Exhibit 99.2 |

|

A GLOBAL LEADER IN

Financial report 2011

|

Tembec

Financial Report 2011

1

Message to Shareholders

4

Management’s Discussion and Analysis

52

Management Responsibility

53

Independent Auditors’ Report

54

Consolidated Financial Statements

95

Directors and Officers

96

Shareholder Information

Design: Communications DG4 Inc.

Printing: Transcontinental Direct Montréal

Cover: Printed on 10pt. FSC-certified Kallima® Coated

Cover C1S Plus, manufactured by Tembec’s Temiscaming,

Quebec coated bleached board mill.

Interior: Printed on 70 lb. text FSC-certified Mohawk®

Beckett Expression Radiance, manufactured using pulp

from Tembec’s Skookumchuck, British Columbia mill.

TEMBEC INC.

©2011 All rights reserved

Printed in Canada

Message

to Shareholders

The financial results for 2011 were below expectations due to low prices for some of the Company’s key products and further strengthening of the Canadian dollar. Nevertheless, this was an important year as the Company made important strides toward its ongoing repositioning. The objective of this process is to raise the overall margins and reduce the volatility of earnings through a combination of focused capital investments and targeted transactions. Ultimately, the Company will reduce its dependency on high commodity prices to generate acceptable rates of return.

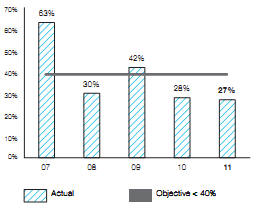

Health and safety performance continued to improve, with the Company’s Occupational Safety and Health Administration (OSHA) incident rate improving by 25% between 2010 and 2011. This reflects an ongoing multi-year plan designed to raise levels of awareness, communications and accountability. Health and safety is the top priority throughout Tembec, from frontline employees to the President and Chief Executive Officer. The objective is to be an industry leader in this critical area. EBITDA was $95 million for the year versus $132 million for the previous year. Market conditions were very favorable for the Company’s Specialty and Commodity Dissolving Pulp and NBSK businesses. However, conditions weakened for the High-Yield Pulp business and remained weak for the ForestProducts business. The Paper results strengthened in the year with the newsprint business accounting for most of the improvement. In the previous year, the Company placed significant focus on the balance sheet achieving both an extension of term debt maturities until 2018 and debt reduction. In 2011, the asset- based loan was replaced with maturity in 2016. With the debt portion of the balance sheet in good shape, and with strong liquidity, the Company can now focus on the repositioning of its asset base. Last year, the Company indicated that a Business Improvement Plan (BIP) had been developed with the objective of achieving first or second quartile cost position for all of its assets. Within the BIP, priorities have been established to drive capital investment strategy and a dominant theme has emerged. A large portion of the investment will be in the Company’s specialty dissolving pulp assets where margins are higher and more predictable. Also, a large portion of the overall BIP will focus on green energy investments, which will involve high return projects with low cash flow volatility. Again, the objective is to improve the overall margins and returns for shareholders and reduce the vulnerability to swings in product prices. | INVESTMENTS Consistent with the above-mentioned strategy, the Company has launched several energy capital projects in 2011. In addition to these projects, some basic reinvestment in the existing asset base has taken place with the objective of improving equipment reliability and productivity. These investments will continue for the next two years and will lead to improved operating results beginning in mid-2012. The Company commenced a new turbine project at the specialty dissolving pulp mill in Tartas, France, to produce approximately 8 megawatts of green electricity generated by biomass. This $21 million project will increase EBITDA at this facility by $8 million per year and position the mill to be one of the lowest cost facilities in this sector. The project is forecasted to start up in July 2012. A $25 million methane biogas reactor project was started at the Matane, Quebec, high-yield pulp mill. This project received grants from the province of Quebec and the Federal Government totalling $24 million, making the net capital cost to the Company $1 million. The project will eliminate the need to burn oil at this facility to dry pulp, improving EBITDA by $6 million per year.This is also forecasted to start up in July 2012. The Company’s Board of Directors has approved a major energy investment at its specialty dissolving pulp mill in Temiscaming, Quebec, to produce green electricity from waste liquor. This $190 million project will involve the installation of a high pressure liquor recovery boiler and an electrical turbine, which will result in the production of 40 megawatts of electricity and 5,000 tonnes of additional specialty dissolving pulp. The project should generate $42 million of incremental EBITDA and position this facility to also be among the lowest cost producers. This project is conditional upon signing a purchase power agreement with Hydro Quebec, which is expected to be finalized in the March 2012 quarter. |

Tembec Financial Report 2011 1

Message to Shareholders

Also under evaluation is the expansion of specialty dissolving pulp production in Temiscaming, Quebec. A study is underway to determine the feasibility of adding 30,000 tonnes of additional pulp capacity and 10 megawatts of additional electricity generation. This study is expected to be completed in 2012. | Specialty dissolving pulp is a highly technical product designed for individual customers in very technical applications. There are significant barriers to enter into this business that include capital costs of equipment and technical expertise. Most of the business in this sector is done under long-term contracts with periodic price negotiations. In 2011, as prices were negotiated, substantial increases were obtained by specialty pulp producers as the prevalent conditions were significantly in favor of producers. The long-term outlook for specialty dissolving pulp appears very positive with various segments of the customer base forecasting growth in the range of 2-6% per year. The three largest producers are contemplating capacity expansion to meet this growth in demand, with some projects officially announced and others under study. Normally, growth in supply in a sector of this size can create imbalances if too much product is brought into the market too quickly. However, this business is in a unique situation where specialty pulp capacity can be swung to produce the commodity grade keeping the specialty markets in balance. Commodity dissolving pulp mills cannot easily swing into the specialty grades. Demand for the commodity dissolving pulp also dramatically increased during the year due to the convergence of unusual global conditions and steady growth in demand. This caused a spike in spot prices to record levels. Over the last several years, Viscose Staple Fibre (VSF) capacity has expanded to satisfy the growing demand for rayon, particularly in the emerging markets. The demand for commodity dissolving pulp, which is the main raw material for VSF, has grown proportionately. Shortages in cotton supply, caused by floods and drought in various producing regions around the globe, began in 2010 and carried over into mid-2011, causing cotton prices to spike. These high cotton prices, coupled with strong demand fundamentals in the VSF market, caused global VSF prices to spike, which in turn pushed commodity dissolving prices to record highs. In the second half of 2011, the markets for cotton, VSF and commodity dissolving pulp have rebalanced and prices have fallen although they remain at profitable levels. The medium to long-term demand outlook for VSF and commodity dissolving pulp is projected to be positive. Significant pulp capacity expansion projects have been announced to supply this growing market. | |

Tembec Financial Report 2011 2

Message to Shareholders

The near-term and long-term fundamentals for the specialty dissolving pulp market are ver y positive, and prices will likely increase in 2012. The commodity grade is expected to experience a well supplied market over the next year, with prices falling from 2011 levels. The Company will further reduce its sales into the commodity market in 2012 in order to satisfy the growing needs of customers in the specialty markets. | This caused a decline in all paper pulp prices in the second half of 2011. It is expected that, due to limitations to growth in supply of softwood paper pulp and the cost structure of this sector, prices will recover early in 2012. Most of the Company’s paper pulp capacity is in the hardwood high-yield pulp sector. This product experienced a decline earlier in 2011 due to the start-up of new capacity in China. This product is influenced by the fundamentals of the hardwood markets, which will take longer to recover as compared to the softwood pulp market. Paper The newsprint business continues to be a sector in steady decline in North America. The decline in demand has been mitigated by a combination of temporary and permanent capacity closures and increased offshore exports. However, these measures have not been enough to raise prices to a profitable level for a large number of North American operations. This has been evident by the severe financial challenges faced by large producers in this sector. Further capacity reductions will be required to restore the profitability of this business to sustainable levels. SUMMARY The Company’s Management and Board of Directors are focused on the implementation of the Strategic Plan. While a number of initiatives have been completed, significant steps remain in the repositioning of Tembec to reach our goal of higher margins and more stable earnings. While this is occurring, the Company will remain focused on cost reductions, operational excellence and becoming a world class health and safety organization. | |

| ||

| JAMES M . LOPEZ | JAMES V. CONTINENZA | |

| President and Chief Executive Officer | Chairman of the Board |

Tembec Financial Report 20113

Management’s

Discussion and Analysis

as at November 30, 2011

The Management’s Discussion and Analysis (MD&A) section provides a review of the significant developments and issues that influenced Tembec Inc.’s financial performance during the fiscal year ended September 24, 2011, as compared to the fiscal year ended September 25, 2010. The MD&A should be read in conjunction with the audited consolidated financial statements for the fiscal year ended September 24, 2011. All references to quarterly or Company information relate to Tembec Inc.’s fiscal quarters. EBITDA, net debt, total capitalization, free cash flow and certain other financial measures utilized in the MD&A are non-GAAP (Generally Accepted Accounting Principles) financial measures. As they have no standardized meaning prescribed by GAAP, they may not be comparable to similar measures presented by other companies.

