Detour Lake Operation Ontario, Canada NI 43-101 Technical Report Report Prepared By: Andre Leite, P.Eng Jean-Francois Dupont, P.Eng Veronika Raizman, P.Geo Paul Andrew Fournier, P.Eng Report Prepared For: Kirkland Lake Gold Ltd. Effective Date: December 31, 2020

CERTIFICATE OF QUALIFIED PERSON I, Andre Leite, P. Eng. am employed as a Detour Lake Mine Technical Service Manager with Kirkland Lake Gold Ltd, with an address at Royal Bank Plaza, South Tower 200 Bay Street, Suite 2800 Toronto, Ontario, M5J 2J1 Canada. This certificate applies to the technical report titled “Detour Lake Operation NI 43-101 Technical Report” that has an effective date of 31 December, 2020 (the “technical report”). I am a Professional Engineer with Professional Engineers Ontario, license number 100153687; a chartered professional member of the Australasian Institute of Mining and Metallurgy (MAusIMM(CP)), member number 301888. I graduated from McGill University (Canada) in 2008 with a Master’ s Degree in Mining Engineering and from Universidade Federal de Minas Gerais in 2004 with a Bachelor’ s Degree in Mining Engineering. I have practiced my profession for 17 years. I have been directly involved in the mineral resource modelling for the Detour Main Pit and have reviewed in detail the mineral resource modelling for the North pit, W est Detour and 58N deposits. I have also participated in life of mine planning. I have two years of experience as the Detour Lake Mine Technical Service Manager. Prior to that I held the positions of Technical Service Manager V ale Base Metals Asia Pacific, responsible for mineral resource and mineral reserve estimates for V ale Base Metal operations in the region; Principal Mine Engineer V ale Base Metals Global, leading the initiatives associated with corporate governance, technical services and technology and innovation for the Base Metals business with a major focus on their open pit operations; as mineral resource and mineral reserve specialist with the Inco (later V ale) Mineral Resources and Mineral Reserves team supporting all operations globally with mineral resource modelling, mine design, mine production planning and mineral reserve definition. As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing. I work at Detour Lake mine site, and this familiarity with the operation serves as my personal inspection. I am responsible for Sections 1.1 to 1.8, 1.10 to 1.14, 1.16, 1.18, 1.23 to 1.25; Section 2; Section 3; Section 4; Section 5; Section 6; Section 7; Section 8; Section 9; Section 10; Section 11; Section 12; Section 14; Section 15; Section 16; Section 18; Section 19; Section 23; Section 24; Sections 25.1 to 25.4, 25.6 to 25.8. 25.10, 25.12, 25.16, 25.17; Section 26, Section 27, and Appendix A of the technical report. I have been involved with the Detour Lake Mine for two years in my role as a Technical Service Manager working at site. I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the technical report not misleading. Dated: 30 March, 2021 “Signed” Andre Leite, P.Eng.

CERTIFICATE OF QUALIFIED PERSON I, Jean-Francois Dupont (P. Eng., OIQ) am employed as the Detour Lake Mine Chief Metallurgist with Kirkland Lake Gold Ltd, with an address at 1B First Avenue, Cochrane, Ontario. This certificate applies to the technical report titled “Detour Lake Operation NI 43-101 Technical Report” that has an effective date of 31 December, 2020 (the “technical report”). I am a Professional Engineer, member of L’ Ordre Des Ingé nieurs du Qué bec, license number 117145. I graduated from Laval University (Canada) in 1996 with a Bachelor’ s Degree in Mining Engineering, majoring in mineral processing. I have practiced my profession for 24 years. I joined Detour Gold Corporation, a predecessor company to Kirkland Lake Gold Ltd. in 2011 and was directly involved in the engineering, construction and commissioning of the Detour Lake Mine processing plant. I have worked in the Detour Lake Mine processing plant for eight years. I have also participated in the elaboration of life-of-mine plans. Prior to that, I held various positions with Barrick Gold for 14 years including five years at the Corporate office as Comminution Metallurgist. This position gave me exposure to the 19 processing plants Barrick Gold had at the time. As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing. I am directly employed at the Detour Operation, and have been since 2011. This familiarity with the operations serves as my personal inspection for the purposes of the technical report. I am responsible for Sections 1.1, 1.2, 1.9, 1.15; Sections 2.1 to 2.6; Section 13; Section 17; Sections 25.1, 25.5, 25.9; and Section 27 of the technical report. I am not independent of Kirkland Lake Gold Ltd, as independence is described by Section 1.5 of NI 43–101. I have been involved with the Detour Operation since 2011 during engineering, construction, commissioning, and operations of the process plant. I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the technical report not misleading. Dated: 30 March, 2021 “Signed” J-F Dupont, P. Eng (OIQ)

CERTIFICATE OF QUALIFIED PERSON I, V eronika Raizman, P. Geo. am employed as a Manager for Reclamation and Geochemistry, with Kirkland Lake Gold Inc., with an address at Royal Bank Plaza, South Tower 200 Bay Street, Suite 2800 Toronto, Ontario, M5J 2J1 Canada. This certificate applies to the technical report titled “Detour Lake Operation NI 43-101 Technical Report” that has an effective date of 31 December, 2020 (the “technical report”). I am a Professional Geoscientist registered with the Professional Geoscientists of Ontario (Membership # 2563). I graduated from the University of Toronto with a Ph.D. in Earth Sciences (2015), a M.Sc. in Geology (2011), and a H .B.Sc. in Environmental and Physical Geography (2010). I have practiced my profession for 10 years. Prior to joining the Detour Lake Mine in 2016, I served as a geochemist with SRK Consulting Ltd., where I gained experience in the prediction and management of acid rock drainage and metal leaching during all phases of the mining cycle, as well as mine waste characterization using static, kinetic, and field testing programs. At the Detour Lake Mine, I have previously served in multiple roles, including Environmental Specialist; Geochemistry, Research and Closure Coordinator; and Senior Advisor for Mine Closure Planning and Geochemistry. My duties have supported, but not been limited to, 1) environmental permitting, reporting and compliance, including Indigenous consultation; 2) management of geochemical monitoring programs, including water quality (i.e. effluent and receiving environment) and mine wastes (i.e. waste rock and tailings); and 3) planning and execution of progressive reclamation and mine closure activities. As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing. I have worked at Detour Lake mine site, and this familiarity with the operation serves as my personal inspection. I am responsible for Sections 1.1, 1.2, 1.17; Sections 2.1 to 2.4, 2.6; Section 20; Sections 25.1, 25.11; and Section 27 of the technical report. I was based at the Detour Lake Mine for four years and five months, followed by my current role as Manager for Reclamation and Geochemistry at the Kirkland Lake Gold Inc. Toronto corporate office, where I have served for five months. I have read NI 43–101, and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the technical report not misleading. Dated: 30 March, 2021 “Signed” V eronika Raizman, P.Geo.

CERTIFICATE OF QUALIFIED PERSON I, Paul Andrew Fournier, P.Eng., am employed as a Manager, Cost Accounting at the Corporate Office of Kirkland Lake Gold Ltd, with an address at Royal Bank Plaza, South Tower 200 Bay Street, Suite 2800 Toronto, Ontario, M5J 2J1, Canada. This certificate applies to the technical report titled “Detour Lake Operation NI 43-101 Technical Report” that has an effective date of 31 December, 2020 (the “technical report”). I am a Professional Engineer with Professional Engineers Ontario, license number 100218548. I graduated from McGill University (Canada) in 2011 with a Bachelor of Materials Engineering degree. I passed the Level II Exam of the CFA® Program of the CFA Institute in 2018. I have practiced my profession since graduation. I have seven years of experience in process and metallurgical engineering in mining and metals, including four years with the processing plant at the Detour Lake Mine. This experience includes five years of metals accounting, cost estimation, production and economic forecasting. I have two years of experience in financial analysis specifically for the Detour Lake Mine. As part of my role with Kirkland Lake Gold Ltd, I prepared the financial model for the Detour Lake Mine consolidated budget for 2020 and 2021. I have intimate knowledge of the cost model for the Detour Lake Mine through experience in budgeting, forecasting, monthly reporting, and variance analysis. As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43– 101 Standards of Disclosure for Mineral Projects (NI 43–101) for those sections of the technical report that I am responsible for preparing. My latest personal inspection of the Detour Lake Mine property was a 14-day rotation from July 2nd to 15th, 2020. I am responsible for Sections 1.1, 1.2, 1.19, 1.20, 1.21, 1.22, 1.23; Sections 2.1 to 2.6; Section 21, Section 22, Sections 25.1, 25.13, 25.14, 25.15, 25.17, and Section 27 of the technical report. I am not independent of Kirkland Lake Gold Ltd as I am currently employed as Manager, Cost Accounting. I have been involved with the Detour Gold Mine since 2014, first with the process plant, and then as a financial analyst. I have read NI 43–101 and the sections of the technical report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the technical report, to the best of my knowledge, information and belief, the sections of the technical report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the technical report not misleading. Dated: 30 March, 2021 “Signed” Paul Andrew Fournier, P.Eng.

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 a Cautionary Statements Cautionary Notes Forward-Looking Information This Technical Report contains certain forward-looking information and forward-looking statements, as defined in applicable securities laws (collectively referred to herein as “forward-looking statements”). Forward-looking statements reflect current expectations or beliefs regarding future events or Kirkland Lake Gold Ltd.’s (Kirkland Lake Gold or the Company) future performance. All statements other than statements of historical fact are forward-looking statements. Often, but not always, forward-looking statements can be identified by the use of words such as “plans”, “expects”, “is expected”, “budget”, “scheduled”, “estimates”, “continues”, “forecasts”, “projects”, “predicts”, “intends”, “anticipates”, “targets”, or “believes”, or variations of, or the negatives of, such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “should”, “might” or “will” be taken, occur or be achieved. Forward-looking statements involve known and unknown risks, uncertainties and other factors which may cause actual results, performance or achievements to be materially different from any of its future results, performance or achievements expressed or implied by forward-looking statements. These risks, uncertainties and other factors include, but are not limited to, assumptions and parameters underlying the life of mine update not being realized, a decrease in the future gold price, discrepancies between actual and estimated production, discrepancies related to the impact of various capital projects and the anticipated benefits therein, required capital investments; estimates of net present value and internal rate of returns; the accuracy of mineral reserve and mineral resource estimates, production estimates and capital and operating cost estimates and the assumptions on which such estimates are based; market competition; ongoing relations with employees and impacted communities changes in costs (including labour, supplies, fuel and equipment), changes to tax rates, environmental compliance and changes in environmental legislation and regulation, exchange rate fluctuations, general economic conditions and other risks involved in the gold exploration and development industry, as well as those risk factors discussed in the Technical Report. Such forward-looking statements are also based on a number of assumptions which may prove to be incorrect, including, but not limited to, assumptions about the following: the availability of financing for exploration and development activities; operating and capital costs; the Company’s ability to attract and retain skilled staff; sensitivity to metal prices and other sensitivities; the supply and demand for, and the level and volatility of the price of gold; the supply and availability of consumables and services; the exchange rates of the Canadian dollar to the U.S. dollar; energy and fuel costs; the accuracy of reserve and resource estimates and the assumptions on which the reserve and resource estimates are based; market competition; ongoing relations with employees and impacted communities and general business and economic conditions. Accordingly, readers should not place undue reliance on forward-looking statements. The

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 b forward-looking statements contained herein are made as of the date hereof, or such other date or dates specified in such statements. All forward-looking statements in this Technical Report are necessarily based on opinions and estimates made as of the date such statements are made and are subject to important risk factors and uncertainties, many of which cannot be controlled or predicted. Kirkland Lake Gold and the Qualified Persons who authored the Technical Report undertake no obligation to update publicly or otherwise revise any forward-looking statements contained herein whether as a result of new information or future events or otherwise, except as may be required by law. Non-IFRS Financial Performance Measures Kirkland Lake Gold has included certain non-IFRS measures in this document. The Company believes that these measures, in addition to conventional measures prepared in accordance with IFRS, provide investors an improved ability to evaluate the underlying performance of the Company. The non-IFRS measures are intended to provide additional information and should not be considered in isolation or as a substitute for measures of performance prepared in accordance with IFRS. These measures do not have any standardized meaning prescribed under IFRS, and therefore may not be comparable to other issuers. Free Cash Flow Before & After Tax In the gold mining industry, free cash flow is a common performance measure with no standardized meaning. Kirkland Lake Gold calculated free cash flow before taxes by deducting site operating costs, royalties and first nations payments, changes in inventory, capital expenditures, reclamation expenditures, and lease payments from net revenues and changes in working capital. Free cash flow after taxes is calculated by deducting tax expenses from free cash flow before taxes. Kirkland Lake Gold discloses free cash flow before and after tax as it believes the measure provides valuable assistance to investors and analysts in evaluating the Company’s ability to generate cash flow after capital investments and build the cash resources of the Company. The most directly comparable measure prepared in accordance with IFRS is net cash provided by operating activities less net cash used in investing activities. Operating Unit Costs Kirkland Lake Gold reports the following operating unit costs: • Mining operating unit cost (C$/t ex-pit): calculated as mining operating costs excluding adjustment for deferred stripping divided by total tonnes mined (ore + waste). • Operating unit cost per tonne (C$/t milled): calculated as operating costs divided by total tonnes milled. This is calculated for the different components of operating cost. Operating costs include mite site operating costs such as mining, processing, and site administration, as well as adjustments for deferred stripping, royalties, and changes in inventory.

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 c • Operating unit cost per ounce (C$/t oz sold): calculated as operating costs per ounce on a gross gold sales basis, where gross gold sales represent gold production after adjustment for changes in gold-in-circuit and dore inventory. Kirkland Lake Gold discloses operating costs and operating unit cost per tonne and per ounce as it believes the measures provide valuable assistance to investors and analysts in evaluating the Company’s operational performance and ability to generate cash flow. The most directly comparable measure prepared in accordance with IFRS is total production expenses. Operating cash costs and operating cash cost per ounce of gold should not be considered in isolation or as a substitute for measures prepared in accordance with IFRS. Operating Margin The operating margin represents net revenue after site operating costs, royalties and First Nations payments, and changes in inventory. Operating margin is an indicator of the Company’s ability to generate liquidity by producing operating cash flow to fund working capital needs, service debt obligations, and fund capital expenditures. Operating Cash Costs and Operating Cash Costs per Ounce Sold Operating cash costs and operating cash cost per tonne and per ounce sold are non-IFRS measures. In the gold mining industry, these metrics are common performance measures but do not have any standardized meaning under IFRS. Operating cash costs include mine site operating costs such as mining, processing and administration, but exclude royalty expenses, depreciation and depletion and share based payment expenses and reclamation costs. Operating cash cost per ounce sold is based on ounces sold and is calculated by dividing operating cash costs by volume of gold ounces sold. Kirkland Lake Gold discloses operating cash costs and operating cash cost per tonne and per ounce as it believes the measures provide valuable assistance to investors and analysts in evaluating the Company’s operational performance and ability to generate cash flow. The most directly comparable measure prepared in accordance with IFRS is total production expenses. Operating cash costs and operating cash cost per ounce of gold should not be considered in isolation or as a substitute for measures prepared in accordance with IFRS. AISC and AISC per Ounce Sold All-in sustaining costs (AISC) and AISC per ounce are non-IFRS measures. These measures are intended to assist readers in evaluating the total costs of producing gold from current operations. While there is no standardized meaning across the industry for this measure, Kirkland Lake Gold’s definition conforms to the definition of AISC as set out by the World Gold Council in its guidance note dated June 27, 2013. The Company defines AISC as the sum of operating costs (as defined and calculated above), royalty expenses, sustaining capital, corporate expenses and reclamation cost accretion related to current operations. Corporate expenses include general and administrative expenses, net of transaction related costs, severance expenses for management changes and interest income. AISC excludes growth capital expenditures,

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 d growth exploration expenditures, reclamation cost accretion not related to current operations, interest expense, debt repayment and taxes. Sustaining and Growth Capital Sustaining capital and growth capital are non-IFRS measures. Sustaining capital is defined as capital required to maintain current operations at existing levels. Growth capital is defined as capital expenditures for major growth projects or enhancement capital for significant infrastructure improvements at existing operations. Both measurements are used by management to assess the effectiveness of investment programs. Working Capital Working capital is a non-IFRS measure. In the gold mining industry, working capital is a common measure of liquidity, but does not have any standardized meaning. The most directly comparable measure prepared in accordance with IFRS is current assets and current liabilities. Working capital is calculated by deducting accounts payables from accounts receivables, supplies inventory, and gold inventory (ore stockpiles, gold-in-circuit, and dore inventory). Working capital should not be considered in isolation or as a substitute from measures prepared in accordance with IFRS. The measure is intended to assist readers in evaluating Kirkland Lake Gold’s liquidity.

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 i Table of Contents 1.0 Summary ............................................................................................... 1-1 1.1 Introduction ......................................................................................................... 1-1 1.2 Terms of Reference ............................................................................................ 1-1 1.3 Property Description and Location ..................................................................... 1-1 1.4 Mineral Tenure, Surface Rights, Water Rights and Royalties ............................ 1-2 1.5 Geology and Mineralization ................................................................................ 1-3 1.6 History ................................................................................................................ 1-5 1.7 Drilling and Sampling ......................................................................................... 1-5 1.8 Data Verification ................................................................................................. 1-8 1.9 Metallurgical Testwork ........................................................................................ 1-9 1.10 Mineral Resource Estimates ............................................................................ 1-10 1.11 Mineral Resource Statement ............................................................................ 1-12 1.12 Mineral Reserve Estimates .............................................................................. 1-15 1.13 Mineral Reserve Statement .............................................................................. 1-16 1.14 Mining Methods ................................................................................................ 1-18 1.15 Recovery Methods ........................................................................................... 1-19 1.16 Project Infrastructure ........................................................................................ 1-20 1.17 Environmental, Permitting and Social Considerations ...................................... 1-21 1.17.1 Environmental and Supporting Studies ............................................................ 1-21 1.17.2 Monitoring ......................................................................................................... 1-21 1.17.3 Tailings Management Area .............................................................................. 1-23 1.17.4 Water Management .......................................................................................... 1-23 1.17.5 Permits ............................................................................................................. 1-24 1.17.6 Closure and Reclamation ................................................................................. 1-25 1.17.7 Social Considerations ....................................................................................... 1-25 1.18 Markets and Contracts ..................................................................................... 1-26 1.19 Capital Cost Estimates ..................................................................................... 1-26 1.20 Operating Cost Estimates ................................................................................ 1-27 1.21 Economic Analysis ........................................................................................... 1-29 1.22 Sensitivity Analysis ........................................................................................... 1-30 1.23 Interpretation and Conclusions ......................................................................... 1-30 1.24 Risks and Opportunities ................................................................................... 1-33 1.25 Recommendations ........................................................................................... 1-34 2.0 Introduction ........................................................................................... 2-1 2.1 Introduction ......................................................................................................... 2-1 2.2 Terms of Reference ............................................................................................ 2-1 2.3 Qualified Persons ............................................................................................... 2-1

