Filed Pursuant to Rule 424(b)(4)

Registration No. 333-192559

PROSPECTUS SUPPLEMENT

(To Prospectus Dated January 22, 2014)

6,400,000 Shares

GLOBAL BRASS AND COPPER HOLDINGS, INC.

Common Stock

All of the 6,400,000 shares of common stock of Global Brass and Copper Holdings, Inc. to be sold in this public offering will be sold by the selling stockholder identified in this prospectus supplement. We will not receive any proceeds from this offering. This prospectus supplement is a supplement to, and should be read together with, the accompanying prospectus, dated January 22, 2014.

Our common stock is listed on the New York Stock Exchange (the “NYSE”) under the symbol “BRSS.” On January 23, 2014, the closing price of our common stock on the NYSE was $16.90 per share.

Investing in shares of our common stock involves risks. See “Risk Factors” beginning on page 22 of the accompanying prospectus to read about factors you should consider before buying shares of our common stock.

Neither the Securities and Exchange Commission nor any other regulatory body has approved or disapproved of these securities or passed upon the accuracy or adequacy of this prospectus supplement or the accompanying prospectus. Any representation to the contrary is a criminal offense.

The underwriter has agreed to purchase 6,400,000 shares of our common stock from the selling stockholder at a price of $16.25 per share, which will result in the selling stockholder receiving approximately $104,000,000 of proceeds. In addition, the underwriter has the option to purchase up to an additional 910,000 shares from the selling stockholder at a price of $16.25. If the underwriter does exercise in full its option to purchase additional shares, this will result in the selling stockholder receiving approximately $118,787,500 of proceeds. The underwriter proposes to offer our shares of common stock from time to time for sale in one or more transactions on the New York Stock Exchange, in the over-the-counter market, through negotiated transactions or otherwise at market prices prevailing at the time of sale, at prices related to prevailing market prices or at negotiated prices, subject to receipt and acceptance by it and subject to its right to reject any order in whole or in part. The underwriter will receive reimbursement for certain expenses in connection with this offering. See “Underwriting”.

The underwriter expects to deliver the shares to purchasers on January 28, 2014.

Morgan Stanley

Prospectus Supplement dated January 22, 2014.

TABLE OF CONTENTS

Prospectus Supplement

Prospectus

ABOUT THIS PROSPECTUS SUPPLEMENT

On December 5, 2013, the Securities and Exchange Commission (the “SEC”) declared effective our shelf registration statement on Form S-1 (File no. 333-192559) that registers a “shelf” registration process under the Securities Act of 1933. Under the shelf registration process, the selling stockholder, Halkos Holdings, LLC, may, from time to time, offer and sell the 7,310,000 shares of common stock described in the registration statement in one or more offerings on a delayed or continuous basis.

On January 22, 2013, we filed a prospectus with the SEC, which accompanies this prospectus supplement. This prospectus supplement supplements the accompanying prospectus and relates to the offering and sale of 6,400,000 shares of our common stock (7,310,000 shares, if the underwriter fully exercises its option to purchase additional shares) whose offering and sale were registered under the registration statement. The information contained in this prospectus supplement updates and supersedes any corresponding information contained in the prospectus. You should read this prospectus supplement together with the accompanying prospectus in connection with your decision to purchase the offered common stock.

S-i

We are responsible for the information contained in this prospectus supplement, the accompanying prospectus and any free writing prospectus prepared by or on behalf of us that we have referred to you. Neither we, the selling stockholder nor the underwriter have authorized anyone to provide you with additional information or information different from that contained in this prospectus supplement, the accompanying prospectus or any free writing prospectus filed with the Securities and Exchange Commission, and we take no responsibility for any other information that others may give you. The selling stockholder is offering to sell, and seeking offers to buy, common stock only in jurisdictions where offers and sales are permitted. The information contained in this prospectus supplement is accurate only as of the date of this prospectus supplement, regardless of the time of delivery of this prospectus supplement or of any sale of our common stock. Our business, operating results or financial condition may have changed since such date.

Unless otherwise specified or the context requires otherwise:

The term “Global Brass and Copper Holdings” refers to Global Brass and Copper Holdings, Inc. and not to any of its subsidiaries;

The term “Global Brass and Copper” refers to Global Brass and Copper, Inc., the principal operating subsidiary of Global Brass and Copper Holdings, and not to any of its subsidiaries or direct or indirect parent companies;

The terms “we,” “us,” “our,” “GBC” and the “Company” refer collectively to Global Brass and Copper Holdings, its subsidiaries and its predecessors;

The term “KPS” refers to KPS Capital Partners, LP; and

The term “Halkos” refers to Halkos Holdings, LLC, the beneficial owner of 34.4% of our common stock as of December 31, 2013. Halkos is the only selling stockholder in the offerings contemplated by this prospectus supplement and the accompanying prospectus. After giving effect to this offering, Halkos will beneficially own 4.3% of our common stock (0% if the underwriters exercise in full their option to purchase additional shares).

The use of these terms is not intended to imply that Halkos, Global Brass and Copper Holdings and Global Brass and Copper or its predecessors are not separate and distinct legal entities.

Amounts and percentages appearing in this prospectus supplement have been rounded to the amounts shown for convenience of presentation. Accordingly, the total of each column of amounts may not be equal to the total of the relevant individual items.

S-ii

GLOBAL BRASS AND COPPER HOLDINGS

Global Brass and Copper Holdings was incorporated in Delaware on October 10, 2007. Global Brass and Copper Holdings acquired the worldwide metals business of Olin Corporation on November 19, 2007. The principal executive offices of Global Brass and Copper Holdings are located at 475 N. Martingale Road, Suite 1050, Schaumburg, IL 60173, and the telephone number is (847) 240-4700. For more information about Global Brass and Copper Holdings, see the information contained in the accompanying prospectus.

We also maintain an internet site at http://www.gbcholdings.com.Our website and the information contained in that website or connected to that website will not be deemed to be incorporated into this prospectus supplement, the accompanying prospectus or the registration statement of which this prospectus supplement forms a part, and you should not consider it part of this prospectus supplement, the accompanying prospectus or rely on any such information in making your decision whether to purchase our common stock.

KPS CAPITAL PARTNERS, LP AND HALKOS HOLDINGS, LLC

KPS Capital Partners, LP is a leading middle market private equity firm with $6.0 billion of assets under management. KPS seeks to realize significant capital appreciation through controlling equity investments in manufacturing and industrial companies going through a period of transition. The KPS investment strategy is based upon partnering with top management teams to materially and permanently improve the operations of a company, and then growing the company, either organically or through strategic acquisitions. The KPS investment strategy and its portfolio companies are described in detail at the KPS website: www.kpsfund.com.The KPS website and the information contained in that website or connected to that website will not be deemed to be incorporated into this prospectus supplement, the accompanying prospectus or the registration statement of which this prospectus supplement forms a part, and you should not consider it part of this prospectus supplement, the accompanying prospectus or rely on any such information in making your decision whether to purchase our common stock.

KPS Special Situations Fund II, L.P., KPS Special Situations Fund II (A), L.P., KPS Special Situations Fund III, L.P. and KPS Special Situations Fund III (A), L.P. (collectively, the “KPS Funds”) are affiliates of KPS and are the majority members of Halkos Holdings, LLC. As of December 31, 2013, Halkos Holdings, LLC beneficially owned 34.4% of Global Brass and Copper Holdings and is the selling stockholder. After giving effect to this offering, Halkos will beneficially own 4.3% of our common stock (0% if the underwriter exercises in full its option to purchase additional shares).

