J.P. Morgan 2017 Energy Equity Investor Conference Gary Heminger, Chairman, President and CEO June 26, 2017

Forward‐Looking Statements This presentation contains forward-looking statements within the meaning of federal securities laws regarding Marathon Petroleum Corporation (“MPC“) and MPLX LP (“MPLX”). These forward-looking statements relate to, among other things, expectations, estimates and projections concerning the business and operations of MPC and MPLX, including proposed strategic initiatives. You can identify forward-looking statements by words such as “anticipate,” “believe,” “design,” “estimate,” “expect,” “forecast,” “goal,” “guidance,” “imply,” “intend,” “objective,” “opportunity,” “outlook,” “plan,” “position,” “pursue,” “prospective,” “predict,” “project,” “potential,” “seek,” “strategy,” “target,” “could,” “may,” “should,” “would,” “will” or other similar expressions that convey the uncertainty of future events or outcomes. Such forward-looking statements are not guarantees of future performance and are subject to risks, uncertainties and other factors, some of which are beyond the companies’ control and are difficult to predict. Factors that could cause MPC’s actual results to differ materially from those implied in the forward-looking statements include: the time, costs and ability to obtain regulatory or other approvals and consents and otherwise consummate the strategic initiatives discussed herein; the satisfaction or waiver of conditions in the agreements governing the strategic initiatives discussed herein; our ability to achieve the strategic and other objectives related to the strategic initiatives discussed herein; adverse changes in laws including with respect to tax and regulatory matters; inability to agree with the MPLX conflicts committee with respect to the timing of and value attributed to assets identified for dropdown; changes to the expected construction costs and timing of projects; continued/further volatility in and/or degradation of market and industry conditions; the availability and pricing of crude oil and other feedstocks; slower growth in domestic and Canadian crude supply; the effects of the lifting of the U.S. crude oil export ban; completion of pipeline capacity to areas outside the U.S. Midwest; consumer demand for refined products; transportation logistics; the reliability of processing units and other equipment; MPC’s ability to successfully implement growth opportunities; modifications to MPLX earnings and distribution growth objectives, and other risks described below with respect to MPLX; compliance with federal and state environmental, economic, health and safety, energy and other policies and regulations, including the cost of compliance with the Renewable Fuel Standard, and/or enforcement actions initiated thereunder; changes to MPC’s capital budget; other risk factors inherent to MPC’s industry; and the factors set forth under the heading “Risk Factors” in MPC’s Annual Report on Form 10-K for the year ended Dec. 31, 2016, filed with Securities and Exchange Commission (SEC). Factors that could cause MPLX’s actual results to differ materially from those implied in the forward-looking statements include: negative capital market conditions, including an increase of the current yield on common units, adversely affecting MPLX’s ability to meet its distribution growth guidance; the time, costs and ability to obtain regulatory or other approvals and consents and otherwise consummate the strategic initiatives discussed herein and other proposed transactions; the satisfaction or waiver of conditions in the agreements governing the strategic initiatives discussed herein and other proposed transactions; our ability to achieve the strategic and other objectives related to the strategic initiatives discussed herein and other proposed transactions; adverse changes in laws including with respect to tax and regulatory matters; inability to agree with respect to the timing of and value attributed to assets identified for dropdown; the adequacy of MPLX’s capital resources and liquidity, including, but not limited to, availability of sufficient cash flow to pay distributions, and the ability to successfully execute its business plans and growth strategy; the timing and extent of changes in commodity prices and demand for crude oil, refined products, feedstocks or other hydrocarbon-based products; continued/further volatility in and/or degradation of market and industry conditions; changes to the expected construction costs and timing of projects; completion of midstream infrastructure by competitors; disruptions due to equipment interruption or failure, including electrical shortages and power grid failures; the suspension, reduction or termination of MPC’s obligations under MPLX’s commercial agreements; modifications to earnings and distribution growth objectives; the level of support from MPC, including dropdowns, alternative financing arrangements, taking equity units, and other methods of sponsor support, as a result of the capital allocation needs of the enterprise as a whole and its ability to provide support on commercially reasonable terms; compliance with federal and state environmental, economic, health and safety, energy and other policies and regulations and/or enforcement actions initiated thereunder; changes to MPLX’s capital budget; other risk factors inherent to MPLX’s industry; and the factors set forth under the heading “Risk Factors” in MPLX’s Annual Report on Form 10-K for the year ended Dec. 31, 2016, filed with the SEC. In addition, the forward-looking statements included herein could be affected by general domestic and international economic and political conditions. Unpredictable or unknown factors not discussed here, in MPC’s Form 10-K or in MPLX’s Form 10-K could also have material adverse effects on forward-looking statements. Copies of MPC’s Form 10-K are available on the SEC website, MPC’s website at http://ir.marathonpetroleum.com or by contacting MPC’s Investor Relations office. Copies of MPLX’s Form 10-K are available on the SEC website, MPLX’s website at http://ir.mplx.com or by contacting MPLX’s Investor Relations office. Non-GAAP Financial Measures EBITDA, Adjusted EBITDA, distributable cash flow and distribution coverage ratio are non-GAAP financial measures provided in this presentation. EBITDA, Adjusted EBITDA and distributable cash flow reconciliations to the nearest GAAP financial measures are included in the Appendix to this presentation. EBITDA, Adjusted EBITDA, distributable cash flow and distribution coverage ratio are not defined by GAAP and should not be considered in isolation or as an alternative to net income attributable to MPC or MPLX, net cash provided by operating activities or other financial measures prepared in accordance with GAAP. Distribution coverage ratio is the ratio of DCF attributable to GP and LP unitholders to total GP and LP distributions declared. Light Product Break Even is a metric used in this presentation and defined on the slides where it is used. The EBITDA forecasts related to certain projects were determined on an EBITDA-only basis. Accordingly, information related to the elements of net income, including tax and interest, are not available and, therefore, reconciliations of these non-GAAP financial measures to the nearest GAAP financial measures have not been provided. 2

Recent Changes to Executive Team 3 Mike Hennigan appointed President of MPLX effective June 20 Don Templin named President of MPC effective July 1

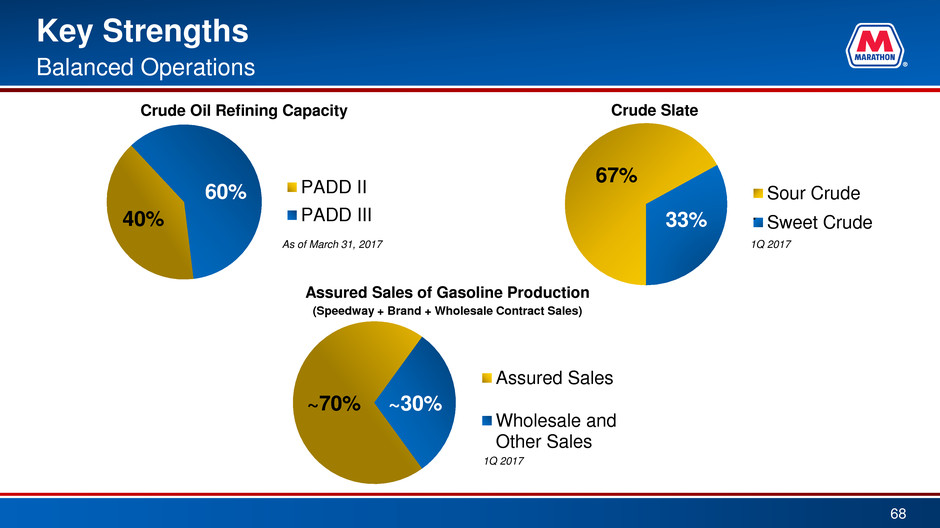

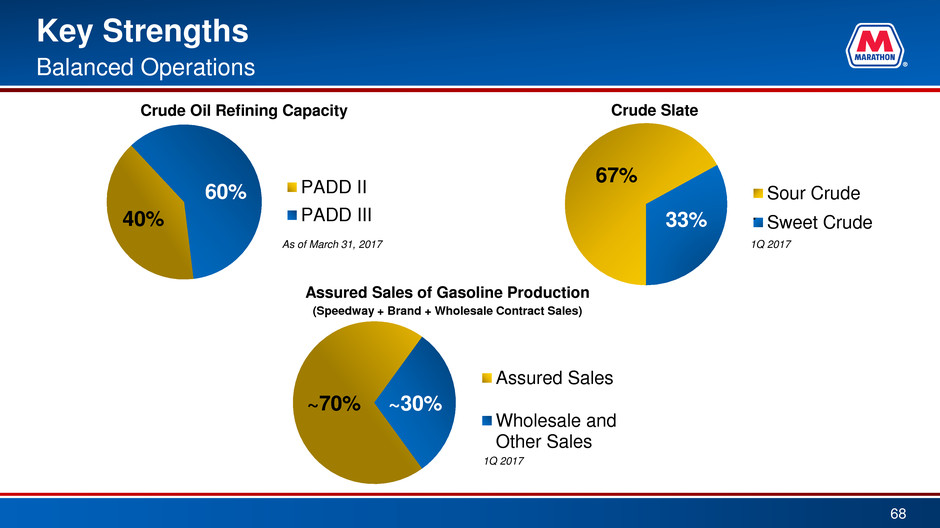

4 High Quality Network of Strategically Located Assets Track Record of Growing our Midstream Business Strong Financial Position Competitively Positioned Marketing Operations • Extensive platform of Midstream, Retail and Refining Assets • Flexibility and optionality to optimize operations in a dynamic market • Maximizes sales value of our products and minimizes costs • One of the largest wholesale suppliers to resellers in our market area • Two strong retail brands: Speedway® and Marathon® • ~70 percent assured sales of gasoline production • Track record of profitability & cash flow generation through cycle • Committed to investment grade credit profiles at MPC and MPLX • Provides financial flexibility to fund growth and business strategies • Significant expansion through MPLX and MarkWest merger • MPLX provides strong foundation to execute midstream growth strategy • Well-positioned in some of the most prolific basins in America Driving Strong Financial Performance Through Sustainable Competitive Advantages

Delivering Significant Returns for Our Shareholders 5 Since becoming an independent company on July 1, 2011 MPC Has Returned Nearly Repurchased $11 of Outstanding Common Shares BILLION To Shareholders ~30% Commitment to Ongoing Return of Capital to Shareholders Dividends Consistently growing dividend 25% CAGR since spin Share Repurchases Expect substantial ongoing activity outlined in strategic plan As of March 31, 2017

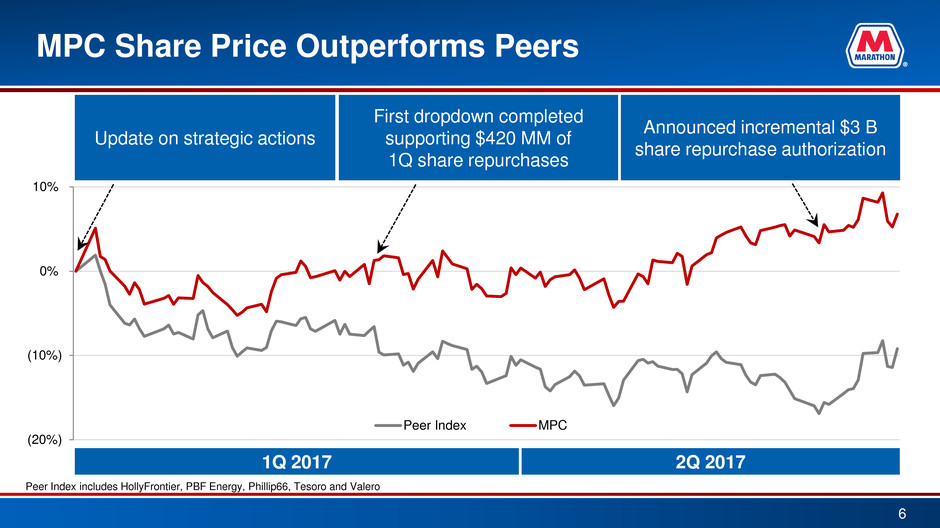

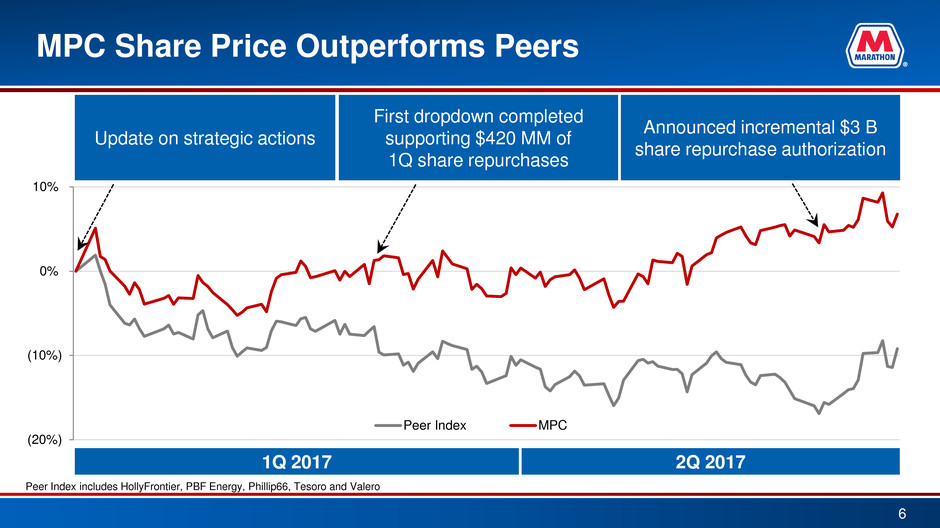

MPC Share Price Outperforms Peers 6 (20%) (10%) 0% 10% Peer Index MPC Peer Index includes HollyFrontier, PBF Energy, Phillip66, Tesoro and Valero 1Q 2017 2Q 2017 Update on strategic actions Announced incremental $3 B share repurchase authorization First dropdown completed supporting $420 MM of 1Q share repurchases

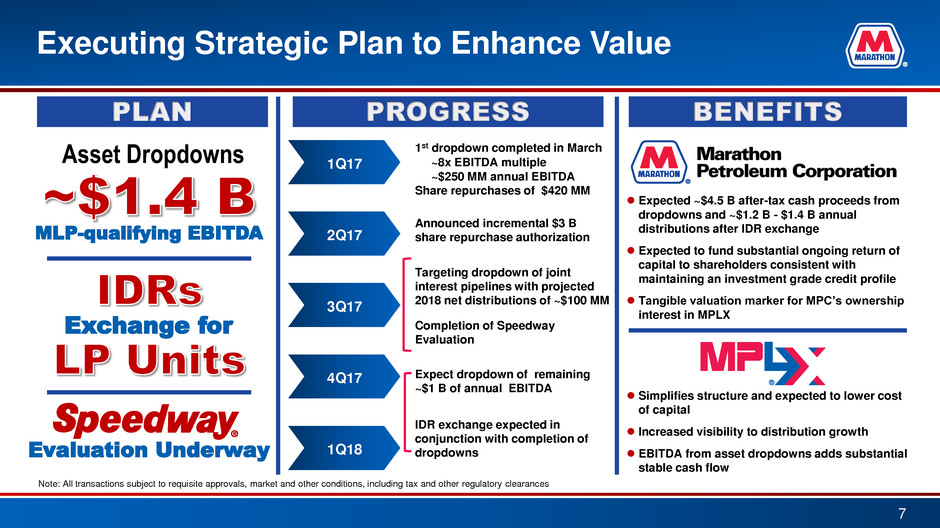

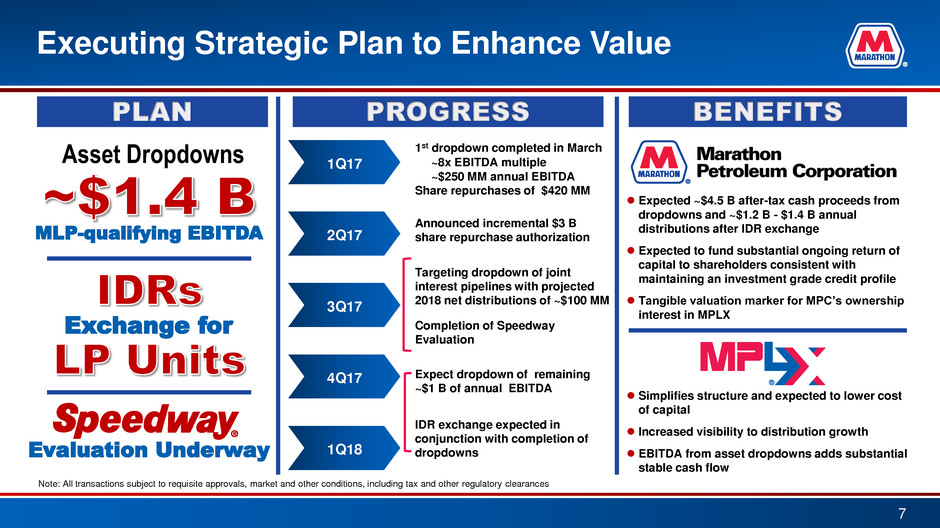

Executing Strategic Plan to Enhance Value 7 Note: All transactions subject to requisite approvals, market and other conditions, including tax and other regulatory clearances Evaluation Underway Exchange for Asset Dropdowns MLP-qualifying EBITDA 1Q17 2Q17 3Q17 4Q17 1Q18 1st dropdown completed in March ~8x EBITDA multiple ~$250 MM annual EBITDA Share repurchases of $420 MM Targeting dropdown of joint interest pipelines with projected 2018 net distributions of ~$100 MM Completion of Speedway Evaluation Expect dropdown of remaining ~$1 B of annual EBITDA IDR exchange expected in conjunction with completion of dropdowns Expected ~$4.5 B after-tax cash proceeds from dropdowns and ~$1.2 B - $1.4 B annual distributions after IDR exchange Expected to fund substantial ongoing return of capital to shareholders consistent with maintaining an investment grade credit profile Tangible valuation marker for MPC’s ownership interest in MPLX Simplifies structure and expected to lower cost of capital Increased visibility to distribution growth EBITDA from asset dropdowns adds substantial stable cash flow Announced incremental $3 B share repurchase authorization

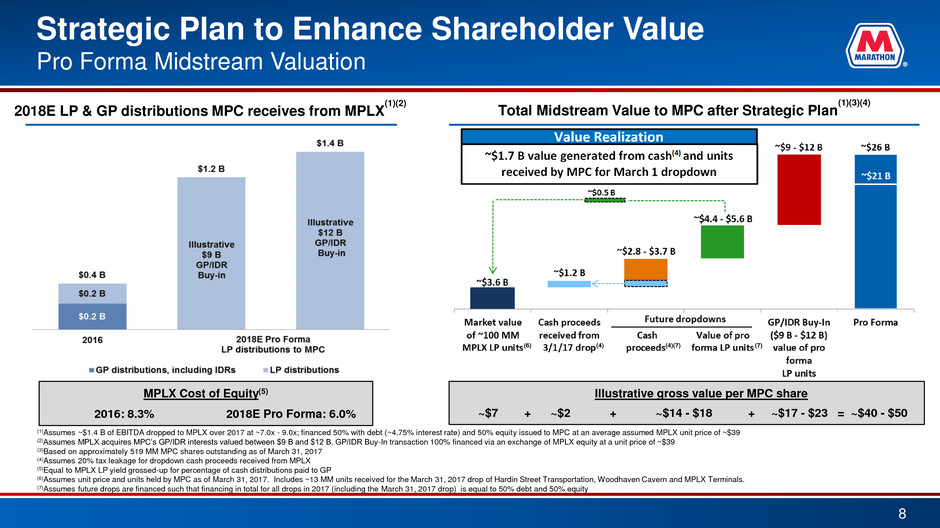

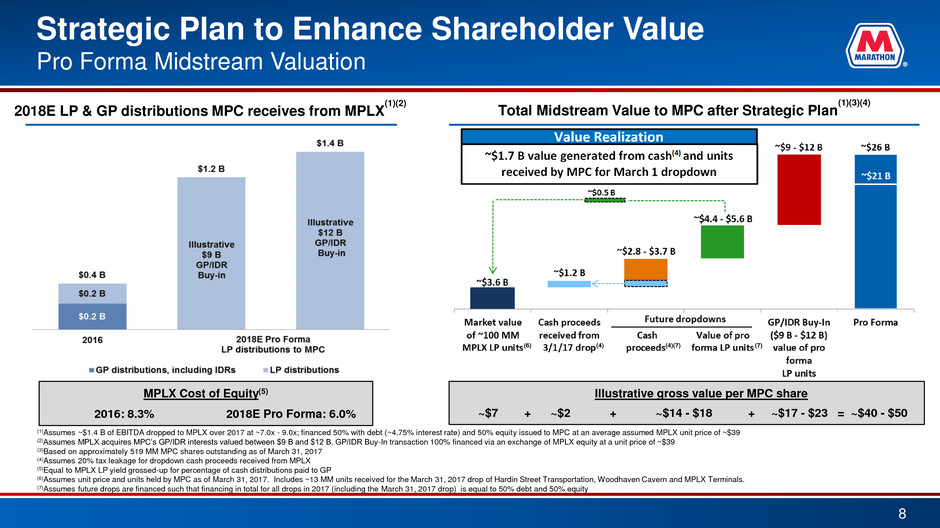

2018E LP & GP distributions MPC receives from MPLX (1)(2) (1)Assumes ~$1.4 B of EBITDA dropped to MPLX over 2017 at ~7.0x - 9.0x; financed 50% with debt (~4.75% interest rate) and 50% equity issued to MPC at an average assumed MPLX unit price of ~$39 (2)Assumes MPLX acquires MPC’s GP/IDR interests valued between $9 B and $12 B. GP/IDR Buy-In transaction 100% financed via an exchange of MPLX equity at a unit price of ~$39 (3)Based on approximately 519 MM MPC shares outstanding as of March 31, 2017 (4)Assumes 20% tax leakage for dropdown cash proceeds received from MPLX (5)Equal to MPLX LP yield grossed-up for percentage of cash distributions paid to GP (6)Assumes unit price and units held by MPC as of March 31, 2017. Includes ~13 MM units received for the March 31, 2017 drop of Hardin Street Transportation, Woodhaven Cavern and MPLX Terminals. (7)Assumes future drops are financed such that financing in total for all drops in 2017 (including the March 31, 2017 drop) is equal to 50% debt and 50% equity Total Midstream Value to MPC after Strategic Plan (1)(3)(4) Strategic Plan to Enhance Shareholder Value Pro Forma Midstream Valuation (6) Illustrative gross value per MPC share ~$7 + ~$2 + ~$14 - $18 + ~$17 - $23 = ~$40 - $50 MPLX Cost of Equity(5) 2016: 8.3% 2018E Pro Forma: 6.0% (4)(7) (7) (4) 8

MPLX - Key Investment Highlights 9 Diversified large-cap MLP positioned to deliver attractive returns over the long term Forecast distribution growth of 12% to 15% for 2017, double digit for 2018 Gathering & Processing Logistics & Storage Stable Cash Flows Cost of Capital Optimization • Largest processor and fractionator in the Marcellus/Utica basins • Strong footprint in STACK play • Growing presence in Permian basin • Supports extensive operations of third-largest U.S. refiner • Expanding third-party business and delivering incremental industry solutions • Substantial fee-based income with limited commodity exposure • Long-term relationships with diverse set of producer customers • Transportation and storage agreements with sponsor MPC • Visibility to growth through robust portfolio of organic projects and strong coverage ratio • Exchange of IDRs for MPLX LP units

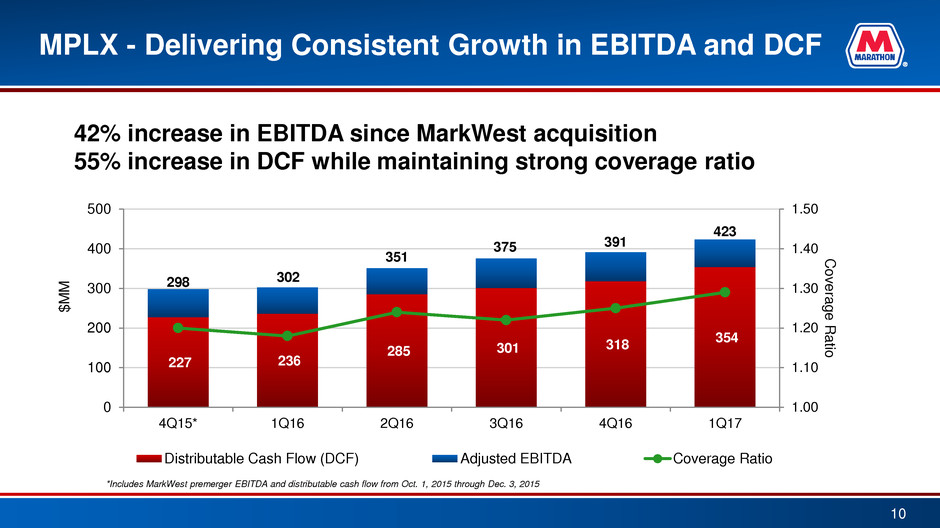

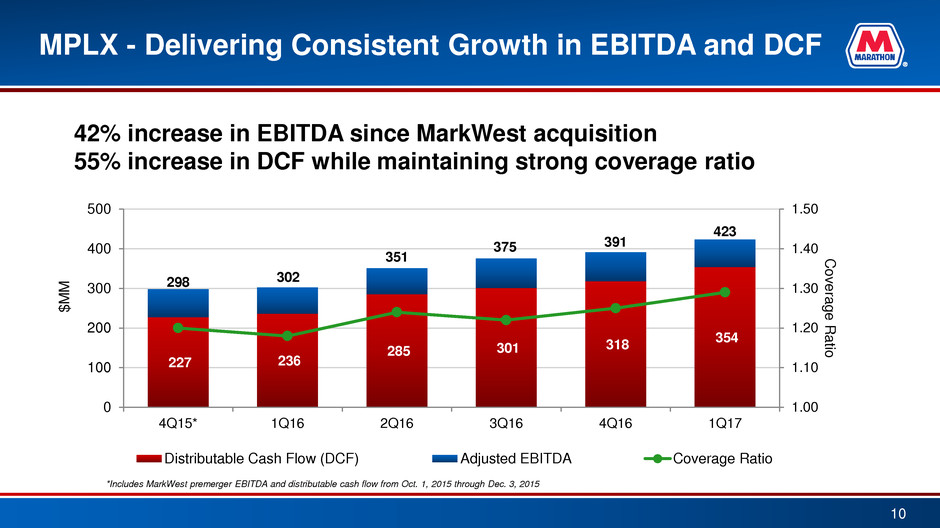

MPLX - Delivering Consistent Growth in EBITDA and DCF 10 227 236 285 301 318 354 298 302 351 375 391 423 1.00 1.10 1.20 1.30 1.40 1.50 0 100 200 300 400 500 4Q15* 1Q16 2Q16 3Q16 4Q16 1Q17 C o vera g e R ati o $ M M Distributable Cash Flow (DCF) Adjusted EBITDA Coverage Ratio 42% increase in EBITDA since MarkWest acquisition 55% increase in DCF while maintaining strong coverage ratio *Includes MarkWest premerger EBITDA and distributable cash flow from Oct. 1, 2015 through Dec. 3, 2015

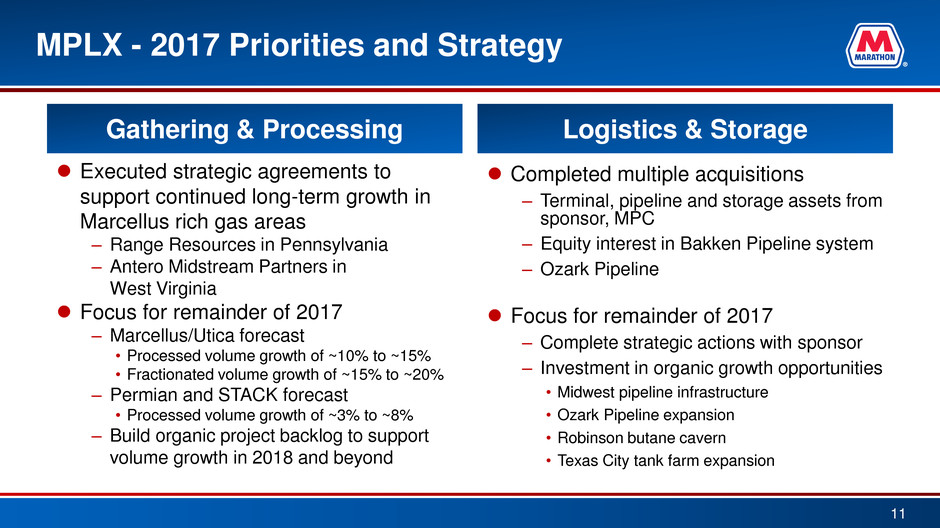

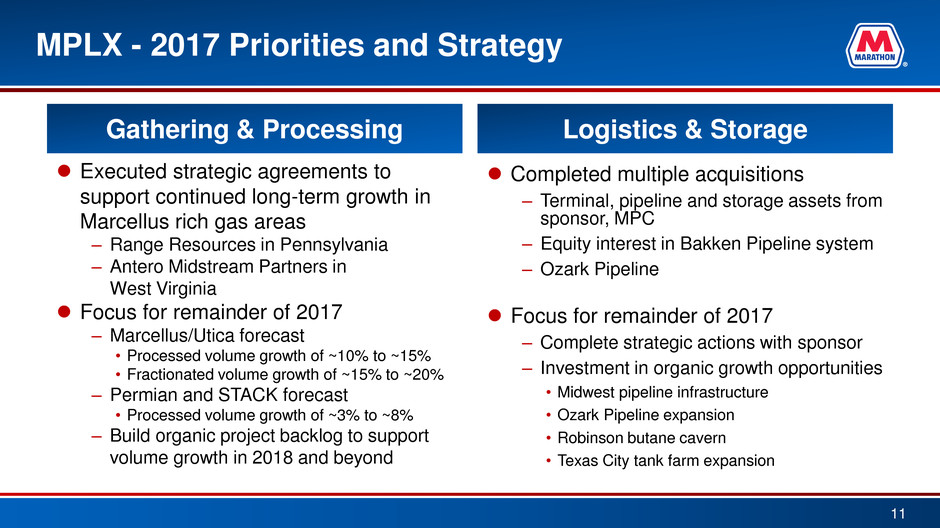

MPLX - 2017 Priorities and Strategy Gathering & Processing Executed strategic agreements to support continued long-term growth in Marcellus rich gas areas – Range Resources in Pennsylvania – Antero Midstream Partners in West Virginia Focus for remainder of 2017 – Marcellus/Utica forecast • Processed volume growth of ~10% to ~15% • Fractionated volume growth of ~15% to ~20% – Permian and STACK forecast • Processed volume growth of ~3% to ~8% – Build organic project backlog to support volume growth in 2018 and beyond Completed multiple acquisitions – Terminal, pipeline and storage assets from sponsor, MPC – Equity interest in Bakken Pipeline system – Ozark Pipeline Focus for remainder of 2017 – Complete strategic actions with sponsor – Investment in organic growth opportunities • Midwest pipeline infrastructure • Ozark Pipeline expansion • Robinson butane cavern • Texas City tank farm expansion 11 Logistics & Storage

