TECHNICAL REPORT SUMMARY ON THE MATERIAL ASSETS OF THE KROONDAL OPERATIONS Situated near Rustenburg, North West Province, South Africa 31 December 2023 Prepared by: Qualified Persons from Sibanye-Stillwater, PGM Operations Exhibit 96.4 ii Important Notices Mineral Resources and Mineral Reserves are declared as attributable to Sibanye-Stillwater Ltd (registrant). Sibanye-Stillwater operates the Kroondal Operations and as such may accrue benefits in addition to the income from the attributable portions of the Mineral Reserves. For the purposes of transparency and because it is not possible to accurately separate out the non-attributable interests in these models, the Life-of-Mine plan and financial analyses are given for the full Mineral Reserve. Wherever mention is made of “Kroondal Operations”, for the purposes of this Technical Report Summary, Kroondal Operations refers to a 50 - 50 Pool and Share Agreement between Kroondal Operations Proprietary Limited and Sibanye-Rustenburg Platinum Mines Proprietary Limited (SRPM) to mine the Mineral Reserves under an exclusive agreement. Kroondal Operations Proprietary Limited manages the operation. In this document, a point is used as the decimal marker, and the comma is used for the text's thousands separator (for numbers larger than 999). In other words, 10,148.32 denotes ten thousand one hundred and forty-eight point three two. The word ‘tonnes’ denotes a metric tonne (1,000 kg). The abbreviation “lb” denotes the weight pounds in the sense understood in the USA. The Platinum, Palladium, Rhodium and Gold (4E) prices are quoted in US dollars per troy ounce (USD/oz.) or South African Rand per kilogram (ZAR/kg). 6E denotes a basket of PGM’s Platinum, Palladium, Rhodium, Gold, Iridium and Ruthenium. Chrome refers to Chromium Oxide Cr2O3. The pay limit (cm.g/t or g/t) of an operation is the average value or grade for that operation which includes all direct and indirect costs i.e., the value at which it is estimated that ore can be mined without profit or loss. The cut-off grade (cm.g/t or g/t) of an operation is the minimum value or grade at which an area can be mined to maintain an average value in line with the pay limit. The cut-off is unique to the orebody being mined and is dependent on maintaining a mining mix that follows the orebody’s value distribution. NOTE: The UG2 Reefs at the Kroondal Operations and the contiguous Sibanye-Stillwater owned Rustenburg Operations are single orebodies and are estimated as single geological units across the two properties. A portion of the SRPM Mineral Reserves will be accessed through the Kroondal Infrastructure through a Pool-and-share agreement. This tonnage is reflected in the Kroondal Operations Life-of-Mine Schedule and financial model, not Rustenburg Operations. However, Mineral Resources and Mineral Reserves are divided and reported within their respective mineral rights boundaries. Trademarks. Certain software and methodologies may be proprietary. Where proprietary names are mentioned, TM or © are omitted for readability.

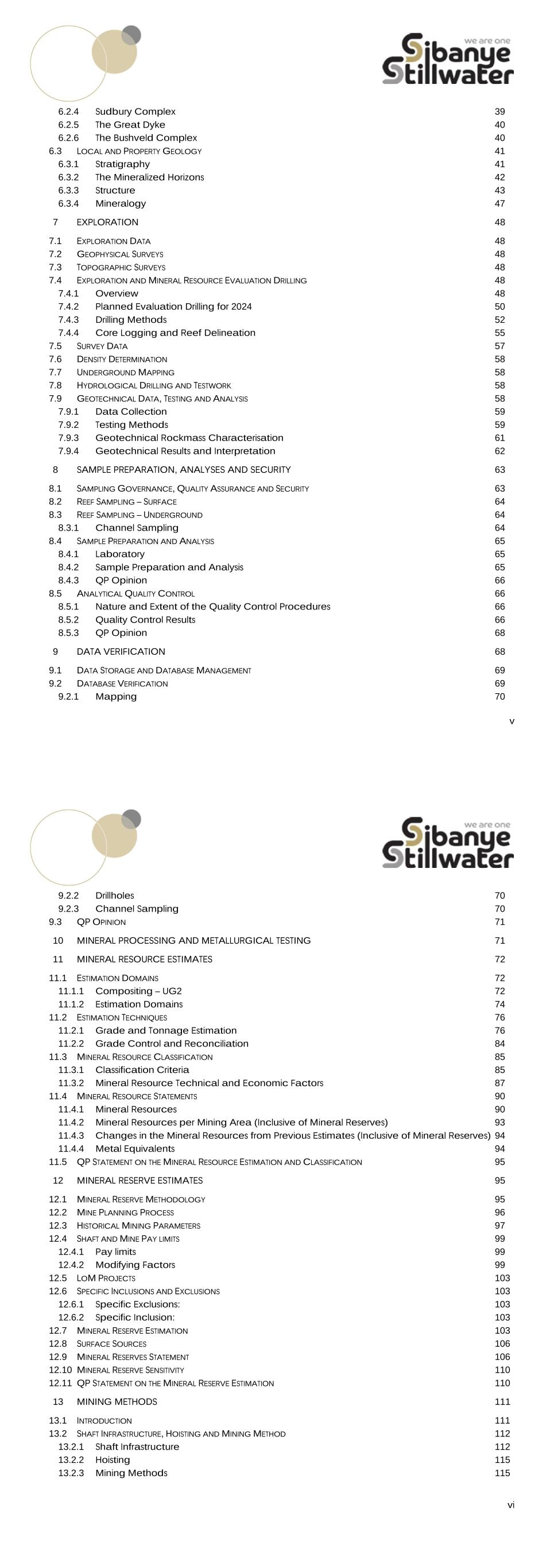

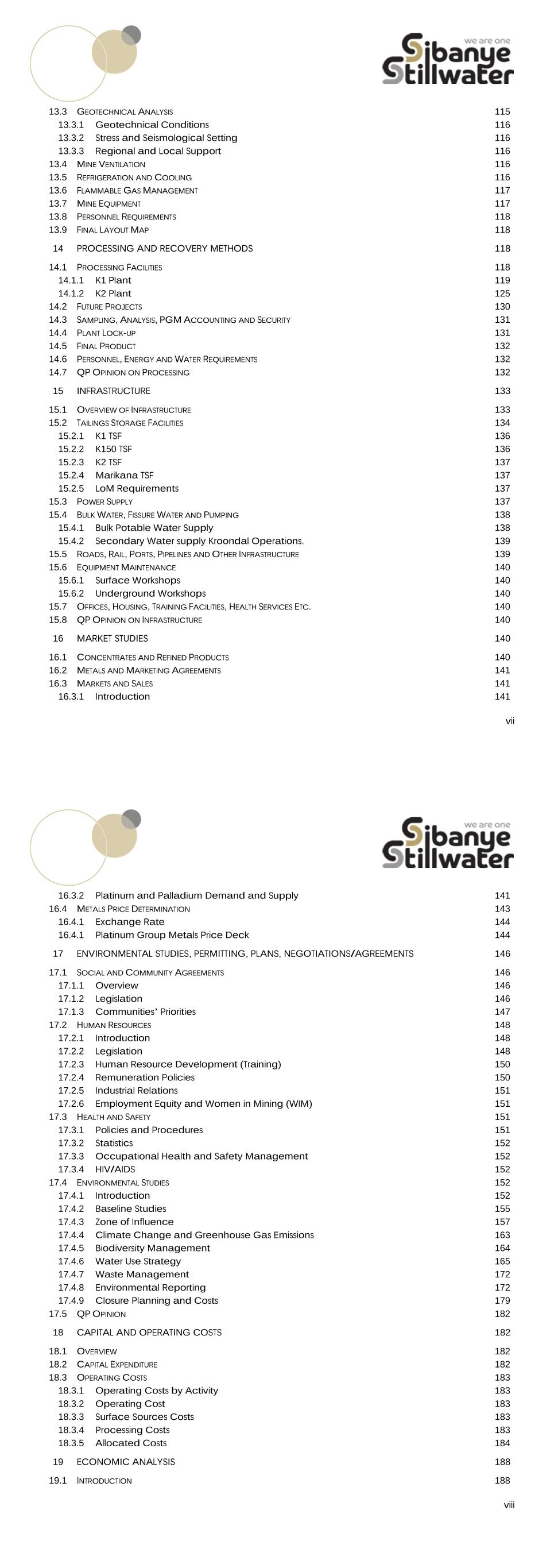

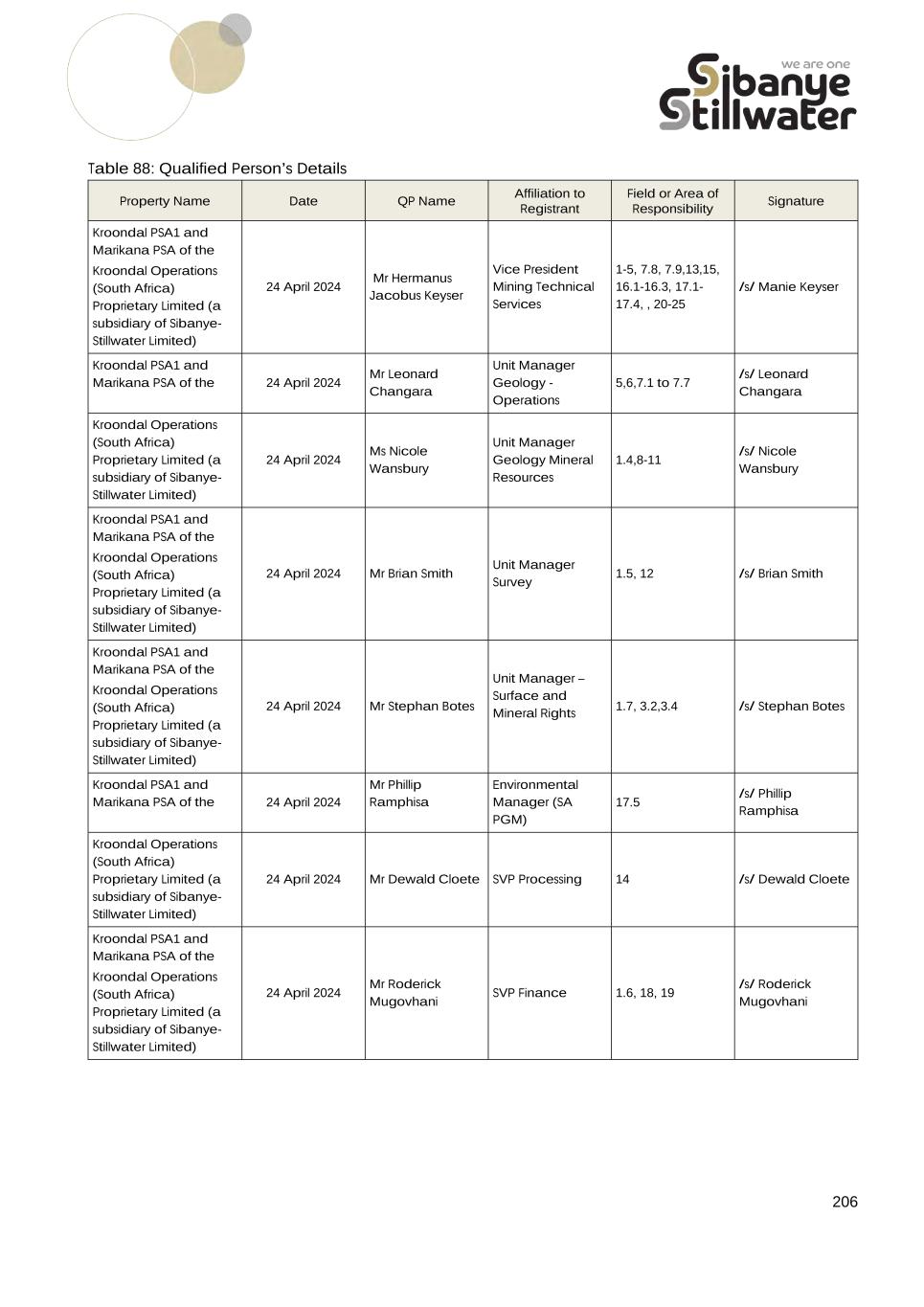

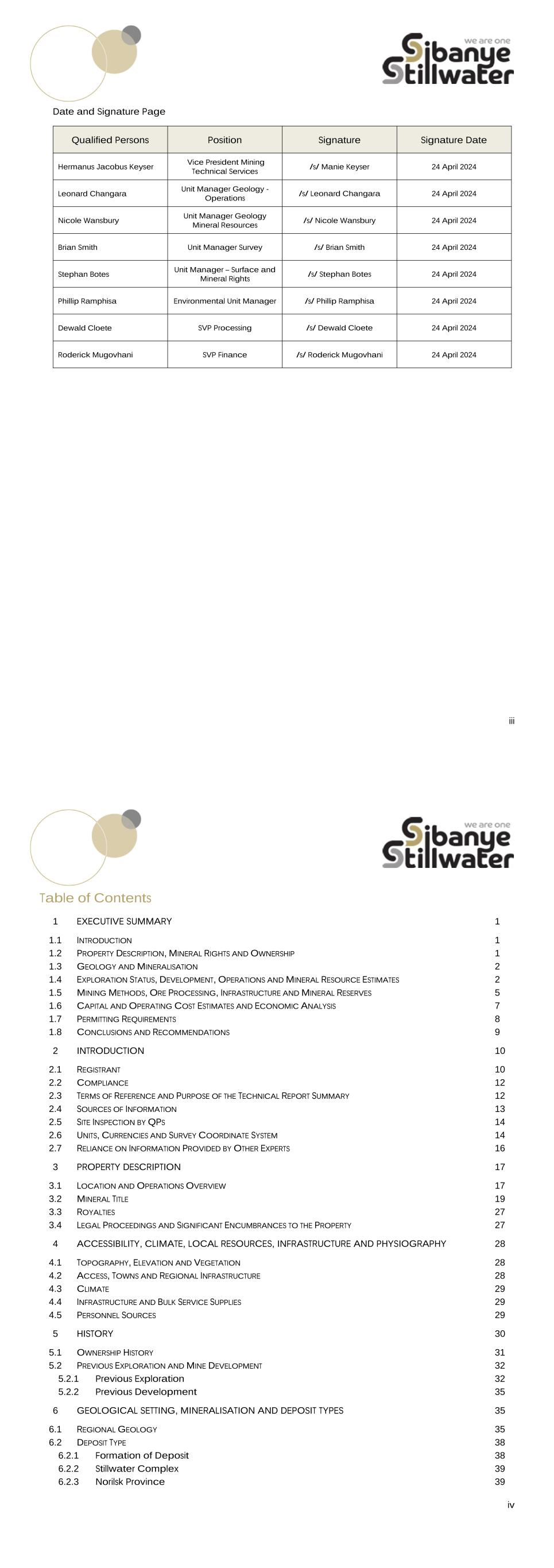

iii Date and Signature Page Qualified Persons Position Signature Signature Date Hermanus Jacobus Keyser Vice President Mining Technical Services /s/ Manie Keyser 24 April 2024 Leonard Changara Unit Manager Geology - Operations /s/ Leonard Changara 24 April 2024 Nicole Wansbury Unit Manager Geology Mineral Resources /s/ Nicole Wansbury 24 April 2024 Brian Smith Unit Manager Survey /s/ Brian Smith 24 April 2024 Stephan Botes Unit Manager – Surface and Mineral Rights /s/ Stephan Botes 24 April 2024 Phillip Ramphisa Environmental Unit Manager /s/ Phillip Ramphisa 24 April 2024 Dewald Cloete SVP Processing /s/ Dewald Cloete 24 April 2024 Roderick Mugovhani SVP Finance /s/ Roderick Mugovhani 24 April 2024 iv Table of Contents 1 EXECUTIVE SUMMARY 1 1.1 INTRODUCTION 1 1.2 PROPERTY DESCRIPTION, MINERAL RIGHTS AND OWNERSHIP 1 1.3 GEOLOGY AND MINERALISATION 2 1.4 EXPLORATION STATUS, DEVELOPMENT, OPERATIONS AND MINERAL RESOURCE ESTIMATES 2 1.5 MINING METHODS, ORE PROCESSING, INFRASTRUCTURE AND MINERAL RESERVES 5 1.6 CAPITAL AND OPERATING COST ESTIMATES AND ECONOMIC ANALYSIS 7 1.7 PERMITTING REQUIREMENTS 8 1.8 CONCLUSIONS AND RECOMMENDATIONS 9 2 INTRODUCTION 10 2.1 REGISTRANT 10 2.2 COMPLIANCE 12 2.3 TERMS OF REFERENCE AND PURPOSE OF THE TECHNICAL REPORT SUMMARY 12 2.4 SOURCES OF INFORMATION 13 2.5 SITE INSPECTION BY QPS 14 2.6 UNITS, CURRENCIES AND SURVEY COORDINATE SYSTEM 14 2.7 RELIANCE ON INFORMATION PROVIDED BY OTHER EXPERTS 16 3 PROPERTY DESCRIPTION 17 3.1 LOCATION AND OPERATIONS OVERVIEW 17 3.2 MINERAL TITLE 19 3.3 ROYALTIES 27 3.4 LEGAL PROCEEDINGS AND SIGNIFICANT ENCUMBRANCES TO THE PROPERTY 27 4 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY 28 4.1 TOPOGRAPHY, ELEVATION AND VEGETATION 28 4.2 ACCESS, TOWNS AND REGIONAL INFRASTRUCTURE 28 4.3 CLIMATE 29 4.4 INFRASTRUCTURE AND BULK SERVICE SUPPLIES 29 4.5 PERSONNEL SOURCES 29 5 HISTORY 30 5.1 OWNERSHIP HISTORY 31 5.2 PREVIOUS EXPLORATION AND MINE DEVELOPMENT 32 5.2.1 Previous Exploration 32 5.2.2 Previous Development 35 6 GEOLOGICAL SETTING, MINERALISATION AND DEPOSIT TYPES 35 6.1 REGIONAL GEOLOGY 35 6.2 DEPOSIT TYPE 38 6.2.1 Formation of Deposit 38 6.2.2 Stillwater Complex 39 6.2.3 Norilsk Province 39

