Exhibit 99.1

Exhibit 99.1

Goldman Sachs

Metals &

Mining/Steel

Conference

November 20, 2013

Forward-Looking Statements TM

Some of the information included in this presentation constitutes “forward-looking statements” as defined in Section 27A of the Securities Act of 1933, as amended and Section 21E of the Securities Exchange Act of 1934, as amended. All statements in this presentation that express opinions, expectations, beliefs, plans, objectives, assumptions or projections with respect to anticipated future performance of SunCoke Energy,

Inc. (“SunCoke”) or SunCoke Energy Partners, L.P. (“Partnership”), in contrast with statements of historical facts, are forward-looking statements. Such forward-looking statements are based on management’s beliefs and assumptions and on information currently available.

Forward-looking statements include information concerning possible or assumed future results of operations, business strategies, financing plans, competitive position, potential growth opportunities, potential operating performance improvements, the effects of competition and the effects of future legislation or regulations. Forward-looking statements include all statements that are not historical facts and may be identified by the use of forward-looking terminology such as the words “believe,” “expect,” “plan,” “intend,” “anticipate,” “estimate,” “predict,” “potential,” “continue,” “may,” “will,” “should” or the negative of these terms or similar expressions.

Although management believes that its plans, intentions and expectations reflected in or suggested by the forward-looking statements made in this presentation are reasonable, no assurance can be given that these plans, intentions or expectations will be achieved when anticipated or at all. Moreover, such statements are subject to a number of assumptions, risks and uncertainties. Many of these risks are beyond the control of SunCoke and the Partnership, and may cause actual results to differ materially from those implied or expressed by the forward-looking statements. Each of SunCoke and the Partnership has included in its filings with the Securities and Exchange Commission (including, in the case of the Partnership, its Form S-1) cautionary language identifying important factors (but not necessarily all the important factors) that could cause actual results to differ materially from those expressed in any forward-looking statement. For more information concerning these factors, see the Securities and Exchange Commission filings of SunCoke and the Partnership. All forward-looking statements included in this presentation are expressly qualified in their entirety by such cautionary statements. Although forward-looking statements are based on current beliefs and expectations, caution should be taken not to place undue reliance on any such forward-looking statements because such statements speak only as of the date hereof. Neither SunCoke nor the Partnership has any intention or obligation to update publicly any forward-looking statement (or its associated cautionary language) whether as a result of new information or future events or after the date of this presentation, except as required by applicable law.

This presentation includes certain non-GAAP financial measures intended to supplement, not substitute for, comparable GAAP measures. Reconciliations of non-GAAP financial measures to GAAP financial measures are provided in the Appendix at the end of the presentation. Investors are urged to consider carefully the comparable GAAP measures and the reconciliations to those measures provided in the Appendix.

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

2

ABOUT SUNCOKE

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

3

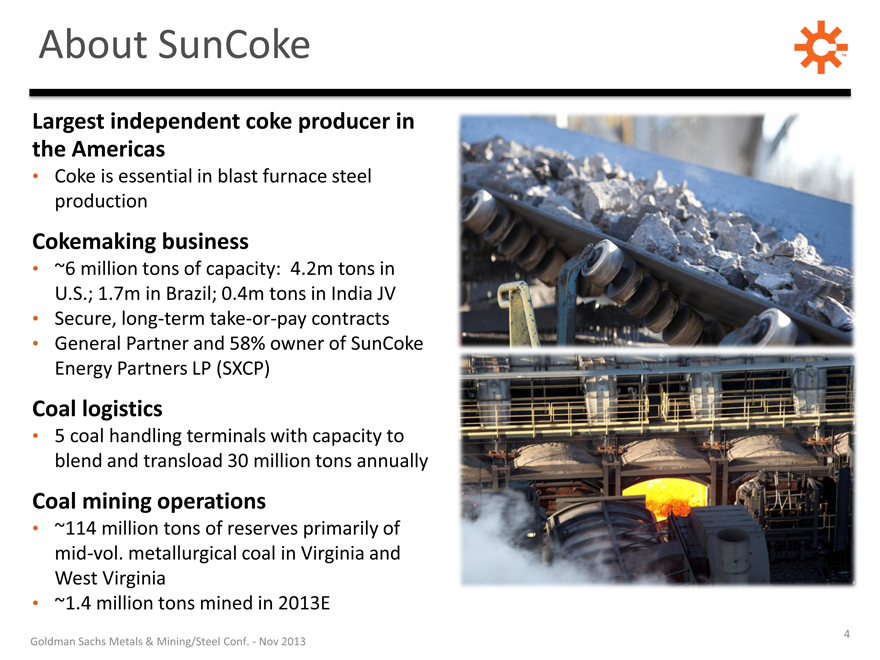

About SunCoke TM

Largest independent coke producer in

the Americas

Coke is essential in blast furnace steel production

Cokemaking business

~6 million tons of capacity: 4.2m tons in U.S.; 1.7m in Brazil; 0.4m tons in India JV

Secure, long-term take-or-pay contracts

General Partner and 58% owner of SunCoke Energy Partners LP (SXCP)

Coal logistics

5 coal handling terminals with capacity to blend and transload 30 million tons annually

Coal mining operations

~114 million tons of reserves primarily of mid-vol. metallurgical coal in Virginia and West Virginia

~1.4 million tons mined in 2013E

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

4

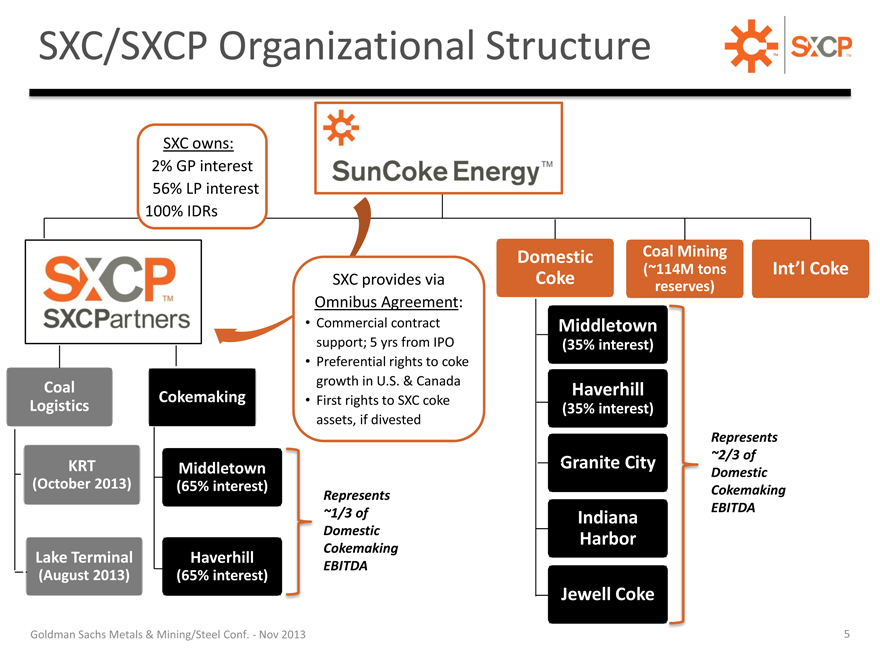

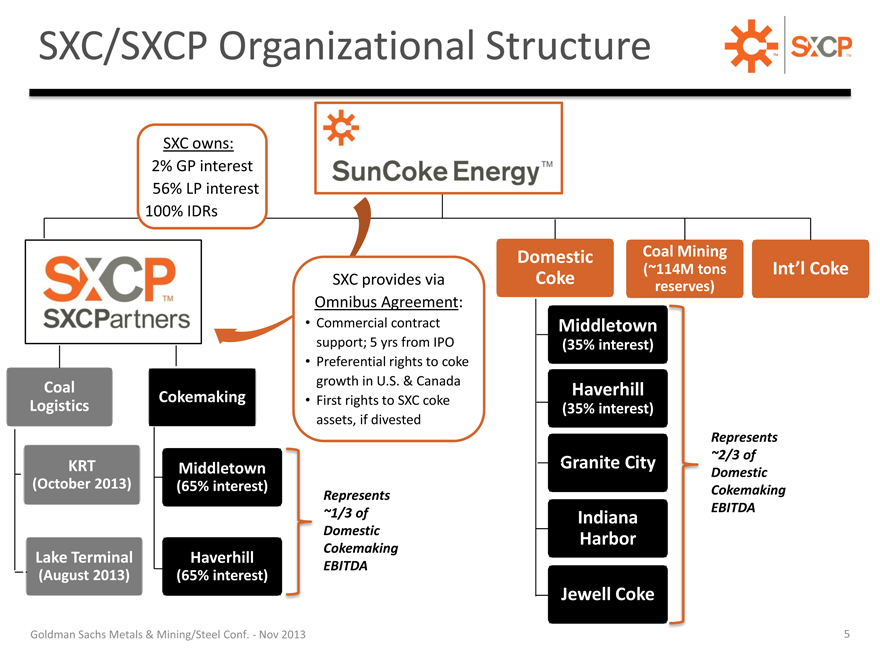

SXC/SXCP Organizational Structure TM

SXC owns:

2% GP interest

56% LP interest

100% IDRs

Domestic Coal Mining

(~114M tons Int’l Coke

SXC provides via Coke reserves)

Omnibus Agreement:

• Commercial contract Middletown

support; 5 yrs from IPO(35% interest)

• Preferential rights to coke

Coal growth in U.S. & Canada Haverhill

Cokemaking • First rights to SXC coke

Logistics(35% interest)

assets, if divested

Represents

Granite City ~2/3 of

KRT Middletown Domestic

(October 2013)(65% interest) Represents Cokemaking

~1/3 of Indiana EBITDA

Domestic Harbor

Cokemaking

Lake Terminal Haverhill EBITDA

(August 2013)(65% interest)

Jewell Coke

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

5

Recent Highlights TM

Continued Operations Excellence

Sustained high-level of operating performance in coke business

Reduced coal cash costs from $144/ton in Q4‘12 to $123/ton in Q3‘13

Maintained top quartile safety performance in coal and coke

Positioned for Future Growth

Indiana Harbor—renewed contract with ArcelorMittal includes return on refurbishment capital; project on track

Financial flexibility at SXC and SXCP can facilitate growth

Leveraged SXCP as Growth Engine

Completed two acquisitions in coal logistics business

Received favorable private letter ruling on iron ore concentrating/pelletizing activities

SXCP raised Q4 distribution outlook; reaching first incentive distribution right (IDR) split

Expect to end year in upper half of initial 2013 Adjusted EBITDA and EPS guidance

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

6

OUR MARKET OPPORTUNITY

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

7

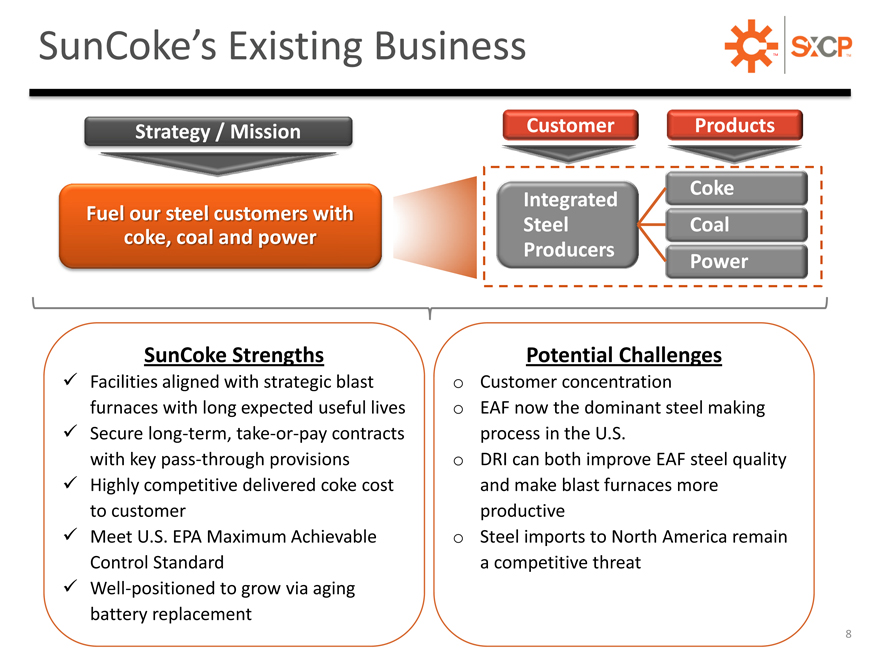

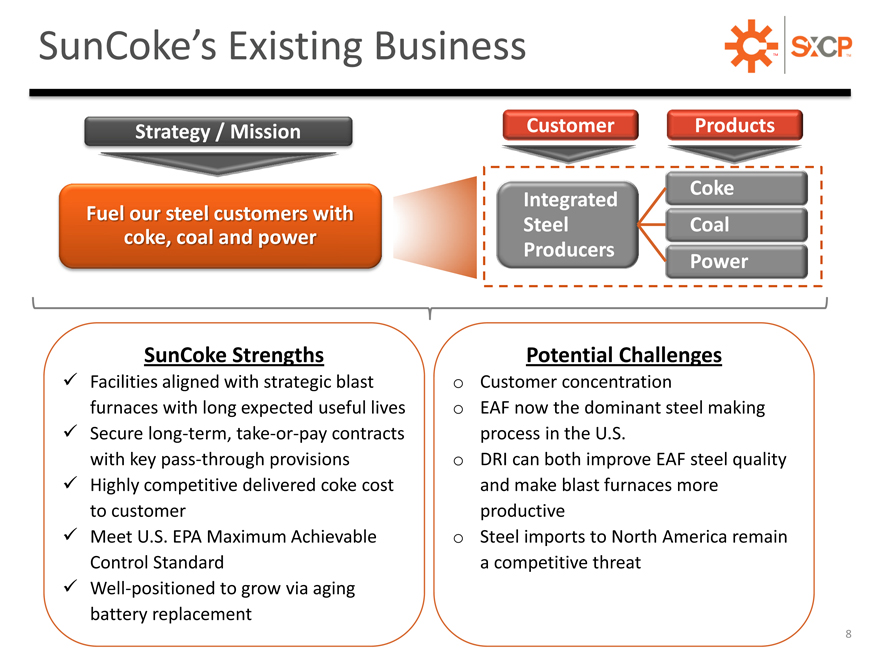

SunCoke’s Existing Business

Strategy / Mission

Fuel our steel customers with coke, coal and power

SunCoke Strengths

Facilities aligned with strategic blast furnaces with long expected useful lives

Secure long-term, take-or-pay contracts with key pass-through provisions

Highly competitive delivered coke cost to customer

Meet U.S. EPA Maximum Achievable Control Standard

Well-positioned to grow via aging battery replacement

Customer Products

Integrated Coke

Steel Coal

Producers Power

Potential Challenges

Customer concentration

EAF now the dominant steel making process in the U.S.

