TIMMINS GOLD CORP.

NI 43-101 F1 TECHNICAL REPORT

UPDATED RESOURCES AND RESERVES

AND MINE PLAN FOR THE

SAN FRANCISCO GOLD PROJECT

SONORA, MEXICO

Report Date: September 30, 2016

Effective Date: July 1, 2016

Prepared by:

William J. Lewis, B.Sc., P.Geo.

Ing. Alan J. San Martin, MAusIMM(CP)

Mani Verma, P.Eng.

Richard M. Gowans, B.Sc. P.Eng.

SUITE 900 - 390 BAY STREET, TORONTO ONTARIO, CANADA M5H 2Y2

Telephone (1) (416) 362-5135 Fax (1) (416) 362 5763

Table of Contents

| | | | | Page |

| | | | | |

| 1.0 | SUMMARY | 1 |

| | 1.1 | GENERAL | 1 |

| | 1.2 | PROPERTY DESCRIPTION AND LOCATION | 2 |

| | 1.3 | ACCESSIBILITY, CLIMATE, PHYSIOGRAPHY, LOCAL RESOURCES AND INFRASTRUCTURE | 4 |

| | 1.4 | HISTORY | 4 |

| | 1.5 | GEOLOGICAL SETTING AND MINERALIZATION | 5 |

| | 1.6 | EXPLORATION PROGRAMS | 6 |

| | | 1.6.1 | 2013 to 2015 Exploration Programs | 6 |

| | | 1.6.2 | Future Exploration Programs | 6 |

| | 1.7 | MINERAL RESOURCE AND RESERVE ESTIMATES | 7 |

| | | 1.7.1 | Mineral Resource Estimate | 7 |

| | | 1.7.2 | Mineral Reserve Estimate | 9 |

| | 1.8 | OPERATIONAL DATA | 10 |

| | | 1.8.1 | Production to Date | 10 |

| | | 1.8.1 | Mine Plans and Activities | 12 |

| | 1.9 | PROCESSING | 12 |

| | 1.10 | CAPITAL AND CASH COSTS | 13 |

| | | 1.10.1 | Capital Expenditures | 13 |

| | | 1.10.2 | Cash Costs | 14 |

| | 1.11 | ECONOMIC ANALYSIS | 14 |

| | 1.12 | CONCLUSIONS AND RECOMMENDATIONS | 15 |

| | | | | |

| 2.0 | INTRODUCTION | 16 |

| | | | | |

| 3.0 | RELIANCE ON OTHER EXPERTS | 20 |

| | | | | |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 22 |

| | 4.1 | GENERAL | 22 |

| | 4.2 | OWNERSHIP | 22 |

| | 4.3 | MEXICAN MINING LAW | 26 |

| | 4.4 | PERMITTING AND ENVIRONMENTAL | 29 |

| | | | | |

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, | 30 |

| | 5.1 | ACCESSIBILITY | 30 |

| | 5.2 | LOCAL RESOURCES AND INFRASTRUCTURE | 31 |

| | 5.3 | CLIMATE AND PHYSIOGRAPHY | 32 |

| | | | | |

| 6.0 | HISTORY | 33 |

| | 6.1 | SAN FRANCISCO PROPERTY AND GOLD MINE | 33 |

| | | 6.1.1 | General History Prior to Timmins Ownership | 33 |

| | | 6.1.2 | Timmins Incorporation and Ownership of the San Francisco Project | 37 |

i

| | | 6.1.3 | Timmins Exploration Programs Since 2005 | 37 |

| | 6.2 | RESOURCE AND RESERVE ESTIMATES, HISTORICAL AND RECENT | 42 |

| | 6.3 | PRODUCTION FROM THE SAN FRANCISCO PROJECT | 43 |

| | | 6.3.1 | Historical Production | 43 |

| | | 6.3.2 | Timmins Production | 44 |

| | | | | |

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 52 |

| | 7.1 | REGIONAL GEOLOGY | 52 |

| | 7.2 | PROPERTY GEOLOGY | 54 |

| | | 7.2.1 | Geology of the La Chicharra Pit | 56 |

| | 7.3 | MINERALIZATION | 57 |

| | 7.4 | OTHER PROJECTS WITHIN THE SAN FRANCISCO PROPERTY | 59 |

| | | 7.4.1 | El Durazno Project | 59 |

| | | 7.4.2 | Vetatierra Project | 61 |

| | | | | |

| 8.0 | DEPOSIT TYPES | 62 |

| | | | | |

| 9.0 | EXPLORATION | 63 |

| | 9.1 | 2013 TO 2015 EXPLORATION PROGRAMS (SAN FRANCISCO AND LA CHICHARRA DEPOSITS) | 63 |

| | 9.2 | EL DURAZNO, VETATIERRA, 1 B AREA AND LA PIMA | |

| | | PROJECTS | 64 |

| | | 9.2.1 | El Durazno Project | 64 |

| | | 9.2.2 | Vetatierra Project | 64 |

| | | 9.2.3 | 1B Area Project | 64 |

| | | 9.2.4 | La Pima Project | 65 |

| | 9.3 | MICON COMMENTS | 68 |

| | | | | |

| 10.0 | DRILLING | 69 |

| | 10.1 | DRILL TYPES AT THE SAN FRANCISCO PROJECT | 69 |

| | | 10.1.1 | Percussion Rotary Air Blast (RAB) Drilling | 69 |

| | | 10.1.2 | Reverse Circulation (RC) Drilling | 70 |

| | | 10.1.3 | Diamond Core Drilling | 71 |

| | 10.2 | EXPLORATION DRILLING 2014 TO 2015 AT THE SAN FRANCISCO MINE | 72 |

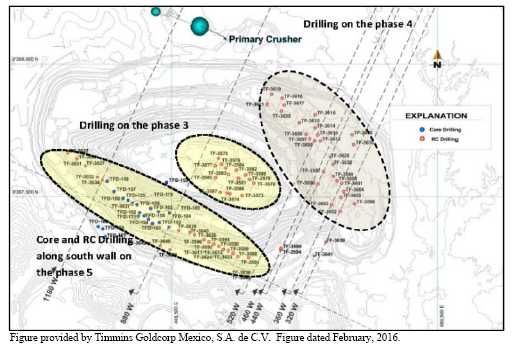

| | | 10.2.1 | 2014 In-fill RC Drilling on Phase 3 from Bench 530 | 73 |

| | | 10.2.2 | 2014 In-fill RC Drilling on Phase 4 from Bench 650 | 75 |

| | | 10.2.3 | Exploration and In-fill Drilling along the South Wall of the San Francisco Pit, Phase 5 | 78 |

| | | 10.2.4 | 2015, In-fill RC Drilling Below Phase 4 of the San Francisco Pit | 84 |

| | 10.3 | EXPLORATION DRILLING 2014 TO 2015 ON THE SAN FRANCISCO PROPERTY | 86 |

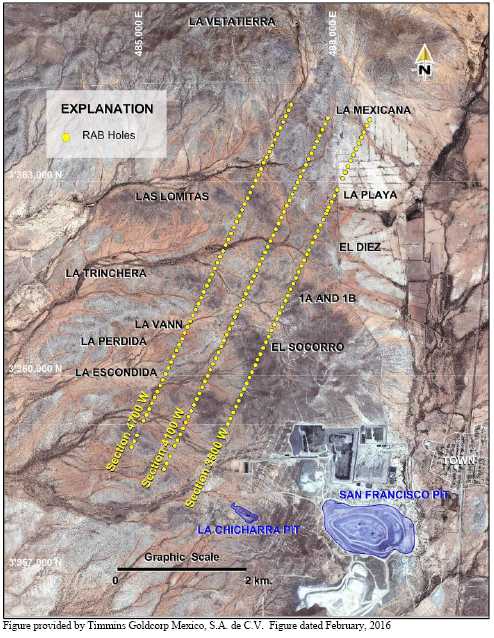

| | | 10.3.1 | RAB Drilling North of the San Francisco Mine | 86 |

| | | 10.3.2 | La Mexicana – Vetatierra RAB Drilling | 90 |

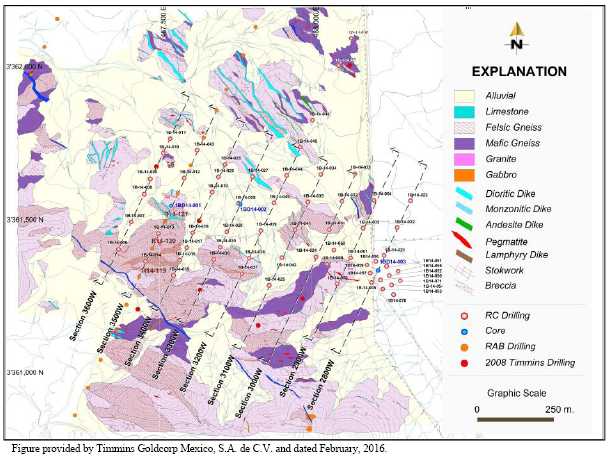

| | | 10.3.3 | 1B Area RC and Core Drilling in 2014 | 90 |

ii

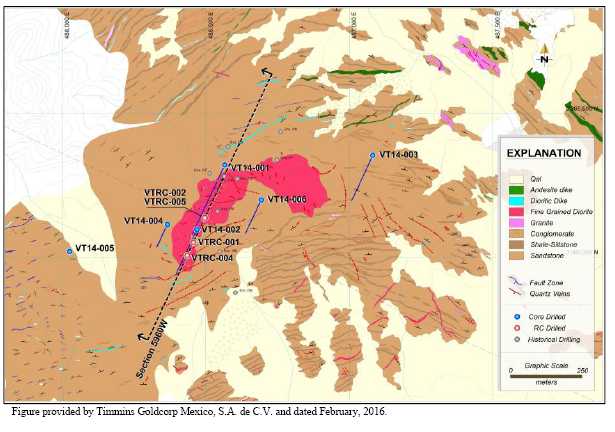

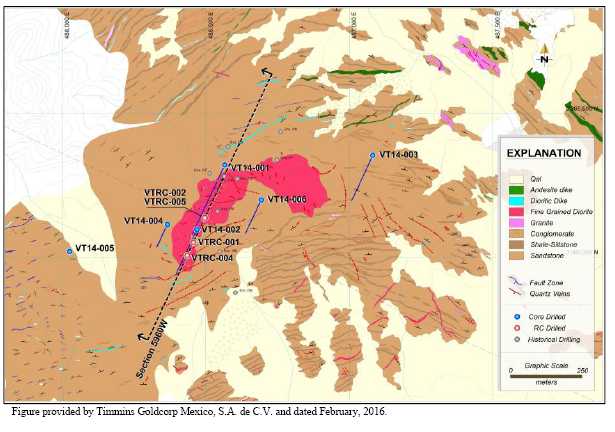

| | | 10.3.4 | Vetatierra Area | 98 |

| | 10.4 | MICON COMMENTS | 105 |

| | | | |

| 11.0 | SAMPLE PREPARATION, ANALYSES AND SECURITY | 106 |

| | 11.1 | REVERSE CIRCULATION DRILLING | 106 |

| | 11.2 | CORE DRILLING | 108 |

| | 11.3 | SAMPLE COLLECTION AND TRANSPORTATION | 109 |

| | | 11.3.1 | Reverse Circulation Drilling | 109 |

| | | 11.3.2 | RAB Drilling | 110 |

| | | 11.3.3 | Core Drilling | 111 |

| | | 11.3.4 | General Quality Control/Quality Assurance (QA/QC) Procedures | 111 |

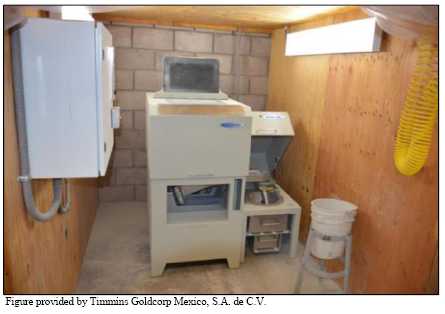

| | | 11.3.5 | Preparation Laboratories | 115 |

| | 11.4 | RESULTS OF THE QA/QC PROGRAM | 122 |

| | | 11.4.1 | Screen Metallic Sampling | 122 |

| | 11.5 | MICON COMMENTS | 125 |

| | | | | |

| 12.0 | DATA VERIFICATION | 126 |

| | 12.1 | SITE VISITS | 126 |

| | 12.2 | 2016 OPERATIONAL REVIEW | 127 |

| | 12.3 | 2016 DATABASE AND RESOURCE REVIEW | 127 |

| | | 12.3.1 | Database Verification | 127 |

| | | 12.3.2 | Resource Audit | 127 |

| | | 12.3.3 | Conclusion of the Database Verification and Resource Audit | 129 |

| | | | | |

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 130 |

| | 13.1 | TESTWORK CONDUCTED BY METCON, 2012 | 130 |

| | | 13.1.1 | Discussion of the 2012 Test Results | 130 |

| | | 13.1.2 | Quality Assurance/Quality Control | 132 |

| | 13.2 | RECENT TESTWORK CONDUCTED IN-HOUSE, 2015 | 132 |

| | | | | |

| 14.0 | MINERAL RESOURCE ESTIMATES | 134 |

| | 14.1 | CIM MINERAL RESOURCE DEFINITIONS AND CLASSIFICATIONS | 134 |

| | 14.2 | JULY 1, 2016 MINERAL RESOURCE ESTIMATE | 136 |

| | 14.3 | MINERAL RESOURCE ESTIMATION PROCEDURES | 137 |

| | | 14.3.1 | Database | 137 |

| | | 14.3.2 | Compositing | 139 |

| | | 14.3.3 | Block Model | 139 |

| | | 14.3.4 | Mineralized Outlines | 140 |

| | | 14.3.5 | Block Model Rock Domains | 140 |

| | | 14.3.6 | Specific Gravity | 141 |

| | | 14.3.7 | Grade Interpolation | 141 |

| | | 14.3.8 | Mineral Resource Classification | 142 |

| | | 14.3.9 | Block Model Validation | 142 |

| | | 14.3.10 | Resource Pit Optimization and Economic Parameters | 142 |

iii

| 15.0 | MINERAL RESERVE ESTIMATES | 145 |

| | 15.1 | CIM MINERAL RESERVE DEFINITIONS AND CLASSIFICATIONS | 145 |

| | 15.2 | MINERAL RESERVE ANALYSIS | 146 |

| | | 15.2.1 | Reserve Pit Optimization and Economic Analysis | 146 |

| | 15.3 | MINING RECOVERY AND DILUTION | 146 |

| | 15.4 | MINERAL RESERVE STATEMENT | 147 |

| | 15.5 | RECONCILIATION | 147 |

| | | 15.5.1 | Review | 147 |

| | | | | |

| 16.0 | MINING METHODS | 149 |

| | 16.1 | PRODUCTION TO DATE | 149 |

| | 16.2 | OPEN PIT MINE DESIGN | 149 |

| | | 16.2.1 | Geotechnical Studies and Slope Design Criteria | 149 |

| | | 16.2.2 | Hydrological Considerations | 153 |

| | | 16.2.3 | Phased Pit Designs | 154 |

| | | 16.2.4 | Waste Rock Management | 155 |

| | | 16.2.5 | Mine Operations | 155 |

| | | | | |

| 17.0 | RECOVERY METHODS | 158 |

| | 17.1 | PROCESSING DESCRIPTION | 158 |

| | | 17.1.1 | Crushing and Conveying | 158 |

| | | 17.1.2 | Leaching | 158 |

| | | 17.1.3 | Adsorption/Desorption/Recovery (ADR) Plants | 160 |

| | | 17.1.4 | Process Plant Layout | 160 |

| | | 17.1.5 | Manpower | 165 |

| | | 17.1.6 | Consumables and Maintenance | 165 |

| | | | | |

| 18.0 | PROJECT INFRASTRUCTURE | 166 |

| | 18.1 | ADMINISTRATION, ENGINEERING AND EXISTING INFRASTRUCTURE | 166 |

| | | 18.1.1 | Manpower Organization | 166 |

| | | 18.1.2 | Offices, Workshops and Stores | 167 |

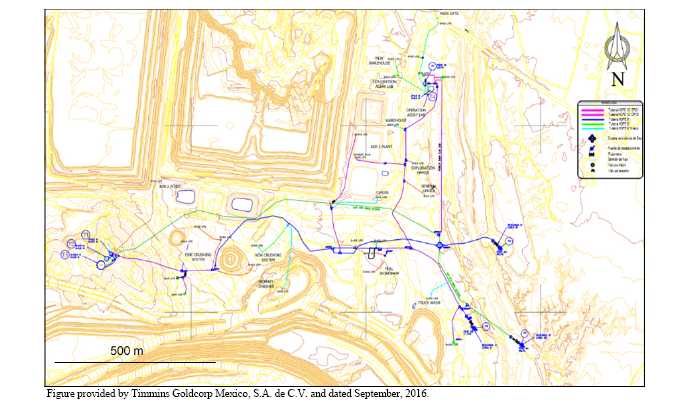

| | | 18.1.3 | Electrical Power Supply | 170 |

| | | 18.1.4 | Water Supply | 170 |

| | | | | |

| 19.0 | MARKET STUDIES AND CONTRACTS | 172 |

| | 19.1 | MARKET AND MARKET STUDIES | 172 |

| | 19.2 | MINING CONTRACTS | 173 |

| | | 19.2.1 | Contractor Requirements | 173 |

| | | 19.2.2 | Owner Mining Requirements | 174 |

| | 19.3 | REFINING AND SALES CONTRACTS | 174 |

| | | 19.3.1 | Refining Agreement | 174 |

| | | 19.3.2 | Master Purchase Contract and Bill of Sale and Trading Agreement | 175 |

| | | 19.3.3 | Blasting Services | 175 |

| | | 19.3.4 | Portable Crushing Services | 175 |

iv

| 20.0 | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL ORCOMMUNITY IMPACT | 177 |

