| T A B L E O F C O N T E N T S |

| 1.0 | SUMMARY | | 1-1 |

| | 1.1 | INTRODUCTION | 1-1 |

| | 1.2 | PROPERTY DESCRIPTION AND LOCATION | 1-3 |

| | 1.3 | GEOLOGY AND MINERALIZATION | 1-3 |

| | 1.4 | RESOURCE ESTIMATE | 1-5 |

| | 1.5 | MINERAL PROCESSING AND METALLURGICAL TESTING | 1-6 |

| | 1.6 | MINING METHODS | 1-7 |

| | 1.7 | RECOVERY METHODS | 1-7 |

| | 1.8 | PROJECT INFRASTRUCTURE | 1-8 |

| | | 1.8.1 | POWER SUPPLY | 1-10 |

| | | 1.8.2 | TAILINGS STORAGE FACILITY | 1-11 |

| | 1.9 | ENVIRONMENTAL | 1-11 |

| | 1.10 | CAPITAL COSTS (INITIAL AND SUSTAINING) | 1-12 |

| | 1.11 | OPERATING COSTS | 1-13 |

| | 1.12 | ECONOMIC ANALYSIS | 1-14 |

| | 1.13 | INTERPRETATION AND CONCLUSIONS | 1-15 |

| | 1.14 | OPPORTUNITIES AND RECOMMENDATIONS | 1-15 |

| 2.0 | INTRODUCTION | | 2-1 |

| | 2.1 | TERMS OF REFERENCE | 2-1 |

| | | 2.1.1 | UNITS OF MEASUREMENT | 2-1 |

| | 2.2 | QUALIFIED PERSONS | 2-2 |

| | 2.3 | SITE VISITS | 2-4 |

| | 2.4 | SCOPE OF PERSONAL INSPECTIONS | 2-4 |

| | 2.5 | INFORMATION SOURCES | 2-4 |

| 3.0 | RELIANCE ON OTHER EXPERTS | 3-1 |

| | 3.1 | MICHAEL F. O’BRIEN, M.SC., PR.SCI.NAT, FGSSA, FAUSIMM, FSAIMM | 3-1 |

| | 3.2 | SABRY ABDEL HAFEZ, PH.D., P.ENG | 3-1 |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 4-1 |

