Exhibit 99.1

Arctic Feasibility Study

Alaska, USA

NI 43-101 Technical Report

| Report Prepared For: | Trilogy Metals Inc. 609 Granville Street, Suite 1150 Vancouver, BC V7Y 1G5 Canada Tel: 604-638-8088 Fax: 604-638-0644 www.trilogymetals.com |

| | |

| Report Prepared By: | Paul Staples, P.Eng., Ausenco Engineering Canada Inc. Bruce Davis, FAusIMM, BD Resource Consulting, Inc.

AJ MacDonald, P.Eng, Integrated Sustainability Consultants |

| | Jeffrey B. Austin, P.Eng., International Metallurgical & Environmental Inc. Robert Sim, P.Geo., SIM Geological Inc. Calvin Boese, P.Eng., M.Sc., SRK Consulting (Canada) Inc. Bruce Murphy, P.Eng., SRK Consulting (Canada) Inc. Tom Sharp, PhD, P.Eng., SRK Consulting (Canada) Inc. Antonio Peralta Romero, PhD, P.Eng., Wood. |

| | |

| Effective Date: | August 20, 2020 |

| | |

| Release Date: | October 2, 2020 |

Important Notice

This report was prepared as National Instrument 43-101 Technical Report for Trilogy Metals Inc. (Trilogy Metals or Trilogy) by Ausenco Engineering Canada Inc., BD Resource Consulting, Inc., Integrated Sustainability Consultants, International Metallurgical & Environmental Inc., SIM Geological Inc., SRK Consulting (Canada) Inc and Wood Canada Limited., collectively the “Report Authors”. The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in the Report Authors’ services, based on i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Trilogy Metals subject to the respective terms and conditions of its contracts with the individual Report Authors. Except for the purposes legislated under Canadian provincial securities law, any other uses of this report by any third party is at that party’s sole risk.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Certificates of Qualified Persons

Paul Staples, P.Eng.

CERTIFICATE OF QUALIFIED PERSON

Paul Staples, P.Eng., Ausenco Engineering Canada Inc.

I, L. Paul Staples, P.Eng., am employed as a Vice President and Global Practice Lead, Minerals and Metals with Ausenco Engineering Canada Inc. with an office address at 855 Homer St., Vancouver, BC, V6B 2W2 and email Paul.Staples@ausenco.com.

This certificate applies to the technical report titled “Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 20 August 2020 (the “technical report”).

I am a registered Professional Engineer of British Columbia, membership number 47367. I graduated from Queens University in 1993 with a degree in Materials and Metallurgical Engineering.

I have practiced my profession for 30 years. I have been directly involved in process operation, design and management from over 50 similar studies or projects in Canada, the United States, Mexico, South America, Africa and Asia Pacific.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

My most recent personal inspection of the Arctic site was on July 25, 2017.

I am responsible for Sections 1.1, 1.2, 1.3.1, 1.4 to 1.6, 1.15, 1.16.1 to 1.16.4, 1.17, 1.19 to 1.22, Section 2, Section 3, Section 4, Section 5, Section 6.1 to 6.2.6, 6.2.8, 6.2.9, Section 17, Section 18.1 to 18.7, 18.12 to 18.16, Section 19, Section 21.1.1 to 21.1.6, 21.1.8.3, 21.1.9, 21.1.12, 21.2.1, 21.2.3 to 21.2.5, Section 22, Section 24, Section 25.1, 25.2, 25.9, 25.10, 25.12 to 25.16, 25.17.1, 25.17.2, 25.17.4, and Section 26.1 of the technical report.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I have been involved with the Arctic Project, Northwest Alaska, USA, NI 43-101 Technical Report on Pre-Feasibility Study that had an effective date of 20 February, 2018.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: 2 October 2020

“Signed and sealed”

L. Paul Staples, P.Eng.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Antonio Peralta Romero, P.Eng.

CERTIFICATE OF QUALIFIED PERSON

Antonio Peralta Romero, PhD, P.Eng., Wood Ltd.

I, Antonio Peralta Romero, P.Eng., am employed as a Principal Mining Engineer with Wood Canada Limited at 400-111 Dunsmuir Street, Vancouver, BC V6B 5W3.

This certificate applies to the technical report titled “Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 20 August 2020 (the “technical report”).

I am a Professional Engineer of Engineers and Geoscientists of British Columbia; License # 45323. I graduated from the University of Guanajuato in 1984 with a B.S. in Mining Engineering, from Queen’s University in 1991 with a M.Sc. in Mining Engineering, and from Colorado School of Mines in 2007 with a Ph.D. in Mining and Earth Systems Engineering.

I have practiced my profession for 36 years. I have been directly involved in mine planning and design, ore control, production forecasting and management, slope stability monitoring, and mineral reserve estimation, mainly for open-pit precious, base metal mines and iron ore mines.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

I visited the Arctic site on July 25, 2017 for one day.

I am responsible for Section 1.3.2, 1.13, 1.14, 1.16.5, Sections 2.3 to 2.6; Section 15; Sections 16.1 to 16.6, 16.8; Sections 21.1.7.1, 21.1.8.1, 21.2.2, 25.7, 25.8, and 26.1.1.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I have been involved with the Arctic Project in the mining engineering work for the pre-feasibility study and the compilation of the corresponding Technical Report: Staples P., Hannon, J., Peralta Romero A., Davis B., DiMarchi J.J., Austin, J.B., Sim R., Boese C., Murphy, B., Sharp T., 2018, Arctic Project, Northwest Alaska, USA, NI 43-101 Technical Report on Pre-Feasibility Study, effective date of February 20, 2018.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated this 2nd day of October 2020

“Signed”

Antonio Peralta Romero, P.Eng.

Principal Mining Engineer

Wood Canada Limited

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Dr. Bruce M. Davis, FAusIMM

CERTIFICATE OF QUALIFIED PERSON

Bruce M. Davis, FAusIMM, BD Resource Consulting, Inc.

I, Bruce M. Davis, FAusIMM, am employed as a Geostatistician with BD Resource Consulting, Inc. (BDRC), with an office address at 4253 Cheyenne Dr., Larkspur, Colorado, USA 80118.

This certificate applies to the technical report titled “Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 20 August 2020 (the “technical report”).

I am a Fellow of the Australasian Institute of Mining and Metallurgy; Number 211185. I have B.S. (1974) and M.S. (1975) degrees from Brigham Young University. I graduated from the University of Wyoming with a Doctor of Philosophy (Geostatistics) in 1978.

I have practiced my profession for 42 years. I have been directly involved in mineral resource and reserve estimations and feasibility studies on numerous open pit and underground base metal and gold deposits in the United States, Canada, Central and South America, Europe, Africa, Asia, and Australia.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

I visited the Arctic site in 2011, 2012, 2015, and 29 August 2019.

I am responsible for sub-sections 1.9, 1.10, 14.2 – 14.16, and 25.4 and sections 11 and 12 of the technical report.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I have been involved with the Arctic property prior to this technical report. I was a coauthor of a previous technical report with an effective data of 25 April 2017.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: 2 October 2020

| “Signed ” | |

| | |

| Bruce M. Davis, FAusIMM | |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Jeffery B. Austin, P.Eng.

CERTIFICATE OF QUALIFIED PERSON

Jeffery B. Austin, P.Eng., International Metallurgical & Environmental Inc.

I, Jeffrey B. Austin, P.Eng., am employed as an independent consultant of International Metallurgical & Environmental Inc., located at 906 Fairway Crescent, Kelowna, B.C., and incorporated in 1995.

This certificate applies to the technical report titled “Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 7 August 2020 (the “technical report”).

I am a member, in good standing, of the Association of Professional Engineers and Geoscientists of British Columbia, license number 15708. I graduated with a B.A.Sc degree from the University of British Columbia in 1984

I have practiced my profession continuously for 33 years and have been involved in the design, evaluation and operation of mineral processing facilities during that time. A majority of my professional practice has been the completion of test work and test work supervision related to feasibility and pre- feasibility studies of projects involving flotation technologies.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

I have not visited the Arctic site.

I am responsible for Section 1.11, Section 13 and Section 25.5 of the technical report.

I am independent of the issuer applying all of the tests in Section 1.5 of National Instrument 43-101.

I have been involved with the Arctic project since 2011 including supervision of metallurgical test work and input to various engineering studies.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: October 2, 2020

“Signed and sealed”

Jeffrey B. Austin, P.Eng.

International Metallurgical and Environmental Inc.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Robert Sim, P.Geo.

CERTIFICATE OF QUALIFIED PERSON

Robert Sim, P.Geo., SIM Geological Inc.

I, Robert Sim, P.Geo., am an independent consultant of SIM Geological Inc., with an office address at 508 – 1950 Robson St. Vancouver BC, Canada, V6G 1E8.

This certificate applies to the technical report titled “Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 7 August 2020 (the “technical report”).

I am a member in good standing of Engineers and Geoscientists British Columbia, License Number 24076. I graduated from Lakehead University with an Honours Bachelor of Science (Geology) in 1984.

I have practiced my profession for 35 years and have been involved in mineral exploration, mine site geology and operations, mineral resource and reserve estimations and feasibility studies on numerous underground and open pit base metal and gold deposits in Canada, the United States, Central and South America, Europe, Asia, Africa and Australia. I have worked on similar VMS-type deposits at Cayeli in Turkey, the Winston Lake mine in Ontario and on several deposits in Rouyn-Noranda, Quebec.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

I visited the Arctic site between September 20-22, 2018.

I am responsible for Sections 7, 8, 9.1 through 9.6, 10, 14 and portions of Sections 1 and 25 of the technical report.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I have had prior involvement with the property that is the subject of the Technical Report. I was an author of a previous technical reports on the Arctic Project, dated November 9, 2017 and April 6, 2018.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: October 2, 2020

“Signed and sealed”

Robert Sim P.Geo.

SIM Geological Inc.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Calvin Boese, PEng.

CERTIFICATE OF QUALIFIED PERSON

Calvin Boese, P.Eng., M.Sc., SRK Consulting (Canada) Inc.

I, Calvin Boese, PEng., am employed as a Principal Consultant (Geotechnical Engineering) with the firm of SRK Consulting (Canada) Inc. (SRK) with an office at Suite 600, 350 3rd Avenue North, Saskatoon, Saskatchewan.

This certificate applies to the technical report titled “Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 20 August 2020 (the “technical report”).

I am a Professional Engineer of the Association of Professional Engineers, Geologists of British Columbia (P.Eng. #29478). I am also a registered Professional Engineer in Alberta and Saskatchewan. I am a Member of the Society for Mining, Metallurgy and Exploration. I am a graduate of the University of Saskatchewan with a B.Sc. in Civil Engineering (1999) and a M.Sc. in Geo-Environmental Engineering (2004).

I have practiced my profession for 20 years. I have been directly involved in geotechnical aspects of mining, including the site selection, design, permitting, operation and closure of mine waste facilities in Canada, the US, Indonesia and Turkey.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

My most recent personal inspection of the Arctic site was from July 10 to July 12, 2018.

I am responsible for Section 1.16.6, 1.16.7 and 1.18, Sections 18.10 and 18.11, Section 20.1.6, 20.1.7, 20.1.8, 20.2, 20.3, 20.4, 20.4.1, 20.4.1.1, 20.4.1.2.1, 20.4.1.2.2, 20.4.1.2.3, 20.4.1.2.4, 20.4.1.2.5, 20.4.1.2.6, 20.4.1.2.8, 20.4.1.3.1, and 20.4.1.4, Section 21.1.10, Section 25.11, and Section 26.1.5 of the technical report.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I was previously involved in the project as the Qualified Person for the “Arctic Project, Northwest Alaska, USA, NI 43-101 Technical Report on Pre-Feasibility Study” dated February 20, 2018.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: October 2, 2020

“Signed and sealed”

Calvin Boese, P.Eng., M.Sc.

Principal Consultant

SRK Consulting (Canada) Inc.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Bruce Murphy, PEng.

CERTIFICATE OF QUALIFIED PERSON

Bruce Murphy, P.Eng., SRK Consulting (Canada) Inc.

I, Bruce Murphy, PEng am employed as a Principal Consultant at SRK Consulting (Canada) Inc, located at 2200 -1066 West Hastings Street, Vancouver, BC.

This certificate applies to the technical report titled Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 20 August 2020 (the “technical report”)

I am a professional engineer registered with the Association of Professional Engineers of British Columbia – PEng License No.: 44271; I am a graduate of University of the Witwatersrand, Johannesburg, South Africa with a M.Sc. degree in Mining Engineering. I have practiced my profession continuously since graduation (1989) working in the rock engineering field on operating mines till 2002 and then in the consulting field.

I have practiced my profession for 30 years. I have been directly involved in the geotechnical data acquisition, characterization and slope stability evaluation of the deposit.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

I have visited the Arctic Site August 27 – 29th, 2019.

I am responsible for Sections 6.2.7.1, 9.7.1; 16.7, 21.1.7.2, 21.1.8.2, 26.1.2, 26.1.3 and Section 26.1.4 of the technical report.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I was previously involved in the project as the Qualified Person for the “Arctic Project, Northwest Alaska, USA, NI 43-101 Technical Report on Pre-Feasibility Study” dated February 20, 2018.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: October 2, 2020

“Signed and sealed”

Bruce Murphy, PEng

Principal Consultant

SRK Consulting (Canada) Inc

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Tom Sharp, PEng.

CERTIFICATE OF QUALIFIED PERSON

Tom Sharp, PhD, P.Eng., SRK Consulting (Canada) Inc.

I, Tom Sharp, PEng, am employed as a Principal Consultant (Water Management and Treatment Engineering) with the firm of SRK Consulting (Canada) Inc. (SRK) with an office at Suite 2200 – 1066 West Hastings Street, Vancouver, British Columbia.

This certificate applies to the technical report titled ““Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 20 August 2020 (the “Technical Report”).

I am a Professional Engineer of the Association of Professional Engineers, Geologists of British Columbia (P.Eng. #36988). I am also a registered Professional Engineer in Northwest Territories, Nunavut, Yukon and Montana. I am a Member of the Society for Mining, Metallurgy and Exploration. I graduated from Montana State University and Montana Tech with a B.Sc. and M.Sc. in Biological Sciences (1988 and 1993), M.Sc. in Environmental Engineering (1996) and a Ph.D. in Civil Engineering (1999).

I have practiced my profession for 28 years. I have been directly involved mine water management and treatment on projects in North America, South America, Europe and Asia.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

I have not visited the Arctic site.

I am responsible for Section 1.16.8, 1.16.9.1; Sections 6.2.7.2; Sections 9.7.2, 9.7.3; Sections 11.3, 11.8.6; Sections 18.8, 18.9; Sections 20.1.1, 20.1.2, 20.1.3, 20.1.4, 20.1.5, 20.1.9, 20.4.1.2.7.1; Section 21.1.11; Section 25.17.3; and Sections 26.1.6, 26.1.7, and 26.1.8.1 of the technical report.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I was previously involved in the project as the Qualified Person for the “Arctic Project, Northwest Alaska, USA, NI 43-101 Technical Report on Pre-Feasibility Study” dated February 20, 2018.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: October 2, 2020

“Signed and sealed”

Tom Sharp, PEng

Principal Consultant

SRK Consulting (Canada) Inc.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

AJ MacDonald, P.Eng.

CERTIFICATE OF QUALIFIED PERSON

AJ MacDonald, P.Eng., Integrated Sustainability Consultants

I, AJ MacDonald, P.Eng., am employed as a Vice President / Senior Technical Specialist with Integrated Sustainability Ltd., with an office address at 1050 West Pender Street, Vancouver BC, V6C 3S7.

This certificate applies to the technical report titled “Arctic Feasibility Study, Alaska, USA, NI 43-101 Technical Report” that has an effective date of 20 August 2020 (the “technical report”).

I am a Professional Engineer of Professional Engineers Yukon, Engineers and Geoscientists British Columbia, Association of Professional Engineers and Geoscientists of Alberta and Professional Engineers Ontario. I graduated from Queen’s University in Kingston, Ontario with Bachelor of Science in 2005 and Carleton University in Ottawa, Ontario with Master of Applied Science in 2007.

I have practiced my profession for 15 years. I have been involved or associated with the mining industry since 2007. I have participated in dozens of mining and other resource sector projects, with a particular focus on water treatment process engineering, primarily in Western North America. My experience spans all phases of project delivery including preliminary analysis, conceptual design, detailed design, construction, commissioning and optimization of infrastructure at industrial water treatment facilities in Canada and around the world.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing.

I have not visited the Arctic site.

I am responsible for Sections 1.16.9, 20.4.1.2, 7.2, 20.4.1.3.2 and 26.1.8.2 of the technical report.

I am independent of Trilogy Metals Inc. as independence is described by Section 1.5 of NI 43–101.

I have had no previous involvement with the Arctic Project.

I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the technical report not misleading.

Dated: October 2, 2020

“Signed”

AJ MacDonald, P.Eng.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020

Table of Contents

| 1 | | | Summary | | | 1-1 | |

| 1.1 | | | Introduction | | | 1-1 | |

| 1.2 | | | Key Outcomes | | | 1-1 | |

| 1.3 | | | Terms of Reference | | | 1-1 | |

| 1.4 | | | Property Description and Location | | | 1-2 | |

| 1.5 | | | Accessibility, Climate, Local Resources and Infrastructure | | | 1-3 | |

| 1.6 | | | Exploration History | | | 1-4 | |

| 1.7 | | | Geological Setting and Mineralization | | | 1-4 | |

| 1.8 | | | Drilling | | | 1-5 | |

| 1.9 | | | Sample Preparation, Analysis and Security | | | 1-6 | |

| 1.10 | | | Data Verification | | | 1-6 | |

| 1.11 | | | Mineral Processing and Metallurgical Testing | | | 1-7 | |

| 1.12 | | | Mineral Resource Estimate | | | 1-9 | |

| 1.13 | | | Mineral Reserve Estimates | | | 1-10 | |

| 1.14 | | | Mining Methods | | | 1-12 | |

| 1.15 | | | Recovery Methods | | | 1-13 | |

| 1.16 | | | Project Infrastructure | | | 1-14 | |

| 1.17 | | | Market Studies | | | 1-16 | |

| 1.18 | | | Environmental Studies, Permitting, Social and Community | | | 1-17 | |

| 1.19 | | | Capital and Operating Cost Estimates | | | 1-19 | |

| 1.20 | | | Economic Analysis | | | 1-20 | |

| 1.21 | | | Interpretations and Conclusions | | | 1-21 | |

| 1.22 | | | Recommendations | | | 1-21 | |

| | | | | | | | |

| 2 | | | Introduction | | | 2-1 | |

| 2.1 | | | Introduction | | | 2-1 | |

| 2.2 | | | Terms of Reference | | | 2-1 | |

| 2.3 | | | Qualified Persons | | | 2-2 | |

| 2.4 | | | Site Visit | | | 2-2 | |

| 2.5 | | | Effective Dates | | | 2-3 | |

| 2.6 | | | Information Sources | | | 2-3 | |

| 2.7 | | | Previous Technical Reports | | | 2-3 | |

| | | | | | | | |

| 3 | | | Reliance on Other Experts | | | 3-1 | |

| 3.1 | | | Introduction | | | 3-1 | |

| 3.2 | | | Legal Considerations | | | 3-1 | |

| 3.3 | | | Taxation | | | 3-1 | |

| 3.4 | | | Marketing and Contracts | | | 3-2 | |

| 3.5 | | | Metal Prices and Exchange Rates | | | 3-2 | |

| | | | | | | | |

| 4 | | | Property Description and Location | | | 4-1 | |

| 4.1 | | | Location | | | 4-1 | |

| 4.2 | | | Ownership | | | 4-1 | |

| 4.3 | | | Mineral Tenure | | | 4-1 | |

| 4.4 | | | Royalties, Agreements and Encumbrances | | | 4-6 | |

| 4.5 | | | State Royalty | | | 4-7 | |

| 4.6 | | | Surface Rights | | | 4-8 | |

| 4.7 | | | Environmental Considerations | | | 4-8 | |

| 4.8 | | | Permits | | | 4-8 | |

| 4.9 | | | Social Considerations | | | 4-8 | |

| 4.10 | | | Comment on Section 4 | | | 4-8 | |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-I |

|  |

| 5 | | | Accessibility, Climate, Local Resources, Infrastructure and Physiography | | | 5-1 | |

| 5.1 | | | Accessibility | | | 5-1 | |

| 5.2 | | | Climate | | | 5-1 | |

| 5.3 | | | Local Resources and Infrastructure | | | 5-2 | |

| 5.4 | | | Physiography | | | 5-2 | |

| 5.5 | | | Comment on Section 5 | | | 5-3 | |

| | | | | | | | |

| 6 | | | History | | | 6-1 | |

| 6.1 | | | Prior Ownership and Ownership Changes – Arctic Deposit and the Ambler Lands | | | 6-2 | |

| 6.2 | | | Previous Exploration and Development Results – Arctic Deposit | | | 6-3 | |

| | | | | | | | |

| 7 | | | Geological Setting and Mineralization | | | 7-1 | |

| 7.1 | | | Regional Geology – Southern Brooks Range | | | 7-1 | |

| 7.2 | | | Ambler Sequence Geology | | | 7-3 | |

| 7.3 | | | Arctic Deposit Geology | | | 7-9 | |

| 7.4 | | | Arctic Deposit Mineralization | | | 7-14 | |

| 7.5 | | | Prospects | | | 7-14 | |

| | | | | | | | |

| 8 | | | Deposit Types | | | 8-1 | |

| 8.1 | | | Deposit Type | | | 8-1 | |

| 8.2 | | | Overview | | | 8-1 | |

| 8.3 | | | Comment on Section 8 | | | 8-2 | |

| | | | | | | | |

| 9 | | | Exploration | | | 9-1 | |

| 9.1 | | | Introduction | | | 9-1 | |

| 9.2 | | | Grids and Surveys | | | 9-2 | |

| 9.3 | | | Geological Mapping | | | 9-2 | |

| 9.4 | | | Geochemistry | | | 9-3 | |

| 9.5 | | | Geophysics | | | 9-4 | |

| 9.6 | | | Petrology, Mineralogy and Research Studies | | | 9-6 | |

| 9.7 | | | Geotechnical, Hydrogeological and Geochemical Acid Base Accounting Studies | | | 9-6 | |

| | | | | | | | |

| 10 | | | Drilling | | | 10-1 | |

| 10.1 | | | Introduction | | | 10-1 | |

| 10.2 | | | Drill Companies | | | 10-3 | |

| 10.3 | | | Drill Core Procedures | | | 10-4 | |

| 10.4 | | | Geotechnical Drill Hole Procedures | | | 10-6 | |

| 10.5 | | | Collar Surveys | | | 10-6 | |

| 10.6 | | | Downhole Surveys | | | 10-7 | |

| 10.7 | | | Recovery | | | 10-7 | |

| 10.8 | | | Drill Intercepts | | | 10-8 | |

| 10.9 | | | Prospect Drilling | | | 10-8 | |

| | | | | | | | |

| 11 | | | Sample Preparation, Analyses, and Security | | | 11-1 | |

| 11.1 | | | Sample Preparation | | | 11-1 | |

| 11.2 | | | Core | | | 11-1 | |

| 11.3 | | | Acid-Base Accounting Sampling | | | 11-2 | |

| 11.4 | | | Density Determinations | | | 11-3 | |

| 11.5 | | | Sample Security | | | 11-4 | |

| 11.6 | | | Assay Laboratories | | | 11-4 | |

| 11.7 | | | Sample Preparation and Analytical Methods | | | 11-5 | |

| 11.8 | | | Quality Assurance/Quality Control | | | 11-5 | |

| 11.9 | | | Comment on Section 11 | | | 11-17 | |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-II |

|  |

| 12 | | | Data Verification | | | 12-1 | |

| 12.1 | | | Drill Hole Collar Verification | | | 12-1 | |

| 12.2 | | | Topography Verification | | | 12-1 | |

| 12.3 | | | Core Logging Verification | | | 12-1 | |

| 12.4 | | | Database Verification | | | 12-1 | |

| 12.5 | | | QA/QC Review | | | 12-2 | |

| 12.6 | | | Comment on Section 12 | | | 12-2 | |

| | | | | | | | |

| 13 | | | Metallurgical Testwork Review | | | 13-1 | |

| 13.1 | | | Introduction | | | 13-1 | |

| 13.2 | | | Historical Testwork Review | | | 13-4 | |

| 13.3 | | | Mineralogical and Metallurgical Testwork – 2012 to 2019 | | | 13-6 | |

| 13.4 | | | Comment on Section 13 | | | 13-22 | |

| | | | | | | | |

| 14 | | | Mineral Resource Estimate | | | 14-1 | |

| 14.1 | | | Introduction | | | 14-1 | |

| 14.2 | | | Sample Database and Other Available Data | | | 14-1 | |

| 14.3 | | | Geologic Model | | | 14-7 | |

| 14.4 | | | Compositing | | | 14-10 | |

| 14.5 | | | Exploratory Data Analysis | | | 14-10 | |

| 14.6 | | | Treatment of Outlier Grades | | | 14-22 | |

| 14.7 | | | Specific Gravity Data | | | 14-22 | |

| 14.8 | | | Variography | | | 14-23 | |

| 14.9 | | | Model Setup and Limits | | | 14-27 | |

| 14.10 | | | Interpolation Parameters | | | 14-28 | |

| 14.11 | | | Block Model Validation | | | 14-31 | |

| 14.12 | | | Resource Classification | | | 14-41 | |

| 14.13 | | | Mineral Resource Estimate | | | 14-42 | |

| 14.14 | | | Mineral Resource Statement | | | 14-42 | |

| 14.15 | | | Grade Sensitivity Analysis | | | 14-44 | |

| 14.16 | | | Factors that May Affect the Mineral Resource Estimates | | | 14-45 | |

| | | | | | | | |

| 15 | | | Mineral Reserve Estimates | | | 15-1 | |

| 15.1 | | | Overview | | | 15-1 | |

| 15.2 | | | Pit Optimization | | | 15-1 | |

| 15.3 | | | Dilution and Ore Losses | | | 15-3 | |

| 15.4 | | | Mineral Reserve Statement | | | 15-4 | |

| 15.5 | | | Factors Affecting Mineral Reserves | | | 15-5 | |

| | | | | | | | |

| 16 | | | Mining Methods | | | 16-1 | |

| 16.1 | | | Mine Design | | | 16-1 | |

| 16.2 | | | Waste Rock Facility and Stockpile Designs | | | 16-3 | |

| 16.3 | | | Production Schedule | | | 16-5 | |

| 16.4 | | | Waste Material Handling | | | 16-7 | |

| 16.5 | | | Operating Schedule | | | 16-7 | |

| 16.6 | | | Mining Equipment | | | 16-9 | |

| 16.7 | | | Open Pit Water Management | | | 16-17 | |

| 16.8 | | | Geotechnical Review | | | 16-19 | |

| | | | | | | | |

| 17 | | | Recovery Methods | | | 17-1 | |

| 17.1 | | | Mineral Processing | | | 17-1 | |

| 17.2 | | | Major Design Criteria | | | 17-4 | |

| 17.3 | | | Process Plant Description | | | 17-4 | |

| 17.4 | | | Plant Process Control | | | 17-14 | |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-III |

|  |

| | | | | | | | |

| 18 | | | Project Infrastructure | | | 18-1 | |

| 18.1 | | | Introduction | | | 18-1 | |

| 18.2 | | | Access Roads | | | 18-4 | |

| 18.3 | | | Airstrip | | | 18-6 | |

| 18.4 | | | Camps | | | 18-6 | |

| 18.5 | | | Fuel Supply, Storage and Distribution | | | 18-7 | |

| 18.6 | | | Power Generation | | | 18-7 | |

| 18.7 | | | Electrical System | | | 18-7 | |

| 18.8 | | | Surface Water Management | | | 18-8 | |

| 18.9 | | | High Density Sludge Water Treatment Plant | | | 18-17 | |

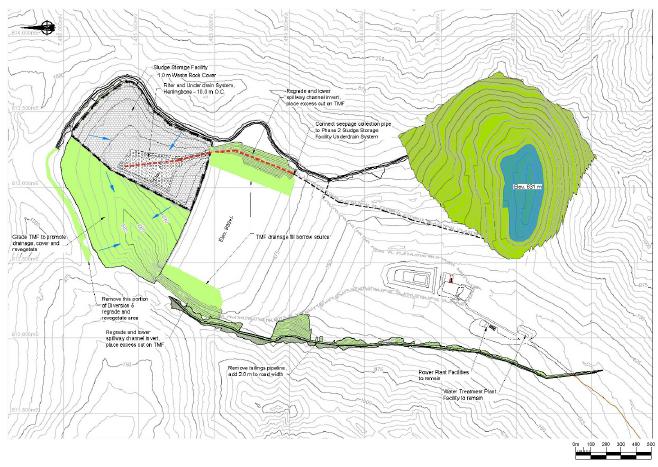

| 18.10 | | | Tailings Management Facility | | | 18-17 | |

| 18.11 | | | Waste Rock Facility and Overburden Stockpiles | | | 18-22 | |

| 18.12 | | | Compressed Air Supply | | | 18-24 | |

| 18.13 | | | Site Communications | | | 18-24 | |

| 18.14 | | | Fire Protection | | | 18-24 | |

| 18.15 | | | Plant Buildings | | | 18-25 | |

| 18.16 | | | Concentrate Transportation | | | 18-26 | |

| | | | | | | | |

| 19 | | | Market Studies and Contracts | | | 19-1 | |

| 19.1 | | | Metal Prices | | | 19-1 | |

| 19.2 | | | Markets and Contracts | | | 19-2 | |

| 19.3 | | | Smelter Term Assumptions | | | 19-4 | |

| 19.4 | | | Transportation and Logistics | | | 19-5 | |

| 19.5 | | | Insurance | | | 19-5 | |

| 19.6 | | | Representation and Marketing | | | 19-6 | |

| 19.7 | | | Comment on Section 19 | | | 19-6 | |

| | | | | | | | |

| 20 | | | Environmental Studies, Permitting and Social or Community Impact | | | 20-1 | |

| 20.1 | | | Environmental Studies | | | 20-1 | |

| 20.2 | | | Permitting | | | 20-8 | |

| 20.3 | | | Social or Community Considerations | | | 20-10 | |

| 20.4 | | | Mine Reclamation and Closure | | | 20-11 | |

| | | | | | | | |

| 21 | | | Capital and Operating Costs | | | 21-1 | |

| 21.1 | | | Capital Costs | | | 21-1 | |

| 21.2 | | | Operating Cost Estimate | | | 21-8 | |

| | | | | | | | |

| 22 | | | Economic Analysis | | | 22-1 | |

| 22.1 | | | Forward-Looking Information Cautionary Statements | | | 22-1 | |

| 22.2 | | | Methodology | | | 22-2 | |

| 22.3 | | | Inputs to the Cash Flow Model | | | 22-2 | |

| 22.4 | | | Basis of Pre-Tax Financial Evaluation | | | 22-2 | |

| 22.5 | | | Pre-Tax Financial Results | | | 22-3 | |

| 22.6 | | | Post-Tax Financial Analysis | | | 22-4 | |

| 22.7 | | | Cash Flow | | | 22-5 | |

| 22.8 | | | Sensitivity Analysis | | | 22-8 | |

| 22.9 | | | Copper and Zinc Metal Price Scenarios | | | 22-9 | |

| | | | | | | | |

| 23 | | | Adjacent Properties | | | 23-1 | |

| | | | | | | | |

| 24 | | | Other Relevant Data and Information | | | 24-1 | |

| 24.1 | | | Project Execution Plan | | | 24-1 | |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-IV |

| 25 | | | Interpretation and Conclusions | | | 25-1 | |

| 25.1 | | | Introduction | | | 25-1 | |

| 25.2 | | | Mineral Tenure, Surface Rights, Royalties and Agreements | | | 25-1 | |

| 25.3 | | | Geology and Mineralization | | | 25-1 | |

| 25.4 | | | Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation | | | 25-1 | |

| 25.5 | | | Metallurgical Testwork | | | 25-2 | |

| 25.6 | | | Mineral Resource Estimates | | | 25-2 | |

| 25.7 | | | Mineral Reserve Estimates | | | 25-2 | |

| 25.8 | | | Mining Recovery | | | 25-3 | |

| 25.9 | | | Recovery Plan | | | 25-3 | |

| 25.10 | | | Project Infrastructure | | | 25-3 | |

| 25.11 | | | Environmental, Permitting and Social | | | 25-4 | |

| 25.12 | | | Markets and Contracts | | | 25-4 | |

| 25.13 | | | Capital Costs | | | 25-5 | |

| 25.14 | | | Operating Costs | | | 25-5 | |

| 25.15 | | | Economic Analysis | | | 25-5 | |

| 25.16 | | | Conclusions | | | 25-6 | |

| 25.17 | | | Risks and Opportunities | | | 25-6 | |

| | | | | | | | |

| 26 | | | Recommendations | | | 26-1 | |

| 26.1 | | | Introduction | | | 26-1 | |

| | | | | | | | |

| 27 | | | References | | | 27-1 | |

Appendix A – List of Claims

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-V |

List of Tables

| Table 1-1 | Summary of Overall Metal Recovery – Arctic Project | 1-8 |

| | |

| Table 1-2 | Parameters Used to Generate a Resource-Limiting Pit Shell | 1-9 |

| | |

| Table 1-3 | Mineral Resource Estimate for the Arctic Deposit | 1-10 |

| | |

| Table 1-4 | Optimization Inputs | 1-11 |

| | |

| Table 1-5 | Mineral Reserve Statement | 1-12 |

| | |

| Table 1-6 | Initial Capital Costs | 1-19 |

| | |

| Table 1-7 | Sustaining Capital and Closure Costs | 1-19 |

| | |

| Table 1-8 | Operating Costs | 1-20 |

| | |

| Table 6-1 | Known Mapping, Geochemical, and Geophysical Programs Targeting VMS Prospects in the Ambler Mining District | 6-4 |

| | |

| Table 6-2 | Summary of Previous Geotechnical and Hydrogeological Work Completed After 1998 | 6-8 |

| | |

| Table 6-3 | Mining and Technical Studies | 6-10 |

| | |

| Table 9-1 | Summary of Trilogy/NovaGold Exploration Activities Targeting VMS-style Mineralization in the Ambler Sequence Stratigraphy and the Arctic Deposit | 9-1 |

| | |

| Table 9-2 | TDEM Loops and Locations | 9-4 |

| | |

| Table 9-3 | Summary of derived rock mass parameter values per rock mass domain. | 9-10 |

| | |

| Table 9-4 | Estimated Pit Inflow | 9-12 |

| | |

| Table 9-5 | Selected slope stability acceptance criteria | 9-13 |

| | |

| Table 10-1 | Companies, Campaigns, Drill Holes and Metres Drilled at the Arctic Deposit | 10-1 |

| | |

| Table 10-2 | Summary of Trilogy/NovaGold Arctic Deposit Drilling | 10-2 |

| | |

| Table 10-3 | Drill Contractors, Drill Holes, Meterage and Core Sizes by Drill Campaign at the Arctic Deposit | 10-3 |

| | |

| Table 10-4 | Recovery and RQD 2004 to 2008 Arctic Drill Campaigns | 10-7 |

| | |

| Table 10-5 | Drill, Meterage and Average Drill Depth for Trilogy Ambler Sequence VMS Targets | 10-8 |

| | |

| Table 10-6 | Trilogy Metals Exploration Drilling – Ambler Schist Belt | 10-9 |

| | |

| Table 11-1 | Analytical Laboratories used for Acid Base Accounting and Kinetic Studies for the Arctic Project | 11-3 |

| | |

| Table 11-2 | Analytical Laboratories Used by Operators of the Arctic Project | 11-4 |

| | |

| Table 13-1 | Summary of Overall Forecast Metal Recovery - Arctic Deposit | 13-1 |

| | |

| Table 13-2 | Summary of Testwork Chronology and Reporting from 2012 to 2019 | 13-2 |

| | |

| Table 13-3 | Head Analyses, Lakefield Research 1999 | 13-5 |

| | |

| Table 13-4 | Flotation Test on Ambler Low Talc Composite | 13-6 |

| | |

| Table 13-5 | SGS Head Grades - Composite Samples - 2012 | 13-7 |

| | |

| Table 13-6 | ALS Metallurgy Head Grades - Composite Samples - 2017 | 13-8 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-VI |

|  |

| Table 13-7 | Mineral Modal Abundance for Composite Samples - SGS 2012 | 13-10 |

| | |

| Table 13-8 | Bond Ball Mill Work Index and Abrasion Index Test Results | 13-11 |

| | |

| Table 13-9 | Summary of SMC Test Results and Additional BWI Data | 13-12 |

| | |

| Table 13-10 | Summary of Locked Cycle Recovery Data for Composite Sample Testing | 13-14 |

| | |

| Table 13-11 | Locked Cycle Metallurgical Test Results – SGS Vancouver 2012 | 13-15 |

| | |

| Table 13-12 | Locked Cycle Metallurgical Test Results – ALS Metallurgy 2017 | 13-16 |

| | |

| Table 13-13 | SGS Vancouver Open Circuit Copper and Lead Separation Test Results | 13-18 |

| | |

| Table 13-14 | ALS Metallurgy Locked Cycle Testing of Copper-Lead Separation Process | 13-19 |

| | |

| Table 13-15 | Summary of Lead Concentrate Grades for Various Talc Grades in Feed | 13-20 |

| | |

| Table 13-16 | Summary of Flotation Reagent and Grind Size Objectives | 13-21 |

| | |

| Table 13-17 | Summary of Lead Concentrate Quality | 13-21 |

| | |

| Table 13-18 | Summary of Copper Concentrate Quality | 13-22 |

| | |

| Table 13-19 | Summary of Zinc Concentrate Quality | 13-22 |

| | |

| Table 14-1 | Summary of Sample Data Used to Develop the Resource Block Model | 14-3 |

| | |

| Table 14-2 | Summary of Lithology Domains | 14-9 |

| | |

| Table 14-3 | Summary of Mineralized Zone (MinZone) Domains | 14-10 |

| | |

| Table 14-4 | Summary of Geotech, Alteration, Talc and Weathering Domains | 14-10 |

| | |

| Table 14-5 | Summary of Estimation Domains | 14-21 |

| | |

| Table 14-6 | Summary of Treatment of Outlier Sample Data | 14-22 |

| | |

| Table 14-7 | Copper Correlogram Parameters | 14-23 |

| | |

| Table 14-8 | Lead Correlogram Parameters | 14-24 |

| | |

| Table 14-9 | Zinc Correlogram Parameters | 14-24 |

| | |

| Table 14-10 | Gold Correlogram Parameters | 14-25 |

| | |

| Table 14-11 | Silver Correlogram Parameters | 14-25 |

| | |

| Table 14-12 | Sulphur Correlogram Parameters | 14-26 |

| | |

| Table 14-13 | AP Correlogram Parameters | 14-26 |

| | |

| Table 14-14 | NP Correlogram Parameters | 14-26 |

| | |

| Table 14-15 | Talc Correlogram Parameters | 14-27 |

| | |

| Table 14-16 | Block Model Limits | 14-27 |

| | |

| Table 14-17 | Interpolation Parameters for Copper | 14-28 |

| | |

| Table 14-18 | Interpolation Parameters for Lead | 14-29 |

| | |

| Table 14-19 | Interpolation Parameters for Zinc | 14-29 |

| | |

| Table 14-20 | Interpolation Parameters for Gold | 14-29 |

| | |

| Table 14-21 | Interpolation Parameters for Silver | 14-29 |

| | |

| Table 14-22 | Interpolation Parameters for Sulphur | 14-30 |

| | |

| Table 14-23 | Interpolation Parameters for AP | 14-30 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-VII |

;

| Table 14-24 | Interpolation Parameters for NP | 14-30 |

| | |

| Table 14-25 | Interpolation Parameters for Specific Gravity | 14-30 |

| | |

| Table 14-26 | Interpolation Parameters for Talc | 14-30 |

| | |

| Table 14-27 | Parameters Used to Generate a Resource-Limiting Pit Shell | 14-42 |

| | |

| Table 14-28 | Mineral Resource Estimate for the Arctic Deposit | 14-43 |

| | |

| Table 14-29 | Sensitivity of Mineral Resource to Cut-off Grade | 14-44 |

| | |

| Table 15-1 | Optimization Inputs | 15-1 |

| | |

| Table 15-2 | Mineral Reserves Statement | 15-4 |

| | |

| Table 16-1 | Mine Design Parameters | 16-1 |

| | |

| Table 16-2 | Production Schedule | 16-6 |

| | |

| Table 16-3 | Gross Operating Hours per Year | 16-8 |

| | |

| Table 16-4 | Productive Utilization Ramp-up | 16-8 |

| | |

| Table 16-5 | Equipment Utilization and Efficiency | 16-9 |

| | |

| Table 16-6 | Blasting Design Input | 16-10 |

| | |

| Table 16-7 | Material Blasted Quantities | 16-11 |

| | |

| Table 16-8 | Blasting products consumed | 16-11 |

| | |

| Table 16-9 | Rock Type Weight and UCS | 16-12 |

| | |

| Table 16-10 | PV271 Drill Penetration Rates | 16-13 |

| | |

| Table 16-11 | Drill Requirements and Performance | 16-13 |

| | |

| Table 16-12 | Loading Requirements and Performance | 16-14 |

| | |

| Table 16-13 | Truck Requirements and Performance | 16-15 |

| | |

| Table 16-14 | Support Equipment | 16-16 |

| | |

| Table 16-15 | Auxiliary Equipment | 16-16 |

| | |

| Table 16-16 | Summary Based Case Cumulative Pit Dewatering Needs | 16-17 |

| | |

| Table 17-1 | Processing Facility Design Criteria | 17-4 |

| | |

| Table 18-1 | Personnel Onsite during Operations | 18-7 |

| | |

| Table 18-2 | Process water supply summary | 18-11 |

| | |

| Table 18-3 | TMF Design Parameters and Design Criteria | 18-19 |

| | |

| Table 18-4 | Mode of Transport and Distances for Concentrate Shipping | 18-27 |

| | |

| Table 19-1 | Concentrate Transport Costs | 19-5 |

| | |

| Table 20-1 | Major Mine Permits Required for the Arctic Project | 20-10 |

| | |

| Table 20-2 | Summary of Closure and Reclamation Costs | 20-20 |

| | |

| Table 21-1 | Estimate Summary Level 1 Major Facility | 21-3 |

| | |

| Table 21-2 | Initial Estimate by Major Discipline | 21-3 |

| | |

| Table 21-3 | Estimate Exchange Rates | 21-5 |

| | |

| Table 21-4 | Mine Capital Costs | 21-6 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-VIII |

;

| Table 21-5 | Sustaining Capital and Closure Costs | 21-8 |

| | |

| Table 21-6 | Overall Operating Cost Estimate | 21-8 |

| | |

| Table 21-7 | Life of Mine Mining Cost | 21-9 |

| | |

| Table 21-8 | Summary of Processing Operating Cost Estimates | 21-9 |

| | |

| Table 21-9 | G&A Cost Estimates | 21-11 |

| | |

| Table 21-10 | Surface Services Cost Estimates | 21-11 |

| | |

| Table 22-1 | Mine and Payable Metal Production for the Arctic Mine | 22-2 |

| | |

| Table 22-2 | Summary of Pre-Tax Financial Results | 22-4 |

| | |

| Table 22-3 | Summary of Post-Tax Financial Results | 22-5 |

| | |

| Table 22-4 | Pre and Post-Tax Arctic Project Production and Cash Flow Forecast | 22-6 |

| | |

| Table 22-5 | Pre-tax Copper Price Scenarios | 22-9 |

| | |

| Table 22-6 | Pre-tax Zinc Price Scenarios | 22-9 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-IX |

