Exhibit 99.1

KULR Technology Group, Inc. OTCQB: KULR ԙ Investor Presentation ԙ July 2019 “Making the World of Electronics Cooler, Lighter & Safer”

OTCQB: KULR | 2 Forward Looking Statements Safe Harbor This presentation and other written or oral statements made from time to time by representatives of KULR Technology Group, In c. and/or its wholly owned subsidiary KULR Technology Corporation contain “forward - looking statements” within the meaning of Section 27A of the Securities Act of 1933 , as amended, and Section 21E of the Securities Exchange Act of 1934. Forward - looking statements reflect the current view about future events. Statements that are not historical in nature, such as our revenue forecast, and which may be identified by the use of words like “expects,” “assumes,” “projects,” “anticipates,” “ est imates,” “we believe,” “could be,” "future" or the negative of these terms and other words of similar meaning, are forward - looking statements. Such statements inc lude, but are not limited to, statements contained in this presentation relating to our expected sales, cash flows and financial performance, business, bus ine ss strategy, expansion, growth, products and services we may offer in the future and the timing of their development, sales and marketing strategy and capita l o utlook. Forward - looking statements are based on management’s current expectations and assumptions regarding our business, the economy and other future condition s a nd are subject to inherent risks, uncertainties and changes of circumstances that are difficult to predict and may cause actual results to differ materially fr om those contemplated or expressed. We caution you therefore against relying on any of these forward - looking statements. These risks and uncertainties include those r isk factors discussed in Part I, “Item 1A. Risk Factors” of our Annual Report on Form 10 - K or other filings we filed with the U.S. Securities Exchange Commission (the “Pub lic Reports”). Any forward - looking statements are qualified in their entirety by reference to the factors discussed in the Public Reports. Should one or more o f t hese risks or uncertainties materialize, or should the underlying assumptions prove incorrect, actual results may differ significantly from those anticipated, believed, est imated, expected, intended or planned. Important factors that could cause actual results to differ materially from those in the forward looking statements include: a d ecline in general economic conditions nationally and internationally; decreased demand for our products and services; market acceptance of our products; the abilit y t o protect our intellectual property rights; impact of any litigation or infringement actions brought against us; competition from other providers and products; r isk s in product development; inability to raise capital to fund continuing operations; changes in government regulation, the ability to complete customer transactions and capital raising transactions. Factors or events that could cause our actual results to differ may emerge from time to time, and it is not possible for us t o p redict all of them. We cannot guarantee future results, levels of activity, performance or achievements. Except as required by applicable law, including the securit ies laws of the United States, we do not intend to update any of the forward - looking statements to conform these statements to actual results. Forecasts All forecasts are provided by management in this presentation and are based on information available to us at this time and m ana gement expects that internal projections and expectations may change over time. In addition, the forecasts are entirely on management’s best estimate of our future financial performance given our current contracts, current backlog of opportunities and conversations with new and existing customers about our products. Reference Material This overview is delivered solely as reference material with respect to our company. This document shall not constitute an of fer to sell or the solicitation of an offer to buy securities in our company in any jurisdiction. The information herein is based on data obtained from sources believed to be reliable. Although we believe that the sources are reliable, we have not independently verified such data. The trademarks included herein are the property of the ow ner s thereof and are used for reference purposes only. © KULR Technology Group, Inc. – 2019. All Rights Reserved.

OTCQB: KULR | 3 KULR Technology Group Overview KULR Technology Group (OTCQB: KUTG) Share Price 1 $1.70 Market Cap 1 $136.2M Revenues (TTM) 2 $1.2M Gross Margin (TTM) 2 80.0% Debt 1 $0.0M Patents Portfolio 3 14 Shares O/S 1 80.1M Fully Diluted Shares O/S 1 81.9M Float 3.7M Customer Engagements 1 25 Headquarters Campbell, CA Employees 1 18 Insider Ownership 1 51.0% ▪ KULR Technology Group (KULR) is a disruptive developer, manufacturer & licensor of proprietary carbon fiber thermal management technologies that help make electronics & battery systems cooler, lighter & safer ▪ Technology with roots in electronic cooling solutions for NASA space missions & transitioning into mass market commercialization. Key target markets include: • Electric Mobility (e.g. Electric Vehicles & Transportation) • Battery Safety and Testing (e.g. Battery pack design & testing) • Consumer Products and Cloud Computing (e.g. IoT & Servers) • Aerospace (e.g. Space/Aircrafts) ▪ Attractive & scalable business model with high gross margins (80.0%) 2 ▪ Robust patent portfolio & 25 customer engagements across several industries ▪ Experienced management team with high insider ownership (+51%) 1) As of July 22, 2019. 2) TTM = Trailing twelve months ended March 31, 2019. 3) Patent portfolio includes granted, licensed and pending IP. Sample Customers

