CERTIFICATE OF QUALIFIED PERSON

Peter Mehrfert, P.Eng.

I, Peter Mehrfert, P. Eng., certify that I am employed as a Process Engineer with Ausenco Engineering Canada ULC, with an office at 1050 W Pender St, Vancouver, BC V6E 3S7.

1. This certificate applies to the technical report titled "Panuco Project NI 43-101 Technical Report & Preliminary Economic Assessment" that has an effective date of July 24, 2024 (the "Effective Date").

2. I graduated from the University of British Columbia in 1996 where I obtained a Bachelor of Applied Science in Mining and Mineral Process Engineering.

3. I am a Professional Engineer, registered with Engineers and Geoscientists of British Columbia, member number 24527.

4. I have practiced my profession continuously for 28 years and have been involved in the design, evaluation, and operation of mineral processing facilities during that time. Approximately half of my professional practice has been the supervision and management of metallurgical test work related to feasibility and prefeasibility studies of projects involving flotation technologies. Previous projects that I have worked on that have similar features to the Panuco Project are Lemhi, Courageous Lake, Springpole, and Eskay Creek. Project financial models that I have reviewed and contributed to the inputs include Berg, Copper Creek, Santo Tomas, Kwanika, and Northisle Copper & Gold.

5. I have read the definition of "Qualified Person" set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101") and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a "Qualified Person" for those sections of the Technical Report that I am responsible for preparing.

6. I have visited the Panuco Project between April 8th and 10th, 2024.

7. I am responsible 1.1, 1.7, 1.10, 1.11.1-1.11.6, 1.12, 1.14-1.17, 2.1-2.4.1, 2.5-2.7, 3.4, 12.4, 12.5, 13, 17, 18.1-18.3.7, 19, 21.1-21.2.2, 21.2.4-21.2.10, 21.3.1, 21.3.2, 21.3.4, 21.3.5, 22, 24, 25.1, 25.5, 25.8, 25.9.1, 25.10, 25.12-25.14, 25.15.1.2, 25.15.1.4, 25.15.1.8, 25.15.2.2, 25.15.2.4,25.15.2.7, 26.1, 26.3, 26.5, 26.9 and 27 of the Technical Report

8. I am independent of the Vizsla Silver Corp. as independence is defined in Section 1.5 of NI 43-101.

9. I have had previous involvement with the Panuco Project, serving as QP and contributing author to the Panuco NI 43-101 Technical Report on the Updated Mineral Resource Estimate with an effective date of September 1, 2023. I have also managed metallurgical test programs on samples from the Panuco deposits on behalf of Vizsla Silver Corp.

10. I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated: August 23, 2024

"Signed and Sealed"

Peter Mehrfert, P. Eng.

CERTIFICATE OF QUALIFIED PERSON

James Millard, P. Geo.

I, James Millard, P. Geo., certify that I am employed as a Director, Strategic Projects with Ausenco Sustainability ULC, a wholly owned subsidiary of Ausenco Engineering Canada ULC ("Ausenco"), with an office address of Suite 100, 2 Ralston Avenue, Dartmouth, NS, B3B 1H7, Canada.

1. This certificate applies to the technical report titled "Panuco Project NI 43-101 Technical Report & Preliminary Economic Assessment" that has an effective date of July 24, 2024 (the "Effective Date").

2. I graduated from Brock University in St. Catharines, Ontario in 1986 with a Bachelor of Science in Geological Sciences, and from Queen's University in Kingston, Ontario in 1995 with a Master of Science in Environmental Engineering.

3. I am a member (P. Geo.) of the Association of Professional Geoscientists of Nova Scotia, Membership No. 021.

4. I have practiced my profession for 25 years. I have worked for mid- and large-size mining companies where I have acted in senior technical and management roles, in senior environmental consulting roles, and provided advise and/or expertise in a number of key subject areas. These key areas included: feasibility-level study reviews; NI 43-101 report writing and review; due diligence review of environmental, social, and governance areas for proposed mining operations and acquisitions, and directing environmental impact assessments and permitting applications to support construction, operations, and closure of mining projects. In addition to the above, I have been responsible for conducting baseline data assessments, surface and groundwater quantity and quality studies, mine rock geochemistry and water quality predictions, mine reclamation and closure plan development, and community stakeholder and Indigenous peoples' engagement initiatives. Recently, I acted in the following project roles: Qualified Person for the environmental/sustainability aspects for "Puquios Project, Feasibility Study Report, La Higuera, Coquimbo Region, Chile", "Volcan Project, NI 43-101 Technical Report on Preliminary Economic Assessment, Tierra Amarilla, Atacama Region, Chile" and, "Colomac Gold Project, NI 43-101 Technical Report and Preliminary Economic Assessment, Northwest Territories, Canada"; and principal author for the environmental/sustainability sections for the "Kwanika- Stardust Project, NI 43-101 Technical Report and, Preliminary Economic Assessment, British Columbia, Canada".

5. I have read the definition of "Qualified Person" set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101") and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a "Qualified Person" for those sections of the Technical Report that I am responsible for preparing.

6. I have not visited the Panuco Project site.

7. I am responsible for 1.13, 3.3, 20, 25.11, 25.15.1.7, 25.15.2.6, 26.8 and 27 of the Technical Report.

8. I am independent of the Vizsla Silver Corp as independence is defined in Section 1.5 of NI 43-101.

9. I have had no previous involvement with Panuco Project.

10. I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated: August 23, 2024

"Signed and Sealed"

James Millard, M. Sc, P. Geo.

CERTIFICATE OF QUALIFIED PERSON

Scott Cameron Elfen, P.E.

I, Scott Cameron Elfen, P.E., certify that I am employed as the Global Lead Geotechnical and Civil Services within Ausenco Engineering Canada ULC, with an office address of 1050 West Pender Street, Suite 1200, Vancouver, BC V6E 3S7, Canada.

1. This certificate applies to the technical report titled "Panuco Project NI 43-101 Technical Report & Preliminary Economic Assessment" that has an effective date of July 24, 2024 (the "Effective Date").

2. I graduated from the University of California, Davis, California, in 1991 with Bachelor of Science degree in Civil Engineering (Geotechnical).

3. I am a Registered Civil Engineer in the State of California (license no. C56527) by exam since 1996 and I am also a member in good standing of the American Society of Civil Engineers (ASCE), and the Society for Mining, Metallurgy & Exploration (SME).

4. I have practiced my profession continuously for 26 years with experience in the development, design, construction and operations of mine waste storage facilities, such as waste rock storage facilities and tailings storage facilities ranging from slurry to dry stack facilities, focusing on precious and base metals, both domestic and international. In addition, I have developed geotechnical design parameters for pit slope design, plant foundation design, and other supporting infrastructure. Examples of projects I have worked on include Skeena's Eskay Creek Project PEA, PFS and FS, O3 Mining's Marban Project PEA and PFS, First Mining Gold's Springpole PEA and PFS. SSR Mining's Puna Silver In-Pit Tailings Disposal PFS, and Detailing Engineering, and the Company's Cangrejos Project PEA.

5. I have read the definition of "Qualified Person" set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101") and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a "Qualified Person" for those sections of the Technical Report that I am responsible for preparing.

6. I visited the Panuco Project on August 15, 2024, for a visit duration of 1 day.

7. I am responsible for sections 1.11.7, 1.11.8, 2.4.4, 18.3.8, 18.3.9, 25.9.2, 25.15.1.5, 26.6, 26.7 and 27 of the Technical Report.

8. I am independent of Vizsla Silver Corp. as independence is described by Section 1.5 of the NI 43-101.

9. I have had no previous involvement with the Panuco Project.

10. I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated: August 23, 2024

"Signed and Sealed"

Scott Cameron Elfen, P.E.

CERTIFICATE OF QUALIFIED PERSON

JONATHAN COOPER, P.ENG.

I, Jonathan Cooper, P. Eng., certify that I am employed as a Water Resources Engineer with Ausenco Sustainability ULC ("Ausenco"), with an office address of 11 King Street West, Suite 1500, Toronto, Ontario M5H 4C7.

11. This certificate applies to the technical report titled "Panuco Project NI 43-101 Technical Report & Preliminary Economic Assessment" that has an effective date of July 24, 2024 (the "Effective Date").

12. I graduated from the University of Western Ontario with a Bachelor of Engineering Science in Civil Engineering in 2008, and University of Edinburgh with a Master of Environmental Management in 2010.

13. I am a Professional Engineer registered and in good standing with Order of Engineers of Quebec (temporary engineer permit #6067376), Professional Engineers Ontario (registration #100191626), Engineers and Geoscientists British Columbia (registration #37864) and Northwest Territories and Nunavut Association of Professional Engineers and Geoscientists (registration # L4227).

14. I have practiced my profession for continuously for over 15 years with experience in the development, design, operation, and commissioning of surface water infrastructure. Previous projects that I have worked on that have similar features to the Novador Project are the Kwanika-Stardust for NorthWest Copper located in British Columbia, Colomac Gold Project located in the Northwest Territories and the Crawford Project located in Ontario.

15. I have read the definition of "Qualified Person" set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101") and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfil the requirements to be a "Qualified Person" for those sections of the Technical Report that I am responsible for preparing.

16. I have not visited the Panuco Project

17. I am responsible for sections 18.3.10, 25.9.3, 25.15.1.6, 25.15.2.5, and 27 of the Technical Report.

18. I am independent of Vizsla Silver Corp Corp. as independence is defined in Section 1.5 of NI 43-101.

19. I have had no previous involvement with the Panuco Project.

20. I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated: August 23, 2024

"Signed and Sealed"

Jonathan Cooper, P.Eng.

CERTIFICATE OF QUALIFIED PERSON

Allan Armitage, P.Geo.

I, Allan E. Armitage, Ph. D., P. Geol. of 62 River Front Way, Fredericton, New Brunswick, hereby certify that, I am a Senior Resource Geologist with SGS Canada Inc., 10 de la Seigneurie E Blvd., Unit 203 Blainville, QC, Canada, J7C 3V5.

1. This certificate applies to the technical report titled "Panuco Project NI 43-101 Technical Report & Preliminary Economic Assessment" that has an effective date of July 24, 2024 (the "Effective Date")

2. I am a graduate of Acadia University having obtained the degree of Bachelor of Science - Honours in Geology in 1989, a graduate of Laurentian University having obtained the degree of Master of Science in Geology in 1992 and a graduate of the University of Western Ontario having obtained a Doctor of Philosophy in Geology in 1998.

3. I have been employed as a geologist for every field season (May - October) from 1987 to 1996. I have been continuously employed as a geologist since March of 1997.

4. I have been involved in mineral exploration and resource modeling at the grass roots to advanced exploration stage, including producing mines, since 1991, including mineral resource estimation and mineral resource and mineral reserve auditing since 2006 in Canada and internationally. I have extensive experience in Archean and Proterozoic load gold deposits, volcanic and sediment hosted base metal massive sulphide deposits, porphyry copper-gold-silver deposits, low and intermediate sulphidation epithermal gold and silver deposits, magmatic Ni-Cu-PGE deposits, and unconformity- and sandstone-hosted uranium deposits. I am a member of the following: the Association of Professional Engineers, Geologists and Geophysicists of Alberta (P.Geol.) (License No. 64456; 1999), the Association of Professional Engineers and Geoscientists of British Columbia (P.Geo.) (Licence No. 38144; 2012), the Professional Geoscientists Ontario (P.Geo.) (Licence No. 2829; 2017), and Northwest Territories and Nunavut Association of Professional Engineers and Geoscientists (NAPEG) (License No. L4375: 2019).

5. I have read the definition of "Qualified Person" set out in National Instrument 43-101 - Standards of Disclosure for Mineral Projects - ("Nl 43-101") and certify that by reason of my education, affiliation with a professional association (as defined in NI 43 101) and past relevant work experience, I fulfill the requirements to be a "Qualified Person" for the purposes of NI 43 101.

6. I am an author of the Technical Report and responsible for sections 1.2, 1.8, 2.4.3, 3.1, 4, 8, 12.2, 12.3, 12.6, 14, 15, 23, 25.2, 25.6, 25.15.1.1, 25.15.2.1, 26.2 and 27. I have reviewed these sections and accept professional responsibility for these sections of the Technical Report.

7. I have conducted three site visits to the Property. I conducted a site visit to the Project on May 29, 2023, a second site visit November 6 to November 8, 2023, and a third site visit on May 23, 2024.

8. I have had prior involvement with the Panuco Property. I was an author of the previous NI 43-101 Technical Reports for the Property, dated March 10, 2023, and February 12, 2024, for Vizsla.

9. I am independent of the Company as described in Section 1.5 of NI 43-101.

10. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. I have read NI 43-101 and Form 43-101F1 (the "Form"), and the Technical Report has been prepared in compliance with NI 43-101 and the Form.

Dated: August 23, 2024

"Signed and Sealed"

Allan E. Armitage, Ph. D., P. Geo.

CERTIFICATE OF QUALIFIED PERSON

Ben Eggers, P. Geo.

I, Benjamin K. Eggers, B.Sc. (Hons), MAIG, P.Geo. of Tofino, British Columbia, hereby certify that, I am a Senior Geologist with SGS Canada Inc., 10 Boulevard de la Seigneurie E., Suite 203, Blainville, QC, J7C 3V5, Canada.

1. This certificate applies to the technical report titled "Panuco Project NI 43-101 Technical Report & Preliminary Economic Assessment" that has an effective date of July 24, 2024 (the "Effective Date").

2. I am a graduate of the University of Otago, New Zealand having obtained the degree of Bachelor of Science (Honours) in Geology in 2004.

3. I have been continuously employed as a geologist since February of 2005.

4. I have been involved in mineral exploration and resource modeling at the greenfield to advanced exploration stages, including at producing mines, in Canada, Australia, and internationally since 2005, and in mineral resource estimation since 2022 in Canada and internationally. I have experience in lode gold deposits, porphyry copper-gold-silver deposits, low and high sulphidation epithermal gold and silver deposits, volcanic and sediment hosted base metal massive sulphide deposits, and albitite-hosted uranium deposits. I am a member of the Association of Professional Engineers and Geoscientists of British Columbia and use the designation (P.Geo.) (EGBC Licence No. 40384; 2014), and I am a member of the Australian Institute of Geoscientists and use the designation (MAIG) (AIG Licence No. 3824; 2013).

5. I have read the definition of "Qualified Person" set out in National Instrument 43-101 - Standards of Disclosure for Mineral Projects - ("Nl 43-101") and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a "Qualified Person" for the purposes of NI 43-101.

6. I am an author of the Technical Report and responsible for sections 1.3-1.6, 5, 6, 7, 9, 10, 11, 12.1, 25.3, 25.4, and 27. I have reviewed these sections and accept professional responsibility for these sections of the Technical Report.

7. I have not personally conducted a site visit.

8. I have had prior involvement with the Panuco Property. I was an author of the previous NI 43-101 Technical Reports for the Property, dated March 10, 2023, and February 12, 2024, for Vizsla.

9. I am independent of the Company as described in Section 1.5 of NI 43-101.

10. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. I have read NI 43-101 and Form 43-101F1 (the "Form"), and the Technical Report has been prepared in compliance with NI 43-101 and the Form.

Dated: August 23, 2024

"Signed and Sealed"

Benjamin K. Eggers, B.Sc. (Hons), MAIG, P.Geo

CERTIFICATE OF QUALIFIED PERSON

Ramon Mendoza Reyes, P.Eng.

I, Ramon Mendoza Reyes, P.Eng., certify that: am employed as a Principal Consultant with Entech Mining Ltd., with an office address of 1100 Melville Street, Vancouver, BC, Canada, V6E 4A6.

1. This certificate applies to the technical report titled "Panuco Project NI 43-101 Technical Report & Preliminary Economic Assessment" that has an effective date of July 24, 2024 (the "Effective Date").

2. I graduated from the National Autonomous University of Mexico with a Bachelor of Science Degree in Mining Engineering in 1989, and also obtained a Master of Science Degree in Mining and Earth Systems Engineering from the Colorado School of Mines in Golden, Colorado, in 2003.

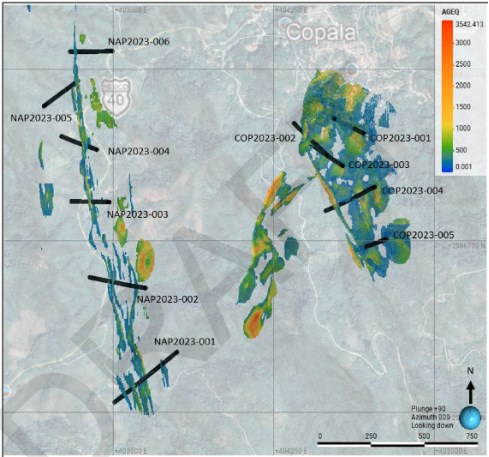

3. I am a professional engineer registered with the Engineers and Geoscientists British Columbia (Reg. No. 158547).

4. I have practiced my profession continuously since 1990 and have been involved in numerous precious and base metal mine projects and operations in Mexico, Canada, the United States of America, Chile, Peru, and Argentina, overseeing technical and operational aspects including mine design, mine planning, mining operations and mineral reserves estimation.

5. I have read the definition of "Qualified Person" set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101") and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a "Qualified Person" for those sections of the Technical Report that I am responsible for preparing.

6. I visited the Panuco project site and carried out a personal inspection on April 9-10 of 2024.

7. I am responsible for Sections 1.9, 2.4.2, 3.2, 16, 21.2.3, 21.3.3, 25.7, 25.15.1.3, 25.15.2.3, 26.4 and 27 of the technical report.

8. I am independent of Vizsla Silver Corp. as independence is defined in Section 1.5 of NI 43-101.

9. I have not been previously involved with the Panuco Project.

10. I have read NI 43-101, and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated: August 23, 2024

"Signed and Sealed"

Ramon Mendoza Reyes, P.Eng.

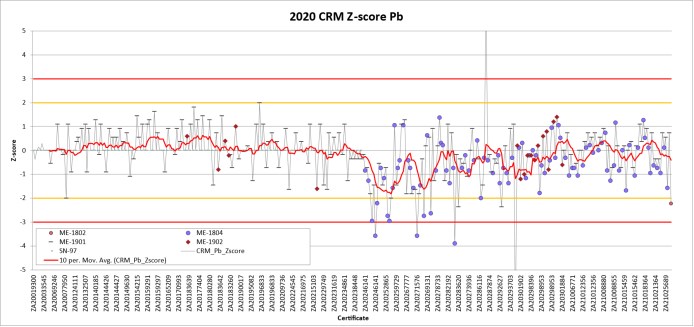

Important Notice

This report was prepared as National Instrument 43-101 Technical Report for Panuco Project by Ausenco Engineering Canada ULC and Ausenco Sustainability ULC (collectively Ausenco), SGS Canada Inc - Geological Services (SGS) and Entech Mining Ltd. (Entech) collectively the Report Authors. The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in the Report Authors' services, based on i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Vizsla subject to terms and conditions of its contracts with each of the Report Authors. Except for the purposed legislated under Canadian provincial and territorial securities law, any other uses of this report by any third party are at that party's sole risk.

Table of Contents

| 1 Summary | 1 |

| 1.1 Introduction | 1 |

| 1.2 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements | 2 |

| 1.3 Geology Mineralization | 2 |

| 1.4 History | 4 |

| 1.5 Exploration | 5 |

| 1.6 Drilling | 5 |

| 1.7 Metallurgical Test Work | 6 |

| 1.8 Mineral Resource Estimate | 8 |

| 1.9 Mining Methods | 11 |

| 1.10 Recovery Methods | 12 |

| 1.11 Project Infrastructure | 15 |

| 1.11.1 Overview | 15 |

| 1.11.2 Site Access | 17 |

| 1.11.3 Power Supply | 17 |

| 1.11.4 Water Supply | 17 |

| 1.11.5 On-Site Roads | 17 |

| 1.11.6 Buildings | 17 |

| 1.11.7 Waste Rock Storage Facility | 17 |

| 1.11.8 Tailings Storage Facility | 17 |

| 1.12 Markets and Contracts | 18 |

| 1.13 Environmental, Permitting and Social Considerations | 18 |

| 1.13.1 Environmental Considerations | 18 |

| 1.13.2 Permitting Considerations | 19 |

| 1.13.3 Social and Community Considerations | 20 |

| 1.13.4 Closure and Reclamation Planning | 20 |

| 1.14 Capital and Operating Cost Estimates | 21 |

| 1.14.1 Capital Cost Estimates | 21 |

| 1.14.2 Average Operating Cost Estimate | 21 |

| 1.15 Economic Analysis | 22 |

| 1.15.1 Sensitivity Analysis | 24 |

| 1.16 Interpretations and Conclusions | 25 |

| 1.17 Recommendations | 25 |

| 2 Introduction | 26 |

| 2.1 Introduction | 26 |

| 2.2 Terms of Reference | 26 |

| 2.3 Qualified Persons | 26 |

| 2.4 Site Visits and Scope of Personal Inspection | 28 |

| 2.4.1 Site Inspection by Peter Mehrfert, P.Eng. | 28 |

| 2.4.2 Site Inspection by Ramon Mendoza Reyes, P.Eng. | 28 |

| 2.4.3 Site Inspection by Allan Armitage, P.Geo | 28 |

| 2.4.4 Site Inspection by Scott Elfen, P.E. | 29 |

| 2.5 Effective Dates | 29 |

| 2.6 Information Sources and References | 29 |

| 2.6.1 Previous Technical Reports | 29 |

| 2.7 Currency, Units, Abbreviations and Definitions | 30 |

| 3 Reliance on Other Experts | 33 |

| 3.1 Property Agreements, Mineral Tenure, Surface Rights and Royalties | 33 |

| 3.2 Property Ownership | 33 |

| 3.3 Environmental, Permitting, Closure, and Social and Community Impacts | 33 |

| 3.4 Taxation | 34 |

| 4 Property Description and Location | 35 |

| 4.1 Introduction | 35 |

| 4.2 Land Tenure and Mining Concessions | 35 |

| 4.3 Underlying Agreements | 41 |

| 4.3.1 Canam Alpine Ventures Ltd. | 41 |

| 4.3.2 Silverstone Resources S.A. de C.V. | 42 |

| 4.3.3 Minera Rio Panuco S.A. de C.V. | 42 |

| 4.3.4 Strategic Investment in Prismo Metals | 42 |

| 4.3.5 Royalty Spin Out | 42 |

| 4.3.6 San Enrique Acquisition | 43 |

| 4.4 Surface Rights | 43 |

| 4.4.1 Canam and Ejido Panuco | 44 |

| 4.4.2 Silverstone Resources S.A. de C.V., Canam, and Ejido Platanar de los Ontiverose | 44 |

| 4.4.3 Canam and Comunidad Copala | 45 |

| 4.4.4 Canam and El Habal Ejido | 45 |

| 4.4.5 Canam and San Miguel Del Carrizal | 45 |

| 4.5 Permits | 45 |

| 4.6 Environmental Considerations | 46 |

| 4.7 Other Relevant Factors | 46 |

| 5 Accessibility, Climate, Local Resources, Infrastructure and Physiography | 47 |