List of Figures

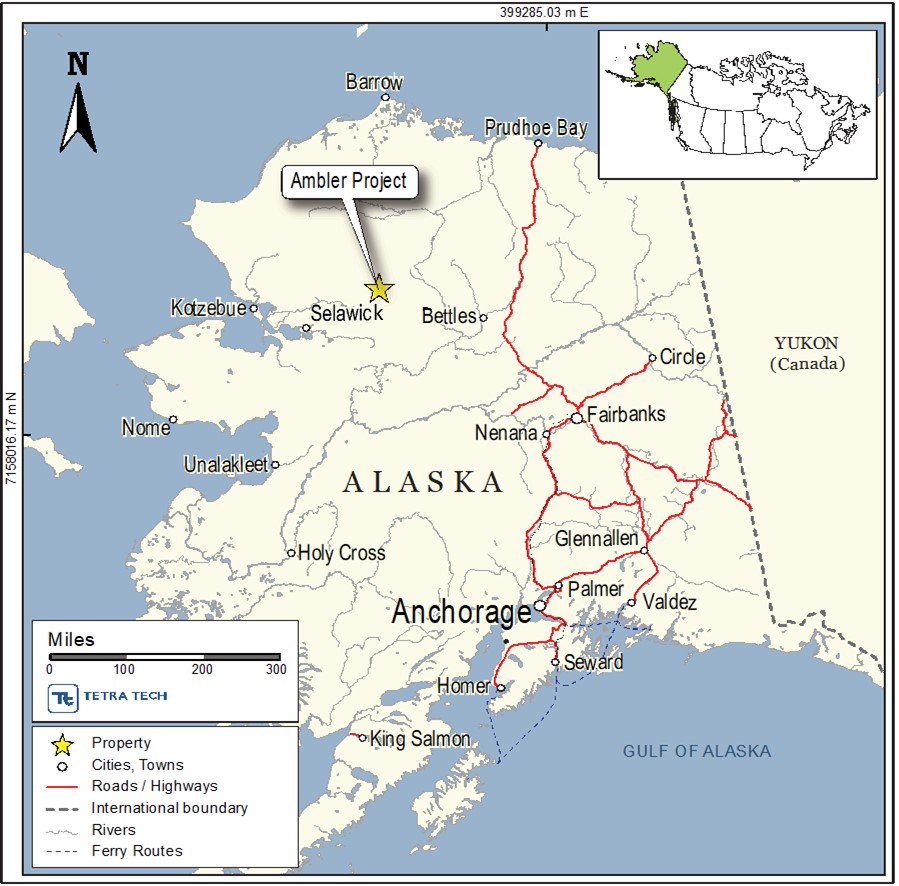

| Figure 2-1 | Property Location Map (Tetra Tech, 2013) | 2-1 |

| | |

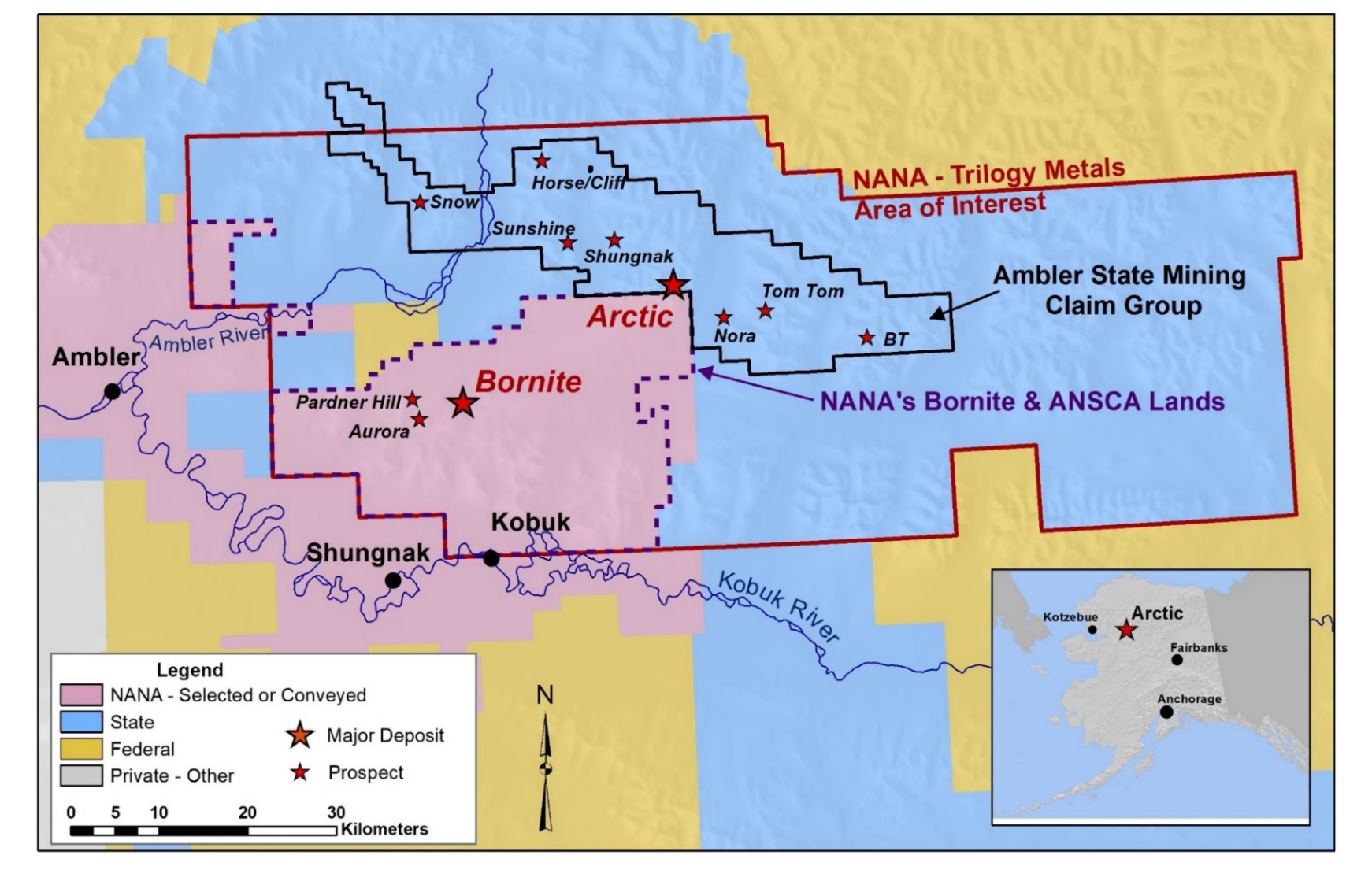

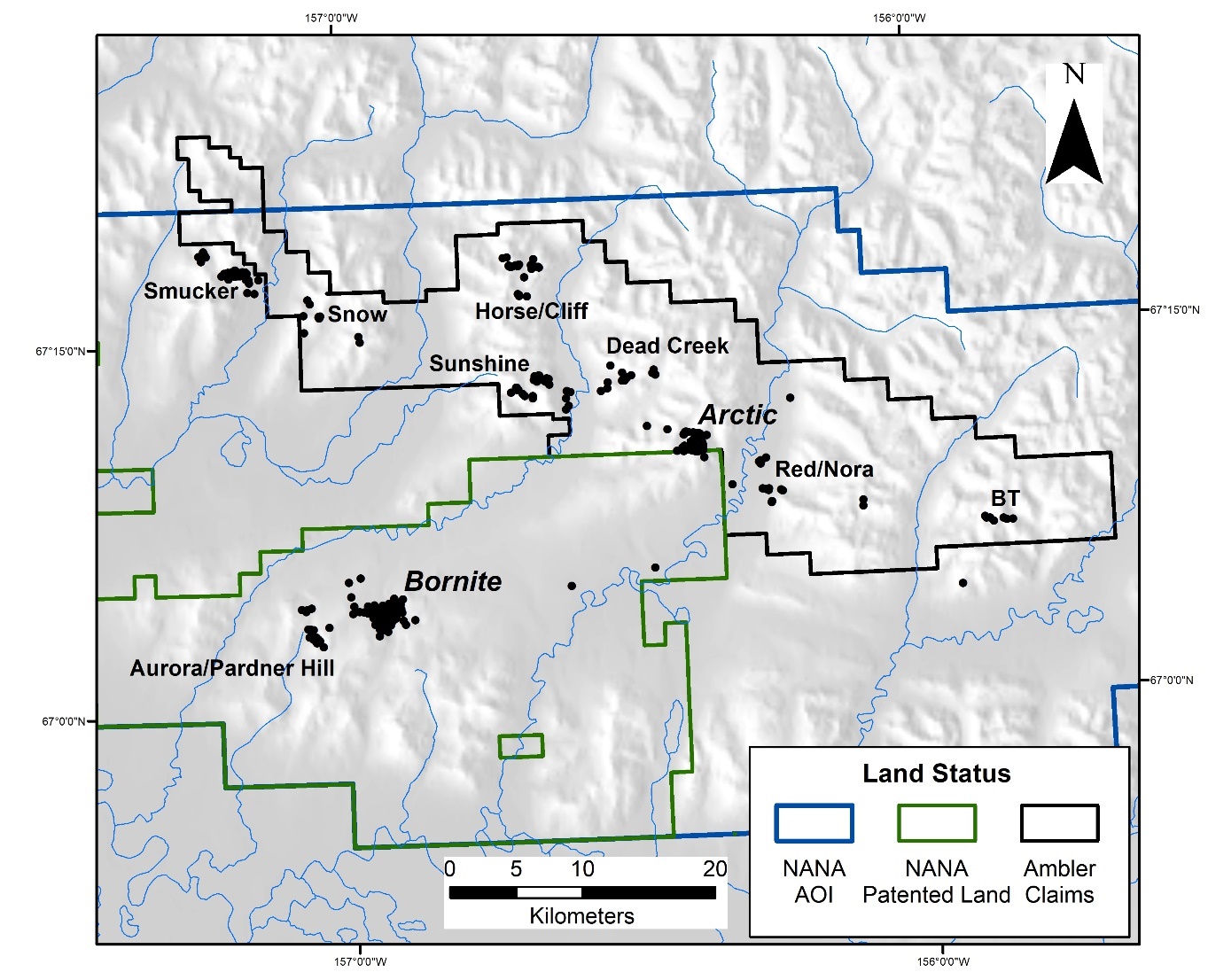

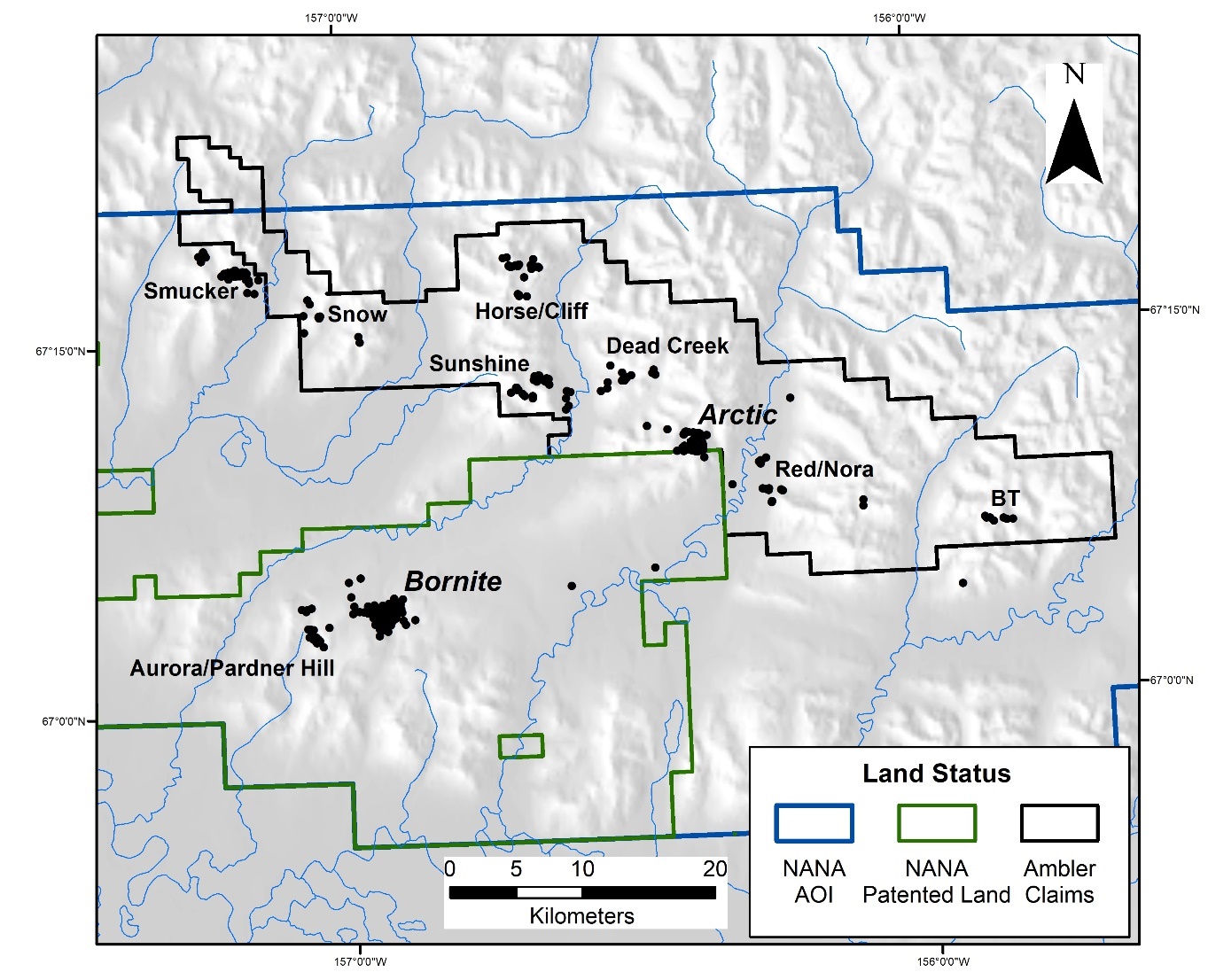

| Figure 4-1 | Upper Kobuk Mineral Projects Lands (Trilogy Metals, 2019) | 4-2 |

| | |

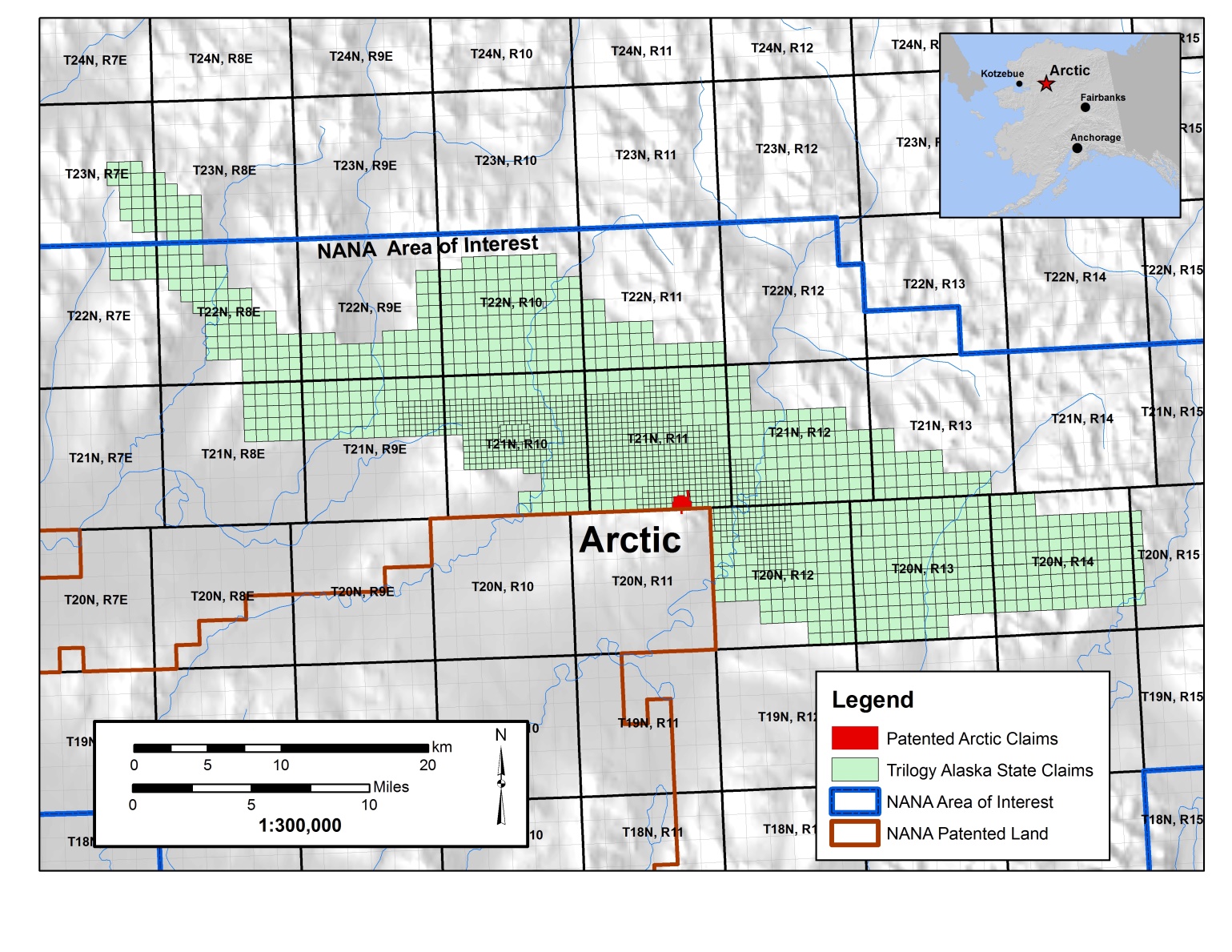

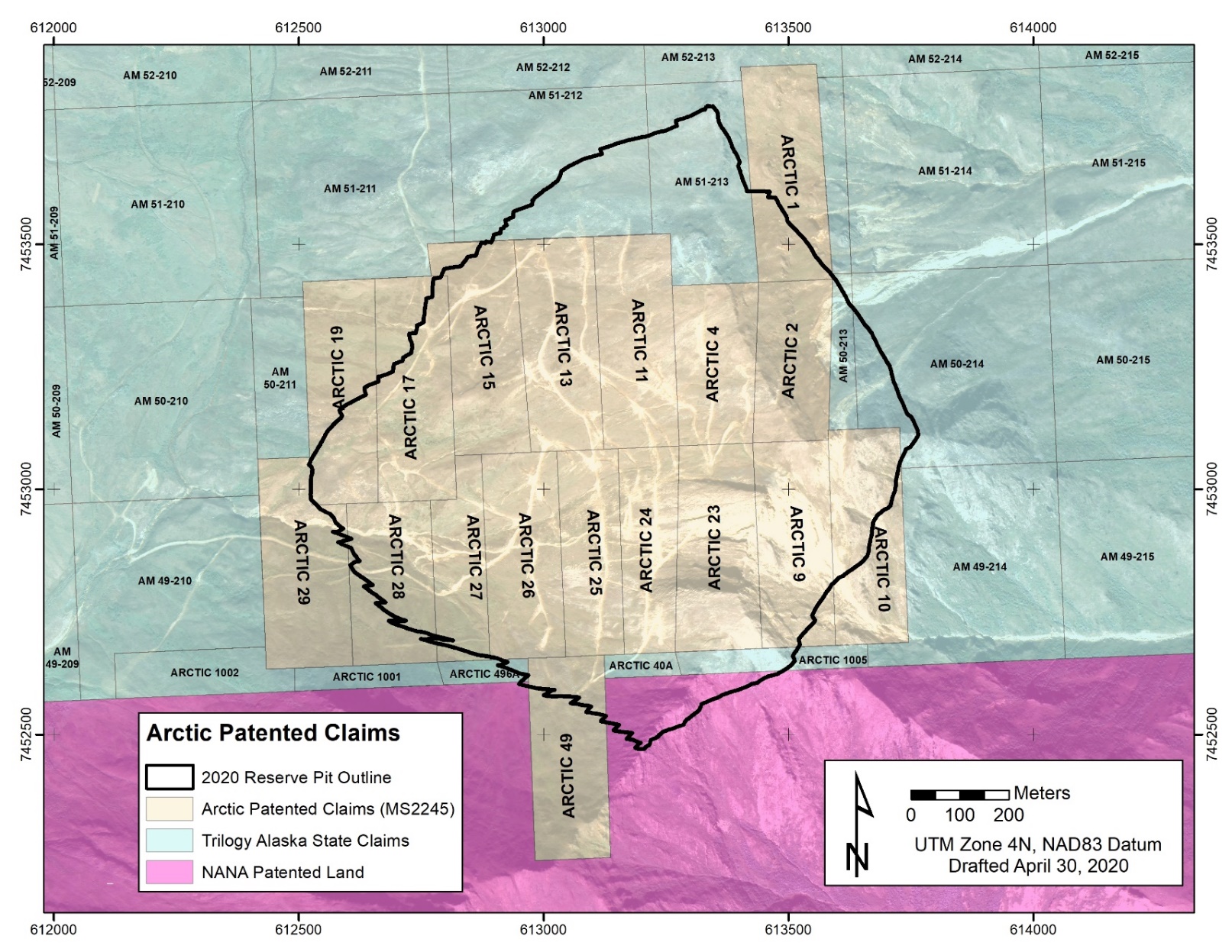

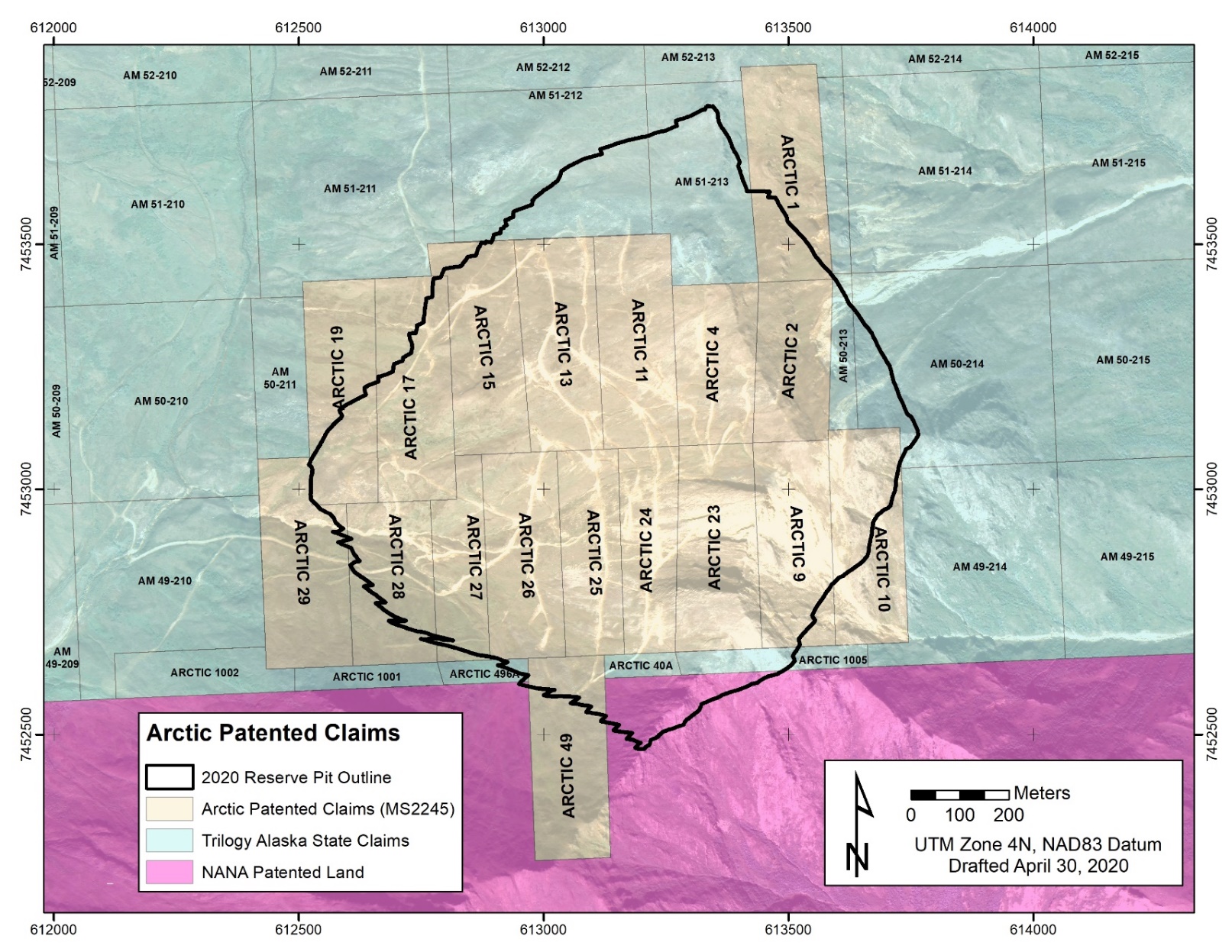

| Figure 4-2 | Arctic Project Mineral Tenure Plan (Trilogy Metals, 2019) | 4-3 |

| | |

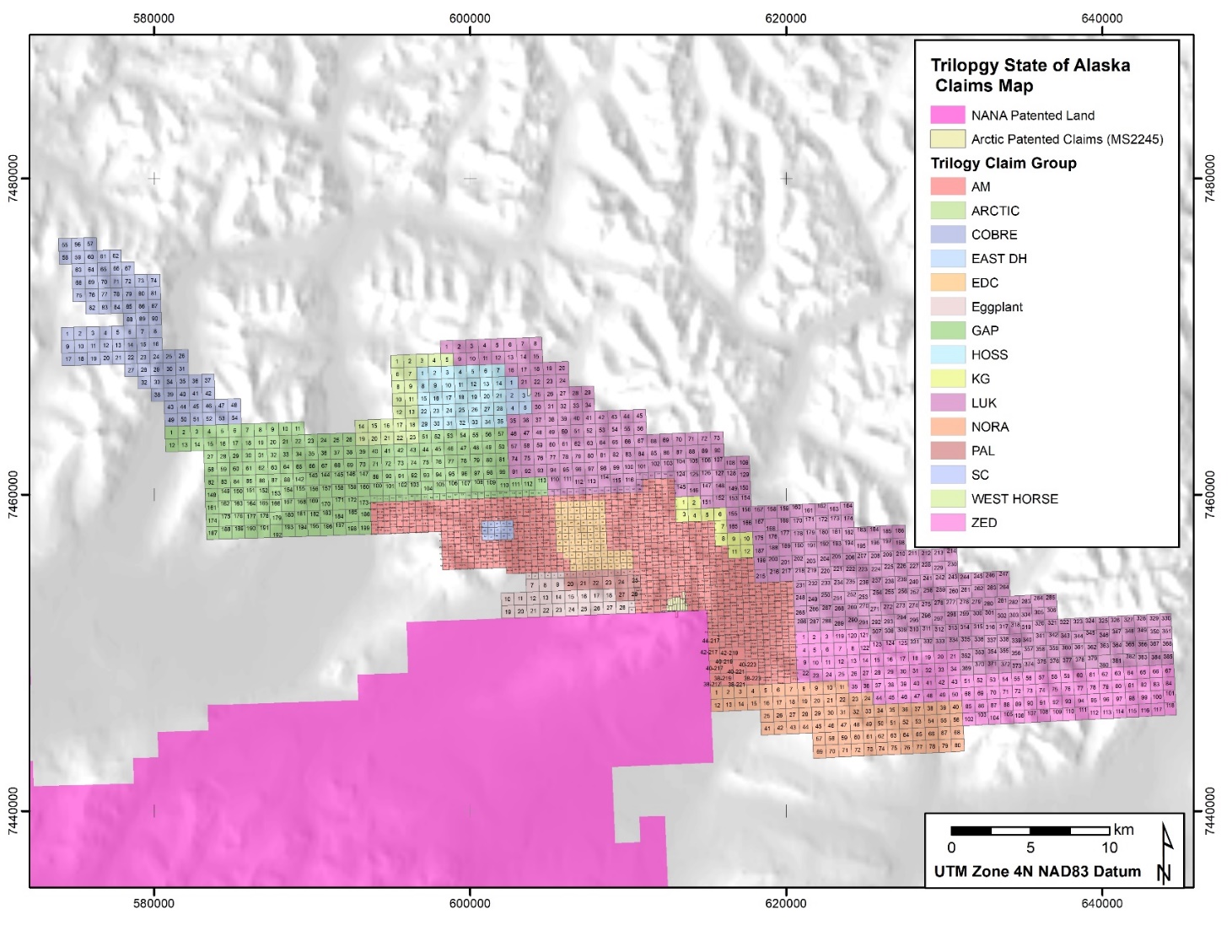

| Figure 4-3 | Mineral Tenure Layout Plan (Trilogy Metals, 2019) | 4-4 |

| | |

| Figure 4-4 | Arctic Deposit Location (Trilogy Metals, 2019) | 4-5 |

| | |

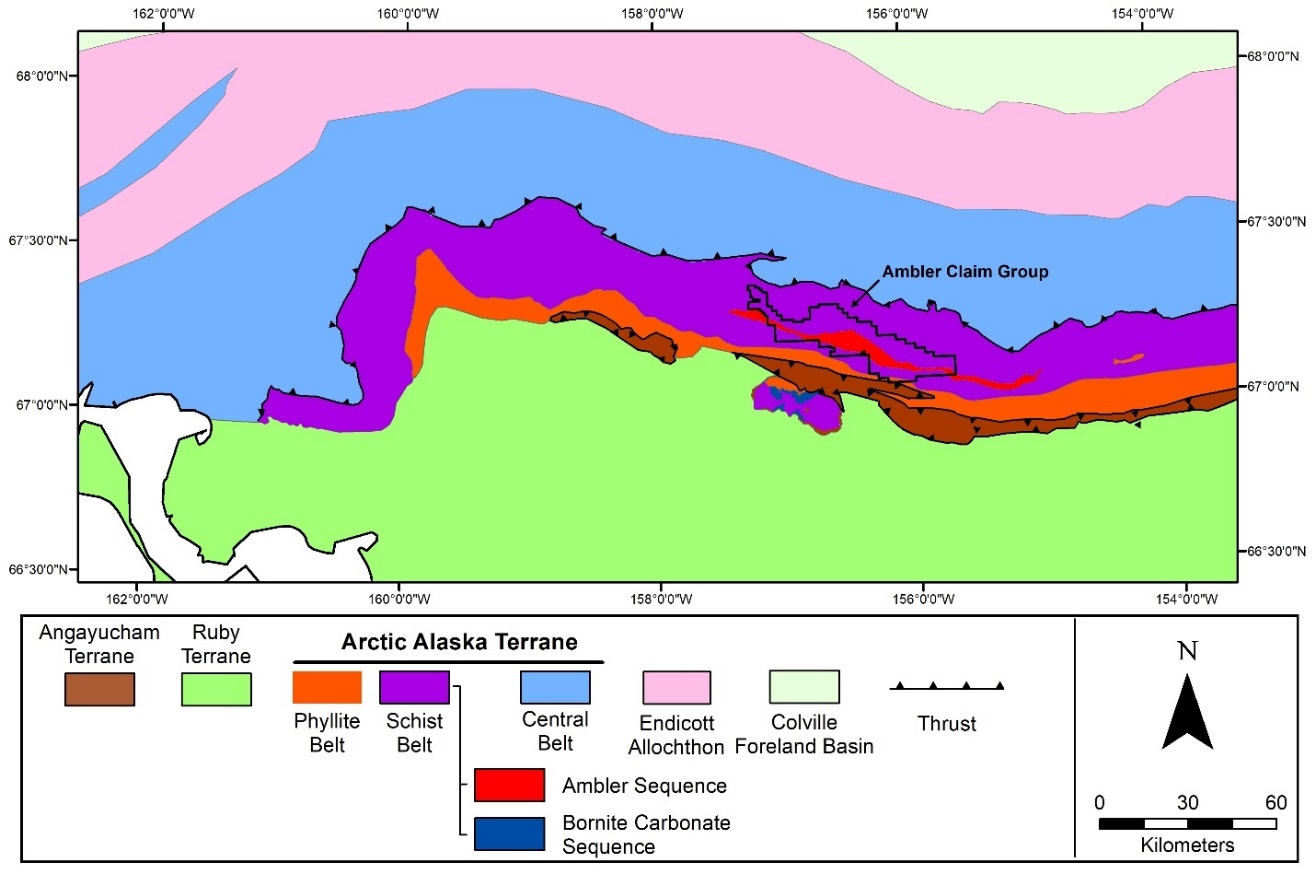

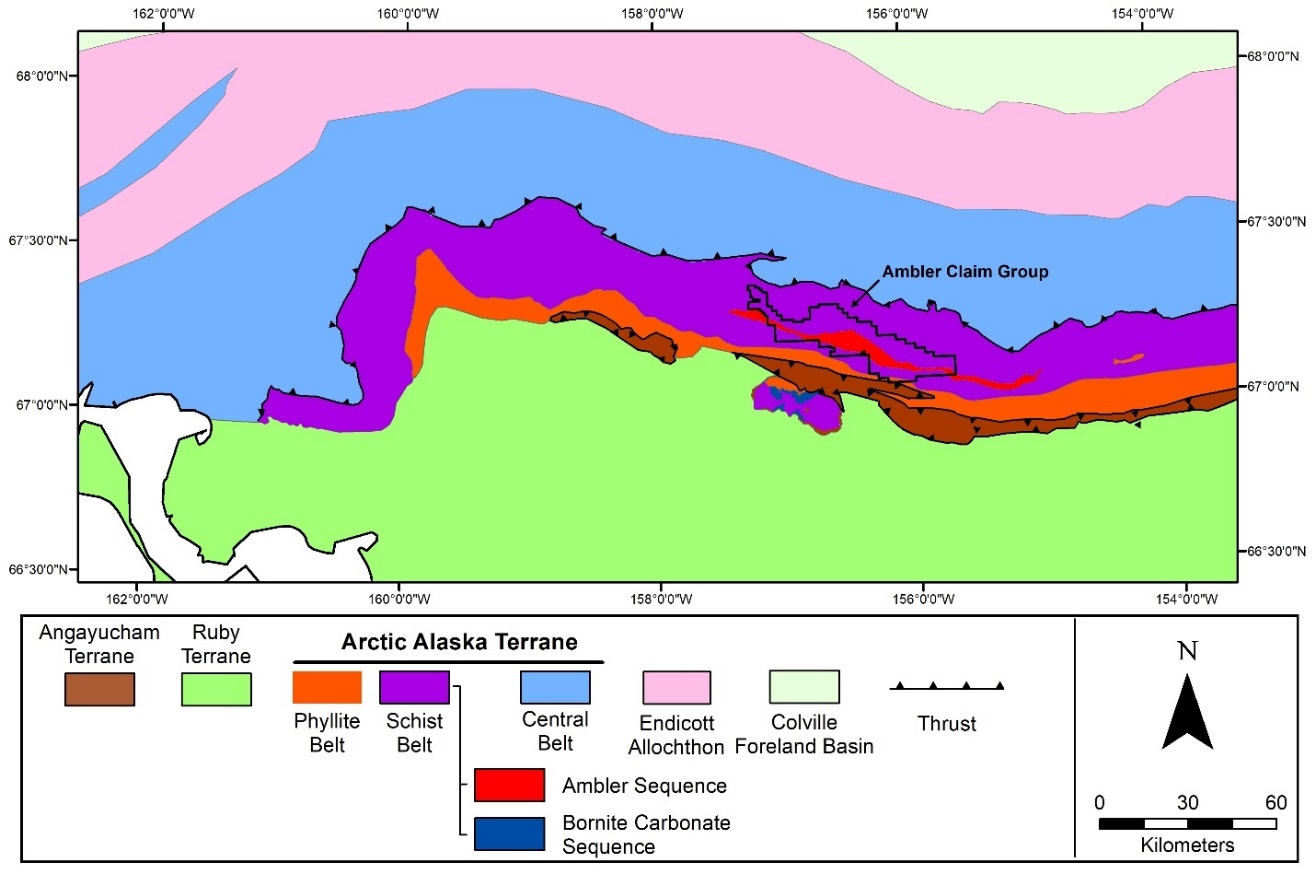

| Figure 7-1 | Geologic Terranes of the Southern Brooks Range (Trilogy Metals, 2019) | 7-2 |

| | |

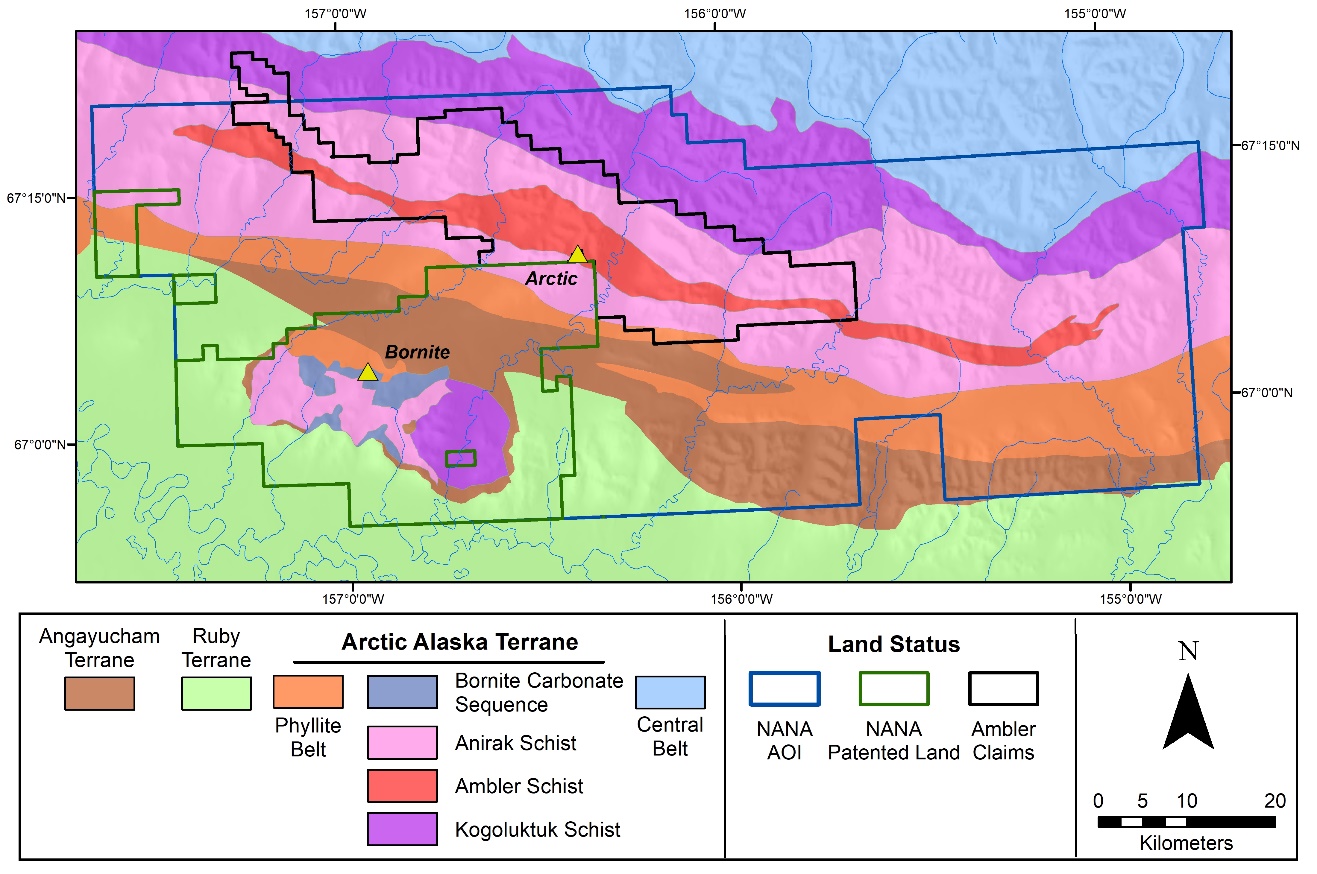

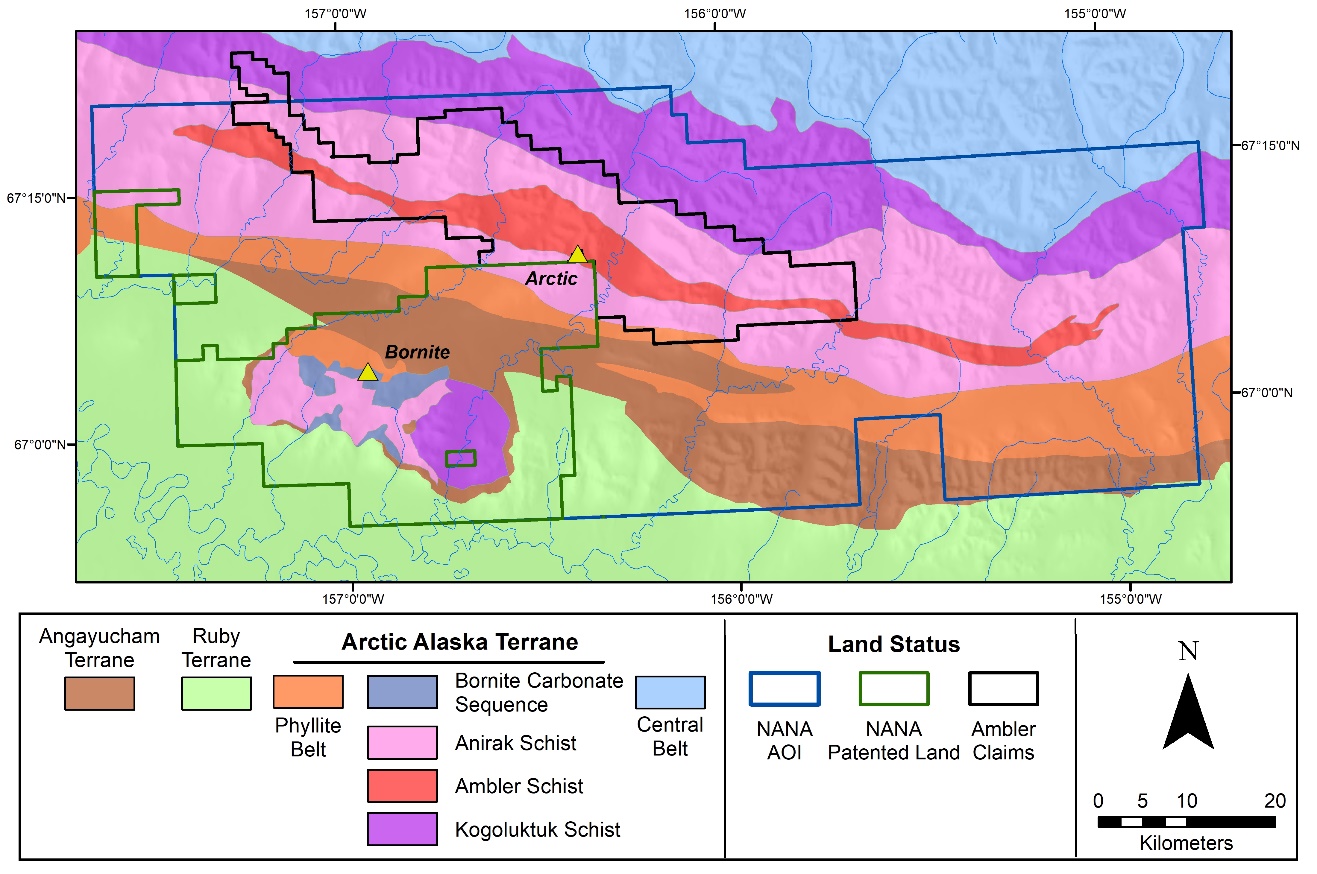

| Figure 7-2 | Geology of the Ambler Mining District (Trilogy Metals, 2019) | 7-4 |

| | |

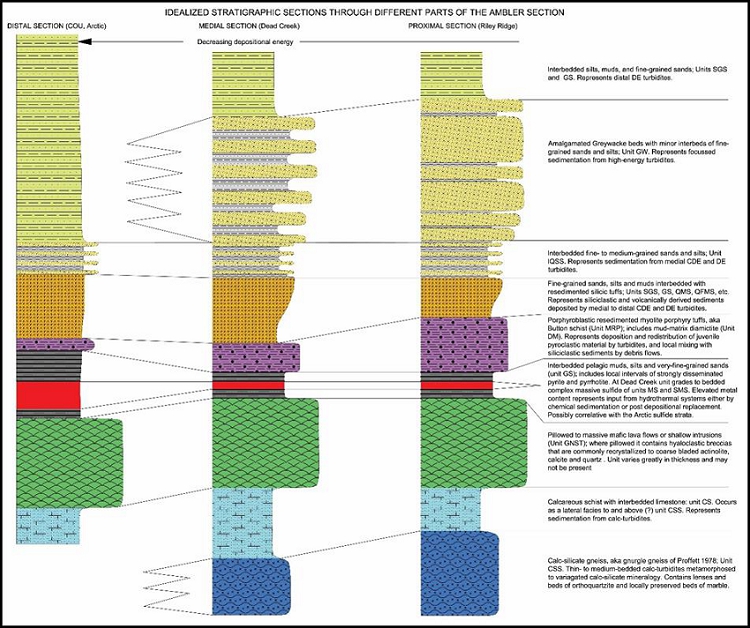

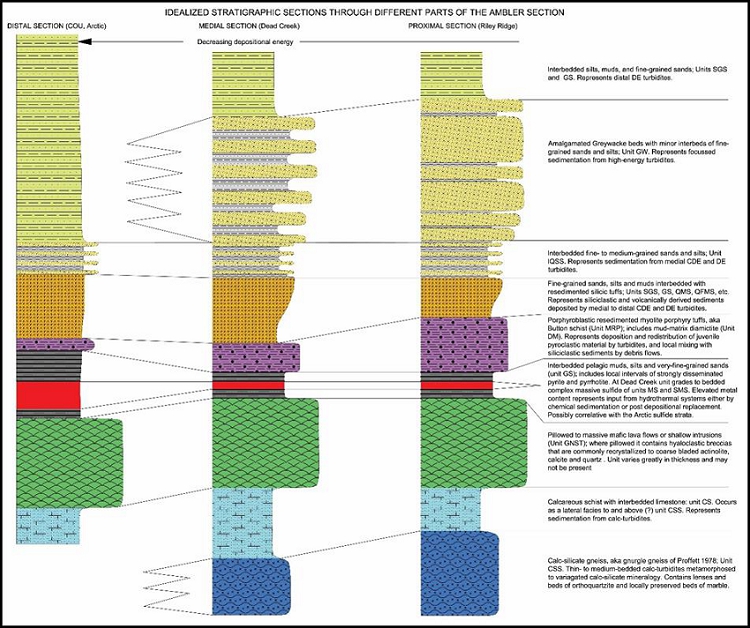

| Figure 7-3 | Ambler Sequence Stratigraphy in the Arctic Deposit Area (Trilogy Metals, 2019) | 7-6 |

| | |

| Figure 7-4 | Generalized Geology of the Central Ambler Mining District (Trilogy Metals, 2019) | 7-7 |

| | |

| Figure 7-5 | Typical F1 Isoclinal Folds Developed in Calcareous Gnurgle Gneiss (Trilogy Metals, 2019) | 7-8 |

| | |

| Figure 7-6 | Generalized Geologic Map of the Arctic Deposit (Trilogy Metals, 2019) | 7-10 |

| | |

| Figure 7-7 | Major Prospects of the Ambler Mining District (Trilogy Metals, 2019) | 7-15 |

| | |

| Figure 9-1 | Mapping Campaigns in and around the Arctic Deposit (Trilogy Metals, 2019) | 9-3 |

| | |

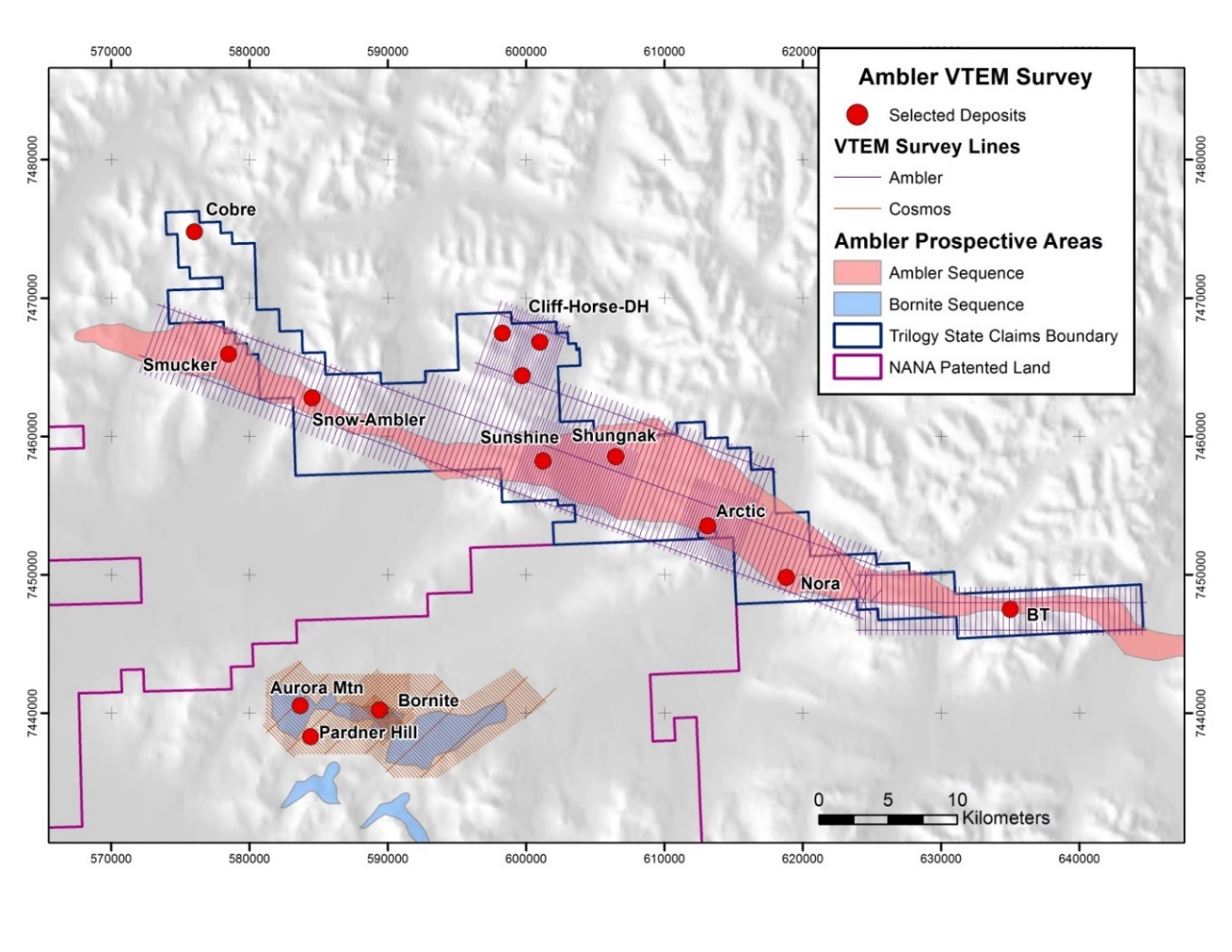

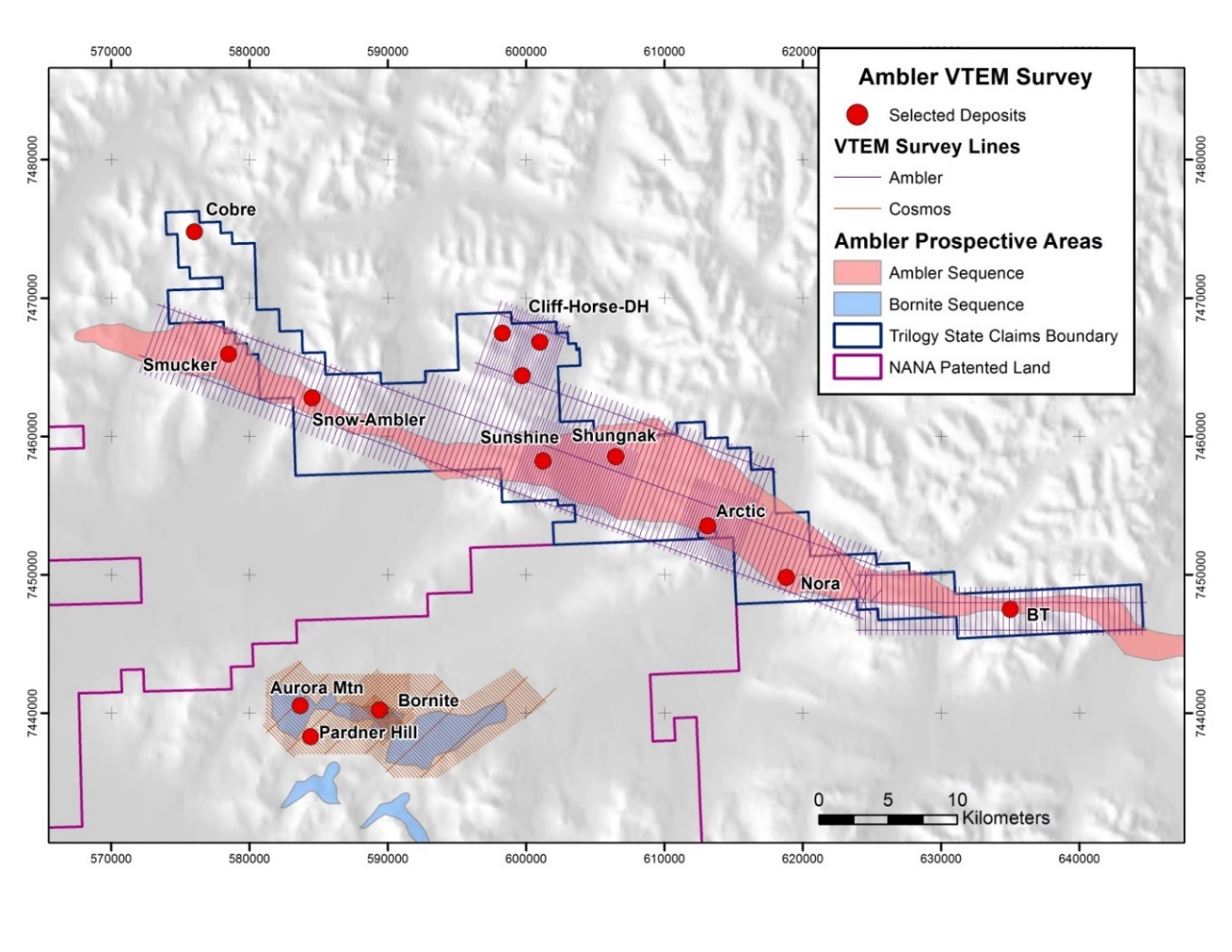

| Figure 9-2 | VTEM flight lines over the Ambler Belt and Cosmos Hill prospective areas (Trilogy Metals, 2019) | 9-5 |

