Exhibit 99.2

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Contents

| 1.0 | executive summary | 1-1 |

| | 1.1 | Introduction | 1-1 |

| | 1.2 | Terms of Reference | 1-2 |

| | 1.3 | Mineral Tenure, Surface Rights and Obligations | 1-2 |

| | 1.4 | Geology and Mineralization | 1-3 |

| | 1.5 | Exploration | 1-4 |

| | 1.6 | Drilling, Sampling, and Data Verification | 1-4 |

| | 1.7 | Metallurgical Testing | 1-5 |

| | 1.8 | Mineral Resource Estimates | 1-5 |

| | 1.9 | Mining Methods | 1-7 |

| | 1.10 | Processing and Recovery Methods | 1-9 |

| | 1.11 | Infrastructure | 1-10 |

| | 1.12 | Market Studies | 1-11 |

| | 1.13 | Capital Costs | 1-11 |

| | 1.14 | Operating Costs | 1-12 |

| | 1.15 | Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups | 1-12 |

| | 1.16 | Financial Model | 1-13 |

| | 1.17 | Conclusions | 1-14 |

| | 1.18 | Risks | 1-14 |

| | 1.19 | Opportunities | 1-16 |

| | 1.20 | Recommendations | 1-18 |

| 2.0 | introduction | 2-1 |

| | 2.1 | Terms of Reference | 2-1 |

| | 2.2 | Qualified Persons | 2-1 |

| | 2.3 | Site Visits | 2-2 |

| | 2.4 | Information Sources | 2-3 |

| 3.0 | project description | 3-4 |

| | 3.1 | Location | 3-4 |

| | 3.2 | Mineral Tenure | 3-5 |

| | 3.3 | Royalties, Agreements and Encumbrances | 3-6 |

| | | 3.3.1 | Agreements | 3-6 |

| | | 3.3.2 | NANA Agreement | 3-7 |

| | 3.4 | Environmental Liabilities | 3-9 |

| | | 3.4.1 | Reclamation of Exploration Activities | 3-9 |

| | 3.5 | Permits | 3-9 |

| | 3.6 | Significant Risk Factors | 3-10 |

| 4.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 4-1 |

| | | | | | |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC i | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | 4.1 | Accessibility | 4-1 |

| | | 4.1.1 | Air | 4-1 |

| | | 4.1.2 | Water | 4-1 |

| | | 4.1.3 | Road | 4-1 |

| | 4.2 | Climate | 4-1 |

| | 4.3 | Local Resources | 4-2 |

| | 4.4 | Infrastructure | 4-3 |

| | 4.5 | Physiography | 4-3 |

| | 4.6 | Sufficiency of Surface Rights | 4-4 |

| 5.0 | history | 5-1 |

| | 5.1 | Bornite Property History | 5-1 |

| | | 5.1.1 | Geochemistry | 5-1 |

| | | 5.1.2 | Geophysics | 5-2 |

| | | 5.1.3 | Drilling and Underground Workings | 5-3 |

| | | 5.1.4 | Petrology, Mineralogy, and Research Studies | 5-5 |

| | | 5.1.5 | Geotechnical and Hydrological Studies | 5-5 |

| | | 5.1.6 | Metallurgical Studies | 5-5 |

| 6.0 | Geological Setting, Mineralization and Deposit | 6-1 |

| | 6.1 | Regional Geology | 6-1 |

| | | 6.1.1 | Tectonic and Metamorphic History | 6-1 |

| | | 6.1.2 | Stratigraphy | 6-2 |

| | | 6.1.3 | Igneous Rocks | 6-3 |

| | | 6.1.4 | Timing of Mineralization in the District | 6-4 |

| | 6.2 | Property Geology | 6-4 |

| | | 6.2.1 | Lithology Units | 6-5 |

| | | 6.2.2 | Lithology Interpretation | 6-10 |

| | | 6.2.3 | Structure | 6-11 |

| | 6.3 | Mineral Deposits | 6-13 |

| | | 6.3.1 | Mineralization | 6-14 |

| | | 6.3.2 | Alteration | 6-16 |

| | 6.4 | Prospects/Exploration Targets | 6-17 |

| | 6.5 | Genesis/Genetic Implications | 6-19 |

| | 6.6 | Deposit Types | 6-20 |

| 7.0 | exploration | 7-1 |

| | 7.1 | Introduction | 7-1 |

| | 7.2 | NOVAGOLD (2006) | 7-1 |

| | 7.3 | NOVAGOLD (2010) | 7-1 |

| | 7.4 | NOVAGOLD (2011) | 7-4 |

| | 7.5 | NovaCopper (2012) | 7-6 |

| | 7.6 | NovaCopper (2013) | 7-8 |

| | 7.7 | NovaCopper (2014) | 7-8 |

| | 7.8 | NovaCopper (2015) | 7-8 |

| | 7.9 | Trilogy Metals (2017) | 7-8 |

| | | | | | |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC ii | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | 7.10 | Trilogy Metals (2018) | 7-9 |

| | 7.11 | Trilogy Metals (2019) | 7-11 |

| | 7.12 | Ambler Metals (2020) | 7-12 |

| | 7.13 | Ambler Metals (2021) | 7-12 |

| | 7.14 | Ambler Metals (2022) | 7-14 |

| | 7.15 | Ambler Metals (2023) | 7-14 |

| | 7.16 | Ambler Metals (2024) | 7-14 |

| | 7.17 | Exploration Potential | 7-15 |

| | 7.18 | Drilling | 7-16 |

| | | 7.18.1 | Drill Core Procedures | 7-19 |

| | | | 7.18.1.1 | BCMC/Kennecott | 7-19 |

| | | | 7.18.1.2 | Trilogy Metals | 7-20 |

| | 7.19 | Drill Core Recovery | 7-21 |

| | 7.20 | Collar Surveys | 7-22 |

| | | 7.20.1 | Kennecott | 7-22 |

| | | 7.20.2 | Trilogy Metals | 7-23 |

| | 7.21 | Down-Hole Surveys | 7-23 |

| | 7.22 | Summary of Drill Results | 7-24 |

| | 7.23 | Hydrogeological | 7-24 |

| | 7.24 | Geotechnical | 7-25 |

| | 7.25 | QP Opinion on Section 7 | 7-25 |

| 8.0 | Sample Preparation, Analyses, and Security | 8-1 |

| | 8.1 | BCMC/Kennecott | 8-1 |

| | 8.2 | NOVAGOLD/Trilogy Metals | 8-1 |

| | | 8.2.1 | Sample Preparation | 8-1 |

| | | 8.2.2 | Density Determinations | 8-2 |

| | 8.3 | Security | 8-3 |

| | 8.4 | Assaying and Analytical Procedures | 8-3 |

| | 8.5 | Quality Assurance Quality Control | 8-5 |

| | | 8.5.1 | Core Drilling Sampling QAQC | 8-5 |

| | | | 8.5.1.1 | Historical Sample Re-assay Review | 8-5 |

| | | | 8.5.1.2 | Review of 2011 to 2019 QC Results | 8-6 |

| | | | 8.5.1.3 | Review of 2011 to 2017 Cobalt Assays | 8-8 |

| | | 8.5.2 | Density Determinations QAQC | 8-8 |

| | 8.6 | QP Opinion on Section 8 | 8-9 |

| 9.0 | data verification | 9-1 |

| | 9.1 | Drill Hole Data Transcription Error Checks | 9-1 |

| | | 9.1.1 | Previous Checks | 9-1 |

| | 9.2 | Drill Collar Validation | 9-2 |

| | | 9.2.1 | Previous Checks | 9-2 |

| | | 9.2.2 | Current Checks | 9-2 |

| | 9.3 | Down Hole Survey Validation | 9-2 |

| | 9.4 | Assessment of Historical Assay Data | 9-3 |

| | 9.5 | Site Visit Observations | 9-3 |

| | 9.6 | Metallurgical Data Verification | 9-3 |

| | | | | | |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC iii | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | 9.7 | Mining Data Verification | 9-4 |

| | 9.8 | Hydrology Data Verification | 9-4 |

| | 9.9 | Hydrogeology Data Verification | 9-4 |

| | 9.10 | Geotechnical (Tailings) Data Verification | 9-4 |

| | 9.11 | QP Opinion on Data Adequacy | 9-5 |

| | | 9.11.1 | Geology and Resource | 9-5 |

| | | 9.11.2 | Metallurgical | 9-5 |

| | | 9.11.3 | Mining | 9-5 |

| | | 9.11.4 | Hydrology | 9-6 |

| | | 9.11.5 | Hydrogeology | 9-6 |

| | | 9.11.6 | Geotechnical (Tailings) Data Verification | 9-6 |

| 10.0 | Mineral Processing and Metallurgical Testing | 10-1 |

| | 10.1 | Introduction | 10-1 |

| | 10.2 | Historical Test Work | 10-1 |

| | 10.3 | Metallurgical Test Work Programs Initiated by Trilogy Metals | 10-2 |

| | | 10.3.1 | Test Samples | 10-3 |

| | | 10.3.2 | Mineralogical Investigation | 10-4 |

| | | 10.3.3 | Sample Hardness Test Results | 10-5 |

| | | 10.3.4 | Flotation Test Results | 10-6 |

| | | 10.3.5 | Concentrate Quality Targets | 10-9 |

| | | 10.3.6 | Cobalt Speciation Studies | 10-9 |

| | | 10.3.7 | Opportunities for Cobalt Recovery | 10-9 |

| | 10.4 | QP Opinion on Data Adequacy | 10-10 |

| | 10.5 | Recommended Test Work | 10-10 |

| 11.0 | mineral resource estimates | 11-1 |

| | 11.1 | Introduction | 11-1 |

| | 11.2 | Sample Database and Other Available Data | 11-1 |

| | | 11.2.1 | Geologic Model | 11-3 |

| | 11.3 | Compositing | 11-7 |

| | 11.4 | Exploratory Data Analysis | 11-9 |

| | | 11.4.1 | Modelling Implications | 11-16 |

| | 11.5 | Treatment of Outlier Grades | 11-16 |

| | 11.6 | Specific Gravity Data | 11-18 |

| | 11.7 | Variography | 11-19 |

| | 11.8 | Model Setup and Limits | 11-20 |

| | 11.9 | Interpolation Parameters | 11-21 |

| | 11.10 | Block Model Validation | 11-22 |

| | | 11.10.1 | Visual Inspection | 11-22 |

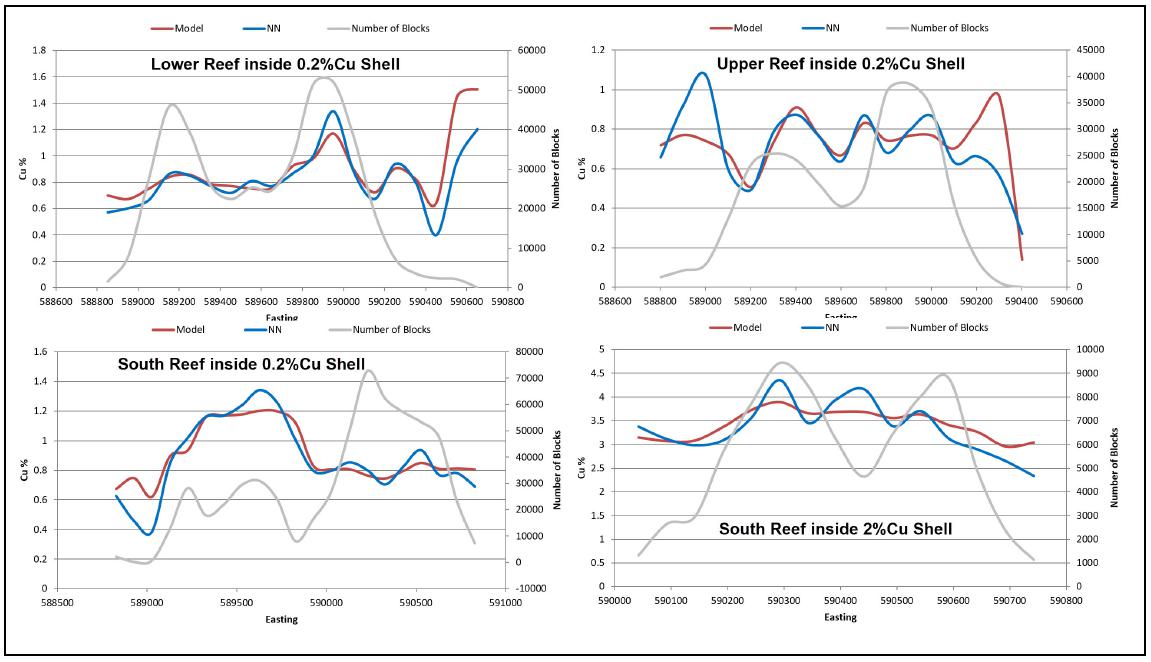

| | | 11.10.2 | Model Checks for Change of Support | 11-23 |

| | | 11.10.3 | Comparison of Interpolation Methods | 11-25 |

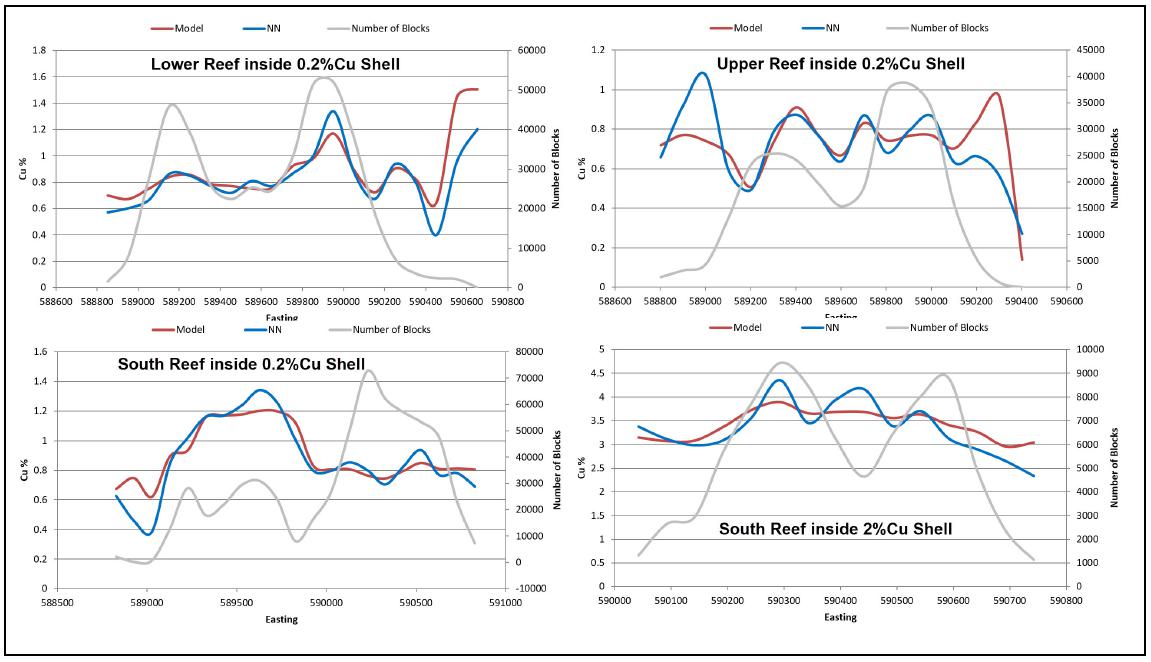

| | | 11.10.4 | Swath Plots | 11-25 |

| | 11.11 | Mineral Resource Classification | 11-28 |

| | 11.12 | Reasonable Prospects for Economic Extraction | 11-29 |

| | | | | | |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC iv | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | | 11.12.1 | Basis of Copper Price and Cost Assumptions | 11-30 |

| | 11.13 | Bornite Mineral Resource Statement | 11-31 |

| | | 11.13.1 | Portions of South Reef Mineral Resource Amenable to Underground Mining | 11-33 |

| | 11.14 | Uncertainties that Could Affect the Mineral Resource Estimate | 11-34 |

| 12.0 | mineral reserve estimates | 12-1 |

| 13.0 | mining Methods | 13-1 |

| | 13.1 | Summary | 13-1 |

| | 13.2 | Advanced Exploration Decline | 13-2 |

| | 13.3 | Geotechnical | 13-2 |

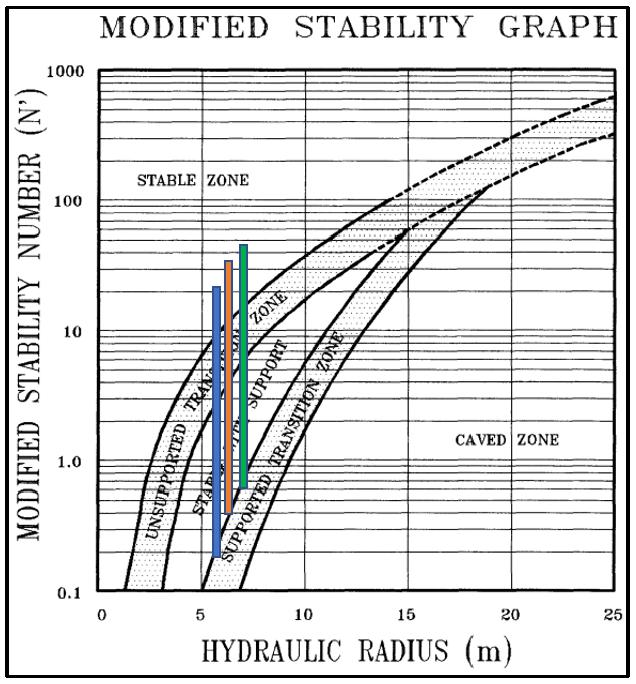

| | 13.4 | Mine Design | 13-6 |

| | | 13.4.1 | Level Design | 13-6 |

| | | 13.4.2 | Stope Design | 13-6 |

| | | 13.4.3 | Dilution and Recovery | 13-10 |

| | | 13.4.4 | Throughput and Cut-off Grade | 13-11 |

| | 13.5 | Underground Infrastructure | 13-13 |

| | | 13.5.1 | Ventilation | 13-13 |

| | | 13.5.2 | Material Handling | 13-15 |

| | | | 13.5.2.1 | Underground Production to Surface ROM Stockpile | 13-15 |

| | | | 13.5.2.2 | Surface ROM Stockpile to Arctic Processing Facility | 13-17 |

| | | | 13.5.2.3 | Development Material to Surface | 13-17 |

| | | | 13.5.2.4 | Development Material to Arctic | 13-17 |

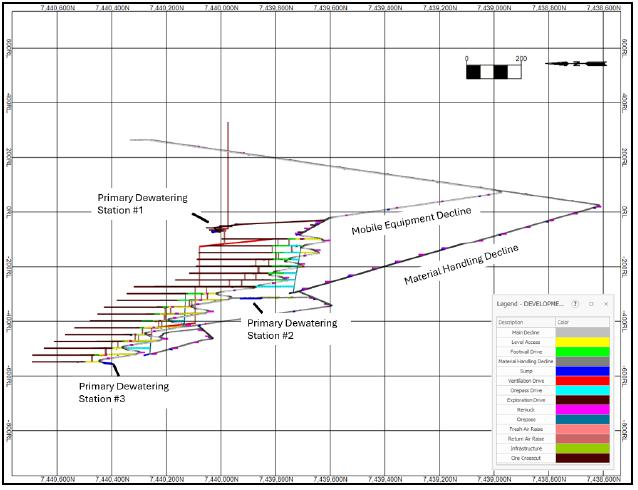

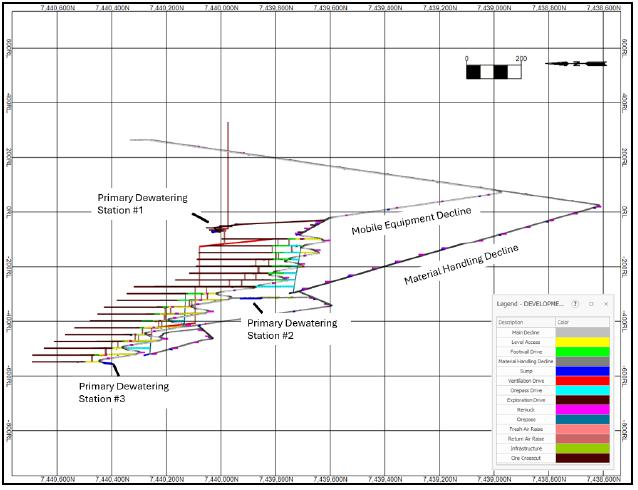

| | | 13.5.3 | Dewatering | 13-18 |

| | | 13.5.4 | Backfill | 13-19 |

| | | 13.5.5 | Explosive Storage | 13-20 |

| | | 13.5.6 | Maintenance Facilities | 13-20 |

| | | 13.5.7 | Services | 13-20 |

| | | | 13.5.7.1 | Mine Water | 13-20 |

| | | | 13.5.7.2 | Compressed Air | 13-20 |

| | | | 13.5.7.3 | Mine Communications | 13-21 |

| | 13.6 | Contingency Through Design | 13-21 |

| | 13.7 | Mobile Equipment | 13-22 |

| | 13.8 | Mine Labour | 13-23 |

| | 13.9 | Production Schedule | 13-24 |

| 14.0 | Processing and recovery methods | 14-1 |

| | 14.1 | Overview | 14-1 |

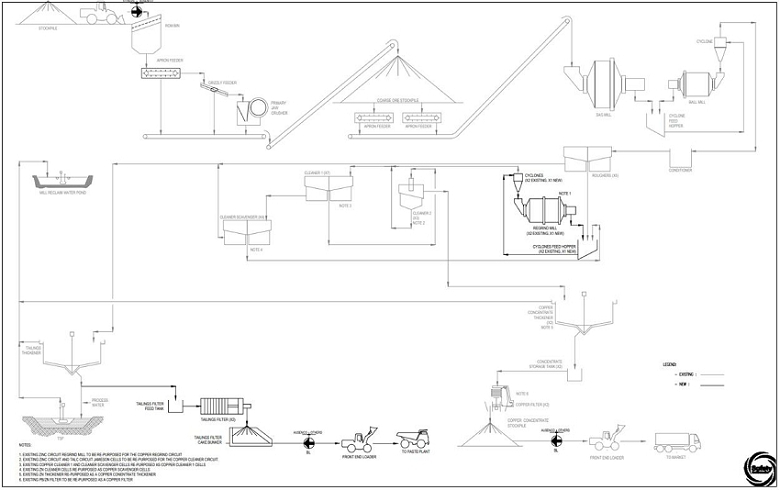

| | 14.2 | Process Flowsheet | 14-1 |

| | 14.3 | Process Design Criteria | 14-1 |

| | 14.4 | Plant Description | 14-5 |

| | | 14.4.1 | Crushing Plant | 14-5 |

| | | 14.4.2 | Coarse Material Storage | 14-5 |

| | | 14.4.3 | Grinding and Classification | 14-6 |

| | | | 14.4.3.1 | Copper Flotation | 14-6 |

| | | | | | |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC v | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | | 14.4.4 | Product Dewatering | 14-7 |

