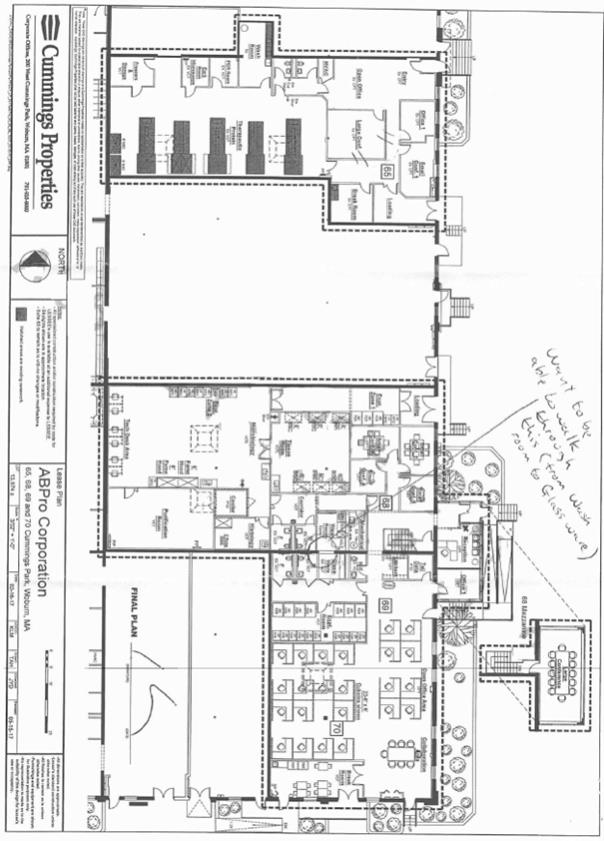

In connection with a lease in effect between Cummings Properties, LLC, LESSOR, and Abpro Corporation, LESSEE, at 65 Cummings Park and 395 West Cummings Park, Woburn, Massachusetts (“premises” or “leased premises”), fully executed on July 2, 2014 and currently scheduled to terminate on August 30, 2017, and in consideration of the mutual benefits to be derived herefrom, the parties hereby agree to amend said lease, including its terms, conditions, covenants, and obligations (“terms”), as follows:

1.

This extension shall not bind any party in any manner whatsoever until it has been executed by all parties. All other terms of the lease shall continue to apply, and to the extent any inconsistency exists between this extension and the lease, including any prior amendments and extensions, the terms herein shall control and supersede any earlier provisions. In witness whereof, LESSOR and LESSEE, intending to be legally bound, have caused this extension to be executed this 22nd day of May, 2017.

2.

| | | | | | | | | | | | |

| | | Qty | | | Unit | | | Total | |

Demolition Suite 65 | | | | | | | | | | | | |

No Construction In Suite 65 | | | | | | | | | | | | |

Demolition Suite 68 | | | | | | | | | | | | |

Masonry | | | | | | | | | | | | |

Construct masonry opening between Suite 68 and Suite 69, Suite 68 and Suite 70. | | | 2 | | | | ea | | | | | |

At Wash Room and at Corridor | | | | | | | | | | | | |

Remove drywall material from each side of masonry partition and patch opening. | | | 2 | | | | ea | | | | | |

Walls | | | | | | | | | | | | |

Arch out drywall partition in Equipment Zone and Wash Room | | | 150 | | | | sf | | | | | |

Soffit to be located 4th below lowest ceiling. Includes patching carpet as needed. | | | | | | | | | | | | |

Remove drywall partitions. | | | 122 | | | | lf | | | | | |

Enlarge door opening (to 48” or 72” wide). | | | 2 | | | | ea | | | | | |

Floors | | | | | | | | | | | | |

Remove carpet and or vinyl composition tile. | | | 2343 | | | | sf | | | | | |

Shot blast floor surface in preparation to receive epoxy flooring in Wash Room. | | | 96 | | | | sf | | | | | |

Remove adhesive from concrete surface before vinyl composition tile installation | | | 2343 | | | | sf | | | | | |

Doors/Windows | | | | | | | | | | | | |

Remove door (or window) with frame. Secure for reinstallation | | | 10 | | | | ea | | | | | |

Ceiling | | | | | | | | | | | | |

Remove ceiling grid systems in areas of demolition. | | | 802 | | | | sf | | | | | |

New ceiling height to remain where applicable. | | | | | | | | | | | | |

Remove ceiling tiles in areas affected by HVAC changes or use. | | | 2268 | | | | sf | | | | | |

Existing ceiling height to remain at11’-10”± above the floor. | | | | | | | | | | | | |

Remove ceiling grid system | | | 352 | | | | sf | | | | | |

Areas that will extend wall partitions and raise ceilings. | | | | | | | | | | | | |

Casework | | | | | | | | | | | | |

Remove plastic laminate casework. Base and wall cabinets. | | | 30 | | | | sf | | | | | |

Secure grayp-lam casework for reinstallation in Suite 70. | | | | | | | | | | | | |

Electrical | | | | | | | | | | | | |

Disconnect electrical and make safe in open ceilings. | | | 12 | | | | hr | | | | | |

Disconnect wiring to deactivated HVAC unit currently serving open area of suite. | | | 4 | | | | hr | | | | | |

Plumbing | | | | | | | | | | | | |

Disconnect and cap plumbing fixtures. | | | 5 | | | | ea | | | | | |

Mechanical | | | | | | | | | | | | |

Remove ductwork associated with RTU to be deactivated. Unit to be stored in place on roof. | | | 16 | | | | hr | | | | | |

Lessor may elect to remove unit at any time for reinstallation at another location without prior notice. | | | | | | | | | | | | |

Miscellaneous | | | | | | | | | | | | |

High lift equipment for the duration of demolition. | | | 1 | | | | wk | | | | | |

30-Yard trash container for use during demolition. | | | 1 | | | | ea | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | $ | 21,675 | |

| | | | | | | | | | | | |

Demolition Suite 69 and 70 | | | | | | | | | | | | |

Walls | | | | | | | | | | | | |

Remove drywall partitions. | | | 115 | | | | lf | | | | | |

Create new door opening (either 36” or 48” wide). | | | 4 | | | | ea | | | | | |

Removenon-standard chair rail molding on walls scheduled to remain. | | | 6 | | | | hr | | | | | |