| | |

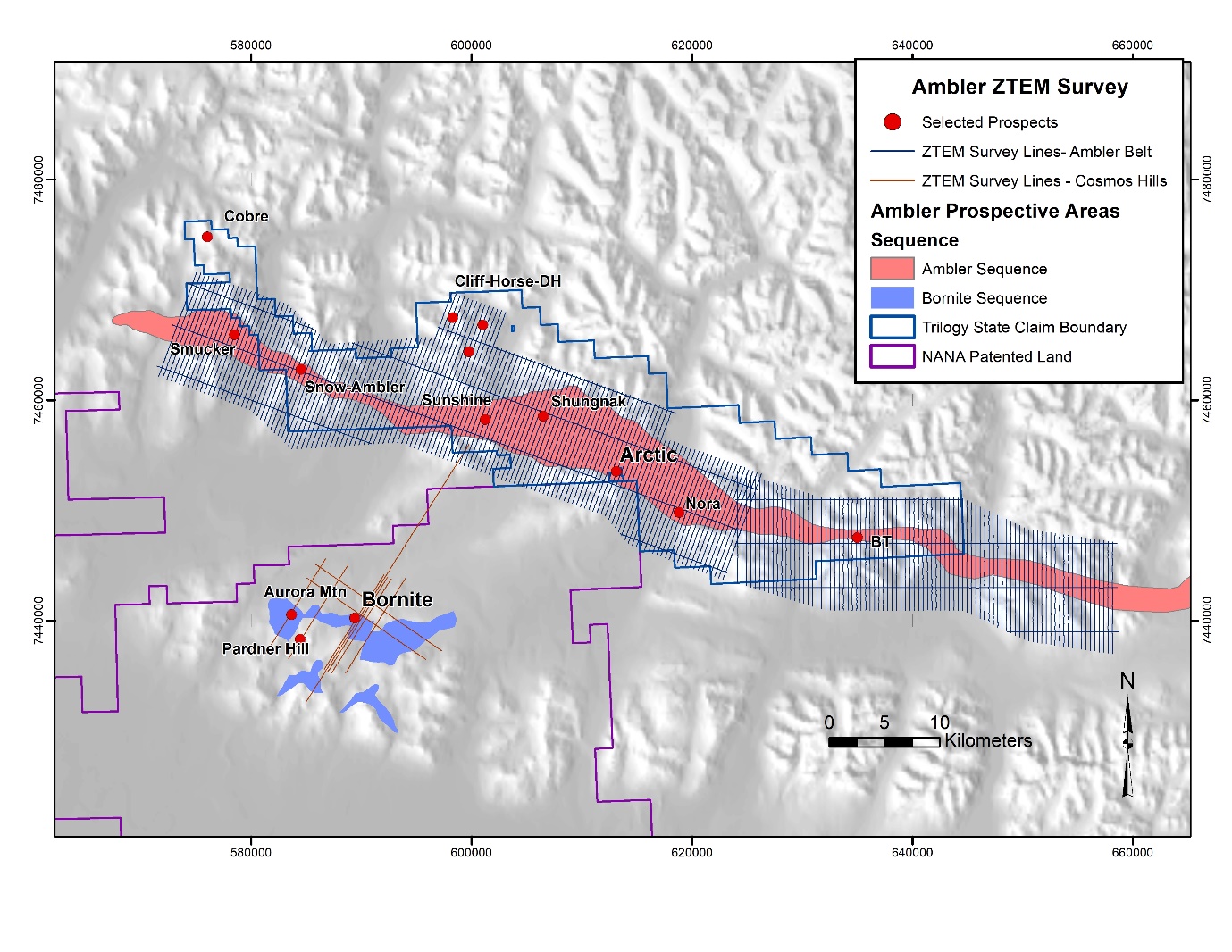

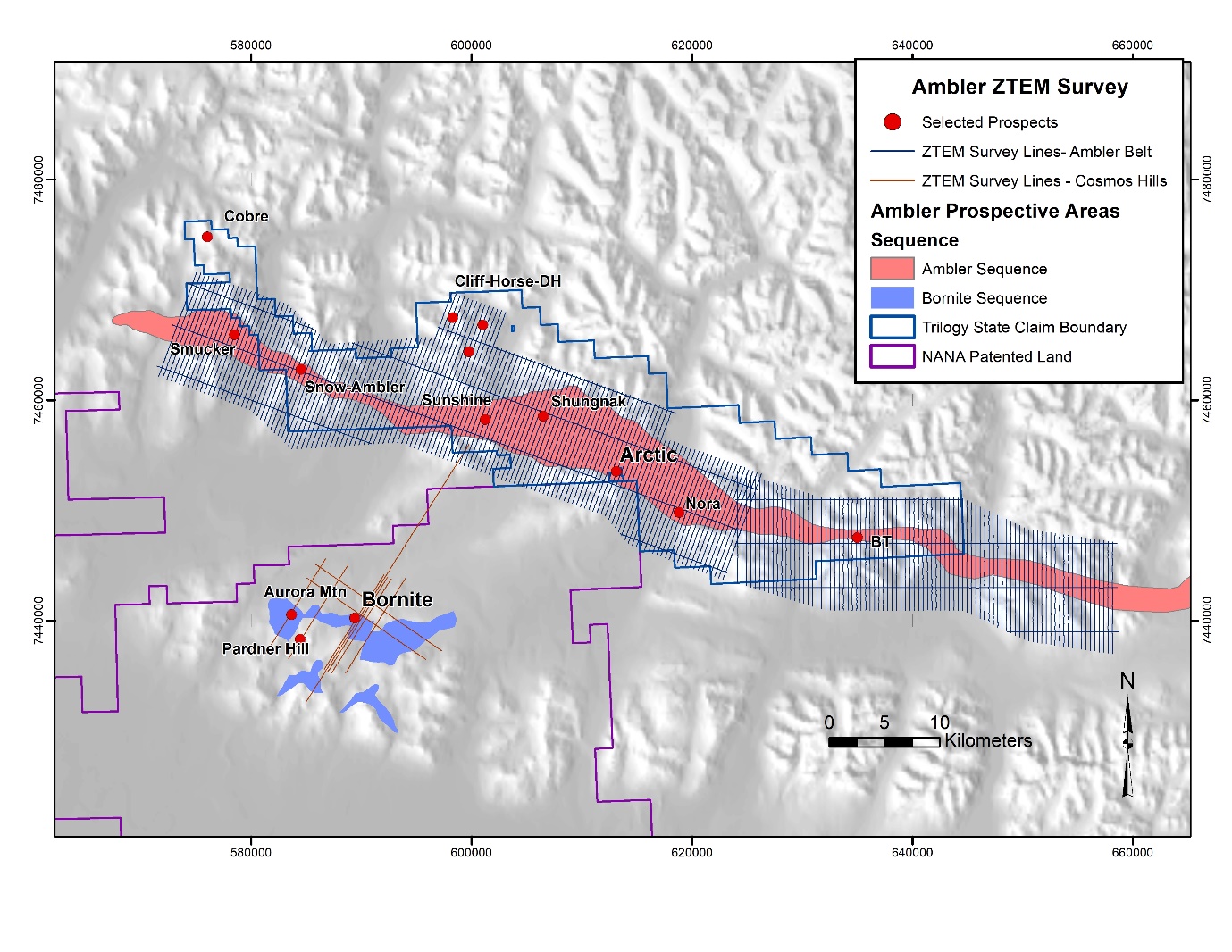

| Figure 9-3 | ZTEM flight lines over the Ambler VMS Belt and the Bornite deposit (Trilogy Metals, 2019) | 9-6 |

| | |

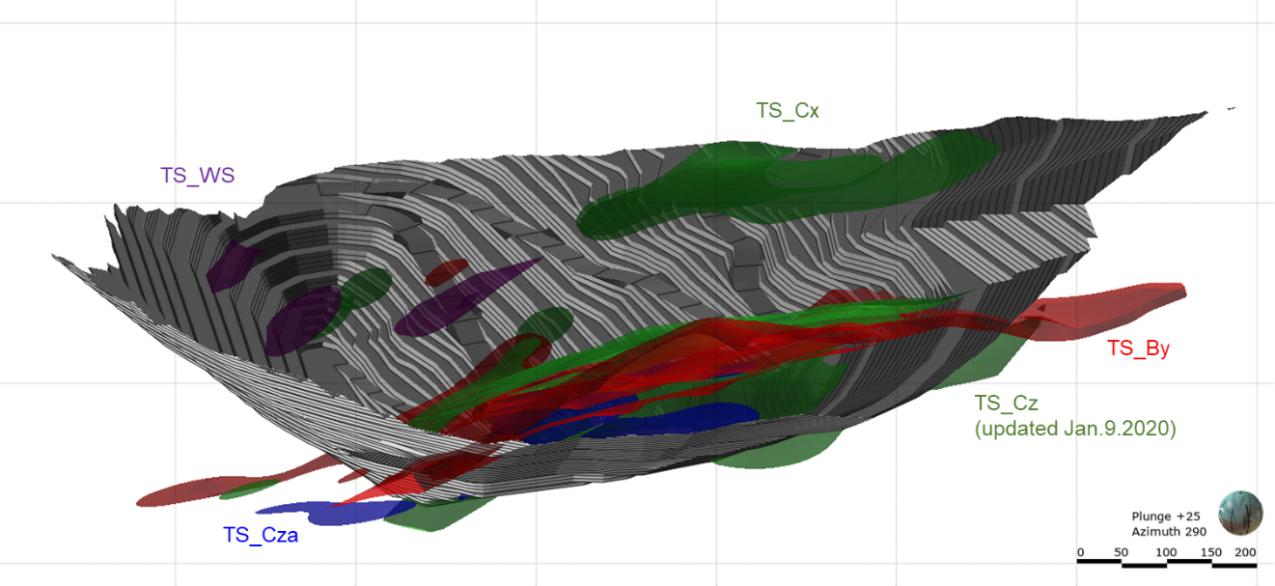

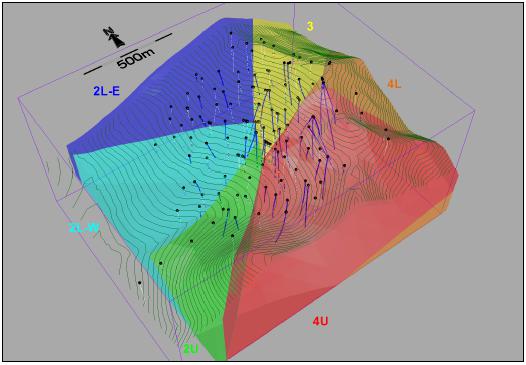

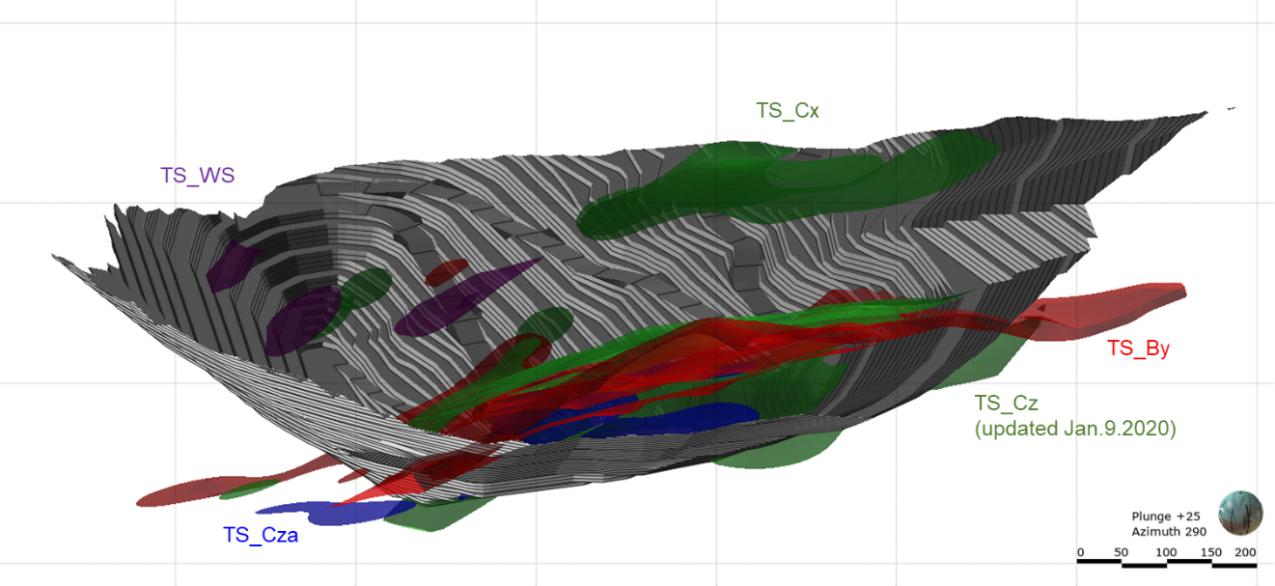

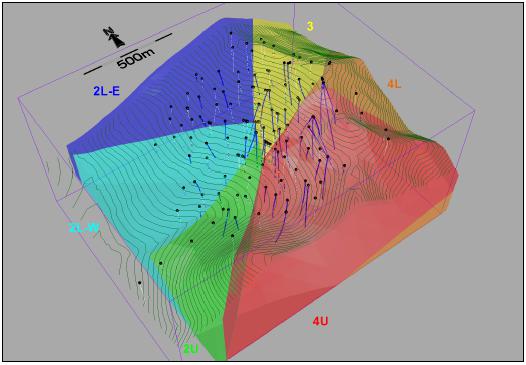

| Figure 9-4 | Isometric view (looking West) of Talc Zone domain modeled by Trilogy (2020) using Leapfrog on the EoY12 design pit (Wood, 2019). | 9-7 |

| | |

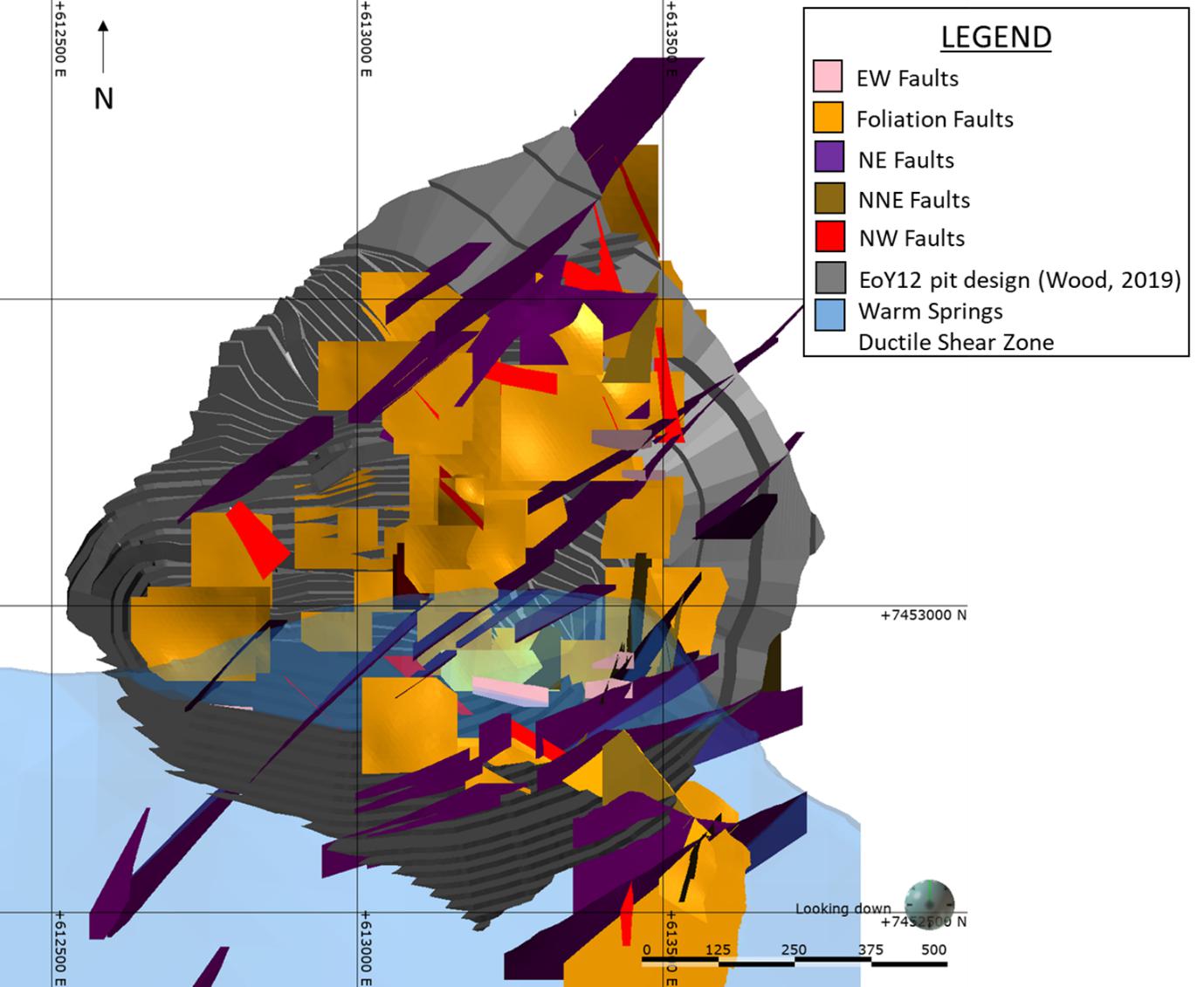

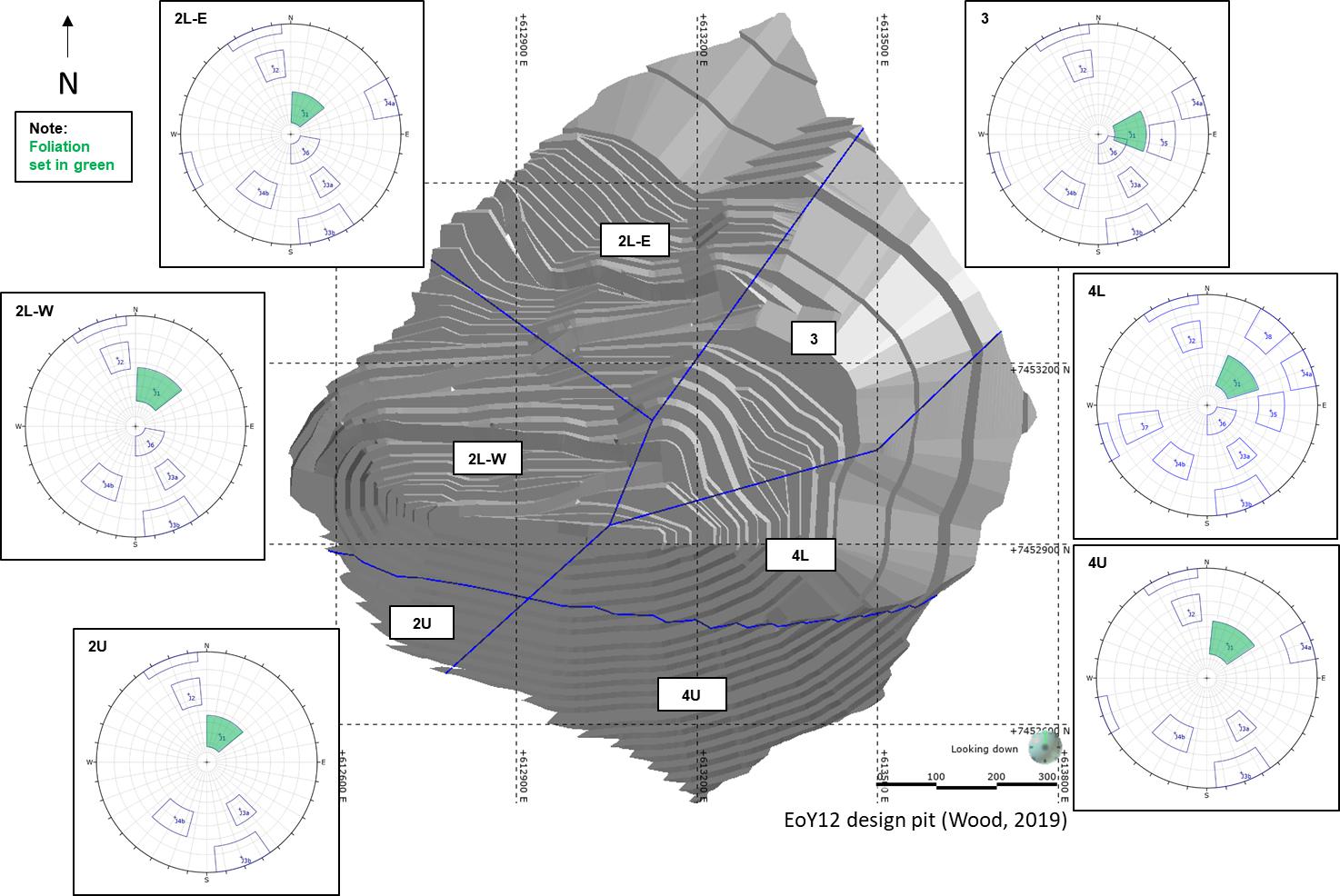

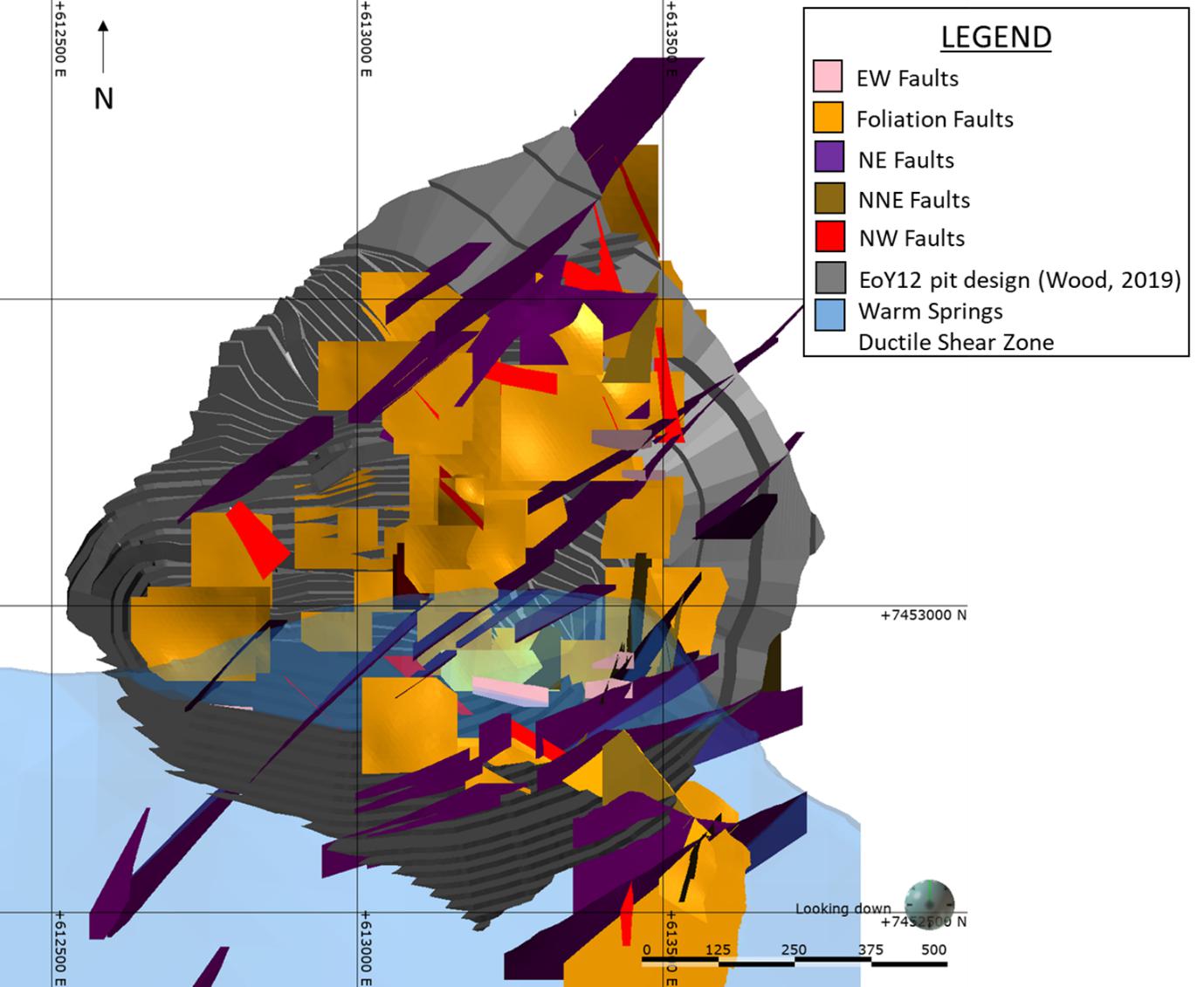

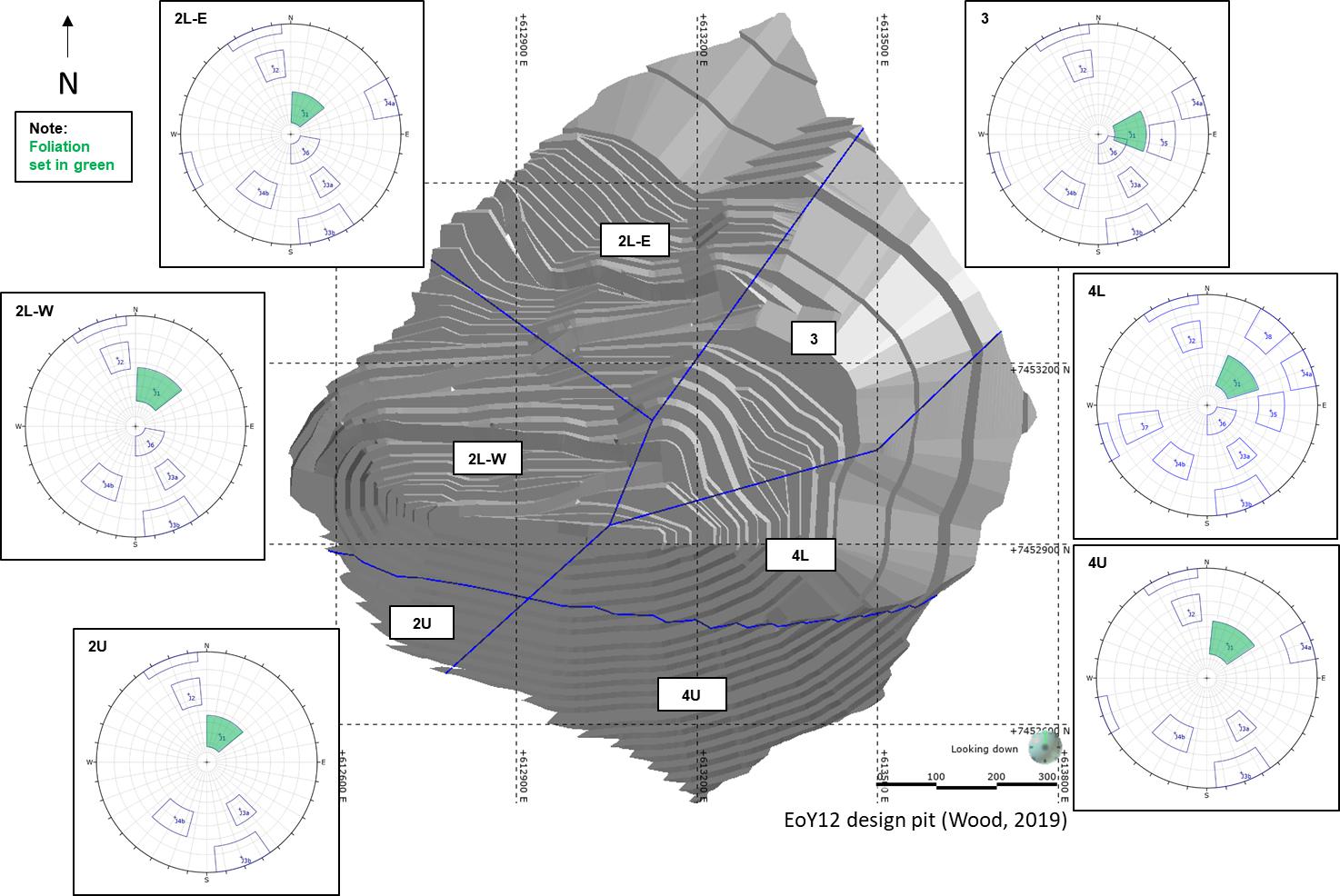

| Figure 9-5 | SRK Structural Model used in the Slope Stability Analysis on the EoY12 design pit (Wood, 2019). | 9-8 |

| | |

| Figure 9-6 | Location Plan, Structural and Geomechanical Domains (Wood, 2019) | 9-9 |

| | |

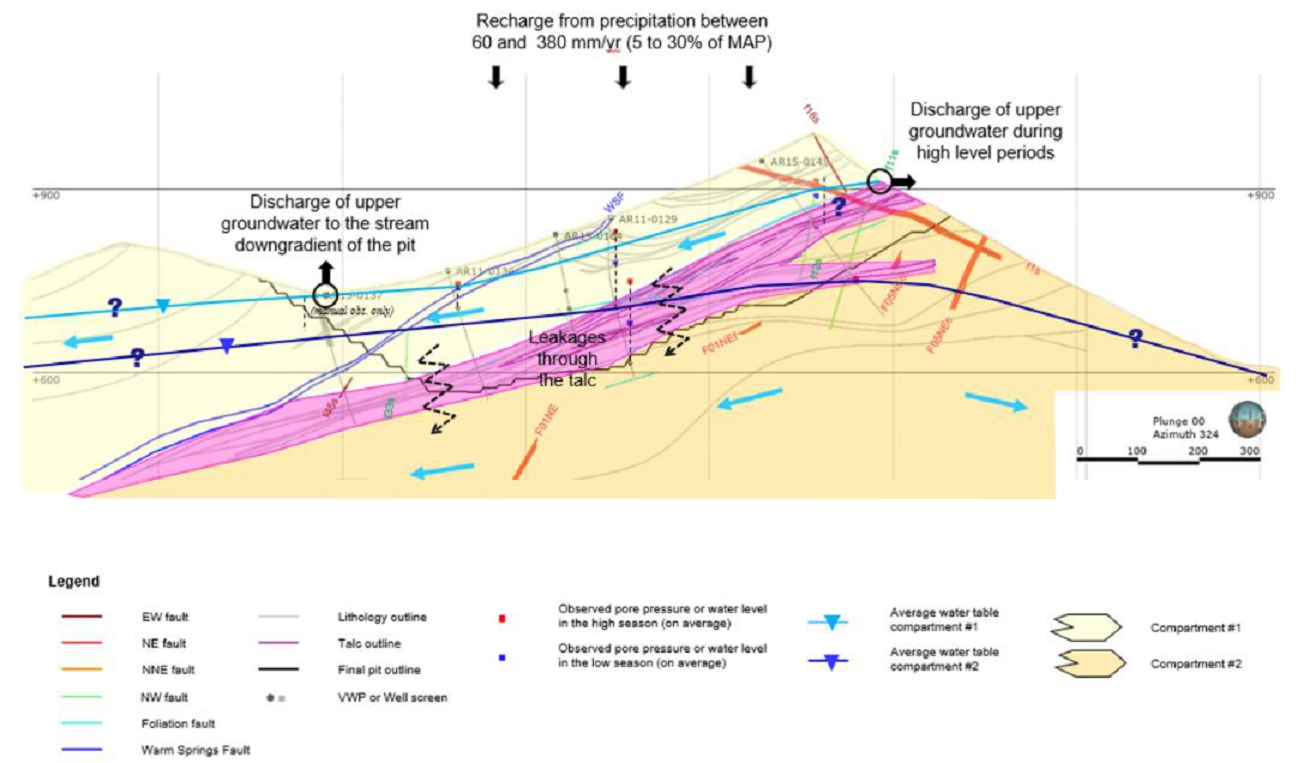

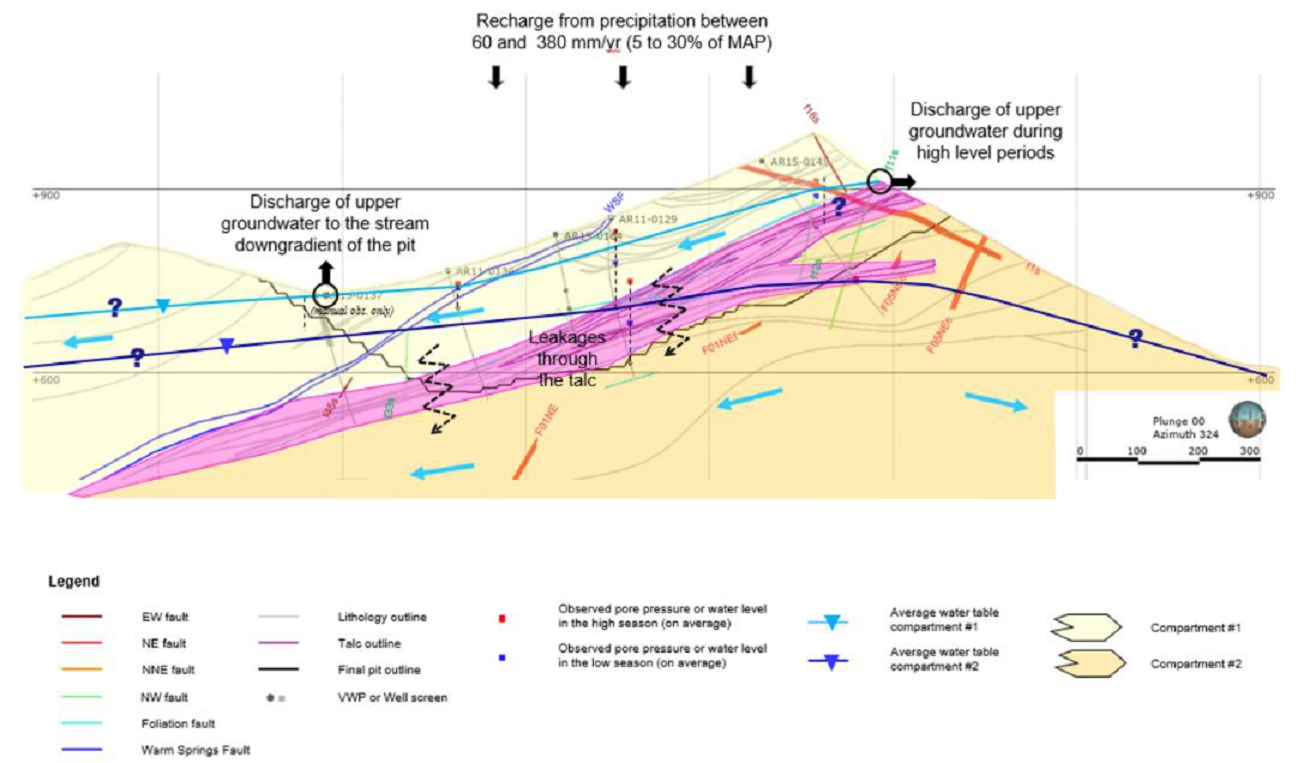

| Figure 9-7 | Summarized Hydrogeological Conceptual Model for Pit Area (Wood, 2019) | 9-12 |

| | |

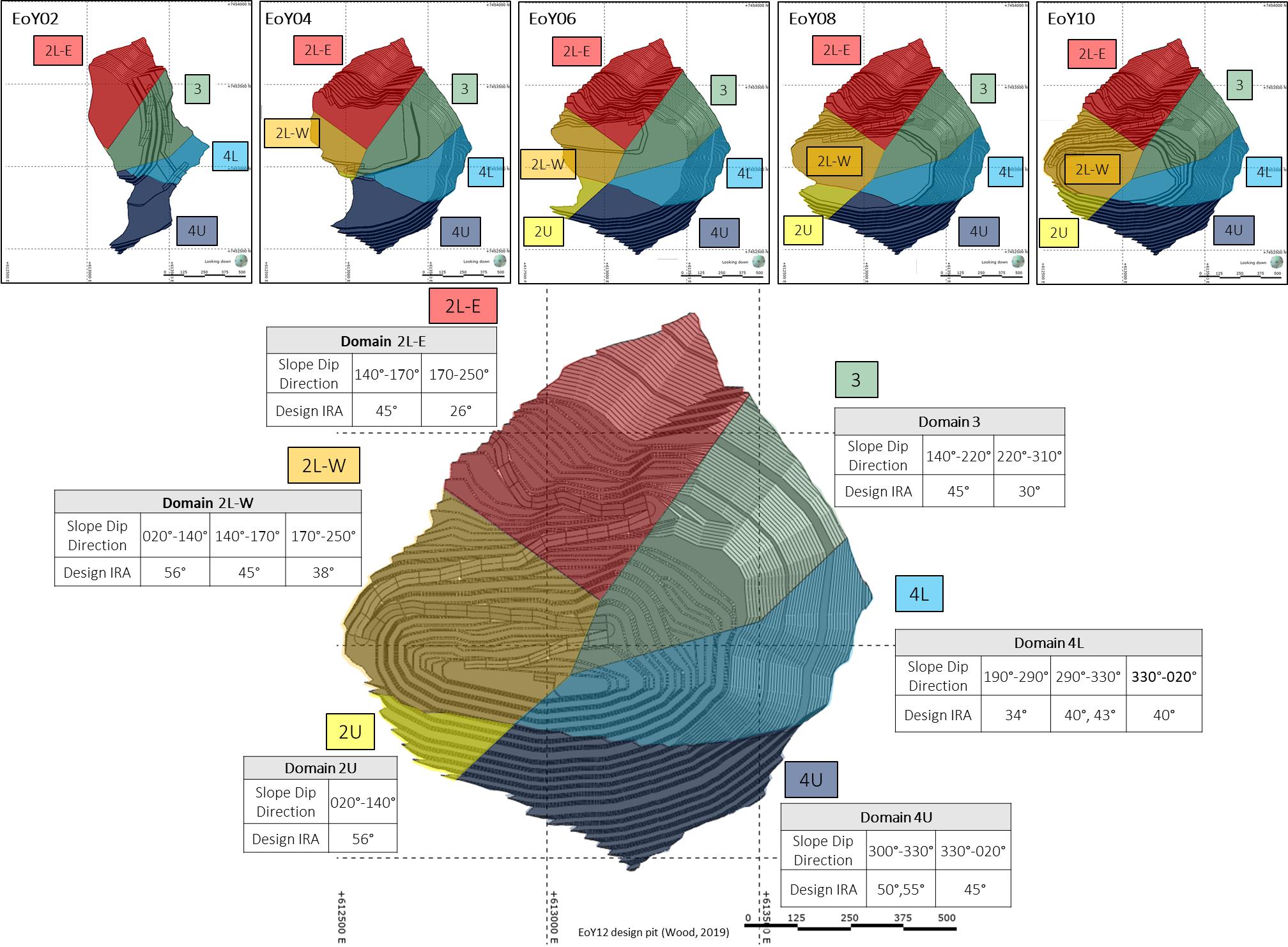

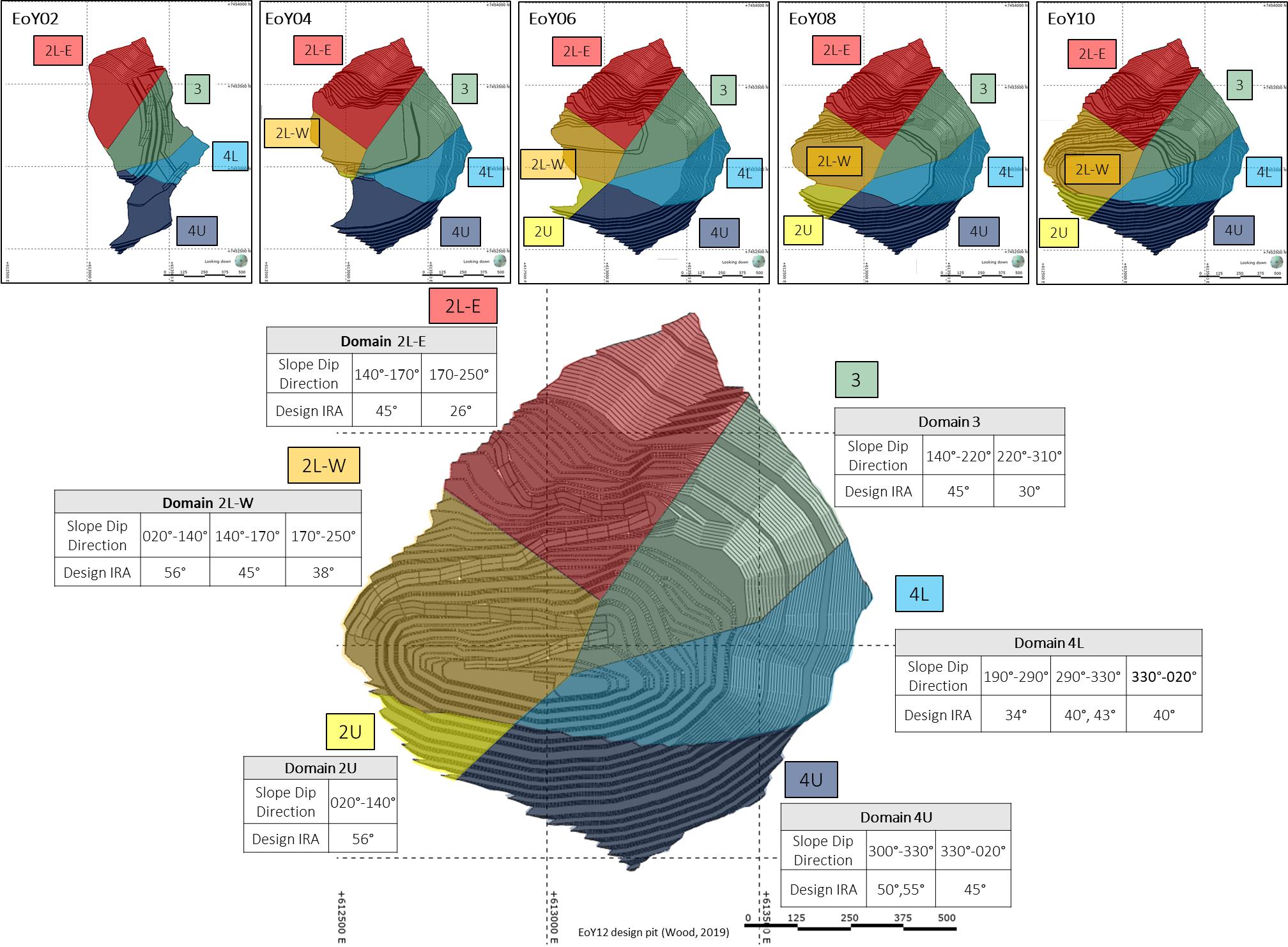

| Figure 9-8 | Recommended Inter-Ramp Angles by Slope Design Sector (Wood, 2019) | 9-14 |

| | |

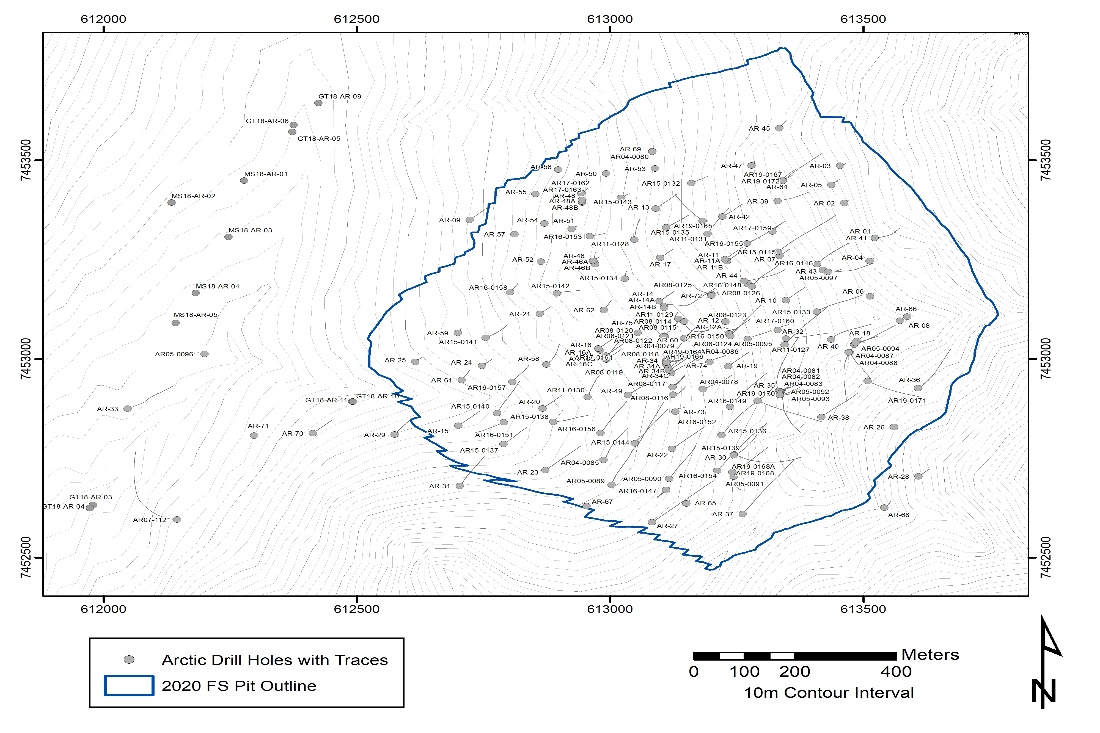

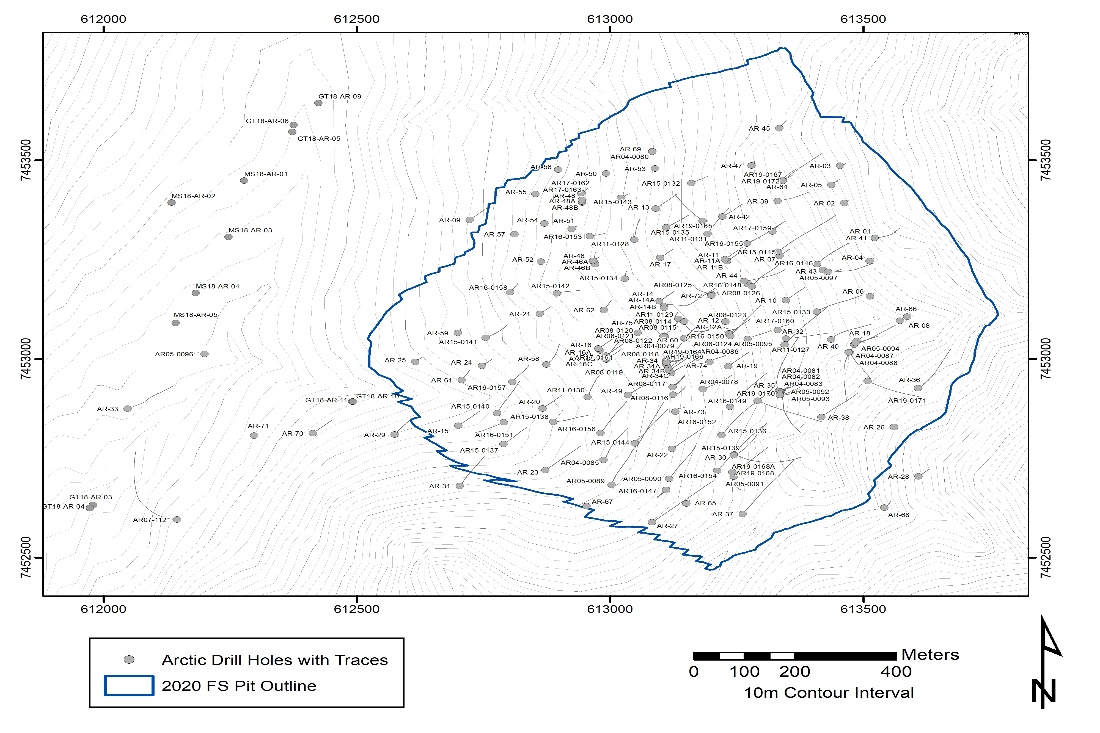

| Figure 10-1 | Plan Map of Drill Holes in the Vicinity of the Arctic Deposit (Trilogy Metals, 2020) | 10-3 |

| | |

| Figure 10-2 | Collar Locations and Principal Target Areas – Ambler Mining District (Trilogy Metals, 2020) | 10-9 |