| | | 14.4.5 | Tailings Disposal and Tailings Filter Cake Production | 14-7 |

| | | 14.4.6 | Reagent Handling and Storage | 14-8 |

| | | | 14.4.6.1 | Collector (Aerophine 3418A) | 14-8 |

| | | | 14.4.6.2 | Frother | 14-9 |

| | | | 14.4.6.3 | Flocculant | 14-9 |

| | | | 14.4.6.4 | Quicklime | 14-9 |

| | | | 14.4.6.5 | Antiscalant | 14-9 |

| | | 14.4.7 | Process Materials | 14-9 |

| | | 14.4.8 | Power Supply | 14-9 |

| | | 14.4.9 | Water Supply | 14-10 |

| | | | 14.4.9.1 | Fresh Water Supply System | 14-10 |

| | | | 14.4.9.2 | Waste Rock Contact Pond Water Supply System | 14-10 |

| | | | 14.4.9.3 | Process Water Supply System | 14-10 |

| | | 14.4.10 | Air Supply | 14-11 |

| 15.0 | infrastructure | 15-1 |

| | 15.1 | Bornite Site | 15-1 |

| | | 15.1.1 | Summary | 15-1 |

| | | 15.1.2 | Advanced Exploration Decline Infrastructure | 15-3 |

| | | 15.1.3 | Site Road Access | 15-3 |

| | | 15.1.4 | Site Roads | 15-4 |

| | | 15.1.5 | Waste Transfer Pad | 15-4 |

| | | 15.1.6 | Topsoil Stockpile | 15-5 |

| | | 15.1.7 | ROM Stockpile | 15-5 |

| | | 15.1.8 | Water Management | 15-5 |

| | | | 15.1.8.1 | Mine Dewatering | 15-6 |

| | | | 15.1.8.2 | Surface Water Management | 15-9 |

| | | | 15.1.8.3 | Water Treatment | 15-12 |

| | | 15.1.9 | Ancillary Buildings | 15-13 |

| | | 15.1.10 | Power and Distribution | 15-14 |

| | | | 15.1.10.1 | Power Consumption | 15-14 |

| | | | 15.1.10.2 | Power Plant | 15-15 |

| | | | 15.1.10.3 | Site Power Distribution | 15-16 |

| | | 15.1.11 | Communications | 15-18 |

| | | 15.1.12 | Diesel Supply, Storage and Distribution | 15-18 |

| | | 15.1.13 | Water Supply | 15-18 |

| | 15.2 | Offsite Infrastructure | 15-18 |

| | | 15.2.1 | Arctic Site | 15-18 |

| | | 15.2.2 | Access to the Arctic Site | 15-19 |

| | | 15.2.3 | Process Plant | 15-21 |

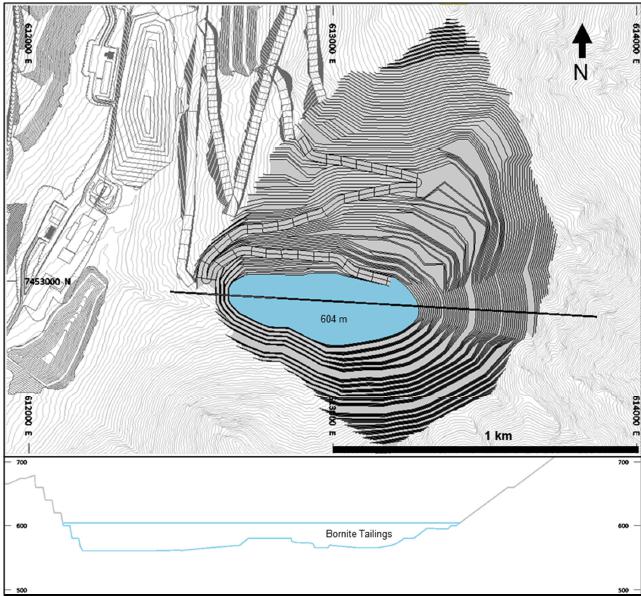

| | | 15.2.4 | Tailings Storage Facility | 15-21 |

| | | | 15.2.4.1 | Assumptions | 15-23 |

| | | | 15.2.4.2 | Design | 15-23 |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC vi | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | | 15.2.5 | Transportation of Concentrate | 15-26 |

| 16.0 | market studies | 16-1 |

| | 16.1 | Introduction | 16-1 |

| | 16.2 | Copper Price | 16-1 |

| | 16.3 | Market for Copper Concentrate | 16-1 |

| | 16.4 | Contracts | 16-1 |

| 17.0 | Environmental Studies, Permitting, and Plans, negotiations, or agreements with local individuals or groups | 17-1 |

| | 17.1 | Environmental Studies | 17-1 |

| | | 17.1.1 | Archaeology | 17-1 |

| | | 17.1.2 | Aquatic Life | 17-2 |

| | | 17.1.3 | Wetlands and Soils | 17-2 |

| | | 17.1.4 | Surface Water Quality and Hydrology | 17-3 |

| | | 17.1.5 | Meteorology, Air Quality and Noise | 17-3 |

| | | 17.1.6 | Subsistence and Traditional Ecological Knowledge | 17-4 |

| | | 17.1.7 | Additional Baseline Requirements | 17-5 |

| | 17.2 | Environmental Management | 17-5 |

| | 17.3 | Permitting | 17-8 |

| | 17.4 | Social and Community Considerations | 17-8 |

| | 17.5 | Reclamation | 17-10 |

| | | 17.5.1 | Bornite Mine Legacy Cleanup | 17-10 |

| | | 17.5.2 | Reclamation of Exploration Activities | 17-11 |

| | | 17.5.3 | Bornite Mine Reclamation and Closure | 17-11 |

| | | | 17.5.3.1 | Conceptual Development | 17-12 |

| | | | 17.5.3.2 | Reclamation and Closure Activities | 17-13 |

| | | | 17.5.3.3 | Closure Costs | 17-14 |

| | 17.6 | QP’s Opinion on Data Adequacy | 17-14 |

| 18.0 | capital and operating cost | 18-1 |

| | 18.1 | Capital Cost Estimate | 18-1 |

| | | 18.1.1 | Summary | 18-1 |

| | | 18.1.2 | Scope of Responsibilities | 18-1 |

| | | 18.1.3 | Mining | 18-2 |

| | | 18.1.3.1 | Underground | 18-3 |

| | | 18.1.4 | Crushing/Process | 18-5 |

| | | 18.1.5 | Tailings | 18-6 |

| | | 18.1.6 | Onsite Infrastructure | 18-6 |

| | | 18.1.7 | Offsite Infrastructure | 18-7 |

| | | 18.1.8 | Indirect Costs | 18-7 |

| | | 18.1.9 | Owners’ Cost | 18-8 |

| | | 18.1.10 | Contingency | 18-8 |

| | | 18.1.11 | Sustaining Capital Costs | 18-9 |

| | | 18.1.12 | Exclusions | 18-9 |

| | 18.2 | Closure Costs | 18-11 |

| | | | | | |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC vii | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

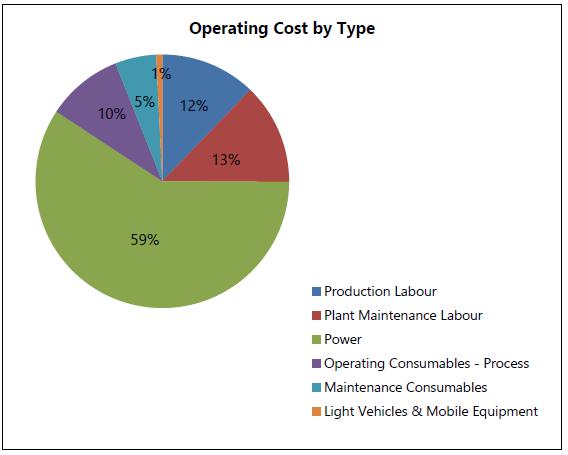

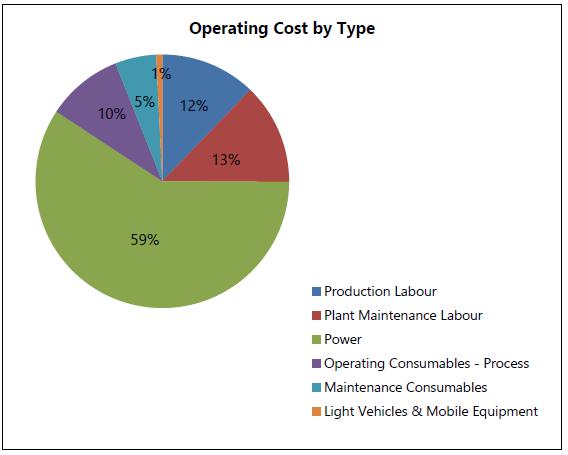

| | 18.3 | Operating Cost Estimate | 18-11 |

| | | 18.3.1 | Summary | 18-11 |

| | | 18.3.2 | Underground Mine Operating Costs | 18-12 |

| | | 18.3.3 | OTR Haulage Costs | 18-14 |

| | | 18.3.4 | Process Operating Costs | 18-14 |

| | | | 18.3.4.1 | Basis of Estimate | 18-14 |

| | | | 18.3.4.2 | Power | 18-16 |

| | | | 18.3.4.3 | Consumables | 18-17 |

| | | | 18.3.4.4 | Maintenance Consumables | 18-17 |

| | | | 18.3.4.5 | Plant Labour | 18-17 |

| | | 18.3.5 | General and Administrative Costs | 18-18 |

| | | | 18.3.5.1 | General and Administrative Cost Summary | 18-18 |

| | | | 18.3.5.2 | Water Treatment | 18-19 |

| | | | 18.3.5.3 | Bornite Dewatering Wells | 18-19 |

| | | 18.3.6 | AAP Road Cost | 18-20 |

| 19.0 | economic analysis | 19-1 |

| | 19.1 | Cautionary Statement | 19-1 |

| | 19.2 | Methodology Used | 19-1 |

| | 19.3 | Financial Model Parameters | 19-2 |

| | | 19.3.1 | Metal Recovery | 19-2 |

| | | 19.3.2 | Metal Price | 19-2 |

| | | 19.3.3 | Smelting and Refining Terms | 19-2 |

| | | 19.3.4 | Exchange Rate | 19-3 |

| | | 19.3.5 | Transportation and Selling Costs | 19-3 |

| | | 19.3.6 | Royalty Agreements | 19-3 |

| | | 19.3.7 | Taxes | 19-3 |

| | | | 19.3.7.1 | US Federal Tax | 19-4 |

| | | | 19.3.7.2 | Alaska State Tax | 19-4 |

| | | | 19.3.7.3 | Alaska Mining License Tax | 19-5 |

| | | 19.3.8 | Working Capital | 19-5 |

| | | 19.3.9 | Closure and Reclamation | 19-5 |

| | | 19.3.10 | Capital Costs | 19-6 |

| | | 19.3.11 | Operating Costs | 19-6 |

| | | 19.3.12 | Salvage Value | 19-6 |

| | | 19.3.13 | Inflation | 19-6 |

| | | 19.3.14 | Financial Results | 19-6 |

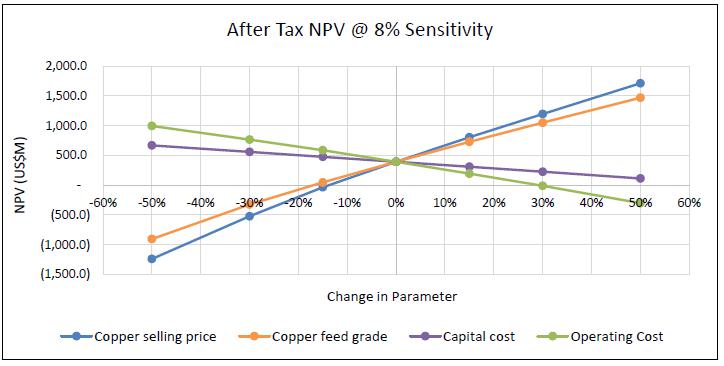

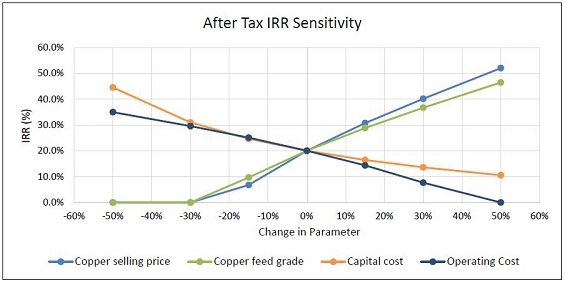

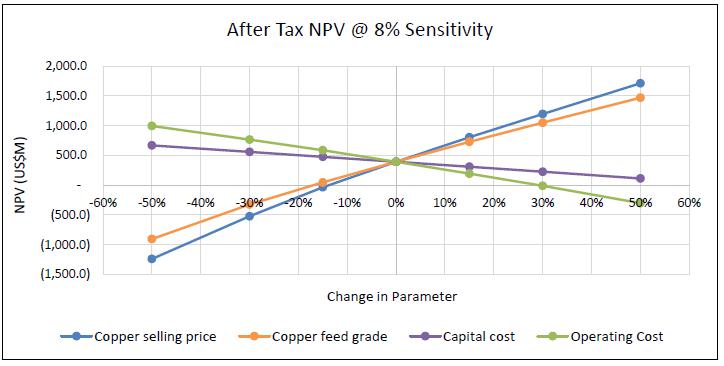

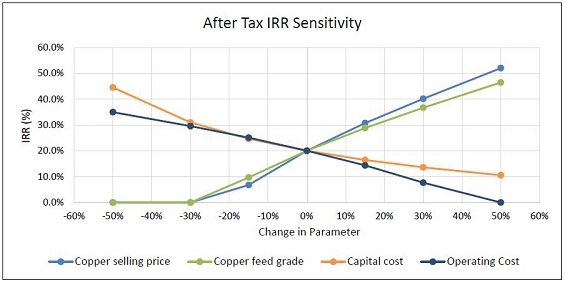

| | 19.4 | Sensitivity Analysis | 19-9 |

| 20.0 | adjacent properties | 20-1 |

| 21.0 | Other Relevant Data and Information | 21-1 |

| 22.0 | interpretation and conclusions | 22-1 |

| | 22.1 | Summary | 22-1 |

| | 22.2 | Mineral Tenure, Surface Rights, Royalties | 22-1 |

| | 22.3 | Geology and Mineralization | 22-1 |

| | | | | | |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC viii | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | 22.4 | Data Collection in Support of Mineral Resource Estimation | 22-1 |

| | 22.5 | Mineral Resources | 22-1 |

| | 22.6 | Metallurgical Test Work | 22-2 |

| | 22.7 | Mine Plan | 22-3 |

| | 22.8 | Processing and Recovery Methods | 22-3 |

| | 22.9 | Infrastructure | 22-4 |

| | 22.10 | Environmental, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups | 22-5 |

| | 22.11 | Markets Studies | 22-5 |

| | 22.12 | Capital and Operating Costs | 22-5 |

| | 22.13 | Economic Analysis | 22-6 |

| | 22.14 | Risks | 22-6 |

| | 22.15 | Opportunities | 22-8 |

| 23.0 | recommendations | 23-1 |

| | 23.1 | Summary | 23-1 |

| | 23.2 | Geology and Mineral Resources | 23-1 |

| | 23.3 | Advanced Exploration Underground Decline | 23-2 |

| | | 23.3.1 | Advanced Exploration Underground Decline Studies | 23-2 |

| | | 23.3.2 | Hydrogeology | 23-2 |

| | | 23.3.3 | Mining Geotechnical | 23-3 |

| | | 23.3.4 | Rock Mechanics | 23-3 |

| | | 23.3.5 | Advanced Exploration Decline Capital Cost | 23-4 |

| | | 23.3.6 | Underground Drill Program | 23-4 |

| | 23.4 | Metallurgical Test Work | 23-5 |

| | 23.5 | Processing and Recovery Methods | 23-5 |

| | 23.6 | Tailings Studies | 23-5 |

| | 23.7 | Water Management | 23-6 |

| | | 23.7.1 | Hydrology | 23-6 |

| | | 23.7.2 | Water Treatment | 23-7 |

| | 23.8 | Infrastructure | 23-7 |

| | 23.9 | Environmental, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups | 23-8 |

| | 23.10 | Summary of Costs | 23-8 |

| 24.0 | references | 24-1 |

| 25.0 | reliance on information provided by the registrant | 25-1 |

| | 25.1 | Legal Status | 25-1 |

| | 25.2 | Taxation | 25-1 |

| | | | | | |

Tables

| Table 1-1: | Mineral Resources for the Bornite Deposit | 1-6 |

| Table 1-2: | Portions of South Reef Mineral Resource Amenable to Underground Mining | 1-7 |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC ix | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| Table 1-3: | Subset of the Bornite Mineral Resource Estimate within the IA Mine Plan | 1-9 |

| Table 1-4: | Summary of Capital Cost Estimate | 1-11 |

| Table 1-5: | Total Operating Costs over LOM | 1-12 |

| Table 1-6: | Financial Results | 1-14 |

| Table 2-1: | Third-Party Firms Who Prepared this Report | 2-2 |

| Table 3-1: | Summary of Bornite Property | 3-6 |

| Table 6-1: | Tectono-Stratigraphic Units of the Cosmos Hills Area | 6-3 |

| Table 6-2: | Lithology Units on the Bornite Property | 6-6 |

| Table 7-1: | Summary Bornite Drill Hole Campaigns | 7-17 |

| Table 7-2: | Kennecott Drill Holes Re-logged and Re-assayed by Trilogy Metals | 7-18 |

| Table 7-3: | Representative Drill Intersections with Cobalt Grades | 7-29 |

| Table 8-1: | Standard Reference Materials Used by Year | 8-2 |

| Table 8-2: | Analytical Laboratories Used by Operators | 8-4 |

| Table 10-1: | Summary of Bornite Metallurgical Test Work Programs Initiated by Trilogy Metals | 10-2 |

| Table 10-2: | Summary of Chemical Analyses of Metallurgical Composites | 10-3 |

| Table 10-3: | Summary of Bond Ball Mill Work Index Determinations | 10-5 |

| Table 10-4: | Summary of Process Simulation Test Work - Locked Cycle Tests Results | 10-7 |

| Table 10-5: | Typical Concentrate Analysis – KM5705 Final Copper Concentrates | 10-9 |

| Table 11-1: | Metal Lost Due to Treatment of Outlier Copper Sample Data | 11-18 |

| Table 11-2: | Copper Correlogram Parameters | 11-20 |

| Table 11-3: | Copper and SG Interpolation Parameters | 11-21 |

| Table 11-4 | Parameters Used to Constrain the Mineral Resource | 11-30 |

| Table 11-5: | Bornite Mineral Resource Statement | 11-31 |

| Table 11-6: | Portions of South Reef Mineral Resource Amenable to Underground Mining | 11-33 |

| Table 13-1: | Subset of the Mineral Resources included in the Underground in the IA Mine Plan | 13-1 |

| Table 13-2: | Advanced Exploration Decline Physicals | 13-2 |

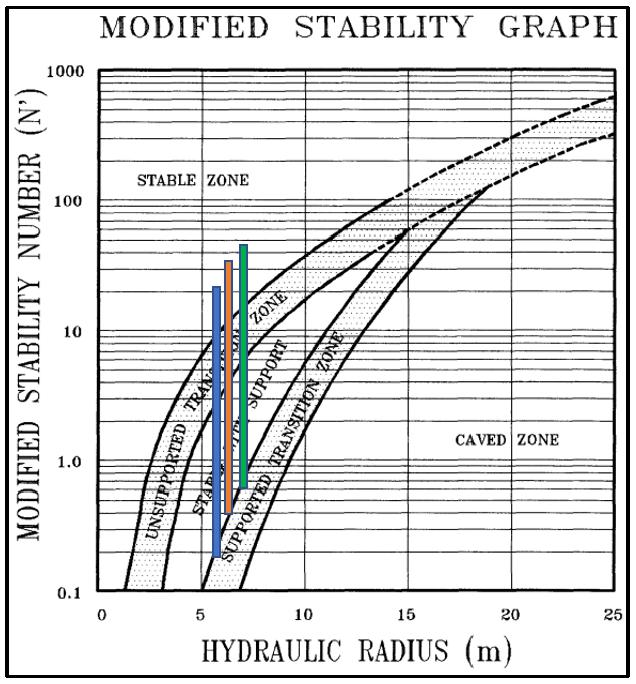

| Table 13-3: | Modified Stability Graph Inputs | 13-4 |

| Table 13-4: | Underground Life of Mine Physicals (excluding AEX Decline) | 13-8 |

| Table 13-5: | Average Stope Parameters | 13-9 |

| Table 13-6: | MSO Parameters | 13-10 |

| Table 13-7: | Mining Dilution Parameters | 13-10 |

| Table 13-8: | Mining Recovery Parameters | 13-11 |

| Table 13-9: | Cut-off Optimization Parameters at 1.6% Cu | 13-12 |

| Table 13-11: | Ventilation Requirements in Year 2 | 13-14 |

| Table 13-12: | Development Contingency | 13-21 |

| Table 13-13: | Operating Hours Contingency | 13-22 |

| Table 13-14: | Mobile Equipment Fleet | 13-22 |

| Table 13-15: | OTR Haulage Mobile Equipment Fleet | 13-23 |

| Table 13-16: | Underground Labour Force (Year 2) | 13-23 |

| Table 13-17: | OTR Haulage Labour Force (Year 2) | 13-24 |

| Table 13-18: | Underground LOM Schedule | 13-25 |

| Table 14-1: | List of Arctic Circuit Status for Bornite | 14-3 |

| Table 14-2: | Process Design Criteria | 14-4 |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC x | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| Table 14-3: | Nominal Reagent Consumption | 14-8 |