S-1

SUMMARY OF THE OFFERING

| | |

| |

Shares of common stock offered by the selling stockholder | | 6,400,000 shares. |

| |

Underwriter’s option to purchase additional common stock from the selling stockholder | |

Up to 910,000 shares. |

| |

Shares of common stock outstanding before and immediately after this offering | |

21,110,000 shares. |

| |

Use of proceeds | | The selling stockholder will receive all net proceeds from the sale of the common stock in this offering. We will not receive any proceeds from this offering. |

| |

Principal Stockholders | | Upon consummation of this offering, Halkos will beneficially own approximately 4.3% of our voting stock (0% if the underwriter exercises in full its option to purchase additional shares). As of October 1, 2013, we no longer qualified as a “controlled company” for purposes of the NYSE corporate governance rules, and we intend to comply with the NYSE corporate governance rule requirements within the applicable phase-in periods. |

| |

Dividends | | On November 7, 2013, we announced that our Board of Directors had approved the initiation of a quarterly dividend to our stockholders. The initial quarterly dividend of $0.0375 per share of our common stock was paid on December 6, 2013 to all stockholders of record as of November 19, 2013. Any future dividends or changes to our dividend policy will be made at the discretion of the Board of Directors and will depend on many factors, including those enumerated in the section entitled “Dividend Policy” in the accompanying prospectus. |

| |

Lock-up Agreements | | The selling stockholder and the officers and directors of Global Brass and Copper Holdings will be subject to customary lock-up agreements with a duration of 90 days. See “Underwriting”. |

| |

Risk Factors | | Please see “Risk Factors” beginning on page 22 of the accompanying prospectus and the other information included in this prospectus supplement and the accompanying prospectus for a discussion of factors you should carefully consider before deciding to invest in our common stock. |

| |

NYSE Trading Symbol | | BRSS |

S-2

OTHER INFORMATION ABOUT THIS PROSPECTUS SUPPLEMENT

Except as otherwise indicated, all information in this prospectus supplement and the accompanying prospectus (including the information set forth under “—The Offering” above):

| | • | | reflects a 211,100-to-1 stock split, which we refer to as the “stock split,” that was effected on May 29, 2013 in connection with the initial public offering; |

| | • | | does not give effect to 1,111,053 shares of common stock reserved for future issuance under our Global Brass and Copper Holdings, Inc. 2013 Omnibus Equity Incentive Plan, which we refer to as the “2013 Plan”; and |

| | • | | does not give effect to 351,135 shares of our common stock issuable under equity awards granted under the 2013 Plan. |

All beneficial ownership percentages reflect 141,486 outstanding shares of restricted stock, which confer on the holder the right to vote such shares, even if such shares have not vested.

S-3

CAUTIONARY STATEMENT CONCERNING FORWARD-LOOKING STATEMENTS

This prospectus supplement and the accompanying prospectus contain “forward-looking statements” that involve risks and uncertainties. You can identify forward-looking statements because they contain words such as “believes”, “expects”, “projects”, “may”, “would”, “should”, “seeks”, “approximately”, “intends”, “plans”, “estimates”, “anticipates” or similar expressions that relate to our strategy, plans or intentions. All statements we make relating to our estimated and projected earnings, margins, costs, expenditures, cash flows, growth rates and financial results or to our expectations regarding future industry trends are forward-looking statements. In addition, we, through our senior management, from time to time make forward-looking public statements concerning our expected future operations and performance and other developments. These forward-looking statements are subject to known and unknown risks, uncertainties and other factors that may change at any time, and, therefore, our actual results may differ materially from those that we expected. We derive many of our forward-looking statements from our operating budgets and forecasts, which are based upon many detailed assumptions. While we believe that our assumptions are reasonable, we caution that it is very difficult to predict the impact of known factors, and, of course, it is impossible for us to anticipate all factors that could affect our actual results. All forward-looking statements contained in this prospectus supplement are based upon information available to us on the date of this prospectus supplement.

Important factors that could cause actual results to differ materially from our expectations, which we refer to as “cautionary statements”, are disclosed under “Risk Factors” in the accompanying prospectus and elsewhere in this prospectus supplement and the accompanying prospectus, including, without limitation, in conjunction with the forward-looking statements included in this prospectus supplement and the accompanying prospectus. All forward-looking information in this prospectus supplement, the accompanying prospectus and subsequent written and oral forward-looking statements attributable to us, or persons acting on our behalf, are expressly qualified in their entirety by the cautionary statements. Some of the factors that we believe could affect our results include:

| | • | | the impact of our substantial indebtedness, including the effect of our ability to borrow money, fund working capital and operations and make new investments; |

| | • | | general economic conditions affecting the markets in which our products are sold; |

| | • | | our ability to implement our business strategies, including acquisition activities; |

| | • | | our ability to continue implementing our balanced book approach to substantially reduce the impact of fluctuations in metal prices on our earnings and operating margins; |

| | • | | shrinkage from processing operations and metal price fluctuations, particularly copper; |

| | • | | the condition of various markets in which our customers operate, including the housing and commercial construction industries; |

| | • | | our ability to maintain business relationships with our customers on favorable terms; |

| | • | | our ability to compete effectively with existing and new competitors; |

| | • | | limitations on our ability to purchase raw materials, particularly copper; |

| | • | | fluctuations in commodity and energy prices and costs; |

| | • | | our ability to maintain sufficient liquidity as commodity and energy prices rise; |

| | • | | the effects of industry consolidation or competition in our business lines; |

| | • | | operational factors affecting the ongoing commercial operations of our facilities, including technology failures, catastrophic weather-related damage, regulatory approvals, permit issues, unscheduled blackouts, outages or repairs or unanticipated changes in energy costs; |

| | • | | supply, demand, prices and other market conditions for our products; |

S-4

| | • | | our ability to accommodate increases in production to meet demand for our products; |

| | • | | our ability to continue our operations internationally and the risks applicable to international operations; |

| | • | | government regulations relating to our products and services, including new legislation relating to derivatives and the elimination of the dollar bill and EPA regulations regarding the registration and marketing of anti-microbial copper products; |

| | • | | our ability to maintain effective internal control over financial reporting as we become subject to public company requirements; |

| | • | | our ability to realize the planned cost savings and efficiency gains as part of our various initiatives; |

| | • | | workplace safety issues; |

| | • | | our ability to retain key employees; |

| | • | | adverse developments in our relationship with our employees or the future terms of our collective bargaining agreements; |

| | • | | rising employee medical costs; |

| | • | | environmental costs and our exposure to environmental claims; |

| | • | | our exposure to product liability claims; |

| | • | | our ability to maintain cost-effective insurance policies; |

| | • | | our ability to maintain the confidentiality of our proprietary information and to protect the validity, enforceability or scope of our intellectual property rights; |

| | • | | our limited experience managing and operating as an SEC reporting company; |

| | • | | our ability to service our substantial indebtedness; |

| | • | | fluctuations in interest rates; and |

| | • | | restrictive covenants in our indebtedness that may adversely affect our operational flexibility. |

We caution you that the foregoing list of factors may not contain all of the material factors that are important to you. In addition, in light of these risks and uncertainties, the matters referred to in the forward-looking statements contained in this prospectus supplement and the accompanying prospectus may not in fact occur. Accordingly, investors should not place undue reliance on those statements. We undertake no obligation to publicly update or revise any forward-looking statement as a result of new information, future events or otherwise, except as otherwise required by law.

S-5

PRINCIPAL AND SELLING STOCKHOLDERS

The following table and accompanying footnotes set forth, as of December 31, 2013, information with respect to the beneficial ownership of our common stock by:

| | • | | each of our directors and each of the executive officers named in the Summary Compensation Table in the accompanying prospectus; |

| | • | | the selling stockholder; |

| | • | | each person or group of affiliated persons who is known to be the beneficial owner of more than 5% of any class or series of our capital stock; and |

| | • | | all of our directors and executive officers as a group. |

The amounts and percentages of common stock beneficially owned prior to the offerings contemplated by this prospectus are based on 21,110,000 shares of common stock issued and outstanding and 141,486 outstanding shares of restricted stock, in each case as of December 31, 2013, which confer on the holder the right to vote such shares, even if such shares have not vested.

The amounts and percentages of common stock beneficially owned are reported on the basis of the regulations of the SEC governing the determination of beneficial ownership of securities. Under these rules, a person is deemed to be a beneficial owner of a security if that person has or shares voting power, which includes the power to vote or to direct the voting of such security, or investment power, which includes the power to dispose of or to direct the disposition of such security. A person is also deemed to be a beneficial owner of any securities of which that person has a right to acquire beneficial ownership within 60 days. Under these rules, more than one person may be deemed to be a beneficial owner of the same securities.

