Technical Report on the Shahuindo Mine

Cajabamba, Peru

Prepared by:

Carl E. Defilippi, SME Registered Member – Kappes, Cassiday & Associates

Charles V. Muerhoff, SME Registered Member – Tahoe Resources Inc.

Tim Williams, FAusIMM – Tahoe Resources Inc.

January 25, 2016

DATE AND SIGNATURE PAGE

The authors of this report,Technical Report on the Shahuindo Mine, Cajabamba, Peru, are Qualified Persons as defined by Canadian National Instrument 43-101. The effective date of this report is 01 January 2016. The effective date of the Mineral Resource estimate is 15 April 2015. The effective date of the Mineral Reserve estimate is 01 November 2015. The report was completed and signed on 25 January 2016.

Signed this 25thday of January, 2016

| /s/Carl E. Defilippi |

| Carl E. Defilippi, M.Sc., C.E.M. |

| SME Registered Member 775870RM |

| Project Manager |

| Kappes, Cassiday & Associates |

| |

| |

| /s/Charles V. Muerhoff |

| Charles V. Muerhoff, B.Sc. |

| SME Registered Member 4182272RM |

| Vice President Technical Services |

| Tahoe Resources Inc. |

| |

| |

/s/Tim Williams |

| Tim Williams, M.Sc. |

| FAusIMM |

| Vice President Operations & Peru Country Manager |

| Tahoe Resources Inc. |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

CONTENTS

| LIST OF FIGURES | XI |

| | |

| LIST OF TABLES | XIV |

| | |

| 1.0 | EXECUTIVE SUMMARY | 1 |

| | | |

| | 1.1 | Introduction | 1 |

| | 1.2 | Principal Findings | 1 |

| | 1.3 | Property Description and Location | 3 |

| | 1.4 | Mineral Tenure | 3 |

| | 1.5 | Permits | 3 |

| | 1.6 | Environment | 4 |

| | 1.7 | History | 4 |

| | 1.8 | Geology and Mineralization | 4 |

| | 1.9 | Drilling | 5 |

| | 1.10 | Sample Preparation and Analysis | 5 |

| | 1.11 | Data Verification | 6 |

| | 1.12 | Mineral Processing and Metallurgical Testing | 6 |

| | 1.13 | Mineral Resource and Mineral Reserve Estimates | 7 |

| | | 1.13.1 | Mineral Resources | 8 |

| | | 1.13.2 | Mineral Reserve Estimate | 9 |

| | 1.14 | Mining Method and Mine Production Schedule | 9 |

| | 1.15 | Processing | 11 |

| | 1.16 | Infrastructure | 12 |

| | 1.17 | Mine Closure | 12 |

| | 1.18 | Capital and Operating Costs | 13 |

| | | 1.18.1 | Operating Costs | 13 |

| | | 1.18.2 | Capital Costs | 13 |

| | | 1.18.3 | Financial Analysis | 14 |

| | 1.19 | Exploration Status | 15 |

| | 1.20 | Conclusions and Recommendations | 15 |

| | | | |

| 2.0 | INTRODUCTION | 17 |

| | | |

| | 2.1 | Purpose and Basis of Report | 17 |

| | 2.2 | Sources of Information | 17 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| | 2.3 | Qualified Persons and Site Visits | 18 |

| | 2.4 | Effective Dates | 18 |

| | 2.5 | Units of Measurements | 19 |

| | 2.6 | Abbreviations and Acronyms | 19 |

| | | | |

| 3.0 | RELIANCE ON OTHER EXPERTS | 21 |

| | | |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 22 |

| | | |

| | 4.1 | Location | 22 |

| | 4.2 | Mineral Tenure and Title | 22 |

| | 4.3 | Surface Rights | 25 |

| | 4.4 | Informal Mining Activity | 25 |

| | 4.5 | Environmental Considerations | 26 |

| | | 4.5.1 | Environmental Regulations | 26 |

| | 4.6 | Permits | 27 |

| | | 4.6.1 | Environmental Laws | 29 |

| | | 4.6.2 | Mine Development, Exploitation and Processing Activities | 30 |

| | | 4.6.3 | Mine Closure and Site Remediation | 30 |

| | | 4.6.4 | Existing Environmental Conditions | 30 |

| | 4.7 | Royalties, Taxes and Fees | 30 |

| | | 4.7.1 | Maintenance Fees | 30 |

| | | 4.7.2 | Minimum Production Obligation | 31 |

| | | 4.7.3 | Royalties, OSINERGMIN Contribution and OEFA Contribution | 31 |

| | | 4.7.4 | Ownership of Mining Rights | 32 |

| | | 4.7.5 | Taxation and Foreign Exchange Controls | 33 |

| | | 4.7.6 | Worker Participation | 33 |

| | | 4.7.7 | Regulatory and Supervisory Bodies | 34 |

| | 4.8 | Risks that may affect Access, Title, or the Right or Ability to Perform Work | 34 |

| | | | | |

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE ANDPHYSIOGRAPHY | 36 |

| | | |

| | 5.1 | Accessibility | 36 |

| | 5.2 | Climate | 37 |

| | 5.3 | Local Resources & Infrastructure | 37 |

| | 5.4 | Physiography | 38 |

| | 5.5 | Seismology | 39 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| | 5.6 | Population Centers | 39 |

| | 5.7 | Local Infrastructure and Services | 40 |

| | | | | |

| 6.0 | HISTORY | 42 |

| | | |

| | 6.1 | Ownership History | 42 |

| | 6.2 | Exploration History | 42 |

| | 6.3 | Historical Mineral Resource and Mineral Reserve Estimates | 44 |

| | | 6.3.1 | Pre-NI 43-101 Mineral Resource Estimates | 44 |

| | | 6.3.2 | Prior NI 43-101 Mineral Resource Estimates | 45 |

| | | 6.3.3 | Prior NI 43-101 Mineral Reserve Estimates | 49 |

| | 6.4 | Historical Production | 51 |

| | | | | |

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 52 |

| | | |

| | 7.1 | Regional Geology | 52 |

| | 7.2 | Project Geology | 56 |

| | 7.3 | Mineralization | 65 |

| | 7.4 | Structural Geology | 66 |

| | 7.5 | Hydrothermal Alteration | 69 |

| | 7.6 | Geometallurgy | 73 |

| | | | | |

| 8.0 | DEPOSIT TYPES | 74 |

| | | |

| | 8.1 | Deposit Types | 74 |

| | | |

| 9.0 | EXPLORATION | 76 |

| | | | |

| | 9.1 | Exploration Strategy | 76 |

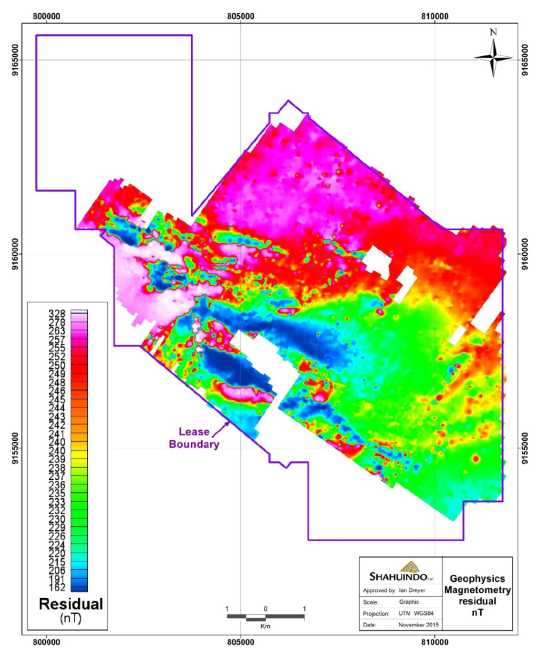

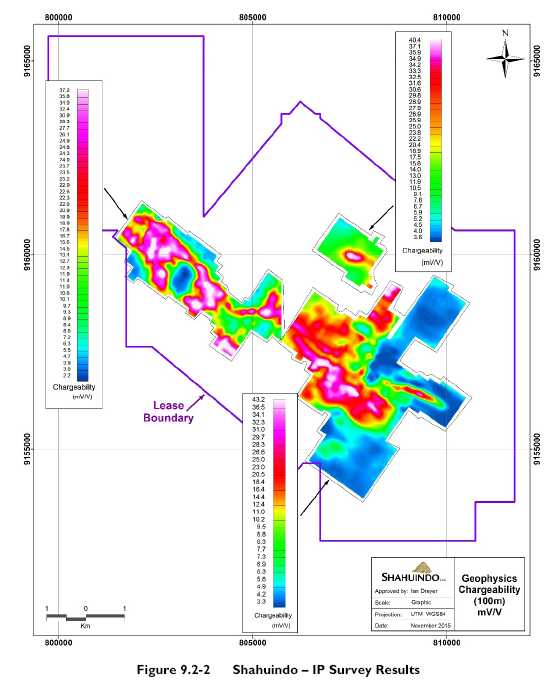

| | 9.2 | Geophysical Surveys | 76 |

| | 9.3 | Geochemistry | 79 |

| | | | |

| 10.0 | DRILLING | 81 |

| | | |

| | 10.1 | Introduction | 81 |

| | 10.2 | Drilling Methods and Equipment | 83 |

| | 10.3 | Collar Surveys | 84 |

| | 10.4 | Downhole Surveys | 85 |

| | 10.5 | Drill Logging | 86 |

| | 10.6 | Drill Database | 86 |

| | 10.7 | Core Recovery | 86 |

| | 10.8 | Comparison of Core and Reverse Circulation Drilling | 87 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

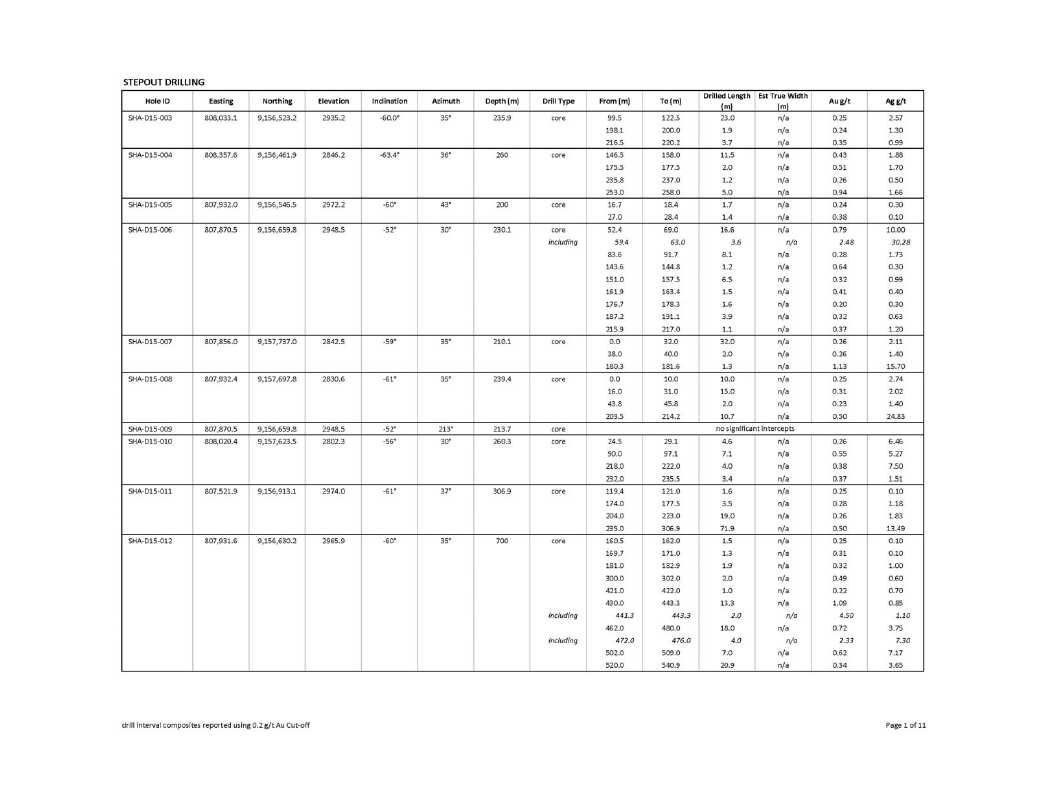

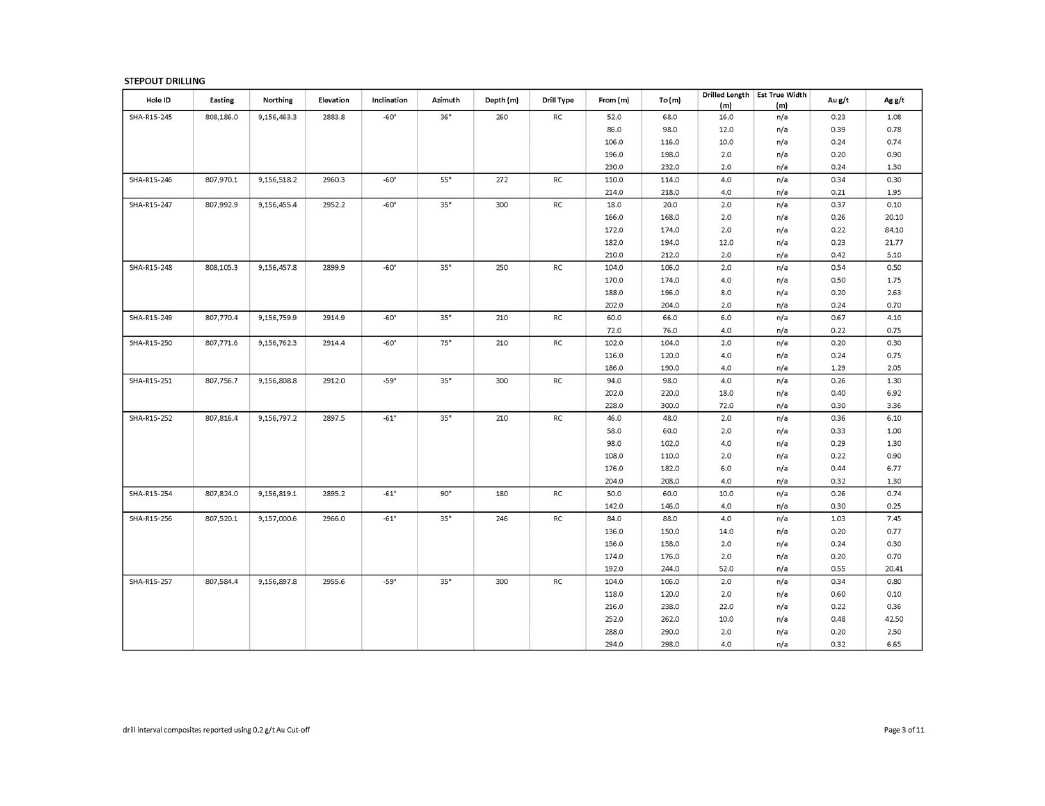

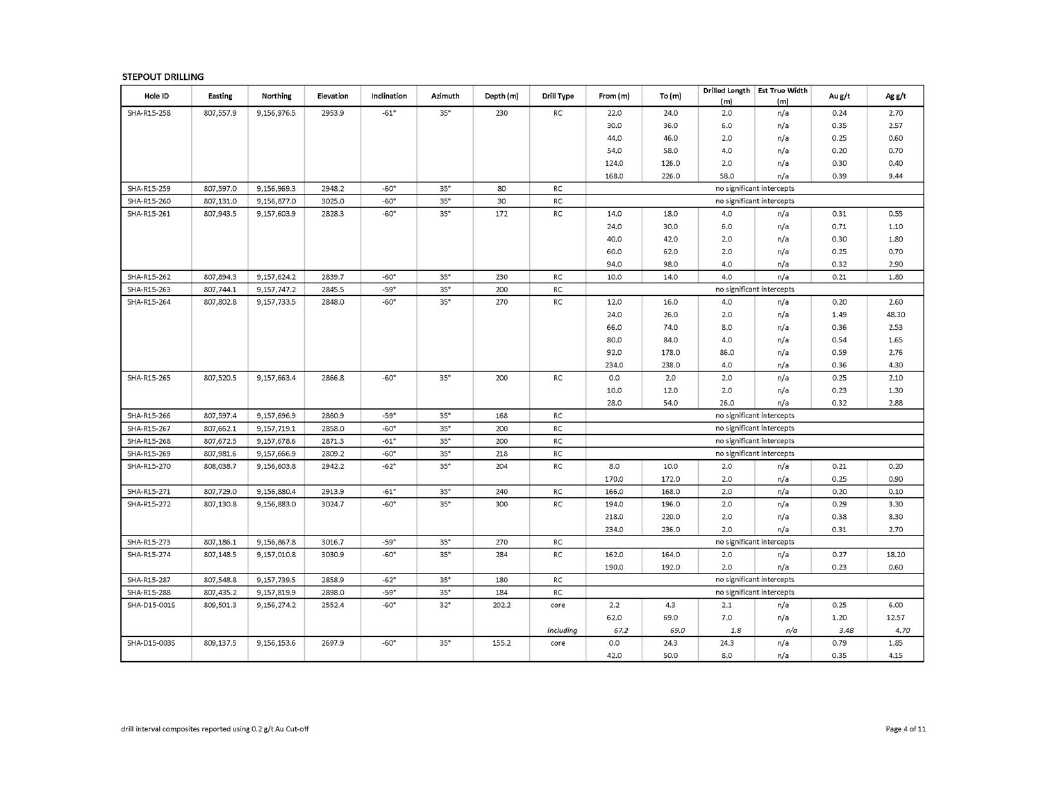

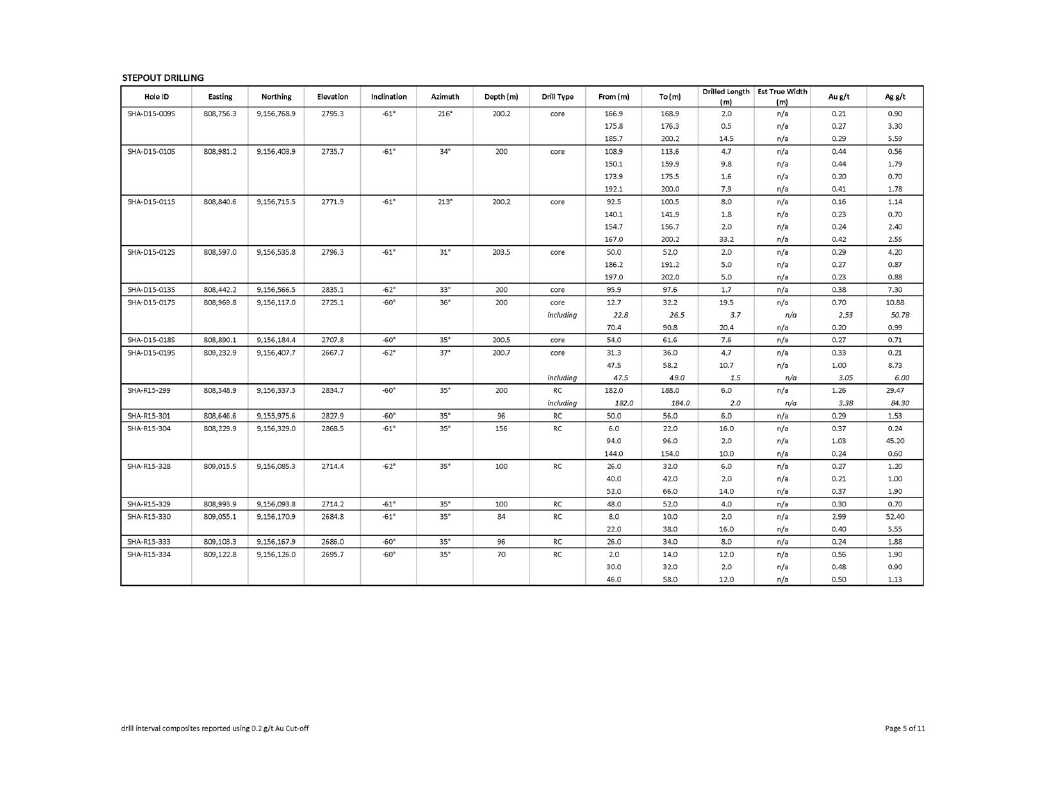

| | 10.9 | Tahoe 2015 Drill Program | 89 |

| | | 10.9.1 | Infill Drilling | 91 |

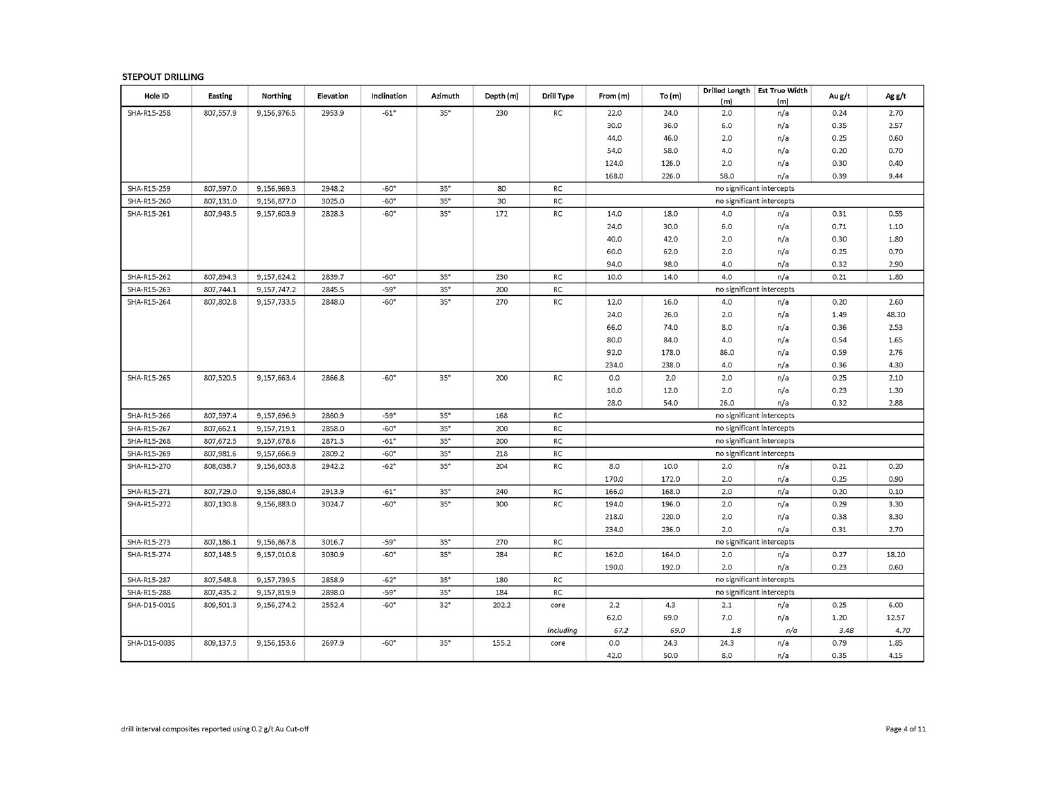

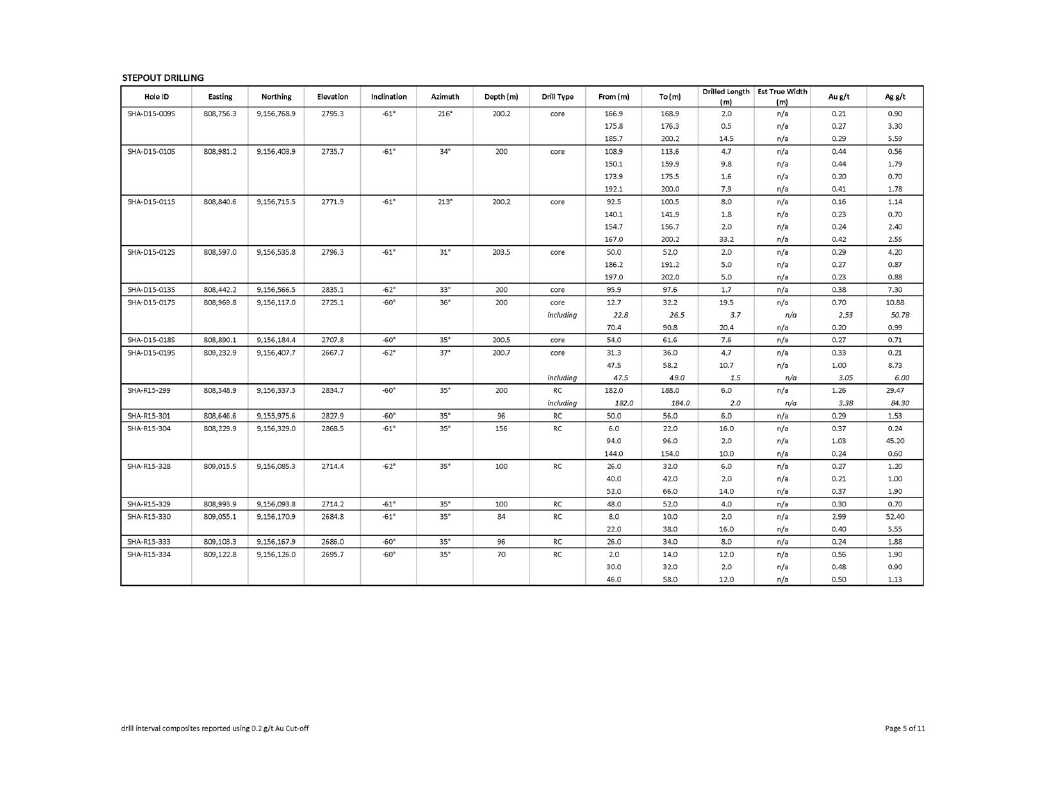

| | | 10.9.2 | Step-Out Drilling | 91 |

| | | 10.9.3 | Exploration | 91 |

| | | 10.9.4 | Other Drilling | 91 |

| | | | | |

| 11.0 | SAMPLE PREPARATION, ANALYSES AND SECURITY | 93 |

| | | | |

| | 11.1 | Drill Sampling | 93 |

| | | 11.1.1 | Diamond Drill Core Sampling | 93 |

| | | 11.1.2 | Reverse Circulation Chip Sampling | 93 |

| | | 11.1.3 | Sample Storage | 95 |

| | 11.2 | Sample Preparation and Analysis | 95 |

| | | 11.2.1 | Atimmsa | 95 |

| | | 11.2.2 | Asarco | 95 |

| | | 11.2.3 | Southern Peru | 96 |

| | | 11.2.4 | Sulliden | 96 |

| | | 11.2.5 | Rio Alto | 97 |

| | 11.3 | Bulk Density Determinations | 97 |

| | 11.4 | Sample Security | 98 |

| | 11.5 | Quality Assurance/Quality Control | 98 |

| | | 11.5.1 | Asarco | 98 |

| | | 11.5.2 | Other Drilling Programs Prior to Sulliden | 98 |

| | | 11.5.3 | Sulliden | 98 |

| | | 11.5.4 | Rio Alto | 100 |

| | | 11.5.5 | Blanks | 100 |

| | | 11.5.6 | Field Duplicates | 101 |

| | | 11.5.7 | Standards | 103 |

| | 11.6 | Summary Statement | 106 |

| | | | |

| 12.0 | DATA VERIFICATION | 107 |

| | | |

| | 12.1 | Met-Chem 2003/2004 Audit | 107 |

| | 12.2 | AMEC 2009 Database Audit and Verification | 107 |

| | 12.3 | MDA 2012 Database Audit | 107 |

| | 12.4 | Tahoe 2015 Database Audit | 108 |

| | 12.5 | Statement on Data Verification | 108 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 109 |

| | |

| | | |

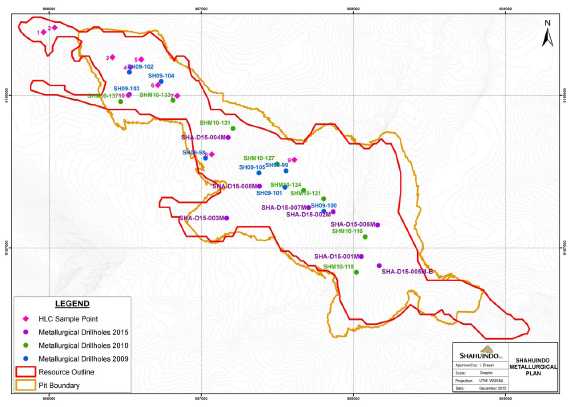

| 13.1 | Metallurgical Testing Summary | 109 |

| 13.2 | Pre-2014 Metallurgical Test Summary | 111 |

| | 13.2.1 | Heap Leach Consultants Test Program | 111 |

| | 13.2.2 | 2009 to 2012 Kappes, Cassiday & Associates Test Program | 112 |

| 13.3 | 2014 Kappes, Cassiday & Associates Test Program | 116 |

| 13.4 | 2014 and 2015 Test Programs | 116 |

| | 13.4.1 | Rio Alto, Tahoe Resources and SGS Column Leach Tests | 116 |

| | 13.4.2 | Discussion on the Results of the Rio Alto and SGS Column Leach Tests | 121 |

| | 13.4.3 | SGS Bottle Roll Tests | 123 |

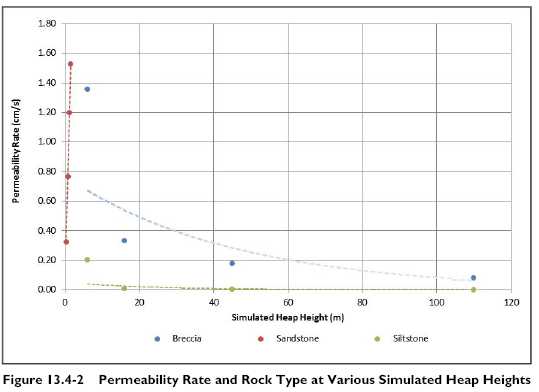

| | 13.4.4 | Compacted Permeability Tests | 124 |

| 13.5 | Estimated Field Recoveries, Leach Times and Reagent Requirements | 127 |

