UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 28, 2013

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file number 333-187556

SUMMIT MATERIALS, LLC

(Exact name of registrant as specified in its charter)

| | |

| Delaware | | 24-4138486 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

| |

1550 Wynkoop Street, 3rd Floor Denver, Colorado | | 80202 |

| (Address of principal executive offices) | | (Zip Code) |

Registrant’s telephone number, including area code: (303) 893-0012

Securities registered pursuant to Section 12(b) of the Act: None

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes x No ¨

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ¨ No x

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| | | | | | |

| Large accelerated filer | | ¨ | | Accelerated filer | | ¨ |

| | | |

| Non-accelerated filer | | x | | Smaller reporting company | | ¨ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

As of March 7, 2014, 100% of the registrant’s outstanding limited liability company interests were held by Summit Materials Intermediate Holdings, LLC.

DISCLOSURE REGARDING FORWARD-LOOKING STATEMENTS

This annual report on Form 10-K (this “report”) contains “forward-looking statements” within the meaning of the federal securities laws, which involve risks and uncertainties. Forward-looking statements include all statements that do not relate solely to historical or current facts, and you can identify forward-looking statements because they contain words such as “believes,” “expects,” “may,” “will,” “should,” “seeks,” “intends,” “trends,” “plans,” “estimates,” “projects” or “anticipates” or similar expressions that concern our strategy, plans, expectations or intentions. All statements made relating to our estimated and projected earnings, margins, costs, expenditures, cash flows, growth rates and financial results are forward-looking statements. These forward-looking statements are subject to risks and uncertainties that may change at any time, and, therefore, our actual results may differ materially from those expected. We derive many of our forward-looking statements from our operating budgets and forecasts, which are based upon many detailed assumptions. While we believe that our assumptions are reasonable, it is very difficult to predict the effect of known factors, and, of course, it is impossible to anticipate all factors that could affect our actual results.

Some of the important factors that could cause actual results to differ materially from our expectations are disclosed under “Risk Factors” and elsewhere in this report. All subsequent written and oral forward-looking statements attributable to us, or persons acting on our behalf, are expressly qualified in their entirety by these cautionary statements.

We undertake no obligation to publicly update or revise any forward-looking statement as a result of new information, future events or otherwise, except as otherwise required by law.

CERTAIN DEFINITIONS

As used in this report, unless otherwise noted or the context otherwise requires:

| | • | | “We,” “our,” “us,” and “the Company” refer to Summit Materials, LLC and its subsidiaries as a combined entity; |

| | • | | “Parent” refers only to Summit Materials Holdings L.P., our indirect parent entity; |

| | • | | “Summit Materials” refers only to Summit Materials, LLC and not its subsidiaries; |

| | • | | “Finance Corp.” refers only to Summit Materials Finance Corp., a 100 percent-owned subsidiary of Summit Materials; |

| | • | | “Hamm” and “Predecessor” refer to Hamm, Inc., our inaugural acquisition and the predecessor entity of Summit Materials; |

| | • | | “Cornejo” refers collectively to Cornejo & Sons, L.L.C., C&S Group, Inc., Concrete Materials Company of Kansas, LLC and Cornejo Materials, Inc.; |

| | • | | “Continental Cement” refers to Continental Cement Company, L.L.C. and its subsidiary; |

| | • | | “Harper Contracting” refers collectively to substantially all the assets of Harper Contracting, Inc., Harper Sand and Gravel, Inc., Harper Excavating, Inc., Harper Ready Mix Company, Inc. and Harper Investments, Inc.; |

| | • | | “Altaview Concrete” refers collectively to Altaview Concrete, LLC, Peak Construction Materials, LLC, Peak Management, L.C. and Wasatch Concrete Pumping, LLC; |

| | • | | “RK Hall” refers collectively to R.K. Hall Construction, Ltd., RHMB Capital, L.L.C., Hall Materials, Ltd., B&H Contracting, L.P. and RKH Capital, L.L.C.; |

| | • | | “B&B” refers collectively to B&B Resources, Inc., Valley Ready Mix, Inc. and Salt Lake Sand & Gravel, Inc.; |

| | • | | “Industrial Asphalt” refers collectively to Industrial Asphalt, LLC, Asphalt Paving Company of Austin, LLC, KBDJ, L.P. and all the assets of Apache Materials Transport, Inc.; |

| | • | | “Ramming Paving” refers collectively to J.D. Ramming Paving Co., LLC, RTI Hot Mix, LLC, RTI Equipment Co., LLC and Ramming Transportation Co., LLC; |

| | • | | “Norris” refers to Norris Quarries, LLC; |

| | • | | “Kay & Kay” refers to certain assets of Kay & Kay Contracting, LLC; |

| | • | | “Sandco” refers to certain assets of Sandco Inc.; |

1

| | • | | “Lafarge” refers to Lafarge North America, Inc.; |

| | • | | “Westroc” refers to Westroc, LLC; |

| | • | | “Alleyton” refers collectively to Alleyton Resource Company, LLC; Alcomat, LLC and Alleyton Services Company, LLC, formerly known as Alleyton Resource Corporation, Colorado Gulf, LP and certain assets of Barten Shepard Investments, LP; |

| | • | | “Blackstone” refers to certain investment funds affiliated with Blackstone Capital Partners V L.P.; |

| | • | | “Silverhawk” refers to certain investment funds affiliated with Silverhawk Summit, L.P.; and |

| | • | | “Sponsors” refers to Blackstone and Silverhawk. |

2

PART I

Overview

We are a leading, vertically-integrated, geographically-diverse, heavy-side building materials company. We supply aggregates, cement and related downstream products such as ready-mixed concrete, asphalt paving mix, concrete products and paving and related construction services for a variety of end uses in the U.S. construction industry, including private residential and non-residential construction, as well as public infrastructure projects. We believe we are a top 15 supplier of aggregates, a top 25 producer of cement and a major producer of asphalt paving mix and ready-mixed concrete in the United States by volume. As of December 28, 2013, we had 1.2 billion tons and 0.4 billion tons of proven and probable aggregates reserves serving our aggregates and cement businesses, respectively, and operated over 200 sites and plants. In the year ended December 28, 2013, we sold 17.5 million tons of aggregates, 1.0 million tons of cement, 1.2 million cubic yards of ready-mixed concrete and 3.9 million tons of asphalt paving mix. For the year ended December 28, 2013, we generated revenue of $916.2 million.

Summit Materials is a limited liability company that was formed under the laws of the State of Delaware in September 2008. Since July 2009, the Sponsors and certain of our officers, directors and employees have made $794.5 million of funding commitments to Parent. We have grown rapidly through our disciplined acquisition strategy, utilizing approximately $463.9 million of equity commitments funded to Parent by the Sponsors and certain other investors. Today, our eight operating companies make up our three distinct geographic regions, spanning 16 states and 23 metropolitan statistical areas. We believe each of our operating companies has a top three market share position in its local market area and an extensive operating history, averaging over 35 years. Our highly experienced management team, led by 30-year industry veteran CEO, Tom Hill, has successfully enhanced the operations of acquired companies by focusing on scale advantages, cost efficiencies and pricing discipline to improve profitability and cash flow.

Our strategy is focused on developing a vertically-integrated, heavy-side building materials company with a strong aggregates base. We strive to be a leading supplier of all four major resource-based products—aggregates, cement, ready-mixed concrete and asphalt paving mix—in the U.S. heavy-side building materials industry. We believe vertical integration across these major products strengthens our market positions and helps us achieve significant cost advantages. We believe a diversified mix of products also provides us with greater stability and insulates against local market fluctuations, pricing dynamics and other individual market variances.