DRI can both improve EAF steel quality and make blast furnaces more productive

Steel imports to North America remain a competitive threat

8

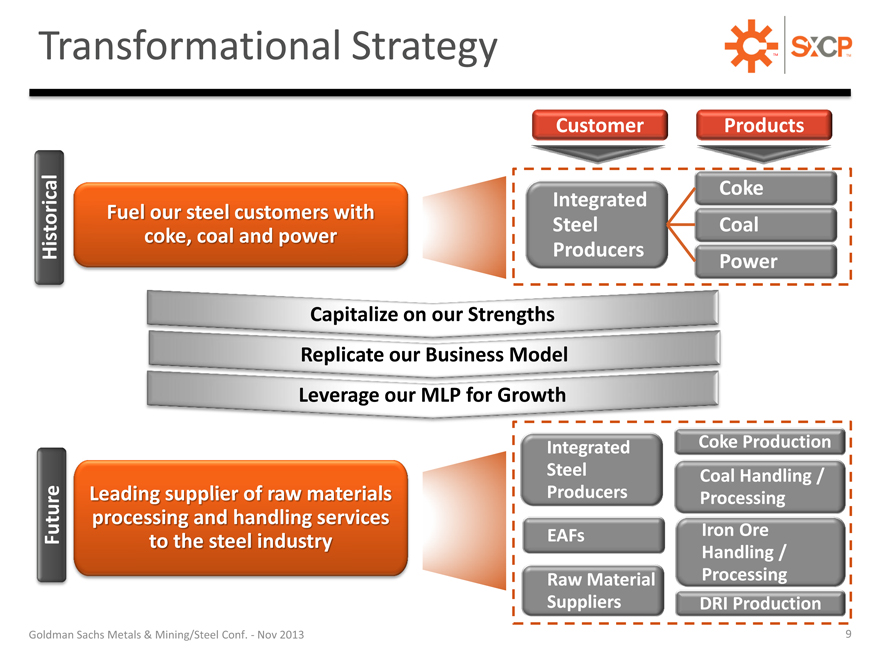

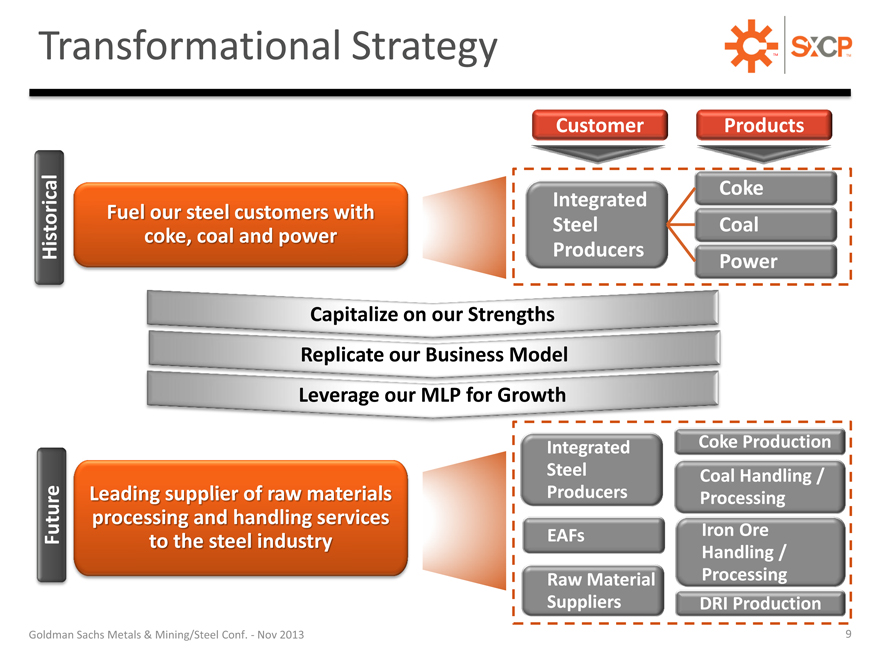

Transformational Strategy TM

Customer Products

Integrated Coke

Fuel our steel customers with

coke, coal and power Steel Coal

Historical Producers Power

Capitalize on our Strengths

Replicate our Business Model

Leverage our MLP for Growth

Integrated Coke Production

Steel Coal Handling /

Leading supplier of raw materials Producers Processing

processing and handling services

Future EAFs Iron Ore

to the steel industry Handling /

Raw Material Processing

Suppliers DRI Production

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013 9

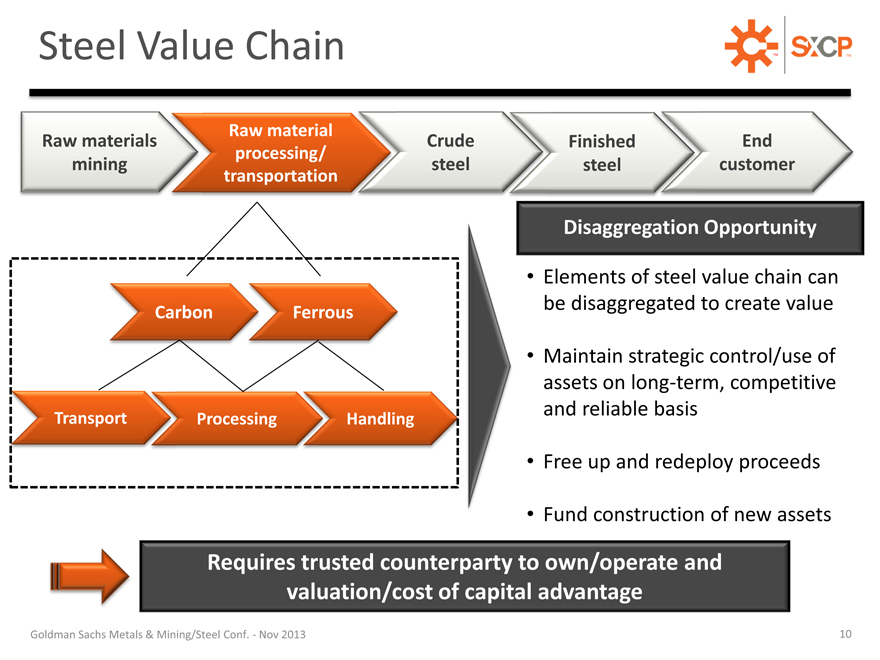

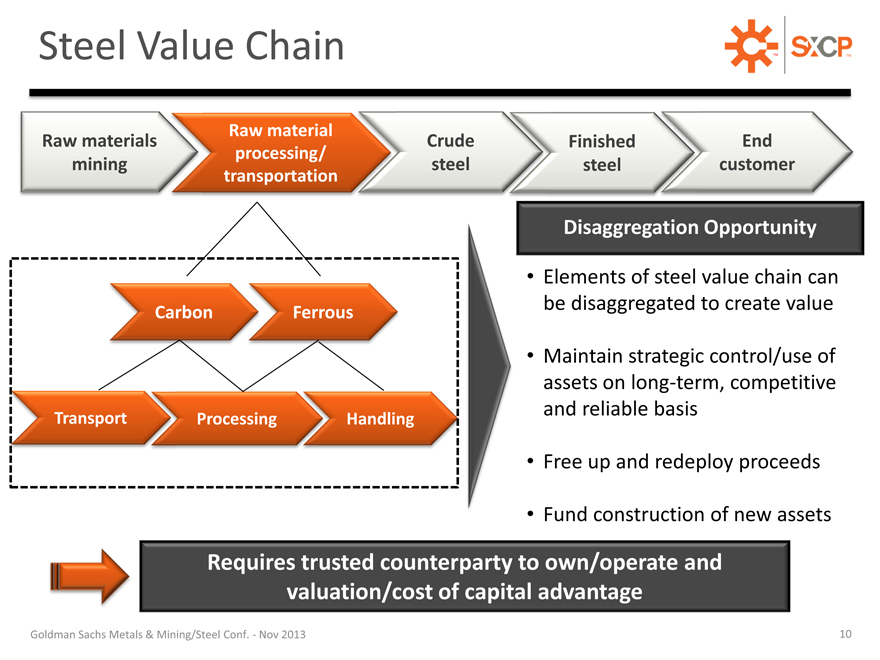

Steel Value Chain TM

Raw material

Raw materials Crude Finished End processing/ mining steel steel customer transportation

Disaggregation Opportunity

Carbon Ferrous

Transport Processing Handling

Elements of steel value chain can

be disaggregated to create value

Maintain strategic control/use of

assets on long-term, competitive

and reliable basis

Free up and redeploy proceeds

Fund construction of new assets

Requires trusted counterparty to own/operate and valuation/cost of capital advantage

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

10

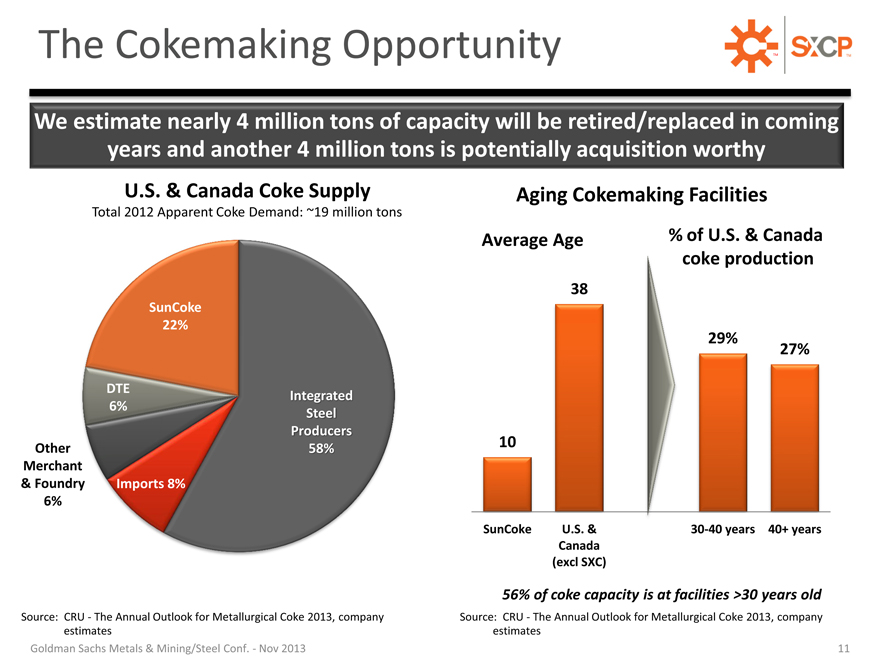

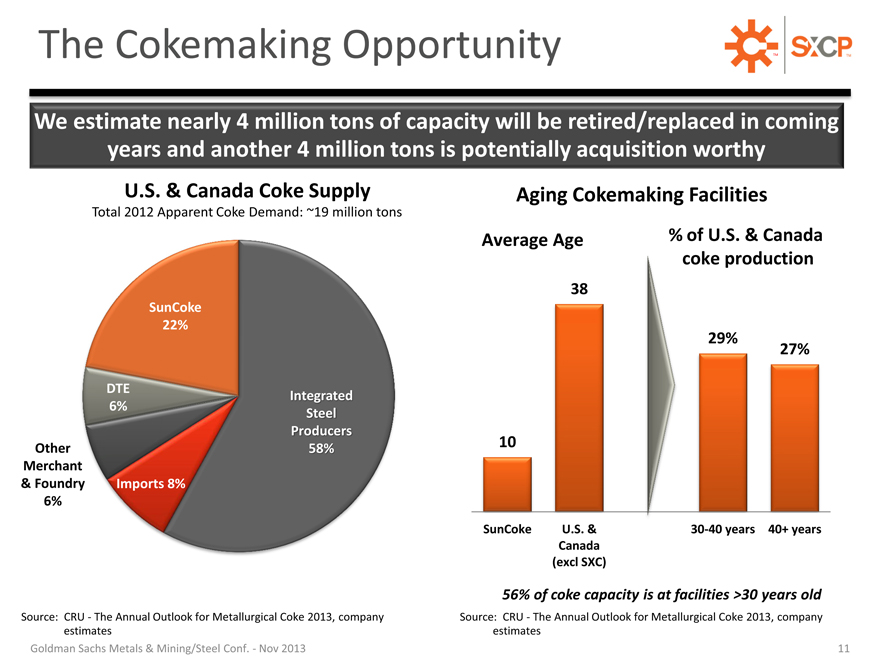

The Cokemaking Opportunity TM

We estimate nearly 4 million tons of capacity will be retired/replaced in coming

years and another 4 million tons is potentially acquisition worthy

U.S. & Canada Coke Supply Aging Cokemaking Facilities

Total 2012 Apparent Coke Demand: ~19 million tons

Average Age% of U.S. & Canada

coke production

38

SunCoke

22%

29%

27%

DTE Integrated

6% Steel

Producers

Other 58% 10

Merchant

& Foundry Imports 8%

6%

SunCoke U.S. & 30-40 years 40+ years

Canada

(excl SXC)