| | |

| Figure 10-3 | Sunshine Prospect and Drill Hole Locations (Trilogy Metals, 2020) | 10-10 |

| | |

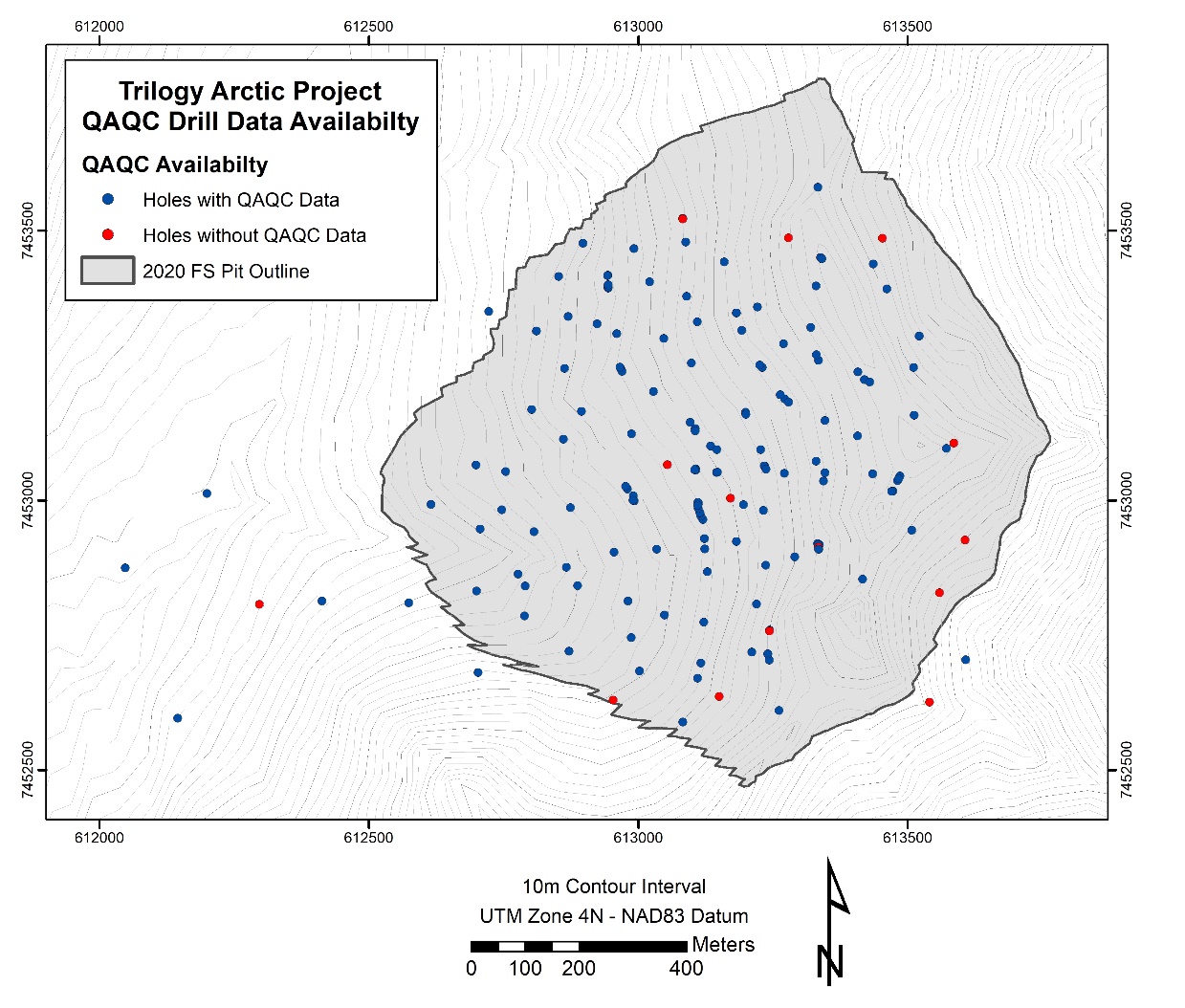

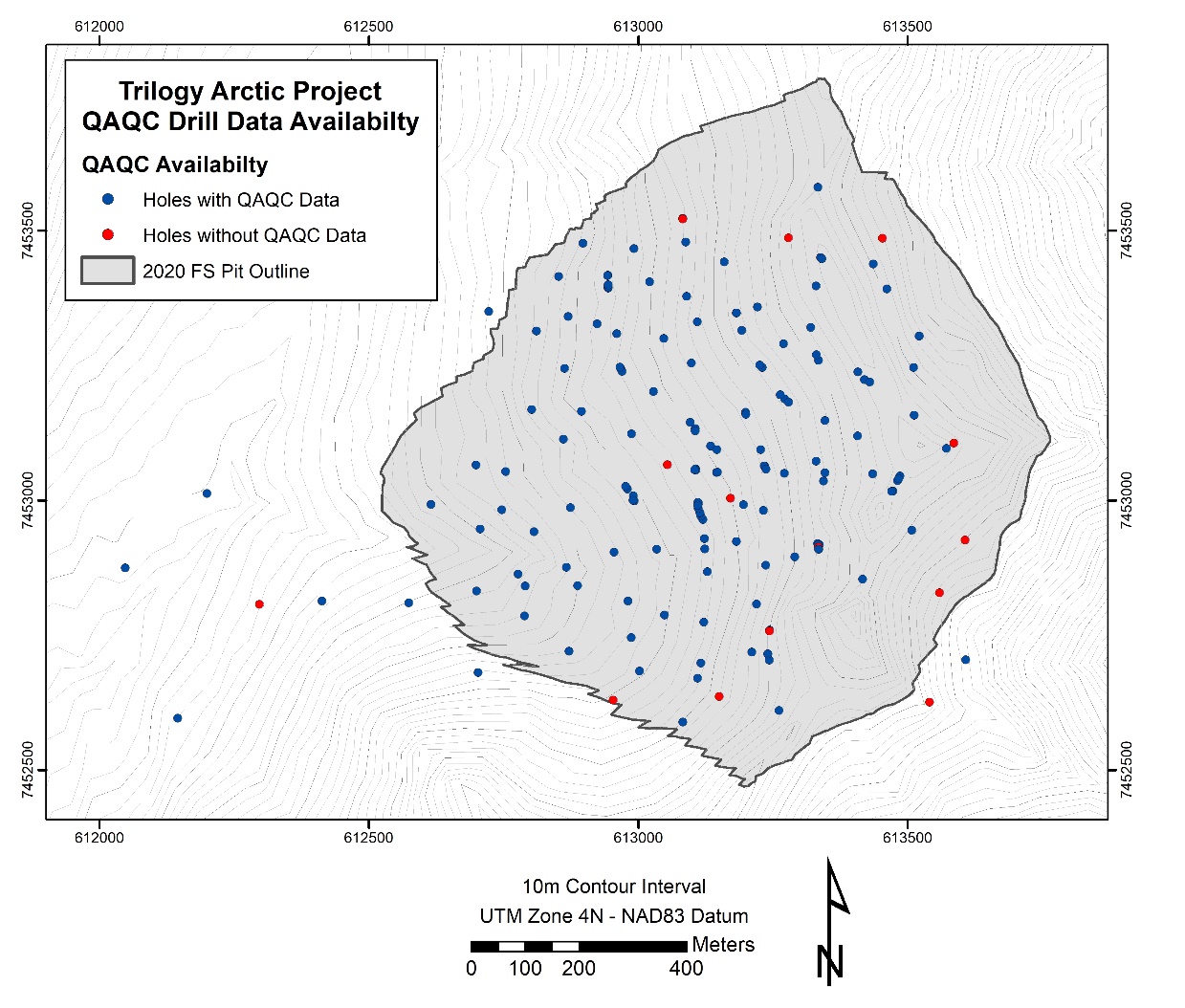

| Figure 11-1 | Spatial Availability of QA/QC Data (Trilogy Metals, 2019) | 11-6 |

| | |

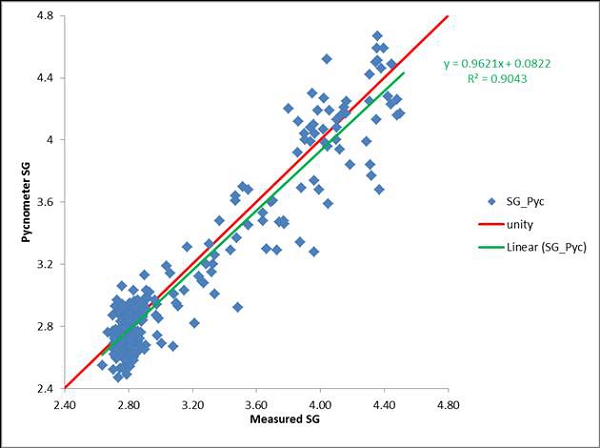

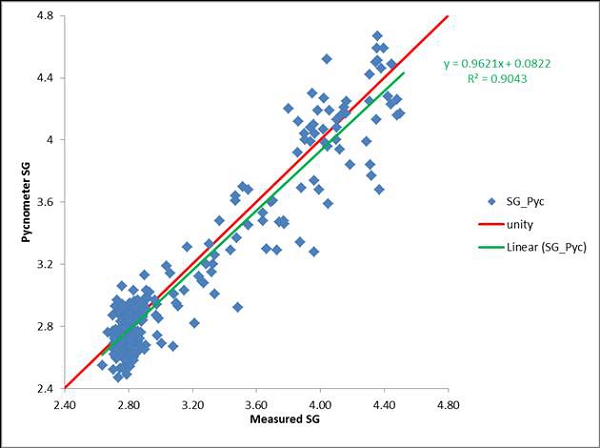

| Figure 11-2 | Graph Showing Good Agreement between Wet-dry Measured Specific Gravity and Pycnometer Measured Specific Gravity (West, A., 2014) | 11-15 |

| | |

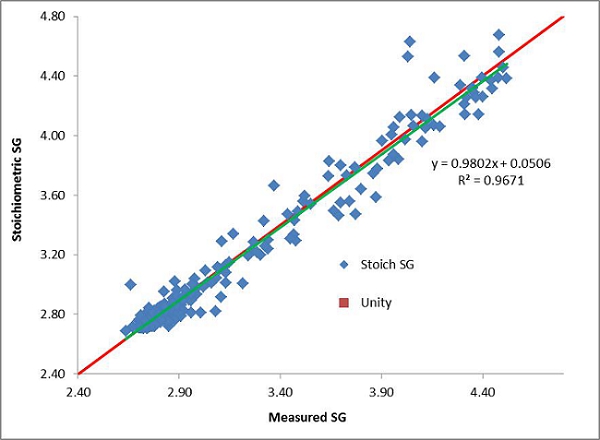

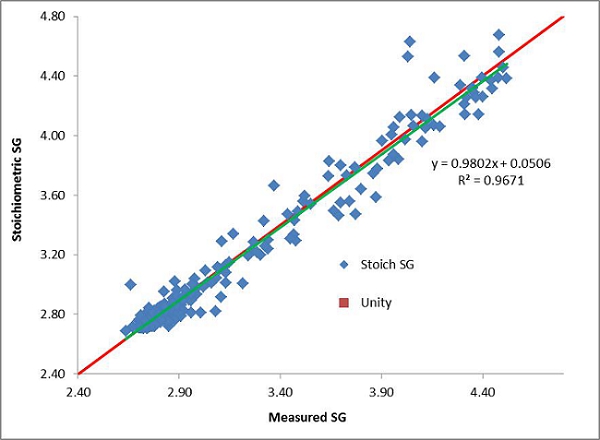

| Figure 11-3 | Measured versus Stoichiometric Specific Gravities (West, A., 2014) | 11-16 |

| | |

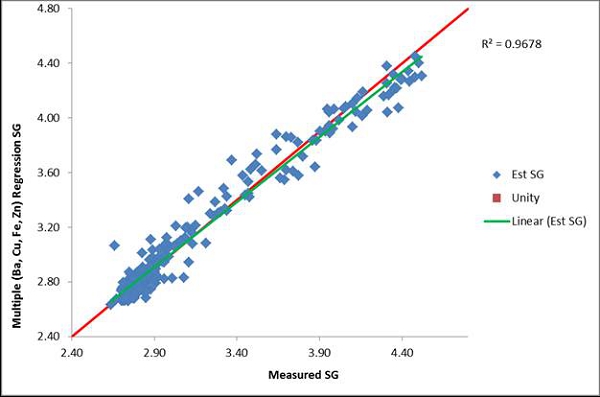

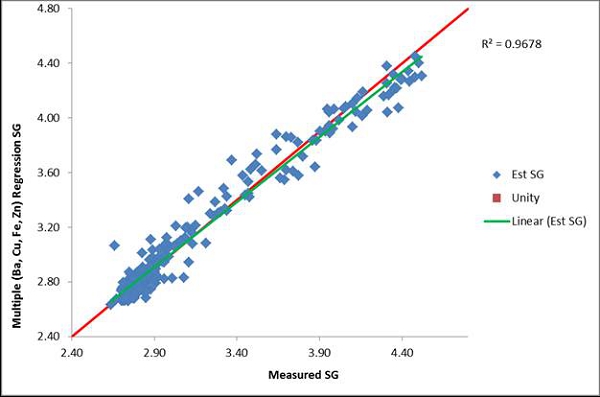

| Figure 11-4 | Scatter Plot Showing the Measured Specific Gravity versus Multiple (Copper, Iron, Zinc, Barium) Regression Estimate (West, A., 2014) | 11-17 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-X |

|  |

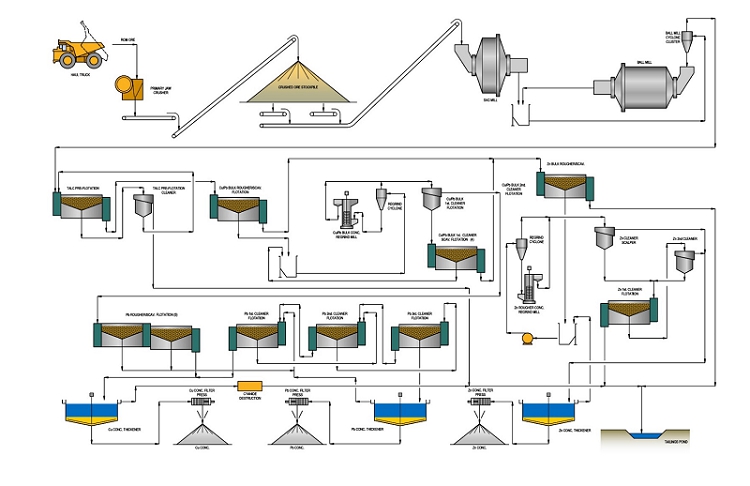

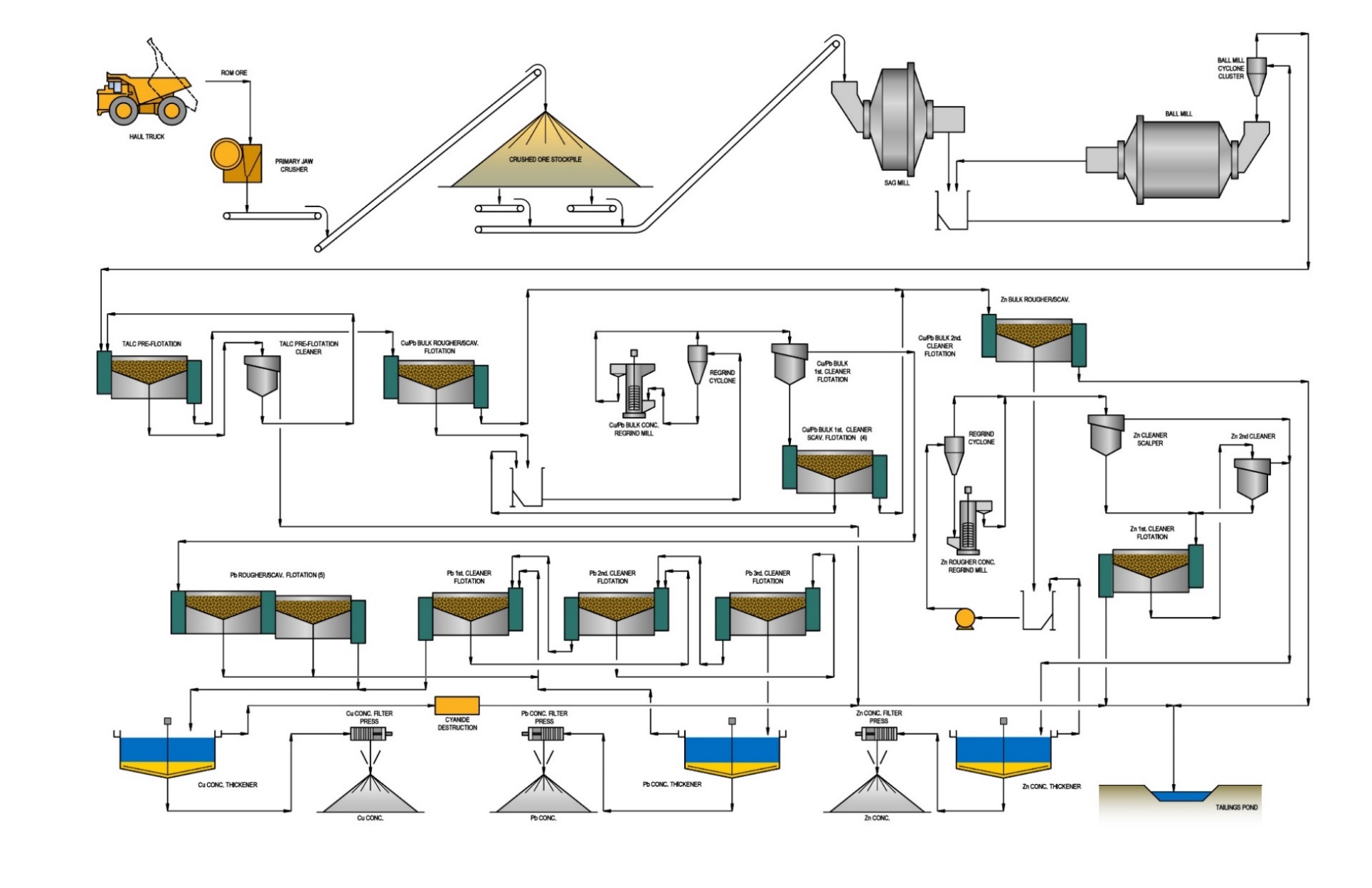

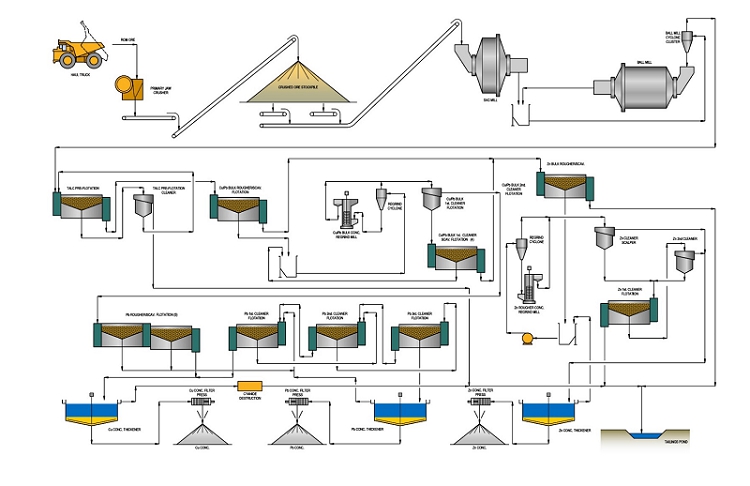

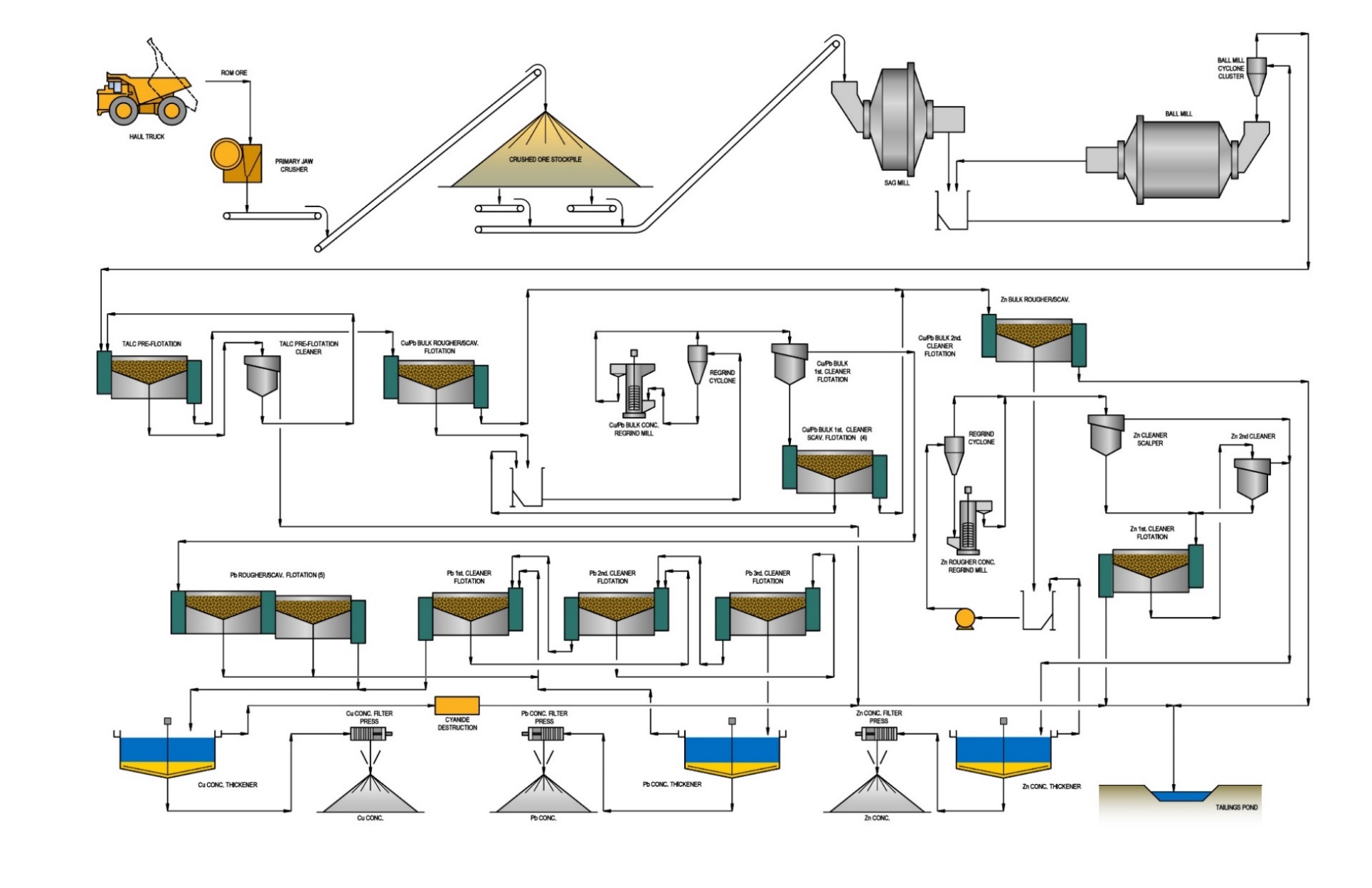

| Figure 13-1 | Proposed Copper-Lead-Zinc Flowsheet including Talc Pre-float (Ausenco, 2020) | 13-3 |

| | |

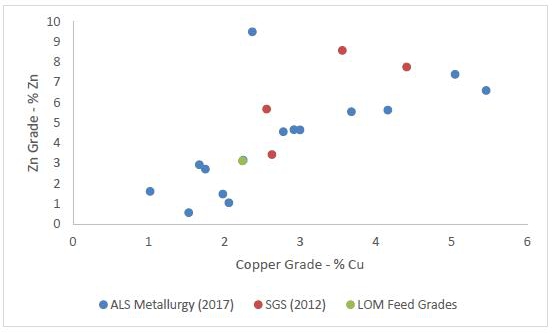

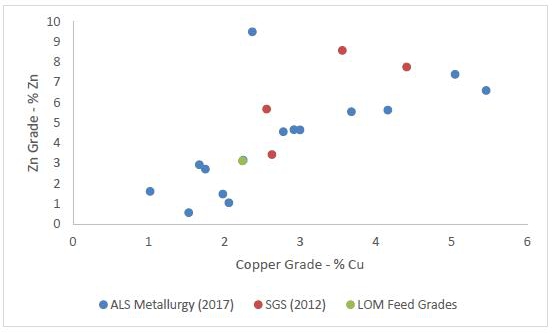

| Figure 13-2 | Cu and Zn Test Sample Grades for ALS Metallurgy/SGS Programs (Austin, 2020) | 13-8 |

| | | |

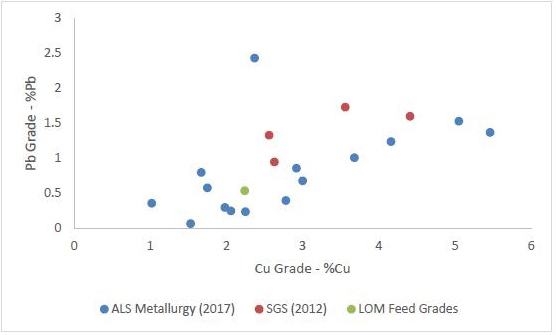

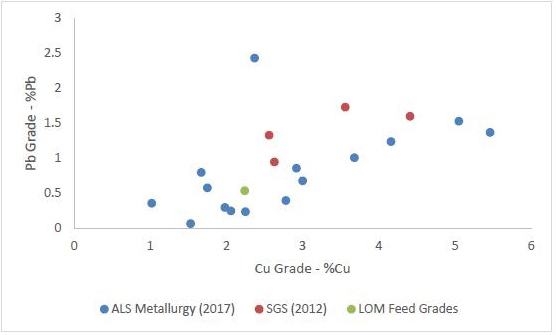

| Figure 13-3 | Cu and Pb Test Sample Grades for ALS Metallurgy/SGS Programs (Austin, 2020) | 13-9 |

| | |

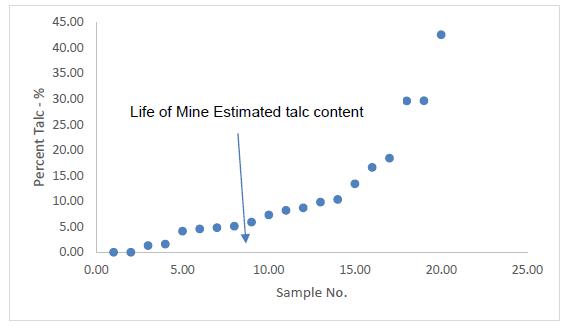

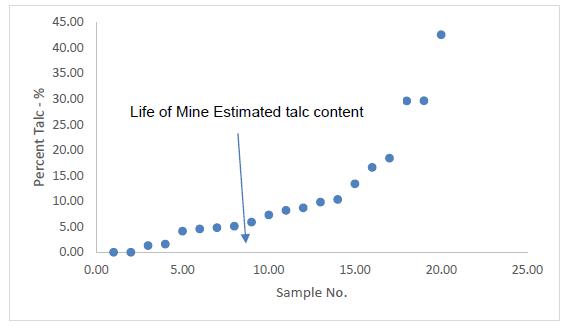

| Figure 13-4 | Distribution of Talc content within the 2012 and 2017 Test Samples (Austin, 2020) | 13-9 |