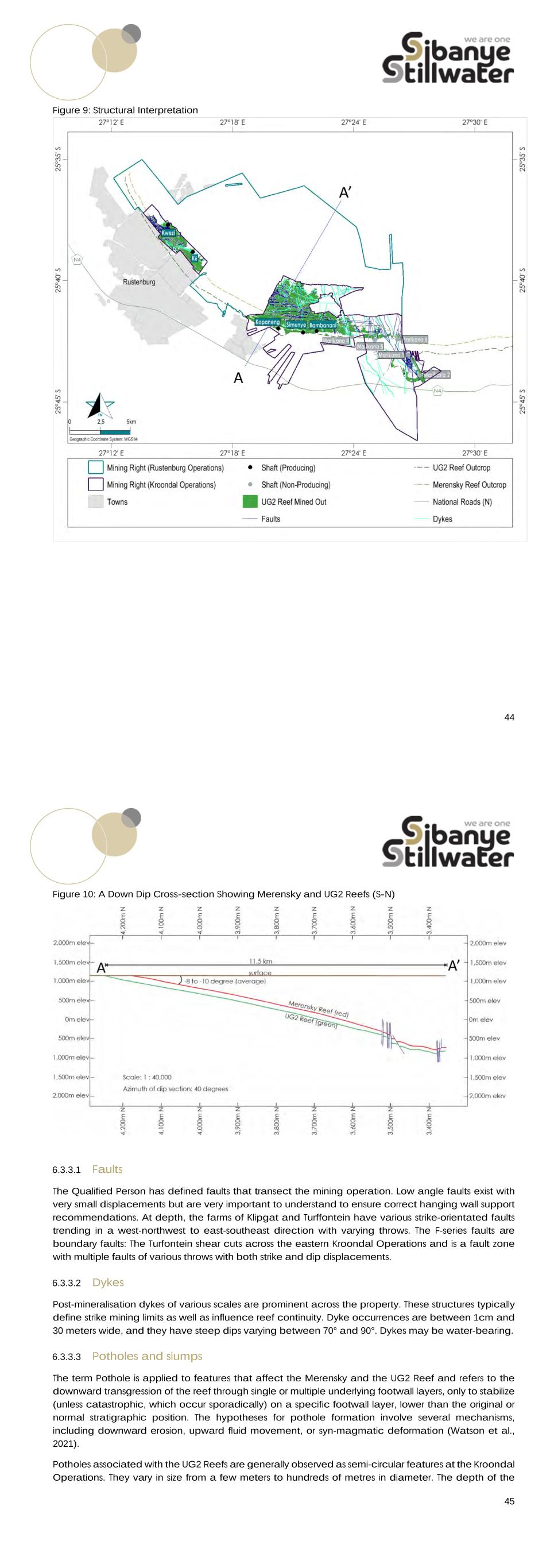

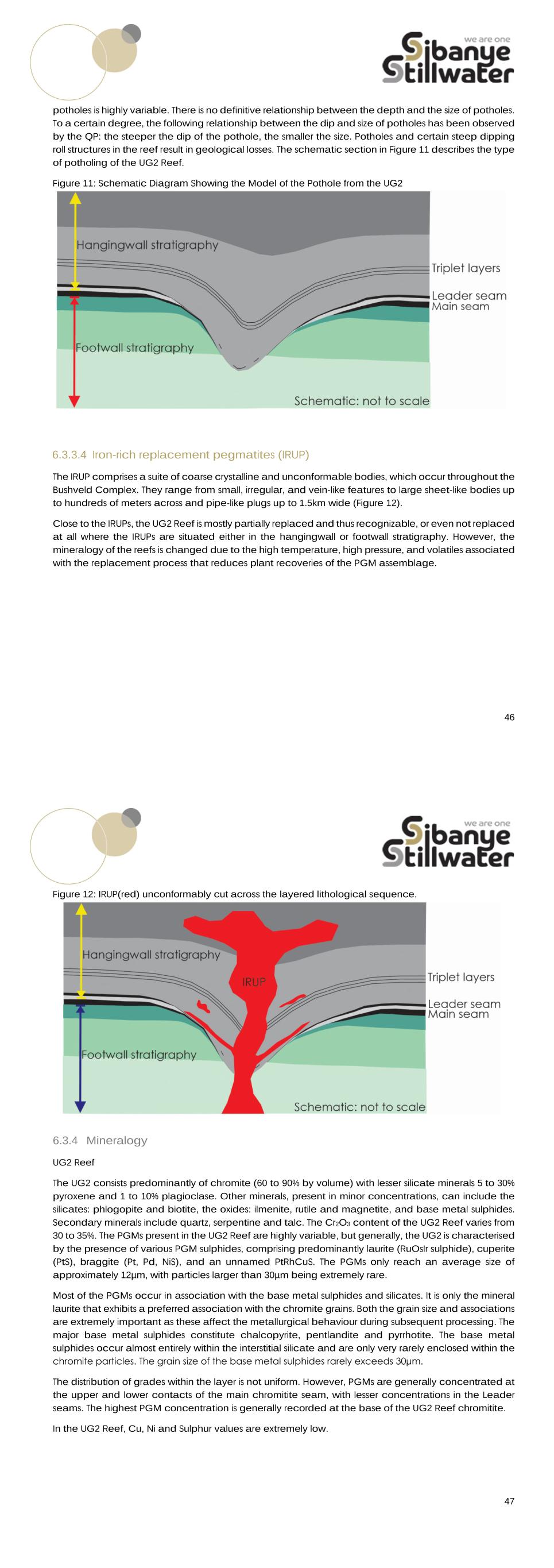

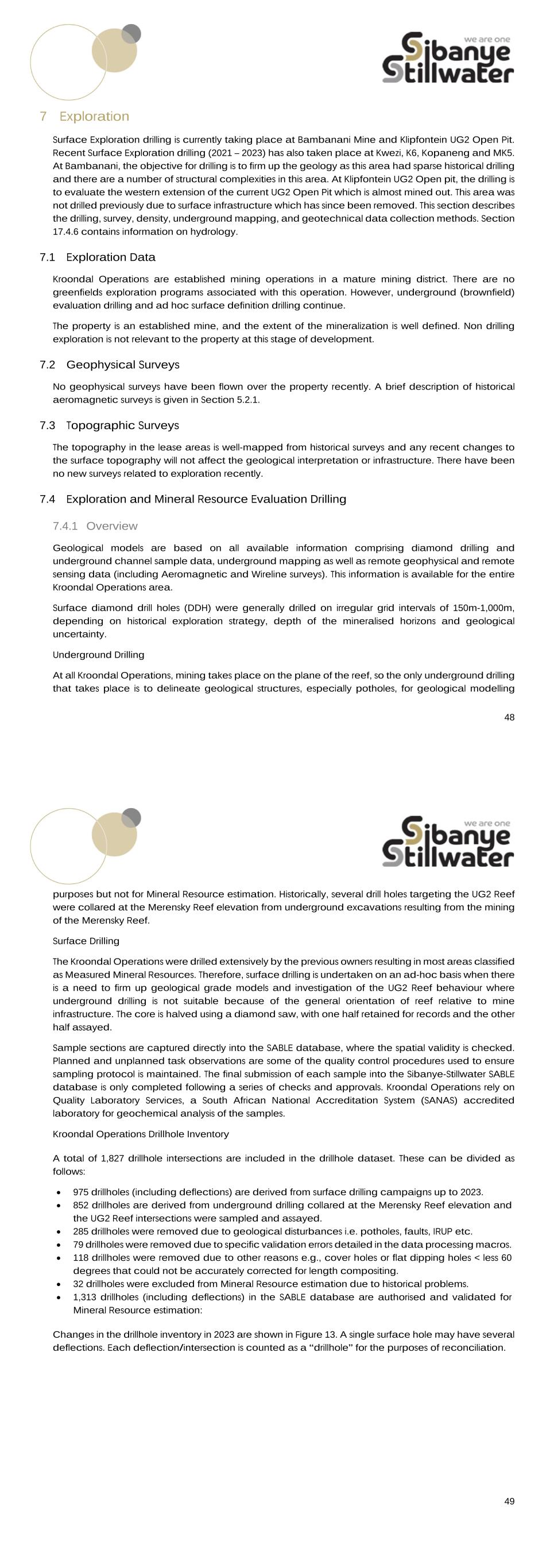

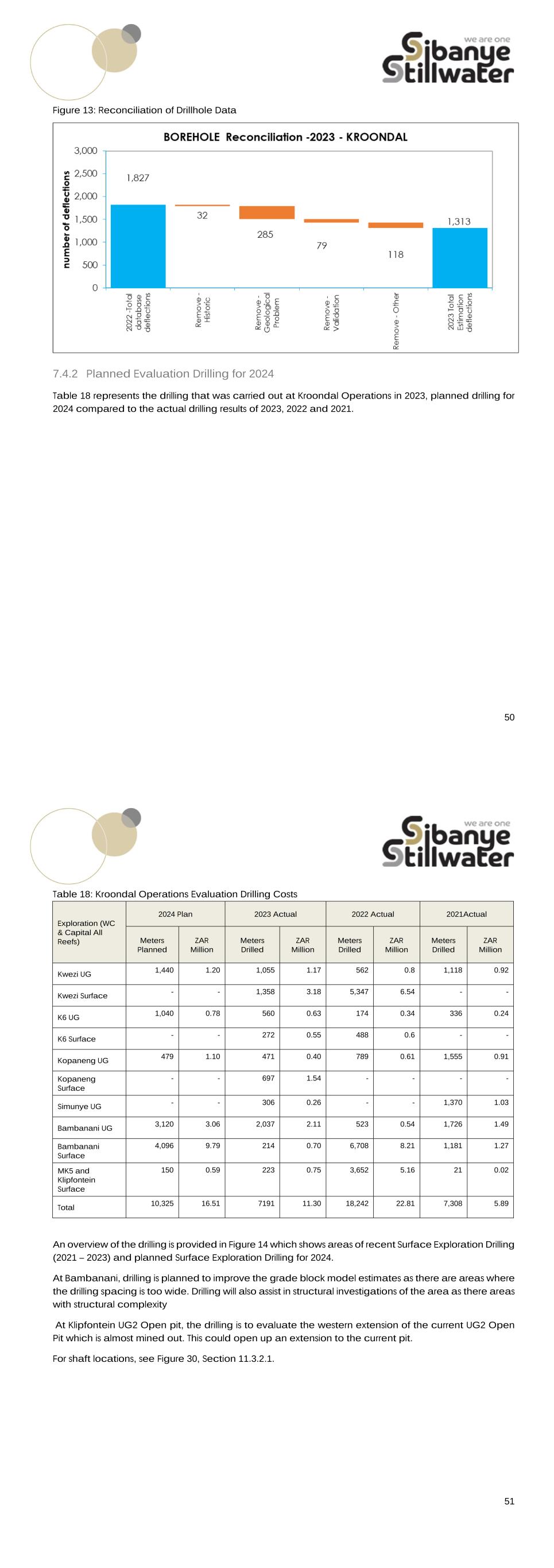

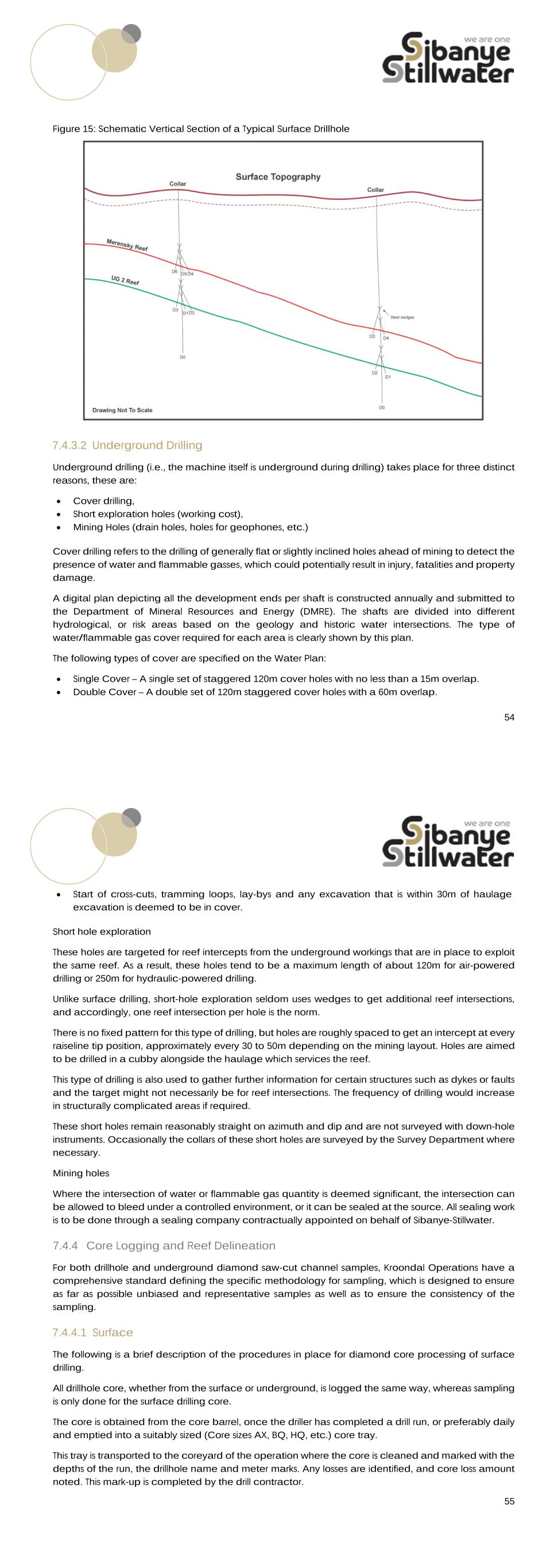

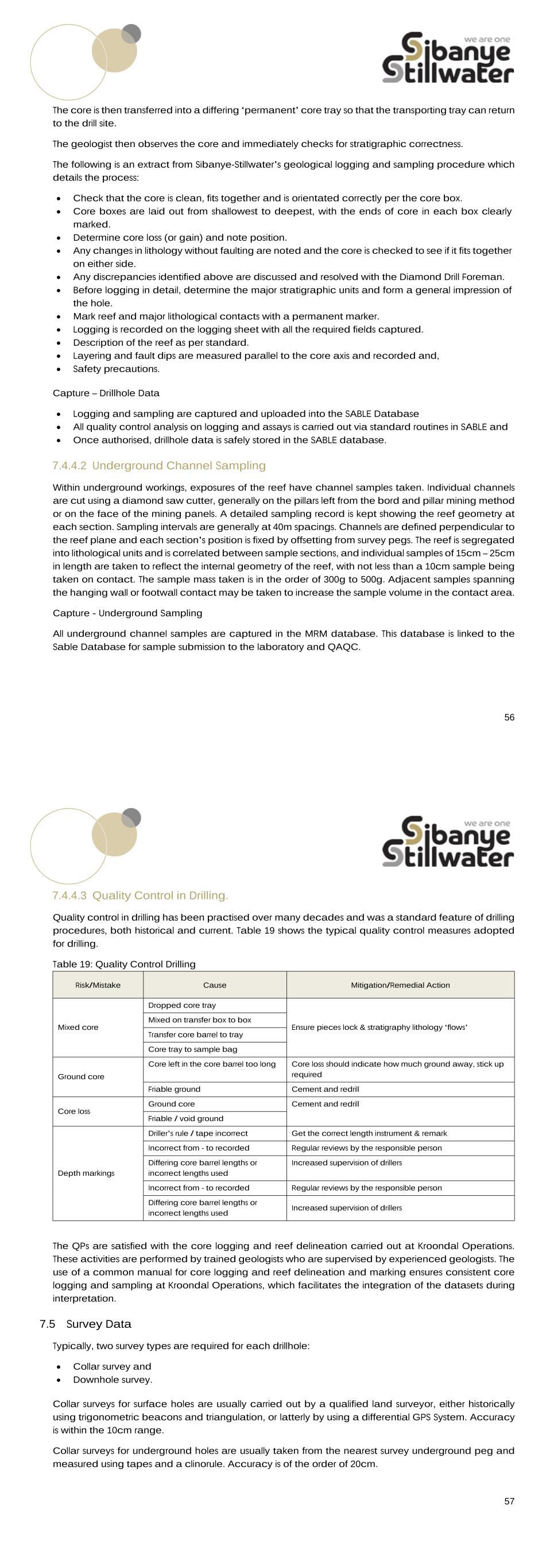

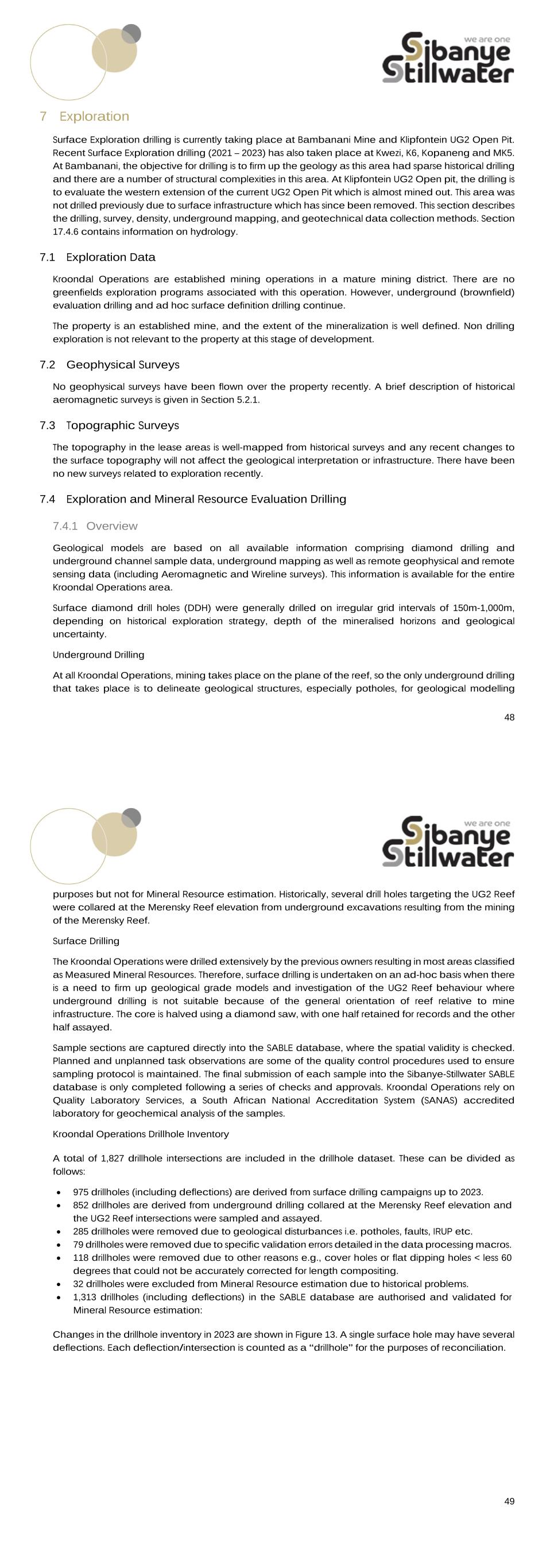

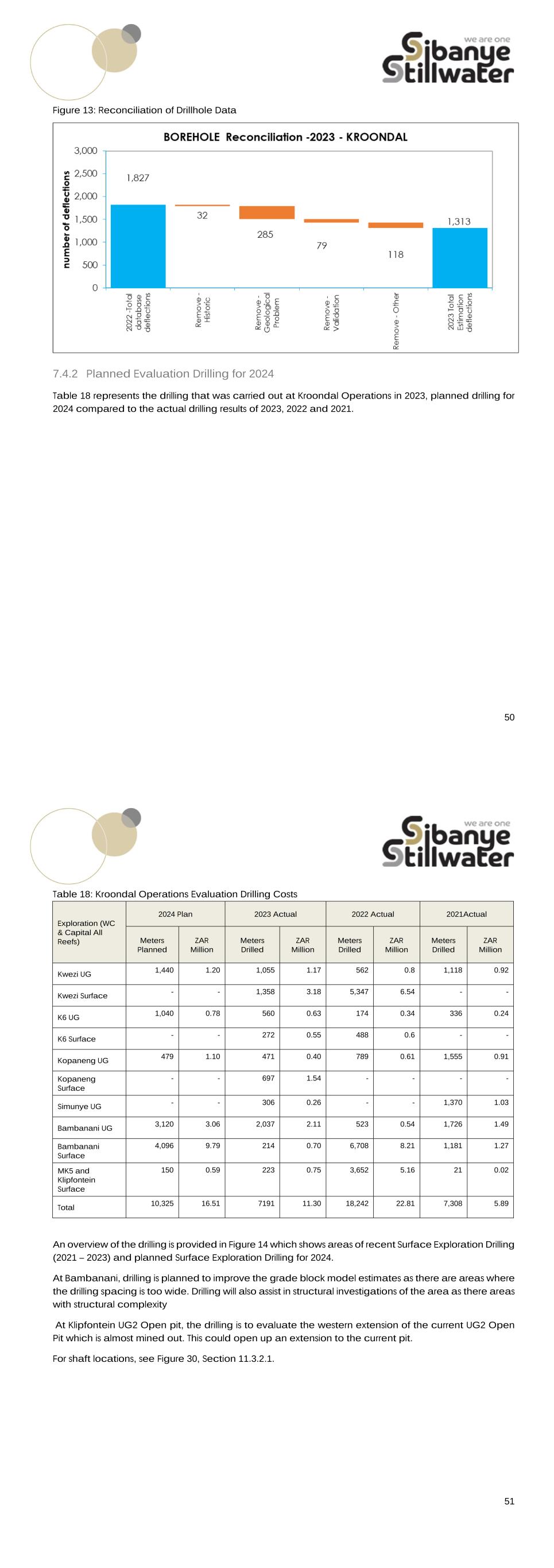

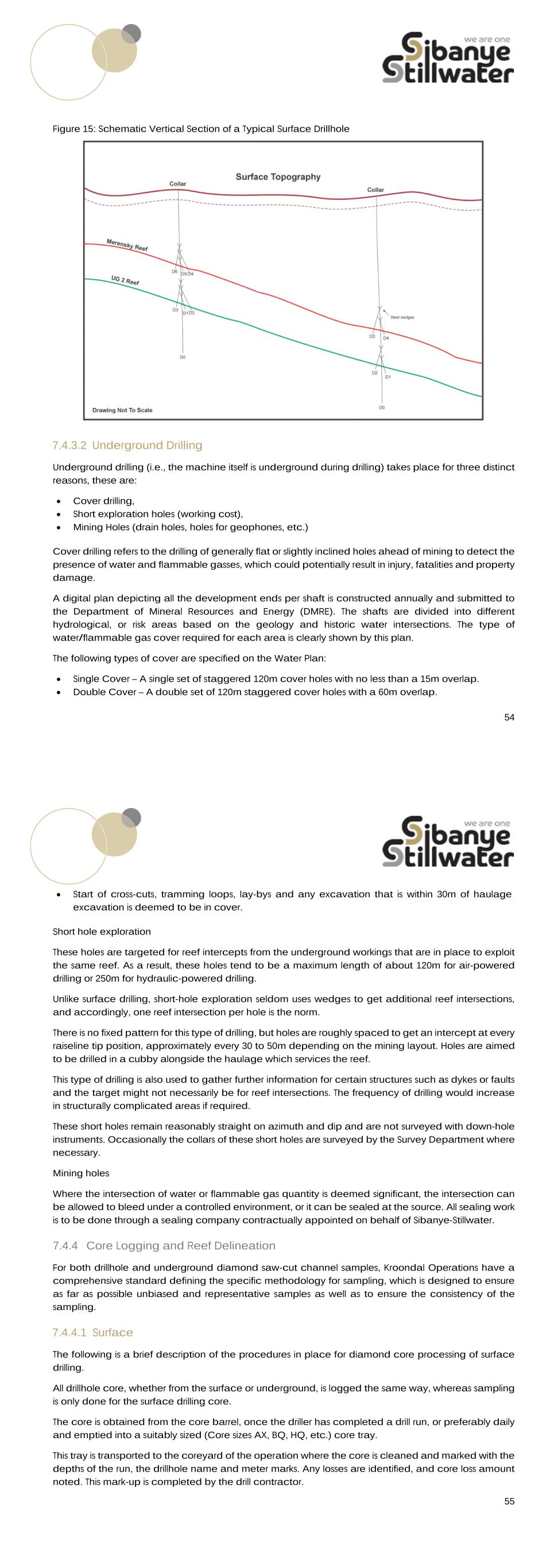

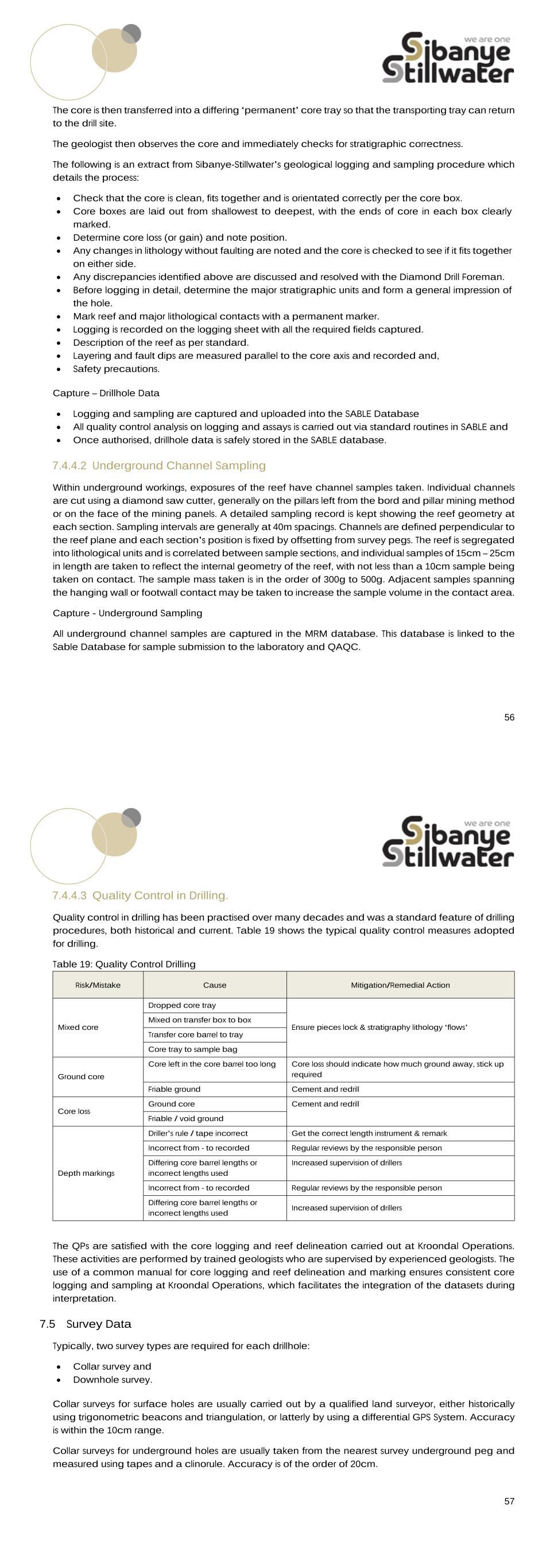

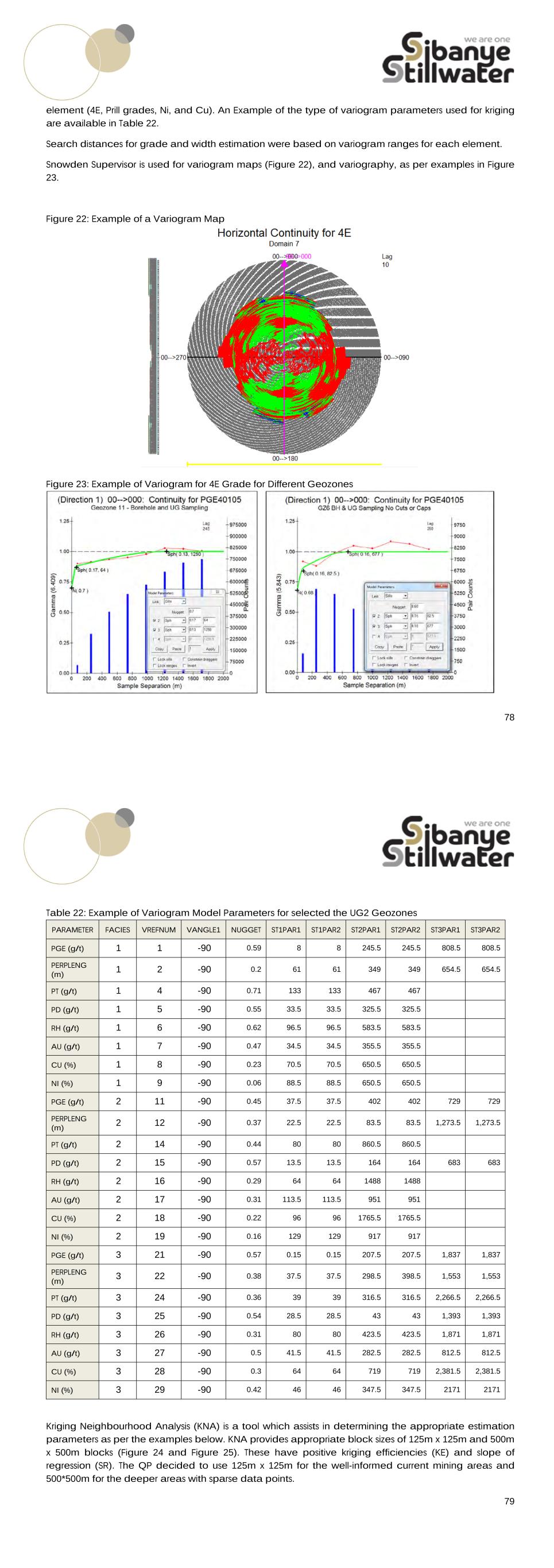

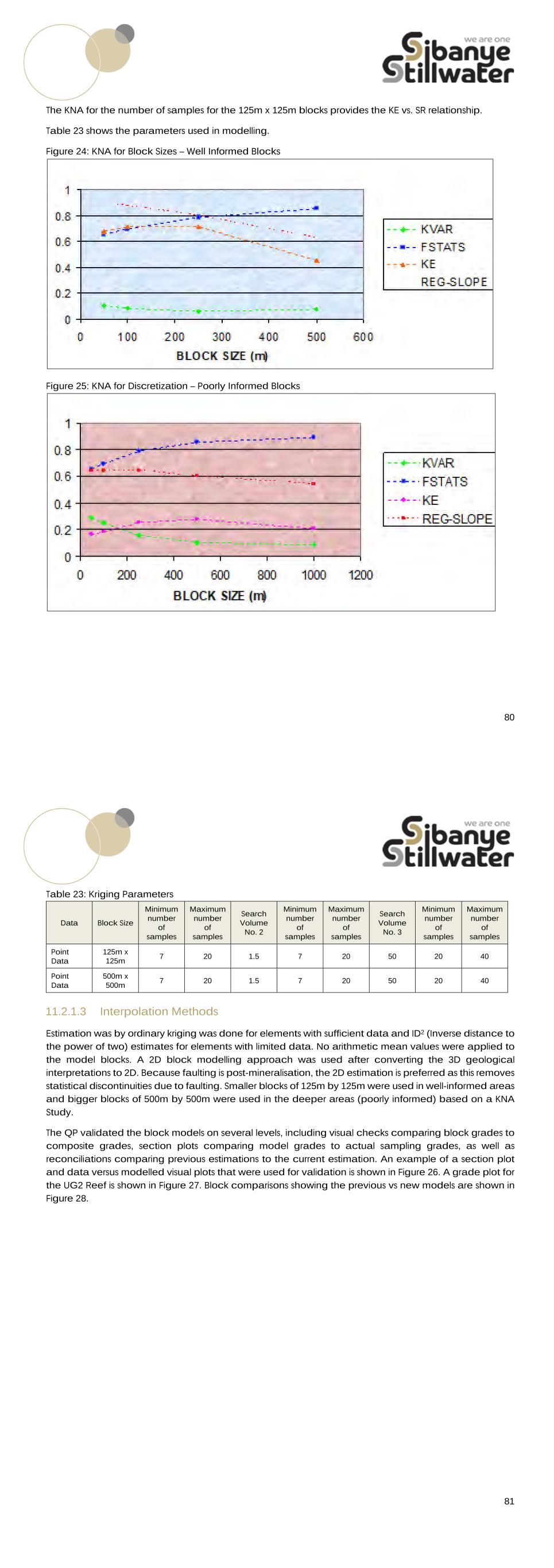

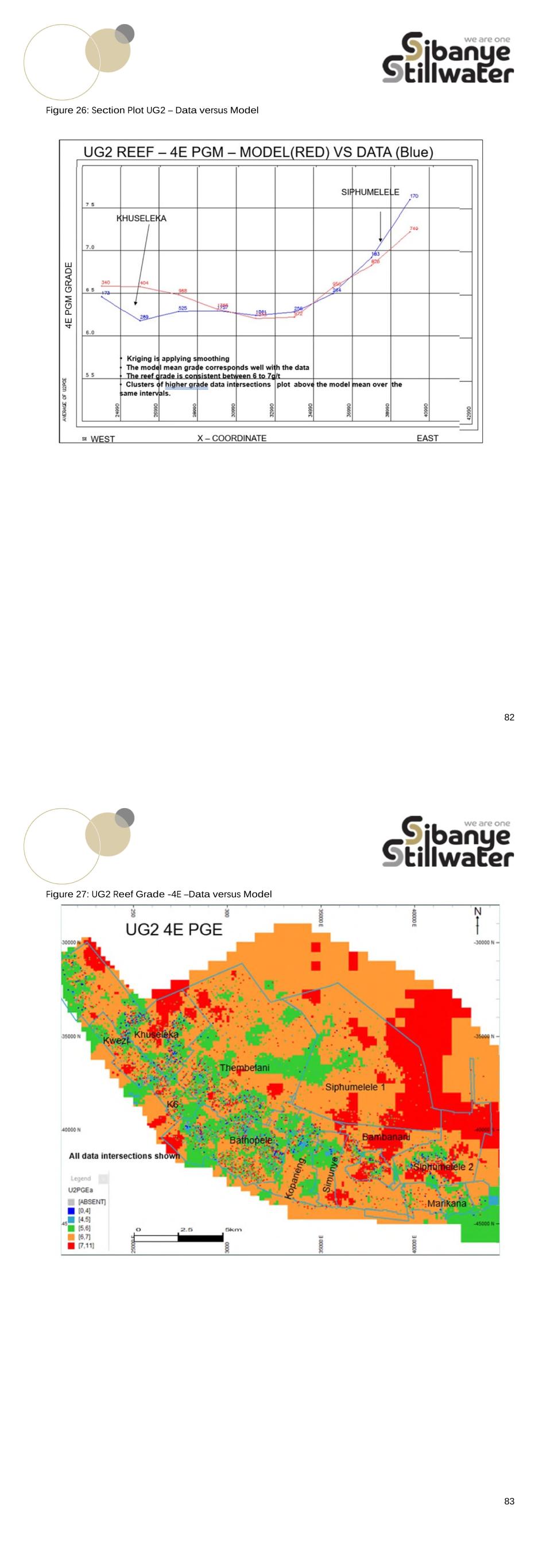

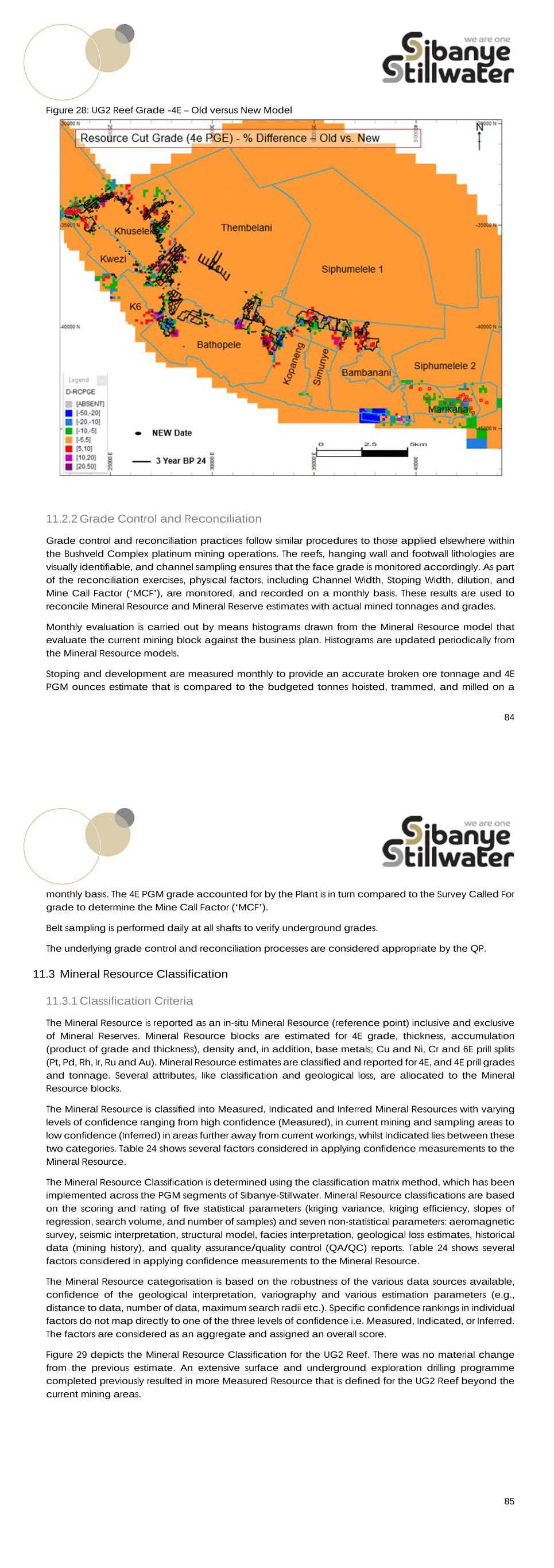

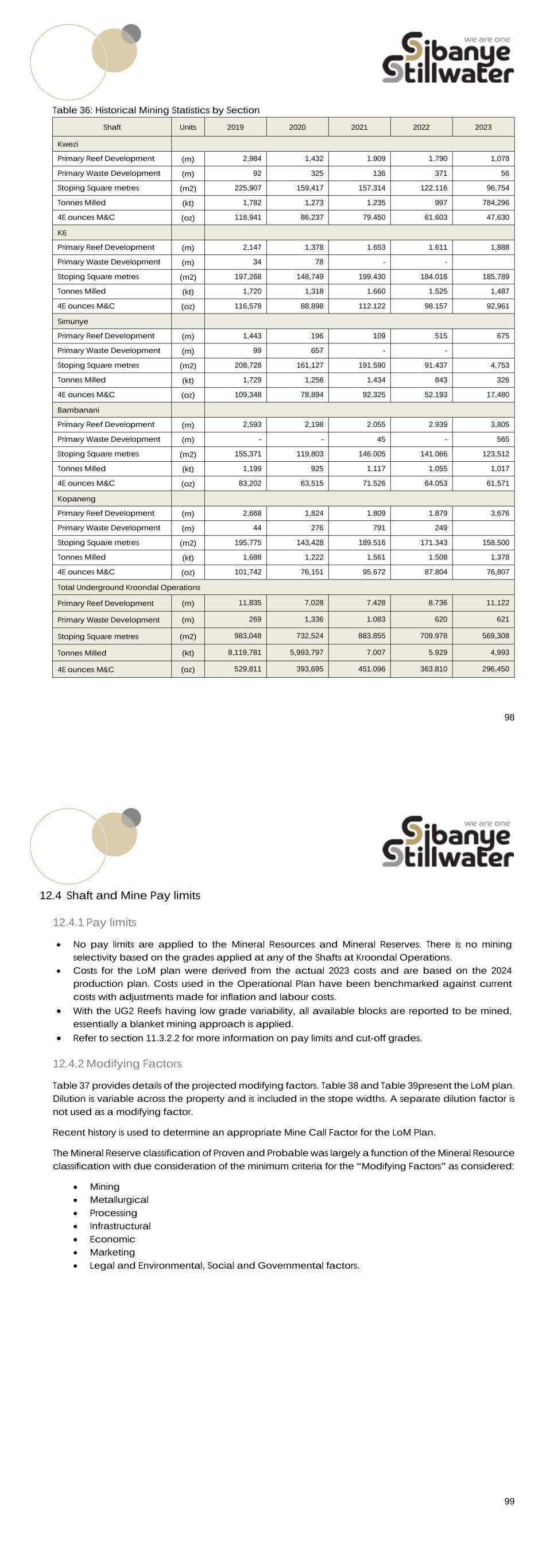

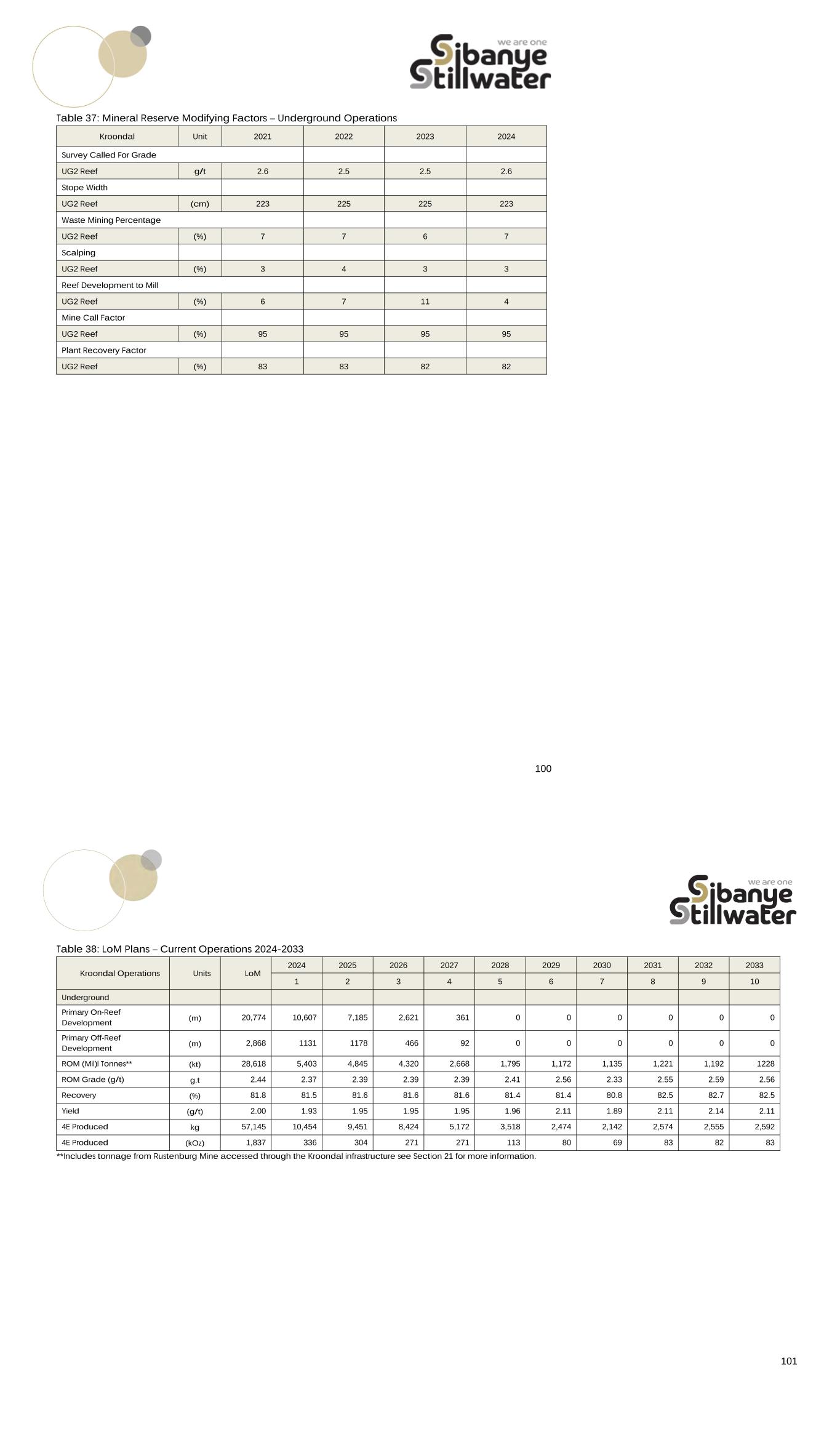

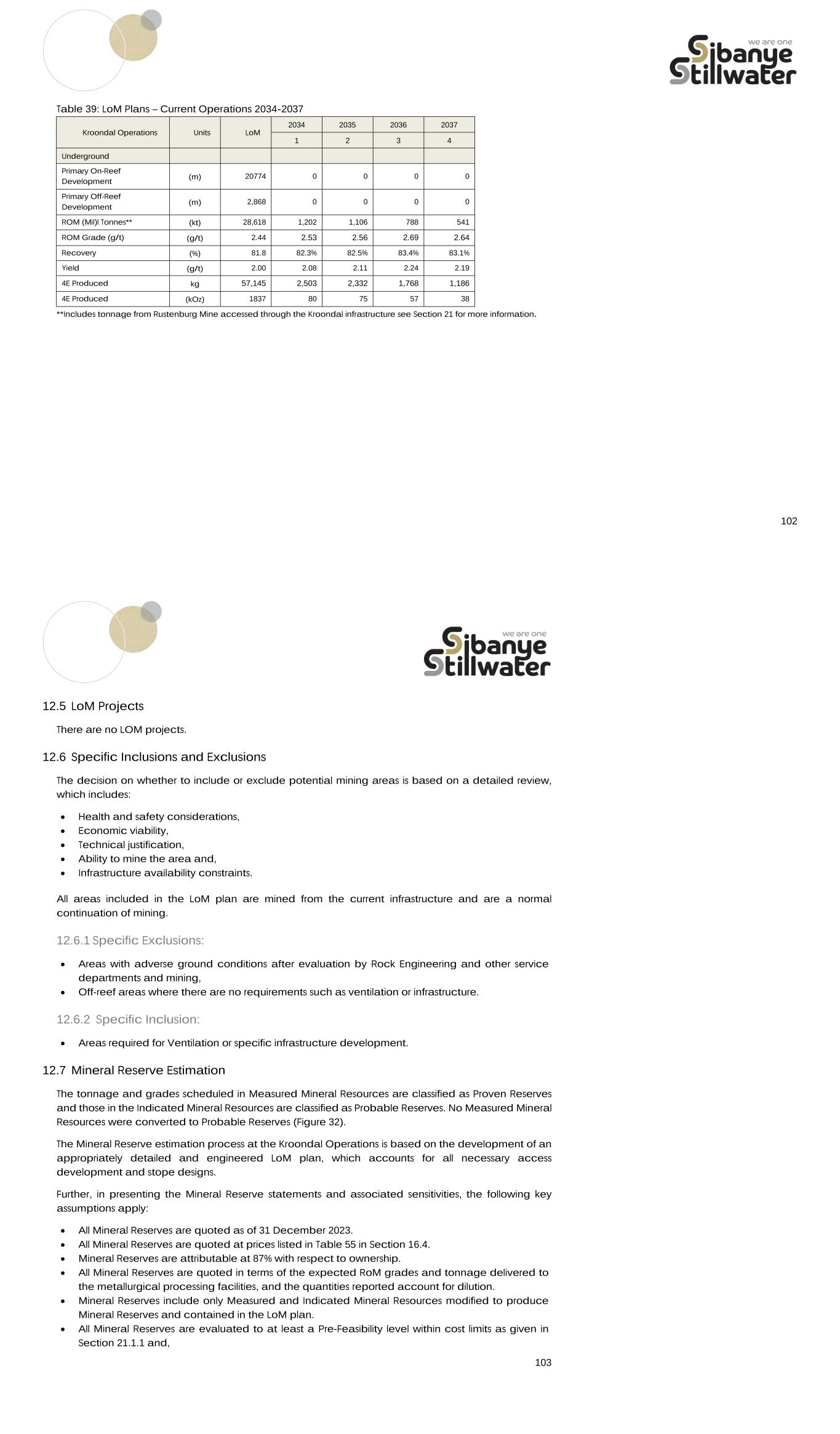

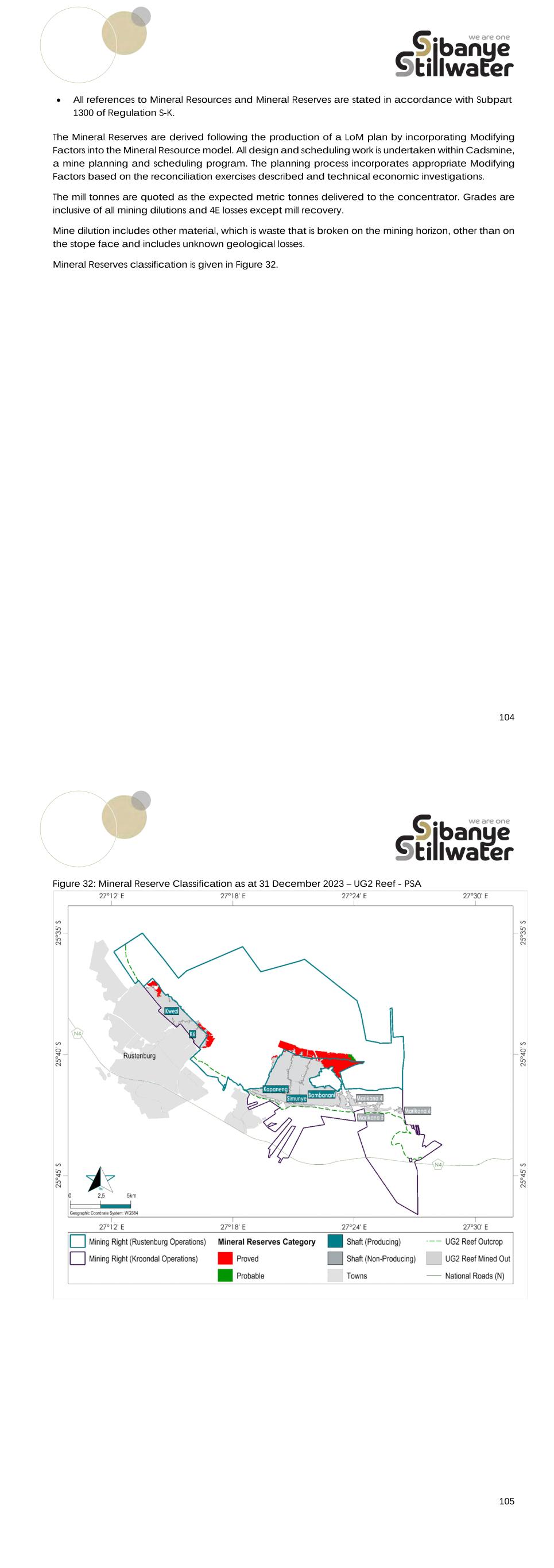

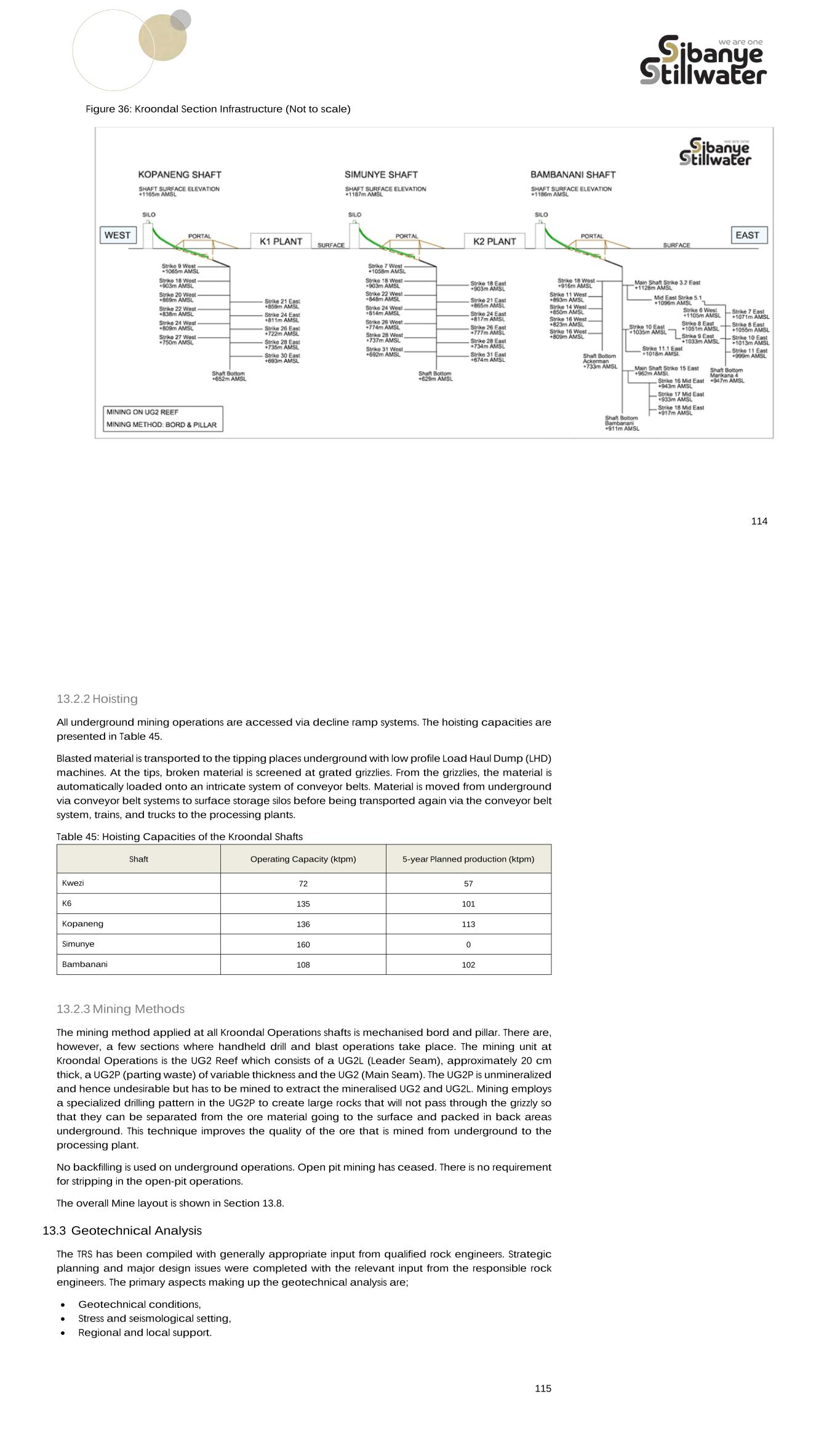

v 6.2.4 Sudbury Complex 39 6.2.5 The Great Dyke 40 6.2.6 The Bushveld Complex 40 6.3 LOCAL AND PROPERTY GEOLOGY 41 6.3.1 Stratigraphy 41 6.3.2 The Mineralized Horizons 42 6.3.3 Structure 43 6.3.4 Mineralogy 47 7 EXPLORATION 48 7.1 EXPLORATION DATA 48 7.2 GEOPHYSICAL SURVEYS 48 7.3 TOPOGRAPHIC SURVEYS 48 7.4 EXPLORATION AND MINERAL RESOURCE EVALUATION DRILLING 48 7.4.1 Overview 48 7.4.2 Planned Evaluation Drilling for 2024 50 7.4.3 Drilling Methods 52 7.4.4 Core Logging and Reef Delineation 55 7.5 SURVEY DATA 57 7.6 DENSITY DETERMINATION 58 7.7 UNDERGROUND MAPPING 58 7.8 HYDROLOGICAL DRILLING AND TESTWORK 58 7.9 GEOTECHNICAL DATA, TESTING AND ANALYSIS 58 7.9.1 Data Collection 59 7.9.2 Testing Methods 59 7.9.3 Geotechnical Rockmass Characterisation 61 7.9.4 Geotechnical Results and Interpretation 62 8 SAMPLE PREPARATION, ANALYSES AND SECURITY 63 8.1 SAMPLING GOVERNANCE, QUALITY ASSURANCE AND SECURITY 63 8.2 REEF SAMPLING – SURFACE 64 8.3 REEF SAMPLING – UNDERGROUND 64 8.3.1 Channel Sampling 64 8.4 SAMPLE PREPARATION AND ANALYSIS 65 8.4.1 Laboratory 65 8.4.2 Sample Preparation and Analysis 65 8.4.3 QP Opinion 66 8.5 ANALYTICAL QUALITY CONTROL 66 8.5.1 Nature and Extent of the Quality Control Procedures 66 8.5.2 Quality Control Results 66 8.5.3 QP Opinion 68 9 DATA VERIFICATION 68 9.1 DATA STORAGE AND DATABASE MANAGEMENT 69 9.2 DATABASE VERIFICATION 69 9.2.1 Mapping 70 vi 9.2.2 Drillholes 70 9.2.3 Channel Sampling 70 9.3 QP OPINION 71 10 MINERAL PROCESSING AND METALLURGICAL TESTING 71 11 MINERAL RESOURCE ESTIMATES 72 11.1 ESTIMATION DOMAINS 72 11.1.1 Compositing – UG2 72 11.1.2 Estimation Domains 74 11.2 ESTIMATION TECHNIQUES 76 11.2.1 Grade and Tonnage Estimation 76 11.2.2 Grade Control and Reconciliation 84 11.3 MINERAL RESOURCE CLASSIFICATION 85 11.3.1 Classification Criteria 85 11.3.2 Mineral Resource Technical and Economic Factors 87 11.4 MINERAL RESOURCE STATEMENTS 90 11.4.1 Mineral Resources 90 11.4.2 Mineral Resources per Mining Area (Inclusive of Mineral Reserves) 93 11.4.3 Changes in the Mineral Resources from Previous Estimates (Inclusive of Mineral Reserves) 94 11.4.4 Metal Equivalents 94 11.5 QP STATEMENT ON THE MINERAL RESOURCE ESTIMATION AND CLASSIFICATION 95 12 MINERAL RESERVE ESTIMATES 95 12.1 MINERAL RESERVE METHODOLOGY 95 12.2 MINE PLANNING PROCESS 96 12.3 HISTORICAL MINING PARAMETERS 97 12.4 SHAFT AND MINE PAY LIMITS 99 12.4.1 Pay limits 99 12.4.2 Modifying Factors 99 12.5 LOM PROJECTS 103 12.6 SPECIFIC INCLUSIONS AND EXCLUSIONS 103 12.6.1 Specific Exclusions: 103 12.6.2 Specific Inclusion: 103 12.7 MINERAL RESERVE ESTIMATION 103 12.8 SURFACE SOURCES 106 12.9 MINERAL RESERVES STATEMENT 106 12.10 MINERAL RESERVE SENSITIVITY 110 12.11 QP STATEMENT ON THE MINERAL RESERVE ESTIMATION 110 13 MINING METHODS 111 13.1 INTRODUCTION 111 13.2 SHAFT INFRASTRUCTURE, HOISTING AND MINING METHOD 112 13.2.1 Shaft Infrastructure 112 13.2.2 Hoisting 115 13.2.3 Mining Methods 115

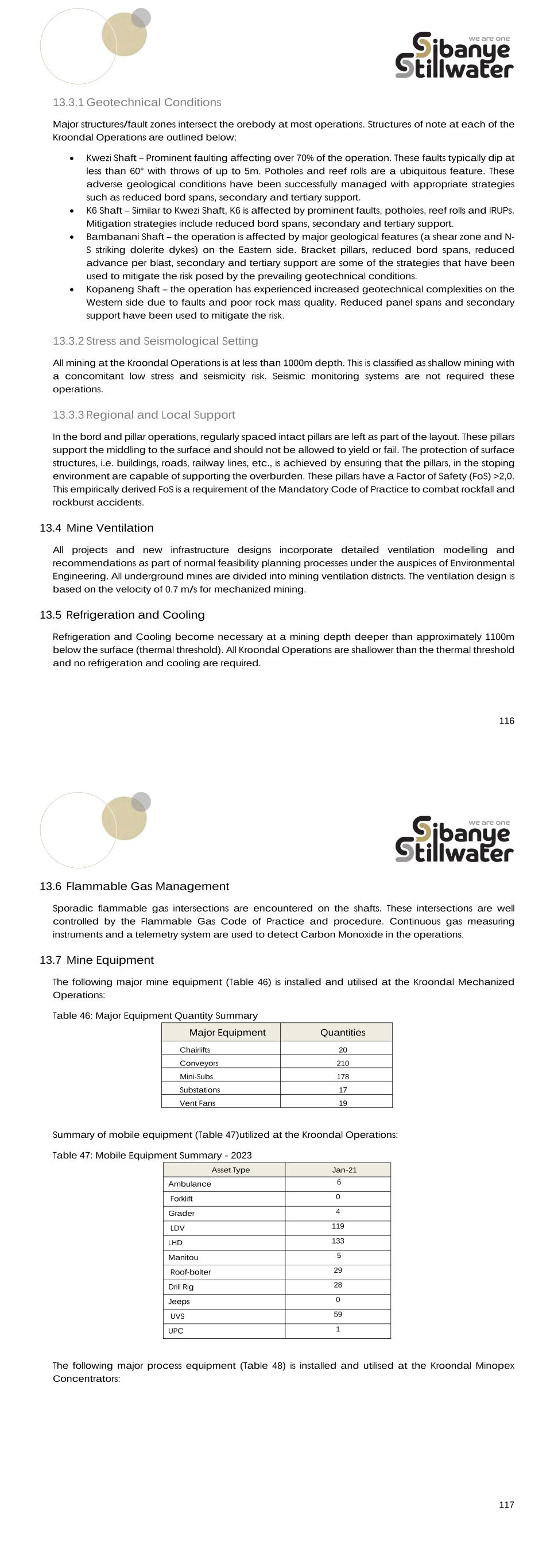

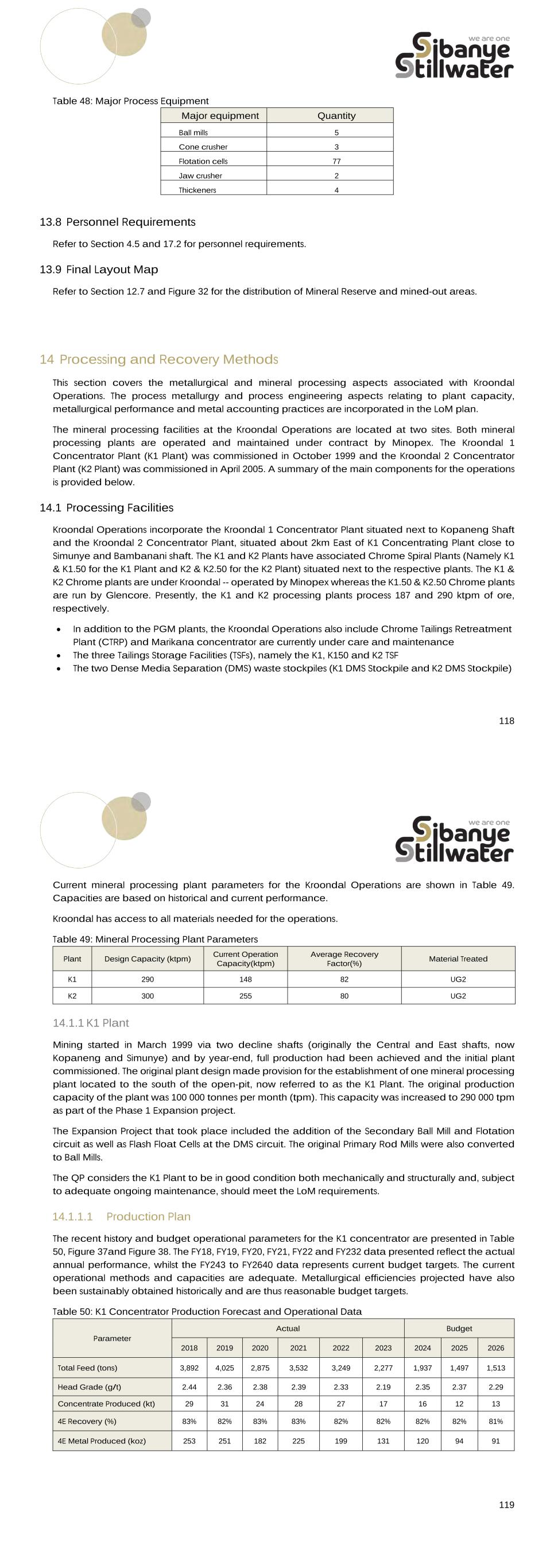

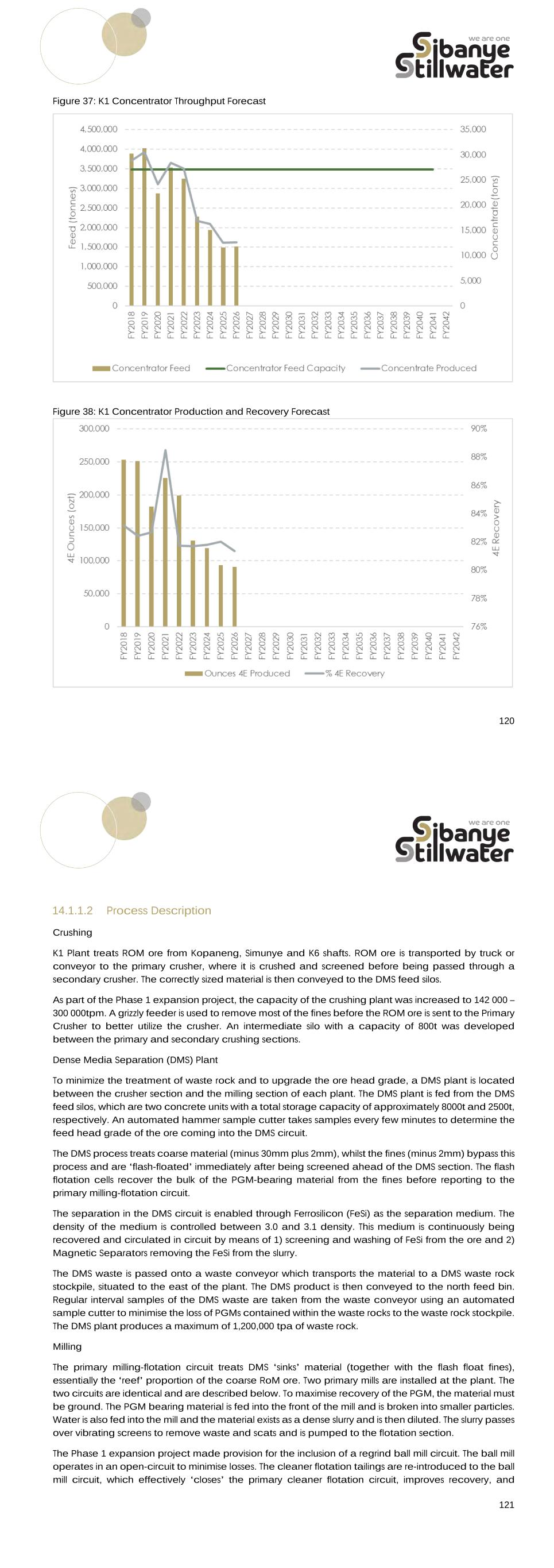

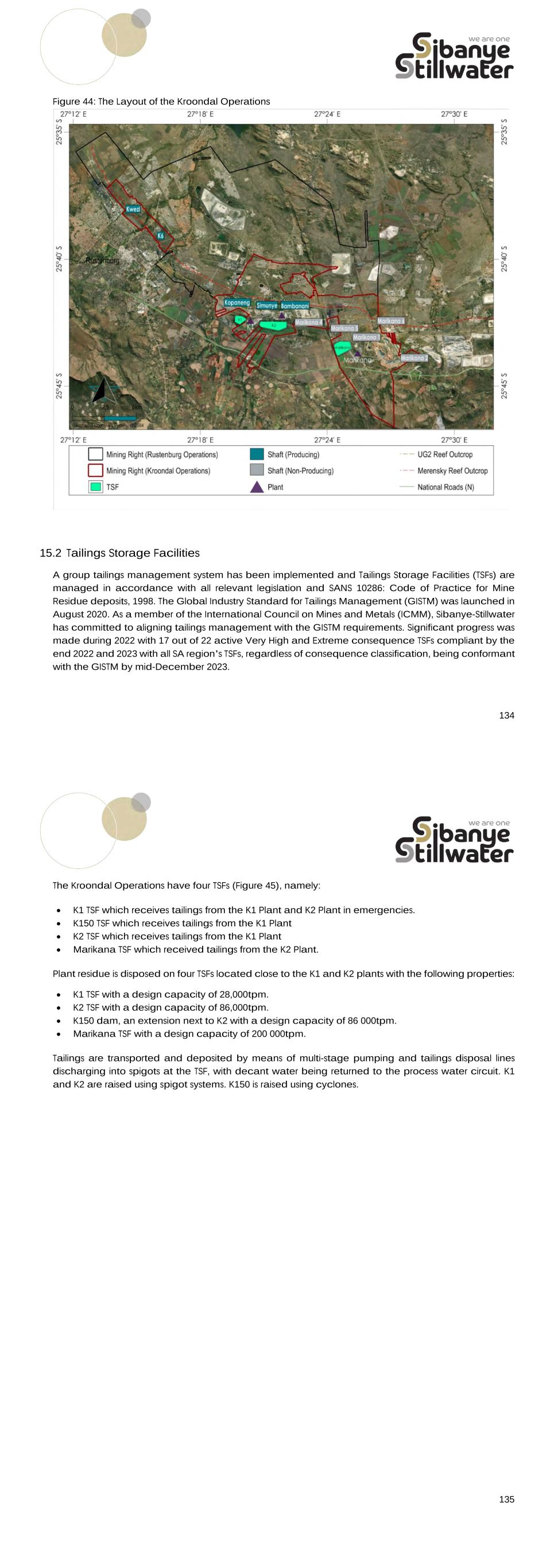

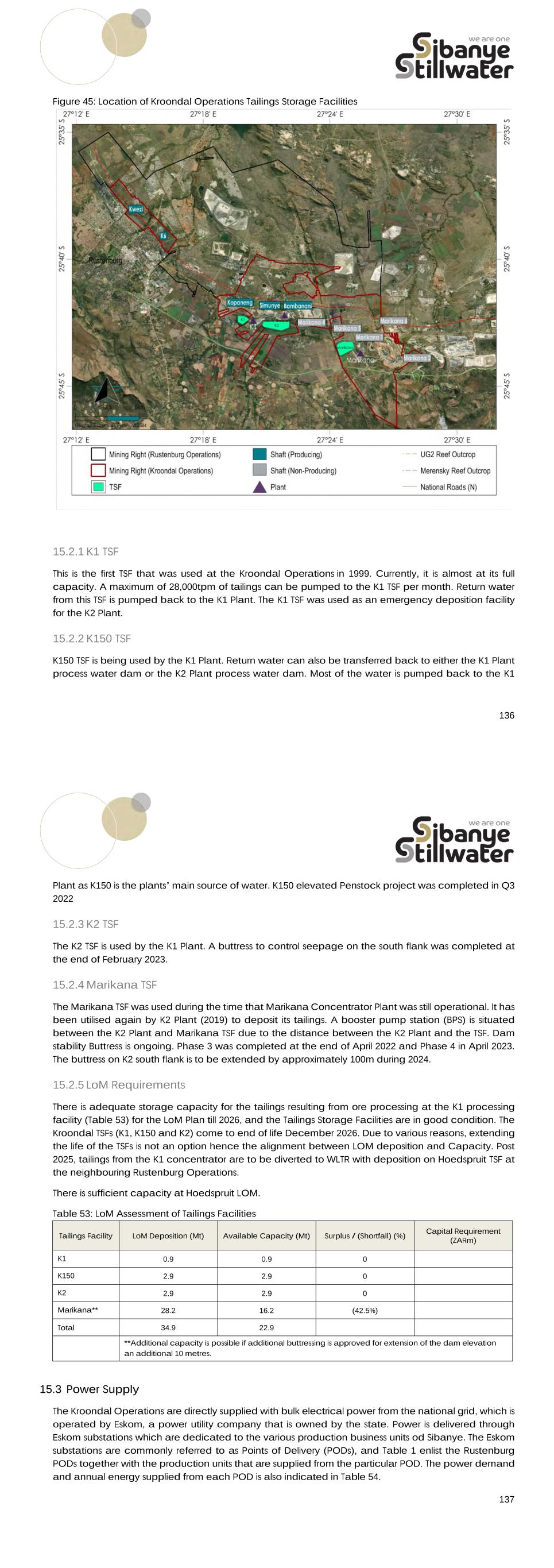

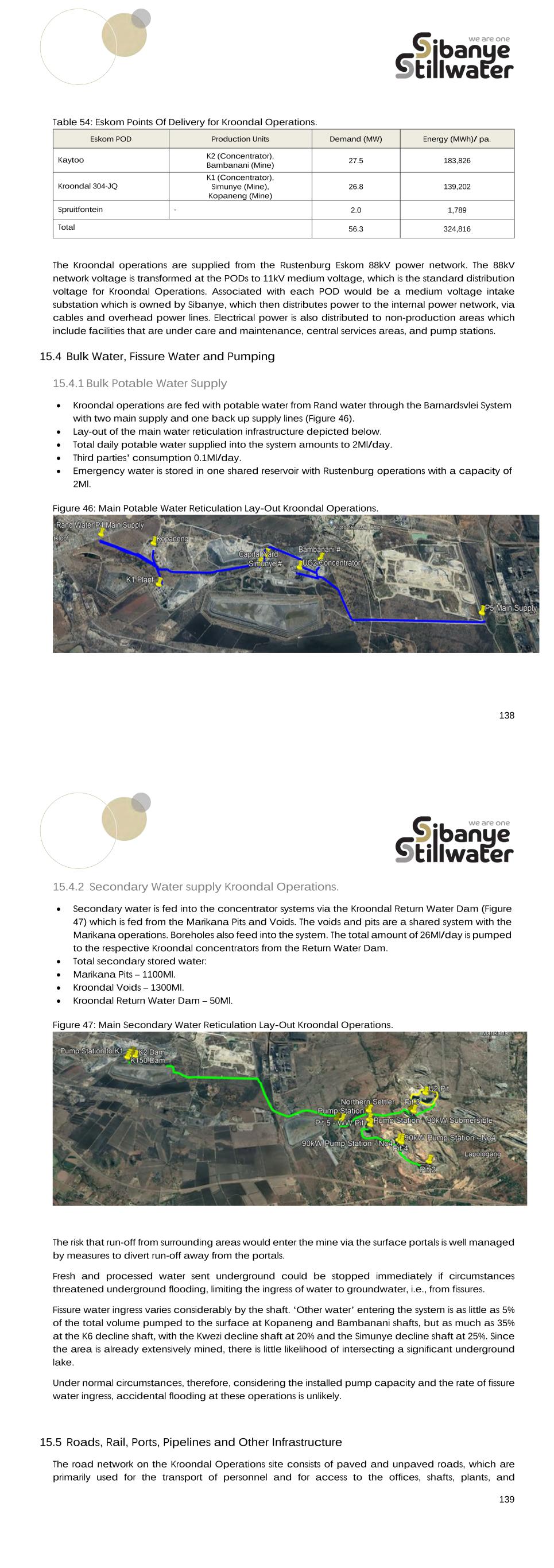

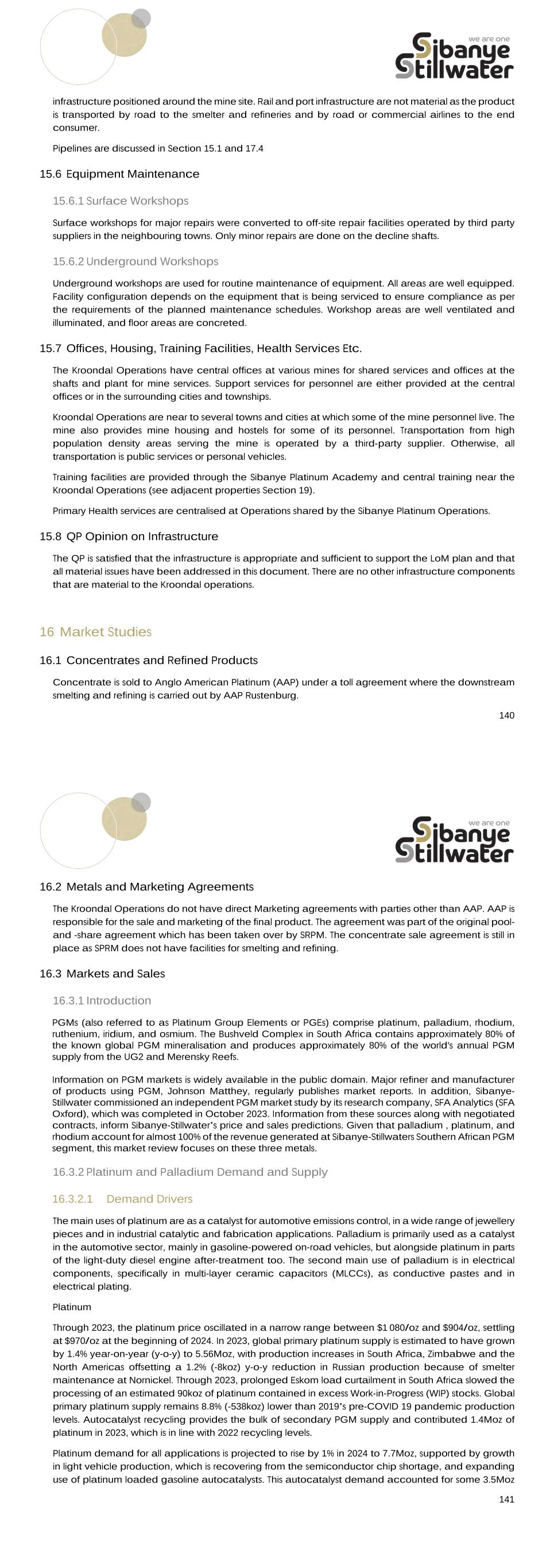

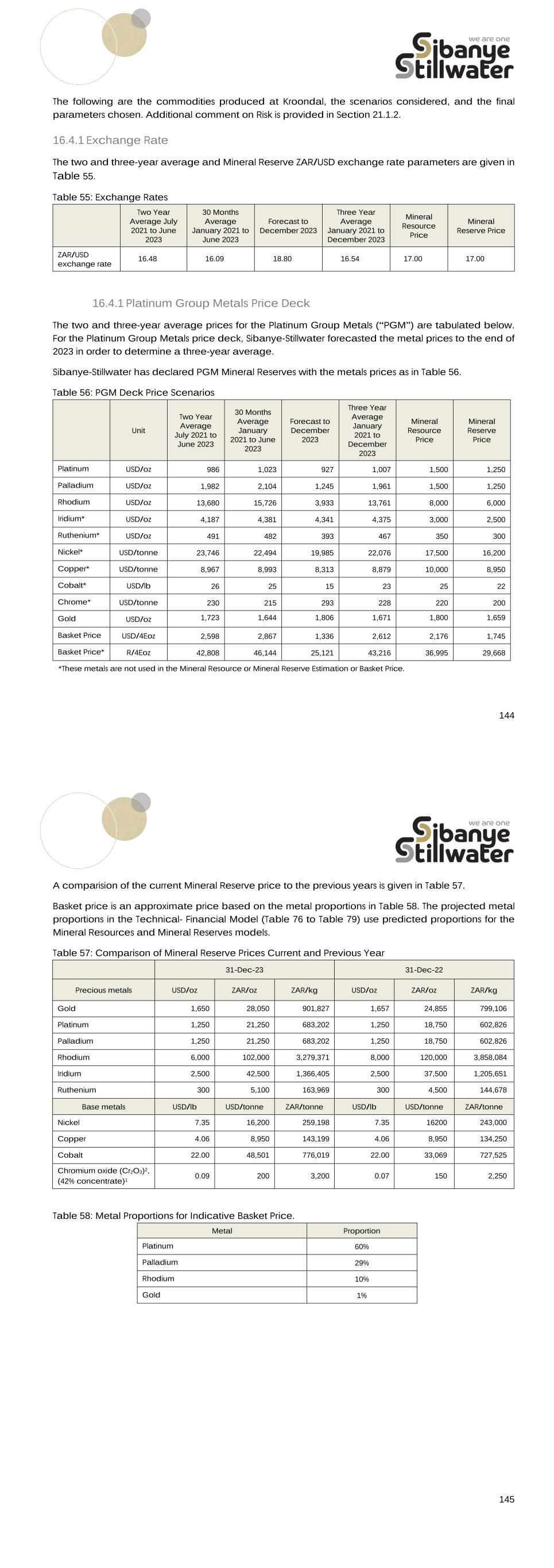

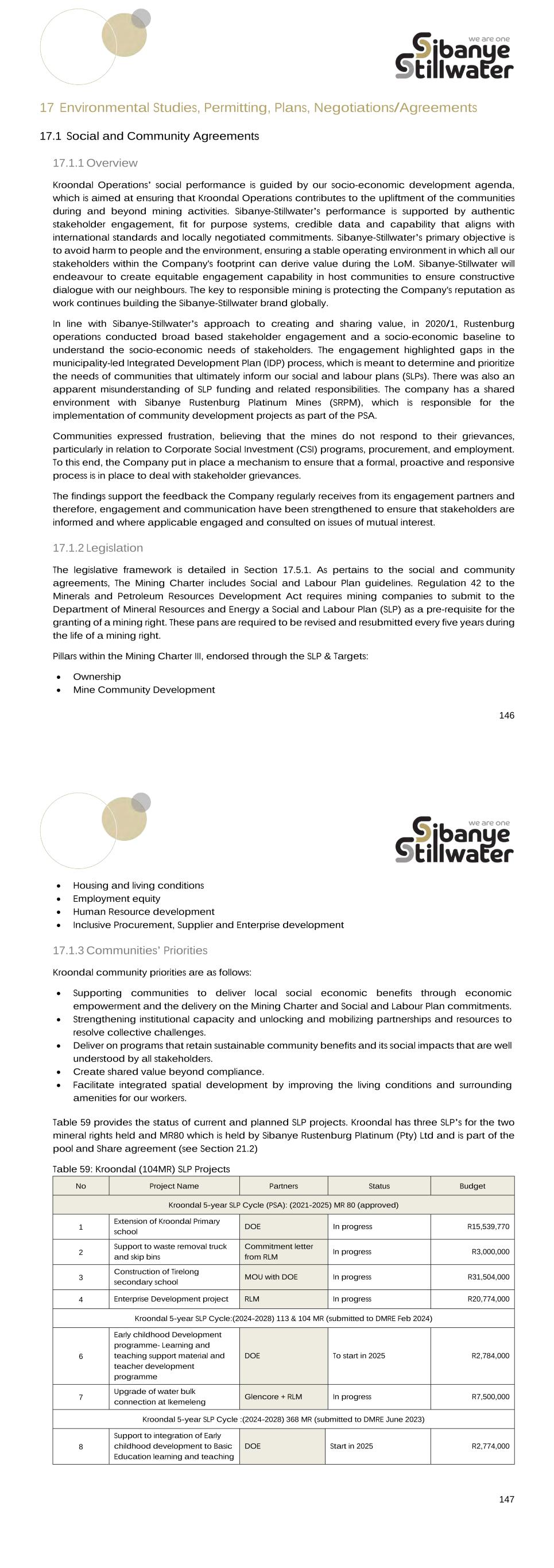

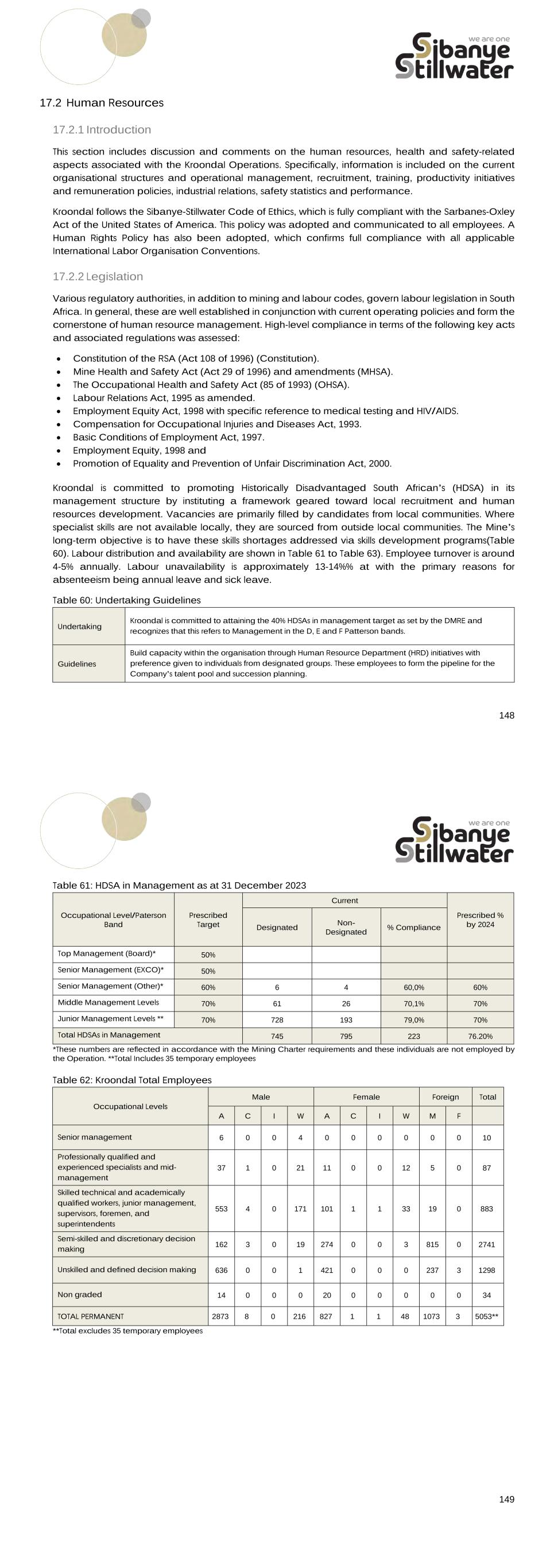

vii 13.3 GEOTECHNICAL ANALYSIS 115 13.3.1 Geotechnical Conditions 116 13.3.2 Stress and Seismological Setting 116 13.3.3 Regional and Local Support 116 13.4 MINE VENTILATION 116 13.5 REFRIGERATION AND COOLING 116 13.6 FLAMMABLE GAS MANAGEMENT 117 13.7 MINE EQUIPMENT 117 13.8 PERSONNEL REQUIREMENTS 118 13.9 FINAL LAYOUT MAP 118 14 PROCESSING AND RECOVERY METHODS 118 14.1 PROCESSING FACILITIES 118 14.1.1 K1 Plant 119 14.1.2 K2 Plant 125 14.2 FUTURE PROJECTS 130 14.3 SAMPLING, ANALYSIS, PGM ACCOUNTING AND SECURITY 131 14.4 PLANT LOCK-UP 131 14.5 FINAL PRODUCT 132 14.6 PERSONNEL, ENERGY AND WATER REQUIREMENTS 132 14.7 QP OPINION ON PROCESSING 132 15 INFRASTRUCTURE 133 15.1 OVERVIEW OF INFRASTRUCTURE 133 15.2 TAILINGS STORAGE FACILITIES 134 15.2.1 K1 TSF 136 15.2.2 K150 TSF 136 15.2.3 K2 TSF 137 15.2.4 Marikana TSF 137 15.2.5 LoM Requirements 137 15.3 POWER SUPPLY 137 15.4 BULK WATER, FISSURE WATER AND PUMPING 138 15.4.1 Bulk Potable Water Supply 138 15.4.2 Secondary Water supply Kroondal Operations. 139 15.5 ROADS, RAIL, PORTS, PIPELINES AND OTHER INFRASTRUCTURE 139 15.6 EQUIPMENT MAINTENANCE 140 15.6.1 Surface Workshops 140 15.6.2 Underground Workshops 140 15.7 OFFICES, HOUSING, TRAINING FACILITIES, HEALTH SERVICES ETC. 140 15.8 QP OPINION ON INFRASTRUCTURE 140 16 MARKET STUDIES 140 16.1 CONCENTRATES AND REFINED PRODUCTS 140 16.2 METALS AND MARKETING AGREEMENTS 141 16.3 MARKETS AND SALES 141 16.3.1 Introduction 141 viii 16.3.2 Platinum and Palladium Demand and Supply 141 16.4 METALS PRICE DETERMINATION 143 16.4.1 Exchange Rate 144 16.4.1 Platinum Group Metals Price Deck 144 17 ENVIRONMENTAL STUDIES, PERMITTING, PLANS, NEGOTIATIONS/AGREEMENTS 146 17.1 SOCIAL AND COMMUNITY AGREEMENTS 146 17.1.1 Overview 146 17.1.2 Legislation 146 17.1.3 Communities’ Priorities 147 17.2 HUMAN RESOURCES 148 17.2.1 Introduction 148 17.2.2 Legislation 148 17.2.3 Human Resource Development (Training) 150 17.2.4 Remuneration Policies 150 17.2.5 Industrial Relations 151 17.2.6 Employment Equity and Women in Mining (WIM) 151 17.3 HEALTH AND SAFETY 151 17.3.1 Policies and Procedures 151 17.3.2 Statistics 152 17.3.3 Occupational Health and Safety Management 152 17.3.4 HIV/AIDS 152 17.4 ENVIRONMENTAL STUDIES 152 17.4.1 Introduction 152 17.4.2 Baseline Studies 155 17.4.3 Zone of Influence 157 17.4.4 Climate Change and Greenhouse Gas Emissions 163 17.4.5 Biodiversity Management 164 17.4.6 Water Use Strategy 165 17.4.7 Waste Management 172 17.4.8 Environmental Reporting 172 17.4.9 Closure Planning and Costs 179 17.5 QP OPINION 182 18 CAPITAL AND OPERATING COSTS 182 18.1 OVERVIEW 182 18.2 CAPITAL EXPENDITURE 182 18.3 OPERATING COSTS 183 18.3.1 Operating Costs by Activity 183 18.3.2 Operating Cost 183 18.3.3 Surface Sources Costs 183 18.3.4 Processing Costs 183 18.3.5 Allocated Costs 184 19 ECONOMIC ANALYSIS 188 19.1 INTRODUCTION 188