The MD&A includes “forward-looking statements” within the meaning of securities laws. Such statements relate, without limitation, to the Company’s or management’s objectives, projections, estimates, expectations or predictions of the future and can be identified by words such as “may”, “will”, “could”, “anticipate”, “estimate”, “expect”, and “project”, the negative or variations thereof, and expressions of similar nature. Forward-looking statements are based on certain assumptions and analyses made by the Company in light of its experience, information available to it and its perception of future developments. Such statements are subject to a number of risks and uncertainties, including, but not limited to, changes in foreign exchange rates, product selling prices, raw material and operating costs and other factors identified in the Company’s periodic filings with securities regulatory authorities. Many of these risks are beyond the control of the Company and, therefore, may cause actual actions or results to materially differ from those expressed or implied herein. The forward-looking statements contained herein reflect the Company’s expectations as of the date hereof and are subject to change after such date. The Company disclaims any intention to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, unless required by applicable securities legislation. The information in this MD&A is as at November 30, 2011. Disclosure contained in this document is current to that date, unless otherwise stated.

Throughout the MD& A, “Tembec” or “Company” means Tembec Inc. and its consolidated subsidiaries. Prior to December 2010, Tembec’s operations consisted of five reportable business segments: Forest Products, Pulp, Paper, Chemicals and Corporate. During the December 2010 quarter, the Company reorganized its internal reporting structure. Subsequent to the organizational changes, the Pulp segment was divided into two segments: Dissolving and Chemical Pulp, and High-Yield Pulp. Each segment includes three pulp mills. As well, the Chemicals segment is now part of the Dissolving and Chemical Pulp segment. A significant portion of Chemicals sales are related to by-products generated by the two dissolving pulp mills. The Forest Products, Paper and Corporate segments were unaffected by the organizational changes. Comparative prior year segment information has been restated to conform with the new segment presentation. On September 24, 2011, the Company had approximately 4,250 employees, as compared to 4,300 at the end of the prior fiscal year. The Company operated manufacturing facilities in Quebec, Ontario, British Columbia, the state of Ohio as well as in Southern France. Principal facilities are described in the subsequent sections of the MD&A.

4Tembec Financial Report 2011

Management’s Discussion and Analysis

2011 vs. 2010

| FINANCIAL SUMMARY | ||||||

| (in millions of dollars, unless otherwise noted) | ||||||

| 2010 | 2011 | |||||

| Sales | 1,877 | 1,743 | ||||

| Freight and sales deductions | 234 | 237 | ||||

| Lumber export taxes | 10 | 13 | ||||

| Cost of sales | 1,426 | 1,324 | ||||

| SG&A | 73 | 72 | ||||

| Share-based compensation | 2 | 2 | ||||

| EBITDA | 132 | 95 | ||||

| Depreciation and amortization | 56 | 45 | ||||

| Other items | 13 | 1 | ||||

| Operating earnings | 63 | 49 | ||||

| Interest, foreign exchange and other | 51 | 32 | ||||

| Exchange loss (gain) on long-term debt | (27 | ) | 1 | |||

| Earnings before income taxes and non-controlling interest | 39 | 16 | ||||

| Income tax expense (recovery) | (15 | ) | 19 | |||

| Non-controlling interest | 2 | – | ||||

| Net earnings (loss) and comprehensive earnings (loss) | 52 | (3 | ) | |||

| Basic and diluted earnings (loss) in dollars per share | 0.52 | (0.03 | ) | |||

| Total assets (at year-end) | 1,104 | 1,107 | ||||

| Total long-term debt (at year-end)(1) | 288 | 289 | ||||

| Total long-term financial liabilities (at year-end) | 480 | 459 | ||||

| (1)includes current portion |

| CONSOLIDATED SALES | CONSOLIDATED SALES BY SEGMENT |

| (in millions of dollars) | (in millions of dollars) |

|  |

Tembec Financial Report 20115

Management’s Discussion and Analysis

| EBITDA BY SEGMENT | FINANCIAL PERFORMANCE |

| (in millions of dollars) | |

|  |

| SALES | |||||||||||||||

| (in millions of dollars) | |||||||||||||||

| Total | Price | Volume & mix | |||||||||||||

| 2010 | 2011 | variance | variance | variance | |||||||||||

| Forest Products | 434 | 471 | 37 | (10 | ) | 47 | |||||||||

| Dissolving and Chemical Pulp | 830 | 693 | (137 | ) | 71 | (208 | ) | ||||||||

| High-Yield Pulp | 395 | 378 | (17 | ) | (53 | ) | 36 | ||||||||

| Paper | 348 | 339 | (9 | ) | 6 | (15 | ) | ||||||||

| Corporate | 5 | 7 | 2 | – | 2 | ||||||||||

| 2,012 | 1,888 | (124 | ) | 14 | (138 | ) | |||||||||

| Less: internal sales | (135 | ) | (145 | ) | (10 | ) | |||||||||

| Sales | 1,877 | 1,743 | (134 | ) |

Sales decreased by $134 million as compared to fiscal 2010. Currency was unfavourable as the Canadian dollar averaged US $1.013, a 5.5% increase from US $0.960 in the prior year. Forest Products segment sales increased by $37 million primarily as a result of higher shipments. Dissolving and Chemical Pulp segment sales declined by $137 million due to significantly lower shipments, partially offset by higher prices. High-Yield Pulp segment sales decreased by $17 million due to lower prices, as higher shipments partially offset the decline. Paper segment sales decreased by $9 million due to lower shipments, partially offset by higher prices.

In terms of geographical distribution, the U.S. remained the Company’s principal market with 34% of consolidated sales in fiscal 2011, as compared to 31% in the prior year. Canadian sales represented 18% of sales, as compared to 20% in the prior year. Sales outside of the U.S. and Canada represented the remaining 48% in fiscal 2011, as compared to 49% a year ago.

6Tembec Financial Report 2011

Management’s Discussion and Analysis

| EBITDA | |||||||||||||||

| (in millions of dollars) | |||||||||||||||

| Total | Price | Cost & volume | |||||||||||||

| 2010 | 2011 | variance | variance | variance | |||||||||||

| Forest Products | (10 | ) | (46 | ) | (36 | ) | (10 | ) | (26 | ) | |||||

| Dissolving and Chemical Pulp | 120 | 138 | 18 | 71 | (53 | ) | |||||||||

| High-Yield Pulp | 47 | (4 | ) | (51 | ) | (53 | ) | 2 | |||||||

| Paper | (2 | ) | 28 | 30 | 6 | 24 | |||||||||

| Corporate | (23 | ) | (21 | ) | 2 | – | 2 | ||||||||

| 132 | 95 | (37 | ) | 14 | (51 | ) |

EBITDA declined by $37 million over the prior year. Forest Products segment EBITDA declined by $36 million due to higher costs and lower prices. Dissolving and Chemical Pulp segment EBITDA increased by $18 million due to higher prices, partially offset by higher costs. High-Yield Pulp segment EBITDA decreased by $51 million due to lower prices. Paper segment EBITDA increased by $30 million on a combination of higher prices and lower costs. Corporate expenses for the current year include a charge of $2 million relating to share-based compensation, unchanged from the prior year.

| OPERATING EARNINGS (LOSS) | ||||||||||||||||||

| (in millions of dollars) | ||||||||||||||||||

| Depreciation & | Other | |||||||||||||||||

| Total | EBITDA | amortization | items | |||||||||||||||

| 2010 | 2011 | variance | variance | variance | variance | |||||||||||||

| Forest Products | (24 | ) | (63 | ) | (39 | ) | (36 | ) | 3 | (6 | ) | |||||||

| Dissolving and Chemical Pulp | 105 | 120 | 15 | 18 | 9 | (12 | ) | |||||||||||

| High-Yield Pulp | 37 | (14 | ) | (51 | ) | (51 | ) | – | – | |||||||||

| Paper | (12 | ) | 25 | 37 | 30 | – | 7 | |||||||||||

| Corporate | (43 | ) | (19 | ) | 24 | 2 | (1 | ) | 23 | |||||||||

| 63 | 49 | (14 | ) | (37 | ) | 11 | 12 | |||||||||||

The Company generated operating earnings of $49 million compared to operating earnings of $63 million in fiscal 2010.

The Forest Products segment generated an operating loss of $63 million in fiscal 2011, compared to an operating loss of $24 million in fiscal 2010. In addition to the previously noted decline in EBITDA, the segment’s current year results include a charge of $3 million relating to the permanent closure of the Taschereau, Quebec, SPF sawmill. It also includes a charge of $1 million related to severance payments at the idled planer facility in Cranbrook, British Columbia. The prior year included a $2 million gain related to land sales. Depreciation expense declined by $3 million as the continued difficult market conditions led to relatively low capital expenditures.

Tembec Financial Report 20117

Management’s Discussion and Analysis

The Dissolving and Chemical Pulp segment generated operating earnings of $120 million during the most recently completed fiscal year, compared to operating earnings of $105million a year ago. In addition to the previously noted $18 million improvement in EBITDA, depreciation expense decreased by $9 million, primarily as a result of the sale of two pulp mills that occurred in early May of fiscal 2010. In the prior year, this segment had recorded a gain of $12 million relating to the sale of the aforementioned pulp mills.

