Exhibit 96.1

SEC Technical Report Summary

Pre-Feasibility Study

Mountain Pass Mine

San Bernardino County, California

Effective Date: September 30, 2021

Report Date: February 16, 2022

Report Prepared for

MP Materials Corp.

67750 Bailey Road

HC1 Box 224

Mountain Pass, CA 92366

Report Prepared by

SRK Consulting (U.S.), Inc.

1125 Seventeenth Street, Suite 600

Denver, CO 80202

SRK Project Number: 536900.070

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 2 |

Table of Contents

| | |

1 Executive Summary | | 18 |

| |

1.1 Property Description and Ownership | | 18 |

| |

1.2 Geology and Mineralization | | 18 |

| |

1.3 Status of Exploration, Development and Operations | | 19 |

| |

1.4 Mineral Processing and Metallurgical Testing | | 19 |

| |

1.4.1 Existing Crushing and Concentrating Operations | | 19 |

| |

1.4.2 Rare Earths Separations | | 20 |

| |

1.5 Mineral Resource Estimate | | 21 |

| |

1.6 Mineral Reserve Estimate | | 22 |

| |

1.7 Mining Methods | | 25 |

| |

1.8 Recovery Methods | | 26 |

| |

1.8.1 Existing Crushing and Concentrating Operations | | 26 |

| |

1.8.2 Modified and Recommissioned Separations Facility | | 26 |

| |

1.9 Project Infrastructure | | 27 |

| |

1.10 Market Studies and Contracts | | 28 |

| |

1.11 Environmental, Closure and Permitting | | 29 |

| |

1.12 Capital and Operating Costs | | 29 |

| |

1.13 Economic Analysis | | 30 |

| |

1.14 Conclusions and Recommendations | | 31 |

| |

2 Introduction | | 33 |

| |

2.1 Registrant for Whom the Technical Report Summary was Prepared | | 33 |

| |

2.2 Terms of Reference and Purpose of the Report | | 33 |

| |

2.3 Sources of Information | | 33 |

| |

2.4 Details of Inspection | | 33 |

| |

2.5 Report Version Update | | 34 |

| |

2.6 Units of Measure | | 34 |

| |

2.7 Mineral Resource and Mineral Reserve Definitions | | 34 |

| |

2.8 Qualified Person | | 35 |

| |

3 Property Description and Location | | 37 |

| |

3.1 Property Location | | 39 |

| |

3.2 Mineral Title | | 39 |

| |

3.2.1 Nature and Extent of Registrant’s Interest | | 42 |

| |

3.3 Royalties, Agreements, and Encumbrances | | 42 |

| |

3.4 Environmental Liabilities and Permitting | | 42 |

| |

3.4.1 Remediation Liabilities | | 43 |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 3 |

| | | | |

| |

3.4.2 Required Permits and Status | | | 43 | |

| |

3.5 Other Significant Factors and Risks | | | 44 | |

| |

4 Accessibility, Climate, Local Resources, Infrastructure, and Physiography | | | 45 | |

| |

4.1 Topography, Elevation, and Vegetation | | | 45 | |

| |

4.2 Accessibility and Transportation to the Property | | | 45 | |

| |

4.3 Climate and Length of Operating Season | | | 45 | |

| |

4.4 Infrastructure Availability and Sources | | | 46 | |

| |

5 History | | | 47 | |

| |

5.1 Prior Ownership and Ownership Changes | | | 47 | |

| |

5.2 Exploration and Development Results of Previous Owners | | | 47 | |

| |

5.3 Historic Production | | | 49 | |

| |

6 Geological Setting, Mineralization and Deposit | | | 53 | |

| |

6.1 Regional Geology | | | 53 | |

| |

6.2 Local and Property Geology | | | 55 | |

| |

6.2.1 Local Lithology | | | 57 | |

| |

6.2.2 Alteration | | | 58 | |

| |

6.2.3 Structure | | | 58 | |

| |

6.3 Significant Mineralized Zones | | | 59 | |

| |

6.4 Surrounding Rock Types | | | 63 | |

| |

6.5 Relevant Geological Controls | | | 63 | |

| |

6.6 Deposit Type, Character, and Distribution of Mineralization | | | 63 | |

| |

7 Exploration and Drilling | | | 64 | |

| |

7.1 Exploration | | | 64 | |

| |

7.2 Drilling | | | 64 | |

| |

8 Sample Preparation, Analysis and Security | | | 66 | |

| |

8.1 Historical Sampling | | | 66 | |

| |

8.2 Sampling 2009-2011 | | | 67 | |

| |

8.3 Sampling 2021 | | | 67 | |

| |

8.4 Laboratory Analysis | | | 67 | |

| |

8.4.1 Note on Assay Terminology | | | 68 | |

| |

8.4.2 Historical | | | 69 | |

| |

8.4.3 Current | | | 69 | |

| |

8.4.4 2009 and 2010 Samples | | | 69 | |

| |

8.4.5 2011 Samples | | | 70 | |

| |

8.4.6 2021 Samples | | | 70 | |

| |

9 Data Verification | | | 71 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 4 |

| | | | |

| |

9.1 Quality Assurance/Quality Control Procedures | | | 71 | |

| |

9.1.1 Historical | | | 71 | |

| |

9.1.2 2009-2010 Program | | | 71 | |

| |

9.1.3 2011 Program | | | 73 | |

| |

9.1.4 2021 Program | | | 73 | |

| |

9.2 2009 Re-Assaying Program | | | 75 | |

| |

9.2.1 Procedures | | | 75 | |

| |

9.2.2 SGS Check Assay Sample Preparation | | | 76 | |

| |

9.2.3 SGS Check Assay XRF Procedures | | | 76 | |

| |

9.2.4 Mountain Pass Laboratory Check Assay XRF Procedures | | | 77 | |

| |

9.2.5 Analysis of Light Rare Earth Oxide Distribution | | | 77 | |

| |

9.2.6 Analysis of Heavy Rare Earth Oxide Assays | | | 79 | |

| |

9.2.7 Results | | | 79 | |

| |

9.3 Data Adequacy | | | 83 | |

| |

10 Mineral Processing and Metallurgical Testing | | | 85 | |

| |

10.1 Background | | | 85 | |

| |

10.2 Flotation Studies Versus Ore Grade | | | 85 | |

| |

10.3 Concentrator Recovery Estimate | | | 87 | |

| |

10.4 Separation of Individual Rare Earths | | | 88 | |

| |

10.4.1 Metallurgical Testwork | | | 89 | |

| |

10.4.2 Representativeness of Test Samples | | | 91 | |

| |

10.4.3 Analytical Laboratories | | | 92 | |

| |

10.4.4 Separations Facility Recovery Estimates | | | 92 | |

| |

10.4.5 Expected Product Specifications | | | 102 | |

| |

11 Mineral Resource Estimate | | | 104 | |

| |

11.1 Topography and Coordinate System | | | 104 | |

| |

11.2 Drillhole Database | | | 104 | |

| |

11.3 Geology | | | 107 | |

| |

11.3.1 Structural Model | | | 107 | |

| |

11.3.2 Lithology Model | | | 108 | |

| |

11.3.3 Mineralogical/Alteration Model | | | 109 | |

| |

11.4 Exploratory Data Analysis | | | 110 | |

| |

11.4.1 Resource Domains | | | 110 | |

| |

11.4.2 Outliers | | | 112 | |

| |

11.4.3 Compositing | | | 116 | |

| |

11.5 Specific Gravity | | | 116 | |

| |

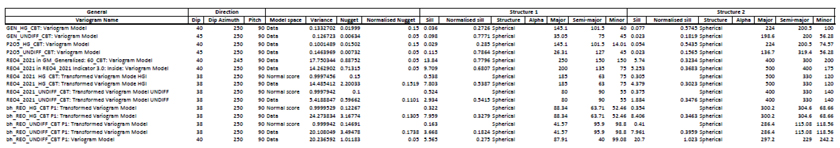

11.6 Variogram Analysis and Modeling | | | 117 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 5 |

| | | | |

| |

11.7 Block Model Limits | | | 119 | |

| |

11.8 Grade Estimation | | | 120 | |

| |

11.8.1 Blasthole Estimate Specifics | | | 121 | |

| |

11.8.2 Exploration Estimate Specifics | | | 122 | |

| |

11.9 Model Validation | | | 122 | |

| |

11.10 Production Reconciliation | | | 124 | |

| |

11.10.1 Blasthole “Bias” | | | 127 | |

| |

11.11 Uncertainty and Resource Classification | | | 130 | |

| |

11.12 Cut-Off Grade and Pit Optimization | | | 131 | |

| |

11.13 Mineral Resource Statement | | | 133 | |

| |

11.14 Mineral Resource Sensitivity | | | 135 | |

| |

11.15 Assumptions, Parameters, and Methods | | | 137 | |

| |

12 Mineral Reserve Estimate | | | 139 | |

| |

12.1 Conversion Assumptions, Parameters, and Methods | | | 139 | |

| |

12.1.1 Model Grade Dilution and Mining Recovery | | | 140 | |

| |

12.1.2 Cut-off Grade Calculation | | | 140 | |

| |

12.2 Reserve Estimate | | | 141 | |

| |

12.3 Relevant Factors | | | 142 | |

| |

13 Mining Methods | | | 144 | |

| |

13.1 Parameters Relevant to Mine or Pit Designs and Plans | | | 145 | |

| |

13.1.1 Geotechnical | | | 145 | |

| |

13.1.2 Hydrogeological | | | 149 | |

| |

13.2 Pit Optimization | | | 154 | |

| |

13.2.1 Mineral Resource Models | | | 154 | |

| |

13.2.2 Topographic Data | | | 155 | |

| |

13.2.3 Pit Optimization Constraints | | | 155 | |

| |

13.2.4 Pit Optimization Parameters | | | 155 | |

| |

13.2.5 Optimization Process | | | 156 | |

| |

13.2.6 Optimization Results | | | 157 | |

| |

13.3 Design Criteria | | | 160 | |

| |

13.3.1 Pit and Phase Designs | | | 160 | |

| |

13.4 Mine Production Schedule | | | 163 | |

| |

13.4.1 Mine Production | | | 163 | |

| |

13.5 Waste and Stockpile Design | | | 169 | |

| |

13.5.1 Waste Rock Storage Facility | | | 169 | |

| |

13.5.2 Stockpiles | | | 171 | |

| |

13.6 Mining Fleet and Requirements | | | 172 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 6 |

| | | | |

| |

13.6.1 General Requirements and Fleet Selection | | | 172 | |

| |

13.6.2 Drilling and Blasting | | | 175 | |

| |

13.6.3 Loading | | | 175 | |

| |

13.6.4 Hauling | | | 176 | |

| |

13.6.5 Auxiliary Equipment | | | 178 | |

| |

13.6.6 Mining Operations and Maintenance Labor | | | 178 | |

| |

14 Processing and Recovery Methods | | | 181 | |

| |

14.1 Historic Production | | | 181 | |

| |

14.2 Current Operations | | | 181 | |

| |

14.2.1 Metallurgical Control and Accounting | | | 183 | |

| |

14.2.2 Plant Performance | | | 183 | |

| |

14.2.3 Significant Factors | | | 186 | |

| |

14.3 Individual Rare Earth Separations | | | 186 | |

| |

15 Infrastructure | | | 190 | |

| |

15.1 Access and Local Communities | | | 191 | |

| |

15.2 Site Facilities and Infrastructure | | | 191 | |

| |

15.2.1 On-Site Facilities | | | 191 | |

| |

15.2.2 Explosives Storage and Handling Facilities | | | 193 | |

| |

15.2.3 Service Roads | | | 193 | |

| |

15.2.4 Mine Operations and Support Facilities | | | 193 | |

| |

15.2.5 Waste and Waste Handling (Non-Tailings/Waste Rock) | | | 193 | |

| |

15.2.6 Waste Rock Handling | | | 194 | |

| |

15.2.7 Power Supply and Distribution | | | 194 | |

| |

15.2.8 Natural Gas | | | 194 | |

| |

15.2.9 Vehicle and Heavy Equipment Fuel | | | 194 | |

| |

15.2.10 Other Energy | | | 194 | |

| |

15.2.11 Water Supply | | | 194 | |

| |

15.3 Tailings Management Area | | | 196 | |

| |

15.4 Security | | | 197 | |

| |

15.5 Communications | | | 197 | |

| |

15.6 Logistics Requirements and Off-Site Infrastructure | | | 197 | |

| |

15.6.1 Rail | | | 197 | |

| |

15.6.2 Port and Logistics | | | 197 | |

| |

16 Market Studies and Contracts | | | 198 | |

| |

16.1 Abbreviations | | | 198 | |

| |

16.2 Introduction | | | 198 | |

| |

16.3 General Market Outlook | | | 199 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 7 |

| | | | |

| |

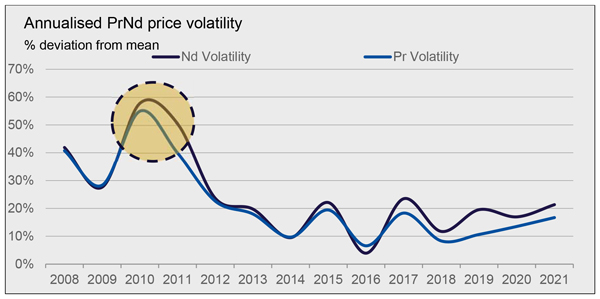

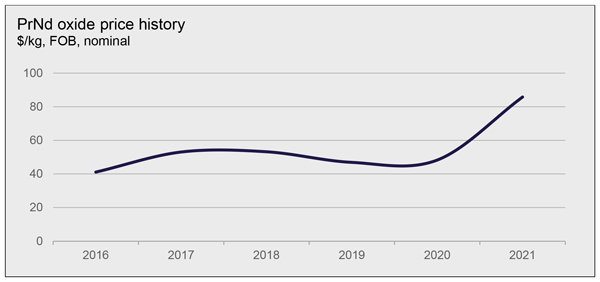

16.3.1 Historical Pricing | | | 199 | |

| |

16.3.2 Market Balance | | | 203 | |

| |

16.3.3 Costs | | | 206 | |

| |

16.4 Products and Markets | | | 208 | |

| |

16.4.1 Mixed Rare Earth Concentrate | | | 208 | |

| |

16.4.2 PrNd Oxide | | | 210 | |

| |

16.4.3 SEG+ Oxalate | | | 213 | |

| |

16.4.4 La Carbonate | | | 216 | |

| |

16.4.5 Cerium Chloride | | | 218 | |

| |

16.5 Specific Products | | | 222 | |

| |

16.5.1 Concentrate | | | 222 | |

| |

16.5.2 PrNd Oxide | | | 223 | |

| |

16.5.3 SEG+ Oxalate | | | 224 | |

| |

16.5.4 La Carbonate | | | 225 | |

| |

16.5.5 Cerium Chloride | | | 225 | |

| |

16.6 Conclusions | | | 226 | |

| |

16.7 Contracts | | | 227 | |

| |

17 Environmental Studies, Permitting, and Closure | | | 229 | |

| |

17.1 Environmental Study Results | | | 229 | |

| |

17.2 Required Permits and Status | | | 229 | |

| |

17.3 Mine Closure | | | 230 | |

| |

18 Capital and Operating Costs | | | 231 | |

| |

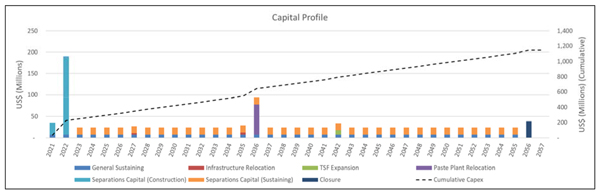

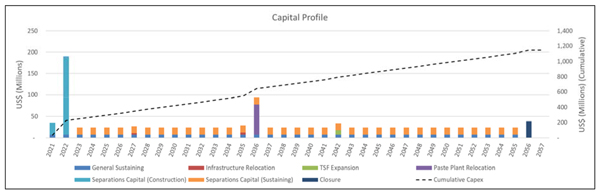

18.1 Capital Cost Estimates | | | 231 | |

| |

18.1.1 Mining Capital Cost | | | 231 | |

| |

18.1.2 Separations Facility Capital Cost | | | 233 | |

| |

18.1.3 Other Sustaining Capital | | | 233 | |

| |

18.1.4 Closure Costs | | | 234 | |

| |

18.1.5 Basis for Capital Cost Estimates | | | 234 | |

| |

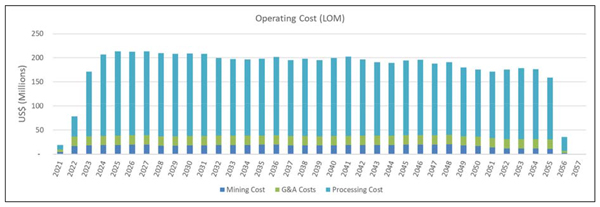

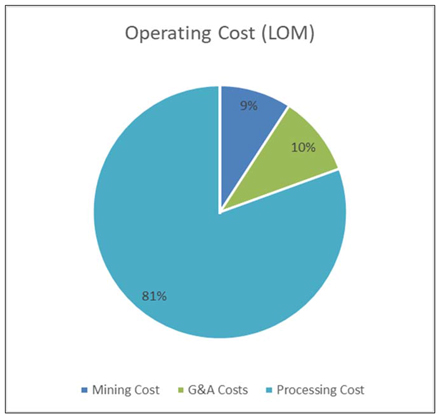

18.2 Operating Cost Estimates | | | 235 | |

| |

18.2.1 Mining Operating Cost | | | 235 | |

| |

18.2.2 Processing Operating Cost | | | 237 | |

| |

18.2.3 Selling, General, and Administrative Operating Costs | | | 239 | |

| |

19 Economic Analysis | | | 240 | |

| |

19.1 General Description | | | 240 | |

| |

19.2 Basic Model Parameters | | | 240 | |

| |

19.3 External Factors | | | 240 | |

| |

19.3.1 Pricing | | | 240 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 8 |

| | | | |

| |

19.3.2 Taxes and Royalties | | | 241 | |

| |

19.3.3 Working Capital | | | 241 | |

| |

19.4 Technical Factors | | | 241 | |

| |

19.4.1 Mining Profile | | | 241 | |

| |

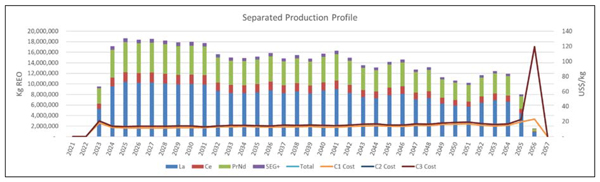

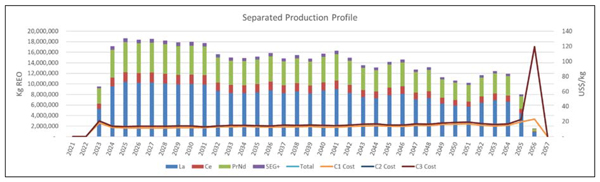

19.4.2 Processing Profile | | | 242 | |

| |

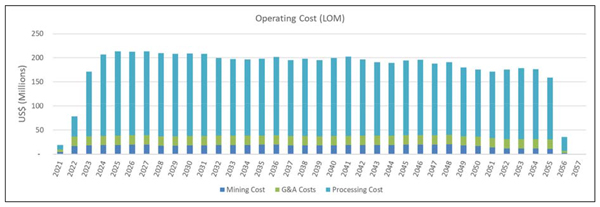

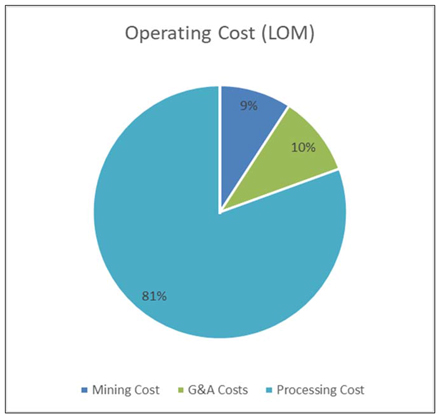

19.4.3 Operating Costs | | | 243 | |

| |

19.4.4 Mining | | | 245 | |

| |

19.4.5 Processing | | | 245 | |

| |

19.4.6 G&A Costs | | | 245 | |

| |

19.4.7 Capital Costs | | | 245 | |

| |

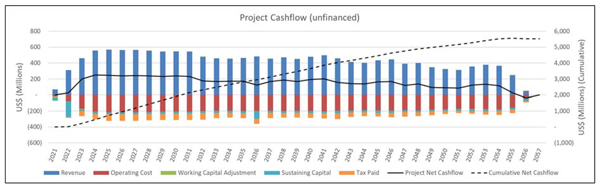

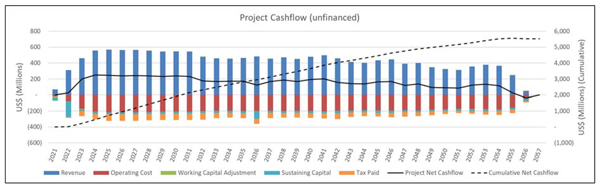

19.4.8 Results | | | 246 | |

| |

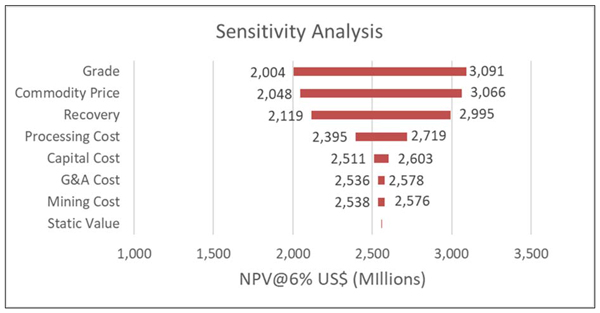

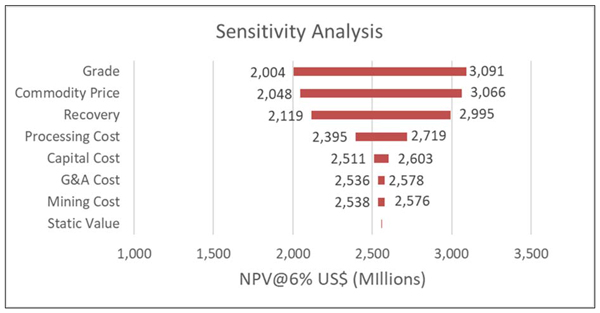

19.4.9 Sensitivity Analysis | | | 247 | |

| |

19.4.10 Cash Flow Snapshot | | | 247 | |

| |

20 Adjacent Properties | | | 249 | |

| |

21 Other Relevant Data and Information | | | 250 | |

| |

22 Interpretation and Conclusions | | | 251 | |

| |

22.1 Mineral Resource Estimate | | | 251 | |

| |

22.2 Mineral Reserve Estimate | | | 251 | |

| |

22.3 Metallurgy and Processing | | | 253 | |

| |

22.3.1 Existing Crushing and Concentration Operations | | | 253 | |

| |

22.3.2 Modified and Recommissioned Separations Facility | | | 253 | |

| |

22.4 Project Infrastructure | | | 253 | |

| |

22.5 Products and Markets | | | 254 | |

| |

22.6 Environmental, Closure, and Permitting | | | 254 | |

| |

22.7 Projected Economic Outcomes | | | 255 | |

| |

23 Recommendations | | | 256 | |

| |

24 References | | | 258 | |

| |

25 Reliance on Information Provided by the Registrant | | | 259 | |

| |

Signature Page | | | 260 | |

List of Tables

| | | | |

Table 1-1: Product Specifications | | | 20 | |

| |

Table 1-2: Mineral Resource Statement for the Mountain Pass Rare Earth Project, September 30, 2021 | | | 22 | |

| |

Table 1-3: Mineral Reserves at Mountain Pass as of September 30, 2021 - SRK Consulting (U.S.), Inc. | | | 24 | |

| |

Table 1-4: Cash Flow Summary | | | 31 | |

| |

Table 2-1: Site Visits | | | 34 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 9 |

| | | | |

| |

Table 3-1: Current Financial Assurance Obligations | | | 43 | |

| |

Table 5-1: Production History, 1952 to 1970 | | | 50 | |

| |

Table 5-2: Mine Production History, 1971 to 2002 | | | 51 | |

| |

Table 5-3: Mountain Pass Production History, 2009 to 2015, as Separated RE Products | | | 51 | |

| |

Table 5-4: Mountain Pass Production History, 2018 to 2021, as Bastnaesite Concentrate | | | 52 | |

| |

Table 8-1: Oxides and TREO Detection Limits, Mountain Pass Laboratory | | | 69 | |

| |

Table 8-2: Oxides and Element Detection Limits, Actlabs Laboratory | | | 70 | |

| |

Table 9-1: Oxides Analyzed with Detection Limits | | | 77 | |

| |

Table 9-2: Light Rare Earth Oxide Distribution Statistics: 2009 and 2010 Analyses | | | 77 | |

| |

Table 9-3: Light Rare Earth Oxide Distribution Statistics: 2011 Analyses | | | 78 | |

| |

Table 9-4: Light Rare Earth Oxide Distribution Statistics: 2009, 2010 and 2011 Analyses | | | 78 | |

| |

Table 9-5: Light Rare Earth Oxide Assay Statistics: 2009 and 2010 Analyses | | | 78 | |

| |

Table 9-6: Heavy Rare Earth Summary | | | 79 | |

| |

Table 9-7: Standards with Expected Analytical Performance | | | 80 | |

| |

Table 10-1: Head Analyses for Grade Range Test Composites | | | 86 | |

| |

Table 10-2: Cumulative Rougher Flotation Concentrate Grade and Recovery Versus Ore Grade | | | 86 | |

| |

Table 10-3: Estimated Rougher and Cleaner Flotation REO Recovery (1) | | | 87 | |

| |

Table 10-4: Analytical Laboratories | | | 92 | |

| |

Table 10-5: Feed Conditions That Resulted in Optimal Extractions at 109 g/L | | | 94 | |

| |

Table 10-6: Test Material Feed Composition by % Solid REO | | | 95 | |

| |

Table 10-7: Outlet Stream Composition by g/L REO at 109 g/L | | | 95 | |

| |

Table 10-8: Settling Test Results Including Overflow Clarity with Various Flocculants and Dosages | | | 95 | |

| |

Table 10-9: Assays of Feed, Cell of Complete Rare Earth Breakthrough, and Cell of Fe/U Bleed | | | 98 | |

| |

Table 10-10: Mass Balance Calculations for Outlet Streams at Various Fractions | | | 98 | |

| |

Table 10-11: Volumetric Flowrates of Different Streams along with Mass Flowrates of Different Components | | | 99 | |

| |

Table 10-12: Impurities in Brine Before and After Treatment | | | 102 | |

| |

Table 11-1: TREO Influence Limitations | | | 113 | |

| |

Table 11-2: 2009 Specific Gravity Results - Carbonatite | | | 117 | |

| |

Table 11-3: Block Model Specifications | | | 120 | |

| |

Table 11-4: Blasthole vs. Exploration Comparison | | | 128 | |

| |

Table 11-5: Cut-Off Grade Input Parameters | | | 131 | |

| |

Table 11-6: Mineral Resource Statement Exclusive of Mineral Reserves for the Mountain Pass Rare Earth Project, September 30, 2021 | | | 134 | |

| |

Table 11-7: Mineral Resources Inclusive of Mineral Reserves for the Mountain Pass Rare Earth Project, September 30, 2021 | | | 135 | |

| |

Table 11-8: TREO Cut-off Sensitivity Analysis Within Resource Pit – Measured and Indicated Category | | | 136 | |

| |

Table 11-9: TREO COG Sensitivity Analysis Within Resource Pit – Inferred Category | | | 136 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 10 |

| | | | |

| |

Table 11-10: Mineralized Material Internal and External to Resource Pit | | | 137 | |

| |

Table 12-1: Pit Optimization Inputs | | | 141 | |

| |

Table 12-2: Mineral Reserves at Mountain Pass as of September 30, 2021, SRK Consulting | | | 142 | |

| |

Table 13-1: Recommended Slope Design Parameters | | | 148 | |

| |

Table 13-2: CNI Preliminary Recommended Slope Design Parameters by Design Sector | | | 149 | |

| |

Table 13-3: CNI Final Recommended Slope Design Parameters by Design Sector | | | 149 | |

| |

Table 13-4: Summary of Pit Water Production in First Half of 2021 | | | 152 | |

| |

Table 13-5: Block Model Block Sizes | | | 154 | |

| |

Table 13-6: Pit Optimization Parameters | | | 156 | |

| |

Table 13-7: Mountain Pass Pit Optimization Result Using Indicated Classification Only | | | 158 | |

| |

Table 13-8: Estimated Storage Capacity for Overburden and Stockpile Grade Material | | | 170 | |

| |

Table 13-9: North, East and West Waste Dump Schedule | | | 172 | |

| |

Table 13-10: Mining Equipment Requirements | | | 174 | |

| |

Table 13-11: Loading Statistics by Unit Type in Waste | | | 175 | |

| |

Table 13-12: Loading Productivities by Unit Type in Waste | | | 176 | |

| |

Table 13-13: Hauling Statistics by Unit Type in Waste | | | 176 | |

| |

Table 13-14: Pit Haulage Cycle Times (minutes) | | | 177 | |

| |

Table 13-15: Hauling Productivities | | | 177 | |

| |

Table 13-16: Mining Operations and Maintenance Labor Requirements | | | 180 | |

| |

Table 14-1: Historic Mill Production, 1980 to 2002 | | | 181 | |

| |

Table 14-2: Concentrator Production Summary - 2020 | | | 185 | |

| |

Table 14-3: Concentrator Production Summary - 2021 (Jan -Sept) | | | 185 | |

| |

Table 16-1: Abbreviations for Market Studies and Contracts | | | 198 | |

| |

Table 16-2: Summary of U.S. Facilities Monitoring and Limiting P-levels | | | 219 | |

| |

Table 16-3: Summary of Long Term Price Forecasts | | | 222 | |

| |

Table 17-1: Current Environmental Permits and Status | | | 230 | |

| |

Table 18-1: Mining Equipment Capital Cost Estimate (US$000’s) | | | 232 | |

| |

Table 18-2: Estimated Remaining Separations Facility Capital Costs | | | 233 | |

| |

Table 18-3: Closure Cost Estimates | | | 234 | |

| |

Table 18-4: Mining Operating Costs | | | 236 | |

| |

Table 18-5: Separations Operating Costs | | | 238 | |

| |

Table 18-6: Summary of MP Materials Site G&A Operating Costs | | | 239 | |

| |

Table 19-1: Basic Model Parameters | | | 240 | |

| |

Table 19-2: LoM Mining Summary | | | 242 | |

| |

Table 19-3: LoM Processing Profile | | | 242 | |

| |

Table 19-4: Mining Cost Summary | | | 245 | |

| |

Table 19-5: Processing Cost Summary | | | 245 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 11 |