The following table shows beneficial ownership of our shares, both under the assumption that the underwriter’s option to purchase additional shares is not exercised and the assumption that the underwriter’s option to purchase additional shares is exercised in full:

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | Shares Offered Hereby | | | Shares Beneficially Owned

After Closing | |

Beneficial Owner | | Shares

Beneficially

Owned as of

December 31,

2013 | | | Assuming No

Exercise of

Option to

Purchase

Additional

Shares | | | Assuming

Full Exercise

of Option to

Purchase

Additional

Shares | | | Assuming No

Exercise of

Option to

Purchase

Additional

Shares | | | Assuming

Full Exercise

of Option to

Purchase

Additional

Shares | |

| | Number | | | % | | | Number | | | Number | | | Number | | | % | | | Number | | | % | |

Halkos Holdings, LLC(1) | | | 7,310,000 | | | | 34.4 | | | | 6,400,000 | | | | 7,310,000 | | | | 910,000 | | | | 4.3 | | | | 0 | | | | 0 | |

John H. Walker(2) | | | 10,000 | | | | * | | | | — | | | | — | | | | 10,000 | | | | * | | | | 10,000 | | | | * | |

Robert T. Micchelli(2) | | | 20,156 | | | | * | | | | — | | | | — | | | | 20,156 | | | | * | | | | 20,156 | | | | * | |

Kevin Bense(2) | | | 1,137 | | | | * | | | | — | | | | — | | | | 1,137 | | | | * | | | | 1,137 | | | | * | |

Daniel B. Becker(2)(4) | | | 5,469 | | | | * | | | | — | | | | — | | | | 5,469 | | | | * | | | | 5,469 | | | | * | |

Devin K. Denner(2) | | | 7,031 | | | | * | | | | — | | | | — | | | | 7,031 | | | | * | | | | 7,031 | | | | * | |

John J. Wasz(2) | | | 25,156 | | | | * | | | | — | | | | — | | | | 25,156 | | | | * | | | | 25,156 | | | | * | |

Scott B. Hamilton(2) | | | 8,569 | | | | * | | | | — | | | | — | | | | 8,569 | | | | * | | | | 8,569 | | | | * | |

Paul Schwind(2) | | | 3,593 | | | | * | | | | — | | | | — | | | | 3,593 | | | | * | | | | 3,593 | | | | * | |

Michael Psaros(2)(3) | | | 7,310,000 | | | | 34.4 | | | | 6,400,000 | | | | 7,310,000 | | | | 910,000 | | | | 4.3 | | | | 0 | | | | 0 | |

Raquel Palmer(2) | | | — | | | | * | | | | — | | | | — | | | | — | | | | * | | | | — | | | | * | |

David Shapiro(2)(3) | | | 7,310,000 | | | | 34.4 | | | | 6,400,000 | | | | 7,310,000 | | | | 910,000 | | | | 4.3 | | | | 0 | | | | 0 | |

Jay Bernstein(2) | | | — | | | | * | | | | — | | | | — | | | | — | | | | * | | | | — | | | | * | |

George Thanopoulos(2) | | | 6,250 | | | | * | | | | — | | | | — | | | | 6,250 | | | | * | | | | 6,250 | | | | * | |

Ronald C. Whitaker(2) | | | 6,250 | | | | * | | | | — | | | | — | | | | 6,250 | | | | * | | | | 6,250 | | | | * | |

Martin E. Welch, III(2) | | | 6,250 | | | | * | | | | — | | | | — | | | | 6,250 | | | | * | | | | 6,250 | | | | * | |

David Burritt(2) | | | 6,250 | | | | * | | | | — | | | | — | | | | 6,250 | | | | * | | | | 6,250 | | | | * | |

All directors and executive officers as a group | | | 7,416,111 | | | | 34.9 | | | | 6,400,000 | | | | 7,310,000 | | | | 1,016,111 | | | | 4.8 | | | | 106,111 | | | | 0.5 | |

S-6

| * | Represents beneficial ownership of less than one percent of shares outstanding. |

| (1) | The address of Halkos is 475 N. Martingale Road, Suite 1050, Schaumburg, IL 60173. The majority members of Halkos are the KPS Funds. |

| (2) | The address for each officer and director is c/o Global Brass and Copper Holdings, Inc., 475 Martingale Road, Suite 1050, Schaumburg, IL 60173. |

| (3) | KPS Special Situations Fund II, L.P., KPS Special Situations Fund II(A), L.P., KPS Special Situations Fund III, LP and KPS Special Situations Fund III(A), L.P. (collectively, the “KPS Funds”) are, collectively, majority members of Halkos. The KPS Funds that control Halkos are ultimately controlled by KPS Capital Partners, LLC, whose managing members, Messrs. Michael Psaros and David Shapiro, have investment and voting control over such KPS Funds and therefore Halkos. Messrs. Psaros and Shapiro disclaim beneficial ownership of the shares of Global Brass and Copper Holdings owned by Halkos. The address for the KPS Funds and KPS Capital Partners, LLC is 485 Lexington Avenue, 31st Floor, New York, NY 10017. |

| (4) | On September 9, 2013, Mr. Becker retired from his position, effective October 1, 2013. Mr. Becker continues to serve in an advisory role to our Chief Operating Officer, including assisting with the transition of the management of the A.J. Oster business to his successor, through December 31, 2013. |

Relationship with Selling Stockholder

All of the shares sold in this offering will be sold by the selling stockholder. The selling stockholder is Halkos, an affiliate of KPS. For additional information with respect to the selling stockholder and its relationships with us please see “Certain Relationships and Related Party Transactions” in the accompanying prospectus.

S-7

UNDERWRITING

Under the terms and subject to the conditions in an underwriting agreement dated the date of this prospectus supplement, Morgan Stanley & Co. LLC, as the sole underwriter, has agreed to purchase, and the selling stockholder has agreed to sell, 6,400,000 shares of our common stock (7,310,000 shares, if the underwriter fully exercises its option to purchase additional shares).

The underwriter is offering the shares of common stock subject to its acceptance of the shares from the selling stockholder and subject to prior sale. The underwriting agreement provides that the obligations of the underwriter to pay for and accept delivery of the shares of common stock offered by this prospectus supplement are subject to the approval of certain legal matters by its counsel and to certain other conditions. The underwriter is obligated to take and pay for all of the shares of common stock offered by this prospectus supplement if any such shares are taken.

The underwriter proposes to offer our shares of common stock from time to time for sale in one or more transactions on the New York Stock Exchange, in the over-the-counter market, through negotiated transactions or otherwise at market prices prevailing at the time of sale, at prices related to prevailing market prices or at negotiated prices, subject to receipt and acceptance by it and subject to its right to reject any order in whole or in part. In connection with the sale of our shares of common stock offered hereby, the underwriter may be deemed to have received compensation in the form of underwriting discounts. The underwriter may effect such transactions by selling our shares of common stock to or through dealers, and such dealers may receive compensation in the form of discounts or commissions from the underwriter and/or purchasers of our shares of common stock for whom they may act as agents or to whom they may sell as principals.

The underwriter has agreed to purchase 6,400,000 shares of our common stock from the selling stockholder at a price of $16.25 per share, which will result in the selling stockholder receiving approximately $104,000,000 of proceeds. In addition, the underwriter has the option to purchase up to an additional 910,000 shares from the selling stockholder at a price of $16.25. If the underwriter does exercise in full its option to purchase additional shares, this will result in the selling stockholder receiving approximately $118,787,500 of proceeds.

The estimated offering expenses payable by us are approximately $675,000. Pursuant to an amendment to the investor rights agreement, dated as of November 22, 2013, Halkos has agreed to pay, subject to certain exceptions and qualifications, 50% of the offering expenses (as defined in the investor rights agreement) relating to this offering. We have agreed to reimburse the underwriter for certain accountable expenses in connection with this offering in an amount not to exceed $15,000.

The selling stockholder may be deemed an “underwriter” within the meaning of Section 2(11) of the Securities Act. The selling stockholder represented to us at the time of its purchase of our common stock that such purchase was made for investment purposes and not with a view towards distribution.