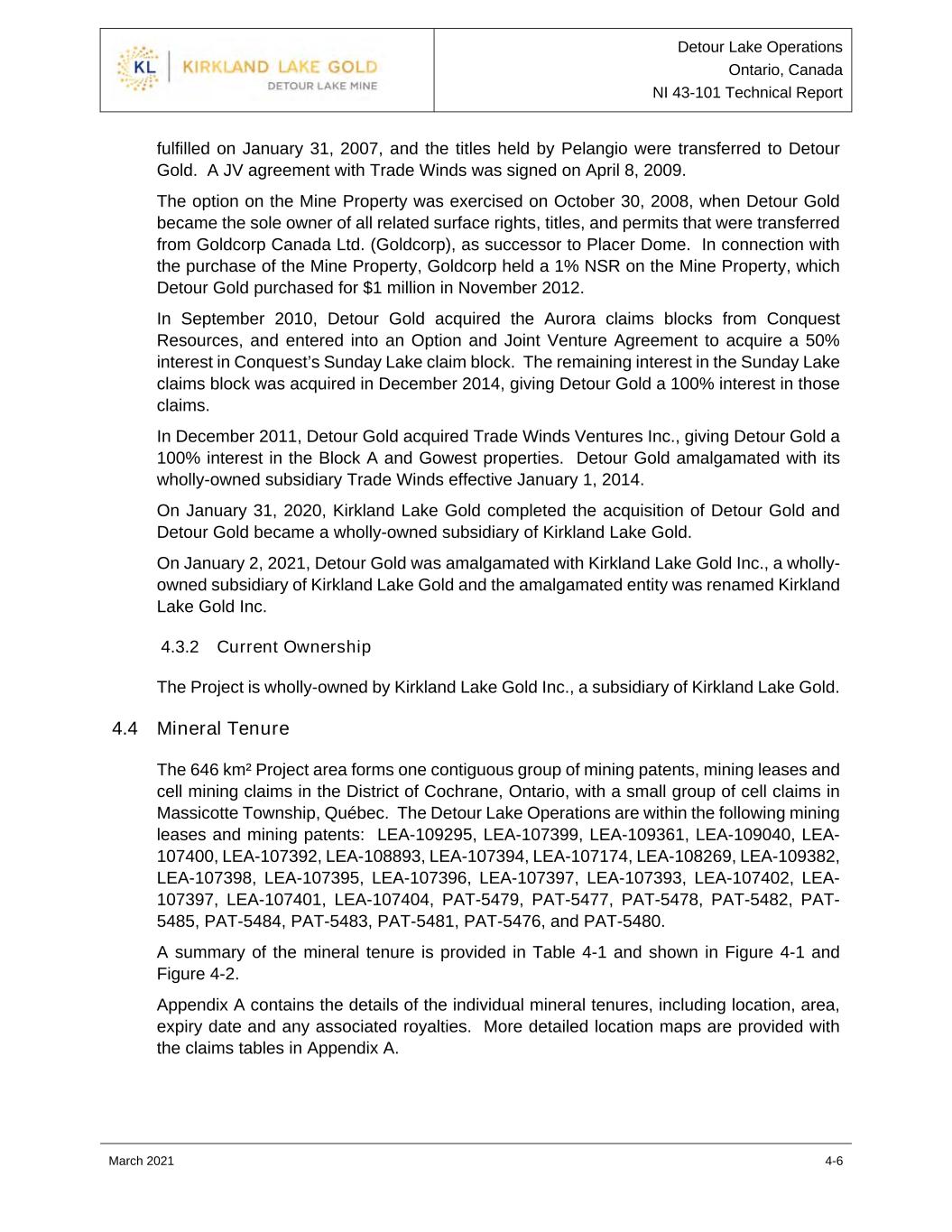

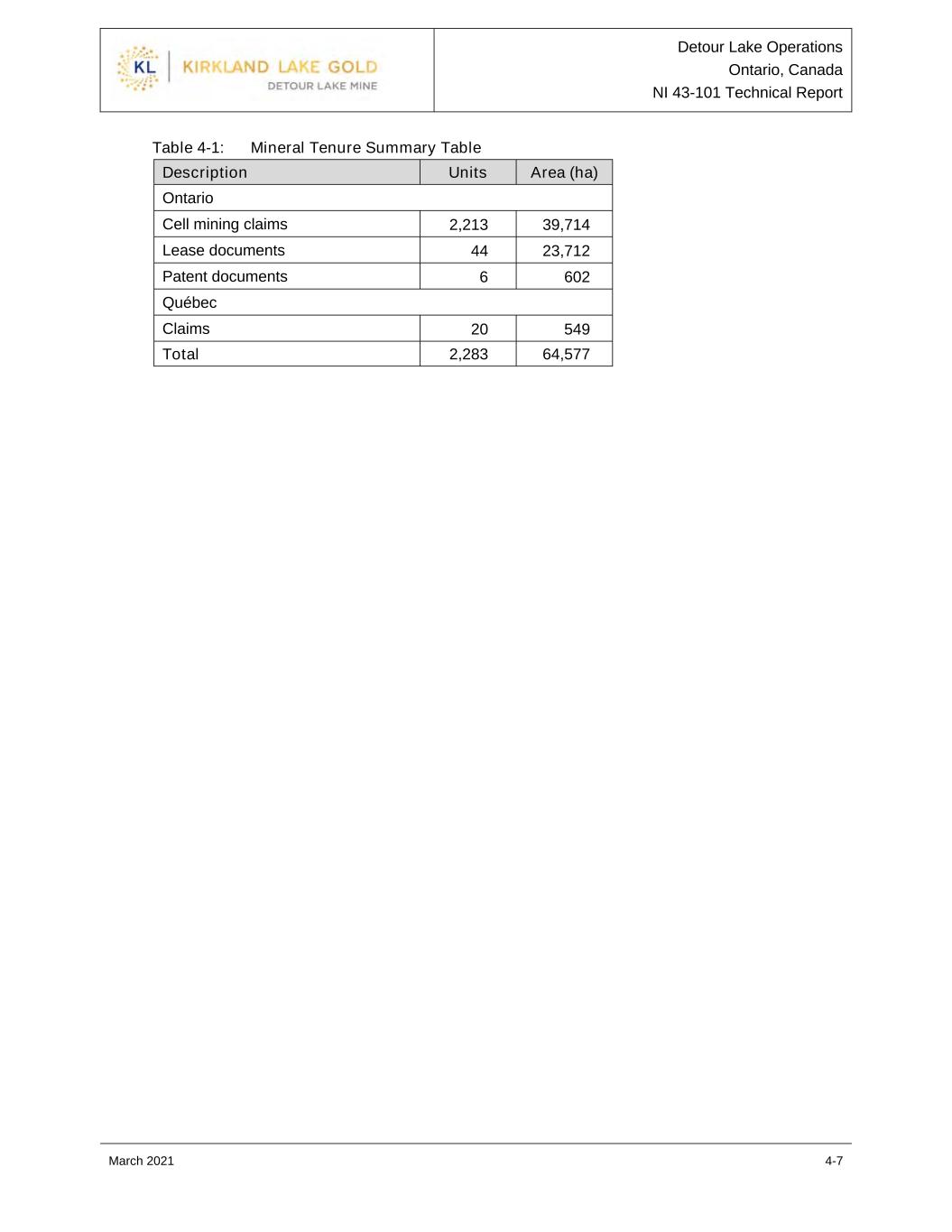

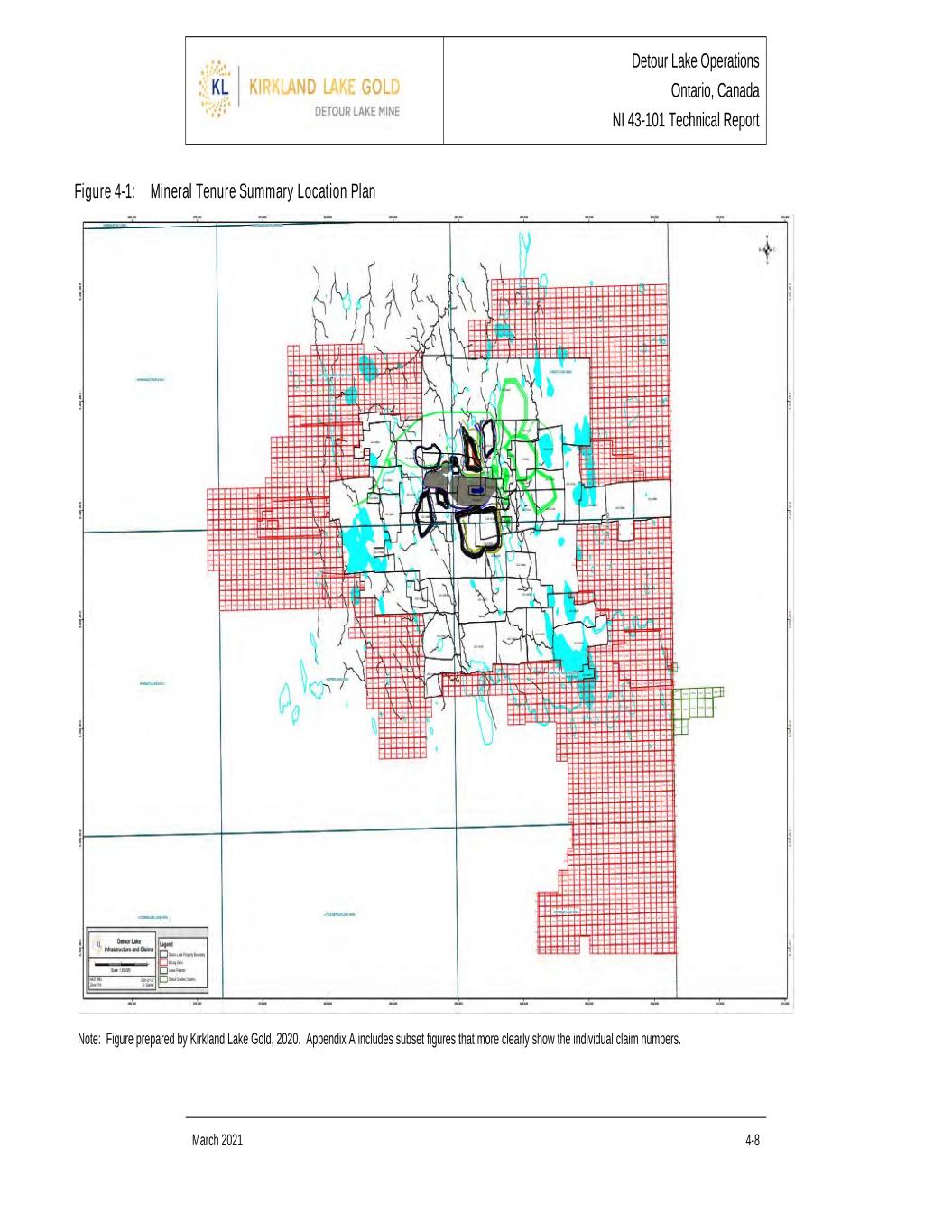

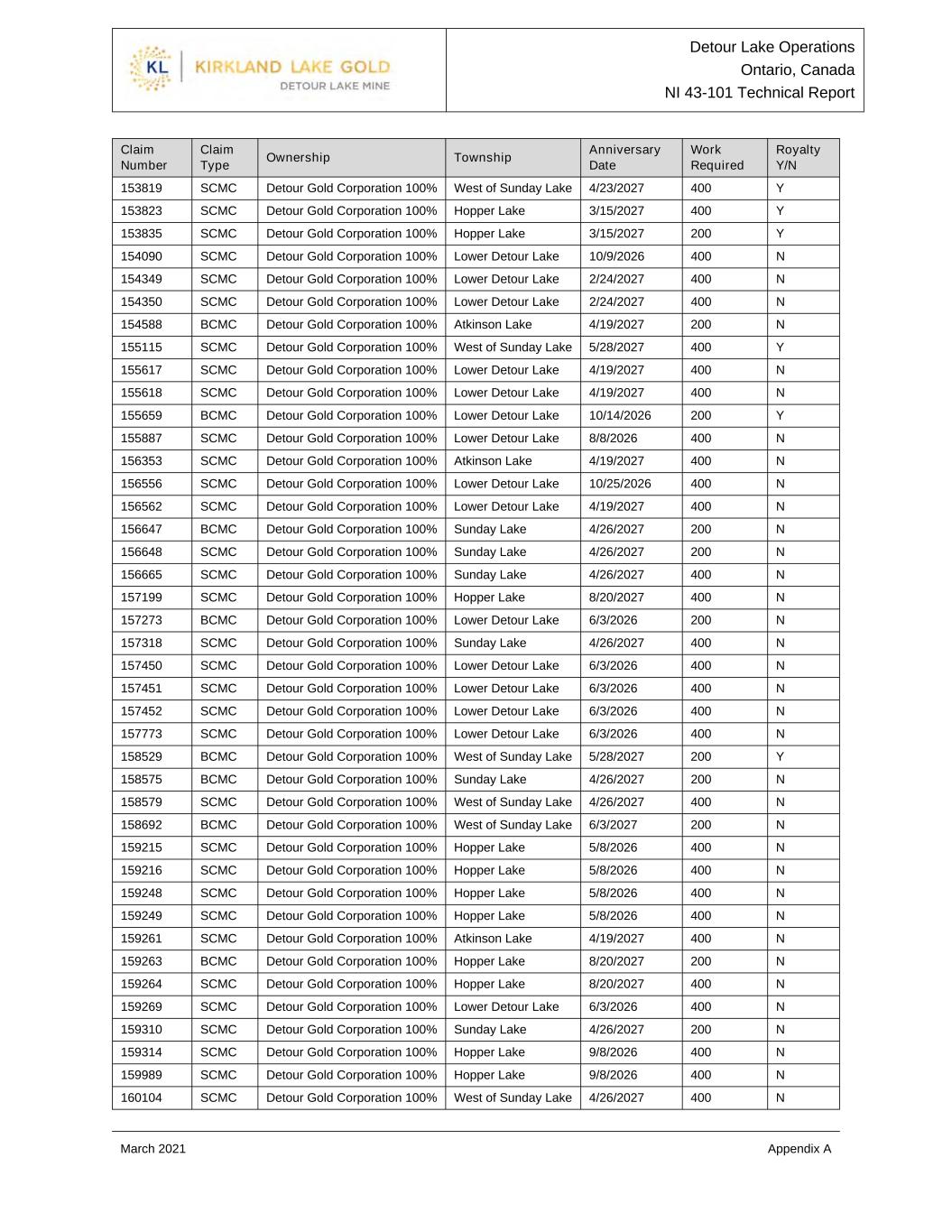

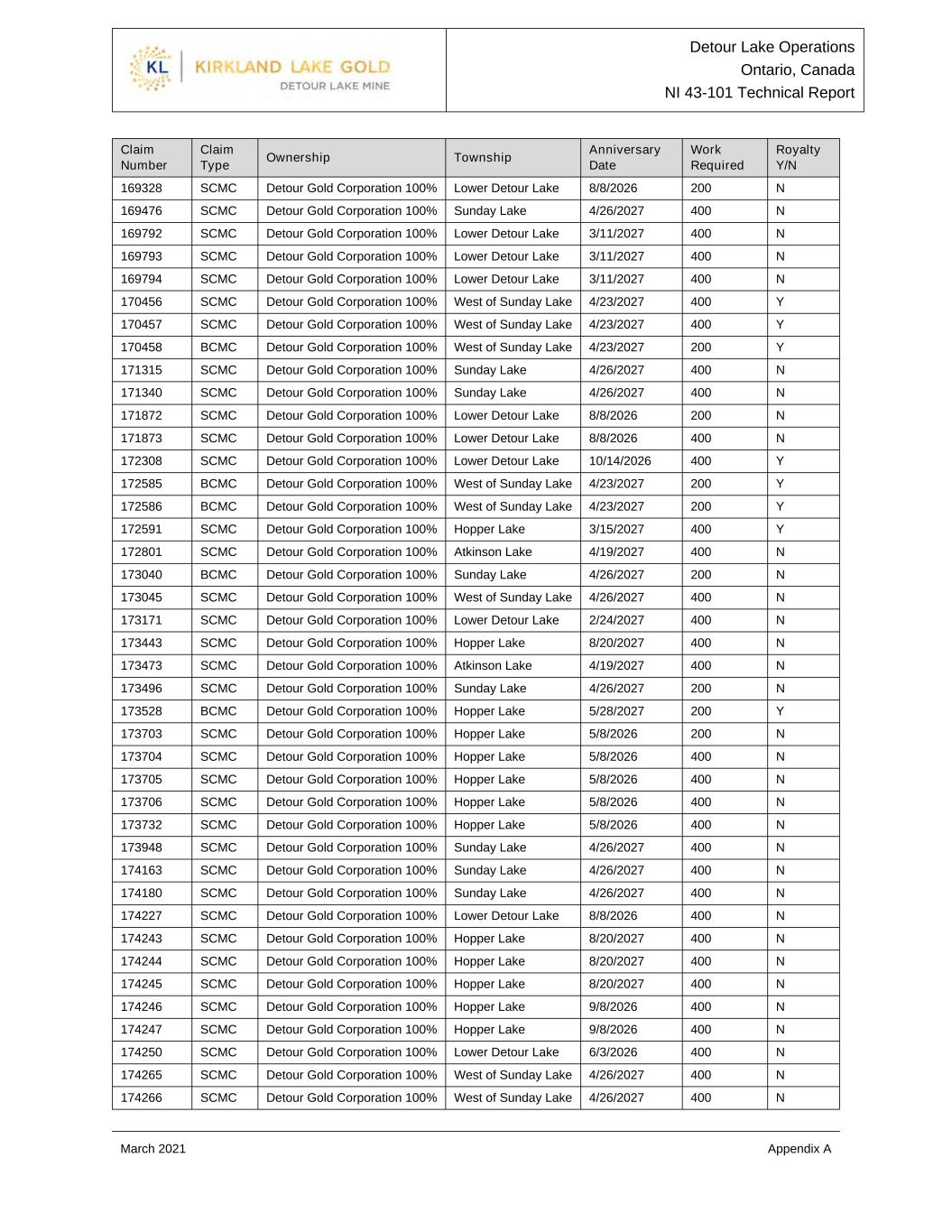

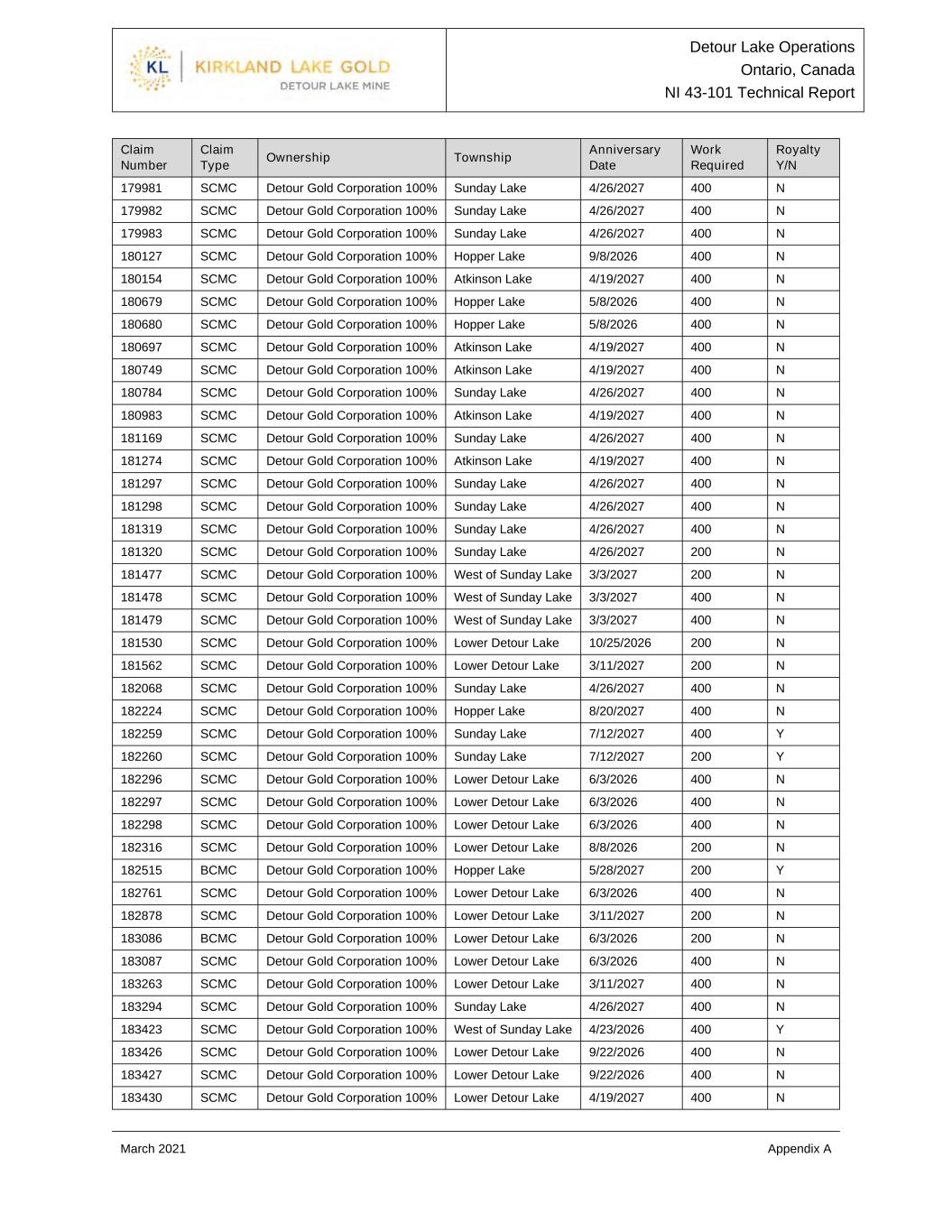

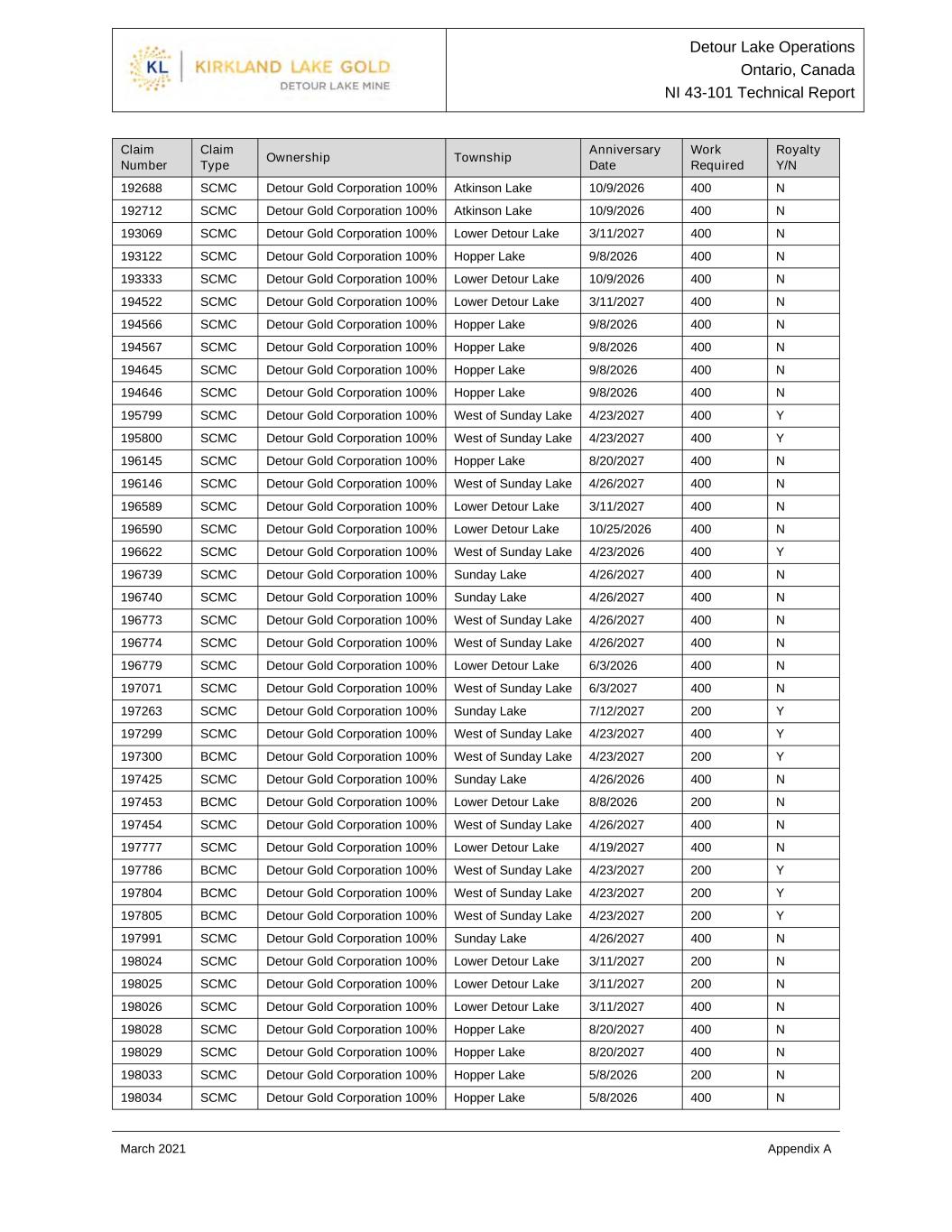

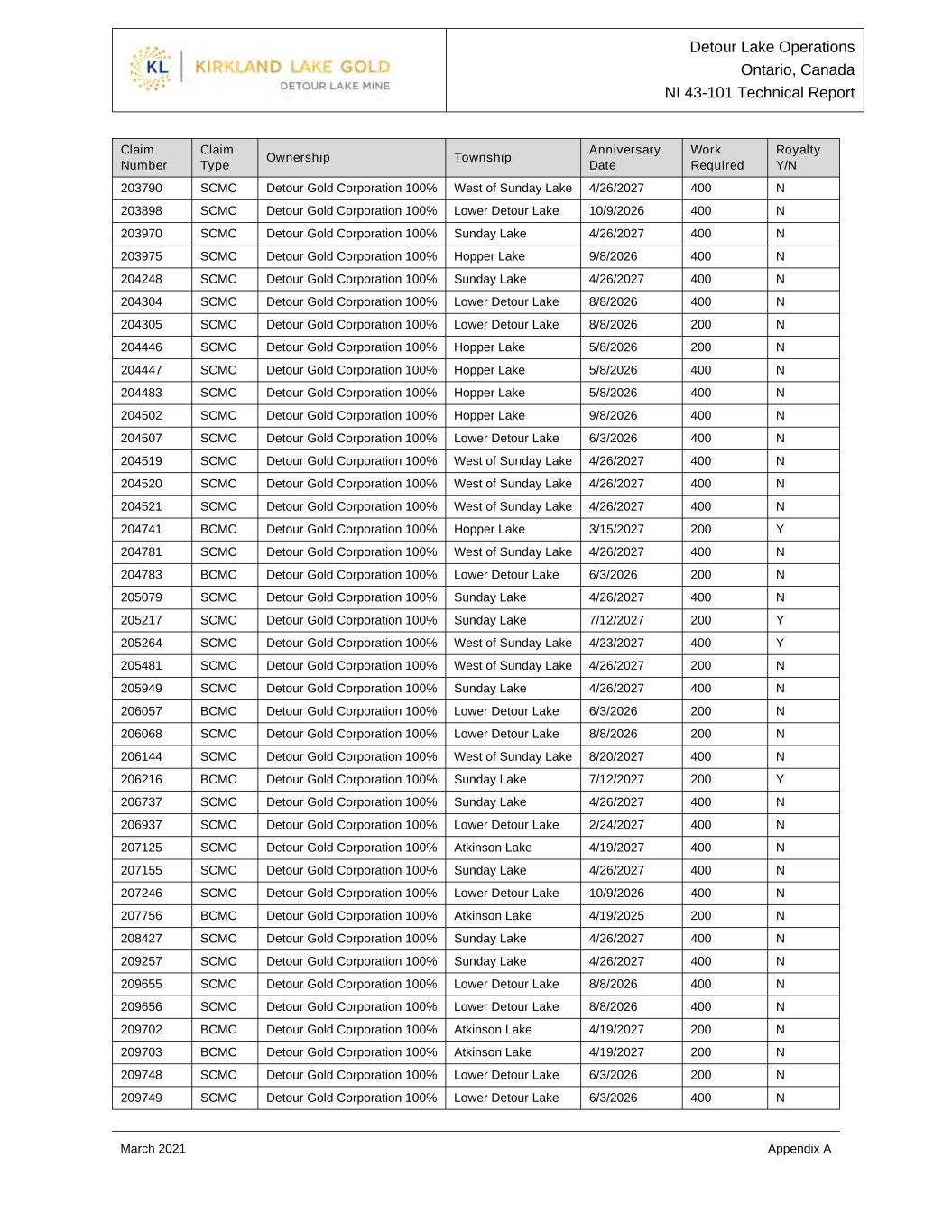

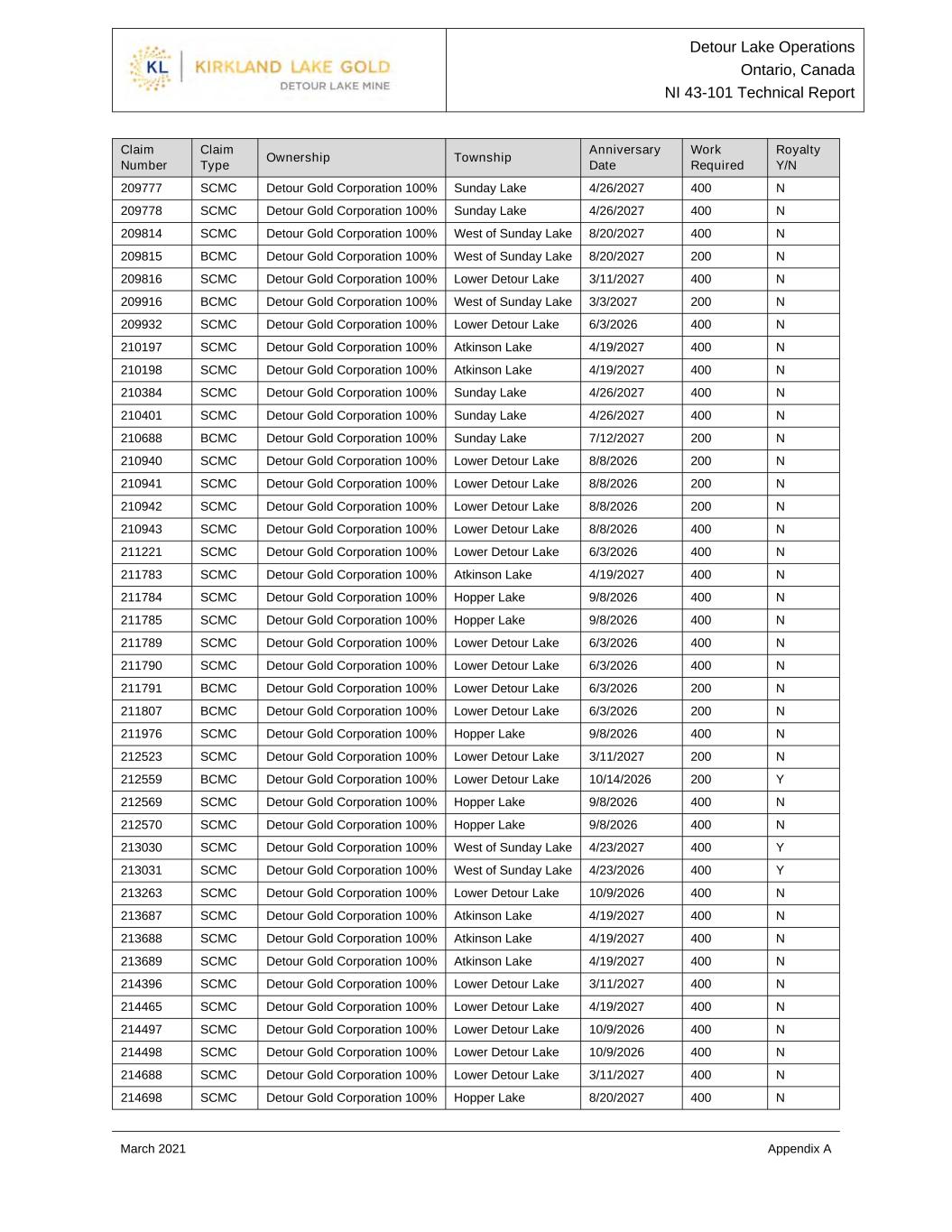

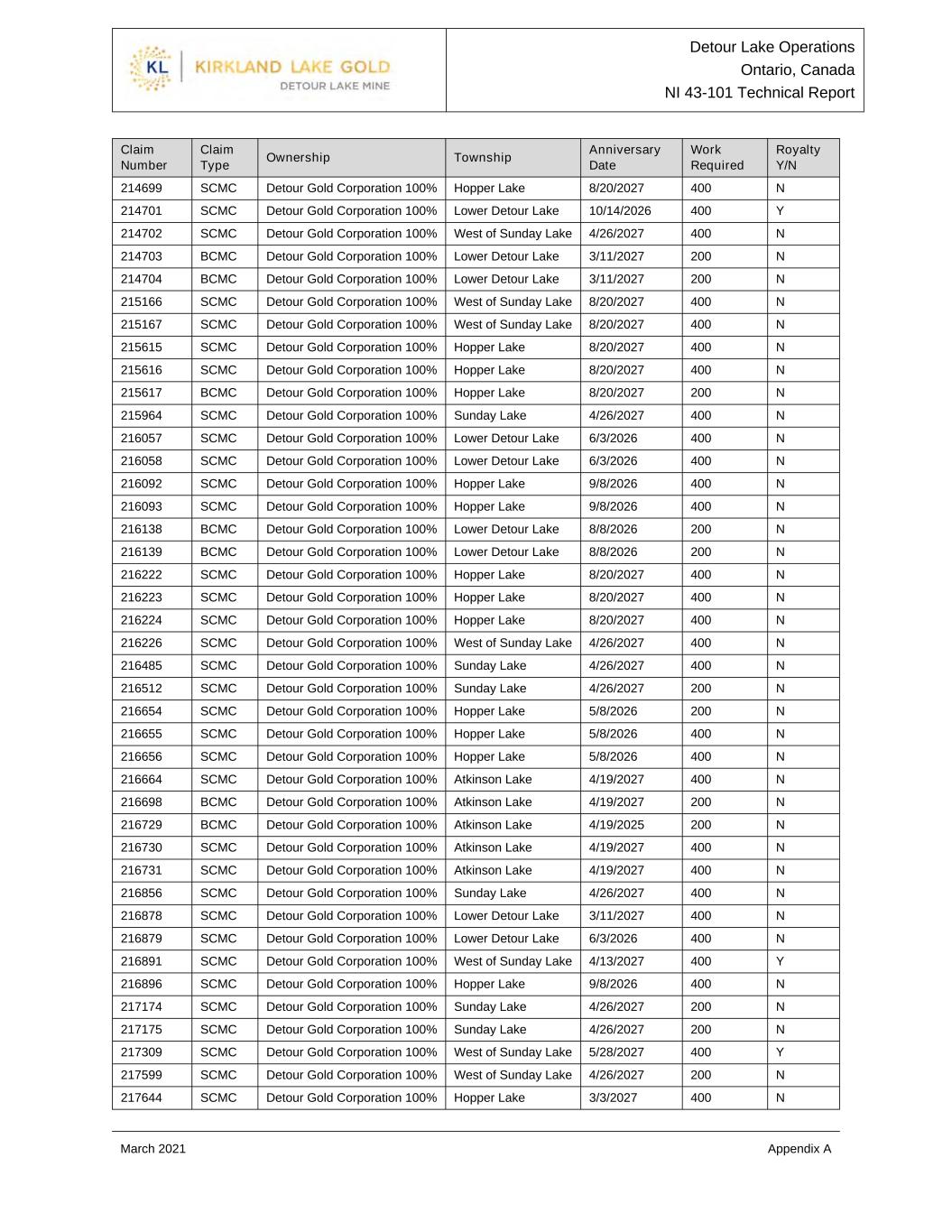

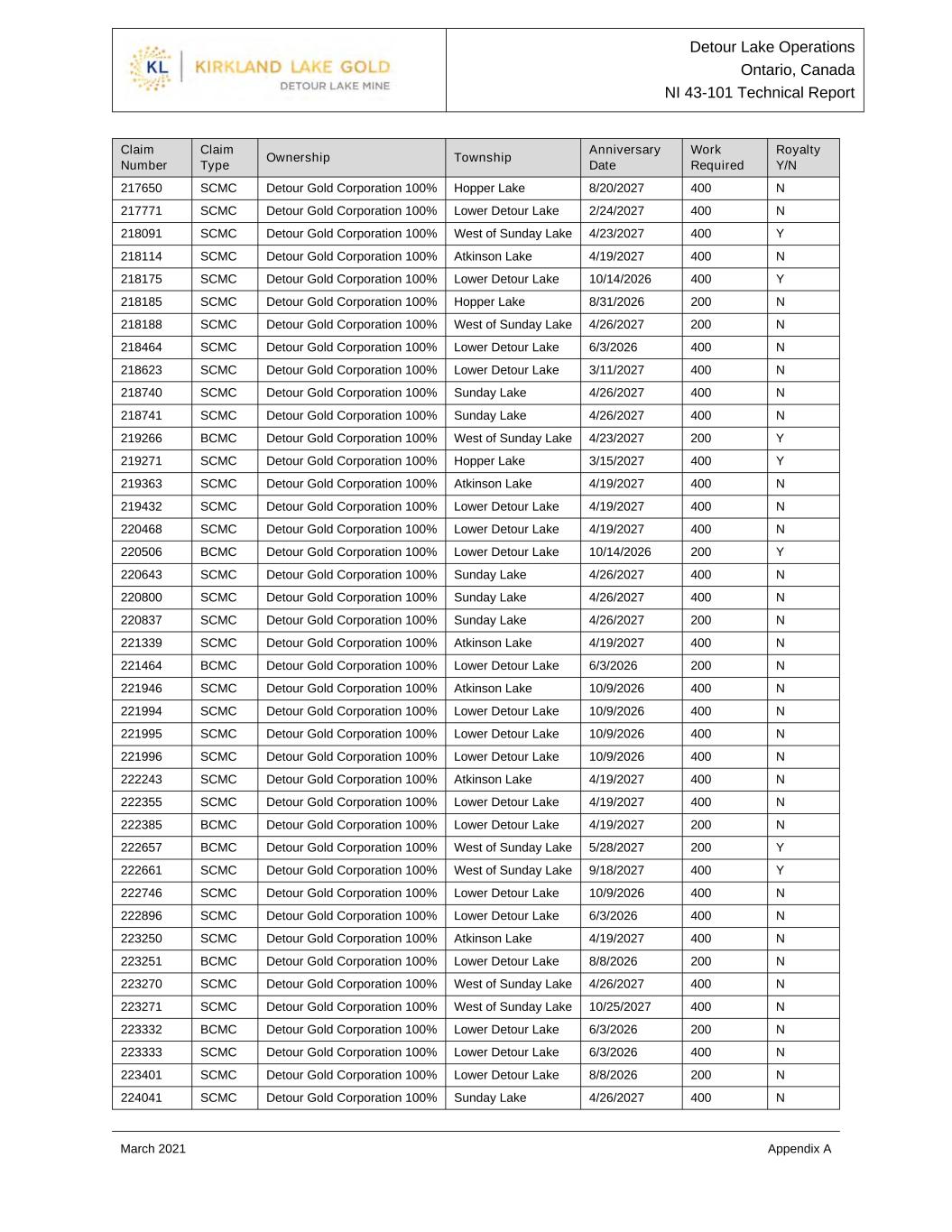

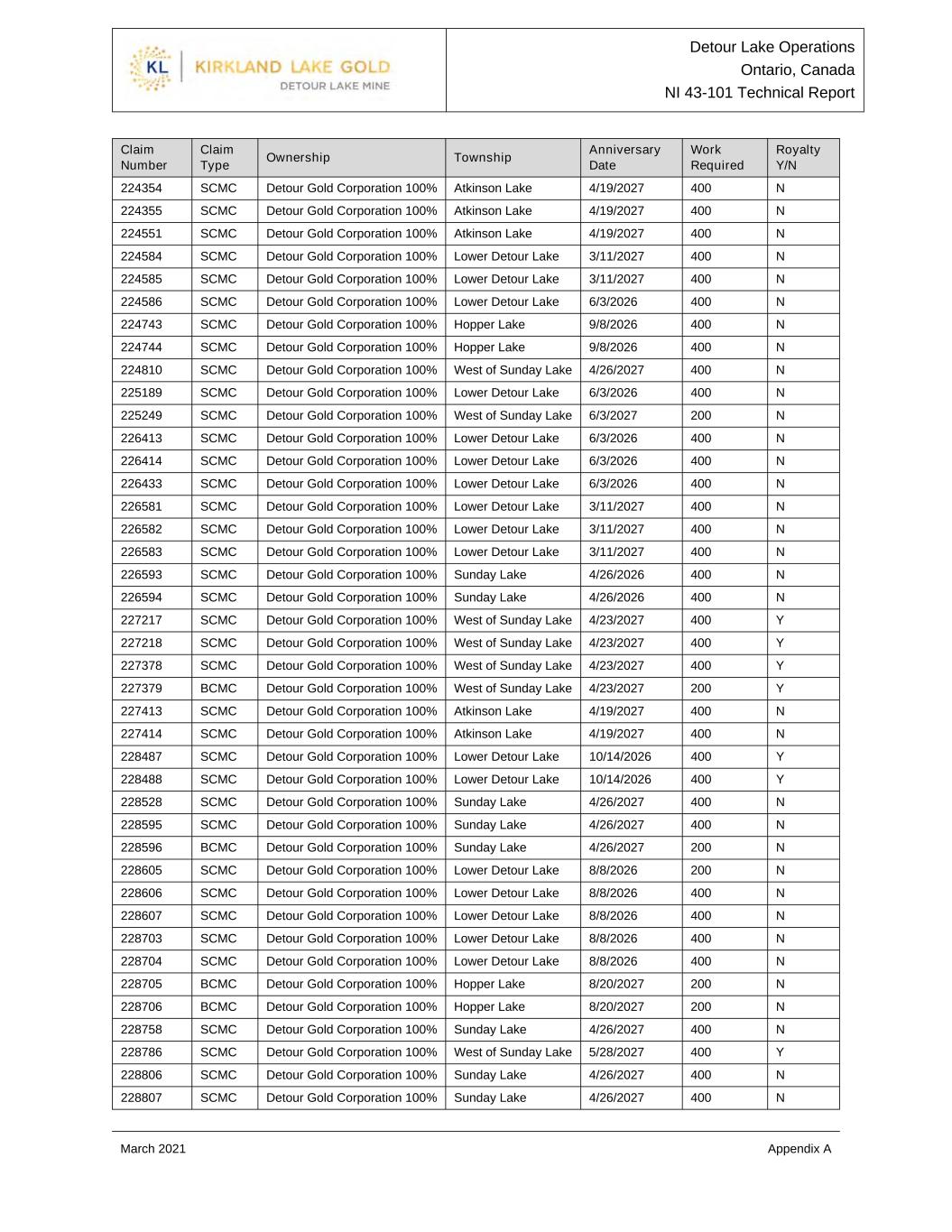

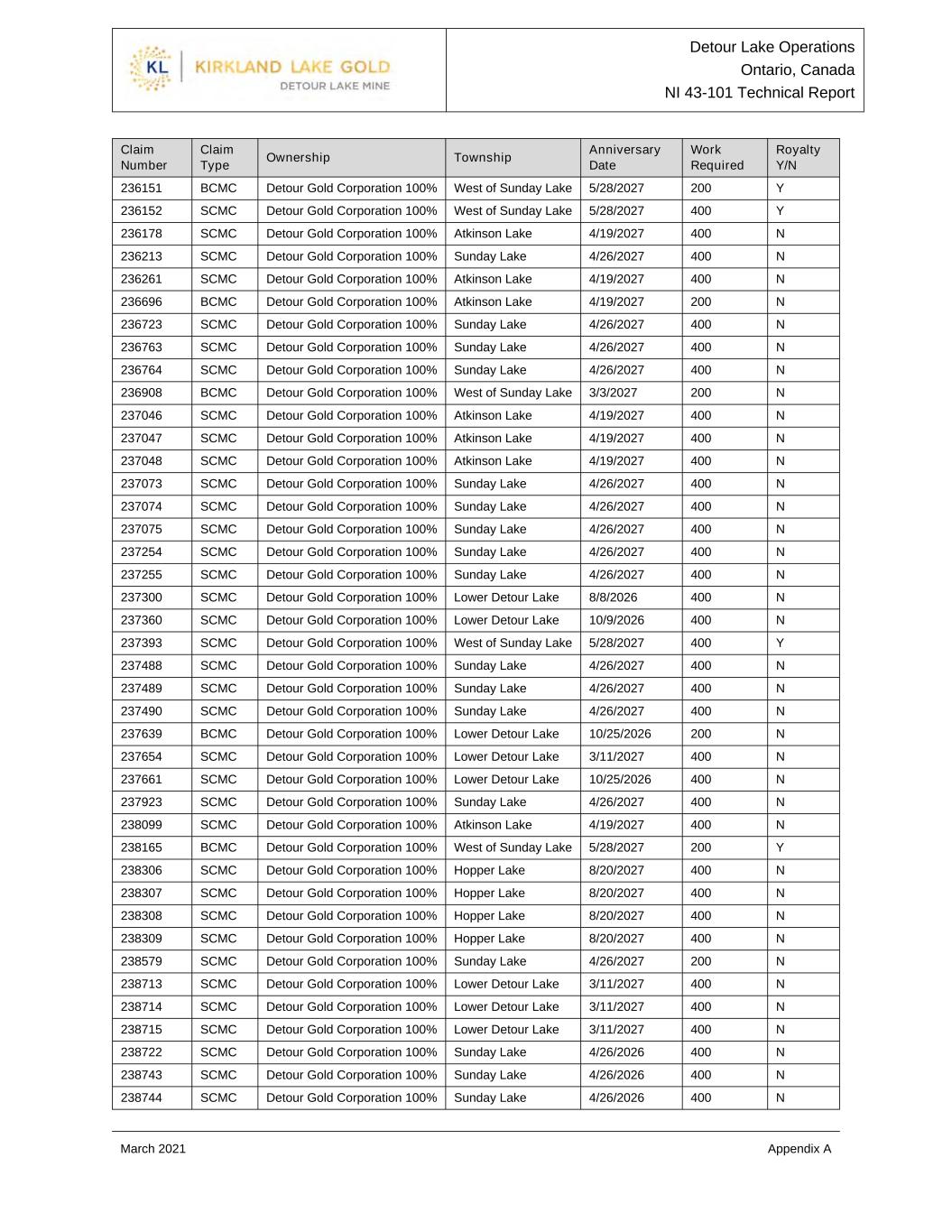

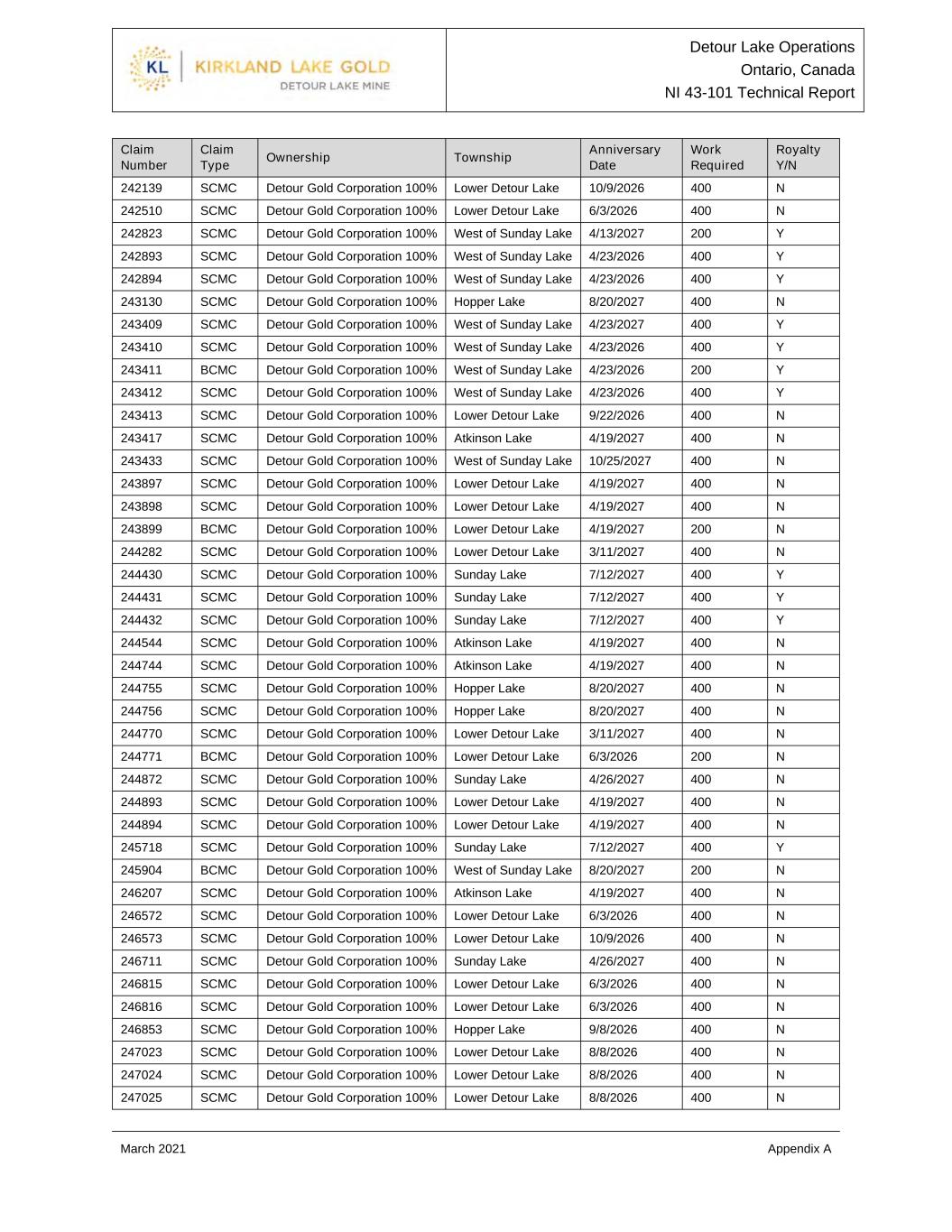

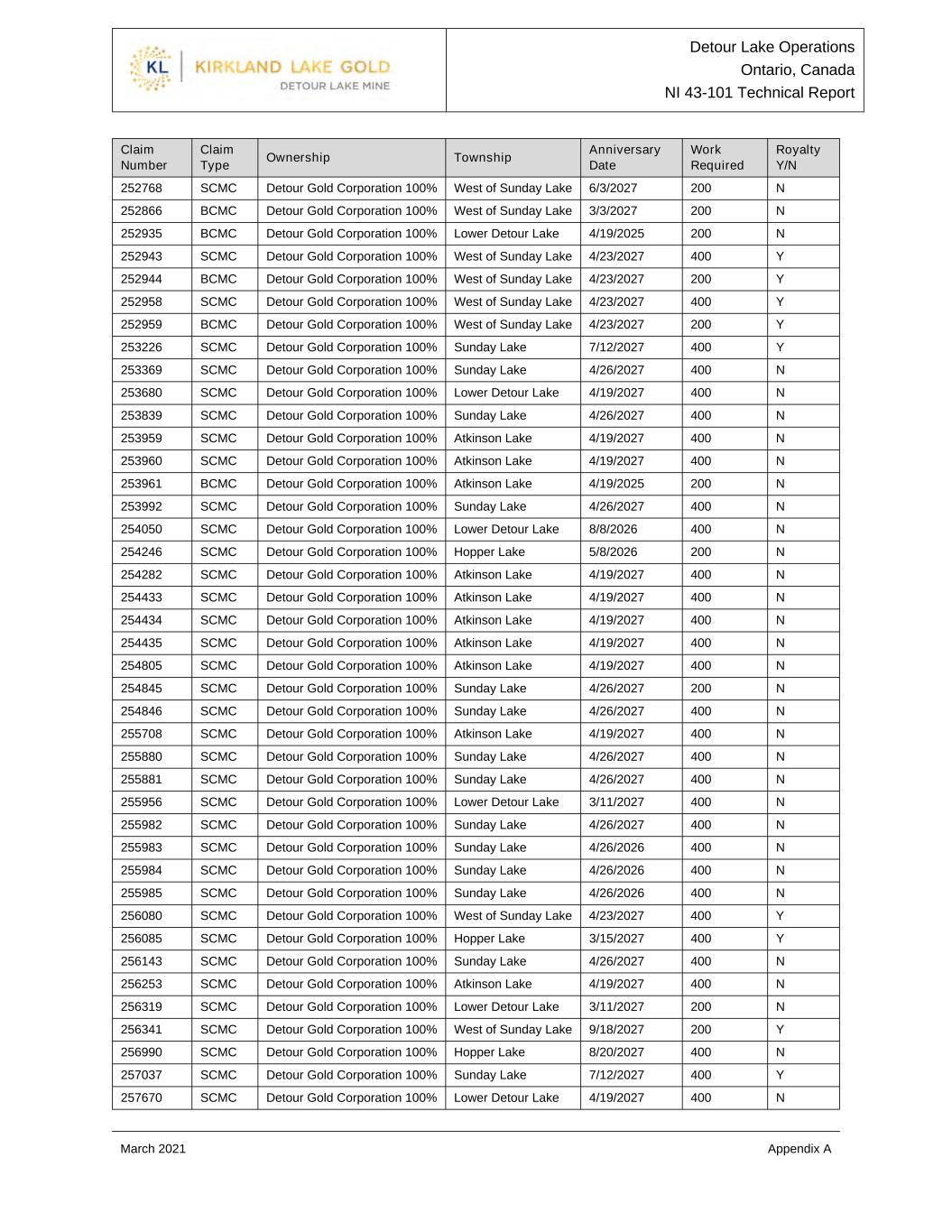

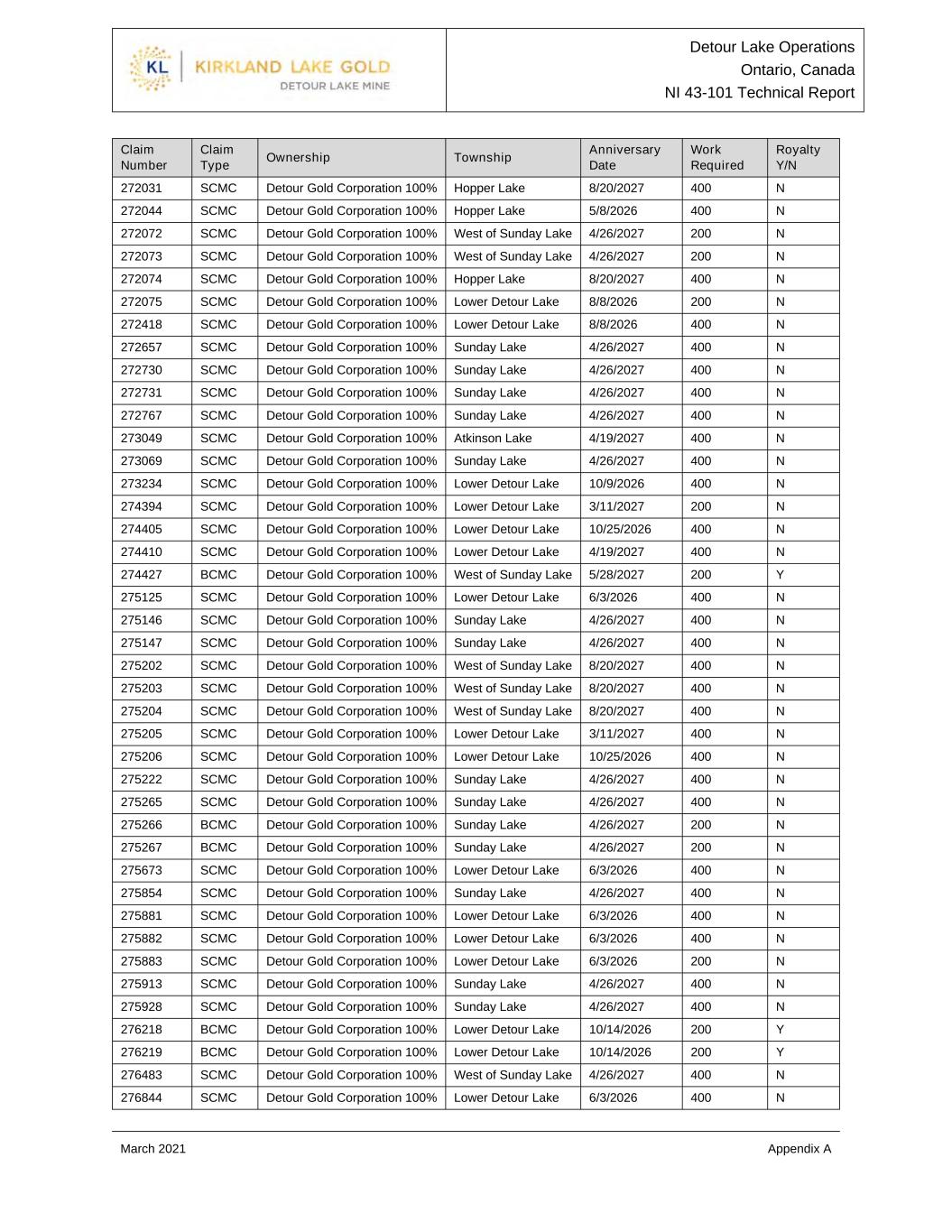

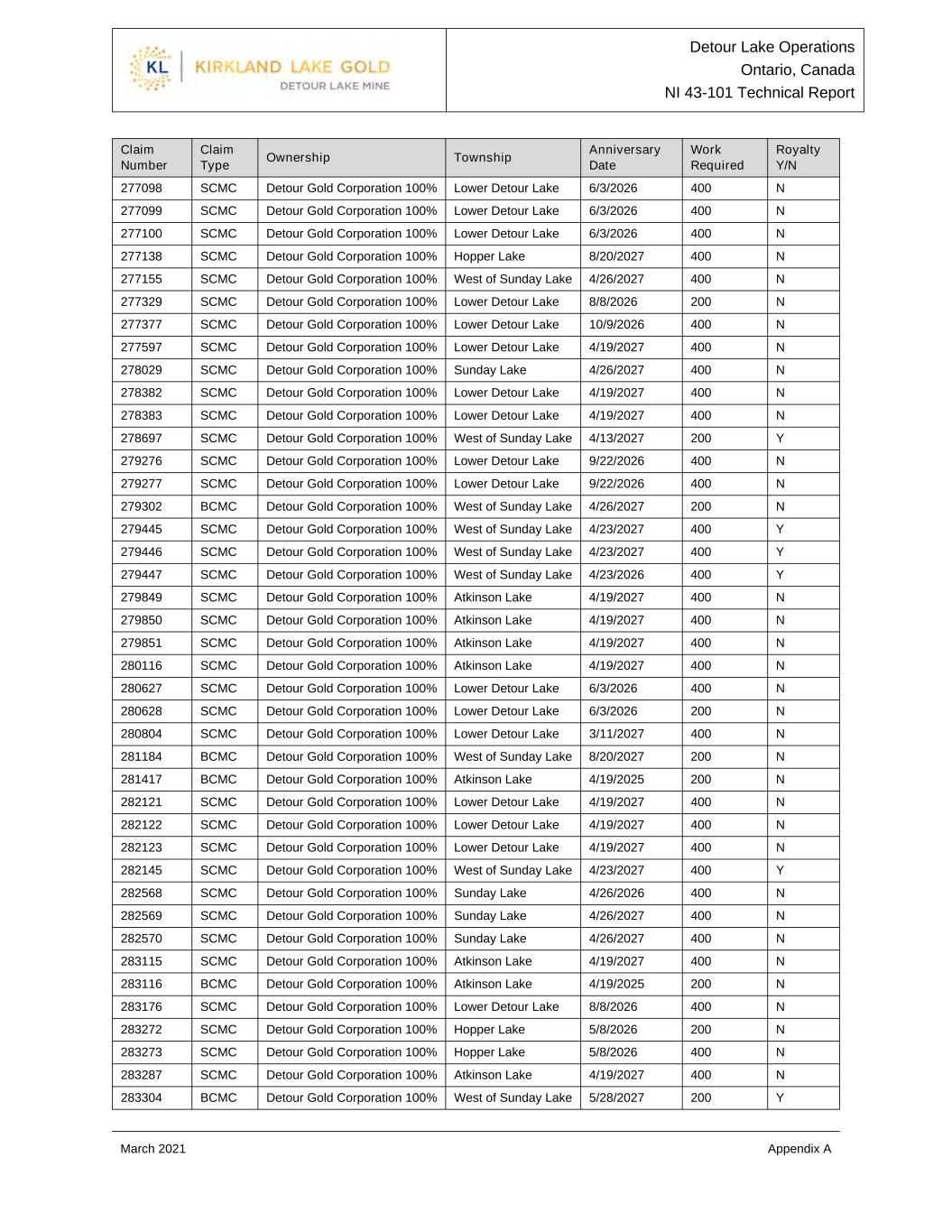

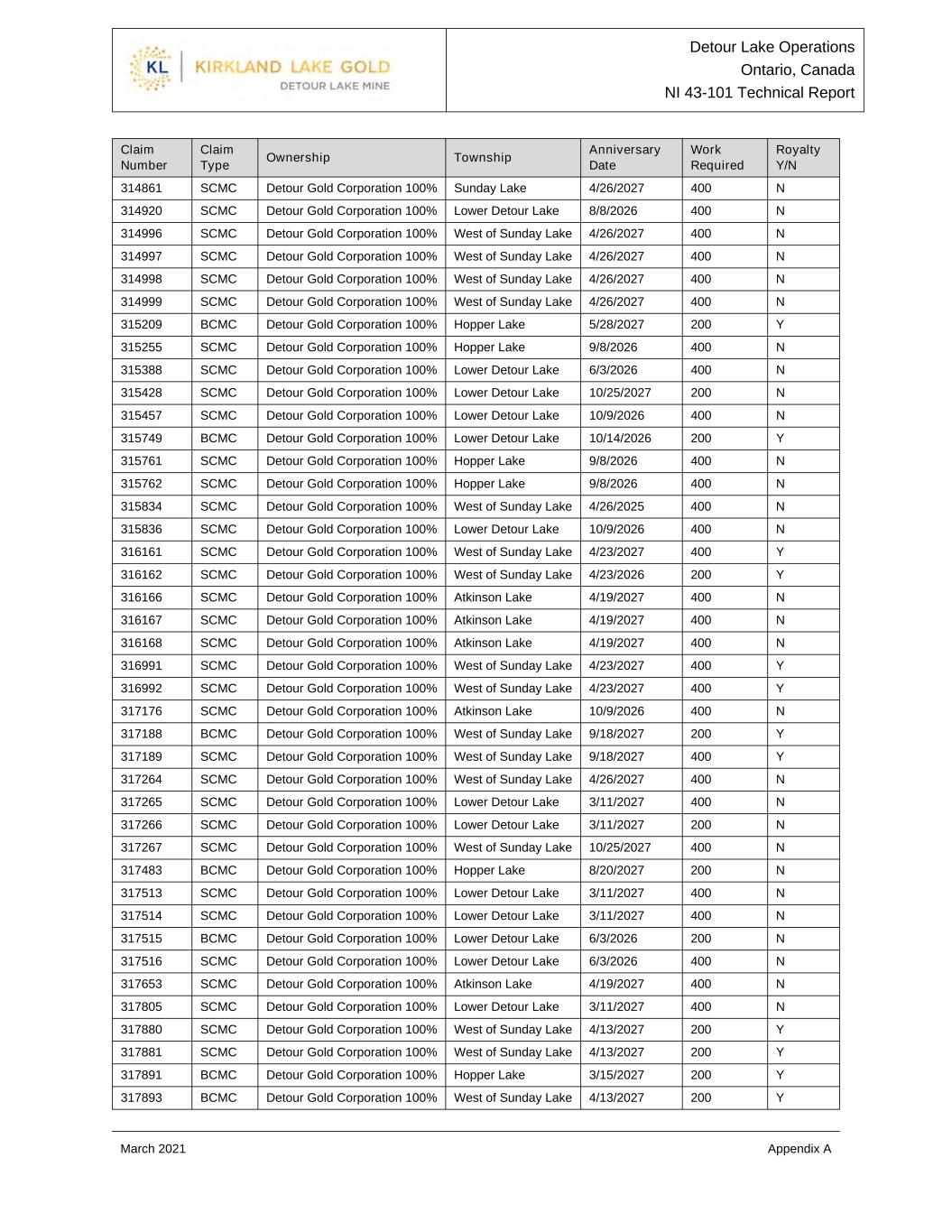

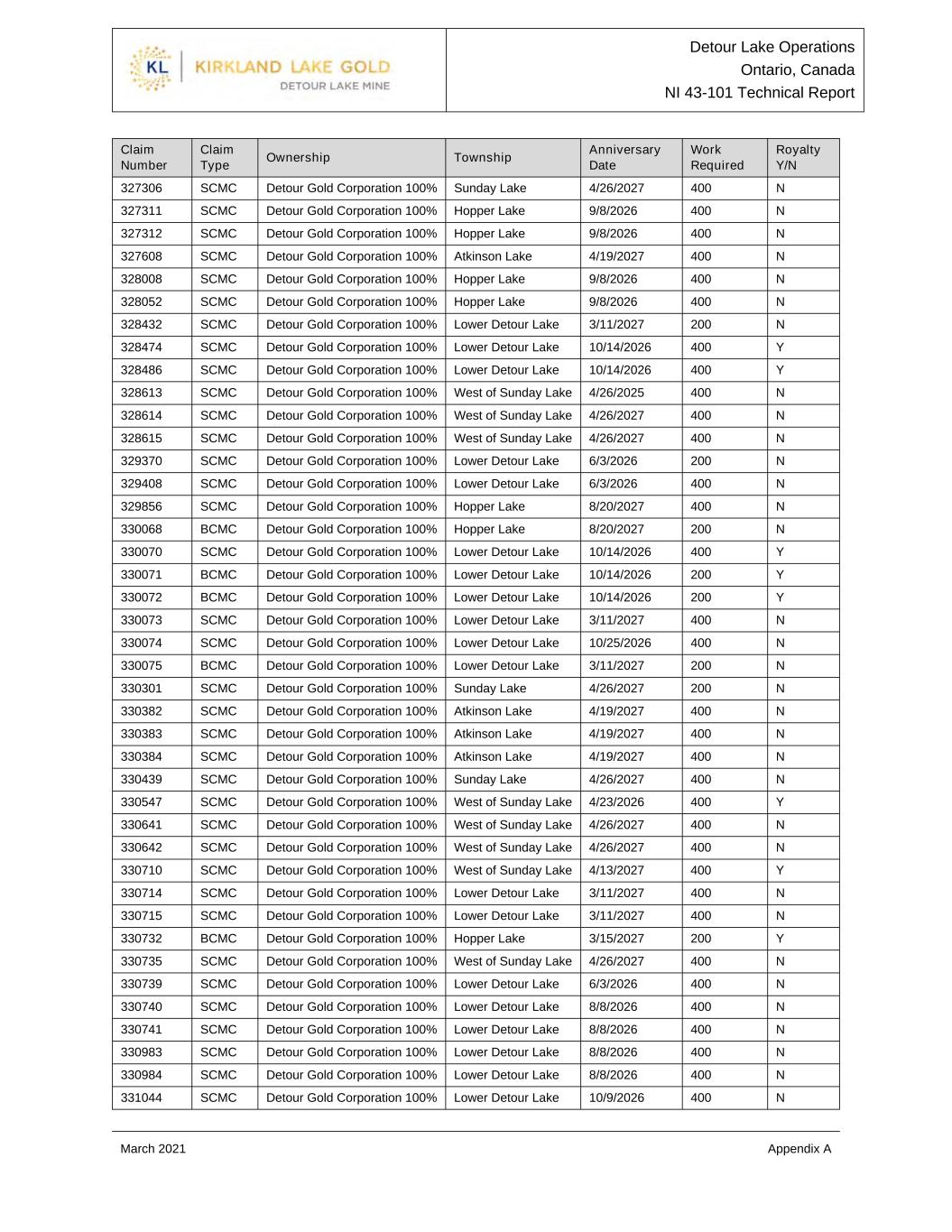

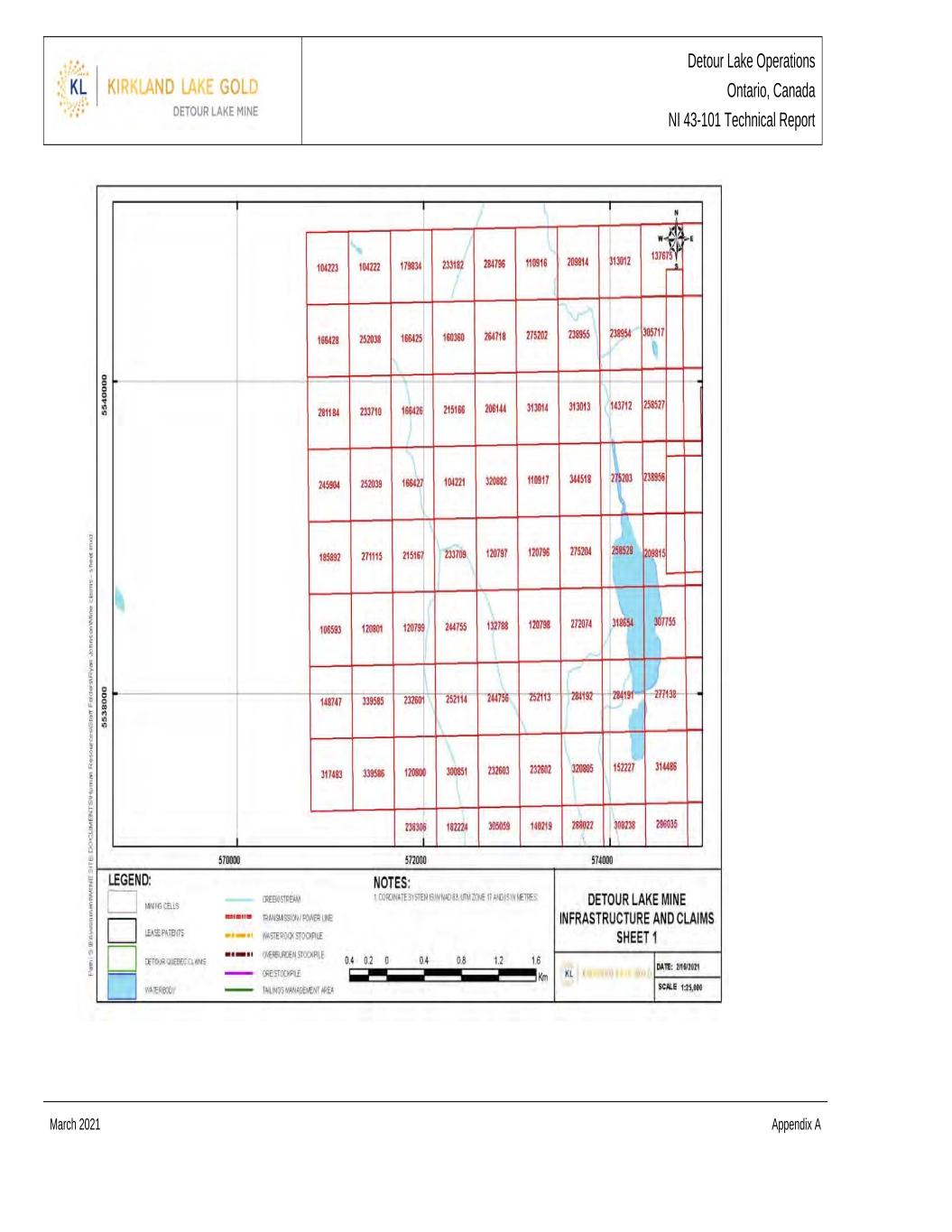

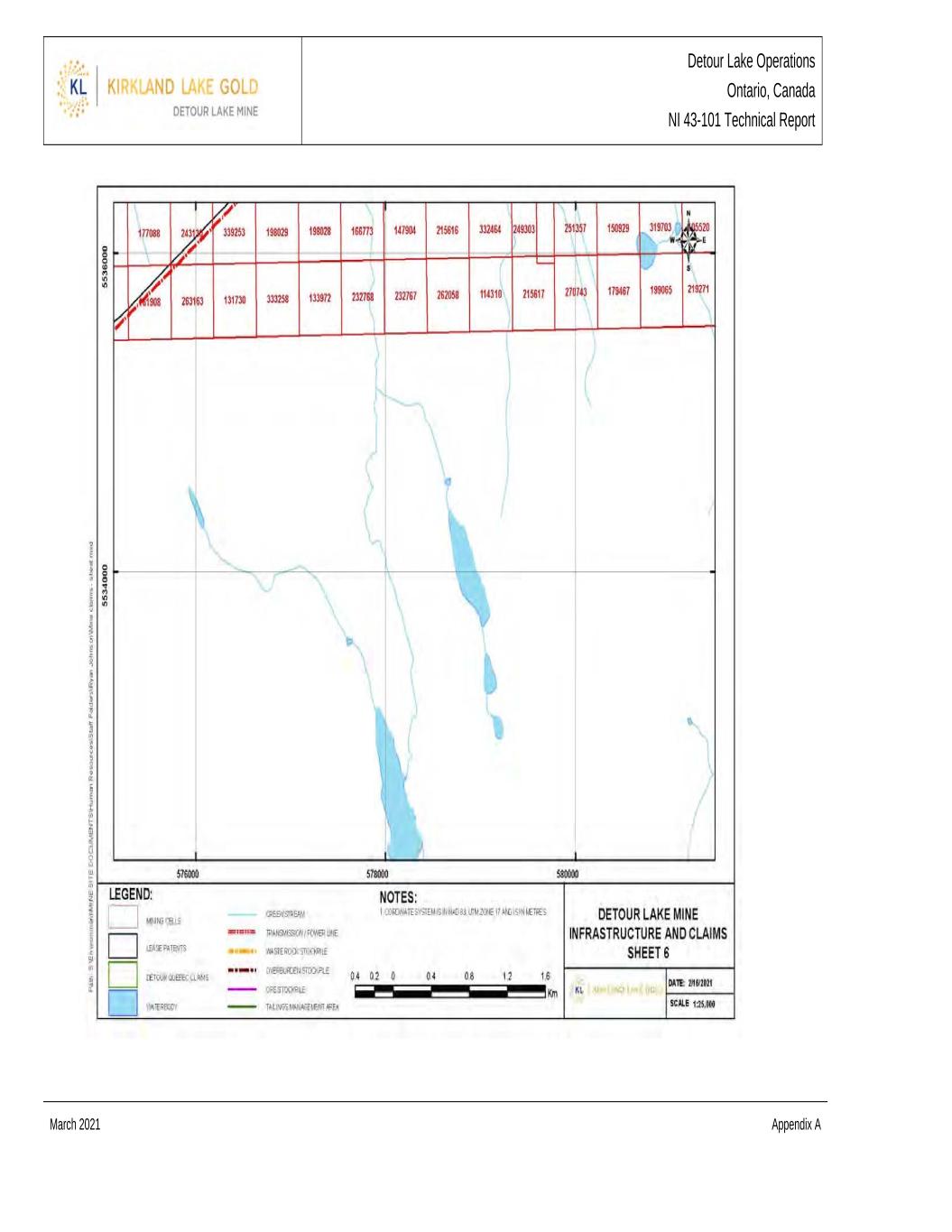

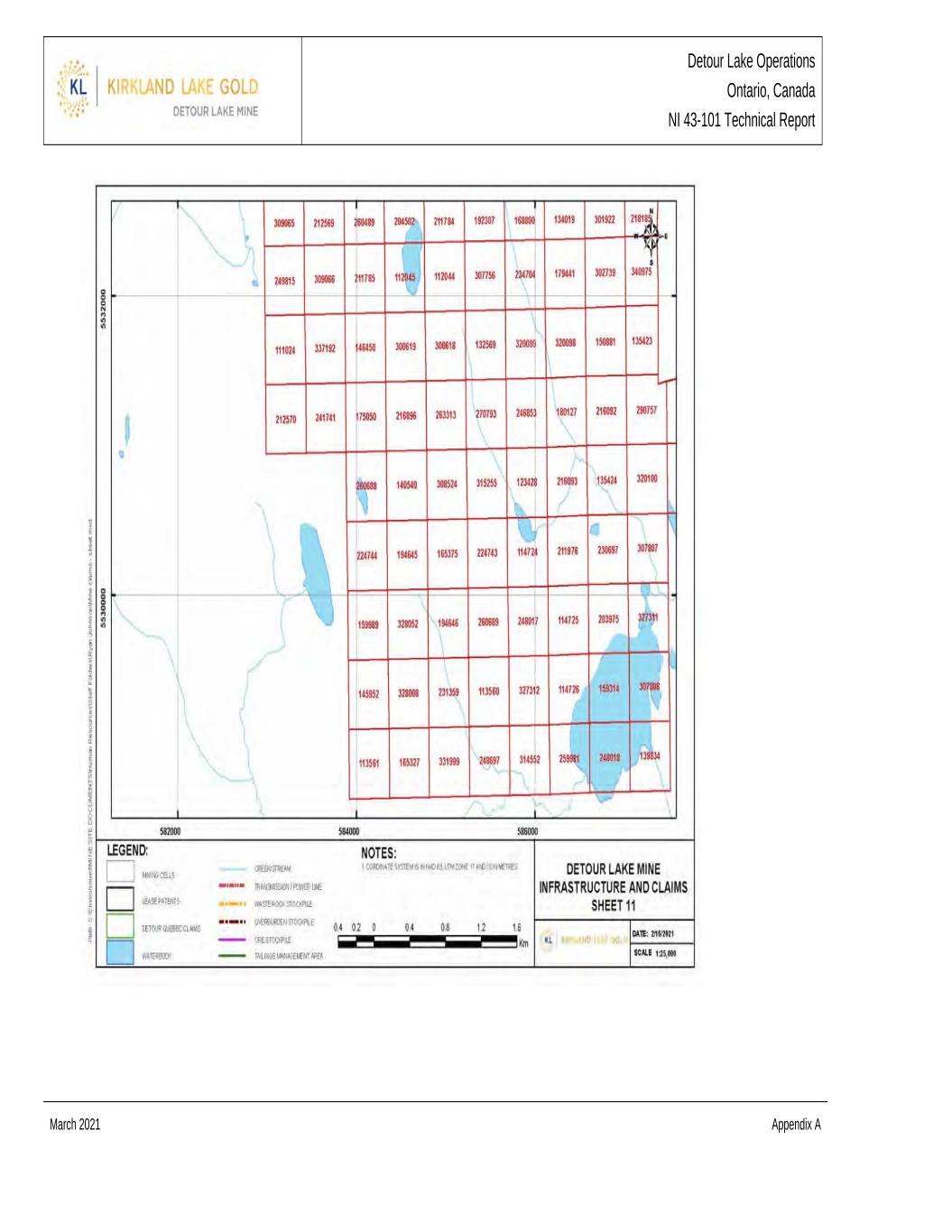

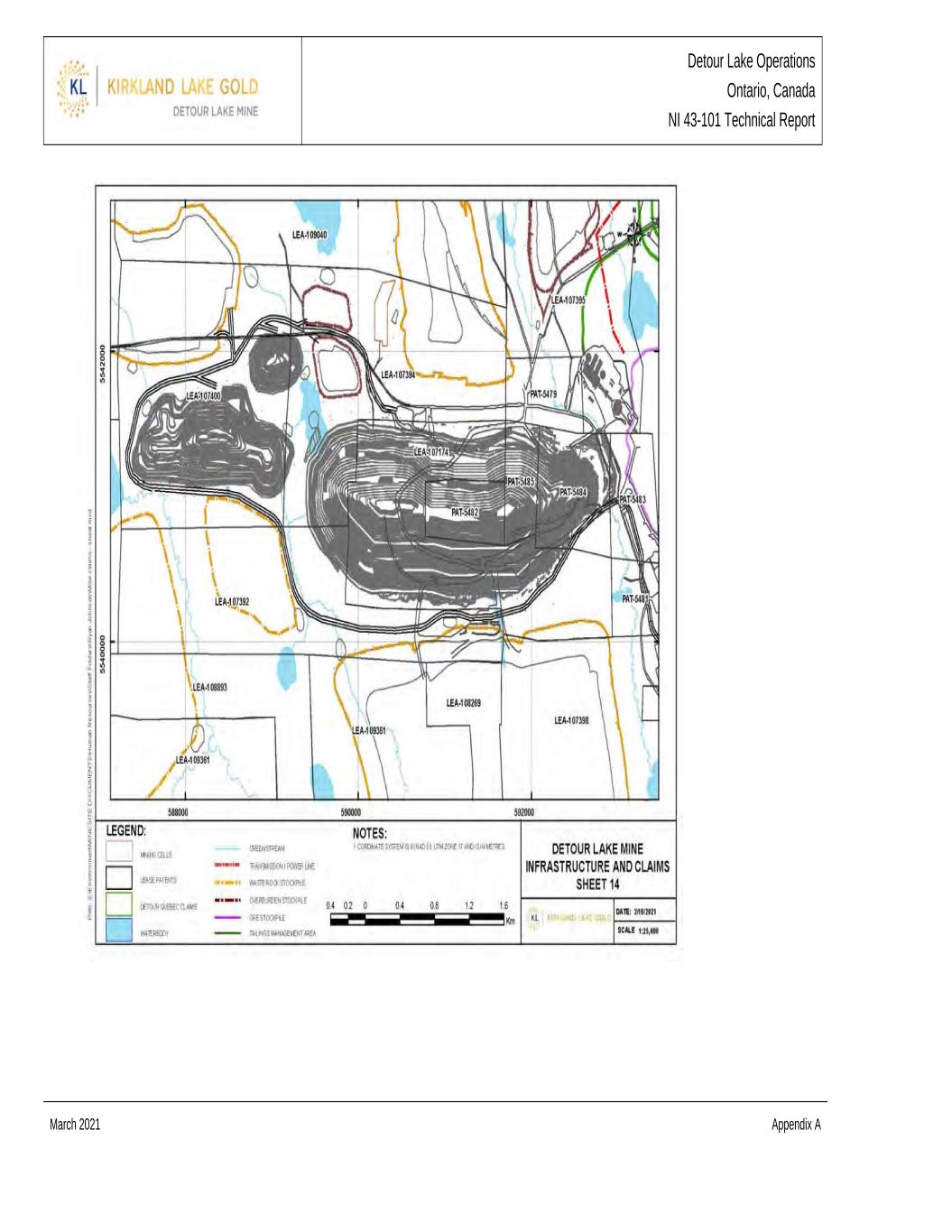

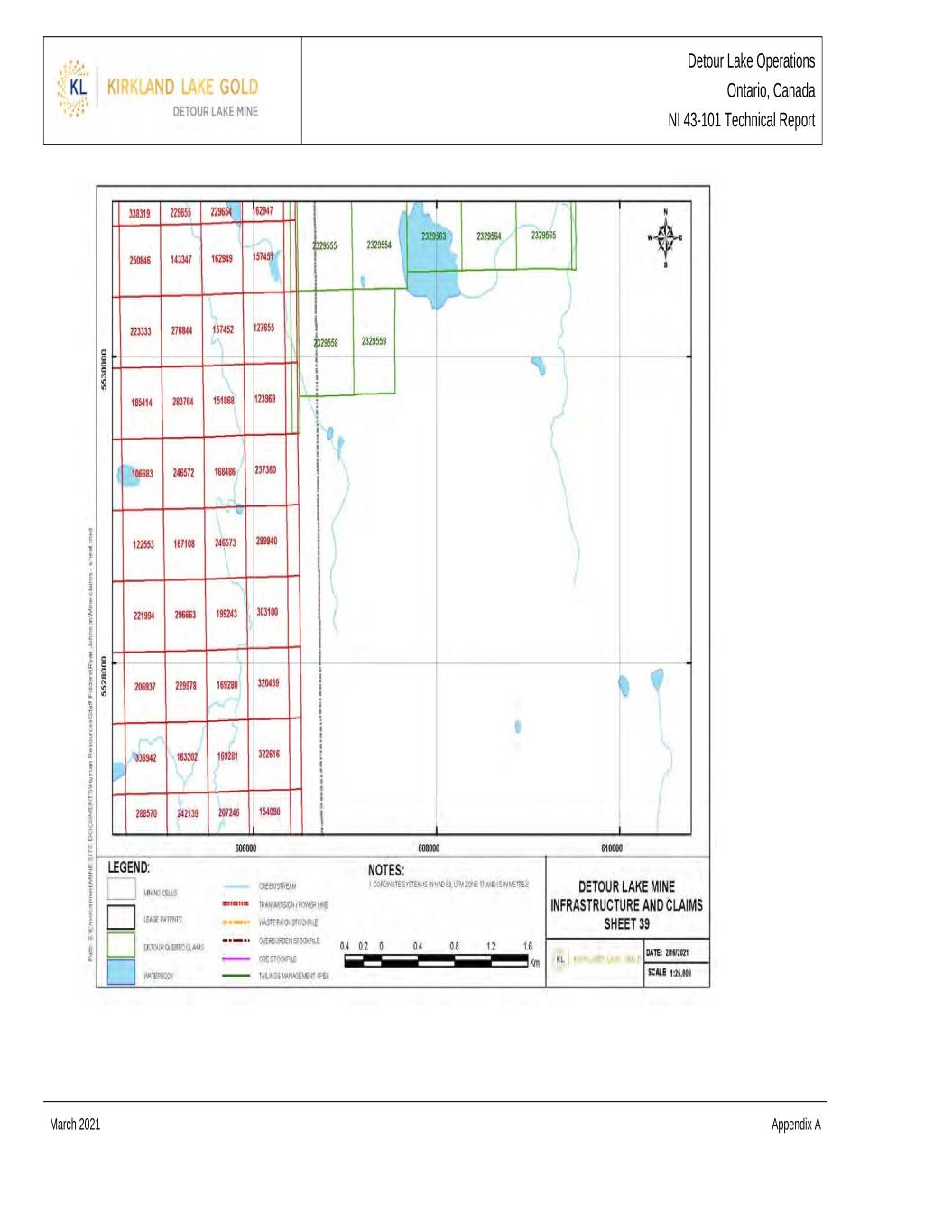

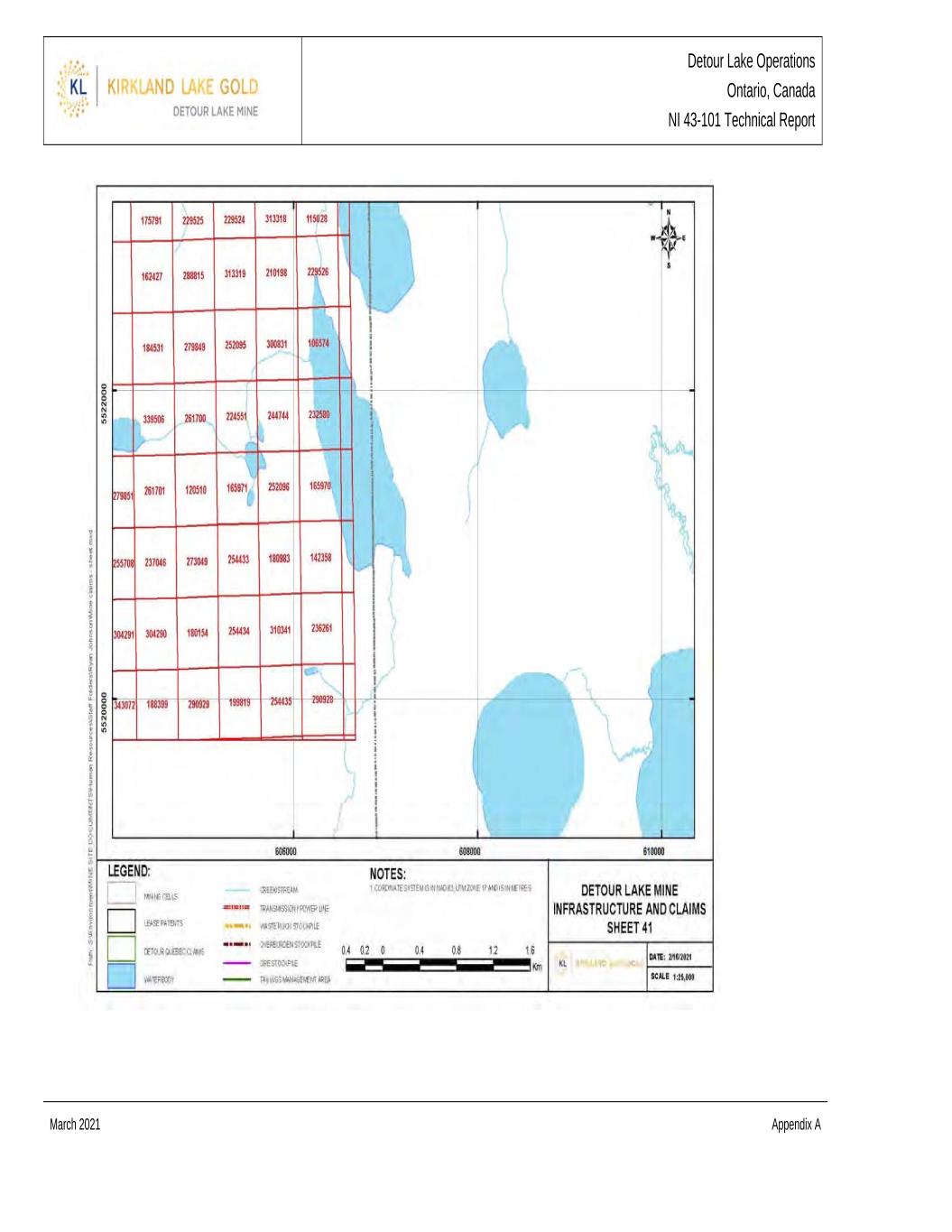

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 ii 2.4 Site Visits and Scope of Personal Inspection ..................................................... 2-2 2.5 Effective Dates ................................................................................................... 2-3 2.6 Information Sources and References ................................................................. 2-3 2.7 Previous Technical Reports ............................................................................... 2-4 3.0 Reliance on Other Experts ................................................................... 3-1 4.0 Property Description and Location ..................................................... 4-1 4.1 Introduction ......................................................................................................... 4-1 4.2 Property and Title in Ontario .............................................................................. 4-1 4.2.1 Introduction ......................................................................................................... 4-1 4.2.2 Mineral Tenure ................................................................................................... 4-1 4.2.3 Ontario Modernizing the Mining Act Process ..................................................... 4-3 4.2.4 Surface Rights .................................................................................................... 4-3 4.2.5 Environmental Considerations............................................................................ 