56% of coke capacity is at facilities >30 years old

Source: CRU—The Annual Outlook for Metallurgical Coke 2013, company Source: CRU—The Annual Outlook for Metallurgical Coke 2013, company

estimates estimates

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013 11

The Coal Logistics Opportunity TM

Coal handling/blending operations are a natural backward integration play

and provide opportunity to broaden our customer base

Potential asset types

Adjacent Integration:

Prep

A business we Plants

understand, providing a Replicate Business Model:

service we are familiar Loadouts

with

Tolling, fee-based off-take Asset Rich:

agreements limit

commodity exposure

Large market size

combined with capital-

Terminals constrained owners

Barges

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013 Private Railcars 12

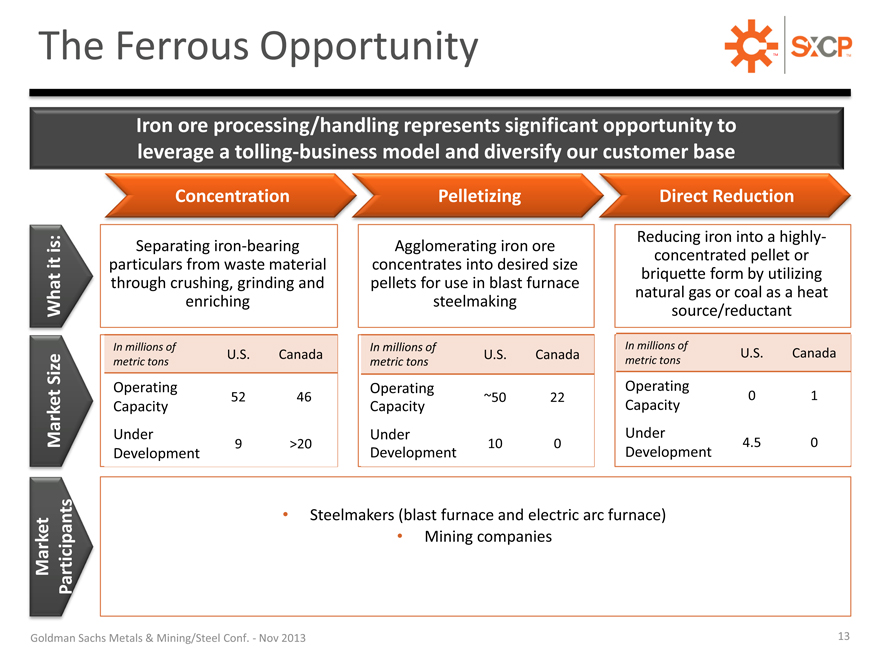

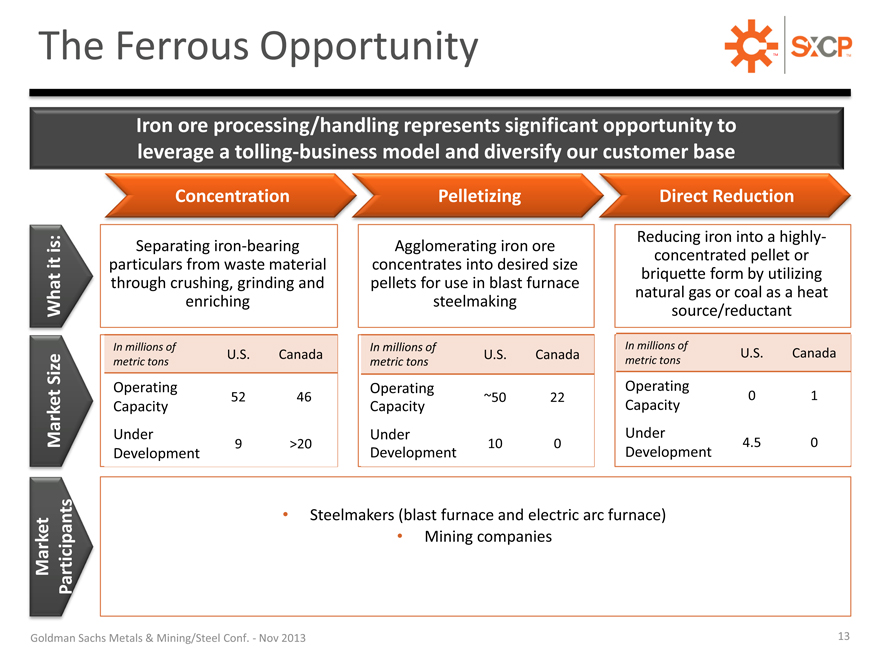

The Ferrous Opportunity TM

Iron ore processing/handling represents significant opportunity to leverage a tolling-business model and diversify our customer base

Concentration Pelletizing

is: Separating iron-bearing Agglomerating iron ore

it particulars from waste material concentrates into desired size

through crushing, grinding and pellets for use in blast furnace

What enriching steelmaking

In millions of In millions of

U.S. Canada U.S. Canada

Size metric tons metric tons

Operating Operating

52 46 ~50 22

Capacity Capacity

Market Under Under

9 >20 10 0

Development Development

Direct Reduction

Reducing iron into a highly-concentrated pellet or briquette form by utilizing natural gas or coal as a heat source/reductant

In millions of U.S. Canada

metric tons

Operating

0 1

Capacity

Under

4.5 0

Development

• Steelmakers (blast furnace and electric arc furnace)

Market Participants • Mining companies

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

13

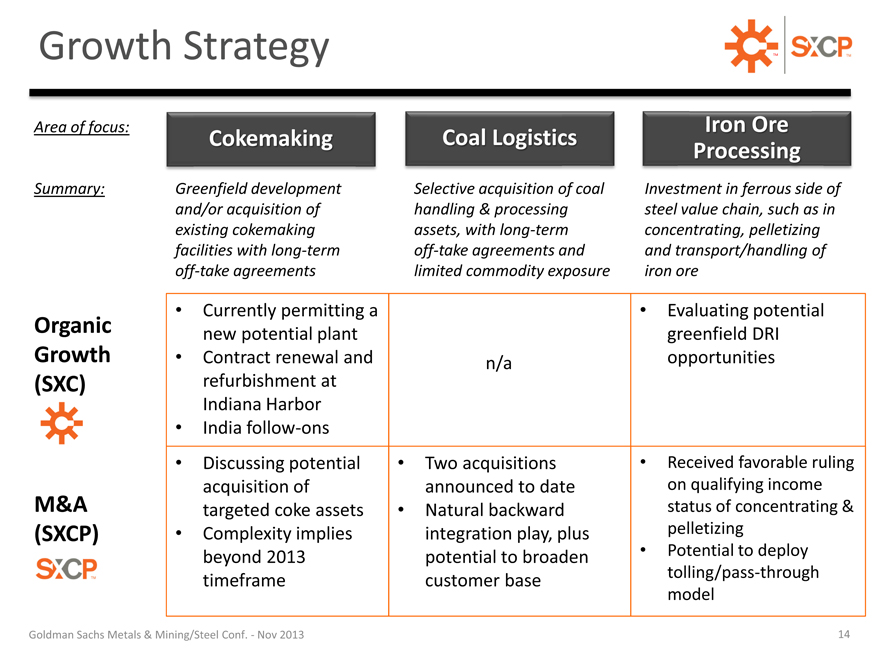

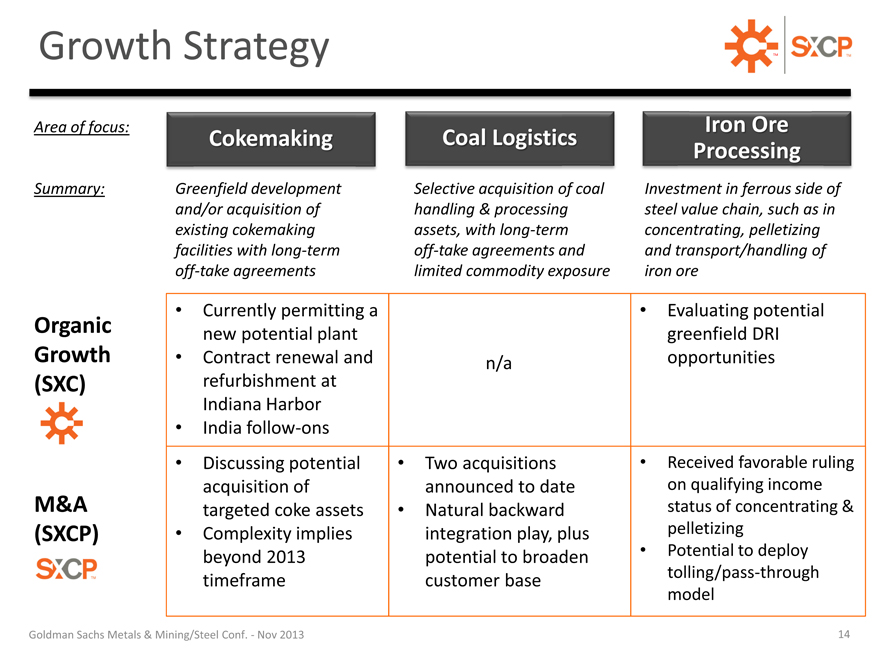

Growth Strategy

TM

Area of focus:

Cokemaking

Coal Logistics

Summary:

Greenfield development

Selective acquisition of coal

and/or acquisition of

handling & processing

existing cokemaking

assets, with long-term

facilities with long-term

off-take agreements and

off-take agreements

limited commodity exposure

Iron Ore

Processing

Investment in ferrous side of steel value chain, such as in concentrating, pelletizing and transport/handling of iron ore

Currently permitting a

Evaluating potential

Organic

new potential plant

greenfield DRI

Growth

Contract renewal and

n/a

opportunities

(SXC)

refurbishment at

Indiana Harbor

India follow-ons

Discussing potential

Two acquisitions

Received favorable ruling

acquisition of

announced to date

on qualifying income

M&A

targeted coke assets

Natural backward

status of concentrating &

(SXCP)

Complexity implies

integration play, plus

pelletizing

beyond 2013

potential to broaden

Potential to deploy

timeframe

customer base

tolling/pass-through

model

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

14

QUESTIONS?

