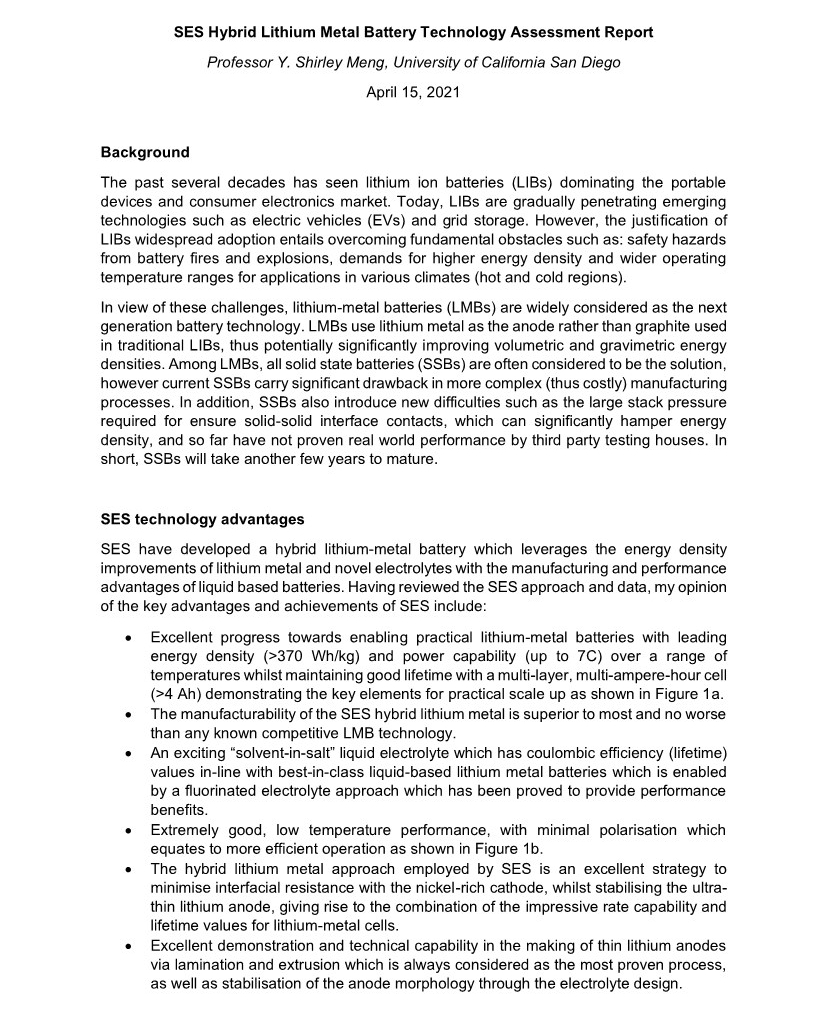

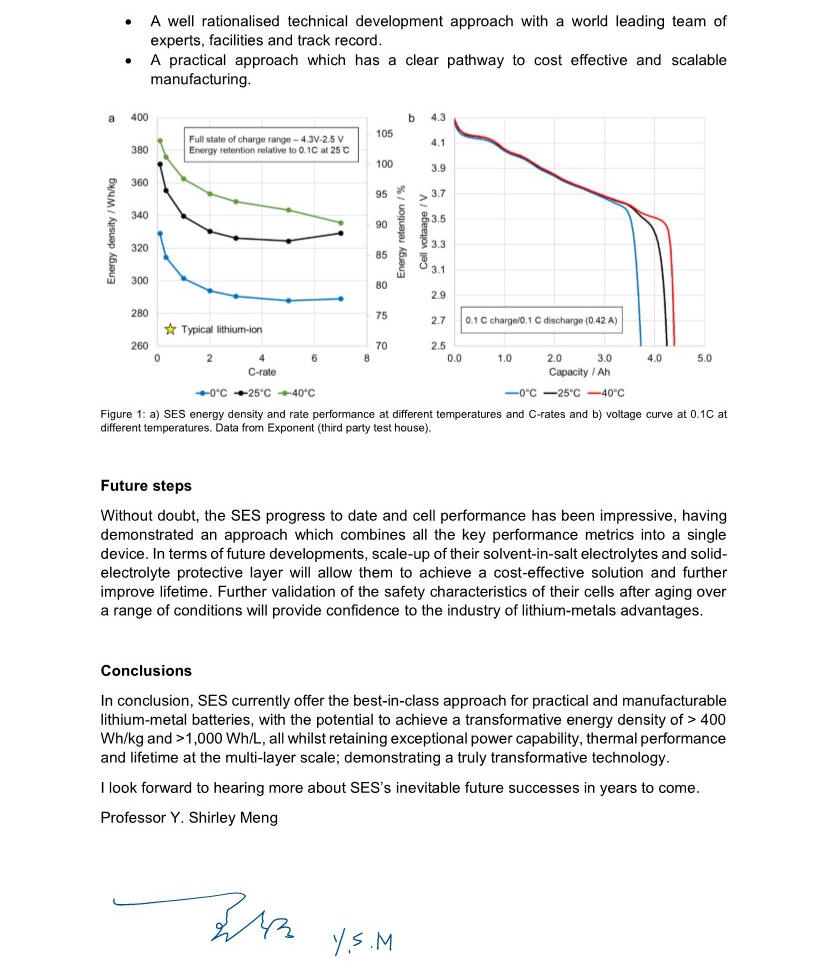

| SES Hybrid Lithium Metal Battery Technology Assessment Report Professor Y. Shirley Meng, University of California San Diego April 15, 2021 Background The past several decades has seen lithium ion batteries (LIBs) dominating the portable devices and consumer electronics market. Today, LIBs are gradually penetrating emerging technologies such as electric vehicles (EVs) and grid storage. However, the justification of LIBs widespread adoption entails overcoming fundamental obstacles such as: safety hazards from battery fires and explosions, demands for higher energy density and wider operating temperature ranges for applications in various climates (hot and cold regions). In view of these challenges, lithium-metal batteries (LMBs) are widely considered as the next generation battery technology. LMBs use lithium metal as the anode rather than graphite used in traditional LIBs, thus potentially significantly improving volumetric and gravimetric energy densities. Among LMBs, all solid state batteries (SSBs) are often considered to be the solution, however current SSBs carry significant drawback in more complex (thus costly) manufacturing processes. In addition, SSBs also introduce new difficulties such as the large stack pressure required for ensure solid-solid interface contacts, which can significantly hamper energy density, and so far have not proven real world performance by third party testing houses. In short, SSBs will take another few years to mature. SES technology advantages SES have developed a hybrid lithium-metal battery which leverages the energy density