OTCQB: KULR | 4 Proven Core Technology ▪ Our proprietary, core technology is a carbon fiber material that provides superior thermal conductivity & heat dissipation in an ultra - lightweight and pliable material ▪ KULR’s technology can be seen in countless NASA & aerospace projects, including the International Space Station, the Mars Rover & several classified technologies ▪ Efficacy of KULR’s proprietary, patented technology proven out through engagements with tier - 1 aerospace operators, including: KULR Technology Usage: PCM Heat Sink (2020) Mars Rover NICER Heat Sink (2017) Int’l Space Station “To date, NASA has not found a design solution with as much promise for preventing Li - ion battery thermal runaway propagation, with as positive temperature margins on the adjacent cells, while also being very lightweight ( as KULR’s HYDRA TRS ) . ” - Dr. Eric Darcy, NASA Battery Systems Lead (Space Tech Expo 2017)

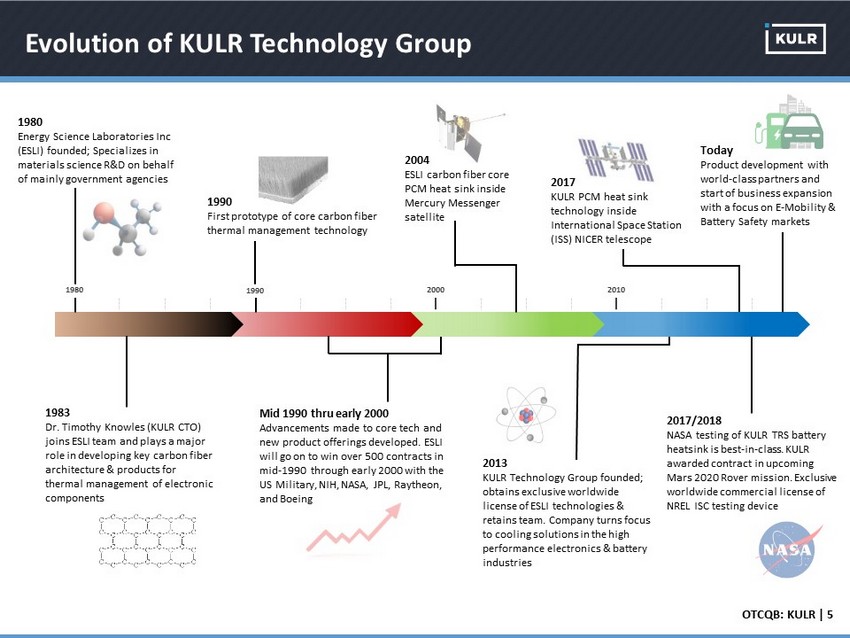

OTCQB: KULR | 5 Evolution of KULR Technology Group 1980 1980 Energy Science Laboratories Inc (ESLI) founded; Specializes in materials science R&D on behalf of mainly government agencies 1983 Dr. Timothy Knowles (KULR CTO) joins ESLI team and plays a major role in developing key carbon fiber architecture & products for thermal management of electronic components 1990 1990 First prototype of core carbon fiber thermal management technology 2000 Mid 1990 thru early 2000 Advancements made to core tech and new product offerings developed. ESLI will go on to win over 500 contracts in mid - 1990 through early 2000 with the US Military, NIH, NASA, JPL, Raytheon, and Boeing 2004 ESLI carbon fiber core PCM heat sink inside Mercury Messenger satellite 2010 2013 KULR Technology Group founded; obtains exclusive worldwide license of ESLI technologies & retains team. Company turns focus to cooling solutions in the high performance electronics & battery industries 2017 KULR PCM heat sink technology inside International Space Station (ISS) NICER telescope Today Product development with world - class partners and start of business expansion with a focus on E - Mobility & Battery Safety markets 2017/2018 NASA testing of KULR TRS battery heatsink is best - in - class. KULR awarded contract in upcoming Mars 2020 Rover mission. Exclusive worldwide commercial license of NREL ISC testing device