| | 13.5.1 | ROM Field Design Parameters | 127 |

| | 13.5.2 | Primary Crushed Ore Field Design Parameters | 130 |

| 13.6 | Recommendations and Conclusions | 133 |

| | | |

| | | |

14.0 | MINERAL RESOURCES ESTIMATE | 135 |

| | | |

| | | |

| 14.1 | Introduction | 135 |

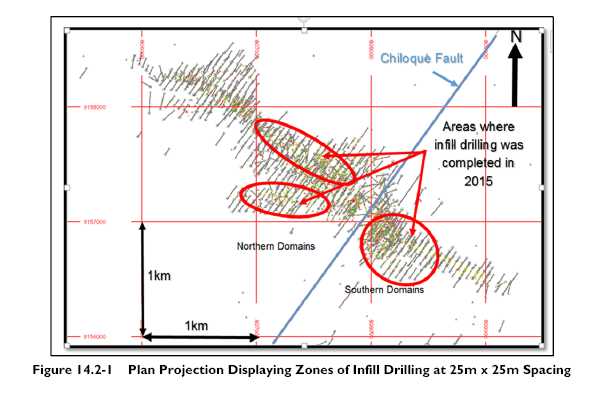

| 14.2 | Database | 135 |

| 14.3 | Geological Modeling | 137 |

| | 14.3.1 | Lithologic Domains | 137 |

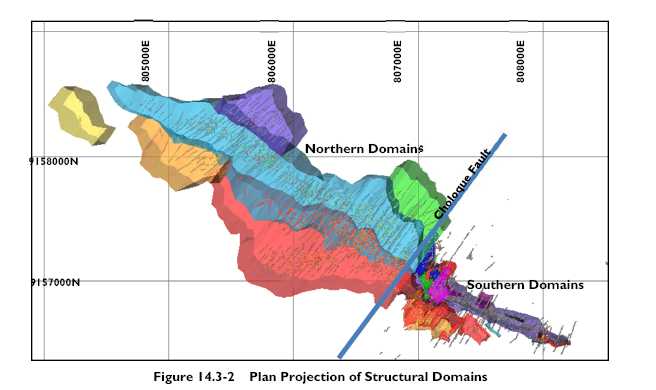

| | 14.3.2 | Structural Domains | 138 |

| | 14.3.3 | Oxidation Domains | 139 |

| 14.4 | Grade Estimation Domains | 139 |

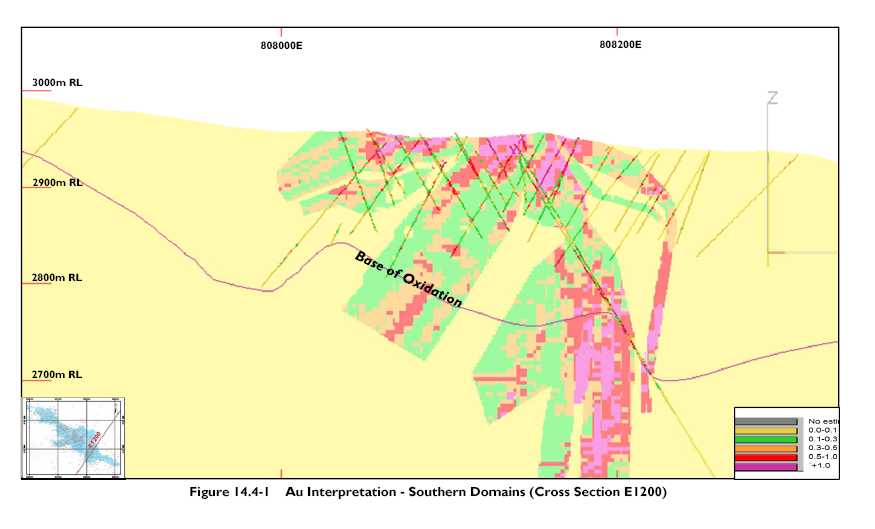

| | 14.4.1 | Gold Estimation Domains | 139 |

| | 14.4.2 | Silver Estimation Domains | 143 |

| | 14.4.3 | Other Estimation Domains | 143 |

| | 14.4.4 | Sample Selection and Compositing | 143 |

| 14.5 | Statistics | 144 |

| | 14.5.1 | Bulk Density | 144 |

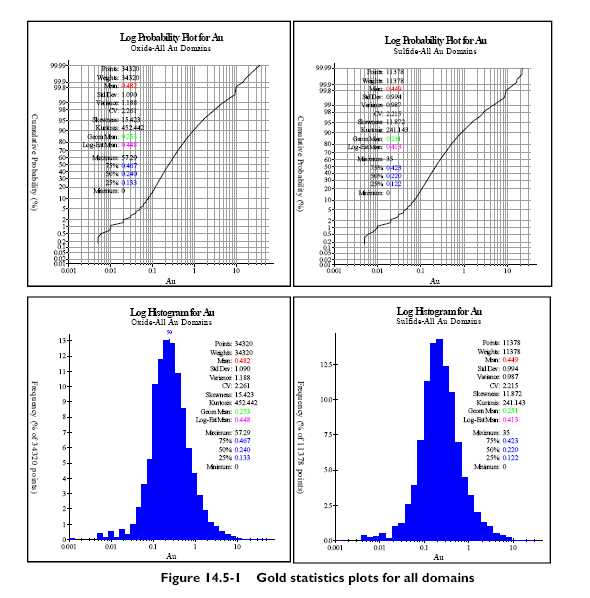

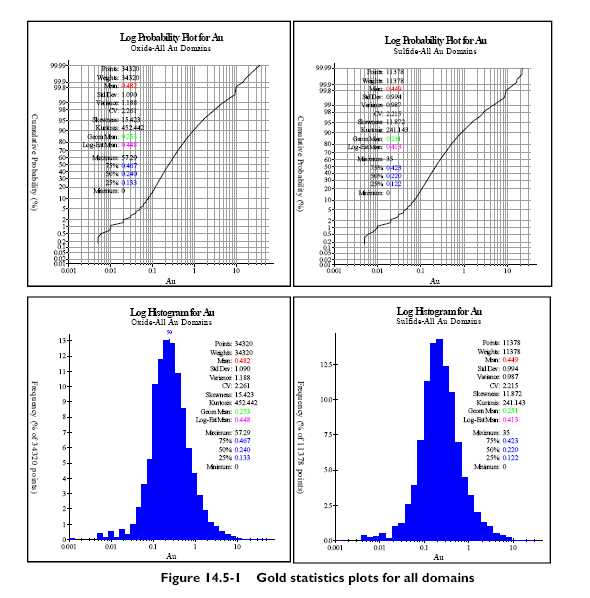

| | 14.5.2 | Gold Statistics | 144 |

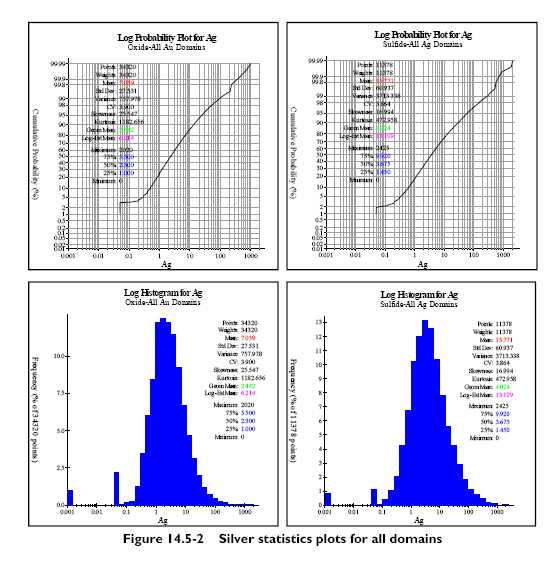

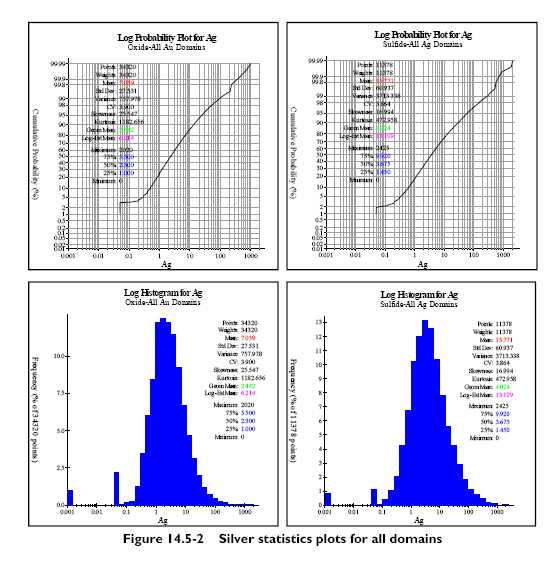

| | 14.5.3 | Silver Statistics | 147 |

| | 14.5.4 | Minor Elements | 149 |

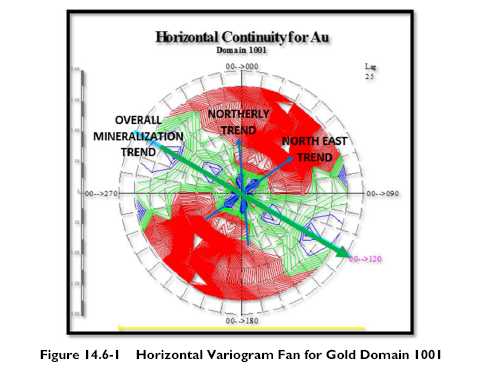

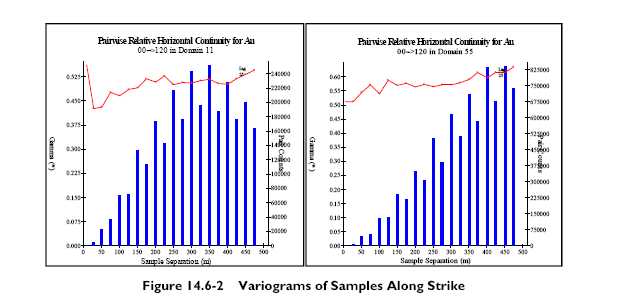

| 14.6 | Variography | 151 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| | 14.7 | Block Modelling | 152 |

| | 14.8 | Grade Estimation | 154 |

| | 14.9 | Mineral Resources | 157 |

| | | 14.9.1 | Mineral Resource Definitions | 157 |

| | | 14.9.2 | Shahuindo Mineral Resources | 158 |

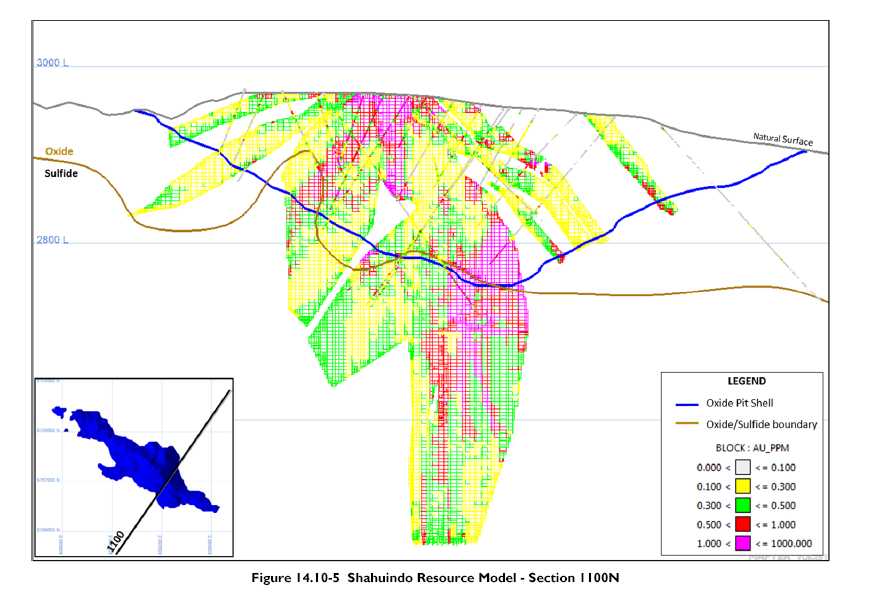

| | 14.10 | Resource Model Checks | 162 |

| | | 14.10.1 | Composites vs Model Grades | 162 |

| | | 14.10.2 | Nearest Neighbor Check Estimate | 163 |

| | | 14.10.3 | Visual Comparisons | 165 |

| | | 14.10.4 | Additional Information and Discussion | 165 |

| | | | |

| 15.0 | MINERAL RESERVE ESTIMATES | 169 |

| | | | |

| | 15.1 | Mineral Reserves | 169 |

| | | 15.1.1 | Mineral Reserve Definitions | 169 |

| | | 15.1.2 | Shahuindo Mineral Reserves | 170 |

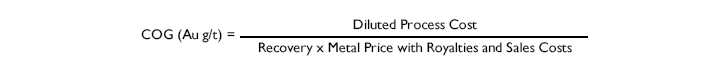

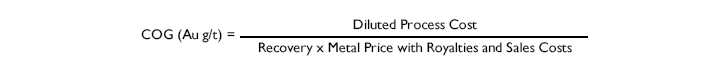

| | 15.2 | Cut-off Grade | 171 |

| | 15.3 | Assumptions and Parameters | 172 |

| | 15.4 | Dilution | 173 |

| | 15.5 | Pit Optimization | 173 |

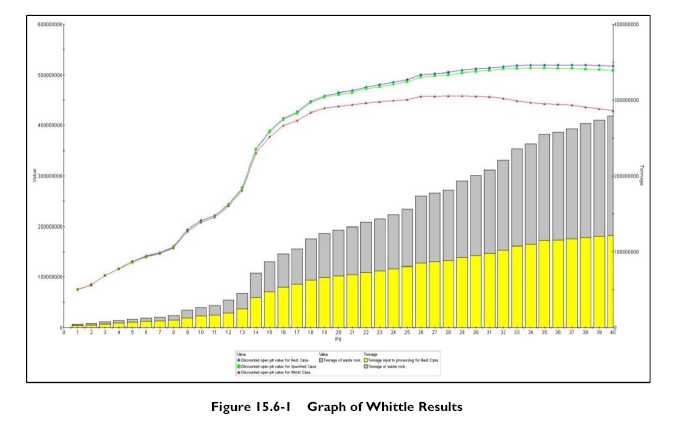

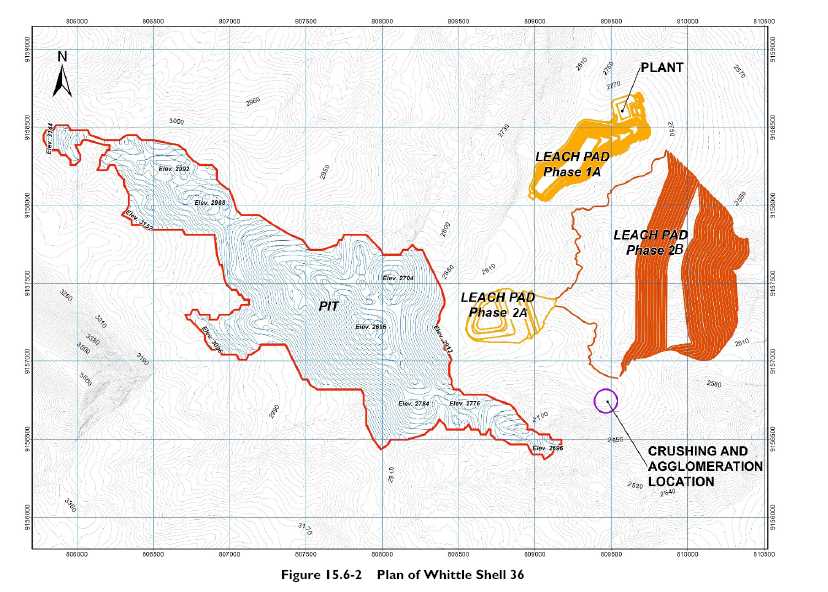

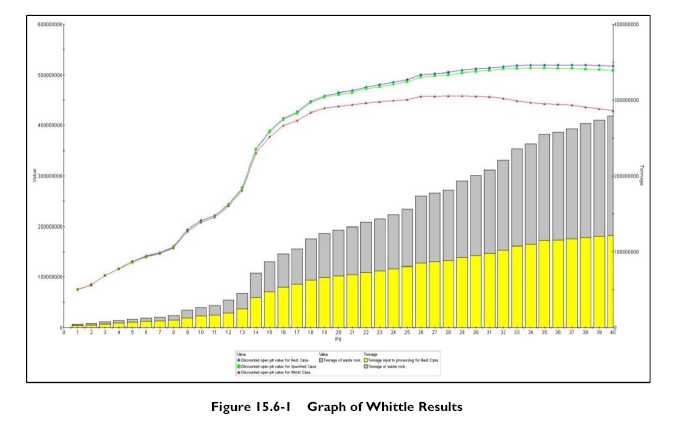

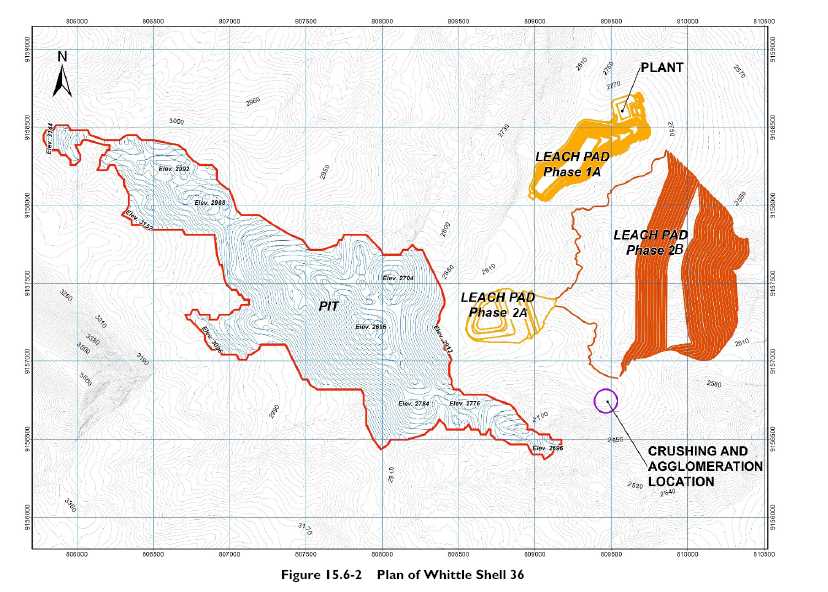

| | 15.6 | Pit Optimization Results | 174 |

| | | | |

| 16.0 | MINING METHODS | 177 |

| | | | |

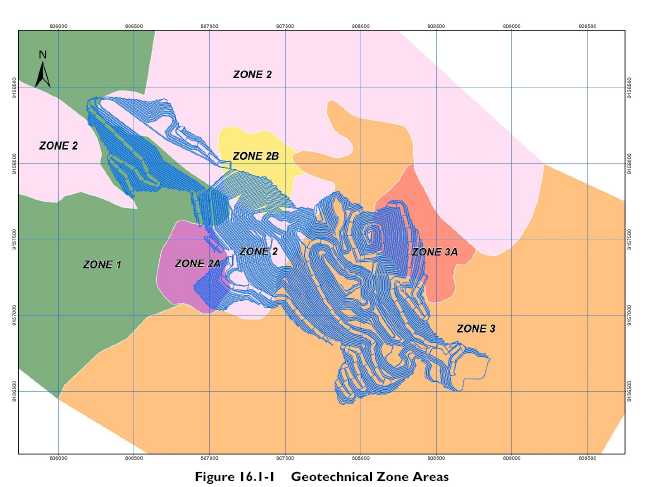

| | 16.1 | Geotechnical | 177 |

| | 16.2 | Hydrogeology and Hydrology | 179 |

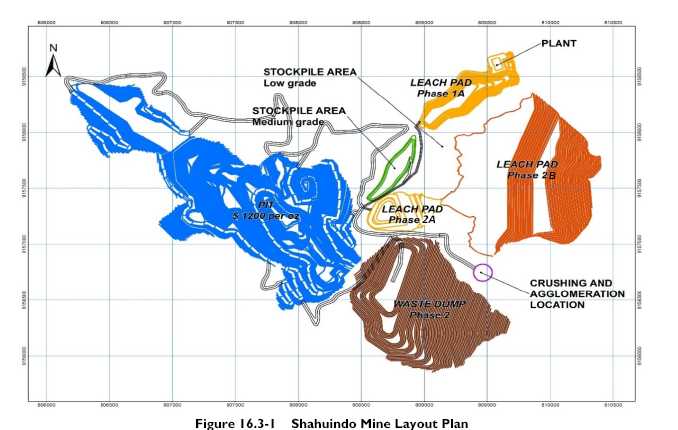

| | 16.3 | Mine Layout | 181 |

| | 16.4 | Mining | 183 |

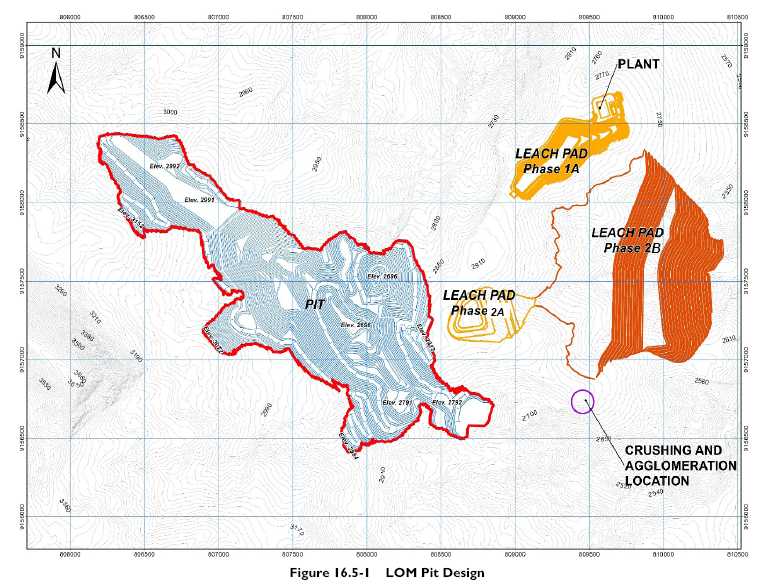

| | 16.5 | Pit Design | 185 |

| | | 16.5.1 | Bench Height | 185 |

| | | 16.5.2 | Final Pit Design | 185 |

| | | 16.5.3 | Comparison of Final Pit Design to the Optimum Whittle shell | 185 |

| | 16.6 | In-pit Inferred Resources | 187 |

| | 16.7 | Mine Production Schedule | 187 |

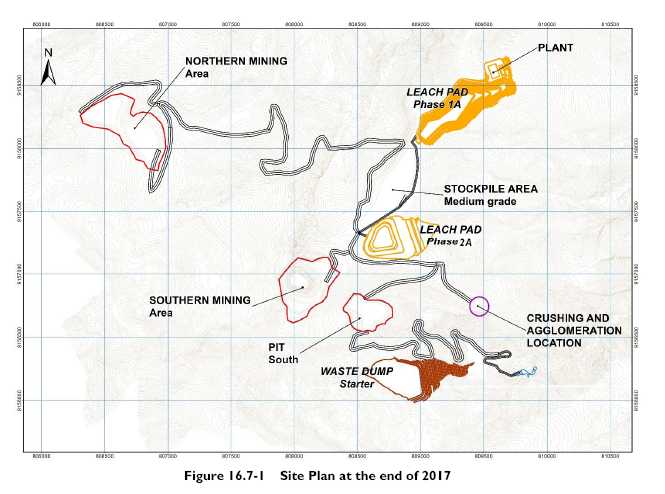

| | | 16.7.1 | Initial Mining Strategy: Phase 1 | 187 |

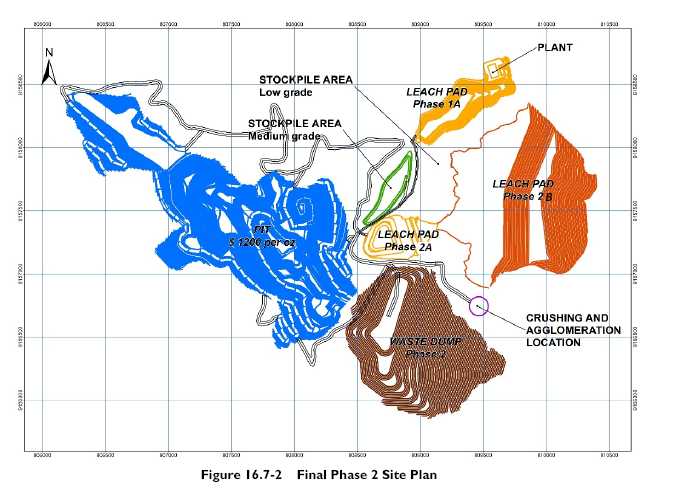

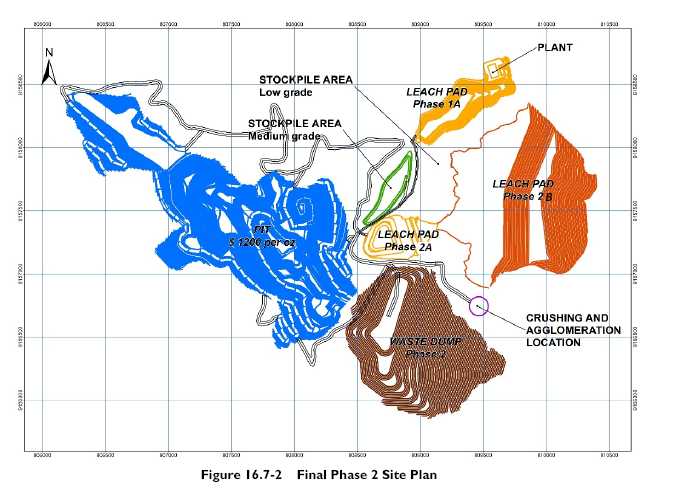

| | | 16.7.2 | Mining Strategy: Phase 2 | 188 |

| | | 16.7.3 | Mining Schedule | 189 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| | 16.8 | Mining Equipment | 191 |

| | | | |

| 17.0 | RECOVERY METHODS | 194 |

| | | |

| | 17.1 | Phase 1 - Run of Mine Processing | 194 |

| | | 17.1.1 | Processing Flow Path – Run of Mine Material | 194 |

| | | 17.1.2 | Run of Mine Leach Process | 197 |

| | | 17.1.3 | Process Plant | 198 |

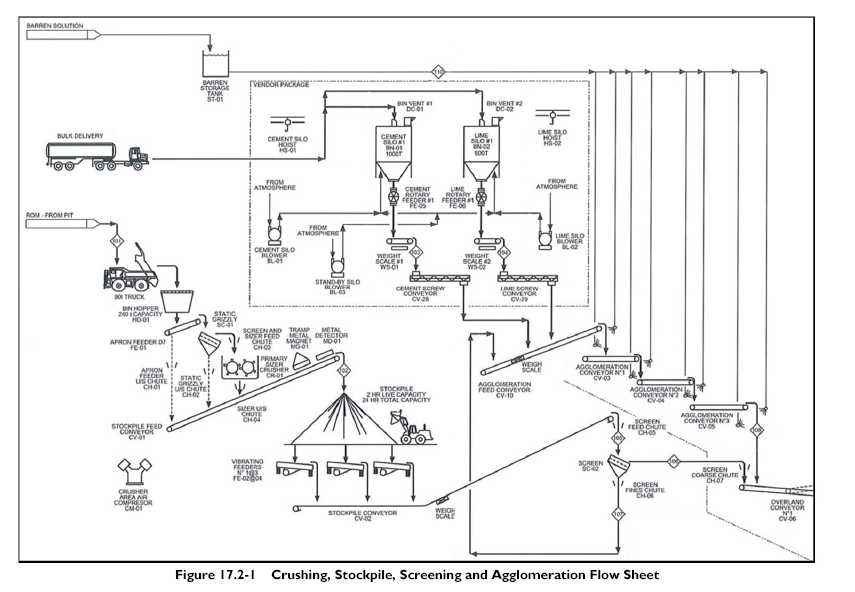

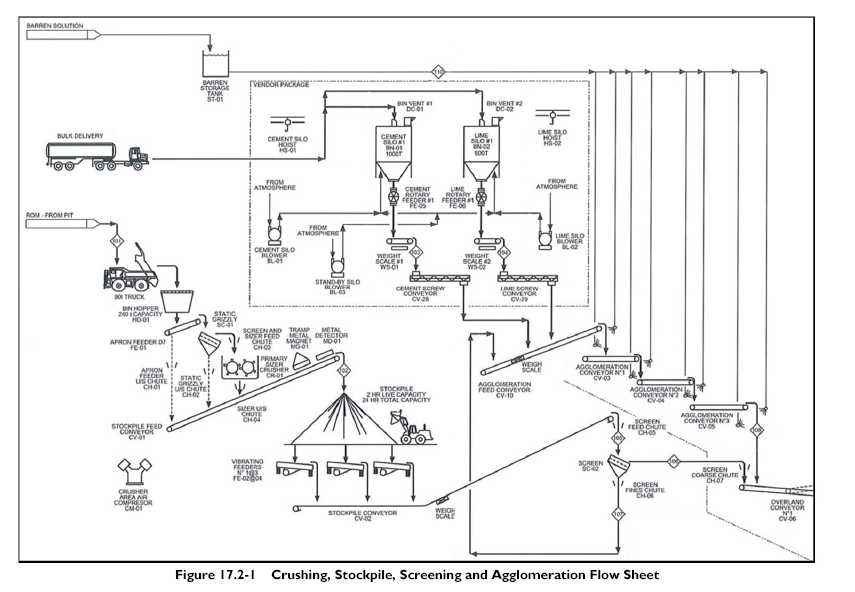

| | 17.2 | Phase 2 – Crushing and Agglomeration | 199 |

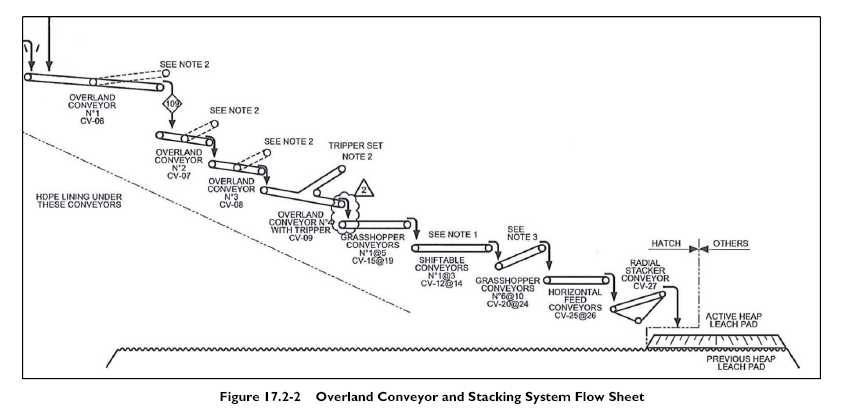

| | | 17.2.1 | Process and Flow Path | 199 |

| | | 17.2.2 | Process Plant | 202 |

| | 17.3 | Heap Leach Pad Design by Anddes | 202 |

| | 17.4 | Phase 1 and 2 Process Parameters | 203 |

| | | | |

| 18.0 | PROJECT INFRASTRUCTURE | 204 |

| | | |

| | 18.1 | Services and Infrastructure | 204 |

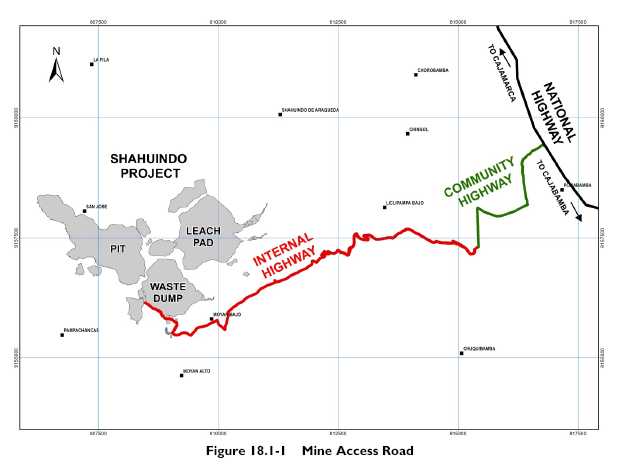

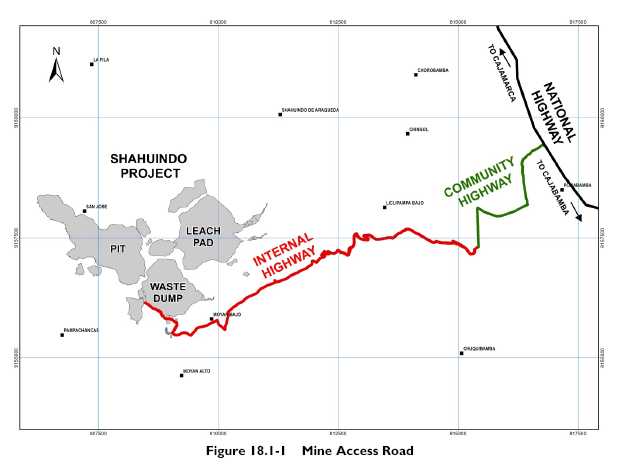

| | | 18.1.1 | Roads | 204 |

| | | 18.1.2 | Power Supply | 205 |

| | | 18.1.3 | Water Supply | 206 |

| | | 18.1.4 | Sewage System | 206 |

| | | 18.1.5 | Solid Waste Disposal | 207 |

| | 18.2 | Project Buildings | 207 |

| | | 18.2.1 | Truck Shop | 207 |

| | | 18.2.2 | Explosive Magazine | 207 |

| | | 18.2.3 | Warehouse and Process Maintenance | 208 |

| | | 18.2.4 | Fuel Stations | 208 |

| | | 18.2.5 | Offices | 208 |

| | | 18.2.6 | Construction and Operations Camps | 208 |

| | | 18.2.7 | Dining Facilities | 209 |

| | 18.3 | Miscellaneous Site Services | 209 |

| | | 18.3.1 | Laboratory | 209 |

| | | 18.3.2 | Security | 209 |

| | | 18.3.3 | Medical Center/Clinic | 209 |

| | | 18.3.4 | Communications | 210 |

| | | | | |

| 19.0 | MARKET STUDIES AND CONTRACTS | 211 |

| | | |

| | 19.1 | Metal Contracts | 211 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| | 19.2 | Mining Alliance | 211 |