Floors | | | | | | | | | | | | |

Remove platform stage in Suite 70. | | | 360 | | | | sf | | | | | |

Remove carpet. | | | 2789 | | | | sf | | | | | |

Doors/Windows | | | | | | | | | | | | |

Remove door (or window) with frame. Secure for reinstallation. | | | 10 | | | | ea | | | | | |

Ceiling | | | | | | | | | | | | |

Remove ceiling grid systems in areas of demolition. | | | 1088 | | | | sf | | | | | |

Existing ceiling height to be raised or lowered as note below in construction entry. | | | | | | | | | | | | |

Remove ceiling tiles in areas affected by HVAC changes or use. | | | 164 | | | | sf | | | | | |

Existing ceiling heights to remain. | | | | | | | | | | | | |

Casework | | | | | | | | | | | | |

Removenon-standard plastic laminate casework. | | | 21 | | | | lf | | | | | |

Electrical | | | | | | | | | | | | |

Disconnect electrical and make safe in open ceilings. | | | 12 | | | | hr | | | | | |

| | | | | | | | | | | | |

Plumbing | | | | | | | | | | | | |

Disconnect and cap plumbing fixtures in proposed Wash Room, Mechanical Room and Microbiology. | | | 5 | | | | ea | | | | | |

Miscellaneous | | | | | | | | | | | | |

High lift equipment for the duration of demolition. | | | 1 | | | | wk | | | | | |

30-Yard trash container for use during demolition. | | | 1 | | | | ea | | | | | |

Construction Suite 65 | | | | | | | | | | | | |

Construction Suite 68 | | | | | | | | | | | | |

General Construction | | | | | | | | | | | | |

Walls | | | | | | | | | | | | |

Constructnon-rate full-height drywall partition from 0’ to 12’. | | | 119 | | | | lf | | | | | |

Construct or extendnon-rated drywall partition from 12’ to metal deck. Includes taped drywall both sides. | | | 61 | | | | lf | | | | | |

To separate Office, Microbiology and Tissue Rooms | | | | | | | | | | | | |

Extendnon-rated drywall partition from 8’ to 10’. | | | 77 | | | | lf | | | | | |

To raise ceiling height in Corridor, Wash Room and Mechanical. | | | | | | | | | | | | |

Install cold roll steel reinforcing at drywall partitions 12’ and higher. | | | 119 | | | | lf | | | | | |

Infill door or window opening with drywall construction. | | | 4 | | | | ea | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | $ | 15,268 | |

| | | | | | | | | | | | |

Mechanical Room | | | | | | | | | | | | |

Ceiling | | | | | | | | | | | | |

Install ceiling grid system with vinyl faced tiles. | | | 60 | | | | sf | | | | | |

Includes existing lights and modifications to sprinklers. | | | | | | | | | | | | |

Ceiling height to be raised to 9’± | | | | | | | | | | | | |

Flooring | | | | | | | | | | | | |

Existing ceramic tile flooring and tile wall to remain as is. | | | | | | | | | | | | |

Doors/Windows | | | | | | | | | | | | |

Install fixed louver in current door panel. | | | 1 | | | | ea | | | | | |

Remove door and cut for louver insert. | | | 2 | | | | hr | | | | | |

Finishes | | | | | | | | | | | | |

Paint interior drywall partitions with water based catalyzed epoxy paint and vapor barrier primer. | | | 28 | | | | lf | | | | | |

Plumbing | | | | | | | | | | | | |

Installgas-fired water heater with sealed combustion potable,non-potable and TW piping. | | | 1 | | | | ea | | | | | |

Water heater located in Mechanical Room. IncludesB-vent, roof work and gas line. | | | | | | | | | | | | |

Capacity based on combined storage and recovery, 120 gallons | | | | | | | | | | | | |

Back-flow valves, located in Wash Room. For hot and cold water. | | | 2 | | | | ea | | | | | |

Install tempered water (TW) loop system (potable water) to emergency shower location. | | | 250 | | | | lf | | | | | |

Insulation wrap at all horizontal runs of TW loop. | | | 200 | | | | lf | | | | | |

Circulation pump for TW loop piping. | | | 1 | | | | ea | | | | | |

Existing utility sink to remain as is. Connect to newnon-potable water supply. | | | 2 | | | | hr | | | | | |

Electrical | | | | | | | | | | | | |

No Changes. | | | | | | | | | | | | |

HVAC | | | | | | | | | | | | |

| | | | | | | | | | | | |

Note:Refer to HVAC section under Tissue Room for additional HVAC information. | | | | | | | | | | $ | 24,517 | |

| | | | | | | | | | | | |

Wash Room | | | | | | | | | | | | |

Ceiling | | | | | | | | | | | | |

Install ceiling grid system with vinyl faced tiles and high temp sprinkler head. | | | 96 | | | | sf | | | | | |

Includes existing lights and modifications to sprinklers. | | | | | | | | | | | | |

Ceiling height to be raised to 9’± | | | | | | | | | | | | |

Flooring | | | | | | | | | | | | |

Install2-part epoxy floor with orange peel texture. | | | 96 | | | | sf | | | | | |

Floor to receive bermed lip at room entrance and at masonry opening. | | | | | | | | | | | | |

Install2-part integrated 4” high epoxy wall base in Wash Room. | | | 40 | | | | lf | | | | | |

Finishes | | | | | | | | | | | | |

Paint interior walls with water based catalyzed epoxy paint. | | | 40 | | | | lf | | | | | |

Plumbing | | | | | | | | | | | | |

Cut floor to access main building drain line. | | | 1 | | | | ea | | | | | |

Trench Floor to extend acid waste drain lines to new resin sink and floor sink locations. | | | 15 | | | | lf | | | | | |

Includes cutting of concrete slab, removal of soil, installation of polypropylene piping, inspection, backfilling trench and patching concrete floor. | | | | | | | | | | | | |

