Investor Presentation November 2013

Forward Looking Statements The following presentation contains forward-looking statements based on management’s current expectations and beliefs, as well as a number of assumptions concerning future events. The assumptions and estimates underlying forward-looking statements are inherently uncertain and, although considered reasonable as of the date of preparation by the management team of our general partner, are subject to a wide variety of significant business, economic, and competitive risks and uncertainties that could cause actual results to differ materially from those contained in the prospective information. Accordingly, there can be no assurance that we will achieve the future results we expect or that actual results will not differ materially from expectations. You are cautioned not to put undue reliance on such forward-looking statements (including forecasts and projections regarding our future performance) because actual results may vary materially from those expressed or implied as a result of various factors, including, but not limited to those set forth under “Risk Factors” in CVR Refining, LP’s Annual Report on Form 10-K, Quarterly Reports on Form 10-Q and any other filings CVR Refining, LP makes with the Securities and Exchange Commission. CVR Refining, LP assumes no obligation to, and expressly disclaims any obligation to, update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law. 2

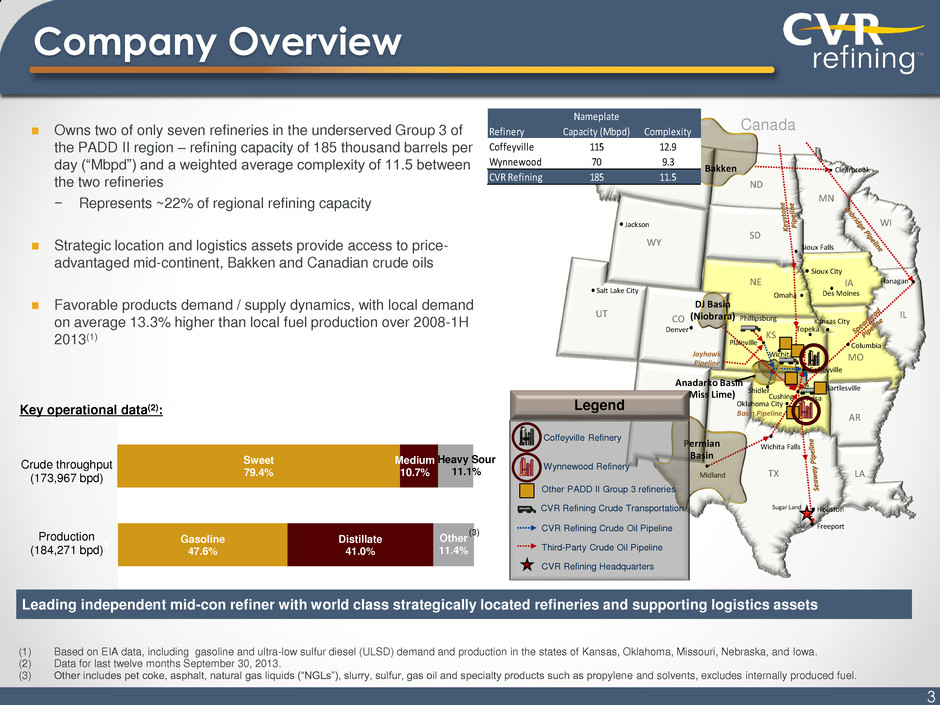

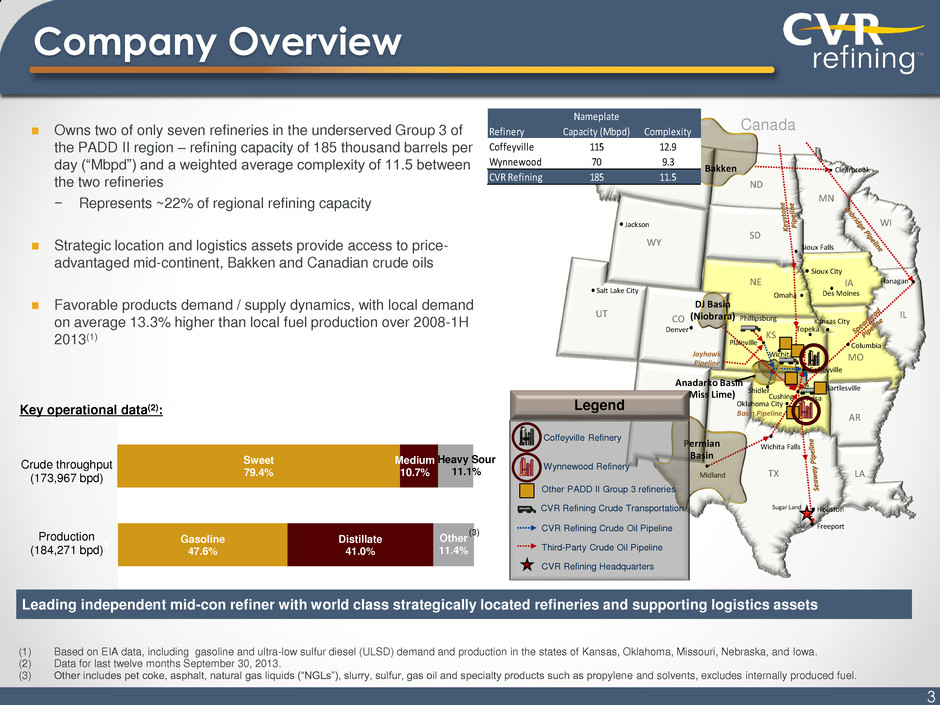

Gasoline 47.6% Distillate 41.0% Other 11.4% 1 Sweet 79.4% Medium 10.7% Heavy Sour 11.1% 1 Company Overview Owns two of only seven refineries in the underserved Group 3 of the PADD II region – refining capacity of 185 thousand barrels per day (“Mbpd”) and a weighted average complexity of 11.5 between the two refineries − Represents ~22% of regional refining capacity Strategic location and logistics assets provide access to price- advantaged mid-continent, Bakken and Canadian crude oils Favorable products demand / supply dynamics, with local demand on average 13.3% higher than local fuel production over 2008-1H 2013(1) Key operational data(2): Crude throughput (173,967 bpd) Production (184,271 bpd) Leading independent mid-con refiner with world class strategically located refineries and supporting logistics assets (1) Based on EIA data, including gasoline and ultra-low sulfur diesel (ULSD) demand and production in the states of Kansas, Oklahoma, Missouri, Nebraska, and Iowa. (2) Data for last twelve months September 30, 2013. (3) Other includes pet coke, asphalt, natural gas liquids (“NGLs”), slurry, sulfur, gas oil and specialty products such as propylene and solvents, excludes internally produced fuel. Canada TX AR OK MO IA NE SD ND WY MT UT MN IL Houston Shidler Kansas City Cushing Midland Des Moines Sioux Falls Sioux City Oklahoma City Tulsa Topeka Basin Pipeline Wichita Falls CO KS Plainville Phillipsburg Jayhawk Pipeline Denver Clearbrook Flanagan NM Bakken WI DJ Basin (Niobrara) Salt Lake City Jackson Anadarko Basin (Miss Lime) Columbia Freeport Sugar Land Wichita Coffeyville Permian Basin LA Omaha Bartlesville Wynnewood Refinery CVR Refining Crude Transportation CVR Refining Crude Oil Pipeline Third-Party Crude Oil Pipeline CVR Refining Headquarters Other PADD II Group 3 refineries Coffeyville Refinery Legend (3) 3 Nameplate Refinery Capacity (Mbpd) Complexity Coffeyville 115 12.9 Wynnewood 70 9.3 CVR Refining 185 11.5

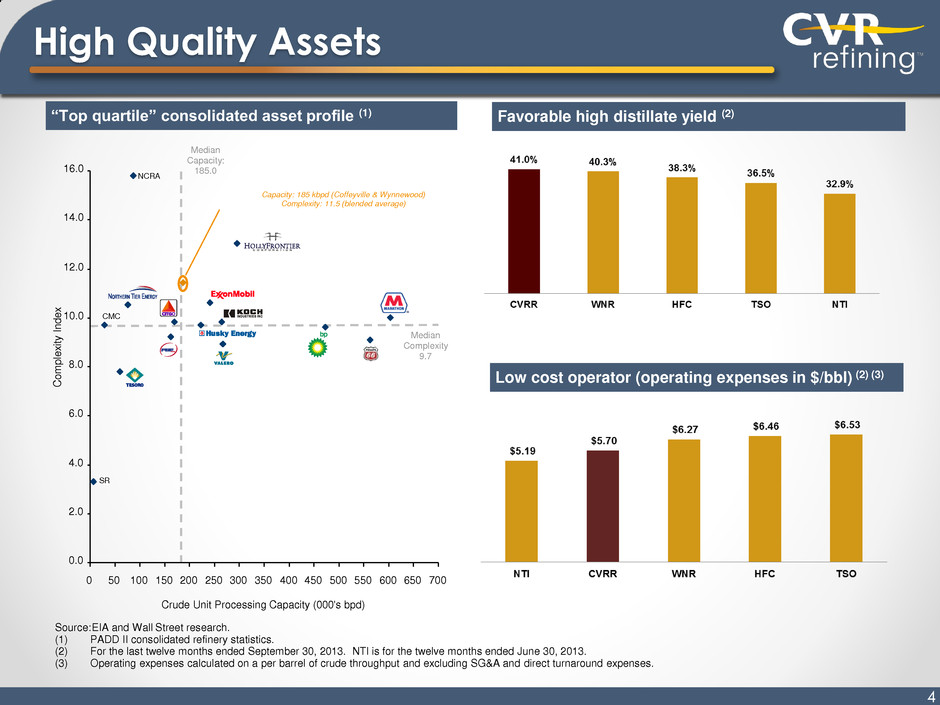

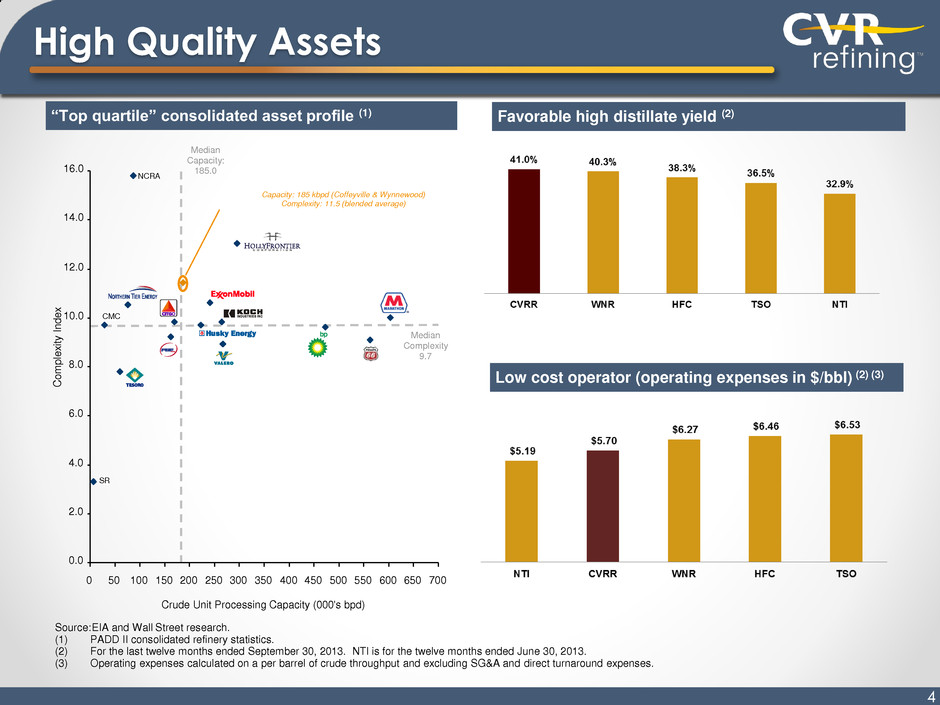

High Quality Assets “Top quartile” consolidated asset profile (1) Favorable high distillate yield (2) Median Capacity: 185.0 Median Complexity 9.7 NCRA CMC SR Capacity: 185 kbpd (Coffeyville & Wynnewood) Complexity: 11.5 (blended average) 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 Crude Unit Processing Capacity (000's bpd) C o m p le xi ty I n d e x Low cost operator (operating expenses in $/bbl) (2) (3) Source: EIA and Wall Street research. (1) PADD II consolidated refinery statistics. (2) For the last twelve months ended September 30, 2013. NTI is for the twelve months ended June 30, 2013. (3) Operating expenses calculated on a per barrel of crude throughput and excluding SG&A and direct turnaround expenses. 4