| | 4.1 | LOCATION | | 4-1 |

| | 4.2 | MINERAL TENURE | 4-4 |

| | 4.3 | ROYALTIES, AGREEMENTS AND ENCUMBRANCES | 4-6 |

| | | 4.3.1 | KENNECOTT AGREEMENTS | 4-6 |

| | | 4.3.2 | NANA AGREEMENT | 4-6 |

| | 4.4 | ENVIRONMENTAL LIABILITIES | 4-8 |

iv

|  |

| | 4.5 | PERMITS | | 4-8 |

| | | | | |

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 5-1 |

| | | | | |

| | 5.1 | ACCESSIBILITY | 5-1 |

| | | 5.1.1 | AIR | 5-1 |

| | | 5.1.2 | WATER | 5-1 |

| | | 5.1.3 | ROAD | 5-1 |

| | 5.2 | CLIMATE | | 5-1 |

| | 5.3 | LOCAL RESOURCES | 5-2 |

| | 5.4 | INFRASTRUCTURE | 5-3 |

| | 5.5 | PHYSIOGRAPHY | 5-3 |

| | | | | |

| 6.0 | HISTORY | | 6-1 |

| | | | | |

| | 6.1 | PRIOR OWNERSHIP AND OWNERSHIP CHANGES – ARCTIC DEPOSIT AND THE AMBLER LANDS |

| | | | | 6-2 |

| | 6.2 | PREVIOUS EXPLORATION AND DEVELOPMENT RESULTS – ARCTIC DEPOSIT | 6-3 |

| | | 6.2.1 | INTRODUCTION | 6-3 |

| | | 6.2.2 | GEOCHEMISTRY | 6-8 |

| | | 6.2.3 | GEOPHYSICS | 6-8 |

| | | 6.2.4 | DRILLING | 6-9 |

| | | 6.2.5 | SPECIFIC GRAVITY | 6-9 |

| | | 6.2.6 | PETROLOGY, MINERALOGY, AND RESEARCH STUDIES | 6-9 |

| | | 6.2.7 | GEOTECHNICAL, HYDROLOGICAL AND ACID-BASE ACCOUNTING STUDIES | 6-10 |

| | | 6.2.8 | METALLURGICAL STUDIES | 6-11 |

| | 6.3 | HISTORICAL MINERAL RESOURCE ESTIMATES | 6-11 |

| | | 6.3.1 | RUSSELL – KENNECOTT (1975/1976) RESOURCE ESTIMATE | 6-11 |

| | | 6.3.2 | BROWN – KENNECOTT (1985) RESOURCE ESTIMATE | 6-11 |

| | | 6.3.3 | RANDOLF – KENNECOTT (1990) RESOURCE ESTIMATE | 6-12 |

| | | 6.3.4 | KENNECOTT (1995) RESOURCE ESTIMATE | 6-12 |

| | | 6.3.5 | DEAD CREEK, SUNSHINE AND HORSE CLIFF HISTORICAL RESOURCES | 6-13 |

| | 6.4 | DEVELOPMENT STUDIES | 6-13 |

| | | 6.4.1 | KENNECOTT TENURE | 6-13 |

| | | | | |

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 7-1 |

| | | | | |

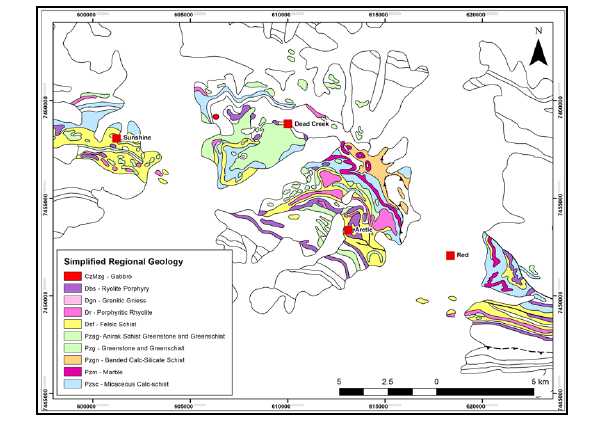

| | 7.1 | REGIONAL GEOLOGY – SOUTHERN BROOKS RANGE | 7-1 |

| | | 7.1.1 | TERRANE DESCRIPTIONS | 7-1 |

| | | 7.1.2 | REGIONAL TECTONIC SETTING | 7-3 |

| | 7.2 | AMBLER SEQUENCE GEOLOGY | 7-4 |

| | | 7.2.1 | GENERAL STRATIGRAPHY OF THE AMBLER SEQUENCE | 7-5 |

| | | 7.2.2 | STRUCTURAL FRAMEWORK OF THE AMBLER DISTRICT | 7-9 |

| | 7.3 | ARCTIC DEPOSIT GEOLOGY | 7-10 |

| | | 7.3.1 | LITHOLOGIES AND LITHOLOGIC DOMAIN DESCRIPTIONS | 7-11 |

| | | 7.3.2 | STRUCTURE | 7-13 |

| | | 7.3.3 | ALTERATION | 7-14 |

| | 7.4 | ARCTIC DEPOSIT MINERALIZATION | 7-15 |

| | 7.5 | GENESIS | | 7-16 |

v

|  |

| | 7.6 | DEPOSITS AND PROSPECTS | 7-17 |

| 8.0 | DEPOSIT TYPES | 8-1 |

| 9.0 | EXPLORATION | | 9-1 |

| | 9.1 | GRIDS AND SURVEYS | 9-2 |

| | 9.2 | GEOLOGICAL MAPPING | 9-2 |

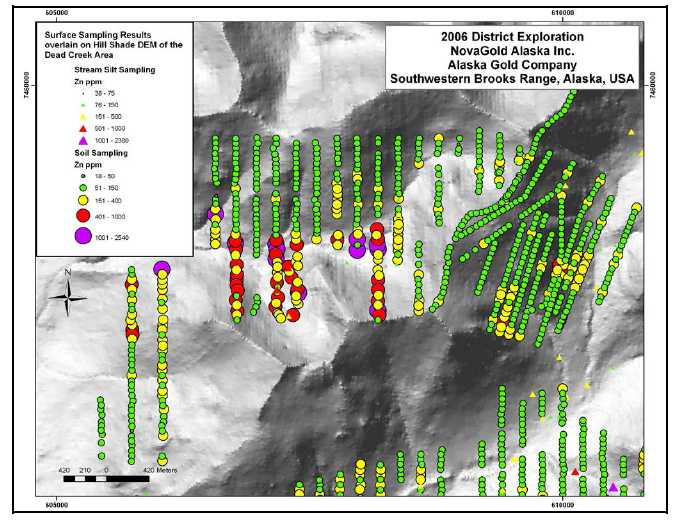

| | 9.3 | GEOCHEMISTRY | 9-4 |

| | 9.4 | GEOPHYSICS | 9-7 |

| | 9.5 | BULK DENSITY | 9-9 |

| | 9.6 | PETROLOGY, MINERALOGY AND RESEARCH STUDIES | 9-9 |

| | 9.7 | GEOTECHNICAL, HYDROGEOLOGICAL AND ACID BASE ACCOUNTING STUDIES | 9-9 |

| | | 9.7.1 | GEOTECHNICAL STUDIES | 9-9 |

| | | 9.7.2 | HYDROLOGICAL STUDIES | 9-9 |

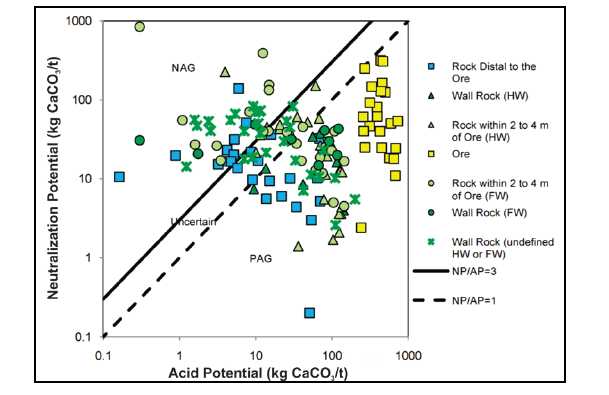

| | | 9.7.3 | ACID-BASE ACCOUNTING STUDIES | 9-10 |

| | | 9.7.4 | METALLURGICAL STUDIES | 9-11 |

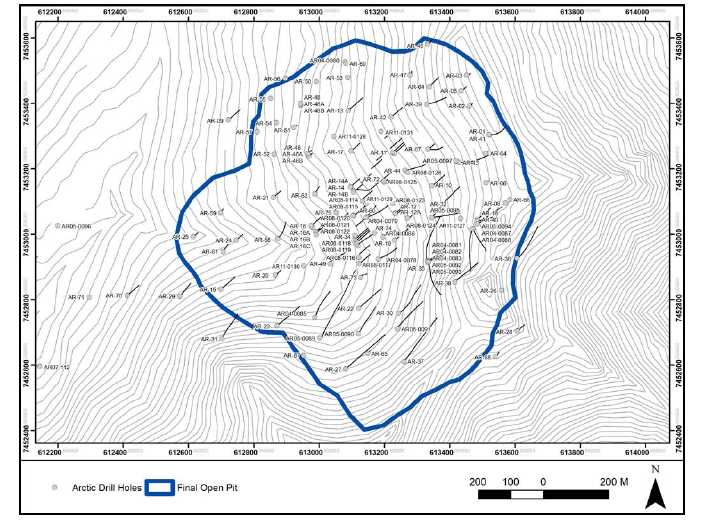

| 10.0 | DRILLING | | 10-1 |

| | 10.1 | DRILL COMPANIES | 10-5 |

| | 10.2 | DRILL CORE PROCEDURES | 10-6 |

| | | 10.2.1 | KENNECOTT TENURE | 10-6 |

| | | 10.2.2 | NOVAGOLD/NOVACOPPER TENURE | 10-6 |

| | 10.3 | GEOTECHNICAL DRILL HOLE PROCEDURES | 10-7 |

| | 10.4 | METALLURGICAL DRILL HOLE PROCEDURES | 10-8 |

| | 10.5 | COLLAR SURVEYS | 10-9 |

| | | 10.5.1 | KENNECOTT TENURE | 10-9 |

| | | 10.5.2 | NOVAGOLD/NOVACOPPER TENURE | 10-9 |

| | 10.6 | DOWNHOLE SURVEYS | 10-9 |

| | 10.7 | RECOVERY | | 10-10 |

| | 10.8 | DRILL INTERCEPTS | 10-10 |

| | 10.9 | DRILLING AT OTHER PROSPECTS | 10-11 |

| 11.0 | SAMPLE PREPARATION, ANALYSES, AND SECURITY | 11-1 |

| | 11.1 | SAMPLE PREPARATION | 11-1 |

| | | 11.1.1 | CORE DRILLING SAMPLING | 11-1 |

| | | 11.1.2 | ACID-BASE ACCOUNTING SAMPLING | 11-3 |

| | | 11.1.3 | DENSITY DETERMINATIONS | 11-3 |

| | 11.2 | SECURITY | | 11-4 |

| | 11.3 | ASSAYING AND ANALYTICAL PROCEDURES | 11-4 |

| | 11.4 | QUALITY ASSURANCE/QUALITY CONTROL | 11-5 |

| | | 11.4.1 | CORE DRILLING SAMPLING QA/QC | 11-5 |

| | | 11.4.2 | ACID-BASE ACCOUNTING SAMPLING QA/QC | 11-12 |

| | | 11.4.3 | DENSITY DETERMINATIONS QA/QC | 11-12 |

| | 11.5 | AUTHOR’S OPINION | 11-15 |

| 12.0 | DATA VERIFICATION | 12-1 |

vi

|  |

| | 12.1 | DRILL HOLE COLLAR VERIFICATION | 12-1 |

| | 12.2 | TOPOGRAPHY VERIFICATION | 12-1 |

| | 12.3 | CORE LOGGING VERIFICATION | 12-2 |

| | 12.4 | DATABASE VERIFICATION | 12-2 |

| | 12.5 | QA/QC REVIEW | 12-3 |

| | 12.6 | QP OPINION | 12-4 |

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 |

| | 13.1 | METALLURGICAL TEST WORK REVIEW | 13-1 |

| | | 13.1.1 | INTRODUCTION | 13-1 |

| | | 13.1.2 | MINERALOGICAL AND METALLURGICAL TEST WORK – SGS 2012 | 13-1 |

| | | 13.1.3 | HISTORICAL TEST WORK REVIEW | 13-14 |

| | 13.2 | RECOMMENDED TEST WORK | 13-19 |

| 14.0 | MINERAL RESOURCE ESTIMATES | 14-1 |

| | 14.1 | INTRODUCTION | 14-1 |

| | 14.2 | PREVIOUS RESOURCE ESTIMATES | 14-2 |

| | | 14.2.1 | KENNECOTT (1990) RESOURCE ESTIMATE | 14-2 |

| | | 14.2.2 | SRK (2008) RESOURCE ESTIMATION | 14-2 |

| | | 14.2.3 | SRK (2011) RESOURCE ESTIMATION UPDATE | 14-5 |

| | | 14.2.4 | SRK (2012) RESOURCE ESTIMATION UPDATE | 14-6 |

| | 14.3 | RESOURCE ESTIMATION PROCEDURES | 14-7 |

| | 14.4 | DATABASE | | 14-7 |

| | 14.5 | GEOLOGICAL MODELLING | 14-8 |

| | | 14.5.1 | MINERALIZATION MODEL | 14-8 |

| | | 14.5.2 | SPECIFIC GRAVITY MODEL | 14-8 |

| | | 14.5.3 | LITHOGEOCHEMICAL MODEL | 14-8 |

| | | 14.5.4 | ESTIMATION DOMAINS | 14-9 |

| | 14.6 | EXPLORATORY DATA ANALYSIS | 14-11 |

| | | 14.6.1 | CONTACT PROFILES | 14-11 |

| | | 14.6.2 | RAW ASSAY DATA AND STATISTICS | 14-12 |

| | 14.7 | COMPOSITING | 14-13 |

| | | 14.7.1 | OUTLIER MANAGEMENT AND CAPPING STRATEGY | 14-13 |

| | | 14.7.2 | COMPOSITE STATISTICS | 14-15 |

| | 14.8 | SPECIFIC GRAVITY ANALYSIS | 14-16 |

| | | 14.8.1 | SPECIFIC GRAVITY STATISTICS AND SPATIAL ANALYSIS | 14-16 |

| | | 14.8.2 | SPECIFIC GRAVITY INTERPOLATION PLAN | 14-16 |

| | 14.9 | ACID BASE ACCOUNTING ANALYSIS | 14-17 |

| | 14.10 | VARIOGRAPHY AND SPATIAL ANALYSIS | 14-18 |

| | 14.11 | RESOURCE ESTIMATION METHODOLOGY | 14-20 |

| | 14.12 | RESOURCE BLOCK MODEL | 14-22 |

| | | 14.12.1 | CONFIGURATION | 14-22 |

| | | 14.12.2 | CELL ATTRIBUTES | 14-22 |

| | 14.13 | MODEL VALIDATION | 14-25 |

| | | 14.13.1 | VISUAL VALIDATION | 14-25 |

vii

|  |

| | | 14.13.2 | STATISTICAL COMPARISONS BETWEEN BLOCK AND COMPOSITE DATA | 14-28 |

| | 14.14 | MINERAL RESOURCE CLASSIFICATION | 14-37 |

| | | 14.14.1 | MEASURED RESOURCE CLASSIFICATION | 14-38 |

| | | 14.14.2 | INDICATED RESOURCE CLASSIFICATION | 14-38 |

| | | 14.14.3 | INFERRED RESOURCE CLASSIFICATION | 14-38 |

| | 14.15 | MINERAL RESOURCE ESTIMATE | 14-38 |

| | 14.16 | GRADE SENSITIVITY ANALYSIS | 14-40 |

| | | | | |

| 15.0 | MINERAL RESERVE ESTIMATES | 15-1 |

| | | | | |

| 16.0 | MINING METHODS | 16-1 |

| | | | | |

| | 16.1 | INTRODUCTION | 16-1 |

| | 16.2 | PIT OPTIMIZATION | 16-1 |

| | | 16.2.1 | BLOCK MODEL | 16-1 |

| | | 16.2.2 | PIT SLOPE ANGLE | 16-1 |

| | | 16.2.3 | SURFACE TOPOGRAPHY | 16-1 |

| | | 16.2.4 | PIT OPTIMIZATION PARAMETERS | 16-1 |

| | | 16.2.5 | PIT OPTIMIZATION RESULTS | 16-5 |

| | 16.3 | MINE DESIGN | 16-7 |

| | | 16.3.1 | BENCH HEIGHT AND PIT WALL SLOPE | 16-7 |

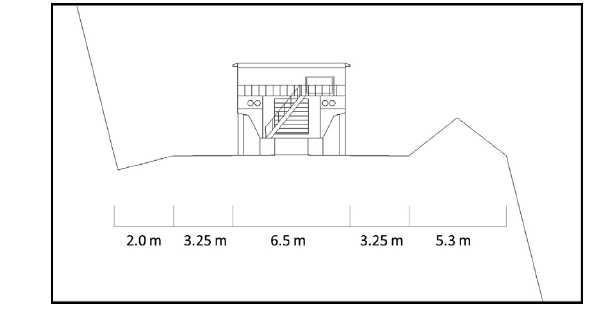

| | | 16.3.2 | MINIMUM WORKING AREA | 16-8 |

| | | 16.3.3 | HAUL ROAD | 16-8 |

| | | 16.3.4 | PIT HYDROLOGY/DEWATERING | 16-9 |

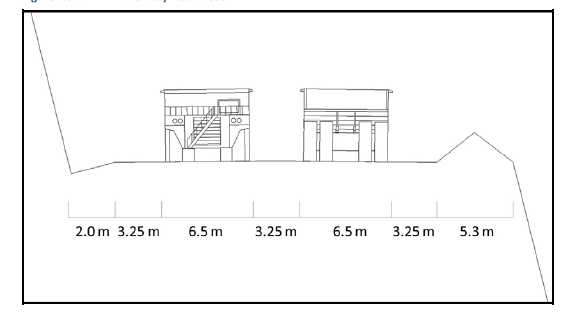

| | | 16.3.5 | PIT DESIGN RESULTS | 16-9 |

| | 16.4 | PRODUCTION SCHEDULE | 16-10 |

| | 16.5 | MINE WASTE ROCK MANAGEMENT | 16-18 |

| | 16.6 | MINING EQUIPMENT | 16-18 |

| | | 16.6.1 | MINE EQUIPMENT FLEET | 16-18 |

| | | 16.6.2 | OPERATING HOURS | 16-18 |

| | | 16.6.3 | PRIMARY EQUIPMENT | 16-18 |

| | | 16.6.4 | SUPPORT AND ANCILLARY EQUIPMENT | 16-19 |

| | 16.7 | MINING LABOUR | 16-20 |

| | | | | |

| 17.0 | RECOVERY METHODS | 17-1 |

| | | | | |

| | 17.1 | MINERAL PROCESSING | 17-1 |

| | | 17.1.1 | FLOWSHEET DEVELOPMENT | 17-1 |

| | | 17.1.2 | PROCESS PLANT DESCRIPTION | 17-4 |

| | | 17.1.3 | COARSE MATERIAL STORAGE | 17-5 |

| | | 17.1.4 | GRINDING AND CLASSIFICATION | 17-5 |

| | | 17.1.5 | FLOTATION | 17-6 |

| | 17.2 | PLANT PROCESS CONTROL | 17-15 |

| | | 17.2.1 | OVERVIEW | 17-15 |

| | | 17.2.2 | PRODUCTION PROJECTION | 17-16 |

| | | | | |

| 18.0 | PROJECT INFRASTRUCTURE | 18-1 |

| | | | | |

| | 18.1 | OVERVIEW | | 18-1 |

| | 18.2 | ROADS AND AIRSTRIP | 18-4 |

viii

|  |

| | | 18.2.1 | AMBLER MINING DISTRICT INDUSTRIAL ACCESS ROAD | 18-4 |

| | | 18.2.2 | ACCESS ROAD | 18-4 |

| | | 18.2.3 | HAUL ROADS, SITE ROADS, AND PAD AREAS | 18-5 |

| | | 18.2.4 | AIRSTRIP | 18-6 |

| | 18.3 | BUILDINGS AND RELEVANT BUILDING SERVICES | 18-7 |

| | | 18.3.1 | PRIMARY CRUSHING BUILDING | 18-7 |

| | | 18.3.2 | CRUSHED MATERIAL STOCKPILE | 18-7 |

| | | 18.3.3 | CONVEYING | 18-7 |

| | | 18.3.4 | MILL BUILDING, MAINTENANCE, TRUCK SHOP, ASSAY AND METALLURGY LAB18-7 |

| | | 18.3.5 | ADMINISTRATION AND MINE DRY | 18-8 |

| | | 18.3.6 | ARCTIC CORRIDORS | 18-8 |

| | | 18.3.7 | COLD STORAGE WAREHOUSE | 18-8 |

| | | 18.3.8 | HVAC AND FIRE PROTECTION | 18-8 |

| | | 18.3.9 | FIRE PROTECTION | 18-9 |

| | | 18.3.10 | DUST CONTROL | 18-9 |

| | 18.4 | WATER SUPPLY AND DISTRIBUTION | 18-9 |

| | 18.5 | WASTE MANAGEMENT | 18-10 |

| | | 18.5.1 | SEWAGE DISPOSAL | 18-10 |

| | | 18.5.2 | DOMESTIC WASTE DISPOSAL | 18-10 |

| | 18.6 | FUEL STORAGE | 18-10 |

| | 18.7 | ON SITE EXPLOSIVES STORAGE | 18-11 |

| | | 18.7.1 | EMULSION PLANT | 18-11 |

| | | 18.7.2 | DETONATOR AND EXPLOSIVE STORAGE MAGAZINE | 18-11 |

| | 18.8 | POWER SUPPLY TO PLANT SITE | 18-11 |

| | 18.9 | TAILINGS STORAGE FACILITY | 18-11 |

| | | 18.9.1 | TSF EMBANKMENT | 18-12 |

| | | 18.9.2 | TAILINGS IMPOUNDMENT | 18-13 |

| | | 18.9.3 | RECLAIM WATER SYSTEM | 18-13 |

| | | 18.9.4 | SEEPAGE COLLECTION SUMP | 18-14 |

| | 18.10 | WASTE ROCK FACILITIES | 18-14 |

| | | 18.10.1 | NON-ACID GENERATING WASTE ROCK | 18-14 |

| | | 18.10.2 | POTENTIALLY ACID GENERATING WASTE ROCK | 18-14 |

| | 18.11 | WATER MANAGEMENT | 18-14 |

| | | 18.11.1 | SITE FACILITIES | 18-16 |

| | 18.12 | WATER TREATMENT PLANT | 18-18 |

| | 18.13 | CONSTRUCTION AND PERMANENT CAMP ACCOMMODATION | 18-18 |

| | 18.14 | COMMUNICATIONS | 18-18 |

| | | | | |

| 19.0 | MARKET STUDIES AND CONTRACTS | 19-1 |

| | | | | |

| 20.0 | ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 20-1 |

| | | | | |

| | 20.1 | ENVIRONMENTAL STUDIES | 20-1 |

| | | 20.1.1 | HYDROLOGY AND WATER QUALITY DATA | 20-1 |

| | | 20.1.2 | WETLANDS DATA | 20-2 |

| | | 20.1.3 | AQUATIC LIFE DATA | 20-2 |

| | | 20.1.4 | SUBSISTENCE DATA | 20-4 |

ix

|  |

| | | 20.1.5 | ACID BASE ACCOUNTING DATA | 20-5 |

| | | 20.1.6 | ADDITIONAL BASELINE DATA REQUIREMENTS | 20-6 |

| | 20.2 | PERMITTING | 20-6 |

| | | 20.2.1 | EXPLORATION PERMITS | 20-6 |

| | | 20.2.2 | MAJOR MINE PERMITS | 20-7 |

| | 20.3 | SOCIAL OR COMMUNITY CONSIDERATIONS | 20-9 |

| | 20.4 | MINE RECLAMATION AND CLOSURE | 20-10 |

| | | 20.4.1 | RECLAMATION AND CLOSURE PLAN | 20-11 |

| | | 20.4.2 | RECLAMATION AND CLOSURE FINANCIAL ASSURANCE | 20-12 |

| | | | | |

| 21.0 | CAPITAL AND OPERATING COSTS | 21-1 |

| | | | | |

| | 21.1 | INTRODUCTION | 21-1 |

| | 21.2 | CAPITAL COST ESTIMATE | 21-1 |

| | | 21.2.1 | INTRODUCTION | 21-1 |

| | | 21.2.2 | CAPITAL COST SUMMARY | 21-1 |

| | | 21.2.3 | TOTAL SUSTAINING CAPITAL COSTS | 21-1 |

| | | 21.2.4 | PURPOSE AND CLASS OF ESTIMATE | 21-2 |

| | | 21.2.5 | ESTIMATE BASE DATE, EXCHANGE RATE, AND VALIDITY PERIOD | 21-2 |

| | | 21.2.6 | CONTRIBUTORS TO THE ESTIMATE | 21-3 |

| | 21.3 | ELEMENTS OF COST | 21-3 |

| | | 21.3.1 | DIRECT COSTS | 21-3 |

| | | 21.3.2 | INDIRECT COSTS | 21-4 |

| | | 21.3.3 | OWNER’S COSTS | 21-4 |

| | | 21.3.4 | CONTINGENCIES | 21-5 |

| | | 21.3.5 | EXCLUSIONS | 21-5 |

| | | 21.3.6 | COSTS INCURRED PRIOR TO RELEASE OF DETAIL ENGINEERING AND CONSTRUCTION |

| | | | ASSUMPTIONS | 21-5 |

| | 21.4 | MINING CAPITAL COST ESTIMATE | 21-6 |

| | 21.5 | OPERATING COST ESTIMATE | 21-9 |

| | | 21.5.1 | SUMMARY | 21-9 |

| | | 21.5.2 | MINING OPERATING COST ESTIMATE | 21-10 |

| | | 21.5.3 | PROCESSING OPERATING COSTS | 21-11 |

| | | 21.5.4 | GENERAL AND ADMINISTRATIVE COSTS AND SURFACE SERVICES COSTS | 21-13 |

| | | 21.5.5 | TAILINGS STORAGE FACILITY COST | 21-15 |

| | | 21.5.6 | ROAD TOLL COST | 21-15 |

| | | | | |

| 22.0 | ECONOMIC ANALYSIS | 22-1 |

| | | | | |

| | 22.1 | PRE-TAX MODEL | 22-2 |

| | | 22.1.1 | MINE/METAL PRODUCTION IN FINANCIAL MODEL | 22-2 |

| | | 22.1.2 | BASIS OF FINANCIAL EVALUATION | 22-2 |

| | 22.2 | SUMMARY OF FINANCIAL RESULTS | 22-4 |

| | 22.3 | SENSITIVITY ANALYSIS | 22-5 |

| | 22.4 | POST-TAX FINANCIAL ANALYSIS | 22-7 |

| | | 22.4.1 | US FEDERAL TAX | 22-7 |

| | | 22.4.2 | ALASKA STATE TAX | 22-8 |

| | | 22.4.3 | ALASKA MINING LICENSE TAX | 22-8 |

| | | 22.4.4 | TAXES AND POST-TAX RESULTS | 22-8 |

x

|  |

| | 22.5 | ROYALTIES | 22-9 |

| | 22.6 | SMELTER TERMS | 22-10 |

| | 22.7 | TRANSPORTATION LOGISTICS | 22-11 |

| | 22.8 | INSURANCE | 22-11 |

| | 22.9 | REPRESENTATION AND MARKETING | 22-11 |

| 23.0 | ADJACENT PROPERTIES | 23-1 |

| | 23.1 | SUN DEPOSIT | 23-1 |

| | 23.2 | SMUCKER DEPOSIT | 23-3 |

| 24.0 | OTHER RELEVANT DATA AND INFORMATION | 24-1 |

| | 24.1 | BORNITE DEPOSIT | 24-1 |

| 25.0 | INTERPRETATION AND CONCLUSIONS | 25-1 |

| | 25.1 | GENERAL | 25-1 |

| | 25.2 | PROPERTY DESCRIPTION AND LOCATION | 25-1 |

| | 25.3 | GEOLOGY | 25-1 |

| | 25.4 | MINERAL RESOURCE ESTIMATION | 25-2 |

| | 25.5 | METALLURGICAL TEST WORK AND PROCESS DESIGN | 25-2 |

| | 25.6 | MINING METHODS | 25-4 |

| | 25.7 | PROJECT INFRASTRUCTURE | 25-4 |

| | 25.8 | TAILINGS AND WATER MANAGEMENT | 25-5 |

| | 25.9 | ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 25-5 |

| | 25.10 | ECONOMIC ANALYSIS | 25-5 |

| 26.0 | RECOMMENDATIONS | 26-1 |

| | 26.1 | GENERAL | 26-1 |

| | 26.2 | GEOLOGY | 26-1 |

| | 26.3 | MINERAL PROCESSING AND METALLURGICAL TESTING | 26-2 |

| | 26.4 | PROCESS PLANT DESIGN | 26-2 |

| | 26.5 | MINING METHODS | 26-3 |

| | 26.6 | PROJECT INFRASTRUCTURE | 26-3 |

| | | 26.6.1 | PROCESS PLANT AND INFRASTRUCTURE LOCATION | 26-3 |

| | | 26.6.2 | ACCESS ROAD | 26-4 |

| | | 26.6.3 | ELECTRICAL POWER GENERATION | 26-4 |

| | | 26.6.4 | AIRSTRIP | 26-4 |

| | | 26.6.5 | TAILINGS AND WASTE MANAGEMENT | 26-4 |

| | 26.7 | ENVIRONMENTAL | 26-6 |

| | 26.8 | ECONOMIC ANALYSIS | 26-6 |

| 27.0 | REFERENCES | | 27-1 |

| | 27.1 | GEOLOGY | 27-1 |

| | 27.2 | ENVIRONMENTAL | 27-5 |

| | 27.3 | MINING | 27-6 |

xi

| | 27.4 | CAPITAL COST ESTIMATE | 27-6 |

| | 27.5 | ECONOMIC ANALYSIS | 27-6 |

| | 27.6 | ELECTRICAL POWER GENERATION | 27-6 |

| 28.0 | CERTIFICATES OF QUALIFIED PERSONS | 28-1 |

| | 28.1 | MICHAEL F. O’BRIEN, M.SC., PR.SCI.NAT, FGSSA, FAUSIMM, FSAIMM | 28-1 |

| | 28.2 | JIANHUI (JOHN) HUANG, PH.D., P.ENG | 28-3 |

| | 28.3 | SABRY ABDEL HAFEZ, PH.D., P.ENG | 28-4 |

| | 28.4 | HASSAN GHAFFARI, P.ENG | 28-5 |

| | 28.5 | HARVEY WAYNE STOYKO, P.ENG | 28-6 |

| | 28.6 | MICHAEL CHIN, P.ENG | 28-7 |

| | 28.7 | GRAHAM WILKINS, P.ENG | 28-8 |

| | 28.8 | MARVIN SILVA, PH.D., PE, P.ENG. | 28-9 |

| | 28.9 | JACK DIMARCHI, CPG | 28-10 |

| APPENDIX A | CLAIMS MAP AND LIST OF CLAIMS |

| APPENDIX B | ACCESS ROAD |

| APPENDIX C | AIRSTRIP |

| APPENDIX D | TSF AND WATER MANAGEMENT |

| APPENDIX E | CAPITAL COST BASIS OF ESTIMATE |

| Table 1.1 | General Project Information | 1-3 |

| Table 1.2 | Resource Estimate for the Arctic Project (NSR Cut-off of $35/t) | 1-6 |

| Table 1.3 | Summary of Key Mining Results | 1-7 |

| Table 1.4 | Capital Cost Summary | 1-13 |

| Table 1.5 | Summary of Total Sustaining Capital Cost for LOM | 1-13 |

| Table 1.6 | Overall Operating Cost Estimate | 1-14 |

| Table 2.1 | Qualified Persons | 2-2 |

| Table 6.1 | Known Mapping, Geochemical, and Geophysical Programs Targeting VMS Prospects in the Ambler Mining District | 6-4 |

| Table 6.2 | Russell 1976 Resource Estimation | 6-11 |

| Table 6.3 | Brown 1985 Resource Estimation | 6-12 |

| Table 6.4 | Randolf 1990 Resource Estimation | 6-12 |

xii

|  |

| Table 6.5 | Kennecott 1995 Resource Estimation | 6-12 |

| Table 6.6 | Historical Resources for the Dead Creek, Sunshine and Horse Cliff Prospects | 6-13 |

| Table 9.1 | Summary of NovaCopper/NovaGold Exploration Activities Targeting VMS-style Mineralization in the Ambler Sequence Stratigraphy and the Arctic Deposit | 9-1 |

| Table 9.2 | TDEM Loops and Locations | 9-7 |

| Table 10.1 | Companies, Campaigns, Drill Holes and Metres Drilled at the Arctic Deposit | 10-1 |

| Table 10.2 | Summary of NovaCopper/NovaGold Drilling | 10-2 |

| Table 10.3 | Drill Contractors, Drill Holes, Metreage and Core Sizes by Drill Campaign at the Arctic Deposit | 10-5 |

| Table 10.4 | Geotechnical Holes and Instrumentation | 10-8 |

| Table 10.5 | Recovery and RQD 2004 to 2008 Arctic Drill Campaigns | 10-10 |

| Table 10.6 | Drill Intercept Summary Table | 10-11 |

| Table 10.7 | Drill, Metreage and Average Drill Depth for NovaCopper Ambler Sequence VMS Targets | 10-11 |

| Table 10.8 | Significant Drill Intercepts – NovaCopper Ambler Sequence Prospects | 10-12 |

| Table 10.9 | NovaCopper Exploration Drilling – Ambler Schist Belt | 10-14 |

| Table 11.1 | Analytical Laboratories Used by Operators of the Arctic Project | 11-5 |

| Table 12.1 | Assay Certificates Reviewed | 12-2 |

| Table 13.1 | Metallurgical Test Work Programs | 13-1 |

| Table 13.2 | Head Grades – Composite Samples – 2012 | 13-2 |

| Table 13.3 | Mineral Modal Abundance for Composite Samples – 2012 | 13-3 |

| Table 13.4 | Bond Ball Mill Grindability and Abrasion Index Test Results | 13-4 |

| Table 13.5 | Locked Cycle Metallurgical Test Results | 13-8 |

| Table 13.6 | Copper and Lead Separation Test Results | 13-11 |

| Table 13.7 | Multi-element Assay Results – Copper Concentrate | 13-13 |

| Table 13.8 | Multi-element Assay Results – Lead Concentrate | 13-13 |

| Table 13.9 | Multi-element Assay Results – Zinc Concentrate | 13-14 |

| Table 13.10 | Metallic Mineral Identified in Arctic Project Samples | 13-14 |

| Table 13.11 | Bond Ball Mill Work Index | 13-16 |

| Table 13.12 | Head Analyses | 13-18 |

| Table 13.13 | Flotation Test on Ambler Low Talc Composite | 13-19 |

| Table 14.1 | Historical Resource Estimate | 14-2 |

| Table 14.2 | Drill Hole Assay Statistics – 2008 SRK Resource Estimation | 14-3 |

| Table 14.3 | Historical SG Data Statistics – Arctic Deposit: 1998–2004 | 14-3 |

| Table 14.4 | SG Measurements Categorized by Rock Type | 14-3 |

| Table 14.5 | Arctic Deposit Resources at $100 GMV Cut-off – 2008 SRK | 14-4 |

| Table 14.6 | Arctic Deposit Resources at $75 NSR Cut-off – 2011 SRK | 14-5 |

| Table 14.7 | Arctic Deposit Resources at $75 NSR Cut-off – 2012 SRK | 14-6 |

| Table 14.8 | Exploration Data within the Resource Area | 14-7 |

| Table 14.9 | Modifications to Database for Resource Estimation | 14-7 |

| Table 14.10 | Arctic Grade Estimation Domains | 14-9 |

| Table 14.11 | Arctic SG Estimation Domains | 14-10 |

| Table 14.12 | Arctic ABA Domains | 14-10 |

| Table 14.13 | Raw Metal Sample Statistics (Length Weighted) | 14-13 |

| Table 14.14 | Sample Length Statistics | 14-13 |

| Table 14.15 | Arctic Deposit Drill Hole Composite Statistics | 14-15 |

| Table 14.16 | Arctic SG Determinations Summary Statistics | 14-16 |

| Table 14.17 | Arctic Density Interpolation Summary Statistics | 14-16 |

| Table 14.18 | PAG and NAG Ratio Assignment for the ABA Domains | 14-17 |

| Table 14.19 | Variogram Models | 14-18 |

| Table 14.20 | Search Ellipse Orientation and Dimensions for Mineralization Domains | 14-21 |

| Table 14.21 | Block Model Cell Attributes | 14-23 |

xiii

|  |

| Table 14.22 | Indicated Mineral Resource Table Restated by Mineralization Zone, Arctic Project, Alaska, Tetra Tech (June 30, 2013) | 14-39 |

| Table 14.23 | Inferred Mineral Resource Table Restated by Mineralization Zone, Arctic Project, Alaska, Tetra Tech (June 30, 2013) | 14-39 |

| Table 14.24 | Material Comprising the Indicated Mineral Resource (Table 14.22) Diluted to Full Blocks, Restated by Mineralization Zone, Arctic Project, Alaska | 14-40 |

| Table 14.25 | Material Comprising the Inferred Mineral Resource (Table 14.23) Diluted to Full Blocks, Restated by Mineralization Zone, Arctic Project, Alaska | 14-40 |

| Table 14.26 | Indicated Mineral Resource Table Sensitivity to NSR Within Whole Blocks | 14-41 |

| Table 14.27 | Inferred Mineral Resource Table Sensitivity to NSR, Arctic Project Within Whole Blocks | 14-41 |