| 5.1 Accessibility | 47 |

| 5.2 Local Resources and Infrastructure | 47 |

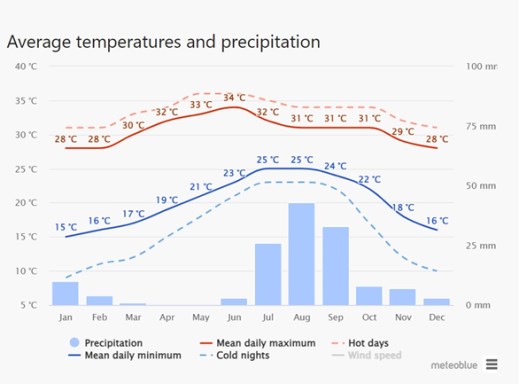

| 5.3 Climate | 47 |

| 5.4 Physiography | 47 |

| 5.5 Vegetation and Wildlife | 48 |

| 6 History | 49 |

| 6.1 Property Exploration History | 49 |

| 7 Geological Setting and Mineralization | 51 |

| 7.1 Regional Geology | 51 |

| 7.2 Project Geology | 54 |

| 7.3 Mineralization | 59 |

| 7.3.1 Animas-Refugio Corridor | 61 |

| 7.3.2 Cordon del Oro Corridor | 64 |

| 7.3.3 Cinco Señores and Napoleon Corridor | 66 |

| 7.3.4 Other Mineralized Structures | 70 |

| 7.4 Structural Controls | 72 |

| 7.5 Alteration | 72 |

| 7.6 Mineral Petrology | 73 |

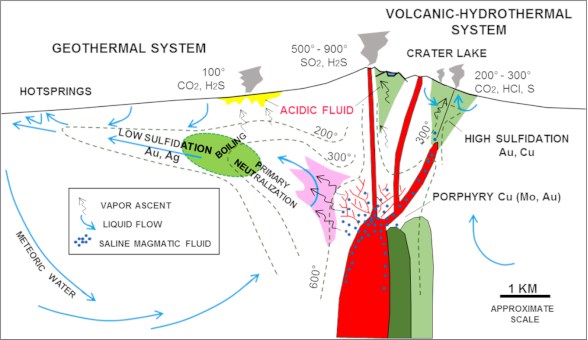

| 8 Deposit Types | 75 |

| 8.1 Deposit Model | 75 |

| 8.2 Epithermal Systems | 75 |

| 9 Exploration | 78 |

| 9.1 Introduction | 78 |

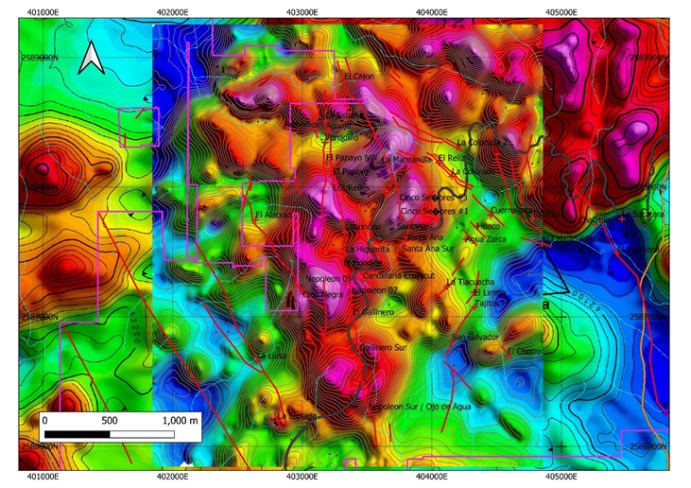

| 9.2 Geological Mapping | 78 |

| 9.3 2019-2021 Surface and Underground Sampling | 79 |

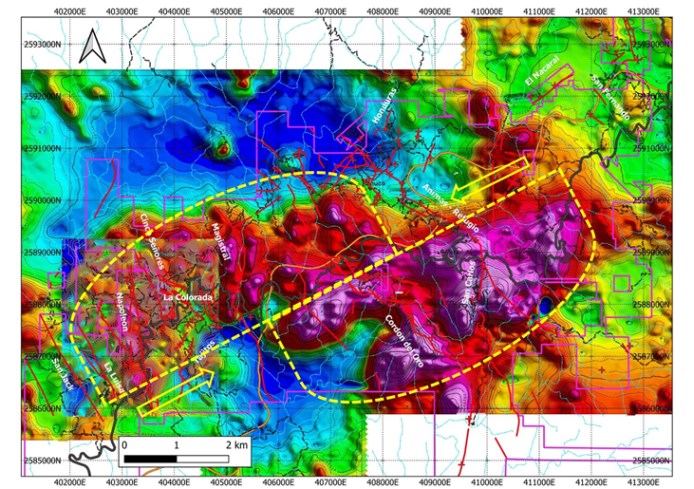

| 9.4 Geophysics | 80 |

| 9.5 2023 LiDAR Survey | 83 |

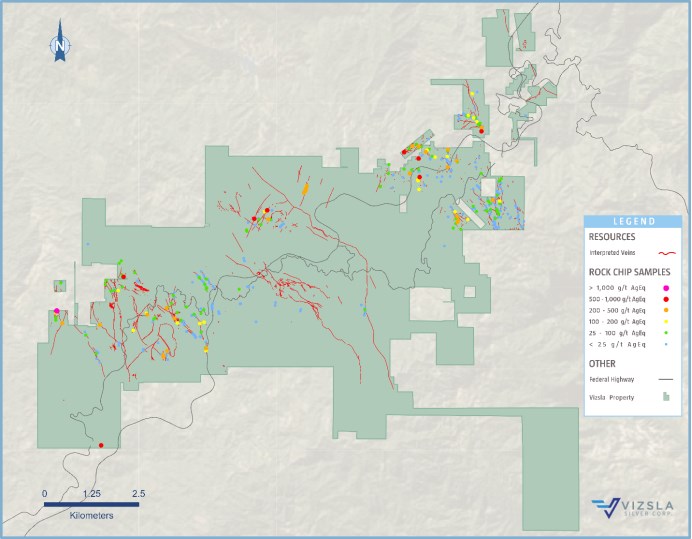

| 9.6 2022 Surface Sampling | 83 |

| 9.7 2023 Surface Sampling | 85 |

| 9.8 2024 Surface Sampling | 87 |

| 10 Drilling | 90 |

| 10.1 Overview | 90 |

| 10.2 2019 Drilling | 92 |

| 10.3 2020 Drilling | 92 |

| 10.4 2021 Drilling | 95 |

| 10.5 2022 Drilling | 99 |

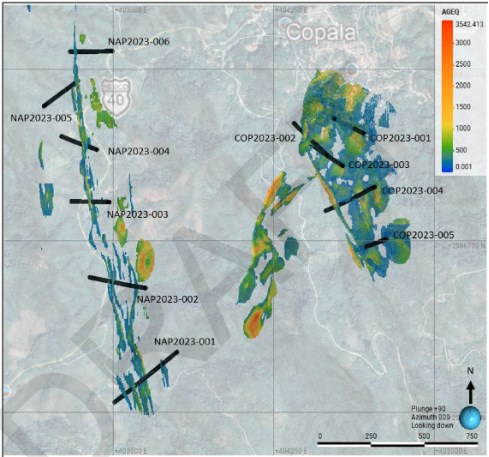

| 10.6 2023 Drilling | 101 |

| 10.7 2024 Drilling | 103 |

| 11 Sample Preparation, Analyses, and Security | 106 |

| 11.1 Overview | 106 |

| 11.2 2019 - 2024 Rock Sampling (Vizsla) | 107 |

| 11.2.1 Sampling Methods and Security | 107 |

| 11.2.2 Sample Preparation and Analyses | 108 |

| 11.3 2019 - 2024 Drilling Programs (Vizsla) | 108 |

| 11.3.1 Sampling Methods | 108 |

| 11.3.2 Sample Security and Storage | 109 |

| 11.3.3 Sample Preparation and Analyses | 110 |

| 11.3.4 Bulk Density | 110 |

| 11.3.5 Data Management | 111 |

| 11.3.6 Quality Assurance/Quality Control | 111 |

| 11.3.7 Certified Reference Material | 112 |

| 11.3.8 Blank Material | 125 |

| 11.3.9 Duplicate Material | 129 |

| 11.3.10 Check Assaying | 132 |

| 11.4 QP's Comments | 135 |

| 12 Data Verification | 136 |

| 12.1 Introduction | 136 |

| 12.2 Drill Sample Database | 136 |

| 12.3 Site Visit - Allan Armitage | 136 |

| 12.3.1 2023 Site Visits | 136 |

| 12.3.2 2024 Site Visit | 137 |

| 12.4 Site Visit - Peter Mehrfert | 138 |

| 12.5 Metallurgical Data Verification - Peter Mehrfert | 138 |

| 12.6 Conclusion | 139 |

| 13 Mineral Processing and Metallurgical Testing | 140 |

| 13.1 Introduction | 140 |

| 13.2 Sample Origin and Composite Assembly | 140 |

| 13.3 Sample Chemistry and Mineralogy | 141 |

| 13.4 Comminution Testing | 143 |

| 13.5 Gravity Concentration | 144 |

| 13.6 Flotation | 145 |

| 13.6.1 Sequential Flotation | 145 |

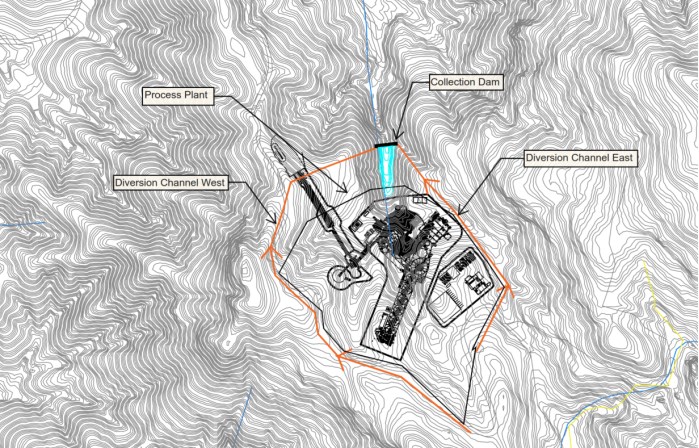

| 13.6.2 Bulk Flotation | 147 |

| 13.7 Cyanidation | 149 |

| 13.7.1 Whole Feed Cyanidation | 149 |

| 13.7.2 Flotation Concentrate Cyanidation | 152 |

| 13.7.3 Flotation Tailings Cyanidation | 154 |

| 13.7.4 Combined Flotation Plus Leach Performance | 155 |

| 13.8 Recovery Estimates | 156 |

| 13.9 Deleterious Elements | 157 |

| 13.10 Comments on Mineral Processing and Metallurgical Testing | 157 |

| 14 Mineral Resource Estimates | 159 |

| 14.1 Introduction | 159 |

| 14.2 Drill Hole Database | 159 |

| 14.3 Mineral Resource Modelling and Wireframing | 161 |

| 14.4 Bulk Density | 165 |

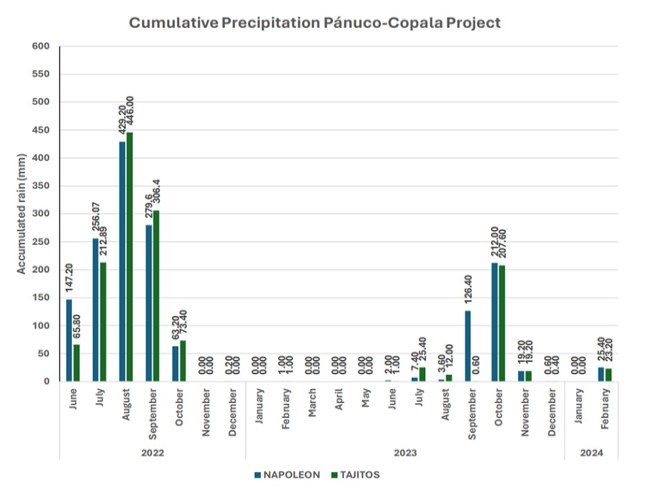

| 14.5 Compositing | 166 |

| 14.6 Grade Capping | 171 |

| 14.7 Block Model Parameters | 173 |

| 14.8 Grade Interpolation | 177 |

| 14.9 Mineral Resource Classification Parameters | 181 |

| 14.9.1 Indicated Mineral Resource | 182 |

| 14.9.2 Inferred Mineral Resource | 182 |

| 14.10 Reasonable Prospects of Eventual Economic Extraction | 183 |

| 14.11 Mineral Resource Statement | 183 |

| 14.12 Model Validation and Sensitivity Analysis | 193 |

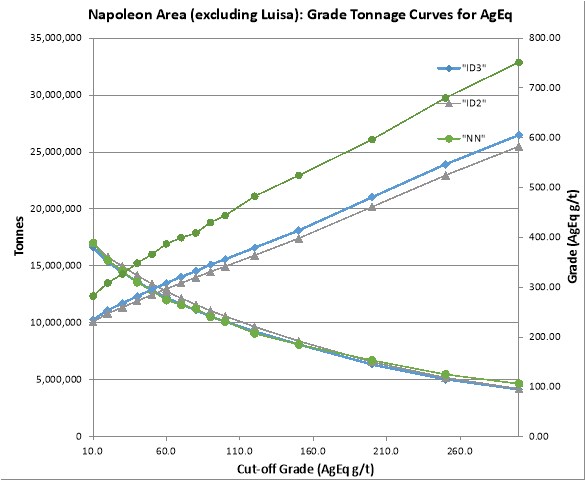

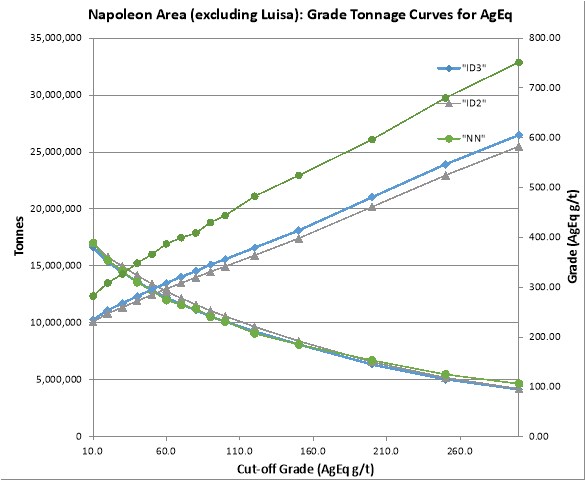

| 14.12.1 Sensitivity to Cut-off Grade | 195 |

| 14.13 Comparison of the current MRE to the January 2023 MRE | 199 |

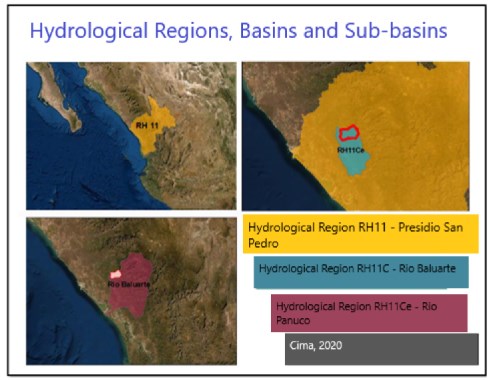

| 14.14 Disclosure | 200 |

| 15 Mineral Reserve Estimates | 201 |

| 16 Mining Methods | 202 |

| 16.1 Introduction | 202 |

| 16.2 Geotechnical and Hydrogeological Considerations | 202 |

| 16.2.1 Hydrogeology Considerations | 202 |

| 16.2.2 Geotechnical | 202 |

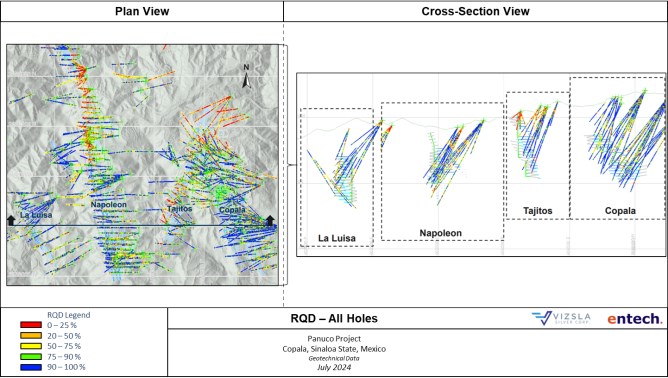

| 16.2.3 Collected Data | 202 |

| 16.2.4 Rock Mass Characterisation | 205 |

| 16.2.5 Stope Sizes | 206 |

| 16.2.6 Geotechnical - Ground Support | 209 |

| 16.2.7 Geotechnical - Backfill | 209 |

| 16.2.8 Geotechnical - Stand-off and Pillar Sizes | 210 |

| 16.3 Mine Dilution and Mining Recovery | 210 |

| 16.4 Proposed Mining Methods | 214 |

| 16.4.1 Net Smelter Return (NSR) | 215 |

| 16.4.2 Cut-Off Value | 215 |

| 16.4.3 Stope Design Parameters | 216 |

| 16.5 Underground Mine Design | 220 |

| 16.5.1 Mine Operations | 220 |

| 16.5.2 Development | 222 |

| 16.5.3 Production | 224 |

| 16.6 Mine Schedule | 226 |

| 16.6.1 Activity and Equipment Rates | 226 |

| 16.6.2 Lateral Development | 227 |

| 16.6.3 Vertical Development | 228 |

| 16.6.4 Longhole Drilling | 230 |

| 16.6.5 Material Movement | 231 |

| 16.6.6 Backfill | 234 |

| 16.6.7 Run-of-Mine Plan | 236 |

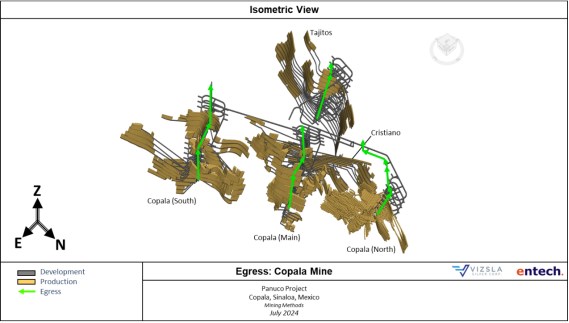

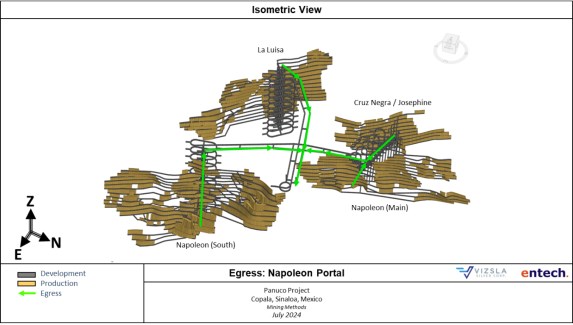

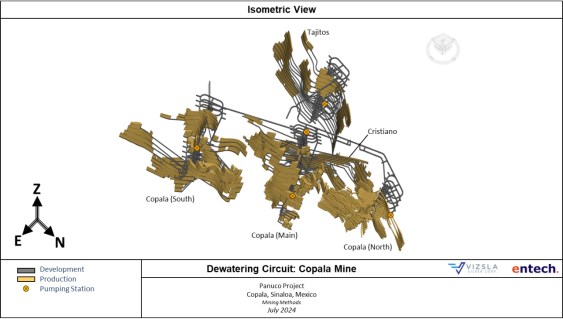

| 16.7 Underground Infrastructure and Services | 237 |

| 16.7.1 Portals | 237 |

| 16.7.2 Primary Ventilation | 237 |

| 16.7.3 Auxiliary Ventilation | 241 |

| 16.7.4 Secondary Means of Egress and Refuge Chambers | 241 |

| 16.7.5 Water Management | 242 |

| 16.7.6 Compressed Air | 244 |

| 16.7.7 Electrical Power | 244 |

| 16.8 Mine Personnel | 244 |

| 17 Recovery Methods | 246 |

| 17.1 Overview | 246 |

| 17.2 Process Design Criteria | 246 |

| 17.3 Process Plant Description | 247 |

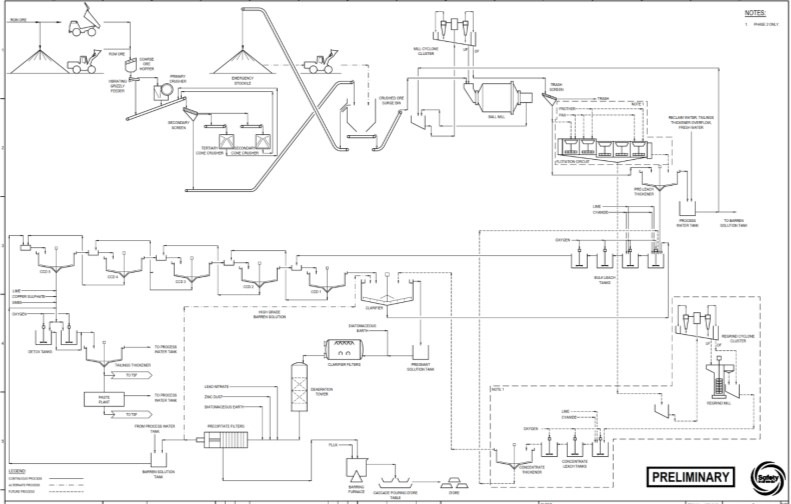

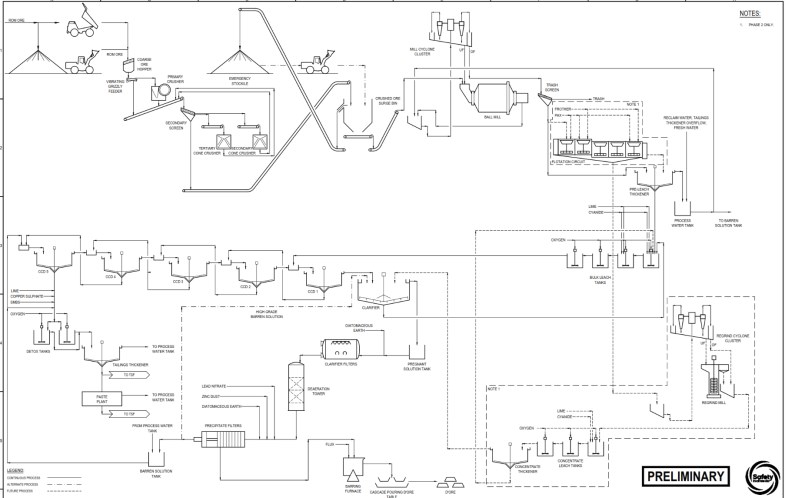

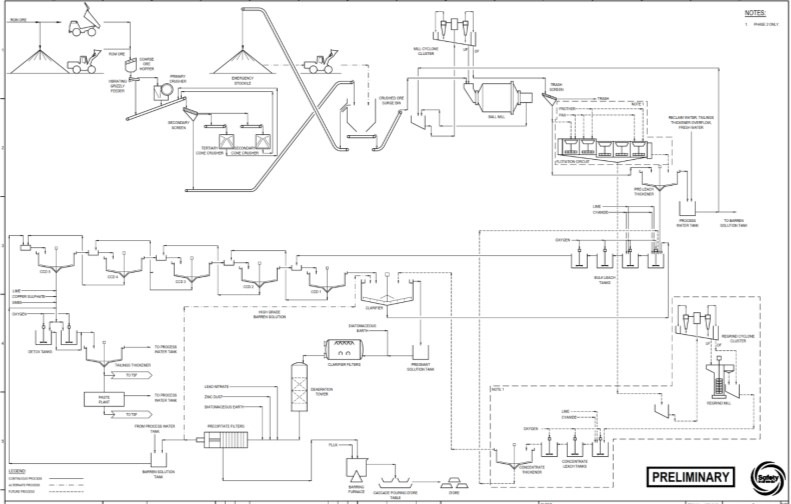

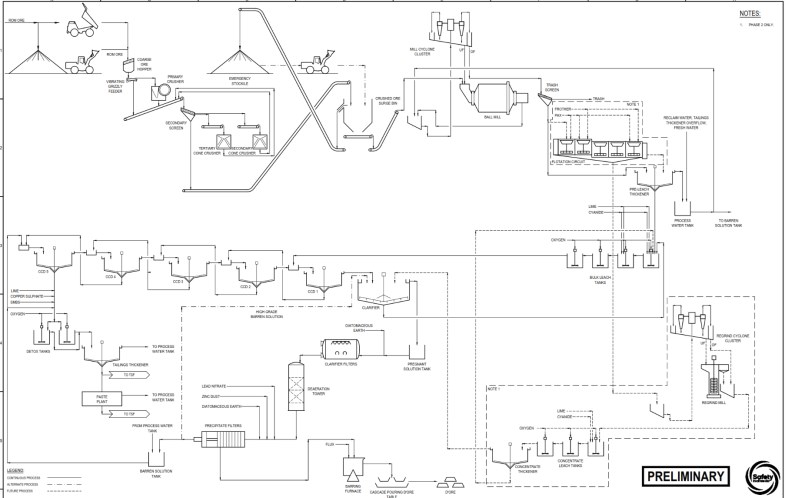

| 17.3.1 Process Flowsheet | 248 |

| 17.3.2 Mill Feed Schedule | 248 |

| 17.3.3 Phase 1 Design | 251 |

| 17.3.4 Phase 2 Design | 254 |

| 17.4 Reagents Handling and Storage | 255 |

| 17.5 Plant Services | 256 |

| 17.5.1 Raw Water | 256 |

| 17.5.2 Process Water | 257 |

| 17.5.3 Gland Seal Water | 257 |

| 17.5.4 Fire Water | 257 |

| 17.5.5 Potable Water | 257 |

| 17.5.6 Air | 257 |

| 17.5.7 Oxygen | 257 |

| 17.5.8 Power | 257 |

| 18 Project Infrastructure | 258 |

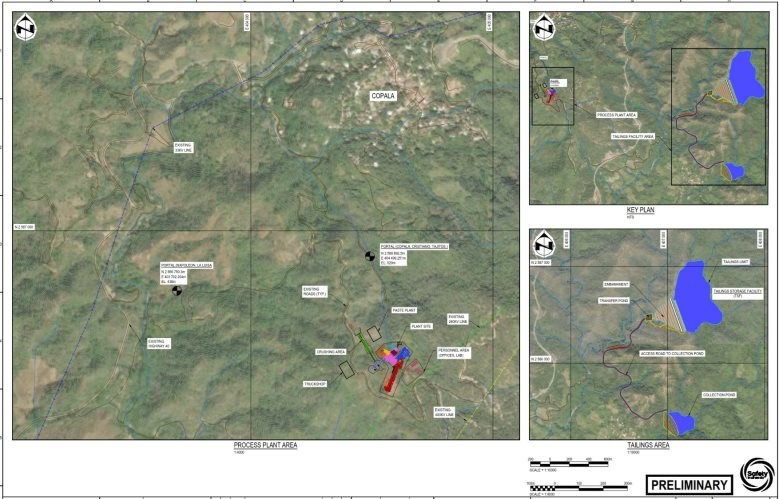

| 18.1 Introduction | 258 |

| 18.2 Off-site Infrastructure | 261 |

| 18.2.1 Site Access | 261 |

| 18.2.2 Water Supply | 261 |

| 18.2.3 Power Supply and Distribution | 261 |

| 18.2.4 Plant Nursery | 261 |

| 18.3 On-site Infrastructure | 262 |

| 18.3.1 Site Preparation | 262 |

| 18.3.2 On-Site Roads | 263 |

| 18.3.3 On-Site Infrastructure | 263 |

| 18.3.4 Fuel System | 264 |

| 18.3.5 Power Distribution | 264 |

| 18.3.6 Mining Infrastructure | 264 |

| 18.3.7 Process Plant Infrastructure | 265 |

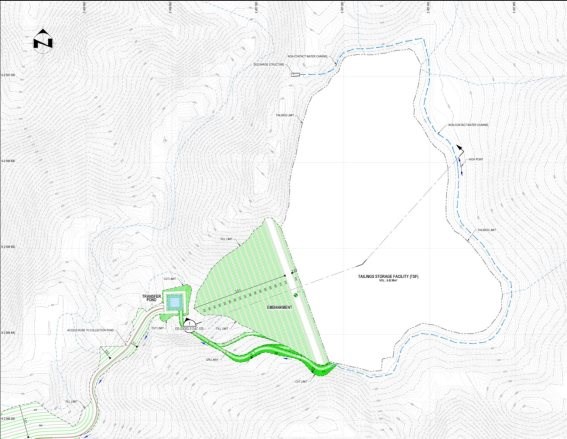

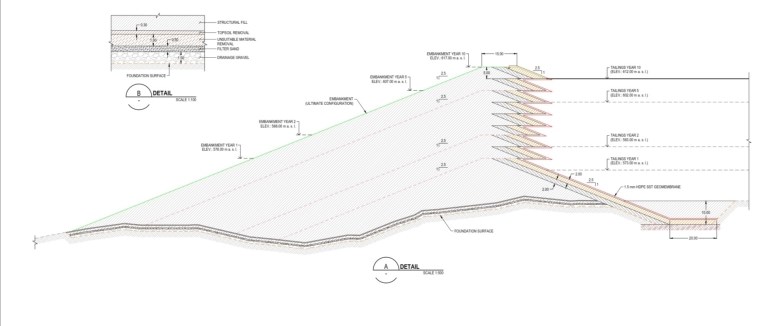

| 18.3.8 Tailings Storage Facility | 265 |

| 18.3.9 Waste Storage Facilities | 271 |

| 18.3.10 Water Supply and Management | 271 |

| 19 Market Studies and Contracts | 277 |

| 19.1 Market Studies | 277 |

| 19.2 Commodity Price Projections | 277 |

| 19.3 Contracts | 277 |

| 20 Environmental Studies, Permitting, and Social or Community Impact | 278 |

| 20.1 Introduction | 278 |

| 20.2 Environmental Baseline and Supporting Studies | 279 |

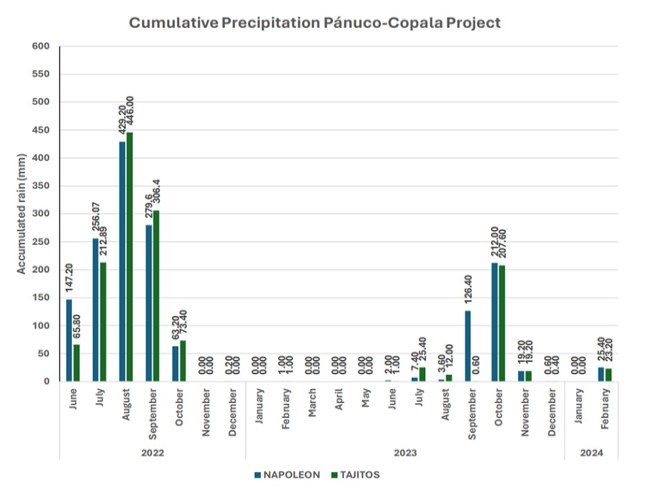

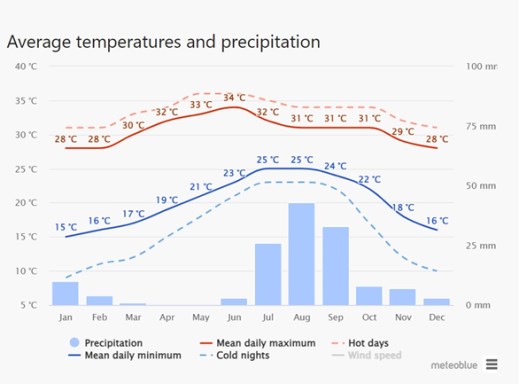

| 20.2.1 Meteorology and Climate | 280 |

| 20.2.2 Hydrogeological Investigation | 282 |

| 20.2.3 Hydrology | 284 |

| 20.2.4 Surface Water Quality | 285 |

| 20.2.5 Regional Groundwater Aquifer Characterization | 287 |

| 20.2.6 Air Quality | 287 |

| 20.2.7 Noise | 288 |

| 20.2.8 Soils | 289 |

| 20.2.9 Fauna | 291 |

| 20.2.10 Flora | 292 |

| 20.2.11 Fauna and Flora - Environmental Management | 292 |

| 20.3 Water and Waste Management | 292 |

| 20.4 Permitting Considerations | 294 |

| 20.4.1 Existing Exploration Permits | 294 |

| 20.4.2 Mexican Legal Framework and Permitting | 294 |

| 20.4.3 Amendments to Mexican Mining Regulation | 300 |

| 20.5 Environmental Management and Monitoring System | 300 |

| 20.6 Closure and Reclamation Planning | 301 |

| 20.7 Socio-Economic and Cultural Baseline Studies | 302 |

| 20.8 Community Engagement | 304 |

| 21 Capital and Operating Costs | 306 |

| 21.1 Introduction | 306 |

| 21.2 Capital Cost Estimate | 306 |

| 21.2.1 Capital Cost Summary | 306 |

| 21.2.2 Basis of Estimate | 307 |

| 21.2.3 Area 1000 - Mining Capital Costs | 307 |

| 21.2.4 Area 2000 - Process Capital Costs | 308 |

| 21.2.5 Area 3000 - Additional Facilities | 309 |

| 21.2.6 Area 4000 - On-Site Infrastructure Capital Costs | 309 |

| 21.2.7 Area 5000 - Off-Site Infrastructure Capital Costs | 310 |

| 21.2.8 Area 6000-9000 - Indirect Capital Costs | 310 |

| 21.2.9 Area 8000 - Owner (Corporate) Capital Costs | 311 |

| 21.2.10 Closure and Reclamation Planning | 312 |

| 21.3 Operating Costs | 312 |

| 21.3.1 Average Operating Cost Summary | 312 |

| 21.3.2 Basis of Estimate | 312 |

| 21.3.3 Mine Operating Costs | 313 |

| 21.3.4 Process Plant Operating Costs | 314 |

| 21.3.5 General & Administrative Costs | 316 |

| 22 Economic Analysis | 318 |

| 22.1 Forward-Looking Information Cautionary Statements | 318 |

| 22.2 Methodologies Used | 319 |

| 22.3 Financial Model Parameters | 319 |

| 22.3.1 Assumptions | 319 |

| 22.3.2 Taxes | 320 |

| 22.3.3 Royalties | 320 |

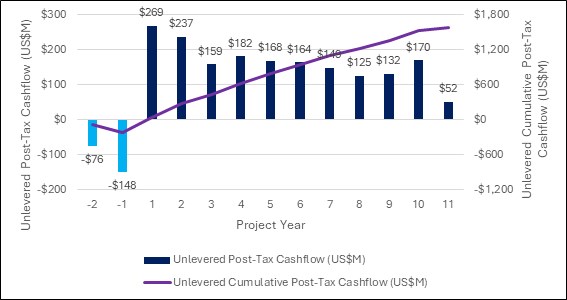

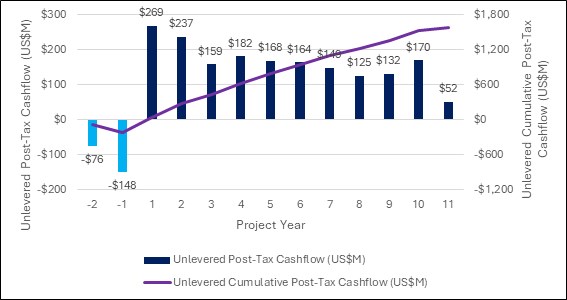

| 22.4 Economic Analysis | 320 |

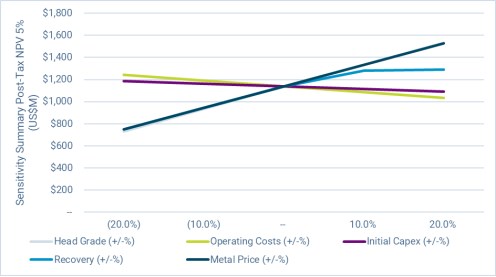

| 22.5 Sensitivity Analysis | 325 |

| 23 Adjacent Properties | 330 |

| 24 Other Relevant Data and Information | 331 |

| 25 Interpretation and Conclusions | 332 |

| 25.1 Introduction | 332 |

| 25.2 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements | 332 |

| 25.3 Geology and Mineralization | 333 |

| 25.4 Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation | 333 |

| 25.5 Metallurgical Test Work | 334 |

| 25.6 Mineral Resource Estimate | 335 |

| 25.6.1 Panuco Project Updated Mineral Resource Estimate Notes: | 337 |

| 25.7 Mining Methods | 338 |

| 25.8 Recovery Methods | 338 |

| 25.9 Infrastructure | 339 |

| 25.9.1 Site Infrastructure | 339 |

| 25.9.2 Tailings Storage Facility | 339 |

| 25.9.3 Water Management | 339 |

| 25.10 Markets and Contracts | 340 |

| 25.11 Environmental, Permitting and Community | 340 |

| 25.12 Capital Cost Estimate | 341 |

| 25.13 Operating Cost Estimate | 342 |

| 25.14 Economic Analysis | 342 |

| 25.15 Risks and Opportunities | 342 |

| 25.15.1 Risks | 342 |

| 25.15.2 Opportunities | 345 |

| 26 Recommendations | 348 |

| 26.1 Overall Recommendations | 348 |

| 26.2 Exploration & Drilling | 348 |

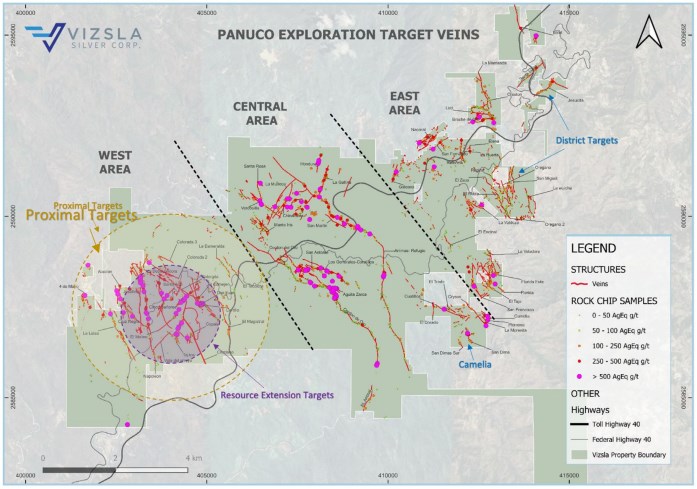

| 26.2.1 Resource Extension Targets | 349 |

| 26.2.2 Proximal Targets | 349 |

| 26.2.3 District Targets | 349 |

| 26.2.4 Bulk Sample / Test Mine | 349 |

| 26.2.5 Key Objectives for 2024 | 349 |

| 26.3 Metallurgical Test Work | 350 |

| 26.4 Mining Methods | 351 |

| 26.5 Process and Infrastructure Engineering | 352 |

| 26.6 Site Geotechnical Field and Laboratory Program | 352 |

| 26.7 Tailings Storage and Waste Rock Storage Design | 354 |

| 26.8 Environmental Studies, Permitting, Social or Community Recommendations | 354 |

| 26.8.1 Water Resources | 354 |

| 26.8.2 Geochemistry | 355 |

| 26.8.3 Other Environmental Baseline Studies | 355 |

| 26.8.4 Socio-Economic, Cultural Baseline Studies and Community Engagement | 356 |

| 26.8.5 Environmental Constraints Mapping | 356 |

| 26.9 Market Studies | 356 |

| 27 References | 357 |

List of Tables

| Table 1-1: Panuco Project Mineral Resource Estimate, September 1, 2023 | 9 |

| Table 1-2: Panuco Project Mineral Resource Estimate by Area, September 1, 2023 | 9 |

| Table 1-3: Total and Annual Material Movement Schedule for the Panuco Project | 12 |

| Table 1-4: Capital Costs Summary | 21 |

| Table 1-5: Average LOM Operating Cost | 22 |

| Table 1-6: Economic Analysis Summary Table | 22 |

| Table 1-7: Cost Summary for the Recommended Future Work | 25 |

| Table 2-1: Report Contributors | 27 |

| Table 2-2: Abbreviations and Acronyms | 30 |

| Table 2-3: Units of Measurement | 31 |

| Table 4-1: Property Mineral Concessions Held 100% By Vizsla | 38 |

| Table 7-1: General Description of Estimated Veins Included in the Mineral Resources Estimate for the Panuco Project | 60 |

| Table 9-1: Summary of Surface and Underground Rock Geochemistry Samples between 2019 and 2021 | 79 |

| Table 9-2: Panuco Project Surface Samples in 2022 | 84 |

| Table 9-3: Selected High-Grade Samples Taken During 2022 Surface Exploration | 84 |

| Table 9-4: Panuco Project Surface Samples in 2023 | 86 |

| Table 9-5: Selected High-Grade Samples Taken During 2023 Surface Exploration | 86 |

| Table 9-6: Panuco Project Surface Samples in 2024, to June 18 | 88 |

| Table 9-7: Selected High-Grade Samples Taken During 2024 Surface Exploration, to June 18 | 88 |

| Table 10-1: Summary Drilling Conducted by Vizsla on the Panuco Project, to June 18, 2024 | 90 |

| Table 10-2: Highlights of the 2019 - 2020 Drilling | 93 |

| Table 10-3: Highlights of the 2021 Drilling | 96 |

| Table 10-4: Highlights of the 2022 Drilling | 100 |

| Table 10-5: Highlights of the 2023 Drilling | 102 |

| Table 10-6: Highlights of the 2024 Drilling (to June 18, 2024) | 104 |

| Table 11-1: Summary of Drilling Samples from the Property by Year | 106 |

| Table 11-2: Summary of Drill Core Analytical Labs and Analysis Methods 2019 - 2024 | 107 |

