolio, our dedication to the complex spine and MIS markets is evidenced by our strong relationships with key opinion leaders and spine societies focused on the complex spine and MIS markets, such as the Scoliosis Research Society and the Pediatric Orthopedic Society of North America. Furthermore, we dedicate significant global resources to educating spine surgeons on the safe and effective use of our complex spine and MIS technologies. |

| |

| • | Comprehensive Portfolio of Innovative Proprietary Technologies. We continue to expand our comprehensive portfolio of products that address a broad array of spinal pathologies, anatomies and surgical approaches in the complex spine and MIS markets. We believe the benefits of our product offerings in |

these two markets include simplified surgical techniques, less invasive access to implant sites, enhanced capabilities to manipulate and correct the spinal column, lower-profile spinal implant technology and improved clinical outcomes as compared to traditional alternatives such as open surgical techniques utilizing higher profile screws and other implants that provide more limited manipulation of the spine and often require the use of more components, including additional locking parts and set screws. Our strength in complex spine and MIS provides us with an opportunity to cross-sell our broad portfolio of product offerings in the degenerative market. To protect our innovative technologies and techniques, we maintain and continue to grow our intellectual property portfolio.

| |

| • | Highly Efficient Product Development Process. Responding quickly and efficiently to the needs of patients, surgeons and hospitals is central to our culture and critical to our success. Our integrated teams of surgeon advisors, product managers, engineers and clinical and regulatory personnel conceptualize, design and develop potential new products through an iterative process that allows for rapid product development, which has enabled us to commercialize products since our inception. We believe that our entrepreneurial culture and integrated approach allows us to (1) quickly assess the market, (2) address evolving patient, surgeon and hospital needs, (3) evaluate new treatment options and (4) accelerate the development of a potential product from concept to commercialization. In 2016, we expect to continue our track record of innovation and introduce an additional five to eight new product lines or line extensions. |

| |

| • | Broad Global Distribution Network. Our global distribution network continues to expand and included 163 direct sales employees and contractual relationships with 95 independent sales agencies and 26 distributor partners as of December 31, 2015. In addition, we continue to broaden our operational capabilities by investing in implants and surgical instrument inventories and maintaining sales offices in strategic markets worldwide, such as the United Kingdom, Italy and Germany. We believe that our significant global distribution footprint provides us with the opportunity to effectively introduce new products in the markets in which we have a sales presence. |

| |

| • | Demonstrated Track Record of Innovation and Execution. Our management team has achieved the following milestones: |

| |

| • | Designed and commercialized 71 product lines as of December 31, 2015; |

| |

| • | Established a global distribution network with a sales presence in 37 countries, including the United States; |

| |

| • | Implemented and maintained a comprehensive compliance program, including educational and training components; |

| |

| • | Developed an efficient clinical and regulatory function; and |

| |

| • | Grew revenue at a compounded annual growth rate of 17% from 2010 to 2015. |

We believe our management has the vision, experience and network of relationships to continue our successful growth.

Our Strategies

For 2016, our primary goals are (i) to drive sustainable growth in revenue and our customer base by servicing the needs of patients, surgeons and hospitals through product innovation and differentiation in the complex spine and MIS markets and continuing to leverage these core competencies in the degenerative spinal surgery market; and, (ii) through a combination of revenue growth and leverage and efficiencies to our sales and operations platforms, reduce our net loss for 2016 and begin to achieve profitability in 2017.

To achieve these goals, we intend to:

| |

| • | Capitalize on Our Highly Efficient Product Development Process to Innovate New Technologies and Techniques. We have a proven history of developing and commercializing new technologies in our core competencies of complex spine and MIS, as well as degenerative spine. We plan to continue developing innovative new products. Our product pipeline includes a number of new product or line extensions of |

which we expect to introduce five to eight to market during 2016. We believe that the strengthening of our product offering will allow us to continue to attract highly qualified sales professionals, strengthen our relationship with existing customers, acquire new customers and, ultimately, compete more effectively in the global spine market.

| |

| • | Leverage Our Investments in Infrastructure to Further Penetrate the Global Spine Market. We plan to leverage our product development process, robust intellectual property portfolio, key opinion leader expertise, compliance infrastructure, comprehensive training and education programs, investments in inventory and global sales and marketing infrastructure to effectively distribute our products and continue our expansion in the approximately $10.5 billion global spine surgery market. |

| |

| • | Expand Our Global Distribution Footprint. We will continue to make significant investments in our global distribution network to increase our penetration in existing markets or expand our geographic presence into new markets. We believe there remains significant opportunity for us to expand our global presence. In 2016, we plan to hire additional direct sales employees on an opportunistic basis, while continuing to develop relationships with independent sales agencies and distributor partners in select markets. We also plan to continue our investments in inventory and specialized training to improve the productivity and efficiency of our sales force. |

| |

| • | Selectively Pursue Opportunities to Enhance Our Product Offerings. We expect to selectively pursue opportunities to license or acquire complementary products and technologies to strengthen our market position. For example, we intend to pursue strategic alliances to develop next generation technologies and techniques for the treatment of complex spine pathologies through MIS approaches. We may also engage in strategic transactions such as acquisitions or joint ventures that allow us to increase our product and service offerings. For instance, in 2015 we acquired a portfolio of complex spine and degenerative intellectual property from K-Spine, Inc. which consisted of 19 issued and 45 pending U.S. and international patents primarily focused on new concepts to develop motion preserving implant and techniques for scoliosis and deformity pathologies. |

Our Products

The tables below group our core products with the primary market in which they are typically used and provide a summary of each technology’s features and market introduction date. Revenue from products that incorporate MESA represented 29%, 31% and 35% of our total revenue for the years ended December 31, 2015, 2014 and 2013, respectively and revenue from products that incorporate EVEREST represented 21%, 16% and 12% of our total revenue for the years ended December 31, 2015, 2014 and 2013, respectively.

Complex Spine

We define complex spine as procedures involving the placement of eight or more pedicle screws or procedures that utilize products specific to the correction of deformity, trauma or tumor conditions such as specialized fixation devices, construct extenders or connectors and corpectomy cages. Many of our products designed for use in complex spine procedures incorporate our proprietary MESA and EVEREST technologies.