We have agreed with the underwriter, subject to certain exceptions, not to offer, sell, contract to sell, pledge, grant any option to purchase, make any short sale or otherwise dispose of, any of our securities that are substantially similar to the shares of our common stock, including but not limited to any options or warrants to purchase shares of our common stock or any securities that are convertible into or exchangeable for, or that represent the right to receive, our common stock or any such substantially similar securities (other than pursuant to employee stock option plans existing on the date hereof, or upon the conversion or exchange of convertible or exchangeable securities issued pursuant to such employee stock plans or outstanding as of the date of this prospectus supplement), during the period from the date of this prospectus supplement continuing through the date that is 90 days from the date of this prospectus supplement, without the prior written consent of the underwriter. This agreement does not apply to any existing employee benefit plans. See “Shares Eligible for Future Sale” in the accompanying prospectus for a discussion of certain transfer restrictions.

Our executive officers, directors and the selling stockholder have agreed with the underwriter, subject to certain exceptions, not to offer, sell, contract to sell, pledge, grant any option to purchase, make any short sale or otherwise dispose of or hedge any of their shares of our common stock or any options or warrants to purchase

S-8

any shares of our common stock or any securities convertible into or exchangeable for or that represent the right to receive shares of our common stock during the period from the date of this prospectus supplement continuing through the date that is 90 days from the date of this prospectus supplement, except with the prior written consent of the underwriter. The foregoing restrictions shall not apply to (a) bona fide gifts, (b) dispositions to any trust for the direct or indirect benefit of the applicable officer, director or selling stockholder or such person’s immediate family, (c) transfers in response to a bona fide third party take-over bid made to all holders of shares of our common stock or any other acquisition transaction whereby all or substantially all of the shares of our common stock are acquired by a bona fide third party, (d) if the party to such agreement is a corporation, limited partnership, limited liability company or other entity, transfers of our common stock by such entity to its partners, members, stockholders or other affiliates, or any wholly owned subsidiary of such entity, or (e) sales of shares of our common stock purchased by such executive officer, director or the selling stockholder in open market transactions following the completion of this offering. For purposes of this paragraph, “immediate family” means any relationship by blood, marriage or adoption, not more remote than first cousin. See “Shares Eligible for Future Sale” in the accompanying prospectus for a discussion of certain transfer restrictions.

The restricted period described in each of the two immediately preceding paragraphs will be automatically extended if: (1) during the last 17 days of the restricted period we issue an earnings release or announce material news or a material event; or (2) prior to the expiration of the restricted period, we announce that we will release earnings results during the 15-day period following the last day of the period, in which case the restrictions described in the preceding paragraph will continue to apply until the expiration of the 18-day period beginning on the issuance of the earnings release of the announcement of the material news or material event. Morgan Stanley & Co. LLC, in its sole discretion, may release the common stock and other securities subject to the lock-up agreements described above in whole or in part at any time with or without notice.

Our common stock is listed on the New York Stock Exchange under the trading symbol “BRSS”.

In order to facilitate the offering of the common stock, the underwriter may engage in transactions that stabilize, maintain or otherwise affect the price of the common stock. Specifically, the underwriter may sell more shares than it is obligated to purchase under the underwriting agreement, creating a naked short position. The underwriter must close out any naked short position by purchasing shares in the open market. A naked short position is more likely to be created if the underwriter is concerned that there may be downward pressure on the price of the common stock in the open market after pricing that could adversely affect investors who purchase in this offering. As an additional means of facilitating this offering, the underwriter may bid for, and purchase, shares of common stock in the open market to stabilize the price of the common stock. These activities may raise or maintain the market price of the common stock above independent market levels or prevent or retard a decline in the market price of the common stock. The underwriter is not required to engage in these activities and may end any of these activities at any time.

We, the selling stockholder and the underwriter have agreed to indemnify each other against certain liabilities, including liabilities under the Securities Act.

The underwriter and its affiliates are full service financial institutions engaged in various activities, which may include securities trading, commercial and investment banking, financial advisory, investment management, investment research, principal investment, hedging, financing and brokerage activities. The underwriter and its affiliates have, from time to time, performed, and may in the future perform, various financial advisory and investment banking services for the issuer, for which they received or will receive customary fees and expenses.

In the ordinary course of their various business activities, the underwriter and its affiliates may make or hold a broad array of investments, including serving as counterparties to certain derivative and hedging arrangements, and actively trade debt and equity securities (or related derivative securities) and financial instruments (including bank loans) for their own account and for the accounts of their customers, and such investment and securities activities may involve securities and/or instruments of the issuer. The underwriter and its affiliates may also

S-9

make investment recommendations and/or publish or express independent research views in respect of such securities or instruments and may at any time hold, or recommend to clients that they acquire, long and/or short positions in such securities and instruments.

European Economic Area

In relation to each Member State of the European Economic Area which has implemented the Prospectus Directive (each, a Relevant Member State), the underwriter has represented and agreed that with effect from and including the date on which the Prospectus Directive is implemented in that Relevant Member State (the Relevant Implementation Date) it has not made and will not make an offer of shares to the public in that Relevant Member State prior to the publication of a prospectus in relation to the shares which has been approved by the competent authority in that Relevant Member State or, where appropriate, approved in another Relevant Member State and notified to the competent authority in that Relevant Member State, all in accordance with the Prospectus Directive, except that it may, with effect from and including the Relevant Implementation Date, make an offer of shares to the public in that Relevant Member State at any time:

| | (a) | | to legal entities which are authorised or regulated to operate in the financial markets or, if not so authorised or regulated, whose corporate purpose is solely to invest in securities; |

| | (b) | | to any legal entity which has two or more of (1) an average of at least 250 employees during the last financial year; (2) a total balance sheet of more than €43,000,000 and (3) an annual net turnover of more than €50,000,000, as shown in its last annual or consolidated accounts; |

| | (c) | | to fewer than 100 natural or legal persons (other than qualified investors as defined in the Prospectus Directive) subject to obtaining the prior consent of the representatives for any such offer; or |

| | (d) | | in any other circumstances which do not require the publication by the Issuer of a prospectus pursuant to Article 3 of the Prospectus Directive. |

For the purposes of this provision, the expression an “offer of shares to the public” in relation to any shares in any Relevant Member State means the communication in any form and by any means of sufficient information on the terms of the offer and the shares to be offered so as to enable an investor to decide to purchase or subscribe the shares, as the same may be varied in that Relevant Member State by any measure implementing the Prospectus Directive in that Relevant Member State and the expression Prospectus Directive means Directive 2003/71/EC and includes any relevant implementing measure in each Relevant Member State.

United Kingdom

The underwriter has represented and agreed that:

| | (a) | | it has only communicated or caused to be communicated and will only communicate or cause to be communicated an invitation or inducement to engage in investment activity (within the meaning of Section 21 of the FSMA) received by it in connection with the issue or sale of the shares of common stock in circumstances in which Section 21(1) of the FSMA does not apply to us; and |

| | (b) | | it has complied and will comply with all applicable provisions of the FSMA with respect to anything done by it in relation to the shares in, from or otherwise involving the United Kingdom. |

Hong Kong

The shares may not be offered or sold by means of any document other than (i) in circumstances which do not constitute an offer to the public within the meaning of the Companies Ordinance (Cap.32, Laws of Hong Kong), or (ii) to “professional investors” within the meaning of the Securities and Futures Ordinance (Cap.571, Laws of Hong Kong) and any rules made thereunder, or (iii) in other circumstances which do not result in the document being a “prospectus” within the meaning of the Companies Ordinance (Cap.32, Laws of Hong Kong), and no advertisement, invitation or document relating to the shares may be issued or may be in the possession of

S-10

any person for the purpose of issue (in each case whether in Hong Kong or elsewhere), which is directed at, or the contents of which are likely to be accessed or read by, the public in Hong Kong (except if permitted to do so under the laws of Hong Kong) other than with respect to shares which are or are intended to be disposed of only to persons outside Hong Kong or only to “professional investors” within the meaning of the Securities and Futures Ordinance (Cap. 571, Laws of Hong Kong) and any rules made thereunder.

Singapore

This prospectus has not been registered as a prospectus with the Monetary Authority of Singapore. Accordingly, this prospectus and any other document or material in connection with the offer or sale, or invitation for subscription or purchase, of the shares may not be circulated or distributed, nor may the shares be offered or sold, or be made the subject of an invitation for subscription or purchase, whether directly or indirectly, to persons in Singapore other than (i) to an institutional investor under Section 274 of the Securities and Futures Act, Chapter 289 of Singapore (the “SFA”), (ii) to a relevant person, or any person pursuant to Section 275(1A), and in accordance with the conditions, specified in Section 275 of the SFA or (iii) otherwise pursuant to, and in accordance with the conditions of, any other applicable provision of the SFA.

