EARNINGS PRESENTATION Second Quarter 2019 Aleris Corporation August 7, 2019

Forward-Looking and Other Information IMPORTANT INFORMATION This information is current only as of its date and may have changed. We undertake no obligation to update this information in light of new information, future events or otherwise. This information contains certain forecasts and other forward looking information concerning our business, prospects, financial condition and results of operations, and we are not making any representation or warranty that this information is accurate or complete. See “Forward-Looking Information” below. BASIS OF PRESENTATION We are a direct wholly owned subsidiary of Aleris Corporation. Aleris Corporation currently conducts its business and operations through us and our consolidated subsidiaries. As used in this presentation, unless otherwise specified or the context otherwise requires, “Aleris,” “we,” “our,” “us,” “ and the “Company” refer to Aleris International, Inc. and its consolidated subsidiaries. Notwithstanding the foregoing, with respect to the historical financial information and other data presented in this presentation, unless otherwise specified or the context requires, “Aleris,” “we,” “our,” “us,” and the “Company’ refer to Aleris Corporation. We completed the sale of our recycling and specification alloys and extrusions businesses in the first quarter of 2015. We have reported these businesses as discontinued operations for all periods presented, and reclassified the results of operations of these businesses as discontinued operations. Except as otherwise indicated, the discussion of the Company’s business and financial information throughout this presentation refers to the Company’s continuing operations and the financial position and results of operations of its continuing operations. FORWARD-LOOKING INFORMATION Certain statements contained in this presentation are “forward-looking statements” within the meaning of the federal securities laws. Statements under headings with “Outlook” in the title and statements about the Merger and our beliefs and expectations and statements containing the words “may,” “could,” “would,” “should,” “will,” “believe,” “expect,” “anticipate,” “plan,” “estimate,” “target,” “project,” “look forward to,” “intend” and similar expressions intended to connote future events and circumstances constitute forward-looking statements. Forward-looking statements include statements about, among other things, future costs and prices of commodities, production volumes, industry trends, anticipated cost savings, anticipated benefits from new products, facilities, acquisitions or divestitures, projected results of operations, achievement of production efficiencies, capacity expansions, future prices and demand for our products and estimated cash flows and sufficiency of cash flows to fund operations, capital expenditures and debt service obligations, as well as statements regarding trade cases, tariffs and other governmental actions. Forward-looking statements involve known and unknown risks and uncertainties, which could cause actual results to differ materially from those contained in or implied by any forward-looking statement. Important factors that could cause actual results to differ materially from the forward-looking statements include, but are not limited to, the following: (1) our ability to successfully implement our business strategy; (2) the success of past and future acquisitions or divestitures; (3) the cyclical nature of the aluminum industry, material adverse changes in the aluminum industry or our end-uses, such as global and regional supply and demand conditions for aluminum and aluminum products, and changes in our customers’ industries; (4) increases in the cost, or limited availability, of raw materials and energy; (5) our ability to enter into effective metal, energy and other commodity derivatives or arrangements with customers to manage effectively our exposure to commodity price fluctuations and changes in the pricing of metals, especially London Metal Exchange-based aluminum prices; (6) our ability to generate sufficient cash flows to fund our operations and capital expenditure requirements and to meet our debt obligations; (7) competitor pricing activity, competition of aluminum with alternative materials and the general impact of competition in the industry end-uses we serve; (8) our ability to retain the services of certain members of our management; (9) the loss of order volumes from any of our largest customers; (10) our ability to retain customers, a substantial number of whom do not have long-term contractual arrangements with us; (11) risks of investing in and conducting operations on a global basis, including political, social, economic, currency and regulatory factors; (12) variability in general economic or political conditions on a global or regional basis; (13) current environmental liabilities and the cost of compliance with and liabilities under health and safety laws; (14) labor relations (i.e., disruptions, strikes or work stoppages) and labor costs; (15) our internal controls over financial reporting and our disclosure controls and procedures may not prevent all possible errors that could occur; (16) our levels of indebtedness and debt service obligations, including changes in our credit ratings, material increases in our cost of borrowing or the failure of financial institutions to fulfill their commitments to us under committed facilities; (17) our ability to access credit or capital markets; (18) the possibility that we may incur additional indebtedness in the future; (19) limitations on operating our business and incurring additional indebtedness as a result of covenant restrictions under our indebtedness, and our ability to pay amounts due under our outstanding indebtedness; and (20) risks related to the Merger, including the possibility that the Merger may not be consummated; and (21) other factors discussed in our filings with the Securities and Exchange Commission, including the sections entitled “Risk Factors” contained therein. Investors, potential investors and other readers are urged to consider these factors carefully in evaluating the forward-looking statements and are cautioned not to place undue reliance on such forward- looking statements. We undertake no obligation to publicly update or revise any forward-looking statements, whether in response to new information, futures events or otherwise, except as otherwise required by law. NON-GAAP INFORMATION The non-GAAP financial measures contained in this presentation (including, without limitation, EBITDA, Adjusted EBITDA, commercial margin, and variations thereof) are not measures of financial performance calculated in accordance with U.S. GAAP and should not be considered as alternatives to net income and loss attributable to Aleris Corporation or any other performance measure derived in accordance with GAAP or as alternatives to cash flows from operating activities as a measure of our liquidity. Non- GAAP measures have limitations as analytical tools and should be considered in addition to, not in isolation or as a substitute for, or as superior to, our measures of financial performance prepared in accordance with GAAP. Management believes that certain non-GAAP financial measures may provide investors with additional meaningful comparisons between current results and results in prior periods. Management uses non-GAAP financial measures as performance metrics and believes these measures provide additional information commonly used by the holders of our 2023 Junior Priority Senior Notes and parties to our Term Loan Facility and the ABL Facility with respect to the ongoing performance of our underlying business activities, as well as our ability to meet our future debt service, capital expenditure and working capital needs. We calculate our non-GAAP financial measures by eliminating the impact of a number of items we do not consider indicative of our ongoing operating performance, and certain other items. You are encouraged to evaluate each adjustment and the reasons we consider it appropriate for supplemental analysis. See “Appendix.” INDUSTRY INFORMATION Information regarding market and industry statistics contained in this presentation is based on information from third party sources as well as estimates prepared by us using certain assumptions and our knowledge of these industries. Our estimates, in particular as they relate to our general expectations concerning the aluminum industry, involve risks and uncertainties and are subject to changes based on various factors, including those discussed under “Risk Factors” in our filings with the Securities and Exchange Commission. WEBSITE POSTING We use our investor website (investor.aleris.com) as a channel of distribution of Company information. The information we post through this channel may be deemed material. Accordingly, investors should monitor this channel, in addition to following our press releases, Securities and Exchange Commission ("SEC") filings, and public conference calls and webcasts. The content of our website is not, however, a part of this presentation. 2

Second Quarter Overview 2Q Adjusted EBITDA ($M) +27% ▪ Record Adjusted EBITDA of $108M compared to $85M in 2018 $108 – Global aerospace volumes increased resulting from $85 strong demand and growth in Asia Pacific 2Q18 2Q19 – Global automotive volumes up due to increased shipments from North America automotive assets; Adjusted EBITDA per ton ($/t) Europe automotive volumes unfavorably impacted by regional demand softness +29% – Favorable metal environment and improved rolling margins in North America $466 $361 2Q18 2Q19 Significant year over year improvement in Adjusted EBITDA & Adjusted EBITDA per ton 3