| | 20.1 | ENVIRONMENTAL CONSIDERATIONS | 177 |

| | 20.2 | COMMUNITY AND SOCIAL CONSIDERATIONS | 178 |

| | | | |

| 21.0 | CAPITAL AND OPERATING COSTS | 181 |

| | 21.1 | CAPITAL EXPENDITURES | 181 |

| | 21.2 | CASH COSTS | 181 |

| | | | |

| 22.0 | ECONOMIC ANALYSIS | 182 |

| | 22.1 | TIMMINS 2016 ECONOMIC GUIDANCE | 182 |

| | 22.2 | SAN FRANCISCO MINE, LIFE OF MINE PLAN | 182 |

| | | | |

| 23.0 | ADJACENT PROPERTIES | 184 |

| | | | |

| 24.0 | OTHER RELEVANT DATA AND INFORMATION | 185 |

| | | | |

| 25.0 | INTERPRETATION AND CONCLUSIONS | 186 |

| | 25.1 | MINERAL RESOURCE ESTIMATE | 186 |

| | 25.2 | MINERAL RESERVES | 188 |

| | 25.3 | CONCLUSIONS | 190 |

| | | | |

| 26.0 | RECOMMENDATIONS | 191 |

| | 26.1 | FURTHER EXPLORATION EXPENDITURES AND BUDGET | 191 |

| | 26.2 | FURTHER RECOMMENDATIONS | 191 |

| | | | |

| 27.0 | DATE AND SIGNATURE PAGE | 193 |

| | | | |

| 28.0 | REFERENCES | 194 |

| | 28.1 | TECHNICAL REPORTS, PAPERS AND OTHER SOURCES | 194 |

| | 28.2 | INTERNET SOURCES | 199 |

| | | | |

| 29.0 | CERTIFICATES OF AUTHORS | 200 |

List of Appendices

| APPENDIX1 | Glossary of Terms | At end of Report |

| | | |

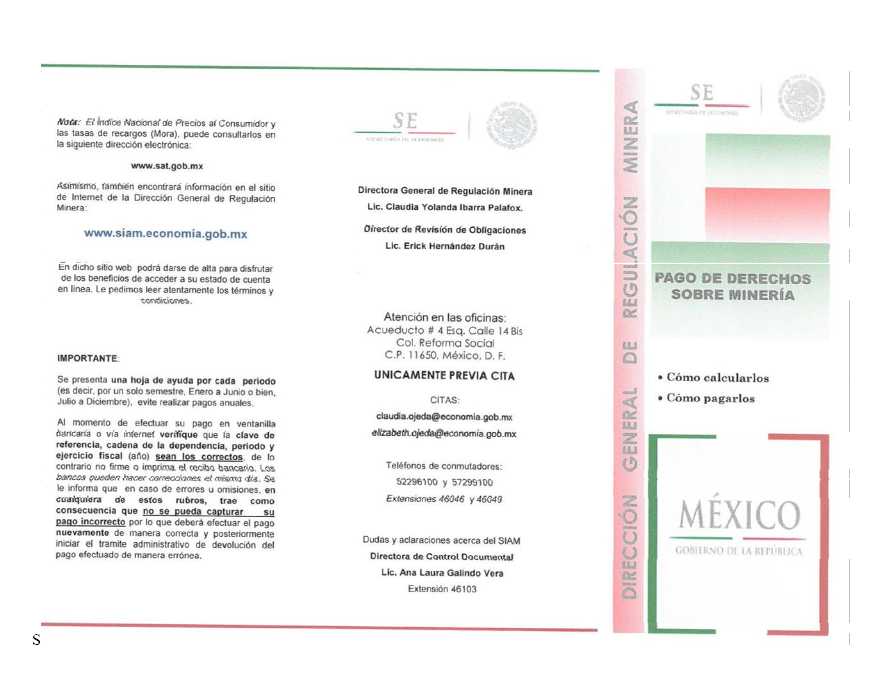

| APPENDIX2 | Official Tax as Published in the “Diario Oficial de la Federacion (DOF) as of January 28, 2016 | At end of Report |

v

List of Tables

| | | Page |

| Table 1.1 | Pit Optimization Parameters for the July 1, 2016 Resource Estimate for the San Francisco and La Chicharra Deposits | 8 |

| Table 1.2 | Mineral Resource Estimate for the San Francisco Project (Inclusive of Mineral Reserves) (USD $1,350/oz Gold Price) | 9 |

| Table 1.3 | Mineral Reserves within the San Francisco and La Chicharra Pit Design (July 1, 2016) after Mining Recovery and Dilution | 10 |

| Table 1.4 | San Francisco Project, Timmins Annual Production from April, 2010 to the End of August, 2016 by Quarter) | 11 |

| Table 1.5 | Summary of the Leach Pad Phases Based Upon the Permits Acquired for the San Francisco Mine | 13 |

| Table 2.1 | List of Abbreviations | 18 |

| Table 4.1 | San Francisco Project, Summary of Mineral Concessions (with Fees for 2016 noted) | 24 |

| Table 4.2 | San Francisco Project, Summary of the Regional Mineral Concessions (with Fees for 2016 Noted) | 27 |

| Table 6.1 | San Francisco Project, Geomaque Annual Production 1996 to 2002 | 43 |

| Table 6.2 | San Francisco Project, Timmins Annual Production from April, 2010 to the End of August, 2016 (by Quarter) | 45 |

| Table 6.3 | San Francisco Project, Timmins Annual Ore Stockpiled from April, 2010 to the End of August, 2016 (by Quarter) | 46 |

| Table 9.1 | Summary of the Exploration Expenditures for the Period July, 2013 to December, 2015 | 63 |

| Table 10.1 | Summary of the Location and Significant Assays for the RC Drilling on Phase 3 from Bench 530 to 536 | 73 |

| Table 10.2 | Summary of the Location and Significant Assays for the RC Drilling on Phase 4 from Bench 650 | 76 |

| Table 10.3 | Summary of the Location and Significant Assays for the RC Drilling on Phase 5 between Sections 880W to 1160W | 79 |

| Table 10.4 | Summary of the Location and Significant Assays for the Core Drilling on Phase 5 between Sections 880W to 1160W | 83 |

| Table 10.5 | Summary of the Location and Significant Assays for the RC Drilling Below Phase 4 of the San Francisco Pit | 85 |

| Table 10.6 | Summary of the Location, Type, Metres Drilled and Number of Drill Holes for the Programs North of the San Francisco Pit | 86 |

| Table 10.7 | Summary of the Most Significant RAB Drill Intersections along Section 3500W | 89 |

vi

| Table 10.8 | Summary of the Most Significant RAB Drill Intersections along Section 4100W | 89 |

| Table 10.9 | Summary of the Significant RAB Drill Intersections along Section 3500W | 89 |

| Table 10.10 | Summary of the Significant RAB Drilling Results for the Area Between the La Mexicana and La Vetatierra Projects | 90 |

| Table 10.11 | Summary of Significant 2014 RC Drilling Intersections in the 1B Area | 91 |

| Table 10.12 | Summary of the Significant Assay Results for the Three Core Holes Drilled in the 1B Area | 96 |

| Table 10.13 | Summary of the Significant 2014 Core Intersections at the Vetatierra Program | 99 |

| Table 10.14 | Summary of the Significant 2014 RC Intersections at the Vetatierra Program | 102 |

| Table 11.1 | Standard Reference Material Samples used During the Drilling Program | 114 |

| Table 11.2 | ALS Method Code and Description for Timmins Sample Preparation | 120 |

| Table 11.3 | ALS Method Code and Description for Timmins Sample Preparation | 120 |

| Table 11.4 | Summary of the Au-AA23 and Au-AA24 Fire Assay Fusion, AAS Finish Assay Details | 121 |

| Table 11.5 | Summary of the ALS Ag-GRA21, Ag-GRA22, Au-GRA21 and Au GRA22 Precious Metals Gravimetric Analysis Methods | 122 |

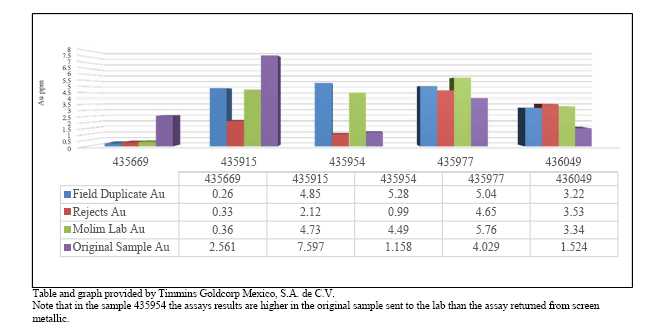

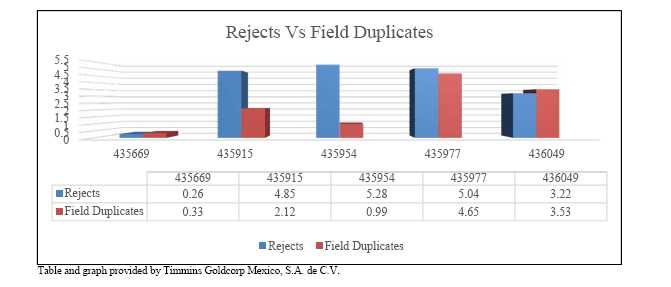

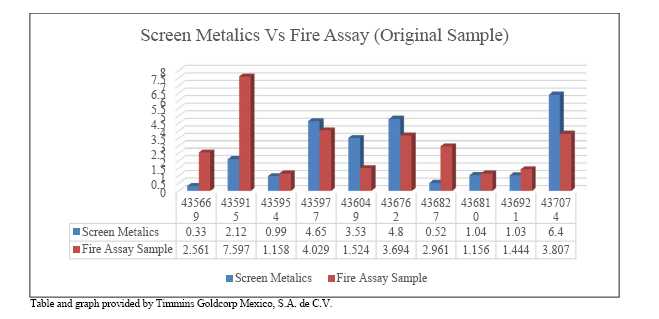

| Table 11.6 | Summary and Graph Showing the Assays Results for the Five Samples | 123 |

| Table 11.7 | Summary and Graph Showing the Gold Variation in the Five Pairs of Samples Rejects Vs Field Duplicates | 124 |

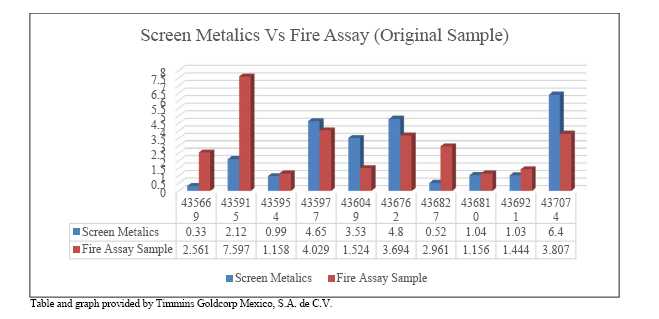

| Table 11.8 | Summary and Graph Showing the Gold Variation in the Samples Screen Metallics Vs Fire Assays | 124 |

| Table 12.1 | Summary of the Data within the Geological Domains of San Francisco and La Chicharra Mines | 128 |

| Table 13.1 | Summary of Column Leach Test Results, Crush Size P80 9.5 mm, 127 Days Leach Time | 131 |

| Table 13.2 | Summary of Column Leach Test Results, Crush Size P80 6.3 mm, 127 Days Leach Time | 131 |

| Table 13.3 | Correlation Coefficient, Daily Pregnant Solution vs. Duplicates | 132 |

| Table 13.4 | Summary of the 2015 In-House Metallurgical Testwork | 132 |

vii

| Table 14.1 | Mineral Resource Estimate for the San Francisco and La Chicharra Deposits as of July 1, 2016 (Inclusive of Mineral Reserves) (Gold Price of USD $1,350) | 136 |

| Table 14.2 | Applied Grade Capping on 3 m Composites for the San Francisco Resource Model | 138 |

| Table 14.3 | 3-D Block Model Limits and Dimensions | 139 |

| Table 14.4 | Rock Domain Code and Specific Gravity | 140 |

| Table 14.5 | Applied Search Parameters for Ordinary Kriging Grade Interpolation | 141 |

| Table 14.6 | Pit Optimization Parameters for the July 1, 2016 Resource Estimate for the San Francisco and La Chicharra deposits | 143 |

| Table 14.7 | Mineral Resource Estimate for the San Francisco Project (Inclusive of Mineral Reserves) | 144 |

| Table 15.1 | Mineral Reserves within the San Francisco and La Chicharra Pit Design (July 1, 2016) after Mining Recovery and Dilution | 147 |

| Table 16.1 | San Francisco Project, Timmins Annual Production from April, 2010 to the End of August, 2016 (by Quarter) | 150 |

| Table 16.2 | San Francisco Project, Timmins Annual Ore Stockpiled from April, 2010 to the End of August, 2016 (by Quarter) | 151 |

| Table 16.3 | Contractor’s Mining Equipment | 157 |

| Table 17.1 | Summary of the Leach Pad Phases Based Upon the Permits Acquired for the San Francisco Mine | 159 |

| Table 17.2 | Manpower at the San Francisco Mine Process Plant and Associated Facilities | 165 |

| Table 17.3 | San Francisco Process Reagents (Consumables) Usage Rates and Costs | 165 |

| Table 18.1 | Total Manpower for the San Francisco Mine | 167 |

| Table 18.2 | Summary of the Installed Transformer Capacity | 170 |

| Table 19.1 | Average Annual High and Low London PM Fix for Gold and Silver from 2002 to September 13, 2016 | 172 |

| Table 19.2 | Contract Mining Rates | 173 |

| Table 25.1 | Pit Optimization Parameters for the July, 2016 Resource Estimate for the San Francisco and La Chicharra Deposits | 187 |

| Table 25.2 | Mineral Resource Estimate for the San Francisco Project (Inclusive of Mineral Reserves) as of July 1, 2016 | 188 |

| Table 25.3 | Mineral Reserves within the San Francisco and La Chicharra Pit Design (July 1, 2016) after Mining Recovery and Dilution | 189 |

viii

List of Figures

| | | Page |

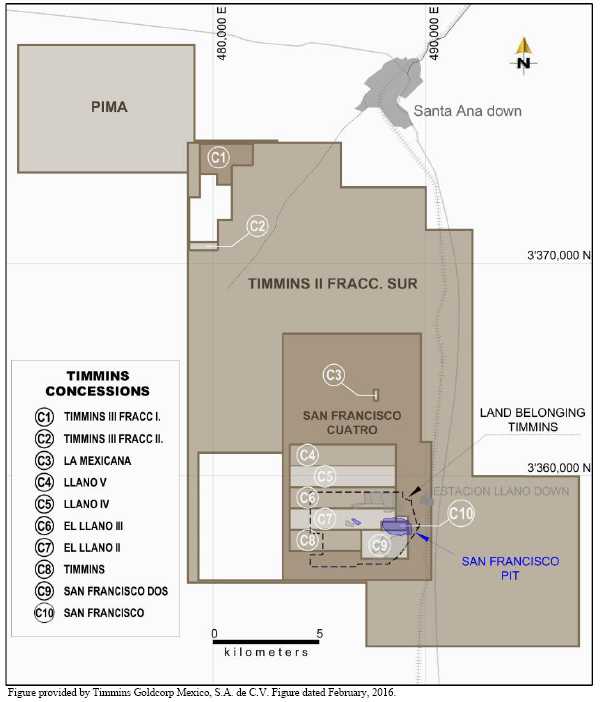

| Figure 4.1 | San Francisco Project Location Map | 23 |

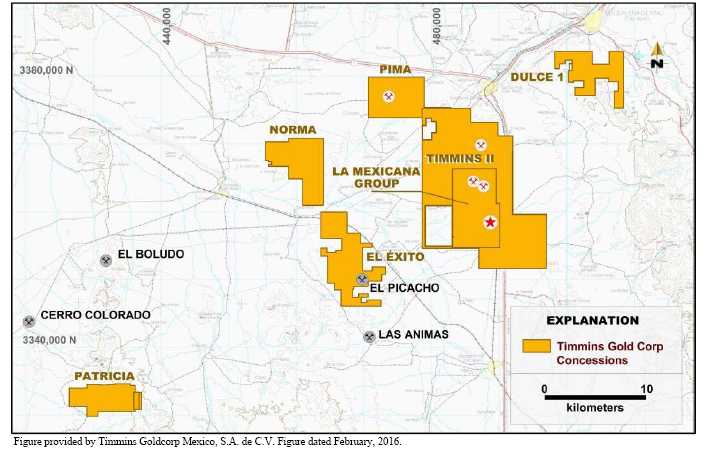

| Figure 4.2 | San Francisco Property (Concessions) Map Updated | 25 |

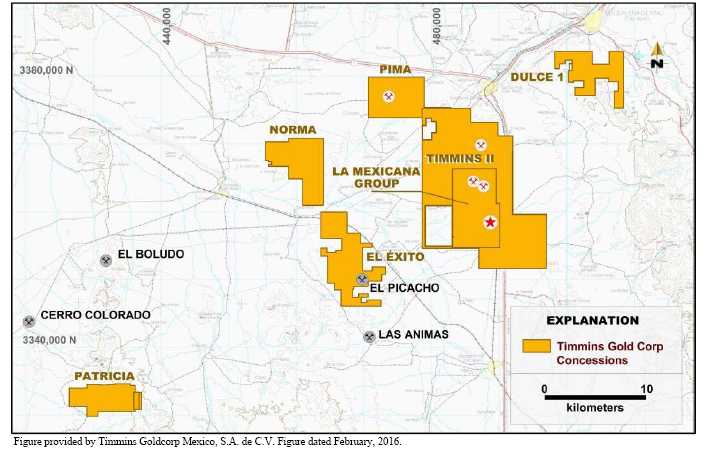

| Figure 4.3 | San Francisco Project Regional Mineral Concessions Map | 28 |

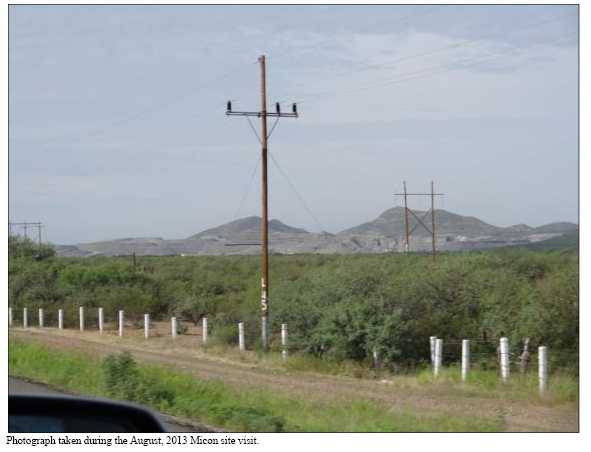

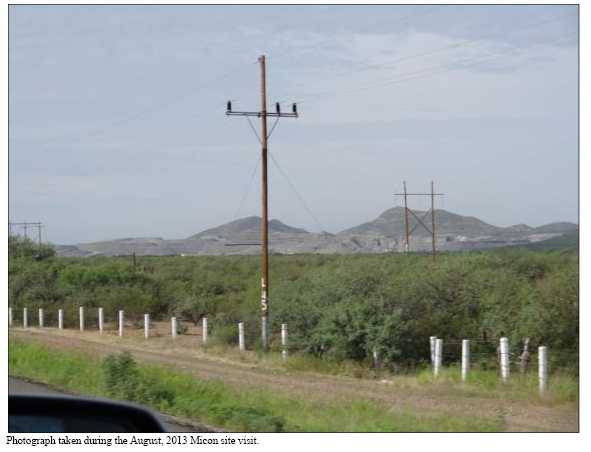

| Figure 5.1 | San Francisco Mine as Viewed from Highway 15 Driving South | 30 |

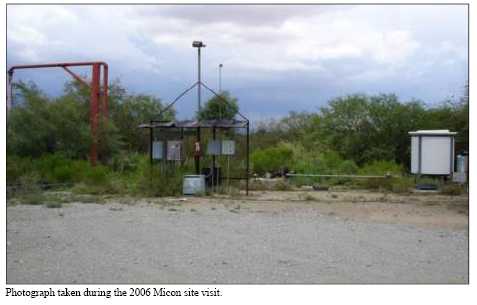

| Figure 5.2 | View of a Water Well Located on the San Francisco Project | 31 |

| Figure 5.3 | View of the Sonora Desert Surrounding the Property | 32 |

| Figure 6.1 | Location of One of the Rotary Drill Sites Located to Southeast of the Main Pit | 34 |