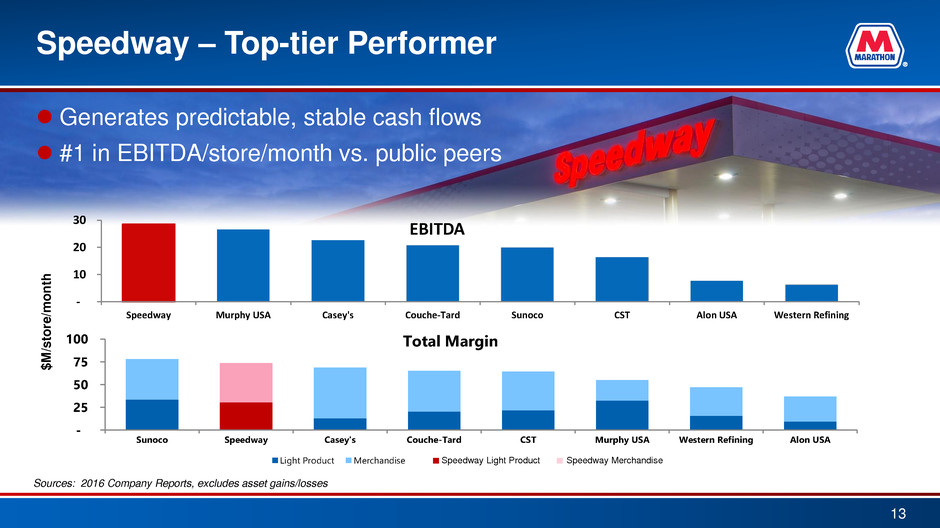

Speedway Serving More Than 2 Million Customers Every Day 12 High Quality Network of Retail Locations Top-tier Performer Delivered on Acquisition Goals Effective Marketing Strategies • Largest company-owned and -operated c-store chain east of Mississippi • Sold ~6 B gallons of transportation fuels and $5 B in merchandise in 2016 • 2017 planned investments of ~$380 MM • #1 in EBITDA/store/month versus public peers • Strong and consistent growth with multiple records set in 2016 • Focus on improving light product breakeven (“LPBE”) • Vision: the Customer’s First Choice for Value and Convenience • Industry leading loyalty program averaging more than 5.7 MM active members • Expanding private label products to drive higher sales, higher margins and deliver a better value to customers • Planned investments achieved under budget and ahead of schedule • ~80% of acquired stores upgraded under remodel plan • 2016 actual synergies of $180 MM significantly exceeded guidance

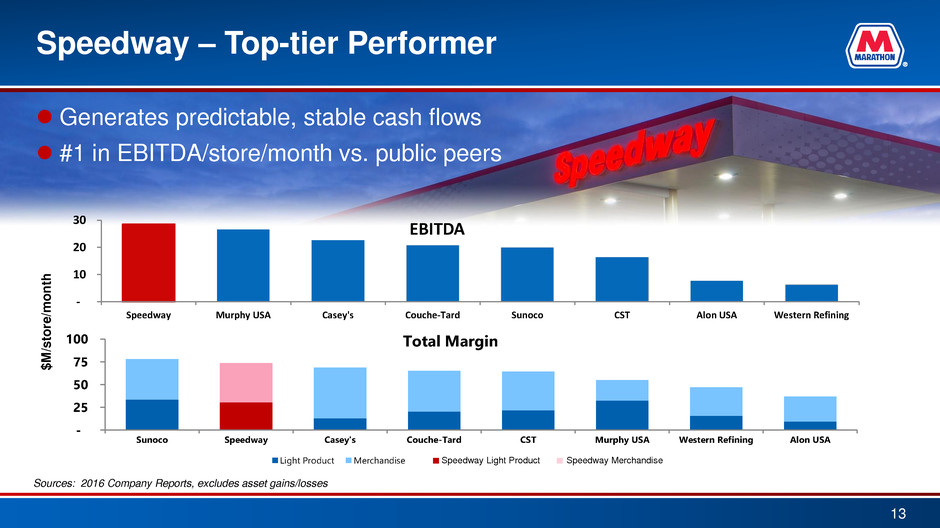

Speedway – Top-tier Performer 13 Sources: 2016 Company Reports, excludes asset gains/losses Speedway Light Product Speedway Merchandise $ M /s tor e /mon th Generates predictable, stable cash flows #1 in EBITDA/store/month vs. public peers - 10 20 30 Speedway Murphy USA Casey's Couche-Tard Sunoco CST Alon USA Western Refining EBITDA - 25 50 75 100 Sunoco Speedway Casey's Couche-Tard CST Murphy USA Western Refining Alon USA Total Margin Light Product Merchandise

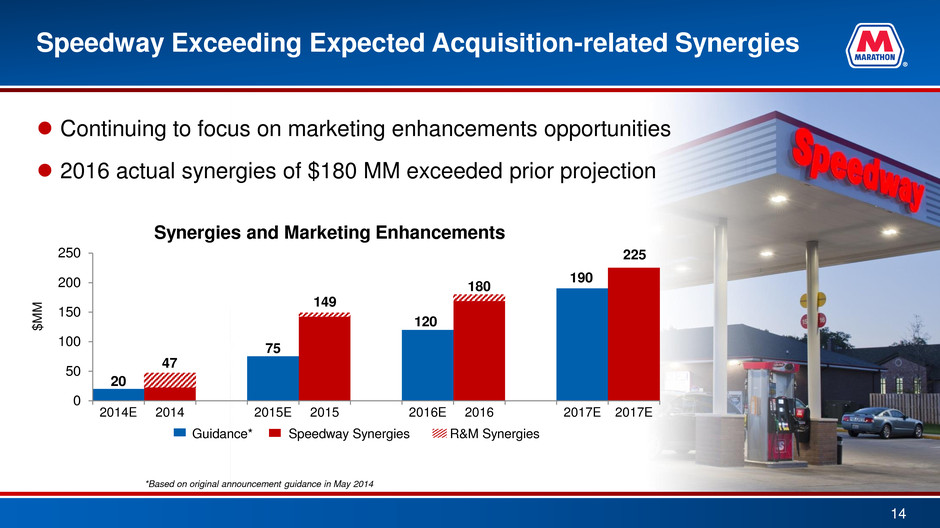

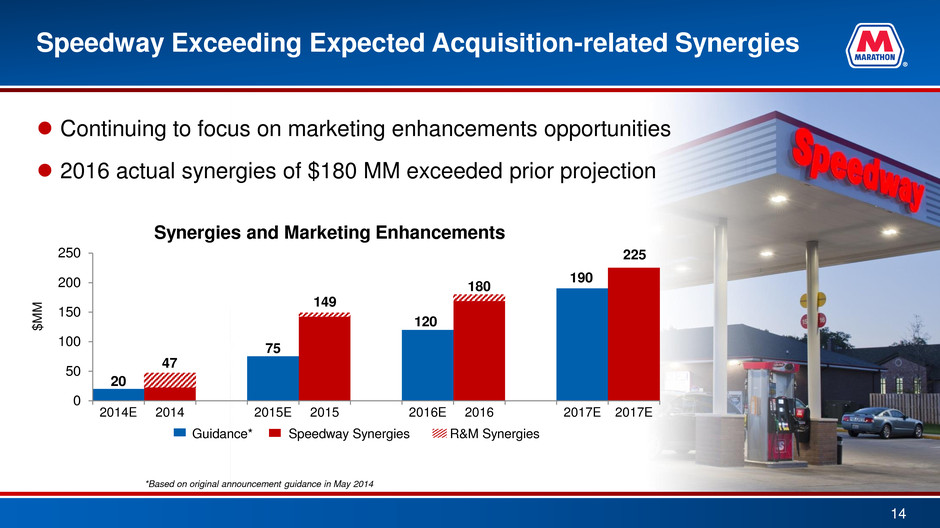

Speedway Exceeding Expected Acquisition-related Synergies 14 20 75 120 180 190 225 0 50 100 150 200 250 2014E 2014 2015E 2015 2016E 2016 2017E 2017E $ M M Synergies and Marketing Enhancements Guidance* Speedway Synergies R&M Synergies 47 149 *Based on original announcement guidance in May 2014 Continuing to focus on marketing enhancements opportunities 2016 actual synergies of $180 MM exceeded prior projection

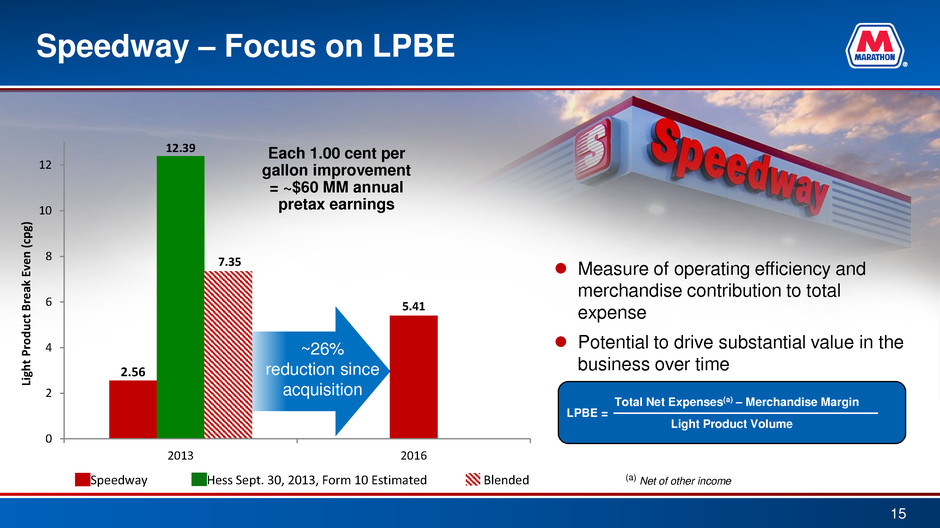

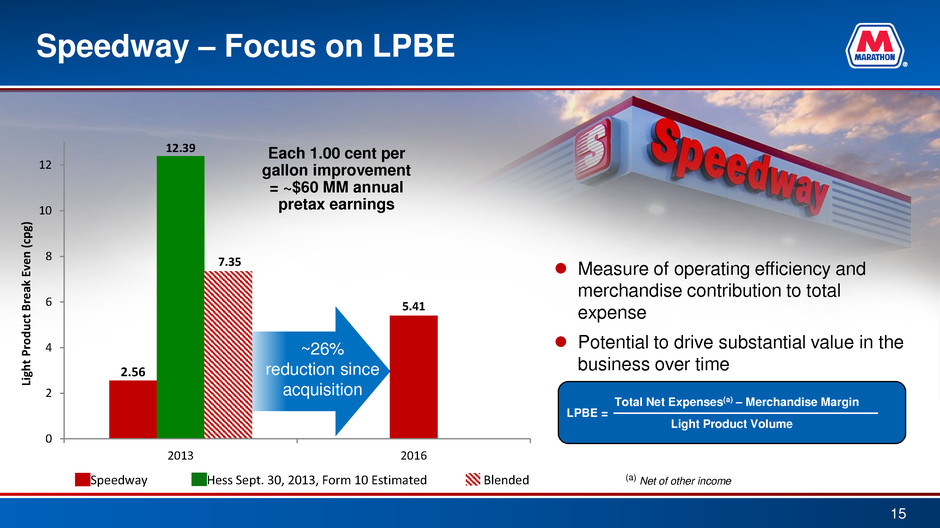

2.56 12.39 5.41 7.35 0 2 4 6 8 10 12 2013 2016 Li gh t P ro d u ct B re ak E ve n ( cp g) Speedway Hess Sept. 30, 2013, Form 10 Estimated Blended LPBE = Total Net Expenses(a) – Merchandise Margin Light Product Volume Speedway – Focus on LPBE 15 Measure of operating efficiency and merchandise contribution to total expense Potential to drive substantial value in the business over time Each 1.00 cent per gallon improvement = ~$60 MM annual pretax earnings ~26% reduction since acquisition (a) Net of other income

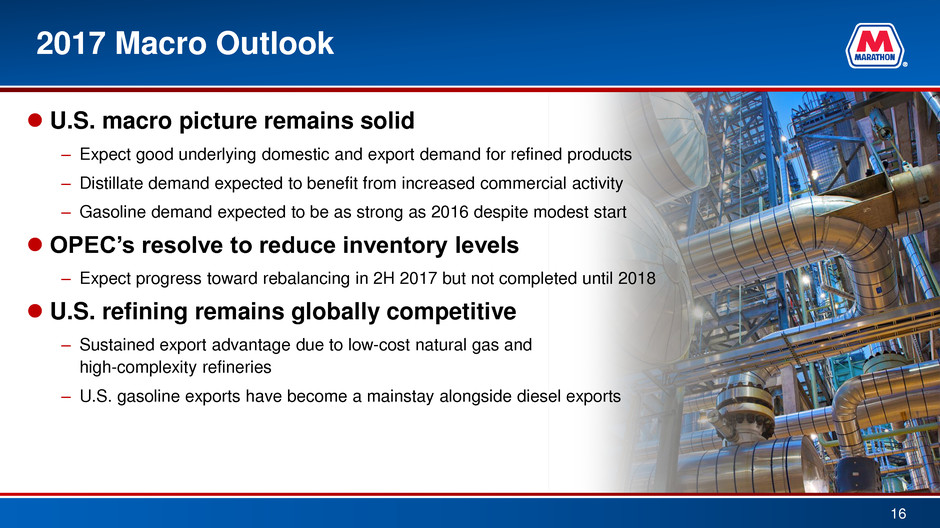

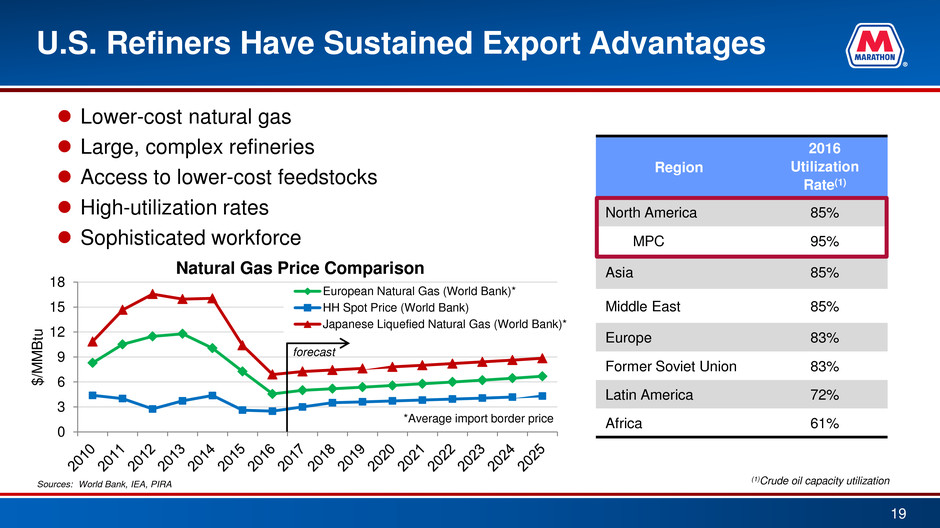

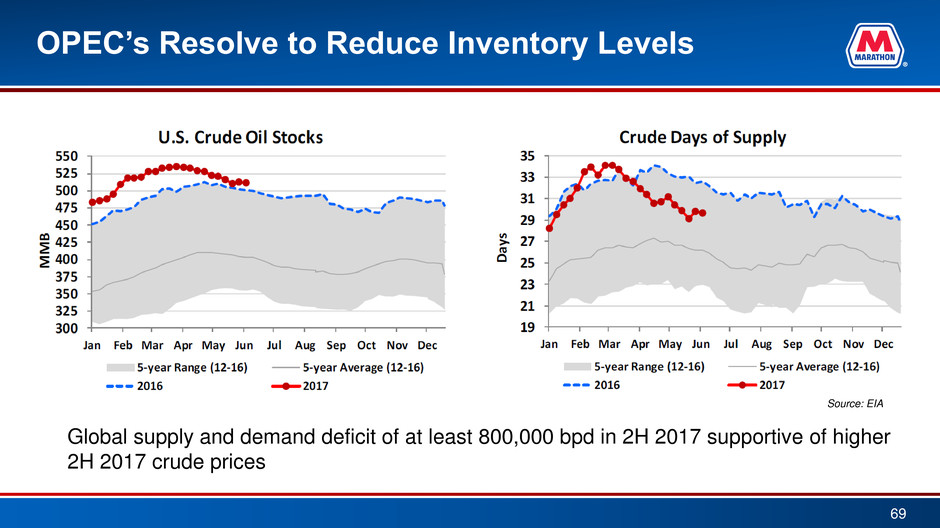

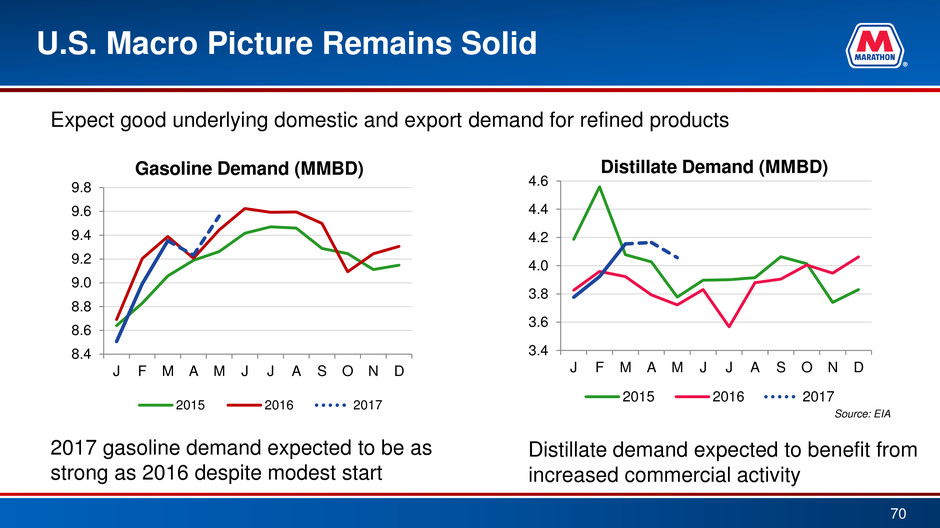

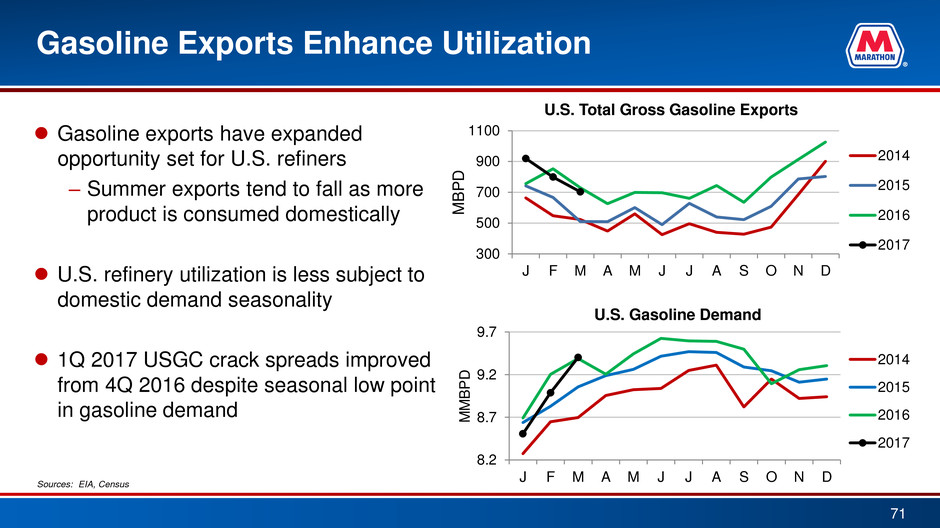

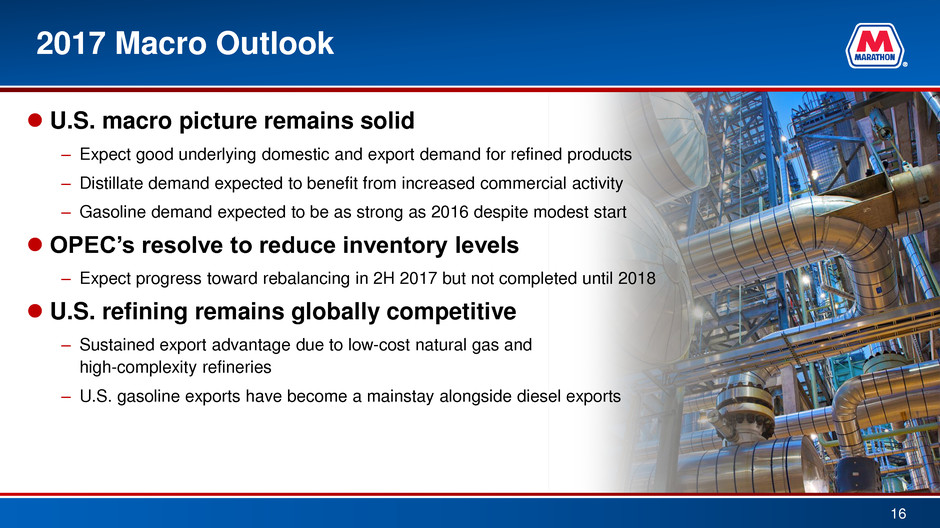

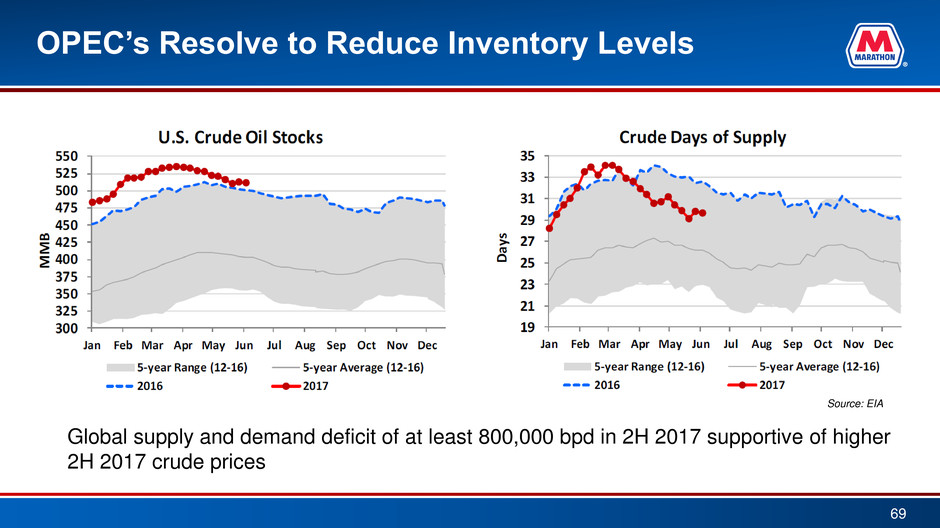

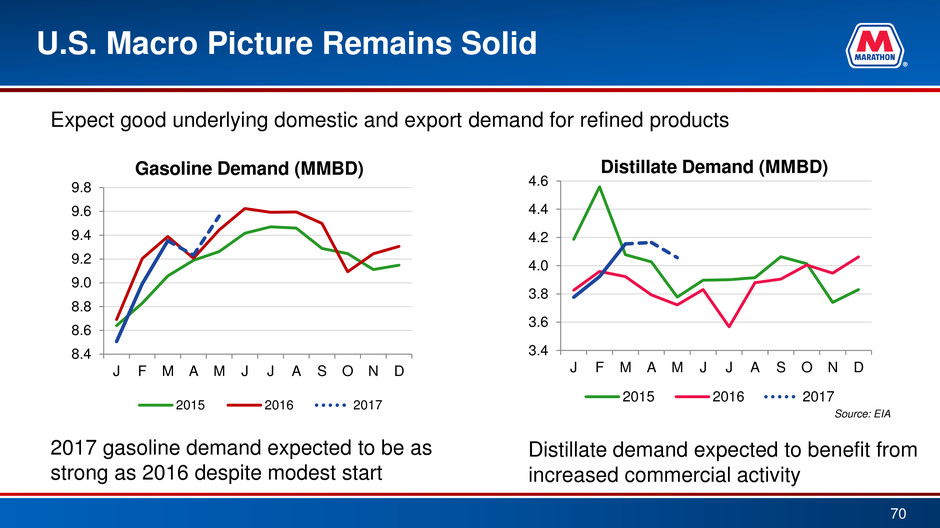

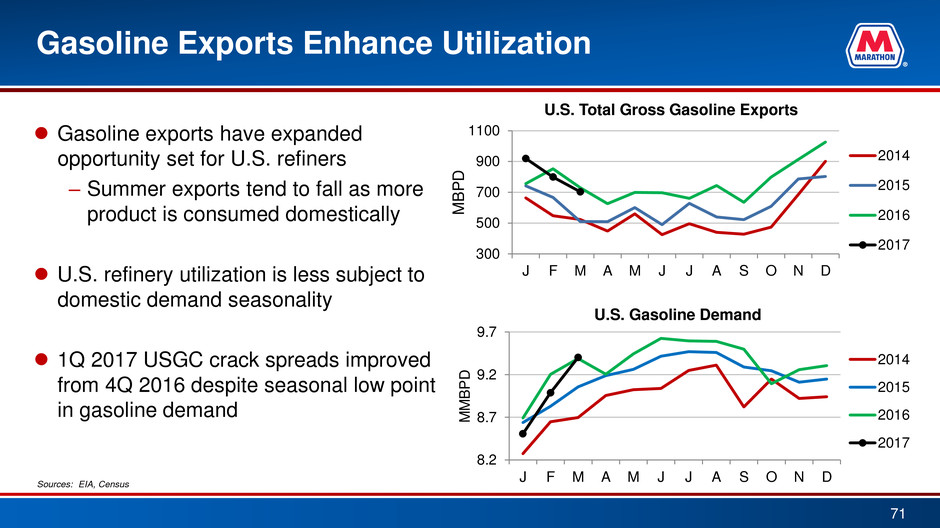

2017 Macro Outlook U.S. macro picture remains solid – Expect good underlying domestic and export demand for refined products – Distillate demand expected to benefit from increased commercial activity – Gasoline demand expected to be as strong as 2016 despite modest start OPEC’s resolve to reduce inventory levels – Expect progress toward rebalancing in 2H 2017 but not completed until 2018 U.S. refining remains globally competitive – Sustained export advantage due to low-cost natural gas and high-complexity refineries – U.S. gasoline exports have become a mainstay alongside diesel exports 16

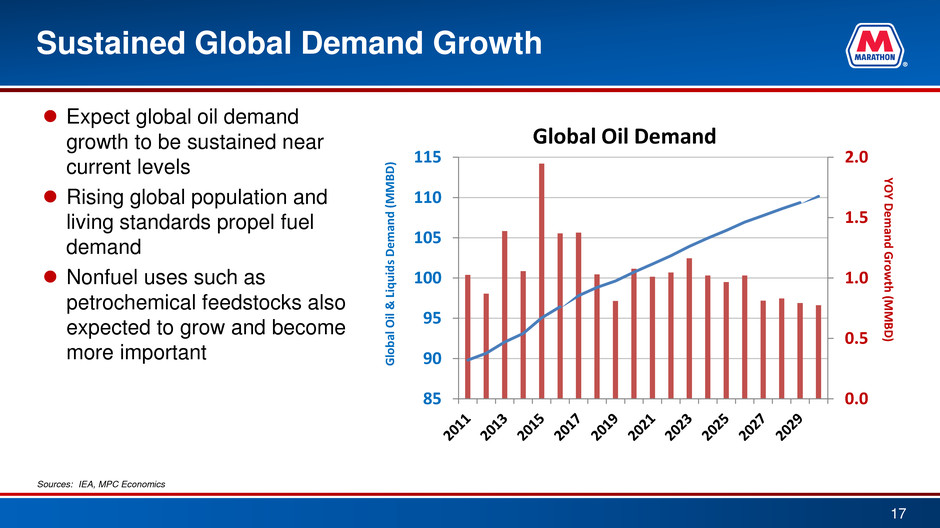

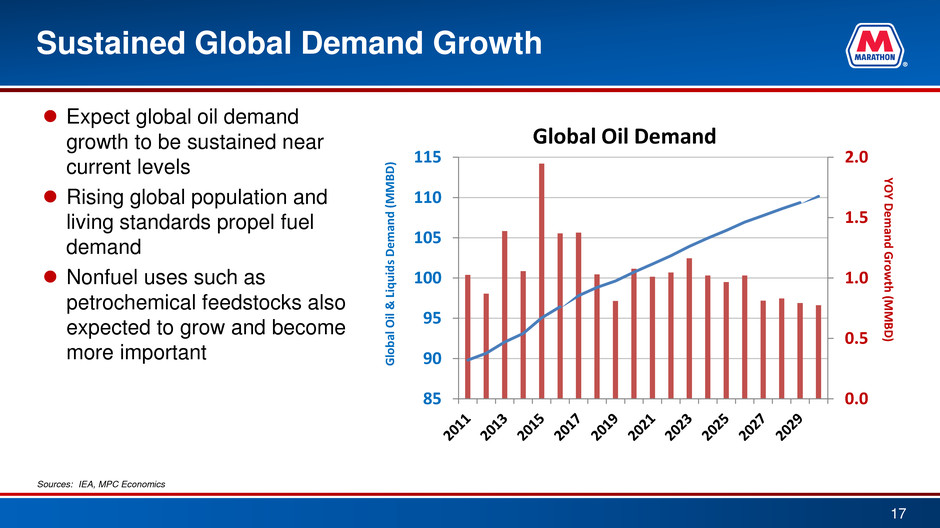

Sustained Global Demand Growth 17 Expect global oil demand growth to be sustained near current levels Rising global population and living standards propel fuel demand Nonfuel uses such as petrochemical feedstocks also expected to grow and become more important Sources: IEA, MPC Economics 0.0 0.5 1.0 1.5 2.0 85 90 95 100 105 110 115 Y O Y D e m an d G ro w th (M M B D ) G lo b al O il & L iq u id s De m an d ( M M B D ) Global Oil Demand

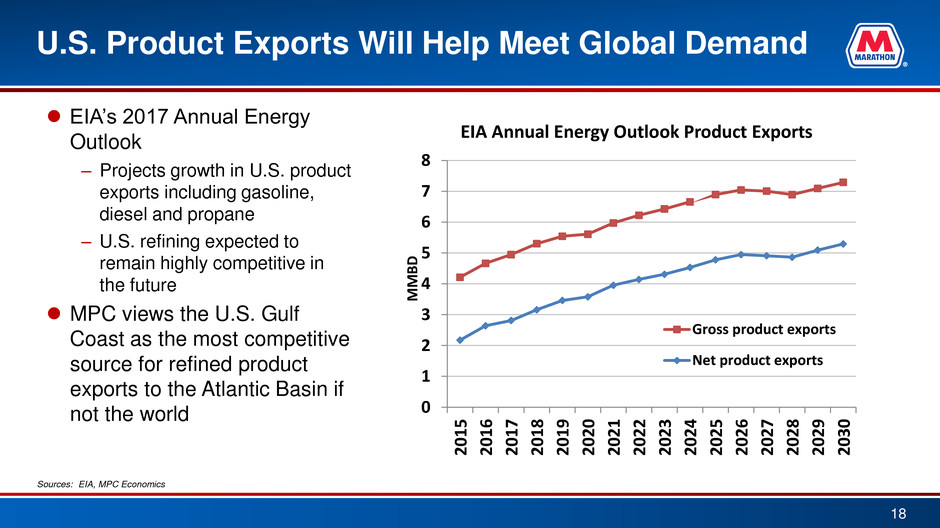

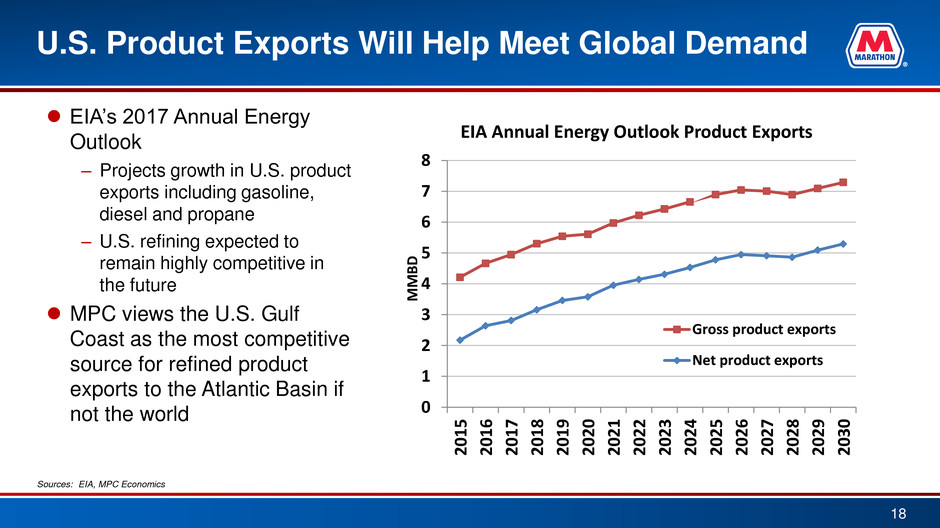

U.S. Product Exports Will Help Meet Global Demand 18 EIA’s 2017 Annual Energy Outlook – Projects growth in U.S. product exports including gasoline, diesel and propane – U.S. refining expected to remain highly competitive in the future MPC views the U.S. Gulf Coast as the most competitive source for refined product exports to the Atlantic Basin if not the world Sources: EIA, MPC Economics 0 1 2 3 4 5 6 7 8 2 0 1 5 2 0 1 6 2 0 1 7 2 0 1 8 2 0 1 9 2 0 2 0 2 0 2 1 2 0 2 2 2 0 2 3 2 0 2 4 2 0 2 5 2 0 2 6 2 0 2 7 2 0 2 8 2 0 2 9 2 0 3 0 M M B D EIA Annual Energy Outlook Product Exports Gross product exports Net product exports

