Advanced Drainage Systems Investor Day Presentation November 15, 2018

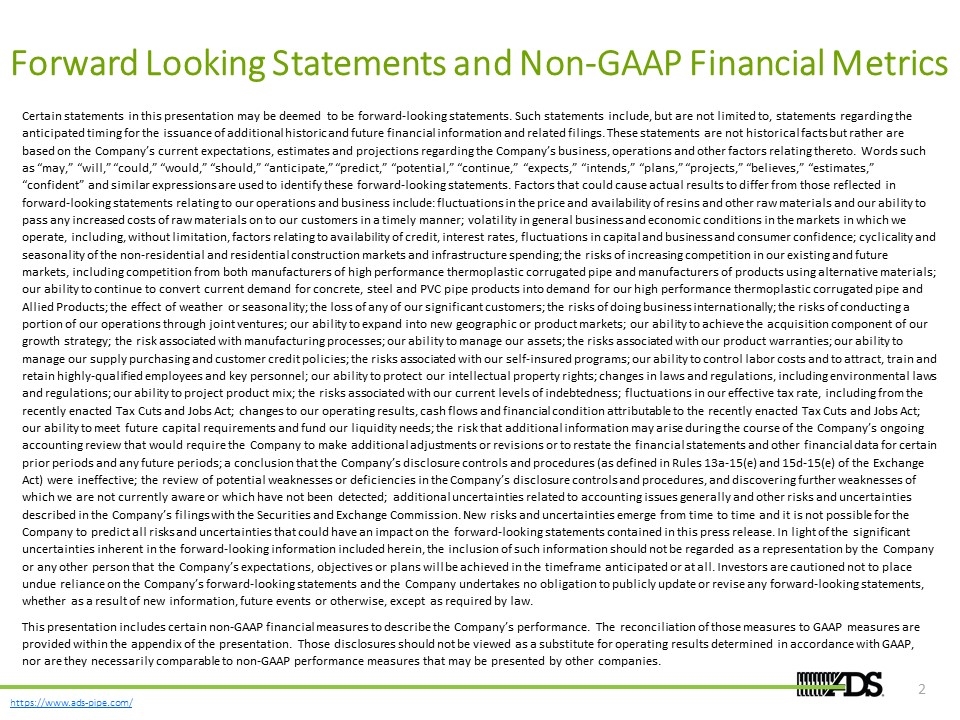

Forward Looking Statements and Non-GAAP Financial Metrics Certain statements in this presentation may be deemed to be forward-looking statements. Such statements include, but are not limited to, statements regarding the anticipated timing for the issuance of additional historic and future financial information and related filings. These statements are not historical facts but rather are based on the Company’s current expectations, estimates and projections regarding the Company’s business, operations and other factors relating thereto. Words such as “may,” “will,” “could,” “would,” “should,” “anticipate,” “predict,” “potential,” “continue,” “expects,” “intends,” “plans,” “projects,” “believes,” “estimates,” “confident” and similar expressions are used to identify these forward-looking statements. Factors that could cause actual results to differ from those reflected in forward-looking statements relating to our operations and business include: fluctuations in the price and availability of resins and other raw materials and our ability to pass any increased costs of raw materials on to our customers in a timely manner; volatility in general business and economic conditions in the markets in which we operate, including, without limitation, factors relating to availability of credit, interest rates, fluctuations in capital and business and consumer confidence; cyclicality and seasonality of the non-residential and residential construction markets and infrastructure spending; the risks of increasing competition in our existing and future markets, including competition from both manufacturers of high performance thermoplastic corrugated pipe and manufacturers of products using alternative materials; our ability to continue to convert current demand for concrete, steel and PVC pipe products into demand for our high performance thermoplastic corrugated pipe and Allied Products; the effect of weather or seasonality; the loss of any of our significant customers; the risks of doing business internationally; the risks of conducting a portion of our operations through joint ventures; our ability to expand into new geographic or product markets; our ability to achieve the acquisition component of our growth strategy; the risk associated with manufacturing processes; our ability to manage our assets; the risks associated with our product warranties; our ability to manage our supply purchasing and customer credit policies; the risks associated with our self-insured programs; our ability to control labor costs and to attract, train and retain highly-qualified employees and key personnel; our ability to protect our intellectual property rights; changes in laws and regulations, including environmental laws and regulations; our ability to project product mix; the risks associated with our current levels of indebtedness; fluctuations in our effective tax rate, including from the recently enacted Tax Cuts and Jobs Act; changes to our operating results, cash flows and financial condition attributable to the recently enacted Tax Cuts and Jobs Act; our ability to meet future capital requirements and fund our liquidity needs; the risk that additional information may arise during the course of the Company’s ongoing accounting review that would require the Company to make additional adjustments or revisions or to restate the financial statements and other financial data for certain prior periods and any future periods; a conclusion that the Company’s disclosure controls and procedures (as defined in Rules 13a-15(e) and 15d-15(e) of the Exchange Act) were ineffective; the review of potential weaknesses or deficiencies in the Company’s disclosure controls and procedures, and discovering further weaknesses of which we are not currently aware or which have not been detected; additional uncertainties related to accounting issues generally and other risks and uncertainties described in the Company’s filings with the Securities and Exchange Commission. New risks and uncertainties emerge from time to time and it is not possible for the Company to predict all risks and uncertainties that could have an impact on the forward-looking statements contained in this press release. In light of the significant uncertainties inherent in the forward-looking information included herein, the inclusion of such information should not be regarded as a representation by the Company or any other person that the Company’s expectations, objectives or plans will be achieved in the timeframe anticipated or at all. Investors are cautioned not to place undue reliance on the Company’s forward-looking statements and the Company undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law. This presentation includes certain non-GAAP financial measures to describe the Company’s performance. The reconciliation of those measures to GAAP measures are provided within the appendix of the presentation. Those disclosures should not be viewed as a substitute for operating results determined in accordance with GAAP, nor are they necessarily comparable to non-GAAP performance measures that may be presented by other companies.

SUBJECT SPEAKER Introduction Mike Higgins, VP of Corporate Strategy & Investor Relations Business Overview Scott Barbour, President and CEO Sales Growth Margin Expansion Financial Overview Scott Cottrill, EVP and CFO Cash Flow Generation Closing Remarks Scott Barbour, President and CEO Q&A ADS Management Agenda

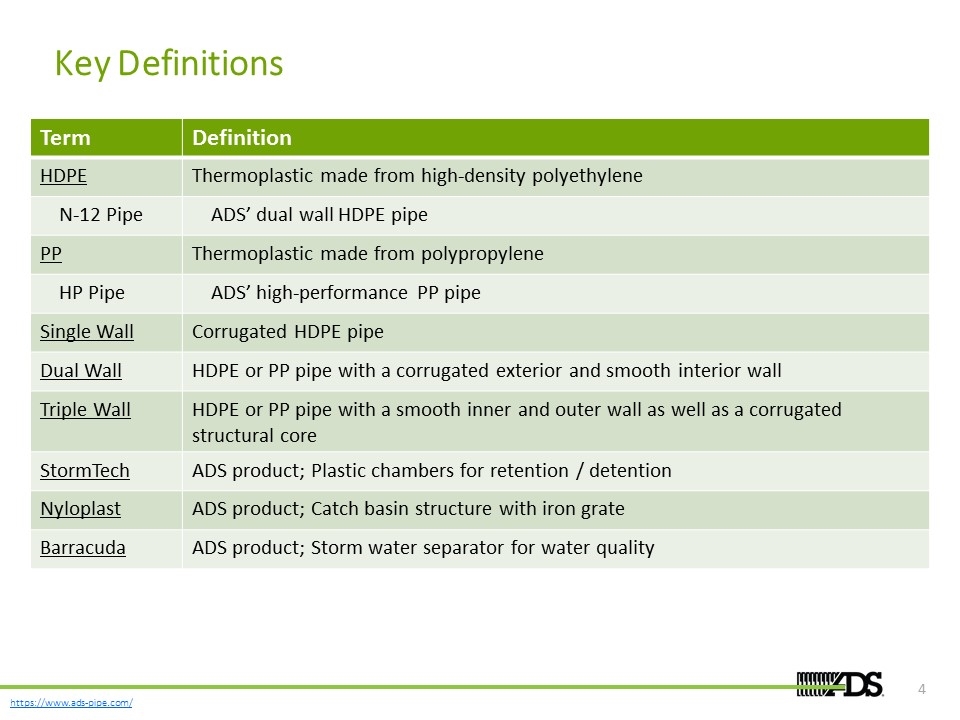

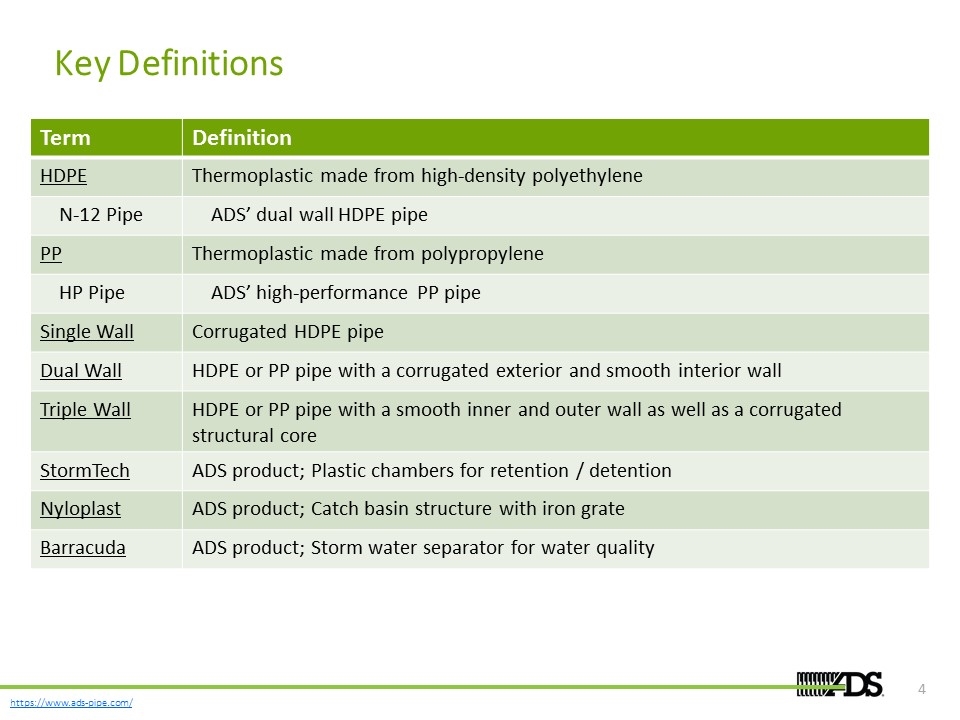

Key Definitions Term Definition HDPE Thermoplastic made from high-density polyethylene N-12 Pipe ADS’ dual wall HDPE pipe PP Thermoplastic made from polypropylene HP Pipe ADS’ high-performance PP pipe Single Wall Corrugated HDPE pipe Dual Wall HDPE or PP pipe with a corrugated exterior and smooth interior wall Triple Wall HDPE or PP pipe with a smooth inner and outer wall as well as a corrugated structural core StormTech ADS product; Plastic chambers for retention / detention Nyloplast ADS product; Catch basin structure with iron grate Barracuda ADS product; Storm water separator for water quality

Business Overview Scott Barbour, President and CEO

Leadership Team in Attendance Scott Barbour President and CEO Scott Cottrill EVP, CFO Bob Klein EVP, Sales & Marketing Ron Vitarelli EVP, Innovation and R&D Darin Harvey EVP, Supply Chain Kevin Talley EVP, Chief Administrative Officer Ewout Leeuwenburg SVP, International Mike Higgins VP, Corporate Strategy & Investor Relations Mike Huebert VP, Field Sales Dean Bruno VP, Treasurer

Investor Day Themes ADS is an industrial growth story with a large market opportunity and long runway for growth Sales Growth Margin Expansion ADS has significant margin upside potential and action plans in place to achieve superior results Cash Flow Generation Successful execution will result in significant cash generation over the next several years See appendix for definitions and reconciliations of Non-GAAP items.

ADS provides innovative water management solutions, protecting a precious natural resource, while keeping millions of pounds of plastic out of landfills each year Innovative Management of a Precious Resource ADS’ solutions are managing billions of gallons of storm water runoff, protecting bodies of water, making cities more livable and improving quality of life

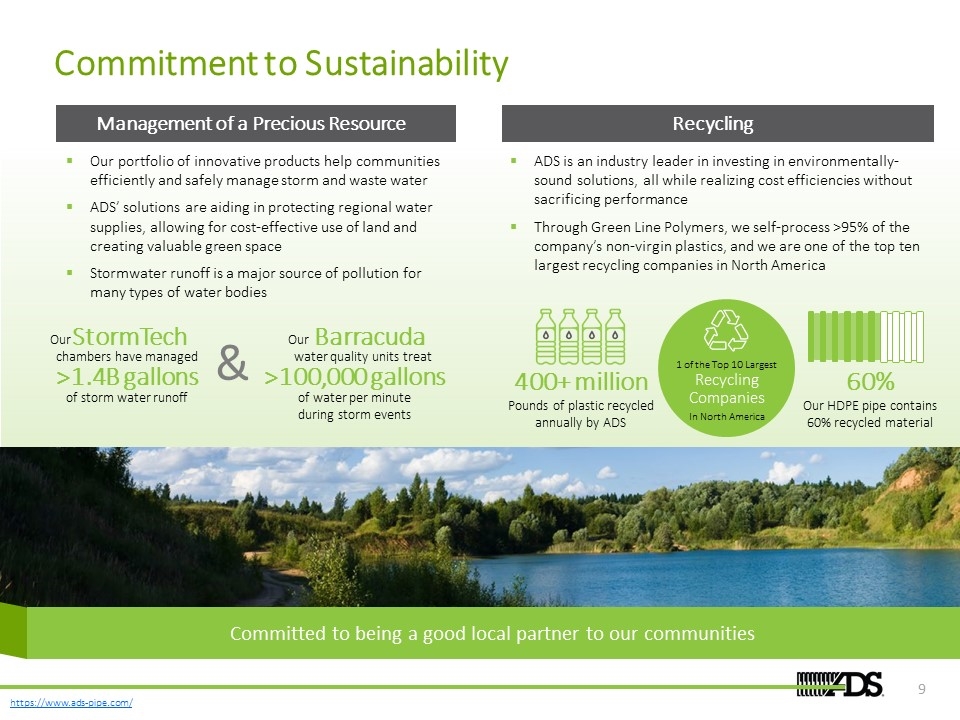

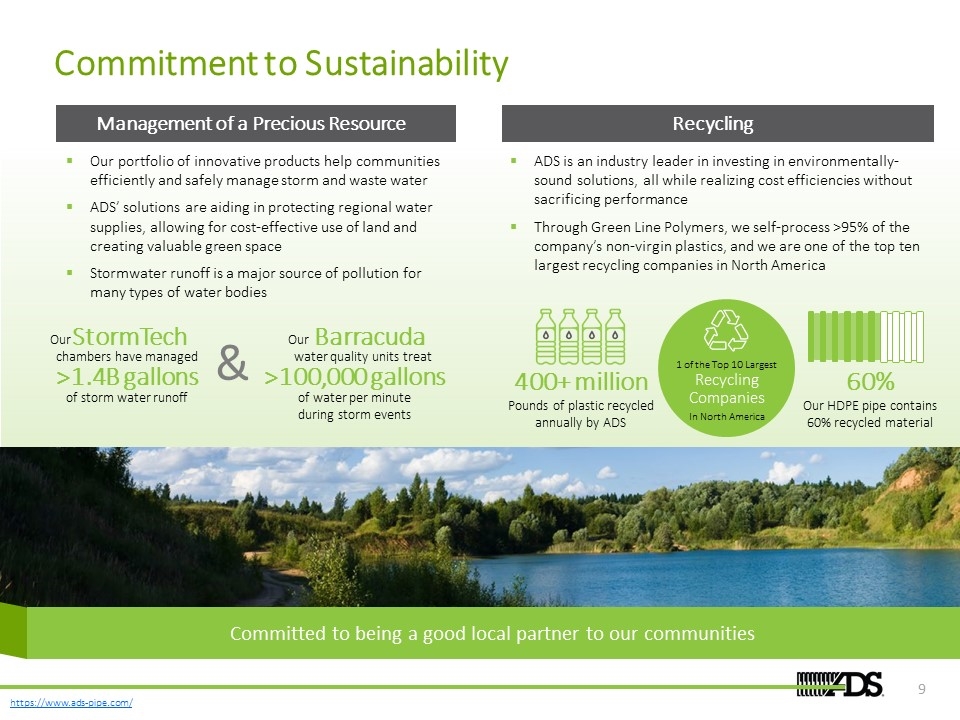

>100,000 gallons Management of a Precious Resource Recycling Commitment to Sustainability Our portfolio of innovative products help communities efficiently and safely manage storm and waste water ADS’ solutions are aiding in protecting regional water supplies, allowing for cost-effective use of land and creating valuable green space Stormwater runoff is a major source of pollution for many types of water bodies ADS is an industry leader in investing in environmentally-sound solutions, all while realizing cost efficiencies without sacrificing performance Through Green Line Polymers, we self-process >95% of the company’s non-virgin plastics, and we are one of the top ten largest recycling companies in North America 400+ million Pounds of plastic recycled annually by ADS Committed to being a good local partner to our communities 1 of the Top 10 Largest Recycling Companies In North America chambers have managed StormTech Our >1.4B gallons of storm water runoff water quality units treat Barracuda Our of water per minute during storm events & 60% Our HDPE pipe contains 60% recycled material

Innovative Water Management Solutions ADS has demonstrated its commitment to management of a precious resource as a complete solutions provider

Comprehensive Portfolio of Products Driving Solutions Conveyance Capture Storage Treatment StormTech® Arc Chambers Duraslot® Nyloplast© FLEXSTORM® Geosynthetics Water Quality Single Wall N-12® HP Triple Wall PolyFlexTM AdvanEDGE® Our leading product position in the storm water management industry allows us to sell the whole package Fittings InsertaTee® N-12® HP

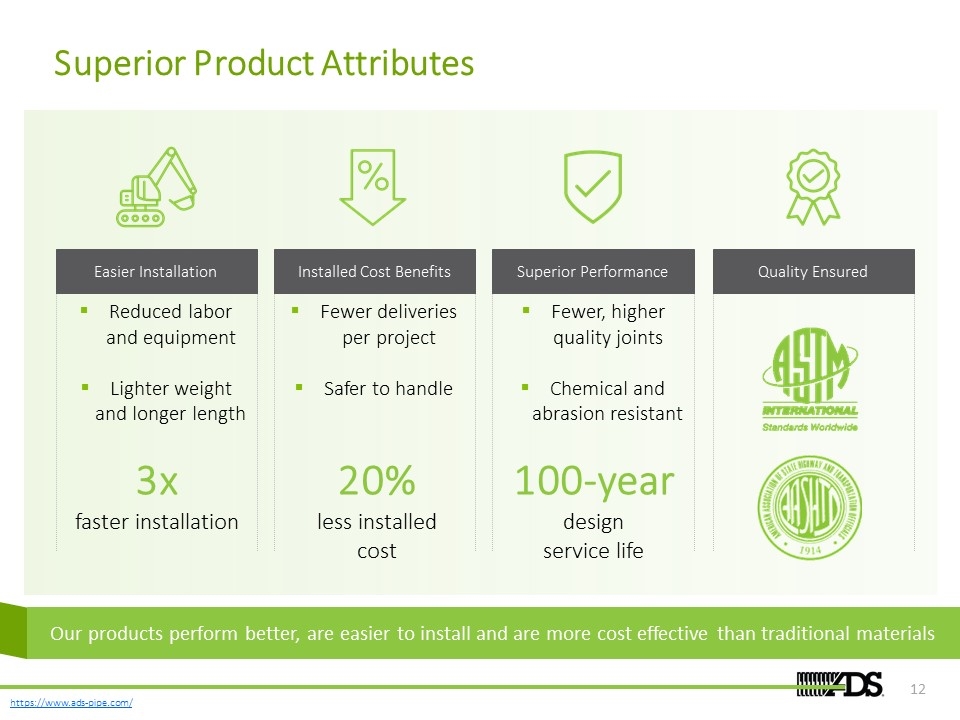

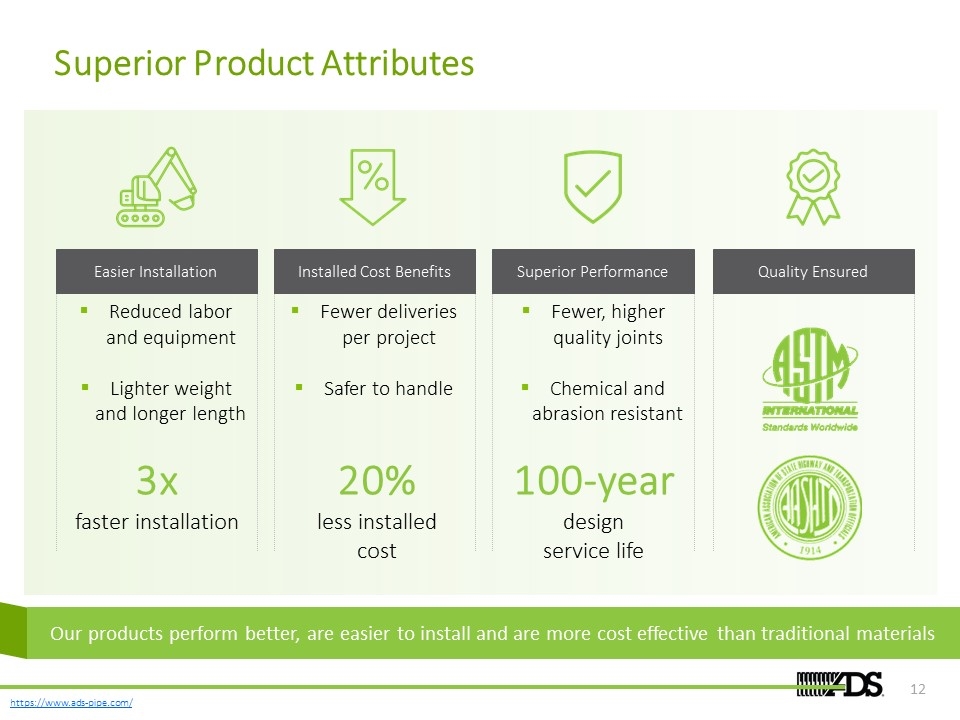

Superior Product Attributes 100-year design service life Superior Performance Our products perform better, are easier to install and are more cost effective than traditional materials 3x faster installation Easier Installation Reduced labor and equipment Lighter weight and longer length 20% less installed cost Installed Cost Benefits Fewer deliveries per project Safer to handle Fewer, higher quality joints Chemical and abrasion resistant Quality Ensured

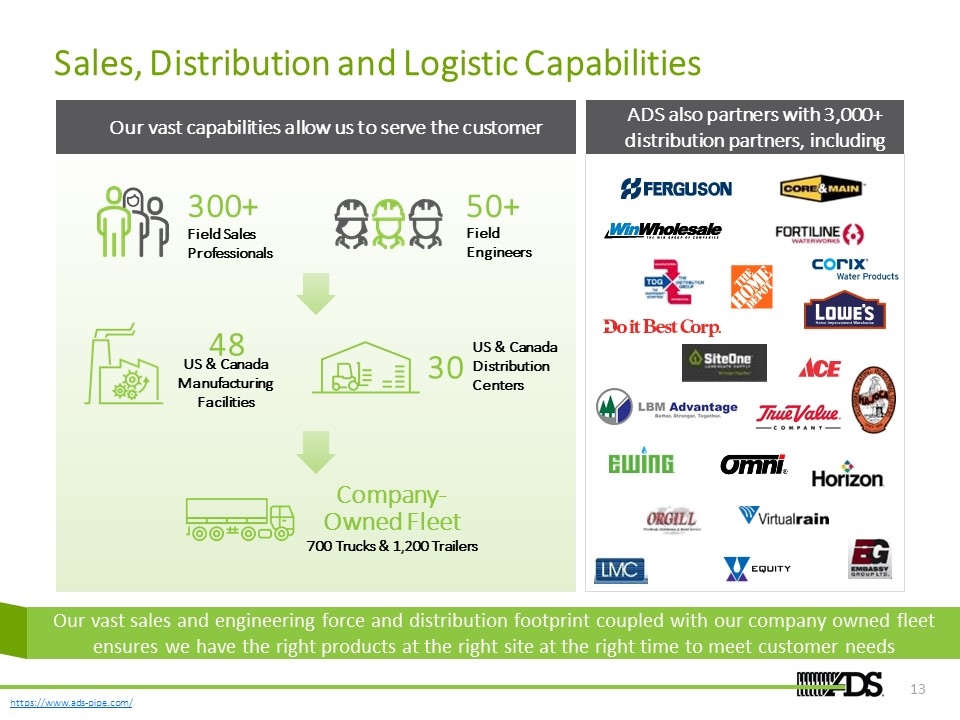

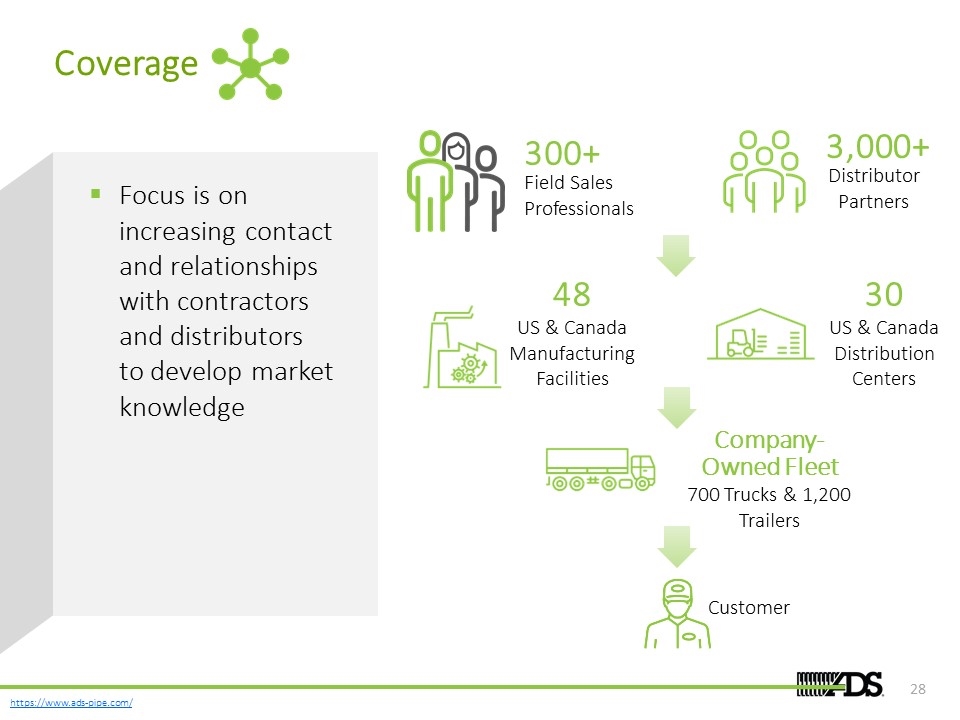

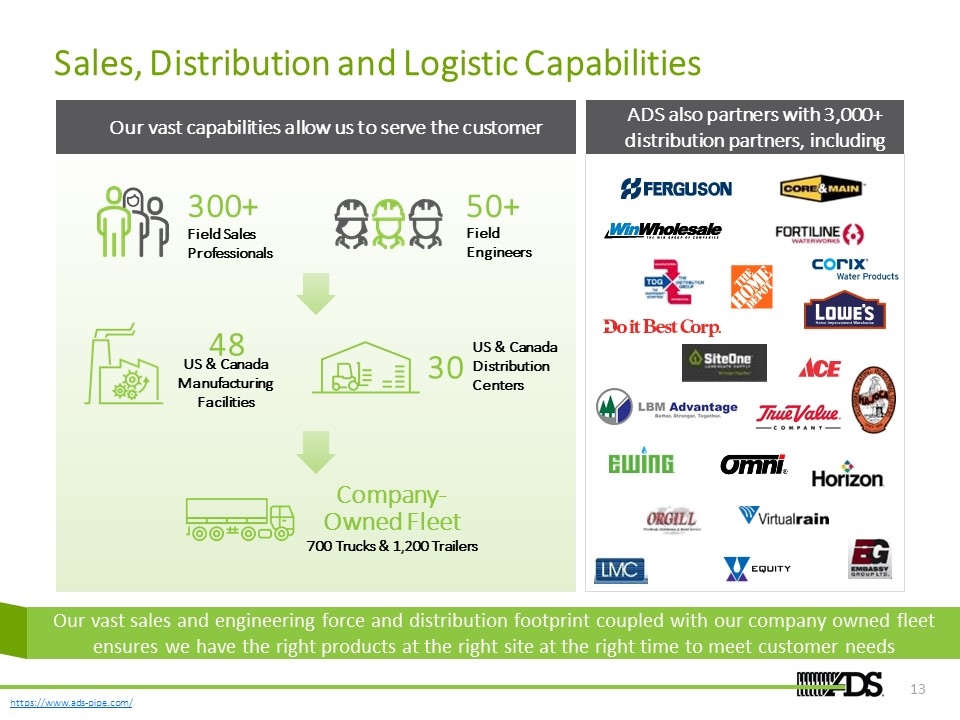

Sales, Distribution and Logistic Capabilities 48 US & Canada Manufacturing Facilities Company-Owned Fleet 700 Trucks & 1,200 Trailers Our vast capabilities allow us to serve the customer 30 US & Canada Distribution Centers ADS also partners with 3,000+ distribution partners, including 300+ Field Sales Professionals 50+ Field Engineers Our vast sales and engineering force and distribution footprint coupled with our company owned fleet ensures we have the right products at the right site at the right time to meet customer needs

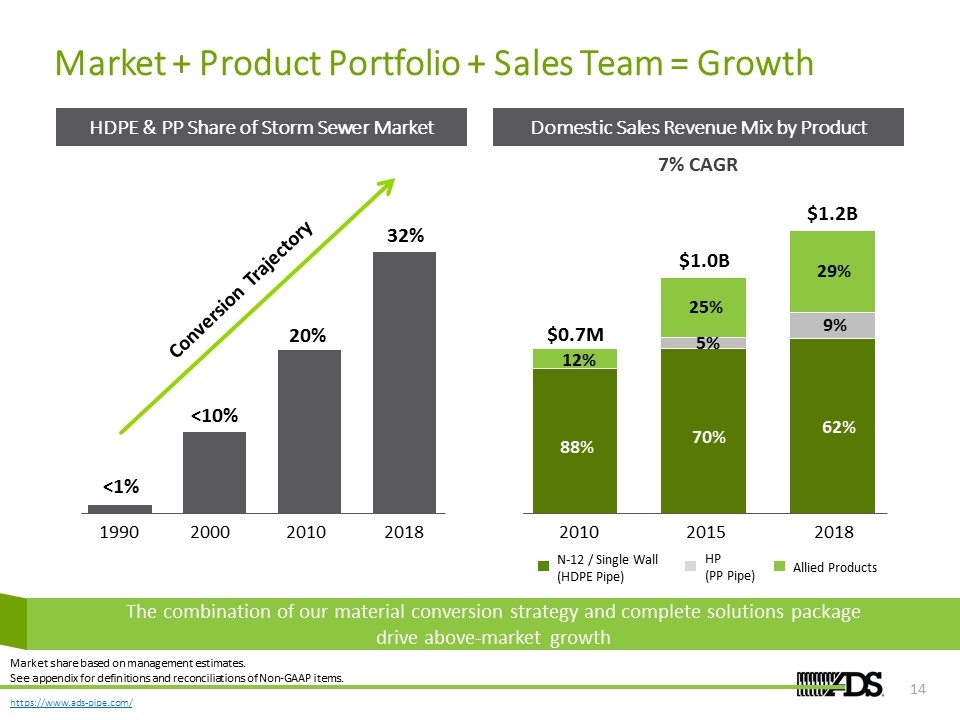

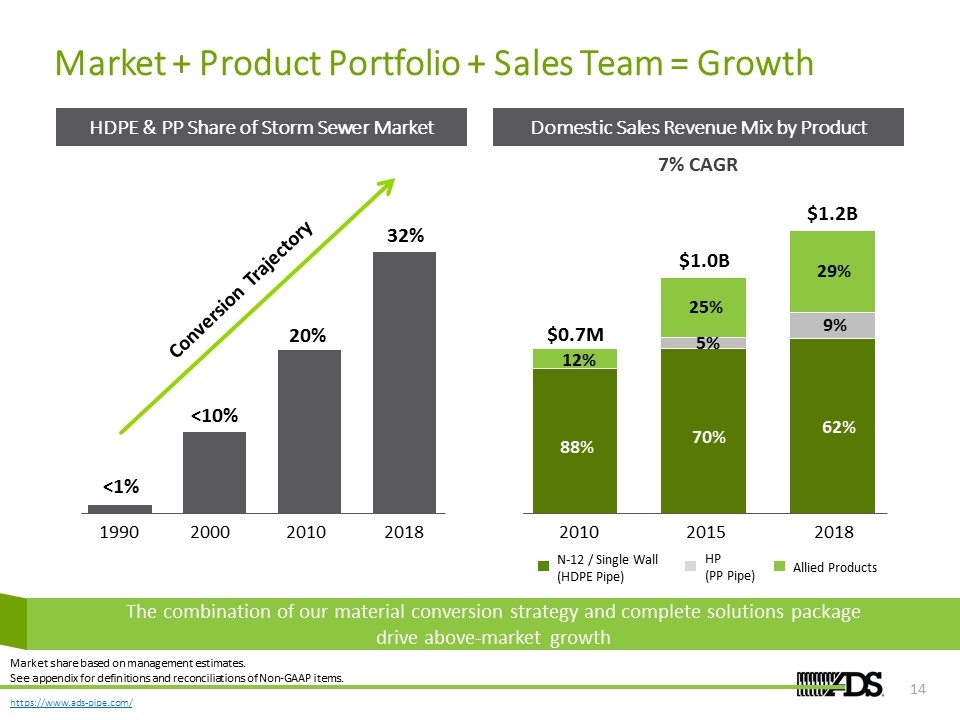

Market + Product Portfolio + Sales Team = Growth <1% <10% HDPE & PP Share of Storm Sewer Market Domestic Sales Revenue Mix by Product 88% 70% 62% 12% 25% 29% 5% 9% Our pipe products have been displacing traditional materials across an expanding range of end markets and our Allied Products allow us to provide a complete storm water management solution, when combined, drive above market growth 1990 2000 2010 2018 2010 2015 2018 N-12 / Single Wall (HDPE Pipe) HP (PP Pipe) Allied Products $1.2B $1.0B $0.7M The combination of our material conversion strategy and complete solutions package drive above-market growth Market share based on management estimates. See appendix for definitions and reconciliations of Non-GAAP items. Conversion Trajectory 7% CAGR

Storm Water Market: Large Addressable Opportunity NON-RESIDENTIAL INFRASTRUCTURE RESIDENTIAL AGRICULTURE Storm Water Market Opportunity $6 Billion Market Size ~$3 Billion Market Size ~$1 Billion Market Size ~$0.2 Billion Market Size ~$2 Billion Market sizes based on management estimates.

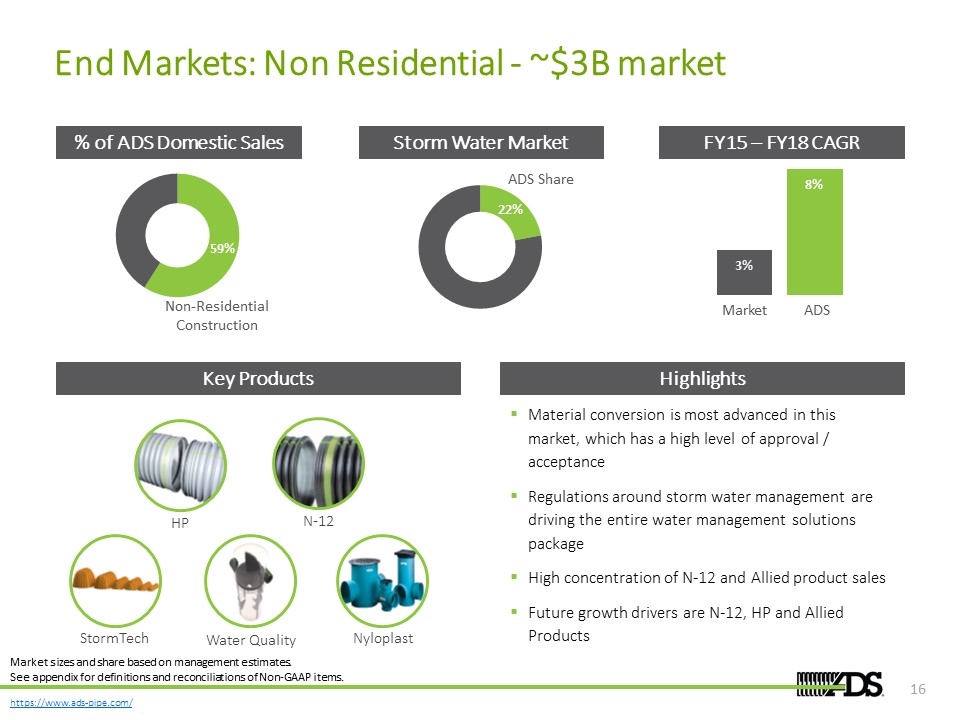

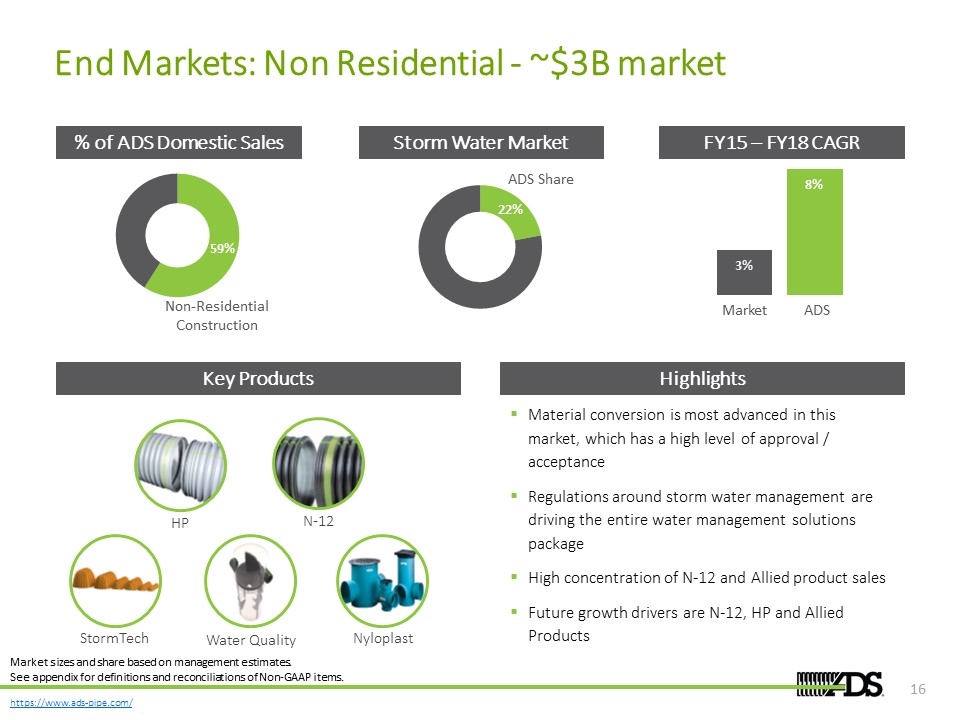

End Markets: Non Residential - ~$3B market % of ADS Domestic Sales FY15 – FY18 CAGR Non-Residential Construction Market ADS Storm Water Market ADS Share Key Products HP N-12 StormTech Nyloplast Water Quality Highlights Material conversion is most advanced in this market, which has a high level of approval / acceptance Regulations around storm water management are driving the entire water management solutions package High concentration of N-12 and Allied product sales Future growth drivers are N-12, HP and Allied Products Market sizes and share based on management estimates. See appendix for definitions and reconciliations of Non-GAAP items.

