ANNUAL INFORMATION FORM

For the year ended December 31, 2020

Dated as of March 25, 2021

FORWARD LOOKING STATEMENTS

This Annual Information Form of SilverCrest Metals Inc. (the "Company" or "SilverCrest") contains "forward-looking statements" within the meaning of Canadian securities legislation. Such forward-looking statements concern the Company's anticipated results and developments in the Company's operations in future periods, planned exploration and development of its properties, planned expenditures and plans related to its business and other matters that may occur in the future. These statements relate to analyses and other information that are based on expectations of future performance, including silver and gold production and planned work programs. In addition, these statements include, but are not limited to: the future price of commodities; the estimation of mineral resources and reserves; the realization of mineral resource and reserve estimates; the timing and amount of estimated future production; costs of production; capital expenditures; costs and timing of the development of new deposits; timing of completion of exploration programs; technical reports and studies; success of exploration and development activities and mining operations; the impact of the COVID-19 pandemic on operations, future financings, the Company's share price and on the timing and completion of exploration programs, technical reports and studies; the timing of construction and mine operation activities (including the plan for production at Las Chispas (as defined below) by the second half ("H2") of 2022); permitting timelines; currency fluctuations; requirements for additional capital; government regulation of exploration and production operations; environmental risks; unanticipated reclamation expenses; title disputes or claims; completion of acquisitions and their potential impact on the Company and its operations; limitations on insurance coverage; maintenance of adequate internal control over financial reporting; the development and advancement of the Company's ESG (as defined below) strategy and the timing and possible outcome of litigation.

Forward-looking statements are made based upon certain assumptions and other important factors that, while considered reasonable by the Company, are inherently subject to significant business economic, competitive, political and social uncertainties and contingencies. The Company has made assumptions based on many of these factors which include, without limitation: present and future business strategies; the environment in which the Company will operate in the future, including the price of silver and gold; currency exchange rates; estimates of capital and operating costs; production estimates; estimates of mineral resources and metallurgical recoveries; mining operational and development risks; commencement of production at Las Chispas (as defined below) by H2, 2022; regulatory restrictions; activities by governmental authorities and changes in legislation; community relations; the speculative nature of mineral exploration; the global economic climate; loss of key employees; additional funding requirements; title to mineral claims or property; and the ultimate impact of the COVID-19 pandemic on operations. The assumptions used in the preparation of such statements, although considered reasonable at the time of preparation, may prove to be imprecise and, as such, readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date the statements were made.

Forward-looking statements are subject to a variety of known and unknown risks, uncertainties and other factors which could cause actual events or results to differ materially from those expressed or implied by the forward-looking statements, including, without limitation: the timing and content of work programs; results of exploration activities; the interpretation of drilling results and other geological data; reliability of mineral resource estimates; receipt, maintenance and security of permits and mineral property titles; enforceability of contractual interests in mineral properties; environmental and other regulatory risks; compliance with changing environmental regulations; dependence on local community relationships; risks of local violence; risks related to natural disasters, terrorism, civil unrest, public health concerns (including health epidemics or outbreaks of communicable diseases such as the coronavirus) and other geopolitical uncertainties; reliability of costs estimates; project cost overruns or unanticipated costs and expenses; precious metals price fluctuations; fluctuations in the foreign exchange rate (particularly the Mexican peso, Canadian dollar and United States dollar); uncertainty in the Company's ability to fund the exploration and development of its mineral properties or the completion of further exploration programs; uncertainty as to whether the Company's exploration programs will result in the discovery, development or production of commercially viable ore bodies or yield reserves; development plans and costs differing materially from the Company's expectations; risks related to mineral properties being subject to prior unregistered agreements, transfers, claims and other defects in title; uncertainty in the ability to obtain financing if required; maintaining adequate internal control over financial reporting; dependence on key personnel; and general market and industry conditions. This list is not exhaustive of the factors that may affect the Company's forward-looking statements. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in the forward-looking statements.

The Company's forward-looking statements are based on beliefs, expectations and opinions of management on the date the statements are made. While the Company has attempted to identify important factors that could cause actual actions, events or results to differ from those described in forward-looking statements, there may be factors that cause actions, events or results not to be as anticipated, estimated or intended. The Company undertakes no obligation to update or revise any forward-looking statements included in this Annual Information Form if these beliefs, expectations and opinions or other circumstances should change, except as otherwise required by applicable law.

TABLE OF CONTENTS

1. GENERAL

1.1 Date of Information

All information in this Annual Information Form is as of March 25, 2021, unless otherwise indicated, and the information contained herein is current as of such date, unless otherwise stated.

1.2 Conversion Table

All data and information is presented in metric units. In this Annual Information Form, the following conversion factors were used:

2.47 acres | = | 1 hectare | 0.4047 hectares | = | 1 acre |

3.28 feet | = | 1 metre | 0.3048 metres | = | 1 foot |

0.62 miles | = | 1 kilometre | 1.609 kilometres | = | 1 mile |

0.032 ounces (troy) | = | 1 gram | 31.103 grams | = | 1 ounce (troy) |

1.102 tons (short) | = | 1 tonne | 0.907 tonnes | = | 1 ton |

0.029 ounces/ton | = | 1 gram/tonne | 34.286 grams/tonne | = | 1 ounce/ton |

1 ppm | = | 1 gram/tonne | | | |

1 ounce/ton | = | 34.286 ppm | | | |

1% | = | 10,000 ppm | | | |

1.3 Technical Abbreviations

Ag | silver | | NI 43-101 | National Instrument 43-101 Standards of Disclosure for Mineral Projects |

AgEq | silver equivalent | | NSR | net smelter returns |

Au | gold | | oz | ounce(s) |

cm | centimetres | | Pb | Lead |

Cu | copper | | RC | reverse circulation |

g | grams | | t | Tonne |

gpt | grams per tonne | | tpd | tonnes per day |

km | kilometres | | | |

m | metres | | | |

1.4 Currency

All dollar ($) amounts stated in this Annual Information Form refer to United States dollars ($ or US$) unless Canadian dollars (C$) are indicated. On March 23, 2021, the noon exchange rate for the United States dollar in terms of Canadian dollars, as quoted by the Bank of Canada, was US$1.00 = C$1.2562 (C$1.00 = US$0.7961). On December 31, 2020, the noon exchange rate for the United States dollar in terms of Canadian dollars, as quoted by the Bank of Canada, was US$1.00 = C$1.2732 (C$1.00 = US$0.7854).

During 2020, the Company changed its presentation currency to US$ from C$. The Company applied the change in presentation currency retrospectively and restated the comparative financial information as if the presentation currency had always been US$.

1.5 Qualified Persons

N. Eric Fier, CPG, P. Eng, is a "qualified person" within the meaning of National Instrument 43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101"), and has reviewed and approved the scientific and technical information relating to the Company's mineral properties disclosed in this Annual Information Form. Mr. Fier is the Chief Executive Officer and a director of SilverCrest. Other qualified persons are responsible for the technical and scientific information contained in the technical reports incorporated by reference in this Annual Information Form. See "Interests of Experts - Names of Experts".

2. CORPORATE STRUCTURE

2.1 Name, Address and Incorporation

SilverCrest Metals Inc. was incorporated under the name "1040669 B.C. Ltd." under the Business Corporations Act (British Columbia) ("BCBCA") on June 23, 2015. The Notice of Articles of the Company was subsequently amended on August 11, 2015, to change the name of the Company to "SilverCrest Metals Inc.". Upon the Company's incorporation on June 23, 2015, the Company was a wholly owned subsidiary of SilverCrest Mines Inc. ("SilverCrest Mines"). The Company was established as part of an arrangement (the "Arrangement") completed under the BCBCA on October 1, 2015, pursuant to which First Majestic Silver Corp. ("First Majestic") acquired SilverCrest Mines after the Company was spun off from SilverCrest Mines to the former shareholders of SilverCrest Mines. The Arrangement resulted in the Company holding title to various exploration properties located in Mexico that were formerly held by SilverCrest Mines. The common shares of the Company (the "Common Shares") commenced trading on the TSX Venture Exchange ("TSX-V") on October 9, 2015 and were listed on the NYSE American ("NYSE") on August 21, 2018. The Common Shares commenced trading on the Toronto Stock Exchange ("TSX") on August 29, 2019, and were concurrently delisted from the TSX-V.