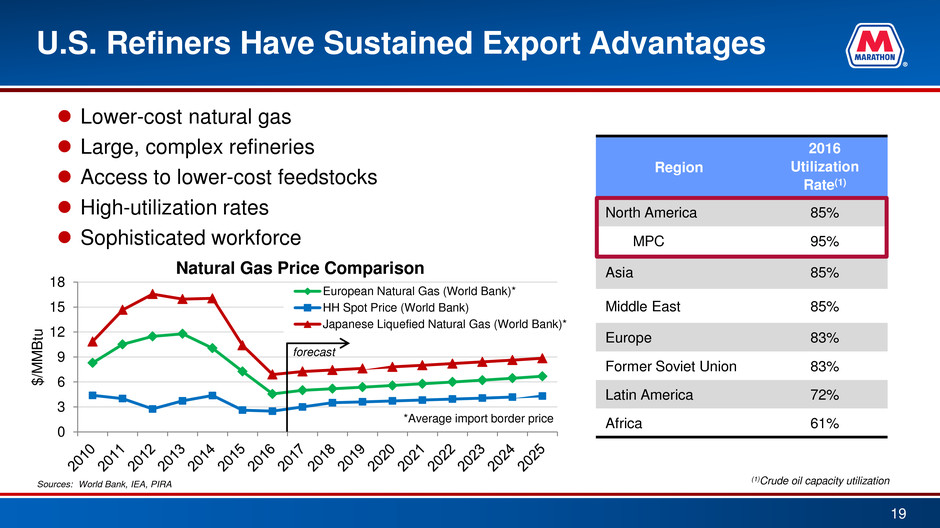

0 3 6 9 12 15 18 $/ M M B tu Natural Gas Price Comparison European Natural Gas (World Bank)* HH Spot Price (World Bank) Japanese Liquefied Natural Gas (World Bank)* Region 2016 Utilization Rate(1) North America 85% MPC 95% Asia 85% Middle East 85% Europe 83% Former Soviet Union 83% Latin America 72% Africa 61% U.S. Refiners Have Sustained Export Advantages 19 Lower-cost natural gas Large, complex refineries Access to lower-cost feedstocks High-utilization rates Sophisticated workforce *Average import border price Sources: World Bank, IEA, PIRA forecast (1)Crude oil capacity utilization

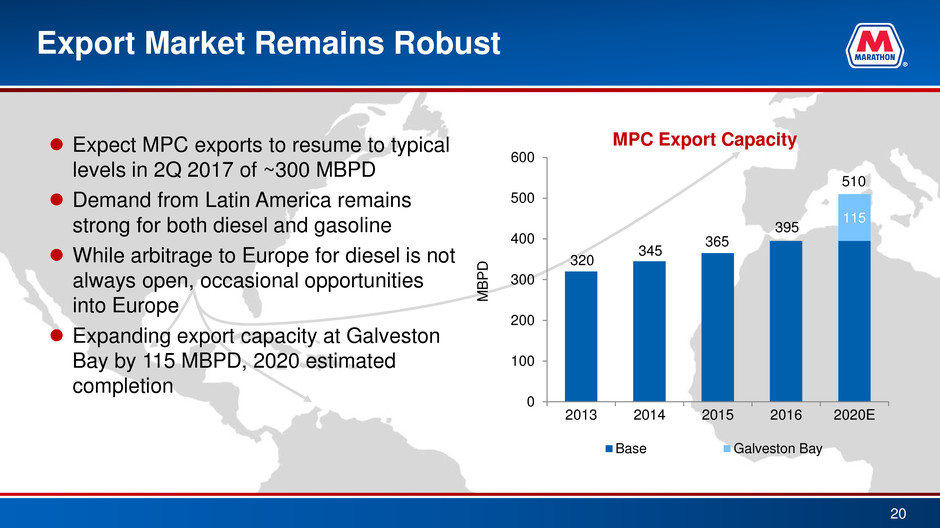

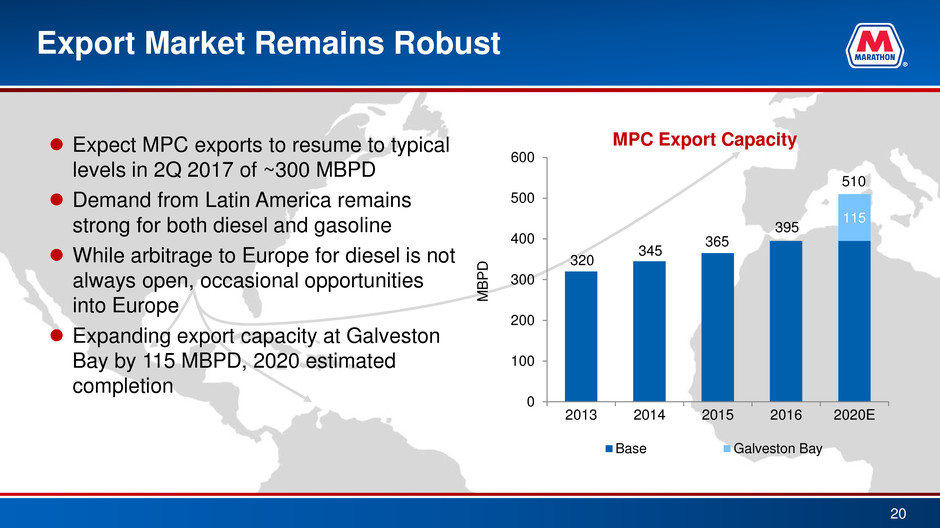

Export Market Remains Robust 20 320 345 395 510 365 115 0 100 200 300 400 500 600 2013 2014 2015 2016 2020E M B P D Base Galveston Bay MPC Export Capacity Expect MPC exports to resume to typical levels in 2Q 2017 of ~300 MBPD Demand from Latin America remains strong for both diesel and gasoline While arbitrage to Europe for diesel is not always open, occasional opportunities into Europe Expanding export capacity at Galveston Bay by 115 MBPD, 2020 estimated completion

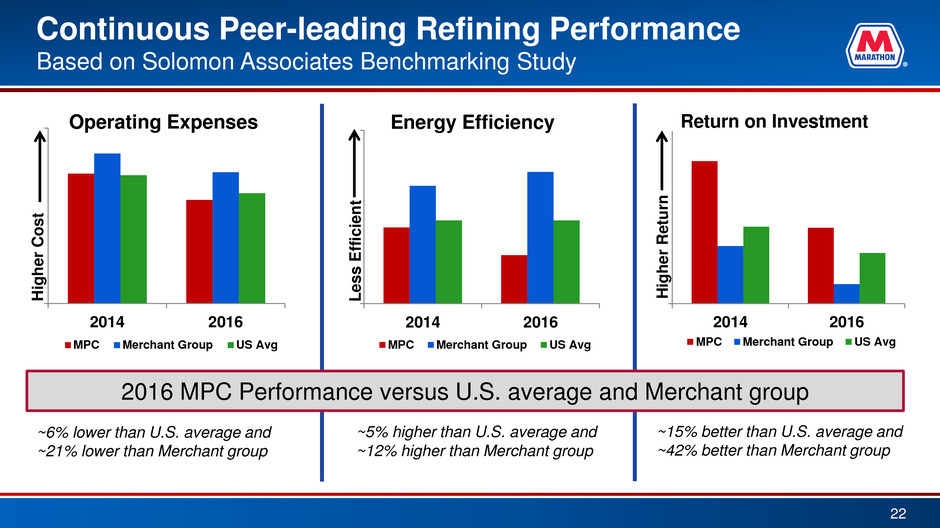

Industry-leading Refining Network 21 High-quality, Strategically Located Refineries Sustained Competitive Advantages Focus on Safe, Efficient and Reliable Operations Focus on Enhancing Margins • Third-largest U.S. refiner linked to extensive logistics and retail network • Process wide range of crude oils, feedstocks and condensate ranging from two-thirds heavy sour to two-thirds light sweet crudes • Peer-leading alkylation and reforming (octane) capacity • Access to plentiful cost advantaged natural gas and feedstocks • Poised to benefit from growing North American crude oil production • Well-positioned to capture export opportunities • Optimizing Galveston Bay and Texas City operations • Increase margins through process improvements • Increase distillate production and export capacity • Refining return on investment and energy efficiency pacesetter(1) • Earned 75% of EPA Energy Star awards • 5 OSHA VPP star refineries (1) Based on Solomon Associates benchmarking study

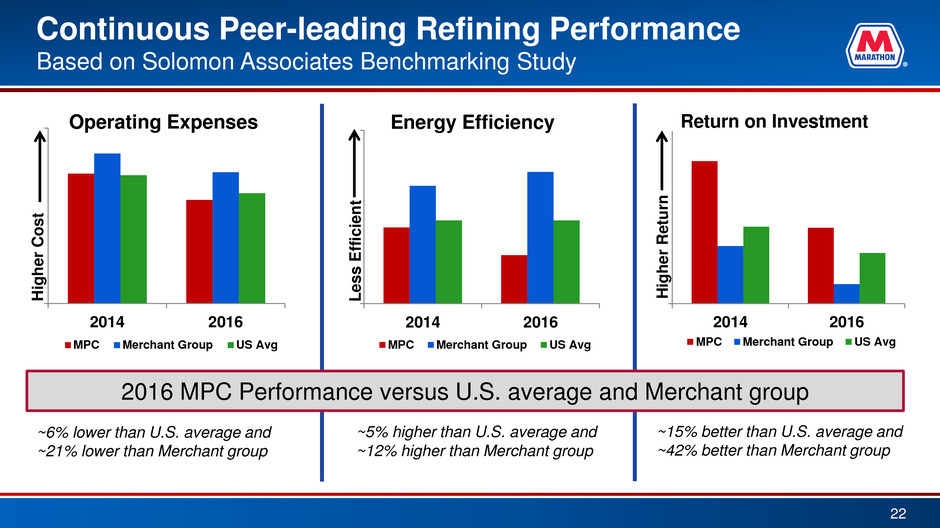

22 2014 2016 H igher R etur n Return on Investment MPC Merchant Group US Avg Continuous Peer-leading Refining Performance Based on Solomon Associates Benchmarking Study 2014 2016 Le s s E ff ic ie n t Energy Efficiency MPC Merchant Group US Avg ~5% higher than U.S. average and ~12% higher than Merchant group ~15% better than U.S. average and ~42% better than Merchant group 2014 2016 Highe r Cost Operating Expenses MPC Merchant Group US Avg ~6% lower than U.S. average and ~21% lower than Merchant group 2016 MPC Performance versus U.S. average and Merchant group

Refining & Marketing Margin Enhancing Investments 23 ~$275 MM planned in 2017 Estimated returns in excess of 20% STAR (South Texas Asset Repositioning program) – Increase residual oil (resid) processing • Expand resid hydrocracker • Improve gas oil recovery – Revamp crude unit • Increase distillate and gas oil recovery • Improve reliability • Increase capacity 40 MBPD – Full integration of Galveston Bay and Texas City refineries Garyville ULSD projects – Additional 10 MBPD ULSD production capacity Galveston Bay export capacity expansion – Additional 115 MBPD refined product export capacity

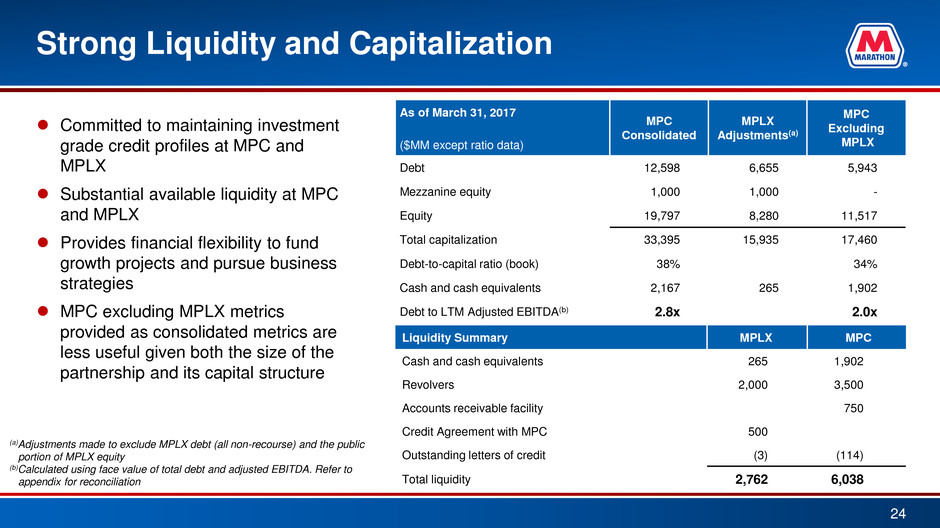

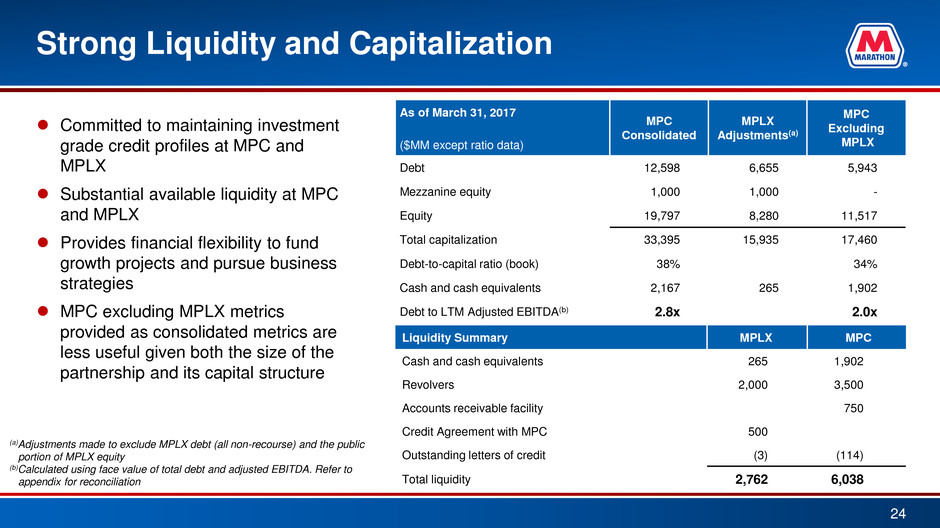

Strong Liquidity and Capitalization Committed to maintaining investment grade credit profiles at MPC and MPLX Substantial available liquidity at MPC and MPLX Provides financial flexibility to fund growth projects and pursue business strategies MPC excluding MPLX metrics provided as consolidated metrics are less useful given both the size of the partnership and its capital structure 24 As of March 31, 2017 MPC Consolidated MPLX Adjustments(a) MPC Excluding MPLX ($MM except ratio data) Debt 12,598 6,655 5,943 Mezzanine equity 1,000 1,000 - Equity 19,797 8,280 11,517 Total capitalization 33,395 15,935 17,460 Debt-to-capital ratio (book) 38% 34% Cash and cash equivalents 2,167 265 1,902 Debt to LTM Adjusted EBITDA(b) 2.8x 2.0x (a)Adjustments made to exclude MPLX debt (all non-recourse) and the public portion of MPLX equity (b)Calculated using face value of total debt and adjusted EBITDA. Refer to appendix for reconciliation Liquidity Summary MPLX MPC Cash and cash equivalents 265 1,902 Revolvers 2,000 3,500 Accounts receivable facility 750 Credit Agreement with MPC 500 Outstanding letters of credit (3) (114) Total liquidity 2,762 6,038

Our Priorities for Value Creation 25 Execute Strategic Actions to Enhance Value for Investors Maintain Top-tier Safety and Environmental performance Increase Capital Return to Shareholders Grow Higher Valued and Stable Cash-flow businesses Enhance Margins for our Refining operations

Appendix 26

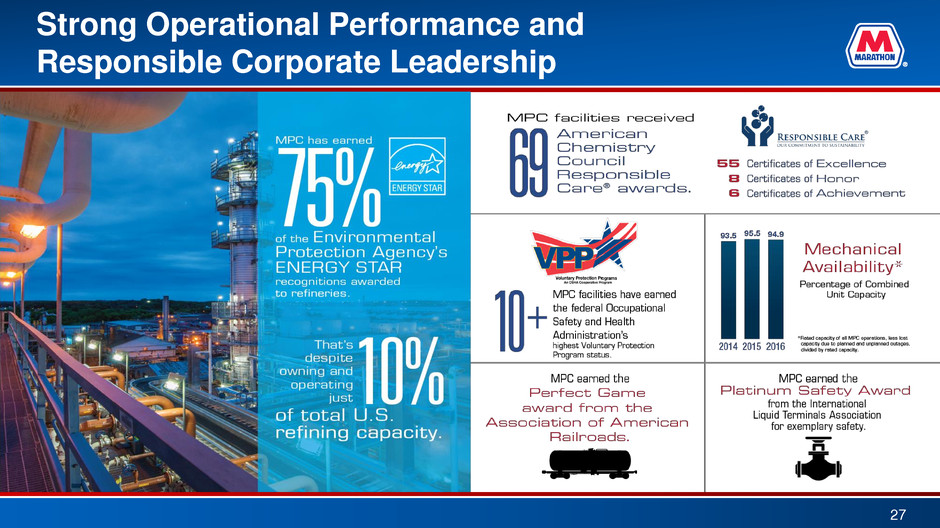

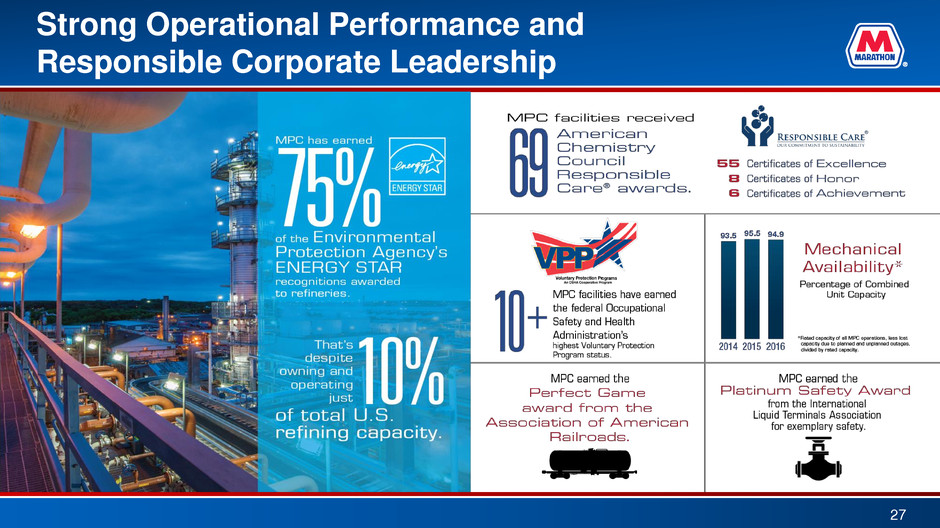

Strong Operational Performance and Responsible Corporate Leadership 27

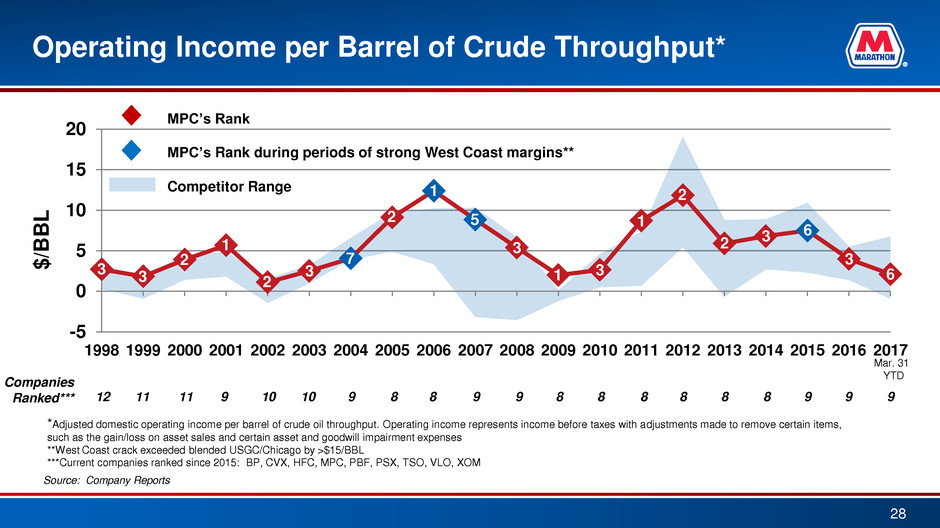

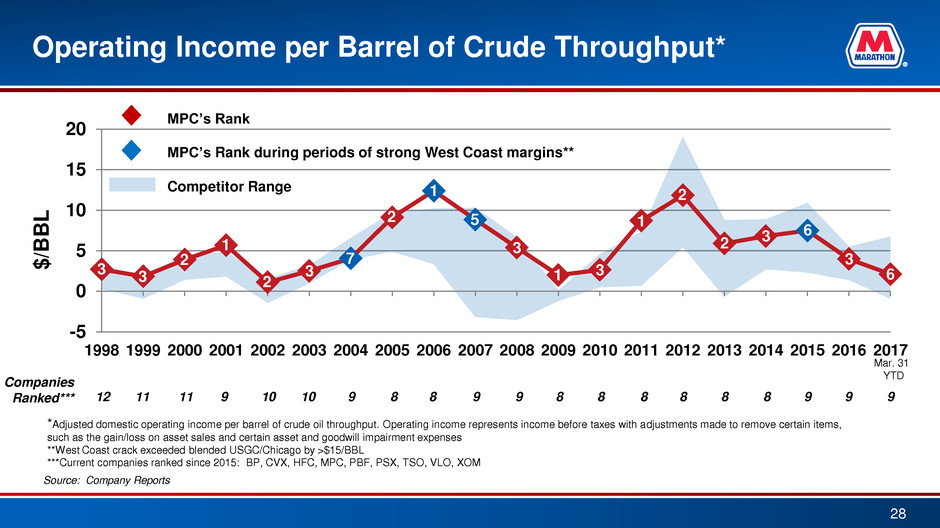

-5 0 5 10 15 20 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 $ /B B L Source: Company Reports 3 3 2 1 2 3 7 2 1 5 3 1 3 1 2 MPC’s Rank MPC’s Rank during periods of strong West Coast margins** Competitor Range Companies Ranked*** *Adjusted domestic operating income per barrel of crude oil throughput. Operating income represents income before taxes with adjustments made to remove certain items, such as the gain/loss on asset sales and certain asset and goodwill impairment expenses **West Coast crack exceeded blended USGC/Chicago by >$15/BBL ***Current companies ranked since 2015: BP, CVX, HFC, MPC, PBF, PSX, TSO, VLO, XOM Operating Income per Barrel of Crude Throughput* 11 12 11 9 10 9 8 9 9 8 10 8 8 8 8 8 8 9 9 2 3 6 3 6 9 Mar. 31 YTD 28

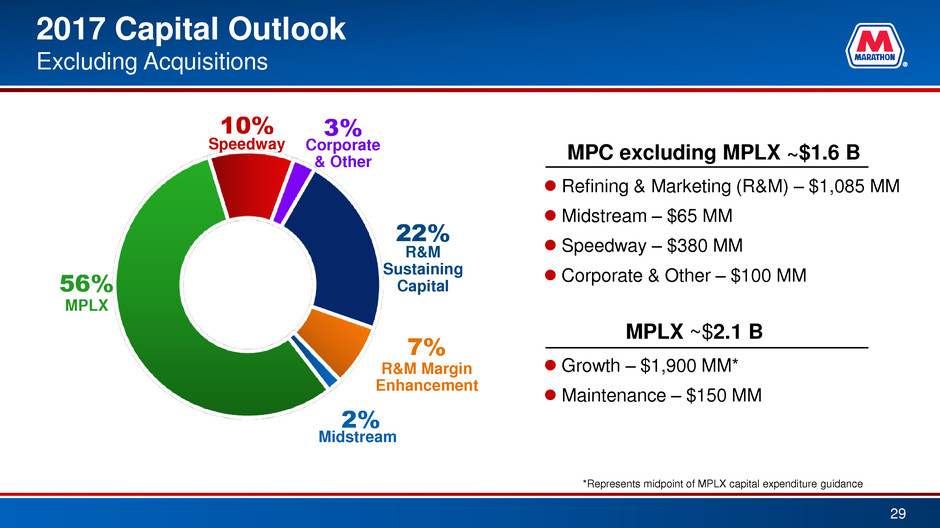

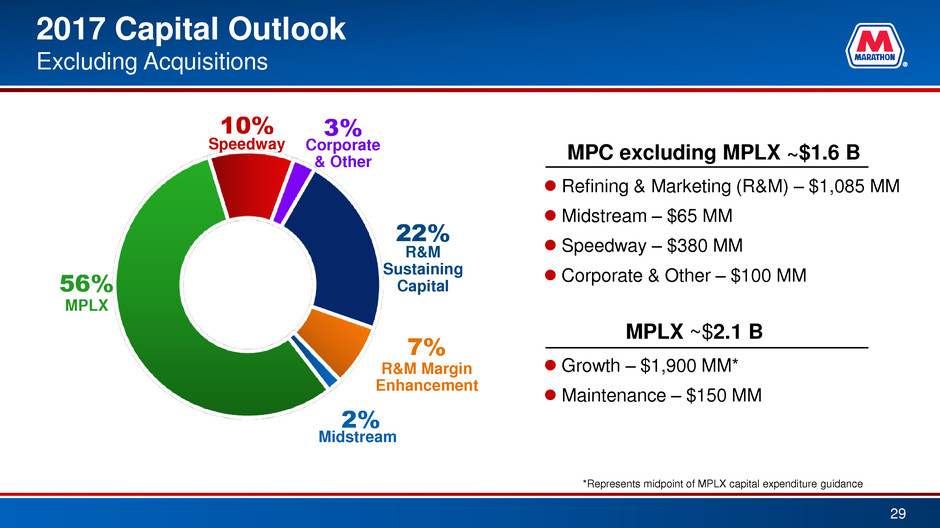

MPC excluding MPLX ~$1.6 B Refining & Marketing (R&M) – $1,085 MM Midstream – $65 MM Speedway – $380 MM Corporate & Other – $100 MM MPLX ~$2.1 B Growth – $1,900 MM* Maintenance – $150 MM Midstream MPLX R&M Margin Enhancement Corporate & Other R&M Sustaining Capital *Represents midpoint of MPLX capital expenditure guidance 2017 Capital Outlook Excluding Acquisitions 29 22% 7% 3% Speedway 10% 56% 2%

About MPLX Growth-oriented, diversified MLP with high-quality, strategically located assets with leading midstream position Two primary businesses – Logistics & Storage includes transportation, storage and distribution of crude oil, refined petroleum products and other hydrocarbon-based products – Gathering & Processing includes gathering, processing, and transportation of natural gas and the gathering, transportation, fractionation, storage and marketing of NGLs Investment-grade credit profile with strong financial flexibility MPC as sponsor has interests aligned with MPLX – MPLX assets are integral to MPC – Growing stable cash flows through continued investment in midstream infrastructure 30 As of March 31, 2017 See appendix for legend

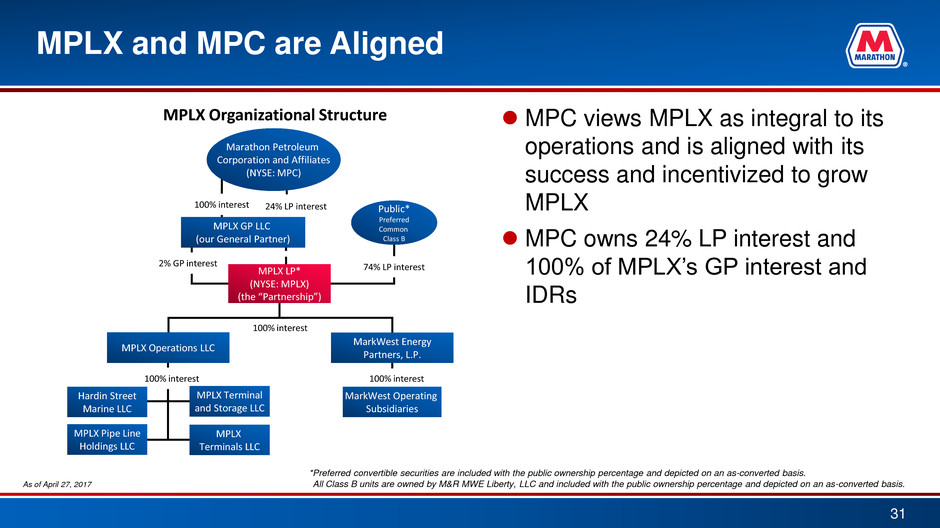

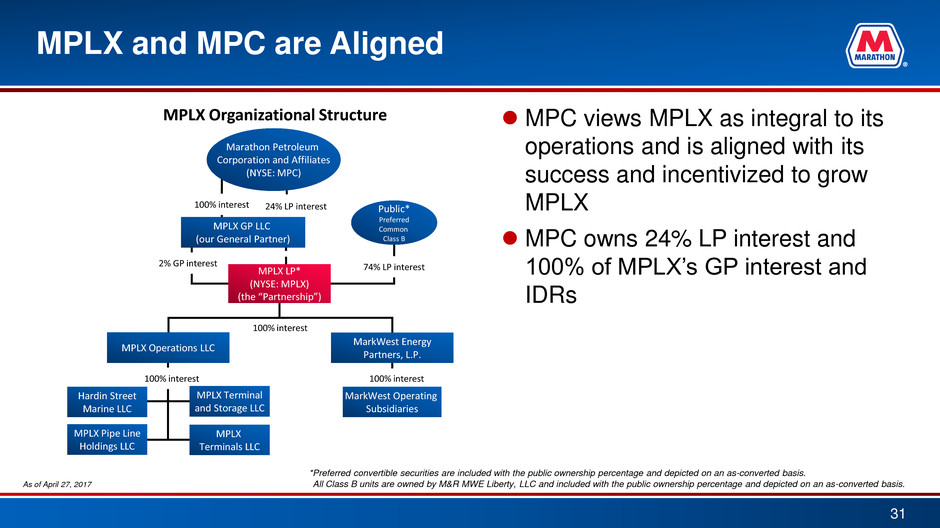

2% GP interest MPLX and MPC are Aligned MPC views MPLX as integral to its operations and is aligned with its success and incentivized to grow MPLX MPC owns 24% LP interest and 100% of MPLX’s GP interest and IDRs 100% interest r 100% interest Public* Preferred Common Class B 74% LP interest 100% interest MPLX GP LLC (our General Partner) 24% LP interest MPLX LP* (NYSE: MPLX) (the “Partnership”) Marathon Petroleum Corporation and Affiliates (NYSE: MPC) MPLX Organizational Structure 31 As of April 27, 2017 *Preferred convertible securities are included with the public ownership percentage and depicted on an as-converted basis. All Class B units are owned by M&R MWE Liberty, LLC and included with the public ownership percentage and depicted on an as-converted basis. MPLX Terminal and Storage LLC MarkWest Energy Partners, L.P. 100% interest MarkWest Operating Subsidiaries MPLX Operations LLC Hardin Street Marine LLC MPLX Pipe Line Holdings LLC MPLX Terminals LLC