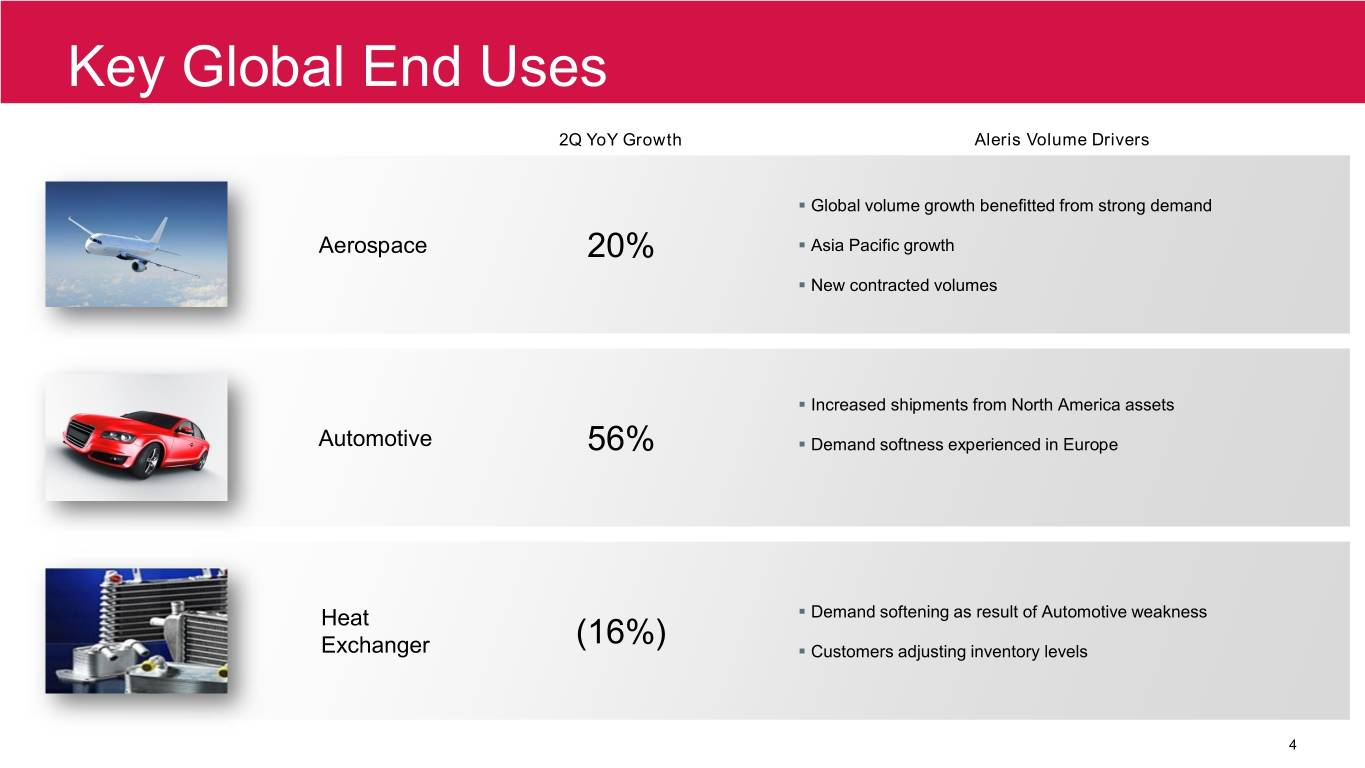

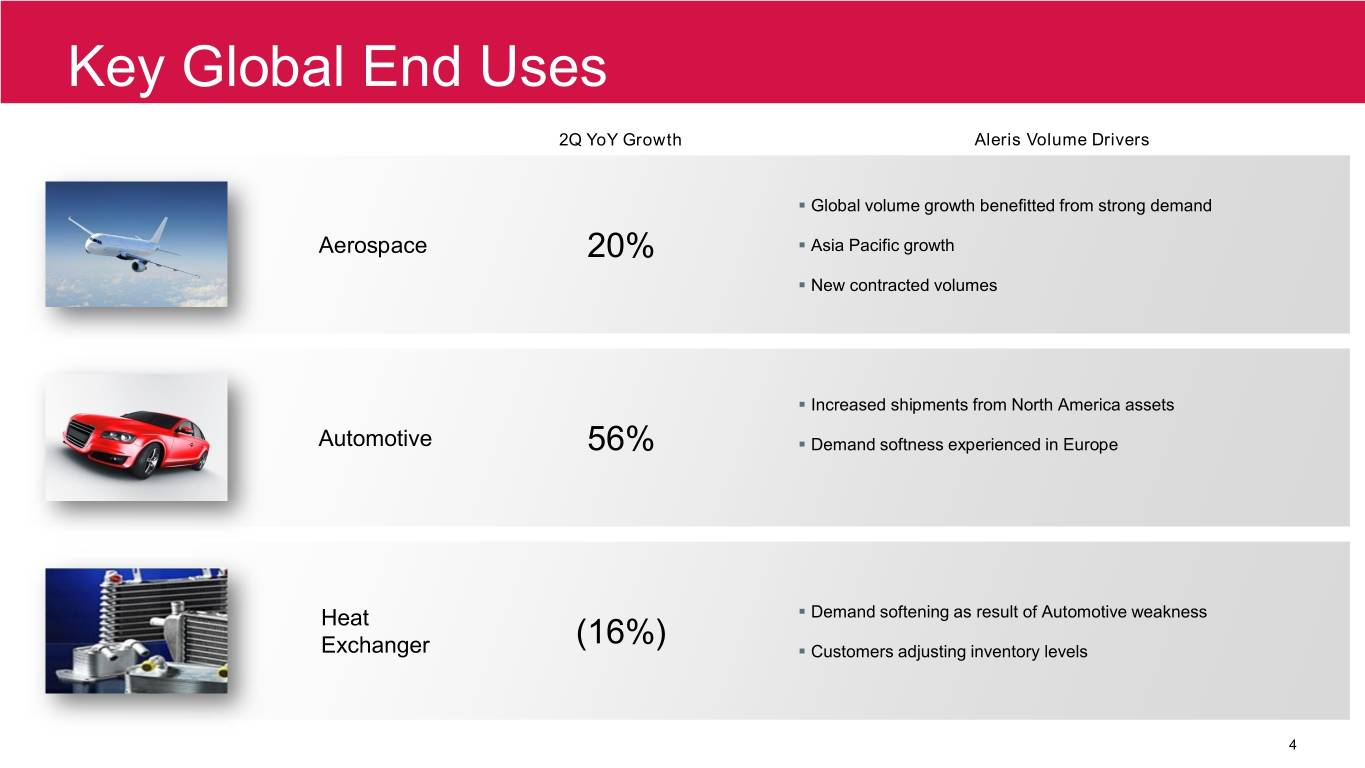

Key Global End Uses 2Q YoY Growth Aleris Volume Drivers ▪ Global volume growth benefitted from strong demand Aerospace 20% ▪ Asia Pacific growth ▪ New contracted volumes ▪ Increased shipments from North America assets Automotive 56% ▪ Demand softness experienced in Europe ▪ Demand softening as result of Automotive weakness Heat (16%) Exchanger ▪ Customers adjusting inventory levels 4

Key Regional End Uses 2Q YoY Growth Aleris Volume Drivers N.A. ▪ Continued demand choppiness in the housing sector Building & (7%) ▪ Wet spring; customers closely managing inventory Construction ▪ Truck Trailer consumed more continuous cast capacity ▪ Shipments impacted by mix shift to Automotive N.A. (39%) Distribution ▪ Customer demand continued to be favorable ▪ Demand continued to be strong N.A. 19% Truck Trailer ▪ Record dry van backlogs EU Regional ▪ Overall bookings and order activity stable Commercial 4% ▪ Continuing to optimize portfolio given capacity limitations Plate & Sheet 5

Adjusted EBITDA Bridge ($M) 2Q19 vs. 2Q18 130 120 ($2) ($7) 110 ($4) $0 100 $35 90 $1 $108 80 $20M of start-up costs from $85 70 prior year absorbed 60 2Q18 Volume / Mix Price / Commodity Inflation Base Inflation Productivity Currency/ 2Q19 Metal Spreads Translation/ Other 1H19 vs. 1H18 220 ($3) 200 ($14) ($10) $3 180 $67 160 $11 140 $193 120 $139 $33M of start-up costs from 100 prior year absorbed 80 1H18 Volume / Mix Price / Commodity Inflation Base Inflation Productivity Currency/ 1H19 Metal Spreads Translation/ Other 6