| Table 16.1 | Pit Optimization Parameters | 16-3 |

| Table 16.2 | Metallurgical Recovery | 16-5 |

| Table 16.3 | Pit Optimization Results | 16-6 |

| Table 16.4 | Haul Road Width | 16-8 |

| Table 16.5 | Pit Design Results | 16-9 |

| Table 16.6 | Production Schedule | 16-12 |

| Table 16.7 | Operational Delays per Shift | 16-18 |

| Table 16.8 | Haulage Cycle Times | 16-19 |

| Table 16.9 | Primary Equipment Requirements | 16-19 |

| Table 16.10 | Support Equipment Requirements | 16-19 |

| Table 16.11 | Ancillary Equipment Requirements | 16-20 |

| Table 16.12 | Operator and Maintenance Staff on Payroll | 16-21 |

| Table 17.1 | Major Design Criteria | 17-4 |

| Table 17.2 | Annual Concentrate Production Projection | 17-17 |

| Table 18.1 | Components for Management of Non-contact Surface Waters | 18-16 |

| Table 18.2 | Components for Management of Contact Surface Waters and Sediments | 18-16 |

| Table 20.1 | Captured or Observed Fish Species | 20-3 |

| Table 20.2 | Additional Recommended Environmental Baseline Studies | 20-6 |

| Table 20.3 | Major Mine Permits Required for the Arctic Project | 20-8 |

| Table 21.1 | Summary of Capital and Operating Costs | 21-1 |

| Table 21.2 | CAPEX Summary | 21-2 |

| Table 21.3 | Summary of Total Sustainable Capital Costs for LOM | 21-2 |

| Table 21.4 | Foreign Exchange Rate Summary | 21-3 |

| Table 21.5 | Summary of Mining Costs | 21-6 |

| Table 21.6 | Mining Pre-production Unit Costs | 21-7 |

| Table 21.7 | Initial Mining Equipment Fleet | 21-7 |

| Table 21.8 | Sustaining Capital Mining Equipment Fleet | 21-8 |

| Table 21.9 | Overall Operating Cost Estimate | 21-10 |

| Table 21.10 | Relevant Consumables Prices | 21-10 |

| Table 21.11 | Mining LOM and Unit Operating Cost Summary | 21-11 |

| Table 21.12 | Summary of Process Operating Cost | 21-12 |

| Table 21.13 | G&A Operating Costs | 21-13 |

| Table 21.14 | Surface Services Operating Costs | 21-14 |

| Table 22.1 | Mine/Metal Production from the Arctic Mine | 22-2 |

| Table 22.2 | Summary of Pre-tax Financial Results | 22-4 |

| Table 22.3 | Components of the Various Taxes | 22-9 |

| Table 22.4 | Summary of Post-tax Financial Results | 22-9 |

| Table 23.1 | Sun Deposit Historical Resources | 23-2 |

| Table 23.2 | Smucker Deposit Historical Resources | 23-4 |

| Table 24.1 | Bornite NI 43-101 Resources | 24-1 |

| Table 25.1 | Resource estimate for the Arctic Project (NSR Cut-off of $35/t) | 25-2 |

xiv

| Table 25.2 | Projected Recoveries and Concentrate Grades | 25-3 |

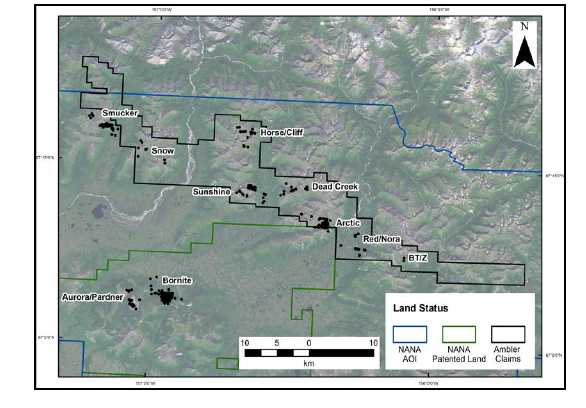

| Figure 1.1 | Property Location Map | 1-2 |

| Figure 1.2 | Arctic Project Site Layout | 1-10 |

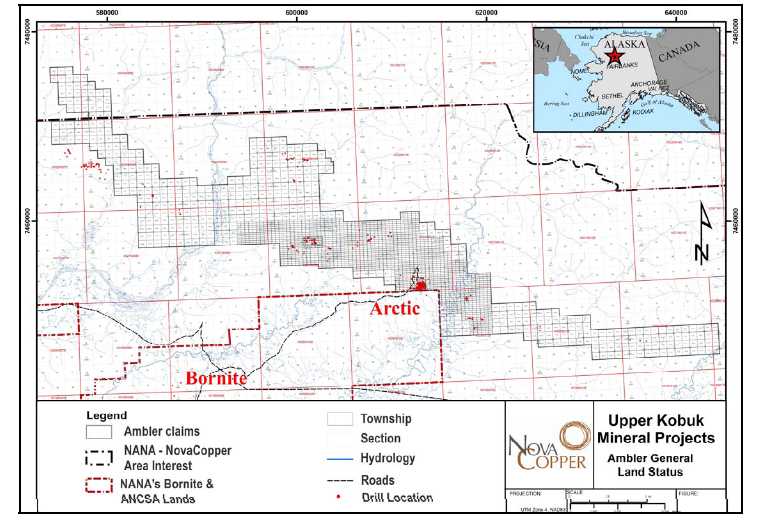

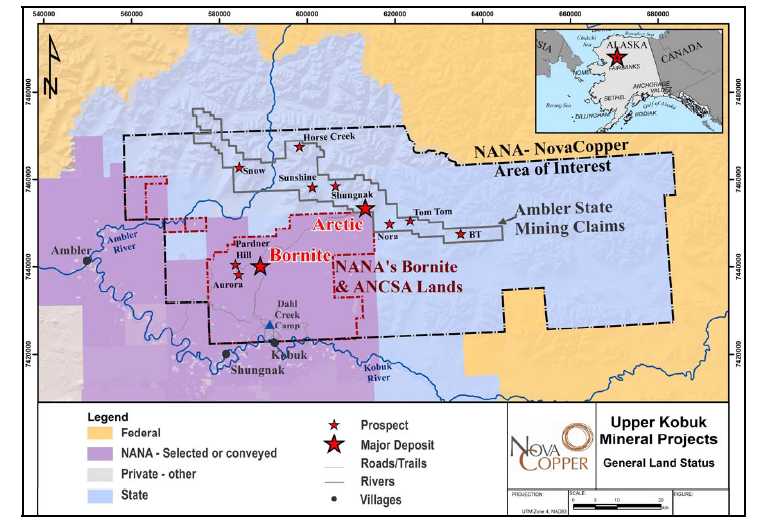

| Figure 4.1 | Location Map of the UKMP – Northwest Alaska | 4-2 |

| Figure 4.2 | Upper Kobuk Mineral Projects Lands | 4-3 |

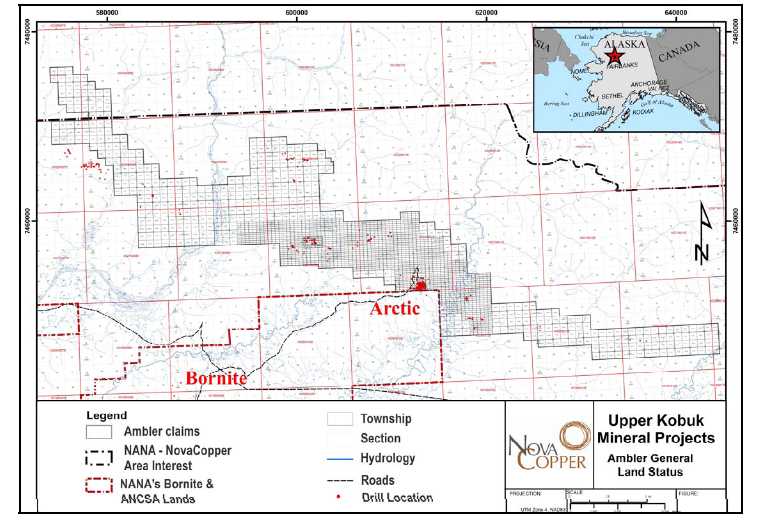

| Figure 4.3 | Mineral Tenure Plan | 4-5 |

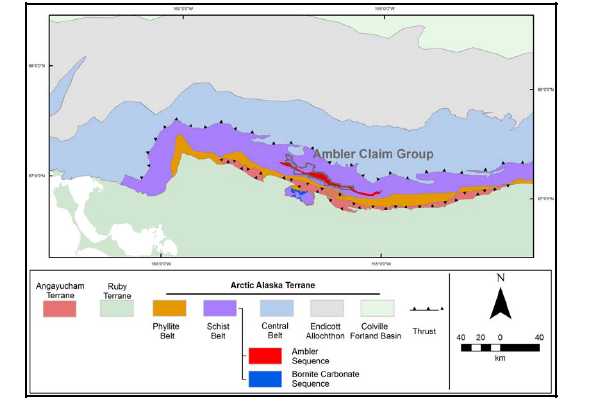

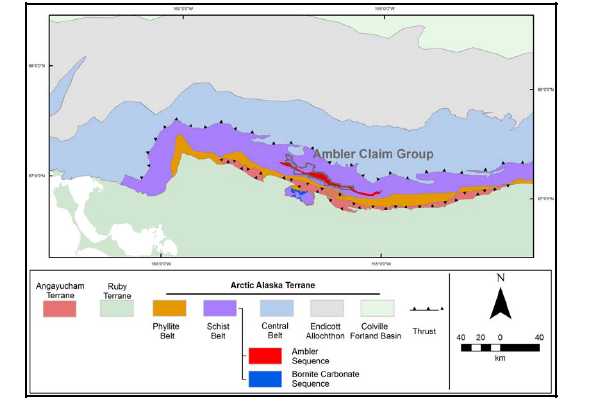

| Figure 7.1 | Geologic Terranes of the Southern Brooks Range | 7-2 |

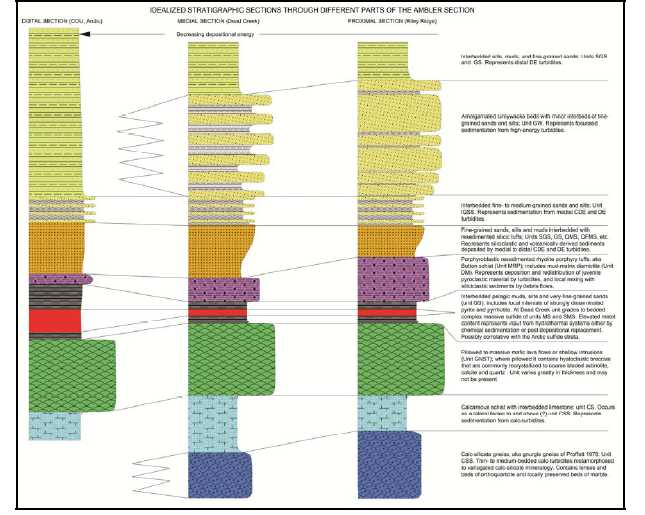

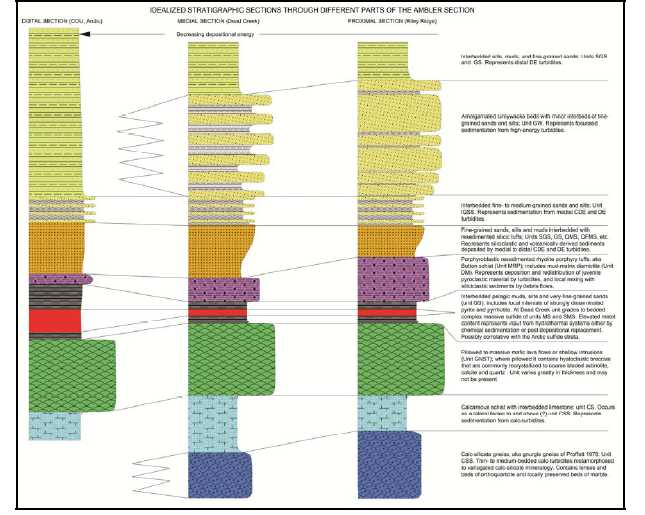

| Figure 7.2 | Geology of the Ambler Mining District | 7-5 |

| Figure 7.3 | Ambler Sequence Stratigraphy in the Arctic Deposit Area | 7-7 |

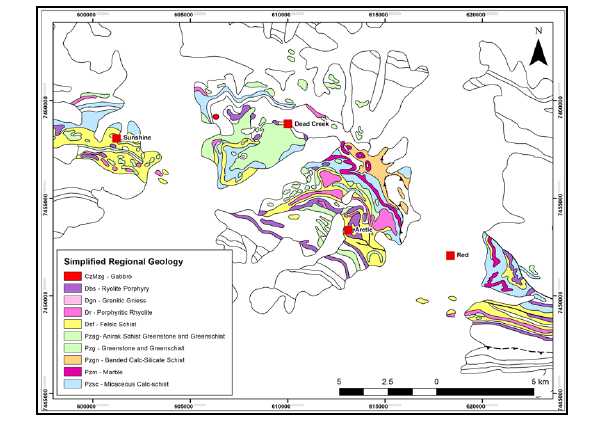

| Figure 7.4 | Generalized Geology of the Central Ambler District | 7-8 |

| Figure 7.5 | Typical F1 Isoclinal Folds Developed in Calcareous Gnurgle Gneiss | 7-9 |

| Figure 7.6 | Generalized Geologic Map of the Arctic Deposit | 7-11 |

| Figure 7.7 | Typical Massive Sulphide Mineralization at the Arctic Deposit | 7-16 |

| Figure 7.8 | Prospects of the Ambler Mining District | 7-18 |

| Figure 9.1 | Mapping Campaigns in and around the Arctic Deposit | 9-3 |

| Figure 9.2 | Arctic Deposit Area Geology | 9-4 |

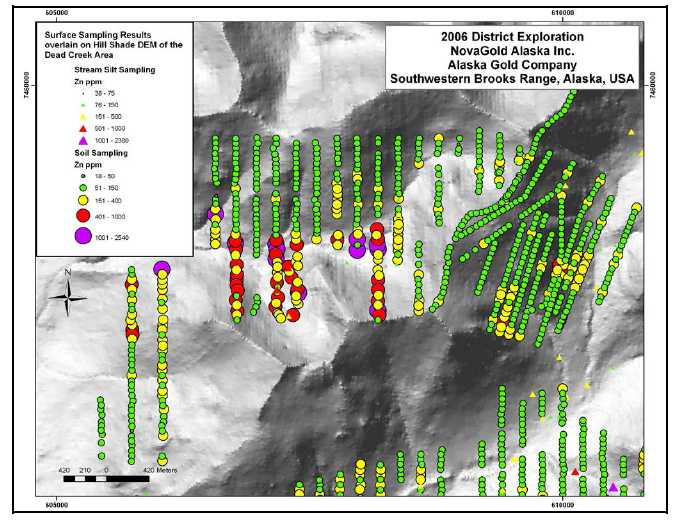

| Figure 9.3 | Copper Distribution in Silt and Soil Samples in the Dead Creek Area | 9-5 |

| Figure 9.4 | Zinc Distribution in Silt and Soil Samples in the Arctic Deposit Area | 9-6 |

| Figure 9.5 | TDEM Loops and Contoured Resistivity – Dead Creek Prospect | 9-8 |

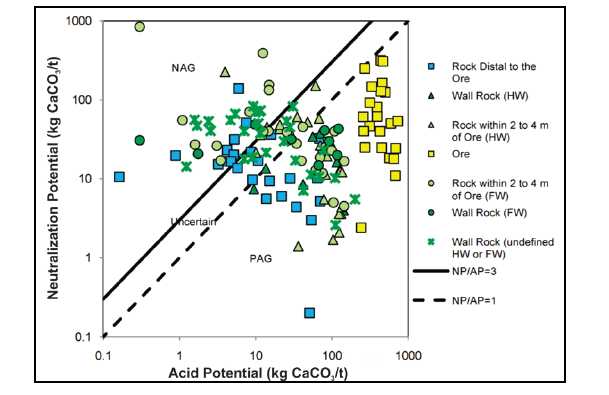

| Figure 9.6 | PAG versus NAG by Rock Type at the Arctic Deposit | 9-11 |

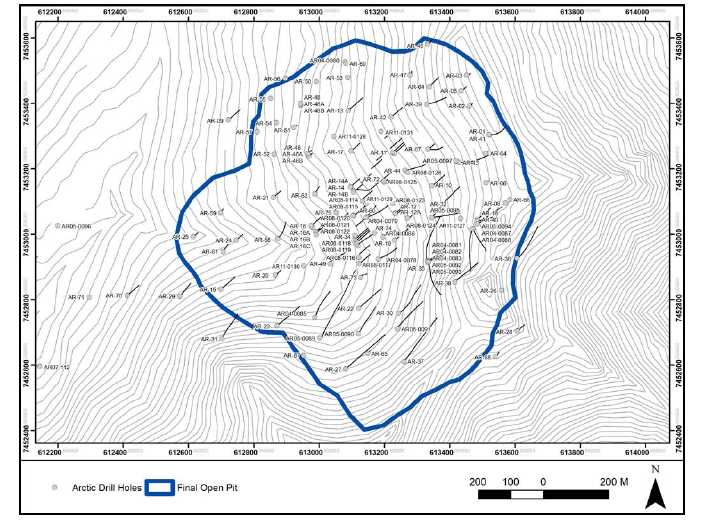

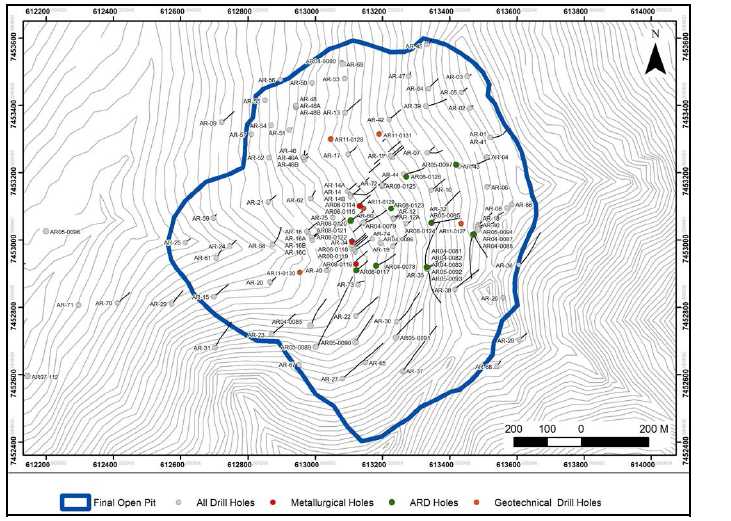

| Figure 10.1 | Plan Map of Drill Holes Utilized in the Mineral Resource Estimation | 10-3 |

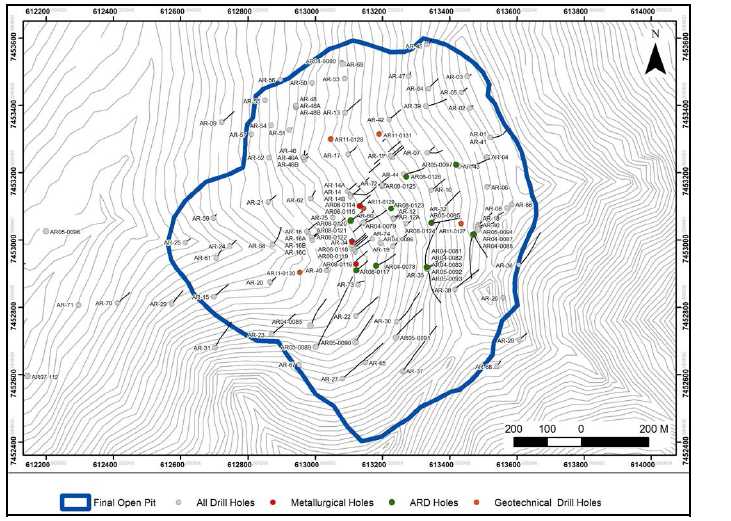

| Figure 10.2 | Drill Holes Utilized for Metallurgical, Geotechnical, Hydrological and Acid-Base Accounting Studies | 10-4 |

| Figure 10.3 | Known Collar Locations and Principal Target Areas – Ambler District | 10-13 |