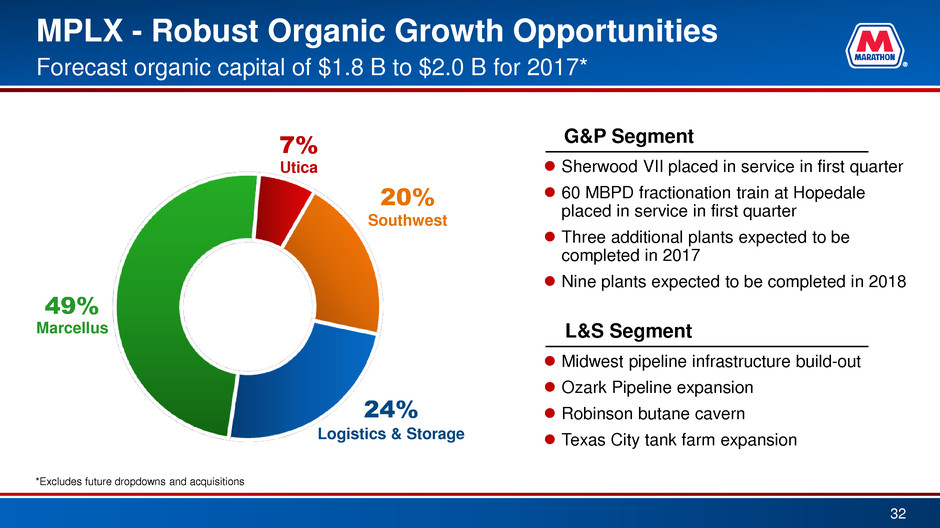

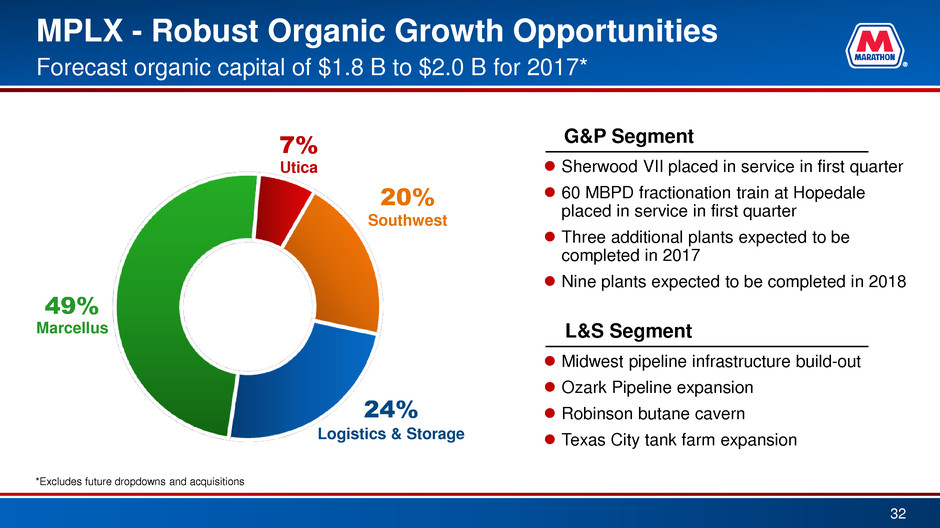

MPLX - Robust Organic Growth Opportunities 32 Forecast organic capital of $1.8 B to $2.0 B for 2017* G&P Segment Sherwood VII placed in service in first quarter 60 MBPD fractionation train at Hopedale placed in service in first quarter Three additional plants expected to be completed in 2017 Nine plants expected to be completed in 2018 L&S Segment Midwest pipeline infrastructure build-out Ozark Pipeline expansion Robinson butane cavern Texas City tank farm expansion Marcellus Southwest Logistics & Storage 24% 20% Utica 7% 49% *Excludes future dropdowns and acquisitions

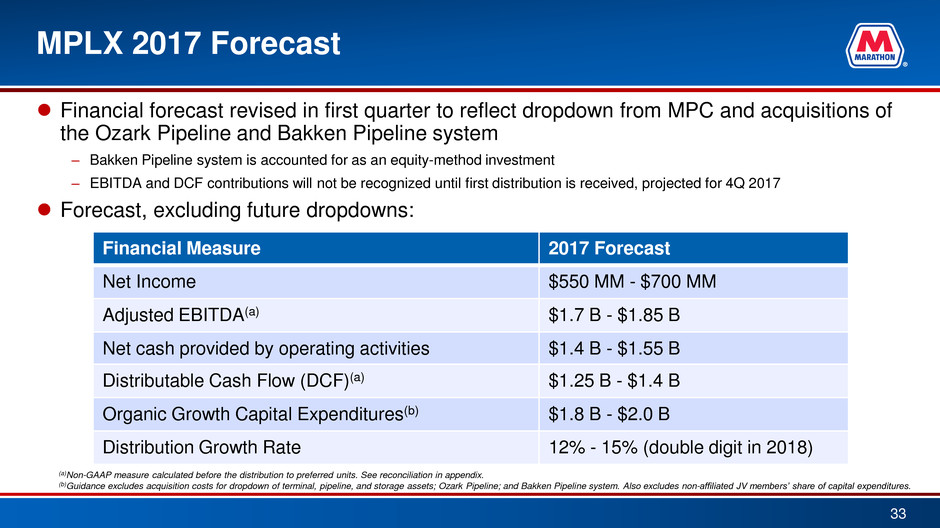

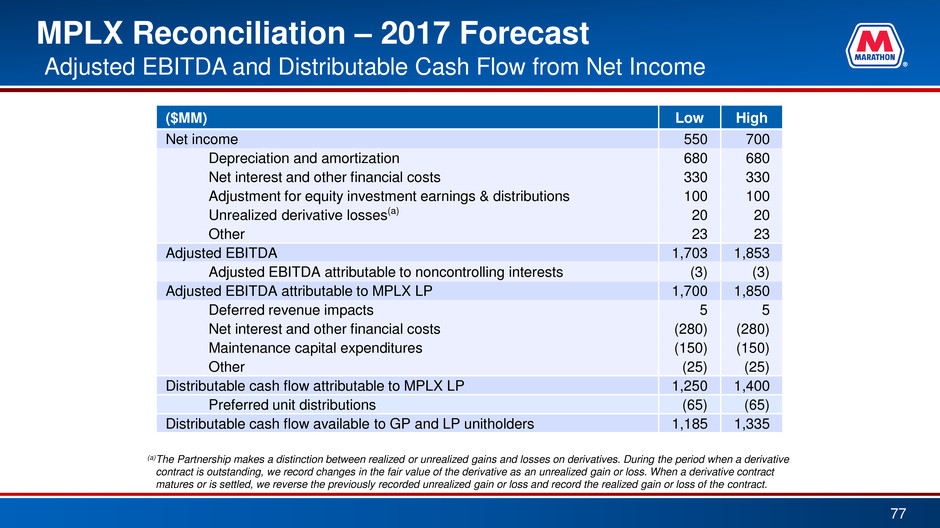

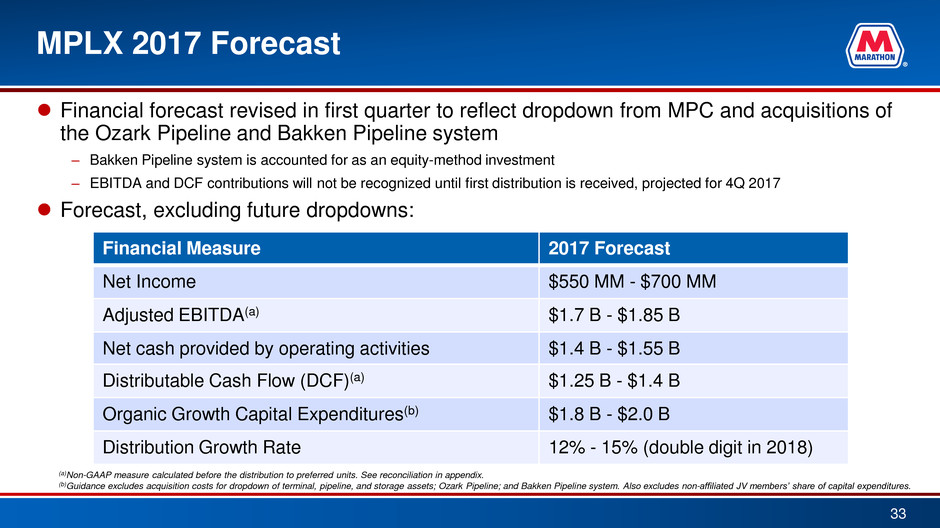

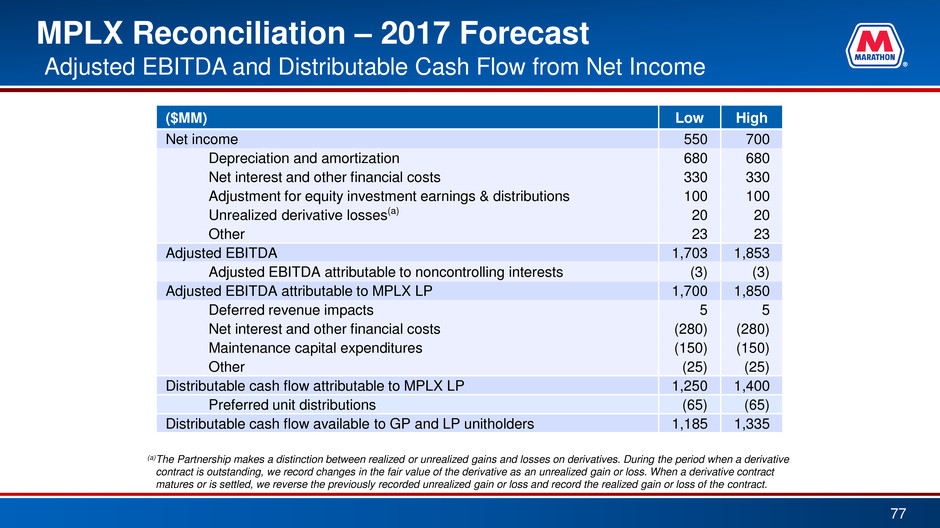

MPLX 2017 Forecast Financial forecast revised in first quarter to reflect dropdown from MPC and acquisitions of the Ozark Pipeline and Bakken Pipeline system – Bakken Pipeline system is accounted for as an equity-method investment – EBITDA and DCF contributions will not be recognized until first distribution is received, projected for 4Q 2017 Forecast, excluding future dropdowns: 33 Financial Measure 2017 Forecast Net Income $550 MM - $700 MM Adjusted EBITDA(a) $1.7 B - $1.85 B Net cash provided by operating activities $1.4 B - $1.55 B Distributable Cash Flow (DCF)(a) $1.25 B - $1.4 B Organic Growth Capital Expenditures(b) $1.8 B - $2.0 B Distribution Growth Rate 12% - 15% (double digit in 2018) (a)Non-GAAP measure calculated before the distribution to preferred units. See reconciliation in appendix. (b)Guidance excludes acquisition costs for dropdown of terminal, pipeline, and storage assets; Ozark Pipeline; and Bakken Pipeline system. Also excludes non-affiliated JV members’ share of capital expenditures.

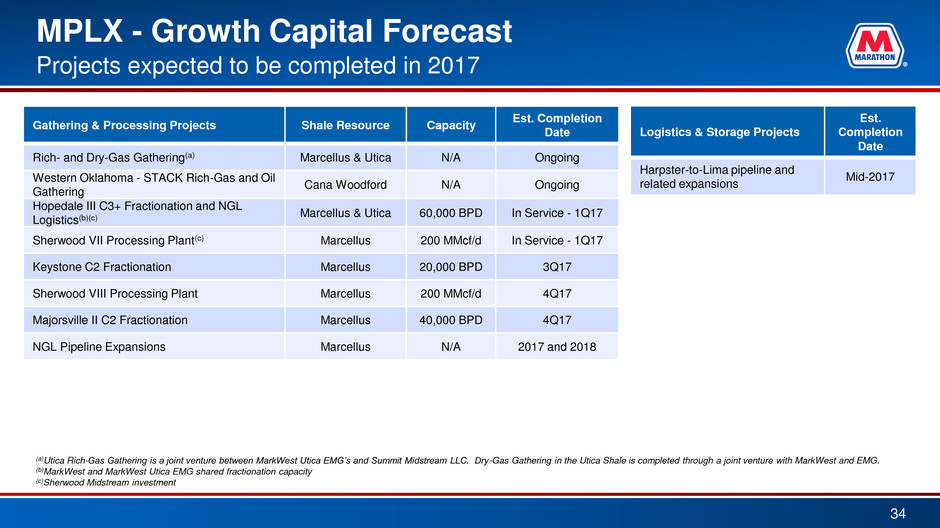

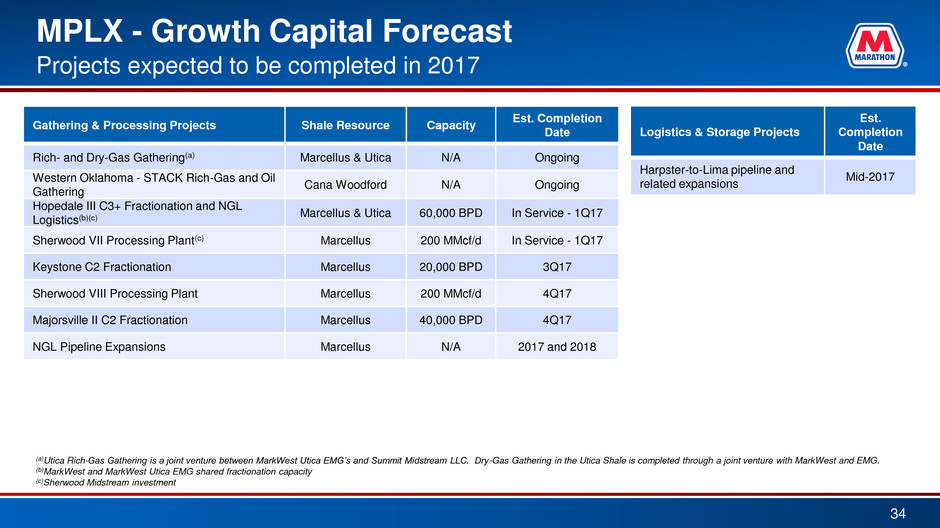

MPLX - Growth Capital Forecast 34 Projects expected to be completed in 2017 (a)Utica Rich-Gas Gathering is a joint venture between MarkWest Utica EMG’s and Summit Midstream LLC. Dry-Gas Gathering in the Utica Shale is completed through a joint venture with MarkWest and EMG. (b)MarkWest and MarkWest Utica EMG shared fractionation capacity (c)Sherwood Midstream investment Gathering & Processing Projects Shale Resource Capacity Est. Completion Date Rich- and Dry-Gas Gathering(a) Marcellus & Utica N/A Ongoing Western Oklahoma - STACK Rich-Gas and Oil Gathering Cana Woodford N/A Ongoing Hopedale III C3+ Fractionation and NGL Logistics(b)(c) Marcellus & Utica 60,000 BPD In Service - 1Q17 Sherwood VII Processing Plant(c) Marcellus 200 MMcf/d In Service - 1Q17 Keystone C2 Fractionation Marcellus 20,000 BPD 3Q17 Sherwood VIII Processing Plant Marcellus 200 MMcf/d 4Q17 Majorsville II C2 Fractionation Marcellus 40,000 BPD 4Q17 NGL Pipeline Expansions Marcellus N/A 2017 and 2018 Logistics & Storage Projects Est. Completion Date Harpster-to-Lima pipeline and related expansions Mid-2017

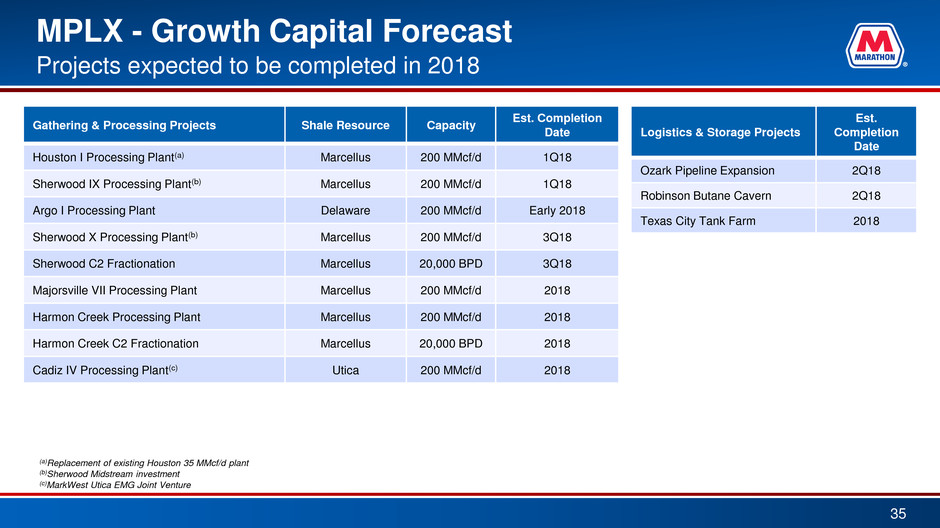

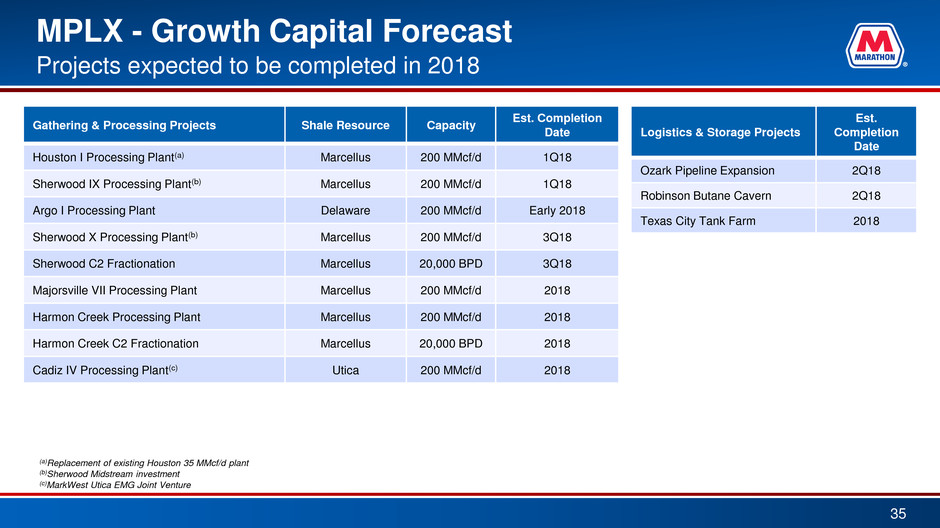

MPLX - Growth Capital Forecast 35 Projects expected to be completed in 2018 (a)Replacement of existing Houston 35 MMcf/d plant (b)Sherwood Midstream investment (c)MarkWest Utica EMG Joint Venture Gathering & Processing Projects Shale Resource Capacity Est. Completion Date Houston I Processing Plant(a) Marcellus 200 MMcf/d 1Q18 Sherwood IX Processing Plant(b) Marcellus 200 MMcf/d 1Q18 Argo I Processing Plant Delaware 200 MMcf/d Early 2018 Sherwood X Processing Plant(b) Marcellus 200 MMcf/d 3Q18 Sherwood C2 Fractionation Marcellus 20,000 BPD 3Q18 Majorsville VII Processing Plant Marcellus 200 MMcf/d 2018 Harmon Creek Processing Plant Marcellus 200 MMcf/d 2018 Harmon Creek C2 Fractionation Marcellus 20,000 BPD 2018 Cadiz IV Processing Plant(c) Utica 200 MMcf/d 2018 Logistics & Storage Projects Est. Completion Date Ozark Pipeline Expansion 2Q18 Robinson Butane Cavern 2Q18 Texas City Tank Farm 2018

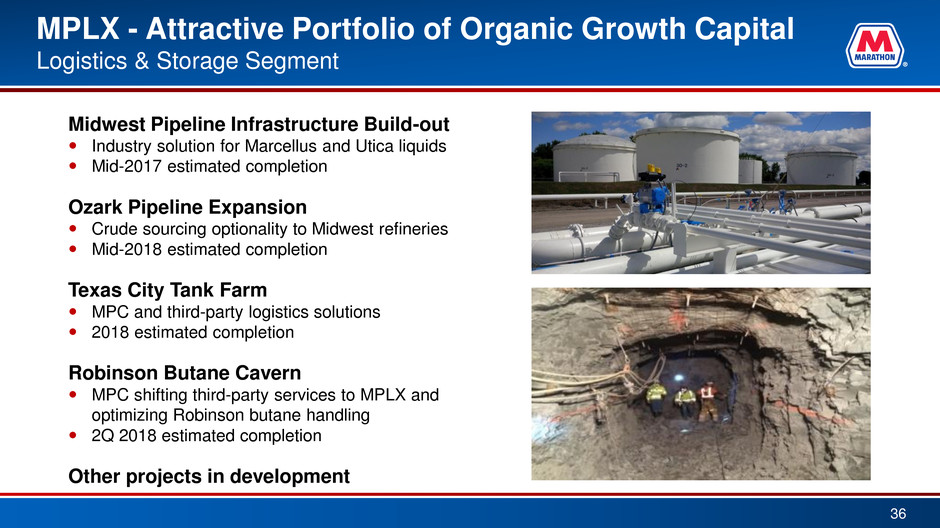

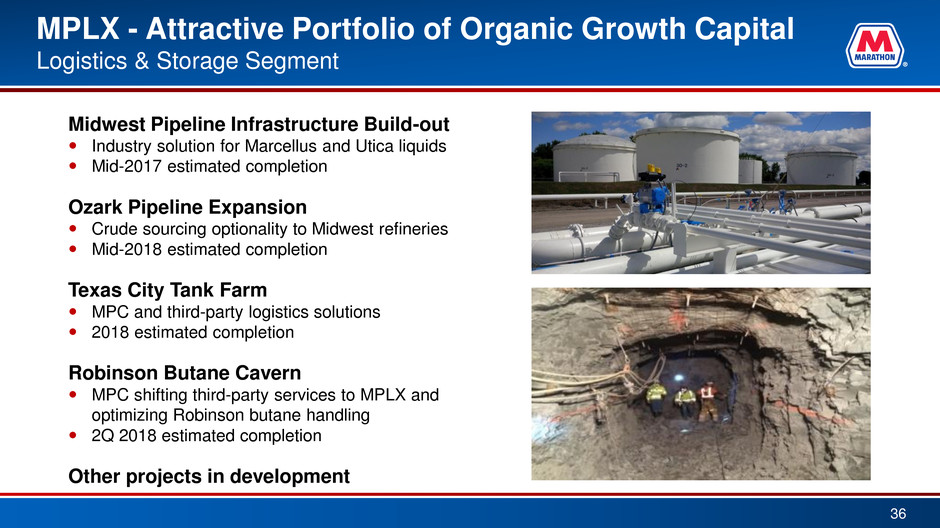

MPLX - Attractive Portfolio of Organic Growth Capital Logistics & Storage Segment Midwest Pipeline Infrastructure Build-out Industry solution for Marcellus and Utica liquids Mid-2017 estimated completion Ozark Pipeline Expansion Crude sourcing optionality to Midwest refineries Mid-2018 estimated completion Texas City Tank Farm MPC and third-party logistics solutions 2018 estimated completion Robinson Butane Cavern MPC shifting third-party services to MPLX and optimizing Robinson butane handling 2Q 2018 estimated completion Other projects in development 36

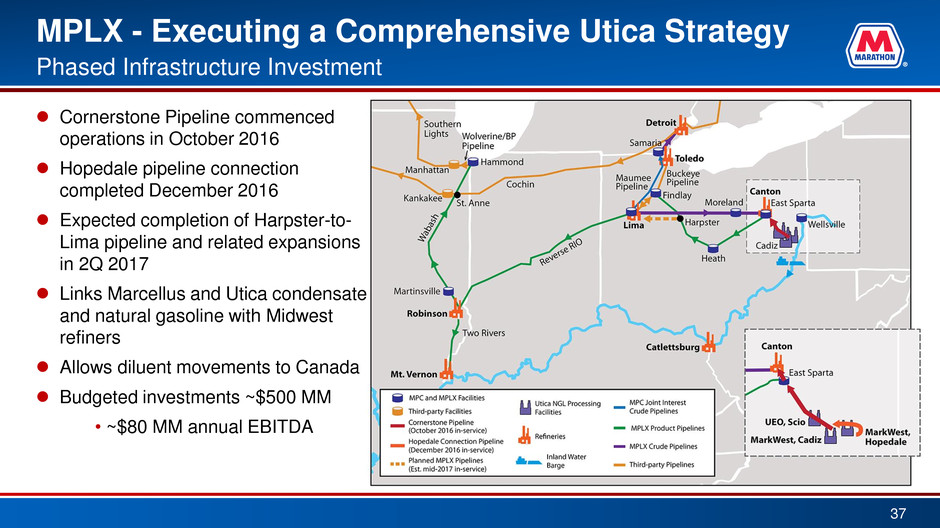

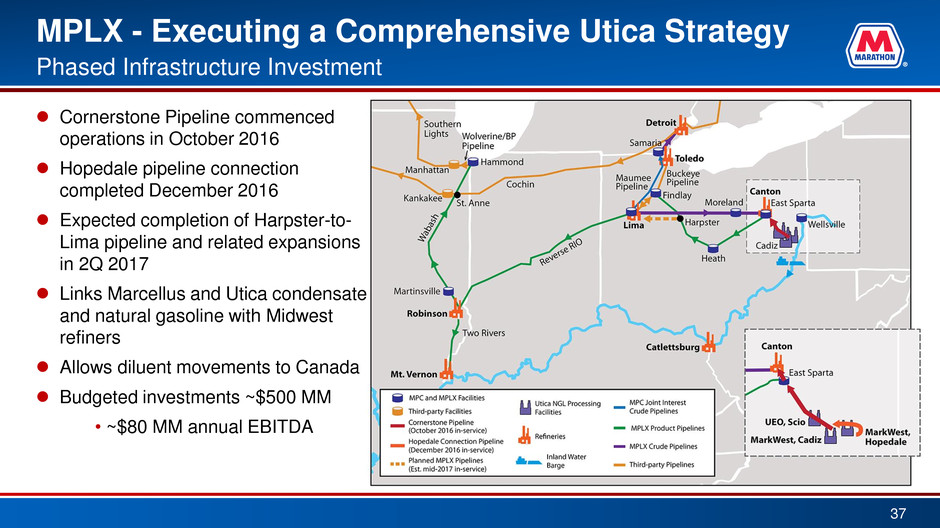

MPLX - Executing a Comprehensive Utica Strategy 37 Phased Infrastructure Investment Cornerstone Pipeline commenced operations in October 2016 Hopedale pipeline connection completed December 2016 Expected completion of Harpster-to- Lima pipeline and related expansions in 2Q 2017 Links Marcellus and Utica condensate and natural gasoline with Midwest refiners Allows diluent movements to Canada Budgeted investments ~$500 MM • ~$80 MM annual EBITDA

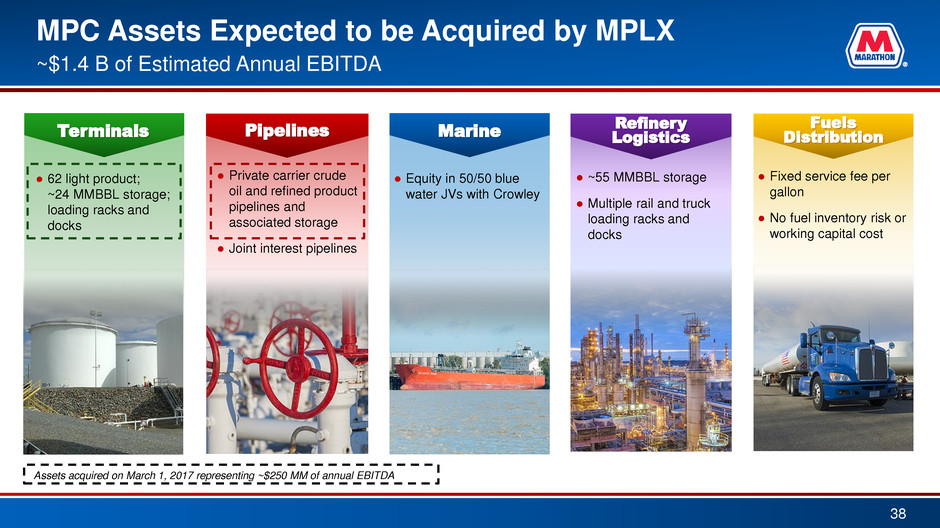

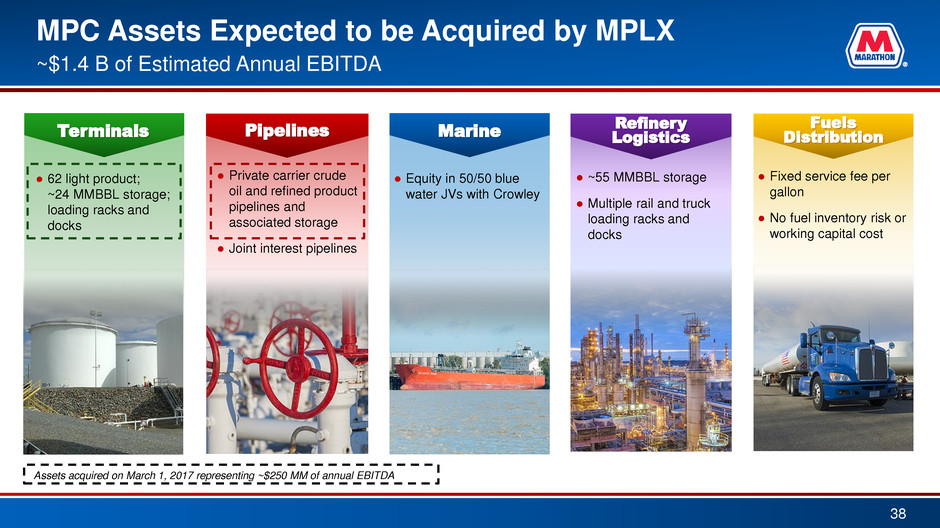

MPC Assets Expected to be Acquired by MPLX 38 ~$1.4 B of Estimated Annual EBITDA ● ~55 MMBBL storage ● Multiple rail and truck loading racks and docks ● Fixed service fee per gallon ● No fuel inventory risk or working capital cost Fuels Distribution Refinery Logistics ● Private carrier crude oil and refined product pipelines and associated storage ● Joint interest pipelines ● Equity in 50/50 blue water JVs with Crowley ● 62 light product; ~24 MMBBL storage; loading racks and docks Pipelines Terminals Marine Assets acquired on March 1, 2017 representing ~$250 MM of annual EBITDA