Where the shares are subscribed or purchased under Section 275 by a relevant person which is: (a) a corporation (which is not an accredited investor) the sole business of which is to hold investments and the entire share capital of which is owned by one or more individuals, each of whom is an accredited investor; or (b) a trust (where the trustee is not an accredited investor) whose sole purpose is to hold investments and each beneficiary is an accredited investor, shares, debentures and units of shares and debentures of that corporation or the beneficiaries’ rights and interest in that trust shall not be transferable for 6 months after that corporation or that trust has acquired the shares under Section 275 except: (1) to an institutional investor under Section 274 of the SFA or to a relevant person, or any person pursuant to Section 275(1A), and in accordance with the conditions, specified in Section 275 of the SFA; (2) where no consideration is given for the transfer; or (3) by operation of law.

Japan

The securities have not been and will not be registered under the Financial Instruments and Exchange Law of Japan (the Financial Instruments and Exchange Law) and each underwriter has agreed that it will not offer or sell any securities, directly or indirectly, in Japan or to, or for the benefit of, any resident of Japan (which term as used herein means any person resident in Japan, including any corporation or other entity organized under the laws of Japan), or to others for re-offering or resale, directly or indirectly, in Japan or to a resident of Japan, except pursuant to an exemption from the registration requirements of, and otherwise in compliance with, the Financial Instruments and Exchange Law and any other applicable laws, regulations and ministerial guidelines of Japan.

S-11

LEGAL MATTERS

Paul, Weiss, Rifkind, Wharton & Garrison LLP, New York, New York, will pass on the validity of the common stock offered hereby for us and the selling stockholder. Paul, Weiss, Rifkind, Wharton & Garrison LLP has represented KPS and its related parties from time to time in various matters. The underwriter has been represented by Cravath, Swaine & Moore LLP, New York, New York.

EXPERTS

The consolidated financial statements of Global Brass and Copper Holdings, Inc. as of December 31, 2012 and 2011 and for each of the three years in the period ended December 31, 2012 included in the accompanying prospectus have been so included in reliance on the report of PricewaterhouseCoopers LLP, an independent registered public accounting firm, given on the authority of said firm as experts in auditing and accounting.

S-12

PROSPECTUS

Up to 7,310,000 Shares

GLOBAL BRASS AND COPPER HOLDINGS, INC.

Common Stock

This prospectus relates to the offering of up to 7,310,000 shares of our common stock, $0.01 par value per share, by the selling stockholder identified in this prospectus. We will not receive any proceeds from any offerings pursuant to this prospectus.

The selling stockholder may offer the shares in amounts, at prices and on terms determined by market conditions at the time of the offering. The selling stockholder may sell shares through agents it selects or through underwriters and dealers it selects. The selling stockholder also may sell shares directly to investors. If the selling stockholder uses agents, underwriters or dealers to sell the shares, we will name them and describe their compensation in a prospectus supplement.

Our common stock is listed on the New York Stock Exchange (the “NYSE”) under the symbol “BRSS.” On January 6, 2014, the closing price of our common stock on the NYSE was $16.89 per share.

Investing in shares of our common stock involves risks. See “Risk Factors” on page 22 to read about factors you should consider before buying shares of our common stock.

Neither the Securities and Exchange Commission nor any other regulatory body has approved or disapproved of these securities or passed upon the accuracy or adequacy of this prospectus. Any representation to the contrary is a criminal offense.

Prospectus dated January 22, 2014.

TABLE OF CONTENTS

Prospectus

ABOUT THIS PROSPECTUS

This prospectus is part of a shelf registration statement that we have filed with the Securities and Exchange Commission (the “SEC”) using a “shelf” registration process. This prospectus supersedes in its entirety the prospectus dated January 9, 2014. Under this shelf registration process, the selling stockholder may, from time to time, offer and sell the common stock described in this prospectus and in an accompanying prospectus supplement in one or more offerings.

This prospectus provides you with a general description of the common stock the selling stockholder may offer. Each time the selling stockholder sells our common stock using this prospectus, to the extent necessary, we will provide a prospectus supplement that will contain specific information about the terms of that offering, including the number of shares being offered, the manner of distribution, the identity of any underwriters or other counterparties and other specific material terms related to the offering. The prospectus supplement may also add, update or change information contained in this prospectus. To the extent that any statement made in an accompanying prospectus supplement is inconsistent with statements made in this prospectus, the statements made in this prospectus will be deemed modified or superseded by those made in the accompanying prospectus supplement. You should read both this prospectus and any prospectus supplement together.

i

We have not authorized anyone to provide any information or to make any representations other than those contained in this prospectus, any prospectus supplement or in any free writing prospectuses we have prepared. We take no responsibility for, and can provide no assurance as to the reliability of, any other information that others may give you. This prospectus is an offer to sell only the shares offered hereby, but only under circumstances and in jurisdictions where it is lawful to do so. The information contained in this prospectus is current only as of its date.

Unless otherwise specified or the context requires otherwise:

The term “Global Brass and Copper Holdings” refers to Global Brass and Copper Holdings, Inc. and not to any of its subsidiaries;

The term “Global Brass and Copper” refers to Global Brass and Copper, Inc., the principal operating subsidiary of Global Brass and Copper Holdings, and not to any of its subsidiaries or direct or indirect parent companies;

The terms “we,” “us,” “our,” “GBC” and the “Company” refer collectively to Global Brass and Copper Holdings, its subsidiaries and its predecessors;

The term “KPS” refers to KPS Capital Partners, LP; and

The term “Halkos” refers to Halkos Holdings, LLC, the beneficial owner of 34.4% of our common stock as of November 1, 2013. Halkos is the only selling stockholder in the offerings contemplated by this prospectus.

The use of these terms is not intended to imply that Halkos, Global Brass and Copper Holdings and Global Brass and Copper or its predecessors are not separate and distinct legal entities.

Amounts and percentages appearing in this prospectus have been rounded to the amounts shown for convenience of presentation. Accordingly, the total of each column of amounts may not be equal to the total of the relevant individual items.

Industry and Market Data

This prospectus includes industry data that we obtained from periodic industry publications and internal company surveys. Industry publications and surveys generally state that the information contained therein has been obtained from sources believed to be reliable. In addition, this prospectus includes market share and industry data that we prepared primarily based on our knowledge of the industry and industry data. We have not independently verified any of the data from third-party sources nor have we ascertained the underlying economic assumptions relied upon therein. Statements as to our market position relative to our competitors are approximated and based on the above-mentioned third-party data and internal analysis and estimates and have not been verified by independent sources. Unless otherwise noted, all information regarding our market share is based on the latest available data. Information herein based on management’s belief or estimate is based upon management’s experience working in, and knowledge of, the metals industry, as well as management’s review of public disclosure of other participants in the metals industry and information provided by industry associations.

ii

Trademarks

This prospectus contains references to our trademarks and service marks and to those belonging to other entities. Solely for convenience, trademarks and trade names referred to in this prospectus may appear without the® orTM symbols, but such references are not intended to indicate, in any way, that we will not assert, to the fullest extent under applicable law, our rights or the rights of the applicable licensor to these trademarks and trade names. We do not intend our use or display of other companies’ trade names, trademarks or service marks to imply a relationship with, or endorsement or sponsorship of us by, any other companies.

iii

PROSPECTUS SUMMARY

This summary highlights material information appearing elsewhere in this prospectus. Because this is a summary, it may not contain all of the information that you should consider before investing in the common stock of Global Brass and Copper Holdings, par value $0.01 per share, which we refer to as the “common stock”, and you should carefully read this entire prospectus, including our consolidated financial statements and related notes and the information presented under the caption “Risk Factors”.