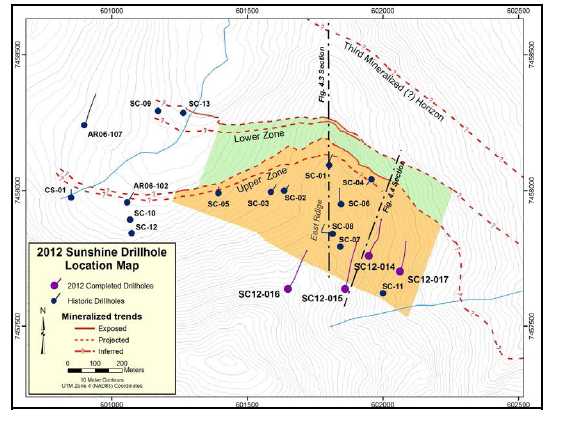

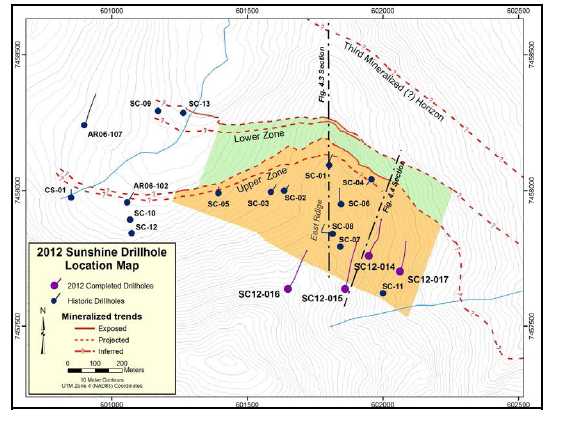

| Figure 10.4 | Sunshine Prospect and Drill Hole Locations | 10-15 |

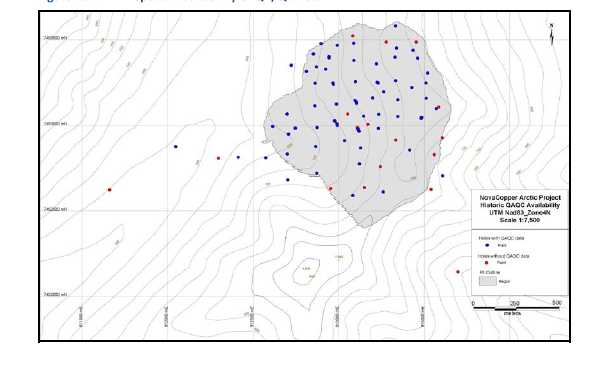

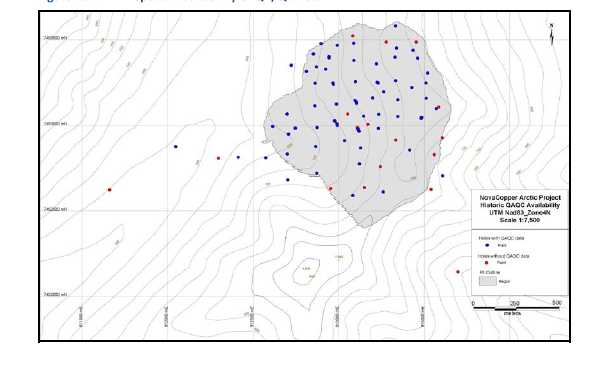

| Figure 11.1 | Spatial Availability of QA/QC Data | 11-6 |

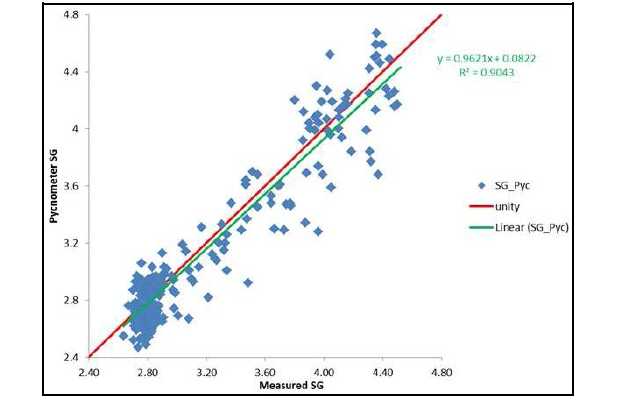

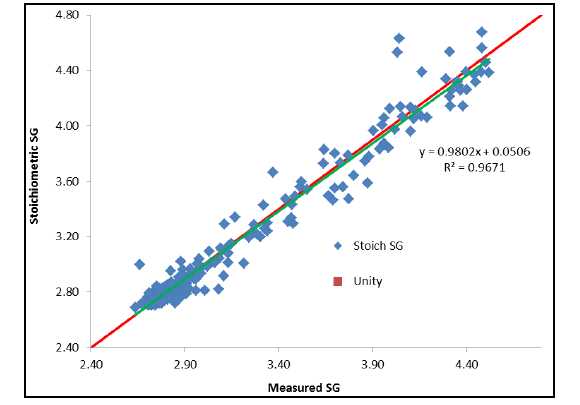

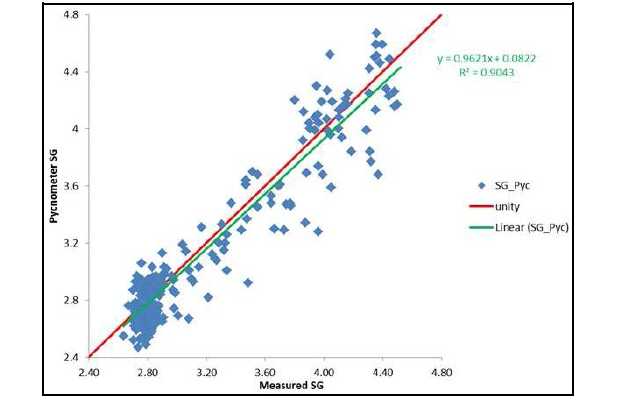

| Figure 11.2 | Graph Showing Good Agreement between Wet-dry Measured Specific Gravity and Pycnometer Measured Specific Gravity | 11-13 |

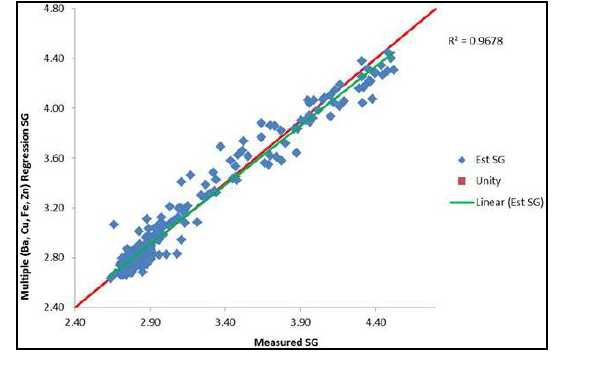

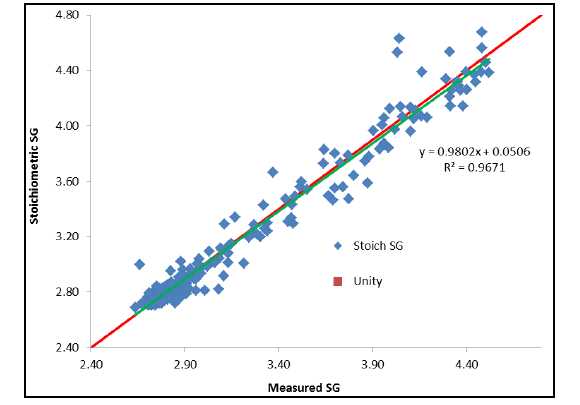

| Figure 11.3 | Measured versus Stoichiometric Specific Gravities | 11-14 |

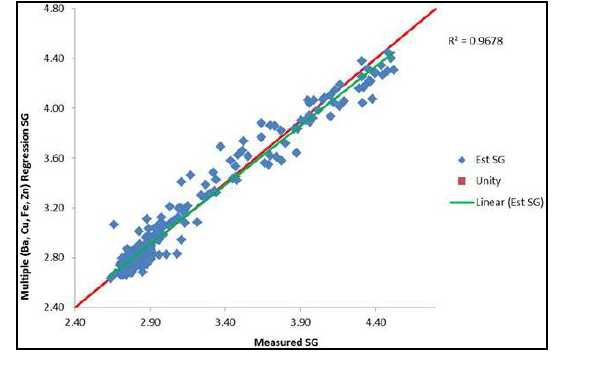

| Figure 11.4 | Scatter Plot Showing the Measured Specific Gravity versus Multiple (Copper, Iron, Zinc, Barium) Regression Estimate | 11-15 |

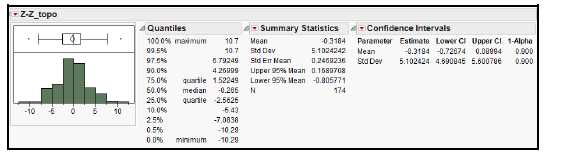

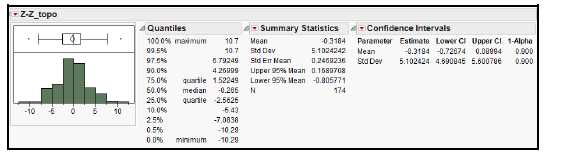

| Figure 12.1 | Distribution of the Differences Between GPS Elevations and the DTM | 12-1 |

| Figure 14.1 | Cross-section Illustrating the Arctic Deposit Geological Model | 14-9 |

| Figure 14.2 | Contact Profile between Zone 1 SMS and Country Rock for Copper | 14-11 |