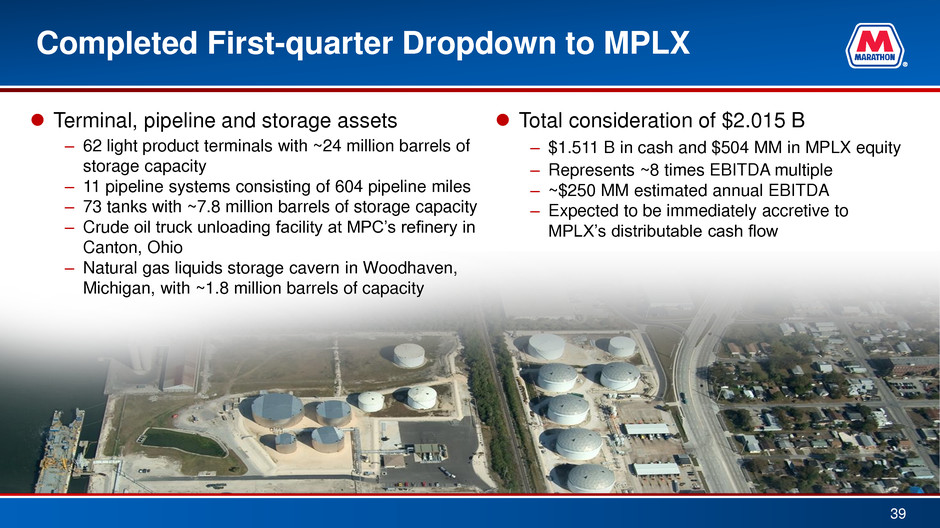

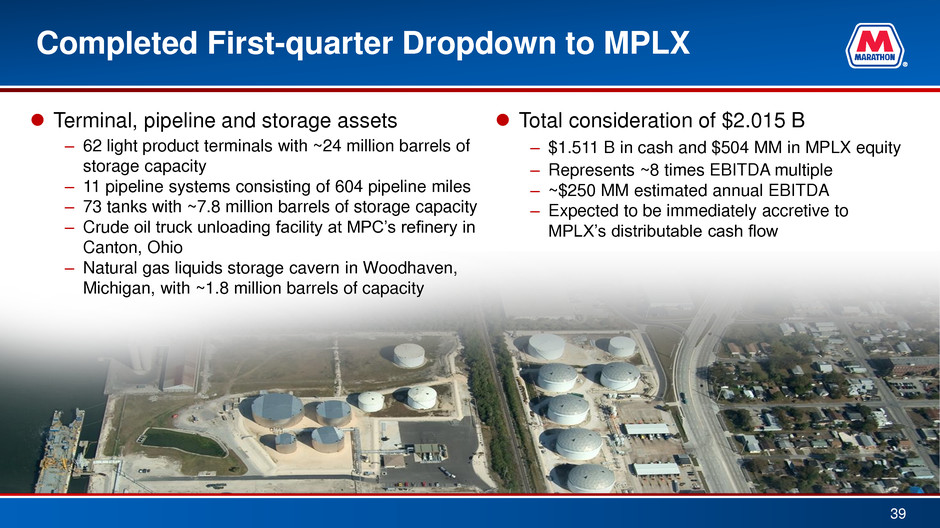

Completed First-quarter Dropdown to MPLX 39 Terminal, pipeline and storage assets – 62 light product terminals with ~24 million barrels of storage capacity – 11 pipeline systems consisting of 604 pipeline miles – 73 tanks with ~7.8 million barrels of storage capacity – Crude oil truck unloading facility at MPC’s refinery in Canton, Ohio – Natural gas liquids storage cavern in Woodhaven, Michigan, with ~1.8 million barrels of capacity Total consideration of $2.015 B – $1.511 B in cash and $504 MM in MPLX equity – Represents ~8 times EBITDA multiple – ~$250 MM estimated annual EBITDA – Expected to be immediately accretive to MPLX’s distributable cash flow

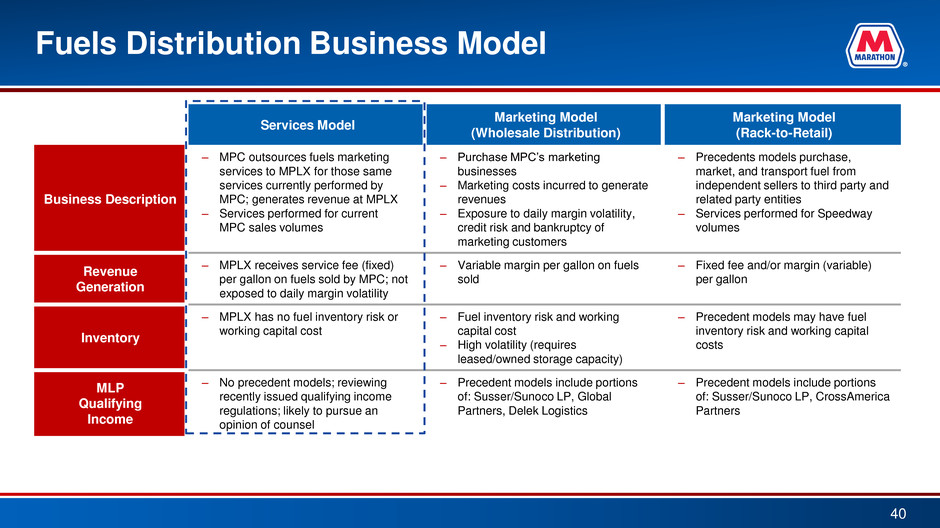

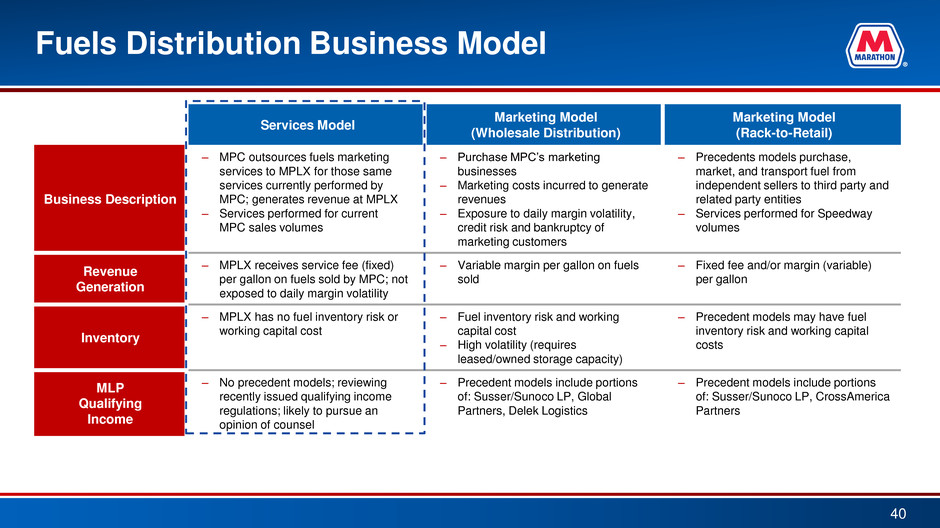

Fuels Distribution Business Model Services Model Marketing Model (Wholesale Distribution) Marketing Model (Rack-to-Retail) Business Description – MPC outsources fuels marketing services to MPLX for those same services currently performed by MPC; generates revenue at MPLX – Services performed for current MPC sales volumes – Purchase MPC’s marketing businesses – Marketing costs incurred to generate revenues – Exposure to daily margin volatility, credit risk and bankruptcy of marketing customers – Precedents models purchase, market, and transport fuel from independent sellers to third party and related party entities – Services performed for Speedway volumes Revenue Generation – MPLX receives service fee (fixed) per gallon on fuels sold by MPC; not exposed to daily margin volatility – Variable margin per gallon on fuels sold – Fixed fee and/or margin (variable) per gallon Inventory – MPLX has no fuel inventory risk or working capital cost – Fuel inventory risk and working capital cost – High volatility (requires leased/owned storage capacity) – Precedent models may have fuel inventory risk and working capital costs MLP Qualifying Income – No precedent models; reviewing recently issued qualifying income regulations; likely to pursue an opinion of counsel – Precedent models include portions of: Susser/Sunoco LP, Global Partners, Delek Logistics – Precedent models include portions of: Susser/Sunoco LP, CrossAmerica Partners 40

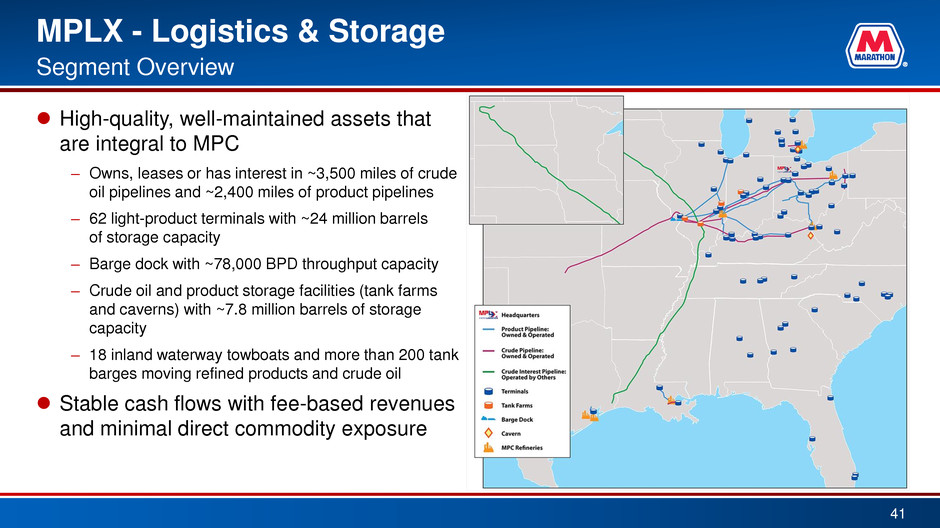

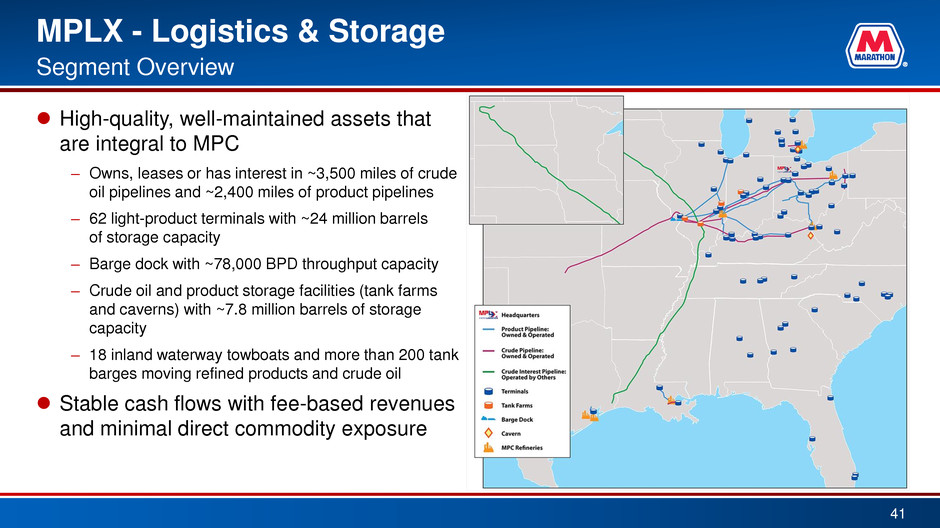

MPLX - Logistics & Storage 41 Segment Overview High-quality, well-maintained assets that are integral to MPC – Owns, leases or has interest in ~3,500 miles of crude oil pipelines and ~2,400 miles of product pipelines – 62 light-product terminals with ~24 million barrels of storage capacity – Barge dock with ~78,000 BPD throughput capacity – Crude oil and product storage facilities (tank farms and caverns) with ~7.8 million barrels of storage capacity – 18 inland waterway towboats and more than 200 tank barges moving refined products and crude oil Stable cash flows with fee-based revenues and minimal direct commodity exposure

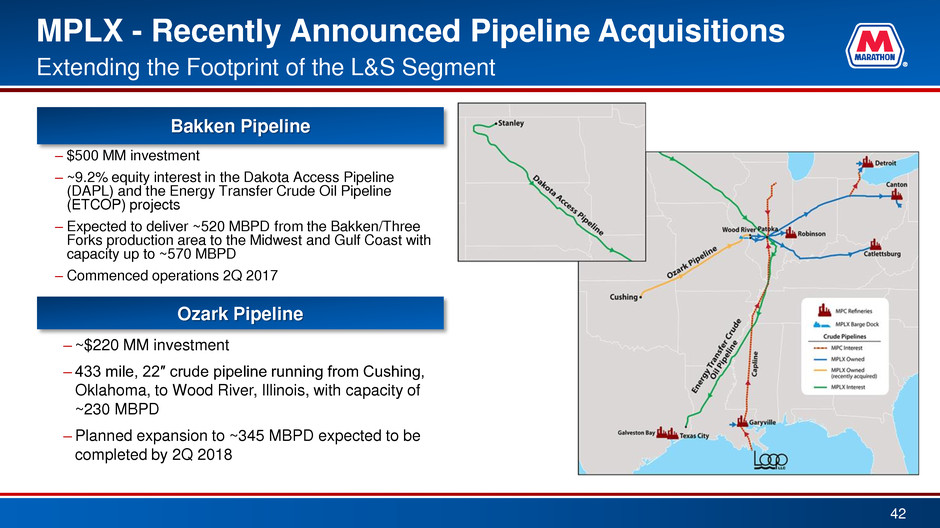

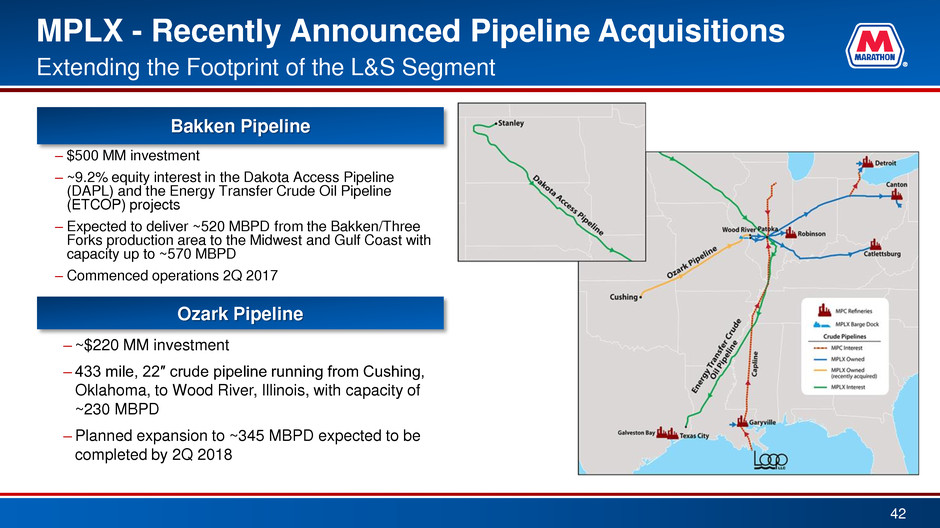

MPLX - Recently Announced Pipeline Acquisitions 42 Extending the Footprint of the L&S Segment – ~$220 MM investment – 433 mile, 22″ crude pipeline running from Cushing, Oklahoma, to Wood River, Illinois, with capacity of ~230 MBPD –Planned expansion to ~345 MBPD expected to be completed by 2Q 2018 Ozark Pipeline Ozark Pipeline Acquisition Bakke Pipeline – $500 MM investment – ~9.2% equity interest in the Dakota Access Pipeline (DAPL) and the Energy Transfer Crude Oil Pipeline (ETCOP) projects – Expected to deliver ~520 MBPD from the Bakken/Three Forks production area to the Midwest and Gulf Coast with capacity up to ~570 MBPD – Commenced operations 2Q 2017

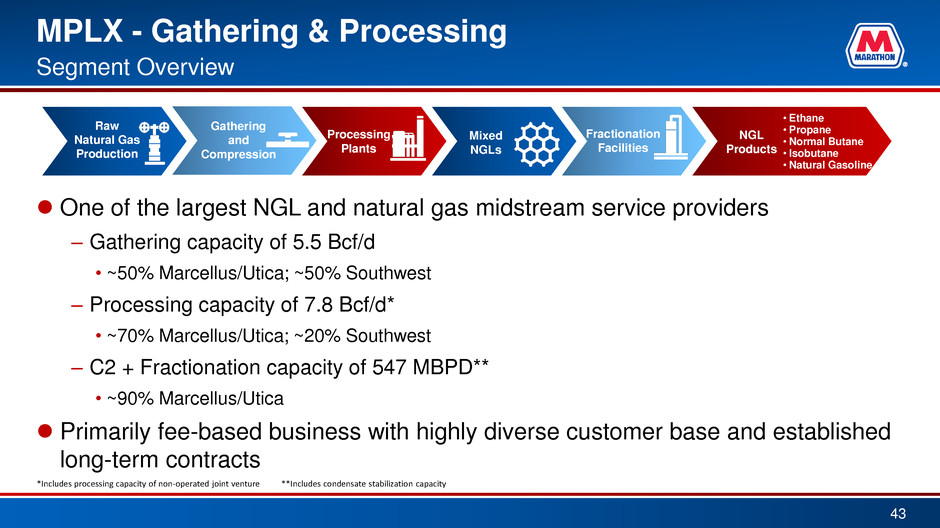

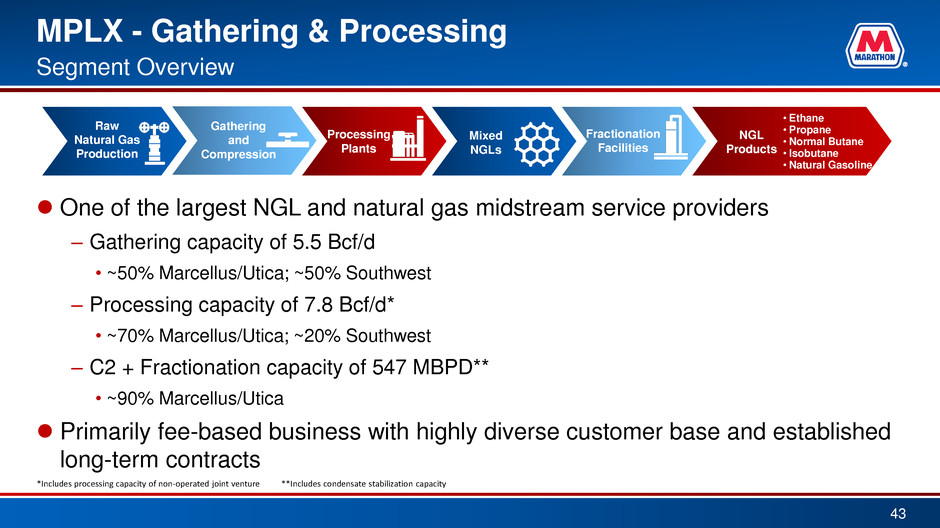

MPLX - Gathering & Processing 43 Segment Overview One of the largest NGL and natural gas midstream service providers – Gathering capacity of 5.5 Bcf/d • ~50% Marcellus/Utica; ~50% Southwest – Processing capacity of 7.8 Bcf/d* • ~70% Marcellus/Utica; ~20% Southwest – C2 + Fractionation capacity of 547 MBPD** • ~90% Marcellus/Utica Primarily fee-based business with highly diverse customer base and established long-term contracts Raw Natural Gas Production Processing Plants Mixed NGLs Fractionation Facilities NGL Products • Ethane • Propane • Normal Butane • Isobutane • Natural Gasoline Gathering and Compression *Includes processing capacity of non-operated joint venture **Includes condensate stabilization capacity

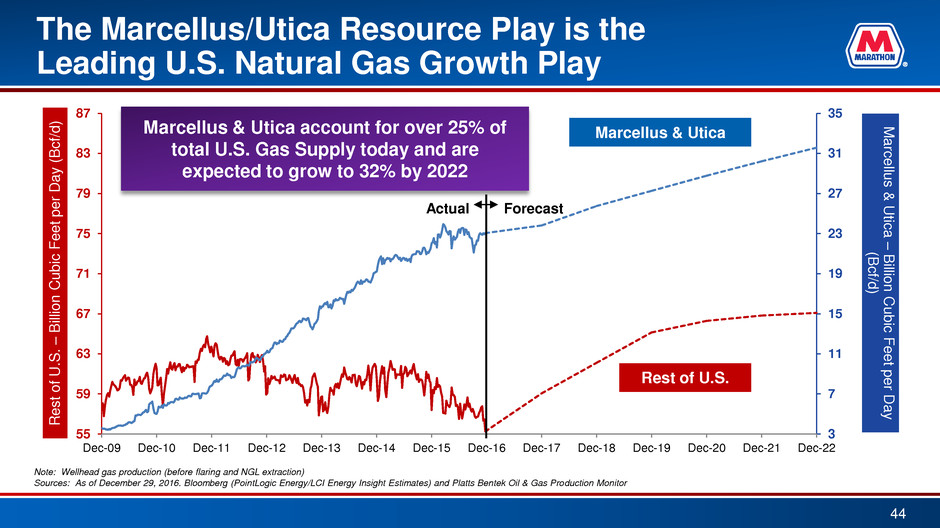

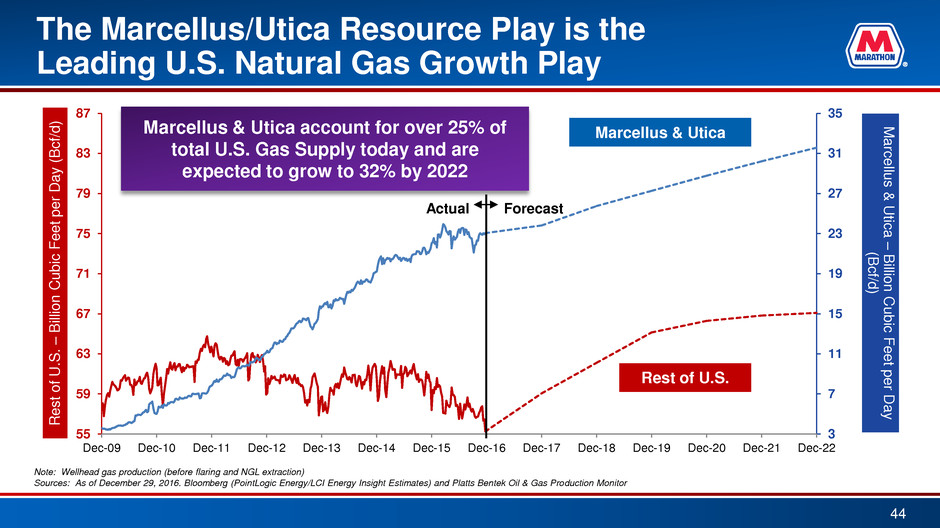

3 7 11 15 19 23 27 31 35 55 59 63 67 71 75 79 83 87 Dec-09 Dec-10 Dec-11 Dec-12 Dec-13 Dec-14 Dec-15 Dec-16 Dec-17 Dec-18 Dec-19 Dec-20 Dec-21 Dec-22 The Marcellus/Utica Resource Play is the Leading U.S. Natural Gas Growth Play 44 R est o f U .S . – B ill io n C u b ic F e et p e r D a y (B c f/ d ) Note: Wellhead gas production (before flaring and NGL extraction) Sources: As of December 29, 2016. Bloomberg (PointLogic Energy/LCI Energy Insight Estimates) and Platts Bentek Oil & Gas Production Monitor M arce llus & U tica – B illio n C u b ic F e et p e r D a y (B c f/d ) Marcellus & Utica account for over 25% of total U.S. Gas Supply today and are expected to grow to 32% by 2022 Marcellus & Utica Rest of U.S. Forecast Actual

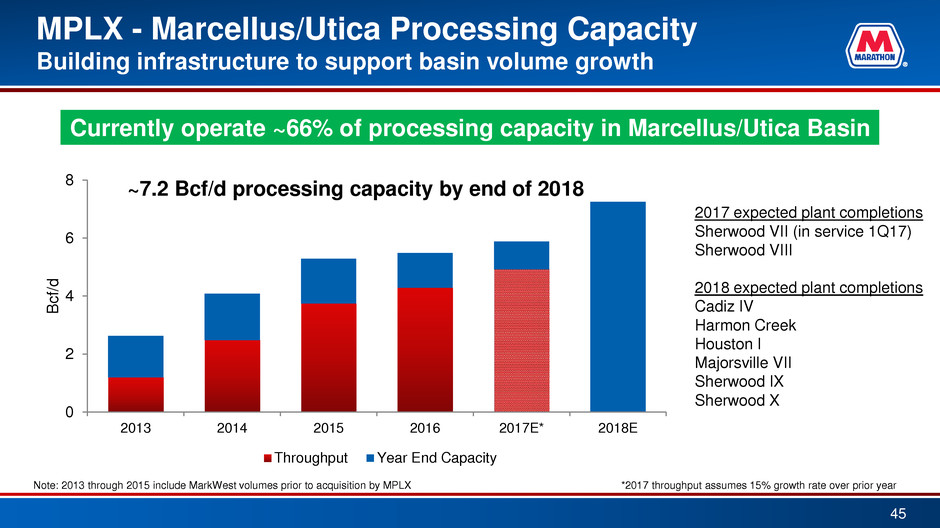

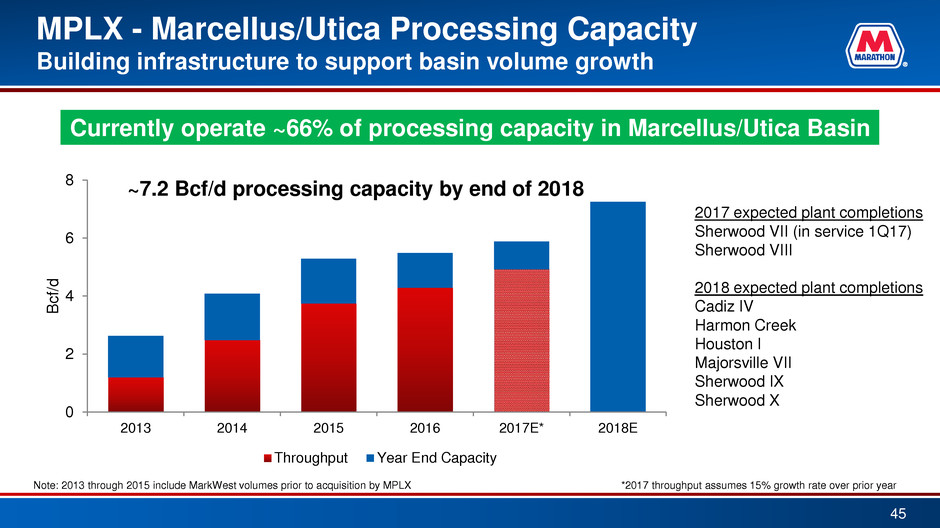

MPLX - Marcellus/Utica Processing Capacity Building infrastructure to support basin volume growth 45 0 2 4 6 8 2013 2014 2015 2016 2017E* 2018E B c f/ d ~7.2 Bcf/d processing capacity by end of 2018 Throughput Year End Capacity Currently operate ~66% of processing capacity in Marcellus/Utica Basin 2017 expected plant completions Sherwood VII (in service 1Q17) Sherwood VIII 2018 expected plant completions Cadiz IV Harmon Creek Houston I Majorsville VII Sherwood IX Sherwood X *2017 throughput assumes 15% growth rate over prior year Note: 2013 through 2015 include MarkWest volumes prior to acquisition by MPLX

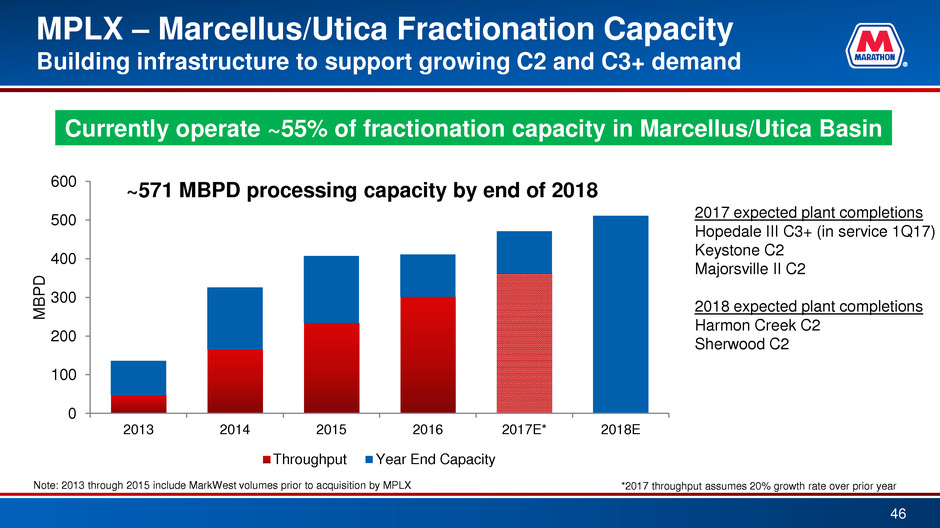

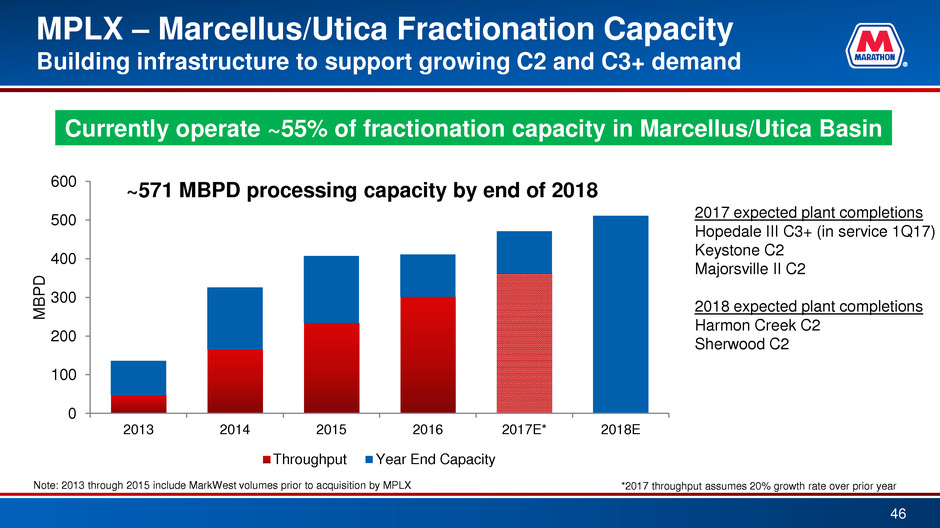

MPLX – Marcellus/Utica Fractionation Capacity Building infrastructure to support growing C2 and C3+ demand 46 0 100 200 300 400 500 600 2013 2014 2015 2016 2017E* 2018E M B P D ~571 MBPD processing capacity by end of 2018 Throughput Year End Capacity Currently operate ~55% of fractionation capacity in Marcellus/Utica Basin 2017 expected plant completions Hopedale III C3+ (in service 1Q17) Keystone C2 Majorsville II C2 2018 expected plant completions Harmon Creek C2 Sherwood C2 *2017 throughput assumes 20% growth rate over prior year Note: 2013 through 2015 include MarkWest volumes prior to acquisition by MPLX