Our revenue is derived from multiple end-use markets, including residential and non-residential construction, as well as public infrastructure construction. For the year ended December 28, 2013, approximately 42% of our revenue related to residential and non-residential construction and approximately 58% related to public infrastructure construction. In general, our aggregates and asphalt paving mix and paving businesses are weighted towards public infrastructure construction. Our cement and ready-mixed concrete businesses serve both the private construction and public infrastructure markets. Private construction includes both new residential and non-residential construction and repair and remodel markets, which have been significantly affected by recent and current economic conditions. We believe exposure to various geographic markets affords us greater stability through economic cycles and positions us to capitalize on upside opportunities when the residential and non-residential construction markets recover. Public infrastructure construction includes spending by federal, state and local governments for roads, highways, bridges, airports and other public infrastructure construction projects. A significant portion of our construction services revenue is from public infrastructure construction projects, a historically more stable portion of state and federal budgets. Our acquisitions to date are primarily focused in states with constitutionally-protected transportation funding sources, which we believe limits our exposure to state and local budgetary uncertainties.

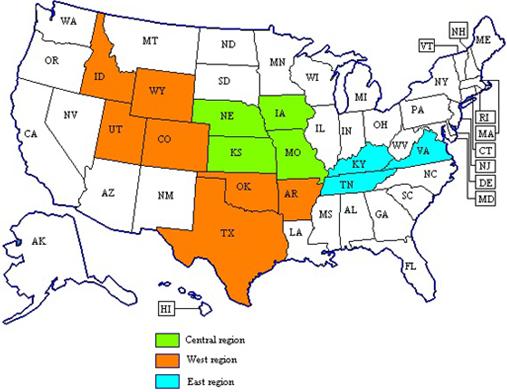

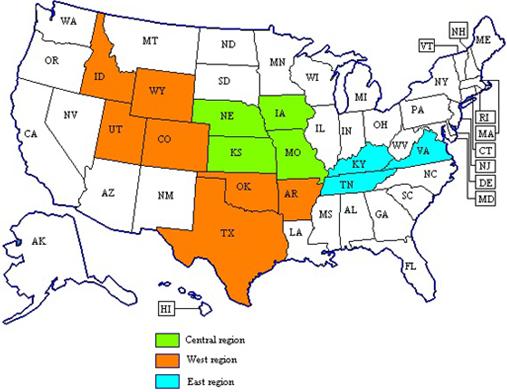

Markets by Region

We currently operate across 16 states through our three regional platforms, which also serve as our reporting segments: Central, West and East. Information concerning revenue, operating income (loss), assets employed and certain additional information attributable to each reporting segment for each year in the three year period ended December 28, 2013 is included in note 20 to our audited consolidated financial information included elsewhere in this report, which information is incorporated herein by reference. Each of our operating businesses has its own management team that, in turn, reports to a regional president who is responsible for overseeing the operating businesses, developing growth opportunities, implementing best practices and integrating acquired businesses within the regional platform. Acquisitions are an important element of our strategy, as we seek to enhance value through increased scale and cost savings from vertical integration within local markets.

3

Central Region. The Central region encompasses our integrated aggregates, cement, ready-mixed concrete, asphalt paving mix, construction and other operations in Kansas, Missouri, Nebraska, Iowa and Illinois. As of December 28, 2013, within the region, we controlled approximately 0.4 billion tons of proven and probable aggregates reserves serving our aggregates business and approximately 0.4 billion tons serving our cement business and $523.2 million of net property, plant and equipment and inventories (“hard assets”). During the years ended December 28, 2013 and December 29, 2012, approximately 36% and 33%, respectively, of our revenue was generated in the Central region. Approximately 57% and 48% of the Central region’s revenue was derived from residential and non-residential construction and the remaining approximately 43% and 52% was derived from public infrastructure spending in the years ended December 28, 2013 and December 29, 2012, respectively.

Our cement business in Missouri, Continental Cement, operates a highly efficient, technologically advanced, integrated manufacturing and distribution system strategically located near Hannibal, Missouri, 100 miles north of St. Louis along the Mississippi River. Continental Cement utilizes an on-site solid and liquid waste fuel processing facility, which can reduce our fuel costs at that facility by up to 50%. The Continental Cement plant is covered by Hazardous Waste Combuster Maximum Achievable Control Technology Standards regulations (“HWC-MACT”), rather than the Environmental Protection Agency’s (“EPA”) National Emission Standards for Hazardous Air Pollutants (“NESHAP”), due to its waste fuel processing capabilities. We believe the facility is well positioned to comply with any potential regulatory changes during the foreseeable future.

West Region. The West region encompasses our integrated aggregates, ready-mixed concrete, asphalt paving mix, construction and other operations in Texas, Utah, Colorado, Idaho and Wyoming. As of December 28, 2013, within the region, we controlled approximately 0.4 billion tons of proven and probable aggregates reserves and $257.0 million of hard assets. During the years ended December 28, 2013 and December 29, 2012, approximately 47% and 52%, respectively, of our revenue was generated in the West region. Approximately 43% and 36% of the West region’s revenue was generated by residential and non-residential construction and the remaining approximately 57% and 64% was derived from public infrastructure spending in the years ended December 28, 2013 and December 29, 2012, respectively.

East Region. The East region encompasses our integrated aggregates, asphalt paving mix, construction and other operations in Kentucky, Tennessee and Virginia. As of December 28, 2013, within the region, we controlled approximately 0.4 billion tons of proven and probable aggregates reserves and $144.1 million of hard assets. During the years ended December 28, 2013 and December 29, 2012, approximately 18% and 15%, respectively, of our revenue was generated in the East region. Approximately 92% and 73% of the East region’s revenue was derived from public infrastructure spending, and the remaining 8% and 27% was generated by residential and non-residential construction in the years ended December 28, 2013 and December 29, 2012, respectively.

Acquisition History

The following table lists acquisitions completed since August 2009:

| | | | |

Company | | Date of Acquisition | | Region |

| | |

Hamm (predecessor) | | August 25, 2009 | | Central |

| | |

Hinkle Contracting Company | | February 1, 2010 | | East |

| | |

Cornejo | | April 16, 2010 | | Central |

| | |

Elmo Greer & Sons, LLC | | April 20, 2010 | | East |

| | |

Continental Cement | | May 27, 2010 | | Central |

| | |

Harshman Construction L.L.C. and Harshman Farms, Inc. | | June 15, 2010 | | Central |

| | |

South Central Kentucky Limestone, LLC | | July 23, 2010 | | East |

| | |

Harper Contracting | | August 2, 2010 | | West |

| | |

Kilgore Pavement Maintenance, LLC and Kilgore Properties, LLC | | August 2, 2010 | | West |

| | |

Con-Agg of MO, L.L.C. | | September 15, 2010 | | Central |

| | |

Altaview Concrete | | September 15, 2010 | | West |

| | |

EnerCrest Products, Inc. | | September 28, 2010 | | West |

4

| | | | |

Company | | Date of Acquisition | | Region |

| | |

RK Hall | | November 30, 2010 | | West |

| | |

SCS Materials, L.P. | | November 30, 2010 | | West |

| | |

Triple C Concrete, Inc. | | January 14, 2011 | | West |

| | |

Elam Construction, Inc. | | March 31, 2011 | | West |

| | |

Bourbon Limestone Company | | May 27, 2011 | | East |

| | |

Fischer Quarries, L.L.C. | | May 27, 2011 | | Central |

| | |

B&B | | June 8, 2011 | | West |

| | |

Grand Junction Pipe, Inc. | | June 10, 2011 | | West |

| | |

Industrial Asphalt | | August 2, 2011 | | West |

| | |

Ramming Paving | | October 28, 2011 | | West |

| | |

Norris | | February 29, 2012 | | Central |

| | |

Kay & Kay | | October 5, 2012 | | East |

| | |

Sandco | | November 30, 2012 | | West |

| | |

Lafarge | | April 1, 2013 | | Central |

| | |

Westroc | | April 1, 2013 | | West |

| | |

Alleyton | | January 17, 2014 | | West |

Our End Markets

Residential Construction. Residential construction includes single family houses and multi-family units such as apartments and condominiums. Demand for residential construction is influenced by employment prospects, new household formation and mortgage interest rates. In recent years, foreclosures have resulted in an oversupply of available houses, which has dampened the demand for new residential construction in many markets in the United States. However, employment prospects are improving, foreclosure rates have stabilized and demand has begun to grow in certain markets over the past several months.