| Figure 14.3 | Contact Profile between Zone 1 SMS and MS for Zinc | 14-12 |

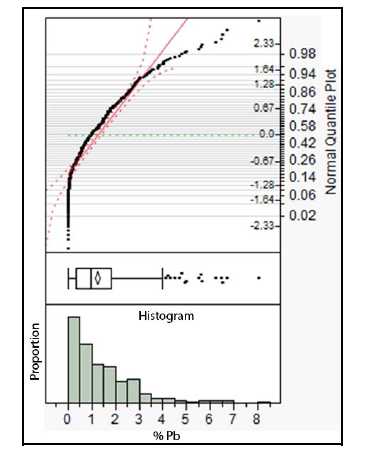

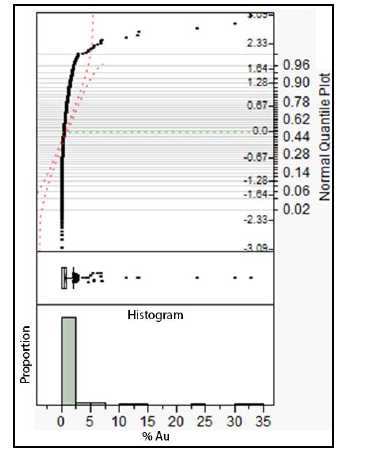

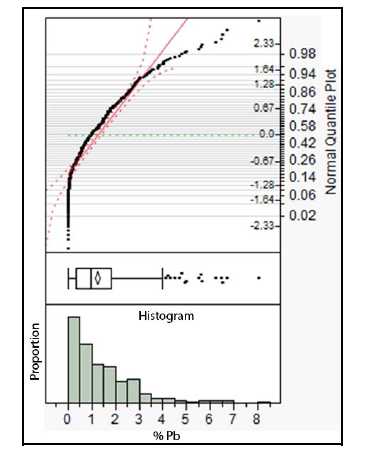

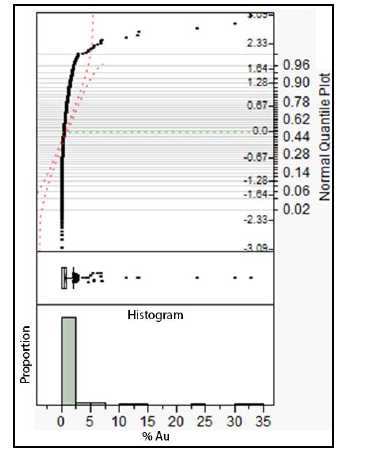

| Figure 14.4 | Lead Histogram | 14-14 |

| Figure 14.5 | Gold Histogram | 14-15 |

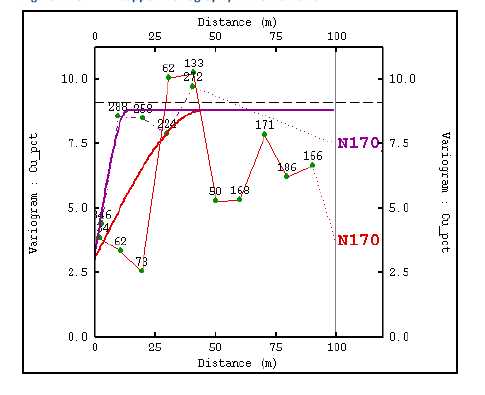

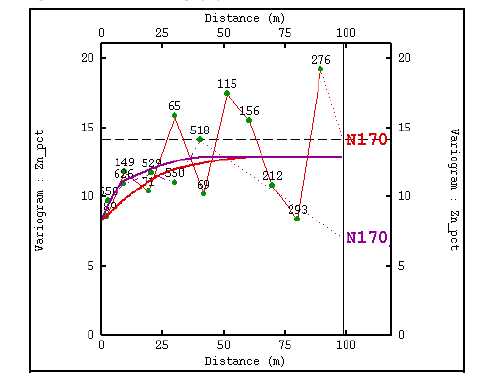

| Figure 14.6 | Copper: Variography in SMS Domains | 14-18 |

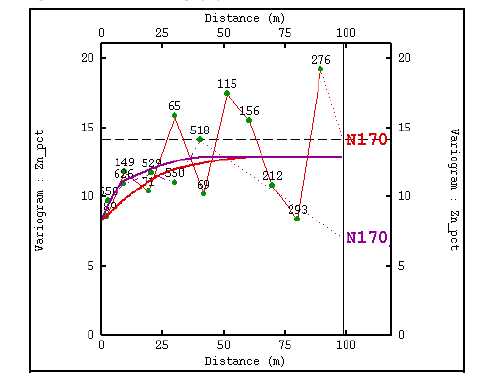

| Figure 14.7 | Zinc: Variography in SMS Domains | 14-19 |

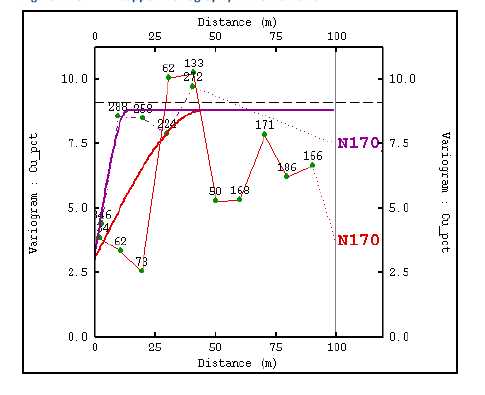

| Figure 14.8 | Copper: Variography in MS Domains | 14-19 |

| Figure 14.9 | Zinc: Variography in MS Domains | 14-20 |

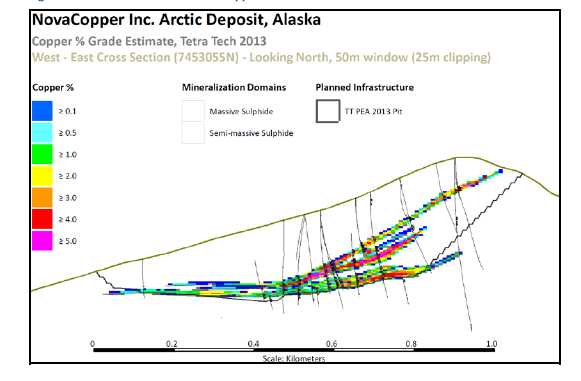

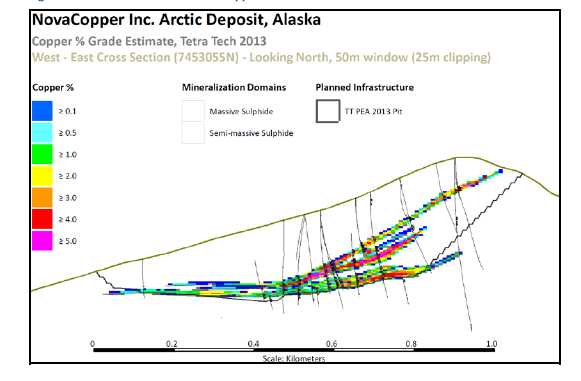

| Figure 14.10 | Cross-section for Copper | 14-25 |

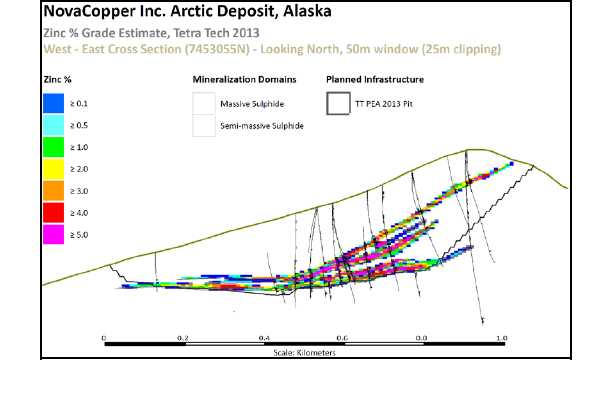

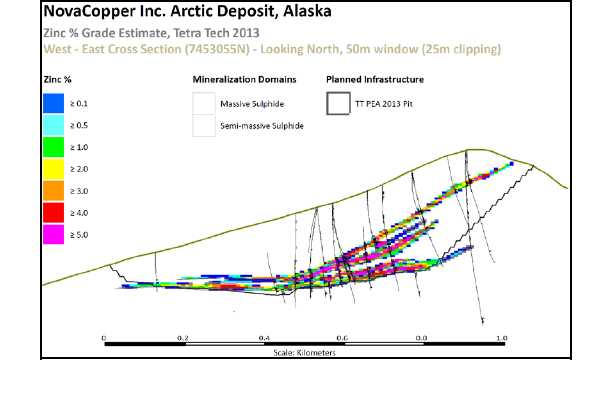

| Figure 14.11 | Cross-section for Zinc | 14-26 |

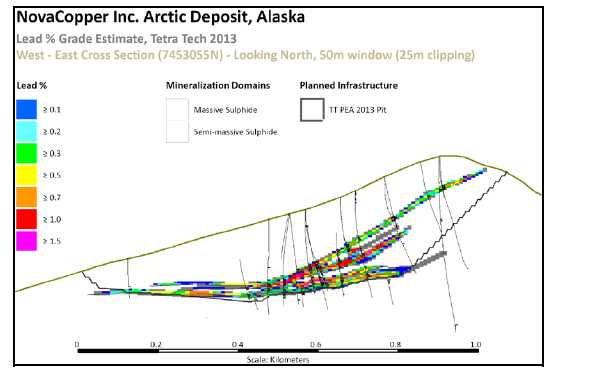

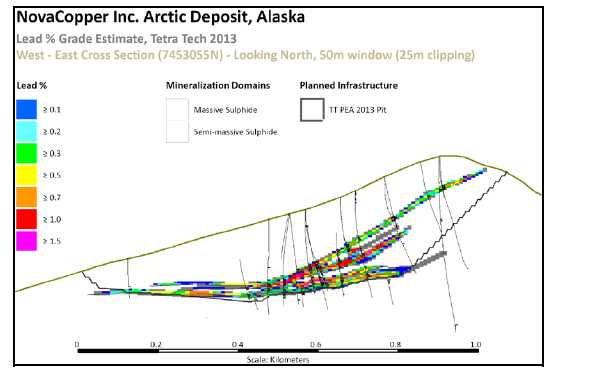

| Figure 14.12 | Cross-section for Lead | 14-27 |

xv

|  |

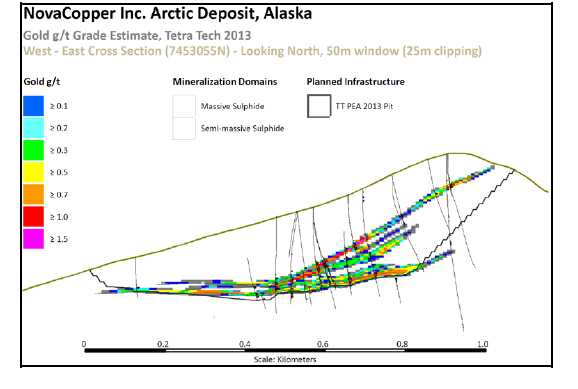

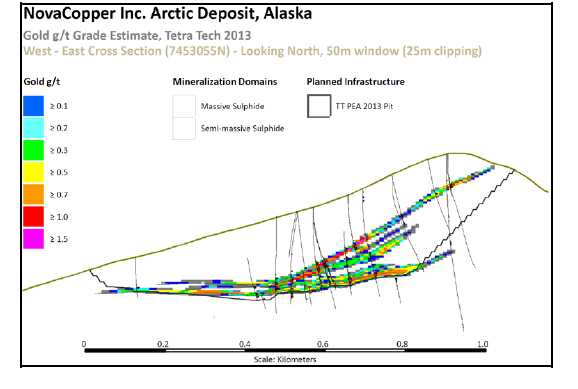

| Figure 14.13 | Cross-section for Gold | 14-27 |

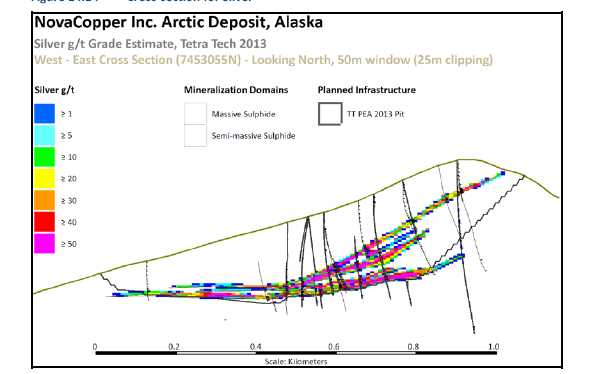

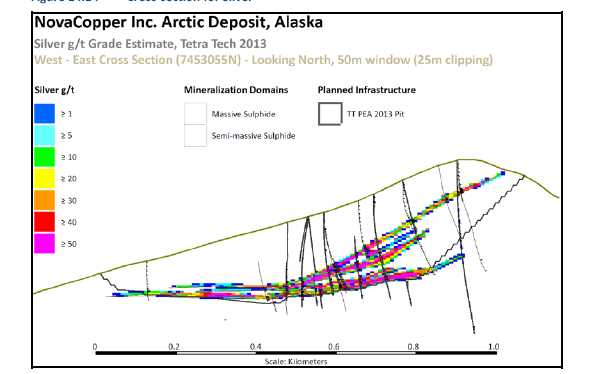

| Figure 14.14 | Cross-section for Silver | 14-28 |

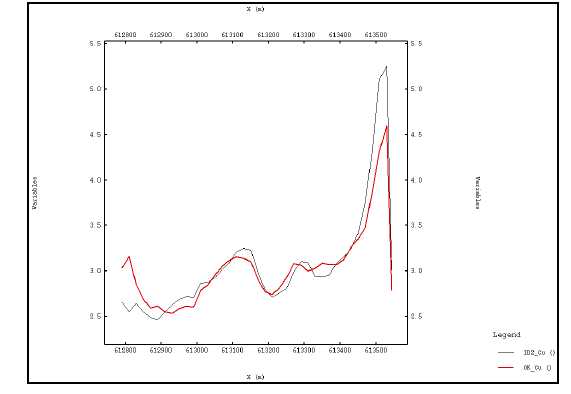

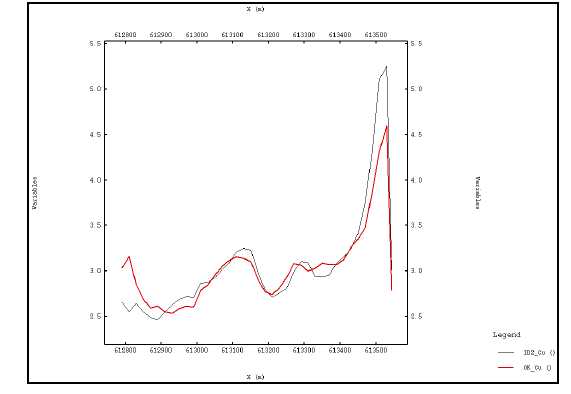

| Figure 14.15 | Swath Plot of Block Copper Grade Values by Northing for the Arctic Deposit | 14-29 |

| Figure 14.16 | Swath Plot of Block Copper Grade Values by Easting for the Arctic Deposit | 14-29 |

| Figure 14.17 | Swath Plot of Block Zinc Grade Values by Northing for the Arctic Deposit | 14-30 |

| Figure 14.18 | Swath Plot of Block Zinc Grade Values by Easting for the Arctic Deposit | 14-31 |

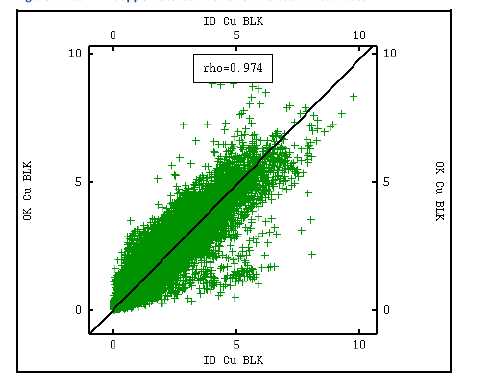

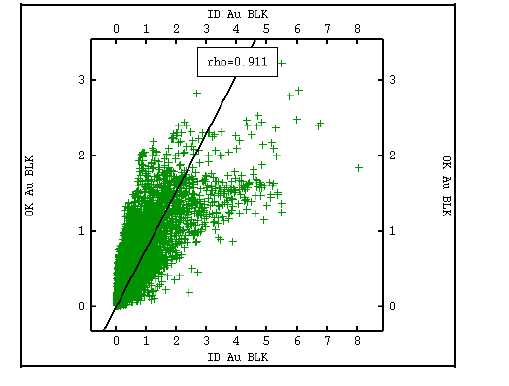

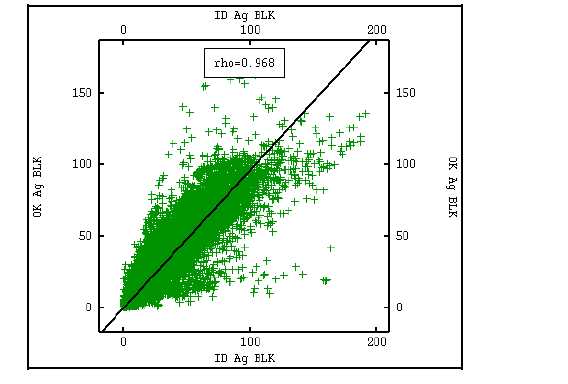

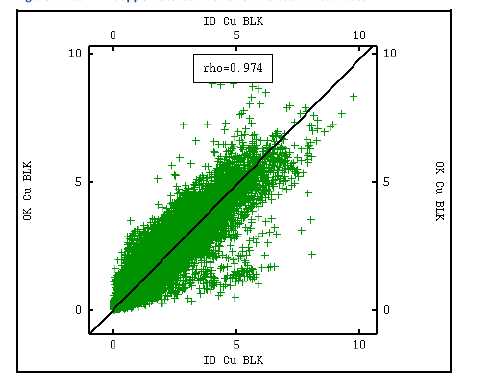

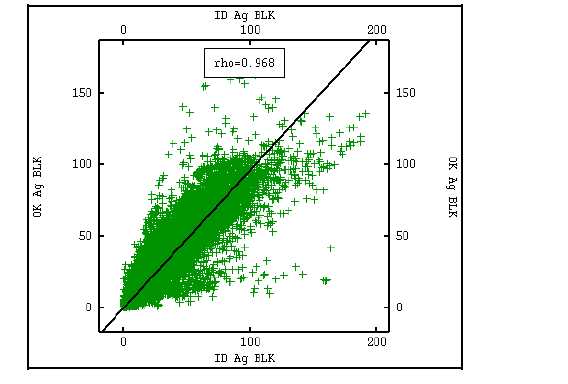

| Figure 14.19 | Copper: Scatter Plot of OK versus ID Estimates | 14-32 |

| Figure 14.20 | Zinc: Scatterplot of OK versus ID Estimates | 14-32 |

| Figure 14.21 | Lead: Scatterplot of OK versus ID Estimates | 14-33 |

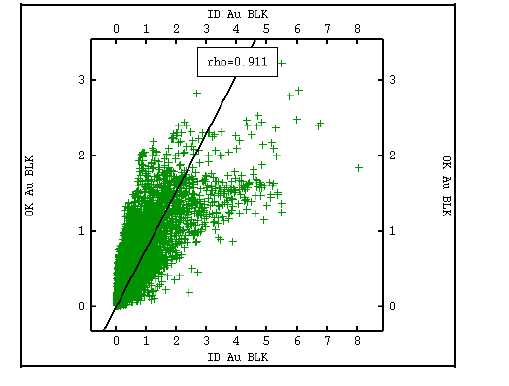

| Figure 14.22 | Gold: Scatterplot of OK versus ID Estimates | 14-33 |

| Figure 14.23 | Silver: Scatterplot of OK versus ID Estimates | 14-34 |

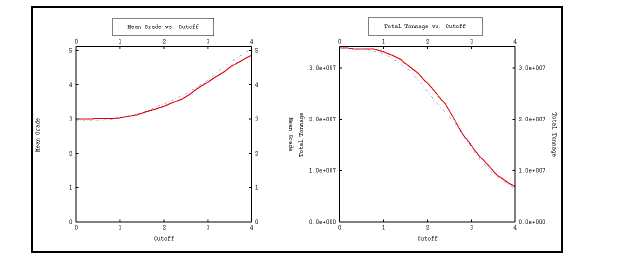

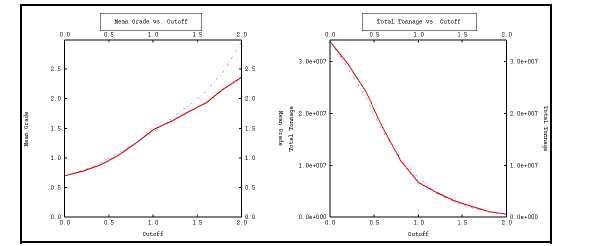

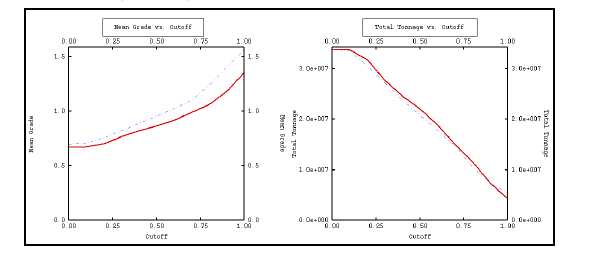

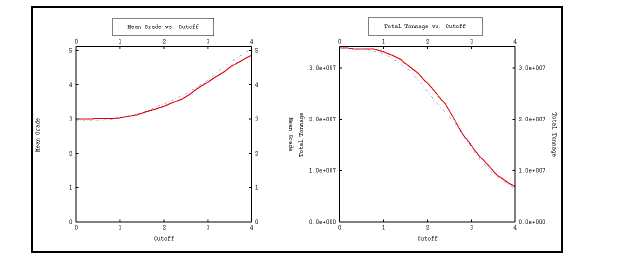

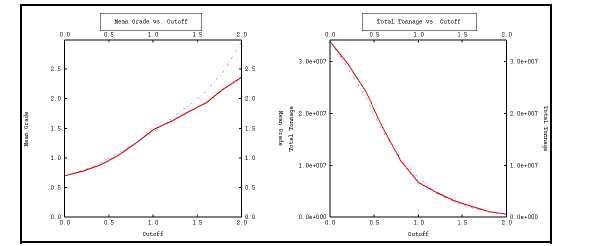

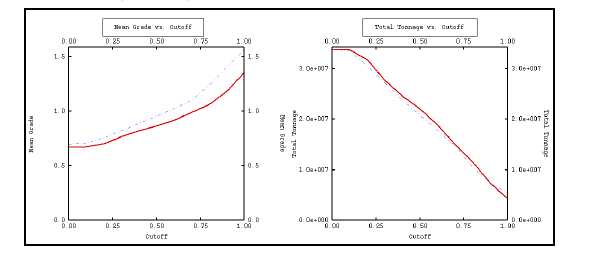

| Figure 14.24 | Block Model Grade Tonnage Comparison: Copper OK (red line) and Copper ID2(broken line) | 14-35 |

| Figure 14.25 | Block Model Grade Tonnage Comparison: Zinc OK (red line) and Zinc ID2 (broken line) | 14-35 |

| Figure 14.26 | Block Model Grade Tonnage Comparison: Lead OK (red line) and Lead ID2 (broken line) | 14-36 |

| Figure 14.27 | Block Model Grade Tonnage Comparison: Gold OK (red line) and Gold ID2 (broken line) | 14-36 |

| Figure 14.28 | Block Model Grade Tonnage Comparison: Silver OK (red line) and Silver ID2 (broken line) | 14-37 |

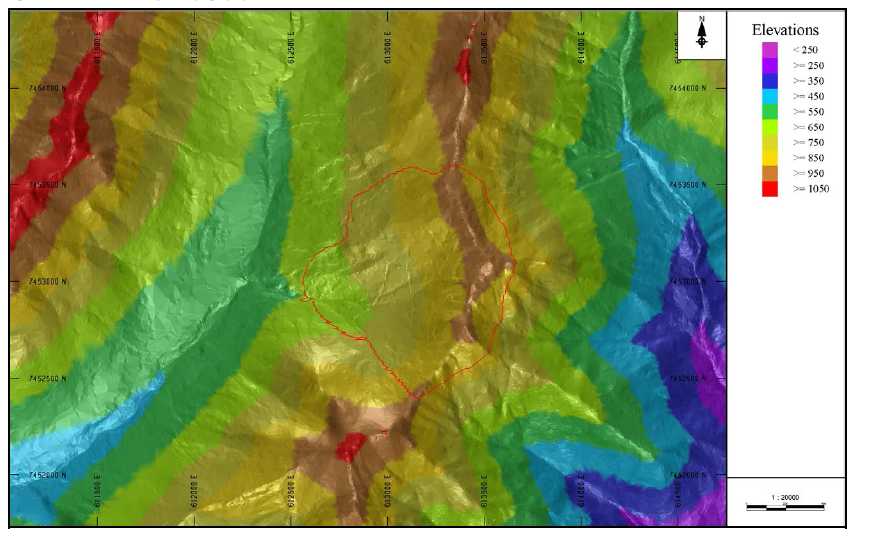

| Figure 16.1 | Arctic Project Topography | 16-2 |

| Figure 16.2 | Pit Wall Slope | 16-7 |

| Figure 16.3 | One-way Haul Road | 16-8 |

| Figure 16.4 | Two-way Haul Road | 16-9 |

| Figure 16.5 | Pit Design | 16-10 |

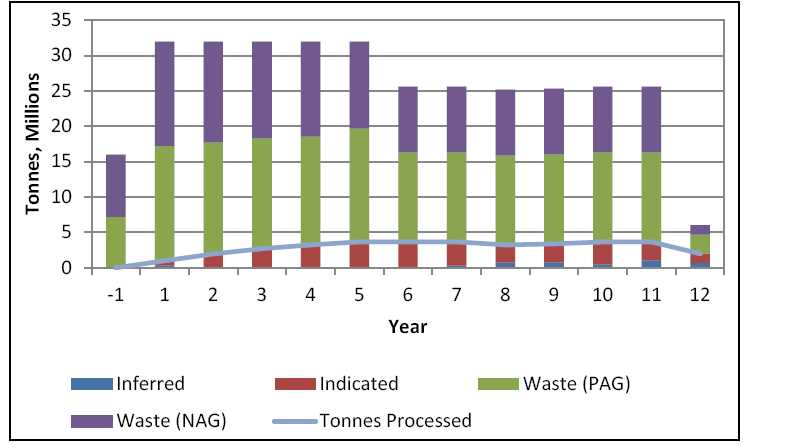

| Figure 16.6 | Production Schedule | 16-13 |

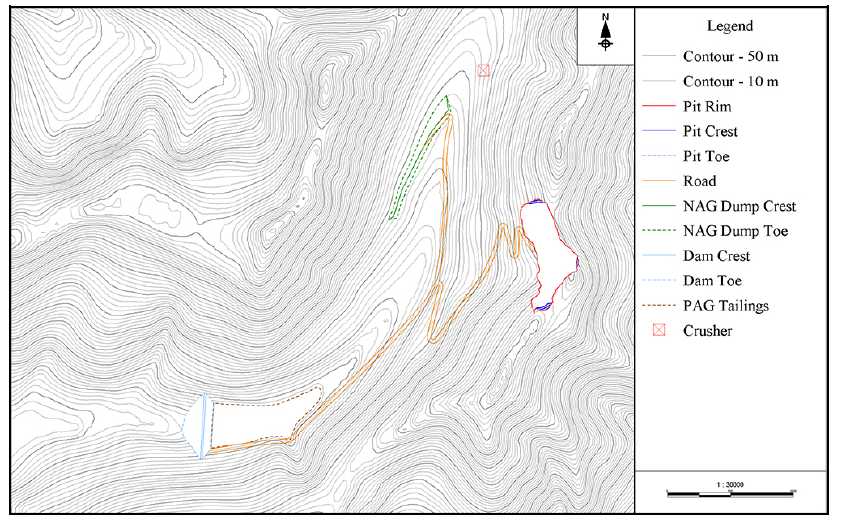

| Figure 16.7 | Pre-production Year Mine Status Map | 16-14 |

| Figure 16.8 | Year 4 Mine Status Map | 16-15 |

| Figure 16.9 | Year 8 Mine Status Map | 16-16 |

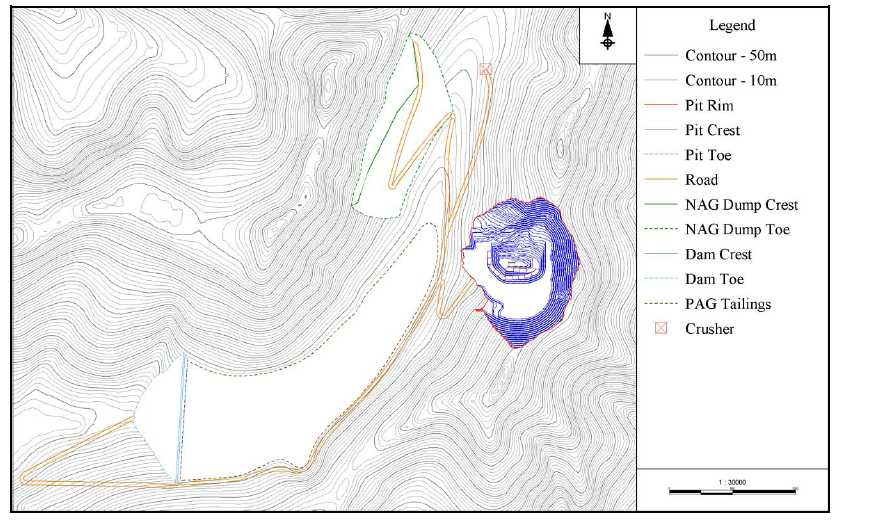

| Figure 16.10 | Year 12 Mine Status Map | 16-17 |

| Figure 17.1 | Simplified Process Flow Diagram | 17-3 |

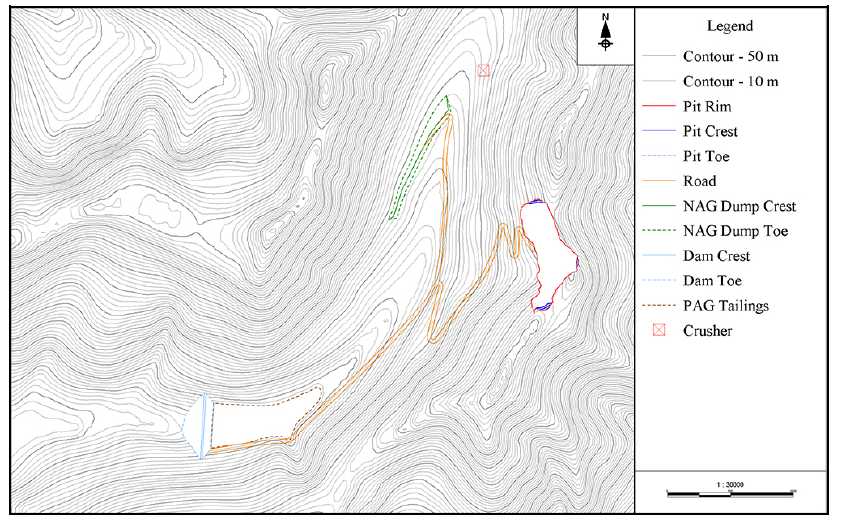

| Figure 18.1 | Final General Arrangement Layout after 12 years of Operation | 18-3 |