Floor sink, approx.. 6” x 6” in wash room. Includes 24” area sloped to sink drain. | | | 1 | | | | ea | | | | | |

Rough and finished plumbing(non-potable HW/CW supply, drain and vent) to resin sink. | | | 1 | | | | ea | | | | | |

Rough and finished plumbing(non-potable HW) to glass washer and autoclave. | | | 2 | | | | ea | | | | | |

Hoy water supply for Glass Washer or Autoclave to be mounted at 60 in. above the floor and terminated with a shutoff valve. Units drain to floor sink. Cool down required for both HW lines. | | | | | | | | | | | | |

Glass Washer and Autoclave supplied and installed by others at Lessee’s expense. | | | | | | | | | | | | |

Core to extend drain line to sink drain for Autoclave and Glass Washer. | | | 2 | | | | ea | | | | | |

Install5-gallon PH tank for sink in Wash Room. | | | 1 | | | | ea | | | | | |

No pH adjustment is included for Autoclave or Glass Washer drain water | | | | | | | | | | | | |

Polypropylene piping above ground from sink to drain line and vent | | | 30 | | | | lf | | | | | |

Includes necessary fittings required for installation. | | | | | | | | | | | | |

Resin Lab Sink, approx.. 15”L x 18”W x 8”D | | | 1 | | | | ea | | | | | |

High arc faucet with aspirator tip and separate HW/CW controls. | | | 1 | | | | ea | | | | | |

Metal sink based (refurbished) with phenolic resin countertop, installed | | | 3 | | | | lf | | | | | |

Electrical (Pending confirmation of Lessee’s equipment requirements) | | | | | | | | | | | | |

Install208V/100A/3ph/4-wire dedicated circuit wired to a disconnect. | | | 1 | | | | ea | | | | | |

For autoclave unit with built in electric steam generator. | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for autoclave control box. | | | 1 | | | | ea | | | | | |

Install208/20A/3ph/4-wire circuit wired to a wall mounted work box with plate cover for Glass Washer. | | | 1 | | | | ea | | | | | |

Installation of glass washer equipment to be supplied and installed by Lessee. | | | | | | | | | | | | |

Connection to power source is not included. Disconnect, if required, is not included. | | | | | | | | | | | | |

HVAC | | | | | | | | | | | | |

5.

| | | | | | | | | | | | |

| | | | | | | | | | | | |

Note:Refer to HVAC section under Tissue Room for additional HVAC information. | | | | | | | | | | $ | 17,311 | |

| | | | | | | | | | | | |

Construction Suite 68, continued | | | | | | | | | | | | |

Corridor | | | | | | | | | | | | |

Ceiling | | | | | | | | | | | | |

Install ceiling grid system with vinyl faced tiles. | | | 210 | | | | sf | | | | | |

Includes existing lights and modifications to sprinklers. | | | | | | | | | | | | |

Ceiling height to be raised to 9’± | | | | | | | | | | | | |

Flooring | | | | | | | | | | | | |

Install building standard vinyl composition tile. | | | 210 | | | | lf | | | | | |

Install 4” high black vinyl wall base. | | | 78 | | | | lf | | | | | |

Finishes | | | | | | | | | | | | |

Paint drywall partitions with water based catalyzed epoxy paint. | | | 78 | | | | lf | | | | | |

Paint existing doors and door frames black on corridor side. | | | 5 | | | | hr | | | | | |

| | | | | | | | | | | | |

Note:Interior finishes at restrooms to remain as is and will receive Lessor’s standard rehab | | | | | | | | | | $ | 3,085 | |

| | | | | | | | | | | | |

Tissue Room | | | | | | | | | | | | |

Ceiling | | | 575 | | | | sf | | | | | |

Install ceiling grid system with vinyl faced tiles. | | | | | | | | | | | | |

Includes existing lights and modifications to sprinklers. | | | | | | | | | | | | |

Ceiling height to be raised to 9’± | | | | | | | | | | | | |

Caulk perimeter of ceiling grid with sealant. | | | 96 | | | | lf | | | | | |

Flooring | | | | | | | | | | | | |

Install building standard vinyl composition tile. | | | 575 | | | | lf | | | | | |

Install 4” high black vinyl wall base. | | | 96 | | | | | | | | | |

Doors | | | | | | | | | | | | |

Install 6’wide double metal door unit with frame and vision kits. | | | 1 | | | | ea | | | | | |

Includes a 24” x 36” tempered glass vision kit in each panel and surface mounted slide bolt on inactive leaf. | | | | | | | | | | | | |

Install surface mounted hydraulic door closer on active door panel. | | | 1 | | | | ea | | | | | |

Install full-gasket (Foam or rubber) on door frame. | | | 1 | | | | ea | | | | | |

Install rubber sweep at each entry door panel. | | | 1 | | | | ea | | | | | |

Drop-sill is available at an additional charge to the Lessee. | | | | | | | | | | | | |

Finishes | | | | | | | | | | | | |

Paint drywall partitions with water based catalyzed epoxy paint. | | | 96 | | | | lf | | | | | |

Casework | | | | | | | | | | | | |

Air flow alarm (located in exhaust ductwork for the two vented BSC). All others are recirculated. | | | 2 | | | | ea | | | | | |

Hardwire airflow to a 120V circuit. | | | 2 | | | | ea | | | | | |

Supply and install refurbished metal sinkbase cabinet. | | | 4 | | | | lf | | | | | |

Supply and install phenolic resin countertop, 30” wide | | | 4 | | | | lf | | | | | |

Plumbing | | | | | | | | | | | | |

Cut floor to access main building drain line. | | | 1 | | | | ea | | | | | |

Trench Floor to extend acid waste drain lines to new resin sink location. | | | 10 | | | | lf | | | | | |

Includes cutting of concrete slab, removal of soil, installation ofpolypropylene piping, inspection, backfilling trench and patchingconcrete floor. | | | | | | | | | | | | |

Rough and finished plumbing(non-potable) to resin sink. | | | 1 | | | | ea | | | | | |