| | |

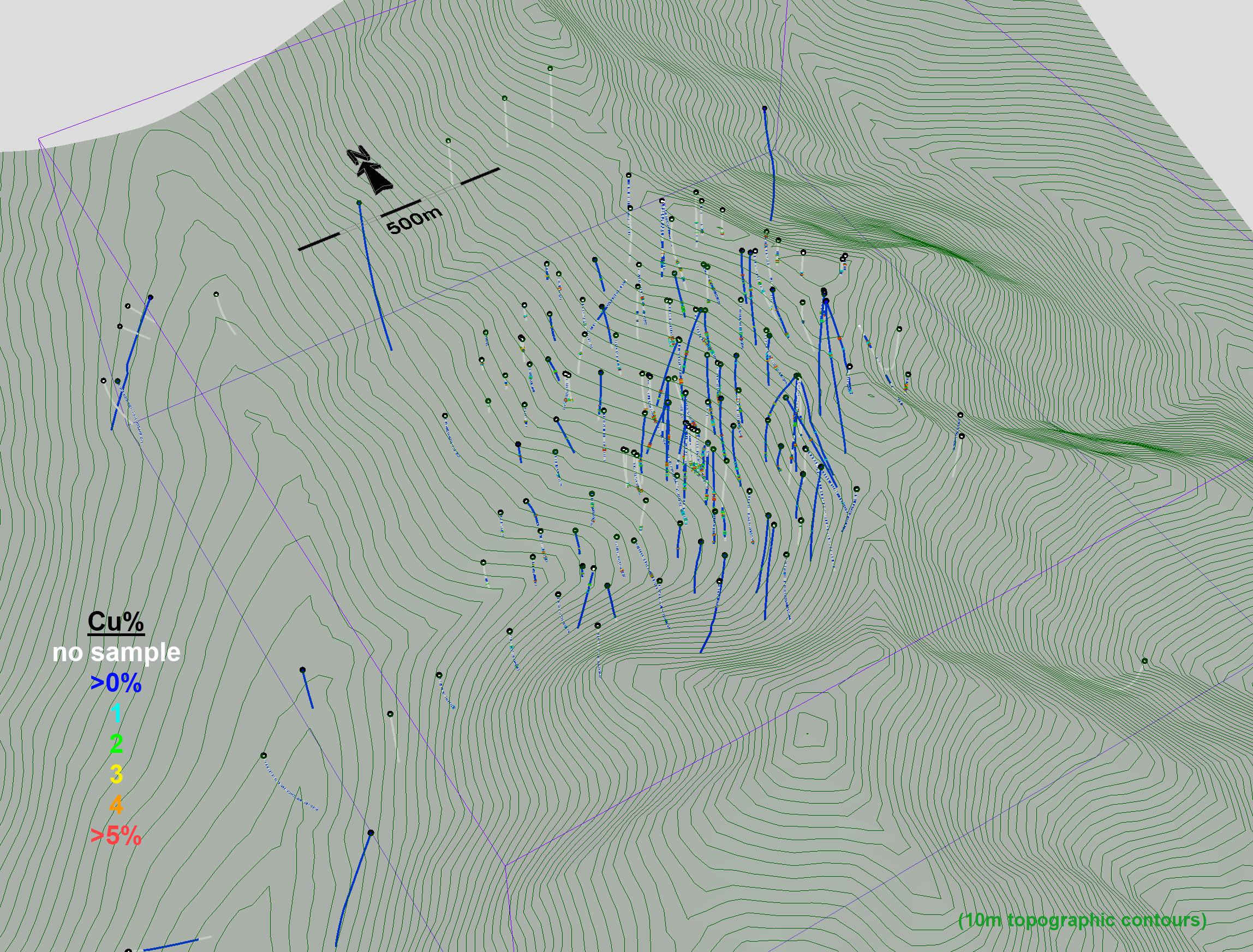

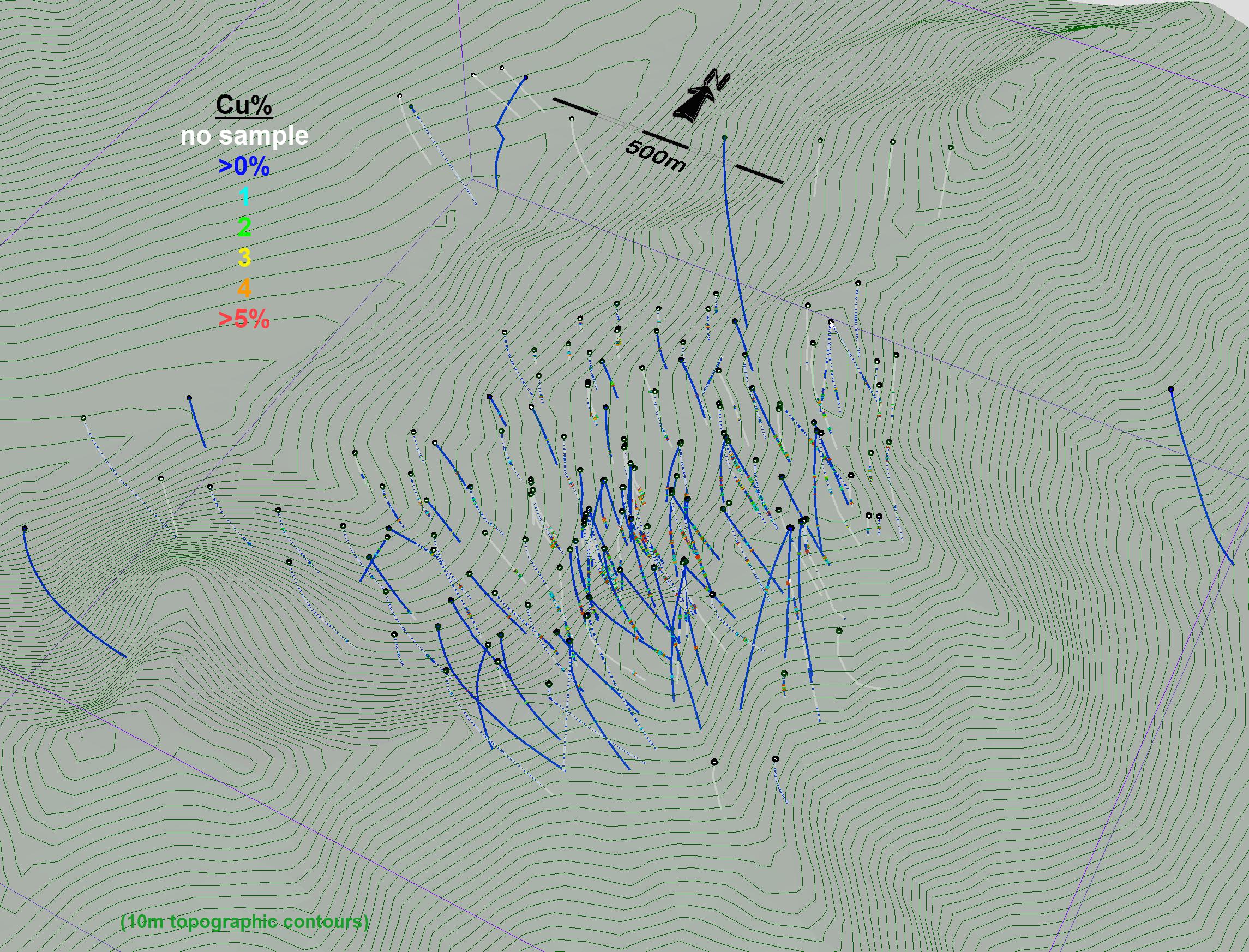

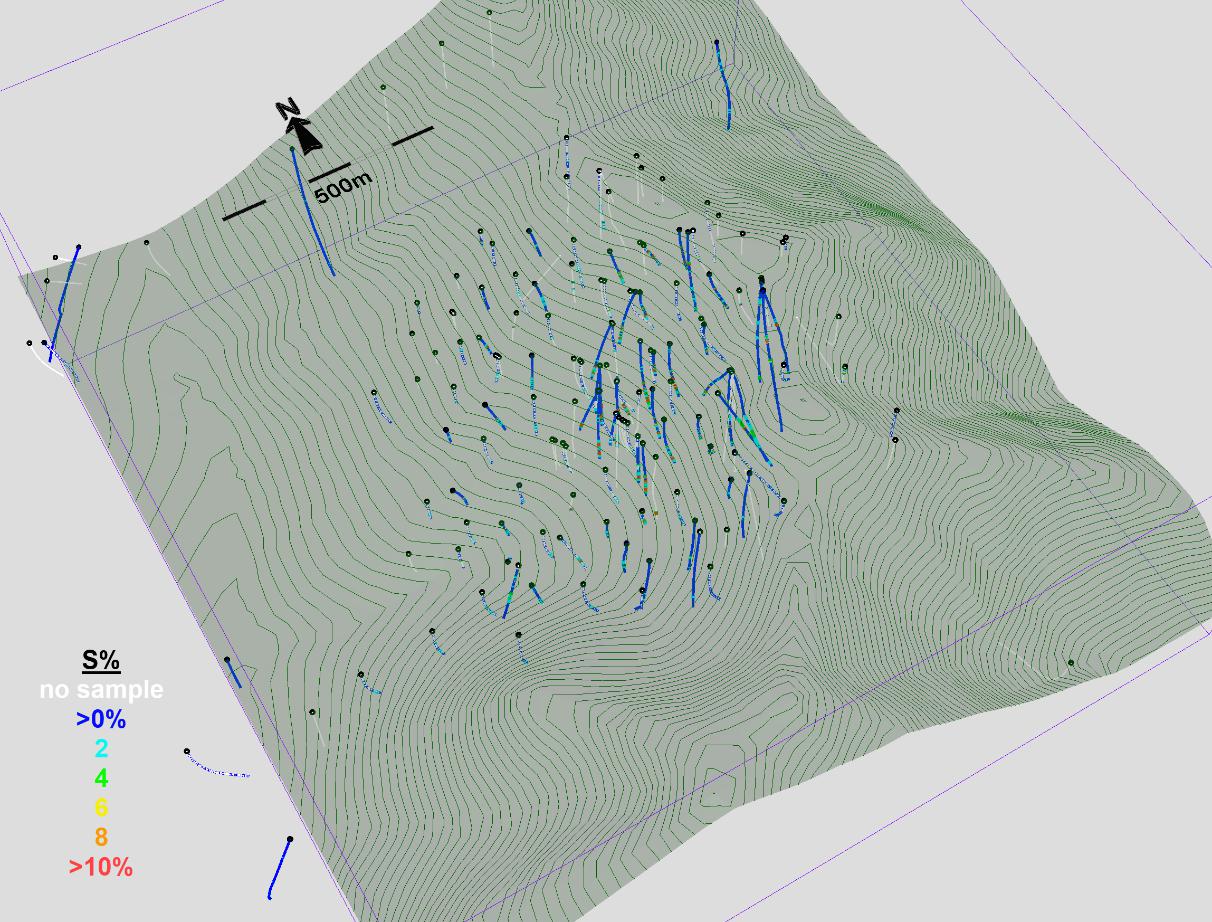

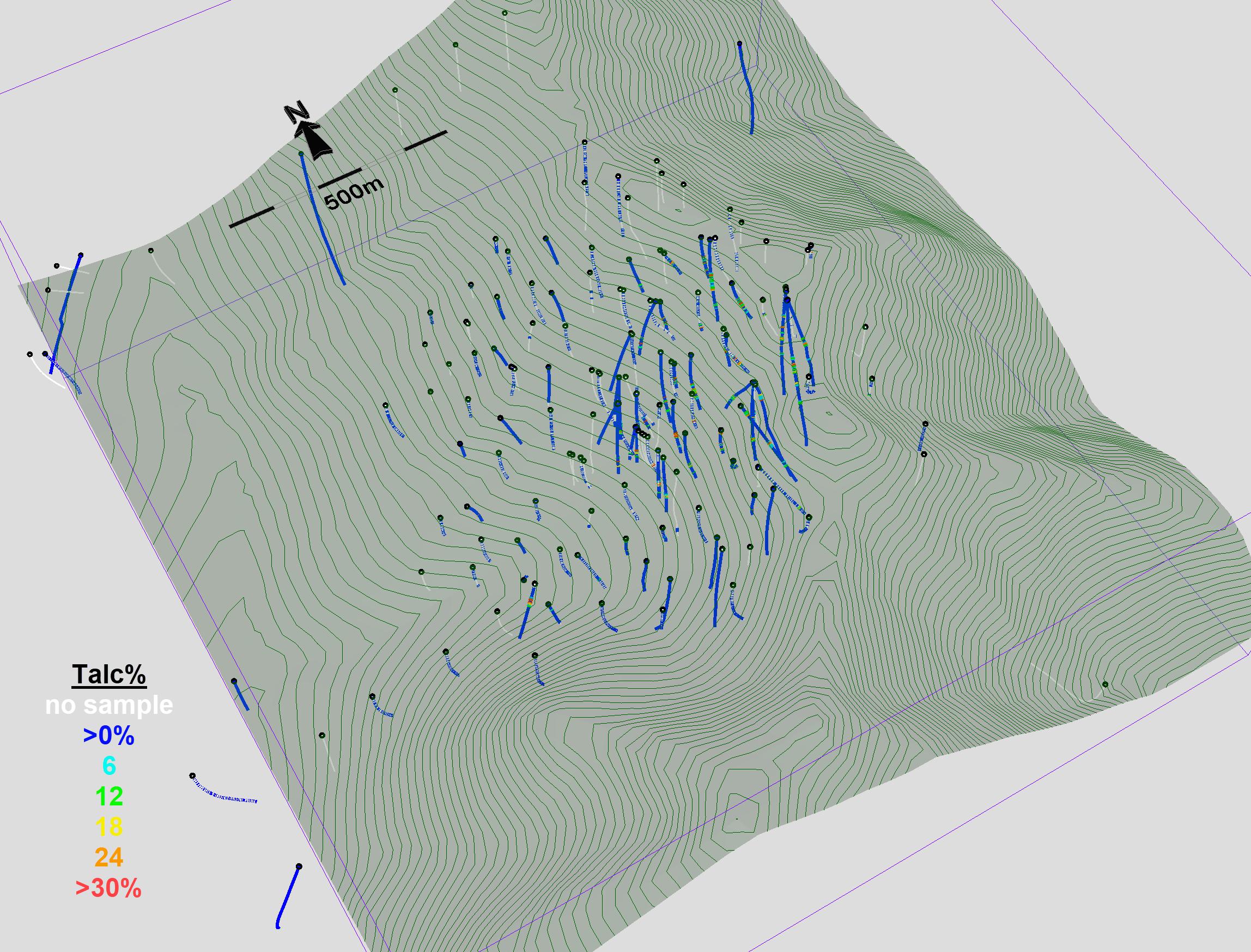

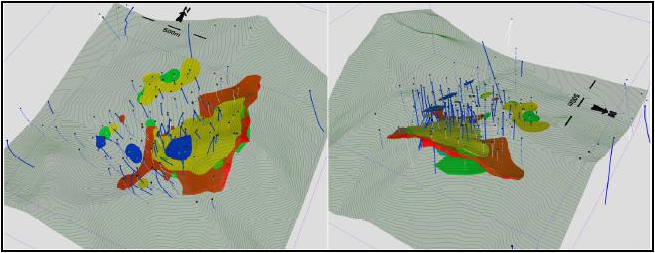

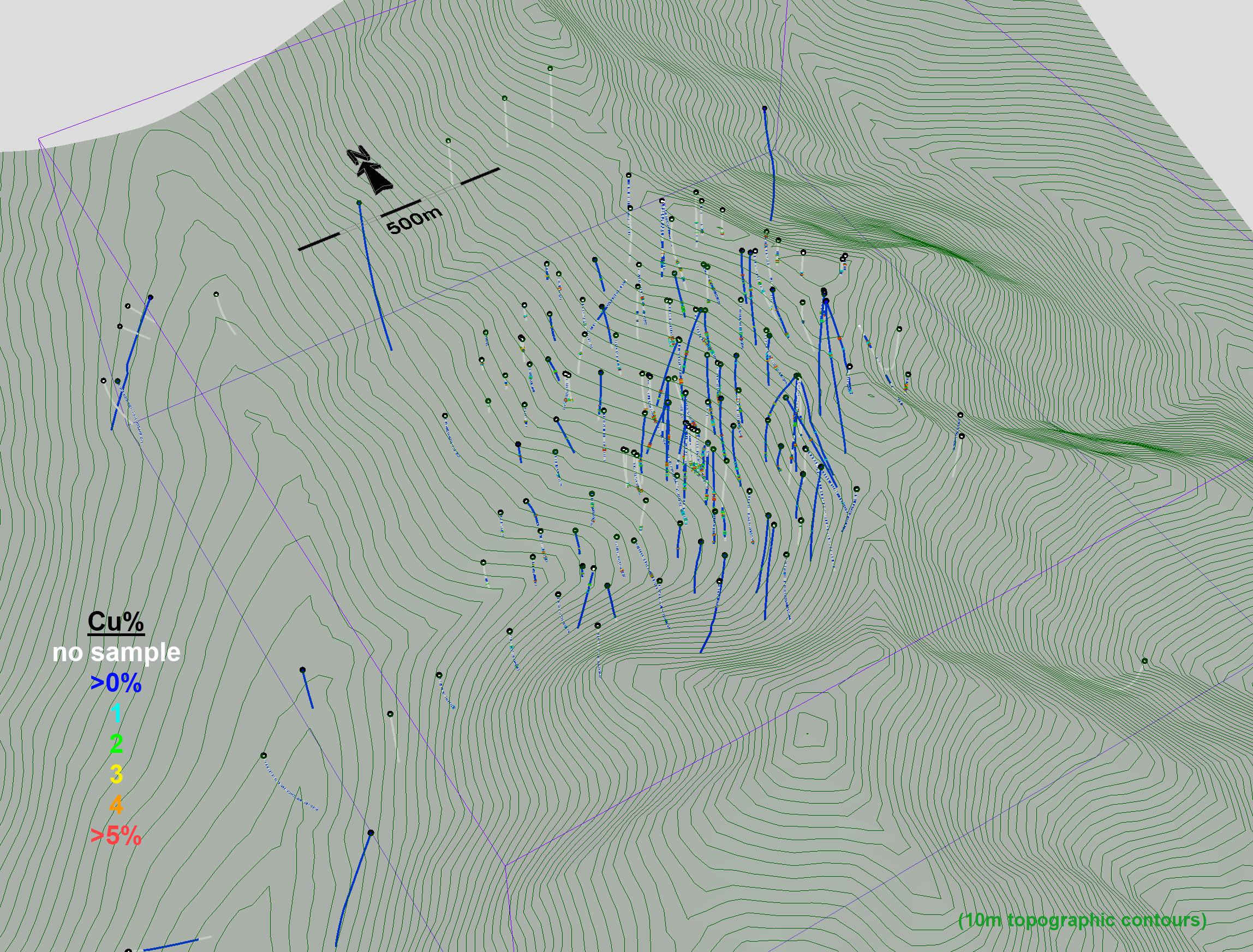

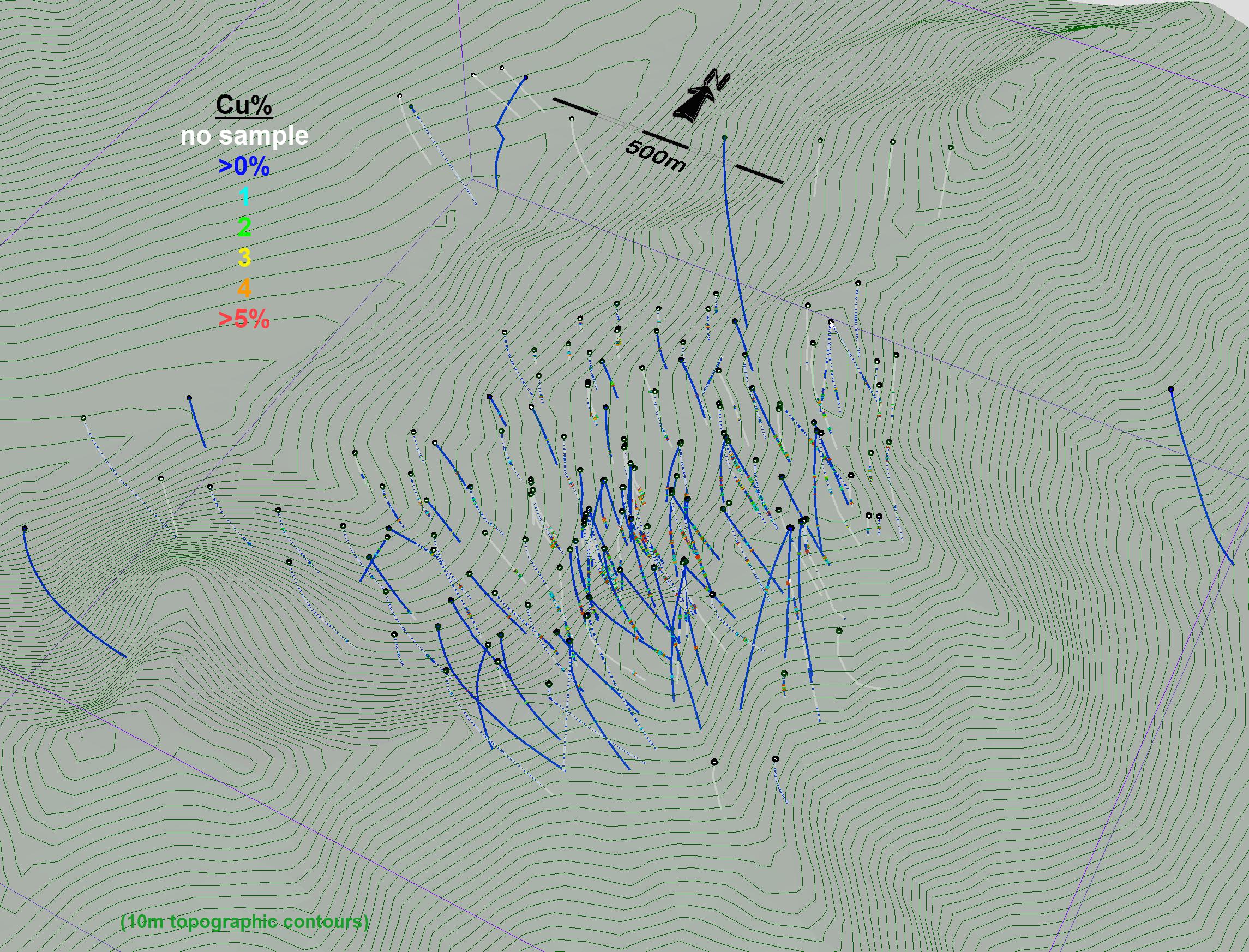

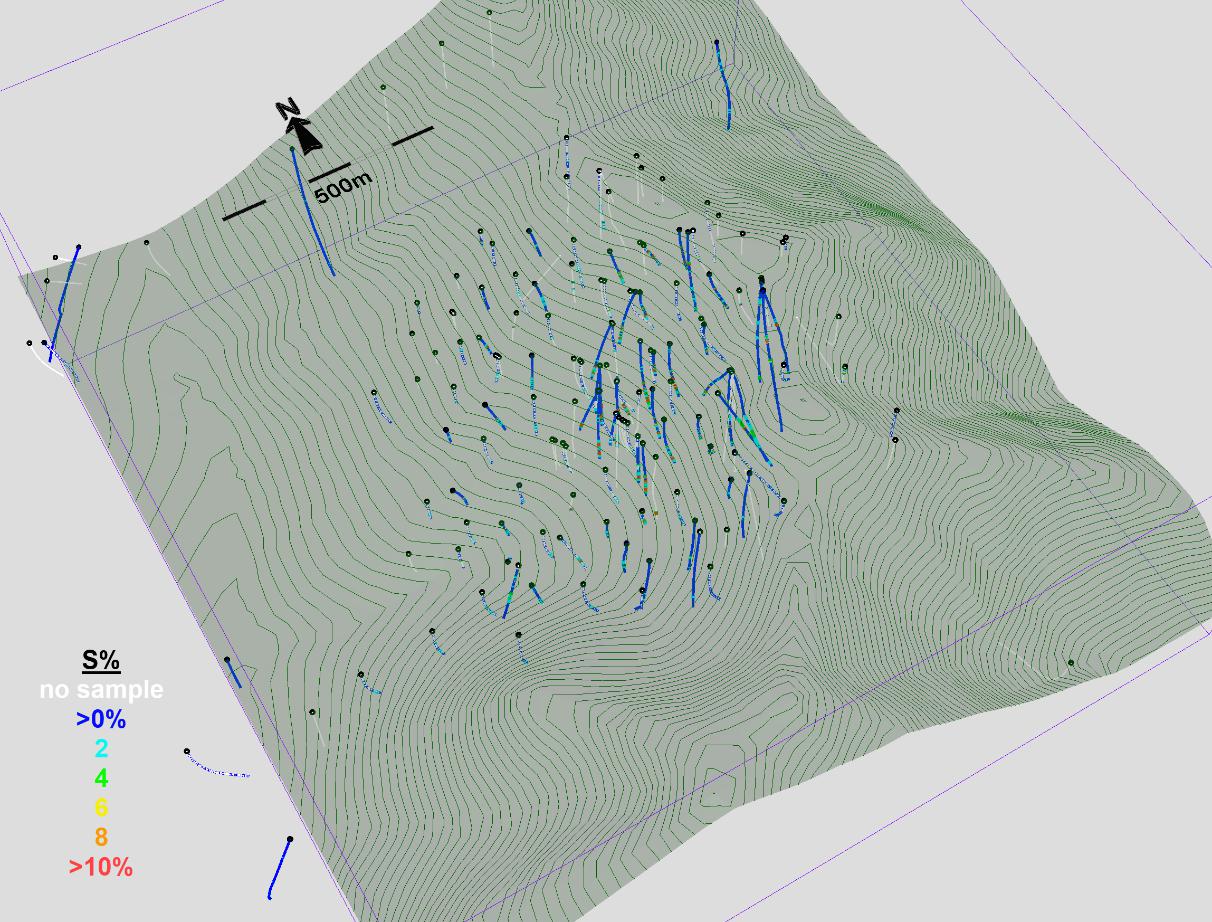

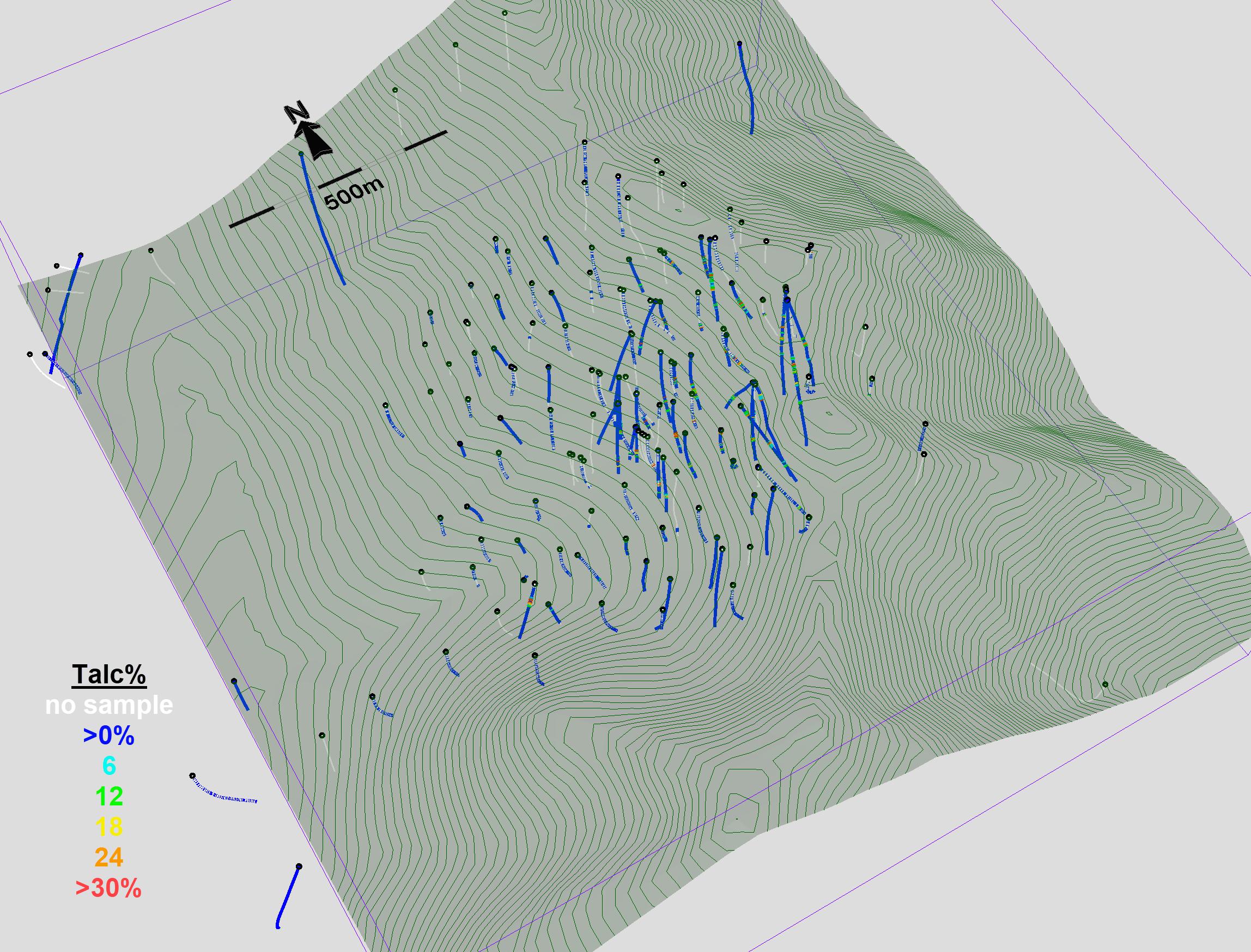

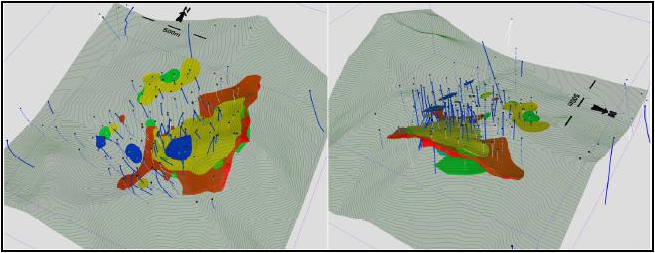

| Figure 14-1 | Isometric View of Copper Grades in Drill Holes (Sim, 2019) | 14-3 |

| | |

| Figure 14-2 | Isometric View of Copper Grades in Drill Holes (Sim, 2019) | 14-4 |

| | |

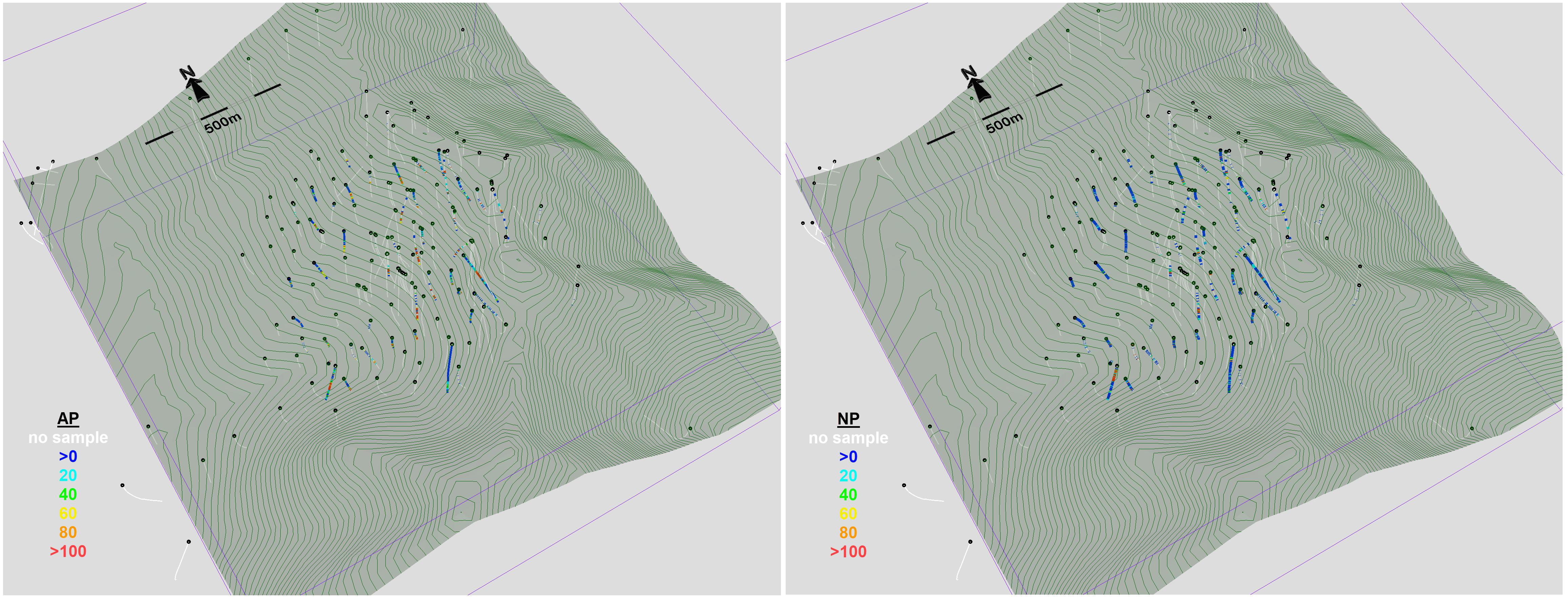

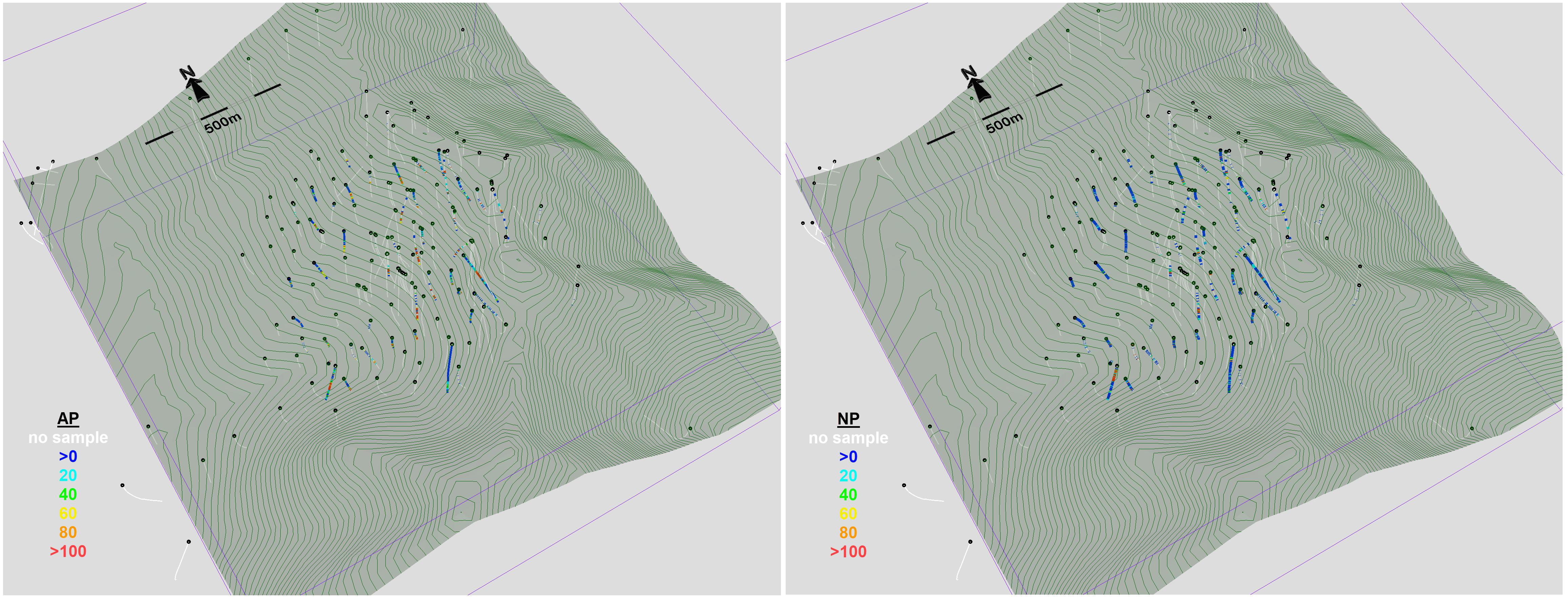

| Figure 14-3 | Isometric Views of Available AP and NP Data (Sim, 2019) | 14-5 |

| | |

| Figure 14-4 | Isometric View of Available Sulphur Data (Sim, 2019) | 14-5 |

| | |

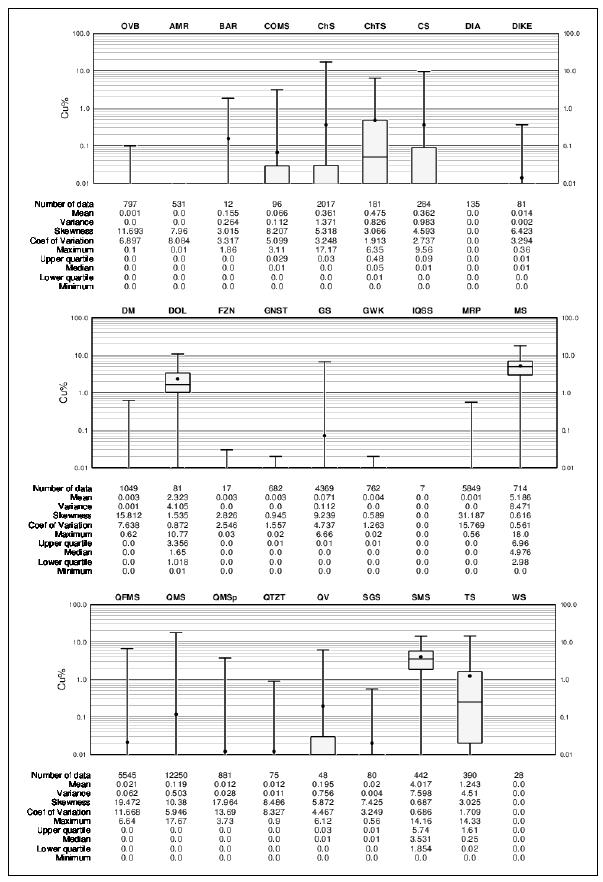

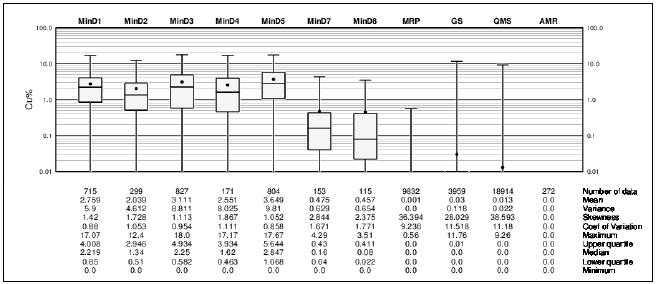

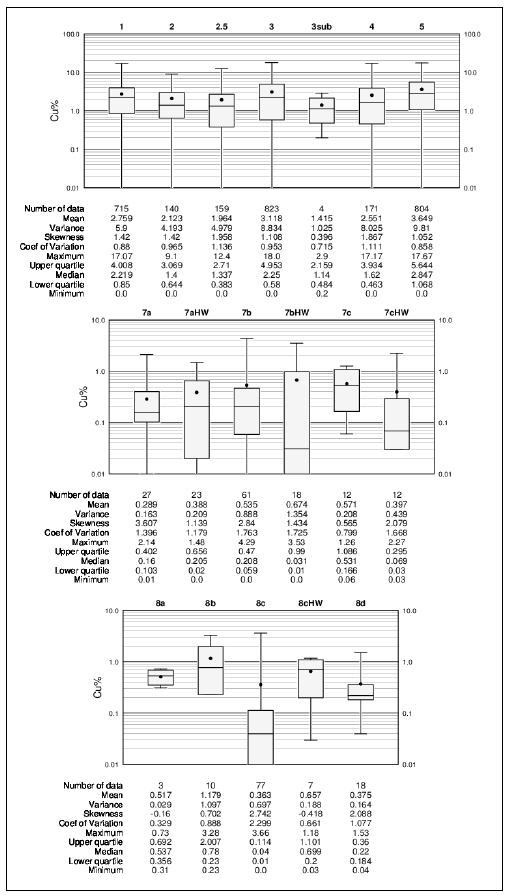

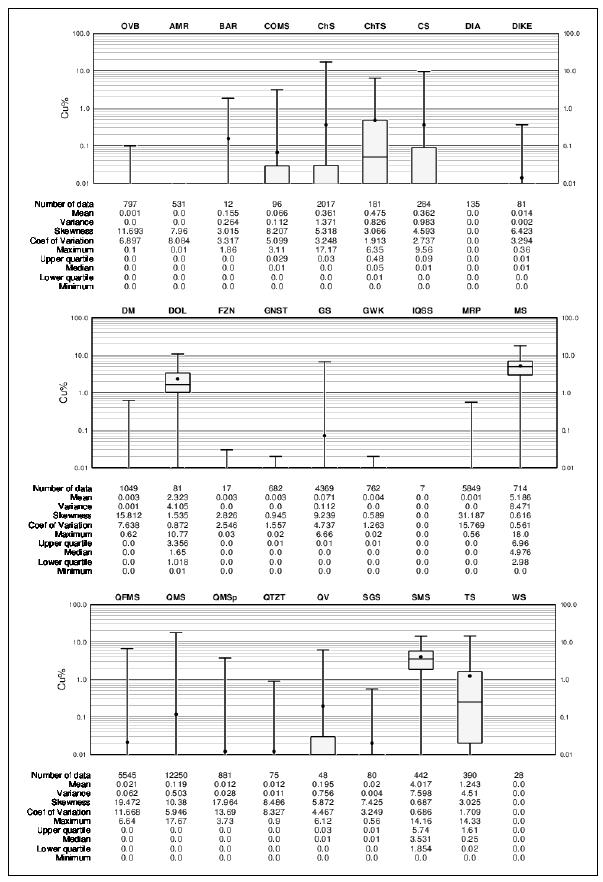

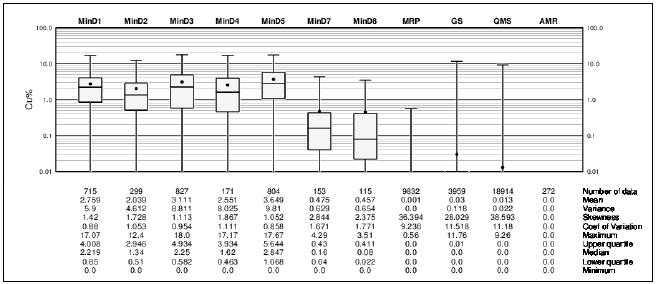

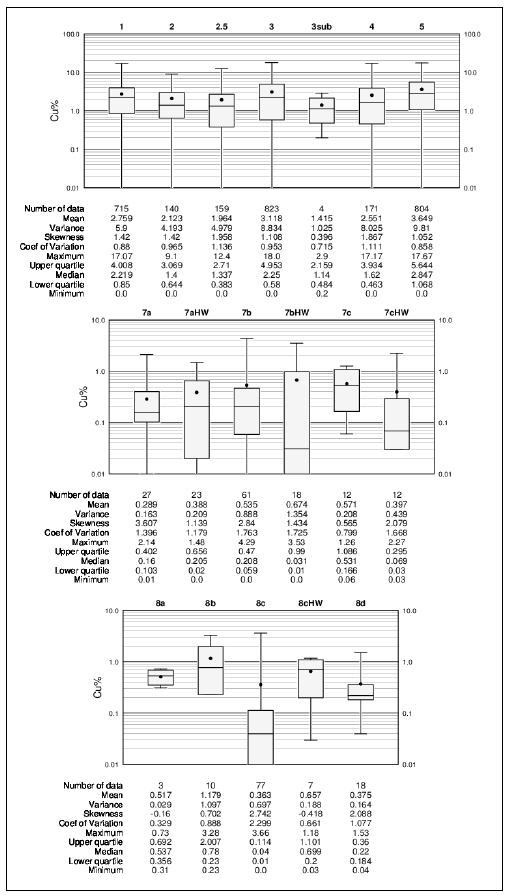

| Figure 14-5 | Boxplots of Copper by Logged Lithology Type (Sim, 2017) | 14-12 |

| | |

| Figure 14-6 | Boxplots of Copper by Lithology Domain (Sim, 2017) | 14-13 |

| | |

| Figure 14-7 | Boxplots of Gold by Lithology Domain (Sim, 2017) | 14-14 |

| | |

| Figure 14-8 | Boxplots of Copper by MinZone Domain (Sim, 2017) | 14-15 |

| | |

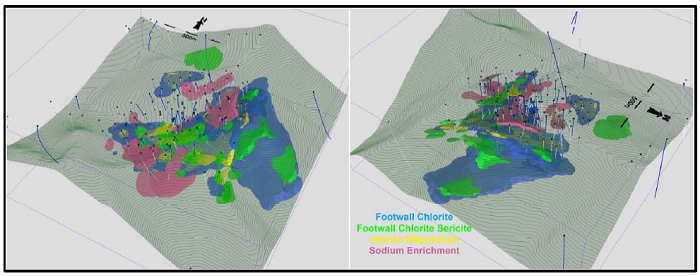

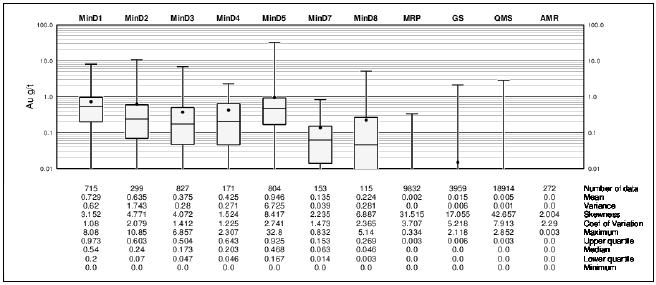

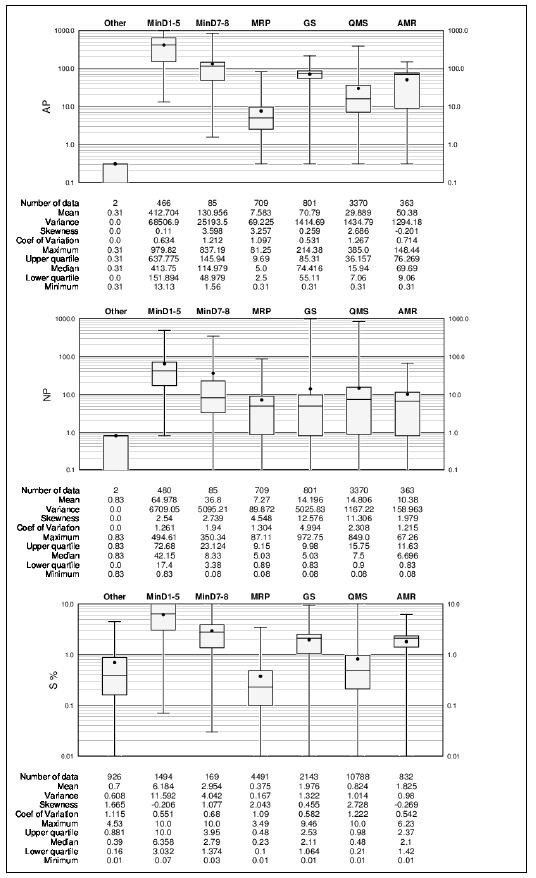

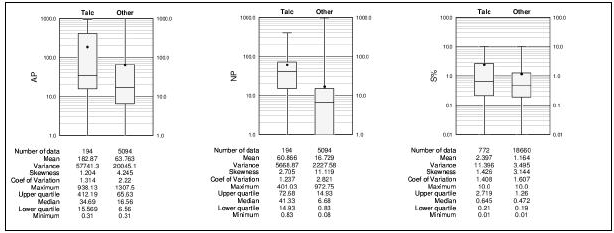

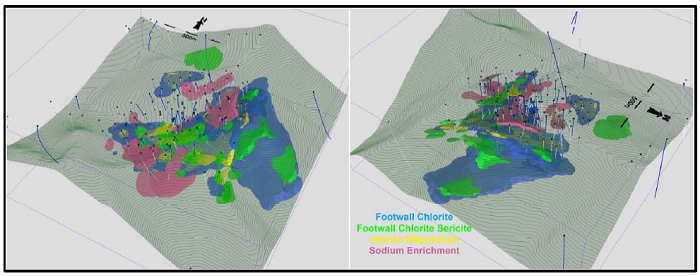

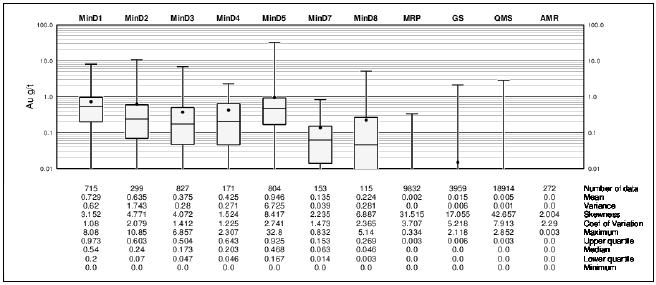

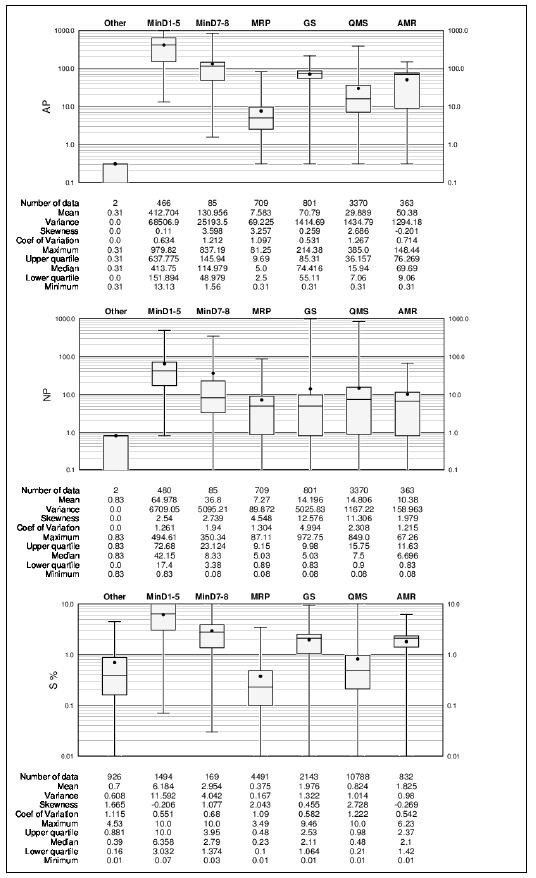

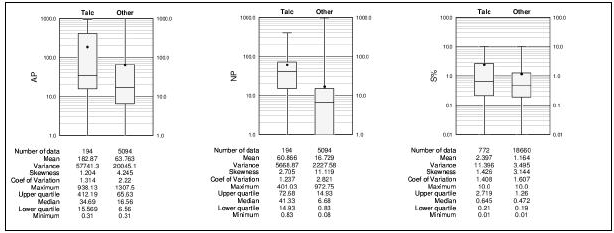

| Figure 14-9 | Boxplots of AP (kg CaCO3/t), NP (kg CaCO3/t) and Sulphur by Lithology Domain (Sim, 2017) | 14-17 |

| | |

| Figure 14-10 | Boxplots of AP (kg CaCO3/t), NP (kg CaCO3/t) and Sulphur by Talc Domain (Sim, 2017) | 14-18 |

| | |

| Figure 14-11 | Boxplots of AP (kg CaCO3/t), NP (kg CaCO3/t) and Sulphur by Weathered Domain (Sim, 2017) | 14-18 |

| | |

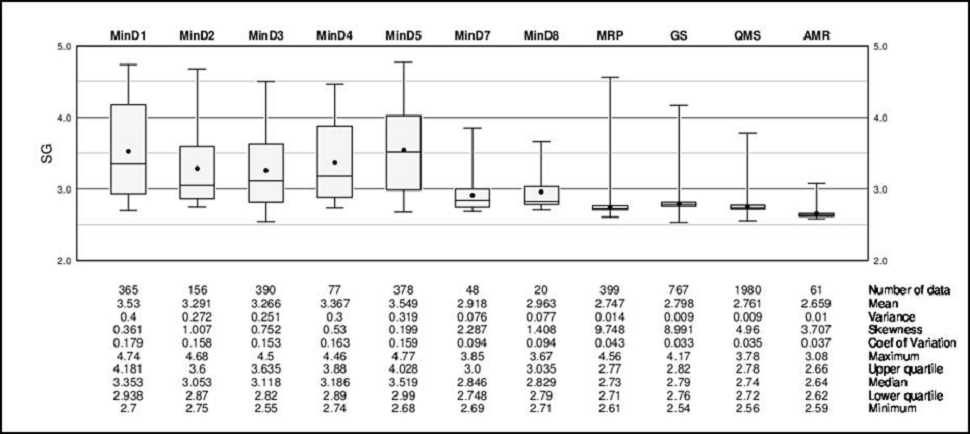

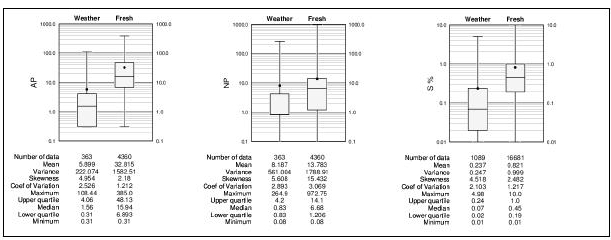

| Figure 14-12 | Boxplots of SG by MinZone and Lithology Group Domains (Sim, 2017) | 14-19 |

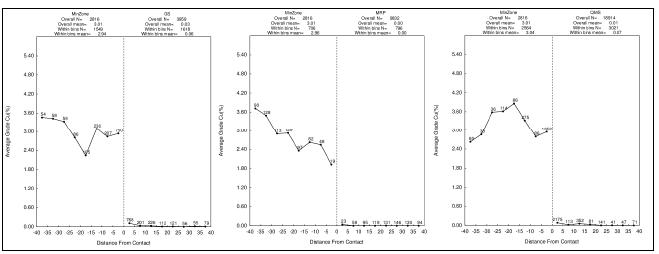

| | |

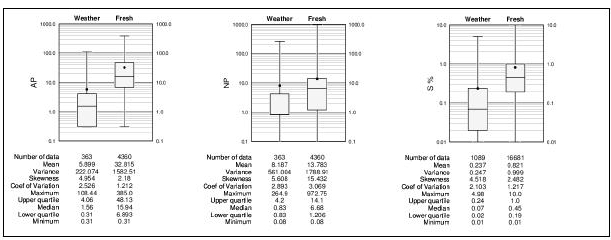

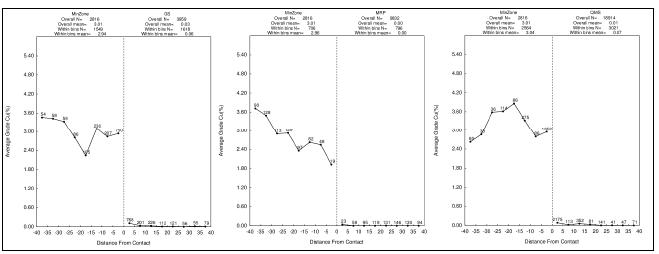

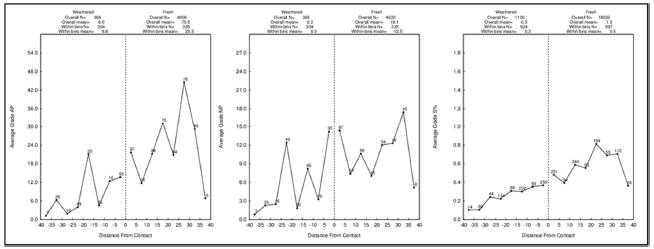

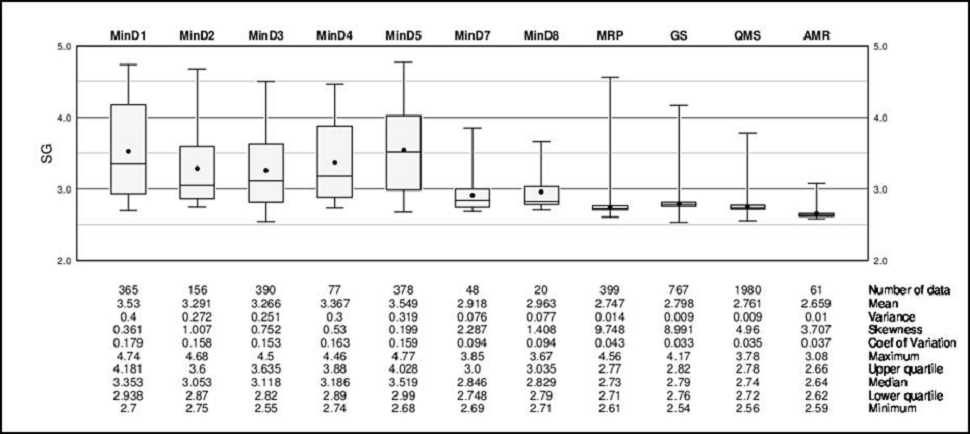

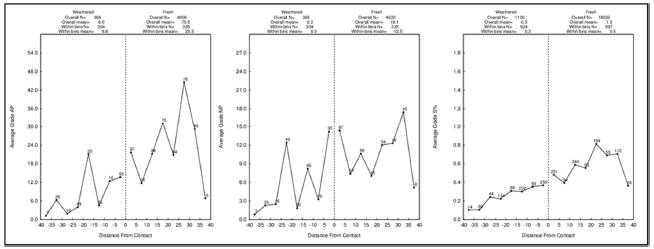

| Figure 14-13 | Contact Profiles of Copper Between MinZone and other Lithology Domain Groups (Sim, 2017) | 14-19 |

| | |

| Figure 14-14 | Contact Profile of AP (kg CaCO3/t), NP (kg CaCO3/t) and Sulphur Between Weathered and Fresh Rocks (Sim, 2017) | 14-20 |

| | |

| Figure 14-15 | Contact Profile of AP (kg CaCO3/t), NP (kg CaCO3/t) and Sulphur Inside / Outside of the Talc Domains (Sim, 2017) | 14-20 |

| | |

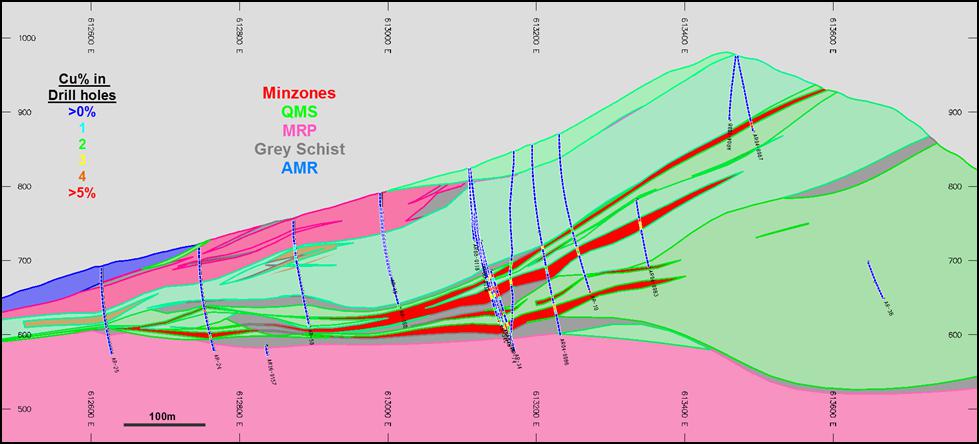

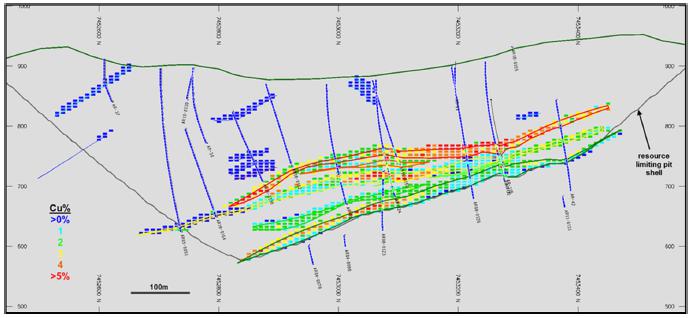

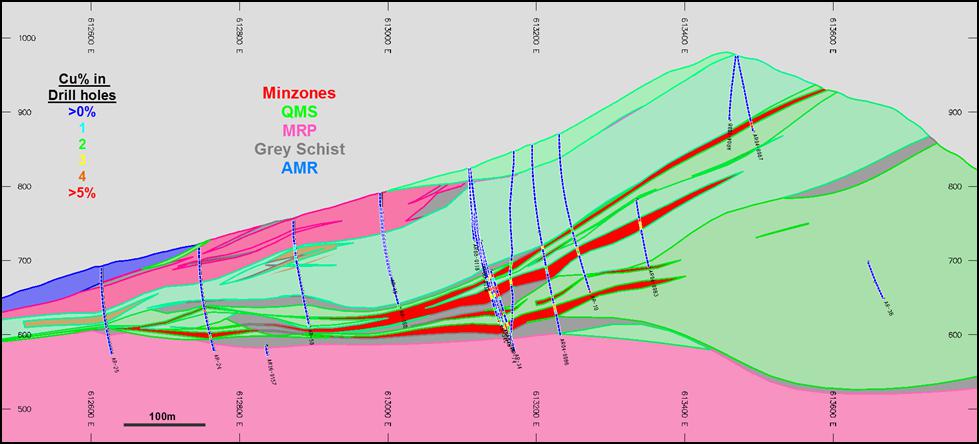

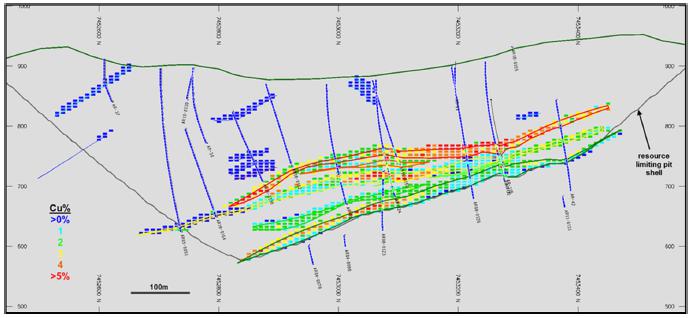

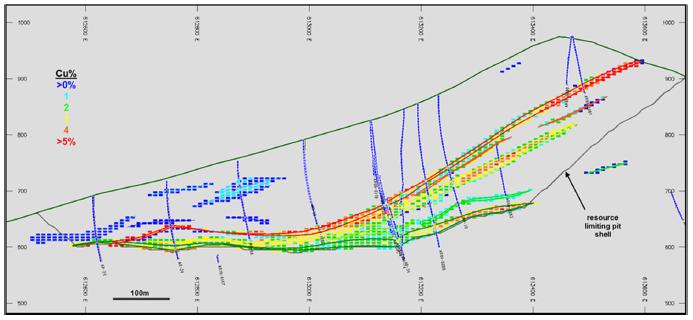

| Figure 14-16 | North-South Vertical Section of Copper Estimates in the Block Model (Section 613250E) (Sim, 2017) | 14-31 |

| | |

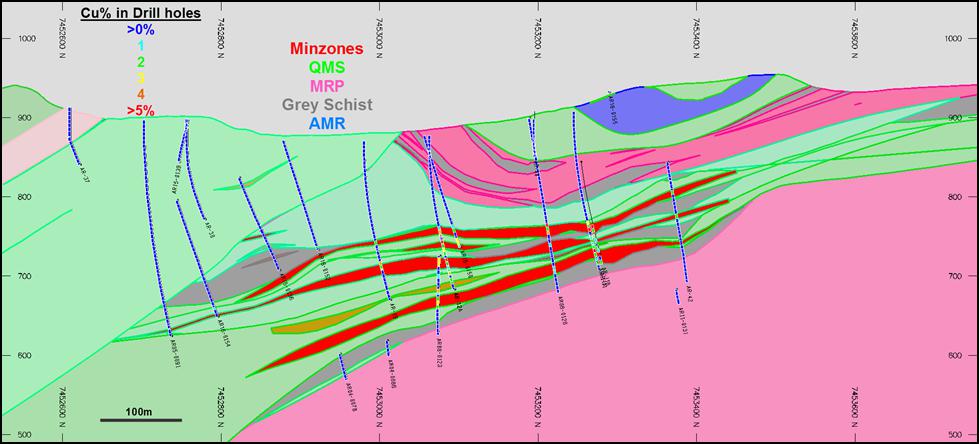

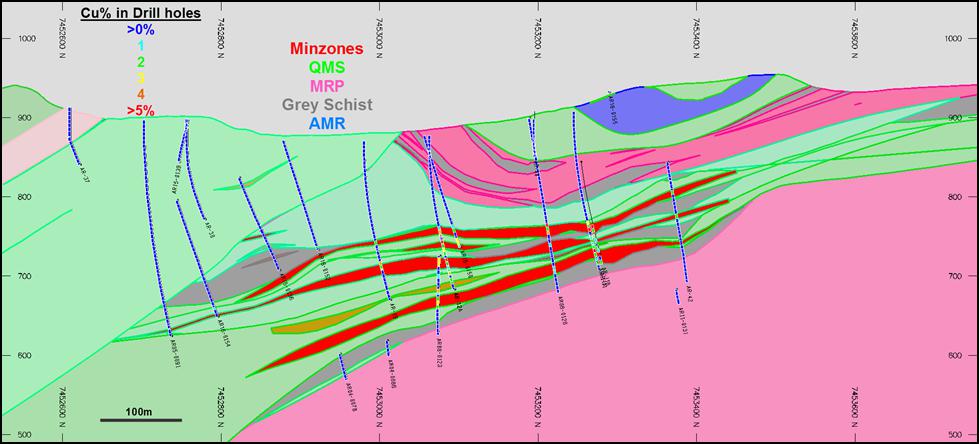

| Figure 14-17 | West-East Vertical Section of Copper Estimates in the Block Model (Section 7453000N) (Sim, 2017) | 14-32 |

| | |

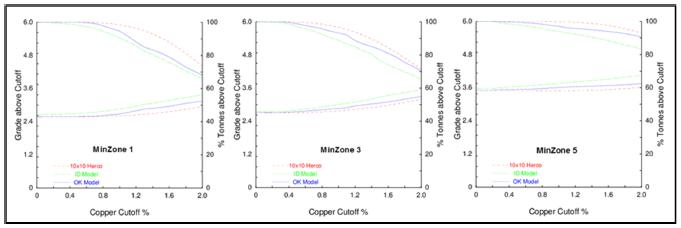

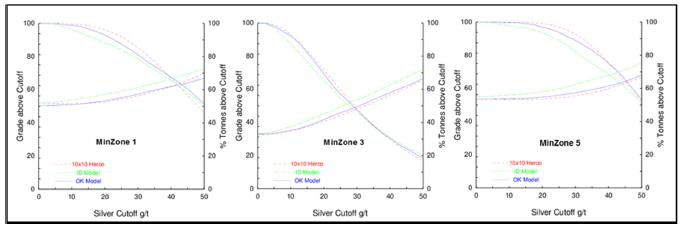

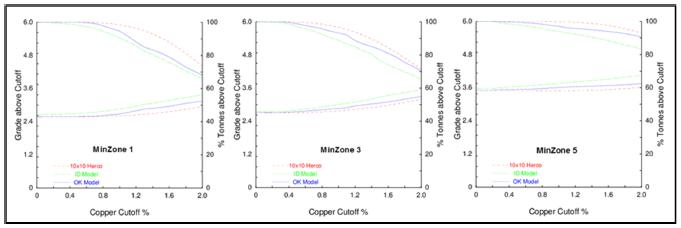

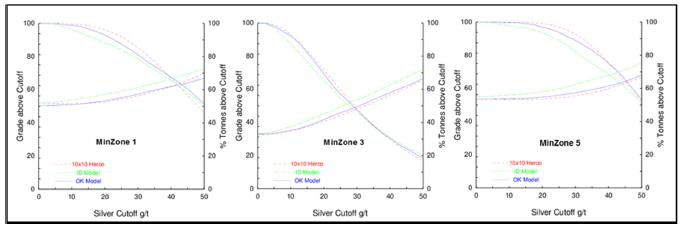

| Figure 14-18 | Herco and Model Grade / Tonnage Plots for Copper in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-32 |

| | |

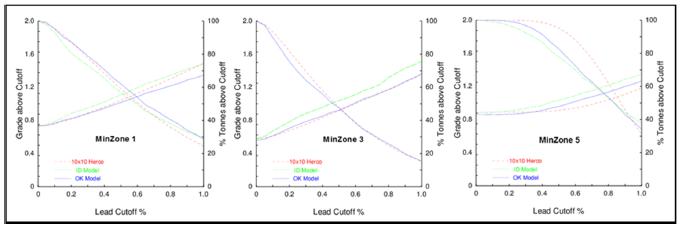

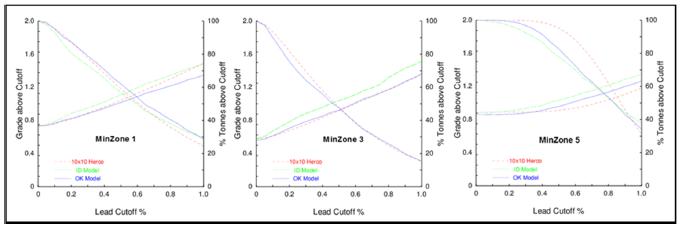

| Figure 14-19 | Herco and Model Grade / Tonnage Plots for Lead in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-33 |