The High-Yield Pulp segment generated an operating loss of $14 million during the most recently completed fiscal year, compared to operating earnings of $37 million a year ago. The decline in EBITDA accounted for the weaker operating results.

The Paper segment generated operating earnings of $25million compared to an operating loss of $12 million in the prior year. Besides the previously noted increase in EBITDA, the segment’s prior year results had absorbed a charge of $7million relating to the permanent closure of the Pine Falls, Manitoba, newsprint facility.

Corporate expenses decreased by $24 million. The prior year results included a non-recurring charge of $12 million relating to the St. Francisville, Louisiana, coated paper mill. The mill property and equipment were sold in April 2009. A portion of the consideration included two US $5 million interest-bearing notes. In January 2010, the purchaser filed for protection under the U.S. Bankruptcy Code. Subsequently, the assets were sold at auction. Based on the amount of the winning bid, it was unlikely that the Company would recover any portion of the interest-bearing notes. As a result, the Company recorded a charge of $12 million. The aforementioned amount included accrued interest as well as certain other unsecured claims. The current year results include a gain of $8 million related to the filing of Tembec USA LLC under Chapter 7 of the Bankruptcy Code of the United States. The Company reduced its accrued benefit obligation by this amount. It also includes a $3million gain related to the sale of its hydro-electric generating facilities located in Smooth Rock Falls, Ontario.

8Tembec Financial Report 2011

Management’s Discussion and Analysis

Segment Review – 2011 vs. 2010

| FOREST PRODUCTS | ||||||

| (in millions of dollars) | ||||||

| 2010 | 2011 | |||||

| Total sales | 434 | 471 | ||||

| Consolidated sales | 346 | 375 | ||||

| EBITDA | (10 | ) | (46 | ) | ||

| EBITDA margin on total sales | (2.3 | )% | (9.8 | )% | ||

| Depreciation and amortization | 16 | 13 | ||||

| Other items | (2 | ) | 4 | |||

| Operating loss | (24 | ) | (63 | ) | ||

| Identifiable assets (excluding cash) | 241 | 264 |

The Forest Products segment is divided into two main areas of activity: forest resource management and manufacturing operations.

The Forest Resource Management group is responsible for managing all of the Company’s Canadian forestry operations. This includes the harvesting of timber, either directly or by contractual agreements, and all silviculture and regeneration work required to ensure a sustainable supply for the manufacturing units. The group is also responsible for third party timber purchases, which are needed to supplement total requirements. The group’s main objective is the optimization of the flow of timber into various manufacturing units. As the Company’s forest activity in Canada is conducted primarily on Crown lands, the Forest Resource Management group works closely with provincial governments to ensure harvesting plans and operations comply with established regulations and that stumpage charged by the provinces is reasonable and reflects the fair value of the timber being harvested. During fiscal 2011, the Company’s operations harvested and delivered 3.9 million cubic metres of timber versus 3.2 million cubic metres in 2010. Additional supply of approximately 0.9 million cubic metres was secured mainly through purchases and exchanges with third parties, compared to 0.7 million cubic metres in the prior year.

The Forest Products segment includes operations located in Quebec, Ontario and British Columbia. The segment focuses on three main product areas: SPF lumber, specialty wood and engineered wood. The SPF lumber operations can produce approximately 1.6 billion board feet of lumber. The specialty wood operations can annually produce 30 million board feet of hardwood lumber and 20 million square feet of hardwood flooring. The Company’s engineered wood operations consist of two finger joint lumber operations, which were idle for all of fiscal 2010 and fiscal 2011.

Tembec Financial Report 20119

Management’s Discussion and Analysis

The following summarizes the annual operating level or capacity of each facility by product group:

| SPF LUMBER | mbf | ||

| Stud lumber - La Sarre, QC | 160,000 | ||

| Stud lumber - Senneterre, QC | 150,000 | ||

| Stud lumber - Cochrane, ON | 170,000 | ||

| Stud lumber - Kapuskasing, ON | 105,000 | ||

| Random lumber - Béarn, QC | 110,000 | ||

| Random lumber - Chapleau, ON | 135,000 | ||

| Random lumber - Timmins, ON | 100,000 | ||

| Random lumber - Hearst, ON | 160,000 | ||

| Random lumber - Canal Flats, BC(1) | 180,000 | ||

| Random lumber - Elko, BC(1) | 270,000 | ||

| Finger joint lumber - Cranbrook, BC | 25,000 | ||

| 1,565,000 | |||

| SPECIALTY WOOD | mbf | ||

| Hardwood lumber - Huntsville, ON | 30,000 | ||

| thousand square ft. | |||

| Flooring - Huntsville, ON / Toronto, ON | 20,000 | ||

| ENGINEERED WOOD | mbf | ||

| Engineered finger joint lumber - La Sarre, QC | 60,000 | ||

| Engineered finger joint lumber - Kirkland Lake, ON | 30,000 | ||

| 90,000 |

(1) The Elko and Canal Flats sawmills rely on the Cranbrook planer mill to dry and dress 80,000 mbf of lumber.

10Tembec Financial Report 2011

Management’s Discussion and Analysis

The segment is dominated by SPF lumber, which represented 85% of building material sales in fiscal 2011, compared to 83% in the prior year. The volume of SPF lumber sold in fiscal 2011 increased by 121 million board feet or 15%. Shipments were equal to 57% of capacity, up from 49% in fiscal 2010. In response to very low lumber demand, the Company continued to reduce production by curtailing operations at several facilities for either indefinite or temporary periods. The split between Eastern/Western shipments was 62/38 as compared to 56/44 a year ago. The Eastern sawmills produced more lumber in fiscal 2011. US $ reference prices for random lumber were up by US $23 per mbf while stud lumber decreased by US $1 per mbf. Currency more than offset the increase in selling prices as the Canadian dollar averaged US $1.013, a 5.5% increase from US $0.960 in fiscal 2010. The net result was a $12 per mbf price decrease from a year ago.

Specialty wood represented 15% of building material sales in fiscal 2011, down from 17% in the prior year. The decline was due to higher SPF sales as absolute levels of specialty wood sales were relatively unchanged. Prices were also unchanged year-over-year.

There were no engineered wood sales in fiscal 2011. The two finger joint facilities were idle for all of fiscal 2010 and fiscal 2011.

The Forest Products segment produced and shipped approximately 1.1 million tonnes of wood chips in fiscal 2011, 85% of which were directed to the Company’s pulp and paper operations. In 2010, the segment produced 1.1 million tonnes and shipped 91% of this volume to the pulp and paper mills. The internal transfer price of wood chips is based on current and expected market transaction prices.

Total sales for this segment reached $471 million, an increase of $37 million over the prior year. After eliminating internal sales, the Forest Products segment generated 22% of Company consolidated sales, up from 18% in the prior year. The segment’s main market is North America, which represented 94% of consolidated sales in fiscal 2011, compared to 98% in the prior year.

| Sales | Shipments | Selling prices | ||||||||||||||||

| ($ millions) | (000 units | ) | ($ / unit) | |||||||||||||||

| 2010 | 2011 | 2010 | 2011 | 2010 | 2011 | |||||||||||||

| SPF lumber (mbf) | 255 | 283 | 786.8 | 907.9 | 324 | 312 | ||||||||||||

| Specialty wood | ||||||||||||||||||

| Pine and hardwood (mbf) | 6 | 6 | 9.4 | 9.5 | 638 | 632 | ||||||||||||

| Hardwood flooring (000 square ft) | 47 | 45 | 9.5 | 9.1 | 4,947 | 4,945 | ||||||||||||

| 53 | 51 | |||||||||||||||||

| Engineered wood | ||||||||||||||||||

| Engineered finger joint lumber (mbf) | – | – | – | – | – | – | ||||||||||||

| Total building materials | 308 | 334 | ||||||||||||||||

| Wood chips, logs and by-products | 126 | 137 | ||||||||||||||||

| Total sales | 434 | 471 | ||||||||||||||||

| Internal wood chips and other sales | (88 | ) | (96 | ) | ||||||||||||||

| Consolidated sales | 346 | 375 |

Tembec Financial Report 201111

Management’s Discussion and Analysis

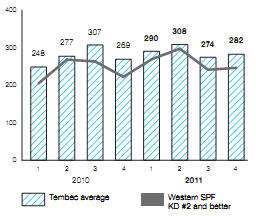

| QUARTERLY PRICES – WESTERN SPF MILL NET | QUARTERLY PRICES – EASTERN SPF DELIVERED |

| (US $ per mbf) | (US $ per mbf) |

|  |

MARKETS

The benchmark random length Western SPF (#2 and better) lumber net price averaged US $263 per mbf in 2011, an increase from US $240 per mbf in 2010. In the East, the random length Eastern SPF average lumber price (delivered Great Lakes) increased from US $327 per mbf to US $350 per mbf in 2011. The Company considers these to be relatively low levels, approximately US $40 to US $50 below normal trend line prices for random lumber. The reference price for stud lumber decreased slightly with the Eastern average lumber price (delivered Great Lakes) down from US $315 per mbf to US $314 per mbf, a level approximately US $70 to US $80 per mbf below trend line prices. The low prices were driven by a very weak U.S. housing market. Housing starts in the U.S., on a seasonally adjusted basis, averaged 577,000 units in fiscal 2011, a decrease over the 592,000 units in fiscal 2010. These remain well below the 2 million unit mark experienced in the 2004-2006 period and the +1.0 million average that would be more indicative of normal market conditions. While the Company recognized several years ago that U.S. housing starts could not maintain the 2 million unit per year run rate, and that a degree of market correction would likely occur at some point, the severity and extent of the correction had not been anticipated. The negative effects of the sub-prime mortgage difficulties, the latter having fuelled the strong demand in 2004-2006, have been much greater in terms of impact and duration than originally foreseen.