| | | | |

| |

Table 19-6: G&A Cost Summary | | | 245 | |

| |

Table 19-7: Economic Result | | | 247 | |

| |

Table 25-1: Reliance on Information Provided by the Registrant | | | 259 | |

List of Figures

| | | | |

| |

Figure 1-1: Final Pit Design and Site Layout | | | 25 | |

| |

Figure 1-2: Project Cashflow | | | 31 | |

| |

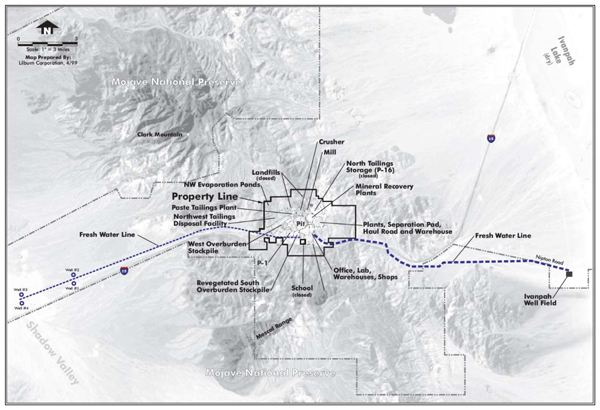

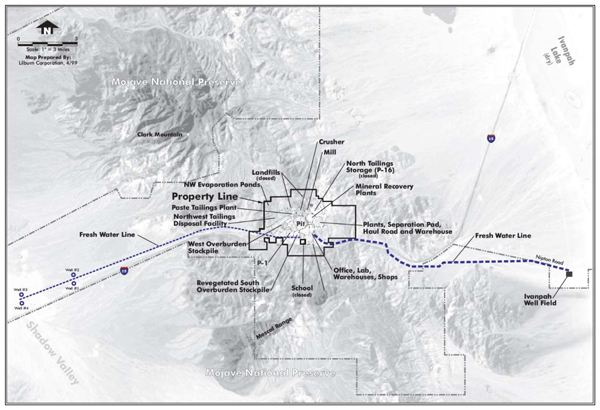

Figure 3-1: General Facility Arrangement (WGS84 Coordinate System) | | | 38 | |

| |

Figure 3-2: Location Map | | | 39 | |

| |

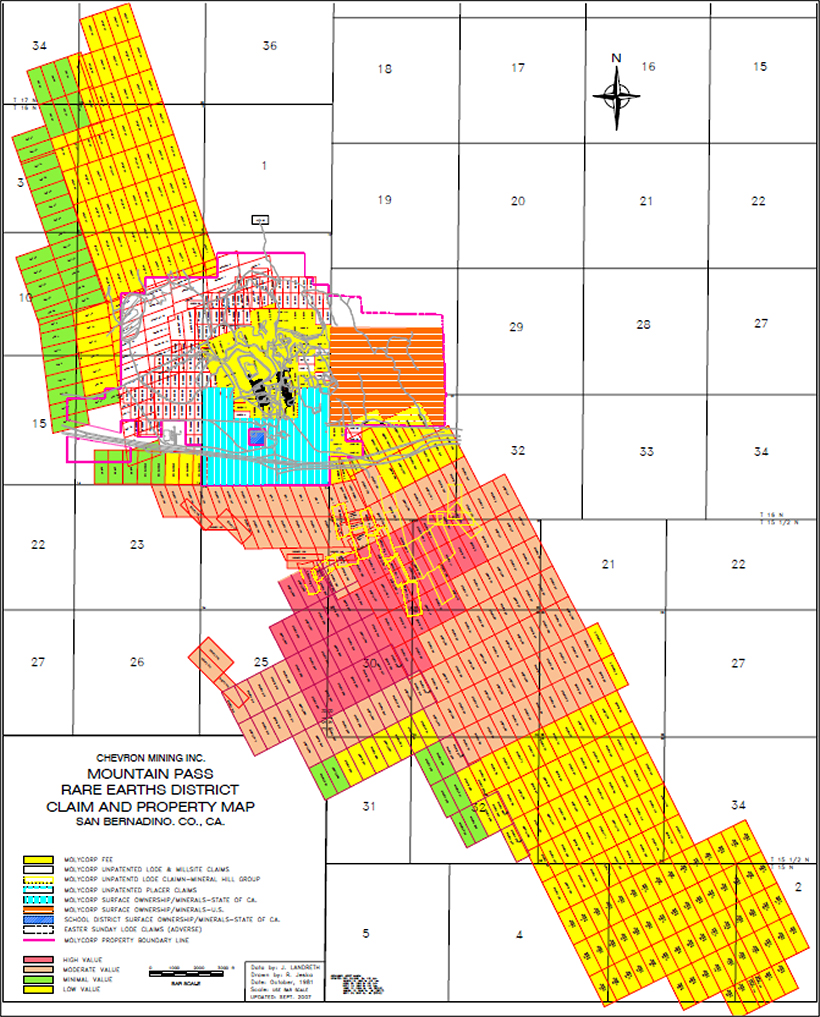

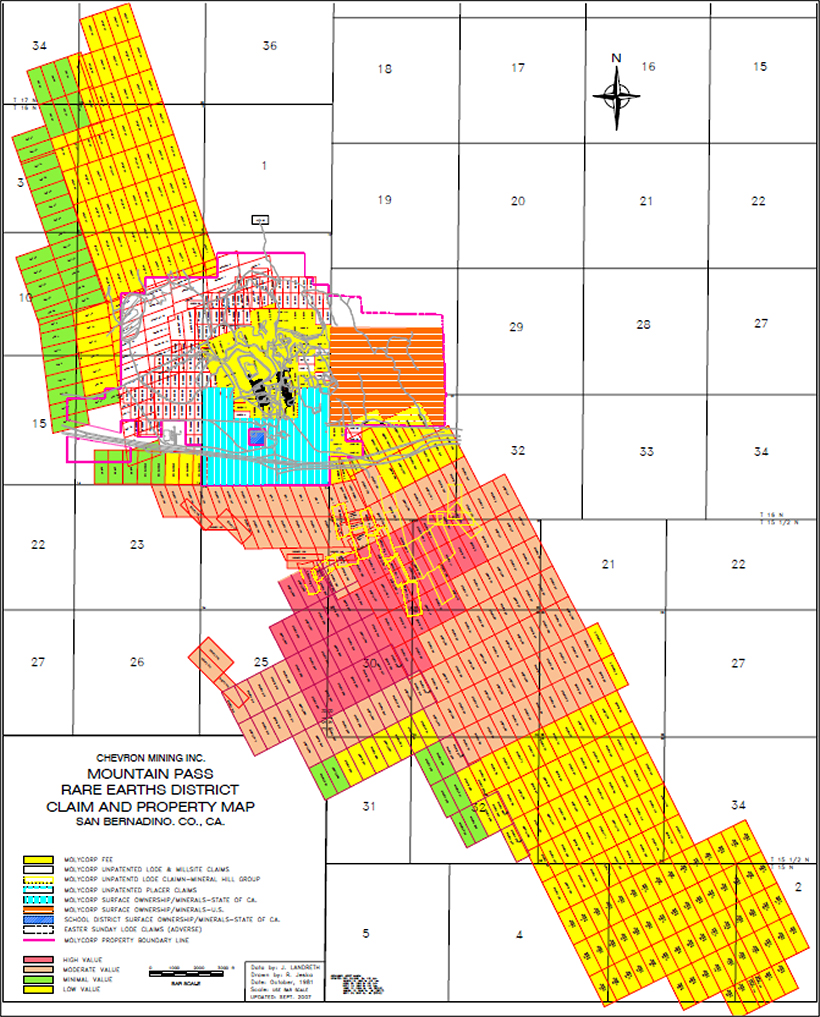

Figure 3-3: Land Tenure Map | | | 41 | |

| |

Figure 6-1: Regional Geological Map | | | 54 | |

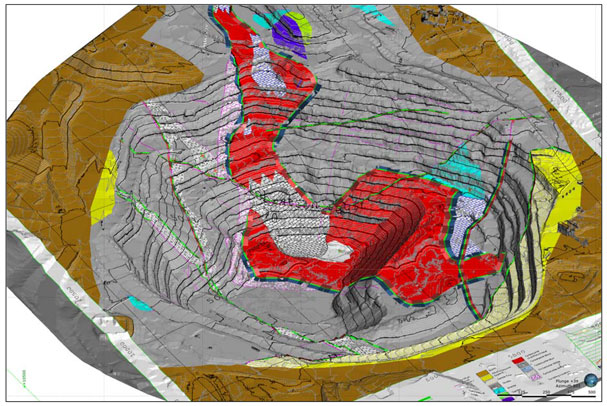

| |

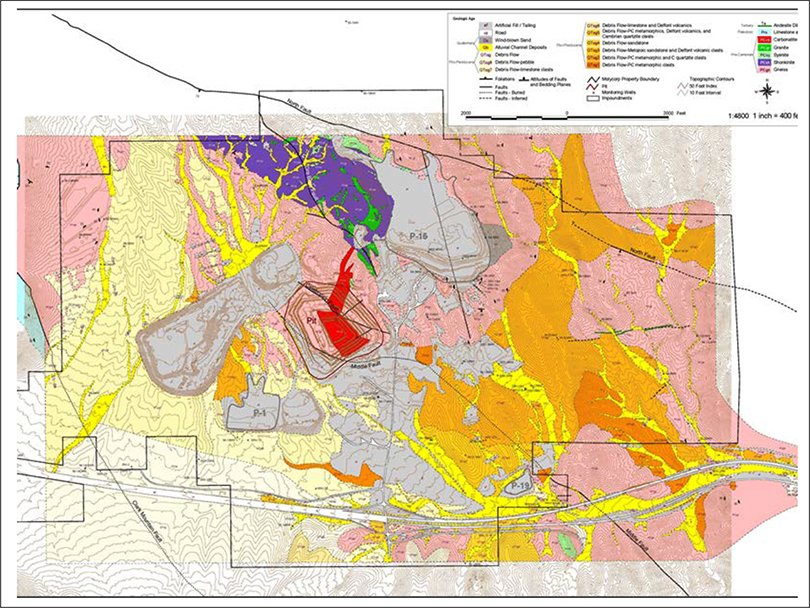

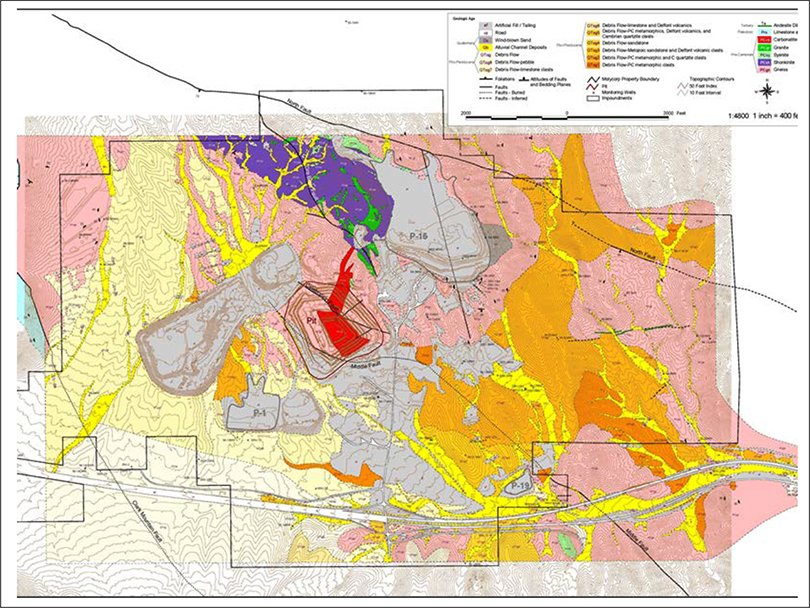

Figure 6-2: Generalized Geologic Map – Sulfide Queen Carbonatite | | | 56 | |

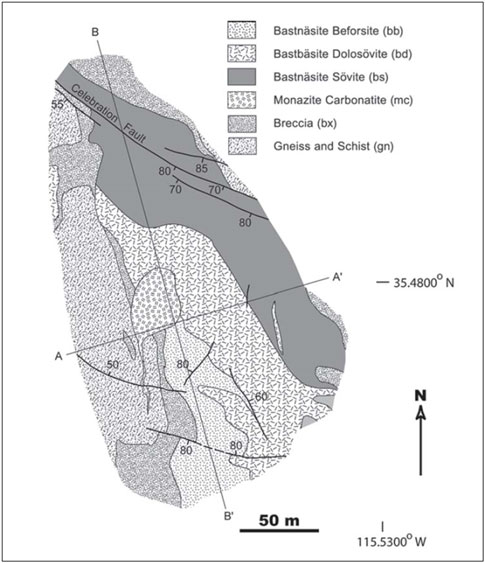

| |

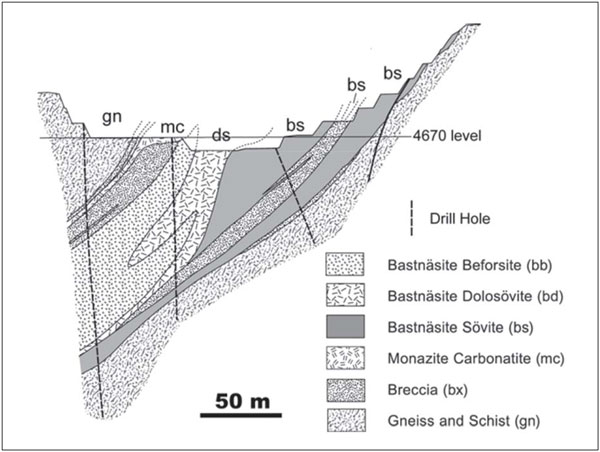

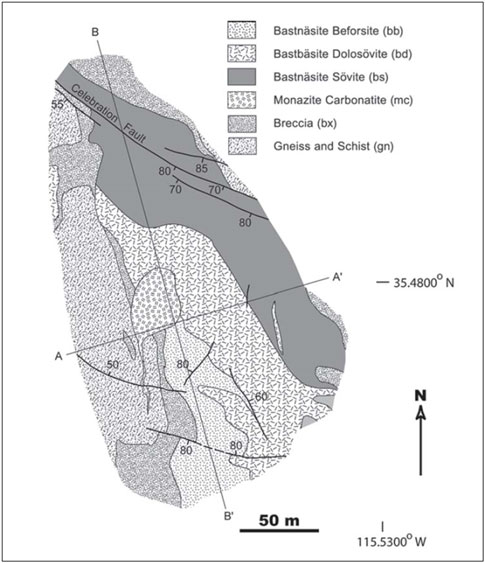

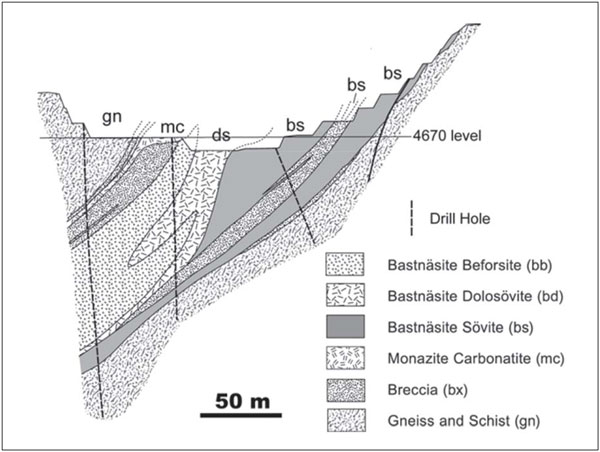

Figure 6-3: Schematic Cross Section (A-A’) of Sulfide Queen Carbonatite | | | 57 | |

| |

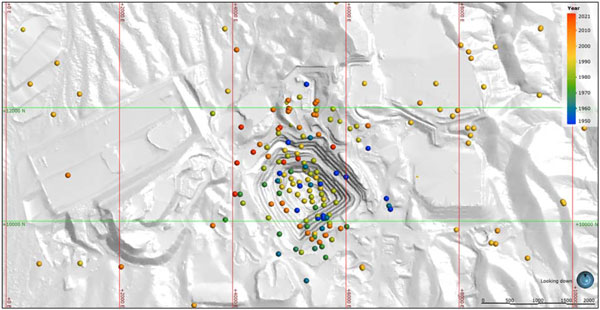

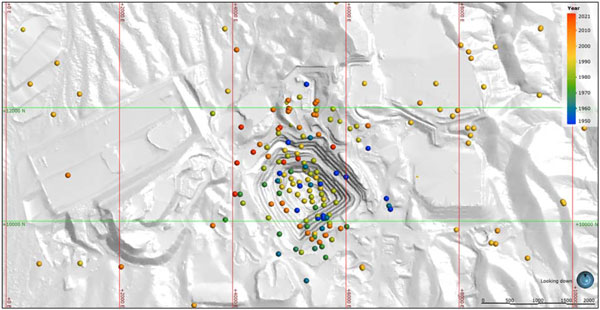

Figure 7-1: Drilling in MP Materials Pit Area | | | 65 | |

| |

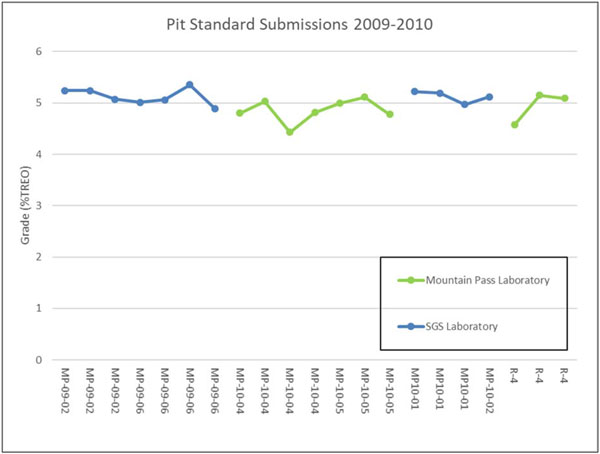

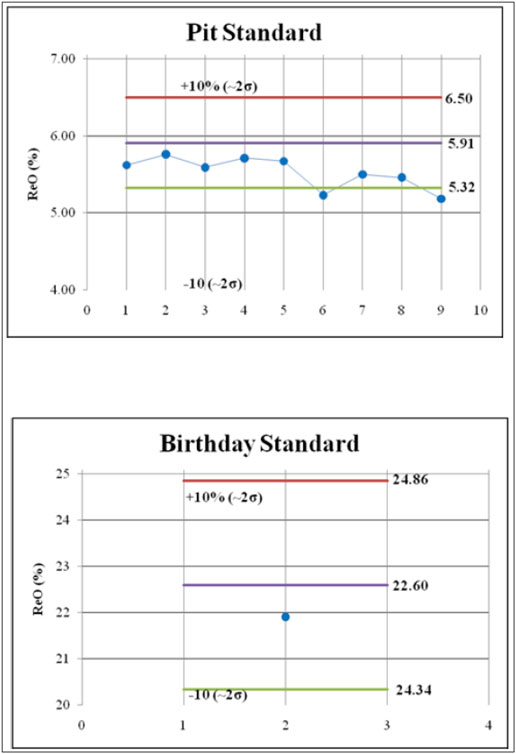

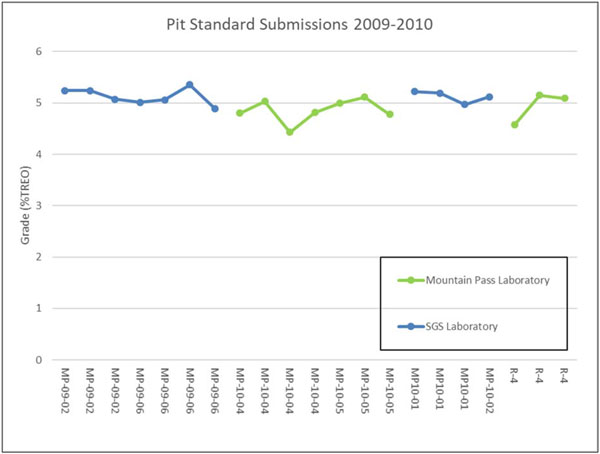

Figure 9-1: 2009 Through 2010 Pit Standard Assays | | | 72 | |

| |

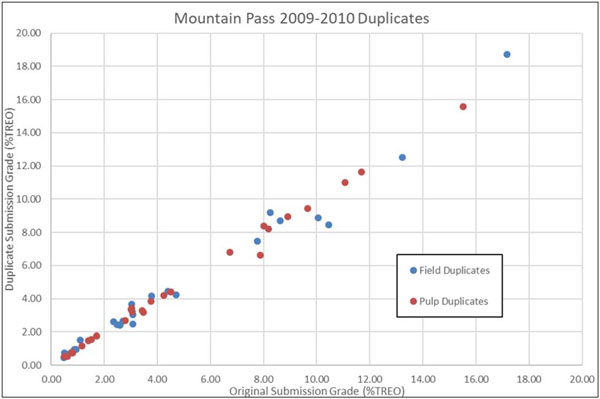

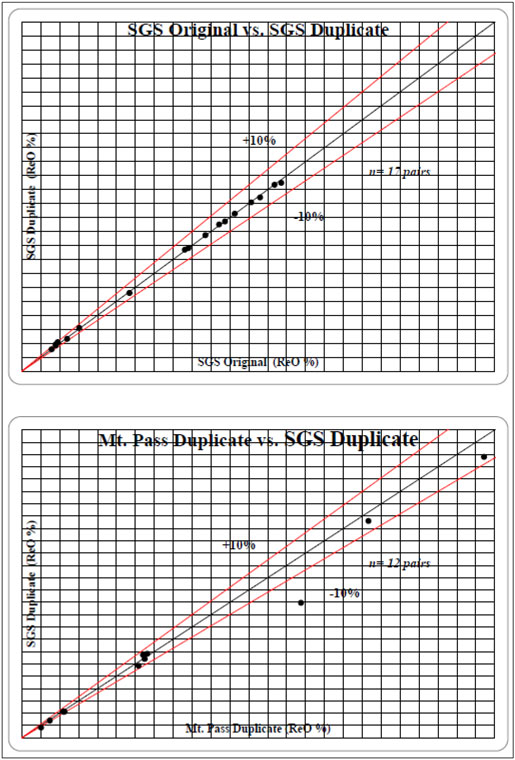

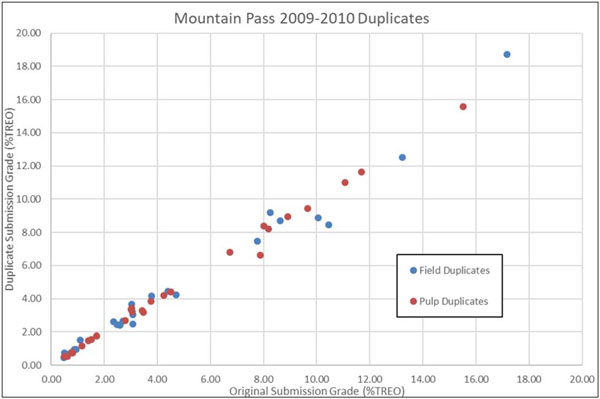

Figure 9-2: 2009 Through 2010 Duplicates | | | 73 | |

| |

Figure 9-3: 2021 Field Duplicate Analyses – MP Materials Lab | | | 74 | |

| |

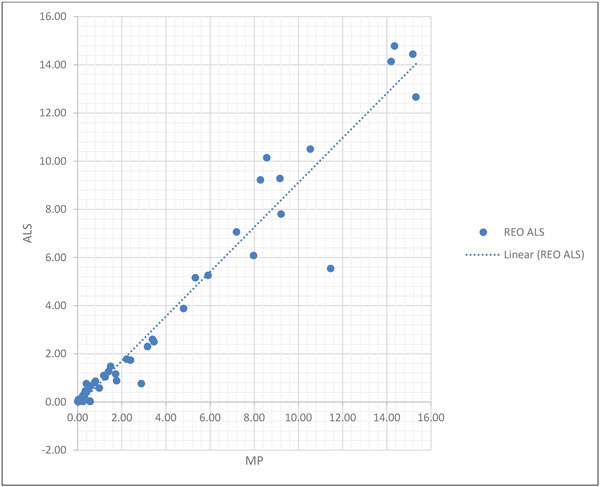

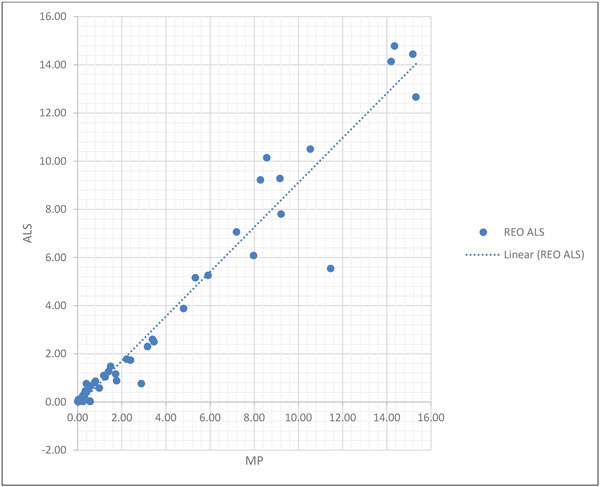

Figure 9-4: External Duplicate Analyses – MP vs. ALS | | | 75 | |

| |

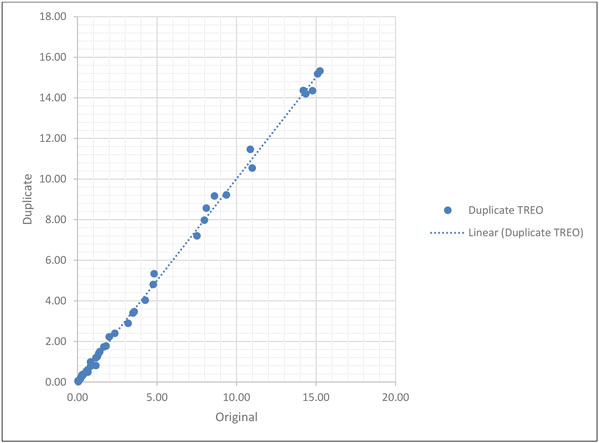

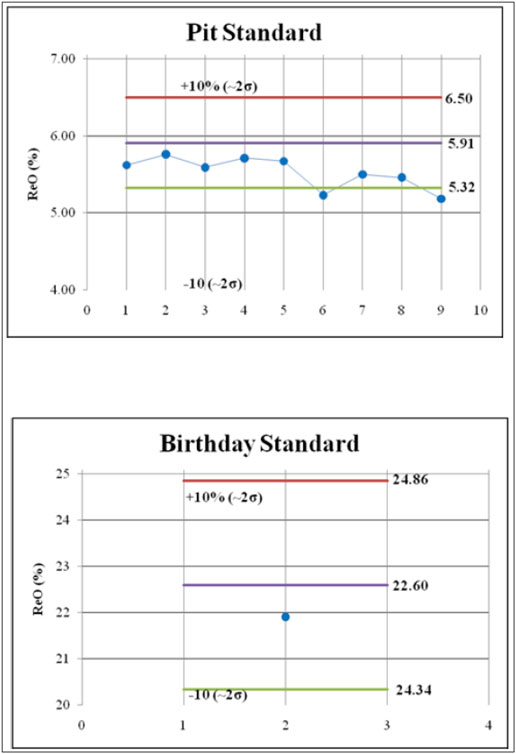

Figure 9-5: Results of Standard Analysis | | | 81 | |

| |

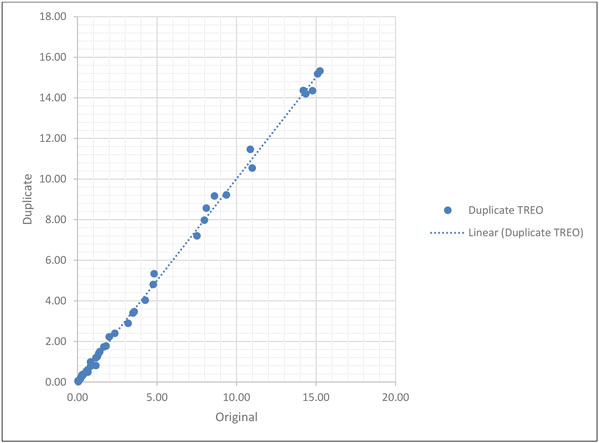

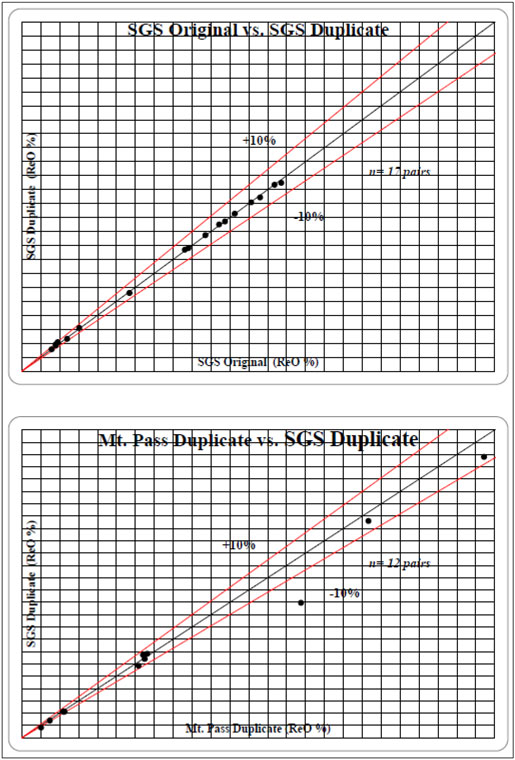

Figure 9-6: Results of Pulp Duplicate Analysis | | | 82 | |

| |

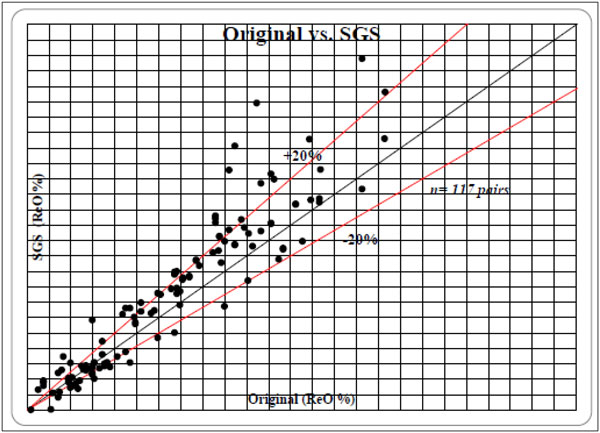

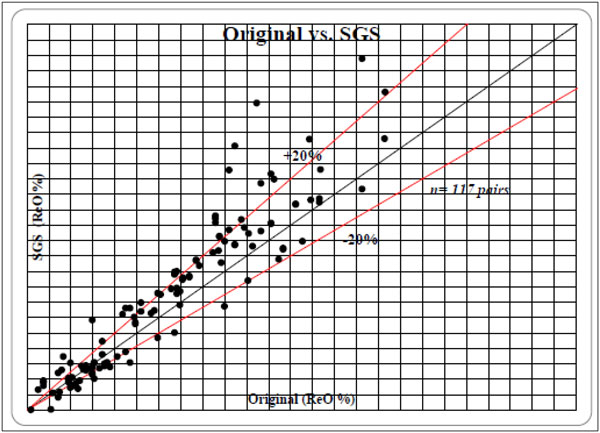

Figure 9-7: Results of Field Duplicate Analysis | | | 83 | |

| |

Figure 10-1: TREO Rougher Flotation Recovery versus Concentrate Grade for Different Feed Grades | | | 87 | |

| |

Figure 10-2: TREO Recovery to Cleaner Flotation Concentrate versus Feed Grade | | | 88 | |

| |

Figure 10-3: Primary Processes for Stage 2 Operation | | | 89 | |

| |

Figure 10-4: Recovery Estimates | | | 93 | |

| |

Figure 10-5: Extraction of Rare Earth Oxides at 109 g/L with 93+% PrNd | | | 94 | |

| |

Figure 10-6: Extraction of Rare Earth Oxides at 127 g/L | | | 94 | |

| |

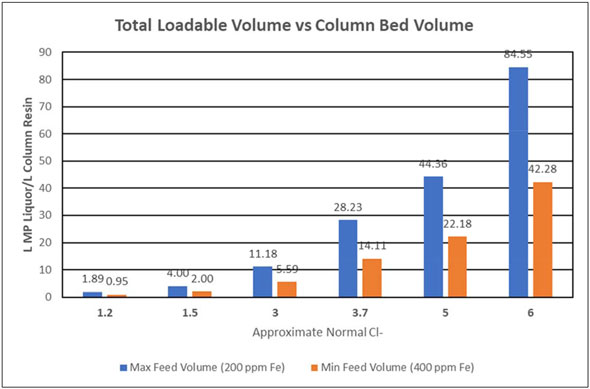

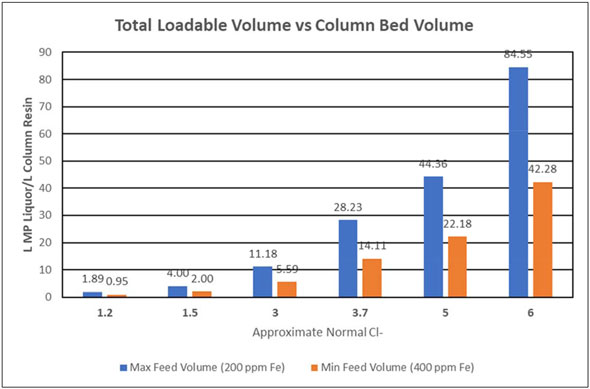

Figure 10-7: Volumes of Leach Liquor per Volume of Resin Required Before a Regeneration Cycle | | | 97 | |

| |

Figure 10-8: Mass Balance | | | 98 | |

| |

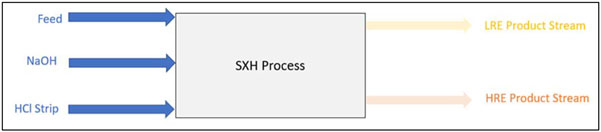

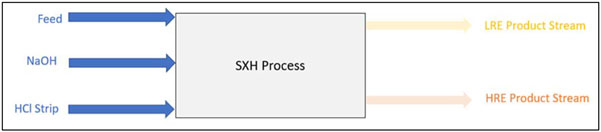

Figure 10-9: Diagram of the SXH Process | | | 99 | |

| |

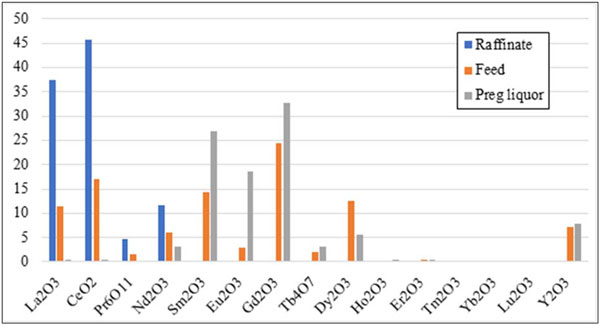

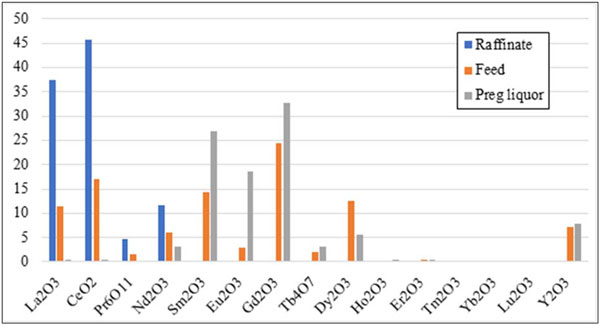

Figure 10-10: % REO in Feed, Raffinate, and Preg Liquor | | | 100 | |

| |

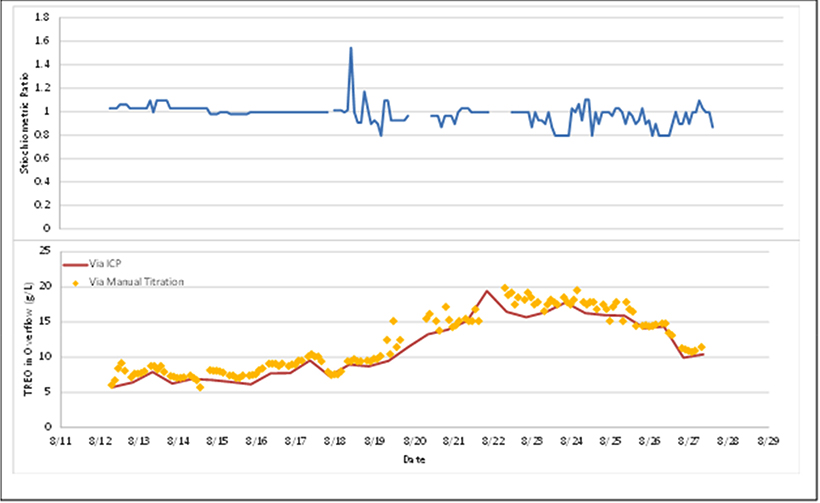

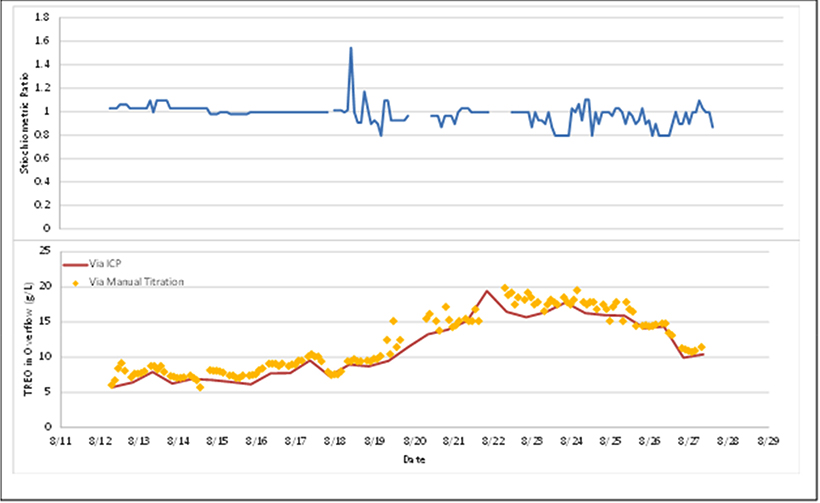

Figure 10-11: TREO in Overflow Liquor Over Time vs Stoichiometric Feed Ratio and pH | | | 101 | |

| |

Figure 10-12: Market Standard PrNd Oxide Specification and Mountain Pass Historical Results | | | 103 | |