End Markets: Residential - ~$2B market % of ADS Domestic Sales FY15 – FY18 CAGR Residential Construction Market ADS Storm Water Market ADS Share Key Products Highlights Sales are split 50/50 in retail channel (i.e., Home Depot, Lowe’s) and new residential construction development (single-family, multi-family housing) New subdivision development should benefit sales of N-12 and HP Sales initiatives in high growth geographies and with national homebuilders Growth driven by HP used for new subdivision construction and N-12 and Allied Products used in multi-family construction N-12 StormTech Nyloplast HP Single Wall Fittings Market sizes and share based on management estimates. See appendix for definitions and reconciliations of Non-GAAP items.

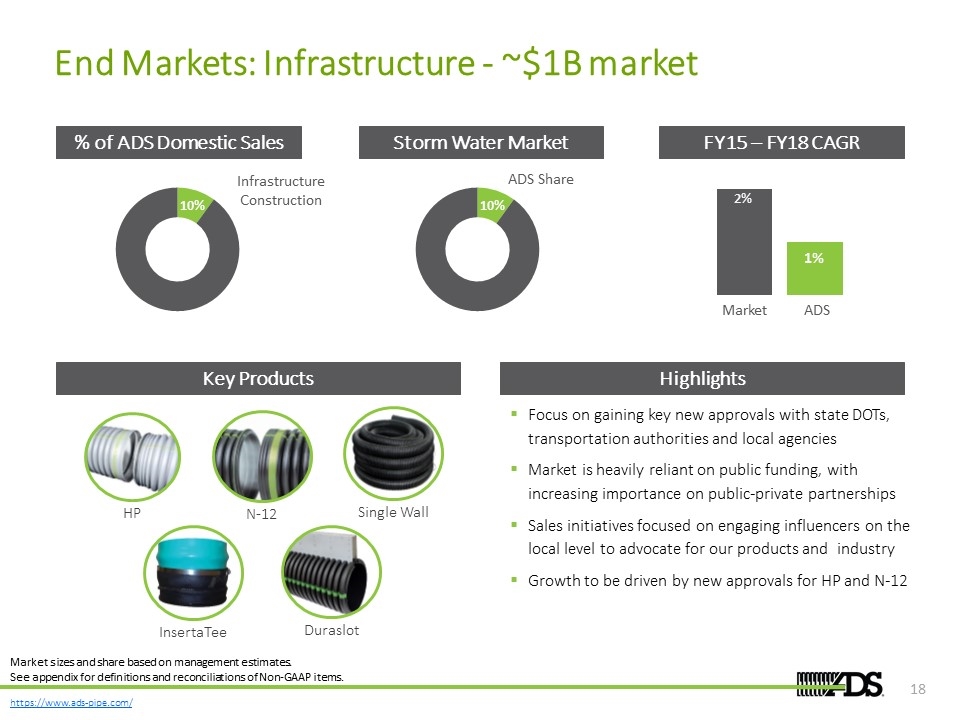

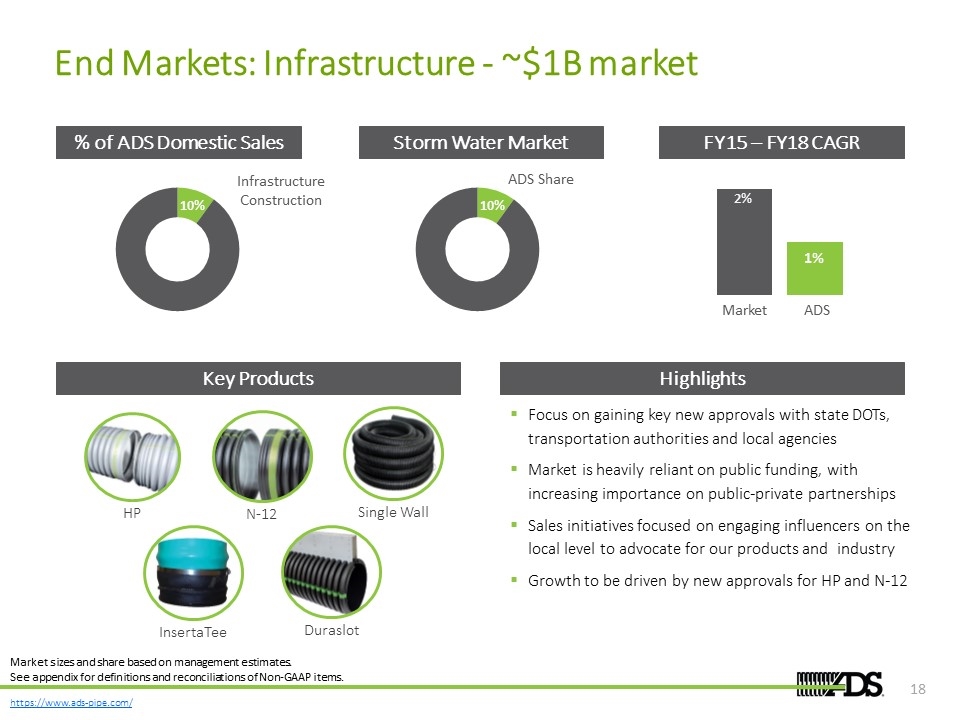

End Markets: Infrastructure - ~$1B market Infrastructure Construction Market ADS Key Products N-12 Highlights Focus on gaining key new approvals with state DOTs, transportation authorities and local agencies Market is heavily reliant on public funding, with increasing importance on public-private partnerships Sales initiatives focused on engaging influencers on the local level to advocate for our products and industry Growth to be driven by new approvals for HP and N-12 HP InsertaTee Single Wall Duraslot % of ADS Domestic Sales FY15 – FY18 CAGR Storm Water Market ADS Share Market sizes and share based on management estimates. See appendix for definitions and reconciliations of Non-GAAP items.

End Markets: Agriculture - ~$0.2B market Agriculture Market ADS ADS Share Key Products Highlights Single Wall Fittings Flexible Dual Wall % of ADS Domestic Sales FY15 – FY18 CAGR Storm Water Market Drainage market is focused on row crops, primarily soybeans and corn Reinventing ADS’ agriculture business model Exploring new geographies and approaches to market Accretive business that gives scale to our recycling operations Market sizes and share based on management estimates. See appendix for definitions and reconciliations of Non-GAAP items.

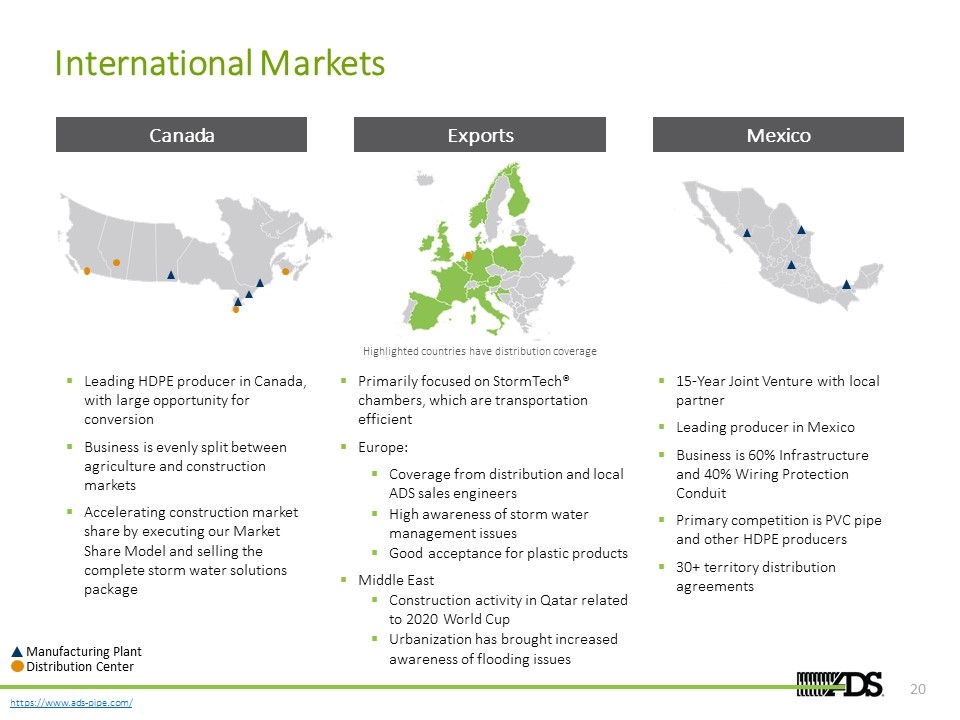

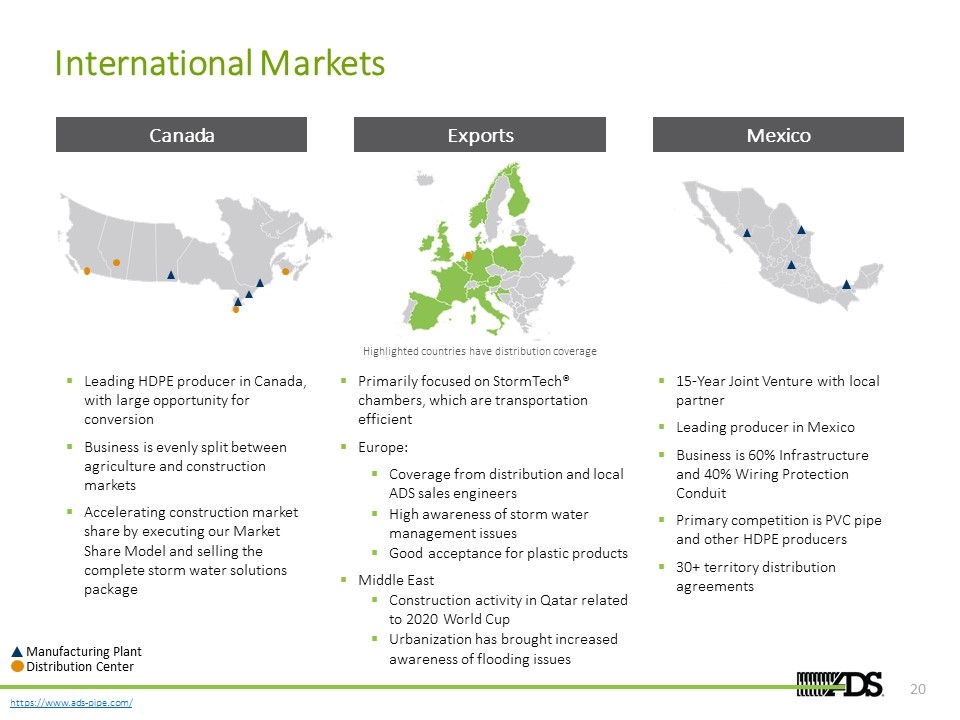

International Markets Canada Exports Mexico Leading HDPE producer in Canada, with large opportunity for conversion Business is evenly split between agriculture and construction markets Accelerating construction market share by executing our Market Share Model and selling the complete storm water solutions package Manufacturing Plant Distribution Center Primarily focused on StormTech® chambers, which are transportation efficient Europe: Coverage from distribution and local ADS sales engineers High awareness of storm water management issues Good acceptance for plastic products Middle East Construction activity in Qatar related to 2020 World Cup Urbanization has brought increased awareness of flooding issues 15-Year Joint Venture with local partner Leading producer in Mexico Business is 60% Infrastructure and 40% Wiring Protection Conduit Primary competition is PVC pipe and other HDPE producers 30+ territory distribution agreements Highlighted countries have distribution coverage

ADS’ Distinct Market Leadership Leading player in the storm water management industry with a track record of gaining market share Consistent above-market growth driven by material conversion strategy and complete solutions package Best-in-class sales force, technical expertise and distribution & logistics network creates barriers to entry and positions ADS as the supplier of choice Large and growing end-markets with favorable tailwinds from regulatory changes and increased focus on sustainability

Investor Day Themes Cash Flow Generation Margin Expansion Sales Growth

Pillars of Accelerating Growth Pipe Growth Allied Products Growth Innovation and Product Development

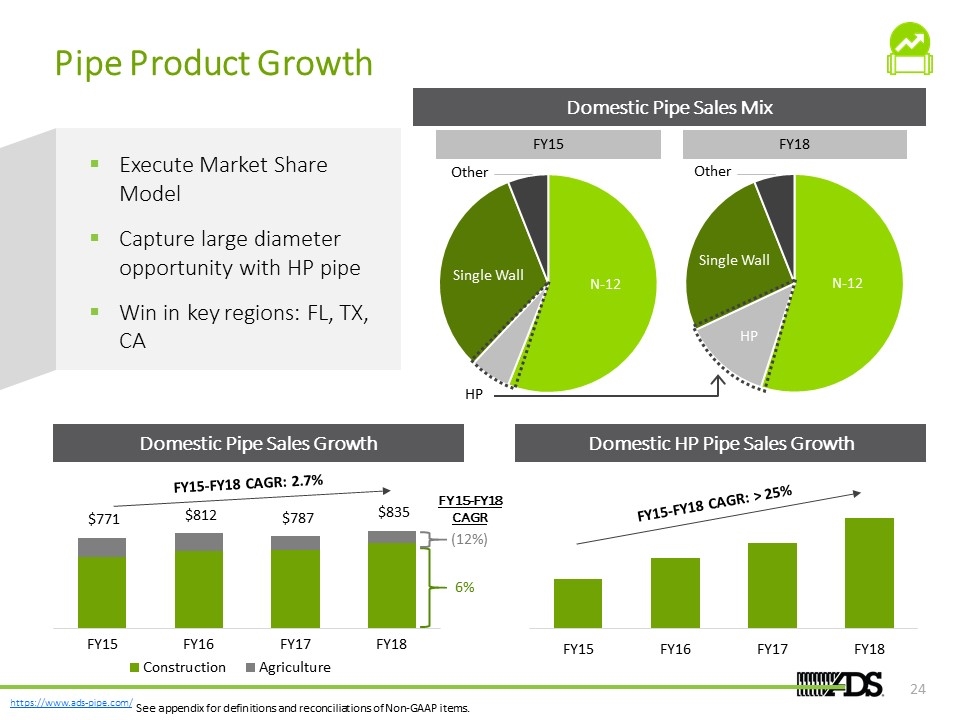

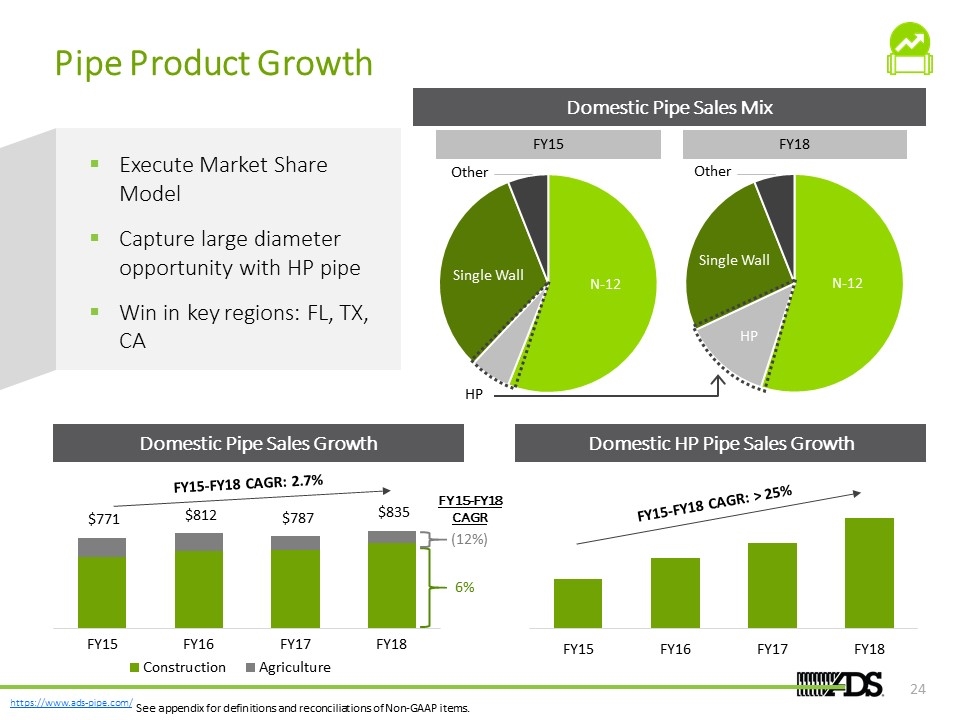

Pipe Product Growth FY15 FY18 Execute Market Share Model Capture large diameter opportunity with HP pipe Win in key regions: FL, TX, CA Domestic Pipe Sales Mix Domestic HP Pipe Sales Growth FY15-FY18 CAGR: > 25% FY15-FY18 CAGR: 2.7% Domestic Pipe Sales Growth 6% (12%) FY15-FY18 CAGR See appendix for definitions and reconciliations of Non-GAAP items. HP Single Wall Other N-12 HP Single Wall Other N-12

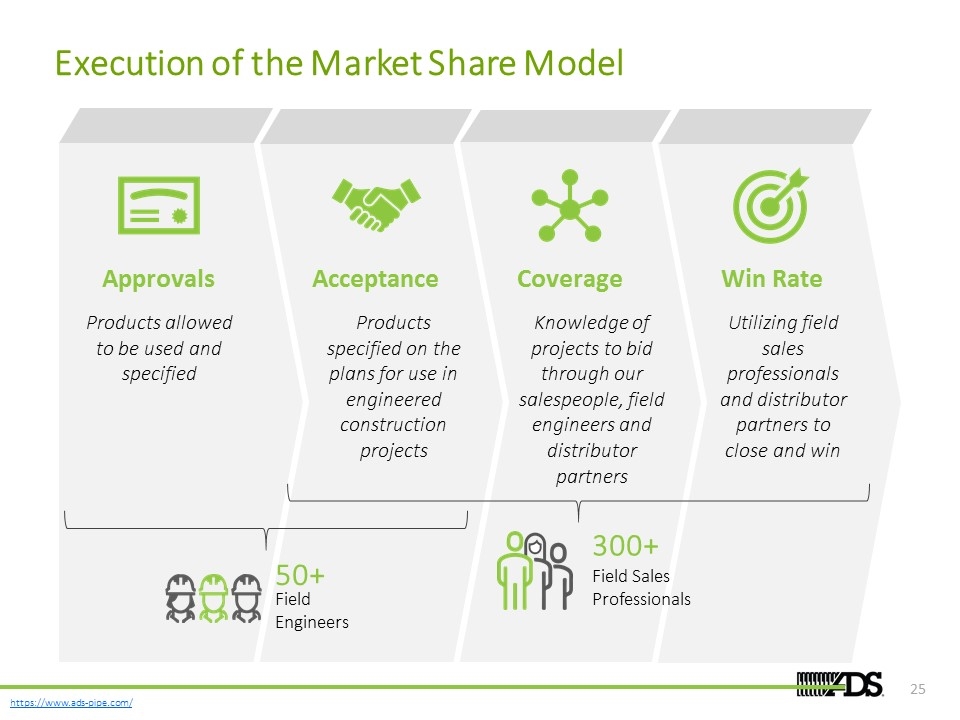

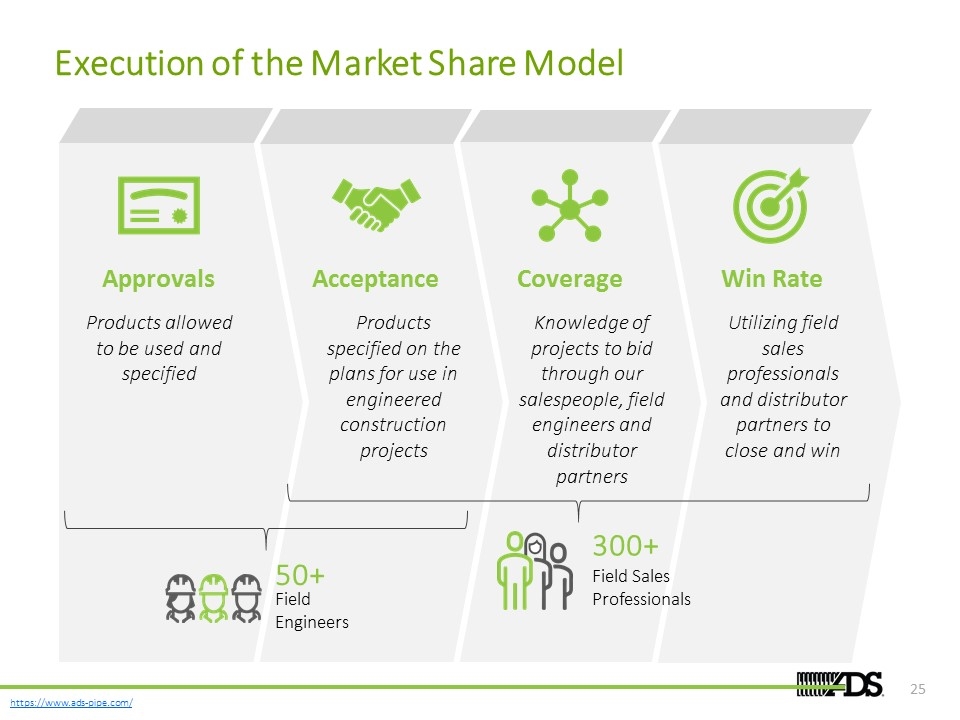

Execution of the Market Share Model Products allowed to be used and specified Products specified on the plans for use in engineered construction projects Knowledge of projects to bid through our salespeople, field engineers and distributor partners Utilizing field sales professionals and distributor partners to close and win 300+ Field Sales Professionals 50+ Field Engineers Approvals Acceptance Win Rate Coverage

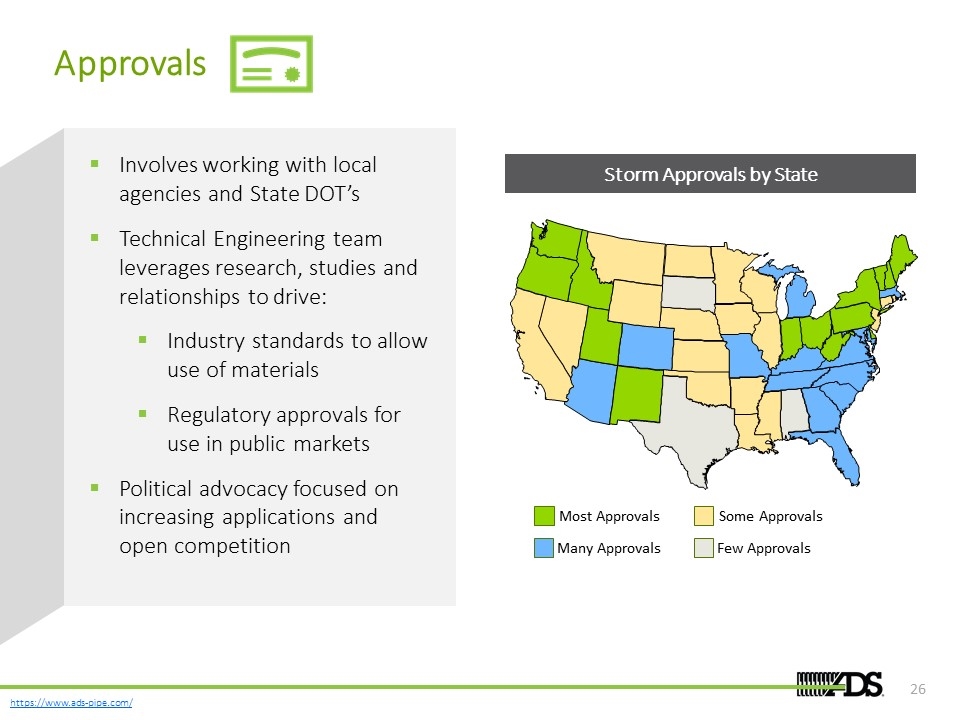

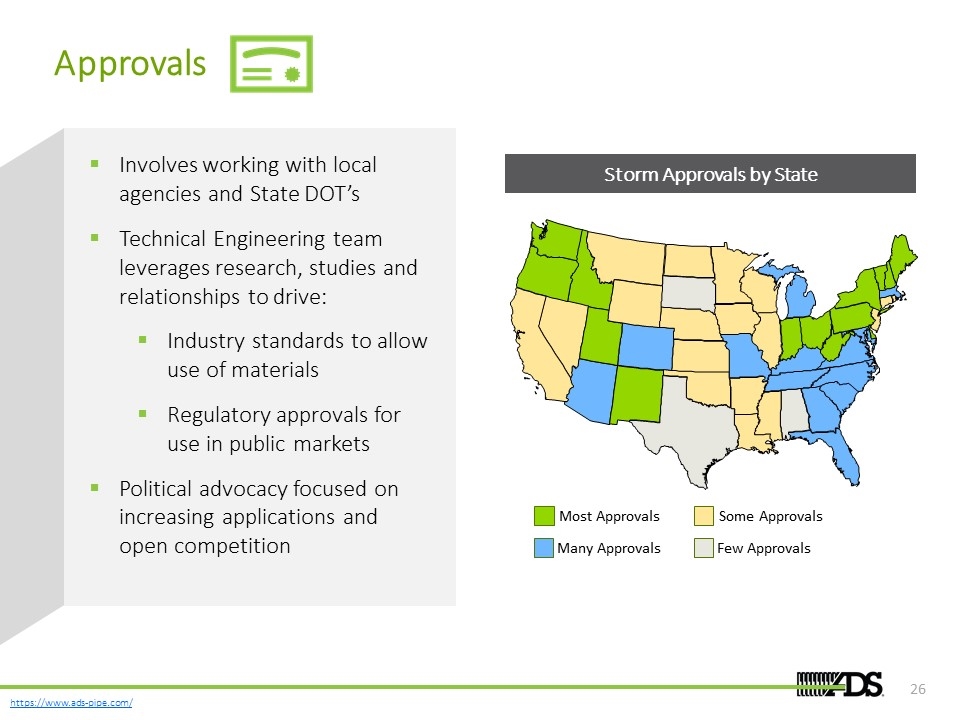

Approvals Many Approvals Few Approvals Most Approvals Some Approvals Storm Approvals by State Involves working with local agencies and State DOT’s Technical Engineering team leverages research, studies and relationships to drive: Industry standards to allow use of materials Regulatory approvals for use in public markets Political advocacy focused on increasing applications and open competition

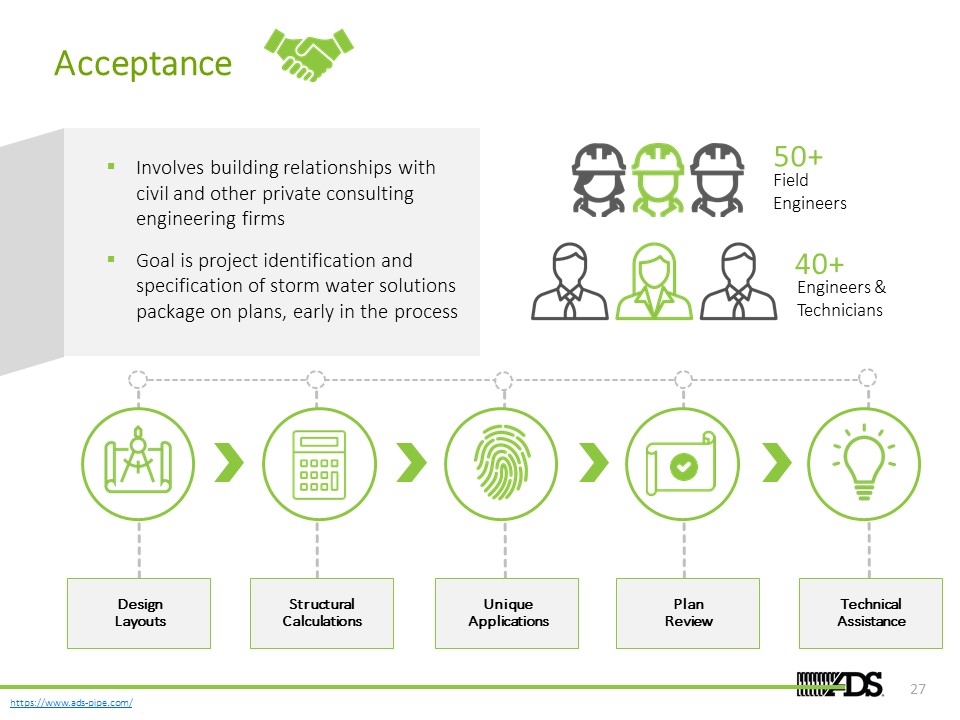

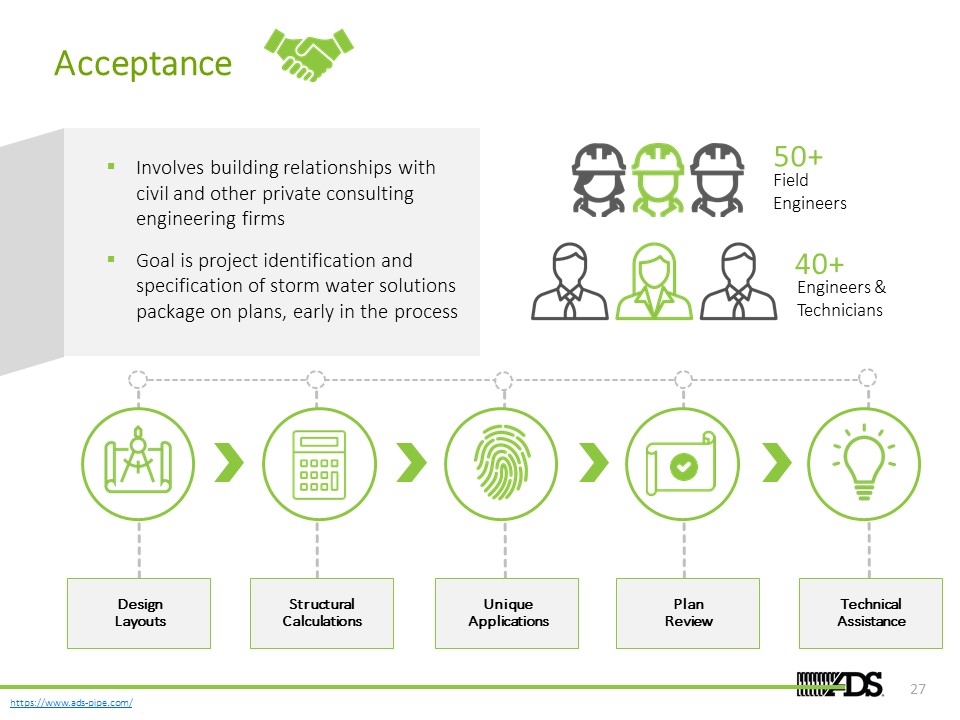

Acceptance Involves building relationships with civil and other private consulting engineering firms Goal is project identification and specification of storm water solutions package on plans, early in the process 40+ Engineers & Technicians 50+ Field Engineers Structural Calculations Design Layouts Unique Applications Plan Review Technical Assistance

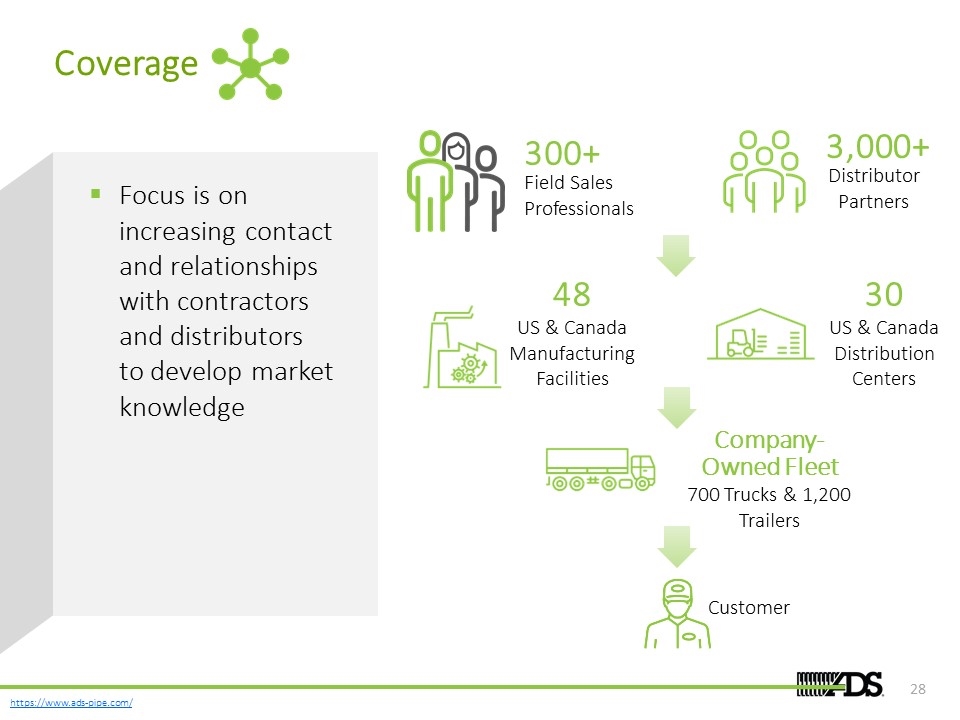

Coverage Focus is on increasing contact and relationships with contractors and distributors to develop market knowledge 300+ Field Sales Professionals 3,000+ Distributor Partners US & Canada Manufacturing Facilities Company-Owned Fleet 700 Trucks & 1,200 Trailers Customer 30 US & Canada Distribution Centers 48

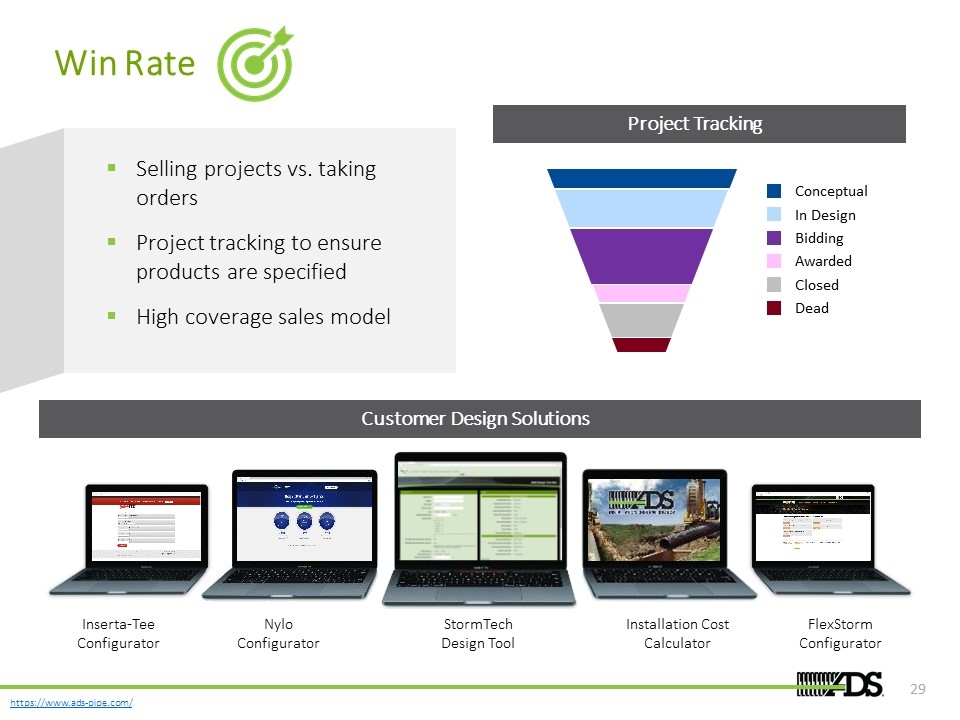

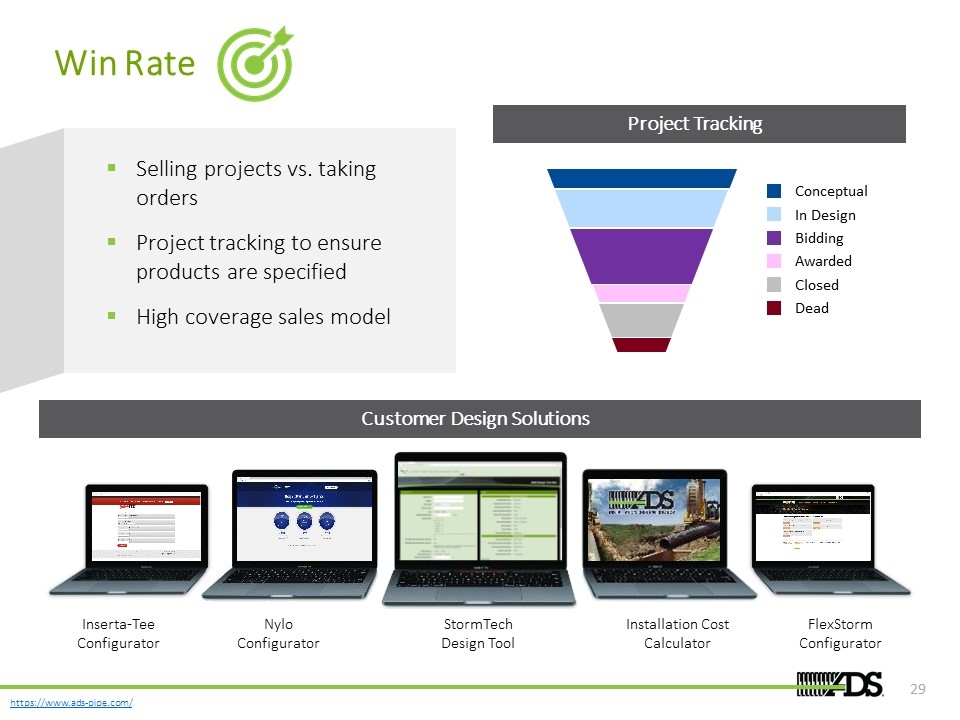

Win Rate Selling projects vs. taking orders Project tracking to ensure products are specified High coverage sales model Customer Design Solutions Inserta-Tee Configurator StormTech Design Tool Installation Cost Calculator FlexStorm Configurator Nylo Configurator Project Tracking Conceptual In Design Bidding Awarded Dead Closed