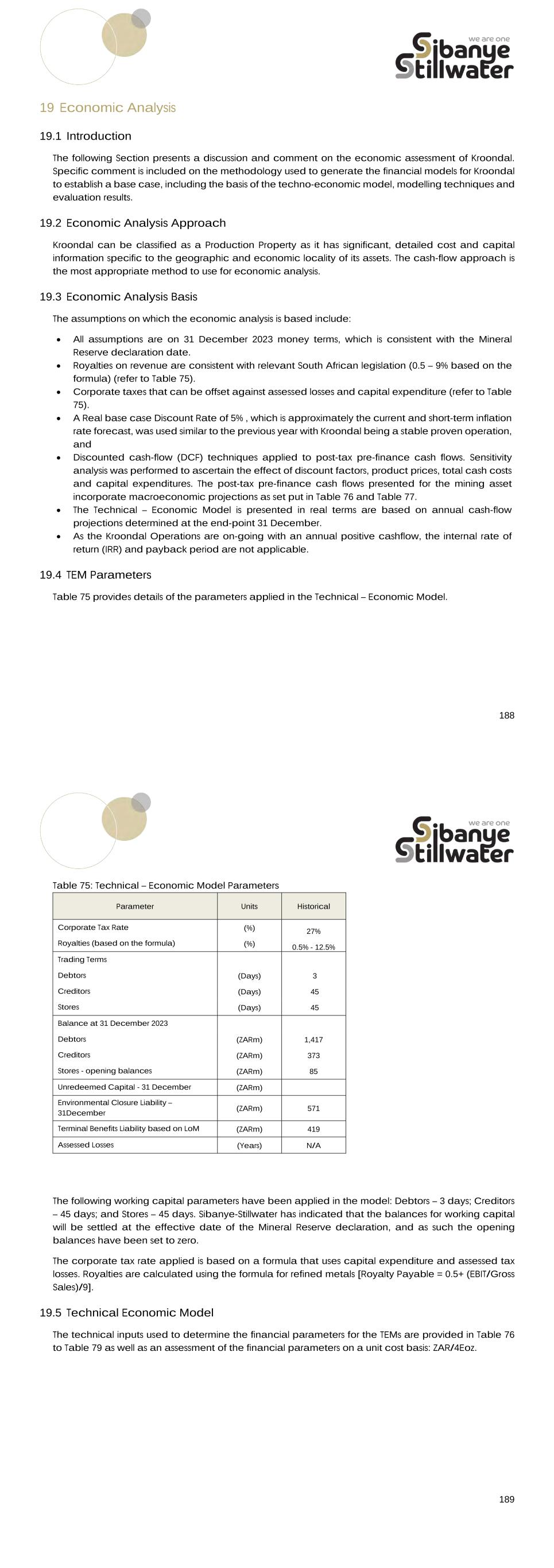

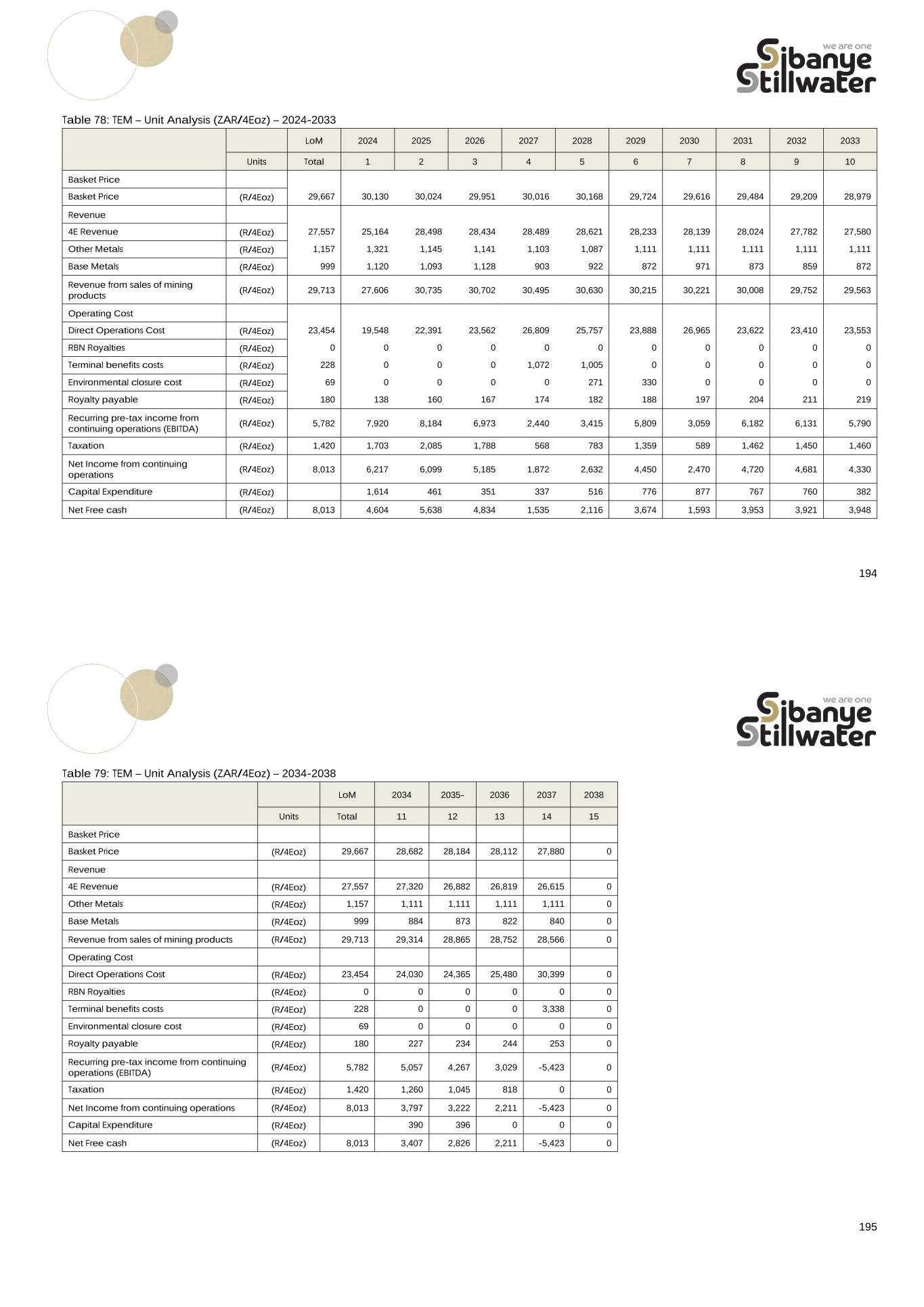

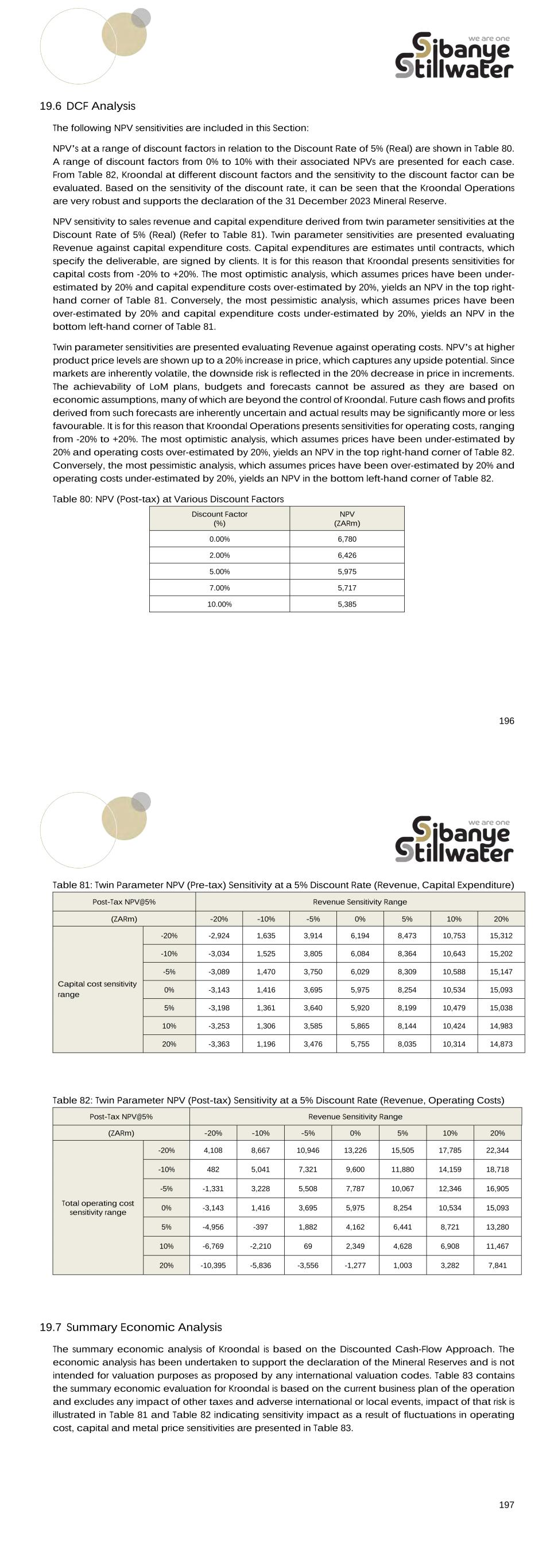

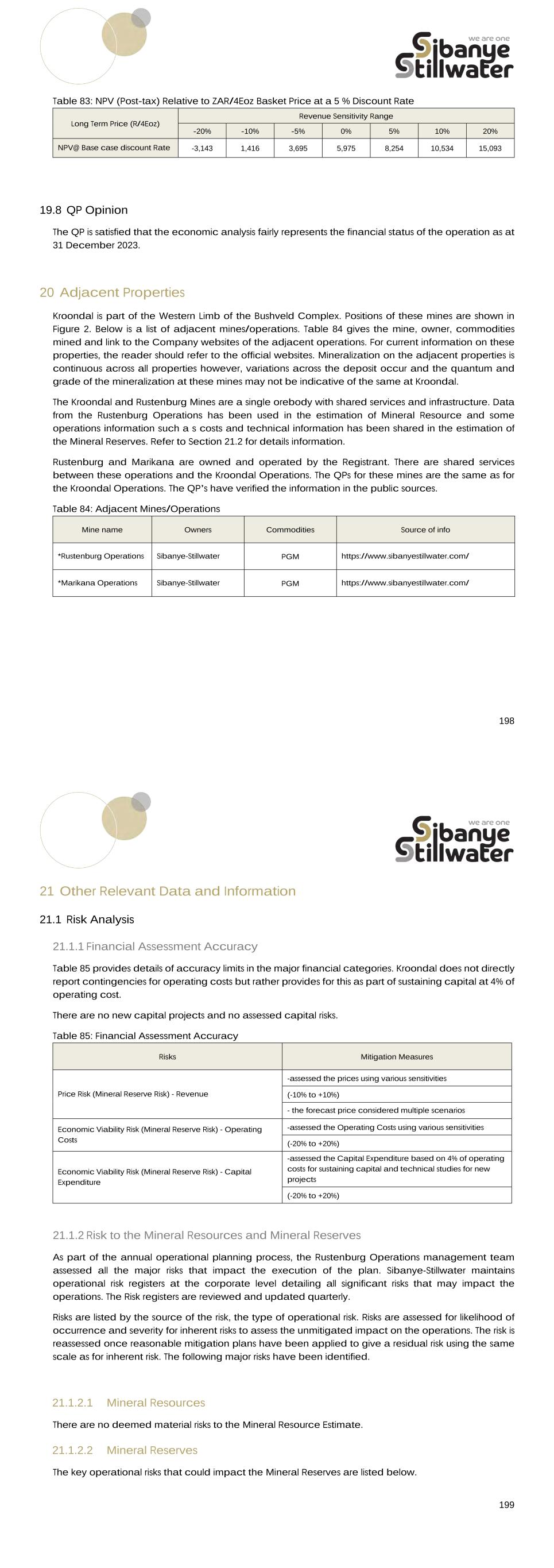

ix 19.2 ECONOMIC ANALYSIS APPROACH 188 19.3 ECONOMIC ANALYSIS BASIS 188 19.4 TEM PARAMETERS 188 19.5 TECHNICAL ECONOMIC MODEL 189 19.6 DCF ANALYSIS 196 19.7 SUMMARY ECONOMIC ANALYSIS 197 19.8 QP OPINION 198 20 ADJACENT PROPERTIES 198 21 OTHER RELEVANT DATA AND INFORMATION 199 21.1 RISK ANALYSIS 199 21.1.1 Financial Assessment Accuracy 199 21.1.2 Risk to the Mineral Resources and Mineral Reserves 199 21.2 RUSTENBURG AND KROONDAL SHARED MINING SERVICES 200 22 INTERPRETATION AND CONCLUSIONS 203 23 RECOMMENDATIONS 203 24 REFERENCES 204 24.1 LIST OF REPORTS AND SOURCES OF INFORMATION 204 24.1.1 Publications and Reports 204 24.2 GLOSSARY OF TERMS 205 25 RELIANCE ON INFORMATION PROVIDED BY THE REGISTRANT. 205 26 QUALIFIED PERSON’S DISCLOSURE 205 x List of Figures Figure 1: Ownership and Company Structure for the Kroondal Operations .......................... 11 Figure 2: General Location of the Material Assets .................................................................... 18 Figure 3: Plan Showing Kroondal Mineral Right and Shafts ...................................................... 26 Figure 4: Aeromagnetic Survey for Kroondal Operations ........................................................ 34 Figure 5: Geology of the Bushveld Complex, South Africa ..................................................... 36 Figure 6: Geology of the Western Limb of the Bushveld Complex, South Africa ................... 37 Figure 7: Regional Stratigraphic Column of the Rustenburg Layered Suite ........................... 38 Figure 8: General Stratigraphic Column of the Local Geological Succession ...................... 42 Figure 9: Structural Interpretation ............................................................................................... 44 Figure 10: A Down Dip Cross-section Showing Merensky and UG2 Reefs (S-N) ..................... 45 Figure 11: Schematic Diagram Showing the Model of the Pothole from the UG2 ................ 46 Figure 12: IRUP(red) unconformably cut across the layered lithological sequence. ............ 47 Figure 13: Reconciliation of Drillhole Data ................................................................................ 50 Figure 14: Overview of Drilled Boreholes Kroondal and Rustenburg....................................... 52 Figure 15: Schematic Vertical Section of a Typical Surface Drillhole ...................................... 54 Figure 16: Example of CRM Result Monitoring .......................................................................... 67 Figure 17: Example of Blank Result Monitoring .......................................................................... 68 Figure 18: Composite Width ....................................................................................................... 73 Figure 19: Example of UG2 Reef Composite cut for the Kroondal mines ............................... 74 Figure 20: UG2 Geozones ........................................................................................................... 75 Figure 21: Examples of Histograms of PGM Distributions – UG2 Reef ...................................... 77 Figure 22: Example of a Variogram Map .................................................................................. 78 Figure 23: Example of Variogram for 4E Grade for Different Geozones ................................. 78 Figure 24: KNA for Block Sizes – Well Informed Blocks ............................................................... 80 Figure 25: KNA for Discretization – Poorly Informed Blocks ....................................................... 80 Figure 26: Section Plot UG2 – Data versus Model ..................................................................... 82 Figure 27: UG2 Reef Grade -4E –Data versus Model ................................................................ 83 Figure 28: UG2 Reef Grade -4E – Old versus New Model ......................................................... 84 Figure 29: Mineral Resource Classification for UG2 .................................................................. 87 Figure 30: Total Geological Losses for the UG2 Reef ................................................................ 88

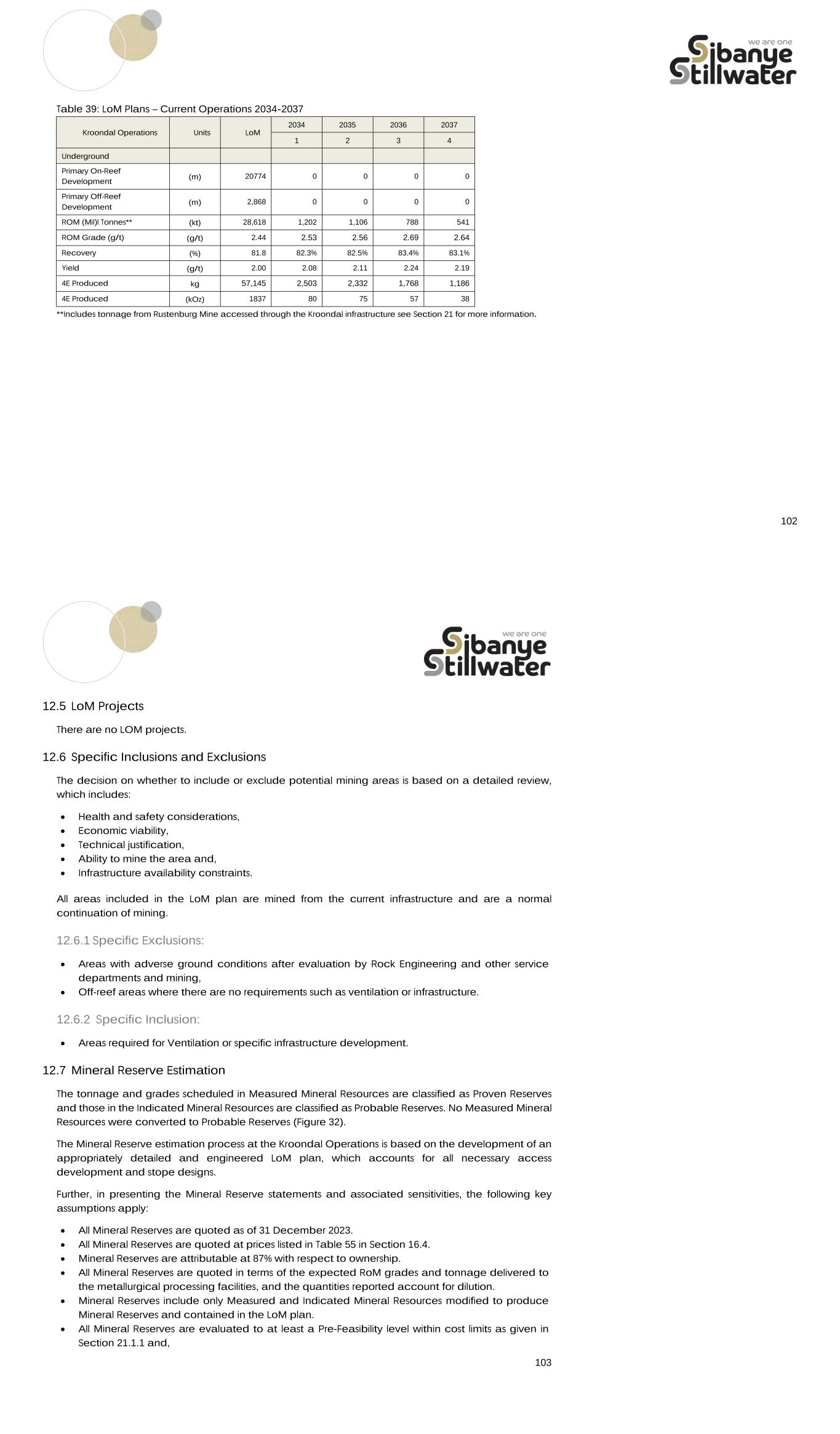

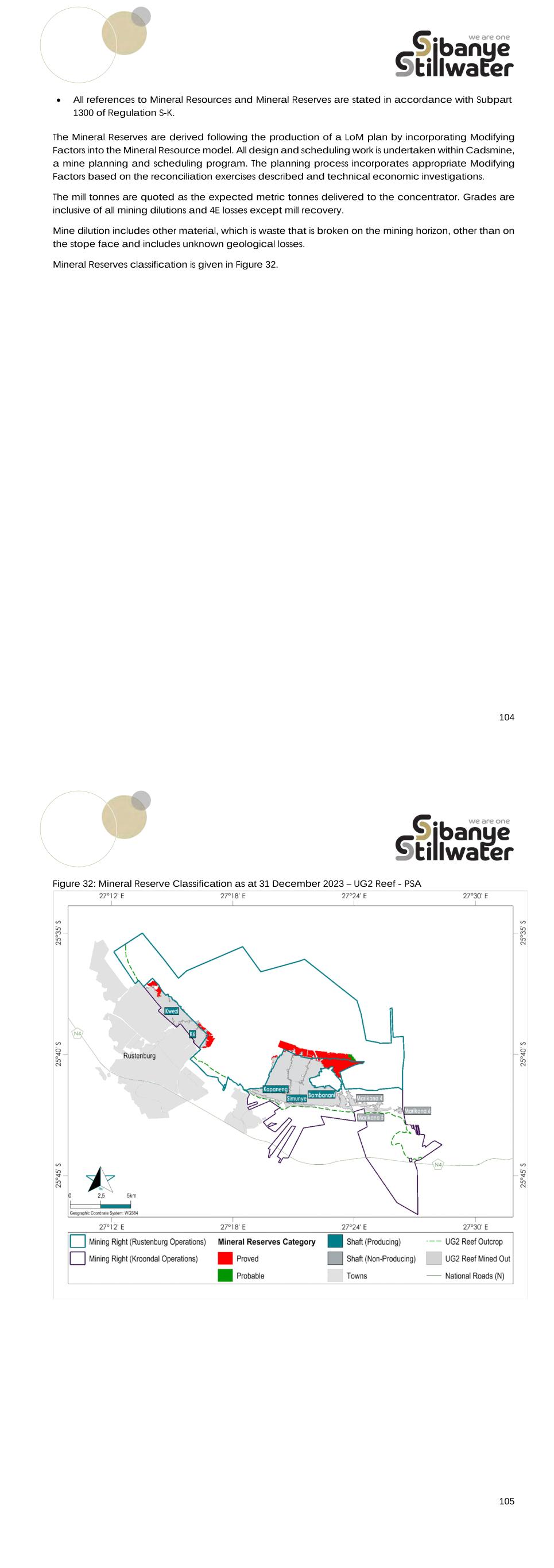

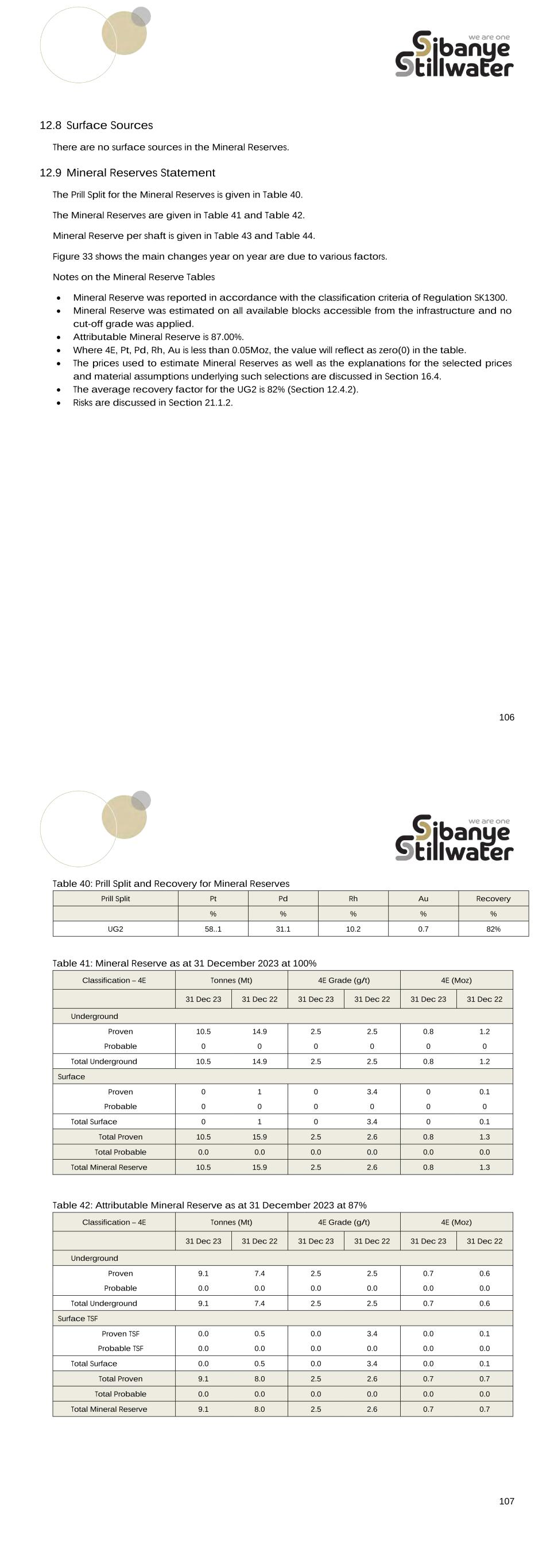

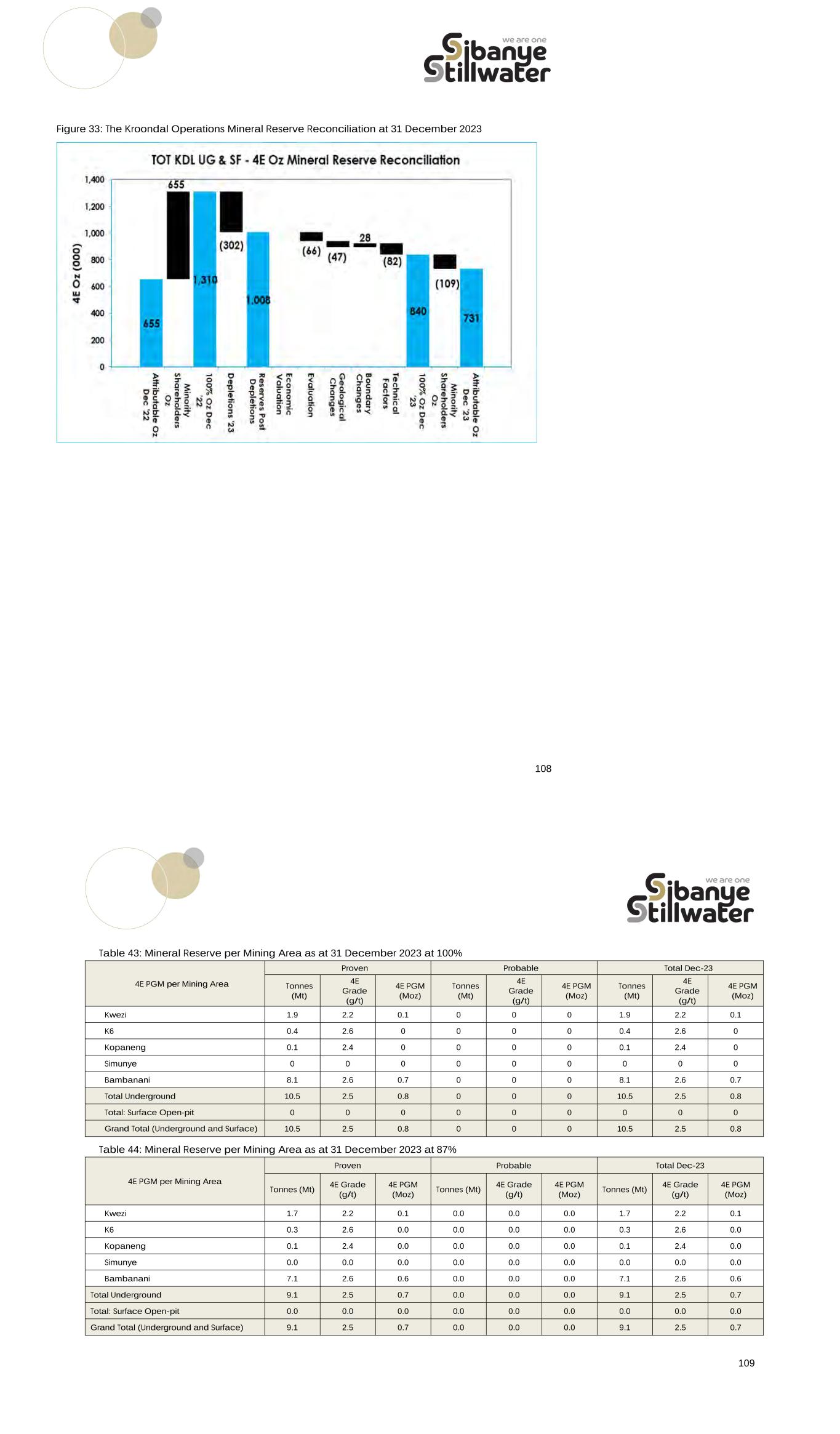

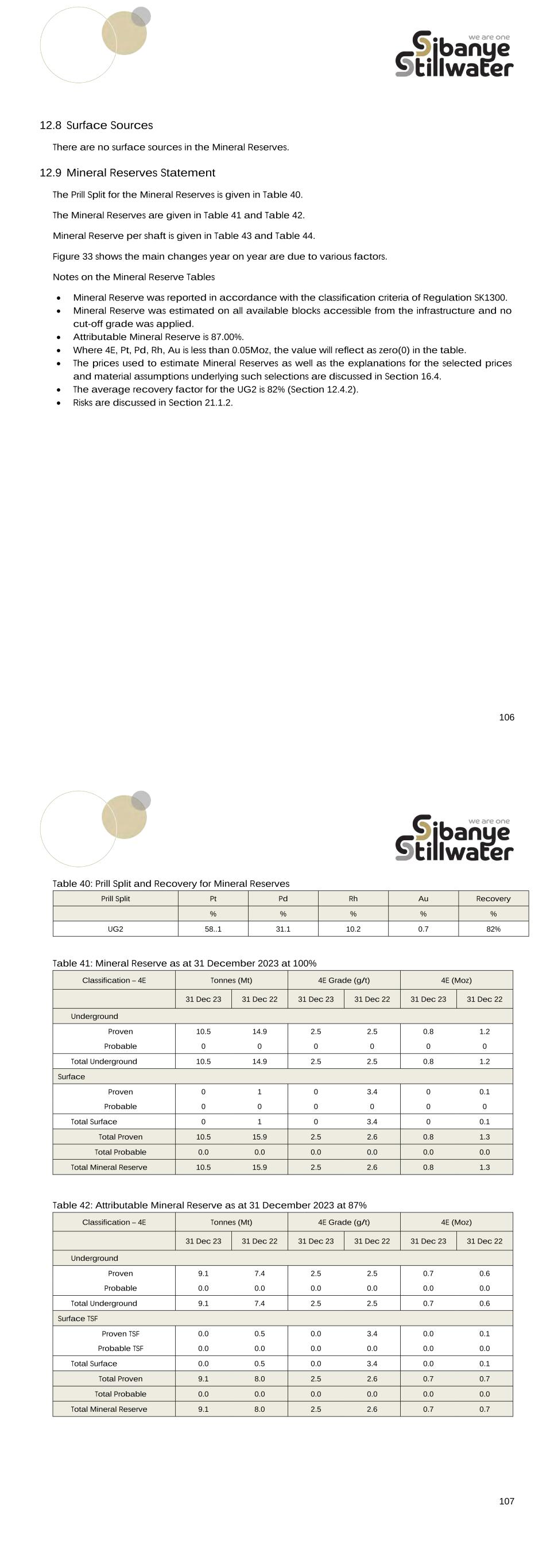

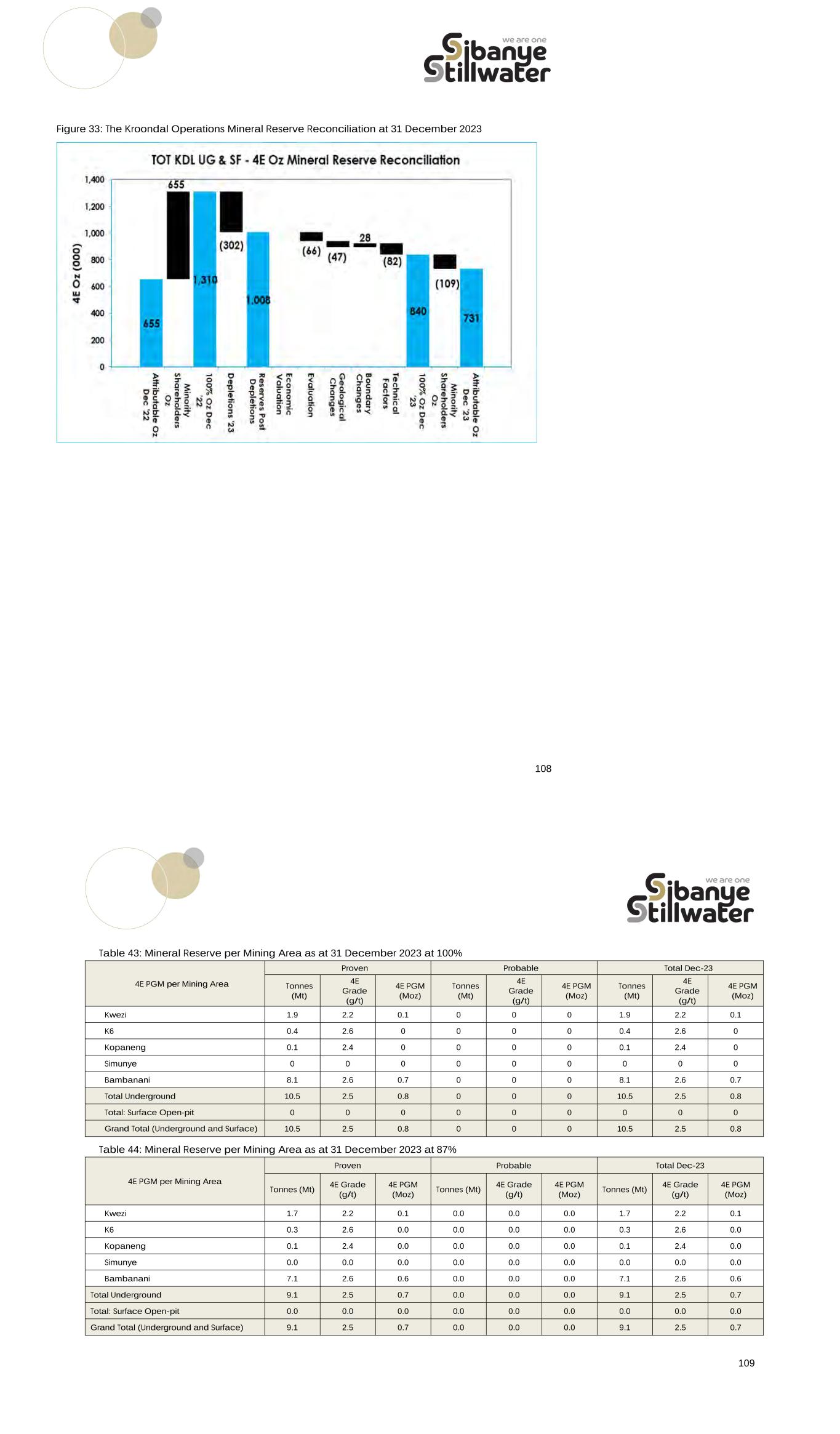

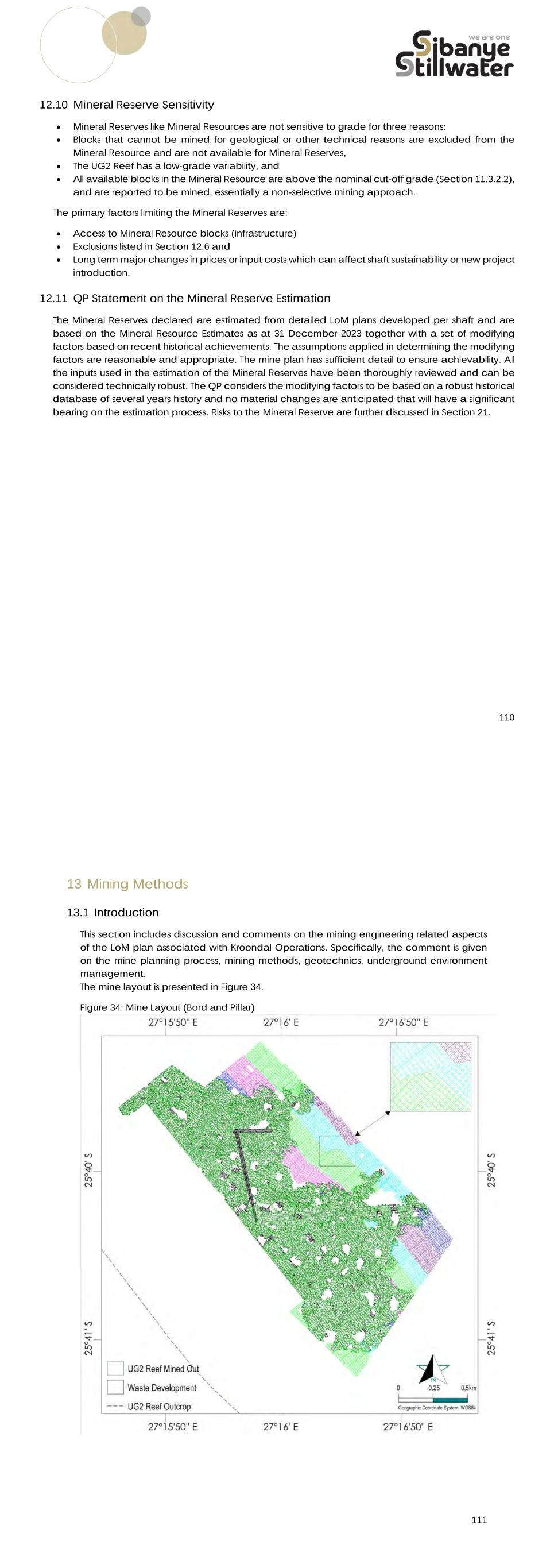

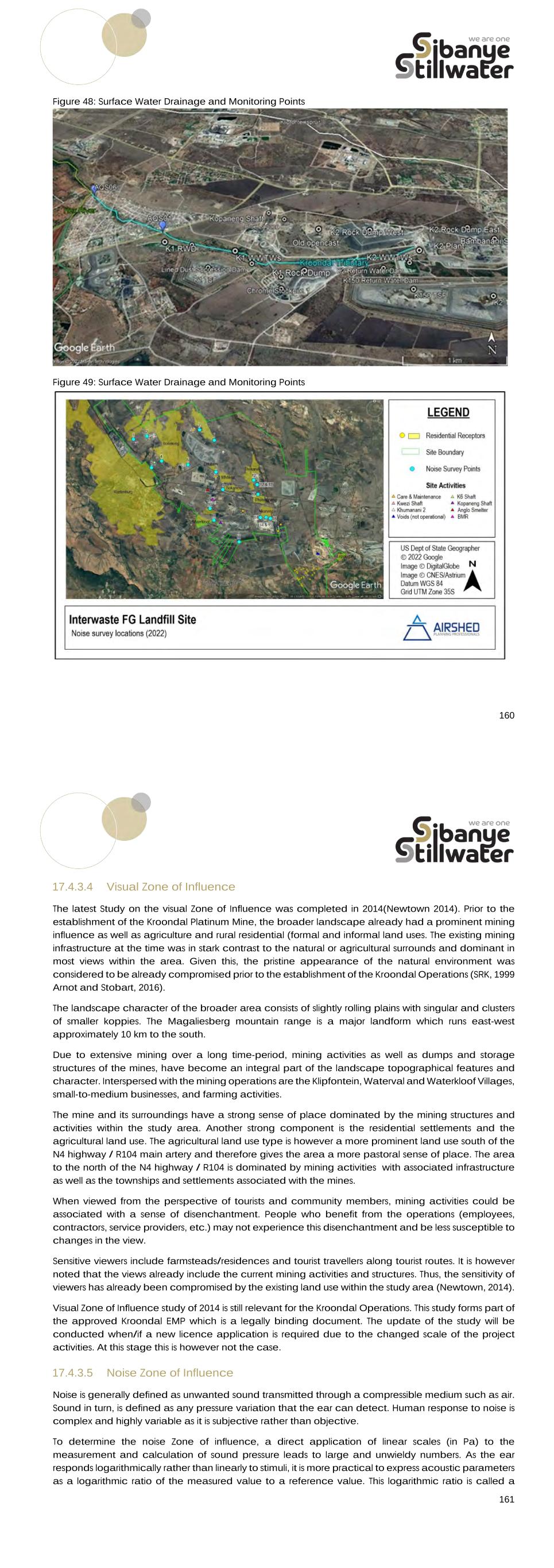

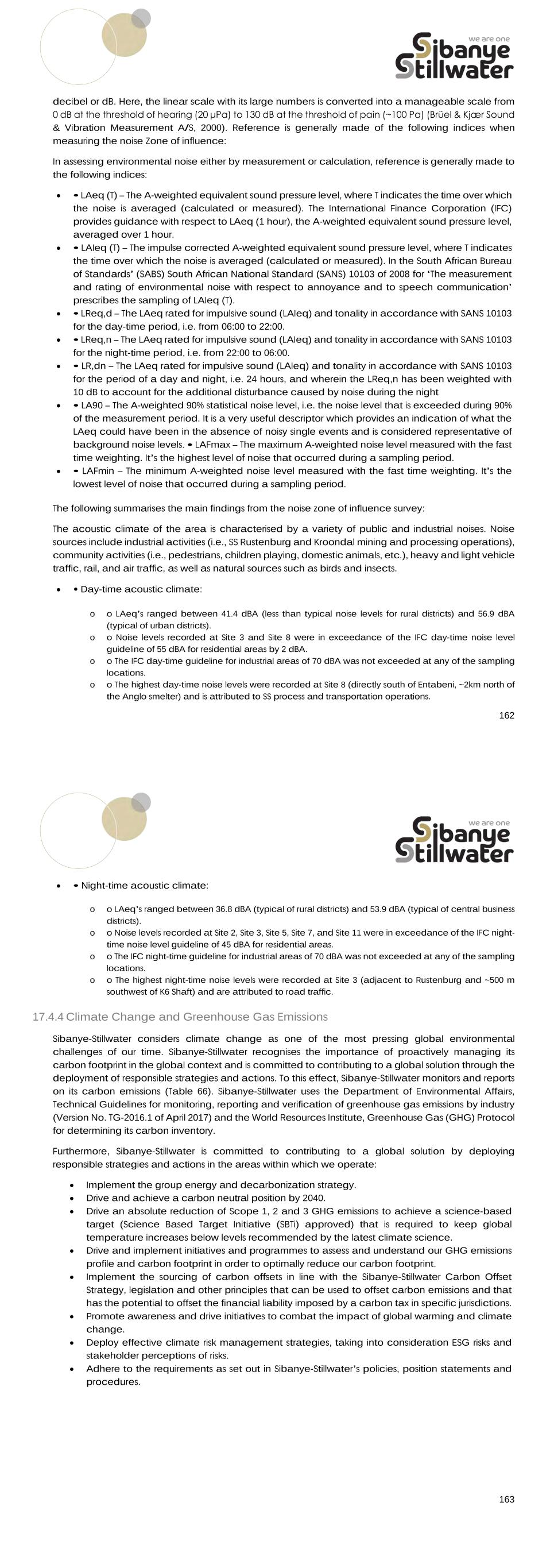

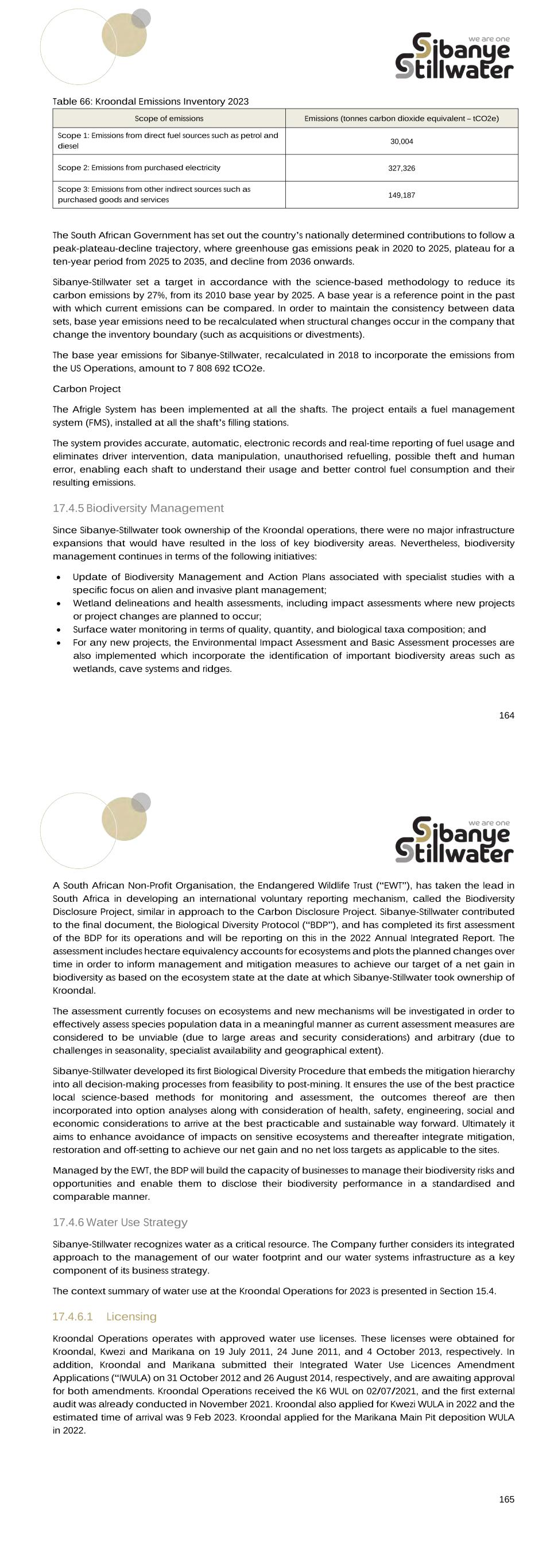

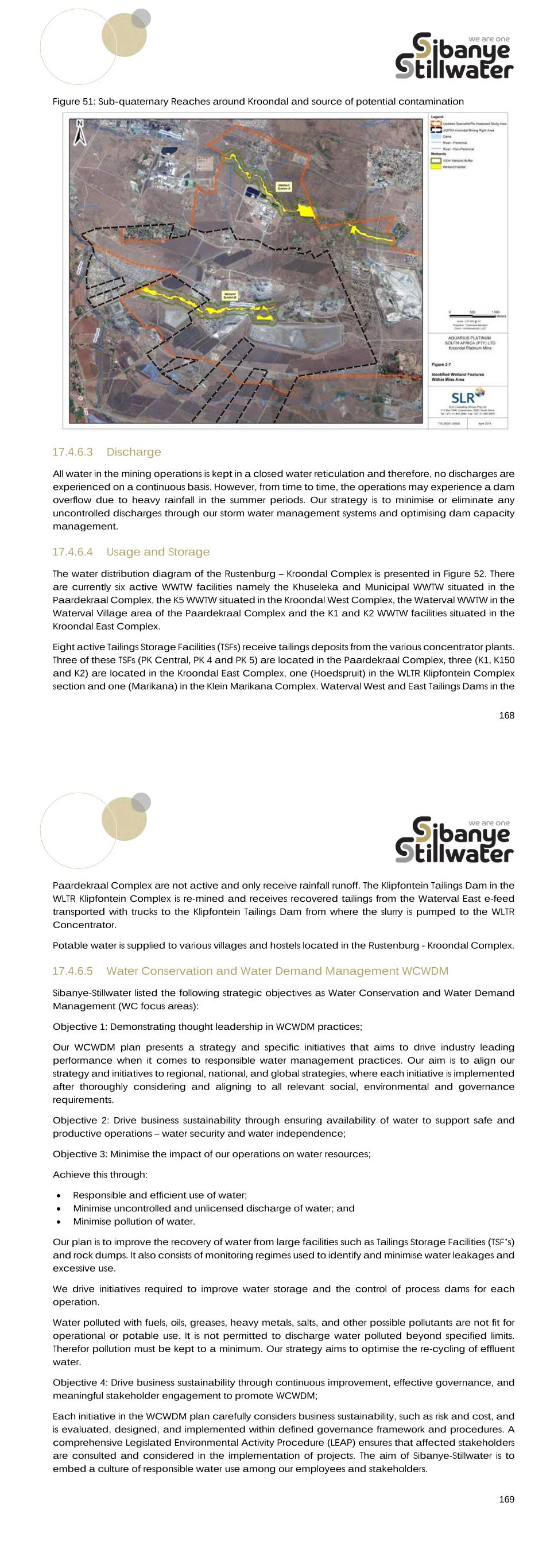

xi Figure 31: Kroondal Operations Underground Mineral Resource Reconciliation .................. 94 Figure 32: Mineral Reserve Classification as at 31 December 2023 – UG2 Reef - PSA......... 105 Figure 33: The Kroondal Operations Mineral Reserve Reconciliation at 31 December 2023 ........................................................................................................................... 108 Figure 34: Mine Layout (Bord and Pillar) .................................................................................. 111 Figure 35: Townlands Section Infrastructure (not to scale) .................................................... 113 Figure 36: Kroondal Section Infrastructure (Not to scale) ...................................................... 114 Figure 37: K1 Concentrator Throughput Forecast .................................................................. 120 Figure 38: K1 Concentrator Production and Recovery Forecast .......................................... 120 Figure 39: The Schematic Process Flow Diagram for K1 Processing Plant ............................ 124 Figure 40: Aerial View of the K2 Plant ...................................................................................... 125 Figure 41: K2 Concentrator Throughput Forecast .................................................................. 127 Figure 42: K2 Concentrator Production and Recovery Forecast. ......................................... 127 Figure 43: Flowsheet for K2 Plant .............................................................................................. 130 Figure 44: The Layout of the Kroondal Operations ................................................................. 134 Figure 45: Location of Kroondal Operations Tailings Storage Facilities ................................. 136 Figure 46: Main Potable Water Reticulation Lay-Out Kroondal Operations. ........................ 138 Figure 47: Main Secondary Water Reticulation Lay-Out Kroondal Operations. .................. 139 Figure 48: Surface Water Drainage and Monitoring Points ................................................... 160 Figure 49: Surface Water Drainage and Monitoring Points ................................................... 160 Figure 50: Rustenburg Regional Structures (Source: Zimmermann et.al., 2009) ................... 167 Figure 51: Sub-quaternary Reaches around Kroondal and source of potential contamination ......................................................................................................... 168 Figure 52: The Schematic Process Flow Diagram for Water Handling at the Rustenburg- Kroondal Complex ................................................................................................... 171 Figure 53: Map of the Mineral Right Properties of Kroondal and SRPM ................................ 202 xii List of Tables Table 1: Prill Split of the area covered by Mineral Resource as at 31 December 2023 ........... 4 Table 2: Attributable Mineral Resource Exclusive of Mineral Reserves as at 31 December 2023 ........................................................................................................... 4 Table 3: Prill Split and Recovery for Mineral Reserves ................................................................. 6 Table 4: Attributable Mineral Reserve as at 31 December 2023 ............................................... 6 Table 5: NPV (Post-tax) Relative to ZAR/4Eoz PGM Basket Prices at 5% Discount Rate ........... 7 Table 6: Twin Parameter NPV (Post-Tax) Sensitivity at 5% Discount Rate (Capital Costs) ........ 8 Table 7: Twin Parameter NPV (Post-Tax) Sensitivity at 5% Discount Rate (Revenue, Operating Costs) .......................................................................................................... 8 Table 8: Details of QPs Appointed by Sibanye-Stillwater ......................................................... 13 Table 9: Units Definitions .............................................................................................................. 15 Table 10: Technical Experts/Specialists Supporting the QPs .................................................... 16 Table 11: Kroondal Mining Right Status ..................................................................................... 21 Table 12: Mining Rights Status for the Kroondal Operations (NW 104, 113, 368, 369, 370, 80) ............................................................................................................................... 27 Table 13: Number of Permanent Employees ............................................................................ 30 Table 14: Origin of Employees .................................................................................................... 30 Table 15: Historical Development .............................................................................................. 31 Table 16: Drilling History ............................................................................................................... 33 Table 17: Historical Production and Financial Parameters ...................................................... 35 Table 18: Kroondal Operations Evaluation Drilling Costs ......................................................... 51 Table 19: Quality Control Drilling ................................................................................................ 57 Table 20: Summary of the material properties of the dominant hanging wall and footwall rock types .................................................................................................... 63 Table 21: Rock mass classes determined from RMR total ratings and meaning ................... 63 Table 22: Example of Variogram Model Parameters for selected the UG2 Geozones ......... 79 Table 23: Kriging Parameters ...................................................................................................... 81 Table 24: Confidence Levels for Key Criteria for Mineral Resource Classification ................. 86 Table 25: Commodity Price and Exchange Rate Assumptions for Mineral Resource Cut- off Calculations .......................................................................................................... 89 Table 26: 6E Prill Split Percentages Applied per Reef ............................................................... 89

xiii Table 27: Parameters used in the cut-off calculation for the UG2 Reef ................................. 90 Table 28: 4E Cut-off grades calculated for the UG2 Reef ....................................................... 90 Table 29: Prill Split of the area covered by Mineral Resource as at 31 December 2023 ....... 90 Table 30: Mineral Resources Exclusive of Mineral Reserves at 100% as at 31 December 2023 ............................................................................................................................. 92 Table 31: Attributable Mineral Resource Exclusive of Mineral Reserves as at 31 December 2023 ......................................................................................................... 92 Table 32: Mineral Resources Inclusive of Mineral Reserves at 100% as at 31 December 2023 ............................................................................................................................. 92 Table 33: Attributable Mineral Resource Inclusive of Mineral Reserves as at 31 December 2023 ......................................................................................................... 92 Table 34: Mineral Resource Exclusive of Mineral Reserves per Mining Area as at 31 December 2023 at 100% ........................................................................................... 93 Table 35: Mineral Resource Inclusive of Mineral Reserves per Mining Area as at 31 December 2023 at 100% ........................................................................................... 93 Table 36: Historical Mining Statistics by Section ........................................................................ 98 Table 37: Mineral Reserve Modifying Factors – Underground Operations ........................... 100 Table 38: LoM Plans – Current Operations 2024-2033 ............................................................. 101 Table 39: LoM Plans – Current Operations 2034-2037 ............................................................. 102 Table 40: Prill Split and Recovery for Mineral Reserves ........................................................... 107 Table 41: Mineral Reserve as at 31 December 2023 at 100% ................................................ 107 Table 42: Attributable Mineral Reserve as at 31 December 2023 at 87% ............................. 107 Table 43: Mineral Reserve per Mining Area as at 31 December 2023 at 100% .................... 109 Table 44: Mineral Reserve per Mining Area as at 31 December 2023 at 87% ...................... 109 Table 45: Hoisting Capacities of the Kroondal Shafts ............................................................ 115 Table 46: Major Equipment Quantity Summary ...................................................................... 117 Table 47: Mobile Equipment Summary - 2023 ......................................................................... 117 Table 48: Major Process Equipment ......................................................................................... 118 Table 49: Mineral Processing Plant Parameters ...................................................................... 119 Table 50: K1 Concentrator Production Forecast and Operational Data ............................. 119 Table 51: K2 Concentrator Production Forecast and Operational Data ............................. 126 Table 52: Kroondal Plants Projected Requirements for Energy, Water and Personnel (2023 Budget) ........................................................................................................... 132 Table 53: LoM Assessment of Tailings Facilities ........................................................................ 137 Table 54: Eskom Points Of Delivery for Kroondal Operations. ................................................ 138 xiv Table 55: Exchange Rates ........................................................................................................ 144 Table 56: PGM Deck Price Scenarios ....................................................................................... 144 Table 57: Comparison of Mineral Reserve Prices Current and Previous Year ...................... 145 Table 58: Metal Proportions for Indicative Basket Price. ........................................................ 145 Table 59: Kroondal (104MR) SLP Projects ................................................................................. 147 Table 60: Undertaking Guidelines ............................................................................................ 148 Table 61: HDSA in Management as at 31 December 2023 ................................................... 149 Table 62: Kroondal Total Employees ........................................................................................ 149 Table 63: Kroondal Total Contractors (excluding Ad- Hoc Contractors) ............................. 150 Table 64: Safety Statistics .......................................................................................................... 152 Table 65: Summary of Anticipated Environmental Impacts (revised EMP,2016) ................. 156 Table 66: Kroondal Emissions Inventory 2023 ........................................................................... 164 Table 67: Kroondal Environmental Audits ................................................................................ 172 Table 68: Summary of 2022 Audits for Kroondal ..................................................................... 173 Table 69: Kroondal Material Risks and Action Plans ............................................................... 174 Table 70: Kroondal Compliance to Legislation ....................................................................... 178 Table 71: Future Actions ............................................................................................................ 179 Table 72: Closure Components ................................................................................................ 180 Table 73: Historical and Forecast Capital Expenditure .......................................................... 185 Table 74: Historical and Forecast Operating Costs ................................................................ 186 Table 75: Technical – Economic Model Parameters .............................................................. 189 Table 76: TEM – Mining, Processing, PGM’s Sold and Revenue, Cash Costs, Taxation, Capital Expenditure and Free Cash - 2022-2033 ................................................... 190 Table 77: TEM – Mining, Processing, PGM’s Sold and Revenue, Cash Costs, Taxation, Capital Expenditure and Free Cash - 2032-2037 ................................................... 192 Table 78: TEM – Unit Analysis (ZAR/4Eoz) – 2024-2033 ............................................................. 194 Table 79: TEM – Unit Analysis (ZAR/4Eoz) – 2034-2038 ............................................................. 195 Table 80: NPV (Post-tax) at Various Discount Factors ............................................................ 196 Table 81: Twin Parameter NPV (Pre-tax) Sensitivity at a 5% Discount Rate (Revenue, Capital Expenditure) ............................................................................................... 197 Table 82: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Revenue, Operating Costs) ...................................................................................................... 197 Table 83: NPV (Post-tax) Relative to ZAR/4Eoz Basket Price at a 5 % Discount Rate ........... 198 Table 84: Adjacent Mines/Operations .................................................................................... 198

xv Table 85: Financial Assessment Accuracy .............................................................................. 199 Table 86: Mineral Right Properties of Kroondal and SRPM ..................................................... 201 Table 87: Kroondal - Rustenburg Reserves and LOM Balance .............................................. 203 Table 88: Qualified Person’s Details ......................................................................................... 206 1 1 Executive Summary 1.1 Introduction Sibanye-Stillwater Limited (Sibanye-Stillwater or Registrant) is a multinational mining and metals processing Group with a diverse portfolio of mining and processing operations and projects and investments across five continents. Sibanye-Stillwater is domiciled in South Africa and listed on both the Johannesburg Stock Exchange (JSE or JSE Limited) and the New York Stock Exchange (NYSE). This report updates of the Technical Report Summary (TRS) filed by Sibanye-Stillwater on the Kroondal Operations on 22 April 2022, named Exhibit 96.5 Technical Report Summary of Kroondal Operations, which was effective 31 December 2021. Owing to the integrated nature of the different shaft complexes and the ore processing operations, Kroondal constitutes a single unit (material property). There has been no material change to the information between the effective date and the signature date of the Report. The effective date of the Mineral Resource and Mineral Reserve is 31 December 2023, and the Report date is 24 April 2024. This TRS for the Kroondal Operations has been prepared in accordance with the disclosure requirements set out under Subpart 1300 of Regulation S-K (SK-1300). 1.2 Property Description, Mineral Rights and Ownership The Kroondal Operations are ongoing, established mines and ore processing plants extracting the UG2 Reef (also known as the UG2 chromitite layer) to produce PGMs and base metals. The site is situated in a well-developed area and is easily accessible by major roads 123km west of Pretoria and 126km northwest of Johannesburg. Mining operations are not affected by climatic extremes. Kroondal Operations comprising Kroondal PSA1 and Marikana PSA (Kroondal Operations) refer to a 50 - 50 Pool and Share Agreement (PSA) between Kroondal Operations (South Africa) Proprietary Limited and Sibanye Rustenburg Platinum Mines (Pty) Ltd (SRPM)to mine the Mineral Reserves under an exclusive agreement. Kroondal Operations (South Africa) Proprietary Limited manages the PSA properties. Detailed information about the PSA is found in Section 21.2. Kroondal Operations (South Africa) Proprietary Limited, a wholly owned subsidiary of Sibanye Platinum Bermuda Proprietary Limited, itself a wholly owned subsidiary of Sibanye-Stillwater, is the holder of five converted mining rights in respect of the Kroondal Operations, under the Department of Mineral Resources and Energy (DMRE) reference numbers NW30/5/1/2/2/104MR, NW30/5/1/2/2/113MR, NW30/5/1/2/2/368MR, NW30/5/1/2/2/369MR, NW30/5/1/2/2/370 MR. The mining rights NW30/5/1/2/2/104MR and NW30/5/1/2/2/113MR expired in October 2022 and are in the process of being renewed. The remaining mining rights are valid until 4 March 2042. The five mining rights total approximately 4,937.88 hectares. The two mining rights held by SRPM and accessed through the Kroondal infrastructure expire in 2040.