| Table 14-4: | Nominal Process Material Consumption | 14-10 |

| Table 15-1: | Dewatering Quantities | 15-6 |

| Table 15-2: | Phase 1 Underground Dewatering Wells | 15-7 |

| Table 15-3: | Phase 2 Underground Dewatering | 15-8 |

| Table 15-4: | Ruby Creek Valley Dewatering Wells | 15-9 |

| Table 15-5: | Diversion Ditches | 15-10 |

| Table 15-6: | Water Treatment Pond Design | 15-11 |

| Table 15-7: | Pipelines | 15-12 |

| Table 15-8: | Power Consumption by Area | 15-14 |

| Table 15-9: | Generator Unit Dispatch Summary | 15-15 |

| Table 17-1: | Recommended Additional Environmental Baseline Studies | 17-6 |

| Table 17-2: | Permits that May Be Required for the Bornite Project | 17-9 |

| Table 18-1: | Summary of Capital Cost Estimate | 18-1 |

| Table 18-2: | Initial Mining Capital Costs | 18-2 |

| Table 18-3: | Initial Underground and Backfill Capital Costs | 18-3 |

| Table 18-4: | Process Direct Capital Costs | 18-5 |

| Table 18-5: | Tailings Capital Costs | 18-6 |

| Table 18-6: | Onsite Infrastructure Capital Costs | 18-7 |

| Table 18-7: | Offsite Infrastructure Capital Costs | 18-7 |

| Table 18-8: | Sustaining Capital Costs | 18-10 |

| Table 18-9: | Reclamation Cost Estimate | 18-11 |

| Table 18-10: | Total Operating Costs Over LOM | 18-12 |

| Table 18-11: | Underground Operating Costs | 18-12 |

| Table 18-12: | OTR Haulage Operating Costs | 18-14 |

| Table 18-13: | Summary of Process Operating Costs | 18-15 |

| Table 18-14: | G&A Summary Costs | 18-19 |

| Table 18-15: | Bornite Dewatering Wells Costs | 18-20 |

| Table 19-1: | Summary of Financial Results | 19-7 |

| Table 19-2: | Cash Flow Summary | 19-8 |

| Table 23-1: | Estimated Costs to Develop the Advanced Exploration Decline | 23-4 |

| Table 23-2: | Costs for Recommended Work Programs | 23-8 |

Figures

| Figure 1-1: | Property Location Map | 1-1 |

| Figure 1-2: | Bornite Site Layout | 1-8 |

| Figure 3-1: | Upper Kobuk Mineral Properties | 3-4 |

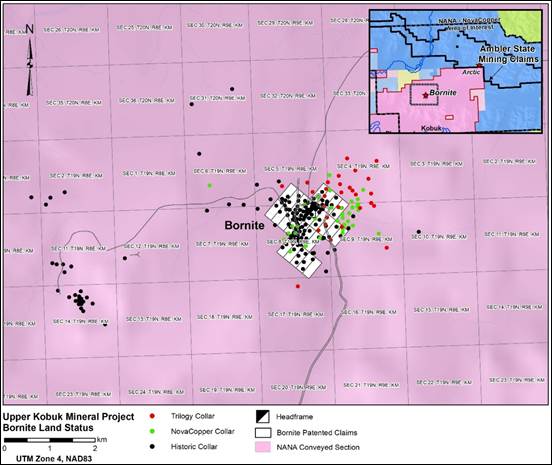

| Figure 3-2: | Bornite Mineral Tenure Plan | 3-5 |

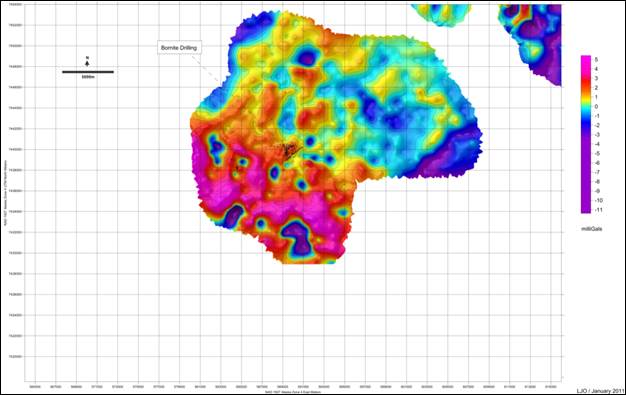

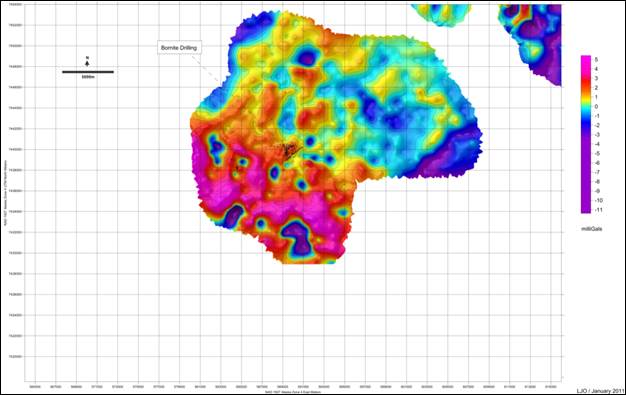

| Figure 5-1: | 1996 Kennecott Residual Gravity | 5-3 |

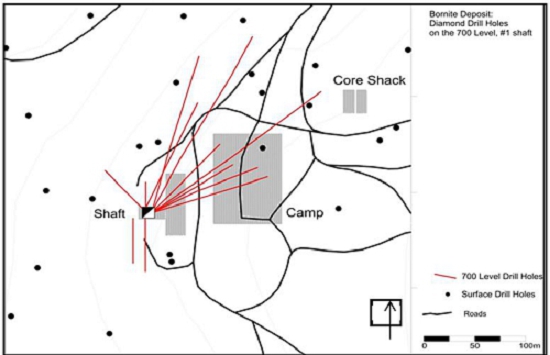

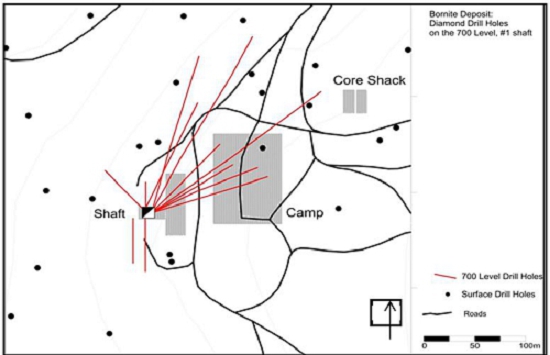

| Figure 5-2: | Diamond Drilling from the 700 Level of the No. 1 Shaft | 5-4 |

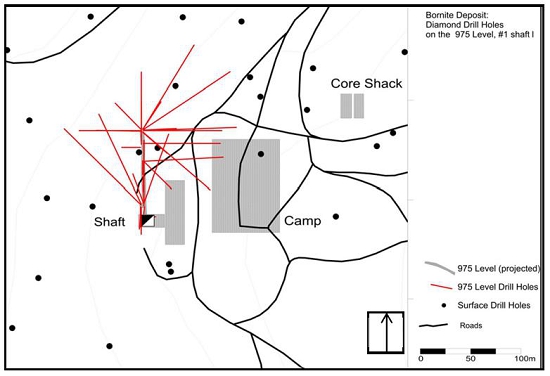

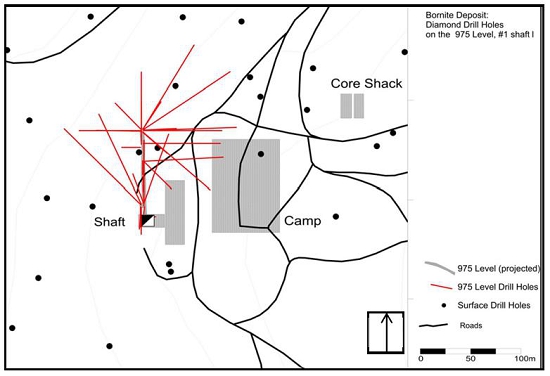

| Figure 5-3: | Diamond Drilling from the 975 Level of the No. 1 Shaft | 5-4 |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC xi | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

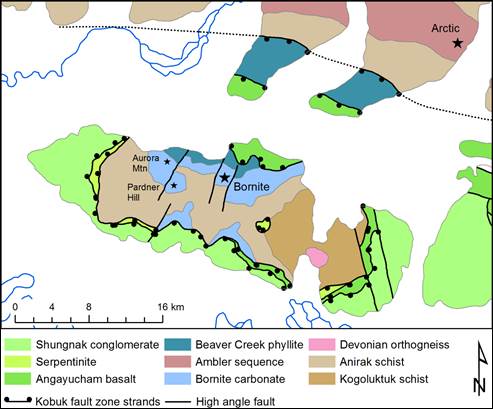

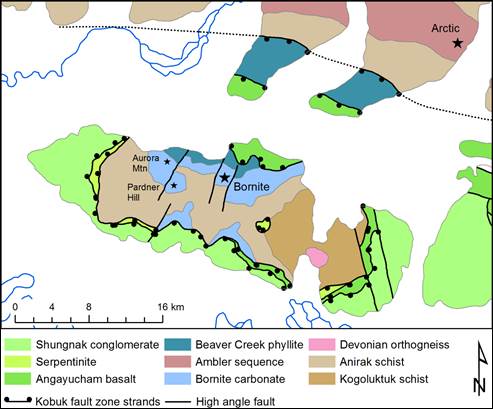

| Figure 6-1: | Generalized Geologic Map of the Local Geology | 6-2 |

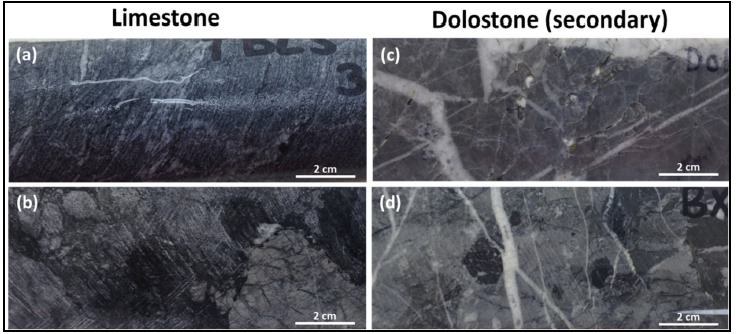

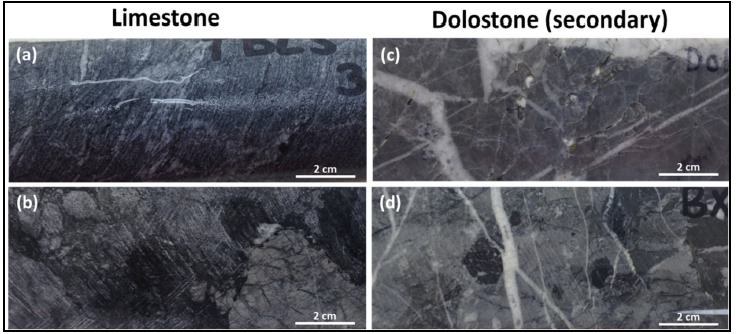

| Figure 6-2: | Typical Limestones and Dolostones of the Bornite Carbonate Sequence | 6-7 |

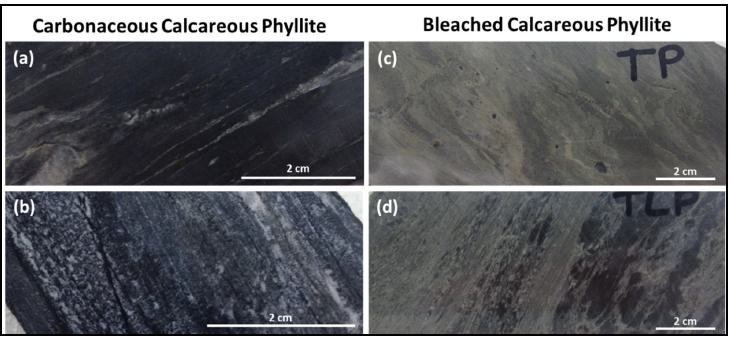

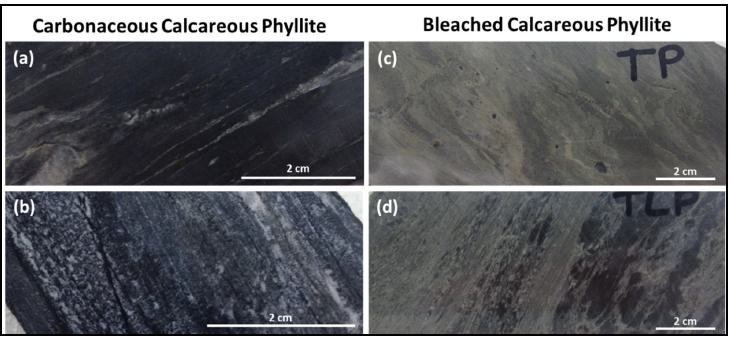

| Figure 6-3: | Typical Phyllites of the Bornite Carbonate Sequence | 6-8 |

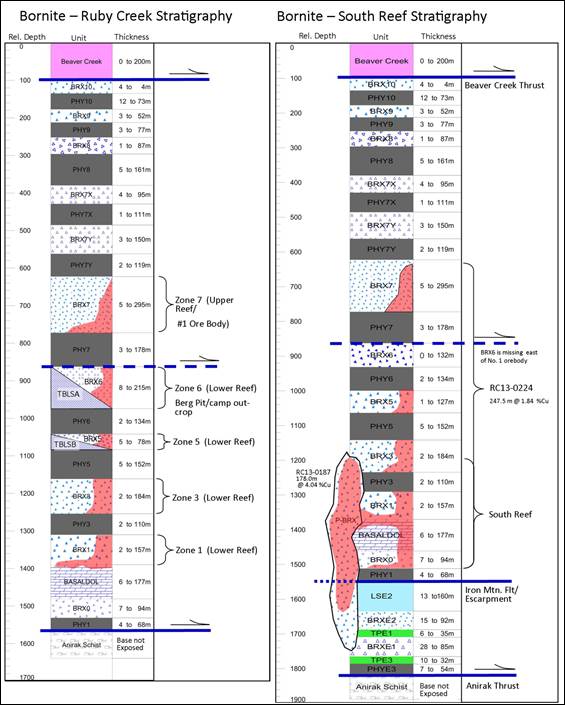

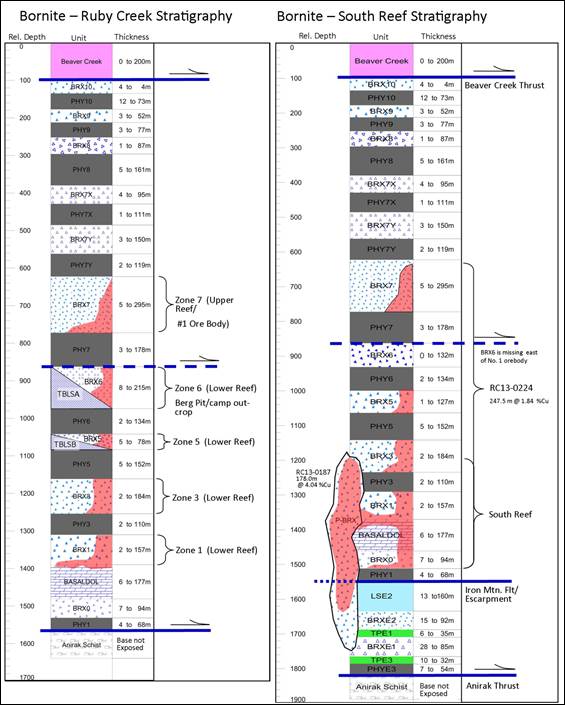

| Figure 6-4: | General Stratigraphic Column for the Ruby Zone and South Reef Lithologies | 6-9 |

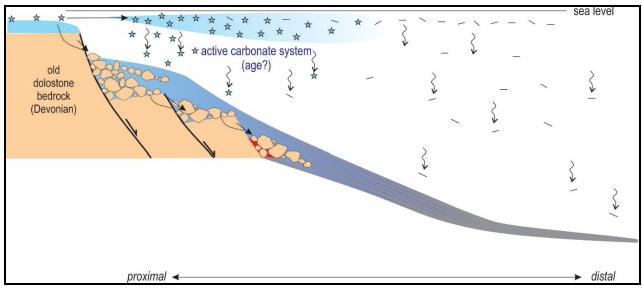

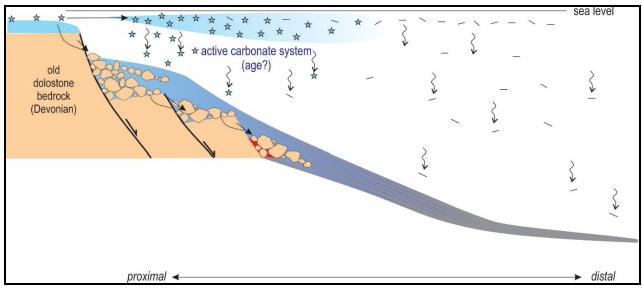

| Figure 6-5: | Schematic Cross-sectional Diagram of Carbonate Environment Showing Position of Mineralization (red) | 6-10 |

| Figure 6-6: | Copper Grade Thickness Plan Map for the Bornite Deposit | 6-14 |

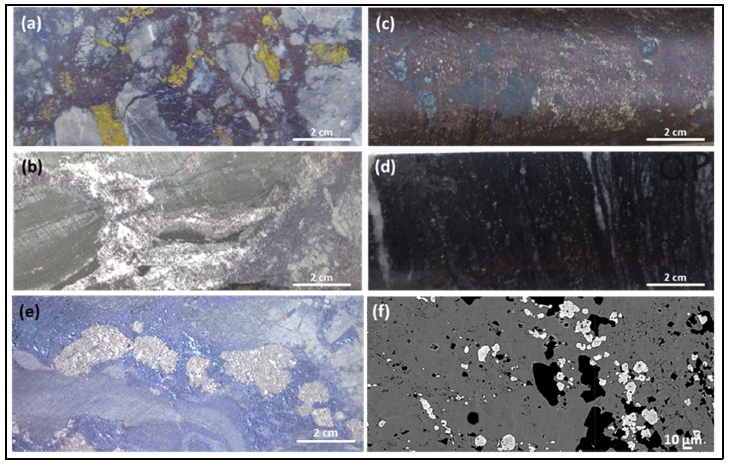

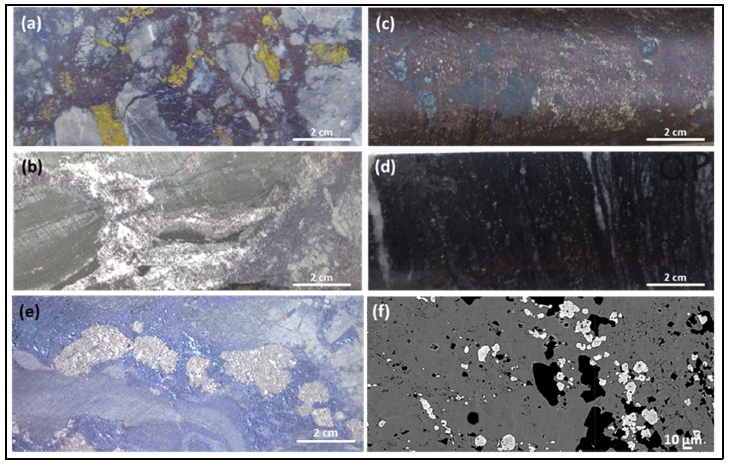

| Figure 6-7: | Typical Mineralization of the Bornite Deposit | 6-15 |

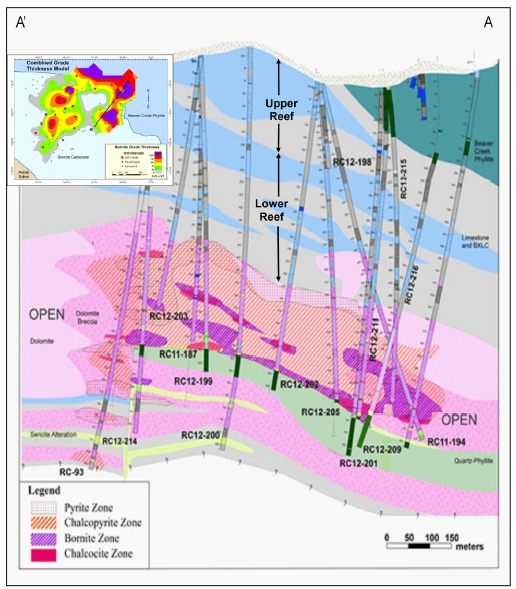

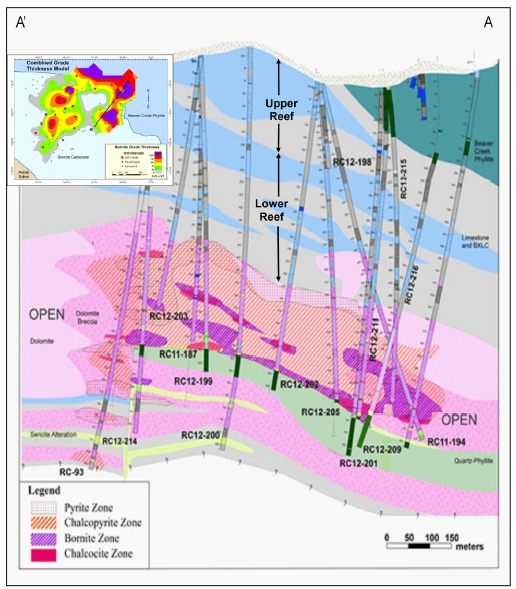

| Figure 6-8: | Southwest-Northeast Schematic Cross-section through South Reef Illustrating Geology, Alteration and Sulphide Mineral Zoning | 6-18 |

| Figure 7-1: | Total Field Magnetics | 7-2 |

| Figure 7-2: | Northwest-Southeast Re-interpreted Profile Across the Bornite Deposit | 7-3 |

| Figure 7-3: | District Airborne Magnetics Compiled from Kennecott, AK DNR and NOVAGOLD Surveys | 7-5 |