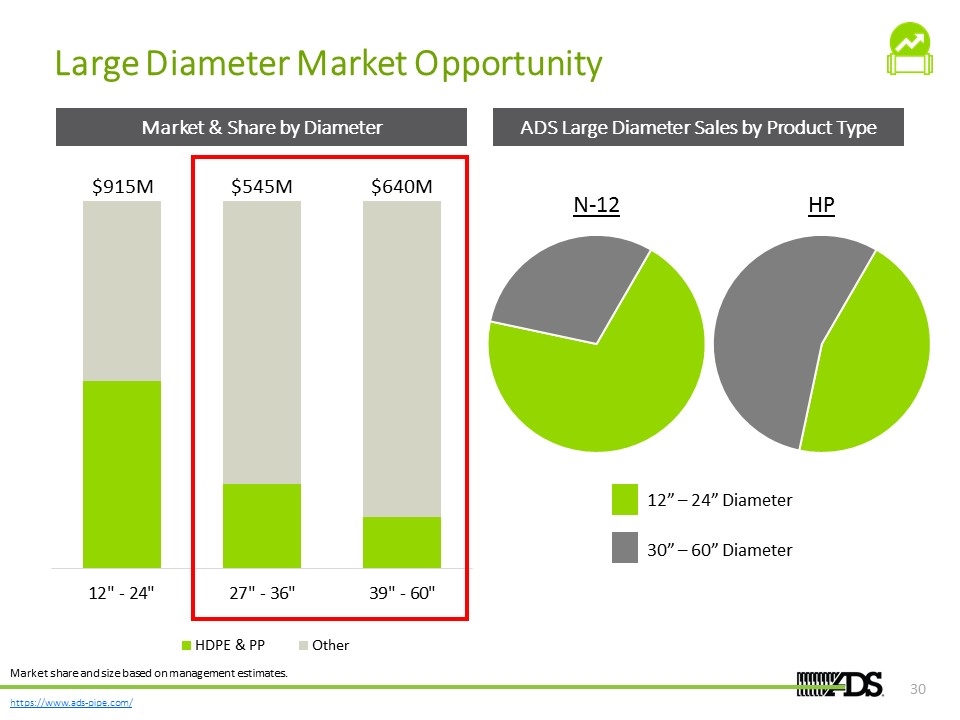

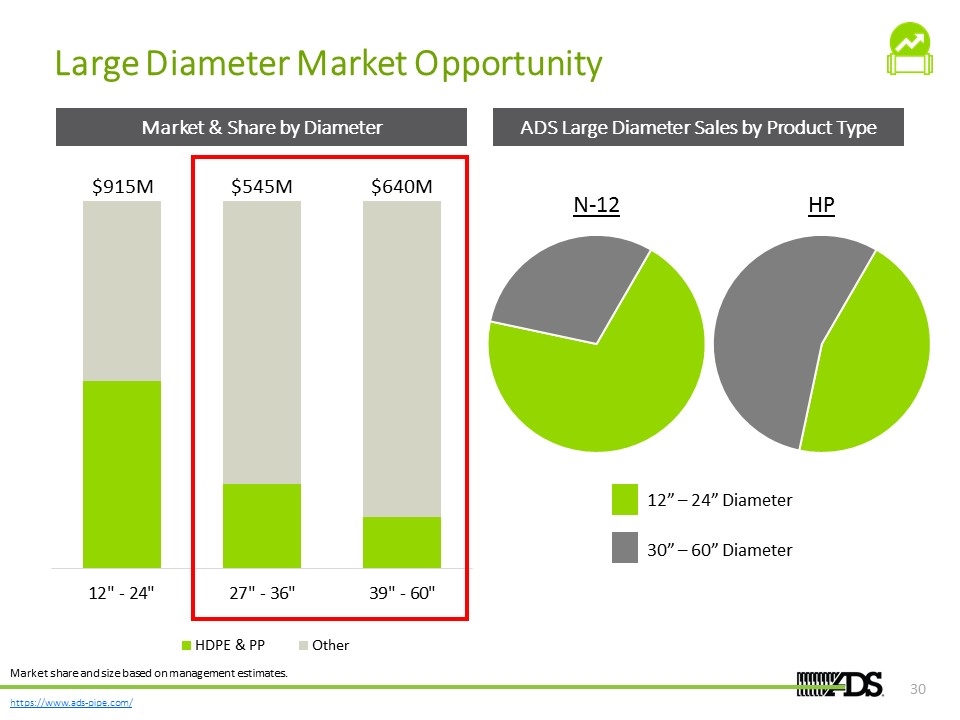

Market & Share by Diameter ADS Large Diameter Sales by Product Type Large Diameter Market Opportunity $545M $640M $915M 12” – 24” Diameter 30” – 60” Diameter Market share and size based on management estimates.

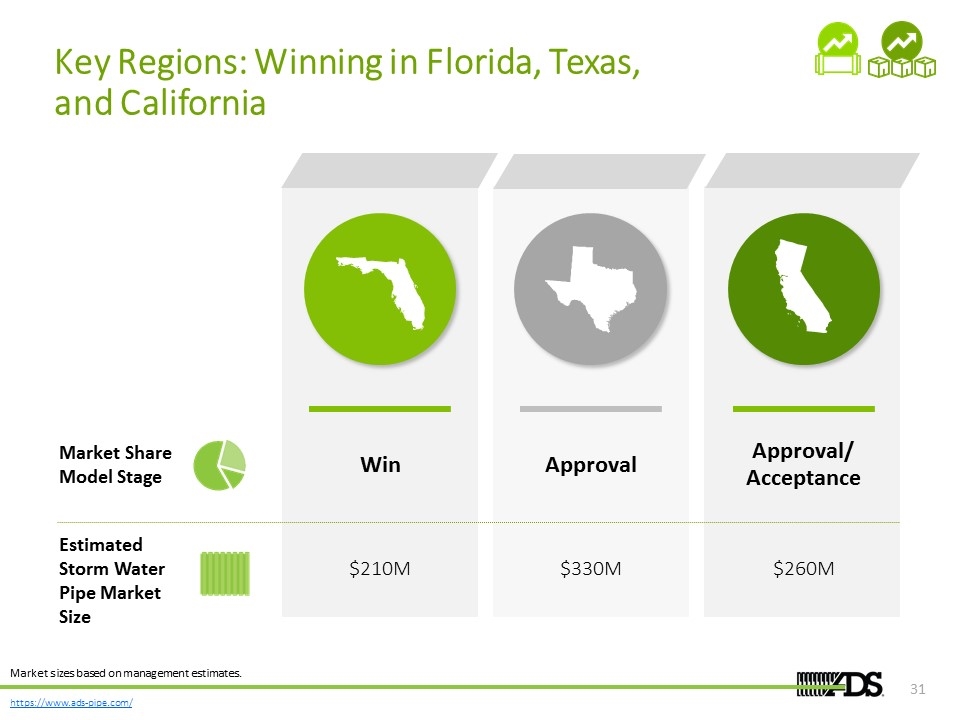

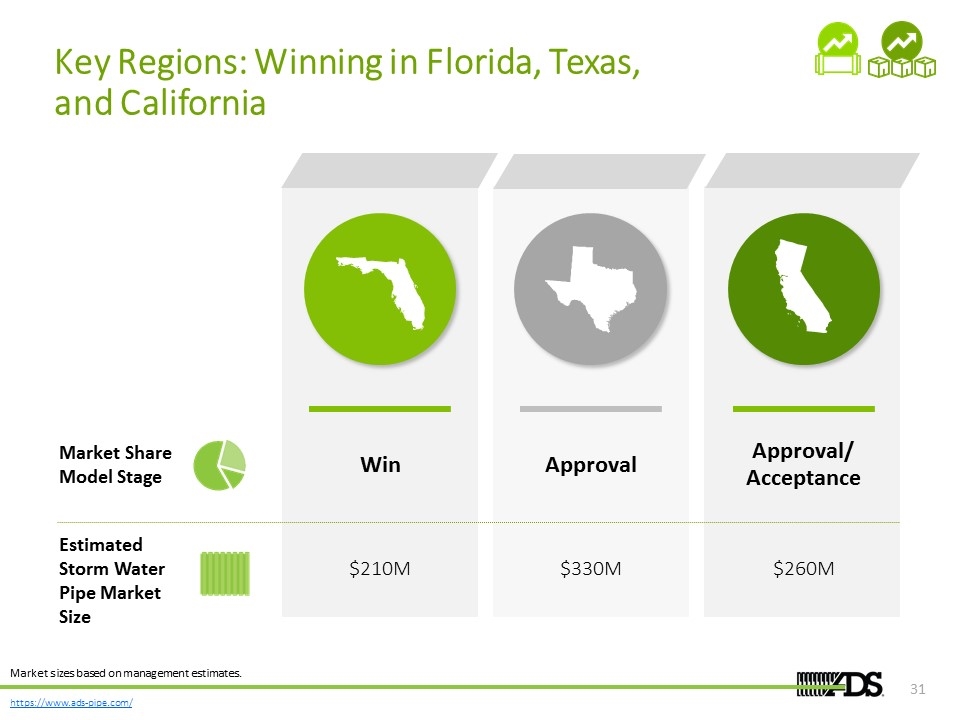

Key Regions: Winning in Florida, Texas, and California Win $210M Approval/ Acceptance $260M Estimated Storm Water Pipe Market Size Market Share Model Stage Approval $330M Market sizes based on management estimates.

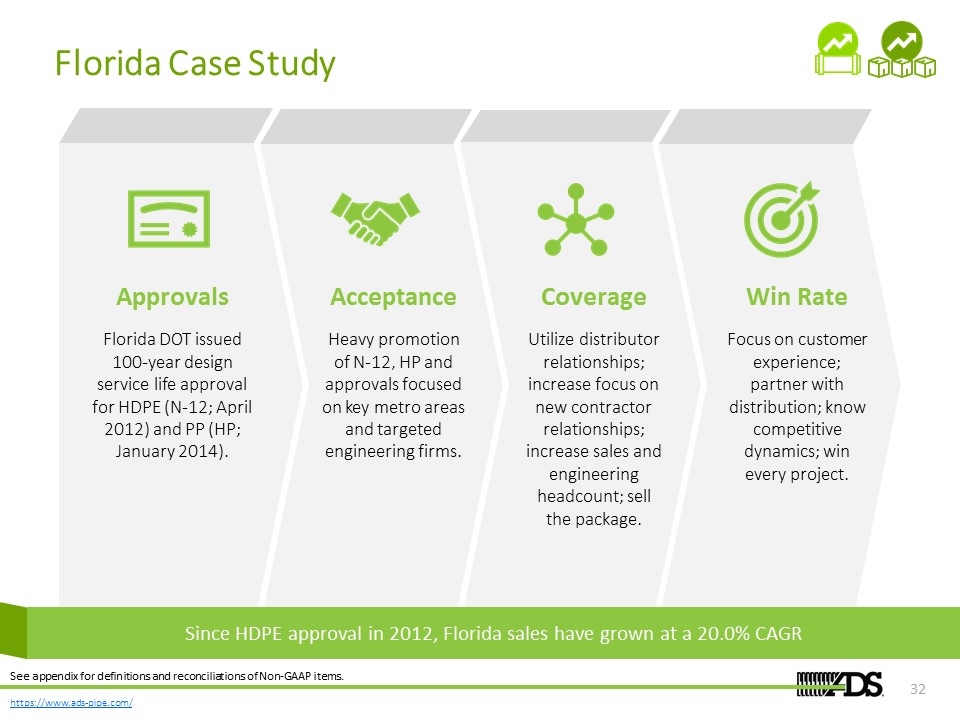

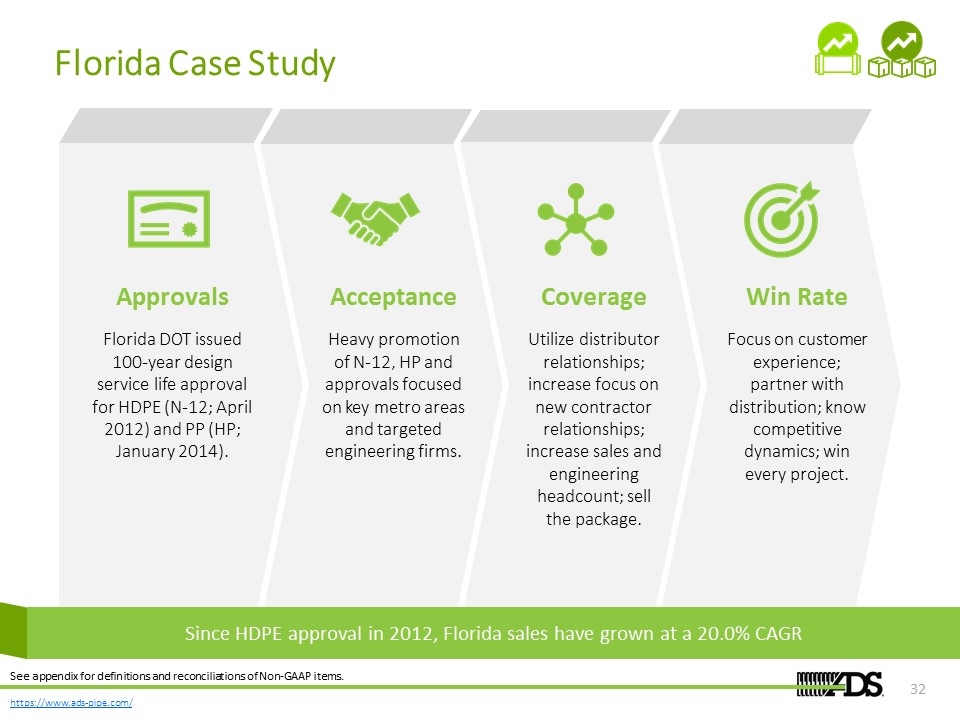

Florida Case Study Since HDPE approval in 2012, Florida sales have grown at a 20.0% CAGR Approvals Florida DOT issued 100-year design service life approval for HDPE (N-12; April 2012) and PP (HP; January 2014). Acceptance Heavy promotion of N-12, HP and approvals focused on key metro areas and targeted engineering firms. Coverage Utilize distributor relationships; increase focus on new contractor relationships; increase sales and engineering headcount; sell the package. Win Rate Focus on customer experience; partner with distribution; know competitive dynamics; win every project. See appendix for definitions and reconciliations of Non-GAAP items.

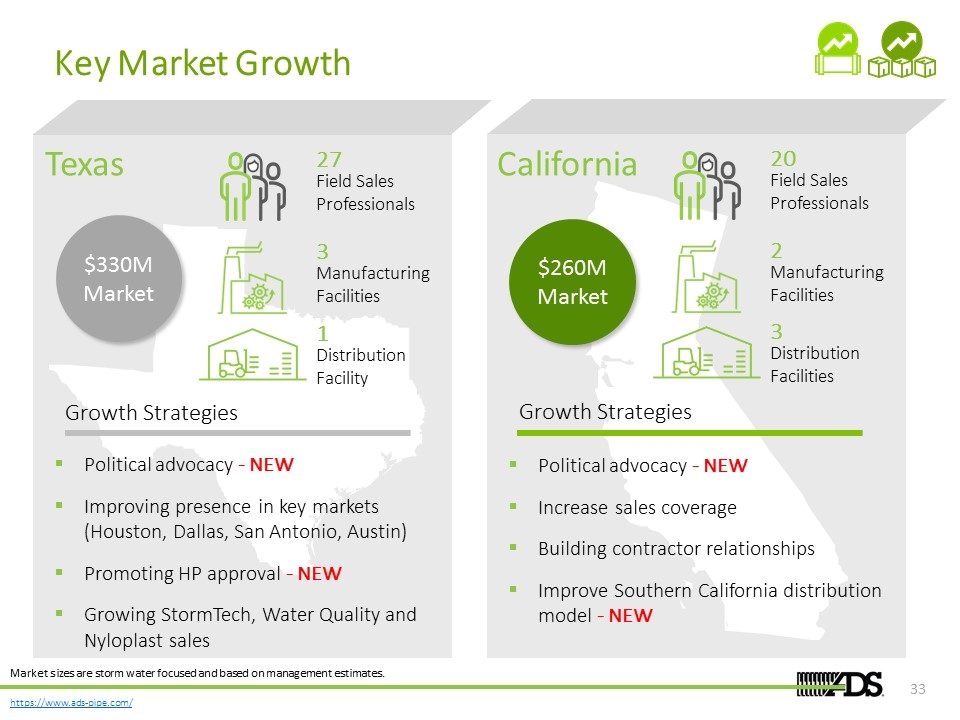

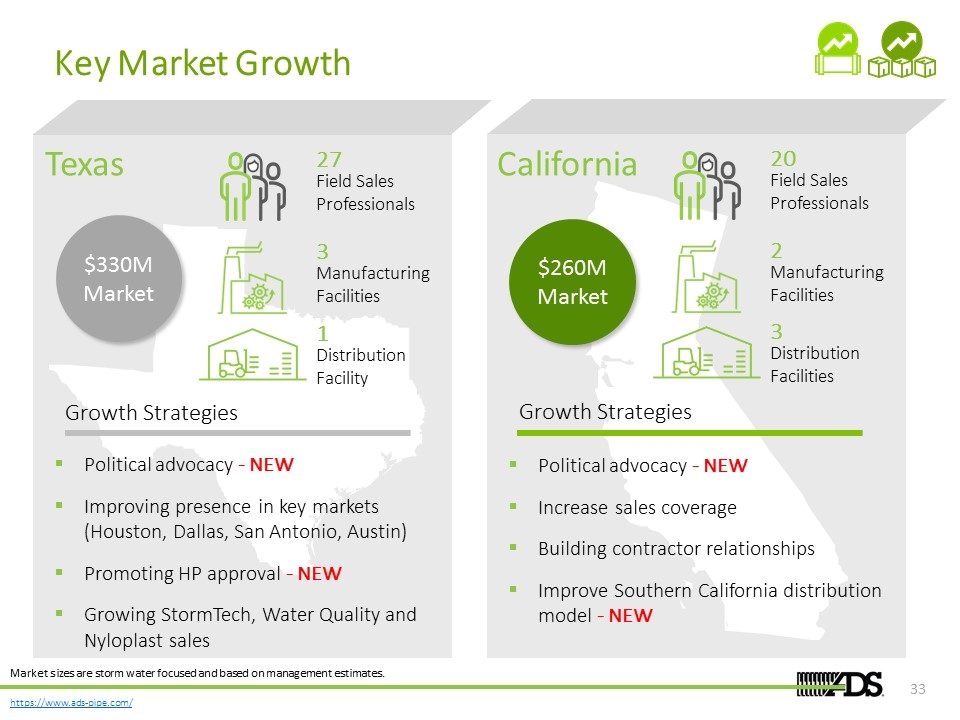

Key Market Growth Political advocacy - NEW Improving presence in key markets (Houston, Dallas, San Antonio, Austin) Promoting HP approval - NEW Growing StormTech, Water Quality and Nyloplast sales Growth Strategies Texas Growth Strategies Political advocacy - NEW Increase sales coverage Building contractor relationships Improve Southern California distribution model - NEW California 20 Field Sales Professionals 2 Manufacturing Facilities 3 Distribution Facilities $260M Market 27 Field Sales Professionals 3 Manufacturing Facilities 1 Distribution Facility $330M Market Market sizes are storm water focused and based on management estimates.

Pillars of Accelerating Growth Pipe Growth Allied Products Growth Innovation and Product Development

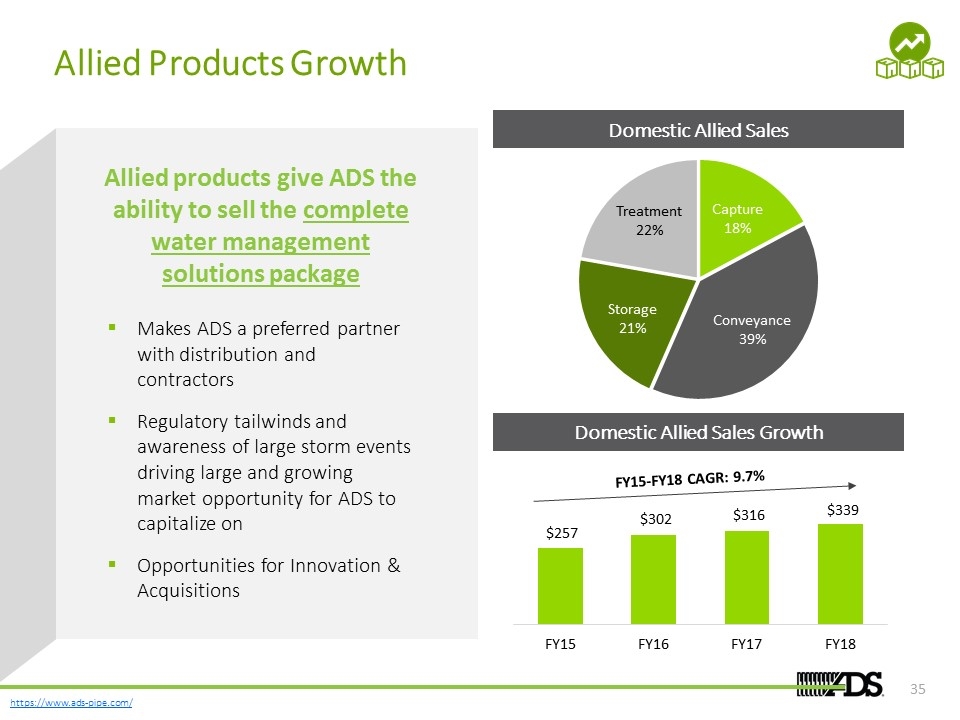

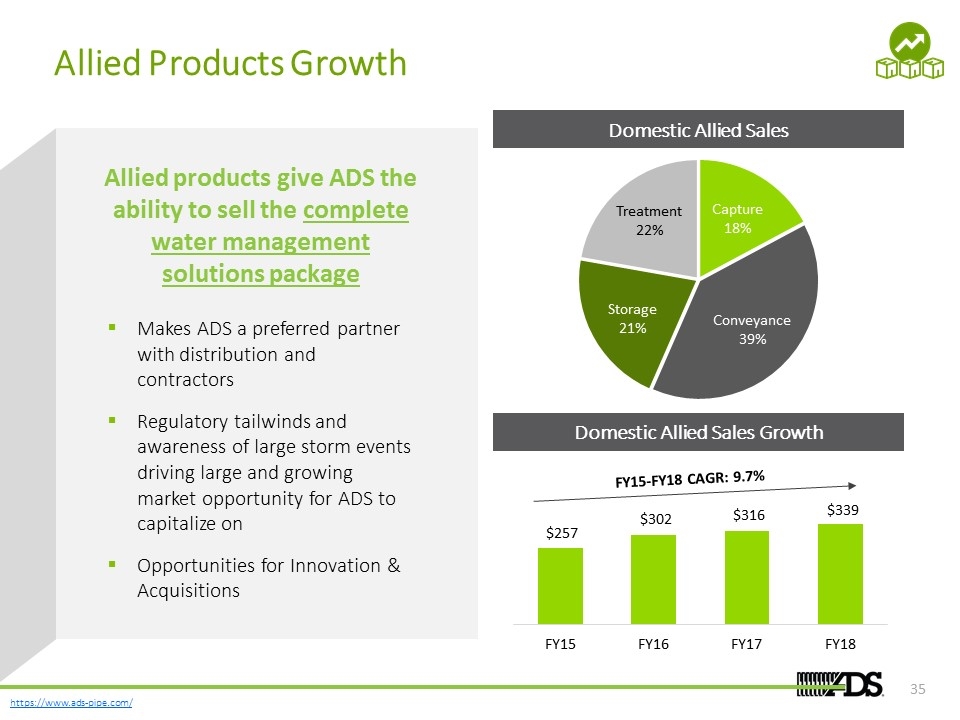

Allied Products Growth Allied products give ADS the ability to sell the complete water management solutions package Makes ADS a preferred partner with distribution and contractors Regulatory tailwinds and awareness of large storm events driving large and growing market opportunity for ADS to capitalize on Opportunities for Innovation & Acquisitions Domestic Allied Sales Domestic Allied Sales Growth Capture 18% Conveyance 39% Storage 21% Treatment 22% FY15-FY18 CAGR: 9.7%

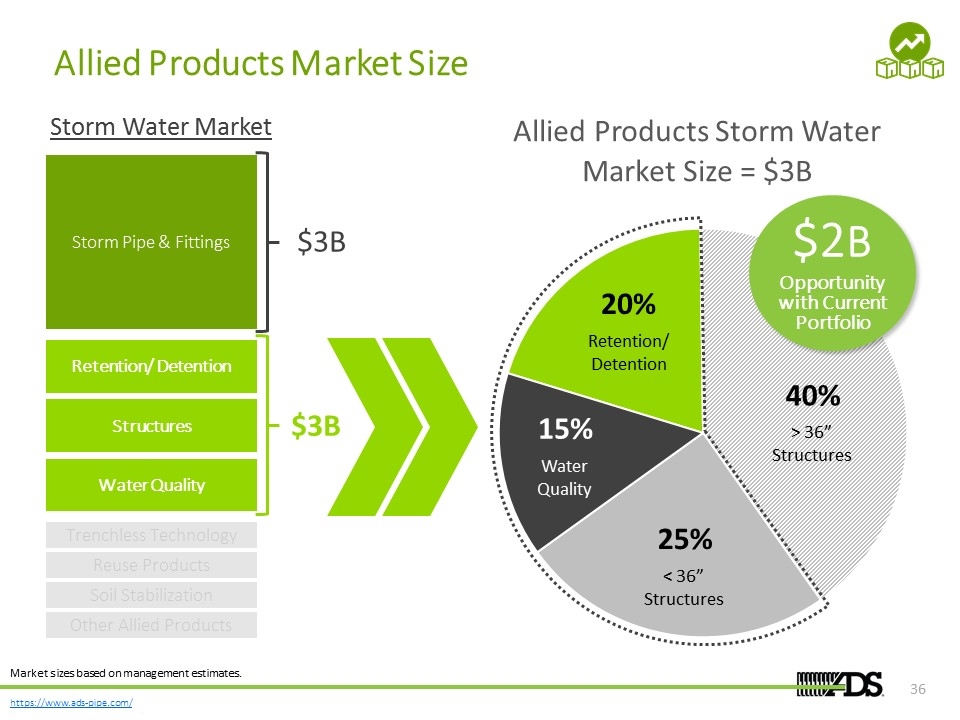

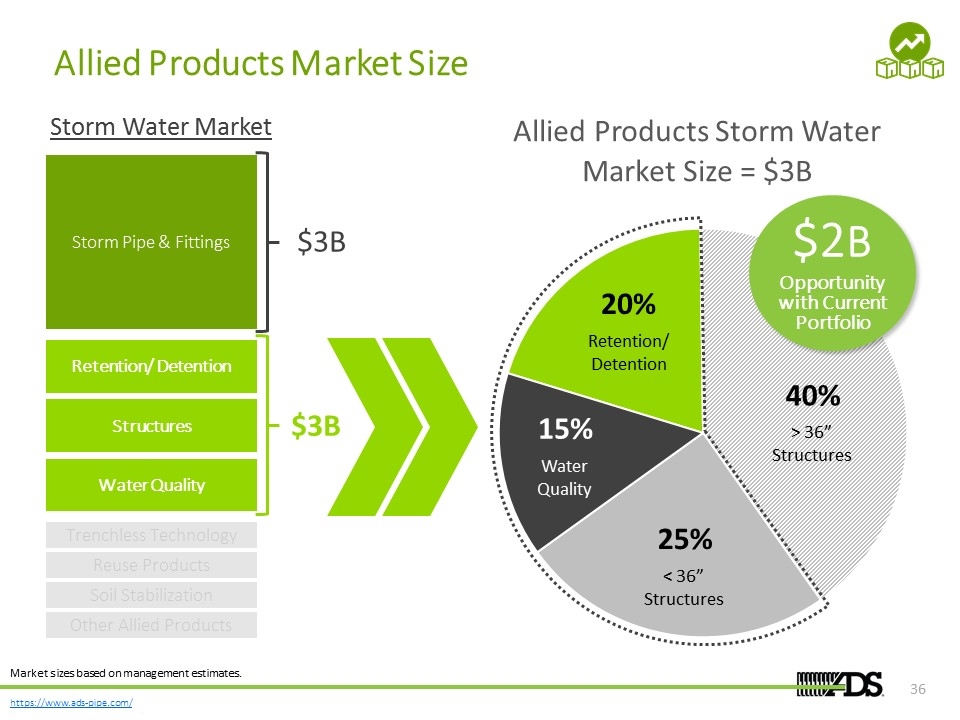

Allied Products Market Size Storm Water Market > 36” Structures 40% < 36” Structures 25% Water Quality 15% Retention/ Detention 20% Opportunity with Current Portfolio $2B Storm Pipe & Fittings Retention/ Detention Structures Water Quality Trenchless Technology Reuse Products Soil Stabilization Other Allied Products $3B $3B Market sizes based on management estimates.

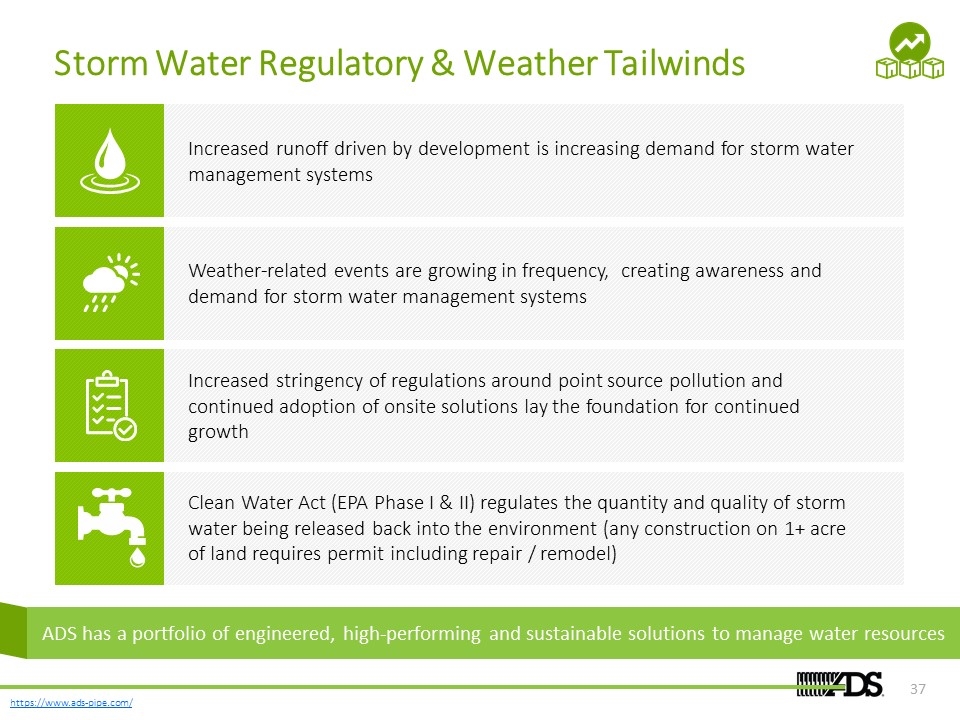

Storm Water Regulatory & Weather Tailwinds ADS has a portfolio of engineered, high-performing and sustainable solutions to manage water resources Increased runoff driven by development is increasing demand for storm water management systems Weather-related events are growing in frequency, creating awareness and demand for storm water management systems Increased stringency of regulations around point source pollution and continued adoption of onsite solutions lay the foundation for continued growth Clean Water Act (EPA Phase I & II) regulates the quantity and quality of storm water being released back into the environment (any construction on 1+ acre of land requires permit including repair / remodel)

Pipes used to move storm water away from developed sites to be discharged Pipes & Fittings Structures Water Management Solutions Package Structures used to collect and direct storm water and move it to underground conveyance system Managed infiltration and recharging of storm water that mitigates erosion and flooding Products removing trash, debris and pollutants from storm water runoff before it is discharged into the environment Retention & Detention Water Quality

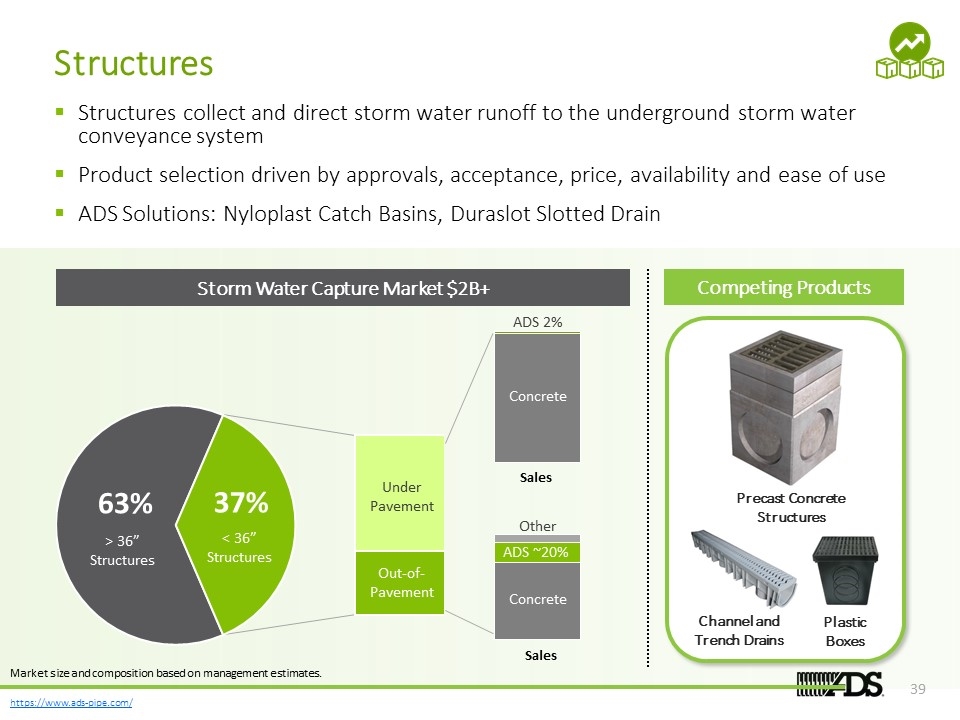

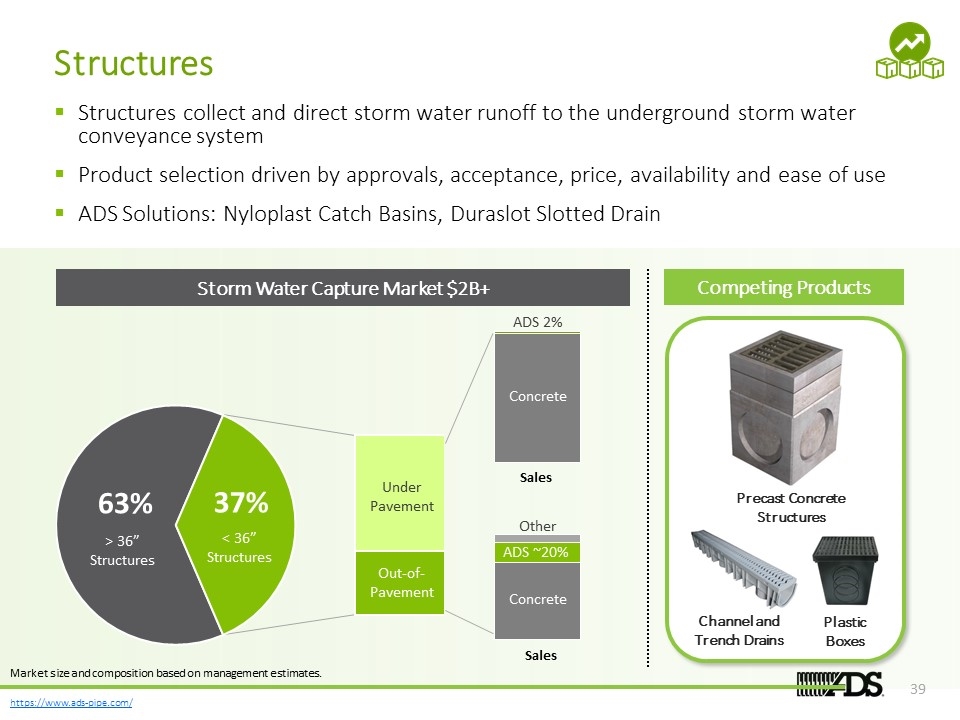

Structures Structures collect and direct storm water runoff to the underground storm water conveyance system Product selection driven by approvals, acceptance, price, availability and ease of use ADS Solutions: Nyloplast Catch Basins, Duraslot Slotted Drain Precast Concrete Structures ADS 2% Concrete ADS ~20% Concrete Other > 36” Structures 63% < 36” Structures 37% Under Pavement Out-of- Pavement Competing Products Storm Water Capture Market $2B+ Sales Sales Channel and Trench Drains Plastic Boxes Market size and composition based on management estimates.