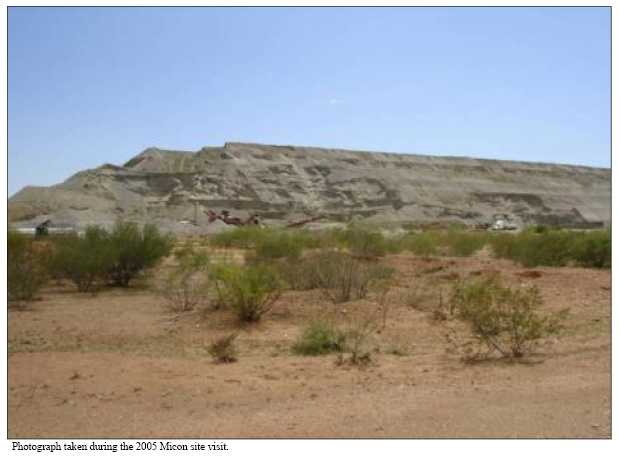

| Figure 6.2 | View of the San Francisco Gold Mine with Estación Llano in the Background (Looking Northeast) | 35 |

| Figure 6.3 | Extraction of Gravel from the Original Leach Pads for Construction Use | 36 |

| Figure 6.4 | View of the San Francisco Pit in July, 2011 (Looking West- Northwest) | 47 |

| Figure 6.5 | View of the San Francisco Pit in August, 2013 (Looking East- Northeast) | 47 |

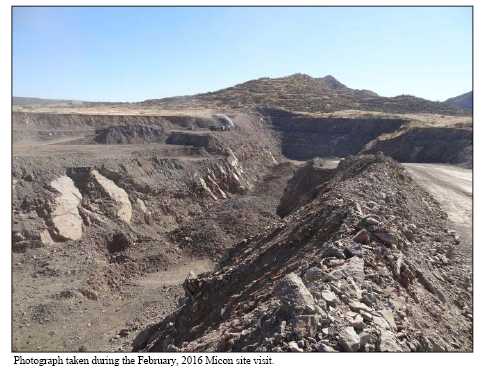

| Figure 6.6 | View of the San Francisco Pit in February, 2016 (Looking East- Northeast) | 48 |

| Figure 6.7 | View of the La Chicharra Pit in February, 2016 (Looking to the East) | 48 |

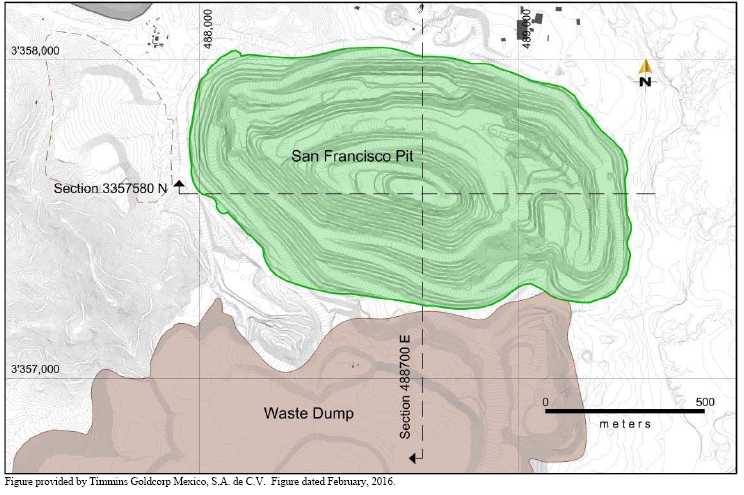

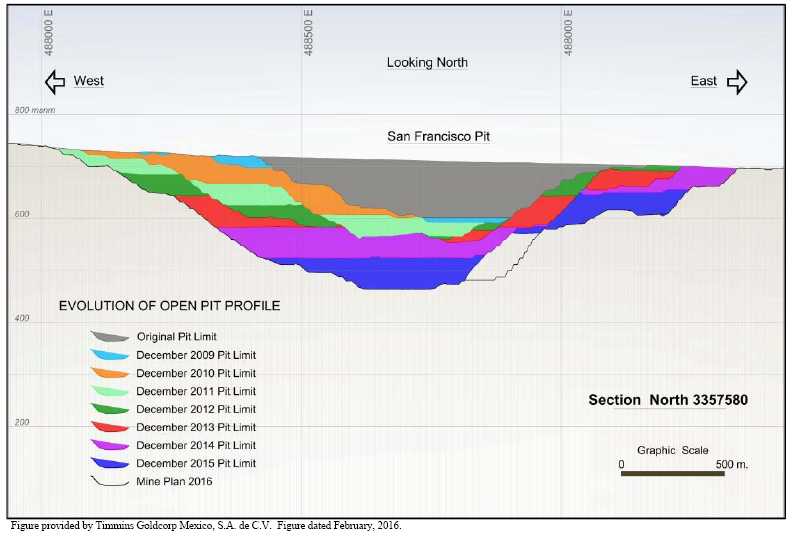

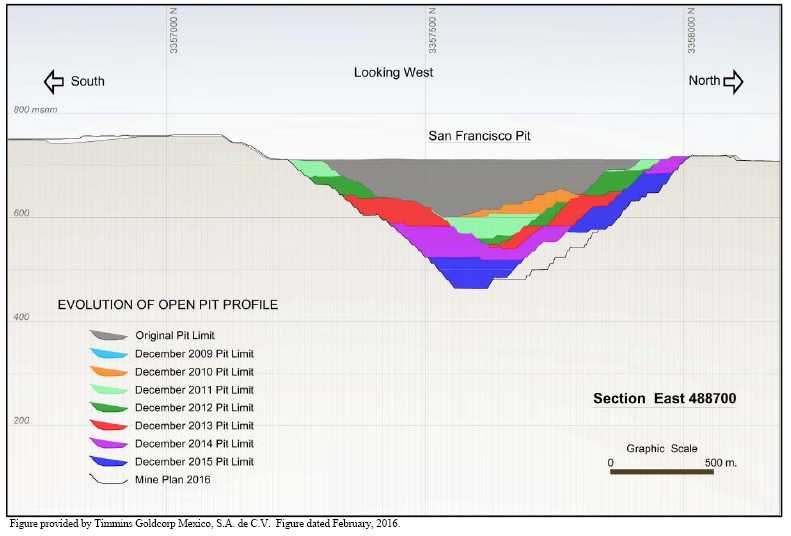

| Figure 6.8 | Plan View of the Current San Francisco Pit Showing the Location of the Longitudinal and Cross-Sections Demonstrating the Growth of the Pit Since 2009 | 49 |

| Figure 6.9 | Longitudinal Section (3357580 North) Demonstrating the Growth of the San Francisco Pit Since 2009 | 50 |

| Figure 6.10 | Cross-Section (488700 East) Demonstrating the Growth of the San Francisco Pit Since 2009 | 51 |

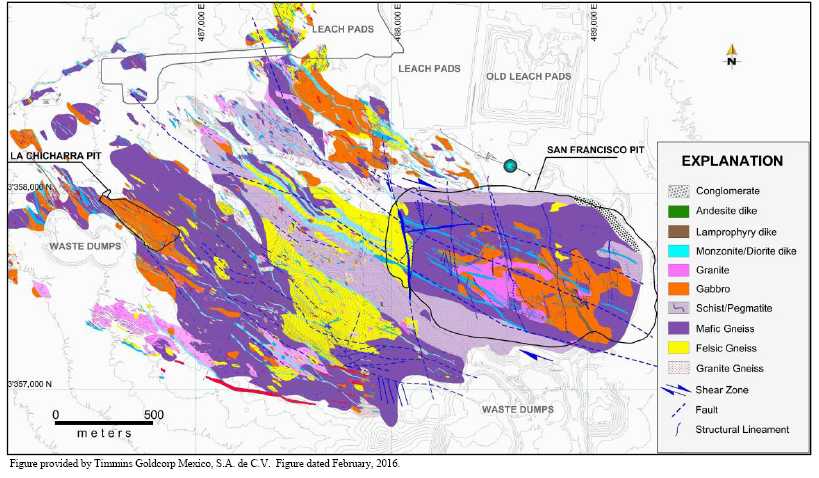

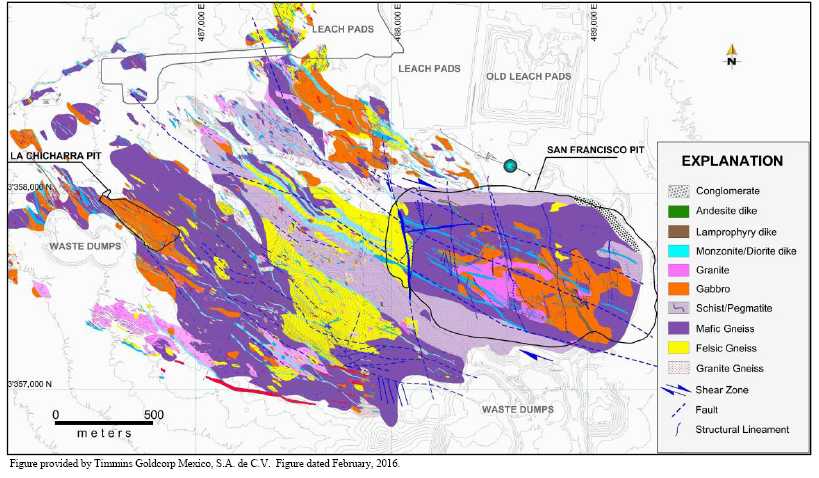

| Figure 7.1 | Geology of the San Francisco Property | 53 |

| Figure 7.2 | San Francisco and La Chicharra Minesite Geology Map | 55 |

| Figure 7.3 | La Chicharra Pit Looking Southwest showing the Lineament | 58 |

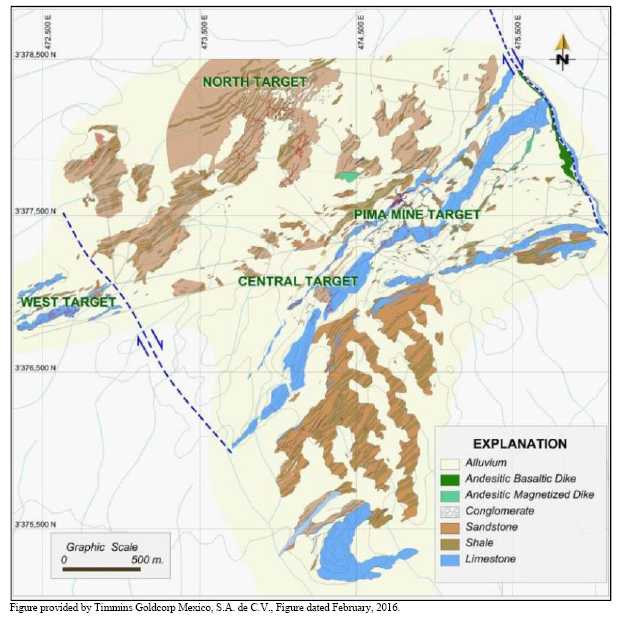

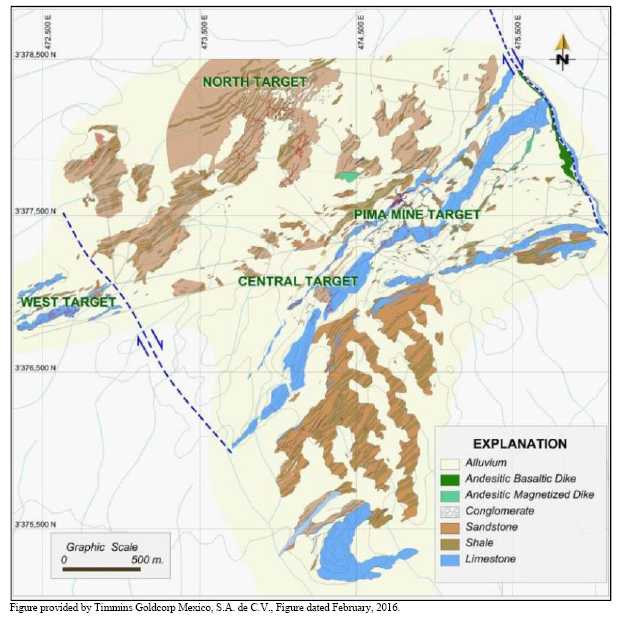

| Figure 9.1 | Geological Map of the La Pima Project Showing the Locations of the Exploration Targets | 66 |

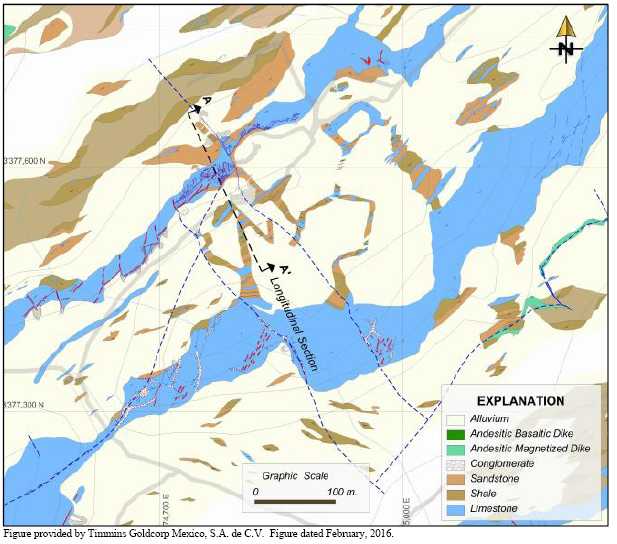

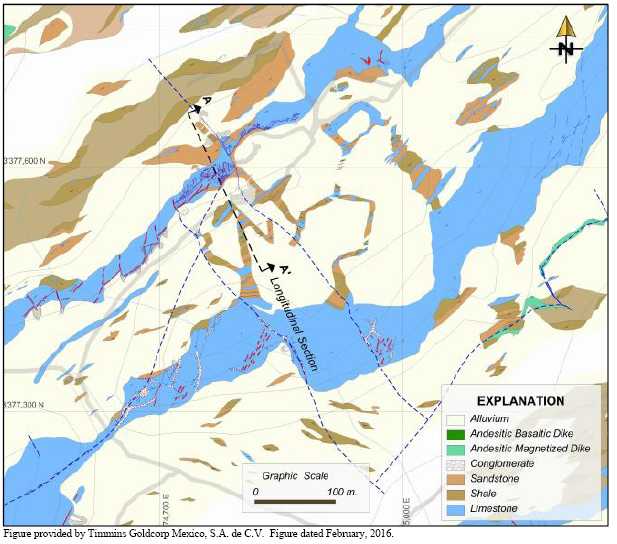

| Figure 9.2 | Geological Map of the La Pima Mine Exploration Target and the Location of the Longitudinal Section | 67 |

ix

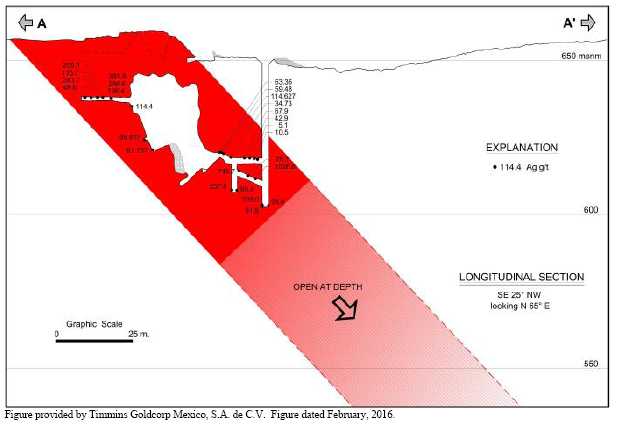

| Figure 9.3 | Longitudinal Section Across the La Pima Mine Exploration Target Showing the Artisanal Workings in the Mineralized Zone | 68 |

| Figure 10.1 | RC Drilling in the San Francisco Pit in July, 2011 | 70 |

| Figure 10.2 | Diamond Drill Rig Set-Up on a Drill Hole Southeast of the San Francisco Pit | 71 |

| Figure 10.3 | Plan View of the Various 2014 In-fill Drilling Programs within the San Francisco Pit | 72 |

| Figure 10.4 | Location Plan of the 2014 Condemnation Drilling Program | 73 |

| Figure 10.5 | Plan View of the November, 2014 Core Drilling Program on the South Wall of the San Francisco Pit | 83 |

| Figure 10.6 | Plan View of the RAB Drilling along Section Lines 3500W, 4100W and 4700W | 88 |

| Figure 10.7 | Plan View of the RAB, RC and Core Drilling Conducted in the 1B Area | 97 |

| Figure 10.8 | Plan View of Geology and the 2014 RC and Core Drilling at the Vetatierra Project | 104 |

| Figure 11.1 | Specimen Trays for Drill Hole TF-1566 | 107 |

| Figure 11.2 | Reverse Circulation Sample Collection | 109 |

| Figure 11.3 | Fragment of Basalt used for Blank Sample | 113 |

| Figure 11.4 | Blank Sample Bag ready to be Inserted into the Sample Sequence | 113 |

| Figure 11.5 | Oven for Drying Samples in the Preparation Facilities | 117 |

| Figure 11.6 | Combo Boyd/RSD Boyd Crusher with Single Split | 117 |

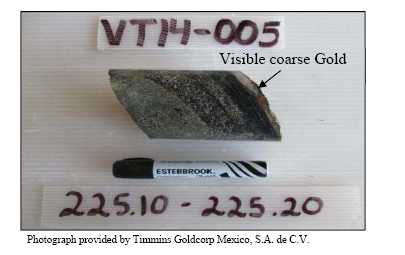

| Figure 11.7 | Drill Hole VT14-005 Showing a Location with Visible Gold in the Core | 123 |