The head office of the Company is located at Suite 501, 570 Granville Street, Vancouver, British Columbia, V6C 3P1. The registered office of the Company is located at 19th Floor, 885 West Georgia Street, Vancouver, British Columbia, V6C 3H4.

2.2 Intercorporate Relationships

| Subsidiary | Location | Ownership | Principal activity |

| NorCrest Metals Inc. (“NorCrest”) | Canada | 100% | Holding Company |

| Compañía Minera La Llamarada, S.A. de C.V. (“La Llamarada”) | Mexico | 100% | Exploration and development |

| Tinto Roca Exploración, S.A. de C.V. | Mexico | 100% | Service company |

| Altadore Energía, S.A. de C.V. | Mexico | 100% | Service company |

| Babicanora Agrícola del Noroeste, S.A. de C.V. | Mexico | 100% | Maintenance of surface rights |

| SilverCrest Metals de México, S.A. de C.V. | Mexico | 100% | Exploration |

3. GENERAL DEVELOPMENT OF THE BUSINESS

3.1 Overview

SilverCrest is a Canadian precious metals exploration and development company headquartered in Vancouver, BC, that is focused on making new discoveries and value-added acquisitions and targeting production in Mexico's historic precious metal districts. The Company's ongoing initiative is to increase its asset base by acquiring and developing substantial precious metal resources, and ultimately operating high grade silver and/or gold mines in Mexico. The Company's principal focus is currently its Las Chispas property ("Las Chispas" or the "Las Chispas Project"), which is located approximately 180 kilometres northeast of Hermosillo, Sonora, Mexico. Las Chispas is in a prolific mining area with nearby precious metal producers, and consists of 28 concessions totalling approximately 1,401 hectares. The Company has recently filed the Las Chispas Feasibility Study (defined below) and is proceeding with mine construction. Startup of production at the Las Chispas Project is targeted for mid-2022.

The Company has a portfolio of four other mineral exploration properties in Sonora, Mexico, comprised of the El Picacho property, Cruz de Mayo property, Angel de Plata property and Estacion Llano property.

The Company's Common Shares are currently traded on the TSX under the symbol "SIL" and on the NYSE under the symbol "SILV".

3.2 Three Year History

2018

Las Chispas

SilverCrest completed its 2017 Phase II exploration program in February 2018 and announced the final results of its exploration program with an initial resource estimate for Las Chispas. The Company filed an independent NI 43-101 technical report disclosing the Las Chispas resource estimate titled, "Technical Report and Mineral Resource Estimate for the Las Chispas Property, Sonora, Mexico", effective February 12, 2018. The resource estimate was focused on an estimated 3.5 kilometres of approximately 12 kilometres of the estimated cumulative vein strike length in the district. Upon completion of its Phase II exploration program in February 2018, the Company commenced a Phase III exploration program, initially estimated to cost $15.0 million, of 140 holes and 45,000 metres of drilling.

In February 2018, La Llamarada purchased the Rancho Cuesta Blanca, covering an area of 671.9 hectares. The Company owns approximately two -thirds of the surface rights covering its optioned mining concessions. A 20--year lease agreement for land access and exploration activities to the remaining one -third of the surface rights on the mineral concessions is in place with a local Ejido.

On September 19, 2018, the Company announced an updated resource estimate for Las Chispas and, on November 21, 2018, filed a technical report pursuant to NI 43-101 titled "Technical Report and Updated Mineral Resource Estimate for the Las Chispas Property, Sonora, Mexico" dated November 19, 2018, with an effective date of September 13, 2018.The mineral resource estimate was based on the Company's Phase I, II and partial Phase III exploration programs from March 2016 to September 13, 2018, which included a total of 82,810 metres of drilling in 305 holes. The resource estimate included an estimated 5.5 kilometres of approximately 20 kilometres of cumulative vein strike length in the district.

As of December 31, 2018, SilverCrest expanded its drilling for Phase III (originally estimated to be 45,000 metres in February 2018) and drilled a further 30,770 metres in 121 holes, for a total of 67,830 metres in 243 holes for its Phase III exploration program. From March 2016 to December 31, 2018, the Company drilled a cumulative 113,580 metres in 426 holes. The Company incurred C$18.3 million in exploration expenditures during 2018 for a total of C$31.3 million since inception of Las Chispas.

Guadalupe Property

In late February, 2018, the Company entered into an assignment of mining concession agreement for the sale of 100% title of the Guadalupe Mining Concession.

Other Properties

In May 2018, the Company reinstated the assignment agreement to purchase a 100% in the El Gueriguito concession by making a payment of $50,000. During 2018, the Company made an additional payment of $50,000 in accordance with the assignment agreement.

While the Company continues to have a 100% ownership or option interest in the Cruz de Mayo, Huasabas, Angel de Plata, and Estacion Llano properties, no substantive exploration expenditures are currently budgeted or planned. As a result, the Company recorded an impairment expense of C$292,336 for all previously capitalized costs related to these properties. The Company considers these properties to be non-material and continues to hold the concessions in good standing under care and maintenance.

Financings

In connection with the appointment of Christopher Ritchie as President of the Company, the Company completed a private placement of C$749,988 with Mr. Ritchie. The private placement, which closed on January 17, 2018, was comprised of 451,800 units at a price of C$1.66 per unit, with each unit consisting of one Common Share and one half of one Common Share purchase warrant. Each whole warrant was exercisable for one Common Share at a price of C$2.29 per Common Share for a term of two years.

In May 2018, the Company completed a short form prospectus offering whereby the Company issued 8,214,450 Common Shares at a price of $2.10 for gross proceeds of C$17.3 million.

In December 2018, the Company completed a private placement with SSR Mining Inc. of 8,220,645 Common Shares at a price of C$3.73 per Common Share for gross proceeds of C$30.6 million.

2019

Las Chispas

During December 2018, the Company selected its contractor to construct an exploration decline (Santa Rosa) to access the Babicanora Vein, Area 51 zone. As of February 2019, the Company obtained the necessary permits and commenced work on the decline, estimated to be 550 metres long, 4.5 metres wide by 4.0 metres in height. On March 14, 2019, the Company announced an updated mineral resource estimate for Las Chispas and filed a technical report on May 14, 2019 titled "Technical Report and Mineral Resource Estimate for the Las Chispas Property, Sonora, Mexico" 2019, effective February 8, 2019 and dated March 14, 2019., This resource estimate was based on the Company's Phase I, II, and partial Phase III exploration programs conducted from March 2016 to February 8, 2019 and was classified as an Indicated and Inferred Mineral Resource.On July 5, 2019, the Company filed a technical report titled "Technical Report and Preliminary Economic Assessment for the Las Chispas Property, Sonora, Mexico, effective May 15, 2019, which report was amended July 19, 2019 and filed July 22, 2019 (the "Las Chispas Preliminary Economic Assessment"). The Las Chispas Preliminary Economic Assessment was the first economic assessment of a potential underground mining operation at Las Chispas and took into account the combined geological, mining, metallurgical, processing, and permitting considerations into a financial assessment. The work was based largely on exploration work completed by SilverCrest and was an early-stage snapshot of a conceptual mining operation which lacked the detailed investigations and engineering required to advance the project towards production. Conclusions drawn from this work provided an estimate for the time and work needed to move the Las Chispas Project from the preliminary economic assessment level to a feasibility study level. Site work, which commenced mid-May 2019, included metallurgical testing, geotechnical work and analysis, hydro-geology, trade-off mining studies, ongoing environmental baseline work, tailings characterization, tailings underground backfill study, and additional survey work.

On July 18, 2019, the Company received notification from the Secretaria de Medio Ambiente y Recuros Naturales ("SEMARNAT") granting approval of the Environmental Impact Statement ("MIA" or the "Operating Permit) for the development of its Las Chispas Project in the State of Sonora, Mexico. The receipt of the MIA provided the Company with conditional approval to construct a 3,000 (maximum capacity) tonne per day underground ("U/G") mine and a conventional processing facility with subsequent dry stack tailings and U/G backfill for Las Chispas. The MIA is based on several conditions and standard requirements.

