Investor Presentation March 2017 Exhibit 99.1

Safe Harbor and Non-GAAP Financial Metrics Certain statements in this presentation may be deemed to be forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. These statements are not historical facts but rather are based on the Company’s current expectations, estimates and projections regarding the Company’s business, operations and other factors relating thereto. Words such as “may,” “will,” “could,” “would,” “should,” “anticipate,” “predict,” “potential,” “continue,” “expects,” “intends,” “plans,” “projects,” “believes,” “estimates,” “confident” and similar expressions are used to identify these forward-looking statements. Factors that could cause actual results to differ from those reflected in forward-looking statements relating to our operations and business include: fluctuations in the price and availability of resins and other raw materials and our ability to pass any increased costs of raw materials on to our customers in a timely manner; volatility in general business and economic conditions in the markets in which we operate, including, without limitation, factors relating to availability of credit, interest rates, fluctuations in capital and business and consumer confidence; cyclicality and seasonality of the non-residential and residential construction markets and infrastructure spending; the risks of increasing competition in our existing and future markets, including competition from both manufacturers of high performance thermoplastic corrugated pipe and manufacturers of products using alternative materials; our ability to continue to convert current demand for concrete, steel and PVC pipe products into demand for our high performance thermoplastic corrugated pipe and Allied Products; the effect of weather or seasonality; the loss of any of our significant customers; the risks of doing business internationally; the risks of conducting a portion of our operations through joint ventures; our ability to expand into new geographic or product markets; our ability to achieve the acquisition component of our growth strategy; the risk associated with manufacturing processes; our ability to manage our assets; the risks associated with our product warranties; our ability to manage our supply purchasing and customer credit policies; the risks associated with our self-insured programs; our ability to control labor costs and to attract, train and retain highly-qualified employees and key personnel; our ability to protect our intellectual property rights; changes in laws and regulations, including environmental laws and regulations; our ability to project product mix; the risks associated with our current levels of indebtedness; our ability to meet future capital requirements and fund our liquidity needs; a conclusion that the Company’s disclosure controls and procedures (as defined in Rules 13a-15(e) and 15d-15(e) of the Exchange Act) were ineffective; the review of potential weaknesses or deficiencies in the Company’s disclosure controls and procedures, and discovering further weaknesses of which we are not currently aware or which have not been detected; additional uncertainties related to accounting issues generally and other risks and uncertainties described in the Company’s filings with the Securities and Exchange Commission. New risks and uncertainties emerge from time to time and it is not possible for the Company to predict all risks and uncertainties that could have an impact on the forward-looking statements contained in this press release. In light of the significant uncertainties inherent in the forward-looking information included herein, the inclusion of such information should not be regarded as a representation by the Company or any other person that the Company’s expectations, objectives or plans will be achieved in the timeframe anticipated or at all. Investors are cautioned not to place undue reliance on the Company’s forward-looking statements and the Company undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law. This presentation includes certain non-GAAP financial measures to describe the Company’s performance. The reconciliation of those measures to GAAP measures are provided within the appendix of the presentation. Those disclosures should not be viewed as a substitute for operating results determined in accordance with GAAP, nor are they necessarily comparable to non-GAAP performance measures that may be presented by other companies.

ADS at a Glance

ADS – An Industrial Growth Company The leading player in the industry The only complete solutions provider for the water management industry, with a history of product innovation Track record of market share gains with material conversion growing steadily over time Large addressable opportunity across diverse construction markets Demonstrated ability to deliver above market growth, EBITDA margin expansion and strong cash flow generation Experienced management team with significant ownership stake 1 2 3 4 5 6

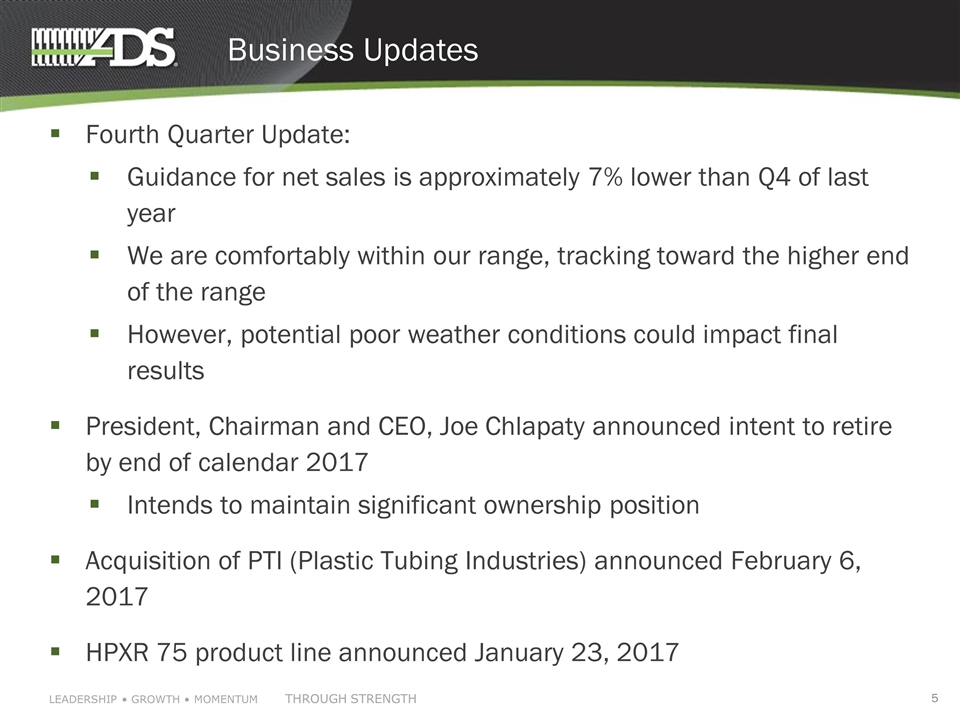

Business Updates Fourth Quarter Update: Guidance for net sales is approximately 7% lower than Q4 of last year We are comfortably within our range, tracking toward the higher end of the range However, potential poor weather conditions could impact final results President, Chairman and CEO, Joe Chlapaty announced intent to retire by end of calendar 2017 Intends to maintain significant ownership position Acquisition of PTI (Plastic Tubing Industries) announced February 6, 2017 HPXR 75 product line announced January 23, 2017

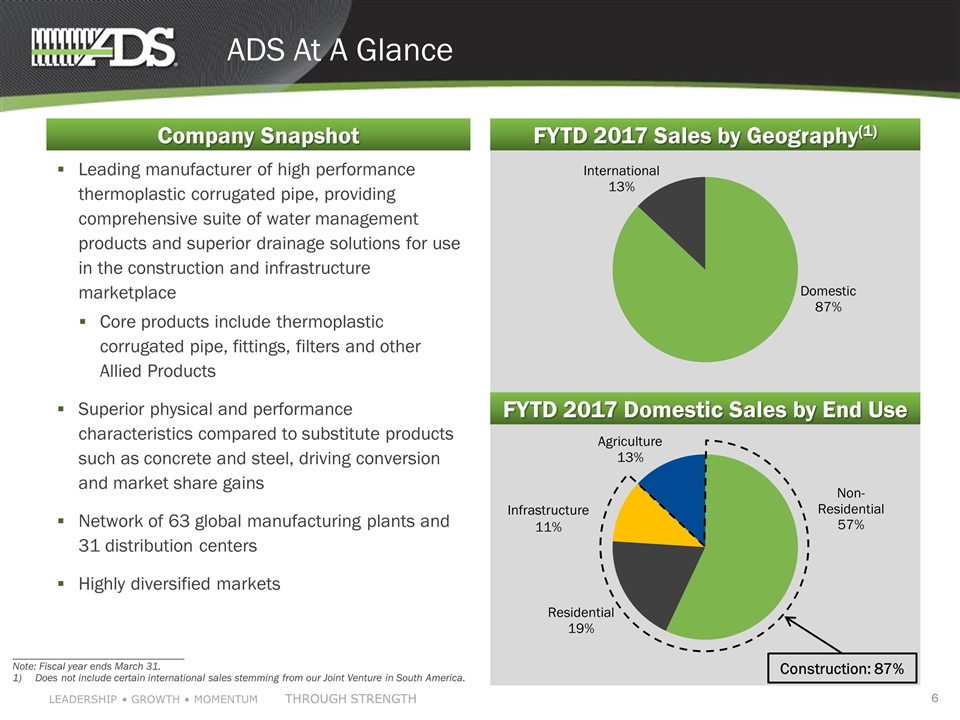

ADS At A Glance Leading manufacturer of high performance thermoplastic corrugated pipe, providing comprehensive suite of water management products and superior drainage solutions for use in the construction and infrastructure marketplace Core products include thermoplastic corrugated pipe, fittings, filters and other Allied Products Superior physical and performance characteristics compared to substitute products such as concrete and steel, driving conversion and market share gains Network of 63 global manufacturing plants and 31 distribution centers Highly diversified markets Company Snapshot ________________________________ Note: Fiscal year ends March 31. 1) Does not include certain international sales stemming from our Joint Venture in South America. FYTD 2017 Domestic Sales by End Use Infrastructure 11% Construction: 87% FYTD 2017 Sales by Geography(1)

Innovative Water Management Solutions Foundation / Sump Wells Culverts / Edge Drains Wastewater Disposal Downspout / Landscape / Window Well Drainage StormTech® Chambers Fittings Pipe Water Quality Nyoplast The only complete solutions provider for the water management industry