Install5-gallon PH tank for sink | | | 1 | | | | ea | | | | | |

Polypropylene piping above ground from sink to drain line and vent. | | | 30 | | | | lf | | | | | |

Includes necessary fittings required for installation. | | | | | | | | | | | | |

Resin Lab Sink, approx.. 15”L x 18”W x 8”D | | | 1 | | | | ea | | | | | |

High arc faucet with aspirator tip and separate HW/CW controls. | | | 1 | | | | ea | | | | | |

Electrical (Pending confirmation of Lessee’s equipment requirements) | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for Lessee’s Biosafety Cabinets. | | | 6 | | | | ea | | | | | |

Install prewired raceway with duplex outlets at 12” OC wired to a dedicated 120v/20A circuit. | | | 4 | | | | ea | | | | | |

Mounted on first fixed reagent shelf. Length of raceway to be either 4’ or 6’ long. | | | | | | | | | | | | |

Install additional fire protection devices or rework existing in Suite 68. | | | 1 | | | | ls | | | | | |

| | | | | | | | | | | | |

HVAC –(MUA-1) Serving Tissue Room (2 vented CL II, B2 Biosafety Cabinet @ 1200 CFM each) | | | | | | | | | | $ | 24,391 | |

| | | | | | | | | | | | |

Note:Biosafety cabinets vented and unvented are supplied and installed by others at Lessee’s expense. | | | | | | | | | | | | |

Make up Air Unit. DX Cooled, gas fired,hot-gas reheat. | | | 12.5 | | | | too | | | | | |

Extend gas line toMUA-1 from main gas line. | | | 30 | | | | lf | | | | | |

MUA controller for set point temperature adjustment. | | | 1 | | | | ea | | | | | |

Roof Curb cut and installation. | | | 1 | | | | sec | | | | | |

Curb supplied by MUA manufacturer. | | | | | | | | | | | | |

Crane equipment to installMUA-1,MUA-2,RTU-1 and fans on roof. | | | 1 | | | | dy | | | | | |

Modify and relocate utilities above ceiling to accommodate new HVAC distribution. | | | 16 | | | | hr | | | | | |

Ductwork supply lines from MUA to diffusers. | | | 12.5 | | | | toa | | | | | |

Includes diffusers, rigid and flexible ductwork. | | | | | | | | | | | | |

Wiring of MUA to power supply. | | | 24 | | | | hr | | | | | |

Startup and commissioning of unit by manufacturer’s representative. | | | 8 | | | | hr | | | | | |

Wrap supply ductwork with insulation. | | | 12.5 | | | | toa | | | | | |

Structural Support forMUA-1 | | | 1 | | | | ls | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | $ | 80,748 | |

| | | | | | | | | | | | |

Make-up Air Unit capability for proposal: | | | | | | | | | | | | |

1) Technical spaces are designed with MUA delivering approx.. 2300 CFM of Supply Air.When outside air temperatures are at 88°F Dry Bulb/74°F Wet Bulb. Air dischargingfrom MUA is 54°F Dry Bulb/S3°F Wet Bulb. | | | | | | | | | | | | |

2) System is not designed to accommodate any sensible heat loads generated by Lessee’s equipment.No specialized filtration included. | | | | | | | | | | | | |

3) No HEPA filter ceiling modules are included. | | | | | | | | | | | | |

4) HVAC system to operate 24hr/7dy without any setback settings. | | | | | | | | | | | | |

HVAC –(EF-1) Serving Tissue Room | | | | | | | | | | | | |

Exhaust fan (rated for approx.. 2,400 CFM) | | | 1 | | | | lf | | | | | |

Includes high efficiency belt driven motor, weather cover, vibrationisolators, drain and type “C” spark resistant construction. | | | | | | | | | | | | |

6.

| | | | | | | | | | | | |

Exhaust duct, 8” to 14” dia. and distribution | | | 20 | | | | lf | | | | | |

Includes ceiling exhaust registers with control dampers. | | | | | | | | | | | | |

Exhaust duct, 15” to 20” dia. and distribution. | | | 20 | | | | lf | | | | | |

Roof cut for curb for fan. | | | 1 | | | | ea. | | | | | |

Roof cut for cone from main exhaust vent. | | | 1 | | | | ea. | | | | | |

Platform curb to support fan | | | 1 | | | | ea. | | | | | |

Cone flashing at roof penetration of duct to fan. | | | 1 | | | | ea. | | | | | |

Repair membrane roof at cone and curb flashing (By certified technician). | | | 2 | | | | ea. | | | | | |

Upblast stack 10’ above roof (total ht.), installed | | | 1 | | | | ea. | | | | | |

VFD or motor starter/ wire/ disconnect/ switch | | | 1 | | | | ea. | | | | | |

Wiring labor & mat’l (Not Class I, Div. I) | | | 1 | | | | set | | | | | |

Duck sealing tape for seams. | | | 40 | | | | lf | | | | | |

Ceiling | | | | | | | | | | | | |

Install ceiling grid system with vinyl faced tiles in Equipment Zone 1. | | | 154 | | | | sf | | | | | |

Includes existing lights and modifications to sprinklers. | | | | | | | | | | | | |

Ceiling height to be raised to 9’±. | | | | | | | | | | | | |

Install ceiling grid system with vinyl faced tiles in Equipment Zone 1. | | | 144 | | | | sf | | | | | |

Includes lights and modifications to sprinklers. | | | | | | | | | | | | |

Ceiling height to be lowered to 9’±. | | | | | | | | | | | | |

Install vinyl faced tiles in existing grid in Microbiology and Equipment Zone 2. | | | 1568 | | | | sf | | | | | |

Includes existing lights and sprinklers. | | | | | | | | | | | | |

Existing ceiling height to remain as is. | | | | | | | | | | | | |

Flooring | | | | | | | | | | | | |

Install building standard vinyl composition tile. | | | 1866 | | | | lf | | | | | |

Install 4” high black vinyl wall base at walls and base of metal casework. | | | 455 | | | | lf | | | | | |