On August 22, 2019, the Company announced its approval from the Secretaria de la Defensa Nacional ("SEDENA") for the operational storage and use of explosives (the "General Explosives Permit") for Las Chispas. Prior to receiving the General Explosives Permit, the Company held a temporary explosives permit for construction until late June 2019.

In 2019, the construction of a 586-metre exploration decline (Santa Rosa) into the high-grade Area 51 zone of the Babicanora Vein was completed, successfully intersecting the Babicanora Vein in June 2019. On October 16, 2019, the Company announced positive reconciliation results for the Babicanora Vein in the 180-metres of mined vein strike length compared to the grades assumed in the Las Chispas Preliminary Economic Assessment.

As of December 31, 2019, a total of approximately 2,800 metres of underground work had been completed including an estimated 650 metres of in-vein development, with approximately 23,500 tonnes of mineralized material stockpiled on the surface for future processing. The Company completed 189,000 metres of infill and expansion drilling during 2019 (142,000 infill and 47,000 expansion) and has drilled a cumulative 1,132 core holes for 302,000 metres since inception.

During 2019, the Company incurred C$50.3 million ($37.9 million) at Las Chispas towards a cumulative amount of C$76.7 million ($58.2 million) since inception. In addition, the Company made the remaining option payments and exercised its option on five mining concessions resulting in 100% ownership of these five concessions.

Other Properties

During 2019, the Company assigned 100% title of the Guadalupe Mining Concession to a third party.

During 2019, the Company formally disposed of its interest in the Huasabas Property located in Sonora, Mexico. The cancellation process for this property began in 2018 and the Company recorded the minor financial impairment of this property during the quarter ended September 30, 2018.

During 2019, the Company delivered a notice of termination to the owner of the El Gueriguito mining concession, one of the two concessions that make up the Cruz de Mayo Property.

Financings

During 2019, the Company successfully completed equity financings to raise aggregate gross proceeds of over C$122 million, as described below.

In connection with Pierre Beaudoin being appointed Chief Operating Officer of SilverCrest effective November 13, 2018, the Company completed a January 2019 private placement with Mr. Beaudoin and his nominees of 100,000 units at C$2.92 per unit for gross proceeds of C$292,000. Each unit consisted of one Common Share of the Company and a half warrant, with each whole warrant being exercisable to purchase one Common Share of the Company at C$4.03 per share until January 11, 2021. Net proceeds from this private placement were used for general working capital purposes.

In August 2019, the Company completed a short-form prospectus offering of 4,326,300 Common Shares at a price of C$5.85 per Common Share for gross proceeds of C$25.3 million.

In August 2019, the Company completed a private placement with SSR Mining Inc. ("SSR Mining") of 780,000 Common Shares at a price of C$5.85 per Common Share for gross proceeds of C$4.6 million. SSR Mining exercised its right to maintain its pro rata ownership interest of up to 9.9% of the outstanding Common Shares of the Company pursuant to an agreement between the Company and SSR Mining dated November 28, 2018.

In December 2019, the Company completed a short-form prospectus offering of 12,650,000 Common Shares at a price of C$7.28 per Common Share for gross proceeds of C$92.1 million.

2020

Las Chispas

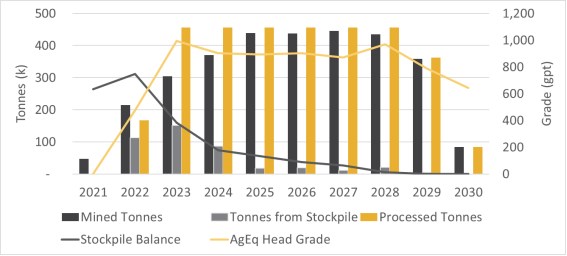

During 2020, the Company completed approximately 173,000 metres of in-fill and expansion drilling and 6.1 kilometres of underground decline development and in-vein drifting despite the temporary suspension of exploration activities due to COVID-19 (see below). The Company also stockpiled an additional estimated 26,600 tonnes of mineralized material. The total stockpile at year end (excluding historic stockpiles) was estimated to be 52,400 tonnes at a diluted grade of 7.0 gpt Au and 587 gpt Ag or 1,192 gpt AgEq (86.9:1,Ag:Au). Other Las Chispas site activities, during 2020, included earthworks, the building of the administration and warehouse facilities, communication system, water pumping station and initial construction of a temporary quarantined COVID-19 camp.

Drilling and assay data information received by the Company up to and including the cut-off date of October 16, 2020, were incorporated into a Mineral Resource Estimate and Mineral Reserve Estimate included in a Feasibility Study (defined below), filed on February 2, 2021 (refer to section 4.4.1 - Las Chispas Project).

In compliance with directives issued by the Mexican government, the Company suspended exploration activities at the Las Chispas Project on April 1, 2020. Exploration activities resumed on May 19, 2020, in accordance with all health-related directives issued by the Mexican government and following strict COVID-19 protocols. The Company continues to adjust to the unprecedented COVID-19 conditions. In May 2020, the Company installed a fully confined temporary camp with a capacity for 160 essential persons to continue its exploration, underground development, and construction of early works with the objective of limiting potential exposure of personnel and nearby communities to the virus. Before entering the confined camp, all persons are tested for COVID-19 (rRT-PCR test) and following receipt of negative tests, are transported to site using strict health and safety protocols. Once on site, all appropriate COVID-19 related protocols are enforced.

In Q4 2020, purchase orders were placed for the insultation of a multi-phased temporary isolated (COVID-19 related) construction camp at Las Chispas. Phase 1 of construction camp, to house approximately 200 workers, was targeted for completion in Q1 2021.

In Q4 2020, the permit for the main road upgrade and access bridge construction was received. Upgrades and construction are anticipated in H1 2021. As at December 31, 2020, the permit for construction of the powerline, to connect the regional electrical grid, was pending. Construction of the powerline is anticipated in to be completed by H1 2022, prior to production startup.

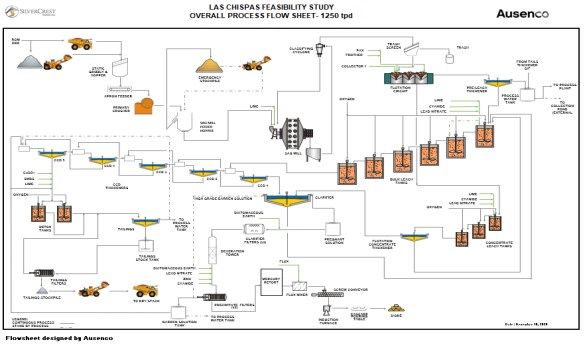

On December 31, 2020, the Company's subsidiary entered into an engineering, procurement and construction ("EPC") contract with Ausenco Engineering Canada Inc. and its affiliate (together as "Ausenco") to construct a 1,250 tonne per day process plant at the Las Chispas Project. The EPC contract has a fixed price of $76.5 million and at December 31, 2020, the Company had incurred $23.2 million in costs for detailed engineering work, long lead orders and an initial mobilization payment. As such, at December 31, 2020, the Company's remaining commitment to Ausenco on the EPC contract was $53.3 million.

Other Properties

During 2020, the Company acquired El Picacho property ("Picacho"), a historic gold and silver producing property located approximately 40 kilometres northeast of Las Chispas in Sonora, Mexico, from American Metal Mining, S.A. de C.V. and an affiliate for $2.4 million, including government back taxes, for 100% ownership in 11 mining concessions. In Q4 2020, the Company received all access rights and necessary drill permits (5-year license) for Picacho and as a result drilled 5,800 metres and incurred $607,769 in total exploration expenditures to December 31, 2020.

Financings

On January 10, 2020, the Company completed a private placement with SSR Mining of 1,819,074 Common Shares at a price of C$7.28 per Common Share for gross proceeds of $9.8 million (C$13.2 million). This resulted from SSR Mining exercising its right to maintain its pro rata ownership interest of up to 9.9% of the outstanding Common Shares of the Company pursuant to an agreement between the Company and SSR Mining dated November 28, 2018.

On April 17, 2020, the Company completed a non-brokered private placement of 13,465,001 Common Shares at a price of C$7.50 per Common Share for gross proceeds of $75.3 million (C$101.0 million).