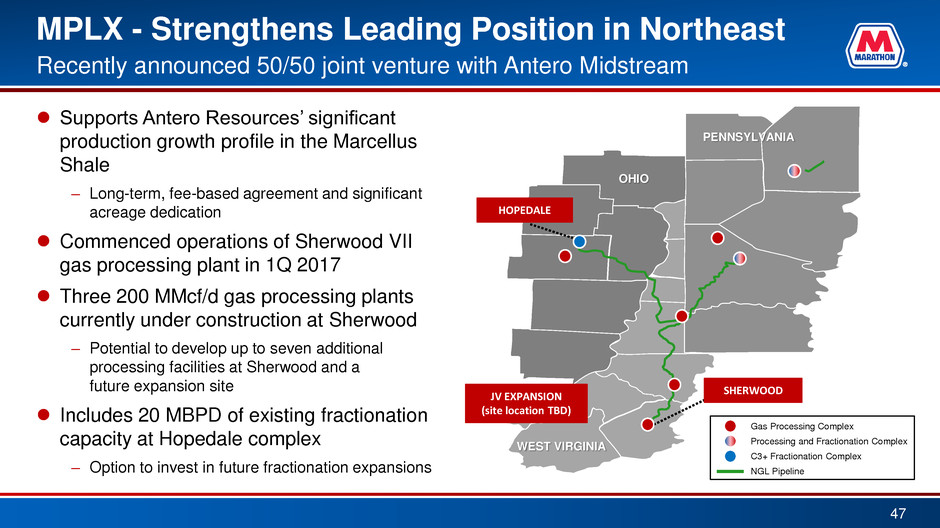

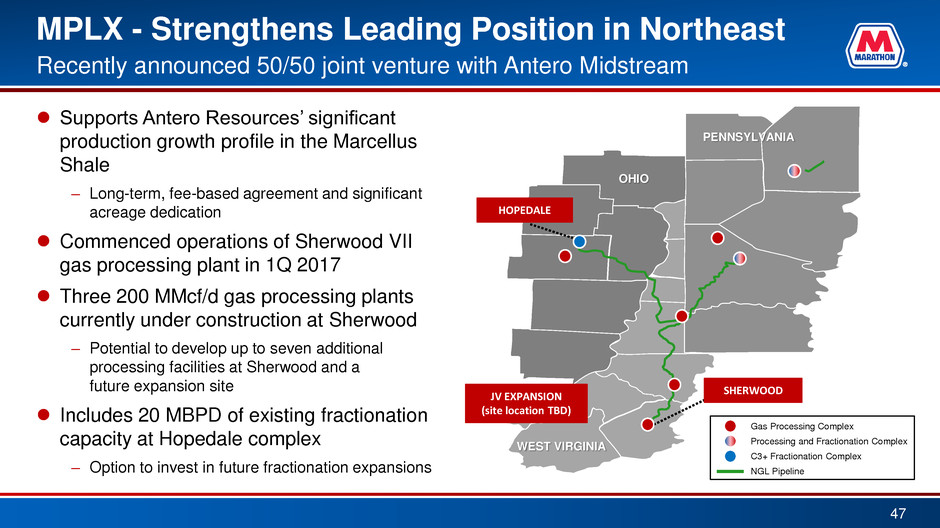

Supports Antero Resources’ significant production growth profile in the Marcellus Shale – Long-term, fee-based agreement and significant acreage dedication Commenced operations of Sherwood VII gas processing plant in 1Q 2017 Three 200 MMcf/d gas processing plants currently under construction at Sherwood – Potential to develop up to seven additional processing facilities at Sherwood and a future expansion site Includes 20 MBPD of existing fractionation capacity at Hopedale complex – Option to invest in future fractionation expansions 47 MPLX - Strengthens Leading Position in Northeast Recently announced 50/50 joint venture with Antero Midstream WEST VIRGINIA PENNSYLVANIA OHIO SHERWOOD JV EXPANSION (site location TBD) HOPEDALE C3+ Fractionation Complex NGL Pipeline Gas Processing Complex Processing and Fractionation Complex

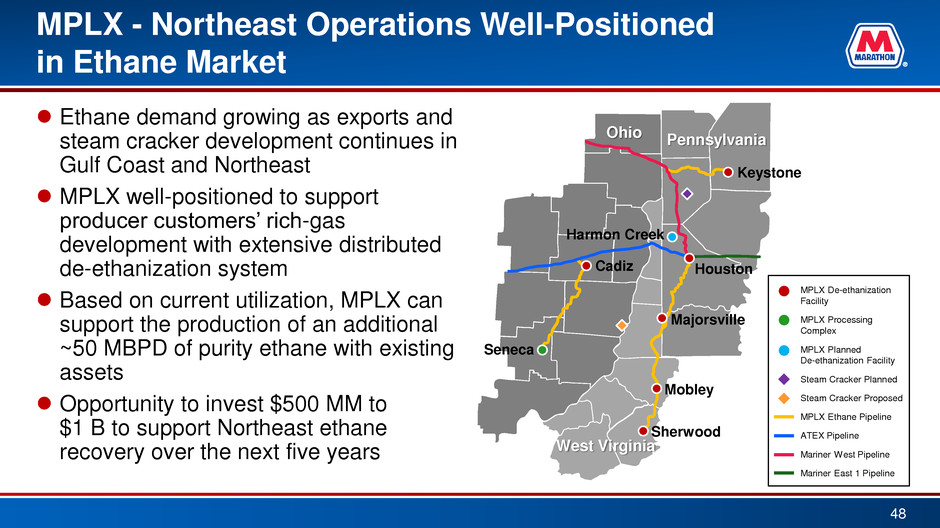

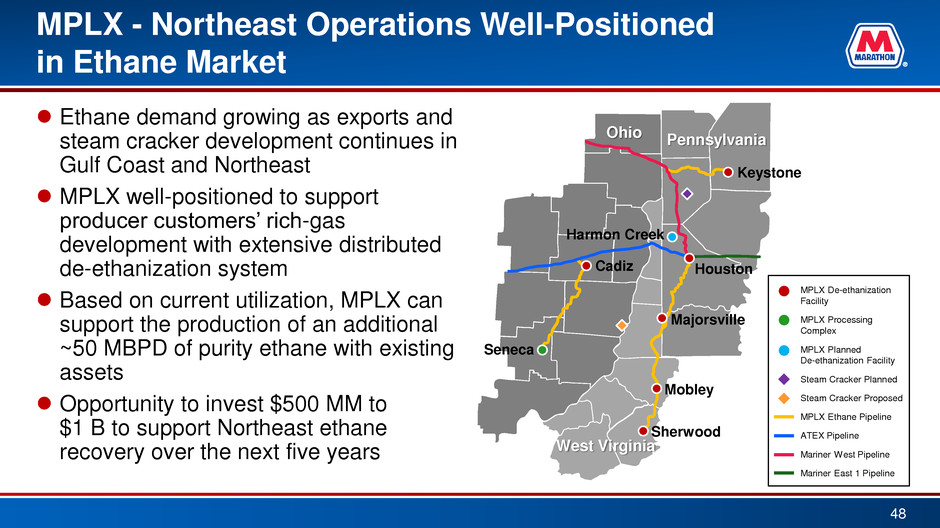

MPLX - Northeast Operations Well-Positioned in Ethane Market Ethane demand growing as exports and steam cracker development continues in Gulf Coast and Northeast MPLX well-positioned to support producer customers’ rich-gas development with extensive distributed de-ethanization system Based on current utilization, MPLX can support the production of an additional ~50 MBPD of purity ethane with existing assets Opportunity to invest $500 MM to $1 B to support Northeast ethane recovery over the next five years 48 West Virginia Pennsylvania Ohio Sherwood Mobley Majorsville Cadiz Houston Keystone Harmon Creek Seneca MPLX De-ethanization Facility MPLX Processing Complex MPLX Planned De-ethanization Facility Steam Cracker Planned Steam Cracker Proposed MPLX Ethane Pipeline ATEX Pipeline Mariner West Pipeline Mariner East 1 Pipeline

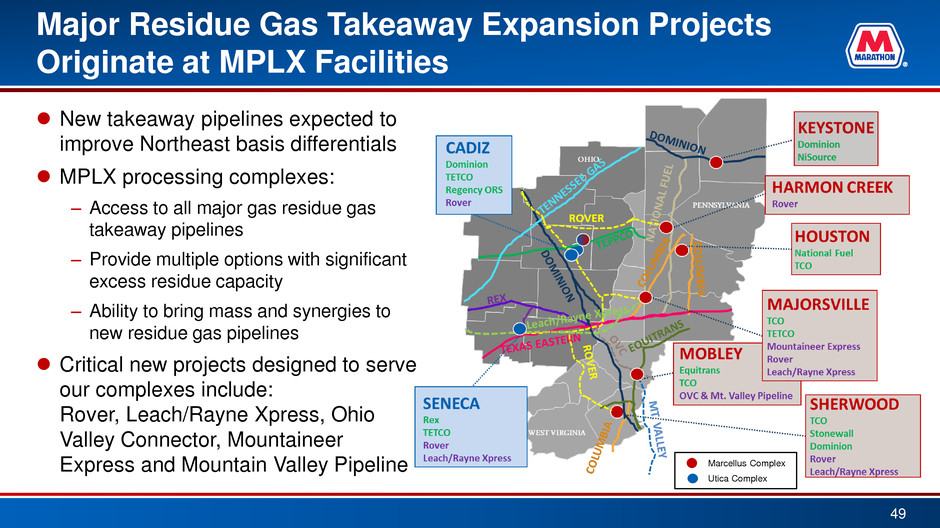

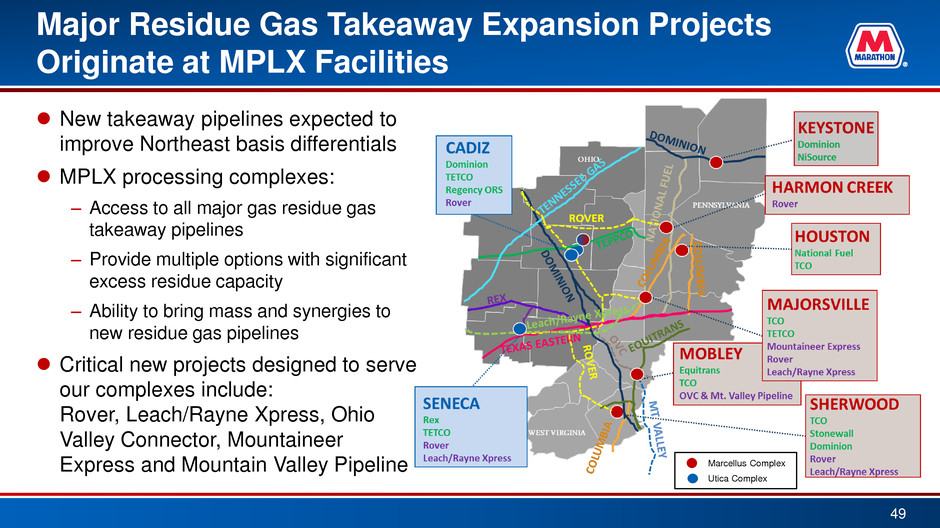

Major Residue Gas Takeaway Expansion Projects Originate at MPLX Facilities New takeaway pipelines expected to improve Northeast basis differentials MPLX processing complexes: – Access to all major gas residue gas takeaway pipelines – Provide multiple options with significant excess residue capacity – Ability to bring mass and synergies to new residue gas pipelines Critical new projects designed to serve our complexes include: Rover, Leach/Rayne Xpress, Ohio Valley Connector, Mountaineer Express and Mountain Valley Pipeline 49 Utica Complex Marcellus Complex

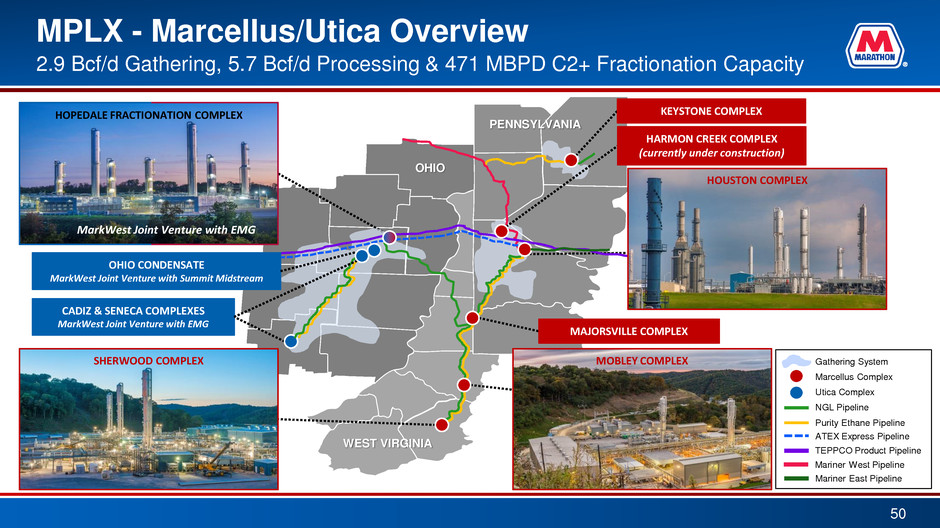

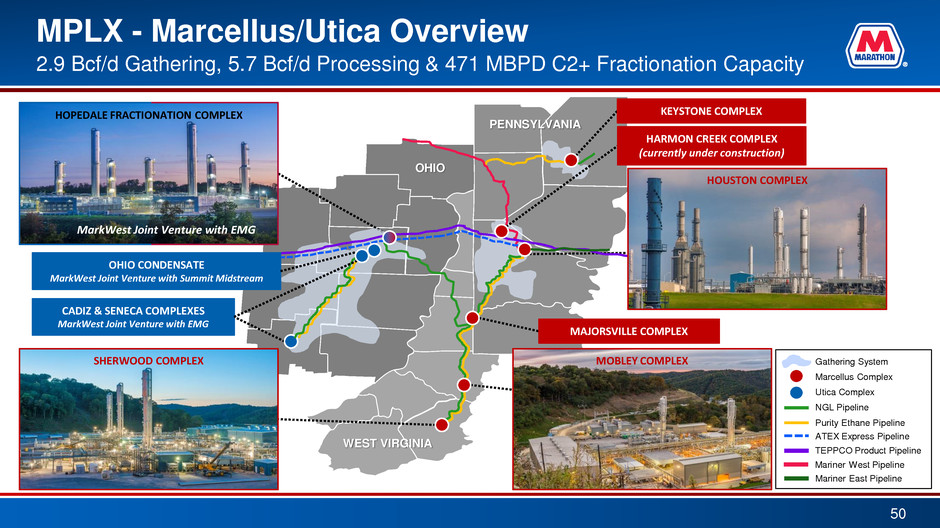

MPLX - Marcellus/Utica Overview 2.9 Bcf/d Gathering, 5.7 Bcf/d Processing & 471 MBPD C2+ Fractionation Capacity WEST VIRGINIA PENNSYLVANIA OHIO KEYSTONE COMPLEX HARMON CREEK COMPLEX (currently under construction) MAJORSVILLE COMPLEX MOBLEY COMPLEX SHERWOOD COMPLEX CADIZ & SENECA COMPLEXES MarkWest Joint Venture with EMG HOPEDALE FRACTIONATION COMPLEX HOUSTON COMPLEX OHIO CONDENSATE MarkWest Joint Venture with Summit Midstream Utica Complex ATEX Express Pipeline Purity Ethane Pipeline NGL Pipeline Mariner East Pipeline Marcellus Complex Gathering System Mariner West Pipeline TEPPCO Product Pipeline MarkWest Joint Venture with EMG 50

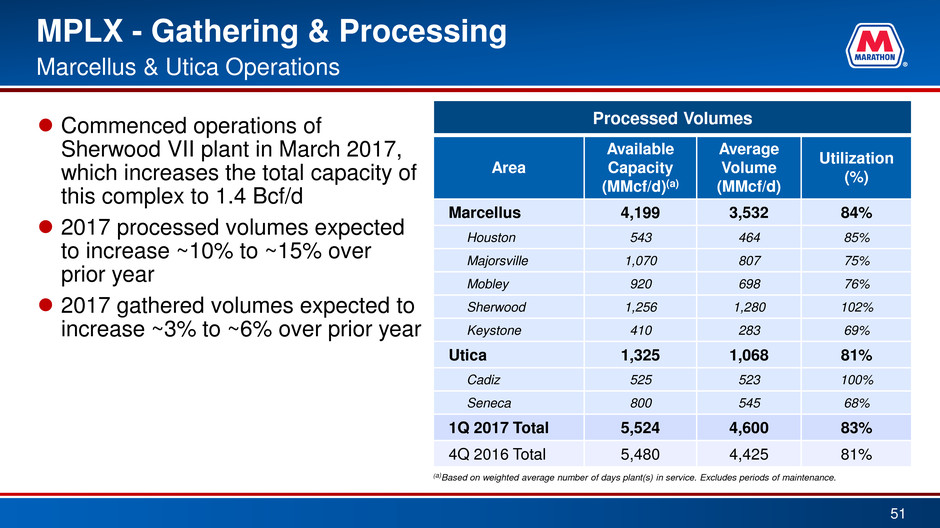

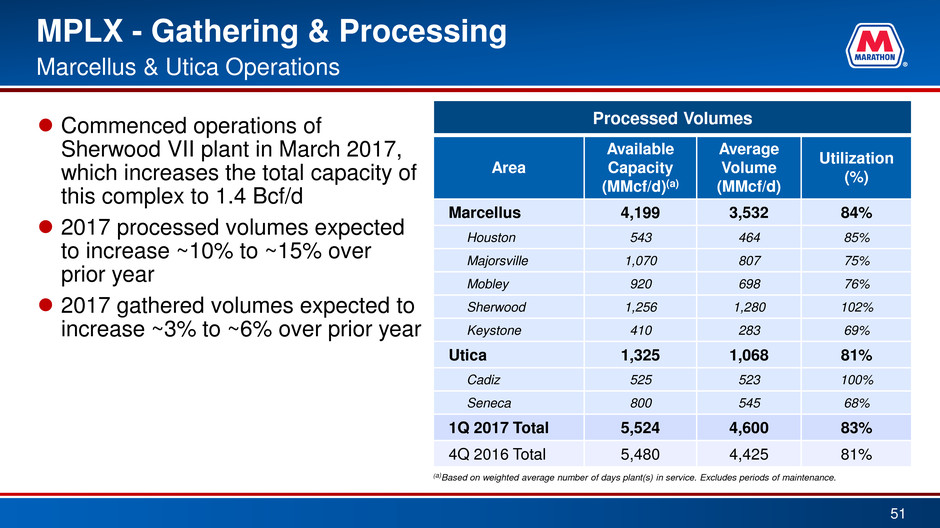

MPLX - Gathering & Processing 51 Marcellus & Utica Operations Commenced operations of Sherwood VII plant in March 2017, which increases the total capacity of this complex to 1.4 Bcf/d 2017 processed volumes expected to increase ~10% to ~15% over prior year 2017 gathered volumes expected to increase ~3% to ~6% over prior year (a)Based on weighted average number of days plant(s) in service. Excludes periods of maintenance. Processed Volumes Area Available Capacity (MMcf/d)(a) Average Volume (MMcf/d) Utilization (%) Marcellus 4,199 3,532 84% Houston 543 464 85% Majorsville 1,070 807 75% Mobley 920 698 76% Sherwood 1,256 1,280 102% Keystone 410 283 69% Utica 1,325 1,068 81% Cadiz 525 523 100% Seneca 800 545 68% 1Q 2017 Total 5,524 4,600 83% 4Q 2016 Total 5,480 4,425 81%

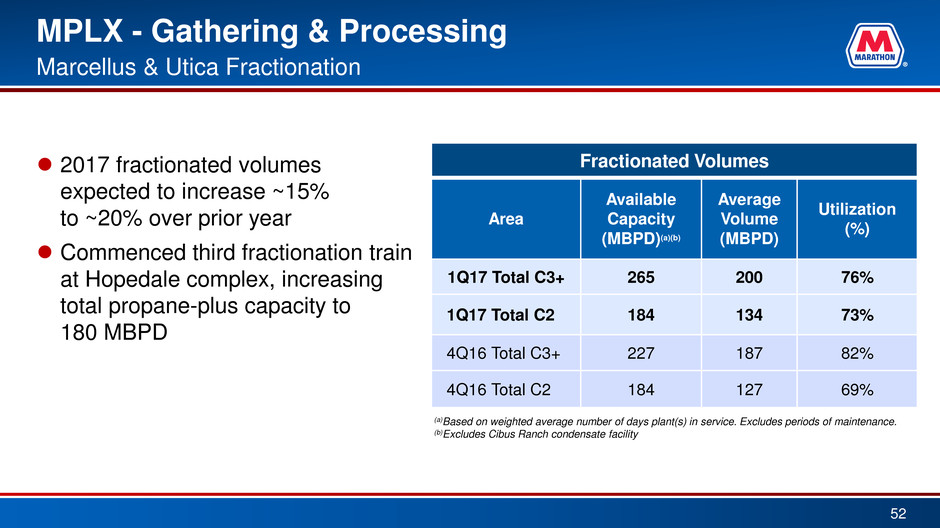

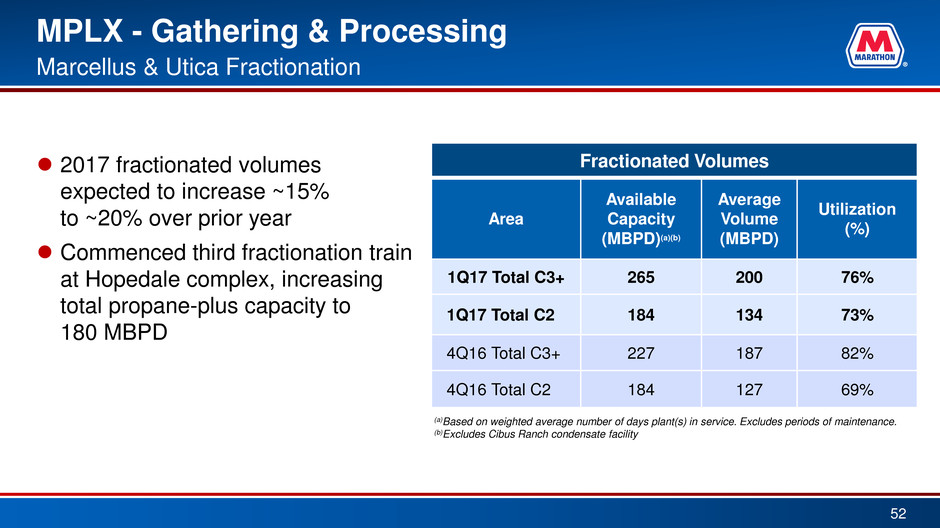

MPLX - Gathering & Processing 52 Marcellus & Utica Fractionation 2017 fractionated volumes expected to increase ~15% to ~20% over prior year Commenced third fractionation train at Hopedale complex, increasing total propane-plus capacity to 180 MBPD Fractionated Volumes Area Available Capacity (MBPD)(a)(b) Average Volume (MBPD) Utilization (%) 1Q17 Total C3+ 265 200 76% 1Q17 Total C2 184 134 73% 4Q16 Total C3+ 227 187 82% 4Q16 Total C2 184 127 69% (a)Based on weighted average number of days plant(s) in service. Excludes periods of maintenance. (b)Excludes Cibus Ranch condensate facility

MPLX - Considerable Scale in the Southwest 2.6 Bcf/d Gathering, 1.5 Bcf/d Processing & 29 MBPD C2+ Fractionation Capacity 53 Southeast Oklahoma 120MMcf/d Processing* 1,205MMcf/d Gathering East Texas Gulf Coast 142MMcf/d Processing Western Oklahoma Oklahoma Texas 425MMcf/d Processing 585MMcf/d Gathering 600MMcf/d Gathering 680MMcf/d Processing Fractionation 29,000BPD *Represents 40% of processing capacity through the Partnership’s Centrahoma JV with Targa Resources Corp. Permian 200MMcf/d Processing

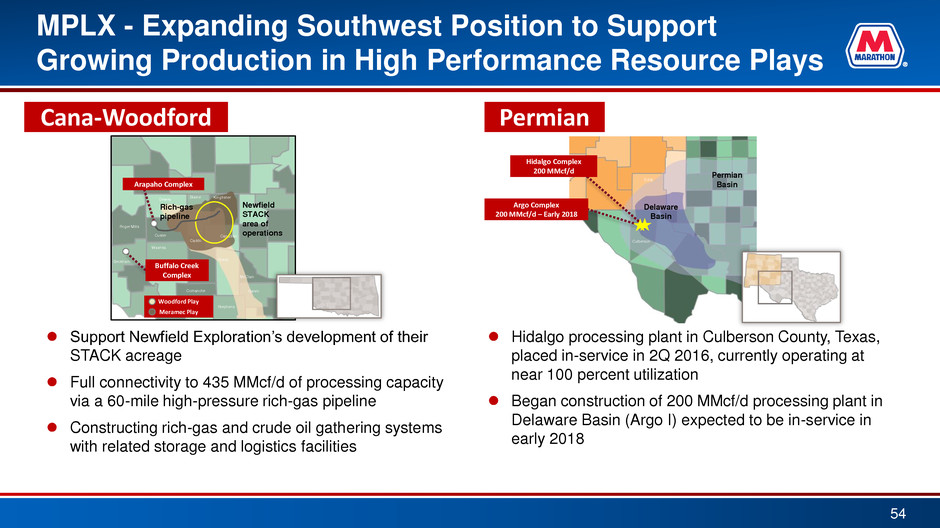

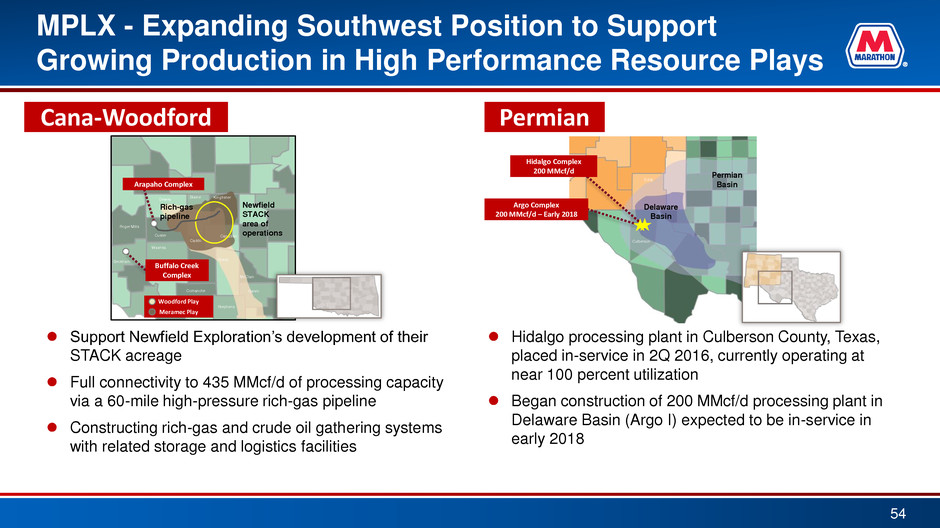

MPLX - Expanding Southwest Position to Support Growing Production in High Performance Resource Plays Hidalgo processing plant in Culberson County, Texas, placed in-service in 2Q 2016, currently operating at near 100 percent utilization Began construction of 200 MMcf/d processing plant in Delaware Basin (Argo I) expected to be in-service in early 2018 Support Newfield Exploration’s development of their STACK acreage Full connectivity to 435 MMcf/d of processing capacity via a 60-mile high-pressure rich-gas pipeline Constructing rich-gas and crude oil gathering systems with related storage and logistics facilities 54 Cana-Woodford Dewey Blaine Kingfisher Canadian Caddo Grady McClain Garvin Comanche Stephens Washita Beckham Roger Mills Custer Buffalo Creek Complex Arapaho Complex Newfield STACK area of operations Rich-gas pipeline Woodford Play Meramec Play Permian Hidalgo Complex 200 MMcf/d Delaware Basin Culberson Eddy Permian Basin Argo Complex 200 MMcf/d – Early 2018

MPLX - Gathering & Processing Southwest Operations 2017 processed volumes expected to increase ~3% to ~8% over 2016 – West Texas (Delaware Basin) and Western Oklahoma (STACK) to support majority of increase 2017 gathered volumes expected to be flat over prior year Began construction of 200 MMcf/d processing plant in Delaware Basin (Argo I); expected to be in-service in 2018 (a)Based on weighted average number of days plant(s) in service. Excludes periods of maintenance (b)West Texas is comprised of the Hidalgo plant in the Delaware Basin (c)Processing capacity includes Partnership’s portion of Centrahoma JV and excludes volumes sent to third parties Processed Volumes Area Available Capacity (MMcf/d)(a) Average Volume (MMcf/d) Utilization (%) West Texas(b) 200 192 96% East Texas 600 419 70% Western OK 425 343 81% Southeast OK(c) 120 120 100% Gulf Coast 142 109 77% 1Q 2017 Total 1,487 1,183 80% 4Q 2016 Total 1,487 1,200 81% 55

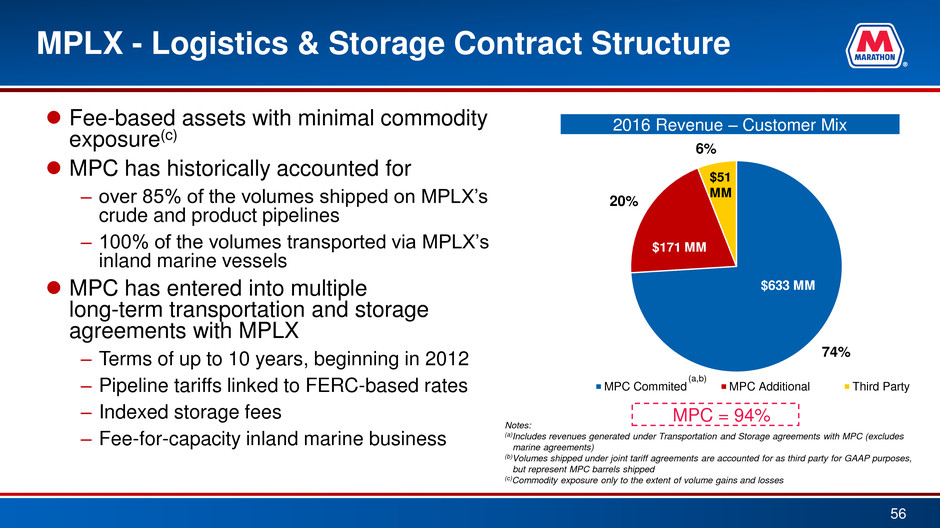

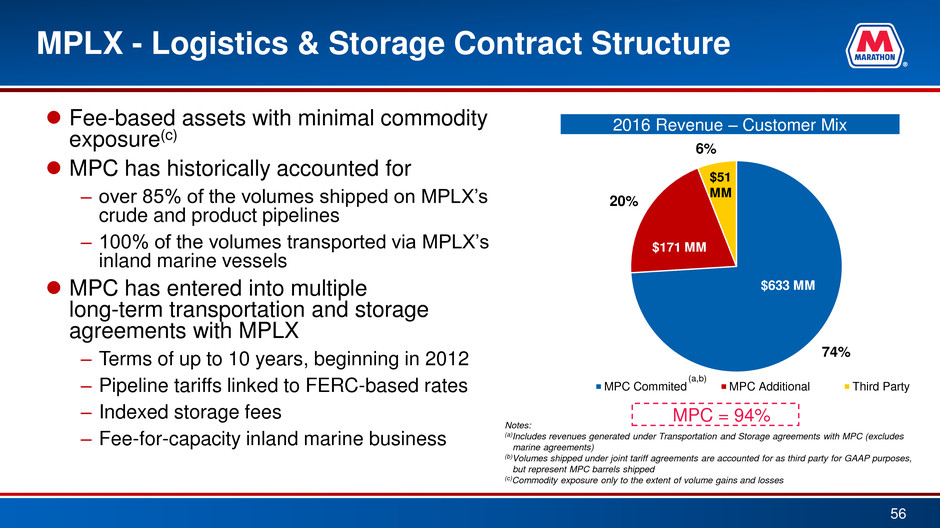

74% 20% 6% MPC Commited MPC Additional Third Party MPLX - Logistics & Storage Contract Structure Fee-based assets with minimal commodity exposure(c) MPC has historically accounted for – over 85% of the volumes shipped on MPLX’s crude and product pipelines – 100% of the volumes transported via MPLX’s inland marine vessels MPC has entered into multiple long-term transportation and storage agreements with MPLX – Terms of up to 10 years, beginning in 2012 – Pipeline tariffs linked to FERC-based rates – Indexed storage fees – Fee-for-capacity inland marine business 56 2016 Revenue – Customer Mix MPC = 94% $633 MM $171 MM $51 MM (a,b) Notes: (a)Includes revenues generated under Transportation and Storage agreements with MPC (excludes marine agreements) (b)Volumes shipped under joint tariff agreements are accounted for as third party for GAAP purposes, but represent MPC barrels shipped (c)Commodity exposure only to the extent of volume gains and losses