Non-Residential Construction. Non-residential construction encompasses all privately financed construction other than residential structures. Demand for non-residential construction is driven by population and economic growth. Population growth spurs demand for stores, shopping centers and restaurants. Economic growth creates demand for projects such as hotels, office buildings, warehouses and factories. The supply of non-residential construction projects is affected by interest rates and the availability of credit to finance these projects.

Public Infrastructure Construction. Public infrastructure construction includes spending by federal, state and local governments for highways, bridges, airports, schools, public buildings and other public infrastructure construction projects. Public infrastructure spending has historically been more stable than private sector construction. We believe that public infrastructure spending is less sensitive to interest rate changes and economic cycles and often is supported by multi-year federal and state legislation and programs. A significant portion of our revenue is derived from public infrastructure construction projects. As a result, the supply of federal and state funding for public infrastructure highway construction significantly affects our public infrastructure end use business.

Historically, public infrastructure funding has been underpinned by a series of six-year federal highway authorization bills. Federal funds are allocated to the states, which are required to match a portion of the federal funds they receive. Federal highway spending uses funds predominantly from the Federal Highway Trust Fund, which derives its revenue from taxes on diesel fuel, gasoline and other user fees. The dependability of federal funding allows the state departments of transportation to plan for their long term highway construction and maintenance needs.

5

Moving Ahead for Progress in the 21st Century Act (“MAP-21”), a 27-month, approximately $105 billion transportation funding program that provides $40.4 billion and $41.0 billion for highway infrastructure investments in fiscal years 2013 and 2014, respectively, was enacted in July 2012 and took effect in October 2012. The spending levels are consistent with the preceding federal transportation funding program. Currently, there is uncertainty as to what will succeed MAP-21, which expires in September 2014. A new highway bill may be passed by the end of 2014, which would require continuing resolutions between September 2014 and the date a new bill is passed. We are not expecting a significant change in funding levels through the continuing resolutions or a new bill. However, given the nation’s aging infrastructure and considering longstanding historical spending trends, management expects U.S. infrastructure investment to grow over the long-term. Management believes that the Company is well-positioned to capitalize on any such increase in investment.

Our Industry

The U.S. heavy-side building materials industry is composed of four primary sectors: (i) aggregates; (ii) cement; (iii) ready-mixed concrete; and (iv) asphalt paving mix, each of which is widely used in most forms of construction activity. Participants in these sectors typically range from small, privately-held companies focused on a single product or market to multinational corporations that offer a wide array of construction materials and services. Competition is constrained in part by the distance materials can be transported efficiently, resulting in predominantly local or regional operations. Due to the lack of product differentiation, competition for all of our products is predominantly based on price and, to a lesser extent, quality of products and service. As a result, the prices we charge our customers are not likely to be materially different from the prices charged by other producers in the same markets. Accordingly, our profitability is generally dependent on the level of demand for our products and our ability to control operating costs.

Transportation infrastructure projects, driven by both state and federal funding programs, represent a significant share of the U.S. heavy-side building materials market. In addition to federal funding under MAP-21, highway construction and maintenance funding is also available through state, county and local agencies. Our five largest states by revenue (Texas, Kansas, Kentucky, Missouri and Utah, which represented approximately 25%, 20%, 17%, 12% and 11%, respectively, of our total revenue for the year ended December 28, 2013) each have funds whose revenue sources are constitutionally protected and may only be spent on transportation projects:

| | • | | Texas Department of Transportation’s budget from 2012 to 2014 is $31.0 billion. |

| | • | | Kansas has a 10 year $8.2 billion highway bill that was passed in May 2010. |

| | • | | Kentucky’s highway program has anticipated 2013-2018 funding of $5.7 billion. |

| | • | | Missouri has an estimated $0.7 billion in annual construction funding committed to essential road and bridge programs through 2017. |

| | • | | Utah’s transportation investment fund had $3.5 billion committed through 2018. |

Demand for our products is observed to have low elasticity in relation to prices. We believe this is partially explained by the absence of competitive replacement products and relatively low contribution of our products to construction costs. We do not believe that increases in our products’ prices are likely to affect the decision to undertake a construction project since these costs usually represent a small portion of total construction costs.

Construction Materials

Aggregates

Aggregates are key material components used in the production of ready-mixed concrete and asphalt paving mixes for the public infrastructure, highway, commercial and residential construction markets and are also widely used for various applications and products, such as road and building foundations, railroad ballast, erosion control, filtration, roofing granules and in solutions for snow and ice control. Generally extracted from the earth using surface or underground mining methods, aggregates are produced from natural deposits of various materials such as limestone, sand and gravel, granite and trap rock. Once extracted, processed and graded, aggregates are supplied directly to their end use or incorporated for further processing into construction materials, such as cement, ready-mixed concrete and asphalt paving mix.

According to the February 2013 U.S. Geological Survey, approximately 1.28 billion tons of crushed stone with a value of approximately $11.5 billion was produced in the United States in 2012, in line with 1.28 billion tons in 2011. Sand and gravel production was approximately 907 million tons in 2012 valued at approximately $6.25 billion, up from 894 million tons in 2011. The U.S. aggregate industry is highly fragmented relative to other building product markets, with numerous participants operating in localized markets and the top players controlling approximately 30% of the national market in 2012. In January 2013, the U.S. Geological Survey (“USGS”) reported that a total of 1,550 companies operating 4,000 quarries and 91 underground mines produced or sold crushed stone in 2012 in the United States.

6

Transportation cost is a major variable in determining aggregate pricing and marketing radius. The cost of transporting aggregate products from the plant to the market often equates to or exceeds the sale price of the product at the plant. As a result of the high transportation costs and the large quantities of bulk material that have to be shipped, finished products are typically marketed locally. High transportation costs are responsible for the wide dispersion of production sites. Where possible, construction material producers maintain operations adjacent to highly populated areas to reduce transportation costs and enhance margins.

We believe that the long-term growth of the market for aggregates is predominantly driven by growth in population, employment and households, which in turn affects transportation infrastructure spending and changes in population density. In recent years, the recession and subsequent slow recovery in the United States has led to a decrease in overall private construction activity. Despite the increase in federal stimulus spending, public infrastructure construction activity also declined over this period, albeit less than private construction markets. While short-term demand for aggregates fluctuates with economic cycles, the declines have historically been followed by strong recovery, with each peak establishing a new historical high.