Doors | | | | | | | | | | | | |

Install 4’ wide metal door unit with a 3’ active panel, 1’ inactive panel and frame. | | | 1 | | | | ea | | | | | |

Includes a 24” x 36” tempered glass vision kit and surface mountain slide bolt on 1’ leaf. | | | | | | | | | | | | |

Install 6’ wide double metal door unit with frame at Loading and Equipment Zone 1. | | | 2 | | | | ea | | | | | |

Includes 10” x 10” vision glass in each panel at loading. Vision kits to be of tempered glass. | | | | | | | | | | | | |

Includes lockset hardware. Inactive panel to receive surface mountain slide bolt. | | | | | | | | | | | | |

Install surface mounted hydraulic door closer on active doors. | | | 2 | | | | ea | | | | | |

Install full-gasket (Foam or rubber) on door frame. | | | 2 | | | | ea | | | | | |

Install rubber sweep at each manufacturing entry door panel. | | | 2 | | | | ea | | | | | |

Drop-sill is available at an additional charge to the Lessee. | | | | | | | | | | | | |

Install wall or floor mounted door stop at new or existing doors. | | | 2 | | | | ea | | | | | |

Where drywall partition is within 6” | | | | | | | | | | | | |

Finishes | | | | | | | | | | | | |

Paint drywall partitions with water based catalyzed epoxy paint. | | | 275 | | | | lf | | | | | |

Casework | | | | | | | | | | | | |

Fume Hood, refurbished 6’ wide unit. | | | 2 | | | | ea | | | | | |

Includes one acid/base or solvent cabinet. Remaining cabinet to be standard metal cabinet. | | | | | | | | | | | | |

Air flow alarm on each fume hood | | | 2 | | | | ea | | | | | |

Hardware airflow alarm to a 120V circuit. | | | 2 | | | | ea | | | | | |

Supply and install refurbished metal sinkbase cabinet. | | | 8 | | | | lf | | | | | |

Supply and install phenolic resin countertop, 30” wide. | | | 8 | | | | lf | | | | | |

Notes: Metal Casework | | | | | | | | | | | | |

1.) Unless noted otherwise, metal casework and fume hoods are refurbished from Lessor’s inventory. | | | | | | | | | | | | |

2.) If refurbished casework or fume hoods are not available, new casework or fume hoods will beprovided at an additional expense of the Lessee. | | | | | | | | | | | | |

3.) Fume hoods to be supplied and installed will not have active cup sinks, water supply or drain. | | | | | | | | | | | | |

4.) Connection of process gases to controls on fume hood are not included. | | | | | | | | | | | | |

5.) Unless noted otherwise, fume hood sash height will be set at 18”. | | | | | | | | | | | | |

6.) Lessor makes no guarantees that fume hoods will have process gas controls. | | | | | | | | | | | | |

7.) Walk-in Cooler with two access doors is not included. Cooley to be supplied and installed by othersat Lessee’s additional expense. | | | | | | | | | | | | |

Electrical (Pending confirmation of Lessee’s equipment requirements) | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for fume hoods. | | | 2 | | | | ea | | | | | |

Install prewired raceway with duplex outlets at 12” OC wired to a dedicated 120v/20A circuit. | | | 14 | | | | ea | | | | | |

Mounted above the floor on first fixed reagent shelf. | | | | | | | | | | | | |

Length of raceway to be either 4’ or 6’ long. | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for Lessee’s equipment. | | | 6 | | | | ea | | | | | |

Mounted 44” above the floor at wall in Microbiology. | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for Lessee’s equipment. | | | 1 | | | | ea | | | | | |

Mounted 44” above the floor at wall in Equipment Zone. | | | | | | | | | | | | |

Install208V/20A/3ph-4wire dedicated circuit wired to a work box for Lessee’s equipment. | | | 3 | | | | ea | | | | | |

Mounted 44” above the floor at wall in Equipment Zone. | | | | | | | | | | | | |

Lessee to confirm NEMA number for specialty outlets prior to construction. | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for equipment in knee space. | | | 12 | | | | ea | | | | | |

| | | | | | | | | | | | |

Notes: | | | | | | | | | | $ | 48,316 | |

| | | | | | | | | | | | |

1.) 120V or 208V Outlets wired to a drop card are available at an additional charge to Lessee. | | | | | | | | | | | | |

2.) Standbygas-fired generator is not included but available at an additional expense to Lessee. | | | | | | | | | | | | |

Plumbing | | | | | | | | | | | | |

Cut door to access main building drain line. | | | 1 | | | | ea | | | | | |

Trench Floor to extend acid waste drain lines to new resin sink locations. | | | 10 | | | | lf | | | | | |

Includes cutting of concrete slab, removal of soil, installation of polypropylene piping,inspection, backfilling trench and patching concrete floor. | | | | | | | | | | | | |

Rough and finished plumbing(non-potable) to resin sink. | | | 2 | | | | ea | | | | | |

Install5-gallon PH tank for sink. | | | 2 | | | | ea | | | | | |

Polypropylene piping above ground from sink to drain line and vent. | | | 30 | | | | lf | | | | | |

Includes necessary fittings required for installation. | | | | | | | | | | | | |

Resin Lab Sink, approx.. 15”L x 18”W x 8”D | | | 2 | | | | ea | | | | | |

High arc faucet with aspirator tip and separate HW/CW controls. | | | 2 | | | | ea | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | $ | 9,397 | |

| | | | | | | | | | | | |

HVAC-(MUA-2) Serving Microbiology, Histology, Purification and Equipment Zone | | | | | | | | | | | | |

7.

| | | | | | | | | | | | |

Make up Air Unit, DX Cooled, gas fired,hot-gas reheat | | | 20 | | | | ton | | | | | |

Install gas line to unit from meter. | | | 80 | | | | lf | | | | | |

MUA controller for set point temperature adjustment. | | | 1 | | | | ea | | | | | |

Roof curb cut and installation. | | | 1 | | | | set | | | | | |

Curb supplied by MUA manufacturer. | | | | | | | | | | | | |

Crane equipment to install MUA and fans on roof. (See entry forMUA-1) | | | | | | | | | | | | |