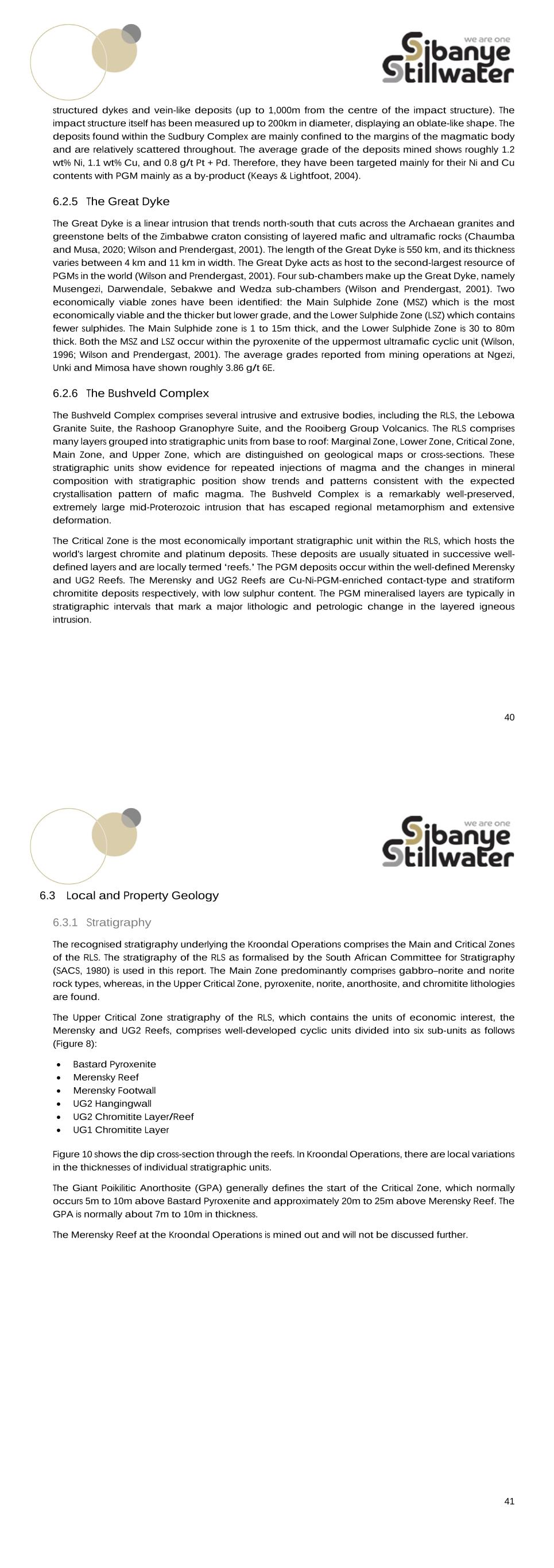

2 All mining rights are located in the Magisterial District of Rustenburg in the North West Province. There are no material legal proceedings in relation to the Kroondal Operations. The Mining Rights referred to in this document are issued in terms of the Mineral and Petroleum Resources Development Act 28 of 2002 in South Africa. The principal terms and conditions are not materially different from other similar operations in South Africa. 1.3 Geology and Mineralisation The majority of PGM resources are located in Southern Africa, which accounts for over 55% of global PGM resources. Most of these are contained in the Bushveld Complex. The Bushveld Complex is approximately 2,060 million years old and is a mafic to ultramafic rock sequence. The Rustenburg Layered Suite (RLS) is the world’s largest known mafic igneous layered intrusion. In addition to PGMs, extensive deposits of iron, tin, chromium, titanium, vanadium, copper, nickel, and cobalt also occur. The Bushveld Complex extends approximately 450km east to west and approximately 250km north to south. It underlies an area of some 67,000km2, spanning parts of Limpopo, North West, Gauteng, and Mpumalanga Provinces. Interlayered in the Upper Critical Zone of the RLS, the Merensky and Upper Group No.2 Chromitite (UG2) Reefs are preserved as narrow tabular structures. The Kroondal Operations are situated on the western limb of the Bushveld Complex and produce the PGMs and associated Base Metals from the mining and processing of the UG2 Reef. 1.4 Exploration Status, Development, Operations and Mineral Resource Estimates The discovery and development of the reefs in the Rustenburg area can be traced back to 1925. After intense exploration in the Rustenburg area, the first vertical shaft (West vertical) was commissioned in 1928 to exploit the Merensky Reef. The Klipfontein Plant (Phase 1) was constructed in 1928. Exploitation of the UG2 Reef began in the 1970’s. The Kroondal Operations have been extensively evaluated by surface and underground exploration drilling, geophysical surveys (airborne magnetic), trenching and geological mapping over a period of more than 55 years. This exploration has proven the extension of the Merensky and UG2 Reefs to the north-northeast. The Initial geological understanding of the area was developed from observations made from the surface and underground mapping, combined with exploration drill hole information and extrapolations of features observed in other platinum mines in the western Bushveld Complex. Current interpretations of the geological and structural framework applicable to the UG2 Reef have evolved as new and more detailed geological information and datasets were obtained. There has been a significant decline in surface exploration drilling over the past five years with a limited amount of surface exploration conducted. Surface drilling comprises 40% of the planned drilling metres for 2024 with the remainder as underground drilling. The Mineral Resource estimation process used at the Kroondal Operations is based on surface and underground drill holes and underground channel samples. 3 The most fundamental control of PGM mineralisation is rock chemistry. PGMs are associated with thin (1-5m) chromitite layers and base metals sulphides. These layers are distinct and consistent over large distances. The facies and structural models that form the basis of this report have evolved over time and are updated annually with the latest drilling and underground sampling results. The Mineral Resources declared (Table 1 and Table 2) are estimated based on the geological facies and constrained by appropriate geostatistical techniques, using Ordinary Kriging for areas with sufficient data and ID2 (Inverse distance to the power of two) estimates for areas with limited data. Areas close to current workings will have smaller block sizes at 125m. Areas further away will have block sizes of 500m. The facies and structural models that form the basis of this report have evolved based on a large amount of data. The Mineral Resource classification follows geostatistical and geological guidelines. The Mineral Resources are declared inside the structural blocks and outside of the mined-out areas. All Mineral Resources reported are considered to be of sufficient quality to justify reasonable prospects for economic extraction. The underlying grade control and reconciliation processes are considered appropriate. The Mineral Resources are in-situ estimates of tonnage and grades reported at a minimum mining width of 200cm, with applicable mechanised bord and pillar mining methods employed at the Operation. The Mineral Resources have been discounted by 1.1860Moz from the 2023 Mineral Resource declaration due to the removal of open pit Mineral Resources that will be sterilised as a result of the planned new Marikana PSA tailings facility.

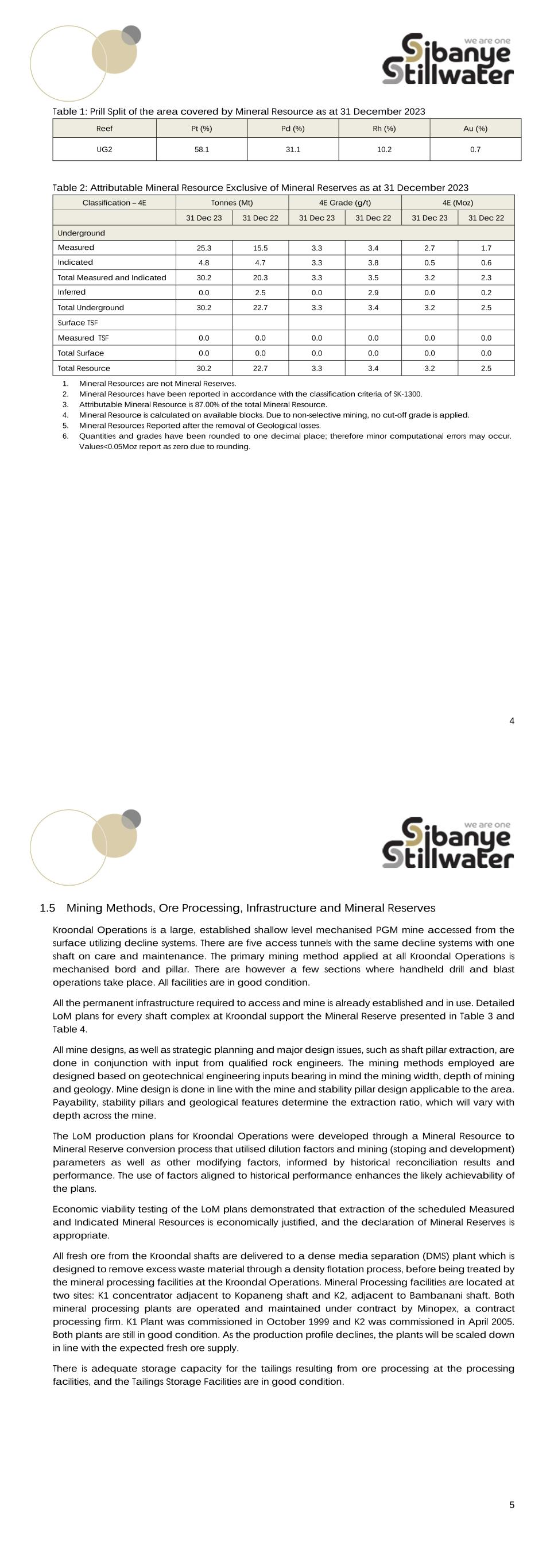

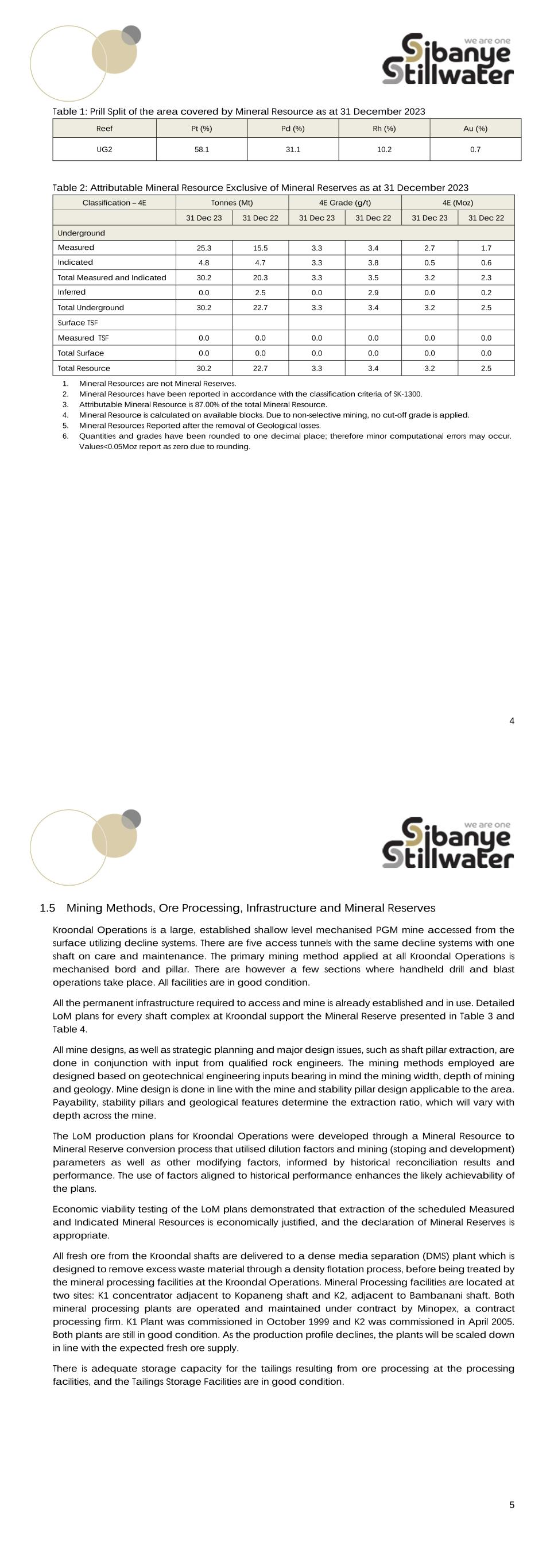

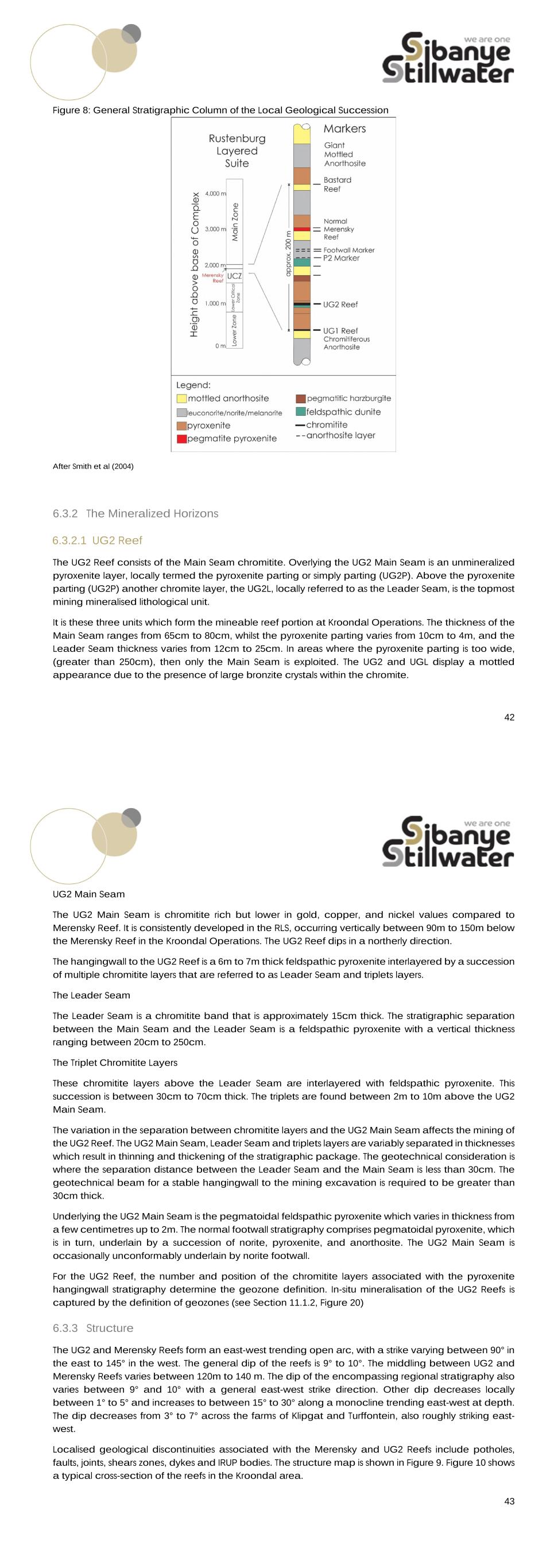

4 Table 1: Prill Split of the area covered by Mineral Resource as at 31 December 2023 Reef Pt (%) Pd (%) Rh (%) Au (%) UG2 58.1 31.1 10.2 0.7 Table 2: Attributable Mineral Resource Exclusive of Mineral Reserves as at 31 December 2023 Classification – 4E Tonnes (Mt) 4E Grade (g/t) 4E (Moz) 31 Dec 23 31 Dec 22 31 Dec 23 31 Dec 22 31 Dec 23 31 Dec 22 Underground Measured 25.3 15.5 3.3 3.4 2.7 1.7 Indicated 4.8 4.7 3.3 3.8 0.5 0.6 Total Measured and Indicated 30.2 20.3 3.3 3.5 3.2 2.3 Inferred 0.0 2.5 0.0 2.9 0.0 0.2 Total Underground 30.2 22.7 3.3 3.4 3.2 2.5 Surface TSF Measured TSF 0.0 0.0 0.0 0.0 0.0 0.0 Total Surface 0.0 0.0 0.0 0.0 0.0 0.0 Total Resource 30.2 22.7 3.3 3.4 3.2 2.5 1. Mineral Resources are not Mineral Reserves. 2. Mineral Resources have been reported in accordance with the classification criteria of SK-1300. 3. Attributable Mineral Resource is 87.00% of the total Mineral Resource. 4. Mineral Resource is calculated on available blocks. Due to non-selective mining, no cut-off grade is applied. 5. Mineral Resources Reported after the removal of Geological losses. 6. Quantities and grades have been rounded to one decimal place; therefore minor computational errors may occur. Values<0.05Moz report as zero due to rounding. 5 1.5 Mining Methods, Ore Processing, Infrastructure and Mineral Reserves Kroondal Operations is a large, established shallow level mechanised PGM mine accessed from the surface utilizing decline systems. There are five access tunnels with the same decline systems with one shaft on care and maintenance. The primary mining method applied at all Kroondal Operations is mechanised bord and pillar. There are however a few sections where handheld drill and blast operations take place. All facilities are in good condition. All the permanent infrastructure required to access and mine is already established and in use. Detailed LoM plans for every shaft complex at Kroondal support the Mineral Reserve presented in Table 3 and Table 4. All mine designs, as well as strategic planning and major design issues, such as shaft pillar extraction, are done in conjunction with input from qualified rock engineers. The mining methods employed are designed based on geotechnical engineering inputs bearing in mind the mining width, depth of mining and geology. Mine design is done in line with the mine and stability pillar design applicable to the area. Payability, stability pillars and geological features determine the extraction ratio, which will vary with depth across the mine. The LoM production plans for Kroondal Operations were developed through a Mineral Resource to Mineral Reserve conversion process that utilised dilution factors and mining (stoping and development) parameters as well as other modifying factors, informed by historical reconciliation results and performance. The use of factors aligned to historical performance enhances the likely achievability of the plans. Economic viability testing of the LoM plans demonstrated that extraction of the scheduled Measured and Indicated Mineral Resources is economically justified, and the declaration of Mineral Reserves is appropriate. All fresh ore from the Kroondal shafts are delivered to a dense media separation (DMS) plant which is designed to remove excess waste material through a density flotation process, before being treated by the mineral processing facilities at the Kroondal Operations. Mineral Processing facilities are located at two sites: K1 concentrator adjacent to Kopaneng shaft and K2, adjacent to Bambanani shaft. Both mineral processing plants are operated and maintained under contract by Minopex, a contract processing firm. K1 Plant was commissioned in October 1999 and K2 was commissioned in April 2005. Both plants are still in good condition. As the production profile declines, the plants will be scaled down in line with the expected fresh ore supply. There is adequate storage capacity for the tailings resulting from ore processing at the processing facilities, and the Tailings Storage Facilities are in good condition.

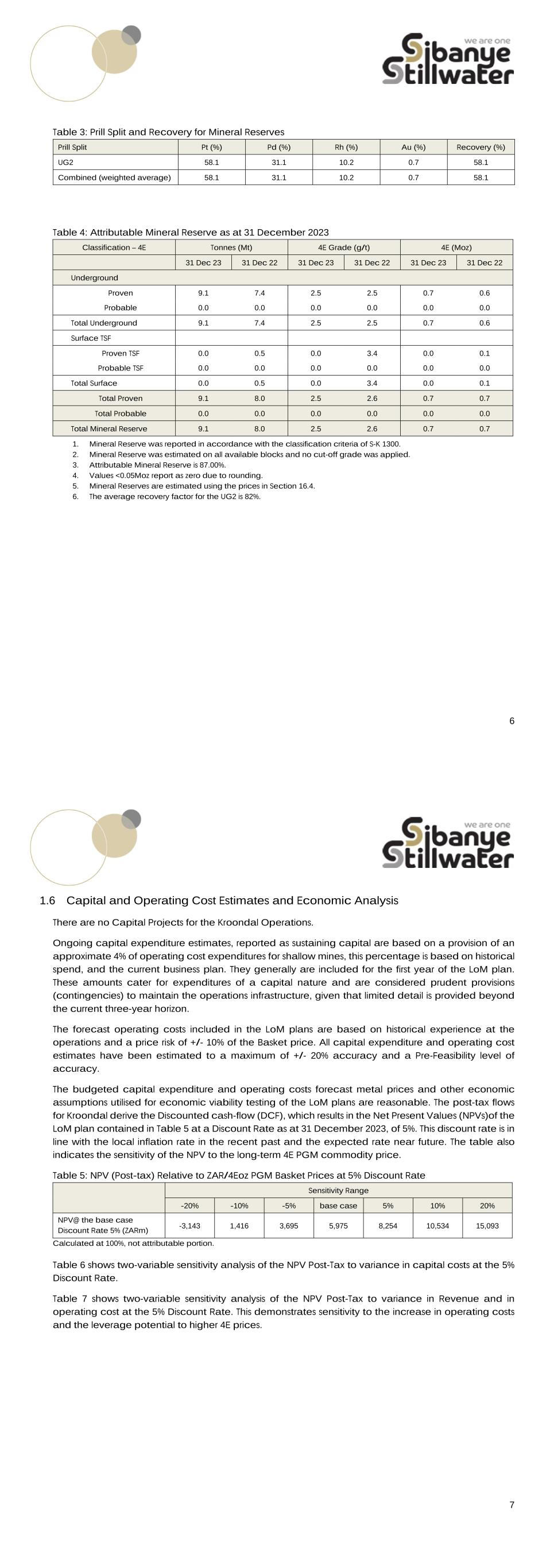

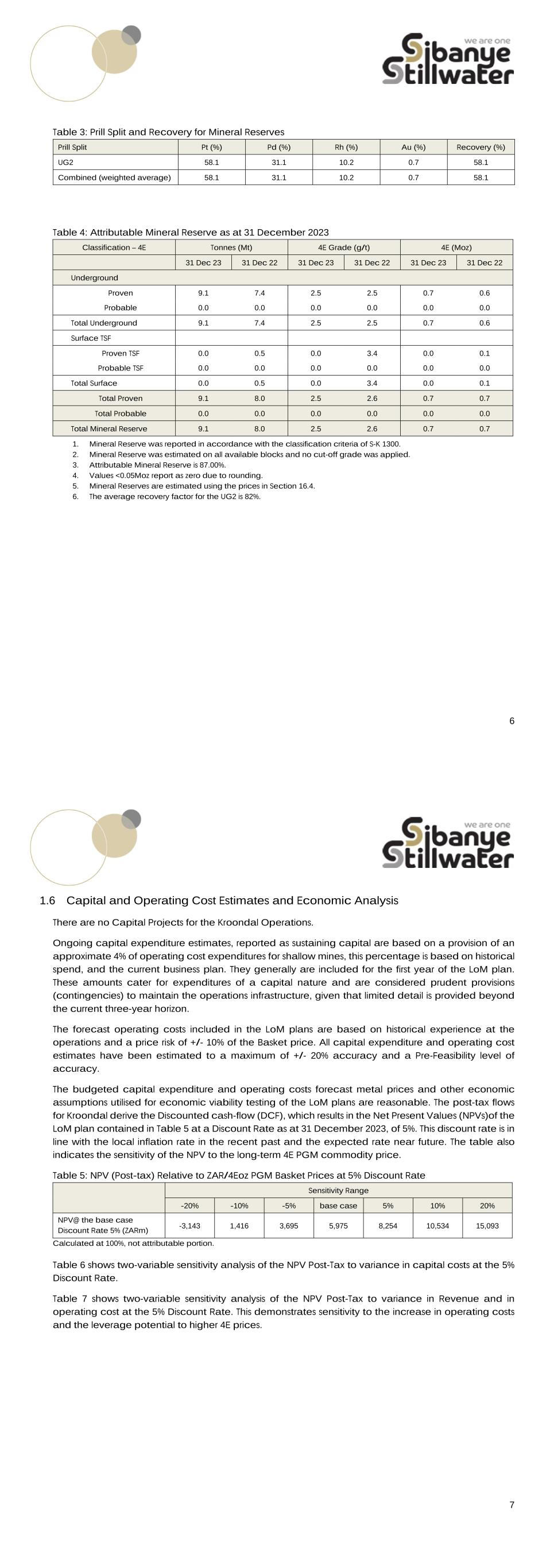

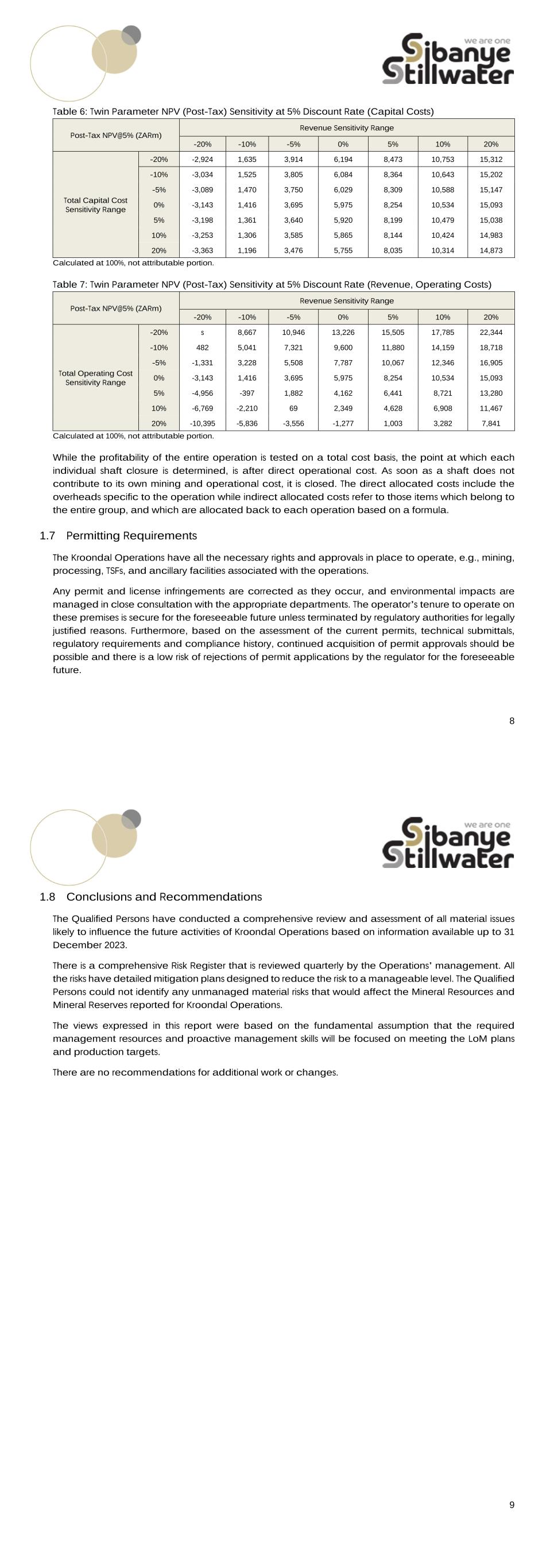

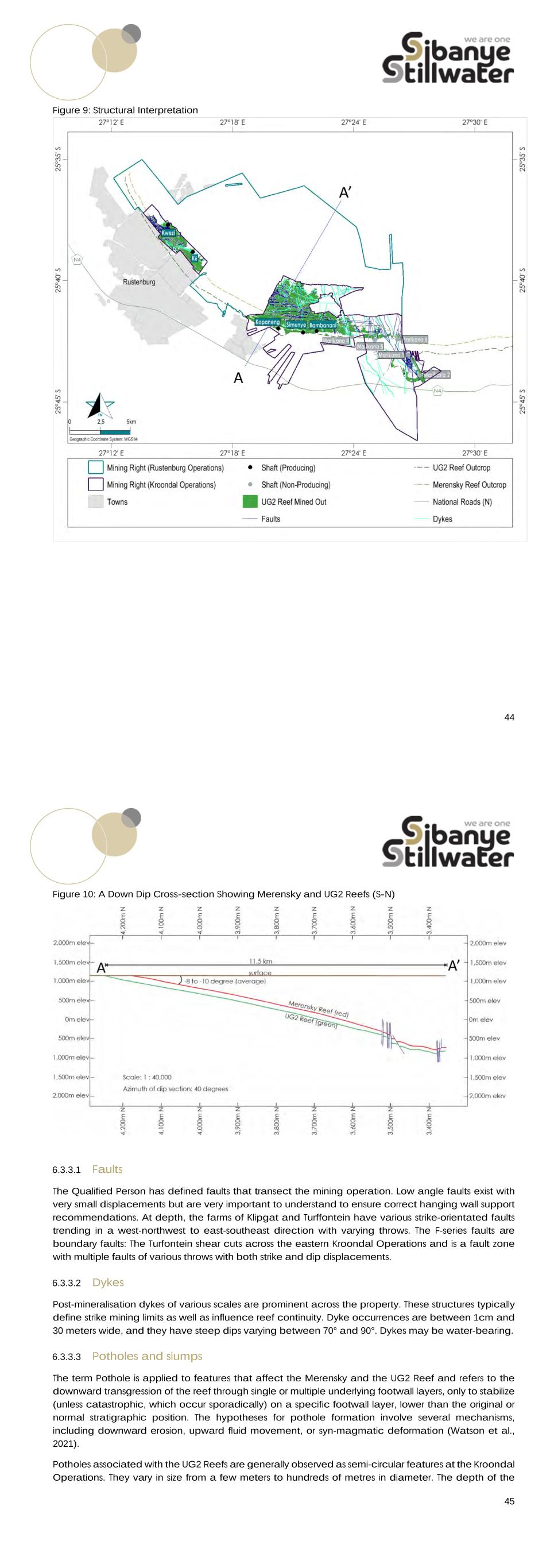

6 Table 3: Prill Split and Recovery for Mineral Reserves Prill Split Pt (%) Pd (%) Rh (%) Au (%) Recovery (%) UG2 58.1 31.1 10.2 0.7 58.1 Combined (weighted average) 58.1 31.1 10.2 0.7 58.1 Table 4: Attributable Mineral Reserve as at 31 December 2023 Classification – 4E Tonnes (Mt) 4E Grade (g/t) 4E (Moz) 31 Dec 23 31 Dec 22 31 Dec 23 31 Dec 22 31 Dec 23 31 Dec 22 Underground Proven 9.1 7.4 2.5 2.5 0.7 0.6 Probable 0.0 0.0 0.0 0.0 0.0 0.0 Total Underground 9.1 7.4 2.5 2.5 0.7 0.6 Surface TSF Proven TSF 0.0 0.5 0.0 3.4 0.0 0.1 Probable TSF 0.0 0.0 0.0 0.0 0.0 0.0 Total Surface 0.0 0.5 0.0 3.4 0.0 0.1 Total Proven 9.1 8.0 2.5 2.6 0.7 0.7 Total Probable 0.0 0.0 0.0 0.0 0.0 0.0 Total Mineral Reserve 9.1 8.0 2.5 2.6 0.7 0.7 1. Mineral Reserve was reported in accordance with the classification criteria of S-K 1300. 2. Mineral Reserve was estimated on all available blocks and no cut-off grade was applied. 3. Attributable Mineral Reserve is 87.00%. 4. Values <0.05Moz report as zero due to rounding. 5. Mineral Reserves are estimated using the prices in Section 16.4. 6. The average recovery factor for the UG2 is 82%. 7 1.6 Capital and Operating Cost Estimates and Economic Analysis There are no Capital Projects for the Kroondal Operations. Ongoing capital expenditure estimates, reported as sustaining capital are based on a provision of an approximate 4% of operating cost expenditures for shallow mines, this percentage is based on historical spend, and the current business plan. They generally are included for the first year of the LoM plan. These amounts cater for expenditures of a capital nature and are considered prudent provisions (contingencies) to maintain the operations infrastructure, given that limited detail is provided beyond the current three-year horizon. The forecast operating costs included in the LoM plans are based on historical experience at the operations and a price risk of +/- 10% of the Basket price. All capital expenditure and operating cost estimates have been estimated to a maximum of +/- 20% accuracy and a Pre-Feasibility level of accuracy. The budgeted capital expenditure and operating costs forecast metal prices and other economic assumptions utilised for economic viability testing of the LoM plans are reasonable. The post-tax flows for Kroondal derive the Discounted cash-flow (DCF), which results in the Net Present Values (NPVs)of the LoM plan contained in Table 5 at a Discount Rate as at 31 December 2023, of 5%. This discount rate is in line with the local inflation rate in the recent past and the expected rate near future. The table also indicates the sensitivity of the NPV to the long-term 4E PGM commodity price. Table 5: NPV (Post-tax) Relative to ZAR/4Eoz PGM Basket Prices at 5% Discount Rate Sensitivity Range -20% -10% -5% base case 5% 10% 20% NPV@ the base case Discount Rate 5% (ZARm) -3,143 1,416 3,695 5,975 8,254 10,534 15,093 Calculated at 100%, not attributable portion. Table 6 shows two-variable sensitivity analysis of the NPV Post-Tax to variance in capital costs at the 5% Discount Rate. Table 7 shows two-variable sensitivity analysis of the NPV Post-Tax to variance in Revenue and in operating cost at the 5% Discount Rate. This demonstrates sensitivity to the increase in operating costs and the leverage potential to higher 4E prices.

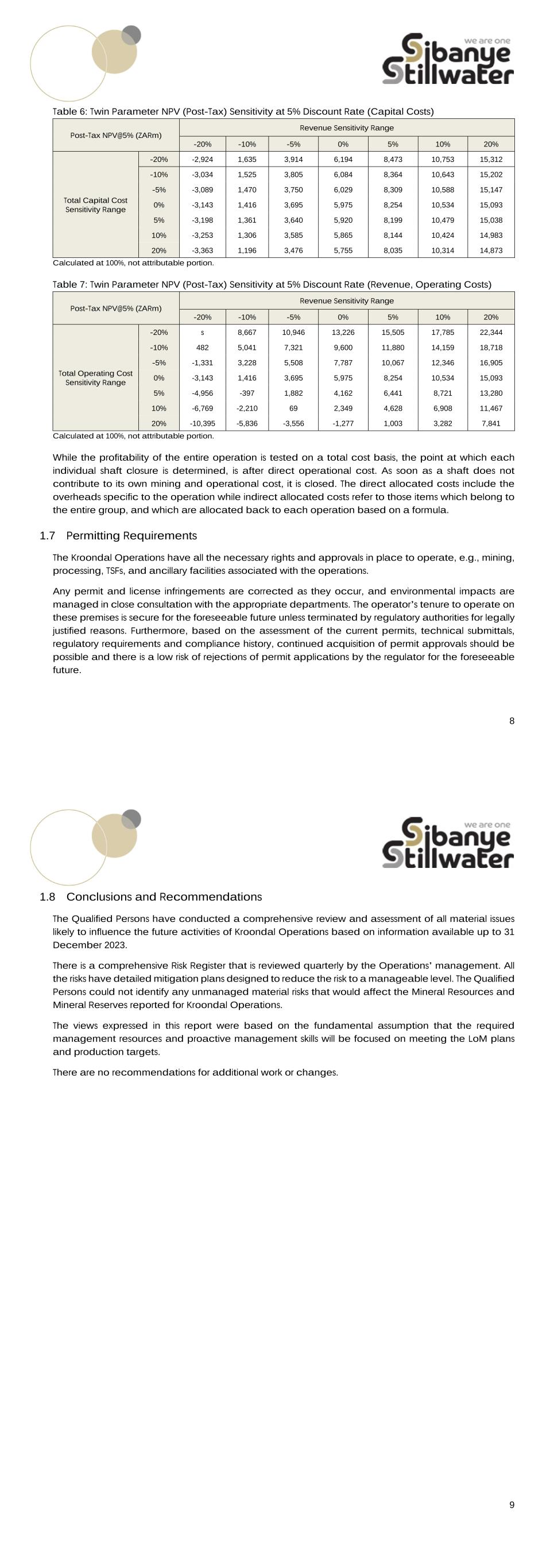

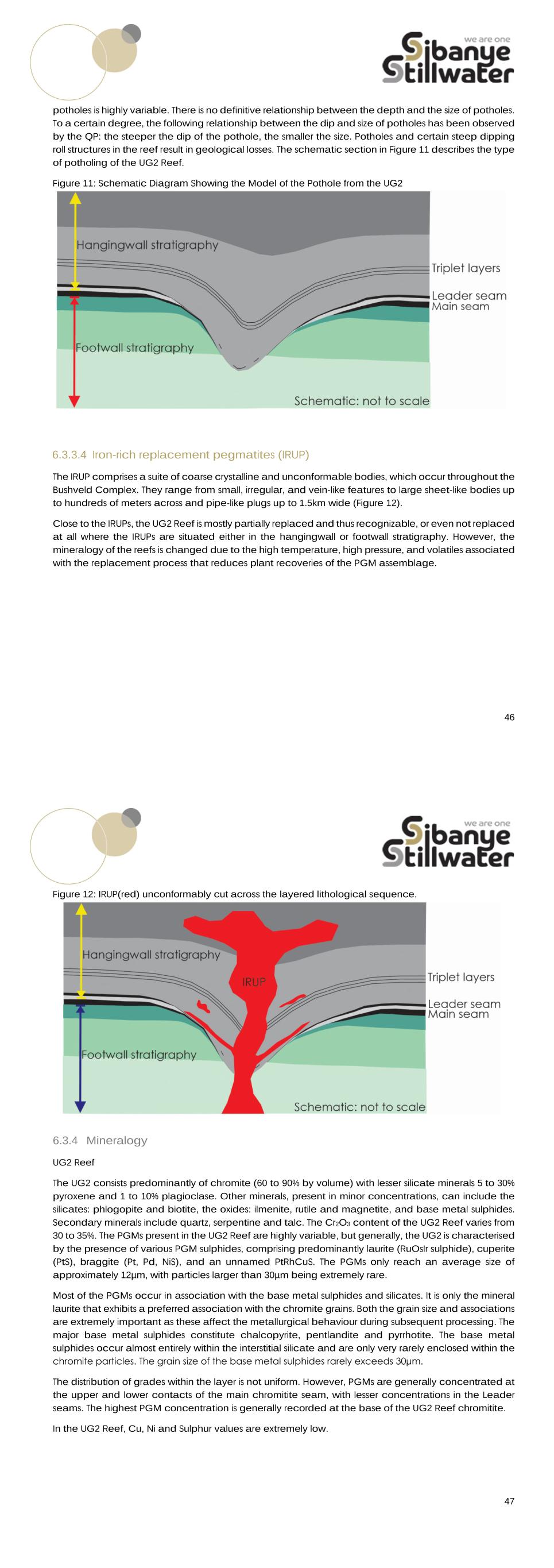

8 Table 6: Twin Parameter NPV (Post-Tax) Sensitivity at 5% Discount Rate (Capital Costs) Post-Tax NPV@5% (ZARm) Revenue Sensitivity Range -20% -10% -5% 0% 5% 10% 20% Total Capital Cost Sensitivity Range -20% -2,924 1,635 3,914 6,194 8,473 10,753 15,312 -10% -3,034 1,525 3,805 6,084 8,364 10,643 15,202 -5% -3,089 1,470 3,750 6,029 8,309 10,588 15,147 0% -3,143 1,416 3,695 5,975 8,254 10,534 15,093 5% -3,198 1,361 3,640 5,920 8,199 10,479 15,038 10% -3,253 1,306 3,585 5,865 8,144 10,424 14,983 20% -3,363 1,196 3,476 5,755 8,035 10,314 14,873 Calculated at 100%, not attributable portion. Table 7: Twin Parameter NPV (Post-Tax) Sensitivity at 5% Discount Rate (Revenue, Operating Costs) Post-Tax NPV@5% (ZARm) Revenue Sensitivity Range -20% -10% -5% 0% 5% 10% 20% Total Operating Cost Sensitivity Range -20% s 8,667 10,946 13,226 15,505 17,785 22,344 -10% 482 5,041 7,321 9,600 11,880 14,159 18,718 -5% -1,331 3,228 5,508 7,787 10,067 12,346 16,905 0% -3,143 1,416 3,695 5,975 8,254 10,534 15,093 5% -4,956 -397 1,882 4,162 6,441 8,721 13,280 10% -6,769 -2,210 69 2,349 4,628 6,908 11,467 20% -10,395 -5,836 -3,556 -1,277 1,003 3,282 7,841 Calculated at 100%, not attributable portion. While the profitability of the entire operation is tested on a total cost basis, the point at which each individual shaft closure is determined, is after direct operational cost. As soon as a shaft does not contribute to its own mining and operational cost, it is closed. The direct allocated costs include the overheads specific to the operation while indirect allocated costs refer to those items which belong to the entire group, and which are allocated back to each operation based on a formula. 1.7 Permitting Requirements The Kroondal Operations have all the necessary rights and approvals in place to operate, e.g., mining, processing, TSFs, and ancillary facilities associated with the operations. Any permit and license infringements are corrected as they occur, and environmental impacts are managed in close consultation with the appropriate departments. The operator’s tenure to operate on these premises is secure for the foreseeable future unless terminated by regulatory authorities for legally justified reasons. Furthermore, based on the assessment of the current permits, technical submittals, regulatory requirements and compliance history, continued acquisition of permit approvals should be possible and there is a low risk of rejections of permit applications by the regulator for the foreseeable future. 9 1.8 Conclusions and Recommendations The Qualified Persons have conducted a comprehensive review and assessment of all material issues likely to influence the future activities of Kroondal Operations based on information available up to 31 December 2023. There is a comprehensive Risk Register that is reviewed quarterly by the Operations’ management. All the risks have detailed mitigation plans designed to reduce the risk to a manageable level. The Qualified Persons could not identify any unmanaged material risks that would affect the Mineral Resources and Mineral Reserves reported for Kroondal Operations. The views expressed in this report were based on the fundamental assumption that the required management resources and proactive management skills will be focused on meeting the LoM plans and production targets. There are no recommendations for additional work or changes.