Goldman Sachs Metals & Mining/Steel Conf.—Nov 2013

15

APPENDIX

16

ABOUT SUNCOKE AND THE COKEMAKING PROCESS

17

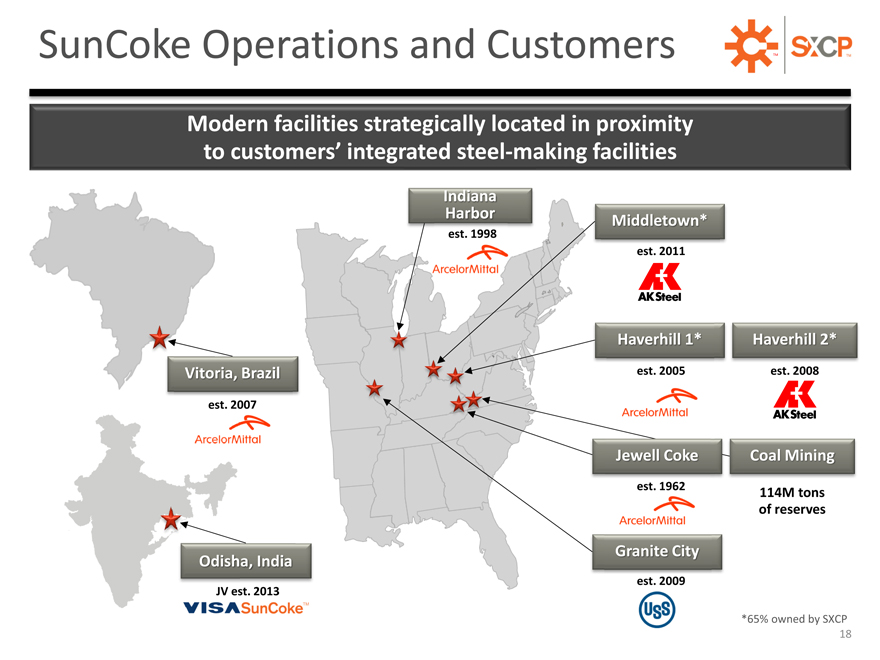

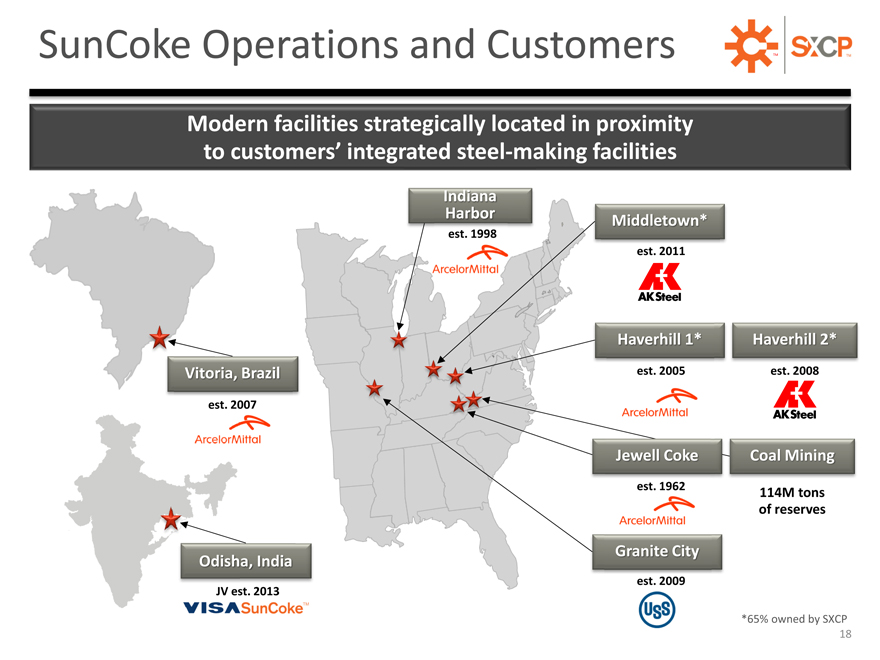

SunCoke Operations and Customers TM

Modern facilities strategically located in proximity

to customers’ integrated steel-making facilities

Indiana

Harbor Middletown*

est. 1998

est. 2011

Haverhill 1* Haverhill 2*

Vitoria, Brazil est. 2005 est. 2008

est. 2007

Jewell Coke Coal Mining

est. 1962 114M tons

of reserves

Granite City

Odisha, India

est. 2009

JV est. 2013

*65% owned by SXCP

18

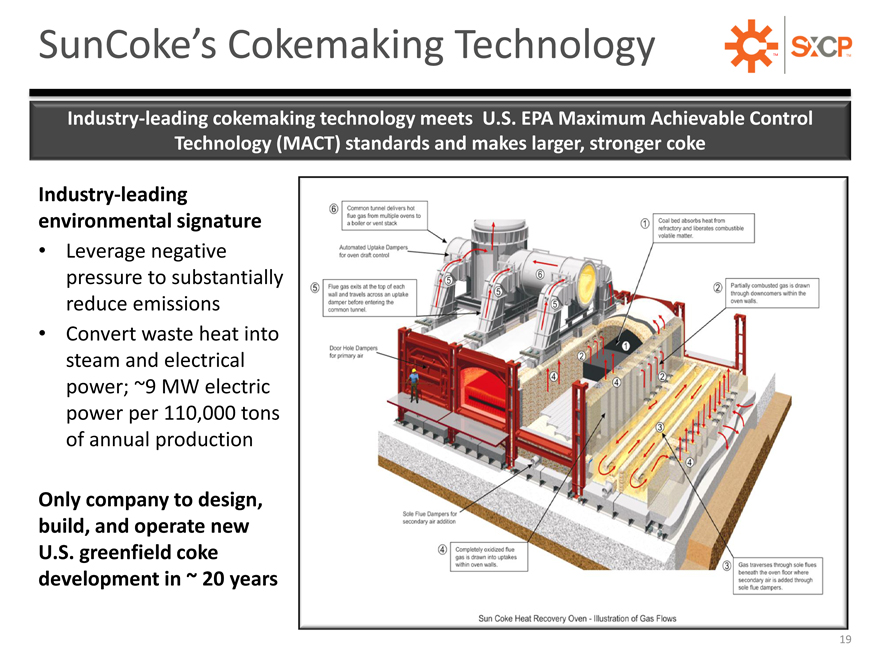

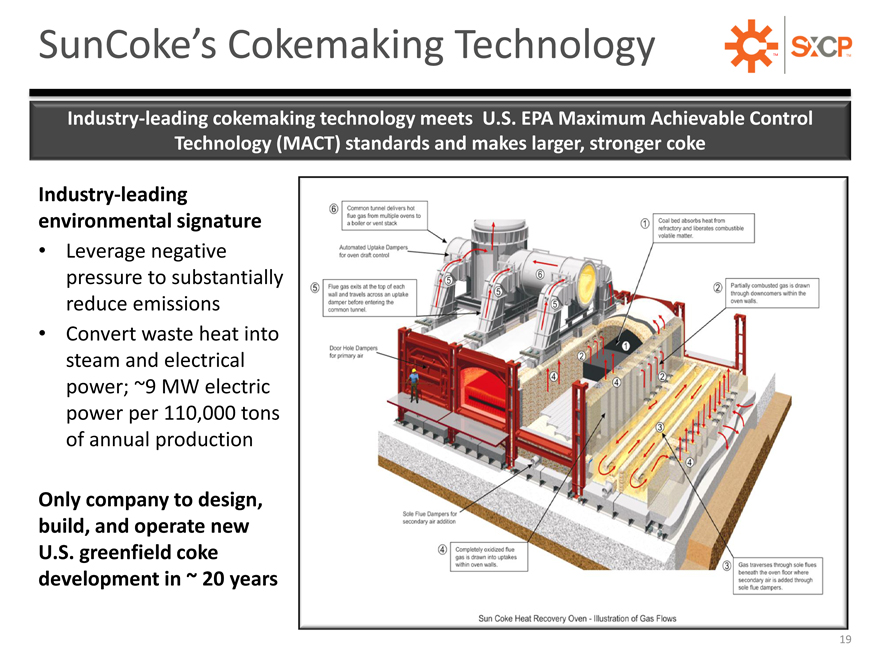

SunCoke’s Cokemaking Technology TM

Industry-leading cokemaking technology meets U.S. EPA Maximum Achievable Control

Technology (MACT) standards and makes larger, stronger coke

Industry-leading

environmental signature

Leverage negative pressure to substantially reduce emissions

Convert waste heat into steam and electrical power; ~9 MW electric power per 110,000 tons of annual production

Only company to design,

build, and operate new

U.S. greenfield coke

development in ~ 20 years

19

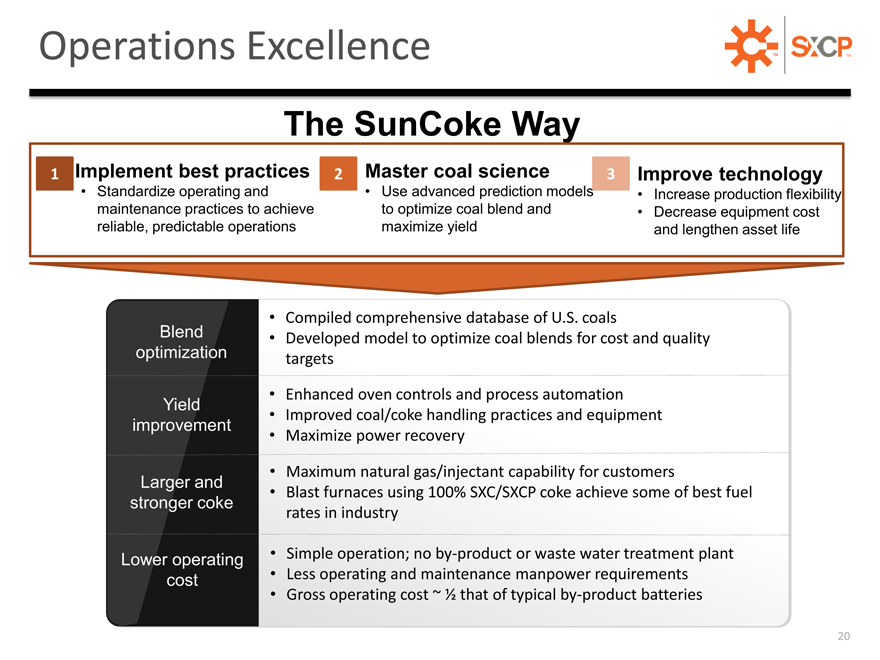

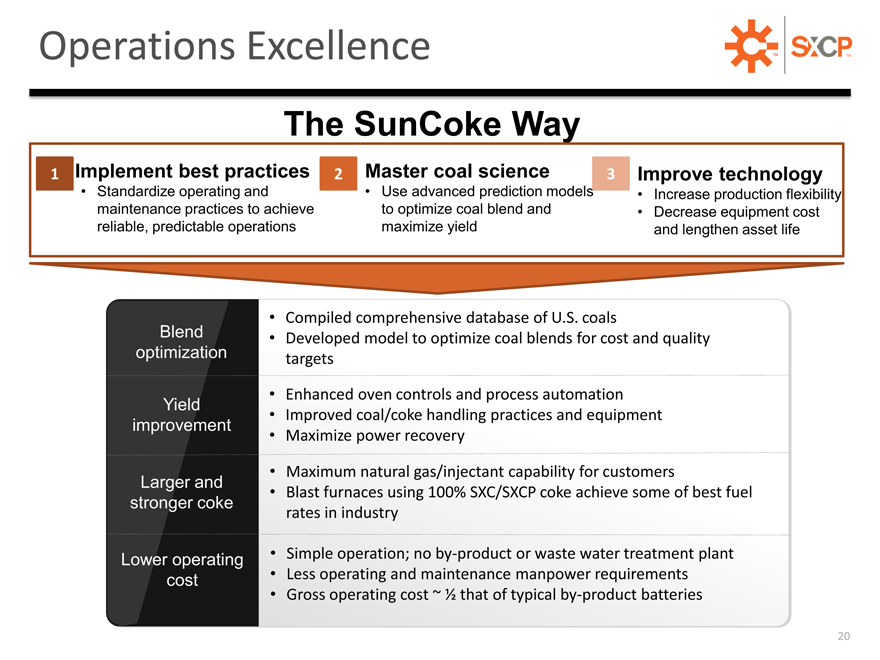

Operations Excellence TM

The SunCoke Way

1 Implement best practices 2 Master coal science 3 Improve technology

Standardize operating and Use advanced prediction models Increase production flexibility

maintenance practices to achieve to optimize coal blend and • Decrease equipment cost