Ductwork supply lines from MUA to diffusers. | | | 20 | | | | ton | | | | | |

Includes diffusers, rigid and flexible ductwork. | | | | | | | | | | | | |

Wiring of MUA to power supply. | | | 24 | | | | hr | | | | | |

Startup and commissioning of unit by manufacturer’s representative. | | | 8 | | | | hr | | | | | |

Wrap supply ductwork with insulation. | | | 20 | | | | ton | | | | | |

Structural support forMUA-2 | | | 1 | | | | ls | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | $ | 111,483 | |

| | | | | | | | | | | | |

Make-up Air Unit capability for proposal: | | | | | | | | | | | | |

1.) Technical spaces are designed with MUA delivering approx.. 3,640 CFM of Supply Air, when outside air temperatures are at 86°F Dry Bulb/74°F Wet Bulb, Air discharging from MUA is 54°F Dry Bulb/53°F Wet Bulb. | | | | | | | | | | | | |

2.) System is not designed to accommodate any sensible heat loads generated by Lessee’s equipment. No specialized filtration included. | | | | | | | | | | | | |

3.) No HEPA filter ceiling modules are included. | | | | | | | | | | | | |

4.) HVAC system to operate 24hr/7dy without any setback settings. | | | | | | | | | | | | |

Construction Suite 68, continued | | | | | | | | | | | | |

HVAC-(EF-2) Serving Microbiology, Histology, Purification and Equipment Zone. | | | | | | | | | | | | |

Exhaust fan (rated for approx.. 4,020 CFM) | | | 1 | | | | ea. | | | | | |

Includes high efficiency belt driven motor, weather cover, vibration isolators, drain and type “C” spark resistant construction. | | | | | | | | | | | | |

Exhaust duct, 8” to 14” dia. and distribution | | | 90 | | | | lf | | | | | |

Includes ceiling exhaust registers with control dampers. | | | | | | | | | | | | |

Exhaust duct, 15” to 20” dia. and distribution. | | | 90 | | | | lf | | | | | |

Roof cut for curb for fan. | | | 1 | | | | ea. | | | | | |

Roof cut for cone from main exhaust vent. | | | 1 | | | | ea. | | | | | |

Platform curb to support fan | | | 1 | | | | ea. | | | | | |

Cone flashing at roof penetration of duct to fan. | | | 1 | | | | ea. | | | | | |

Repair membrane roof at cone and curb flashing (By certified technician). | | | 2 | | | | ea. | | | | | |

Upblast stack 10’ above roof (total ht.), installed | | | 1 | | | | ea. | | | | | |

VFD or motor starter/ wire/ disconnect/ switch | | | 1 | | | | ea. | | | | | |

Wiring labor & mat’l (Not Class I, Div. I) | | | 1 | | | | ea. | | | | | |

Duct sealing tape for seams. | | | 180 | | | | lf | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | $ | 24,673 | |

| | | | | | | | | | | | |

| | | | | | | | | | | | |

Histology | | | | | | | | | | | | |

Ceiling | | | | | | | | | | | | |

Install ceiling grid system with vinyl faced tiles. | | | 136 | | | | sf | | | | | |

Includes existing lights and modifications to sprinklers. | | | | | | | | | | | | |

Ceiling height to be raised to 9’± | | | | | | | | | | | | |

Flooring | | | | | | | | | | | | |

Install building standard vinyl composition tile. | | | 136 | | | | lf | | | | | |

Install 4” high black vinyl wall base at walls and base of metal casework. | | | 50 | | | | lf | | | | | |

Doors | | | | | | | | | | | | |

Install 4” wide metal door unit with a 3’ active panel, 1’ inactive panel and frame. | | | 1 | | | | ea | | | | | |

Includes a 24” x 36” tempered glass vision kit and surface mounted slide bolt on 1’ leaf. | | | | | | | | | | | | |

Install surface mounted hydraulic door closer on manufacturing doors. | | | 1 | | | | ea | | | | | |

Install full-gasket (Foam or rubber) at each manufacturing door frame. | | | 1 | | | | ea | | | | | |

Install rubber sweep at each manufacturing entry door panel. | | | 1 | | | | ea | | | | | |

Drop-sill is available at an additional charge to the Lessee. | | | | | | | | | | | | |

Install wall or floor mounted door stop at new or existing doors. | | | 1 | | | | ea | | | | | |

Where drywall partition is within 6” | | | | | | | | | | | | |

Finishes | | | | | | | | | | | | |

Paint drywall partitions with water based catalyzed epoxy paint. | | | 50 | | | | lf | | | | | |

Casework | | | | | | | | | | | | |

Fume Hood, refurbished 5’ wide unit. | | | 1 | | | | ea | | | | | |

Includes one acid/base or solvent cabinet. Remaining cabinet to be standard metal cabinet. | | | | | | | | | | | | |

Air flow alarm on each fume hood | | | 1 | | | | ea | | | | | |

Supply and install refurbished metal base cabinets. | | | 3 | | | | lf | | | | | |

Supply and install phenolic resin countertop, 30” wide. | | | 3 | | | | lf | | | | | |

Notes: Metal Casework | | | | | | | | | | | | |

1.) Unless noted otherwise, metal casework and fume hoods are refurbished from Lessor’s Inventory. | | | | | | | | | | | | |

2.) If refurbished casework or fume hoods are not available, new casework or fume hoods will be provided at an additional expense to the Lessee. | | | | | | | | | | | | |

3.) Fume hoods to be supplied and installed will not have active cup sinks, water supply or drain. | | | | | | | | | | | | |

4.) Connection of process gases to controls on fume hood are not included. | | | | | | | | | | | | |

5.) Unless noted otherwise, fume hood sash height will be set at 18”. | | | | | | | | | | | | |

6.) Lessor makes no guarantees that fume hoods will have process gas controls. | | | | | | | | | | | | |

Plumbing | | | | | | | | | | | | |

Trench Floor to extend acid waste drain lines to new resin sink locations. | | | 20 | | | | lf | | | | | |