| |

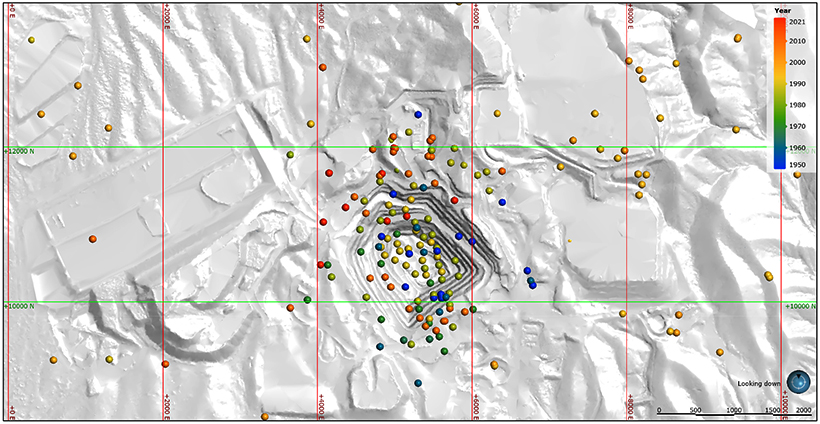

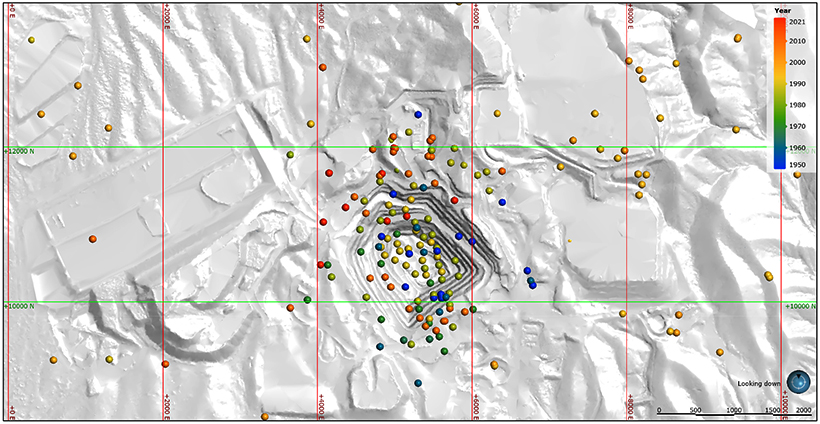

Figure 11-1: Drilling Distribution near Mountain Pass Mine | | | 105 | |

| |

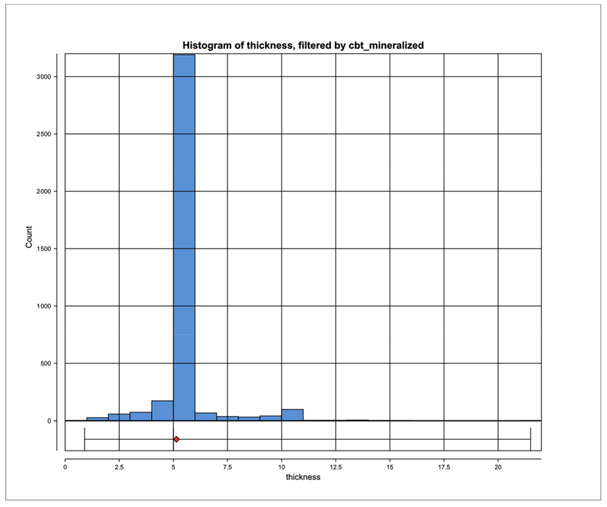

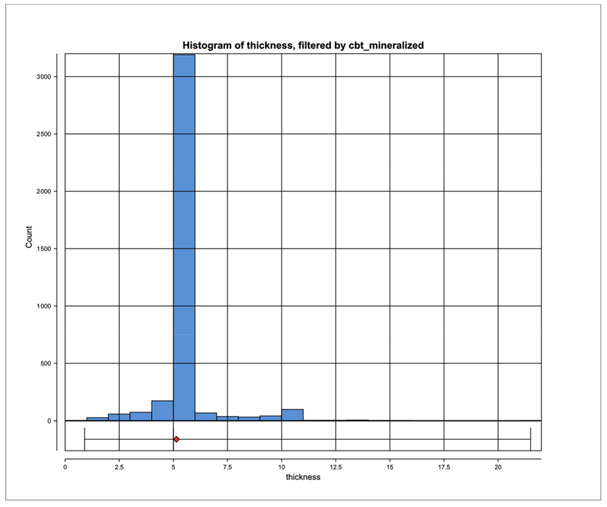

Figure 11-2: Sample Length Histogram – Mineralized CBT | | | 106 | |

| |

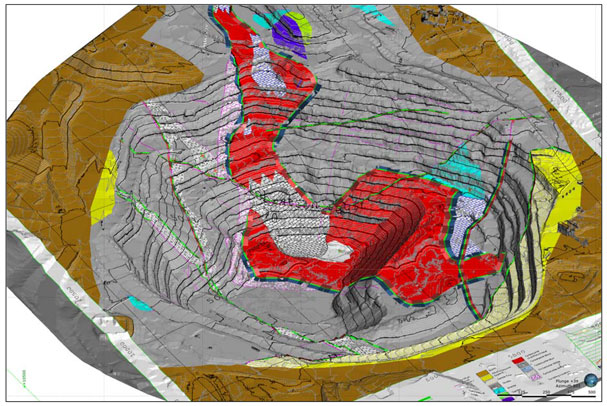

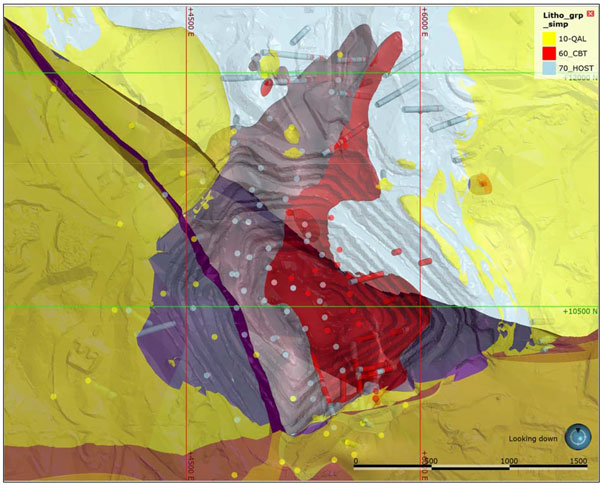

Figure 11-3: Geological Mapping and Fault Expressions – August 2021 | | | 107 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 12 |

| | | | |

| |

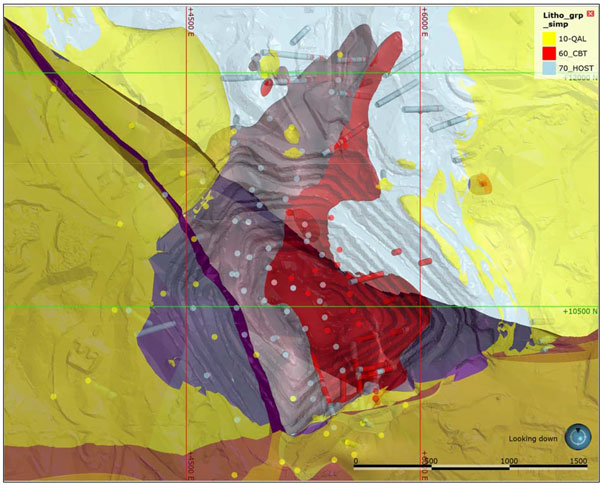

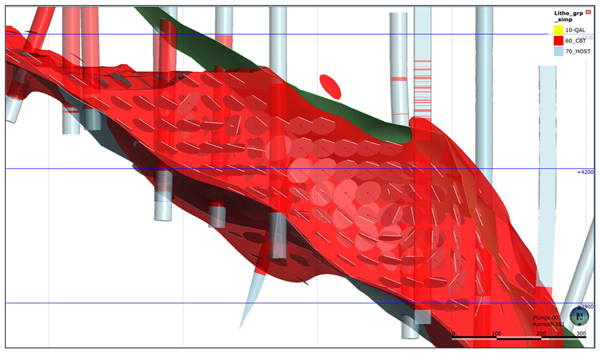

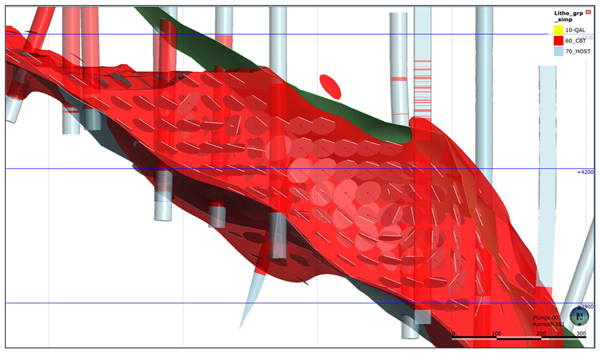

Figure 11-4: Plan View of 3D Geological Model | | | 109 | |

| |

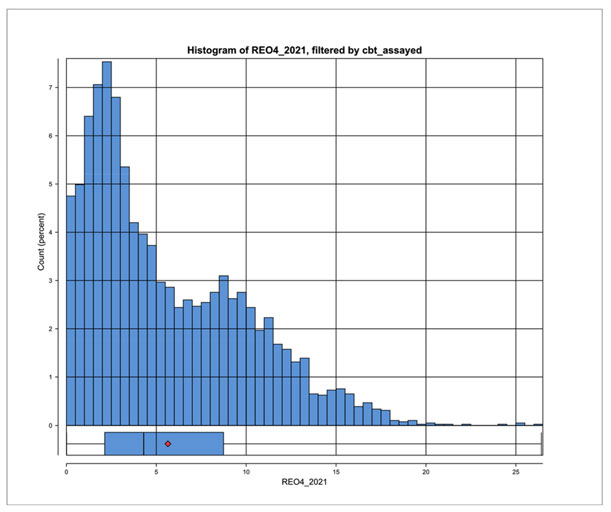

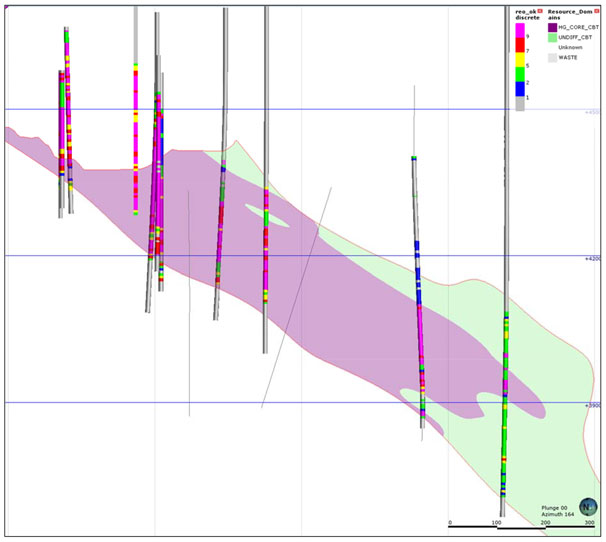

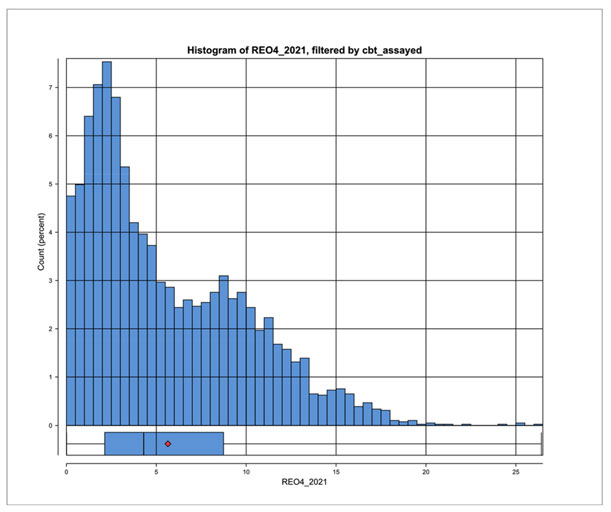

Figure 11-5: Histogram of TREO% within CBT | | | 111 | |

| |

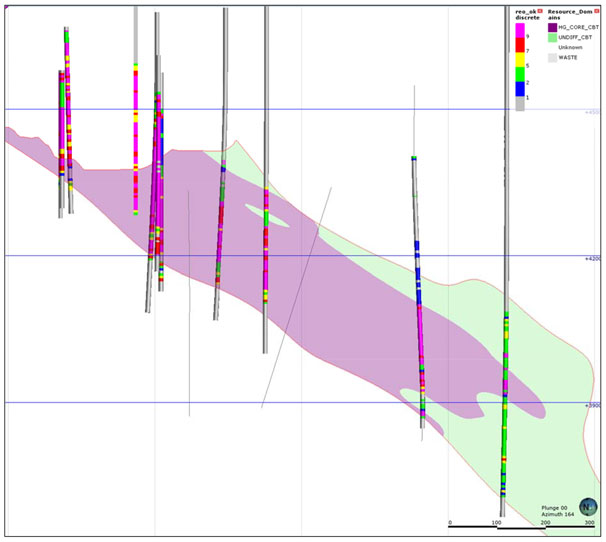

Figure 11-6: Cross Section Illustrating CBT Domains and TREO Grades | | | 112 | |

| |

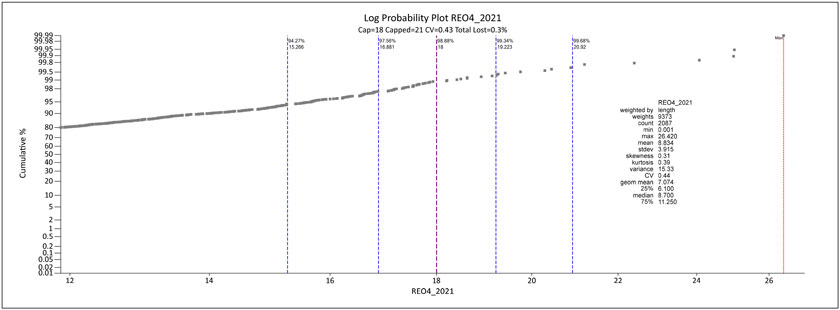

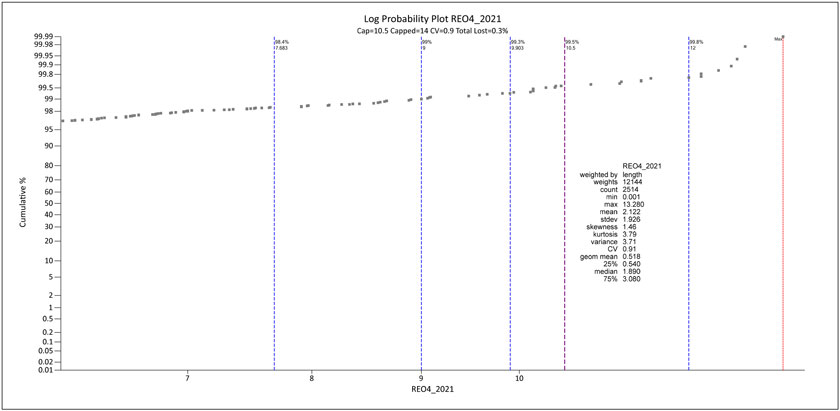

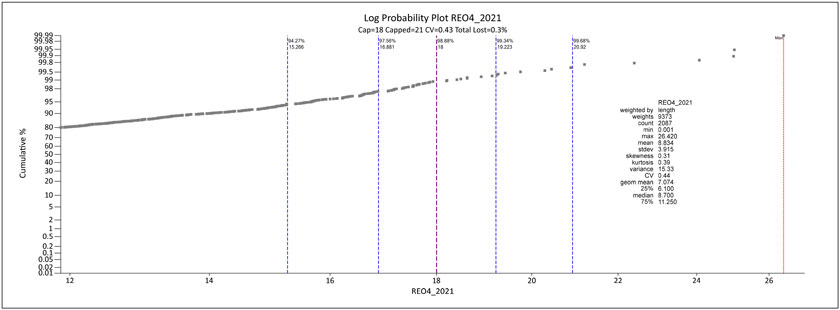

Figure 11-7: Log Probability Plot for TREO – HG Core | | | 114 | |

| |

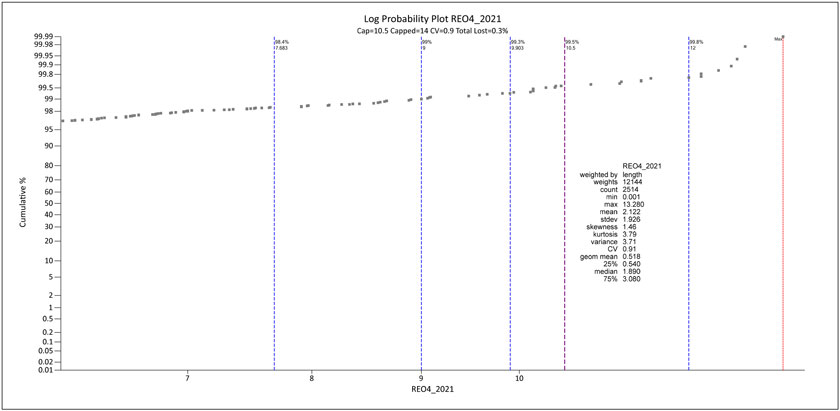

Figure 11-8: Log Probability Plot for TREO – Undifferentiated CBT | | | 115 | |

| |

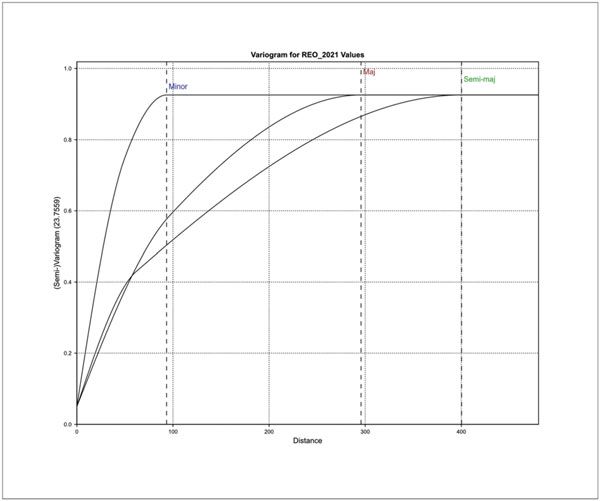

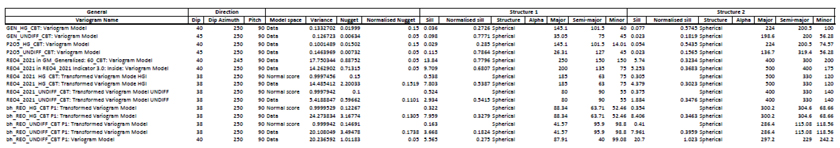

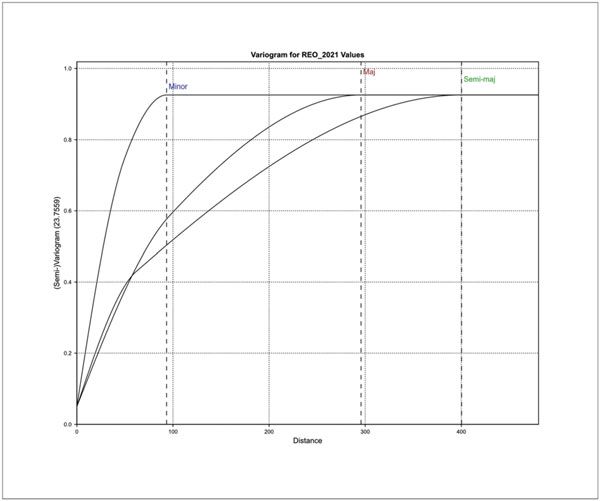

Figure 11-9: Example of Directional Variogram – Blastholes TREO | | | 118 | |

| |

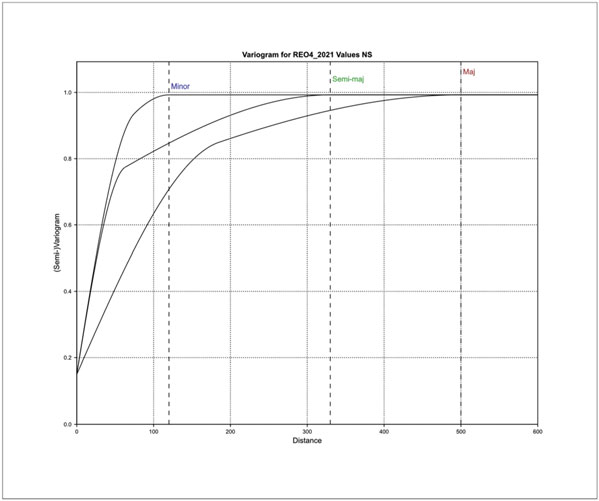

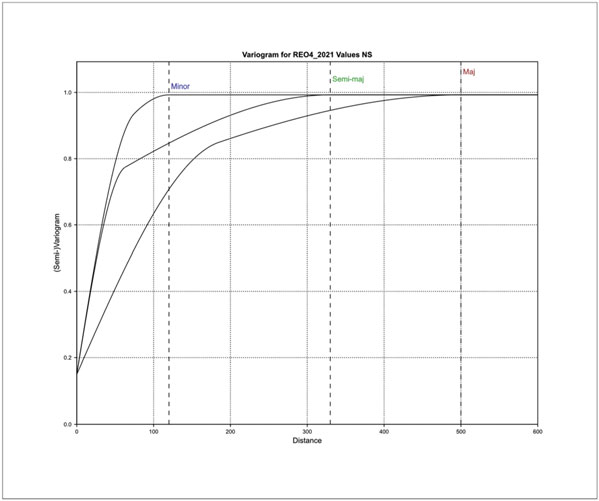

Figure 11-10: Example of Directional Variogram – Exploration TREO | | | 119 | |

| |

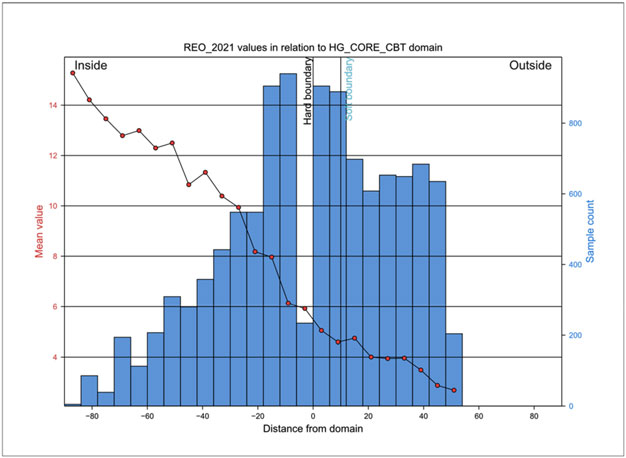

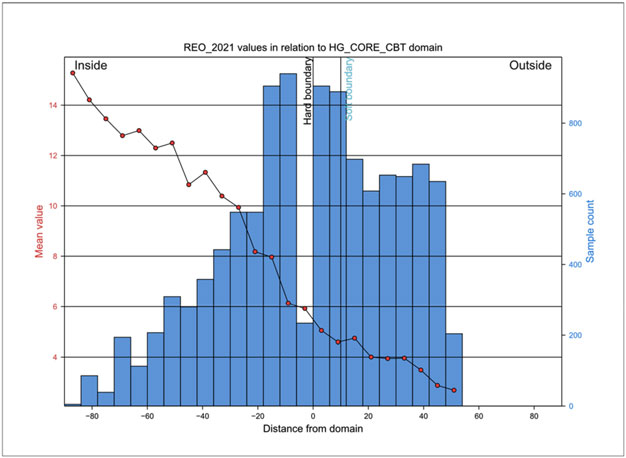

Figure 11-11: Domain Boundary Analysis | | | 120 | |

| |

Figure 11-12: Variable Orientation Surfaces for Estimation Orientation | | | 121 | |

| |

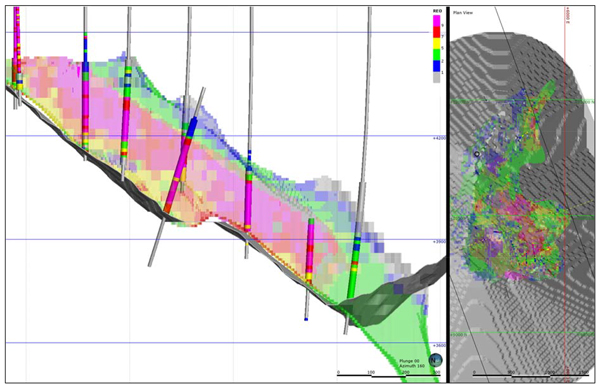

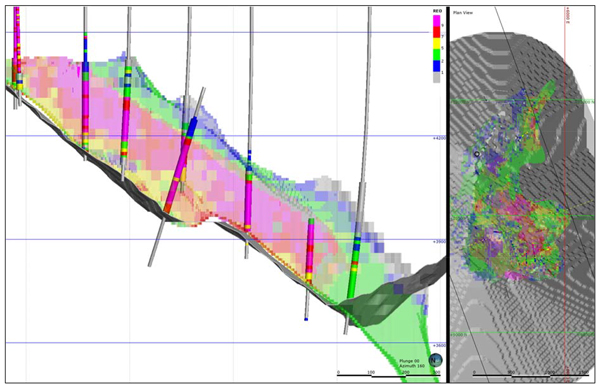

Figure 11-13: NW-SE Cross Section Showing Block Grades, Composite Grades, Resource Pit Outline | | | 123 | |

| |

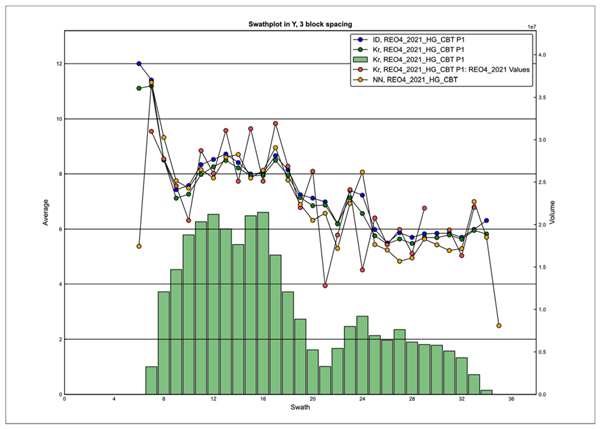

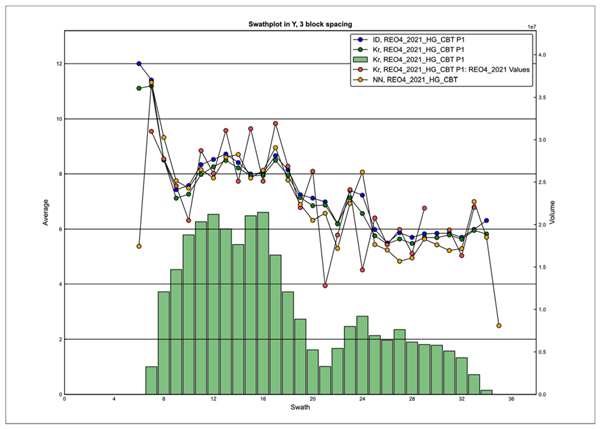

Figure 11-14: Swath Plot (NS orientation) Comparison Between TREO Block Grades and Composite Grades | | | 124 | |

| |

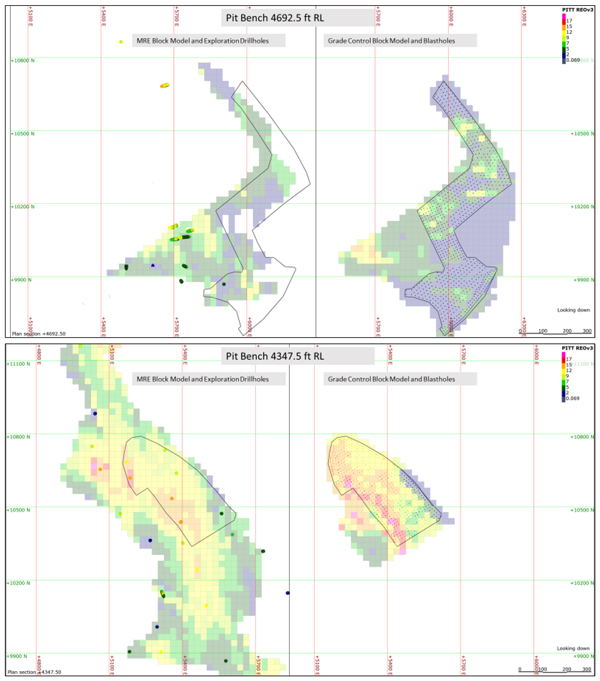

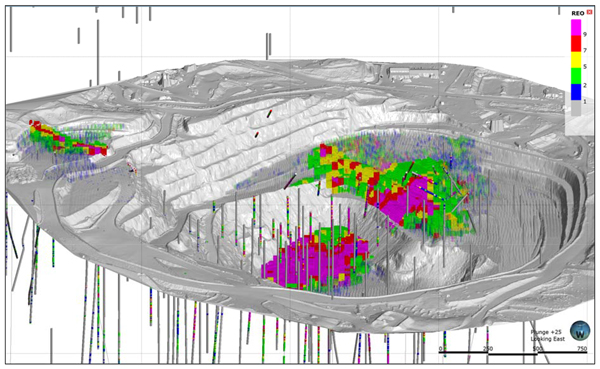

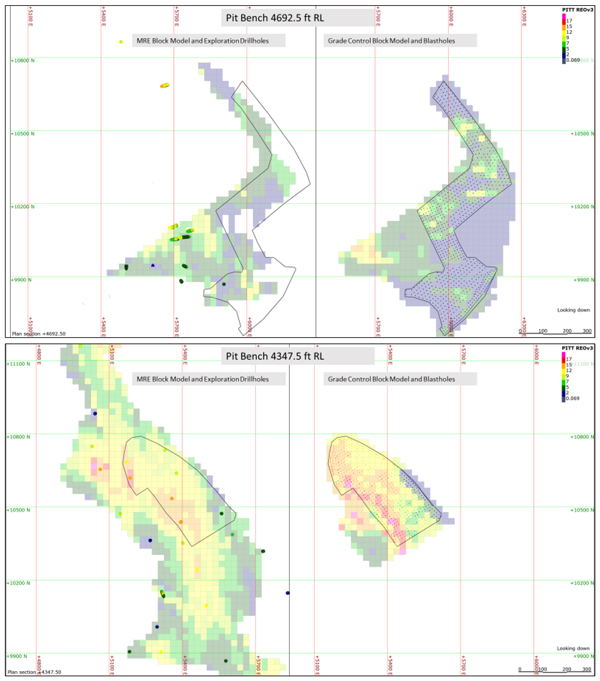

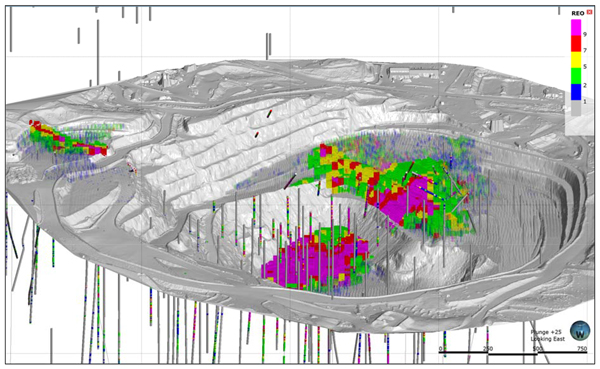

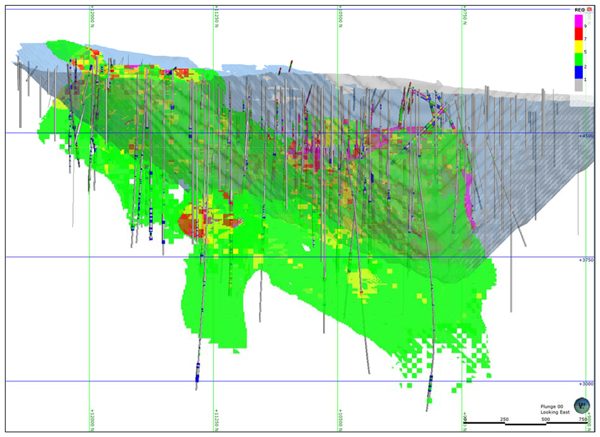

Figure 11-15: Spatial Comparison of MRE Grade Distribution with Blasthole Grade Distribution | | | 125 | |

| |

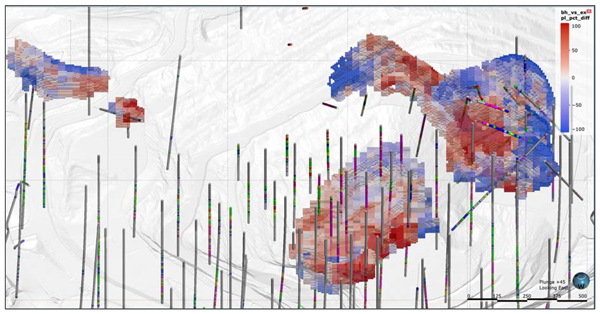

Figure 11-16: Comparison of Resource and Grade Control Models | | | 126 | |

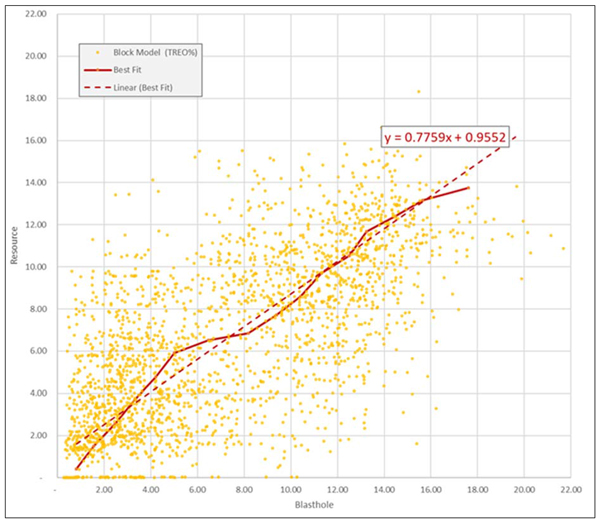

| |

Figure 11-17: Previous Production Areas for Reconciliation Validation | | | 128 | |