On April 24, 2020, the Company completed a private placement with SSR Mining of 3,597,291 Common Shares at a price of C$7.50 per Common Share for gross proceeds of $20.1 million (C$27.0 miilon). This resulted from SSR Mining exercising its right to maintain its pro rata ownership interest of up to 9.9% of the outstanding Common Shares of the Company pursuant to an agreement between the Company and SSR Mining dated November 28, 2018.

On May 14, 2020, SSR Mining issued a news release announcing that it had sold its SilverCrest equity position and no longer held any Common Shares of the Company. As a result, SSR Mining's equity participation right pursuant to the agreement between the Company and SSR Mining dated November 28, 2018 expired.

On June 9, 2020, the Company filed a final short form base shelf prospectus to offer common shares, warrants, subscription receipts, debt and convertible debt securities or units of up to an aggregate initial offering price of C$200 million at any time during the 25-month effective period of the prospectus.

On December 31, 2020, NorCrest (as borrower), and the Company, La Llamarada, Babicanora Agricola Del Noroeste, S.A. de C.V., SilverCrest Metals de Mexico, S.A. de C.V., Tinto Roca Exploracion, S.A. de C.V., Altadore Energia. S.A. de C.V. (as guarantors), and RK Mine Finance Bermuda 4 Limited (as lender) entered into a credit agreement (the "Credit Facility") in the amount of $120 million. On closing of the Credit Facility on December 31, 2020, NorCrest drew down $30 million. Subsequent drawdowns under the Credit Facility are available upon satisfaction of certain customary conditions precedent, but are not tied to any construction milestones. There are no hedges, offtake agreements or warrants required as part of this Credit Facility. The amounts borrowed under the Credit Facility are due December 31, 2024. The Company may voluntarily prepay amounts owing under the Credit Facility at any time, subject to a prepayment fee (4% before Year 1; 3% for Years 1 to 3; and 1.5% beyond Year 3). The Credit Facility has an availability period of up to 20 months if: (a) 50% or greater of the Credit Facility is drawn by August 31, 2021 (with the commitment to draw provided by June 30, 2021), and (b) 75% or greater of the Credit Facility is drawn by December 31, 2021. Interest under the Credit Facility is payable at a rate of 6.95% plus the greater of: (i) 3-month London Interbank Offered Rate (or agreed upon equivalent) and (ii) 1.5% and is payable quarterly, with a Company option to accrue during the availability period. Up to $30 million of the Credit Facility can be used for exploration and acquisitions within Sonora, Mexico.

3.3 Significant Acquisitions

The Company has not made any significant acquisitions since it became a reporting issuer.

4. DESCRIPTION OF BUSINESS

4.1 General

The Business of the Company

The Company is a Canadian precious metals exploration and development company that is focused on new discoveries and value-added acquisitions and targeting production in Mexico's historic precious metal districts.

The Company’s ongoing initiative is to increase its asset base by expanding current resources and reserves, acquiring and developing high-margin precious metal projects, and ultimately operating multiple silver-gold mines in the Americas.

For the majority of the last three fiscal years, the Company has been focused on the exploration program of Las Chispas. In 2020, the Company began development work at Las Chispas. For a summary of the activities at Las Chispas, see "General Development of the Business - Three Year History".

Specialized Skill and Knowledge

Most aspects of the Company's business require specialized skills and knowledge in geology, exploration, development, construction, mineral production, accounting and capital markets. The Company has a number of executive officers and employees with extensive experience in mining, geology, metallurgy, exploration and development in Mexico and other parts of North, Central and South America and elsewhere, as well as executive officers and employees with relevant accounting and capital markets experience.

Competitive Conditions

The Company competes with major mining companies and other smaller natural resource companies in the acquisition, exploration, financing and development of new properties and projects in North America. Many of these companies are more experienced, larger and have greater financial resources for, among other things, financing and the recruitment and retention of qualified personnel. See "Risk Factors".

Employees

As at the date hereof, the Company and its subsidiaries have an aggregate of approximately 19 full-time employees and contractors based in Canada and estimated 500 employees and contractors based in Sonora, Mexico. All management functions of the Company are performed by the executive officers of the Company, either directly or through their consulting companies.

Foreign Operations

The Company's activities are currently focused on the exploration and development of the Las Chispas property located in Sonora, Mexico, which exposes it to various levels of political, economic and other risks and uncertainties associated with operating in a foreign jurisdiction. Operating in Mexico, an emerging economy, has certain risks, including changes to or invalidation of government mining regulations; expropriation or revocation of land or property rights; changes in foreign ownership rights; changes in foreign taxation rates; corruption; uncertain political climate; terrorist actions or war; and lack of a stable economic climate. See "Risk Factors".

4.2 Risk Factors

The following factors are those which are the most applicable to the Company. The discussion which follows is not inclusive of all potential risks. Risk management is an ongoing exercise upon which the Company spends a substantial amount of time. While it is not possible to eliminate all of the risks inherent in the mining business, the Company strives to manage these risks to the greatest extent possible, to ensure that its assets are protected.

Activities of the Company may be impacted by the spread of COVID-19.

The Company's business could be adversely affected by the effects of the outbreak of respiratory illness caused by the novel coronavirus ("COVID-19"). Since early March 2020, several significant measures have been implemented in Canada, Mexico and the rest of the world by authorities in response to the increased impact from COVID-19. The Company cannot accurately predict the impact COVID-19 will have on the ability of third parties to meet their obligations with the Company, including due to uncertainties relating to the ultimate geographic spread of the virus, the severity of the disease, the duration of the outbreak, and the length of travel and quarantine restrictions imposed by governments of affected countries. In particular, the continued spread of COVID-19 globally and in Mexico could materially and adversely impact the Company's business including without limitation, employee health, limitations on travel, the availability of industry experts and personnel, delays in the construction schedule, restrictions on planned operations and other factors that depend on future developments beyond the Company's control. In addition, the significant outbreak of a contagious disease has resulted in a widespread health crisis that has adversely affected the economies and financial markets of many countries (including Canada and Mexico), resulting in an economic downturn that may negatively impact the Company's financial position, financial performance, and cash flows. While the impact of COVID-19 is expected to be temporary, the current circumstances are dynamic and the impacts of COVID-19 on the Company's exploration and development activities cannot be reasonably estimated at this time.

The Company has a history of losses and may not be able to generate sufficient revenue to be profitable or to generate positive cash flow on a sustained basis.

The Company has no history of revenue or earnings from operations. The Company is an exploration and development stage company and no cash flow or operating revenues are anticipated until one of the Company's projects comes into production, which may or may not occur. There can be no assurance that production at its Las Chispas Project will commence in H2, 2022 as planned. The Company has had negative cash flow since the date of its incorporation and is subject to many risks common to such enterprises, including possible undercapitalization, cash shortages, limitations with respect to personnel, financial and other resources, and lack of revenues. The Company expects to continue to expend substantial financial and other resources on exploration and development of Las Chispas. These investments may not result in revenue or growth in the business. If the Company cannot eventually earn revenue at a rate that exceeds the costs associated with its business, it will not be able to achieve or sustain profitability or generate positive cash flow on a sustained basis and its revenue growth rate may decline. There is no assurance that an investor will be successful in achieving a return on an investment in the Common Shares of the Company and the likelihood of success must be considered in light of its early stage of development. If the Company fails to eventually earn revenue, its business, results of operations, financial condition and prospects could be materially adversely affected.

There is no assurance that the Company's exploration and development programs and properties will result in the discovery, development or production of a commercially viable ore body or develop new resources.

The business of exploration for minerals and mining involves a high degree of risk. Few properties that are explored are ultimately developed into producing mines. At this time, apart from the mineral Resources and Reserves defined at Las Chispas, the Company does not have any properties with mineral resources.