Includes cutting of concrete slab, removal of soil, installation of polypropylene piping, inspection, backfilling trench and patching concrete floor. | | | | | | | | | | | | |

Rough and finished plumbing(non-potable) to resin sink,. | | | 1 | | | | ea | | | | | |

InstallS-gallon PH tank for sink in Wash Room | | | 1 | | | | ea | | | | | |

Polypropylene piping above ground rom sink to drain line and vent. | | | 30 | | | | lf | | | | | |

Includes necessary fittings required for installation. | | | | | | | | | | | | |

Resin Lab Sink, approx.. 15”L x 18”W x 18”D | | | 1 | | | | ea | | | | | |

High arc faucet with aspirator tip and separate HW/CW controls. | | | 1 | | | | ea | | | | | |

8.

| | | | | | | | | | | | |

Electrical (Pending confirmation of Lessee’s equipment requirements) | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for Fume Hood. | | | 1 | | | | ea | | | | | |

Mounted 72” above the floor at wall. | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for Lessee’s equipment. | | | 1 | | | | ea | | | | | |

Mounted 44” above the floor at countertop. | | | | | | | | | | | | |

HVAC | | | | | | | | | | | | |

| | | | | | | | | | | | |

Note: Refer to HVAC section under Microbiology Room for additional HVAC information. | | | | | | | | | | $ | 18,588 | |

| | | | | | | | | | | | |

Purification Room | | | | | | | | | | | | |

Ceiling | | | | | | | | | | | | |

Install vinyl faced tiles in existing ceiling grid. | | | 544 | | | | sf | | | | | |

Includes existing lights and modifications to sprinklers | | | | | | | | | | | | |

Ceiling height to remain at11’-10’± | | | | | | | | | | | | |

Flooring | | | | | | | | | | | | |

Install building standard vinyl composition tile. | | | 544 | | | | lf | | | | | |

Install 4” high black vinyl wall base at walls and base of metal casework. | | | 98 | | | | lf | | | | | |

Doors | | | | | | | | | | | | |

Install 4” wide metal door unit with a 3’ active panel, 1’ inactive panel and frame. | | | 1 | | | | ea | | | | | |

Includes a 24” x 36” tempered glass vision kit and surface mounted slide bolt on 1’ leaf. | | | | | | | | | | | | |

Install surface mounted hydraulic door closer on manufacturing doors. | | | 1 | | | | ea | | | | | |

Install full-gasket (Foam or rubber) at each manufacturing door frame. | | | 1 | | | | ea | | | | | |

Install rubber sweep at each manufacturing entry door panel. | | | 1 | | | | ea | | | | | |

Drop-sill is available at an additional charge to the Lessee. | | | | | | | | | | | | |

Finishes | | | | | | | | | | | | |

Paint drywall partitions with water based catalyzed epoxy paint. | | | 98 | | | | lf | | | | | |

Plumbing | | | | | | | | | | | | |

None specified. | | | | | | | | | | | | |

Electrical (Pending confirmation of Lessee’s equipment requirements) | | | | | | | | | | | | |

Install 120V/20A/1ph dedicated circuit wired to a duplex outlet for Lessee’s equipment. | | | 16 | | | | ea | | | | | |

Mounted 44” above the floor at wall. | | | | | | | | | | | | |

Install 208V/20A/3ph 4wire dedicated circuit wired to a work box for Lessee’s equipment. | | | 4 | | | | ea | | | | | |

Mounted 44” above the floor at wall. | | | | | | | | | | | | |

Lessee to confirm NEMA number for specialty outlets prior to construction. | | | | | | | | | | | | |

Note: | | | | | | | | | | | | |

120V or 208V Outlets wired to a drop card are available at an additional charge to Lessee. | | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | $ | 12,587 | |

| | | | | | | | | | | | |

HVAC | | | | | | | | | | | | |

Note: Refer to HVAC section under Microbiology Room for additional HVAC information. | | | | | | | | | | | | |

Construction Suites 69 and 70 | | | | | | | | | | | | |

Walls | | | | | | | | | | | | |

Constructnon-rated drywall partition from 0’ to 12’ above the floor for Equipment room and Corridor. | | | 54 | | | | If | | | | | |

Constructnon-rated drywall partition from 0’ to 8’ above the floor between Locker and Tel/Data closet. | | | 8 | | | | If | | | | | |

Repaint existing walls in suite as part of standard rehab. | | | No Charge | | | | | | | | | |

Floors | | | | | | | | | | | | |

Install building standard gray level loop carpet. | | | 2260 | | | | sf | | | | | |

Install building standard gray vinyl composition tile (VCT) in Locker Room, Tel/Data, Break Room and in Equipment Room | | | 728 | | | | sf | | | | | |

Doors/Windows | | | | | | | | | | | | |

Install metal door with frame from demolition stock. | | | 1 | | | | ea | | | | | |

Install 4’ wide metal door unit with a 3’ active panel, 1’ inactive panel and frame. | | | 3 | | | | ea | | | | | |

Includes a 24” cx 36” tempered glass vision kit and surface mounted slide bolt. | | | | | | | | | | | | |

Paint door and frame after installation. | | | 8 | | | | hr | | | | | |

Install surface mounted hydraulic door closer. | | | 3 | | | | ea | | | | | |

Premium for lockset hardware at Tel/Data and Equipment Room. | | | 2 | | | | ea | | | | | |

Doors will be keyed separately. | | | | | | | | | | | | |

Ceiling | | | | | | | | | | | | |

Install ceiling grid system in Equipment Room, Break room, Tel/Data and Locker Room. | | | 728 | | | | sf | | | | | |

Ceiling height to remain as is. | | | | | | | | | | | | |

Premium for vinyl faced ceiling tiles in Equipment Room. | | | 308 | | | | sf | | | | | |

Casework | | | | | | | | | | | | |

Install refurbishedp-lam sink base and base cabinet in Proposed Break Room. | | | 2 | | | | ea | | | | | |

Includes refurbished sink, faucet and countertop from salvaged inventory. | | | | | | | | | | | | |