|

| | | |

| Selected Products | Image | Description | Market Introduction |

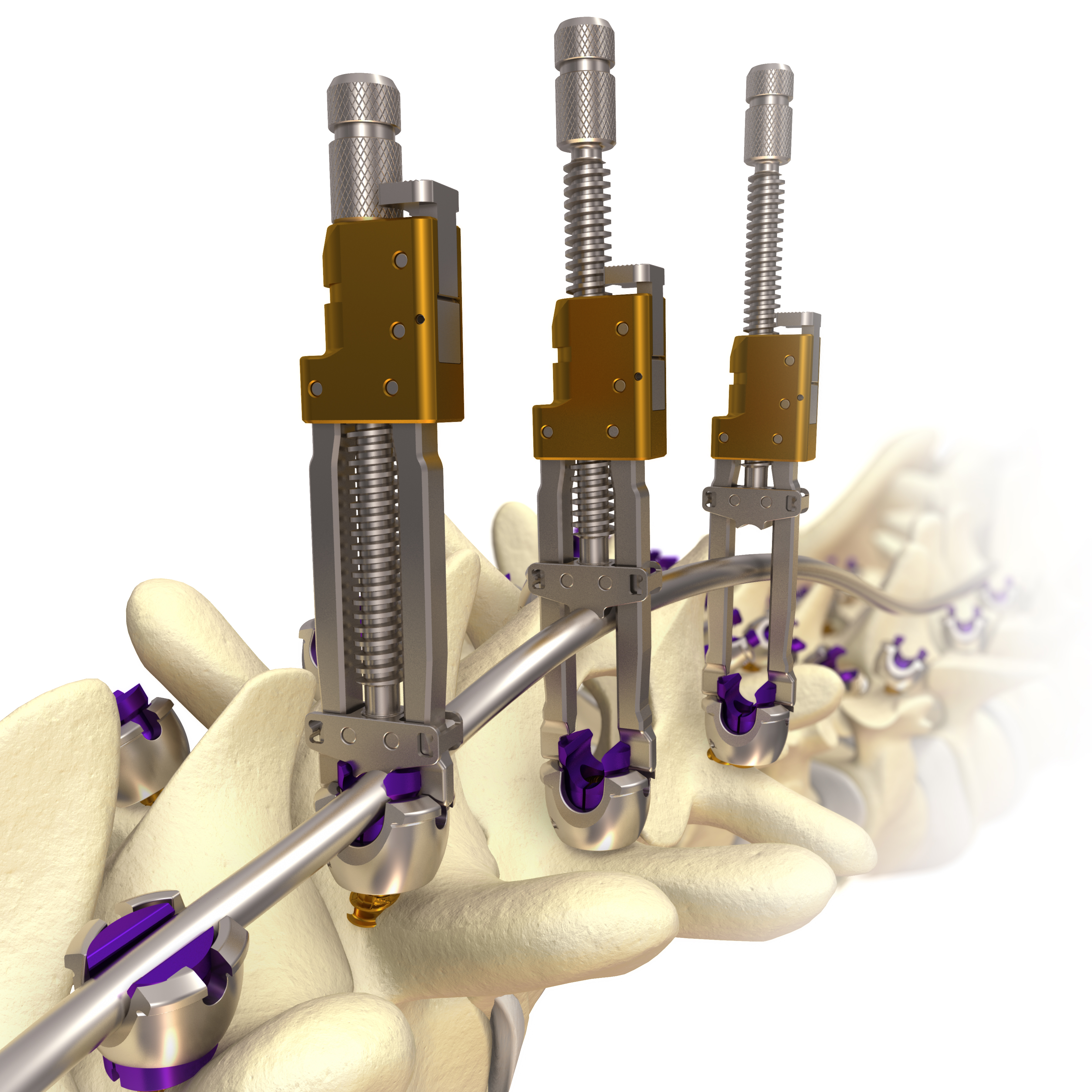

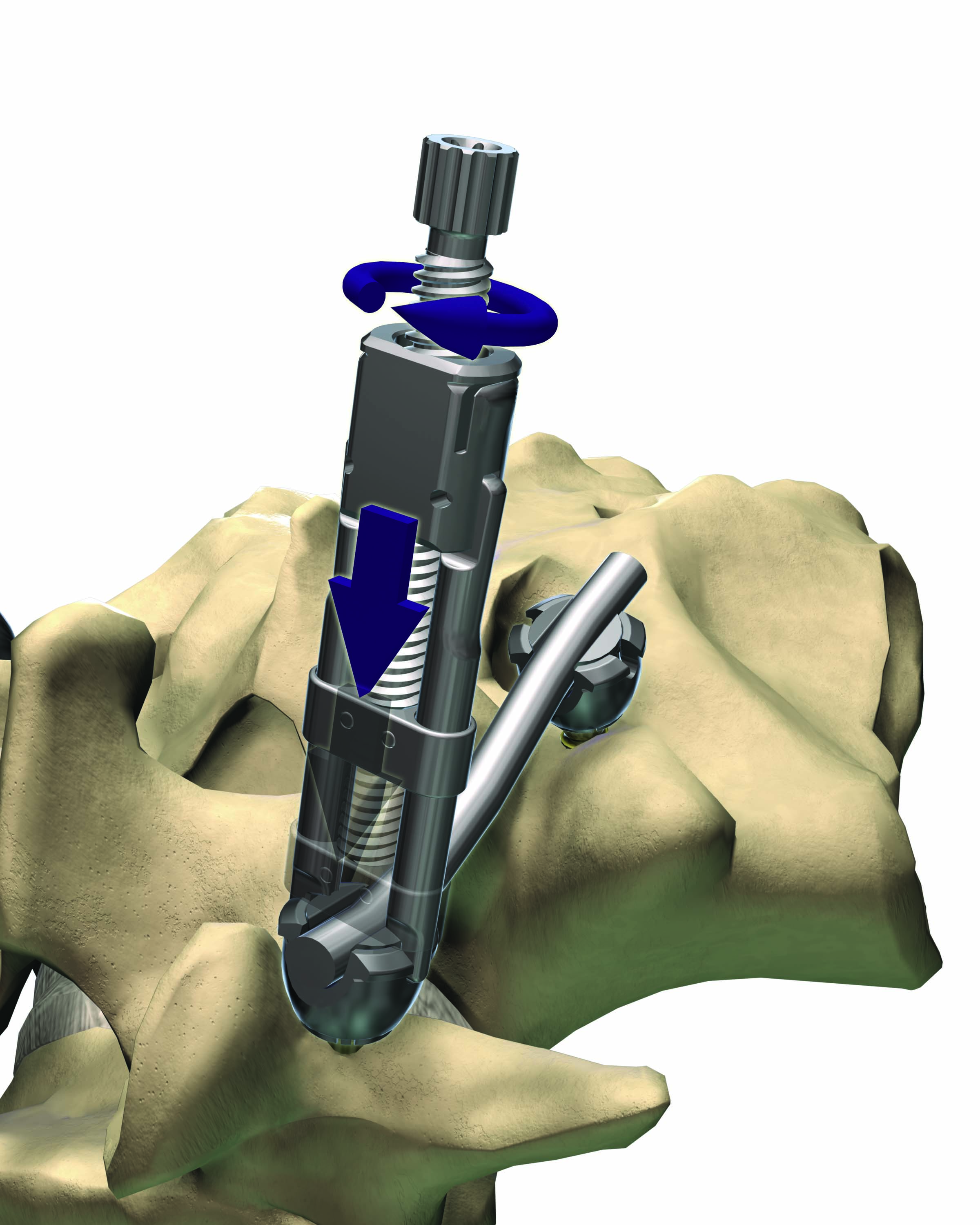

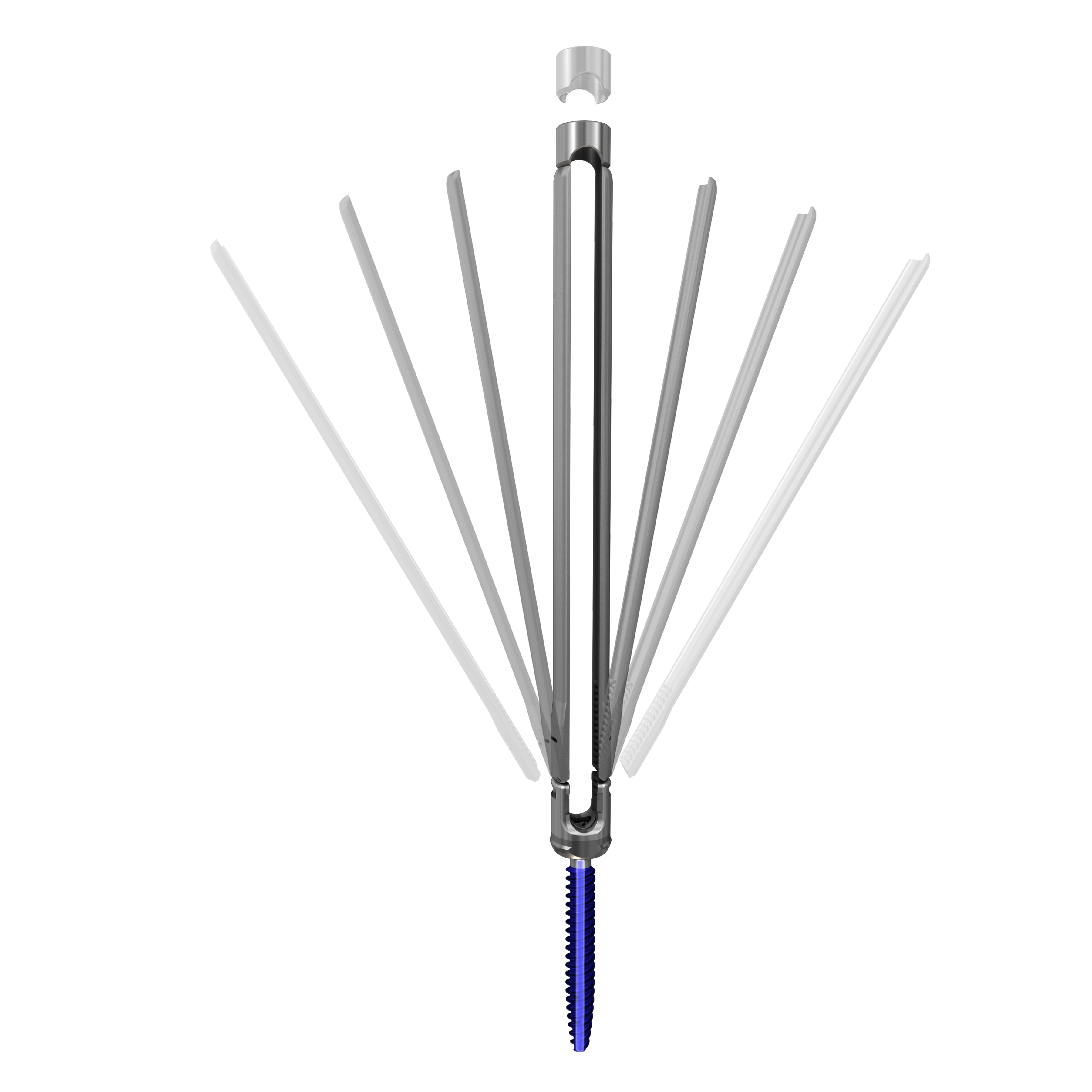

MESA Deformity Spinal System | | A low-profile spinal screw technology, used during deformity correction, featuring our proprietary locking mechanism that eliminates the need for a secondary locking feature and reduces rotational force on the spine during implantation, coupled with instrumentation to address complex spine conditions. | 2006 |

| | | | |

|

| | | |

| Selected Products | Image | Description | Market Introduction |

| MESA 2 Deformity Spinal System | | Our next-generation MESA technology poised to address the most difficult correction maneuvers for complex spinal pathologies, featuring top-loading, low-profile, screws and Zero-Torque Technology. The streamlined instrumentation is designed for efficiency and speed.

| 2015 |

| | | | |

| EVEREST Deformity Spinal System | | Top-loading pedicle screw system featuring

a variety of screw types and the ability

to accommodate titanium and cobalt chrome rods

of two different diameters. The instrumentation is designed to address the most difficult correction maneuvers for complex spinal pathologies.

| 2015 |

| | | | |

NILE Alternative Fixation | | Alternative non-pedicle based fixation technology featuring low-profile, robust implants coupled with intuitive and light ergonomic instruments, to provide solution for the most complex deformity cases. | 2015 |

| | | | |

| MESA Rail Deformity Spinal System | | An innovative “beam-like” design, used with our proprietary MESA spinal systems, that aids in the restoration of spinal balance or sagittal alignment while providing enhanced rigidity and significantly greater strength as compared to existing titanium and cobalt chrome rod offerings. | 2011 |

| | | | |

Cricket Deformity | | Spinal correction instrumentation, used with our proprietary MESA spinal screws, that provides surgeons with an innovative approach to more easily capture, manipulate and align a deformed spine as compared to traditional deformity correction instrumentation, such as threaded rod reducers or rod forks. | 2008 |

| | | | |

| Quicket Deformity | | Next generation spinal correction rod reduction instrumentation, used with our proprietary MESA spinal screws, that provides surgeons with an innovative approach to more easily capture, manipulate and align a deformed spine as compared to traditional deformity correction instrumentation.