12Tembec Financial Report 2011

Management’s Discussion and Analysis

In addition to difficult market conditions, the Company’s financial performance continued to be impacted by export taxes on lumber shipped to the U.S. Effective October 12, 2006, the governments of Canada and the United States implemented an agreement for the settlement of the softwood lumber dispute. The Softwood Lumber Agreement (SLA) requires that an export tax be collected by the Government of Canada, which is based on the price and volume of lumber shipped. Beginning on that date, the Company’s Eastern Canadian sawmills, located in Quebec and Ontario, were subject to export quota limitations and 5% export tax on lumber shipped to the U.S. In April2009, the effective tax on Eastern lumber shipments increased from 5% to 15% as a result of an arbitration decision relating to alleged over-shipments of lumber between January2007 and June2007. During fiscal2010, the Eastern Canadian sawmills’ export tax rate declined to 10% in the month of June and returned to 15% in the month of August. The SLA provides that during periods of relatively high prices, as was the case during the early summer months, the export tax rate declines. In fiscal2010, the average rate on all shipments to the U.S. was 14.1% and the total cost was $4million. During fiscal2011, a second arbitration penalty of approximately 1% was imposed on Eastern lumber shipments beginning in March2011. However, the first arbitration penalty of 10% expired in June2011. Overall, the average rate on all Eastern lumber shipments to the U.S. was 11.7% and the total cost was $6 million. The increase in cost was caused by higher shipments to the U.S., which more than doubled year-over-year.

As to the Company’s two Western sawmills, which are both located in British Columbia, they are currently subject to a 15% export tax, but shipments are not quota limited. Under certain circumstances, the tax may be increased to 22.5%, which was not the case in either fiscal 2010 or fiscal 2011. During fiscal 2010, the Western Canadian sawmills’ export tax rate declined to 0% in the month of June and returned to 15% in the month of August. Similarly to what had occurred for the Eastern Canadian sawmills, higher prices led to the reduction in the export tax rate. In fiscal 2010, the average rate on shipments to the U.S. was 11.6% and the total cost was $6 million. During fiscal 2011, the average rate on shipments to the U.S was 15% and the total cost was $7 million.

Tembec Financial Report 201113

Management’s Discussion and Analysis

OPERATING RESULTS

The following summarizes EBITDA variances by major element:

| Variance - favourable (unfavourable) | ||||||||||||||||||

| Export | Mill | Inventory NRV | ||||||||||||||||

| (in millions of dollars) | Price | taxes | costs | adjustments | Other | TOTAL | ||||||||||||

| SPF lumber | (10 | ) | (3 | ) | (12 | ) | (10 | ) | 1 | (34 | ) | |||||||

| Specialty wood | – | – | (1 | ) | – | – | (1 | ) | ||||||||||

| Engineered wood | – | – | – | – | – | – | ||||||||||||

| Other segment items | – | – | – | – | (1 | ) | (1 | ) | ||||||||||

| (10 | ) | (3 | ) | (13 | ) | (10 | ) | – | (36 | ) | ||||||||

In fiscal 2011, EBITDA was negative $46 million compared to negative EBITDA of $10 million in the prior year. SPF lumber EBITDA declined by $34 million. In addition to the previously noted decrease in selling prices and higher export taxes on lumber shipped to the U.S., the sawmills absorbed significantly higher cost of sales. Sawmill manufacturing costs increased by $11 million. The current year absorbed higher costs of $12 million, primarily for timber. In the prior year, the segment had benefited from an $11 million favourable adjustment to the carrying values of logs and lumber inventories compared to a favourable adjustment of $1 million in the current year. Specialty wood EBITDA decreased by $1 million due to higher costs. Engineered wood results were unchanged as both plants remained idle for the entire year. The EBITDA margin to total sales was negative 9.8% compared to negative 2.3% in the prior year.

The following summarizes operating results variances by major element:

| Variance | |||||||||

| favourable | |||||||||

| (in millions of dollars) | 2010 | 2011 | (unfavourable) | ||||||

| EBITDA | (10 | ) | (46 | ) | (36 | ) | |||

| Depreciation and amortization | 16 | 13 | 3 | ||||||

| Other items | (2 | ) | 4 | (6 | ) | ||||

| Operating loss | (24 | ) | (63 | ) | (39 | ) |

The Forest Products segment generated an operating loss of $63 million in fiscal 2011, compared to an operating loss of $24million in fiscal 2010. Depreciation expense continued to trend downwards primarily as a result of relatively low fixed asset additions. In view of operating rates that are approximately 50%, capital expenditures have only averaged $8million per year over the last three years. The segment’s current year results include a charge of $3 million relating to the permanent closure of the Taschereau, Quebec, SPF sawmill. It also includes a charge of $1 million related to severance payments at the idled planer facility in Cranbrook, British Columbia. The prior year included a $2million gain related to land sales.

14Tembec Financial Report 2011

Management’s Discussion and Analysis

| DISSOLVING AND CHEMICAL PULP | ||||||

| (in millions of dollars) | ||||||

| 2010 | 2011 | |||||

| Total sales - Pulp | 737 | 600 | ||||

| Total sales - Chemicals | 93 | 93 | ||||

| Total sales | 830 | 693 | ||||

| Consolidated sales | 816 | 681 | ||||

| EBITDA | 120 | 138 | ||||

| EBITDA margin on total sales | 14.4% | 19.9% | ||||

| Depreciation and amortization | 27 | 18 | ||||

| Other items | (12 | ) | – | |||

| Operating earnings | 105 | 120 | ||||

| Identifiable assets (excluding cash) | 444 | 437 |

The Dissolving and Chemical Pulp segment consists of three market pulp manufacturing facilities. The facilities are divided into two main types. Two dissolving pulp mills produce specialty and commodity dissolving pulps. The remaining facility produces chemical softwood kraft paper pulp (NBSK). During fiscal 2010, the Company also owned two kraft paper pulp mills located in Southern France. The two pulp mills, with an annual capacity of 565,000 tonnes, were sold in May 2010.

The two dissolving pulp mills can produce approximately 310,000 tonnes per year. The softwood kraft mill has an annual capacity of 270,000 tonnes. The specialty dissolving pulp produced at the two dissolving pulp mills is a high purity cellulose utilized in a wide variety of specialized products such as pharmaceuticals, food additives, and industrial chemicals. T he Temiscaming dissolving pulp mill also produces “commodity” dissolving pulp, which is utilized in the production of viscose staple fibre, which in turn is used to produce rayon for the textile industry. The Tartas mill also produced specialized fluff pulp, which is utilized in the production of sanitary products. The production of specialized fluff pulp was discontinued in September 2011.

The two dissolving pulp mills generate lignin as a by-product of the sulphite process, which is sold to third parties. The Temiscaming mill also includes a facility that produces ethanol as a by-product that is also sold to third parties.

The segment also includes a stand-alone resin business, which produces powder and liquid phenolic resins at three operating sites in Quebec: Temiscaming, Longueuil, and Trois-Pistoles. The Company also operates a fourth facility located in Toledo, Ohio, which manufactures powder and liquid amino-resins. The chemical business also purchases and resells pulp mill by-product chemicals from third parties.

The following summarizes the annual operating level or capacity of each facility:

| DISSOLVING PULP | tonnes |

| Specialty and commodity dissolving pulp | |

| - Temiscaming, QC | 160,000 |

| Specialty dissolving pulp - Tartas, France | 150,000 |

| 310,000 | |

| SOFTWOOD KRAFT PULP | |

| Softwood kraft - Skookumchuck, BC | 270,000 |

| CHEMICALS | |

| Resin and related products | 170,000 |

| Lignin | 190,000 |

| Ethanol (million litres) | 12.1 |

Tembec Financial Report 201115

Management’s Discussion and Analysis

Dissolving pulp shipments represented 53% of segment shipments in fiscal 2011, compared to 35% in the prior year. The increase in percentage was not due to higher shipments, but rather to a decline in chemical paper pulp shipments as a result of the sale of two kraft pulp mills. Dissolving pulp sales as a percentage of total segment pulp sales increased from 48% to 68% due to previously noted shipment impact and significant price increase.

Chemical paper pulp represented 47% of segment shipments in fiscal 2011, compared to 65% in the prior year. The volume of chemical paper pulp shipped in fiscal 2011 declined by 278,700 tonnes. In May 2010, the Company completed the sale of two kraft pulp mills and related operations located in Southern France. In the prior fiscal year, the two mills had shipped 272,500 tonnes of pulp, generating sales of $191million and EBITDA of $19 million.