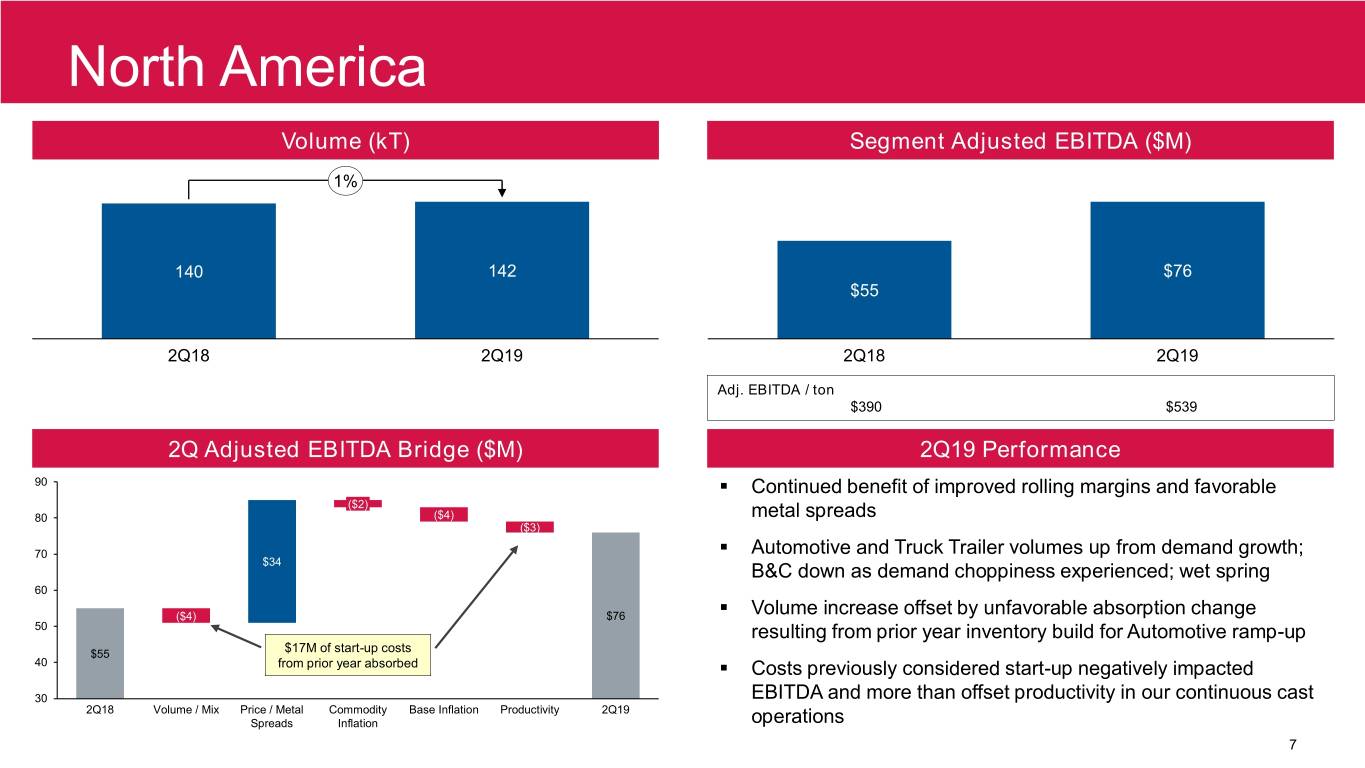

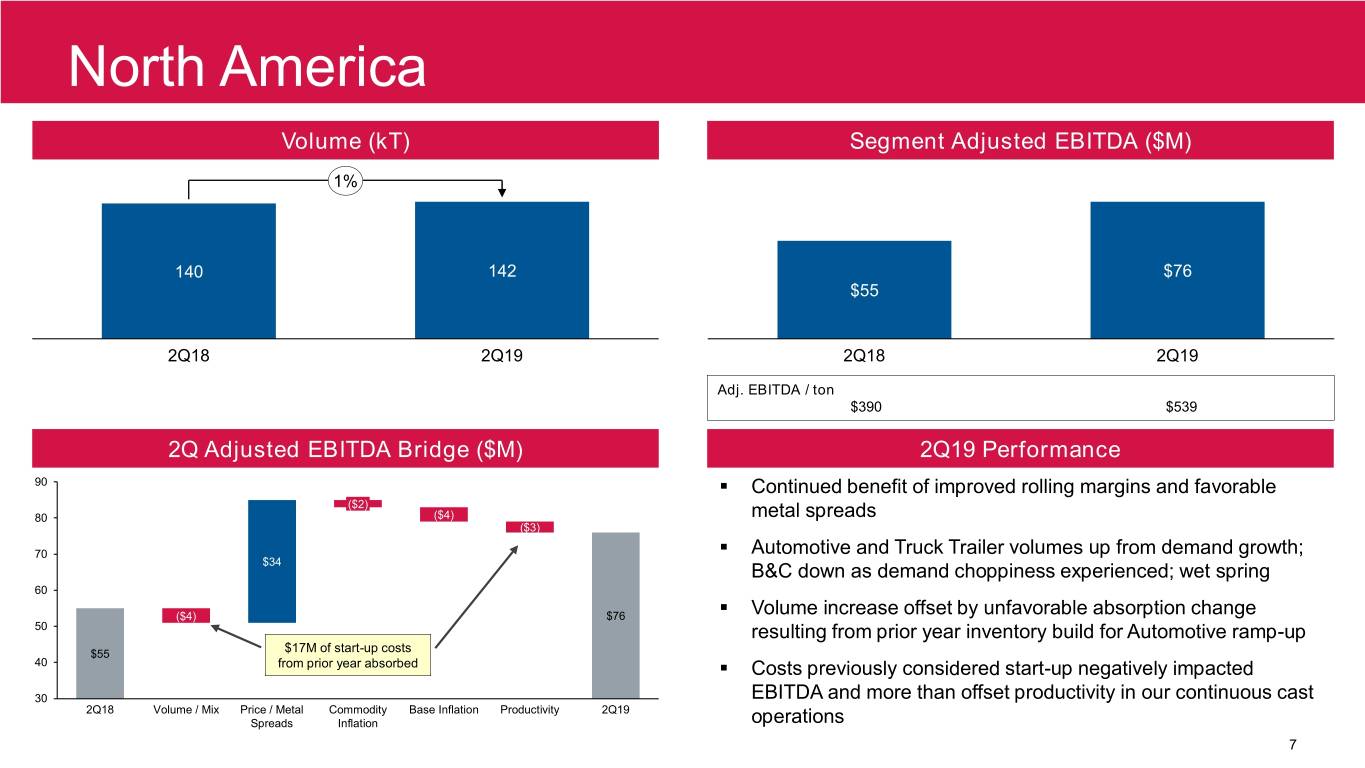

North America Volume (kT) Segment Adjusted EBITDA ($M) 1% 140 142 $76 $55 2Q18 2Q19 2Q18 2Q19 Adj. EBITDA / ton $390 $539 2Q Adjusted EBITDA Bridge ($M) 2Q19 Performance 90 ▪ Continued benefit of improved rolling margins and favorable ($2) 80 ($4) metal spreads ($3) 70 ▪ Automotive and Truck Trailer volumes up from demand growth; $34 B&C down as demand choppiness experienced; wet spring 60 ($4) $76 ▪ Volume increase offset by unfavorable absorption change 50 resulting from prior year inventory build for Automotive ramp-up $55 $17M of start-up costs 40 from prior year absorbed ▪ Costs previously considered start-up negatively impacted 30 EBITDA and more than offset productivity in our continuous cast 2Q18 Volume / Mix Price / Metal Commodity Base Inflation Productivity 2Q19 Spreads Inflation operations 7