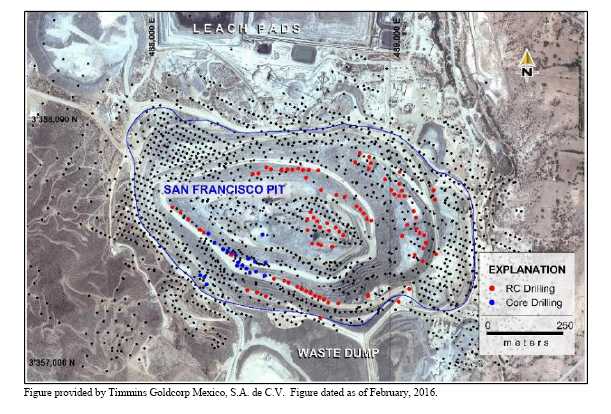

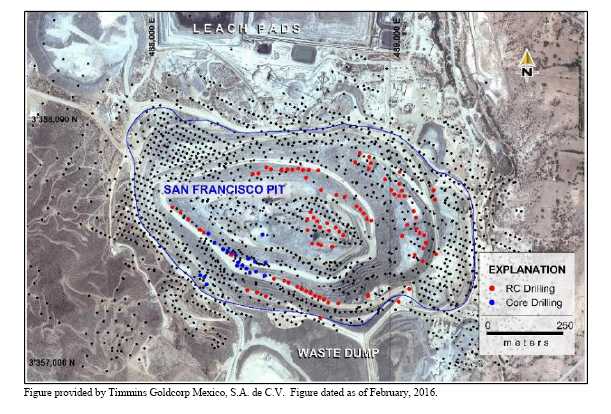

| Figure 14.1 | Plan View of the Drill Hole Collars at the San Francisco Deposit | 138 |

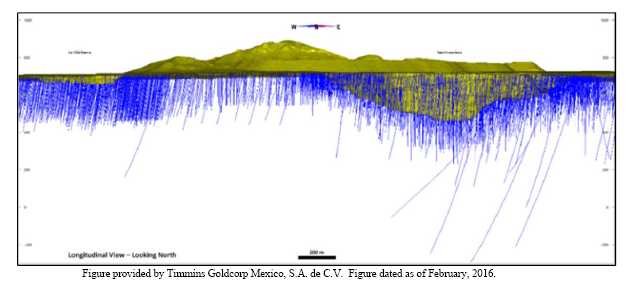

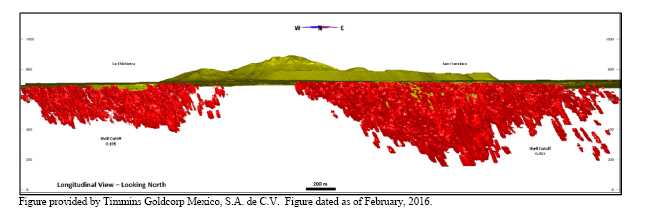

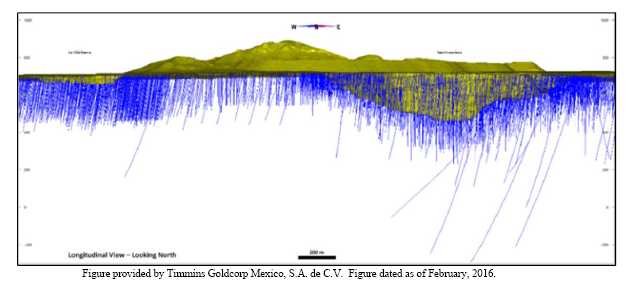

| Figure 14.2 | 3-D Profile of the Current Topography and the Drill Holes at the San Francisco Mine (Looking North) | 139 |

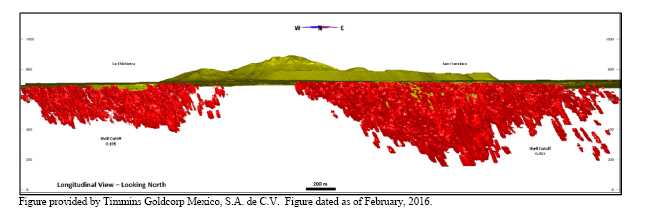

| Figure 14.3 | 3-D View of the Current Topography and Interpreted Mineralized Constraints at the San Francisco and La Chicharra Deposits | 140 |

| Figure 16.1 | Piezometer (PFP-01A) Installed to Monitor Water Flow Surrounding the Pit | 154 |

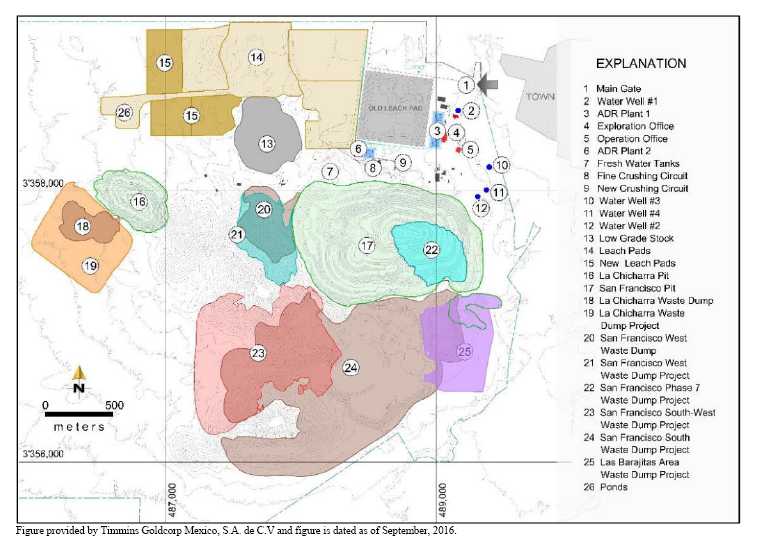

| Figure 16.2 | San Francisco and La Chicharra Final Pit Designs, Dumps and Low Grade Stockpile Layout | 156 |

| Figure 17.1 | Heap Leach Pads as Viewed from the La Chicharra Pit | 159 |

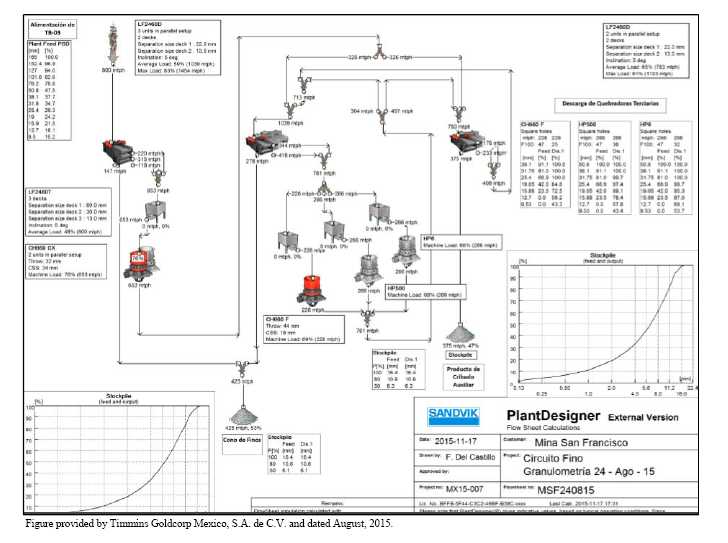

| Figure 17.2 | Fine Crushing Circuit Flowsheet | 161 |

x

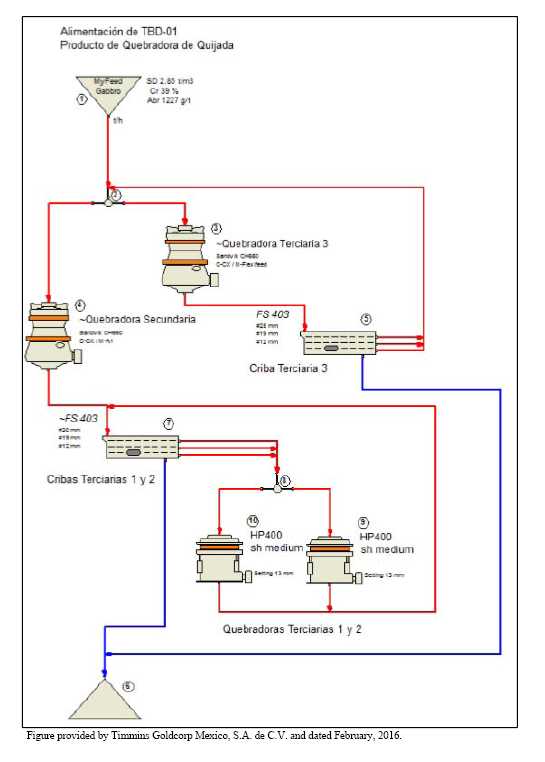

| Figure 17.3 | New Crushing Circuit Diagram | 162 |

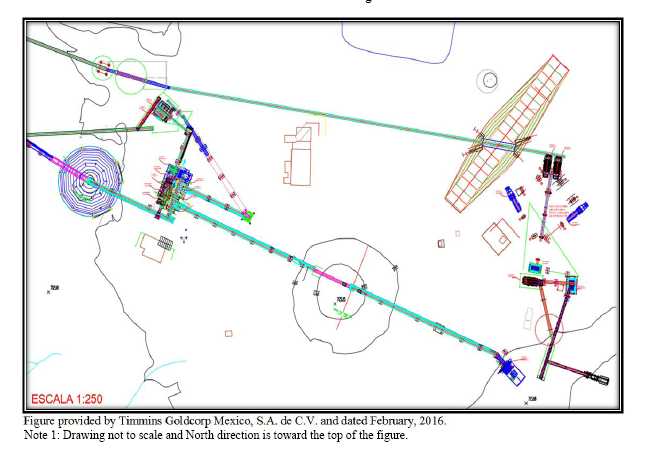

| Figure 17.4 | Plan View of the Crushing Facilities1 | 163 |

| Figure 17.5 | View of the Crushing Facilities and Heap Leach Pads as Seen from the Lookout at the San Francisco Pit | 163 |

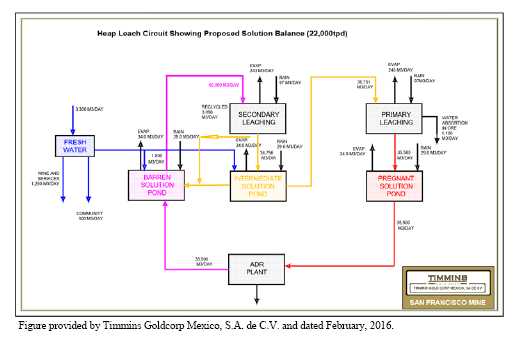

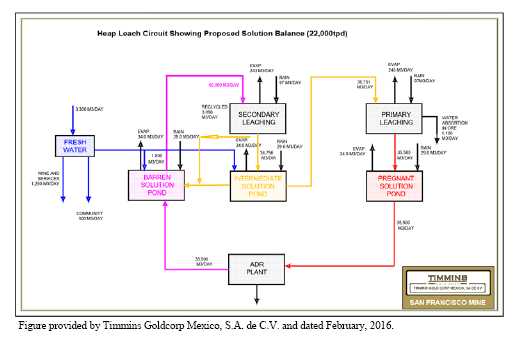

| Figure 17.6 | Heap Leach Circuit Showing the Solution Balance | 164 |

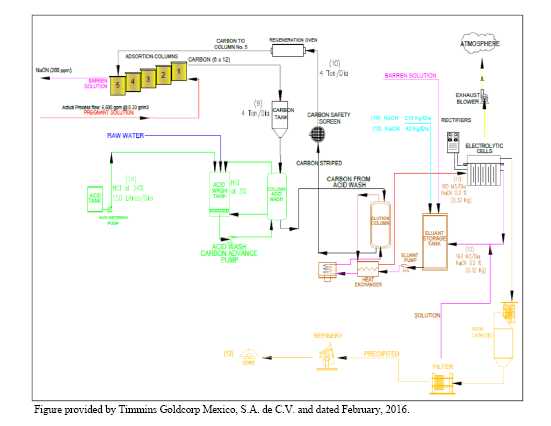

| Figure 17.7 | Overall Gold Recovery Circuit (ADR) Flowsheet | 164 |

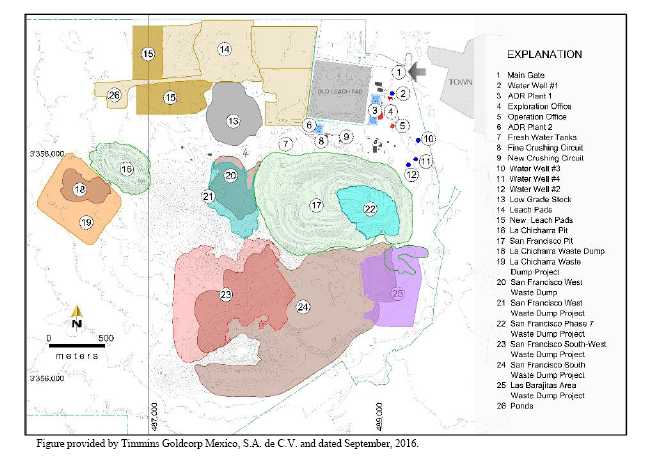

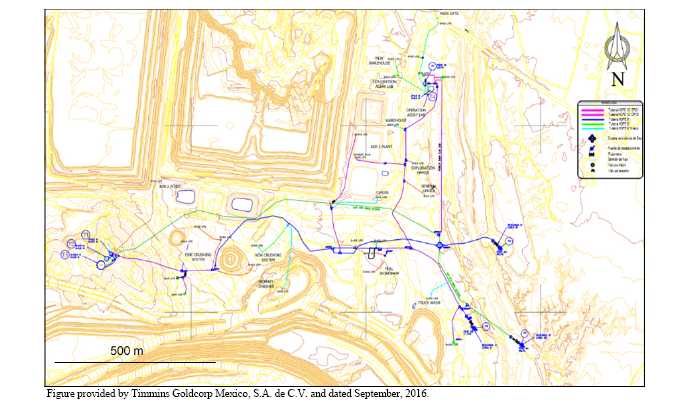

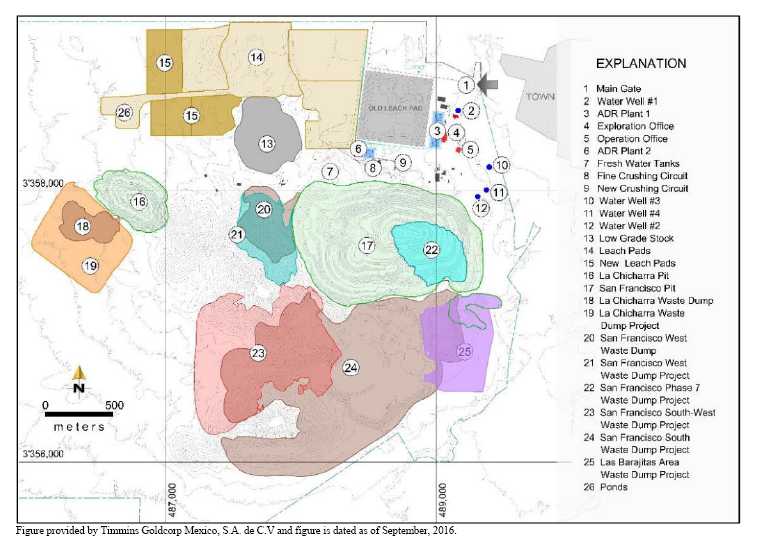

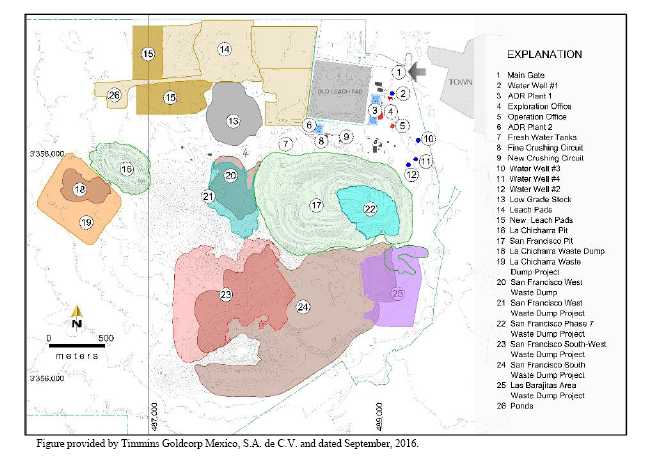

| Figure 18.1 | 2016 General Site Layout | 166 |

| Figure 18.2 | Exploration Sample Storage and Preparation Facility | 168 |

| Figure 18.3 | Core Stored in the Exploration Sample Storage and Preparation Facility | 169 |

| Figure 18.4 | Pulp Samples Stored in the Exploration Sample Storage and Preparation Facility | 169 |

| Figure 18.5 | Fresh Water Distribution Network at the San Francisco Mine | 171 |

xi

1.0 SUMMARY

Timmins Gold Corp. (TSX: TMM) (TMM, or Timmins) has retained Micon International Limited (Micon) to conduct an audit of its resource and reserve estimates and prepare an update of its February, 2016 Technical Report on the San Francisco Gold Project (San Francisco Project or the Project) in the state of Sonora, Mexico. The purpose of this Technical Report is to support disclosure of the results of Micon’s resource and reserve audit and the updated mining plan, compliant with National Instrument NI 43-101 (NI 43-101) and Canadian National Instrument (NI) 43-101.