| Table 11-3: QC Sample Statistics for Vizsla Core Sampling 2019 - 2024 | 111 |

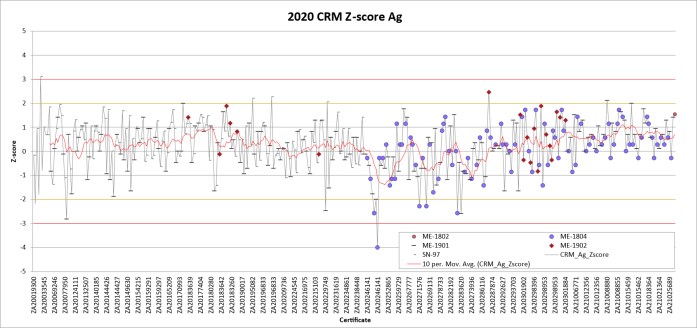

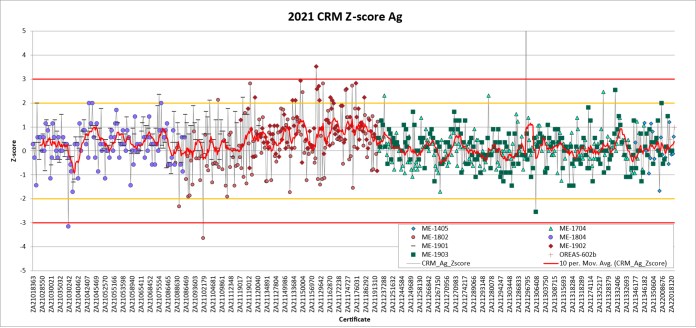

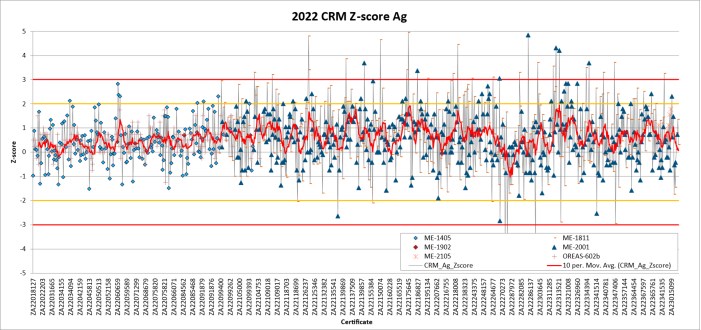

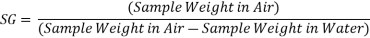

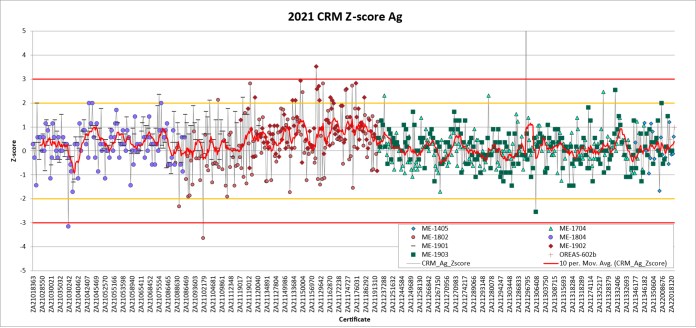

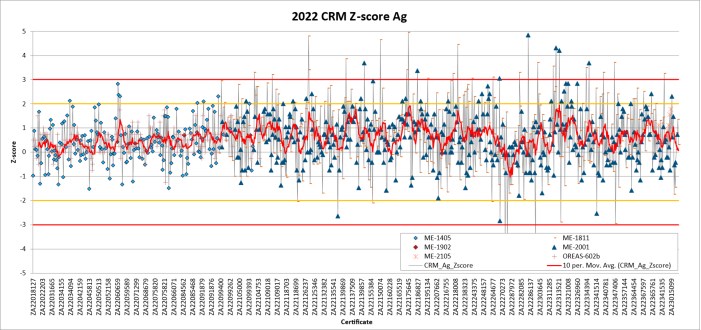

| Table 11-4: CRM Sample Ag Performance for the 2019-2024 Drill Programs | 113 |

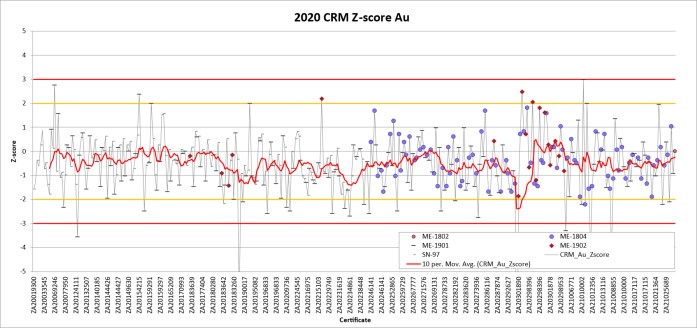

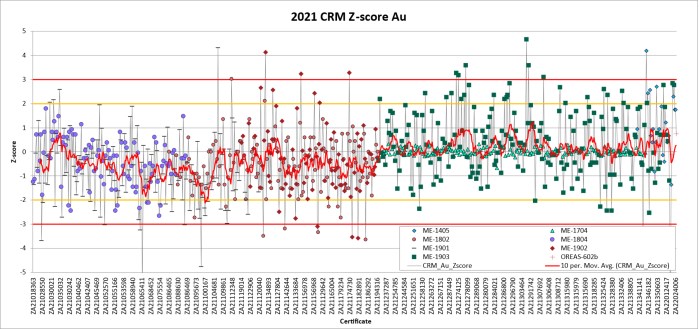

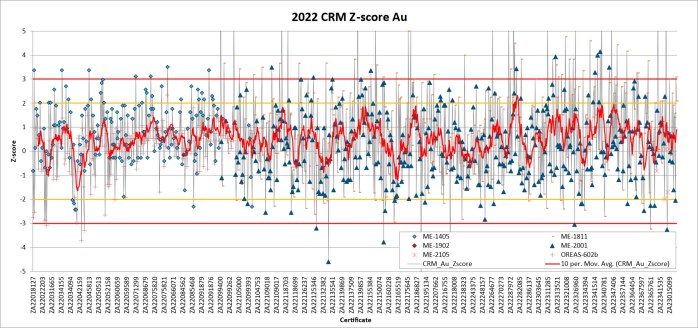

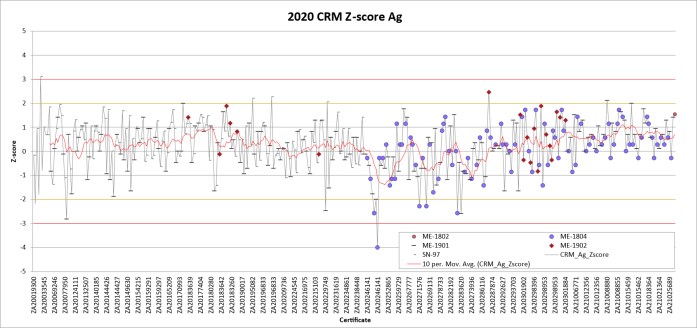

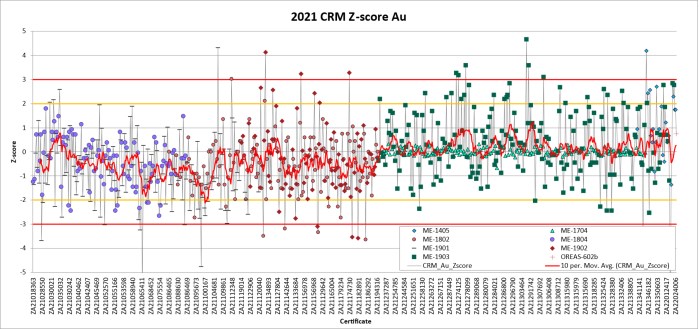

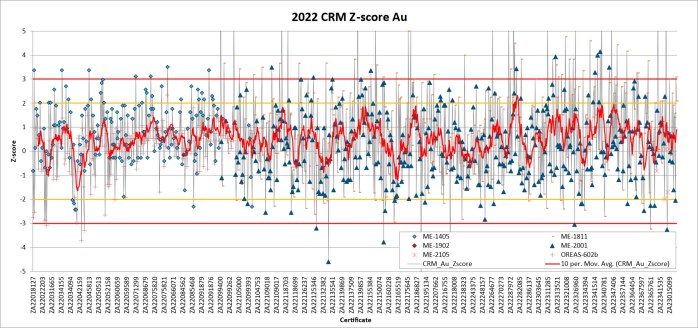

| Table 11-5: CRM Sample Au Performance for the 2019-2024 Drill Programs | 113 |

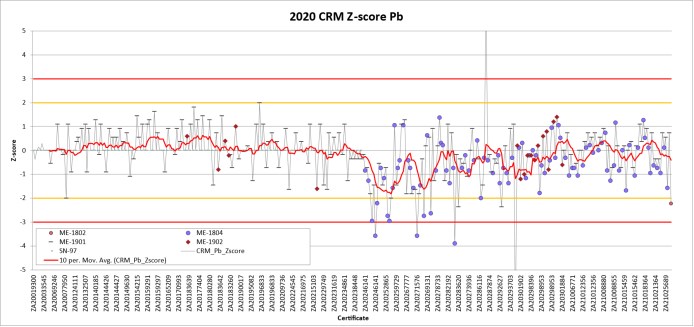

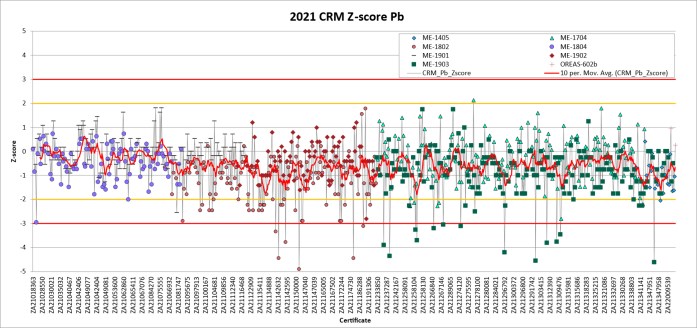

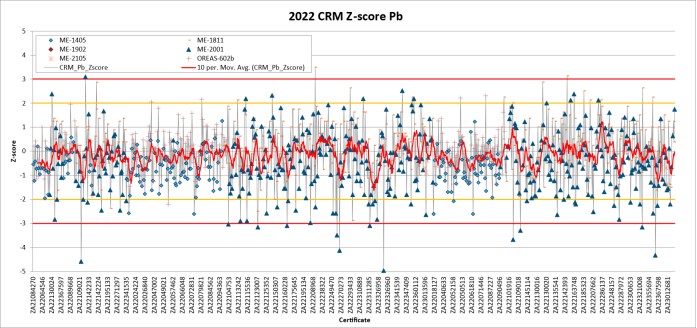

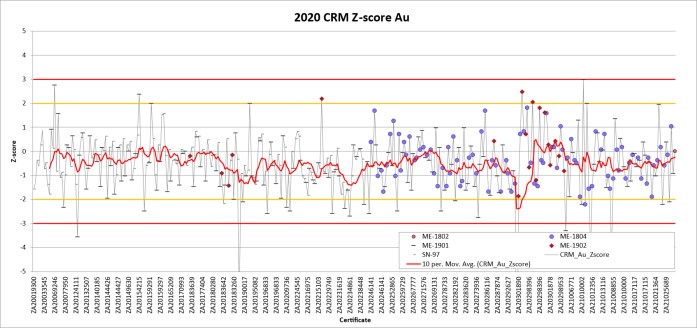

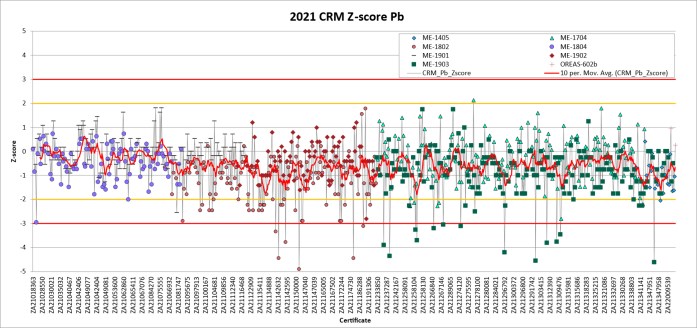

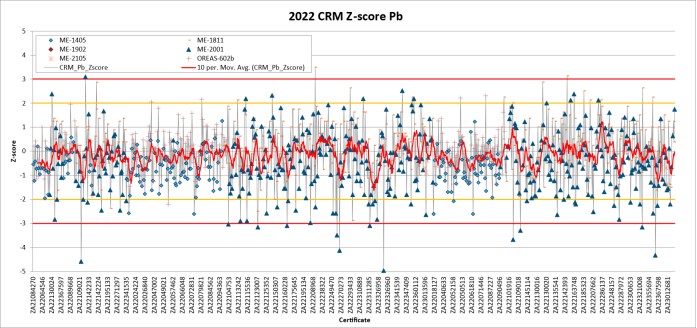

| Table 11-6: CRM Sample Pb Performance for the 2019-2024 Drill Programs | 114 |

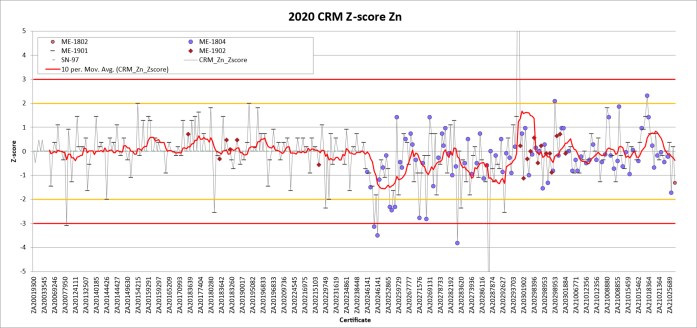

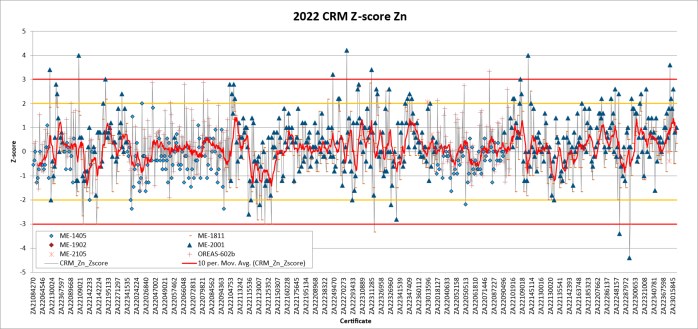

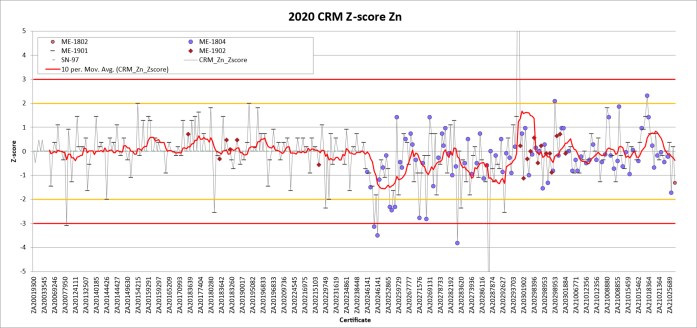

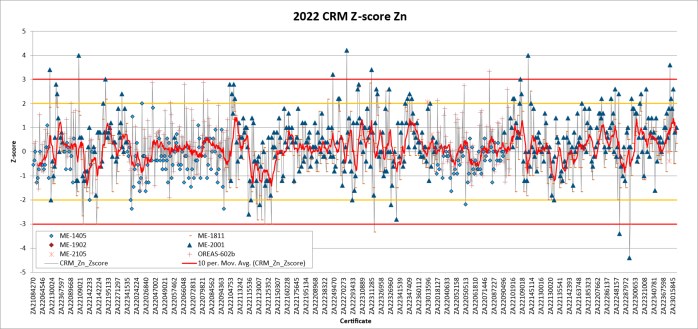

| Table 11-7: CRM Sample Zn Performance for the 2019-2024 Drill Programs | 114 |

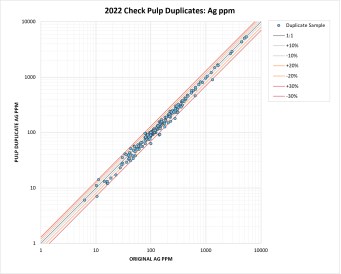

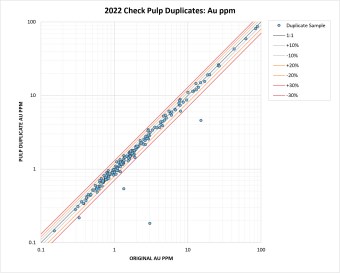

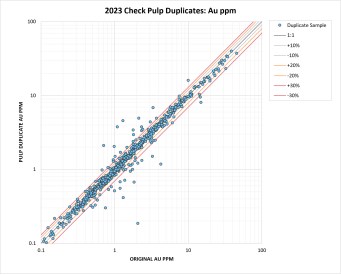

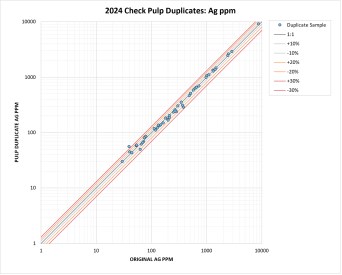

| Table 11-8: Average Relative Error of Duplicate Samples for Ag, Au, Pb, and Zn from 2019-2024 | 129 |

| Table 11-9: Relative Bias and Average Relative Error of Check Samples for Ag from 2022-2024 | 133 |

| Table 11-10: Relative Bias and Average Relative Error of Check Samples for Au from 2022-2024 | 133 |

| Table 13-1: Metallurgical Test Work Summary Table | 140 |

| Table 13-2 Metallurgical Sample Origin Details | 140 |

| Table 13-3: Chemical Composition of the Composites and Variability Samples | 141 |

| Table 13-4: Mineralogical Composition of the Composites | 142 |

| Table 13-5: Liberation Characteristics of the Composites - % Distribution | 142 |

| Table 13-6: Comminution Test Results | 143 |

| Table 13-7: Gravity Concentration Test Results | 144 |

| Table 13-8: Sequential Rougher Flotation Data - Master Composites | 145 |

| Table 13-9: Metallurgical Balance - Napoleon Cleaner Test 14 | 147 |

| Table 13-10: Bulk Flotation Rougher Recoveries | 148 |

| Table 13-11: Whole Feed Leach Results | 150 |

| Table 13-12: Flotation Concentrate Leach Results | 152 |

| Table 13-13: Rougher Flotation Tailings Leach Results | 154 |

| Table 13-14: Combined Flotation Plus Leach Results - Copala | 156 |

| Table 13-15: Whole Ore Leach Recovery Estimates | 157 |

| Table 13-16: Flotation Plus Leach Recovery Estimates | 157 |

| Table 14-1: Project Drill Hole Totals | 160 |

| Table 14-2: Property Domain Descriptions | 162 |

| Table 14-3: Statistical Analysis of the Drill Assay Data from Within the Deposit Mineral Domains - by Area | 166 |

| Table 14-4: Statistical Analysis of the 1.5M Composite Data from Within the Deposit Mineral Domains by Area | 169 |

| Table 14-5: Composite Capping Summary - by Domain/Deposit Area | 172 |

| Table 14-6: Deposit Block Model Geometry | 173 |

| Table 14-7: Grade Interpolation Parameters by Area and Domain | 178 |

| Table 14-8: Parameters used for Underground Cut-off Grade Calculation | 183 |

| Table 14-9: Panuco Project Mineral Resource Estimate, September 1, 2023 | 184 |

| Table 14-10: Panuco Project Mineral Resource Estimate by Area, September 1, 2023 | 186 |

| Table 14-11: Comparison of Average Composite Grades with Block Model Grades | 193 |

| Table 14-12: Underground Mineral Resource Estimate at Various AgEq Cut-off Grades, September 1, 2023 | 196 |

| Table 14-13: Comparison of the January 2023 MRE to the September 2023 MRE for the Project | 200 |

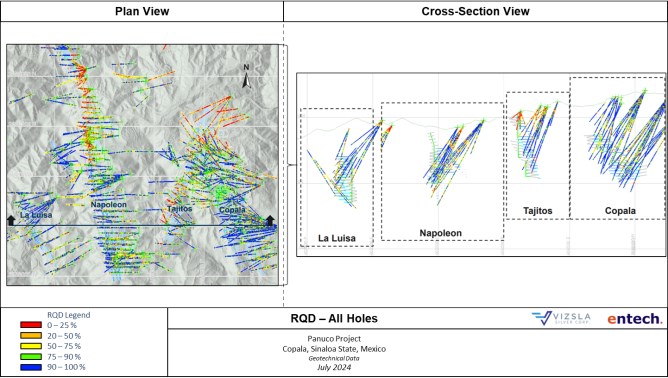

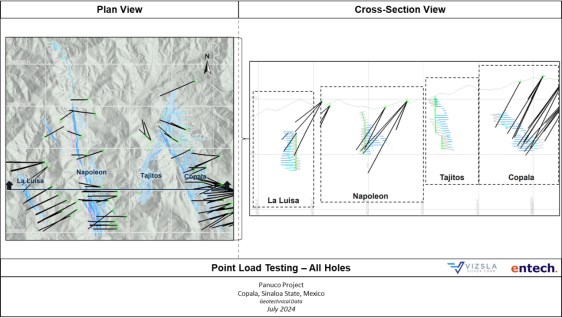

| Table 16-1: Geotechnical Logged Drillholes to Date | 203 |

| Table 16-2: Results of Machine Learning Rock Mass Categorization | 205 |

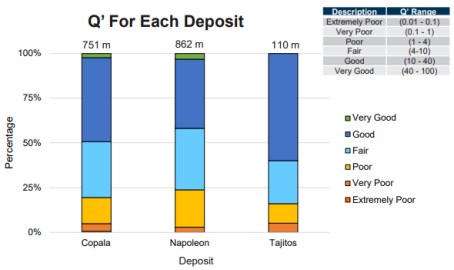

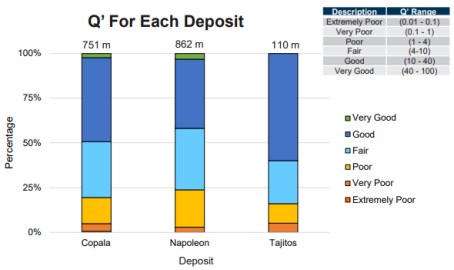

| Table 16-3: 2023 Geotechnical Drilling Campaign Results (Q') | 205 |

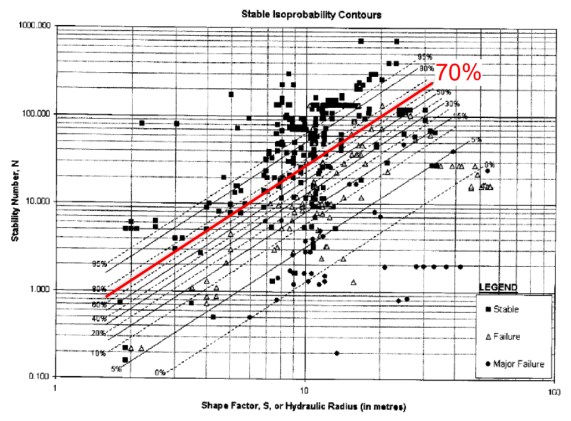

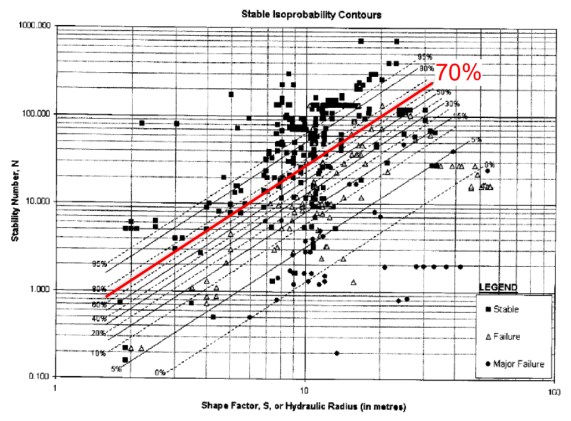

| Table 16-4: Stope Spans for the Panuco Project | 207 |

| Table 16-5: Stope Stability Assessment (Factor A) | 207 |

| Table 16-6: Stope Stability Assessment (Factor B) | 207 |

| Table 16-7: Stope Stability Assessment (Factor C) | 208 |

| Table 16-8: Excavation and Ground Support Standards for the Panuco Project | 209 |

| Table 16-9: Mineralization (M), Waste (W) and Fill (F) Surface Contacts for Each Mining Method | 213 |

| Table 16-10: Dilution and Recovery Summary | 214 |

| Table 16-11: Stope Dimensions by Mining Method | 214 |

| Table 16-12: Parameters used to estimate NSR | 215 |

| Table 16-13: Grade Multipliers ($USD / unit) Used to Estimate NSR in the Block Model | 215 |

| Table 16-14: Costs to be Included in the Various Cut-Off Values | 216 |

| Table 16-15: Summary of the Various Cut-Off Values - Preliminary Estimates | 216 |

| Table 16-16: Preliminary MSO Parameters | 217 |

| Table 16-17: Key Economic Screening Parameters | 217 |

| Table 16-18: Development Profiles for the Panuco Project | 223 |

| Table 16-19: Development Activity and Equipment Rates for the Panuco Project | 226 |

| Table 16-20: Production Activity and Equipment Rates the Panuco Project | 226 |

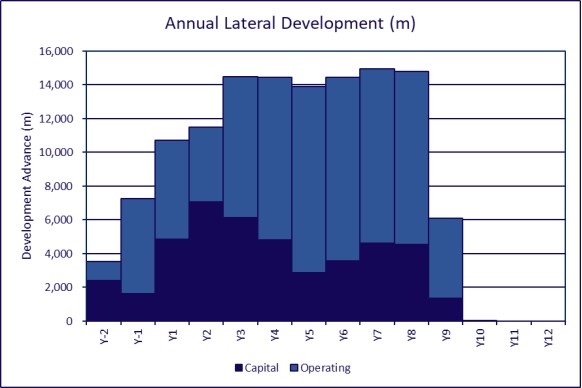

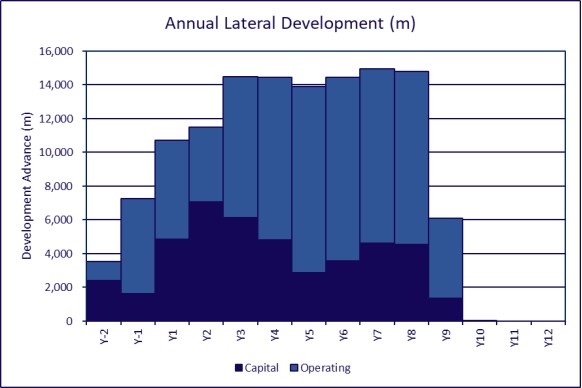

| Table 16-21: Total and Annual Lateral Development Schedule for the Panuco Project | 228 |

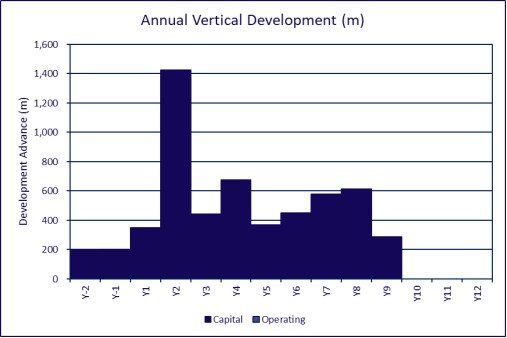

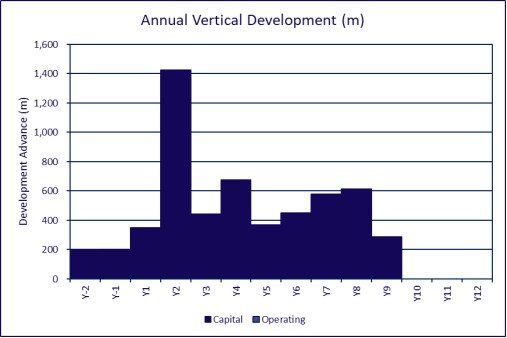

| Table 16-22: Total and Annual Vertical Development Schedule for the Panuco Project | 229 |

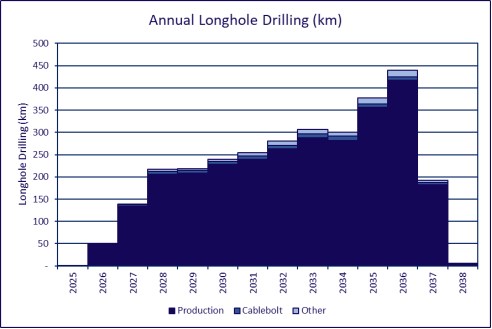

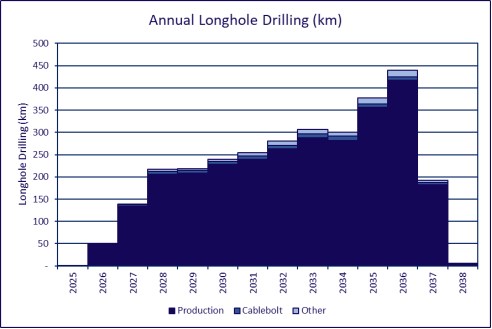

| Table 16-23: Total and Annual Longhole Drilling Schedule for the Panuco Project | 231 |

| Table 16-24: Load and Haul Fleet for the Panuco Project | 231 |

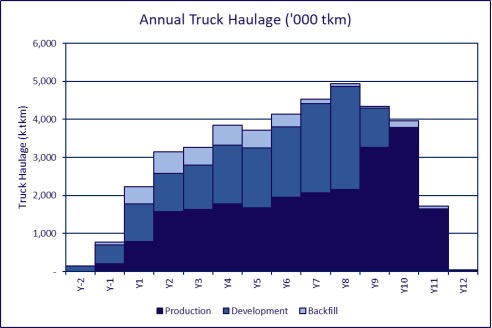

| Table 16-25: Total and Annual Material Movement Schedule for the Panuco Project | 233 |

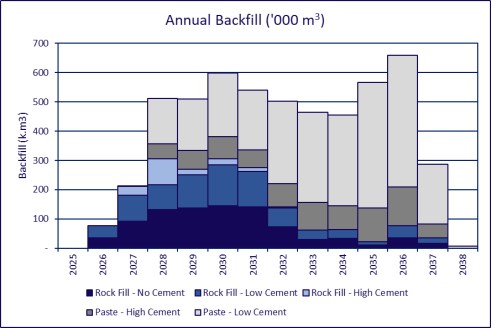

| Table 16-26: Backfill Schedule by type for the Panuco Project | 235 |

| Table 16-27: Waste Backfill Balance for the Panuco Project | 236 |

| Table 16-28: Annualized Mineralised Material Delivered to ROM | 237 |

| Table 16-29: Mineralised Material Classification Summary | 237 |

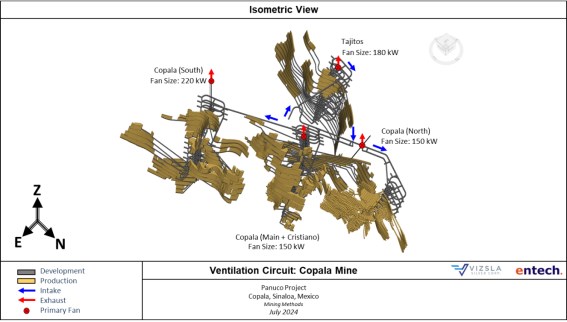

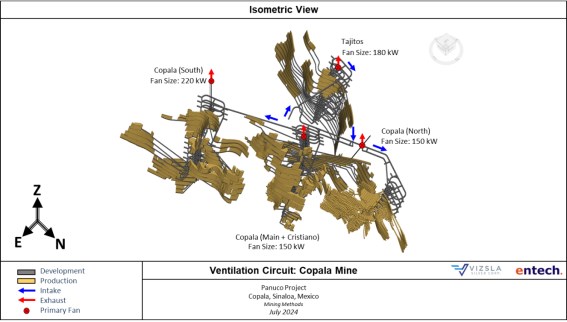

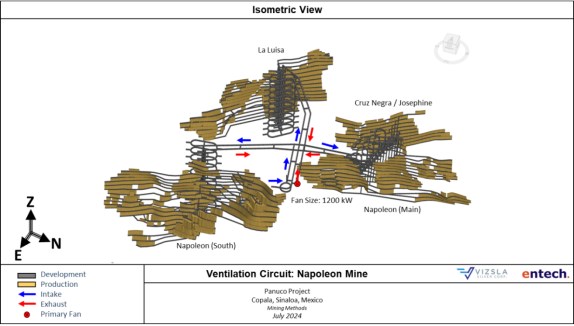

| Table 16-30: Ventilation Demand Estimate for the Copala Mine | 239 |

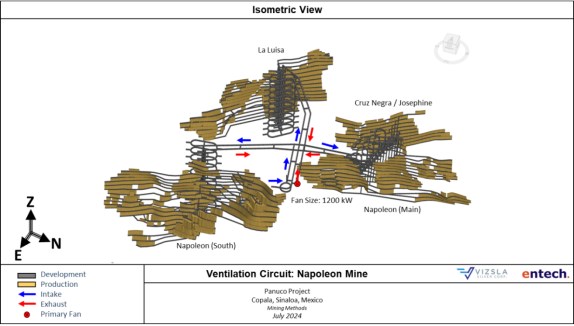

| Table 16-31: Ventilation Demand Estimate for the Napoleon Mine | 240 |

| Table 16-32: Panuco Project Power Estimate (Mining Activities Only) | 244 |

| Table 16-33: Panuco Project Mine Personnel Estimate | 245 |

| Table 17-1: Process Design Criteria | 246 |

| Table 17-2: Mill Production Schedule | 250 |

| Table 17-3: Reagents Handling and Storage | 255 |

| Table 17-4: Major Reagent and Operating Consumable Consumption Summary | 256 |

| Table 18-1: Panuco Building List | 263 |

| Table 18-2: Life-of-Mine Tailings Deposition Schedule | 269 |

| Table 18-3: Details of Climate Stations Including Name, ID, Coordinates, and Distance to Site | 272 |

| Table 18-4: Summary of Temperature, Precipitation ad Evaporation Data at Potrerillos Station | 272 |

| Table 18-5: Intensity-Duration-Frequency Values for Panuco Site | 272 |

| Table 18-6: Dimensions of the Collection Dam | 273 |

| Table 18-7: Water Balance Summary | 275 |

| Table 18-8: Site Wide Water Balance for an Average Year - Scenario 1 | 276 |

| Table 19-1: Metal Price Projections | 277 |

| Table 20-1: Baseline Characterization / Monitoring Rounds and Their Focuses | 280 |