Our Competitive Advantages

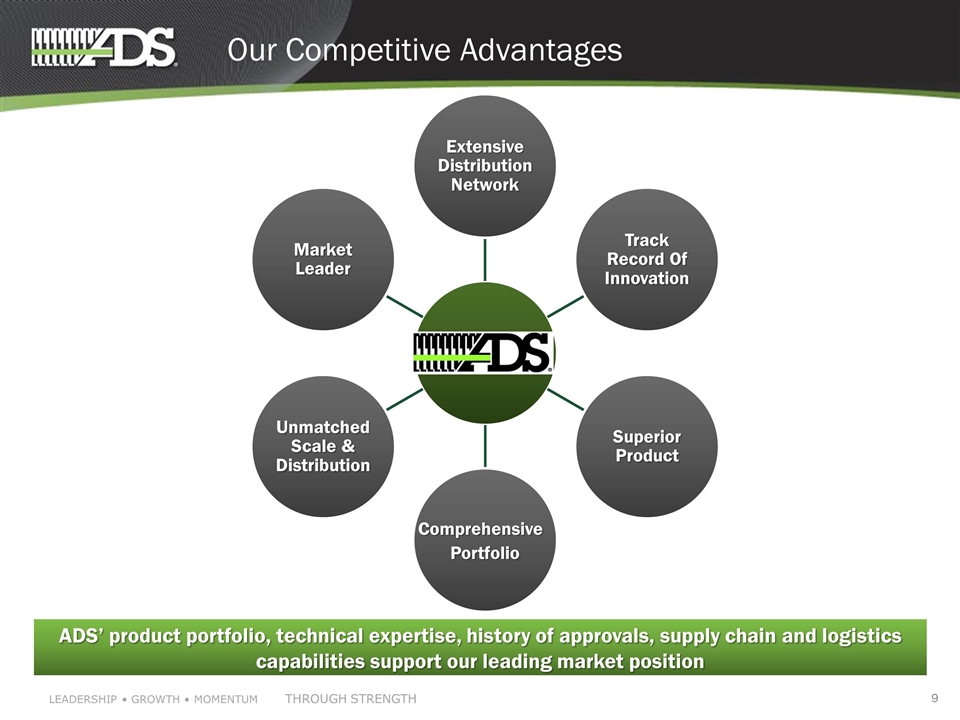

Our Competitive Advantages ADS’ product portfolio, technical expertise, history of approvals, supply chain and logistics capabilities support our leading market position Comprehensive Extensive Distribution Network Track Record Of Innovation Superior Product Portfolio Unmatched Scale & Distribution Market Leader

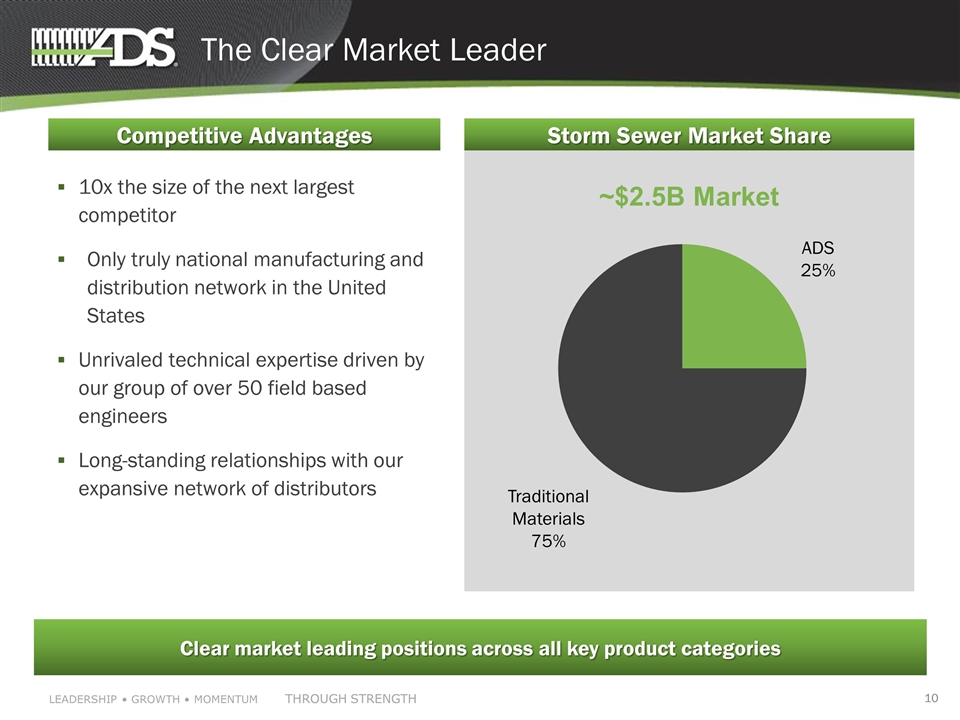

The Clear Market Leader Storm Sewer Market Share 10x the size of the next largest competitor Only truly national manufacturing and distribution network in the United States Unrivaled technical expertise driven by our group of over 50 field based engineers Long-standing relationships with our expansive network of distributors Competitive Advantages Traditional Materials 75% ADS 25% ~$2.5B Market Clear market leading positions across all key product categories

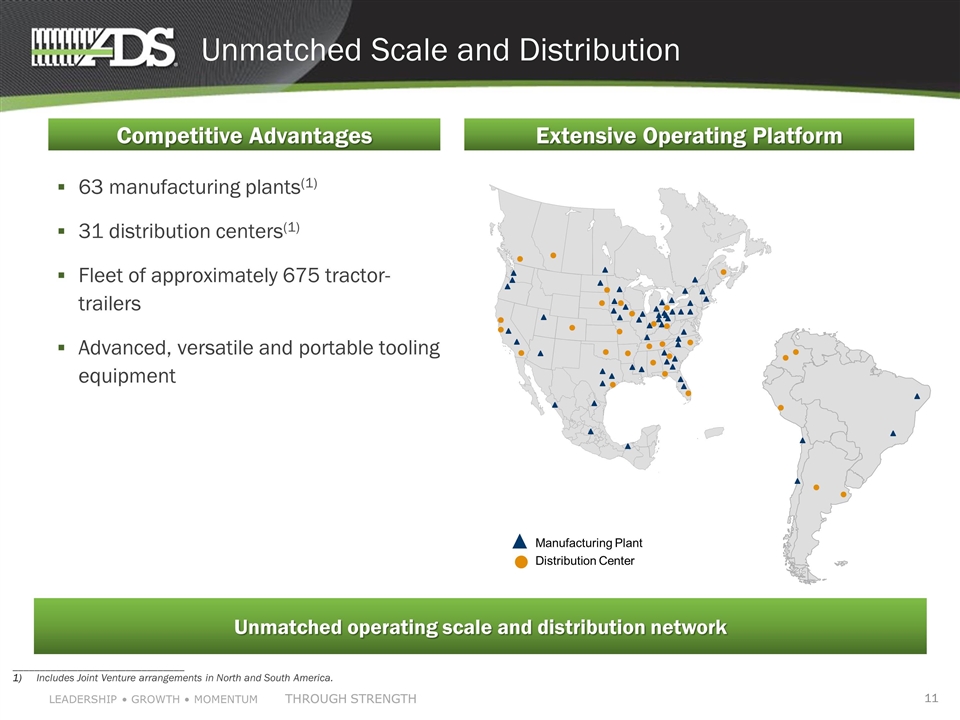

Unmatched Scale and Distribution Extensive Operating Platform Manufacturing Plant Distribution Center 63 manufacturing plants(1) 31 distribution centers(1) Fleet of approximately 675 tractor-trailers Advanced, versatile and portable tooling equipment Competitive Advantages Unmatched operating scale and distribution network ________________________________ Includes Joint Venture arrangements in North and South America.

Comprehensive Product Portfolio Dual Wall (N-12) HP Storm & Sanitary Single Wall Triple Wall Pipe Products Portfolio Allied Products Portfolio StormTech® Chambers Fittings Water Quality Flex Storm Nyoplast Inserta Tee HPXR 75 Comprehensive product offering with attractive growth opportunities

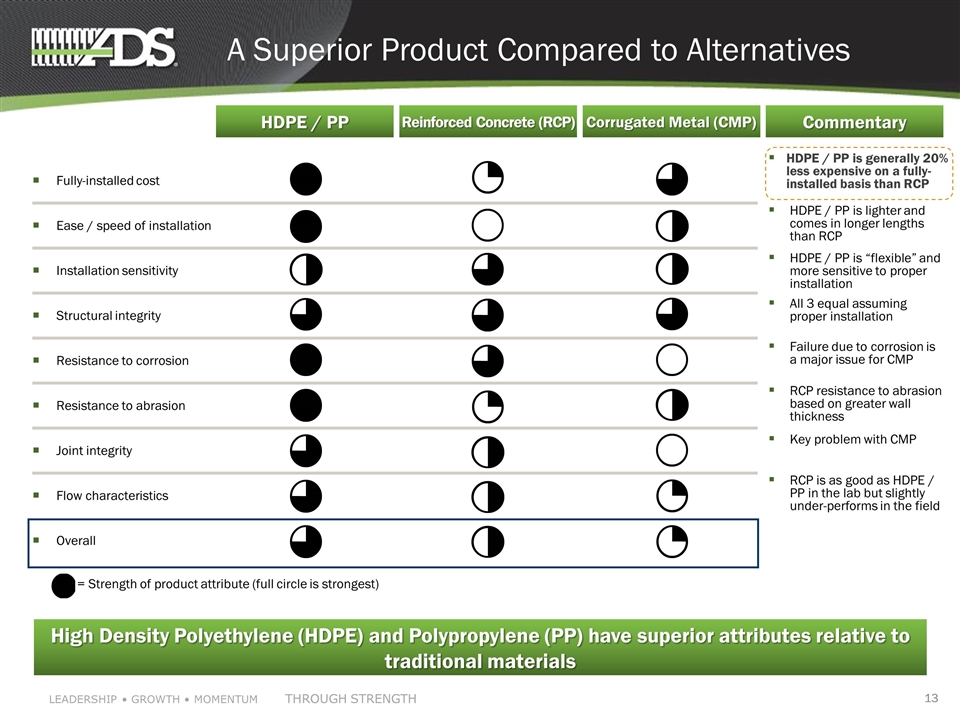

A Superior Product Compared to Alternatives HDPE / PP is generally 20% less expensive on a fully-installed basis than RCP Fully-installed cost Ease / speed of installation Installation sensitivity Structural integrity Resistance to corrosion Resistance to abrasion Joint integrity Flow characteristics Overall = Strength of product attribute (full circle is strongest) RCP resistance to abrasion based on greater wall thickness HDPE / PP is lighter and comes in longer lengths than RCP HDPE / PP is “flexible” and more sensitive to proper installation Key problem with CMP Failure due to corrosion is a major issue for CMP All 3 equal assuming proper installation HDPE / PP Reinforced Concrete (RCP) Corrugated Metal (CMP) Commentary RCP is as good as HDPE / PP in the lab but slightly under-performs in the field High Density Polyethylene (HDPE) and Polypropylene (PP) have superior attributes relative to traditional materials