Micon’s most recent Technical Report for TMM was entitled “NI 43-101 F1 Technical Report, Updated Resources and Reserves and Mine Plan for the San Francisco Gold Mine, Sonora, Mexico”, dated February 29, 2016. That Technical Report was filed by TMM on the System for Electronic Document Analysis and Retrieval (SEDAR, www.sedar.com) which is an electronic filing system developed for the Canadian Securities Administrators (CSA). Prior to this current Technical Report, Micon has written eight prior reports on the San Francisco Project for TMM since 2005.

Micon does not have nor has it previously had any material interest in TMM or related entities. The relationship with TMM is solely a professional association between the client and the independent consultant. This report is prepared in return for fees based upon agreed commercial rates and the payment of these fees is in no way contingent on the results of this report.

This report includes technical information which requires subsequent calculations or estimates to derive sub-totals, totals and weighted averages. Such calculations or estimations inherently involve a degree of rounding and consequently introduce a margin of error. Where these occur, Micon does not consider them to be material.

This report is intended to be used by TMM subject to the terms and conditions of its agreement with Micon. That agreement permits TMM to file this report as a Technical Report with the CSA pursuant to provincial securities legislation or with the SEC in the United States. Except for the purposes legislated under provincial securities laws, any other use of this report, by any third party, is at that party’s sole risk.

The conclusions and recommendations in this report reflect the authors’ best independent judgment in light of the information available to them at the time of writing. The authors and Micon reserve the right, but will not be obliged, to revise this report and conclusions if additional information becomes known to them subsequent to the date of this report. Use of this report acknowledges acceptance of the foregoing conditions.

1

The requirements of electronic document filing on SEDAR necessitate the submission of this report as an unlocked, editable pdf (portable document format) file. Micon accepts no responsibility for any changes made to the file after it leaves its control.

| 1.2 | PROPERTYDESCRIPTION ANDLOCATION |

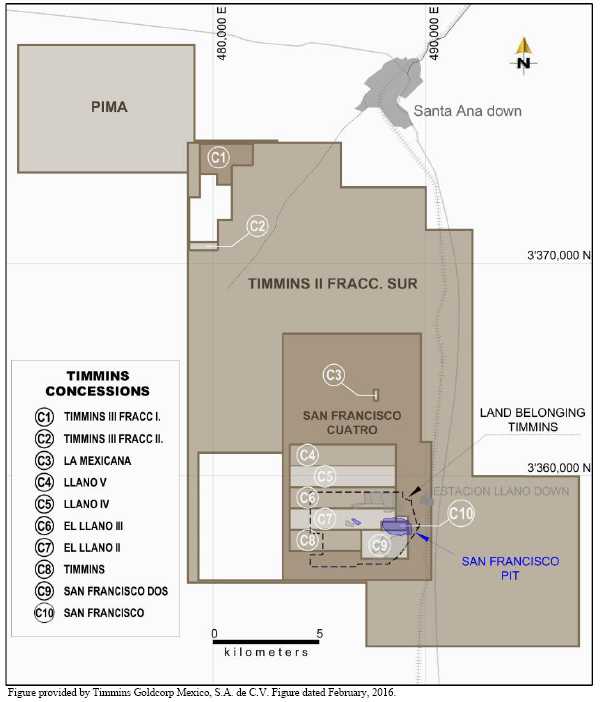

The San Francisco property is situated in the north central portion of the state of Sonora, Mexico, approximately 150 kilometres (km) north of the state capital, Hermosillo. In this report, the term San Francisco Project refers to the area within the exploitation or mining concessions controlled by TMM, while the term San Francisco property (the property) refers to the entire land package (mineral exploitation and exploration concessions) under TMM’s control.

The Project is comprised of two previously mined open pits (San Francisco and La Chicharra), together with heap leach processing facilities and associated infrastructure located close to the San Francisco pit.

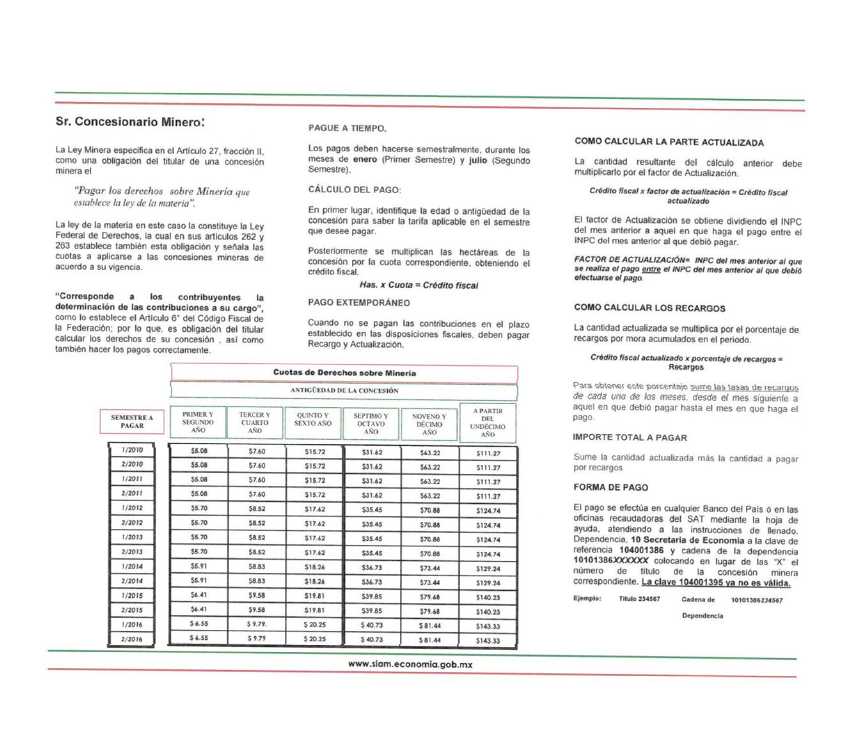

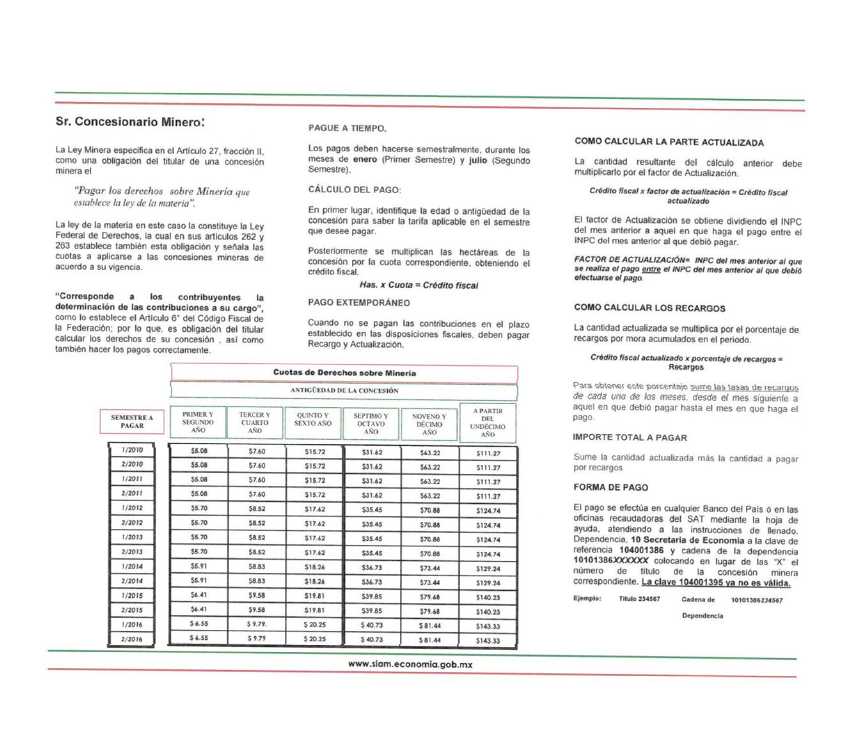

TMM advises that it holds the San Francisco Project, which consists of 13 mining concessions, through its wholly-owned Mexican subsidiary Timmins Goldcorp Mexico, S.A. de C.V. (Timmins). All concessions are contiguous and each varies in size for a total property area of 33,667.72 hectares (ha). In late 2005, the original Timmins II concession was subdivided into two concessions (Timmins II Fraccion Sur and Pima), as part of separate exploration strategies for the original Timmins II concession. All concessions are subject to a bi-annual fee and the filing of reports in May of each year covering the work accomplished on the property between January and December of the preceding year. The tax rates are estimated in US dollars based on the rates published in the “Diario Oficial de la Federacion (DOF)” as of January 28, 2016.

Timmins reduced the size of the primary mineral concessions in 2015 by eliminating those areas deemed to have very little exploration potential, while maintaining the integrity of the overall concessions. It has retained approximately 19,713 ha, which it believes contain the most prospective geology and mineralized targets upon which to base further exploration once metal prices have recovered. The reduction in the size of the concessions has also resulted in a reduction in the bi-annual fees for the Project.

Timmins advises that it acquired the first seven concessions covering the San Francisco mine through its purchase of Molimentales del Noroeste de S.A. de C.V. (Molimentales) in April, 2007.

In 2006, Timmins signed a temporary occupancy agreement with an agrarian community (Ejido) in Mexico called Los Chinos, whereby Timmins was granted access privileges to 674 ha, the use of the Ejido’s roads, as well as being able to perform all exploration work on the area covered by the agreement. The agreement is for a period of 10 years with an option to extend the access beyond the 10-year period.

2

During August and September, 2009, Molimentales acquired the 800 ha of surface land on which the San Francisco mine is located, by means of five purchase agreements covering all of the Ejido Jesus Garcia Heroe de Nacozari’s five former parcels that together form the 800 ha.

Other parties control two mineral concessions which are contained within the area of the mineral concessions owned by Timmins but neither of these concessions impacts the main area of the San Francisco Project.

On February 23, 2011, TMM announced that it had staked an additional 95,000 ha of claims along the highly prospective Sonora-Mojave Megashear structural province in northern Sonora. TMM continued to stake additional concessions since February, 2011 and the total additional regional mineral concessions amounted to approximately 152,279.6 ha in 2013.

On July 6, 2011, Molimentales acquired (through a straight purchase) a 10-ha mineral concession called La Mexicana. This purchase agreement has been filed with the Mexican Federal Mining Registrar. Prior to this purchase, the La Mexicana mineral concession was the last area in the metamorphic package that did not belong to Timmins.

Molimentales has completed the process (before the Mexican Federal Agrarian Secretariat) of converting the 674 hectares contracted from the Los Chinos Ejido into private property, and formalizing the purchase of the 674 ha, before a notary public, according to the Sonora State Civil Code. The 674 ha was purchased by Molimentales, in 2011, and the final public instrument documenting the purchase was issued on February 9, 2015.

Since completing the purchase of the 674 ha from the Los Chinos Ejido, Molimentales has not undertaken any further land purchases and believes no further purchases are necessary at this time.

The Mexican mining laws were changed in 2005 and, as a result, all mineral concessions granted by the Dirección General de Minas (DGM) became mining concessions. There are no longer separate specifications for a mineral exploration or exploitation concession. A second change to the mining laws was that all mining concessions are granted for 50 years, provided that the concessions remain in good standing. As part of this change, all former exploration concessions which were previously granted for 6 years became eligible for the 50-year term.

For any concession to remain valid, the bi-annual fees must be paid and a report has to be filed during the month of May of each year which covers the work conducted during the preceding year. Concessions are extendable provided that the application is made within the five-year period prior to the expiry of the concession and the bi-annual fee and work requirements are in good standing. The bi-annual fee payable to the Mexican government for Timmins to hold the group of contiguous mining concessions for the San Francisco operations is USD $536,179. The bi-annual fee for Timmins to hold the group of contiguous mining concessions which comprise the regional mineral property is USD $128,648.

3

| 1.3 | ACCESSIBILITY, CLIMATE, PHYSIOGRAPHY, LOCALRESOURCES ANDINFRASTRUCTURE |

The Project is located in the Arizona-Sonora desert in the northern portion of the Mexican state of Sonora, 2 km west of the town of Estación Llano (Estación), approximately 150 km north of Hermosillo and 120 km south of the United States/Mexico border city of Nogales along Highway 15 (Pan American highway). The closest accommodations are in Santa Ana, a small city located 21 km to the north on Highway 15.

The climate at the Project site ranges from semi-arid to arid. The average ambient temperature is 21°C, with minimum and maximum temperatures of -5ºC and 50ºC, respectively. The average annual rainfall for the area is 330 mm with an upper extreme of 880 mm. The desert vegetation surrounding the San Francisco mine is composed of low lying scrub, thickets and various types of cacti, with the vegetation type classified as Sarrocaulus Thicket.

Physiographically, the San Francisco property is situated within the southern Basin and Range Province, characterized by elongate, northwest-trending ranges separated by wide alluvial valleys. The San Francisco mine is located in a relatively flat area of the desert with the topography ranging between 700 and 750 m above sea level.

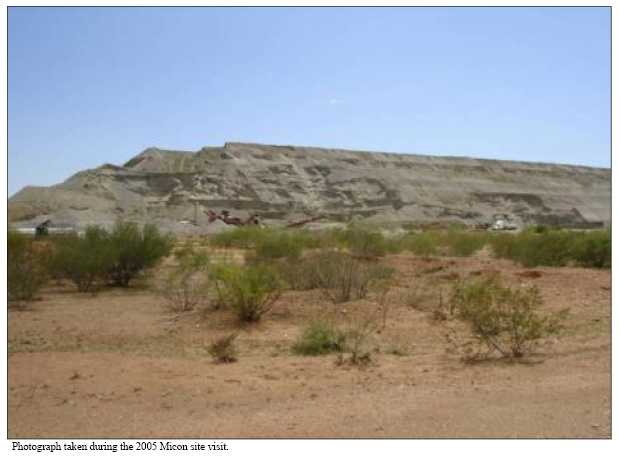

After conducting exploration on the Project between 1983 and 1992, Compania Fresnillo S.A. de C.V. (Fresnillo) sold the property in 1992 to Geomaque Explorations Ltd. (Geomaque). After conducting further exploration, Geomaque decided to bring the Project into production in 1995. Due to economic conditions, mining ceased and the operation entered into the leach-only mode in November, 2000. In May, 2002, the last gold pour was conducted; the plant was mothballed, and clean-up activities at the mine site began.

In 2003, Geomaque sought and received shareholder approval to amalgamate the corporation under a new Canadian company, Defiance Mining Corporation (Defiance). On November 24, 2003, Defiance sold its Mexican subsidiaries (Geomaque de Mexico and Mina San Francisco), which held the San Francisco gold mine, to the Astiazaran family of Sonora and their private company.

Since June, 2006, the Astiazaran family and their company Desarrollos Prodesa S.A. de C.V. have been extracting sand and gravel intermittently from both the waste dumps and the leach pads for use in highway construction as well as other construction projects.

Timmins acquired an option to earn an interest in the property in early 2005, whereupon they conducted a review of the available data and started a reverse circulation drilling program in August and September, 2005. This was followed by a second drilling program comprised of both reverse circulation and diamond drilling in 2006, based on the results of the 2005 drilling program.

4

From 2007 to 2009, concurrent with the feasibility study, which focused on re-starting the mining operations, TMM conducted exploration comprised mainly of in-fill and confirmation drilling in and around of the San Francisco and La Chicharra pits. The drilling results as of the end of 2009 indicated that the mineralization extended both along strike and down dip of the known deposit, a situation which led to the decision to accelerate the drilling in the first 6 months of 2010. The results from the 2010 drilling, when combined with the previous results, led to Timmins updating the resource and reserve estimations, as well as its mine plan.

Between July, 2010 and June, 2011, Timmins conducted an intensive exploration drilling program which included deeper drilling to explore the mineralization at depth, both in and around the La Chicharra and San Francisco pits. The results of this drilling indicated that the mineralization is located in parallel mineralized bodies both along strike and at depth. Timmins believes that the conclusion that the mineralization is located in parallel bodies may lead to further increases in the mineral resources.

From July, 2011 to June, 2013, 1,464 reverse circulation (RC) and core holes were drilled for a total of 327,853 metres (m). Most of the drilling was undertaken in and around the San Francisco pit and the La Chicharra pit. The RC drilling included 13,219 m in 62 holes of condemnation drilling and 3,842 m in 20 holes for water monitoring. A further 8 RC holes totalling 107 m were drilled on the low grade stockpile for grade control.