| 2015 |

| | | | |

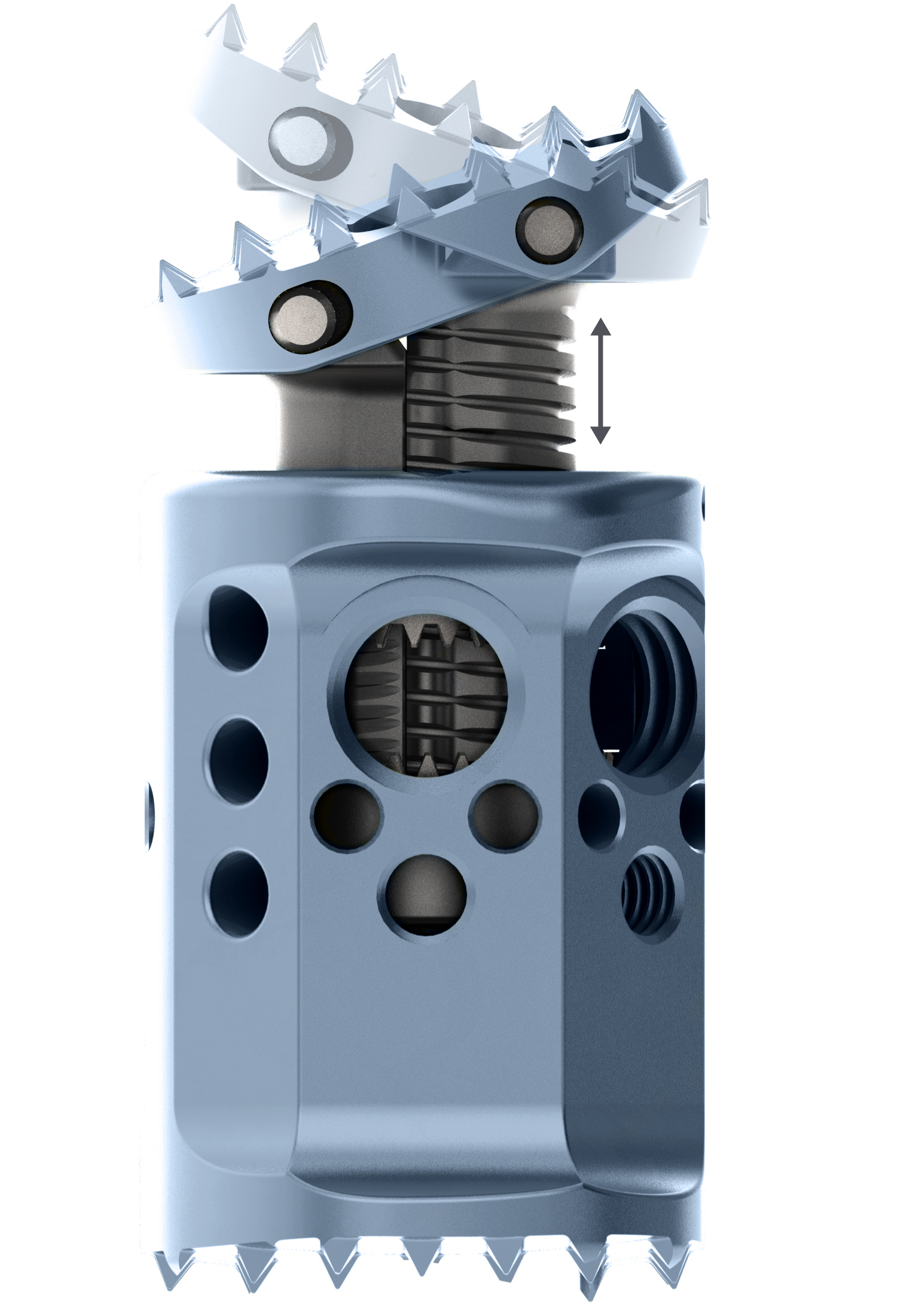

CAPRI Corpectomy Cage System | | A corpectomy cage system which provides an innovative solution for stabilization of the spine in cases of vertebral body resections resulting from trauma or tumor. Offered in various configurations, this versatile system allows for in-situ height expansion and endplate angulation. | 2015 |

| | | | |

| DENALI Deformity Spinal System | | A top loading spinal screw technology featuring off-axis screw height adjustments for ease of implant insertion. | 2006 |

|

| | | |

| Selected Products | Image | Description | Market Introduction |

| MESA Small Stature Spinal System | | A low-profile spinal screw technology, used primarily during deformity correction, featuring our proprietary locking mechanism that eliminates the need for a secondary locking feature and reduces rotational force on the spine during implantation, coupled with instrumentation to address complex spine conditions in smaller stature patients. | 2012 |

| | | | |

MESA Rail Small Stature Spinal System | | An innovative “beam-like” implant, used with our proprietary MESA spinal screws, that aids in the restoration and maintenance of spinal alignment or sagittal balance in smaller stature patients, while providing enhanced rigidity and strength as compared to existing titanium and cobalt chrome rod offerings. | 2012 |

| | | | |

MESA Mini Spinal System | | A low-profile spinal screw technology, used during deformity correction, featuring our proprietary locking mechanism that eliminates the need for a secondary locking feature and reduces rotational force on the spine during implantation, coupled with instrumentation to address complex spine conditions in the upper regions of the spine. | 2008 |

| | | | |

| SERENGETI Complex Spine Minimally Invasive Retractor System | | A minimally invasive retractor system featuring one- step placement of screws and retractors, thereby reducing the number of surgical steps, while allowing for direct visualization, improved access to the spine and specialized instrumentation to facilitate multi-level corrections of complex spine pathologies. | 2011 |

| | | | |

RAVINE Complex Spine Lateral Access System | | A minimally invasive retractor system that represents an innovative design departure from standard tubular retractors, facilitating retractor placement, positioning and fixation to the patient’s anatomy to allow for endplate to endplate visualization and multi-level alignment through a lateral access approach for large construct resection procedures. | 2013 |

| | | | |

| SANTORINI Corpectomy Cage System | | An expandable vertebral body replacement device made of biocompatible polymer (polyether ether ketone, or PEEK) for radiographic visibility that allows for intra-operative height adjustment. | 2012 |

Minimally Invasive Surgery

We define MIS technologies and techniques as spinal implants and instruments used to facilitate and treat spinal pathologies through minimally invasive approaches to the spine. These include patented technologies for a lateral approach, oblique approach and posterior access to the patient's spinal anatomy.

|

| | | |

| Selected Products | Image | Description | Market Introduction |

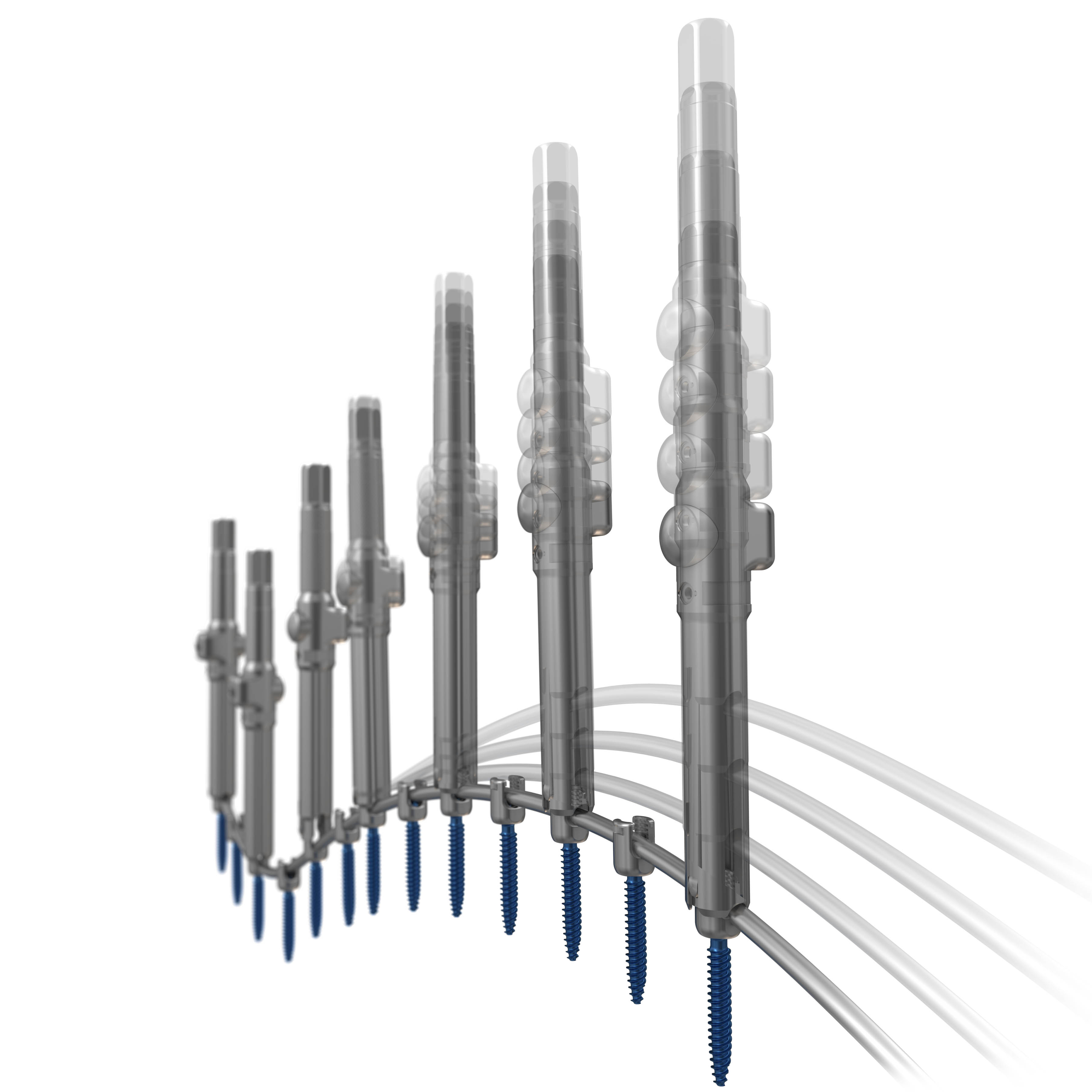

| SERENGETI Minimally Invasive Retractor System | | A minimally invasive retractor system featuring one-step placement of screws and retractors, thereby reducing the number of surgical steps, while allowing for direct visualization and improved access to the spine. | 2006 |