| | |

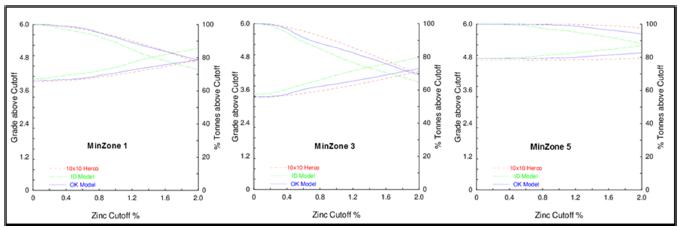

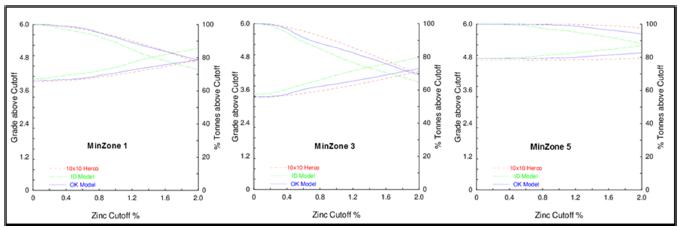

| Figure 14-20 | Herco and Model Grade / Tonnage Plots for Zinc in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-33 |

| | |

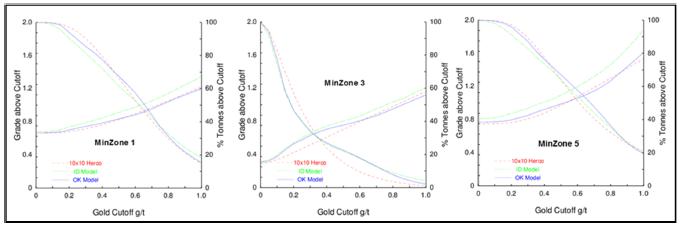

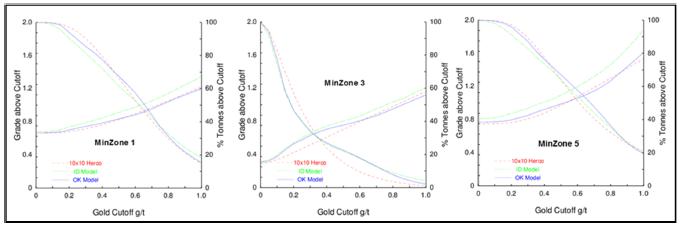

| Figure 14-21 | Herco and Model Grade / Tonnage Plots for Gold in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-33 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-XI |

|  |

| Figure 14-22 | Herco and Model Grade / Tonnage Plots for Silver in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-34 |

| | |

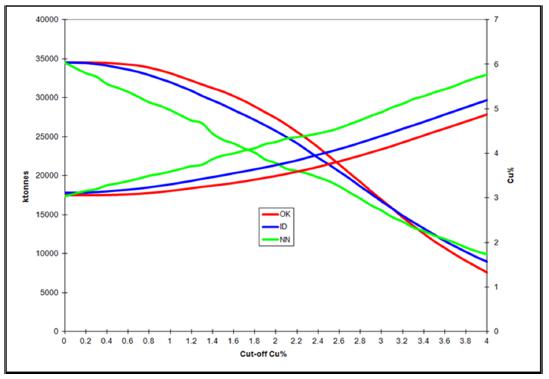

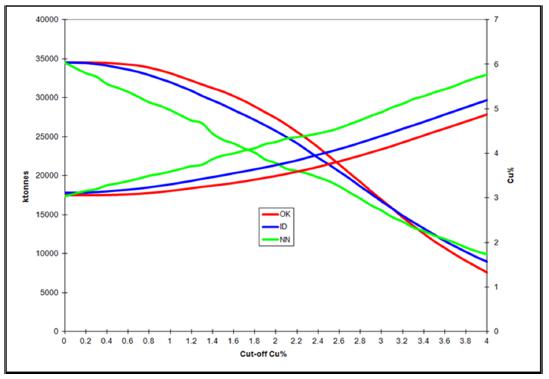

| Figure 14-23 | Comparison of Copper Model Types in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-35 |

| | |

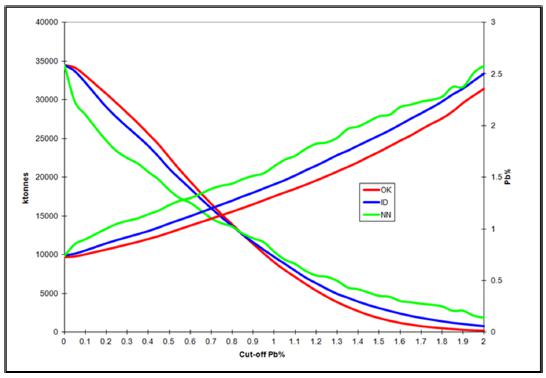

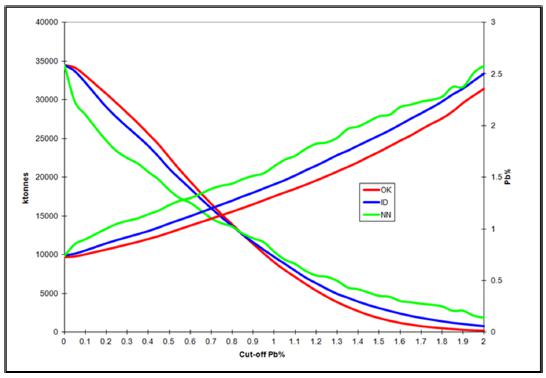

| Figure 14-24 | Comparison of Lead Model Types in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-35 |

| | |

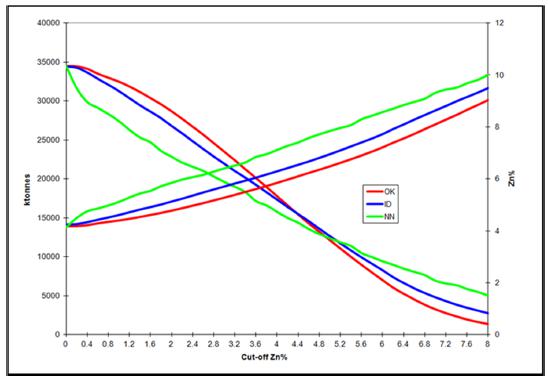

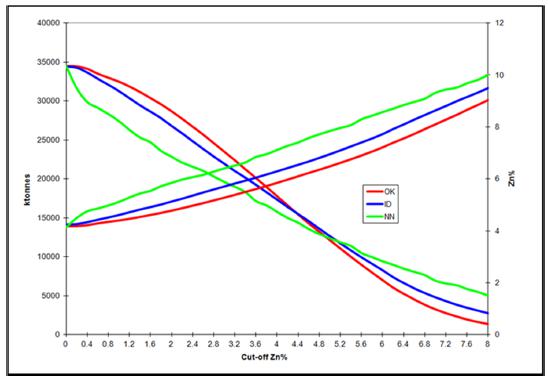

| Figure 14-25 | Comparison of Zinc Model Types in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-36 |

| | |

| Figure 14-26 | Comparison of Gold Model Types in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-36 |

| | |

| Figure 14-27 | Comparison of Silver Model Types in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-37 |

| | |

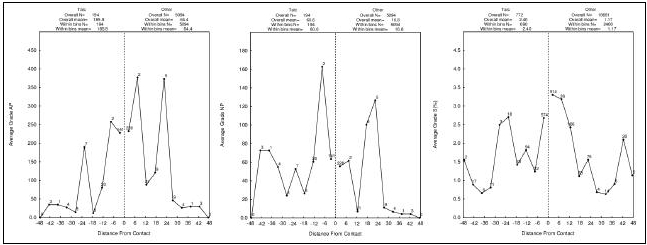

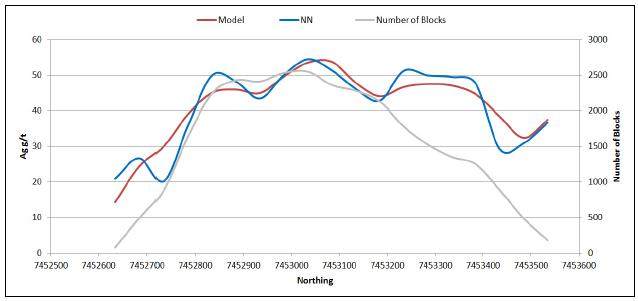

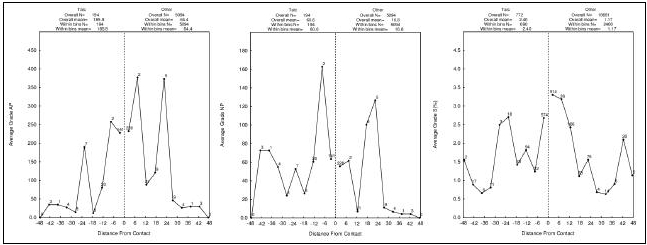

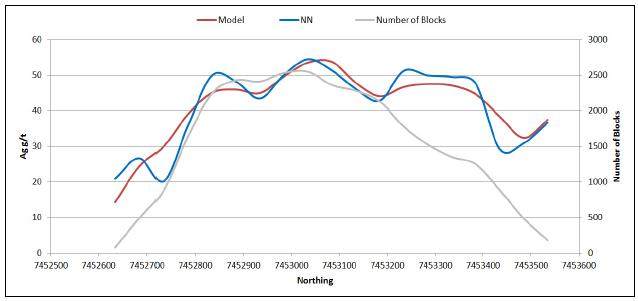

| Figure 14-28 | Swath Plot of Copper in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-37 |

| | |

| Figure 14-29 | Swath Plot of Lead in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-38 |

| | |

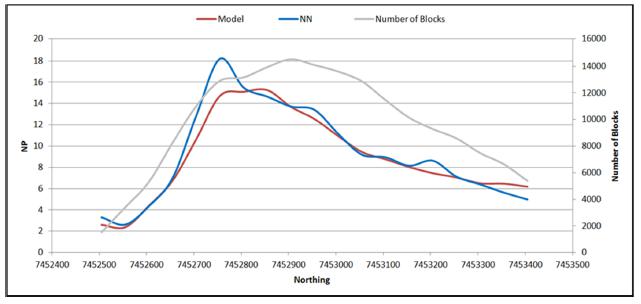

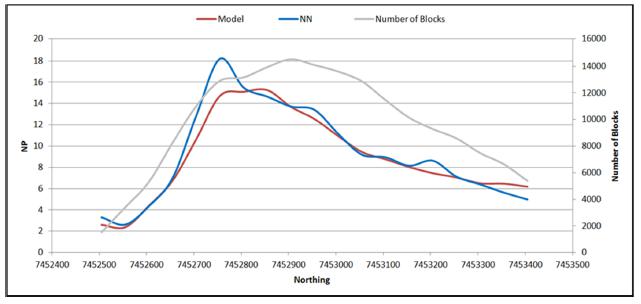

| Figure 14-30 | Swath Plot of Zinc in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-38 |

| | |

| Figure 14-31 | Swath Plot of Gold in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-39 |

| | |

| Figure 14-32 | Swath Plot of Silver in MinZone Domains 1, 3 and 5 (Sim, 2017) | 14-39 |

| | |

| Figure 14-33 | Swath Plot of AP (kg CaCO3/t) in Rocks Outside of the MinZone Domains (Sim, 2017) | 14-40 |

| | |

| Figure 14-34 | Swath Plot of NP (kg CaCO3/t) in Rocks Outside of the MinZone Domains (Sim, 2017) | 14-40 |

| | |

| Figure 14-35 | Swath Plot of Sulphur Rocks Outside of the MinZone Domains (Sim, 2017) | 14-41 |

| | |

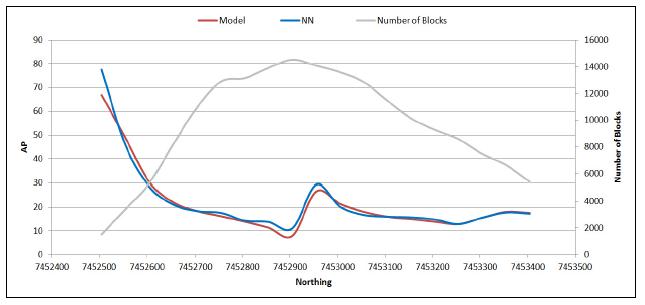

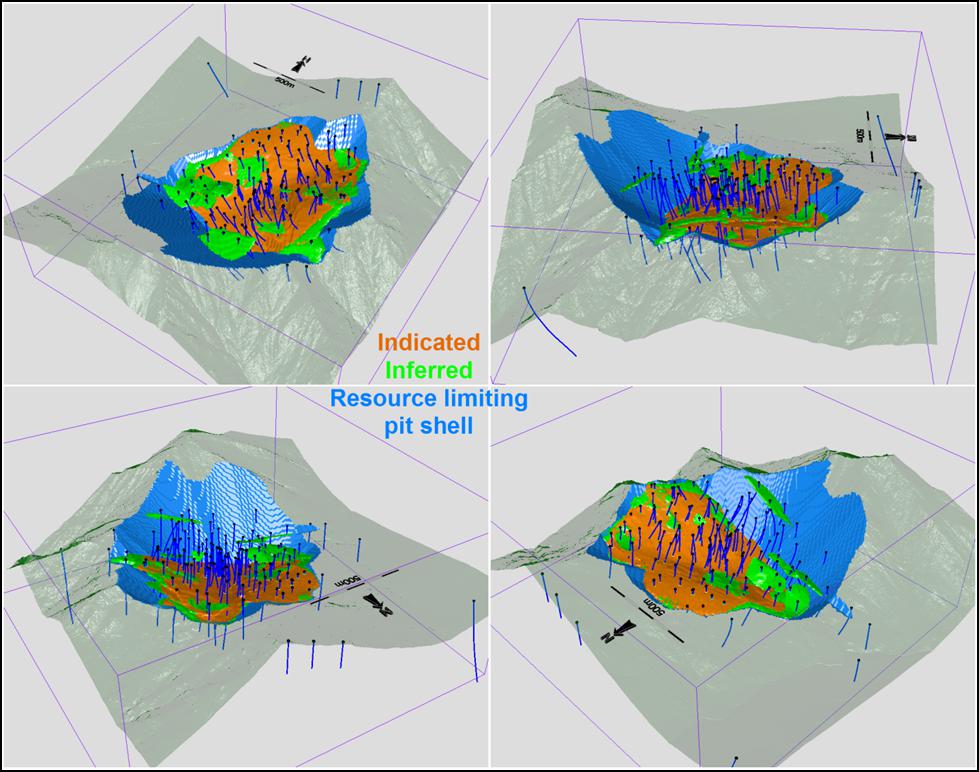

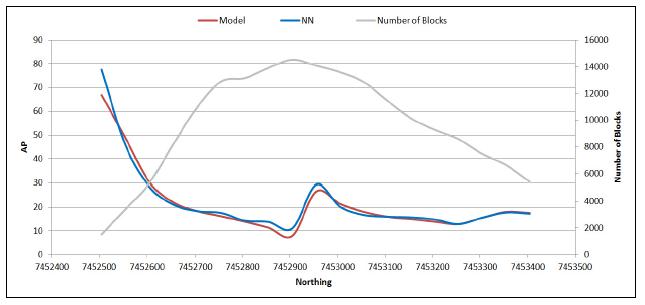

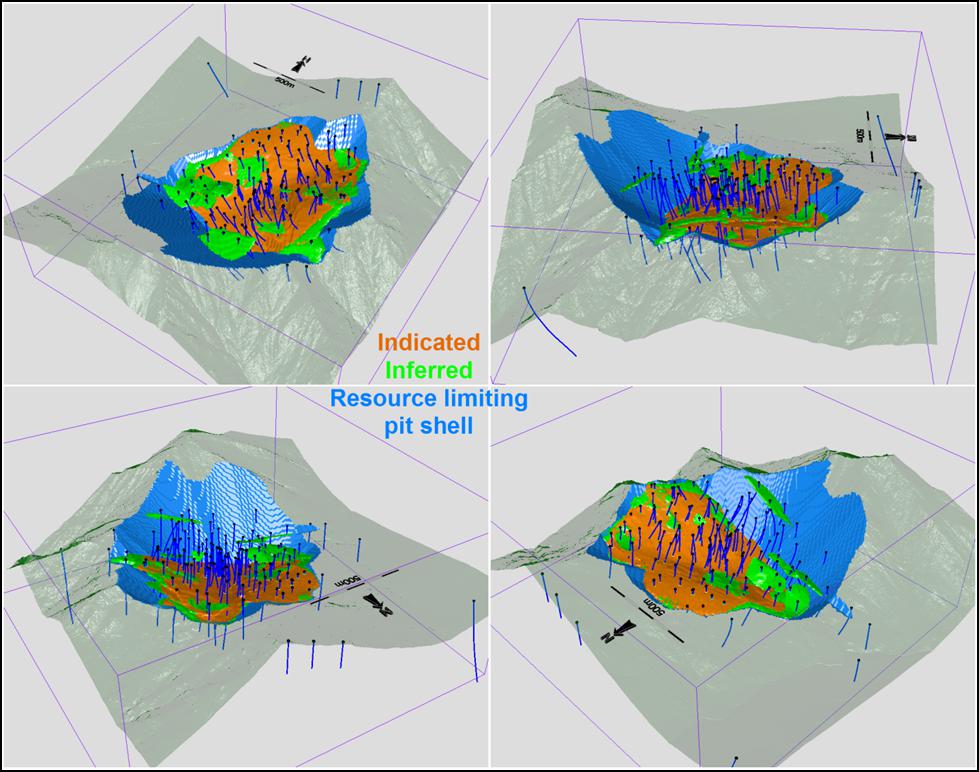

| Figure 14-36 | Isometric Views of Arctic Mineral Resource (Sim, 2017) | 14-44 |

| | |

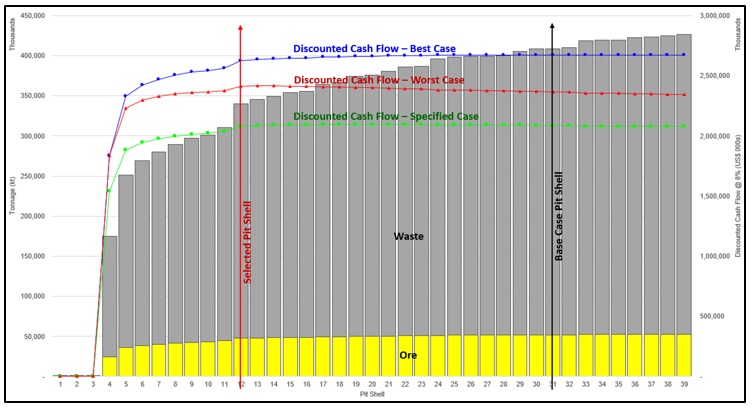

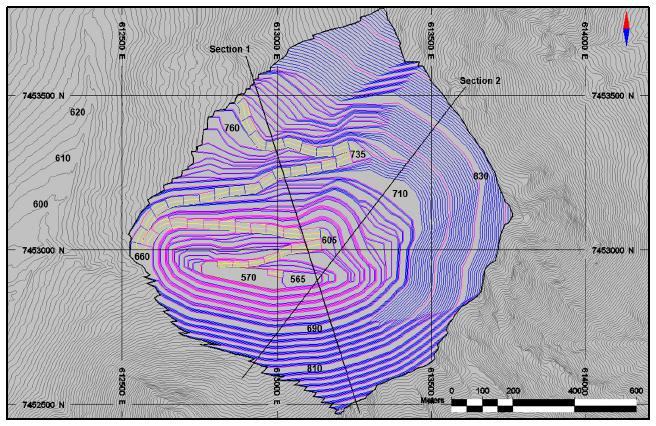

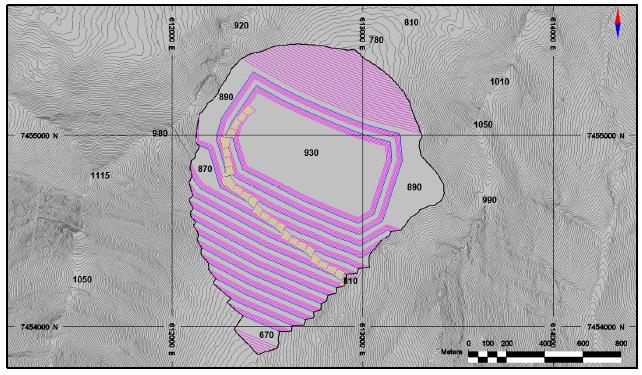

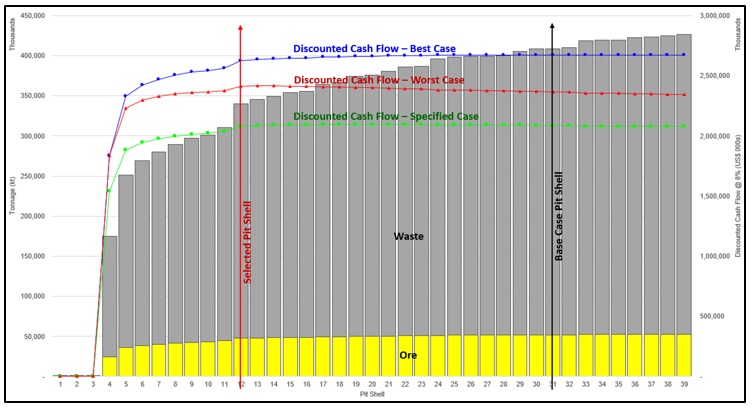

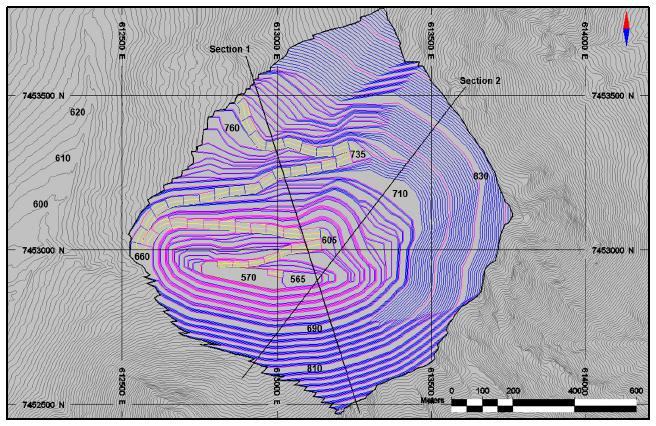

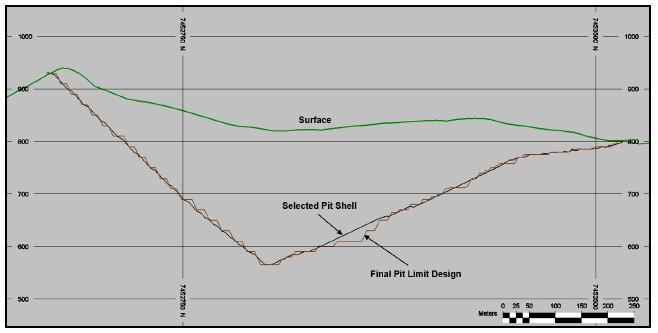

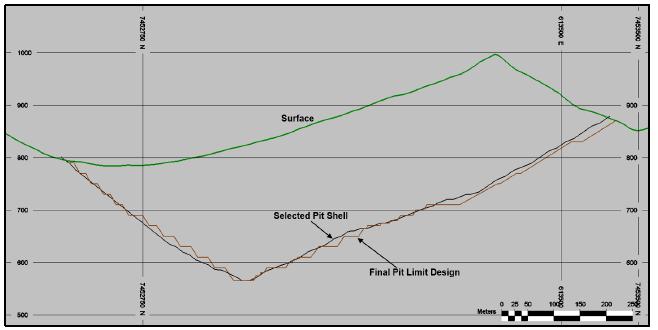

| Figure 15-1 | Pit-by-Pit Analysis (Wood, 2020) | 15-3 |

| | |

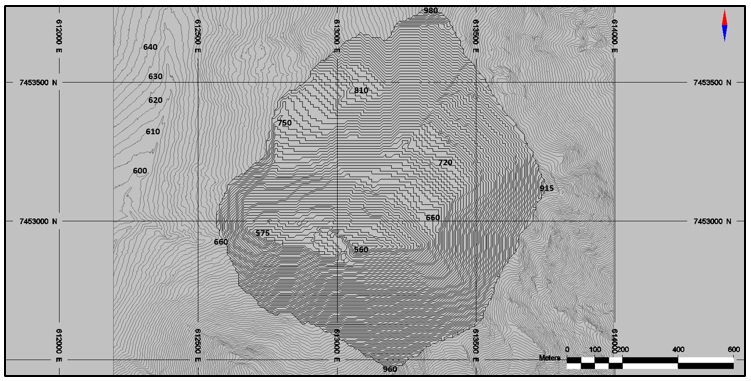

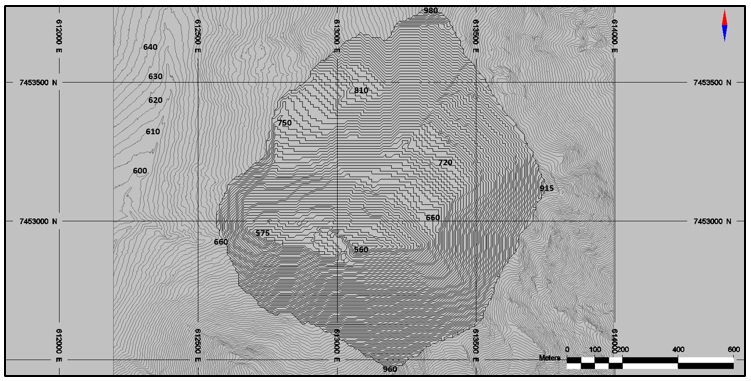

| Figure 15-2 | Selected Pit Shell (Wood, 2020) | 15-3 |

| | |

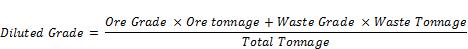

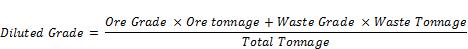

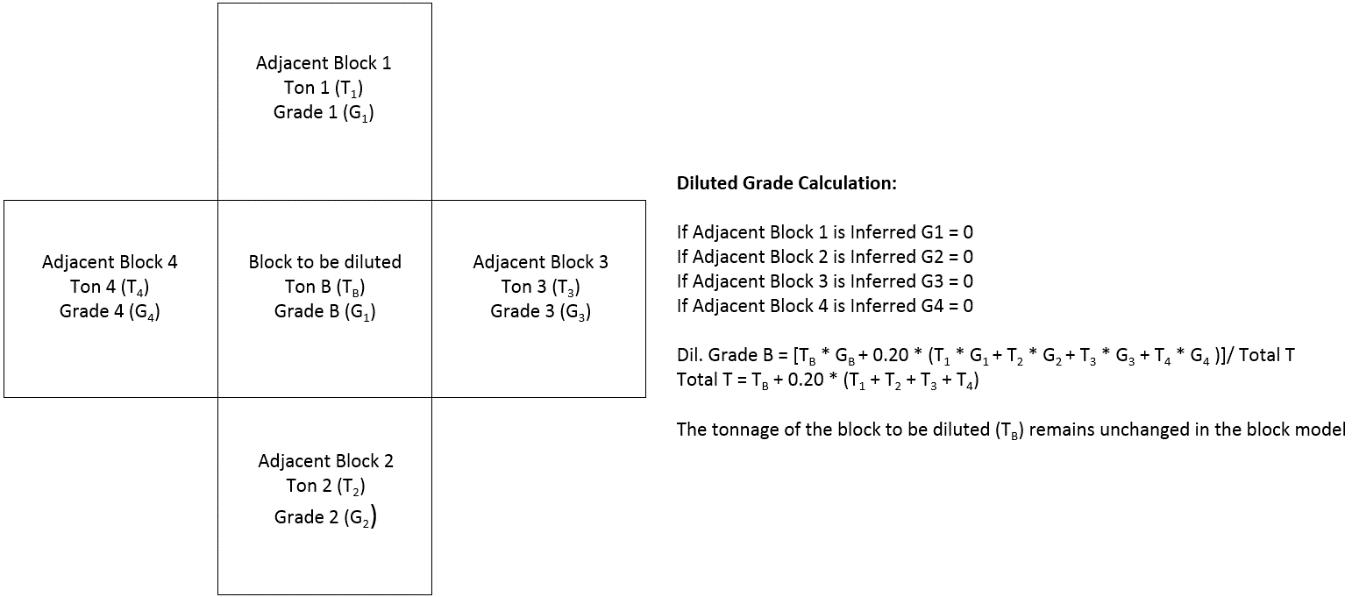

| Figure 15-3 | Contact Dilution Estimation Procedure (Wood, 2020) | 15-4 |

| | |

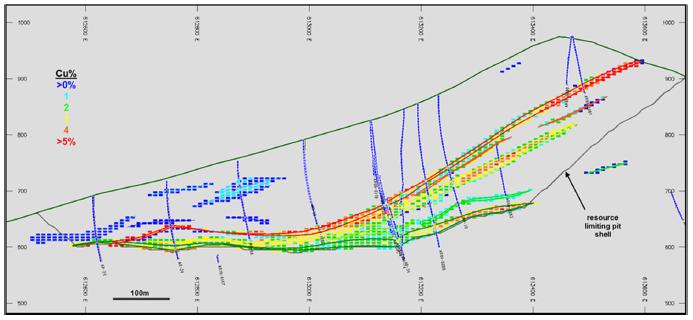

| Figure 16-1 | Ultimate Pit Design (Wood, 2020) | 16-2 |

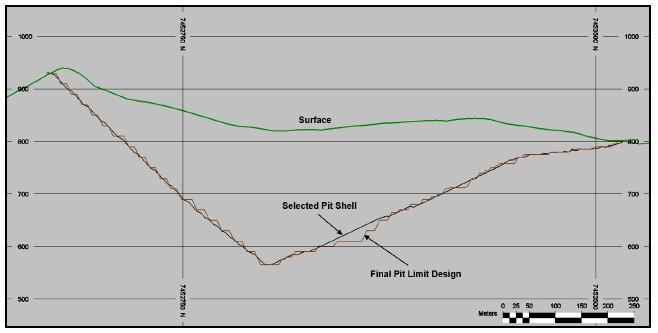

| | |

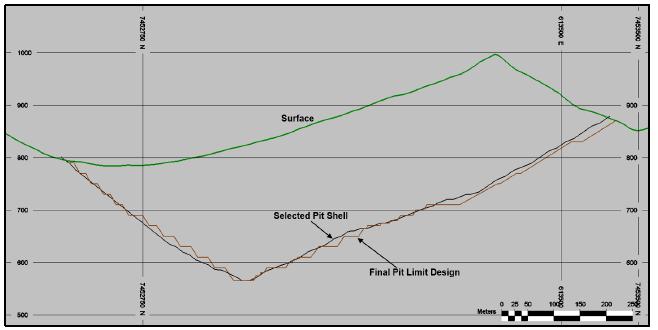

| Figure 16-2 | Section 1 Showing Mine Design and Selected Pit Shell (looking west) (Wood, 2020) | 16-2 |

| | |

| Figure 16-3 | Section 2 Showing Mine Design and Selected Pit Shell (looking north-west) (Wood, 2020) | 16-3 |

| | |

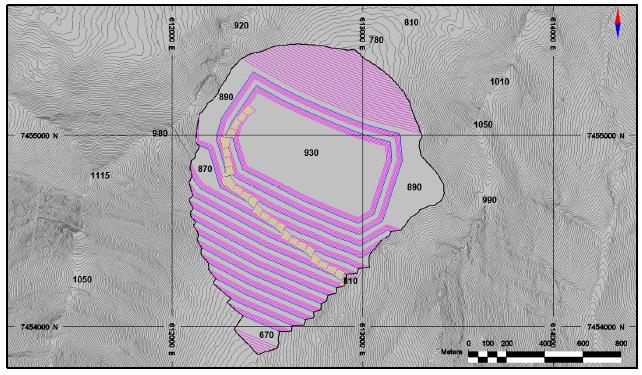

| Figure 16-4 | Waste Rock Facility (Wood, 2020) | 16-4 |

| | |

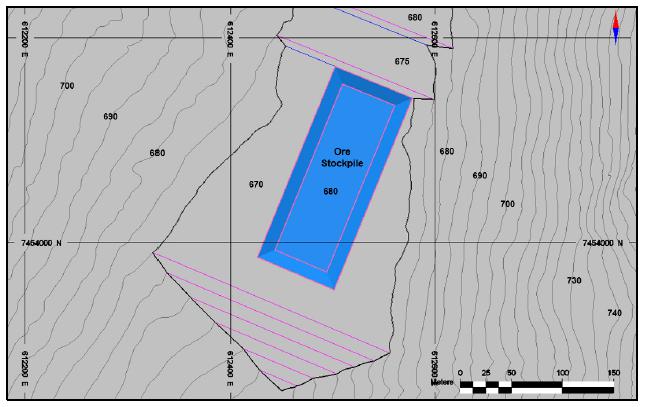

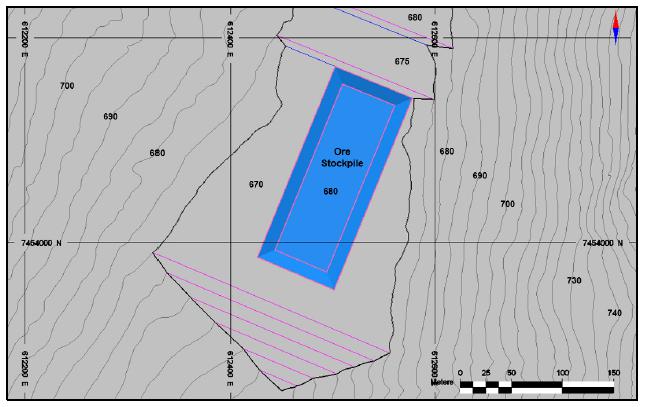

| Figure 16-5 | Ore Stockpile (Wood, 2020) | 16-4 |

| | |

| Figure 16-6 | Production Schedule (Wood, 2020) | 16-6 |

| | |

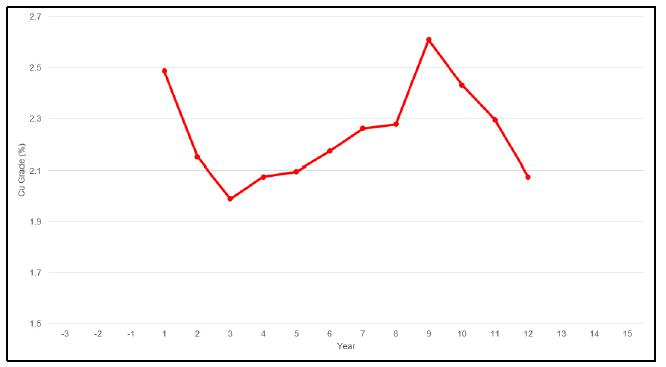

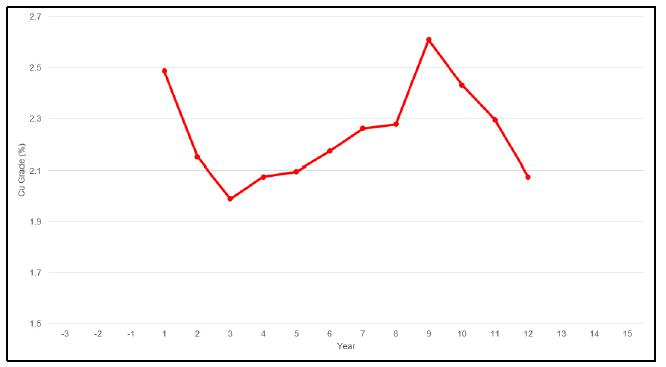

| Figure 16-7 | Scheduled Cu Feed Grade (Wood, 2020) | 16-7 |

| | |

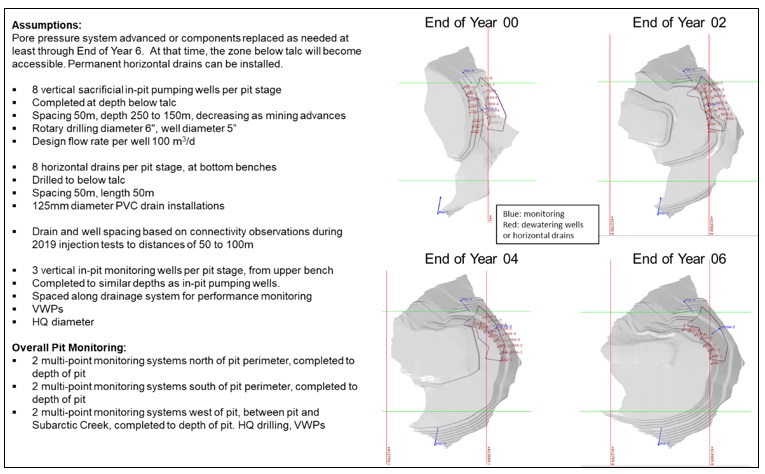

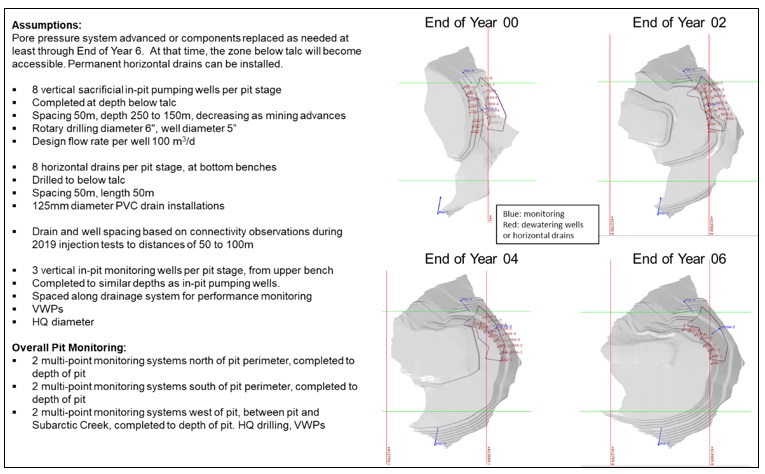

| Figure 16-8 | Pore Pressure Management Assumptions for East and Northeast Pit Walls (SRK 2020) | 16-19 |

| | |

| Figure 17-1 | Simplified Process Flowsheet (Ausenco 2020) | 17-3 |

| | |

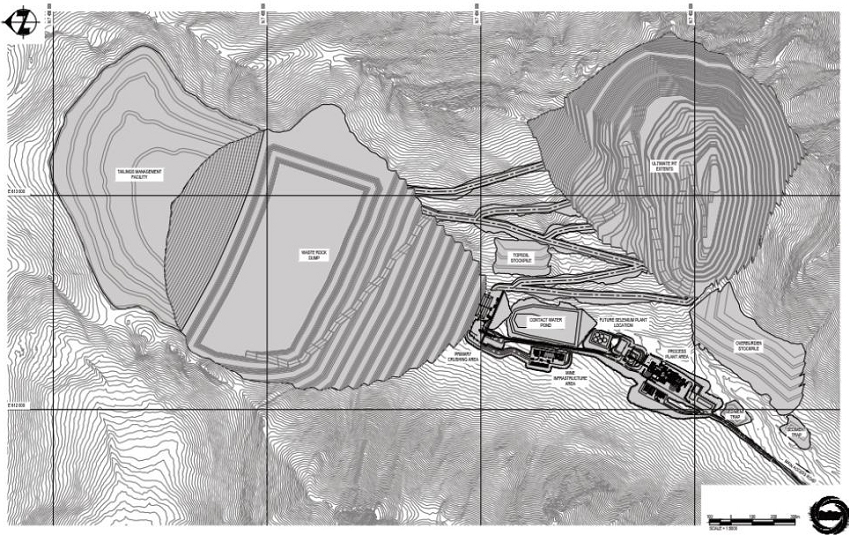

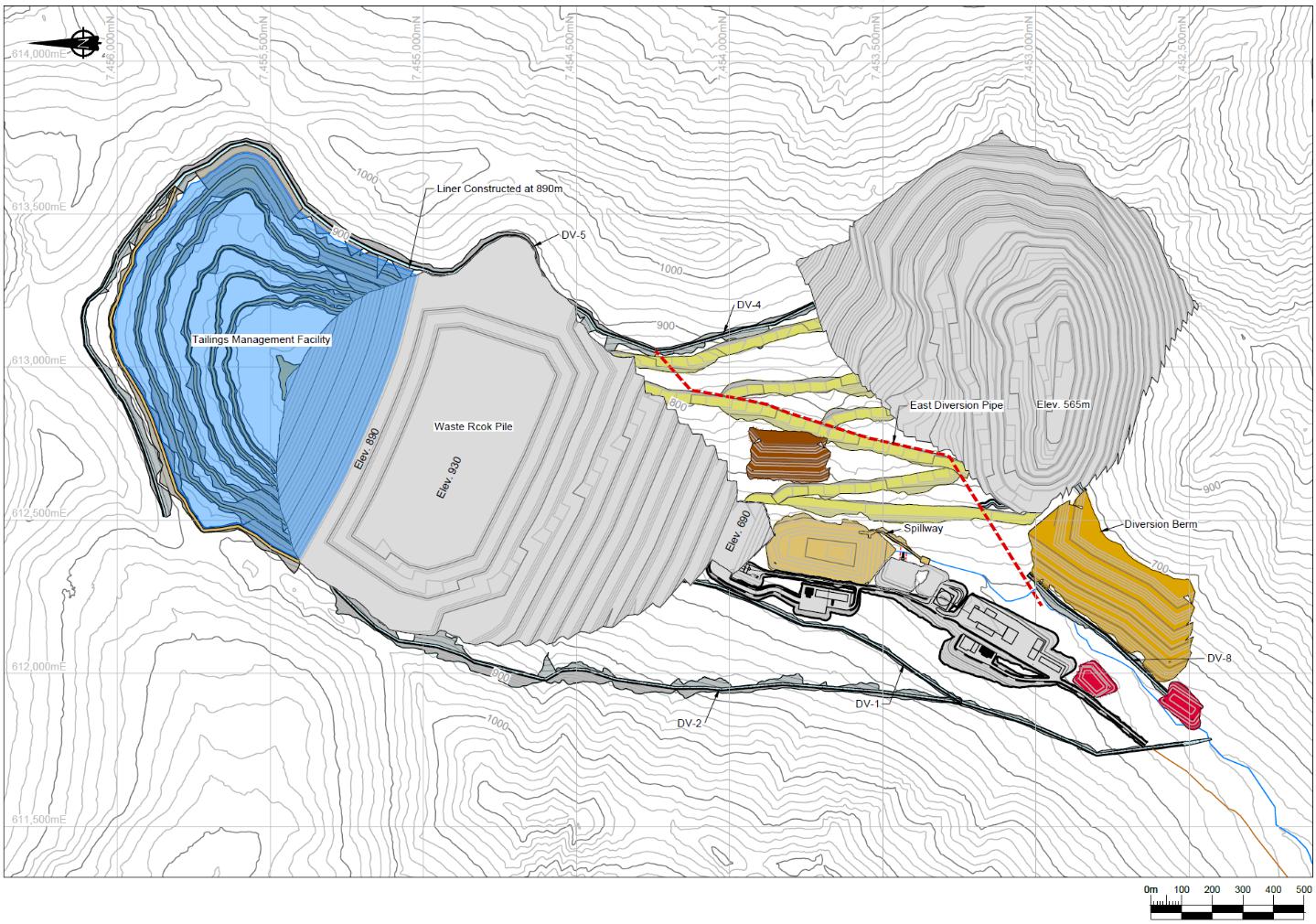

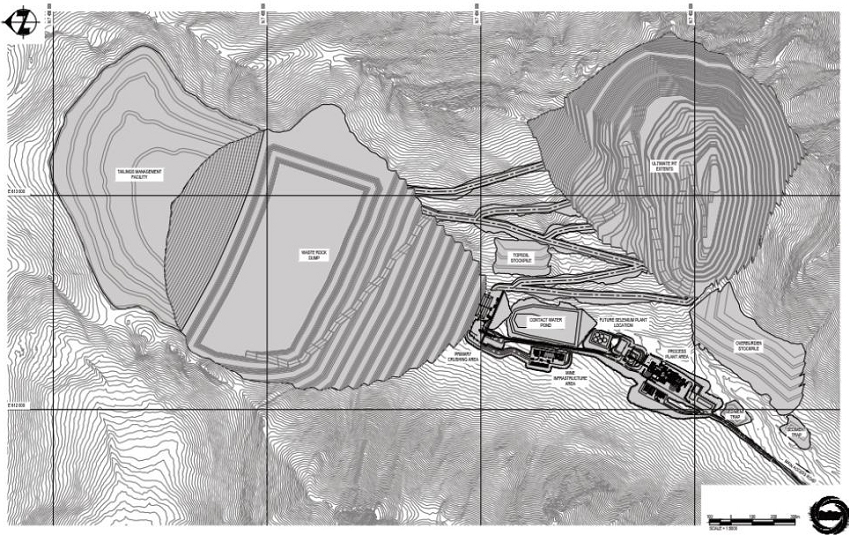

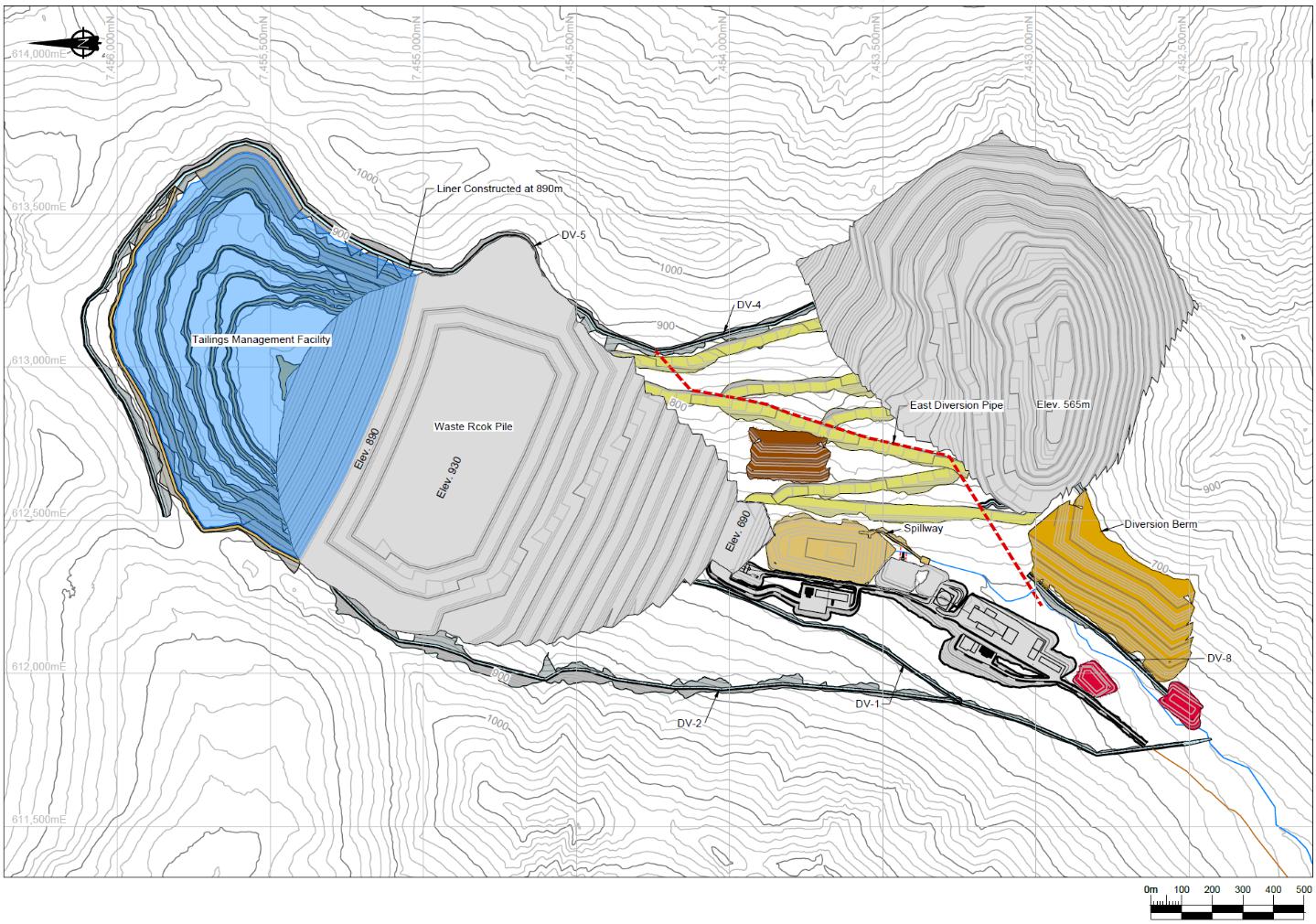

| Figure 18-1 | Proposed Site Layout (Ausenco, 2020) | 18-2 |

| | |

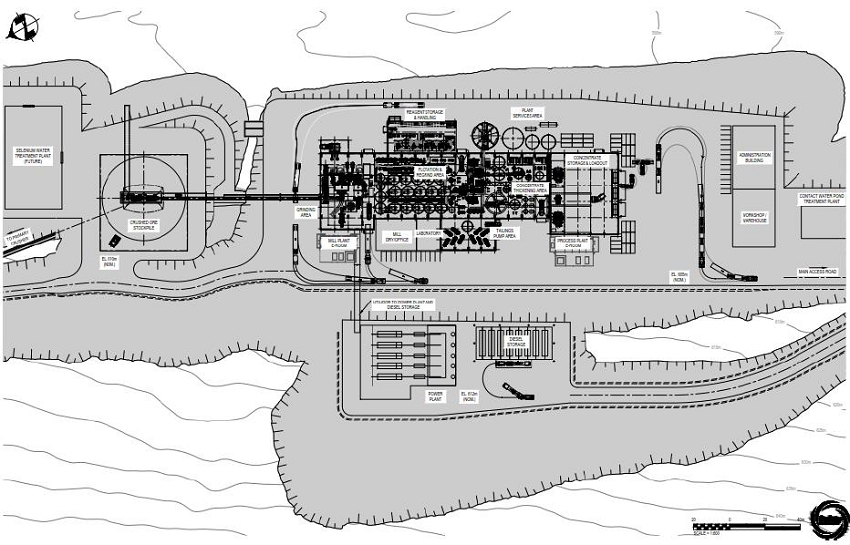

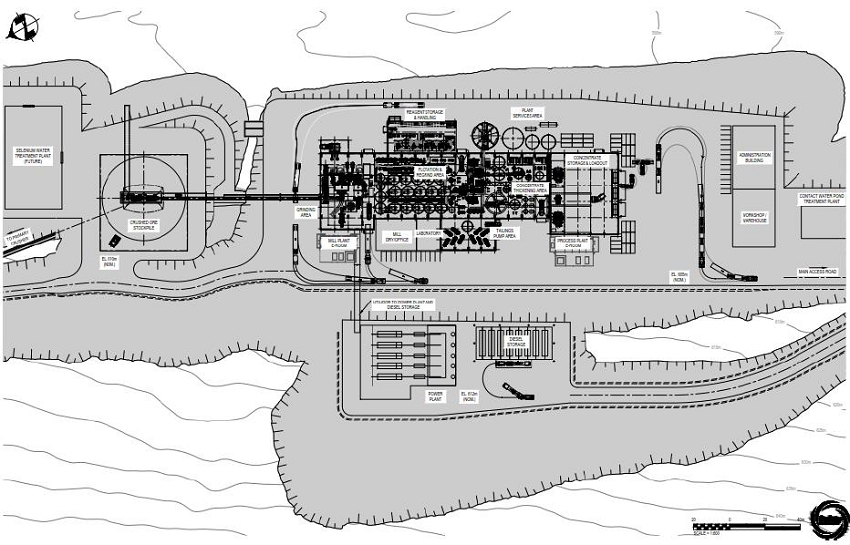

| Figure 18-2 | Proposed Location of the Processing Plant and Other Buildings (Ausenco, 2020) | 18-3 |

| | | |

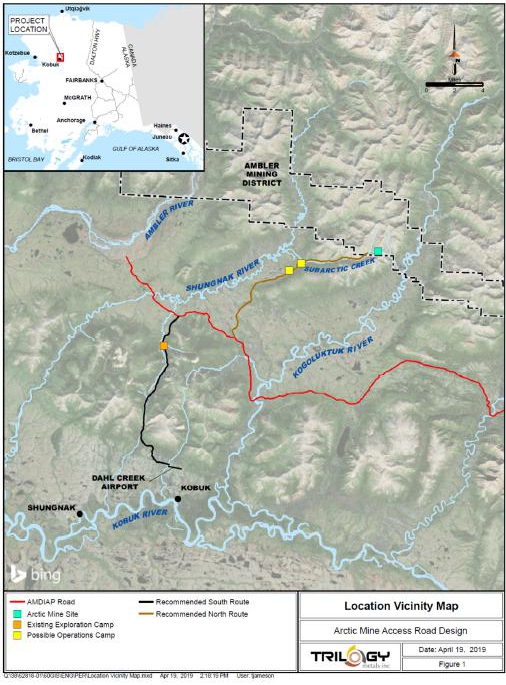

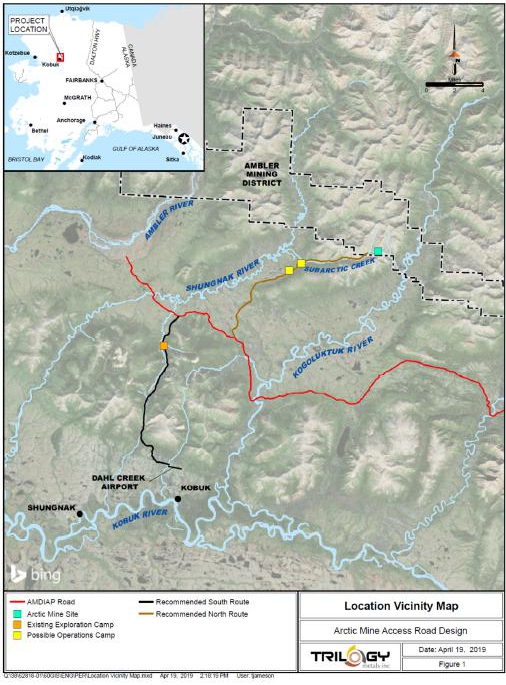

| Figure 18-3 | Proposed Route of AMDIAP Road (Ambler Access Website 2018) | 18-4 |

| | |

| Figure 18-4 | Arctic Access Road (Trilogy Metals, 2019) | 18-5 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-XII |