Total 2011 pulp shipments of 507,300 tonnes include 15,300 tonnes of softwood kraft pulp consumed by the Company’s paperboard operations as compared to 17,700 tonnes in the prior year.

Total sales for the Dissolving and Chemical Pulp segment were $693 million, a decrease of $137 million from the prior year. After eliminating internal sales, the Dissolving and Chemical Pulp segment generated 39% of Company consolidated sales, down from 43% in the prior year. The Dissolving and Chemical Pulp segment is a global business. In 2011, 64% of consolidated pulp sales were generated outside of Canada and the U.S., as compared to 66% in the prior year.

| Sales | Shipments | Selling prices | ||||||||||||||||

| ($ millions) | (000 units | ) | ($ / unit) | |||||||||||||||

| 2010 | 2011 | 2010 | 2011 | 2010 | 2011 | |||||||||||||

| Dissolving pulps | ||||||||||||||||||

| Specialty dissolving (tonnes) | 238 | 311 | 189.2 | 209.5 | 1,258 | 1,484 | ||||||||||||

| Commodity dissolving (tonnes) | 83 | 85 | 62.1 | 52.4 | 1,337 | 1,622 | ||||||||||||

| Specialty fluff (tonnes) | 28 | 9 | 35.1 | 8.1 | 798 | 1,111 | ||||||||||||

| 349 | 405 | 286.4 | 270.0 | |||||||||||||||

| Chemical paper pulps | ||||||||||||||||||

| Softwood kraft (tonnes) | 293 | 195 | 381.4 | 237.3 | 768 | 822 | ||||||||||||

| Hardwood kraft (tonnes) | 91 | – | 134.6 | – | 676 | – | ||||||||||||

| 384 | 195 | 516.0 | 237.3 | |||||||||||||||

| Total dissolving and chemical pulp sales | 733 | 600 | 802.4 | 507.3 | ||||||||||||||

| Chemicals | ||||||||||||||||||

| Resin and related products (tonnes) | 54 | 55 | 58.8 | 55.2 | 918 | 996 | ||||||||||||

| Lignin (tonnes) | 30 | 29 | 123.3 | 131.5 | 243 | 221 | ||||||||||||

| Ethanol (000 litres) | 8 | 7 | 9.9 | 8.9 | 808 | 787 | ||||||||||||

| 92 | 91 | |||||||||||||||||

| Other sales | 5 | 2 | ||||||||||||||||

| Total sales | 830 | 693 | ||||||||||||||||

| Internal pulp sales | (14 | ) | (12 | ) | (17.7 | ) | (15.3 | ) | ||||||||||

| Consolidated sales | 816 | 681 |

16Tembec Financial Report 2011

Management’s Discussion and Analysis

MARKETS

The Company markets its pulp on a world-wide basis, primarily through its own sales force. Sales offices are maintained in Toronto, Canada; Dax, France; and Beijing, China.

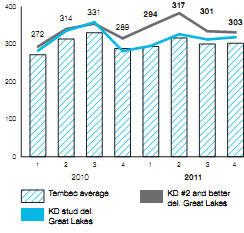

The shipments to capacity ratio for dissolving pulp was at 87% in fiscal 2011 versus 89% in the prior year. These are relatively high percentages, which reflect strong demand and favourable market conditions. The decrease in shipment ratio was due to a decrease of 16,400 tonnes in dissolving pulp shipments. This was due to the Company’s objective of focusing on “specialty” or higher purity dissolving pulps and reducing its exposure to commodity and fluff pulps. Specialty dissolving pulps have a lesser yield, which in turn reduces the production capacity of the two mills. During fiscal 2010 and 2011, both mills operated at full rates and no downtime was taken for market conditions. The strong market conditions led to higher US dollar and euro prices, which more than offset the negative currency impact of a weaker US dollar. Pricing for specialty dissolving increased by $226 per tonne, commodity grade dissolving increased by $285 per tonne and specialty fluff increased by $313 per tonne on average. The favourable market conditions also kept inventory levels of finished pulp below 30 days for most of the year and ending fiscal 2011 at only 22 days of supply.

The shipments to capacity ratio for chemical paper pulp was 88% in fiscal 2011 versus 84% in the prior year. The 88% level is also reflective of favourable market conditions, as the mill operated at full capacity and no downtime was taken for market conditions. The strong market led to higher US dollar prices as the benchmark NBSK pulp price (delivered U.S.) increased by US $66 per tonne and the benchmark NBSK pulp price (delivered China) increased by US $77 per tonne. This more than offset the negative impact of the weaker US dollar and prices increased by $27 per tonne year-over-year. The $54 per tonne increase for softwood kraft shown in the table includes a positive mix variance as fiscal 2011 no longer includes sales from the French mills, which had traditionally sold their pulp for less than the Skookumchuck mill. The favourable market conditions also kept inventory levels of finished pulp below 20days for most of the year. Fiscal 2011 inventory of NBSK ended the year at only six days, as year-end coincided with the annual maintenance shutdown. This level does not allow for effective customer service and will need to be increased in the first quarter of fiscal 2012.

| QUARTERLY PRICES – DISSOLVING PULP | QUARTERLY PRICES – NBSK |

| (US $ per tonne) | (US $ per tonne) |

|  |

Tembec Financial Report 201117

Management’s Discussion and Analysis

OPERATING RESULTS

The following summarizes EBITDA variances by major element:

| Variance - favourable (unfavourable) | |||||||||||||||||||||

| Foreign | |||||||||||||||||||||

| Inventory | exchange | ||||||||||||||||||||

| Mill | NRV | impact | |||||||||||||||||||

| (in millions of dollars) | Price | Freight | costs | adjustments | on costs | Other | TOTAL | ||||||||||||||

| Dissolving pulps | 66 | (1 | ) | (33 | ) | 2 | 3 | 4 | 41 | ||||||||||||

| Chemical paper pulps | 6 | (3 | ) | – | (1 | ) | – | (3 | ) | (1 | ) | ||||||||||

| Chemicals | (1 | ) | – | – | – | – | – | (1 | ) | ||||||||||||

| Other segment costs | – | – | – | – | – | (21 | ) | (21 | ) | ||||||||||||

| 71 | (4 | ) | (33 | ) | 1 | 3 | (20 | ) | 18 | ||||||||||||

Fiscal 2011 EBITDA was $138 million compared to $120million in the prior year. The previously noted increases in pulp selling prices increased EBITDA by $72 million. Higher freight and shipping costs reduced EBITDA by $4 million. Manufacturing costs at the two dissolving pulp mills increased by $33million. Higher fibre, chemicals and supplies costs caused the majority of the increase. The mills produced more “specialty” dissolving pulp grades, which have lower yields and are more costly to produce. Costs were also impacted by an increase in maintenance downtime. During fiscal 2011, the three pulp mills incurred 30,200 tonnes of maintenance downtime compared to 14,100 tonnes in the prior year. The translation of the euro costs of the French dissolving pulp mill decreased the Canadian dollar equivalent costs by $3 million. The $21million unfavourable variance in the “Other” category relates to the sale of two kraft pulp mills and related operations located in Southern France. The mills were sold part way through the prior year and had contributed $19 million to fiscal 2010 reported EBITDA.

The two North American pulp mills purchased approximately 845,000 bone dry tonnes of wood chips in fiscal 2011, down from 873,000 in the prior year. Of this amount, approximately 67% was supplied by the Forest Products segment, compared to 69% in the prior year. The remaining requirements were purchased from third parties under contracts and agreements of various durations. The pulp mill located in Southern France purchased 308,000 bone dry tonnes of wood in fiscal 2011 as compared to 307,000 tonnes in the prior year. The fibre is sourced from many private landowners.

Overall, higher pr ices were partially offset by higher manufacturing costs, which led to EBITDA margins of 19.9% compared to 14.4% in the prior year.

The following summarizes operating results variances by major element:

| Variance | |||||||||

| favourable | |||||||||

| (in millions of dollars) | 2010 | 2011 | (unfavourable) | ||||||

| EBITDA | 120 | 138 | 18 | ||||||

| Depreciation and amortization | 27 | 18 | 9 | ||||||

| Other items | (12 | ) | – | (12 | ) | ||||

| Operating earnings | 105 | 120 | 15 |

The Dissolving and Chemical Pulp segment generated operating earnings of $120 million during the most recently completed fiscal year, compared to operating earnings of $105 million in the prior year. In addition to the previously noted increase in EBITDA, the segment depreciation expense declined by $9 million. The sale of two pulp mills located in Southern France in May 2010 accounted for a significant portion of the decline in depreciation expense. In the prior year, the Company had recorded a gain of $12 million related to the sale of the aforementioned pulp mills.