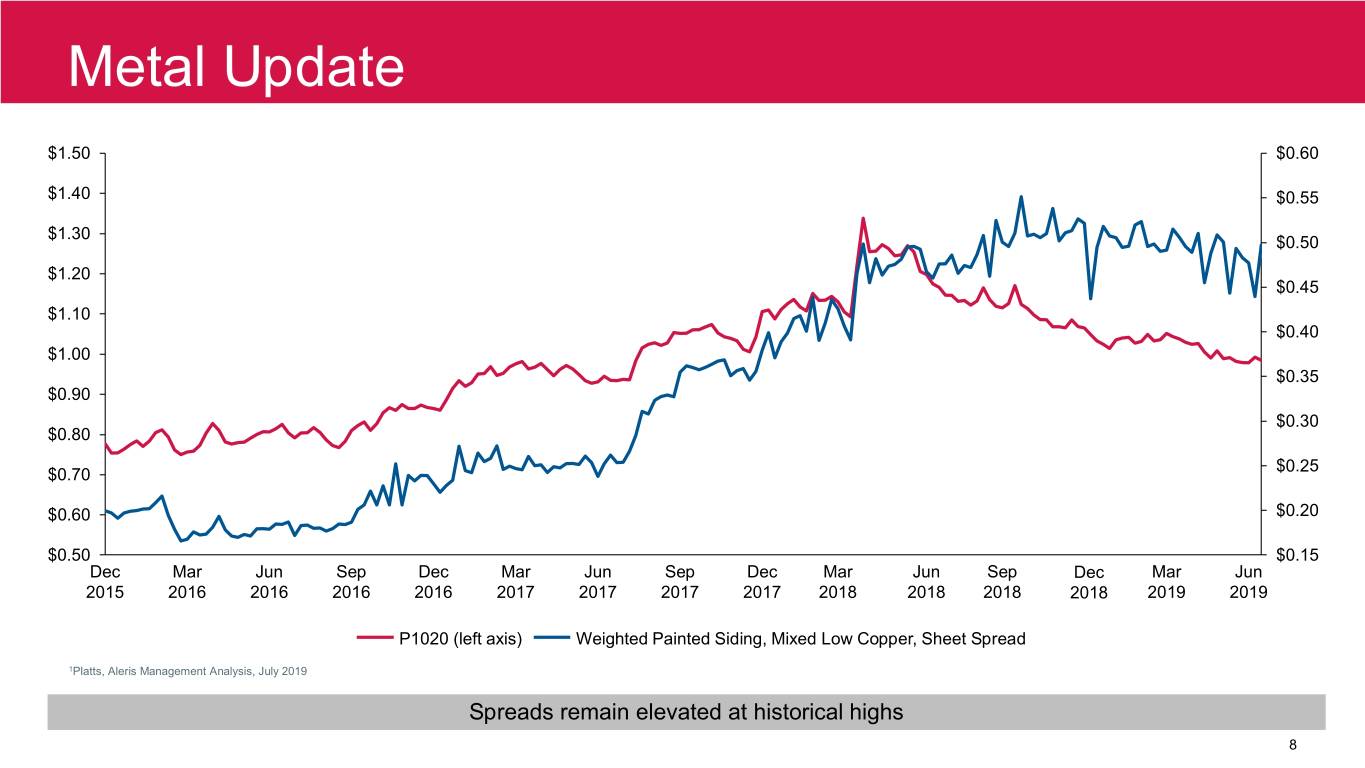

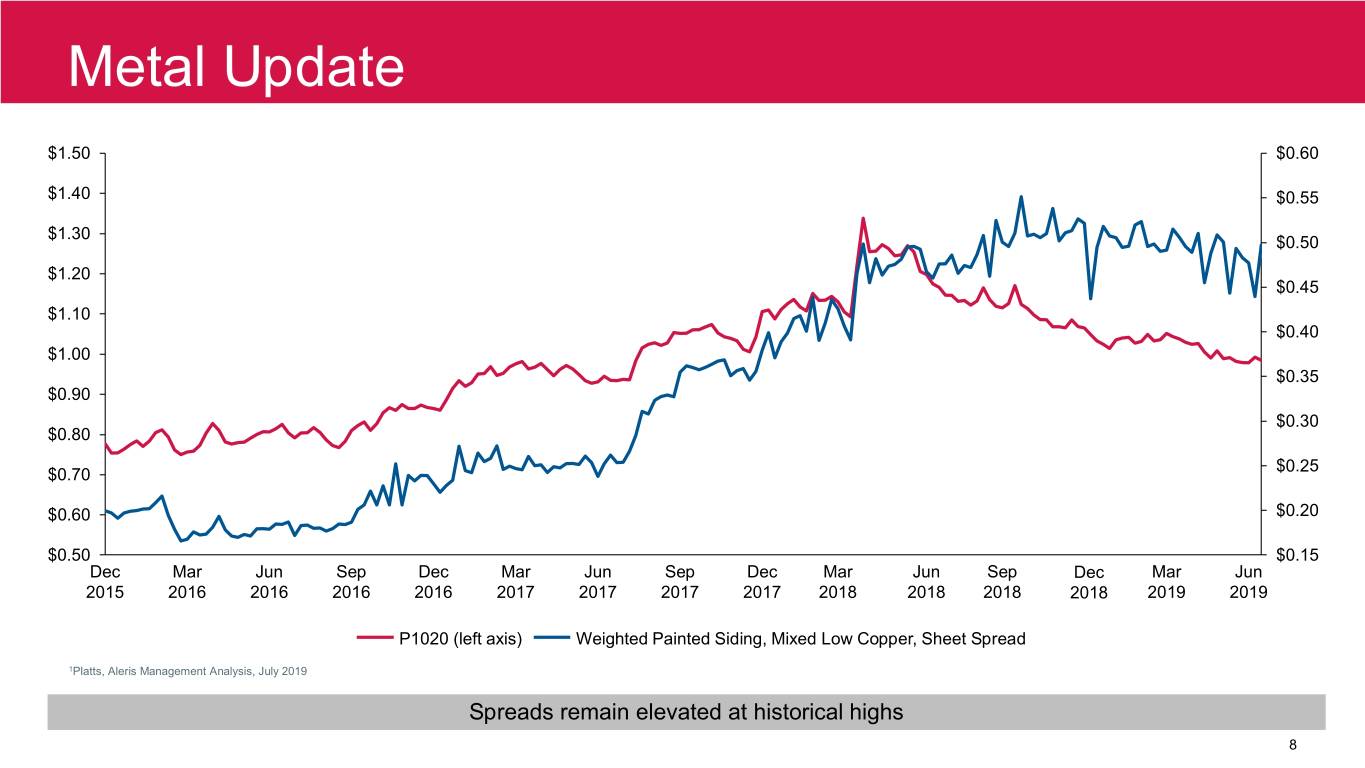

Metal Update $1.50 $0.60 $1.40 $0.55 $1.30 $0.50 $1.20 $0.45 $1.10 $0.40 $1.00 $0.35 $0.90 $0.30 $0.80 $0.25 $0.70 $0.60 $0.20 $0.50 $0.15 Dec Mar Jun Sep Dec Mar Jun Sep Dec Mar Jun Sep Dec Mar Jun 2015 2016 2016 2016 2016 2017 2017 2017 2017 2018 2018 2018 2018 2019 2019 P1020 (left axis) Weighted Painted Siding, Mixed Low Copper, Sheet Spread 1Platts, Aleris Management Analysis, July 2019 Spreads remain elevated at historical highs 8