| | | | |

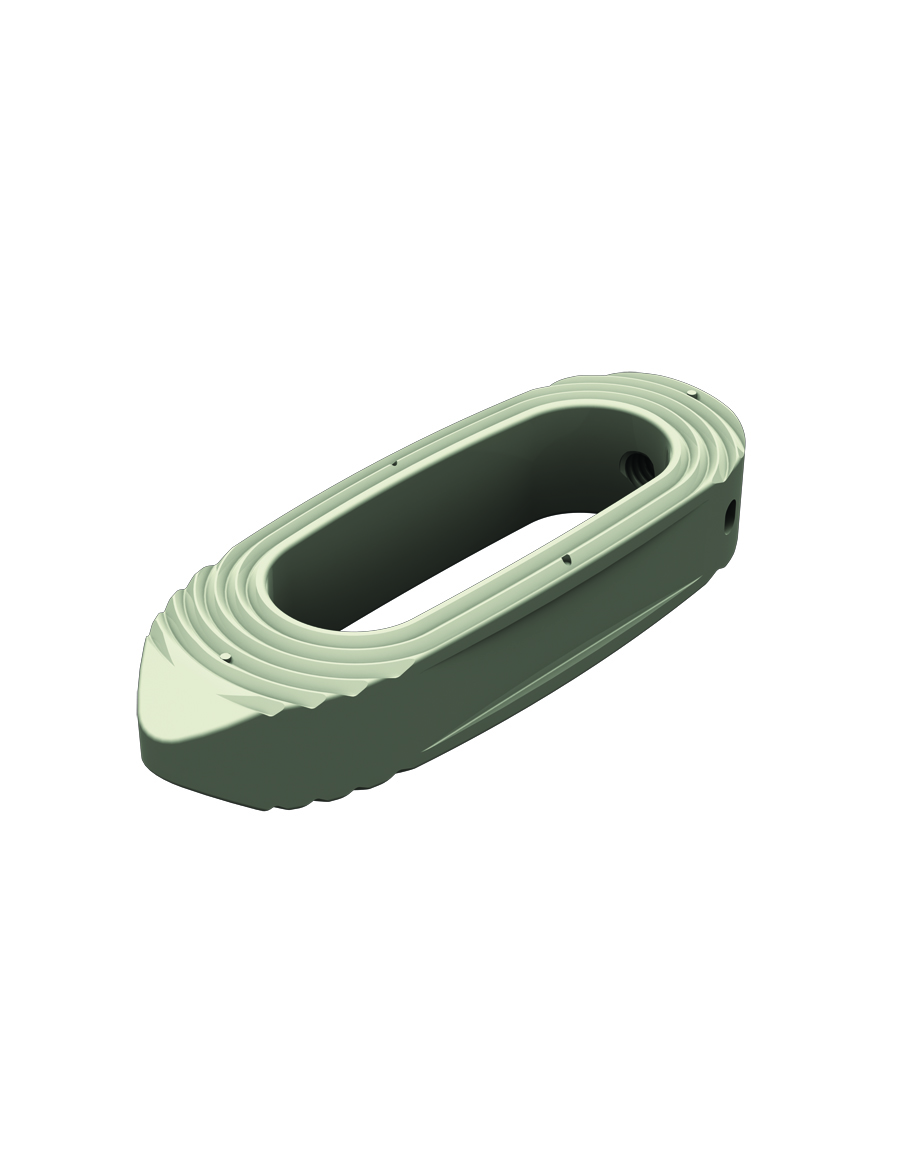

RAVINE Lateral Access System | | A minimally invasive retractor system that represents an innovative design departure from standard tubular retractors, facilitating retractor placement, positioning and fixation to the patient’s anatomy to allow for endplate to endplate visualization and multi-level alignment through a lateral access approach. | 2010 |

| �� | | | |

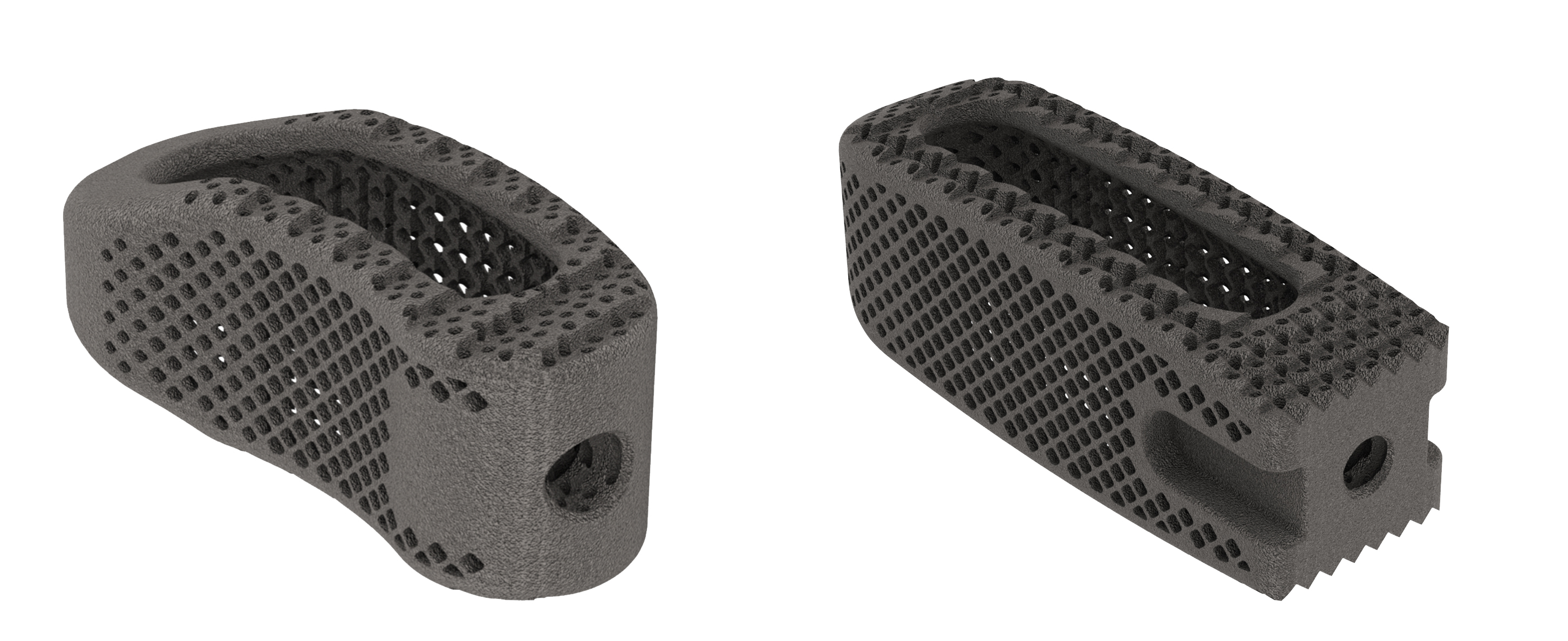

CASCADIA Lateral Interbody System

| | A 3D-printed titanium interbody device utilizing our innovative Lamellar Titanium Technology to allow the potential for both bony ongrowth and ingrowth while maintaining a high degree of radiolucency and an overall stiffness similar to PEEK. The system is designed to work in conjunction with the RAVINE Lateral Access System.