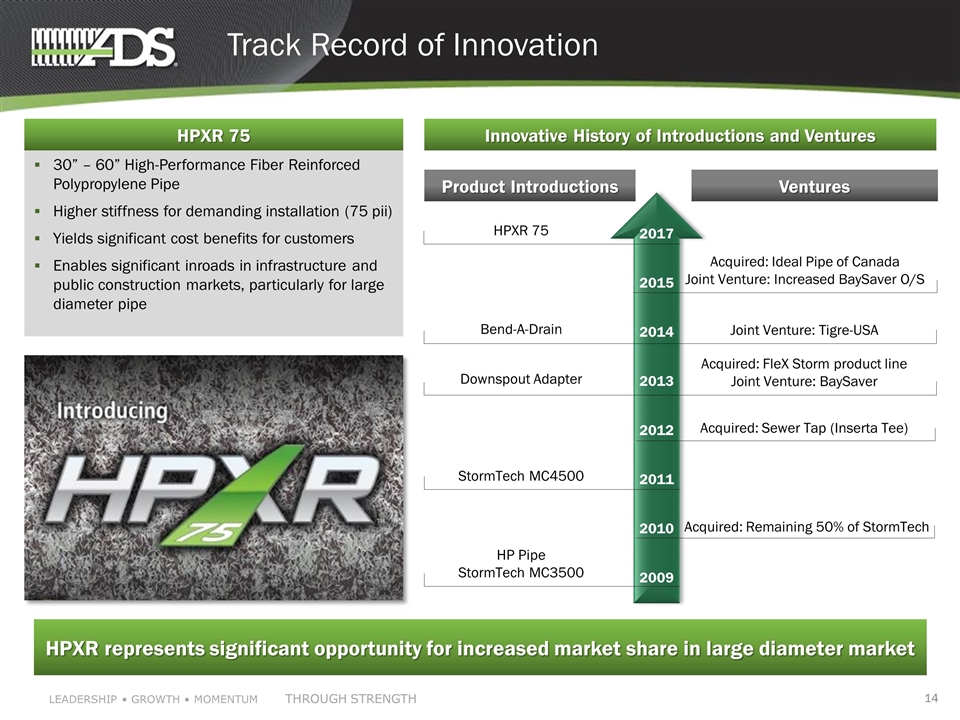

HPXR 75 Track Record of Innovation 30” – 60” High-Performance Fiber Reinforced Polypropylene Pipe Higher stiffness for demanding installation (75 pii) Yields significant cost benefits for customers Enables significant inroads in infrastructure and public construction markets, particularly for large diameter pipe 2010 2012 2013 2009 2011 2014 Innovative History of Introductions and Ventures 2015 2017 Product Introductions Ventures HP Pipe StormTech MC3500 Acquired: Remaining 50% of StormTech StormTech MC4500 Acquired: Sewer Tap (Inserta Tee) Acquired: FleX Storm product line Joint Venture: BaySaver Downspout Adapter Bend-A-Drain Joint Venture: Tigre-USA Acquired: Ideal Pipe of Canada Joint Venture: Increased BaySaver O/S HPXR 75 HPXR represents significant opportunity for increased market share in large diameter market

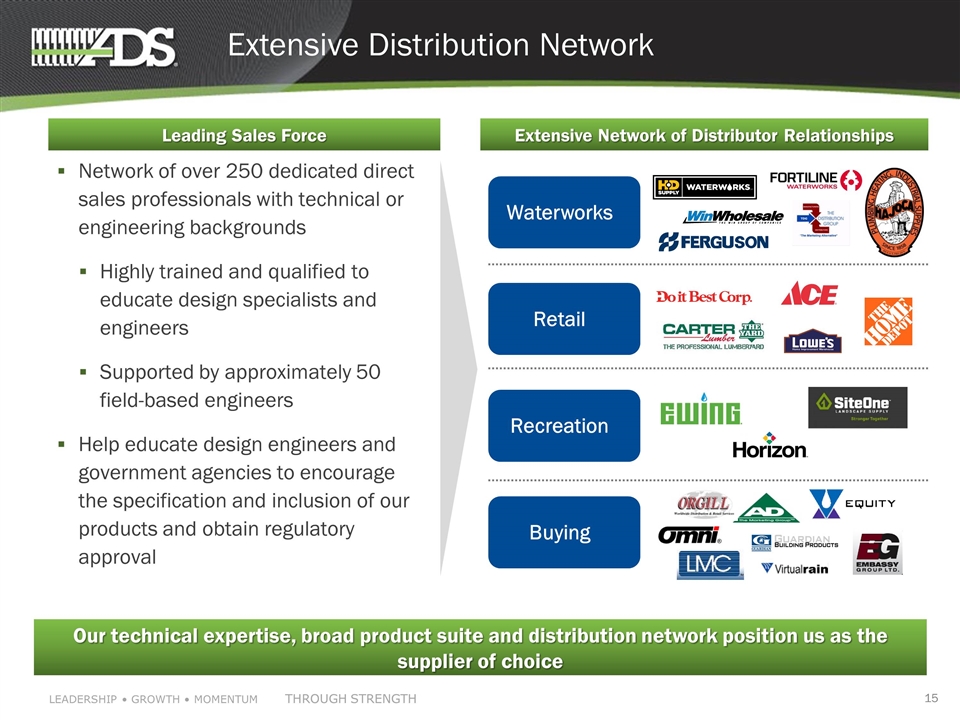

Extensive Distribution Network Network of over 250 dedicated direct sales professionals with technical or engineering backgrounds Highly trained and qualified to educate design specialists and engineers Supported by approximately 50 field-based engineers Help educate design engineers and government agencies to encourage the specification and inclusion of our products and obtain regulatory approval Leading Sales Force Extensive Network of Distributor Relationships Waterworks Retail Recreation Buying Our technical expertise, broad product suite and distribution network position us as the supplier of choice

Our Strategy

Strategic Pillars Increase integrated supply chain planning Optimize network footprint Improve logistics and customer sourcing Build out broader continuous improvement initiatives Operational Excellence Commercial Excellence Strategic Growth Optimize sales force effectiveness Engineering services transformation Customer service transformation Organic investments Innovation Capacity expansion Conversion strategy Allied Products Bolt-on acquisitions International growth Strategic pillars supported by disciplined capital allocation strategy including investments in the business and cash returns to shareholders

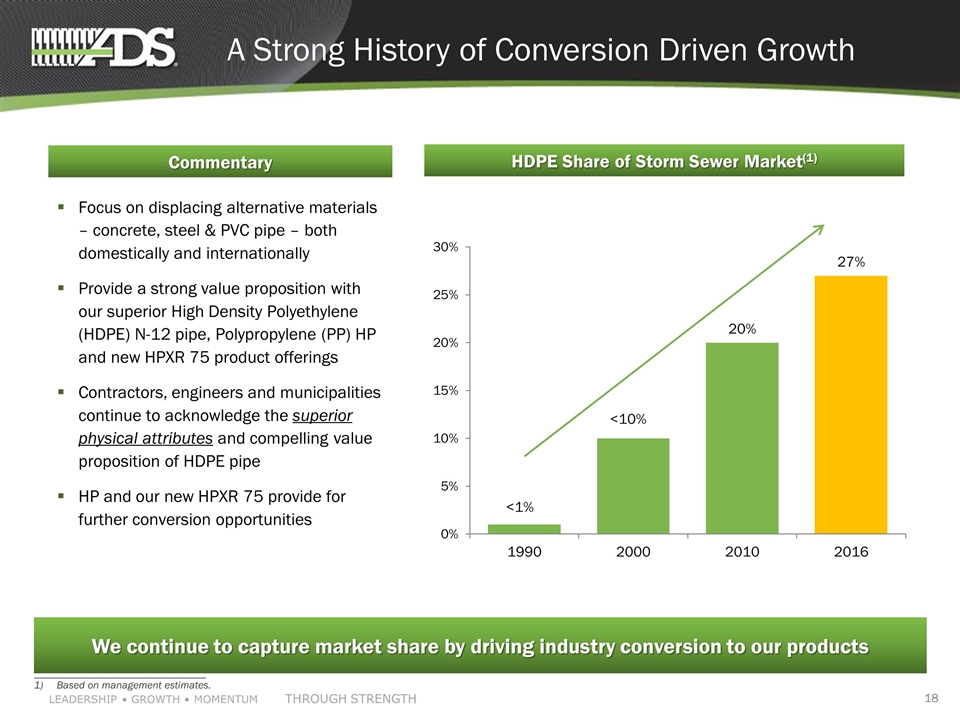

A Strong History of Conversion Driven Growth Commentary HDPE Share of Storm Sewer Market(1) <1% <10% Focus on displacing alternative materials – concrete, steel & PVC pipe – both domestically and internationally Provide a strong value proposition with our superior High Density Polyethylene (HDPE) N-12 pipe, Polypropylene (PP) HP and new HPXR 75 product offerings Contractors, engineers and municipalities continue to acknowledge the superior physical attributes and compelling value proposition of HDPE pipe HP and our new HPXR 75 provide for further conversion opportunities ________________________________ 1) Based on management estimates. We continue to capture market share by driving industry conversion to our products