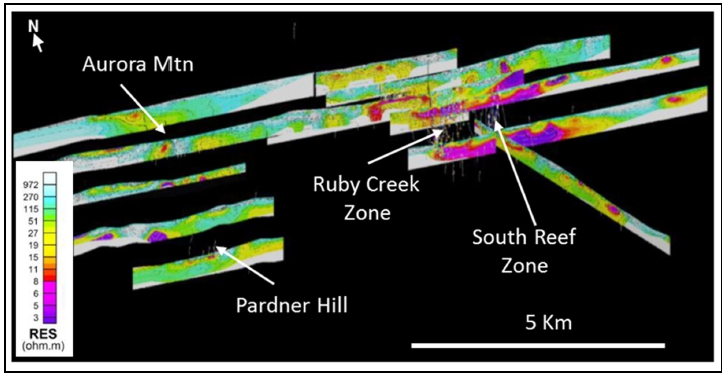

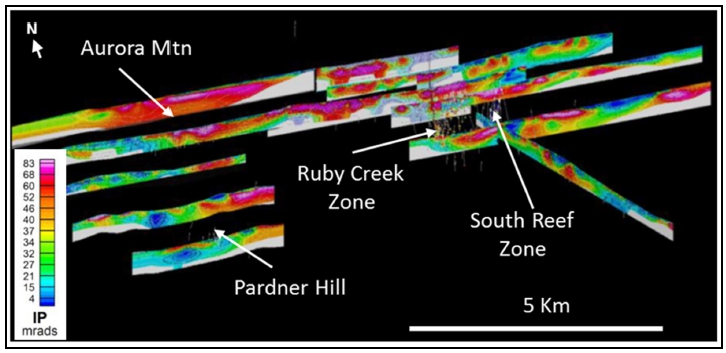

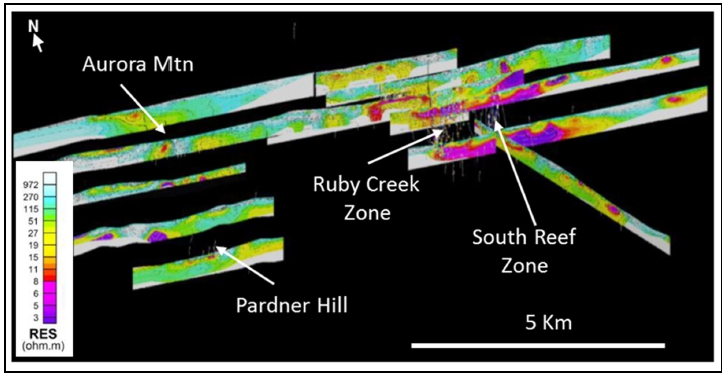

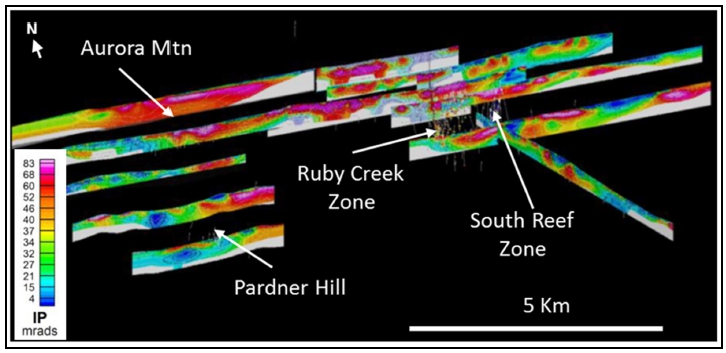

| Figure 7-4: | Isometric View of 2011 and 2012 Resistivity Profiles | 7-7 |

| Figure 7-5: | Isometric View of 2011 and 2012 Chargeability Profiles | 7-7 |

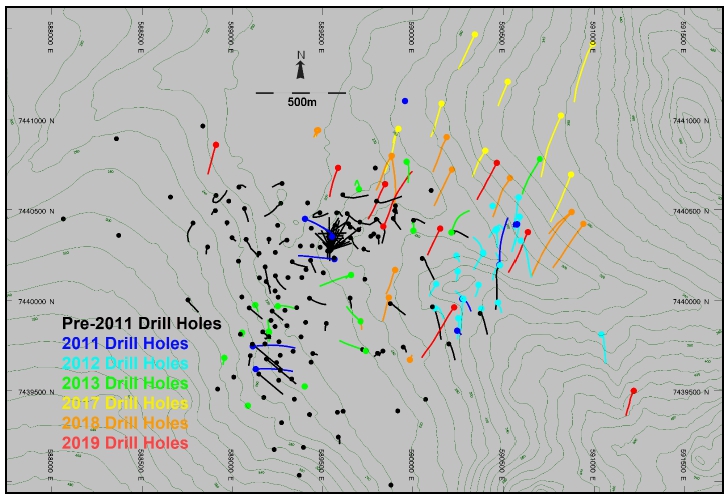

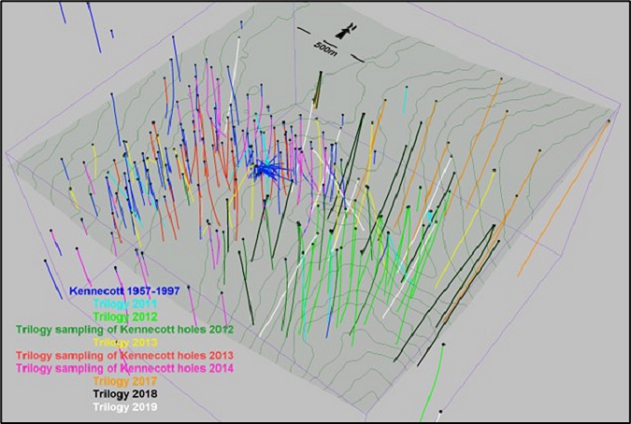

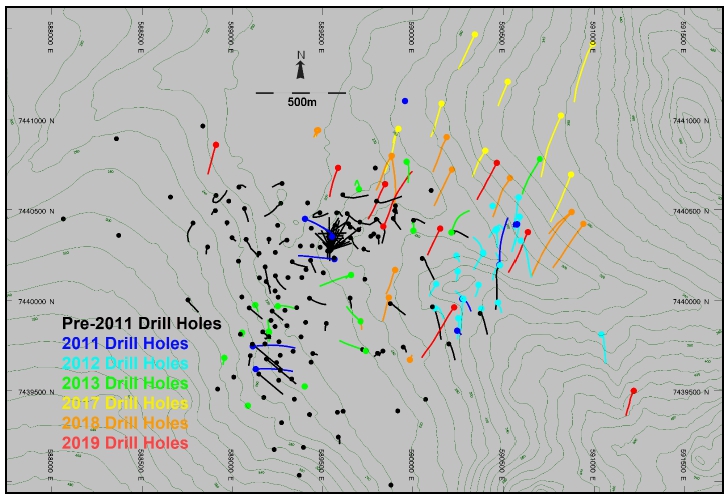

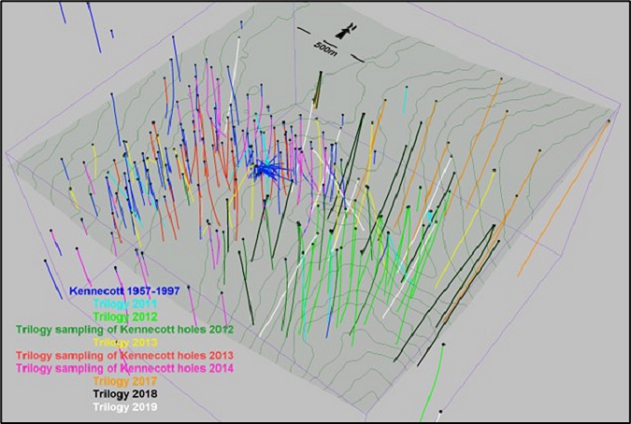

| Figure 7-6: | Plan Map Showing Drill Hole Locations by Year | 7-18 |

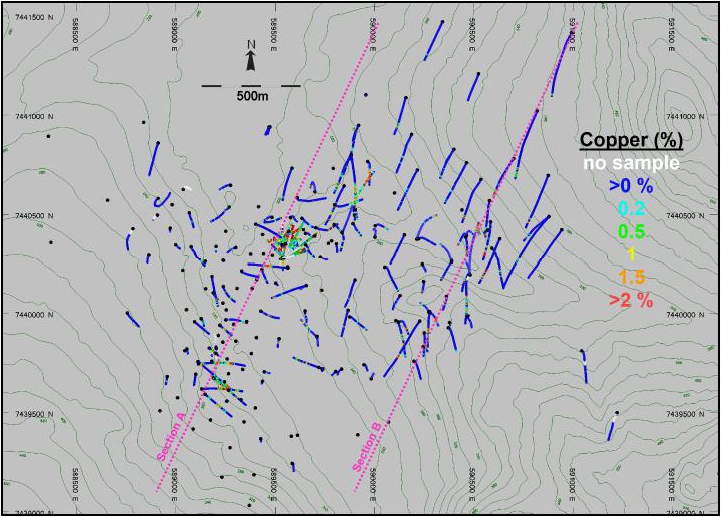

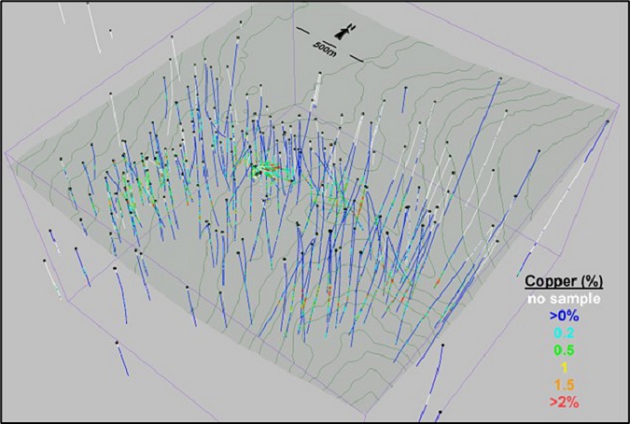

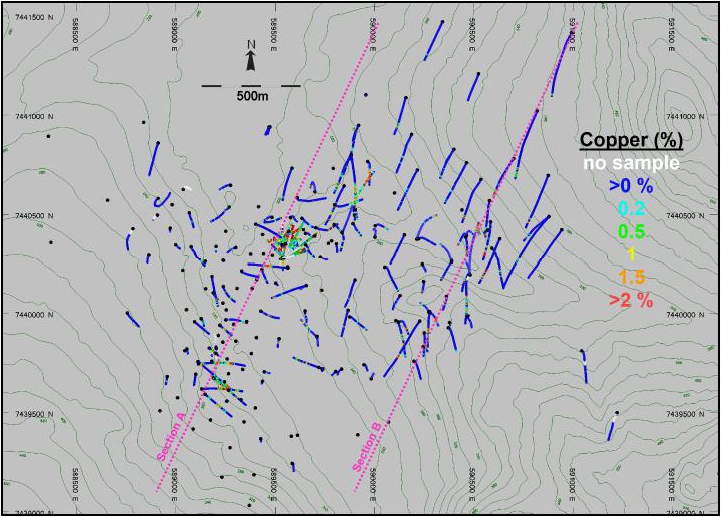

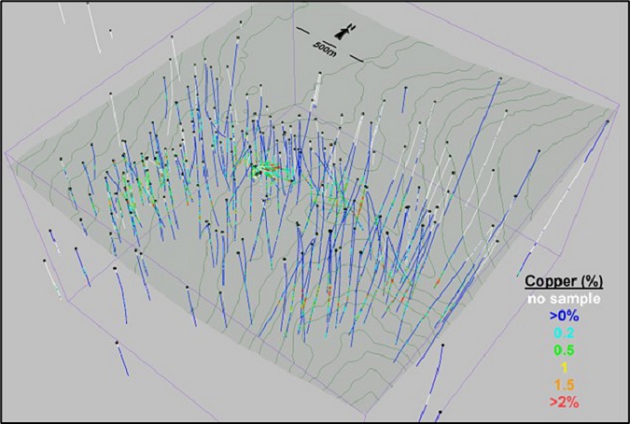

| Figure 7-7: | Plan Map Showing Copper in Drilling on the Bornite Deposit | 7-26 |

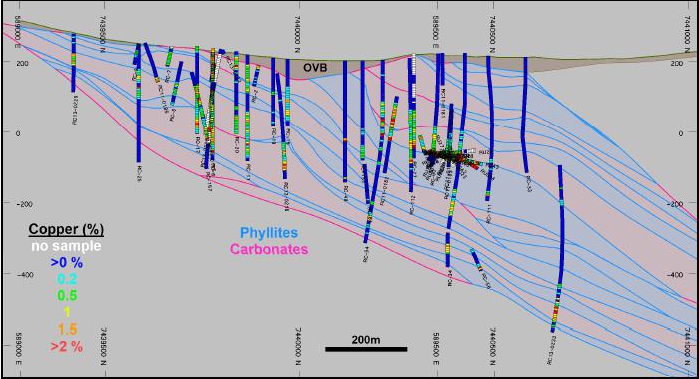

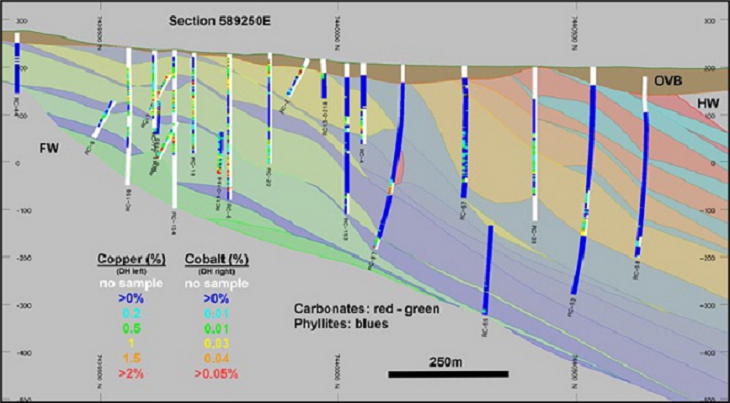

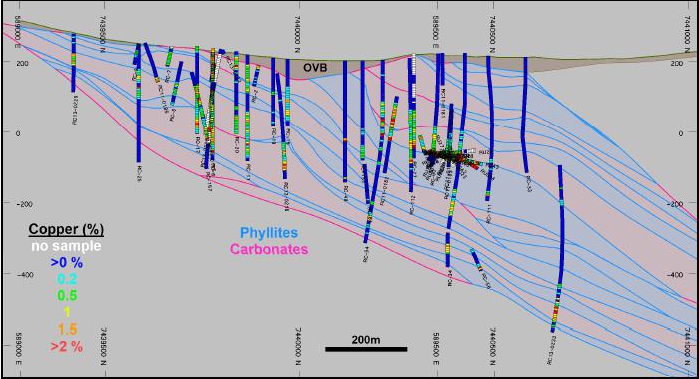

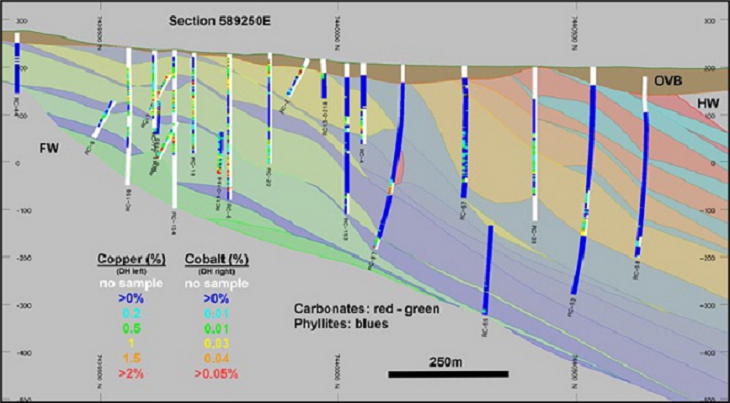

| Figure 7-8: | Vertical Cross-section (Section A) Showing Copper in Drilling in the Ruby Zone Area | 7-27 |

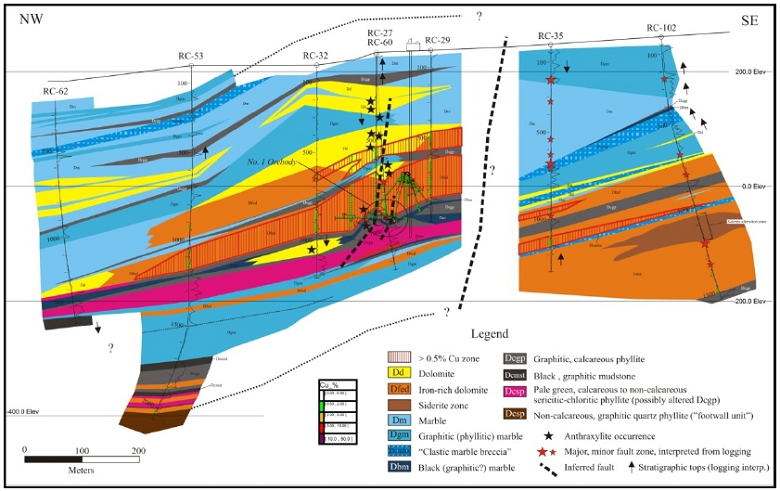

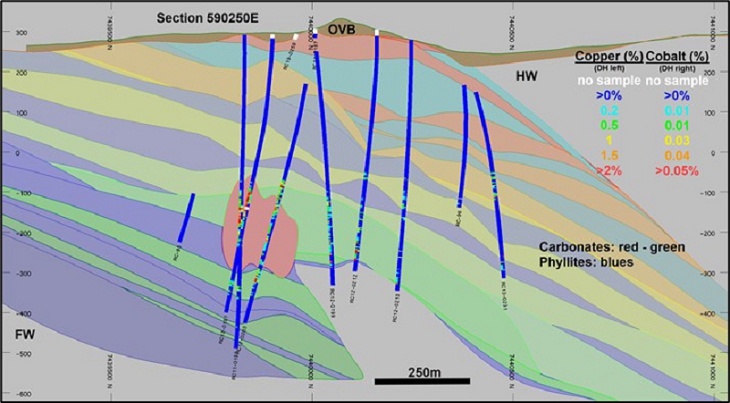

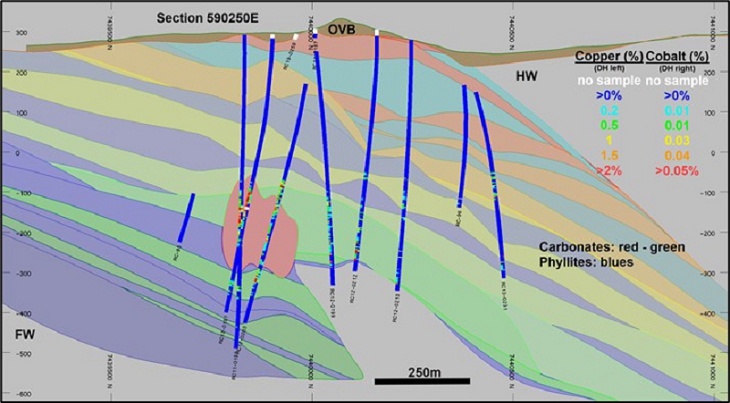

| Figure 7-9: | Vertical Cross-section (Section B) Showing Copper in Drilling in the South Reef Area | 7-27 |