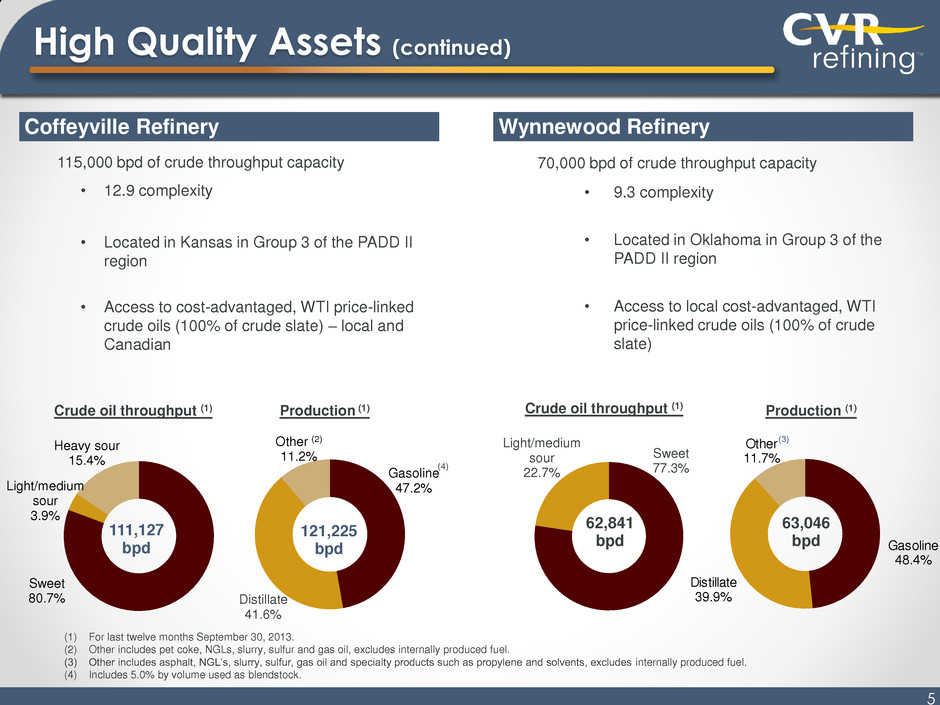

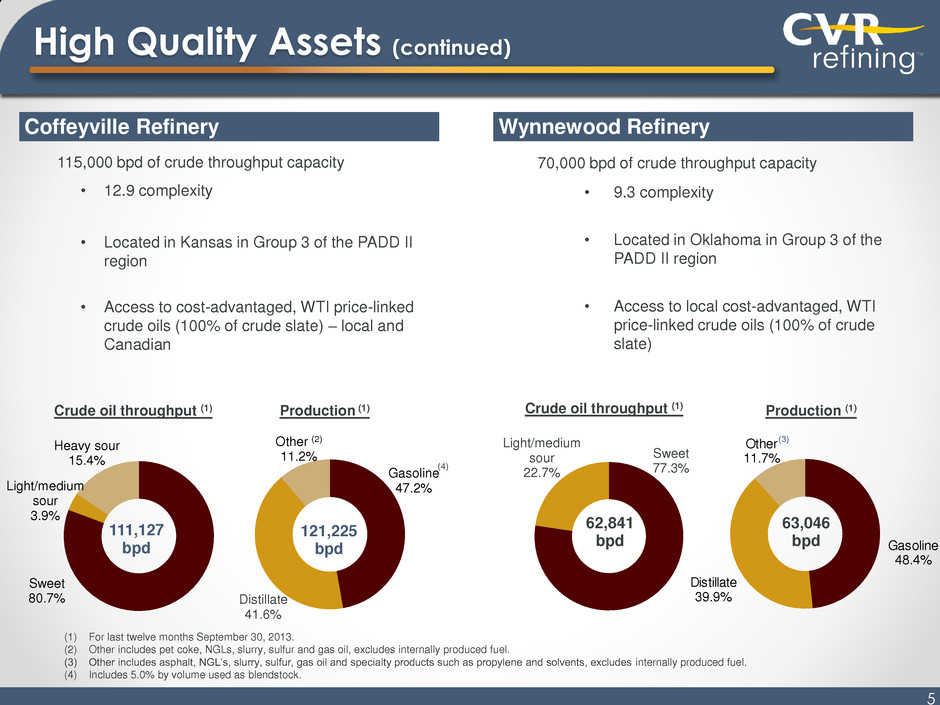

High Quality Assets (continued) 5 Gasoline 48.4% Distillate 39.9% Other 11.7% 115,000 bpd of crude throughput capacity • 12.9 complexity • Located in Kansas in Group 3 of the PADD II region • Access to cost-advantaged, WTI price-linked crude oils (100% of crude slate) – local and Canadian Coffeyville Refinery (1) For last twelve months September 30, 2013. (2) Other includes pet coke, NGLs, slurry, sulfur and gas oil, excludes internally produced fuel. (3) Other includes asphalt, NGL’s, slurry, sulfur, gas oil and specialty products such as propylene and solvents, excludes internally produced fuel. (4) Includes 5.0% by volume used as blendstock. 5 Crude oil throughput (1) Production (1) 111,127 bpd 121,225 bpd Heavy sour 15.4% Light/medium sour 3.9% Sweet 80.7% Other (2) 11.2% Distillate 41.6% Gasoline 47.2% (4) Wynnewood Refinery 70,000 bpd of crude throughput capacity • 9.3 complexity • Located in Oklahoma in Group 3 of the PADD II region • Access to local cost-advantaged, WTI price-linked crude oils (100% of crude slate) Light/medium sour 22.7% Production (1) 62,841 bpd 63,046 bpd Crude oil throughput (1) Sweet 77.3% (3)