18Tembec Financial Report 2011

Management’s Discussion and Analysis

| HIGH-YIELD PULP | ||||||

| (in millions of dollars) | ||||||

| 2010 | 2011 | |||||

| Total sales | 395 | 378 | ||||

| Consolidated sales | 367 | 348 | ||||

| EBITDA | 47 | (4 | ) | |||

| EBITDA margin on total sales | 11.9% | (1.1 | )% | |||

| Depreciation and amortization | 10 | 10 | ||||

| Operating earnings (loss) | 37 | (14 | ) | |||

| Identifiable assets (excluding cash) | 213 | 174 |

The High-Yield Pulp segment consists of three market pulp manufacturing facilities. High-yield pulps are produced with a combination of mechanical and chemical processes. The Company produces hardwood grades made from maple, aspen and birch. High-yield pulps have a lower tensile and tear strength than kraft pulps, but they offer advantages on bulk and opacity. They compete against other hardwood or “short fibre” grades, with Bleached Eucalyptus Kraft (BEK) being the most prominent.

The following summarizes the annual operating level or capacity of each facility:

| HIGH-YIELD PULP | tonnes | ||

| Hardwood high-yield - Temiscaming, QC | 315,000 | ||

| Hardwood high-yield - Matane, QC | 250,000 | ||

| Hardwood high-yield - Chetwynd, BC | 240,000 | ||

| TOTAL | 805,000 |

Total 2011 shipments of 664,300 tonnes include 57,500 tonnes of high-yield pulp consumed by the Company’s paperboard operations as compared to 56,700 tonnes in the prior year.

Total sales for the High-Yield Pulp segment were $378 million, a decrease of $17 million from the prior year. After eliminating internal sales, the High-Yield Pulp segment generated 20% of Company consolidated sales, unchanged from the prior year. The High-Yield Pulp segment is more export oriented than the other business segments within the Company. In 2011, 99% of consolidated pulp sales were generated outside of Canada and the U.S., as compared to 98% in the prior year. China alone accounted for 49% of sales compared to 57% in the prior year.

| Sales | Shipments | Selling prices | ||||||||||||||||

| ($ millions) | (000 units | ) | ($ / unit) | |||||||||||||||

| 2010 | 2011 | 2010 | 2011 | 2010 | 2011 | |||||||||||||

| Hardwood high-yield | 395 | 378 | 615.6 | 664.3 | 642 | 569 | ||||||||||||

| Internal sales | (28 | ) | (30 | ) | (56.7 | ) | (57.5 | ) | 494 | 522 | ||||||||

| Consolidated sales | 367 | 348 | 558.9 | 606.8 | 657 | 573 |

Tembec Financial Report 201119

Management’s Discussion and Analysis

MARKETS

The Company markets its pulp on a world-wide basis, primarily through its own sales force. Sales offices are maintained in Toronto, Canada; Dax, France; and Beijing, China.

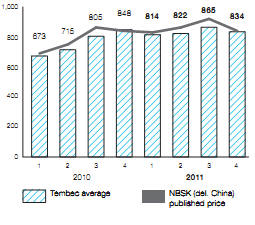

The shipments to capacity ratio for high-yield pulp was at 83% versus 76% in the prior year. These are relatively low percentages, which are not indicative of a strong market. Fiscal2010 began with weak prices and demand. As a result, the Company idled the Chetwynd mill for 110 days, resulting in 67,200 tonnes of market downtime. The mill was restarted in January 2010 as demand and pricing were on an upturn. By summer, prices were more than $100 per tonne higher than at the beginning of the fiscal year. The average selling price for third party sales was $657 per tonne. Inventory levels of finished goods ended the prior fiscal year at 26 days, indicative of a relatively balanced market. However, as fiscal 2011 began, new high-yield pulp capacity was started in China, which had a negative impact on the market in terms of pricing. The effect was grade specific to high-yield pulp as other hardwood grades, such as BEK, were not as severely impacted. As the fiscal year progressed, prices continued to decline, compounded by a stronger Canadian dollar, which averaged US $1.013 in fiscal2011, a 5.5% increase versus the prior year. The combined effect reduced prices by approximately $100 per tonne during the fiscal year. The average selling price for third party sales was $573 per tonne, a decrease of $84 per tonne from the prior year average. Inventory levels ended the year at 15days of supply. The abnormally low level of inventory was related to a labour strike that occurred at the Matane mill in the second half of fiscal 2011. The impact of the strike is analysed in the section that follows.

QUARTERLY PRICES – HIGH-YIELD

(US $ per tonne)

20Tembec Financial Report 2011

Management’s Discussion and Analysis

OPERATING RESULTS

The following summarizes EBITDA variances by major element:

| Variance - favourable (unfavourable) | |||||||||||||||||||||

| Inventory | |||||||||||||||||||||

| Mix & | Freight | Mill | NRV | ||||||||||||||||||

| (in millions of dollars) | Price | volume | and SGA | costs | adjustments | Other | TOTAL | ||||||||||||||

| High-yield pulps | (53 | ) | (6 | ) | 5 | 5 | (4 | ) | 2 | (51 | ) | ||||||||||

Fiscal 2011 EBITDA was negative $4 million compared to positive $47million in the prior year. The previously noted decrease in pulp selling prices decreased EBITDA by $53million. While costs were relatively unchanged across the combined three mills, there were significant variances at individual mills. At Chetwynd, the mill had experienced significant downtime in the prior year. In addition to the previously noted 110-day market curtailment, the mill lost 29days in June2010 related to a fire at the mill site. In fiscal2011, the mill experienced “full” operations and production increased by 85,600 tonnes. Cost of manufacturing improved by $18 million year-over-year. The opposite effect occurred at the Matane mill. In the prior year, the mill had experienced “full”operations. In the most recent year, a labour strike began in May 2011 and resulted in 127days of downtime before the mill resumed operations in mid-September 2011. The mill produced 102,200tonnes less than in the prior year and its costs increased by $12 million.

The three pulp mills purchased approximately 682,800 bone dry tonnes of wood chips in fiscal 2011, up from 621,100 in the prior year. Of this amount, approximately 19% was supplied by the Forest Products segment, compared to 14% in the prior year. The remaining requirements were purchased from third parties under contracts and agreements of various durations.

Overall, lower prices reduced profitability with a negative EBITDA margin of 1.1% compared to a positive margin of 11.9% in the prior year.

The following summarizes operating results variances by major element: Variance

| favourable | |||||||||

| (in millions of dollars) | 2010 | 2011 | (unfavourable) | ||||||

| EBITDA | 47 | (4 | ) | (51 | ) | ||||

| Depreciation and amortization | 10 | 10 | – | ||||||

| Operating earnings (loss) | 37 | (14 | ) | (51 | ) |

The High-Yield Pulp segment generated an operating loss of $14 million during the most recently completed fiscal year, compared to operating earnings of $37 million in the prior year. The previously noted decrease in EBITDA led to the weaker operating results.

Tembec Financial Report 201121

Management’s Discussion and Analysis

| PAPER | ||||||

| (in millions of dollars) | ||||||

| 2010 | 2011 | |||||

| Consolidated sales | 348 | 339 | ||||

| EBITDA | (2 | ) | 28 | |||

| EBITDA margin | (0.6 | )% | 8.3% | |||

| Depreciation and amortization | 3 | 3 | ||||

| Other items | 7 | – | ||||

| Operating earnings (loss) | (12 | ) | 25 | |||

| Identifiable assets (excluding cash) | 123 | 119 |

The Paper segment currently includes two paper manufacturing facilities with a total of three paper machines. The mill located in Kapuskasing, Ontario, produces newsprint on two machines. The facility located in Temiscaming, Quebec, produces multiply coated bleached board on one machine. The board mill is partially integrated with a high-yield pulp mill and also consumes pulp manufactured by the Company at its British Columbia paper pulp mill. In late fiscal2010, the Company announced the permanent closure of the Pine Falls, Manitoba, newsprint mill, removing 185,000tonnes of newsprint capacity. A third newsprint machine at the Kapuskasing mill with an annual capacity of 90,000tonnes has been idle for several years and is no longer included in the capacity figures. The total capacity of the Paper segment is now 420,000tonnes. Prior to April2010, the Paper segment also included the financial results of a hydro-electric dam located in Smooth Rock Falls, Ontario. The dam was sold on March 29, 2011.

The following summarizes the products and operating level or capacity of each facility:

| COATED BLEACHED BOARD | tonnes | ||

| Temiscaming, QC | 180,000 | ||

| NEWSPRINT | |||

| Kapuskasing, ON | 240,000 | ||

| TOTAL | 420,000 |

Coated bleached board shipments represented 42% of Paper segment shipments in fiscal 2011, unchanged from the prior year. As a percentage of total segment sales, coated bleached board represented 57% of sales compared to 59% in the prior year.

Newsprint shipments represented 58% of Paper segment shipments in fiscal 2011, unchanged from the prior year. In terms of total segment sales, newsprint represented 42% of sales compared to 40% in the prior year.

Sales for the Paper segment totalled $339 million, as compared to $348 million in the prior year. The segment generated 19% of Company consolidated sales, the same as in fiscal 2010. The focus of the paper business is North America, which accounted for 92% of consolidated sales in 2011, compared to 95% in the prior year. The U.S. alone accounted for 74% of sales in fiscal 2011, unchanged from the prior year.