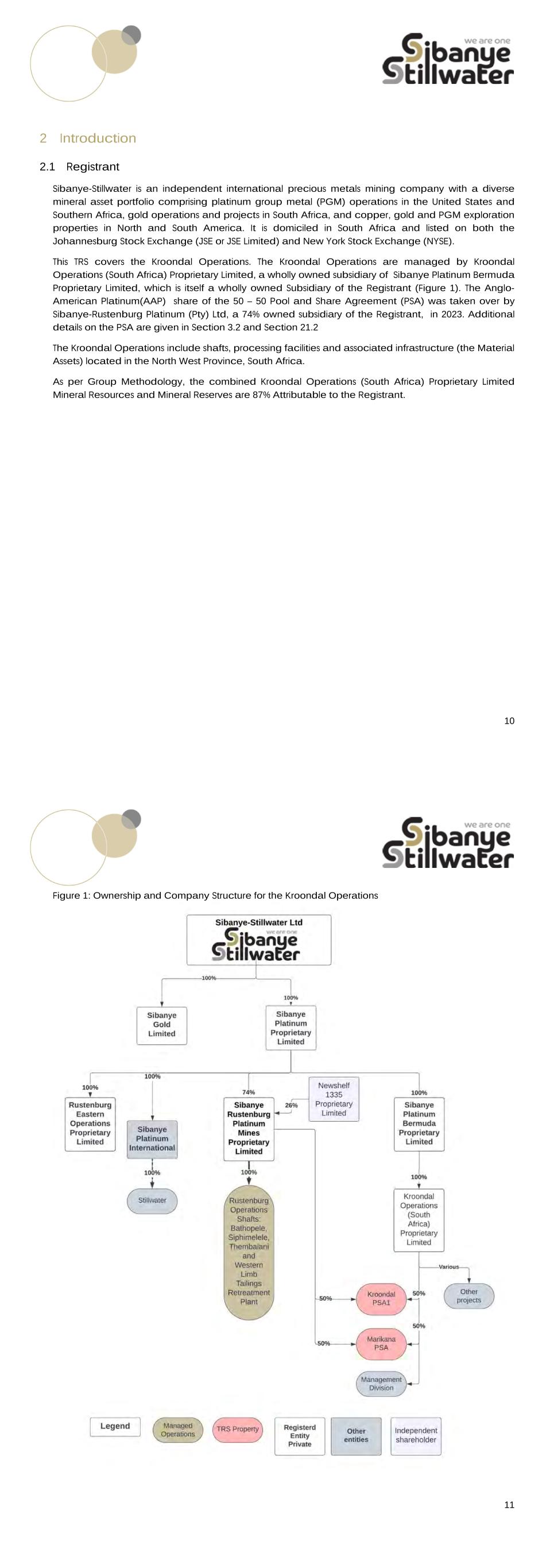

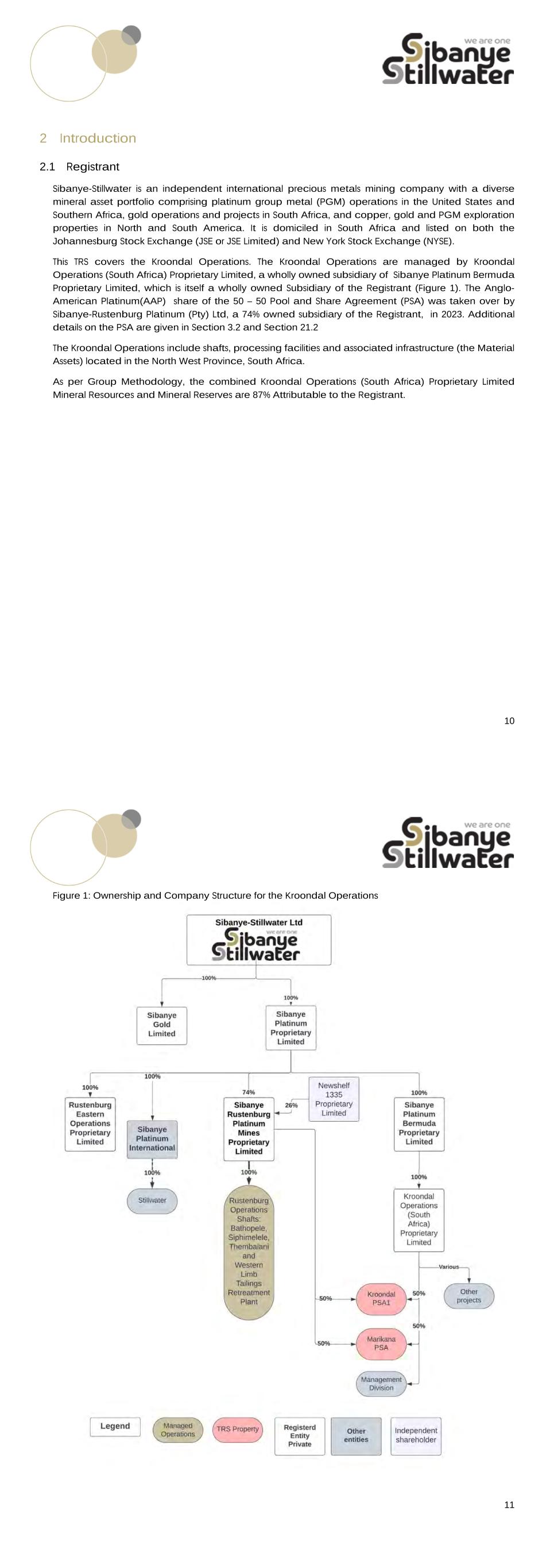

10 2 Introduction 2.1 Registrant Sibanye-Stillwater is an independent international precious metals mining company with a diverse mineral asset portfolio comprising platinum group metal (PGM) operations in the United States and Southern Africa, gold operations and projects in South Africa, and copper, gold and PGM exploration properties in North and South America. It is domiciled in South Africa and listed on both the Johannesburg Stock Exchange (JSE or JSE Limited) and New York Stock Exchange (NYSE). This TRS covers the Kroondal Operations. The Kroondal Operations are managed by Kroondal Operations (South Africa) Proprietary Limited, a wholly owned subsidiary of Sibanye Platinum Bermuda Proprietary Limited, which is itself a wholly owned Subsidiary of the Registrant (Figure 1). The Anglo- American Platinum(AAP) share of the 50 – 50 Pool and Share Agreement (PSA) was taken over by Sibanye-Rustenburg Platinum (Pty) Ltd, a 74% owned subsidiary of the Registrant, in 2023. Additional details on the PSA are given in Section 3.2 and Section 21.2 The Kroondal Operations include shafts, processing facilities and associated infrastructure (the Material Assets) located in the North West Province, South Africa. As per Group Methodology, the combined Kroondal Operations (South Africa) Proprietary Limited Mineral Resources and Mineral Reserves are 87% Attributable to the Registrant. 11 Figure 1: Ownership and Company Structure for the Kroondal Operations

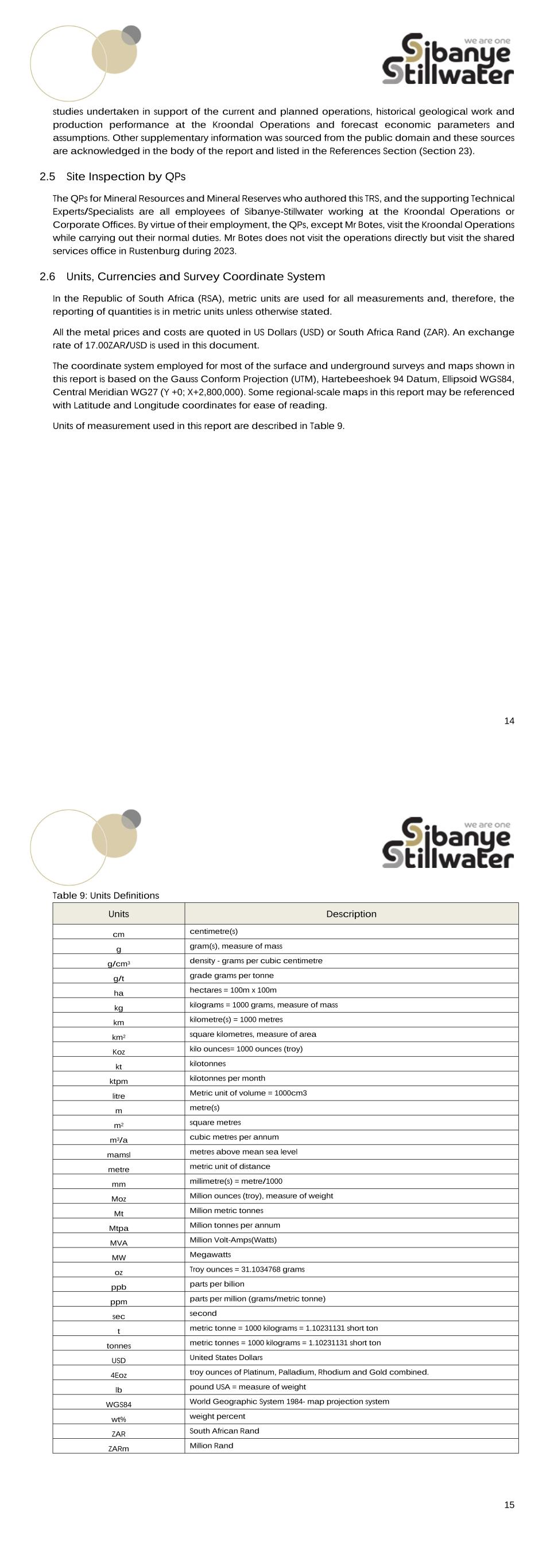

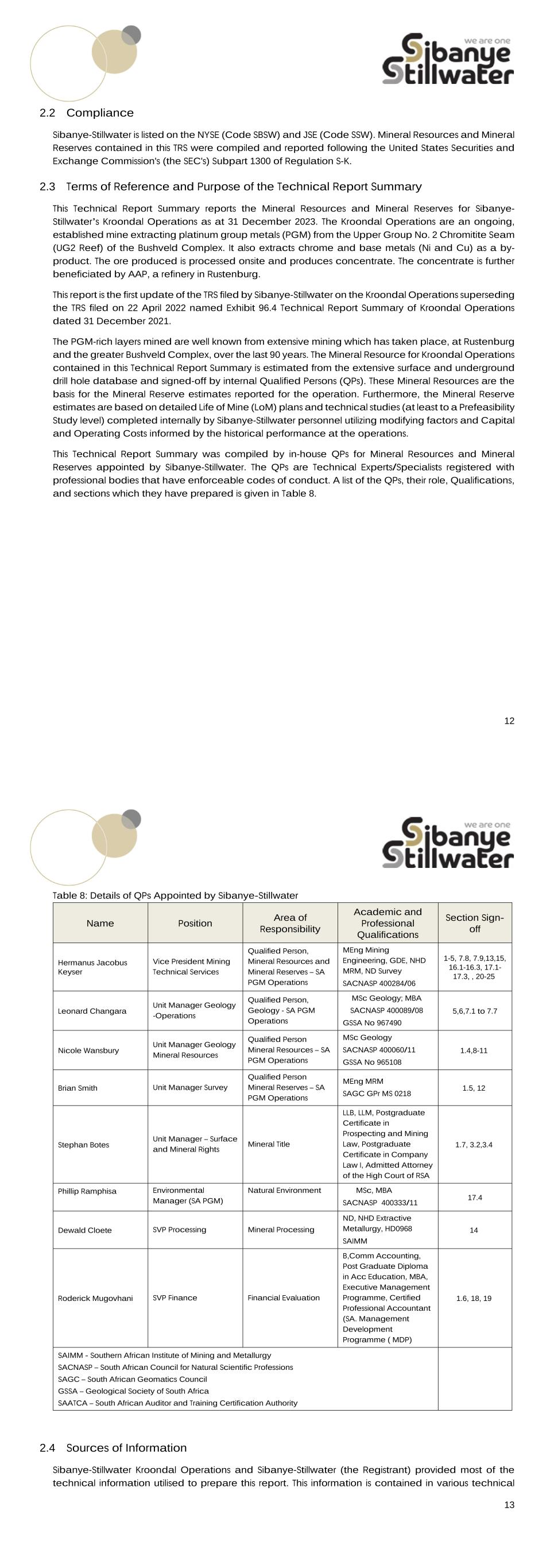

12 2.2 Compliance Sibanye-Stillwater is listed on the NYSE (Code SBSW) and JSE (Code SSW). Mineral Resources and Mineral Reserves contained in this TRS were compiled and reported following the United States Securities and Exchange Commission's (the SEC's) Subpart 1300 of Regulation S-K. 2.3 Terms of Reference and Purpose of the Technical Report Summary This Technical Report Summary reports the Mineral Resources and Mineral Reserves for Sibanye- Stillwater’s Kroondal Operations as at 31 December 2023. The Kroondal Operations are an ongoing, established mine extracting platinum group metals (PGM) from the Upper Group No. 2 Chromitite Seam (UG2 Reef) of the Bushveld Complex. It also extracts chrome and base metals (Ni and Cu) as a by- product. The ore produced is processed onsite and produces concentrate. The concentrate is further beneficiated by AAP, a refinery in Rustenburg. This report is the first update of the TRS filed by Sibanye-Stillwater on the Kroondal Operations superseding the TRS filed on 22 April 2022 named Exhibit 96.4 Technical Report Summary of Kroondal Operations dated 31 December 2021. The PGM-rich layers mined are well known from extensive mining which has taken place, at Rustenburg and the greater Bushveld Complex, over the last 90 years. The Mineral Resource for Kroondal Operations contained in this Technical Report Summary is estimated from the extensive surface and underground drill hole database and signed-off by internal Qualified Persons (QPs). These Mineral Resources are the basis for the Mineral Reserve estimates reported for the operation. Furthermore, the Mineral Reserve estimates are based on detailed Life of Mine (LoM) plans and technical studies (at least to a Prefeasibility Study level) completed internally by Sibanye-Stillwater personnel utilizing modifying factors and Capital and Operating Costs informed by the historical performance at the operations. This Technical Report Summary was compiled by in-house QPs for Mineral Resources and Mineral Reserves appointed by Sibanye-Stillwater. The QPs are Technical Experts/Specialists registered with professional bodies that have enforceable codes of conduct. A list of the QPs, their role, Qualifications, and sections which they have prepared is given in Table 8. 13 Table 8: Details of QPs Appointed by Sibanye-Stillwater Name Position Area of Responsibility Academic and Professional Qualifications Section Sign- off Hermanus Jacobus Keyser Vice President Mining Technical Services Qualified Person, Mineral Resources and Mineral Reserves – SA PGM Operations MEng Mining Engineering, GDE, NHD MRM, ND Survey SACNASP 400284/06 1-5, 7.8, 7.9,13,15, 16.1-16.3, 17.1- 17.3, , 20-25 Leonard Changara Unit Manager Geology -Operations Qualified Person, Geology - SA PGM Operations MSc Geology; MBA SACNASP 400089/08 GSSA No 967490 5,6,7.1 to 7.7 Nicole Wansbury Unit Manager Geology Mineral Resources Qualified Person Mineral Resources – SA PGM Operations MSc Geology SACNASP 400060/11 GSSA No 965108 1.4,8-11 Brian Smith Unit Manager Survey Qualified Person Mineral Reserves – SA PGM Operations MEng MRM SAGC GPr MS 0218 1.5, 12 Stephan Botes Unit Manager – Surface and Mineral Rights Mineral Title LLB, LLM, Postgraduate Certificate in Prospecting and Mining Law, Postgraduate Certificate in Company Law I, Admitted Attorney of the High Court of RSA 1.7, 3.2,3.4 Phillip Ramphisa Environmental Manager (SA PGM) Natural Environment MSc, MBA SACNASP 400333/11 17.4 Dewald Cloete SVP Processing Mineral Processing ND, NHD Extractive Metallurgy, HD0968 SAIMM 14 Roderick Mugovhani SVP Finance Financial Evaluation B,Comm Accounting, Post Graduate Diploma in Acc Education, MBA, Executive Management Programme, Certified Professional Accountant (SA. Management Development Programme ( MDP) 1.6, 18, 19 SAIMM - Southern African Institute of Mining and Metallurgy SACNASP – South African Council for Natural Scientific Professions SAGC – South African Geomatics Council GSSA – Geological Society of South Africa SAATCA – South African Auditor and Training Certification Authority 2.4 Sources of Information Sibanye-Stillwater Kroondal Operations and Sibanye-Stillwater (the Registrant) provided most of the technical information utilised to prepare this report. This information is contained in various technical

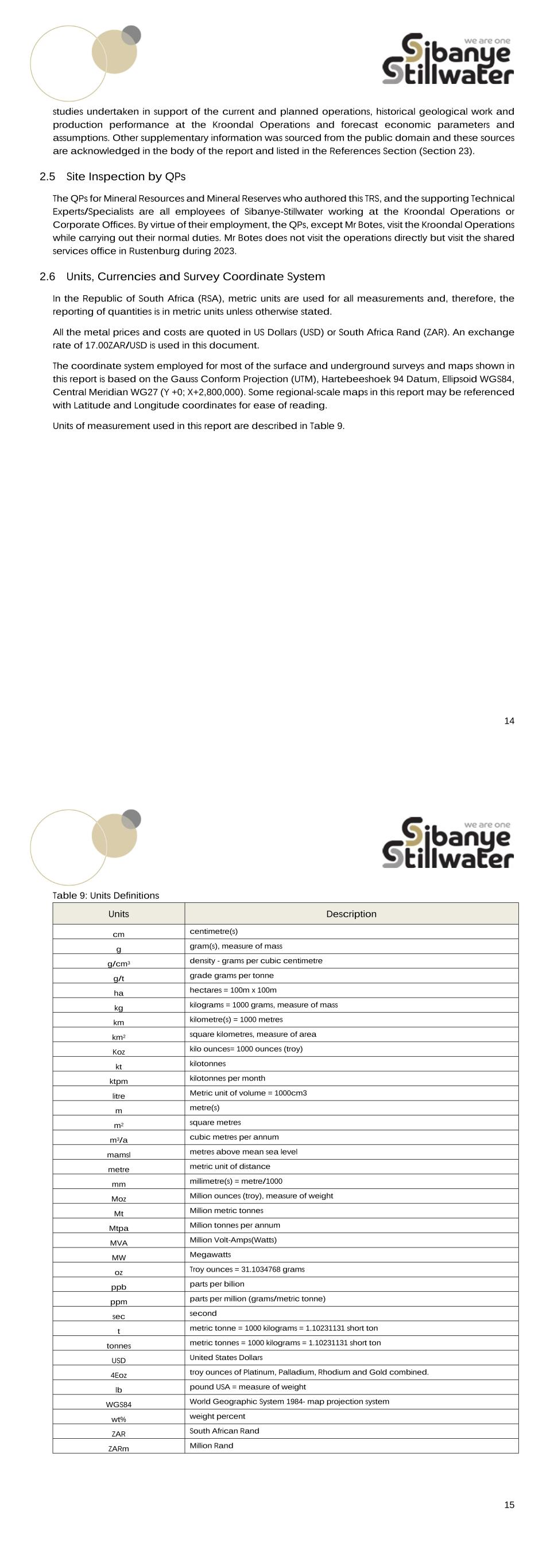

14 studies undertaken in support of the current and planned operations, historical geological work and production performance at the Kroondal Operations and forecast economic parameters and assumptions. Other supplementary information was sourced from the public domain and these sources are acknowledged in the body of the report and listed in the References Section (Section 23). 2.5 Site Inspection by QPs The QPs for Mineral Resources and Mineral Reserves who authored this TRS, and the supporting Technical Experts/Specialists are all employees of Sibanye-Stillwater working at the Kroondal Operations or Corporate Offices. By virtue of their employment, the QPs, except Mr Botes, visit the Kroondal Operations while carrying out their normal duties. Mr Botes does not visit the operations directly but visit the shared services office in Rustenburg during 2023. 2.6 Units, Currencies and Survey Coordinate System In the Republic of South Africa (RSA), metric units are used for all measurements and, therefore, the reporting of quantities is in metric units unless otherwise stated. All the metal prices and costs are quoted in US Dollars (USD) or South Africa Rand (ZAR). An exchange rate of 17.00ZAR/USD is used in this document. The coordinate system employed for most of the surface and underground surveys and maps shown in this report is based on the Gauss Conform Projection (UTM), Hartebeeshoek 94 Datum, Ellipsoid WGS84, Central Meridian WG27 (Y +0; X+2,800,000). Some regional-scale maps in this report may be referenced with Latitude and Longitude coordinates for ease of reading. Units of measurement used in this report are described in Table 9. 15 Table 9: Units Definitions Units Description cm centimetre(s) g gram(s), measure of mass g/cm3 density - grams per cubic centimetre g/t grade grams per tonne ha hectares = 100m x 100m kg kilograms = 1000 grams, measure of mass km kilometre(s) = 1000 metres km2 square kilometres, measure of area Koz kilo ounces= 1000 ounces (troy) kt kilotonnes ktpm kilotonnes per month litre Metric unit of volume = 1000cm3 m metre(s) m2 square metres m3/a cubic metres per annum mamsl metres above mean sea level metre metric unit of distance mm millimetre(s) = metre/1000 Moz Million ounces (troy), measure of weight Mt Million metric tonnes Mtpa Million tonnes per annum MVA Million Volt-Amps(Watts) MW Megawatts oz Troy ounces = 31.1034768 grams ppb parts per billion ppm parts per million (grams/metric tonne) sec second t metric tonne = 1000 kilograms = 1.10231131 short ton tonnes metric tonnes = 1000 kilograms = 1.10231131 short ton USD United States Dollars 4Eoz troy ounces of Platinum, Palladium, Rhodium and Gold combined. lb pound USA = measure of weight WGS84 World Geographic System 1984- map projection system wt% weight percent ZAR South African Rand ZARm Million Rand

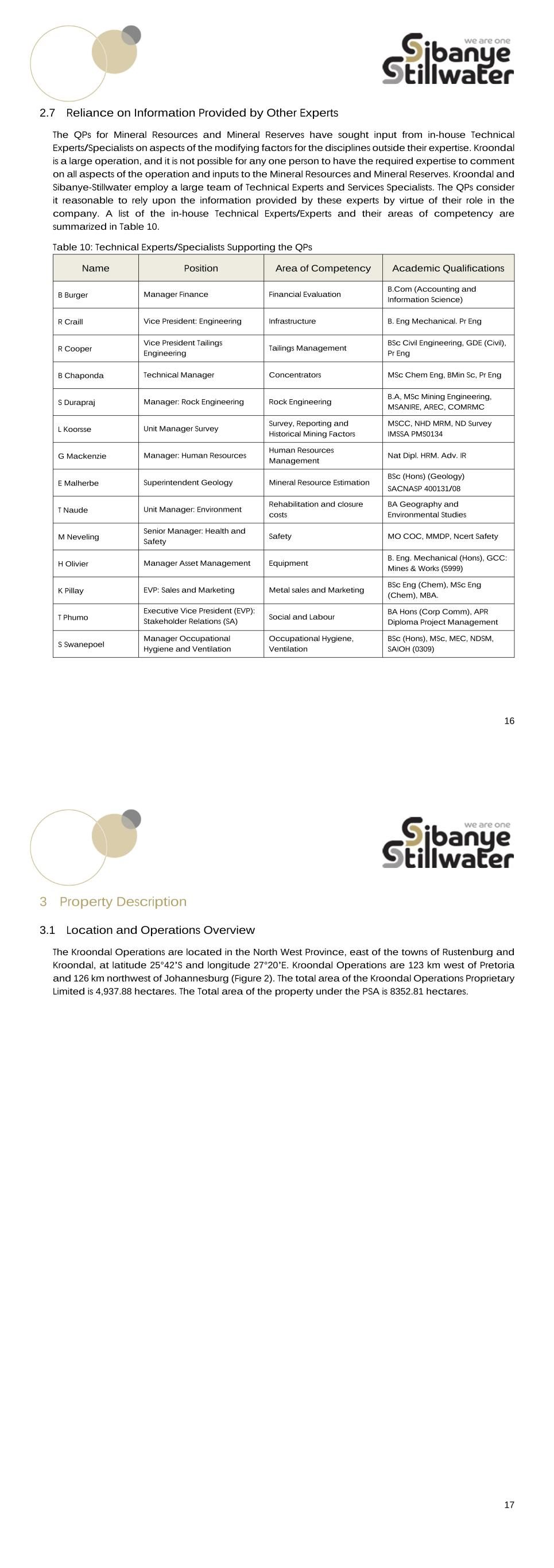

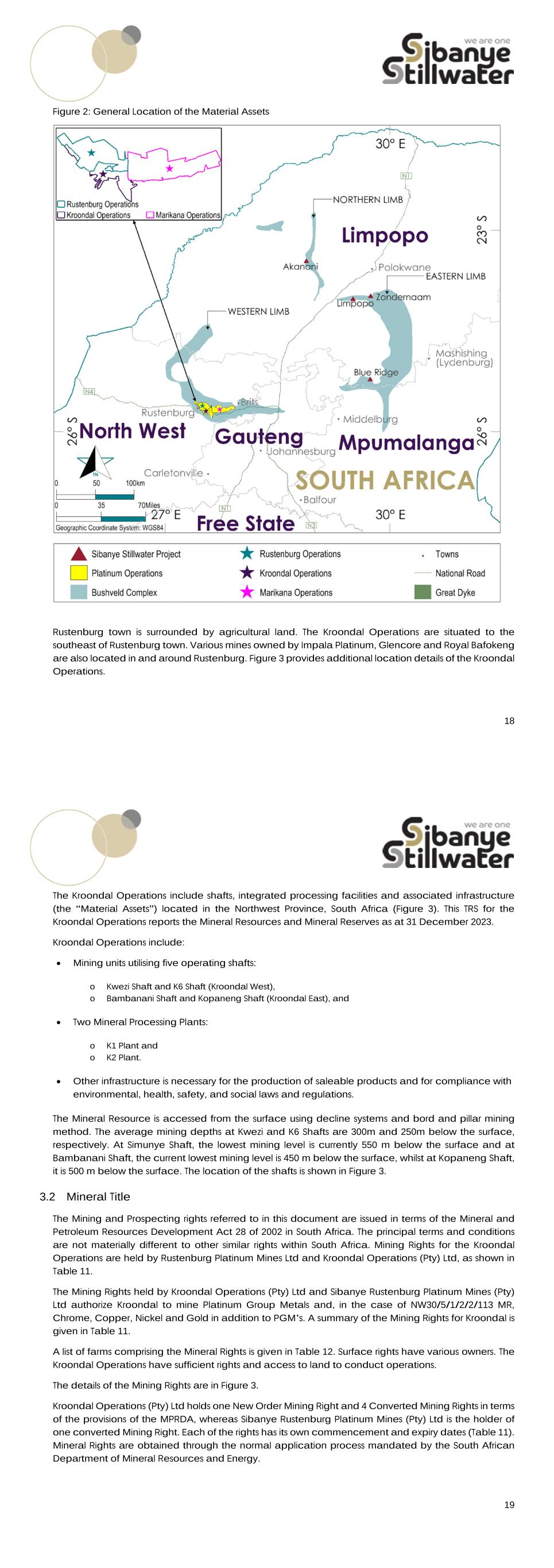

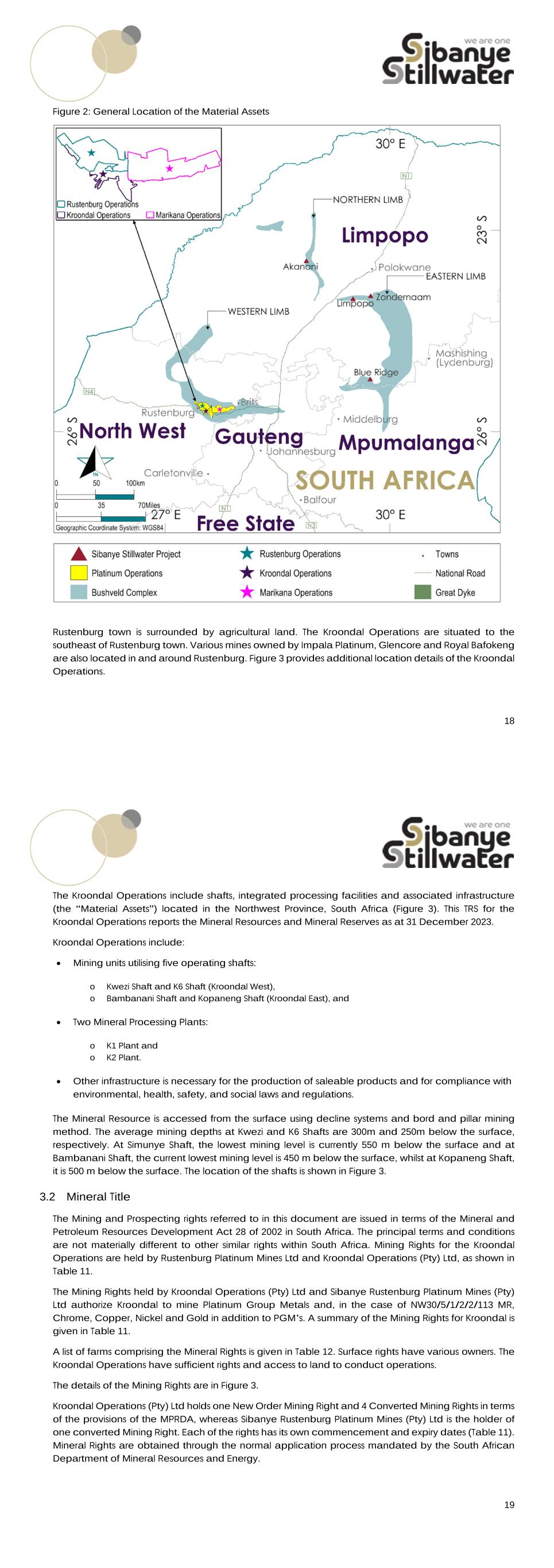

16 2.7 Reliance on Information Provided by Other Experts The QPs for Mineral Resources and Mineral Reserves have sought input from in-house Technical Experts/Specialists on aspects of the modifying factors for the disciplines outside their expertise. Kroondal is a large operation, and it is not possible for any one person to have the required expertise to comment on all aspects of the operation and inputs to the Mineral Resources and Mineral Reserves. Kroondal and Sibanye-Stillwater employ a large team of Technical Experts and Services Specialists. The QPs consider it reasonable to rely upon the information provided by these experts by virtue of their role in the company. A list of the in-house Technical Experts/Experts and their areas of competency are summarized in Table 10. Table 10: Technical Experts/Specialists Supporting the QPs Name Position Area of Competency Academic Qualifications B Burger Manager Finance Financial Evaluation B.Com (Accounting and Information Science) R Craill Vice President: Engineering Infrastructure B. Eng Mechanical. Pr Eng R Cooper Vice President Tailings Engineering Tailings Management BSc Civil Engineering, GDE (Civil), Pr Eng B Chaponda Technical Manager Concentrators MSc Chem Eng, BMin Sc, Pr Eng S Durapraj Manager: Rock Engineering Rock Engineering B.A, MSc Mining Engineering, MSANIRE, AREC, COMRMC L Koorsse Unit Manager Survey Survey, Reporting and Historical Mining Factors MSCC, NHD MRM, ND Survey IMSSA PMS0134 G Mackenzie Manager: Human Resources Human Resources Management Nat Dipl. HRM. Adv. IR E Malherbe Superintendent Geology Mineral Resource Estimation BSc (Hons) (Geology) SACNASP 400131/08 T Naude Unit Manager: Environment Rehabilitation and closure costs BA Geography and Environmental Studies M Neveling Senior Manager: Health and Safety Safety MO COC, MMDP, Ncert Safety H Olivier Manager Asset Management Equipment B. Eng. Mechanical (Hons), GCC: Mines & Works (5999) K Pillay EVP: Sales and Marketing Metal sales and Marketing BSc Eng (Chem), MSc Eng (Chem), MBA. T Phumo Executive Vice President (EVP): Stakeholder Relations (SA) Social and Labour BA Hons (Corp Comm), APR Diploma Project Management S Swanepoel Manager Occupational Hygiene and Ventilation Occupational Hygiene, Ventilation BSc (Hons), MSc, MEC, NDSM, SAIOH (0309) 17 3 Property Description 3.1 Location and Operations Overview The Kroondal Operations are located in the North West Province, east of the towns of Rustenburg and Kroondal, at latitude 25°42’S and longitude 27°20’E. Kroondal Operations are 123 km west of Pretoria and 126 km northwest of Johannesburg (Figure 2). The total area of the Kroondal Operations Proprietary Limited is 4,937.88 hectares. The Total area of the property under the PSA is 8352.81 hectares.

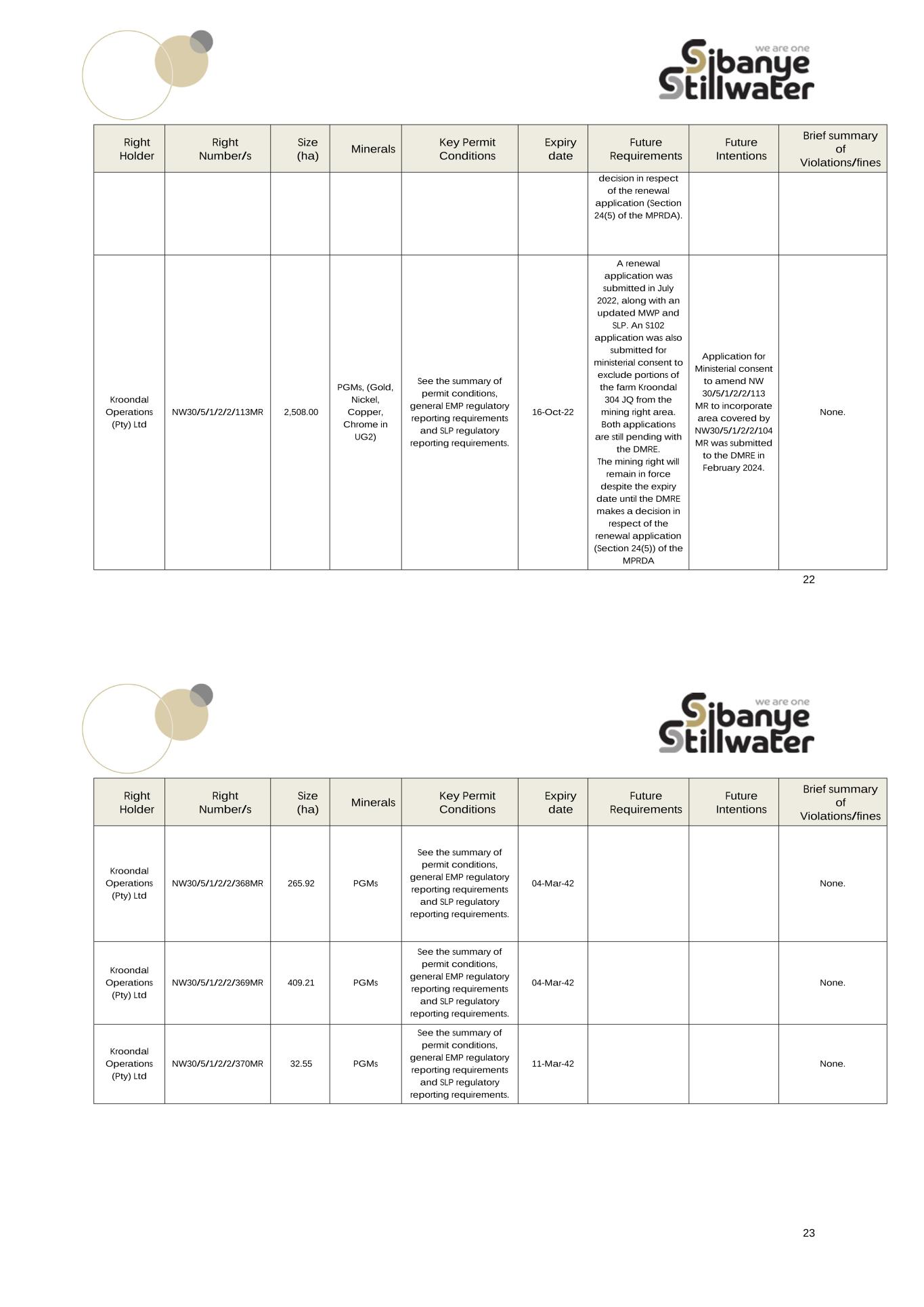

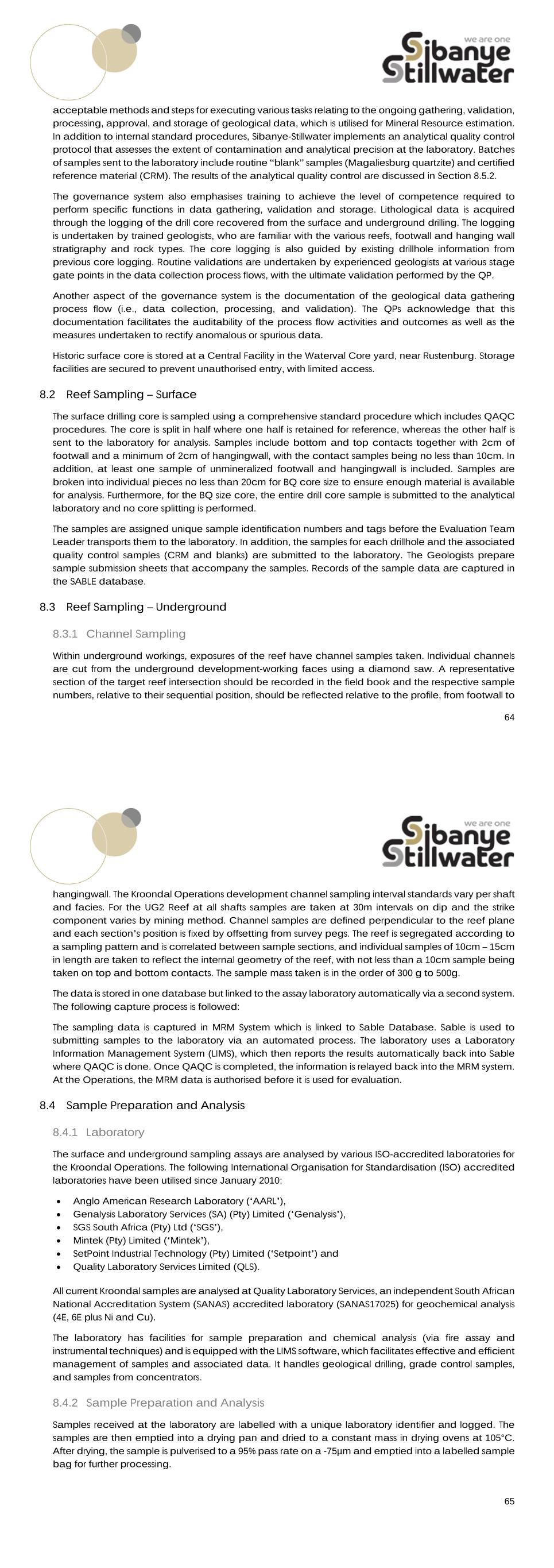

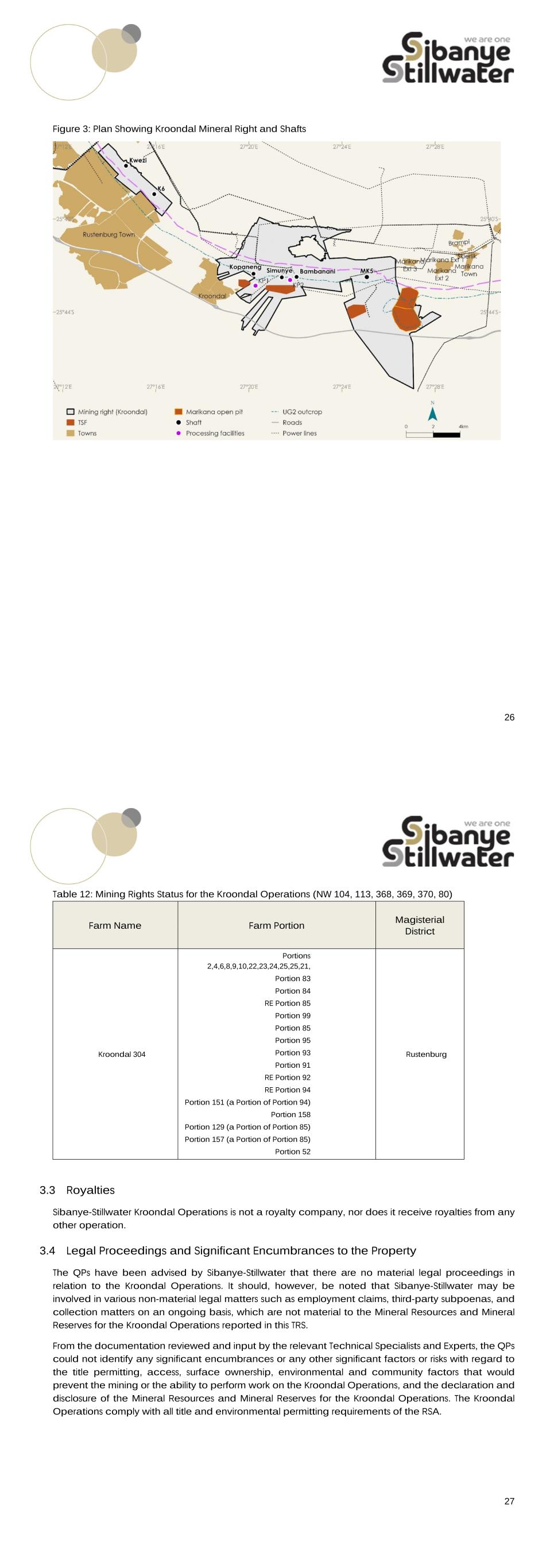

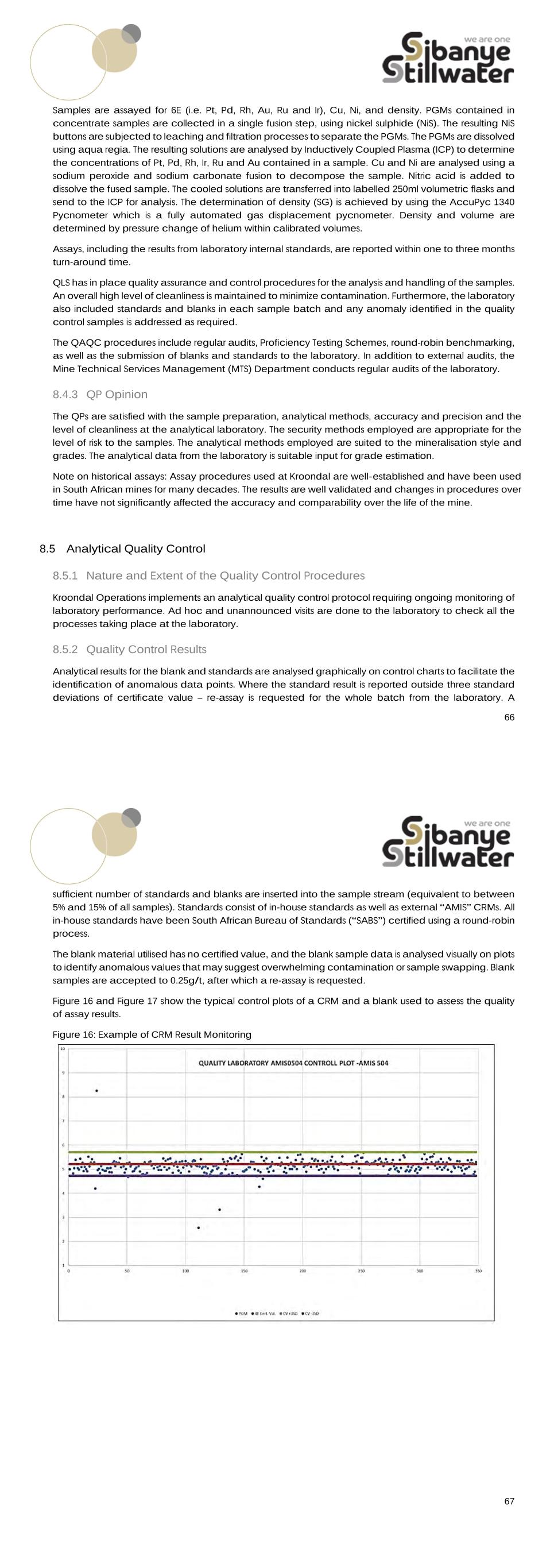

18 Figure 2: General Location of the Material Assets Rustenburg town is surrounded by agricultural land. The Kroondal Operations are situated to the southeast of Rustenburg town. Various mines owned by Impala Platinum, Glencore and Royal Bafokeng are also located in and around Rustenburg. Figure 3 provides additional location details of the Kroondal Operations. 19 The Kroondal Operations include shafts, integrated processing facilities and associated infrastructure (the “Material Assets”) located in the Northwest Province, South Africa (Figure 3). This TRS for the Kroondal Operations reports the Mineral Resources and Mineral Reserves as at 31 December 2023. Kroondal Operations include: Mining units utilising five operating shafts: o Kwezi Shaft and K6 Shaft (Kroondal West), o Bambanani Shaft and Kopaneng Shaft (Kroondal East), and Two Mineral Processing Plants: o K1 Plant and o K2 Plant. Other infrastructure is necessary for the production of saleable products and for compliance with environmental, health, safety, and social laws and regulations. The Mineral Resource is accessed from the surface using decline systems and bord and pillar mining method. The average mining depths at Kwezi and K6 Shafts are 300m and 250m below the surface, respectively. At Simunye Shaft, the lowest mining level is currently 550 m below the surface and at Bambanani Shaft, the current lowest mining level is 450 m below the surface, whilst at Kopaneng Shaft, it is 500 m below the surface. The location of the shafts is shown in Figure 3. 3.2 Mineral Title The Mining and Prospecting rights referred to in this document are issued in terms of the Mineral and Petroleum Resources Development Act 28 of 2002 in South Africa. The principal terms and conditions are not materially different to other similar rights within South Africa. Mining Rights for the Kroondal Operations are held by Rustenburg Platinum Mines Ltd and Kroondal Operations (Pty) Ltd, as shown in Table 11. The Mining Rights held by Kroondal Operations (Pty) Ltd and Sibanye Rustenburg Platinum Mines (Pty) Ltd authorize Kroondal to mine Platinum Group Metals and, in the case of NW30/5/1/2/2/113 MR, Chrome, Copper, Nickel and Gold in addition to PGM’s. A summary of the Mining Rights for Kroondal is given in Table 11. A list of farms comprising the Mineral Rights is given in Table 12. Surface rights have various owners. The Kroondal Operations have sufficient rights and access to land to conduct operations. The details of the Mining Rights are in Figure 3. Kroondal Operations (Pty) Ltd holds one New Order Mining Right and 4 Converted Mining Rights in terms of the provisions of the MPRDA, whereas Sibanye Rustenburg Platinum Mines (Pty) Ltd is the holder of one converted Mining Right. Each of the rights has its own commencement and expiry dates (Table 11). Mineral Rights are obtained through the normal application process mandated by the South African Department of Mineral Resources and Energy.

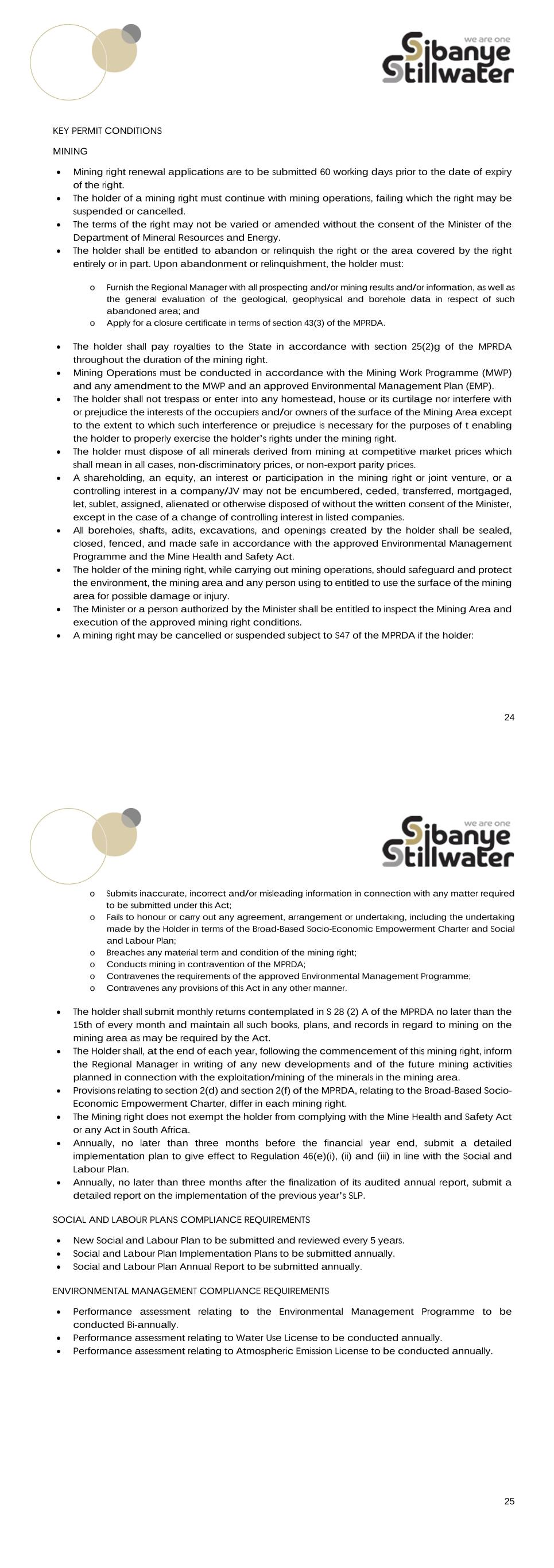

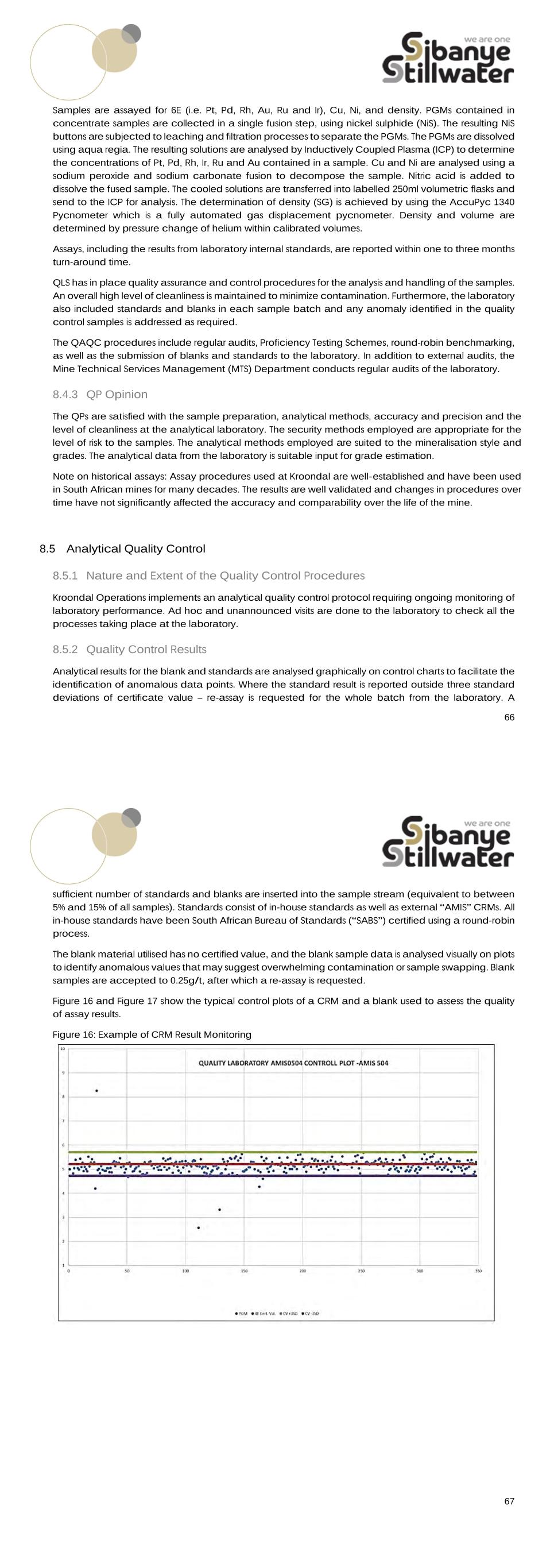

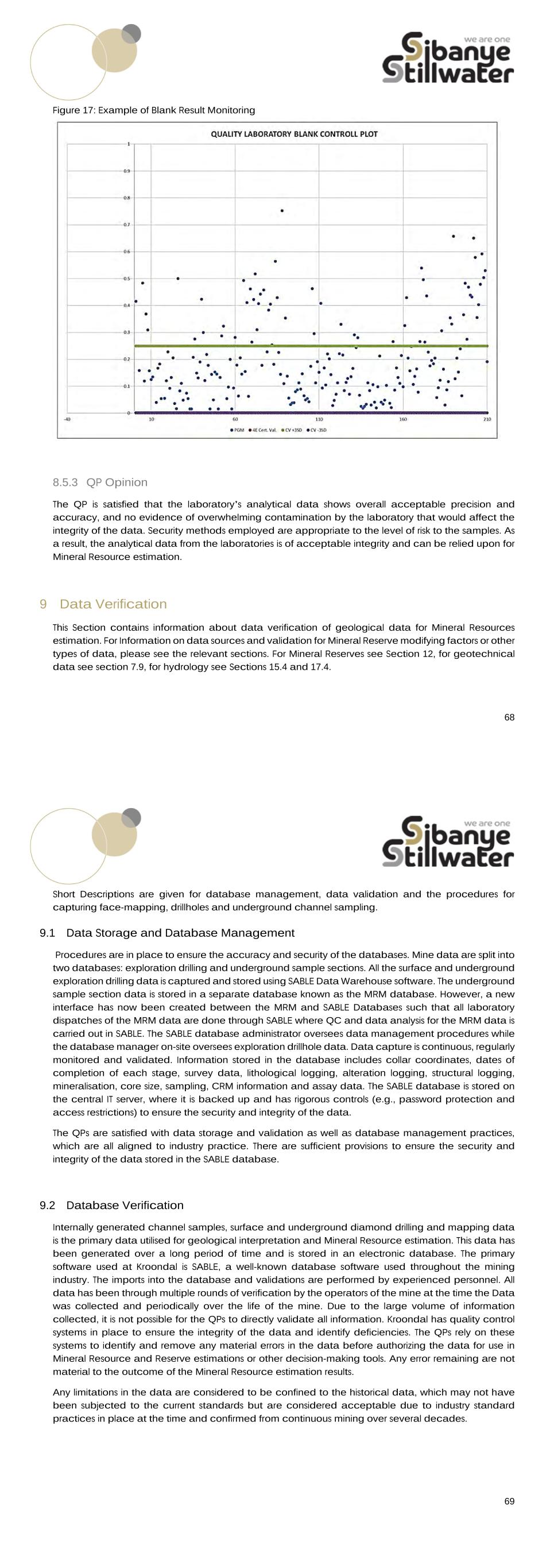

20 Only the Mining Rights under Kroondal Operations (South Africa) Proprietary Limited are shown in the table below. 21 Table 11: Kroondal Mining Right Status Right Holder Right Number/s Size (ha) Minerals Key Permit Conditions Expiry date Future Requirements Future Intentions Brief summary of Violations/fines Kroondal Operations (Pty) Ltd NW30/5/1/2/2/104MR 1,722.20 PGMs See the summary of permit conditions, general EMP regulatory reporting requirements and SLP regulatory reporting requirements. 16-Oct-22 A renewal application was submitted in July 2022, along with an updated MWP and SLP. An S102 application was also submitted for ministerial consent to incorporate portions of the farm Kroondal 304 JQ (being the location of the Kroondal Operations KP1 TSF) and exclude other portions of the said farm which the company has no interest. The mentioned applications remain pending with the DMRE. The mining right will remain in force despite the expiry date until the DMRE makes a Application for Ministerial consent to amend NW 30/5/1/2/2/113 MR to incorporate area covered by NW30/5/1/2/2/104 MR was submitted to the DMRE in February 2024. None.