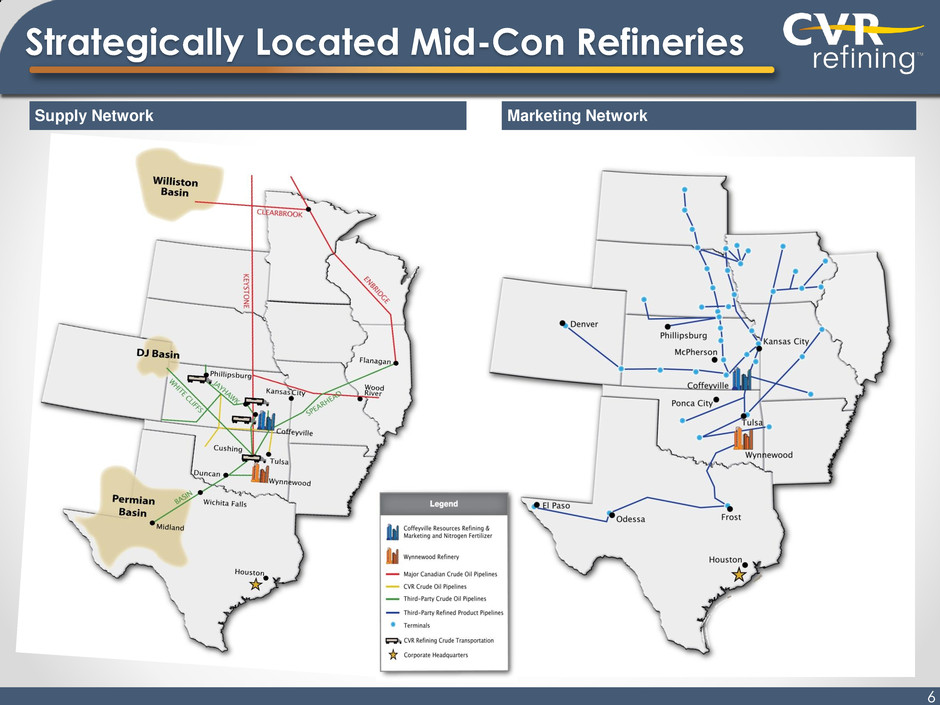

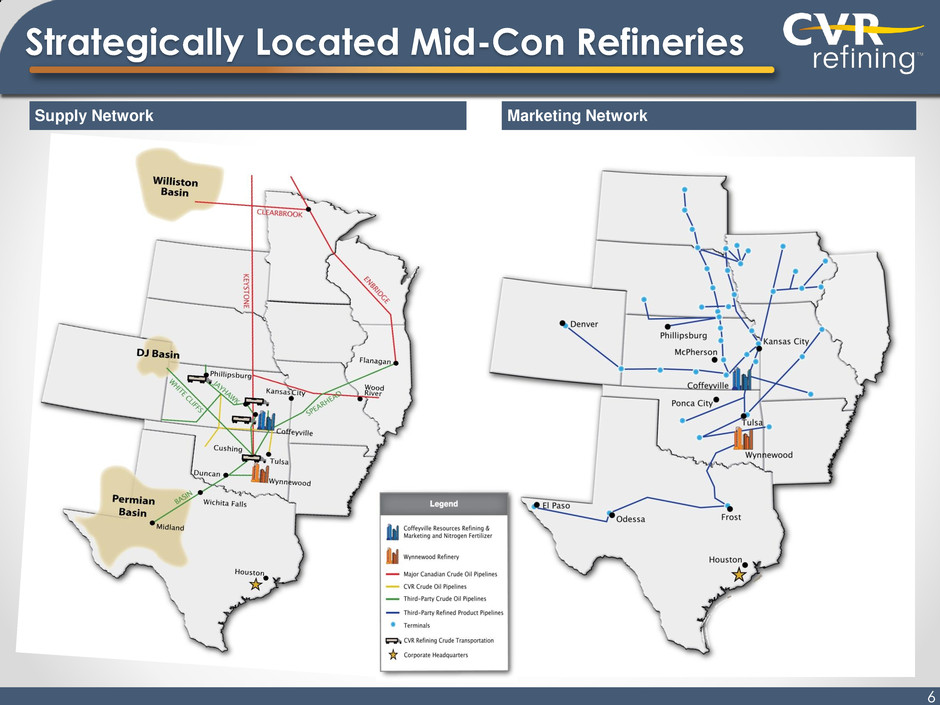

Strategically Located Mid-Con Refineries Supply Network Marketing Network 6

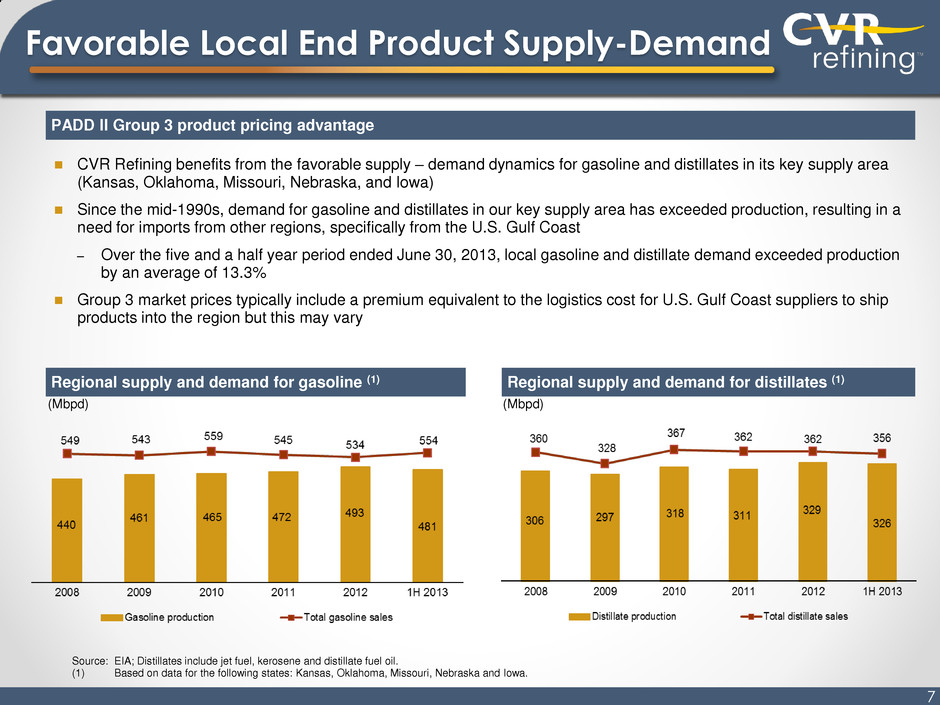

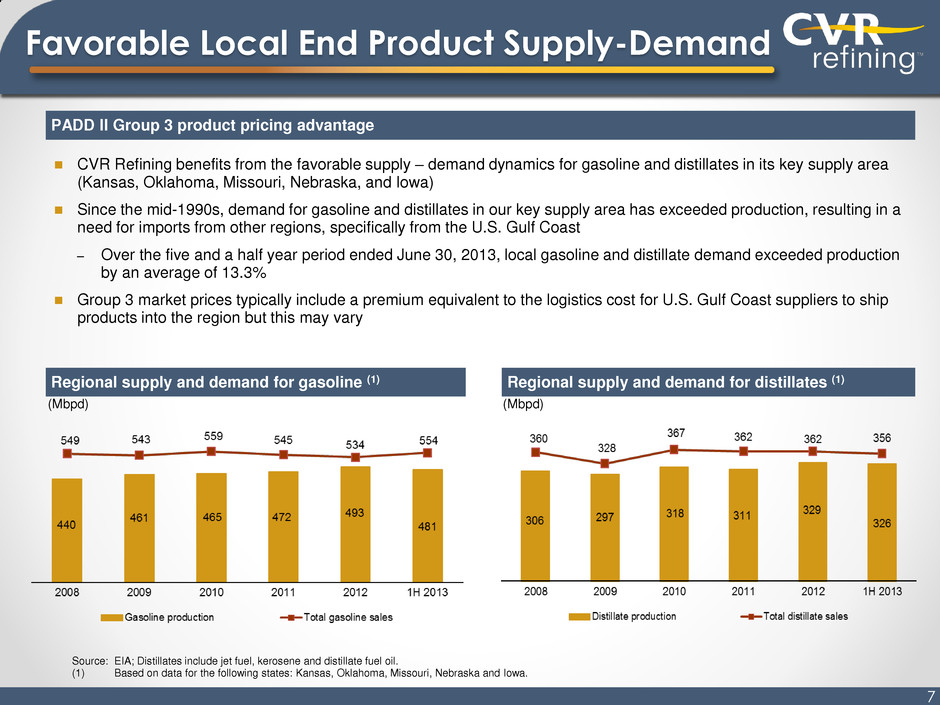

Favorable Local End Product Supply-Demand PADD II Group 3 product pricing advantage CVR Refining benefits from the favorable supply – demand dynamics for gasoline and distillates in its key supply area (Kansas, Oklahoma, Missouri, Nebraska, and Iowa) Since the mid-1990s, demand for gasoline and distillates in our key supply area has exceeded production, resulting in a need for imports from other regions, specifically from the U.S. Gulf Coast – Over the five and a half year period ended June 30, 2013, local gasoline and distillate demand exceeded production by an average of 13.3% Group 3 market prices typically include a premium equivalent to the logistics cost for U.S. Gulf Coast suppliers to ship products into the region but this may vary Regional supply and demand for gasoline (1) Regional supply and demand for distillates (1) (Mbpd) (Mbpd) Source: EIA; Distillates include jet fuel, kerosene and distillate fuel oil. (1) Based on data for the following states: Kansas, Oklahoma, Missouri, Nebraska and Iowa. 7

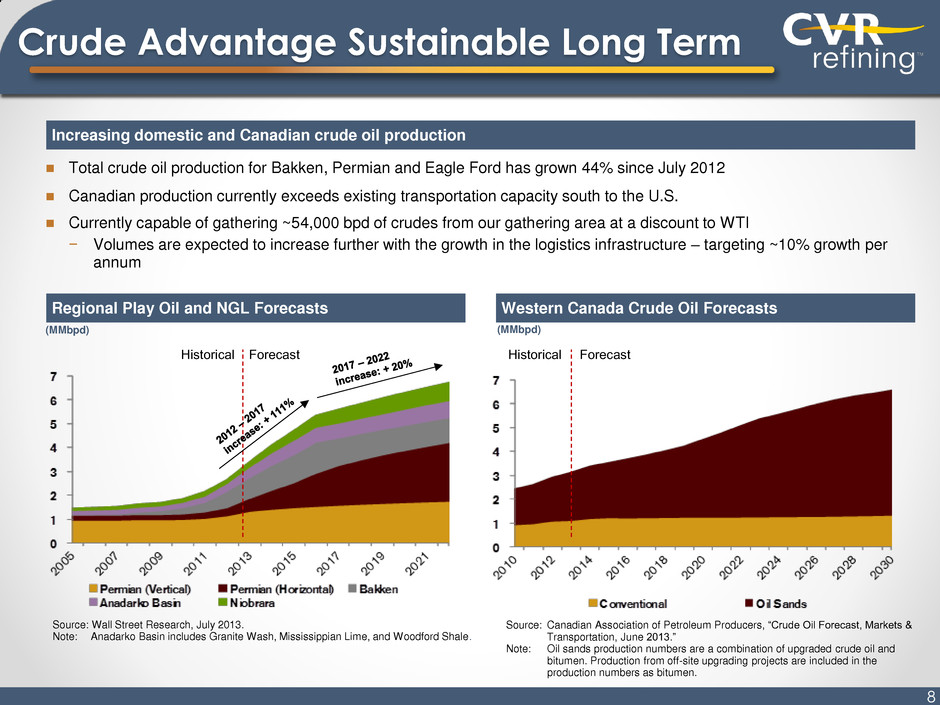

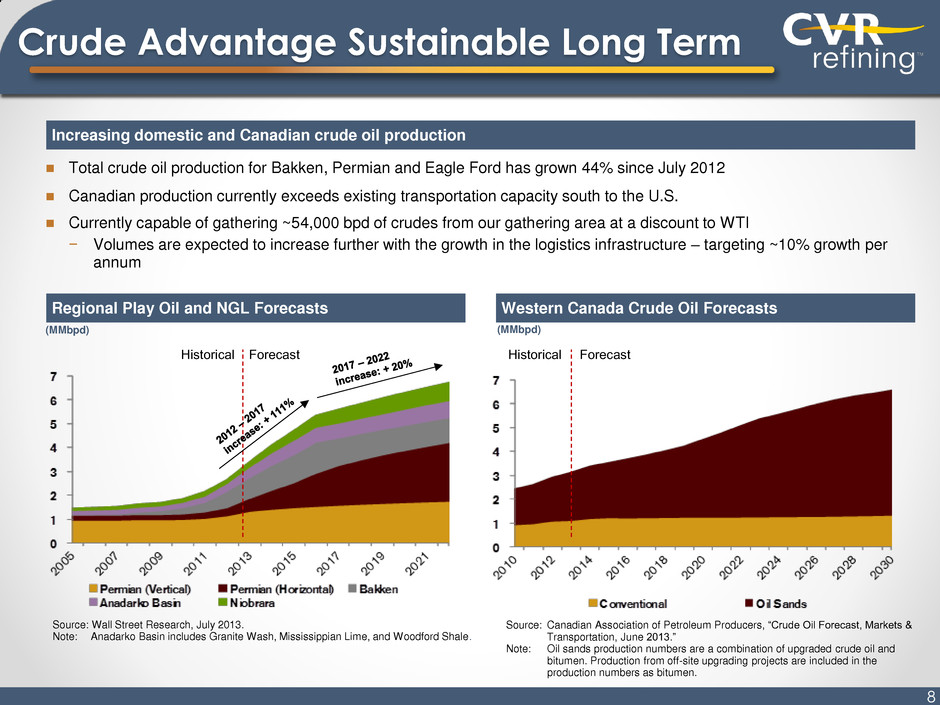

Crude Advantage Sustainable Long Term Increasing domestic and Canadian crude oil production Total crude oil production for Bakken, Permian and Eagle Ford has grown 44% since July 2012 Canadian production currently exceeds existing transportation capacity south to the U.S. Currently capable of gathering ~54,000 bpd of crudes from our gathering area at a discount to WTI − Volumes are expected to increase further with the growth in the logistics infrastructure – targeting ~10% growth per annum Regional Play Oil and NGL Forecasts Western Canada Crude Oil Forecasts Historical Forecast (MMbpd) (MMbpd) Historical Forecast Source: Wall Street Research, July 2013. Note: Anadarko Basin includes Granite Wash, Mississippian Lime, and Woodford Shale. Source: Canadian Association of Petroleum Producers, “Crude Oil Forecast, Markets & Transportation, June 2013.” Note: Oil sands production numbers are a combination of upgraded crude oil and bitumen. Production from off-site upgrading projects are included in the production numbers as bitumen. 8