| Table 20-2: Groundwater balance parameters for the aquifer | 287 |

| Table 20-3: Types of soils in the Project area | 290 |

| Table 20-4: List of Fauna Detected (CIMA Consultants MIA, 2020). | 291 |

| Table 20-5: Permitting Requirements | 295 |

| Table 21-1: Capital Costs Summary | 306 |

| Table 21-2: Mining Capital Costs | 308 |

| Table 21-3: Process Plant Initial Capital Cost | 309 |

| Table 21-4: Additional Facilities Cost | 309 |

| Table 21-5: On-Site Infrastructure Capital Costs | 310 |

| Table 21-6: Off-Site Infrastructure Capital Costs | 310 |

| Table 21-7: Indirect Capital Cost Summary | 311 |

| Table 21-8: Average LOM Operating Cost | 312 |

| Table 21-9: Mining Operating Costs Summary | 313 |

| Table 21-10: Mining Production Costs | 313 |

| Table 21-11: Process Plant Operating Cost Summary | 314 |

| Table 21-12: Reagents and Consumables Cost Summary | 315 |

| Table 21-13: G&A Cost Summary | 317 |

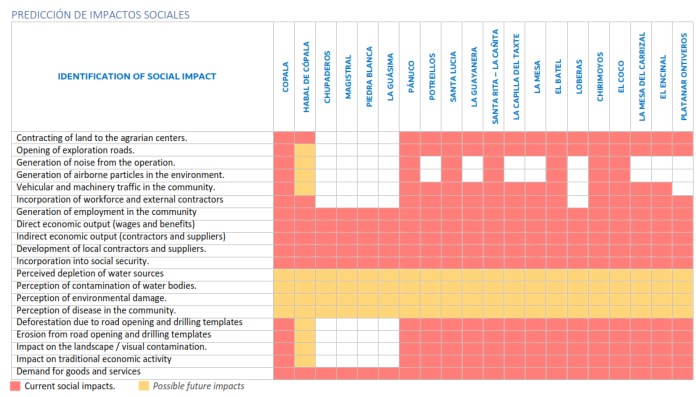

| Table 22-1: Economic Analysis Summary Table | 322 |

| Table 22-2: Life of Mine Economics | 323 |

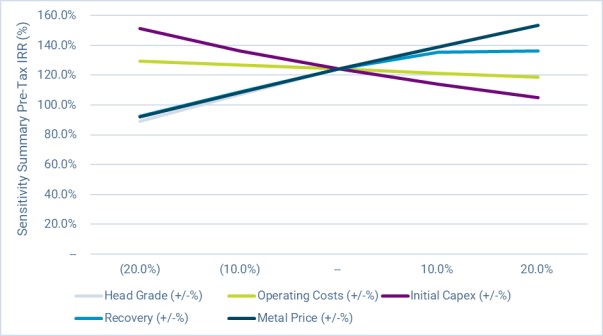

| Table 22-3: Pre-Tax NPV (US$M) and IRR (%) Sensitivity Analysis | 326 |

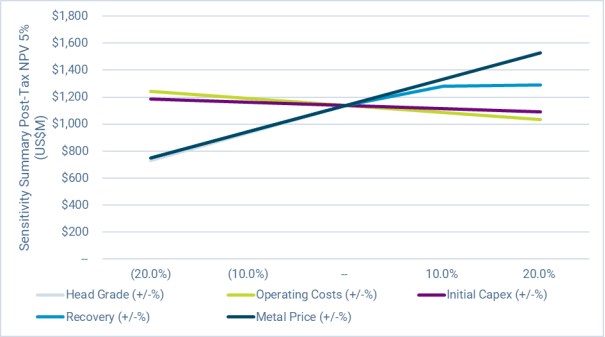

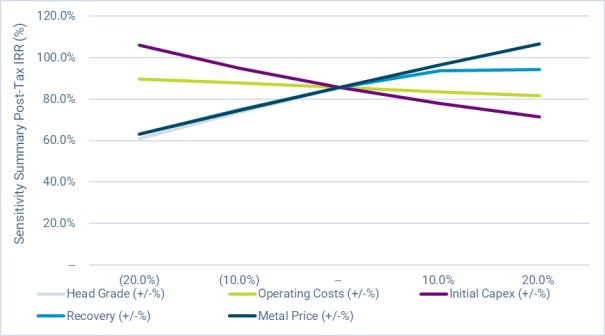

| Table 22-4: Post-Tax NPV (US$M) and IRR (%) Sensitivity Analysis | 327 |

| Table 25-1: Panuco Project Mineral Resource Estimate, September 1, 2023 | 336 |

| Table 25-2: Panuco Project Mineral Resource Estimate by Area, September 1, 2023 | 336 |

| Table 25-3: Metal Price Projections | 340 |

| Table 26-1: Cost Summary for the Recommended Future Work | 348 |

List of Figures

| Figure 1-1: Process Flow Diagram | 14 |

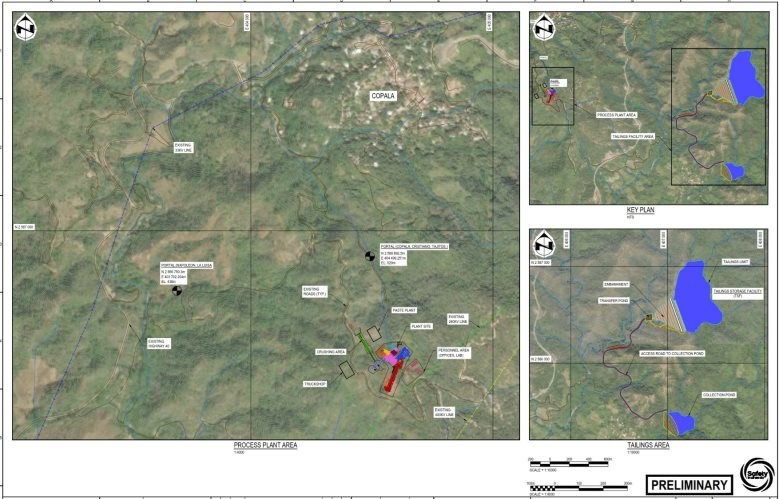

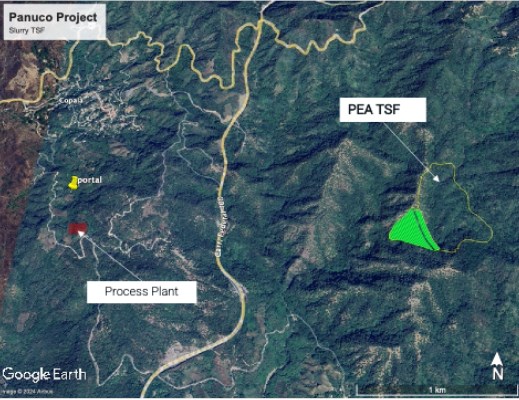

| Figure 1-2: Panuco Project Site Layout | 16 |

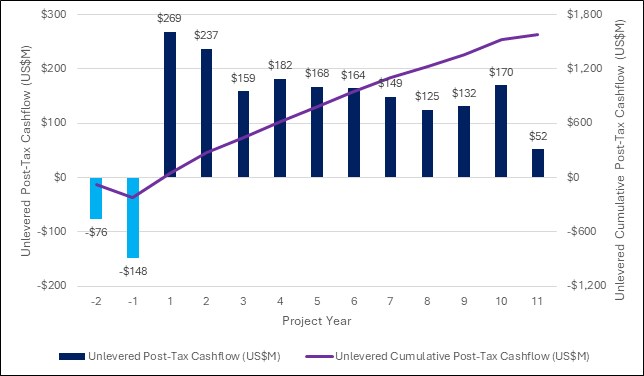

| Figure 1-3: Project Post-Tax Unlevered Cashflow | 23 |

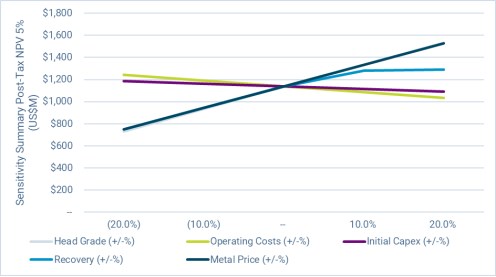

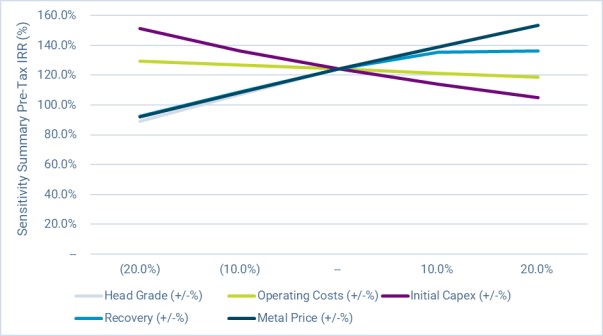

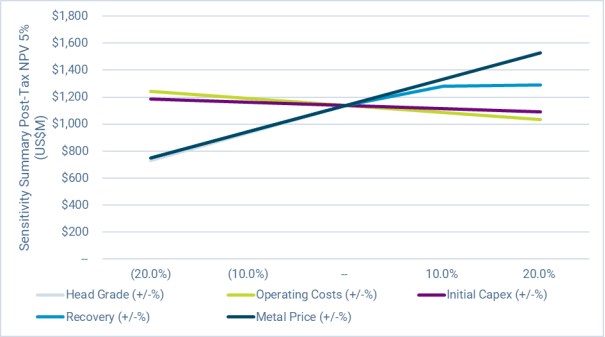

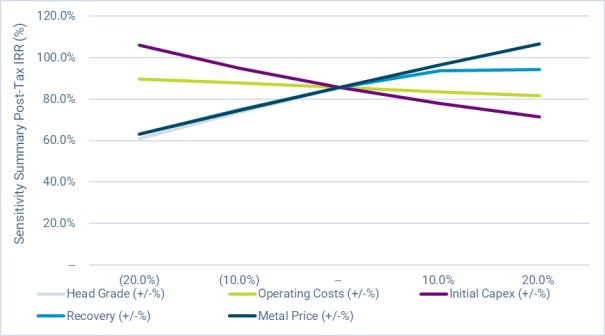

| Figure 1-4: Post-Tax NPV and IRR Sensitivity Results | 24 |

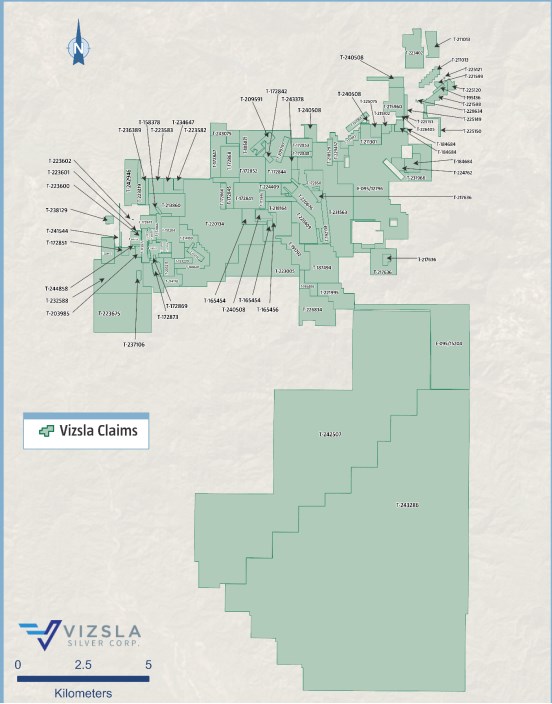

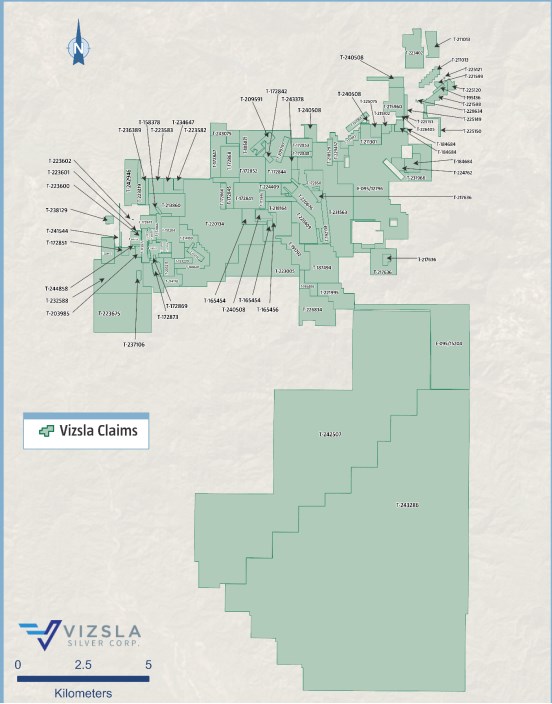

| Figure 4-1: Property Location Map | 36 |

| Figure 4-2: Mining Concessions (WGS 84 UTM Zone 13N) | 37 |

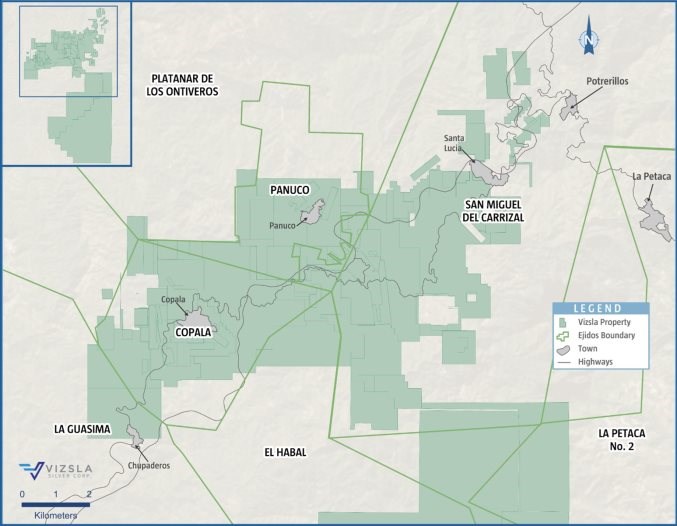

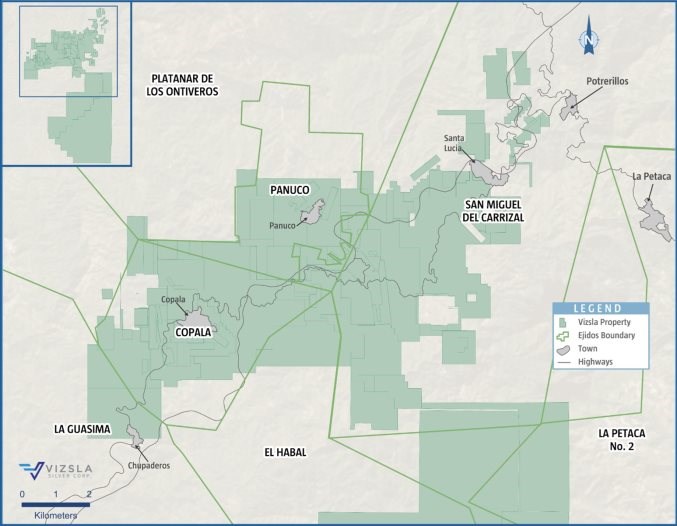

| Figure 4-3: Location of Ejidos and Outline of Panuco Project | 44 |

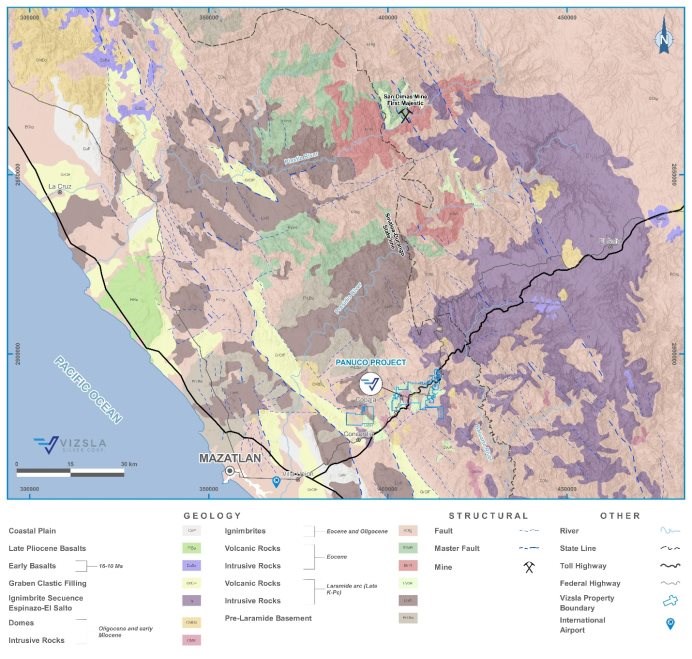

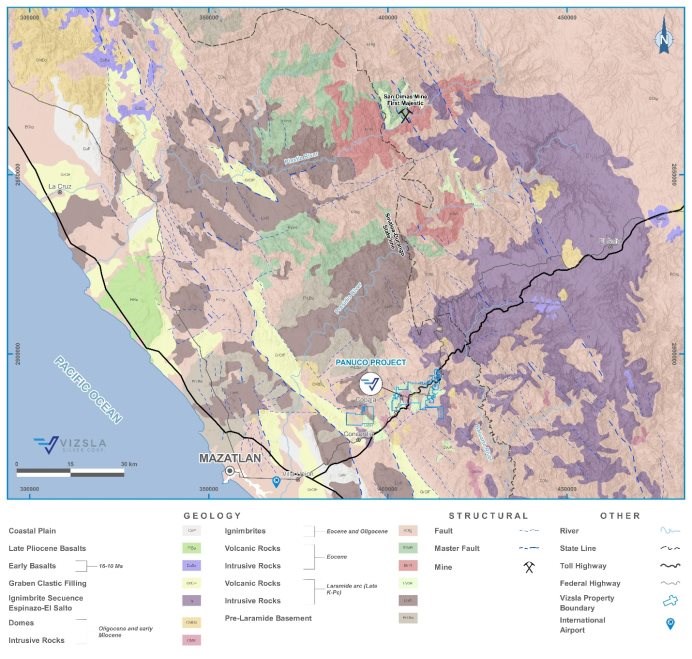

| Figure 7-1: Metallogenic Setting Map. Illustrates Geological Setting of Western Mexico with Main Porphyry and Epithermal Deposits of the Sierra Madre Occidental | 52 |

| Figure 7-2: Regional Geologic Setting Map. Illustrates Regional Geological Central Sierra Madre Occidental | 53 |

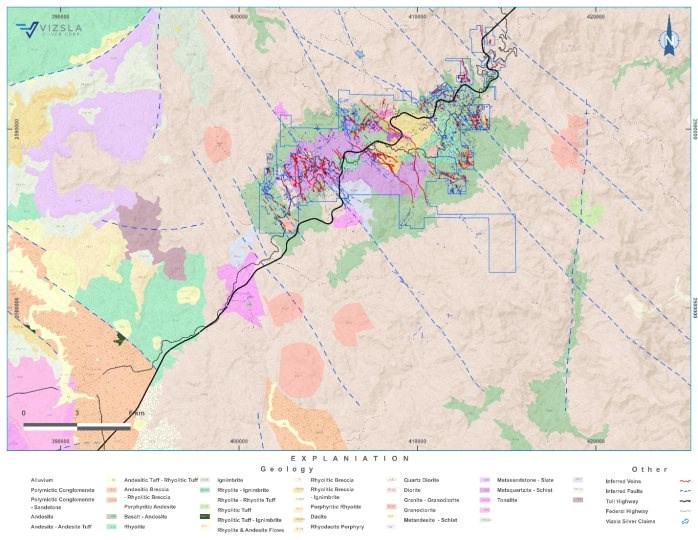

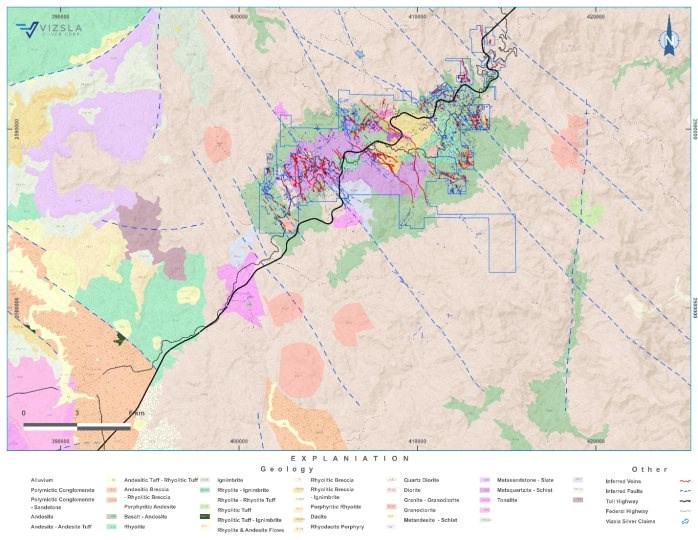

| Figure 7-3: Regional Geology Map | 54 |

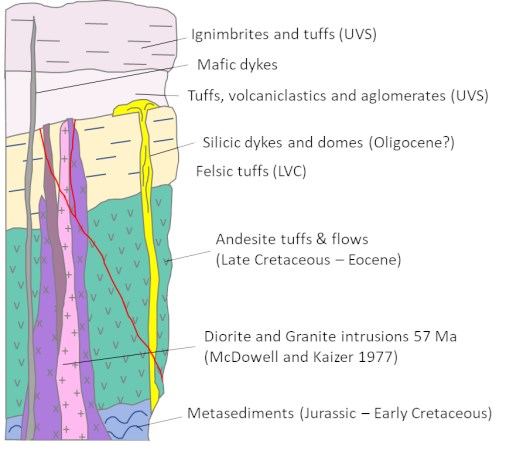

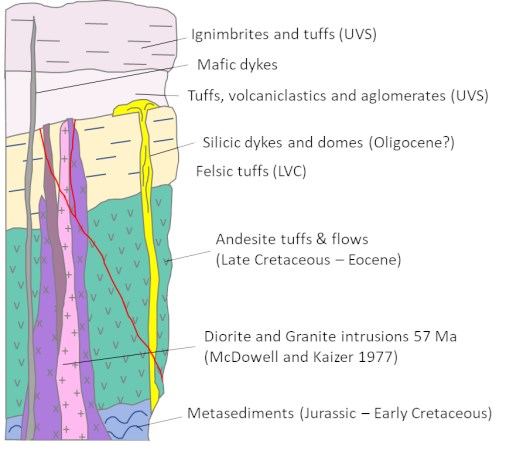

| Figure 7-4: Stratigraphic Column for the Project Area | 55 |

| Figure 7-5: Property Geology Map Showing Claim Outline and Known Mineralized Structures | 58 |

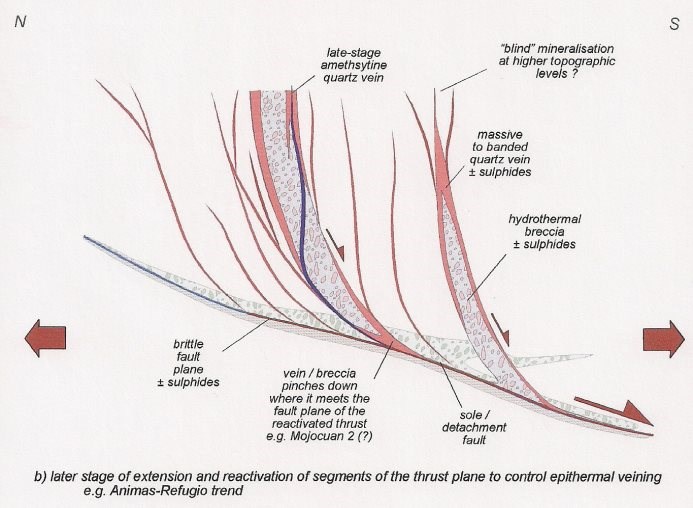

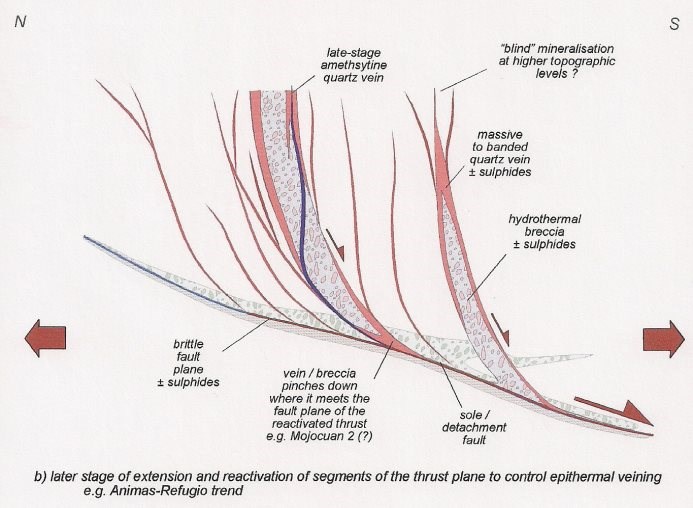

| Figure 7-6: Schematic Cross-Section of Panuco Veining Illustrating that Veins May Be Listric Faults Developed from Reactivated Laramide Thrust Faults (Starling 2019) | 59 |

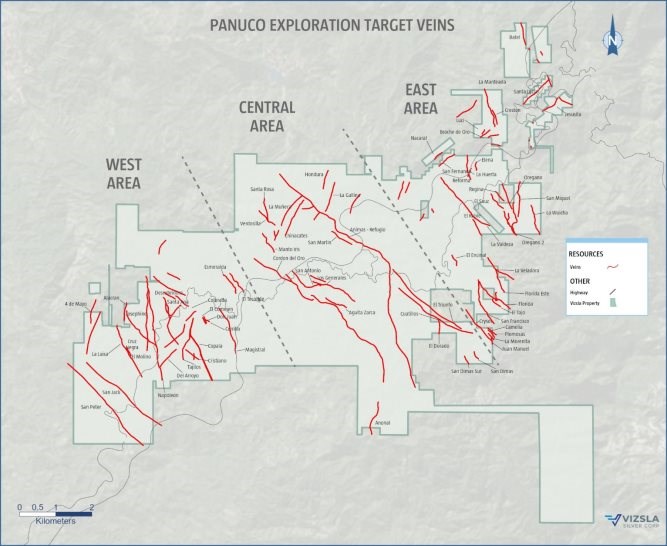

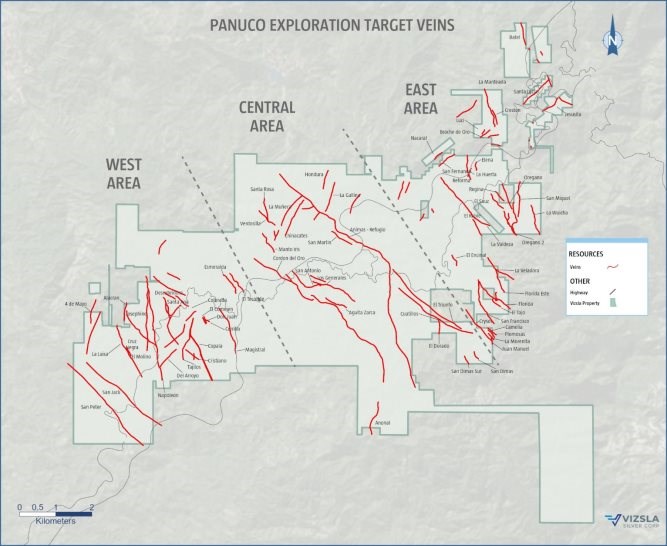

| Figure 7-7: Panuco Project Claims Showing Known Veins, Including the Four Resource Areas Comprising Eleven Veins Included in the Mineral Resource Estimate | 61 |

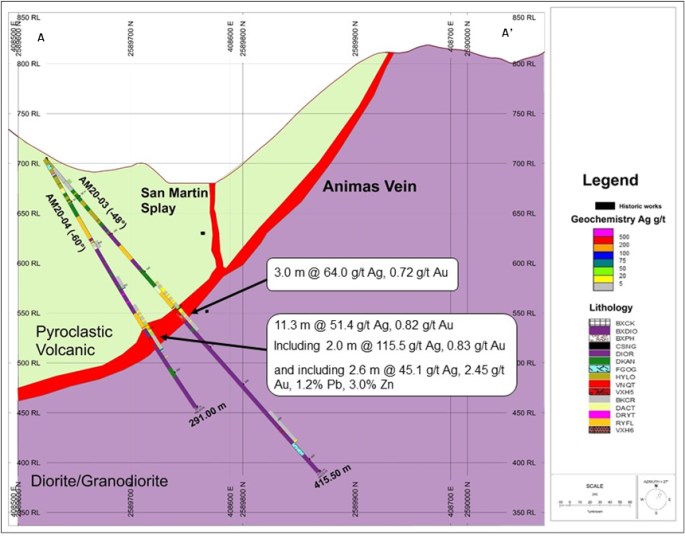

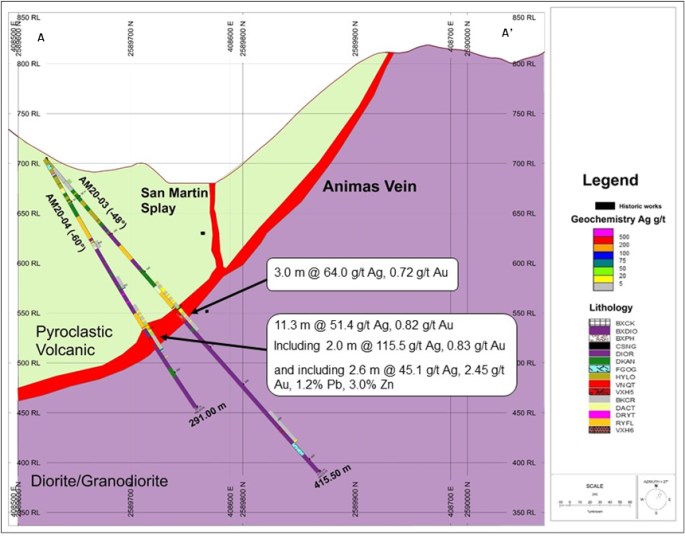

| Figure 7-8: Animas-Refugio Geology and Silver Geochemistry (Section A-A' Shown in Figure 7-9) | 63 |

| Figure 7-9: Animas-Refugio Vein Cross-Section Looking Northwest | 64 |

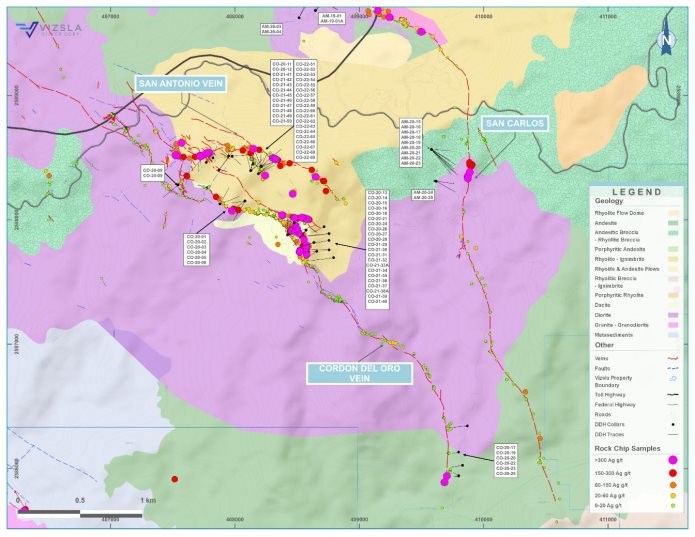

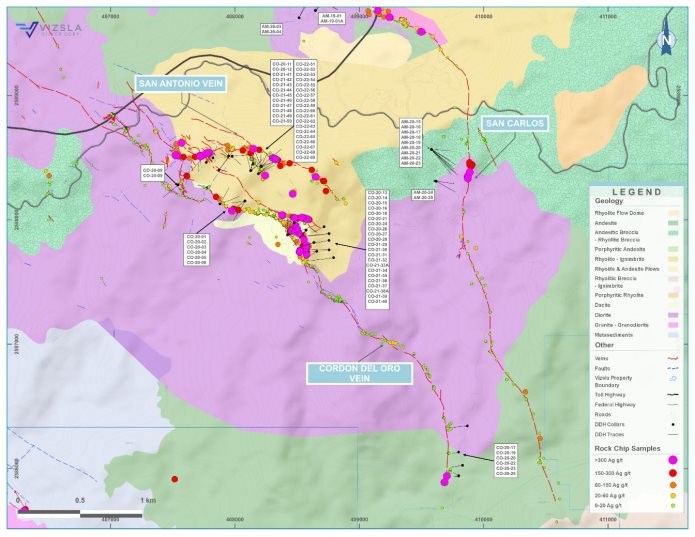

| Figure 7-10: Cordon del Oro Geology and Silver Geochemistry | 66 |

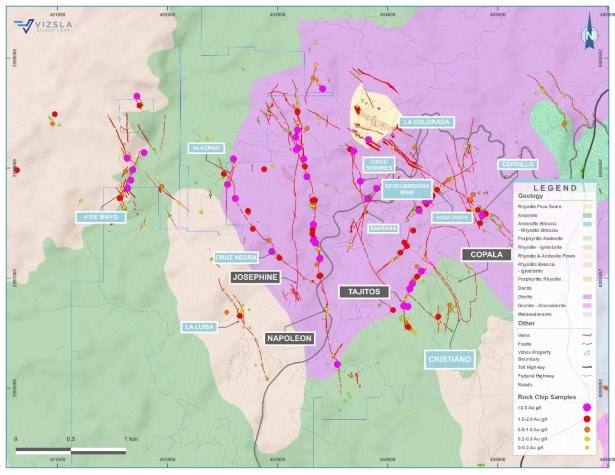

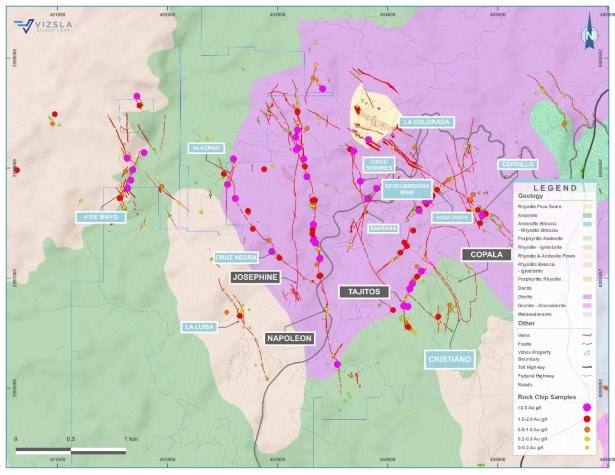

| Figure 7-11: Cinco Señores-Napoleon Geology and Silver Geochemistry | 67 |

| Figure 7-12: Descubridora Mine Geology and Geochemistry | 68 |

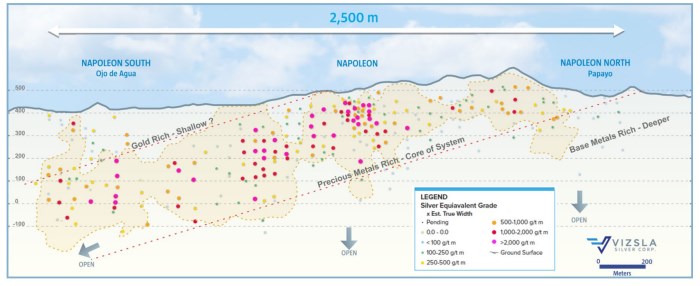

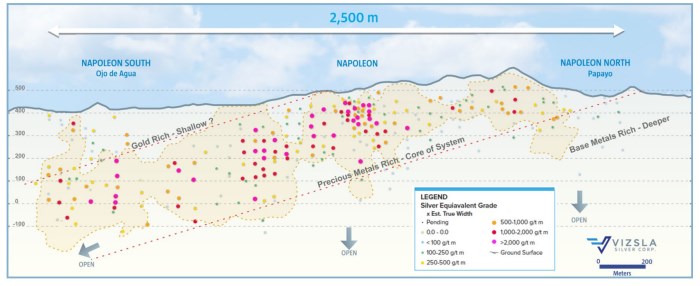

| Figure 7-13: Drill-hole Intercepts Showing Tilted Mineralization on Napoleon Main Vein | 69 |