| Figure 18.2 | Access to the Arctic Project | 18-4 |

| Figure 18.3 | Tailings Storage Facility | 18-12 |

| Figure 18.4 | Tailings Embankment Cross Section | 18-13 |

| Figure 20.1 | Comparison of Benthic Macroinvertebrate Community Measures | 20-4 |

| Figure 21.1 | LOM Average Operating Cost Distribution | 21-10 |

| Figure 22.1 | Pre-tax Undiscounted Annual and Cumulative NCF | 22-4 |

| Figure 22.2 | Pre-tax NPV Sensitivity Analysis | 22-6 |

| Figure 22.3 | Pre-tax IRR Sensitivity Analysis | 22-6 |

| Figure 22.4 | Pre-tax Payback Period Sensitivity Analysis | 22-7 |

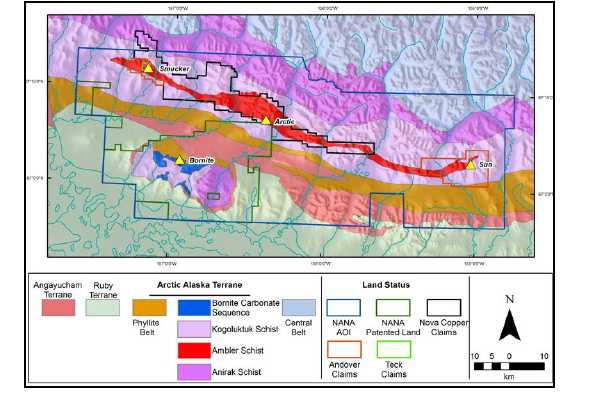

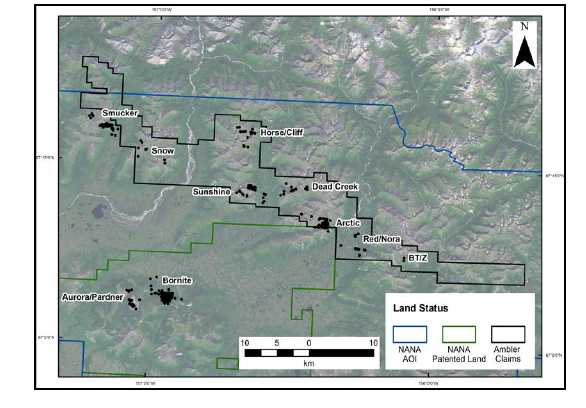

| Figure 23.1 | Adjacent Properties and Land Status | 23-1 |

| Figure 23.2 | Sun Project Prospect Location Map | 23-3 |

xvi

| UNITS OFMEASURE | |

| above mean sea level | amsl |

| acre | ac |

| ampere | A |

| annum (year) | a |

| billion | B |

| billion tonnes | Bt |

| billion years ago | Ga |

| British thermal unit | BTU |

| centimetre | cm |

| cubic centimetre | cm3 |

| cubic feet per minute | cfm |

| cubic feet per second | ft3/s |

| cubic foot | ft3 |

| cubic inch | in3 |

| cubic metre | m3 |

| cubic yard | yd3 |

| Coefficients of Variation | CVs |

| day | d |

| days per week | d/wk |

| days per year (annum) | d/a |

| dead weight tonnes | DWT |

| decibel adjusted | dBa |

| decibel | dB |

| degree | ° |

| degrees Celsius | °C |

| diameter | ø |

| dollar (American) | US$ |

| dollar (Canadian) | Cdn$ |

| dry metric ton | dmt |

| foot | ft |

| gallon | gal |

| gallons per minute (US) | gpm |

| Gigajoule | GJ |

| gigapascal | GPa |

| gigawatt | GW |

| gram | g |

| grams per litre | g/L |

xvii

| grams per tonne | g/t |

| greater than | > |

| hectare (10,000 m2) | ha |

| hertz | Hz |

| horsepower | hp |

| hour | h |

| hours per day | h/d |

| hours per week | h/wk |

| hours per year | h/a |

| inch | in |

| kilo (thousand) | k |

| kilobar | kb |

| kilogram | kg |

| kilograms per cubic metre | kg/m3 |

| kilograms per hour | kg/h |

| kilograms per square metre | kg/m2 |

| kilometre | km |

| kilometres per hour | km/h |

| kilopascal | kPa |

| kilotonne | kt |

| kilovolt | kV |

| kilovolt-ampere | kVA |

| kilovolts | kV |

| kilowatt | kW |

| kilowatt hour | kWh |

| kilowatt hours per tonne | kWh/t |

| kilowatt hours per year | kWh/a |

| less than | < |

| litre | L |

| litres per minute | L/m |

| megabytes per second | Mb/s |

| megapascal | MPa |

| megavolt-ampere | MVA |

| megawatt | MW |

| metre | m |

| metres above mean sea level | mamsl |

| metres above sea level | masl |

| metres Baltic sea level | mbsl |

| metres per minute | m/min |

| metres per second | m/s |

| microns | µm |

| milligram | mg |

| milligrams per litre | mg/L |

| millilitre | mL |

| millimetre | mm |

xviii

| million | M |

| million bank cubic metres | Mbm3 |

| million bank cubic metres per annum | Mbm3/a |

| million tonnes | Mt |

| minute (plane angle) | ' |

| minute (time) | min |

| month | mo |

| ounce | oz |

| pascal | Pa |

| centipoise | mPa·s |

| parts per million | ppm |

| parts per billion | ppb |

| percent | % |

| pound(s) | lb |

| pounds per square inch | psi |

| revolutions per minute | rpm |

| second (plane angle) | " |

| second (time) | s |

| short ton (2,000 lb) | st |

| short tons per day | st/d |

| short tons per year | st/y |

| specific gravity | SG |

| square centimetre | cm2 |

| square foot | ft2 |

| square inch | in2 |

| square kilometre | km2 |

| square metre | m2 |

| three-dimensional | 3D |

| tonne (1,000 kg) (metric ton) | t |

| tonnes per day | t/d |

| tonnes per hour | t/h |

| tonnes per year | t/a |

| tonnes seconds per hour metre cubed | ts/hm3 |

| volt | V |

| week | wk |

| weight/weight | w/w |

| wet metric ton | wmt |

| | |

| ABBREVIATIONS ANDACRONYMS | |

| abrasion index | Ai |

| acid potential | AP |

| acid rock drainage | ARD |

| acid-base accounting | ABA |

| Acme Analytical Laboratories Ltd | AcmeLabs |

xix

|  |

| Alaska Department of Environmental Conservation | ADEC |

| Alaska Department of Fish and Game | ADF&G |

| Alaska Department of Natural Resources | ADNR |

| Alaska Department of Transportation | ADOT |

| Alaska Industrial Development Export Authority | AIDEA |

| Alaska Mining Licence Tax | AMLT |

| Alaska National Interest Lands Conservation Act | ANILCA |

| Alaska Native Claims Settlement Act | ANCSA |

| Alaska Native Regional Corporations | ANCSA Corporations |

| Alaska Pollution Discharge Elimination System | APDES |

| Alaska State Tax | AST |

| ALS Chemex Laboratories | ALS Chemex |

| Alternative Minimum Tax | AMT |

| aluminium oxide | Al2O3 |

| Ambler Mining District Industrial Access Road | AMDIAR |

| ammonium nitrate/fuel oil | ANFO |

| Analytical Spectral Devices | ASD |

| Andover Mining Corp. | Andover |

| Annual Hardrock Exploration Activity | AHEA |

| Arctic Property | the Property |

| atomic absorption spectroscopy | AAS |

| atomic absorption | AA |

| average relative difference | AD |

| barium | Ba |

| Bear Creek Mining Corporation | BCMC |

| BGC Engineering Inc. | BGC |

| Bond ball mill work index | BWi |

| Canadian Institute of Mining, Metallurgy and Petroleum | CIM |

| capital cost estimate | CAPEX |

| carboxymethyl cellulose | CMC |

| Center of the Universe | COU |

| Clean Water Act | CWA |

| Controlled Source Audio Magnetotelluric | CSAMT |

| copper equivalent | CuEq |

| copper | Cu |

| cumulative net cash flow | CNCF |

| Democratic Republic of the Congo | DRC |

| digital terrain model | DTM |

| distributed control system | DCS |

| Document Management System | DMS |

| domain electromagnetic | DEM |

| EBA, A Tetra Tech Company | EBA |

| effective grinding length | EGL |

| Electromagnetic | EM |

| engineering, procurement and construction management | EPCM |

xx

|  |

| environmental impact statement | EIS |

| Environmental Protection Agency | EPA |

| Ephemeroptera, Plecoptera, Trichoptera | EPT |

| Ernst & Young LLP | EY |

| Exploration Incentive Credits | EICs |

| Fine Sediment Biotic Index | FSBI |

| general and administrative | G&A |

| GeoSpark Consulting Inc. | GeoSpark |

| global positioning system | GPS |

| gold | Au |

| Gross Metal Value | GMV |

| heating, ventilation and air conditioning | HVAC |

| inductively coupled plasma | ICP |

| inductively coupled plasma-atomic emission spectroscopy | ICP-AES |

| inductively coupled plasma-mass spectrometry | ICP-MS |

| input/output | I/O |

| Interior Energy Project | IEP |

| internal rate of return | IRR |

| International Electrotechnical Commission | IEC |

| International Organization for Standardization | ISO |

| inverse distance squared | ID2 |

| iron | Fe |

| Kennecott Mining Company | Kennecott |

| Kennecott Research Center | KRC |

| kriging efficiency | KE |

| Lakefield Research Ltd. | Lakefield |

| lead | Pb |

| Lerchs-Grossmann | LG |

| life-of-mine | LOM |

| light-emitting diode | LED |

| liquefied natural gas | LNG |

| Localizer Performance with Vertical Guidance | LPV |

| magnesium oxide | MgO |

| magnesium | Mg |

| massive sulphide | MS |

| memorandum of understanding | MOU |

| metal leaching | ML |

| methyl isobutyl carbinol | MIBC |

| motor control centres | MCCs |

| Multi-Sector General Permit | MSGP |

| NANA Regional Corporation Inc. | NANA |

| National Environmental Policy Act | NEPA |

| National Instrument 43-101 | NI 43-101 |

| nearest neighbour | NN |

| net cash flow | NCF |

xxi

|  |

| net present value | NPV |

| neutralization potential | NP |

| non-acid generating | NAG |

| North American Datum | NAD |

| Northwest Alaska Native Association | NANA |

| Northwest Arctic Borough | NWAB |

| NovaCopper Inc. | NovaCopper |

| NovaGold Resources Inc. | NovaGold |

| operating cost estimate | OPEX |

| operator interface stations | OIS |

| ordinary kriging | OK |

| potentially acid generating | PAG |

| Precision Approach Path Indicators | PAPIs |

| preliminary economic assessment | PEA |

| programmable logic controllers | PLCs |

| Qualified Person | QP |

| quality assurance/quality control | QA/QC |

| Quantitative Evaluation of Minerals by Scanning Electronic Microscopy | QEMSCAM® |

| Quantitative Kriging Neighbourhood Analysis | QKNA |

| Resource Associates of Alaska | RAA |

| Robertson Geoconsultants Inc | Robertson |

| rock mass rating | RMR |

| rock quality designation | RQD |

| run-of-mine | ROM |

| Runway End Identification Lighting System | REILS |

| SAG mill and ball mill | SAB |

| semi-autogenous grinding | SAG |

| semi-massive sulphide | SMS |

| SGS Mineral Services | SGS |

| short wave infrared | SWIR |

| silver | Ag |

| sodium isopropyl xanthate | SIPX |

| sodium | Na |

| SRK Consulting | SRK |

| sulphur | S |

| tailings storage facility | TSF |

| Teck Resources Ltd. | Teck |

| theoretical slope of regression | ZZ* |

| thermal ionization mass spectrometry | TIMS |

| Thompson-Howarth Precision Versus Concentration | THPVC |

| time domain electromagnetic | TDEM |

| titanium dioxide | TiO2 |

| total inorganic carbon | TIC |

| Universal Transverse Mercator | UTM |

| Upper Kobuk Mineral Projects | UKMP |

xxii

| US Army Corps of Engineers | USACE |

| US Geological Survey | USGS |

| vibrating wire piezometers | VWPs |

| volcanogenic massive sulphide | VMS |

| water quality standards | WQS |

| Watts, Griffis and McOuat Ltd. | WGM |

| Wide Area Augmentation System | WAAS |

| x-ray fluorescence | XRF |

| zinc | Zn |

xxiii

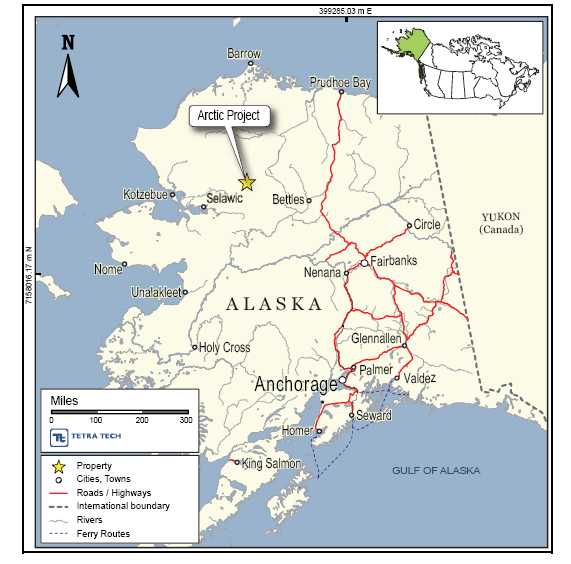

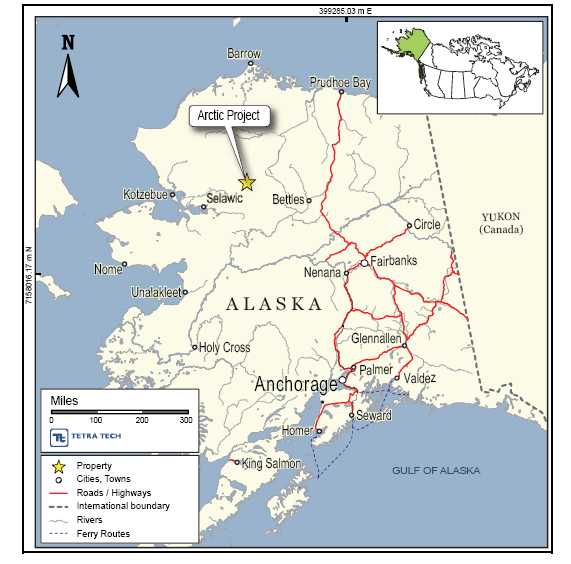

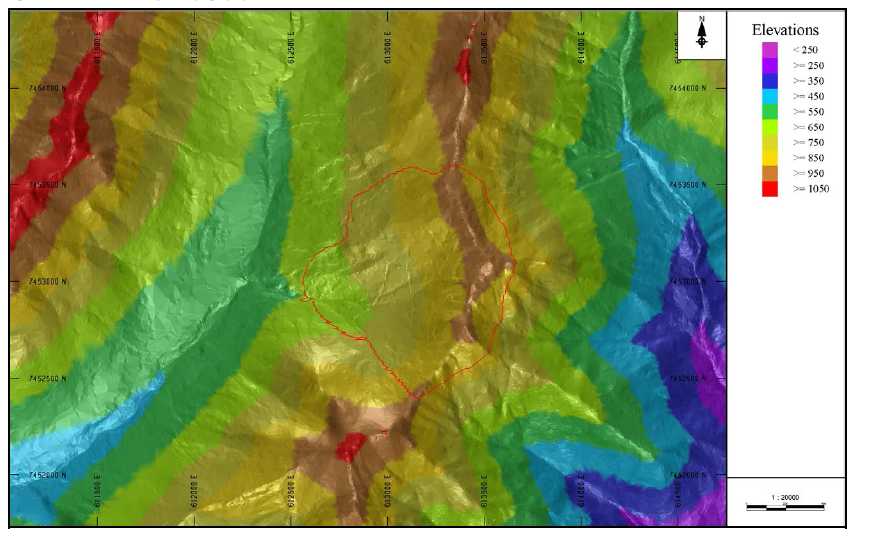

NovaCopper Inc. (NovaCopper) retained Tetra Tech and EBA, a Tetra Tech Company (EBA) to prepare a preliminary economic assessment (PEA) for the Arctic Project and disclose it in a technical report prepared in accordance with National Instrument 43-101 (NI 43-101) and Form 43-101F1. The Arctic Property (the Property) is located in the Ambler mining district (Ambler District) of the southern Brooks Range, in the Northwest Arctic Borough (NWAB) of Alaska. The Property is located 270 km east of the town of Kotzebue, 36 km northeast of the village of Kobuk, and 260 km west of the Dalton Highway, an all-weather state maintained highway. Figure 1.1 illustrates the location of the Property.

The PEA describes the potential technical and economic viability of establishing a conventional open-pit mine, a mill complex and related infrastructure to process massive and semi-massive copper-zinc-lead-silver-gold mineralization from the Arctic Deposit. A minimum 12-year mine life supporting a nominal 10,000 t/d conventional grinding mill-and-flotation circuit is envisaged. The base case scenario assumes long-term metal prices of $2.90/lb for copper, $0.85/lb for zinc, $0.90/lb for lead, $22.70/oz for silver and $1,300/oz for gold. The PEA was prepared on a 100% ownership basis and all amounts are stated in US dollars unless otherwise noted.

The effective date of this report is September 12, 2013 and the effective date of the resource model is July 30, 2013.

General information for the Arctic Project is summarized in Table 1.1.

| NovaCopper Inc. | 1-1 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

Figure 1.1 Property Location Map

| NovaCopper Inc. | 1-2 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

Table 1.1 General Project Information

| Description | Unit | Amount |

| Mill Feed | Mt | 35.7 |

| Life-of-mine (LOM) | years | 12 |

| Milling Rate | t/d | 10,000 |

| Strip Ratio | waste:mineralized material | 8.4 |

| Total Project Capital Cost | $ million | 717.7 |

| Average Overall Operating Cost* | $/t milled | 63.93 |

| Pre-tax Net Present Value (NPV) at 8% Discount Rate** | $ million | 927.7 |

| Pre-tax Internal Rate of Return (IRR) | % | 22.8 |

| Pre-tax Payback Period | years | 4.6 |

| Post-tax NPV at 8% Discount Rate | $ million | 537.2 |

| Post-tax IRR | % | 17.9 |

| Post-tax Payback Period | years | 5.0 |

| | Notes: | *Excludes pre-production cost. |

| | **The base case utilizes long-term metal prices of $2.90/lb for copper, $0.85/lb for zinc, $0.90/lb for lead, $22.70/oz for silver and $1,300/oz for gold. |

The PEA should not be considered to be a prefeasibility or feasibility study, as the economics and technical viability of the Arctic Project have not been demonstrated at this time. The PEA is preliminary in nature and includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. Furthermore, there is no certainty that the PEA results will be realized.

| 1.2 | PROPERTY DESCRIPTION AND LOCATION |

The Arctic Project is located in the Ambler District of the southern Brooks Range, in the NWAB of Alaska. The Property is geographically isolated with no current road access or nearby power infrastructure. The Property is located 270 km east of the town of Kotzebue, 36 km northeast of the village of Kobuk, and 260 km west of the Dalton Highway, an all-weather state maintained highway.