| Figure 7-10: | Cobalt Grades in the Drill Holes | 7-28 |

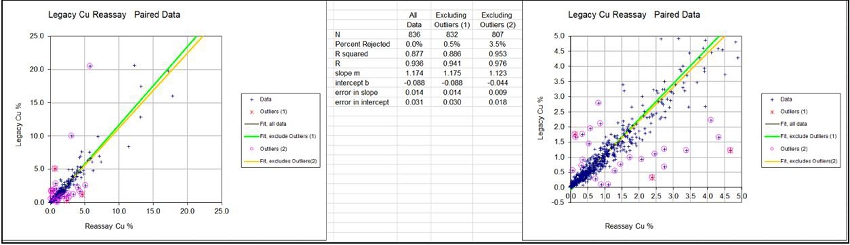

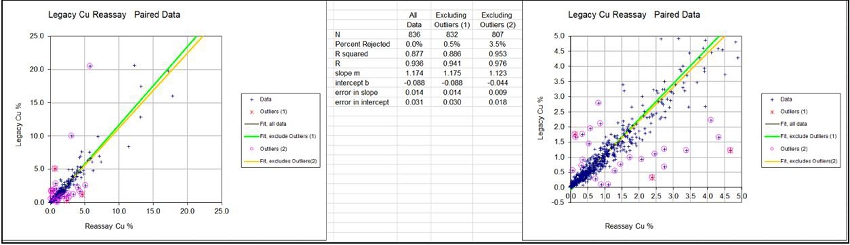

| Figure 8-1: | Historical Copper Re-assay RMA Chart | 8-7 |

| Figure 10-1: | Typical Grain-Size Distribution Observed (KM3621) | 10-5 |

| Figure 10-2: | Proposed Bornite Flotation Flowsheet | 10-6 |

| Figure 10-3: | Copper Recovery versus Copper Feed Grades | 10-8 |

| Figure 11-1: | Copper Grades in Drill Holes | 11-2 |

| Figure 11-2: | Drilling by Campaign | 11-3 |

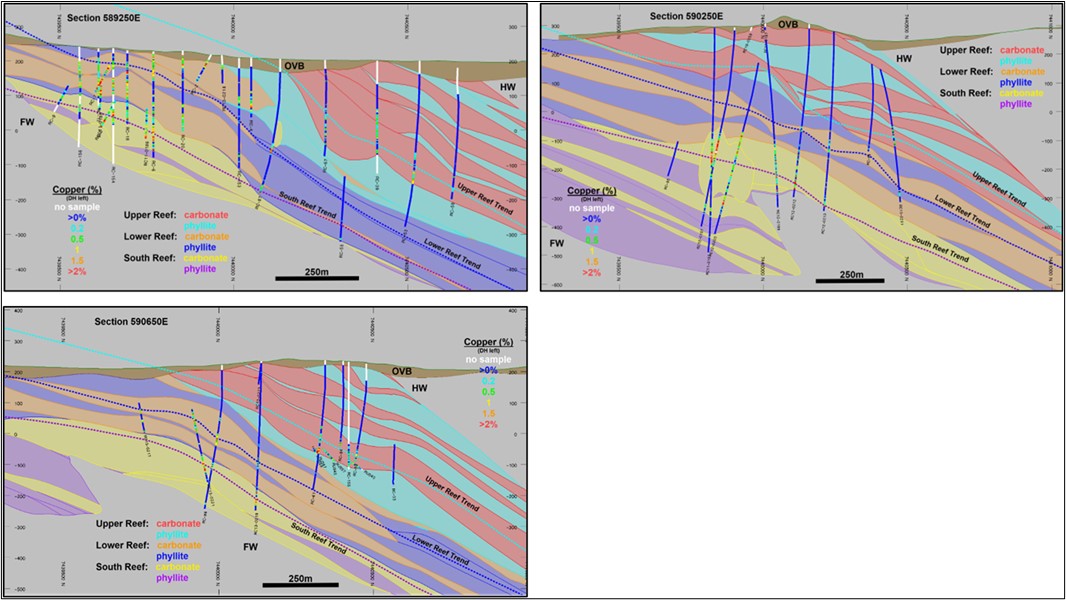

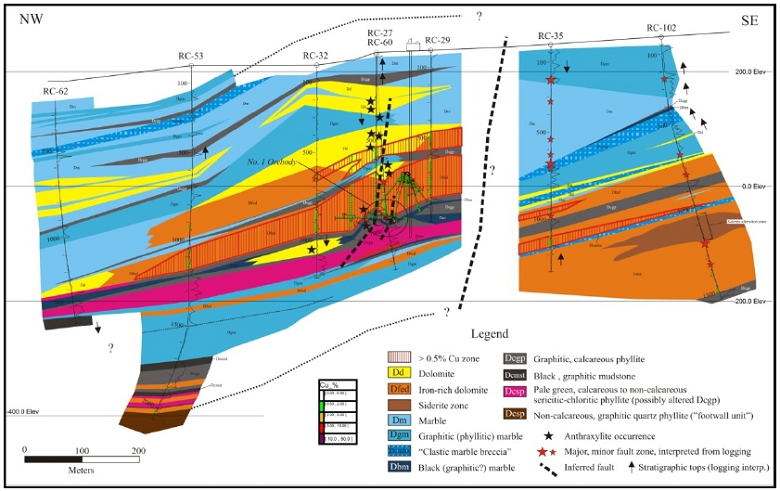

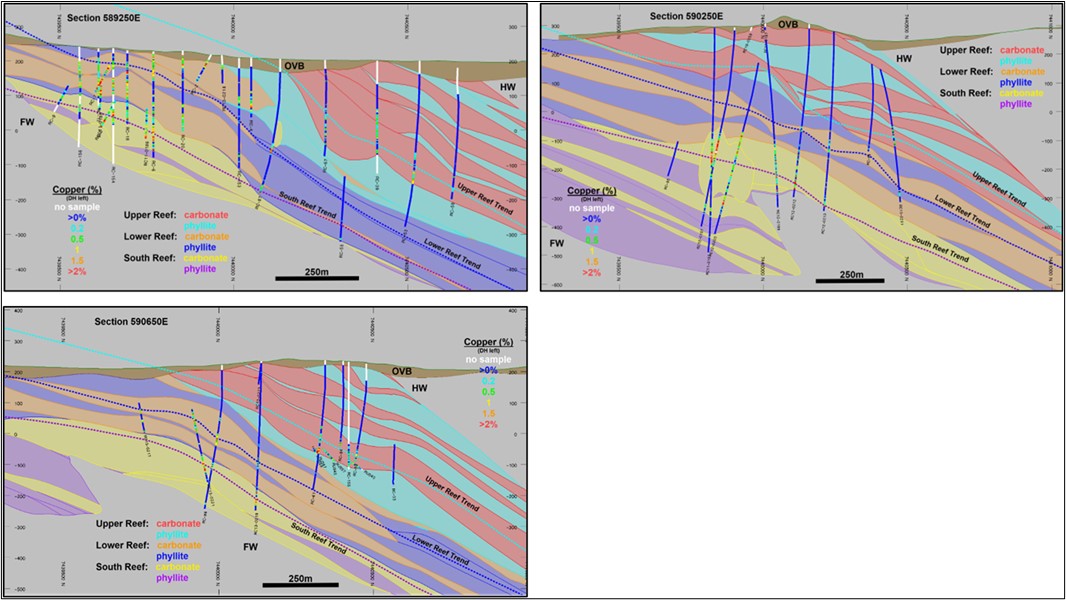

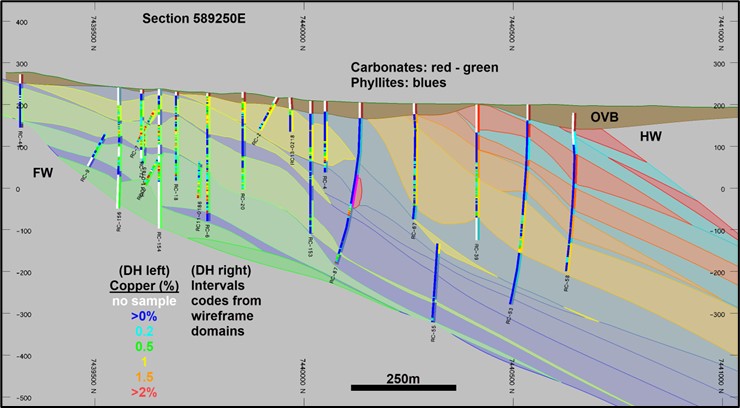

| Figure 11-3: | Cross-section Showing Lithology Domains in the Ruby Zone | 11-4 |

| Figure 11-4: | Cross-section Showing Lithology Domains in the South Reef Area | 11-4 |

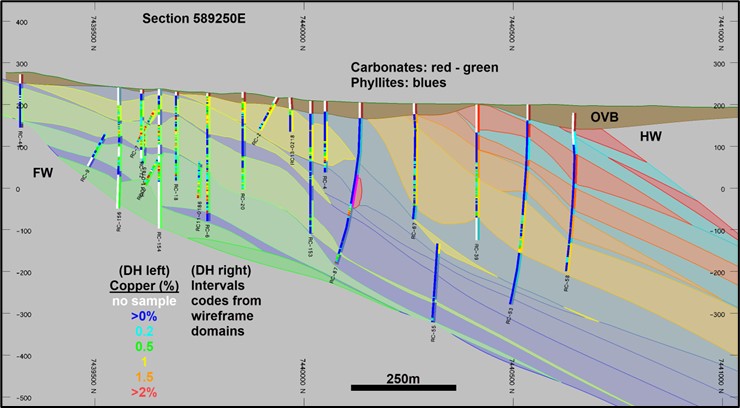

| Figure 11-5: | Vertical Cross-sections Showing Trend Planes Used to Control Dynamic Isotropy | 11-6 |

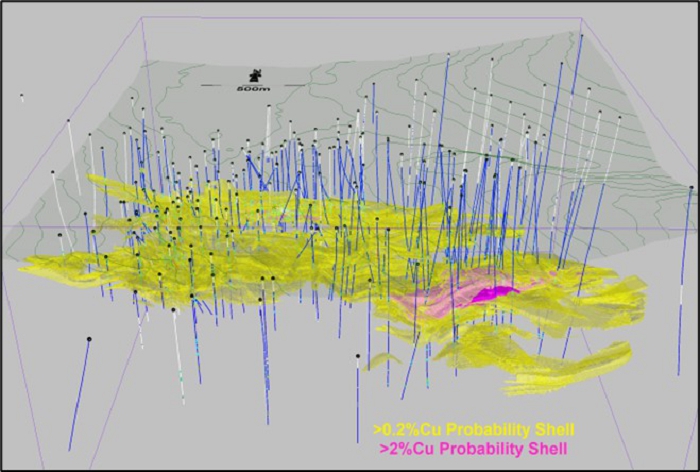

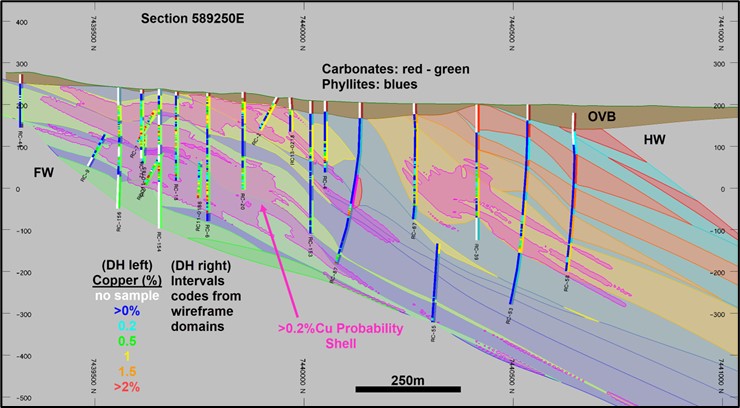

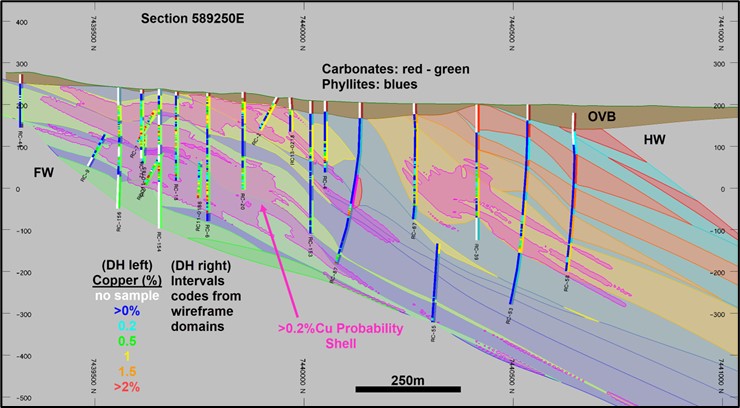

| Figure 11-6: | Copper Probability Shells | 11-8 |

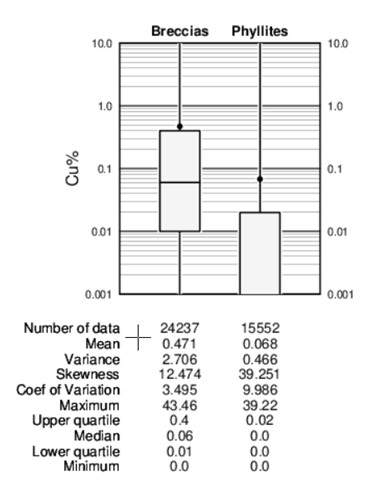

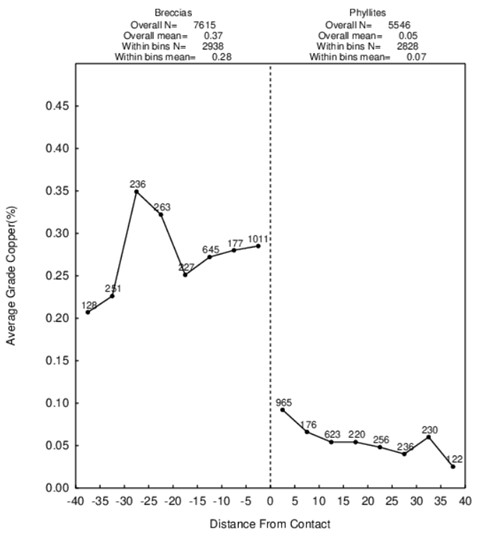

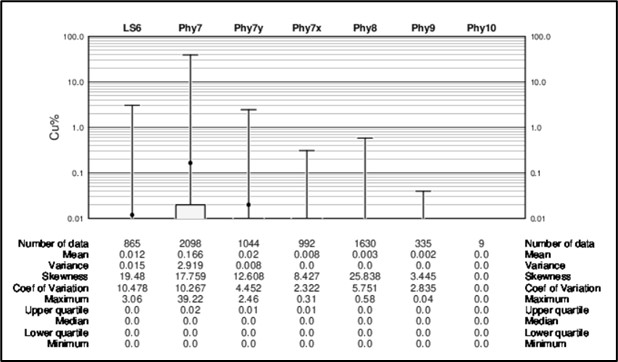

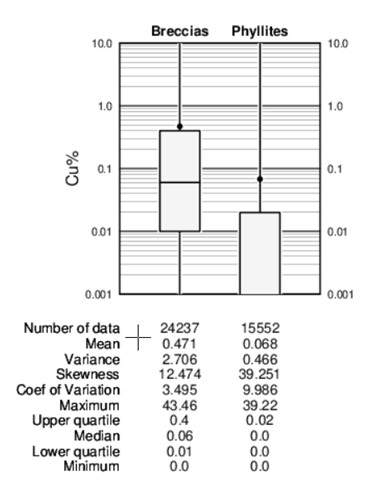

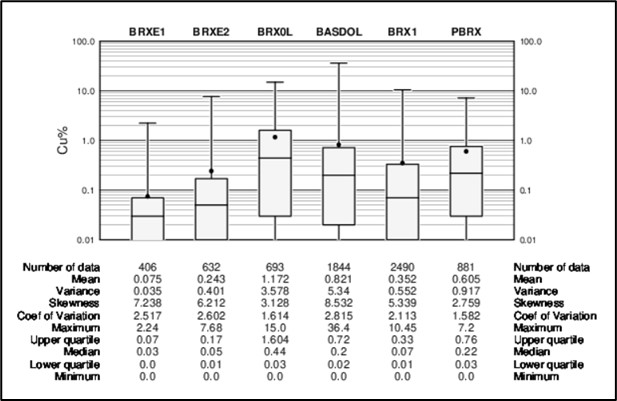

| Figure 11-7: | Boxplots of Total Copper in Carbonate Breccias and Phyllites | 11-11 |

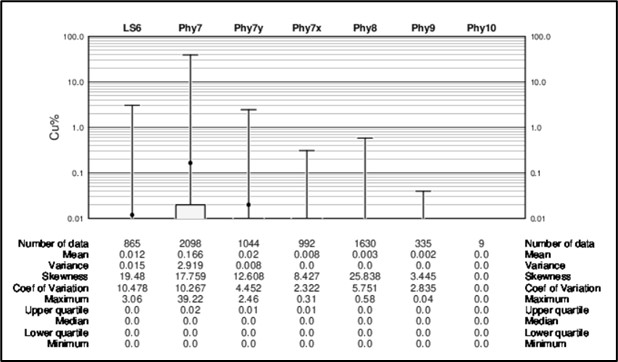

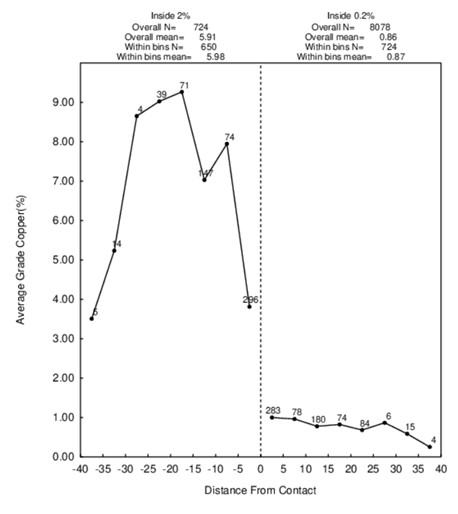

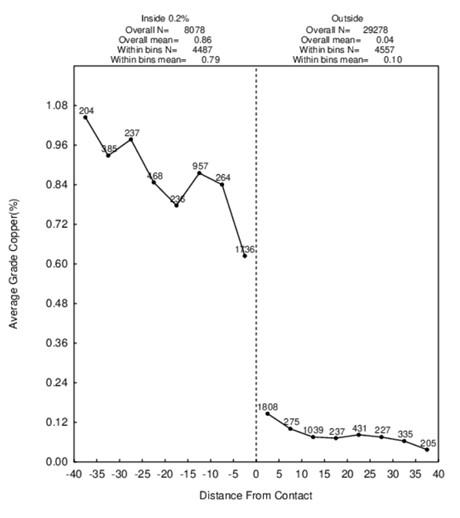

| Figure 11-8: | Contact Profiles for Total Copper between Carbonate Breccias and Phyllites | 11-11 |

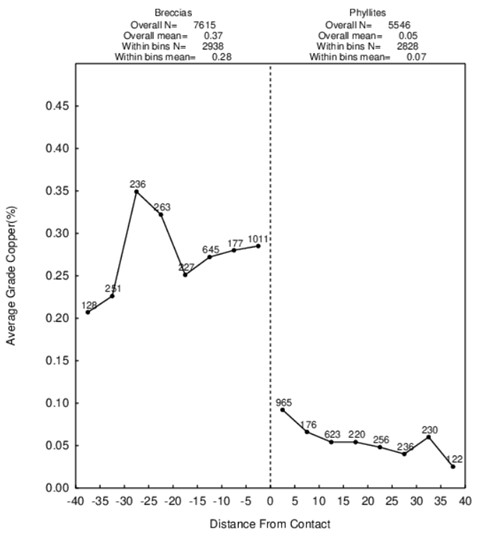

| Figure 11-9: | Boxplots for Copper in the Lower Reef Phyllite Domains | 11-12 |

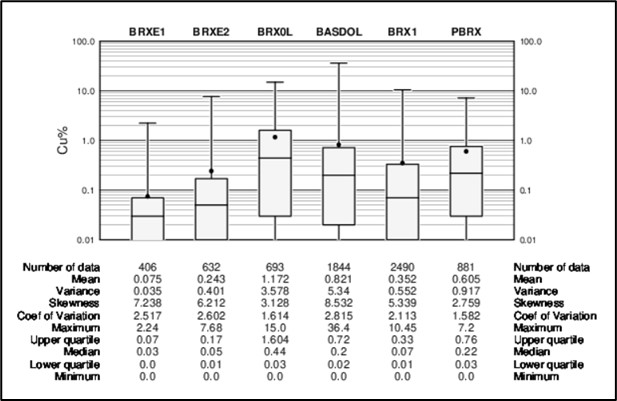

| Figure 11-10: | Boxplots for Copper in the Lower Reef Carbonate Breccia Domains | 11-12 |

| Figure 11-11: | Boxplots for Copper in the Upper Reef Phyllite Domains | 11-13 |

| Figure 11-12: | Boxplots for Copper in the Upper Reef Carbonate Breccia Domains | 11-13 |

| Figure 11-13: | Boxplots for Copper in the South Reef Phyllite Domains | 11-14 |

| Figure 11-14: | Boxplots for Copper in the South Reef Carbonate Breccia Domains | 11-14 |

| Figure 11-15: | Section 589250 E with Interpreted Stratigraphic Units | 11-15 |

| Figure 11-16: | Section 589250 E with 0.2% Cu Probability Shell | 11-15 |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC xii | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

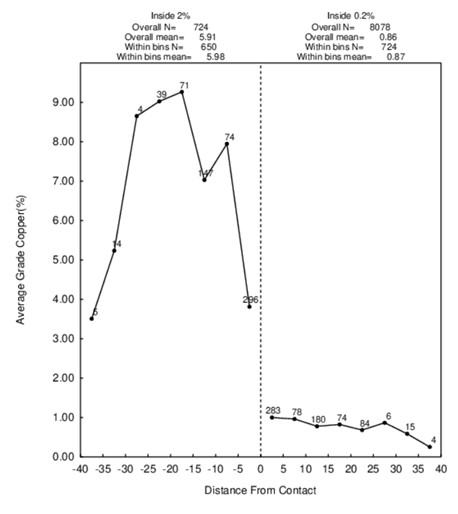

| Figure 11-17: | Contact Profile of Copper in 2% and 0.2% Cu Shells | 11-17 |

| Figure 11-18: | Contact Profile of Copper In/Out of the 0.2% Cu Shell | 11-17 |

| Figure 11-19: | North-South Vertical Section of Copper Estimates in the Block Model in the Ruby Zone | 11-22 |

| Figure 11-20: | North-South Vertical Section of Copper Estimates in the Block Model in the South Reef Area | 11-23 |

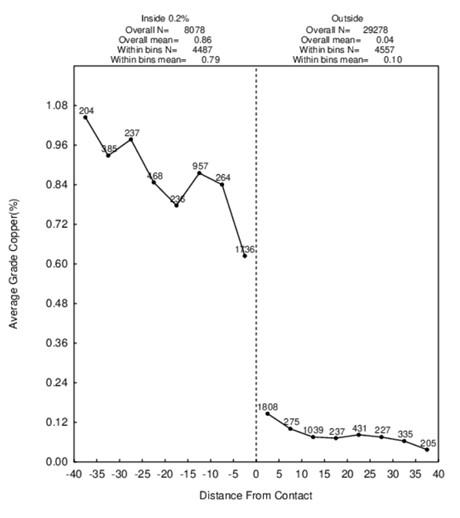

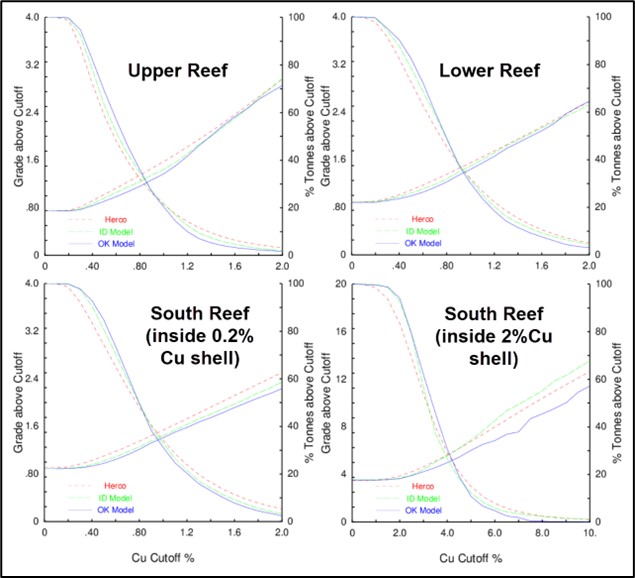

| Figure 11-21: | Herco and Model Grade/Tonnage Plots for Copper Inside Probability Shells | 11-24 |

| Figure 11-22: | Comparison of Copper Model Types in Carbonates Inside Grade Shell Domains | 11-26 |

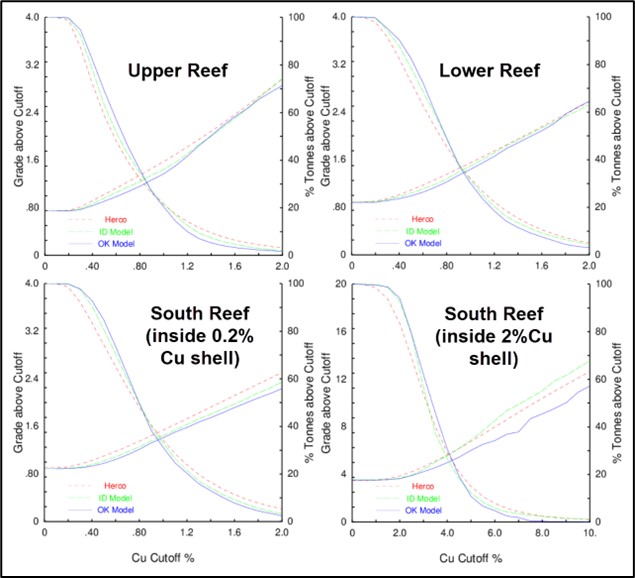

| Figure 11-23: | Swath Plots of Copper in Carbonates Inside Grade Shell Domains | 11-27 |