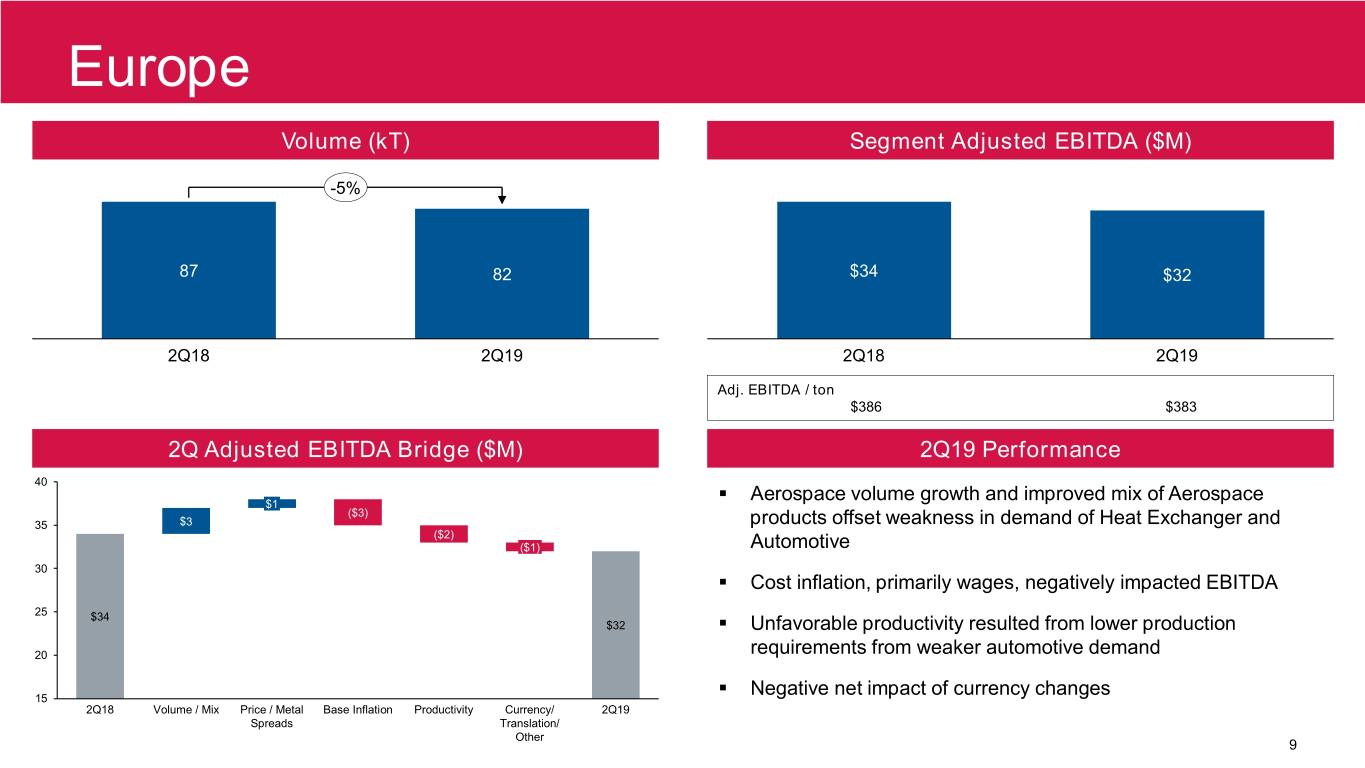

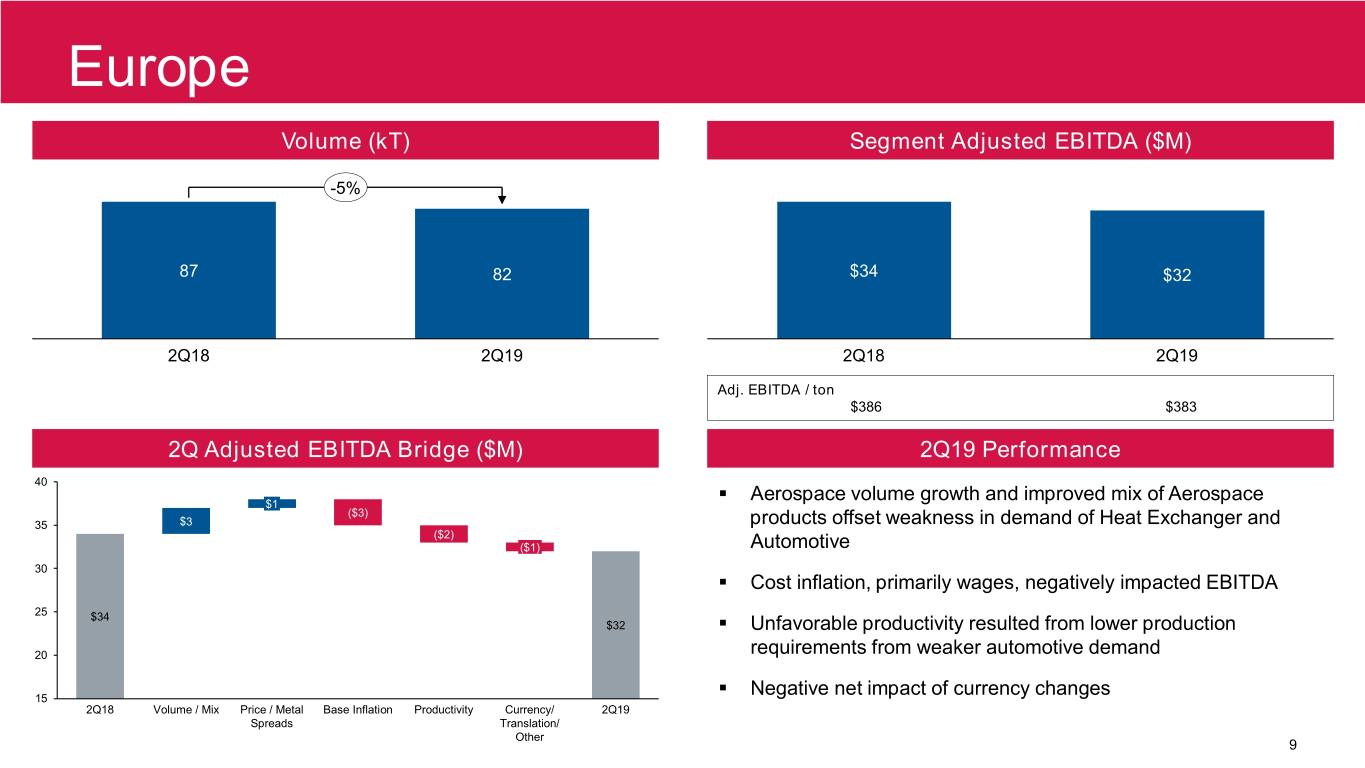

Europe Volume (kT) Segment Adjusted EBITDA ($M) -5% 87 82 $34 $32 2Q18 2Q19 2Q18 2Q19 Adj. EBITDA / ton $386 $383 2Q Adjusted EBITDA Bridge ($M) 2Q19 Performance 40 ▪ Aerospace volume growth and improved mix of Aerospace $1 ($3) 35 $3 products offset weakness in demand of Heat Exchanger and ($2) ($1) Automotive 30 ▪ Cost inflation, primarily wages, negatively impacted EBITDA 25 $34 $32 ▪ Unfavorable productivity resulted from lower production 20 requirements from weaker automotive demand 15 ▪ Negative net impact of currency changes 2Q18 Volume / Mix Price / Metal Base Inflation Productivity Currency/ 2Q19 Spreads Translation/ Other 9