| | | | |

| 20.0 | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITYIMPACT | 213 |

| | | |

| | 20.1 | Environmental Management Plan | 213 |

| | 20.2 | Environmental Studies | 213 |

| | | 20.2.1 | Environmental Impact Statement | 213 |

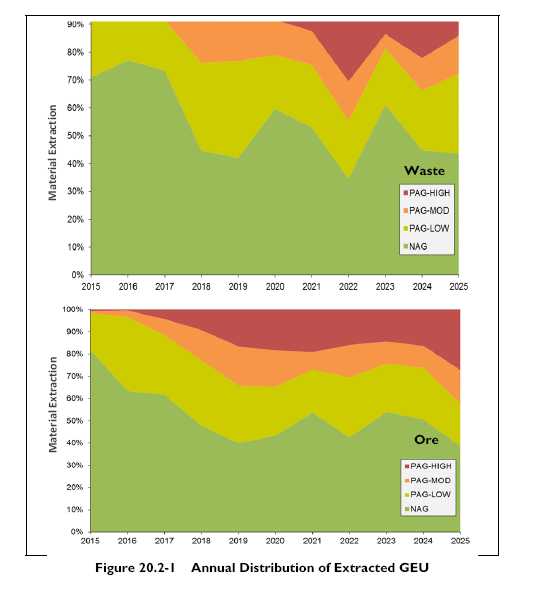

| | | 20.2.2 | Geochemical Characterization | 214 |

| | | 20.2.3 | Site Monitoring | 218 |

| | | 20.2.4 | Closure Plan | 218 |

| | | 20.2.5 | Existing Environmental Conditions | 220 |

| | 20.3 | Permits | 220 |

| | | 20.3.1 | Exploration | 220 |

| | | 20.3.2 | Mine Construction and Operations | 221 |

| | 20.4 | Social Impact | 223 |

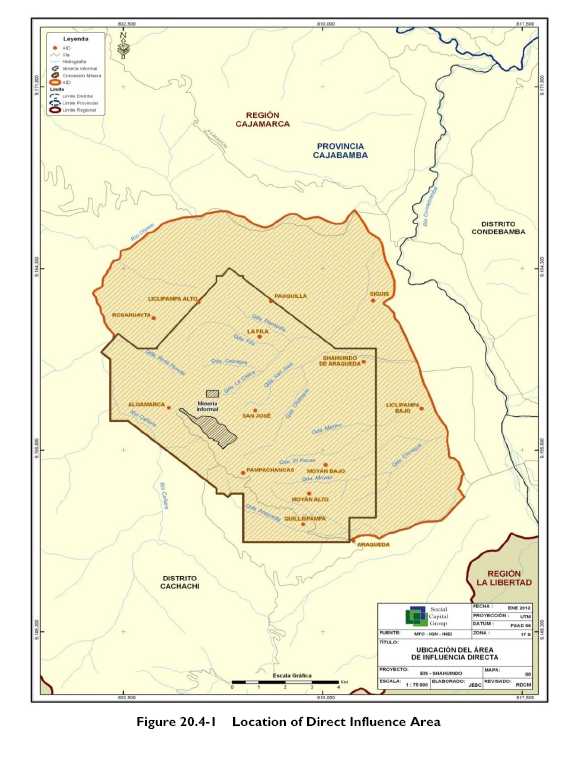

| | | 20.4.1 | Location of the Study Area | 223 |

| | | 20.4.2 | Social Baseline Study | 223 |

| | | 20.4.3 | Public Consultation and Engagement Plan | 225 |

| | | 20.4.4 | Community Development Program | 225 |

| | 21.0 | CAPITAL AND OPERATING COSTS | 227 |

| | | | |

| | 21.1 | Capital Cost Estimate | 227 |

| | | | |

| | | 21.1.1 | List of Areas | 227 |

| | | 21.1.2 | Basis of Estimate | 227 |

| | | 21.1.3 | Capital Estimate | 227 |

| | 21.2 | Operating Cost Estimate | 228 |

| | | | |

| 22.0 | ECONOMIC ANALYSIS | 230 |

| | | |

| | 22.1 | Mine Production Statistics | 230 |

| | 22.2 | Process Plant Production Statistics | 230 |

| | 22.3 | Capital Expenditures | 231 |

| | | 22.3.1 | Project Capital | 231 |

| | | 22.3.2 | Sustaining Capital | 231 |

| | | 22.3.3 | Working Capital | 231 |

| | 22.4 | Salvage Value | 232 |

| | 22.5 | Revenue | 232 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| | 22.6 | Shipping and Refining | 232 |

| | 22.7 | Operating Costs | 232 |

| | 22.8 | Total Cash Cost | 233 |

| | | 22.8.1 | Worker Profit Share and other production taxes | 233 |

| | | 22.8.2 | Reclamation and Closure | 233 |

| | | 22.8.3 | Depreciation | 233 |

| | | 22.8.4 | Taxation | 233 |

| | 22.9 | Project Financing | 234 |

| | 22.10 | Net Income After Tax | 234 |

| | 22.11 | NPV and IRR | 234 |

| | 22.12 | Sensitivities | 234 |

| | 22.13 | Shahuindo Financial Model | 236 |

| | | | |

| 23.0 | ADJACENT PROPERTIES | 240 |

| | | |

| 24.0 | OTHER RELEVANT DATA AND INFORMATION | 241 |

| | | |

| | 24.1 | Construction and Mining Activities through 01 January 2016 | 241 |

| | | 24.1.1 | Construction | 241 |

| | | 24.1.2 | Mine and Plant Commissioning | 250 |

| | 24.2 | Exploration Potential | 253 |

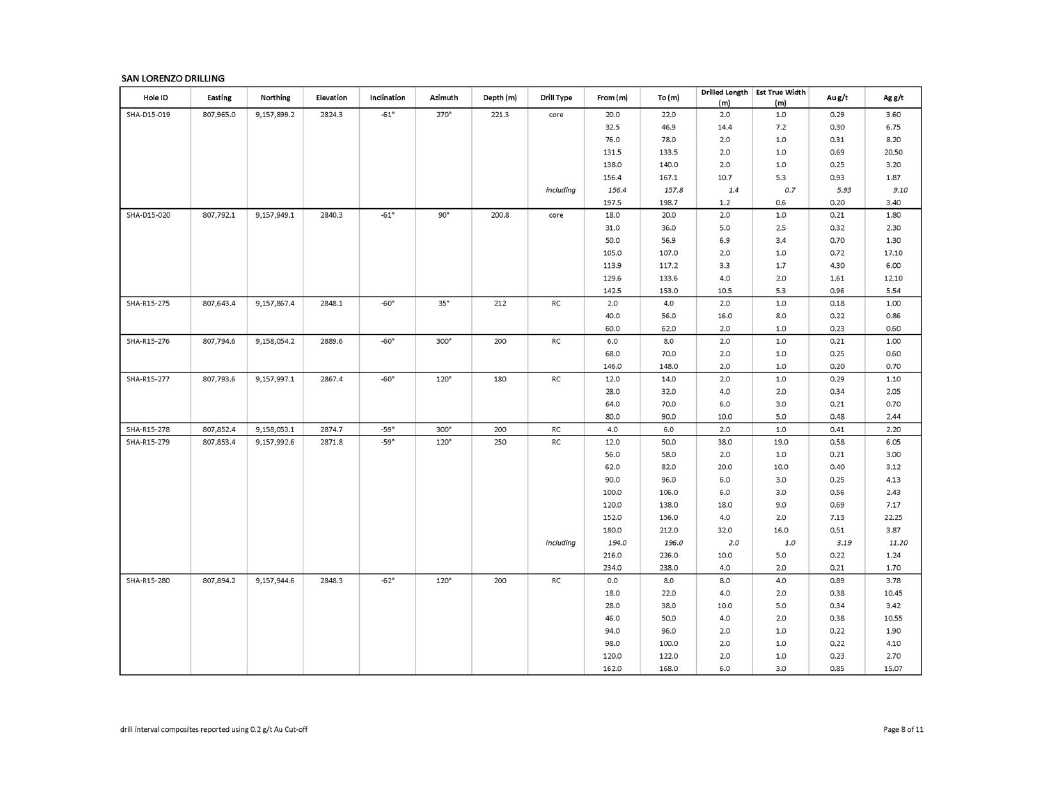

| | | 24.2.1 | San Lorenzo and Choloque | 253 |

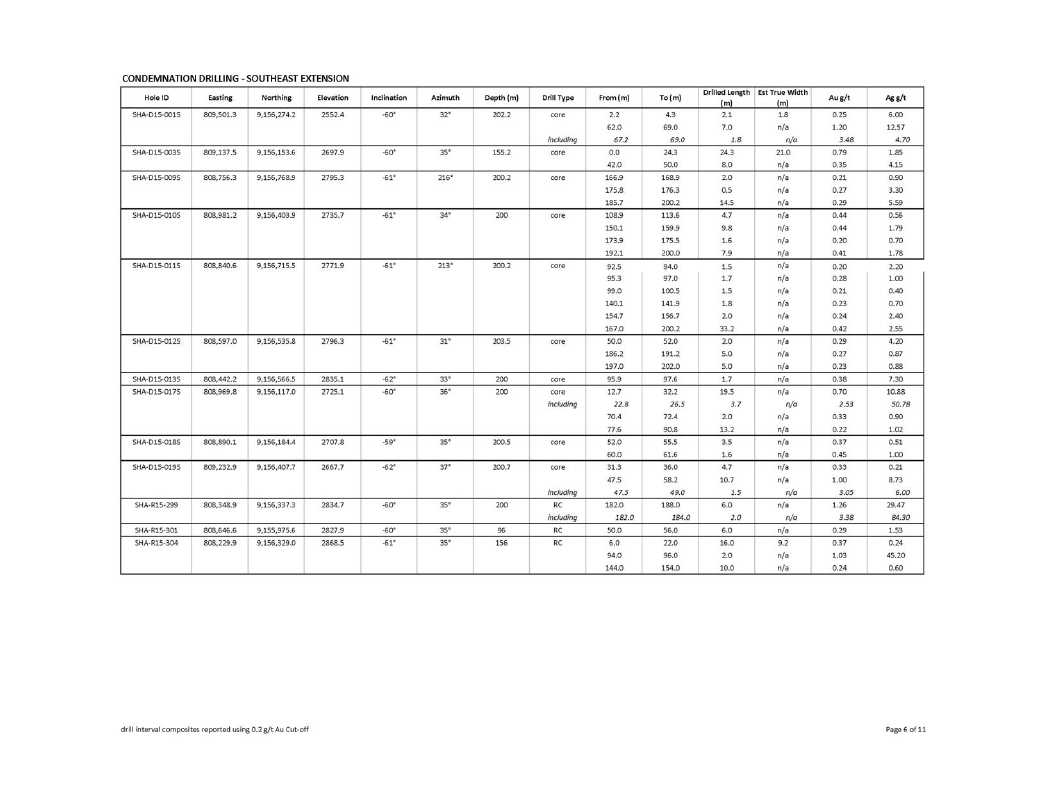

| | | 24.2.2 | Shahuindo Southeast Extension and El Sauce | 256 |

| | | 24.2.3 | La Chilca Baja Cu-Au porphyry | 257 |

| | | 24.2.4 | La Chilca Alta | 257 |

| | | 24.2.5 | Azules | 258 |

| | | 24.2.6 | Algamarca Au-Ag-Cu Vein system | 260 |

| | | 24.2.7 | Cantera | 262 |

| | | 24.2.8 | Malvas | 263 |

| | | | | |

| 25.0 | INTERPRETATION AND CONCLUSIONS | 264 |

| | | | |

| 26.0 | RECOMMENDATIONS | 266 |

| | | | |

| 27.0 | REFERENCES | 269 |

| | | | |

| 28.0 | AUTHORS CERTIFICATES | 273 |

| | | | |

| | 28.1 | Certificate of Qualified Person – Carl E. Defilippi | 274 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| | 28.2 | Certificate of Qualified Person–Charles V. Muerhoff | 275 |

| | 28.3 | Certificate of Qualified Person–Tim Williams | 276 |

Appendix

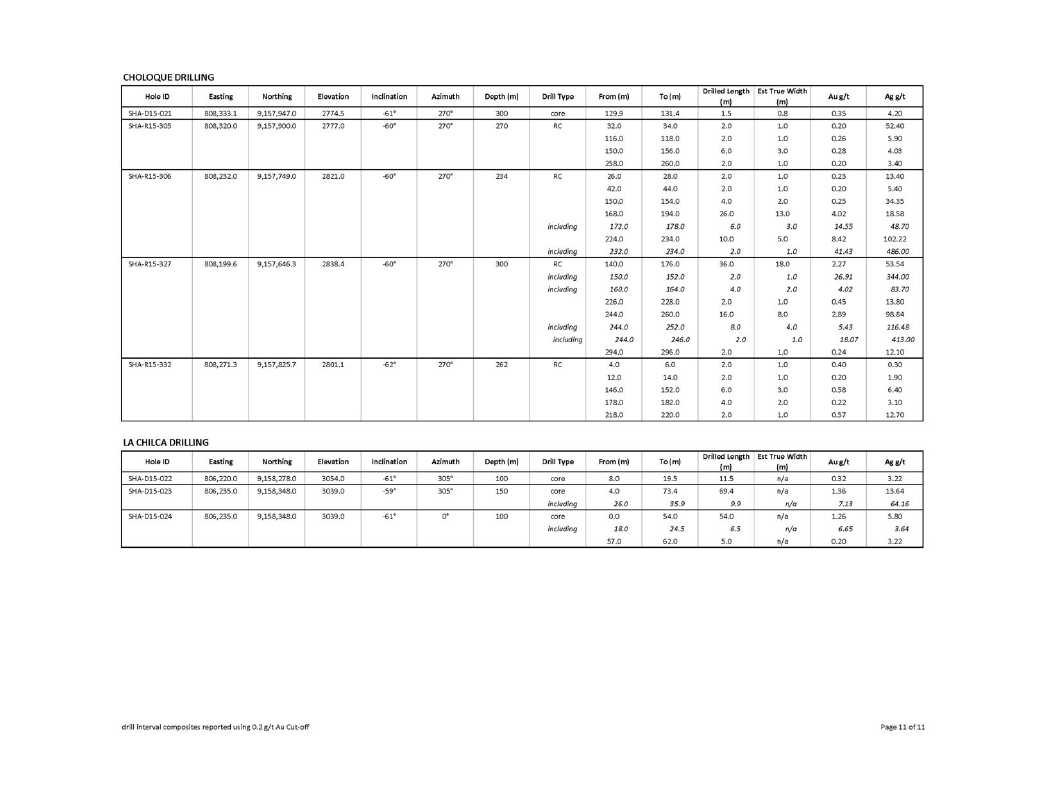

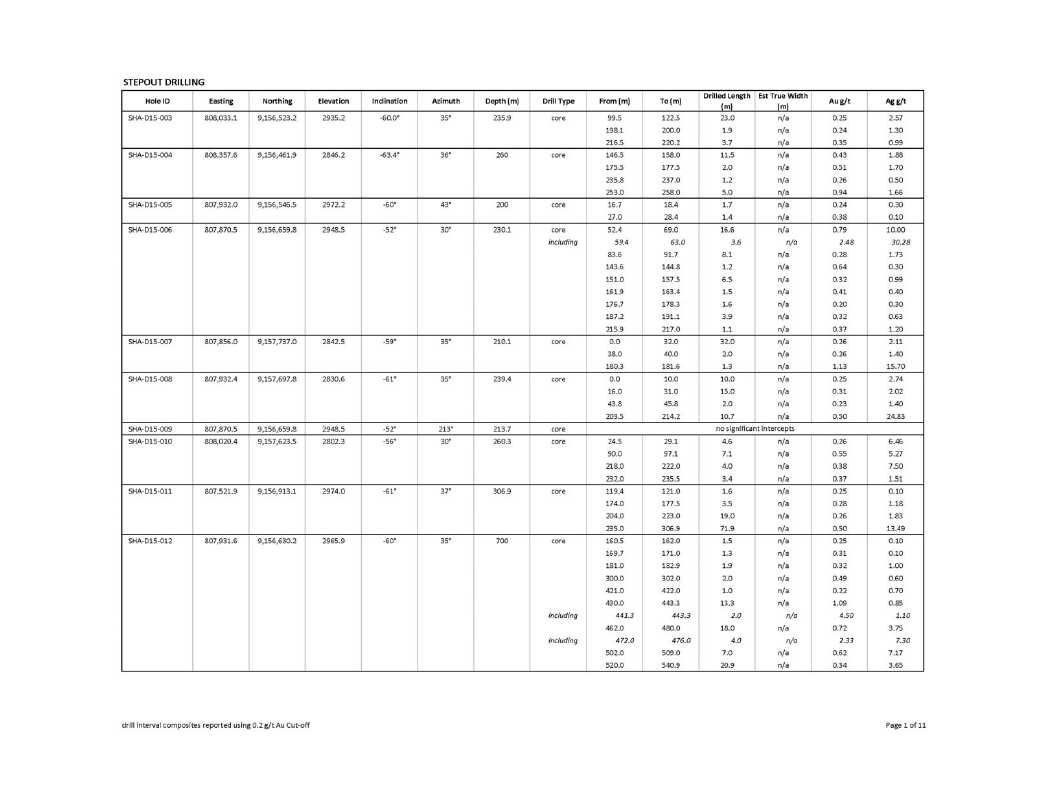

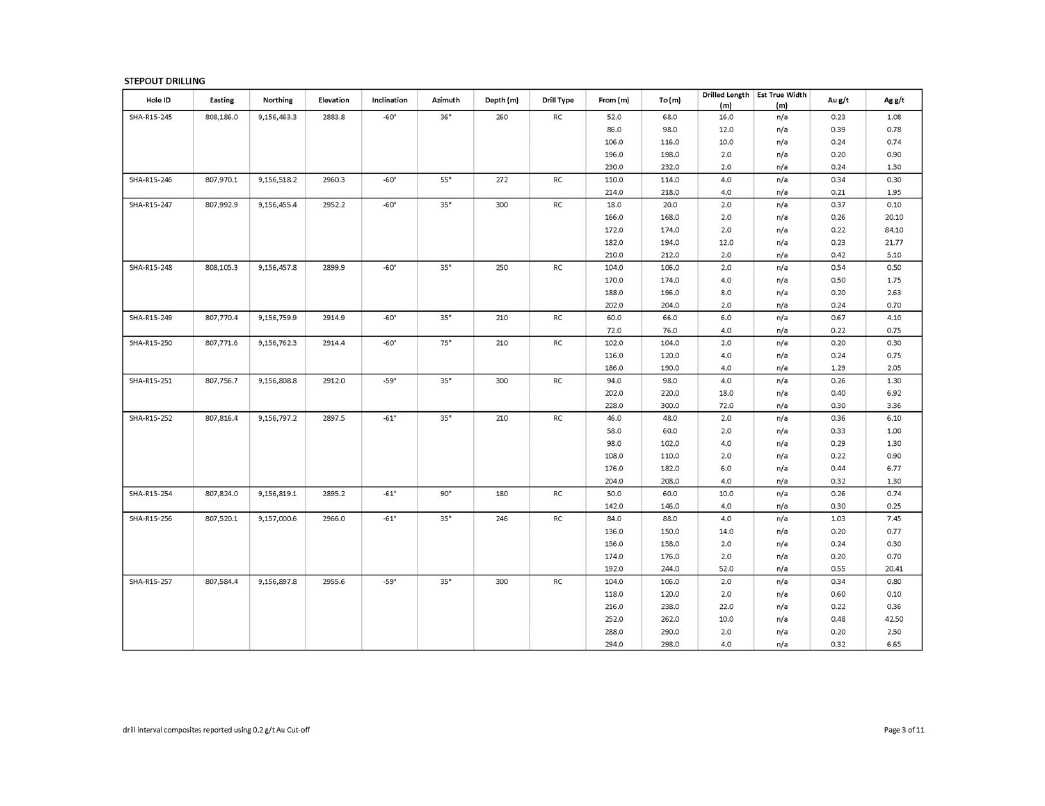

Post-Resource Drill Intercepts

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

LIST OF FIGURES

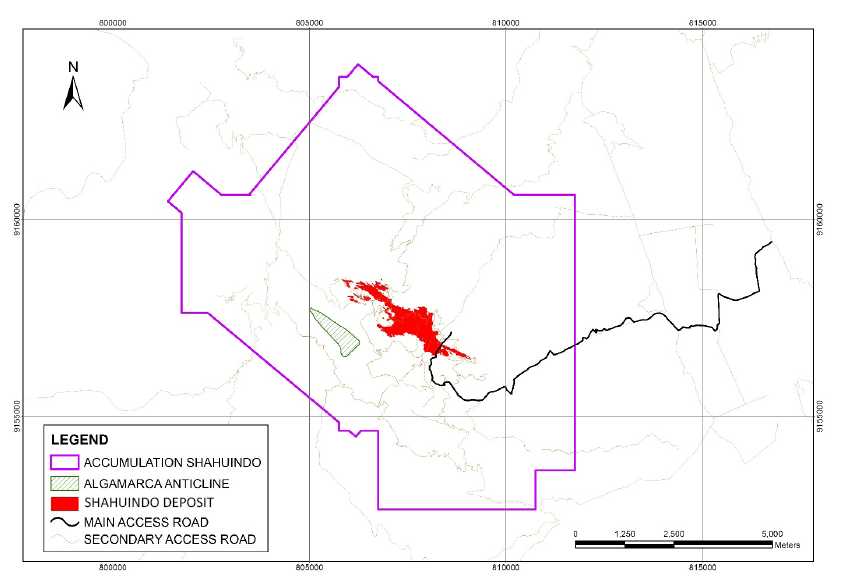

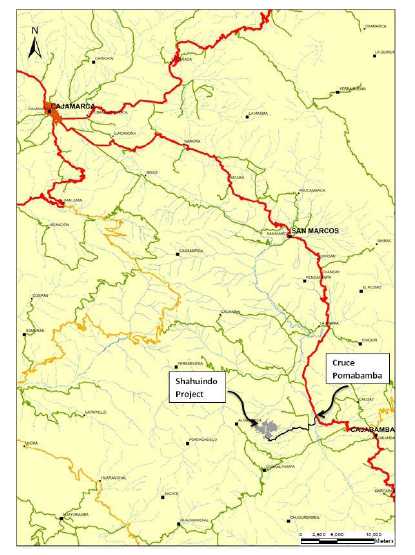

| Figure 4.1-1 | Shahuindo Project Location Map | 22 |

| Figure 4.2-1 | Mineral Claim Location Map | 24 |

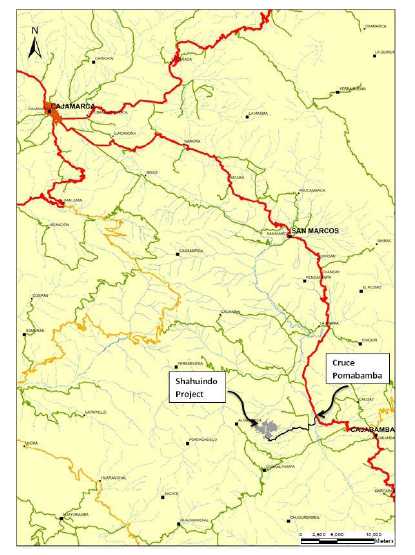

| Figure 5.1-1 | Shahuindo Road Route from Cajamarca | 36 |

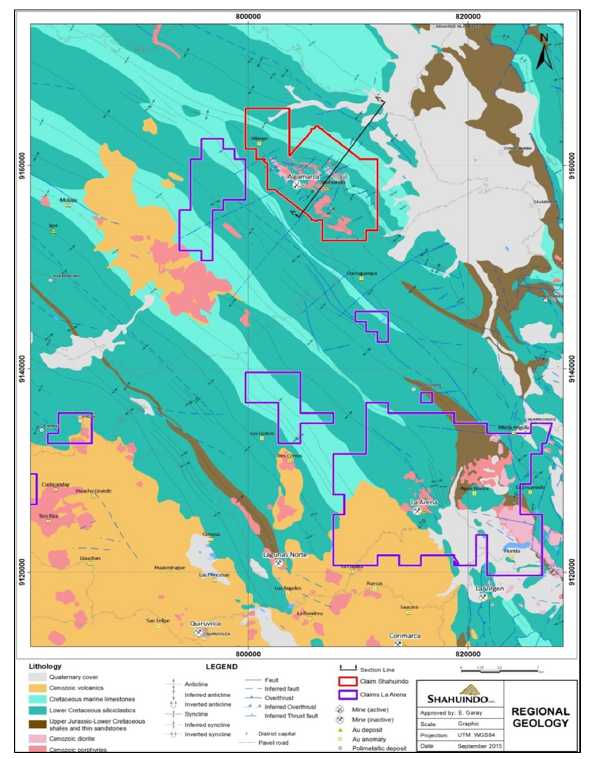

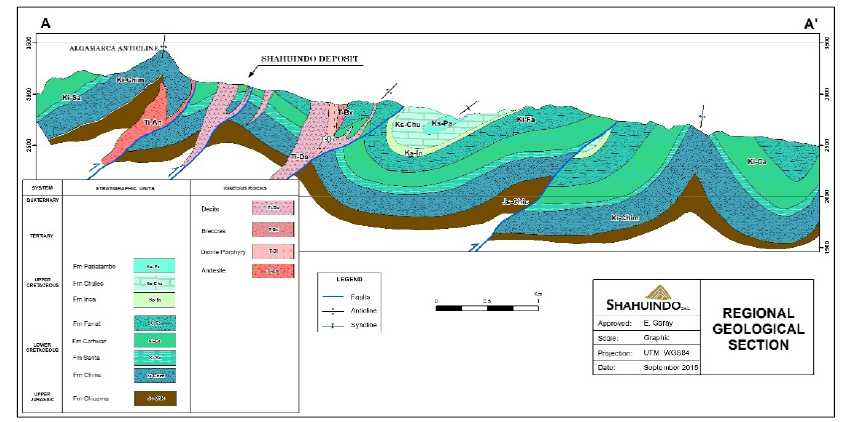

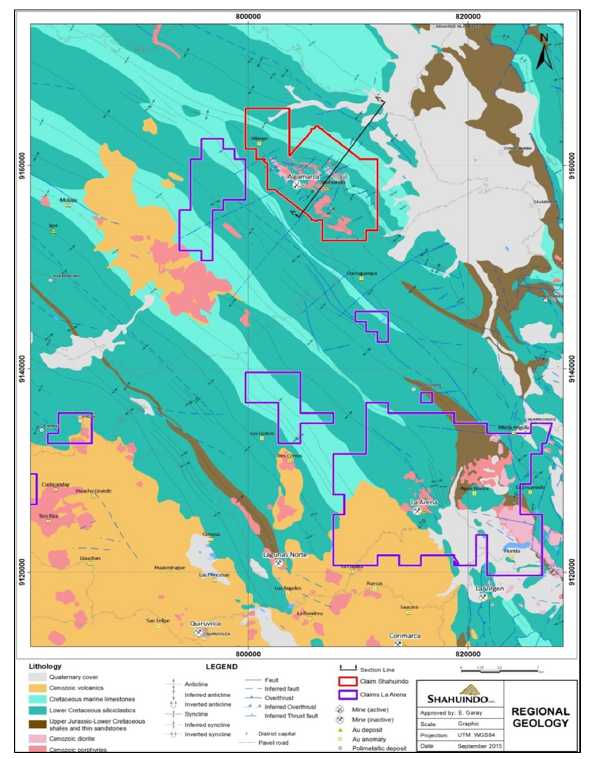

| Figure 7.1-1 | Shahuindo Regional Geology | 54 |

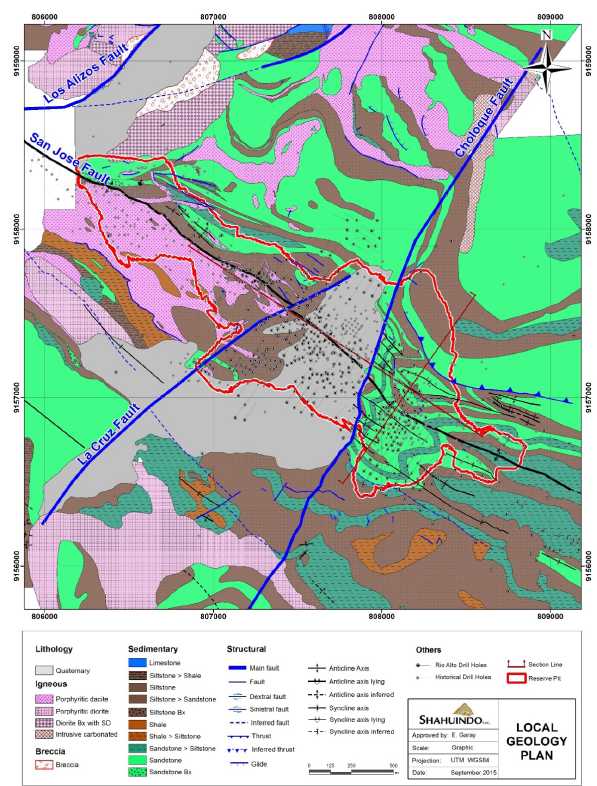

| Figure 7.1-2 | Shahuindo Regional Cross Section | 55 |

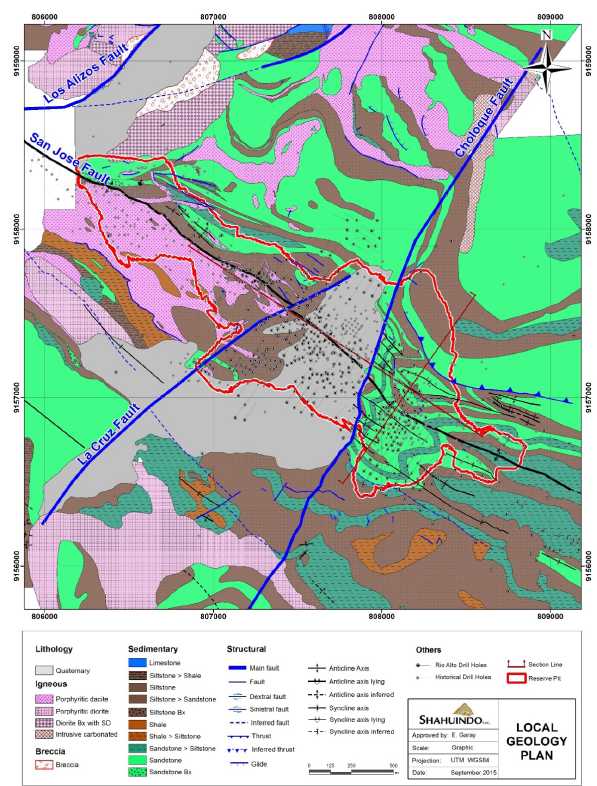

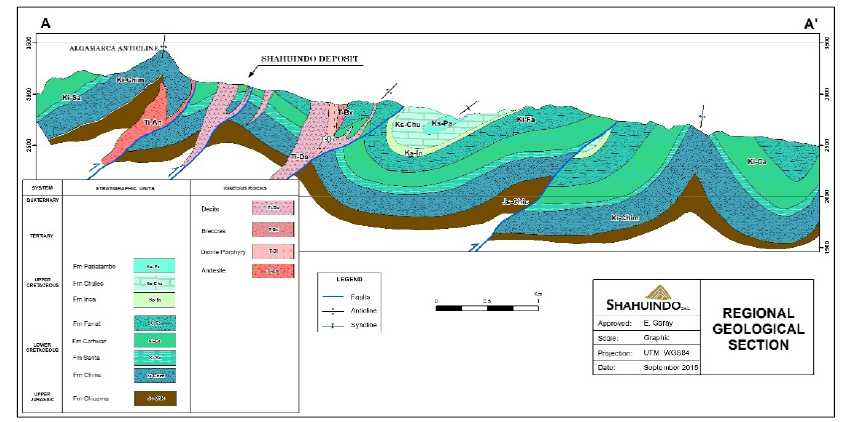

| Figure 7.2-1 | Shahuindo Local Geology | 57 |

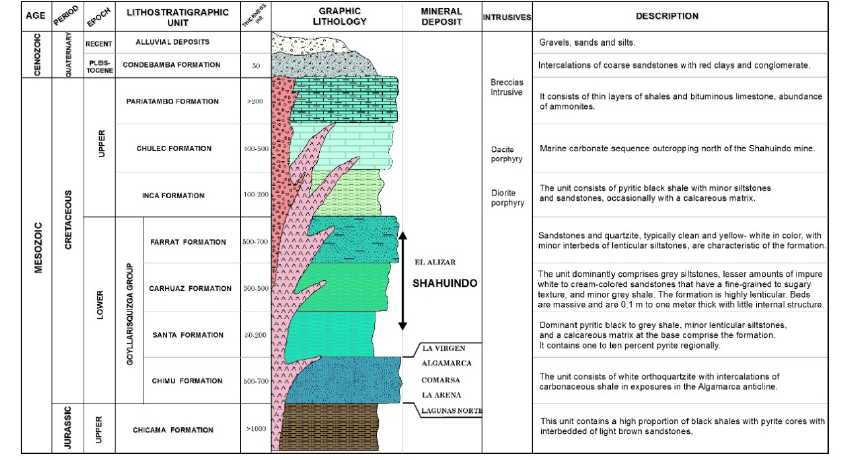

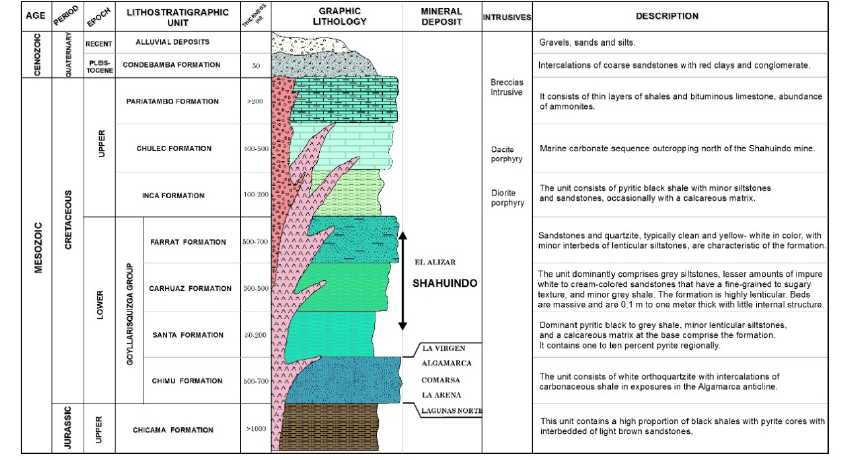

| Figure 7.2-2 | Local Stratigraphic Column for the Carhuaz/Farrat Formations | 58 |