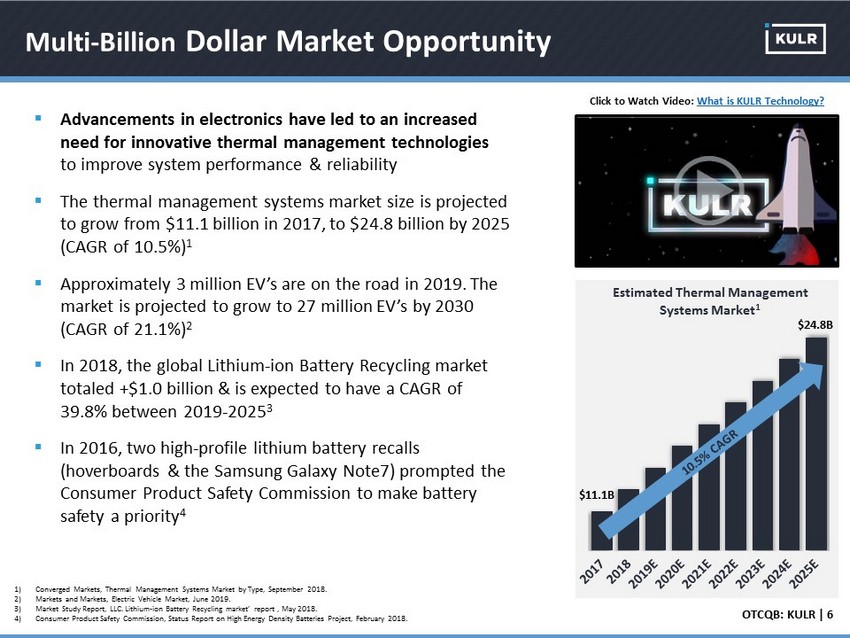

OTCQB: KULR | 6 Multi - Billion Dollar Market Opportunity Click to Watch Video: What is KULR Technology? ▪ Advancements in electronics have led to an increased need for innovative thermal management technologies to improve system performance & reliability ▪ The thermal management systems market size is projected to grow from $11.1 billion in 2017, to $24.8 billion by 2025 (CAGR of 10.5%) 1 ▪ Approximately 3 million EV’s are on the road in 2019. The market is projected to grow to 27 million EV’s by 2030 (CAGR of 21.1%) 2 ▪ In 2018, the global Lithium - ion Battery Recycling market totaled +$1.0 billion & is expected to have a CAGR of 39.8% between 2019 - 2025 3 ▪ In 2016, two high - profile lithium battery recalls (hoverboards & the Samsung Galaxy Note7) prompted the Consumer Product Safety Commission to make battery safety a priority 4 $11.1B $24.8B Estimated Thermal Management Systems Market 1 1) Converged Markets, Thermal Management Systems Market by Type, September 2018. 2) Markets and Markets, Electric Vehicle Market, June 2019. 3) Market Study Report, LLC. Lithium - ion Battery Recycling market’ report , May 2018. 4) Consumer Product Safety Commission, Status Report on High Energy Density Batteries Project, February 2018.

OTCQB: KULR | 7 Key Market: Li - ion Battery Safety ▪ Lithium - ion batteries (LiBs) have a high energy density & as a result are inherently dangerous ▪ Modern electronics have high energy consumption, generating excess heat which impairs performance & shortens the life of the products/battery systems ▪ Safety issues surrounding LiBs attracts significant media, legal and consumer attention, prompting an OEM response ▪ Public safety concerns have driven urgent OEM interest in improving battery management systems ▪ KULR’s thermal management technology is a natural fit for consumer technologies and is currently being tested by 25 companies for implementation into next - gen technologies across several industries, including: “Tesla and NIO Fires in China Spur Electric Car Safety Checkups” – June 2019, Bloomberg “Apple recalls older 15 - inch MacBook Pros because the batteries could catch fire” – June 2019, The Verge “Man badly burned after vape battery explodes in his pocket at work” - June 2019, Fox News Los Angeles • Electric Vehicles • Consumer Electronics • Battery Storage & Shipping • Aerospace • Cloud Computing Pictured Above: Tesla after battery exploded (left) and standard 18650 lithium - ion battery exploding (right).