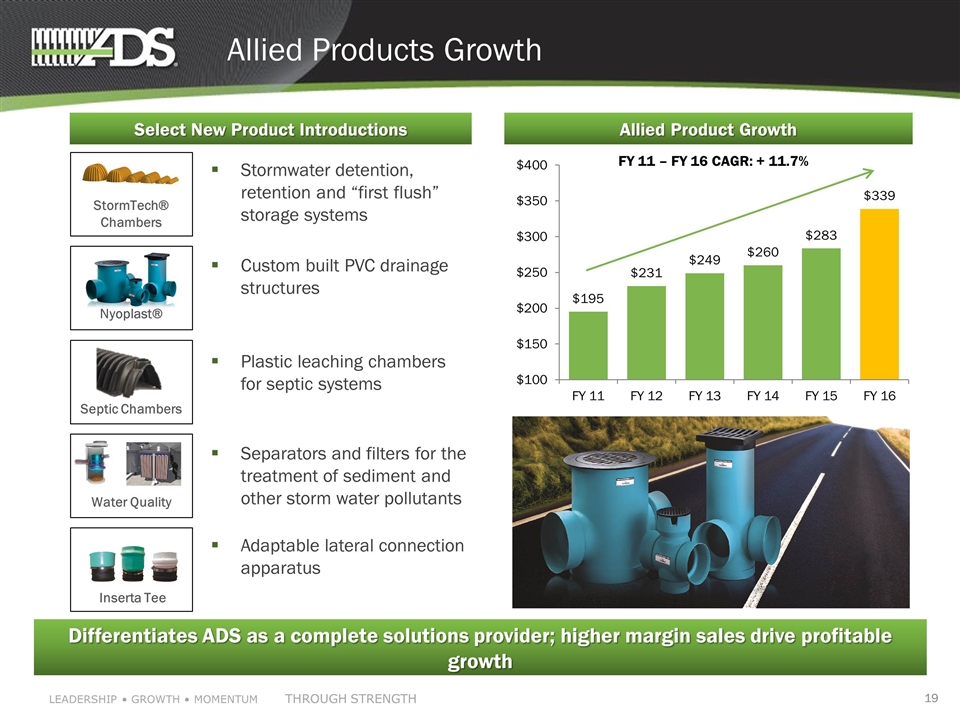

Allied Products Growth Allied Product Growth FY 11 – FY 16 CAGR: + 11.7% Select New Product Introductions StormTech® Chambers Nyoplast® Septic Chambers Water Quality Stormwater detention, retention and “first flush” storage systems Custom built PVC drainage structures Plastic leaching chambers for septic systems Separators and filters for the treatment of sediment and other storm water pollutants Adaptable lateral connection apparatus Differentiates ADS as a complete solutions provider; higher margin sales drive profitable growth Inserta Tee

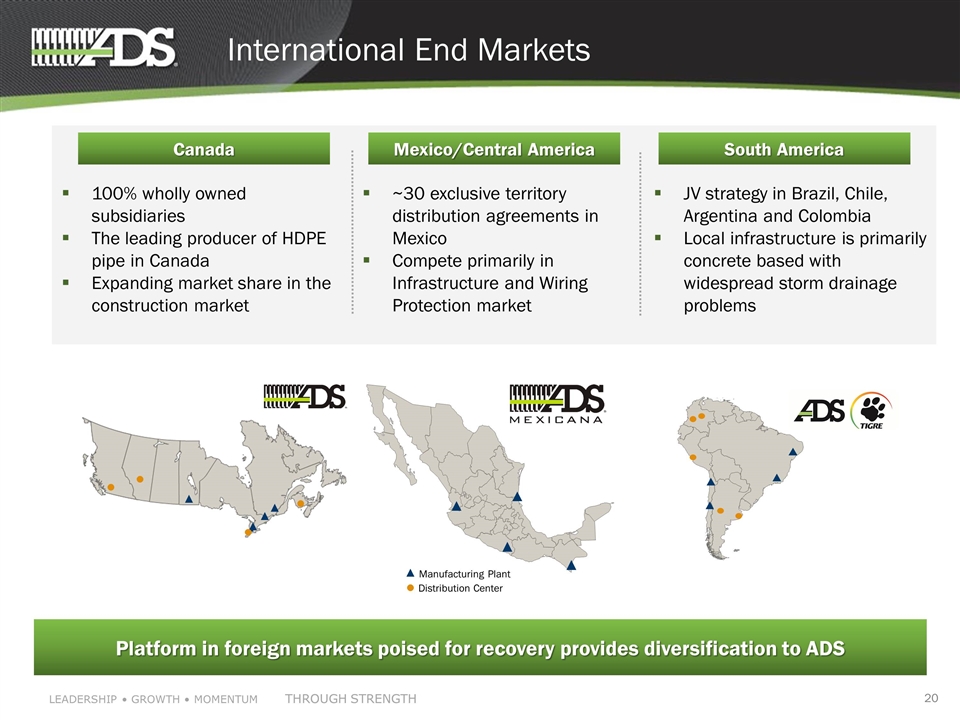

International End Markets Manufacturing Plant Distribution Center CANADA Canada Mexico/Central America South America 100% wholly owned subsidiaries The leading producer of HDPE pipe in Canada Expanding market share in the construction market ~30 exclusive territory distribution agreements in Mexico Compete primarily in Infrastructure and Wiring Protection market JV strategy in Brazil, Chile, Argentina and Colombia Local infrastructure is primarily concrete based with widespread storm drainage problems Platform in foreign markets poised for recovery provides diversification to ADS

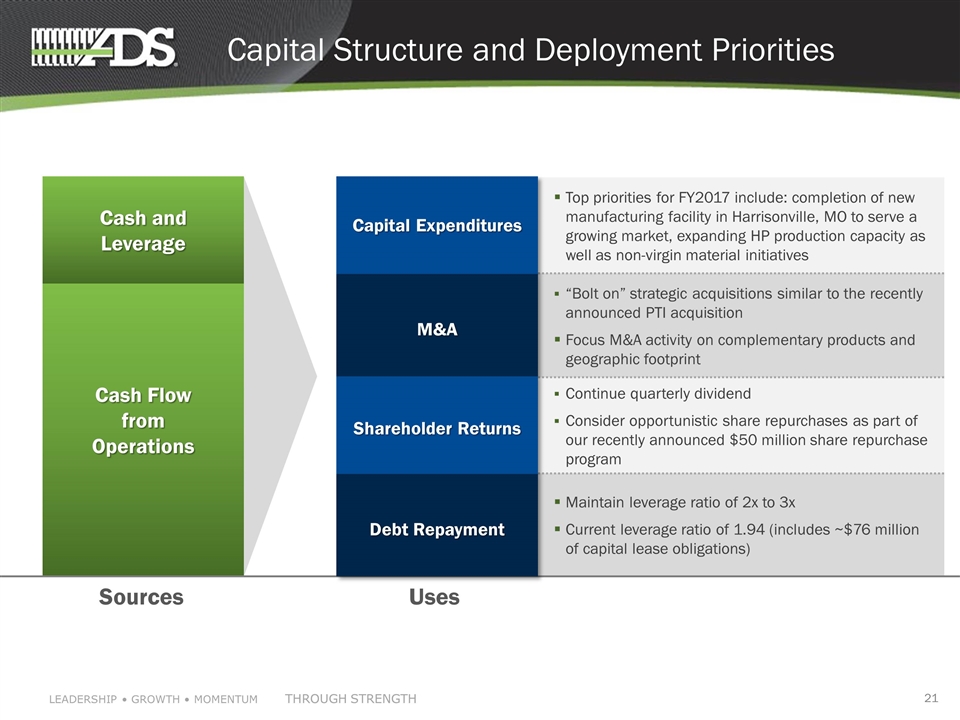

Capital Structure and Deployment Priorities Cash and Leverage Cash Flow from Operations Sources Uses Top priorities for FY2017 include: completion of new manufacturing facility in Harrisonville, MO to serve a growing market, expanding HP production capacity as well as non-virgin material initiatives “Bolt on” strategic acquisitions similar to the recently announced PTI acquisition Focus M&A activity on complementary products and geographic footprint Continue quarterly dividend Consider opportunistic share repurchases as part of our recently announced $50 million share repurchase program Maintain leverage ratio of 2x to 3x Current leverage ratio of 1.94 (includes ~$76 million of capital lease obligations) Capital Expenditures M&A Shareholder Returns Debt Repayment