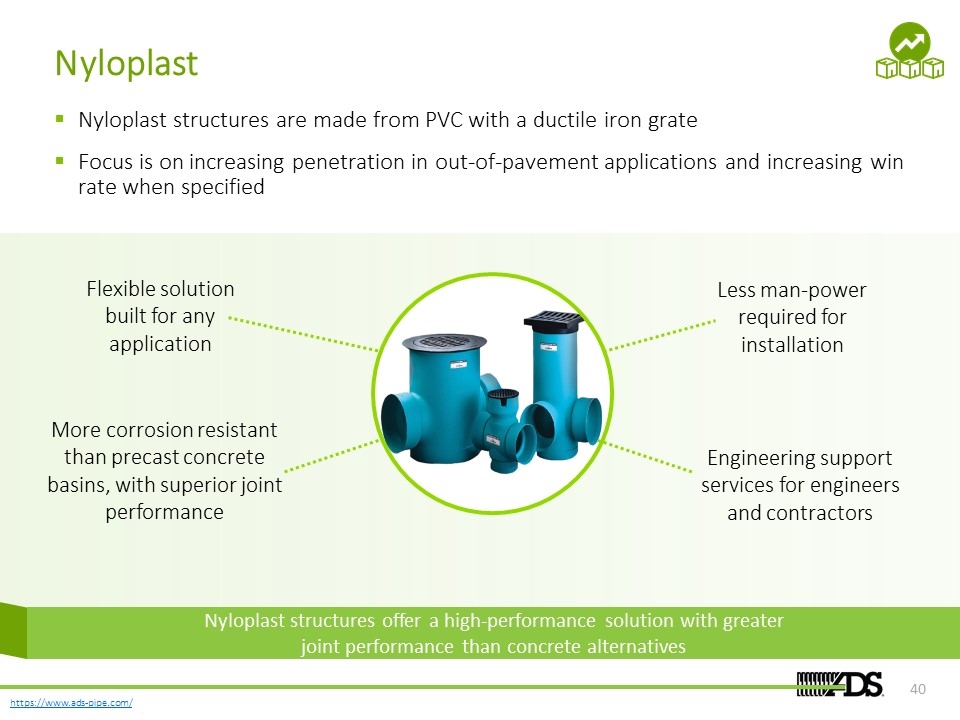

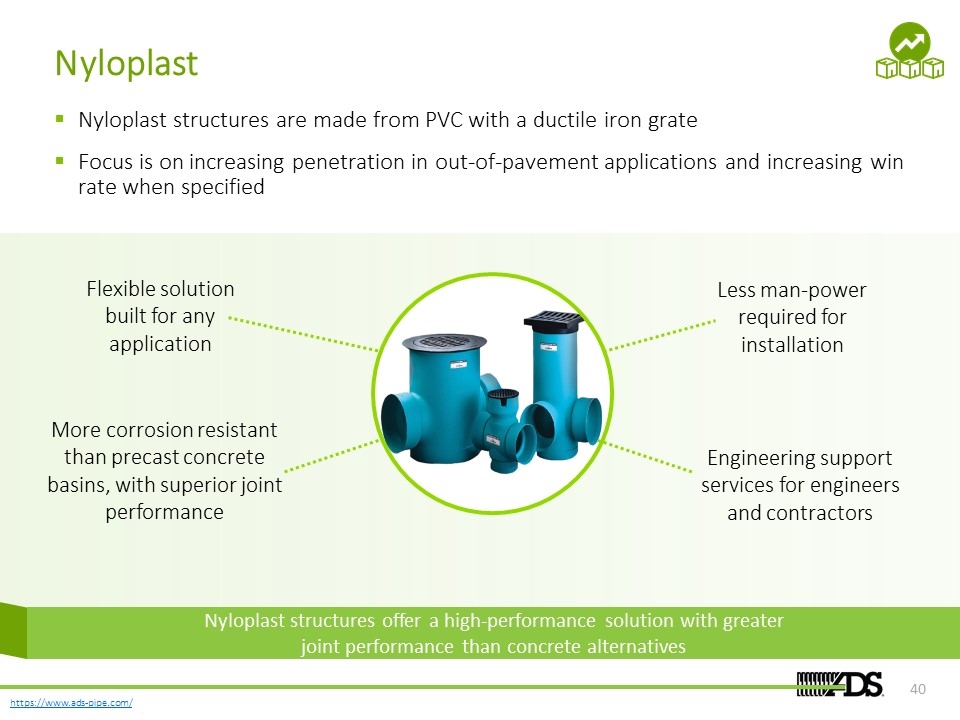

Nyloplast Nyloplast structures are made from PVC with a ductile iron grate Focus is on increasing penetration in out-of-pavement applications and increasing win rate when specified Less man-power required for installation Flexible solution built for any application More corrosion resistant than precast concrete basins, with superior joint performance Engineering support services for engineers and contractors Nyloplast structures offer a high-performance solution with greater joint performance than concrete alternatives

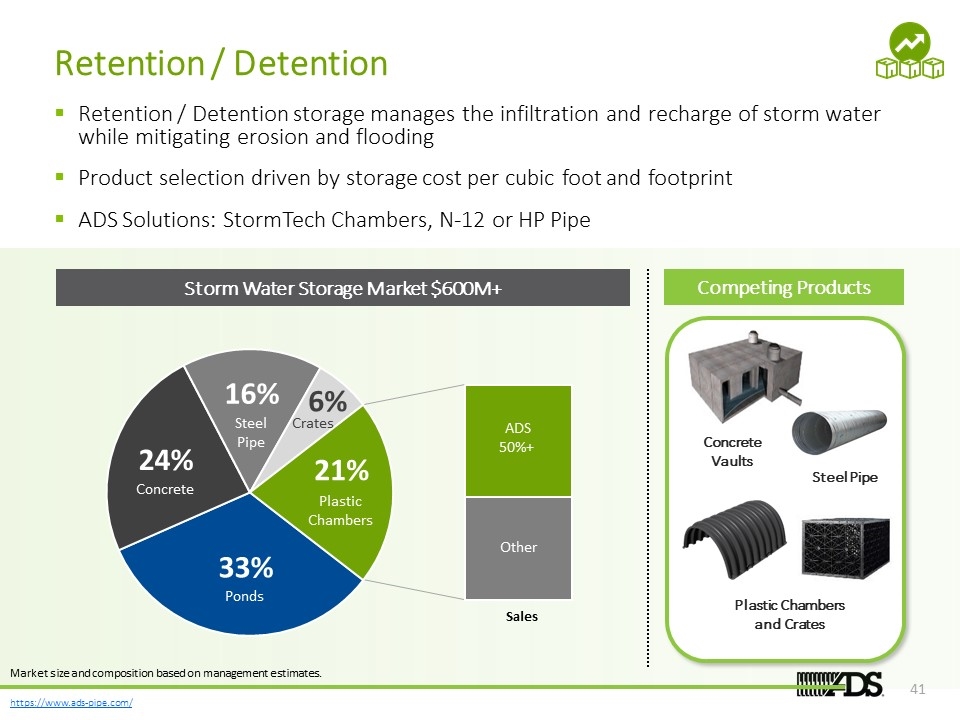

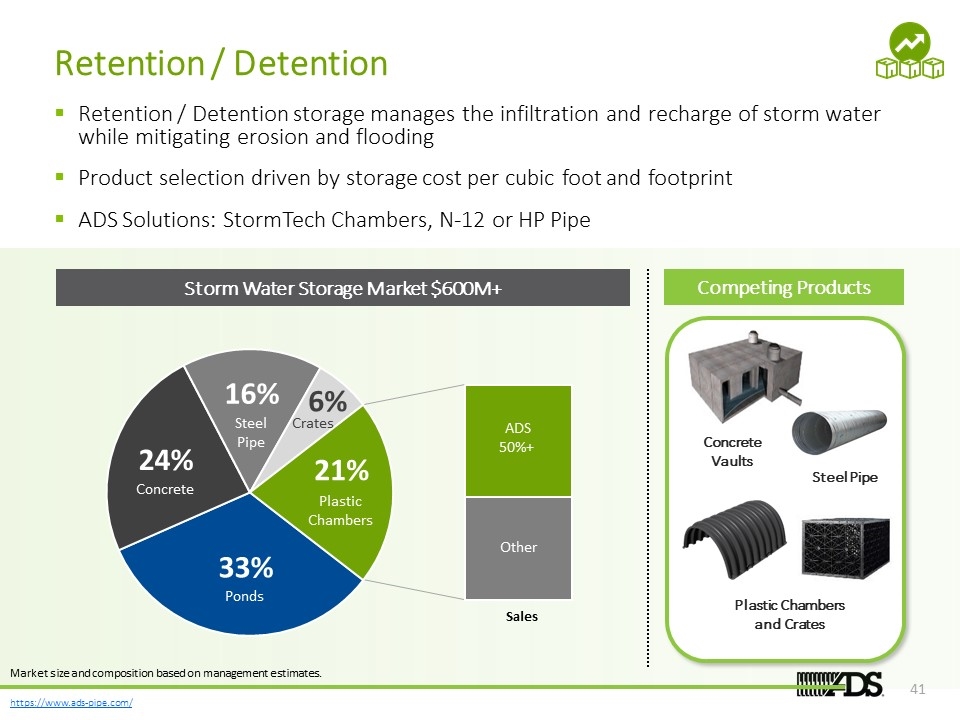

Competing Products Retention / Detention Retention / Detention storage manages the infiltration and recharge of storm water while mitigating erosion and flooding Product selection driven by storage cost per cubic foot and footprint ADS Solutions: StormTech Chambers, N-12 or HP Pipe 11% Plastic Chambers 21% Concrete Vaults Plastic Chambers and Crates Steel Pipe Storm Water Storage Market $600M+ Ponds 33% Sales Concrete 24% Steel Pipe 16% Crates 6% Plastic Chambers 21% 50%+ ADS Other Market size and composition based on management estimates.

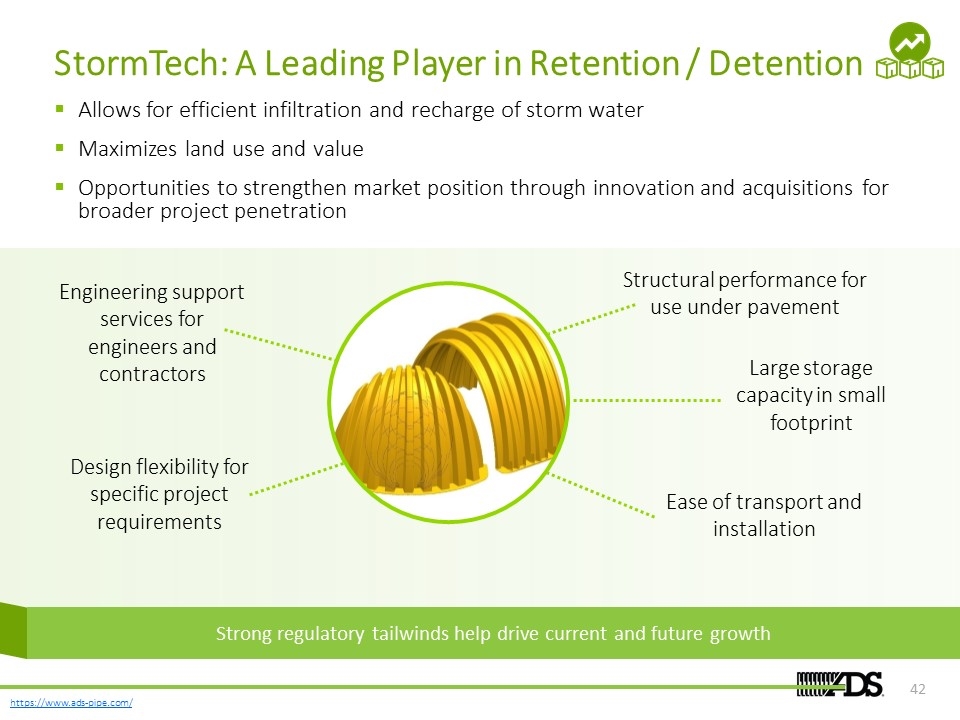

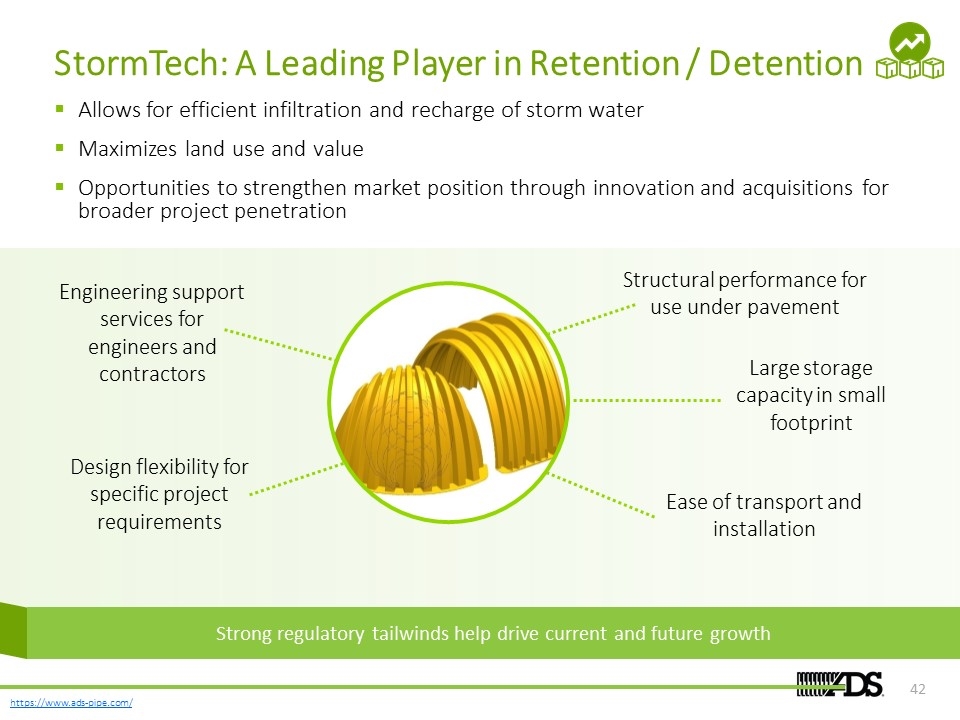

StormTech: A Leading Player in Retention / Detention Allows for efficient infiltration and recharge of storm water Maximizes land use and value Opportunities to strengthen market position through innovation and acquisitions for broader project penetration Ease of transport and installation Large storage capacity in small footprint Structural performance for use under pavement Engineering support services for engineers and contractors Design flexibility for specific project requirements Strong regulatory tailwinds help drive current and future growth

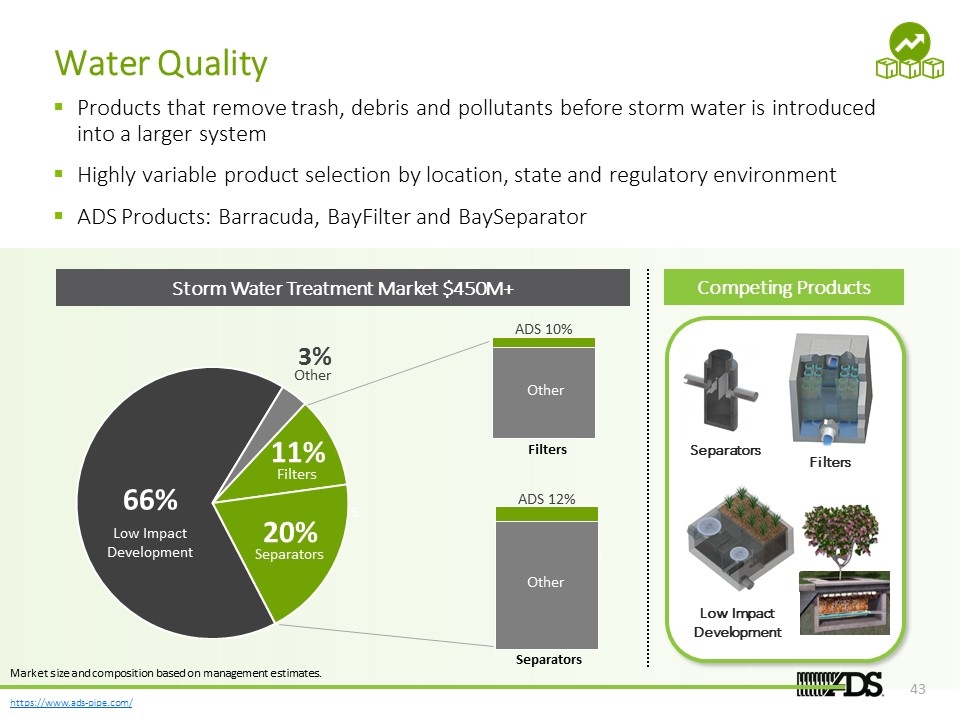

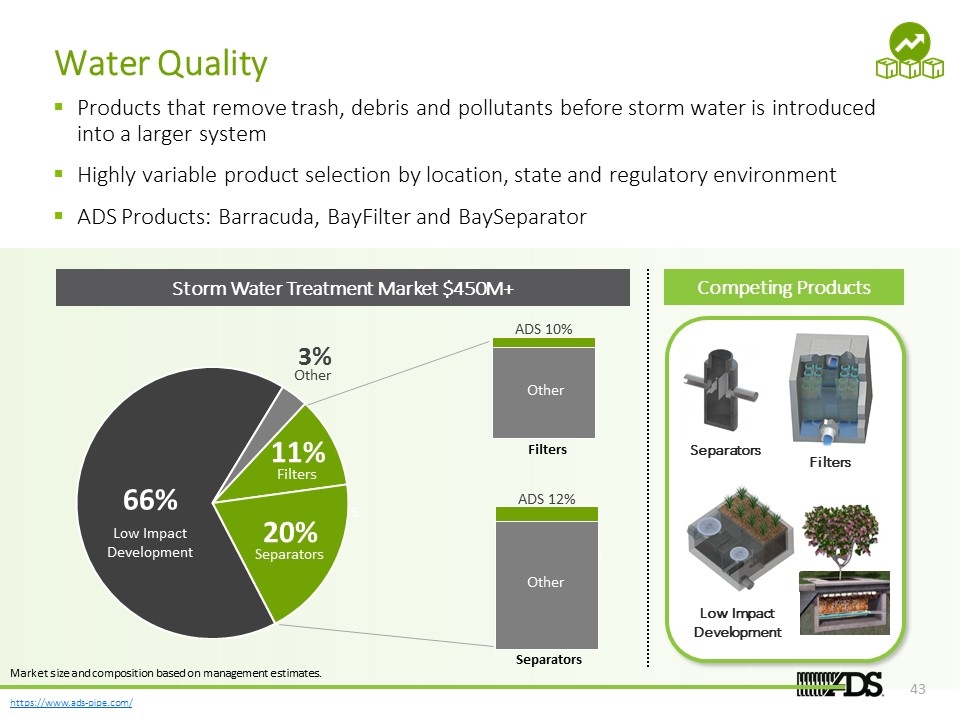

Water Quality Products that remove trash, debris and pollutants before storm water is introduced into a larger system Highly variable product selection by location, state and regulatory environment ADS Products: Barracuda, BayFilter and BaySeparator Separators Filters Low Impact Development Plastic Chambers 21% < 36” Structures 37% ADS 2% ADS 10% ADS 12% Competing Products Storm Water Treatment Market $450M+ Low Impact Development 66% Separators 20% Filters 11% Other 3% Filters Separators Other Other Market size and composition based on management estimates.

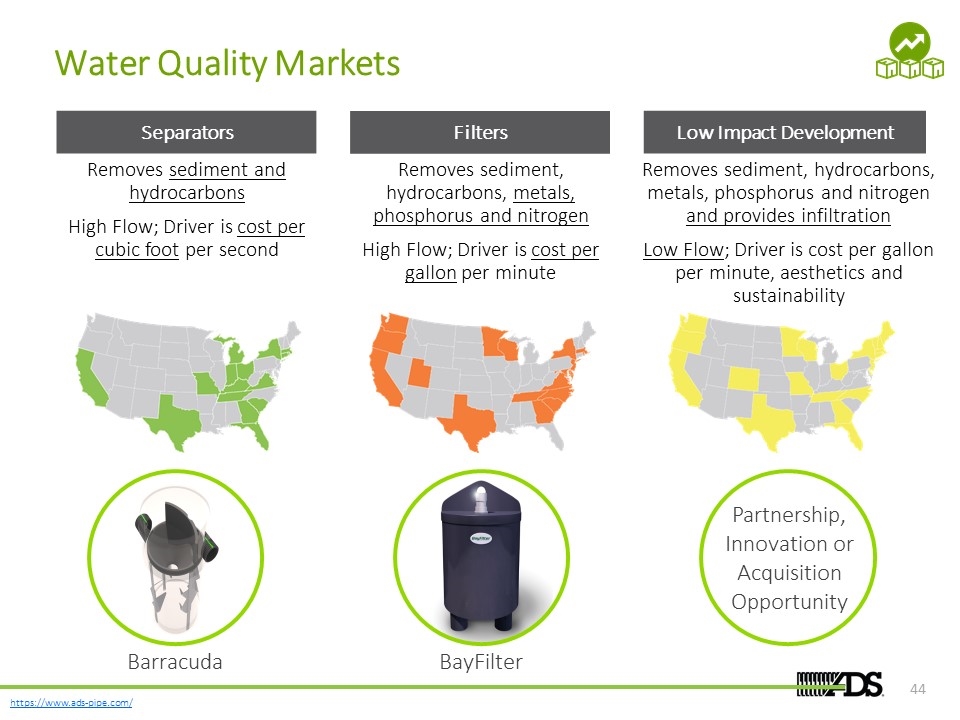

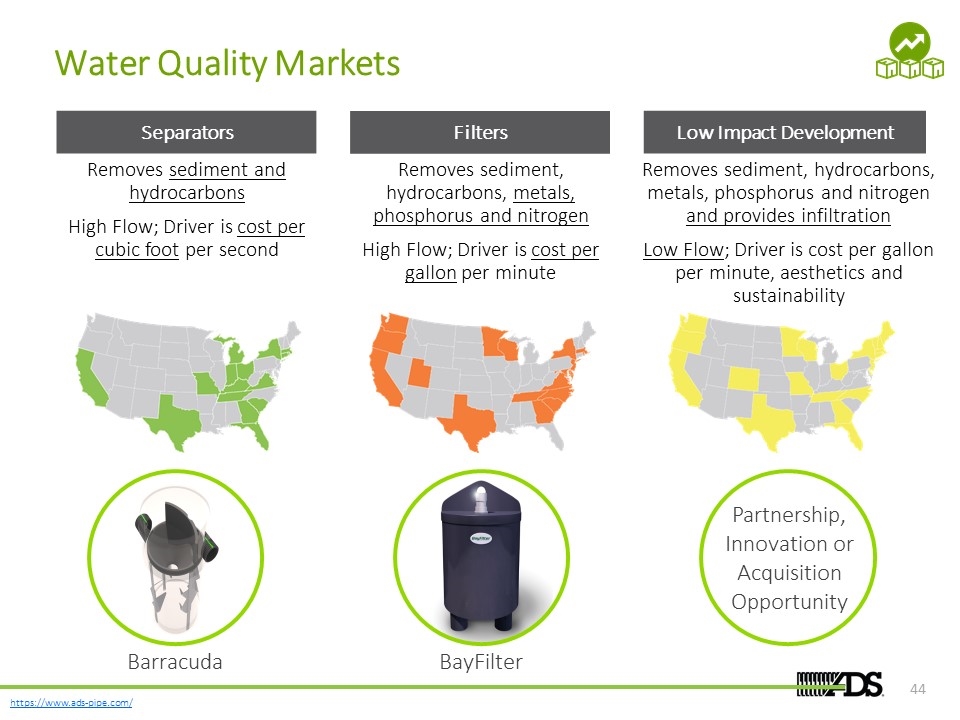

Water Quality Markets Separators Filters Low Impact Development Partnership, Innovation or Acquisition Opportunity Barracuda BayFilter Removes sediment and hydrocarbons High Flow; Driver is cost per cubic foot per second Removes sediment, hydrocarbons, metals, phosphorus and nitrogen High Flow; Driver is cost per gallon per minute Removes sediment, hydrocarbons, metals, phosphorus and nitrogen and provides infiltration Low Flow; Driver is cost per gallon per minute, aesthetics and sustainability

Why Solutions Are Important Pipe Manufacturer Solutions Provider $50K Opportunity $150K Opportunity Providing solutions increases our share of wallet with our customers Opportunity amounts above are for illustrative purposes only and may not be indicative of actual project value.

Pillars of Accelerating Growth Pipe Growth Allied Products Growth Innovation and Product Development

Innovation and Product Development Market-Leading Product Portfolio to Drive Future Growth Advancing Core Products Lead the storm water industry with PRODUCT INNOVATION Provide ECONOMIC SOLUTIONS for our customers while ensuring the SAFETY of our employees

Innovation Focus: Water Management Solutions Higher stiffness >48” pipe to further grow market share Profile and weight optimization for current diameters Polypropylene recycling and material characterization Structures Pipes Retention & Detention Water Quality New products to further market penetration in urban applications Cost effective products for green space applications Combining water quality and retention capabilities in a single design Bio-Retention and Low Impact Development (LID) solutions Expanding Barracuda separator water quality product Higher-performing, cost-effective Filter products Innovation Focus

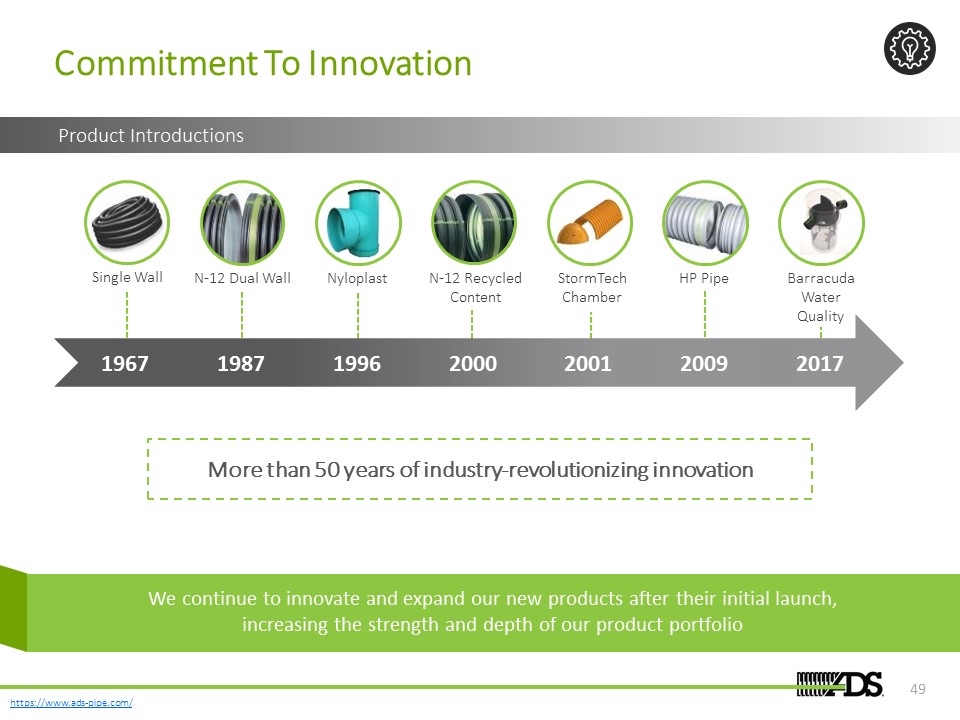

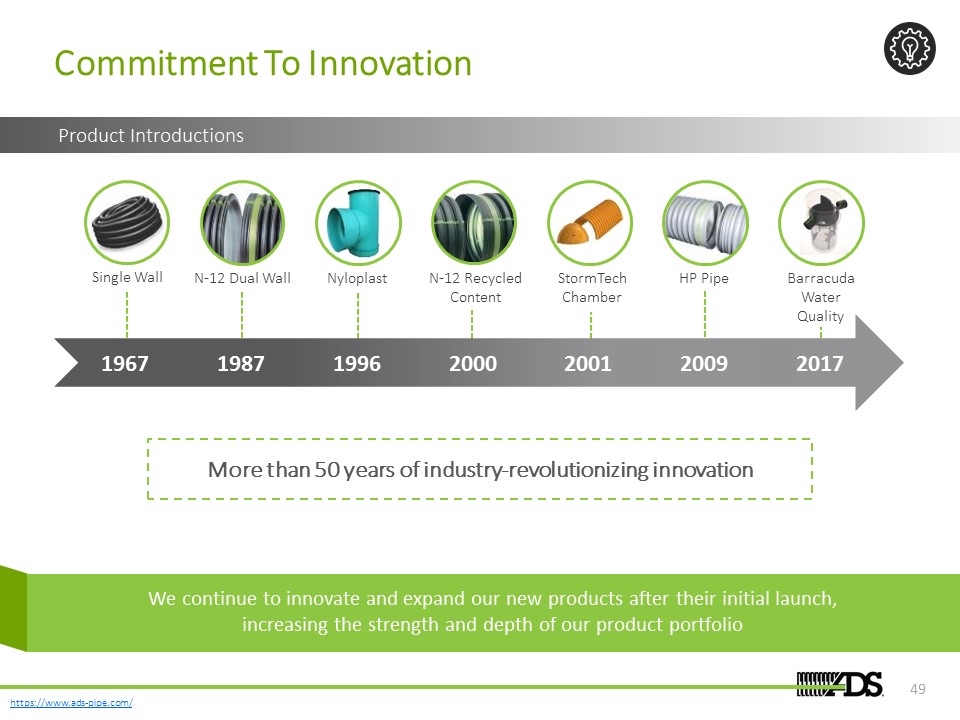

Commitment To Innovation Product Introductions More than 50 years of industry-revolutionizing innovation StormTech Chamber Single Wall HP Pipe Nyloplast N-12 Dual Wall 1987 1996 2000 2001 2017 Barracuda Water Quality N-12 Recycled Content 2009 1967 We continue to innovate and expand our new products after their initial launch, increasing the strength and depth of our product portfolio

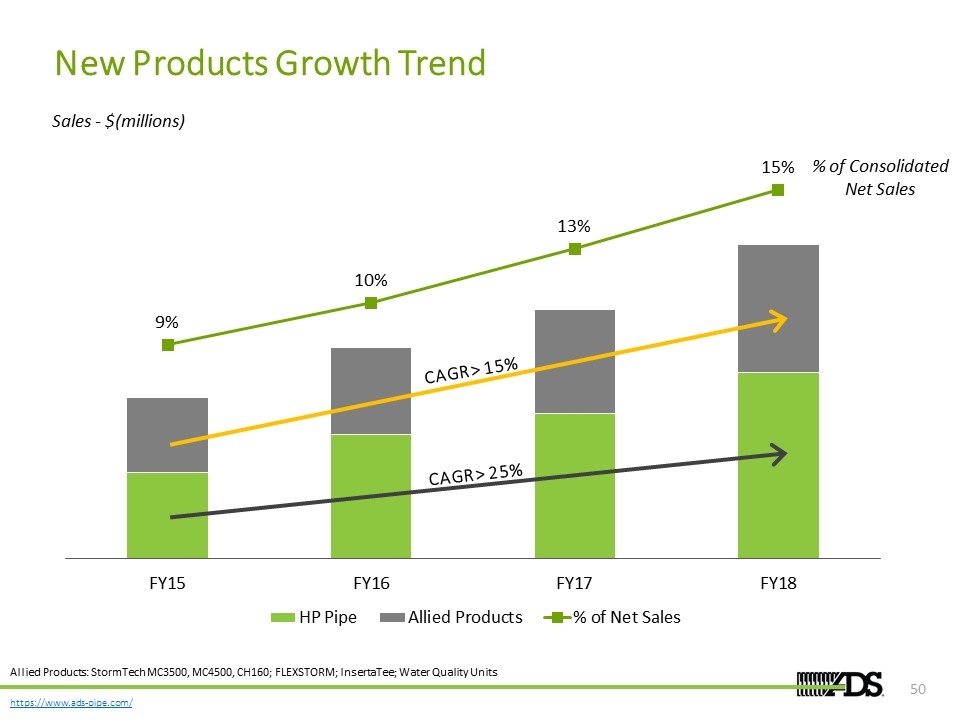

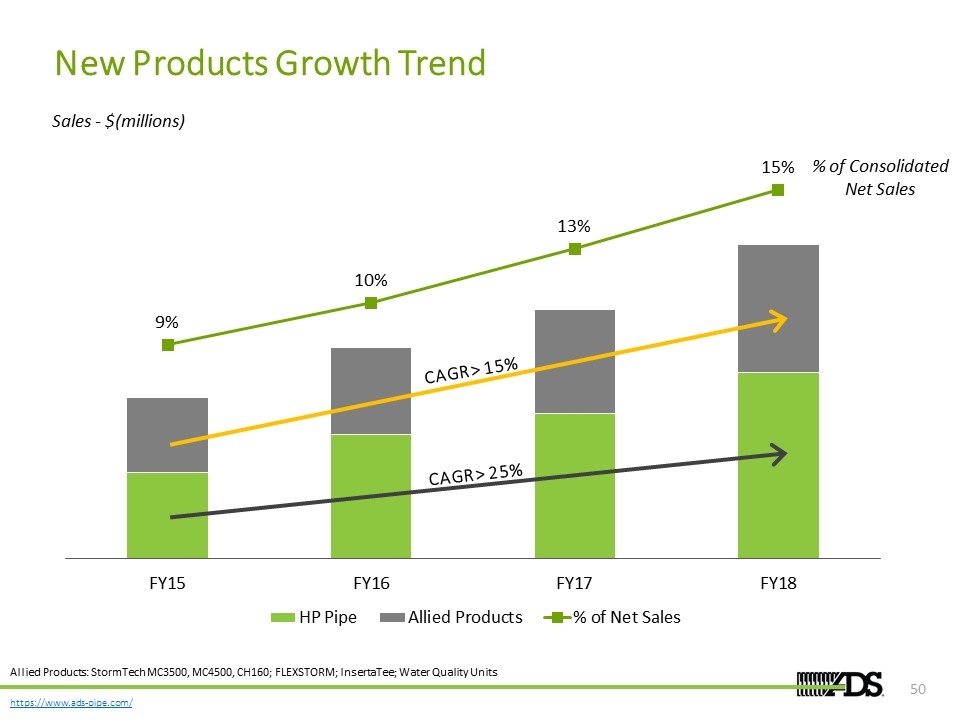

New Products Growth Trend Allied Products: StormTech MC3500, MC4500, CH160; FLEXSTORM; InsertaTee; Water Quality Units Sales - $(millions) % of Consolidated Net Sales CAGR > 15% CAGR > 25%

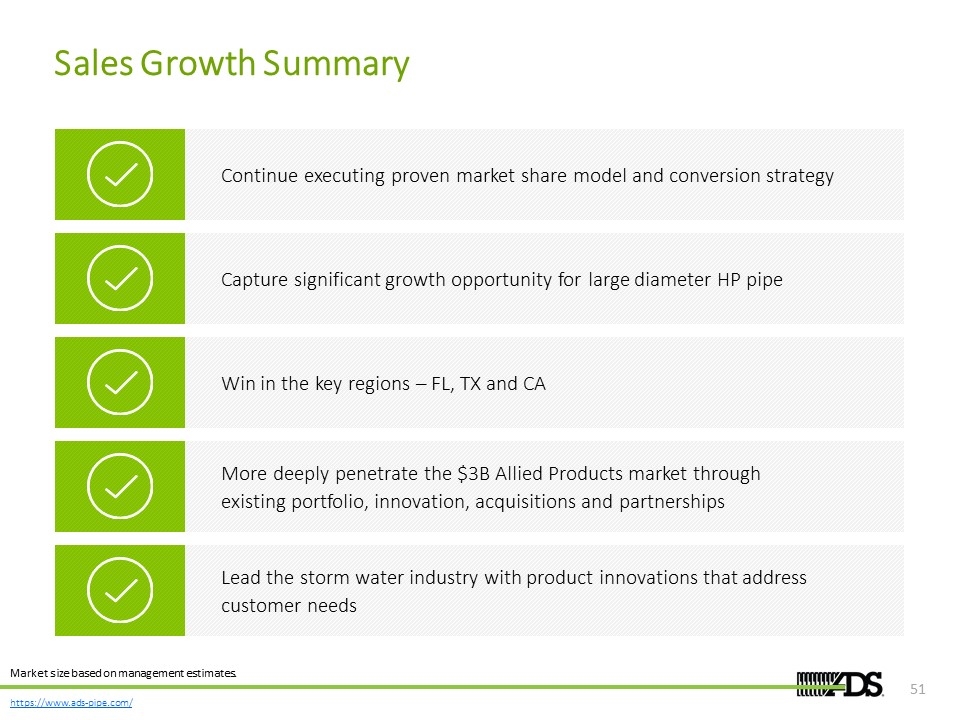

Sales Growth Summary Continue executing proven market share model and conversion strategy Lead the storm water industry with product innovations that address customer needs Capture significant growth opportunity for large diameter HP pipe Win in the key regions – FL, TX and CA More deeply penetrate the $3B Allied Products market through existing portfolio, innovation, acquisitions and partnerships Market size based on management estimates.