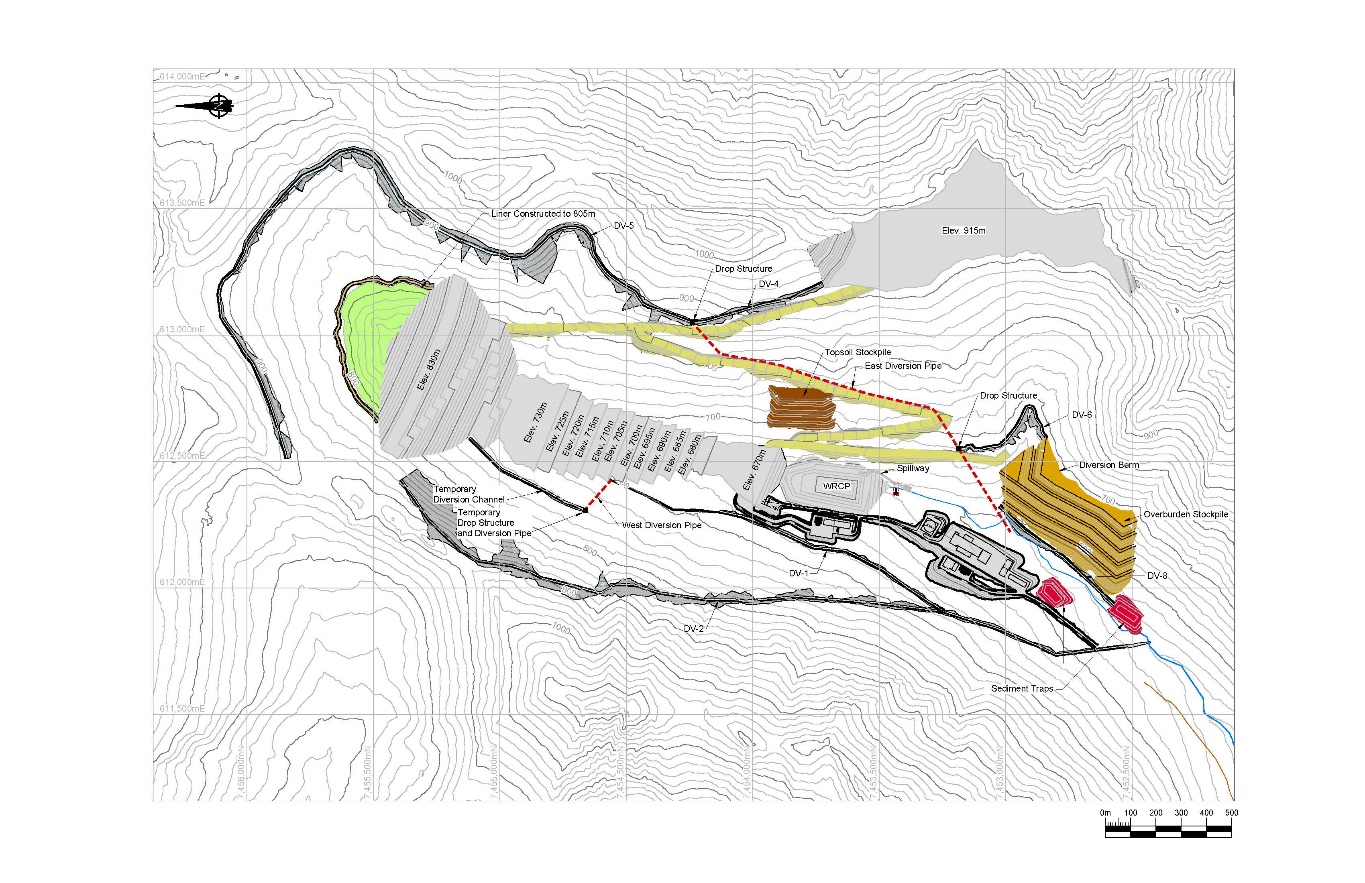

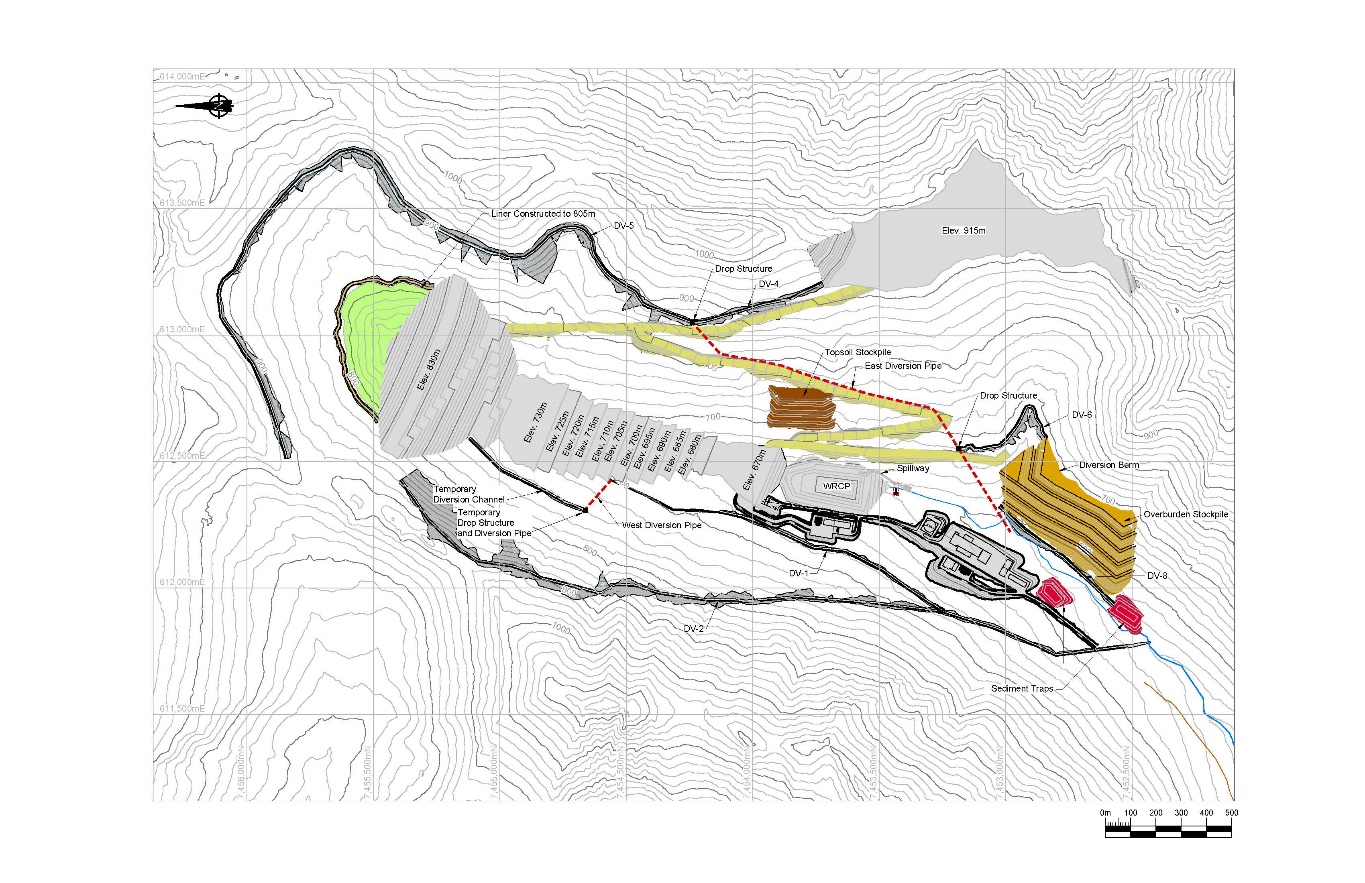

| Figure 18-5 | Surface Water Management Plan during Operations (SRK, 2020) | 18-9 |

| | |

| Figure 18-6 | Surface Water Management Plan Life of Mine (SRK, 2020) | 18-10 |

| | |

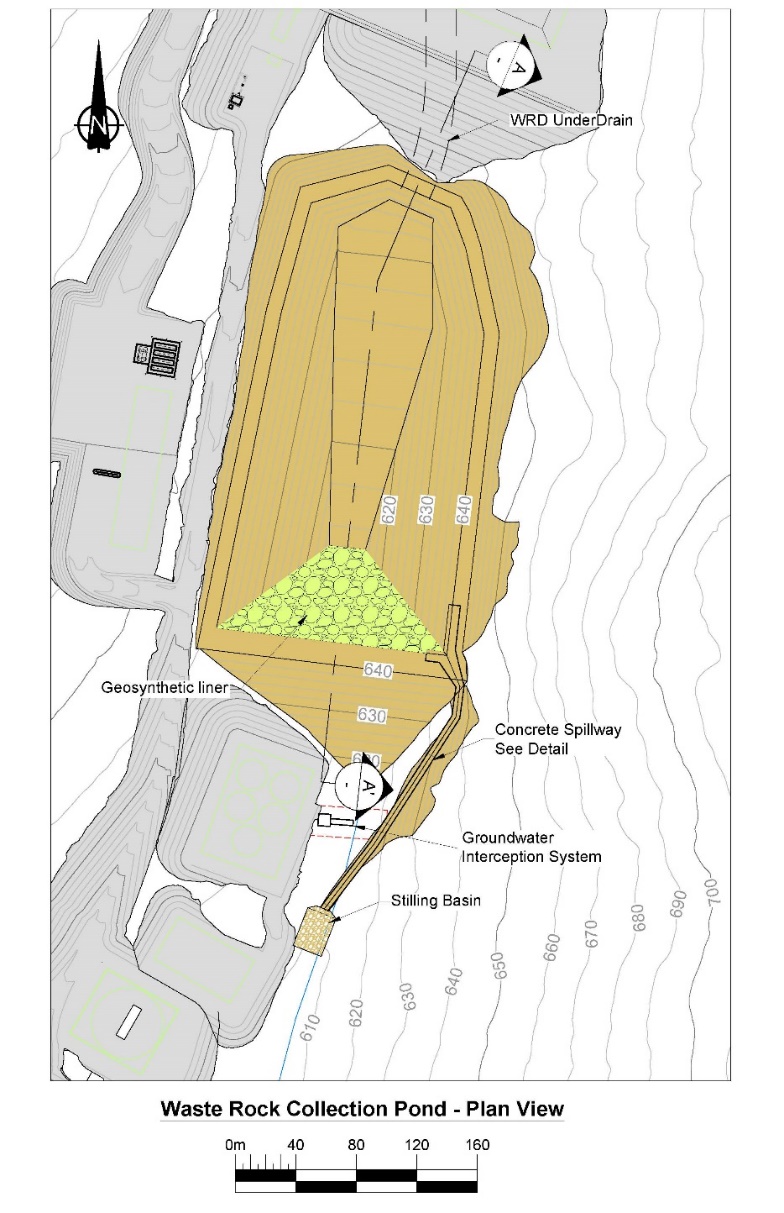

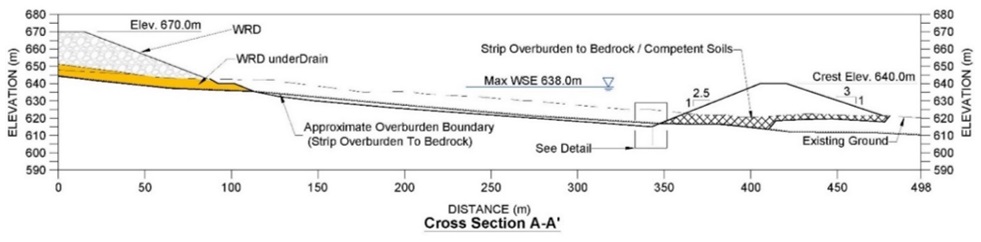

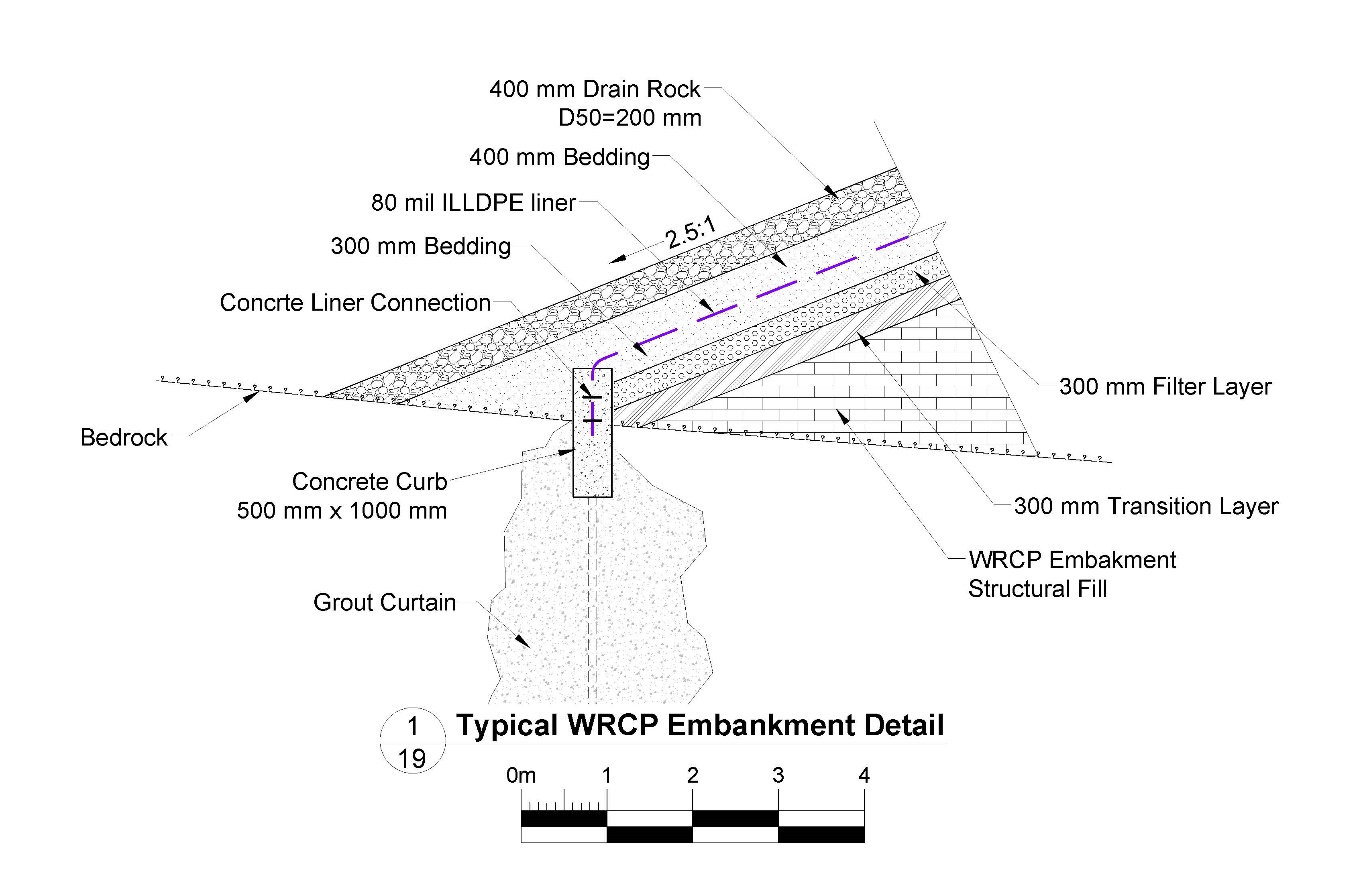

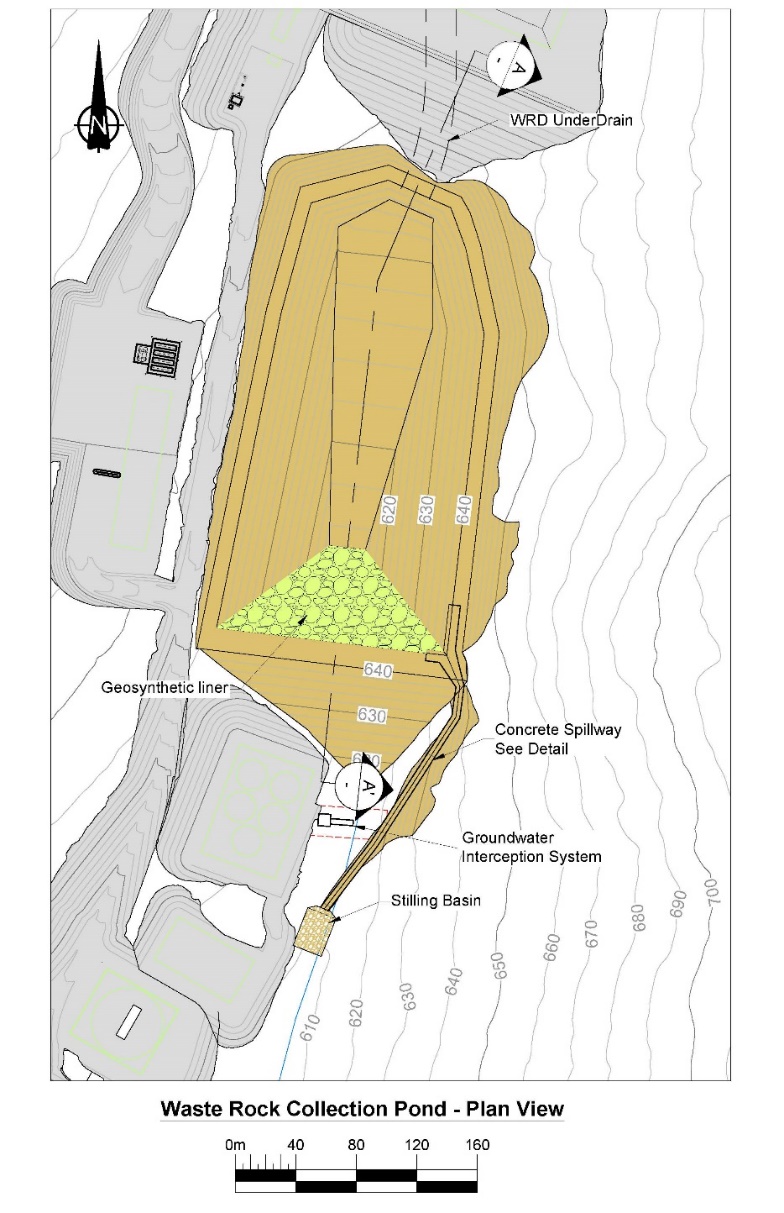

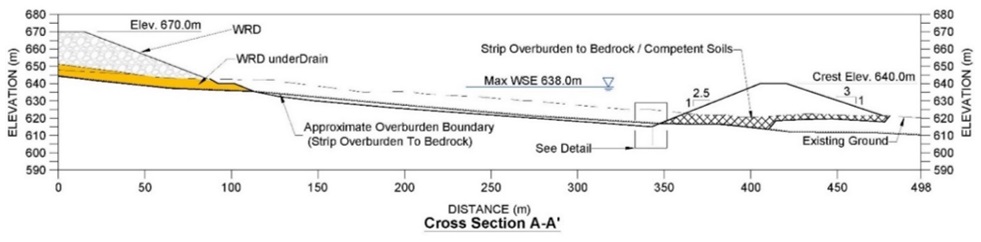

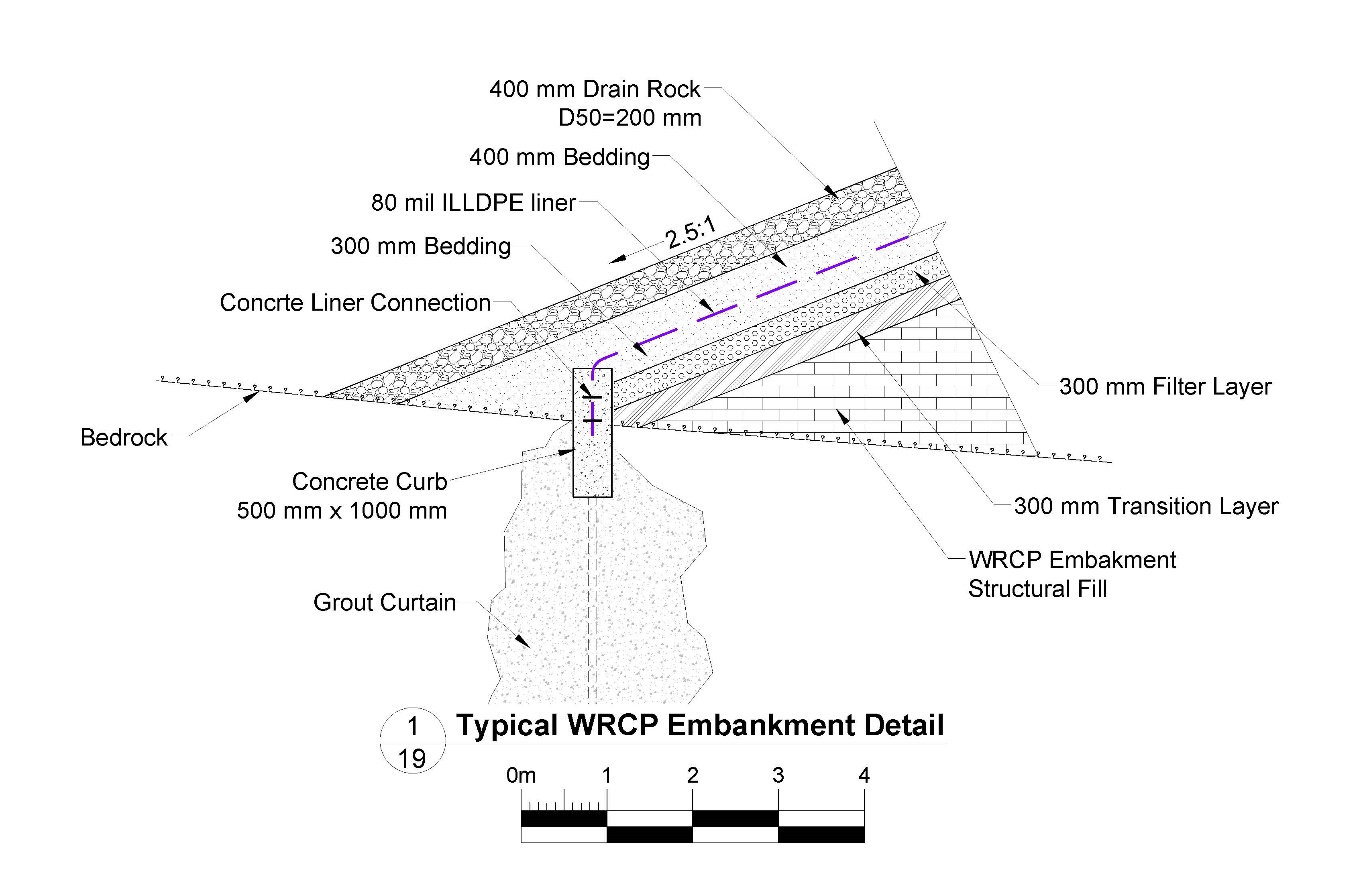

| Figure 18-7 | WRCP Proposed Construction (SRK, 2020) | 18-14 |

| | |

| Figure 18-8 | WRCP Typical Section (SRK, 2020) | 18-14 |

| | |

| Figure 18-9 | WRCP Typical Embankment Detail (SRK, 2020) | 18-15 |

| | |

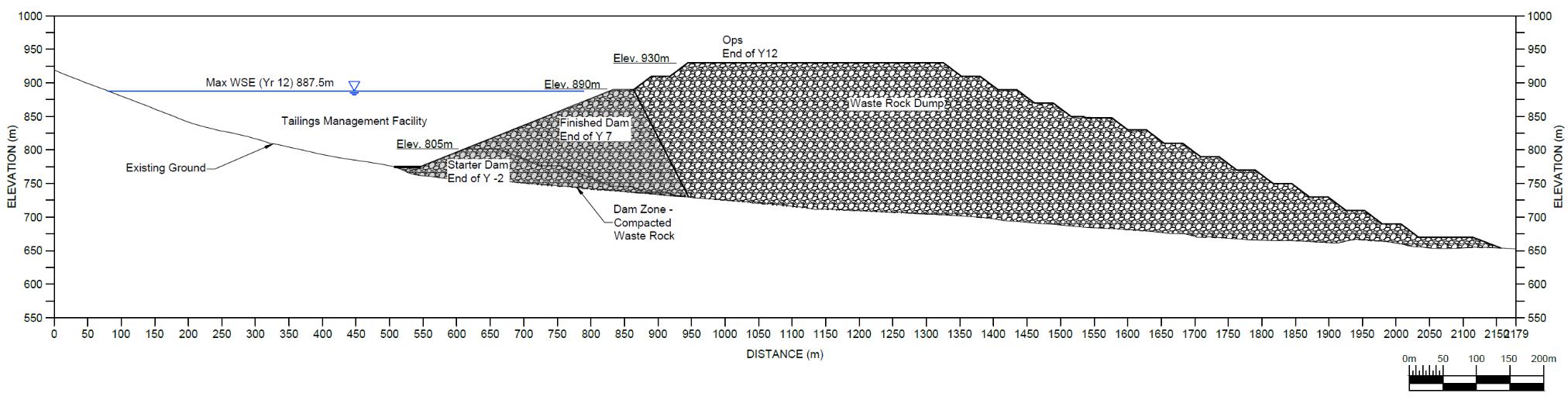

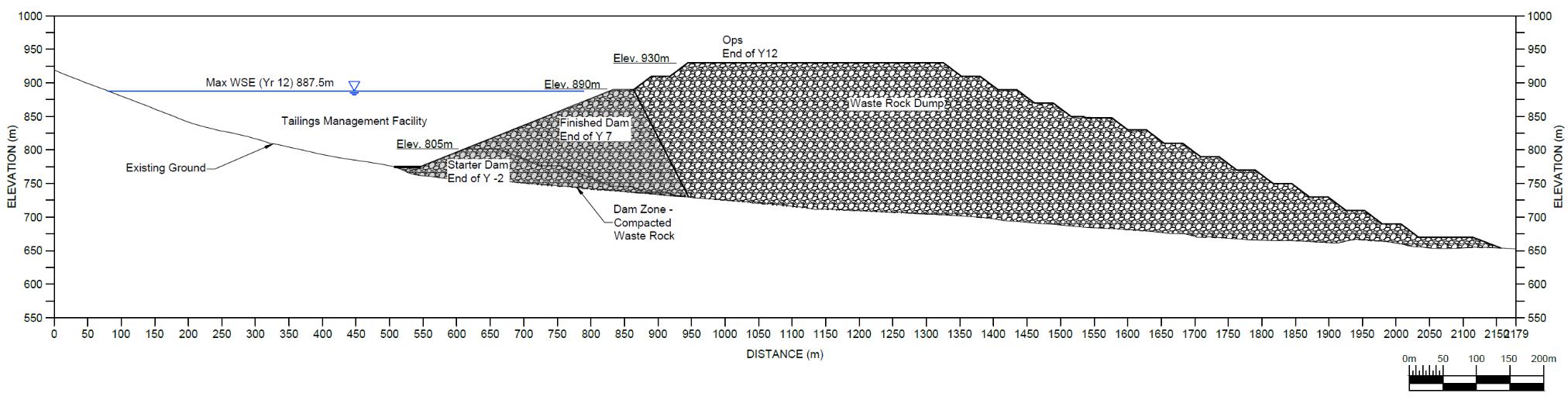

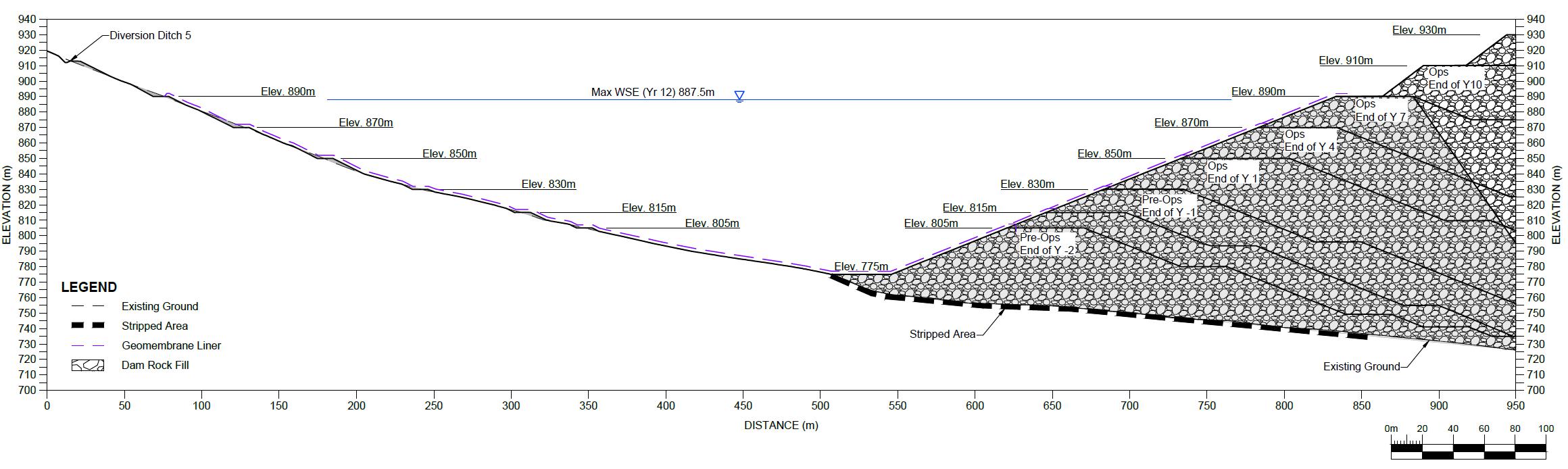

| Figure 18-10 | Cross Section through the TMF & WRF showing Starter Dam to Elevation 805 m (SRK, 2020) | 18-21 |

| | |

| Figure 18-11 | Cross Section of the TMF and raises to Final Design Elevation (SRK, 2020) | 18-21 |

| | |

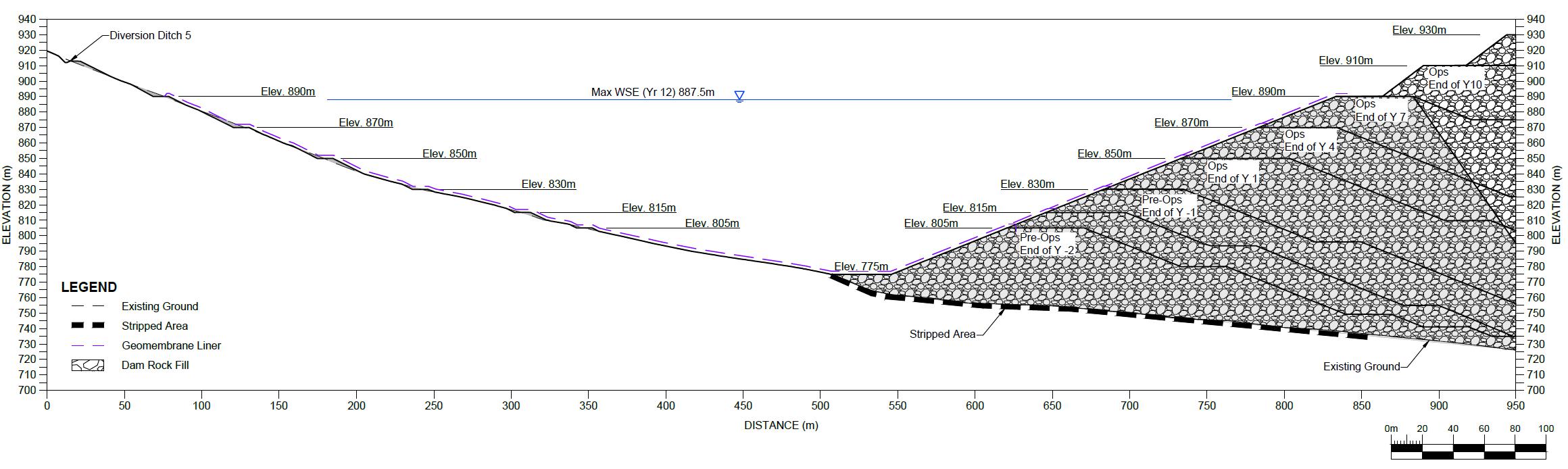

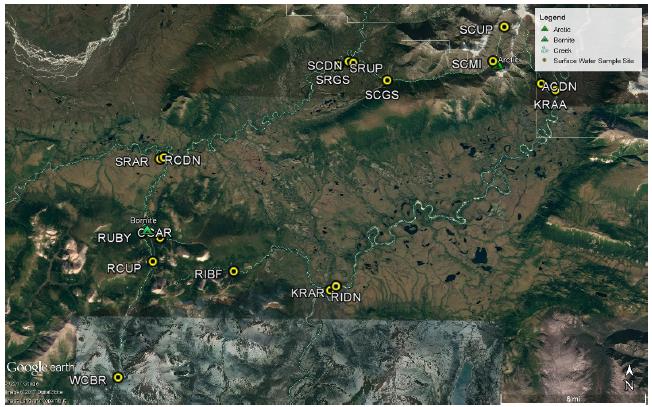

| Figure 20-1 | Current Water Quality and Hydrology Stations Location Map | 20-2 |

| | |

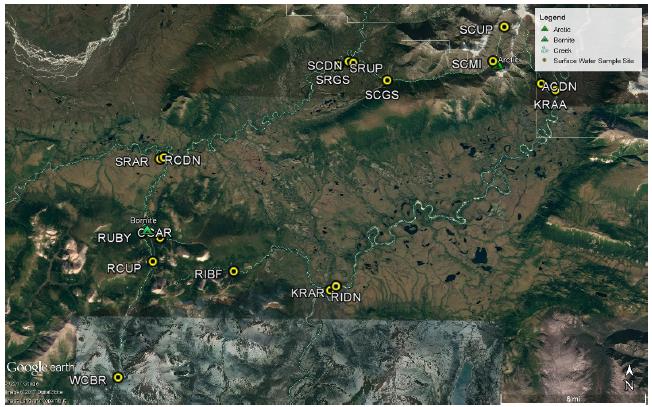

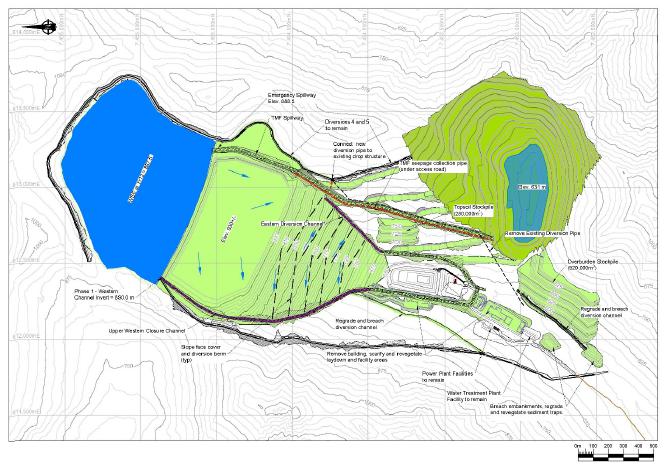

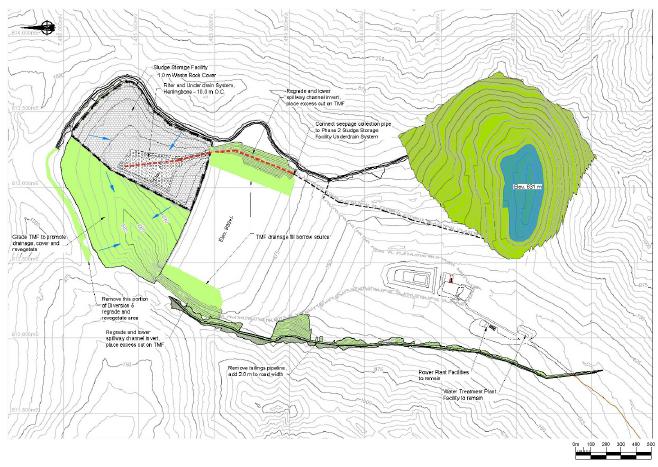

| Figure 20-2 | Phase One Closure (SRK, 2020) | 20-13 |

| | |

| Figure 20-3 | Phase Two Closure (SRK, 2020) | 20-14 |

| | |

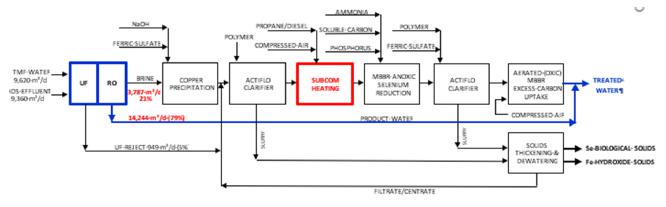

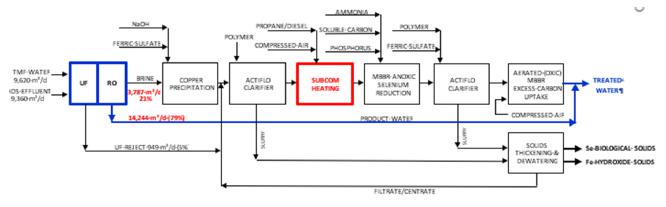

| Figure 20-4 | Selenium Water Treatment Plant Process (Integrated Sustainability, 2020) | 20-19 |

| | |

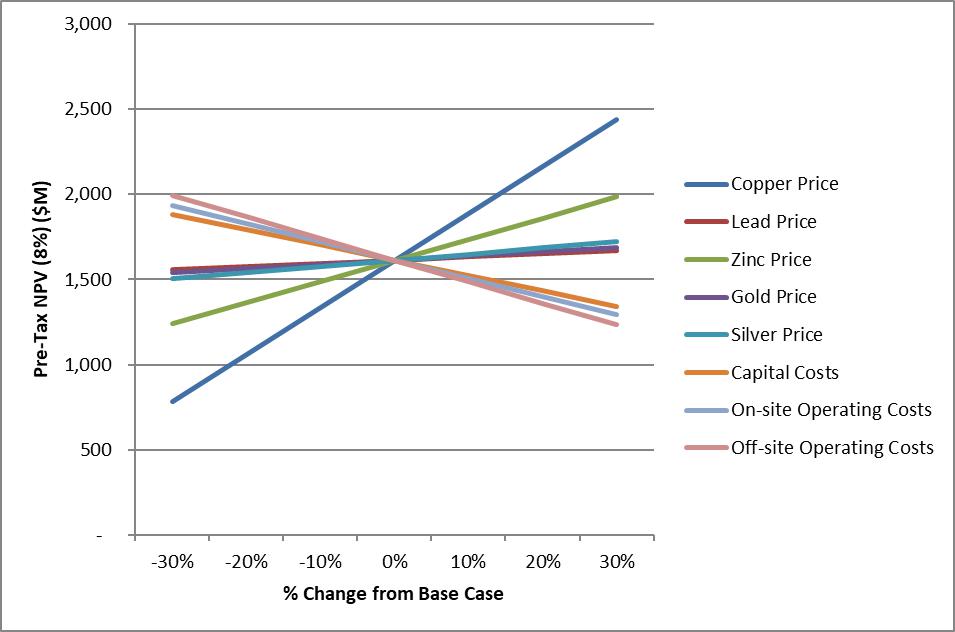

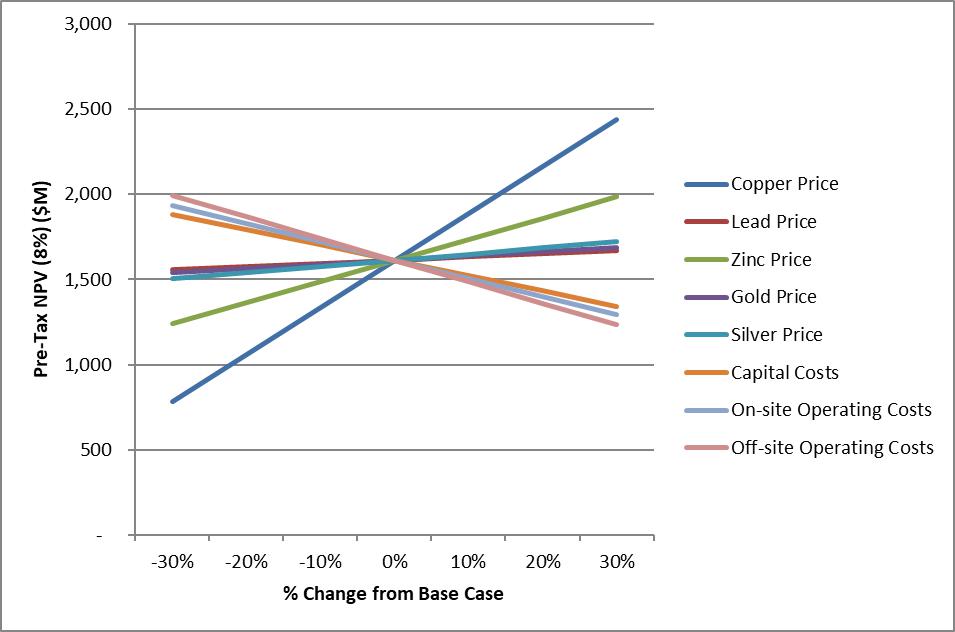

| Figure 22-1 | Pre-tax NPV Sensitivity Analysis (Ausenco, 2020) | 22-8 |

| | |

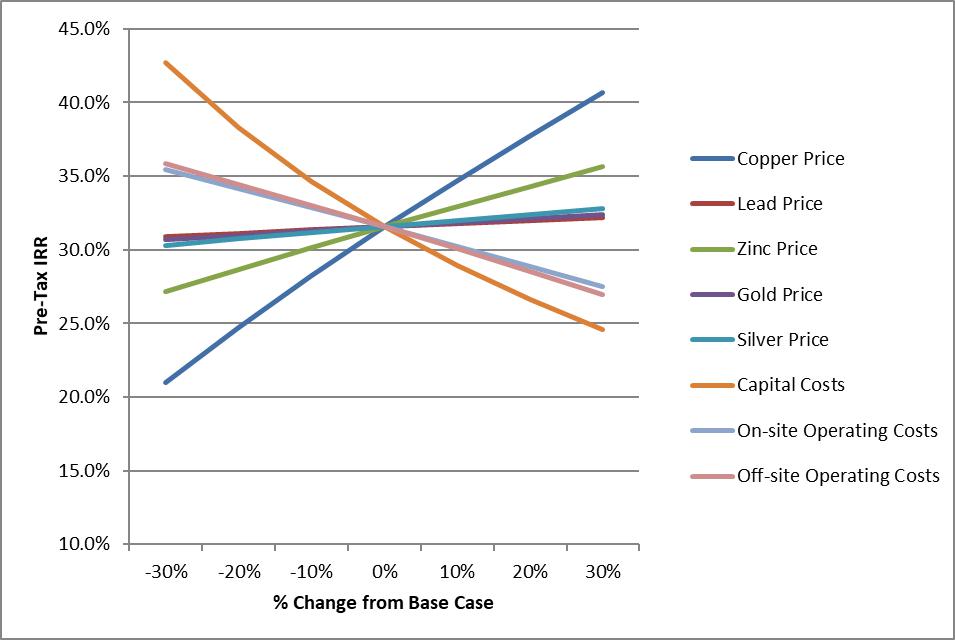

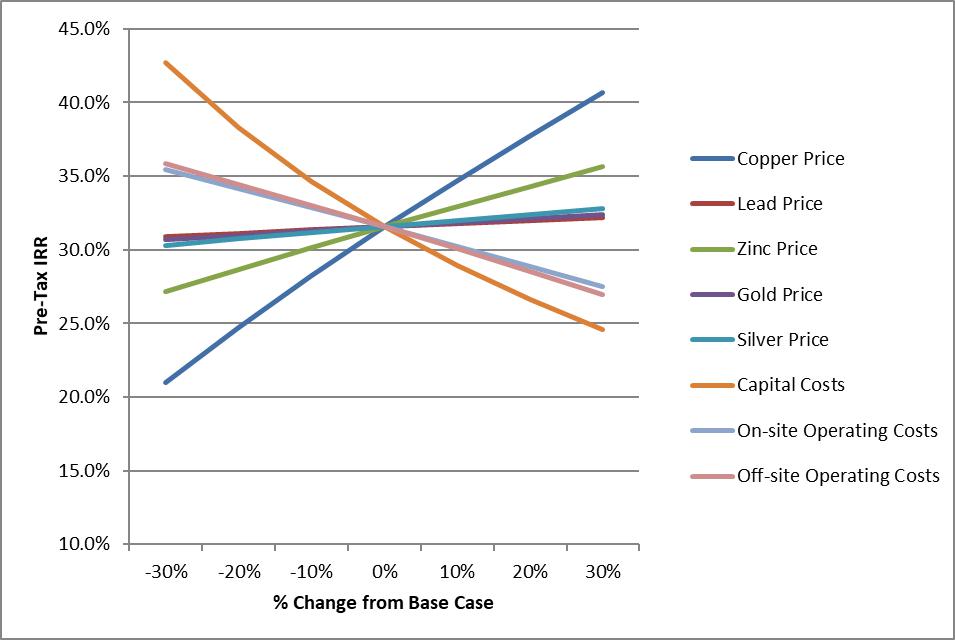

| Figure 22-2 | Pre-tax IRR Sensitivity Analysis (Ausenco, 2020) | 22-9 |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-XIII |

Glossary

| | |

| Acme Analytical Laboratories Ltd. | AcmeLabs |

| Alaska Department of Environmental Conservation | ADEC |

| Alaska Department of Fish and Game | ADFG |

| Alaska Department of Natural Resources | ADNR |

| Alaska Department of Transportation | ADOT |

| Alaska Industrial Development and Export Authority | AIDEA |

| Alaska Native Claims Settlement Act | ANCSA |

| Alaska Native Regional Corporations | ANCSA Corporations |

| Ambler Mining District Industrial Access Project | AMDIAP |

| Andover Mining Corp. | Andover |

| Annual Hardrock Exploration Activity | AHEA |

| atomic absorption | AA |

| atomic absorption spectroscopy | AAS |

| atomic emission spectroscopy | ICP_AES |

| Audio-Frequency Magneto-Telluric | AMT |

| BD Resource Consulting, Inc. | BDRC |

| Bear Creek Mining Corporation | BCMC |

| Arctic Project | the Project |

| Canadian Institute of Mining, Metallurgy, and Petroleum | CIM |

| Circular corrugated steel pipes | CSP |

| complex resistivity induced polarization | CRIP |

| Controlled Source Audio-frequency Magneto-Telluric | CSAMT |

| Electromagnetic EM Environmental Impact Statement | EIS |

| Environmental Protection Agency | EPA |

| Dry Metric Tonne/s | dmt |

| Exploration Agreement and Option to Lease | NANA Agreement |

| Fugro Airborne Surveys | Fugro |

| GeoSpark Consulting Inc. | GeoSpark |

| General and Administrative. | G&A |

| Grams per tonne | gpt |

| High density sludge | HDS |

| inductively coupled plasma | ICP |

| inductively coupled plasma-mass | ICP-MS |

| Internal Rate of Return | IRR |

| International Organization for Standardization | ISO |

| Kennecott Exploration Company and Kennecott Arctic Company | Kennecott |

| Kennecott Research Centre | KRC |

| LiDAR Light Detection and Ranging life of mine | LOM |

| Mine Development Associates | MDA |

| meters above sea level | masl |

| NANA Regional Corporation, Inc. | NANA |

| National Environmental Policy Act | NEPA |

| National Instrument 43-101 | NI 43-101 |

| natural source audio-magnetotelluric | NSAMT |

| naturally occurring asbestos | NOA |

| net present value | NPV |

| net smelter return | NSR |

| North American Datum | NAD |

| Northern Land Use Research Inc. | NLUR Inc. |

| Northwest Arctic Borough | NWAB |

| Trilogy Metals Inc. | Trilogy Metals |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-XIV |

| NovaGold Resources Inc. | NovaGold |

| Polarized Light Microscopy | PLM |

| Quality Assurance/Quality Control | QA/QC |

| Selenium Water Treatment Plant | SeWTP |

| SIM Geological Inc. | SGI |

| single point | SP |

| Teck Resources Ltd. | Teck |

| Tailings management facility | TMF |

| Tonnes per annum | t/a |

| Tonnes per day | tpd |

| Universal Transverse Mercator | UTM |

| US Army Corps of Engineers | USACE |

| US Geological Survey | USGS |

| volcanogenic massive sulphide | VMS |

| WH Pacific, Inc. | WHPacific |

| Waste rock collection pond | WRCP |

| Waste rock facility | WRF |

| Water treatment plant | WTP |

| Wet Metric Tonne/s | wmt |

| Zonge International Inc. | Zonge |

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | TOC-XV |

Trilogy Metals Inc. (Trilogy Metals or Trilogy) commissioned Ausenco Engineering Canada Inc. (Ausenco) to compile a Technical Report (the Report) on the Arctic deposit, part of the Arctic Project (the Project) in the Ambler Mining District of northwest Alaska.