| |

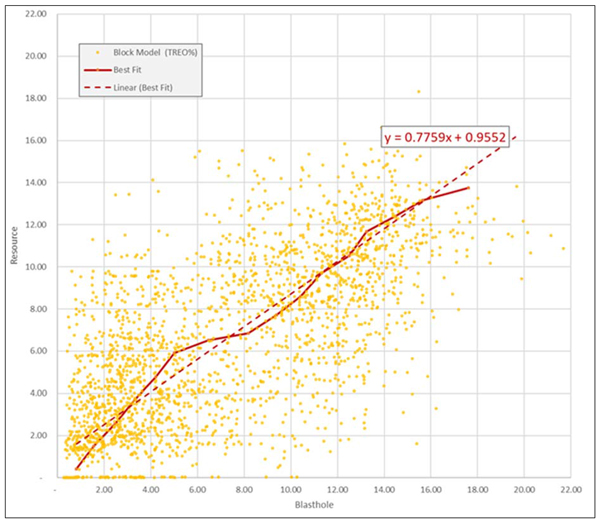

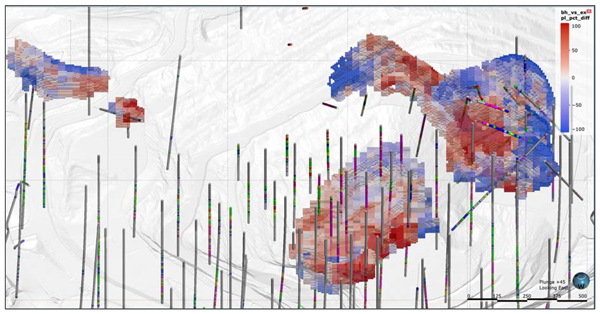

Figure 11-18: Percent Difference BH/EXP Estimate | | | 129 | |

| |

Figure 11-19: Extents of Optimized Pit Shape Relative to Surface Topography | | | 133 | |

| |

Figure 11-20: Optimized pit shell and blocks >= 2.28% TREO | | | 137 | |

| |

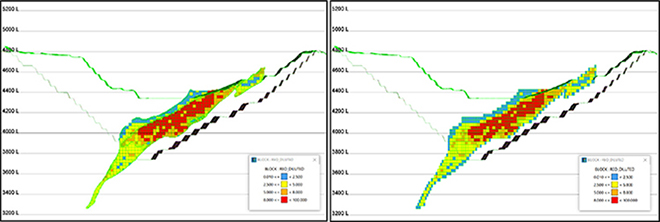

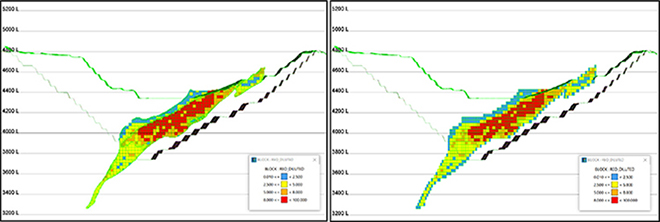

Figure 12-1: Side by Side Comparison Non-Diluted (Left) Block Model and Diluted (Right) Block Model | | | 140 | |

| |

Figure 13-1: Final Pit Design and Site Layout | | | 145 | |

| |

Figure 13-2: Recommended Double Bench IRA from CNI | | | 146 | |

| |

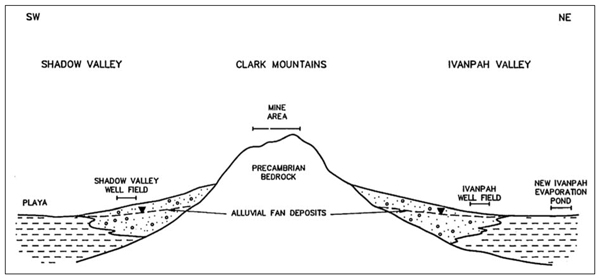

Figure 13-3: Idealized Cross Section Through Mine Area and Adjacent Valleys | | | 150 | |

| |

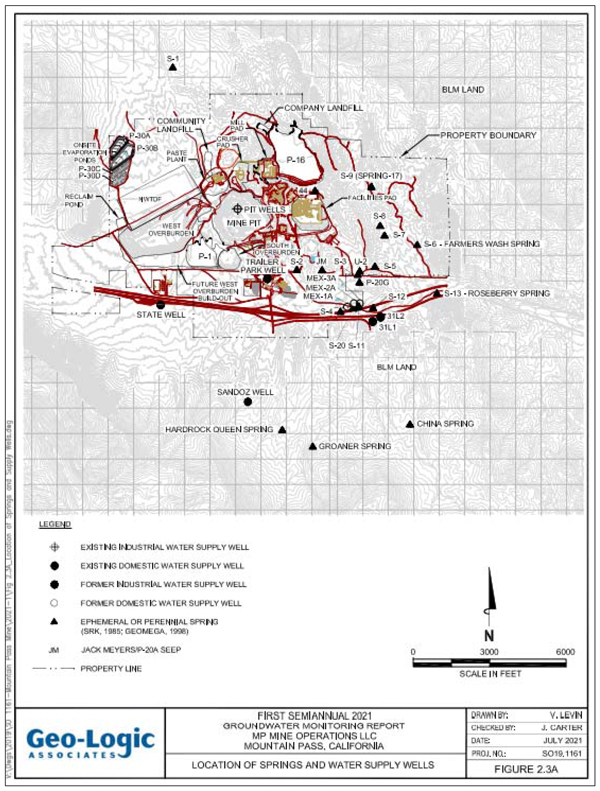

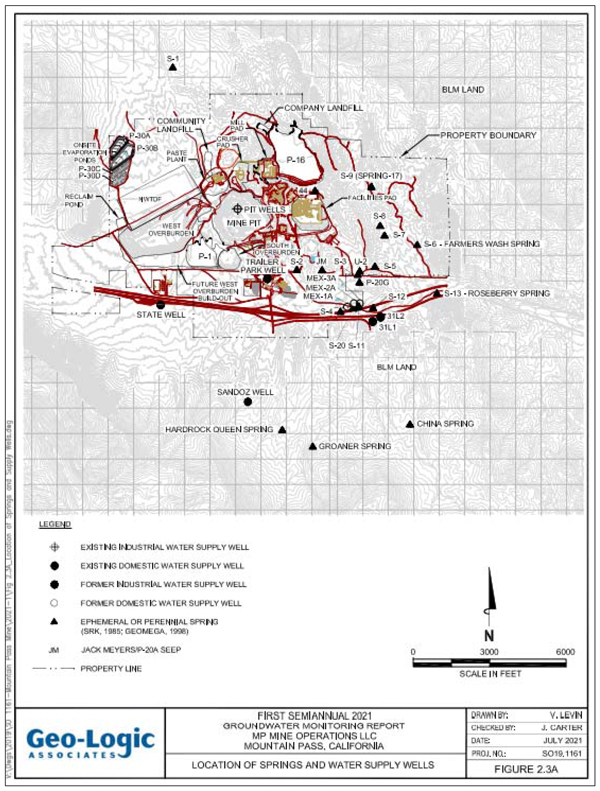

Figure 13-4: Location of Industrial and Domestic Water Supply Wells and Mine Facilities | | | 151 | |

| |

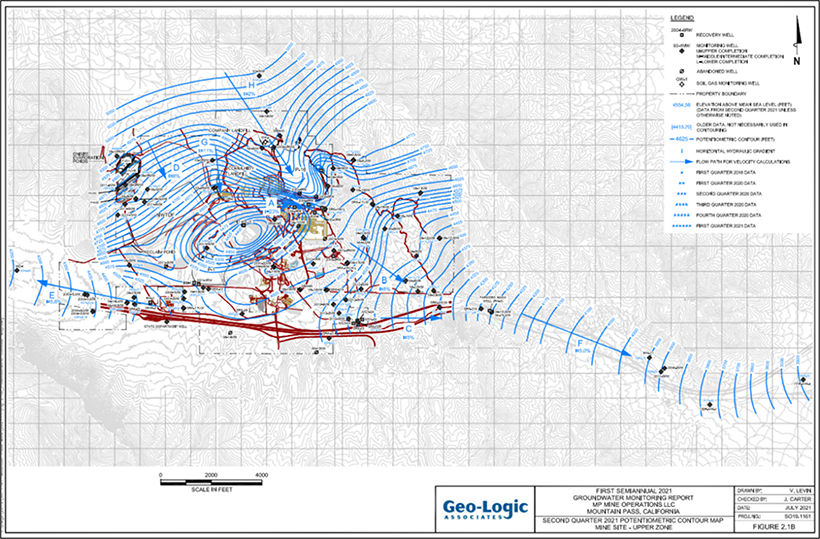

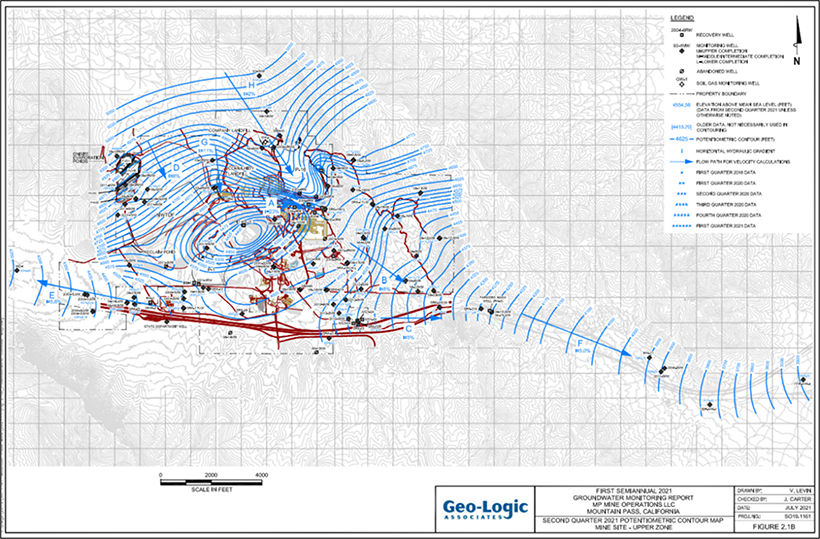

Figure 13-5: Location of Monitoring Wells, Measured Water Table Elevation, and Direction of Groundwater Flow (as Q2 2021) | | | 152 | |

| |

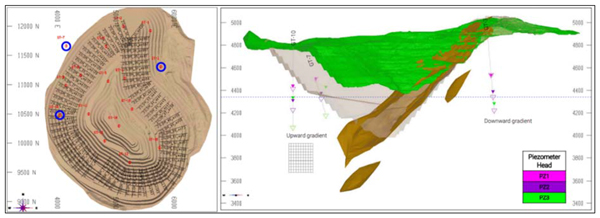

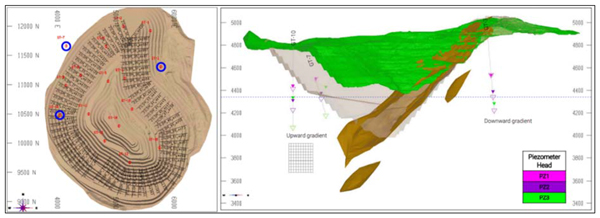

Figure 13-6: Location of Piezometers and Measured Water Levels in Pit Walls | | | 153 | |

| |

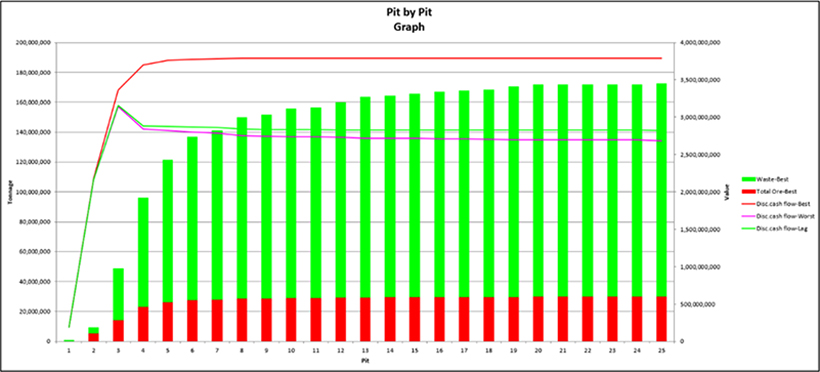

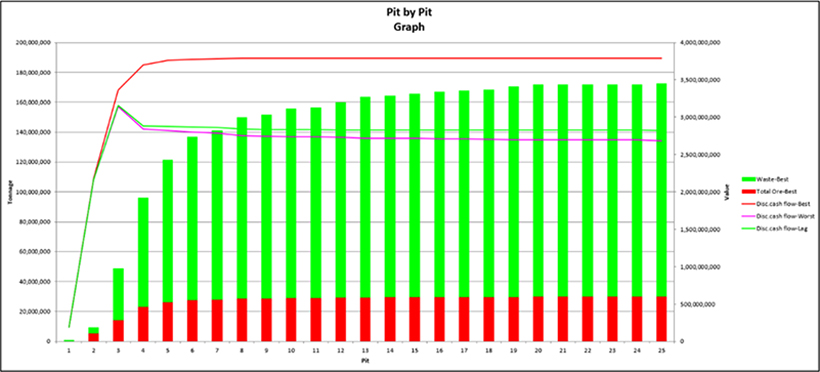

Figure 13-7: Mountain Pass Pit by Pit Optimization Result | | | 159 | |

| |

Figure 13-8: Mountain Pass Mineral Reserves Pit (red line) and Mineral Resources Shell (magenta line) Surface Intersection | | | 160 | |

| |

Figure 13-9: Phase Design Locations | | | 161 | |

| |

Figure 13-10: Final Pit Design | | | 162 | |

| |

Figure 13-11: Reserve Starting Topography, September 30, 2021 | | | 163 | |

| |

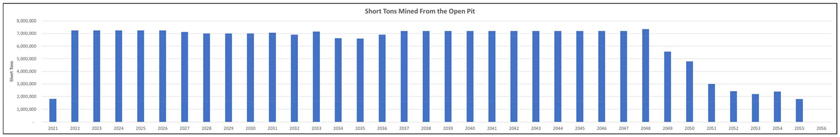

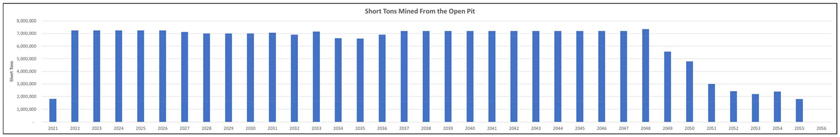

Figure 13-12: Total Mined Material from the Open Pit (ore and waste) | | | 164 | |

| |

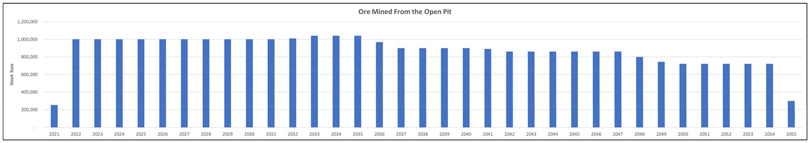

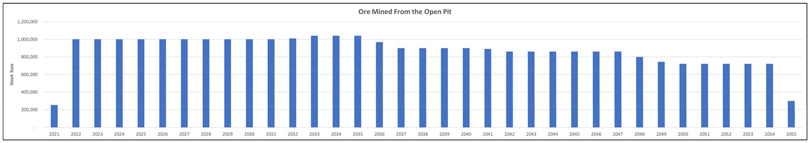

Figure 13-13: Ore Mined from the Open Pit | | | 164 | |

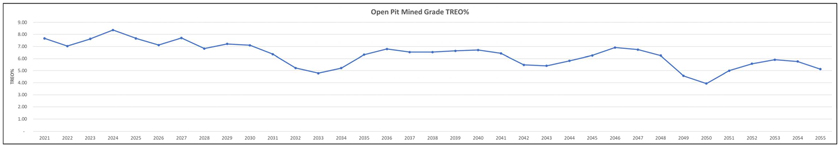

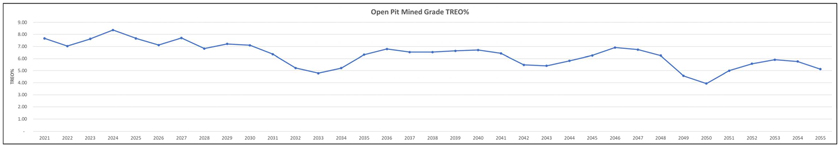

| |

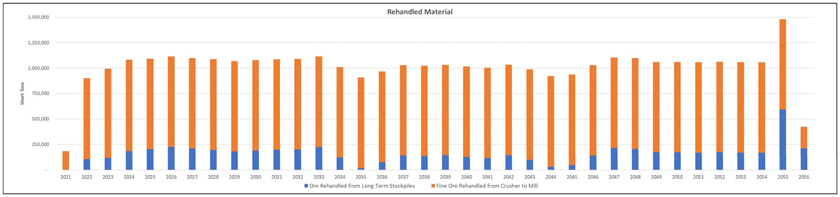

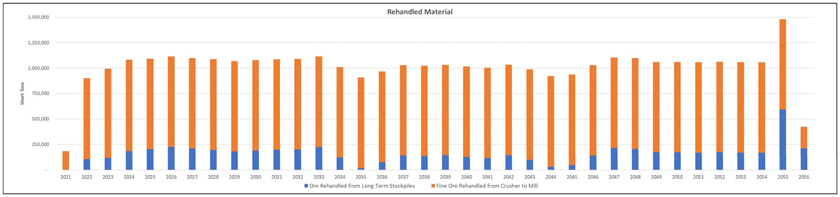

Figure 13-14: Mined Ore Grade | | | 165 | |

| |

Figure 13-15: Rehandled Material | | | 165 | |

| |

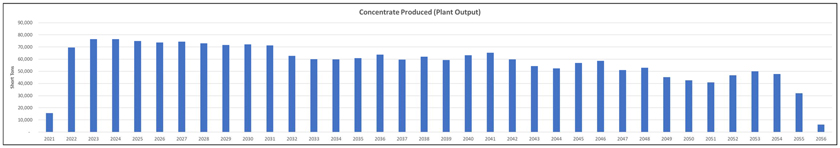

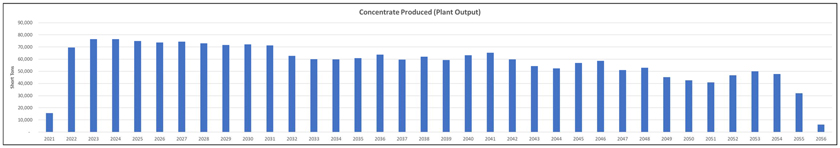

Figure 13-16: Mill Concentrate Production | | | 166 | |

| |

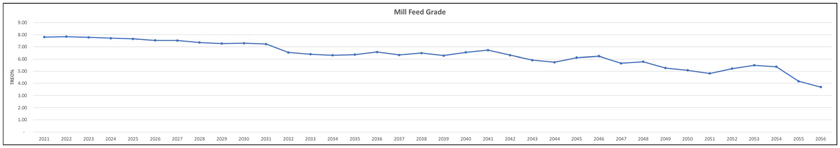

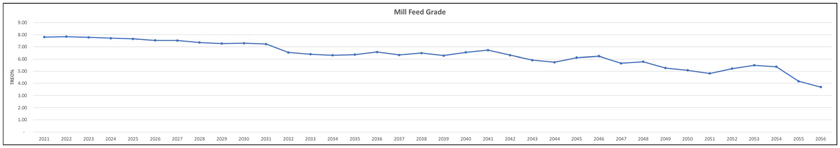

Figure 13-17: Mill Feed Grade | | | 166 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 13 |

| | | | |

| |

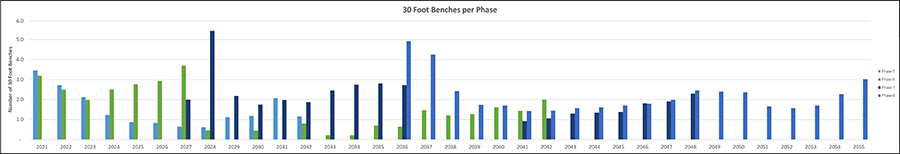

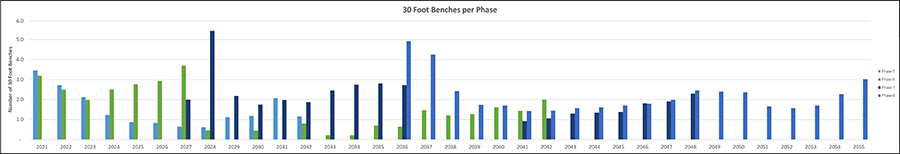

Figure 13-18: Number of Benches Mined | | | 167 | |

| |

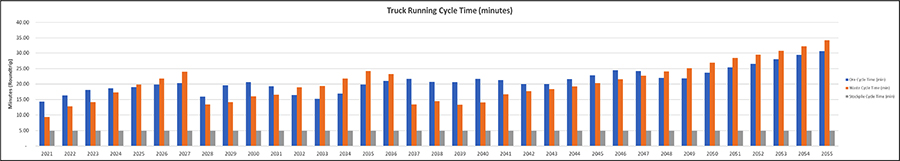

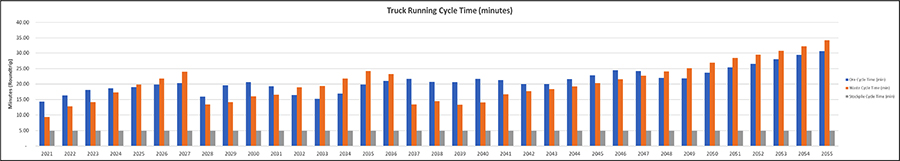

Figure 13-19: Haul Truck Cycle Time | | | 167 | |

| |

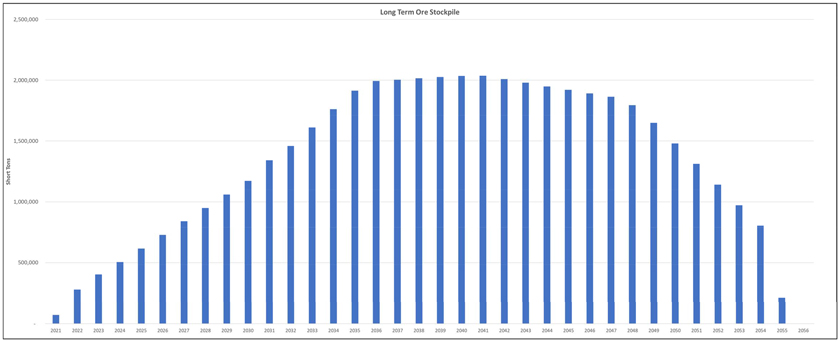

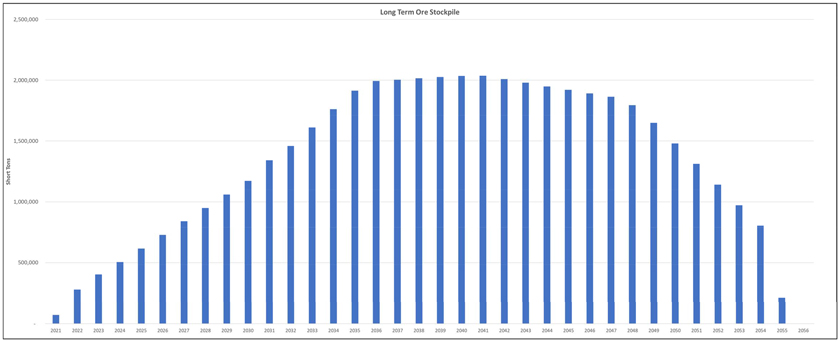

Figure 13-20: Long-Term Ore Stockpile End of Period Balance | | | 168 | |

| |

Figure 13-21: Final Pit Design and Waste Dump Locations | | | 171 | |

| |

Figure 14-1: MP Materials Concentrator Flowsheet | | | 182 | |

| |

Figure 14-2: Rare Earth Distribution in Flotation Concentrate | | | 187 | |

| |

Figure 15-1: Facilities General Location | | | 192 | |

| |

Figure 15-2: Water Supply System | | | 195 | |

| |

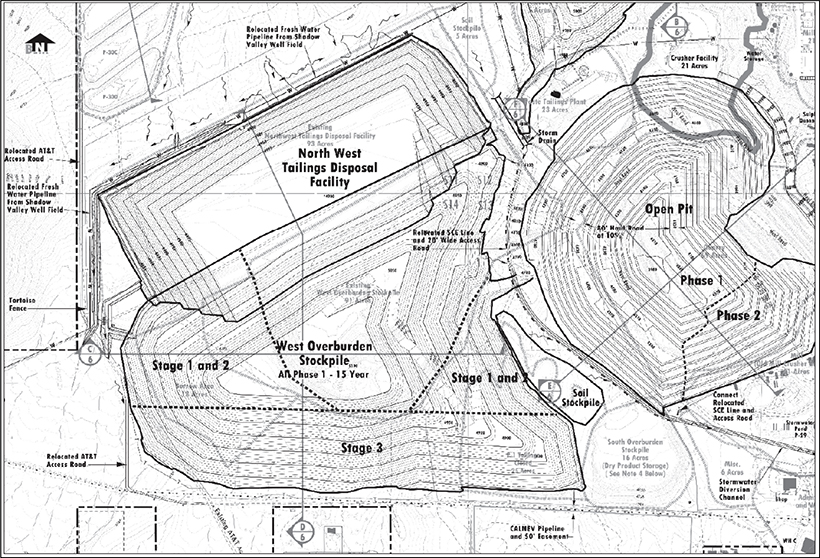

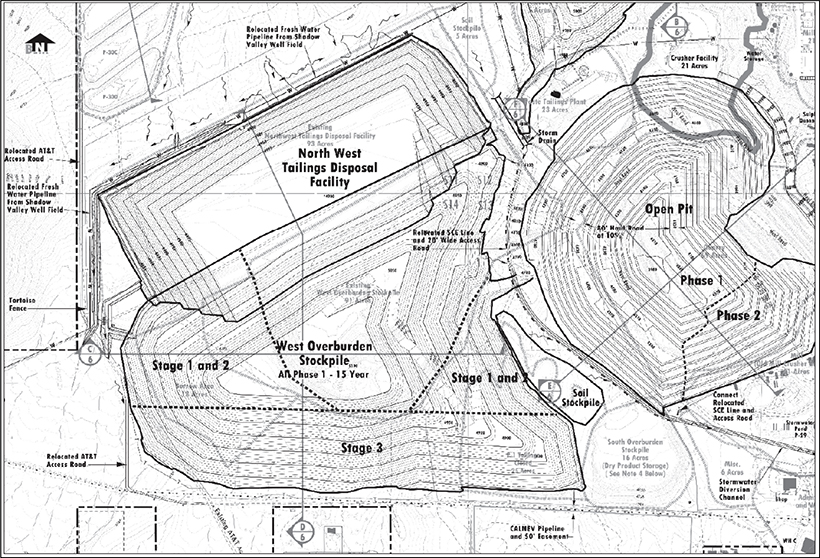

Figure 15-3: Northwest Tailings Disposal Facility | | | 196 | |

| |

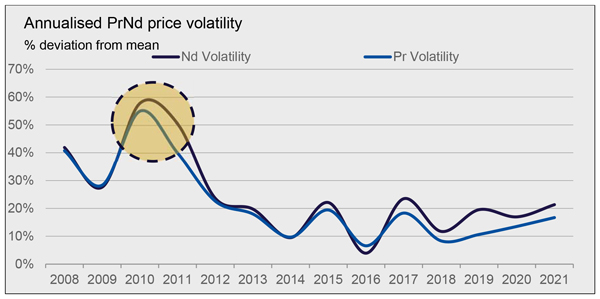

Figure 16-1: Annualized PrNd Price Volatility | | | 200 | |

| |

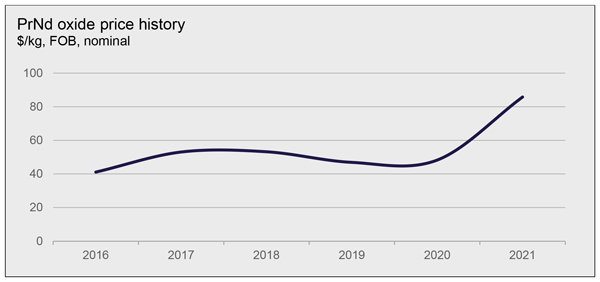

Figure 16-2: PrNd Oxide Price History | | | 201 | |

| |

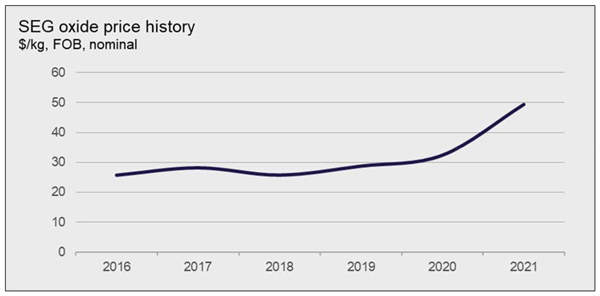

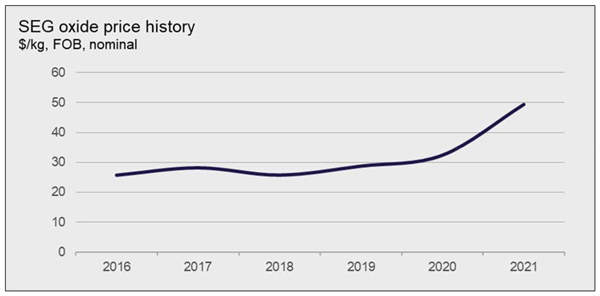

Figure 16-3: SEG Oxide Price History | | | 202 | |

| |

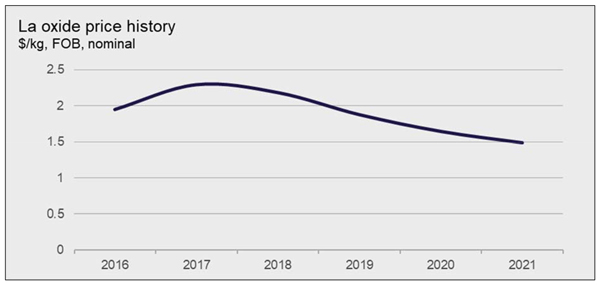

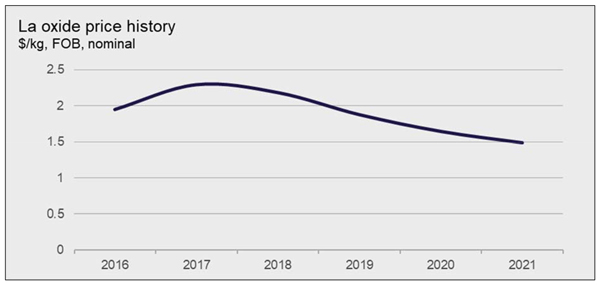

Figure 16-4: La Oxide Price History | | | 202 | |

| |

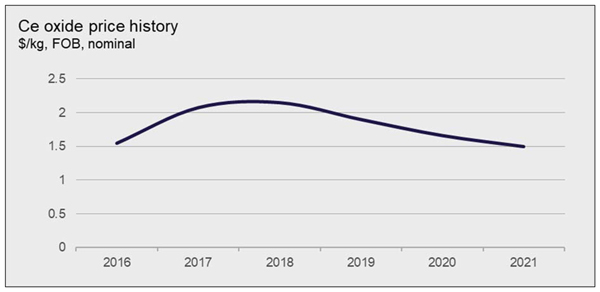

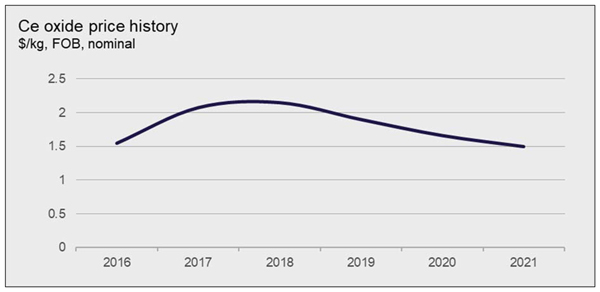

Figure 16-5: Ce Oxide Price History | | | 203 | |

| |

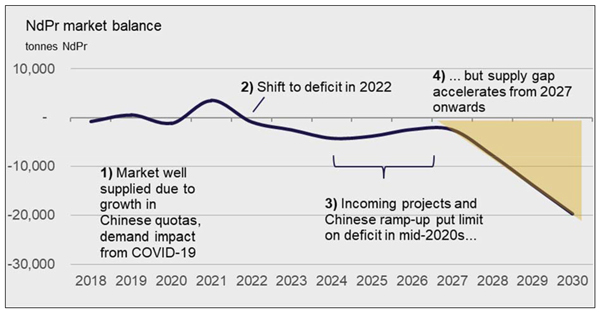

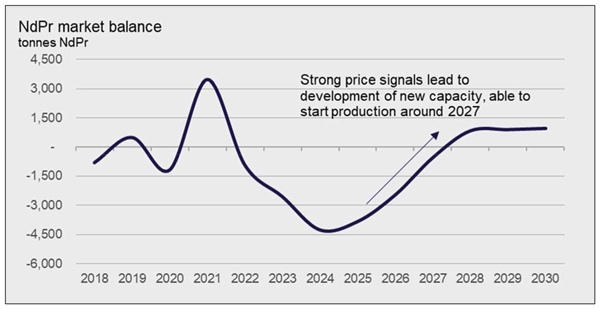

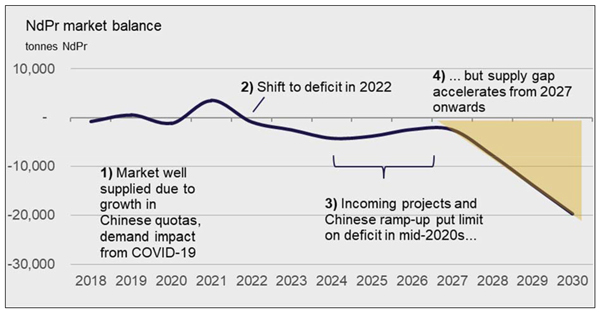

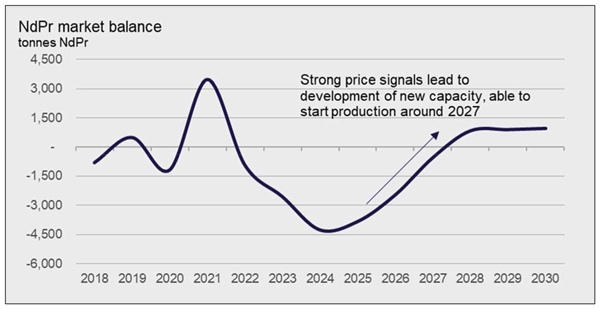

Figure 16-6: Sizeable Supply Gap Emerges in the Late-2020s without Prompt New Investment | | | 204 | |

| |

Figure 16-7: CRU’s LT Base Case Envisages enough Supply to Meet 10-15 Weeks’ Worth of Global Stocks | | | 204 | |