| 2015 |

| | | | |

ALEUTIAN Lateral Interbody System | | An intervertebral implant made of biocompatible polymer (PEEK) for radiographic visibility, designed to be inserted with RAVINE refractor systems to provide spinal column support through lateral MIS access. | 2010 |

| | | | |

| TERRA NOVA Minimally Invasive Access System | | A distractor blade system designed to be used in conjunction with the SERENGETI retractor systems to provide the ability to simultaneously retract tissue while distracting the intervertebral disc space to allow for decompression and access for implant insertion. | 2007 |

|

| | | |

EVEREST Minimally Invasive Spinal System | | Cannulated top-loading polyaxial pedicle screw system featuring the ability to accommodate titanium and cobalt chrome rods of two different diameters. The innovative dual-lead thread pattern allows for faster insertion and demonstrates increased pullout strength. The mixed metal tulip minimizes head splay and improves mechanical performance. | 2014 |

| | | | |

EVEREST Minimally Invasive XT Spinal System | | Cannulated top-loading polyaxial pedicle screw featuring rigid closed top break-off extension tabs for MI rod passage. Inner threads provide 25 mm of reduction while streamlined instrumentation provides a simple two step extension tab removal technique. The innovative dual-lead thread pattern allows for faster insertion and demonstrates increased pullout strength.

| 2016 |

Degenerative Spine

Our degenerative spine technologies are used to treat degenerative spine disorders and include products such as cervical, thoracic and lumbar spinal fusion devices and interbody devices. Many of our products designed for use in degenerative spine procedures incorporate our proprietary EVEREST technology.

|

| | | |

| Selected Products | Image | Description | Market Introduction |

| EVEREST Degenerative Spinal System | | A spinal screw technology that we believe, based on internal testing, provides for improved insertion speed, industry-leading pull-out strength and the versatility to accommodate a variety of titanium and cobalt chrome rods of two different diameters. | 2011 |

| Selected Products | Image | Description | Market Introduction |

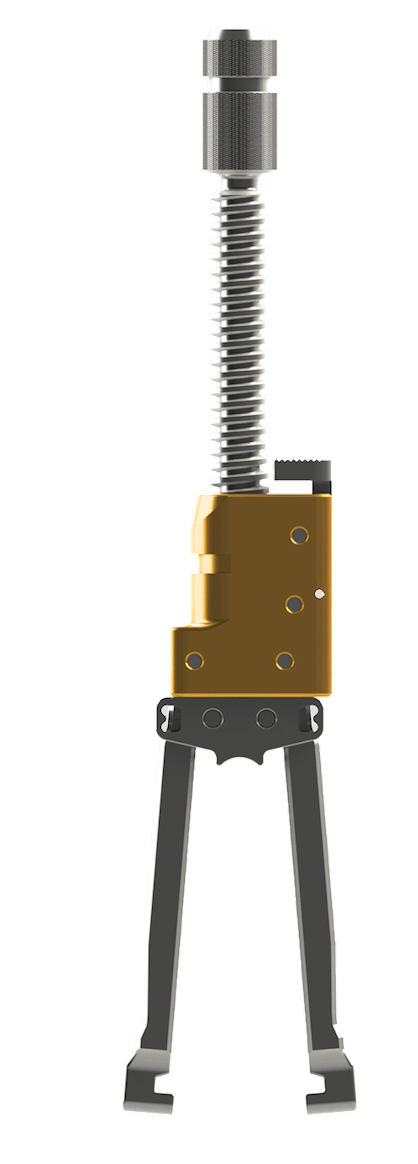

BaseCamp Rod Reduction Technology | | Versatile rod reduction technology which allows for controlled symmetrical and asymmetrical reduction of the vertebral body for spondylolithesis. | 2014 |

| | | | |

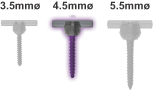

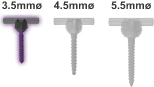

| CASCADIA AN and TL Interbody Systems | | 3D-printed titanium interbody devices in AN and TL configurations utilizing our innovative Lamellar Titanium Technology to allow the potential for both bony ongrowth and ingrowth while maintaining a high degree of radiolucency and an overall stiffness similar to PEEK. | 2015 |

| | | | |

| ALEUTIAN Interbody Systems | | Full range of anatomically designed intervertebral implants made of biocompatible polymer (PEEK) for radiographic visibility and use in multiple spinal applications | 2005 |

| | | | |

RHINE Cervical Disc System

| | Cervical disc system featuring a one-piece compressible polymer core design with dome-shaped, plasma-coated endplates and a central-split keel, with proprietary molding technology incorporated to minimize wear between the polymer core and metal titanium alloy endplates.

| 2016 |

| | | | |

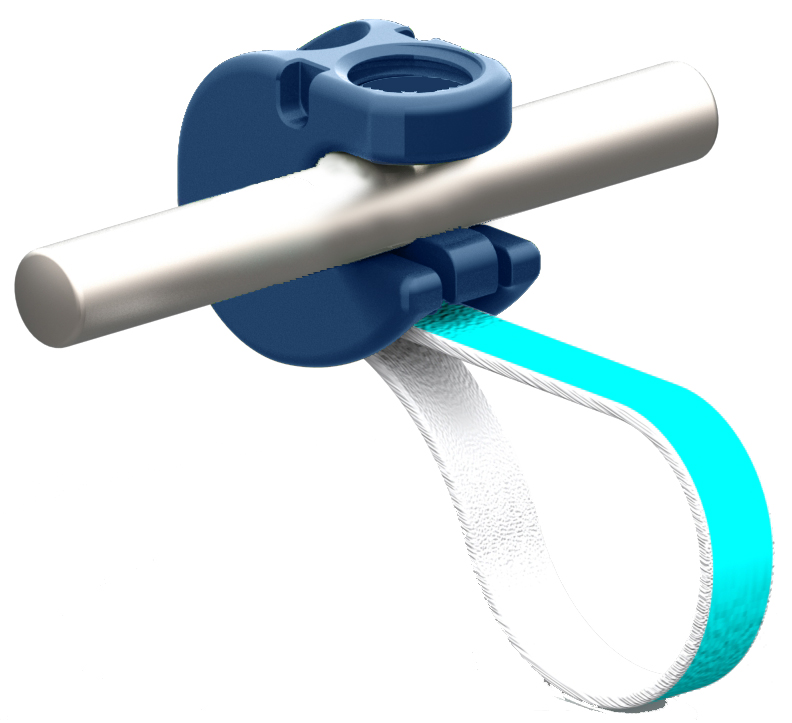

| CHESAPEAKE Interbody Systems | |

Multi-screw intervertebral implants providing surgeons with the flexibility to insert screws at various angles and lock them to an implant with our tifix one-step locking mechanism to stabilize the spine while reducing the need for supplemental fixation. | 2010 |

| | | | |

|

| | | |

| Selected Products | Image | Description | Market Introduction |

| PYRENEES Cervical Plate Systems | | Low-profile plates for treating the cervical spine that provide surgeons with the flexibility to insert screws at various angles and lock them to an implant with our tifix one-step locking mechanism. | 2005 |

| | | | |

| BLUE RIDGE Hybrid Cervical Plate System | | A plate technology for treating the cervical spine providing surgeons with the flexibility to create constrained, semi-constrained or hybrid screw constructs. | 2011 |

Product Pipeline

In addition to our comprehensive commercialized product portfolio, we plan to continue developing innovative new technologies and techniques to enhance our robust product pipeline. Our next generation product development efforts will remain focused on the complex spine and MIS markets.