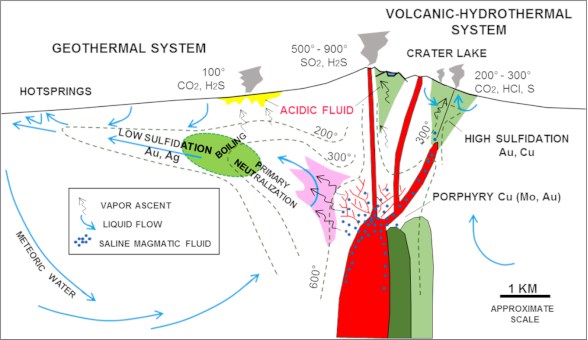

| Figure 8-1: Genetic Model for Epithermal Deposits | 76 |

| Figure 8-2: Schematic of Alteration and Mineralization in Low Sulphidation Precious Metal Deposits | 77 |

| Figure 9-1: Panuco District Mapped Areas at 1:1,000 Scale as of December 2023 | 78 |

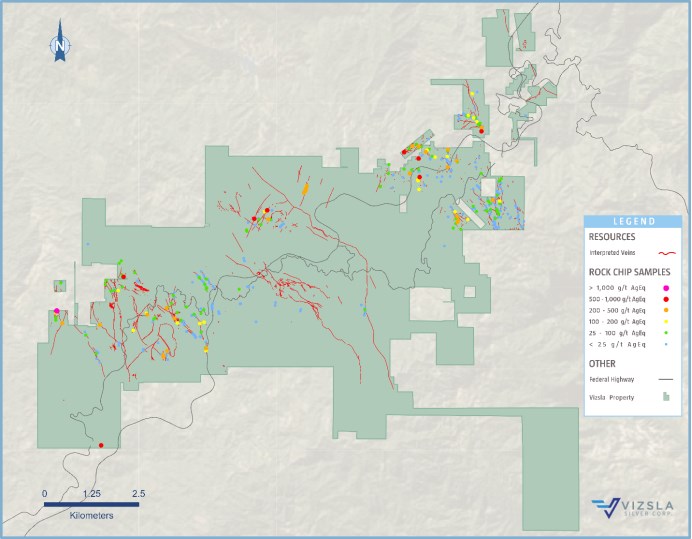

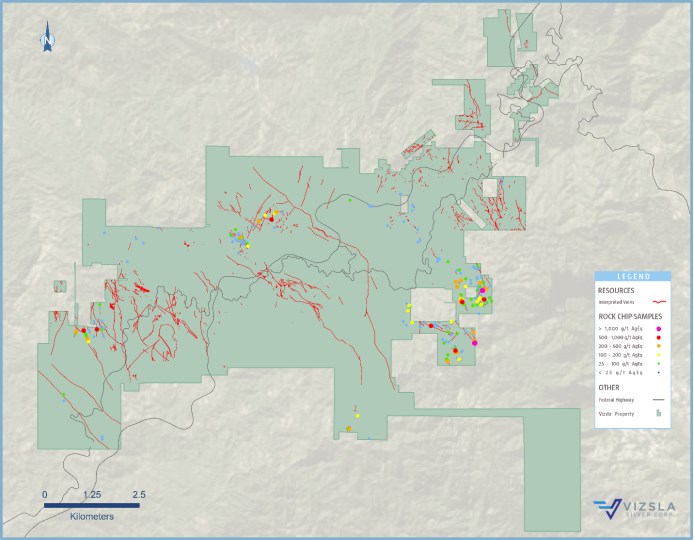

| Figure 9-2: Surface Sampling at Panuco Project between 2019 and 2021 | 80 |

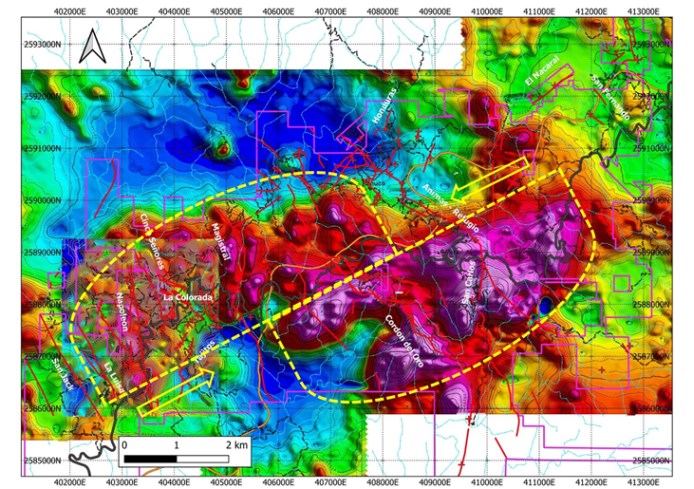

| Figure 9-3: Airborne Magnetics RTP from 2016 with Known Veining and Possible Fault Offset Shown in Diorite | 82 |

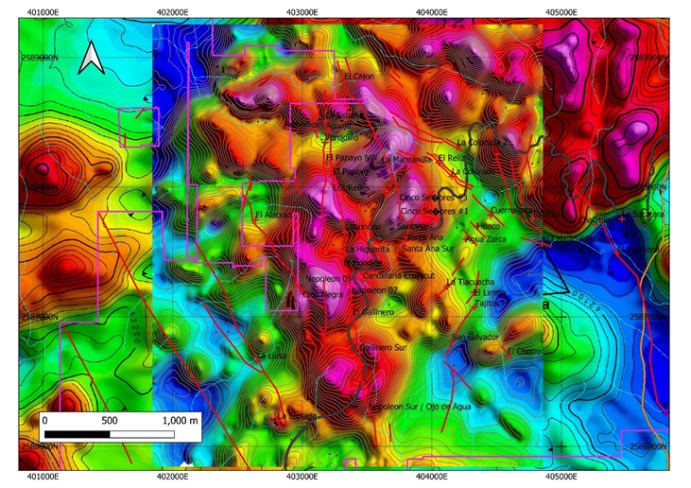

| Figure 9-4: Results from 2021 Airborne Magnetics RTP Geophysical Survey Over the Napoleon Area | 83 |

| Figure 9-5: Surface Sampling at Panuco Project in 2022 | 85 |

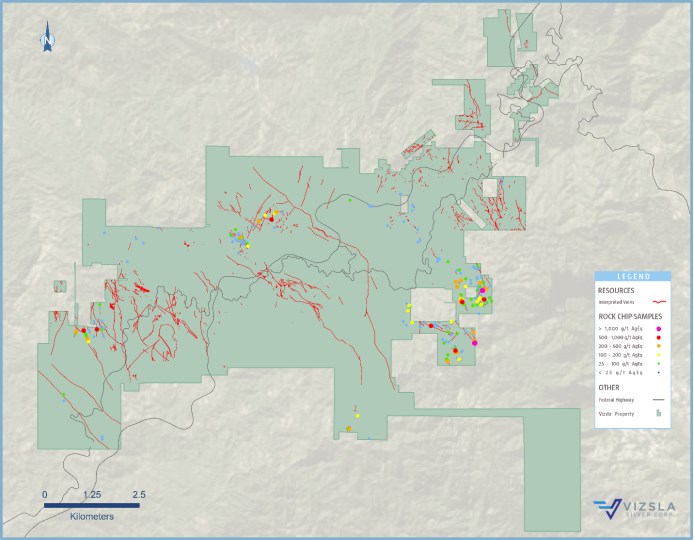

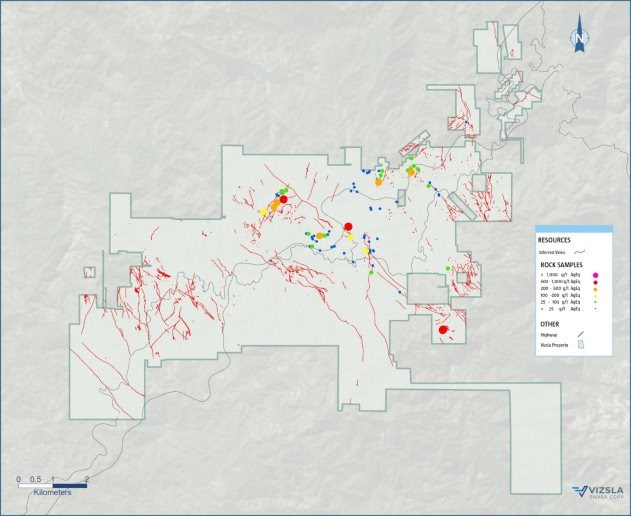

| Figure 9-6: Surface Sampling at Panuco Project in 2023 | 87 |

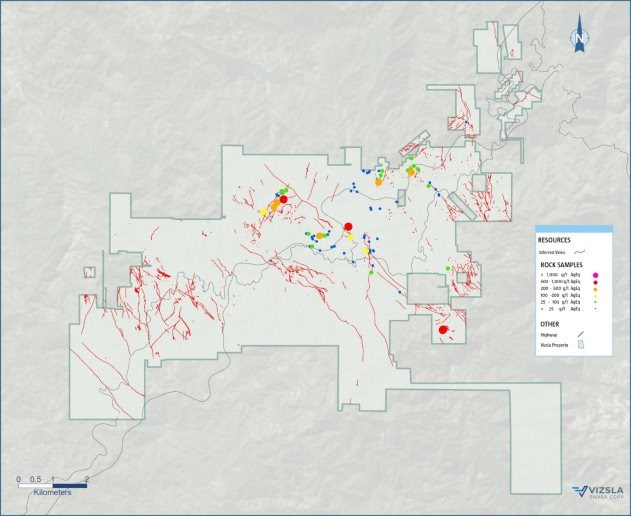

| Figure 9-7: Surface Sampling at Panuco Project in 2024, to June 18 | 89 |

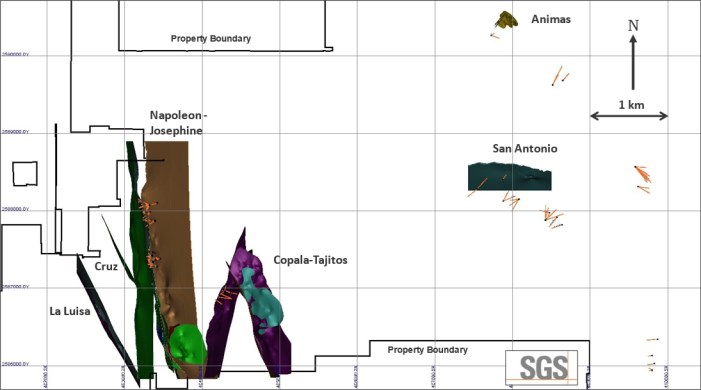

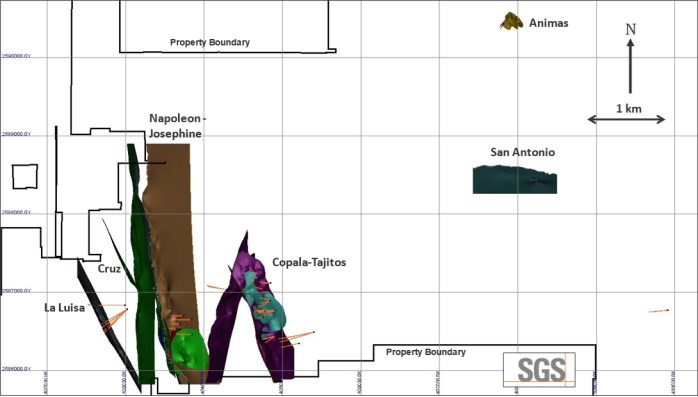

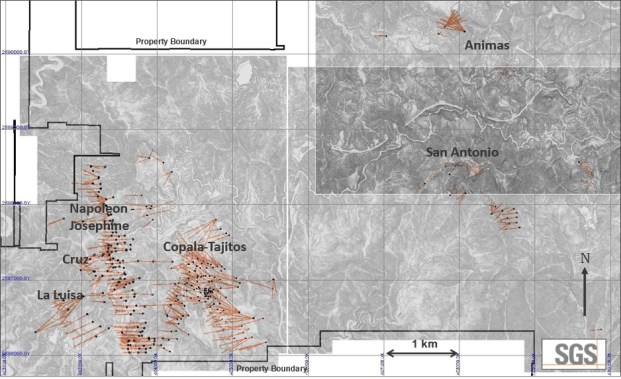

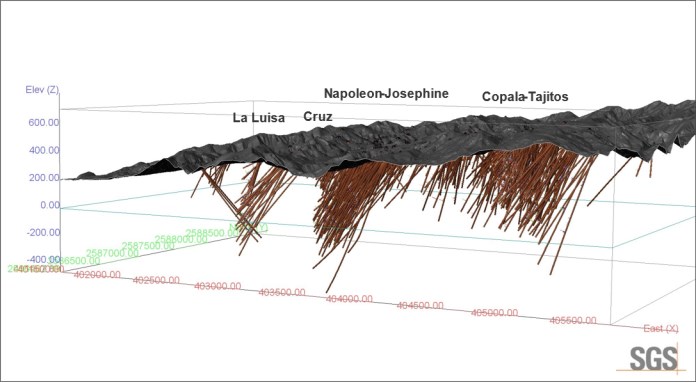

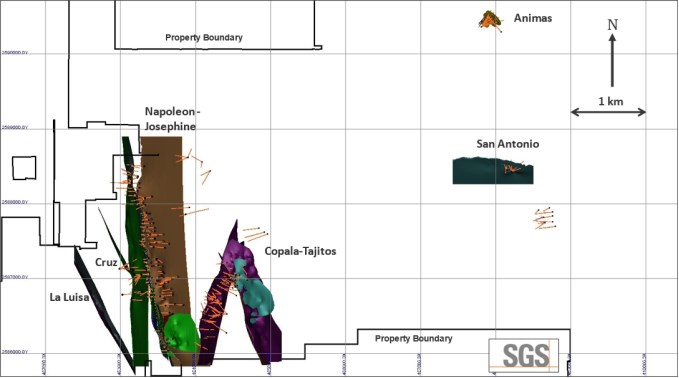

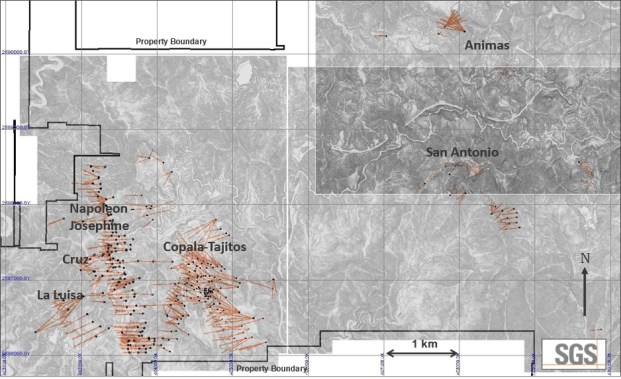

| Figure 10-1: Resource Models and Location of Drill Holes on the Panuco Project from 2019-2024 | 91 |

| Figure 10-2: Resource Models and Location of 2019 - 2020 Drill Holes on the Panuco Project | 93 |

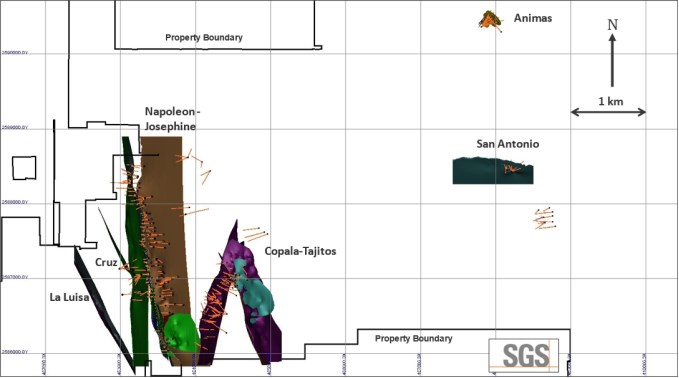

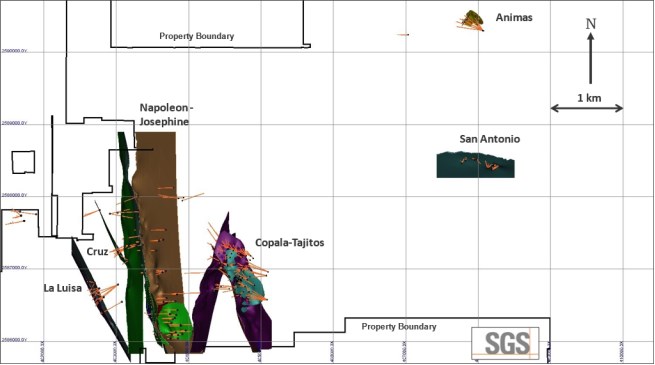

| Figure 10-3: Resource Models and Location of Drill Holes on the Panuco Project from 2021 | 96 |

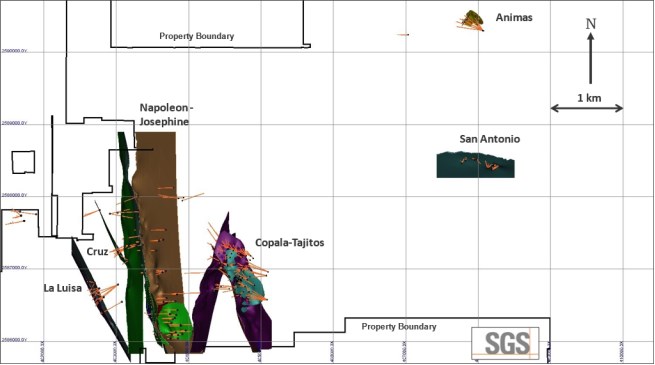

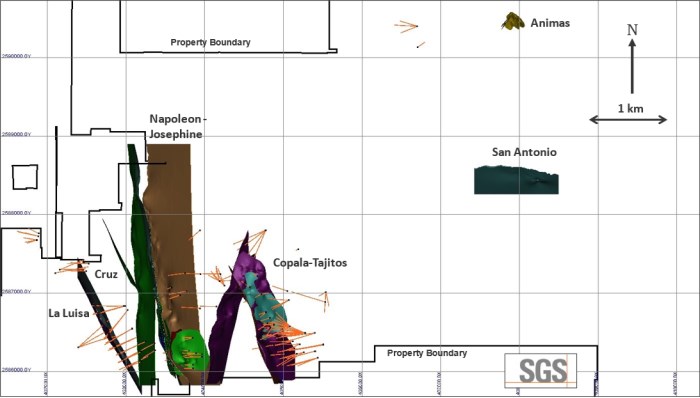

| Figure 10-4: Resource Models and Location of Drill Holes on the Panuco Project from 2022 | 100 |

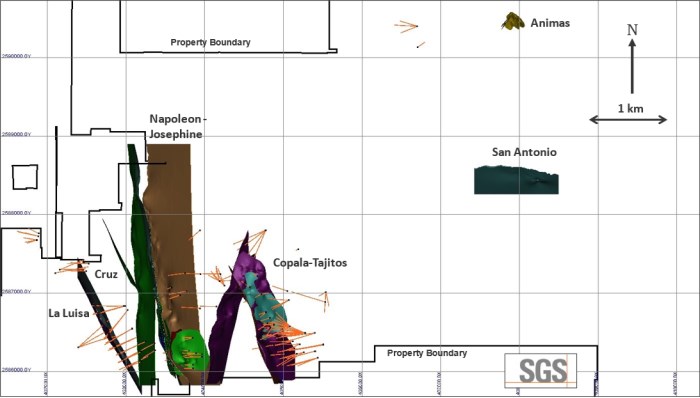

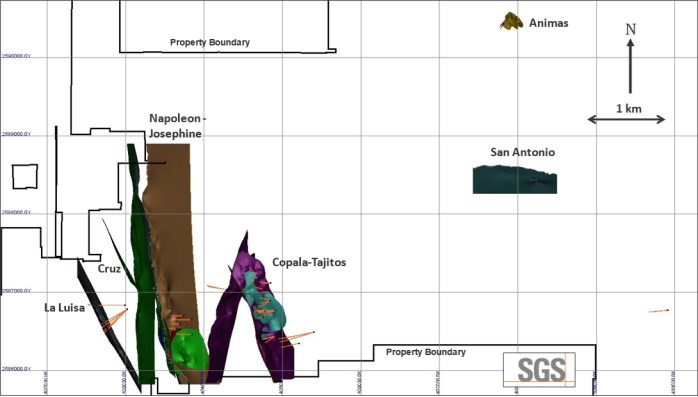

| Figure 10-5: Resource Models and Location of Drill Holes on the Panuco Project from 2023 | 102 |

| Figure 10-6: Resource Models and Location of Drill Holes on the Panuco Project from 2024 (to June 18) | 104 |

| Figure 11-1: Vizsla Core-Logging Facility in Concordia, Sinaloa. Left: Core logging area; Right: Long-Term, Covered and Fenced, Core Storage Area | 109 |