| |

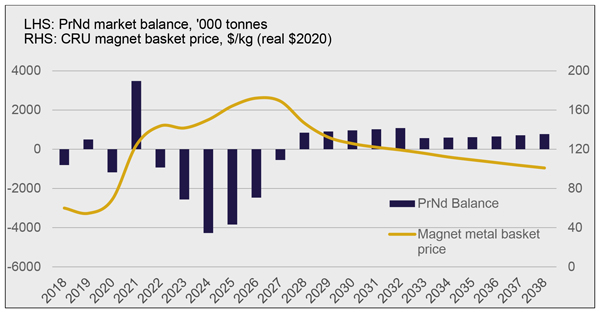

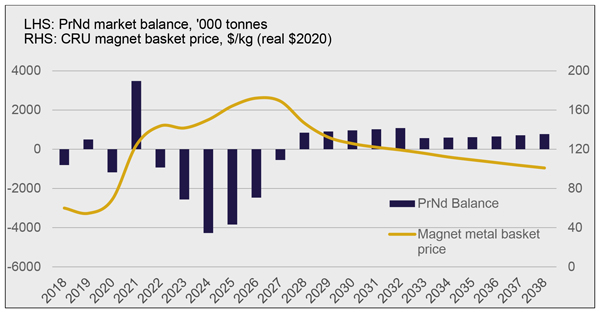

Figure 16-8: Magnet Material Prices will Need to Rise to Stimulate a Supply Response | | | 205 | |

| |

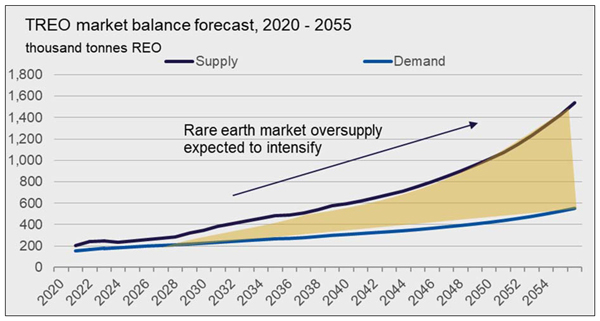

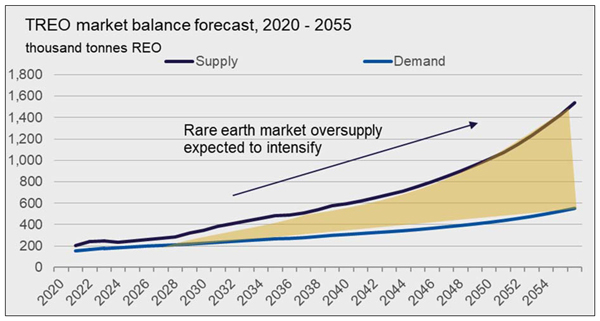

Figure 16-9: Rare Earth Market Balance Forecast | | | 206 | |

| |

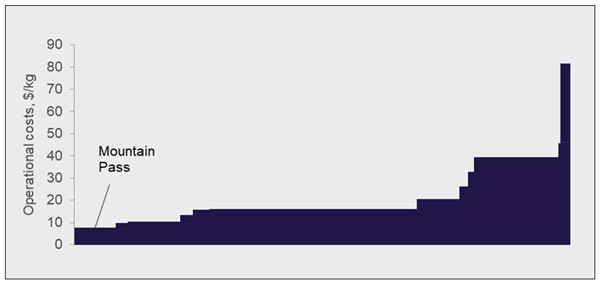

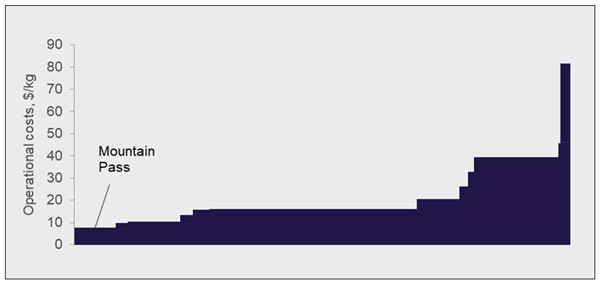

Figure 16-10: Operational Rare Earths Mining Cost Curve, 2025, US$/kg REO | | | 207 | |

| |

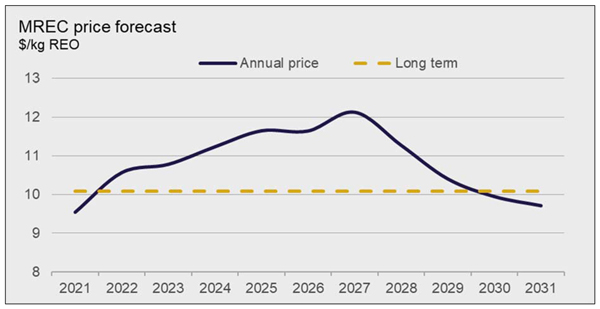

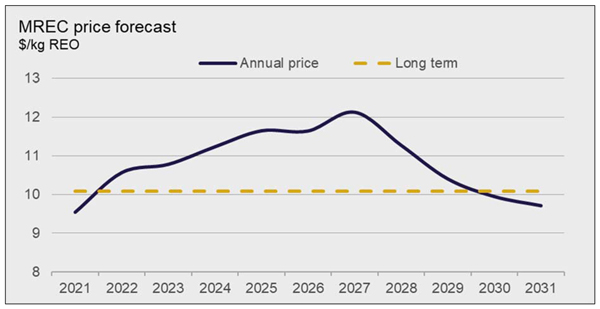

Figure 16-11: Mixed Rare Earth Concentrate Price Forecast | | | 209 | |

| |

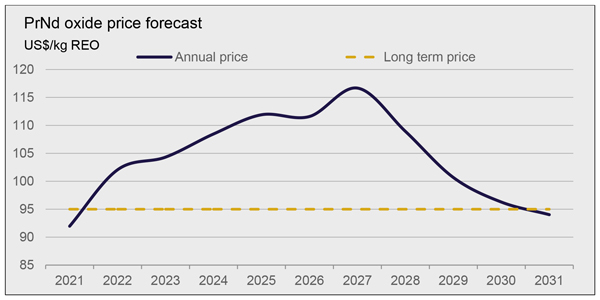

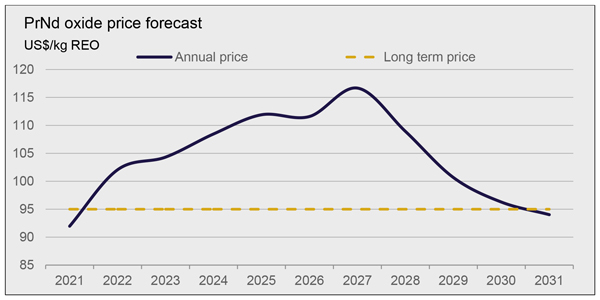

Figure 16-12: PrNd Oxide Price Forecast | | | 211 | |

| |

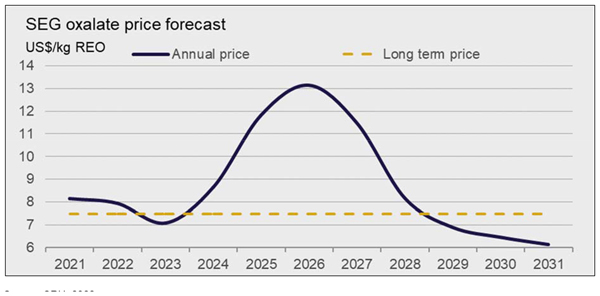

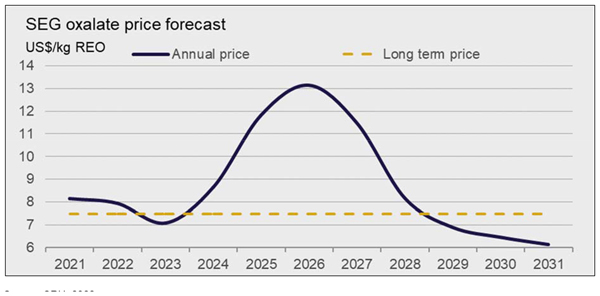

Figure 16-13: SEG Oxalate Price Forecast | | | 214 | |

| |

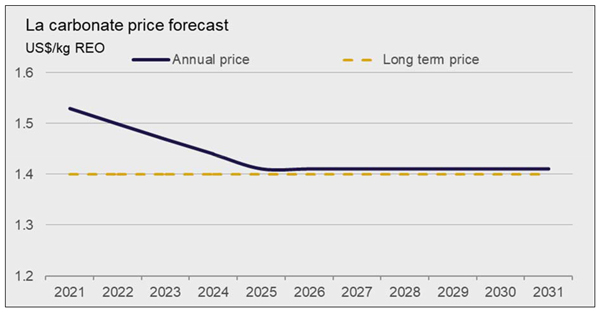

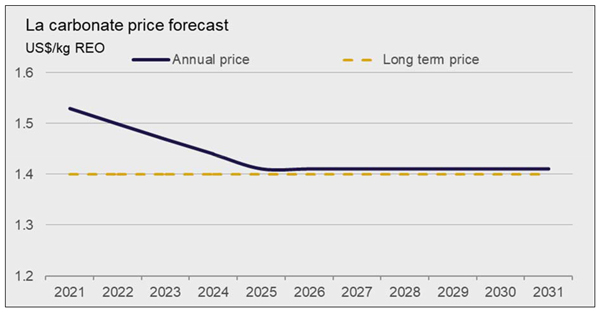

Figure 16-14: La Carbonate Price Forecast | | | 217 | |

| |

Figure 16-15: CeCl3 Price Forecast | | | 220 | |

| |

Figure 18-1: Mining Unit Cost Profile | | | 236 | |

| |

Figure 19-1: Mining Profile | | | 242 | |

| |

Figure 19-2: Concentrate Production | | | 243 | |

| |

Figure 19-3: Separations Production Profile | | | 243 | |

| |

Figure 19-4: Annual Operating Costs | | | 244 | |

| |

Figure 19-5: LoM Operating Costs | | | 244 | |

| |

Figure 19-6: Capital Expenditure Profile | | | 246 | |

| |

Figure 19-7: Annual Cash Flow | | | 246 | |

| |

Figure 19-8: After-Tax Sensitivity Analysis | | | 247 | |

| |

Figure 19-9: Mountain Pass Annual Cashflow (US$ millions) | | | 248 | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 14 |