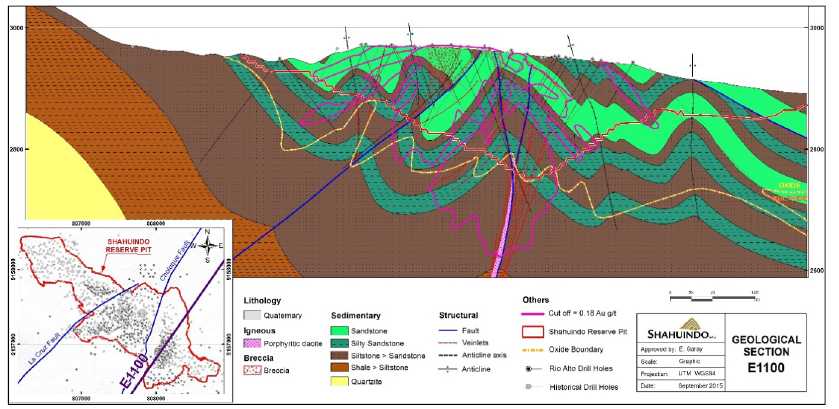

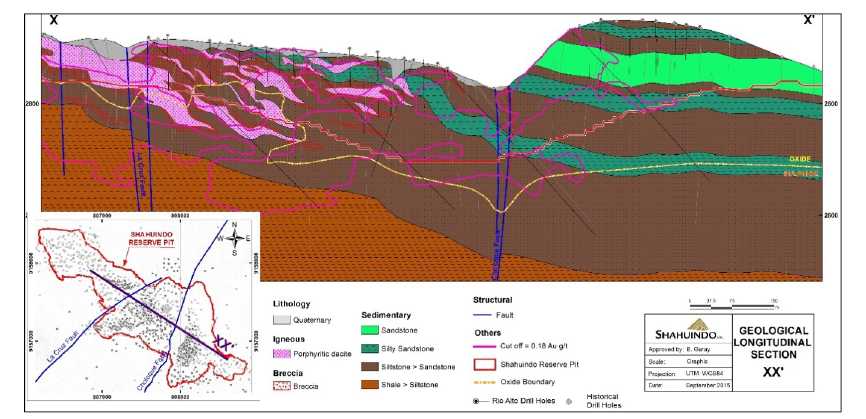

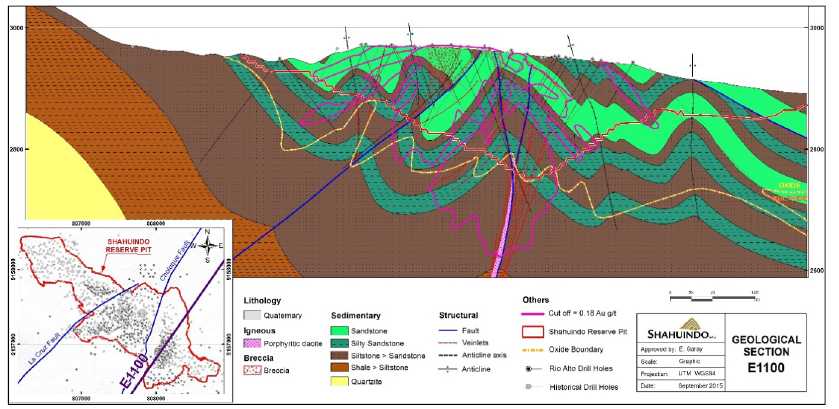

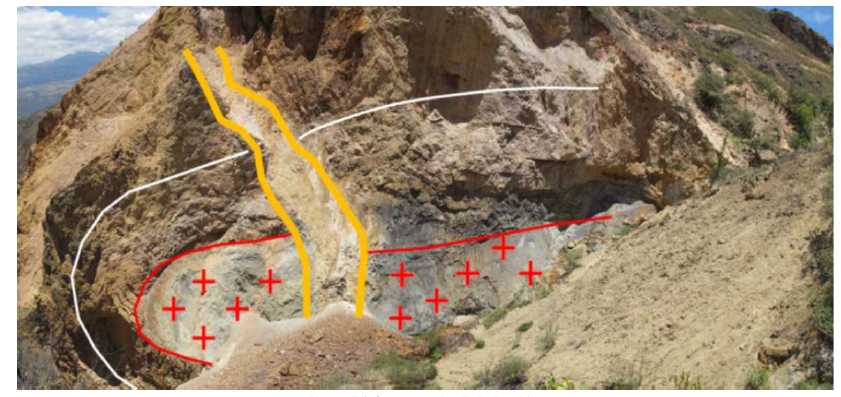

| Figure 7.2-3 | Multiphase Intrusion Crosscutting Sedimentary Rocks (Section E1100) | 61 |

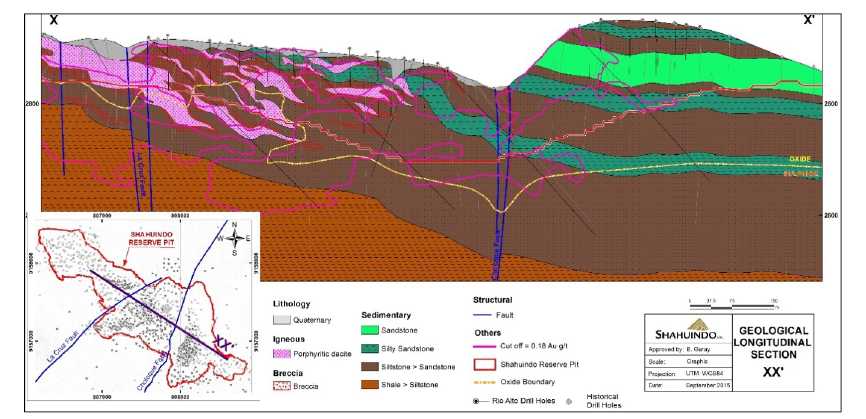

| Figure 7.2-4 | Multiphase Intrusion Crosscutting the Sedimentary Rocks (Section X-X’) | 62 |

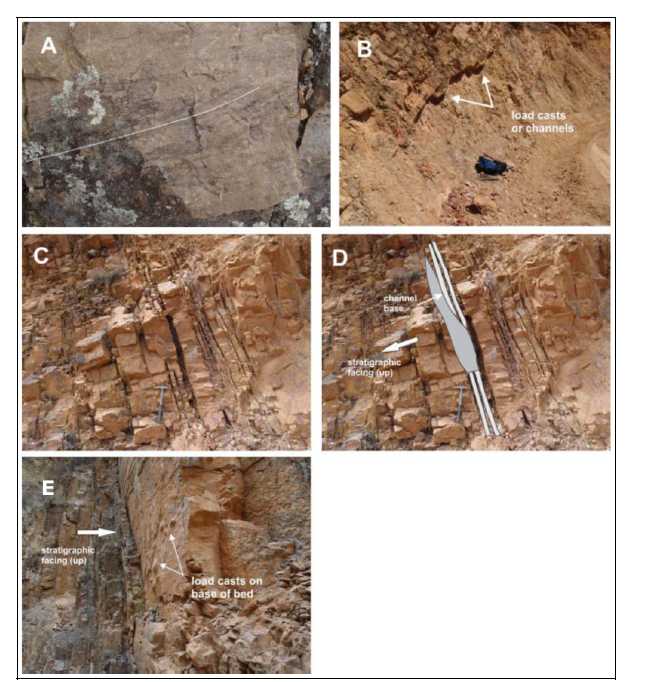

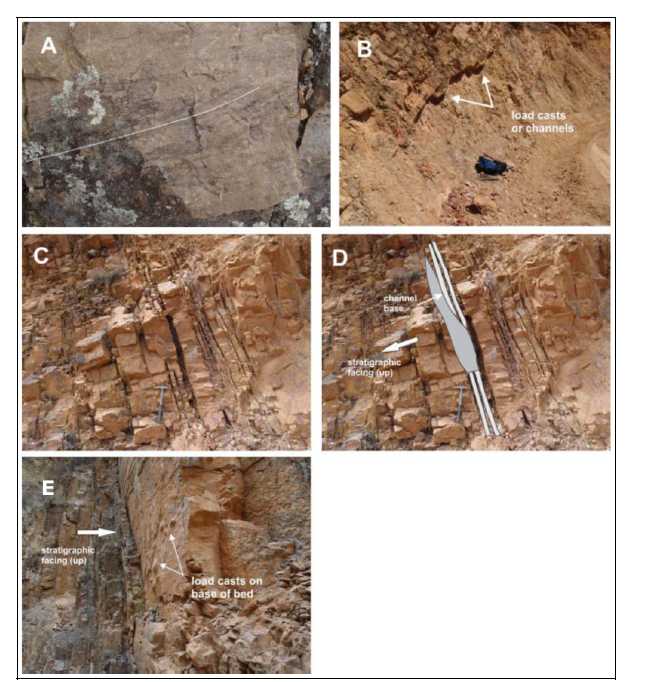

| Figure 7.2-5 | Sedimentological Features for Determining Stratigraphic Sequencing | 63 |

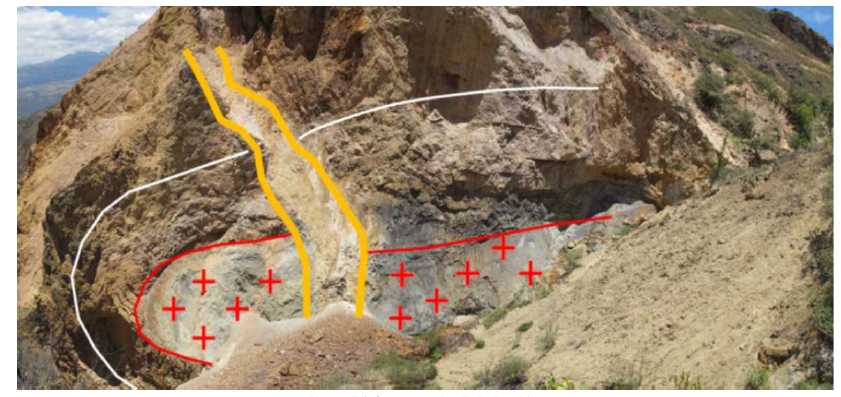

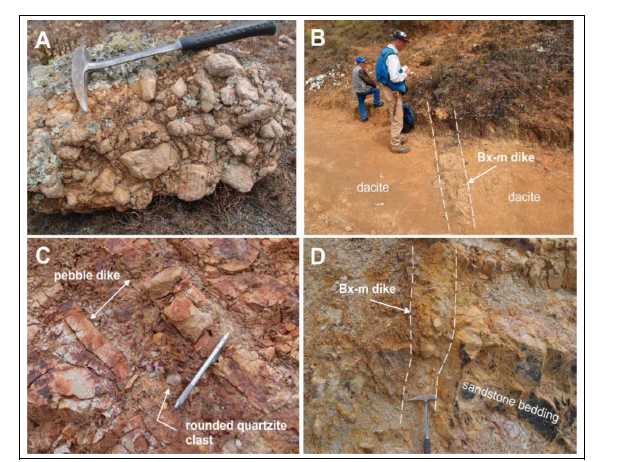

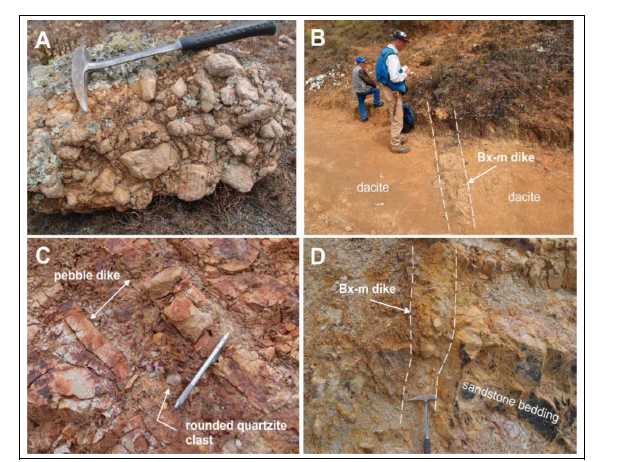

| Figure 7.2-6 | Intrusive Relationships | 64 |

| Figure 7.2-7 | Monolithic-Clast Breccia | 65 |

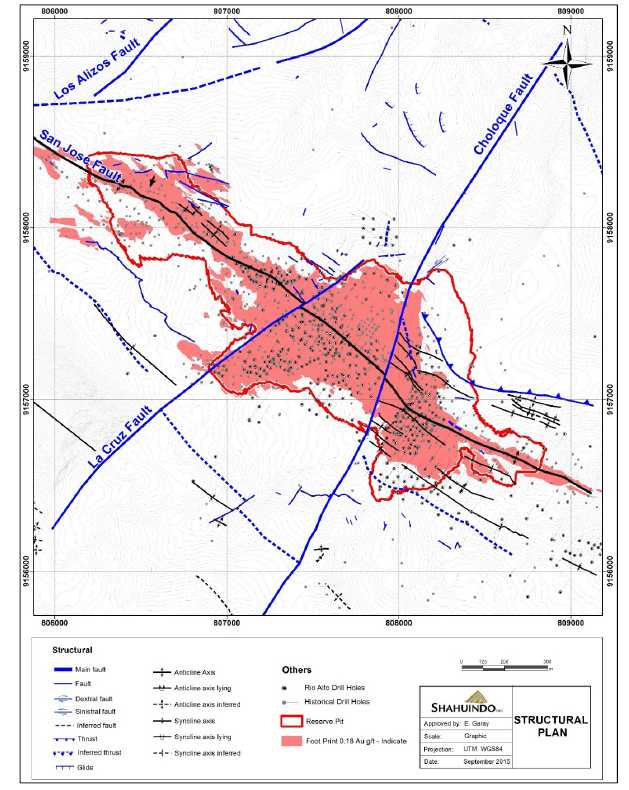

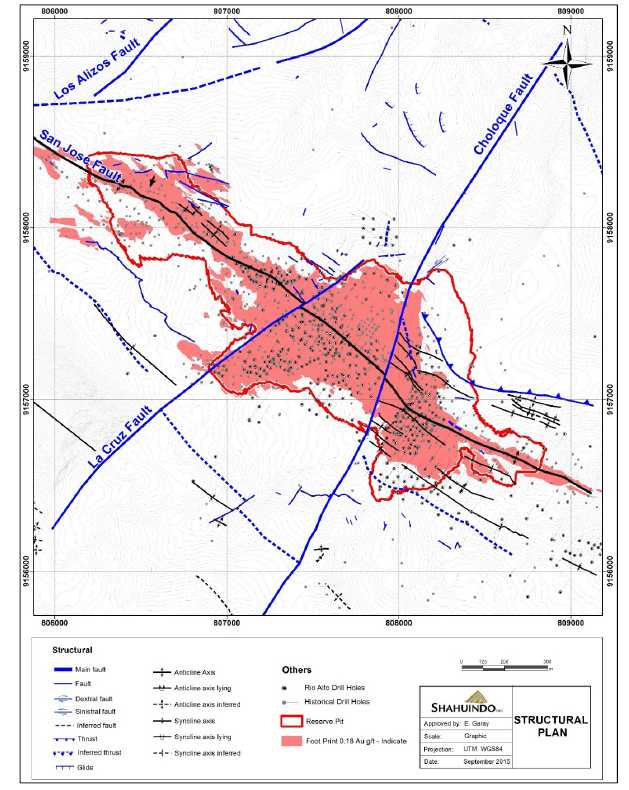

| Figure 7.4-1 | Combined Structure and Mineralization Map - Shahuindo Project | 68 |

| Figure 7.5-1 | Jarosite in Outcrop. | 70 |

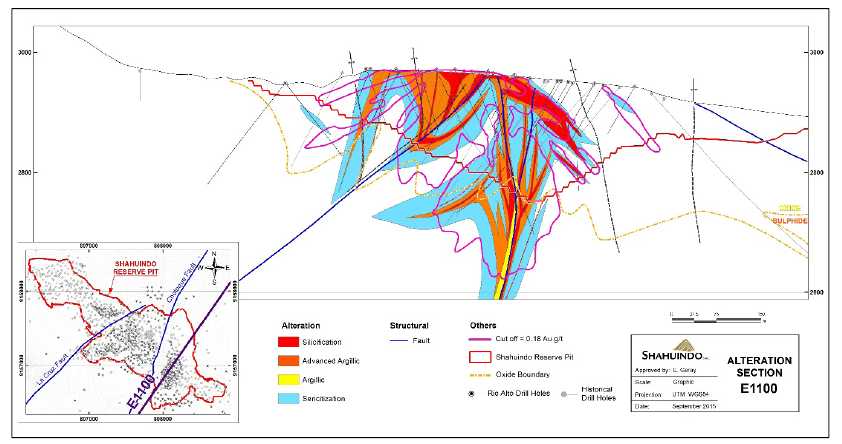

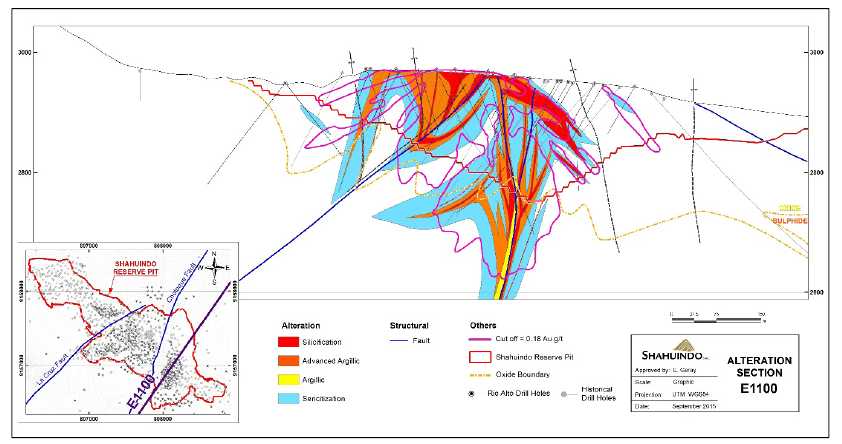

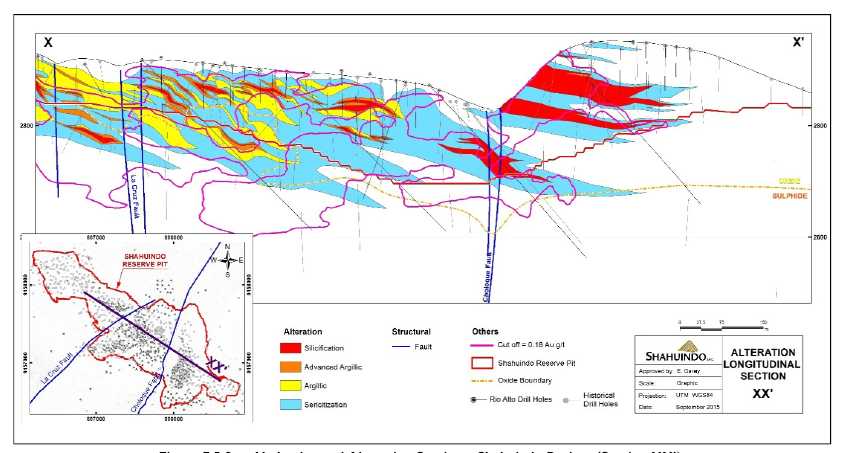

| Figure 7.5-2 | Hydrothermal Alteration Section – Shahuindo Project (Section E1100) | 71 |

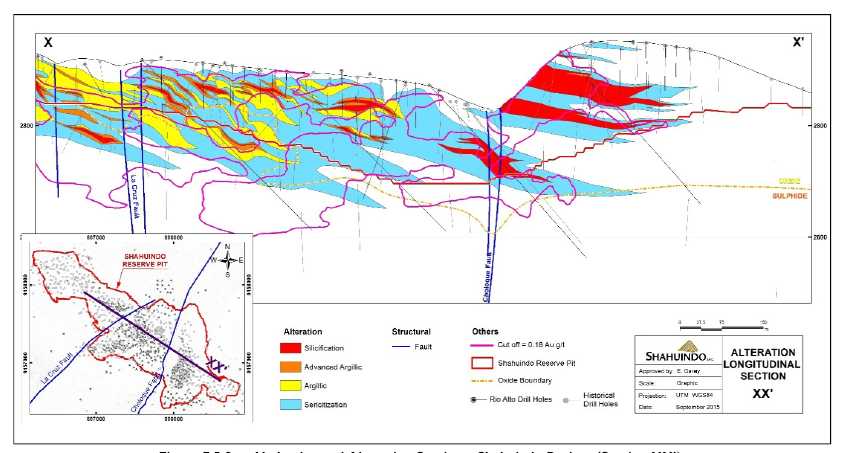

| Figure 7.5-3 | Hydrothermal Alteration Section – Shahuindo Project (Section XX’) | 72 |

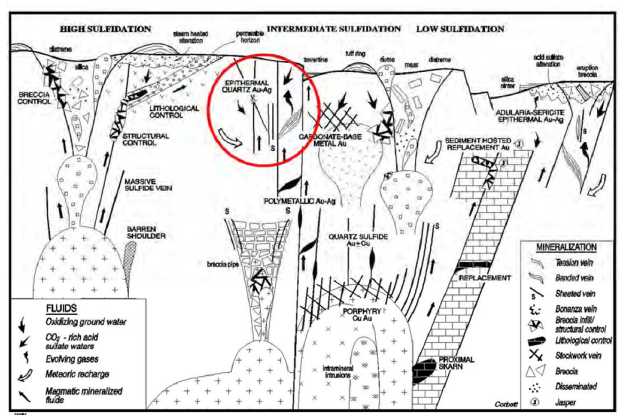

| Figure 8.1-1 | Spatial Relationship of Intermediate Sulfidation Deposits | 75 |

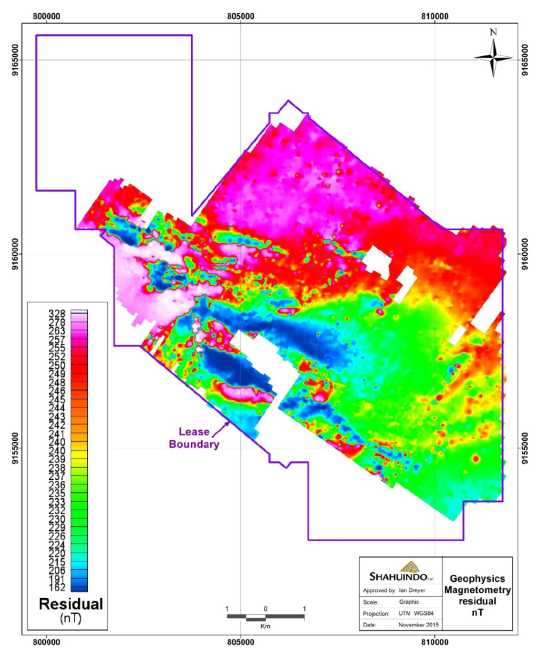

| Figure 9.2-1 | Shahuindo – Magnetic Survey Results | 77 |

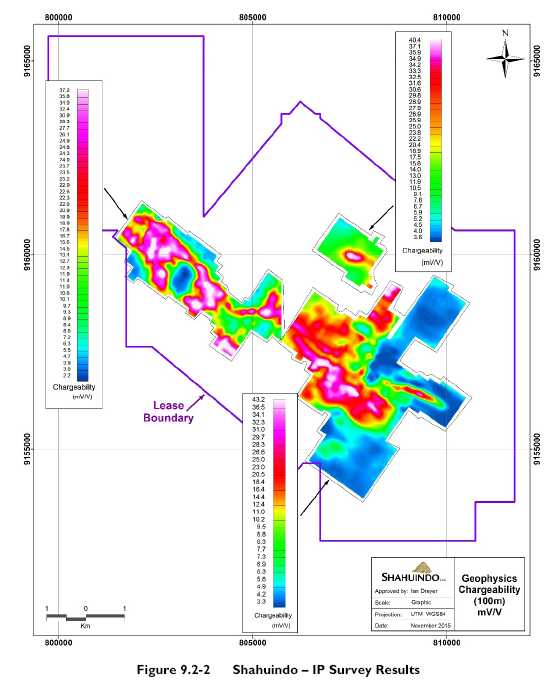

| Figure 9.2-2 | Shahuindo – IP Survey Results | 78 |

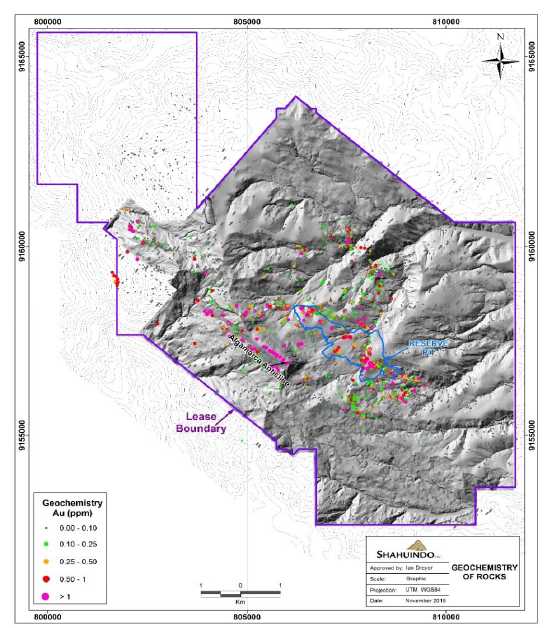

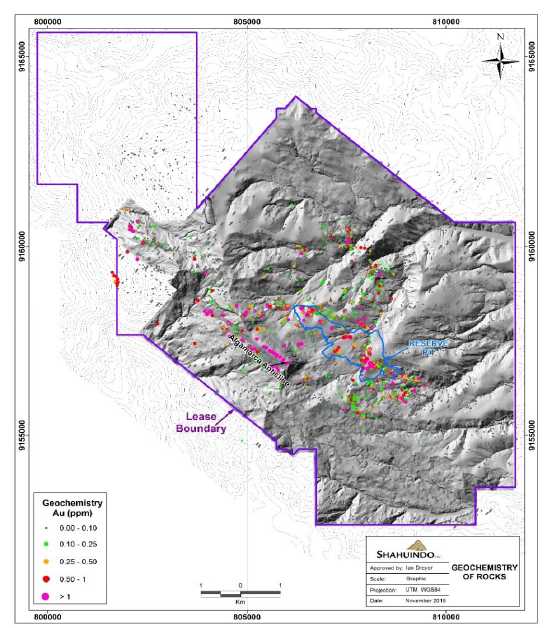

| Figure 9.3-1 | Shahuindo – Rock Geochemistry | 79 |

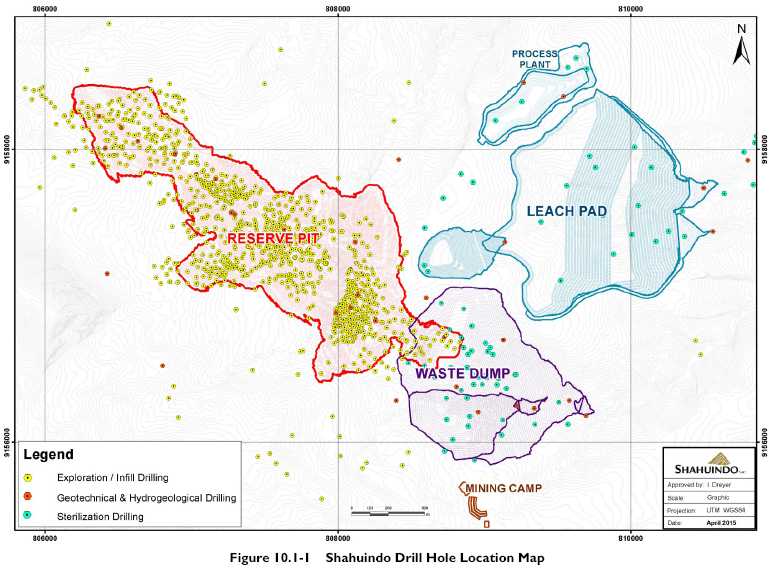

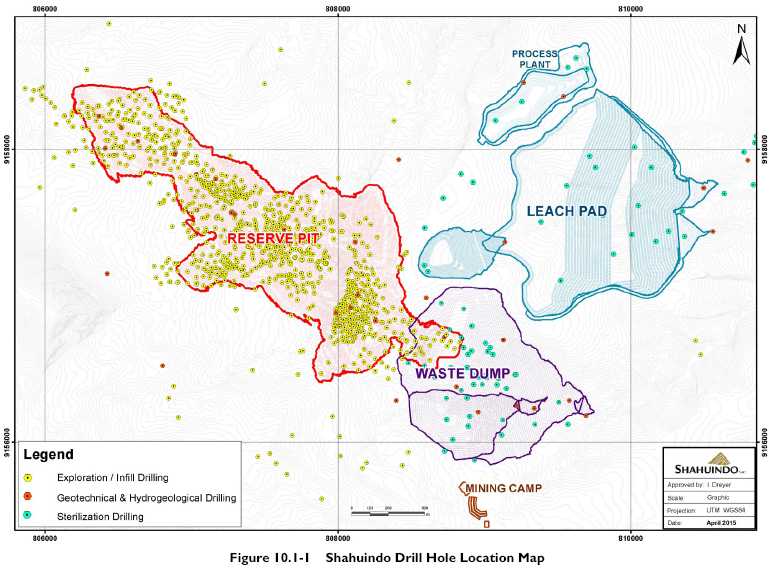

| Figure 10.1-1 | Shahuindo Drill Hole Location Map | 82 |

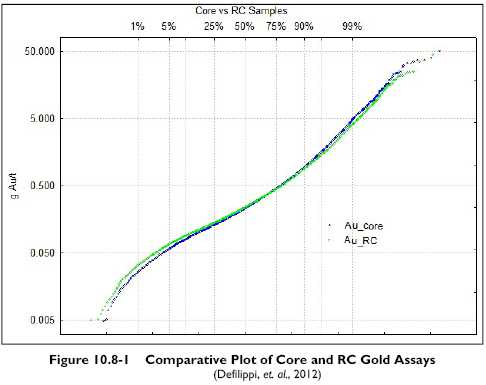

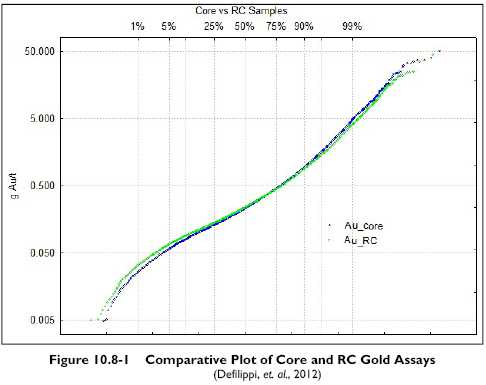

| Figure 10.8-1 | Comparative Plot of Core and RC Gold Assays | 88 |

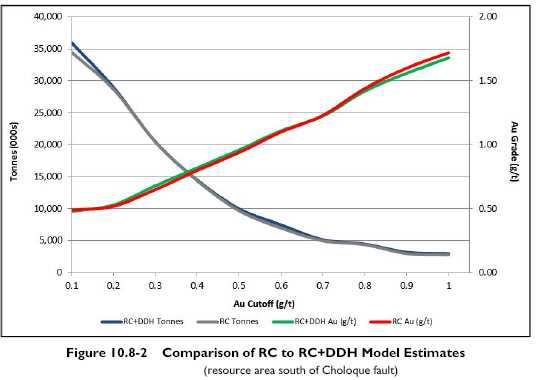

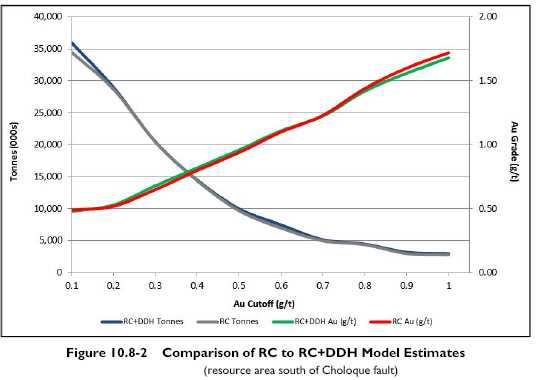

| Figure 10.8-2 | Comparison of RC to RC+DDH Model Estimates | 89 |

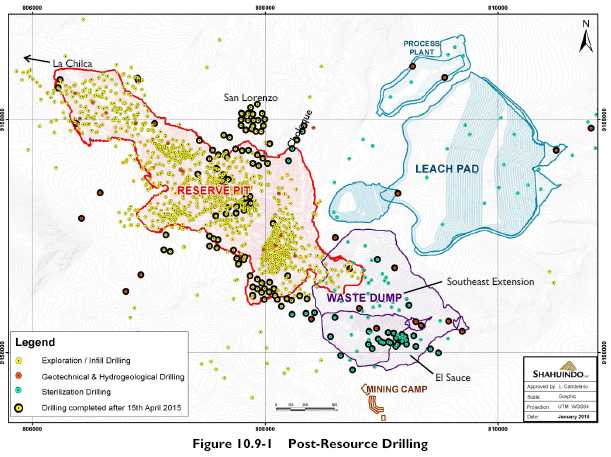

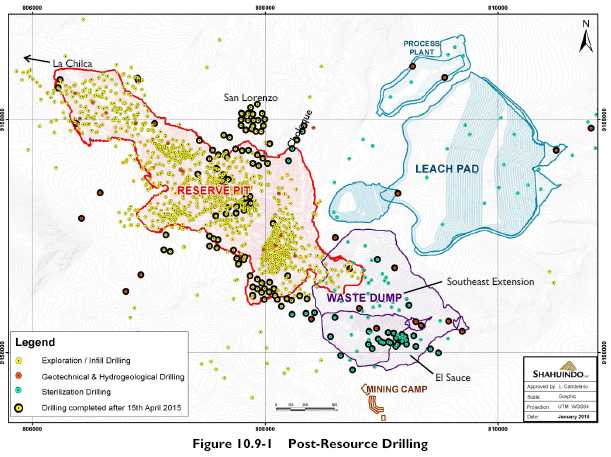

| Figure 10.9-1 | Post-Resource Drilling | 90 |

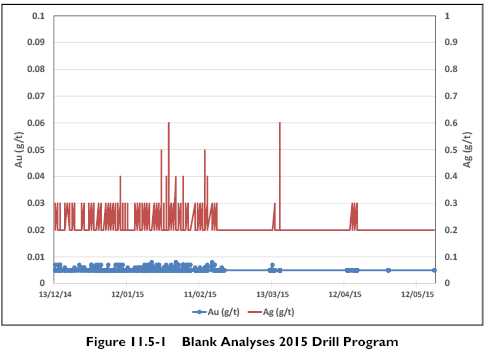

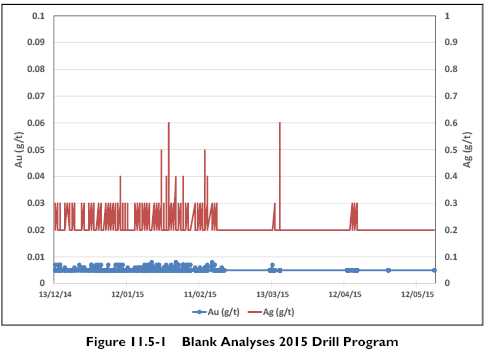

| Figure 11.5-1 | Blank Analyses 2015 Drill Program | 101 |

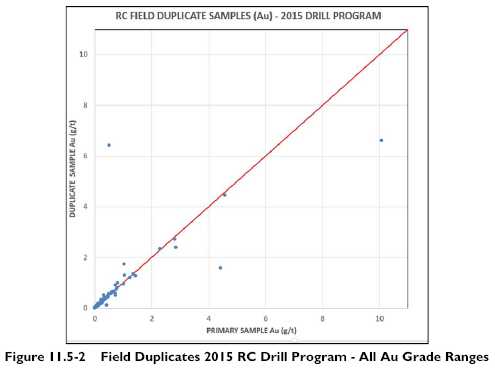

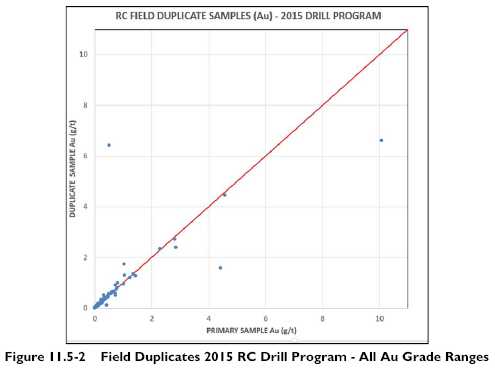

| Figure 11.5-2 | Field Duplicates 2015 RC Drill Program - All Au Grade Ranges | 102 |