The drilling conducted within and around the San Francisco and La Chicharra pits comprised more than 92.8% of the drilling undertaken between July, 2011 and June, 2013. Both the RC and core drilling in these areas has identified the extent of the mineralization along strike, as well as the extent down-dip, which remains open. The drilling surrounding the San Francisco and La Chicharra pits has been completed, except for defining the extent of the mineralization to the southeast of the San Francisco pit which remains open along strike and at depth. In 2013, Timmins had completed its planned exploration drilling programs. Additional in-fill drilling is necessary to confirm the extension in the up-dip direction from the newly discovered mineral zones identified at the northern extremity of the pit but it was still undecided if these areas were going to be exploited due to the lower gold price.

| 1.5 | GEOLOGICALSETTING ANDMINERALIZATION |

The San Francisco Project is a gold occurrence with trace to small amounts of other metallic minerals. The gold occurs in granitic gneiss and the deposit contains principally free gold and occasionally electrum. The mineralogy, the possibility of associated tourmaline, the style of mineralization and fluid inclusion studies suggest that the San Francisco deposits may be of mesothermal origin.

The San Francisco deposits are roughly tabular with multiple phases of gold mineralization. The deposits strike 60° to 65° west, dip to the northeast, range in thickness from 4 to 50 m, extend over 1,500 m along strike and are open ended. Another deposit, the La Chicharra zone, was mined by Geomaque, as a separate pit.

5

| 1.6.1 | 2013 to 2015 Exploration Programs |

Since 2013, Timmins has reduced its exploration significantly as a result of low gold prices. As a result, Timmins has only conducted a small number of exploration drilling programs comprised of in-fill drilling in the San Francisco pit to cover gaps in drilling on the lower benches, exploration drilling to outline preliminary underground resources beneath the south wall of the pit and exploration drilling to the north of the San Francisco pit to potentially identify a secondary deposit which would supply feed to the heap leach pad and processing facilities at the San Francisco mine.

The in-fill drilling in the San Francisco pit on the lower benches was successful in allowing a better understanding of the mineralization being extracted in these areas. The drilling in the south wall, along with preliminary underground mining, has helped to identify the extent and mining potential for this areas but further drilling will be necessary to fully identify the extent of the mineralized lenses in this area. The exploration drilling to the north produced mixed results with areas of good mineralization identified but the extent of the mineralization is still not fully understood and these areas will need further work to identify if they are amenable to open pit mining methods.

As part of its future production plans, Timmins now plans to conduct a pushback along the southern wall of the pit and as a result the drilling in this area to potentially identify an underground resource will no longer be conducted as the mineralization will be mined via open pit methods.

| 1.6.2 | Future Exploration Programs |

Timmins is not planning any further exploration programs on the San Francisco property, at the current time. However, should the price of gold continue to remain at its current price, greater than USD $1,300/oz gold, Timmins can revisit this decision.

While Timmins is not planning any further exploration, Micon did review the work that Timmins conducted to the north of the San Francisco pit, as well as the work conducted on the south wall of the pit during its February, 2016 site visit, and considers that further exploration is warranted in these areas. As always, any proposal for further exploration and budget for the work will be subject to either funding or other matters which may cause a proposed program to be altered in the normal course of its business activities, or alterations which may affect the program as a result of the exploration activities themselves.

6

| 1.7 | MINERALRESOURCE ANDRESERVEESTIMATES |

| 1.7.1 | Mineral Resource Estimate |

The resource block model is based on 5 m by 5 m by 6 m high blocks. The coordinate limits of the previous model were retained for this current work. The topography was updated to reflect the mined surface as of July 1, 2016. The undisturbed pre-mining topographic surfaces are also available in the model.

Since the 2011 update, Timmins has continued to conduct a manual interpretation of the mineralized zones, based on all of the drilling intersections now available in its database. This approach allows for more precise geological modelling and mineralization interpretation, which is enabling Timmins to plan better drilling programs to explore the extent of the mineralization and also to prepare better engineering designs regarding the ore and waste split in the pit for planning purposes. Overall, the method is similar to the previous method, except that the grade envelopes and geological domains are directly interpreted by the geologists using the drilling information they have gathered.

The database of the San Francisco and La Chicharra deposits consists of 4,071 drill holes with 380,031 intervals, amounting to 592,435 m of drilling. A total of 126 of the drill holes lie beyond the model limits and have not been included in the study. The current database includes 13,345 m of drilling from 114 new holes drilled in 2014 and 2015.

Approximately 13% of the sampling intervals are greater than or equal to a 2 m length, about 84% of the intervals are between 1.5 and 2.0 m in length, and about 3% are less than 1.5 m in length. In the case of duplicate samples, the original sample was used in the database.

High grade outlier assays were capped at different gold grades, according to the domains, as with the previous 2013 estimate.

Once Micon had audited and accepted Timmins’s block model, Timmins proceeded to run a pit optimization program in order to estimate the resources. The gold price used for estimating the resources at the San Francisco Project was USD 1,350 per ounce.

The parameters used in the pit optimization for the estimation of the resources are summarized in Table 1.1. They are a combination of the parameters determined by Micon and Timmins, taking into account the actual costs obtained from the operation.

Pit bench heights were set at 6 m (the block height used in the model) and slope angles were based on inter-ramp angles recommended by Golder Associates in its December, 1996, report, adjusted to allow for haul roads of 25 m width.

The pit shell adopted for reporting resources was estimated at a gold price of USD $1,350/troy ounce, using the economic parameters summarized in Table 1.1, the drilling database as of November, 2015 and the topographic surface as of July 1, 2016. The mineral resource, as estimated by Timmins and audited by Micon, is presented in Table 1.2. This resource estimate includes the mineral reserve described subsequently, and has an effective date of July 1, 2016.

7

Table 1.1

Pit Optimization Parameters for the July 1, 2016 Resource Estimate for the San Francisco and La Chicharra Deposits

| Area | Costs |

| San Francisco Mine | Description | Units | Amount |

| Waste mining cost | USD/t | 2.00 |

| Ore mining cost | USD/t | 2.00 |

| Process cost | USD/t | 3.86 |

| G & A cost | USD/t | 1.04 |

| Gold price | USD/oz | 1,350 |

| Rock Densities and Recoveries |

| Name/code | Density | Recovery % |

| Diorite (2) | 2.72 | 65.00 |

| Gneiss felsic (4) | 2.75 | 65.00 |

| Granite (5) | 2.76 | 65.00 |

| Schist (6) | 2.75 | 65.00 |

| Lamprophrite dike (8) | 2.76 | 65.00 |

| Pegmatite (10) | 2.85 | 65.00 |

| Gabbro (11) | 2.81 | 65.00 |

| Conglomerate (12) | 2.00 | 65.00 |

| General Recovery | 65.00 |

| La Chicharra Mine | Costs |

| Waste mining cost | USD/t | 1.45 |

| Ore mining cost | USD/t | 1.45 |

| Process cost | USD/t | 4.107 |

| G & A cost | USD/t | 0.50 |

| Gold price | USD/oz | 1,350 |

| Rock Densities and Recoveries |

| Name/code | Density | Recovery % |

| All Rock (100-500) | 2.90 | 65.00 |

| General Recovery | 65.00 |

Table provided by Timmins Goldcorp Mexico, S.A. de C.V.

The underground resource estimate presented in the previous report in January 2016 has been moved back to open pit resource and no underground resource has been considered this time.

Micon recommends that Timmins use the July 1, 2016 mineral resource estimate contained in Table 1.2 as the stated mineral resource estimate for the San Francisco Project as this estimate recognizes the use of 0.18 g/t for the San Francisco deposit and 0.17 g/t gold for the La Chicharra deposit as the open pit cut-off grades, at which the mineralization would meet the parameters for potential economic extraction, as defined by the CIM standards and definitions for resources.

8

Table 1.2

Mineral Resource Estimate for the San Francisco Project (Inclusive of Mineral Reserves)

(USD $1,350/oz Gold Price)

| Area | Cut-off

(Au g/t) | Category | Tonnage

(x1,000) | Avg. Grade

(Au g/t) | Gold Ounces |

San Francisco

Mine OP | 0.18 | Measured | 26,731 | 0.60 | 515,000 |

| Indicated | 15,239 | 0.61 | 299,000 |

| Total Measured & Indicated | 41,970 | 0.60 | 814,000 |

| Inferred* | 246 | 0.72 | 6,000 |

La Chicharra

Deposit OP | 0.17 | Measured | 9,902 | 0.50 | 160,000 |

| Indicated | 3,575 | 0.48 | 55,000 |

| Total Measured & Indicated | 13,477 | 0.50 | 215,000 |

| Inferred* | 79 | 0.43 | 1,000 |

Total

Resources | | Measured | 36,633 | 0.57 | 675,000 |

| Indicated | 18,814 | 0.58 | 354,000 |

| Total Measured & Indicated | 55,447 | 0.58 | 1,029,000 |

| Total Inferred* | 324 | 0.65 | 7,000 |

*Inferred resources in this table do not include material outside of the pits limit.

Micon believes that no environmental, permitting, legal, title, taxation, socio-economic, marketing or political issues exist which would adversely affect the mineral resources estimated above, at this time. However, mineral resources that are not mineral reserves do not have demonstrated economic viability. The mineral resource figures in Table1.2 have been rounded to reflect that they are estimates and therefore, the totals in the table may not add due to the rounding errors.

The mineral resource estimate has been reviewed and audited by Micon. It is Micon’s opinion that the July 1, 2016 mineral resource estimate has been prepared in accordance with the CIM standards and definitions for mineral resource estimates and that Timmins can use this estimate as a basis for further exploration and economic evaluation of the San Francisco Project.

| 1.7.2 | Mineral Reserve Estimate |

Once Micon had audited and accepted Timmins resource estimate, Timmins proceeded to run a pit optimization program in order to estimate the reserves. The gold price used for estimating the reserves at the San Francisco Project was USD $1,250 per ounce.

Mining recovery has been estimated at 96% for the San Francisco and 98% for the La Chicharra deposits. Micon agrees with this estimate, as it is based on actual experience at the mine.

The dilution for the San Francisco and La Chicharra deposits varies, up to 4%, depending on the pit phases.

The parameters used in the pit optimization for the estimation of reserves are the same as those used for the resource estimation.

9

Table 1.3 presents the total reserves estimated within the pit design outline, including mine recovery and dilution factors.

Table 1.3

Mineral Reserves within the San Francisco and La Chicharra Pit Design (July 1, 2016) after Mining Recovery and Dilution

| PIT | Classification | Metric tonnes

(x1,000) | Gold g/t | Contained Gold

Ounces |

| San Francisco Pit | Proven | 16,666 | 0.58 | 313,000 |

| Probable | 8,644 | 0.54 | 144,000 |

| Total | 24,934 | 0.57 | 457,000 |

| La Chicharra Pit | Proven | 6,596 | 0.51 | 108,000 |

| Probable | 579 | 0.45 | 8,000 |

| Total | 7,175 | 0.51 | 117,000 |

| Total | Proven | 23,262 | 0.56 | 421,000 |

| Probable | 8,846 | 0.54 | 153,000 |

| Total | 32,109 | 0.56 | 574,000 |

| |

| San Francisco Pit | Stockpile | 7,371 | 0.26 | 61,000 |

The proven and probable reserves in Table 1.3 have been derived from the measured and indicated mineral resources summarized in Table 1.2 and account for mining recovery and dilution. The figures in Table1.3 have been rounded to reflect that they are an estimate and therefore, the totals in the table may not add due to the rounding errors.

The mineral reserve estimate has been reviewed and audited by Micon. It is Micon’s opinion that the July 1, 2016 mineral reserve estimate has been prepared in accordance with the CIM standards and definitions for mineral reserve estimates and that Timmins can use this estimate as a basis for further mine planning and operational optimization at the San Francisco Project (San Francisco and La Chicharra pits).

The San Francisco mine resumed commercial production in April, 2010. Table 1.4 summarizes production from April, 2010 to the end of August, 2016, by quarter. Ore of lower grade is being stockpiled for processing at the end of the mine life. Timmins reports that, as of the end of August, 2016, a total of 8,121 Mt at an average grade of 0.260 g/t gold had been placed on the low grade stockpile since 2010. However, since 2010, Timmins has processed some of the stockpile material and the actual low grade stockpile contains 7,371 MT at an average grade of 0.26 oz/t gold as of the date of this report.

10

Table 1.4

SanFranciscoProject,TimminsAnnualProduction from April, 2010 to the End ofAugust, 2016 byQuarter)

| Year | Quarter | Mined Ore*(Dry Tonnes) | Average Grade

(g/t Gold) | Processed Ore

(Dry Tonnes) | Average Grade

(g/t Gold) | Gold OuncesPlaced on LeachPad | Gold OuncesRecoverable | Silver OuncesRecoverable | Gold OuncesSold | Waste Mined | Strip Ratio | Days inQuarter | Average OreMined(tonnes/day) | Average OreProcessed(tonnes/day) | Total Mined(tonnes/day) |

| 2010 | April - June | 911,319 | 0.802 | 905,296 | 0.718 | 20,904 | 14,145 | 6,050 | 10,375 | 4,057,842 | 4.1 | 91 | 10,014 | 9,948 | 55,461 |

| July - September | 1,085,845 | 0.873 | 1,090,768 | 0.817 | 28,667 | 19,375 | 8,398 | 15,685 | 3,630,021 | 3.27 | 92 | 11,803 | 11,856 | 51,524 |

| October - December | 1,222,551 | 0.972 | 1,208,677 | 0.939 | 36,483 | 25,034 | 11,030 | 20,031 | 4,498,925 | 3.54 | 92 | 13,289 | 13,138 | 62,720 |

| 2011 | January - March | 1,229,043 | 0.870 | 1,207,339 | 0.895 | 34,743 | 24,088 | 10,501 | 17,020 | 4,701,677 | 2.89 | 90 | 13,656 | 13,415 | 70,289 |

| April - June | 1,268,454 | 0.907 | 1,239,075 | 0.859 | 34,235 | 22,138 | 8,622 | 16,676 | 4,239,137 | 2.57 | 91 | 13,939 | 13,616 | 64,696 |

| July - September | 1,359,091 | 0.835 | 1,364,290 | 0.804 | 35,282 | 22,667 | 8,640 | 17,287 | 5,097,292 | 2.51 | 92 | 14,773 | 14,829 | 77,474 |

| October - December | 1,285,035 | 0.777 | 1,327,299 | 0.778 | 33,195 | 21,686 | 11,635 | 21,524 | 4,160,488 | 1.98 | 92 | 13,968 | 14,427 | 68,023 |

| 2012 | January - March | 1,287,804 | 0.794 | 1,255,477 | 0.772 | 31,150 | 19,721 | 11,740 | 21,532 | 3,879,662 | 1.85 | 91 | 14,152 | 13,796 | 65,627 |

| April - June | 1,306,312 | 0.901 | 1,347,112 | 0.901 | 39,028 | 25,507 | 14,453 | 23,203 | 4,342,495 | 2.07 | 91 | 14,355 | 14,803 | 70,776 |

| July - September | 1,423,531 | 0.893 | 1,420,414 | 0.887 | 40,490 | 26,075 | 13,857 | 25,154 | 4,210,428 | 1.86 | 92 | 15,473 | 15,439 | 70,401 |

| October - December | 1,340,712 | 0.880 | 1,493,623 | 0.819 | 39,339 | 24,886 | 16,203 | 24,556 | 5,295,383 | 2.84 | 87 | 14,573 | 16,235 | 77,858 |

| 2013 | January - March | 1,713,827 | 0.817 | 1,787,262 | 0.825 | 47,434 | 30,501 | 14,313 | 28,328 | 6,375,048 | 3.02 | 90 | 19,043 | 19,858 | 94,318 |

| April - June | 1,776,833 | 0.818 | 1,848,832 | 0.814 | 48,380 | 31,800 | 16,124 | 28,024 | 6,235,920 | 2.79 | 91 | 19,526 | 20,317 | 93,074 |

| July – September | 1,665,064, | 0.799 | 1,815,709 | 0.771 | 45,016 | 29,666 | 16,228 | 29,139 | 5,441,889 | 2.58 | 92 | 18,099 | 19,736 | 82,093 |

| October – December | 1,934,903 | 0.824 | 2,014,968 | 0.872 | 56,504 | 38,784 | 21,849 | 34,166 | 5,307,526 | 2.32 | 92 | 21,032 | 21,902 | 82,519 |

| 2014 | January - March | 2,085,582 | 0.792 | 2,122,650 | 0.760 | 51,838 | 34,544 | 26,648 | 35,413 | 5,520,468 | 2.37 | 90 | 23,173 | 23,585 | 87,712 |

| April - June | 2,061,943 | 0.699 | 2,184,316 | 0.650 | 45,616 | 30,007 | 23,489 | 32,932 | 5,810,088 | 2.38 | 91 | 22,659 | 24,003 | 90,891 |

| July – September | 1,949,924 | 0.571 | 2,213,740 | 0.504 | 35,889 | 23,783 | 18,800 | 26,675 | 6,208,303 | 3.08 | 92 | 21,195 | 24,062 | 89,411 |

| October – December | 1,785,811 | 0.688 | 2,101,873 | 0.563 | 38,078 | 24,604 | 16,327 | 25,007 | 6,417,044 | 3.30 | 92 | 19,411 | 22,846 | 90,886 |

| 2015 | January - March | 1,974,125 | 0.581 | 2,074,788 | 0.532 | 35,469 | 21,473 | 15,309 | 24,155 | 5,997,897 | 2.87 | 90 | 21,935 | 23,053 | 89,825 |

| April - June | 2,070,769 | 0.571 | 2,252,591 | 0.527 | 38,176 | 23,242 | 13,041 | 22,869 | 7,151,798 | 3.38 | 91 | 22,756 | 24,754 | 101,868 |

| July – September | 1,946,848 | 0.549 | 2,200,292 | 0.510 | 36,072 | 23,010 | 10,526 | 23,387 | 7,000,474 | 3.57 | 92 | 21,161 | 23,916 | 97,428 |

| October – December | 1,711,899 | 0.487 | 1,921,060 | 0.458 | 28,314 | 18,084 | 13,151 | 22,787 | 6,857,052 | 4.00 | 92 | 18,608 | 20,881 | 93,151 |

| 2016 | January - March | 1.995,354 | 0.621 | 2,003,712 | 0.622 | 40,038 | 25,723 | 14,671 | 24,667 | 4,708,661 | 2.36 | 91 | 21,927 | 22,019 | 73,714 |

| April - June | 1,848,675 | 0.604 | 1,939,567 | 0.604 | 37,640 | 24,801 | 14,884 | 26,474 | 3,729,153 | 2.02 | 91 | 20,315 | 21,314 | 61,295 |

| July – August1 | 1,148,317 | 0.647 | 1,197,975 | 0.649 | 24,981 | 16,744 | 9,761 | 17,739 | 2,611,423 | 2.27 | 62 | 18,521 | 19,322 | 60,641 |

| Total | | 41,389,574 | 0.735 | 43,538,704 | 0.702 | 982,962 | 642,088 | 366,250 | 614,805 | 133,486,093 | 2.66 | 90 | 17,668 | 18,580 | 77,834 |

*Excluding lower grade ore stockpiled.