Appendices

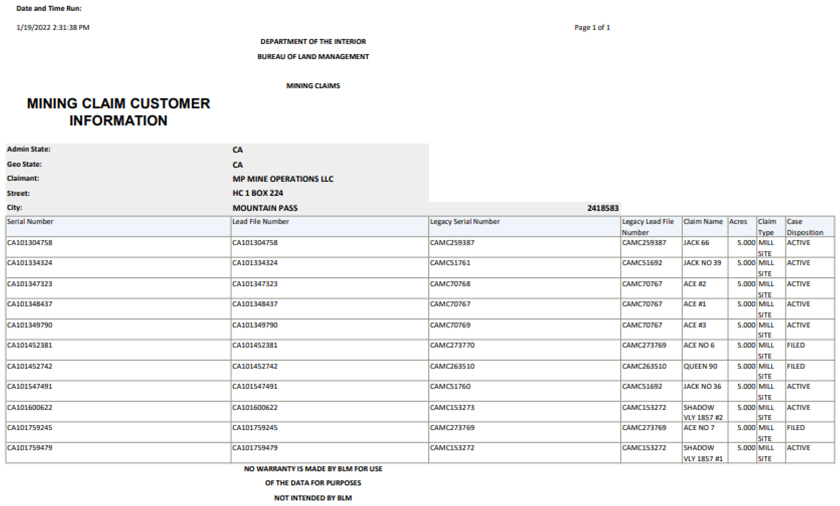

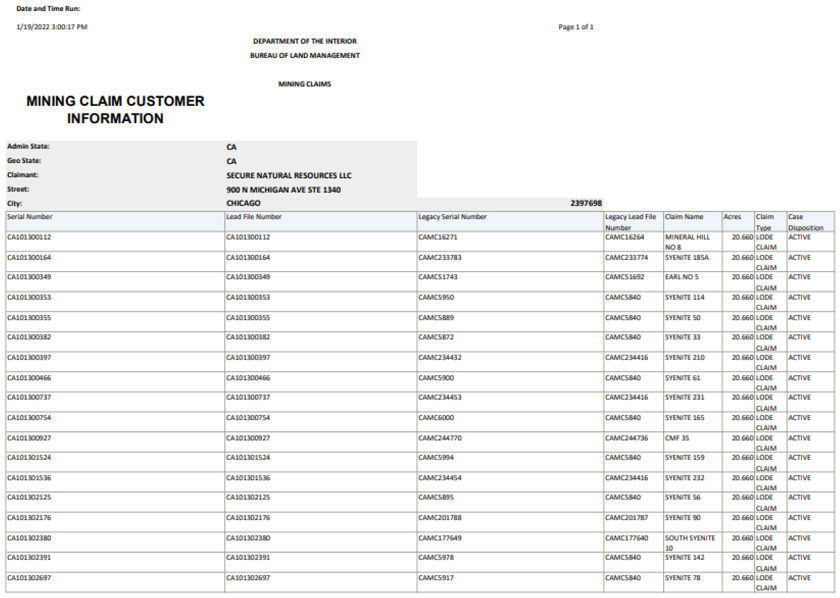

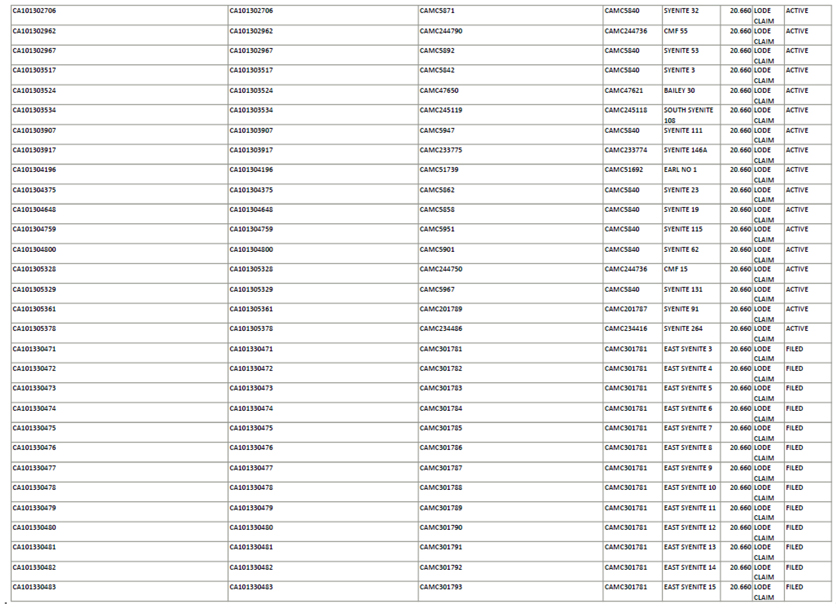

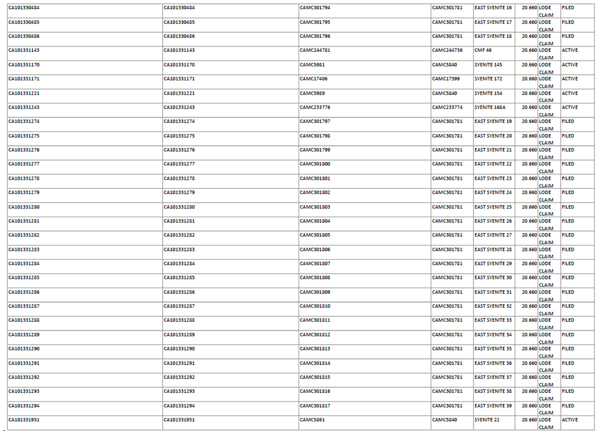

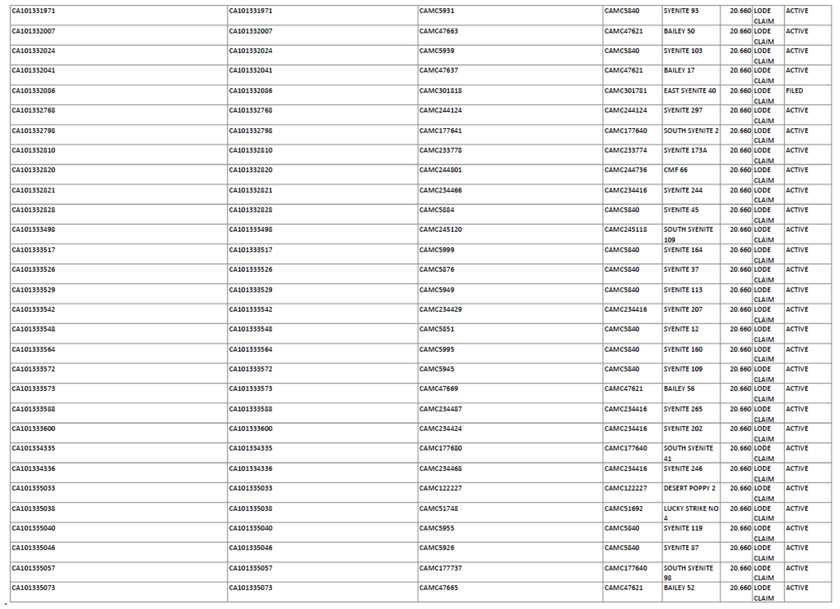

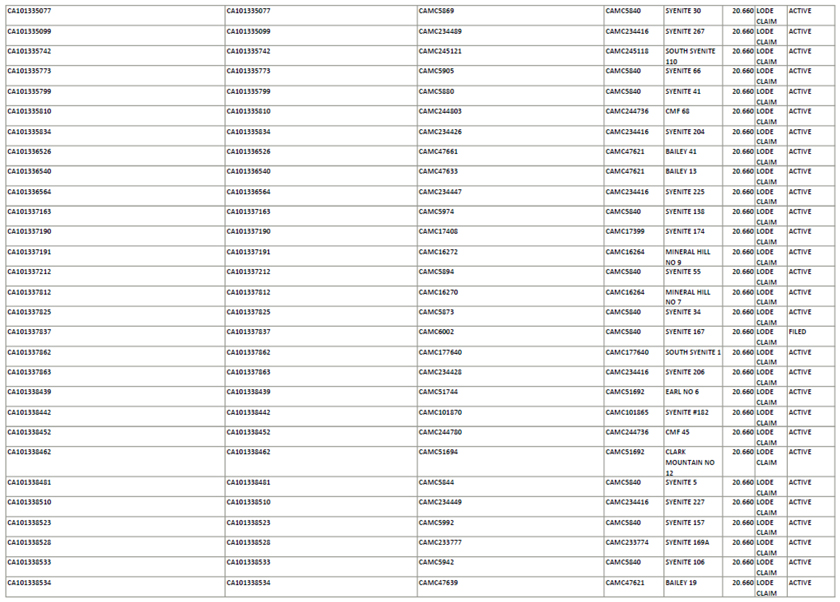

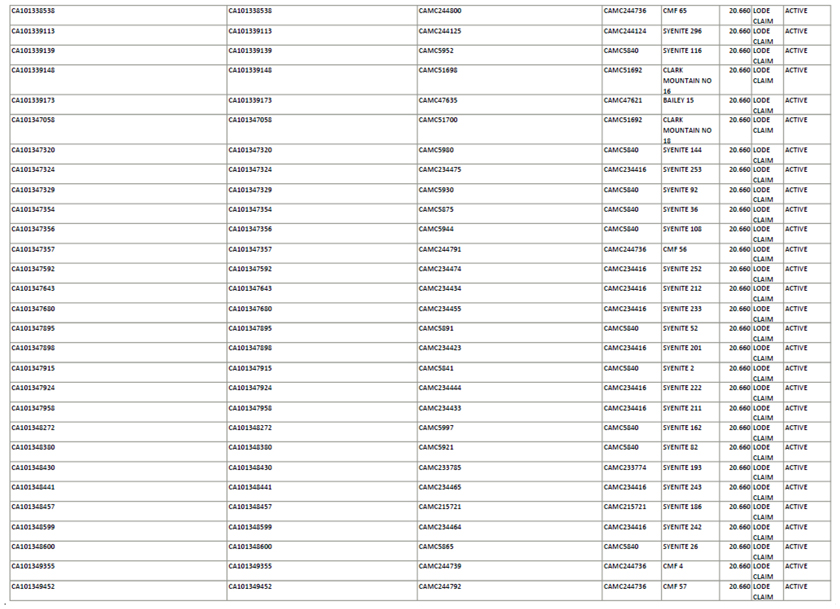

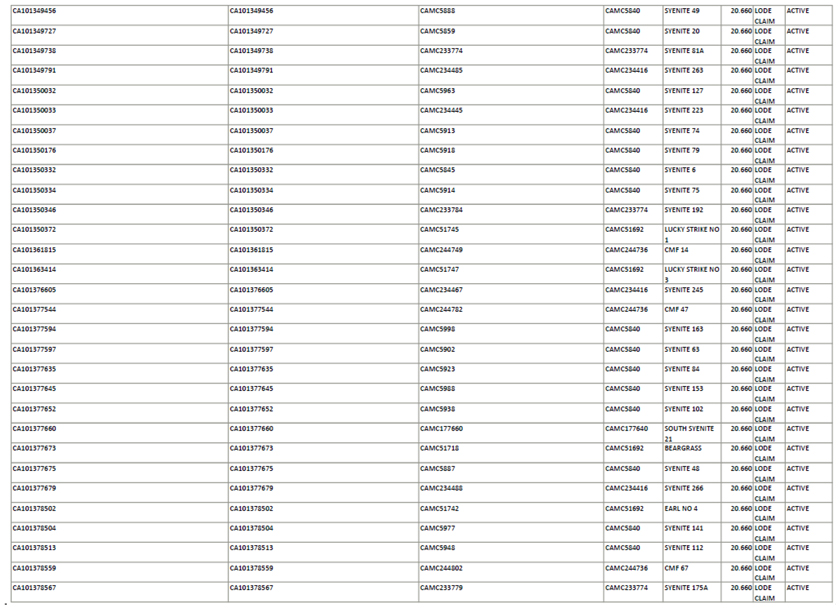

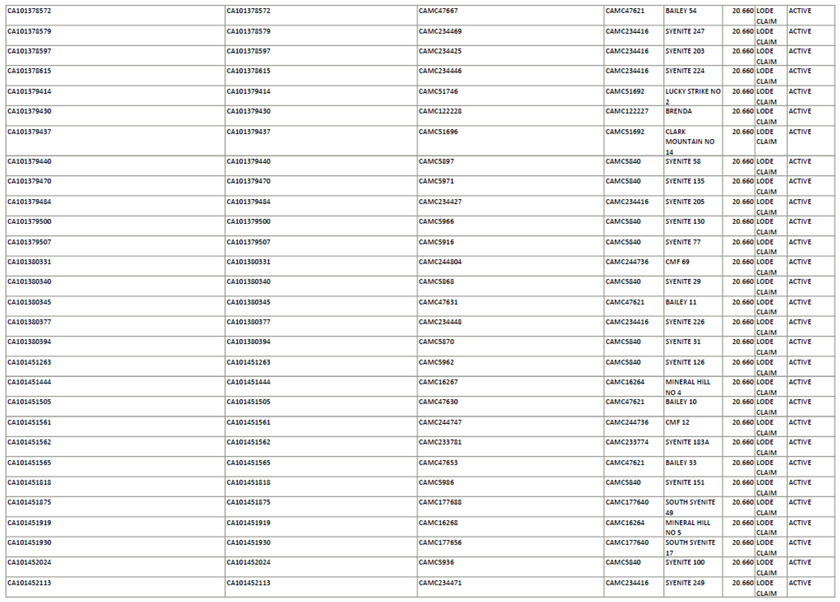

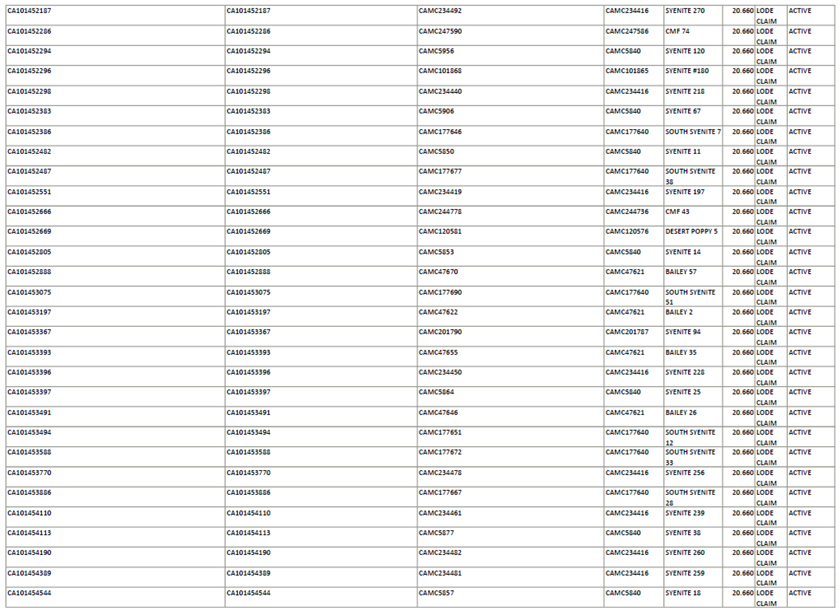

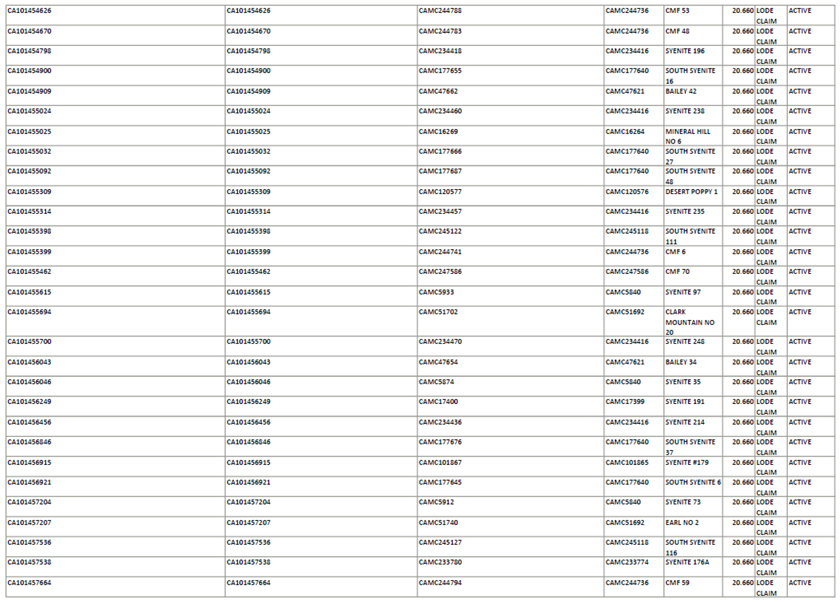

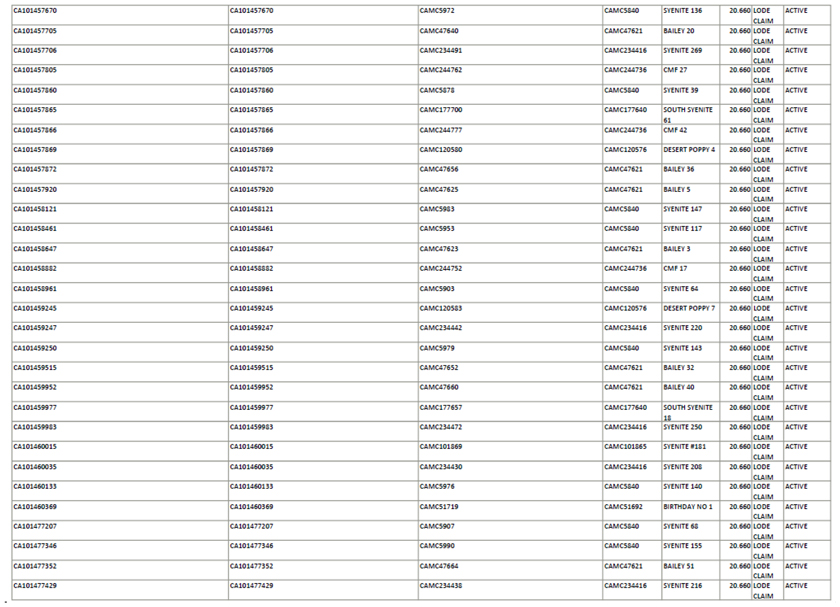

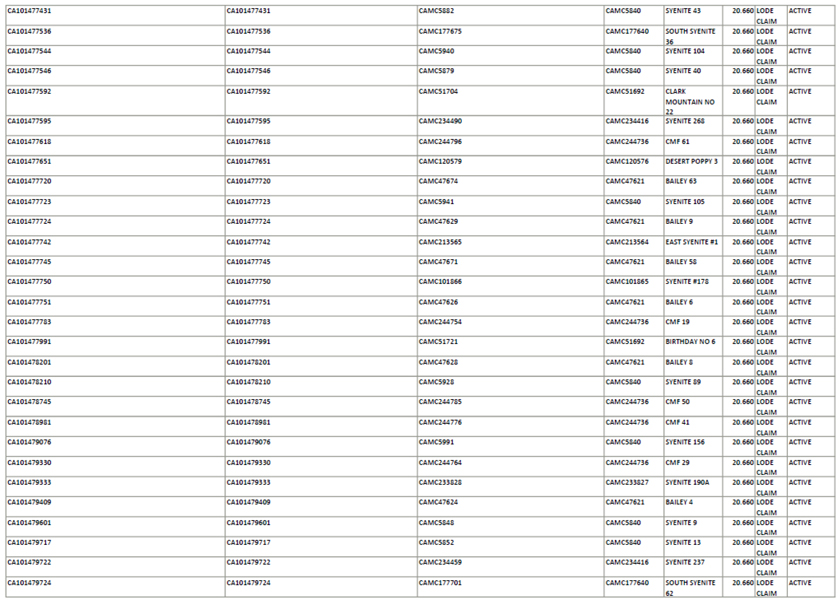

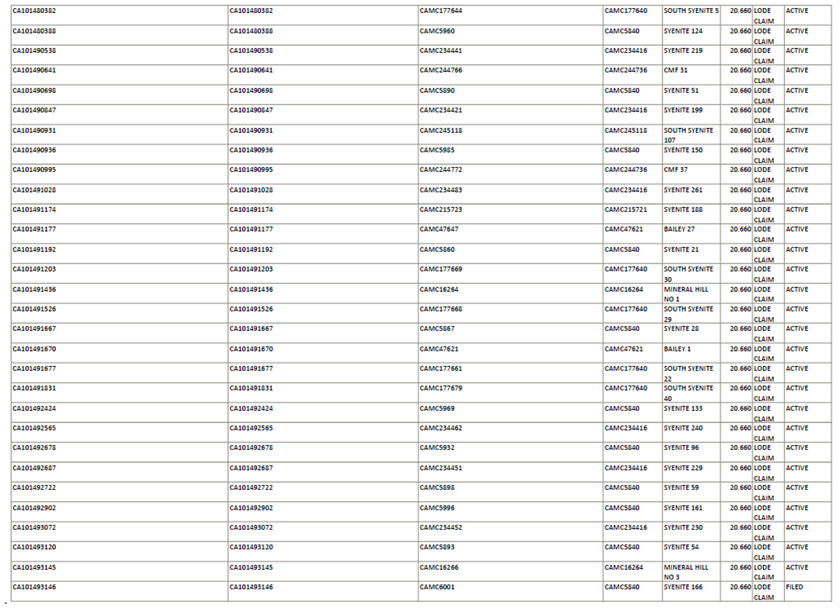

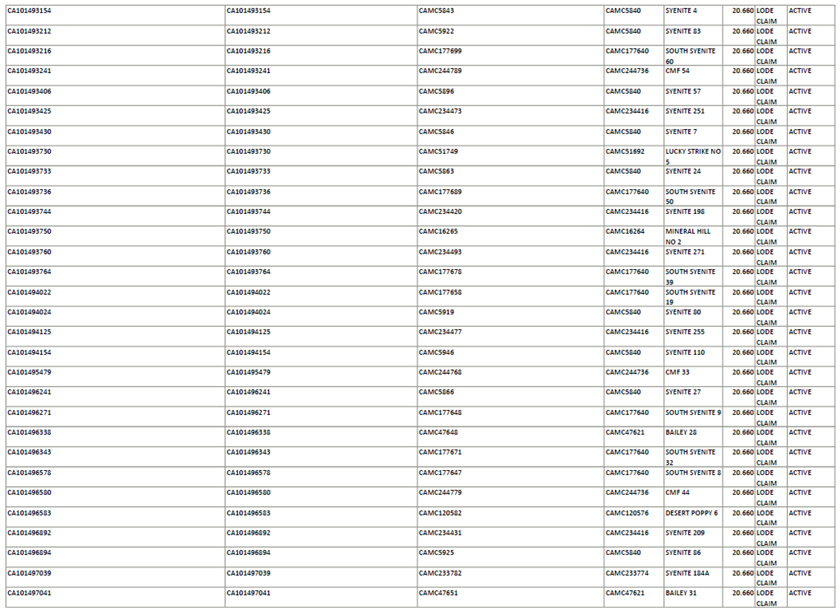

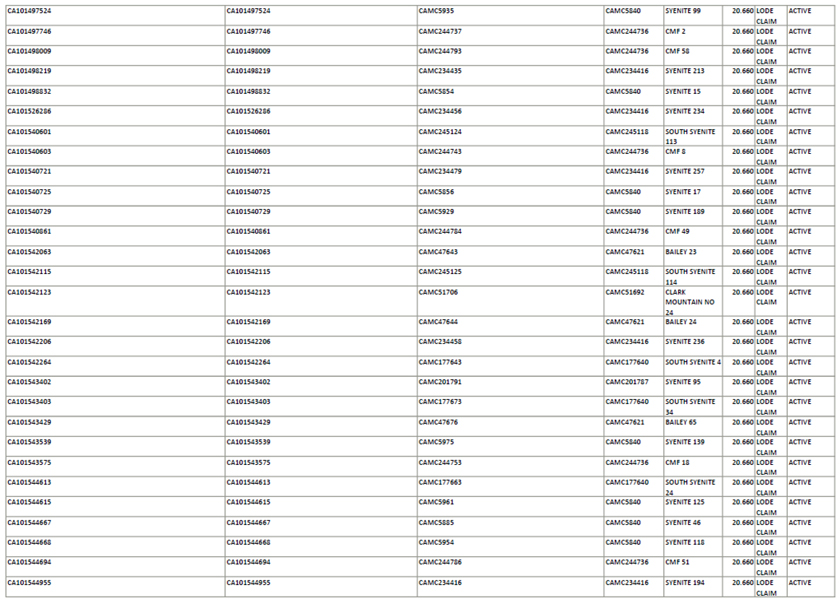

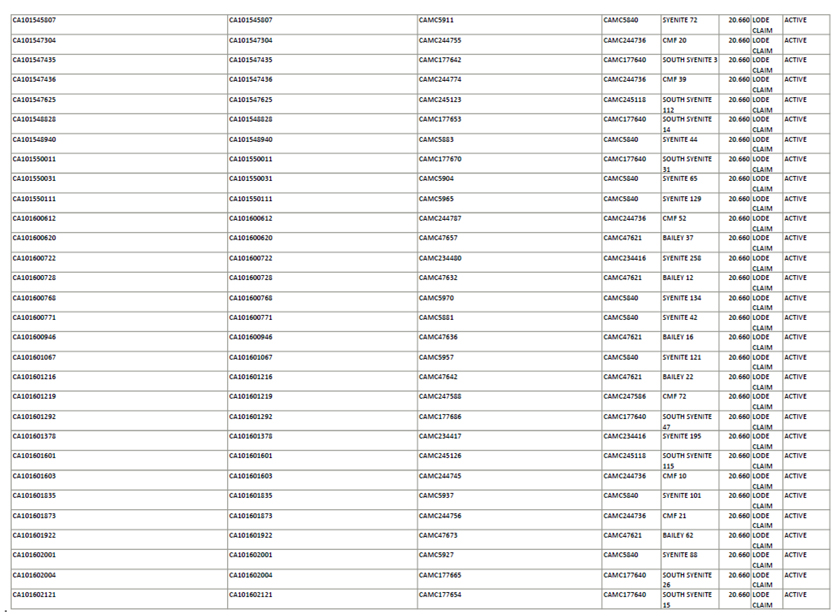

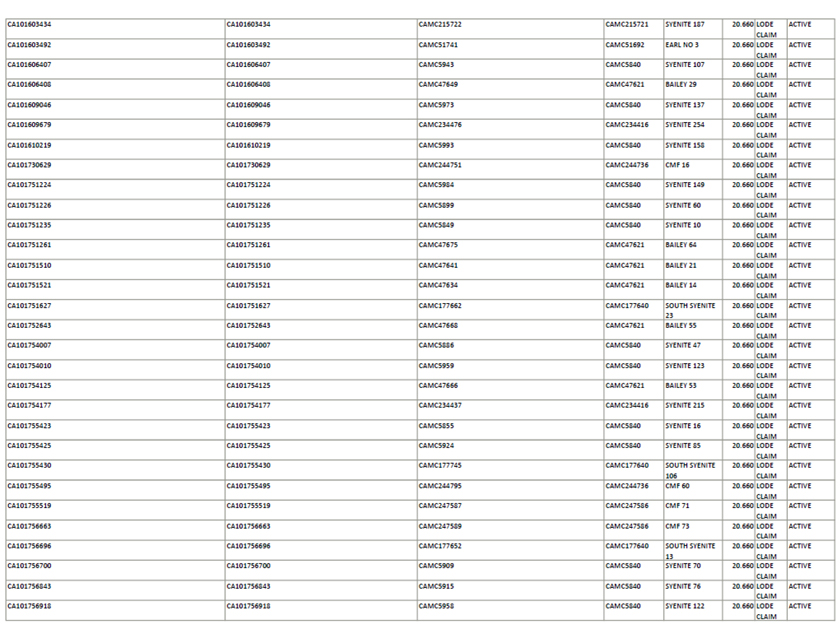

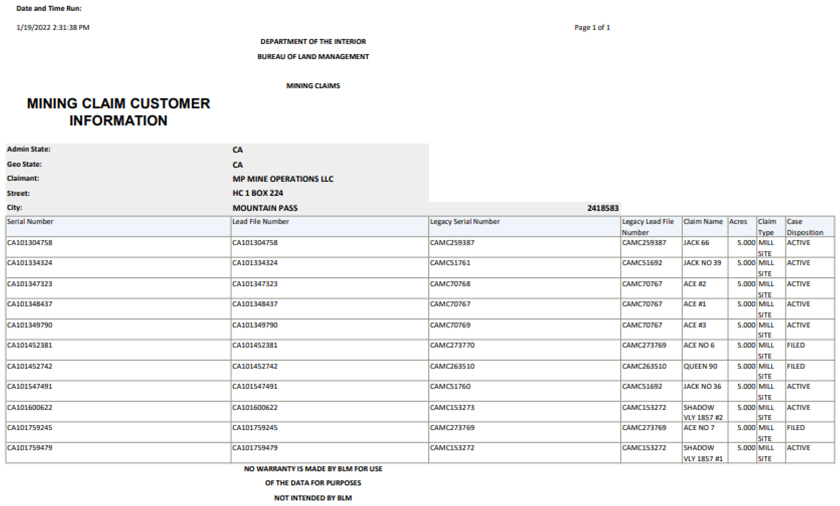

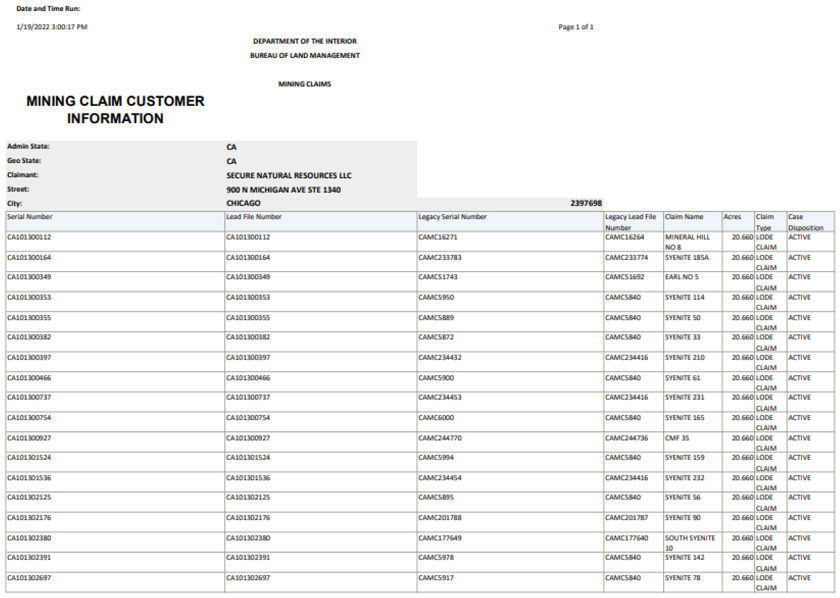

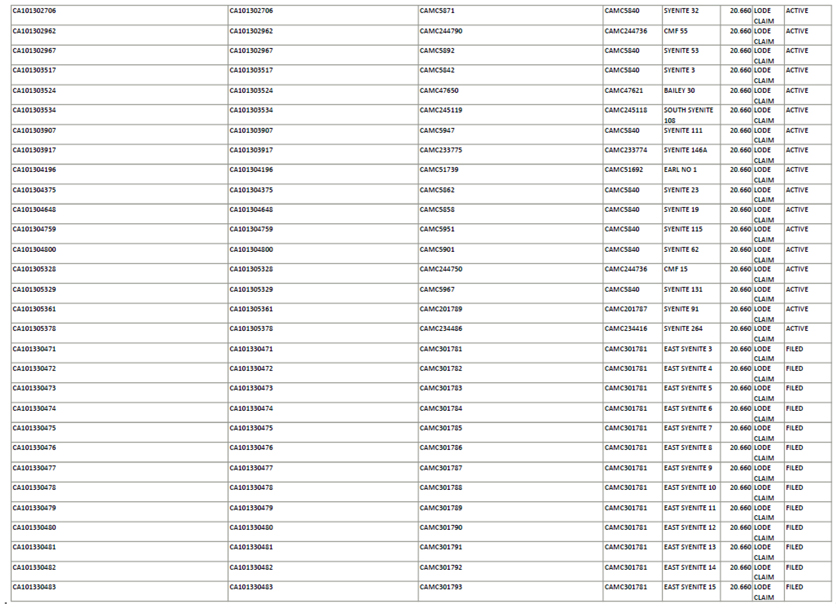

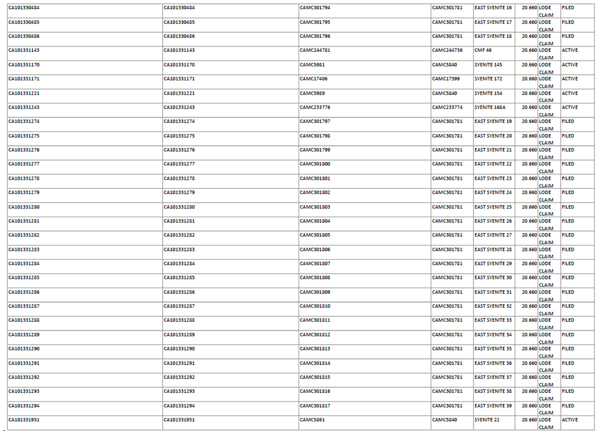

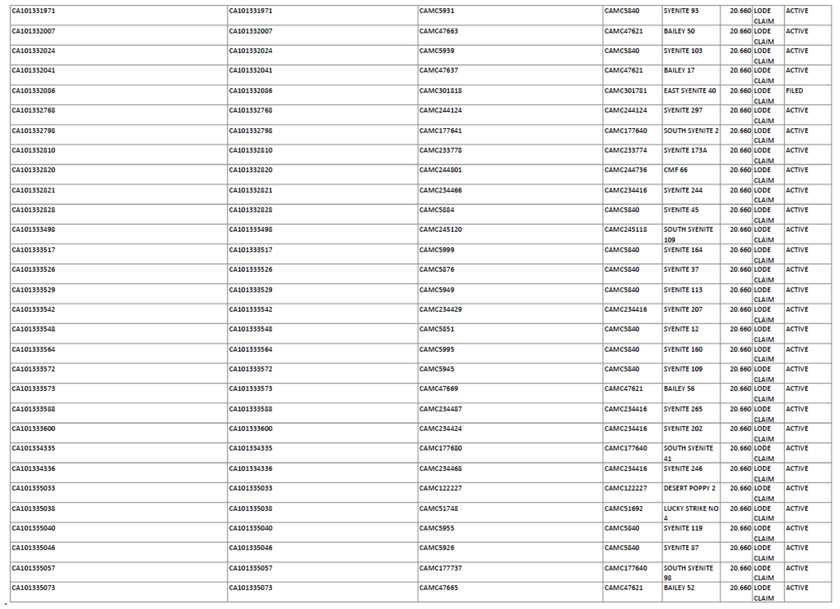

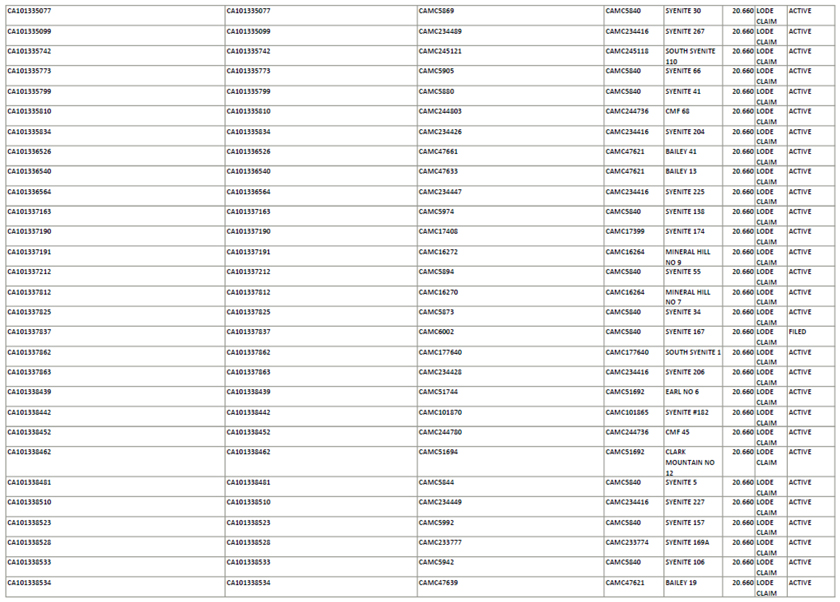

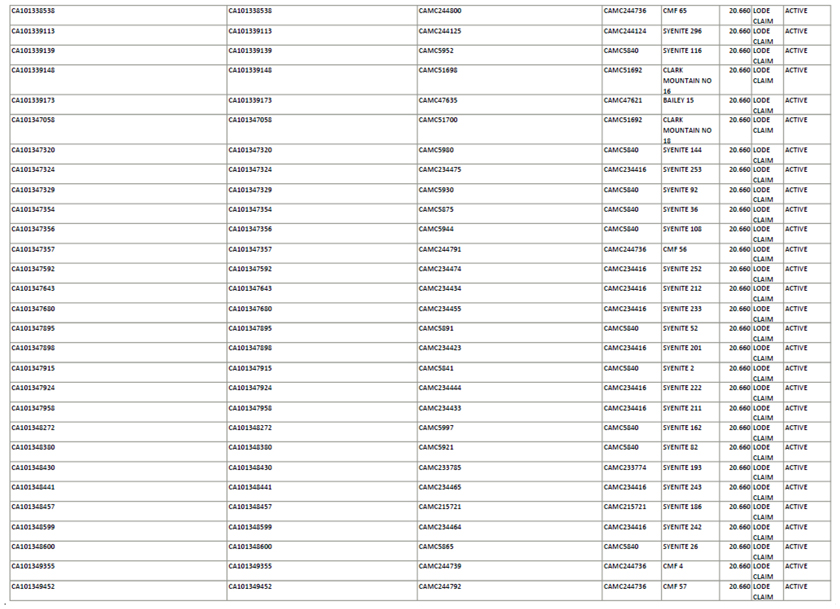

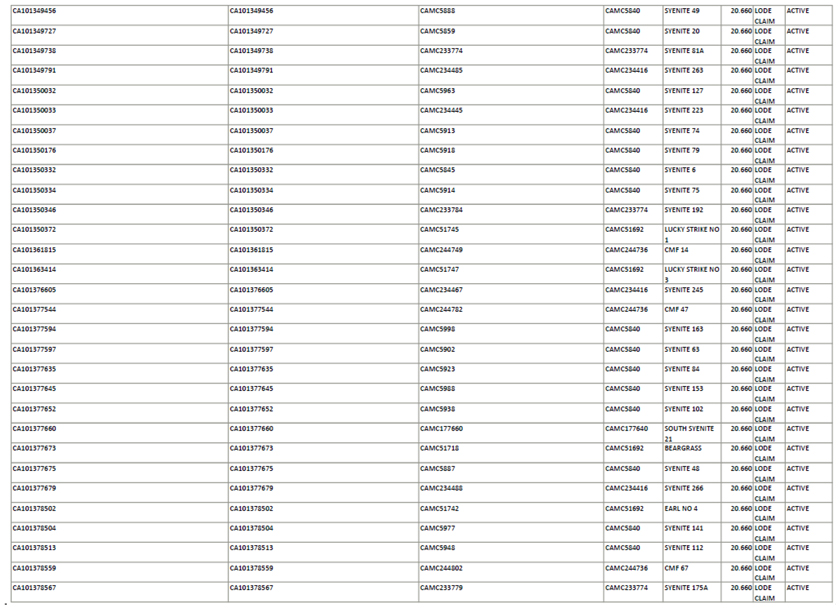

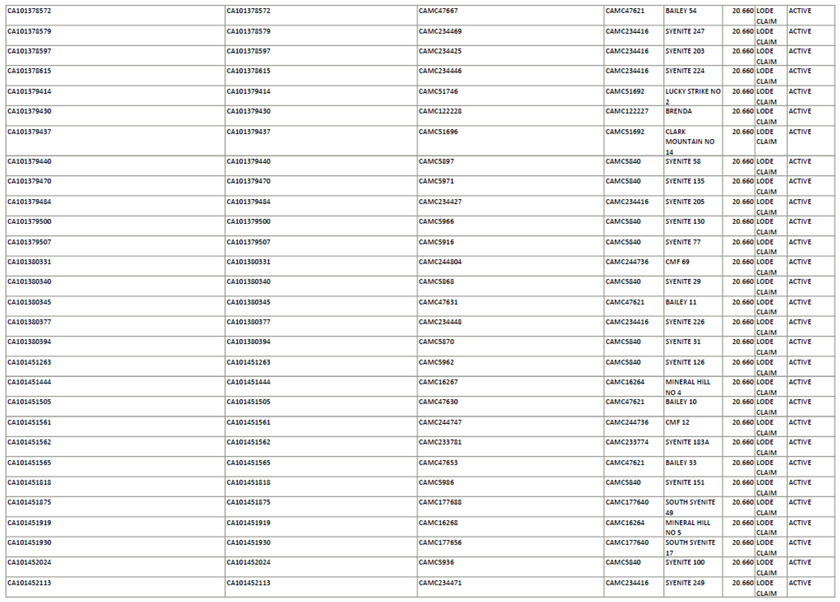

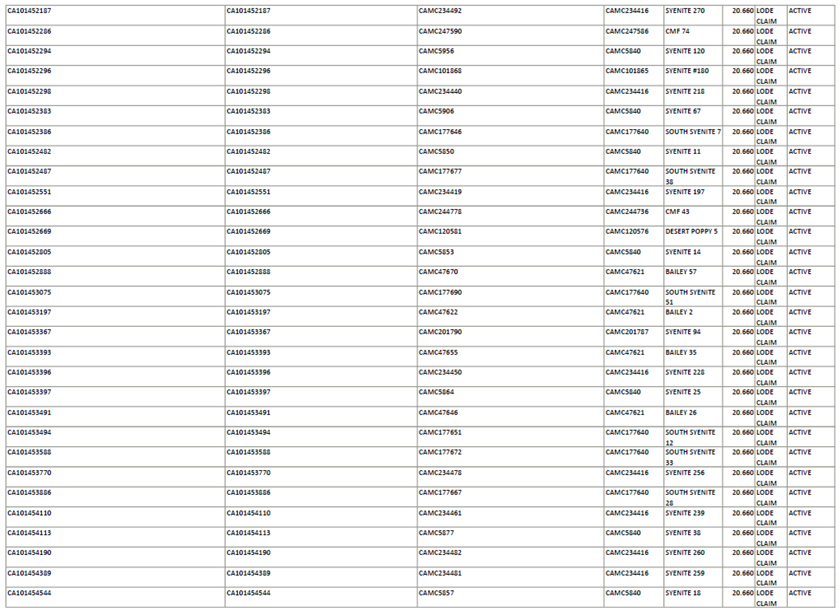

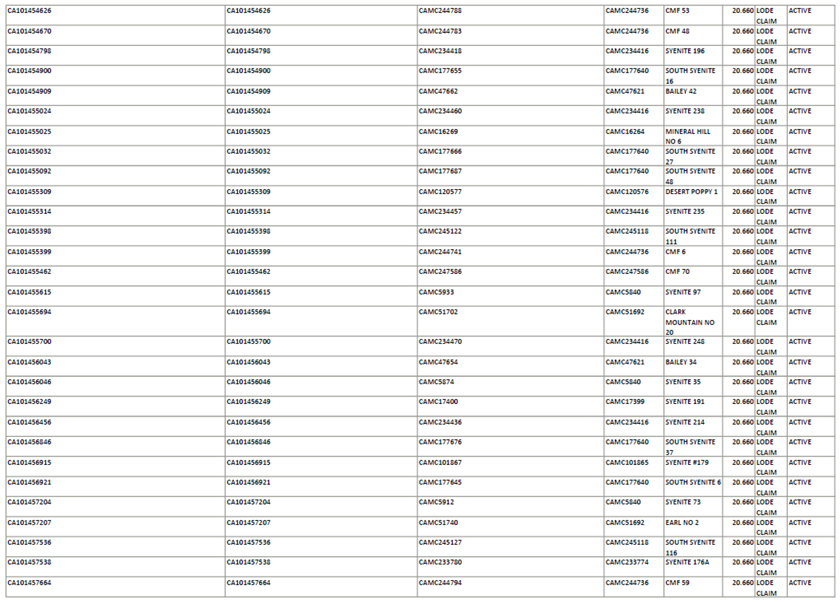

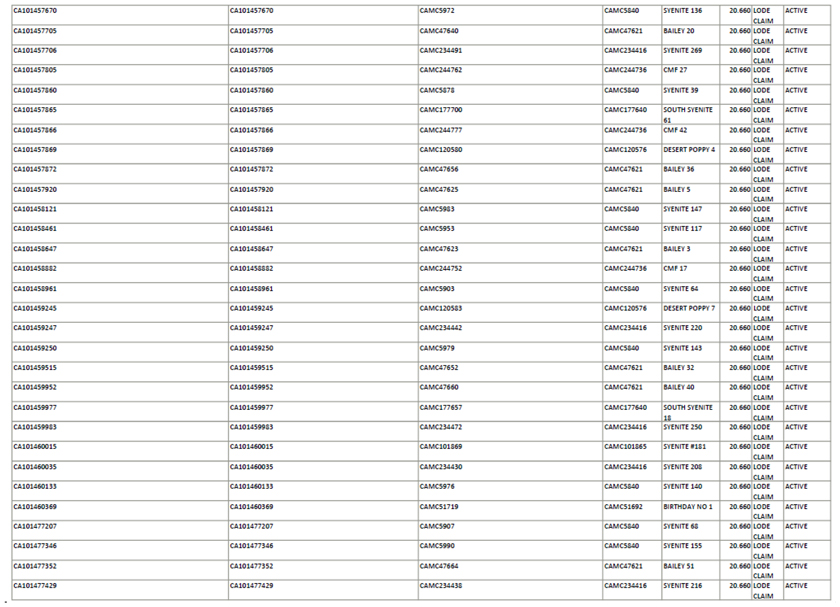

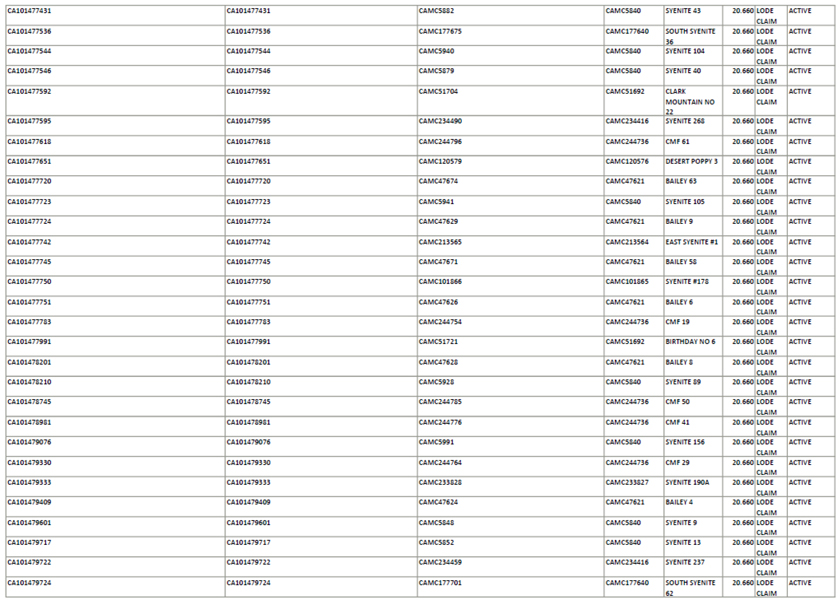

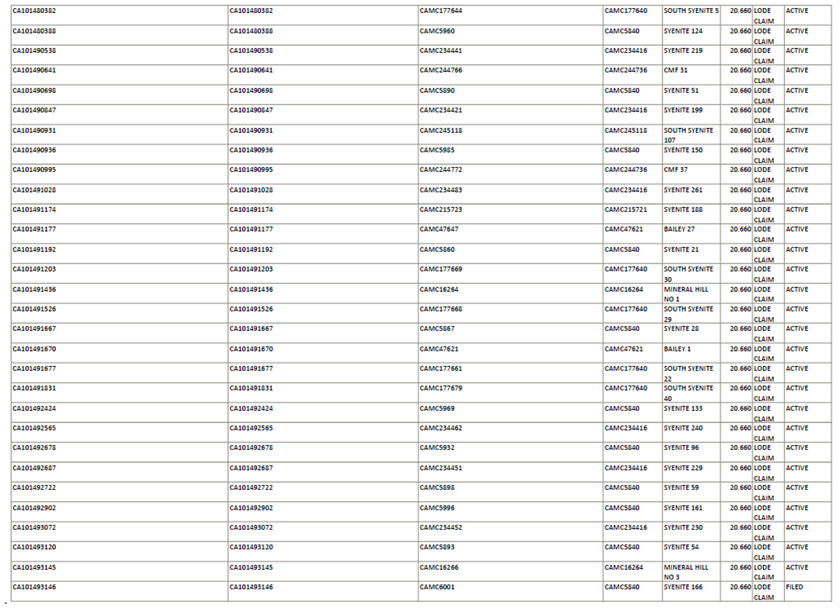

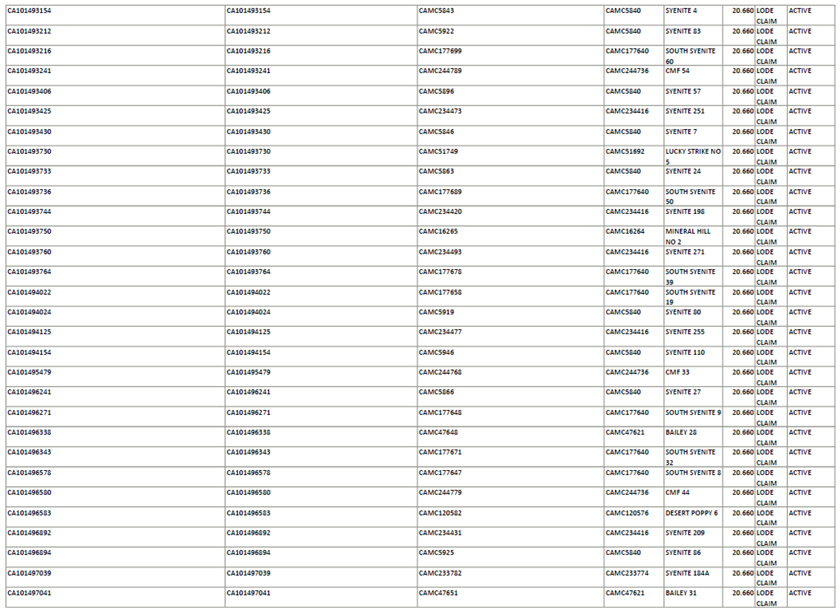

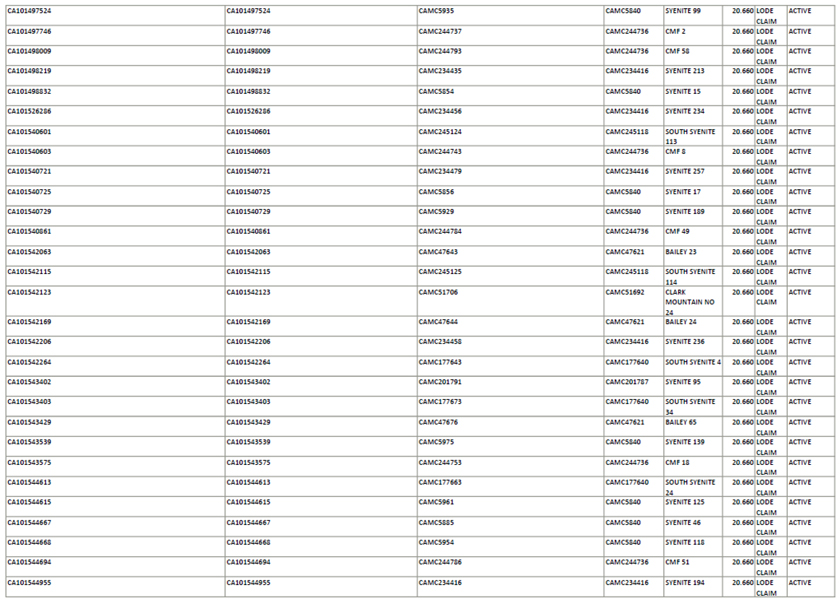

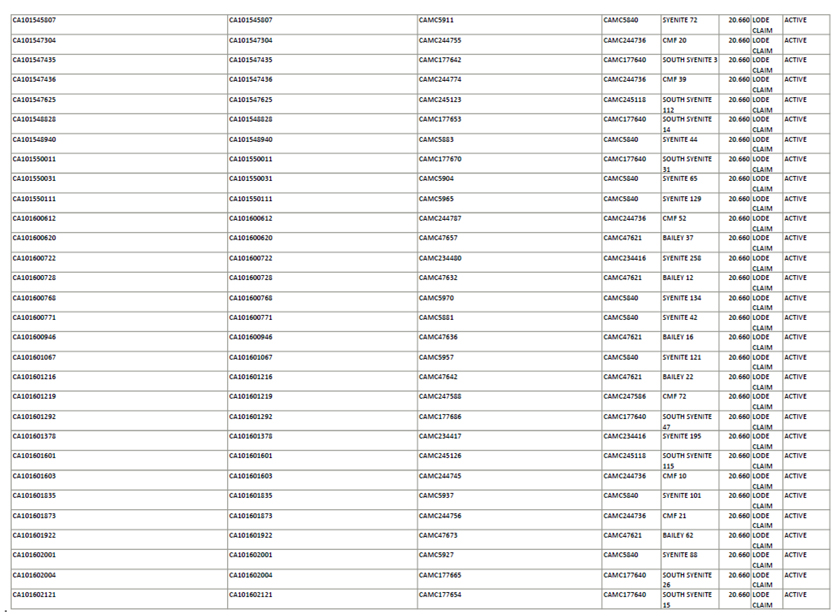

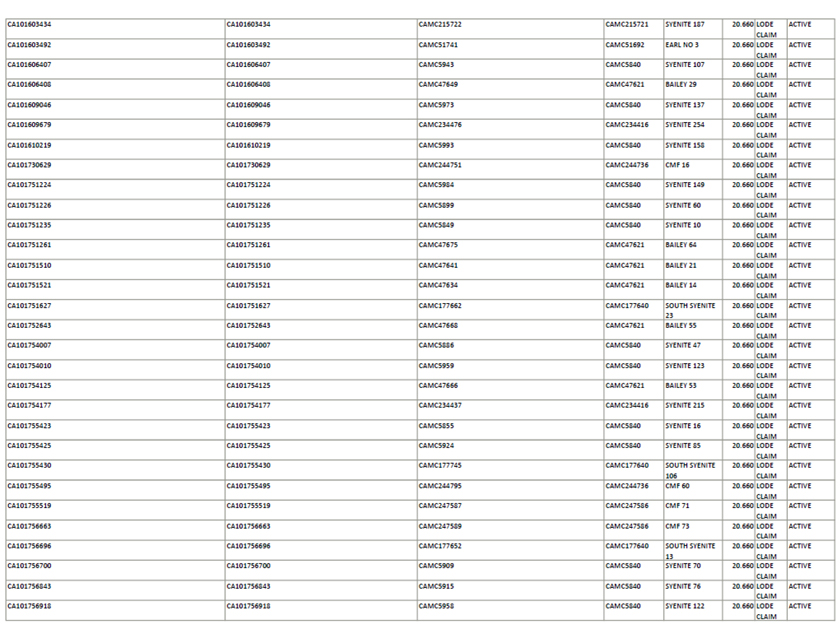

Appendix A: Claims List

Appendix B: Grade Estimation Details

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 15 |

List of Abbreviations

The US System for weights and units has been used throughout this report. Tons are reported in short tons of 2,000 lb, drilling and resource model dimensions and map scales are in ft. All currency is in U.S. dollars (US$) unless otherwise stated.

The following abbreviations may be used in this report.

| | | | |

Abbreviation | | Unit or Term | | |

| A | | ampere | | |

| AA | | atomic absorption | | |

| A/m2 | | amperes per square meter | | |

| amsl | | meters above mean sea level | | |

| ANFO | | ammonium nitrate fuel oil | | |

| AP | | Action Plan | | |

| °C | | degrees Centigrade | | |

| CCD | | counter-current decantation | | |

| CIL | | carbon-in-leach | | |

| cm | | centimeter | | |

| cm2 | | square centimeter | | |

| cm3 | | cubic centimeter | | |

| cfm | | cubic feet per minute | | |

| CHP | | combined heat and power plant | | |

| COG | | cut-off grade | | |

| ConfC | | confidence code | | |

| CRec | | core recovery | | |

| CSS | | closed-side setting | | |

| CTW | | calculated true width | | |

| CUP | | Conditional Use Permit | | |

| ° | | degree (degrees) | | |

| dia. | | diameter | | |

| EIR | | Environmental Impact Report | | |

| EIS | | Environmental Impact Statement | | |

| EMP | | Environmental Management Plan | | |

| FA | | fire assay | | |

| Factor of Safety | | FoS | | |

| ft | | foot (feet) | | |

| ft2 | | square foot (feet) | | |

| ft3 | | cubic foot (feet) | | |

| g | | gram | | |

| gal | | gallon | | |

| g/L | | gram per liter | | |

| g-mol | | gram-mole | | |

| gpm | | gallons per minute | | |

| g/t | | grams per metric tonne | | |

| ha | | hectares | | |

| HDPE | | Height Density Polyethylene | | |

| hp | | horsepower | | |

| HREE | | heavy rare earth elements | | |

| HRSG | | heat recovery steam generators | | |

| HTW | | horizontal true width | | |

| ICP | | inductively coupled plasma | | |

| ID2 | | inverse-distance squared | | |

| ID3 | | inverse-distance cubed | | |

| IFC | | International Finance Corporation | | |

| ILS | | Intermediate Leach Solution | | |

| kA | | kiloamperes | | |

| kg | | kilograms | | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 16 |

| | | | |

Abbreviation | | Unit or Term | | |

| km | | kilometer | | |

| km2 | | square kilometer | | |

| koz | | thousand troy ounce | | |

| kt | | thousand tonnes | | |

| kt/d | | thousand tonnes per day | | |

| kt/y | | thousand tonnes per year | | |

| kV | | kilovolt | | |

| kW | | kilowatt | | |

| kWh | | kilowatt-hour | | |

| kWh/t | | kilowatt-hour per metric tonne | | |

| L | | liter | | |

| L/sec | | liters per second | | |

| L/sec/m | | liters per second per meter | | |

| lb | | pound | | |

| LLDDP | | Linear Low Density Polyethylene Plastic | | |

| LOI | | Loss on Ignition | | |

| LoM | | life-of-mine | | |

| LREE | | light rare earth elements | | |

| LUS | | Land Use Services | | |

| m | | meter | | |

| m2 | | square meter | | |

| m3 | | cubic meter | | |

| mg/L | | milligrams/liter | | |

| mL | | milliliter | | |

| mm | | millimeter | | |

| mm2 | | square millimeter | | |

| mm3 | | cubic millimeter | | |

| MME | | Mine & Mill Engineering | | |

| Moz | | million troy ounces | | |

| Million short tons | | million short tons | | |

| mtw | | measured true width | | |

| MW | | million watts | | |

| m.y. | | million years | | |

| NGO | | non-governmental organization | | |

| NTU | | nephelometric turbidity unit | | |

| oz | | troy ounce | | |

| % | | percent | | |

| PLC | | Programmable Logic Controller | | |

| PLS | | Pregnant Leach Solution | | |

| PMF | | probable maximum flood | | |

| ppb | | parts per billion | | |

| ppm | | parts per million | | |

| QA/QC | | Quality Assurance/Quality Control | | |

| RC | | rotary circulation drilling | | |

| RCRA | | Resource Conservation and Recovery Act | | |

| REE | | rare earth elements | | |

| REO | | rare earth oxide | | |

| RF | | Revenue Factor | | |

| RO | | reverse osmosis | | |

| RoM | | Run-of-Mine | | |

| RQD | | Rock Quality Description | | |

| SEC | | U.S. Securities & Exchange Commission | | |

| sec | | second | | |

| SG | | specific gravity | | |

| SLS | | spent leach solution | | |

| SPT | | standard penetration testing | | |

| st | | short ton (2,000 pounds) | | |

| SX | | solvent extraction | | |

| SXD | | solvent extraction didymium | | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 17 |

| | | | |

Abbreviation | | Unit or Term | | |

| SXH | | solvent extraction heavies | | |

| SXI | | solvent extraction impurities | | |

| t | | tonne (metric tonne) (2,204.6 pounds) | | |

| t/h | | tonnes per hour | | |

| t/d | | tonnes per day | | |

| t/y | | tonnes per year | | |

| TEM | | technical economic model | | |

| TREO | | total rare earth oxide | | |

| TSF | | tailings storage facility | | |

| TSP | | total suspended particulates | | |

| TVR | | thermal vapor recompression | | |

| µm | | micron or microns | | |

| V | | volts | | |

| VFD | | variable frequency drive | | |

| W | | watt | | |

| XRD | | x-ray diffraction | | |

| y | | year | | |

| yd3 | | cubic yard | | |

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 18 |

This report was prepared as a pre-feasibility level Technical Report Summary in accordance with the Securities and Exchange Commission (“SEC”) S-K regulations (Title 17, Part 229, Items 601 and 1300 until 1305) for MP Materials Corp. (“MP Materials”) by SRK Consulting (U.S.), Inc. (“SRK”) on the Mountain Pass Mine (“Mountain Pass”).