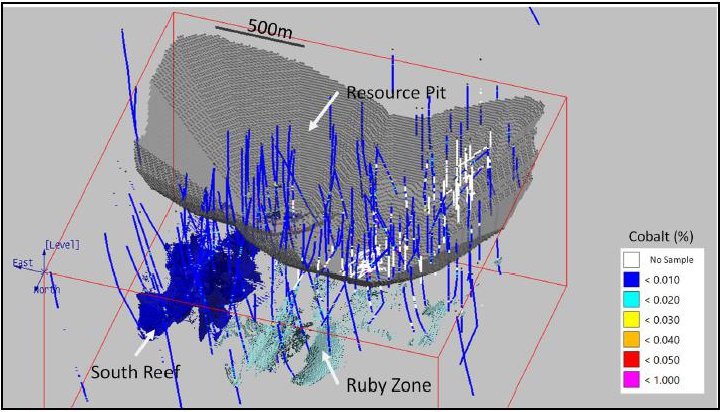

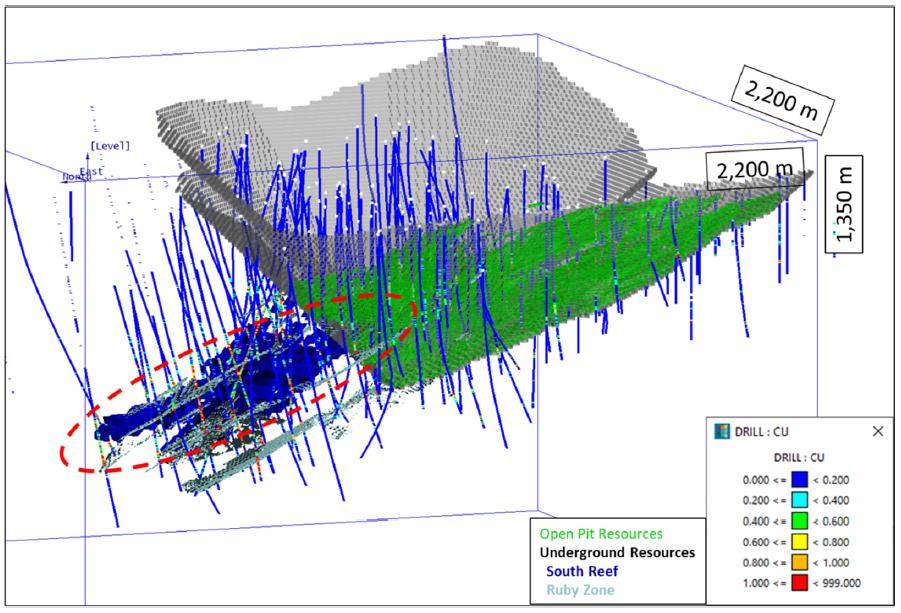

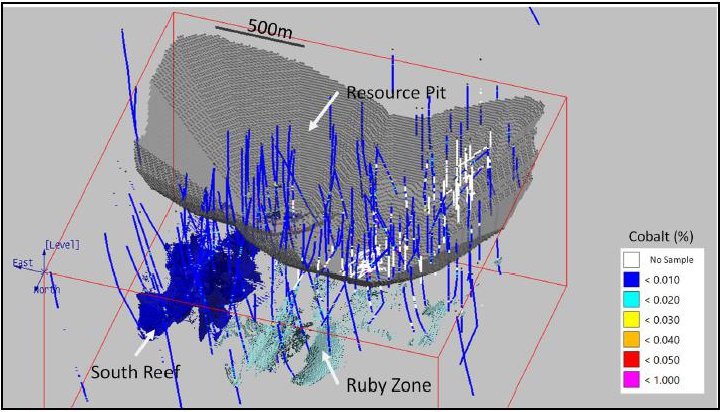

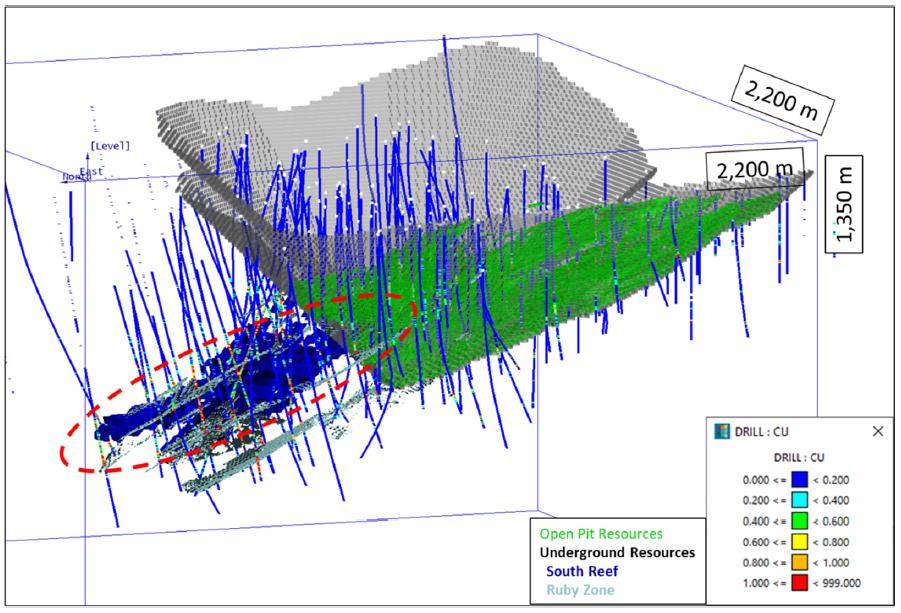

| Figure 11-24: | Isometric Views of the Bornite Inferred Mineral Resource | 11-32 |

| Figure 11-25: | Area of South Reef Amenable to Underground Mining Methods (depicted by dashed red line) | 11-34 |

| Figure 13-1: | Advanced Exploration Decline, Section View Looking South | 13-3 |

| Figure 13-2: | Modified Stability Graph | 13-5 |

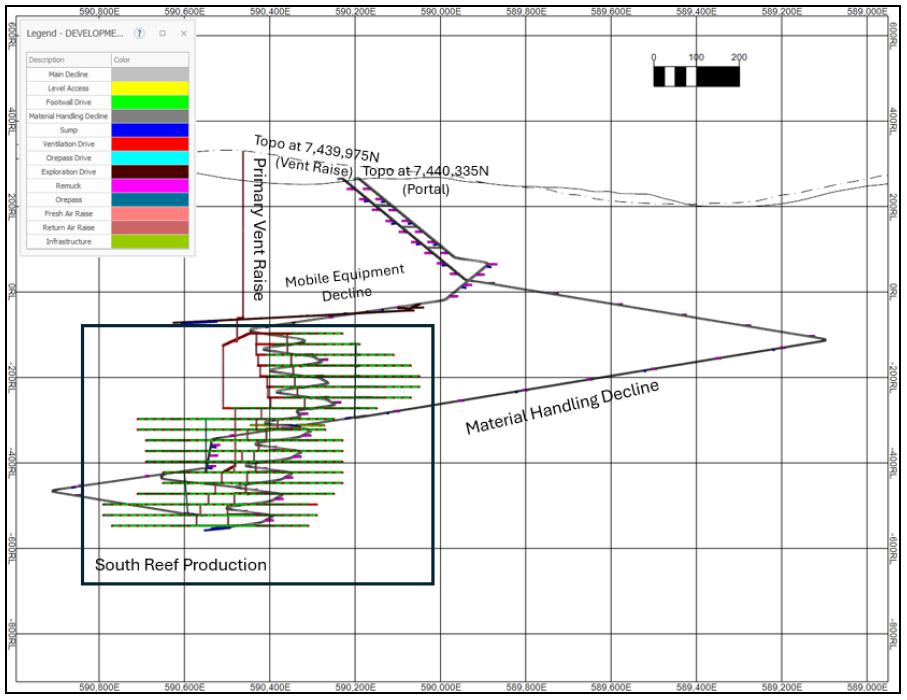

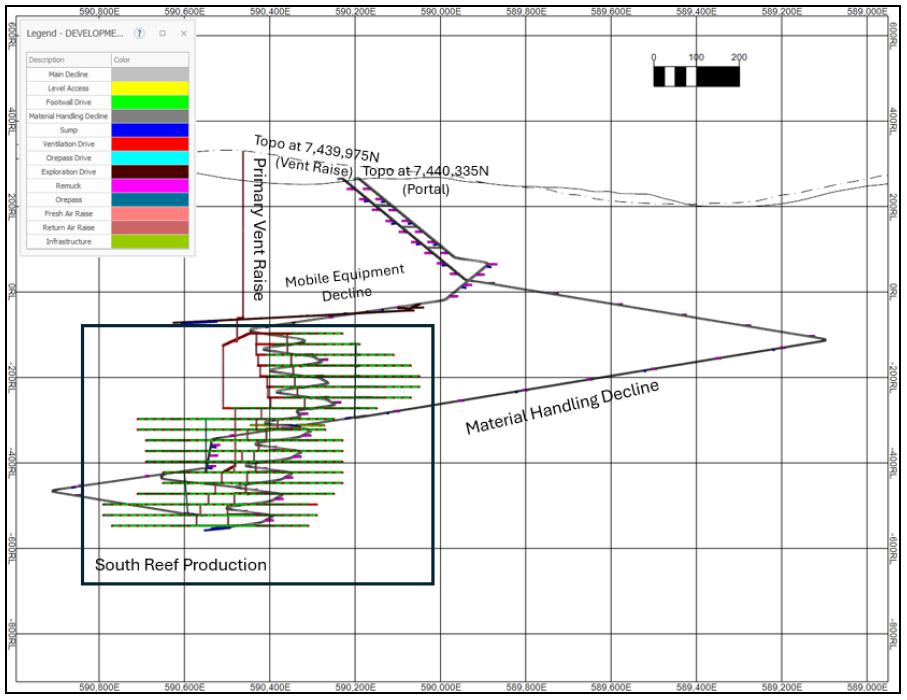

| Figure 13-3: | Bornite Development Layout, Section View Looking South | 13-7 |

| Figure 13-4: | South Reef Stopes, Section View Looking South | 13-8 |

| Figure 13-5: | Typical Level Design Plan, View Showing 700L | 13-9 |

| Figure 13-6: | Cut-off Grade Optimization | 13-12 |

| Figure 13-7: | Ventilation Network, Section View Looking South | 13-15 |

| Figure 13-8: | Material Handling System Layout, Section View Looking East | 13-16 |

| Figure 13-9: | Dewatering System Layout, Section View Looking East | 13-19 |

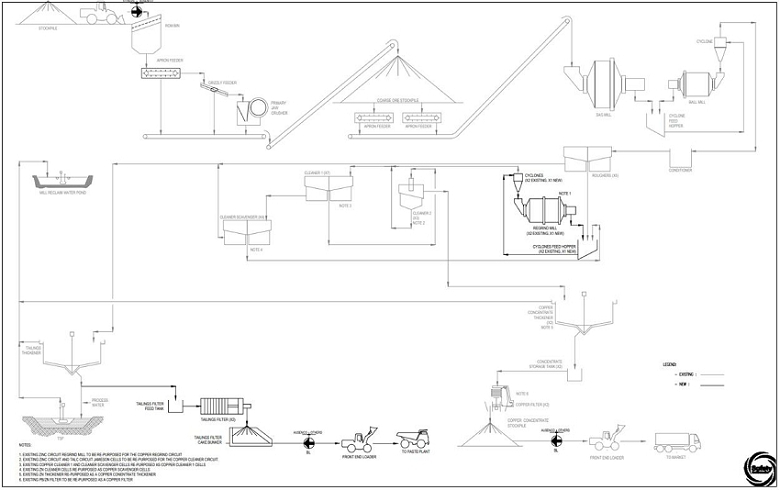

| Figure 14-1: | Bornite Process Flowsheet | 14-2 |

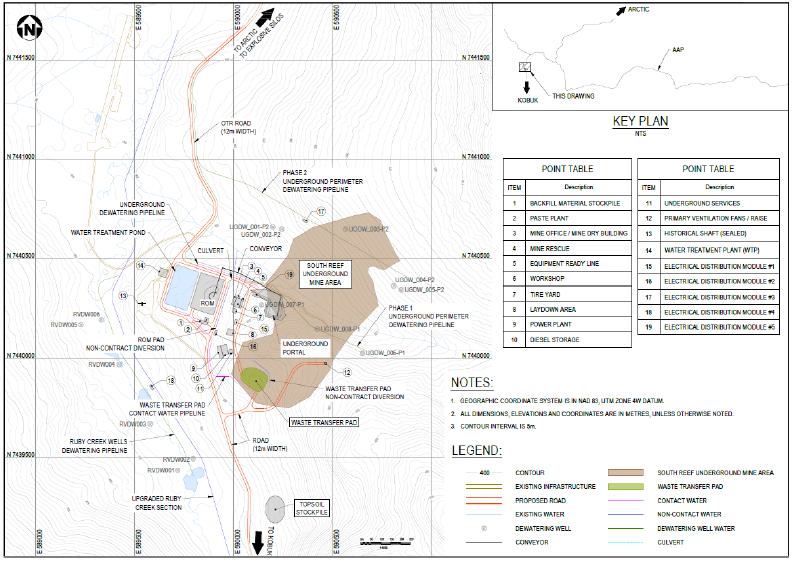

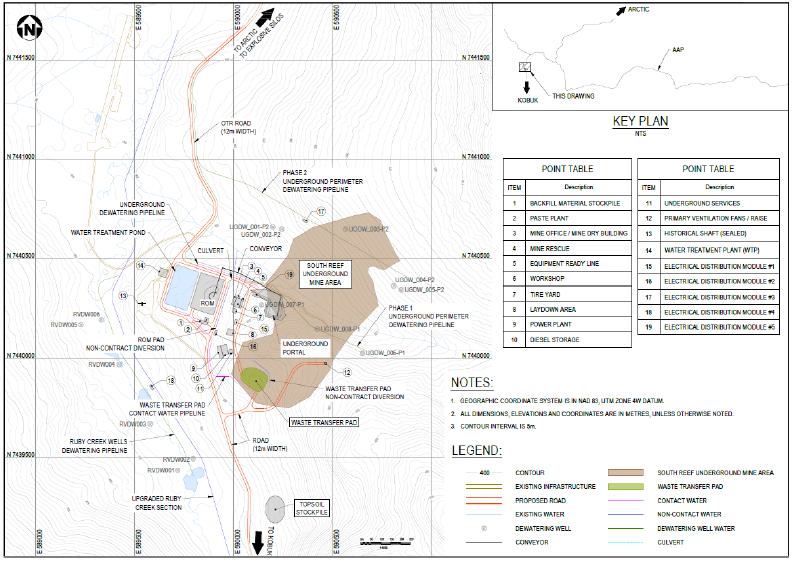

| Figure 15-1: | Bornite Site Layout | 15-2 |

| Figure 15-2: | Site Road Access | 15-4 |

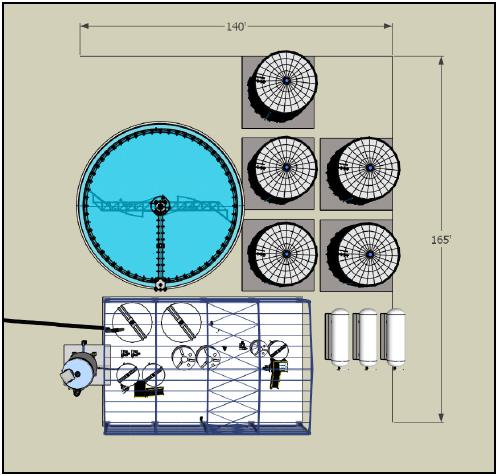

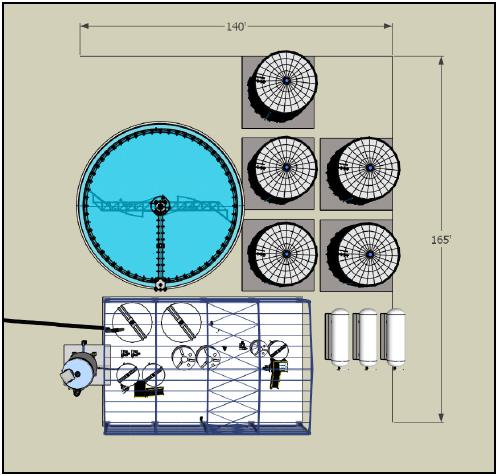

| Figure 15-3: | Representative Treatment Plant Footprint and Layout | 15-13 |

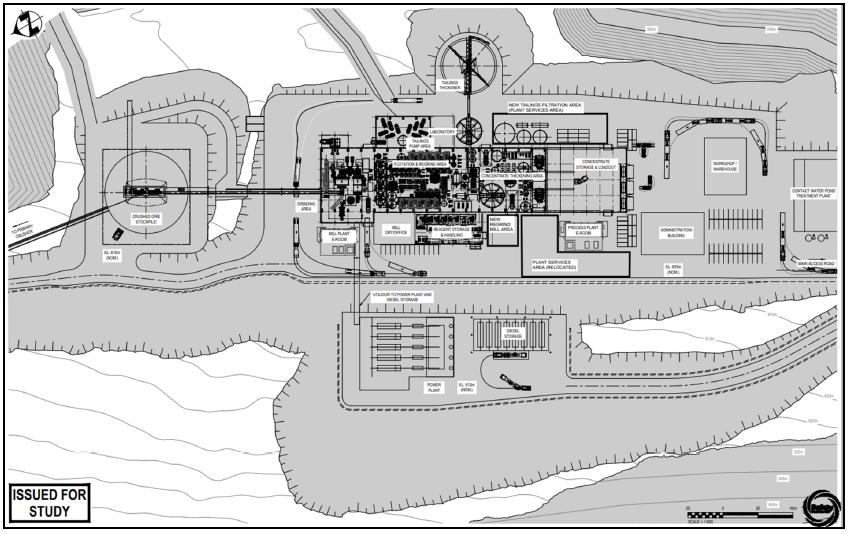

| Figure 15-4: | Arctic Site Layout | 15-20 |

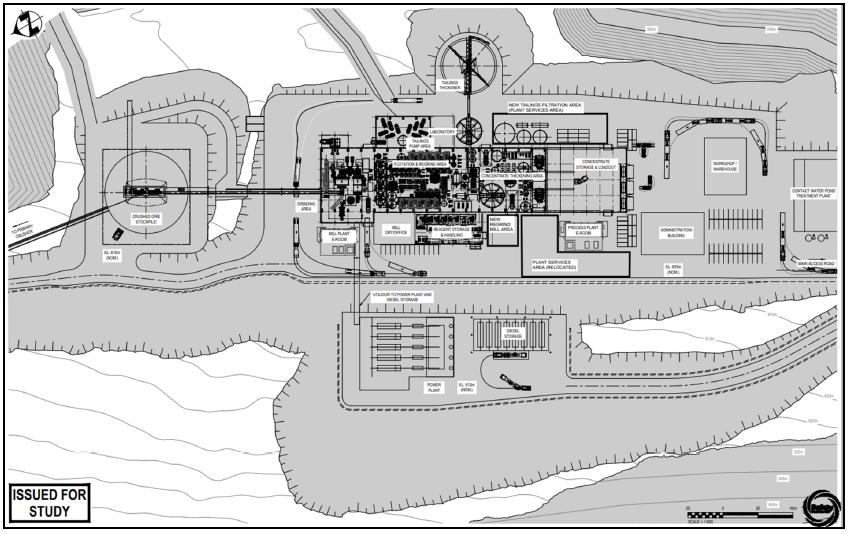

| Figure 15-5: | Simplified Process Plant Layout | 15-22 |

| Figure 15-6: | Expanded Arctic Tailings Storage Facility | 15-24 |

| Figure 15-7: | Arctic Pit Tailings Capacity | 15-25 |

| Figure 18-1: | Plant Operating Cost Breakdown over the LOM | 18-16 |

| Figure 19-1: | After-Tax NPV @ 8% - Sensitivity | 19-9 |

| Figure 19-2: | After-Tax IRR - Sensitivity | 19-10 |

| Project No.: 253821 | | Table of Contents | |  |

| January 2025 | | TOC xiii | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Trilogy Metals Inc. (Trilogy Metals) retained Wood Canada Limited (Wood), SRK Consulting (Canada) Inc. (SRK), Ausenco Engineering Canada ULC. (Ausenco), International Metallurgical & Environmental and Core Geoscience LLC (Core Geoscience) to prepare a technical report summary (Report) on the initial assessment (IA) of their Bornite project in Alaska (Bornite Project).

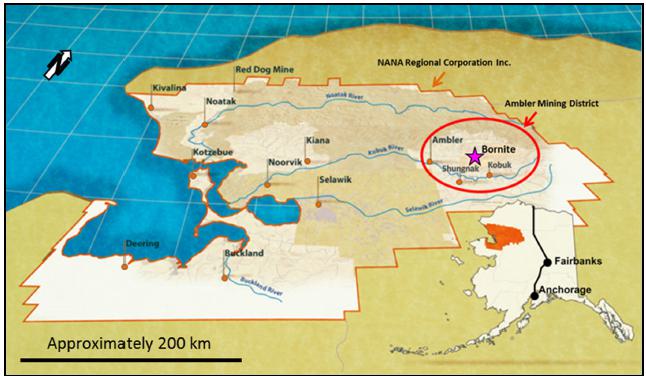

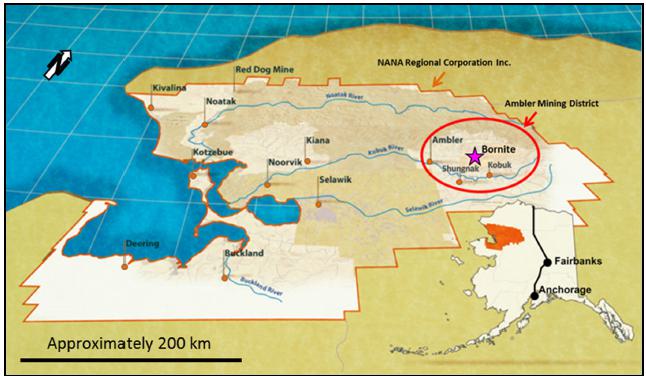

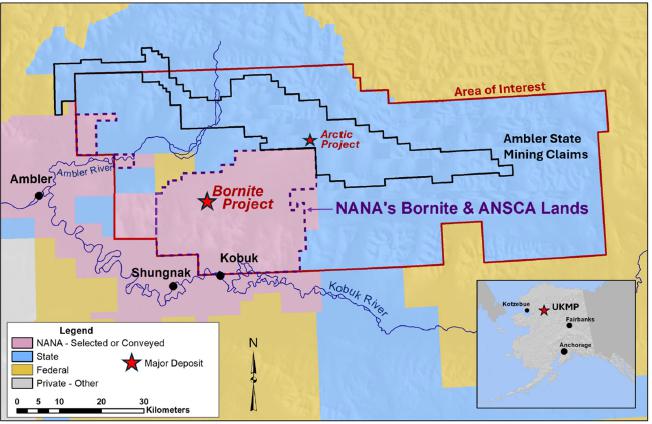

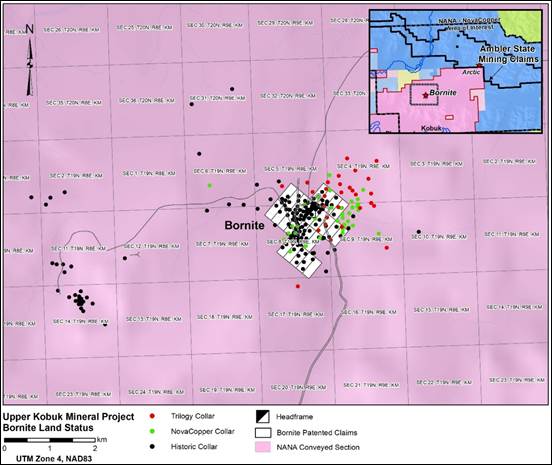

The Bornite property is part of the Upper Kobuk Mineral Projects (UKMP) mineral tenure package, which includes the Bornite deposit, as well as numerous additional mineral showings/deposits. The property is located in the Ambler Mining District of the southern Brooks Range, in the Northwest Arctic Borough (NWAB) of Alaska. The property is located 248 km east of the town of Kotzebue, 19 km north of the village of Kobuk, and 275 km west of the Dalton Highway, an all-weather state-maintained highway. Figure 1-1 shows the location of the property.