| Figure 11-2: CRM Control Chart for Ag for the 2020 Drill Program | 115 |

| Figure 11-3: CRM Control Chart for Au for the 2020 Drill Program | 116 |

| Figure 11-4: CRM Control Chart for Pb for the 2020 Drill Program | 116 |

| Figure 11-5: CRM Control Chart for Zn for the 2020 Drill Program | 117 |

| Figure 11-6: CRM Control Chart for Ag for the 2021 Drill Program | 117 |

| Figure 11-7: CRM Control Chart for Au for the 2021 Drill Program | 118 |

| Figure 11-8: CRM Control Chart for Pb for the 2021 Drill Program | 118 |

| Figure 11-9: CRM Control Chart for Zn for the 2021 Drill Program | 119 |

| Figure 11-10: CRM Control Chart for Ag for the 2022 Drill Program | 119 |

| Figure 11-11: CRM Control Chart for Au for the 2022 Drill Program | 120 |

| Figure 11-12: CRM Control Chart for Pb for the 2022 Drill Program | 120 |

| Figure 11-13: CRM Control Chart for Zn for the 2022 Drill Program | 121 |

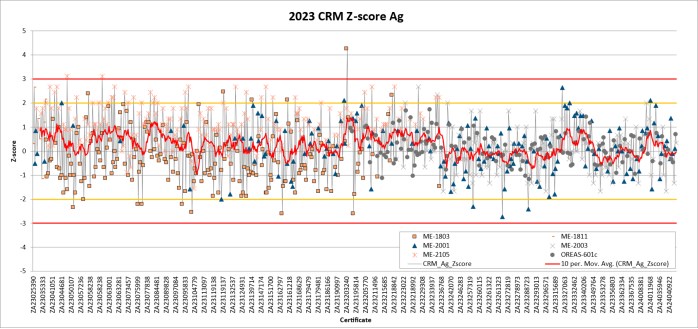

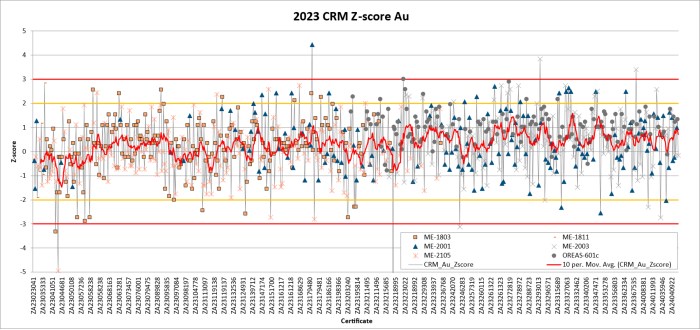

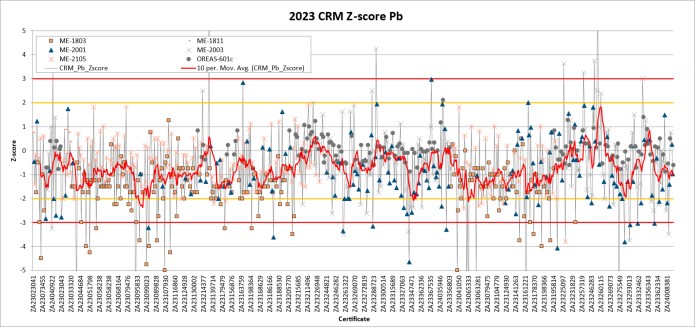

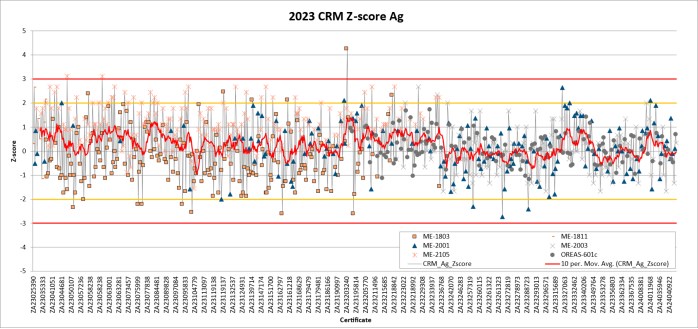

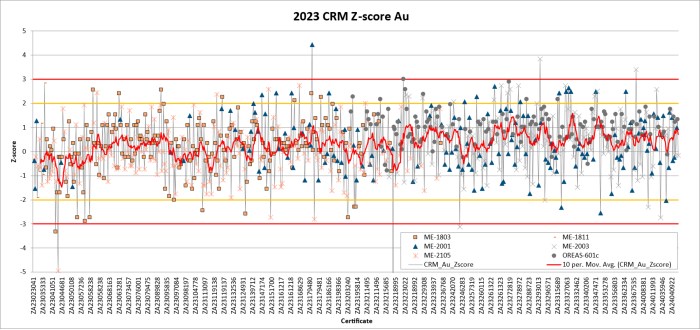

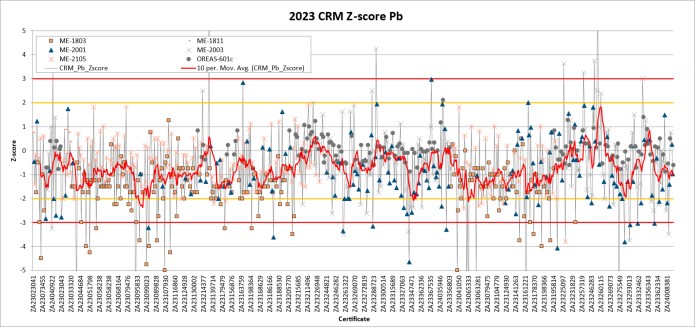

| Figure 11-14: CRM Control Chart for Ag for the 2023 Drill Program | 121 |

| Figure 11-15: CRM Control Chart for Au for the 2023 Drill Program | 122 |

| Figure 11-16: CRM Control Chart for Pb for the 2023 Drill Program | 122 |

| Figure 11-17: CRM Control Chart for Zn for the 2023 Drill Program | 123 |

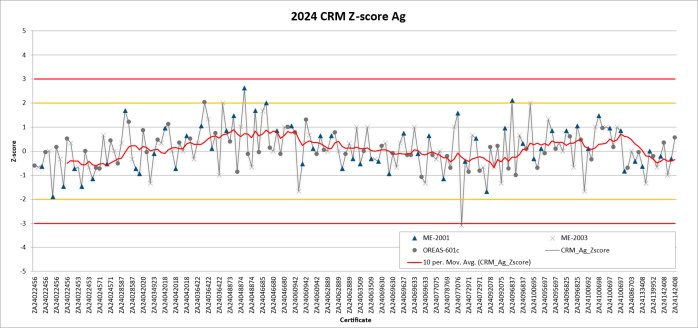

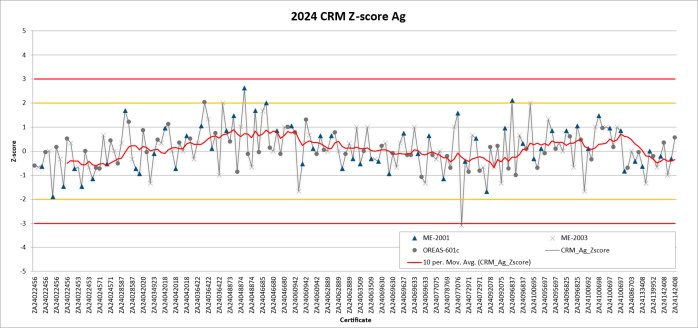

| Figure 11-18: CRM Control Chart for Ag for the 2024 Drill Program | 123 |

| Figure 11-19: CRM Control Chart for Au for the 2024 Drill Program | 124 |

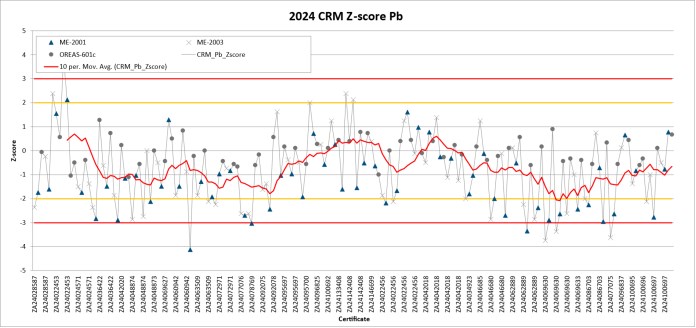

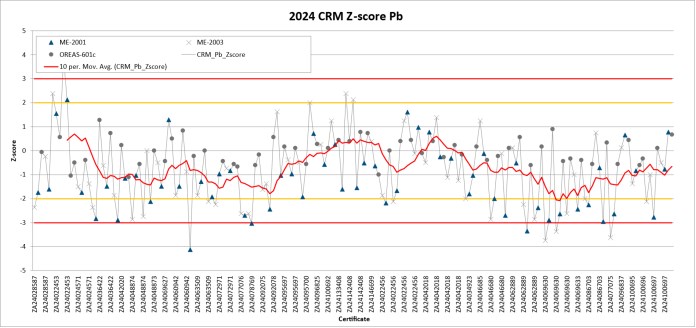

| Figure 11-20: CRM Control Chart for Pb for the 2024 Drill Program | 124 |

| Figure 11-21: CRM Control Chart for Zn for the 2024 Drill Program | 125 |

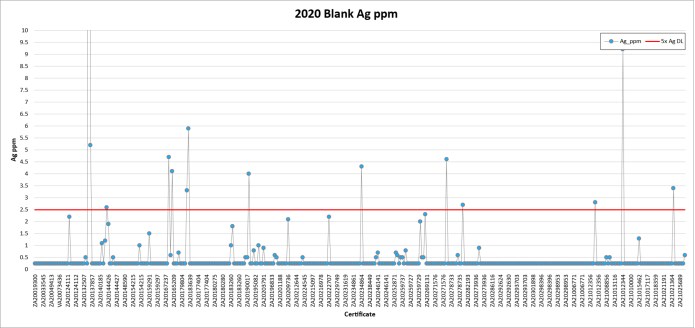

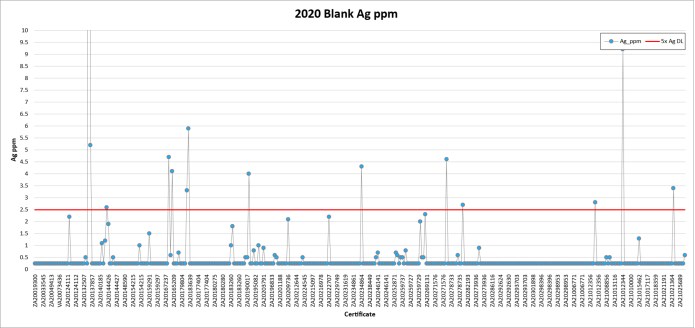

| Figure 11-22: Blank Sample Chart for Ag for the 2020 Drill Program | 126 |

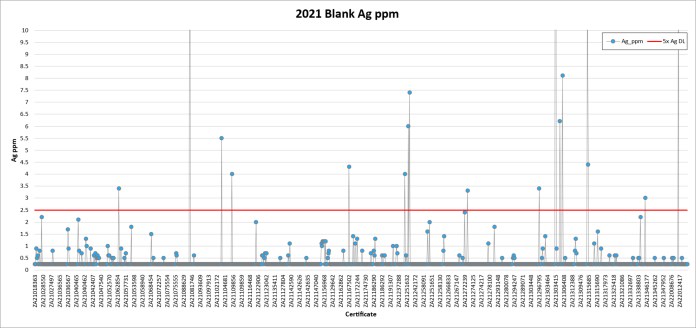

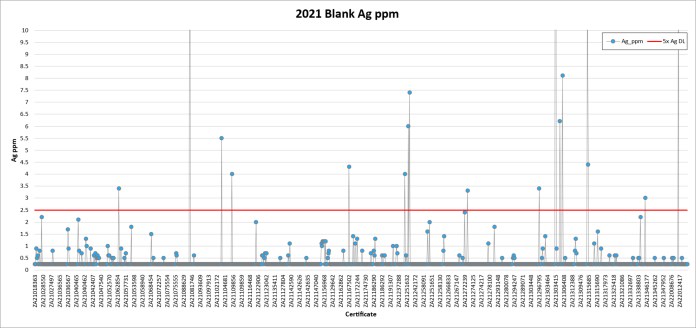

| Figure 11-23: Blank Sample Chart for Ag for the 2021 Drill Program | 127 |

| Figure 11-24: Blank Sample Chart for Ag for the 2022 Drill Program | 127 |

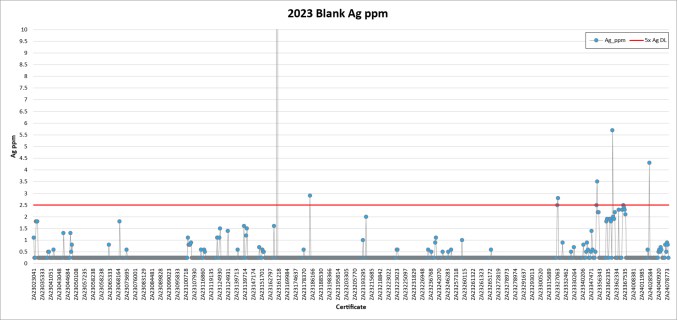

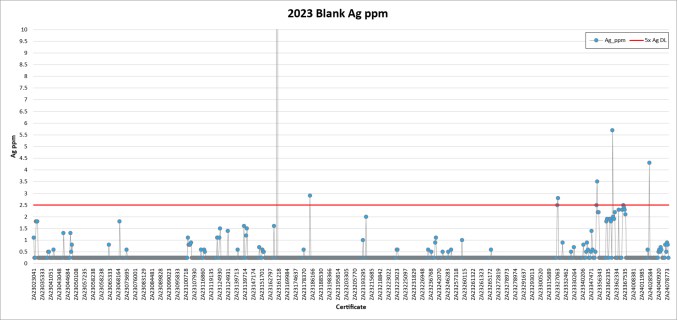

| Figure 11-25: Blank Sample Chart for Ag for the 2023 Drill Program | 128 |

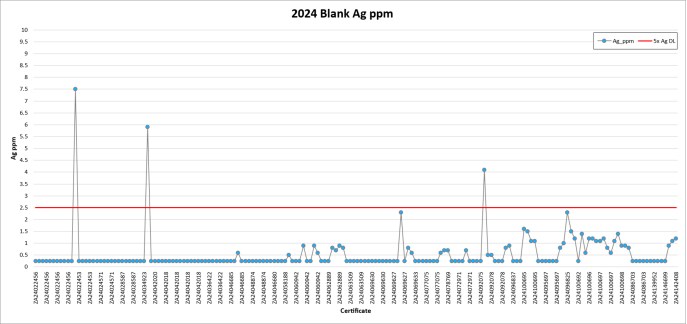

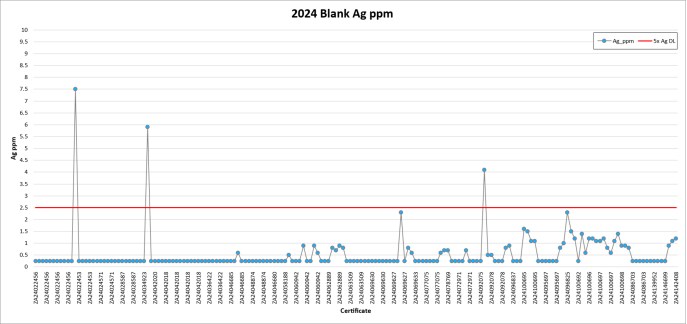

| Figure 11-26: Blank Sample Chart for Ag for the 2024 Drill Program | 128 |

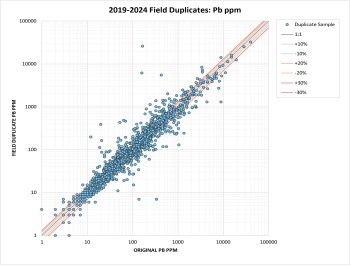

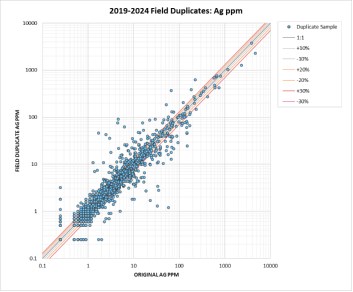

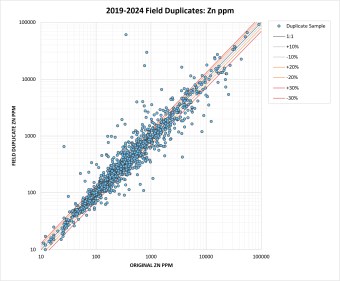

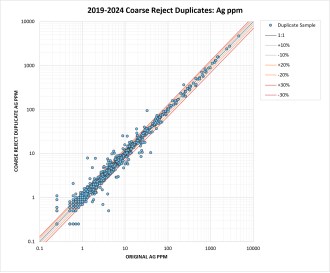

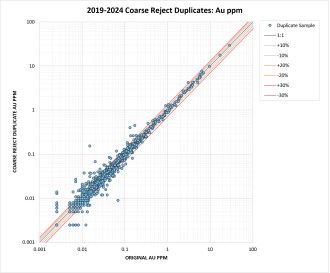

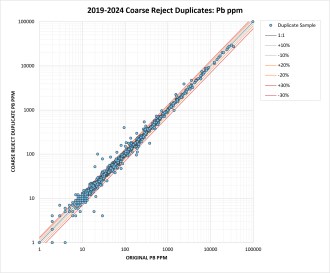

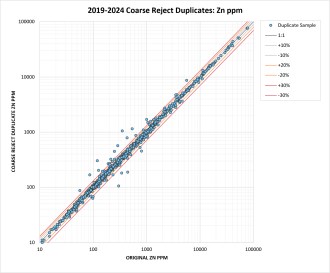

| Figure 11-27: Plots of Field Duplicate Samples for Ag, Au, Pb, and Zn from the 2019-2024 Drill Program | 130 |

| Figure 11-28: Plots of Coarse Reject Duplicate Samples for Ag, Au, Pb, and Zn from the 2019-2024 Drill Program | 131 |

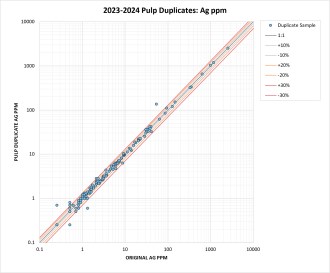

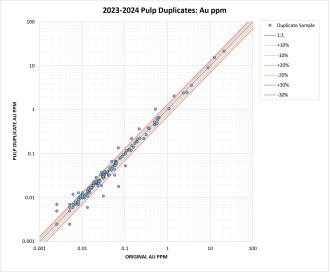

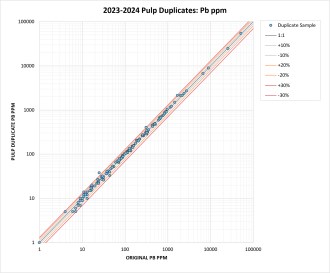

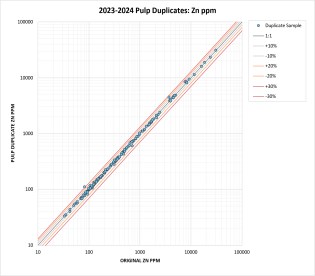

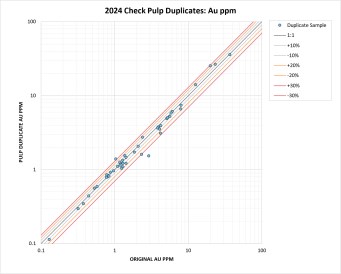

| Figure 11-29: Plots of Pulp Duplicate Samples for Ag, Au, Pb, and Zn from the 2023-2024 Drill Program | 132 |

| Figure 11-30: Plots of SGS Check Samples for Ag and Au Assayed in 2022 | 134 |

| Figure 11-31: Plots of SGS Check Samples for Ag and Au Assayed in 2023 | 134 |

| Figure 11-32: Plots of SGS Check Samples for Ag and Au Assayed in 2024 | 135 |

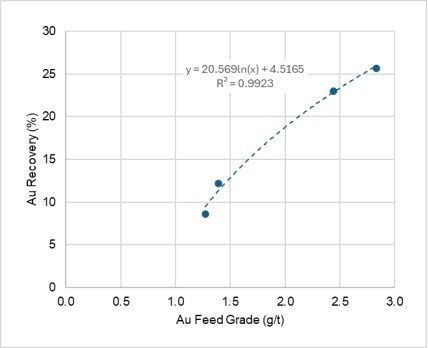

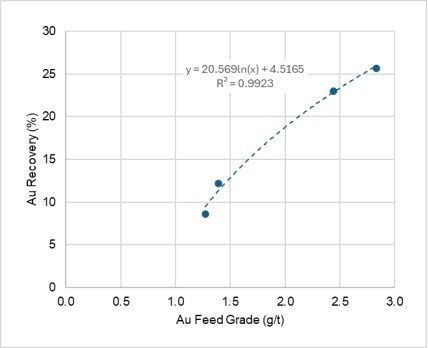

| Figure 13-1: Gravity Gold Recovery Vs. Feed Grade | 144 |

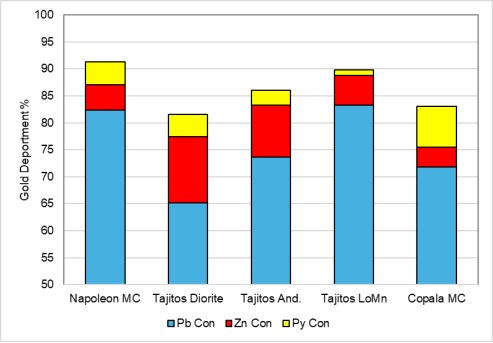

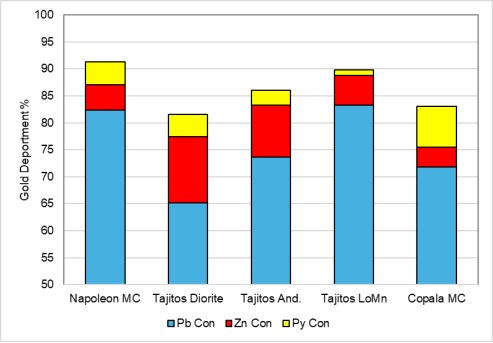

| Figure 13-2: Sequential Rougher Flotation Results - Silver Deportment | 146 |

| Figure 13-3: Sequential Rougher Flotation Results - Gold Deportment | 146 |

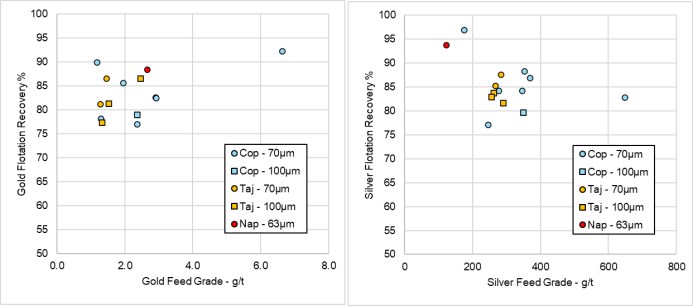

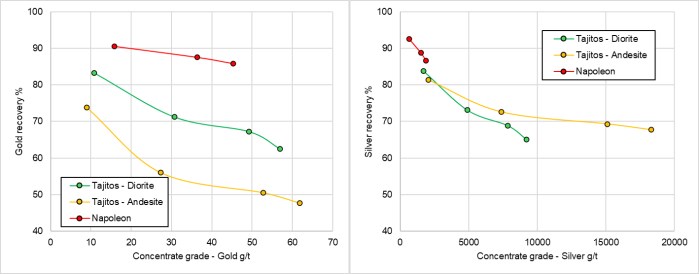

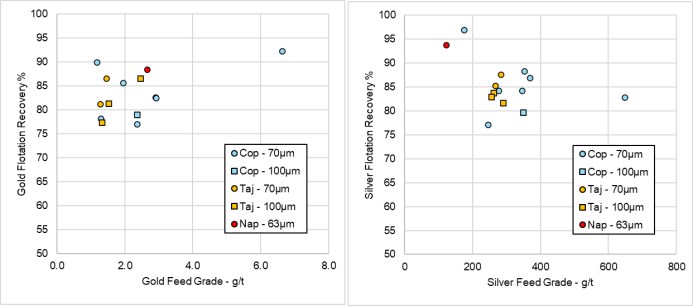

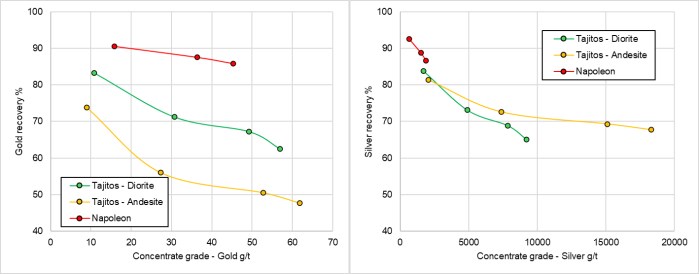

| Figure 13-4: Bulk Flotation Recoveries Vs Feed Grades | 148 |

| Figure 13-5: Bulk Cleaner Flotation Upgrading Results | 149 |

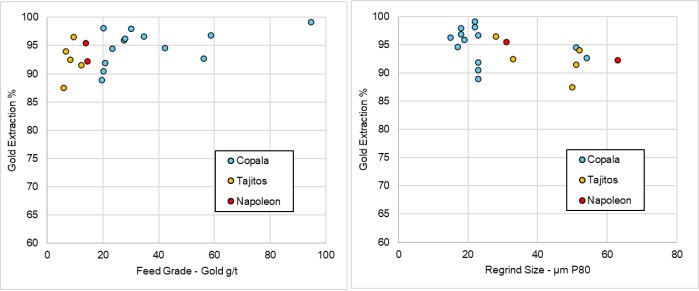

| Figure 13-6: Whole Feed Leach Results - Silver Extraction Vs. Silver in Feed | 151 |

| Figure 13-7: Whole Feed Leach Results - Gold Extraction Vs. Gold in Feed | 151 |

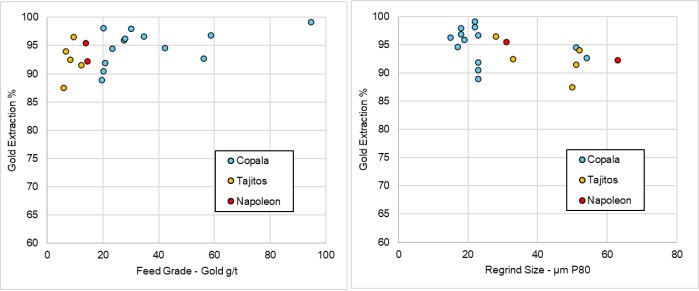

| Figure 13-8: Silver Leach Results on Flotation Concentrates Vs. Leach Feed Grade and Regrind Size | 153 |

| Figure 13-9: Gold Leach Results on Flotation Concentrates Vs. Leach Feed Grade and Regrind Size | 153 |

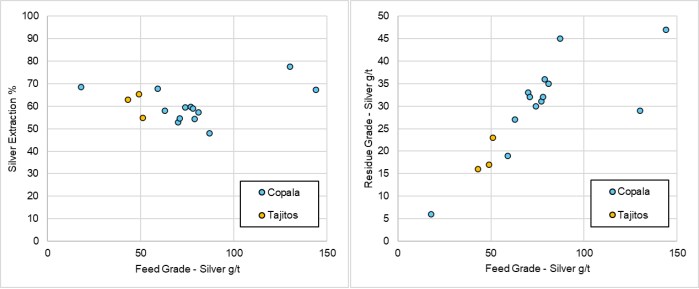

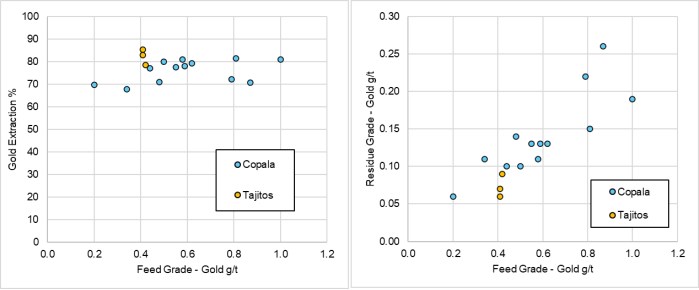

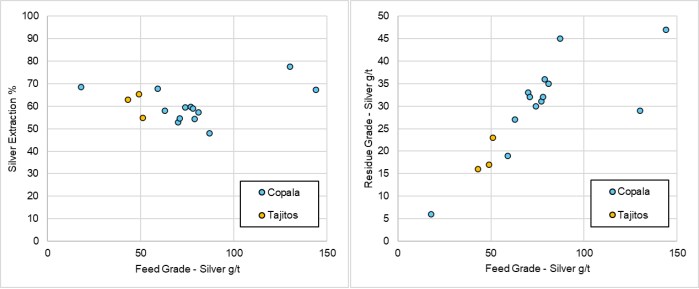

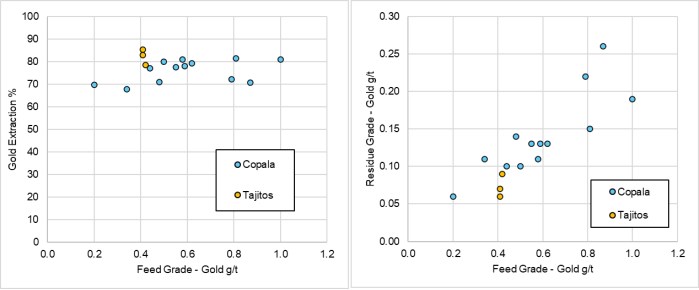

| Figure 13-10: Silver Leach Data on Flotation Tailings | 155 |

| Figure 13-11: Gold Leach Data on Flotation Tailings | 155 |

| Figure 14-1: Plan View: Distribution of Surface Drill Holes on the Property (WGS 84) as of September 2023, on Topography | 160 |

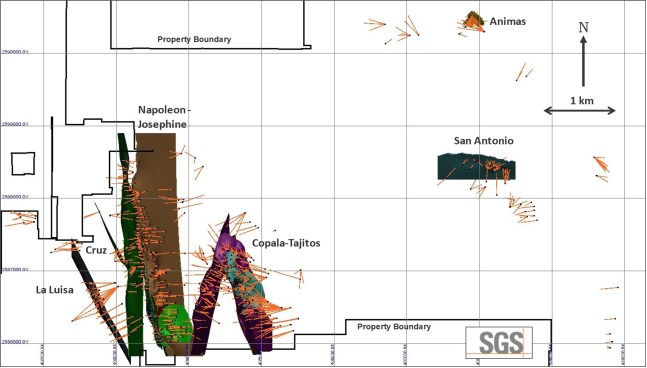

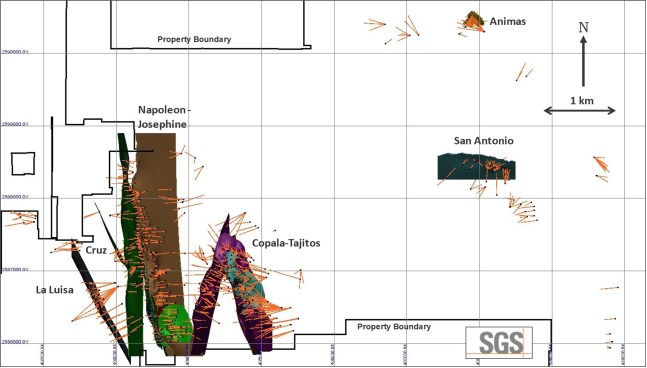

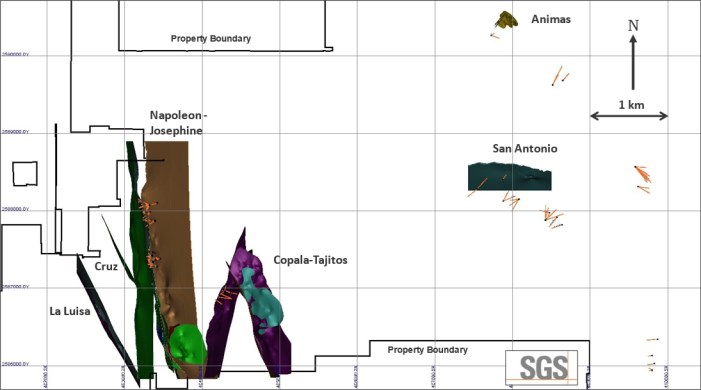

| Figure 14-2: Isometric View Looking Northwest: Distribution of Surface Drill Holes in the Copala-Napoleon-Cruz-La Luisa Area (WGS84) | 161 |

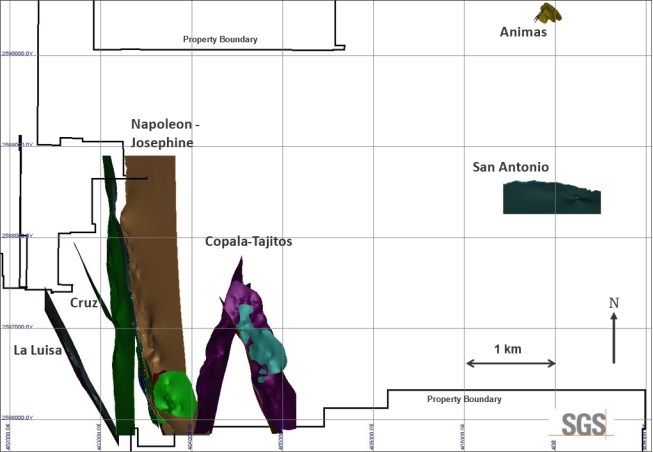

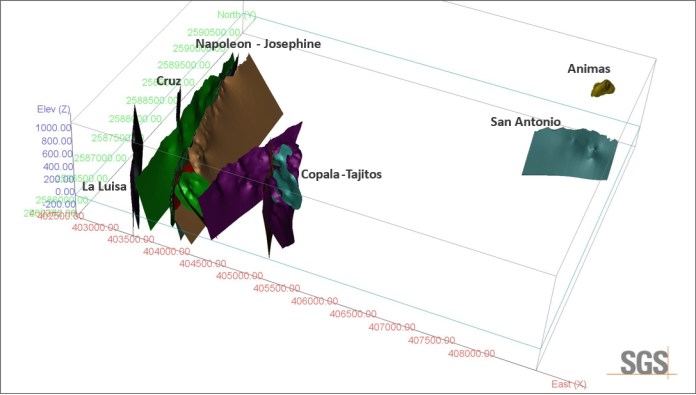

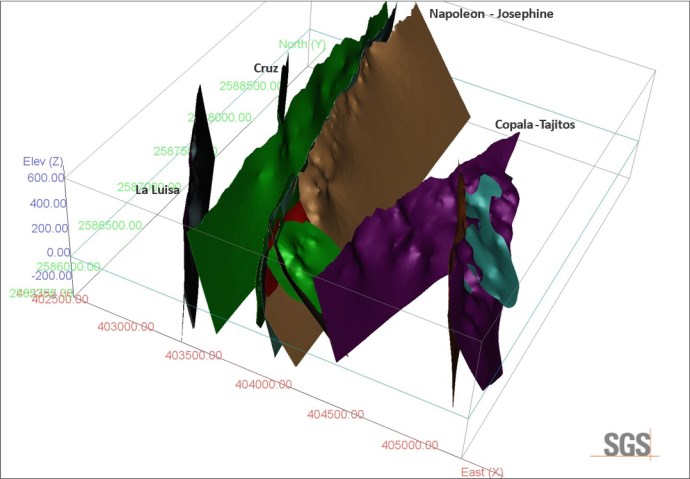

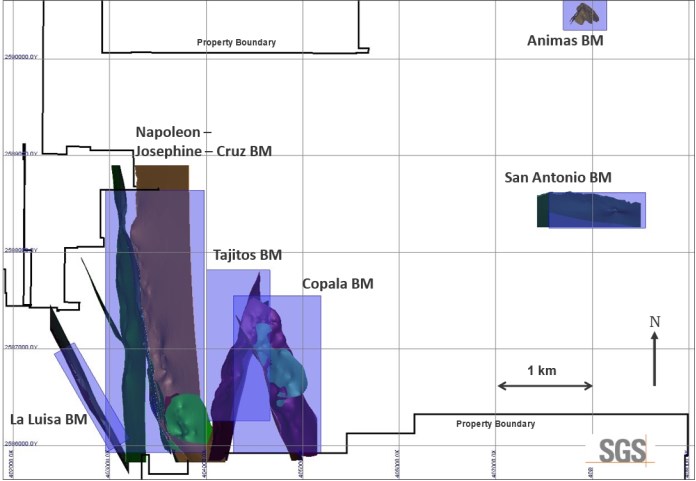

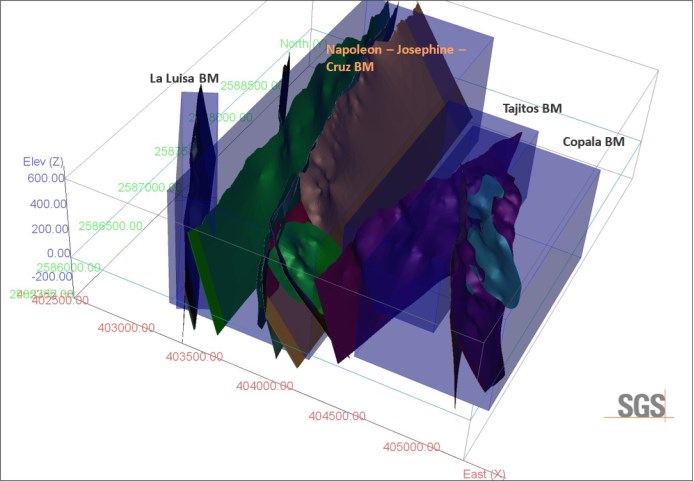

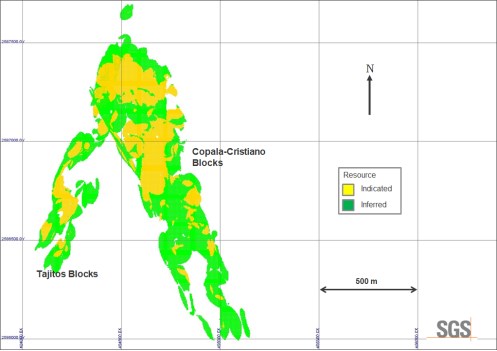

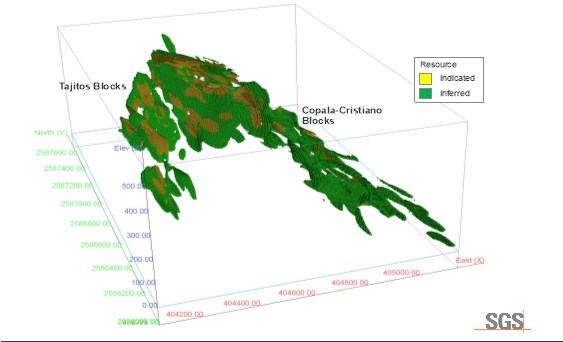

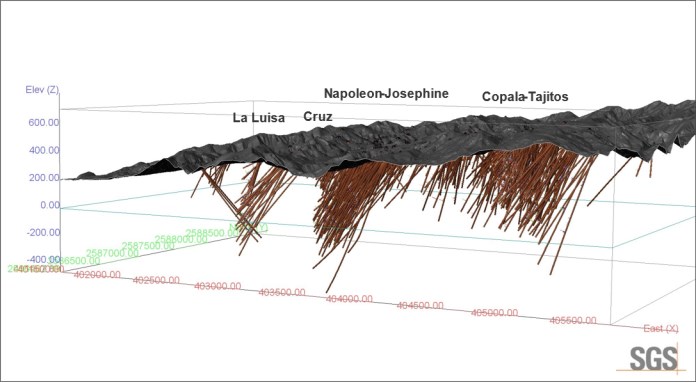

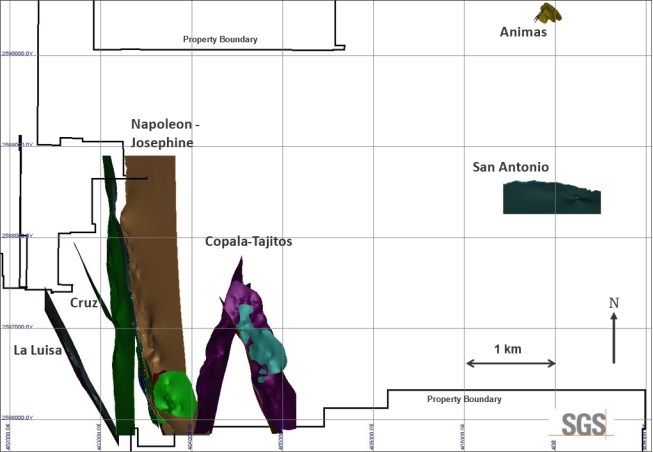

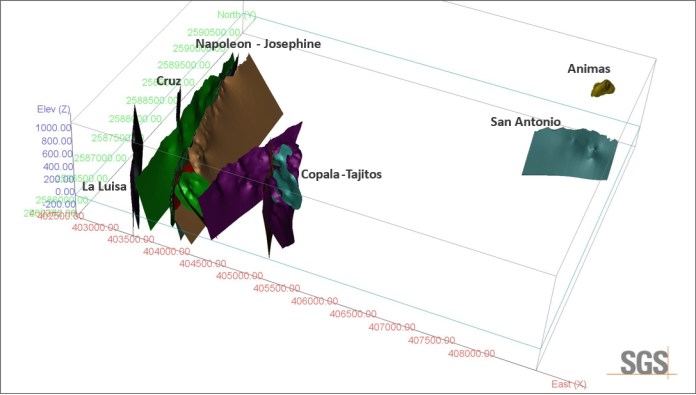

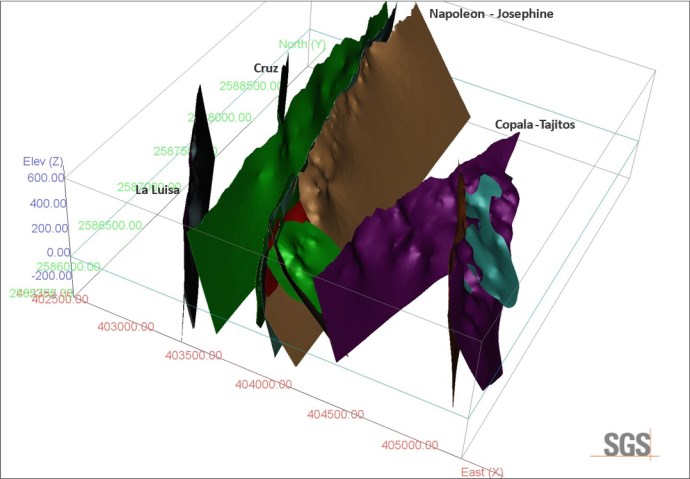

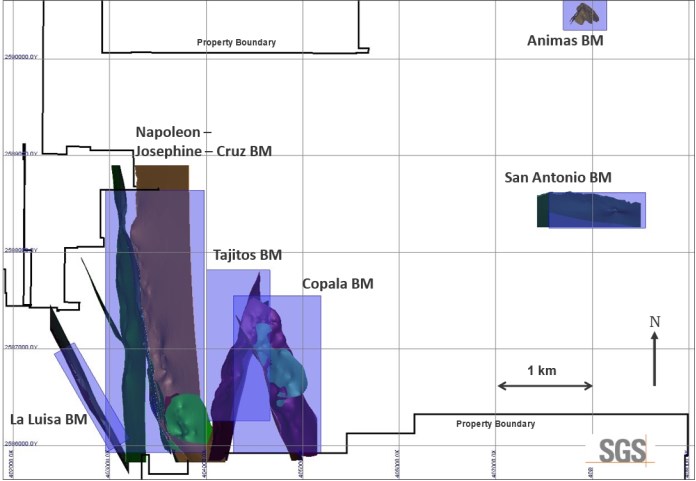

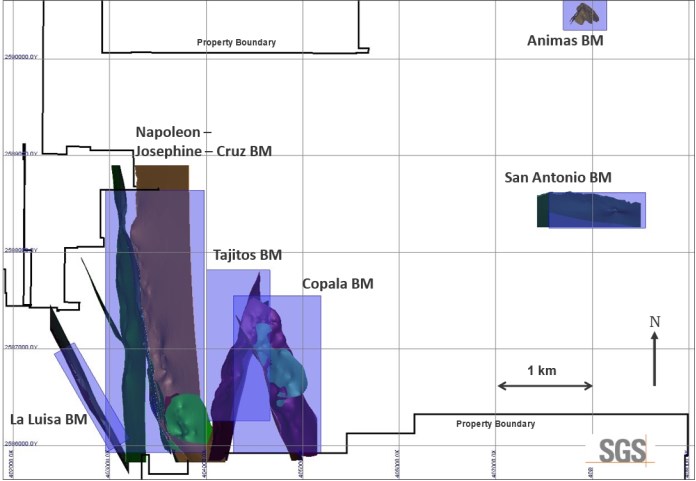

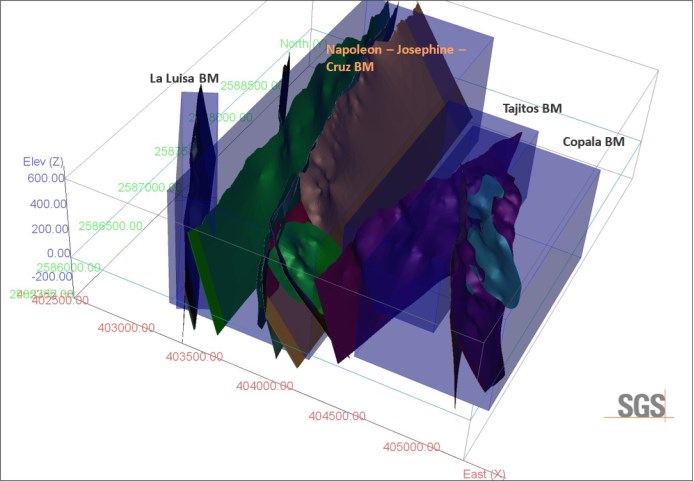

| Figure 14-3: Plan View: Property Mineral Resource Models | 163 |

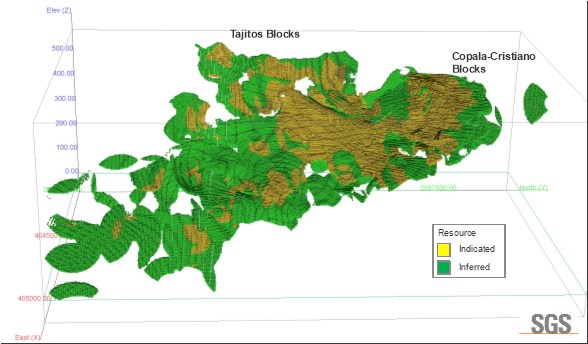

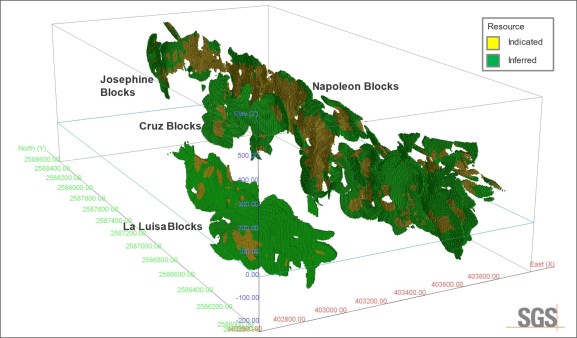

| Figure 14-4: Isometric View Looking Northeast: Property Mineral Resource Models | 164 |

| Figure 14-5: Isometric View Looking Northwest: Property Mineral Resource Models, Copala-Napoleon-La Luisa Areas | 165 |

| Figure 14-6: Plan View: Distribution of Mineral Resource Block Models and Mineralization Domains | 175 |

| Figure 14-7: Isometric View looking NW: Distribution of Mineral Resource Block Models and Mineralization Domains on the Property | 176 |

| Figure 14-8: Isometric View looking NW: Distribution of Mineral Resource Block Models and Mineralization Domains in the Napoleon-Copala Areas | 177 |