Sections of this report pertaining to the modification and recommissioning of the rare earth element (REE) separations facility at Mountain Pass were authored by SGS North America Inc. (“SGS”). Portions of this report pertaining to products and markets, including long term price forecast for REE products, were authored by CRU International Limited (“CRU”).

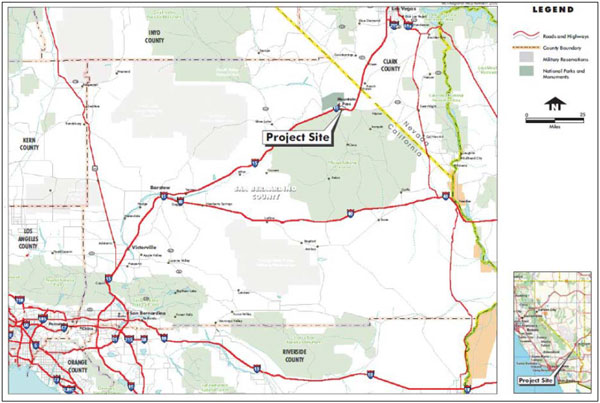

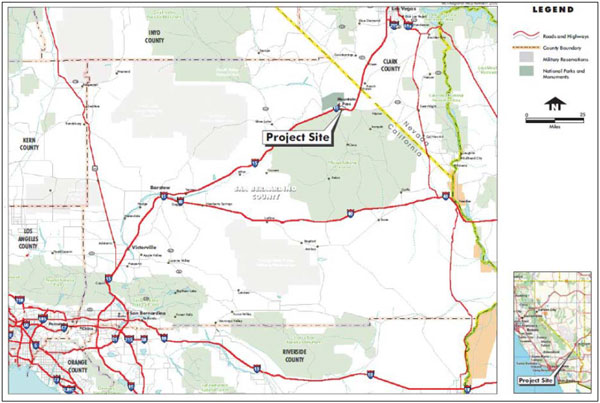

| 1.1 | Property Description and Ownership |

Mountain Pass is located in San Bernardino County, California, north of and adjacent to Interstate-15 (I-15), approximately 15 miles (mi) southwest of the California-Nevada state line and 30 mi northeast of Baker, California, at geographic coordinates 35°28’56”N latitude and 115°31’54”W longitude. This area is part of the historic Clark Mining District established in 1865. Mountain Pass is the only rare earth deposit identified within this district. The Project lies within portions of Sections 11, 12, 13, and 14 of Township 16 North, Range 14 East, San Bernardino Base and Meridian.

On November 17, 2020, pursuant to a merger agreement dated July 15, 2020, MP Mine Operations LLC (“MPMO”) and Secure Natural Resources LLC (“SNR”), the company that holds the mineral rights to the mine, were combined with Fortress Value Acquisition Corp., a special purpose acquisition company (“FVAC”) (the “Business Combination”). In connection with the Business Combination, MPMO and SNR became subsidiaries of FVAC, which was in turn renamed MP Materials Corp.

Mining claims and surface rights associated with the Project include:

| | • | | Patented claims with surface rights owned by MPMO and mineral rights held by SNR |

| | • | | Unpatented lode and mineral claims held by SNR |

| | • | | Surface ownership by MPMO and mineral rights controlled by the State of California |

| | • | | Surface ownership by MPMO and mineral rights controlled by the U.S. |

| | • | | Surface ownership by School District and mineral rights controlled by the U.S. |

The rare earth mineralization at the Project is located within land either owned or leased by MP Materials.

| 1.2 | Geology and Mineralization |

The Mountain Pass deposit is a rare-earth-element-enriched carbonatite historically referred to as the Sulfide Queen orebody. The carbonatite and numerous other alkaline intrusives in the vicinity are hosted in gneissic rocks which have been altered (fenitized) by the intrusive bodies. Multiple carbonatite dikes are present throughout the area. Small dikes and breccia bodies surround the Sulfide Queen orebody which comprises several different types of carbonatite (sovite, beforsite, dolosolvite, and white sovite) which are interlayered within a relatively large carbonatite package, this is unique in terms of size of the concession, and globally significant in terms of its enrichment in rare-earth minerals.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 19 |

The southern part of the Sulfide Queen orebody strikes to the south southeast and dips at 40° to the west southwest; the northern part of the orebody strikes to the north northeast and dips at some 40° to the west north-west. A number of post-mineralization faults result in slight offsets to the otherwise simple tabular/lensoid geometry. The total orebody strike length is approximately 2,750 feet (ft) and dip extent is 3,000 ft; true thickness of the more than 2% total rare earth oxide (TREO) grade zone ranges between 15 ft and 250 ft.

The main rare-earth-bearing mineral, bastnaesite, is present in all carbonatite subtypes, but in relatively lower proportions in the breccias and the monazitic carbonatites which typically occur mainly outside of and close to the main orebody. Monazite and crocidolite (“blue ore” found on the hangingwall contact in the northern part of the orebody) are both undesirable in the processing plant. In some areas, post mineral fault zones provide a conduit for water which results in localized alteration of the fresh carbonatite. Alteration dissolves the calcite and dolomite gangue minerals, leaving behind elevated concentrations of bastnaesite with limonite resulting in what is referred to as brown and black ore types, the most altered of which become a loosely consolidated very high grade bastnaesite sand. The altered ore types are mined, stockpiled separately and blended at a minor proportion to maintain target ore grades in the mill feed blend.

| 1.3 | Status of Exploration, Development and Operations |

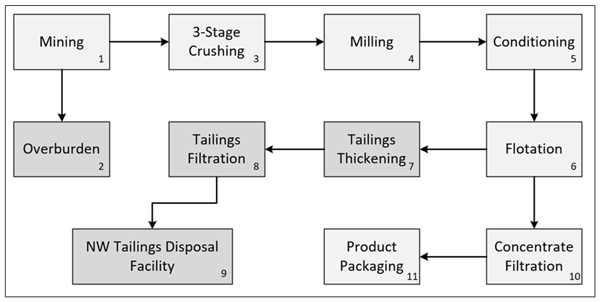

The Mountain Pass mine is an active operating mine. The primary mineral of economic interest is bastnaesite. MP Materials mines ore from the open pit, transports the ore to a primary crushing/stockpile facility and transports the ore to the mill. At the mill, the crushed material is ground further with a ball mill and conveyed via a slurry pipeline to the flotation plant to separate the bastnaesite from the gangue minerals. The primary product of the flotation process is a bastnaesite concentrate, which is filter dried and then transported to customers for sale. MP Materials is in the process of recommissioning a rare earths separations facility that is scheduled to be operational by year-end 2022. The separations facility, once operational, will allow the Company to separate the bastnaesite concentrate into four saleable products: praseodymium and neodymium (PrNd) oxide, samarium, europium, and gadolinium (SEG+) oxalate, lanthanum (La) carbonate, and cerium (Ce) chloride.

MP Materials relies on predecessor companies, the United States Geological Survey (USGS) (Olson and others, 1954), and various consulting companies for interpretations related to the regional and mine area geology and hydrogeology, regional and local structure, and deposit geology. Mineral Processing and Metallurgical Testing.

| 1.4 | Mineral Processing and Metallurgical Testing |

| 1.4.1 | Existing Crushing and Concentrating Operations |

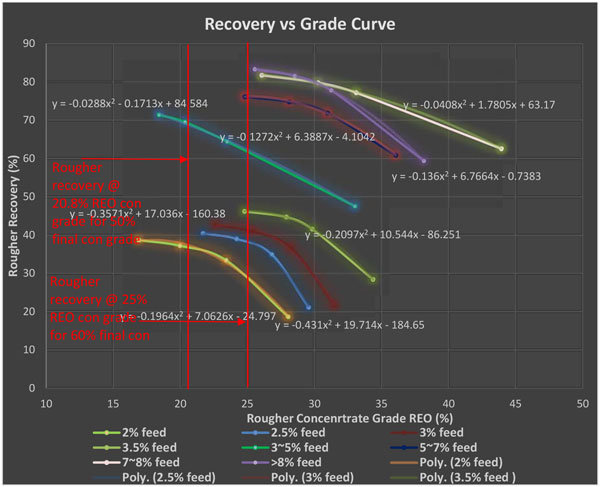

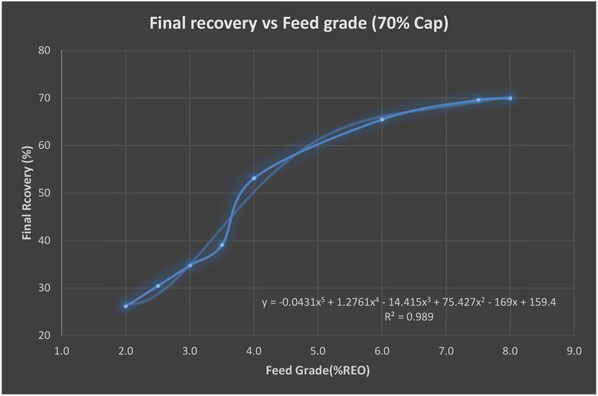

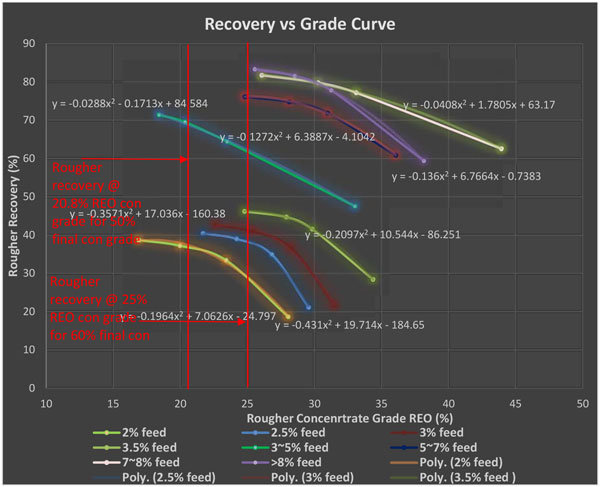

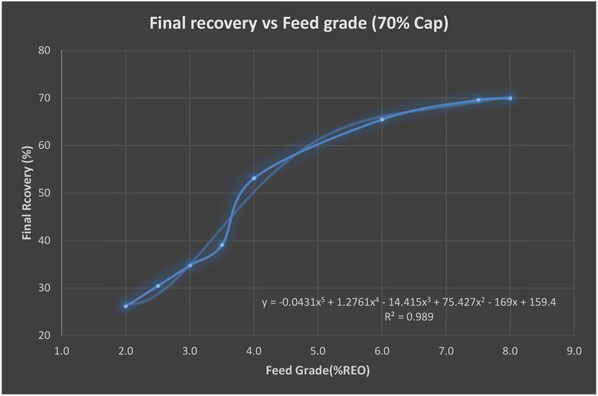

During the later years of mining operations at Mountain Pass, the ore grade is expected to decline. To assess TREO (total rare earth oxide) recovery from lower grade ore, MP Materials conducted rougher flotation tests on ore samples over a grade range from 1.86 - 8.10% TREO using standard concentrator test conditions. Based on the results of this testwork, MP Materials has developed a mathematical relationship to estimate overall TREO recovery versus ore grade. This relationship has been used to estimate TREO recovery from lower grade ores later in the mine life.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 20 |

| 1.4.2 | Rare Earths Separations |

It is the intention of MP Materials to modify the current operations to produce four marketable rare earth products in the future (PrNd oxide, SEG+ oxalate, La carbonate/La oxide, and Ce chloride). The specifications for the four products are shown in Table 1-1, with further discussion on the product specification provided in Section 14.6

Table 1-1: Product Specifications

| | | | | | | | |

| Product | | Compound | | w/w % TREO | | Purity | | |

| PrNd Oxide | | 75% Nd2O3 + 25% Pr6O11 (+/-2%) | | 99% | | 99.5%+ PrNd/TREO | | |

| SEG+ Oxalate/Concentrate | | - | | 25% to 45% | | 99% SEG+/TREO | | |

| Lanthanum Carbonate | | La2(CO3)3 + La2O3 | | 99% | | 99% La/TREO | | |

| Cerium Chloride | | LaCeCl3 | | 45% | | 85% Ce/TREO | | |

Note: w/w % is the weight concentration of the solution.

Source: MP Materials, 2021

The work effort to develop the design criteria for processing facility modifications are briefly described below and are detailed in Section 10.4. Unit operations for the modified facilities are described below.

Concentrate Drying and Roasting

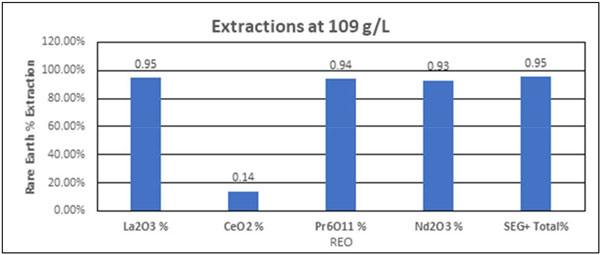

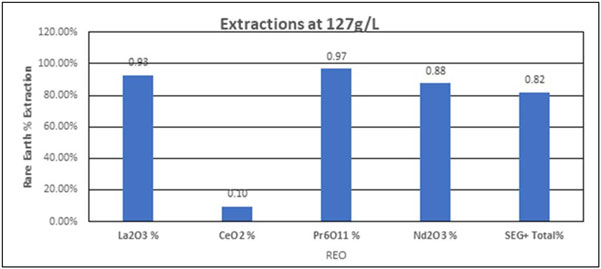

Concentrate drying and roasting was practiced at Mountain Pass commencing in the mid 1960’s. Tonnage quantity roasting test work to confirm optimum operating parameters was conducted at Hazen Research. Studies involving the definition of specific leaching conditions were conducted at SGS Lakefield and at Mountain Pass facilities. These studies served to elucidate optimum operational conditions. Of major importance was the adjustment of roasting parameters such that leaching dissolved trivalent rare earths and left the majority of the cerium undissolved.

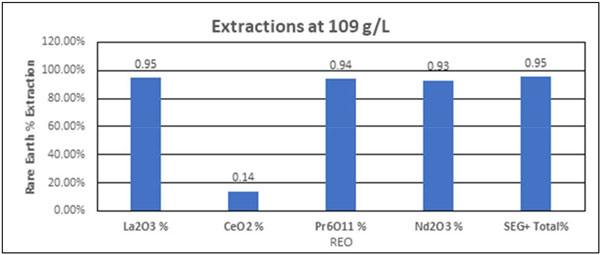

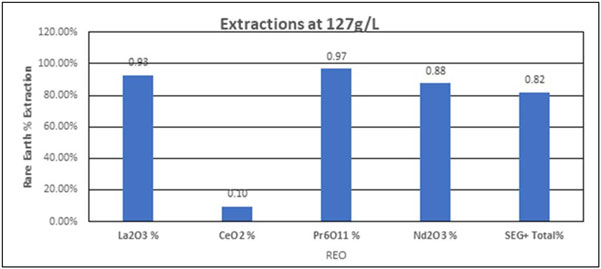

Leaching

Optimization studies to specify the most appropriate leaching parameters were conducted at several external laboratories and at MP Materials Cerium 96 leaching facility. MP Materials upgraded a small-scale onsite leaching pilot facility which provided superior temperature control so as to define the optimum leach facility operating conditions. The leaching operations produced an undissolved cerium concentrate and solubilized trivalent rare earths plus dissolved impurities.

Impurity Removal

Soluble impurities in the leach solution include iron, aluminum, uranium, calcium, magnesium, and other minor quantities of dissolved elements. The MP Materials solvent extraction system used for this duty has been successfully used for a number of years.

SXH and SXD

The solvent extraction heavies (SXH) circuit makes a bulk separation of heavy rare earths and the solvent extraction didymium (SXD) circuit separates a PrNd stream. These circuits have been piloted and have been demonstrated to function as designed.

Brine Recovery, Treatment, Crystallizing: MP Materials has conducted several rounds of pilot studies taking appropriate mixtures of brine from previously operated facilities and solvent extraction (SX) pilot plant investigations to produce a representative brine. Past experience coupled with recent modeling work indicate that the system has sufficient capacity to handle anticipated feed volumetric changes.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 21 |

Conclusions

As with any extensive process modification effort, all possible contingencies may not be anticipated. However, based upon the project documentation provided, a site visit to the MP Materials installations at Mountain Pass, an interview with the manager of ongoing construction and conversations with MP Materials engineers who will be directly involved with the commissioning efforts, it is the opinion of SGS North America Inc. (SGS) that the Mountain Pass modification and modernization project has been performed in a professional manner. It is also SGS’s opinion that it is likely that the project schedule and commissioning efforts will be accomplished in the stipulated time frame, which is currently assumed to be year-end 2022.

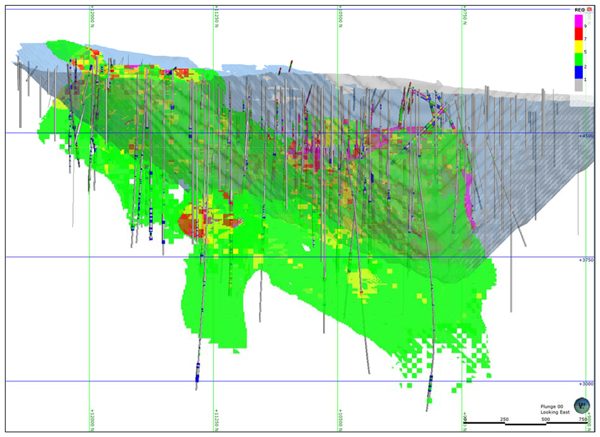

| 1.5 | Mineral Resource Estimate |

The Mineral Resources are reported in accordance with the S-K regulations (Title 17, Part 229, Items 601 and 1300 until 1305). Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. There is no certainty that all or any part of the Mineral Resource will be converted into Mineral Reserves. The Mineral Resource modelling and reporting was completed by SRK Consulting (U.S.) Inc.

The mineral resource estimate has been constrained by a geological model considering relevant rock types, structure, and mineralization envelopes as defined by TREO content within relevant geological features. This geological model is informed principally by diamond core drilling and multiple phases of geological mapping. Sectional interpretation based on the combination of these data were used to influence implicit modeling of the geological data with manual controls where appropriate.

SRK has dealt with uncertainty and risk at Mountain Pass by classifying the contained resource by varying degrees of confidence in the estimate. The mineral resources at the Mountain Pass deposit have been classified in accordance with the S-K 1300 regulations. The classification parameters are defined by both the distance to composite data, the number of drillholes used to inform block grades and a geostatistical indicator of relative estimation quality (kriging efficiency). Density is based on average density measurements collected from the various rock types over the years, and carbonatite density in particular is supported by extensive mining and processing experience with the materials.

A cut-off grade (COG) of 2.28% TREO has been developed to ensure that material reported as a mineral resource can satisfy the definition of reasonable potential for eventual economic extraction (RPEEE). Mineral resources have been constrained within an economic pit shell based on reserve input parameters. For mineral resources, a revenue factor of 1.0 is selected which corresponds to a break-even pit shell. SRK notes that the pit selected for mineral resources has been influenced by setbacks relative to critical infrastructure such as the tailing storage and the rare earth oxide (REO) concentrator.

The September 30, 2021, mineral resource statement is shown in Table 1-2. The reference point for the mineral resources is in situ material.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 22 |

Table 1-2: Mineral Resource Statement for the Mountain Pass Rare Earth Project, September 30, 2021

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Category | | Resource Type | |

| Cut-Off

TREO% |

| |

| Mass

(million sh. ton) |

| | | Average Value | | | |

| |

| TREO(1)

(%) |

| |

| La2O3(2)

(%) |

| |

| CeO2

(%) |

| |

| Pr6O11

(%) |

| |

| Nd2O3

(%) |

| |

| Sm2O3

(%) |

| | |

Indicated | | Within the Reserve Pit | | | 2.28-2.49 | | | | 0.9 | | | | 2.38 | | | | 0.78 | | | | 1.19 | | | | 0.10 | | | | 0.29 | | | | 0.02 | | | |

| | Within the Resource Pit | | | 2.28 | | | | 0.5 | | | | 3.61 | | | | 1.18 | | | | 1.80 | | | | 0.16 | | | | 0.44 | | | | 0.03 | | | |

Total Indicated | | | | | | | | | 1.4 | | | | 2.82 | | | | 0.92 | | | | 1.41 | | | | 0.12 | | | | 0.34 | | | | 0.03 | | | |

Inferred | | Within the Reserve Pit | | | 2.28-2.49 | | | | 7.1 | | | | 5.48 | | | | 1.78 | | | | 2.73 | | | | 0.24 | | | | 0.66 | | | | 0.05 | | | |

| | Withing the Resource Pit | | | 2.28 | | | | 2.1 | | | | 3.81 | | | | 1.24 | | | | 1.90 | | | | 0.16 | | | | 0.46 | | | | 0.03 | | | |

Total Inferred | | | | | | | | | 9.1 | | | | 5.10 | | | | 1.66 | | | | 2.54 | | | | 0.22 | | | | 0.62 | | | | 0.05 | | | |

Source: SRK 2021

(1): TREO% represents the total of individually assayed light rare earth oxides on a 99.7% basis of total contained TREO, based on the historical site analyses.

(2): Percentage of individual light rare earth oxides are based on the average ratios; La2O3 is calculated at a ratio of 32.6% grade of TREO% equivalent estimated grade, CeO2 is calculated at a ratio of 49.9% of TREO% equivalent estimated grade, Pr6O11 is calculated at a ratio of 4.3% of TREO% equivalent estimated grade, Nd2O3 is calculated at a ratio of 12.1% of TREO% equivalent estimated grade, and Sm2O3 is calculated at a ratio of 0.90% of TREO% equivalent estimated grade. The sum of light rare earths averages 99.7%; the additional 0.3% cannot be accounted for based on the analyses available to date and has been discounted from this resource statement.

General Notes:

| | • | | Mineral Resources are reported exclusive of Mineral Reserves. |

| | • | | Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. There is no certainty that all or any part of the Mineral Resources estimated will be converted into Mineral Reserves estimate. |

| | • | | Mineral Resource tonnage and contained metal have been rounded to reflect the accuracy of the estimate, any apparent errors are insignificant. |

| | • | | Mineral Resource tonnage and grade are reported as diluted. |

| | • | | The Mineral Resource model has been depleted for historical and forecast mining based on the September 30, 2021, pit topography. |

| | • | | Pit optimization cut-off grade is based on an average TREO% equivalent concentrate price of US$7,059/st of dry concentrate (60% TREO, net of the incremental benefits and costs related to REE separations), average mining cost at the pit exit of US$1.825/st mined plus US$0.018/st mined for each 15 ft bench above or below the pit exit, combined milling and G&A costs of US$69.90/st milled, concentrate freight of US$177/st of dry concentrate, and an average overall pit slope angle of 42° including ramps. |

| | • | | The mineral resource statement reported herein only includes the rare earth elements cerium, lanthanum, neodymium, praseodymium, and samarium (often referred to as light rare earths). While other rare earth elements, often referred to as heavy rare earths, are present in the deposit, they are not accounted for in this estimate due to historic data limitations (see Section 9.2.6). |

| 1.6 | Mineral Reserve Estimate |

SRK developed a life-of-mine (LoM) plan for the Mountain Pass operation in support of mineral reserves. For economic modeling, 2022 production was assumed to be bastnaesite concentrate. From 2023 onward, it was assumed that MP Materials will operate a separations facility at the Mountain Pass site that will allow the Company to separate bastnaesite concentrate into four individual REO products for sale (PrNd oxide, SEG+ oxalate, La carbonate/La oxide, and Ce chloride). Forecast economic parameters are based on current cost performance for process, transportation, and administrative costs, as well as a first principles estimation of future mining costs. Forecast revenue from concentrate sales and individual separated product sales is based on a preliminary market study commissioned by MP Materials, as discussed in Section 16 of this report.

From this evaluation, pit optimization was performed based on an equivalent concentrate price of US$6,139 per dry st of 60% TREO concentrate (net of the incremental benefits and costs related to REE separations). The results of pit optimization guided the design and scheduling of the ultimate pit.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 23 |

SRK generated a cash flow model which indicated positive economics for the LoM plan, which provides the basis for the reserves. Reserves within the new ultimate pit are sequenced for the full 35-year LoM. There is a partial year of stockpile processing after mining of in situ reserves is completed.

The costs used for pit optimization include estimated mining, processing, sustaining capital, transportation, and administrative costs, including an allocation of corporate costs. Processing and G&A costs used for pit optimization were based on 12-month rolling average actual costs from August 2020 – July 2021. Processing and G&A costs used for economic modeling were updated subsequent to pit optimization and are based on January 2021 – September 2021 actual costs.

Processing recovery for concentrate is variable based on a mathematical relationship to estimate overall TREO recovery versus ore grade. The calculated COG for the reserves is 2.49% TREO, which was applied to indicated blocks contained within an ultimate pit, the design of which was guided by economic pit optimization.

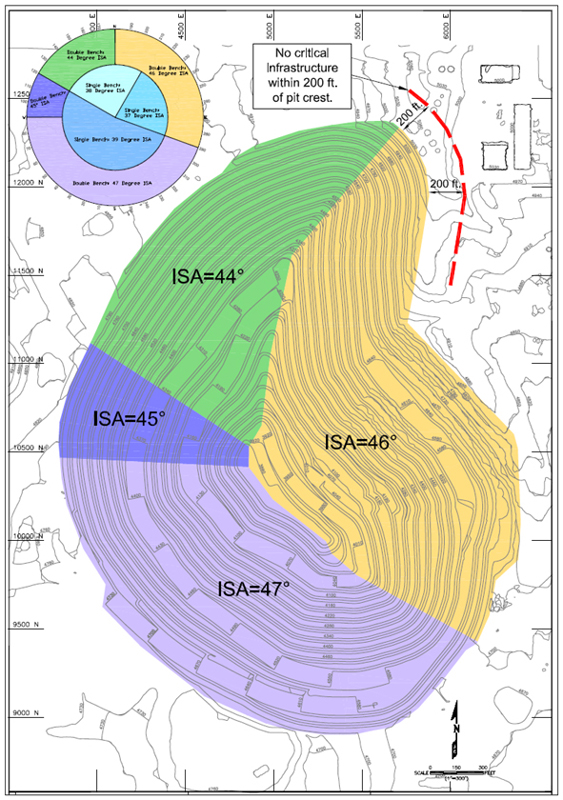

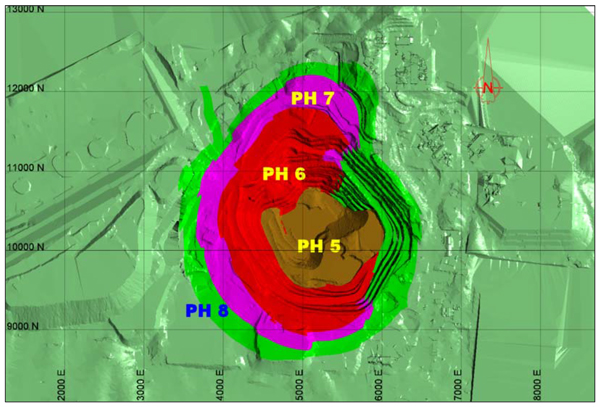

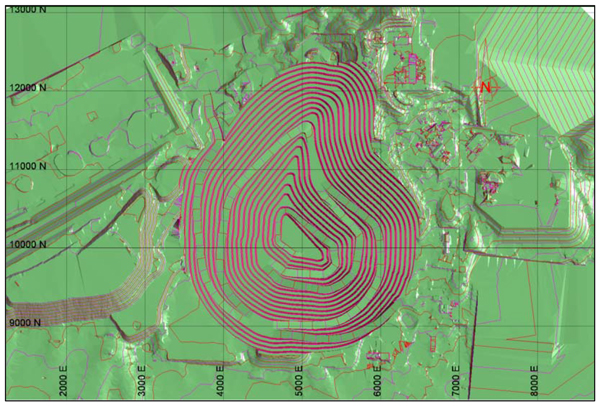

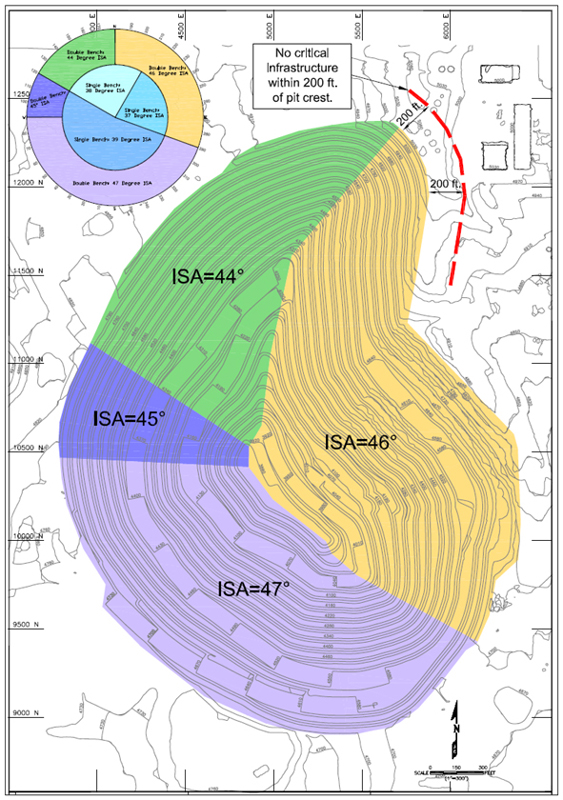

The optimized pit shell selected to guide final pit design was based on a combination of the revenue factor (RF) 0.45 pit (used on the north half of the deposit) and the RF 1.00 pit shell (used on the south half of the deposit). The inter-ramp pit slopes used for the design are based on geotechnical studies and range from 42° to 47°.

Measured resources in stockpiles were converted to proven reserves. Indicated pit resources were converted to probable reserves by applying the appropriate modifying factors, as described herein, to potential mining pit shapes created during the mine design process. Inferred resources present within the LoM pit are treated as waste.

The mine design process results in in situ open pit mining reserves of 30.45 million st with an average grade of 6.35% TREO. Table 1-3 presents the mineral reserve statement, as of September 30, 2021, for the Mountain Pass mine (MP Materials’ mining engineers provided a month-end September 2021 topography as a reserve starting point). The reference point for the mineral reserves is ore delivered to the Mountain Pass concentrator.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 24 |

Table 1-3: Mineral Reserves at Mountain Pass as of September 30, 2021 - SRK Consulting (U.S.), Inc.

| | | | | | | | | | | | | | | | | | | | | | |

| Category | | Description | | Run-of-Mine (RoM) | | | TREO% | | | MY% | | | Concentrate | | | | |

| | Million Short Tons (dry) | | | Million Short Tons (dry) | | | | |

Proven | | Current Stockpiles | | | 0.05 | | | | 9.45 | | | | 10.88 | | | | 0.01 | | | | | |

| | In situ | | | - | | | | - | | | | - | | | | - | | | | | |

| | Proven Totals | | | 0.05 | | | | 9.45 | | | | 10.88 | | | | 0.01 | | | | | |

Probable | | Current Stockpiles | �� | | - | | | | - | | | | - | | | | - | | | | | |

| | In situ | | | 30.4 | | | | 6.35 | | | | 6.74 | | | | 2.05 | | | | | |

| | Probable Totals | | | 30.4 | | | | 6.35 | | | | 6.74 | | | | 2.05 | | | | | |

Proven + Probable | | Current Stockpiles | | | 0.05 | | | | 9.45 | | | | 10.88 | | | | 0.01 | | | | | |

| | In situ | | | 30.4 | | | | 6.35 | | | | 6.74 | | | | 2.05 | | | | | |

| | Proven + Probable Totals | | | 30.45 | | | | 6.36 | | | | 6.75 | | | | 2.05 | | | | | |

Source: SRK, 2021

General Notes:

| | • | | Reserves stated as contained within an economically minable open pit design stated above a 2.49% TREO COG. |

| | • | | Mineral reserves tonnage and contained metal have been rounded to reflect the accuracy of the estimate, and numbers may not add due to rounding. A small difference of approximately 0.3% between the reserve tonnage and the ore tonnage used in the cashflow model is not considered to be material. |

| | • | | MY% calculation is based on 60% concentrate grade of the product and the ore grade dependent metallurgical recovery. MY% = (TREO% * Met recovery)/60% concentrate TREO grade. |

| | • | | Indicated mineral resources have been converted to Probable reserves. Measured mineral resources have been converted to Proven reserves. |

| | • | | Reserves are diluted at the contact of the 2% TREO geological model triangulation (further to dilution inherent to the resource model and assume selective mining unit of 15 ft x 15 ft x30 ft). |

| | • | | Mineral reserves tonnage and grade are reported as diluted. |

| | • | | Pit optimization COG is based on an average TREO% equivalent concentration price of US$6,139/st of dry concentrate (60% TREO, net of the incremental benefits and costs related to REE separations), average mining cost at the pit exit of US$1.825/st mined plus US$0.018/st mined for each 15 ft bench above or below the pit exit, combined milling and G&A costs of US$69.90/st milled, concentrate freight of US$177/st of dry concentrate, and an average overall pit slope angle of 42° including ramps. |

| | • | | The topography used was from September 30, 2021. |

| | • | | Reserves contain material inside and outside permitted mining but within mineral lease. |

| | • | | Reserves assume 100% mining recovery. |

| | • | | The strip ratio was 6.1 to 1 (waste to ore ratio). |

| | • | | The mineral reserves were estimated by SRK Consulting (U.S.) Inc. |

The reserve estimate herein is subject to potential change based on changes to the forward-looking cost and revenue assumptions utilized in this study. It is assumed that MP Materials will produce and sell bastnaesite concentrate to customers in 2022. It is further assumed that MP Materials will ramp its on-site separations facilities (currently undergoing modification and recommissioning) as discussed in Section 10.4 and will transition to selling separated rare earth products starting in 2023.