In the complex spine market, we are continuing the rollout of several products, including our next-generation MESA 2 Deformity Spinal System, our NILE Alternative Fixation System, our EVEREST Deformity Spinal System and our CAPRI Corpectomy Cage System. Our product development efforts include an offering to provide a mechanical solution to treat patients suffering from proximal junctional kyphosis, or PJK, one of the most challenging post-surgical complications found in approximately 30% of deformity procedures. Our PJK product development effort is being led by a number of global key opinion leaders in complex spine surgery.

In the MIS market, we received 510(k) clearance in September 2015 and performed the first U.S. and abroad, surgical cases for our EVEREST Minimally Invasive (MI) XT Spinal System, intended for treating patients with degenerative disc disease and spondylolisthesis through a minimally invasive approach. We expect to fully launch EVEREST MI XT in 2016.

In addition to our product development efforts in complex spine and MIS, we also innovate products to address the degenerative spine market with new technologies. We recently received a CE Marking for the RHINE Cervical Disc System, our new cervical artificial disc that includes a proprietary polymeric core that provides motion and loading characteristics identified to us by spine surgeons interested in motion preservation. We expect to introduce RHINE in Europe in 2016. We will also continue to expand our CASCADIA family of interbody systems, featuring our innovative Lamellar Titanium Technology that incorporates a porous structure along with rough surfaces to allow for bony integration throughout the implant. Overall, we expect to introduce five to eight new product or product line extensions during 2016.

Research and Product Development

We have made significant investments in our product development capabilities to enhance our product lines, and believe that ongoing research and development efforts are essential to our success. Our product design teams consist of surgeon advisors, product managers, engineers and clinical and regulatory personnel who work closely together in an integrated product development process to design, enhance and validate our technologies and techniques.

These product design teams conceptualize technologies and then build and test prototypes utilizing in-house and third- party prototyping and testing facilities. As part of the development process, spine surgeons evaluate the implantation of the product in our cadaveric laboratory to ensure it meets the needs of both surgeons and patients. Prototypes are then quickly refined or redesigned as necessary based on the results of the product testing, allowing us to perform rapid iterations of the design-prototype-test development cycle.

Our regulatory and clinical affairs personnel allow us to anticipate and resolve any potential issues at early stages in the development cycle. Our regulatory and clinical affairs personnel are able to submit regulatory filings shortly after the final development testing has been completed and are committed to timely and responsive communication with regulatory agencies. We have demonstrated an ability to gain rapid regulatory approvals of our technologies.

Our research and development expense was $19.9 million, $16.3 million and $12.4 million for the years ended December 31, 2015, 2014 and 2013, respectively.

Global Spine Community Involvement, Education and Training

We devote significant resources towards global surgeon education on the proper use of our technologies and techniques. This education includes approved patient indications, contra-indications and overviews of the features and clinical benefits of our products. For example, we support local, regional, national and global educational courses, intensive hands-on cadaveric training and product-based programs that include didactic sessions coupled with hands-on-lab segments to allow surgeons to learn and experience new technologies.

We believe that our success has been, and will continue to be driven by, the quality of our products and reputation within the spine surgeon community. We collaborate with spine surgeons in various aspects of our strategy and product development. These spine surgeons are compensated pursuant to written agreements with us. These written agreements generally provide for compensation on an hourly-basis for time spent on our projects and may entitle such surgeons to royalties. We also work with surgeons and other healthcare professionals in the area of clinical research in order to gain a better understanding of the safety and efficacy of our products and support the necessary requirements for product clearances and registrations internationally.

As an active member of the global spine community, we support and maintain a presence in trade and industry organizations, including the Scoliosis Research Society and the Pediatric Orthopedic Society of North America, as well as other local, regional, national and international spine societies. At these meetings, we demonstrate the clinical benefits of our products to surgeons and generate awareness among these societies as to the clinical benefits of our innovative technologies and techniques.

We provide charitable support to the medical community and the community in general. We also provide financial and product support to international medical missions in underdeveloped countries around the world and to local community charitable causes.

Sales and Marketing

We promote, market and sell our products through a global hybrid sales organization comprised of direct sales employees, including complex spine and MIS product specialists, independent agencies and distributor partners. Our hybrid U.S. sales organization consists of 124 direct sales employees and 85 independent sales agencies. Each direct sales employee and independent sales agency is assigned a defined territory.

In 2015, international sales represented approximately 28.1% of our revenue. Our international sales organization includes over 39 direct sales employees, primarily located in the United Kingdom and Germany. In addition, we directly manage 10 independent agencies in Italy and Canada and sell to 26 distributors in certain other international markets. Combined, these international distribution efforts permit us to market and sell our products in 36 countries. To support our international sales force, we deploy a number of international market managers, who leverage product fluency and local market expertise to broaden and deepen our relationships with our independent agency and distributor partners as well as to provide a direct line of communication to our surgeon customers. Our hybrid global sales organization provides us with broad geographic coverage in regions where our products are sold, including North, Central and South America, Europe, Middle East, South Africa and Asia/Pacific. We continually evaluate new market opportunities and expect to expand our international market presence.

The contractual relationships with our independent sales agencies and distributor partners generally have terms of one to five years, with automatic renewal unless otherwise terminated. Our independent sales agents are compensated based on a commission structure while our distributor partners purchase and take title to our products and resell them to their customers. These contractual arrangements may generally be terminated by us for failure to meet certain sales quotas or minimum purchase requirements or upon breach of the agreement by the counterparty. The nature of these contractual relationships vary, with certain contracts that are exclusive, some of which have limited exceptions to the exclusivity provisions, and others that are nonexclusive.

We support the efforts of both our direct sales employees and independent agency partners through the deployment of product specialists with expertise in complex spine and MIS. These specialists provide technical expertise relating to our products and engage surgeons and hospitals directly to assist them in better understanding product capabilities, value

propositions and market trends.

We have also implemented certification programs designed to ensure a sophisticated proficiency within our global sales organization in the effective promotion, marketing and selling of our complex spine and MIS products, respectively. These certification programs include in-depth training on our products and promote a detailed proficiency in and understanding of the anatomical issues, clinical pathologies and diagnosis challenges associated with complex spine surgery and MIS technologies and techniques. We make decisions on whether to be direct or utilize independent agencies or distributor partners on a market-by-market basis using a number of parameters, including the availability of sales talent with the necessary level of spinal expertise, the reputation of the sales talent with surgeons and hospitals, the results of our compliance diligence and the overall potential of the market.

We continually evaluate and refine the performance of our global sales organization using a number of tools, including metric-driven scorecards and reviews of performance relative to budgets. Our direct sales force is compensated through a combination of base salaries, individual and company-based performance bonuses, commissions and stock-based compensation. Our independent agencies are compensated with commissions and individual-based performance bonuses. Our compensation programs are designed to balance rewarding performance, incentivizing the desired sales behaviors to align with our corporate strategy and maximizing sales force retention.