A significant portion of annual demand for aggregates is derived from large public infrastructure and highway construction projects. According to the Montana Contractors’ Association, approximately 38,000 tons of aggregate are required to construct a one mile stretch of a typical four-lane interstate highway. Highways located in markets with significant seasonal temperature variances are particularly vulnerable to freeze-thaw conditions that exert excessive stress on pavement and lead to more rapid surface degradation. Surface maintenance repairs, as well as general highway construction, occur in the warmer months, resulting in a majority of aggregates production and sales in the eight months from April through November in most states.

Cement

Portland cement, an industry term for the common cement in general use around the world, is made from a combination of limestone, shale, clay, silica and iron ore. It is a fundamental building material consumed in several stages throughout the construction cycle of residential, non-residential and public infrastructure projects. It is a binding agent that, when mixed with sand or aggregates and water, produces either ready-mixed concrete or mortar and is an important component of other essential building materials. Cement is sold either in bulk or in bags as branded products, depending on its final user. Few construction projects can take place without utilizing Portland cement somewhere in the design, making it a key ingredient used in the construction industry. The majority of all cement shipments are sent to ready-mixed concrete operators. The remaining shipments are directed to manufacturers of concrete related products such as block and precast.

The principal raw materials in cement are a blend of approximately 80% limestone and approximately 5% shale, with the remaining raw materials being clay and iron ore. Generally, the limestone and shale are mined from quarries located on site with the production plant. These core ingredients are blended and crushed into a fine grind and then preheated and ultimately introduced into a kiln heated to about 3,000°F. Under this extreme heat, a chemical transformation occurs uniting the elements to form a new substance with new physical and chemical characteristics. This new substance is called clinker and it is formed into pieces about the size of marbles. The clinker is then cooled and later ground into a fine powder that then is classified as Portland cement.

Cement production in the United States is distributed among 98 production facilities located across 35 states. It is a capital-intensive business with variable costs dominated by raw materials and energy required to fuel the kiln. Building new plants is challenging given the extensive permitting that is required and significant costs. We believe new plant construction costs in the United States to be approximately $250-300 per ton, not including costs for property or securing raw materials and the required distribution network. Assuming construction costs of $275 per ton, a 1.25 million ton facility, comparable to the Continental Cement plant’s potential annual capacity, would cost approximately $343.8 million to construct.

As reported by the PCA in the 2013 North American Cement Industry Annual Yearbook, consumption is down significantly from the industry peak of 141 million tons in 2005 to 86 million tons in 2012 because of the decline in U.S. construction sector activity. Domestic cement consumption has at times outpaced domestic production capacity with the shortfall being supplied with imports, primarily from China, Canada, Greece, Mexico and South Korea. The PCA reports that cement imports have declined since their peak of 39 million tons in 2006 to 8 million tons in 2012, in a manner indicative of the industry’s general response to the current demand downturn. In addition to the reduction in imports, U.S. capacity utilization declined from 95% in 2006 to 66% in 2012 according to the PCA. Continental Cement operated above the industry mean at 78% capacity utilization in 2013 as its markets did not suffer the pronounced demand declines seen in states like Florida, California and Arizona. Demand is seasonal in nature with nearly two-thirds of U.S. consumption occurring between May and October, coinciding with end-market construction activity.

NESHAP is due to come into effect in 2015. On December 20, 2012, the EPA signed the final NESHAP rule, which was less stringent than previous drafts. The PCA had estimated based on the draft rule that 18 plants could be forced to close due to the inability to meet NESHAP standards or because the compliance investment required may not be justified on a financial basis. Continental Cement’s plant utilizes alternative fuel (hazardous and non-hazardous) as well as coal and petroleum coke and, as a result, is subject to HWC-MACT standards, rather than NESHAP. We expect HWC-MACT standards to generally conform to NESHAP, for which we are mostly in compliance, ahead of the effective date of the HWC-MACT standards. Any additional costs to comply with the HWC-MACT standards are not expected to be material.

7

Ready-Mixed Concrete

Ready-mixed concrete is one of the most versatile and widely used materials in construction today. Its flexible recipe characteristics allow for an end product that can assume almost any color, shape, texture and strength to meet the many requirements of end users that range from bridges, foundations, skyscrapers, pavements, dams, houses, parking garages, water treatment facilities, airports, tunnels, power plants, hospitals and schools. The versatility of ready-mixed concrete gives engineers significant flexibility when designing these projects.

Cement, coarse aggregate, fine aggregate, water and admixtures are the primary ingredients that constitute a basic ready-mixed concrete. The cement and water are combined and a chemical reaction is produced called hydration. This paste or binder represents between 15 to 20% of the volume of the mix that coats each particle of aggregate and serves as the agent that binds the aggregates together, according to the National Ready Mixed Concrete Association (the “NRMCA”). The aggregates represent 60 to 75% of the mix by volume, with a small portion of volume (5 to 8%) consisting of entrapped air that was generated by using air entraining admixtures. Once fully hydrated, the workable concrete will then harden and take on the shape of the form in which it was placed.

The quality of a concrete mix is generally determined by the weight ratio of water to cement. Higher quality concrete is produced by lowering the water-cement ratio as much as possible without sacrificing the workability of the fresh concrete. Specialty admixtures such as high range water reducers can aid in achieving this condition without sacrificing quality.

Other materials commonly used in the production of ready-mixed concrete include fly-ash, a waste by-product from coal burning power plants, silica fume, a waste by-product generated from the manufacture of silicon and ferro-silicon metals, and ground granulated blast furnace slag, a by-product of the iron and steel manufacturing process. All of these products have cemetitious properties that enhance the strength, durability and permeability of the concrete. These materials are available directly from the producer or via specialist distributors who intermediate between the source producers and the ready-mixed concrete user.

Given the high weight-to-value ratio, delivery of ready-mixed concrete is typically limited to a one-hour haul from a production plant location and is further limited by a 90 minute window in which newly-mixed concrete must be poured to maintain quality and performance. As a result of the transportation constraints, the ready-mixed concrete market is highly localized, with an estimated 5,500 ready-mixed concrete plants in the United States according to the NRMCA. According to the NRMCA, 290 million cubic yards of ready-mixed concrete was produced in 2012, which is a 9% increase from the 266 million cubic yards produced in 2011 but a 36% decrease from the industry peak of 458 million cubic yards in 2005.

Asphalt Paving Mix

Asphalt paving mix is the most common roadway material used today. It is a versatile and essential building material that has been used to surface 90% of the more than 2.5 million miles of paved roadways in the United States, according to National Geographic News.

Typically, asphalt paving mix is placed in three distinct layers to create a flexible pavement structure. These layers consist of a base course, an intermediate or binder course, and a surface or wearing course. These layers vary in thicknesses of three to six inches for base mix, two to four inches for intermediate mix and one to two inches for surface mix.

According to the National Asphalt Pavement Association, the components of asphalt paving mix by weight are approximately 95% aggregates and 5% asphalt cement, a petroleum based product that serves as the binder. The ingredients are then metered, mixed and heated to a temperature in excess of 300° F before being placed in a truck and delivered to the jobsite for final placement.

Asphalt pavement is generally 100% recyclable and reusable and is the most reused and recycled pavement material in the United States. Reclaimed asphalt pavement can be incorporated into new pavement at replacement rates in excess of 30% depending upon the mix and the application of the product. We actively engage in the recycling of previously used asphalt pavement and concrete. This material is crushed and repurposed in the construction cycle. Approximately 68 million tons of used asphalt is recycled annually by the industry.