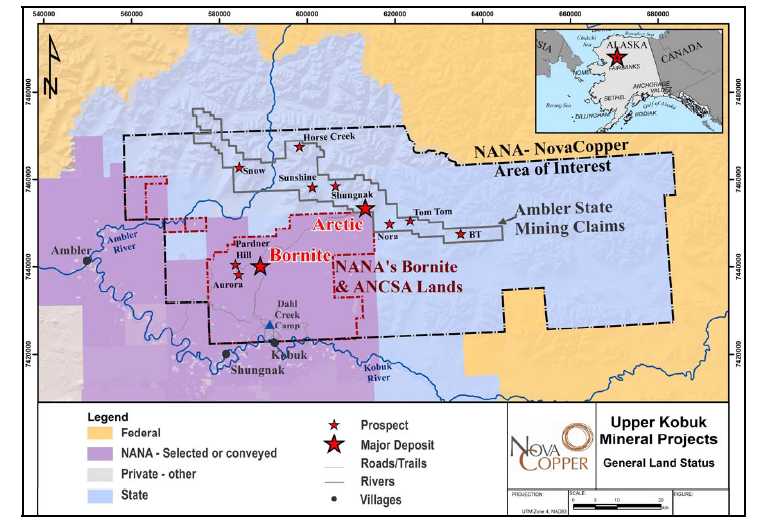

The Property is part of the Upper Kobuk Mineral Projects (UKMP), which includes the Arctic and Bornite deposits. In October 2011, NovaCopper entered into an exploration agreement with NANA Regional Corporation, Inc. (NANA) for the development of the parties’ collective resource interests in the Ambler District. The agreement consolidates certain land holdings of the parties into an area of interest consisting of an approximately 143,000 ha land package.

| 1.3 | GEOLOGY AND MINERALIZATION |

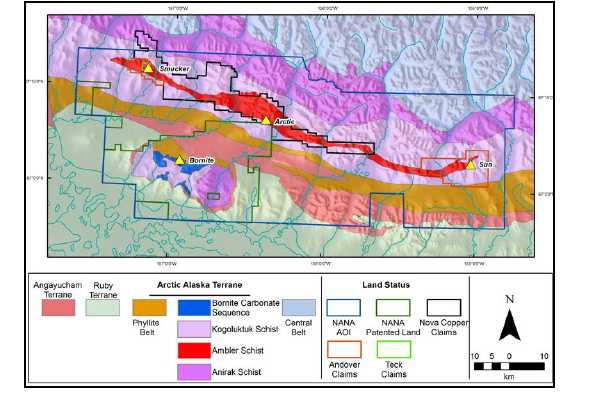

The Ambler District is located on the southern margin of the Brooks Range and hosts: 1) a belt of Devonian volcanogenic massive sulphide (VMS) deposits, including the Property which contains the Arctic Deposit; and 2) a belt of Devonian epigenetic carbonate-hosted copper deposits including the Bornite Deposit.

The district encompasses an east-west trending zone of Devonian to Jurassic age submarine volcanic and sedimentary rocks occurring as structurally bound, imbricate allochtons (Hitzman et al. 1986) and further characterized by increasing metamorphic grade to the north. The district shows isoclinal folding in the northern portion and thrust faulting to south (Schmidt 1983).

| NovaCopper Inc. | 1-3 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

On the Property, VMS-style deposits and prospects (including the Arctic Deposit) are hosted in the Ambler Sequence, a group of Middle Devonian to Early Mississippian, metamorphosed, bimodal volcanic rocks with interbedded tuffaceous, graphitic, and calcareous volcaniclastic metasediments. The Ambler sequence occurs in the upper part of the regional Anirak Schist. VMS-style mineralization is found along the entire 110 km strike length of the district.

The Ambler Sequence has undergone two periods of intense, penetrative deformation. The first deformation period is characterised by upper greenschist-facies metamorphism and formation of a penetrative schistosity. Folding varies from isoclinal folding with local transposition of bedding units, to pervasive upright or slightly overturned folds verging north on all scales. This fold event deforms the transposed bedding and schistosity, and defines the subsequent event.

Stratigraphically, the Ambler Sequence consists of variably metamorphosed calc-turbidites, overlain by calcareous schists with irregularly distributed mafic sills and pillow lavas. These are overlain by the Arctic-sulphide host section which consists mainly of fine-grained, carbonaceous siliciclastic rocks which are in turn overlain by reworked silicic volcanic rocks, including meta-rhyolite porphyries and most notably the regionally extensive Button Schist with its characteristically large relic phenocrysts. Greywacke sandstones, interpreted to be turbidites, occur throughout the section but are concentrated higher in the stratigraphy. Several rock units within the stratigraphy show substantial variation in local thickness as a consequence of basin morphology at the time of deposition.

Alteration at the Arctic Deposit is characterized by magnesium alteration, primarily as talc, chlorite and phengite alteration products associated with the sulphide-bearing horizons and continuing in the footwall. Stratigraphically above the sulphide-bearing horizons, significant muscovite as paragonite is developed and results in a marked shift in Na/Mg (sodium/magnesium) ratios across the sulphide bearing horizons.

Mineralization occurs as stratiform semi-massive sulphide (SMS) to massive sulphide (MS) beds within primarily graphitic chlorite schists and fine-grained quartz sandstones. The sulphide beds average 4 m in thickness but vary from less than 1 m up to as much as 18 m in thickness.

The bulk of the mineralization is within six modelled SMS zones cored by five MS zones lying along the upper and lower limbs of the Arctic isoclinal anticline. Wireframes of the mineralized horizons have been modeled based on MS defined by more than 50% sulphide minerals and SMS defined by 35 to 50% sulphide minerals. All of the zones are within an area of roughly 1 km2 with mineralization extending to a depth of approximately 250 m below the surface. Mineralization is predominately coarse-grained sulphides consisting mainly of chalcopyrite, sphalerite, galena, tetrahedrite, arsenopyrite, pyrite and pyrrhotite. Trace amounts of electrum and enargite are also present.

| NovaCopper Inc. | 1-4 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

A new mineral resource has been estimated by Mr. Michael F. O’Brien, M.Sc., Pr.Sci.Nat, FGSSA, FAusIMM, FSAIMM, who is an independent Qualified Person (QP), as defined in section 1.5 of NI 43-101. The mineral resource is listed in Table 1.2 and the effective date of this resource estimate is July 30, 2013.

The mineral resource estimate prepared by Tetra Tech considers diamond drill holes drilled by different operators from 1965 to 2011. The majority of the drilling has been completed in recent years by NovaCopper and its previous parent company NovaGold Resources Inc. (NovaGold). The mineral resource for the Arctic Project is supported by 43 core holes (approximately 13,500 m) drilled by NovaGold and 92 core holes (approximately 17,600 m) drilled by previous owners Kennecott Mining Company (Kennecott), and/or a Kennecott subsidiary. The geological and assay database have been reviewed and verified by Tetra Tech. It is Tetra Tech’s opinion that the current drilling information is adequate to support a mineral resource estimate.

Leapfrog™ software (version 2.5.1) was used to review and verify the resource estimation domains, prior to being imported into Isatis™ software (version 2012.1) to prepare assay data for geostatistical analysis, variography, block model construction, metal grade estimation and mineral resource tabulation. Mineral Resources were estimated into five massive-sulphide and six semi-massive sulphide lenses and then grades for the mineralized material portion of a 10 m by 10 m by 5 m block were calculated based on the proportion of MS and SMS within each block. Whole block model grades were calculated based on the weighted value of the estimated grade item based on the proportion of the mineralization domain. Whole blocks, including internal dilution, were used in pit optimization. Extreme lead and gold assays were capped prior to compositing. Ordinary kriging (OK) and inverse distance squared (ID2) estimates were run, with OK used for resource reporting and ID2 used for validation. Search parameters were constrained within each mineralized domain and required an optimum number of 15 composites, minimum number of 5 composites, minimum number of 2 drill holes, and maximum search distance range of 200 m. In general, blocks categorized as Indicated were supported by at least 2 drill holes within a 75 m search radii, and blocks categorized as Inferred were supported by at least 2 drill holes within a 150 m search radii.

Differences between the previously reported mineral resource estimate (as reported in the Technical Report dated April 24, 2012) are primarily related to additional drilling, updated geological interpretation, additional specific gravity determinations, and reporting of grades and tonnes within an open pit designed to support the requirements for reasonable prospects for economic extraction.

| NovaCopper Inc. | 1-5 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

Table 1.2 Resource Estimate for the Arctic Project (NSR Cut-off of $35/t)

Category |

Mt | Cu

(%) | Zn

(%) | Pb

(%) | Au

(g/t) | Ag

(g/t) | Cu

(Mlb) | Zn

(Mlb) | Pb

(Mlb) | Au

(Moz) | Ag

(Moz) |

| Indicated | 23.848 | 3.26 | 4.45 | 0.76 | 0.71 | 53.2 | 1,713 | 2,338 | 400.9 | 0.55 | 40.8 |

| Inferred | 3.363 | 3.22 | 3.84 | 0.58 | 0.59 | 41.5 | 239 | 285 | 43.2 | 0.06 | 4.5 |

| Notes: | 1. | These resource estimates have been prepared in accordance with NI 43-101 and the Canadian Institute of Mining, Metallurgy and Petroleum ( CIM) Definition Standards. Mineral resources that are not mineral reserves do not have demonstrated economic viability. Inferred resources have a great amount of uncertainty as to their existence and whether they can be mined legally or economically. It cannot be assumed that all or any part of the Inferred resources will ever be upgraded to a higher category. |

| | 2. | Mineral Resources are reported within mineralization wireframes, contained within an Indicated and Inferred pit design using an assumed copper price of $2.90/lb, zinc price of $0.85/lb, lead price of $0.90/lb, silver price of $22.70/oz, and gold price of $1,300/oz. |

| | 3. | Appropriate mining costs, processing costs, metal recoveries and inter ramp pit slope angles were used to generate the pit design. |

| | 4. | The $35.01/t milled cut-off is calculated based on a process operating cost of $19.03/t, G&A of $7.22/t and site services of $8.76/t. NSR equals payable metal values, based on the metal prices outlined in Note 2 above, less applicable treatment, smelting, refining costs, penalties, concentrate transportation costs, insurance and losses and royalties. |

| | | 5. | The LOM strip ratio is 8.39. |

| | 6. | Rounding as required by reporting guidelines may result in apparent summation differences between tonnes, grade and contained metal content. |

| | 7. | Tonnage and grade measurements are in metric units. Contained copper, zinc and lead pounds are reported as imperial pounds, contained silver and gold ounces as troy ounces. |

| 1.5 | MINERAL PROCESSING AND METALLURGICAL TESTING |

Since 1970, metallurgical test work has been conducted to determine the flotation response of various samples extracted from the Arctic Deposit. In general, the samples tested produced similar metallurgical performances. In 2012, SGS Mineral Services (SGS) conducted a metallurgical test program to further study metallurgical responses of the samples produced from Zones 1, 2, 3, and 5 of the Arctic Deposit. The flotation test procedures used talc pre-flotation, conventional copper-lead bulk flotation and zinc flotation, followed by copper and lead separation. In general, the 2012 test results indicated that the samples responded well to the flowsheet tested. The average results of the locked cycle tests (without copper and lead separation) were as follows:

| • | The copper recoveries to the bulk copper-lead concentrates ranged from 89 to 93% excluding the Zone 1 & 2 composite which produced a copper recovery of approximately 84%; the copper grades of the bulk concentrates were 24 to 28%. |

| | | |

| • | Approximately 92 to 94% of the lead was recovered to the bulk copper-lead concentrates containing 9 to 13% lead. |

| | | |

| • | The zinc recovery was 84.2% from Composite Zone 1 & 2, 93.0% from Composite Zone 3 and 90.5% from Composite Zone 5. On average, the zinc grades of the concentrates produced were higher than 55%, excluding the concentrate generated from Composite Zone 1 & 2, which contained only 44.5% zinc. |

| | | |

| NovaCopper Inc. | 1-6 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

| • | Gold and silver were predominantly recovered into the bulk copper-lead concentrates. Gold recoveries to this concentrate ranged from 65 to 80%, and silver recoveries ranged from 80 to 86%. |

Using an open circuit procedure, the copper and lead separation tests on the bulk copper-lead concentrate produced from the locked cycle tests generated reasonable copper and lead separation. The copper concentrates produced contained approximately 28 to 31% copper, while the grades of the lead concentrates were in the range of 41% to 67% lead. Also, it appears that most of the gold reported to the copper concentrate and on average the silver was equally recovered into the copper and lead concentrates.

The 2012 grindability test results showed that the Bond ball millwork index (BWi) tests ranged from 6.5 to 11 kWh/t and abrasion index (Ai) tests fluctuated from 0.017 to 0.072 g for the mineralized samples. The data indicates that the samples are neither resistant nor abrasive to ball mill grinding. The materials are considered to be soft or very soft in terms of grinding requirements.

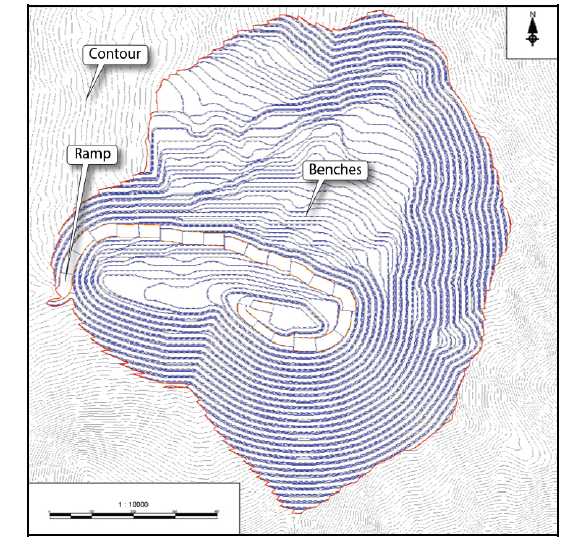

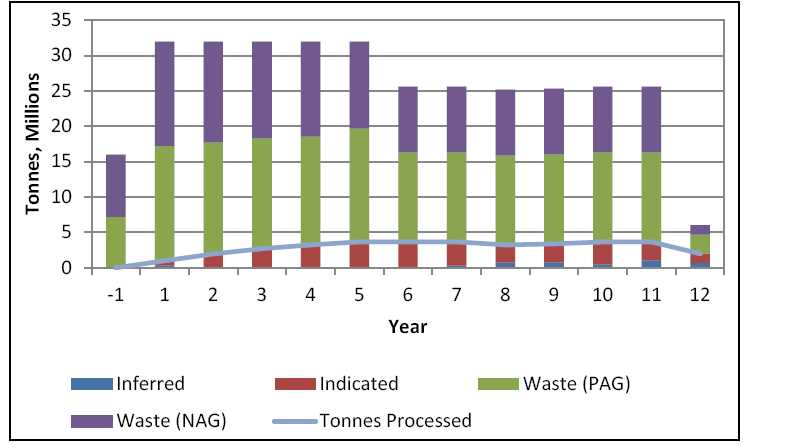

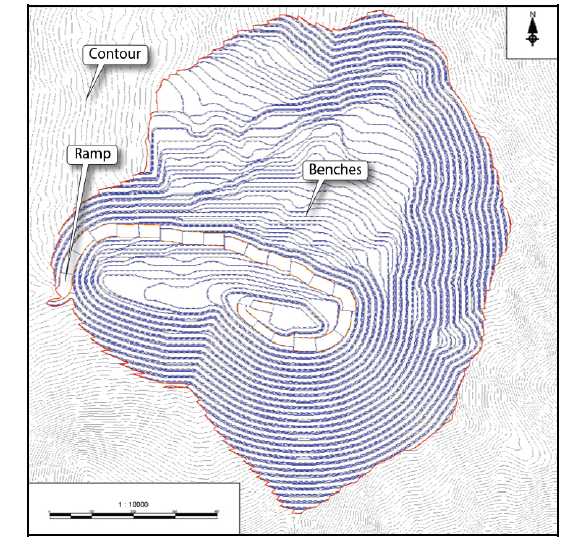

The PEA is based on a conventional truck-and-shovel, open-pit mine design at a single pit. The mining schedule was developed based on a maximum mill capacity of 10,000 t/d. The Arctic Project’s total mine life is 13 years, including 1 year of pre-stripping followed by 12 years of production. The pit uses four pushbacks and a minimum mining width of 40 m. Over the 13-year life, the pit is producing 35.7 Mt of mineralized material and 299.4 Mt of waste rock. The LOM stripping ratio is 8.39 and the stripping ratio excluding the pre-stripping waste rock is 7.94. The pit design incorporates a bench height of 5 m and a 45° inter-ramp angle. After adding the ramps, the overall slope angle will be within 43°, as recommended by EBA (2013). Key mining results are summarized in Table 1.3.

Table 1.3 Summary of Key Mining Results

| Item | Units | Value |

| Mining Pre-stripping | years | 1 |

| LOM | years | 12 |

| Mineralized Material | Mt | 35.7 |

| Waste Material | Mt | 299.4 |

| Stripping Ratio | waste:mineralized material | 8.4 |

| Average Mining Operating Cost | US$/t milled | 28.40 |

A 10,000 t/d process plant has been designed to process the massive/semi-massive sulphide mineralization that will be supplied from the open pit mine. The main economic elements found in the deposit are copper, lead, zinc, and associated gold and silver. The process plant will operate two shifts per day and 365 d/a with an overall plant availability of 92%. The process plant will produce copper, lead, and zinc concentrates.

| NovaCopper Inc. | 1-7 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

The mill feed will be hauled from the pit to a primary crushing facility where the material will be crushed by a jaw crusher to a particle size of 80% passing 125 mm.

The crushed material will be ground by two stages of grinding, consisting of one semi-autogenous grinding (SAG) mill and one ball mill in closed circuit with hydrocyclones (SAG mill and ball mill (SAB) circuit). The hydrocyclone overflow with a grind size of approximately 80% passing 70 µm will be processed by talc pre-flotation, conventional bulk flotation (to recover copper, lead, and associated gold and silver), and then zinc flotation. The rougher bulk copper-lead concentrate will be reground and cleaned, and then followed by copper and lead separation to produce a lead concentrate and a copper concentrate. The zinc rougher flotation concentrate will be reground and upgraded by cleaner flotation to produce a zinc concentrate. The final tailings from the zinc flotation circuit will be pumped to the tailings storage facility (TSF). Copper, lead, and zinc concentrates will be thickened and pressure-filtered separately before being shipped to smelters.

The LOM average mill feed is expected to contain 2.28% copper, 0.53% lead, 3.13% zinc, 0.5 g/t gold, and 37 g/t silver. According to the mine plan developed for the PEA study and metallurgical test results, the LOM average metal recoveries and concentrate grades are projected below:

| | • | copper concentrate: | |

| | | - | recovery: 87.1% copper; 57.9% gold; 40.2% silver |

| | | - | copper grade: 29% |

| | | | |

| | • | lead concentrate: | |

| | | - | recovery: 74.0% lead; 6.8% gold; 40.2% silver |

| | | - | lead grade: 50% |

| | | | |

| | • | zinc concentrate: | |

| | | - | recovery: 86.8% zinc |

| | | - | zinc grade: 56%. |

| 1.8 | PROJECT INFRASTRUCTURE |

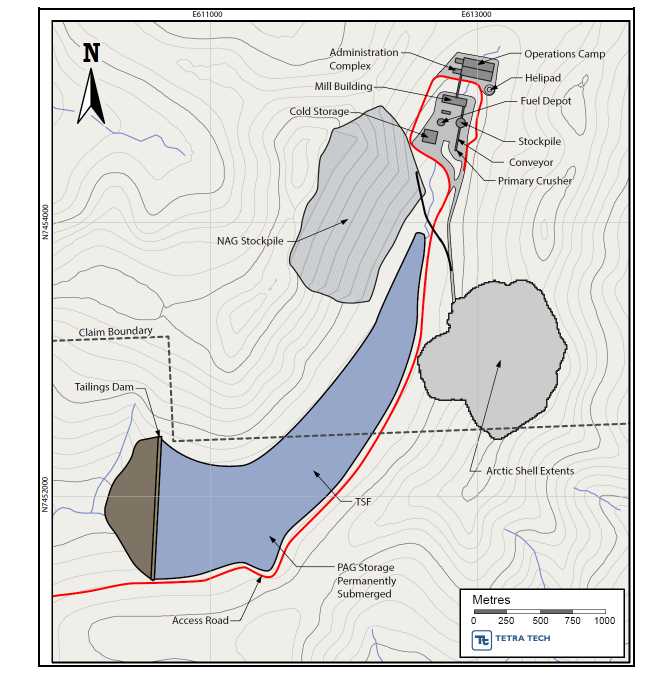

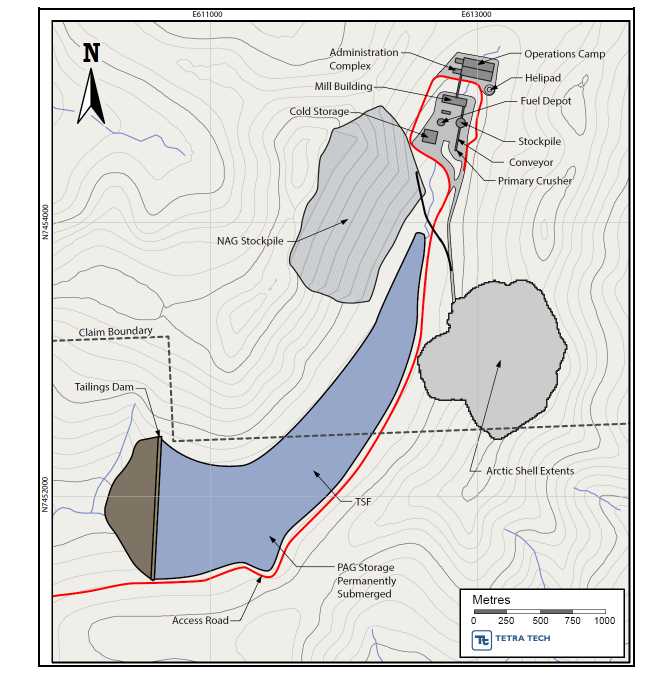

The proposed Arctic mine site is spread over a distance of approximately 6 km within the upper reaches of the Sub-Arctic Creek Valley.