4-4 4.2.6 Closure Considerations ...................................................................................... 4-4 4.2.7 First Nations Considerations .............................................................................. 4-4 4.2.8 Fraser Institute Survey ....................................................................................... 4-4 4.3 Project Ownership .............................................................................................. 4-5 4.3.1 Ownership History .............................................................................................. 4-5 4.3.2 Current Ownership ............................................................................................. 4-6 4.4 Mineral Tenure ................................................................................................... 4-6 4.4.1 Patented Documents ........................................................................................ 4-10 4.4.2 Leasehold Documents ...................................................................................... 4-10 4.4.3 Cell Mining Claims ............................................................................................ 4-10 4.4.4 Claims .............................................................................................................. 4-10 4.5 Surface Rights .................................................................................................. 4-10 4.6 Water Rights ..................................................................................................... 4-11 4.7 Royalties and Encumbrances ........................................................................... 4-11 4.8 Permitting Considerations ................................................................................ 4-12 4.9 Environmental Considerations.......................................................................... 4-13 4.10 Social License Considerations ......................................................................... 4-13 4.11 Comment on Property Description and Location .............................................. 4-13 5.0 Accessibility, Climate, Local Resources, Infrastructure, and Physiography ........................................................................................ 5-1 5.1 Accessibility ........................................................................................................ 5-1 5.2 Climate ............................................................................................................... 5-1 5.3 Local Resources and Infrastructure.................................................................... 5-1 5.4 Physiography ...................................................................................................... 5-1 5.5 Sufficiency of Surface Rights.............................................................................. 5-2 6.0 History ................................................................................................... 6-1