The use of warm mix asphalt (“WMA”) or “green” asphalt is gaining popularity. The immediate benefit to producing WMA is the reduction in energy consumption required by burning fuels to heat traditional hot mix asphalt (“HMA”) to temperatures in excess of 300°F at the production plant. These high production temperatures are needed to allow the asphalt binder to become viscous enough to completely coat the aggregate in the HMA, have good workability during laying and compaction, and durability during traffic exposure. According to the Federal Highway Administration, WMA can reduce the temperature by 50 to 70°F, resulting in lower emissions, fumes and odors generated at the plant and the paving site.

8

According to the National Asphalt Pavement Association, there are approximately 4,000 asphalt paving mix plants in the United States. As reported by the National Asphalt Pavement Association, an estimated 360 million tons of asphalt paving mix was produced in 2012 which was broadly in line with the estimated 366 million tons produced in 2011.

Our Operations

We operate our construction materials and construction services businesses through local operations and marketing teams, which work closely with our end customers to deliver the products and services that meet each customer’s specific needs for a project. We believe that this strong local presence gives us a competitive advantage by keeping our costs low and allowing us to obtain a unique understanding for the evolving needs of our customers.

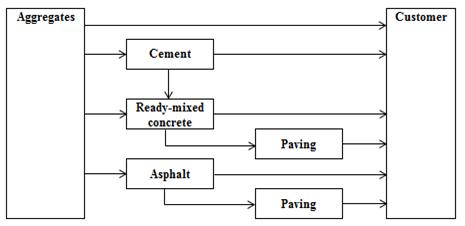

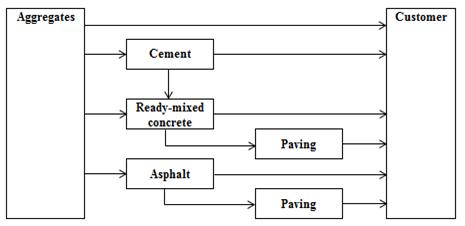

We have construction materials operations in 16 states across the Central, West and East regions. Our business in each region is vertically-integrated in the aggregates, asphalt paving mix, and paving and related construction services businesses. In addition, we manufacture cement, produce ready-mixed concrete, and operate a municipal waste landfill and one construction and demolition debris landfill in our Central region, we manufacture ready-mixed concrete in our West region and we have liquid asphalt terminal operations in our East region.

As a result of our vertically-integrated operations, our end products are generally sold downstream to contractors and shipped directly to the job site. In the year ended December 28, 2013, approximately 73% of our aggregates production was sold directly to outside customers with the remaining amount being further processed by us and sold as a downstream product.

Additionally, approximately 83% of our asphalt paving mix products was installed by our paving and related construction services businesses in the year ended December 28, 2013. We charge a market price and competitive margin at each stage of the production process in order to optimize profitability across our operations.

Production Value Chain

Customer

Construction Materials

We are a leading provider of construction materials in the markets we serve. Our construction materials operations are composed of aggregates production, including, crushed stone and construction sand and gravel, ready-mixed concrete, hot mix asphalt production and the production of cement.

Our Aggregates Operations

Aggregates Products

We mine limestone, gravel, and other natural resources from 78 crushed stone quarries and 46 sand and gravel deposits throughout the United States. Aggregates are produced mainly from blasting hard rock from quarries and then crushing and screening it to various sizes to meet our customers’ needs. The production of aggregates also involves the extraction of sand and gravel, which requires less crushing, but still requires screening for different sizes. Aggregate production utilizes capital intensive heavy equipment which includes the use of loaders, large haul trucks, crushers, screens and other heavy equipment at quarries.

Once extracted, the minerals are processed and/or crushed on site into crushed stone, concrete and masonry sand, specialized sand, pulverized lime or agricultural lime. The minerals are processed to meet customer specifications or to meet industry standard sizes. Crushed stone is used primarily in ready-mixed concrete, asphalt paving mix, and the construction of road base for highways.

9

Transportation costs are a major variable in determining aggregate pricing and marketing radius. The cost of transporting aggregate products from the plant to the market often equates to or exceeds the sale price of the products at the plant. As a result of high transportation costs and the large quantities of bulk material that have to be shipped, finished products are typically marketed locally. High transportation costs are responsible for the wide dispersion of production sites. Where possible, construction material producers maintain operations adjacent to highly populated areas to reduce transportation costs and enhance margins.

However, more recently, rising land values combined with local environmental concerns are forcing production sites to move further away from the end-use locations. Our extensive network of quarries, plants and facilities, located throughout our three regions enables us to have a nearby operation to meet the needs of customers in each of our markets.

Aggregates Markets

The cost of transportation from each quarry and the proximity of competitors are key factors that determine the effective market area for each quarry. Each quarry location is unique with regards to demand for each product, proximity to competition and distribution network.

Aggregates Reserves

Our current estimate of 1.6 billion tons of proven and probable reserves of recoverable stone, and sand and gravel of suitable quality for economic extraction is based on drilling and studies by geologists and engineers, recognizing reasonable economic and operating restraints as to maximum depth of extraction and permit or other restrictions.

Reported proven and probable reserves include only quantities that are owned in fee or under lease, and for which all required zoning and permitting have been obtained. Of the 1.6 billion tons of proven and probable aggregates reserves, 1.0 billion, or 63%, are located on owned land and 0.6 billion are located on leased land.

Aggregates Sales and Marketing

Each of our aggregates operations is responsible for the sale and marketing of its aggregates products. Approximately 73% of our aggregates production is sold directly to outside customers and the remaining amount is further processed by us and sold as a downstream product. Even though aggregates are a commodity product, we work to optimize pricing depending on the site location, availability of particular product, customer type, project type and haul cost. We sell aggregates to internal downstream operations at market prices.

Aggregates Competition

The U.S. aggregate industry is highly fragmented with numerous participants operating in localized markets. The January 2013 USGS reported that a total of 1,550 companies operating 4,000 quarries and 91 underground mines produced or sold crushed stone in 2012 in the United States. This fragmentation is a result of the cost of transporting aggregates, which typically limits producers to a market area within approximately 40 miles of their production facilities.

The primary national players are large vertically integrated companies, including Vulcan Materials Company, Martin Marietta Materials, Inc., CRH plc, Heidelberg, Lafarge and Cemex, S.A.B. de C.V. with a combined estimated market share of approximately 30%.

Competitors by region include:

Central—Martin Marietta, CRH plc, Holcim and various local suppliers.

West—CRH plc, Heidelberg Cement plc, Martin Marietta and various local suppliers.

East—CRH plc, Heidelberg Cement plc, Vulcan and various local suppliers.

We believe we have a strong competitive advantage in aggregates through our well located reserves in key markets, high quality reserves and our logistic networks. We further share and implement best practices relating to strategy, sales and marketing, production, safety, and environmental and land management. As a result of our vertical integration and local market knowledge, we have a strong understanding of the needs of our aggregates customers. Finally, our companies have a reputation for responsible environmental stewardship and land restoration, which assists us in obtaining new permits and new reserves.

10

Our Cement Operations

Cement Products

We operate a highly-efficient, technologically-advanced integrated cement manufacturing and distribution system located near Hannibal, Missouri, 100 miles north of St. Louis along the Mississippi River. We also operate an on-site waste fuel processing facility, which can reduce fuel costs for the plant by up to 50%. Our cement plant is one of only 12 with hazardous waste fuel facilities permitted and operating out of 98 total cement plants in the United States. Our cement plant’s potential capacity is 1.25 million tons per annum and is in substantial compliance with the 2013 NESHAP pollution limits for cement plants, in advance of the effective date.