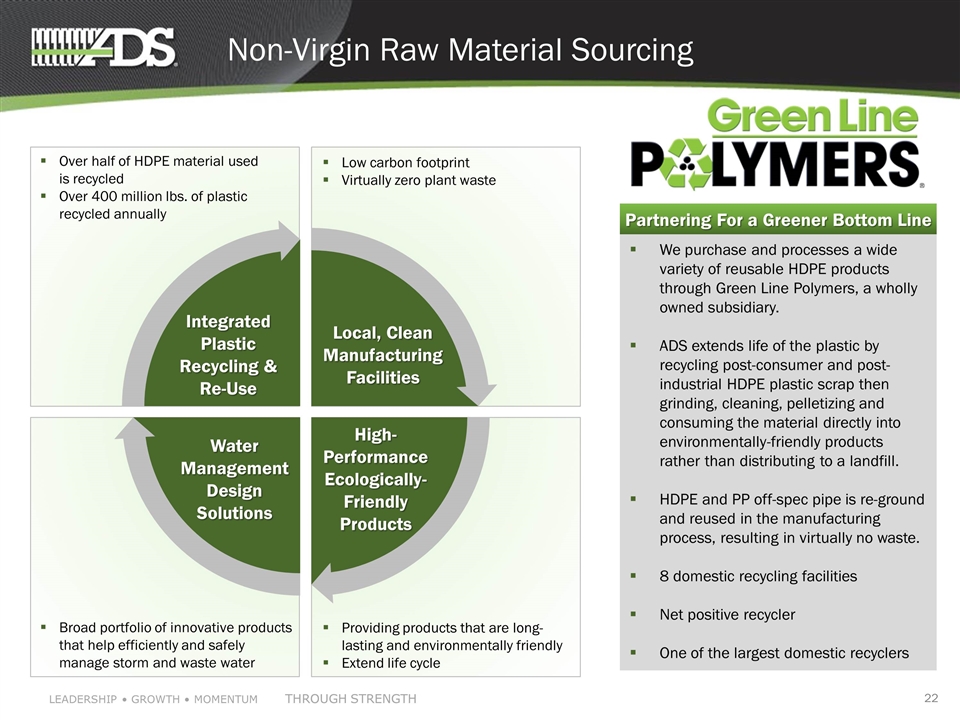

Non-Virgin Raw Material Sourcing We purchase and processes a wide variety of reusable HDPE products through Green Line Polymers, a wholly owned subsidiary. ADS extends life of the plastic by recycling post-consumer and post-industrial HDPE plastic scrap then grinding, cleaning, pelletizing and consuming the material directly into environmentally-friendly products rather than distributing to a landfill. HDPE and PP off-spec pipe is re-ground and reused in the manufacturing process, resulting in virtually no waste. 8 domestic recycling facilities Net positive recycler One of the largest domestic recyclers Partnering For a Greener Bottom Line Local, Clean Manufacturing Facilities High- Performance Ecologically- Friendly Products Water Management Design Solutions Integrated Plastic Recycling & Re-Use Low carbon footprint Virtually zero plant waste Broad portfolio of innovative products that help efficiently and safely manage storm and waste water Over half of HDPE material used is recycled Over 400 million lbs. of plastic recycled annually Providing products that are long-lasting and environmentally friendly Extend life cycle

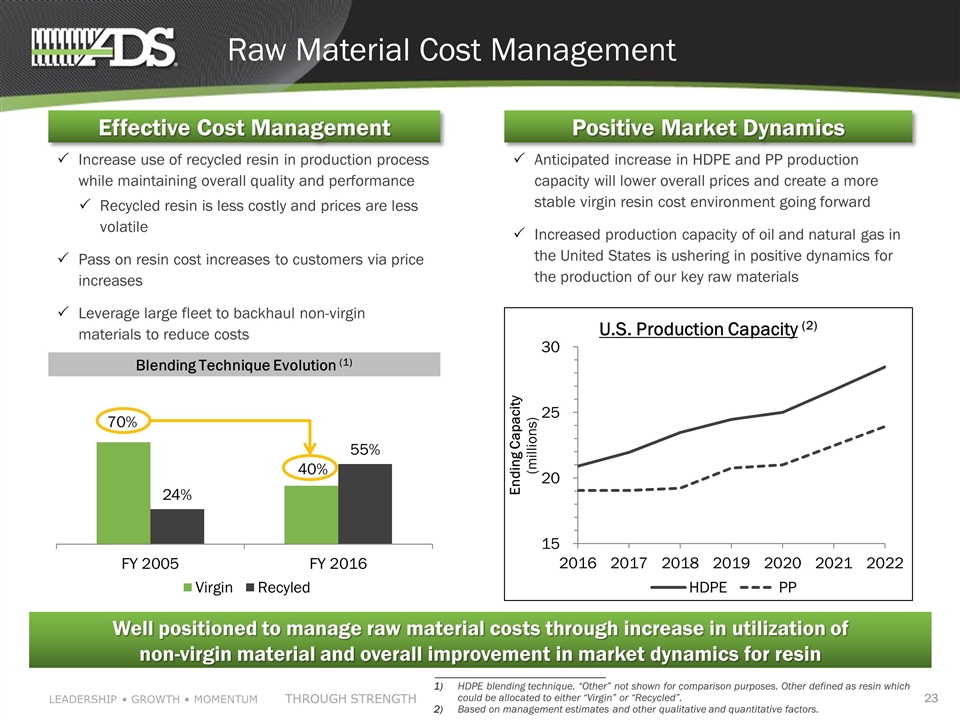

Raw Material Cost Management Increase use of recycled resin in production process while maintaining overall quality and performance Recycled resin is less costly and prices are less volatile Pass on resin cost increases to customers via price increases Leverage large fleet to backhaul non-virgin materials to reduce costs Anticipated increase in HDPE and PP production capacity will lower overall prices and create a more stable virgin resin cost environment going forward Increased production capacity of oil and natural gas in the United States is ushering in positive dynamics for the production of our key raw materials Effective Cost Management Positive Market Dynamics Blending Technique Evolution (1) HDPE blending technique. “Other” not shown for comparison purposes. Other defined as resin which could be allocated to either “Virgin” or “Recycled”. Based on management estimates and other qualitative and quantitative factors. Well positioned to manage raw material costs through increase in utilization of non-virgin material and overall improvement in market dynamics for resin

Our End Markets

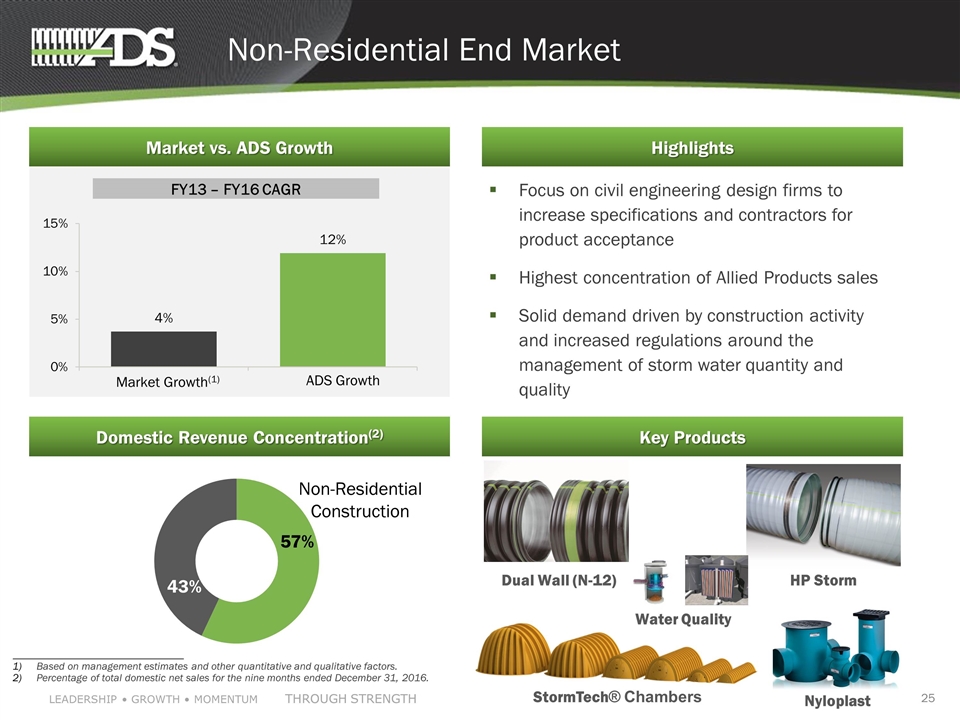

Non-Residential End Market Focus on civil engineering design firms to increase specifications and contractors for product acceptance Highest concentration of Allied Products sales Solid demand driven by construction activity and increased regulations around the management of storm water quantity and quality Market vs. ADS Growth Highlights Domestic Revenue Concentration(2) Market Growth(1) FY13 – FY16 CAGR ADS Growth Non-Residential Construction Key Products Dual Wall (N-12) HP Storm StormTech® Chambers Nyloplast Based on management estimates and other quantitative and qualitative factors. Percentage of total domestic net sales for the nine months ended December 31, 2016. Water Quality

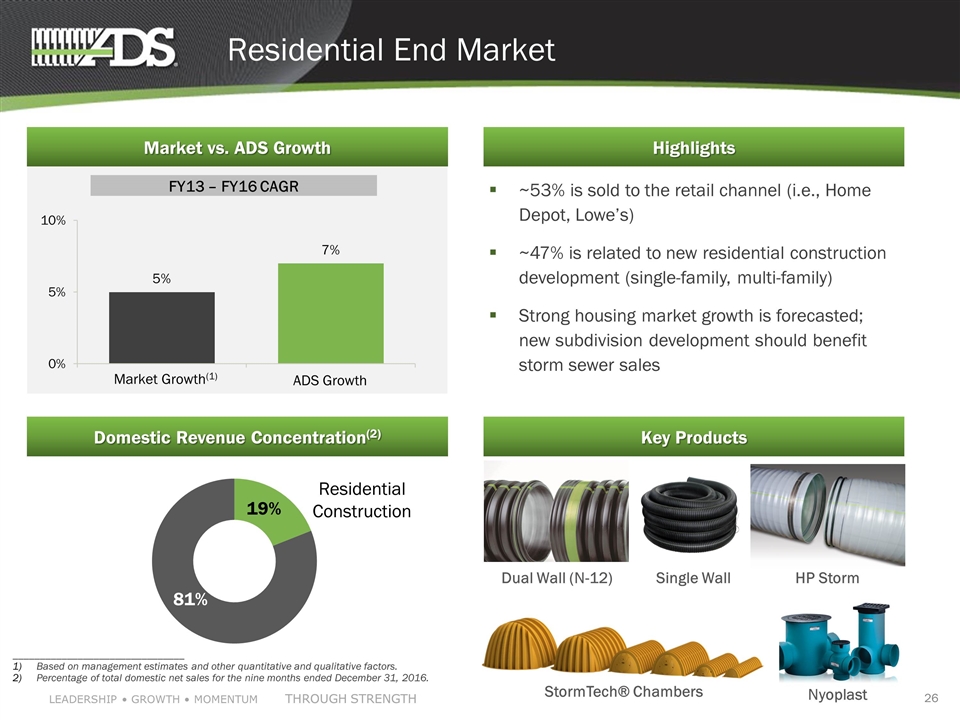

Market Growth(1) FY13 – FY16 CAGR Residential End Market ~53% is sold to the retail channel (i.e., Home Depot, Lowe’s) ~47% is related to new residential construction development (single-family, multi-family) Strong housing market growth is forecasted; new subdivision development should benefit storm sewer sales Market vs. ADS Growth Highlights Domestic Revenue Concentration(2) ADS Growth Residential Construction Key Products Dual Wall (N-12) HP Storm StormTech® Chambers Nyoplast ________________________________ Based on management estimates and other quantitative and qualitative factors. Percentage of total domestic net sales for the nine months ended December 31, 2016. Single Wall