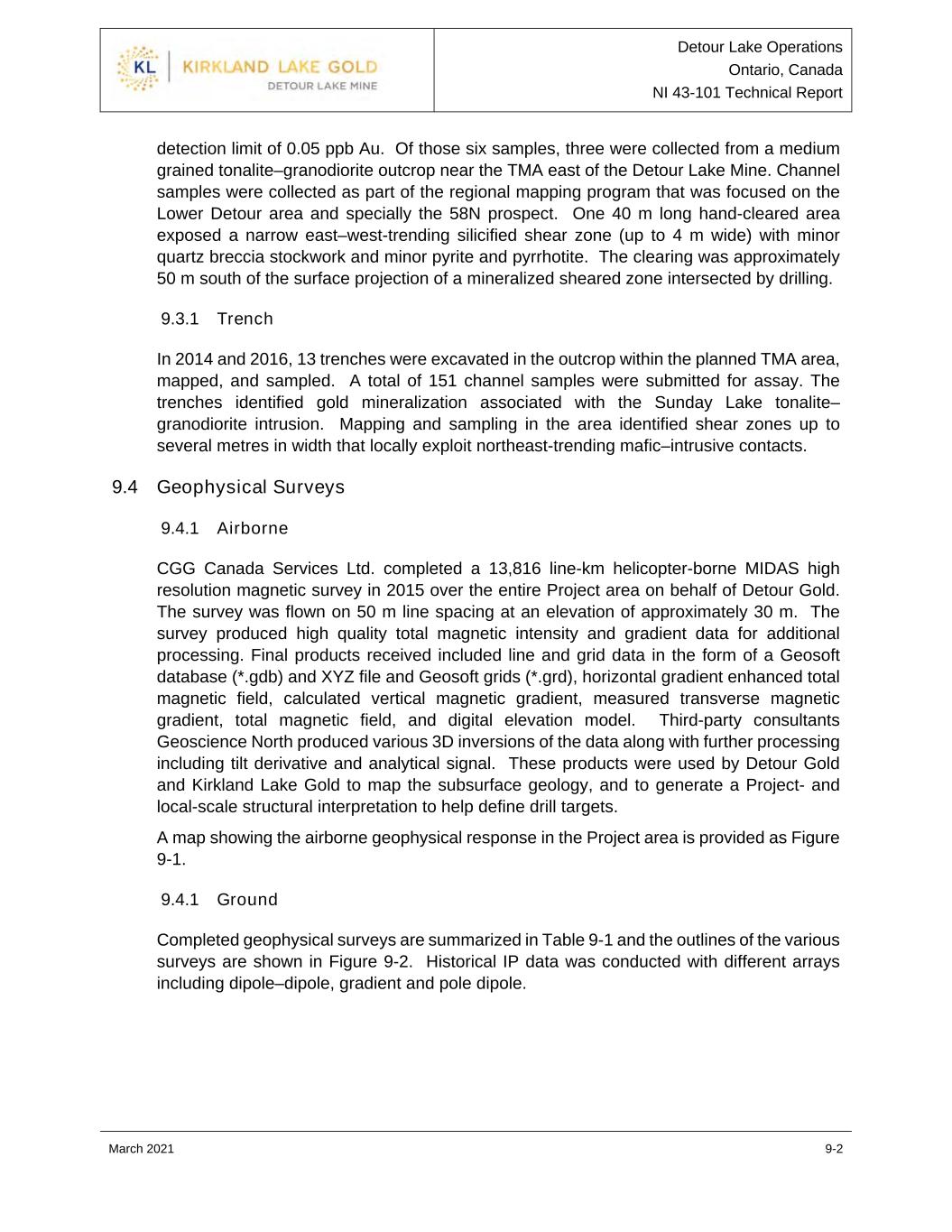

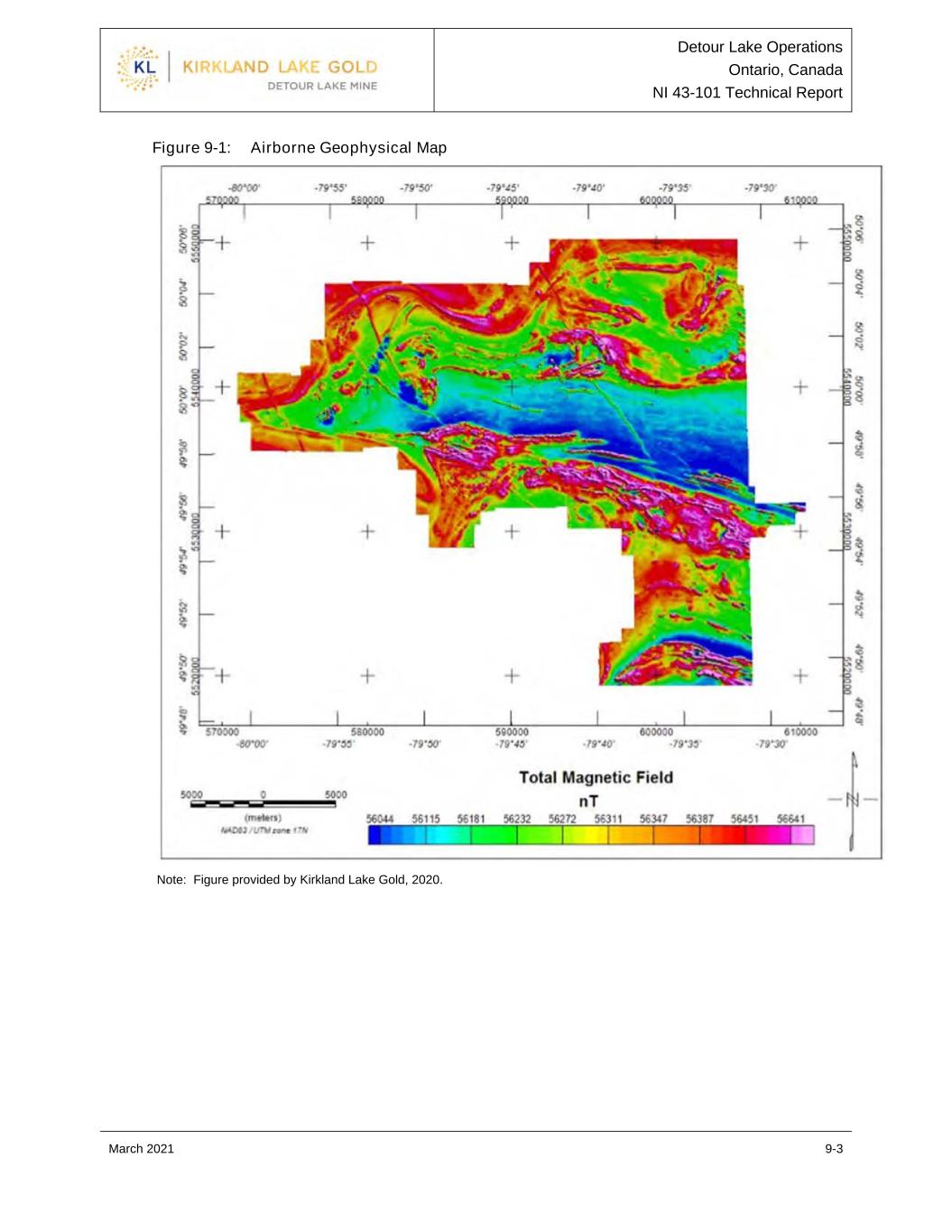

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 iii 6.1 Exploration History ............................................................................................. 6-1 6.2 Production History .............................................................................................. 6-1 7.0 Geological Setting and Mineralization ................................................ 7-1 7.1 Regional Geology ............................................................................................... 7-1 7.2 Project Geology .................................................................................................. 7-1 7.2.1 Lithologies .......................................................................................................... 7-1 7.2.2 Structure ............................................................................................................. 7-5 7.2.3 Metamorphism .................................................................................................... 7-7 7.2.4 Alteration ............................................................................................................ 7-7 7.2.5 Mineralization ..................................................................................................... 7-7 7.3 Deposit Descriptions .......................................................................................... 7-7 7.3.1 Detour Lake ........................................................................................................ 7-7 7.3.2 West Detour and North Pit Areas ..................................................................... 7-13 7.3.3 Zone 58N .......................................................................................................... 7-14 7.3.1 Zone 75 ............................................................................................................ 7-16 8.0 Deposit Types ....................................................................................... 8-1 8.1 Deposit Model .................................................................................................... 8-1 8.2 Comment on Deposit Types ............................................................................... 