Cement Markets

Cement is a product that is costly to transport over land. Consequently, the radius within which a typical cement plant is competitive extends for no more than 150 miles. Cement is distributed to local customers primarily by truck from our plant and distribution terminals in St. Louis, Missouri and Bettendorf, Iowa. We also transport cement by inland barges on the Mississippi River to our storage and distribution terminals. Continental Cement’s markets include eastern Missouri, southeastern Iowa and central/northwestern Illinois.

Cement Sales and Marketing

Continental Cement’s customers are ready-mixed concrete and concrete products producers and contractors within its markets. Sales are made on the basis of competitive prices in each market and, as is customary in the industry, we do not typically enter into long-term sales contracts.

Cement Competition

Construction of cement production facilities is highly capital intensive and requires long lead times to complete engineering design, obtain regulatory permits, acquire equipment and construct a plant. Most U.S. cement producers are owned by large foreign companies operating in multiple international markets. Continental Cement’s largest competitors are Holcim (US) Inc., Lafarge North America Inc., Buzzi Unicem USA, Inc. and Eagle Materials Inc. Competitive factors include price, reliability of deliveries, location, quality of cement and support services. With a new cement plant, on-site raw material aggregate supply, a network of cement terminals, and longstanding customer relationships, we believe we are well positioned to serve our customers vis-à-vis our competitors.

Our Ready-mixed Concrete Operations

Ready-mixed Concrete Products

We believe our Central and West regions are leaders in the supply of ready-mixed concrete in their respective markets. Our Central region supplies concrete to the Wichita, Kansas and Columbia, Missouri markets and surrounding areas. The West region has ready-mixed concrete operations in the Salt Lake Valley, Utah, Twin Falls, Idaho and Grand Junction, Colorado markets. We produce ready-mixed concrete by blending aggregates, cement, chemical admixtures in various ratios and water at our concrete production plants and placing the resulting product in ready-mixed concrete trucks where it is then delivered to our customers.

Our aggregates business serves as the primary source of the raw materials for our concrete production, functioning essentially as a supplier to our ready-mixed concrete operations. Different types of concrete include lightweight concrete, high performance concrete, self compacting/consolidating concrete and architectural concrete and are used in a variety of activities ranging from building construction to highway paving.

We operate 16 ready-mixed concrete plants and 141 concrete delivery trucks in the Central region. We also operate 30 ready-mixed concrete plants and 319 concrete delivery trucks in the West region, including the assets obtained in the January 17, 2014 acquisition of Alleyton.

Ready-mixed Concrete Competition

Ready-mixed concrete production requires relatively small amounts of capital to build a concrete batching plant and acquire delivery trucks. As a result, in each local market, we face competition from numerous small producers, as well as other large vertically integrated companies with facilities in multiple markets. There are approximately 5,500 ready-mixed concrete plants in the United States, and in 2012 the United States ready-mixed industry produced approximately 291 million cubic yards of ready-mixed concrete according to the NRMCA.

Our ready-mixed concrete operations compete with CRH plc in Utah and Colorado and various other privately owned competitors in other parts of the Central and West regions.

11

Competition among ready-mixed concrete suppliers is generally based on product characteristics, delivery times, customer service and price. Product characteristics such as tensile strength, resistance to pressure, durability, set times, ease of placing, aesthetics, workability under various weather and construction conditions as well as environmental effect are the main criteria that our customers consider for selecting their product. Our quality assurance program produces results in excess of design strengths while optimizing material costs. Additionally, we believe our strategic network of locations and superior customer service gives us a competitive advantage relative to other producers.

Our Asphalt Paving Mix Operations

Asphalt Paving Mix Products

Our asphalt paving mix products are produced by first heating carefully measured amounts of aggregates at high temperatures to remove the moisture from the materials in an asphalt paving mix plant. As the aggregates are heated, liquid asphalt is then introduced to coat the aggregates. Depending on the specifications of a particular mix, recycled asphalt may be added to the mix, which lowers the production costs. The aggregates used for our production of these products are generally supplied from our quarries or sand and gravel plants. The ingredients are metered, mixed and brought up to a temperature in excess of 300°F before being placed in a truck and delivered to the jobsite for final placement.

We operate five asphalt paving mix plants in the Central region, 22 plants in the West region and 15 plants in the East region. 95% of our plants can utilize recycled asphalt pavement.

Asphalt Paving Mix Markets

Asphalt paving mix is generally applied at high temperatures. Prolonged exposure to air causes the mix to lose temperature and harden. Therefore, delivery is typically within close proximity to the asphalt paving mix plant. Local market demand, proximity to competition, transportation costs and supply of aggregates and liquid asphalt vary widely from market to market. Most of our hot mix asphalt operations use a combination of company-owned and hired haulers to deliver materials to job sites.

Asphalt Paving Mix Sales and Marketing

Approximately 83% of the asphalt paving mix we produce is installed by our own paving crews. The rest is sold on a per ton basis to road contractors for the construction of roads, driveways and parking lots, as well as directly to state departments of transportation and local authorities.

Asphalt Paving Mix Competition

According to the National Asphalt Pavement Association, there are approximately 4,000 asphalt paving mix plants in the United States and an estimated 360 million tons of asphalt paving mix was produced in 2012. Our asphalt paving mix operations compete with CRH plc and other local suppliers in each of our three regions. Based on availability of internal aggregate supply, quality, operating efficiencies, and location advantages, we believe we are well-positioned vis-à-vis our competitors.

Asphalt Paving and Related Construction Services

As part of our vertical integration strategy, we provide asphalt and concrete paving and related construction services to both the public infrastructure and private sectors as either a prime or sub-contractor. These services complement our heavy construction materials business by providing a reliable downstream outlet, in addition to our external distribution channels.

Our asphalt paving and construction services businesses bid on both public infrastructure and private construction projects in their respective local markets. We only provide construction services operations as a complement to our heavy construction materials operation, which we believe is a major competitive strength. Factors affecting competitiveness in this business segment include price, estimating abilities, knowledge of local markets and conditions, project management, financial strength, reputation for quality and the availability of machinery and equipment.

Our contracts with our customers are primarily “fixed unit price” or “fixed price.” Under fixed unit price contracts, we provide materials or services at fixed unit prices (for example, dollars per ton of asphalt placed). While the fixed unit price contract shifts the risk of estimating the quantity of units required for a particular project to the customer, any increase in our unit cost over the expected unit cost in the bid, whether due to inflation, inefficiency, errors in our estimates or other factors, is borne by us unless otherwise provided in the contract. Most of our contracts contain escalators for increases in liquid asphalt prices.

12

Customers

Our business is not dependent on any single customer or a few customers. Therefore, the loss of any single or particular small number of customers would not have a material adverse effect on any individual respective market in which we operate or on us as a whole. No individual customer accounted for more than 10% of our 2013 revenue.

Seasonality

Use and consumption of our products fluctuate due to seasonality. Nearly all of the products used by us, and by our customers, in the public infrastructure or private construction industry are used outdoors. Our highway operations and production and distribution facilities are also located outdoors. Therefore, seasonal changes and other weather-related conditions, in particular extended rainy and cold weather in the spring and fall and major weather events, such as hurricanes, tornadoes, tropical storms and heavy snows, can adversely affect our business and operations through a decline in both the use of our products and demand for our services. In addition, the construction materials business production and shipment levels follow activity in the construction industry, which typically occurs in the spring, summer and fall. Warmer and drier weather during the second and third quarters of our fiscal year typically result in higher activity and revenue levels during those quarters. The first quarter of our fiscal year has typically lower levels of activity due to weather conditions.

Backlog

Our products are generally delivered upon receipt of orders or requests from customers, or shortly thereafter. Accordingly, the backlog associated with product sales is converted into revenue within a relatively short period of time. Inventory for products is generally maintained in sufficient quantities to meet rapid delivery requirements of customers.