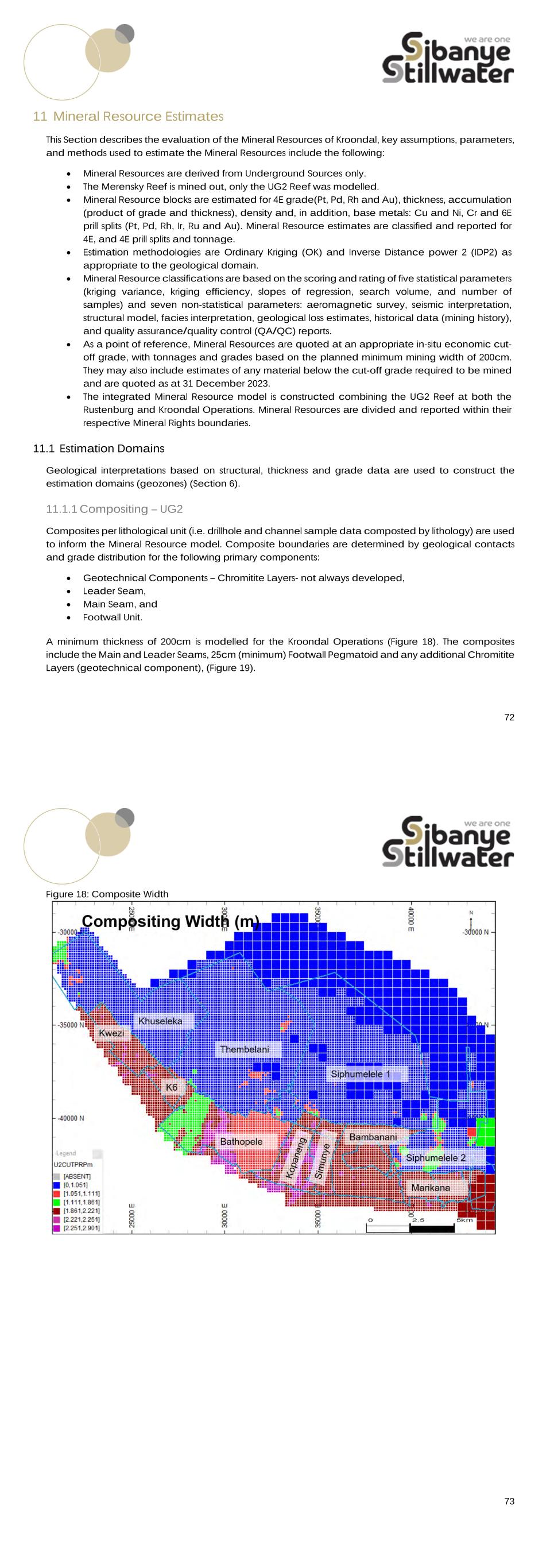

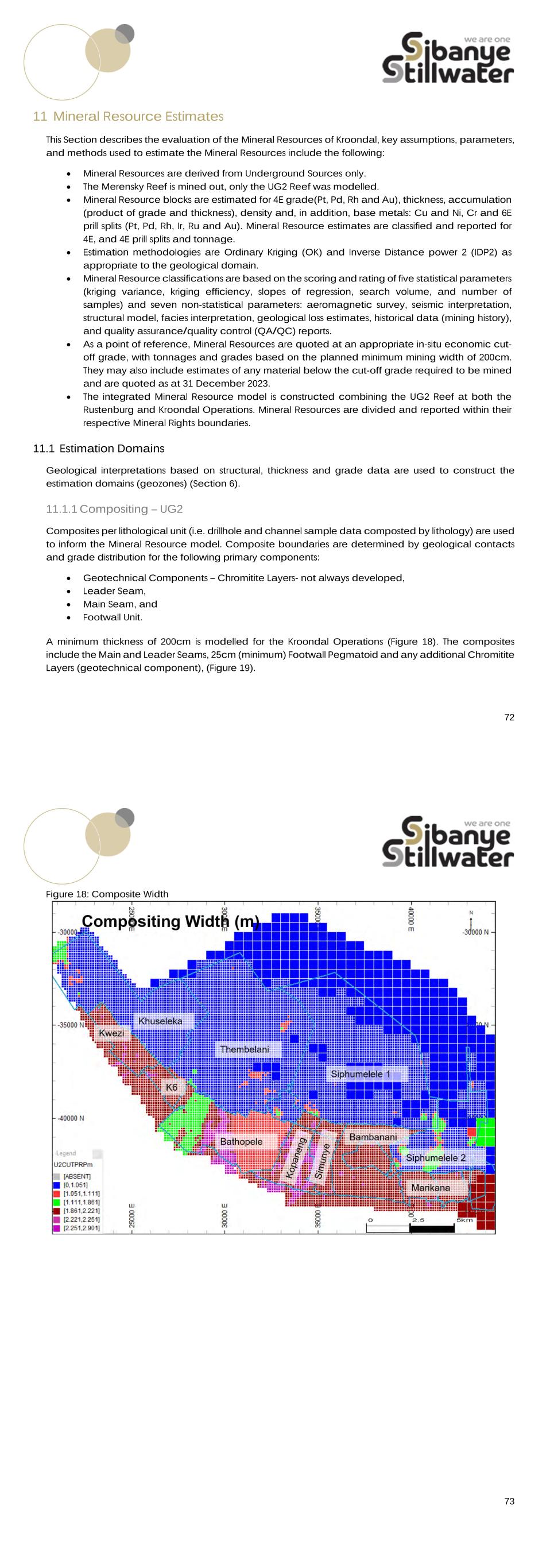

22 Right Holder Right Number/s Size (ha) Minerals Key Permit Conditions Expiry date Future Requirements Future Intentions Brief summary of Violations/fines decision in respect of the renewal application (Section 24(5) of the MPRDA). Kroondal Operations (Pty) Ltd NW30/5/1/2/2/113MR 2,508.00 PGMs, (Gold, Nickel, Copper, Chrome in UG2) See the summary of permit conditions, general EMP regulatory reporting requirements and SLP regulatory reporting requirements. 16-Oct-22 A renewal application was submitted in July 2022, along with an updated MWP and SLP. An S102 application was also submitted for ministerial consent to exclude portions of the farm Kroondal 304 JQ from the mining right area. Both applications are still pending with the DMRE. The mining right will remain in force despite the expiry date until the DMRE makes a decision in respect of the renewal application (Section 24(5)) of the MPRDA Application for Ministerial consent to amend NW 30/5/1/2/2/113 MR to incorporate area covered by NW30/5/1/2/2/104 MR was submitted to the DMRE in February 2024. None. 23 Right Holder Right Number/s Size (ha) Minerals Key Permit Conditions Expiry date Future Requirements Future Intentions Brief summary of Violations/fines Kroondal Operations (Pty) Ltd NW30/5/1/2/2/368MR 265.92 PGMs See the summary of permit conditions, general EMP regulatory reporting requirements and SLP regulatory reporting requirements. 04-Mar-42 None. Kroondal Operations (Pty) Ltd NW30/5/1/2/2/369MR 409.21 PGMs See the summary of permit conditions, general EMP regulatory reporting requirements and SLP regulatory reporting requirements. 04-Mar-42 None. Kroondal Operations (Pty) Ltd NW30/5/1/2/2/370MR 32.55 PGMs See the summary of permit conditions, general EMP regulatory reporting requirements and SLP regulatory reporting requirements. 11-Mar-42 None.

24 KEY PERMIT CONDITIONS MINING Mining right renewal applications are to be submitted 60 working days prior to the date of expiry of the right. The holder of a mining right must continue with mining operations, failing which the right may be suspended or cancelled. The terms of the right may not be varied or amended without the consent of the Minister of the Department of Mineral Resources and Energy. The holder shall be entitled to abandon or relinquish the right or the area covered by the right entirely or in part. Upon abandonment or relinquishment, the holder must: o Furnish the Regional Manager with all prospecting and/or mining results and/or information, as well as the general evaluation of the geological, geophysical and borehole data in respect of such abandoned area; and o Apply for a closure certificate in terms of section 43(3) of the MPRDA. The holder shall pay royalties to the State in accordance with section 25(2)g of the MPRDA throughout the duration of the mining right. Mining Operations must be conducted in accordance with the Mining Work Programme (MWP) and any amendment to the MWP and an approved Environmental Management Plan (EMP). The holder shall not trespass or enter into any homestead, house or its curtilage nor interfere with or prejudice the interests of the occupiers and/or owners of the surface of the Mining Area except to the extent to which such interference or prejudice is necessary for the purposes of t enabling the holder to properly exercise the holder’s rights under the mining right. The holder must dispose of all minerals derived from mining at competitive market prices which shall mean in all cases, non-discriminatory prices, or non-export parity prices. A shareholding, an equity, an interest or participation in the mining right or joint venture, or a controlling interest in a company/JV may not be encumbered, ceded, transferred, mortgaged, let, sublet, assigned, alienated or otherwise disposed of without the written consent of the Minister, except in the case of a change of controlling interest in listed companies. All boreholes, shafts, adits, excavations, and openings created by the holder shall be sealed, closed, fenced, and made safe in accordance with the approved Environmental Management Programme and the Mine Health and Safety Act. The holder of the mining right, while carrying out mining operations, should safeguard and protect the environment, the mining area and any person using to entitled to use the surface of the mining area for possible damage or injury. The Minister or a person authorized by the Minister shall be entitled to inspect the Mining Area and execution of the approved mining right conditions. A mining right may be cancelled or suspended subject to S47 of the MPRDA if the holder: 25 o Submits inaccurate, incorrect and/or misleading information in connection with any matter required to be submitted under this Act; o Fails to honour or carry out any agreement, arrangement or undertaking, including the undertaking made by the Holder in terms of the Broad-Based Socio-Economic Empowerment Charter and Social and Labour Plan; o Breaches any material term and condition of the mining right; o Conducts mining in contravention of the MPRDA; o Contravenes the requirements of the approved Environmental Management Programme; o Contravenes any provisions of this Act in any other manner. The holder shall submit monthly returns contemplated in S 28 (2) A of the MPRDA no later than the 15th of every month and maintain all such books, plans, and records in regard to mining on the mining area as may be required by the Act. The Holder shall, at the end of each year, following the commencement of this mining right, inform the Regional Manager in writing of any new developments and of the future mining activities planned in connection with the exploitation/mining of the minerals in the mining area. Provisions relating to section 2(d) and section 2(f) of the MPRDA, relating to the Broad-Based Socio- Economic Empowerment Charter, differ in each mining right. The Mining right does not exempt the holder from complying with the Mine Health and Safety Act or any Act in South Africa. Annually, no later than three months before the financial year end, submit a detailed implementation plan to give effect to Regulation 46(e)(i), (ii) and (iii) in line with the Social and Labour Plan. Annually, no later than three months after the finalization of its audited annual report, submit a detailed report on the implementation of the previous year’s SLP. SOCIAL AND LABOUR PLANS COMPLIANCE REQUIREMENTS New Social and Labour Plan to be submitted and reviewed every 5 years. Social and Labour Plan Implementation Plans to be submitted annually. Social and Labour Plan Annual Report to be submitted annually. ENVIRONMENTAL MANAGEMENT COMPLIANCE REQUIREMENTS Performance assessment relating to the Environmental Management Programme to be conducted Bi-annually. Performance assessment relating to Water Use License to be conducted annually. Performance assessment relating to Atmospheric Emission License to be conducted annually.

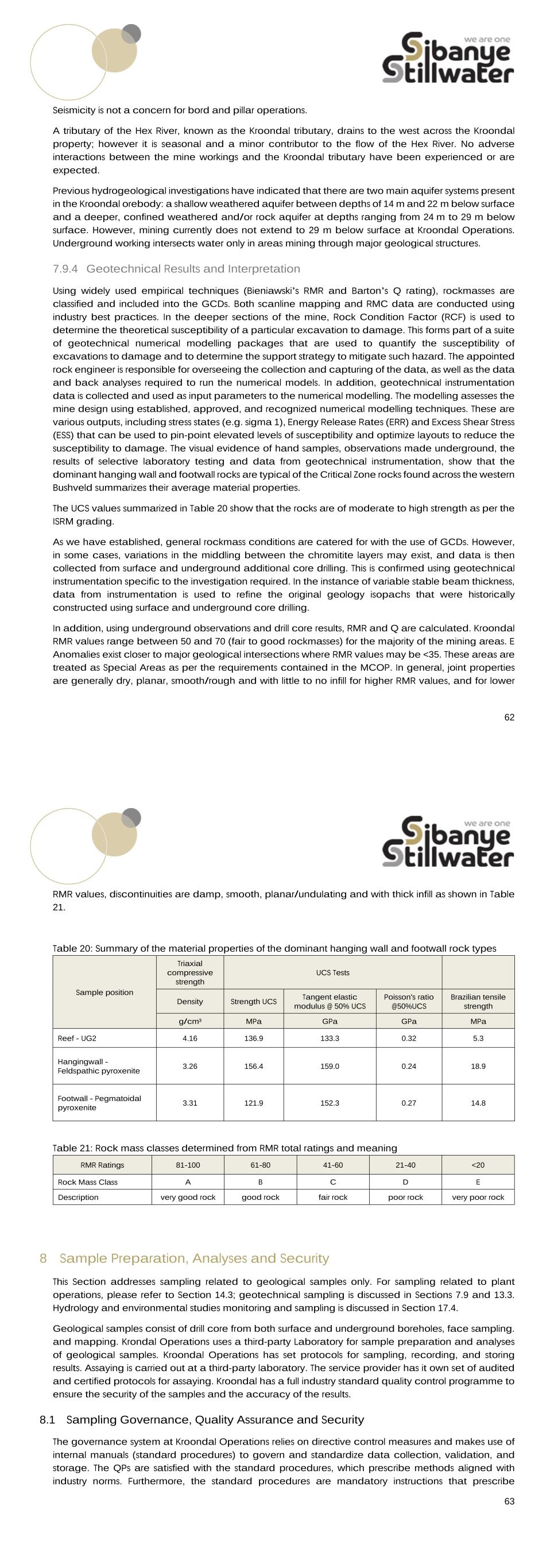

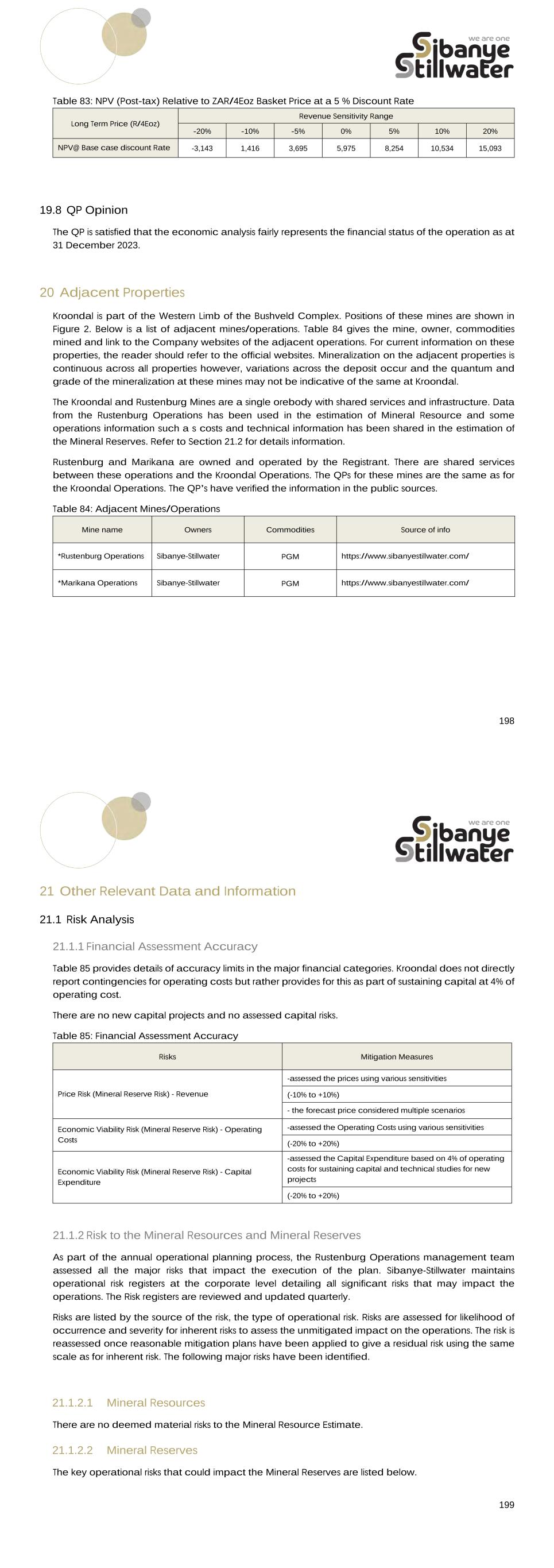

26 Figure 3: Plan Showing Kroondal Mineral Right and Shafts 27 Table 12: Mining Rights Status for the Kroondal Operations (NW 104, 113, 368, 369, 370, 80) Farm Name Farm Portion Magisterial District Kroondal 304 Portions 2,4,6,8,9,10,22,23,24,25,25,21, Portion 83 Portion 84 RE Portion 85 Portion 99 Portion 85 Portion 95 Portion 93 Portion 91 RE Portion 92 RE Portion 94 Portion 151 (a Portion of Portion 94) Portion 158 Portion 129 (a Portion of Portion 85) Portion 157 (a Portion of Portion 85) Portion 52 Rustenburg 3.3 Royalties Sibanye-Stillwater Kroondal Operations is not a royalty company, nor does it receive royalties from any other operation. 3.4 Legal Proceedings and Significant Encumbrances to the Property The QPs have been advised by Sibanye-Stillwater that there are no material legal proceedings in relation to the Kroondal Operations. It should, however, be noted that Sibanye-Stillwater may be involved in various non-material legal matters such as employment claims, third-party subpoenas, and collection matters on an ongoing basis, which are not material to the Mineral Resources and Mineral Reserves for the Kroondal Operations reported in this TRS. From the documentation reviewed and input by the relevant Technical Specialists and Experts, the QPs could not identify any significant encumbrances or any other significant factors or risks with regard to the title permitting, access, surface ownership, environmental and community factors that would prevent the mining or the ability to perform work on the Kroondal Operations, and the declaration and disclosure of the Mineral Resources and Mineral Reserves for the Kroondal Operations. The Kroondal Operations comply with all title and environmental permitting requirements of the RSA.