8-1 9.0 Exploration ............................................................................................ 9-1 9.1 Grids and Surveys .............................................................................................. 9-1 9.2 Geological Mapping ............................................................................................ 9-1 9.3 Geochemical Surveys ........................................................................................ 9-1 9.3.1 Soil ..................................................................................................................... 9-1 9.3.2 Channel .............................................................................................................. 9-1 9.3.1 Trench ................................................................................................................ 9-2 9.4 Geophysical Surveys .......................................................................................... 9-2 9.4.1 Airborne .............................................................................................................. 9-2 9.4.1 Ground ............................................................................................................... 9-2 9.5 Petrology, Mineralogy, and Research Studies ................................................... 9-6 9.6 Exploration Potential .......................................................................................... 9-6 10.0 Drilling ................................................................................................. 10-1 10.1 Introduction ....................................................................................................... 10-1 10.2 Drill Methods .................................................................................................... 10-1 10.3 Logging Procedures ......................................................................................... 10-4 10.3.1 Legacy .............................................................................................................. 10-4 10.3.2 Pelangio ........................................................................................................... 10-5 10.3.3 Trade Winds ..................................................................................................... 10-5 10.3.4 Detour Gold ...................................................................................................... 10-5 10.3.5 Kirkland Lake Gold ........................................................................................... 10-6