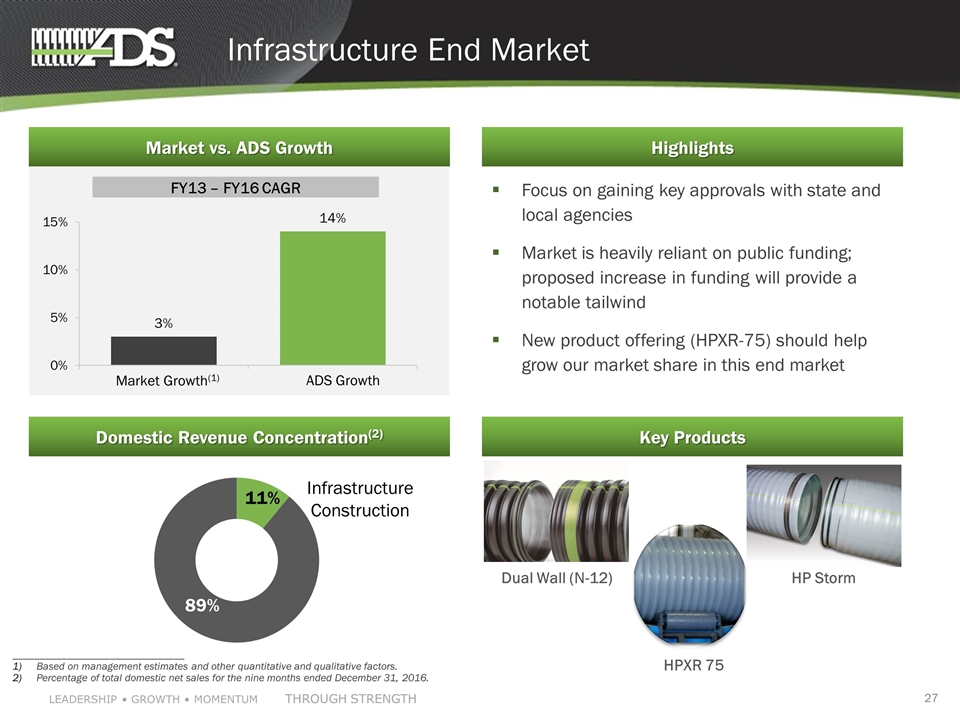

Market Growth(1) FY13 – FY16 CAGR Infrastructure End Market Focus on gaining key approvals with state and local agencies Market is heavily reliant on public funding; proposed increase in funding will provide a notable tailwind New product offering (HPXR-75) should help grow our market share in this end market Market vs. ADS Growth Highlights Domestic Revenue Concentration(2) ADS Growth Infrastructure Construction Key Products Dual Wall (N-12) HP Storm ________________________________ Based on management estimates and other quantitative and qualitative factors. Percentage of total domestic net sales for the nine months ended December 31, 2016. HPXR 75

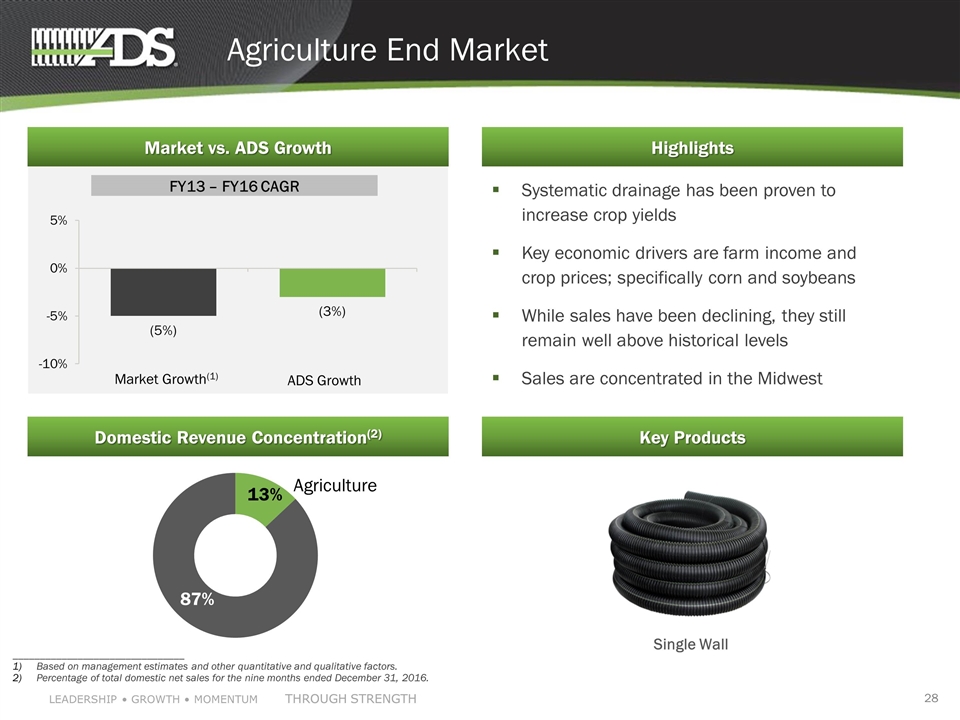

Market Growth(1) FY13 – FY16 CAGR Agriculture End Market Systematic drainage has been proven to increase crop yields Key economic drivers are farm income and crop prices; specifically corn and soybeans While sales have been declining, they still remain well above historical levels Sales are concentrated in the Midwest Market vs. ADS Growth Highlights Domestic Revenue Concentration(2) ADS Growth Agriculture Key Products ________________________________ Based on management estimates and other quantitative and qualitative factors. Percentage of total domestic net sales for the nine months ended December 31, 2016. Single Wall

Financial Outlook

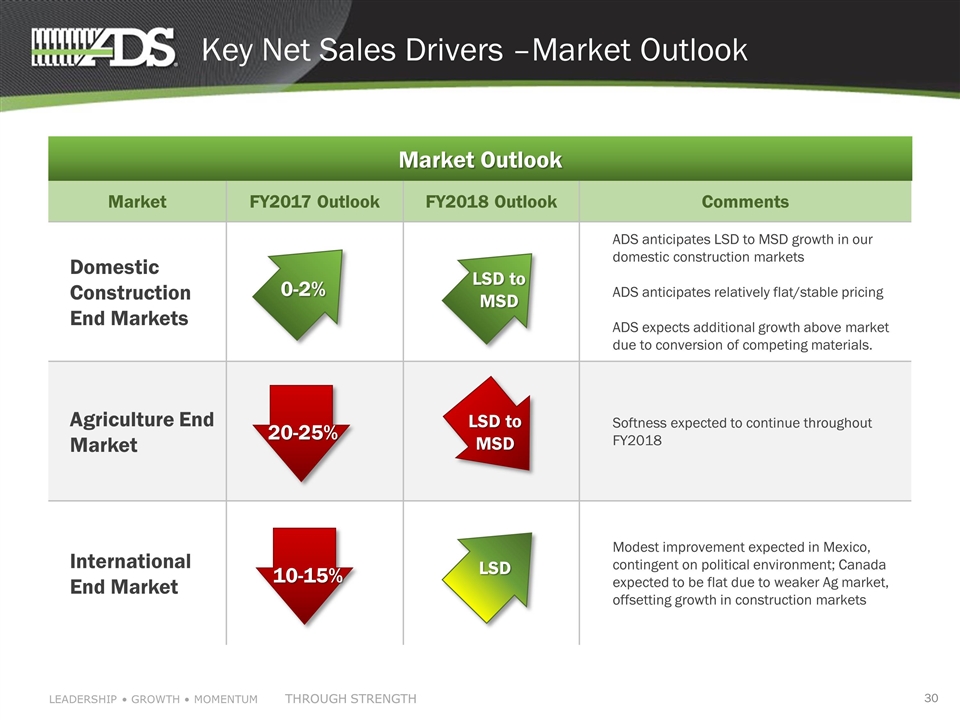

Market FY2017 Outlook FY2018 Outlook Comments Domestic Construction End Markets ADS anticipates LSD to MSD growth in our domestic construction markets ADS anticipates relatively flat/stable pricing ADS expects additional growth above market due to conversion of competing materials. Agriculture End Market Softness expected to continue throughout FY2018 International End Market Modest improvement expected in Mexico, contingent on political environment; Canada expected to be flat due to weaker Ag market, offsetting growth in construction markets Key Net Sales Drivers –Market Outlook Market Outlook 10-15% 20-25% 0-2% LSD to MSD LSD to MSD LSD