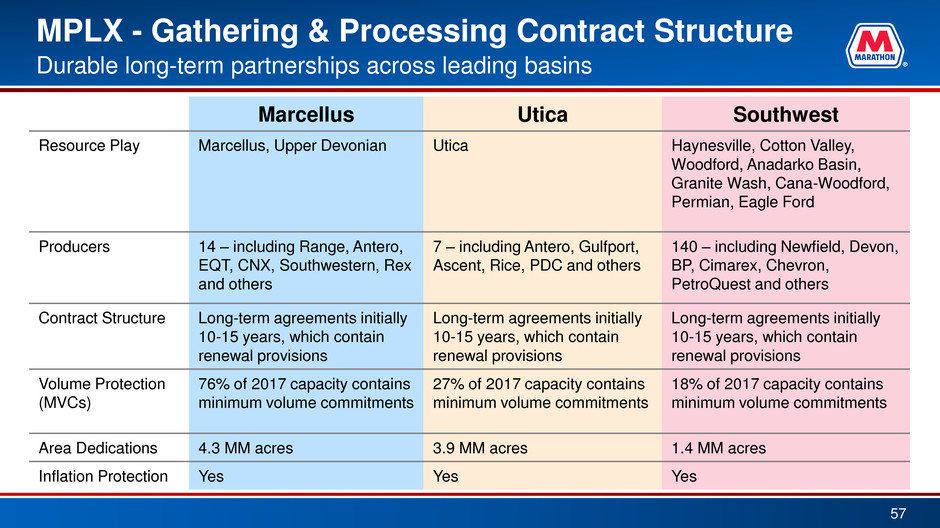

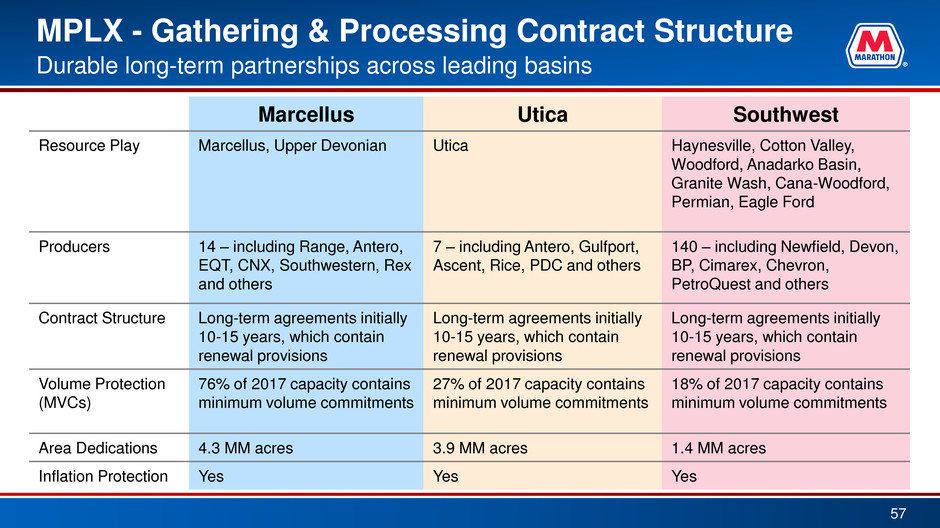

MPLX - Gathering & Processing Contract Structure 57 Durable long-term partnerships across leading basins Marcellus Utica Southwest Resource Play Marcellus, Upper Devonian Utica Haynesville, Cotton Valley, Woodford, Anadarko Basin, Granite Wash, Cana-Woodford, Permian, Eagle Ford Producers 14 – including Range, Antero, EQT, CNX, Southwestern, Rex and others 7 – including Antero, Gulfport, Ascent, Rice, PDC and others 140 – including Newfield, Devon, BP, Cimarex, Chevron, PetroQuest and others Contract Structure Long-term agreements initially 10-15 years, which contain renewal provisions Long-term agreements initially 10-15 years, which contain renewal provisions Long-term agreements initially 10-15 years, which contain renewal provisions Volume Protection (MVCs) 76% of 2017 capacity contains minimum volume commitments 27% of 2017 capacity contains minimum volume commitments 18% of 2017 capacity contains minimum volume commitments Area Dedications 4.3 MM acres 3.9 MM acres 1.4 MM acres Inflation Protection Yes Yes Yes

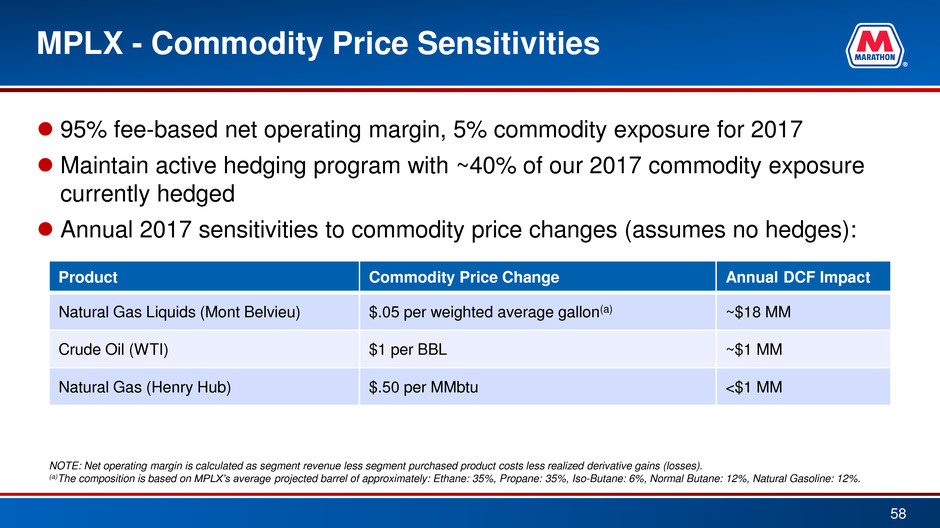

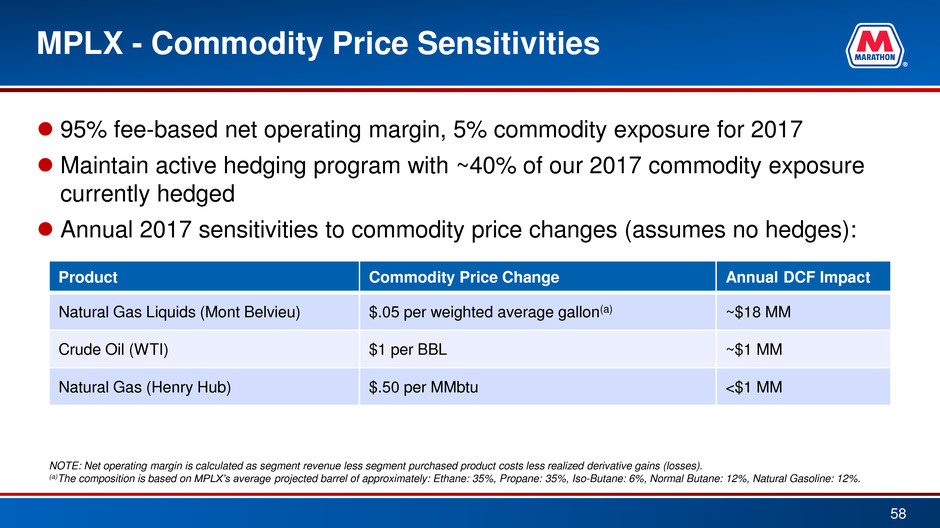

MPLX - Commodity Price Sensitivities 95% fee-based net operating margin, 5% commodity exposure for 2017 Maintain active hedging program with ~40% of our 2017 commodity exposure currently hedged Annual 2017 sensitivities to commodity price changes (assumes no hedges): 58 NOTE: Net operating margin is calculated as segment revenue less segment purchased product costs less realized derivative gains (losses). (a)The composition is based on MPLX’s average projected barrel of approximately: Ethane: 35%, Propane: 35%, Iso-Butane: 6%, Normal Butane: 12%, Natural Gasoline: 12%. Product Commodity Price Change Annual DCF Impact Natural Gas Liquids (Mont Belvieu) $.05 per weighted average gallon(a) ~$18 MM Crude Oil (WTI) $1 per BBL ~$1 MM Natural Gas (Henry Hub) $.50 per MMbtu <$1 MM

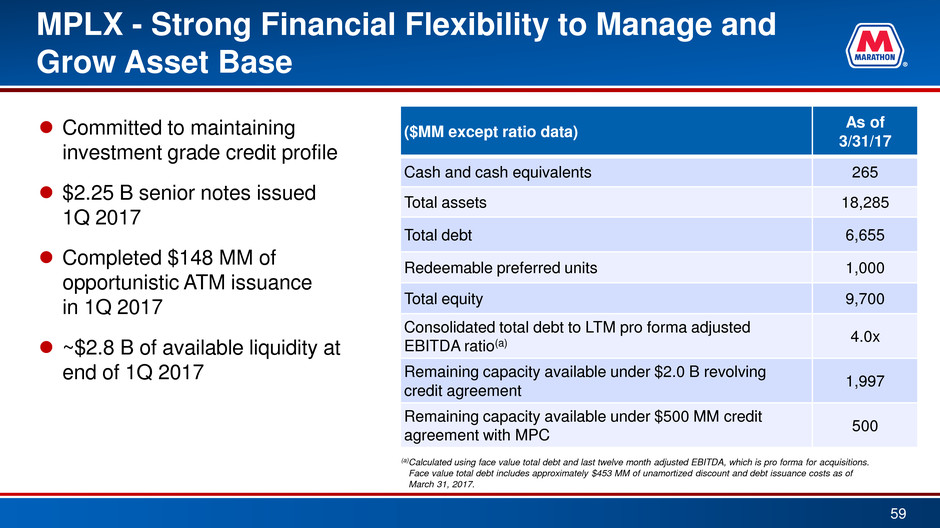

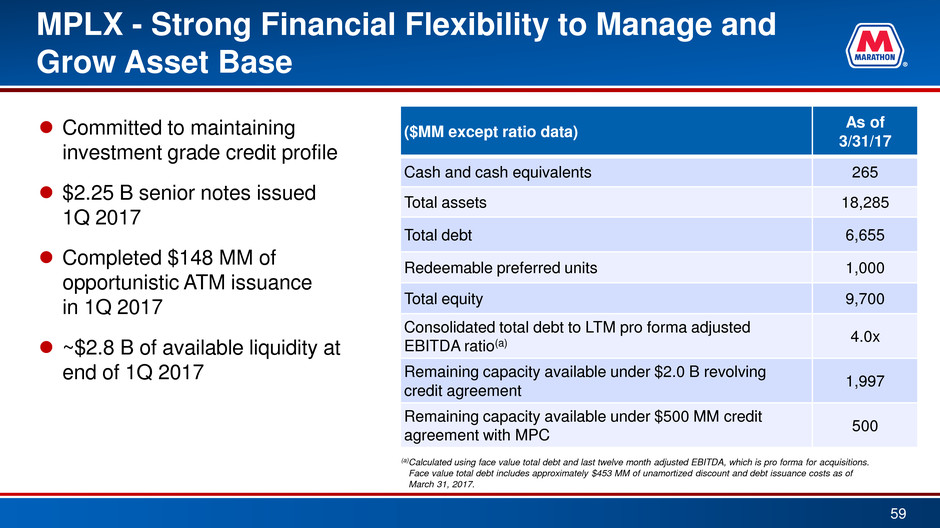

MPLX - Strong Financial Flexibility to Manage and Grow Asset Base 59 Committed to maintaining investment grade credit profile $2.25 B senior notes issued 1Q 2017 Completed $148 MM of opportunistic ATM issuance in 1Q 2017 ~$2.8 B of available liquidity at end of 1Q 2017 ($MM except ratio data) As of 3/31/17 Cash and cash equivalents 265 Total assets 18,285 Total debt 6,655 Redeemable preferred units 1,000 Total equity 9,700 Consolidated total debt to LTM pro forma adjusted EBITDA ratio(a) 4.0x Remaining capacity available under $2.0 B revolving credit agreement 1,997 Remaining capacity available under $500 MM credit agreement with MPC 500 (a)Calculated using face value total debt and last twelve month adjusted EBITDA, which is pro forma for acquisitions. Face value total debt includes approximately $453 MM of unamortized discount and debt issuance costs as of March 31, 2017.

MPLX - Long-Term Value Objectives Deliver Sustainable Distribution Growth rate that provides attractive total unitholder returns Drive Lower Cost of Capital to achieve most efficient mix of growth and yield Develop Backlog of Organic Growth Projects benefiting producer customers and overall energy infrastructure build-out Maintain Investment Grade Credit profile Become Consolidator in midstream space 60

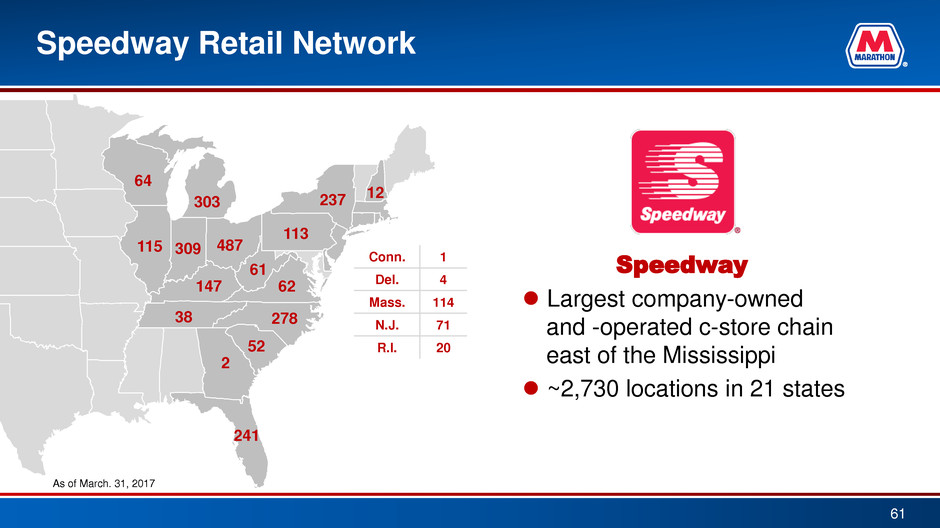

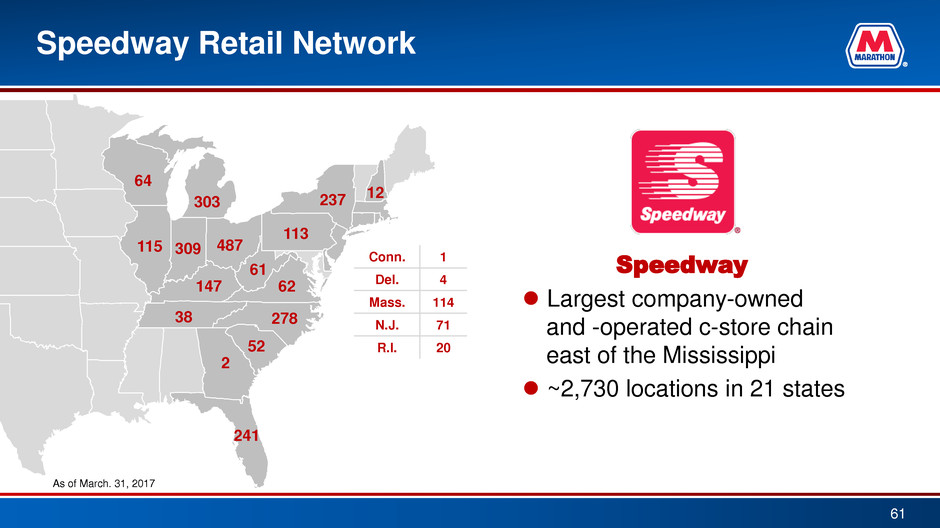

Speedway Retail Network 61 Speedway Largest company-owned and -operated c-store chain east of the Mississippi ~2,730 locations in 21 states 487 303 309 147 115 64 61 38 113 2 52 278 62 241 237 12 Conn. 1 Del. 4 Mass. 114 N.J. 71 R.I. 20 As of March. 31, 2017

2017 Speedway Capital Investment Plan Planned investments of ~$380 MM – Build new stores and remodel and rebuild existing retail locations in core markets Delivered on goals for acquired locations – Expect to complete remodel plan in 2017 – Planned investments achieved under budget and ahead of schedule – ~80% of acquired stores upgraded under remodel plan – Foundation for sales uplift, merchandise margin enhancements and synergy capture 62

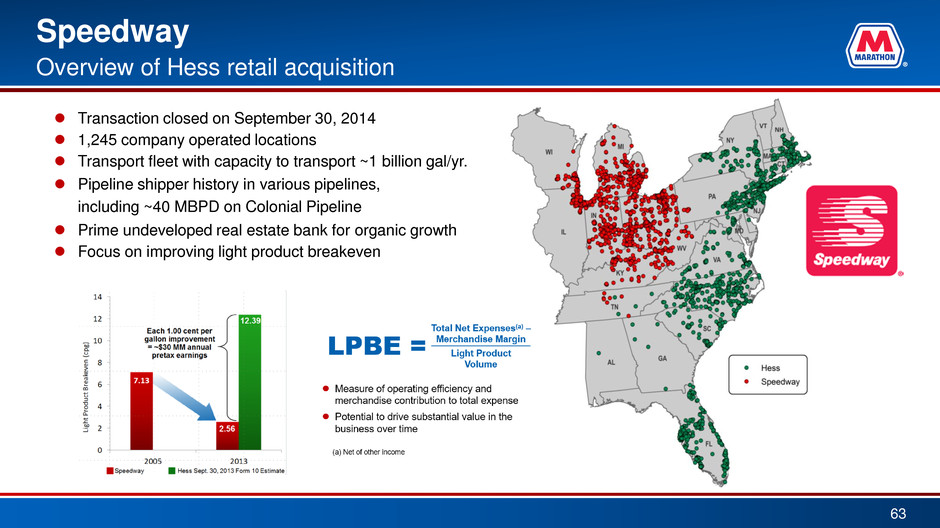

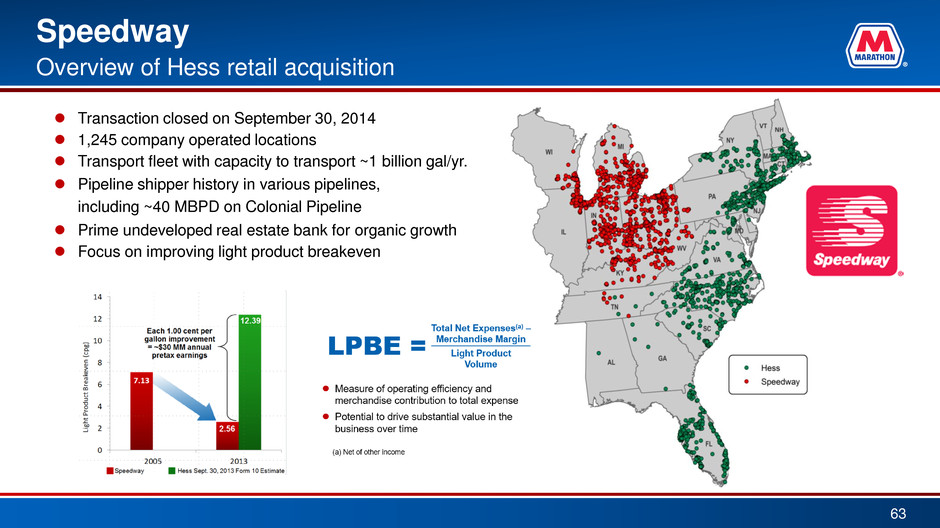

Speedway Overview of Hess retail acquisition Transaction closed on September 30, 2014 1,245 company operated locations Transport fleet with capacity to transport ~1 billion gal/yr. Pipeline shipper history in various pipelines, including ~40 MBPD on Colonial Pipeline Prime undeveloped real estate bank for organic growth Focus on improving light product breakeven 63

Speedy Rewards ® Loyalty Program Highly successful loyalty program Customers earn points on every purchase Customers redeem points for free merchandise and fuel discounts Averaged more than 5.7 million active Speedy Rewards members in 2016, and continues to grow as we attract new members in the markets we serve Heavy vendor support due to one-on-one marketing capabilities Upgrade to Speedy Rewards Pay Card and use of alternate ID Speedy Rewards MasterCard that is a Speedy Rewards card and MasterCard all in one Partnerships provide additional value to members 64

65 Higher Sales and Margins Better Value Proposition For Consumers Differentiation From Competitors Promotes Brand Awareness and Loyalty Private Label Products

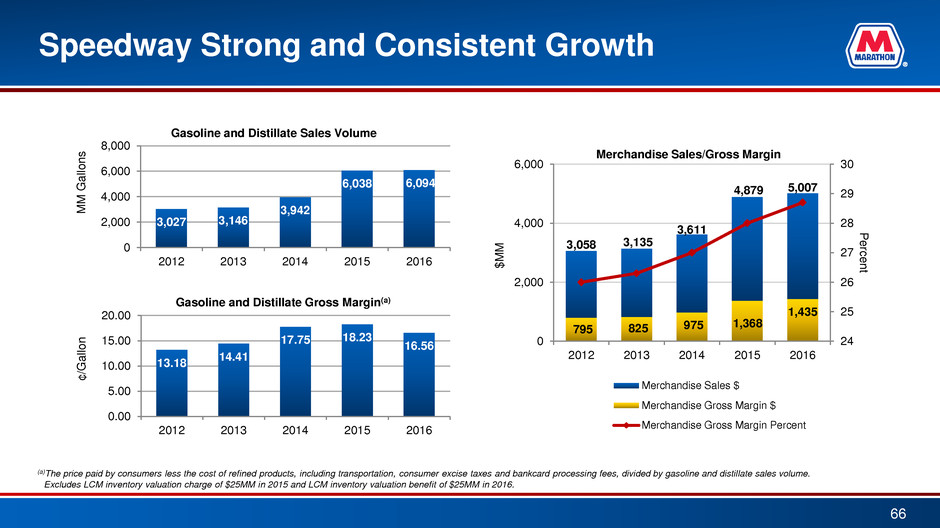

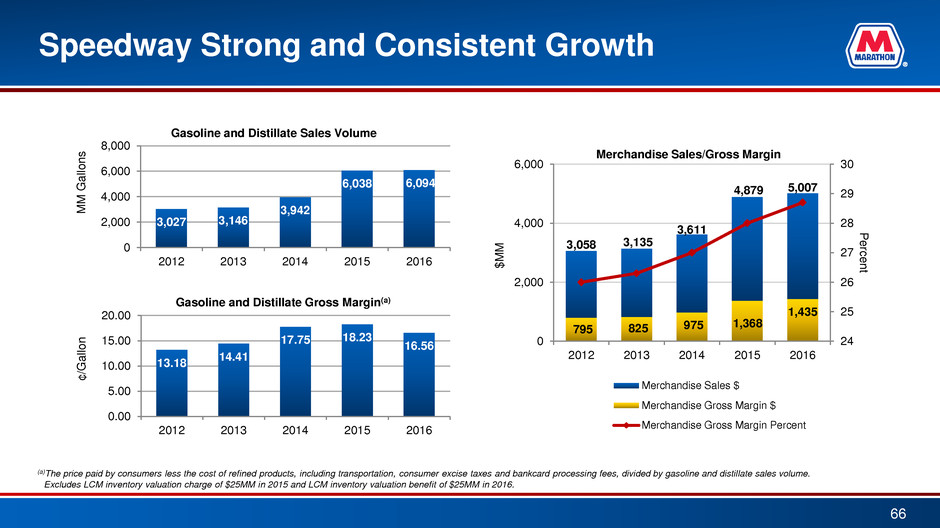

Speedway Strong and Consistent Growth 66 3,027 3,146 3,942 6,038 6,094 0 2,000 4,000 6,000 8,000 2012 2013 2014 2015 2016 M M Ga llo n s Gasoline and Distillate Sales Volume 13.18 14.41 17.75 18.23 16.56 0.00 5.00 10.00 15.00 20.00 2012 2013 2014 2015 2016 ¢ /Ga llo n Gasoline and Distillate Gross Margin(a) 795 825 975 1,368 1,435 3,058 3,135 3,611 4,879 5,007 24 25 26 27 28 29 30 0 2,000 4,000 6,000 2012 2013 2014 2015 2016 P e rc e n t $ M M Merchandise Sales/Gross Margin Merchandise Sales $ Merchandise Gross Margin $ Merchandise Gross Margin Percent (a)The price paid by consumers less the cost of refined products, including transportation, consumer excise taxes and bankcard processing fees, divided by gasoline and distillate sales volume. Excludes LCM inventory valuation charge of $25MM in 2015 and LCM inventory valuation benefit of $25MM in 2016.

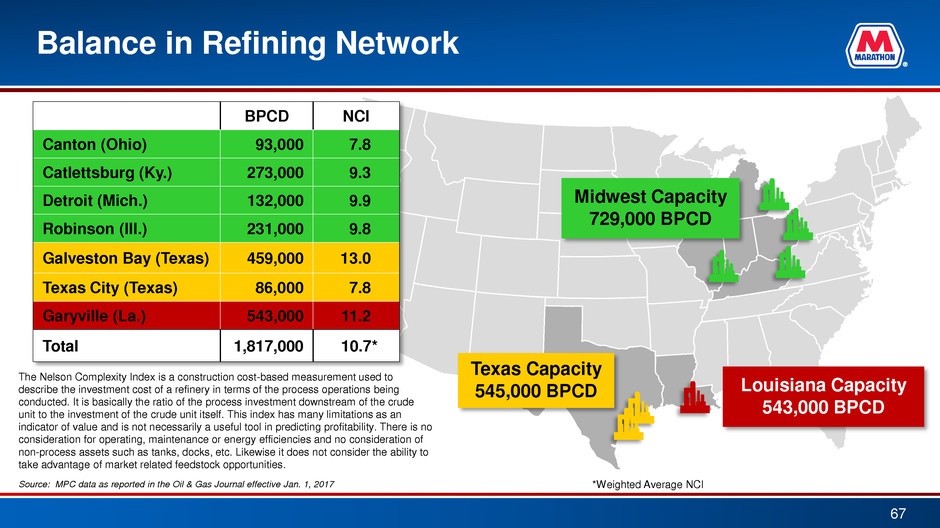

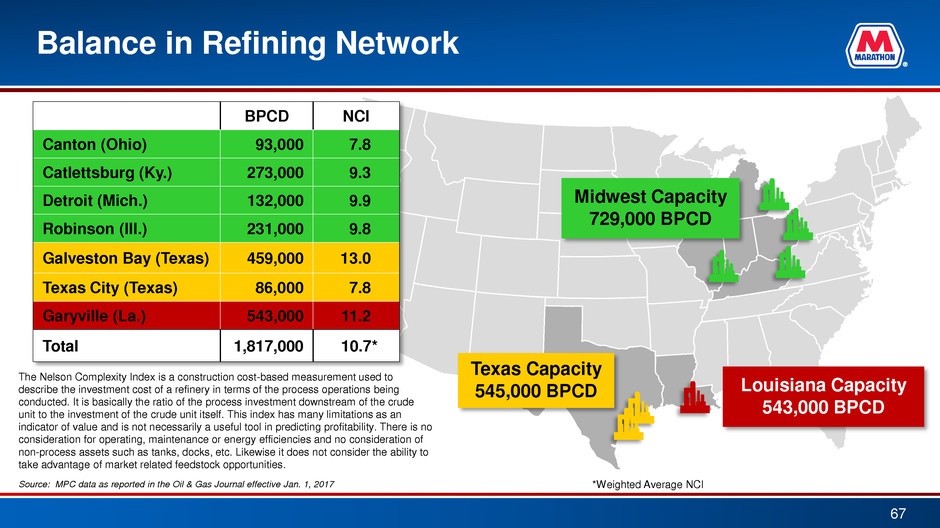

Balance in Refining Network Midwest Capacity 729,000 BPCD Louisiana Capacity 543,000 BPCD Texas Capacity 545,000 BPCD 67 *Weighted Average NCI The Nelson Complexity Index is a construction cost-based measurement used to describe the investment cost of a refinery in terms of the process operations being conducted. It is basically the ratio of the process investment downstream of the crude unit to the investment of the crude unit itself. This index has many limitations as an indicator of value and is not necessarily a useful tool in predicting profitability. There is no consideration for operating, maintenance or energy efficiencies and no consideration of non-process assets such as tanks, docks, etc. Likewise it does not consider the ability to take advantage of market related feedstock opportunities. Source: MPC data as reported in the Oil & Gas Journal effective Jan. 1, 2017 BPCD NCI Canton (Ohio) 93,000 7.8 Catlettsburg (Ky.) 273,000 9.3 Detroit (Mich.) 132,000 9.9 Robinson (Ill.) 231,000 9.8 Galveston Bay (Texas) 459,000 13.0 Texas City (Texas) 86,000 7.8 Garyville (La.) 543,000 11.2 Total 1,817,000 10.7*

Key Strengths 68 Balanced Operations 40% 60% Crude Oil Refining Capacity PADD II PADD III 67% 33% Crude Slate Sour Crude Sweet Crude As of March 31, 2017 1Q 2017 ~70% ~30% Assured Sales Wholesale and Other Sales Assured Sales of Gasoline Production (Speedway + Brand + Wholesale Contract Sales) 1Q 2017

OPEC’s Resolve to Reduce Inventory Levels 69 Source: EIA Global supply and demand deficit of at least 800,000 bpd in 2H 2017 supportive of higher 2H 2017 crude prices

U.S. Macro Picture Remains Solid Expect good underlying domestic and export demand for refined products 70 Source: EIA 8.4 8.6 8.8 9.0 9.2 9.4 9.6 9.8 J F M A M J J A S O N D Gasoline Demand (MMBD) 2015 2016 2017 3.4 3.6 3.8 4.0 4.2 4.4 4.6 J F M A M J J A S O N D Distillate Demand (MMBD) 2015 2016 2017 2017 gasoline demand expected to be as strong as 2016 despite modest start Distillate demand expected to benefit from increased commercial activity

Gasoline Exports Enhance Utilization 71 Gasoline exports have expanded opportunity set for U.S. refiners – Summer exports tend to fall as more product is consumed domestically U.S. refinery utilization is less subject to domestic demand seasonality 1Q 2017 USGC crack spreads improved from 4Q 2016 despite seasonal low point in gasoline demand Sources: EIA, Census 300 500 700 900 1100 J F M A M J J A S O N D M B P D U.S. Total Gross Gasoline Exports 2014 2015 2016 2017 8.2 8.7 9.2 9.7 J F M A M J J A S O N D M M B P D U.S. Gasoline Demand 2014 2015 2016 2017