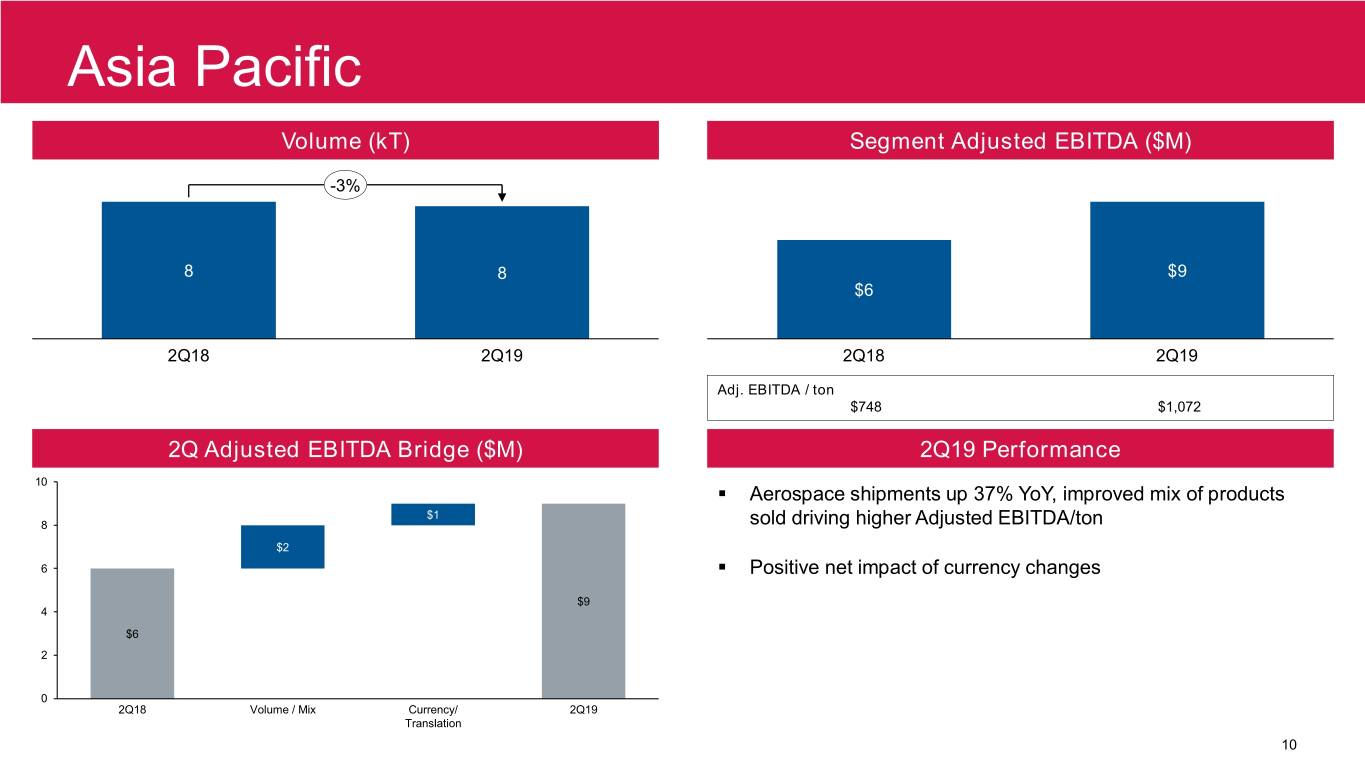

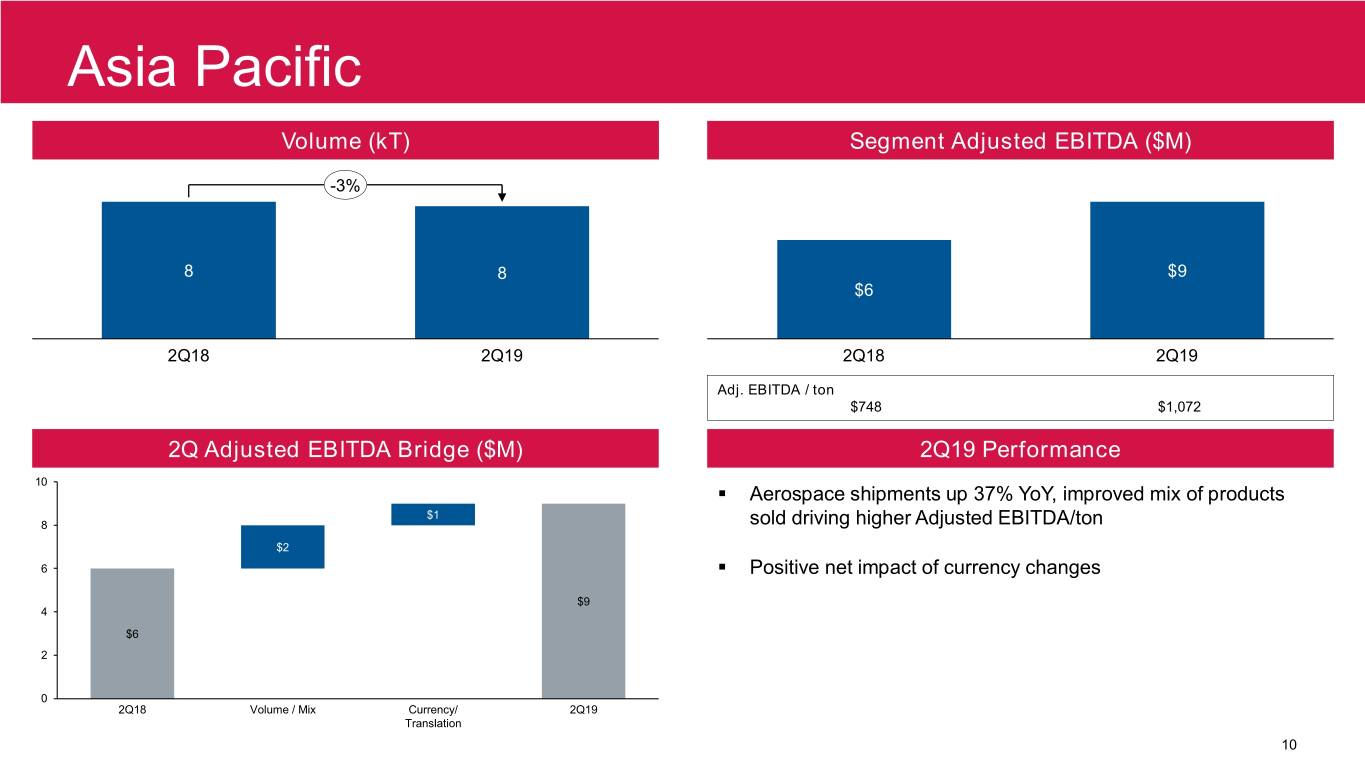

Asia Pacific Volume (kT) Segment Adjusted EBITDA ($M) -3% 8 8 $9 $6 2Q18 2Q19 2Q18 2Q19 Adj. EBITDA / ton $748 $1,072 2Q Adjusted EBITDA Bridge ($M) 2Q19 Performance 10 ▪ Aerospace shipments up 37% YoY, improved mix of products $1 8 sold driving higher Adjusted EBITDA/ton $2 6 ▪ Positive net impact of currency changes $9 4 $6 2 0 2Q18 Volume / Mix Currency/ 2Q19 Translation 10

Cash Flow and LTM Working Capital Net Cash Flow ($M) Total LTM Working Capital Days 23% 85 22% 22% 2Q18 2Q19 80 75 Cash (Used) Provided by Operating Activities ($72) $73 70 84 65 78 78 Capital Expenditures (21) (20) 60 Net Cash Before Financing ($93) $53 55 50 2017 2018 2Q19 Days % of Sales Strong cash flow in 2Q after seasonal 1Q working capital build 11