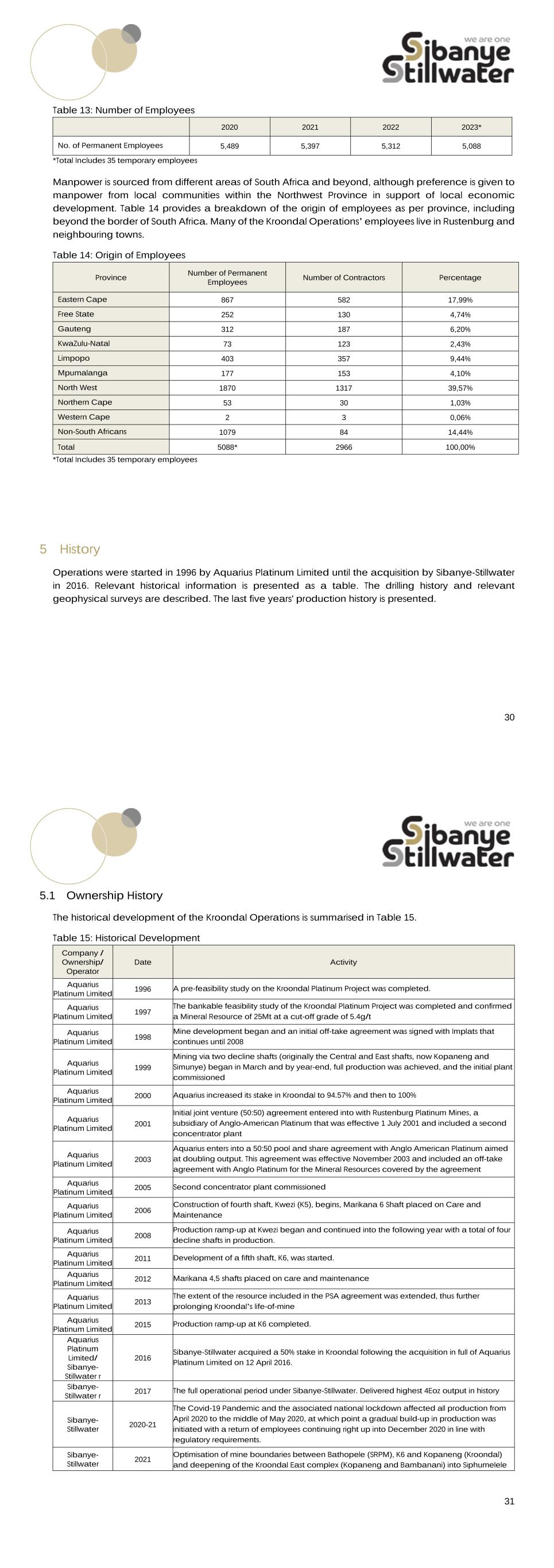

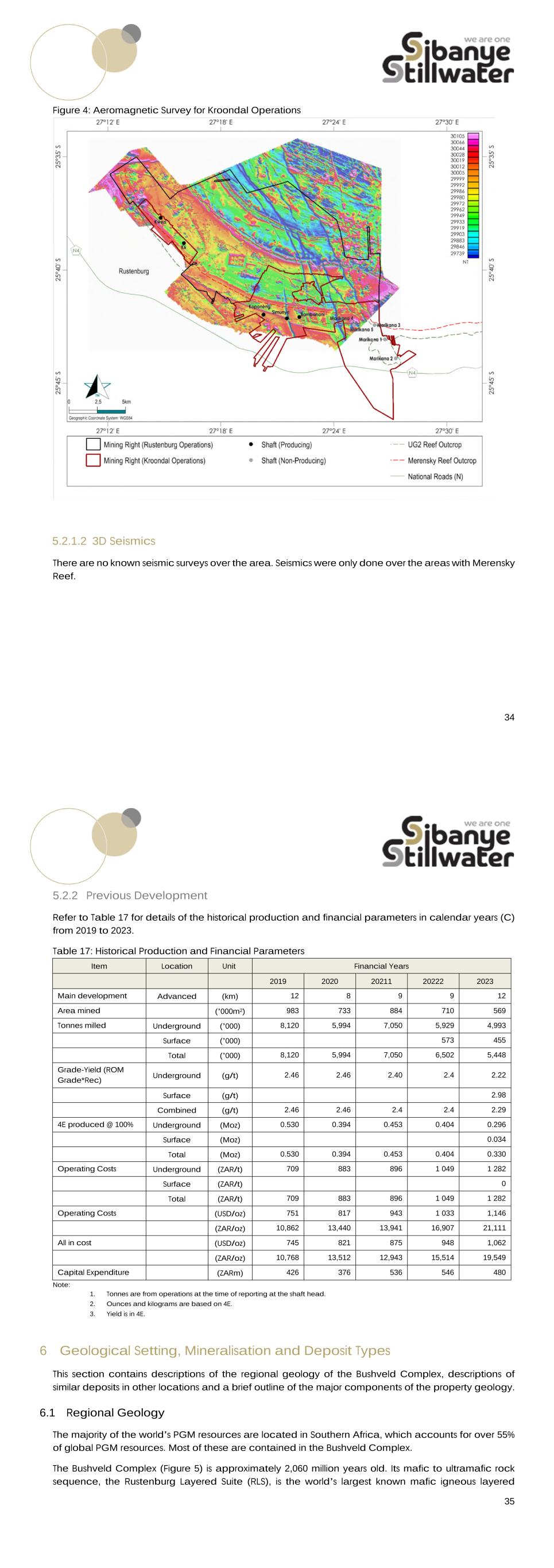

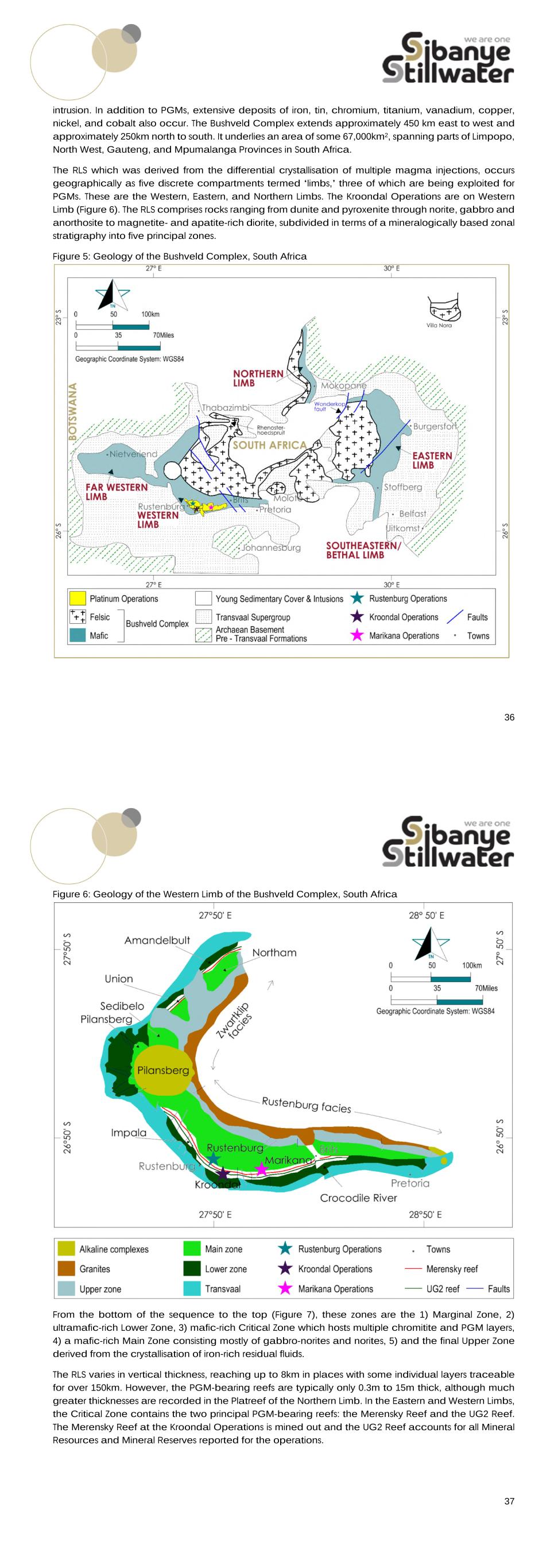

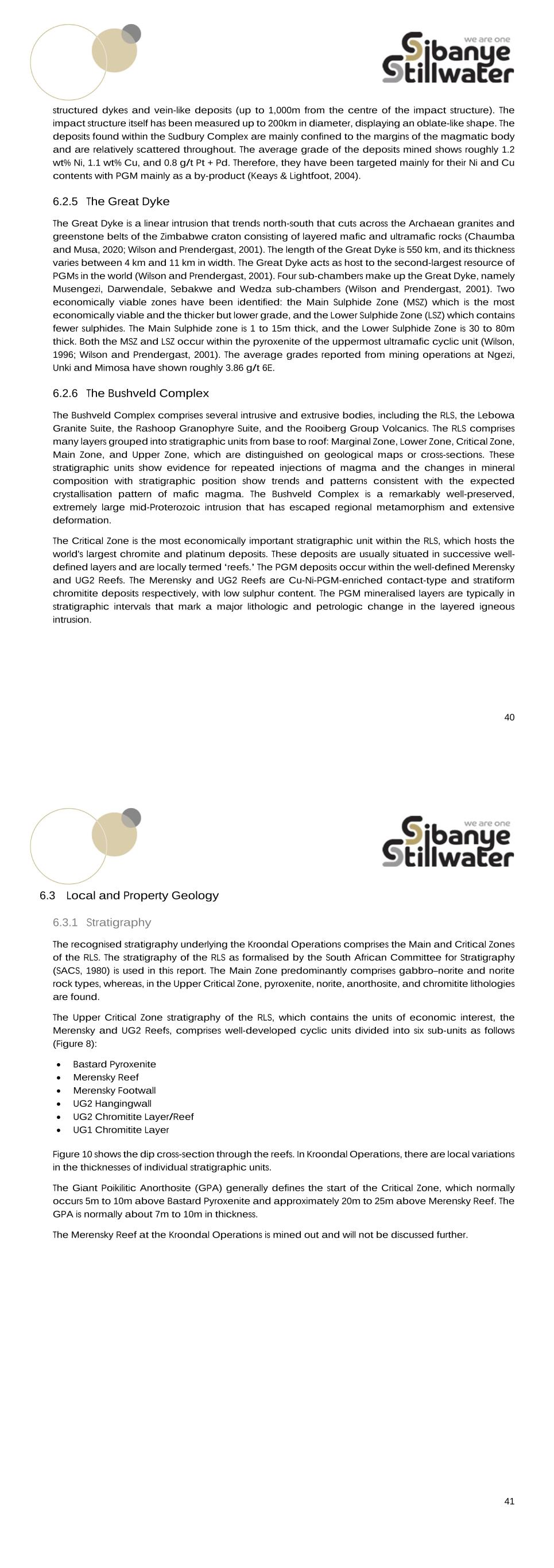

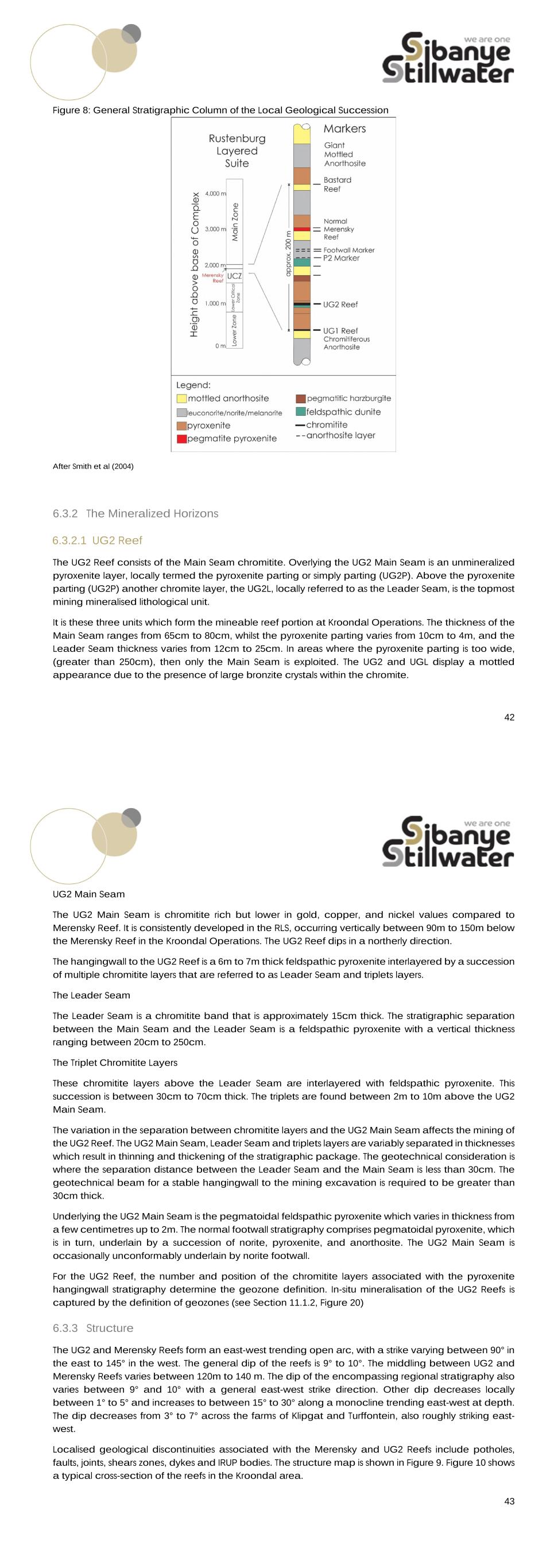

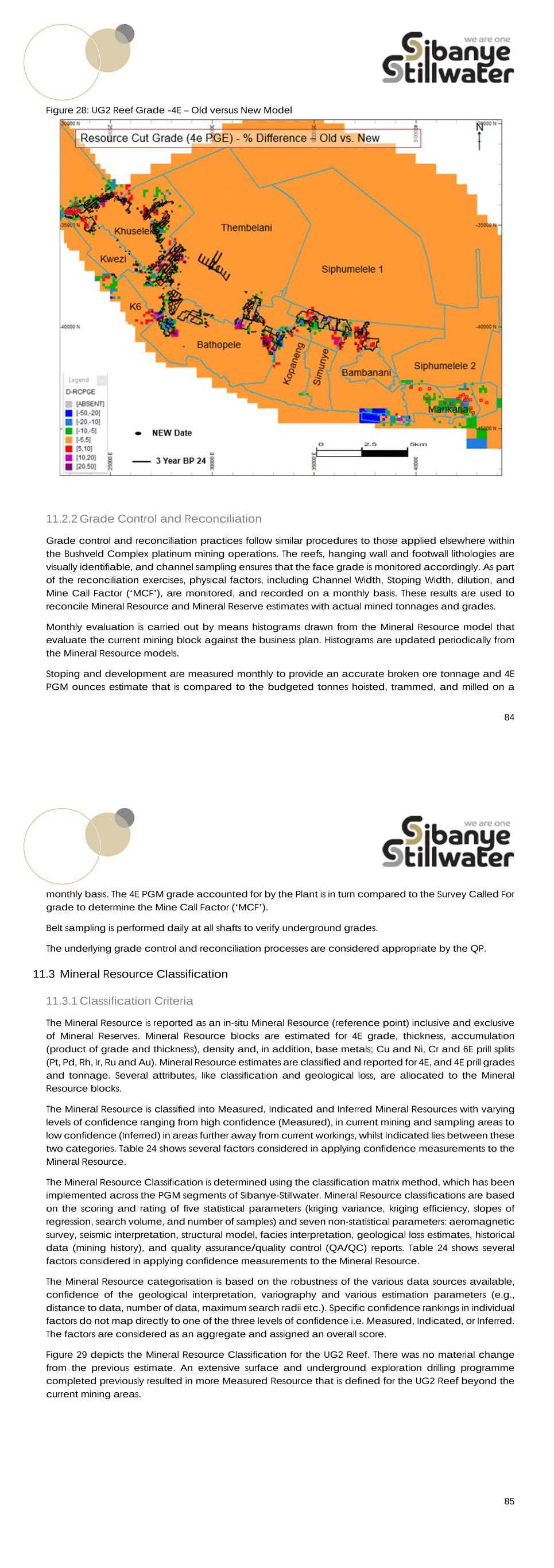

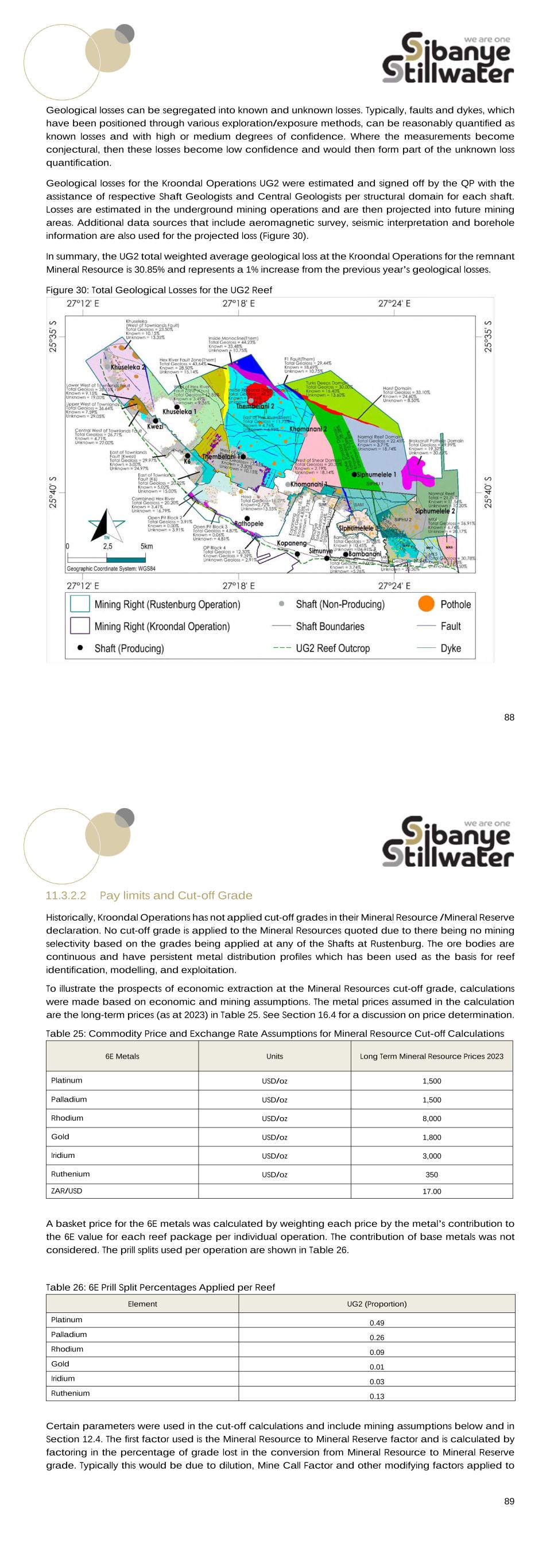

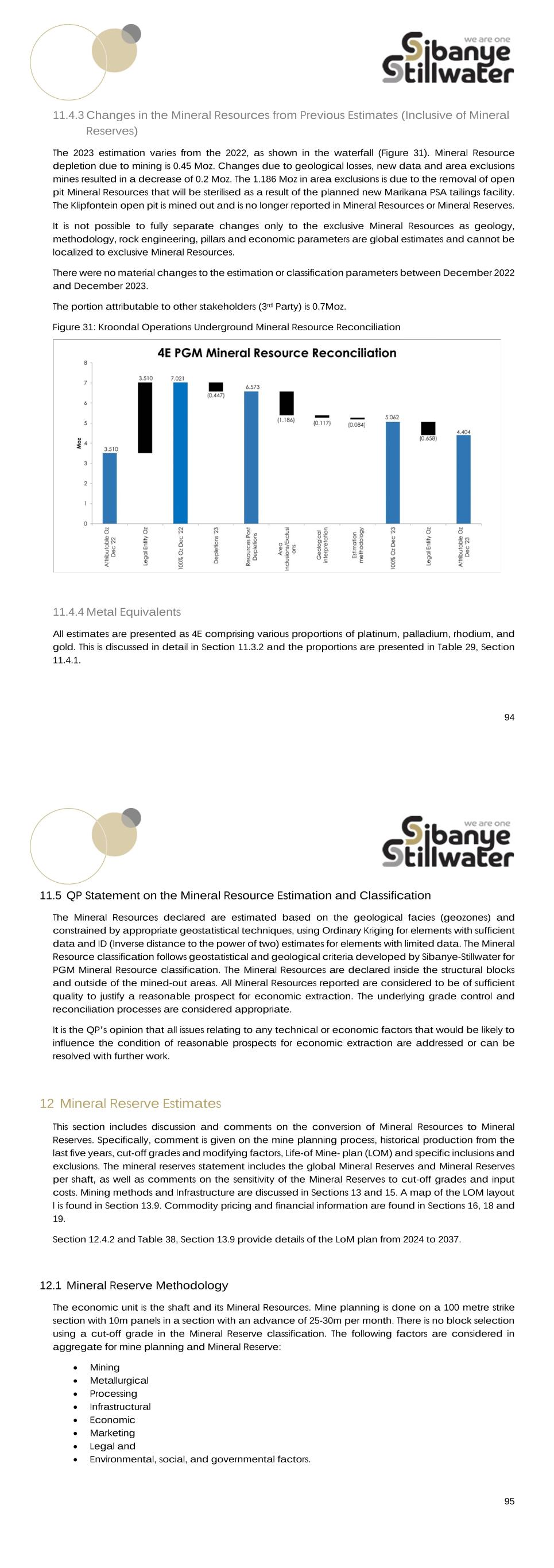

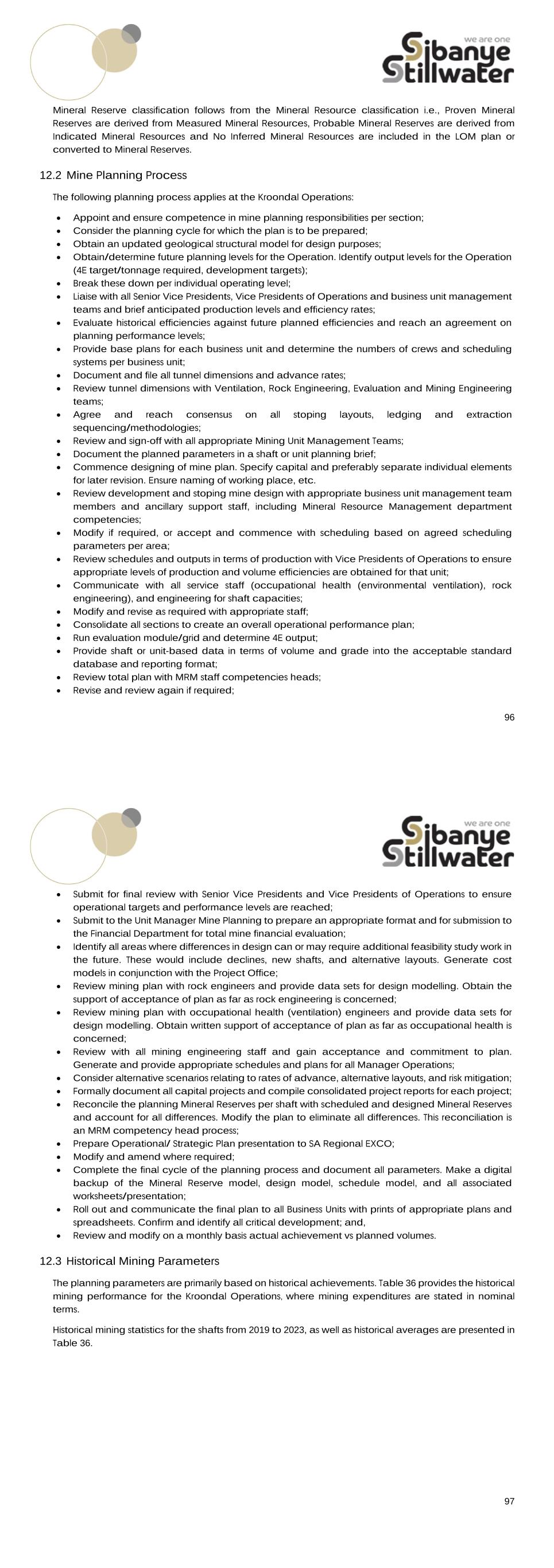

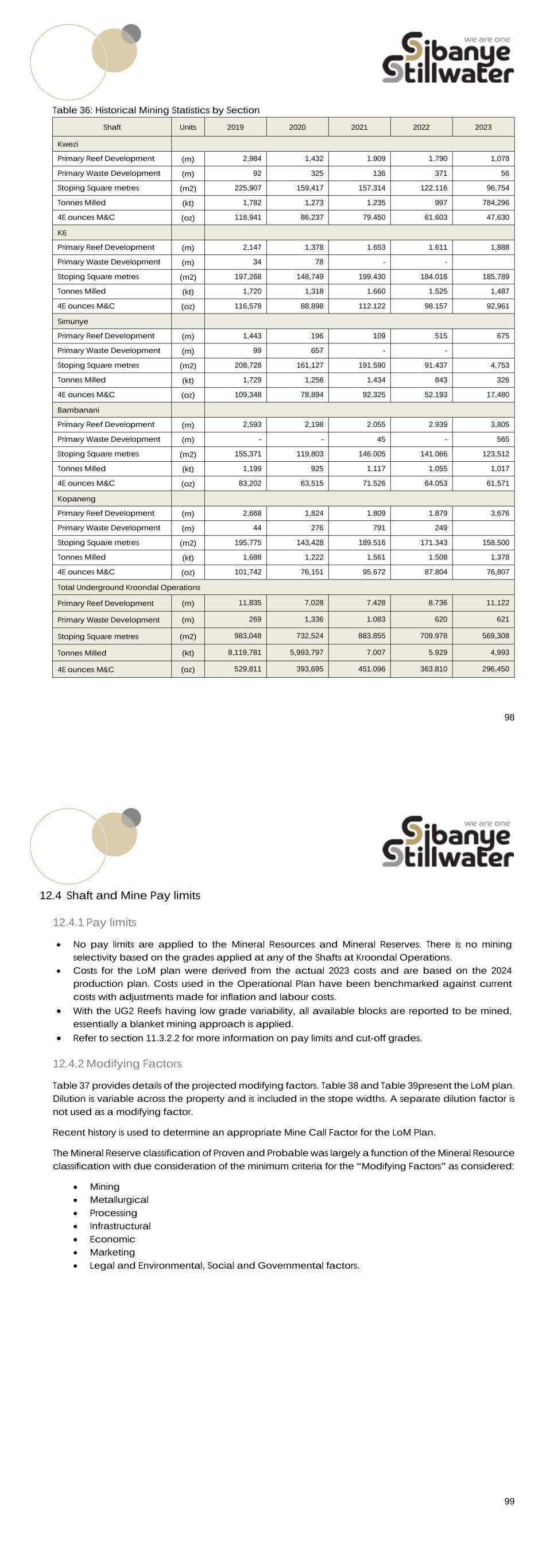

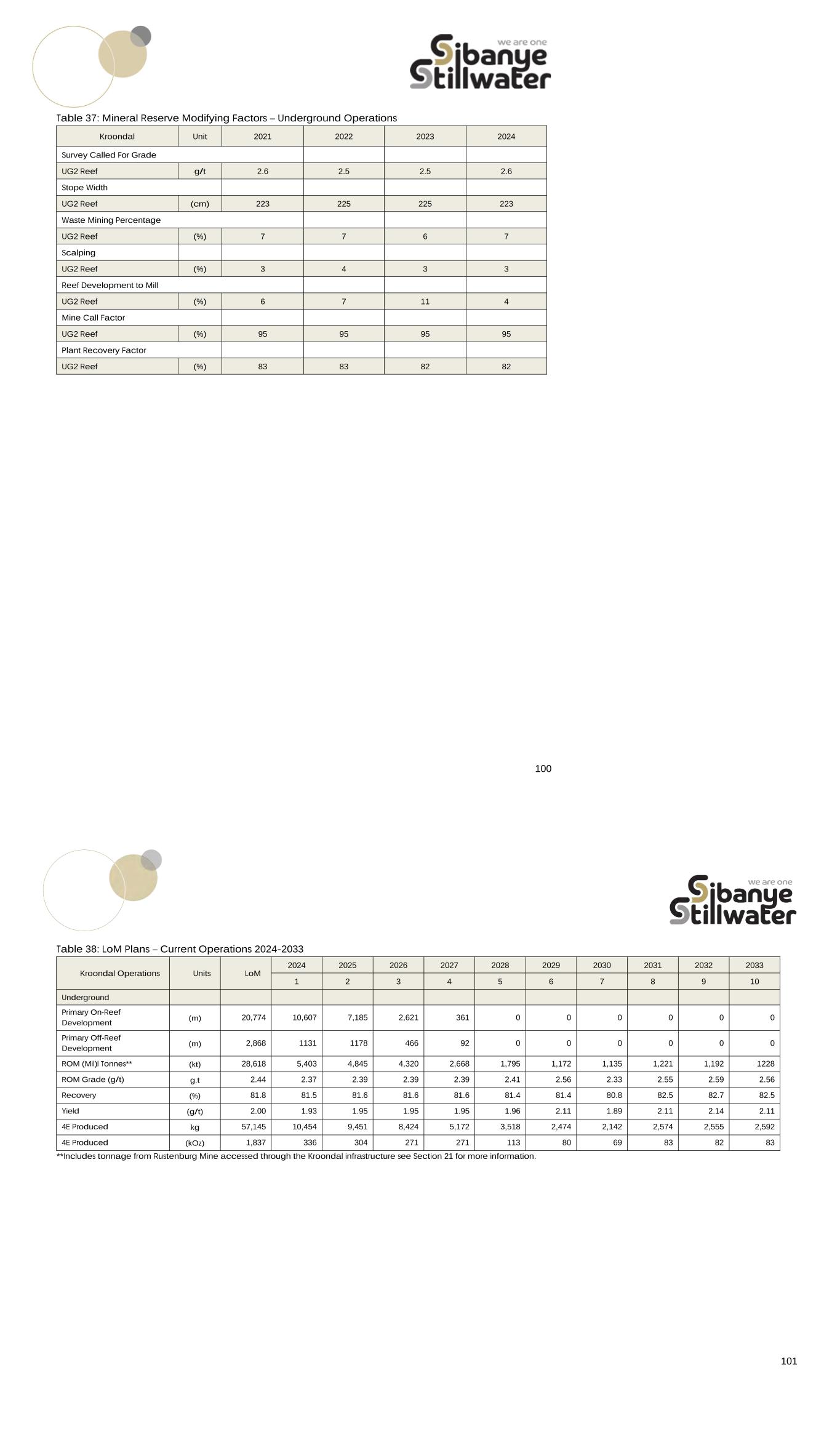

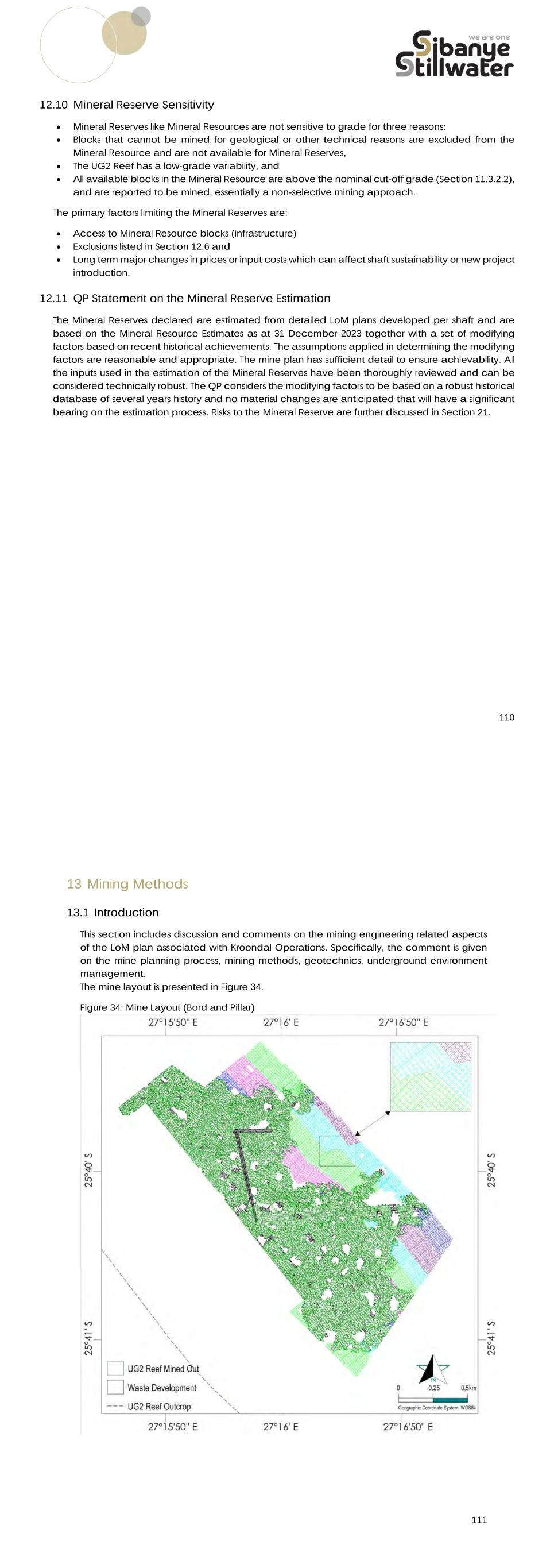

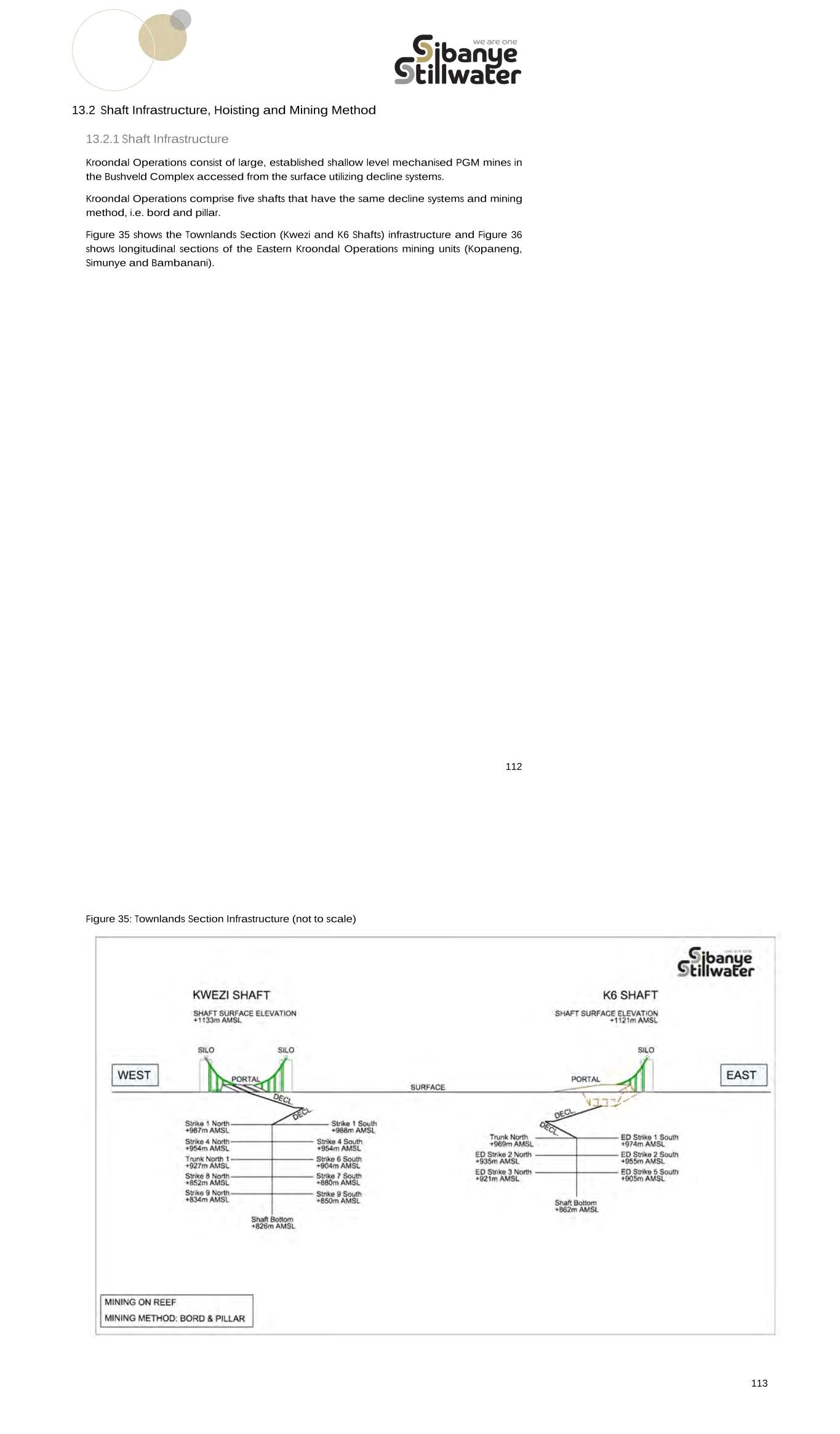

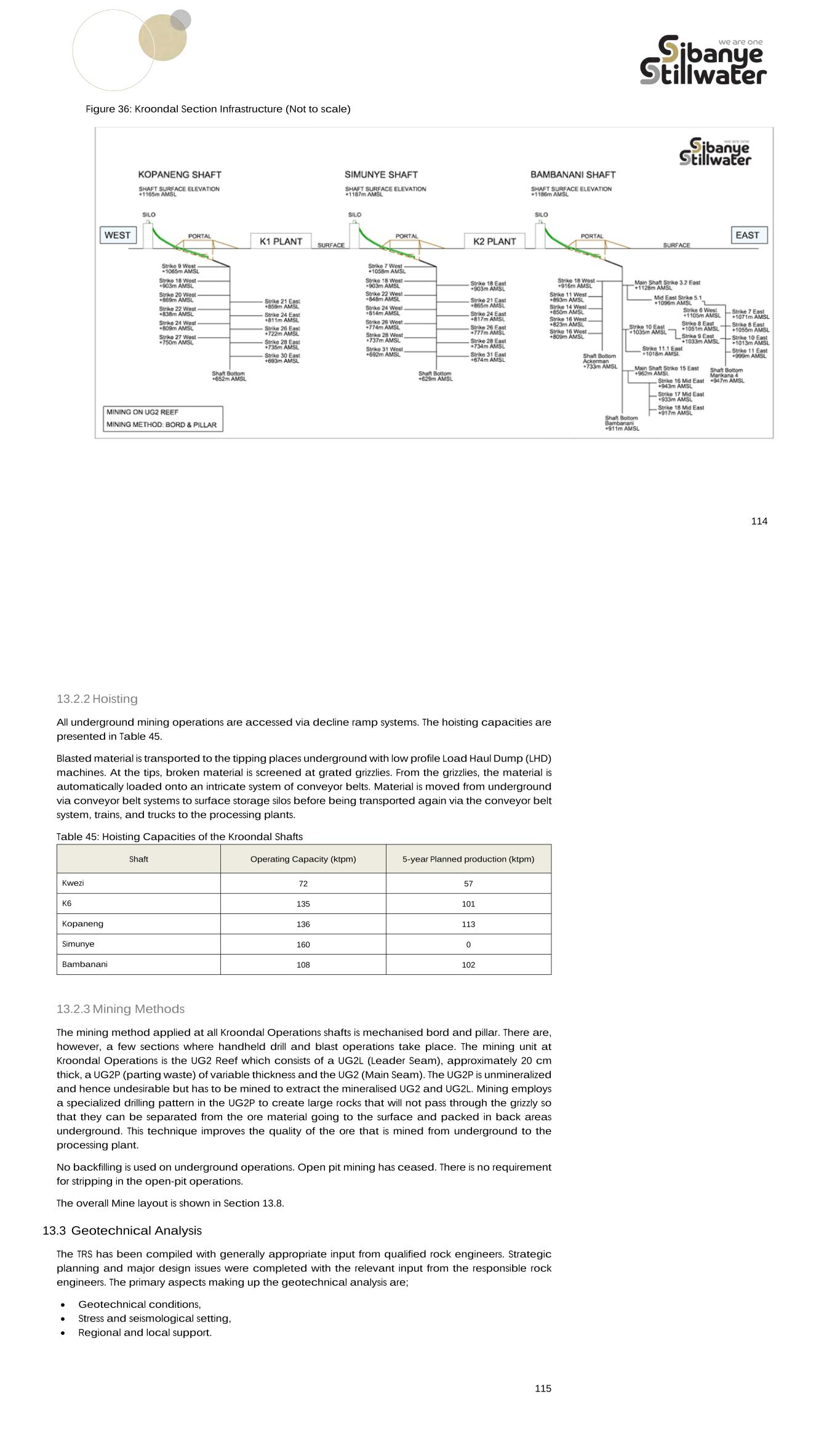

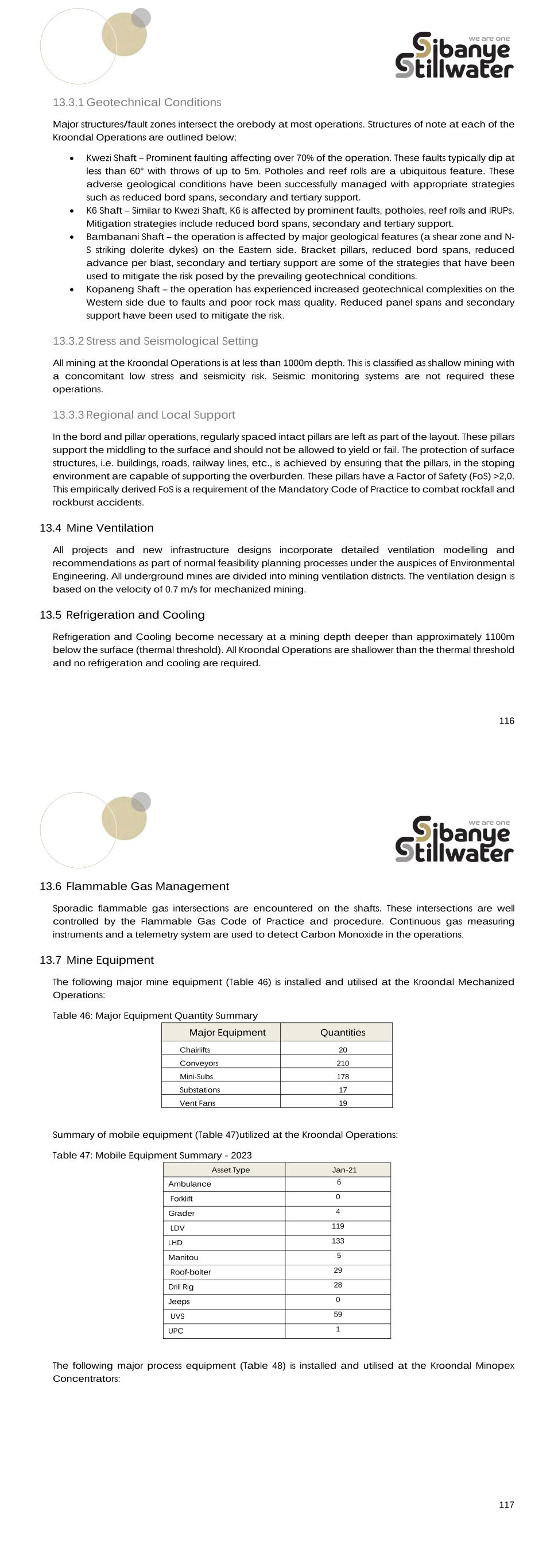

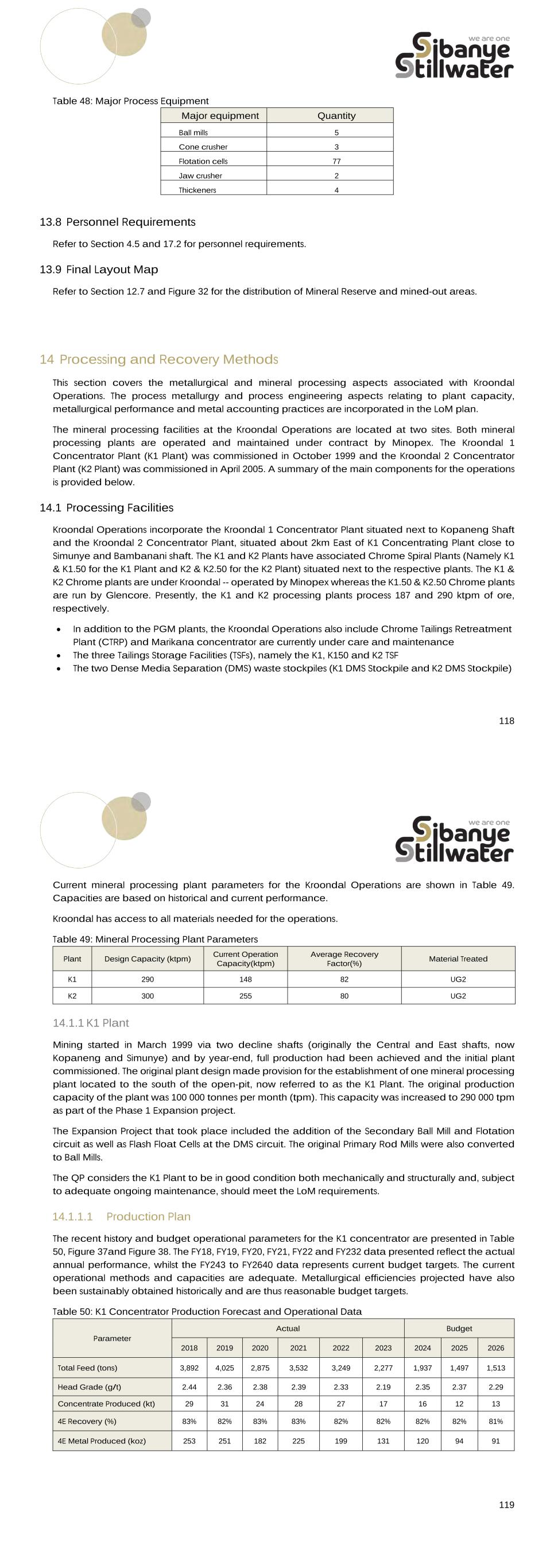

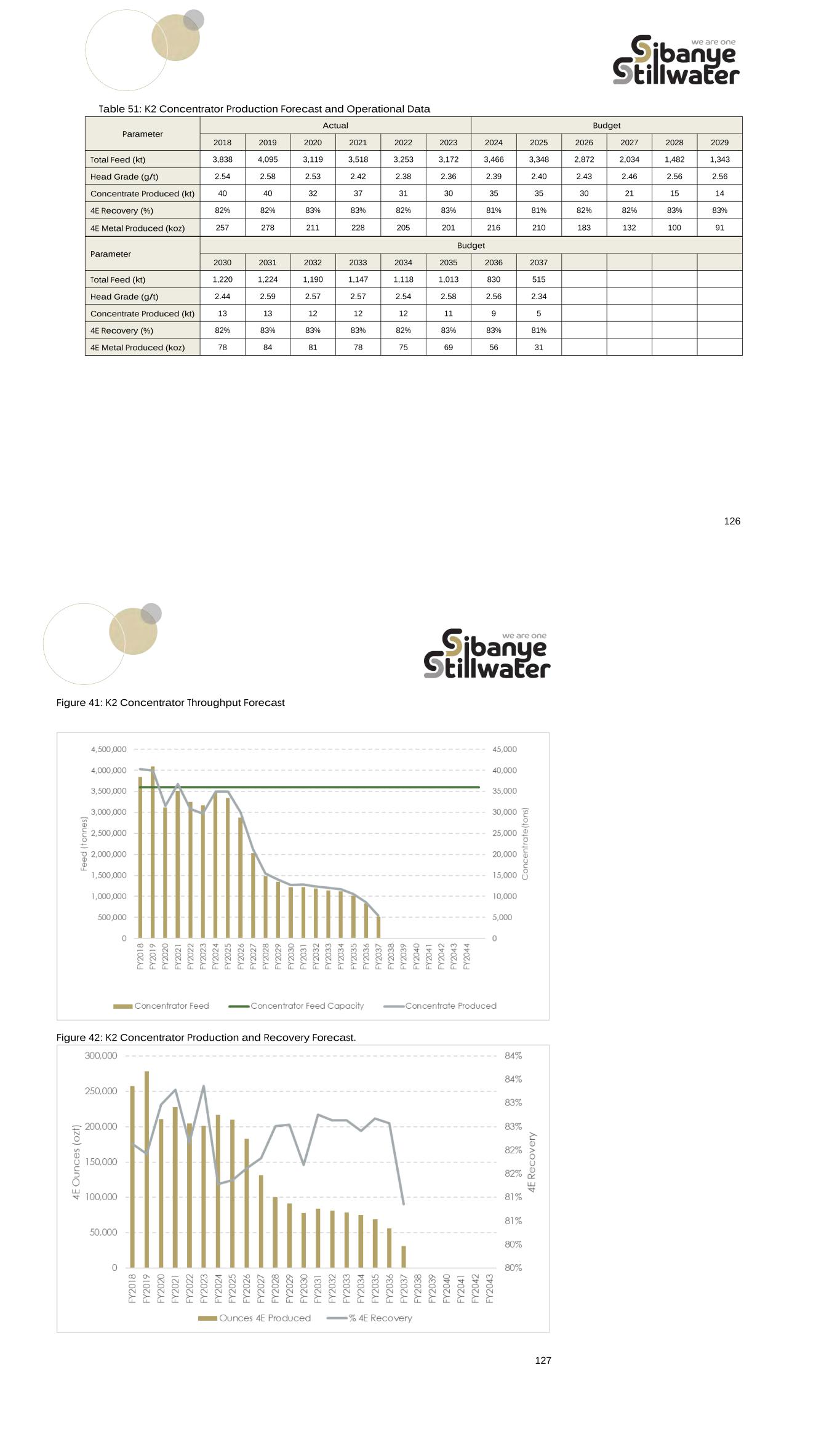

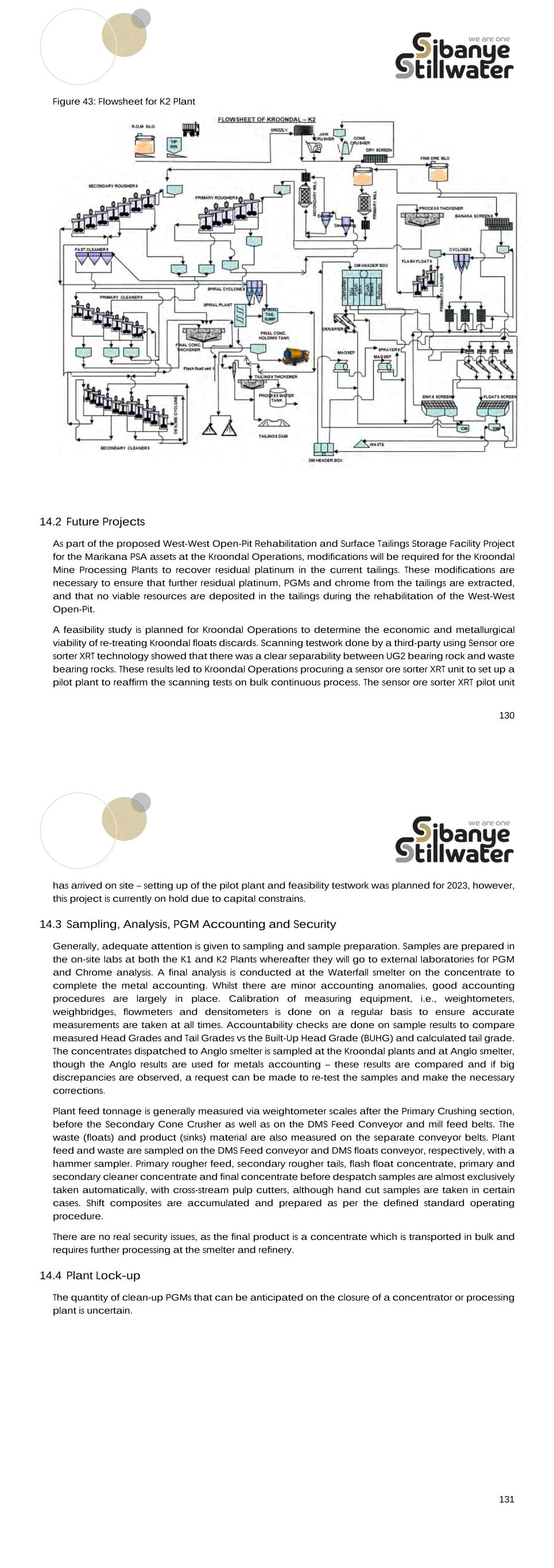

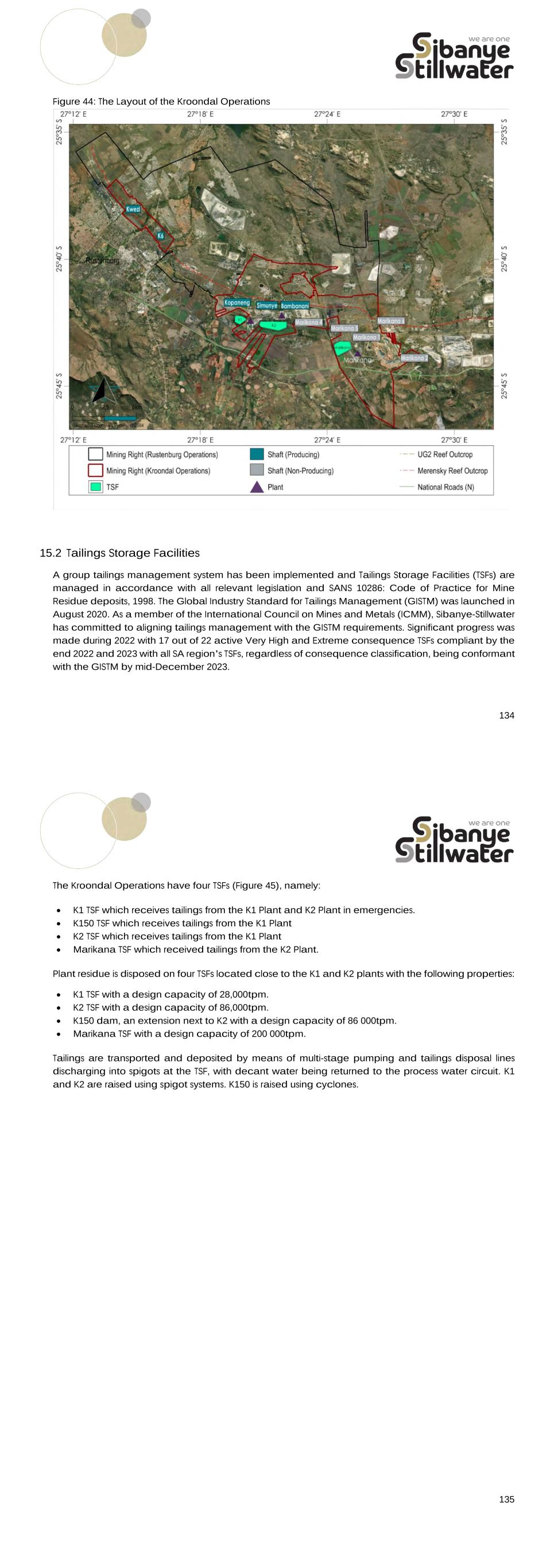

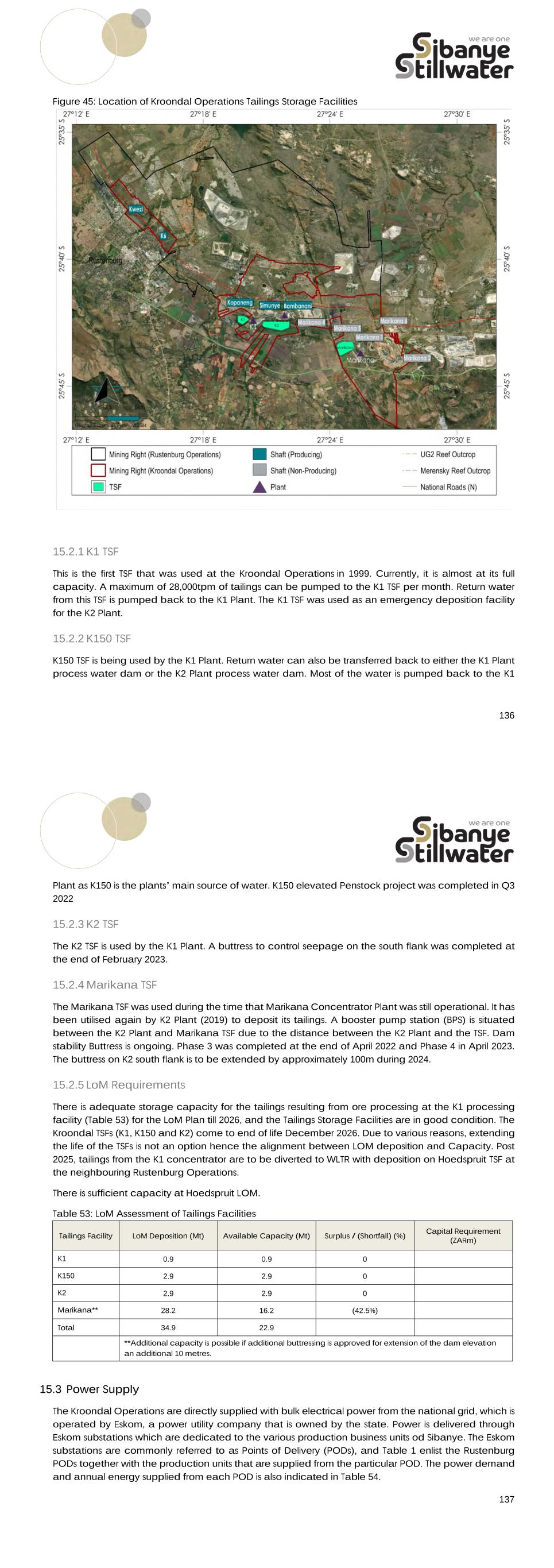

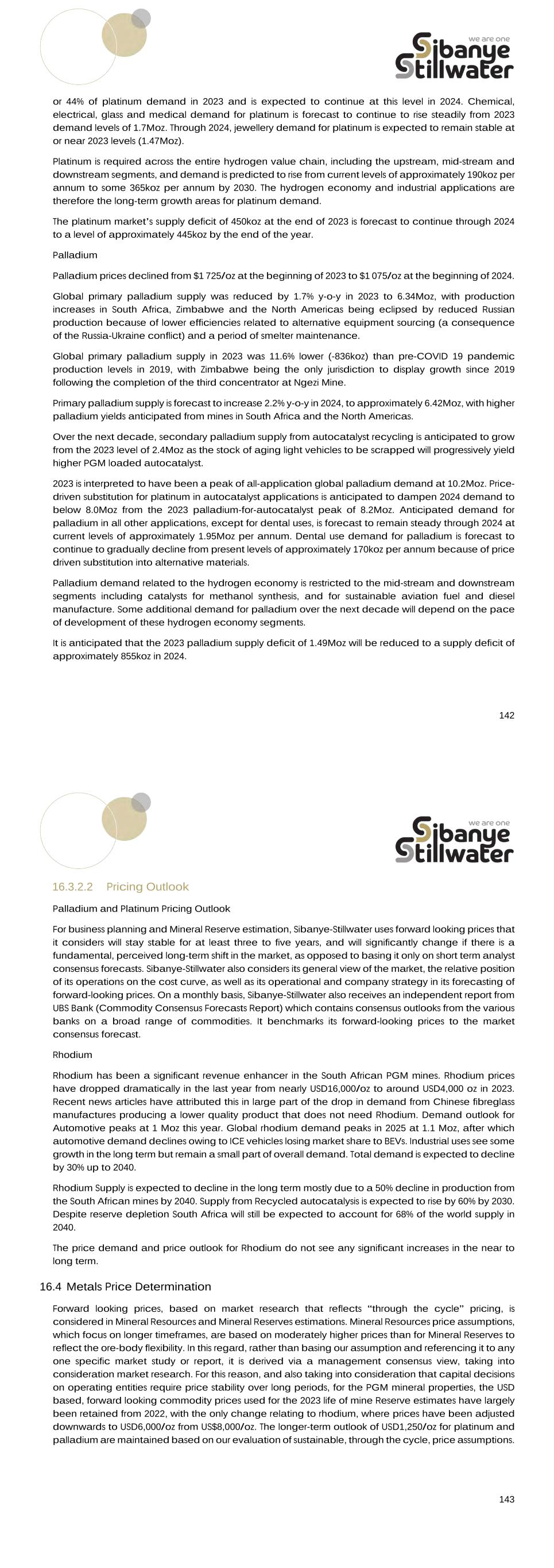

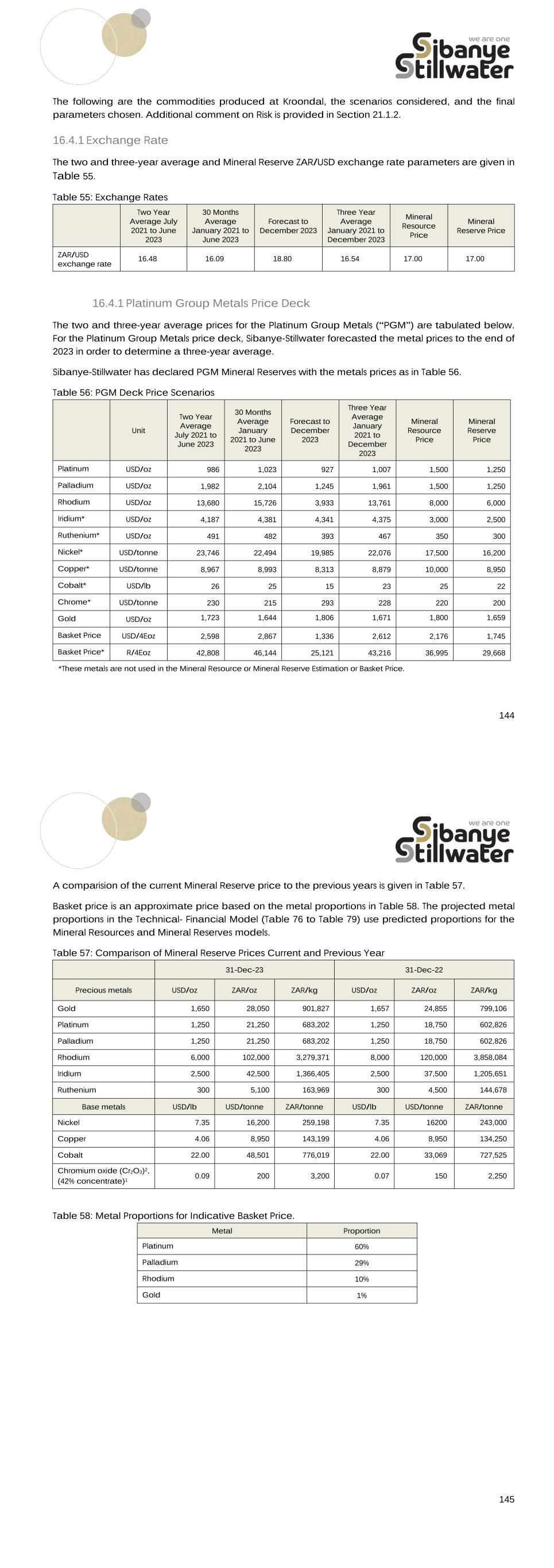

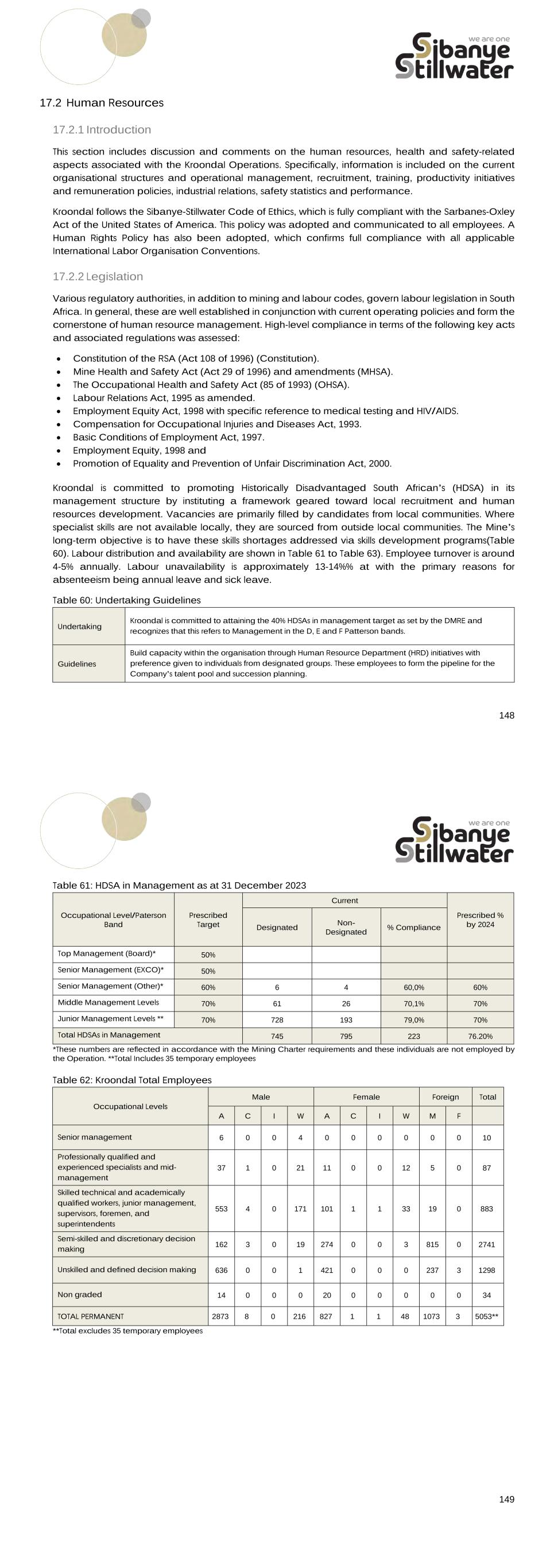

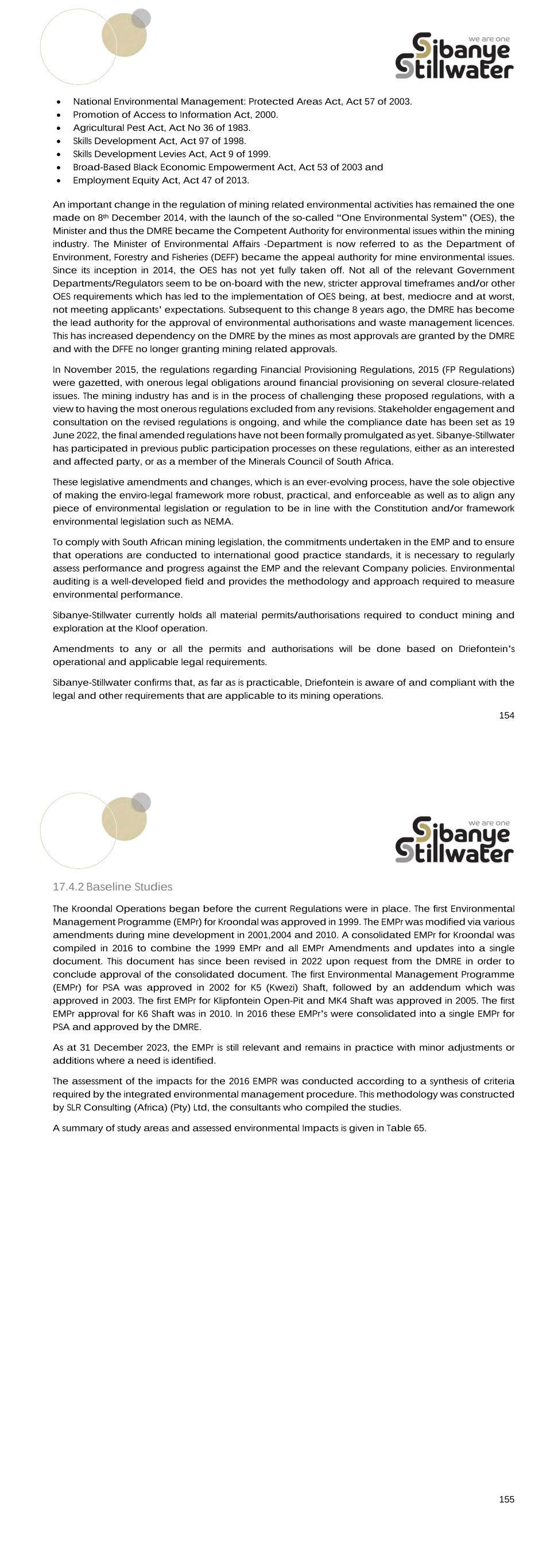

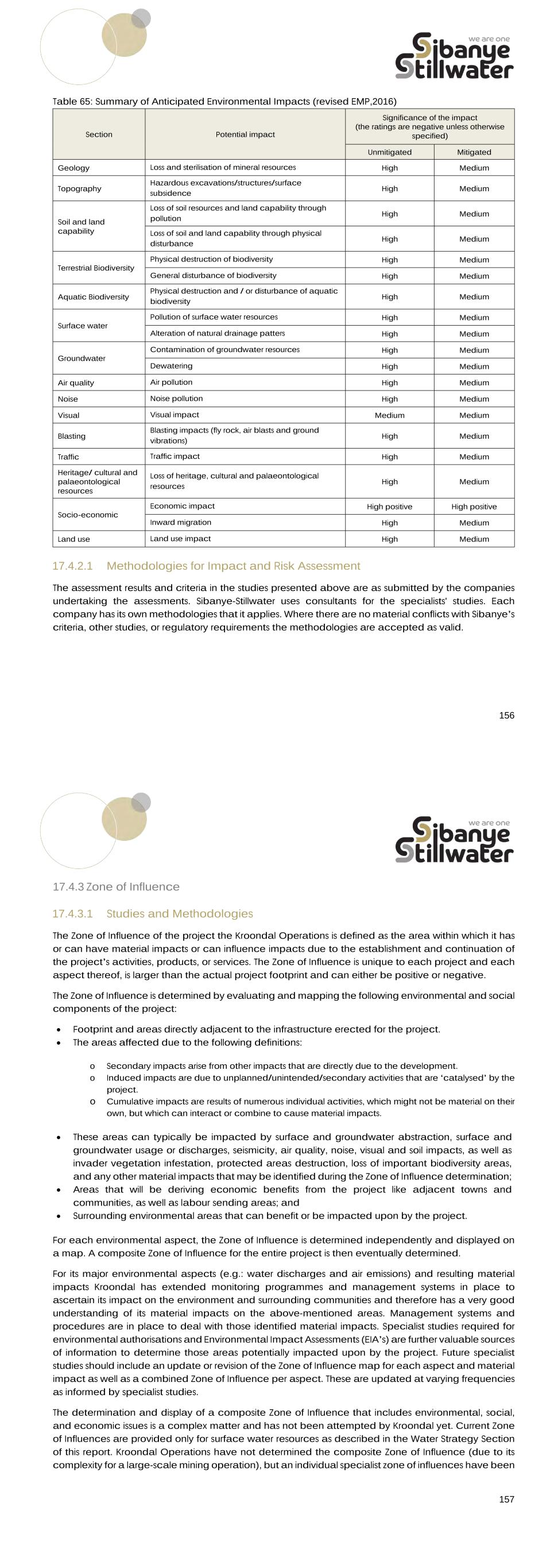

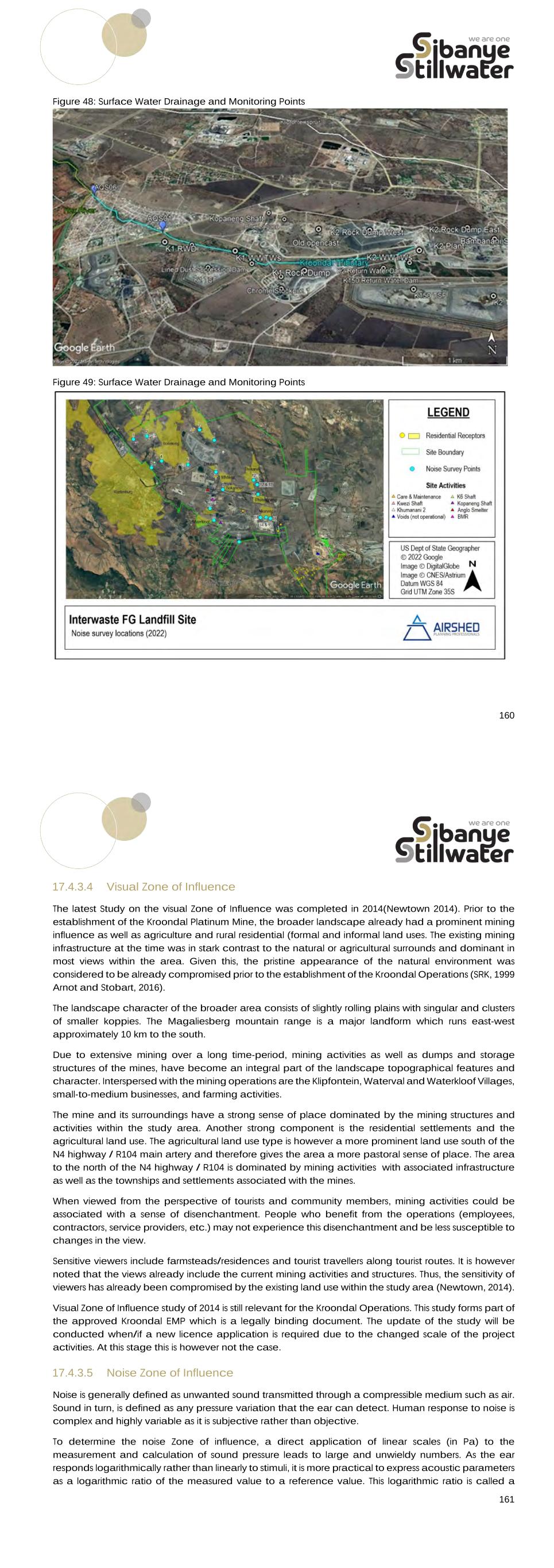

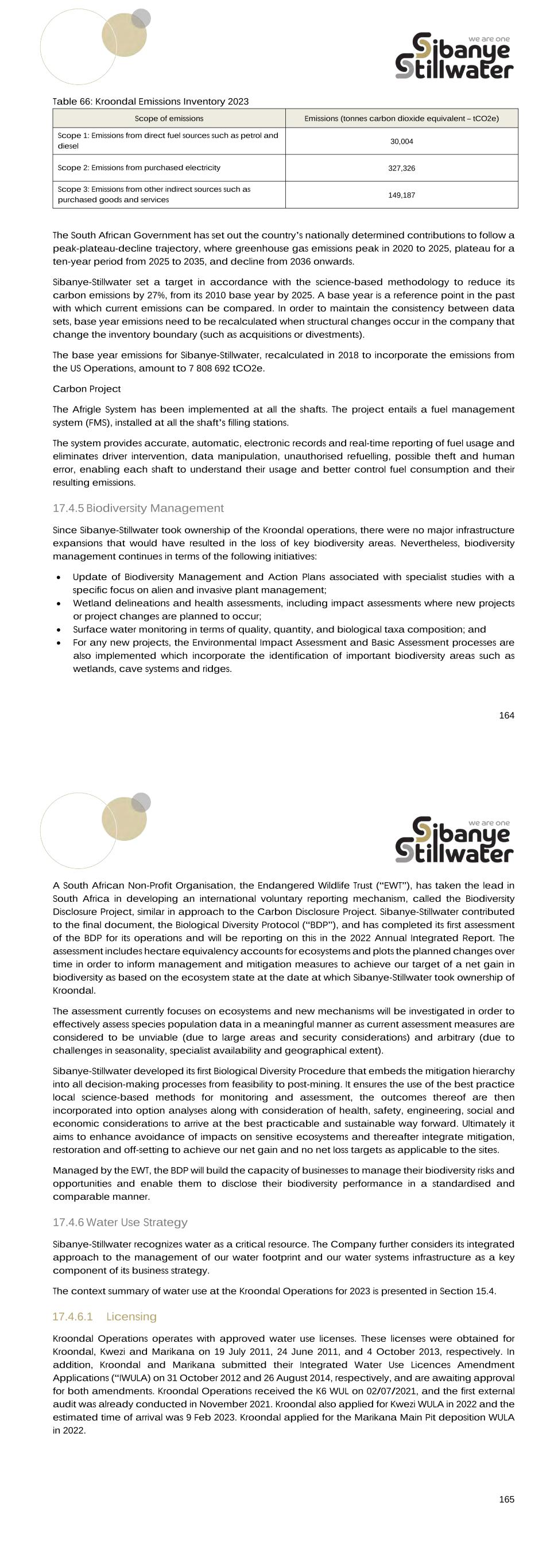

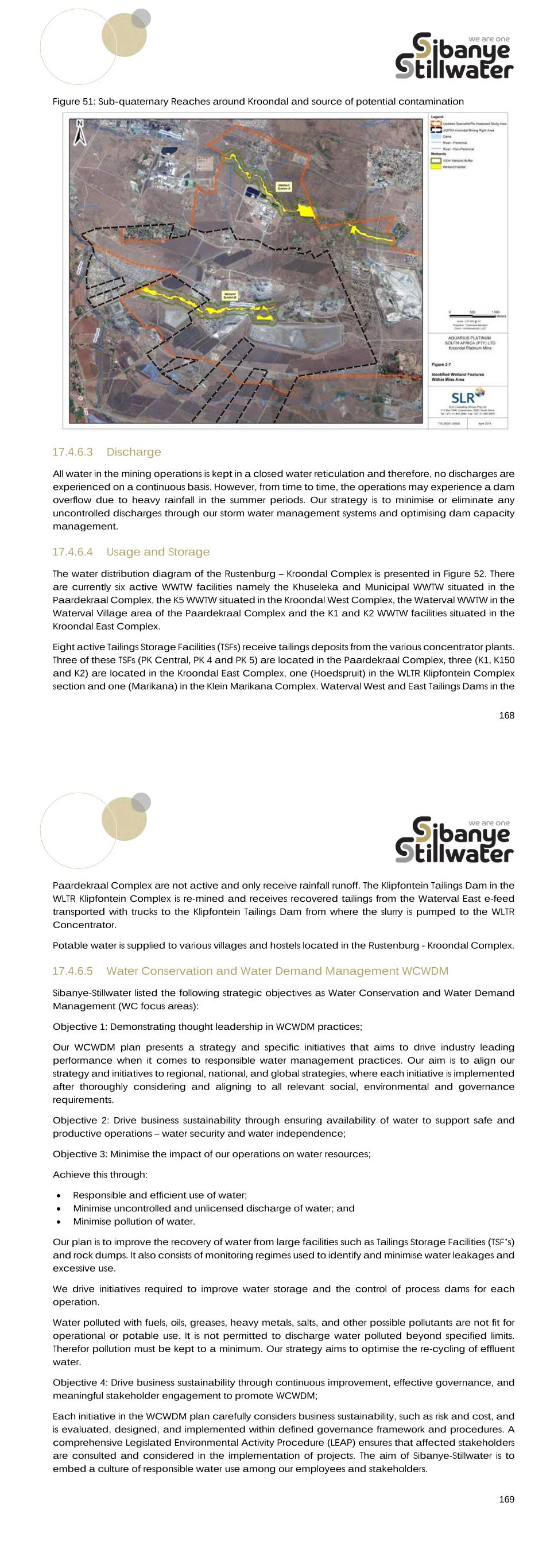

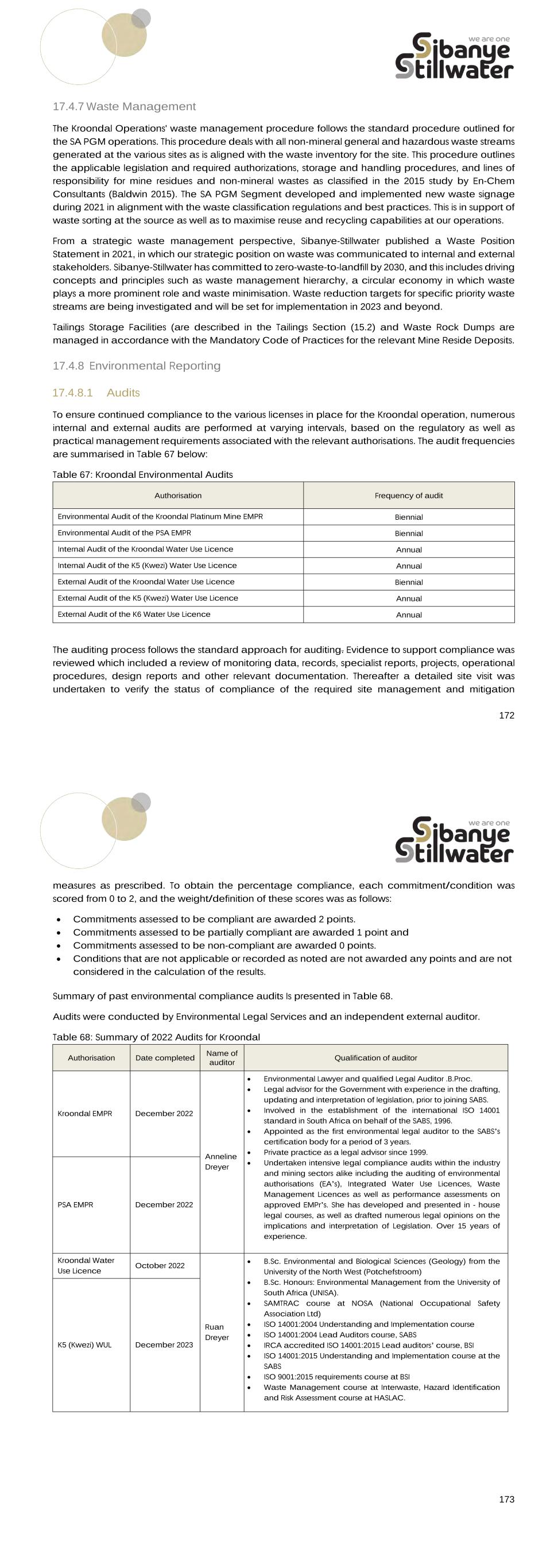

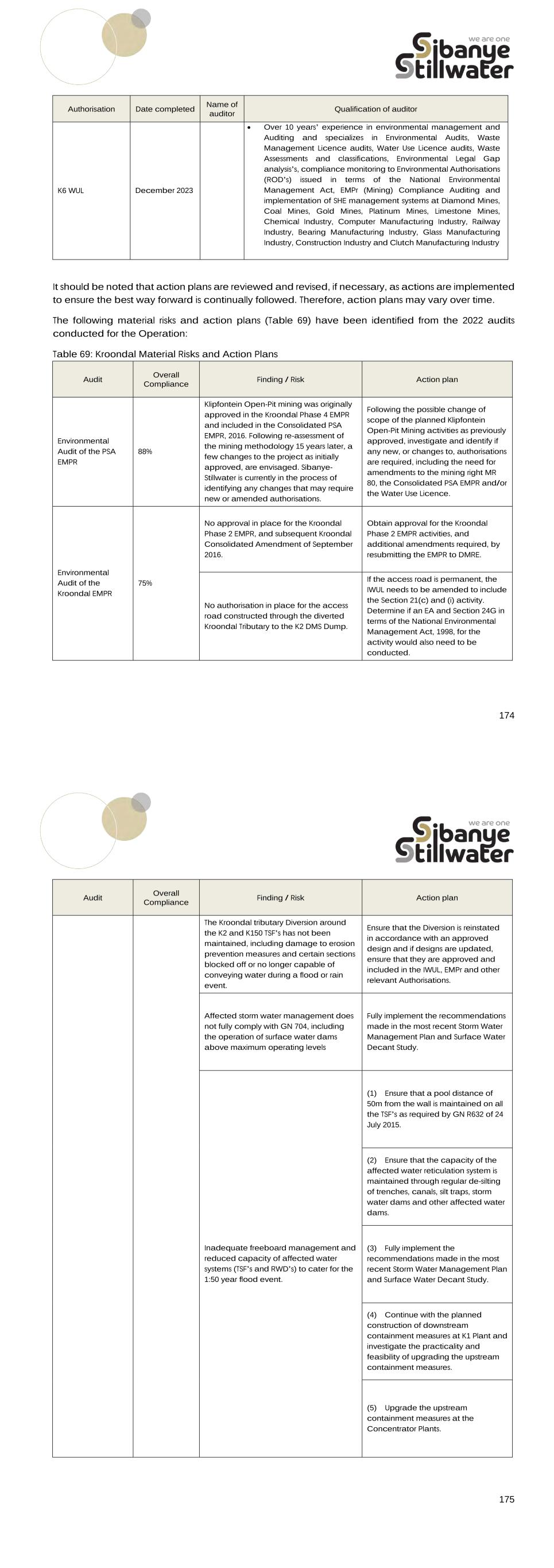

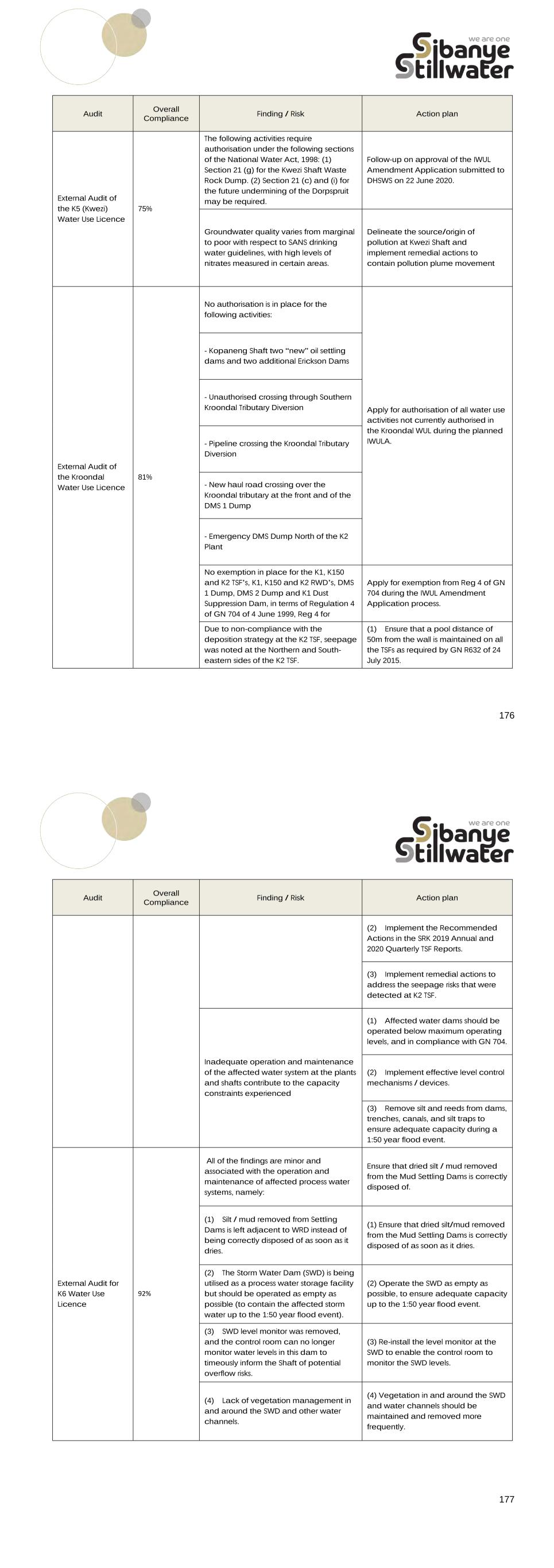

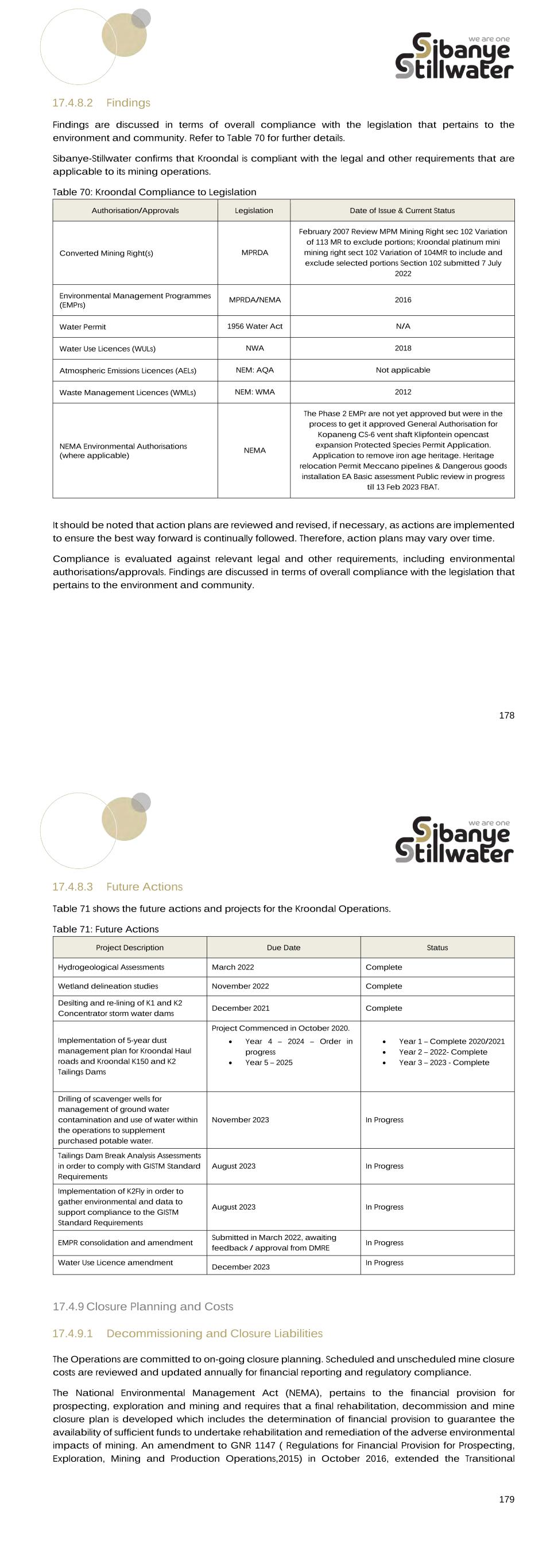

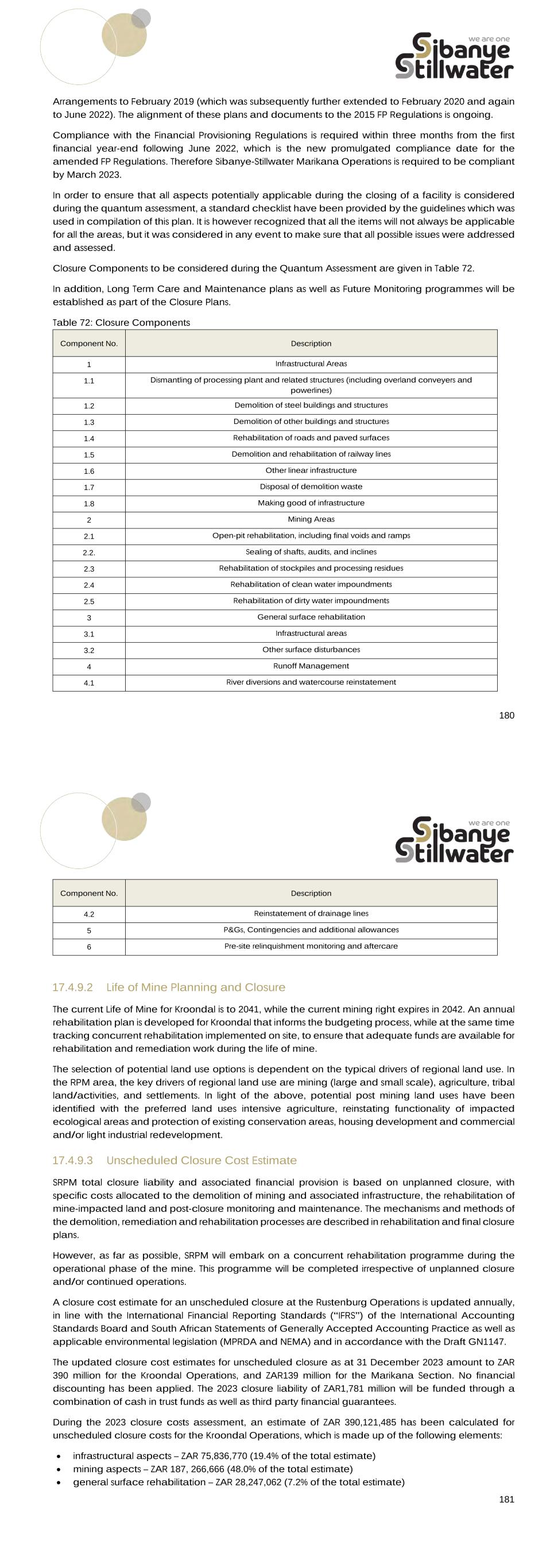

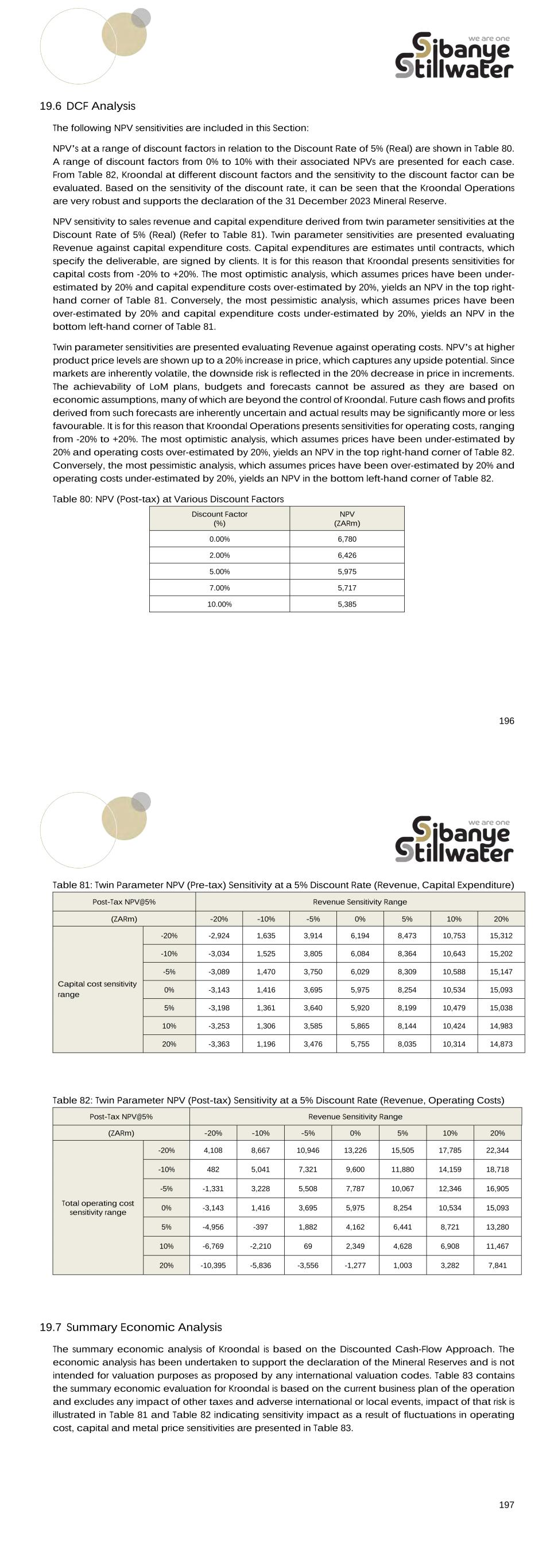

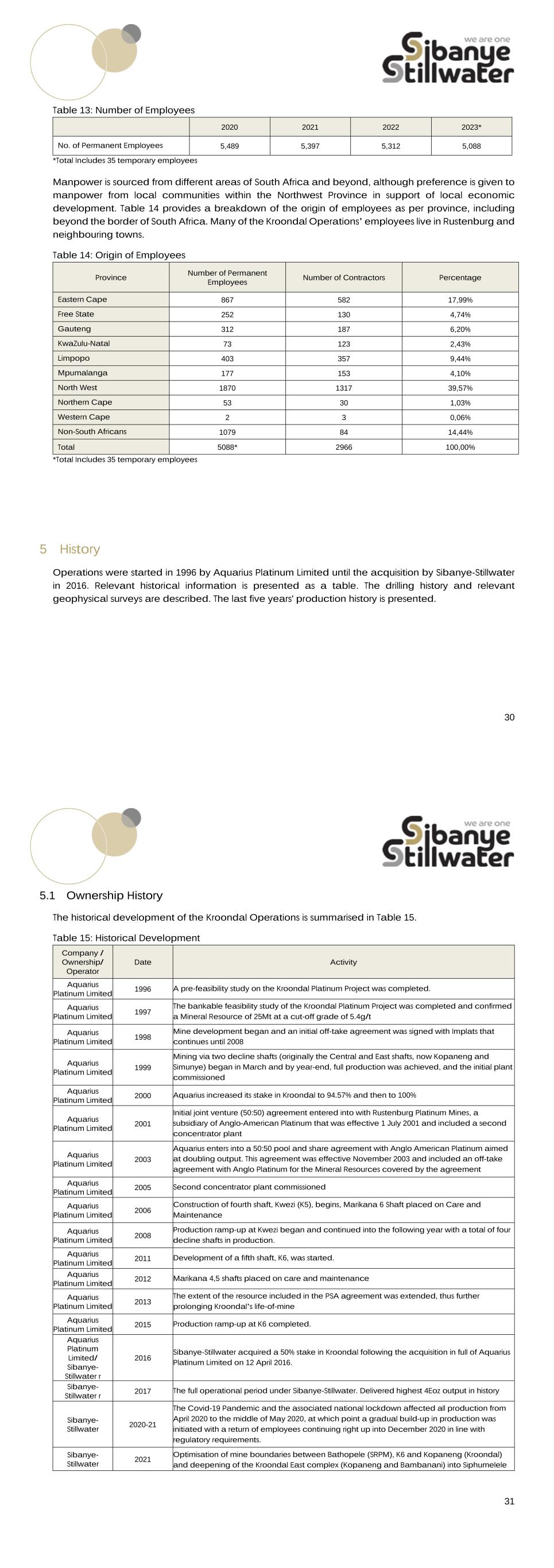

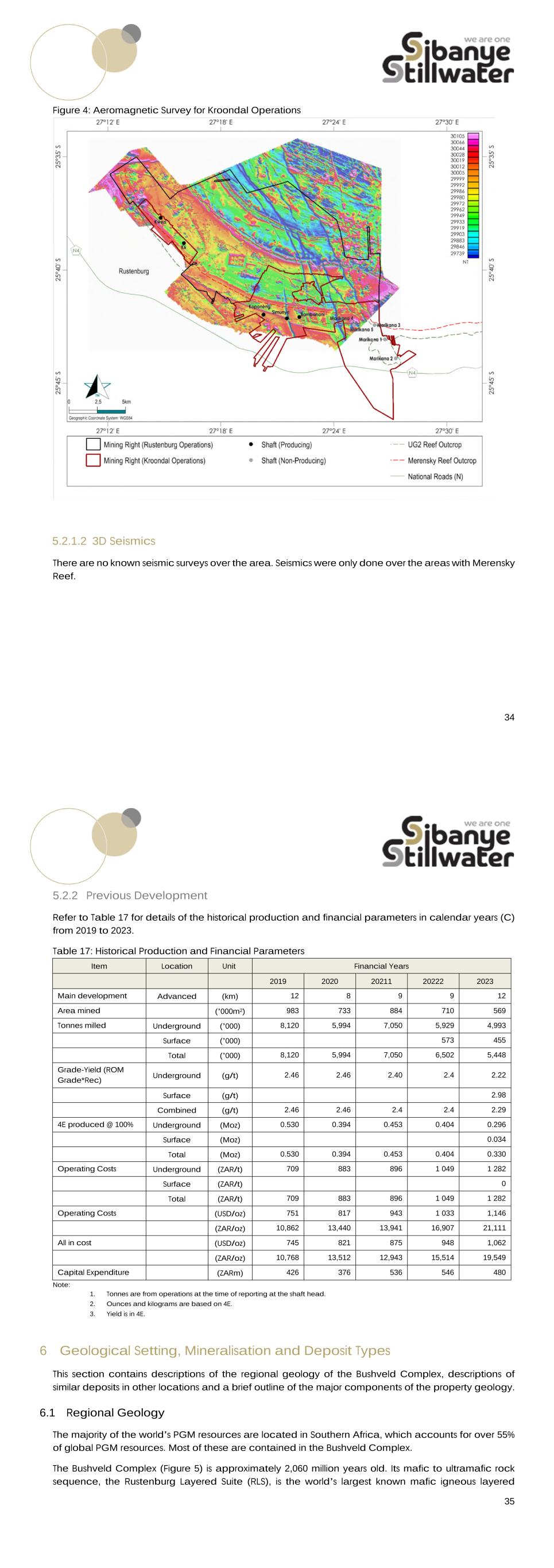

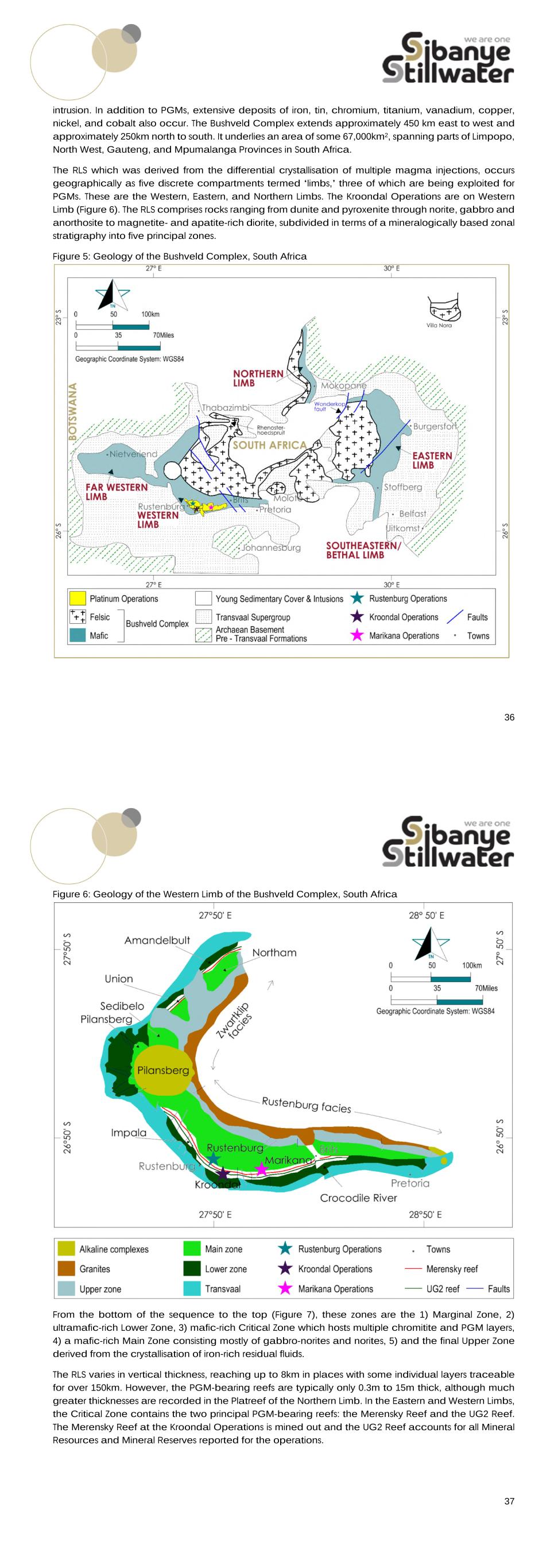

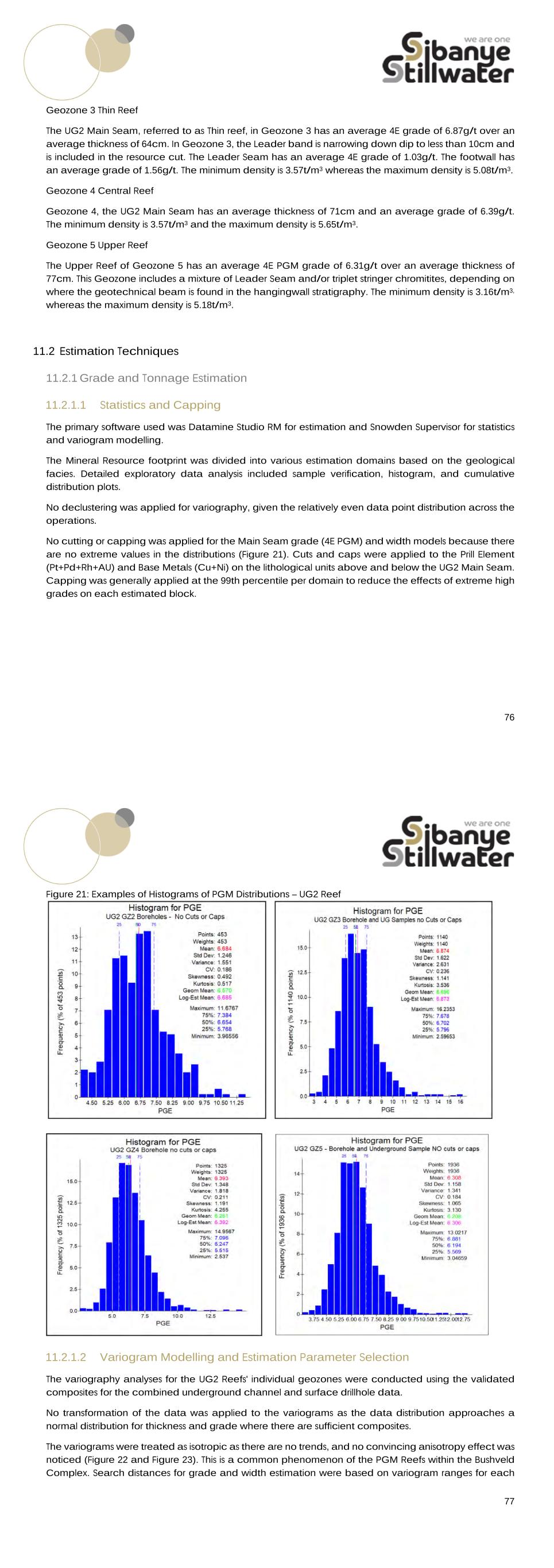

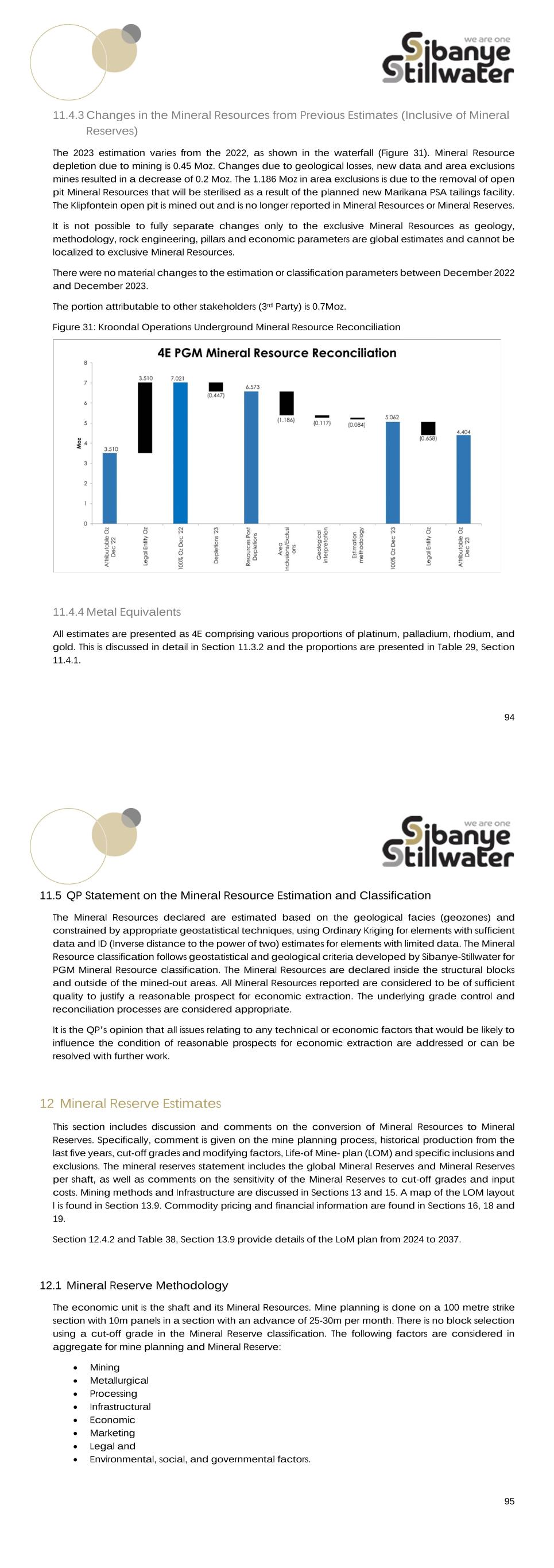

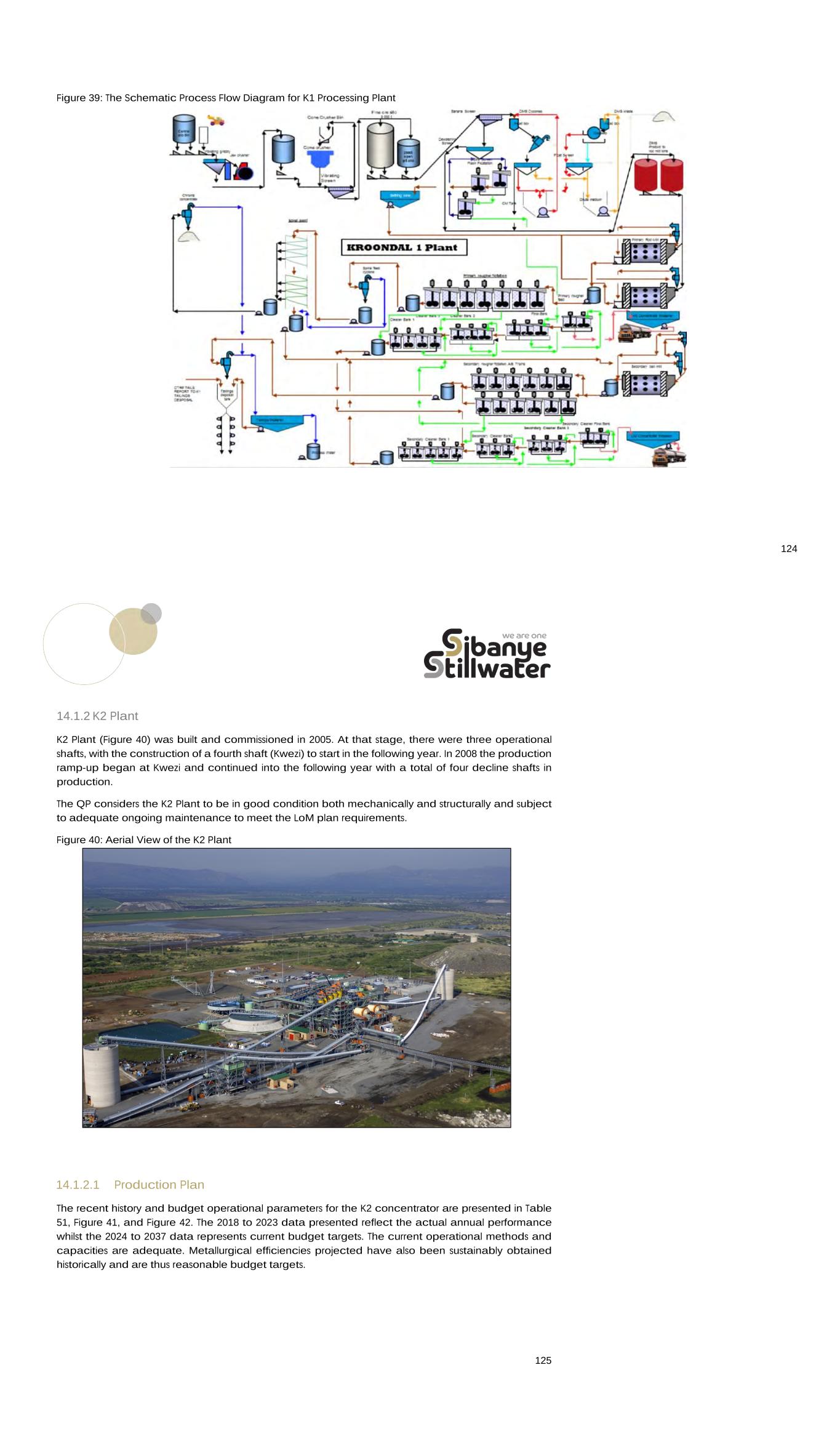

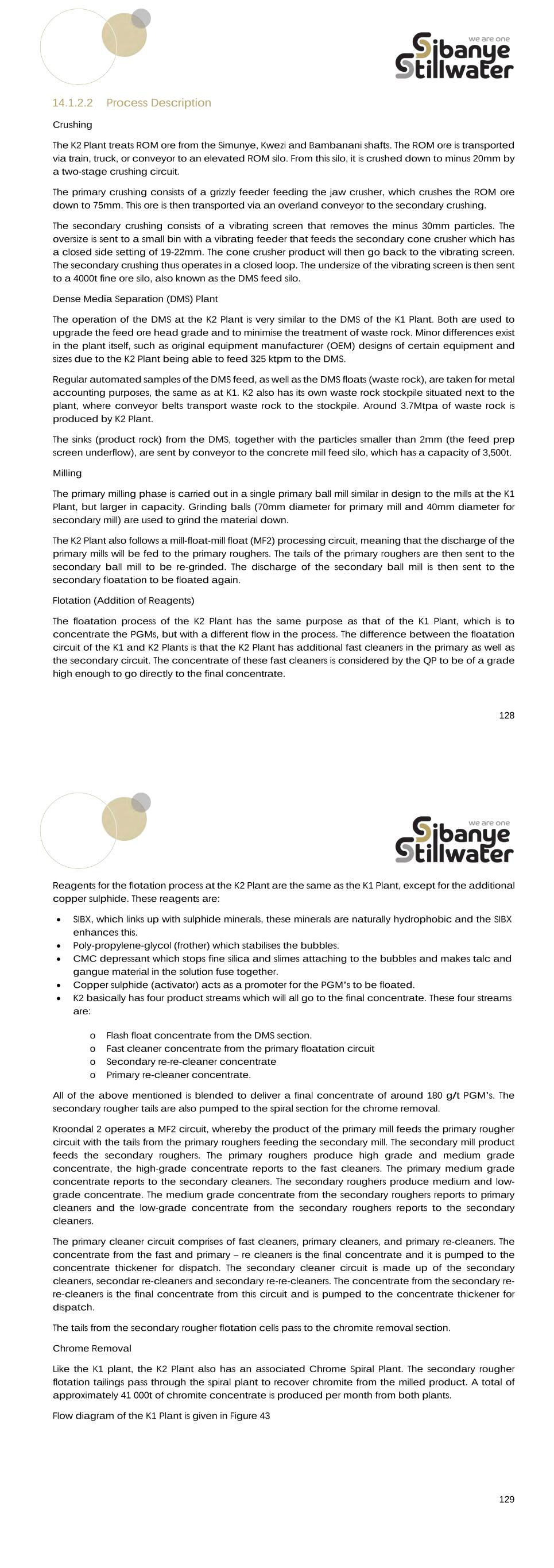

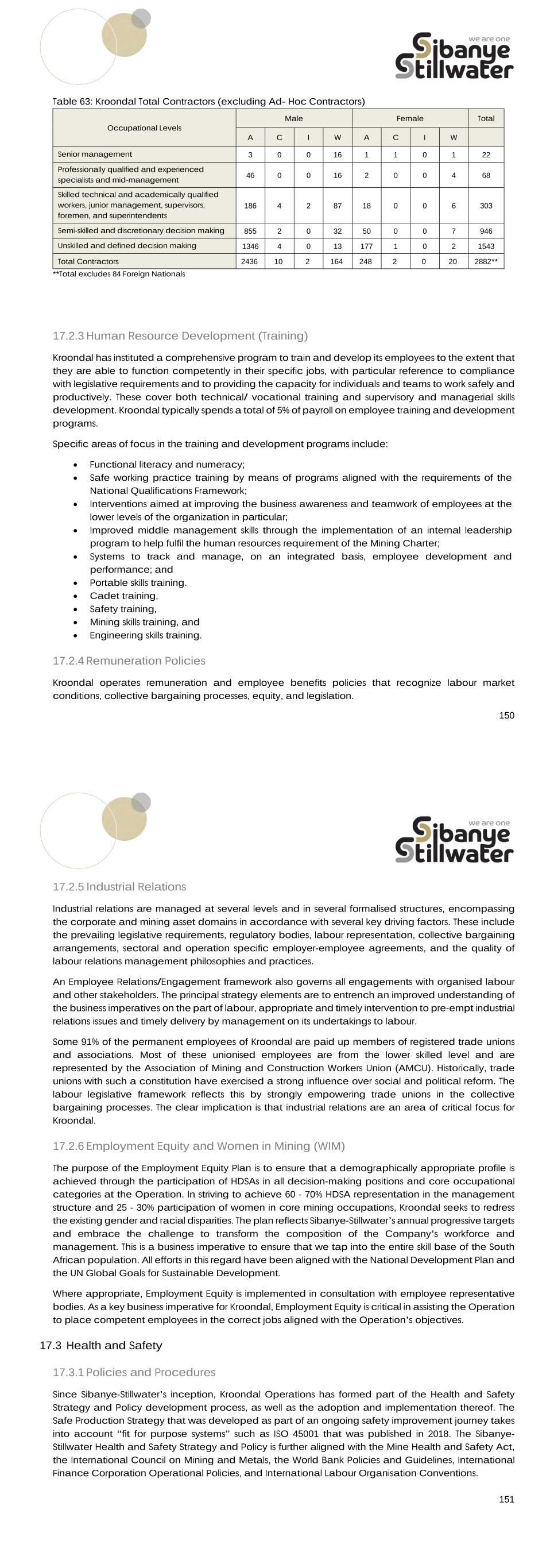

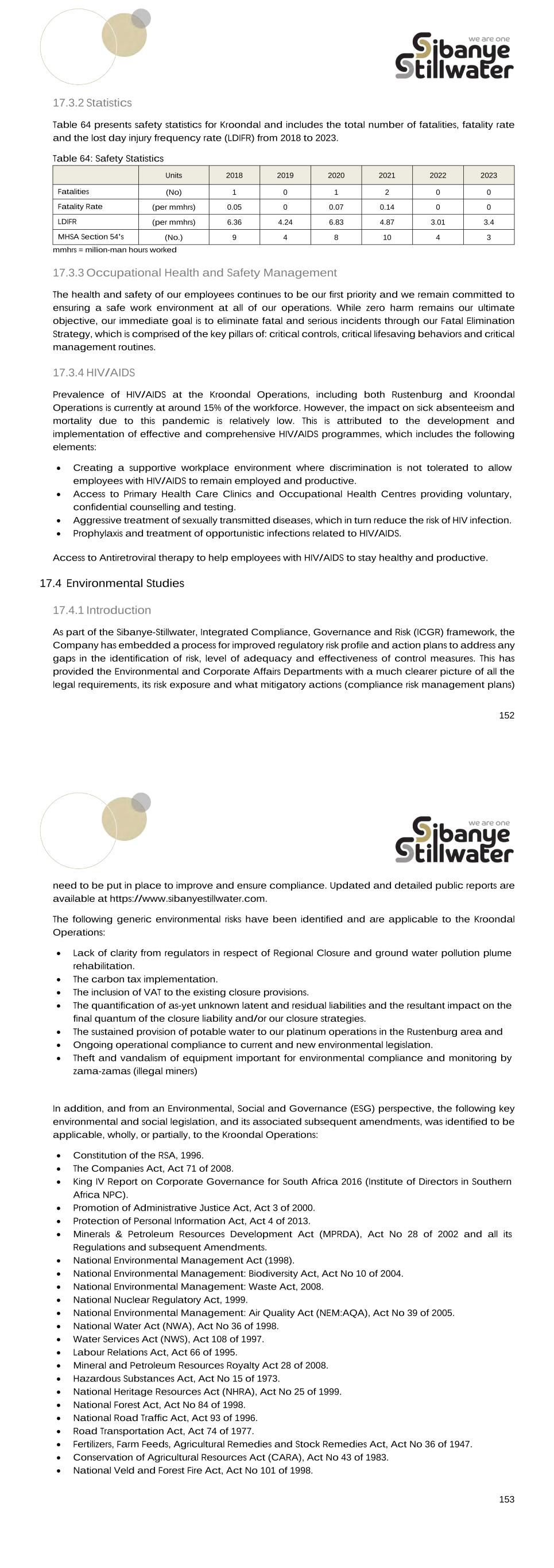

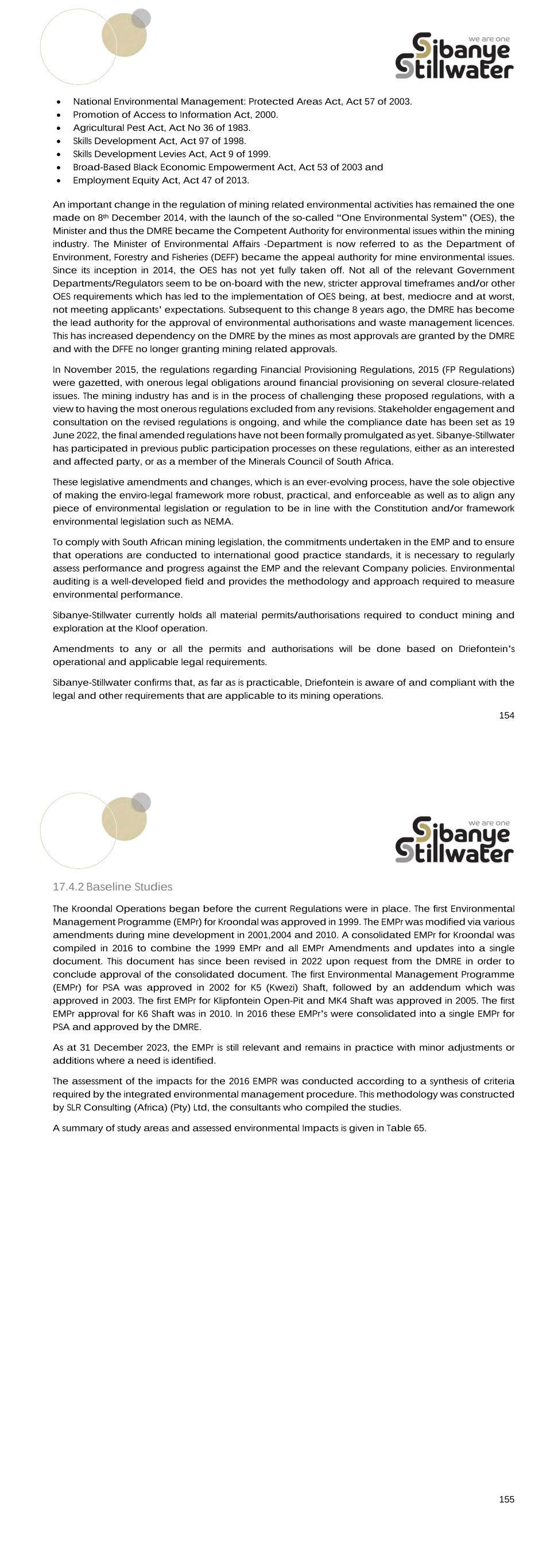

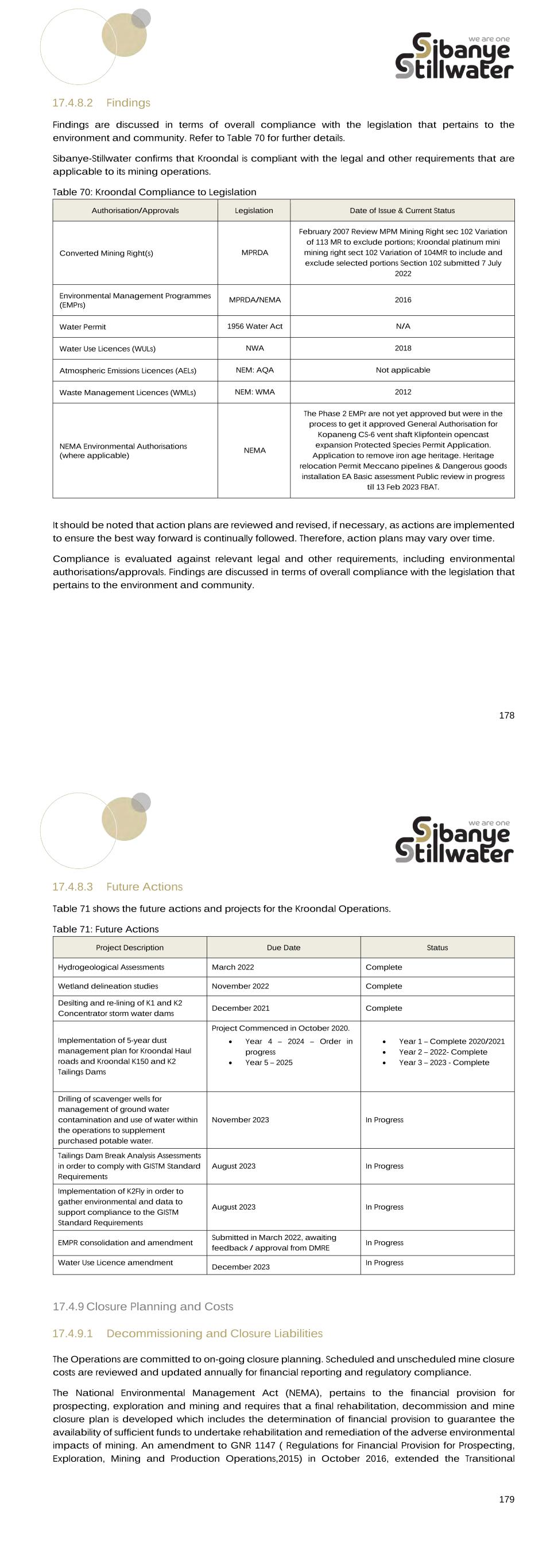

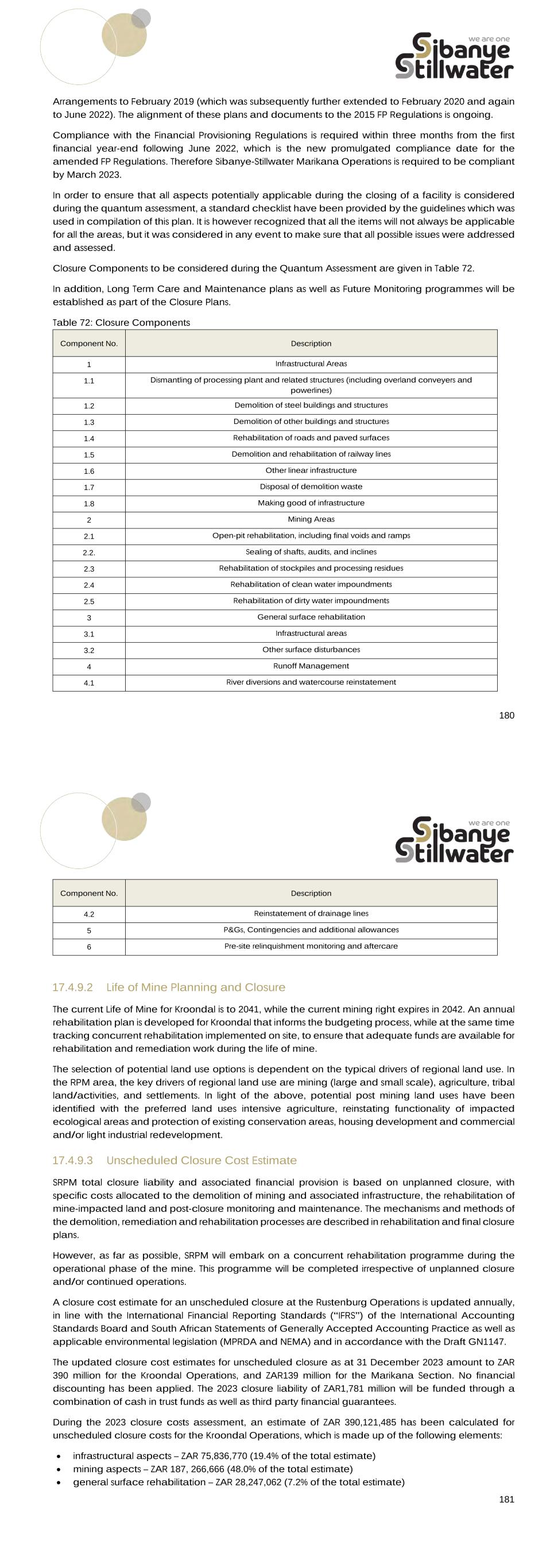

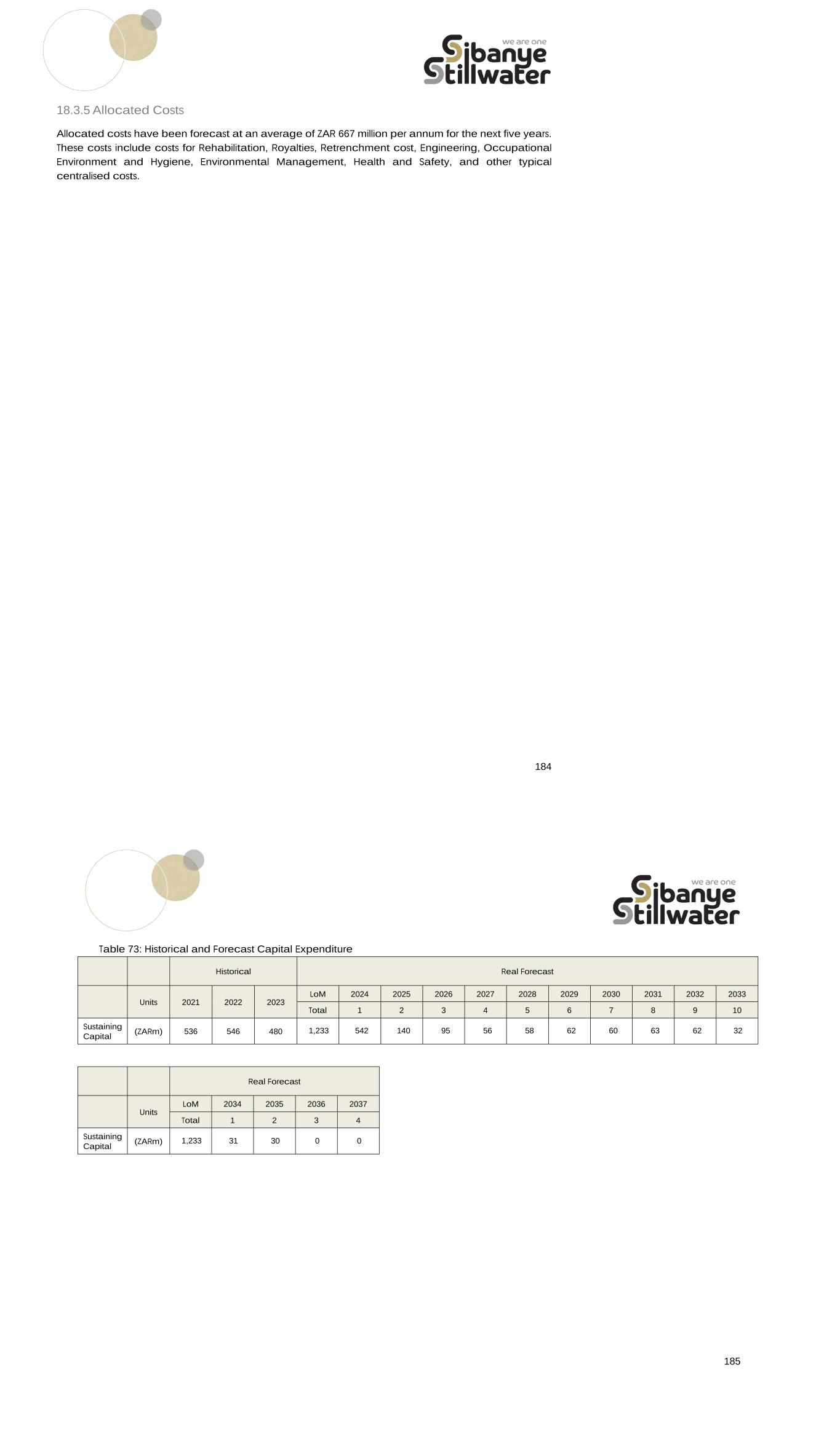

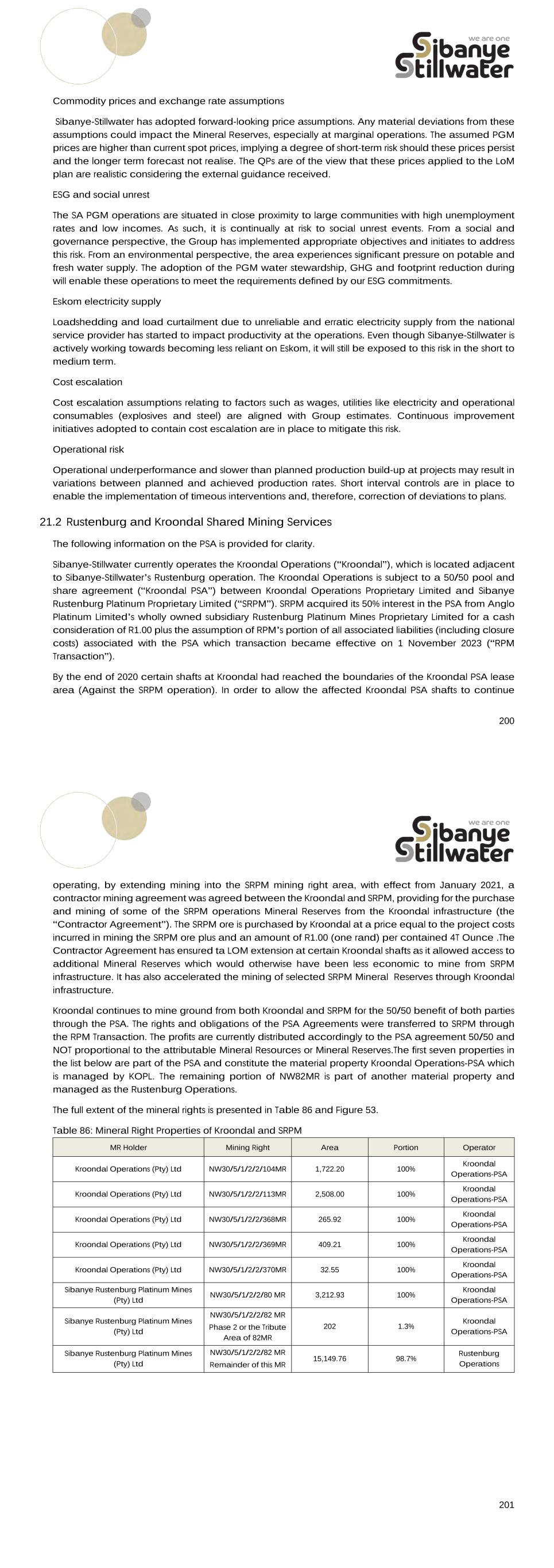

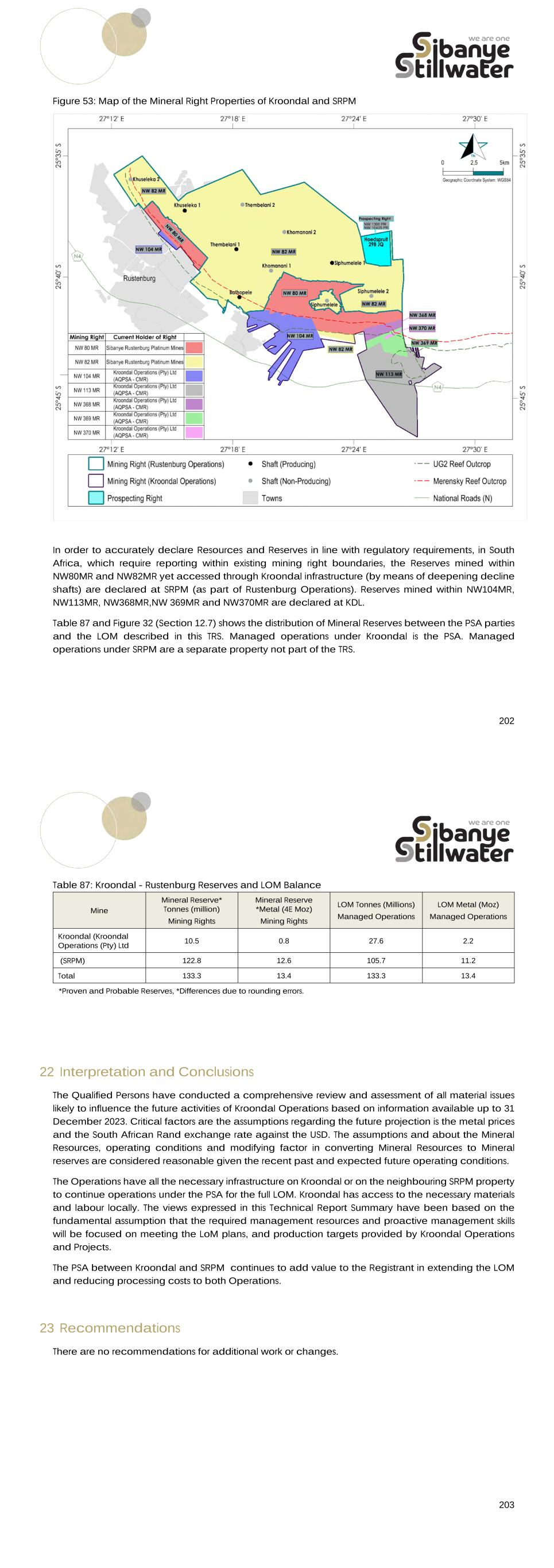

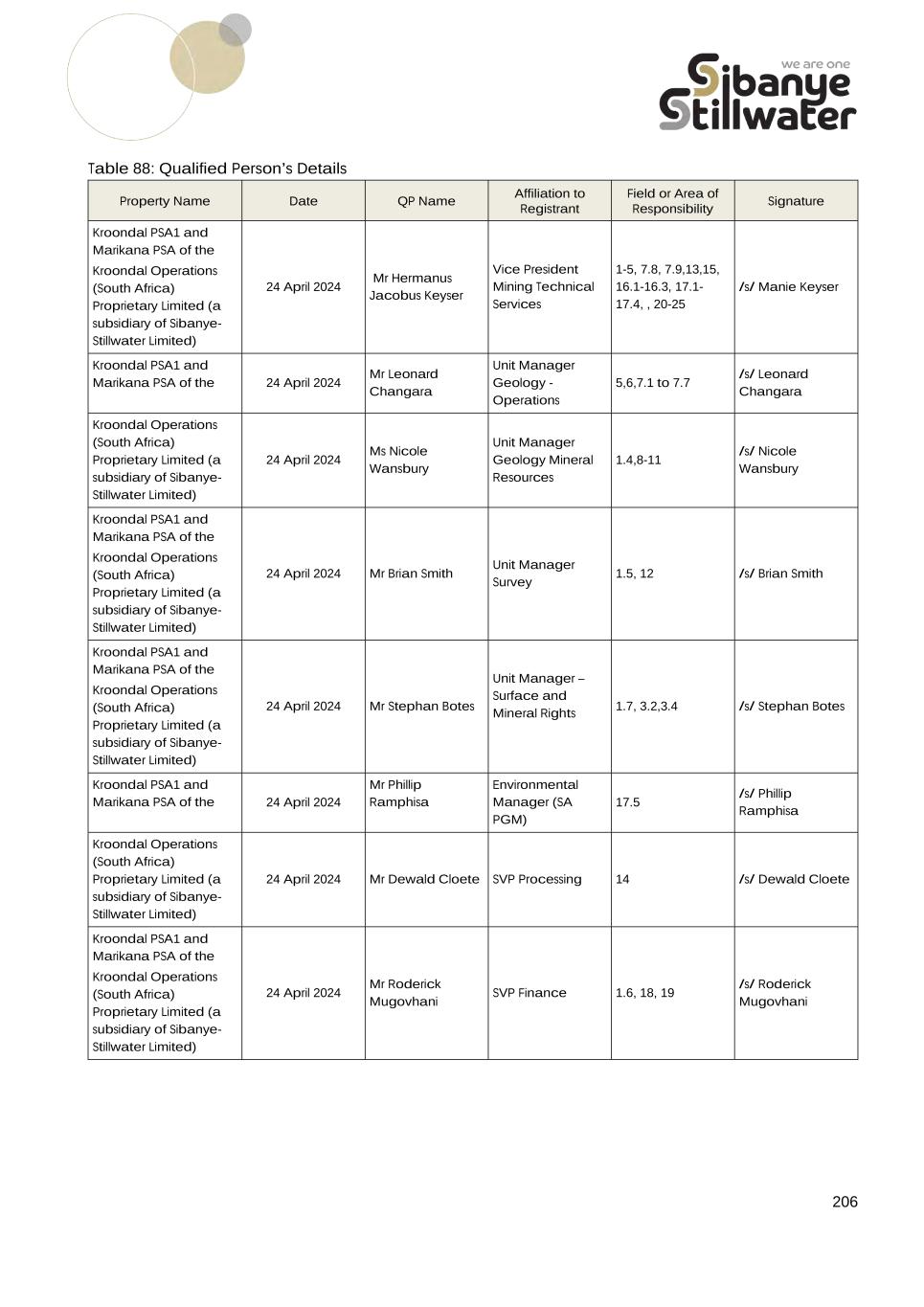

28 4 Accessibility, Climate, Local Resources, Infrastructure and Physiography 4.1 Topography, Elevation and Vegetation The Rustenburg area within which the Kroondal Operations are situated is characterised by undulating terrain, varying between 1,050m above mean sea level (mamsl) and 1,180 mamsl. The topography to the north, west and east of Kroondal Operations is dominated by well-established non-perennial watercourses. The topography of the mine area is relatively flat, with sporadic hillocks and rocky outcrops. To the south of the mine area is the Magalies mountain range and to the east is a number of small hills. The major rivers in the Kroondal Operations area include the Hex River bisecting through the western and central sections of the licence area and the Sterkstroom River on the eastern perimeter. The natural vegetation comprises open grasslands and shrubs, but most of the area surrounding Rustenburg has been and is, to a certain extent, still used for agriculture developments, in particular sunflowers and tobacco. With the growth in the mining sector due to extensive platinum and chrome deposits in the region, agriculture is on the decline. Urban development has taken place mainly in the town of Rustenburg, but informal settlements also exist, including in the Rustenburg Operations Lease Area. The licence area comprises two primary vegetation types, namely: Clay Thorn bushveld/ Other Turf Thornveld o This veld type occurs on the black vertic clay soils of the flat plains of the North West and Northern Provinces. Acacia tortilis, Acacia karroo and Acacia nilotica dominate the tree layer within this vegetation type. The Clay Thorn Bushveld is the main veld type found within the Rustenburg Operations area. Mixed Bushveld o This veld type is very variable depending