OTCQB: KULR | 8 Key Market: Battery Storage & Shipping ▪ Through our work with NASA/Leidos for the International Space Station (ISS), we’ve developed the most efficient & high - performance materials to safely store/ship lithium - ion batteries ▪ We are now bringing this technology to commercial markets , such as recycled batteries, recalled batteries, used battery shipments & shipment of all battery powered CE products ▪ FAA recently reported incidents at an increasing rate involving shipment of lithium batteries that created smoke, fire, extreme heat or explosion 1 • Reported Incidents (FY 2019): 49 • Reported Incidents (through May 22, 2019): 19 ▪ We will also work with auto OEMs to modularize their battery pack for cost effective storage & shipment in aftermarket services. This is a key (and often overlooked) area that will have big impact on the economics of EVs. 1) FAA Office of Security and Hazardous Materials Safety, May 2019. “Phone battery pack suspected cause of fire on Virgin Atlantic plane diverted to Boston” – July 2019, USA Today “US bars lithium batteries as cargo on passenger aircrafts” – February 2019, CNBC “No One is Fixing Flying's Fire Problem” - August 2018, Popular Mechanic Pictured Above: UPS Flight Catches Fire After Lithium - Ion Battery Explosion

OTCQB: KULR | 9 KULR’s Safety Platform – Addressing a Key Problem KULR Safety Platform Standard EV Cooling Passive Materials Solution ISC Safety Testing Exclusive NASA ISC testing Nail, overheating, overcharge None Battery Calorimetry Partnership with NASA None Thermal Runaway Propagation Mitigation Patented HYDRA TRS solution. Completely passive. Can integrate with other active solutions Mostly active solutions with liquid or air Passive high - temperature insulating materials Battery Enclosure Protection Integrated HYDRA TRS + High Temperature material for total solution Aluminum and composite enclosure High - temperature insulating materials. NASA Battery enclosure shows it's not efficient Fast Charge Thermal Management Passive PCM Solution Liquid and Active cooling PCM solution Storage & Shipping Solution HYDRA TRS bag for DOT specialty permit. Lightweight & cost effective Third - party solution Metal drum enclosure for 100Wh+ battery KULR Provides The Most Compressive Lithium - Ion Safety & Thermal Management Solutions, From Testing to Shipping