22Tembec Financial Report 2011

Management’s Discussion and Analysis

| Sales | Shipments | Selling prices | ||||||||||||||||

| ($ millions) | (000 units | ) | ($ / unit) | |||||||||||||||

| 2010 | 2011 | 2010 | 2011 | 2010 | 2011 | |||||||||||||

| Coated bleached board (rolls and sheets) | 204 | 194 | 173.0 | 165.2 | 1,179 | 1,174 | ||||||||||||

| Newsprint | 141 | 143 | 236.0 | 228.5 | 597 | 626 | ||||||||||||

| Electricity sales | 3 | 2 | ||||||||||||||||

| Consolidated sales | 348 | 339 | 409.0 | 393.7 |

MARKETS

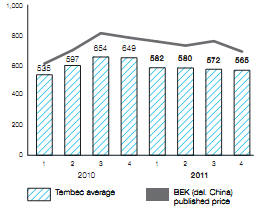

The benchmark for coated bleached board (16 point) averaged US $1,150 per short ton in fiscal 2011, a US $98 per short ton increase over the prior year. A favourable pricing trend was supported by good market demand. The benchmark began the year at US $1,110 per short ton. It increased to US $1,150 in October 2010 and remained at that level for the next 12months. The shipments to capacity ratio for coated bleached board was 92% in fiscal 2011 compared to 96% in the prior year. These high percentages reflect the very strong market fundamentals of the North American coated bleached board market over the last two years. The small decrease in ratio was due to inventory reduction in the prior year as production volumes cannot sustain a ratio above 95%. The board mill operated at “full” capacity in both fiscal 2010 and fiscal 2011, with no market downtime taken in either year. While US $ reference prices increased, the impact was offset by the negative currency impact of the stronger Canadian dollar. As a result, Canadian dollar prices were relatively unchanged year-over-year. Inventory levels at year-end were at 52 days. This is a normal level given the product sales mix, which includes both rolls and sheets.

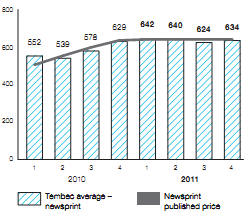

The benchmark newsprint grade (48.8 gram – East Coast) averaged US $640 per tonne in fiscal 2011, a US $67 per tonne increase over the prior year. The increase was due to improved pricing that occurred in the latter half of fiscal 2010. The benchmark began the current year at US $638 per tonne. It increased to US $640 per tonne in October 2010 and remained at that level for the next 12 months. The shipments to capacity ratio for newsprint was 69% as compared to 46% in the prior year. The increase in the ratio was not due to increased shipments as they declined by 7,500 tonnes year-over-year. It was caused by a 185,000 tonnes capacity reduction related to the permanent closure of the Pine Falls newsprint mill that was announced at the end of the prior fiscal year. The relatively low ratios are a reflection of the relatively weak North American newsprint market. In response to continued declines in demand, the Company continued to curtail production. A newsprint machine at the Kapuskasing mill remained idle for the entire year, removing approximately 91,000tonnes of production. This compares to 273,000 tonnes in the prior year, which included the same machine in Kapuskasing and the entire capacity of the idled mill in Pine Falls, which was removed from the current year figures as a result of its closure. While US $ reference prices increased by US $67 per tonne, the impact was partially offset by the negative impact of the stronger Canadian dollar. As a result, Canadian dollar prices increased by $29 per tonne. Inventory levels at year-end were at 14 days, a normal level for the newsprint mill.

| QUARTERLY PRICES – COATED BLEACHED BOARD | QUARTERLY PRICES – NEWSPRINT |

| (US $ per short ton) | (US $ per tonne) |

|  |

Tembec Financial Report 201123

Management’s Discussion and Analysis

OPERATING RESULTS

The following summarizes EBITDA variances by major element:

| Variance - favourable (unfavourable) | ||||||||||||||||||

| Inventory | ||||||||||||||||||

| Mill | Mix & | NRV | ||||||||||||||||

| (in millions of dollars) | Price | costs | volume | adjustments | Other | TOTAL | ||||||||||||

| Coated bleached board | - | (1 | ) | (3 | ) | – | 1 | (3 | ) | |||||||||

| Newsprint | 6 | 17 | – | (2 | ) | 1 | 22 | |||||||||||

| Other segment items | - | – | – | – | 11 | 11 | ||||||||||||

| 6 | 16 | (3 | ) | (2 | ) | 13 | 30 | |||||||||||

Fiscal 2011 EBITDA was $28 million compared to negative $2 million in the prior year. Higher newsprint prices increased EBITDA by $6 million. Manufacturing costs at the newsprint mill also declined by $17 million, primarily as a result of lower energy costs. The operation benefited from lower electricity costs as new industrial user rates were implemented at the beginning of the 2011 calendar year. The favourable $11 million variance in other segment items relates to the permanent closure of the Pine Falls newsprint mill, which had negative EBITDA of $11 million in the prior year. Custodial and legacy costs for the facility were $3 million in fiscal 2011 and were included in the Corporate segment.

The coated bleached board mill utilizes a combination of chemical kraft and high-yield pulps to produce a three-ply sheet. During fiscal 2011, the mill utilized 15,300 tonnes of NBSK supplied by the Company’s Skookumchuck pulp mill as compared to 17,700 tonnes in the prior year. The mill also consumed 57,500 tonnes of high-yield pulp supplied by the Temiscaming mill versus 56,700 tonnes in fiscal 2010. The balance of pulp requirements is purchased from third parties.

The newsprint mill utilizes virgin fibre, primarily in the form of wood chips. During fiscal 2011, the operations purchased 257,400 bone dry tonnes of virgin fibre, of which approximately 81% was internally sourced. In the prior year, 244,200 bone dry tonnes of virgin fibre were purchased, with 68% being sourced internally.

Overall, the higher news print prices and the lower costs increased EBITDA margins from negative 0.6% to positive 8.3%.

The following summarizes operating results variances by major element:

| Variance | |||||||||

| favourable | |||||||||

| (in millions of dollars) | 2010 | 2011 | (unfavourable) | ||||||

| EBITDA | (2 | ) | 28 | 30 | |||||

| Depreciation and amortization | 3 | 3 | – | ||||||

| Other items | 7 | – | 7 | ||||||

| Operating earnings (loss) | (12 | ) | 25 | 37 |

The Paper segment generated operating earnings of $25 million compared to an operating loss of $12 million in the prior year. In addition to the previously noted improvement in EBITDA, the segment was impacted by other items. In the prior year, the Company had absorbed a charge of $7 million related to the permanent closure of the Pine Falls newsprint mill.

24Tembec Financial Report 2011

Management’s Discussion and Analysis

| CORPORATE | ||||||

| (in millions of dollars) | ||||||

| 2010 | 2011 | |||||

| General and administrative expenses | 21 | 19 | ||||

| Share-based compensation | 2 | 2 | ||||

| Other items | 20 | (3 | ) | |||

| Depreciation and amortization | – | 1 | ||||

| Operating expenses | 43 | 19 |

The Company incurred a $2 million share-based compensation expense in the current year, unchanged from the prior year. The expense relates to two long-term incentive programs maintained by the Company. Senior executives participate in a “Performance Conditioned Restricted Share Unit” (PCRSU) plan. The PCRSUs have a defined vesting period and performance conditions that will ultimately determine the amount of PCRSUs that will vest and be paid to participating employees. Non-executive members of the Board of Directors receive a portion of their fees in the form of “Deferred Share Units” (DSU). The DSUs vest at specified dates. Details regarding both of these plans can be found in note 9 of the 2011 annual audited financial statements and in the Management Information Circular. The period expense for these two plans consists of normal periodic variation in the number of units based on anticipated or normal vesting, but is also impacted by the changes in the value of the Company’s share price, as the PCRSUs and DSUs have the same value as one common share.

The Corporate segment’s “other items” include expenses relating to several permanently idled facilities. The costs include legal costs, site security and custodial. These “legacy” costs totalled $8 million in fiscal 2011, unchanged from the prior year. The current year “other items” also includes a gain of $8million related to the filing of Tembec USA LLC under Chapter 7 of the Bankruptcy Code of the United States. The Company reduced its accrued benefit obligation by this amount. It also includes a $3 million gain related to the sale of its hydro-electric generating facilities located in Smooth Rock Falls, Ontario. The prior year included a non-recurring charge of $12 million relating to the St. Francisville, Louisiana, coated paper mill. The mill property and equipment were sold in April 2009. A portion of the consideration included two US $5 million interest-bearing notes. In January 2010, the purchaser filed for protection under the U.S. Bankruptcy Code. Subsequently, the assets were sold at auction. Based on the amount of the winning bid, it was unlikely that the Company would recover any portion of the interest-bearing notes. As a result, the Company recorded a charge of $12 million. The aforementioned amount included accrued interest as well as certain other unsecured claims.