on soil type, soil depth and aspect, and is represented by many different plant communities and habitat types. It occurs mainly on the undulating to flat plains of the Northern and North-West Provinces. The soil is mostly shallow, sandy, sometimes coarse, and gravelly, overlying granite, quartzite, sandstone, or shale. The vegetation may vary from short, dense, sometimes shrubby bushveld to tall, open tree savanna. Mixed Bushveld occurs in small parts of the Rustenburg Operations licence area. 4.2 Access, Towns and Regional Infrastructure The Kroondal Operations are situated near Rustenburg town in the North West Province of South Africa. The site is accessed via the multiple networks of well-maintained tarred roads. From Pretoria, the operations are accessed via the N4 highway into Rustenburg town, then the R104 to the Operations. From Johannesburg, Rustenburg town is accessed via the R24 road passing through Magaliesburg or the R512 (regional dual carriage tarred road) from Johannesburg, which intersects with the N4. A railway line runs through the town of Rustenburg. Major international airports including OR Tambo and Lanseria international airports are in Gauteng Province. Sections 4.4 and 14 and Figure 2 contain additional information on Infrastructure. 29 4.3 Climate Rainfall occurs throughout the year, but predominantly between November and March, mainly as thunderstorms. Annual rainfall averages approximately 650 mm. The wettest month of the year is January, with an average monthly total rainfall of 132 mm. The driest month is July, with an average monthly rainfall of approximately 2 mm. Mean annual air temperatures range from 11.8°C in June/July to 23.8°C in January. Average daily maxima range from 20.4°C to 30.3°C, and minima from 2.8°C to 17.2°C. Winds are mainly light to moderate and blow from the north-easterly sector, except for short periods during thunderstorms or weather changes when they have a southerly component. The lightning ground flash density in the area is a moderate risk to the concentrators with between 5 to 7 strikes/km2/year (on a scale of 0 to 19). No severe climatic effects influence the mining and ore processing operations at the Kroondal Operations, which proceed all year round. 4.4 Infrastructure and Bulk Service Supplies The Kroondal Operations have been operational for decades. The regional and onsite infrastructure for mining and ore processing is well established. There is a good supply chain for all required consumables and equipment in or near the mine site. The Kroondal Operations, through Sibanye-Stillwater, is well connected to the international supply markets for any materials and equipment not available locally. The Kroondal Operations are supplied with bulk electricity from the regional grid owned and operated by the state-owned company, Eskom. Details for Power supplies are supplied in Section 15.3 and for Water supplies in Sections 15.4 and 17.4.6. Most services and supplies needed are found in the surrounding towns and cities. 4.5 Personnel Sources The Kroondal Operations have specific policies, procedures, and practices in place, which address, on an integrated basis, its human resource requirements. Recruitment is informed in the main by the operational requirements of the Kroondal Operations for specific skills, by the extent of labour turnover levels and by relevant legislation. The organisational structure currently in place, together with operational management, will remain until such time as planned shaft closures occur, following which downsizing will be assessed. Organisational structures and staffing requirements (Table 13) are, by and large, determined by operational requirements and the production profile of the operation. The economic climate, cost infrastructure and Mineral Reserve profile also influence the organisation structures and required labour complement.