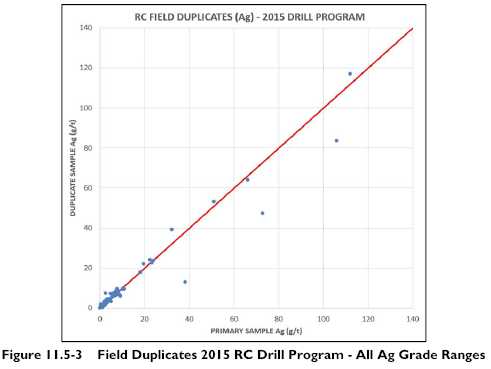

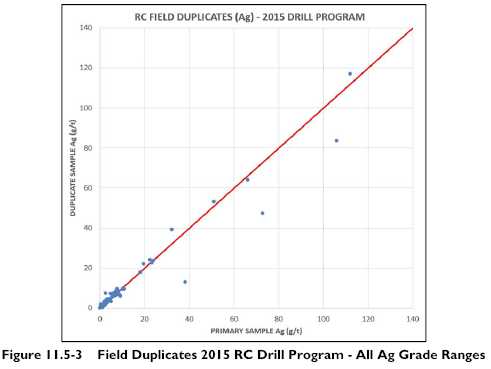

| Figure 11.5-3 | Field Duplicates 2015 RC Drill Program - All Ag Grade Ranges | 102 |

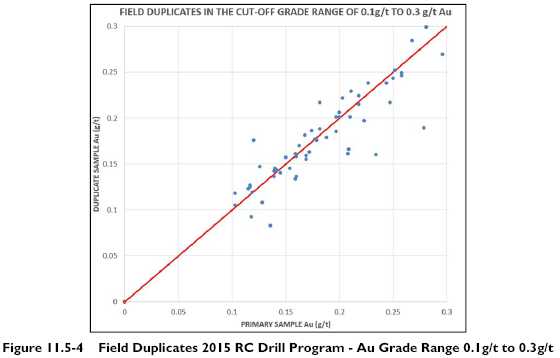

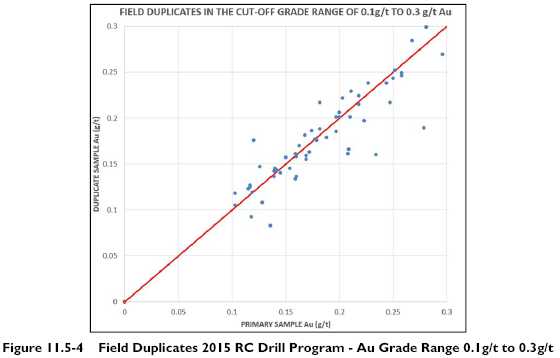

| Figure 11.5-4 | Field Duplicates 2015 RC Drill Program - Au Grade Range 0.1g/t to 0.3g/t | 103 |

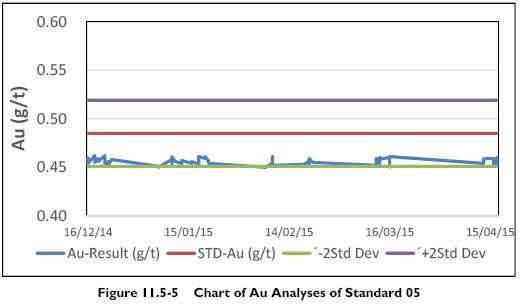

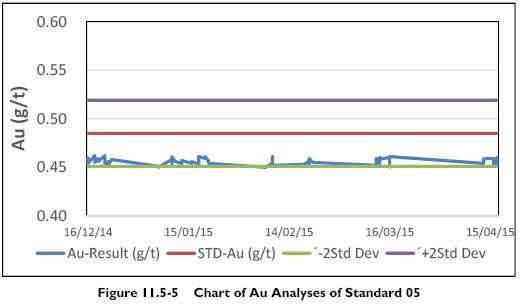

| Figure 11.5-5 | Chart of Au Analyses of Standard 05 | 104 |

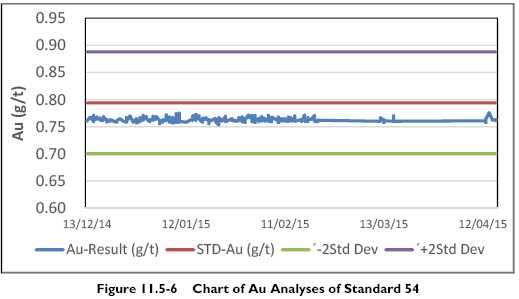

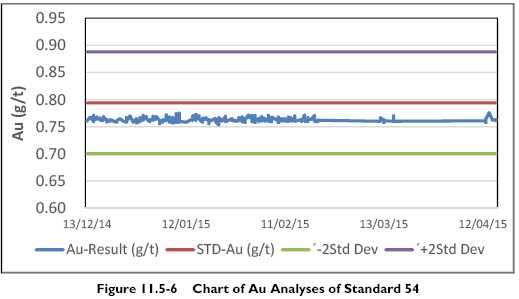

| Figure 11.5-6 | Chart of Au Analyses of Standard 54 | 104 |

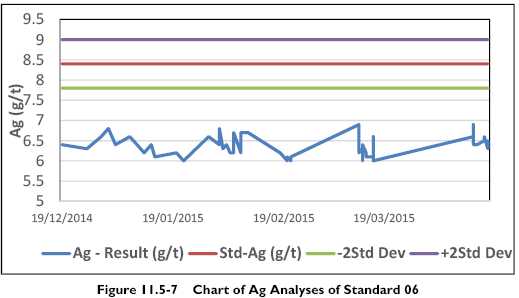

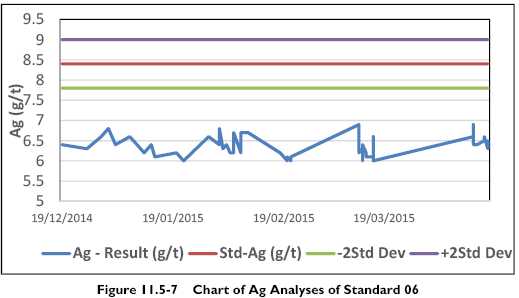

| Figure 11.5-7 | Chart of Ag Analyses of Standard 06 | 105 |

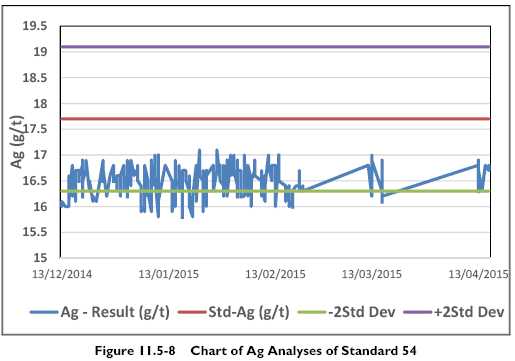

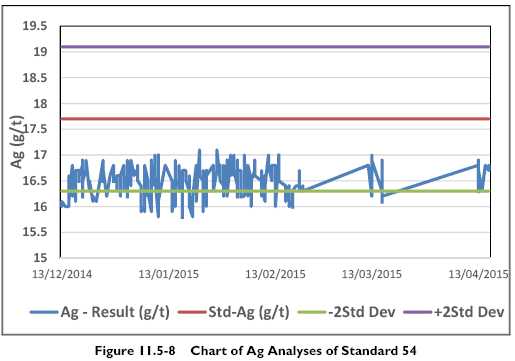

| Figure 11.5-8 | Chart of Ag Analyses of Standard 54 | 105 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

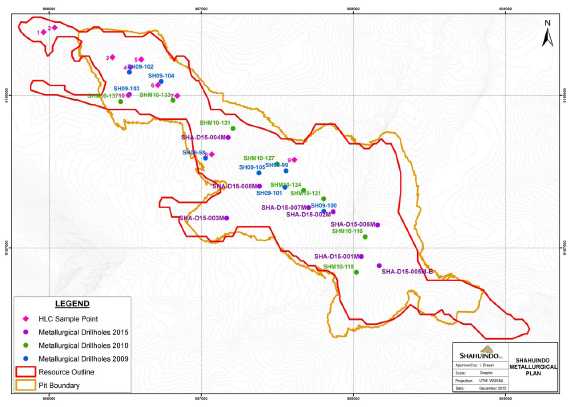

| Figure 13.1-1 | Location of Metallurgical Drill Holes | 110 |

| Figure 13.4-1 | Permeability Rate and Fines Content at Various Simulated Heap Heights | 126 |

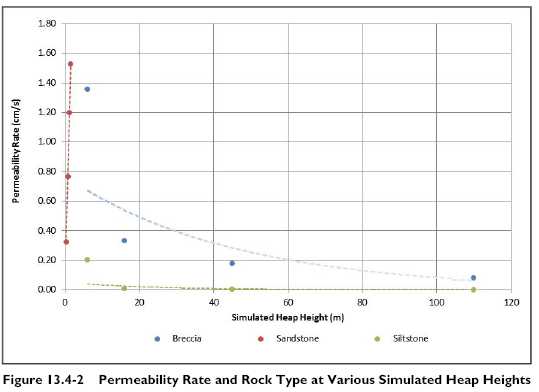

| Figure 13.4-2 | Permeability Rate and Rock Type at Various Simulated Heap Heights | 126 |

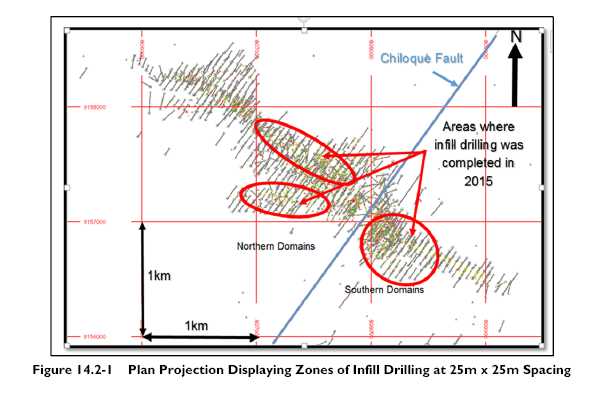

| Figure 14.2-1 | Plan Projection Displaying Zones of Infill Drilling at 25m x 25m Spacing | 136 |

| Figure 14.3-1 | Lithologic Domains – Section E400 | 138 |

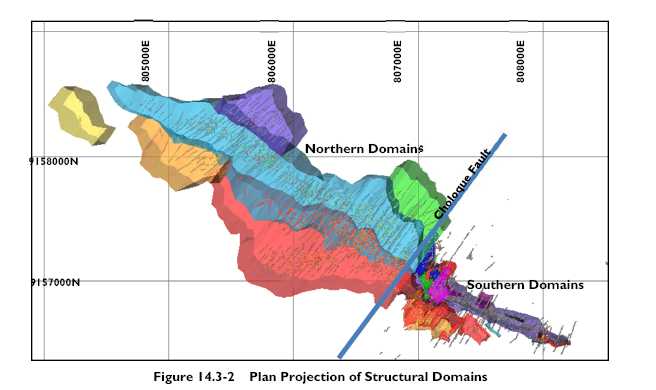

| Figure 14.3-2 | Plan Projection of Structural Domains | 139 |

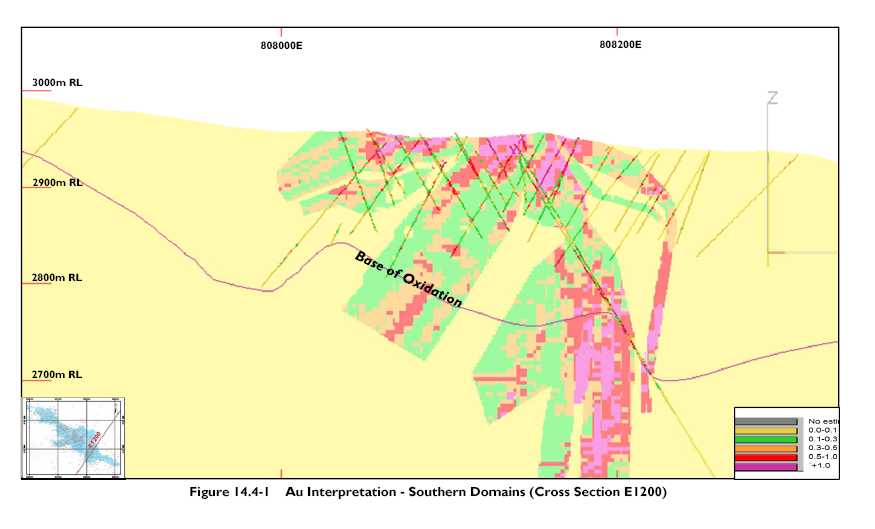

| Figure 14.4-1 | Au Interpretation - Southern Domains (Cross Section E1200) | 141 |

| Figure 14.4-2 | Au Interpretation - Northern Domains (Cross Section E400) | 142 |

| Figure 14.5-1 | Gold statistics plots for all domains | 145 |

| Figure 14.5-2 | Silver statistics plots for all domains | 147 |

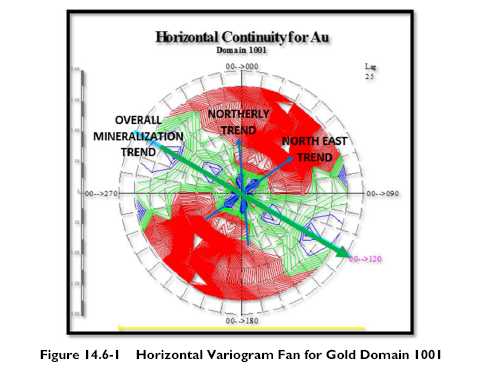

| Figure 14.6-1 | Horizontal Variogram Fan for Gold Domain 1001 | 151 |

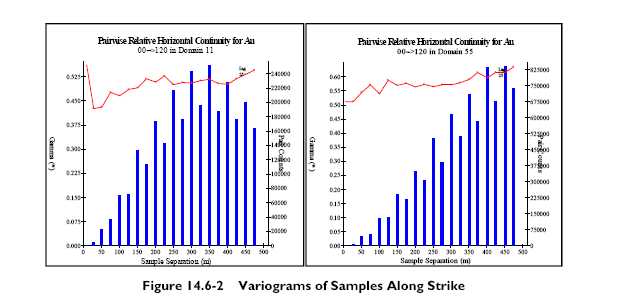

| Figure 14.6-2 | Variograms of Samples Along Strike | 152 |

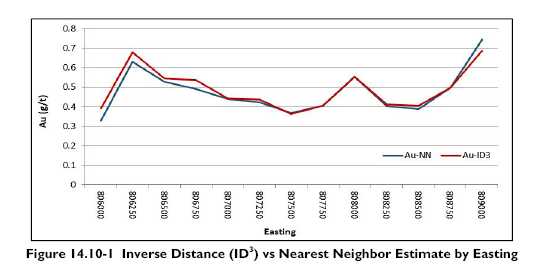

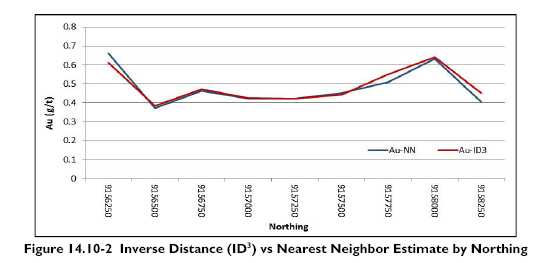

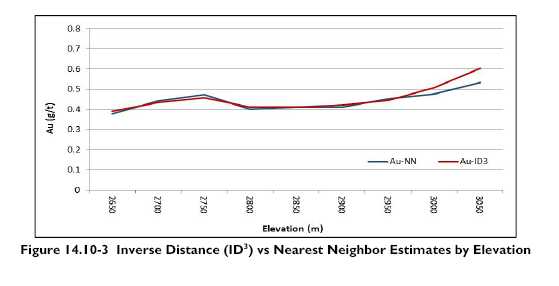

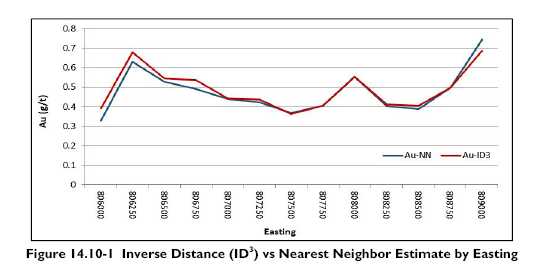

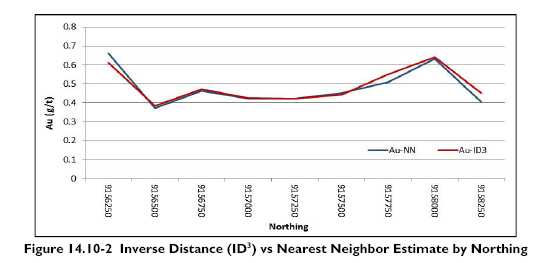

| Figure 14.10-1 | Inverse Distance (ID3) vs Nearest Neighbor Estimate by Easting | 164 |

| Figure 14.10-2 | Inverse Distance (ID3) vs Nearest Neighbor Estimate by Northing | 164 |

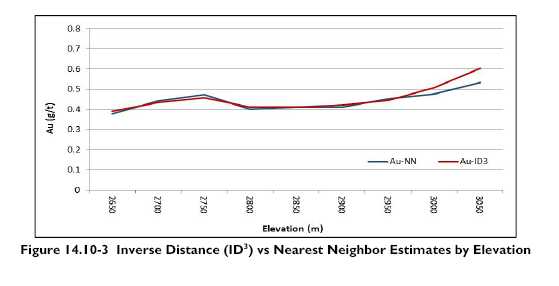

| Figure 14.10-3 | Inverse Distance (ID3) vs Nearest Neighbor Estimates by Elevation | 164 |

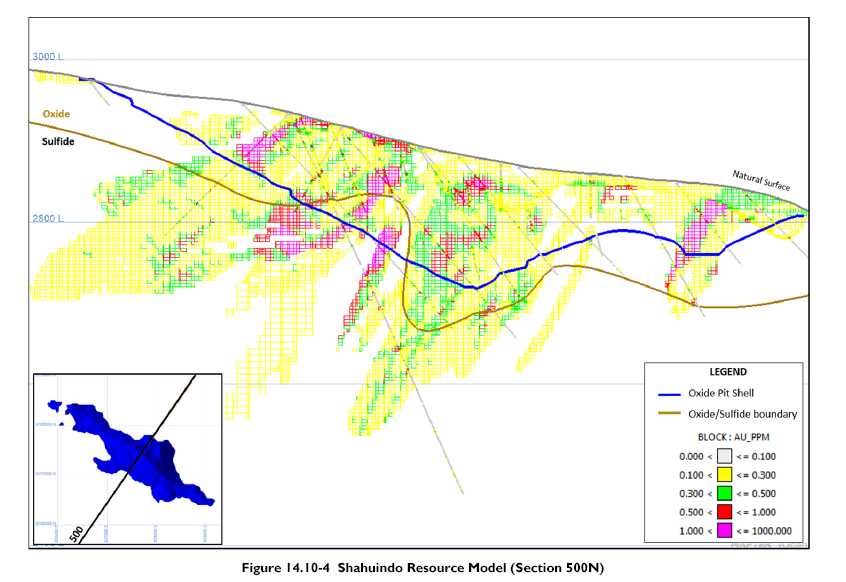

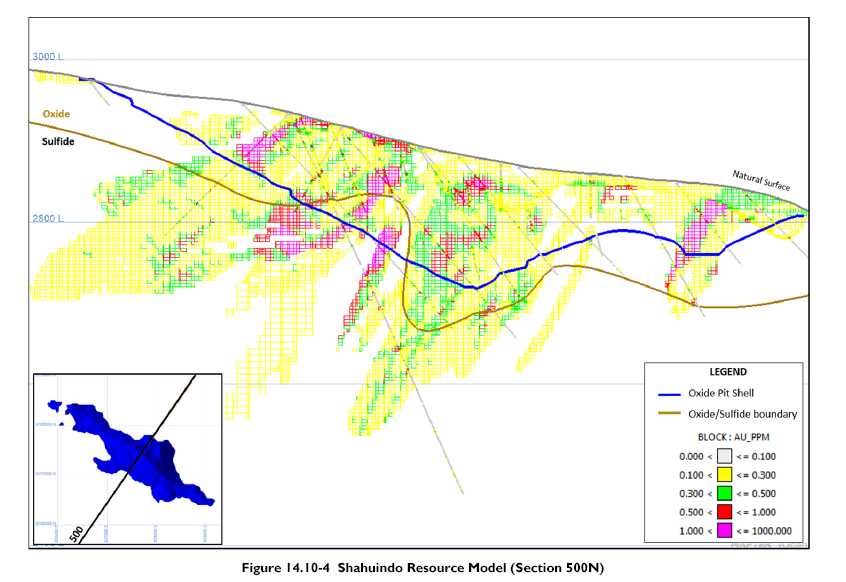

| Figure 14.10-4 | Shahuindo Resource Model (Section 500N) | 167 |

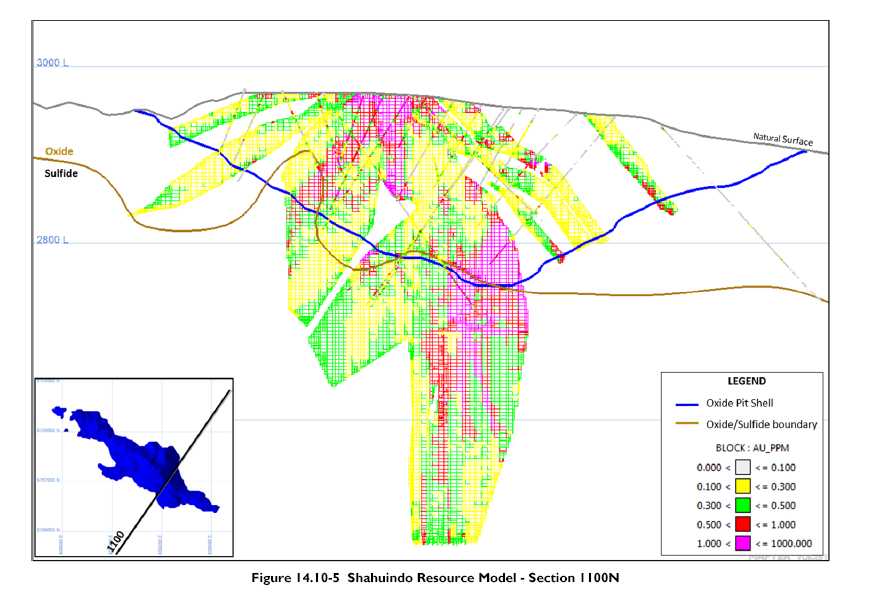

| Figure 14.10-5 | Shahuindo Resource Model - Section 1100N | 168 |

| Figure 15.6-1 | Graph of Whittle Results | 174 |

| Figure 15.6-2 | Plan of Whittle Shell 36 | 176 |

| Figure 16.1-1 | Geotechnical Zone Areas | 179 |

| Figure 16.3-1 | Shahuindo Mine Layout Plan | 183 |

| Figure 16.5-1 | LOM Pit Design | 186 |

| Figure 16.7-1 | Site Plan at the end of 2017 | 188 |

| Figure 16.7-2 | Final Phase 2 Site Plan | 189 |

| Figure 17.1-1 | ROM Process Flow Sheet | 196 |

| Figure 17.2-1 | Crushing, Stockpile, Screening and Agglomeration Flow Sheet | 200 |

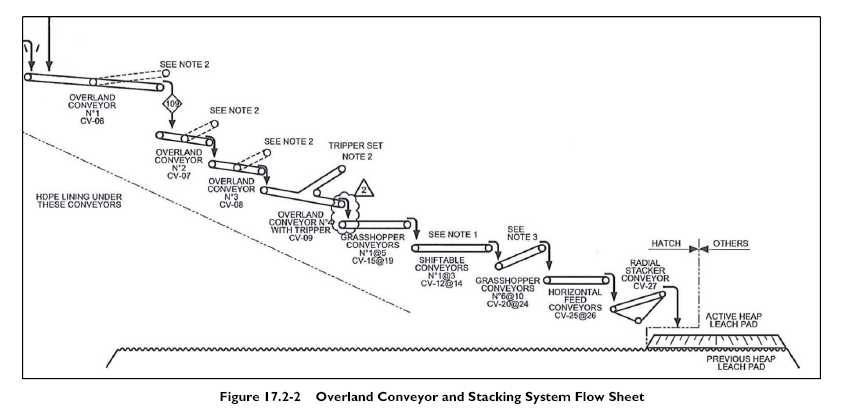

| Figure 17.2-2 | Overland Conveyor and Stacking System Flow Sheet | 201 |

| Figure 18.1-1 | Mine Access Road | 205 |

| Figure 20.2-1 | Annual Distribution of Extracted GEU | 217 |

| Figure 20.4-1 | Location of Direct Influence Area | 224 |

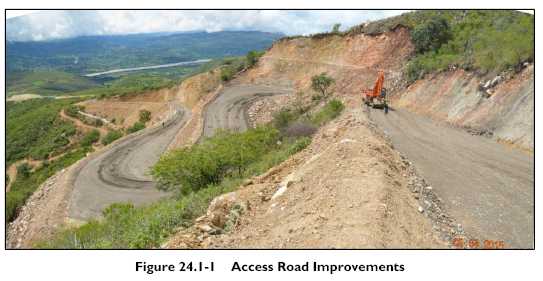

| Figure 24.1-1 | Access Road Improvements | 241 |

| Figure 24.1-2 | Water Storage Pond | 242 |

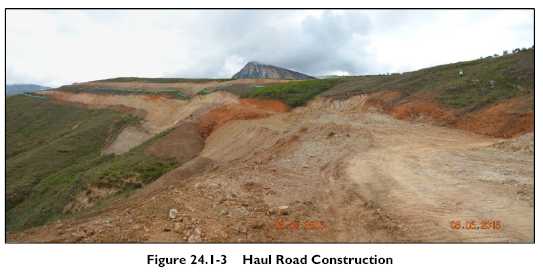

| Figure 24.1-3 | Haul Road Construction | 242 |

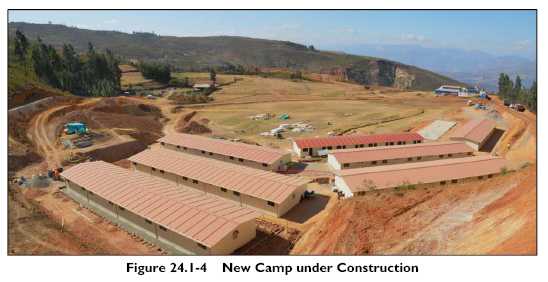

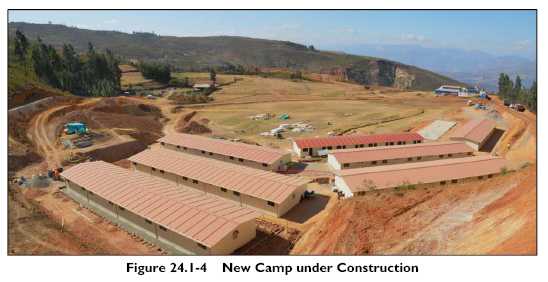

| Figure 24.1-4 | New Camp under Construction | 243 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