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 iv 10.4 Recovery .......................................................................................................... 10-7 10.5 Collar Surveys .................................................................................................. 10-7 10.5.1 Legacy .............................................................................................................. 10-7 10.5.2 Trade Winds/Detour Gold ................................................................................. 10-8 10.5.3 Kirkland Lake Gold ........................................................................................... 10-8 10.6 Downhole Surveys ........................................................................................... 10-9 10.6.1 Legacy .............................................................................................................. 10-9 10.6.2 Trade Winds/Detour Gold ................................................................................. 10-9 10.6.3 Kirkland Lake Gold ......................................................................................... 10-10 10.7 Sample Length/True Thickness ...................................................................... 10-10 10.8 Grade Control ................................................................................................. 10-10 10.9 Twin Hole Drilling ........................................................................................... 10-10 10.10 Drilling Since Database Close-out Date ......................................................... 10-11 10.11 Comments on Drilling ..................................................................................... 10-11 11.0 Sample Preparation, Analyses, and Security ................................... 11-1 11.1 Drill Sampling Methods .................................................................................... 11-1 11.1.1 Legacy .............................................................................................................. 11-1 11.1.2 Trade Winds ..................................................................................................... 11-2 11.1.3 Detour Gold ...................................................................................................... 11-3 11.1.4 Kirkland Lake Gold ........................................................................................... 11-3 11.1.5 Grade Control ................................................................................................... 11-3 11.2 Underground Sampling Methods ...................................................................... 11-3 11.3 Bulk Sampling Methods .................................................................................... 11-4 11.4 Density Determinations .................................................................................... 11-5 11.4.1 Detour Lake ...................................................................................................... 11-5 11.4.2 West Detour ..................................................................................................... 11-5 11.4.3 Zone 58N .......................................................................................................... 11-6 11.5 Analytical and Test Laboratories ...................................................................... 11-6 11.5.1 Primary Laboratories ........................................................................................ 11-6 11.5.2 Secondary/Check Laboratories ........................................................................ 11-7 11.5.3 Grade Control ................................................................................................... 11-7 11.6 Sample Preparation and Analysis .................................................................... 11-7 11.6.1 Legacy .............................................................................................................. 11-7 11.6.2 Trade Winds/Detour Gold ................................................................................. 11-9 11.6.3 Kirkland Lake Gold ......................................................................................... 11-11 11.6.1 Grade Control ................................................................................................. 11-11 11.7 Quality Assurance and Quality Control........................................................... 11-11 11.7.1 Legacy ............................................................................................................ 11-11 11.7.2 Detour Gold .................................................................................................... 11-12 11.7.3 Kirkland Lake Gold ......................................................................................... 11-14 11.7.4 Grade Control ................................................................................................. 11-14

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 v 11.8 Databases ...................................................................................................... 11-14 11.9 Sample Security ............................................................................................. 11-15 11.9.1 Legacy ............................................................................................................ 11-15 11.9.2 Detour Gold .................................................................................................... 11-16 11.9.3 Kirkland Lake Gold ......................................................................................... 11-16 11.10 Sample Storage .............................................................................................. 11-16 11.11 Comments on Sample Preparation, Analyses and Security ........................... 11-17 12.0 Data Verification ................................................................................. 12-1 12.1 Historical Verification Programs ....................................................................... 12-1 12.1.1 2005–2006 ....................................................................................................... 12-1 12.1.2 2009 ................................................................................................................. 12-1 12.1.3 2009–2010 ....................................................................................................... 12-2 12.1.4 2010–2011 ....................................................................................................... 12-3 12.1.5 2012–2013 ....................................................................................................... 12-4 12.1.6 Verification of the Detour Gold Drill Holes ........................................................ 12-4 12.1.7 Verification of the Trade Winds Drill Holes ....................................................... 12-4 12.1.8 Follow up on Trade Winds Drills Hole Verification ............................................ 12-5 12.1.9 Zone 58N Deposit Data Verification ................................................................. 12-6 12.2 External Data Verification ................................................................................. 12-6 12.3 Kirkland Lake Gold Verification Programs ........................................................ 12-7 12.4 Verification Completed by the QP .................................................................... 12-7 12.5 Comments on Data Verification ........................................................................ 12-7 13.0 Mineral Processing and Metallurgical Testing ................................. 13-1 13.1 Introduction ....................................................................................................... 13-1 13.2 Historical Metallurgical Testwork ...................................................................... 13-1 13.3 Detour Lake/West Detour Testwork Programs and Results ............................. 13-1 13.3.1 Comminution .................................................................................................... 13-1 13.3.2 Grinding Circuit Simulation ............................................................................... 13-2 13.3.3 Gravity Gold Recovery ..................................................................................... 13-2 13.3.4 Leach Test Work .............................................................................................. 13-5 13.3.5 West Detour ..................................................................................................... 13-9 13.3.6 Impact of Copper On Recovery and Cyanide Consumption ............................. 13-9 13.3.7 Carbon-in-Pulp Solution Losses Reduction ...................................................... 13-9 13.3.8 Carbon Losses Minimization .......................................................................... 13-10 13.3.9 Cyanide Destruction ....................................................................................... 13-10 13.4 Zone 58N Testwork ........................................................................................ 13-11 13.4.1 Metallurgical Testing ...................................................................................... 13-11 13.4.1 Phase I Results .............................................................................................. 13-11 13.4.2 Phase II Results ............................................................................................. 13-12 13.4.3 Consumables ................................................................................................. 13-12 13.4.4 Additional Sample Characterization ............................................................... 13-12

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 vi 13.4.5 Conclusions .................................................................................................... 13-13 13.5 Recovery Model ............................................................................................. 13-13 13.5.1 Recovery Equations ....................................................................................... 13-13 13.5.2 LOM Recovery Forecasts ............................................................................... 13-14 13.5.3 Recovery Improvement Initiatives .................................................................. 13-14 13.6 Metallurgical Variability ................................................................................... 13-15 13.7 Deleterious Elements ..................................................................................... 13-16 14.0 Mineral Resource Estimates .............................................................. 14-1 14.1 Introduction ....................................................................................................... 14-1 14.2 Geological Interpretation .................................................................................. 14-1 14.3 Underground Void and Stope Interpretation ..................................................... 14-3 14.4 Grade Capping ................................................................................................. 14-3 14.4.1 Reconciliation Study ......................................................................................... 14-3 14.4.2 Grade Capping ................................................................................................. 14-6 14.5 Compositing ..................................................................................................... 14-9 14.6 Variography .................................................................................................... 14-10 14.7 Block Models .................................................................................................. 14-13 14.8 Density ........................................................................................................... 14-14 14.9 Grade Interpolation ......................................................................................... 14-14 14.10 Model Validation ............................................................................................. 14-18 14.11 Mineral Resource Classification ..................................................................... 14-21 14.12 Reasonable Prospects for Eventual Economic Extraction ............................. 14-25 14.13 Mineral Resource Statement .......................................................................... 14-25 14.14 Factors that May Affect the Resource Estimate ............................................. 14-30 14.15 Comments on Mineral Resource Estimates ................................................... 14-30 15.0 Mineral Reserve Estimates ................................................................ 15-1 15.1 Introduction ....................................................................................................... 15-1 15.2 Block Model ...................................................................................................... 15-1 15.3 Pit Optimization ................................................................................................ 15-1 15.3.1 Basis of Optimization ........................................................................................ 15-1 15.3.2 Engineered Pit Designs .................................................................................... 15-2 15.4 Cut-off Grade .................................................................................................... 15-2 15.5 Dilution ............................................................................................................. 15-2 15.6 Mineral Reserves Statement ............................................................................ 15-4 15.7 Factors that May Affect the Mineral Reserves Estimate ................................... 15-4 15.8 Comment on Mineral Reserves Estimates ....................................................... 15-4 16.0 Mining Methods .................................................................................. 16-1 16.1 Overview .......................................................................................................... 16-1

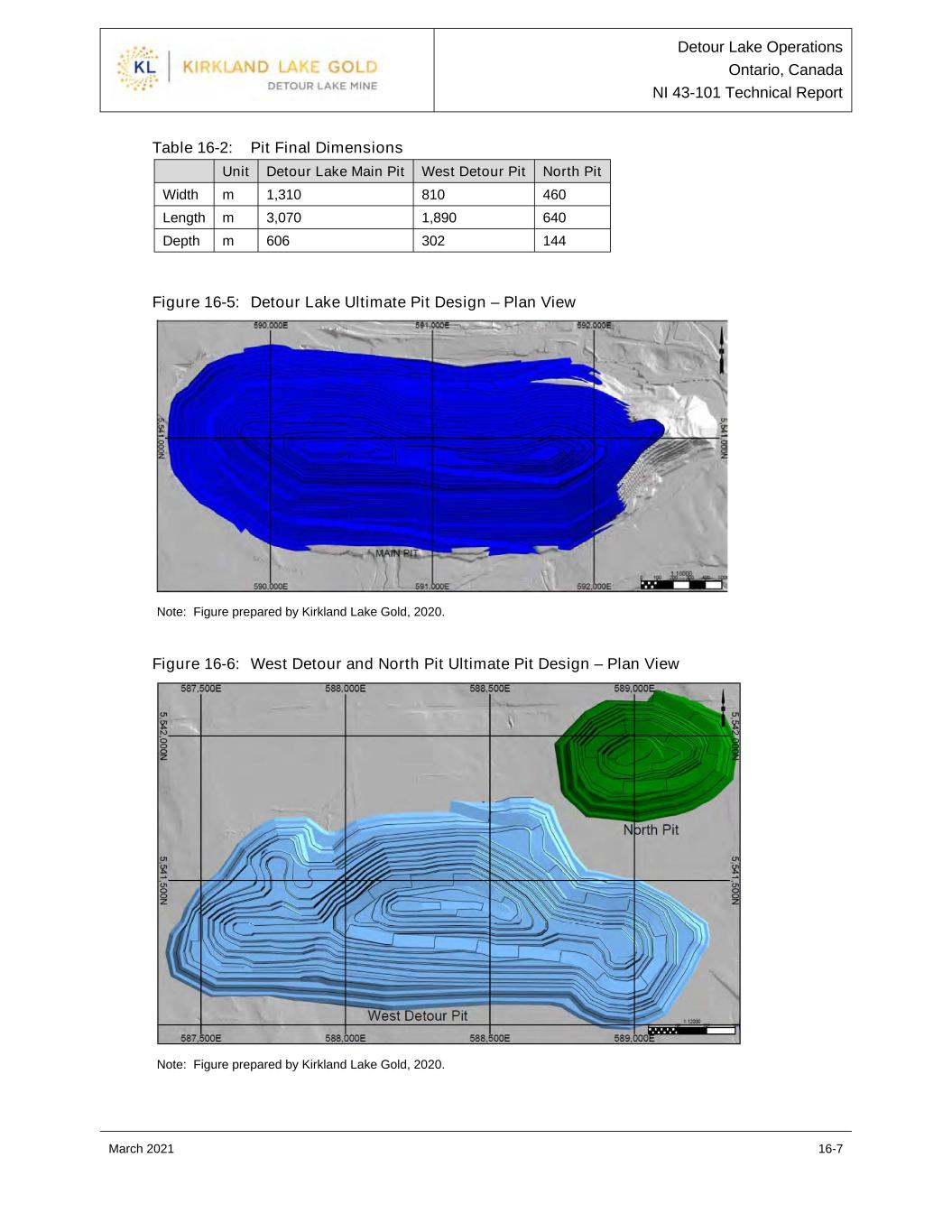

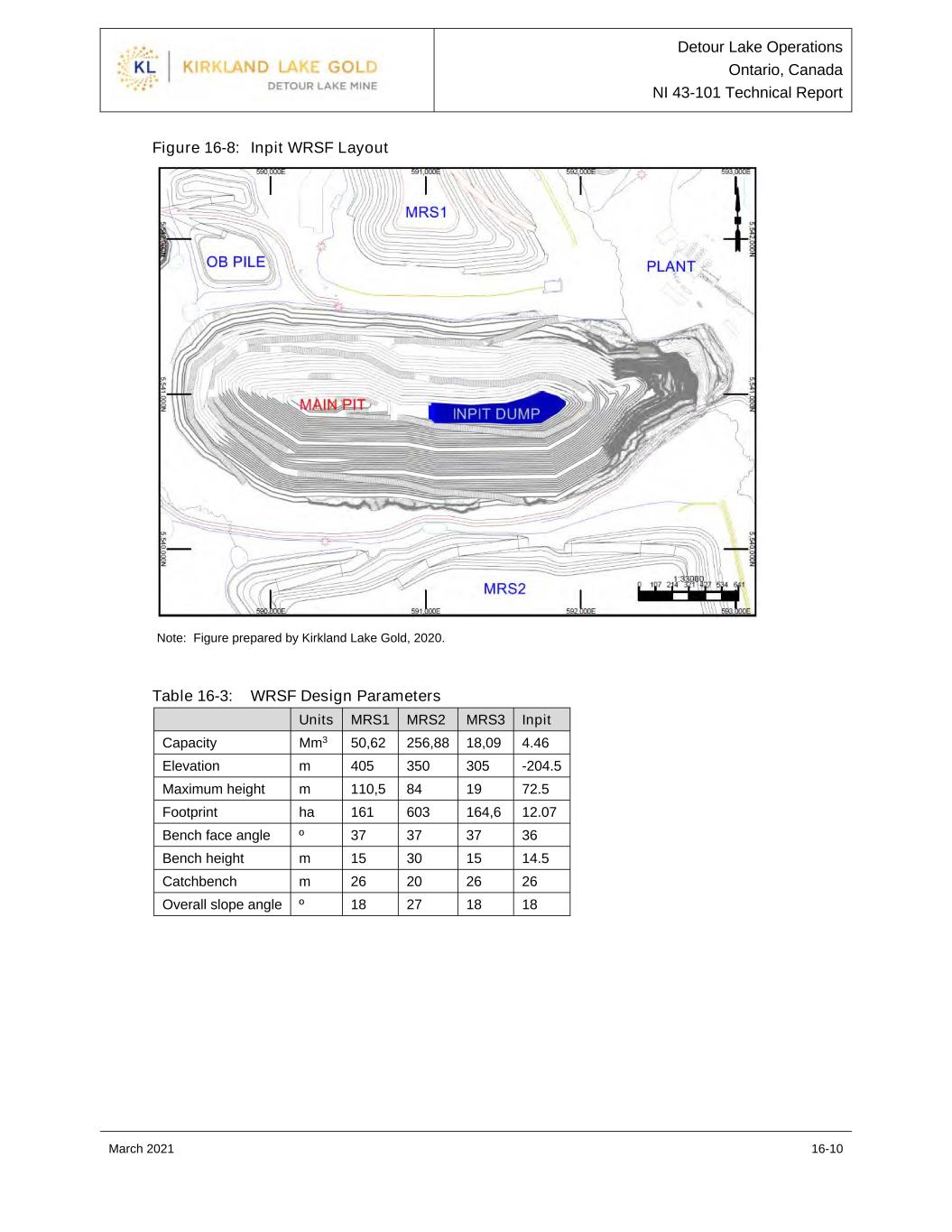

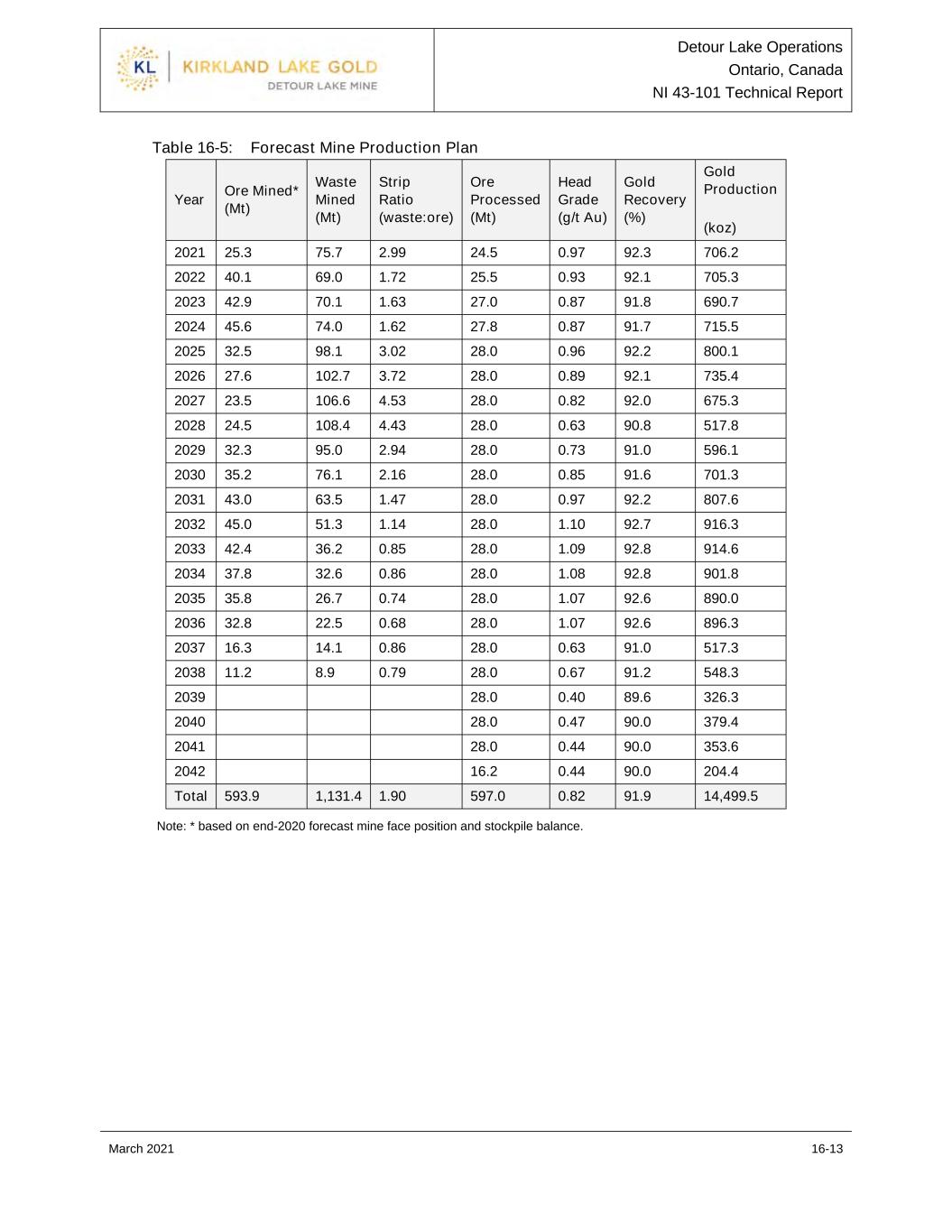

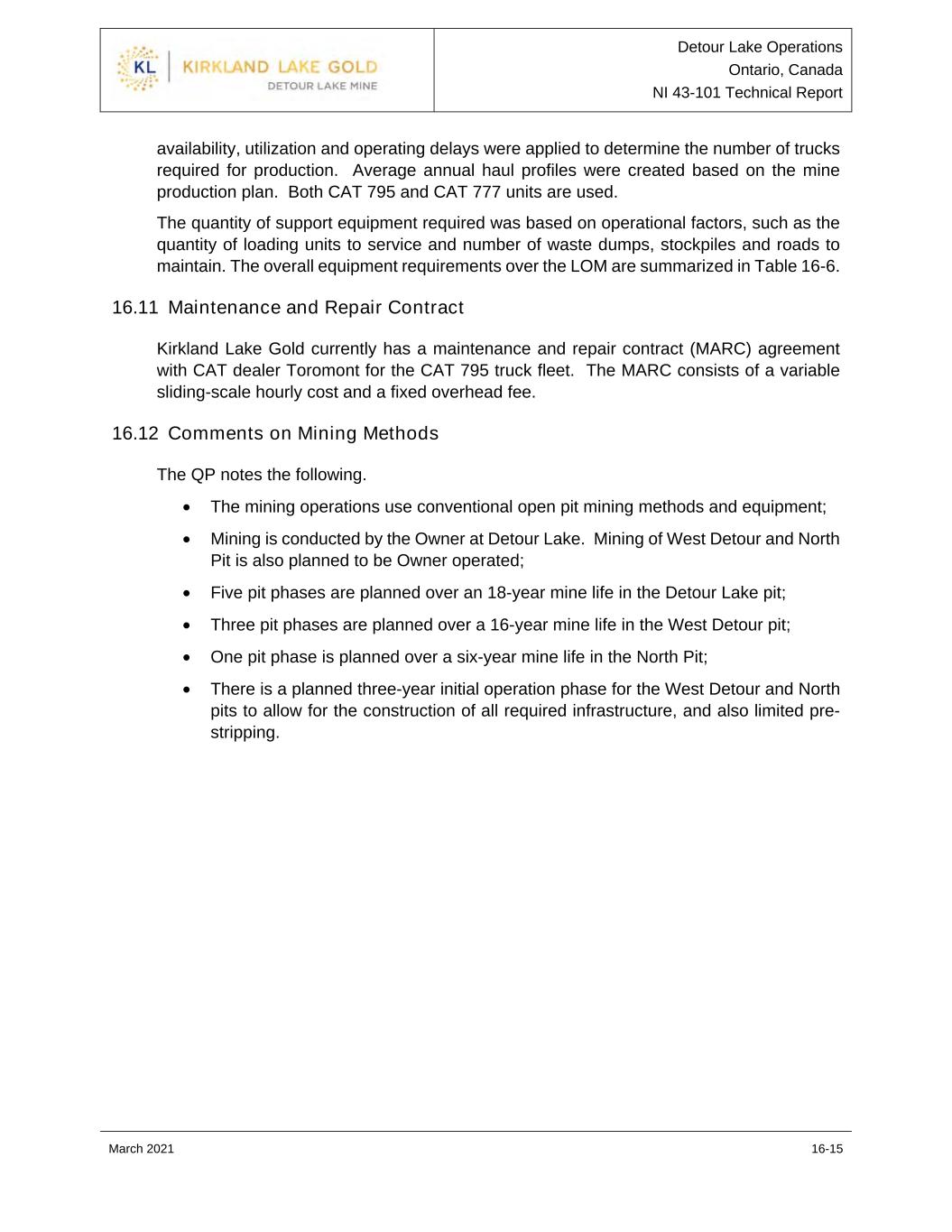

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 vii 16.2 Geotechnical Considerations............................................................................ 16-1 16.3 Hydrological Considerations ............................................................................. 16-3 16.4 Open Pit Designs ............................................................................................. 16-4 16.4.1 Design Constraints ........................................................................................... 16-4 16.4.2 Pit Phases ........................................................................................................ 16-5 16.4.3 Pit Sizes ........................................................................................................... 16-5 16.5 Overburden and Pre-Stripping ......................................................................... 16-5 16.6 Stockpile and Waste Rock Storage Facilities ................................................... 16-5 16.6.1 Strategy ............................................................................................................ 16-5 16.6.2 Design Criteria .................................................................................................. 16-8 16.7 Mining Operations ............................................................................................ 16-8 16.7.1 Ore Mining and Stockpiles ............................................................................. 16-11 16.7.2 Waste Mining .................................................................................................. 16-11 16.8 Mine Production Plan ..................................................................................... 16-11 16.9 Drilling and Blasting ........................................................................................ 16-12 16.10 Equipment ...................................................................................................... 16-12 16.11 Maintenance and Repair Contract .................................................................. 16-15 16.12 Comments on Mining Methods ....................................................................... 16-15 17.0 Recovery Methods .............................................................................. 17-1 17.1 Overview .......................................................................................................... 17-1 17.2 Flowsheet ......................................................................................................... 17-2 17.3 Plant Design ..................................................................................................... 17-2 17.3.1 Crushing and Grinding ..................................................................................... 17-2 17.3.2 Leach and Carbon-in-PuIp ............................................................................. 17-10 17.3.3 Acid Wash, Stripping, Electrowinning, and Refining ....................................... 17-10 17.3.4 Thickening ...................................................................................................... 17-11 17.3.5 Tailings ........................................................................................................... 17-11 17.4 Energy, Water, and Process Materials Requirements .................................... 17-11 17.4.1 Power ............................................................................................................. 17-11 17.4.2 Water .............................................................................................................. 17-12 17.4.3 Consumables ................................................................................................. 17-12 18.0 Infrastructure ...................................................................................... 18-1 18.1 Overview .......................................................................................................... 18-1 18.2 Road and Logistics ........................................................................................... 18-1 18.3 Stockpiles ......................................................................................................... 18-3 18.4 Tailings Management Area .............................................................................. 18-3 18.5 Mine Site Built Infrastructure ............................................................................ 18-3 18.5.1 Mine Service Facilities ...................................................................................... 18-3 18.5.2 Process Plant ................................................................................................... 18-3 18.5.3 Administration ................................................................................................... 18-4