improvements of lithium metal and novel electrolytes with the manufacturing and performance advantages of liquid based batteries. Having reviewed the SES approach and data, my opinion of the key advantages and achievements of SES include: • Excellent progress towards enabling practical lithium-metal batteries with leading energy density (>370 Wh/kg) and power capability (up to 7C) over a range of temperatures whilst maintaining good lifetime with a multi-layer, multi-ampere-hour cell (>4 Ah) demonstrating the key elements for practical scale up as shown in Figure 1a. • The manufacturability of the SES hybrid lithium metal is superior to most and no worse than any known competitive LMB technology. • An exciting “solvent-in-salt” liquid electrolyte which has coulombic efficiency (lifetime) values in-line with best-in-class liquid-based lithium metal batteries which is enabled by a fluorinated electrolyte approach which has been proved to provide performance benefits. • Extremely good, low temperature performance, with minimal polarisation which equates to more efficient operation as shown in Figure 1b. • The hybrid lithium metal approach employed by SES is an excellent strategy to minimise interfacial resistance with the nickel-rich cathode, whilst stabilising the ultra- thin lithium anode, giving rise to the combination of the impressive rate capability and lifetime values for lithium-metal cells. • Excellent demonstration and technical capability in the making of thin lithium anodes via lamination and extrusion which is always considered as the most proven process, as well as stabilisation of the anode morphology through the electrolyte design. |