Full extraction of this reserve is dependent upon modification of current permitted boundaries. Failure to achieve modification of these boundaries would result in MP Materials not being able to extract the full reserve estimated in this study. It is MP Materials’ expectation that it will be successful in modifying this permit condition. In SRK’s opinion, MP Materials’ expectation in this regard is reasonable.

A portion of the pit encroaches on an adjoining mineral right holder’s concession. This portion of the pit only includes waste stripping (i.e., no rare earth mineralization is assumed to be extracted from this concession). The prior owner of Mountain Pass had an agreement with this concession holder to allow this waste stripping (with the requirement that aggregate mined be stockpiled for the owner’s use). MP Materials does not currently have this agreement in place, but SRK believes it is reasonable to assume that MP Materials will be able to negotiate a similar agreement.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 25 |

Mountain Pass is currently being mined using conventional open-pit methods. The open pit is in gently undulating topography intersecting natural drainages that require diversion to withstand some rainfall events during the summer and winter months. Waste dumps are managed according to the Action Plan (AP), are located on high ground, and are designed for control of drainage (contact water) if required.

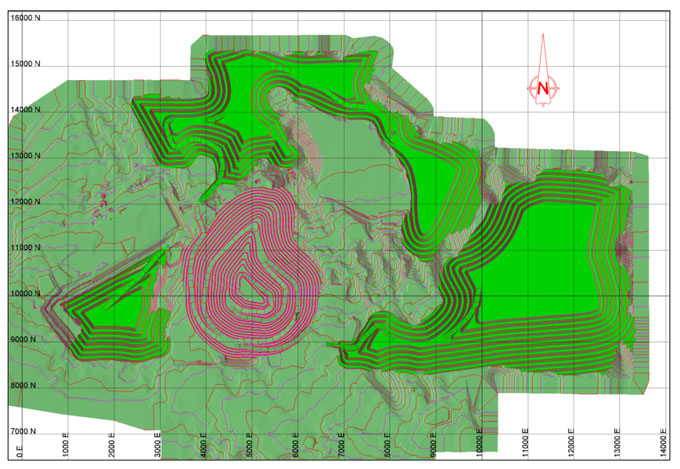

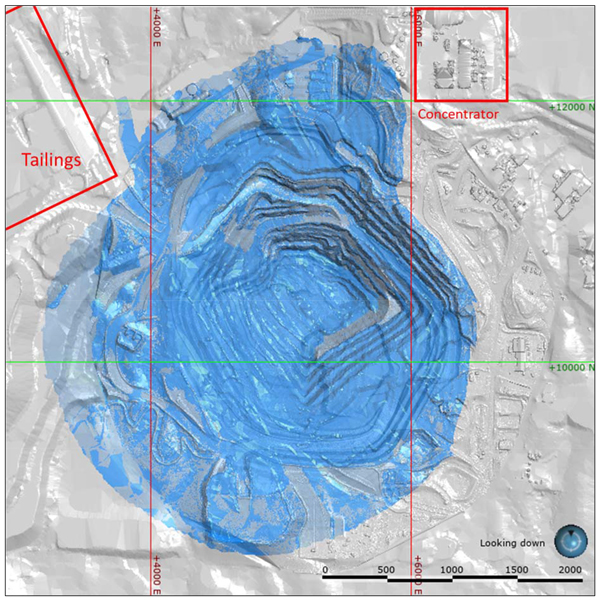

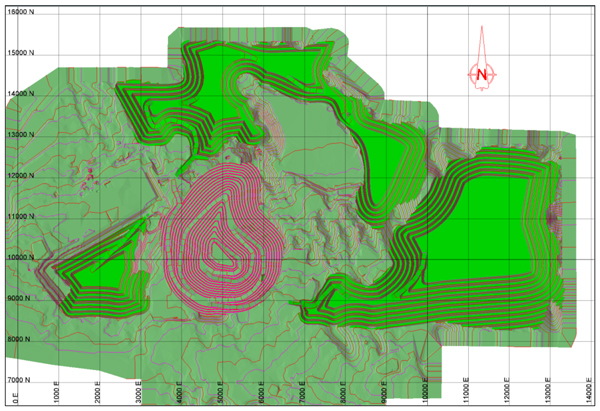

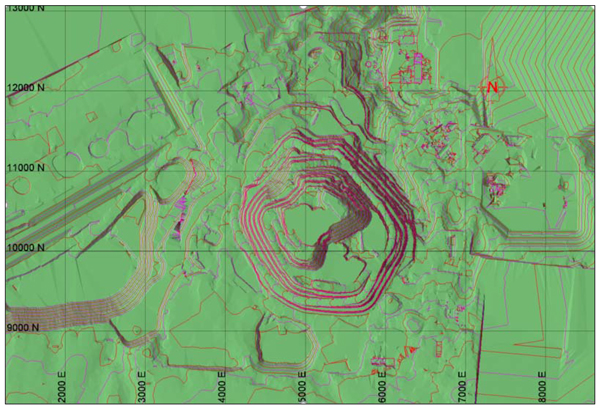

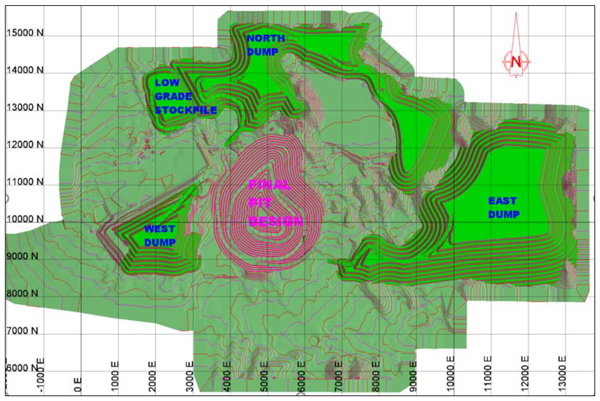

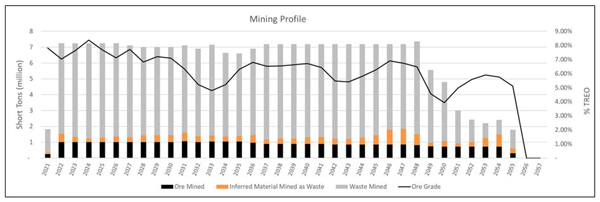

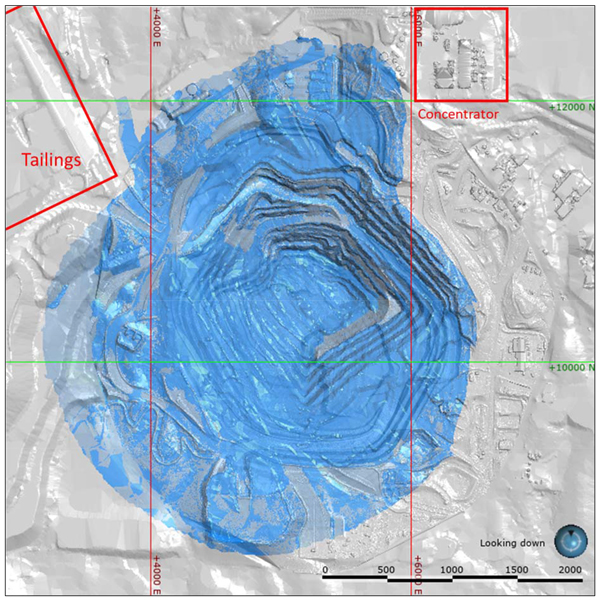

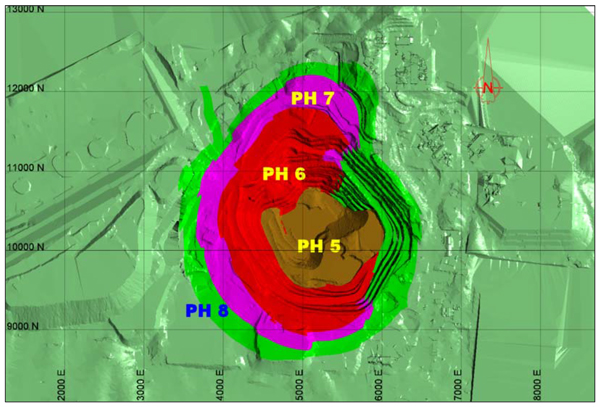

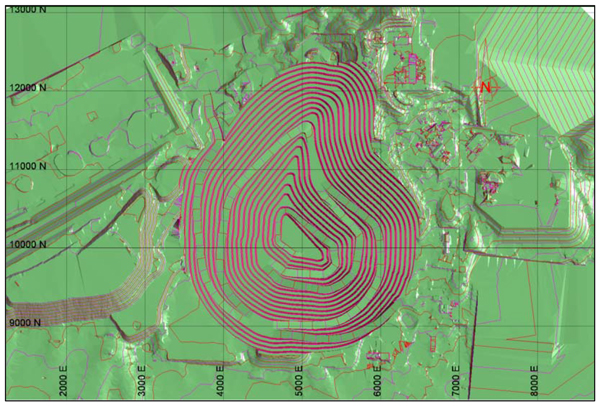

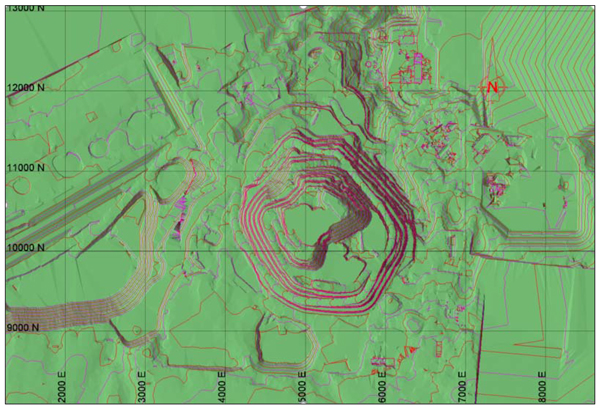

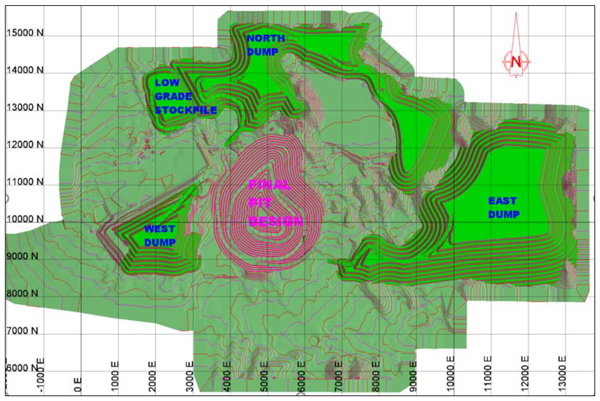

The open pit that forms the basis of the mineral reserves and the LoM production schedule is approximately 3,100 ft from east to west and 3,800 ft from north to south with a maximum depth of 1,400 ft. Total mining is estimated at 216 million st comprised of 30.4 million st of ore and 186 million st of waste, resulting in a strip ratio of 6.1 (waste to ore). Mined ore grade averages 6.35% TREO yielding over 2.05 million dry st of recoverable 60% TREO concentrate. SRK designed four pit pushbacks that adhere to proper minimum mining widths. Bench sinking rates are approximated to no more than six benches per year per pushback.

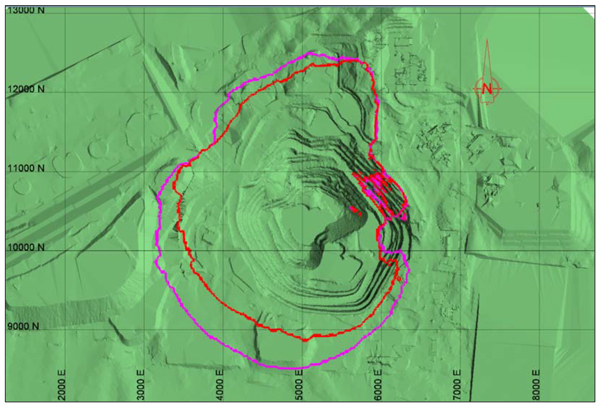

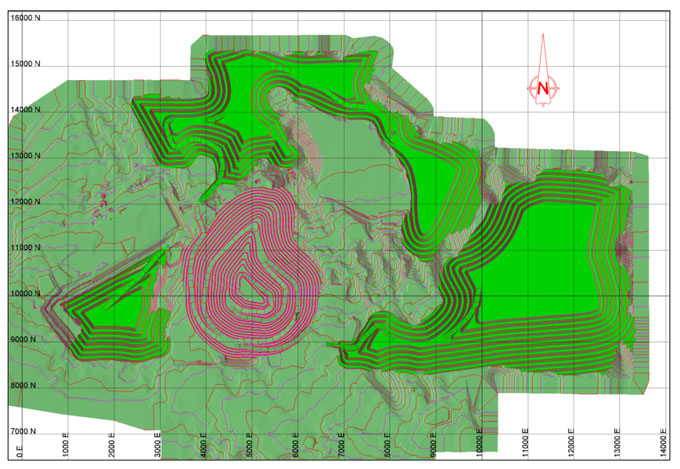

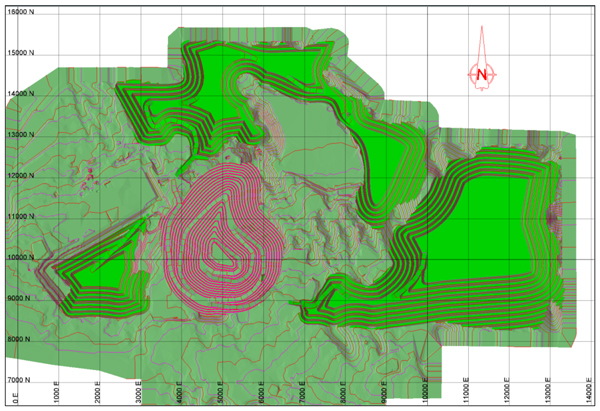

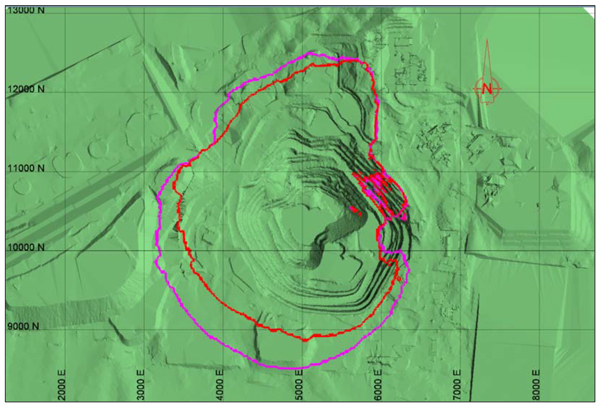

Figure 1-1 illustrates the site layout and final pit design (the tailings area is not highlighted in this image).

16000 N 15000 N 14000 N 13000 N 12000 N 11000 N 10000 N 9000 N 8000 N 7000 N 1000 E 2000 E 3000N 4000 E 5000 E 6000 E 7000 E 8000 E 9000 N 10000 E 11000 E 12000 E 13000 E 14000 E

Source SRK, 2021

Figure 1-1: Final Pit Design and Site Layout

Mine activities include drilling, blasting, loading, hauling, and mining support activities. Drill and blast operations are performed by a contractor, and this will continue for the foreseeable future. All other mine operations are performed by MP Materials. The primary loading equipment is front-end loaders

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 26 |

(15 cubic yards (yd3)), which were selected for operational flexibility. Rigid frame haul trucks with 102 wet short tons (wst) capacity were selected to match with the loading units.

Material within the pit will be blasted on 30 ft high benches. Material classified as reserves (>2.49% TREO) will be sent to the RoM stockpiles for near-term blending to the primary crusher or, alternatively, to long-term stockpiles for processing later in the mine life. Waste dumps will be used for material below 2.49% TREO.

The mine operations schedule includes one 12-hour day shift, seven days per week for 365 days per year.

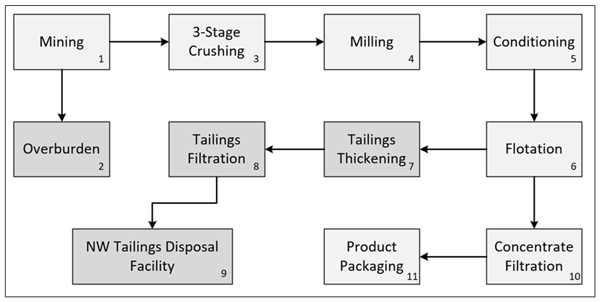

| 1.8.1 | Existing Crushing and Concentrating Operations |

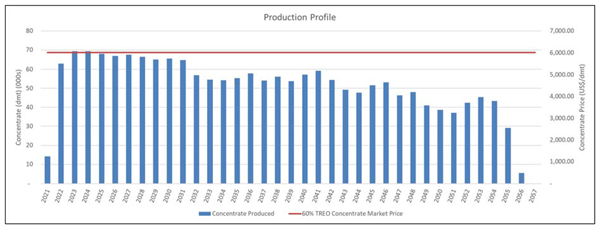

MP Materials operates a 2,000 t/d flotation concentrator that produces concentrates that are currently sold to customers who further process the concentrates to produce separated rare earth oxides. The concentrator flowsheet includes crushing, grinding, rougher/scavenger flotation, cleaner flotation, concentrate thickening and filtration and tailings thickening and filtration followed by dry stack tailings disposal. Significant improvements in concentrator performance have occurred since inception of operations, which are attributed primarily to new reagent and ore blending schemes as well as the introduction of steam boiler to support process kinetics. During 2020 TREO recovery averaged 66.8% into concentrates containing an average of 60.6% TREO. During 2021 (January – September) TREO recovery has averaged 69.8% into concentrates averaging 61.2% TREO, reflecting ongoing operational improvements in the concentrator.

| 1.8.2 | Modified and Recommissioned Separations Facility |

MP Materials is in the process of modifying and recommission its on-site separations facility to produce individual rare earth products as previously summarized in Table 1-3. The incentive for this substantial process change is the enhancement of revenue that would be realized for producing individual rare earth products as compared to the current practice of producing a single rare earth containing flotation concentrate which is then sold to various entities that separate and market individual rare earth products. MP Materials has investigated the marketability of the proposed new products and has reached the conclusion that the process modifications specified herein should go forward and has made substantial technical and financial commitments to that end.

Consequently, based upon the value of the rare earth products defined in the table above, coupled with a site visit to the MP Materials installations at Mountain Pass, an interview with the manager of ongoing construction, and conversations with MP Materials engineers that will be directly involved with the commissioning efforts, it is the opinion of SGS that the Mountain Pass modification and modernization project has been performed in an expeditious and professional manner. It is likely that the project construction completion schedule presently anticipated to complete by year-end 2022 will be realized. It is also likely that the ramp schedule assumed for economic modeling purposes, which estimated feeding 50%, 90%, and 100% of concentrate production into the facility in 2023, 2024, and 2025, respectively, is conservative and will be achieved.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 27 |

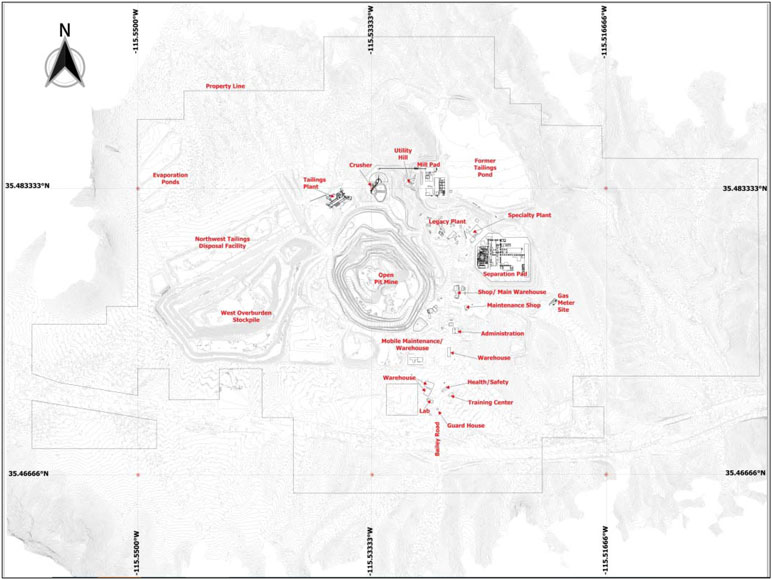

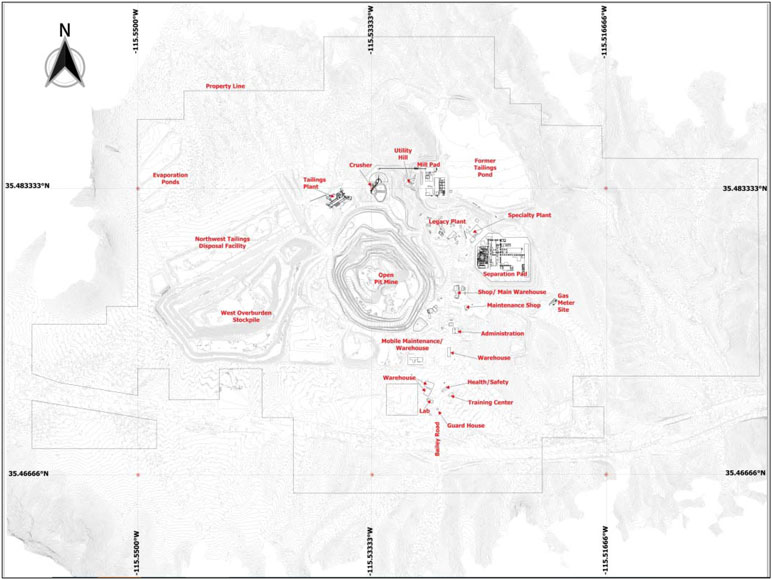

| 1.9 | Project Infrastructure |

The Project is in San Bernardino County, California, north of and adjacent to Interstate 15 (I-15), approximately 15 mi southwest of the California-Nevada state line and 30 mi northeast of Baker, California (Figure 3-2).

The nearest major city is Las Vegas, Nevada, located 50 mi to the east on I-15. The Project lies immediately north of I-15 at Mountain Pass and is accessed by the Bailey Road Exit (Exit 281 of I-15), which leads directly to the main gate. The mine is approximately 15 mi southwest of the California-Nevada state line in an otherwise undeveloped area, enclosed by surrounding natural topographic features.

Outside services include industrial maintenance contractors, equipment suppliers and general service contractors. Access to qualified contractors and suppliers is excellent due to the proximity of population centers such as Las Vegas, Nevada as well as Elko, Nevada (an established large mining district) and Phoenix, Arizona (servicing the copper mining industry).

Access to the site, as well as site haul roads and other minor roads are fully developed and controlled by MP Materials. There is no public access through the Project area. All public access roads that lead to the Project are gated at the property boundary.

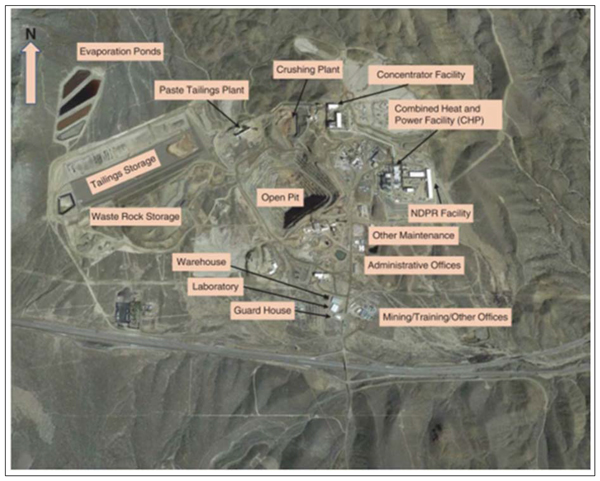

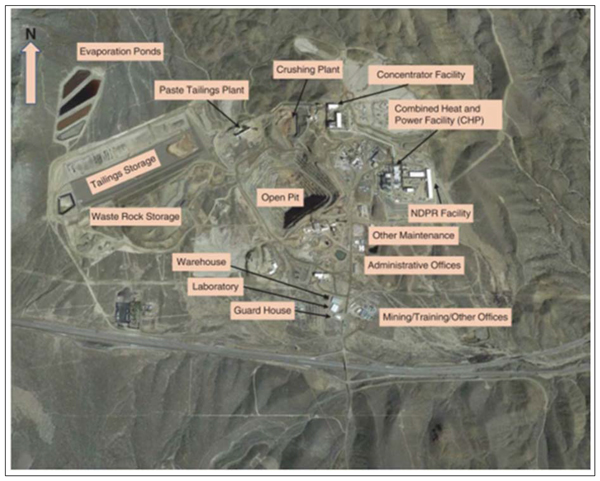

MP Materials has fully developed an operating infrastructure for the Project in support of extraction and concentrating activities. A manned security gate is located on Bailey Road for providing required site-specific safety briefings and monitoring personnel entry and exit to the Project.

The site has a 12-kV electrical powerline that supplies the full power needs of the Project in its current configuration. The site also uses piped natural gas to supply a rental boiler used to provide steam for the concentrator plant. Development activities completed by the prior Project owner included the construction of a Combined Heat and Power (CHP) or co-generation (cogen) power facility to address the increased electrical demands associated with the process flow sheet utilized at that time. This CHP plant is in the final stages of being recommissioned and is expected to provide for all the electricity and steam needs for all process areas of the site in early 2022, replacing the need for grid power and the rental boiler.

Water is supplied through active water wells, legacy treatment wells, mine dewatering, and natural precipitation. The Project has a net positive water balance and excess water is evaporated in evaporation ponds. Fire systems are supplied by separate fire water tanks and pumps.

The site has all facilities required for operation, including the open pit, concentrator, access and haul roads, explosives storage, fuel tanks and fueling systems, warehouse, security guard house and perimeter fencing, tailings filter plant, tailings storage area, waste rock storage area, administrative and office buildings, surface water control systems, evaporation ponds, miscellaneous shops, truck shop, laboratory, multiple laydown areas, power supply, water supply, gas-fired boiler and support equipment, waste handling bins and temporary storage locations, and a fully developed communications system.

The LoM plan will require the relocation in 2036 of the paste tailings plant and the water tanks currently northeast of the pit highwall near the concentration plant. Additionally, the crusher will be relocated in 2027 to allow the pit to expand to the north. Capital cost provisions are included in the economic model for these relocations.

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 28 |

The design capacity of the tailings storage facility is approximately 24 million st. The project has utilized approximately 3.6 million st of that space. The existing facility will have a remaining capacity of approximately 20.4 million st which will provide over 23 years of storage. MP Materials will expand the existing tailings facility to the northwest in approximately 2042 to provide an additional 13 years of storage capacity. A capital cost provision has been included in the economic model for this expansion.

Site logistics are straightforward with the current concentrate product shipped in Super Sacks within a shipping container by truck approximately 4.5 hours to the port of Los Angeles. At the port, the containers are loaded onto a container ship and shipped to the final customers.

| 1.10 | Market Studies and Contracts |

Section 16 of this report highlights key trends within the REE market, which can be categorized by a significant degree of variation in the demand profiles for various REE and their associated products.

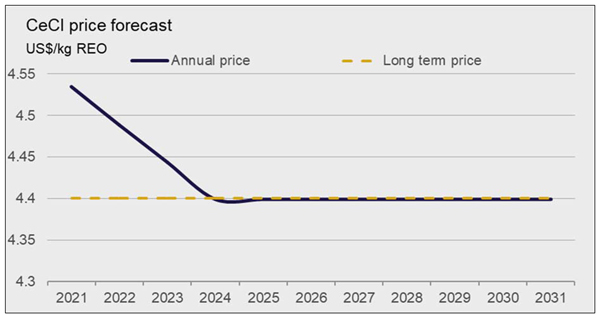

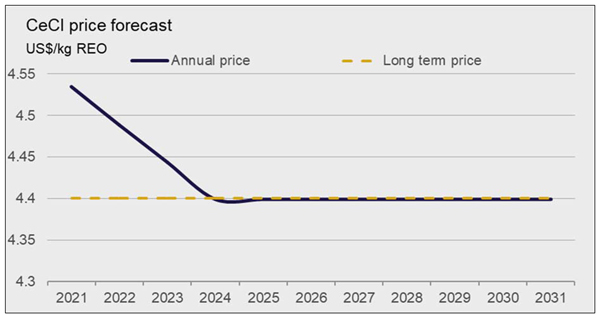

Products outlined in this report (PrNd oxide, SEG+ oxalate, La carbonate, and Ce chloride) are considered marketable from an economic perspective, provided market standards and requirements are met. As shown in Table 1-4, and based on outlined product specifications, CRU forecasts a long-term price of US$95/kg REO for PrNd oxide, US$7.5/kg REO for SEG+ oxalate, US$1.4/kg REO for Lanthanum carbonate, and US$4.4/kg REO for Cerium chloride. The mixed rare earth concentrate price of US$10/kg of contained REO will be principally driven by trends in PrNd and dysprosium (Dy), price swings of which will be mirrored by concentrates.

Table 1-4: Summary of Long Term Price Forecasts

| | | | |

| Product | | Long term price forecast, real 2020 US$/kg | | |

| Mixed Rare Earth Concentrate | | US$10 per kg of contained REO | | |

| PrNd Oxide | | US$95 per kg | | |

| SEG+ Oxalate | | US$7.5 per kg | | |

| La Carbonate | | US$1.4 per kg | | |

| Cerium Chloride | | US$4.4 per kg | | |

Source: CRU, 2022

At a high level, when constructing an average non-China rare earths project, the long-run incentive price for PrNd is calculated at ~US$85/kg. Expectations of a potentially persistent market deficit, with PrNd prices staying well above US$100/kg out to 2028 elevate the long term price forecast to US$95/kg. The SEG+ oxalate price forecast is based on projected terms at which Chinese separation facilities with heavy rare earth capacity will aim to purchase the oxalate as feedstock. The carbonate and chloride price forecasts are based on end-use production cost analysis. These forecasts are therefore based on a variation of product-specific market trends and long-run cost methodologies specific to rare earth operations.

A strong demand profile for PrNd oxide drives a weaker profile for Ce and La products, with the basket problem driving oversupplied Ce and La markets. As a result, the long-run price for PrNd is centered on the principle that it carries the cost of production for most operations. Heavy rare earth operations also contribute to economic value beyond the cost of their extraction, but separation is generally more expensive and therefore only feasible in higher quantities than average bastnaesite or monazite orebodies. Although the Mountain Pass facility may derive value for the mixed heavy rare earth product (SEG+ oxalate), PrNd oxide contains the most economic value at the present market view. Where

| | |

SRK Consulting (U.S.), Inc. | | |

SEC Technical Report Summary – Mountain Pass Mine | | Page 29 |

geopolitical tensions may intercede with standard market operations, Mountain Pass appears well positioned to provide market-standard products.

| 1.11 | Environmental, Closure and Permitting |

As of September 30, 2021, MP Materials holds the necessary operating permits, including conditional use and minor use permits from the County of San Bernardino (SBC), which currently allows continued operations of the Mountain Pass facility through 2042.

MP Materials maintains financial assurance cost estimates for closure, post-closure maintenance (PCM), and All Known and Reasonably Foreseeable Releases (AKRFR) for current and planned operations at the Mountain Pass property. The Lahontan Regional Water Quality Control Board (LRWQCB) administers the groundwater and surface water related financial assurance obligations. The SBC administers financial assurance requirements for surface reclamation of the property. The California Department of Resource, Recycling and Recovery administers financial assurance requirements for decontamination and decommissioning activities. MP Materials maintains miscellaneous financial assurance instruments for other closure-related obligations. As of September 2021, the total financial assurance obligation is approximately US$39 million.

| 1.12 | Capital and Operating Costs |

Capital and operating costs are incurred and reported in US dollars and are estimated at a pre-feasibility level with an accuracy of approximately +/-25%.

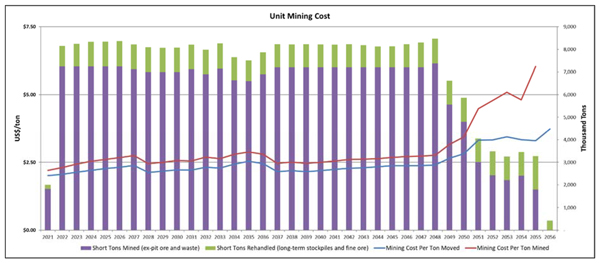

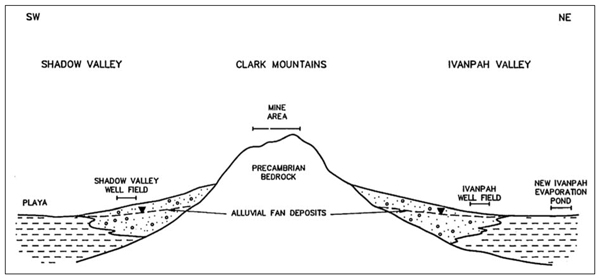

Capital Costs