Figure 1-1: Property Location Map

(Source: Trilogy Metals, 2013)

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-1 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Trilogy Metals is traded on the Toronto Stock Exchange (TSX) and New York Stock Exchange (NYSE) American stock exchanges. Trilogy Metals must file a current technical report summary with the United States Securities and Exchange Commission (SEC) under Subpart 229.1300-Disclosure by Registrants Engaged in Mining Operations under Regulation S-K (S-K 1300) to support their annual report on Form 10-K. Under S-K 1300 Trilogy Metals has prepared a current IA to support the mineral resources of the Bornite Project.

The Bornite Project is an IA supporting a high-grade copper mineral resource amenable to both open pit and underground mining methods. Within the Bornite resource is a relatively high-grade copper deposits that can be mined using underground mining methods which is illustrated through a mine plan and cash flow in this Report.

The Arctic Project is located on the Arctic property which is adjacent to the Bornite property. Through the Ambler Joint Venture, the Bornite Project has access to the Arctic project’s processing facility, TSF and waste rock facility once the Arctic deposit has been developed and mined to depletion. The IA assumes Arctic process and waste management facilities will be available after the Arctic project has been completed. and the Arctic deposit has been depleted.

The IA and the mineral resource estimates are prepared in accordance with the S-K 1300 definitions and standards. All units of measurement in this Report are metric, unless otherwise stated.

Currency is expressed in US dollars, unless otherwise stated.

| 1.3 | Mineral Tenure, Surface Rights and Obligations |

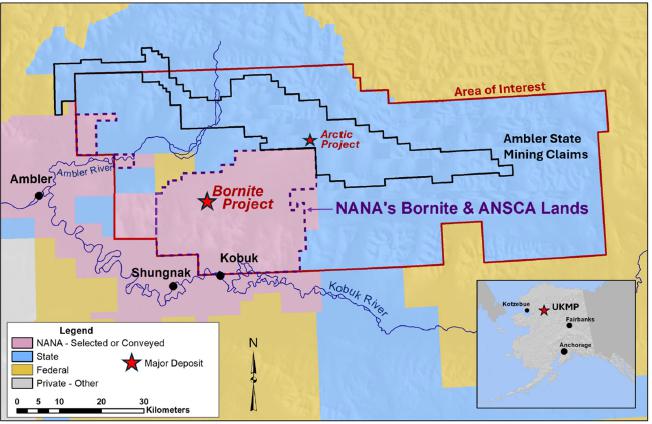

In October 2011, Trilogy Metals entered into an exploration agreement with NANA Regional Corporation, Inc. (NANA), the owner of the property, for the development of the parties’ collective resource interests in the Ambler Mining District. The agreement consolidated certain land holdings of the parties into a land package that currently totals approximately 181,387 ha of which the property contributes 97,483 ha (Bornite Property).

On February 11, 2020, Trilogy Metals transferred the UKMP to a 50/50 joint venture named Ambler Metals LLC (Ambler Metals). With NANA’s approval, Trilogy Metals also contributed, along with the UKMP, its rights under the NANA Agreement to Ambler Metals while its joint venture partner, South32 Limited (South32) an Australian Securities Exchange (ASX) listed company, contributed $145 million dedicated to advancing the development of the properties.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-2 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

The Project is subject to two net smelter return (NSR) royalties payable to NANA on production from the Bornite Lands (2%) and a on production from the Alaska Native Claims Settlement Act (ANSCA) Lands (2.5%).

It is assumed that the Bornite Project would have access to the Arctic facilities through the existing agreements.

| 1.4 | Geology and Mineralization |

Mineralization in the UKMP area is characterized by two mineralized belts: the Devonian Ambler Schist Belt and the Devonian Bornite carbonate sequence. The Ambler Schist Belt hosts volcanogenic massive sulphide (VMS) deposits related to metamorphosed and strongly deformed bimodal Devonian volcanic and sedimentary rocks. A series of notable VMS deposits, including the Arctic, Dead Creek (Shungnak), Sunshine, Horse Creek, Sun, and Smucker deposits, occur in this belt. Bornite Property mineralization is hosted in less deformed Devonian clastic and carbonate sedimentary rocks lying 20 km south of the Ambler Schist Belt across the Ambler Lowlands. Widespread hydrothermal dolomitization is characteristic of the belt and locally hosts the associated copper and cobalt mineralization.

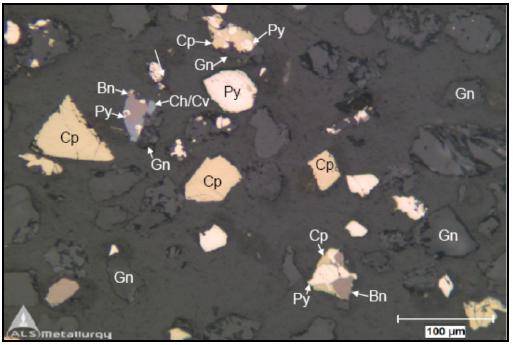

Copper mineralization at Bornite is comprised of chalcopyrite, bornite, and chalcocite as stringers, veinlets, and breccia fillings distributed in stacked, stratabound zones exploiting favourable stratigraphy. Stringer and massive pyrite and locally significant sphalerite occur above and around the copper zones, while locally massive pyrite and sparse pyrrhotite occur in association with siderite alteration below and adjacent to copper mineralization.

Cobalt mineralization at Bornite is comprised of carrollite and cobaltite directly associated with copper bearing minerals as well as cobaltiferous pyrite within and enveloping the copper mineralized zones. Germanium is associated with copper mineralization and is present as germanite and renierite.

Bornite has characteristics similar to a series of districts and deposits including the Mount Isa and McArther River districts in Australia, the Tynagh deposit in Ireland, the Kipushi deposit in the Congo, and the Tsumeb deposit in Namibia. All of these deposits show: early epigenetic characteristics; emplacement in carbonate stratigraphy; and early pyrite-dolomite alteration followed by copper dominant sulphide mineralization. All occur in intra-continental to continental margin settings undergoing extensional tectonics and bimodal volcanism. Basin margin faults seem to play an important role in localizing mineralizing fluids.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-3 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Regional exploration began in the area in the late 1800s with prospectors discovering several small gold placer deposits in the southern Cosmos Hills. Copper mineralization was explored using short adits and shafts around 1906. In 1947 prospector Rhinehart Berg carried out extensive trenching and the first diamond drilling on the Bornite Property that led to an option agreement with BCMC (a Kennecott subsidiary). BCMC discovered the “No. 1 Ore Body” in 1961 which led to the development of an exploration shaft for underground drilling. After the discovery of Arctic, Kennecott paused exploration until 1997-1998. Since then, the Bornite Property has been explored using integrated programs, including geologic mapping; soil, stream, and rock chip geochemistry; geophysics; underground shaft sinking and drifting; and diamond and reverse circulation drilling. Trilogy Metals geologists continue to use these integrated programs to explore for other Bornite-style mineral systems on the Bornite Property.

| 1.6 | Drilling, Sampling, and Data Verification |

There are 106,406 m of diamond drilling in 273 surface (222) and underground (51) holes completed between 1957 and 2019. Drill campaigns before 2011 were completed by Kennecott or its exploration subsidiary, Bear Creek Mining Company (BCMC), and drill campaigns since 2011 were completed by the predecessor companies to Trilogy Metals being NOVAGOLD RESOURCES INC., (NOVAGOLD), NovaCopper Inc. (NovaCopper), or Trilogy Metals.

The assay interval table contains 39,740 copper assays of which 14% are original historical values. Sampling and assaying since 2011 is supported by quality control (QC) sample result monitoring following standard industry practice. There is limited documentation available describing the sample preparation, security, analysis, and QC of drill core samples collected by Kennecott. Re-assaying of a significant amount of historical drill core which was generally confirmatory of the original assays, but did indicate a risk of a 12% high bias in zones of historical high copper grade. Only a few historical samples within the high-grade Lower Reef zone and no samples within the Upper Reef zone were re-assayed. The risk associated with the observed high bias for historical copper assays that remain in the database used for resource estimation, and the absence of any re-assaying within the Upper and Lower Reef zones is taken into consideration during mineral resource classification. Issues identified during data verification process are considered manageable by the restriction of the mineral resource to the Inferred category.

This issue discussed above only impacts the data within the Upper and Lower Reef and does not impact the South Reef.

A site visit was performed by the Wood geology and SRK geotechnical qualified persons (QP) .

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-4 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

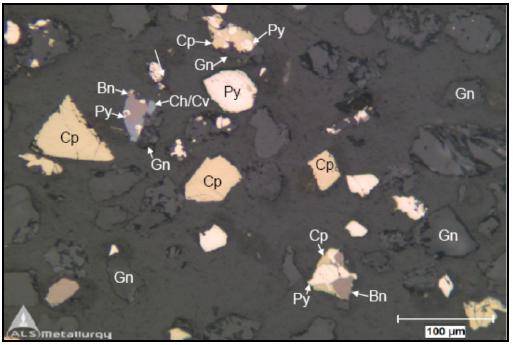

Kennecott conducted metallurgical test work programs between 1960 and 1990 on targeted copper mineralization from Ruby Zone Upper Reef (No. 1 Ore Body). Lock-cycle test work suggested copper was recoverable in a concentrate, while mineralogy work showed high-grade mineralization of the Ruby Zone Upper Reef to be dominated by bornite with subordinate chalcocite and chalcopyrite. It was also confirmed cobalt was present in the Bornite materials occurring as carrollite, cobaltite and cobaltiferous pyrite.

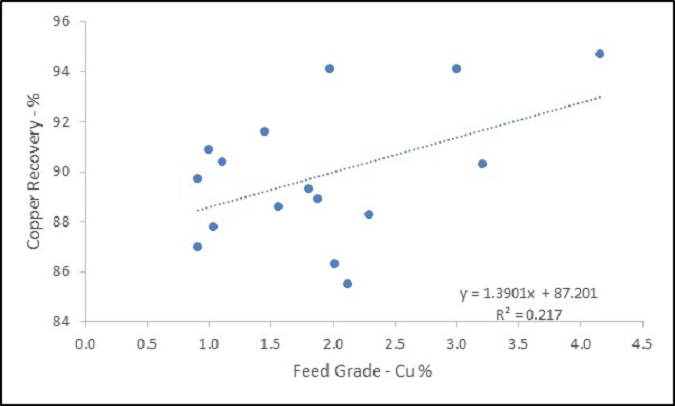

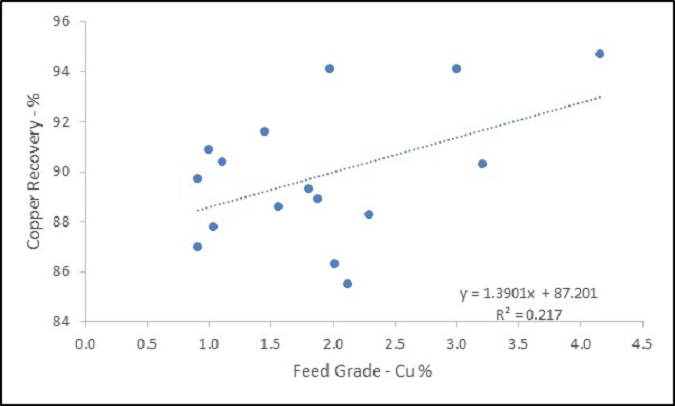

In 2012, Trilogy conducted sample characterization and flotation test work on samples from South Reef aim at producing a saleable copper concentrate. Later, Trilogy Metals continued metallurgical test work on samples of lower grade mineralization within a constraining pit shell. Bond ball mill work index determination shows Bornite materials to be soft or easily ground in traditional grinding mills and consistent in hardness. Flotation work shows a consistent trend of copper recovery increasing with higher copper feed grades.

Test work has demonstrated that the Bornite materials can be processed using conventional copper flotation processes, producing a high-grade copper concentrate with traces of cobalt, gold and silver. A copper recovery to copper feed grade relationship was developed from test work results. The grade-recovery relationship predicts a copper recovery of 90.89% at a copper feed grade of 2.66%. Final copper concentrate grades are expected to be in the range of 28 to 30% Cu.

To date, test work has not been able to identify a process route to recover cobalt. Some work has been done to investigate cobalt recovery in copper and pyrite concentrate with limited success. There have been no detailed studies that have evaluated the potential to mine cobalt rich areas separately present at the Bornite deposit or to apply differential flotation techniques.

| 1.8 | Mineral Resource Estimates |

Wood’s geology QP reviewed and performed validation checks on the mineral resource model and based on the results prepared a revised mineral resource statement that is summarized in Table 1-1. The mineral resources are reported in place (point of reference). The mineral resource estimates are based on a combination of open pit and underground mining methods and a copper price of $4.60/lb. Mineral resources amenable to open pit methods are constrained within a pit shell above a marginal cut-off grade of 0.50% Cu. Mineral resources amenable by underground methods are constrained within a grade shell defined by a breakeven cut-off grade of 1.79% Cu for Ruby Zone reflecting cut-and-fill mining method and an optimized underground mineable stope shape based on 1.45% for South Reef reflecting a sublevel stoping mine method. Underground development material not included within the mineable stope shape that is mined to gain access to the stopes and is above a marginal cut-off grade of 0.70% Cu can be selectively handled and stored in a low-grade stockpile to be processed at the end of the mine life and was included in the mineral resource estimate. A portion of the in-pit mineral resource is well above the copper cut-off and would be amenable to underground mining methods providing flexibility on how to develop the deposit (Table 1-2).

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-5 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| Table 1-1: | Mineral Resources for the Bornite Deposit as at November 30, 2024 |

| Class | | Type/Area | | Cut-off

(Cu %) | | | Tonnes

(Mt) | | | Average Grade

(Cu %) | | | Contained

Cu (Mlb) | |

| Inferred | | In-Pit | | | 0.50 | | | | 170.4 | | | | 1.15 | | | | 4,303 | |

| | | Outside-Pit South Reef | | | 1.45 | | | | 27.5 | | | | 2.78 | | | | 1,687 | |

| | | Outside-Pit Ruby Zone | | | 1.79 | | | | 10.4 | | | | 2.28 | | | | 521 | |

| | | Underground Development | | | 0.70 | | | | 0.7 | | | | 0.98 | | | | 16 | |

| Total Inferred | | | | | | | | | 208.9 | | | | 1.42 | | | | 6,527 | |

| Note: | (1) | Wood is the third-party firm responsible for preparing the mineral resource estimate. |

| | (2) | Mineral resources are prepared in accordance with S-K 1300 definitions. Mineral resources are exclusive of mineral reserves. There have been no mineral reserves estimated on the Bornite Property |

| | (3) | The assessment is preliminary in nature, it includes Inferred mineral resources that are considered too speculative geologically to have modifying factors applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that this economic assessment will be realized. |

| | (4) | Mineral resources are reported in place (point of reference). |

| | (5) | Mineral resources are constrained by: an open pit shell at a cut-off grade of 0.50% Cu, with an average pit slope of 43 degrees; and underground mining shapes assuming cut-and-fill mining method based on a 1.79% Cu grade shell for Ruby Zone and an optimized underground mineable stope shape assuming sublevel stoping mine method based on a break-even cut-off grade of 1.45% for South Reef. The cut-off grades assume a $4.60/lb Cu price over the expected 17-year LOM, process recovery of 90.47%, process cost of $21.00/t processed, treatment, refining, sales cost of $0.78/lb Cu in concentrate, road use cost of $8.04/t processed, and 2% NSR royalty. For the open pit, costs include mining costs of $3.34/t mined and G&A cost of $4.30/t processed. For mining at South Reef, costs include mining costs of $65.00/t mined and G&A cost of $14.50/t processed. For mining at Ruby Zone, costs include mining costs of $90.00/t mined and G&A cost of $14.50/t processed. |

| | (6) | Underground development material uses a marginal cut-off of 0.70% Cu where the mining costs are excluded. |

| | (7) | Figures may not sum due to rounding. |

| | (8) | The mineral resource estimates are shown on a 100% ownership basis, of which Trilogy Metals’ share is 50%. |

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-6 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| Table 1-2: | Portions of South Reef Mineral Resource Amenable to Underground Mining |

| Class | | Type/Area | | Cut-off (Cu %) | | | Tonnes

(Mt) | | | Average Grade

(Cu %) | | | Contained

Cu (Mlb) | |

| Inferred | | In-Pit South Reef1 | | | 1.45 | | | | 14.2 | | | | 2.80 | | | | 876 | |

| | | Outside-Pit South Reef2 | | | 1.45 | | | | 27.5 | | | | 2.78 | | | | 1,687 | |

| | | Total/Average South Reef | | | | | | | 41.7 | | | | 2.79 | | | | 2,563 | |

| Note: | (1) | The 1.45% Cu break-even cut-off assumes sublevel stoping mine method. The cut-off grades assume a $4.60/lb Cu price, process recovery of 90.47%, process cost of $21.00/t processed, mining costs of $65.00/t mined and G&A cost of $14.50/t processed, treatment, refining, sales cost of $0.78/lb Cu in concentrate, road use cost of $8.04/t processed, and 2% NSR royalty. |

| | (2) | Subset of the mineral resource using a higher cut-off to what was used in Table 1-1 and is not additive to the in-pit mineral resource reported in Table 1-1. |

| | (3) | Restatement of the mineral resources outside of the pit as reported in Table 1-1 and is not additive to Table 1-1. |

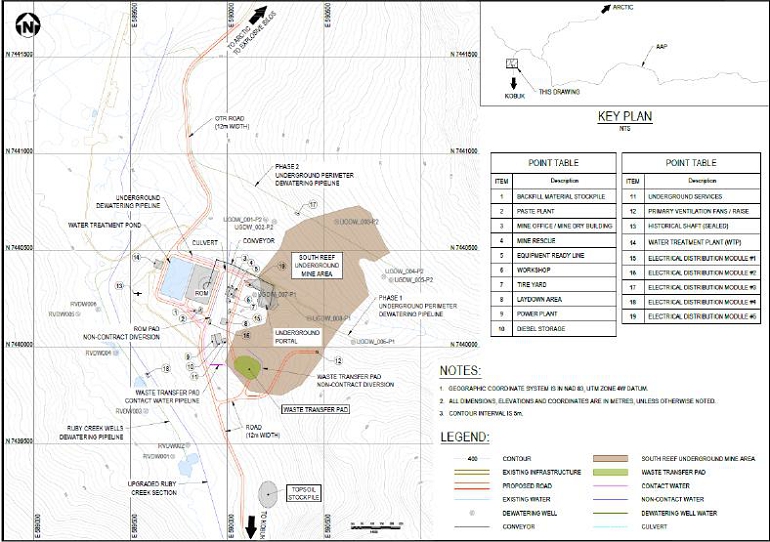

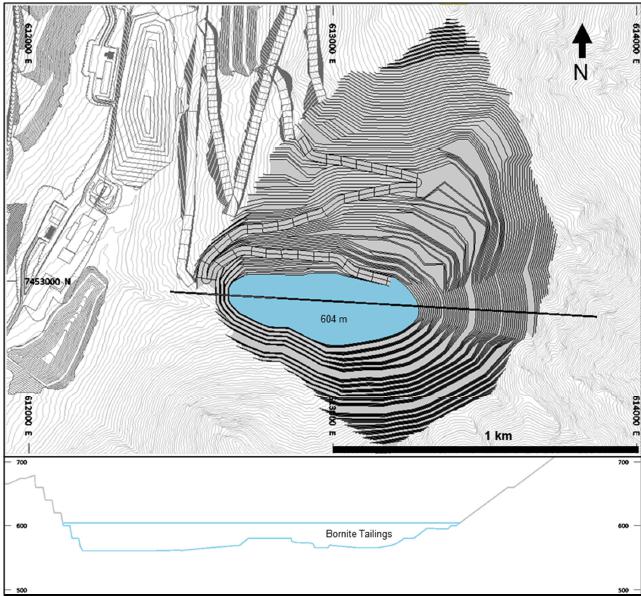

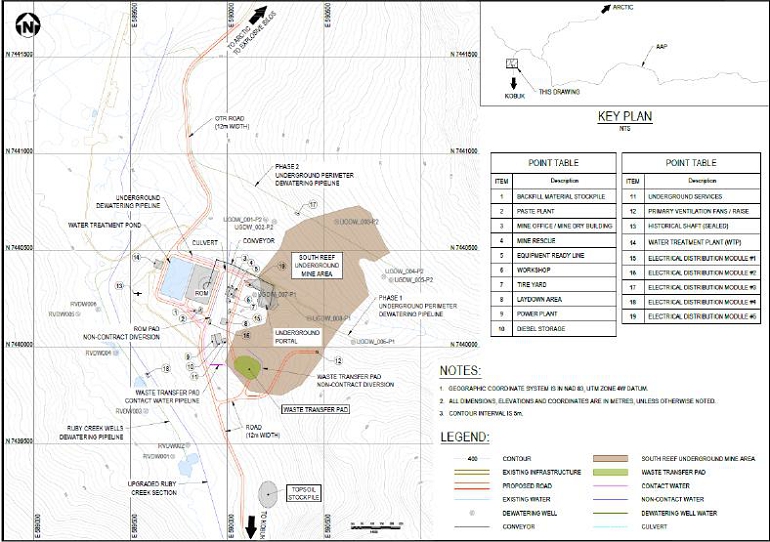

The Bornite mine consists of an underground operation to exploit South Reef (Figure 1-2).