Break 15 Minutes

Investor Day Themes Cash Flow Generation Margin Expansion Sales Growth

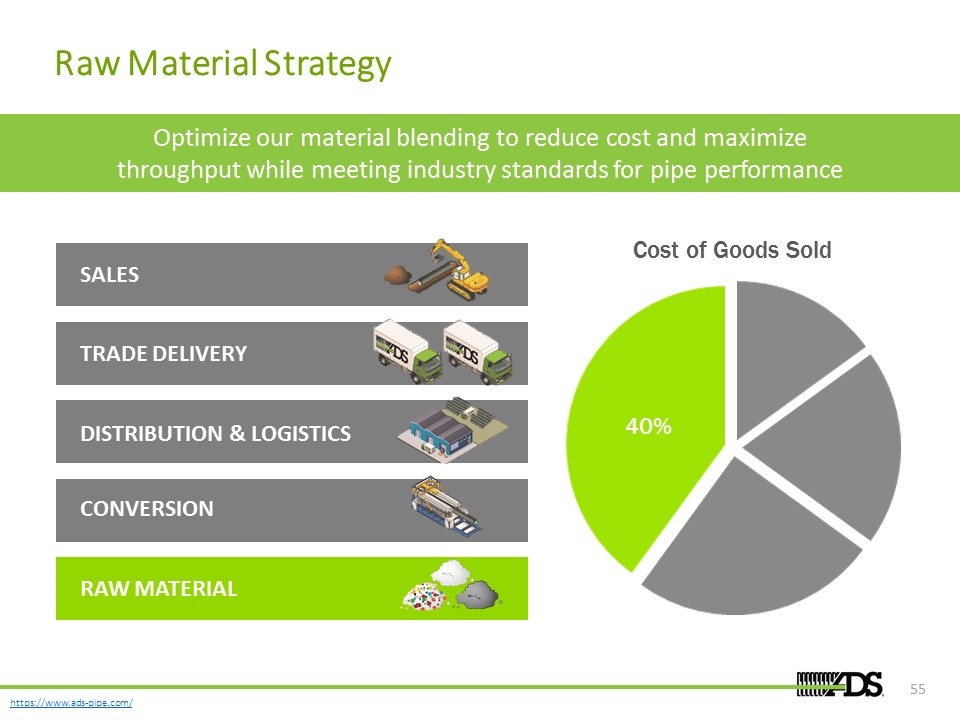

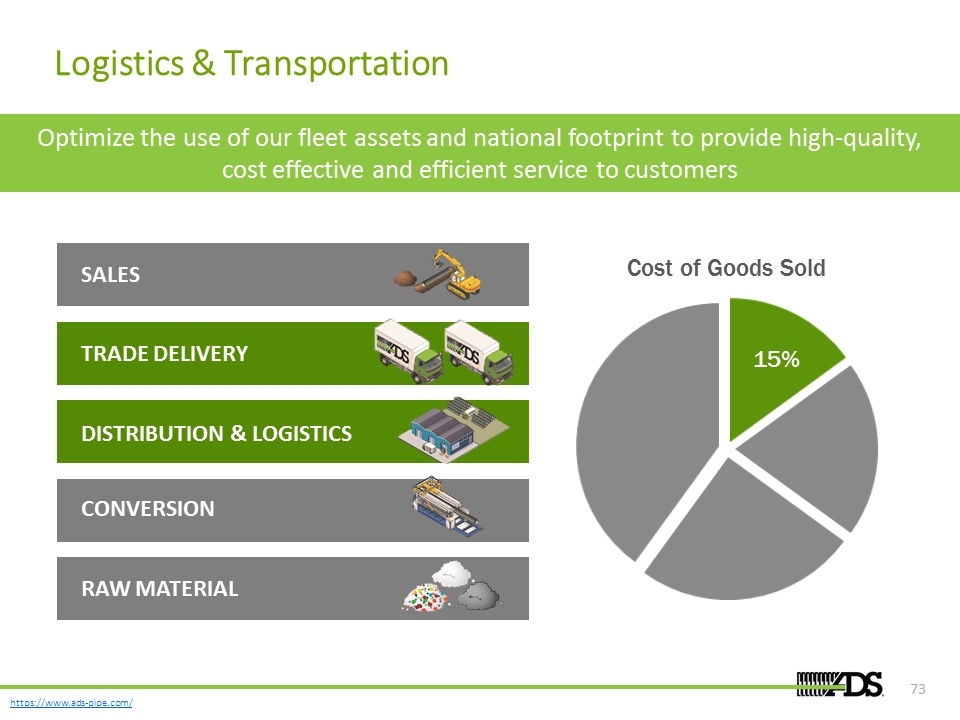

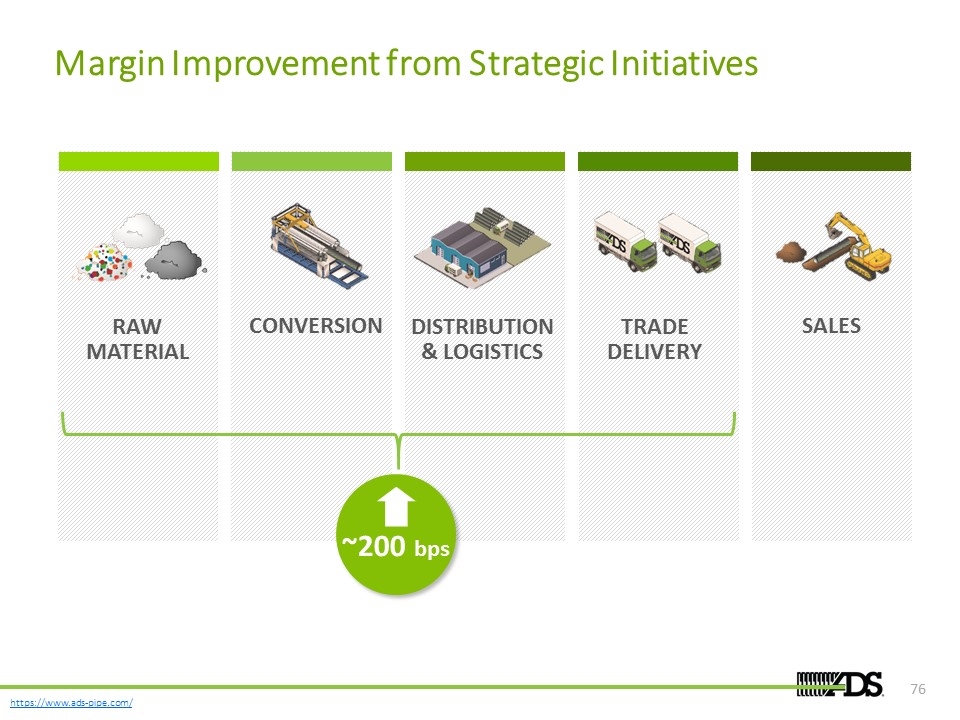

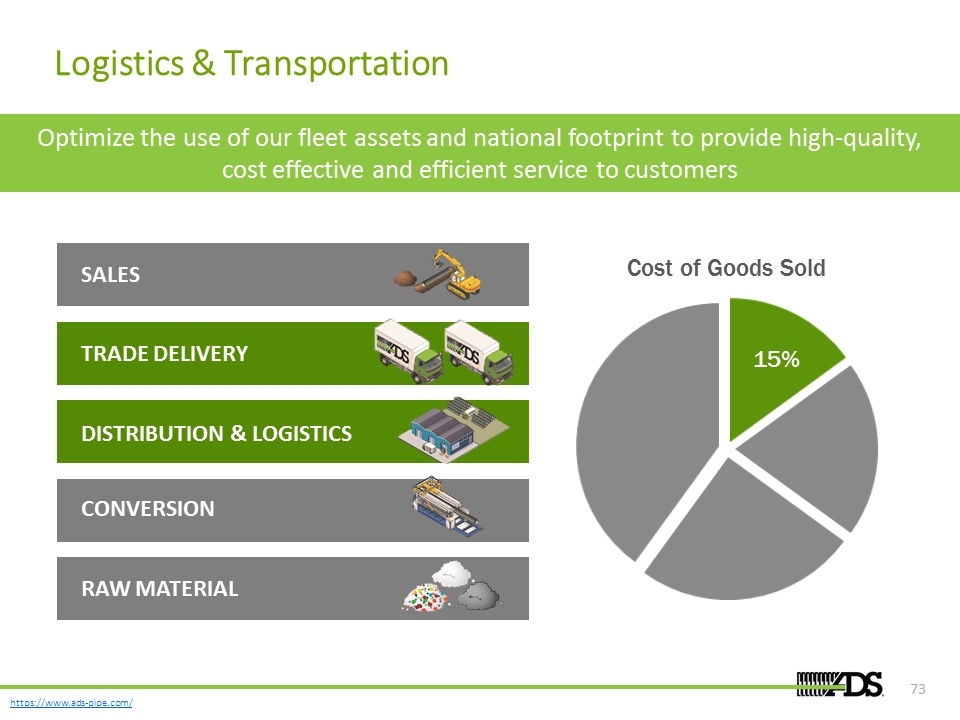

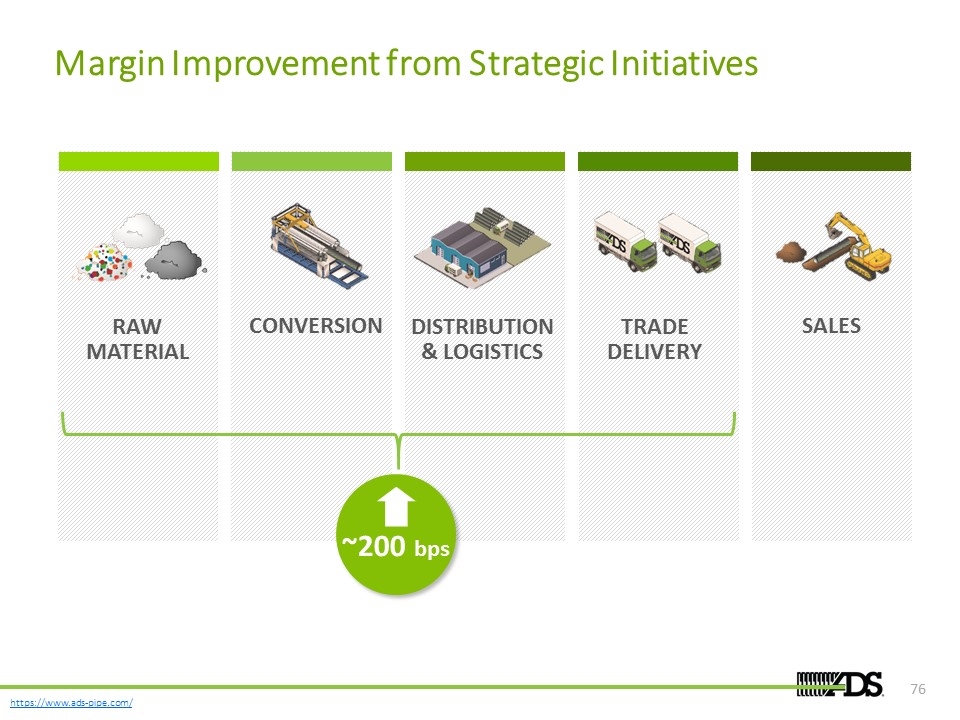

ADS Business Model SALES TRADE DELIVERY DISTRIBUTION & LOGISTICS CONVERSION RAW MATERIAL Initiatives in place to drive ~200 basis points of margin improvement by FY21

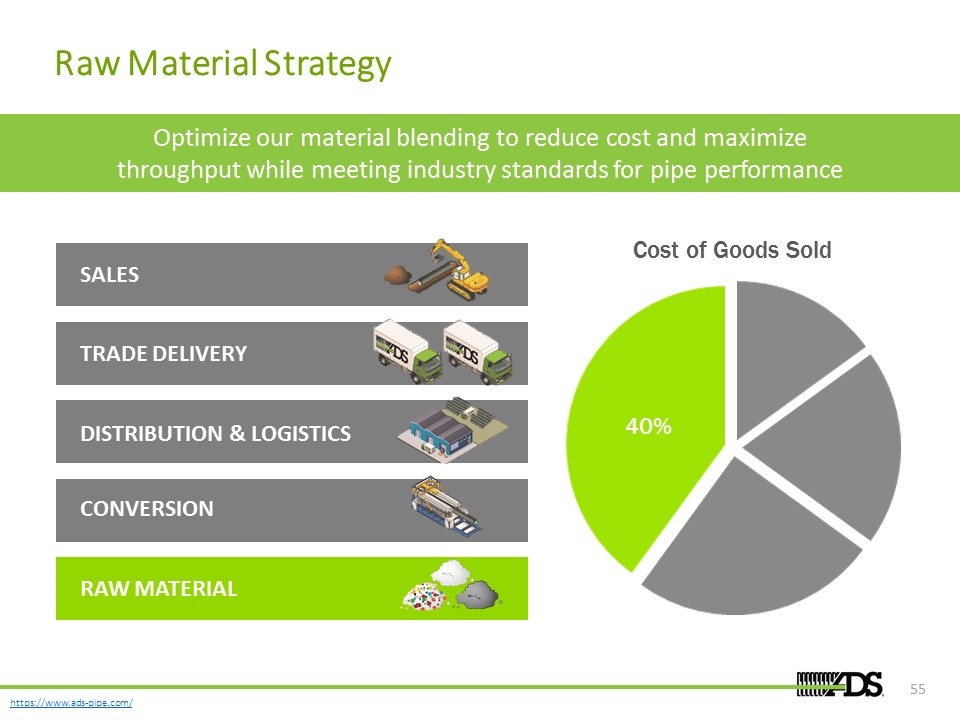

Raw Material Strategy 40% SALES TRADE DELIVERY DISTRIBUTION & LOGISTICS CONVERSION RAW MATERIAL Optimize our material blending to reduce cost and maximize throughput while meeting industry standards for pipe performance

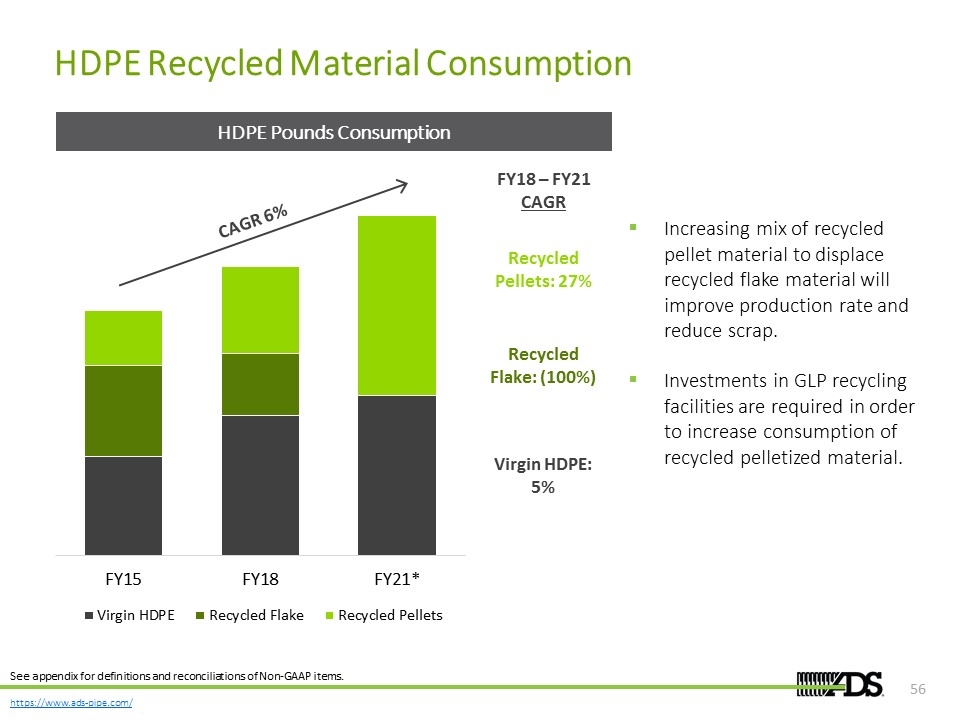

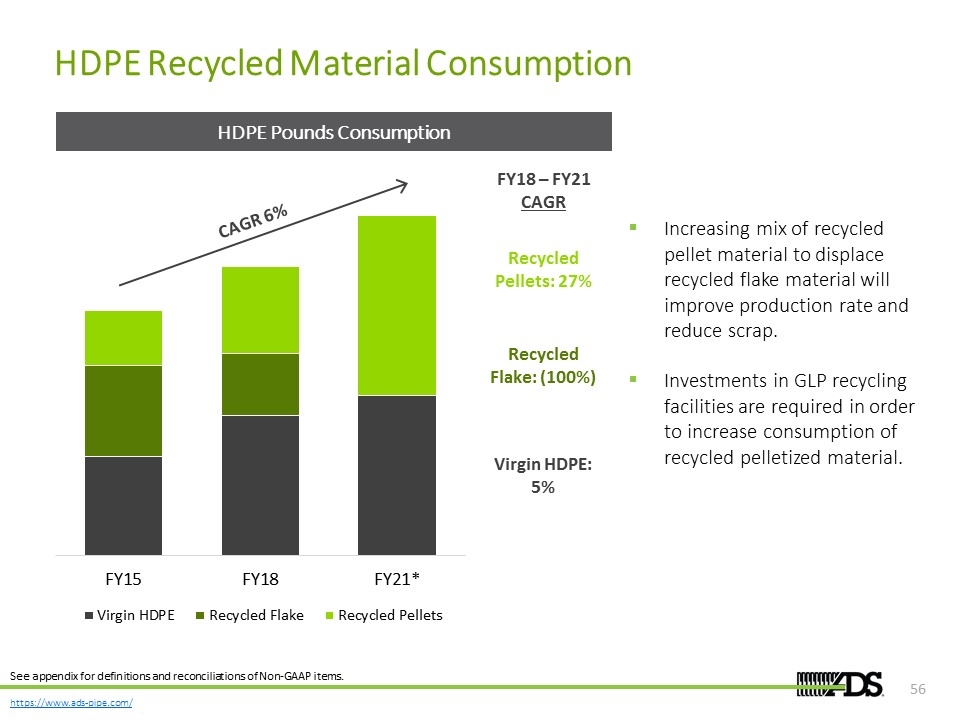

HDPE Recycled Material Consumption FY18 – FY21 CAGR Recycled Pellets: 27% Virgin HDPE: 5% Increasing mix of recycled pellet material to displace recycled flake material will improve production rate and reduce scrap. Investments in GLP recycling facilities are required in order to increase consumption of recycled pelletized material. HDPE Pounds Consumption Recycled Flake: (100%) CAGR 6% See appendix for definitions and reconciliations of Non-GAAP items.

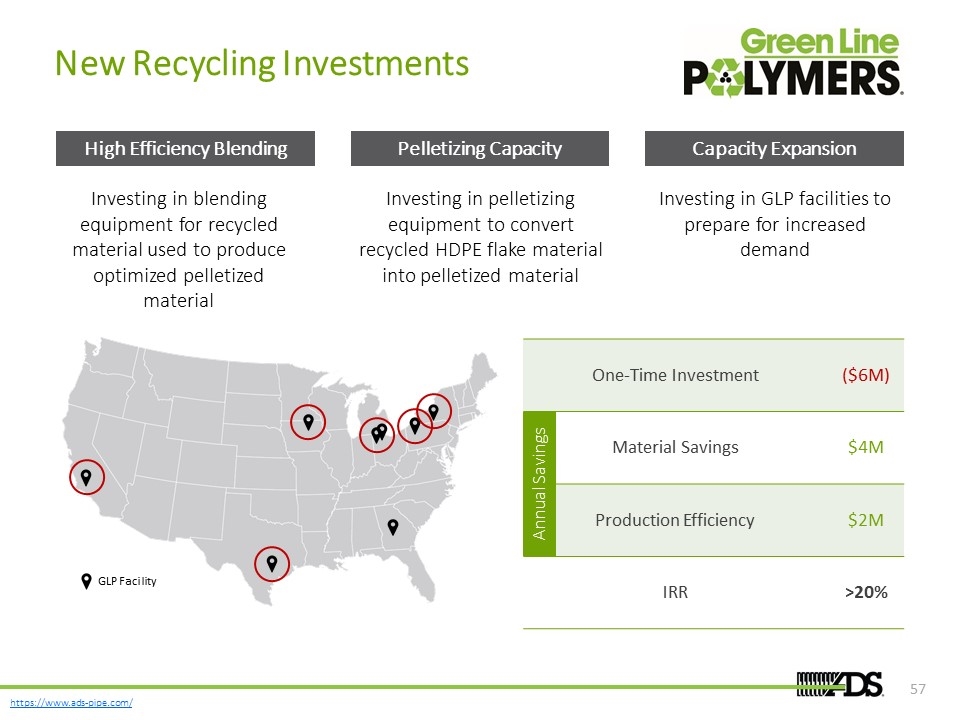

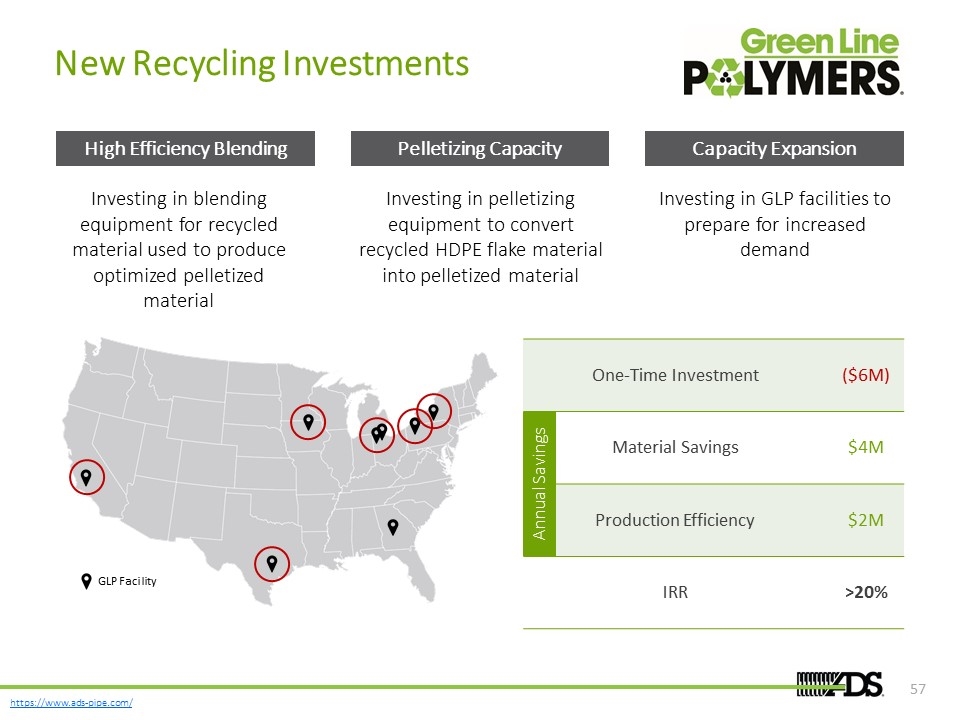

New Recycling Investments High Efficiency Blending Pelletizing Capacity Capacity Expansion Investing in blending equipment for recycled material used to produce optimized pelletized material Investing in pelletizing equipment to convert recycled HDPE flake material into pelletized material Investing in GLP facilities to prepare for increased demand One-Time Investment ($6M) Material Savings $4M Production Efficiency $2M IRR >20% Annual Savings GLP Facility

Impact of Pelletizing RECYCLED MATERIAL FLAKE MATERIAL PIPE EXTRUSION PELLETIZED MATERIAL Throughput for pelletized material is 7% to 10% better than flake material

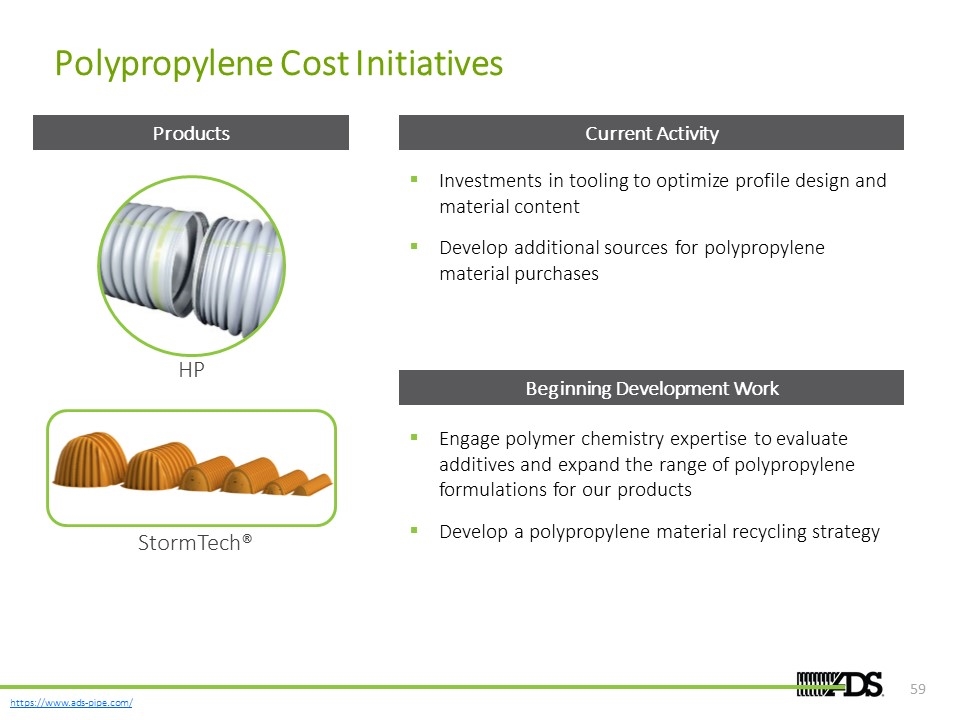

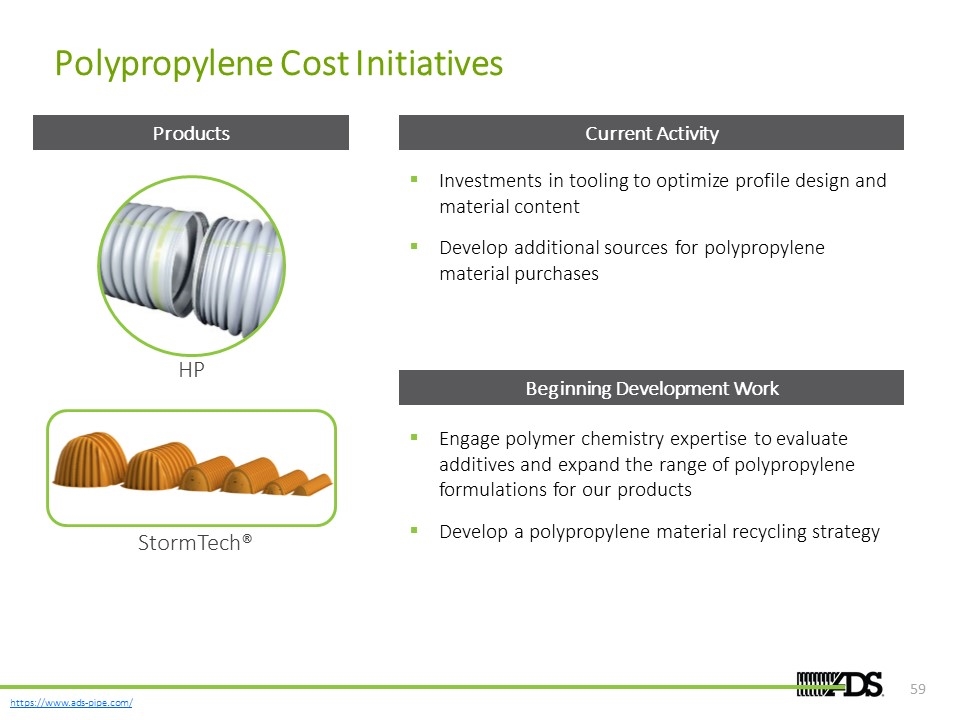

Investments in tooling to optimize profile design and material content Develop additional sources for polypropylene material purchases Polypropylene Cost Initiatives Products Current Activity HP StormTech® Beginning Development Work Engage polymer chemistry expertise to evaluate additives and expand the range of polypropylene formulations for our products Develop a polypropylene material recycling strategy

Conversion Improvement Strategy 25% SALES TRADE DELIVERY DISTRIBUTION & LOGISTICS CONVERSION RAW MATERIAL Through SPP, drive continuous improvement within four wall manufacturing while optimizing manufacturing network

Conversion Improvement Strategy Continuous Improvement Startups & Changeovers Machine Maintenance & Upgrades Automation Network Rationalization Integrated Supply Chain Planning Tooling & Capacity Investments Manufacturing Network Optimization Inside the Four Walls

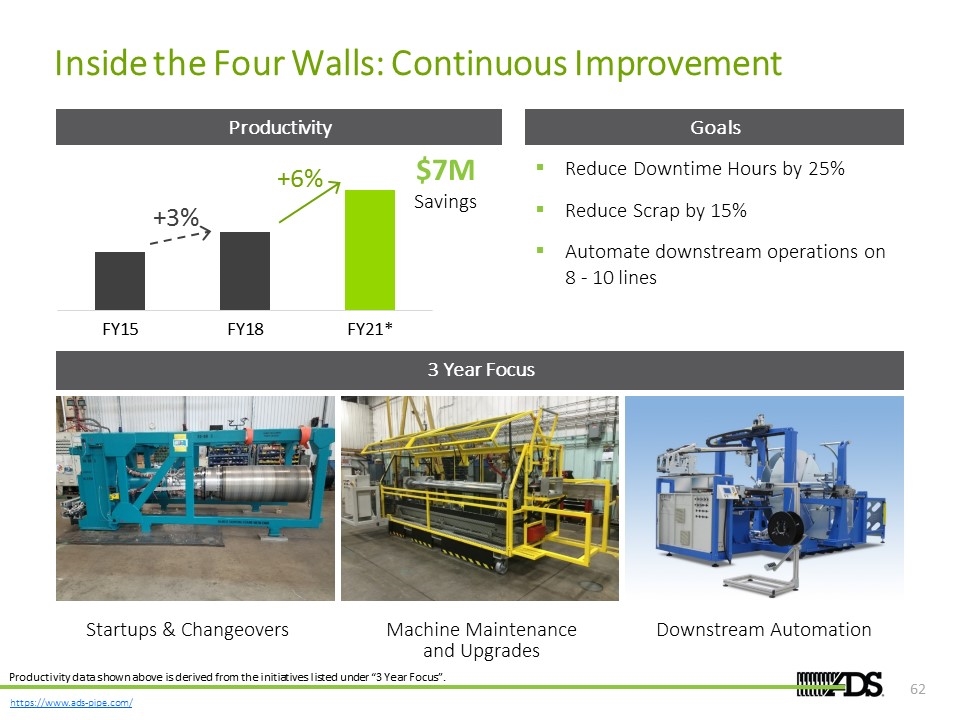

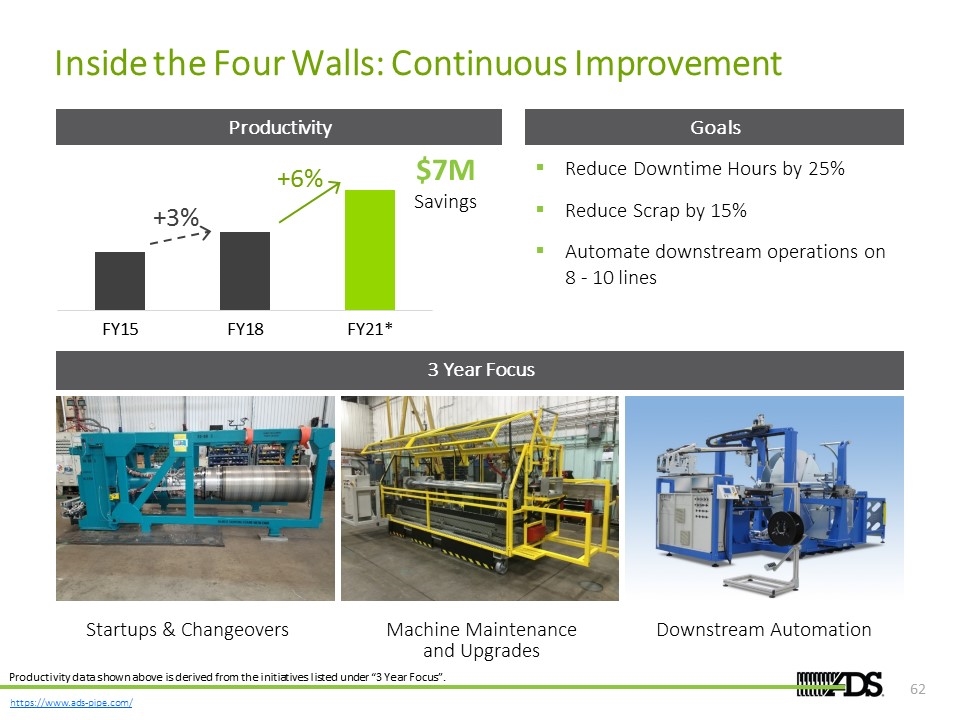

Reduce Downtime Hours by 25% Reduce Scrap by 15% Automate downstream operations on 8 - 10 lines Inside the Four Walls: Continuous Improvement 3 Year Focus Productivity Goals Startups & Changeovers Machine Maintenance and Upgrades Downstream Automation +3% +6% $7M Savings Productivity data shown above is derived from the initiatives listed under “3 Year Focus”.