Appendix

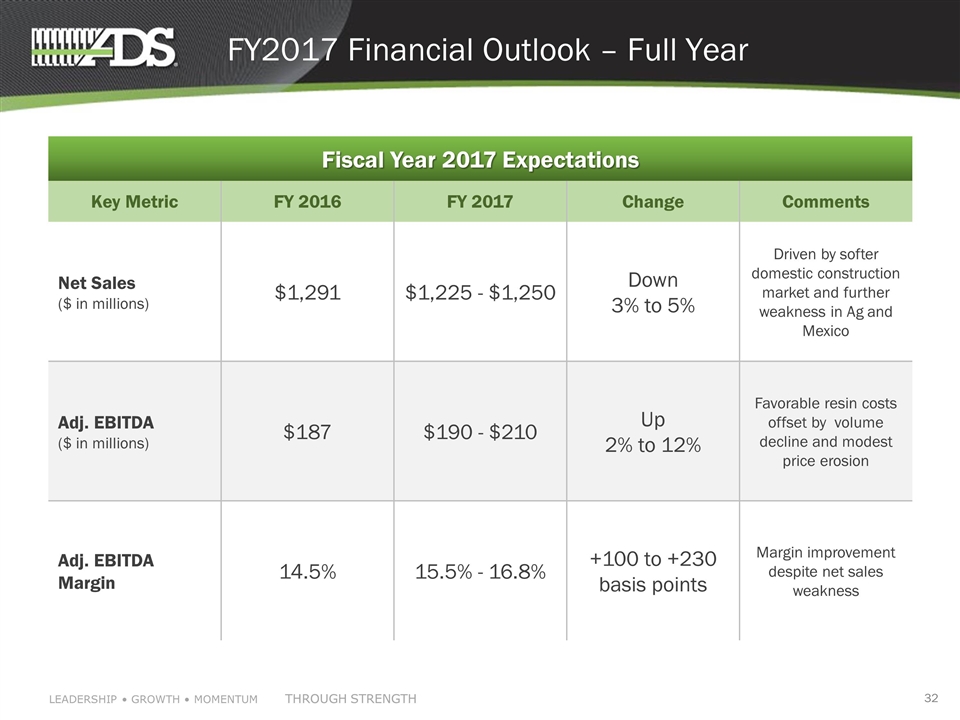

FY2017 Financial Outlook – Full Year Key Metric FY 2016 FY 2017 Change Comments Net Sales ($ in millions) $1,291 $1,225 - $1,250 Down 3% to 5% Driven by softer domestic construction market and further weakness in Ag and Mexico Adj. EBITDA ($ in millions) $187 $190 - $210 Up 2% to 12% Favorable resin costs offset by volume decline and modest price erosion Adj. EBITDA Margin 14.5% 15.5% - 16.8% +100 to +230 basis points Margin improvement despite net sales weakness Fiscal Year 2017 Expectations

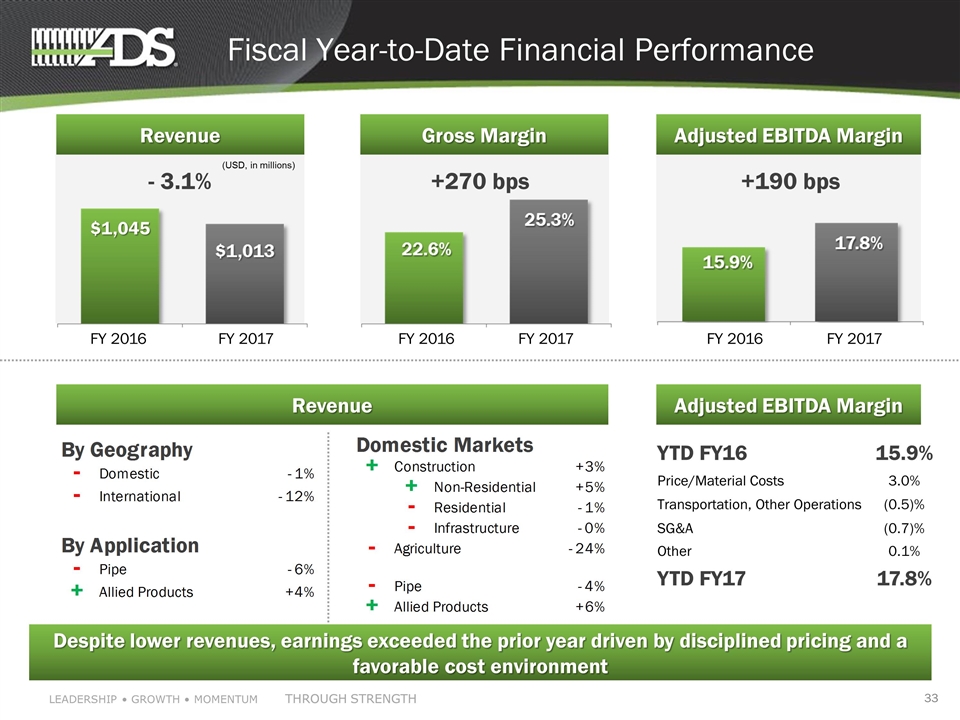

Fiscal Year-to-Date Financial Performance Revenue Gross Margin Adjusted EBITDA Margin FY 2017 FY 2016 FY 2017 FY 2016 FY 2017 FY 2016 - 3.1% +270 bps +190 bps (USD, in millions) $1,045 Revenue Adjusted EBITDA Margin YTD FY16 15.9% Price/Material Costs 3.0% Transportation, Other Operations (0.5)% SG&A (0.7)% Other 0.1% YTD FY17 17.8% Despite lower revenues, earnings exceeded the prior year driven by disciplined pricing and a favorable cost environment Operating Income By Geography • Vol/price/mix/other: Op Margin: +60 bps EPS: +0.03 - Domestic - 1% Operating Margin - International - 12% • Cost reductions: Op Margin: +320 bps EPS: +$0.13 Segment Results By Application • Investments: Op Margin: -90 bps EPS -$0.04 Pipe Products - Pipe - 6% • Acquisitions: Op Margin: -20 bps EPS: $0.00 Revenue + Allied Products +4% • Other: Tax Rate 20.9% Share Count 179.9M Overall Growth Constant Currency Growth Organic Growth Operating Income Operating Margin Allied Products Revenue Overall Growth Constant Currency Growth Organic Growth Operating Income Operating Margin GAAPQ2 2016 Adjusted*Q2 2016 GAAPYTD - Q2 2016 Adjusted*YTD - Q2 2016 Domestic Markets Xylem Consolidated + Construction +3% Xylem Consolidated + Non-Residential +5% Revenue - Residential - 1% Overall Growth - Infrastructure - 0% Key Performance Drivers - Agriculture - 24% - Pipe - 4% Constant Currency Growth + Allied Products +6% • Organic growth in-line with expectations Earnings per Share • Cost inflation: Op Margin: -170 bps EPS: -$0.07 Segment Results • Investments: Op Margin: -90 bps EPS -$0.04 Pipe Products • Acquisitions: Op Margin: -20 bps EPS: $0.00 Revenue • Other: Tax Rate 20.9% Share Count 179.9M Overall Growth Constant Currency Growth Organic Growth Operating Income Operating Margin Allied Products Revenue Overall Growth Constant Currency Growth Organic Growth Operating Income Operating Margin

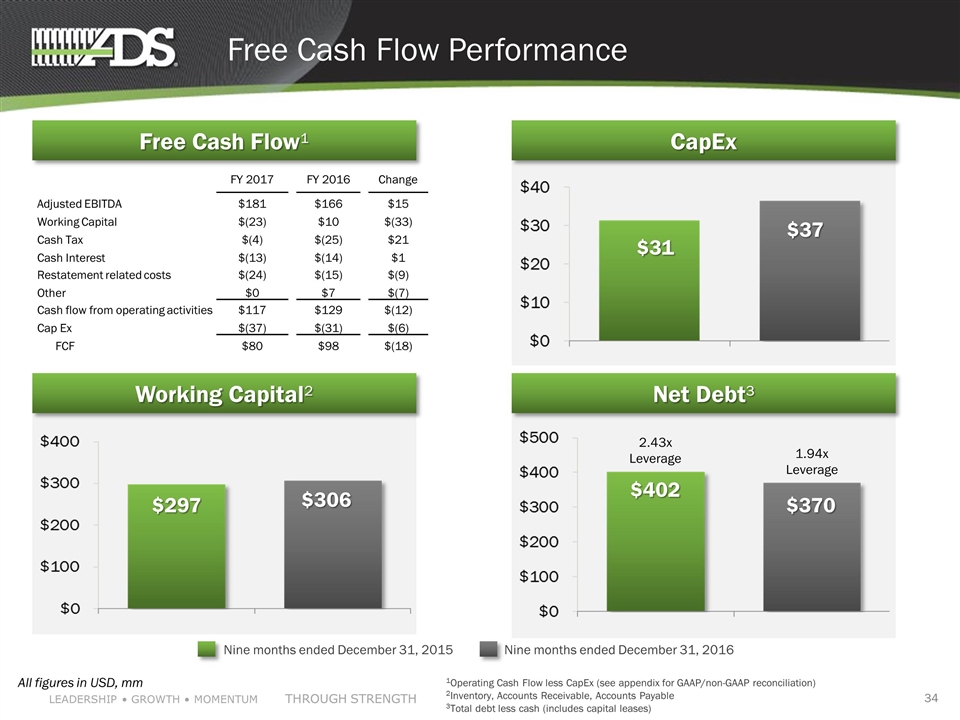

Nine months ended December 31, 2015 Nine months ended December 31, 2016 Free Cash Flow¹ Free Cash Flow Performance % of Sales 2.7% 3.5% All figures in USD, mm Working Capital² CapEx Net Debt³ $31 $37 $402 $370 $297 $306 FY 2017 FY 2016 Change Adjusted EBITDA $181 $166 $15 Working Capital $(23) $10 $(33) Cash Tax $(4) $(25) $21 Cash Interest $(13) $(14) $1 Restatement related costs $(24) $(15) $(9) Other $0 $7 $(7) Cash flow from operating activities $117 $129 $(12) Cap Ex $(37) $(31) $(6) FCF $80 $98 $(18) 1Operating Cash Flow less CapEx (see appendix for GAAP/non-GAAP reconciliation) 2Inventory, Accounts Receivable, Accounts Payable 3Total debt less cash (includes capital leases) 2.43x Leverage 1.94x Leverage