Suppliers and Raw Materials

We have a strong base of over 50 third-party suppliers located primarily in the United States, with a small number located in the European Economic Area (“EEA”), that manufacture our products. We work with these suppliers in support of our supply chain strategy, which involves minimizing our capital investment, controlling costs and shortening cycle times. We believe this allows us to compete with larger volume manufacturers of spine surgery products. We work closely with our suppliers to ensure our inventory needs are met while maintaining high quality and reliability.

We select our suppliers carefully. Our internal Quality Assurance and Supply Chain groups conduct on-site audits of our suppliers. As suppliers meet our internal quality control standards they are added to our approved supplier list. We regularly audit our suppliers to ensure they meet FDA, International Organization for Standardization (“ISO”) and other country-specific requirements as necessary. In addition, suppliers of our biomaterials products are certified by the American Association of Tissue Banks. Our Quality Assurance and Supply Chain groups conduct annual audits to ensure continued compliance with our standards; our suppliers provide a certificate of compliance with every shipment of inventory that we receive in conformance with our quality control standards. Our Quality Control group also performs incoming inspection of our products, in-process inspections and packaging and labeling inspections onsite at our headquarters facility.

We generally do not have long-term supply contracts with our suppliers and they are not required to provide us with any guaranteed minimum production levels. In most cases, we maintain redundant manufacturing capabilities for each of our products to ensure our inventory needs are met. We do, however, have single or limited source contracts with certain suppliers, who provide our biomaterials and materials for select interbody products.

We believe our supplier relationships will be able to support our potential capacity needs for the foreseeable future. To date, we have not experienced any significant difficulty locating and obtaining the suppliers or materials necessary to fulfill our production requirements.

Intellectual Property

Our success depends upon our ability to protect our intellectual property. We proactively protect our innovations by filing

U.S. and foreign patent applications, and our growing intellectual property portfolio reflects significant investment. We have also acquired intellectual property rights via the strategic purchase and license of patents from third parties to complement our internally-developed intellectual property holdings. We utilize specialist intellectual property lawyers to oversee our intellectual property assets. As of December 31, 2015, we owned 175 issued U.S. patents, 123 issued foreign patents, 127 pending U.S. patent applications and 101 pending foreign patent applications. As of December 31, 2015, we also had 28 U.S. trademark registrations, 83 foreign trademark registrations, seven pending U.S. applications to register trademarks and seven foreign applications to register trademark registrations.

We license certain technologies used in our MESA products from Spinal LLC pursuant to an exclusive license agreement, which provides us with an exclusive license to the MESA technology and related patents and patent applications to treat diseases of or injuries to the spine until the expiration of all patents licensed pursuant to the agreement, which is expected

to be in February 2024 for the material patents currently licensed under this agreement. Under this license agreement, we are required to make royalty payments equal to 6.0% of the net sales of our products that incorporate the MESA technology, subject to an annual minimum royalty payment of $0.4 million.

In addition, we license our tifix one-step locking technology from Dr. Dietmar Wolter pursuant to a license agreement, which provides us with an exclusive license to use such technology in the field of spinal surgery in the United States and a non-exclusive license to use such technology internationally until the expiration of all patents licensed pursuant to the agreement, which is expected to be in December 2019. Under the terms of this license agreement, we are required to make payments equal to 9.0% of net sales of products that incorporate tifix technology.

In 2011, we acquired certain proprietary spinal disc implant technologies that were developed and used in our recently commercialized RHINE™ Cervical Disc System, pursuant to an asset purchase agreement, which could require additional payments up to approximately $13.4 million if certain milestones are met, including milestones related to U.S. regulatory applications and approvals as of December 31, 2015. In addition, milestone payments of $0.5 million, $2.0 million and $4.0 million are due upon the achievement of net sales from products incorporating such proprietary technologies of $10.0 million, $25.0 million and $50.0 million, respectively. We will also be required to make royalty payments equal to 7.0% of net sales from patented products, up to an aggregate amount of $20.0 million.

In 2010, we acquired all rights to certain technologies used in our EVEREST pedicle screw system from Dr. John Carbone, pursuant to an asset purchase agreement, which requires us to make payments to Dr. Carbone equal to 3.5% of the net sales from EVEREST pedicle screws and 1.5% of the net sales from any of our other products that incorporate certain elements of our EVEREST screw technology until the expiration of the last to expire U.S. patent related to such technologies, which is expected to be in August 2031, or, if no U.S. patent issues, for 10 years from product launch, (except that we will have no obligation to make such payments on any sales of products made after February 23, 2031).

In 2007, we acquired all rights to certain technologies used in our SERENGETI retractor system from Dr. Josef Gorek, which requires us to make royalty payments equal to 3.0% of net sales from products that incorporate the SERENGETI retractor technology, subject to a minimum annual royalty of the greater of (1) $25 for each retractor sold or used in surgery or (2) $178,375. If we market a non-disposable reusable product incorporating the SERENGETI retractor technology, we will pay to Dr. Gorek a royalty of $25 for each use of such reusable product to place a screw implant in surgery, with a minimum royalty of $100 per surgery in which such reusable product is used. We are required to make such royalty payments on the net sales of any such product until the expiration of the last to expire U.S. patent used in the SERENGETI retractor, which is expected to be in May 2029. In the event we fail to pay the minimum royalties, and do not cure such non-payment after receiving notice of such non-payment, Dr. Gorek would have the right to have one partner other than us for the assigned intellectual property.

In 2004, we acquired all rights to certain technologies used in our DENALI pedicle screw system from Fastenetix LLC and certain other persons, pursuant to an assignment agreement, which requires us to make payments to the assignors equal to 6.0% of net sales of products that incorporate our DENALI screw technology that are covered by an issued patent or described in a patent application assigned to us under this agreement until the expiration of the last to expire patent related to such technologies, which is expected to be in February 2017, and 2.0% to 3.0% of such net sales thereafter. We are also obligated to make payments to the assignors on a product-by-product basis equal to 4.0% of net sales of products that incorporate our DENALI screw technology and that are covered by intellectual property assigned to us under this agreement other than patents and patent applications until either the expiration of the last to expire issued patent relating to such intellectual property or the abandonment of all patent applications relating to such intellectual property, and 2.0% to 3.0% of such net sales thereafter. The Fastenetix parties may have the right to re-purchase the contributed intellectual property in the event we cease operations (other than due to a sale or merger) or we enter into bankruptcy, insolvency or similar proceedings.

We also rely upon trade secrets and know-how to develop and maintain our competitive position. We protect our proprietary rights in trade secrets and know-how through a variety of methods, including confidentiality agreements and proprietary information agreements with suppliers, employees, consultants, and others who may have access to our proprietary information.

Although we believe our patents are valuable, we also believe that our knowledge and experience and our trade secret information with respect to development and manufacturing processes, materials and product design have been equally important in maintaining our proprietary product lines. As a condition of employment, we generally require employees to execute a confidentiality agreement relating to proprietary information and assignment of patents and other intellectual property to us.

Seasonality

Our revenue is typically higher in the late Spring and Summer and in the fourth quarter of our fiscal year, driven by higher sales of our complex spine products, which is influenced by the higher incidence of adolescent surgeries during these periods to coincide with the beginning of summer vacation and holiday periods, In addition, due to seasonal changes in mortality rates, some scarce tissues used in our biomaterials products may be, at times, in particularly short supply.

Competition

Our currently marketed products are, and any future products we commercialize will be, subject to intense competition. We believe that the principal competitive factors in our markets are:

| |