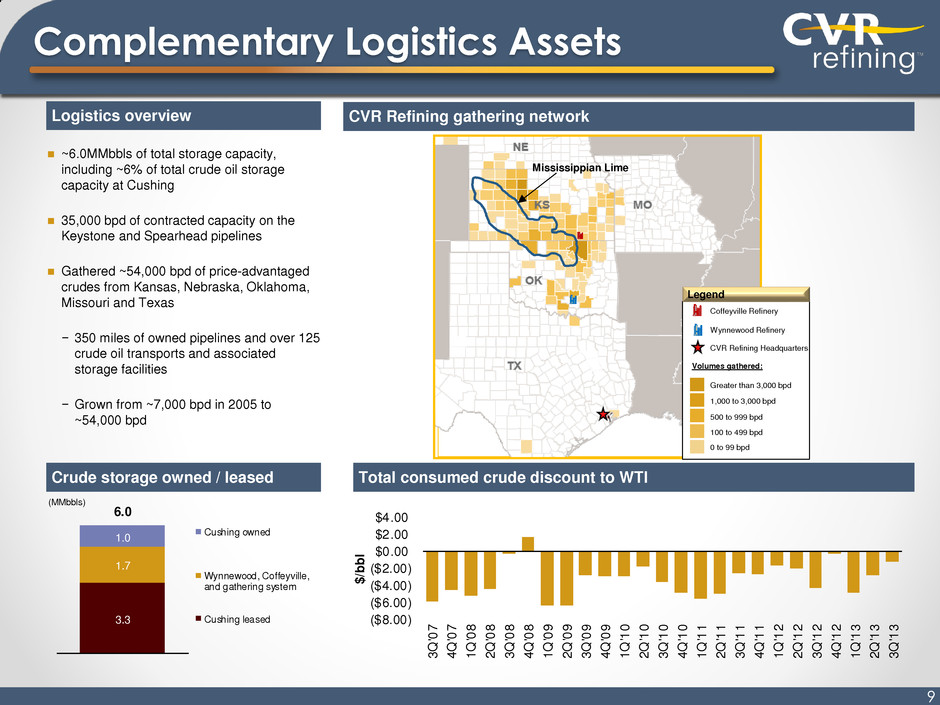

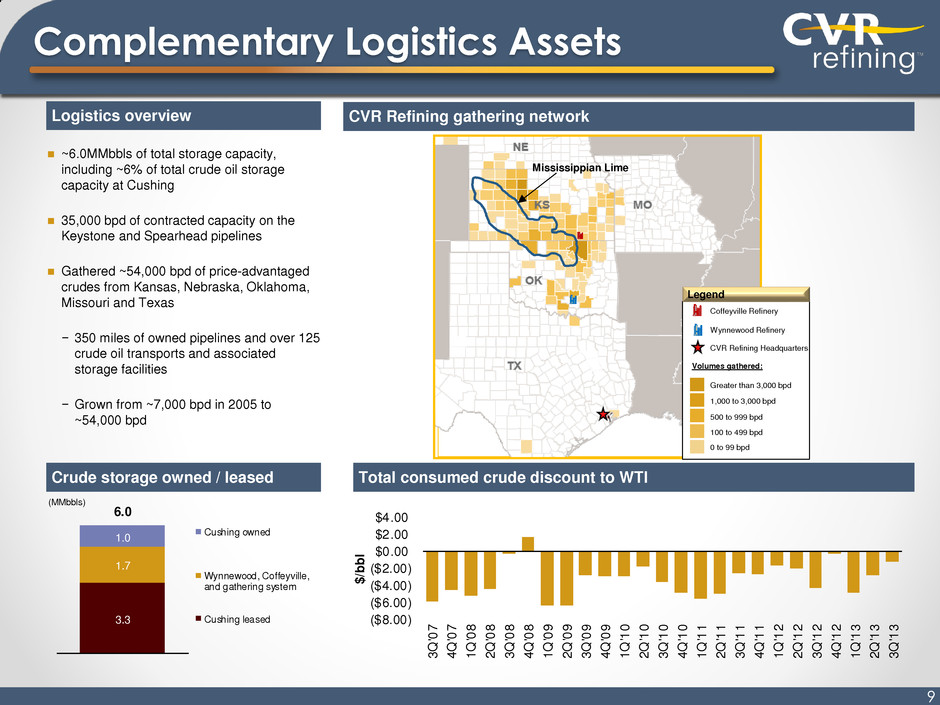

Complementary Logistics Assets Logistics overview CVR Refining gathering network ~6.0MMbbls of total storage capacity, including ~6% of total crude oil storage capacity at Cushing 35,000 bpd of contracted capacity on the Keystone and Spearhead pipelines Gathered ~54,000 bpd of price-advantaged crudes from Kansas, Nebraska, Oklahoma, Missouri and Texas − 350 miles of owned pipelines and over 125 crude oil transports and associated storage facilities − Grown from ~7,000 bpd in 2005 to ~54,000 bpd Mississippian Lime Greater than 3,000 bpd 1,000 to 3,000 bpd 500 to 999 bpd 100 to 499 bpd 0 to 99 bpd Coffeyville Refinery Wynnewood Refinery CVR Refining Headquarters Legend Volumes gathered: Crude storage owned / leased Total consumed crude discount to WTI (MMbbls) ($8.00) ($6.00) ($4.00) ($2.00) $0.00 $2.0 $4.0 3Q'0 7 4Q'0 7 1Q'0 8 2Q'0 8 3Q'0 8 4Q'0 8 1Q'0 9 2Q'0 9 3Q'0 9 4Q'0 9 1Q'1 0 2Q'1 0 3Q'1 0 4Q'1 0 1Q'1 1 2Q'1 1 3Q'1 1 4Q'1 1 1Q'1 2 2Q'1 2 3Q'1 2 4Q'1 2 1Q'1 3 2Q'1 3 3Q'1 3 $/bb l 1.7 3.3 1.0 Cushing owned Wynnewood, Coffeyville, and gathering system Cushing leased 6.0 9

Financial Overview

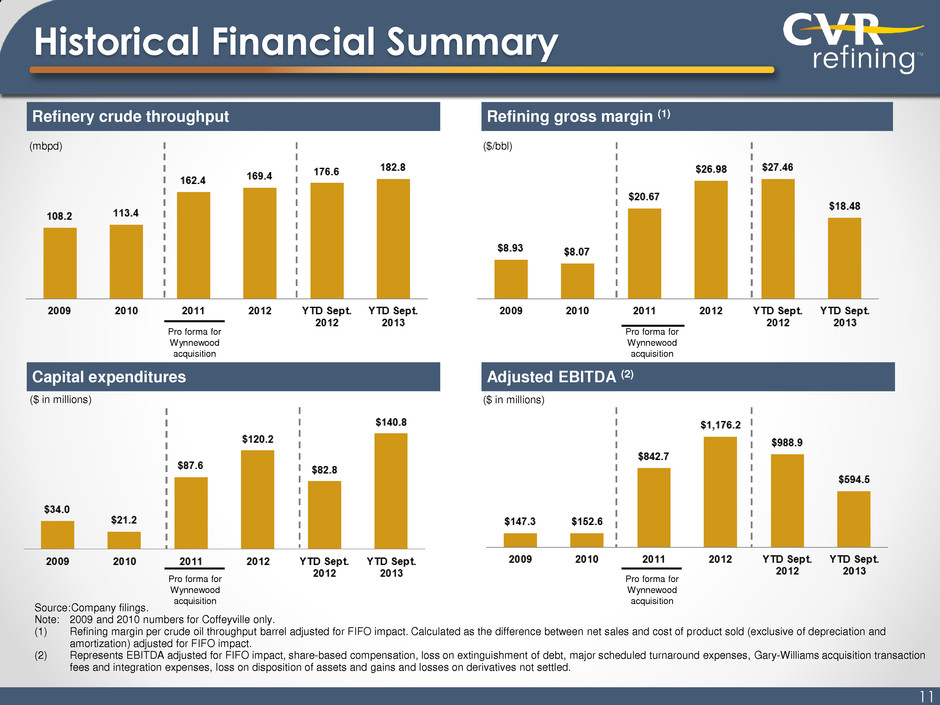

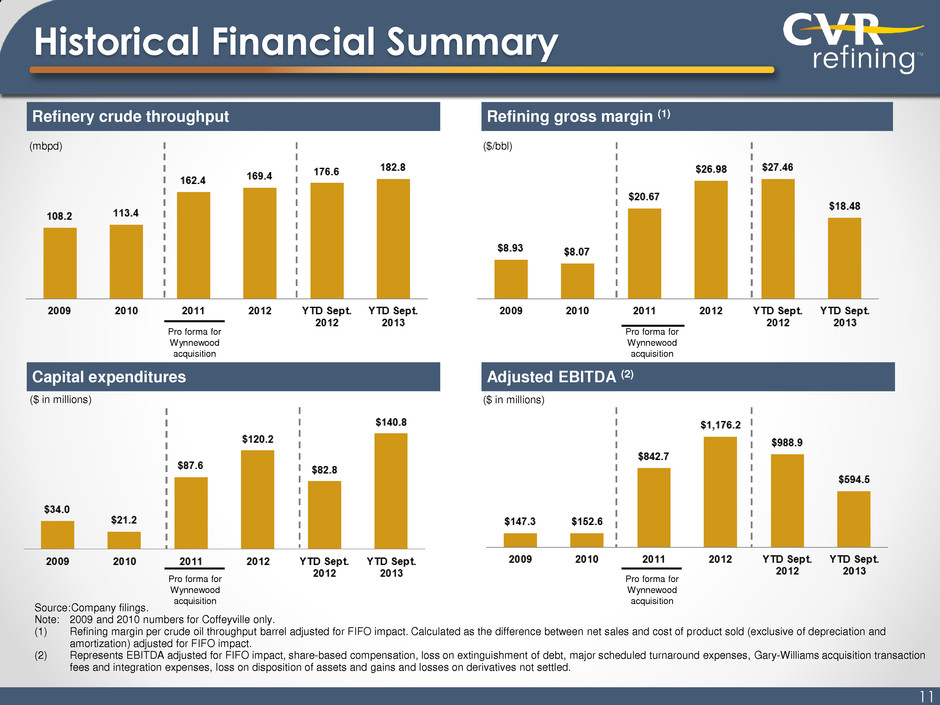

Historical Financial Summary Refinery crude throughput Refining gross margin (1) Pro forma for Wynnewood acquisition Pro forma for Wynnewood acquisition Capital expenditures Adjusted EBITDA (2) Pro forma for Wynnewood acquisition Pro forma for Wynnewood acquisition Source: Company filings. Note: 2009 and 2010 numbers for Coffeyville only. (1) Refining margin per crude oil throughput barrel adjusted for FIFO impact. Calculated as the difference between net sales and cost of product sold (exclusive of depreciation and amortization) adjusted for FIFO impact. (2) Represents EBITDA adjusted for FIFO impact, share-based compensation, loss on extinguishment of debt, major scheduled turnaround expenses, Gary-Williams acquisition transaction fees and integration expenses, loss on disposition of assets and gains and losses on derivatives not settled. (mbpd) ($/bbl) ($ in millions) ($ in millions) 11