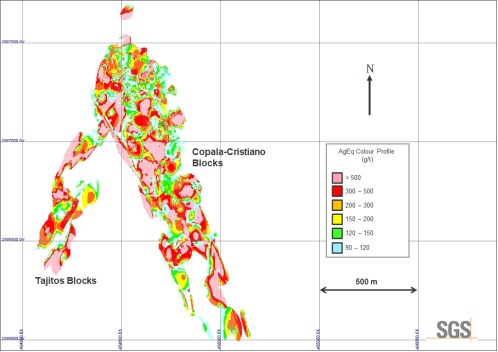

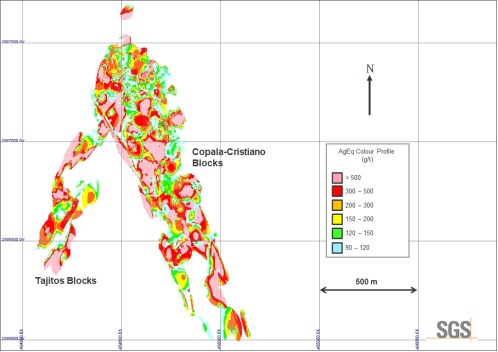

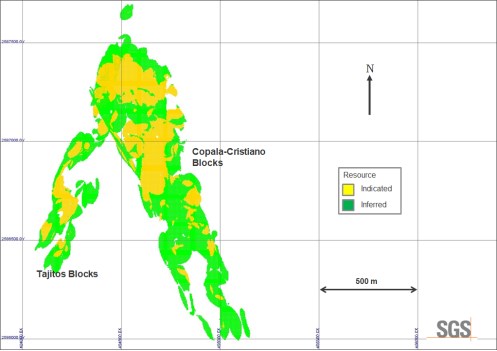

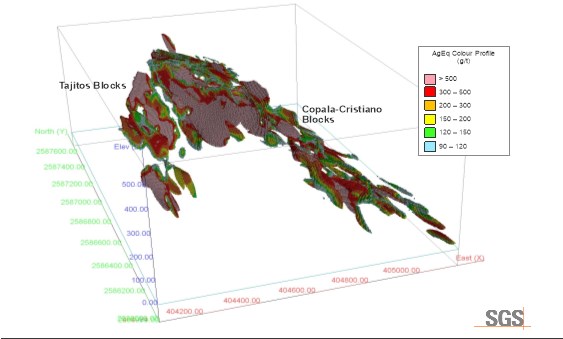

| Figure 14-9: Plan View: Mineral Resource Block Grades and Block Class for the Copala-Cristiano-Tajitos Deposit Area | 187 |

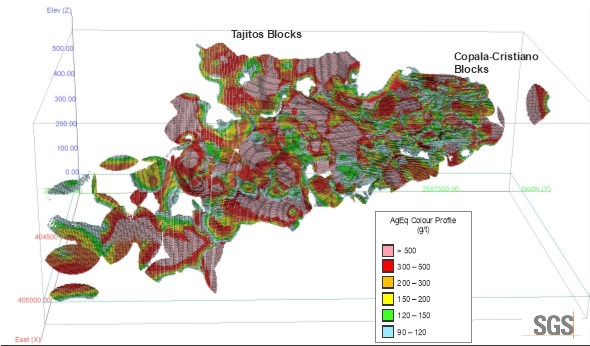

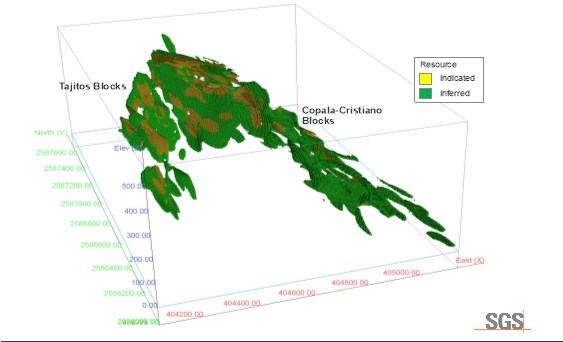

| Figure 14-10: Isometric View Looking West: Mineral Resource Block Grades and Block Class for the Copala-Cristiano-Tajitos Deposit Area | 88 |

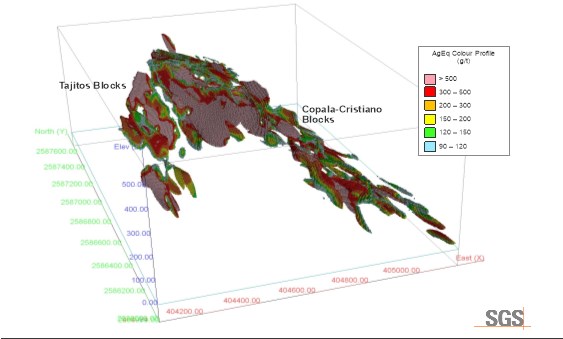

| Figure 14-11: Isometric View Looking NNE: Mineral Resource Block Grades and Block Class for the Copala-Cristiano-Tajitos Deposit Area | 189 |

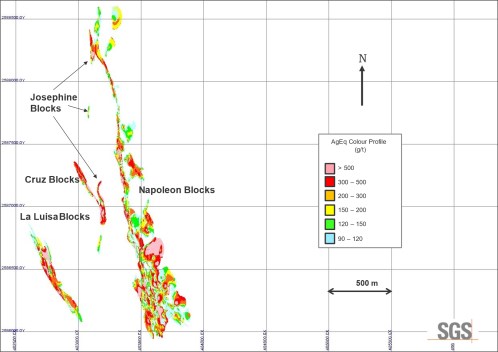

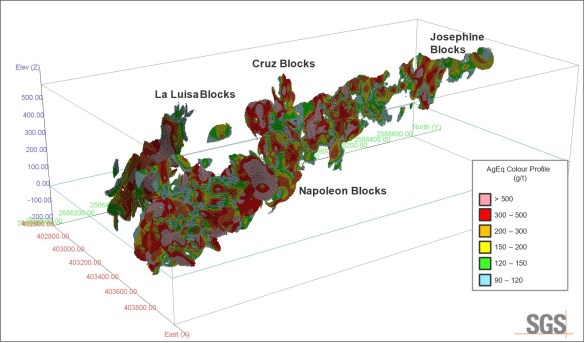

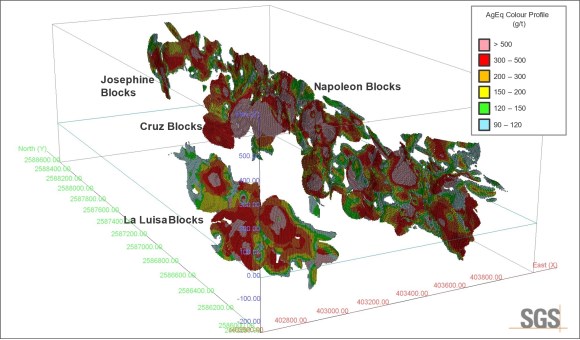

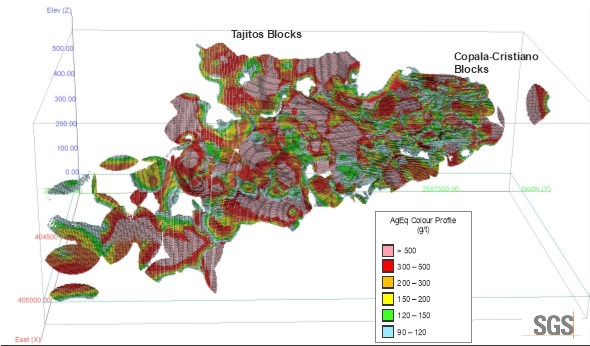

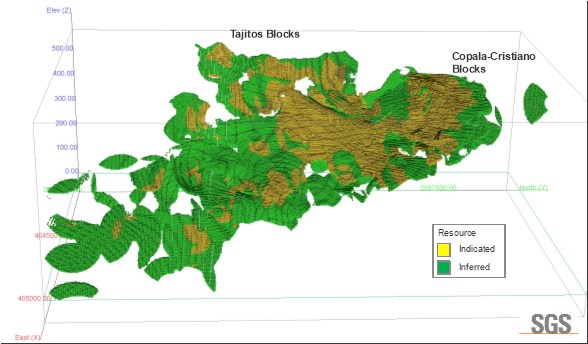

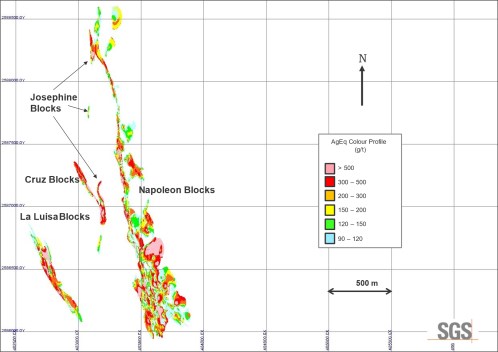

| Figure 14-12 Plan View: Mineral Resource Block Grades and Block Class for the Napoleon, Cruz, Josephine and La Luisa Areas | 190 |

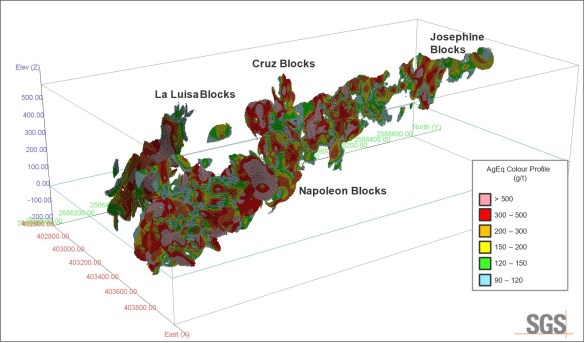

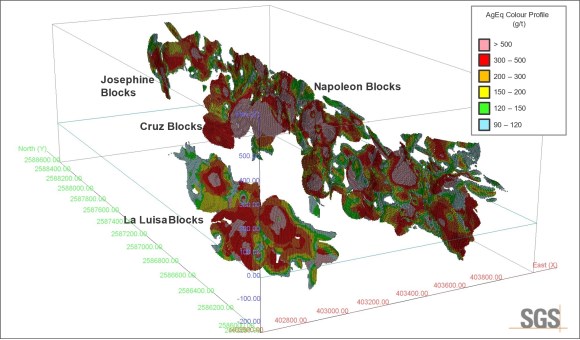

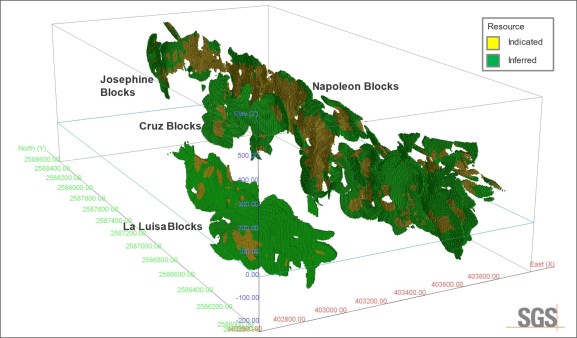

| Figure 14-13: Isometric View Looking Northwest: Mineral Resource Block Grades and Block Class for the Napoleon, Cruz, Josephine and La Luisa Areas | 191 |

| Figure 14-14: Isometric View Looking NNE: Mineral Resource Block Grades and Block Class for the Napoleon, Cruz, Josephine and La Luisa Areas | 192 |

| Figure 14-15: Comparison of ID3, ID2 & NN Models for the Napoleon-Josephine-Cruz Deposit Area | 194 |

| Figure 14-16: Comparison of ID3, ID2 & NN Models for the Copala-Cristiano Deposit Area | 195 |

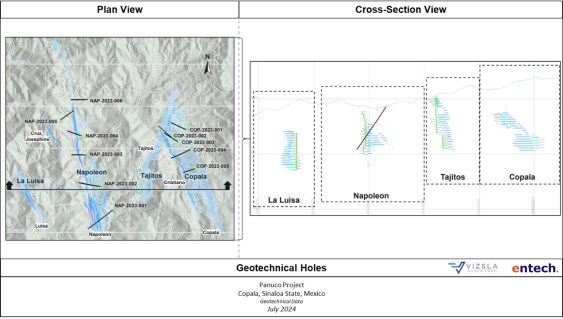

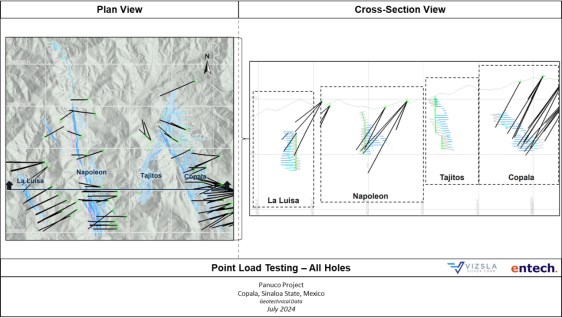

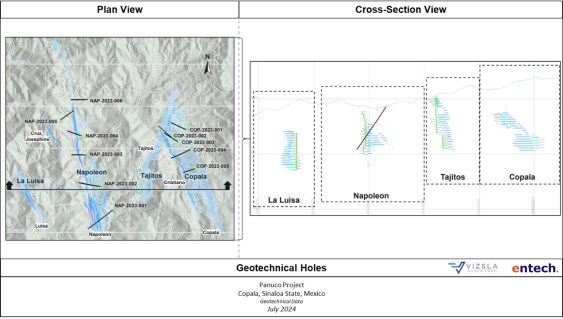

| Figure 16-1: Geotechnically Logged Diamond Drill Hole Locations - RQD | 203 |

| Figure 16-2: Geotechnically Logged Diamond Drill Hole Locations - Point Load Testing | 204 |

| Figure 16-3: Geotechnically Logged Diamond Drill Hole Locations - Geotehnical Holes | 204 |

| Figure 16-4: Estimated Domain Conditions (Q') | 206 |

| Figure 16-5: Extended Matthews Stability Graph (Mawdesley et al. 2001) | 208 |

| Figure 16-6: Dilution - Longhole Stoping | 211 |

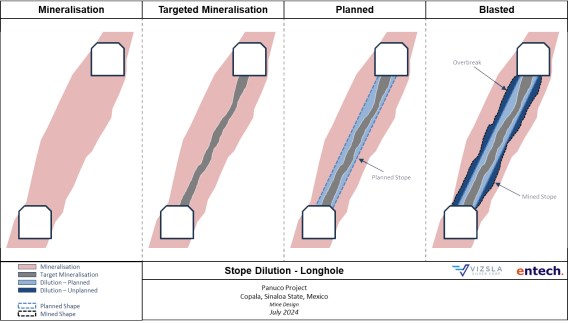

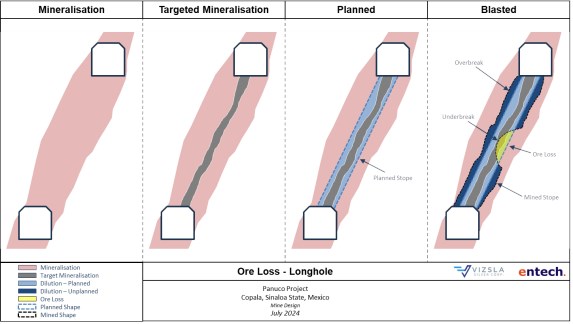

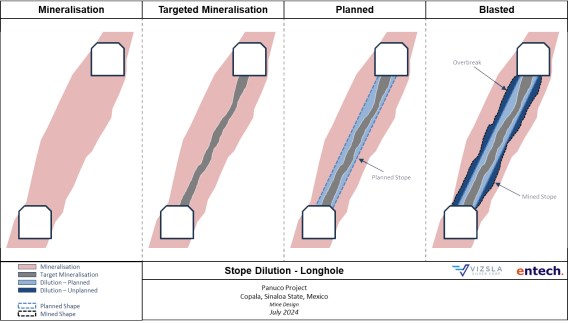

| Figure 16-7: Ore Loss - Longhole Stoping | 212 |

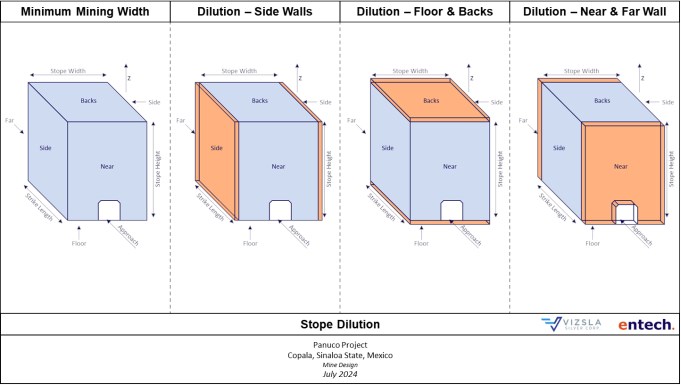

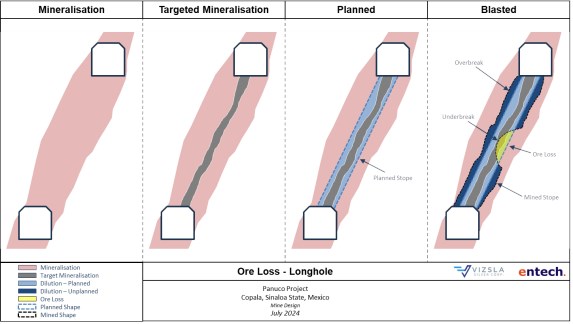

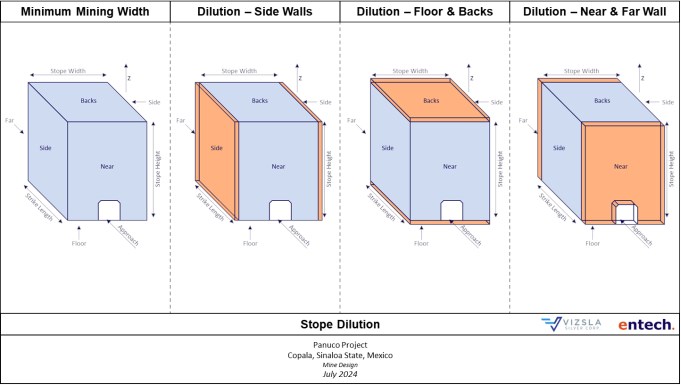

| Figure 16-8: Stope Shapes (Blue) and Dilution Contacts (Orange) | 213 |

| Figure 16-9: MSO Selection following Orphans and Width | 218 |

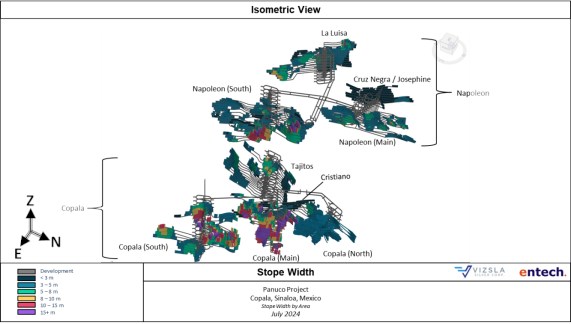

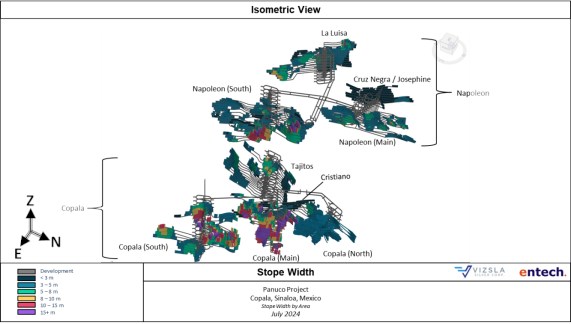

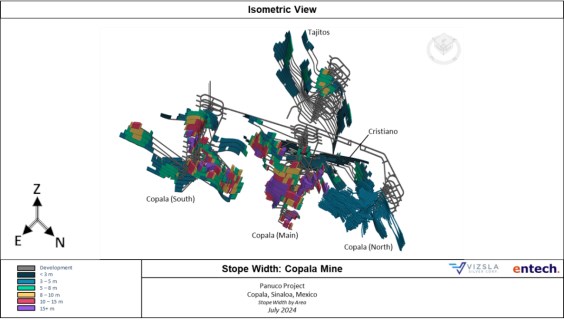

| Figure 16-10: Stope Shape Width for the Panuco Project | 219 |

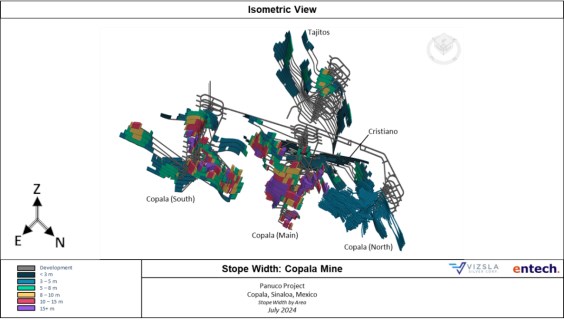

| Figure 16-11: Stope Shape Width for the Panuco Project - Copala Mine | 219 |

| Figure 16-12: Stope Shape Width for the Panuco Project - Napoleon Mine | 220 |

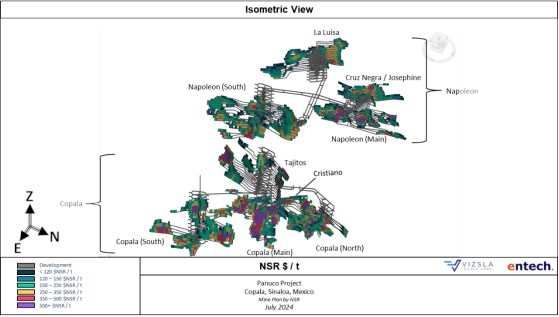

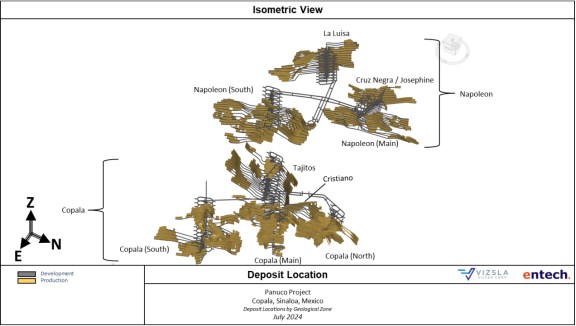

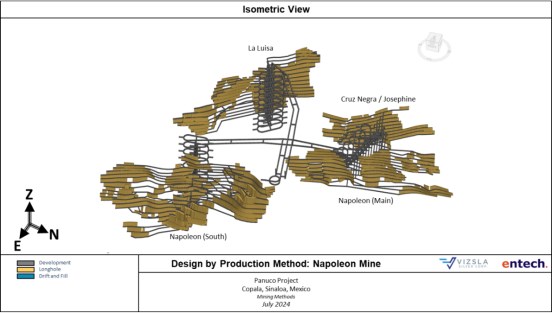

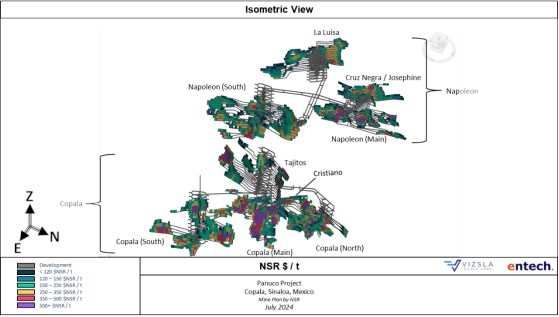

| Figure 16-13: MSO Outputs and Proposed Development by Geological Domain | 221 |

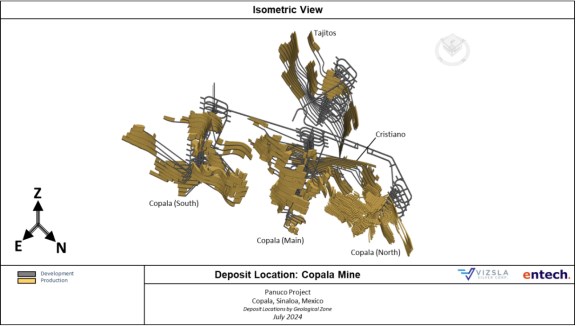

| Figure 16-14: MSO Output and Proposed Development by Geological Domain: Copala Mine | 221 |

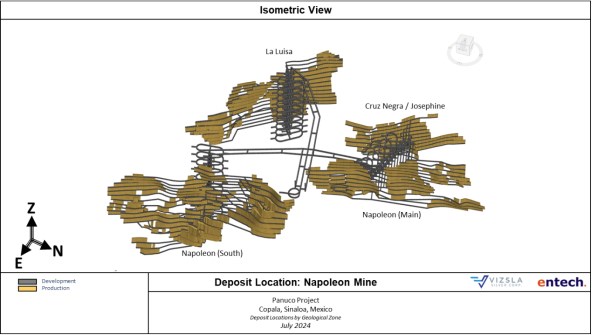

| Figure 16-15: MSO Output and Proposed Development by Geological Domain: Napoleon Mine | 222 |

| Figure 16-16: Panuco Project Development Level Layout | 223 |

| Figure 16-17: Proposed Mining Method for the Copala Mine | 224 |

| Figure 16-18: Proposed Mining Method for the Napoleon Mine | 225 |

| Figure 16-19: Proposed Stope Shapes by NSR ($US /t) for the Panuco Project | 225 |

| Figure 16-20: Annual Lateral Development Schedule for the Panuco Project | 227 |

| Figure 16-21: Annual Vertical Development Schedule for the Panuco Project | 229 |

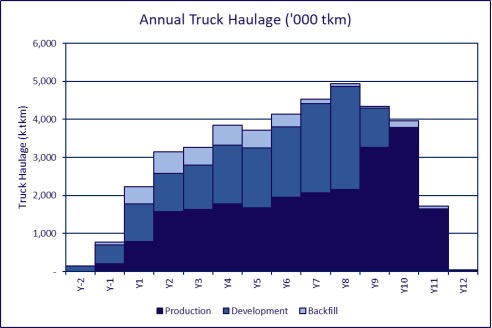

| Figure 16-22: Annual Longhole Drilling Schedule for the Panuco Project | 230 |

| Figure 16-23: Annual Trucking Requirements & Capacity (Peak) | 232 |

| Figure 16-24: Mineralised Material Plan for the Panuco Project | 233 |

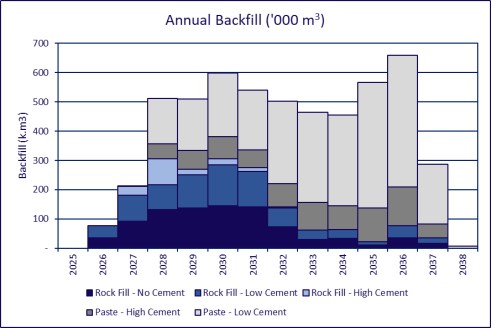

| Figure 16-25: Annual Backfill Schedule for the Panuco Project | 234 |

| Figure 16-26: Primary Ventilation Layout of the Copala Mine | 239 |

| Figure 16-27: Primary Ventilation Layout of the Napoleon Mine | 240 |

| Figure 16-28: Egress Layout of the Copala Mine | 241 |

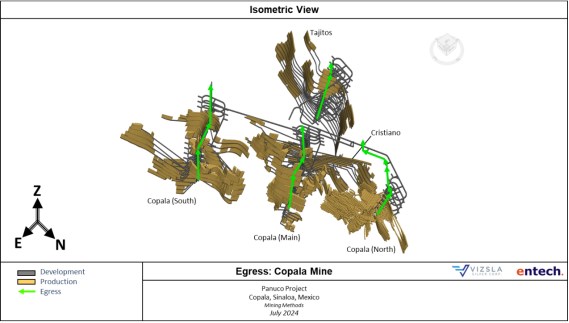

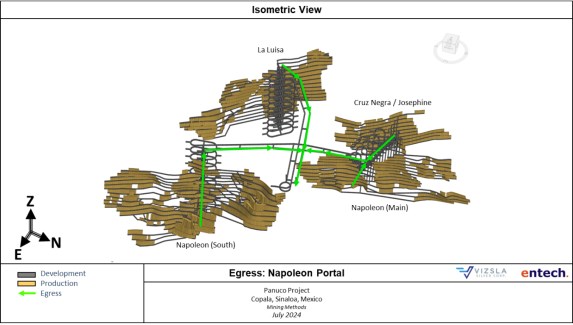

| Figure 16-29: Egress Layout of the Napoleon Mine | 242 |

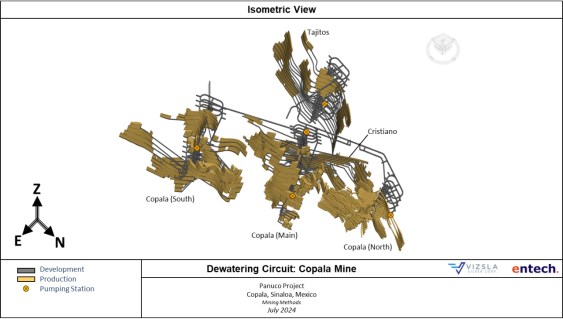

| Figure 16-30: Proposed Primary Dewatering - Copala Mine | 243 |

| Figure 16-31: Proposed Primary Dewatering - Napoleon Mine | 243 |

| Figure 17-1: Process Flow Diagram | 249 |

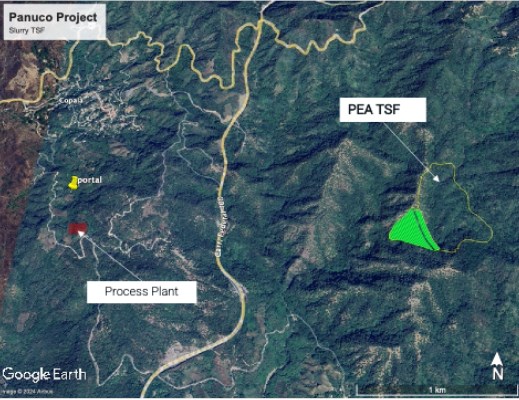

| Figure 18-1: Panuco Project Site Layout | 259 |

| Figure 18-2: Process Plant Layout | 260 |

| Figure 18-3: Plant Nursery | 262 |

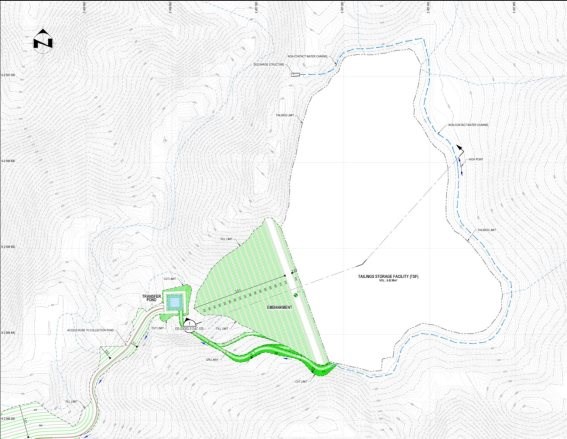

| Figure 18-4: TSF General Layout | 266 |

| Figure 18-5: TSF Ultimate LOM Configuration | 268 |

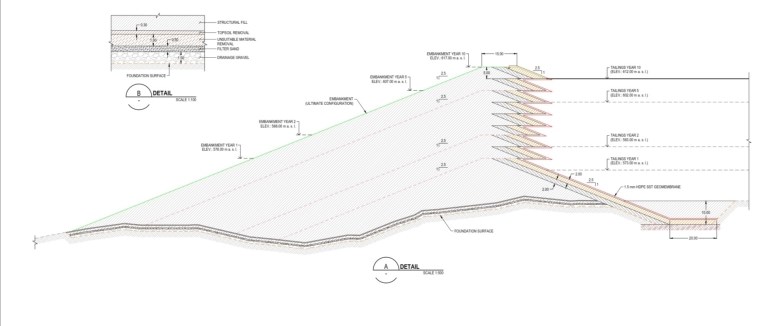

| Figure 18-6: TSF Embankment Section | 270 |

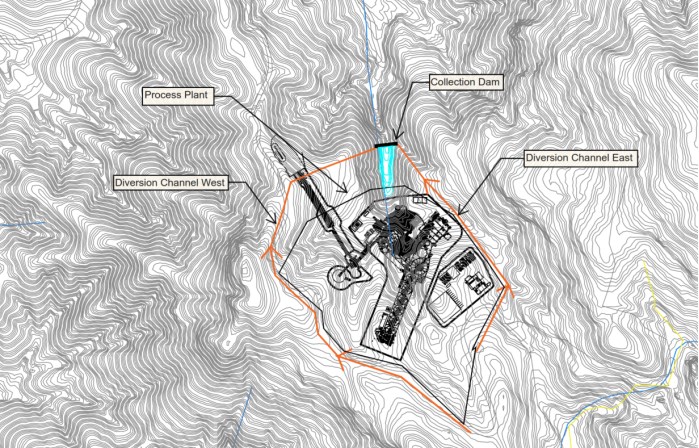

| Figure 18-7: Water Management Structures for Panuco Mine Site | 274 |

| Figure 20-1: Property Location Map | 279 |

| Figure 20-2: Average Monthly Precipitation at the Panuco-Capala Project | 281 |