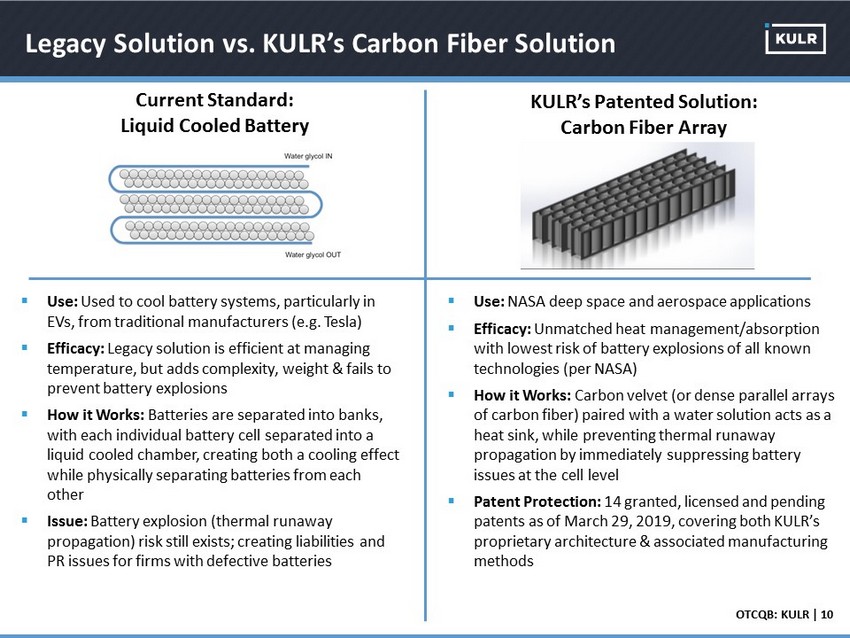

OTCQB: KULR | 10 Legacy Solution vs. KULR’s Carbon Fiber Solution ▪ Use: Used to cool battery systems, particularly in EVs, from traditional manufacturers (e.g. Tesla) ▪ Efficacy: Legacy solution is efficient at managing temperature, but adds complexity, weight & fails to prevent battery explosions ▪ How it Works: Batteries are separated into banks, with each individual battery cell separated into a liquid cooled chamber, creating both a cooling effect while physically separating batteries from each other ▪ Issue: Battery explosion (thermal runaway propagation) risk still exists; creating liabilities and PR issues for firms with defective batteries Current Standard: Liquid Cooled Battery KULR’s Patented Solution: Carbon Fiber Array ▪ Use: NASA deep space and aerospace applications ▪ Efficacy: Unmatched heat management/absorption with lowest risk of battery explosions of all known technologies (per NASA) ▪ How it Works: Carbon velvet (or dense parallel arrays of carbon fiber) paired with a water solution acts as a heat sink, while preventing thermal runaway propagation by immediately suppressing battery issues at the cell level ▪ Patent Protection: 14 granted, licensed and pending patents as of March 29, 2019, covering both KULR’s proprietary architecture & associated manufacturing methods

OTCQB: KULR | 11 KULR’s Thermal Management Product Line Applying Space Proven Technologies to Transform eMobility, Consumer Electronics & Aerospace Industries HYDRA Thermal Runaway Shield (TRS) ▪ URSA products are high performance, flexible thermally conductive materials that will increase contact between two irregular surfaces and limit the loss of heat conduction across the surfaces ▪ Increases overall product performance and reliability and reduces manufacturing costs ▪ Carbon - fiber infused heat sink used to absorb/provide heat and eliminates the need for active cooling ▪ ARA is useful for compact and high - performance devices that require bursts of power in short intervals, such as batteries in space, high power lasers and RF components ▪ Exclusive commercialization partner of NREL and NASA ▪ Testing tool for battery manufacturers used to analyze and identify failure modes in rechargeable batteries ▪ Provides the industry with a safe and reliable way to test and ultimately create a better battery pack ▪ Used in aerospace, defense customers and electric vehicle applications ▪ Offers a safe and reliable, light - weight battery management solution which prevents lithium - ion batteries from overheating and combusting ▪ Reduces risk of battery combustion for consumers, significantly limiting legal liability for OEMs ARA Thermal Capacitor – PCM heat sink URSA Fiber Thermal Interface (FTI) Material LYRA Internal Short Circuit (ISC) Trigger Cell