The economics of developing silver, gold and other mineral properties are affected by many factors including capital and operating costs, variations of the tonnage and grade of ore mined, fluctuating mineral markets, and such other factors as government regulations, including regulations relating to royalties, allowable production, importing and exporting of minerals and environmental protection. Depending on the prices of silver, gold or other minerals produced, the Company may determine that it is impractical to commence or continue commercial production. Substantial expenditures are required to discover an ore-body, to establish reserves, to identify the appropriate metallurgical processes to extract metal from ore, and to develop the mining and processing facilities and infrastructure. The marketability of any minerals acquired or discovered may be affected by numerous factors which are beyond the Company's control and which cannot be accurately foreseen or predicted, such as market fluctuations, conditions for precious and base metals, the proximity and capacity of milling and smelting facilities, and such other factors as government regulations, including regulations relating to royalties, allowable production, importing and exporting minerals, and environmental protection. In order to commence exploitation of certain properties presently held under exploration concessions, it is necessary for the Company to apply for an exploitation concession. There can be no guarantee that such a concession will be granted. Unsuccessful exploration or development programs could have a material adverse impact on the Company's operations and profitability.

Mineral resource and mineral reserve estimates are based on interpretations and assumptions that may not be accurate.

There are numerous uncertainties inherent in estimating quantities of mineral resource and mineral reserve estimates and grades of mineralization, including many factors beyond the Company's control. In making determinations about whether to advance a project to development, mineral resources and grades of mineralization must be considered as estimates only. These estimates are imprecise and depend upon geological interpretation and statistical inferences drawn from drilling and sampling which may prove to be unreliable. Mineral resources, mineral reserves or other mineralization estimates may not be accurate.

Any material changes in mineral resource and mineral reserve estimates and grades of mineralization will affect the economic viability of placing a property into production and a property's return on capital. Estimates of mineral resource and mineral reserve estimates have been determined and valued based on assumed future prices, cut-off grades and operating costs that may prove to be inaccurate. Extended declines in market prices for gold, silver and other precious metals may render portions of the Company's resources uneconomic.

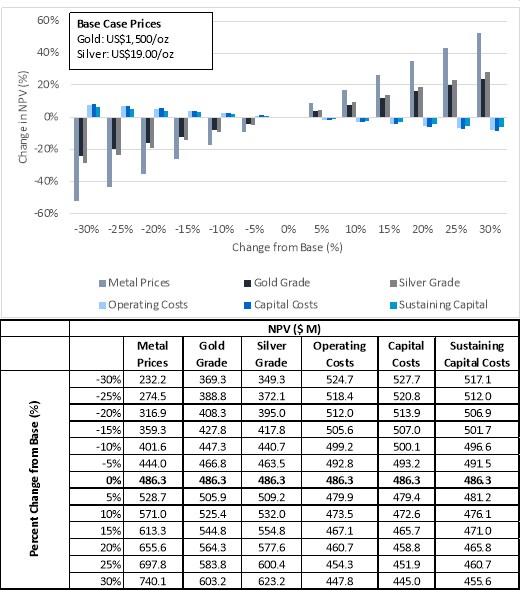

Uncertainties and Risks Relating to the Las Chispas Feasibility Study.

The Las Chispas Feasibility Study includes estimates of future production, development plans, operating costs and capital costs and other economic and technical estimates for Las Chispas. These estimates are based on a variety of factors and assumptions and there is no assurance that such production plans, costs or other estimates will be achieved. Actual production, costs and financial returns may vary significantly from the estimates depending on a variety of factors, many of which are not within the Company's control. Consequently, there is no certainty that the results set out in the Las Chispas Feasibility Study will be realized.

The Company may be involved in disputes related to its contractual interests in certain properties.

The Company is a party to agreements pursuant to which it may earn interests in certain properties. Title to such properties may be held in the names of parties other than the Company. Any of such properties may become the subject of an agreement which conflicts with the agreement pursuant to which the Company may earn its interest, in which case the Company may incur expenses in resolving any dispute relating to its interest in such property and such a dispute could result in the delay, indefinite postponement of further exploration and development of properties or the possible loss of such properties.

Enforcement of judgments against the Company or its officers or directors may be difficult.

The Company is organized under the laws of, and headquartered in, British Columbia, Canada and all of its officers are residents of Canada. Six of the seven directors are residents of Canada and one is a resident of Mexico. All of the Company's operating assets are located outside of Canada and the United States. As a result, it may be difficult for investors to enforce within Canada or the United States any judgments obtained against the Company or its officers or directors, including judgments predicated upon the civil liability provisions of applicable securities laws. In addition, there is uncertainty as to whether the courts of Mexico and other jurisdictions would recognize or enforce judgments of Canadian or United States courts obtained against the Company or its directors and officers predicated upon the civil liability provisions of the securities laws of Canada or the United States, or be competent to hear original actions brought in Mexico or other jurisdictions against the Company or its directors and officers predicated upon the securities laws of Canada or the United States. Further, any payments as a result of judgments obtained in Mexico would be in pesos and service of process in Mexico must be effectuated personally and not by mail.

The Company's operations are subject to extensive climate change, environmental, health and safety regulations.

The Company's operations are subject to extensive laws and regulations governing environmental protection and employee health and safety promulgated by governments and government agencies. Environmental regulation provides for restrictions on, and the prohibition of, spills and the release and emission of various substances related to mining industry operations which could result in environmental pollution.

Environmental laws and regulations are complex and have become more stringent over time. The Company is required to obtain governmental permits and in some instances air, water quality, waste disposal, hazardous substances and mine reclamation permits. Although the Company makes provisions for reclamation costs, it cannot be assured that these provisions will be adequate to discharge the Company's future obligations for these costs. Failure to comply with applicable environmental and health and safety laws may result in injunctions, damages, suspension or revocation of permits and imposition of penalties. Environmental regulation is evolving in a manner resulting in stricter standards and the enforcement of, and fines and penalties for, non-compliance are becoming more stringent. In addition, certain types of operations require environmental impact assessments. Environmental assessments of proposed projects carry a heightened degree of responsibility for companies and directors, officers and employees.

Climate change regulations may become more onerous over time as governments implement policies to further reduce carbon emissions, including the implementation of taxation regimes based on aggregate carbon emissions. Some of the costs associated with reducing emissions can be offset by increased energy efficiency and technological innovation. However, the cost of compliance with environmental regulation and changes in environmental regulation has the potential to result in increased costs of operations, reducing the potential profitability of the Company's future operations.

Due to increased global attention regarding the use of cyanide in mining operations, the regulations may be imposed restricting or prohibiting the use of cyanide and other hazardous substances in mineral processing activities. If such legislation were to be adopted in a region in which the Company relies on the use of cyanide, it would have a significant adverse impact on the Company's results of operations and financial condition as there are few, if any, substitutes for cyanide in extracting metals from certain types of ore.

While the Company intends to, fully comply with all applicable environmental regulations there can be no assurance that the Company has been or will at all times be in complete compliance with such laws, regulations and permits, or that the costs of complying with current and future environmental and health and safety laws and permits will not materially and adversely affect the Company's future business, results of operations or financial condition.

The Company's future success depends on its relationships with the communities in which it operates.

The Company's relationships with the communities in which the Company operates are critical to ensuring the future success of existing operations and the construction and development of future projects. There is an increasing level of public interest worldwide relating to the perceived effect of mining activities on the environment and on communities impacted by such activities. Certain non-governmental organizations ("NGOs"), some of which oppose globalization and resource development, are often vocal critics and attempt to interfere with the mining industry and its practices, including the use of cyanide and other hazardous substances in processing activities. Adverse publicity generated by such NGOs or others related to extractive industries generally, or their operations specifically, could have an adverse effect on the Company's reputation or financial condition and may impact the Company's relationship with the communities in which it operates. While the Company believes that it operates in a socially responsible manner, there is no guarantee that the Company's efforts in this respect will mitigate this potential risk.

Violence and other criminal activities in Mexico could have an adverse effect on the results and the financial condition of the Company.

Certain areas of Mexico have experienced outbreaks of localized violence, thefts, kidnappings and extortion associated with drug cartels and other criminal organizations in various regions. Any increase in the level of violence, or a concentration of violence in areas where the projects and properties of the Company are located, could have an adverse effect on the results and the financial condition of the Company.

The Company may not be able to complete acquisitions it pursues and any completed acquisitions or business arrangements may ultimately not benefit its business.