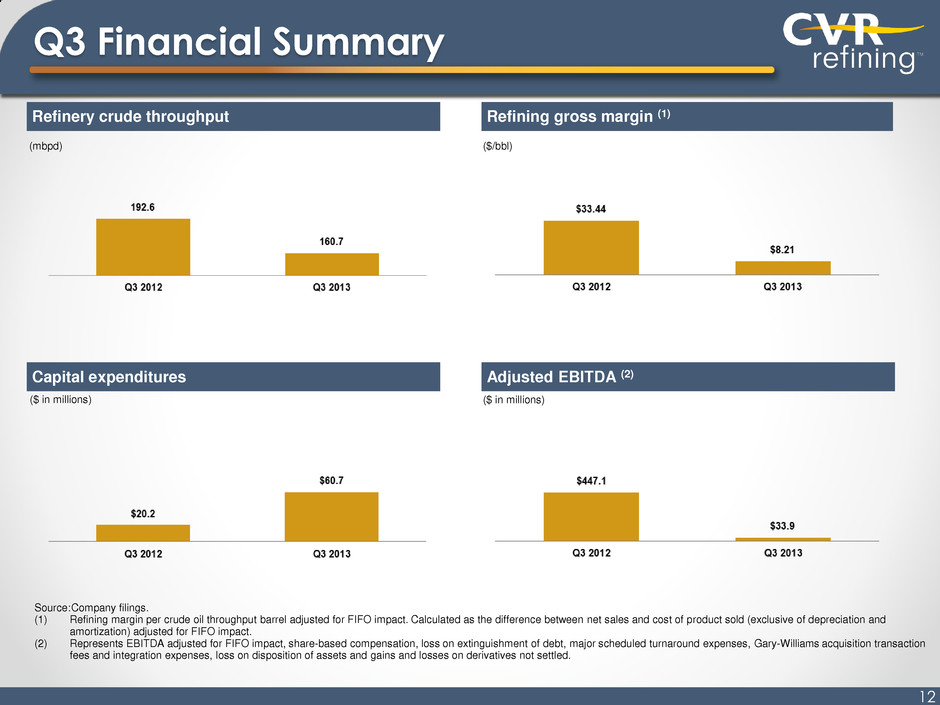

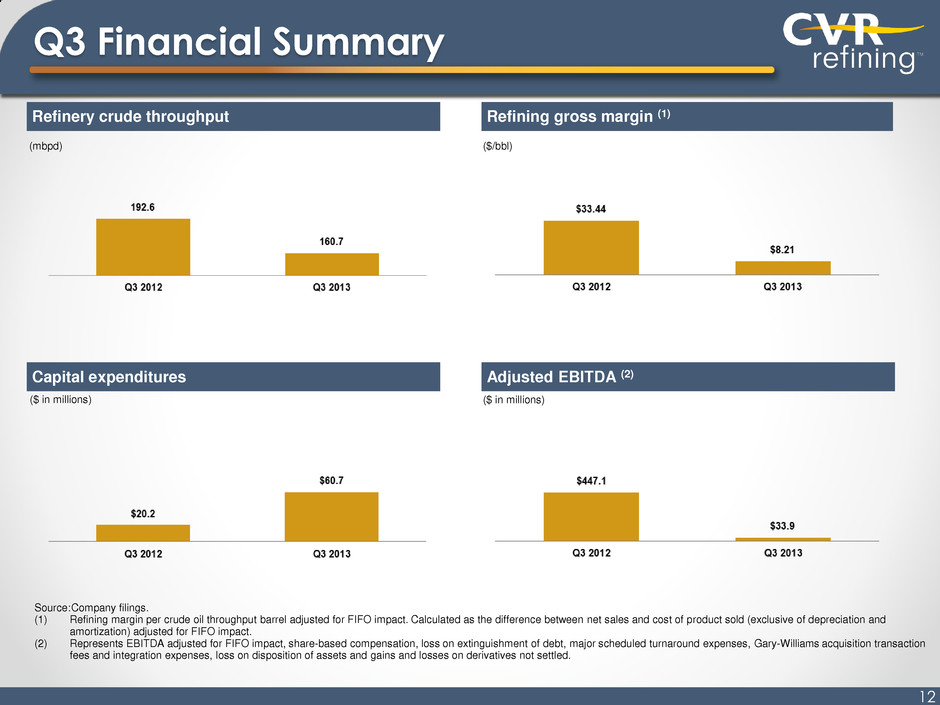

Q3 Financial Summary Refinery crude throughput Refining gross margin (1) Capital expenditures Adjusted EBITDA (2) Source: Company filings. (1) Refining margin per crude oil throughput barrel adjusted for FIFO impact. Calculated as the difference between net sales and cost of product sold (exclusive of depreciation and amortization) adjusted for FIFO impact. (2) Represents EBITDA adjusted for FIFO impact, share-based compensation, loss on extinguishment of debt, major scheduled turnaround expenses, Gary-Williams acquisition transaction fees and integration expenses, loss on disposition of assets and gains and losses on derivatives not settled. (mbpd) ($/bbl) ($ in millions) ($ in millions) 12

Hedging Policy Locks in Attractive Spreads Hedged an average of ~67,000 bpd of production for 2013 and ~47,000 bpd in 2014 − Crack spreads hedged at an average $26.77/bbl for 2013 and $27.93/bbl for 2014 Hedging provides protection in a downside scenario − Ability to cover costs in a severe downside scenario Hedging Summary(1) (1) Hedged crack spreads represent weighted-average price of all positions for respective quarters. Data as of October 28, 2013. 13 6.6 7.7 5.4 4.7 4.1 4.7 4.7 3.8 $15.00 $17.00 $19.00 $21.00 $23.00 $25.00 $27.00 $29.00 $31.00 0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 Q1 '13 Q2 '13 Q3 '13 Q4 '13 Q1 '14 Q2 '14 Q3 '14 Q4 '14 Hedged bbls (millions) Hedged crack spread ($/bbl)

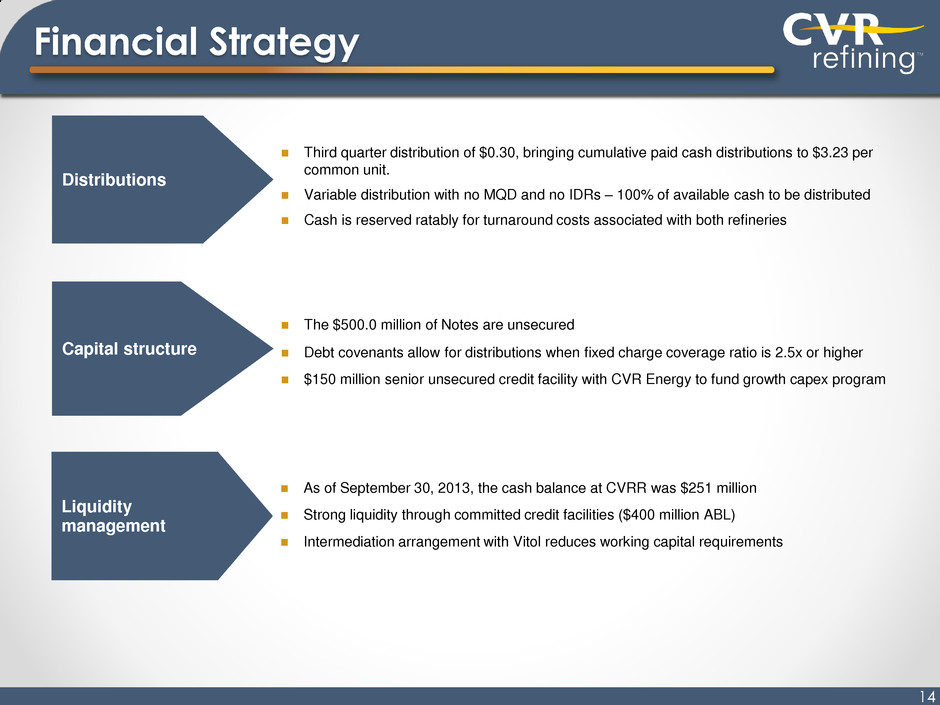

Financial Strategy Distributions Third quarter distribution of $0.30, bringing cumulative paid cash distributions to $3.23 per common unit. Variable distribution with no MQD and no IDRs – 100% of available cash to be distributed Cash is reserved ratably for turnaround costs associated with both refineries Capital structure The $500.0 million of Notes are unsecured Debt covenants allow for distributions when fixed charge coverage ratio is 2.5x or higher $150 million senior unsecured credit facility with CVR Energy to fund growth capex program Liquidity management As of September 30, 2013, the cash balance at CVRR was $251 million Strong liquidity through committed credit facilities ($400 million ABL) Intermediation arrangement with Vitol reduces working capital requirements 14