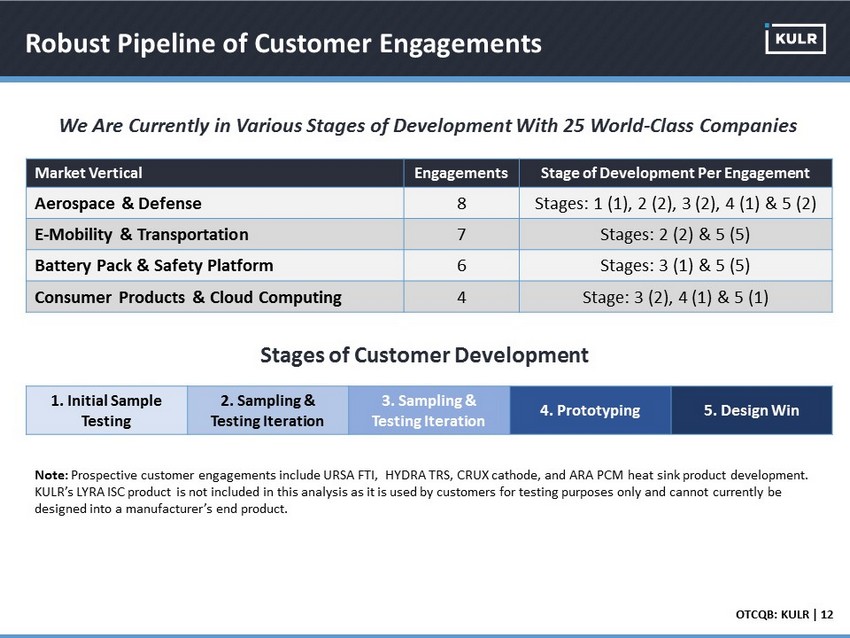

OTCQB: KULR | 12 Robust Pipeline of Customer Engagements We Are Currently in Various Stages of Development With 25 World - Class Companies 1. Initial Sample Testing 2. Sampling & Testing Iteration 3. Sampling & Testing Iteration 4. Prototyping 5. Design Win Market Vertical Engagements Stage of Development Per Engagement Aerospace & Defense 8 Stages: 1 (1), 2 (2), 3 (2), 4 (1) & 5 (2) E - Mobility & Transportation 7 Stages: 2 (2) & 5 (5) Battery Pack & Safety Platform 6 Stages: 3 (1) & 5 (5) Consumer Products & Cloud Computing 4 Stage: 3 (2), 4 (1) & 5 (1) Stages of Customer Development Note: Prospective customer engagements include URSA FTI, HYDRA TRS, CRUX cathode, and ARA PCM heat sink product development. KULR’s LYRA ISC product is not included in this analysis as it is used by customers for testing purposes only and cannot curr ent ly be designed into a manufacturer’s end product.

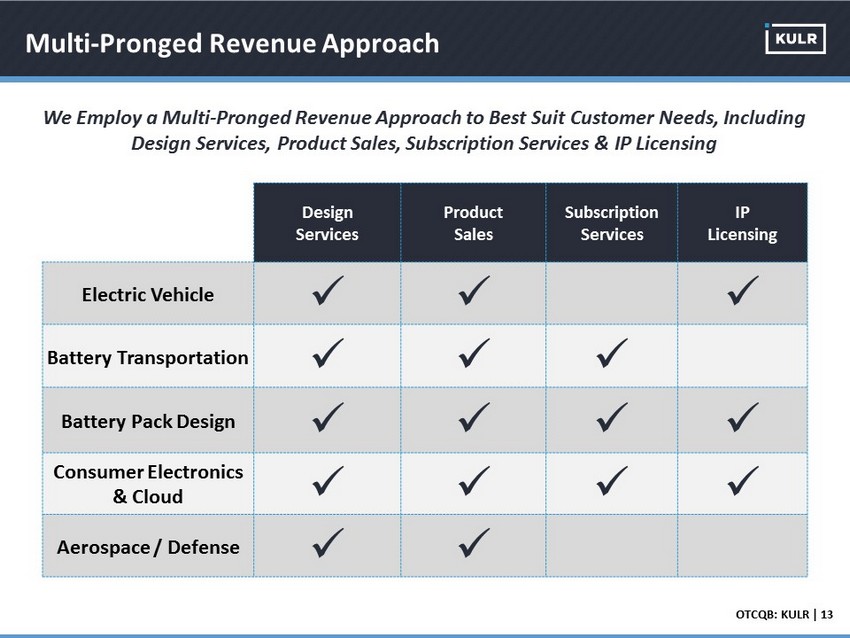

OTCQB: KULR | 13 Multi - Pronged Revenue Approach Design Services Product Sales Subscription Services IP Licensing Electric Vehicle x x x Battery Transportation x x x Battery Pack Design x x x x Consumer Electronics & Cloud x x x x Aerospace / Defense x x We Employ a Multi - Pronged Revenue Approach to Best Suit Customer Needs, Including Design Services, Product Sales, Subscription Services & IP Licensing

OTCQB: KULR | 14 Strong Patent Protecti on ▪ KULR maintains a strong intellectual property portfolio, consisting of: • 4 patents granted • 4 licensed patents • 6 pending patents • Trade secrets ▪ IP encompasses proprietary material architecture & the underlying manufacturing methods Robust IP Portfolio Patent Number Type US 10147921 Granted US 6913075 Granted US 7132161 Granted US 7144624 Granted US 9142829 Licensed 60 2010 042 606.8 Licensed EP [FR] 2 633 585 Licensed EP [GB] 2 633 585 Licensed