Our Company

We are a leading, value-added converter, fabricator, distributor and processor of specialized copper and brass products in North America. We engage in metal melting and casting, rolling, drawing, extruding and stamping to fabricate finished and semi-finished alloy products from processed scrap, copper cathode and other refined metals. Our products include a wide range of sheet, strip, foil, rod, tube and fabricated metal component products that we sell under the Olin Brass, Chase Brass and A.J. Oster brand names. Our products are used in a variety of applications across diversified end markets, including the building and housing, munitions, automotive, transportation, coinage, electronics/electrical components, industrial machinery and equipment and general consumer end markets. We access these end markets through direct mill sales, our captive distribution network and third-party distributors. We believe the diversity of our product portfolio, the breadth of our value-added customer services, our vertical integration and our technical expertise underpin the long-standing relationships we have with our broad customer base. Over the past three years, we have significantly enhanced our profitability and operational flexibility, which we believe positions us to benefit from growth in customer demand across the majority of the key end markets we service as macroeconomic conditions improve. In addition, we expect to capitalize on new market and product growth opportunities, which we are currently pursuing.

We service over 1,700 customers in 28 countries across 5 continents. We employ approximately 1,900 people and operate 11 manufacturing facilities and distribution centers across the United States, Puerto Rico and Mexico to service our North American customers. Through our 80% owned joint venture in China and our 50/50 joint venture in Japan, together with sales offices in China and Singapore, we supply our products in China and throughout Asia, where we believe we are positioned to take advantage of the region’s expanding copper, brass strip and foil markets. We service our European customers through distribution arrangements in the United Kingdom and Germany.

Our leading market positions in each of our operating segments allow us to achieve attractive operating margins. Our strong operating margins are a function of four key characteristics of our business: (1) we earn a premium margin over the cost of metal because of our value-added processing capabilities, patent-protected technologies and first-class service; (2) we have strategically shifted our product portfolio toward value-added, higher margin products; (3) we are driving a lean cost structure through variable cost reductions, process improvements and workforce flexibility initiatives; and (4) we employ our “balanced book” approach to substantially reduce the financial impact of metal price volatility on our earnings and operating margins. We have undertaken substantial cost reduction activities since our formation in 2007, which have reduced our fixed costs, improved our net working capital balances and improved our competitive positioning which has increased operating margins.

Our financial performance is primarily driven by metal conversion economics, not by the underlying movements in the price of copper and the other metals we use. Through our balanced book

1

approach, we match the timing, quantity and price of our metal sales with the timing, quantity and price of our replacement metal purchases. This practice substantially reduces the financial impact of metal price movements on our earnings and operating margins.

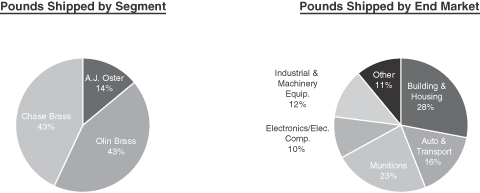

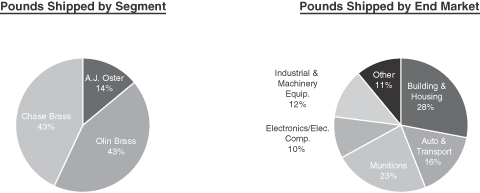

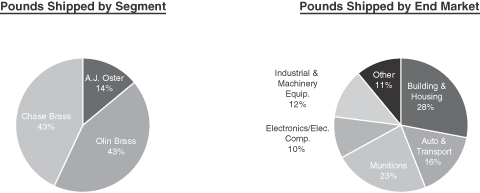

For the year ended December 31, 2012, we shipped 503.2 million pounds of products, and we generated net sales of $1,650.5 million, adjusted sales (as defined in note 4 under “Summary Historical Consolidated Financial Data”) of $524.9 million, net income attributable to Global Brass and Copper Holdings, Inc. of $12.5 million and Consolidated Adjusted EBITDA (as defined in note 5 under “Summary Historical Consolidated Financial Data”) of $115.4 million. Our U.S. operations generated 94% of our total net sales in the year ended December 31, 2012. The following charts show our pounds shipped by our three operating segments and our pounds shipped by key end market for the year ended December 31, 2012.

For the year ended December 31, 2012:

| | Note: | For the Chase Brass segment, pounds shipped by end market in the above chart reflects management’s allocation among end markets of pounds shipped by Chase Brass to distributors, job shops and forging shops. In addition, management estimates that approximately 50% of the Company’s pounds shipped to the electronics/electrical components end market are directly associated with the building sector. |

2

Segments Overview

We have three operating segments: Olin Brass, Chase Brass and A.J. Oster.

| | | | | | |

| |  | |  | |  |

Description | | • Leading manufacturer, fabricator and converter of specialized copper and brass sheet, strip, foil, tube and fabricated products | | • Leading manufacturer and supplier of brass rod | | • Leading distributor and processor of copper and brass products |

| | | |

| | • #1 North American Position (by 2012 pounds shipped) | | • #1 or #2 North American Position (by 2012 pounds shipped) | | • #1 North American Position (by 2012 pounds shipped) |

| | | | | | | |

Key Products / Services | | • As of December 31, 2012, produced 55 copper-based alloys, including 15 high performance alloys (“HPAs”), which provide superior strength, conductivity and formability | | • As of December 31, 2012, produced nine brass alloys which provide superior strength and corrosion resistance, sold under the Blue Dot® brass rod brand name | | • Network of strategically located distribution centers, providing inventory management, distribution and value-added metal processing services to customers |

| | • Over the past three twelve-month periods ended September 30, 2013, a per-period average of 17.8% of Olin Brass’s copper-based products have been sold to A.J. Oster | | • Holds exclusive rights for the production and sale of lead-free brass rod in North America, sold under the Green Dot™ rod and Eco Brass® alloy brand names | | • Over the past three twelve-month periods ended September 30, 2013, a per-period average of 68.3% of A.J. Oster’s copper-based products have been sourced from Olin Brass |

| | • Products sold throughout the U.S., Puerto Rico, Mexico, Asia and Europe | | • Products sold throughout the U.S., Mexico and Canada | | • Products sold throughout the U.S., Puerto Rico and Mexico |

| | | | | | | |

Key End Markets | | • Munitions, Automotive, Coinage, Building and Housing, Electronics/Electrical Components | | • Building and Housing, Transportation, Electronics/Electrical Components, Industrial Machinery and Equipment and Distribution | | • Building and Housing, Automotive, Electronics/Electrical Components |

| | | | | | | |

Operations | | • 4 strategically located sites in the U.S. and 1 in China | | • 1 strategically located manufacturing site and 1 warehouse facility in the U.S. | | • 4 strategically located sites in the U.S., 1 in Puerto Rico and 1 in Mexico |

| | • Marketing and sales joint venture office in Japan • Sales office in Singapore • 1,382 employees; 1,344 in the U.S. and 38 in Asia as of December 31, 2012 | | • 316 employees as of December 31, 2012 | | • 268 employees as of December 31, 2012 |

3

Our Competitive Strengths

Market Leader in Key Industrial Segments.We believe we have leading market positions in the industry sectors served by each of our three operating segments. Management estimates that our strategically located plants represent approximately 40% of North American capacity for copper and copper-alloy sheet, strip and plate (“SSP”) and brass rod production, supplying over 1,700 customers with over 15,000 stock keeping units (“SKUs”), with approximately 10%, 24% and 66% of those SKUs being sold by Chase Brass, Olin Brass and A.J. Oster, respectively. We believe our customers value our ability to provide a diverse range of products, many of which are exclusively offered by us. For example, at Olin Brass, we produce 55 alloys (including 15 HPAs), which, management estimates, based on available market information, is nearly twice as many types of alloys as produced by our closest competitor. Our ability to provide high quality product in varying quantities at attractive prices and in a timely manner to meet the product needs of our customers has resulted in long-standing customer relationships, many of whom we have served for more than 30 years. Our leading market positions and scale also enable us to negotiate favorable arrangements with our suppliers. During 2012, we operated at approximately 57% to 65% capacity utilization across our portfolio of facilities. As a result, we believe it would require a significant investment to become a substantial new participant in the industry, and any such investment might not yield attractive returns for a significant period of time.