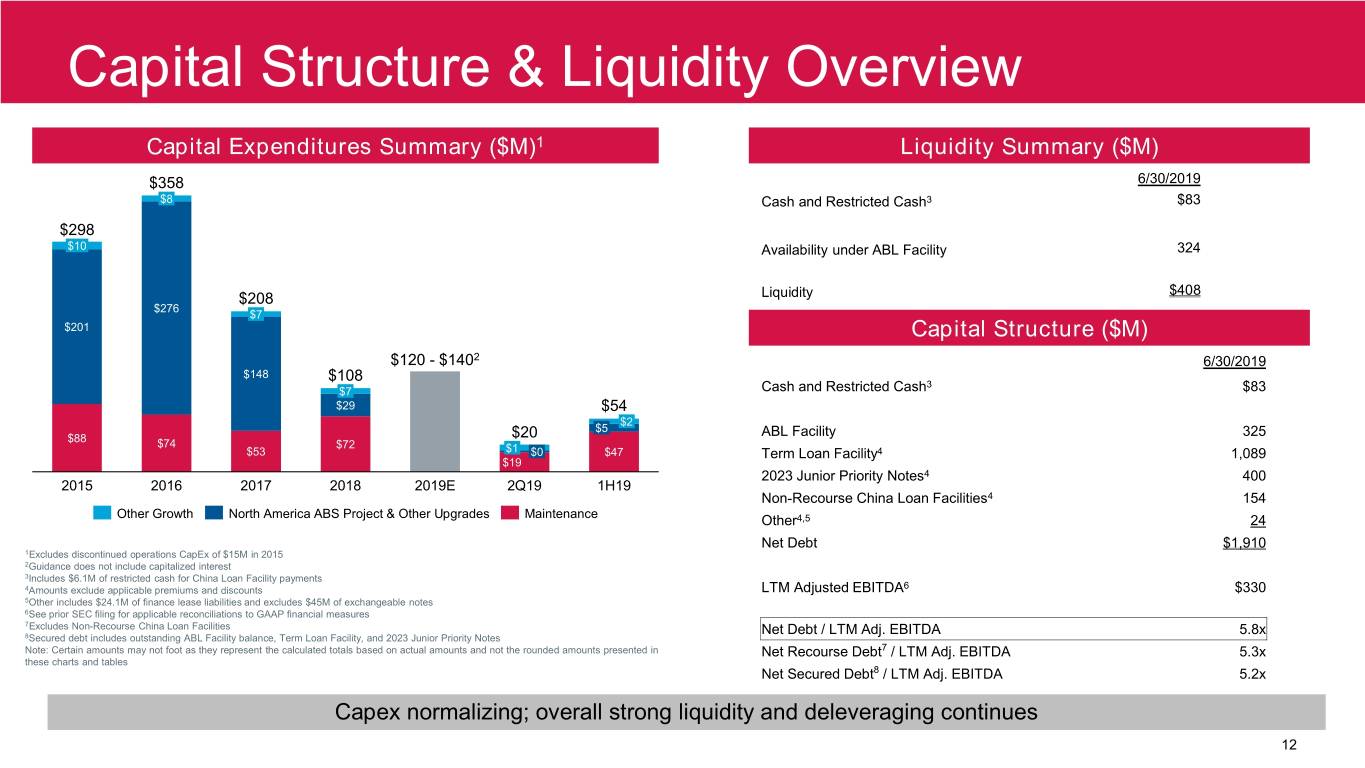

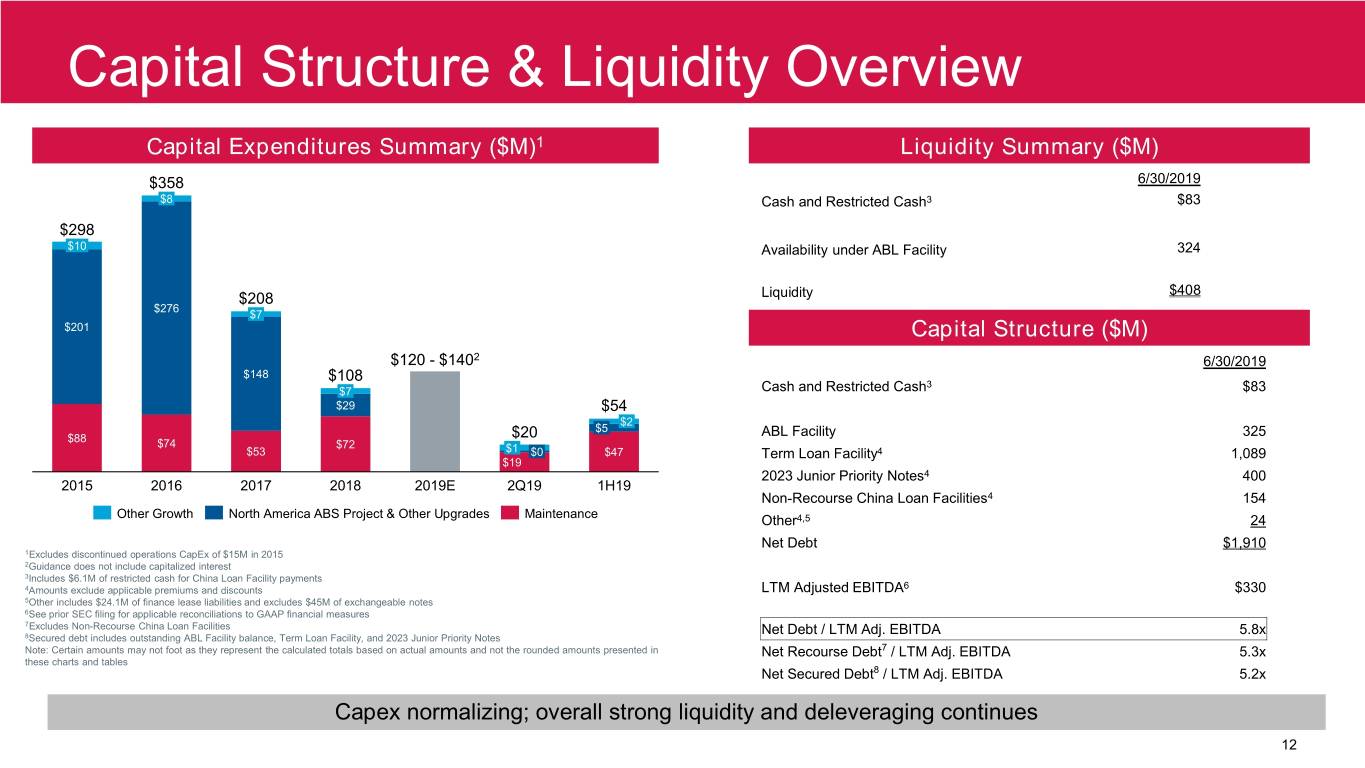

Capital Structure & Liquidity Overview Capital Expenditures Summary ($M)1 Liquidity Summary ($M) $358 6/30/2019 $8 Cash and Restricted Cash3 $83 $298 $10 Availability under ABL Facility 324 $408 $208 Liquidity $276 $7 $201 Capital Structure ($M) $120 - $1402 6/30/2019 $148 $108 3 $7 Cash and Restricted Cash $83 $29 $54 $2 $5 ABL Facility 325 $88 $20 $74 $72 $53 $1 $0 $47 Term Loan Facility4 1,089 $19 2023 Junior Priority Notes4 400 2015 2016 2017 2018 2019E 2Q19 1H19 Non-Recourse China Loan Facilities4 154 Other Growth North America ABS Project & Other Upgrades Maintenance Other4,5 24 Net Debt $1,910 1Excludes discontinued operations CapEx of $15M in 2015 2Guidance does not include capitalized interest 3Includes $6.1M of restricted cash for China Loan Facility payments 6 4Amounts exclude applicable premiums and discounts LTM Adjusted EBITDA $330 5Other includes $24.1M of finance lease liabilities and excludes $45M of exchangeable notes 6See prior SEC filing for applicable reconciliations to GAAP financial measures 7Excludes Non-Recourse China Loan Facilities Net Debt / LTM Adj. EBITDA 5.8x 8Secured debt includes outstanding ABL Facility balance, Term Loan Facility, and 2023 Junior Priority Notes Note: Certain amounts may not foot as they represent the calculated totals based on actual amounts and not the rounded amounts presented in Net Recourse Debt7 / LTM Adj. EBITDA 5.3x these charts and tables Net Secured Debt8 / LTM Adj. EBITDA 5.2x Capex normalizing; overall strong liquidity and deleveraging continues 12

Outlook ▪ Third quarter 2019 segment income and Adjusted EBITDA expected to be comparable sequentially and higher than the third quarter of 2018 ▪ Global aerospace volumes expected to benefit from strong demand ▪ North America automotive sales expected to continue to increase based on committed volumes ▪ Continued softness expected for European automotive and heat exchanger end-uses ▪ Favorable year-over-year rolling margins and metal spreads expected in North America 13