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 viii 18.5.4 Explosives Plant ............................................................................................... 18-4 18.6 Off-Site Built Infrastructure ............................................................................... 18-4 18.7 Camp and Accommodations ............................................................................ 18-4 18.8 Communications ............................................................................................... 18-4 18.9 Water Management .......................................................................................... 18-5 18.10 Water Supply .................................................................................................... 18-5 18.11 Power Supply ................................................................................................... 18-6 19.0 Market Studies and Contracts ........................................................... 19-1 19.1 Market Studies ................................................................................................. 19-1 19.2 Commodity Prices ............................................................................................ 19-1 19.3 Material Contracts ............................................................................................ 19-1 19.4 Comments on Market Studies and Contracts ................................................... 19-1 20.0 Environmental Studies, Permitting and Social or Community Impact .................................................................................................. 20-1 20.1 Environmental and Supporting Studies ............................................................ 20-1 20.2 Site Monitoring ................................................................................................. 20-1 20.2.1 Air Quality ......................................................................................................... 20-1 20.2.2 Metals Leaching and Acid Rock Drainage........................................................ 20-2 20.2.3 Ground Water, Surface Water and Aquatic Resources .................................... 20-2 20.2.4 Vegetation and Wildlife ..................................................................................... 20-3 20.2.5 Cultural and Heritage Resources ..................................................................... 20-4 20.3 Tailings Management Area .............................................................................. 20-4 20.3.1 Tailings Management Area .............................................................................. 20-4 20.3.2 Cell 1 ................................................................................................................ 20-6 20.3.3 Cell 2 ................................................................................................................ 20-6 20.3.4 Cell 3 ................................................................................................................ 20-6 20.3.5 Performance Monitoring ................................................................................... 20-6 20.4 Water Management .......................................................................................... 20-7 20.5 Permitting Considerations ................................................................................ 20-9 20.6 Social and Community Impact Considerations ............................................... 20-10 20.6.1 Consultation Principles ................................................................................... 20-10 20.6.2 First Nations ................................................................................................... 20-12 20.7 Closure and Reclamation Planning ................................................................ 20-12 21.0 Capital and Operating Costs .............................................................. 21-1 21.1 Capital Cost Estimates ..................................................................................... 21-1 21.1.1 Summary .......................................................................................................... 21-1 21.1.2 Mining ............................................................................................................... 21-1 21.1.3 Processing Plant .............................................................................................. 21-1 21.1.4 Site Administration ........................................................................................... 21-2

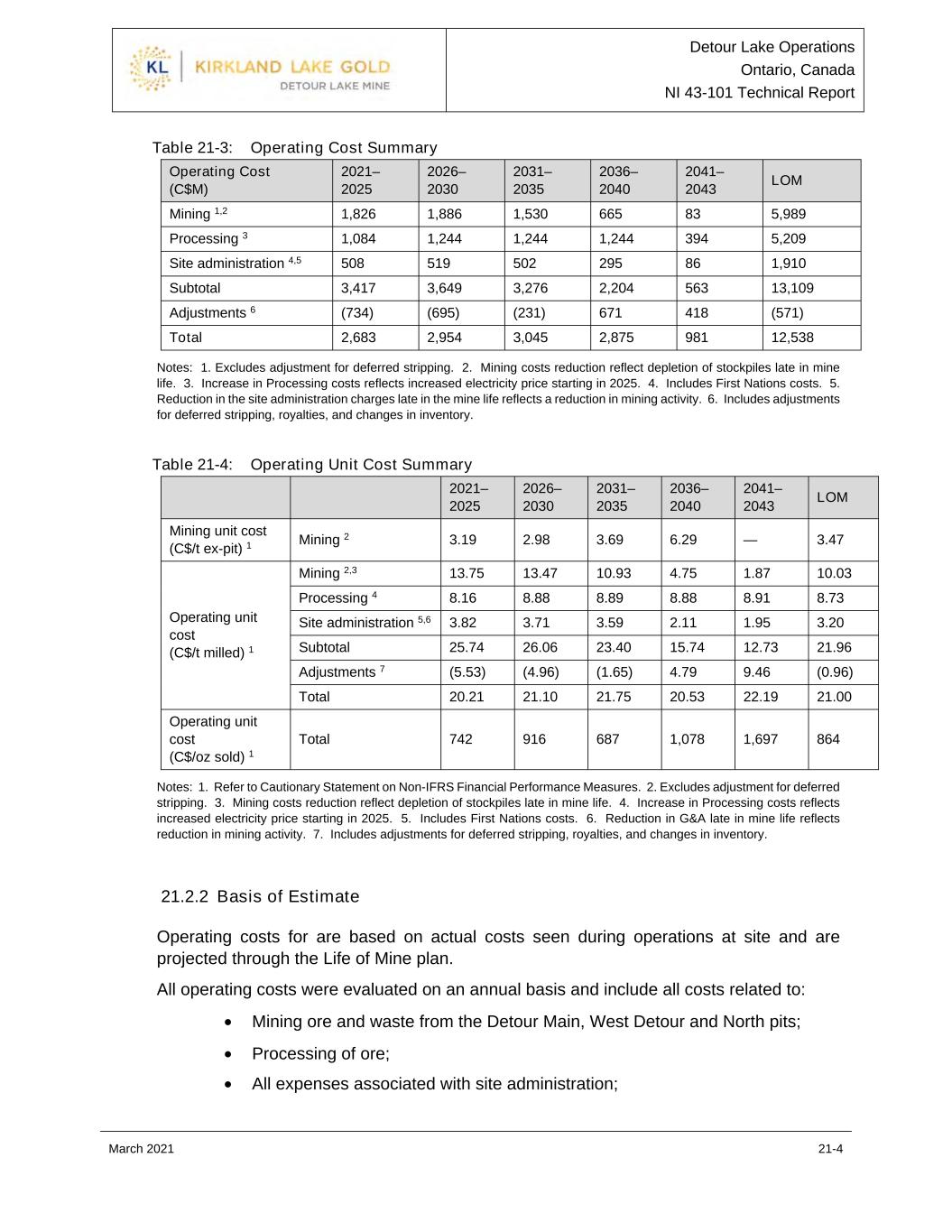

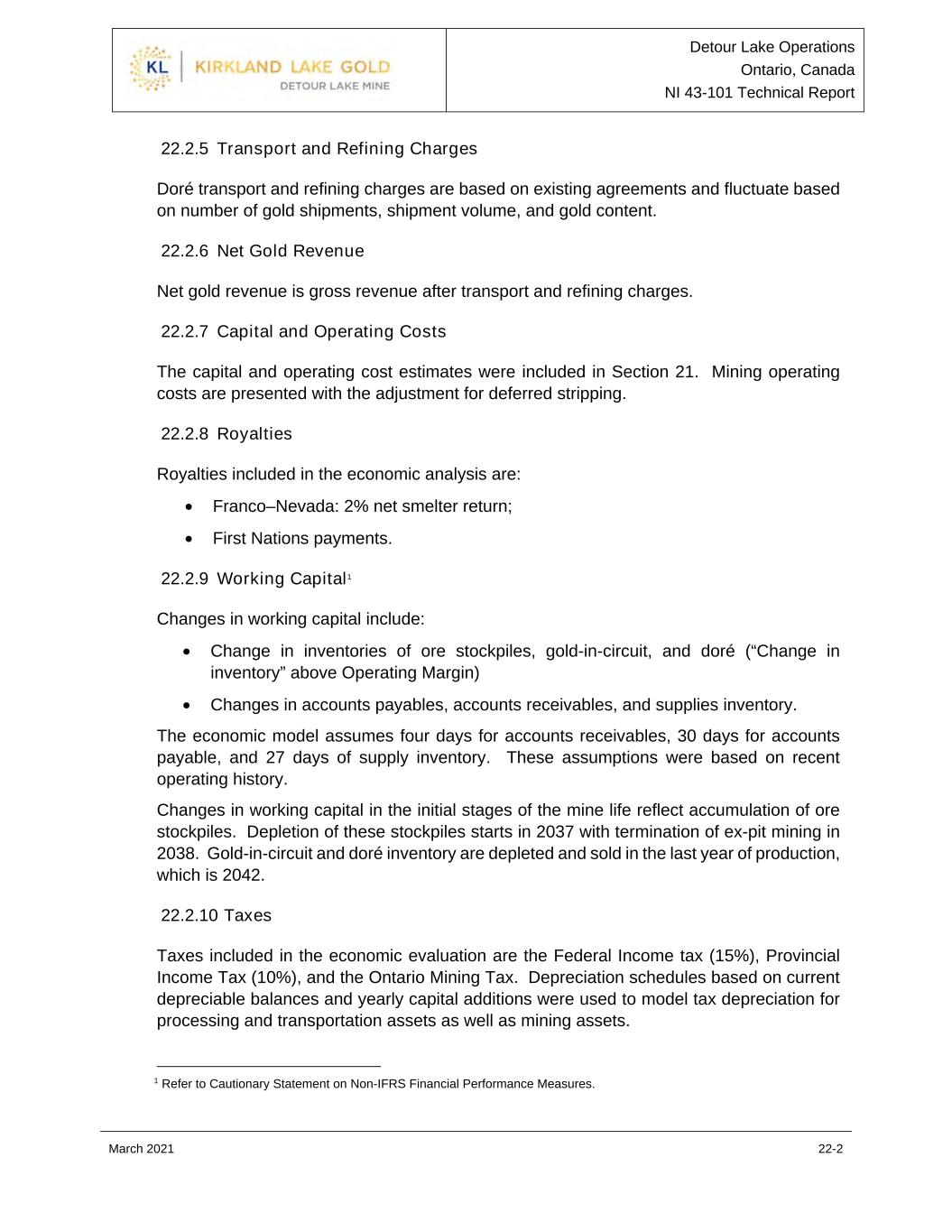

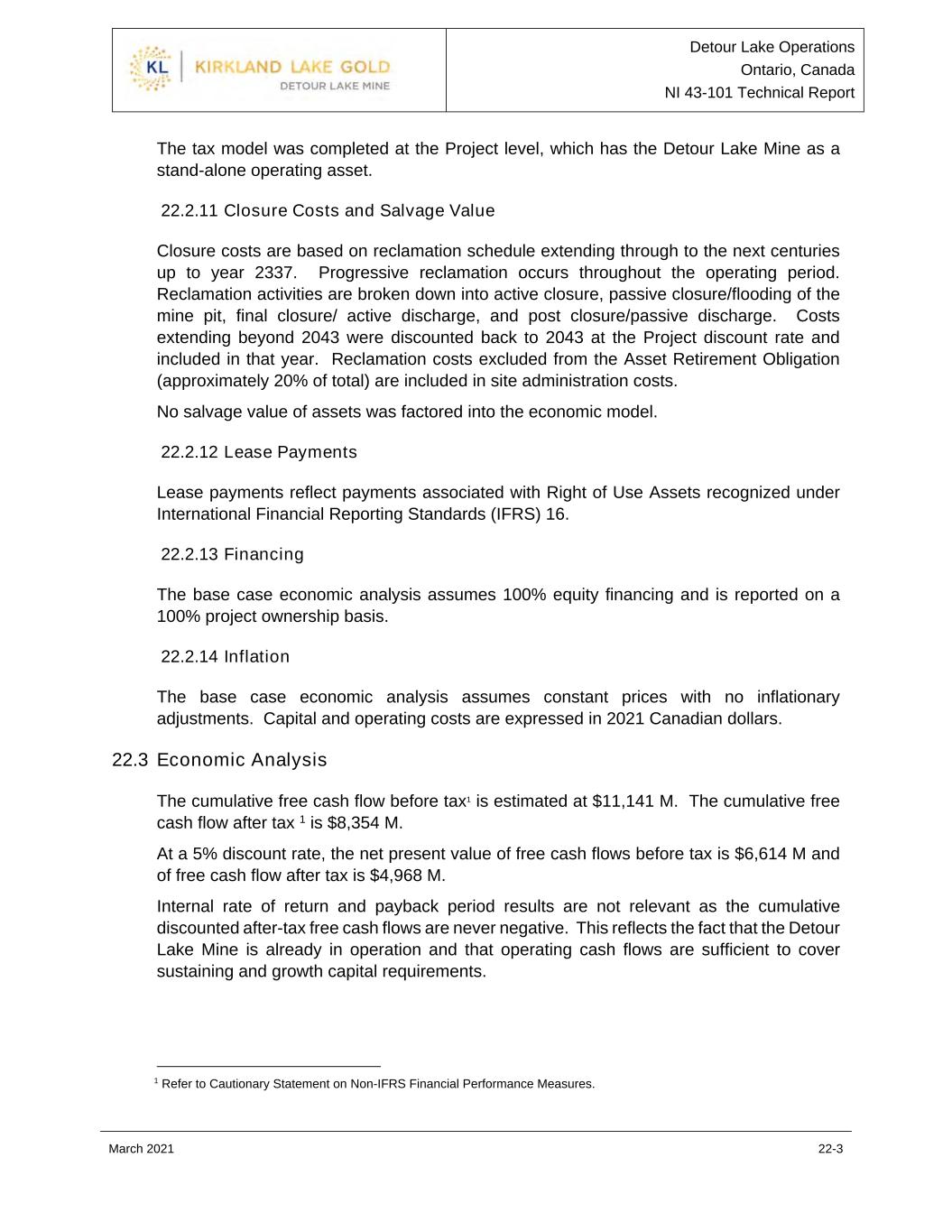

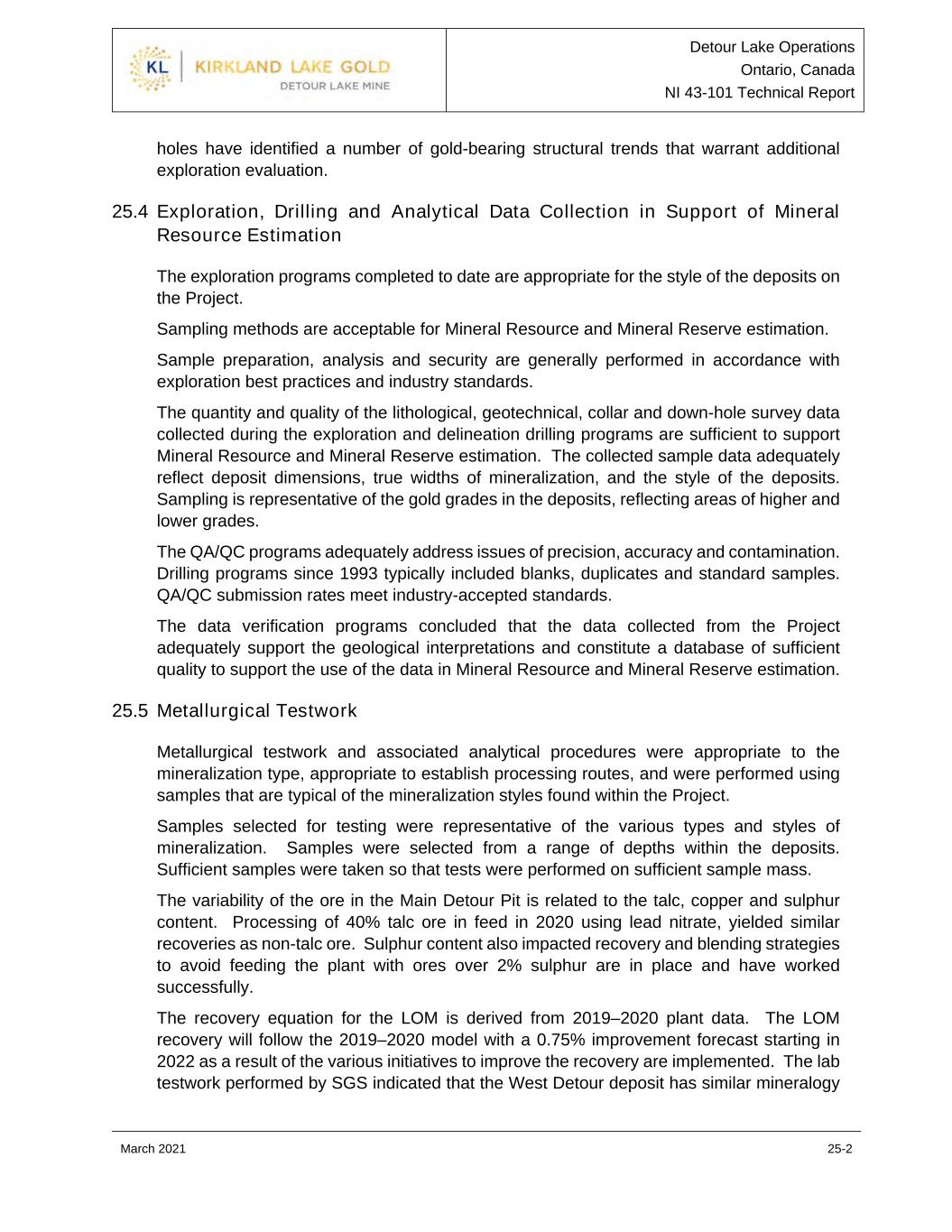

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 ix 21.1.5 Tailings Management Area .............................................................................. 21-3 21.1.6 Deferred Stripping Costs .................................................................................. 21-3 21.1.7 West Detour ..................................................................................................... 21-3 21.2 Operating Cost Estimates ................................................................................ 21-3 21.2.1 Summary .......................................................................................................... 21-3 21.2.2 Basis of Estimate .............................................................................................. 21-4 21.2.3 Mining Costs ..................................................................................................... 21-5 21.2.4 Processing Costs ............................................................................................. 21-5 21.2.5 Site Administration Costs ................................................................................. 21-5 21.3 Comments on Capital and Operating Costs ..................................................... 21-6 22.0 Economic Analysis ............................................................................. 22-1 22.1 Methodology Used ........................................................................................... 22-1 22.2 Financial Model Parameters ............................................................................. 22-1 22.2.1 Mineral Reserves and Mine Life ....................................................................... 22-1 22.2.2 Metallurgical Recoveries .................................................................................. 22-1 22.2.3 Metal Prices and Exchange Rates ................................................................... 22-1 22.2.4 Gross Gold Revenue ........................................................................................ 22-1 22.2.5 Transport and Refining Charges ...................................................................... 22-2 22.2.6 Net Gold Revenue ............................................................................................ 22-2 22.2.7 Capital and Operating Costs ............................................................................ 22-2 22.2.8 Royalties ........................................................................................................... 22-2 22.2.9 Working Capital ................................................................................................ 22-2 22.2.10 Taxes .......................................................................................................... 22-2 22.2.11 Closure Costs and Salvage Value .............................................................. 22-3 22.2.12 Lease Payments ......................................................................................... 22-3 22.2.13 Financing .................................................................................................... 22-3 22.2.14 Inflation ....................................................................................................... 22-3 22.3 Economic Analysis ........................................................................................... 22-3 22.4 Sensitivity Analysis ........................................................................................... 22-4 22.5 Comments on Economic Analysis .................................................................... 22-4 23.0 Adjacent Properties ............................................................................ 23-1 24.0 Other Relevant Data and Information ................................................ 24-1 25.0 Interpretation and Conclusions ......................................................... 25-1 25.1 Introduction ....................................................................................................... 25-1 25.2 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements ..... 25-1 25.3 Geology and Mineralization .............................................................................. 25-1 25.4 Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation ........................................................................................ 25-2 25.5 Metallurgical Testwork ...................................................................................... 25-2 25.6 Mineral Resource Estimates ............................................................................ 25-3