Exposure to Cyclical, End Market and New Product Growth.In 2012, approximately 49% of our pounds shipped served end markets principally influenced by new residential construction, repair and remodeling activity and light vehicle sales in the United States. Our operations are well-positioned to take advantage of the recovery that we believe is underway in the U.S. housing market. According to management estimates, U.S. housing starts are expected to grow from 783,000 in 2012 at a compound annual growth rate (“CAGR”) of 19.2% through 2015. According to management estimates, U.S. existing home sales are expected to grow from 4.7 million in 2012 at a CAGR of 6.0% through 2015. While our sales into the building and housing end market are positively affected by housing starts and construction and remodeling activity, the correlation between housing statistics and our sales is not entirely direct. Our key products are typically installed late in the housing construction cycle, meaning there is an inherent lag in volumes, and sales of our building and housing products can be affected by factors such as housing mix (unit size, unit price point and the mix of multi-family versus single-family construction). Sales of our products can also be impacted by the actual timing of housing starts and completions as well as to changes in the materials and fixtures used in construction that may contain fewer copper products or materials and fixtures than were used in the past. We also believe there is considerable growth potential in the U.S. automotive sector. According to management estimates, North American light vehicle production is forecast to grow from 15.4 million in 2012 at a CAGR of 3.3% through 2015. Additionally, we believe further growth will be driven by demand for our new products. We hold exclusive production and sales rights for “lead-free” Eco Brass® rod and control the licensing of Eco Brass® ingot in North America. This “lead-free” alloy can be used to make products that comply with Federal legislation that requires a reduction of lead content in all plumbing devices that come into contact with drinking water sold after January 1, 2014. In addition, we believe that the Company is well positioned to become an industry leader in anti-microbial copper products through its CuVerro product line. In 2011, Olin Brass completed the U.S. Environmental Protection Agency (“EPA”) and state registration processes necessary to market its CuVerro™ materials as having anti-microbial properties and has licensed more than a dozen exclusive component manufacturers to market CuVerro™ products to the healthcare industry. We believe there is significant opportunity for us to expand our customer base to include companies that develop copper products for use in the healthcare, food service and other industries, replacing stainless steel and aluminum. We also anticipate a significant increase in the size of the coinage market if the U.S. transitions to the $1 coin and eliminates the dollar bill. As a certified supplier to the United States Mint, we expect to capture a

4

material portion of this new demand. Finally, we currently believe that demand levels for rod and strip products in the U.S. are significantly below historical averages and that with the expected continued recovery in our key end-markets, we will observe increases in demand for our products. Given our current installed operating capacity and associated utilization rates, we believe we can meet this increase in demand with very low capital investment.

Significant Expected Profit Growth through Volume Increases. Since our formation in 2007, we have implemented various cost reduction initiatives and workforce flexibility programs focused on reducing our fixed and non-metal variable costs. We believe the largely automated nature of our operations at our Chase Brass facility and the absence of defined benefit pension obligations or retiree healthcare obligations have contributed to a lean, flexible cost structure, which should position us to achieve strong operating margins going forward. Specifically:

| | • | | During 2012, we operated at approximately 57% to 65% capacity utilization across our portfolio of facilities. As such, we have available operating capacity that we can bring online quickly to respond to increased demand for our products and value-added services; |

| | • | | We believe we can increase production at our facilities with minimal change in our fixed costs and without significant additional capital investment; and |

| | • | | We believe we have the financial capacity and balance sheet strength to meet the working capital requirements that would accompany production increases in response to growing customer demand. |

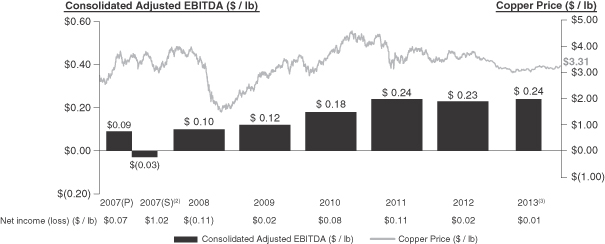

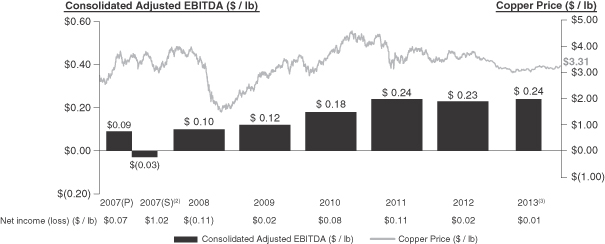

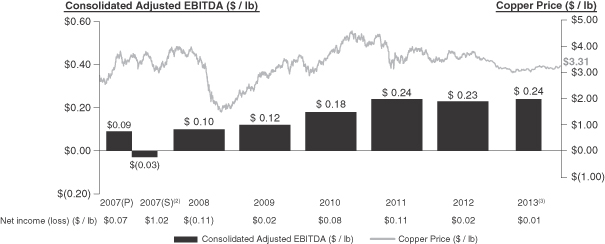

Since our formation in 2007, we have consistently improved our Consolidated Adjusted EBITDA per pound, a metric that management monitors to assess our profitability and operating efficiency, from $0.10 per pound for the year ended December 31, 2008 to $0.23 per pound for the year ended December 31, 2012.

Margin and Cash Flow Profile Insulated from Metal Price Volatility.Approximately 70% to 75% of our cost structure consists of variable metal costs, for which we use our balanced book approach to substantially reduce the financial impact of metal price volatility on our earnings and operating margins. Our business model is principally based on the conversion and fabrication of the metal we purchase into finished and semi-finished alloy products. Our financial performance is driven by metal conversion economics (i.e., the prices we charge for our products and value-added services and our ability to control our operating costs); we do not seek to profit from movements in underlying metal prices. Through our balanced book approach, we match the timing, quantity and price of our metal sales with the timing, quantity and price of our replacement metal purchases. Our balanced book approach allows us to substantially reduce the financial impact of metal price volatility on our earnings and operating margins. Our balanced book approach and low fixed cost position have historically allowed us to generate substantial cash flows. For the nine months ended September 30, 2013, net cash provided by operating activities was $4.5 million, and in the nine months ended September 30, 2012, net cash provided by operating activities was $58.3 million. For the fiscal years ended December 31, 2012, 2011 and 2010, net cash provided by operating activities was $81.9 million, $64.8 million and $69.4 million, respectively. In addition, we have low capital expenditure requirements. We estimate annual capital expenditures from 2013 to 2017 to range between $25 million to $30 million per annum, of which $20 million to $24 million per annum will consist of capital improvements or replacement of existing capital items. Our total capital expenditures as a percentage of our adjusted sales have ranged from approximately 2% to 4% for the last three fiscal years.

Net income attributable to Global Brass and Copper Holdings, Inc. per pound was $0.01 and $0.01 for the nine months ended September 30, 2013, and 2012, respectively. Net income (loss) attributable to Global Brass and Copper Holdings, Inc. per pound was $0.02, $0.11, $0.08, $0.02 and

5

$(0.11) for the years ended December 31, 2012, 2011, 2010, 2009 and 2008, respectively. Net income attributable to Global Brass and Copper Holdings, Inc. per pound was $1.02 for the successor period from October 10, 2007 to December 31, 2007, and net income per pound of our predecessor was $0.07 for the predecessor period from January 1, 2007 to November 18, 2007.

As illustrated in the following chart, we have increased our historical Consolidated Adjusted EBITDA(1) per pound over the period from 2007 to the nine months ended September 30, 2013, despite relatively volatile underlying copper prices:

Source: Copper prices from the London Metal Exchange reported by Bloomberg

(1) See note 5 to “Summary Historical Consolidated Financial Data” for the calculation of Consolidated Adjusted EBITDA and a reconciliation to net income (loss) attributable to Global Brass and Copper Holdings, Inc., which is the most directly comparable U.S. GAAP financial measure to Consolidated Adjusted EBITDA.