Appendix

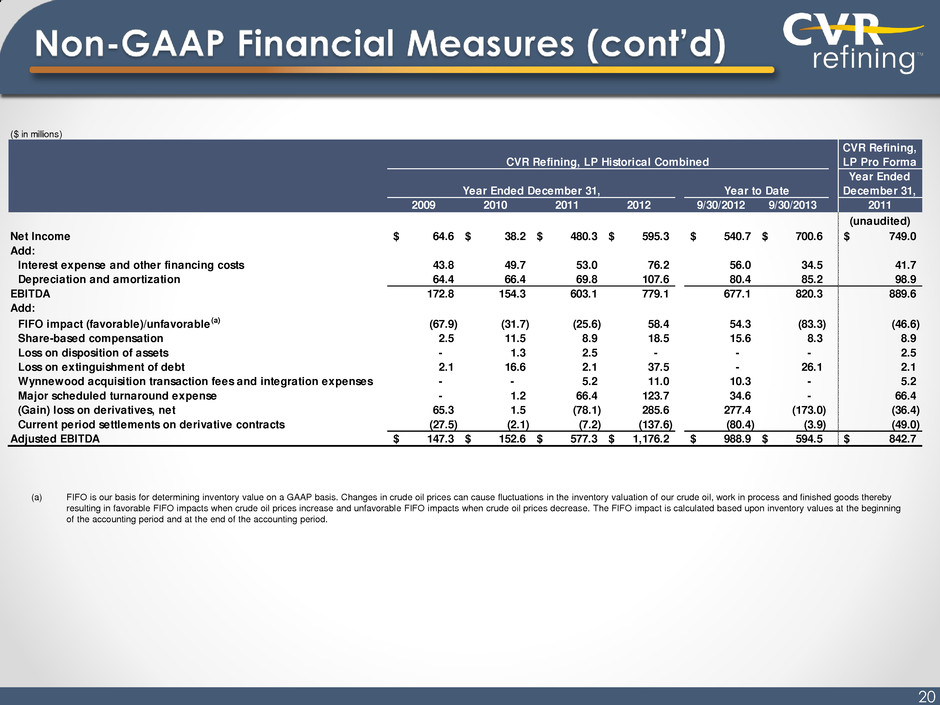

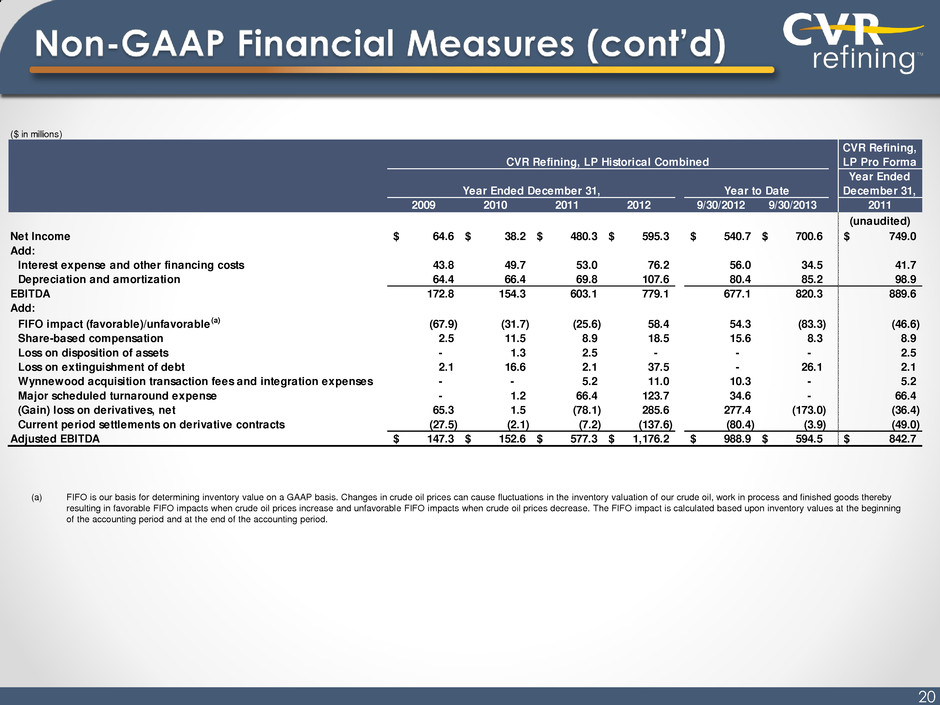

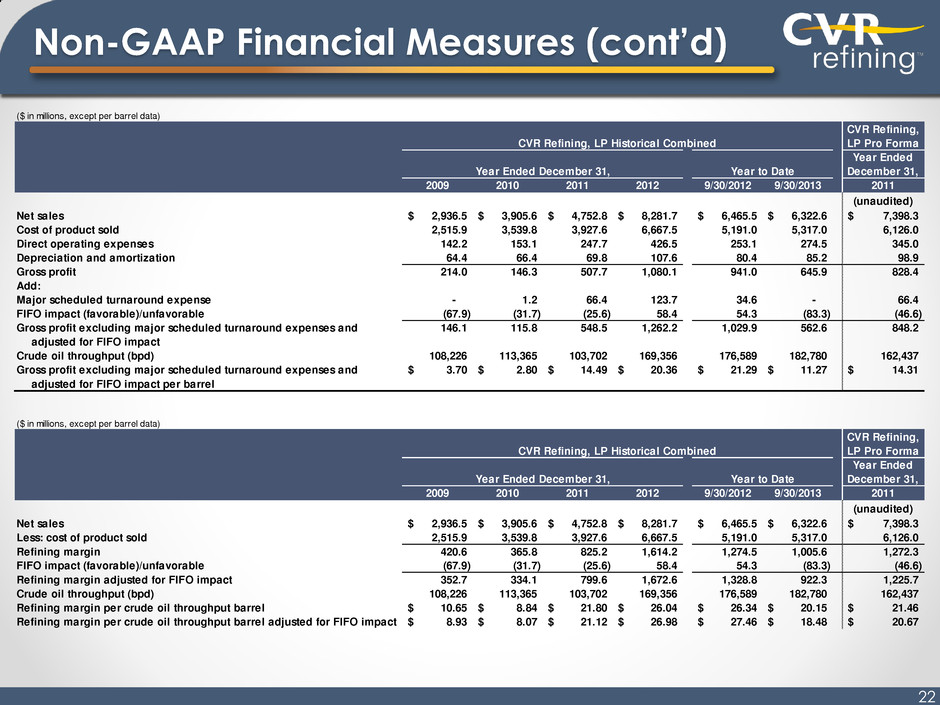

Non-GAAP Financial Measures EBITDA represents net income before income tax expense, interest expense and other financing costs, net of interest income and depreciation and amortization. 16 Adjusted EBITDA represents EBITDA adjusted for FIFO impacts (favorable) unfavorable, non-cash share-based compensation, major scheduled turnaround expenses, loss on disposition of fixed assets, (gain) loss on derivatives net of current period settlements on derivative contracts, loss on extinguishment of debt and expenses associated with the Gary-Williams acquisition. EBITDA and Adjusted EBITDA are not recognized terms under GAAP and should not be substituted for net income or cash flow from operations. Management believes that EBITDA and Adjusted EBITDA enables investors to better understand our ability to make distributions to our common unit holders, evaluate our ongoing operating results and allows for greater transparency in the reviewing of our overall financial, operational and economic performance. EBITDA and Adjusted EBITDA presented by other companies may not be comparable to our presentation, since each company may define these terms differently.

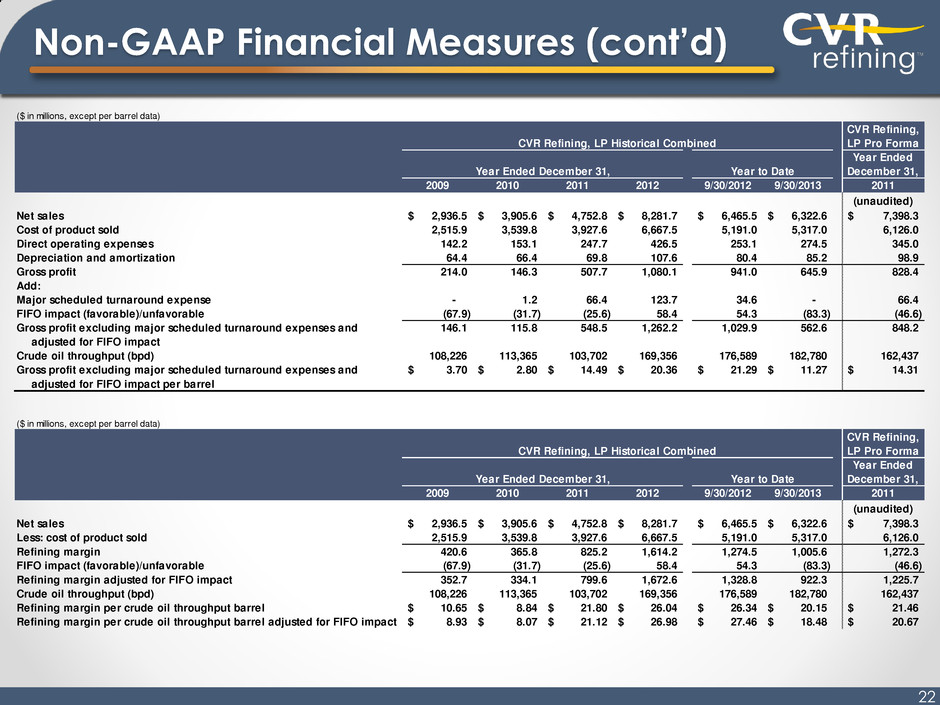

Non-GAAP Financial Measures (cont’d) Direct Operating Expenses (Excluding Major Scheduled Turnaround Expenses) Per Crude Oil Throughput Barrel is a measurement calculated by excluding major scheduled turnaround expenses from direct operating expenses (exclusive of depreciation and amortization) divided by our refineries’ crude oil throughput volumes for the respective periods presented. Direct operating expenses excluding major scheduled turnaround expenses per crude oil throughput barrel is a supplemental measure of our performance that is not required by, nor presented in accordance with, GAAP. Management believes direct operating expenses excluding major scheduled turnaround expenses per crude oil throughput most directly represents ongoing direct operating expenses at our refineries. 17 Gross Profit (Excluding Major Scheduled Turnaround Expenses and Adjusted for FIFO Impact) Per Crude Oil Throughput Barrel is calculated as the difference between net sales, cost of product sold (exclusive of depreciation and amortization) adjusted for FIFO impact, direct operating expenses (exclusive of depreciation and amortization) excluding scheduled turnaround expenses divided by our refineries’ crude oil throughput volumes for the respective periods presented. Gross profit excluding major scheduled turnaround expenses and adjusted for FIFO impact is a non-GAAP measure that should not be substituted for operating income. Management believes it is important to investors in evaluating our refineries’ performance and our ongoing operating results. Our calculation of gross profit excluding major scheduled turnaround expenses and adjusted for FIFO impact per crude oil throughput may differ from similar calculations of other companies in our industry, thereby limiting its usefulness as a comparative measure.

Non-GAAP Financial Measures (cont’d) 18 Refining Margin Per Crude Oil Throughput barrel is a measurement calculated as the difference between net sales and cost of product sold (exclusive of depreciation and amortization). Refining margin is a non-GAAP measure that we believe is important to investors in evaluating our refineries' performance as a general indication of the amount above our cost of product sold that we are able to sell refined products. Each of the components used in this calculation (net sales and cost of product sold exclusive of depreciation and amortization) can be taken directly from our Statement of Operations. Our calculation of refining margin may differ from similar calculations of other companies in our industry, thereby limiting its usefulness as a comparative measure. In order to derive the refining margin per crude oil throughput barrel, we utilize the total dollar figures for refining margin as derived above and divide by the applicable number of crude oil throughput barrels for the period. We believe that refining margin is important to enable investors to better understand and evaluate our ongoing operating results and allow for greater transparency in the review of our overall financial, operational and economic performance.