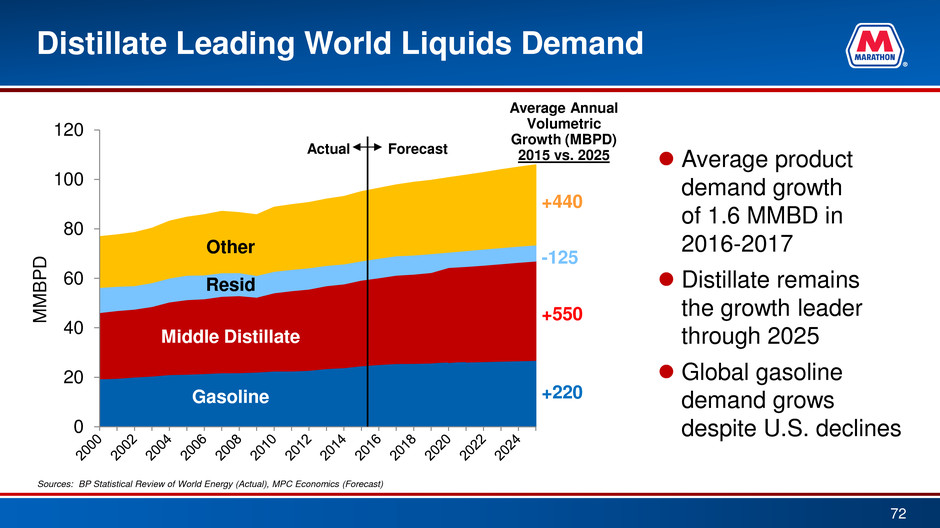

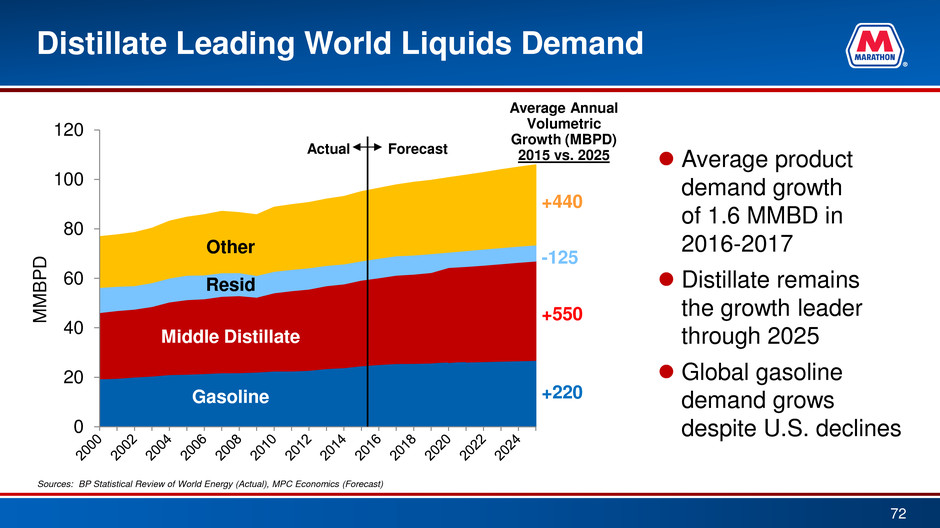

0 20 40 60 80 100 120 M M BP D Distillate Leading World Liquids Demand Average product demand growth of 1.6 MMBD in 2016-2017 Distillate remains the growth leader through 2025 Global gasoline demand grows despite U.S. declines 72 Sources: BP Statistical Review of World Energy (Actual), MPC Economics (Forecast) Middle Distillate Gasoline Resid Other Average Annual Volumetric Growth (MBPD) 2015 vs. 2025 +440 -125 +550 +220 Forecast Actual

Distillate Leads U.S. Domestic Petroleum Fuels Demand 73 0 1 2 3 4 5 6 7 8 9 10 MM B P D Compounded Annual Growth Rates 2016 vs. 2030 Sources: U.S. Energy Information Administration (EIA), MPC Gasoline Gasoline ex ethanol Distillate Jet Fuel Resid -0.8% -0.8% +1.7% +0.4% -4.7% Forecast Actual Distillate expected to lead U.S. domestic fuels demand growth – Primarily due to growth in freight transportation and substitution for high sulfur bunker fuels Resid is expected to continue its structural decline, largely as a result of international marine bunker regulations

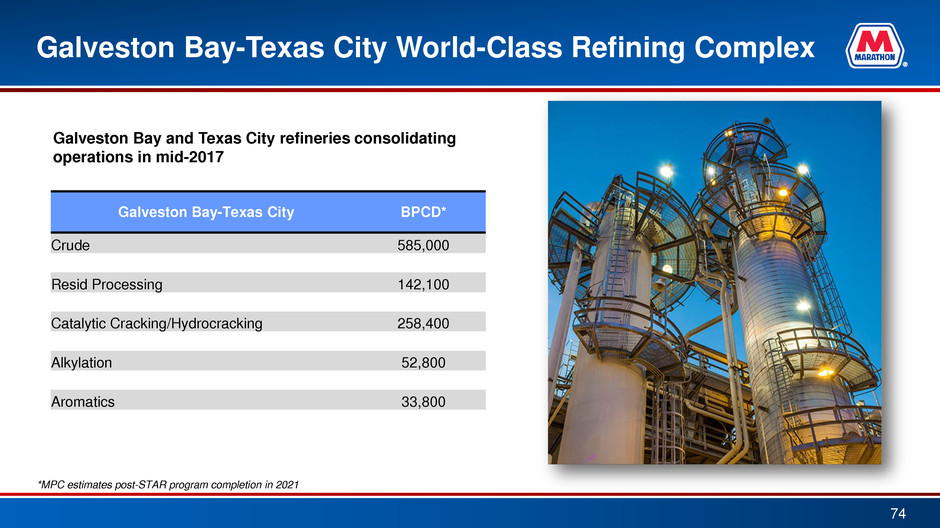

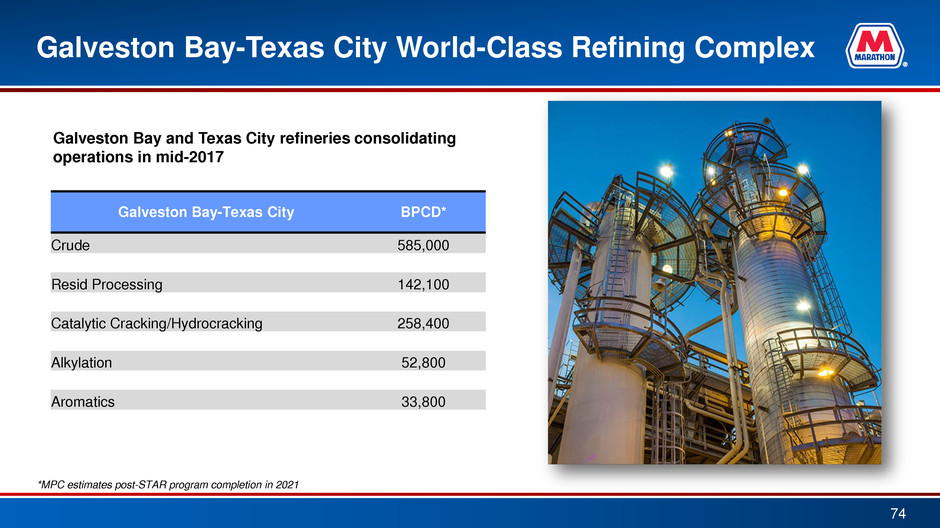

Galveston Bay-Texas City World-Class Refining Complex 74 *MPC estimates post-STAR program completion in 2021 Galveston Bay and Texas City refineries consolidating operations in mid-2017 Galveston Bay-Texas City BPCD* Crude 585,000 Resid Processing 142,100 Catalytic Cracking/Hydrocracking 258,400 Alkylation 52,800 Aromatics 33,800

ENERGY STAR Program ENERGY STAR labels for refining industry began in 2006 47 labels awarded during 11 labeling years 9 labels to Phillips 66/ConocoPhillips 1 label to ExxonMobil 1 label to former MPC site in St. Paul Park, Minnesota Remaining 36 labels to MPC refineries 75 75 Operating Year ---> 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 EPA Certification Year ---> 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 Canton 1 1 1 1 1 1 1 1 1 1 1 Detroit 1 1 1 1 1 1 Garyville 1 1 1 1 1 1 1 1 1 1 1 Robinson 1 1 1 Texas City 1 1 1 1 1 Conoco Phillips, Billings 1 1 1 Conoco Phillips, Lake Charles 1 Former Marathon, St Paul Park 1 Exxon/Mobil, Baton Rouge 1 Conoco Phillips, Bayway 1 Phillips 66 Company, Bayway 1 Phillips 66 Company, Ferndale 1 1 1 EPA ENERGY STAR History as of 6-15-16 Source: EPA ENERGY STAR Website

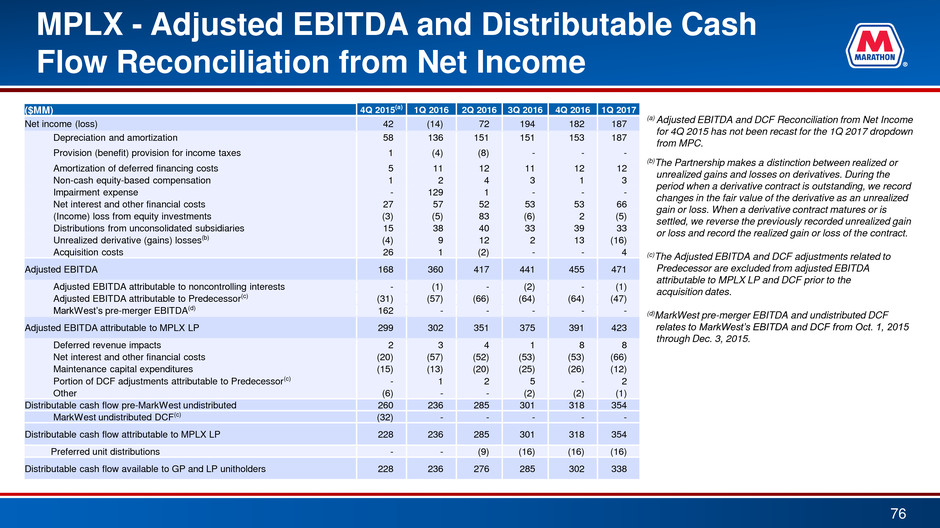

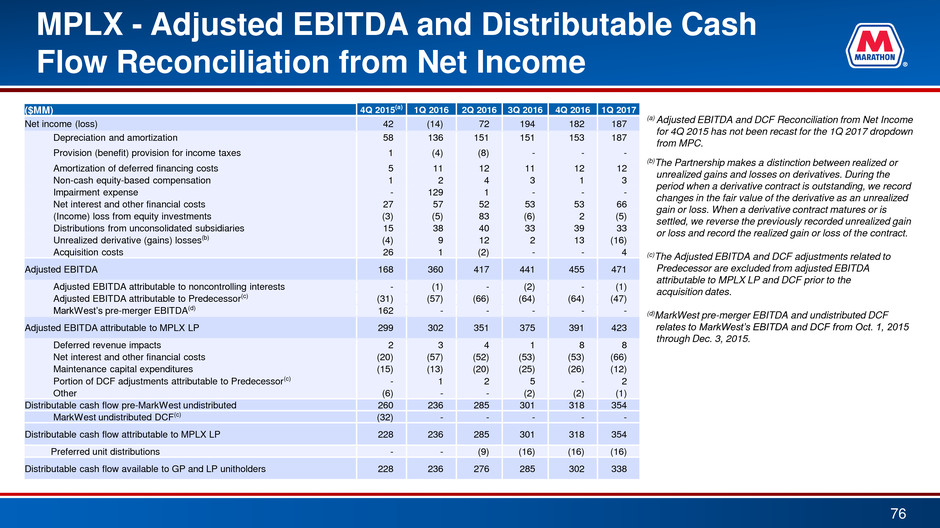

MPLX - Adjusted EBITDA and Distributable Cash Flow Reconciliation from Net Income 76 (a) Adjusted EBITDA and DCF Reconciliation from Net Income for 4Q 2015 has not been recast for the 1Q 2017 dropdown from MPC. (b)The Partnership makes a distinction between realized or unrealized gains and losses on derivatives. During the period when a derivative contract is outstanding, we record changes in the fair value of the derivative as an unrealized gain or loss. When a derivative contract matures or is settled, we reverse the previously recorded unrealized gain or loss and record the realized gain or loss of the contract. (c)The Adjusted EBITDA and DCF adjustments related to Predecessor are excluded from adjusted EBITDA attributable to MPLX LP and DCF prior to the acquisition dates. (d)MarkWest pre-merger EBITDA and undistributed DCF relates to MarkWest’s EBITDA and DCF from Oct. 1, 2015 through Dec. 3, 2015. ($MM) 4Q 2015(a) 1Q 2016 2Q 2016 3Q 2016 4Q 2016 1Q 2017 Net income (loss) 42 (14) 72 194 182 187 Depreciation and amortization 58 136 151 151 153 187 Provision (benefit) provision for income taxes 1 (4) (8) - - - Amortization of deferred financing costs 5 11 12 11 12 12 Non-cash equity-based compensation 1 2 4 3 1 3 Impairment expense - 129 1 - - - Net interest and other financial costs 27 57 52 53 53 66 (Income) loss from equity investments (3) (5) 83 (6) 2 (5) Distributions from unconsolidated subsidiaries 15 38 40 33 39 33 Unrealized derivative (gains) losses(b) (4) 9 12 2 13 (16) Acquisition costs 26 1 (2) - - 4 Adjusted EBITDA 168 360 417 441 455 471 Adjusted EBITDA attributable to noncontrolling interests - (1) - (2) - (1) Adjusted EBITDA attributable to Predecessor(c) (31) (57) (66) (64) (64) (47) MarkWest’s pre-merger EBITDA(d) 162 - - - - - Adjusted EBITDA attributable to MPLX LP 299 302 351 375 391 423 Deferred revenue impacts 2 3 4 1 8 8 Net interest and other financial costs (20) (57) (52) (53) (53) (66) Maintenance capital expenditures (15) (13) (20) (25) (26) (12) Portion of DCF adjustments attributable to Predecessor(c) - 1 2 5 - 2 Other (6) - - (2) (2) (1) Distributable cash flow pre-MarkWest undistributed 260 236 285 301 318 354 MarkWest undistributed DCF(c) (32) - - - - - Distributable cash flow attributable to MPLX LP 228 236 285 301 318 354 Preferred unit distributions - - (9) (16) (16) (16) Distributable cash flow available to GP and LP unitholders 228 236 276 285 302 338

MPLX Reconciliation – 2017 Forecast 77 ($MM) Low High Net income 550 700 Depreciation and amortization 680 680 Net interest and other financial costs 330 330 Adjustment for equity investment earnings & distributions 100 100 Unrealized derivative losses(a) 20 20 Other 23 23 Adjusted EBITDA 1,703 1,853 Adjusted EBITDA attributable to noncontrolling interests (3) (3) Adjusted EBITDA attributable to MPLX LP 1,700 1,850 Deferred revenue impacts 5 5 Net interest and other financial costs (280) (280) Maintenance capital expenditures (150) (150) Other (25) (25) Distributable cash flow attributable to MPLX LP 1,250 1,400 Preferred unit distributions (65) (65) Distributable cash flow available to GP and LP unitholders 1,185 1,335 (a)The Partnership makes a distinction between realized or unrealized gains and losses on derivatives. During the period when a derivative contract is outstanding, we record changes in the fair value of the derivative as an unrealized gain or loss. When a derivative contract matures or is settled, we reverse the previously recorded unrealized gain or loss and record the realized gain or loss of the contract. Adjusted EBITDA and Distributable Cash Flow from Net Income

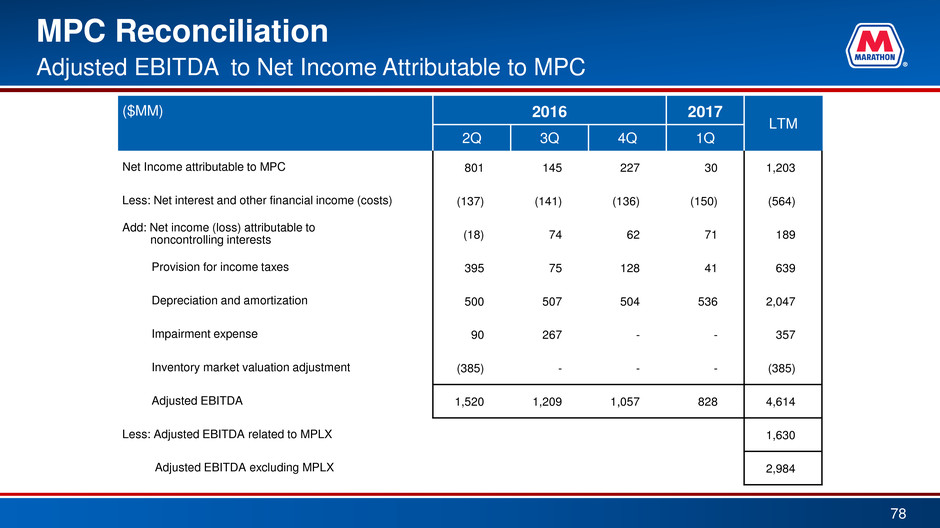

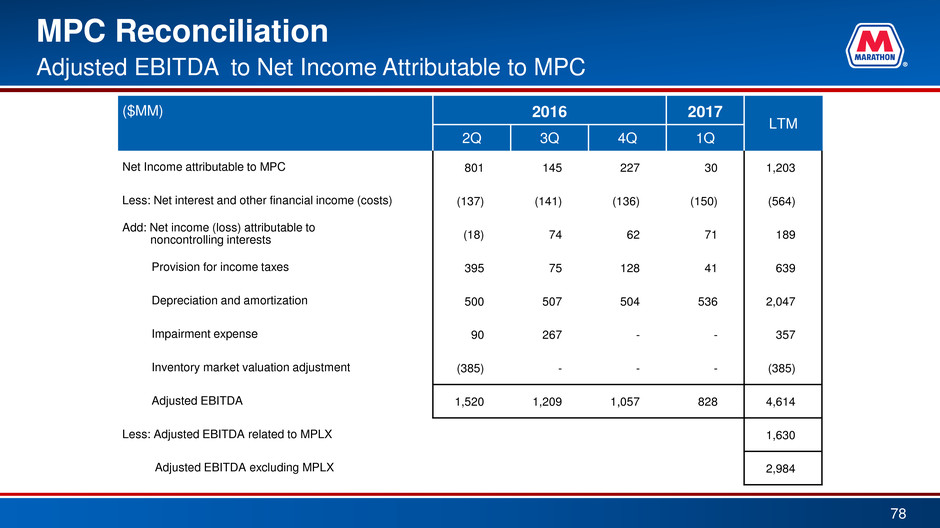

MPC Reconciliation 78 Adjusted EBITDA to Net Income Attributable to MPC ($MM) 2016 2017 LTM 2Q 3Q 4Q 1Q Net Income attributable to MPC 801 145 227 30 1,203 Less: Net interest and other financial income (costs) (137) (141) (136) (150) (564) Add: Net income (loss) attributable to inco noncontrolling interests (18) 74 62 71 189 Provision for income taxes 395 75 128 41 639 Depreciation and amortization 500 507 504 536 2,047 Impairment expense 90 267 - - 357 Inventory market valuation adjustment (385) - - - (385) Adjusted EBITDA 1,520 1,209 1,057 828 4,614 Less: Adjusted EBITDA related to MPLX 1,630 Adjusted EBITDA excluding MPLX 2,984

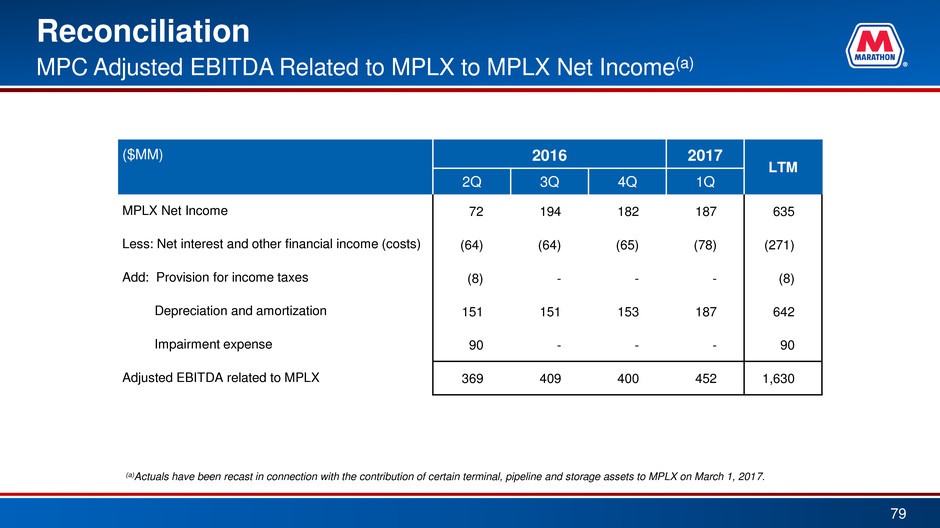

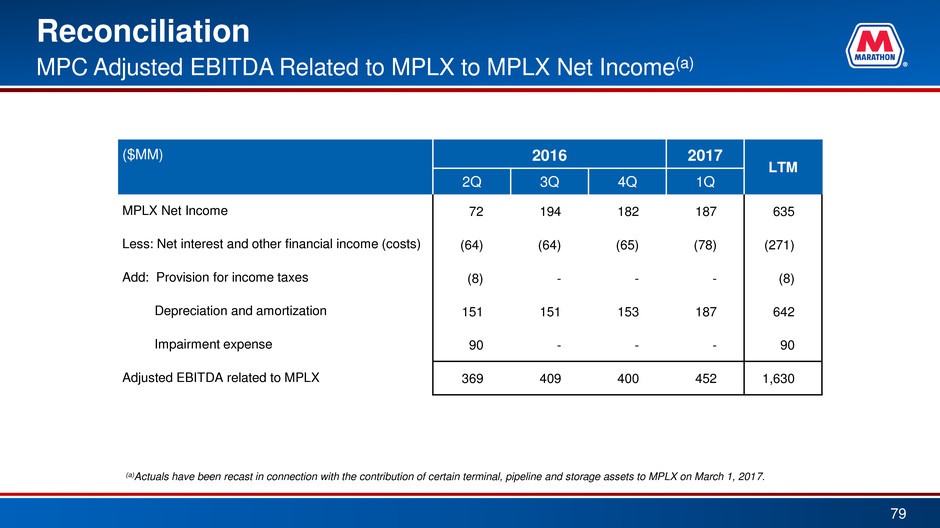

Reconciliation 79 MPC Adjusted EBITDA Related to MPLX to MPLX Net Income(a) ($MM) 2016 2017 LTM 2Q 3Q 4Q 1Q MPLX Net Income 72 194 182 187 635 Less: Net interest and other financial income (costs) (64) (64) (65) (78) (271) Add: Provision for income taxes (8) - - - (8) Depreciation and amortization 151 151 153 187 642 Impairment expense 90 - - - 90 Adjusted EBITDA related to MPLX 369 409 400 452 1,630 (a)Actuals have been recast in connection with the contribution of certain terminal, pipeline and storage assets to MPLX on March 1, 2017.

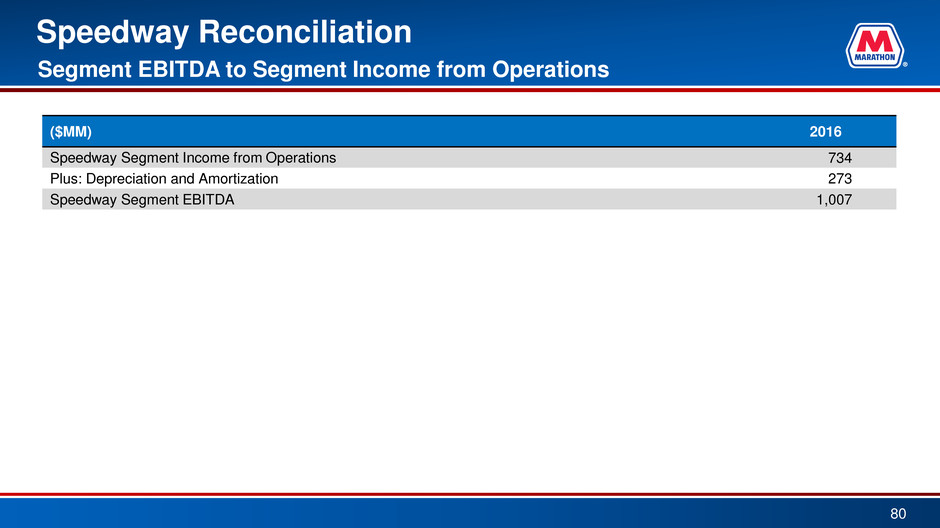

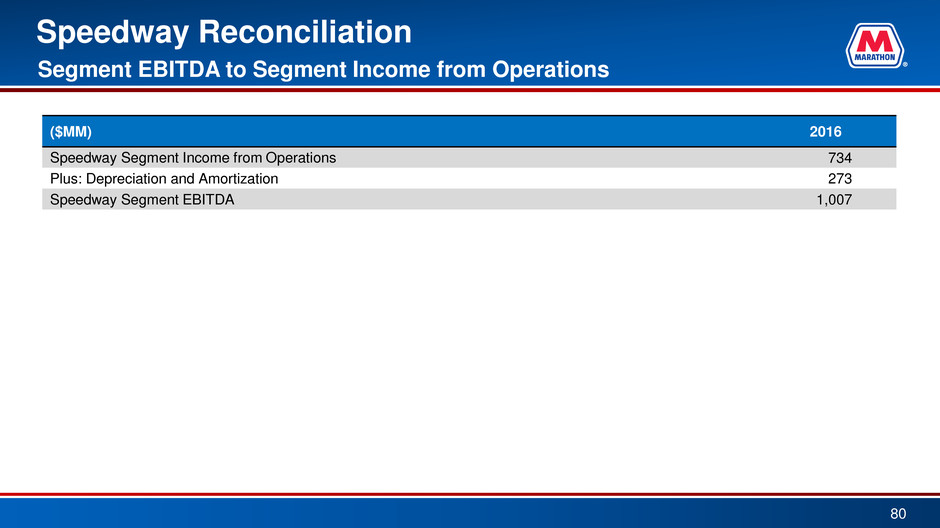

Speedway Reconciliation 80 Segment EBITDA to Segment Income from Operations ($MM) 2016 Speedway Segment Income from Operations 734 Plus: Depreciation and Amortization 273 Speedway Segment EBITDA 1,007

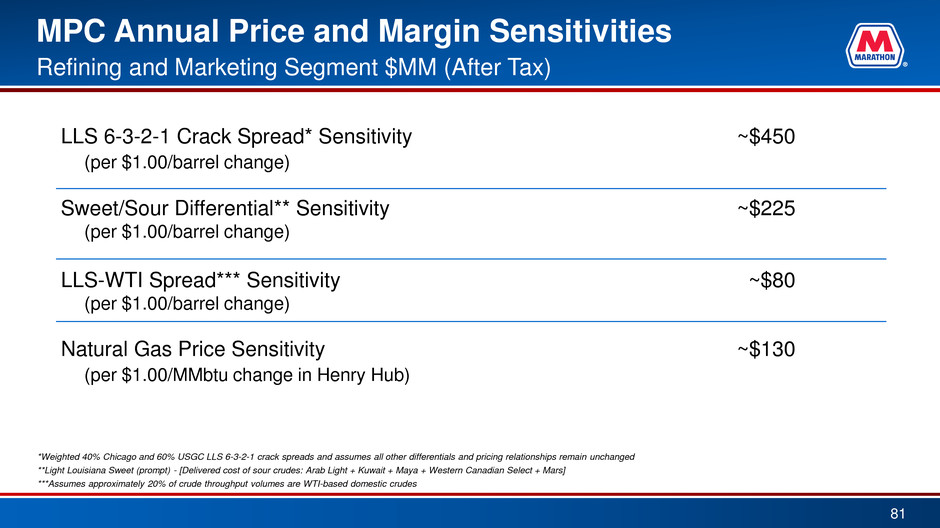

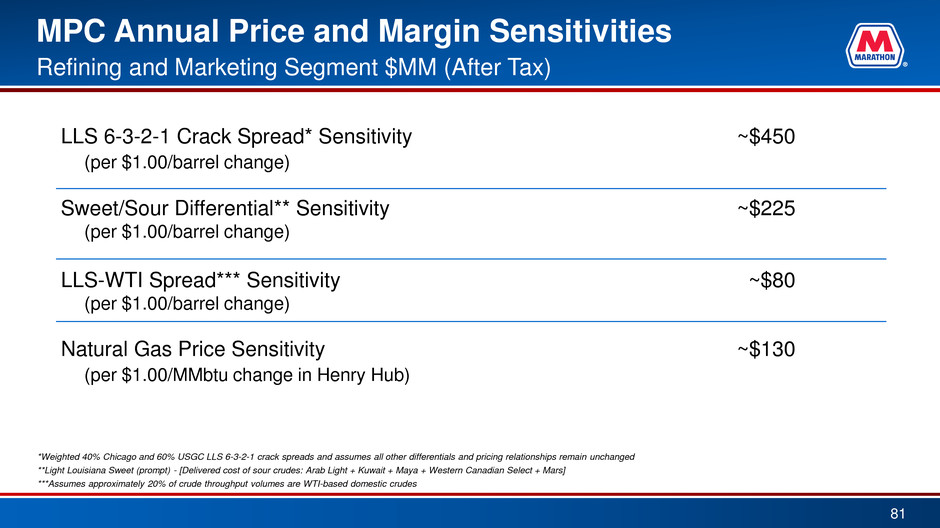

MPC Annual Price and Margin Sensitivities Refining and Marketing Segment $MM (After Tax) LLS 6-3-2-1 Crack Spread* Sensitivity ~$450 (per $1.00/barrel change) Sweet/Sour Differential** Sensitivity ~$225 (per $1.00/barrel change) LLS-WTI Spread*** Sensitivity ~$80 (per $1.00/barrel change) Natural Gas Price Sensitivity ~$130 (per $1.00/MMbtu change in Henry Hub) *Weighted 40% Chicago and 60% USGC LLS 6-3-2-1 crack spreads and assumes all other differentials and pricing relationships remain unchanged **Light Louisiana Sweet (prompt) - [Delivered cost of sour crudes: Arab Light + Kuwait + Maya + Western Canadian Select + Mars] ***Assumes approximately 20% of crude throughput volumes are WTI-based domestic crudes 81

MPC’s Fully Integrated Downstream System Refining and Marketing Seven-plant refining system with ~1.8 MMBPCD capacity One biodiesel facility and interest in three ethanol facilities One of the largest wholesale suppliers in our market area One of the largest producers of asphalt in the U.S. ~5,500 Marathon Brand retail outlets across 19 states Owns/operates 20 asphalt/light product terminals, while utilizing third-party terminals at 121 light product and two asphalt locations 2,074 owned/leased railcars, 163 owned transport trucks Speedway ~2,730 locations in 21 states Second largest U.S. owned/operated c-store chain Midstream (including MPLX) Owns, leases or has interest in ~10,800 miles of crude and refined product pipelines 62 light product terminals with ~24 million barrels of storage capacity 18 owned inland waterway towboats with more than 200 barges Owns/operates over 5,600 miles of gas gathering and NGL pipelines Owns/operates 55 gas processing plants, 14 NGL fractionation facilities and two condensate stabilization facilities 82 Marketing Area Ethanol Facility Biodiesel Facility Renewable Fuels MPC Interest: Operated by MPC MPC Owned & Operated MPC Interest: Operated by Others Pipelines Pipelines Used by MPC Water Supplied Terminals Coastal Inland MPC Refineries Light Product Terminals MPC Owned and Part-owned Third Party Asphalt/Heavy Oil Terminals MPC Owned Third Party MarkWest Complex MPLX Terminals: Owned and Part-owned Tank Farms MPLX Pipelines: Owned & Operated MPLX Interest Pipelines: Operated by Others Cavern Barge Dock As of March 31, 2017