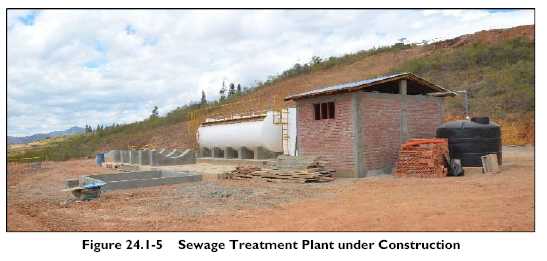

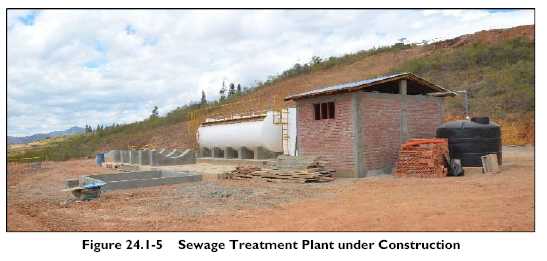

| Figure 24.1-5 | Sewage Treatment Plant under Construction | 243 |

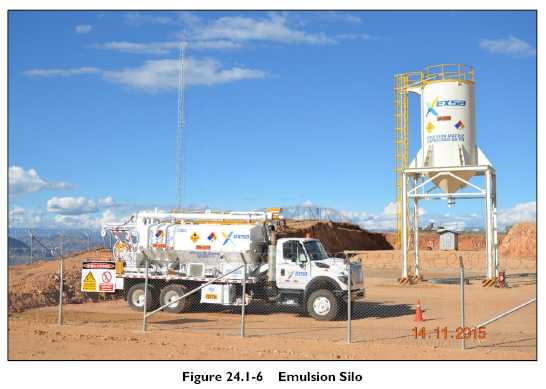

| Figure 24.1-6 | Emulsion Silo | 244 |

| Figure 24.1-7 | Temporary Workshop under Construction | 245 |

| Figure 24.1-8 | Fuel Farm under Construction | 245 |

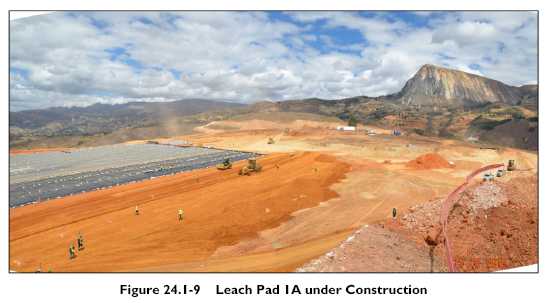

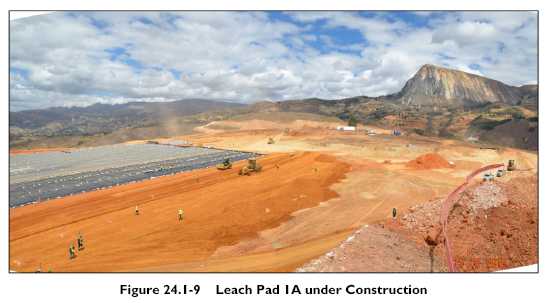

| Figure 24.1-9 | Leach Pad 1A under Construction | 246 |

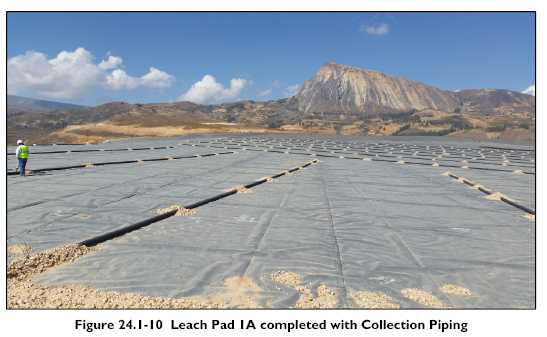

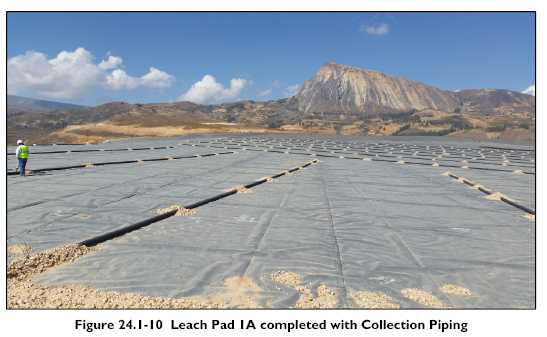

| Figure 24.1-10 | Leach Pad 1A completed with Collection Piping | 246 |

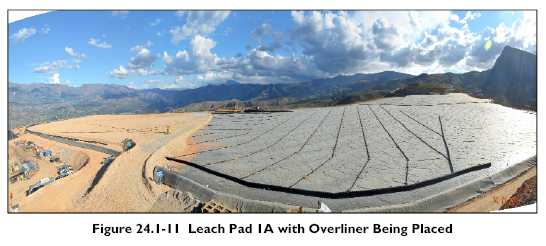

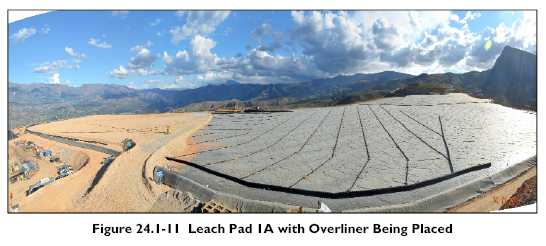

| Figure 24.1-11 | Leach Pad 1A with Overliner Being Placed | 247 |

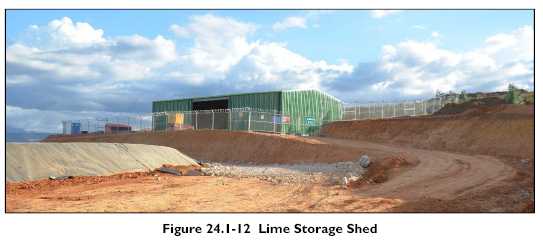

| Figure 24.1-12 | Lime Storage Shed | 247 |

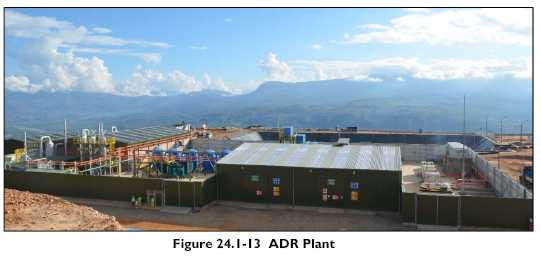

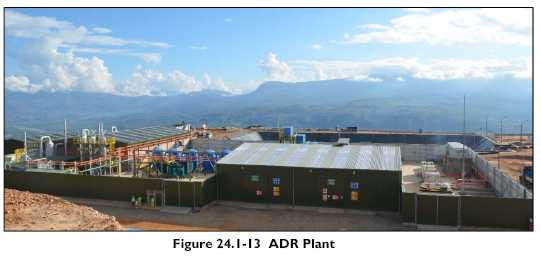

| Figure 24.1-13 | ADR Plant | 248 |

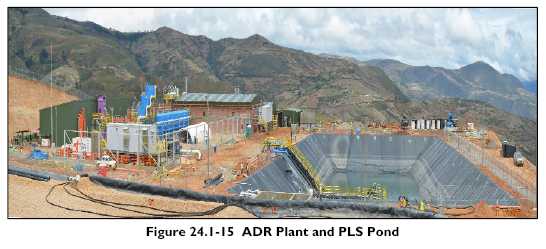

| Figure 24.1-14 | PLS Pond | 248 |

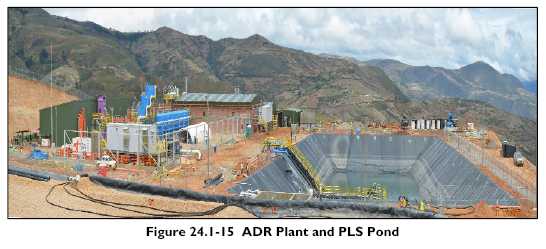

| Figure 24.1-15 | ADR Plant and PLS Pond | 248 |

| Figure 24.1-16 | Leach Pad 2B Foundation and Sub-Drain Excavation | 249 |

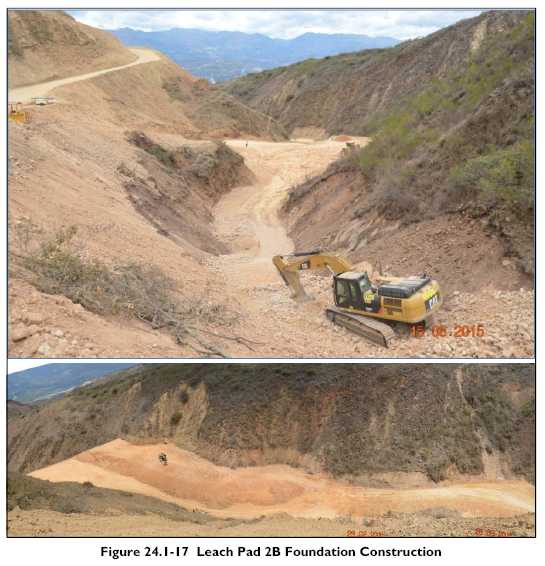

| Figure 24.1-17 | Leach Pad 2B Foundation Construction | 250 |

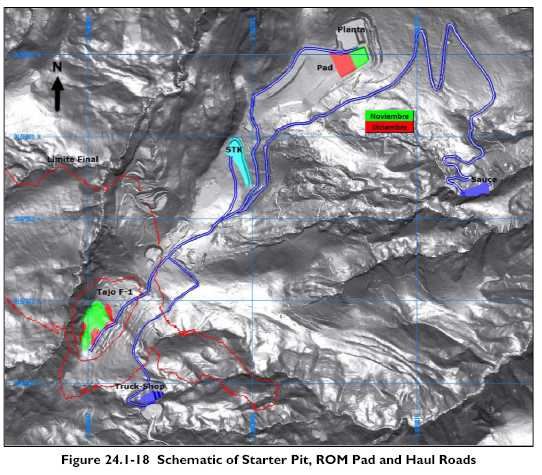

| Figure 24.1-18 | Schematic of Starter Pit, ROM Pad and Haul Roads | 251 |

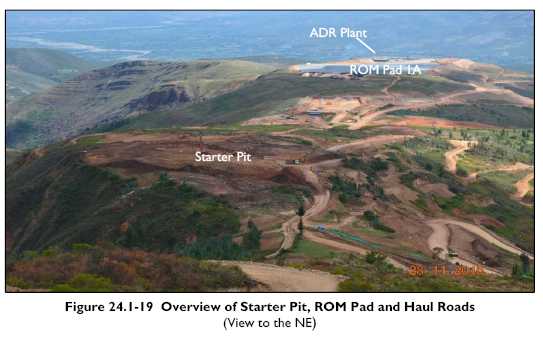

| Figure 24.1-19 | Overview of Starter Pit, ROM Pad and Haul Roads | 251 |

| Figure 24.1-20 | Initial Drill Pattern – November 2015 | 252 |

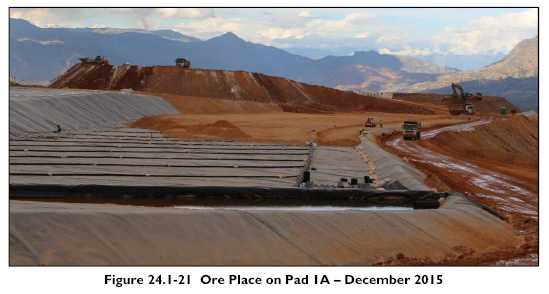

| Figure 24.1-21 | Ore Place on Pad 1A – December 2015 | 252 |

| Figure 24.1-22 | Pad 1A Irrigation Commissioning – December 2015 | 252 |

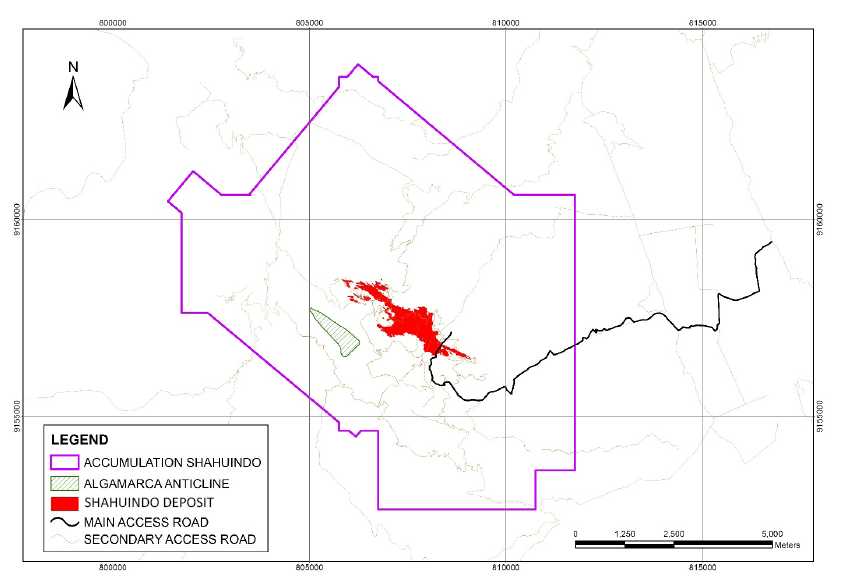

| Figure 24.2-1 | Major Exploration Targets around the Shahuindo Project | 253 |

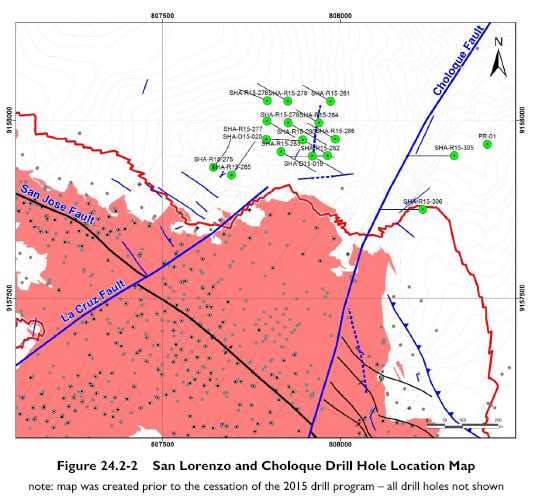

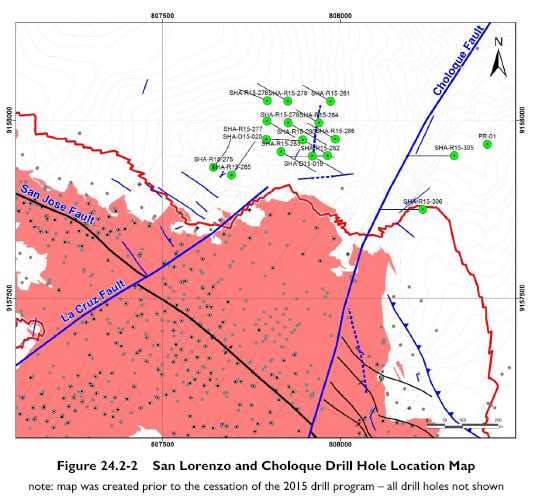

| Figure 24.2-2 | San Lorenzo and Choloque Drill Hole Location Map | 255 |

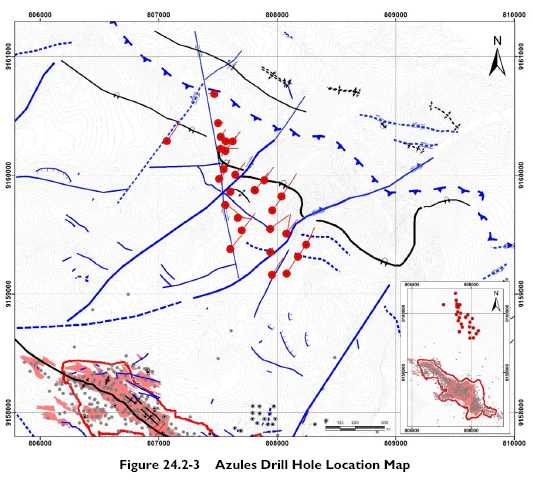

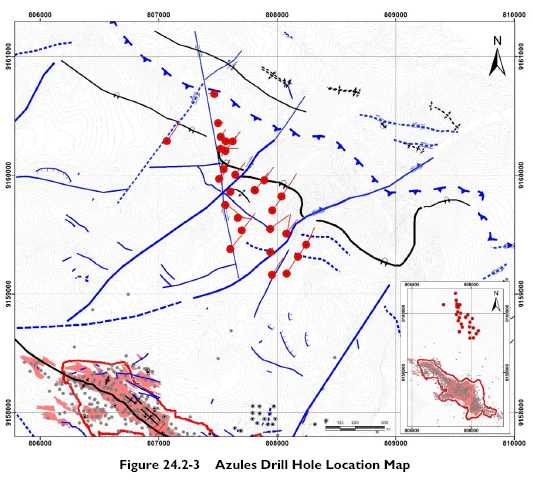

| Figure 24.2-3 | Azules Drill Hole Location Map | 260 |

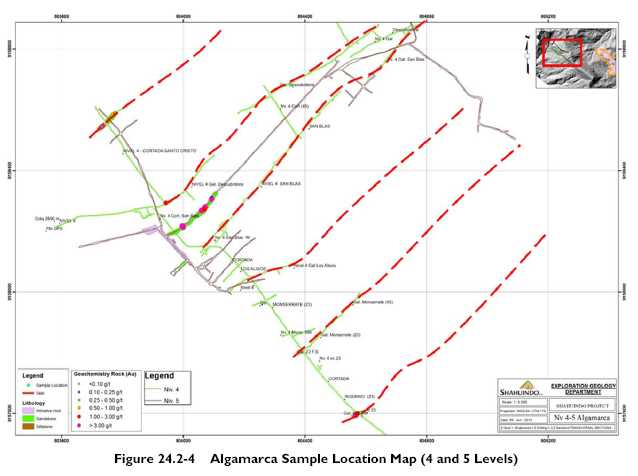

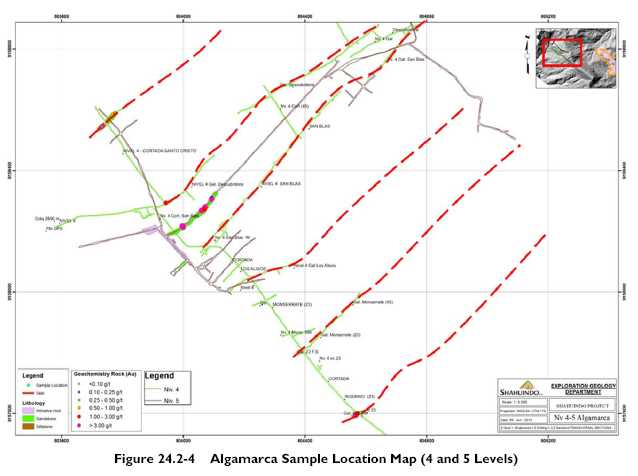

| Figure 24.2-4 | Algamarca Sample Location Map (4 and 5 Levels) | 261 |

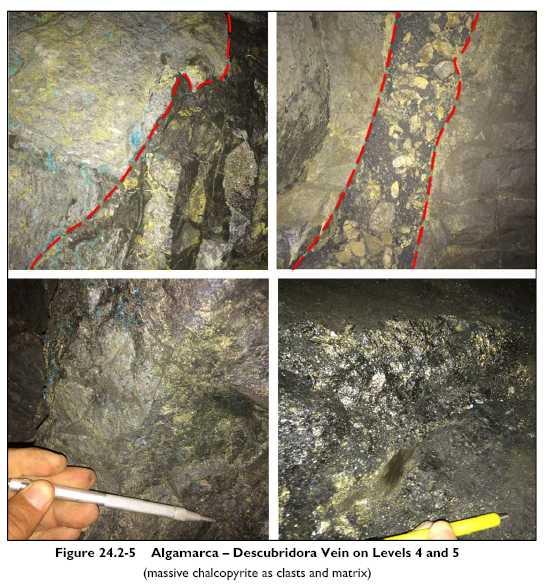

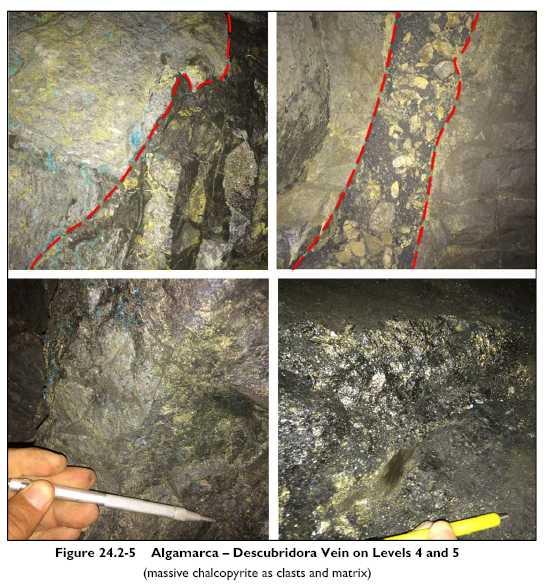

| Figure 24.2-5 | Algamarca – Descubridora Vein on Levels 4 and 5 | 262 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

LIST OF TABLES

| Table 1.12-1 | Metallurgical Test Results | 7 |

| Table 1.13-1 | Shahuindo Mineral Resources | 8 |

| Table 1.13-2 | Shahuindo Mineral Reserve | 9 |

| Table 1.14-1 | Life of Mine Mining Schedule | 10 |

| Table 1.15-1 | Processing Design Parameters | 11 |

| Table 1.15-2 | Life of Mine Process Plant Throughput | 12 |

| Table 1.18-1 | Operating Cost Summary | 13 |

| Table 1.18-2 | Project Capital | 13 |

| Table 1.18-3 | Sensitivity Analysis – NPV and IRR after Taxes | 14 |

| Table 2.3-1 | Qualified Persons – Site Visits and Report Responsibilities | 18 |

| Table 2.6-1 | List of Abbreviations | 20 |

| Table 4.2-1 | Mineral Title Summary | 23 |

| Table 4.5-1 | Summary of Environmental Requirements for Mining Exploration Programs | 27 |

| Table 4.6-1 | List of Permits and Status | 28 |

| Table 4.7-1 | Corporate Income Tax | 33 |

| Table 5.5-1 | Summary of PGA Values for Different Return Periods | 39 |

| Table 6.2-1 | Summary of Prior Exploration Activities on the Shahuindo Property | 43 |

| Table 6.2-2 | Summary of Sulliden Exploration Activities | 44 |

| Table 6.3-1 | Pre-NI 43-101 Mineral Resource Estimates | 45 |

| Table 6.3-2 | Prior NI 43-101 Mineral Resource Estimate Summary | 45 |

| Table 6.3-3 | 2004 Mineral Resource Estimate | 46 |

| Table 6.3-4 | 2005 Mineral Resource Estimate | 46 |

| Table 6.3-5 | 2009 Mineral Resource Estimate | 47 |

| Table 6.3-6 | 2011 Mineral Resource Estimate | 48 |

| Table 6.3-7 | 2012 Mineral Resource Estimate | 49 |

| Table 6.3-8 | 2012 Pit Optimization Parameters | 50 |

| Table 6.3-9 | 2012 Mineral Reserve Estimate | 51 |

| Table 7.1-1 | Shahuindo Regional Stratigraphic Column | 52 |

| Table 10.1-1 | Shahuindo Drilling Summary | 81 |

| Table 10.8-1 | Core and RC Gold Analyses | 87 |

| Table 10.9-1 | Post-Resource Drilling | 90 |

| Table 11.5-1 | Summary of QAQC Program Applicable for 2015 Resource Estimate | 100 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| Table 11.5-2 | Summary of Analysis of Standards Used in 2015 Drill Program | 103 |

| Table 13.1-1 | Cyanide and Flotation Testing Programs on Shahuindo | 109 |

| Table 13.1-2 | Metallurgical Test Work Results | 110 |

| Table 13.2-1 | Summary of HLC Column Leach Tests | 111 |

| Table 13.2-2 | Summary of KCA Column Leach Tests | 113 |

| Table 13.2-3 | Summary of KCA Bottle Roll Leach Tests | 114 |

| Table 13.4-1 | Rock Type Summary | 117 |

| Table 13.4-2 | Rio Alto Column Leach Test Results on Surface Samples | 118 |

| Table 13.4-3 | Rio Alto Column Leach Test Results on Drill Core Composites | 119 |

| Table 13.4-4 | SGS Column Leach Test Results | 120 |

| Table 13.4-5 | SGS and Rio Alto Column Leach Test Results by Size and Rock Type | 122 |

| Table 13.4-6 | Summary of SGS 72-hour Bottle Roll Tests | 123 |

| Table 13.4-7 | Copper, Iron, Arsenic and Sulfur Levels in the SGS Composites | 124 |

| Table 13.4-8 | Compacted Permeability Test Results | 125 |

| Table 13.5-1 | KCA Oxide Ore Parameters - No Permeability or Fines Migration Issues | 128 |

| Table 13.5-2 | Column Test Results Used in Estimating Field Design Criteria | 129 |

| Table 13.5-3 | KCA Oxide Ore Recommendation - Crushed to p80 (60mm - 85mm range) | 131 |

| Table 13.5-4 | Test Results Used to Determine Field Parameters on Coarse Crushed Ore | 132 |

| Table 14.2-1 | Grid Transformation Applied to Collar Data in Database. | 135 |

| Table 14.5-1 | Descriptive Statistics of Shahuindo Density Values by Rock Type | 144 |

| Table 14.5-2 | Descriptive Statistics for Gold Oxide Domains | 146 |

| Table 14.5-3 | Descriptive Statistics for Silver Oxide Domains | 148 |

| Table 14.5-4 | Hard Domains Used for Minor Element Estimation | 149 |

| Table 14.5-5 | Description Statistics for Minor Elements | 150 |

| Table 14.7-1 | Block Model Parameters | 152 |

| Table 14.7-2 | Block Model Attributes List | 153 |

| Table 14.8-1 | Search Parameters Used for Gold and Silver Estimation | 155 |

| Table 14.9-1 | Shahuindo Mineral Resources – Oxide | 159 |

| Table 14.9-2 | Measured Oxide Resources - Grade Tonnage | 159 |

| Table 14.9-3 | Indicated Oxide Resources - Grade Tonnage | 160 |

| Table 14.9-4 | Inferred Oxide Resources - Grade Tonnage | 160 |

| Table 14.9-5 | Shahuindo Mineral Resources – Sulfide | 161 |

| Table 14.9-6 | Inferred Sulfide Resources - Grade Tonnage | 162 |

| Table 14.10-1 | Composites vs Resource Model Grades | 163 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| Table 14.10-2 | Confidence Levels of Key Criteria | 165 |

| Table 15.1-1 | Shahuindo Mineral Reserves | 170 |

| Table 15.2-1 | Cut-Off Grade Assumptions | 172 |

| Table 15.3-1 | Pit Optimization Parameters for Shahuindo Mineral Reserve | 172 |

| Table 15.6-1 | Pit Size vs Value | 175 |

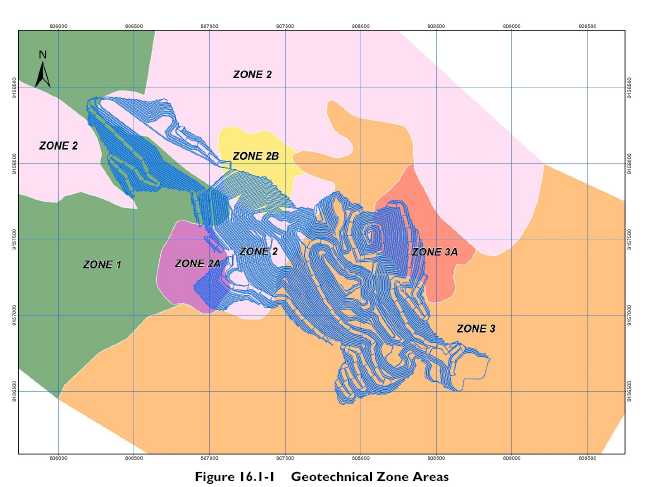

| Table 16.1-1 | Anddes and Associates Geotechnical Parameter Recommendations | 177 |

| Table 16.1-2 | Shahuindo Geotechnical Parameters | 178 |

| Table 16.2-1 | Predicted Water Inflows during Mining | 180 |

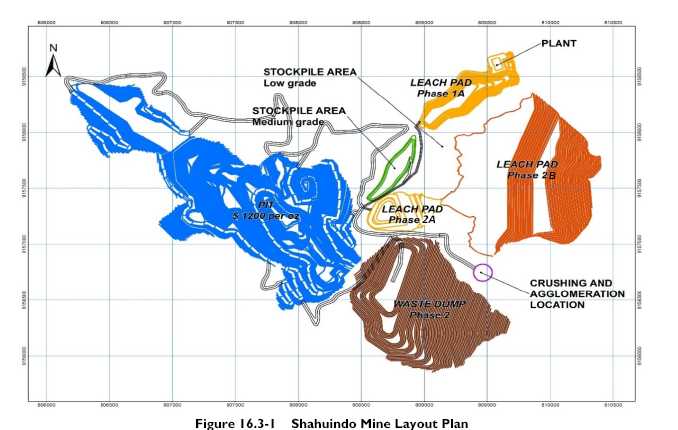

| Table 16.3-1 | Waste Dump Volumes | 182 |

| Table 16.4-1 | Drill and Blast Technical Parameters | 184 |

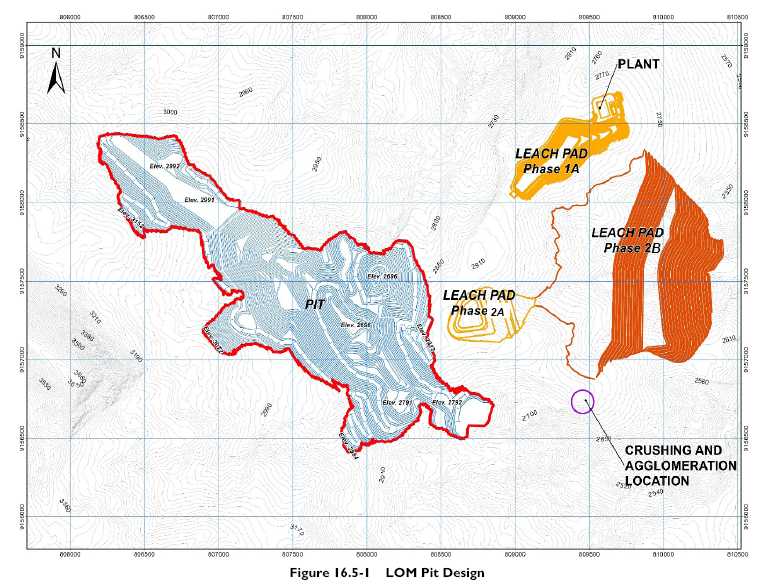

| Table 16.5-1 | Comparison of Pit Design to Whittle Shell | 185 |

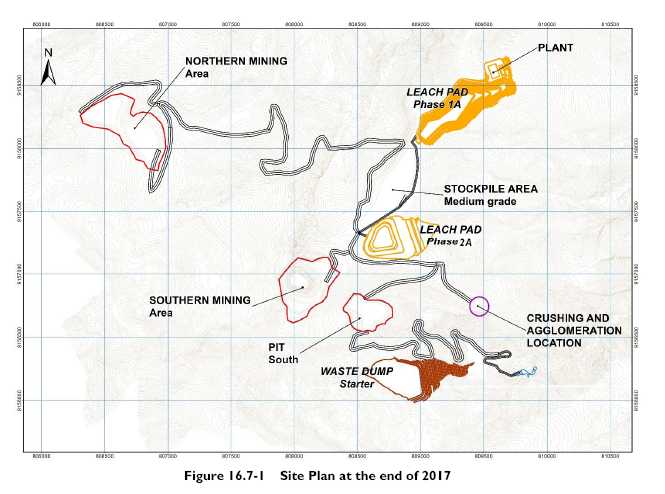

| Table 16.7-1 | Mine Production Schedule | 190 |

| Table 16.8-1 | Primary Mining Equipment Required for Shahuindo | 191 |

| Table 16.8-2 | Ancillary Equipment Fleet Size | 192 |

| Table 16.8-3 | Maximum Loader Productivity Estimate | 192 |

| Table 17.1-1 | Phase 1 Leach Pad Schedule | 198 |

| Table 17.3-1 | Phase 2 Leach Pad Design Criteria | 202 |

| Table 17.4-1 | Phase 1 and Phase 2 Process Parameters | 203 |

| Table 20.2-1 | Sulfur Analysis | 215 |

| Table 21.1-1 | Estimated Capital Expenditure Summary by Year (US$M) | 228 |

| Table 21.1-2 | Major Component Capital Expenditures – Life of Mine | 228 |

| Table 21.2-1 | Operating Cost Summary | 229 |

| Table 22.1-1 | Life of Mine Production | 230 |

| Table 22.3-1 | Project Capital | 231 |

| Table 22.3-2 | Sustaining Capital | 231 |

| Table 22.5-1 | Gold and Silver Prices | 232 |

| Table 22.6-1 | Gold and Silver Refining Terms | 232 |

| Table 22.7-1 | Life of Mine Operating Cost | 233 |

| Table 22.11-1 | Economic Indicators (US$M) | 234 |

| Table 22.12-1 | NPV Sensitivity Analysis on Metal Prices | 235 |

| Table 22.12-2 | NPV Sensitivity Analysis on Operating Cost | 235 |

| Table 22.12-3 | NPV Sensitivity Analysis on Total Capital | 235 |

| Table 22.12-4 | Sensitivity Analysis on Metal Recovery | 235 |

| Table 22.13-1 | LOM Base Case Summary - Assumptions | 236 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