(2) We acquired the worldwide metals business of Olin Corporation on November 19, 2007. As a result, the 2007 fiscal year is composed of a predecessor period from January 1, 2007 to November 18, 2007 (represented by “2007(P)” in the chart above), and a successor period from the date of our formation, October 10, 2007, to December 31, 2007 (represented by “2007(S)” in the chart above). We had no material operations or assets prior to November 19, 2007. Data for the period from January 1, 2007 to November 18, 2007 are based on books and records provided to us by Olin Corporation in connection with the acquisition, which we believe were prepared on a basis consistent with Olin Corporation’s accounting policies and procedures but have not been subject to an audit or review. Data for the predecessor period of 2007 are not prepared using our accounting policies and procedures, do not reflect the application of purchase accounting (which has been applied to the successor period financial statements) and also do not reflect the allocation of Olin Corporation’s selling, general and administrative expenses to the metals business unit. We believe that the unaudited financial information for the predecessor period of 2007 may be useful to investors for purposes of illustrating trends in our business. Although we have no reason to believe that the unaudited financial information for the predecessor period of 2007 is materially deficient, there is a risk that this unaudited financial information may contain errors that might have been detected in a review or audit process or might have been different if prepared in accordance with our policies and procedures instead of those of Olin Corporation. See note 5 to “Summary Historical Consolidated Financial Data” and note (a) to the reconciliation table contained in such note and “Risk Factors—Risks Related to Our Business—You should not place undue reliance on the selected financial and other information of our predecessor as of November 18, 2007 and for the period from January 1, 2007 to November 18, 2007, which are summarized in this prospectus.”

(3) For the nine months ended September 30, 2013.

Over the past three years, we have demonstrated the ability to generate significant operating cash flow despite the relatively difficult operating environment. Our strong cash flow generation has enabled us to significantly reduce our leverage from approximately 7.9x gross debt to Consolidated Adjusted EBITDA upon formation in 2007 to 3.4x as of December 31, 2012. Our debt reduction achievements have also been delivered while distributing dividends to our shareholders. We believe we will continue to generate significant operating cash flow, which will provide us the opportunity to

6

deploy future excess cash flow to fund dividends or value-enhancing acquisitions. We will continue to manage our capital with financial discipline with the objective of maximizing value for our shareholders.

Highly Experienced Management Team.Since our formation in 2007, we have assembled a highly experienced management team, which combines our predecessor’s legacy experience with new team members who have many years of relevant industry experience. The members of our senior management team have, on average, over 26 years of metals industry experience. Since our formation, our senior management team has implemented a new business strategy and successfully transformed the cost structure and operating strategy of the business. Our management team has also instilled a culture that promotes performance excellence with a strong focus on driving profitability and, as a direct result, our operational and financial performance has improved significantly since 2007.

Our Growth Strategy

Participate in Demand Recovery as Economic Conditions Strengthen. Our premium products and services have allowed us to achieve leading positions across a number of attractive end markets. In addition, we maintain strong relationships with a diverse set of customers across those end markets. As U.S. macroeconomic conditions continue to improve, we expect to see increased activity in many of our key end markets, especially building and housing, automotive, coinage and industrial machinery and equipment, which we expect will drive increased demand for our products and services. In the beginning of 2013, the U.S. housing market has experienced a recovery from the sharp downturn that began in 2007. We believe that our available production capacity will allow us to effectively and efficiently respond to increasing demand.

Capitalize on Growth Opportunities for Our Existing Products and Services. We believe there are opportunities to expand the supply of our existing products and services in several keyhigh-value end markets. Examples include:

| | • | | Lead-free andLow-lead Plumbing Products. New regulations designed to reduce lead content in drinking water plumbing devices provide a key opportunity for future growth. Chase Brass is a premier provider of specialized lead-free products andlow-lead alloys. Federal legislation in the United States (the Reduction of Lead in Drinking Water Act, which was patterned after legislation enacted in California and Vermont) will require the reduction of lead content in all drinking water plumbing devices sold after January 2014. This legislation presents a significant growth opportunity for Chase Brass. Our Eco Brass® products meet Federal, California and Vermont standards and can be used to produce cast, machined and forged faucet parts. We currently supply major faucet, valve and fitting manufacturers who produce multiple products using machined Eco Brass® parts. |

| | • | | Transition to the Dollar Coin. On September 20, 2011, the Currency Optimization Innovation and National Savings Act, or “COINS Act”, was first introduced in the U.S. House of Representatives, which is intended to modernize the U.S. currency system by replacing $1 notes with $1 coins. On January 31, 2012, the COINS Act was first introduced in the U.S. Senate. On June 6, 2013, the COINS Act was reintroduced in the U.S. Senate, and on October 22, 2013, the COINS Act was reintroduced in the U.S. House of Representatives.Although it is uncertain when or if a transition to the $1 coin will be implemented, we anticipate a significant increase in the size of the coinage market if the U.S. transitions to the $1 coin and eliminates the dollar bill. As a certified supplier to the United States Mint, we expect to capture a material portion of this new demand. |

7

Pursue New Growth Opportunities. We have identified a number of important trends in key growth markets which we believe will drive significant incremental growth for our company, including anti-microbial applications for certain copper products. Olin Brass is well positioned to become a leader in commercializing anti-microbial copper products through its CuVerro™ anti-microbial product line. The EPA recently recognized that copper is inherently capable of neutralizing potentially harmful viruses and bacteria and began accepting registrations of copper-alloys with anti-microbial properties. Olin Brass manufactures several such alloys, which were EPA-registered in 2011, and we believe there is significant opportunity for us to expand our customer base to include companies that develop copper products for use in the healthcare, food service, heating, ventilation and air conditioning industries, replacing stainless steel and aluminum. Olin Brass has completed the Federal EPA and state registration processes necessary to market its CuVerro™ materials as having anti-microbial properties.

In addition, we plan to continue to identify opportunities to extend our existing range of products and services through ongoing investment in technology research and development through our Materials Research Laboratory. The Materials Research Laboratory is a copper-alloy research, manufacturing and production innovation lab and is responsible for numerous patents held by our Company and also by our customers. The Materials Research Laboratory was instrumental in developing patented products such as CopperBond®, CopperBond® XTF and other unique foil products such as C7025 for computer disk drives.

Pursue Strategic Opportunities to Expand Our Business. The North American copper and brass distribution industry includes numerous small, regional players. We believe future industry consolidation and possible strategic acquisitions in key growth markets will provide opportunities to increase our presence in these markets and to create shareholder value. In addition, we may pursue strategic acquisition and/or partnership opportunities to increase the breadth and distribution of our product portfolio and metal distribution services in the future.

Recent Developments

On January 22, 2014, we reaffirmed our expectation that our shipment volume would range from 520-530 million pounds for full year 2013 (as previously disclosed in our current report on Form 8-K dated November 12, 2013). In addition, we reaffirmed our outlook with respect to full-year 2013 Adjusted Sales that was previously disclosed in our third quarter 2013 earnings conference call and stated that we expected to be at or around the bottom of the range of Consolidated Adjusted EBITDA for full year 2013 that was disclosed in the third quarter 2013 earnings conference call.

The foregoing is based on preliminary management estimates, which have not been audited for conformity with GAAP. As a result, the foregoing information and the information on which the foregoing is based is subject to change as a result of the process of preparing GAAP financials, and there may be further changes as a result of the GAAP consolidation process or the upcoming audit process. The foregoing should not be viewed as a substitute for full financial statements prepared in accordance with GAAP.

8

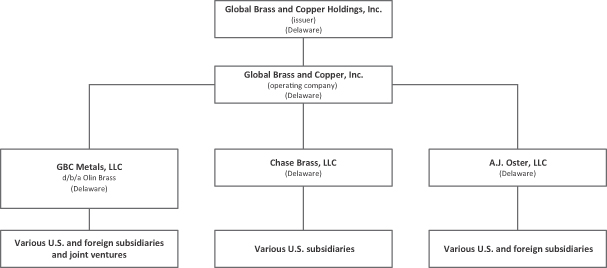

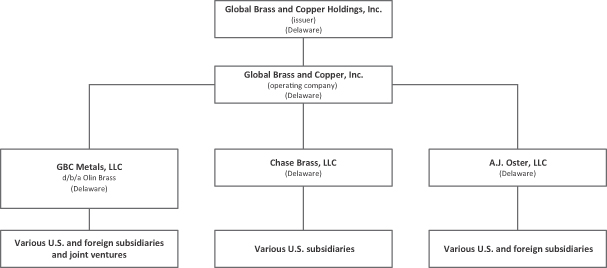

Organizational Structure

The chart below is a summary of our organizational structure as of November 1, 2013. All entities depicted are currently (and will be following this offering) 100% owned subsidiaries of Global Brass and Copper Holdings. As of November 1, 2013, Halkos beneficially owned 34.4% of the outstanding common stock of Global Brass and Copper Holdings. Halkos is the only selling stockholder in the offerings contemplated by this prospectus.

Industry Overview