Refining Margin Per Crude Oil Throughput Barrel Adjusted for FIFO Impact is a measurement calculated as the difference between net sales and cost of product sold (exclusive of depreciation and amortization) adjusted for FIFO impacts. Refining margin adjusted for FIFO impact is a non-GAAP measure that we believe is important to investors in evaluating our refineries’ performance as a general indication of the amount above our cost of product sold (taking into account the impact of our utilization of FIFO) that we are able to sell refined products. Our calculation of refining margin adjusted for FIFO impact may differ from calculations of other companies in our industry, thereby limiting its usefulness as a comparative measure. Under our FIFO accounting method, changes in crude oil prices can cause fluctuations in the inventory valuation of our crude oil, work in process and finished goods, thereby resulting in favorable FIFO impacts when crude oil prices increase and unfavorable FIFO impacts when crude oil prices decrease. 19

(a) FIFO is our basis for determining inventory value on a GAAP basis. Changes in crude oil prices can cause fluctuations in the inventory valuation of our crude oil, work in process and finished goods thereby resulting in favorable FIFO impacts when crude oil prices increase and unfavorable FIFO impacts when crude oil prices decrease. The FIFO impact is calculated based upon inventory values at the beginning of the accounting period and at the end of the accounting period. 20 ($ in millions) CVR Refining, LP Pro Forma Year Ended December 31, 2009 2010 2011 2012 9/30/2012 9/30/2013 2011 (unaudited) Net Income 64.6$ 38.2$ 480.3$ 595.3$ 540.7$ 700.6$ 749.0$ Add: Interest expense and other financing costs 43.8 49.7 53.0 76.2 56.0 34.5 41.7 Depreciation and amortization 64.4 66.4 69.8 107.6 80.4 85.2 98.9 EBITDA 172.8 154.3 603.1 779.1 677.1 820.3 889.6 Add: FIFO impact (favorable)/unfavorable (a) (67.9) (31.7) (25.6) 58.4 54.3 (83.3) (46.6) Share-based compensation 2.5 11.5 8.9 18.5 15.6 8.3 8.9 Loss on disposition of assets - 1.3 2.5 - - - 2.5 Loss on extinguishment of debt 2.1 16.6 2.1 37.5 - 26.1 2.1 Wynnewood acquisition transaction fees and integration expenses - - 5.2 11.0 10.3 - 5.2 Major scheduled turnaround expense - 1.2 66.4 123.7 34.6 - 66.4 (Gain) loss on derivatives, net 65.3 1.5 (78.1) 285.6 277.4 (173.0) (36.4) Current period settlements on derivative contracts (27.5) (2.1) (7.2) (137.6) (80.4) (3.9) (49.0) Adjusted EBITDA 147.3$ 152.6$ 577.3$ 1,176.2$ 988.9$ 594.5$ 842.7$ Year Ended December 31, CVR Refining, LP Historical Combined Year to Date

Non-GAAP Financial Measures (cont’d) 21 ($ in millions, except per barrel data) CVR Refining, LP Pro Forma Year Ended December 31, 2009 2010 2011 2012 9/30/2012 9/30/2013 2011 (unaudited) Direct operating expenses 142.2$ 153.1$ 247.7$ 426.5$ 253.1$ 274.5$ 345.0$ Less: major scheduled turnaround expense - (1.2) (66.4) (123.7) (34.6) - (66.4) Direct operating expenses excluding major scheduled turnaround expenses 142.2 151.9 181.3 302.8 218.5 274.5 278.6 Crude oil throughput (bpd) 108,226 113,365 103,702 169,356 176,589 182,780 162,437 Direct operating expenses excluding major scheduled turnaround expenses per crude oil throughput barrel 3.60$ 3.67$ 4.79$ 4.89$ 4.52$ 5.50$ 4.70$ Year Ended December 31, Year to Date CVR Refining, LP Historical Combined

Non-GAAP Financial Measures (cont’d) 22 ($ in millions, except per barrel data) CVR Refining, LP Pro Forma Year Ended December 31, 2009 2010 2011 2012 9/30/2012 9/30/2013 2011 (unaudited) Net sales 2,936.5$ 3,905.6$ 4,752.8$ 8,281.7$ 6,465.5$ 6,322.6$ 7,398.3$ Less: cost of product sold 2,515.9 3,539.8 3,927.6 6,667.5 5,191.0 5,317.0 6,126.0 Refining margin 420.6 365.8 825.2 1,614.2 1,274.5 1,005.6 1,272.3 FIFO impact (favorable)/unfavorable (67.9) (31.7) (25.6) 58.4 54.3 (83.3) (46.6) Refining margin adjusted for FIFO impact 352.7 334.1 799.6 1,672.6 1,328.8 922.3 1,225.7 Crude oil throughput (bpd) 108,226 113,365 103,702 169,356 176,589 182,780 162,437 Refining margin per crude oil throughput barrel 10.65$ 8.84$ 21.80$ 26.04$ 26.34$ 20.15$ 21.46$ Refining margin per crude oil throughput barrel adjusted for FIFO impact 8.93$ 8.07$ 21.12$ 26.98$ 27.46$ 18.48$ 20.67$ Year Ended December 31, Year to Date CVR Refining, LP Historical Combined ($ in millions, except per barrel data) CVR Refining, LP Pro Forma Year Ended December 31, 2009 2010 2011 2012 9/30/2012 9/30/2013 2011 (unaudited) Net sales 2,936.5$ 3,905.6$ 4,752.8$ 8,281.7$ 6,465.5$ 6,322.6$ 7,398.3$ Cost of product sold 2,515.9 3,539.8 3,927.6 6,667.5 5,191.0 5,317.0 6,126.0 Direct operating expenses 142.2 153.1 247.7 426.5 253.1 274.5 345.0 Depreciation and amortization 64.4 66.4 69.8 107.6 80.4 85.2 98.9 Gross profit 214.0 146.3 507.7 1,080.1 941.0 645.9 828.4 Add: Major scheduled turnaround expense - 1.2 66.4 123.7 34.6 - 66.4 FIFO impact (favorable)/unfavorable (67.9) (31.7) (25.6) 58.4 54.3 (83.3) (46.6) Gross profit excluding major scheduled turnaround expenses and 146.1 115.8 548.5 1,262.2 1,029.9 562.6 848.2 adjusted for FIFO impact Crude oil throughput (bpd) 108,226 113,365 103,702 169,356 176,589 182,780 162,437 Gross profit excluding major scheduled turnaround expenses and 3.70$ 2.80$ 14.49$ 20.36$ 21.29$ 11.27$ 14.31$ adjusted for FIFO impact per barrel Year Ended December 31, Year to Date CVR Refining, LP Historical Combined

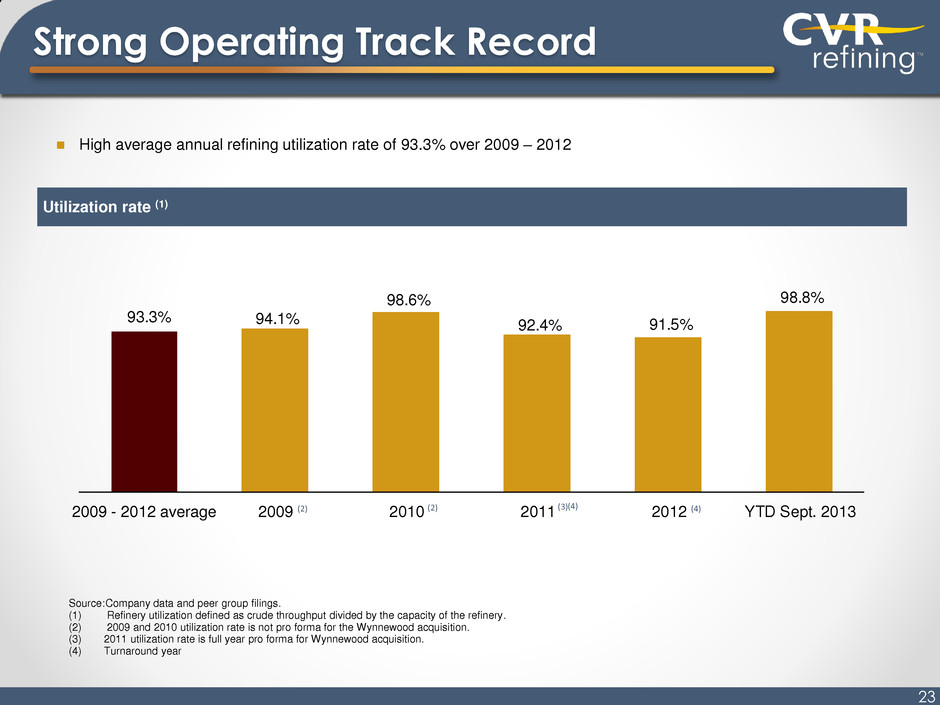

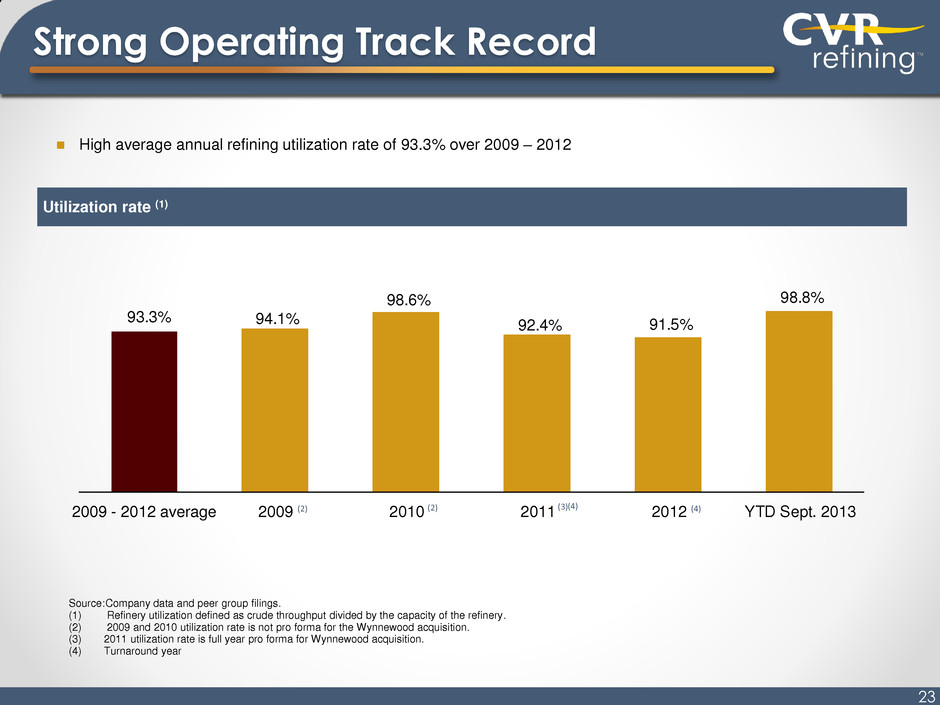

93.3% 94.1% 98.6% 92.4% 91.5% 98.8% 2009 - 2012 average 2009 2010 2011 2012 YTD Sept. 2013 Strong Operating Track Record High average annual refining utilization rate of 93.3% over 2009 – 2012 Utilization rate (1) Source: Company data and peer group filings. (1) Refinery utilization defined as crude throughput divided by the capacity of the refinery. (2) 2009 and 2010 utilization rate is not pro forma for the Wynnewood acquisition. (3) 2011 utilization rate is full year pro forma for Wynnewood acquisition. (4) Turnaround year 23 (2) (2) (3) (4) (4)