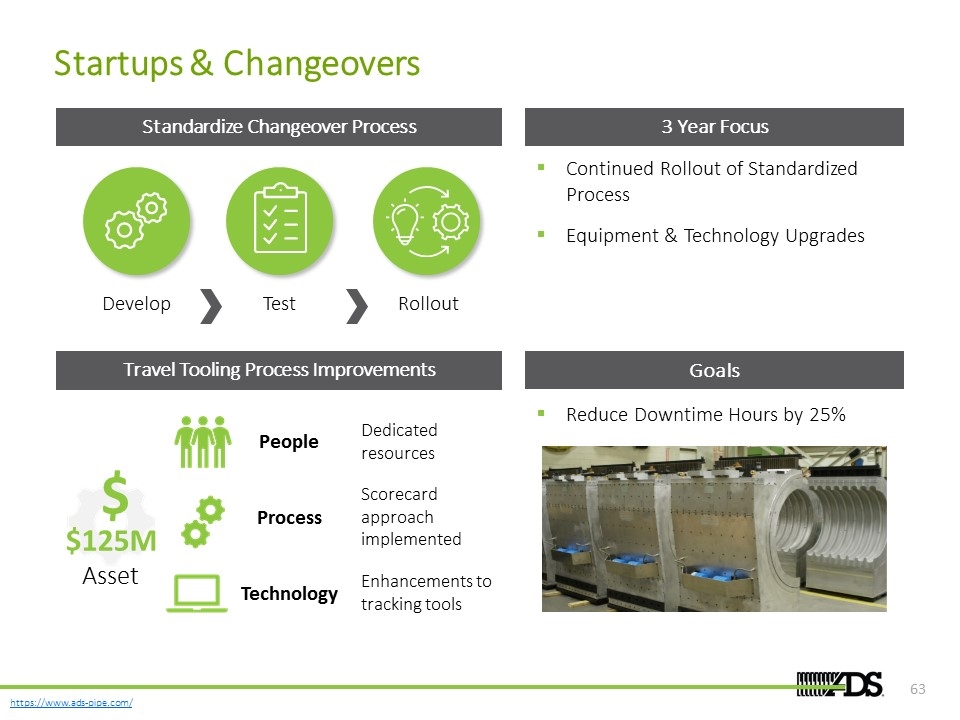

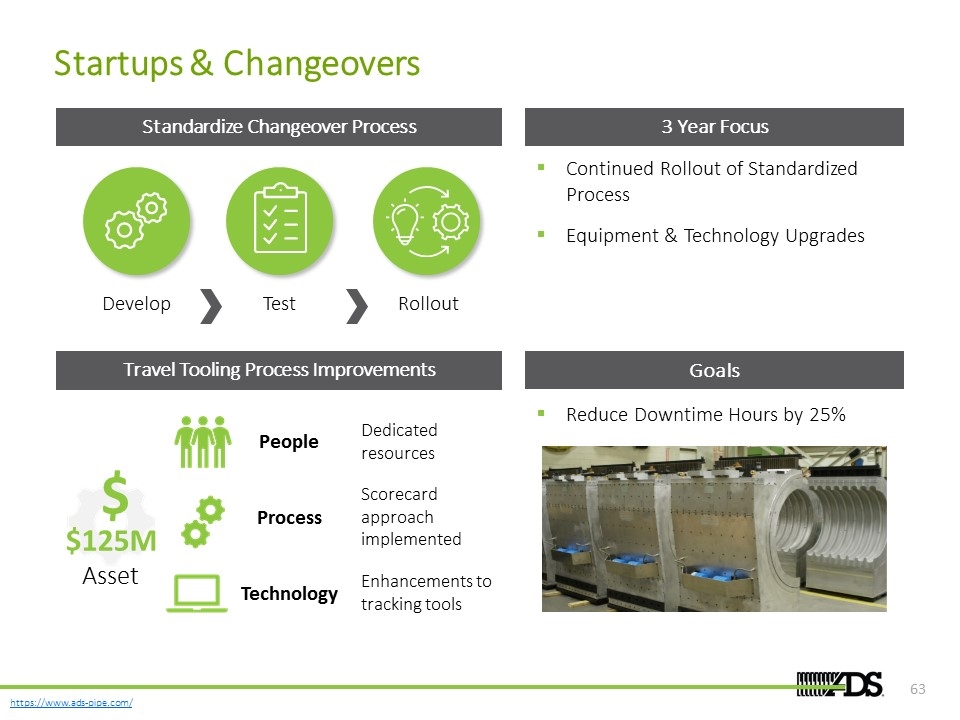

Startups & Changeovers Standardize Changeover Process 3 Year Focus Goals Travel Tooling Process Improvements $125M Asset Develop Test Rollout People Dedicated resources Process Scorecard approach implemented Technology Enhancements to tracking tools Continued Rollout of Standardized Process Equipment & Technology Upgrades Reduce Downtime Hours by 25% $

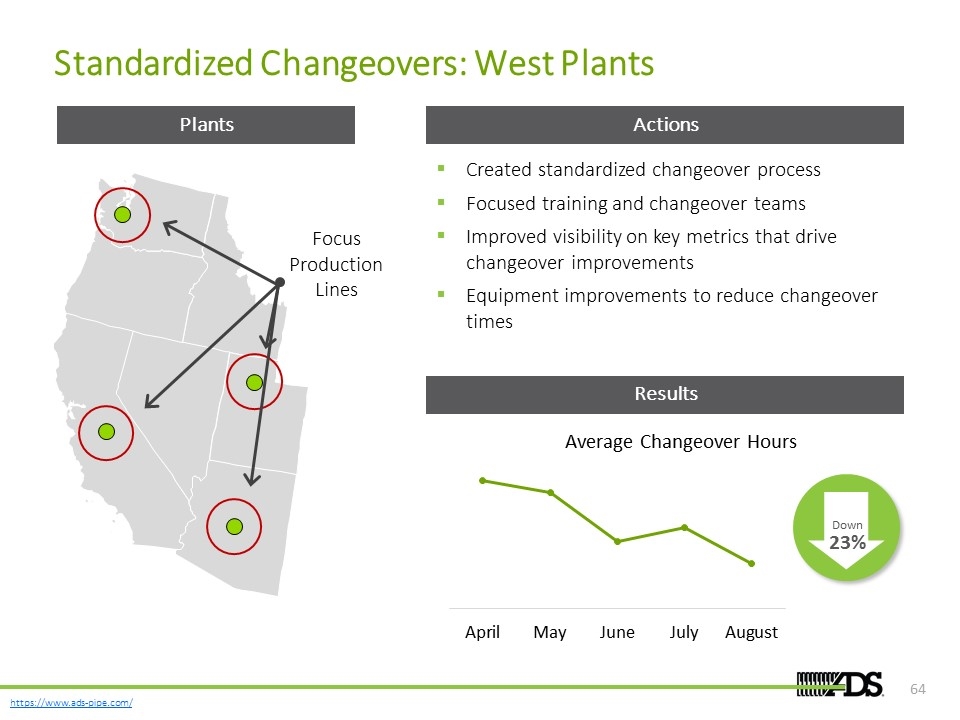

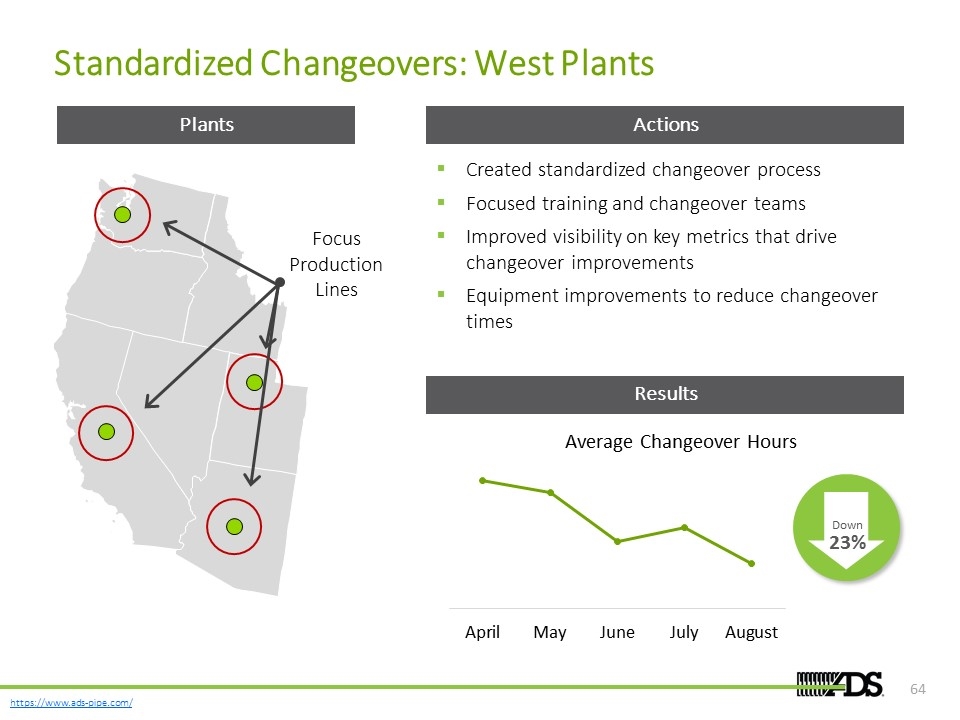

Standardized Changeovers: West Plants Plants Results Actions Created standardized changeover process Focused training and changeover teams Improved visibility on key metrics that drive changeover improvements Equipment improvements to reduce changeover times Focus Production Lines Down 23%

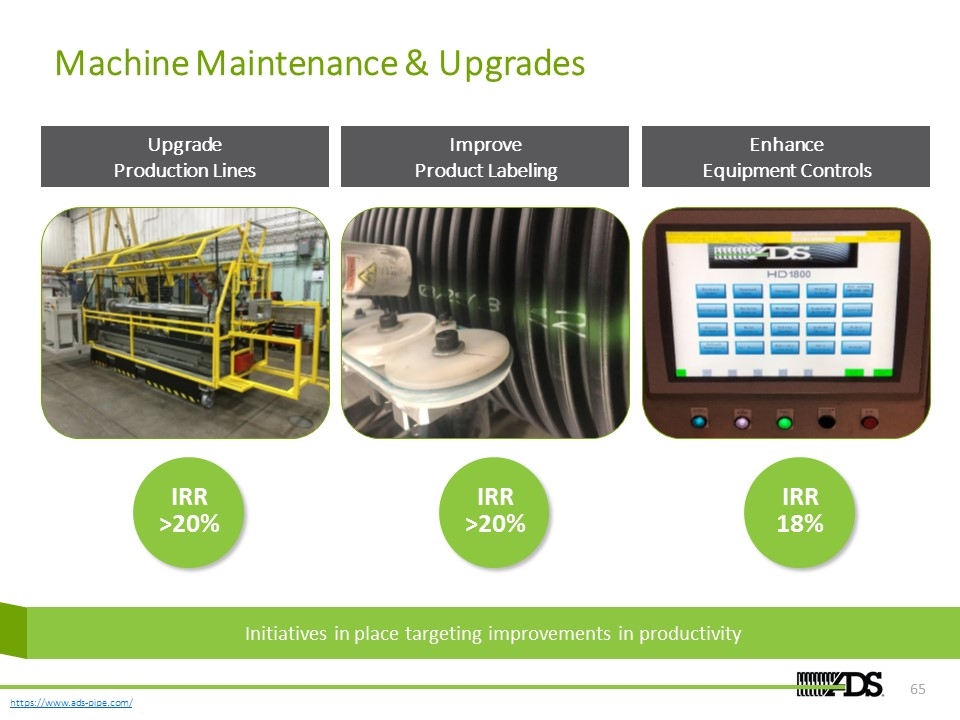

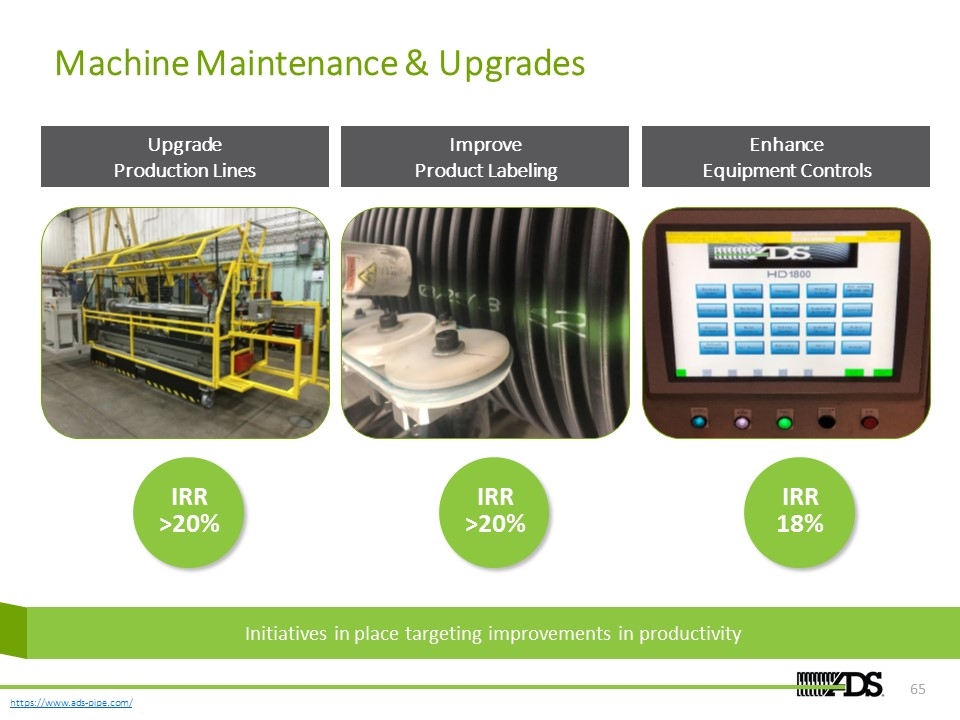

Machine Maintenance & Upgrades Initiatives in place targeting improvements in productivity IRR >20% IRR >20% IRR 18% Upgrade Production Lines Improve Product Labeling Enhance Equipment Controls

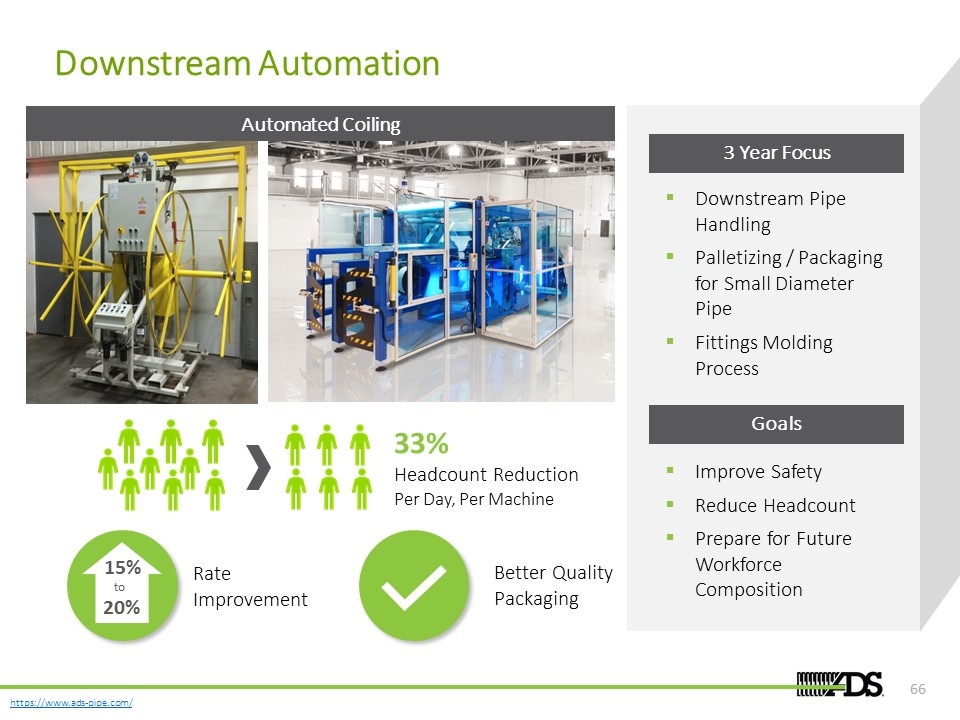

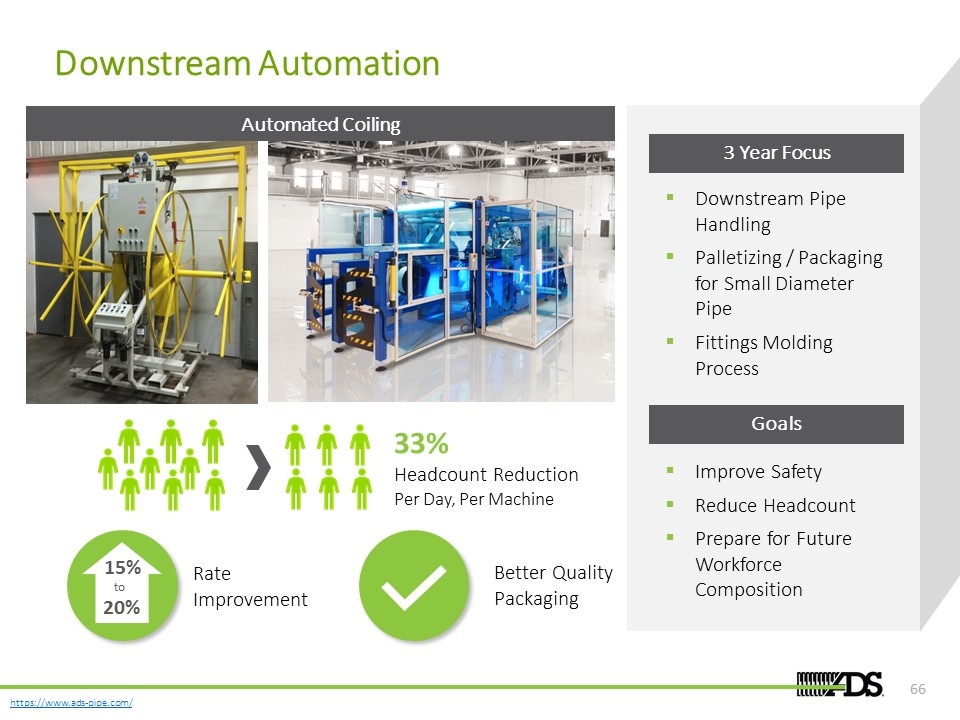

Downstream Automation Rate Improvement Better Quality Packaging 33% Headcount Reduction Per Day, Per Machine 3 Year Focus Goals Downstream Pipe Handling Palletizing / Packaging for Small Diameter Pipe Fittings Molding Process Improve Safety Reduce Headcount Prepare for Future Workforce Composition 20% 15% to Automated Coiling

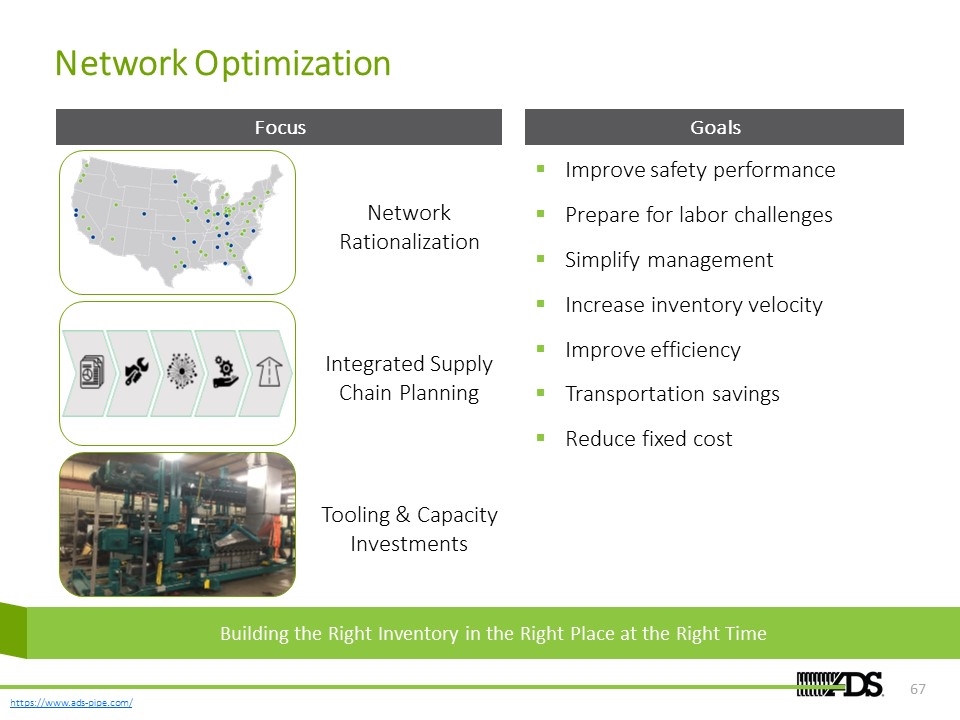

Network Optimization Network Rationalization Integrated Supply Chain Planning Tooling & Capacity Investments Focus Goals Building the Right Inventory in the Right Place at the Right Time Improve safety performance Prepare for labor challenges Simplify management Increase inventory velocity Improve efficiency Transportation savings Reduce fixed cost

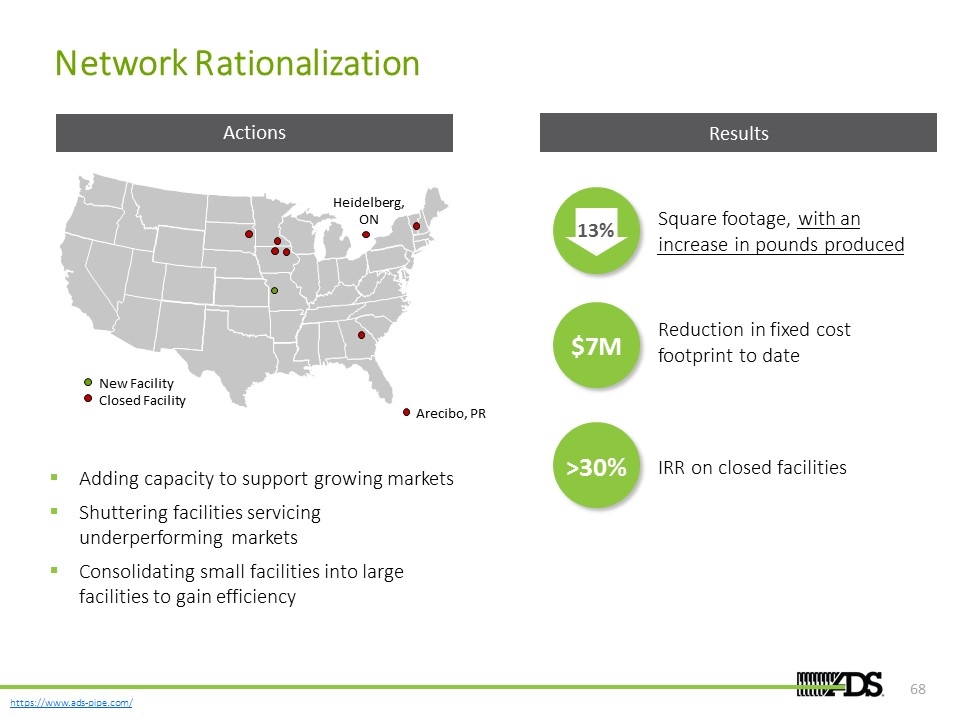

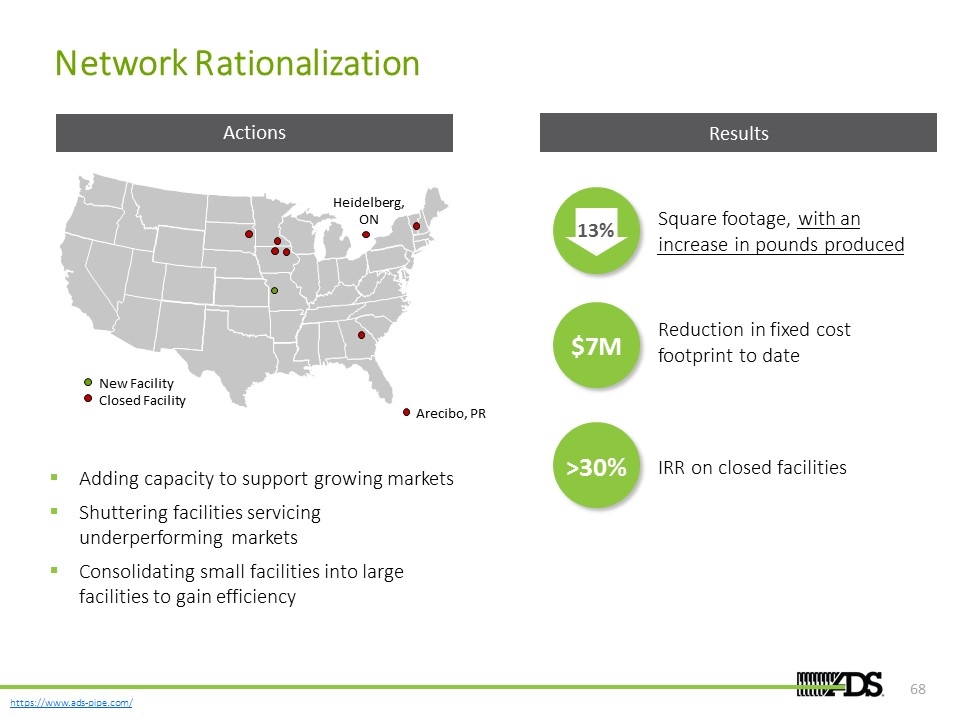

Network Rationalization Adding capacity to support growing markets Shuttering facilities servicing underperforming markets Consolidating small facilities into large facilities to gain efficiency Actions Results Square footage, with an increase in pounds produced 13% $7M Reduction in fixed cost footprint to date >30% IRR on closed facilities Heidelberg, ON Arecibo, PR New Facility Closed Facility

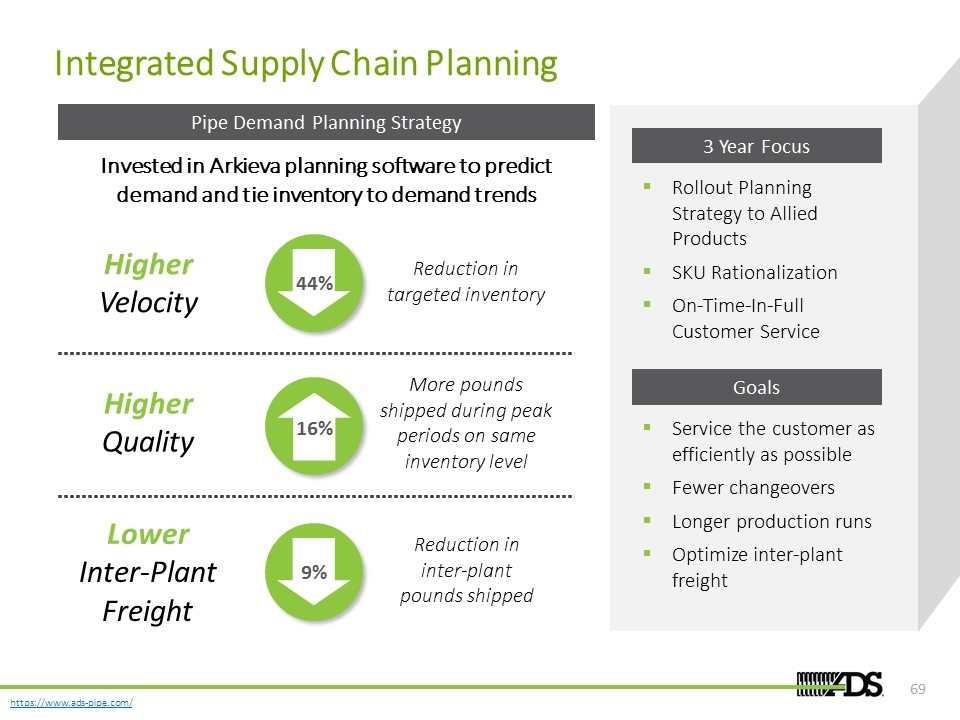

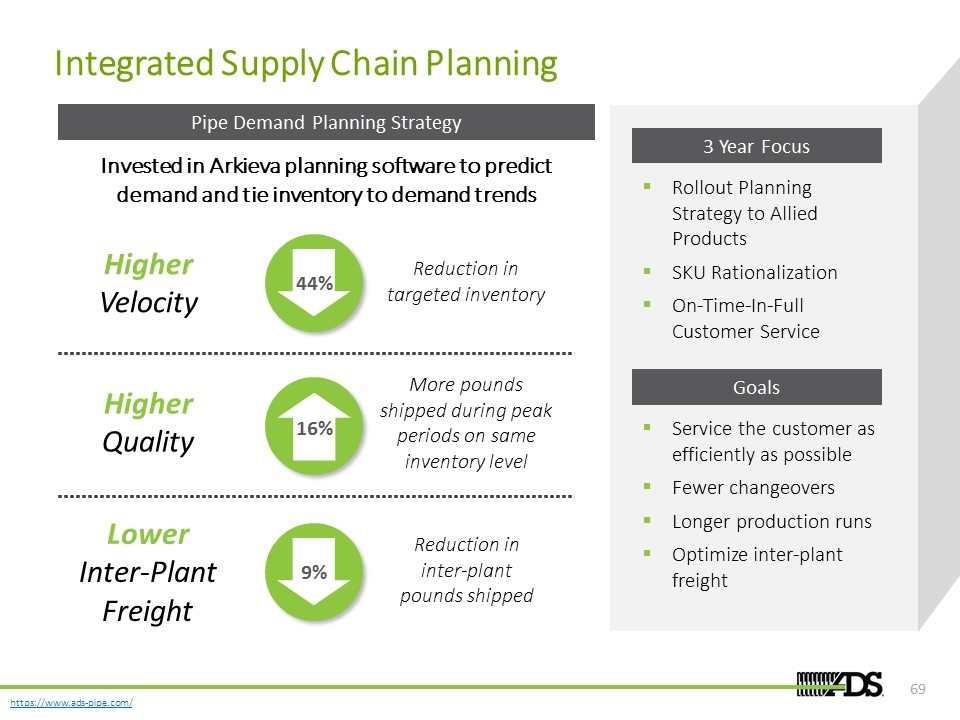

Integrated Supply Chain Planning Pipe Demand Planning Strategy Invested in Arkieva planning software to predict demand and tie inventory to demand trends 3 Year Focus Goals Rollout Planning Strategy to Allied Products SKU Rationalization On-Time-In-Full Customer Service Service the customer as efficiently as possible Fewer changeovers Longer production runs Optimize inter-plant freight Reduction in targeted inventory More pounds shipped during peak periods on same inventory level Reduction in inter-plant pounds shipped 44% 16% 9% Higher Velocity Higher Quality Lower Inter-Plant Freight

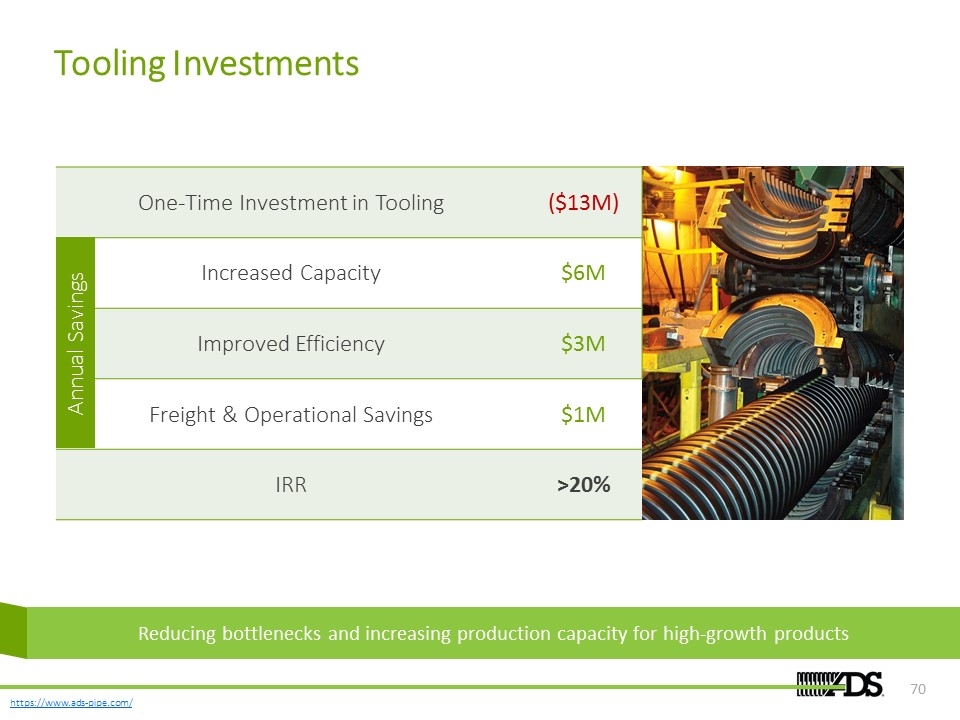

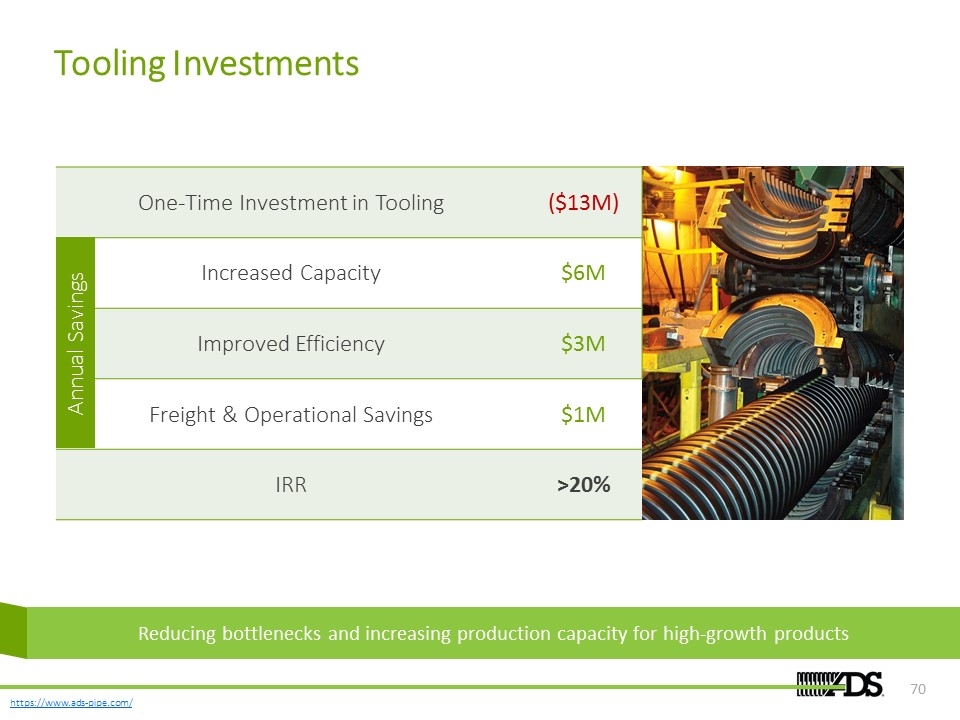

Tooling Investments One-Time Investment in Tooling ($13M) Increased Capacity $6M Improved Efficiency $3M Freight & Operational Savings $1M IRR >20% Annual Savings Reducing bottlenecks and increasing production capacity for high-growth products

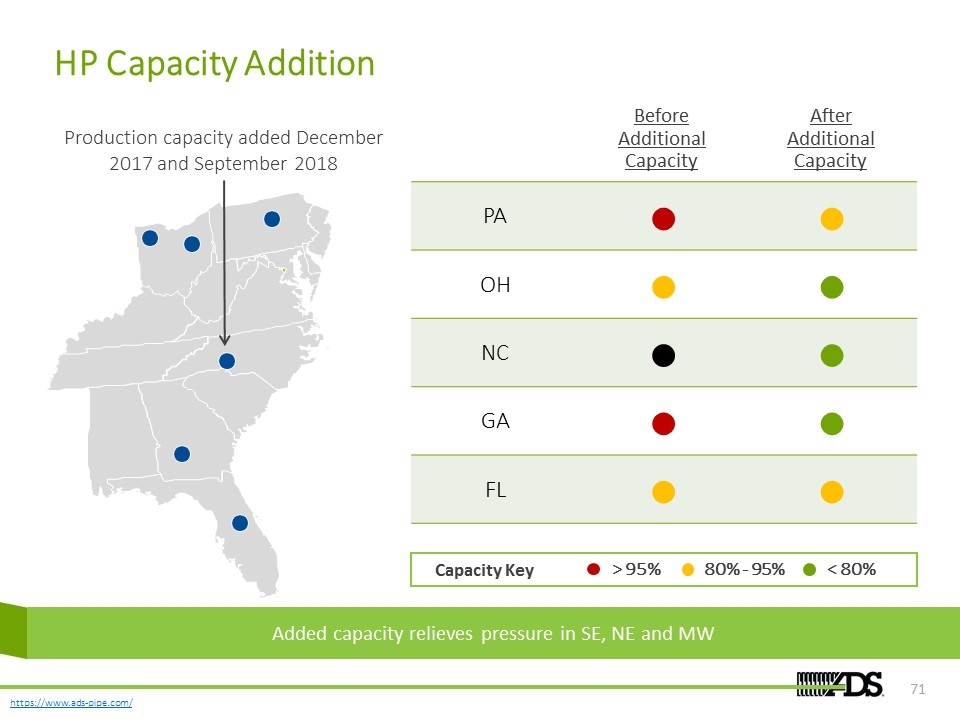

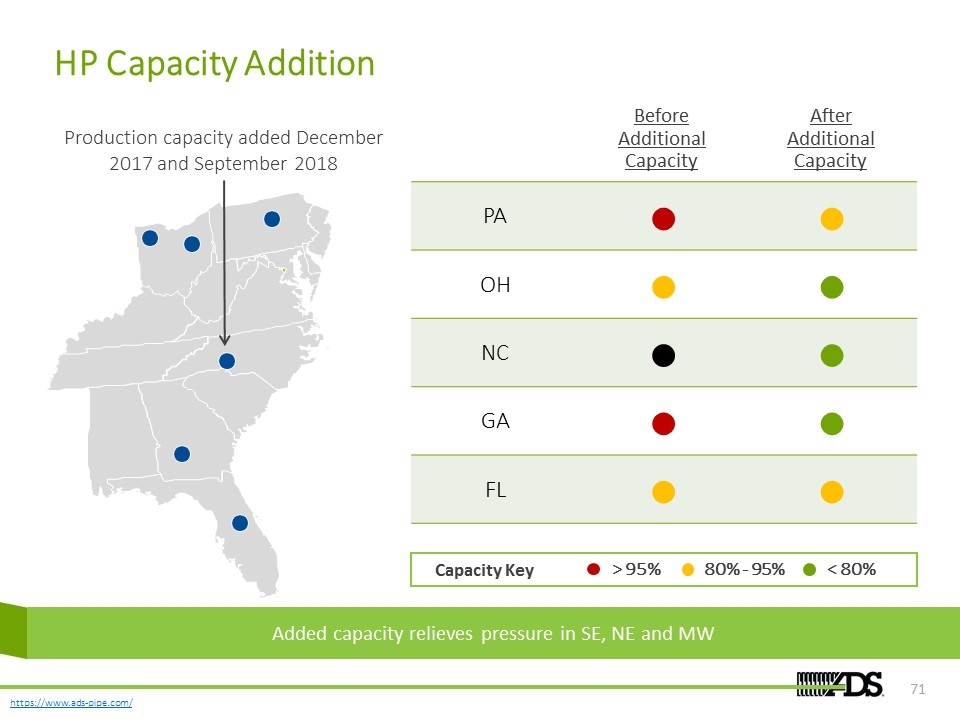

HP Capacity Addition Added capacity relieves pressure in SE, NE and MW PA ● ● OH ● ● NC ● ● GA ● ● FL ● ● Production capacity added December 2017 and September 2018 Before Additional Capacity After Additional Capacity > 95% 80% - 95% < 80% Capacity Key

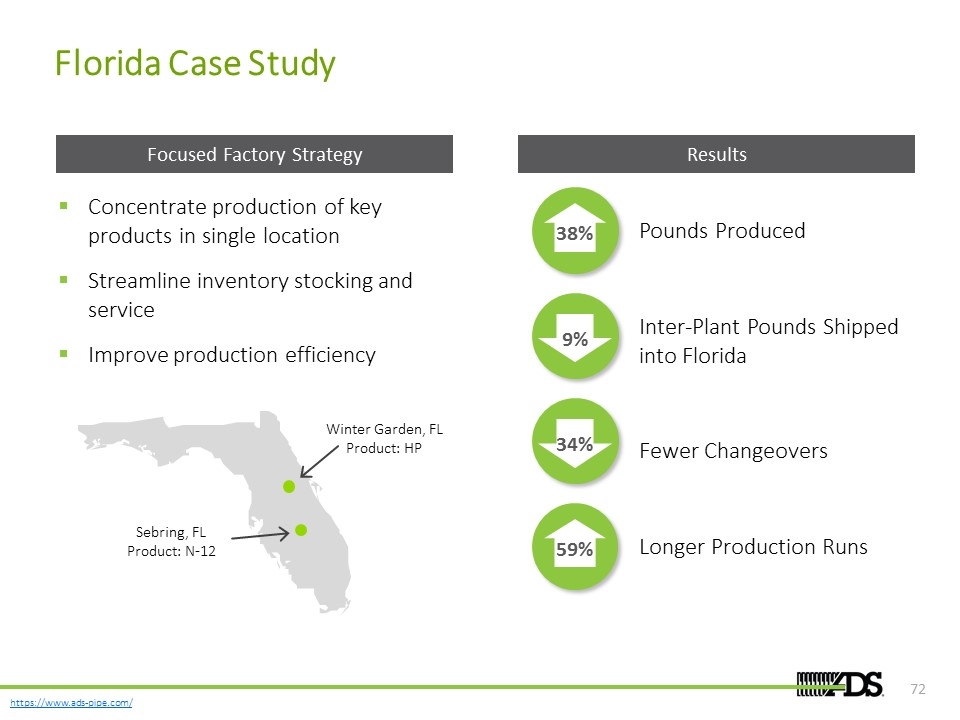

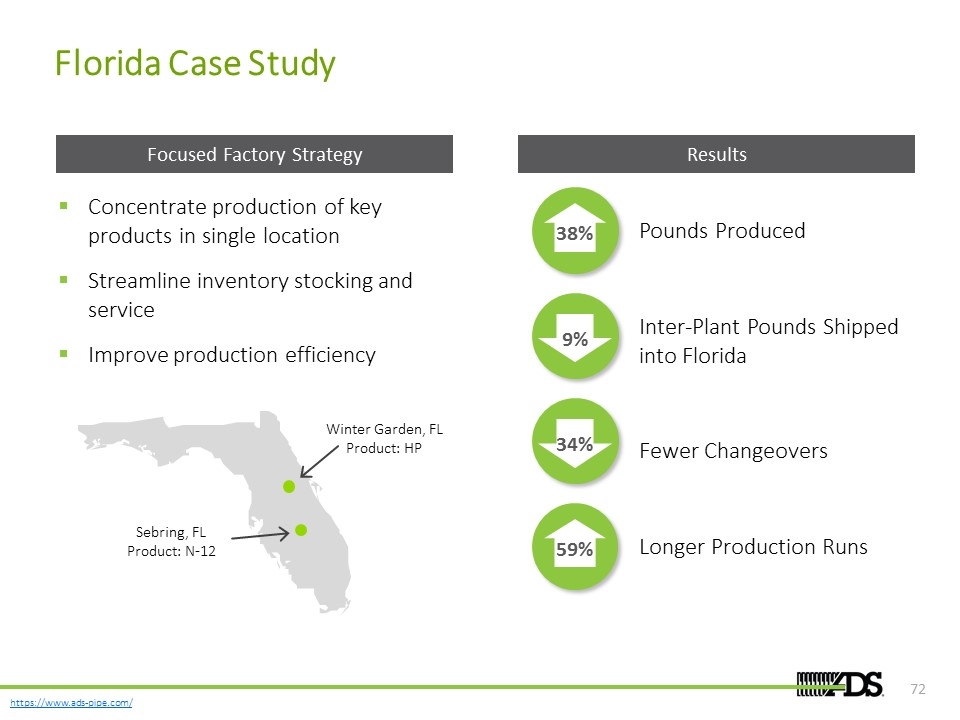

Florida Case Study Winter Garden, FL Product: HP Sebring, FL Product: N-12 Focused Factory Strategy Concentrate production of key products in single location Streamline inventory stocking and service Improve production efficiency Results Pounds Produced Fewer Changeovers Inter-Plant Pounds Shipped into Florida Longer Production Runs 38% 9% 34% 59%