As part of the Company's business strategy, it has sought and will continue to seek new mining and development opportunities in the mining industry. In pursuit of such opportunities, it may fail to select appropriate acquisition candidates, negotiate appropriate acquisition terms, conduct sufficient due diligence to determine all related liabilities or to negotiate favourable financing terms. The Company may encounter difficulties in transitioning the business, including issues with the integration of the acquired businesses or its personnel into the Company. The Company cannot assure that it can complete any acquisition or business arrangement that it pursues, or is pursuing, on favourable terms, or that any acquisitions or business arrangements completed will ultimately benefit its business.

The mining industry is very competitive.

The Company competes with other exploration and production companies, many of which are better capitalized, have greater financial resources, operational experience and technical capabilities, or are further advanced in their development or are significantly larger and have access to greater mineral resources than the Company, for the acquisition of mineral claims, leases and other mineral interests as well as for the recruitment and retention of qualified employees and other personnel. If the Company is unsuccessful in acquiring additional mineral properties or qualified personnel, it may not be able to grow at the rate it desires, or at all.

The Company's competitors may be able to devote greater resources to the expansion and efficiency of their operations or respond more quickly to new laws and regulations or emerging technologies than the Company. The Company may not be able to compete successfully against current and future competitors, and any failure to do so could have a material adverse effect on the Company's business, financial condition or results of operations.

Reputational damage could adversely affect the Company's operations and profitability.

Damage to the Company's reputation can be the result of the actual or perceived occurrence of any number of events, and could include negative publicity (for example, with respect to the Company's handling of environmental matters or dealings with community groups). The increased use of social media and other web-based tools used to generate, publish and discuss user-generated content and to connect with other users has made it increasingly easier for individuals and groups to communicate and share opinions and views regarding the Company and its activities. The Company does not ultimately have direct control over how it is perceived by others and reputational damage could adversely affect the Company's operations and profitability.

Lack or delay of necessary infrastructure could adversely affect the Company's operations and profitability.

Mining, processing, development and exploration activities depend, to one degree or another, on adequate infrastructure. Reliable roads, bridges, power sources and water supply are important determinants, which affect capital and operating costs. The lack of availability on acceptable terms or the delay in the availability of any one or more of these items could prevent or delay exploration or development of the Company's projects. If adequate infrastructure is not available in a timely manner, there can be no assurance that the exploration or development of the Company's projects will be commenced or completed on a timely basis, if at all, that the resulting operations will achieve the anticipated production volume, or that the construction costs and ongoing operating costs associated with the exploration and/or development of the Company's projects will not be higher than anticipated. In addition, unusual or infrequent weather phenomena, sabotage, government or other interference in the maintenance or provision of such infrastructure could adversely affect the Company's operations and profitability.

The Company is subject to government regulation and failure to comply could have an adverse effect on the Company's operations.

The Company's operations, exploration and development activities are subject to extensive foreign federal, state and local laws and regulations governing such matters as environmental protection, management and use of toxic substances and explosives, management of natural resources, health, exploration and development of mines, production and post-closure reclamation, safety and labour, mining law reform, price controls, import and export laws, taxation, maintenance of claims, tenure, government royalties and expropriation of property. There is no assurance that future changes in such regulation, if any, will not adversely affect the Company's operations. The activities of the Company require licenses and permits from various governmental authorities.

The costs associated with compliance with these laws and regulations are substantial and possible future laws and regulations, changes to existing laws and regulations and more stringent enforcement of current laws and regulations by governmental authorities could cause additional expenses, capital expenditures, restrictions on or suspensions of the Company's operations and delays in the development of its properties. Moreover, these laws and regulations may allow governmental authorities and private parties to bring lawsuits based upon damages to property and injury to persons resulting from the environmental, health and safety practices of the Company's past and current operations, or possibly even those actions of parties from whom the Company acquired its mines or properties, and could lead to the imposition of substantial fines, penalties or other civil or criminal sanctions. The Company retains competent and well trained individuals and consultants in jurisdictions in which it does business; however, even with the application of considerable skill, the Company may inadvertently fail to comply with certain laws. Such events can lead to financial restatements, fines, penalties, and other material negative impacts on the Company.

The Company may not be successful in obtaining and renewing government permits.

In the ordinary course of business, the Company is required to obtain and renew government permits for the operation and expansion of existing operations or for the development, construction and commencement of new operations. Obtaining or renewing the necessary governmental permits is a complex and time-consuming process involving numerous jurisdictions and possibly involving public hearings and costly undertakings on the Company's part. The duration and success of the Company's efforts to obtain and renew permits are contingent upon many variables not within its control, including the interpretation of applicable requirements implemented by the permitting authority. The Company may not be able to obtain or renew permits that are necessary to its operations, or the cost to obtain or renew permits may exceed what the Company believes it can recover from a given property once in production. Any unexpected delays or costs associated with the permitting process could delay the development or impede the operation of a mine, which could adversely impact the Company's operations and profitability.

The Company's exploration and development activities are subject to foreign currency exchange fluctuations which could result in foreign exchange losses.

Exploration and development activities in Canada and Mexico are subject to foreign currency exchange fluctuations. The Company has raised majority of its funds through equity issues, which up to December 31, 2020, have been priced in Canadian dollars, cash flow from exploration activities is received in US dollars and the majority of the exploration and development costs of the Company are denominated in United States dollars or Mexican Pesos. The Company may suffer losses due to adverse foreign currency fluctuations.

Interest Rate and Credit Facility risk

In respect of financial assets, the Company's policy is to invest cash at floating rates of interest and cash reserves are to be maintained in cash equivalents in order to maintain liquidity. Fluctuations in interest rates impact the value of cash equivalents. The Credit Facility is subject to interest rate risk as amounts outstanding are subject to changes based on fluctuations in the LIBOR. Furthermore, the Company has only drawn down $30 million of the $120 million Credit Facility. Draw down of the balance is subject to the Company meeting draw down conditions. Failure to meet such conditions or the breach of certain covenants under the Credit Facility could result in the Company being unable to do further draw downs or triggering default provisions under the Credit Facility, requiring early repayment of the amounts drawn down.

The Company may not be successful in maintaining internal control over financial reporting.

The Company documents and tests its internal control procedures in order to maintain adequate internal control over our financial reporting and satisfy the requirements of applicable regulations, including Section 404 of the Sarbanes Oxley Act of 2002 (the "Sarbanes Oxley Act") in the United States. The Sarbanes Oxley Act requires, among other things, an annual assessment by management of the effectiveness of the Company's internal control over financial reporting. The Company may fail to maintain the adequacy of its internal control over financial reporting as such standards are modified, supplemented or amended from time to time, and management may not be able to conclude, on an ongoing basis, that the Company has effective internal control over financial reporting in accordance with applicable regulations. The Company's failure to satisfy the requirements of applicable regulations on an ongoing, timely basis could result in the loss of investor confidence in the reliability of the Company's financial statements which, in turn, could harm the Company's business and negatively impact the trading price or the market value of the Company's securities. In addition, any failure to implement required new or improved controls, or difficulties encountered in their implementation, could cause the Company to fail to meet its reporting obligations. Future acquisitions of companies, if any, may provide the Company with challenges in implementing the required processes, procedures and controls in the Company's acquired operations. No evaluation can provide complete assurance that the Company's internal control over financial reporting will detect or uncover all failures of persons within the Company to disclose material information otherwise required to be reported. The effectiveness of the Company's processes, procedures and controls could also be limited by simple errors or faulty judgments. In addition, as the Company expands, the challenges involved in implementing appropriate internal control over financial reporting will increase and will require the Company to continue to monitor its internal control over financial reporting. Although the Company intends to expend substantial time and incur substantial costs, as necessary, to ensure ongoing compliance, the Company cannot be certain that it will be successful.

The Company may be involved in litigation which may have a material adverse impact on the Company's operations and financial condition.

The Company is or may be subject to various claims and legal proceedings, including adverse rulings in current or future litigation against it or its directors or officers. The outcome of these claims may be subject to uncertainty and it is possible that some of these claims may be resolved unfavourably against the Company. The Company carries liability insurance coverage and establishes reserves for matters that are probable and can be reasonably estimated. In addition, the Company may be involved in disputes with other parties in the future that may result in litigation, which may have a material adverse impact on the Company's operations and financial condition.

The Company may use certain financial instruments that subject it to a number of inherent risks.