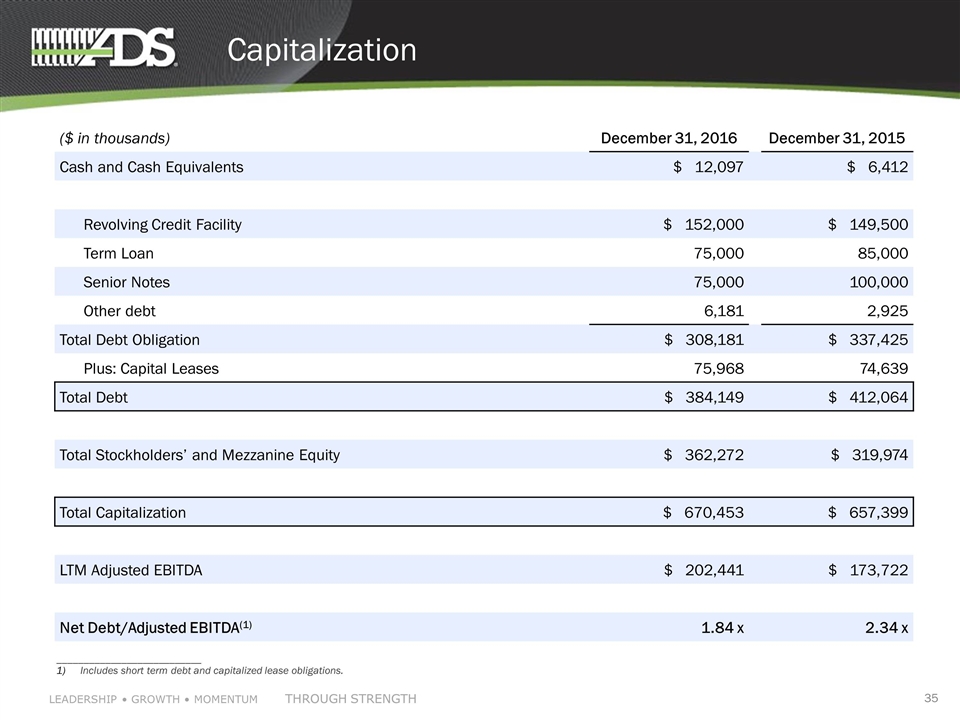

Capitalization ($ in thousands) December 31, 2016 December 31, 2015 Cash and Cash Equivalents $ 12,097 $ 6,412 Revolving Credit Facility $ 152,000 $ 149,500 Term Loan 75,000 85,000 Senior Notes 75,000 100,000 Other debt 6,181 2,925 Total Debt Obligation $ 308,181 $ 337,425 Plus: Capital Leases 75,968 74,639 Total Debt $ 384,149 $ 412,064 Total Stockholders’ and Mezzanine Equity $ 362,272 $ 319,974 Total Capitalization $ 670,453 $ 657,399 LTM Adjusted EBITDA $ 202,441 $ 173,722 Net Debt/Adjusted EBITDA(1) 1.84 x 2.34 x ___________________________ Includes short term debt and capitalized lease obligations.

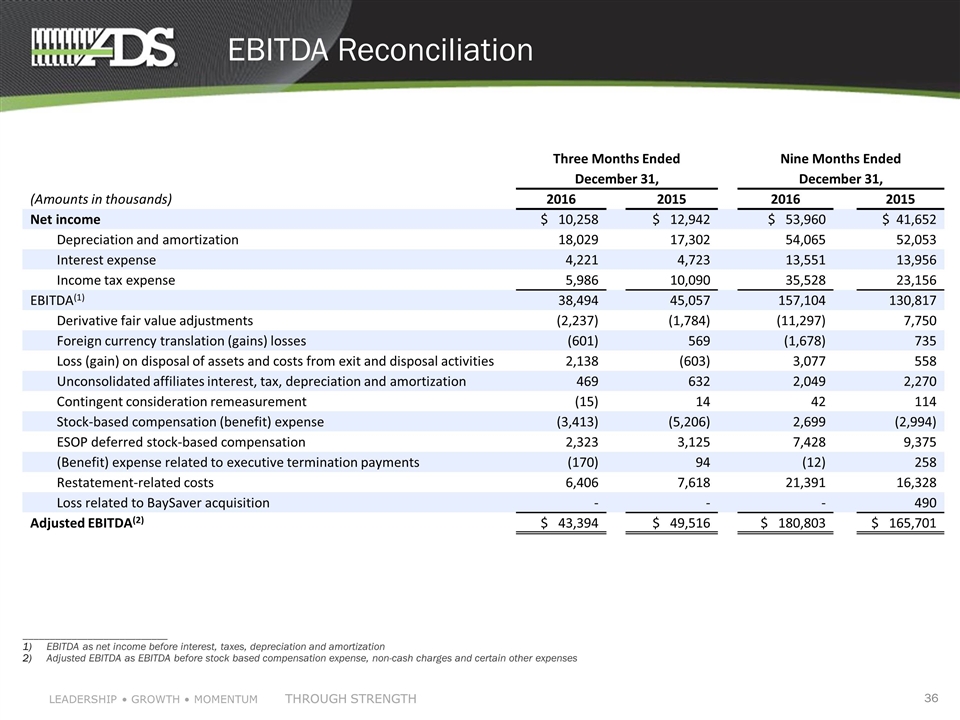

EBITDA Reconciliation ___________________________ EBITDA as net income before interest, taxes, depreciation and amortization Adjusted EBITDA as EBITDA before stock based compensation expense, non-cash charges and certain other expenses Three Months Ended Nine Months Ended December 31, December 31, (Amounts in thousands) 2016 2015 2016 2015 Net income $ 10,258 $ 12,942 $ 53,960 $ 41,652 Depreciation and amortization 18,029 17,302 54,065 52,053 Interest expense 4,221 4,723 13,551 13,956 Income tax expense 5,986 10,090 35,528 23,156 EBITDA(1) 38,494 45,057 157,104 130,817 Derivative fair value adjustments (2,237) (1,784) (11,297) 7,750 Foreign currency translation (gains) losses (601) 569 (1,678) 735 Loss (gain) on disposal of assets and costs from exit and disposal activities 2,138 (603) 3,077 558 Unconsolidated affiliates interest, tax, depreciation and amortization 469 632 2,049 2,270 Contingent consideration remeasurement (15) 14 42 114 Stock-based compensation (benefit) expense (3,413) (5,206) 2,699 (2,994) ESOP deferred stock-based compensation 2,323 3,125 7,428 9,375 (Benefit) expense related to executive termination payments (170) 94 (12) 258 Restatement-related costs 6,406 7,618 21,391 16,328 Loss related to BaySaver acquisition - - - 490 Adjusted EBITDA(2) $ 43,394 $ 49,516 $ 180,803 $ 165,701

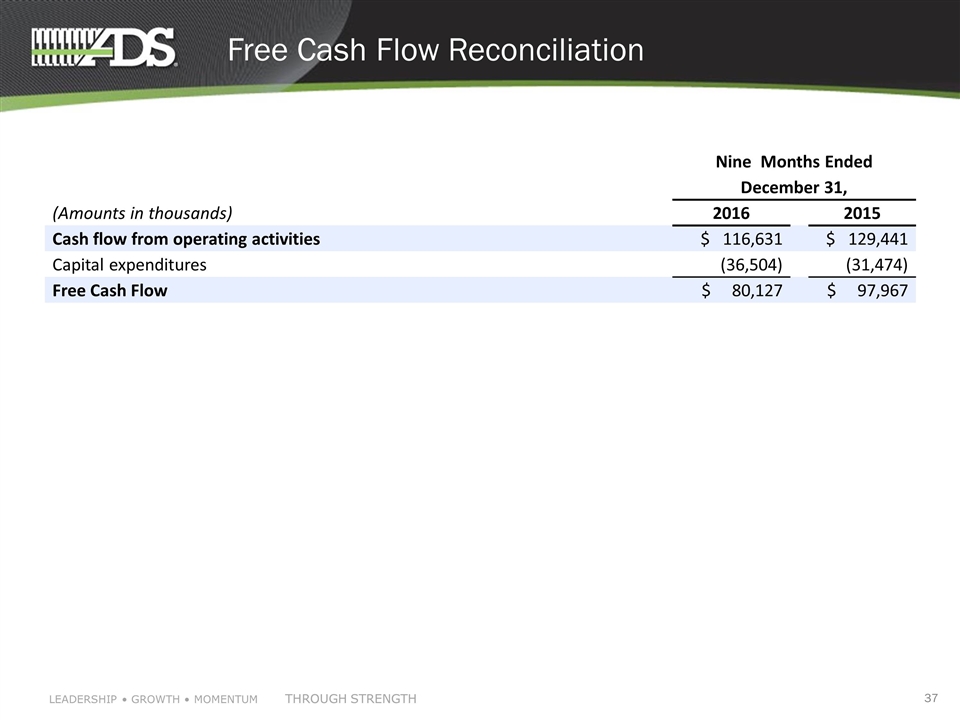

Free Cash Flow Reconciliation Nine Months Ended December 31, (Amounts in thousands) 2016 2015 Cash flow from operating activities $ 116,631 $ 129,441 Capital expenditures (36,504) (31,474) Free Cash Flow $ 80,127 $ 97,967