Notes:P-lam Casework 1.) Base and sink cabinets are 30”W x 24”D x 26”H 2.) Cabinets are of building standard gray plastic laminate with white melamine interior. | | | | | | | | | | | | |

Includes one drawer, fixed shelf, ‘C’ style cabinet pull andside-by-side cabinet doors. | | | | | | | | | | | | |

Electrical | | | | | | | | | | | | |

Install dedicated 120V/20A circuit wired to a duplex outlet for refrigerator or above the countertop. | | | 3 | | | | ea | | | | | |

Located in Break Room. Refrigerators to be supplied and installed by others at Lessee’s expense. | | | | | | | | | | | | |

Install dedicated 120V/20A circuit wired to a workbox above the ceiling for cubicles. | | | 6 | | | | ea | | | | | |

Cubicle furniture to be supplied and installed by others at an additional expense to Lessee. One circuit for every four cubicles. | | | | | | | | | | | | |

Install dedicated 120V/20A circuit wired to a quadruplex outlet in Tel/Data room. | | | 2 | | | | ea | | | | | |

Final location to be verified by Lessee prior to construction. | | | | | | | | | | | | |

Install dedicated 208V/20A circuit wired to a duplex outlet in Equipment Room. | | | 5 | | | | ea | | | | | |

For each pair of-20 Freezers. | | | | | | | | | | | | |

Install dedicated 208V/20A circuit wired to a duplex outlet in Equipment Room. | | | 7 | | | | ea | | | | | |

for each-80 Freezer. | | | | | | | | | | | | |

Install additional fire protection devices or rework existing in Suites 69 and 70. | | | 12 | | | | Is | | | | | |

9.

| | | | | | | | | | | | |

Plumbing | | | | | | | | | | | | |

Cut floor to access main building drain line. | | | 1 | | | | ea | | | | | |

Trench Floor to extend building drain line to new sink location in Break Room. | | | 40 | | | | if | | | | | |

Includes cutting of concrete slab, removal of soil, installation of cast iron piping. Inspection, backfilling trench and patching concrete floor. | | | | | | | | | | | | |

Rough and finished plumbing (potable) to Break room sink. | | | 1 | | | | ea | | | | | |

HVAC-(RTU 1) Serving Equipment Room | | | | | | | | | | | | |

Install2-stage recirculating roof top unit for cooling only. | | | 7.5 | | | | ton | | | | | |

Low ambient kit to allow AC to operate down to 32 deg. F. One for each stage. | | | 2 | | | | ea | | | | | |

Roof Curb cut and installation. | | | 1 | | | | set | | | | | |

Curb supplied by manufacturer. | | | | | | | | | | | | |

Modify and relocate utilities above ceiling to accommodate new HVAC distribution | | | 8 | | | | hr | | | | | |

Ductwork supply and return air lines from RTU to room. | | | 7.5 | | | | ton | | | | | |

Includes diffusers, rigid and flexible ductwork. | | | | | | | | | | | | |

Wiring of RTU to power supply. | | | 16 | | | | hr | | | | | |

Wrap supply ductwork with insulation. | | | 7.5 | | | | Ton | | | | | |

Miscellaneous Electrical for Suites 68, 69 and 70 Electrical | | | | | | | | | | | | |

Installsub-panel for new circuits. | | | 2 | | | | ea | | | | | |

Marking of dedicated circuits and identification at panels | | | 8 | | | | hr | | | | | |

Door bell buzzer at loading door. | | | 1 | | | | ea | | | | | |

Chime located in Microbiology. | | | | | | | | | | | | |

Note:No electrical service upgrade is included. In addition, there is no guarantee that a service upgrade is available at this location. | | | | | | | | | | | | |

Miscellaneous HVAC for Suite 68, 69 and 709 | | | | | | | | | | | | |

Air balancing with report. | | | 24 | | | | hr | | | | | |

HVAC technician to assist in equipment adjustment and roof access | | | 24 | | | | hr | | | | | |

Mechanical Notes: | | | | | | | | | | | | |

1.) Exhaust fans and makeup air unit for Suite 68 to operate continuously 24hrs/7days. | | | | | | | | | | | | |

2.) Temperature and/or volume setbacks are available for an additional charge. | | | | | | | | | | | | |

3.) Fume hoods sashes to be set between 15: to 18” high when HVAC system is balanced. | | | | | | | | | | | | |

4.) BMS control system is not included. | | | | | | | | | | | | |

Management | | | | | | | | | | | | |

Architectural, HVAC, Electrical & Engineering planning, coordination | | | 1 | | | | chg | | | | | |

Project Management | | | 1 | | | | chg | | | | | |

Construction supervision, Construction team leader, Purchasing coordination. and design drafting limited to this scope of work. | | | | | | | | | | | | |

Project general labor (runner/loading/unloading, etc.) | | | 1 | | | | chg | | | | | |

Project documentation and Owner’s Manual | | | 12 | | | | hrs | | | | | |

Project meetings with Construction and Purchasing. | | | 10 | | | | hrs | | | | | |

Permits: building, plumbing & electrical only | | | 1 | | | | Is | | | | | |

Coordination and inspections for above permits only | | | 10 | | | | hr | | | | | |

Clean-up after construction. | | | 16035 | | | | sf | | | | | |

| | | | | | | | | | | | |

Management: | | | | | | | | | | $ | 79,160 | |

| | | | | | | | | | | | |

Total Charge: | | | | | | | | | | $ | 590,496 | |

| | | | | | | | | | | | |

10.

We are pleased to enclose for your records a fully executed original of Lease Extension #1 for Abpro’s facility at 65, 68, 69 and 70 Cummings Park. We appreciate your decision to expand your business in a Cummings Properties facility and look forward to continuing our relationship.

As you review the document, you will note we made updates to two sections. In Section 7, we added “modified” to specify “the entire modified premises.” In Section 14(ii), we inserted “LESSOR’s then-current standard form lease or amendment to lease” and to execute “said” lease.

Please call me or Erica Wright, Operations Manager, if we may be of further assistance at any time.

/s/ Kara L. Murphy

Kara L. Murphy

11.