The Project demonstrates the financial outcomes summarized below:

o NPV of $1,550.9 million at an 8% discount rate

o IRR of 30.8%

o Payback period of 2.4 years

o NPV of $1,134.7 million at an 8% discount rate

o IRR of 27.1%

o Payback period of 2.6 years

| · | Total capital costs of $1,224.7 million, comprised of: |

o Initial capital cost of $905.6 million

o Sustaining capital cost of $113.8 million

o Closure cost of $205.4 million

| · | Total onsite operating costs of $2,200.5 million |

| · | Total offsite operating costs of $2,555.5 million |

1.3.1 General

The Report supports disclosure by Trilogy Metals in the news release dated August 20, 2020, entitled “Trilogy Metals Announces Positive Feasibility Study Results for the Arctic Project Located in Alaska, USA”.

The firms and consultants who are providing Qualified Persons (QPs) responsible for the content of this Report, which is based on the Feasibility Study completed in 2020 (the 2020 FS) and supporting documents prepared for the 2020 FS, are, in alphabetical order: Ausenco Engineering Canada Inc. (Ausenco); BD Resource Consulting, Inc., (BDRC); Integrated Sustainability Consultants; International Metallurgical & Environmental Inc (IME); SIM Geological Inc. (SIM); SRK Consulting (Canada) Inc. (SRK), and Wood Canada Limited (previously Amec Foster Wheeler Americas Ltd.) (Wood).

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | Page 1-1 |

The Report presents Mineral Resource and Mineral Reserve estimates for the Project, and an economic assessment based on open pit mining operations and a conventional processing circuit that would produce copper, zinc and lead concentrates.

All units of measurement in this Report are metric, unless otherwise stated. The monetary units are in US dollars, unless otherwise stated.

1.3.2 Mineral Resources and Reserves

Mineral Resources and Mineral Reserves are reported in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves (May 2014; the 2014 CIM Definition Standards).

| 1.4 | Property Description and Location |

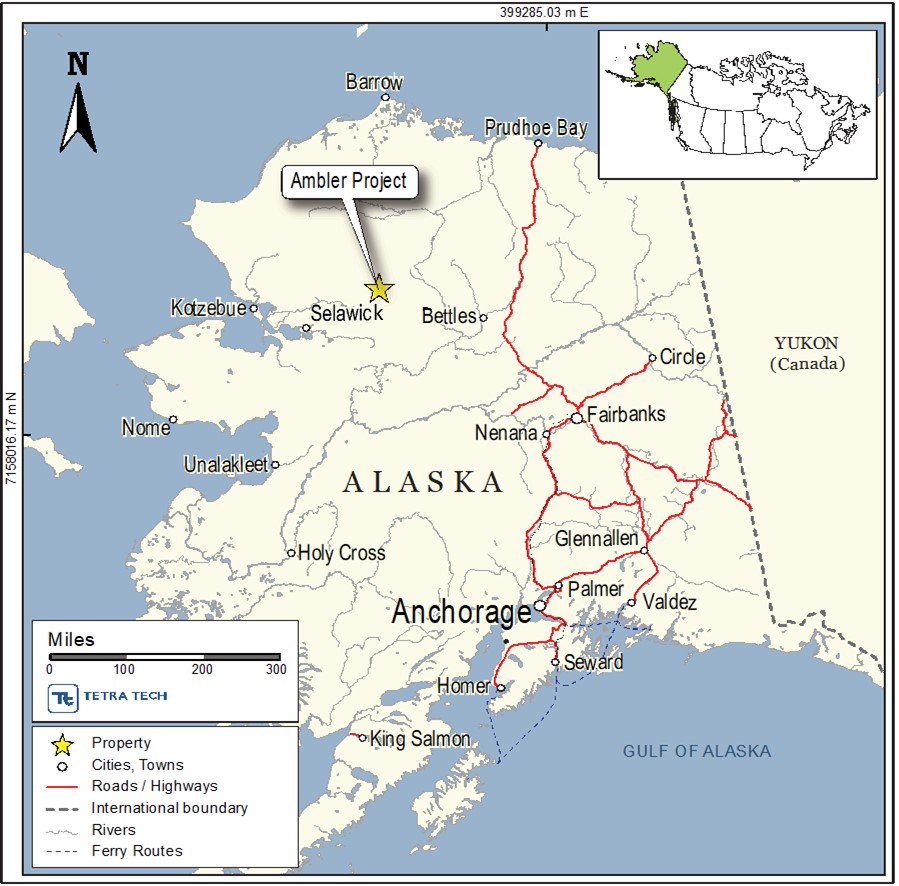

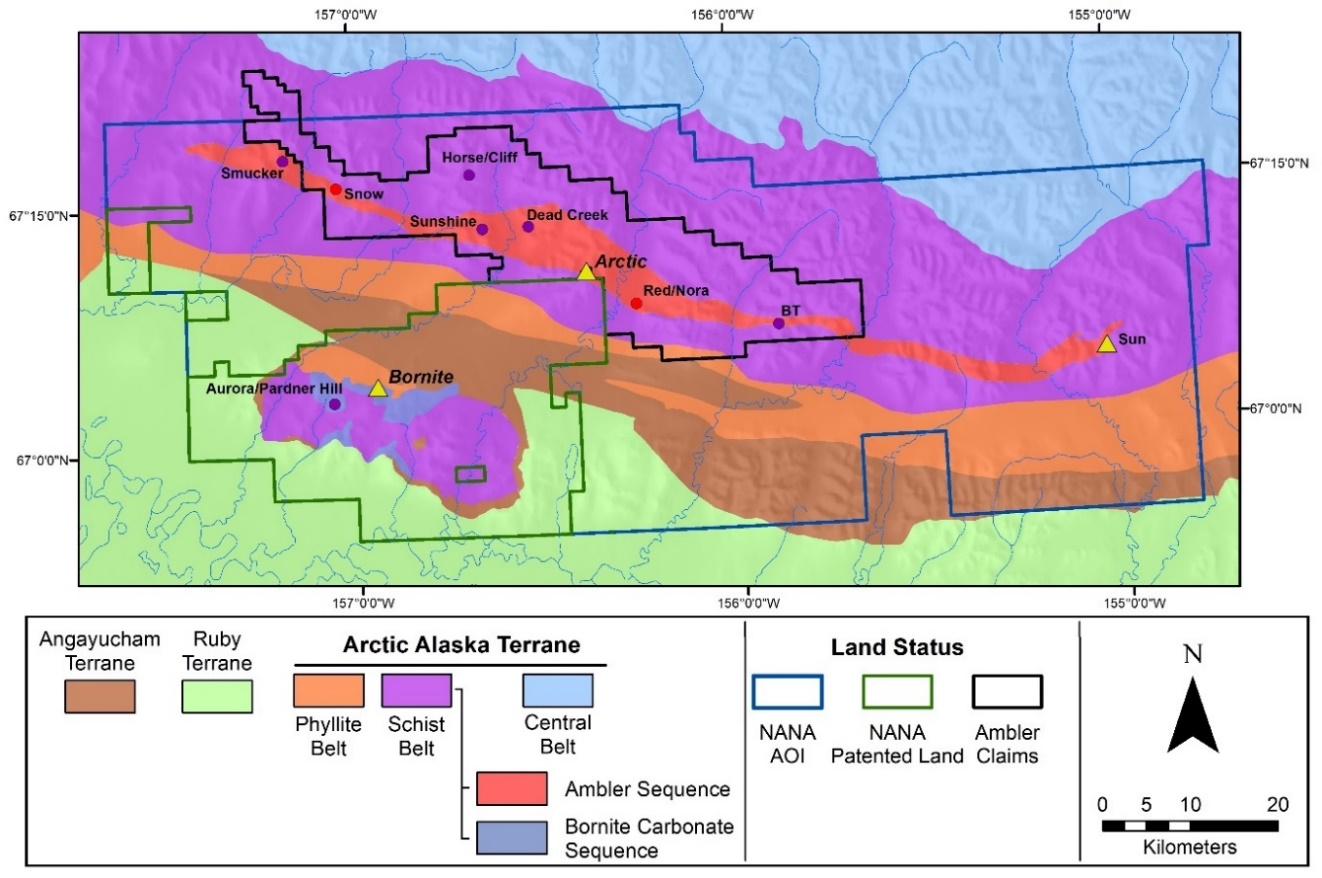

The Arctic Project is located in the Ambler mining district (Ambler Mining District) of the southern Brooks Range, in the Northwest Arctic Borough (NWAB) of Alaska. The Property is geographically isolated with no current road access or nearby power infrastructure. The Project is located 270 km east of the town of Kotzebue, 37 km northeast of the village of Kobuk, and 260 km west of the Dalton Highway, an all-weather state-maintained highway.

NovaGold Resources Inc. (NovaGold) acquired the Arctic Project from Kennecott Exploration Company and Kennecott Arctic Company (collectively, Kennecott) in 2004. In 2011, NovaGold transferred all copper projects to NovaCopper Inc. and spun-out NovaCopper to its then existing shareholders in 2012. NovaCopper Inc. subsequently underwent a name change to Trilogy Metals Inc. in 2016. Under the Kennecott Purchase and Termination Agreement, Kennecott retained a 1% net smelter return (NSR) royalty that has been subsequently sold by Kennecott. The 1% NSR runs with the lands and is purchasable at any time from the royalty holder for a one-time payment of $10 million.

The Project is directly held by Ambler Metals LLC (Ambler Metals), a 50/50 joint venture formed between South32 Limited (South32) and Trilogy Metals Inc. (Trilogy Metals) in February 2020. Upon the formation of the joint venture, Trilogy Metals contributed all of its Alaskan assets, including the Project and Trilogy’s agreement with NANA (see below), to Ambler Metals in exchange for a 50% membership interest and at the same time, South32 contributed $145 million in cash for a 50% membership interest.

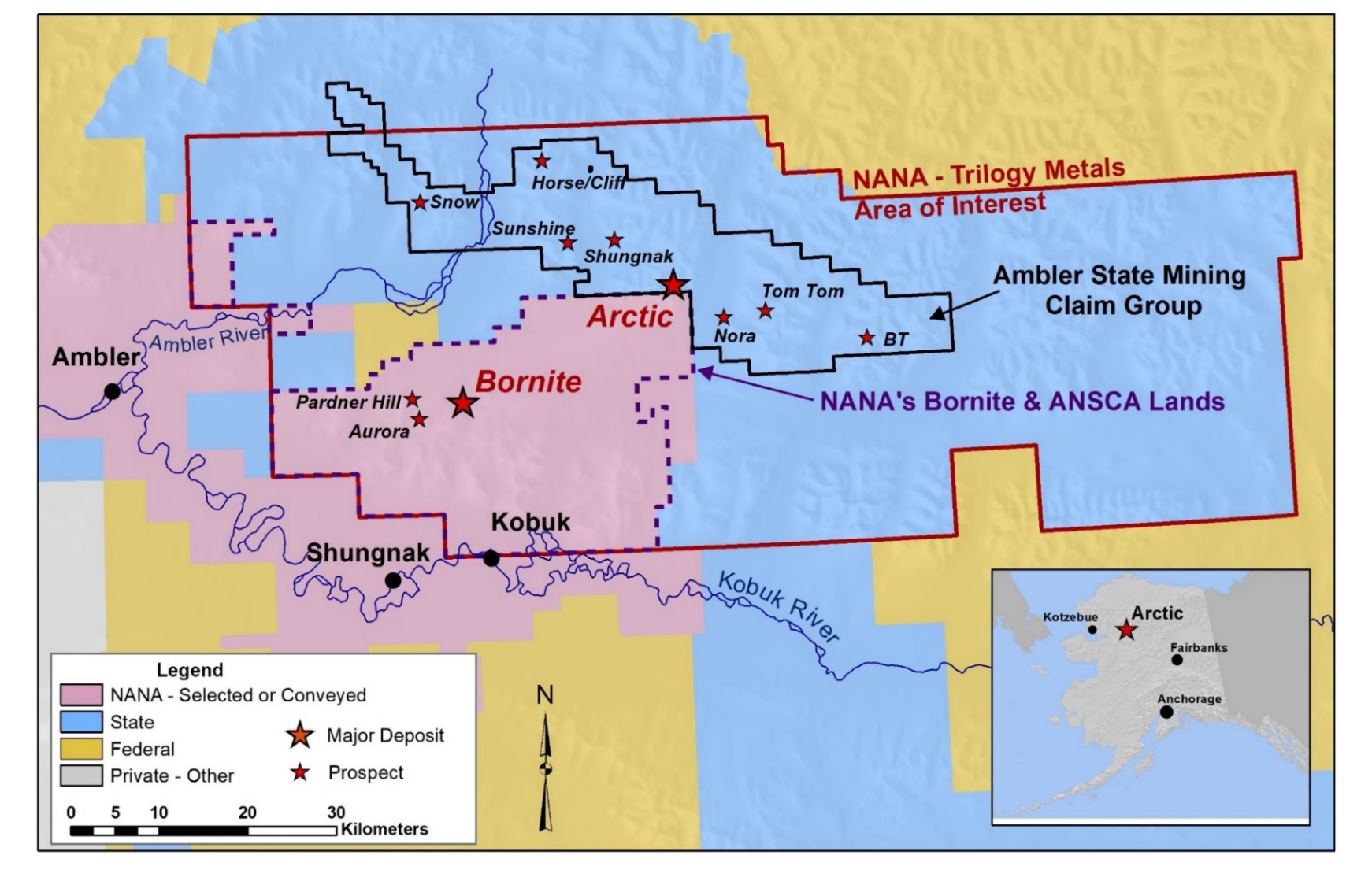

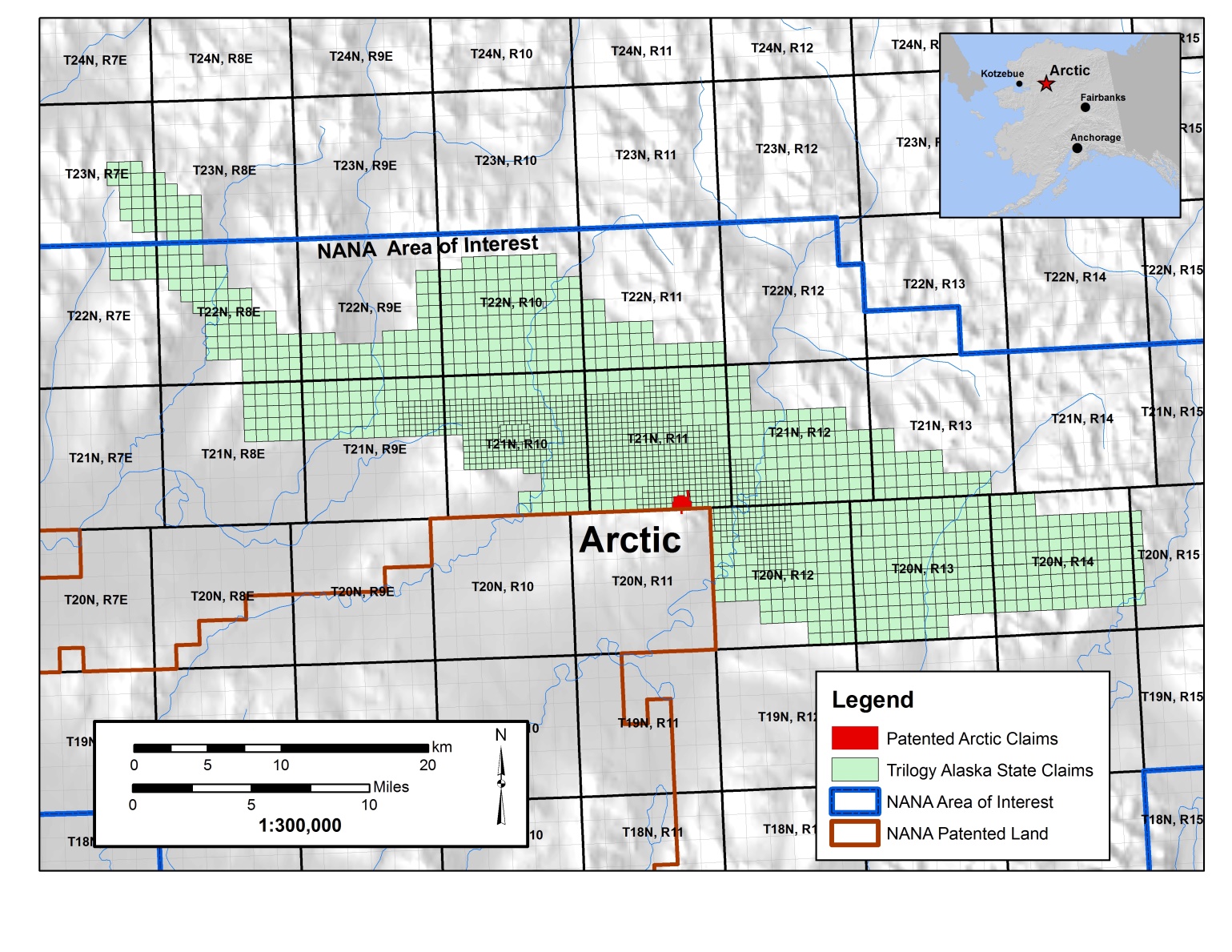

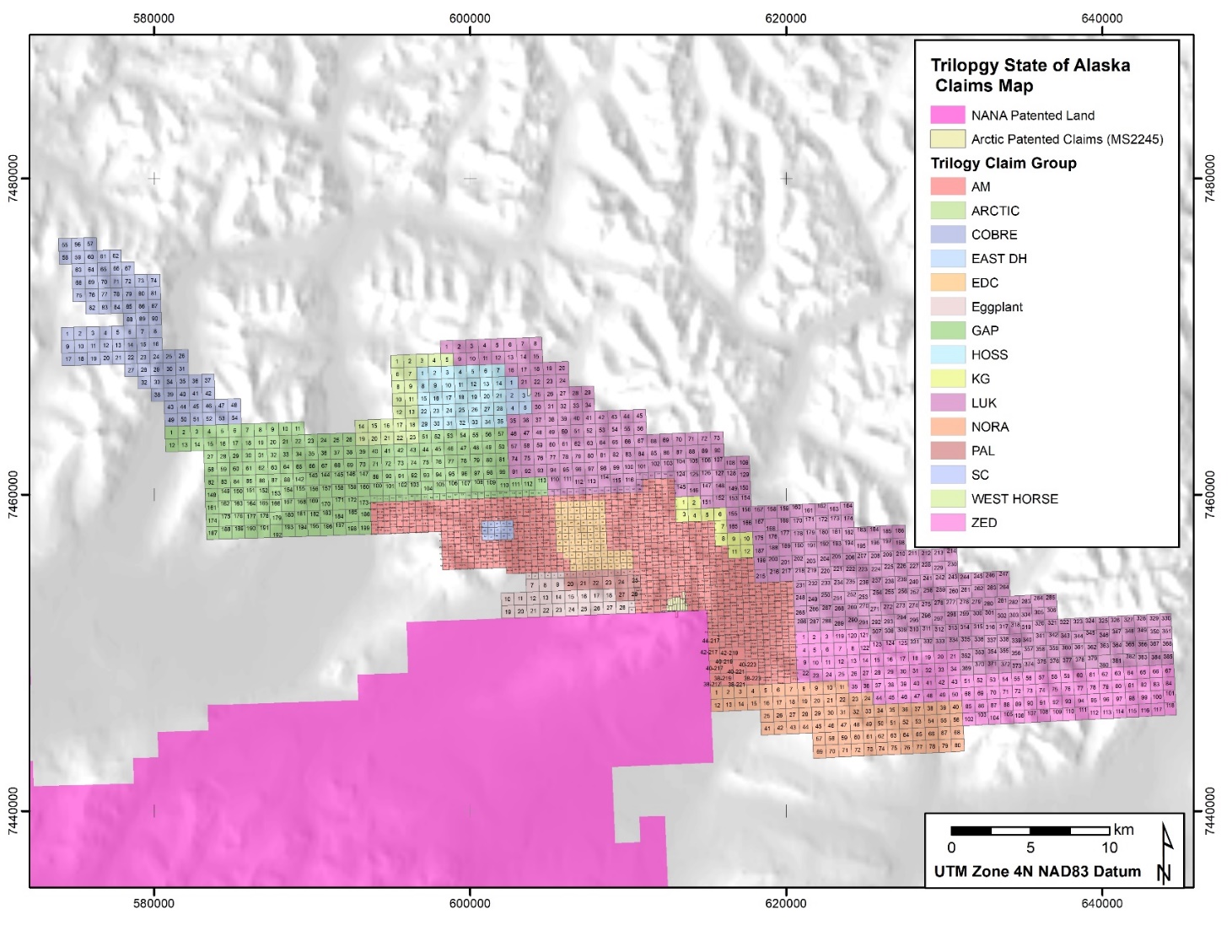

Ambler Metals holds approximately 185,805 acres (75,192 ha) of State of Alaska mining claims and US Federal patented mining claims in the Kotzebue Recording District. The Arctic Project land tenure consists of 1,851 contiguous State mining claims, including 905 40-acre claims, 946 160-acre claims, and 18 Federal patented claims comprising 271.9 acres (110 ha) held in the name of Ambler Metals.

Surface use of the private land held as Federal patented claims is limited only by reservations in the patents and by generally-applicable environmental laws. Surface use of State claims allows the owner of the mining claim to make such use of the surface as is “necessary for prospecting for, extraction of, or basic processing of minerals.”

The NANA Regional Corporation, Inc. (NANA) controls lands granted under the Alaska Native Claims Settlement Act (ANCSA) to the south of the Project boundary. Ambler Metals and NANA are parties to an agreement (the NANA Agreement) that consolidates the parties’ land holdings into an approximately 172,675 ha land package and provides a framework for the exploration and development of the area. The NANA Agreement has a term of 20 years, with an option in favour of Ambler Metals to extend the term for an additional 10 years. If, following receipt of a feasibility study and the release for public comment of a related draft environmental impact statement, a decision is made to proceed with construction of a mine on the lands subject to the NANA Agreement, NANA will have 120 days to elect to either (a) exercise a non-transferrable back-in-right to acquire between 16% and 25% (as specified by NANA) of that specific project; or (b) not exercise its back-in-right, and instead receive a net proceeds royalty equal to 15% of the net proceeds realized from such project. In the event that NANA elects to exercise its back-in-right, the parties will, as soon as reasonably practicable, form a joint venture with NANA electing to participate between 16% to 25%, and Ambler Metals owning the balance of the interest in the joint venture. If Ambler Metals decides to proceed with construction of a mine on its own lands subject to the NANA Agreement, NANA will enter into a surface use agreement which will afford Ambler Metals access to the project along routes approved by NANA. In consideration for the grant of such surface use rights, NANA will receive a 1% net smelter royalty on production and provide an annual payment on a per acre basis.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | Page 1-2 |

| 1.5 | Accessibility, Climate, Local Resources and Infrastructure |

Primary access to the Project is by air, using both fixed wing aircraft and helicopters.

There are four well-maintained, approximately 1,500 m-long gravel airstrips located near the Project, capable of accommodating charter fixed wing aircraft. These airstrips are located 64 km west at Ambler, 46 km southwest at Shungnak, 37 km southwest at Kobuk, and 34 km southwest at Dahl Creek. There is daily commercial air service from Kotzebue to the village of Kobuk, the closest community to the Project. During the summer months, the Dahl Creek Camp airstrip is suitable for larger aircraft, such as a C-130 and DC-6.

In addition to the four 1,500 m airstrips, there is a 700 m airstrip located at the Bornite Camp. The airstrip at Bornite is suited to smaller aircraft, which support the Bornite Camp with personnel and supplies. There is also a 450 m airstrip (Arctic airstrip) located at the base of Arctic Ridge that can support smaller aircraft.

A winter trail and a one-lane dirt track suitable for high-clearance vehicles or construction equipment links the Arctic Project’s main camp located at Bornite to the Dahl Creek airstrip southwest of the Arctic deposit. An unimproved gravel track connects the Arctic airstrip with the Arctic deposit.

The climate in the region is typical of a sub-arctic environment. Weather conditions on the Project can vary significantly from year to year and can change suddenly. During the summer exploration season, average maximum temperatures range from 10 °C to 20 °C, while average lows range from -2 °C to 7 °C (Western Regional Climate Center: WRCC - Alaska Climate Summaries: Kobuk 1971 to 2000). By early October, unpredictable weather limits safe helicopter travel to the Project. During winter months, the Project can be accessed by snow machine, track vehicle, or fixed wing aircraft. Winter temperatures are routinely below -25 °C and can exceed -50 °C. Annual precipitation in the region varies with elevation.

It is expected that any future mining activity will be conducted on a year-round basis. Exploration activities are generally confined to the period from late May to late September.

Kotzebue is a potential source of limited mining-related supplies and labourers, and is the nearest centre serviced by regularly scheduled, large commercial aircraft (via Nome or Anchorage). In addition, there are seven other villages in the region that will be a potential source of some of the workforce for the Project. Fairbanks (population 31,036; 2010 US Census) has a long mining history along with currently operating mines and can provide most mining-related supplies and support that cannot be sourced closer to the Project area.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | Page 1-3 |

Drilling and mapping programs are seasonal and have been supported out of the Bornite Camp and Dahl Creek Camp. The Bornite Camp facilities are located on Ruby Creek on the northern edge of the Cosmos Hills. The camp provides office space and accommodations for the geologists, drillers, pilots, and support staff. Power is supplied by two Caterpillar diesel generators – one 300kW and one 225 kW. Water was supplied by the permitted artesian well located 250 m from camp; however, a water well was drilled in camp during the 2017 field season that was permitted by 2019 to provide all potable water for the Bornite Camp.

Prior to Trilogy Metals’ Project interest, work programs were conducted by Bear Creek Mining Company (BCMC), an exploration subsidiary of Kennecott Exploration (Kennecott) and Anaconda. Exploration activities included geological and reconnaissance mapping, geochemical sampling, airborne and ground geophysical surveys, drilling, metallurgical testwork, petrological and mineralogical studies, and resource estimates.

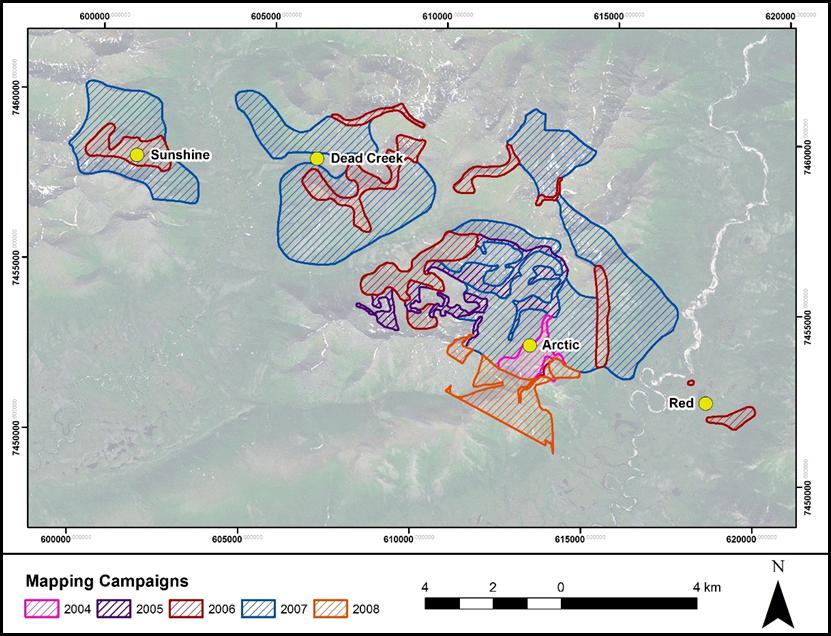

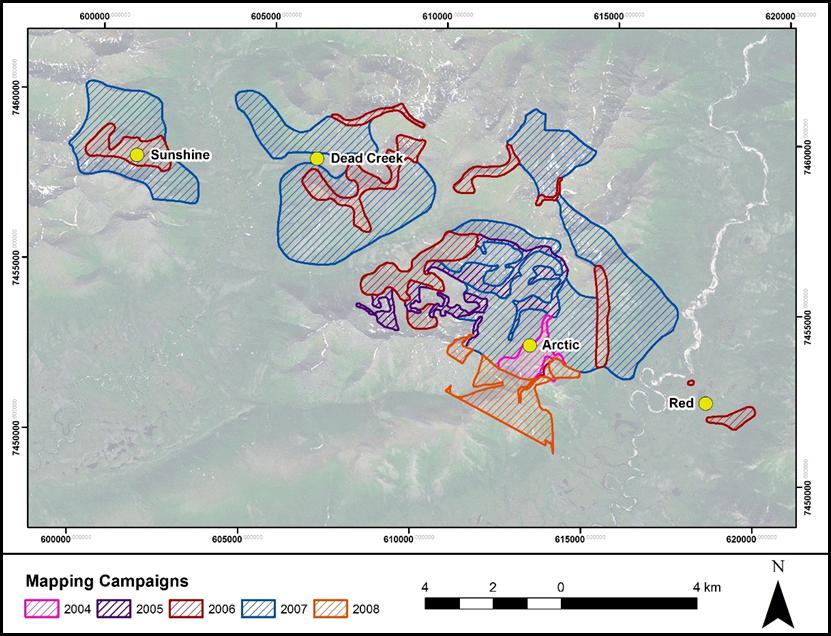

Trilogy Metals obtained its project interest in 2004, when the Alaska Gold Company, a wholly-owned subsidiary of NovaGold completed an Exploration and Option Agreement with Kennecott to earn an interest in the Ambler land holdings. In 2010, NovaGold acquired a 100% controlling interest by buying out Kennecott’s interest, although Kennecott retained an NSR royalty. Work conducted by NovaGold, its successor NovaCopper and Trilogy Metals included geological mapping, soil and silt geochemical sampling, time-domain electromagnetic (TDEM) ground geophysical surveys, airborne DIGHEM geophysical surveys, down-hole geophysics, drilling programs, metallurgical testwork, Mineral Resource and Mineral Reserve estimates, mining studies, and baseline environmental studies.

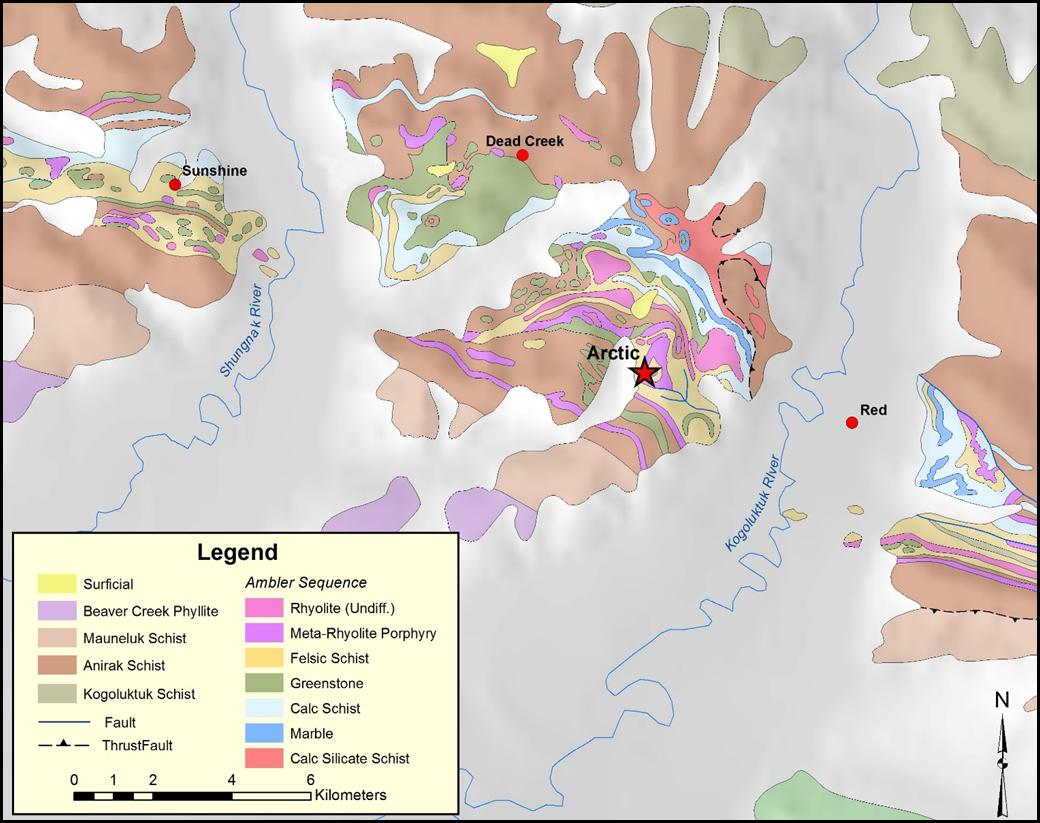

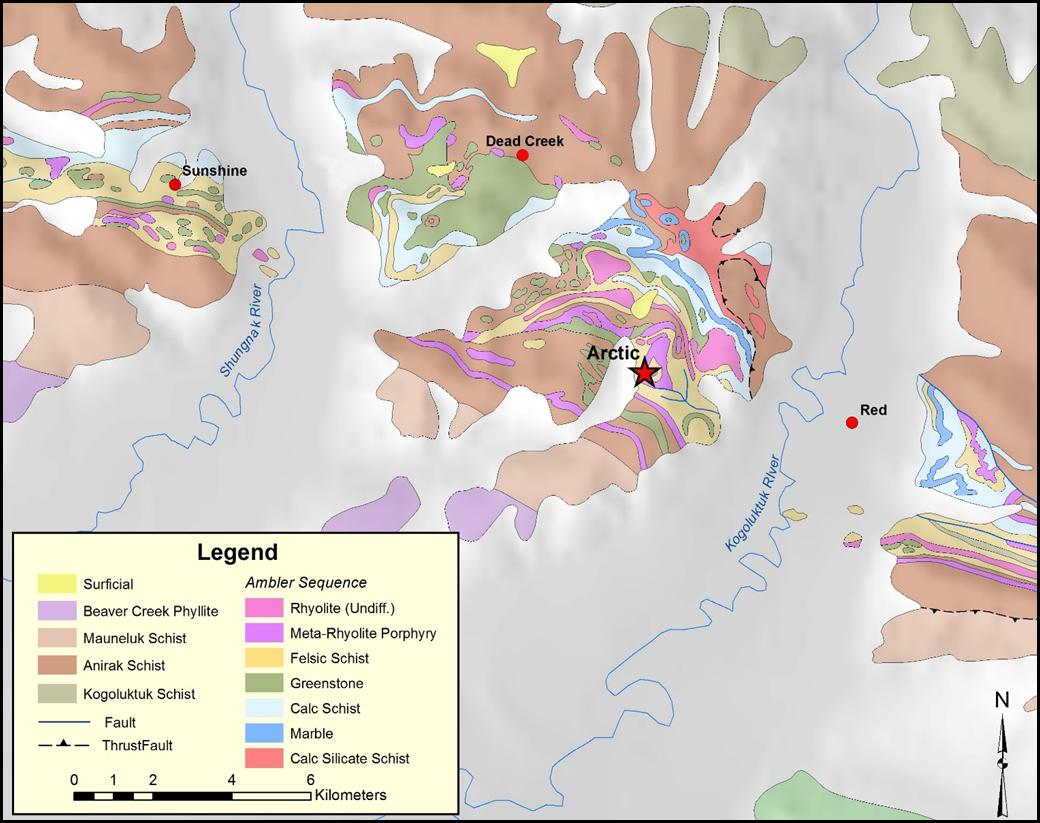

| 1.7 | Geological Setting and Mineralization |

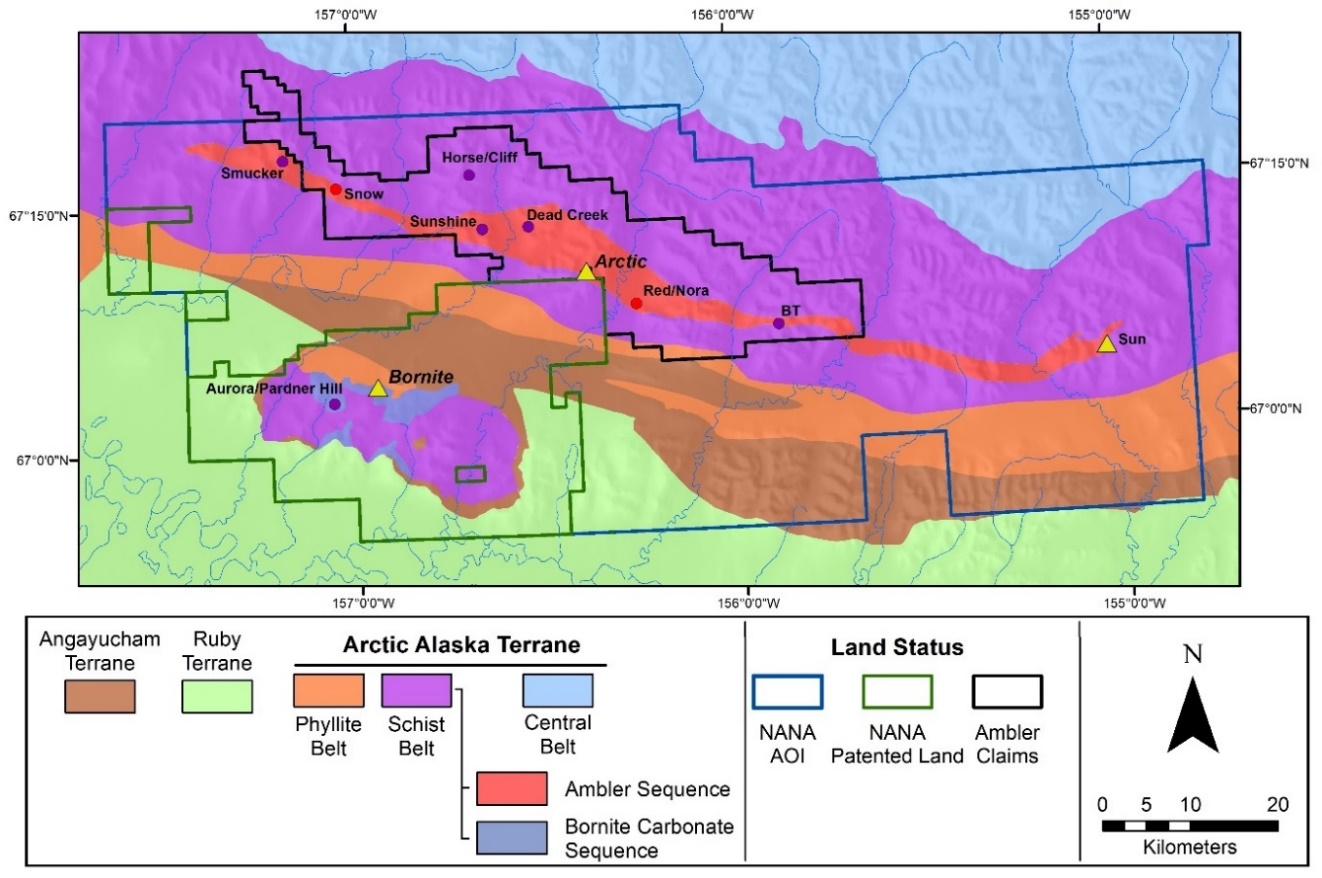

The Arctic deposit is considered to be a volcanogenic massive sulphide (VMS) deposit based on its geologic setting, associated host rocks, stratiform ore morphology, and ore mineralogy.

The Ambler Mining District is located on the southern margin of the Brooks Range. Within the VMS belt, several deposits and prospects (including the Arctic deposit) are hosted in the Ambler Sequence, a group of Middle Devonian to Early Mississippian, metamorphosed, bimodal volcanic rocks with interbedded tuffaceous, graphitic, and calcareous volcaniclastic metasediments. The Ambler Sequence occurs in the upper part of the regional Anirak Schist. VMS-style mineralization is found along the entire 110 km strike length of the Ambler Sequence.

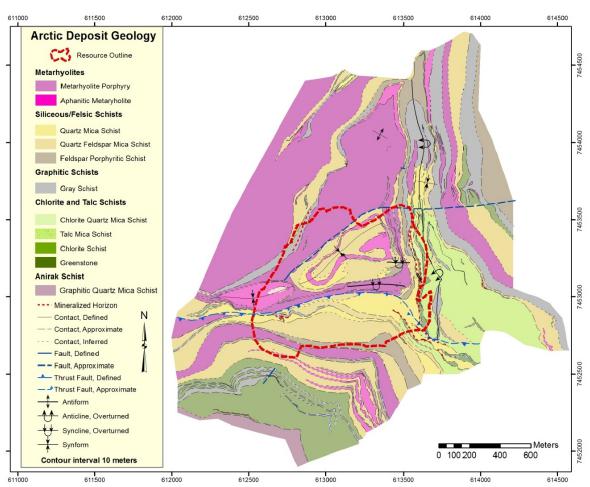

Stratigraphically, the Ambler Sequence consists of variably metamorphosed calc-turbidites, overlain by calcareous schists with irregularly distributed mafic sills and pillow lavas. These are overlain by the Arctic-sulphide host section which consists mainly of fine-grained, carbonaceous siliciclastic rocks which are in turn overlain by reworked silicic volcanic rocks, including meta-rhyolite porphyries and most notably the regionally extensive Button Schist with its characteristically large relic porphyroblasts. Greywacke sandstones, interpreted to be turbidites, occur throughout the section but are concentrated higher in the stratigraphy. Several rock units within the stratigraphy show substantial variation in local thickness as a consequence of basin morphology at the time of deposition and later deformation.

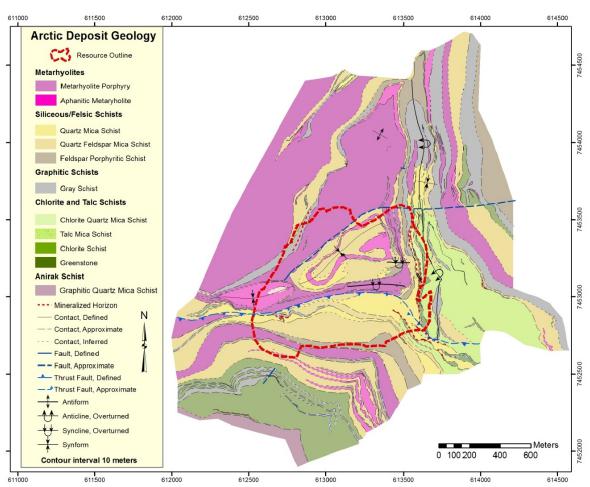

Alteration at the Arctic deposit is characterized by magnesium metasomatism, primarily as talc, Mg-rich chlorite, and phengite alteration products associated with the sulphide-bearing horizons and continuing in the footwall. Stratigraphically above the sulphide-bearing horizons, significant muscovite as paragonite is developed and results in a marked shift in Na/Mg (sodium/magnesium) ratios across the sulphide bearing horizons.

Trilogy Metals Inc.

NI 43-101 Technical Report

Date: September 2020 | | Page 1-4 |

Mineralization occurs as stratiform semi-massive sulphide (SMS) to massive sulphide (MS) beds within primarily graphitic chlorite schists and fine-grained quartz schists. The sulphide beds average 4 m in thickness but vary from less than 1 m up to as much as 18 m in thickness.

The bulk of the mineralization occurs within eight modelled SMS and MS zones lying along the upper and lower limbs of the interpreted Arctic isoclinal anticline. All of the zones are within an area of roughly 1 km2 with mineralization extending to a depth of approximately 250 m below the surface. Mineralization is predominately coarse-grained sulphides consisting mainly of chalcopyrite, sphalerite, galena, tetrahedrite-tennantite, pyrite, arsenopyrite, and pyrrhotite. Trace amounts of electrum are also present.

Drilling at the Arctic deposit and within the Ambler Mining District has been ongoing since its initial discovery in 1967. Approximately 60,857 m of drilling was completed within the Ambler Mining District, including 42,571 m of drilling in 207 drill holes at the Arctic deposit or on potential extensions in 29 campaigns spanning 52 years. Drill programs were completed by Kennecott and its subsidiaries, Anaconda, and Trilogy Metals and its predecessor companies.

Core recoveries are acceptable. Geological and geotechnical logging is in line with industry generally-accepted practices. Drill collar and downhole survey data were collected using industry-recognized instrumentation and methods at the time the data were collected.