reliable, predictable operations maximize yield and lengthen asset life

• Compiled comprehensive database of U.S. coals

Blend • Developed model to optimize coal blends for cost and quality

optimization targets

• Enhanced oven controls and process automation

Yield • Improved coal/coke handling practices and equipment

improvement • Maximize power recovery

• Maximum natural gas/injectant capability for customers

Larger and • Blast furnaces using 100% SXC/SXCP coke achieve some of best fuel

stronger coke rates in industry

Lower operating • Simple operation; no by-product or waste water treatment plant

cost • Less operating and maintenance manpower requirements

• Gross operating cost ~ 1/2 that of typical by-product batteries

20

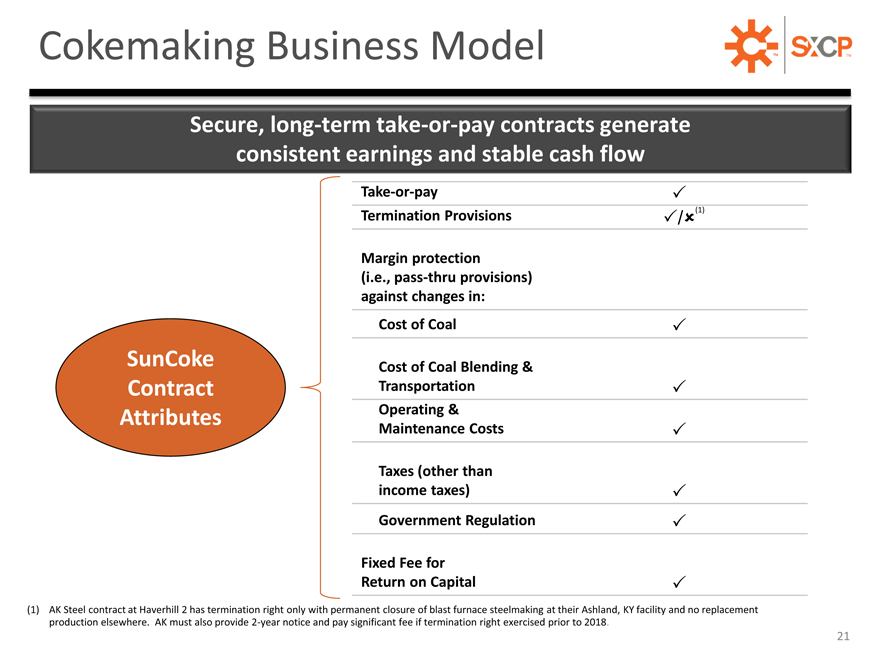

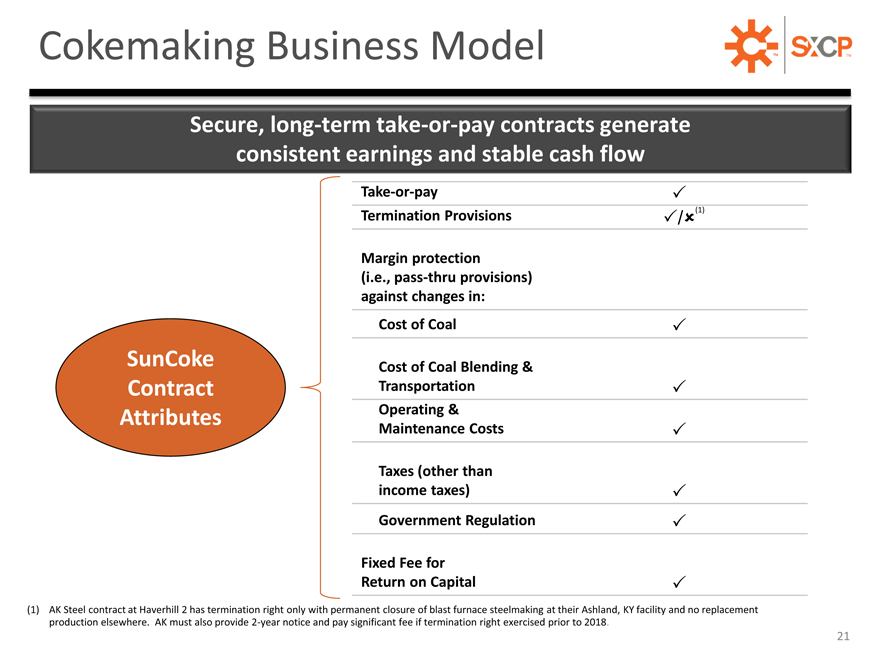

Cokemaking Business Model TM

Secure, long-term take-or-pay contracts generate consistent earnings and stable cash flow

Take-or-pay

Termination Provisions / (1)

Margin protection

(i.e., pass-thru provisions)

against changes in:

Cost of Coal

SunCoke Cost of Coal Blending &

Contract Transportation

Attributes Operating &

Maintenance Costs

Taxes (other than

income taxes)

Government Regulation

Fixed Fee for

Return on Capital

(1) AK Steel contract at Haverhill 2 has termination right only with permanent closure of blast furnace steelmaking at their Ashland, KY facility and no replacement production elsewhere. AK must also provide 2-year notice and pay significant fee if termination right exercised prior to 2018.

21

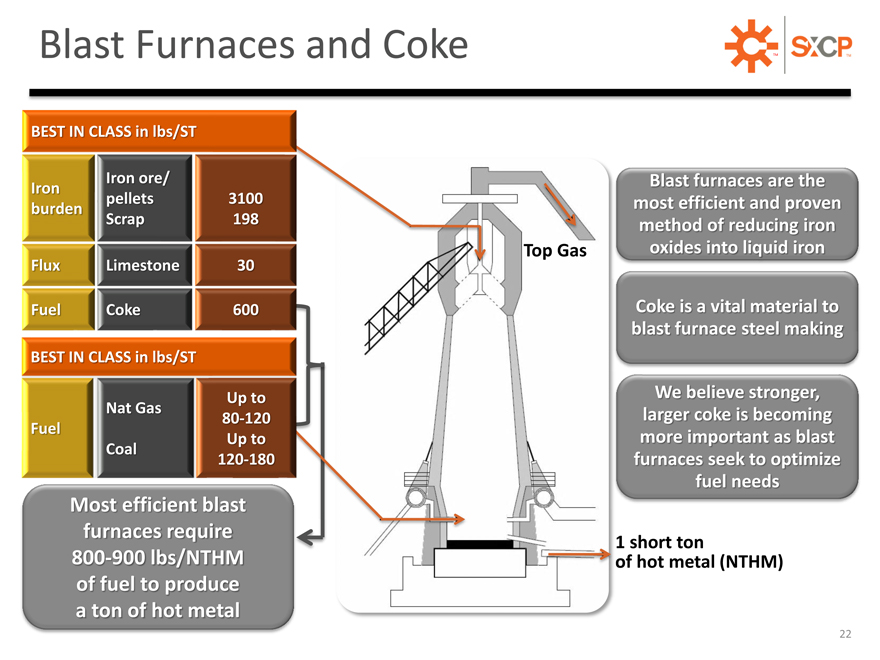

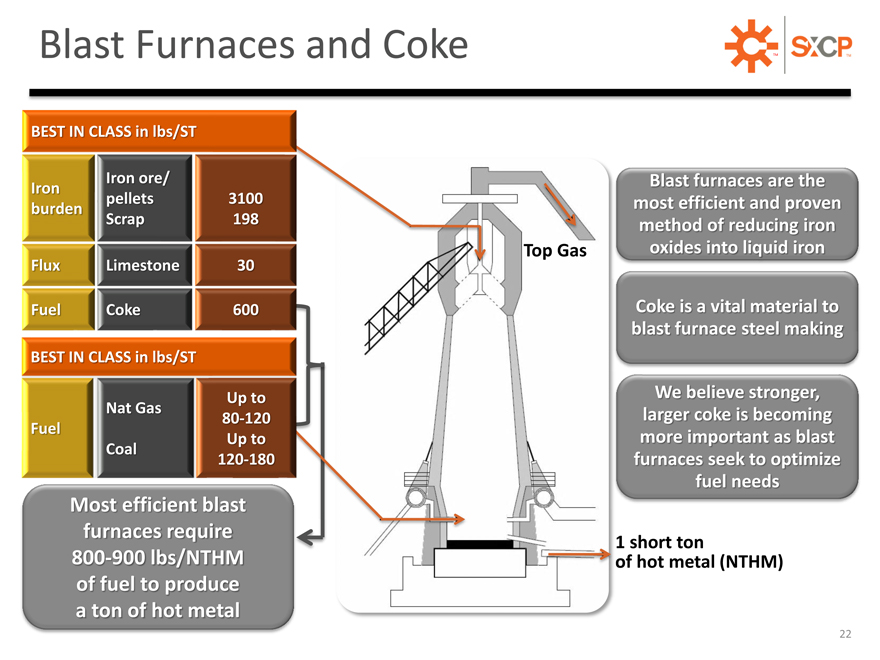

Blast Furnaces and Coke TM

BEST IN CLASS in lbs/ST

Iron Iron ore/ Blast furnaces are the

burden pellets 3100 most efficient and proven

Scrap 198 method of reducing iron

Top Gas oxides into liquid iron

Flux Limestone 30

Fuel Coke 600 Coke is a vital material to

blast furnace steel making

BEST IN CLASS in lbs/ST

Up to We believe stronger,

Nat Gas 80-120 larger coke is becoming

Fuel Up to more important as blast

Coal 120-180 furnaces seek to optimize

fuel needs

Most efficient blast

furnaces require 1 short ton

800 900 lbs/NTHM of hot metal (NTHM)