| Table 22.13-2 | Shahuindo Life of Mine Financial Model | 237 |

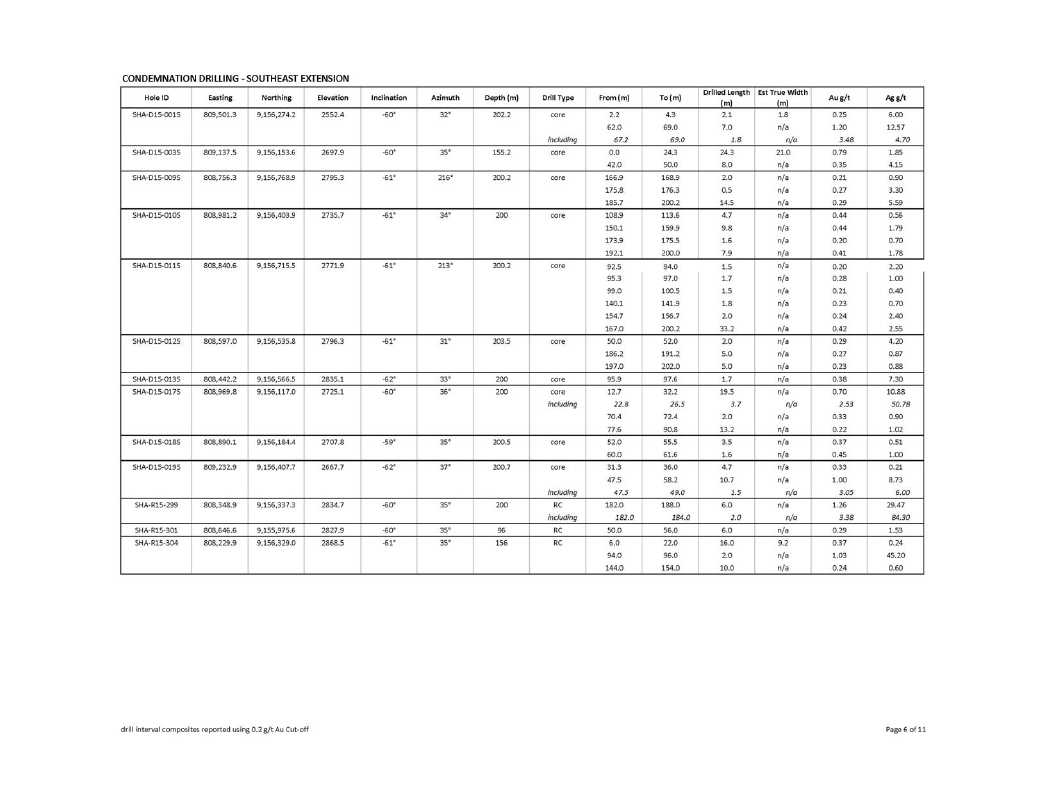

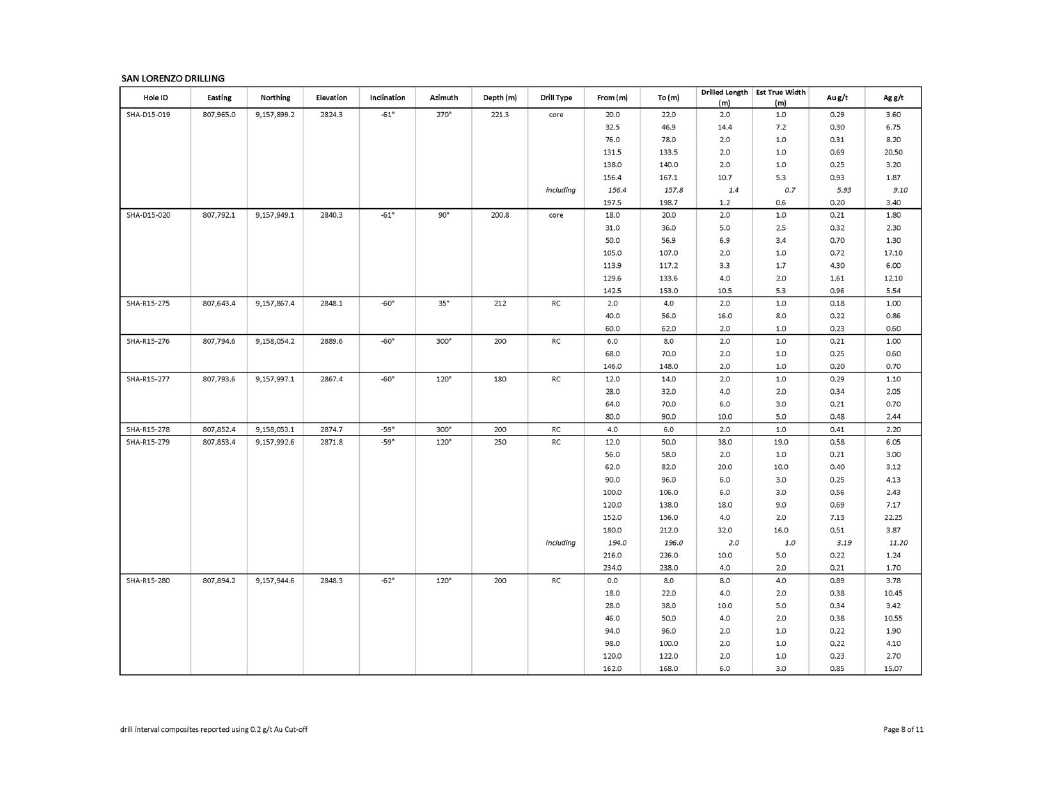

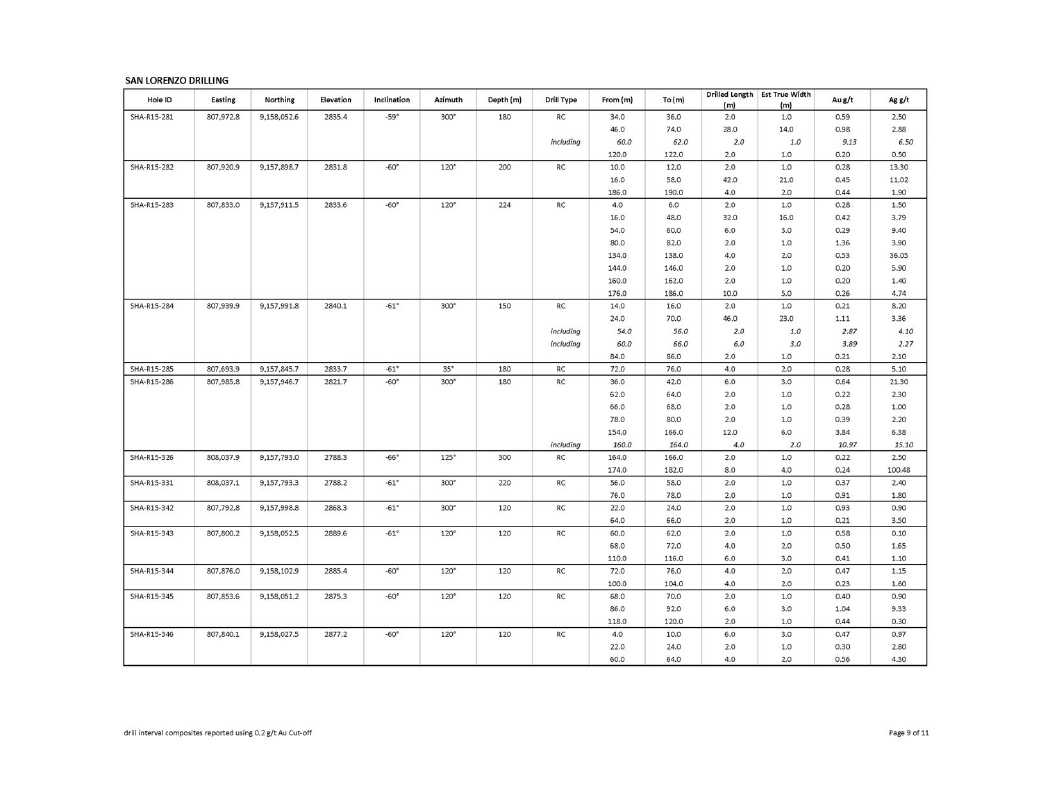

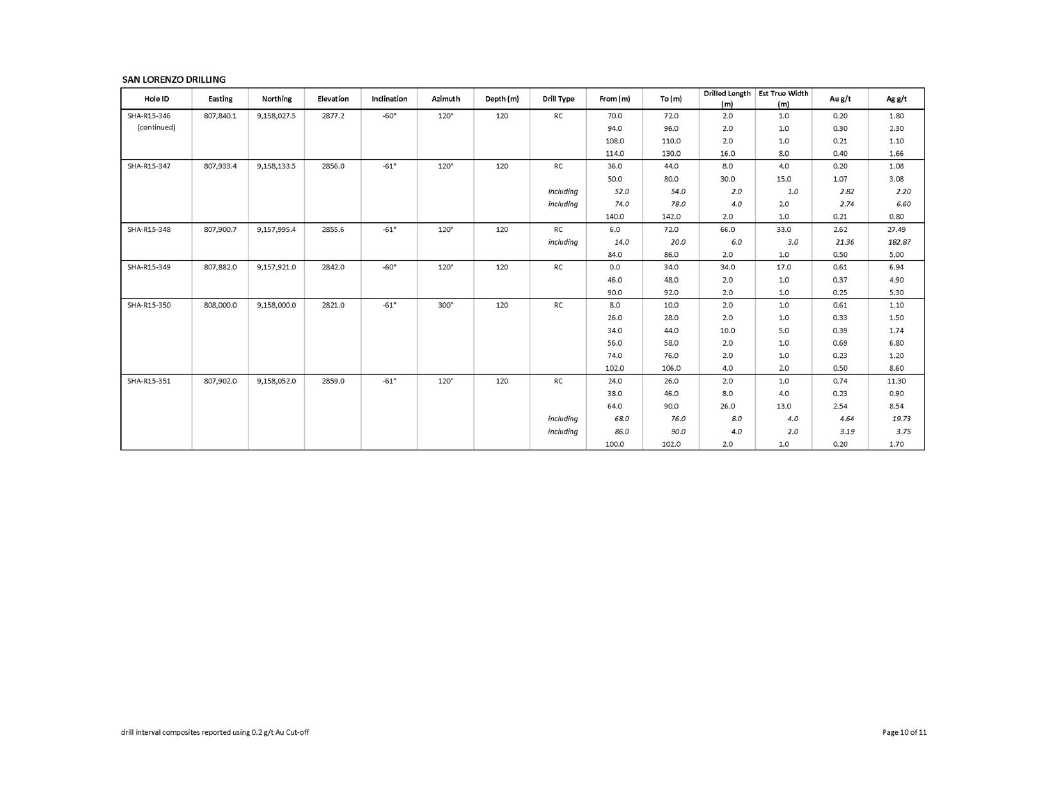

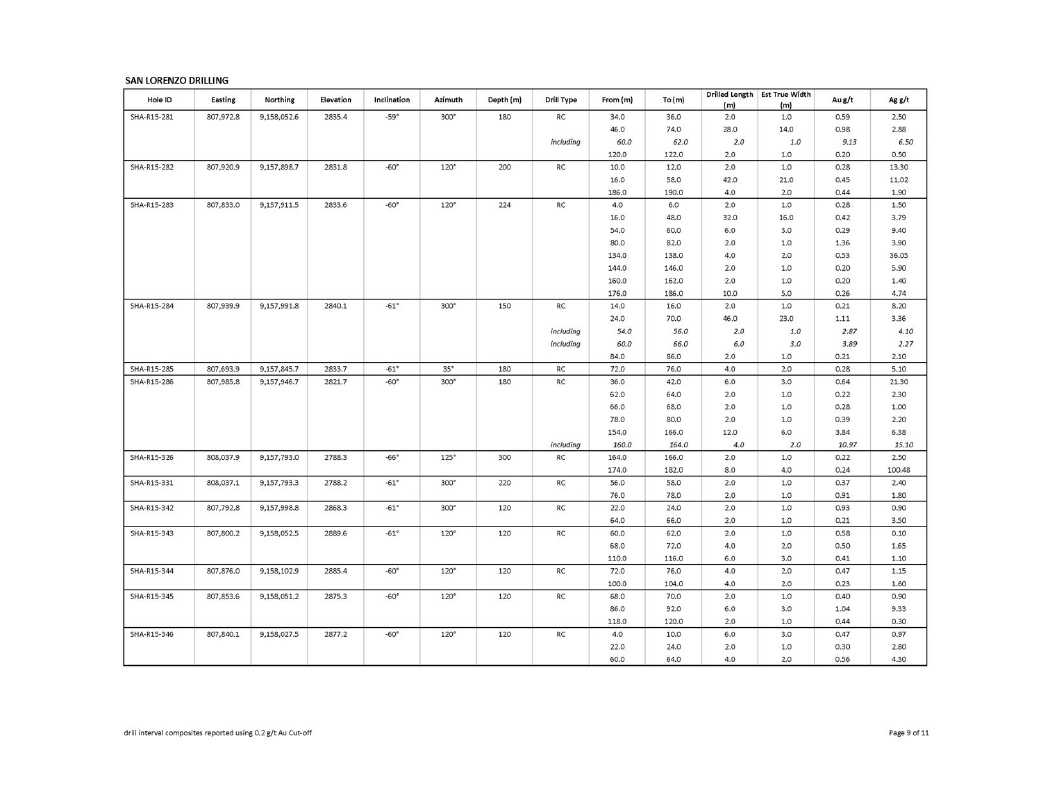

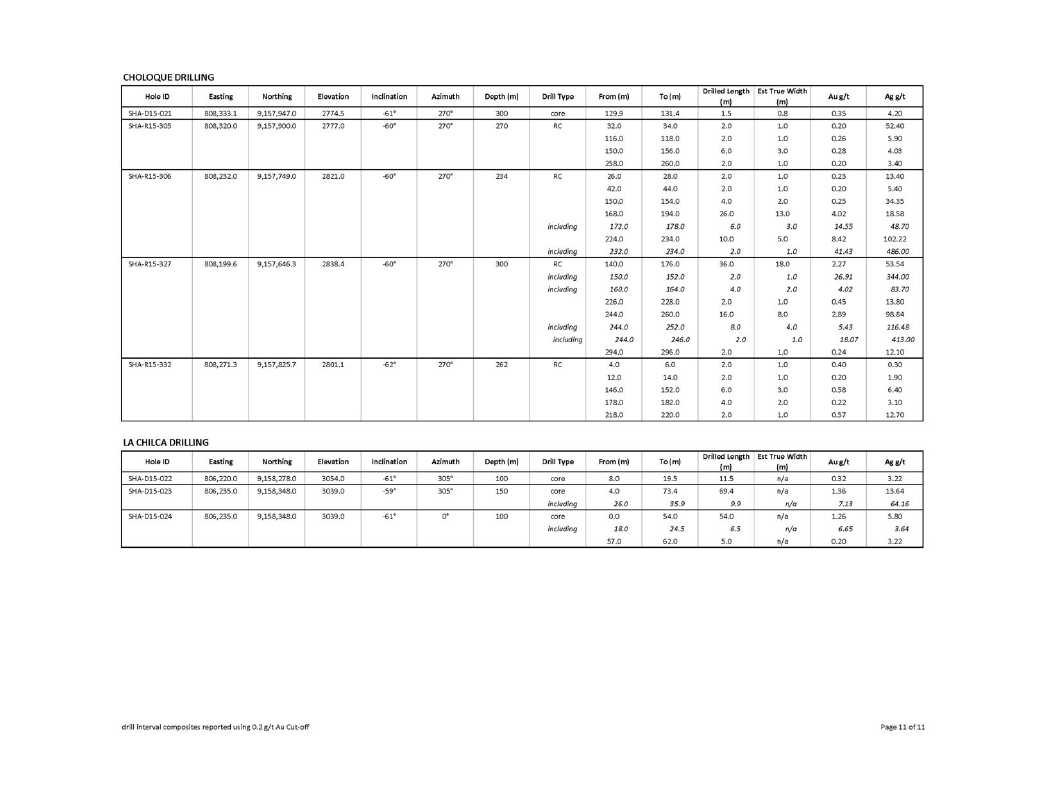

| Table 24.2-1 | San Lorenzo – Select Drill Results | 254 |

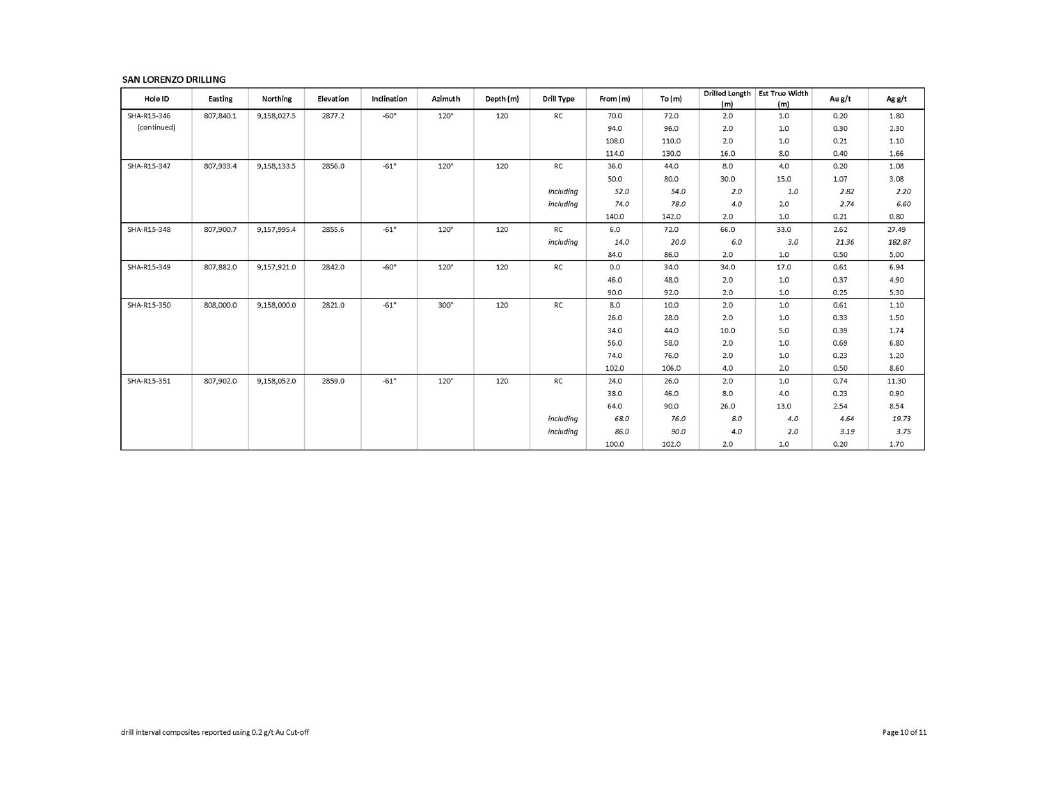

| Table 24.2-2 | Choloque – Select Drill Results | 255 |

| Table 24.2-3 | Southeast Extension – Select Drill Results | 256 |

| Table 24.2-4 | El Sauce – Select Drill Results | 256 |

| Table 24.2-6 | La Chilca Baja – Select Drill Results | 257 |

| Table 24.2-7 | Azules – Sulliden Drill Results | 259 |

| Table 24.2-8 | Algamarca – Sample Results from the Descubridora Vein | 261 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

Tahoe Resources Inc. (Tahoe or Company), whose common shares are listed for trading on the Toronto Stock Exchange (TSX:THO), New York Stock Exchange (NYSE:TAHO) and Bolsa de Valores: Peru (BVL:THO), has prepared this Technical Report in accordance with Canadian National Instrument 43-101 (NI 43-101) for the Shahuindo mine, Cajabamba, Peru. This technical report summarizes the prefeasibility study of the technical and economic viability of the Shahuindo mine.

The following events triggered an updated NI 43-101 report for the Shahuindo mine:

| • | On 09 February 2015, Tahoe and Rio Alto Gold (Rio Alto) entered into a definitive agreement to combine their respective businesses and finalized the transaction on 01 April 2015. Through this merger, Tahoe Resources acquired 100% ownership of the mining assets of Rio Alto which included the Shahuindo project. |

| | |

| • | The Mineral Resources and Mineral Reserves estimates have been updated as the result of data obtained from drilling and additional engineering studies conducted in 2014 and 2015. Mining studies incorporate updated cost estimates and financial analyses. |

| | | |

| | • | Tahoe has revised the mining strategy for the Shahuindo mine. |

| | |

| • | Tahoe has conducted further metallurgical testing on the ore at Shahuindo and has revised the metallurgical assumptions and flowsheet for the project. |

This report has been completed having an effective date of 01 January 2016. The effective dates of the Mineral Resources estimate and Mineral Reserves estimate are 15 April 2015 and 01 November 2015, respectively. Unless otherwise noted, monetary values are expressed in United States dollars ($) and units are metric.

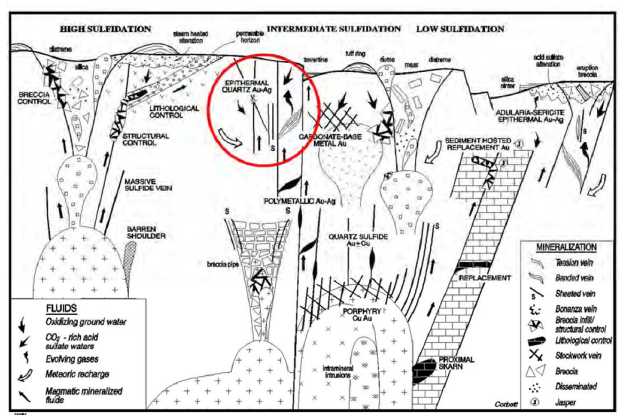

Tahoe, through its wholly owned subsidiary, Shahuindo SAC, owns and operates the Shahuindo mine in Peru. The Shahuindo deposit is an intermediate-sulfidation sediment-hosted epithermal gold-silver deposit which the Company has initiated open pit mining and heap leaching of oxide ore. Metal recovery is by carbon-in-column adsorption-desorption-refining (ADR) processes which produces a gold-rich doré for sale to international refineries.

Construction of the Shahuindo mine commenced in mid-2014, with commissioning of the mine and processing facilities in the fourth quarter of 2015. The Company anticipates achieving commercial production at Shahuindo in the second quarter of 2016.

Shahuindo Mine, Peru

NI 43-101 Technical Report |  |

|

Production at Shahuindo is scheduled in two phases: Phase 1 processes coarse-grain run-of-mine (ROM, i.e., no crushing required) material at an initial rate of 10,000 tonnes of ore per day (tpd) in 2016; a second adsorption column circuit will be installed in mid-2016 to increase the plant processing capacity to accommodate increased mining rates. Phase 2 begins in 2018 and continues through the end of the current mine life with the plant capacity increased to 36,000 tpd to process mixed coarse- and fine-grain ore that requires crushing and agglomeration prior to leaching. The phased approach enables gold production as soon as possible with minimal capital expenditure, thus generating cash flow early in the project.

Throughout this report, references made to Phase 1 and Phase 2 production rates refer to process plant capacity rather than mining rates, though plant capacity and mining rates (ore placed on leach pads) do coincide later in the mine life. An ore stockpile will be utilized to store mine production in excess of plant capacity, with stockpiled ore incrementally added to the leach pads over the life of mine.

The prefeasibility study supports the declaration of Proven and Probable Mineral Reserves. The study provides economic parameters for the Shahuindo mine from 01 January 2016 forward.

Highlights of the study include:

| • | Measured and Indicated Mineral Resources of 143.1 million tonnes and 2.28 million oxide gold ounces at an average gold grade of 0.50 gram per tonne (g/t). |

| | |

| • | Proven and Probable Mineral Reserves of 111.9 million tonnes at an average gold grade of 0.53 g/t, containing 1.91 million ounces of gold. |

| | |

| • | Average annual gold production (i.e., gold in doré) of 78,000 ounces in the first two years of production (Phase 1) and 169,000 ounces in years three through ten (Phase 2). Total gold produced in doré over the LOM is estimated to be 1.504 million ounces. |

| | |

| • | As of 01 January 2016, capital costs are estimated at $179.6 million for project (construction) capital and $140.7 million for sustaining capital over the LOM. |

| | |

| • | After tax net present value at a 5% discount rate (NPV5) of $318.9 million and an internal rate of return (IRR) of 40.6% with a payback period of 4.1 years at the base case metal prices. |

| | |

| • | Exploration conducted by previous owners and by Tahoe demonstrates considerable potential to add additional gold ounces to the production profile at Shahuindo and has identified multiple exploration prospects in the district. |

Mineral Resources and Mineral Resources are reported using metal prices of $1,200/oz Au and $15/oz Ag. Mineral Resources are reported within a $1,400/oz Au pit shell at a gold-equivalent (AuEq) cut-off grade of 0.14 g/t. The financial analysis uses escalating metal prices over the LOM beginning with $1,100/oz Au in 2016 and increasing in $100/oz increments annually to $1,400/oz Au in 2019 where it remains constant through the end of the mine life. Likewise, silver prices used are $14.75/oz in 2016, $17.25/oz in 2017, $20.00/oz in 2018, and $23.50/oz in 2019 and forward to the end of the mine life. Silver has a negligible contribution to the mine economics.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

| 1.3 | Property Description and Location |

The Shahuindo mine is located in the district of Cachachi, province of Cajabamba, department and region of Cajamarca, Peru. It is situated approximately 59 kilometers southeast of the town of Cajamarca and 14 kilometers west of the town of Cajabamba. The project can be accessed from Cajabamba via a combination of asphalt, gravel and dirt roads. Access can be gained all year round.

The local climate consists of two major seasons; a cold and dry “dry season” between the months of May to September, and a humid “wet season” between the months of October to April. The average annual precipitation is 999.7mm a year, with an average temperature of 15.7ºC.

The Shahuindo property comprises one mineral concession, Acumulacion Shahuindo, which includes 26 mineral titles with an approximate area of 7,339 hectares. The concession is 100% controlled by Tahoe’s wholly owned subsidiary, Shahuindo SAC. The mining rights and surface rights are registered under the name of Shahuindo SAC in the government title registry office. All claims are in good standing as of the effective date of this report.

Shahuindo SAC has acquired 381 surface rights within the Shahuindo project area to date, covering a total area of about 2,559 hectares. Some of these surface rights were used to relocate local land owners into new areas.

The Shahuindo mine operates under an initial Environmental Impact Statement (EIA, Estudio de Impacto Ambiental) approved in 2013. The EIA was prepared according to the Ministry of Energy and Mines (MEM) requirements and complies with Peruvian regulations.

As of the effective date of this report, most required permits have been obtained, with the remaining permits being in the final stages of approval. The following list describes the status of the required permits for operations as of 01 January 2016:

| | • | Certificate for the inexistence of Archaeological Remains – Approval granted. |

| | | |

| | • | Environmental Impact Assessment (EIA) - Approval granted. Expansion EIA in process. |

| | | |

| | • | Mine Closure Plan – Approval granted |

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

| | • | Beneficiation Concession – Approval granted. |

| | | |

| | • | Water usage permit – Approval granted. |

| | | |

| | • | Mining Plan – Final stage of evaluation with Ministry of Energy and Mines. |

| | | |

| | • | Operations Permits – In process; approvals expected in January 2016. |

All permits and any new permits will be renewed or obtained as required. It is expected that all remaining permits required for full operations will be obtained in January 2016.

The operating plan will adhere to Tahoe’s mandate that the Shahuindo Project meet or exceed the standards of sustainability and environmental management based on North American practice and regulation. The Company has implemented a comprehensive environmental management plan to regularly and systematically monitor air quality, surface water and groundwater quality, stream sediment geochemistry, blast vibration, noise levels, waste rock geochemistry (ARD monitoring), waste disposal practices, reagent handling and storage, and reclamation and reforestation progress.

Modern exploration activities have been conducted on the Shahuindo property since 1945 by Minera Algamarca SA (1945-1989), Alta Tecnología e Inversión Minera y Metalúrgica S.A. (Atimmsa, 1990), Asarco LLC (Asarco, 1994-1996), Southern Peru Copper Corporation (Southern Peru, 1997-1998) and Sulliden Gold Corporation (Sulliden, 2002-2012). Rio Alto initiated infill drilling of the resource upon their acquisition of Sulliden in 2014 and Tahoe has continued infill and exploration drilling in the district.

| 1.8 | Geology and Mineralization |

The Shahuindo deposit is located on the eastern flank of the Andean Western Cordillera in northern Peru, within a regional fold and thrust belt of predominantly sedimentary rocks. The region is particularly well-endowed with mineral occurrences varying from low-to-high sulfidation systems and from porphyry through polymetallic to epithermal deposits.

Mineralization at Shahuindo is best described as an intermediate-sulfidation epithermal system, though high-sulfidation mineralization occurs at depth and in the core of hydrothermal breccias. Oxidation of mineralization extends to a depth of 150m below surface. In the weathered oxide facies, gold and silver are associated with the presence of jarosite and hematite. In the underlying fresh sulfide facies, gold is typically extremely fine grained with the related mineral species not yet identified.

The principal zone of mineralization in the Shahuindo district occurs in a belt between two large-amplitude regional-scale folds, the Algamarca anticline and the San Jose Anticline. The Algamarca anticline is upright and symmetrical with amplitude of at least 400m, whereas the San Jose fold is an asymmetric, overturned, northeast-vergent fold with a shallowly dipping axial surface and amplitude of at least 300m. Important structural elements include fold limbs and fold axial surfaces, fold-related fractures, faults and related extension fractures, breccia dikes and irregular bodies, and igneous intrusive contacts.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Both structure and lithology control the location, shape, and orientation of the mineralization. The mineralization is hosted within the siliciclastic sandstone-dominant Farrat Formation and the underlying sedimentary Carhuaz formation. These sedimentary rocks have been intruded by at least three felsic stocks which tend to be located along faults and cores of anticlinal structures. In addition, the metallurgical recovery of gold is affected by lithology with the identification of five primary geometallurgical domains based on the relationship between lithology and grain size and gold recovery. Modelling the distribution and occurrence of lithologic units / geometallurgical domains is critical to mine planning.

Mineral Resources were estimated using data from 1,039 diamond core and reverse circulation (RC) drill holes, totaling 164,015 meters, from drilling conducted by Atimmsa, Asarco, Southern Peru, Sulliden and Rio Alto. The cut-off date for drill data inclusion in the mineral resource model was 15 April 2015.

Prior to the acquisition by Tahoe in April 2015, Rio Alto drilled predominantly RC holes in the oxide portion of the deposit to bring the drill density to a nominal 25m x 25m spacing. Tahoe has continued drilling diamond core and RC for infill, step-out, geotechnical, hydrology, and condemnation purposes.

| 1.10 | Sample Preparation and Analysis |

Tahoe has limited information about sample preparation and analyses for the drill programs prior to the major drill programs by Sulliden beginning in 2003. The drilling prior to Sulliden’s work is considered to be a minimal risk to the estimate of Mineral Resources, as this dataset accounts for only 15% of the data used in the estimate and many of the holes drilled prior to Sulliden have been twinned or offset with new drill holes.

From 2003 to 2012, Sulliden’s sampling and sample dispatch for the Shahuindo project were carried out under the supervision of Sulliden staff. Samples were sent to ALS Minerals (ALS, formerly known as ALS Chemex) in Lima for sample preparation and analysis. Samples were prepared and analyzed using industry-standard practices, including the use of quality assurance and quality control (QA/QC) duplicates, blanks, and assay standards. The ALS laboratory in Lima is ISO 9001:2008 and ISO 17025:2005 certified.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Samples from Rio Alto’s 2014-2015 drill programs were analyzed by CERTIMIN (Lima). Gold was assayed with a 50-gram fire assay using an atomic adsorption finish. Fire assays were repeated using with a gravimetric finish for samples whose initial fire assay results were greater than 10 g/t Au. Rio Alto employed a QA/QC program of field duplicates, blanks and assay standards. The CERTIMIN laboratory is ISO 9001 certified for geochemical, metallurgical and environmental sample analyses. Tahoe continues to use the CERTIMIN laboratory in Lima as its primary assay lab for its continued drilling at the Shahuindo project.

Drill core and RC sampling procedures, sample analyses, QAQC procedures and sample security employed at Shahuindo are of sufficient quality for use in the resource estimate.

The drill hole database has been the subject of three major audits between 2003 and 2012 by independent consulting firms and one audit by Tahoe in 2015. The results of these audits, including the 2015 Tahoe audit, found the database integrity and QAQC results sufficient to ensure the dataset used is reliable for resource estimation purposes. Some discrepancies with silver standards used by Rio Alto and Tahoe in 2015 were identified, though this is not considered material due to the minimal contribution of silver to the value of the project.

The result of the verification programs support the estimation of the Shahuindo Mineral Resources and the assignment of Measured, Indicated and Inferred resource classifications.

| 1.12 | Mineral Processing and Metallurgical Testing |

The mineral processing and metallurgical testing that included cyanidation and flotation testing programs have been conducted on composite samples from the Shahuindo project by various companies starting in 1996. These companies include Asarco, Compania Minera Algamarca, Sulliden, Rio Alto and Tahoe, with test work conducted at Dawson Metallurgical Laboratories, Kappes, Cassiday & Associates (KCA), Heap Leach Consultants (HLC), SGS and Tahoe’s La Arena laboratory.

Results from the cyanidation tests conducted by KCA from 2009 to 2012 and in 2014, and by Tahoe (Rio Alto) in 2014 and 2015 on core drill hole and surface composites were used in the development of the recovery and leach design parameters for use in the prefeasibility study. The results of the testing program indicate excellent gold recoveries at both run-of-mine (ROM) and coarse crush sizes with low to moderate reagent requirements, implying amenability to heap leaching. Silver recoveries were generally low.

Compacted permeability tests on -25mm crushed samples were conducted, both with and without cement. The results are variable with one-third of the tests conducted in 2015 failing. The results from KCA’s compacted permeability tests on -32mm composites conducted in 2012 indicated that mixing of the more weathered samples with competent material would be required to maintain permeability at 6 kg of cement per tonne of ore. Two of the three KCA tests passed the compacted permeability tests at a simulated heap height of approximately 110 meters.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Table 1.12 -1 includes the field gold and silver recoveries, reagent consumptions, and leach times on oxide material, based on the available test work results from both ROM and single-stage crushing tests.

Table 1.12 -1 Metallurgical Test Results

| Parameter | ROM | Crush |

| % Au Recovery | 73% | 80% |

| % Ag Recovery | 7% | 12% |

| NaCN Consumption | 0.2 kg/t | 0.3 kg/t |

| Cement | 0 | 6 kg/t* |

| Lime | 2 kg/t | 1 kg/t |

| Leach Time | 80 days | 70 days |

| Size, p80 | ~150mm | 60 to 85mm |

*Cement addition based on screened minus 75mm material

Maintaining heap permeability and minimizing channeling at higher heap heights constitutes a risk to the project, as additional agglomeration and compacted permeability testing is required. Tahoe will conduct further test work on the agglomeration circuit before operations in 2018 (Phase 2). This will include further work on maximizing recovery and determining the maximum leach pad height.

| 1.13 | Mineral Resource and Mineral Reserve Estimates |

The Mineral Resource estimate has been classified as Measured, Indicated and Inferred based on the confidence of the input data, geological interpretation and grade estimation parameters. The Mineral Reserve estimate has been classified as Proven and Probable, applying applicable mining, metallurgical, economic, permitting, and other relevant factors to the Measured and Indicated Mineral Resources. The Mineral Resource and Mineral Reserve estimates have been prepared and reported in accordance with Canadian National Instrument 43-101 (NI 43-101), Standards of Disclosure for Mineral Projects, and classifications adopted by the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Council.