Our construction services backlog represents our estimate of the revenue that will be realized under the portion of the construction contracts remaining to be performed. We generally include a project in our contract backlog at the time a contract is awarded and funding is in place. Many of our construction services are awarded and completed within one year and, therefore, may not be reflected in our beginning or ending contract backlog. Substantially all of the contracts in our contract backlog may be canceled or modified at the customer’s discretion. However, we have not been materially adversely affected by contract cancellations or modifications in the past.

As a vertically-integrated business, approximately 27% of our aggregates production is further processed and sold as a downstream product, such as asphalt paving mix or ready-mixed concrete, or used in our construction services business. Approximately 83% of the asphalt paving mix we produce is installed by our own paving crews. A period over period increase or decrease of backlog does not necessarily result in an improvement or a deterioration of our business. Our backlog includes only those products and projects for which we have obtained a purchase order or a signed contract with the customer and does not include products purchased and sold or services awarded and provided within the period. The following table sets forth, by product, our backlog as of the indicated dates:

| | | | | | | | | | | | |

| | | December 28,

2013 | | | December 29,

2012 | | | December 31,

2011 | |

| (in thousands) | | | | | | | | | |

Aggregate (in tons) | | | 5,153 | | | | 3,881 | | | | 2,905 | |

Ready-mixed concrete (in cubic yards) | | | 138 | | | | 155 | | | | 259 | |

Asphalt (in tons) | | | 2,387 | | | | 2,314 | | | | 2,267 | |

Construction services | | $ | 359,263 | | | $ | 288,673 | | | $ | 329,802 | |

Intellectual Property

We do not own or have a license or other rights under any patents that are material to any of our businesses.

Employees

As of December 28, 2013, we had approximately 3,300 employees of whom approximately 75.0% were hourly workers and the remainder were full time salaried employees. Because of the seasonal nature of our industry, many of our hourly and certain of our full time employees are subject to seasonal layoffs. The scope of layoffs varies greatly from season to season as they are predominantly a function of the type of projects in process and the weather during the late fall through early spring.

Approximately 6.8% of our hourly employees are union members and approximately 0.4% of our full time salaried employees are union members. We believe we enjoy a satisfactory working relationship with our employees and their unions.

13

Environmental and Government Regulation

Our operations are subject to federal, state and local laws and regulations relating to the environment and to health and safety, including noise, discharges to air and water, waste management including the management of hazardous waste used as a fuel substitute at our Hannibal, Missouri cement kiln, remediation of contaminated sites, mine reclamation, operation of landfills, dust control and zoning and permitting. While we believe our operations are in substantial compliance with applicable requirements, there can be no assurance that compliance costs will not be significant.

In addition, our operations are subject to environmental, zoning and land use regulations and require numerous governmental approvals and permits. Environmental operating permits are subject to modification, renewal and revocation and can require us to make capital, maintenance and operational expenditures to comply with the applicable requirements. Although not expected to be a significant impediment, stricter laws and regulations, or more stringent interpretations of existing laws or regulations, may impose new liabilities on us, reduce operation hours, require additional investment by us in pollution control equipment or impede our opening new or expanding existing plants or facilities. We regularly monitor and review our operations, procedures and policies for compliance with existing environmental laws and regulations, changes in interpretations of existing laws and enforcement policies, new laws that are adopted, and new requirements that we anticipate will be adopted that could affect our operations.

For our operations, we are subject to zoning requirements and permit limitations. Applicable permits may include conditional use permits to allow us to operate in certain areas absent zoning approval and operational permits governing particulate matter and storm water management and control. In addition, we are often required to obtain bonding for future reclamation costs, most commonly specific to restorative grading and seeding of disturbed surface areas.

Multiple permits are required to operate our cement plant. Like others in the cement business, we expend substantial amounts to comply with these environmental laws and regulations and permit limitations, which include amounts for pollution control equipment required to monitor and regulate air emissions. Since many of these requirements are likely to be affected by future legislation or rule making by government agencies, and are therefore not quantifiable, it is not possible to accurately predict the aggregate future costs of compliance and their effect on our future results of operations, financial condition or liquidity.

At most of our quarries, we incur reclamation obligations as part of our mining activities. Reclamation methods and requirements can vary depending on the individual site and state regulations. Generally, we are required to grade the mined properties to a certain slope and seed the property to prevent erosion. We record a mining reclamation liability in our consolidated financial statements to reflect the estimated fair value of the cost to reclaim each property including active and closed sites.

Our operations in Kansas include one municipal waste landfill and two construction and demolition debris landfills, one of which has been closed. Among other environmental, health and safety requirements, we are subject to obligations to appropriately close those landfills at the end of their useful lives and provide for appropriate post-closure care. Asset retirement obligations relating to these landfills are recorded in our consolidated financial statements.

Health and Safety

Our facilities and operations are subject to a variety of worker health and safety requirements, particularly those administered by the federal Mine Safety and Health Administration and the Occupational Safety and Health Administration, which are likely to become stricter in the future. Throughout our organization, we strive for a zero-incident safety culture and full compliance with safety regulations. Failure to comply with these requirements can result in fines and penalties and claims for personal injury and property damage. These requirements may also result in increased operating and capital costs in the future. We believe we are in substantial compliance with such requirements, but we cannot guarantee that violations will not occur, and any violations could result in additional costs.

At Summit Materials and our operating companies, worker safety and health matters are overseen by our corporate Risk Management and Safety department as well as company level safety managers. We provide leadership and support, comprehensive training, and other tools designed to accomplish health and safety goals, reduce risk, eliminate hazards, and ultimately make our work places safer.

We believe that the continuous support and leadership of our management team, along with the commitment and desire of all our employees to eliminate injuries and other incidents, will aid our journey towards our goal of zero incidents.

Insurance

Our insurance program is structured using multiple “A” rated insurance carriers, and a variety of deductible amounts. In particular, our workers compensation and auto liability policies are subject to a $250,000 per occurrence deductible, and the general liability policy has a $100,000 deductible. Losses within these deductibles are accrued for using projections based on past loss history.

We also maintain $50.0 million in combined umbrella insurance. Other policies have smaller deductibles and include property, contractors equipment, contractors pollution and professional, directors and officers, employment practices liability and fiduciary and crime. We also have a separate marine insurance policy for our Continental Cement business.

14

Risks Related to Our Business and Our Industry

Industry Risks

Our business depends on activity within the construction industry and the strength of the local economies in which we operate.

We sell most of our building materials and provide all of our highway construction and paving services to the construction industry, so our results depend on the strength of the construction industry. Demand for our products, particularly in the residential and non-residential construction markets, could remain weak, and decline, if companies and consumers cannot obtain credit for construction projects or if the slow pace of economic activity results in delays or cancellations of capital projects. In addition, federal and state budget issues may continue to hurt the funding available for infrastructure spending, particularly highway construction, which constitutes a significant portion of our business.

Our earnings depend on the strength of the local economies in which we operate because of the high cost to transport our products relative to their price. In recent years, many states reduced their construction spending due to budget shortfalls resulting from lower tax revenue as well as uncertainty relating to long-term federal highway funding. As a result, there has been a reduction in many states’ investment in infrastructure spending. If economic and construction activity diminish in one or more areas, particularly in our top revenue-generating markets of Texas, Kansas, Kentucky, Missouri and Utah, our results of operations and liquidity may be materially adversely affected and there is no assurance that reduced levels of construction activity will not continue to affect our business in the future.