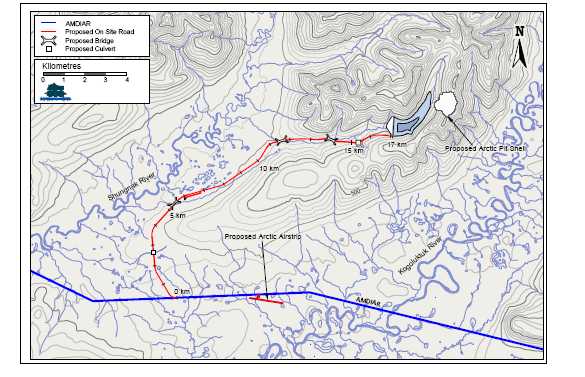

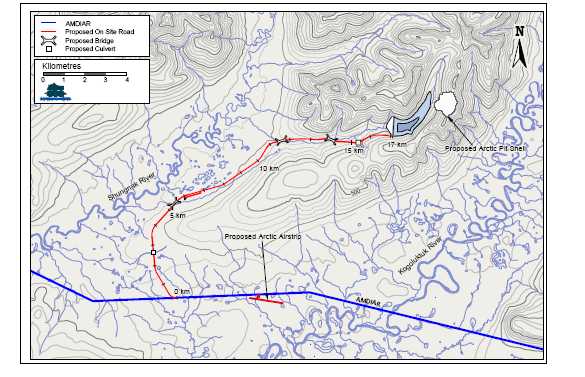

Primary access to the Property is currently by air, using both fixed wing aircraft and helicopters. No surface access is currently in place. A memorandum of understanding (MOU) has been signed with the Alaska Industrial Development Export Authority (AIDEA) for the development of the Ambler Mining District Industrial Access Road (AMDIAR) which would provide access from the Dalton Highway (Highway 11) to within 17 km of the Arctic Project.

| NovaCopper Inc. | 1-8 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

The proposed development for the Arctic Project consists of the following major infrastructure:

| | • | roads and an airstrip |

| | | |

| • | mill buildings and related services facilities including maintenance and truck shops, and assay lab |

| | | |

| | • | water supply and distribution |

| | | |

| | • | waste management |

| | | |

| | • | fuel storage |

| | | |

| | • | on site explosive storage |

| | | |

| | • | power supply |

| | | |

| | • | TSF and water management |

| | | |

| | • | water treatment plant |

| | | |

| | • | construction and permanent camp accommodation |

| | | |

| | • | waste rock storage facilities |

| | | |

| | • | communication. |

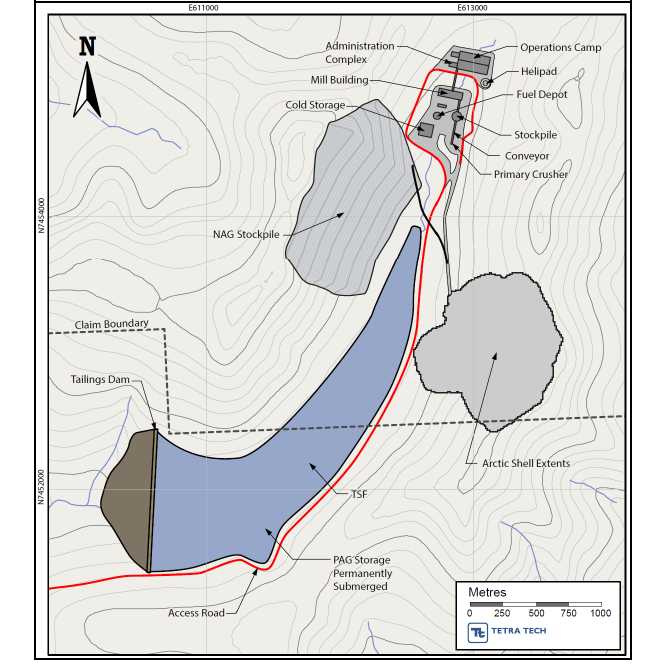

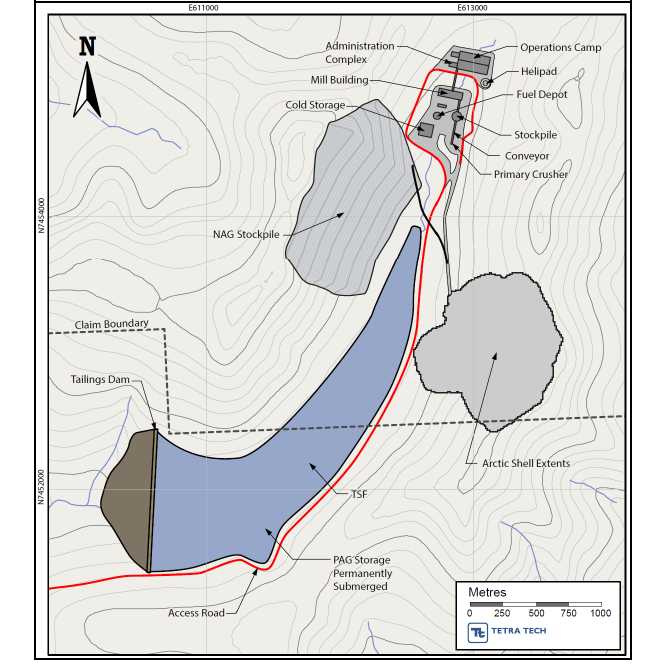

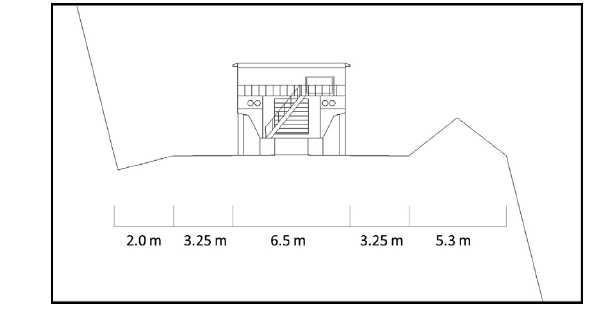

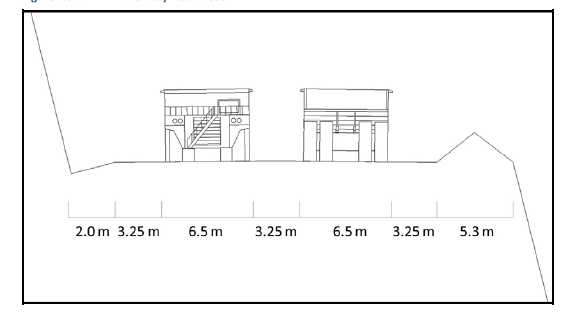

All buildings and facilities will be constructed with appropriate heating, ventilation and air conditioning (HVAC) and fire protection systems, water distribution and plumbing systems, and dust control systems. Figure 1.2 illustrates the overall Project site layout.

A series of mine haul roads will be constructed from the open pit to the primary crusher, and as well as site roads to and from the truck shop, TSF, and to the Arctic Project airstrip.

| NovaCopper Inc. | 1-9 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

Figure 1.2 Arctic Project Site Layout

The Arctic Project requires 15 MW of peak load for 10,000 t/d operation demand. Power will be generated by 4+1 self-contained 3.6 MW Prime diesel generators. Four units will be in service with the fifth unit reserved for maintenance. Heat will be recovered from the generators and used to heat the mill.

| NovaCopper Inc. | 1-10 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

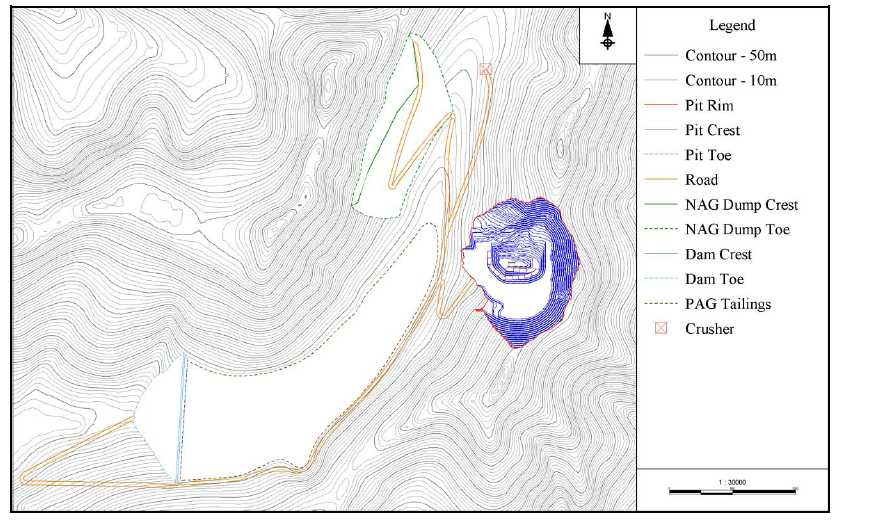

| 1.8.2 | TAILINGS STORAGE FACILITY |

The co-disposal TSF will be a fully lined facility consisting of rockfill embankment constructed across the Sub-Arctic Creek drainage, creating an impoundment that will extend up the drainage. The rockfill embankment will be constructed to an ultimate crest elevation of 655 mamsl with the embankment being raised in stages to minimize the initial capital construction cost. During operations, potentially acid generating (PAG) waste rock will be placed at the bottom and sides of the basin forming layers with consecutive disposal on tailings that will be filling the voids. The tailings has the potential to generate acid and, therefore, the tailings and the PAG waste rock will be placed under water and remain permanently submerged in order to reduce the potential for acid generation. Additional studies will be required to determine the most suitable method of co-disposal and potential requirements for acid rock drainage (ARD) management and mitigation programs will need to be part of the design of the TSF.

The TSF will be required to contain 110.5 Mm3 total over the 12-year LOM, with 23.8 Mm3to accommodate the tailings at an assumed stored dry density of 1.5 t/m3 and 86.7 Mm3 of PAG waste rock at an assumed stored dry density of 1.9 t/m3. The TSF will be sited as a staged rockfill embankment with an upstream geomembrane liner. The starter embankment will have a crest elevation of 560 m and impound 1 year of mining production, which is approximately 670,000 m3 of tailings and 12.3 Mm3 of waste rock.

NovaCopper initiated baseline environmental data collection in 2007, including surface water quality sampling, wetlands mapping, stream flow monitoring, aquatic life surveys, subsistence, meteorological monitoring, and acid base accounting sampling. Additional baseline environmental data in the Ambler Lowlands, the Subarctic Creek drainage, the Shungnak River drainage and downstream receiving environments will be required to support future mine design, development of an environmental impact statement (EIS), permitting, construction and operations.

The Arctic Project has the potential to significantly improve work opportunities for local and regional residents. In October 2011, NovaCopper signed an agreement with NANA. In addition to consolidating landholdings in the Ambler District, the agreement has language establishing native hiring preferences and preferential use of NANA subsidiaries for contract work. Furthermore, the agreement formalized an Oversight Committee, with equal representation from NovaCopper and NANA, to regularly review project plans and activities. In addition, a Subsistence Subcommittee has been formed to protect subsistence and the Iñupiaq way of life and a Workforce Development Subcommittee is also in place to address current and future employment needs. NovaCopper meets monthly, during summer months, with the residents of Kobuk, Shungnak and Ambler, the three villages closest to the project area. NovaCopper also meets annually with eight other NANA region villages including Noatak, Kivalina, Kotzebue, Kiana, Deering, Buckland, Selawik and Noorvik, for the purpose of updating residents on project plans and fielding their questions and concerns. NovaCopper has also developed a good working relationship with the NWAB government.

| NovaCopper Inc. | 1-11 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

The Arctic Project will be subject to a mine permitting process which will include compliance with theNational Environmental Policy Act (NEPA) and will require a number of major mine permits from state and federal agencies as well as a significant number of minor permits. Although a number of federal conservation units are located in the general vicinity of the Arctic Project, including but not limited to the Gates of the Arctic National Parks, Kobuk Preserve, Selawik National Wildlife Refuge, and Kobuk Valley and Selawik Wilderness areas, there presence does not change the permitting process nor add to the number of permits required for the Arctic Project.

NovaCopper will be required to develop a formal project description and detailed reclamation and closure plan to support a successful permit application strategy. The mine plan will embrace the concept of “design for closure”. In order to reduce any lasting risk of environmental impacts, the plan will minimize surface disturbances during operations and promote long-term stability of the site after closure.

| 1.10 | CAPITAL COSTS (INITIAL AND SUSTAINING) |

The total estimated capital cost for the design, construction, installation and commissioning of the Arctic Project is estimated to be $717.7 million. A summary of the estimated capital cost is shown in Table 1.4. The total sustaining capital costs of $164.4 million for the 12 year LOM including equipment, tailings and other items are summarized in Table 1.5.

This capital cost estimate has been prepared in accordance with the recommended practices of the AACE International. In accordance with the AACE’s International Estimate Classification System, this cost estimate meets or exceeds the specifications for a Class 5 Estimate and has a deemed accuracy of ±35%.

Tetra Tech prepared this estimate with a base date of Q2 2013. No escalation beyond Q2 2013 was applied to the estimate. Quotations provided by vendors are budgetary and non-binding.

The capital cost estimate uses US dollars as the base currency.

| NovaCopper Inc. | 1-12 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

Table 1.4 Capital Cost Summary

|

Item | Total Cost

($ million) |

| | Direct Costs | |

| 10 | Overall Site | 82.5 |

| 20 | Open Pit Mining | 119.7 |

| 35 | Mineralized Material Handling | 17.4 |

| 40 | Process | 122.2 |

| 50 | Tailings and Water Management | 21.0 |

| 70 | On-Site Infrastructure | 49.1 |

| 75 | Airstrip | 14.2 |

| 86 | External Access Roads | 27.2 |

| 87 | Temporary Services | 23.1 |

| Subtotal Direct Costs | 476.4 |

| 90 | Indirect Costs | 130.9 |

| 98 | Owner’s Costs | 18.6 |

| 99 | Contingency | 91.9 |

| Total Capital Costs | 717.7 |

Note: Total may not add up due to rounding.

Table 1.5 Summary of Total Sustaining Capital Cost for LOM

Item | Total Cost

($ million) |

| Mining Equipment | 45.6 |

| Tailings | 112.8 |

| Other Equipment | 6.0 |

| Total Sustaining Capital | 164.4 |

The total LOM average operating cost for the proposed mine is estimated at $63.93/t milled. The estimate includes mining, processing, tailings management, general and administrative (G&A), surface services and public road toll costs. The cost is estimated based on a total LOM mill feed of 35.68 Mt from the open pit mine. The nominal annual process rate is approximately 3,650,000 t/a (LOM average annual process rate is approximately 2,973,435 t/a) or 10,000 t/d (LOM daily average rate is 8,146 t/d) at 365 d/a.

Tetra Tech has not estimated the road toll cost that NovaCopper will pay to use the AMDIAR proposed to be built by the Government of Alaska. Since this cost is determined by confidential negotiations between NovaCopper and the AIDEA, a State-owned private corporation, Tetra Tech has relied on NovaCopper management to provide the road toll cost. For the purposes of this PEA study, it has been assumed that a toll would be paid based on a $150 million 30-year bond at a 5% interest rate, which would result in the Arctic Project paying approximately $9.7 million each year for its 12-year mine life. The toll payments are assumed in the PEA to commence when the Arctic Project has reached commercial production.

| NovaCopper Inc. | 1-13 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

The accuracy for the operating cost estimate is expected to be within a range of ±35%. The operating cost estimate uses US dollars as the base currency. The breakdown of the estimated operating costs is presented in Table 1.6.

Table 1.6 Overall Operating Cost Estimate

Area | LOM Average

Unit Operating Cost

($/t milled) |

| Mining* | 28.40 |

| Processing** | 19.86 |

| G&A | 8.92 |

| Plant Services | 3.48 |

| Road Toll | 3.27 |

| Total | 63.93 |

| | Notes: | *Excluding preproduction cost |

| | | **Including tailings management operation cost |

This PEA is preliminary in nature and includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. Furthermore, there is no certainty that this PEA will be realized. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

Tetra Tech prepared an economic evaluation of the Arctic Project based on a pre-tax financial model. NPV was estimated at the beginning of the two-year construction period.

As of May 30, 2013, the long-term metal prices applied in the economic analysis are as follows:

| | • | copper: $2.90/lb |

| | | |

| | • | lead: $0.90/lb |

| | | |

| | • | zinc: $0.85/lb |

| | | |

| | • | gold: $1,300.00/oz |

| | | |

| | • | silver: $22.70/oz. |

The pre-tax financial results are:

| NovaCopper Inc. | 1-14 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

| | • | 4.6-year payback on the $717.7 million initial capital costs |

| | | |

| | • | $927.7 million NPV at an 8% discount rate. |

NovaCopper engaged the Canadian firm of Ernst & Young LLP (EY) in Vancouver, BC to prepare tax calculations for use in the post-tax economic evaluation of the Arctic Project with the inclusion of US federal and Alaska income taxes and Alaska Mining License tax (Section 22.0) ..

The following post-tax financial results were calculated:

| | • | 17.9% IRR |

| | | |

| | • | 5.0-year payback on the $717.7 million initial capital costs |

| | | |

| | • | $537.2 million NPV at an 8% discount rate. |

| 1.13 | INTERPRETATION AND CONCLUSIONS |

Based on the work carried out in this PEA and the resultant economic evaluation, this study should be followed by further technical and economic studies leading to a prefeasibility study.

| 1.14 | OPPORTUNITIES AND RECOMMENDATIONS |

Tetra Tech recommends the following actions further outlined in Section 26.0 which may support the Arctic Project advancement should NovaCopper proceed with a prefeasibility study. As part of the recommended work program, the following areas of work should be considered:

| | • | resource model integration and additional drilling to upgrade the Inferred Resource |

| | | |

| | • | geotechnical studies, including geotechnical investigations of the pit area, plant site, TSF site, airstrip and other project related locations |

| | | |

| | • | engineering studies, including power supply and optimization of the layout of the process and service related facilities |

| | | |

| | • | metallurgical studies, including process flowsheet and condition optimization and determination of process design related parameters |

| | | |

| | • | additional waste characterization studies |

| | | |

| | • | additional baseline studies and environmental permitting activities |

| | | |

| | • | marketing studies |

| | | |

| | • | trade-off studies to maximize project economics. |

| NovaCopper Inc. | 1-15 | 1297650100-REP-R0002-03 |

| Preliminary Economic Assessment Report on the Arctic | | |

| Project, Ambler Mining District, Northwest Alaska | | |

NovaCopper retained Tetra Tech to conduct a PEA on its Arctic Project in the Ambler District of northwestern Alaska (Figure 1.1). The results of that PEA are disclosed in this technical report, which has been prepared in accordance with NI 43-101 and Form 43-101F1.

The PEA describes the potential technical and economic viability of establishing a conventional open-pit copper-zinc-lead-silver-gold mine-and-mill complex for the Arctic Project.

This report supersedes and replaces a previous PEA, prepared for NovaGold by SRK in 2012. The SRK report was based on an underground mine plan with significantly different parameters. On this basis, the previous PEA is considered neither current nor relevant to current development planning on the Property. For completeness, the previous PEA report is available to the interested reader on NovaCopper’s’s SEDAR profile.