| Figure 20-3: Average Temperature and Precipitation for the Project Area | 282 |

| Figure 20-4: Completed Drillhole Locations | 283 |

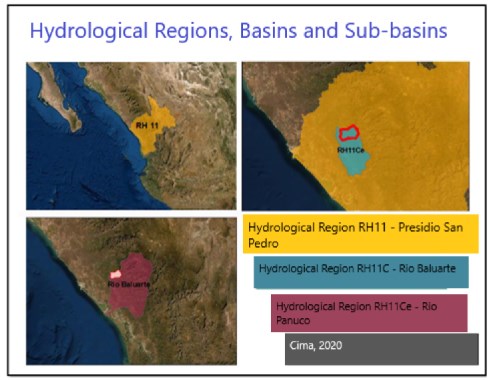

| Figure 20-5: Rivers and Basins in the Region | 284 |

| Figure 20-6: Panuco Hydrological Region, Basin and Sub-basin. | 285 |

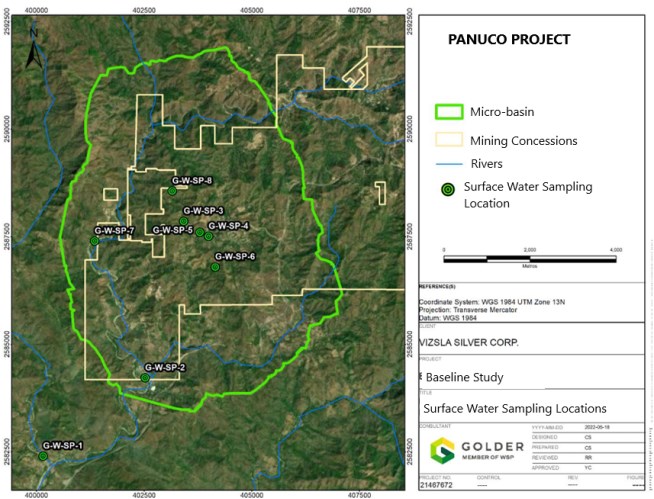

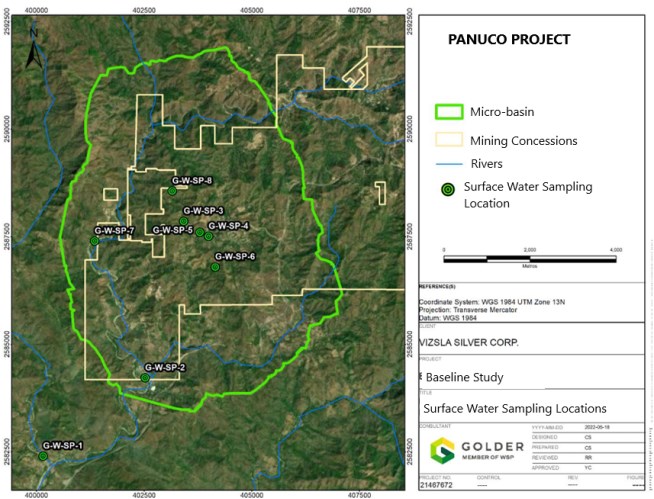

| Figure 20-7: Location of Water Sampling Points | 286 |

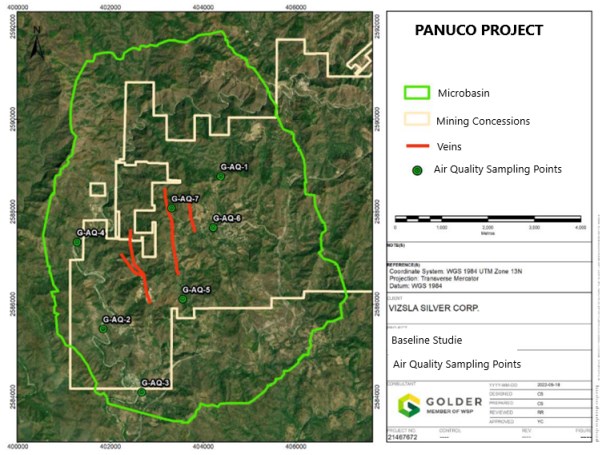

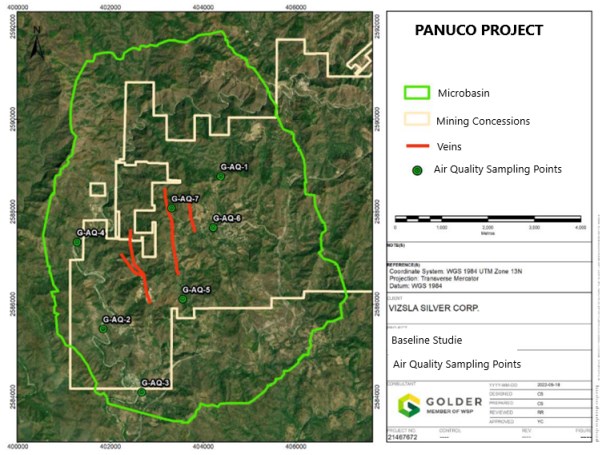

| Figure 20-8: Air Quality Monitoring Points | 288 |

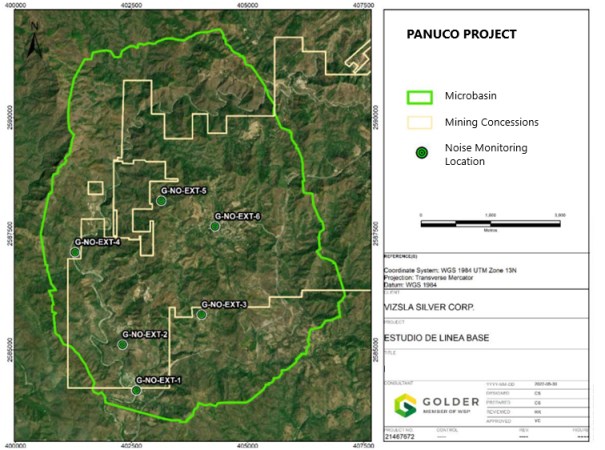

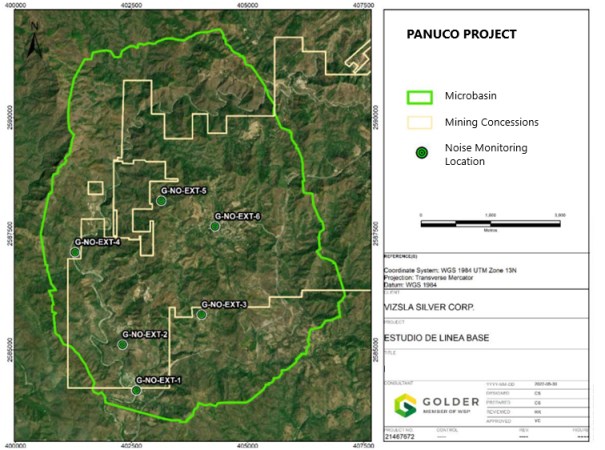

| Figure 20-9: Noise Monitoring Points | 289 |

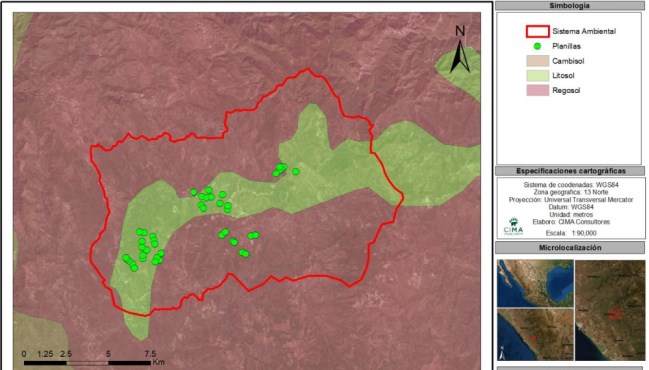

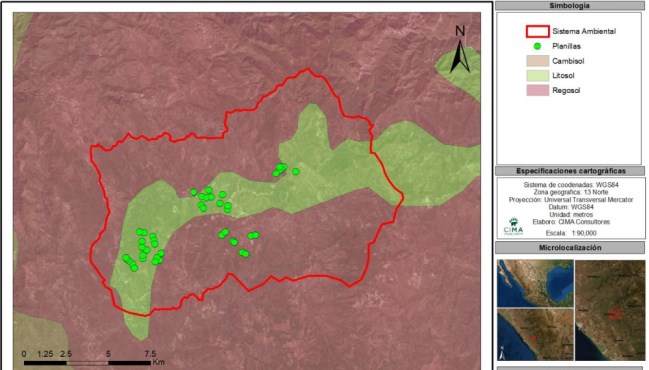

| Figure 20-10: Soil Units | 290 |

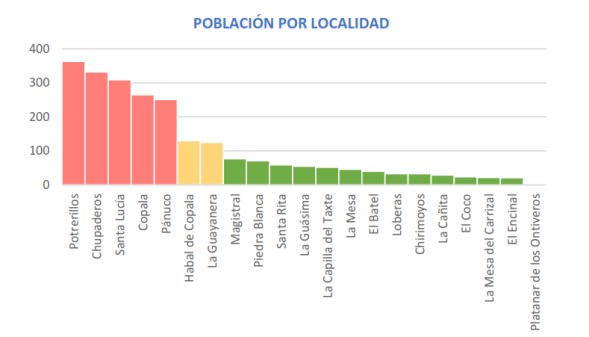

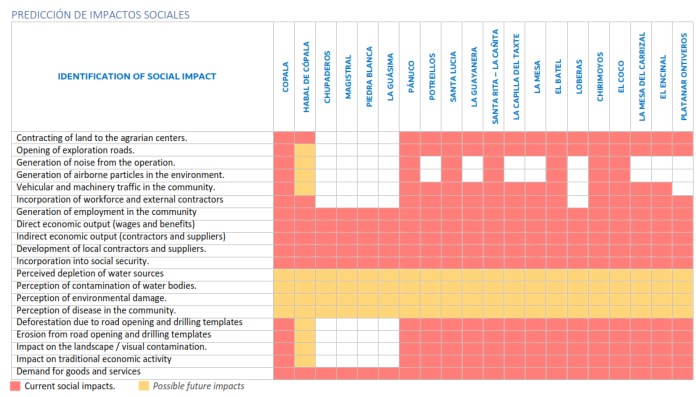

| Figure 20-11: Population per Locality | 303 |

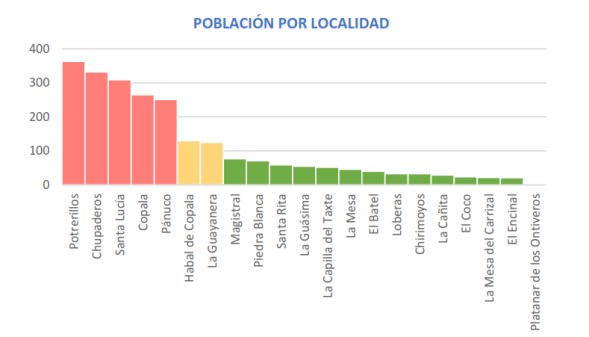

| Figure 20-12: Prediction of Social Impacts | 304 |

| Figure 22-1: Project Post-Tax Unlevered Cashflow | 321 |

| Figure 22-2: Pre-Tax Sensitivity Analysis Results | 328 |

| Figure 22-3: Post-Tax Sensitivity Analysis Results | 329 |

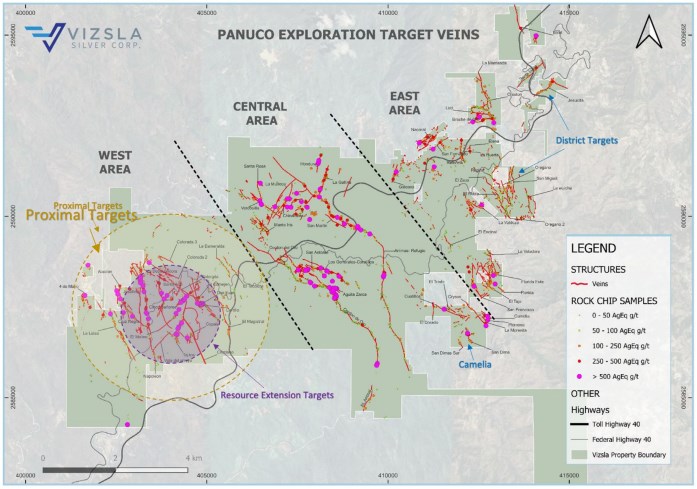

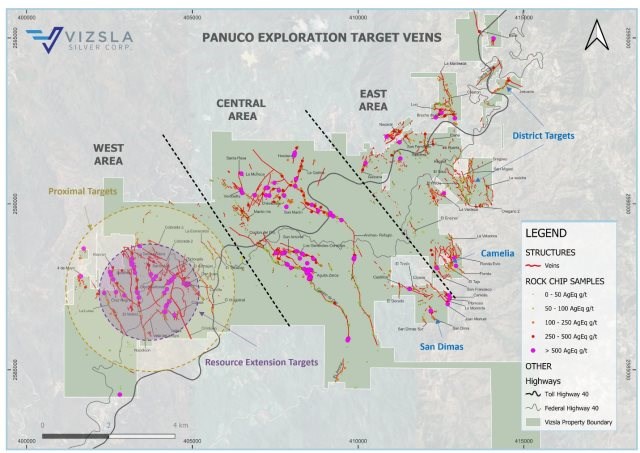

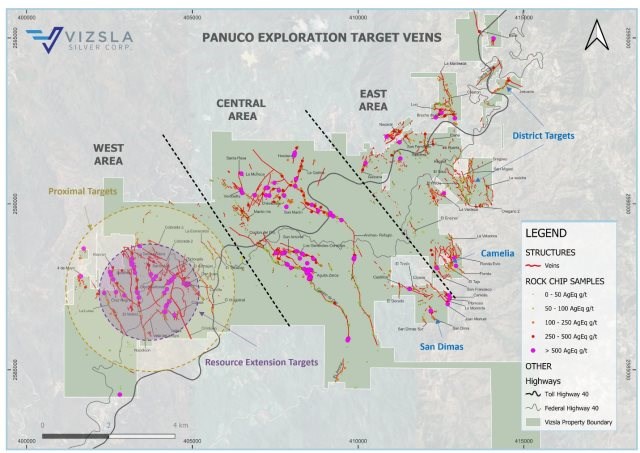

| Figure 26-1: Plan Map of the Panuco District Highlighting Primary 2024 Exploration Targets Relative to Mapped and Sampled Mineralized Veins. | 350 |

1 SUMMARY

1.1 Introduction

Vizsla Silver Corp. (Vizsla or the Company) commissioned Ausenco Engineering Canada ULC and Ausenco Sustainability ULC (Ausenco) to compile a preliminary economic assessment (PEA) of the Panuco Project (the Property or the Project). The PEA was prepared in accordance with the Canadian disclosure requirements of National Instrument 43-101 - Standards and Disclosure for Mineral Projects (NI 43-101) and the requirements of Form 43-101 F1.

The responsibilities of the engineering companies contracted by Vizsla to prepare this report are as follows:

Ausenco managed and coordinated the work related to the technical report, developed PEA-level design, capital and operating cost estimates for the process plant and general site infrastructure. Ausenco also undertook the review of the environment and permitting studies and completed the economic analysis.

SGS prepared the mineral resource estimate (MRE) for the Project and completed the work related to the geological setting, deposit type, drilling, exploration works, sample preparation and analysis and data verification.

Entech completed the mine design, mine production schedule and provided the mining capital and operating costs.

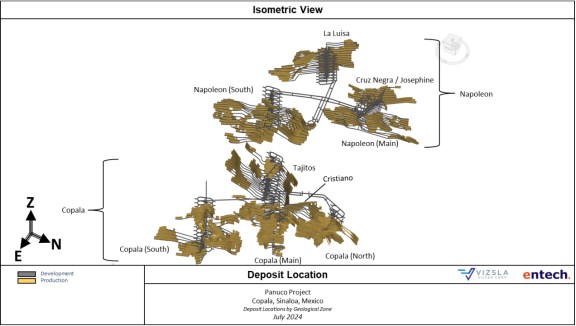

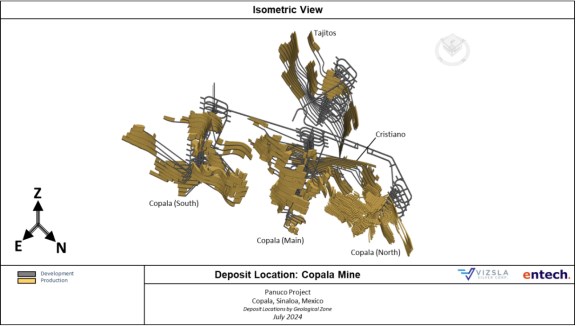

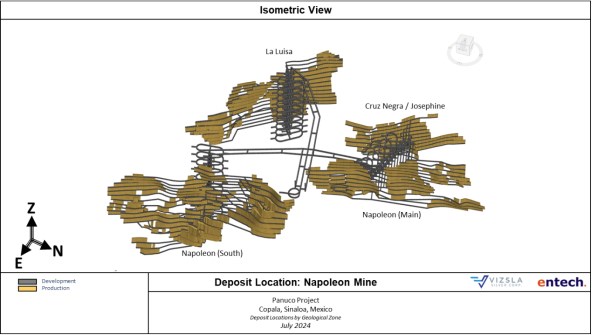

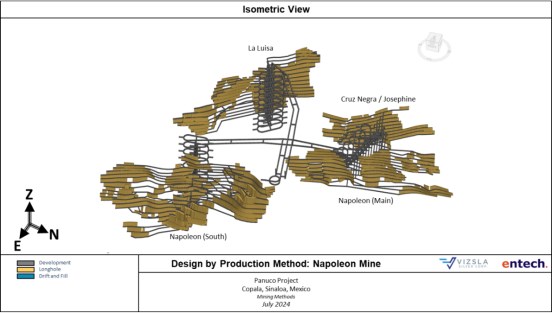

The property hosts nine known polymetallic precious metal deposits:

Copala,

Cristiano,

Tajitos,

Napoleon,

La Luisa,

Cruz Negra,

Josephine,

San Antonio, and

Animas.

Silver and gold are the metals of interest.

1.2 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements

The Panuco Project is in the Panuco-Copala mining district in the municipality of Concordia, southern Sinaloa state, along the western margin of the Sierra Madre Occidental physiographic province in western Mexico. The Project comprises 119 titled mining concessions in nineteen blocks, covering a total area of 16,536.87 ha, and two mineral concessions covering 1,321.15 ha. The mining concessions are held 100% by Vizsla. The concessions are granted for 50 years, except San Carlos that was originally granted for 100 years, provided semi-annual property tax payments are made in January and July each year and if minimum annual investment requirements are met, or if there is minimum annual production equal to the amount of the annual investment requirement. The concession owner may apply for a second 50-year term. Property tax payments of MX$2.03M were made in January and July of 2023 and MX$2.116M were paid in January of 2024 by Vizsla. Additionally, the company paid MX$2.421M of outstanding taxes in May 2024, for the recently acquired El Richard and San Enrique claims.

On January 17, 2024, Vizsla announced its intention to spin out the shares of Vizsla Royalties Corp, a wholly owned subsidiary of Vizsla, to the Company's shareholders. Vizsla Royalties currently holds, indirectly, a net smelter royalty (the "Royalty") on any potential future mineral production at Vizsla's flagship, 100% owned Panuco silver-gold project located in Sinaloa, Mexico. The Royalty consists of: (i) a 2.0% net smelter return royalty on certain unencumbered concessions comprising the Project; and (ii) a 0.5% net smelter return royalty on certain encumbered concessions comprising the Project, which have a pre-existing 3.0% net smelter return royalty (the "Underlying Royalty"). Vizsla is also expected to: (i) transfer to Vizsla Royalties the right to purchase one-half of the 3% Underlying Royalty; (ii) grant Vizsla Royalties the right to acquire a royalty on any future projects acquired by Vizsla in the 24-month period after completion of the Spinout, which right would automatically terminate upon a change of control of Vizsla Royalties or Vizsla and (iii) make a cash injection into Vizsla Royalties.

Most of the surface rights in the municipality of Concordia are owned by ejidos, which are areas of communal land used for agriculture. Community members individually farm designated parcels and collectively maintain communal holdings comprising the ejido. Ejidos are registered with Mexico's National Agrarian Registry (Registro Agrario Nacional). Surface rights to most of the land underlying the Project area are owned by six ejidos. Mining concession owners have the right to obtain the expropriation, temporary occupancy, or creation of land easements required to complete exploration and mining work, including the deposit of rock dumps, tailings, and slag. Vizsla has agreements in place with 5 ejidos covering a total of 15,029.63 ha within the Property with rights to extend the area as required with the same consideration per hectare.

1.3 Geology Mineralization

The Project is on the western margin of the Sierra Madre Occidental (SMO), a high plateau and physiographic province that extends from the U.S.A.-Mexico border to the east-trending Trans-Mexican Volcanic Belt. The SMO is a Large Igneous Province (LIP) recording continental magmatic activity from the Late Cretaceous to the Miocene in three main episodes. The first episode, termed the Lower Volcanic Complex (LVC), comprises a suite of intrusive bodies, including the Sonora, Sinaloa, and Jalisco batholiths and andesitic volcanic rock units with minor dacite and rhyolite tuffs and ignimbrites that are correlative with the Tarahumara Formation in Sonora of Late Cretaceous to Eocene age. The second magmatic episode is dominated by rhyolitic ignimbrites and tuffs that built one of the earth's largest silicic volcanic provinces and has been termed the Upper Volcanic Supergroup (UVS). These dominantly rhyolitic units were extruded in two episodes, from about 32 to 28 Ma and 24 to 20 Ma. These two periods of magmatic activity are associated with the subduction of the Farallon plate under North America and the Laramide orogeny that occurred between the Upper Cretaceous - Paleocene and the Eocene. The third episode comprises post-subduction alkali basalts and ignimbrites associated with the opening of the Gulf of California between the late Miocene and Pleistocene - Quaternary.

The western part of the SMO in Sonora and Sinaloa is cut by north-northwest-trending normal fault systems developed during the opening of the Gulf of California between 27 and 15 Ma. The normal fault systems favoured the formation of elongated basins that were subsequently filled with continental sedimentary rocks. The basins occur in a north-northwest-trending belt extending from western Sonora to most of Sinaloa.

The basement to the SMO is locally exposed in northern Sinaloa, near Mazatlan and on small outcrops within the project area. It comprises folded metasedimentary and metavolcanic rocks, deformed granitoids, phyllitic sandstones, quartzites, and schists of the Tahue terrane of Jurassic to Early Cretaceous age (Montoya-Lopera et al., 2019, Sedlock et al., 1993 and Campa and Coney 1982).

In the broader Project area, the LVC comprises granite, granodiorite, and diorite intrusive phases correlative with the Late Cretaceous to Early Paleocene San Ignacio and Eocene Piaxtla batholiths in San Dimas district. The andesite lavas, rhyolite-dacite tuffs, and ignimbrites are locally intruded by the Late Cretaceous to Early Paleocene intrusive phases and younger Eocene-Oligocene felsic dikes and domes. Northwest trending intermontane basins filled with continental conglomerates and sandstones incise the UVS and LVC in the Project area. The Oligocene age ignimbrites of the UVS occur east of the property towards Durango state.

The structure of the Project area is dominated by north-northwest-trending extensional and transtensional faults developed or reactivated during the Basin and Range tectonic event (~28 to 18 Ma). The extensional belt is associated with aligned rhyolite domes and dikes and Late Oligocene to Middle Miocene grabens.

Mineralization on the Panuco Property comprises several epithermal quartz veins. Previous workers and recent mapping and prospecting works conducted by Vizsla's geologists determined a cumulate length of veins traces of 86 km. Individual vein corridors are up to 7.6 km long, and individual veins range from decimetres to greater than 10 m wide. Veins have narrow envelopes of silicification, and local argillic alteration, commonly marked by clay gouge. Propylitic alteration consisting of chlorite-epidote in patches and veins affecting the andesites and diorite are common either proximal or distal to the veins.

The primary mineralization along the vein corridors comprises hydrothermal quartz veins and breccias with evidence of four to five different quartz stages: generally white, grey, and translucent and varying grain size from amorphous-microcrystalline-coarse. A late stage of amethyst quartz is also observed in some veins. The grey colour in quartz is due to the presence of fine-grained disseminated sulphides, believed to be mainly pyrite and acanthite. Vizsla has delineated several hydrothermal breccias with grey quartz occurring more commonly at lower levels of the vein structures. Barren to low grade, quartz is typically white and is more common in the upper parts of the veins and breccias. Locally, mineralized structures are cut by narrow, banded quartz veins with thin, dark argentite/acanthite, sphalerite, galena, and pyrite bands. Bladed and lattice quartz pseudomorphs after calcite have been noted at several locations within the veins and indicate boiling conditions during mineral deposition. Later quartz veinlets cut all the mineralized zones with a mix of white quartz and purple amethyst. The amethyst is related to mixing near-surface waters as the hydrothermal system is collapsing, as has been noted in the nearby San Dimas district (Montoya-Lopera et al., 2019).

The Mineral Resource includes ten mineralized vein systems: the Napoleon, Napoleon hanging wall, Josephine, and Cruz Negra veins; the Copala, Cristiano, Tajitos and Copala 2 veins; the San Antonio vein; and the Rosarito vein. These trends are west to east within the Napoleon, Cinco Senores, Cordon del Oro, and Animas-Refugio corridors. The bulk of the resource veins strike north-northwest to north-northeast, with thicknesses varying from 1.5 m to over 10 m.

1.4 History

Capitan Francisco de Ibarra founded Concordia in 1565 and gold and silver veins in Panuco and Copala were first exploited in the centuries that followed, Sim (2008) and Robinson (2019). Although production has been carried out on the Panuco Project over the last 460 years, no production records are available to Vizsla.

The first recorded modern mining activity commenced late in the 20th century. The Mineral Resources Council (Consejo de Recursos Minerales [CRM], the predecessor of the Mexican Geological Service [SGM]) carried out 1:50,000 scale mapping on map sheets, F13-A37, F13-A36, and F13-A46 and fine-fraction stream sediment sampling in 1999, 2003, and 019 respectively (Avila-Ramirez, 1999, Polanco-Salas et al., 2003, Rosendo-Brito et al., 2019).

In 1989 the CRM optioned and sold several mineral concessions in the district, including to Grupo Minero Bacis (Bacis). Bacis drilled 19 holes totalling 2,822.8 m along the Animas-Refugio corridor, but only collar and survey records exist of this work.

From 1999 to 2001, Minera Rio Panuco S.A de C.V. (Rio Panuco) explored the Animas-Refugio and Cordon del Oro structures culminating in 45 holes, for 8,358.6 m. No geological drill logs, downhole survey data, downhole sample data or downhole geochemical assay data have been preserved.

Capstone Mining Corp. (Capstone) optioned the Bacis concessions in 2004 and carried out geologic mapping and sampling of the Animas-Refugio and Cordon del Oro structures. In 2005, Capstone drilled 15,374 m in 131 holes on down-dip extensions of the Clemens and El Muerto mines on the Animas-Refugio vein. In 2007, Capstone explored the La Colorada structure with surface mapping and sampling followed by 6,659 m of drilling in 64 holes.

Also, in 2007, Capstone transferred the claims of the Copala, Claudia, Promontorio, Montoros, and Martha projects to Silverstone Corp. (Silverstone). Capstone and Silverstone completed 21,641 m of drilling in 200 holes from 2005 to 2008 (Christopher and Sim, 2008).

Christopher and Sim (2008) prepared two Mineral Resource estimates on the property for Silverstone on October 16, 2008. The Mineral Resource estimates were prepared for the La Colorada vein-manto and the La Pipa, El Muerto and Clemens portions of the Animas-Refugio Vein.

Silverstone merged with Silver Wheaton Ltd. (Silver Wheaton) in 2009 and Silver Wheaton subsequently sold the shares of concession owner Silverstone to Mexican owners. The Silverstone owners mined out a portion of the Mineral Resource defined in 2008 over the next decade. Silverstone mined parts of the Clemens, El Muerto, La Pipa, Mariposa, El 40, and San Martin mineralized shoots until mining encountered the water table, preventing further mining. Silverstone or unauthorized mining activity in the intervening years exploited most of the Mineral Resources estimated by Christopher and Sim (2008).

Rio Panuco contracted Geophysical Surveys S.A. de C.V. of Mexico City in 2016 to conduct an airborne magnetics survey. However, no data are available, and no survey or flight specifications are included in the report. The survey was flown in two blocks.

In 2019, Silverstone and Rio Panuco optioned their mineral concessions to Minera CANAM.

1.5 Exploration

Vizsla commenced exploration on the Project in July 2019. Surface exploration to date has included geological mapping, rock geochemical sampling, geophysical surveys. The 1:1,000 scale geological mapping of the Property completed as of December 2023 amounts to 4,330 ha mapped out of a total of 7,074 ha held by the company, which represents 61.4% of the total area mapped. Rock geochemical sampling completed between 2019 and 2024 amounts to 5,930 samples. Vizsla has conducted airborne and ground surveys since 2019. These include Fixed Loop Electromagnetic surveys (FLEM) or ground EM surveys, drone magnetic surveys, and LiDAR.

1.6 Drilling

Since initiating drilling on the Property in November 2019, Vizsla has conducted a number of significant drill campaigns in the Napoleon, Copala-Tajitos, Animas and San Antonio areas. Up to June 18, 2024 (data cut-off date for the PEA technical report), Vizsla has completed 973 drill holes totaling 371,576.72 m and collected 56,198 assays. Vizsla has continued to drill at the Project since June 2024.

In November 2019, Vizsla began drilling on the Panuco Project on the Animas-Refugio corridor near the La Pipa and Mariposa mine areas. A total of 820.50 m in three drill holes was completed in 2019.

Drilling for 2020 totalled 28,643.42 m in 129 drill holes. The four main corridors of Napoleon, Cinco Senores, Cordon del Oro, and Animas-Refugio were tested. Drilling was focused on initially on targets proximal to areas of historical mapped and worked veins.

Drilling at the Panuco Project in 2021 totalled 100,242.55 m in 320 drill holes. The drilling focused along the Napoleon and Tajitos vein areas, with 54,759.15 m in 180 drill holes and 34,769.35 m in 104 drill holes, respectively. Additionally, 4,438.50 m in 14 drill holes were drilled in the Animas-Refugio corridor, and 6,275.55 m in 22 drill holes in the Cordon del Oro corridor.

At Napoleon and Tajitos, infill and delineation drilling focussed on denser drilling to inform the Mineral Resource estimate and expand the structure's strike length. Drilling discoveries in 2021 included the Josephine and Copala veins. Further drill testing included the Cruz Negra, Alacran, Cinco Senores, and Colorada vein areas. In the Animas-Refugio corridor, drilling tested the Rosarito segment included in the Mineral Resource estimate, in addition to the Peralta and Cuevillas veins. Drilling at the Cordon del Oro corridor targeted the San Antonio structure in addition to exploration near the Aguita Zarca vein.

Drilling for 2022 totalled 121,582.40 m in 297 drill holes. The four main corridors of Napoleon, Cinco Senores, Cordon del Oro, and Animas-Refugio were tested. Drilling at the Napoleon corridor included 109 drill holes tested the Napoleon structure, for 53,412.80 m. At the Cordon del Oro corridor, drilling totalled 7,225.80 m in 30 drill holes. Drilling at the Copala/Tajitos veins included 135 drill holes for 52,045.10 m. Additionally, 6,588.90 m in 16 drill holes were drilled in the Animas-Refugio corridor and 2,309.80 m in 7 drill holes were drilled in the Broche de Oro area.