Logistics & Transportation 15% SALES TRADE DELIVERY DISTRIBUTION & LOGISTICS CONVERSION RAW MATERIAL Optimize the use of our fleet assets and national footprint to provide high-quality, cost effective and efficient service to customers

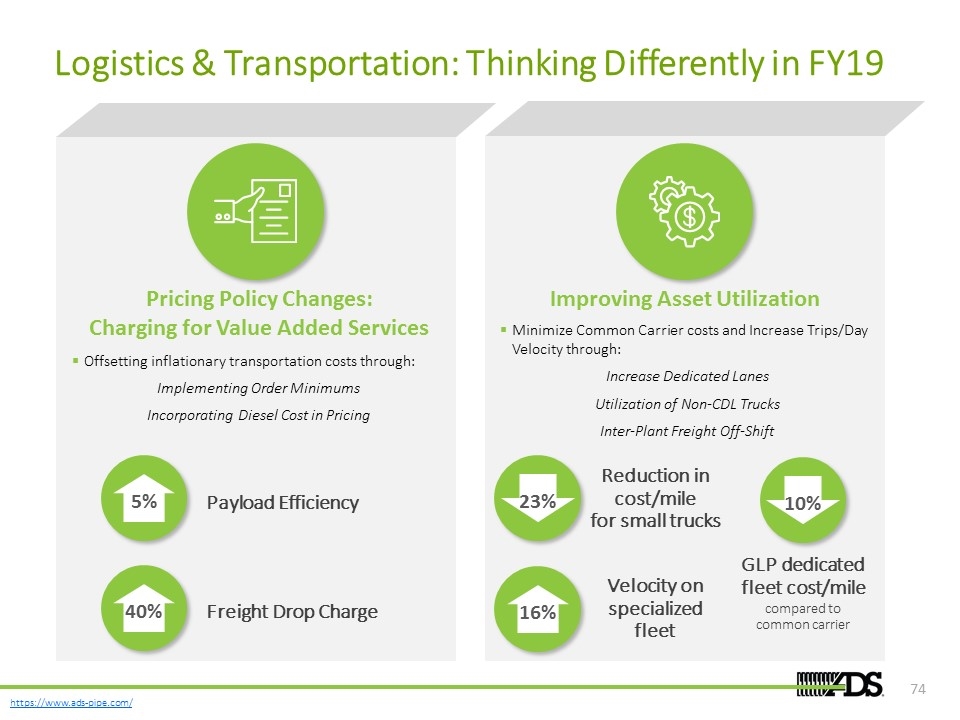

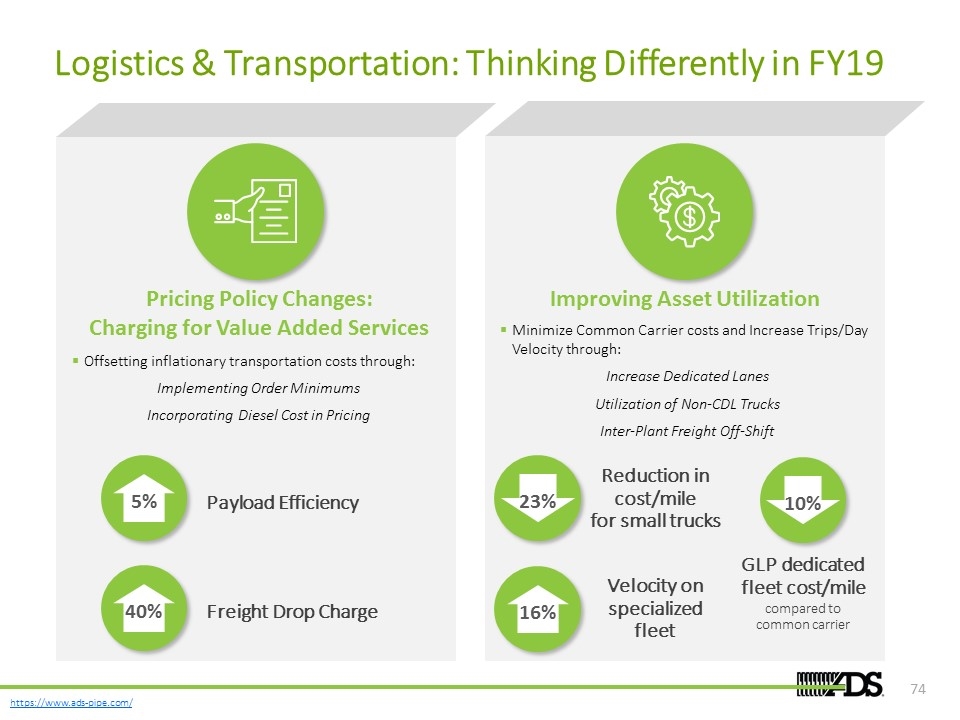

Logistics & Transportation: Thinking Differently in FY19 Offsetting inflationary transportation costs through: Implementing Order Minimums Incorporating Diesel Cost in Pricing Pricing Policy Changes: Charging for Value Added Services Improving Asset Utilization Minimize Common Carrier costs and Increase Trips/Day Velocity through: Increase Dedicated Lanes Utilization of Non-CDL Trucks Inter-Plant Freight Off-Shift Payload Efficiency Freight Drop Charge 5% 40% GLP dedicated fleet cost/mile Velocity on specialized fleet 16% 10% 23% Reduction in cost/mile for small trucks compared to common carrier

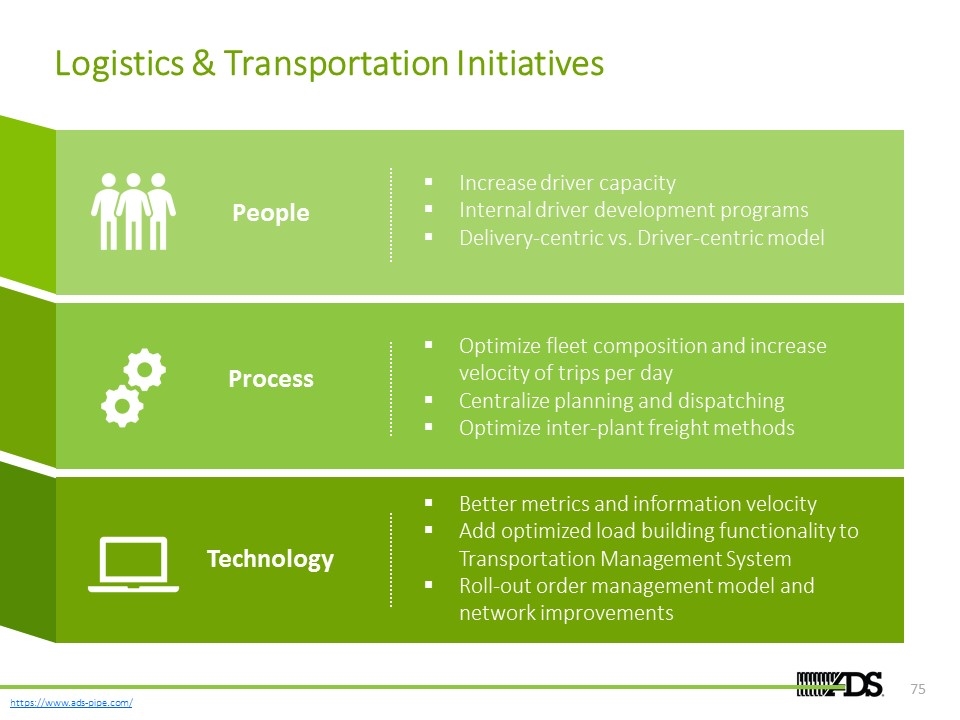

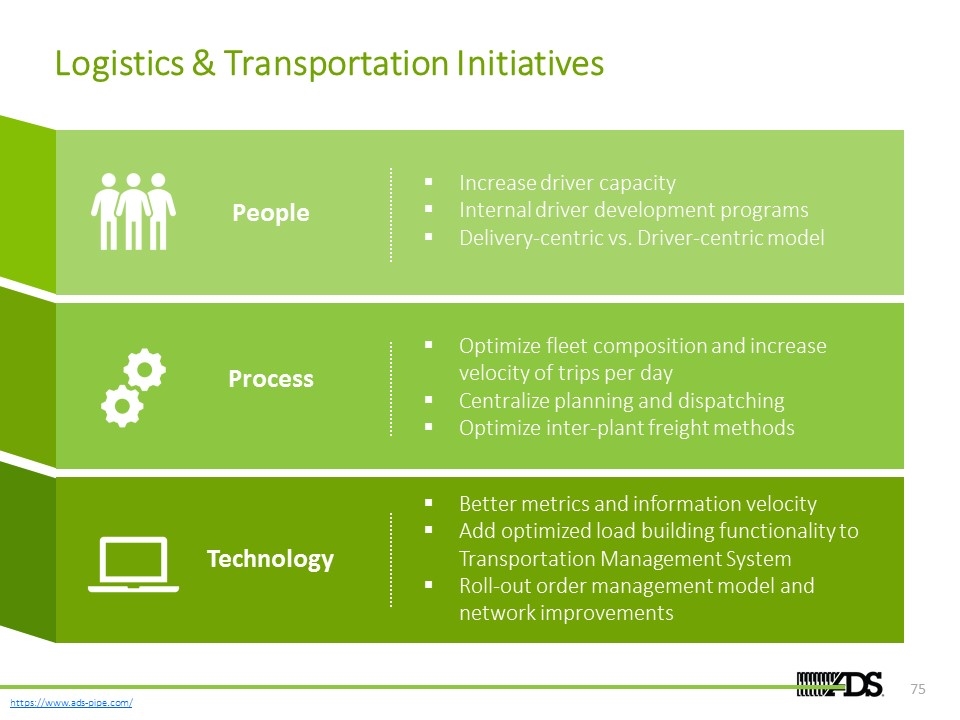

Logistics & Transportation Initiatives People Process Technology Increase driver capacity Internal driver development programs Delivery-centric vs. Driver-centric model Optimize fleet composition and increase velocity of trips per day Centralize planning and dispatching Optimize inter-plant freight methods Better metrics and information velocity Add optimized load building functionality to Transportation Management System Roll-out order management model and network improvements

Margin Improvement from Strategic Initiatives SALES TRADE DELIVERY DISTRIBUTION & LOGISTICS CONVERSION RAW MATERIAL ~200 bps

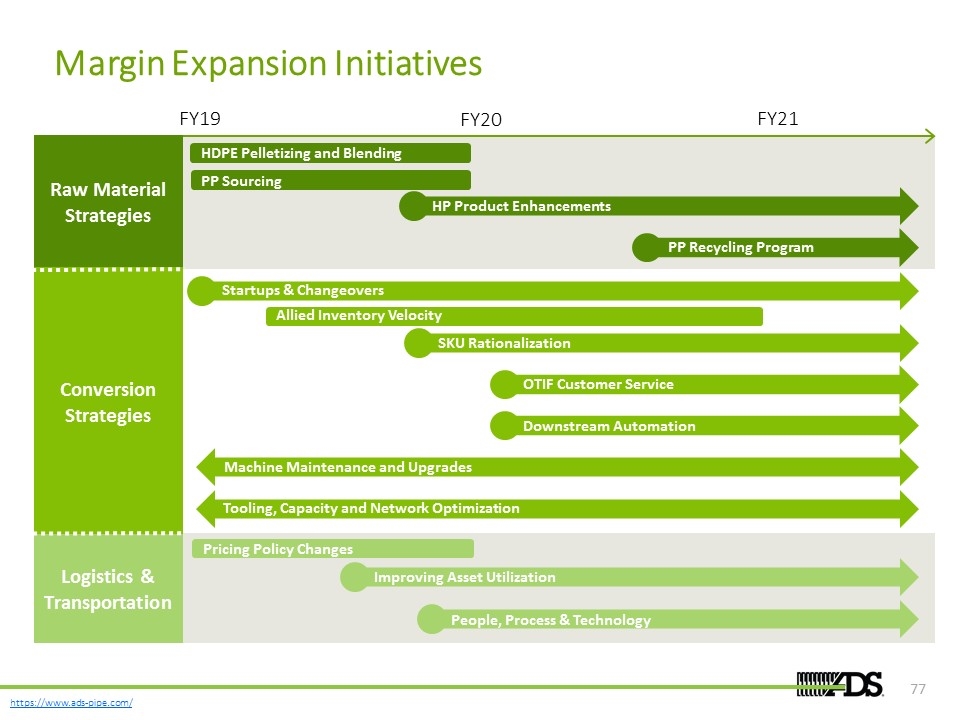

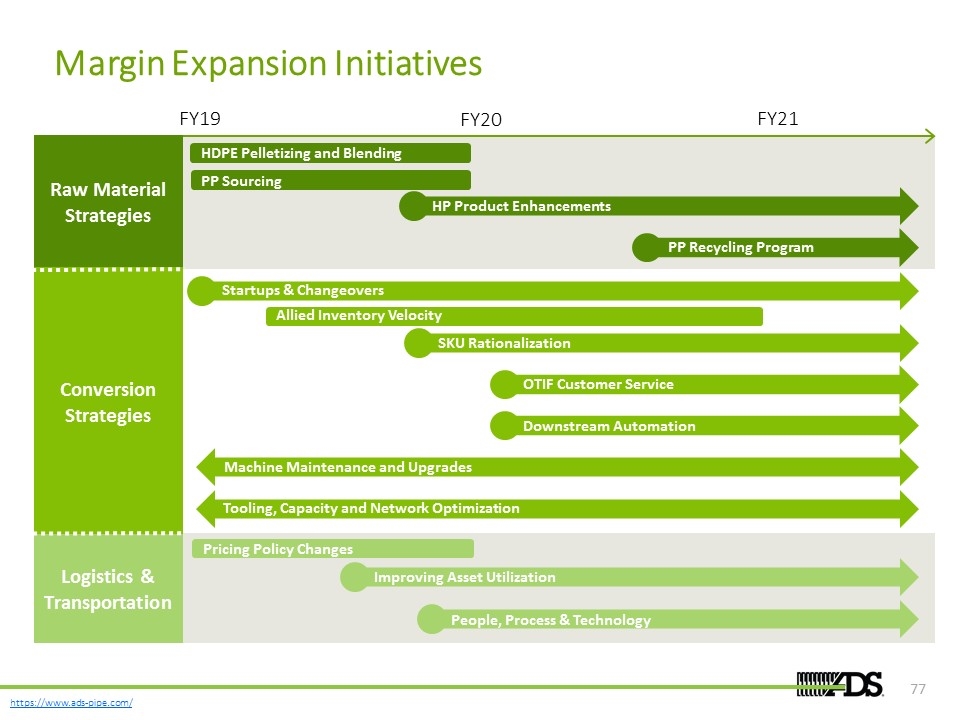

Margin Expansion Initiatives FY19 FY20 FY21 HDPE Pelletizing and Blending PP Recycling Program PP Sourcing HP Product Enhancements Startups & Changeovers Machine Maintenance and Upgrades Downstream Automation Tooling, Capacity and Network Optimization Pricing Policy Changes People, Process & Technology Improving Asset Utilization SKU Rationalization OTIF Customer Service Allied Inventory Velocity Raw Material Strategies Conversion Strategies Logistics & Transportation

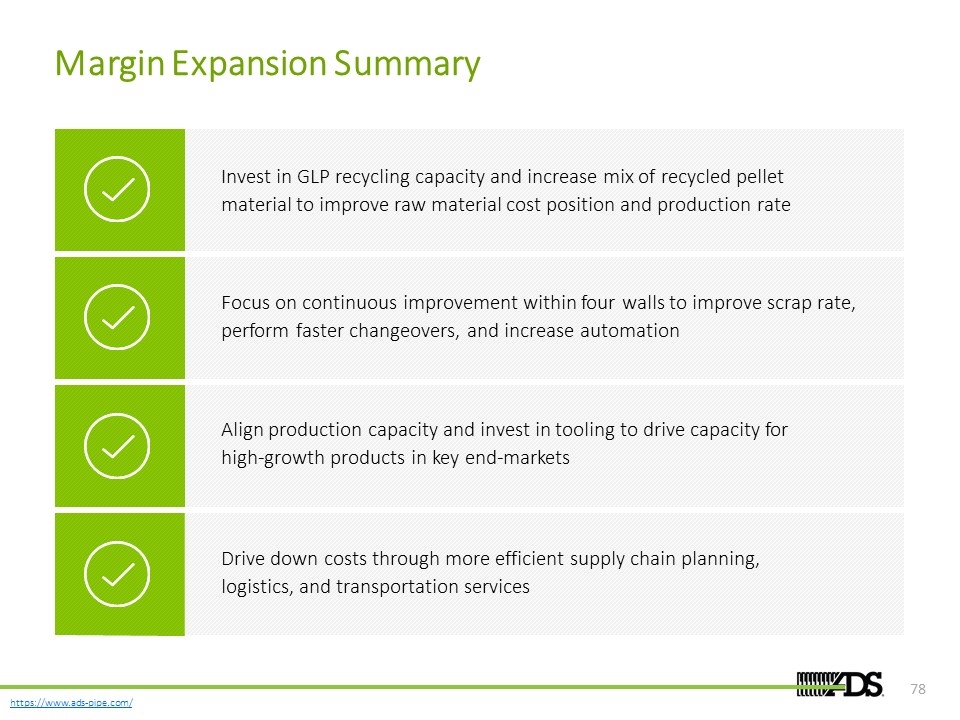

Drive down costs through more efficient supply chain planning, logistics, and transportation services Invest in GLP recycling capacity and increase mix of recycled pellet material to improve raw material cost position and production rate Align production capacity and invest in tooling to drive capacity for high-growth products in key end-markets Focus on continuous improvement within four walls to improve scrap rate, perform faster changeovers, and increase automation Margin Expansion Summary

Financial Overview Scott Cottrill, EVP and CFO

Investor Day Themes Cash Flow Generation Margin Expansion Sales Growth

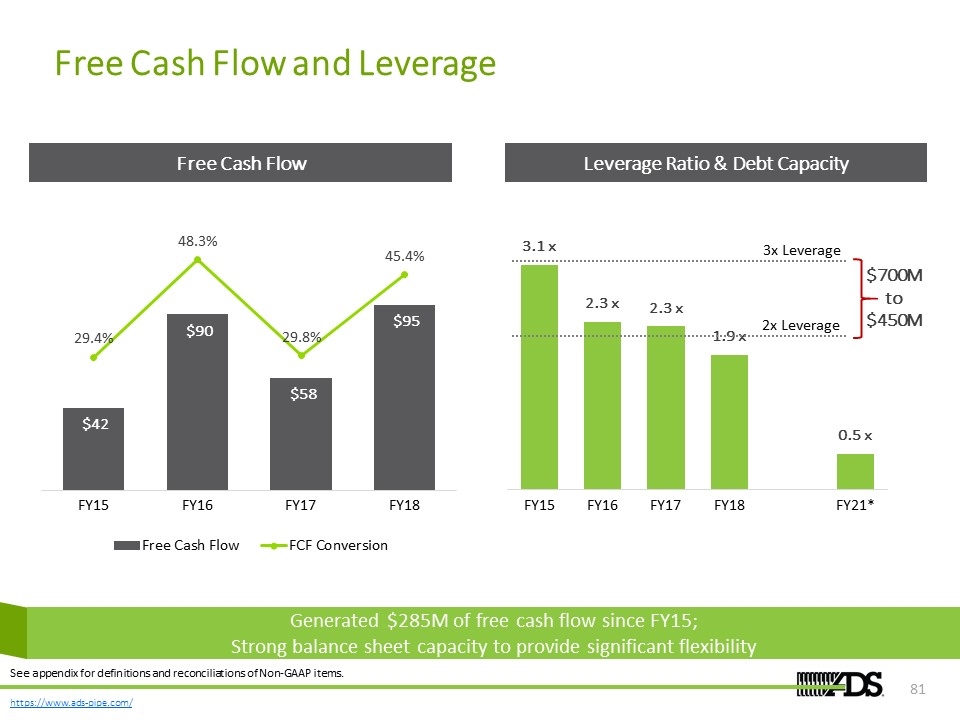

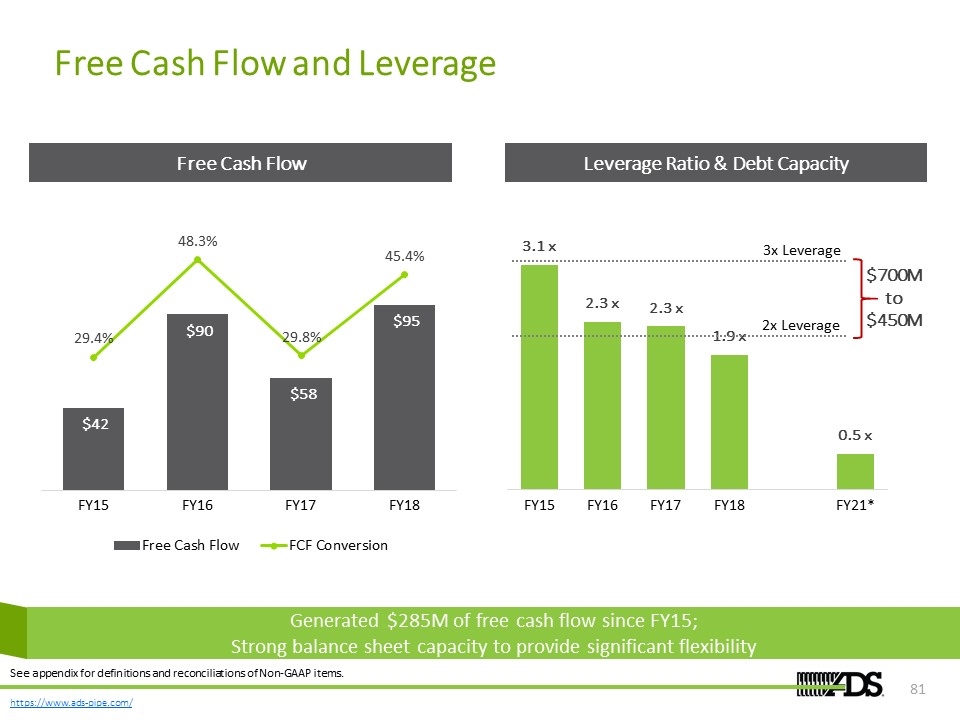

3x Leverage Free Cash Flow and Leverage $700M to $450M Free Cash Flow Leverage Ratio & Debt Capacity See appendix for definitions and reconciliations of Non-GAAP items. 2x Leverage Generated $285M of free cash flow since FY15; Strong balance sheet capacity to provide significant flexibility

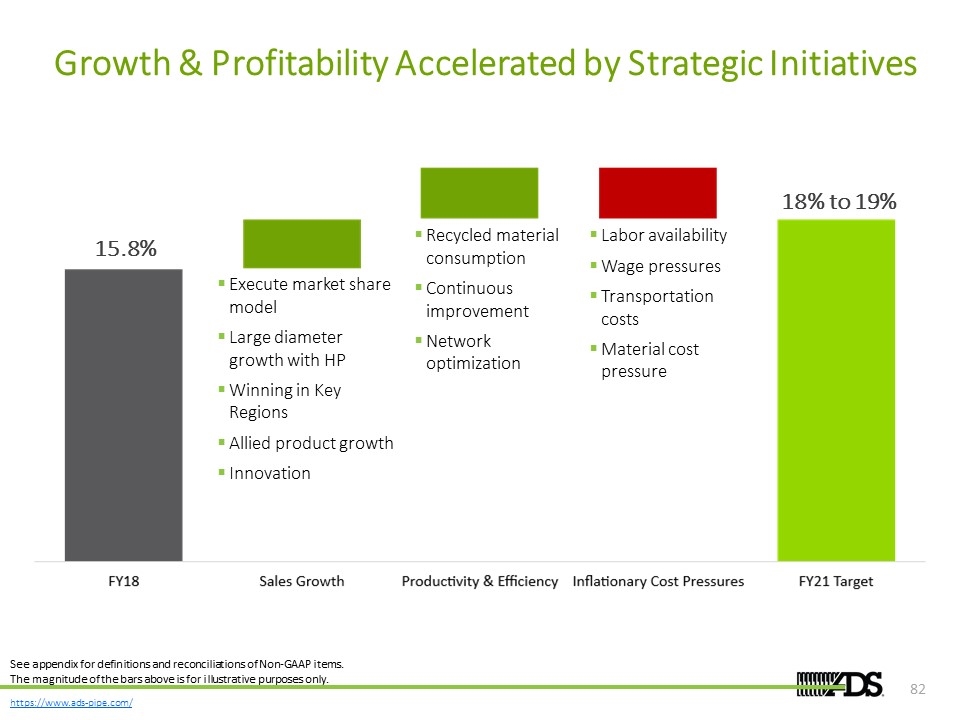

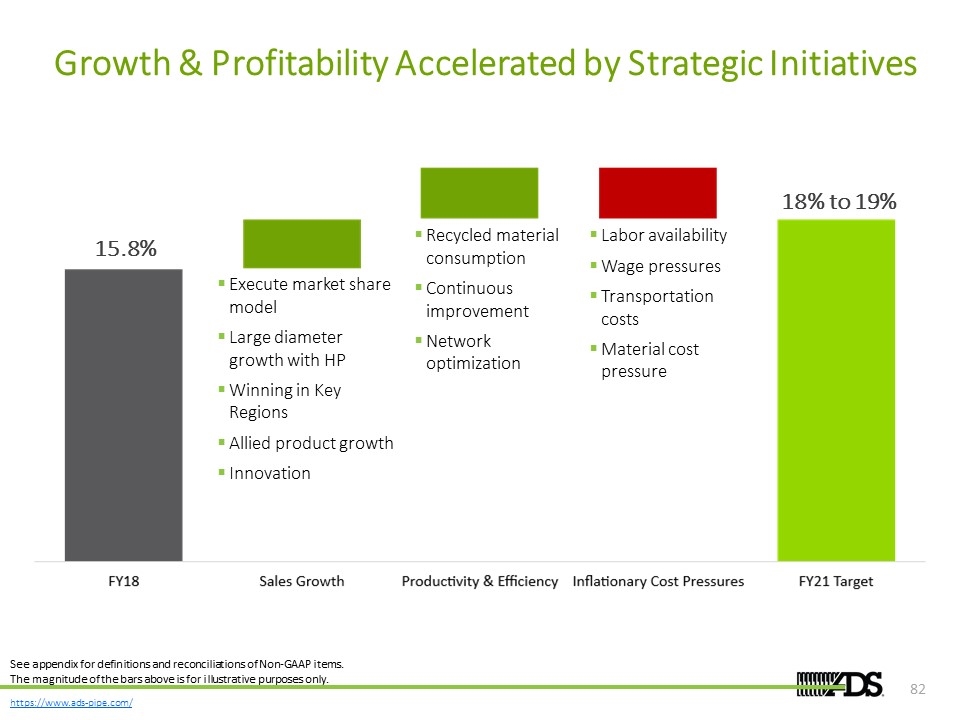

Growth & Profitability Accelerated by Strategic Initiatives 15.8% 18% to 19% Execute market share model Large diameter growth with HP Winning in Key Regions Allied product growth Innovation Recycled material consumption Continuous improvement Network optimization Labor availability Wage pressures Transportation costs Material cost pressure See appendix for definitions and reconciliations of Non-GAAP items. The magnitude of the bars above is for illustrative purposes only.

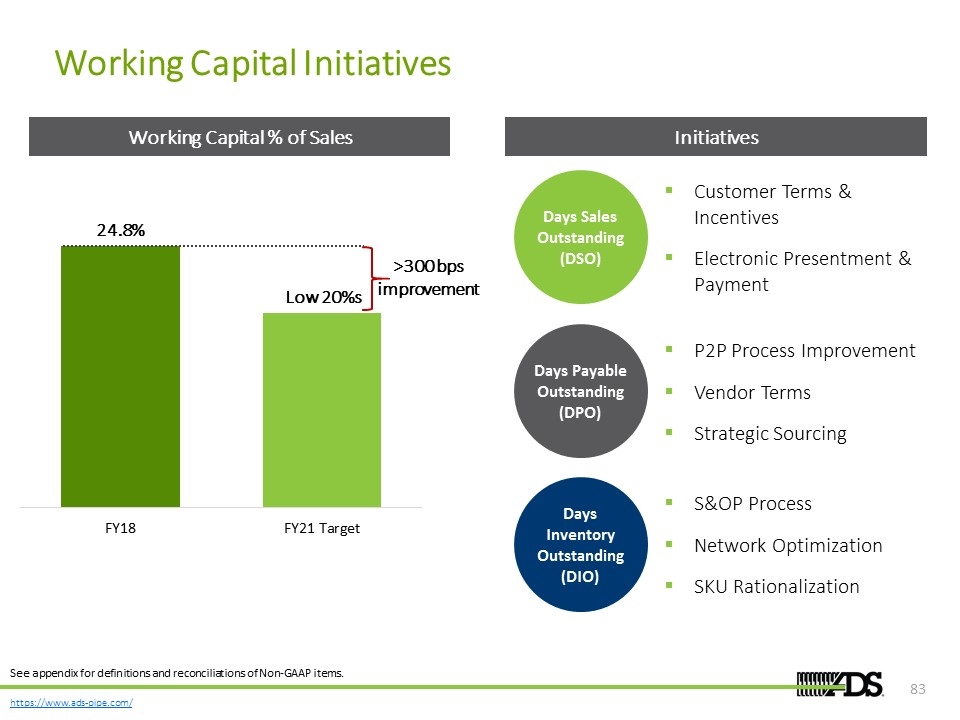

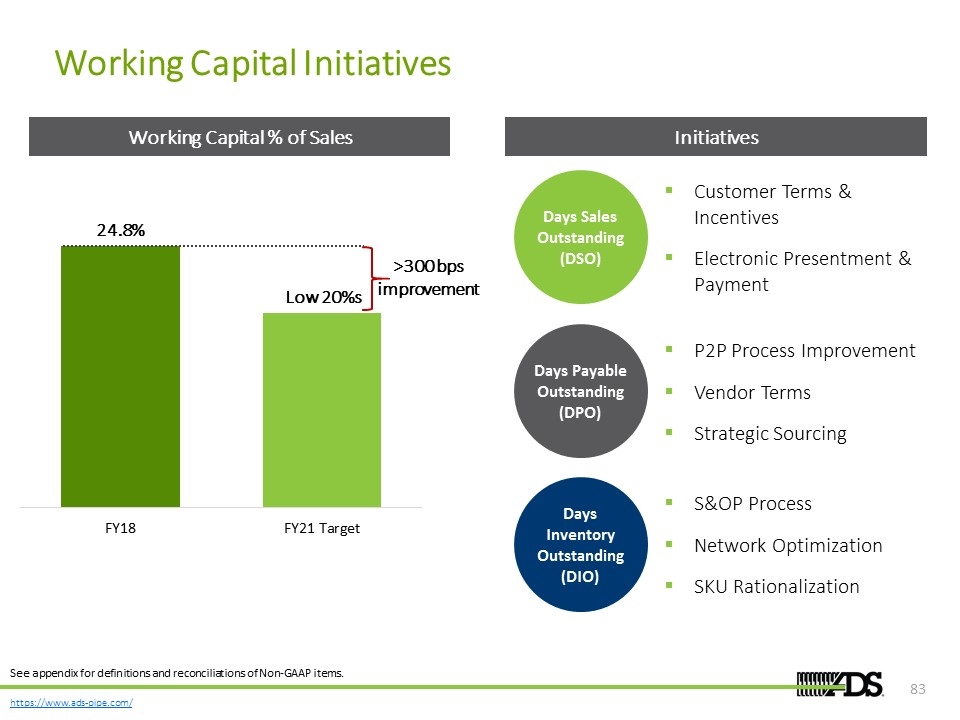

Initiatives Working Capital Initiatives Working Capital % of Sales 24.8% Low 20%s Days Sales Outstanding (DSO) Days Payable Outstanding (DPO) Days Inventory Outstanding (DIO) Customer Terms & Incentives Electronic Presentment & Payment P2P Process Improvement Vendor Terms Strategic Sourcing S&OP Process Network Optimization SKU Rationalization >300 bps improvement See appendix for definitions and reconciliations of Non-GAAP items.