From time to time, the Company may use certain financial instruments to manage the risks associated with changes in gold and silver prices, interest rates and foreign currency exchange rates. The use of financial instruments involves certain inherent risks including, among other things: (i) credit risk, the risk of default on amounts owing to the Company by the counterparties with which Company has entered into such transaction; (ii) market liquidity risk, the risk that the Company has entered into a position that cannot be closed out quickly, either by liquidating such financial instrument or by establishing an offsetting position; (iii) unrealized mark-to-market risk, the risk that, in respect of certain financial instruments, an adverse change in market prices for commodities, currencies or interest rates will result in the Company incurring an unrealized mark-to-market loss in respect of such derivative products.

The Company may be unable to obtain adequate insurance to cover risks.

The Company's business is subject to a number of risks and hazards generally, including adverse environmental conditions, industrial accidents, labour disputes, unusual or unexpected geological conditions, ground or slope failures, cave ins, changes in the regulatory environment, natural phenomena such as inclement weather conditions, floods and earthquakes. Such occurrences could result in damage to mineral properties, personal injury or death, environmental damage to the Company's properties or the properties of others, delays in the ability to undertake exploration, monetary losses and possible legal liability.

The Company may also be unable to maintain insurance to cover these risks at economically feasible premiums. Insurance coverage may not continue to be available or may not be adequate to cover any resulting liability. Moreover, insurance against risks such as environmental pollution or other hazards as a result of exploration and production is not generally available to the Company or to other companies in the mining industry on acceptable terms. The Company might also become subject to liability for pollution or other hazards which it may not be insured against or which the Company may elect not to insure against because of premium costs or other reasons. Losses from these events may cause the Company to incur significant costs that could have a material adverse effect upon its financial performance and results of operations.

Loss of key personnel could materially affect the Company's operations and financial condition.

The Company depends on the business and technical expertise of a number of key personnel, including its directors and executive officers and key personnel working full-time in management and administrative capacities or as consultants. The number of persons skilled in the acquisition, exploration and development of mining properties is limited and competition for such persons is intense. As the Company's exploration and development activities expand, it will require additional key personnel. The Company does not maintain life insurance for such personnel. The loss of any key personnel, or the failure to retain such personnel, could have a material adverse effect on the Company's future operations and financial condition.

The Company may be subject to potential conflicts of interest with its directors and/or officers.

The directors and officers of the Company may serve as directors and/or officers of other public and private companies, and may devote a portion of their time to manage other business interests. This may result in certain conflicts of interest.

To the extent that such other companies may participate in ventures in which the Company is also participating, such directors and officers of the Company may have a conflict of interest. The laws of British Columbia, Canada, require the directors and officers to act honestly, in good faith, and in the best interests of the Company and its shareholders. However, in conflict of interest situations, directors and officers of the Company may owe the same duty to another company and will need to balance the competing obligations and liabilities of their actions.

The Company may not be able to acquire surface rights to its mineral concessions.

A mineral concession in Mexico does not confer any ownership of surface rights. The majority of the Company's mineral properties are located in remote and relatively uninhabited areas. There are currently no areas of interest within the Company's mineral concessions that are overlain by significant habitation or industrial users, however there are potential overlapping surface usage issues in some areas. Some surface rights are owned by local communities or "Ejidos", and some surface rights are owned by private ranching or residential interests. The Company will be required to negotiate the acquisition of surface rights in those areas where it may wish to develop mining operations. The Company's mineral interests are located on community or private land, and it is necessary to deal with the owners for access and any potential development or exploitation rights. There can be no assurance that the Company will be able to negotiate and acquire surface access rights on terms acceptable to the Company or at all.

There are differences in US and Canadian reporting of mineral resources so that information may not be comparable.

The Company's mineral resource estimates are not directly comparable to those made in filings pursuant to SEC Industry Guide 7 under the United States Securities Act of 1933, as amended, as the Company generally reports mineral resources in accordance with Canadian practices. These practices are different from those used to report mineral resource estimates in reports and other materials filed pursuant to SEC Industry Guide 7. It is Canadian practice to report Measured, Indicated and Inferred resources, which historically has not been permitted in disclosure filed in accordance with SEC Industry Guide 7 by United States issuers. Under SEC Industry Guide 7, historically, mineralization was not classified as a "reserve" unless the determination has been made that the mineralization could be economically and legally produced or extracted at the time the reserve determination is made. United States investors are cautioned not to assume that all or any part of measured or indicated resources will ever be converted into reserves.

Further, "inferred mineral resources" have a great amount of uncertainty as to their existence and as to whether they can be mined legally or economically. Disclosure of "contained ounces" is permitted disclosure under Canadian regulations; however, SEC Industry Guide 7 historically has only permitted issuers to report mineralization that does not constitute "reserves" as in-place tonnage and grade without reference to unit of metal measures.

Accordingly, information concerning descriptions of mineralization, reserves and resources contained in this Annual Information Form, or in the documents incorporated herein by reference, may not be comparable to information made public by United States companies pursuant to SEC Industry Guide 7.

The Company could be subject to indirect anti-corruption and anti-bribery enforcement proceedings that could adversely affect the Company.

The Company's operations are governed by, and involve interactions with, various levels of government in foreign countries. The Company is required to comply with anti‐corruption and anti‐bribery laws, including the Corruption of Foreign Public Officials Act (Canada) and the Foreign Corrupt Practices Act (US) and similar laws in México. In recent years, there has been a general increase in both the frequency of enforcement and the severity of penalties under such laws, resulting in greater scrutiny and punishment to companies convicted of violating anti‐corruption and anti‐bribery laws. A company may be found liable for violations by not only its employees, but also by its contractors and third party agents. The Company's internal procedures and programs may not always be effective in ensuring that it, its employees, contractors or third party agents will comply strictly with all such applicable laws. If the Company becomes subject to an enforcement action or is found to be in violation of such laws, this may have a material adverse effect on the Company's reputation, result in significant penalties or sanctions, and have a material adverse effect on the Company's operations.

Any enforcement proceedings under Canada's Extractive Sector Transparency Measures Act against the Company could adversely affect the Company.

The Extractive Sector Transparency Measures Act (Canada) ("ESTMA") requires public disclosure of certain payments to governments by companies engaged in the commercial development of minerals which are publicly listed in Canada. Mandatory annual reporting is required for extractive companies with respect to payments made to foreign and domestic governments, including aboriginal groups. ESTMA requires reporting on the payments of any taxes, royalties, fees, production entitlements, bonuses, dividends, infrastructure reporting or structuring payments to avoid reporting. If the Company becomes subject to an enforcement action or is in violation of ESTMA, this may result in significant penalties or sanctions which may also have a material adverse effect on the Company's reputation.

Security breaches of the Company's information systems could adversely affect the Company.

The Company's operations depend, in part, upon information technology systems. The Company's information technology systems are subject to disruption, damage or failure from a number of sources, including, but not limited to, hacking, computer viruses, security breaches, natural disasters, power loss, vandalism, theft and defects in design. Any of these and other events could result in information technology systems failures, operational delays, production downtimes, destruction or corruption of data, security breaches or other manipulation or improper use of our data, systems and networks, any of which could have adverse effects on our reputation, business, results of operations, financial condition and share price.

The Company's risk and exposure to these matters cannot be fully mitigated because of, among other things, the evolving nature of these threats. As a result, cyber security and the continued development and enhancement of controls, processes and practices designed to protect our systems, computers, software, data and networks from attack, damage or unauthorized access remain a priority. As cyber threats continue to evolve, the Company may be required to expend additional resources to continue to modify or enhance protective measures or to investigate and remediate any security vulnerabilities.

Human Rights Matters

Various international and national laws, codes, resolutions, conventions, guidelines and other provisions governing human rights impose obligations on government and companies to respect human rights.

The obligations of government and private entities under the various international and national provisions pertaining to human rights continue to evolve and be defined. One or more groups of people may oppose the Company’s current and future operations on human rights grounds. Such opposition may be directed through legal or administrative proceedings or expressed in manifestations such as protests, roadblocks or other forms of public expression against the Company’s activities, may have a negative impact on the Company’s reputation and have a material adverse effect on the Company’s business.