of fuel to produce

a ton of hot metal

22

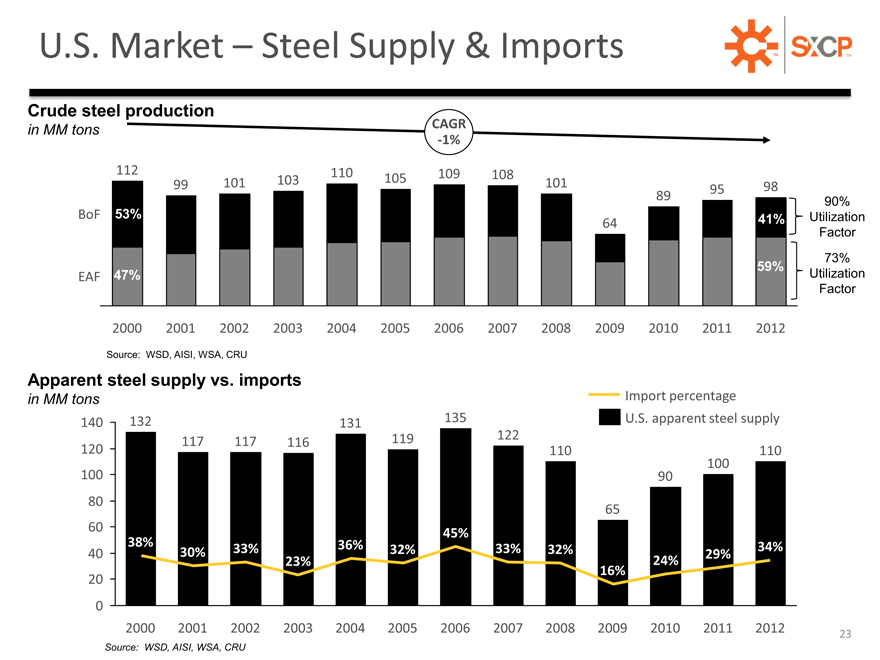

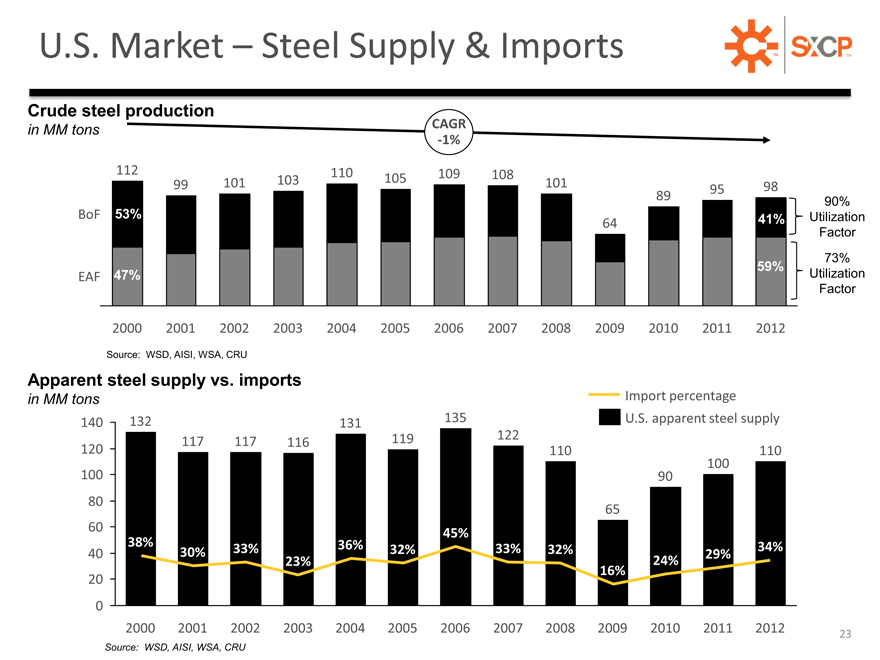

U.S. Market – Steel Supply & Imports TM

Crude steel production

in MM tons CAGR

-1%

112 110 105 109 108

99 101 103 101 95 98

89 90%

BoF 53% 41% Utilization

64

Factor

59% 73%

EAF 47% Utilization

Factor

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012

Source: WSD, AISI, WSA, CRU

Apparent steel supply vs. imports

in MM tons Import percentage

140 132 131 135 U.S. apparent steel supply

117 117 116 119 122

120 110 110

100

100 90

80 65

60 45%

40 38% 30% 33% 36% 32% 33% 32% 29% 34%

23% 24%

16%

20

0

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 23

Source: WSD, AISI, WSA, CRU

SXC AND SXCP FINANCIAL RESULTS

24

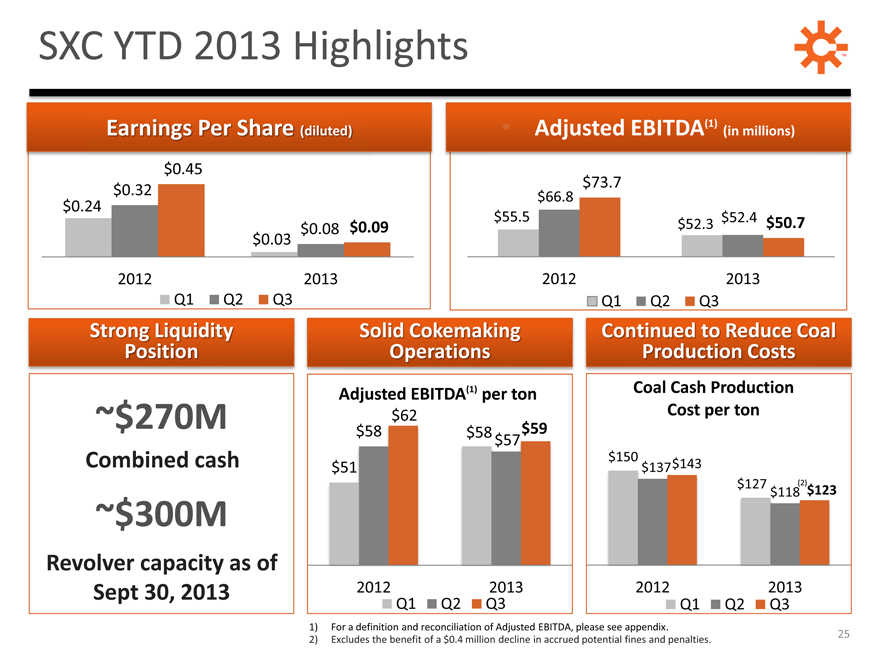

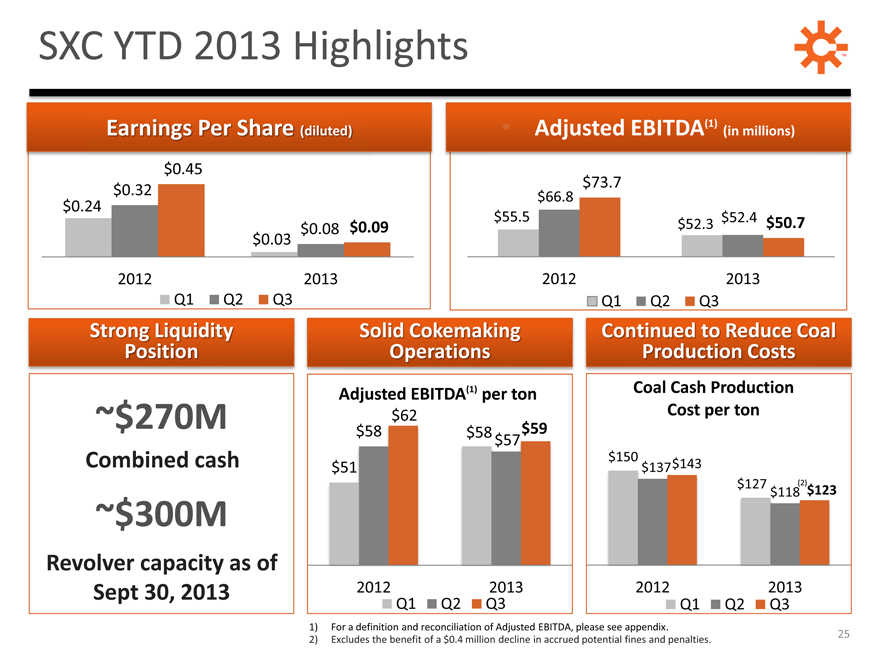

SXC YTD 2013 Highlights TM

Earnings Per Share (diluted) • Adjusted EBITDA(1) (in millions)

$0.45

$73.7

$0.32 $66.8

$0.24

$0.08 $0.09 $55.5 $52.3 $52.4 $50.7

$0.03

2012 2013 2012 2013

Q1 Q2 Q3 Q1 Q2 Q3

Strong Liquidity Solid Cokemaking Continued to Reduce Coal

Position Operations Production Costs

Adjusted EBITDA(1) per ton Coal Cash Production

~$270M $62 Cost per ton

$58 $58 $59

$57

Combined cash $51 $150 $137 $143

$127 $118(2) $123

~$300M

Revolver capacity as of

Sept 30, 2013 2012 2013 2012 2013

Q1 Q2 Q3 Q1 Q2 Q3

1) For a definition and reconciliation of Adjusted EBITDA, please see appendix.

2) Excludes the benefit of a $0.4 million decline in accrued potential fines and penalties. 25

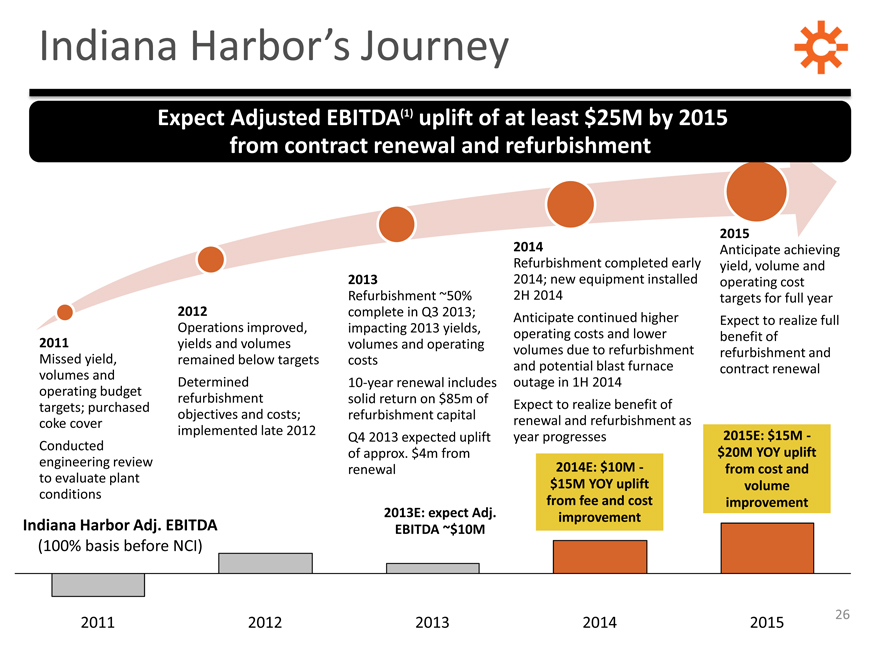

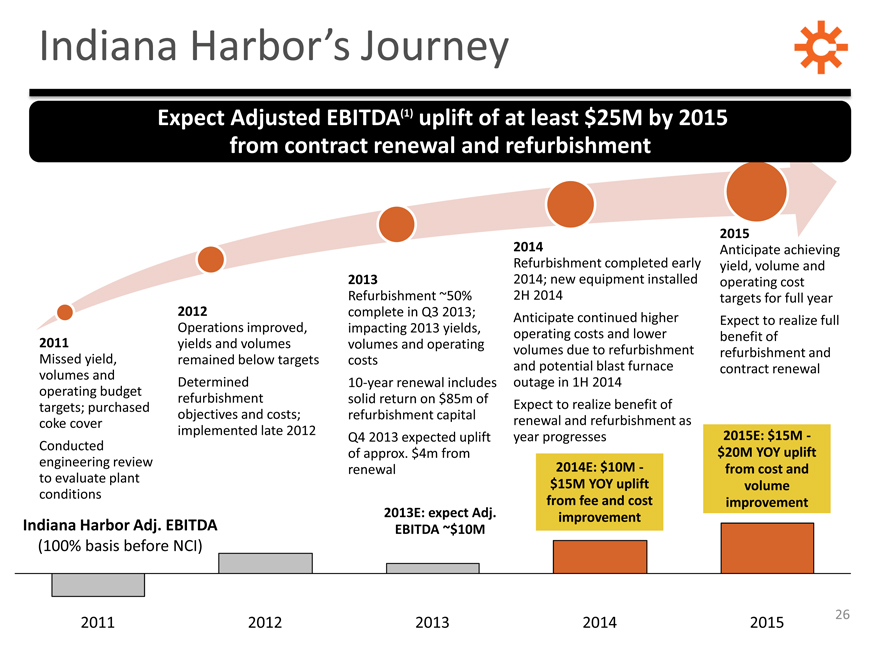

Indiana Harbor’s Journey

Expect Adjusted EBITDA(1) uplift of at least $25M by 2015

from contract renewal and refurbishment

2013

Refurbishment ~50%

2012 complete in Q3 2013;

Operations improved, impacting 2013 yields,

2011 yields and volumes volumes and operating

Missed yield, remained below targets costs

volumes and Determined 10-year renewal includes

operating budget refurbishment solid return on $85m of

targets; purchased objectives and costs; refurbishment capital

coke cover

implemented late 2012 Q4 2013 expected uplift

Conducted of approx. $4m from

engineering review renewal

to evaluate plant

conditions

2013E: expect Adj.

Indiana Harbor Adj. EBITDA EBITDA ~$10M

(100% basis before NCI)

2014

Refurbishment completed early 2014; new equipment installed

2H 2014

Anticipate continued higher operating costs and lower volumes due to refurbishment and potential blast furnace outage in 1H 2014 Expect to realize benefit of renewal and refurbishment as year progresses

2014E: $10M -$15M YOY uplift from fee and cost improvement

2015

Anticipate achieving yield, volume and operating cost targets for full year Expect to realize full benefit of refurbishment and contract renewal

2015E: $15M -$20M YOY uplift from cost and volume improvement

2011

2012

2013

2014

2015

26

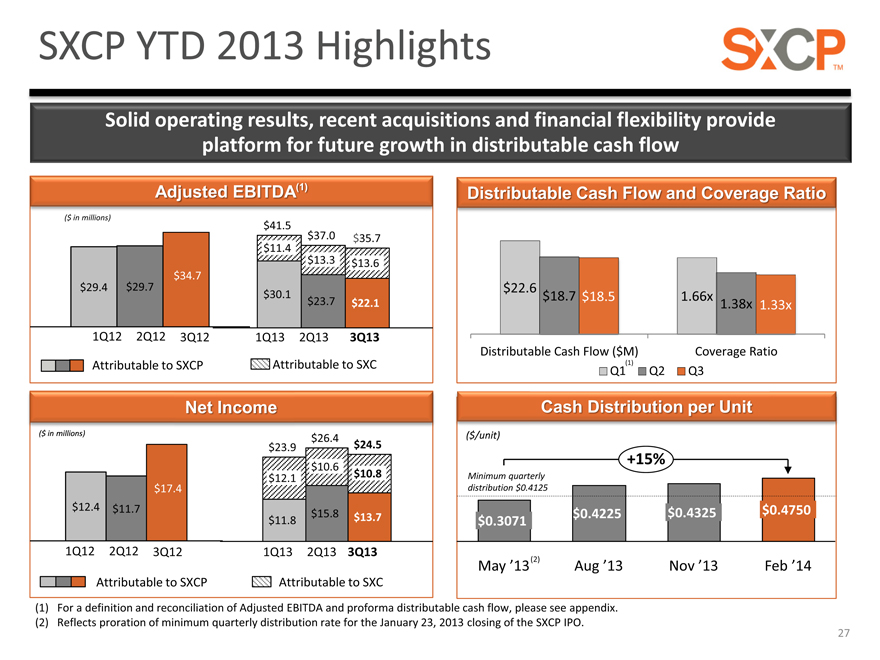

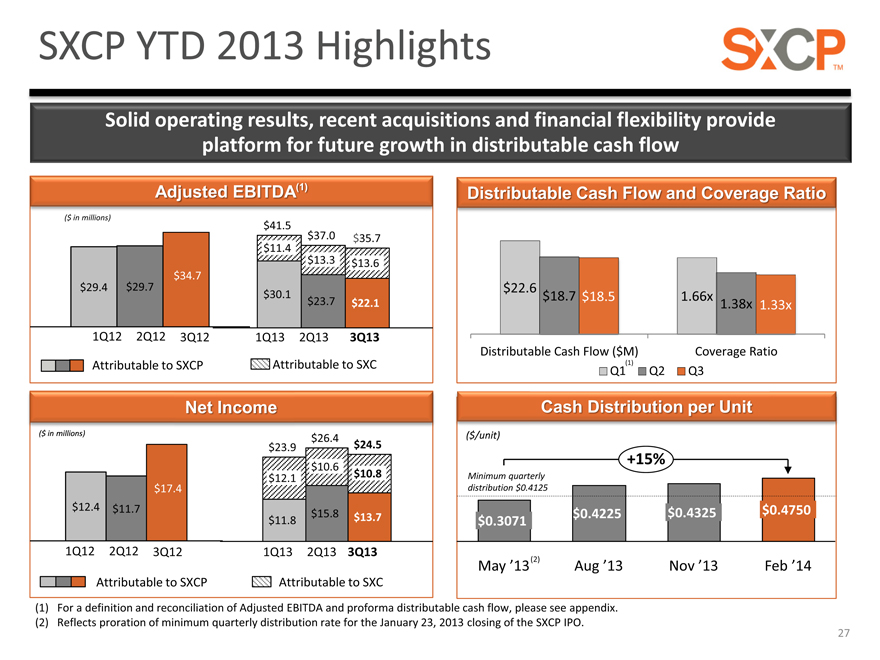

SXCP YTD 2013 Highlights

Solid operating results, recent acquisitions and financial flexibility provide

platform for future growth in distributable cash flow

Adjusted EBITDA(1)

($ in millions)

$41.5

$37.0 $35.7

$11.4

$13.3 $13.6

$34.7

$29.4 $29.7

$30.1

$23.7 $22.1

1Q12 2Q12 3Q12 1Q13 2Q13 3Q13

Attributable to SXCP Attributable to SXC

Net Income

($ in millions)

$26.4

$23.9 $24.5

$10.6

$12.1 $10.8

$17.4

$12.4 $11.7 $15.8

$11.8 $13.7

1Q12 2Q12 3Q12 1Q13 2Q13 3Q13

Attributable to SXCP Attributable to SXC

Distributable Cash Flow and Coverage Rati

$22.6

$18.7 $18.5 1.66x 1.38x 1.33x

Distributable Cash Flow ($M) Coverage Ratio

Q1(1) Q2 Q3

Cash Distribution per Unit

+15%

($/unit)

Minimum quarterly

distribution $0.4125

$0.3071 $0.4225 $0.4325 $0.4750

May ’13(2) Aug ’13 Nov ’13 Feb ’14

(1) For a definition and reconciliation of Adjusted EBITDA and proforma distributable cash flow, please see appendix.