Tahoe is not aware of any specific metallurgical, infrastructural, environmental, legal, title, political, taxation, socio-economic or marketing issues that would impact the Mineral Reserve Estimate as presented.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

The Mineral Resource estimate for the Shahuindo deposit contains Measured and Indicated Mineral Resources (oxide) of 143.1 million tonnes at average grades of 0.50 g/t Au and 6.7 g/t Ag, containing 2.28 million ounces of gold and 30.7 million ounces of silver. Inferred Mineral Resources (oxide) total 2.6 million tonnes at average grades of 0.42 g/t Au and 7.4 g/t Ag; containing 36,000 ounces of gold and 626,000 ounces of silver. Sulfide resources total 87.7 million tonnes at average grades of 0.71 g/t Au and 21.1 g/t Au; containing 2.0 million ounces of gold and 59.4 million ounces of silver. All sulfide resources are classified as Inferred Mineral Resources. The effective date of the Shahuindo Mineral Resource estimate is 15 April 2015.

Table 1.13 -1 is a summary of the Shahuindo Mineral Resources, at cut-off grades for oxide material of 0.14 g/t AuEq and sulfide material of 0.50 g/t AuEq.

Table 1.13 -1 Shahuindo Mineral Resources

Material

Type | Resource

Classification | Tonnes

(M) | Au

(g/t) | Ag

(g/t) | Au Ounces

(koz) | Ag Ounces

(koz) |

Oxide

| Measured | 96.5 | 0.50 | 6.7 | 1,546 | 20,901 |

| Indicated | 46.6 | 0.49 | 6.5 | 736 | 9,778 |

| Measured and Indicated | 143.1 | 0.50 | 6.7 | 2,282 | 30,679 |

| Inferred | 2.6 | 0.42 | 7.4 | 36 | 626 |

| Sulfide | Inferred | 87.7 | 0.71 | 21.1 | 2,002 | 59,441 |

Numbers may not add due to rounding

Oxide resources are reported within a $1,400/oz Au optimized open pit shell. Gold-equivalent grades were calculated in the Shahuindo resource block model using the individual gold and silver grades for each block and metal prices of $1,200/oz Au and $15/oz Ag using the formula:

AuEq g/t = Au g/t + (Ag g/t x 15/1200)

The sulfide Mineral Resources at Shahuindo are classified entirely as Inferred due to limited metallurgical characterization and wider drill spacing than in the oxide portion of the deposit. There have been no economic or mining studies of the sulfide portion of the Shahuindo deposit completed to date; the Inferred sulfide resource is reported at a 0.5 AuEq g/t cut-off using the same metal prices as used for calculating the oxide gold-equivalent values.

The drill data used for the estimate of Mineral Resources includes data from all drilling completed through April 2015. The drill hole information includes collar location, downhole survey, assay, lithology and oxidation data.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Lithological, oxidation and structural models were created to model the distribution of mineralization to the pertinent geologic domains. Gold mineralization domains were created using a 0.1 g/t Au cut-off; these domains were used as hard boundaries to constrain the grade estimate. Silver values have been estimated inside the gold domains. A suite of other elements were also modeled and estimated into the block model, including sulfur, copper, lead, zinc, arsenic, molybdenum, calcium, total iron, sodium and manganese. The economic contribution of these elements is not material to the project.

| 1.13.2 | Mineral Reserve Estimate |

The Shahuindo Proven and Probable Mineral Reserves total 111.9 million tonnes of oxide material at average grades of 0.53 g/t Au and 6.8 g/t silver; containing 1.91 million ounces of gold and 24.5 million ounces of silver at a cut-off grade of 0.18 g/t Au. Mineral Reserves are inclusive of Mineral Resources. There are no sulfide Mineral Reserves reported. The effective date of the Shahuindo Mineral Reserve is 01 November 2015.

The Shahuindo Mineral Reserve estimate is summarized in Table 1.13 -2.

Table 1.13 -2 Shahuindo Mineral Reserve

Reserve Classification | Tonnes

(M) | Au Grade

(g/t) | Ag Grade

(g/t) | Au Ounces

(000s) | Ag Ounces

(000s) |

| Proven | 82.7 | 0.54 | 6.92 | 1,424 | 18,400 |

| Probable | 29.2 | 0.51 | 6.54 | 483 | 6,142 |

| Proven & Probable | 111.9 | 0.53 | 6.82 | 1,906 | 24,541 |

Numbers may not add due to rounding

Metal prices used for reporting Mineral Reserves are $1,200 per ounce gold and $15.00 per ounce silver. The Mineral Reserve estimate does not include process recovery factors or plant losses.

The cut-off grade for the Mineral Reserve was calculated from operating costs experienced at Tahoe’s La Arena mine, the estimated metallurgical performance sourced from test work and engineering first principles. Proven and Probable reserves include five percent dilution at zero grade and mining losses of two percent. Resources within the mine plan classified as Inferred were considered to have no economic value and have been classified as waste in the mining schedule.

| 1.14 | Mining Method and Mine Production Schedule |

The Shahuindo mine is an open pit heap leach operation. The mining method used is a conventional drill/blast, shovel and dump truck operation. The mining will be executed under an alliance style contract similar to the mining operation at the Company’s La Arena mine.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

The mining schedule at Shahuindo consists of two phases. Phase 1 entails mining higher grade starter pits providing ROM material to the Phase 1 leach pads in 2016 and 2017; the average mining rates in 2016 and 2017 are approximately 15,800 tonnes of ore per day and 15,300 tonnes of ore per day, respectively. Phase 2, beginning in 2018, includes the addition of a crushing and agglomeration facility, increased plant capacity and an additional leach pad. The mining rate in Phase 2 increases production to meet the Phase 2 plant capacity of 36,000 tonnes of ore per day, which will require an upgraded mining fleet.

The LOM production schedule as of 01 January 2016 forecasts the Shahuindo mine to produce and deliver to the processing facilities a total of 110.9 million tonnes of ore at an average gold grade of 0.53 g/t, and average silver grade of 6.86 g/t. The LOM plan is summarized in Table 1.14 -1.

Table 1.14 -1 Life of Mine Mining Schedule

| | Unit | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

| Ore Tonnes | k tonnes | 5,756 | 5,602 | 10,289 | 13,412 | 13,039 | 12,352 |

| Au Grade | g/t | 0.68 | 0.54 | 0.64 | 0.48 | 0.48 | 0.51 |

| Ag Grade | g/t | 5.95 | 5.73 | 7.24 | 6.45 | 7.05 | 6.47 |

| Waste Tonnes | k tonnes | 4,954 | 4,113 | 21,835 | 18,895 | 19,246 | 19,893 |

| Strip Ratio | waste:ore | 0.86 | 0.73 | 2.12 | 1.41 | 1.48 | 1.61 |

| Total Tonnes | k tonnes | 10,710 | 9,715 | 32,124 | 32,306 | 32,285 | 32,245 |

| Au Mined | k oz | 126 | 97 | 212 | 206 | 200 | 201 |

| Ag Mined | k oz | 905 | 1,090 | 2,524 | 2,741 | 2,954 | 2,568 |

| | Unit | 2022 | 2023 | 2024 | 2025 | Total |

| Ore Tonnes | k tonnes | 16,066 | 14,405 | 12,732 | 7,236 | 110,890 |

| Au Grade | g/t | 0.50 | 0.59 | 0.52 | 0.49 | 0.53 |

| Ag Grade | g/t | 7.79 | 7.16 | 6.36 | 7.30 | 6.86 |

| Waste Tonnes | k tonnes | 16,395 | 15,922 | 17,497 | 11,106 | 149,855 |

| Strip Ratio | waste:ore | 1.02 | 1.11 | 1.37 | 1.53 | 1.35 |

| Total Tonnes | k tonnes | 32,461 | 30,327 | 30,230 | 18,342 | 260,485 |

| Au Mined | k oz | 258 | 273 | 215 | 113 | 1,900 |

| Ag Mined | k oz | 3,599 | 3,143 | 2,663 | 2,246 | 24,470 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Gold from the Shahuindo mine will be extracted from the ore via heap leach and then processed by carbon-in-column, adsorption-desorption-refining (ADR) operations. The civil and geotechnical design of the leach pads were engineered by Anddes Asociados SAC; the process plant was engineered by Heap Leaching Consulting SAC, both of Lima, Peru.

The start-up production plan for the processing of Shahuindo ore is 10,000 tpd (Phase 1) with processing capacity expanded early in the second half of 2016. Average processing rates in 2016 and 2017 are about 12,200 tonnes of ore per day and 16,500 tonnes of ore per day, respectively. The process plant facilities will be further expanded in Phase 2 to 36,000 tonnes per day. The Phase 2 expansion to be implemented in 2018 will include a crushing and agglomeration circuit that includes a single-stage crusher and screen, cement and lime addition to the fines, agglomeration in belt conveyors and stacking system to place ore onto the leach pad.

The processing parameters are shown in Table 1.15 -1.

Table 1.15 -1 Processing Design Parameters

| Parameter | Phase 1 | Phase 2 |

| Leach Pad Area | 41 Ha | 153 |

| Dry Tonnes of Ore/Day | 10,000 | 36,000 |

| Head Grade | 0.64 g/t Au | 0.52 g/t Au |

| Average Flow Rates | 400 m3/H | 1600-1800 m3/H |

| Leach Time | 80-90 days | 75-85 days |

| Lift Height | 8 meters | 8-16 meters |

| Material Size | 100% minus 300mm | 100% minus 75mm |

| NaCN Consumption | 0.2 kg/tonne of ore | 0.3 kg/tonne of ore |

| Lime Consumption | no addition | 1.0 kg/tonne of ore |

| Cement Consumption | n/a | 4-6 kg/tonne |

| Average Au Recovery | 73% | 80% |

The Shahuindo mine is scheduled to produce a total of 1.504 million ounces of gold and 2.8 million ounces of silver in doré over a 10 year period. Table 1.15 -2 summarizes the life of mine process plant throughput schedule and ounce production.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Table 1.15 -2 Life of Mine Process Plant Throughput

| | Unit | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

| Heap Leach Process Tonnes | k tonnes | 4,446 | 6,022 | 11,179 | 13,000 | 13,039 | 12,352 |

| Process Au Head Grade | g/t | 0.79 | 0.52 | 0.60 | 0.48 | 0.48 | 0.51 |

| Process Ag Head Grade | g/t | 6.59 | 5.63 | 6.84 | 6.56 | 7.05 | 6.47 |

| Au ounces recovered | k oz | 82.6 | 74.1 | 172.9 | 161.8 | 160.0 | 160.8 |

| Ag ounces recovered | k oz | 65.9 | 76.3 | 294.9 | 328.9 | 354.5 | 308.2 |

| | Unit | 2022 | 2023 | 2024 | 2025 | Total |

| Heap Leach Process Tonnes | k tonnes | 13,140 | 13,140 | 13,140 | 11,431 | 110,890 |

| Process Au Head Grade | g/t | 0.55 | 0.62 | 0.52 | 0.41 | 0.53 |

| Process Ag Head Grade | g/t | 8.52 | 7.44 | 6.30 | 6.28 | 6.86 |

| Au ounces recovered | k oz | 186.5 | 209.5 | 174.5 | 120.8 | 1,503.7 |

| Ag ounces recovered | k oz | 431.9 | 377.2 | 319.6 | 276.9 | 2,834.2 |

The Shahuindo mine is approximately 25 kilometers by road from the town of Cajabamba and 130 kilometers by road from the town of Cajamarca. Access from Cajamarca is via asphalt-paved highway and gravel and dirt roads.

During Phase 1 operations, power at the site will be provided by on-site diesel generation capable of sustaining 1.2 MW of power. In 2018, power will be provided via the National Commercial Grid. The long term power requirement for the Shahuindo mine is 7.4MW.

All process and domestic water for the operation will be supplied from an 18,000 cubic meter rainwater run-off collection pond, a water well located 300m west of the Shahuindo open pit, and from pit dewatering which will be pumped at the beginning of the second year of operation. Hydrogeological studies indicate sufficient water will be available to supply process and potable water requirements for the life of the mine.

At the effective date of this report, buildings required for the initial start-up are in place and are tailored for Phase 1 production. Some of the infrastructure from Phase 1 will be upgraded before Phase 2 production commences.

The entire facility was designed with closure in mind to the greatest extent practicable. The facilities are designed and operated to minimize the footprints and areas of disturbance and utilize the most advanced planning and reclamation techniques available. The disturbance footprint of Shahuindo mine site is approximately 1,348 Ha. Reclamation will commence as soon as practical during operations by placing salvaged topsoil on outer slopes and encouraging vegetation.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

| 1.18 | Capital and Operating Costs |

| | |

| 1.18.1 | Operating Costs |

The operating costs for the Shahuindo mine were calculated for each year during the life of mine using the forecasted annual production tonnages. The mining, processing and site general and administration (G&A) costs were derived from first principals, or based on operating costs experienced at Tahoe’s La Arena mine which is comparable to the Shahuindo mine.

Table 1.18 -1 includes the summary of the anticipated life-of-mine costs.

Table 1.18 -1 Operating Cost Summary

| Operating Cost | Value |

| Mining Cost ($/tonne mined) | $1.91 |

| Mining Cost ($/ore tonne mined) | $4.50 |

| Process Plant Operating Cost ($/tonne processed) | $2.55 |

| General Administration ($/tonne processed) | $2.23 |

*includes $1.42/tonne ore for crushing and agglomeration beginning in 2018

The capital expenditure requirement for the Shahuindo mine is $320.3 million dollars beginning on 01 January 2016. This includes construction capital of $179.6 million and $140.7 million in sustaining capital. Capital expenditures incurred prior to 01 January 2016 are considered as ‘sunk’ costs.

The project capital is summarized in Table 1.18 -2. The total project capital carried in the financial model for new construction is expended over a three year period.

Table 1.18 -2 Project Capital

| Project Capital | $ (millions) |

| Mining | $27.5 |

| Process Plant | $105.6 |

| Other | $46.6 |

| Total | $179.6 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

The Shahuindo mine economic analysis indicates that the project has an Internal Rate of Return (IRR) of 40.6% with a payback period of 4.1 years after taxes and an after-tax Net Present Value using a five percent discount rate (NPV5) of $318.9 M after taxes.

Sensitivity analyses were conducted using changes in metal prices, operating cost, initial capital, and recovery; the results of which are summarized in Table 1.18 -3. Changes to metal prices have the greatest impact on the NPV and IRR of the project.

Table 1.18 -3 Sensitivity Analysis – NPV and IRR after Taxes

| | | NPV @

0% | NPV @

5% | NPV @

10% | | |

| Variable | Change | IRR% | Payback |

| | | | |

| | +20% | $723,045 | $508,619 | $362,690 | 67.7% | 3.3 |

| | +10% | $597,309 | $413,960 | $289,289 | 53.1% | 3.6 |

| Change in | Base Case | $471,200 | $318,863 | $215,413 | 40.6% | 4.1 |

| Metal Prices | -10% | $342,701 | $221,333 | $139,143 | 29.0% | 4.8 |

| | -20% | $202,022 | $113,741 | $54,457 | 17.1% | 6.1 |

| | +20% | $348,725 | $225,158 | $141,508 | 29.0% | 4.9 |

| Change in | +10% | $411,022 | $273,026 | $179,417 | 34.8% | 4.4 |

| Operating | Base Case | $471,200 | $318,863 | $215,413 | 40.6% | 4.1 |

| Cost | -10% | $530,361 | $363,820 | $250,632 | 46.7% | 3.8 |

| | -20% | $588,728 | $407,955 | $285,031 | 53.1% | 3.6 |

| | +20% | $409,200 | $263,661 | $165,625 | 29.1% | 4.8 |

| Change in | +10% | $440,142 | $291,213 | $190,477 | 34.2% | 4.5 |

| Total | Base Case | $471,200 | $318,863 | $215,413 | 40.6% | 4.1 |

| Capital | -10% | $502,354 | $346,596 | $240,419 | 49.0% | 3.7 |

| | -20% | $533,592 | $374,233 | $265,224 | 60.2% | 3.4 |

| | 2% | $508,599 | $347,156 | $237,466 | 44.2% | 3.9 |

| Change in | 1% | $489,905 | $333,014 | $226,443 | 42.4% | 4.0 |

| Metal | Base Case | $471,200 | $318,863 | $215,413 | 40.6% | 4.1 |

| Recovery | -1% | $452,456 | $304,682 | $204,358 | 38.9% | 4.2 |

| | -2% | $433,662 | $290,459 | $193,265 | 37.2% | 4.3 |

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Numerous oxide and sulfide exploration targets that have considerable potential to increase the resource and reserve base at Shahuindo have been identified through surface mapping, rock-chip and soil sampling surveys, geophysical surveys and drilling conducted by previous owners of the Shahuindo property and by drilling conducted by Tahoe subsequent to its merger with Rio Alto in April 2015.

Drilling around the periphery of the currently-designed pit limits in the second half of 2015 successfully identified mineralization outside of the northeast and southwest margins of the Phase 2 pit shell that will be incorporated into future mine plans. Likewise, condemnation drilling in the planned waste dump area identified shallow mineralization that represents an extension to the known resource; a portion of which will be mined and delivered to the leach pad or stockpile prior to construction of the waste dump foundation.

Other drilling in 2015 identified metal grades and mineralogy similar to Shahuindo at the San Lorenzo, Choloque and La Chilca prospects proximal to the Shahuindo pit. These targets represent near-term opportunities to increase the resource base as Shahuindo.

| 1.20 | Conclusions and Recommendations |

The results of this study demonstrate that:

| | 1. | The Shahuindo mine is economically viable from 01 January 2016 through to the end of the estimated mine life, supporting the declaration of Proven and Probable Mineral Reserves. |

| | | |

| | 2. | The Shahuindo mining strategy consists of two phases. The first phase will process ROM ore at an initial rate of 10,000 tonnes of ore per day, ramping up to an average of 12,200 tonnes of ore per day in 2016 and 16,500 tonnes of ore per day in 2017; the second phase will include a crushing and agglomeration circuit that will increase production to 36,000 tonnes per day. The phased approach enables gold production as soon as possible with minimal capital expenditure, generating cash flow early in the project. |

| | | |

| | 3. | The results of laboratory testing program indicate excellent gold recoveries at both ROM and moderate crush sizes with low to moderate reagent requirements, implying amenability to heap leaching. Silver recoveries are generally low. |

| | | |

| | 4. | The Shahuindo district holds excellent opportunities for further discovery and definition of additional oxide and sulfide mineralized bodies that have potential to increase the resource base at Shahuindo. |

The authors of this report recommend the Company to:

| | 1. | Initiate field and laboratory studies investigate the potential to reduce capital and operating costs related to the Phase 2 crushing and agglomeration scheme. Conduct pilot scale heap leach tests on the current ROM leach pad to investigate field-scale performance on composites with varying degrees of coarse-to-fines ratios. The metallurgical facilities at the Company’s La Arena mine should be utilized to conduct further permeability and compaction tests. |

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

| | 2. | Investigate the ability of the siltstones and breccia with high fines content to percolate in the ROM leach pad. |

| | | |

| | 3. | Conduct additional metallurgical testing on drill samples. |

| | | |

| | 4. | Improve the geometallurgical model. Further refinement of the geologic model at Shahuindo will greatly aid in mine planning and scheduling, and increase confidence in the material types scheduled for delivery to the leach pad to optimize material blending schemes. |

| | | |

| | 5. | Aggressively explore the Shahuindo district and accelerate district exploration with the goal of discovering additional resources amenable to the Shahuindo processing facility. |

| | | |

| | 6. | Evaluate the mineralized zones on the periphery of the Shahuindo deposit to expand the resource and incorporate these extensions into a new pit design. |

| | | |

| | 7. | Improve the QA/QC procedures by including a wider-range of certified assay standards, particularly assay standards at or near the operational gold cut-off grade. Create assay blanks from coarse RC drilling rejects. Utilize a second commercial laboratory or the La Arena laboratory for check assays of exploration samples. |

| | | |

| | 8. | Update and refine the resource estimate as additional drill hole information becomes available. |

| | | |

| | 9. | Evaluate the economic potential of the sulfide mineralization below the Shahuindo pit. |

After reaching commercial production, the authors recommend the Company systematically evaluate mining, processing and other surface operations to optimize processes and procedures and reduce capital and operating costs. Examples include the following trade-off studies to evaluate:

| | a) | the potential to reduce or eliminate the requirement for the crushing and or agglomeration circuit, and the impact to metal recoveries; |

| | | |

| | b) | the economic benefit of implementing a secondary crushing circuit to increase recovery; |

| | | |

| | c) | the potential to increase the overall slope angle of the pit to increase the NPV of the project through further geotechnical and hydrogeological analyses; and |

| | | |

| | d) | the potential to reduce operating costs by evaluating the suitability by backfilling mined waste rock into the pit. |

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

| 2.1 | Purpose and Basis of Report |

Tahoe Resources Inc. (Tahoe or Company), whose common shares are listed for trading on the Toronto Stock Exchange (TSX:THO), New York Stock Exchange (NYSE:TAHO) and Bolsa de Valores: Peru (BVL:THO), has prepared an updated Technical Report (the Report) for the Company’s Shahuindo mine in Peru. This report presents the results of a prefeasibility study of the technical and economic viability of the Shahuindo mine.

The following events have triggered an updated NI 43-101 Technical Report for the Shahuindo mine:

| • | On 09 February 2015, Tahoe and Rio Alto Gold (Rio Alto) entered into a definitive agreement to combine their respective businesses and finalized the transaction on 01 April 2015. Through this merger, Tahoe Resources acquired 100% ownership of the mining assets of Rio Alto which included the Shahuindo project. |

| | | |

| • | The Mineral Resources and Mineral Reserves estimates have been updated as the result of data obtained from drilling and additional engineering studies conducted in 2014 and 2015. Mining studies incorporate updated cost estimates and financial analyses. |

| | | |

| | • | Tahoe has revised the mining strategy for the Shahuindo mine. |

| | | |

| • | Tahoe has conducted further metallurgical testing on the ore at Shahuindo and has revised the metallurgical assumptions and flowsheet for the project. |

This report has been completed in accordance with the disclosure and reporting requirements set forth in the Toronto Stock Exchange Manual, National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101), Companion Policy 43-101CP to NI 43-101, and Form 43-101F1 of NI 43-101.

| 2.2 | Sources of Information |

Information contained in this Report was obtained from prior Technical Reports and from work completed by independent consultants on behalf, and under the direction, of Rio Alto and Tahoe, and by work completed by Rio Alto and Tahoe personnel under the guidance of the authors. Information included herein derived from this work is cited in the text of this Report, with references listed in Section 27.0. The authors have made all reasonable effort to establish the completeness and authenticity of the information provided in this Report.

Prior Technical Reports filed on the Shahuindo project include:

| | • | Resources Estimation, Shahuindo Project, Peru(Saucier and Poulin, 2004) |

| | | |

| | • | Resources Estimation, Shahuindo Project, Peru(Saucier and Buchanan, 2005) |

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

| • | Shahuindo Gold Project, CajabambaProvince, Peru, NI 43-101 Technical Report on PreliminaryAssessment(Wright et al., 2010a) |

| | | |

| • | Shahuindo Gold Project, CajabambaProvince, Peru, NI 43-101 Technical Report on PreliminaryAssessment(Wright et al., 2010b) |

| | | |

| | • | Technical Report on the Shahuindo Project, Cajabamba, Peru(Tietz and Kappes, 2011) |

| | | |

| | • | Updated Technical Report on the Shahuindo Project, Cajabamba, Peru(Tietz and Defilippi, 2012) |

| | | |

| | • | Technical Report on the Shahuindo Heap Leach Project(Defilippi,et. al., 2012) |

| 2.3 | Qualified Persons and Site Visits |

Mr. Tim Williams, Tahoe’s Vice President Operations and Peru Country Manager, Mr. Charles V. Muerhoff, Tahoe’s Vice President Technical Services and Mr. Carl E. Defilippi of Kappes, Cassiday & Associates prepared this Technical Report. Each is a Qualified Person (QP) by NI 43-101 definitions.

Dates of site visits and specific sections of the Report that the Qualified Persons are responsible for are listed in Table 2.3 -1.

Table 2.3 -1 Qualified Persons – Site Visits and Report Responsibilities

| QP Author | Company | Designation | Site Visit | Section Responsibility |

| Tim Williams | Tahoe Resources Inc. | FAusIMM | Multiple Site Visits 2014 & 2015 | Sections 4, 15, 16, 18, 20 and corresponding items in Sections 1, 25, 26 |

| | | | | |

| Charles V. Muerhoff | Tahoe Resources Inc. | SME Registered Member | May 19-20, 2015

November 13-14, 2015 | Sections 2, 3, 5 through 12, 14, 19, 21 through 24 and corresponding items in Sections 1, 25, 26 |

| | | | | |

| Carl E. Defilippi | Kappes, Cassiday & Associates | SME Registered Member | May 4-7, 2010

April 6-8, 2010

September 2-3, 2015 | Sections 13, 17 and corresponding items in Sections 1, 25, 26 |

The effective date of this Technical Report is 01 January 2016. The effective date of the Shahuindo Mineral Resource estimate is the 15 April 2015. The effective date of the Shahuindo Mineral Reserve Estimate is 01 November 2015.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Unless otherwise specified, all monetary dollars expressed in this Report are in United States dollars ($). Metal grades are expressed in grams per metric tonne (g/t) and metal content is expressed in troy ounces. All units of measure, unless otherwise specified, are metric.

| 2.6 | Abbreviations and Acronyms |

A list of abbreviations and acronyms commonly used in this report is provided in Table 2.6 -1.

Shahuindo Mine, Peru

NI 43-101 Technical Report |

|

|

Table 2.6 -1 List of Abbreviations

| Abbr. | Description | Abbr. | Description |

| $ | United States of America dollars | m | meters |

| µ | microns | m2 | square meters |

| ADR | adsorption-desorption-refining | m3 | cubic meters |

| Ag | silver | MCE | maximum considered earthquake |

| ARD | acid rock drainage | MEM | Ministry of Energy and Mines |

| Au | gold | mm | millimeters |

| AuEq | gold-equivalent | MMR | Minimum Mining Royalty |

| bcm | bank cubic meters | Moz | million troy ounces |

| CAPEX | capital expenditure | MPa | million Pascal |

| CIM | Canadian Institute of Mining, Metallurgy and Petroleum | Mt | millions of dry metric tonnes |

| CIRA | Certificate for the Inexistence of Archaeological Remains | Mt/y | million tonnes per year |

| CN | cyanide | MW | megawatt |

| dmt | dry metric tonne | NAG | non acid generating |

| DSHA | deterministic seismic hazard assessment | NI 43-101 | Canadian National Instrument 43-101 |

| EIA | Estudio de Impacto Ambiental (environmental impact study) | NPV | net present value |

| GEU | Geo Environmental Unit | NSR | net smelter return |

| g/t | grams per metric tonne | oz | troy ounce |

| in | inches | PAG | potentially acid generating |

| ha | hectare | PGA | peak ground acceleration |

| HDPE | high-density polyethylene | PLS | pregnant leach solution |

| hp | horsepower | ppm | parts per million |

| IBC | International Building Code | PSAD | Peru Central Zone |

| IGV | impuesto general a las ventas | PSHA | probabilistic seismic hazard assessment |

| IP | induced polarization | QA/QC | quality assurance and quality control |

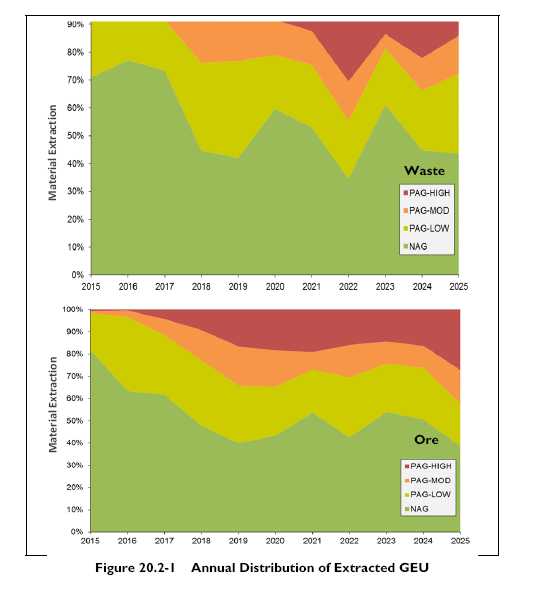

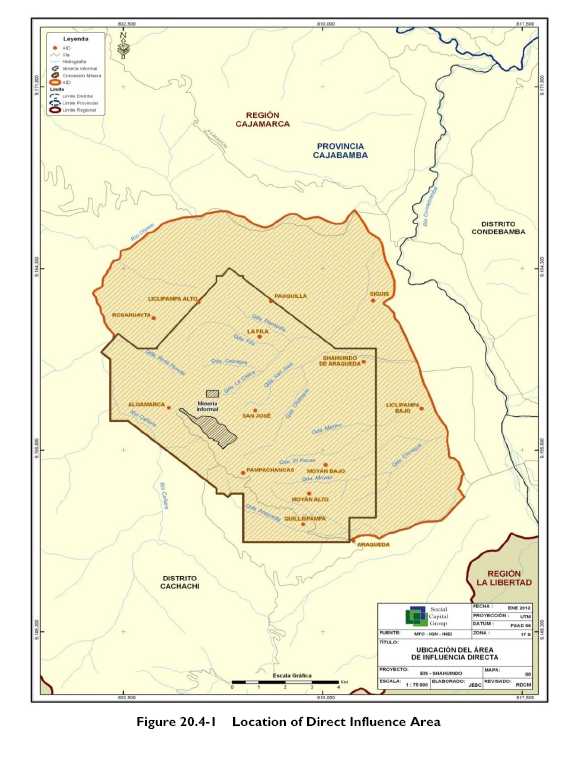

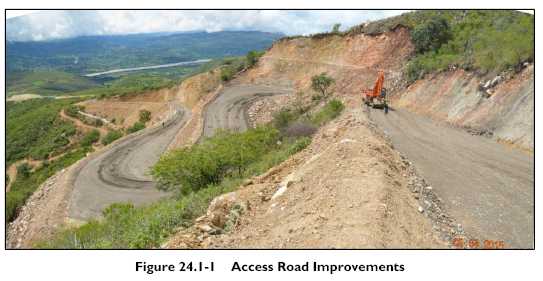

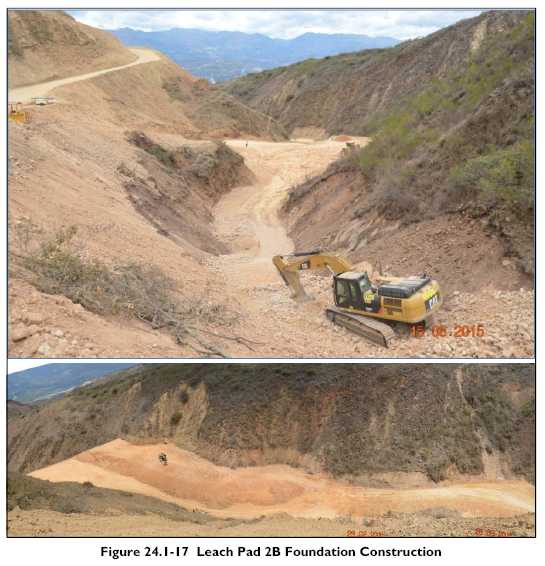

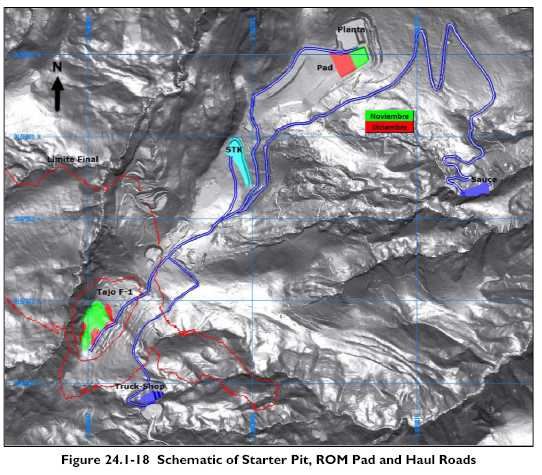

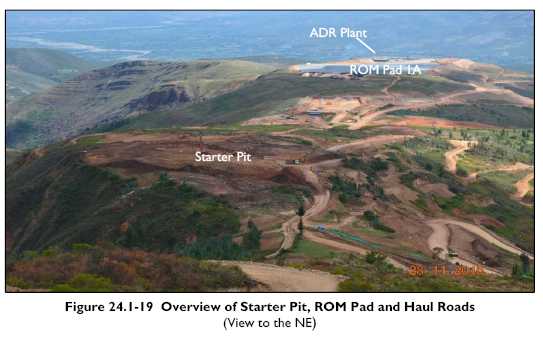

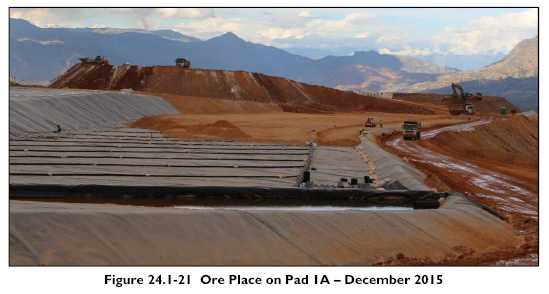

| IRR | internal rate of return | QP | Qualified Person |