The underground mine will focus on South Reef using sublevel stoping. Stope shape optimizations were run to generate production stopes using cut-off grades determined from preliminary cost modelling, stope optimization parameters and process recoveries. Throughput and cut-off grade were optimized resulting in 6,000 t/d and 1.6% Cu cut-off, respectively.

South Reef will be accessed from surface via twin declines, one for the material handling system and the second for mobile equipment and personnel access. It is expected that an exploration decline will have been developed prior to the start of underground development allowing access to the deposit quicker. The material handling system utilizes 63-tonne diesel trucks to haul development mineralized material and waste and a conveyor system to transport production mineralized material to the run-of-mine (ROM) pad on surface.

Underground development will require two years pre-production and a year of ramp up before reaching 6,000 t/d production. The Bornite life-of-mine (LOM) is 17 years.

A subset of the mineral resources within the LOM plan is summarized in Table 1-3.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-7 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Figure 1-2: Bornite Site Layout

(Source: Wood, 2024)

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-8 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Table 1-3: Subset of the Bornite Mineral Resource Estimate within the IA Mine Plan

| Confidence Category | | Tonnes

(Mt) | | | Average Grade

(Cu %) | | | Contained Cu

(Mlb) | |

| Inferred | | | 36.9 | | | | 2.61 | | | | 2,125 | |

| | Note: | (1) | The assessment is preliminary in nature. It includes Inferred mineral resources that are considered too speculative geologically to have modifying factors applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that this economic assessment will be realized. |

| | | (2) | Mineral resources within the mine plan were estimated using sublevel stoping underground mining method and includes variable dilution explained in Table 16-7 and a mine recovery of 95%. |

| | | (3) | Input assumptions used to determine mineable stope shapes include a copper price of $4.20/lb, mine operating cost of $73.29/t, process operating cost of $19.84/t, G&A and surface costs of $9.64/t, haulage and road use costs of $28.78/t, closure and water treatment costs of $1.26/t, shipping, treatment, refining and selling costs of $0.78/lb Cu, process recovery of 90%, and NSR royalty of 2% |

| | | (4) | Production stope cut-off of 1.6% Cu and development cut-off 0.7% Cu. The production stope cut-off input assumptions include a copper price of $4.20/lb, mine operating cost of $44.08/t, process operating cost of $24.82/t, G&A and surface cost of $17.3/t, and sustaining costs of $8.52/t, road use costs of $14.4/t, shipping, treatment, refining and selling costs of $0.78/lb Cu, process recovery of 90.89%, and average NSR royalty of 2.25%. |

| 1.10 | Processing and Recovery Methods |

Bornite material will be processed in the Arctic process plant that has currently been designed to a feasibility study (FS) level (Murray et al., 2023). The process plant will process 10,000 t/d of material on a two week on, one week off campaign basis. The process plant will operate at an overall availability of 64%, processing an annual average of 2,215,000 tonnes of mineralized material to produce a copper concentrate.

Modifications to the Arctic flowsheet to allow the processing of Bornite material at the end of the Arctic LOM include:

| · | decommissioning the talc, zinc and lead flotation circuits as these are not required to process Bornite material. |

| · | incorporating some of the zinc circuit flotation and dewatering equipment in the copper flotation and dewatering circuit which is anticipated to handle higher copper loadings. |

| · | a new regrind mill will be required to operate in parallel to the existing copper and zinc regrind mills. |

A new tailings filtration plant will dewater up to 50% of the plant tailings for paste backfill purposes. Filtered tailings will be transported by dual tractor trailer from the Arctic plant to the Bornite paste backfill plant. Power consumption will be less than the total output capacity currently required for the Arctic process plant.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-9 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Surface infrastructure is limited at the Bornite site as the Bornite Project will leverage off of existing infrastructure at Arctic once Arctic mineral reserves have been exhausted. Onsite infrastructure and services required to support the Bornite Project include mining facilities including a paste fill plant, waste transfer pad, ROM stockpile, topsoil stockpile, underground portal, power plant, fuel storage, upgraded Ruby Creek section, dewatering wells, water treatment pond, contact and non-contact diversions/ditches (Figure 1-2). It is assumed that the Arctic camp will be sufficient to accommodate Bornite personnel.

Access to site will be from the north, along the south route from the Ambler Access Project (AAP) road and from the south from the Dahl Creek airport.

A waste transfer pad with capacity of 40,000 tonnes will temporarily store waste and low-grade mineralized material from underground and will be hauled to the Arctic waste rock facility for long term storage. Low-grade mineralized material will be processed at the end of mine life. A ROM stockpile with a capacity of 30,000 tonnes equating to five days of production will store mineralized material and serve as a loading point for haulage to the Arctic mill by the over-the-road (OTR) truck fleet.

Tailings produced from processing the mineralized material from Bornite at the Arctic mill, will be stored in an expanded Arctic tailings storage facility (TSF) and within the Arctic pit. The existing TSF will be expanded to hold the additional 16 Mm3 while the pit will store 2.5 Mm3 with the possibility of storing more if required. It is assumed that approximately 50% of the tailings would be sent to the filter press at the Arctic mill to be used to produce paste backfill and is backhauled to the Bornite site.

A portal diesel power plant comprising of six diesel gensets will provide power for peak site demand of 13.3 MWe.

Perimeter dewatering wells are planned to limit the inflow of water into the underground mine. This water will be conveyed back into Ruby Creek. The upgraded Ruby Creek section and Ruby Creek valley dewatering wells are intended to disconnect flow in Ruby Creek from the underlying groundwater system and reduce infiltration into the mine. Diversion ditches around site will intercept water runoff water before it becomes contact water. Contact water will be treated before release into the environment.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-10 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Trilogy Metals has not completed any market analysis for the Bornite copper concentrate, nor are there any contracts in place with any buyers for the concentrate. Given the average copper concentrate grade is expected to exceed 28% and there are no significant amounts of deleterious elements contained in the concentrate, there should be no barriers to obtain sales contracts with third-party smelters.

The long-term forecast copper price of $4.20/lb used for mine planning and cash flow analysis was provided by an analyst consensus reflecting the average forecasted price from 18 financial institutions.

The capital cost estimate was prepared in accordance with S-K 1300 standards for an IA and developed a Class 5 using AACE International Guidelines Practice No. 47R-11 with an expected accuracy of ±50% and a contingency of 14.4% overall. All costs are expressed in fourth-quarter 2024 US dollars.

The Bornite Project’s initial capital cost, as summarized in Table 1-4 is $503.4 million, including indirect costs of $80.6 million and contingency of $72.5 million. A sustaining capital of $363.1 million considers equipment replacement costs and pipeline and ditch construction for water management and electrical. The total Bornite Project capital, inclusive of initial and sustaining costs is estimated at $866.5 million.

Table 1-4: Summary of Capital Cost Estimate

| WBS | | Description | | Initial Capital

($M) | | | Sustaining Capital

($M) | | | Total Capital

($M) | |

| 1000 | | Mining | | | 214.9 | | | | 300.6 | | | | 515.5 | |

| 2000 | | Crushing | | | - | | | | - | | | | - | |

| 3000 | | Process | | | 28.6 | | | | - | | | | 28.6 | |

| 4000 | | Tailings | | | 10.4 | | | | - | | | | 10.4 | |

| 5000 | | Onsite Infrastructure | | | 85.3 | | | | 20.7 | | | | 106.0 | |

| 6000 | | Offsite Infrastructure | | | 1.7 | | | | - | | | | 1.7 | |

| Subtotal | | | | | 340.8 | | | | 321.3 | | | | 662.1 | |

| 7000 | | Indirect Costs | | | 80.6 | | | | 4.1 | | | | 84.7 | |

| 9000 | | Owners’ Costs | | | 9.5 | | | | 1.2 | | | | 10.7 | |

| 8000 | | Provisions/Contingency | | | 72.5 | | | | 36.5 | | | | 109.0 | |

| Total | | | | | 503.4 | | | | 363.1 | | | | 866.5 | |

Note: Figures may not sum due to rounding.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-11 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Total operating costs over the LOM have been estimated at $3,651.6 million with a breakdown summarized in Table 1-5. The operating cost accuracy is ±50% with a contingency of less than 25%.

Table 1-5: Total Operating Costs over LOM

| Cost Area | | LOM Cost

($M) | | | Avg. Unit Cost of Mineralized Material Processed

($/t) | |

| Underground Mining | | | 1,392.5 | | | | 37.74 | |

| OTR Haulage | | | 197.3 | | | | 5.35 | |

| Process | | | 915.8 | | | | 24.82 | |

| AAP Road | | | 528.7 | | | | 14.33 | |

| G&A | | | 495.2 | | | | 13.42 | |

| Water Management | | | 105.8 | | | | 2.87 | |

| Surface Operations Cost | | | 16.4 | | | | 0.44 | |

| Total | | | 3,651.6 | | | | 98.97 | |

Note: (1) G&A = general and administrative

(2) Figures may not sum due to rounding.

| 1.15 | Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups |

Environmental baseline studies have been conducted since 2007 including archaeology, aquatic life surveys, wetlands mapping, surface water quality sampling, hydrology, and subsistence. Additional baseline studies for the Bornite Project area have been recommended to generate the data to support future mine design, development of an Environmental Impact Statement (EIS), permitting, construction, operations and closure.

A significant number of permits from state, federal and local governments will be necessary to develop a mine at Bornite. Most agencies must comply with the requirements of the National Environmental Policy Act (NEPA) before issuing their permits. NEPA planning includes the development of an Environmental Assessment (EA) or an Environmental Impact Statement (EIS).

The NANA Agreement made in October 2011 includes the promotion of education opportunities for shareholders in the region. Ambler Metals have been periodically meeting with neighbouring communities providing updates on project plans and participate in a subsistence advisory committee with representatives from NANA Region villages and NANA.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-12 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

A preliminary conceptual reclamation plan has been estimated to leave the site stable in terms of erosion and avoids the degradation of water quality on site.

The results of the economic analysis in the IA represents forward-looking information that is subject to a number of known and unknown risks, uncertainties, and other factors that may cause actual results to differ materially from those presented here. Forward-looking information includes mineral resource estimates in the IA mine plan and the cash flows derived from them, forecast copper prices used, capital and operating cost estimates, estimated copper production, and payback period. Actual results may vary from the forward-looking information with the mineral resource estimates, costs, copper prices, metallurgical recoveries, and taxes being different from what was assumed in the IA.

The assessment is preliminary in nature, it includes Inferred mineral resources that are considered too speculative geologically to have modifying factors applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that this economic assessment will be realized.

The IA has been evaluated using a discounted cash flow (DCF) analysis. Cash inflows consist of annual revenue projections for the mine. Cash outflows such as capital, pre-production mining costs, operating costs, taxes, and royalties, are subtracted from the inflows to arrive at the annual cash flow projections. Cash flows are taken to occur at the end of each period.

The after-tax evaluation of the Bornite Project under the assumptions used in this Report generates positive results. Before-tax and after-tax financial results are presented in Table 1-6. The financial analysis is presented on a 100% basis on which Trilogy Metals has a 50% attributable interest.

The financial model on which the analysis is based includes 100% Inferred mineral resources. The results of the economic analysis excluding Inferred mineral resources would not be economically viable.

The Bornite Project is most sensitive to changes in copper selling price and copper feed grade, followed by changes to operating costs and total capital costs.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-13 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Table 1-6: Financial Results

| Description | | Unit | | Value | |

| Before-Tax Valuation Indicators | | | | | | |

| Undiscounted Cumulative Cash Flow | | $M | | | 1,582.5 | |

| NPV @ 8% | | $M | | | 552.1 | |

| Payback Period (from start of operations) | | years | | | 4.0 | |

| IRR Before Tax | | % | | | 23.6 | |

| After-Tax Valuation Indicators | | | | | | |

| Undiscounted Cumulative Cash Flow | | $M | | | 1,218.8 | |

| NPV @ 8% | | $M | | | 393.9 | |

| Payback Period (undiscounted from start of operations) | | years | | | 4.4 | |

| IRR After Tax | | % | | | 20.0 | |

Note: NPV = net present value; IRR = internal rete of return

Under the assumptions in this Report, the Bornite Project shows a positive financial return. The QPs of the third-party firms have identified additional test work and engineering studies required to support further mining studies.

| 1.18.1 | Geology and Mineral Resources |

| · | Risks to the mineral resource estimate are listed in Section 11.14. |

| · | The available geotechnical information indicates that sublevel stoping should be a viable mining method for Bornite, but further studies and core drilling are required to validate this assumption. |

| · | Dewatering quantities may be significant at Bornite based on historical rapid flooding of the exploration shaft when it intersected a specific zone at depth. The plan for Bornite has include substantial dewatering and water management efforts; however, further studies are required to validate the assumptions about dewatering flow quantity and quality. |

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-14 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| · | The IA has assumed the Arctic process plant copper, zinc and tailings thickeners will have sufficient capacity for the Bornite copper concentrate and tailings streams based on benchmarking reference projects and existing operations; however, thickening test work to confirm this has not been completed. |

| · | The IA has assumed the two Arctic process plant copper and zinc filters will have sufficient dewatering capacity for the Bornite copper concentrate based on benchmarking reference projects and existing operations; however, filtration test work to confirm this has not been completed. |

| · | Regrind milling power requirements have been calculated using signature plots and comminution data available from benchmark and reference projects; however, Bornite copper concentrate regrind test work to confirm this has not been completed. |

| · | The tailings filters have been sized from benchmark and reference project filtration data. Bornite tailings material filtration test work to confirm this has not been completed at this level of study. |

| · | Tailings filter cake handleability or transport material test work has not been completed and further work will be required to confirm the filter cake can be adequately transported from Arctic for disposal at Bornite. |

| · | Existing Arctic infrastructure and process equipment must be in good enough condition to be repurposed for processing Bornite material. Increased process capital costs could result should the process infrastructure and plant equipment require replacement at the end of the Arctic mine life. |

| · | Process plant operators may not be familiar with the non-standard campaigned nature of the Arctic plant operation (two week on, one week off schedule), resulting in sub-optimal throughput as a result of the ramp up/down cycling. |

| 1.18.5 | Geotechnical (Tailings) |

| · | Backfilling the Bornite underground mine may not be possible if the plant tailings can’t be processed adequately to provide bulk feed for backfilling, which would significantly affect the mine design and require additional tailings storage. |

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-15 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| · | Water treatment needs are poorly constrained, and assumptions may not actually be conservative which could lead to higher water treatment costs or significant permitting needs/delays. |

| · | Contact water may originate from various sources at the site, including temporary stockpiles, construction earthworks, mine water, and intercepted ground and surface waters. Waste rock characterization and management assumes that long-term (post-reclamation) water treatment is not required because the most likely source (stockpiles) will be relocated to Arctic. However, depending on further analysis and refinement of development plans, water treatment may be required during closure and early post-closure for an indetermined length of time, until water quality standards are achieved. |

| · | Permitting and construction of the upgraded Ruby Creek section may be more challenging than anticipated. Similarly, reclamation of the upgrades could require multiple stakeholder approvals. |

| 1.18.7 | Project Infrastructure |

| · | Actual ground conditions along proposed infrastructure are not suitable for proposed structures, which must be moved or redesigned resulting in higher costs. |

| · | AAP road not being permitted limiting access to the Bornite Project. |

| · | The uncertainty in the cost of the AAP road could materially affect the results of the economic analysis for the Bornite Project. |

| · | A portion of the Ruby Zone deposit is near surface that is amenable to open pit mining. This material was not included in the mine plan to limit surface capital related to a required expansion of the tailings facility at Arctic, but pending further study work, could be in a future mine plan. |

| · | A portion of the Ruby Zone deposit is amenable to underground mining. A preliminary design included 6.3 Mt at 2.38% Cu utilizing a cut-and-fill mining method, but this was removed to improve project economics by limiting sustaining capital and the required expansion of the tailings facility at Arctic. Depending on copper price and geological interpretation of the resource, sublevel stoping could be an appropriate mining method. |

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-16 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| · | Converting the talc pre-float circuit into the copper rougher-scavengers would improve the flow routing for the treatment of Bornite material. |

| · | Completing additional comminution characterization test work (Axb, rod mill, ball mill and abrasion) to better represent the mineable resource. |

| · | Expand the number of geological samples subjected to detailed mineralogy and flotation test work, to confirm the current operational parameters are providing optimal metallurgical results for the resource. |

| · | Complete thickening tests for both Bornite copper concentrate and tailings material to confirm the existing Arctic thickeners are adequate for the upgrade and the flocculant dosages required. |

| · | Complete filtration test work on both Bornite copper concentrate and tailings material to confirm the existing Arctic concentrate filters are adequate for the upgrade and to size the tailings filters. |

| · | Complete regrind comminution test work to confirm the regrind mill power requirements and to test various regrind technologies. |

| · | The expansion and re-configuration of the Arctic flowsheet should be considered in the layout of the initial Arctic process plant site to ensure the Bornite process plant upgrade strategy is understood and to minimize brownfield operating impacts and shutdown costs. This would involve: |

| – | Ensuring there is adequate free space on the process pad for the additional regrind mill and tailings filter plant |

| – | Optimizing flotation cell orientation to allow for faster repurposing for the Bornite flowsheet, reducing downtime. |

| · | Complete project execution, shutdown and schedule planning in future project phases to confirm construction shutdown durations for the required process plant modifications at the end of the Arctic deposit mine life. |

| · | Thorough testing may provide an opportunity to custom design an economically viable solution to backfill Bornite. |

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-17 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| 1.19.3 | Geotechnical (Tailings) |

| · | Integration of Bornite tailings on top of the Arctic tailings may provide positive impacts to the closure water treatment requirements. |

| · | Hydraulic connection between Ruby Creek/Ruby Creek valley and the underground is not as significant as assumed resulting in lower water management and dewatering costs than assumed. |

| · | Optimization of water management infrastructure is likely possible, which could simplify the overall system and possibly reduce capital costs. |

The QPs of the third-party firms have identified recommendations around developing an advanced exploration decline to access South Reef for further drilling, hydrogeology, geotechnical and rock mechanics work, metallurgical test work, investigations around re-purposing the Arctic process plant to receive Bornite mineralized material, tailings studies considering additional locations and technologies, a hydrological program, geochemistry assessments, a site water and load balance (water quality predictions) and water treatment needs, and environmental baseline studies with estimated costs totaling $172.4 million.

| Project No.: 253821 | | Executive Summary | |  |

| January 2025 | | Page 1-18 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

Trilogy Metals, a company involved in the exploration and development of projects in the UKMP in Alaska’s Ambler Mining District, retained Wood, SRK, Ausenco, International Metallurgical & Environmental and Core Geoscience to prepare a Report disclosing the results of an IA of their Bornite project in Alaska.

Trilogy Metals is traded on the TSX and NYSE American stock exchanges. Trilogy Metals must file a current technical report summary with the United States SEC under Subpart 229.1300-Disclosure by Registrants Engaged in Mining Operations under Regulation S-K (S-K 1300) to support their annual report on Form 10-K. Under S-K 1300 Trilogy Metals has prepared a current IA to support the mineral resources of the Bornite Project.

The Bornite Project is an IA supporting a high-grade copper mineral resource amenable to both open pit and underground mining methods. Within the Bornite resource is a relatively high-grade copper deposits that can be mined using underground mining methods which is illustrated through a mine plan and cash flow in this Report.

The Arctic Project is located on the Arctic property which is adjacent to the Bornite property. Through the Ambler Joint Venture, the Bornite Project has access to the Arctic project’s processing facility, TSF and waste rock facility once the Arctic deposit has been developed and mined to depletion. The IA assumes Arctic process and waste management facilities will be available after the Arctic project has been completed and the Arctic deposit has been depleted.

All units of measurement in this Report are metric, unless otherwise stated.

Currency is expressed in US dollars, unless otherwise stated.

This Report was prepared by appropriate QPs from Wood, SRK, Ausenco, International Metallurgical & Environmental and Core Geoscience, whose firms are considered third-party firms comprising of mining experts. Table 2-1 lists the sections of the Report prepared by or contributed to by each third-party firm.

| Project No.: 253821 | | Introduction | |  |

| January 2025 | | Page 2-1 | |

| Bornite Project |

| Northwest Alaska, USA |

| S-K 1300 Technical Report Summary on the Initial Assessment |

| | Table 2-1: | Third-Party Firms Who Prepared this Report |

| Third-Party Firms | | Report Sections |

| Wood | | 1.1-1.6, 1.8-1.9, 1.11-1.14, 1.16, 1.17, 1.18.1, 1.18.7, 1.18.2, 1.19.1, 1.20, 2-6, 7.1-7.22, 7.24, 7.25, 8, 9.1-9.5, 9.7, 9.11.1, 9.11.3, 11-13, 15.1.1-15.1.7, 15.1.9-15.1.13, 15.2.5, 16, 18.1.1-18.1.3, 18.1.6-18.1.12, 18.3.1-18.3.3, 18.3.5.1, 18.3.5.3, 18.3.6, 19-21 22.1-22.5, 22.7, 22.9, 22.11-22.13, 22.14.1, 22.14.2, 22.15.1 23.1, 23.2, 23.3.1, 23.3.3-23.3.6, 23.8, 23.10, 24-25 |

| SRK | | 1.11, 1.18.3, 1.18.5, 1.18.6, 1.19.3, 1.19.4, 1.20, 2.2, 2.3, 7.23, 9.8-9.10, 9.11.4-9.11.6, 15.1.8, 15.2.4, 17.5, 18.1.1, 18.1.2, 18.1.5, 18.1.6, 18.1.8, 18.1.11, 18.2, 18.3.1, 18.3.5.2, 18.3.5.3, 22.1, 22.9, 22.12, 22.14.3, 22.14.5, 22.14.6, 22.15.3, 22.15.4 23.1, 23.3.2, 23.6, 23.7, 23.10, 24 |

| Ausenco | | 1.10, 1.13, 1.14, 1.18.4, 1.19.2, 1.20, 2.2, 2.3, 9.6, 9.11.2, 14, 15.2.1-15.2.3, 18.1.1, 18.1.2, 18.1.4, 18.1.8, 18.3.1, 18.3.4, 18.3.5.1, 22.1, 22.8, 22.12, 22.14.4, 25.15.2, 23.1, 23.5, 23.10, 24 |

| International Metallurgical & Environmental | | 1.7, 1.20, 2.2, 2.3, 9.6, 9.11.2, 10, 22.1, 22.6, 23.1, 23.4, 23.10, 24 |