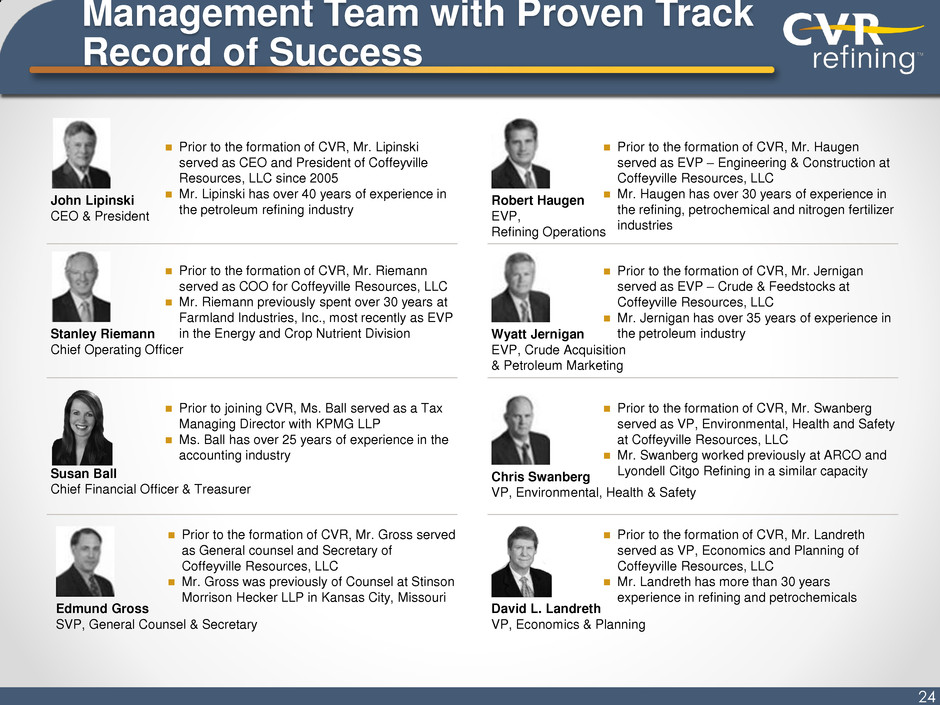

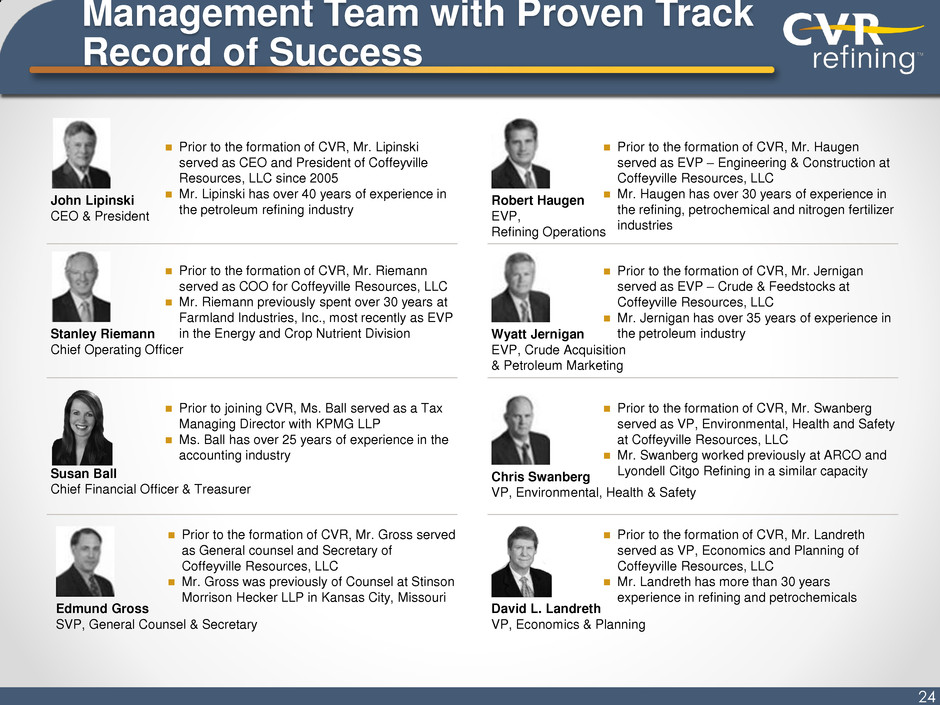

Management Team with Proven Track Record of Success 24 John Lipinski CEO & President Edmund Gross SVP, General Counsel & Secretary Prior to the formation of CVR, Mr. Lipinski served as CEO and President of Coffeyville Resources, LLC since 2005 Mr. Lipinski has over 40 years of experience in the petroleum refining industry Prior to the formation of CVR, Mr. Gross served as General counsel and Secretary of Coffeyville Resources, LLC Mr. Gross was previously of Counsel at Stinson Morrison Hecker LLP in Kansas City, Missouri Susan Ball Chief Financial Officer & Treasurer Wyatt Jernigan EVP, Crude Acquisition & Petroleum Marketing Prior to joining CVR, Ms. Ball served as a Tax Managing Director with KPMG LLP Ms. Ball has over 25 years of experience in the accounting industry Prior to the formation of CVR, Mr. Jernigan served as EVP – Crude & Feedstocks at Coffeyville Resources, LLC Mr. Jernigan has over 35 years of experience in the petroleum industry Chris Swanberg VP, Environmental, Health & Safety Prior to the formation of CVR, Mr. Swanberg served as VP, Environmental, Health and Safety at Coffeyville Resources, LLC Mr. Swanberg worked previously at ARCO and Lyondell Citgo Refining in a similar capacity Stanley Riemann Chief Operating Officer Robert Haugen EVP, Refining Operations Prior to the formation of CVR, Mr. Riemann served as COO for Coffeyville Resources, LLC Mr. Riemann previously spent over 30 years at Farmland Industries, Inc., most recently as EVP in the Energy and Crop Nutrient Division Prior to the formation of CVR, Mr. Haugen served as EVP – Engineering & Construction at Coffeyville Resources, LLC Mr. Haugen has over 30 years of experience in the refining, petrochemical and nitrogen fertilizer industries David L. Landreth VP, Economics & Planning Prior to the formation of CVR, Mr. Landreth served as VP, Economics and Planning of Coffeyville Resources, LLC Mr. Landreth has more than 30 years experience in refining and petrochemicals

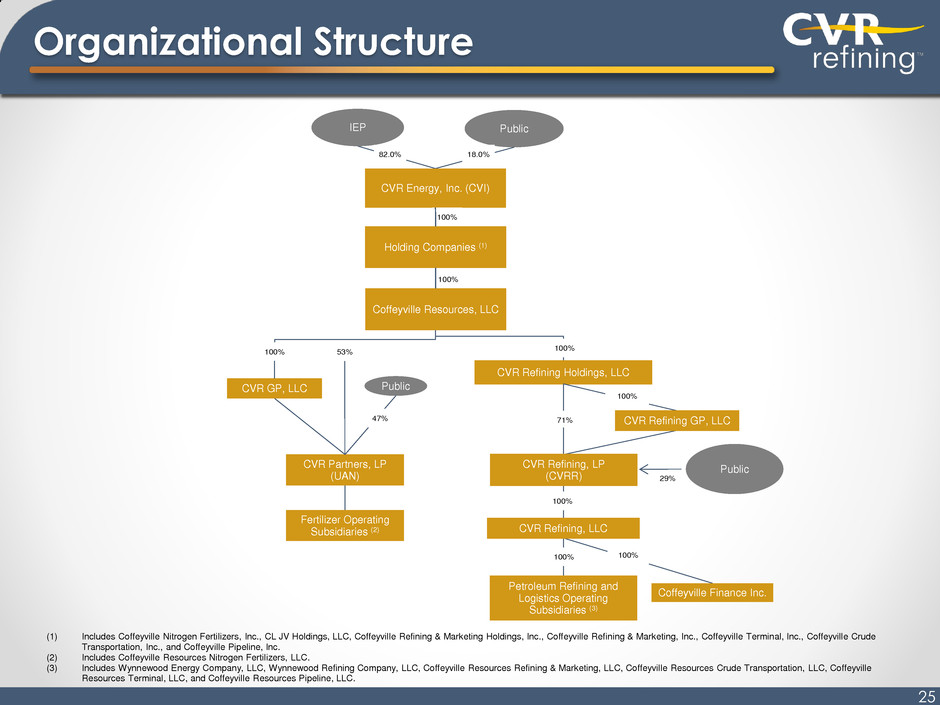

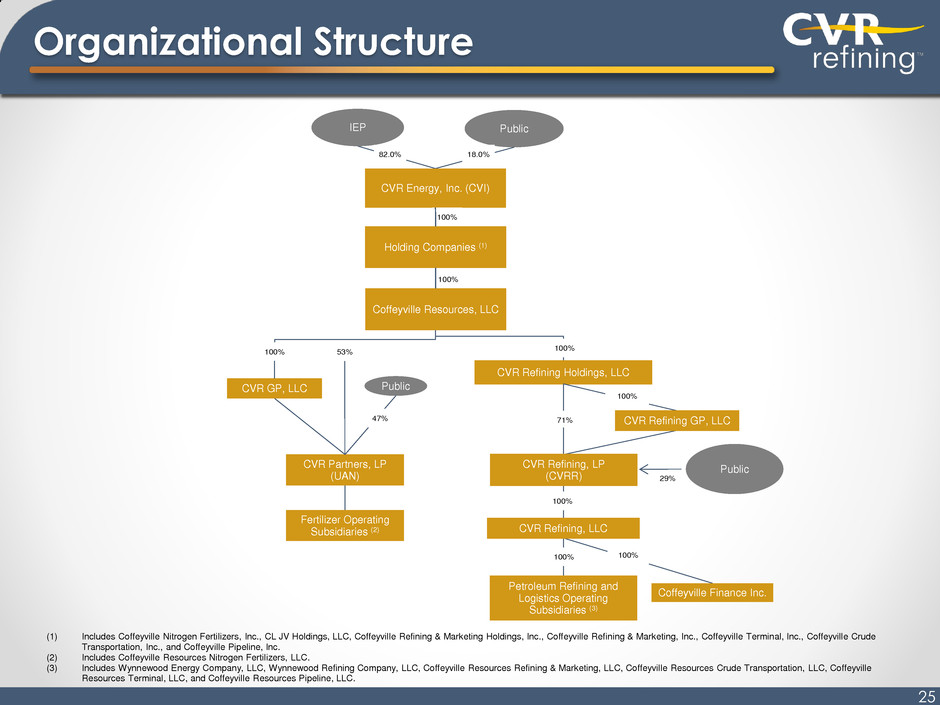

Organizational Structure 25 Petroleum Refining and Logistics Operating Subsidiaries (3) CVR Refining, LLC CVR Refining, LP (CVRR) Coffeyville Finance Inc. CVR Refining Holdings, LLC 100% 100% 100% CVR Partners, LP (UAN) 100% Public Public 47% 100% 71% CVR Refining GP, LLC Public 29% CVR GP, LLC 100% CVR Energy, Inc. (CVI) Coffeyville Resources, LLC 53% IEP 82.0% 18.0% 100% Fertilizer Operating Subsidiaries (2) Holding Companies (1) 100% (1) Includes Coffeyville Nitrogen Fertilizers, Inc., CL JV Holdings, LLC, Coffeyville Refining & Marketing Holdings, Inc., Coffeyville Refining & Marketing, Inc., Coffeyville Terminal, Inc., Coffeyville Crude Transportation, Inc., and Coffeyville Pipeline, Inc. (2) Includes Coffeyville Resources Nitrogen Fertilizers, LLC. (3) Includes Wynnewood Energy Company, LLC, Wynnewood Refining Company, LLC, Coffeyville Resources Refining & Marketing, LLC, Coffeyville Resources Crude Transportation, LLC, Coffeyville Resources Terminal, LLC, and Coffeyville Resources Pipeline, LLC.