1 Third Quarter 2016, only includes July and August production figures.

Table provided by Timmins Goldcorp Mexico, S.A. de C.V.

11

During July, 2011, Timmins tested the expansion of the crushing system to 15,000 t/d and announced that it is quickly reaching this target.

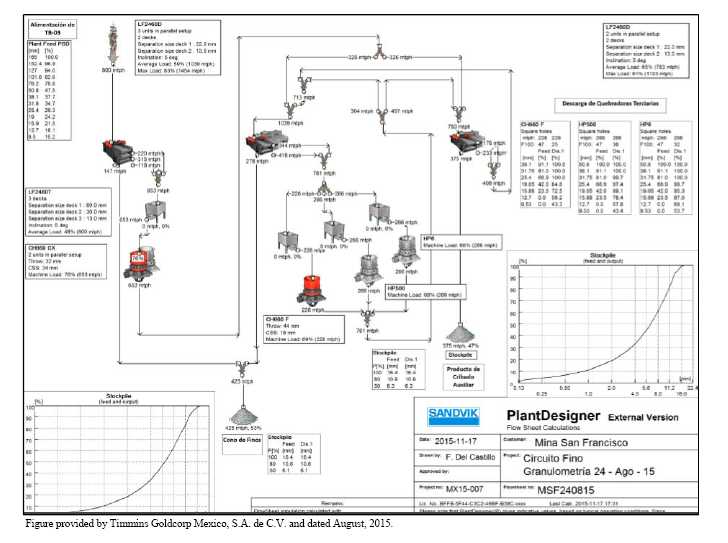

In December, 2012, a new additional 5,000 t/d crushing circuit was installed. The equipment initially installed was one jaw crusher, one secondary crusher, two tertiary crushers and two screens. In August, 2013, an expansion was made to this crushing circuit, installing an additional secondary crusher, along with a screen, for a further capacity of 2,000 t/d. Total capacity for the new crushing circuit is 7,000 t/d.

With the original plant equipment and additions mentioned, and some fine tuning the crushing capacity currently operates at 22,000 t/d.

| 1.8.1 | Mine Plans and Activities |

Production from the La Chicharra deposit recommenced in late 2015. The San Francisco and La Chicharra pits will be mined at the same time.

The La Chicharra pit, previously mined by Geomaque, is located 1,000 m west of the San Francisco pit.

All mining activities are being carried out by the contractor, Peal Mexico, S.A. de C.V., of Navojoa, Mexico. The contractor is obliged to supply and maintain the appropriate principal and auxiliary mining equipment and personnel required to produce the tonnage mandated by Timmins, in accordance with the mining plan.

Timmins provides contract supervision, geology, engineering and planning and survey services, using its own employees.

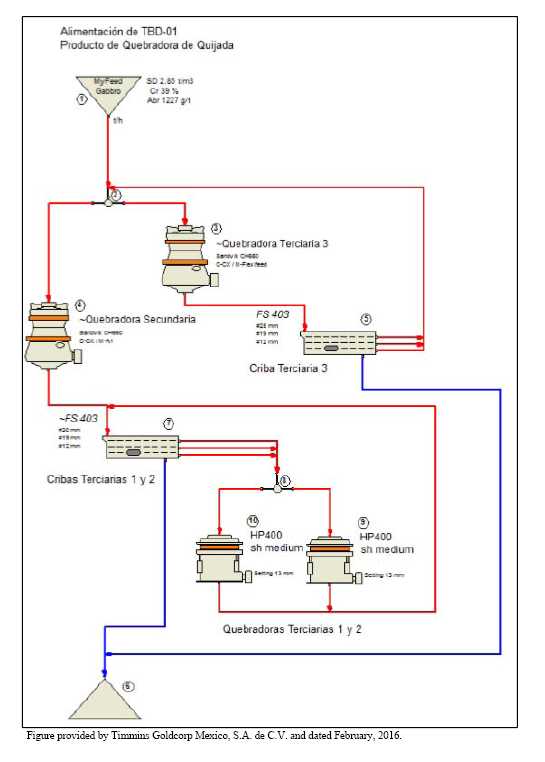

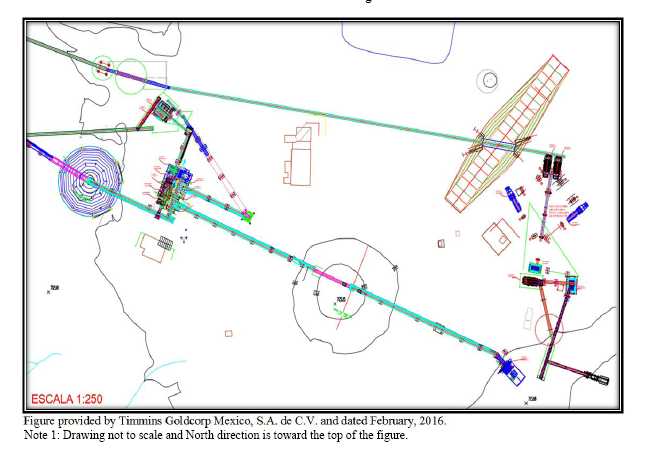

Ore extracted from the pit is transported in 100 t capacity haulage trucks, which feed directly into the gyratory primary crusher with dimensions of 42” x 65”. The crusher has nominal capacity of 900 t/h. The crushed product is then transported on conveyor belts to a stockpile with a capacity of 6,000 tonnes.

Two feeders beneath the stockpile deliver the ore onto a conveyor belt which feeds the secondary crushing circuit. The ore is screened and the screen undersize (minus 0.5 inch) reports to the final product, while screen oversize is fed to two parallel secondary crushers.

Product from the secondary crushers is transported on conveyor belts to the tertiary crushing circuit, which consists of three tertiary crushers in parallel operating in closed circuit with screens. The minus 0.5 inch undersize from the screens is delivered to the leach pad.

Product from the crushing plant is transported to the leach pad on overland conveyors and deposited on the pad with a stacker, forming lifts between 8 m and 12 m in height. A bulldozer is used to level the surface of each lift. The irrigation pipelines are then installed to distribute the leach solution over the entire surface of the lift.

12

Timmins has constructed the leach pad and has five different phases for depositing, based on the permits granted by the Mexican Environmental Agency (PROFEPA, Procuraduría Federal de Protección al Ambiente). Table 1.5 summarizes the leach pad phases.

Table 1.5

Summary of the Leach Pad Phases Based Upon the Permits Acquired for the San Francisco Mine

| # Phase | Duration | Surface | Nominal

Capacity | Capacity

to date | Status |

| 1 & 2 | November, 2009 to

November, 2013 | 36 ha | 23 Mt | 22 Mt | Releached |

| 3 | November, 2013 to

August, 2015 | 25 ha | 16 Mt | 15 Mt | On Irrigation |

| 4 | August, 2015 to date | 16 ha | 8 Mt | 4 Mt | Depositing ore |

| 5 | From October, 2016 on

forward (projected) | 12 Ha | 7 Mt | ----- | In Construction |

Table provided by Timmins Goldcorp Mexico, S.A. de C.V.

The 0.05% sodium cyanide leach solution with a pH of 10.5 to 11, flows downward through the crushed ore dissolving the precious metals. The solution percolates to the bottom of the lift and is collected in the channel that carries the pregnant solution to a storage pond, from which it is pumped to the gold recovery plant. The gold contained in pregnant solution is adsorbed in the carbon columns.

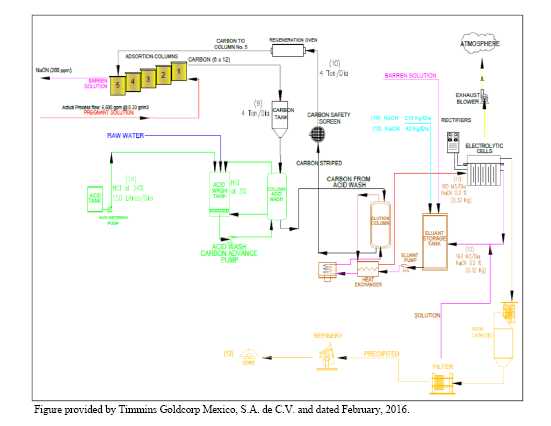

The gold recovery operation comprises two adsorption-desorption-recovery (ADR) plants with a total of three parallel sets of carbon columns with a total feed capacity of 1,475 m3/h (6,500 US gpm) of pregnant solution.

Barren solution exiting the ADR plant flows to a second storage pond where fresh water and sodium cyanide are added, before the solution is pumped back to the leach pad.

| 1.10.1 | Capital Expenditures |

The San Francisco Project was originally designed for a production rate of 12,000 t/d of ore to be placed on the leach pad. It has now been expanded to 22,000 t/d.

Future capital expenditures over the mine life which includes all development and sustaining capital (i.e. leach pad expansions, on-going maintenance, and resource drilling) are estimated to total USD 18 million. On a year-by-year basis the capital expenditures are estimated at USD 4 million for 2016 and 2017, decreasing to USD 2 million from 2018 to 2021 and drop off to USD 1 million for the last two years in 2022 and 2023.

13

Micon has reviewed Timmins’ estimate of the future capital expenditures for the San Francisco Project and regards it as reasonable.

Timmins’ projected production and average cash cost per ounce of gold from 2016 to 2018 is estimated to be as follows:

| | • | 2016 production between 90,000 and 100,000 gold ounces at cash costs of USD $750 to USD $800 per gold ounce. |

| | • | 2017 production between 65,000 and 70,000 gold ounces at cash costs of USD $900 to USD $950 per gold ounce. |

| | • | 2018 production between 80,000 and 85,000 gold ounces at cash costs of USD $1,000 to USD $1,050 per gold ounce. |

Timmins latest estimates of its Life-of-Mine production is between 450,000 and 500,000 ounces of gold at cash costs of USD $900 to USD $950 per ounce of gold. Cost per ounce of gold are quoted net of by-product credits.

Micon has reviewed Timmins’ operating cost forecasts for the life of the San Francisco Project and regards them as reasonable.

Since the last Technical Report conducted on the San Francisco Project in February, 2016, TMM has continued to meet the requirements necessary to be considered a producing issuer, according to the definition contained in NI 43-101.

Based upon the price of gold in the fourth quarter of 2015, TMM announced that mining operations at the San Francisco mine would continue into the fourth quarter of 2016 at which point the mine would be placed on care and maintenance, while the heap leach operations would continue into 2017. However, in the first quarter of 2016 the price of gold increased and so far, this year has averaged over USD $1,250/oz gold. The increase in the gold price led Timmins to announce in August that it will continue to operate the San Francisco mine through to 2023.

Timmins’ updated economic guidance, since the February, 2016 Technical Report was published, considers that the 2016 fiscal year production is estimated to range from 90,000 to 100,000 ounces of gold with the cash costs ranging from USD $750 to USD $800 per ounce of gold sold. The estimated operating parameters for 2016, include an average ore throughput of 22 kt/d at a processed grade of 0.59 g/t Au with a strip ratio in the 2.0:1 range. The total 2016 capital expenditures (sustaining and development) are estimated to be approximately USD $4 million.

14

Timmins updated 2016 to 2023 guidance calls for a Life-of-Mine production of between 450,000 and 500,000 ounces of gold at a cash cost of between USD $900 to USD $950 per ounce of gold and a total capital expenditure of approximately USD $18 million or USD $38 per ounce of gold.

| 1.12 | CONCLUSIONS ANDRECOMMENDATIONS |

The San Francisco mine commenced commercial production in April, 2010, and by the end of August, 2016, Timmins had sold 614,805 ounces of gold. Between April, 2010 and the end of August, 2016, production at the San Francisco mine has totalled 41,389,574 tonnes at a grade of 0.735 g/t gold. In addition, a total of 8,121,428 tonnes grading 0.260 g/t gold has been placed on a low grade stockpile for potential processing in the future. However, since 2010, Timmins has processed some of the stockpile material and currently the low grade stockpile contains 7,371 MT at an average grade of 0.26 oz/t gold.

Micon has audited the resource and reserve estimates, and has reviewed the mine design, the mining schedule, the mining contract terms and the ability of the contractor to meet the mining production targets, and concludes that the estimations and designs have been properly carried out and that the contractor is capable of meeting the schedule.

Micon has reviewed the crushing, heap leach and ADR facilities and concludes that they are adequate for the treatment of the scheduled process feed material and the recovery of gold in doré, as forecast in the production plan.

Micon has reviewed the economics of the San Francisco operation and concludes that it is viable and meets the criteria for publication of a mineral reserve.

Given the known extent of mineralization on the property, compared to the amount of mining activity, the San Francisco Project has the potential to host further deposits or lenses of gold mineralization, similar in character and grade to those exploited in the past, outside the present resource base. In Micon’s opinion, further exploration is warranted when precious metal prices improve.

Micon agrees with the general direction of Timmins’ exploration and development program for the property and makes the following additional recommendations:

| | 1) | Micon recommends that when applicable Timmins continues to conduct exploration on the other areas of mineralization on the property, as well as to the east-southeast of the San Francisco pit, in order to continue to realize the full potential of its property. |

| | | |

| | 2) | Micon recommends that Timmins continues to optimize costs, where applicable in the current precious metal market. |

15

2.0 INTRODUCTION

At the request of Mr. Arturo Bonillas, President of Timmins Gold Corp. (TSX:TMM or Timmins), Micon International Limited (Micon) has been retained to provide an audit of the current internal resource and reserve estimates and an update of its February, 2016 Technical Report on the San Francisco Gold Project (San Francisco Project) in the state of Sonora, Mexico. The previous Micon Technical Report was entitled “NI 43-101 F1 Technical Report, Updated Resources and Reserves and Mine Plan for the San Francisco Gold Project, Sonora, Mexico” and dated February 29, 2016. That Technical Report was filed by TMM on the System for Electronic Document Analysis and Retrieval (SEDAR, www.sedar.com) which is an electronic filing system developed for the Canadian Securities Administrators (CSA) and on its US equivalent the System for Electronic Data Gathering, Analysis and Retrieval (EDGAR) developed for the US Securities and Exchange Commission.

TMM advises that it holds its interest in the San Francisco property through its wholly-owned Mexican subsidiary Timmins Goldcorp Mexico, S.A. de C.V. (Timmins), which holds thirteen mining concessions through a wholly-owned subsidiary, Molimentales del Noroeste de S.A. de C.V. (Molimentales).

In this Technical Report, TMM and its subsidiary Timmins are used interchangeably and for the purposes of the report are considered to be one and the same.

The current study is based on the resource and reserve estimates and mine plan prepared in-house by Timmins and Molimentales personnel and their consultants. Micon has audited the resource and reserve estimates as well as conducting a review of the mine plan and its various components. The material in this report was derived from a number of sources in addition to the material provided by Timmins and these sources are noted in Section 28 of this report.