4.3 Environmental and Social Sustainability

General

The Company is committed to conducting business in a socially and environmentally responsible manner and meeting or surpassing regulatory requirements in all its exploration, development, mining and closure activities. SilverCrest’s commitment not only stems from the Company’s acknowledgement of the significant impacts that extractive mining activities can have on both host communities and the local environment, but also the changing risk landscape that requires the Company to adapt to emerging threats to protect employees, contractors, suppliers, communities, the environment and all corporate assets.

SilverCrest is committed to balancing all our stakeholders' interests in order to maintain competitiveness and business resilience. In 2020 the Company developed an ESG strategy. This strategy formalizes the Company’s commitment and will inform business decisions to ensure sustainable future operations. The ESG strategy will continue to be refined and integrated into all levels of the Company during 2021, as SilverCrest moves closer towards production. The Company continues to be actively engaged with local communities with COVID-19 educational and support projects, as well as through the non-profit Impulso Korea Foundation. More details on the ESG strategy and the Company’s commitments are listed in the below sections.

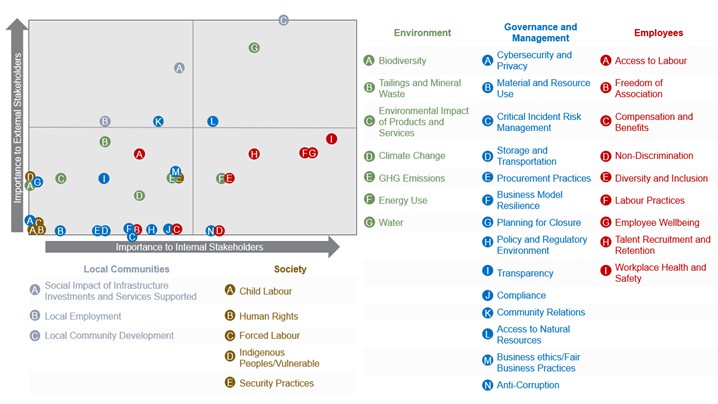

Materiality Assessment

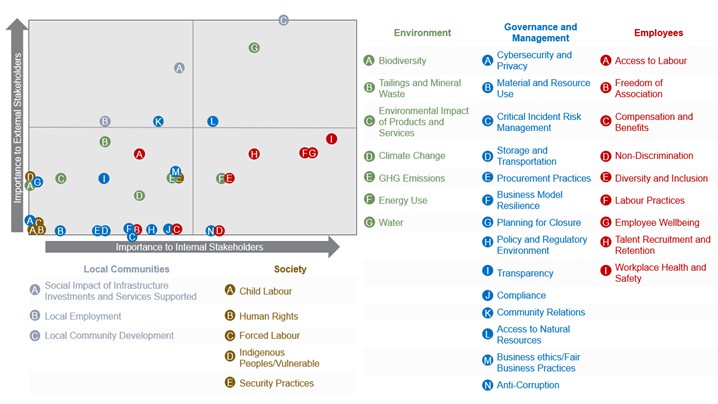

To build a stakeholder aligned ESG strategy, the Company engaged third-party consultants to conduct an in-depth materiality assessment with its consultants. A materiality assessment is the process of identifying, refining, and assessing the most material environmental, social and governance issues that could affect the Company and/or stakeholders. The short-list of material issues informs strategy, targets, and reporting. All issues included in the materiality assessment were deemed to be important by stakeholders. The materiality assessment matrix shown below displays these top issues and their importance in relative terms.

The results from the Company’s materiality assessment formulated SilverCrest’s ESG Strategy Framework.

ESG Strategy Framework

Based on the key issues identified by the materiality assessment, SilverCrest and its third-party consultants developed an ESG Strategy Framework. There are five pillars upon which the ESG strategy is based: Environment, Social Capital, Human Capital, Leadership & Governance and Business Resilience. Corporate commitments under each pillar are outlined in the graphic below.

Within each pillar the Company identified focus areas. There are 23 focus areas across the five pillars that have performance measures associated with them to allow the Company to measure the process over time and optimize the corporate and operational performance. Given SilverCrest is in development stage, data for some performance measures is not yet available. These performance measures, however, are being identified in advance of production to allow for data collection as soon as required. In order to integrate environmental and social risk management into the culture of the organization, the Company has allocated 20% of its total 2021 corporate key performance indicators ("KPIs") towards sustainability factors. Focus areas for each pillar are listed in the graphic below.

In 2020, the Company prioritized three key pillars of our strategy: Human Capital, Social Capital, and Business Resilience. This reflects SilverCrest’s desire to engage the Company’s stakeholders to understand core ESG issues and to build an ESG strategy that strengthens corporate risk management practices and prepares the Company for efficient and safe operations in advance of production. Moreover, the COVID-10 pandemic required SilverCrest to focus intensely on addressing the health and well being of the Company’s employees, contractors, and community members.

The following are some highlights from our 2020 ESG investments.

• Human Capital – A significant focus for SilverCrest is ensuring a safe and healthy working environment for employees, contractors, and community, and even more so in 2020 given the emergence of COVID-19. The Company is proud to have achieved no lost time injuries (LTI) or fatalities in 2020.

In response to the global pandemic, SilverCrest implemented numerous site and travel protocols, a comprehensive testing program, and invested in an on-site isolated construction camp. SilverCrest also put a number of safety systems in place during 2020 with certifications expected in 2021.

• Social Capital – SilverCrest continued to invest in its strong relationships with the communities in which it operates throughout 2020. A major focus was supporting the local communities of Arizpe and Banamichi in addressing the challenges of COVID-19. Among other efforts, this included providing health care supplies and services, installing sinks and sanitization liquids throughout the communities, providing personal protective equipment such as face masks, and providing COVID-19 tests and medication.

• Business Resilience – The completion of a materiality assessment and development of an ESG Strategy Framework were significant achievements in 2020 to ensure the resiliency of the Company’s business. In further support of this pillar, the Company remained well capitalized to execute its goals through completion of $105.2 million in equity financings and a $120 million debt financing.

For details on environmental and social impacts from planned operations, please refer to section 4.4.1 Las Chispas Project.

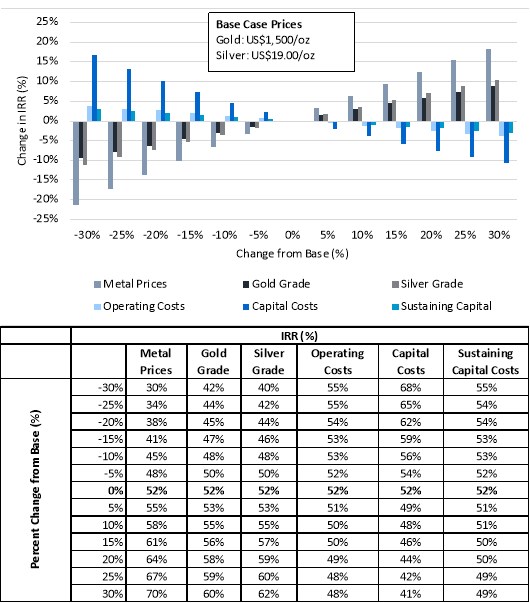

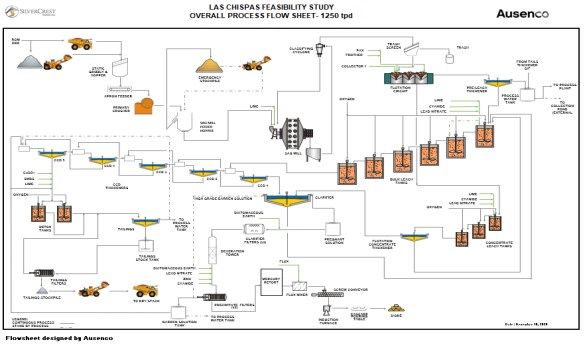

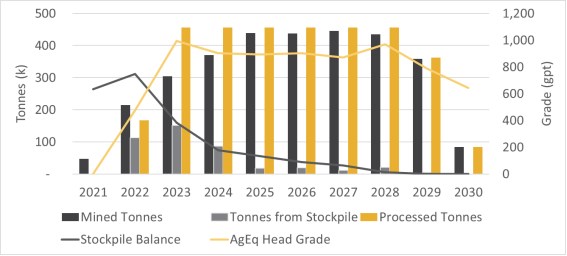

ESG Governance Structure