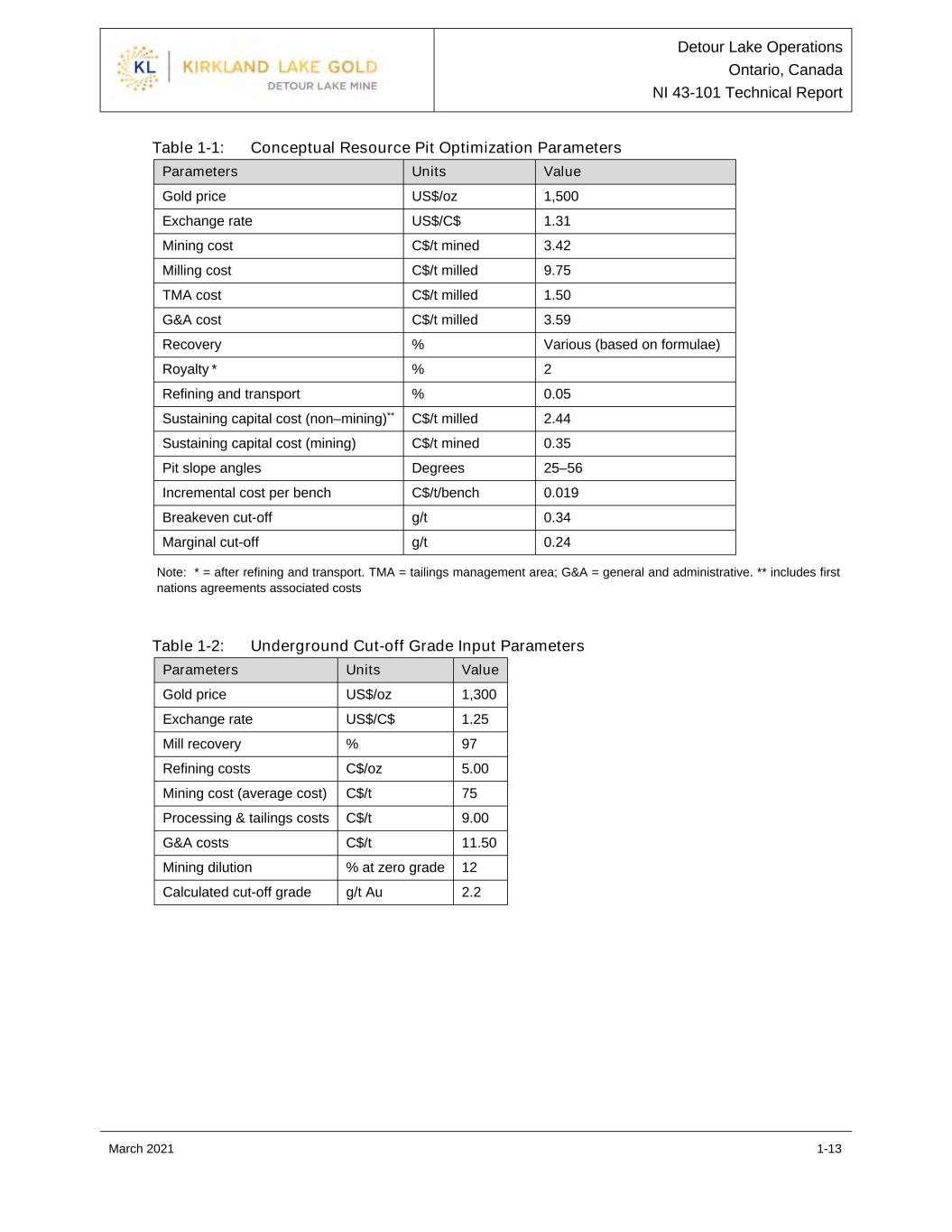

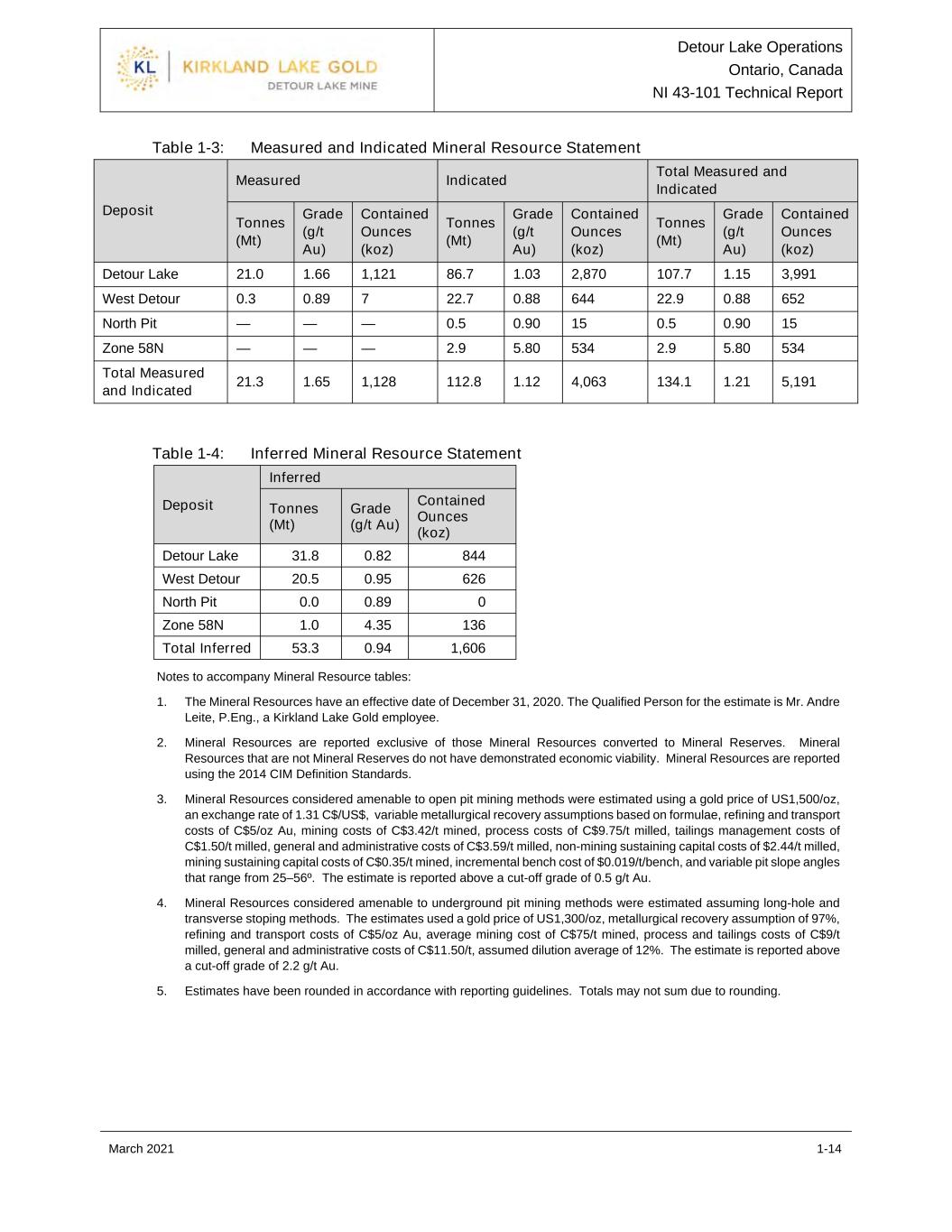

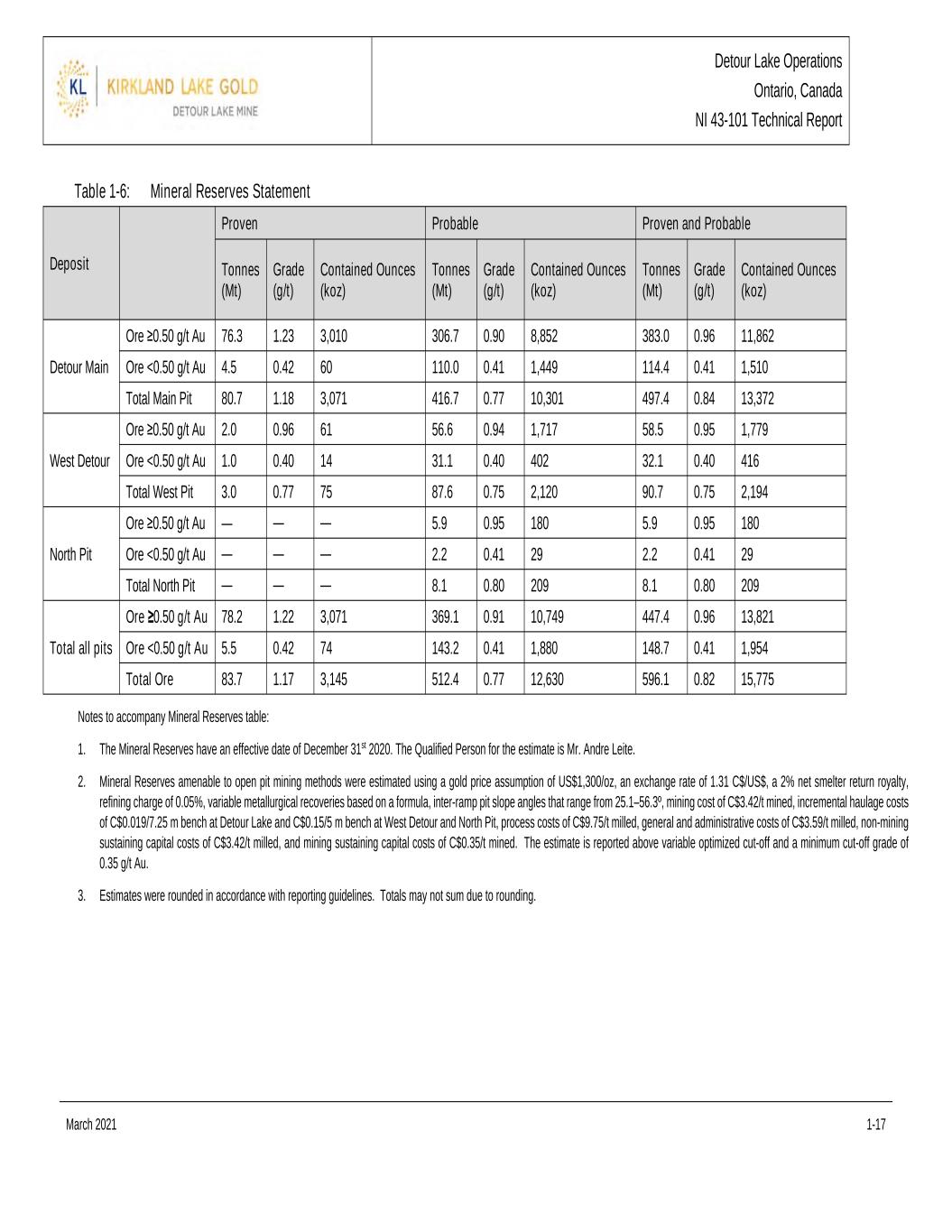

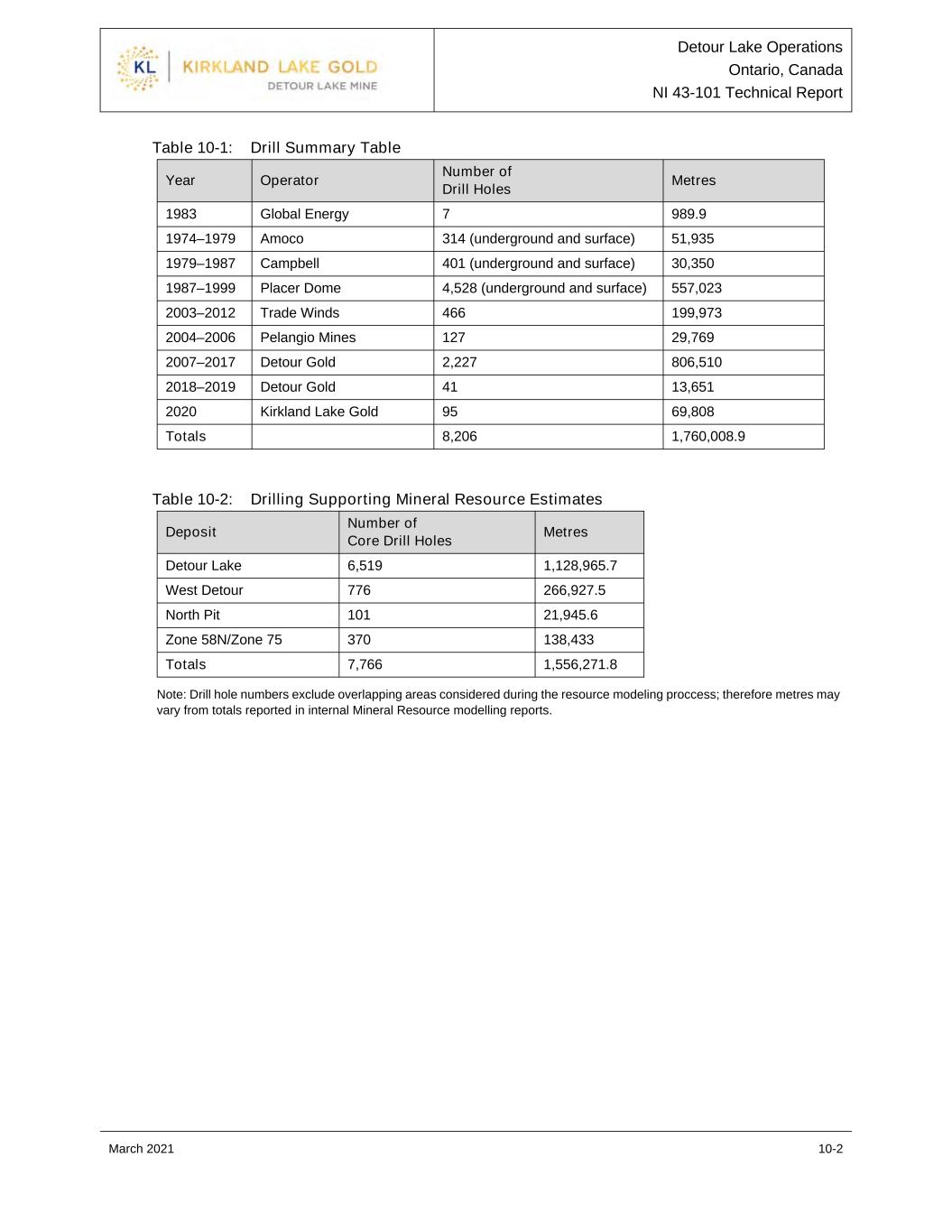

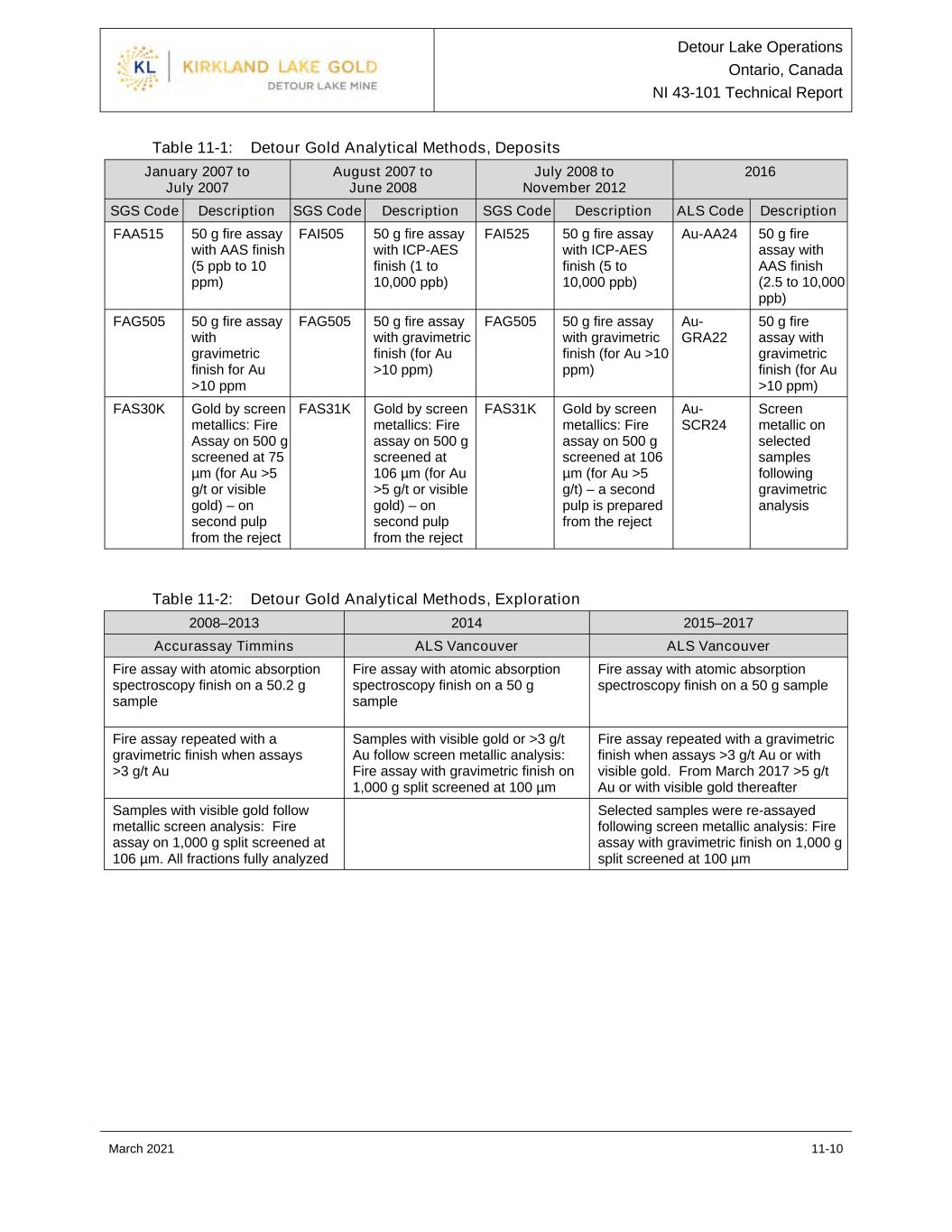

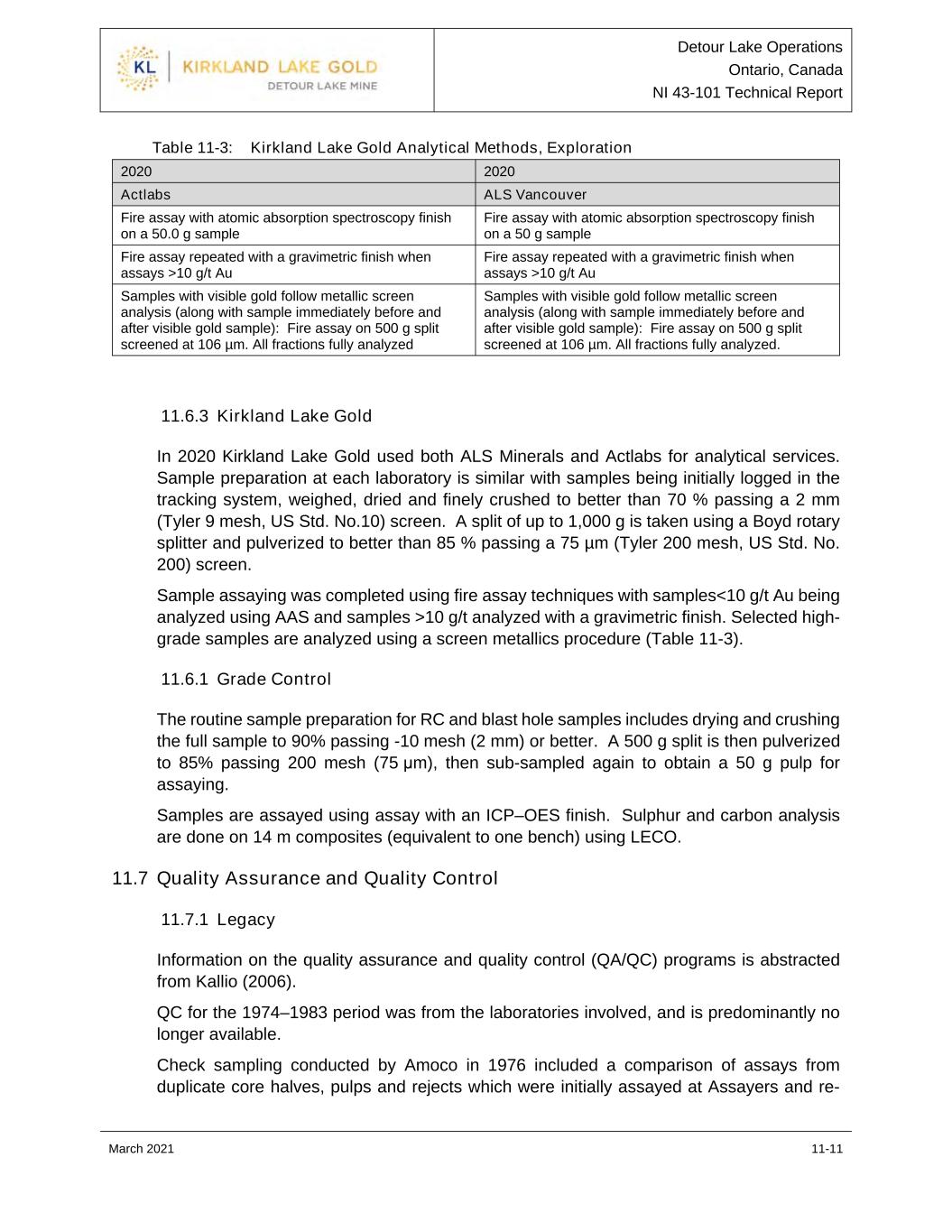

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 x 25.7 Mineral Reserve Estimates .............................................................................. 25-3 25.8 Mine Plan ......................................................................................................... 25-3 25.9 Recovery Plan .................................................................................................. 25-4 25.10 Infrastructure .................................................................................................... 25-4 25.11 Environmental, Permitting and Social Considerations ...................................... 25-5 25.12 Markets and Contracts ..................................................................................... 25-6 25.13 Capital Cost Estimates ..................................................................................... 25-6 25.14 Operating Cost Estimates ................................................................................ 25-6 25.15 Economic Analysis ........................................................................................... 25-7 25.16 Risks and Opportunities ................................................................................... 25-7 25.17 Conclusions ...................................................................................................... 25-8 26.0 Recommendations .............................................................................. 26-1 27.0 References .......................................................................................... 27-1 Table of Tables Table 1-1: Conceptual Resource Pit Optimization Parameters ......................................... 1-13 Table 1-2: Underground Cut-off Grade Input Parameters ................................................. 1-13 Table 1-3: Measured and Indicated Mineral Resource Statement .................................... 1-14 Table 1-4: Inferred Mineral Resource Statement ............................................................... 1-14 Table 1-5: Pit Optimization Parameters ............................................................................. 1-16 Table 1-6: Mineral Reserves Statement ............................................................................. 1-17 Table 1-7: Capital Cost Summary by Area ......................................................................... 1-28 Table 1-8: Operating Cost Summary ................................................................................. 1-28 Table 1-9: Operating Unit Cost Summary .......................................................................... 1-29 Table 1-10: Summary of Discounted Free Cash Flow Analysis. .......................................... 1-31 Table 4-1: Mineral Tenure Summary Table ......................................................................... 4-7 Table 4-2: Royalty Summary Table .................................................................................... 4-12 Table 6-1: Exploration History .............................................................................................. 6-2 Table 6-2: Production History, Kirkland Gold ....................................................................... 6-3 Table 7-1: Lithology Table .................................................................................................... 7-3 Table 9-1: Ground Geophysical Surveys ............................................................................. 9-4 Table 10-1: Drill Summary Table ......................................................................................... 10-2 Table 10-2: Drilling Supporting Mineral Resource Estimates .............................................. 10-2 Table 11-1: Detour Gold Analytical Methods, Deposits ..................................................... 11-10 Table 11-2: Detour Gold Analytical Methods, Exploration ................................................. 11-10 Table 11-3: Kirkland Lake Gold Analytical Methods, Exploration ...................................... 11-11 Table 13-1: Comminution Testwork, Detour Lake ............................................................... 13-3 Table 13-2: Comminution Testwork Comparison, Detour Lake vs West Detour ................. 13-3 Table 13-3: Plant Recoveries, 2013–2020 ........................................................................... 13-6 Table 13-4: Recovery Gains, Intensive Releach .................................................................. 13-7 Table 13-5: CIP Solution Grades, 2017–2020 ................................................................... 13-10 Table 14-1: Capping Thresholds, Detour Lake .................................................................... 14-7

Detour Lake Operations Ontario, Canada NI 43-101 Technical Report March 2021 xi Table 14-2: West Detour Deposit Capping Limits for GTs of Original Sample Data ........... 14-8 Table 14-3: North Pit Deposit Descriptive Statistics for Uncapped and Capped 3 m Composite Gold Values .................................................................................... 14-8 Table 14-4: Zone 58N Grade Capping by Mineralized Domain ........................................... 14-9 Table 14-5: Variogram Parameters, Detour Lake Mine ..................................................... 14-12 Table 14-6: Dynamic Anisotropy Surfaces, Detour Lake ................................................... 14-15 Table 14-7: Dynamic Anisotropy Search Parameters, Detour Lake .................................. 14-15 Table 14-8: Detour Lake Block Model Estimation Parameters .......................................... 14-16 Table 14-9: West Detour Block Model Estimation Parameters .......................................... 14-16 Table 14-10: North Pit Search Ellipse Parameters for Gold Grade Estimation for Domain 40 and Domain 9 ............................................................................................. 14-19 Table 14-11: Mineral Domain 1 – Capped ........................................................................... 14-19 Table 14-12: Conceptual Resource Pit Optimization Parameters ....................................... 14-27 Table 14-13: Underground Cut-off Grade Input Parameters ............................................... 14-28 Table 14-14: Measured and Indicated Mineral Resource Statement .................................. 14-29 Table 14-15: Inferred Mineral Resource Statement ............................................................. 14-29 Table 15-1: Pit Optimization Parameters ............................................................................. 15-3 Table 15-2: LOM Mill Cut-off Grades by Year ...................................................................... 15-3 Table 15-3: Mineral Reserves Statement ............................................................................. 15-5 Table 16-1: Detour Lake Pit Geotechnical Design Parameter ............................................. 16-2 Table 16-2: Pit Final Dimensions ......................................................................................... 16-7 Table 16-3: WRSF Design Parameters .............................................................................. 16-10 Table 16-4: Stockpile Design Parameters .......................................................................... 16-12 Table 16-5: Forecast Mine Production Plan ....................................................................... 16-13 Table 16-6: LOM Mining Equipment Fleet (maximum per period) ..................................... 16-16 Table 17-1: Production Rates, 2016–2020 .......................................................................... 17-2 Table 17-2: Key Design Parameters .................................................................................... 17-4 Table 17-3: Choke Feed Events, 2019–2021 (year to date) ................................................ 17-8 Table 19-1: Material Contracts Currently in Place ............................................................... 19-2 Table 20-1: Cell 2 TMA Raise Schedule .............................................................................. 20-7 Table 20-2: Cell 3 TMA Raise Schedule .............................................................................. 20-7 Table 20-3: List of Anticipated Environmental Approvals Required ................................... 20-11 Table 20-4: Financial Assurance Timing Summary ........................................................... 20-13 Table 21-1: Capital Cost Summary by Area ......................................................................... 21-2 Table 21-2: Capital Cost Summary by Sustaining/Growth ................................................... 21-2 Table 21-3: Operating Cost Summary ................................................................................. 21-4 Table 21-4: Operating Unit Cost Summary .......................................................................... 21-4 Table 22-1: Cash Flow Analysis ................................................................................................. 22-5 Table 22-2: Sensitivity of After-Tax Net Present Value to Gold Price and Exchange Rate .......................................................................................................................... 22-6 Table of Figures Figure 1-1: Sensitivity of After-Tax Net Present Value to Gold Price, Exchange Rate, Operating Cost, and Capital Cost ..................................................................... 1-32 Figure 1-2: Sensitivity of After-Tax Net Present Value to Gold Price and Exchange Rate .......................................................................................................................... 1-32 Figure 1-3: Sensitivity of After-Tax Net Present Value to Discount Rate ............................ 1-33