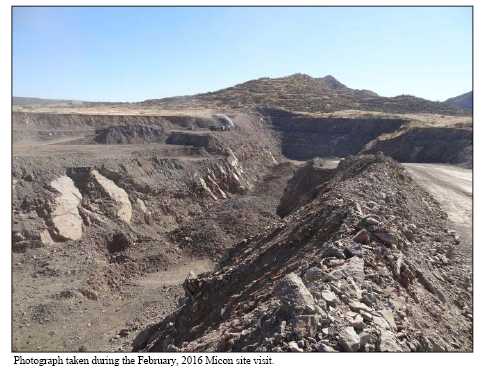

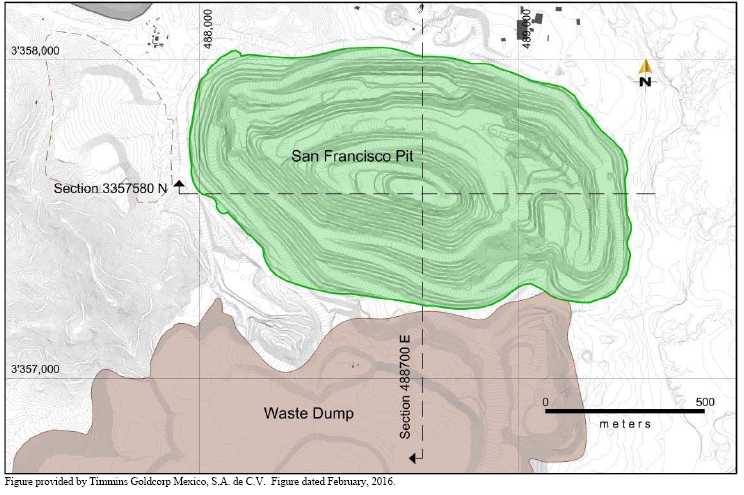

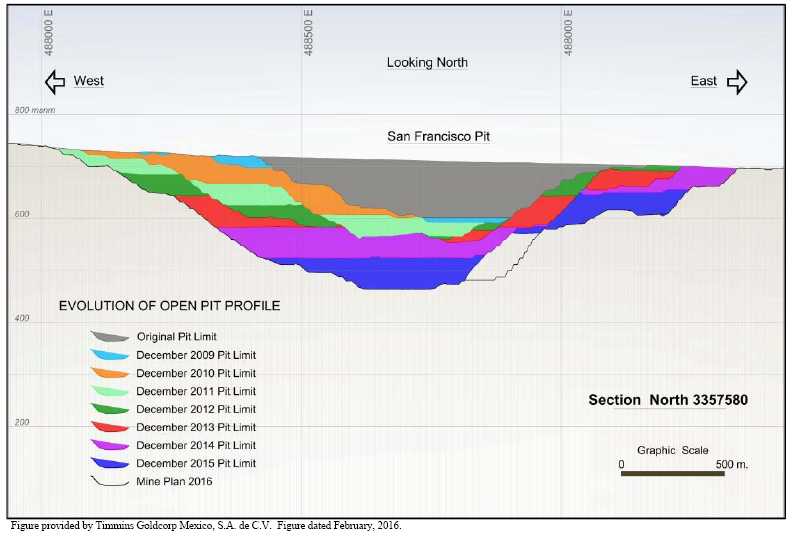

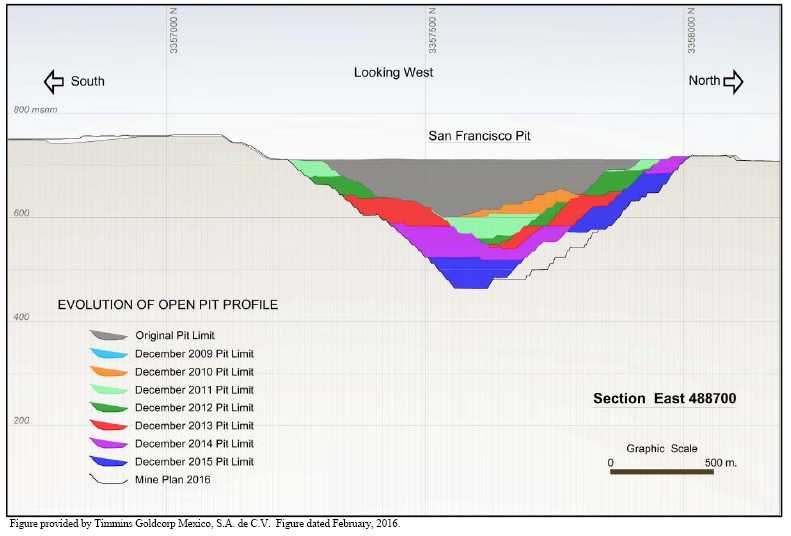

Micon’s most recent site visit was conducted between February 2 and 6, 2016, during which the resources and reserves, as well as various aspects of the operation and mine plan, were discussed. The current and future exploration programs were also discussed. The site visit included a tour through the open pit, leach pad, crushing circuit and the process plant. A site visit was not conducted in conjunction with the publication of this September, 2016, report update as the previous site visit had been conducted in February and only regular mining operations have been conducted at the San Francisco mine since the previous site visit.

A number of discussions were held via skype and telephone conference calls between Micon personnel in Toronto and Timmins personnel in Hermosillo regarding the database, block model and parameters for the mineral resource estimate, as well as other topics related to the audit and preparation of this Technical Report.

The qualified persons responsible for the preparation of this report are William J. Lewis, B.Sc., P.Geo., Alan J. San Martin, MAusIMM (CP)., Mani Verma, P.Eng. and Richard M. Gowans, P.Eng.

16

Mr. Lewis conducted the February, 2016, site visit. Messrs. Verma, San Martin and Lewis conducted the previous 2013 site visit. Mr. Gowans conducted his desk top review in Toronto, based on the information provided to him by Timmins. Mr. Lewis has conducted a number of site visits to the San Francisco Project since 2005 and is familiar with the Project.

Mr. Lewis, a Senior Geologist with Micon, is responsible for the independent summary and review of the exploration on the San Francisco Project, the comments on the propriety of Timmins’ exploration drilling program, the plans and budget for the next phase of exploration and the review of Timmins Quality Assurance/Quality Control (QA/QC) program at the mine site. Mr. Lewis and Mr. San Martin, a Mineral Resource Modeller with Micon, conducted the review and audit of the resource estimate.

Mr. Verma, an Associate Mining Engineer with Micon, is responsible for the review of the mine plan, production scheduling, operations and the terms of the existing mining contract. Mr. Verma also reviewed the capital and operating cost estimates for the Project and reviewed the discounted cash flow and sensitivity analyses used to evaluate Project economics. Mr. Gowans, President and Principal Metallurgist of Micon, reviewed the metallurgical aspects of the San Francisco Project.

All currency amounts are stated in US dollars (USD) or Mexican pesos (MXN), as specified, with costs and commodity prices typically expressed in US dollars. Quantities are generally stated in metric units, the standard Canadian and international practice, including metric tons (tonnes, t) and kilograms (kg) for weight, kilometres (km) or metres (m) for distance, hectares (ha) for area, grams (g) and grams per metric tonne (g/t) for gold and silver grades (g/t Au, g/t Ag). Wherever applicable, Imperial units have been converted to Système International d’Unités (SI) units for reporting consistency. Precious metal grades may be expressed in parts per million (ppm) or parts per billion (ppb) and their quantities may also be reported in troy ounces (ounces, oz), a common practice in the mining industry. A list of abbreviations is provided in Table 2.1. Appendix 1 contains a glossary of mining and other related terms.

The review of the San Francisco Project was based on published material researched by Micon, as well as data, professional opinions and unpublished material submitted by the professional staff of Timmins or its consultants. Much of these data came from reports prepared and provided by Timmins.

Micon does not have nor has it previously had any material interest in TMM, Timmins or related entities. The relationship with TMM and Timmins is solely a professional association between the client and the independent consultant. This report is prepared in return for fees based upon agreed commercial rates and the payment of these fees is in no way contingent on the results of this report. This is the eighth Technical Report written by Micon on the San Francisco Project for TMM since 2005.

17

Table 2.1

List ofAbbreviations

| Name | Abbreviation | Name | Abbreviation |

| Accurassay Laboratories | Accurassay | Metre(s) | m |

| Acme Analytical Laboratories Ltd. | ACME | Mexican peso | MXN |

| Adsorption/desorption/reactivation | ADR | Micon International Limited | Micon |

| ALS-Chemex Laboratories | ALS-Chemex | Million (eg million tonnes, million ounces, million years) | M (Mt, Moz, Ma) |

| Canadian Institute of Mining, Metallurgy and Petroleum | CIM | Milligram(s) | mg |

| Canadian National Instrument 43-101 | NI 43-101 | Millimetre(s) | mm |

| Canadian Securities Administrators | CSA | Molimentales del Noroeste de S.A. de C.V. | Molimentales |

| Centimetre(s) | cm | North American Datum | NAD |

| Compania Fresnillo S.A. de C.V. | Fresnillo | Net present value, at discount rate of 8%/y | NPV, NPV8 |

| Defiance Mining Corporation | Defiance | Net smelter return | NSR |

| Degree(s), Degrees Celsius | o,oC | Not available/applicable | n.a. |

| Digital elevation model | DEM | Ounces (troy)/ounces per year | oz, oz/y |

| Dirección General de Minas | DGM | Parts per billion, part per million | ppb, ppm |

| Discounted cash flow | DCF | Percent(age) | % |

| Diversified Drilling, S.A. de C.V. | Diversified | Quality Assurance/Quality Control | QA/QC |

| Electronic Data Gathering, Analysis and Retrieval | EDGAR | Run of mine | ROM |

| Explotaciones Mineras Del Noroeste S.A. de C.V. | Explotaciones Mineras | Servicios Industriales Peñoles, S.A. de C.V. | Peñoles |

| Geomaque de Mexico, S.A. de C.V. | Geomaque de Mexico | SGS Mineral Services | SGS |

| Geomaque Explorations Inc. | Geomaque | Sol & Adobe Ingenieros Asociados S.A. de C.V. | Sol & Adobe. |

| Golder Associates Ltd. | Golder Associates | Specific gravity | SG |

| Grams per metric tonne | g/t | Square kilometre(s) | km2 |

| Hectare(s) | ha | System for Electronic Document Analysis and Retrieval | SEDAR |

| Hour | h | Three-dimensional | 3-D |

| Inch(es) | in | Timmins Gold Corp. | TMM |

| Independent Mining Consultants, Inc. | IMC | Timmins Goldcorp Mexico, S.A. de C.V. | Timmins |

| Inductively Coupled Plasma – Emission Spectrometry | ICP-ES | Tonne (metric)/tonnes per day, tonnes per hour | t, t/d, t/h |

| Internal diameter | ID | Tonne-kilometre | t-km |

| Internal rate of return | IRR | Tonnes per cubic metre | t/m3 |

| Impuesto al Valor Agregado (or VAT) | IVA | TSL Laboratories Inc. | TSL |

| Kappes, Cassiday and Associates | Kappes Cassiday | United States Dollar(s) | USD |

| Kilogram(s) | kg | US gallons per minute | USgpm |

| Kilometre(s) | km | US Securities and Exchange Commission | SEC |

| Life of mine | LOM | Universal Transverse Mercator | UTM |

| Litre(s) | L | Value Added Tax (or IVA) | VAT or IVA |

| McCelland Laboratories Inc. | McCelland | Year | y |

| METCON Research Inc. | METCON | | |

18

This report includes technical information which requires subsequent calculations or estimates to derive sub-totals, totals and weighted averages. Such calculations or estimations inherently involve a degree of rounding and consequently introduce a margin of error. Where these occur, Micon does not consider them to be material.

The conclusions and recommendations in this report reflect the authors’ best independent judgment in light of the information available to them at the time of writing. The authors and Micon reserve the right, but will not be obliged, to revise this report and conclusions if additional information becomes known to them subsequent to the date of this report. Use of this report acknowledges acceptance of the foregoing conditions.

This report is intended to be used by TMM subject to the terms and conditions of its agreement with Micon. That agreement permits TMM to file this report as a Technical Report with the Canadian Securities Administrators pursuant to provincial securities legislation or with the SEC in the United States. Except for the purposes legislated under provincial securities laws, any other use of this report, by any third party, is at that party’s sole risk.

The requirements of electronic document filing on SEDAR necessitate the submission of this report as an unlocked, editable pdf (portable document format) file. Micon accepts no responsibility for any changes made to the file after it leaves its control.

19

3.0 RELIANCE ON OTHER EXPERTS

Micon has reviewed and analyzed data provided by TMM and Timmins, its consultants and the previous operator of the Project, and has drawn its own conclusions therefrom, augmented by its direct field examination. Micon has not carried out any independent exploration work, drilled any holes or carried out an extensive program of sampling and assaying on the property. Previous sampling (Lewis, 2006) was conducted to independently substantiate the mineralization at the San Francisco Project and further samples were not obtained during the 2006, 2007, 2010, 2011, 2013 or 2016 site visits. Micon does not believe that further independent sampling of the mineralization at the San Francisco Project is warranted for a Technical Report, as the Project is currently an operating mine and the production records are a more reliable indication of the extent and grade of the mineralization.

Micon has reviewed and audited the work conducted by TMM and Timmins on the resource and reserve estimates, the mine plan and other material related to the operating San Francisco mine. While exercising all reasonable diligence in checking, confirming and testing it, Micon has relied upon Timmins’ presentation of the project data, including data from the previous operator, in formulating its opinion with respect to the San Francisco property.

Micon offers no legal opinion as to the validity of the title to the mineral concessions claimed by TMM and its wholly-owned Mexican subsidiaries, Timmins and Molimentales. A description of the property, and ownership thereof, is provided for general information purposes only. A legal opinion regarding the mineral concessions and its subsidiaries was provided to Micon by Timmins for the November, 2011, Technical Report. The legal opinion, which was included as Appendix 2 in the 2011 report, was prepared in conjunction with the public offering of common shares held by funds managed or advised by Pacific Road Capital Management Pty. Limited. The legal opinions were dated July 12 and 15, 2011 and were prepared and executed by Roberto Herrera Piñon in Hermosillo, Mexico. The legal opinions were not updated for this Technical Report and Micon has relied upon Timmins for the information regarding title to the mineral concessions.

The existing environmental conditions, liabilities and remediation have been described where required by NI 43-101 regulations. These statements are provided for information purposes only and Micon offers no opinion in this regard.

The existing contracts regarding the sale of bullion and any other products produced by the Timmins operations have been described where required by NI 43-101 regulations. These statements are provided for information purposes only and Micon offers no opinion regarding the legal interpretation of these contracts.

The descriptions of geology, mineralization and exploration used in this report are taken from reports prepared by various organizations and companies or their contracted consultants, as well as from various government and academic publications. The conclusions of this report use in part data available in published and unpublished reports supplied by the companies which have conducted exploration on the property, and information supplied by Timmins. The information provided to Timmins was supplied by reputable companies and Micon has no reason to doubt its validity.

20

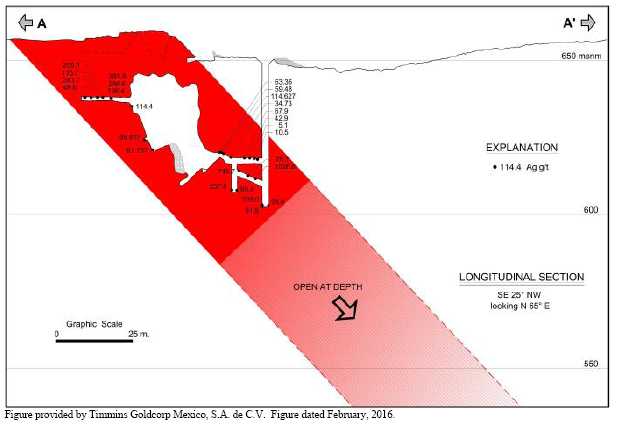

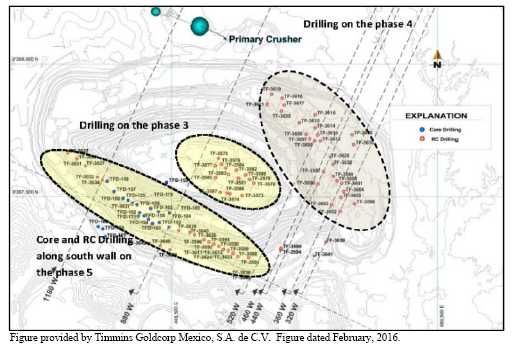

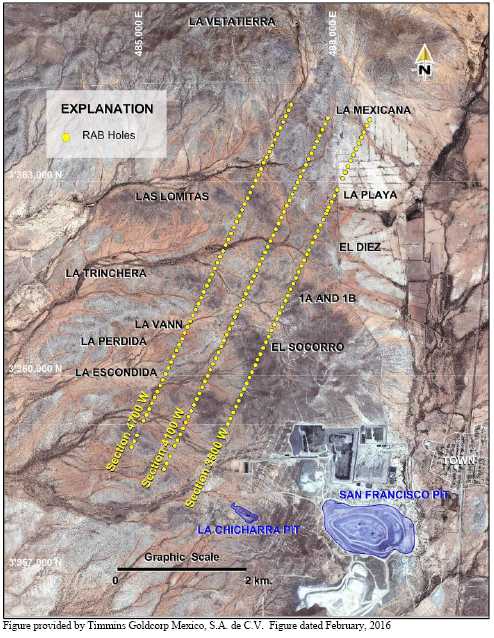

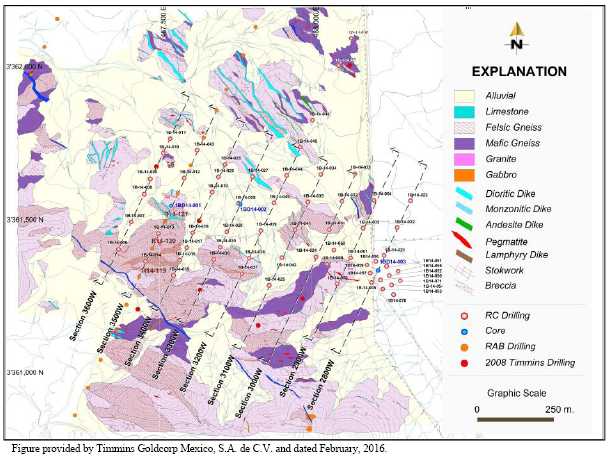

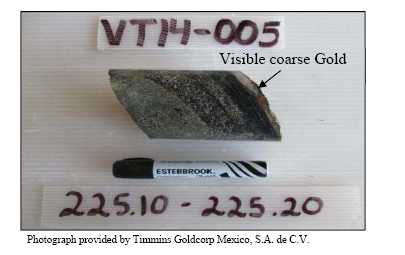

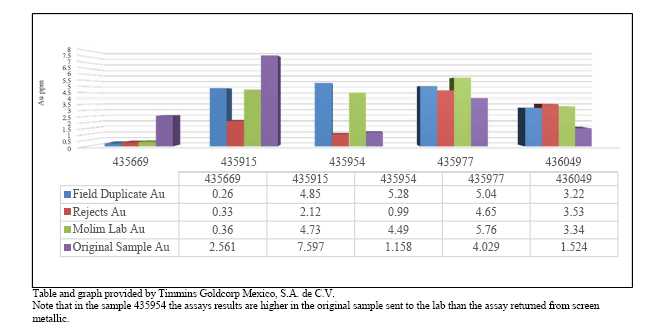

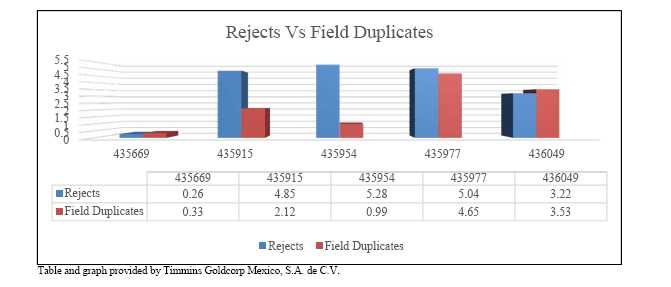

Micon is pleased to acknowledge the helpful cooperation of Timmins management and consulting field staff, all of whom made any and all data requested available and responded openly and helpfully to all questions, queries and requests for material.