APPENDIX 14

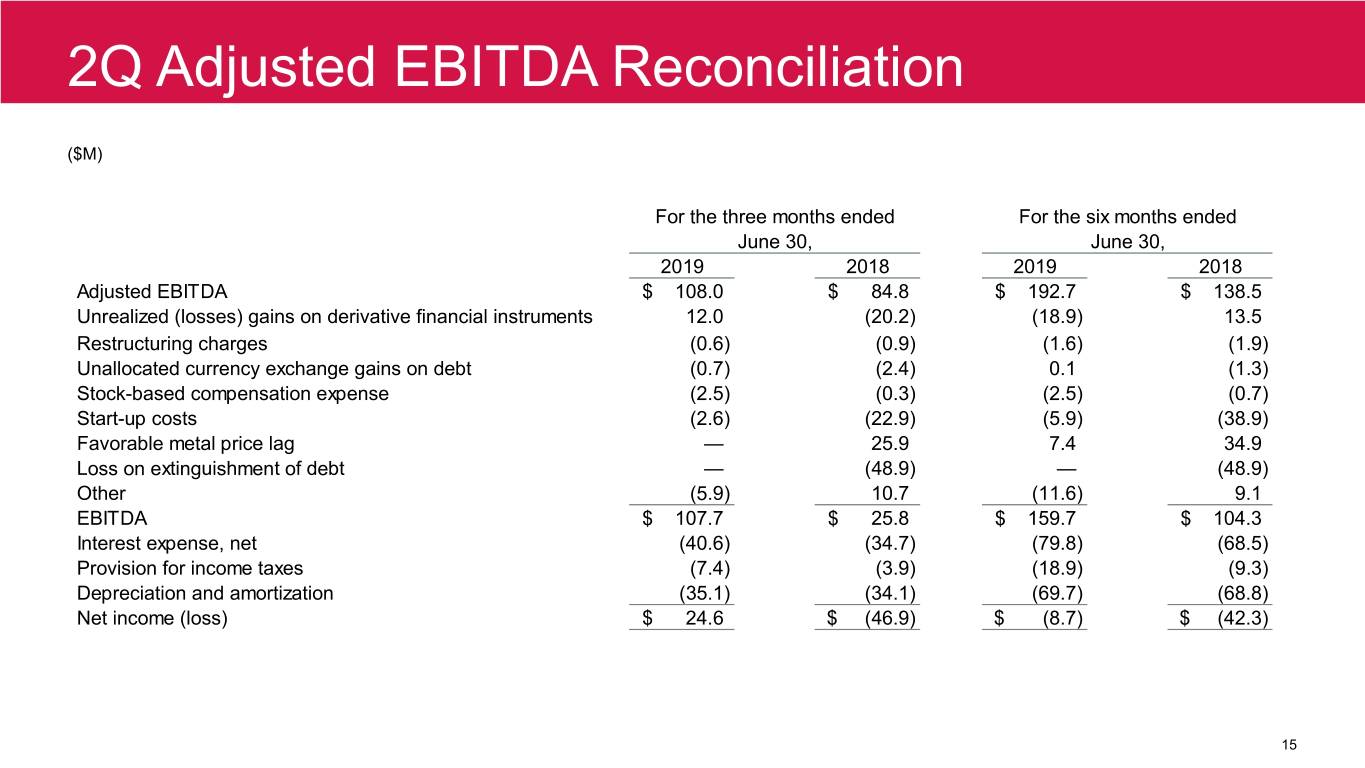

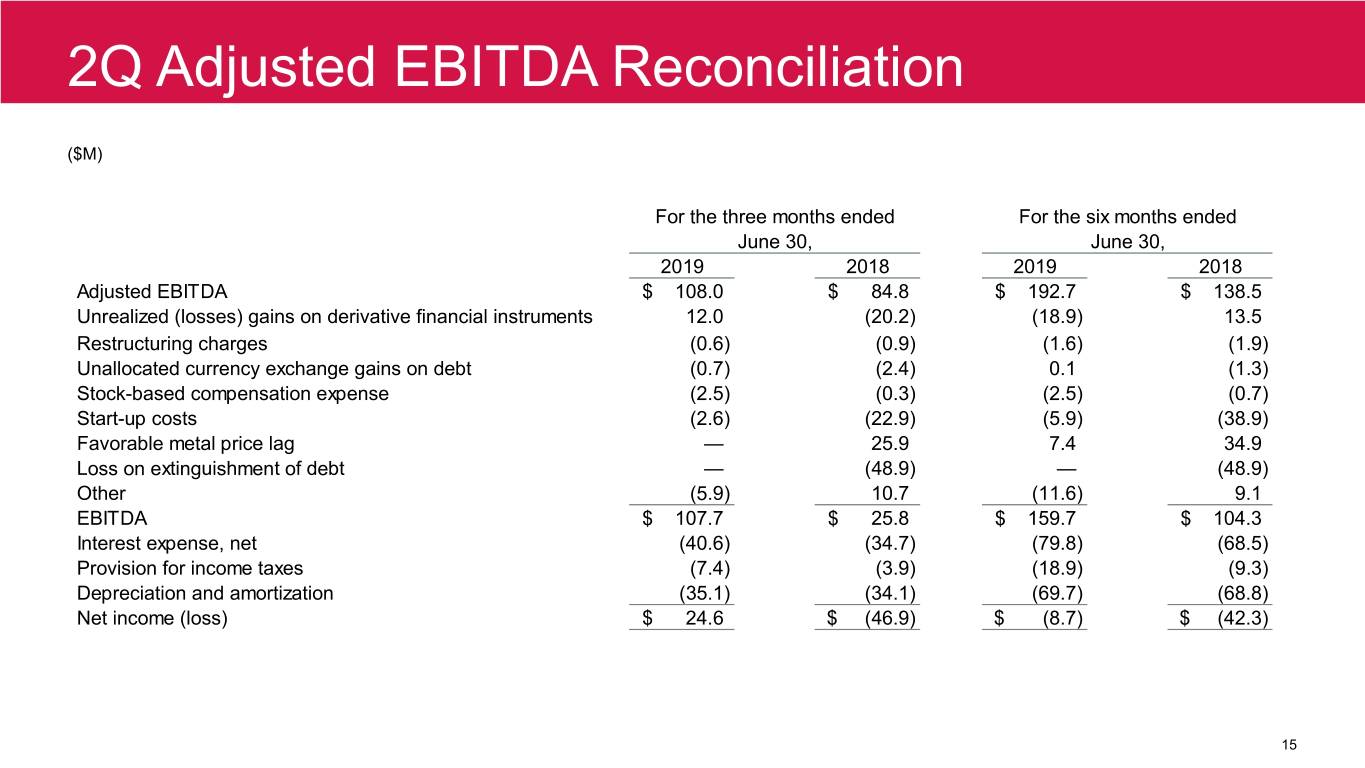

2Q Adjusted EBITDA Reconciliation ($M) For the three months ended For the six months ended June 30, June 30, 2019 2018 2019 2018 Adjusted EBITDA $ 108.0 $ 84.8 $ 192.7 $ 138.5 Unrealized (losses) gains on derivative financial instruments 12.0 (20.2) (18.9) 13.5 Restructuring charges (0.6) (0.9) (1.6) (1.9) Unallocated currency exchange gains on debt (0.7) (2.4) 0.1 (1.3) Stock-based compensation expense (2.5) (0.3) (2.5) (0.7) Start-up costs (2.6) (22.9) (5.9) (38.9) Favorable metal price lag — 25.9 7.4 34.9 Loss on extinguishment of debt — (48.9) — (48.9) Other (5.9) 10.7 (11.6) 9.1 EBITDA $ 107.7 $ 25.8 $ 159.7 $ 104.3 Interest expense, net (40.6) (34.7) (79.8) (68.5) Provision for income taxes (7.4) (3.9) (18.9) (9.3) Depreciation and amortization (35.1) (34.1) (69.7) (68.8) Net income (loss) $ 24.6 $ (46.9) $ (8.7) $ (42.3) 15

2Q Adjusted EBITDA Reconciliation by Segment ($M) For the three months ended For the six months ended June 30, June 30, 2019 2018 2019 2018 North America Segment income $ 74.4 $ 71.6 $ 131.5 $ 113.1 Unfavorable (favorable) metal price lag 2.0 (16.9) (4.8) (24.3) 1 Segment Adjusted EBITDA $ 76.5 $ 54.7 $ 126.7 $ 88.8 Europe Segment income $ 33.1 $ 42.3 $ 69.7 $ 70.6 Favorable metal price lag (1.5) (8.6) (2.4) (10.0) 1 Segment Adjusted EBITDA $ 31.5 $ 33.7 $ 67.3 $ 60.6 Asia Pacific Segment income $ 9.3 $ 6.7 $ 17.7 $ 9.1 Favorable metal price lag (0.5) (0.4) (0.2) (0.6) 1 Segment Adjusted EBITDA $ 8.8 $ 6.4 $ 17.4 $ 8.5 1Amounts may not foot as they represent the calculated totals based on actual amounts and not the rounded amounts presented in this table 16

2Q Adjusted EBITDA Per Ton Reconciliation ($M) For the three months ended For the six months ended June 30, June 30, 2019 2018 2019 2018 Metric tons of finished product shipped: North America 141.9 140.3 269.7 259.8 Europe 82.3 87.3 168.3 172.7 Asia Pacific 8.2 8.5 16.9 14.9 Intra-entity shipments (0.6) (1.0) (1.7) (3.0) Total metric tons of finished product shipped 231.8 235.1 453.2 444.4 Segment Adjusted EBITDA:1 North America2 $ 76.5 $ 54.7 $ 126.7 $ 88.8 Europe 31.5 33.7 67.3 60.6 Asia Pacific 8.8 6.4 17.4 8.5 Corporate (8.8) (10.0) (18.7) (19.4) Total Adjusted EBITDA $ 108.0 $ 84.8 $ 192.7 $ 138.5 Segment Adjusted EBITDA per metric ton shipped: North America $ 538.7 $ 390.2 $ 469.9 $ 341.8 Europe $ 383.1 $ 385.6 $ 400.1 $ 350.7 Asia Pacific $ 1,071.9 $ 748.1 $ 1,030.0 $ 569.4 Aleris Corporation $ 465.9 $ 360.8 $ 425.2 $ 311.6 1See prior slides for a reconciliation to the applicable GAAP financial measures 2Segment Adjusted EBITDA excludes start-up operating expenses and losses incurred during the start-up period. For the three months ended June 30, 2019 and 2018, start-up costs were $2.9 million and $19.8 million, respectively. For the six months ended June 30, 2019 and 2018, start-up costs were $6.1 million and $34.3 million, respectively 17

Metal Hedging Practices Risk Mitigation Strategy Impact ▪ LME and regional premium volatility ▪ Pass through pricing and tolling ✓ Lowers margin volatility (inventory exposure) ▪ Minimize inventory levels ✓ Minimizes earnings impact ▪ Sell 100% of open inventory forward ✓ Risk limited to turn of inventory (“metal lag”) ▪ Forward price sales ▪ Match sales with physical purchases or LME forwards ✓ Locks in rolling margin ▪ Attempt to minimize LT fixed price sales ✓ Reduces multiyear dated derivatives Adjusted EBITDA vs. Metal Price Lag 3Q 2017 4Q 2017 1Q 2018 2Q 2018 3Q 2018 4Q 2018 1Q 2019 2Q 2019 Metal price lag impact on gross profit ($5) $16 $10 $27 ($13) ($11) ($18) ($8) (+) Realized (losses) / gains on metal 4 (19) (1) (1) 17 8 25 8 derivatives Favorable / (unfavorable) metal price lag ($1) ($3) $9 $26 $4 ($3) $7 $0 net of realized derivative gains / losses Adj. EBITDA including metal lag $45 $34 $63 $111 $81 $58 $92 $108 (–) Income / (expense) from metal price lag (1) (3) 9 26 4 (3) 7 0 Adj. EBITDA as reported $46 $37 $54 $85 $77 $61 $85 $108 Risk management helps minimize commodity price exposure 18