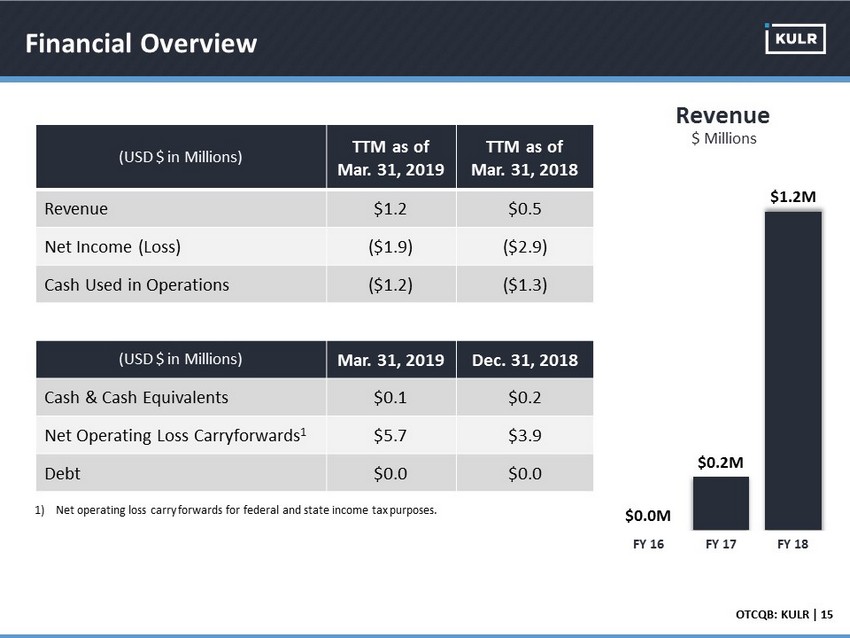

OTCQB: KULR | 15 Financial Overview $0.0M $0.2M $1.2M FY 16 FY 17 FY 18 Revenue $ Millions (USD $ in Millions) TTM as of Mar. 31, 2019 TTM as of Mar. 31, 2018 Revenue $1.2 $0.5 Net Income (L oss) ($1.9) ($2.9) Cash Used in Operations ($1.2) ($1.3) (USD $ in Millions) Mar. 31, 2019 Dec. 31, 2018 Cash & Cash Equivalents $0.1 $0.2 Net Operating Loss Carryforwards 1 $5.7 $3.9 Debt $0.0 $0.0 1) Net operating loss carry forwards for federal and state income tax purposes.

OTCQB: KULR | 16 Management Team KULR Technology Group, Inc. ( OTCQB: KUTG) – Q2’ 2019 ▪ Family co - founded IC software simulation company, Epic Design Technology (acquired by Synopsis for $427M in 1997) ▪ Co - founded Sympeer Technology in 2005 (acquired by Amlogic in 2007) ▪ Managed OTT product line with majority market share of China's OTT - STB market ▪ Established business relationships with high profile tech leaders in the U.S. and China ▪ Earned a MS in Electrical Engineering from UC Santa Barbara ▪ 30+ years of thermal management R&D experience having performed work on some of the most challenging aerospace & industrial applications ▪ Led team that built the X - 38 battery heat sink, Mercury Messenger PCM heat sink, NICER telescope PCM heat sink, and Mars Rover battery enclosure ▪ Conceived and developed KULR's proprietary Carbon Fiber Cooling solutions and was awarded hundreds of contracts from numerous customers including NASA, JPL, Raytheon, and Boeing ▪ Earned a Ph.D. in Physics from UC San Diego ▪ Founded and served as an officer of Aargo , Inc, a company specializing in financial consulting services to corporations in various tech related industries ▪ Served as CFO of Amber Network and Sage, Inc. (Nasdaq: SAGI) ▪ Held senior financial positions at Creative Technology (Nasdaq: CREAF) and Atari (AMEX: ATC) ▪ Multiple initial and secondary public offerings and public and private M&A transactions ▪ Master of Economics from Trinity College, Cambridge University ▪ Former Director of PCM Heat Sink Group and Safety Officer for Energy Science Laboratories Inc. ▪ Served as Quality Manager and Facility Security Officer in the Defense Industrial Security Program from 1988 to 1995 ▪ Earned a B.S. in Applied Mechanics from UC San Diego Michael Mo Chief Executive Officer Simon Westbrook Chief Financial Officer Dr. Timothy Knowles Chief Technology Officer Michael Carpenter VP of Engineering

OTCQB: KULR | 17 Key Takeaways ▪ We are a disruptive developer, manufacturer & licensor of proprietary carbon fiber thermal management technologies that help make electronics & battery systems cooler, lighter & safer ▪ Transitioning from niche space projects with tier - 1 customers to mass market commercialization targeting the consumer electronics, EV and aerospace industries ▪ KULR’s proven thermal management solutions can: • Reduce the risk of battery explosions • Extend the life of lithium - ion batteries • Increase product performance ▪ Attractive & scalable business model with high gross margins (80.0%) 1 ▪ Robust patent portfolio & 25 customer engagements across several industries ▪ Experienced management team with deep industry relationships & high insider ownership (+51%) 1) Trailing twelve months ended March 31, 2019. Pictured Above: KULR Carbon Fiber Array