Building Shareholder Value Sales Growth Margin Expansion Balanced Approach to Creating Shareholder Value Disciplined Capital Allocation

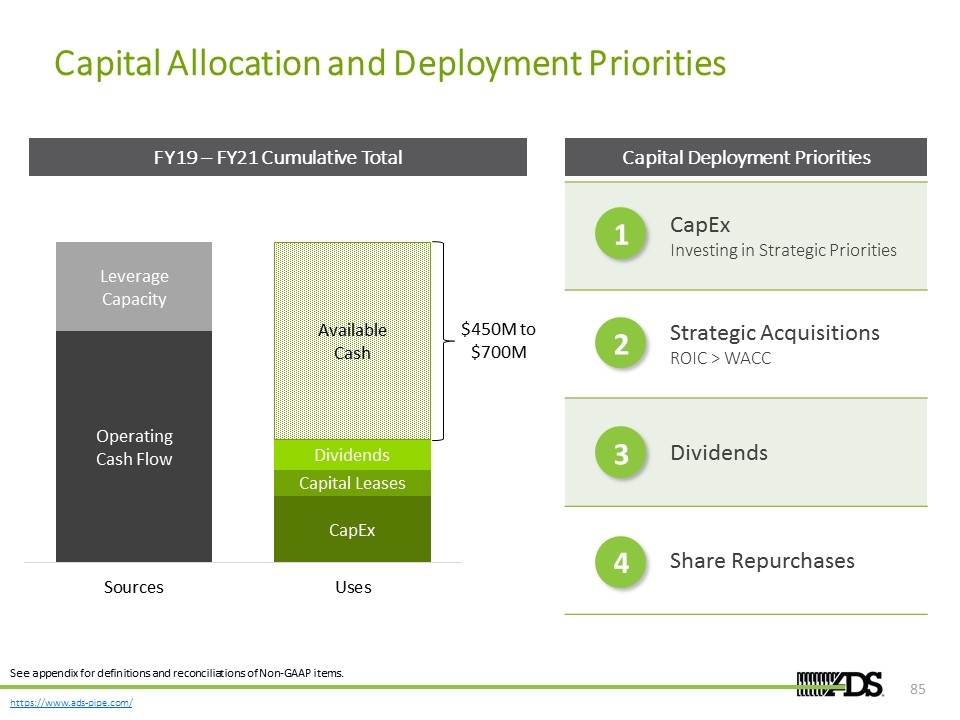

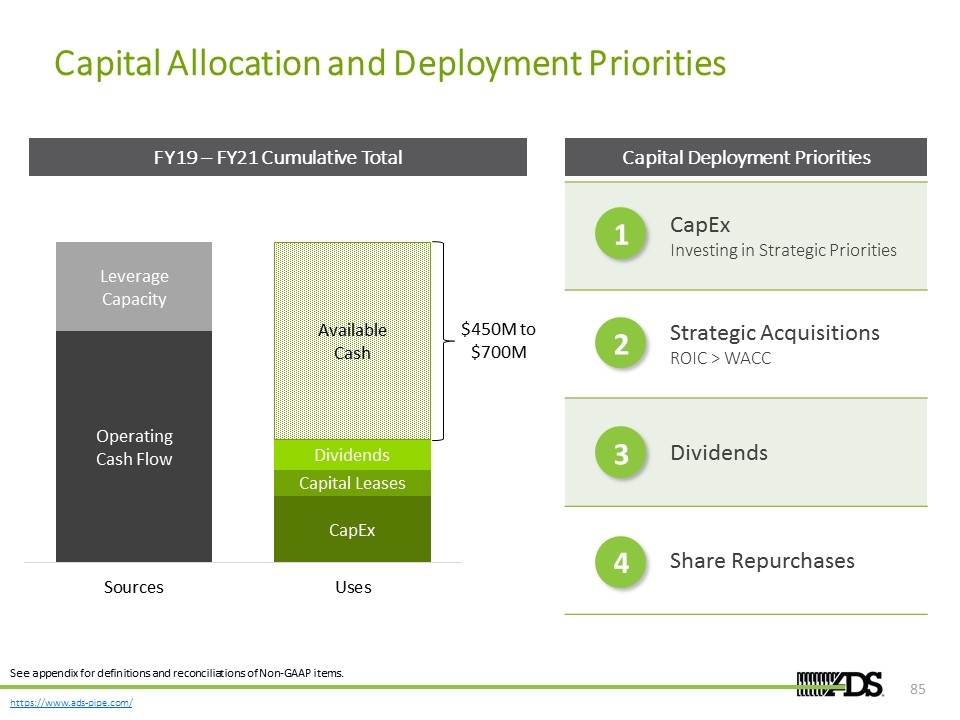

FY19 – FY21 Cumulative Total Capital Allocation and Deployment Priorities $450M to $700M Capital Deployment Priorities CapEx Investing in Strategic Priorities Strategic Acquisitions ROIC > WACC Dividends Share Repurchases See appendix for definitions and reconciliations of Non-GAAP items. 1 2 3 4

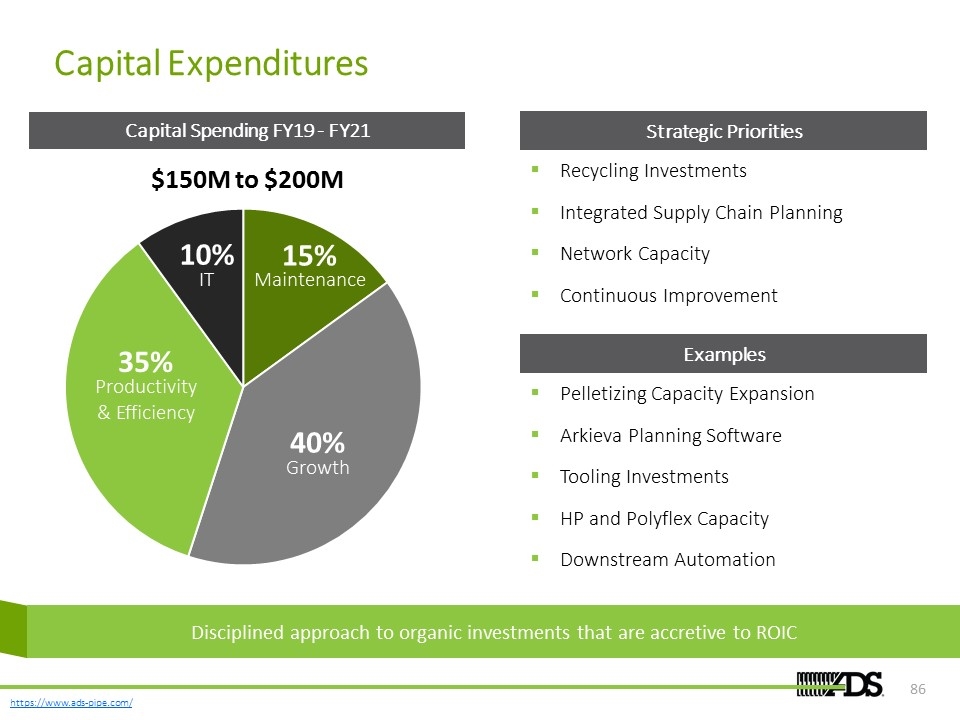

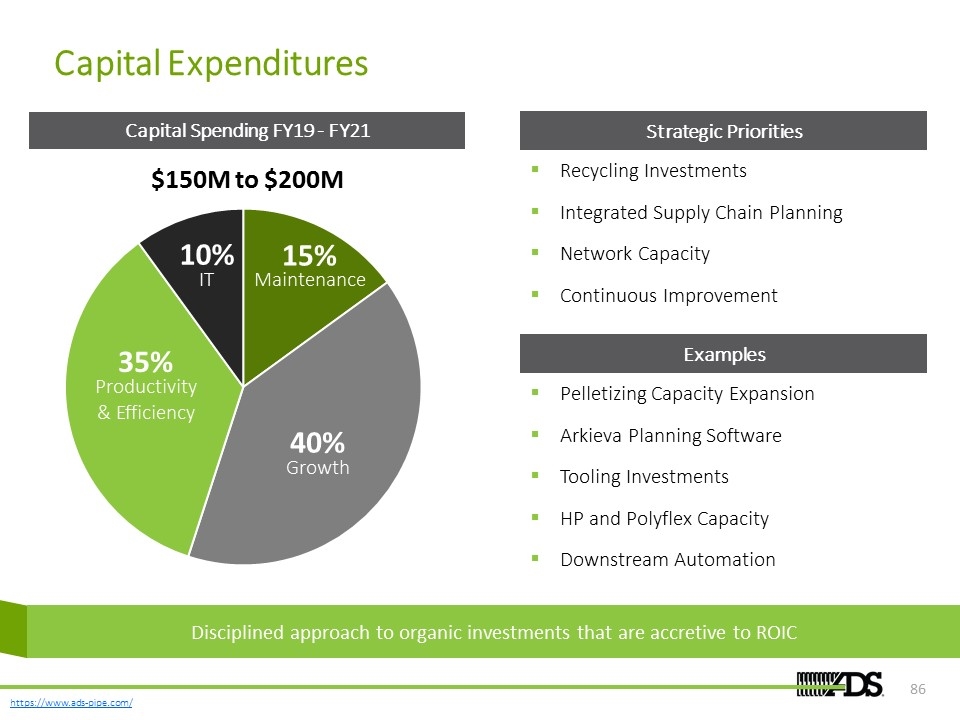

Capital Expenditures Capital Spending FY19 - FY21 Strategic Priorities Examples Recycling Investments Integrated Supply Chain Planning Network Capacity Continuous Improvement Pelletizing Capacity Expansion Arkieva Planning Software Tooling Investments HP and Polyflex Capacity Downstream Automation Disciplined approach to organic investments that are accretive to ROIC Growth 40% Productivity & Efficiency 35% IT 10% Maintenance 15% $150M to $200M

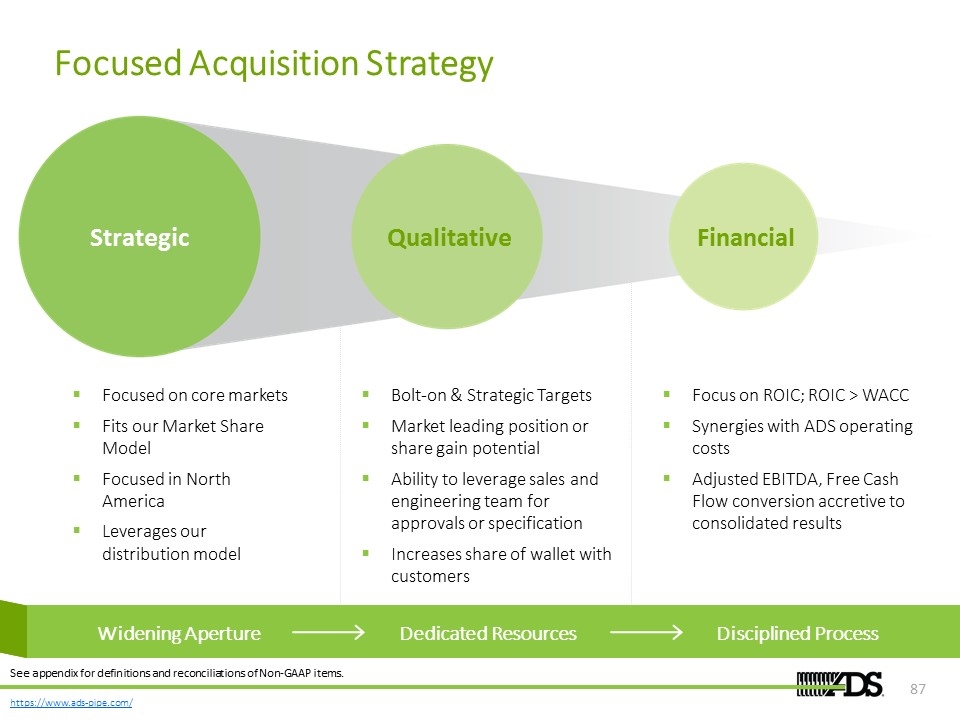

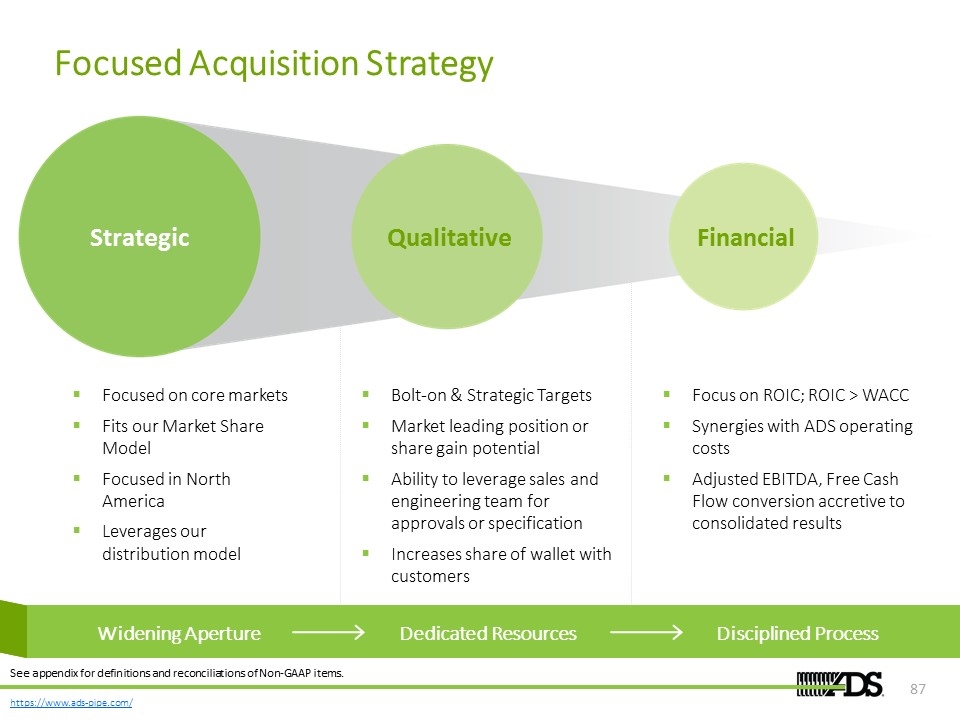

Qualitative Financial Strategic Focused Acquisition Strategy See appendix for definitions and reconciliations of Non-GAAP items. Widening Aperture Dedicated Resources Disciplined Process Focused on core markets Fits our Market Share Model Focused in North America Leverages our distribution model Focus on ROIC; ROIC > WACC Synergies with ADS operating costs Adjusted EBITDA, Free Cash Flow conversion accretive to consolidated results Bolt-on & Strategic Targets Market leading position or share gain potential Ability to leverage sales and engineering team for approvals or specification Increases share of wallet with customers Widening Aperture Dedicated Resources Disciplined Process

Key Highlights Solid track record of growth and profitability, supported by favorable end market dynamics Balanced approach to creating shareholder value through sales growth, margin expansion and disciplined capital allocation Working capital initiatives combined with margin expansion expected to accelerate free cash flow generation Strong balance sheet with significant flexibility to fund organic investments and strategic acquisitions See appendix for definitions and reconciliations of Non-GAAP items.

FY21 Financial Targets Organic Sales Growth 4% to 6% CAGR Driven by execution of the market share model, large diameter growth, winning in key regions, allied product growth and innovation Adj. EBITDA Margin 18% to 19% Driven by continuous improvement, network optimization, recycled material strategies and logistics & transportation initiatives Free Cash Flow Conversion >50% of Adjusted EBITDA Margin expansion together with working capital management initiatives to reduce working capital as a % of sales by >300 bps Capital Available for Deployment $450M to $700M Strong balance sheet and cash flow to leave significant cash for deployment FY19 – FY21 Comments See appendix for definitions and reconciliations of Non-GAAP items.

Closing Remarks Scott Barbour, President and CEO

ADS’ Distinct Market Leadership Leading player in the storm water management industry with a track record of market share gains Consistent above-market growth driven by material conversion strategy and complete solutions package Best-in-class sales force, technical expertise and distribution & logistics network creates barriers to entry and positions ADS as the supplier of choice Large and growing end-markets with favorable tailwinds from regulatory changes and increased focus on sustainability

Investor Day Themes Cash Flow Generation Successful execution will result in significant cash generation over the next several years Margin Expansion ADS has significant margin upside potential and action plans in place to achieve superior results ADS is an industrial growth story with a large market opportunity and long runway for growth Sales Growth Sales +4% to 6% CAGR Adjusted EBITDA Margin 18% to 19% Free Cash Flow Conversion > 50% of Adjusted EBITDA See appendix for definitions and reconciliations of Non-GAAP items.

Q&A

Appendix

Get Social With Us! LinkedIn Facebook Twitter Google+ YouTube Links to ADS social media sites are available at the ADS Website

Featured Projects Skanska Walsh was hired to manage the $8BN rebuilding of LaGuardia Airport, including new terminals, roads, retail shops, restaurants and garages. Along with the aboveground work, an underground stormwater drainage system was constructed using ~10 miles of two types of thermoplastic pipe. Skanska elected to use 23,000+ feet of ADS HP Storm pipe for the airside and ~25,000 feet of ADS N-12 corrugated HDPE pipe ranging in diameter from 12 to 60 inches on the landside Key Takeaways ADS’ lighter, less expensive, more efficient and easier to lay thermoplastic pipe cut the time necessary to complete the job with RCP by 50% ADS’ easily-nestled pipe cut the number of truck deliveries by 2/3 compared with RCP, saving money and time while complying with security standards The innovative design and high strength-to-weight ratio of the N-12 and HP Storm Pipes can help LaGuardia achieve LEED Gold certification for sustainable design LaGuardia Airport Rebuild New York, NY | 2017 – 2022 (expected)

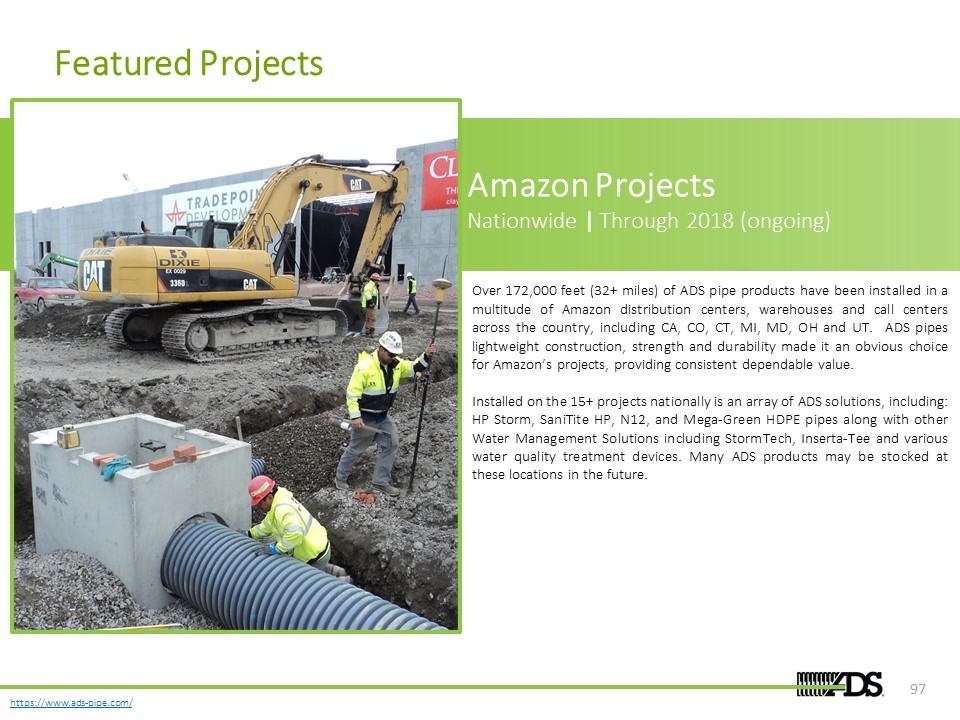

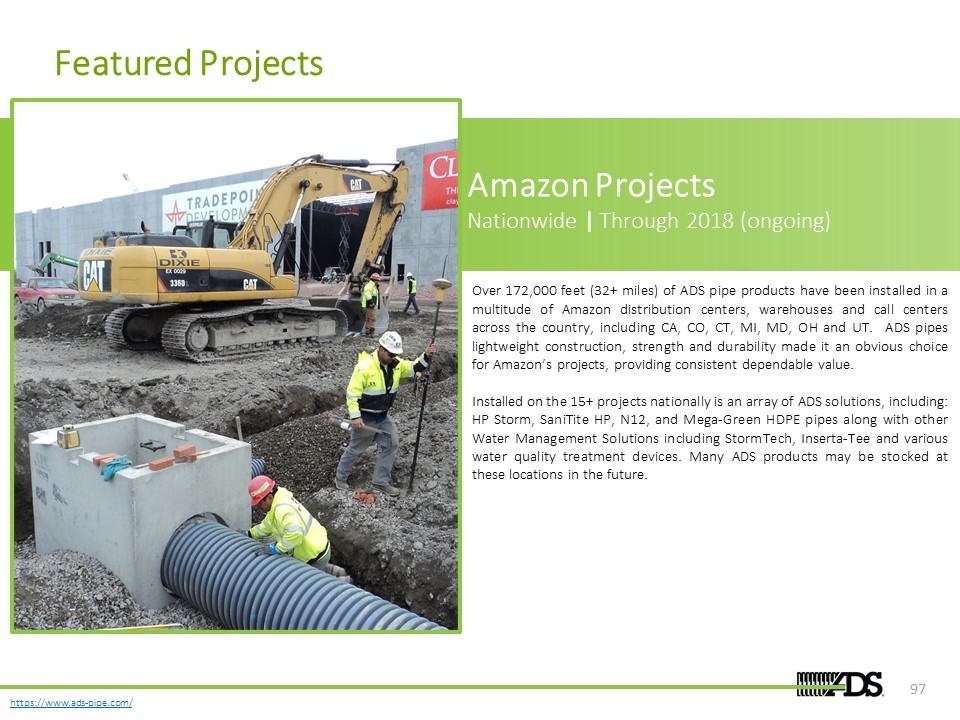

Featured Projects Over 172,000 feet (32+ miles) of ADS pipe products have been installed in a multitude of Amazon distribution centers, warehouses and call centers across the country, including CA, CO, CT, MI, MD, OH and UT. ADS pipes lightweight construction, strength and durability made it an obvious choice for Amazon’s projects, providing consistent dependable value. Installed on the 15+ projects nationally is an array of ADS solutions, including: HP Storm, SaniTite HP, N12, and Mega-Green HDPE pipes along with other Water Management Solutions including StormTech, Inserta-Tee and various water quality treatment devices. Many ADS products may be stocked at these locations in the future. Amazon Projects Nationwide | Through 2018 (ongoing)

Featured Projects At UPS’s warehouse facility in Lathrop, CA, the site required an existing retention pond to be replaced with additional parking space for UPS trucks. The site had very poor clays with minimal infiltration capabilities, so a very large amount of underground storage was required underneath the proposed parking area. ADS’s INNOVATIVE StormTech MC4500 chamber provided an efficient footprint to meet the site’s stormwater storage requirement, creating a winning solution for the engineer, developer and owner. Additionally, the logistics were difficult as traffic had to keep moving through the site and the contractors were on a tight schedule. Key Takeaways ADS’s portable StormTech MC-4500 Chambers minimized the site’s footprint, providing the ultimate solution for the engineer and developer ADS’ efficient and simple installation was critical for a tight schedule ADS’ team of experts were able to effectively manage a logistically difficult project UPS California Warehouse Lathrop, CA | 2017

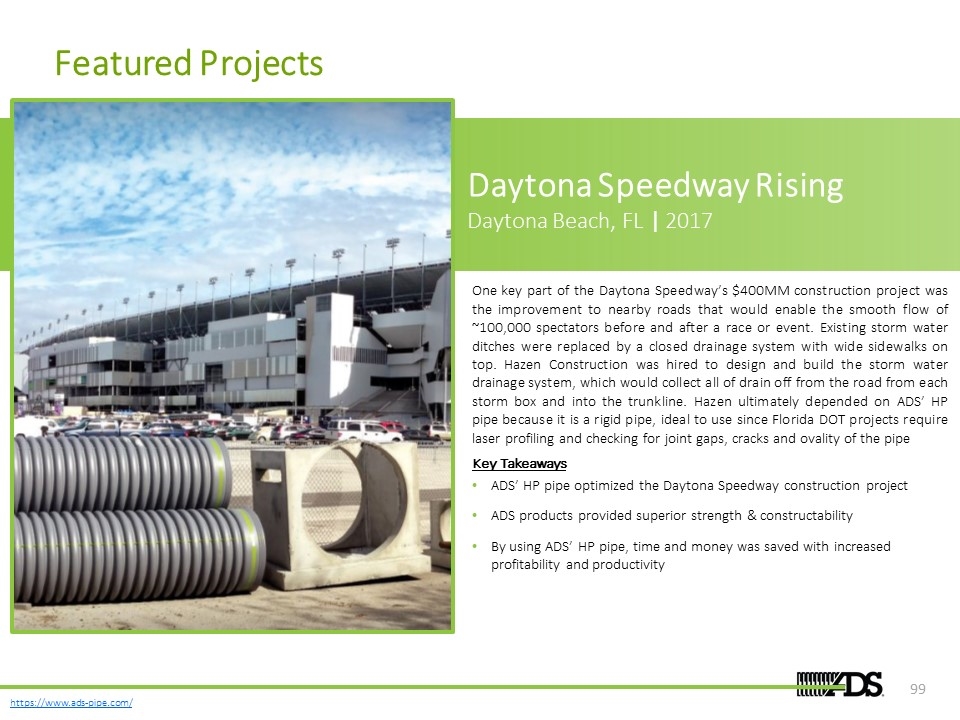

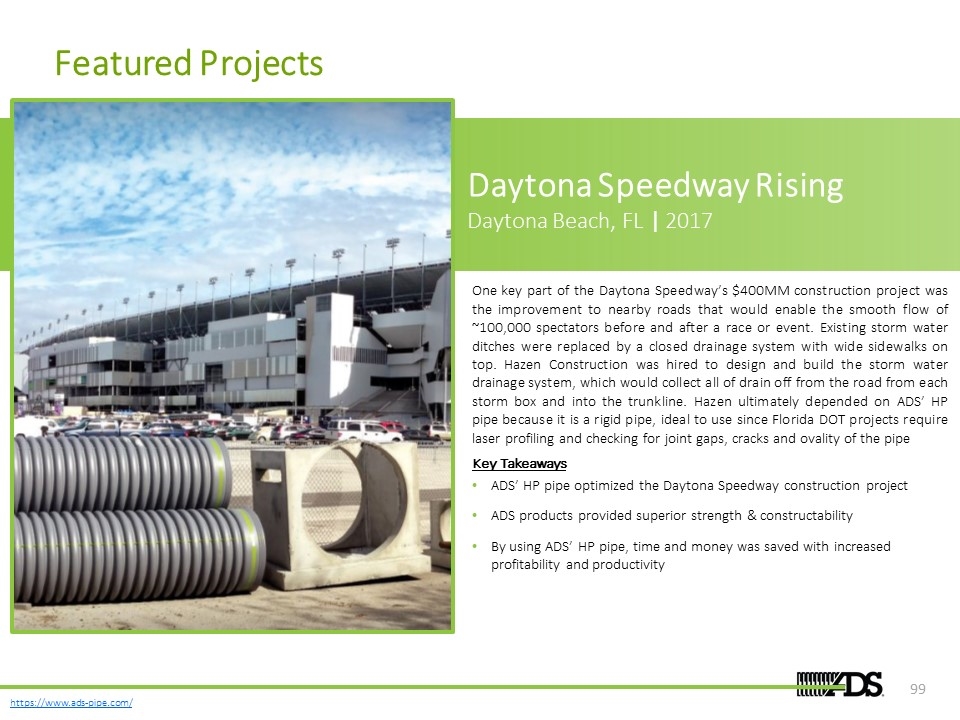

Featured Projects One key part of the Daytona Speedway’s $400MM construction project was the improvement to nearby roads that would enable the smooth flow of ~100,000 spectators before and after a race or event. Existing storm water ditches were replaced by a closed drainage system with wide sidewalks on top. Hazen Construction was hired to design and build the storm water drainage system, which would collect all of drain off from the road from each storm box and into the trunkline. Hazen ultimately depended on ADS’ HP pipe because it is a rigid pipe, ideal to use since Florida DOT projects require laser profiling and checking for joint gaps, cracks and ovality of the pipe Key Takeaways ADS’ HP pipe optimized the Daytona Speedway construction project ADS products provided superior strength & constructability By using ADS’ HP pipe, time and money was saved with increased profitability and productivity Daytona Speedway Rising Daytona Beach, FL | 2017

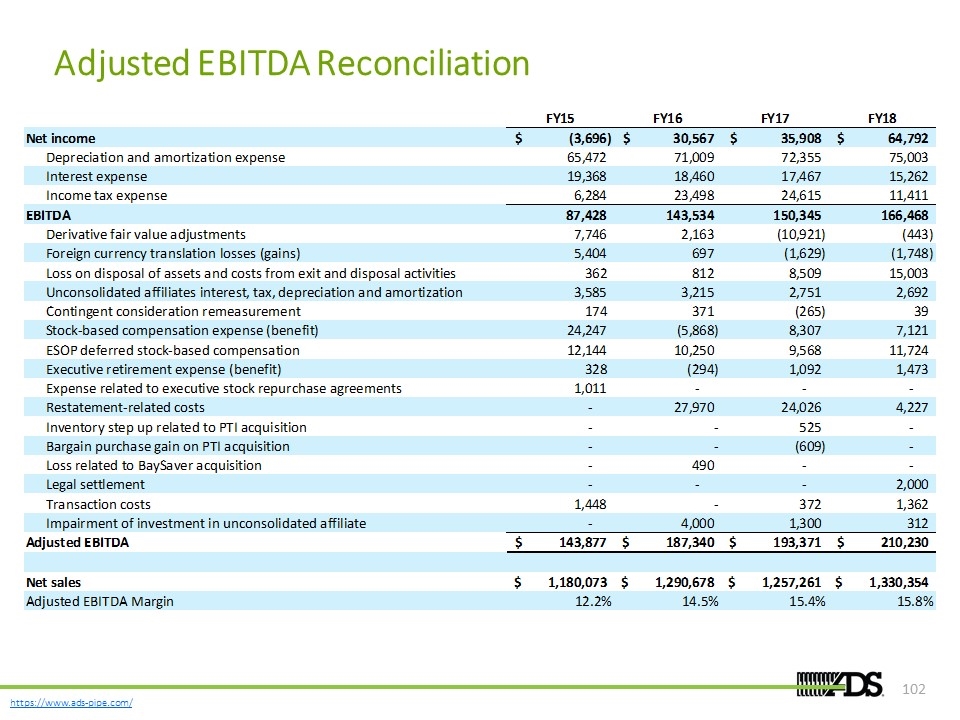

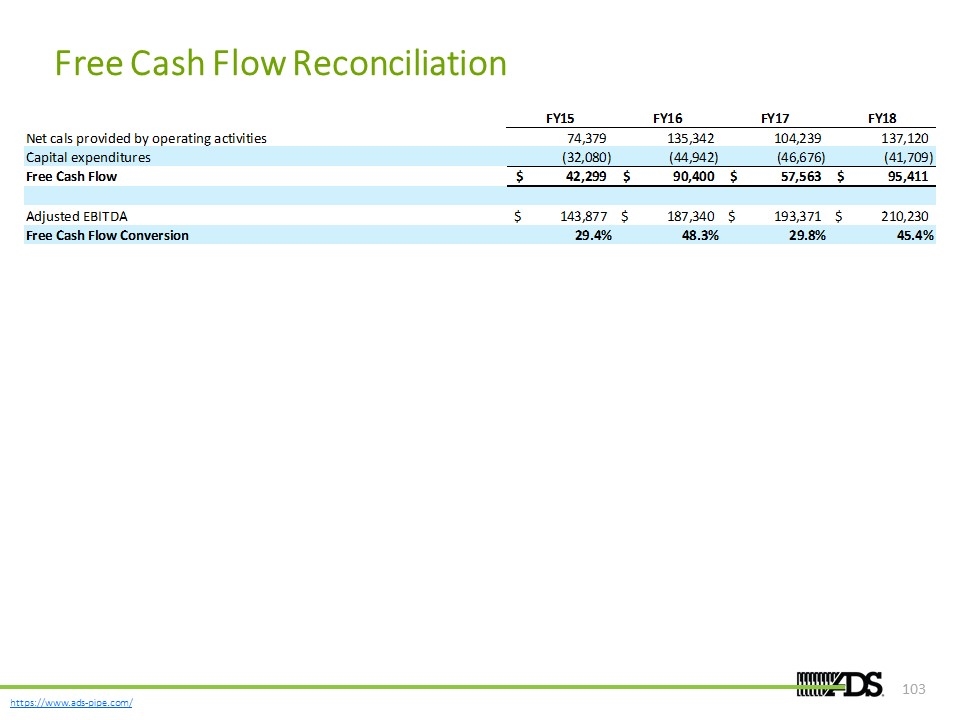

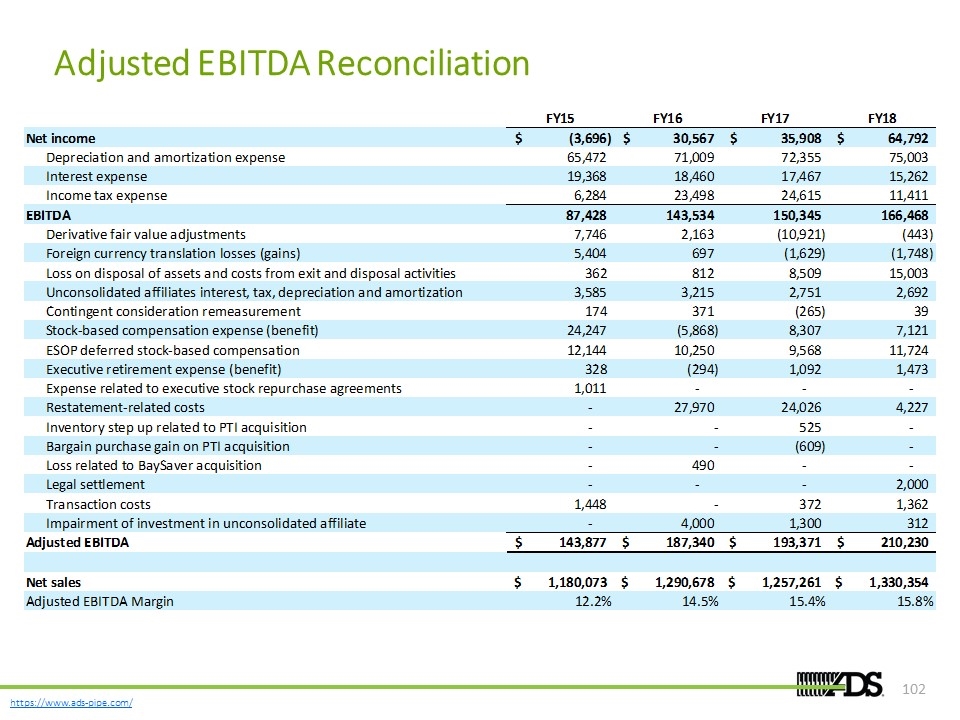

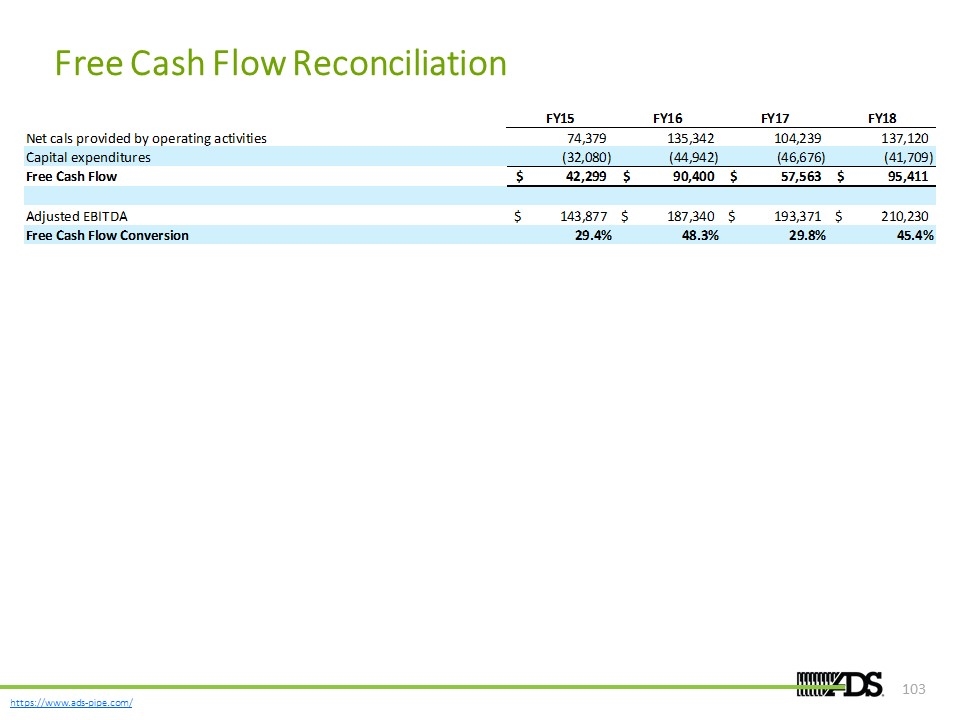

Financial Definitions Adjusted EBITDA: Net income before interest, income taxes, depreciation and amortization, stock-based compensation, non-cash charges and certain other expenses. Reconciliation provided on slide 102. Adjusted EBITDA Margin: Adjusted EBITDA calculated as a percentage of net sales. Reconciliation provided on slide 102. Compound Annual Growth Rate (“CAGR”): Growth rate from the initial value to ending value assuming the value is compounding over the time period. Calculated as (Ending Value / Beginning Value)1/Number of Years – 1. Free Cash Flow (“FCF”): Cash flow from operating activities less capital expenditures. Reconciliation provided on slide 103. Free Cash Flow Conversion: Free cash flow calculated as a percentage of Adjusted EBITDA. Reconciliation provided on slide 103. Return on Invested Capital (“ROIC”): Net operating profit after tax divided by invested capital. Working Capital: Accounts Receivable plus Inventory reduced by Accounts Payable.

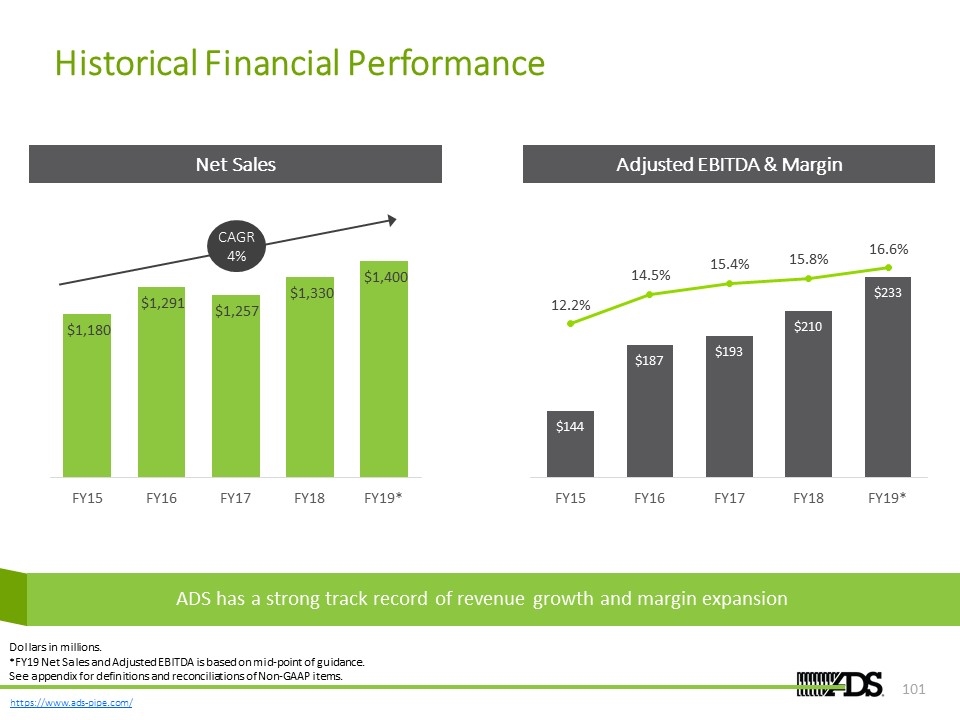

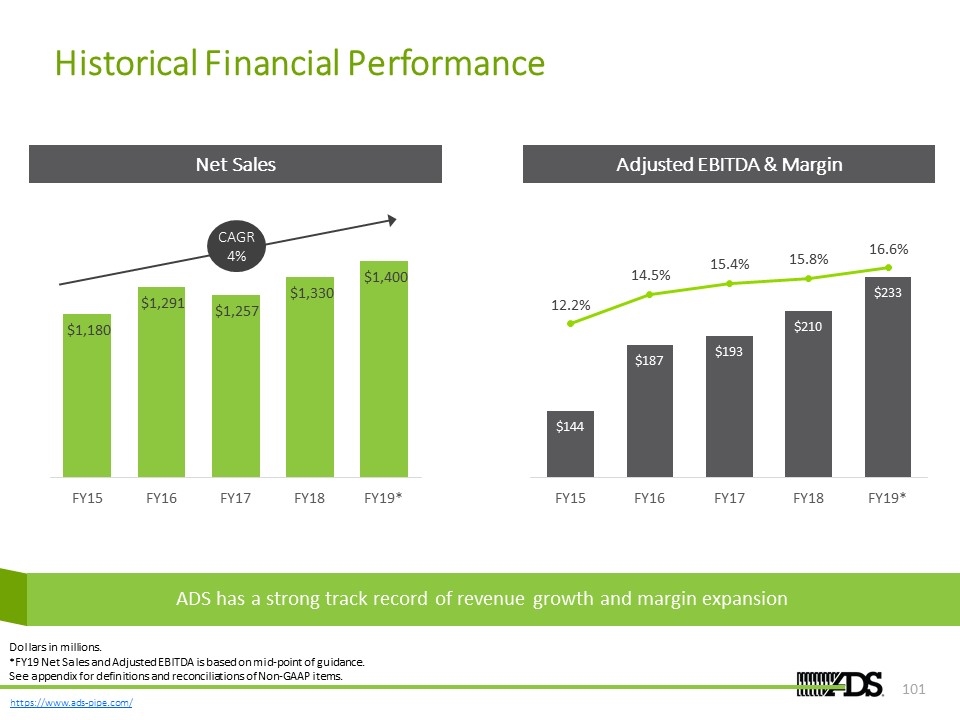

Historical Financial Performance Net Sales Adjusted EBITDA & Margin CAGR 4% Dollars in millions. *FY19 Net Sales and Adjusted EBITDA is based on mid-point of guidance. See appendix for definitions and reconciliations of Non-GAAP items. ADS has a strong track record of revenue growth and margin expansion

Adjusted EBITDA Reconciliation

Free Cash Flow Reconciliation