Our business is cyclical and requires significant working capital to fund operations.

Our business is cyclical and requires that we maintain significant working capital to fund our operations. Our ability to generate sufficient cash flow depends on future performance, which will be subject to general economic conditions, industry cycles and financial, business and other factors affecting our operations, many of which are beyond our control. If we are unable to generate sufficient cash to operate our business and service our outstanding debt and other obligations, we may be required, among other things, to further reduce or delay planned capital or operating expenditures, sell assets or take other measures, including the restructuring of all or a portion of our debt, which may only be available, if at all, on unsatisfactory terms.

Weather can materially affect our business and we are subject to seasonality.

Nearly all of the products used by us, and by our customers, in the public infrastructure or private construction industry are used outdoors. In addition, our highway operations and production and distribution facilities are located outdoors. Therefore, seasonal changes and other weather-related conditions can adversely affect our business and operations through a decline in both the use of our products and demand for our services.

Adverse weather conditions such as extended rainy and cold weather in the spring and fall can reduce demand for our products by contractors and reduce sales or render our contracting operations less efficient. Occasionally, major weather events such as hurricanes, tornadoes, tropical storms and heavy snows with quick rainy melts adversely affect sales in the short term.

The construction materials business production and shipment levels follow activity in the construction industry, which typically occurs in the spring, summer and fall. Warmer and drier weather during the second and third quarters of our fiscal year typically result in higher activity and revenue levels during those quarters. The first quarter of our fiscal year has typically lower levels of activity due to the weather conditions. Our second quarter varies greatly with the spring rains and wide temperature variations. A cool wet spring increases drying time on projects, possibly delaying sales in the second quarter, while a warm dry spring may enable earlier project startup.

Our industry is capital intensive and portions of our business have significant fixed and semi-fixed costs. Therefore, our earnings are sensitive to changes in volume.

The property and machinery needed to produce our products can be very expensive. Therefore, we need to spend a substantial amount of capital to purchase and maintain the equipment necessary to operate our business. Although we believe that our current cash balance, along with our projected internal cash flows and our available financing resources, will be enough to give us the cash we need to support our currently anticipated operating and capital needs, if we are unable to generate sufficient cash to purchase and maintain the property and machinery necessary to operate our business, we may be required to reduce or delay planned capital expenditures or incur additional debt. In addition, given the level of fixed and semi-fixed costs within our business, particularly at our cement production facility, decreases in volumes can negatively affect our financial position, results of operations and liquidity.

15

Within our local markets, we operate in a highly competitive industry.

The U.S. construction aggregates industry is highly fragmented with a large number of independent local producers in a number of our markets. Additionally, in most markets, we compete against large private and public infrastructure companies, some of which are also vertically-integrated. Therefore, there is intense competition in a number of the markets in which we operate. This significant competition could lead to lower prices, lower sales volumes and higher costs in some markets, negatively affecting our financial position, results of operations and liquidity.

Growth Risks

The success of our business depends, in part, on our ability to execute on our acquisition strategy, the successful integration of acquisitions and the retention of key employees of our acquired businesses.

A significant portion of our historical growth has occurred through acquisitions and we will likely enter into acquisitions in the future. We have evaluated and expect to continue to evaluate possible acquisition transactions on an ongoing basis. At any time we may be engaged in discussions or negotiations with respect to several possible acquisitions. From time to time we enter into letters of intent to allow us to conduct due diligence on a confidential basis. Currently, we are in preliminary discussions with several potential acquisition targets. There can be no assurance that we will enter into definitive agreements with respect to such transactions or that they will be completed. Our growth has placed, and will continue to place, significant demands on our management and operational and financial resources. Acquisitions involve risks that the businesses acquired will not perform in accordance with expectations and that business judgments concerning the value, strengths and weaknesses of businesses acquired will prove incorrect.

Our interest expense will increase in connection with acquisitions as a result of the assumption or incurrence of debt and contingent liabilities and to the extent we finance such acquisitions with draws on our senior secured revolving credit facility. We may become liable for certain liabilities of any acquired business, whether or not known to us. These risks could include, among others, tax liabilities, product liabilities, environmental liabilities and liabilities for employment practices, and they could be significant.

Acquisitions may require integration of the acquired companies’ sales and marketing, distribution, engineering, purchasing, finance and administrative organizations. We may not be able to integrate successfully any business we acquire or acquired into our existing business and any acquired businesses may not be profitable or as profitable as we had expected. The successful integration of our acquisitions may also require substantial attention from our senior management and the management of the acquired business, which could decrease the time that they have to service and attract customers and develop new products and services. In addition, we may not effectively utilize new equipment that we acquire through acquisitions or otherwise at utilization and rental rates consistent with that of our existing equipment. Furthermore, the complete integration of companies we acquire depends, to a certain extent, on the full implementation of our financial systems and policies. Moreover, because we may actively pursue a number of opportunities simultaneously, we may encounter unforeseen expenses, complications and delays, including difficulties in employing sufficient staff and maintaining operational and management oversight. Our inability to complete the integration of new businesses in a timely and orderly manner could increase costs and lower profits.

We cannot assure you that we will achieve synergies and cost savings in connection with acquisitions. In addition, many of the businesses that we have acquired and will acquire have unaudited financial statements that have been prepared by the management of such companies and have not been independently reviewed or audited. We cannot assure you that the financial statements of companies we have acquired or will acquire would not be materially different if such statements were audited. Finally, we cannot assure you that we will continue to acquire businesses at valuations consistent with our prior acquisitions or that we will complete future acquisitions at all. We cannot assure you that there will be attractive acquisition opportunities at reasonable prices, that financing will be available or that we can successfully integrate such acquired businesses into our existing operations. In addition, our results of operations from these acquisitions could in the future result in impairment charges for any of our intangible assets, including goodwill, or other long-lived assets, particularly if economic conditions materially negatively affect our results of operations, financial condition or liquidity.

Our long-term success is dependent upon securing and permitting aggregate reserves in strategically located areas. The inability to secure and permit such reserves could negatively affect our earnings in the future.

Construction aggregates are bulky and heavy and, therefore, difficult to transport efficiently. Because of the nature of the products, the freight costs can quickly surpass the production costs. Therefore, except for geographic regions that do not possess commercially viable deposits of aggregates and are served by rail, barge or ship, the markets for our products tend to be very localized around our quarry sites and are served by truck. New quarry sites often take a number of years to develop and our strategic planning and new site development must stay ahead of actual growth. Additionally, in a number of urban and suburban areas in which we operate, it is increasingly difficult to permit new sites or expand existing sites due to community resistance. Therefore, our future success is dependent, in part, on our ability to accurately forecast future areas of high growth in order to locate optimal facility sites and on our ability to either acquire existing quarries or secure operating and environmental permits to open new quarries. If we are unable to accurately forecast areas of future growth, acquire existing quarries or secure the necessary permits to open new quarries, our financial condition, results of operations and liquidity may be materially adversely affected.

16

Economic Risks

Our business relies on private investment in infrastructure and a slower than expected recovery will adversely affect our results.

A significant portion of our sales are for projects with non-public owners. Construction spending is affected by developers’ ability to finance projects. The credit environment has negatively affected the U.S. economy and demand for our products in the recent past. Residential and non-residential construction could decline if companies and consumers are unable to finance construction projects or if the economic slowdown continues to cause delays or cancellations of capital projects. If housing starts and non-residential projects do not continue to rise steadily with the economic recovery as they normally do when recessions end, our construction materials and contracting services sales may decline further and our financial position, results of operations and liquidity may be materially adversely affected.