(2) Reflects proration of minimum quarterly distribution rate for the January 23, 2013 closing of the SXCP IPO.

27

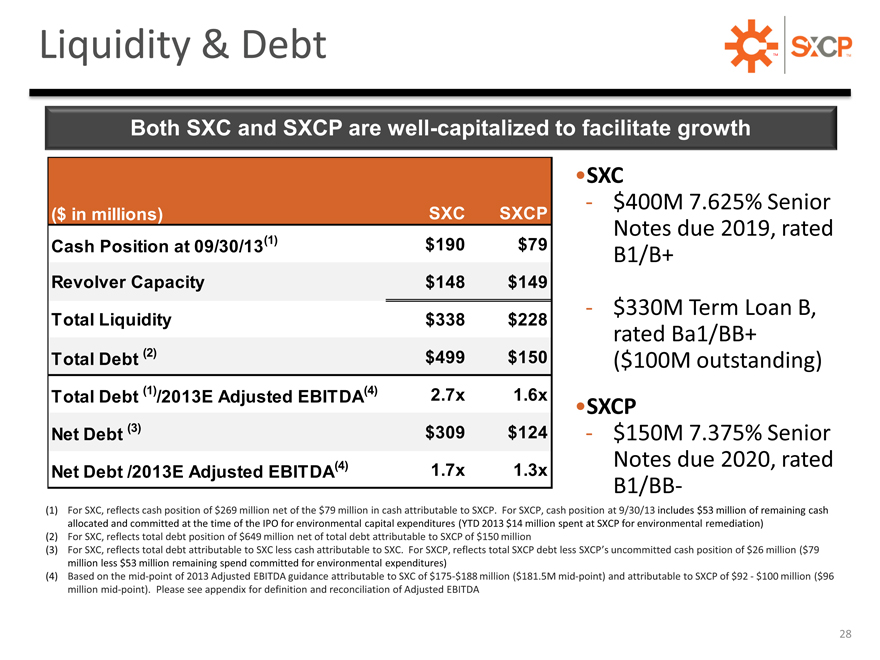

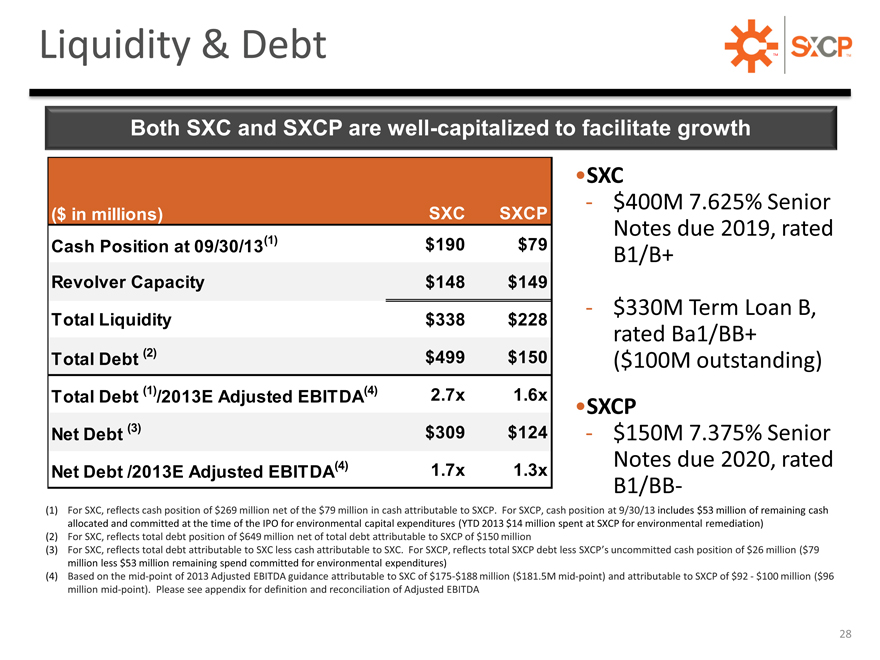

Liquidity & Debt TM

Both SXC and SXCP are well-capitalized to facilitate growth

($ in millions) SXC SXCP

Cash Position at 09/30/13(1) $190 $79

Revolver Capacity $148 $149

Total Liquidity $338 $228

Total Debt (2) $499 $150

Total Debt (1) /2013E Adjusted EBITDA(4) 2.7x 1.6x

Net Debt (3) $309 $124

Net Debt /2013E Adjusted EBITDA(4) 1.7x 1.3x

SXC

$400M 7.625% Senior Notes due 2019, rated B1/B+

$330M Term Loan B, rated Ba1/BB+ ($100M outstanding)

SXCP

$150M 7.375% Senior Notes due 2020, rated B1/BB-

For SXC, reflects cash position of $269 million net of the $79 million in cash attributable to SXCP. For SXCP, cash position at 9/30/13 includes $53 million of remaining cash allocated and committed at the time of the IPO for environmental capital expenditures (YTD 2013 $14 million spent at SXCP for environmental remediation)

For SXC, reflects total debt position of $649 million net of total debt attributable to SXCP of $150 million

For SXC, reflects total debt attributable to SXC less cash attributable to SXC. For SXCP, reflects total SXCP debt less SXCP’s uncommitted cash position of $26 million ($79 million less $53 million remaining spend committed for environmental expenditures)

Based on the mid-point of 2013 Adjusted EBITDA guidance attributable to SXC of $175-$188 million ($181.5M mid-point) and attributable to SXCP of $92—$100 million ($96 million mid-point). Please see appendix for definition and reconciliation of Adjusted EBITDA

28

DEFINITIONS AND RECONCILIATIONS

29

Definitions

Adjusted EBITDA represents earnings before interest, taxes, depreciation, depletion and amortization (“EBITDA”) adjusted for sales discounts and the interest, taxes, depreciation, depletion and amortization attributable to our equity method investment.

EBITDA reflects sales discounts included as a reduction in sales and other operating revenue. The sales discounts represent the sharing with customers of a portion of nonconventional fuel tax credits, which reduce our income tax expense. However, we believe our Adjusted EBITDA would be inappropriately penalized if these discounts were treated as a reduction of EBITDA since they represent sharing of a tax benefit that is not included in EBITDA. Accordingly, in computing Adjusted EBITDA, we have added back these sales discounts. Our Adjusted EBITDA also includes EBITDA attributable to our equity method investment. EBITDA and Adjusted EBITDA do not represent and should not be considered alternatives to net income or operating income under GAAP and may not be comparable to other similarly titled measures in other businesses. Management believes Adjusted EBITDA is an important measure of the operating performance of the Company’s net assets. We believe Adjusted EBITDA is an important measure of operating performance and provides useful information to investors because it highlights trends in our business that may not otherwise be apparent when relying solely on GAAP measures and because it eliminates items that have less bearing on our operating performance. Adjusted EBITDA is a measure of operating performance that is not defined by GAAP, does not represent and should not be considered a substitute for net income as determined in accordance with GAAP. Calculations of Adjusted EBITDA may not be comparable to those reported by other companies.

EBITDA represents earnings before interest, taxes, depreciation, depletion and amortization.

Adjusted EBITDA attributable to SXC/SXCP equals Adjusted EBITDA less Adjusted EBITDA attributable to noncontrolling interests.

Adjusted EBITDA/Ton represents Adjusted EBITDA divided by tons sold. When applicable to Adjusted EBITDA attributable to SXC or SXCP, tons sold are prorated according to the respective ownership interest of SXC or SXCP as applicable.

30

Definitions

Distributable Cash Flow equals Adjusted EBITDA less net cash paid for interest expense, on-going capital expenditures, accruals for replacement capital expenditures, and cash distributions to noncontrolling interests; plus amounts received under the Omnibus Agreement and acquisition expenses deemed to be Expansion Capital under our Partnership Agreement. Distributable Cash Flow is

a non-GAAP supplemental financial measure that management and external users of the Partnership’s financial statements, such as

industry analysts, investors, lenders and rating agencies use to assess:

the Partnership’s operating performance as compared to other publicly traded partnerships, without regard to historical cost basis; the ability of the Partnership’s assets to generate sufficient cash flow to make distributions to the Partnership’s unitholders; the Partnership’s ability to incur and service debt and fund capital expenditures; and the viability of acquisitions and other capital expenditure projects and the returns on investment of various investment opportunities.

The Partnership believes that Distributable Cash Flow provides useful information to investors in assessing the Partnership’s financial condition and results of operations. Distributable Cash Flow should not be considered an alternative to net income, operating income, cash flows from operating activities, or any other measure of financial performance or liquidity presented in accordance with generally accepted accounting principles (GAAP). Distributable Cash Flow has important limitations as an analytical tool because it excludes some, but not all, items that affect net income and net cash provided by operating activities and used in investing activities.

Additionally, because Distributable Cash Flow may be defined differently by other companies in the industry, the Partnership’s definition of Distributable Cash Flow may not be comparable to similarly titled measures of other companies, thereby diminishing their utility.

Ongoing capital expenditures (“capex”) are capital expenditures made to maintain the existing operating capacity of our assets and/or to extend their useful lives. Ongoing capex also include new equipment that improves the efficiency, reliability or effectiveness of existing assets. Ongoing capex does not include normal repairs and maintenance, which are expensed as incurred, or significant capital expenditures. For purposes of calculating distributable cash flow, the portion of ongoing capex attributable to SXCP is used.

Replacement capital expenditures (“capex”) represents an annual accrual necessary to fund SXCP’s share of the estimated costs to replace or rebuild our facilities at the end of their working lives. This accrual is estimated based on the average quarterly anticipated replacement capital that we expect to incur over the long term to replace our major capital assets at the end of their working lives. The replacement capex accrual estimate will be subject to review and prospective change by SXCP’s general partner at least annually and whenever an event occurs that causes a material adjustment of replacement capex, provided such change is approved by our conflicts committee.

31

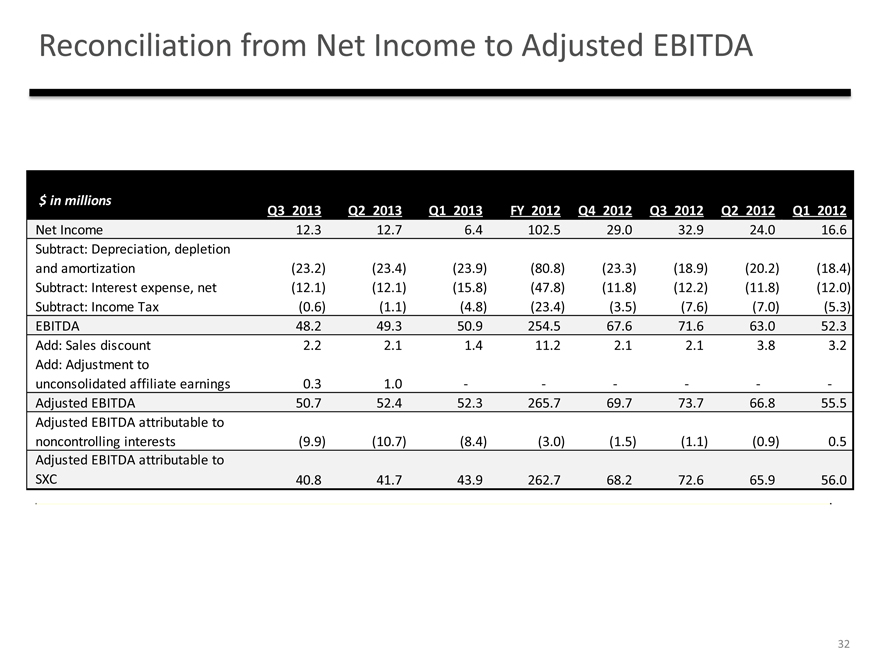

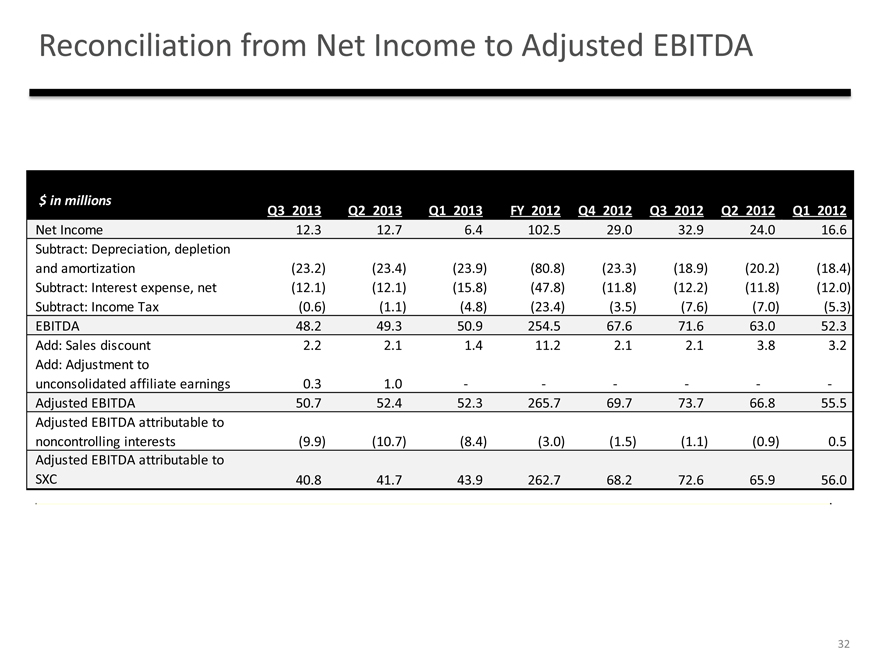

Reconciliation from Net Income to Adjusted EBITDA

$ in millions

Q3 2013 Q2 2013 Q1 2013 FY 2012 Q4 2012 Q3 2012 Q2 2012 Q1 2012

Net Income 12.3 12.7 6.4 102.5 29.0 32.9 24.0 16.6

Subtract: Depreciation, depletion

and amortization(23.2)(23.4)(23.9)(80.8)(23.3)(18.9)(20.2)(18.4)