Tembec Financial Report 201125

Management’s Discussion and Analysis

Non-operating Items

| INTEREST, FOREIGN EXCHANGE AND OTHER | ||||||

| (in millions of dollars) | ||||||

| 2010 | 2011 | |||||

| Interest on indebtedness | 30 | 32 | ||||

| Fees - new working capital facility | – | 2 | ||||

| Debt prepayment premium | 6 | – | ||||

| Foreign exchange items | 14 | (1 | ) | |||

| Bank charges and other | 2 | (1 | ) | |||

| 52 | 32 |

There were no significant interest variances. The major portion of the prior year interest on debt related to a US $300 million term loan. This credit facility was repaid in August 2010. The Company incurred a $6 million debt prepayment premium. The Company issued US $255 million of senior secured notes maturing in December 2018. In March 2011, the Company entered into a new working capital facility and incurred $2million in expenses. Foreign exchange items relate primarily to gains or losses on the translation of US $ net monetary assets. When the Canadian dollar strengthens versus the US dollar, as was the case during the prior year, losses are generated.

| TRANSLATION OF FOREIGN DEBT |

During fiscal 2011, the Company recorded a loss of $1 million on the translation of its US $ denominated debt as the relative value of the Canadian dollar decreased from US $0.975 to US $0.971. There was no gain or loss on the translation of euro-denominated debt as the value of the euro versus the Canadian dollar was relatively unchanged.

During fiscal 2010, the Company recorded a gain of $19 million on the translation of its US $ denominated debt as the relative value of the Canadian dollar increased from US $0.916 to US$0.975. The Company recorded a gain of $8 million on the translation of its euro-denominated debt as the relative value of the euro versus the Canadian dollar decreased from C $1.602 to C $1.384.

| INCOME TAXES |

During fiscal 2011, the Company recorded an income tax expense of $19 million on earnings before income taxes and non-controlling interest of $16 million. The income tax expense reflected a $15 million unfavourable variance versus an anticipated tax expense of $4 million based on the Company’s effective tax rate of 27.8%. The current year absorbed an $11million unfavourable change in valuation allowance. Based on past financial performance, future income tax assets of the Company’s Canadian operations have not been recognized as it has not been determined that the future realization of these assets is “more likely than not” to occur.

During fiscal 2010, the Company recorded an income tax recovery of $15 million on earnings before income taxes and non-controlling interest of $39 million. This income tax recovery reflected a $27 million favourable variance versus an anticipated income tax expense of $12 million based on the Company’s effective tax rate of 29.8%. The change in valuation allowance increased the recovery by $20 million. The most significant item included in the above was a $19 million favourable adjustment relating to the recognition of future tax assets of the Company’s remaining operations in France as it was determined that the future realization of these assets was “more likely than not” to occur. The non-taxable portion of the gain on consolidation of foreign integrated subsidiaries increased the income tax recovery by $10 million.

26Tembec Financial Report 2011

Management’s Discussion and Analysis

Net Earnings (Loss)

The Company generated a net loss of $3 million or $0.03 per share for the year ended September 24, 2011, compared to net earnings of $52 million or $0.52 per share for the year ended September 25, 2010. As noted previously, the Company’s financial results were impacted by certain specific items. The following table summarizes the impact of these items on the reported financial results. The Company believes it is useful supplemental information as it provides an indication of results excluding the specific items. This supplemental information is not intended as an alternative measure for net earnings as determined by Canadian GAAP. The table below contains one recurring item, namely the gain or loss on translation of foreign debt. Because the Company has a substantial amount of US$ denominated debt, relatively minor changes in the value of the Canadian dollar versus the US dollar can lead to large unrealized periodic gains or losses. As well, this item receives capital gain/loss tax treatment and is not tax-affected at regular business income rates.

| Year ended | Year ended | |||||||||||

| September 25, 2010 | September 24, 2011 | |||||||||||

| $ millions | $ per share | $ millions | $ per share | |||||||||

| Net earnings (loss) as reported | ||||||||||||

| - in accordance with GAAP | 52 | 0.52 | (3 | ) | (0.03 | ) | ||||||

| Specific items (after-tax): | ||||||||||||

| Gain on translation of foreign debt | (23 | ) | (0.23 | ) | – | – | ||||||

| Gain on derivative financial instruments | – | – | (1 | ) | (0.01 | ) | ||||||

| Gain on sale of land | (1 | ) | (0.01 | ) | – | – | ||||||

| Write-down of notes receivable | 10 | 0.10 | – | – | ||||||||

| Sale of French pulp mills | (16 | ) | (0.16 | ) | – | – | ||||||

| Recognition of future tax asset | ||||||||||||

| - French operations | (19 | ) | (0.19 | ) | – | – | ||||||

| Pine Falls closure charge | 6 | 0.06 | – | – | ||||||||

| Debt prepayment premium | 4 | 0.04 | – | – | ||||||||

| Taschereau sawmill closure charge | – | – | 2 | 0.02 | ||||||||

| Cranbrook planer mill severance charge | – | – | 1 | 0.01 | ||||||||

| Gain on Tembec USA LLC filing | – | – | (8 | ) | (0.08 | ) | ||||||

| Gain on sale of Smooth Rock Falls hydro dam | – | – | (2 | ) | (0.02 | ) | ||||||

| Costs for permanently idled facilities | 6 | 0.06 | 7 | 0.07 | ||||||||

| Net earnings (loss) excluding specific items | ||||||||||||

| - not in accordance with GAAP | 19 | 0.19 | (4 | ) | (0.04 | ) | ||||||

Tembec Financial Report 201127

Management’s Discussion and Analysis

Quarterly Financial Information

(in millions of dollars, except per share amounts)

| 2010 | 2011 | |||||||||||||||||||||||

| Dec. 09 | March 10 | June 10 | Sept. 10 | Dec. 10 | March 11 | June 11 | Sept. 11 | |||||||||||||||||

| Sales | 412 | 476 | 545 | 444 | 422 | 452 | 448 | 421 | ||||||||||||||||

| EBITDA | 4 | 32 | 60 | 36 | 11 | 33 | 32 | 19 | ||||||||||||||||

| Depreciation and amortization | 15 | 15 | 14 | 12 | 12 | 11 | 11 | 11 | ||||||||||||||||

| Other items | (1 | ) | 15 | (10 | ) | 9 | 3 | 6 | (10 | ) | 2 | |||||||||||||

| Operating earnings (loss) | (10 | ) | 2 | 56 | 15 | (4 | ) | 16 | 31 | 6 | ||||||||||||||

| Net earnings (loss) and comprehensive earnings (loss) | (9 | ) | – | 59 | 2 | (12 | ) | 7 | 19 | (17 | ) | |||||||||||||

| Basic and fully diluted net earnings (loss) in dollars per share | (0.09 | ) | – | 0.59 | 0.02 | (0.12 | ) | 0.07 | 0.19 | (0.17 | ) | |||||||||||||

| FOURTH QUARTER ANALYSIS |

The Company reported a net loss of $17 million or $0.17 per share in the fourth quarter ended September 24, 2011, compared to net earnings of $2 million or $0.02 per share in the same quarter of fiscal 2010. The weighted average number of common shares outstanding was 100 million, unchanged from the prior year.

Sales decreased by $23 million as compared to the same quarter a year ago. Currency was unfavourable as the Canadian dollar averaged US $1.023, a 6.3% increase from US $0.962 in the prior year quarter. Forest Products segment sales increased by $8 million primarily as a result of higher shipments. Dissolving and Chemical Pulp segment sales increased by $14 million due to significantly higher prices. High-Yield Pulp segment sales decreased by $28 million due to lower shipments and prices. Paper segment sales decreased by $12 million due to lower shipments and prices.

EBITDA declined by $17 million over the prior year quarter. Forest Products segment EBITDA declined by $5 million due primarily to higher costs. Dissolving and Chemical Pulp segment EBITDA was unchanged, with higher prices offsetting higher costs. High-Yield Pulp segment EBITDA declined by $22 million due mainly to lower prices. Paper segment EBITDA increased by $2 million because of lower costs. Corporate expenses for the current quarter include a credit of $6 million relating to share-based compensation. There was no charge for share-based compensation in the prior year quarter.

The Company generated operating earnings of $6 million compared to operating earnings of $15 million in the same quarter a year ago. The previously noted decline in EBITDA was the main cause of the reduction in operating earnings. The prior year quarter “other items” included a charge of $7million related to the permanent closure of the Pine Falls, Manitoba, newsprint mill. It also included a $2 million charge relating to legal costs, site security and custodial costs for several permanently idled facilities. The current year “other items” of $2million were also for costs related to permanently idled facilities.

There were no significant interest variances. The expense relates primarily to interest on the US $255 million senior secured notes maturing in December 2018. Foreign exchange items relate primarily to gains or losses on the translation of US$ net monetary assets. When the Canadian dollar weakens versus the US dollar, as was the case during the current quarter, gains are generated.

28Tembec Financial Report 2011

Management’s Discussion and Analysis

During the September 2011 quarter, the Company recorded a loss of $11 million on the translation of its US $ denominated debt as the relative value of the Canadian dollar decreased from US $1.013 to US $0.971. The Company did not record a gain or loss on the translation of its euro-denominated debt as the relative value of the euro versus the Canadian dollar decreased from C $1.399 to C $1.392.

During the September 2010 quarter, the Company recorded a gain of $3 million on the translation of its US $ denominated debt as the relative value of the Canadian dollar increased from US $0.965 to US $0.975. The Company recorded a loss of $2million on the translation of its euro-denominated debt as the relative value of the euro versus the Canadian dollar increased from C $1.283 to C $1.384.