OTCQB: KULR | 18 Contact Us KULR Technology Group, Inc. www.kulrtechnology.com 1999 S. Bascom Ave. Suite 700 Campbell, California Company Contact: Mario de Souza Director of Corporate Development KULR Technology Main: 408 - 675 - 7002 x110 mario.desouza@kulrtechnology.com www.kulrtechnology.com Investor Relations Contact: Greg Falesnik Managing Director MZ North America Main: 949 - 385 - 6449 greg.falesnik@mzgroup.us www.mzgroup.us

OTCQB: KULR | 19 Appendix: E - Mobility Customer Development Case Study Developmental Partnership Year of Engagement 2017 Company Global Auto Maker Stage of Customer Development (1 - 5) 5 Product Development Electric Vehicle Battery Pack KULR Product Solution HYDRA TRS KULR Product Solution Legend HYDRA TRS - HYDRA Thermal Runaway Shield URSA FTI – URSA Fiber Thermal Interface (material) ARA PCM – ARA Thermal Capacitor (PCM heat sink) VEGA ISC – VEGA Internal Short Circuit (Testing) 1 2 3 4 Prototyping 5 Stages of Customer Development Design Win Iterations of Sampling & Testing Design win indicates that KULR’s product solution has been selected to be incorporated into a manufacturer’s end product Initial sample testing based on prospective customer’s product specifications (i.e. size, weight, and thermal requirements)

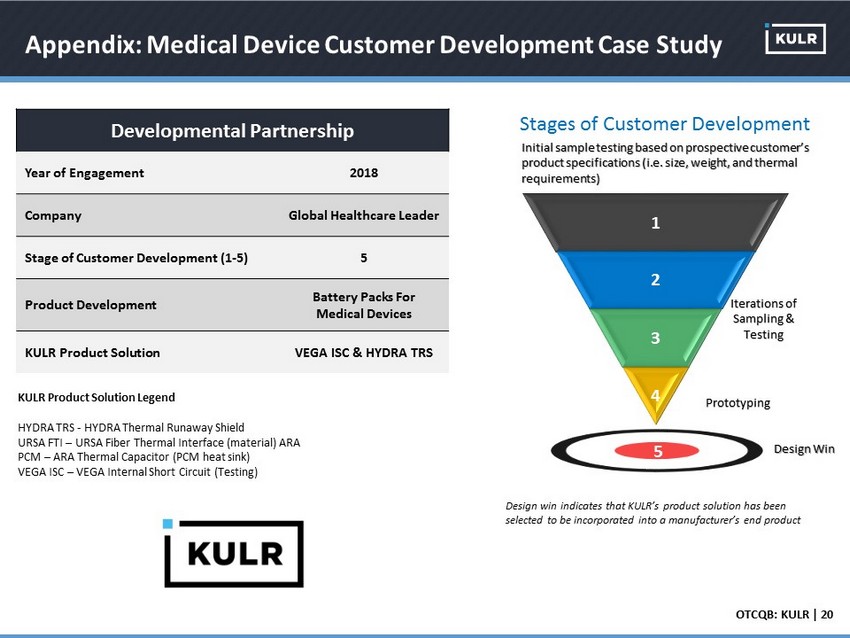

OTCQB: KULR | 20 Developmental Partnership Year of Engagement 2018 Company Global Healthcare Leader Stage of Customer Development (1 - 5) 5 Product Development Battery Packs For Medical Devices KULR Product Solution VEGA ISC & HYDRA TRS Appendix: Medical Device Customer Development Case Study 1 2 3 4 Prototyping 5 Stages of Customer Development Design Win Iterations of Sampling & Testing Design win indicates that KULR’s product solution has been selected to be incorporated into a manufacturer’s end product Initial sample testing based on prospective customer’s product specifications (i.e. size, weight, and thermal requirements) KULR Product Solution Legend HYDRA TRS - HYDRA Thermal Runaway Shield URSA FTI – URSA Fiber Thermal Interface (material) ARA PCM – ARA Thermal Capacitor (PCM heat sink) VEGA ISC – VEGA Internal Short Circuit (Testing)