Subtract: Interest expense, net(12.1)(12.1)(15.8)(47.8)(11.8)(12.2)(11.8)(12.0)

Subtract: Income Tax(0.6)(1.1)(4.8)(23.4)(3.5)(7.6)(7.0)(5.3)

EBITDA 48.2 49.3 50.9 254.5 67.6 71.6 63.0 52.3

Add: Sales discount 2.2 2.1 1.4 11.2 2.1 2.1 3.8 3.2

Add: Adjustment to

unconsolidated affiliate earnings 0.3 1.0 — — —

Adjusted EBITDA 50.7 52.4 52.3 265.7 69.7 73.7 66.8 55.5

Adjusted EBITDA attributable to

noncontrolling interests(9.9)(10.7)(8.4)(3.0)(1.5)(1.1)(0.9) 0.5

Adjusted EBITDA attributable to

SXC 40.8 41.7 43.9 262.7 68.2 72.6 65.9 56.0

32

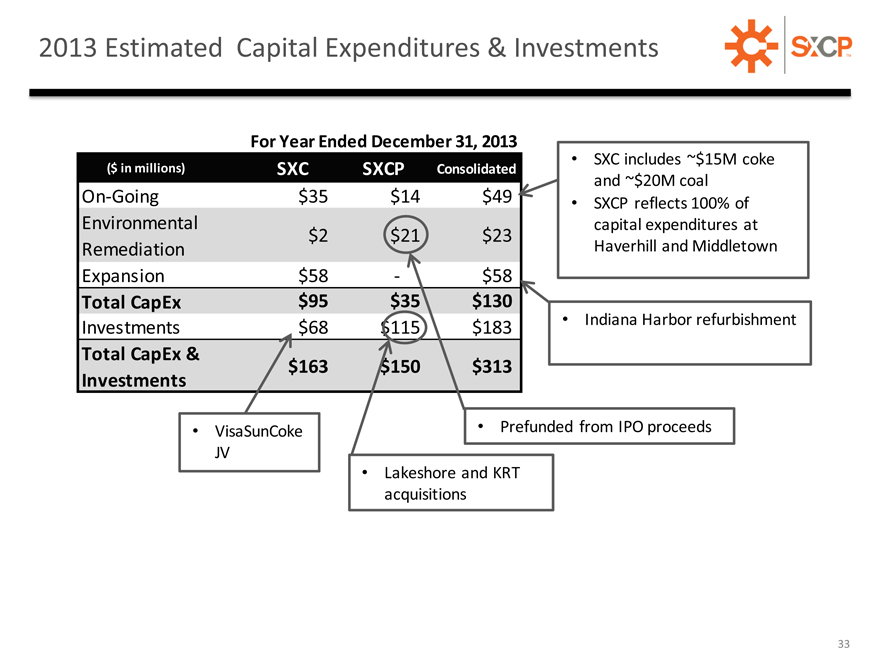

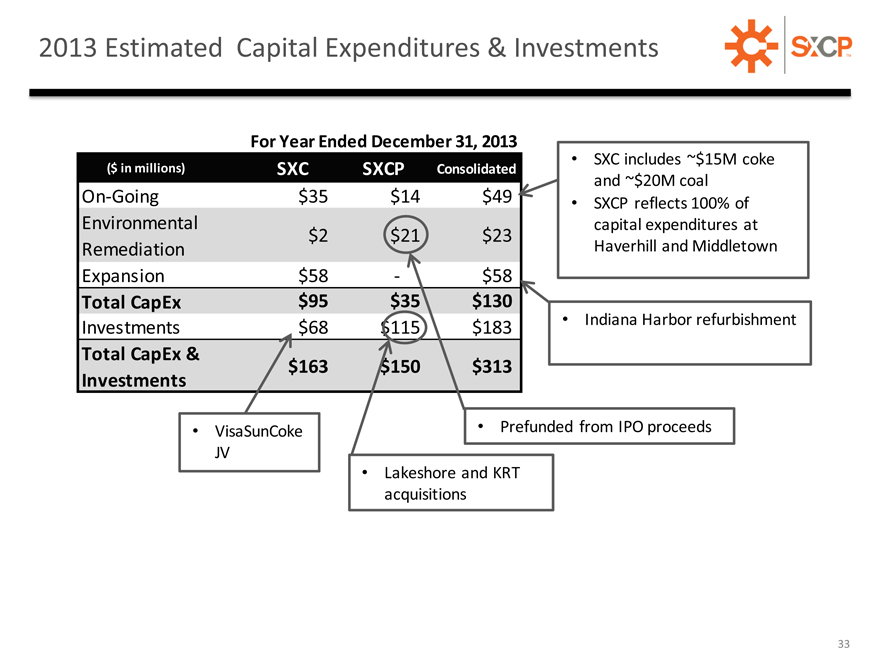

2013 Estimated Capital Expenditures & Investments

For Year Ended December 31, 2013

($ in millions)

SXC

SXCP

Consolidated

SXC includes ~$15M coke

and ~$20M coal

On-Going

$35

$14

$49

SXCP reflects 100% of

Environmental

capital expenditures at

$2

$21

$23

Remediation

Haverhill and Middletown

Expansion

$58

-

$58

Total CapEx

$95

$35

$130

Investments

$68

$115

$183

Indiana Harbor refurbishment

Total CapEx &

$163

$150

$313

Investments

VisaSunCoke

Prefunded from IPO proceeds

JV

Lakeshore and KRT acquisitions

33

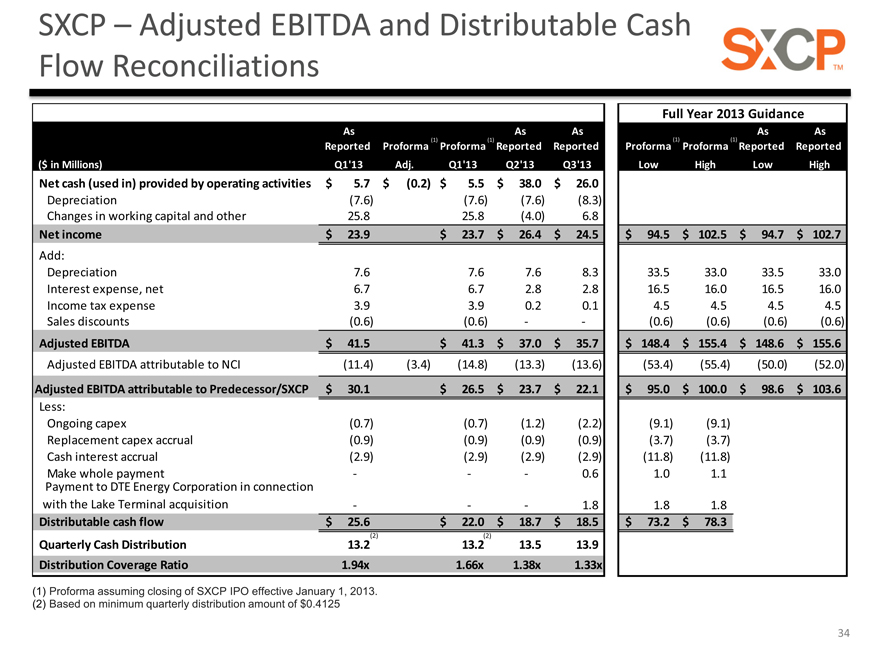

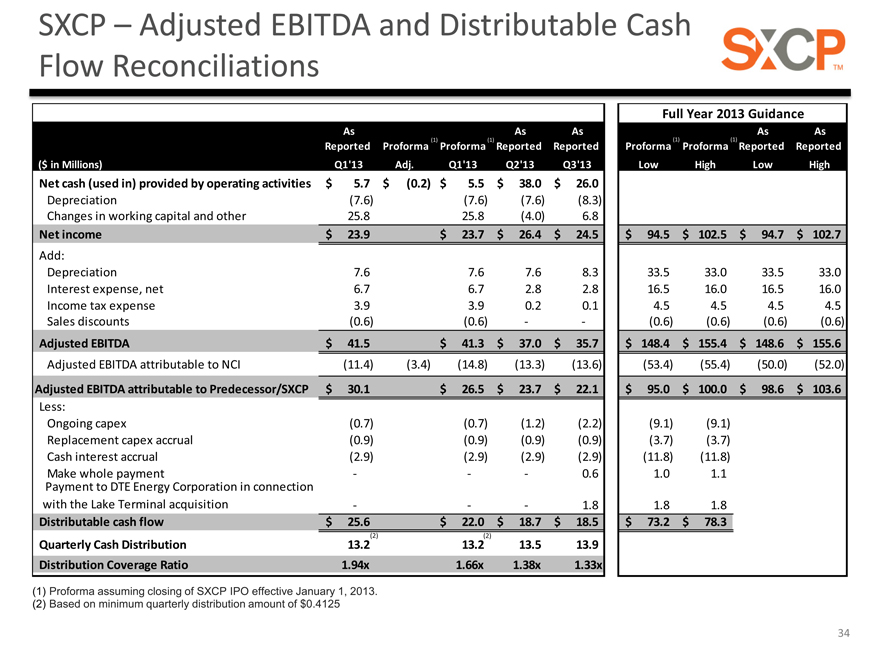

SXCP – Adjusted EBITDA and Distributable Cash

Flow Reconciliations

Full Year 2013 Guidance

As As As As As

Reported Proforma (1) Proforma (1) Reported Reported Proforma (1) Proforma (1) Reported Reported

($ in Millions) Q1’13 Adj. Q1’13 Q2’13 Q3’13 Low High Low High

Net cash (used in) provided by operating activities $ 5.7 $ (0.2) $ 5.5 $ 38.0 $ 26.0

Depreciation(7.6)(7.6)(7.6)(8.3)

Changes in working capital and other 25.8 25.8(4.0) 6.8

Net income $ 23.9 $ 23.7 $ 26.4 $ 24.5 $ 94.5 $ 102.5 $ 94.7 $ 102.7

Add:

Depreciation 7.6 7.6 7.6 8.3 33.5 33.0 33.5 33.0

Interest expense, net 6.7 6.7 2.8 2.8 16.5 16.0 16.5 16.0

Income tax expense 3.9 3.9 0.2 0.1 4.5 4.5 4.5 4.5

Sales discounts(0.6)(0.6) —(0.6)(0.6)(0.6)(0.6)

Adjusted EBITDA $ 41.5 $ 41.3 $ 37.0 $ 35.7 $ 148.4 $ 155.4 $ 148.6 $ 155.6

Adjusted EBITDA attributable to NCI(11.4)(3.4)(14.8)(13.3)(13.6)(53.4)(55.4)(50.0)(52.0)

Adjusted EBITDA attributable to Predecessor/SXCP $ 30.1 $ 26.5 $ 23.7 $ 22.1 $ 95.0 $ 100.0 $ 98.6 $ 103.6

Less:

Ongoing capex(0.7)(0.7)(1.2)(2.2)(9.1)(9.1)

Replacement capex accrual(0.9)(0.9)(0.9)(0.9)(3.7)(3.7)

Cash interest accrual(2.9)(2.9)(2.9)(2.9)(11.8)(11.8)

Make whole payment ——0.6 1.0 1.1

Payment to DTE Energy Corporation in connection

with the Lake Terminal acquisition ——1.8 1.8 1.8

Distributable cash flow $ 25.6 $ 22.0 $ 18.7 $ 18.5 $ 73.2 $ 78.3

(2)(2)

Quarterly Cash Distribution 13.2 13.2 13.5 13.9

Distribution Coverage Ratio 1.94x 1.66x 1.38x 1.33x

(1) Proforma assuming closing of SXCP IPO effective January 1, 2013.

(2) Based on minimum quarterly distribution amount of $0.4125

34

Investor Relations:

630-824-1987

www.suncoke.com